HL-FFQH environment-friendly drilling fluid system and preparation method thereof

A drilling fluid and environmental protection technology, applied in the field of petroleum drilling fluid system, can solve the problems of certain risks in the use of long shale sections, compatibility, unspecified addition amount, poor performance of shale inhibition indicators, etc., to avoid Drilling complex accidents, improving drilling quality and efficiency, and good wall-building effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

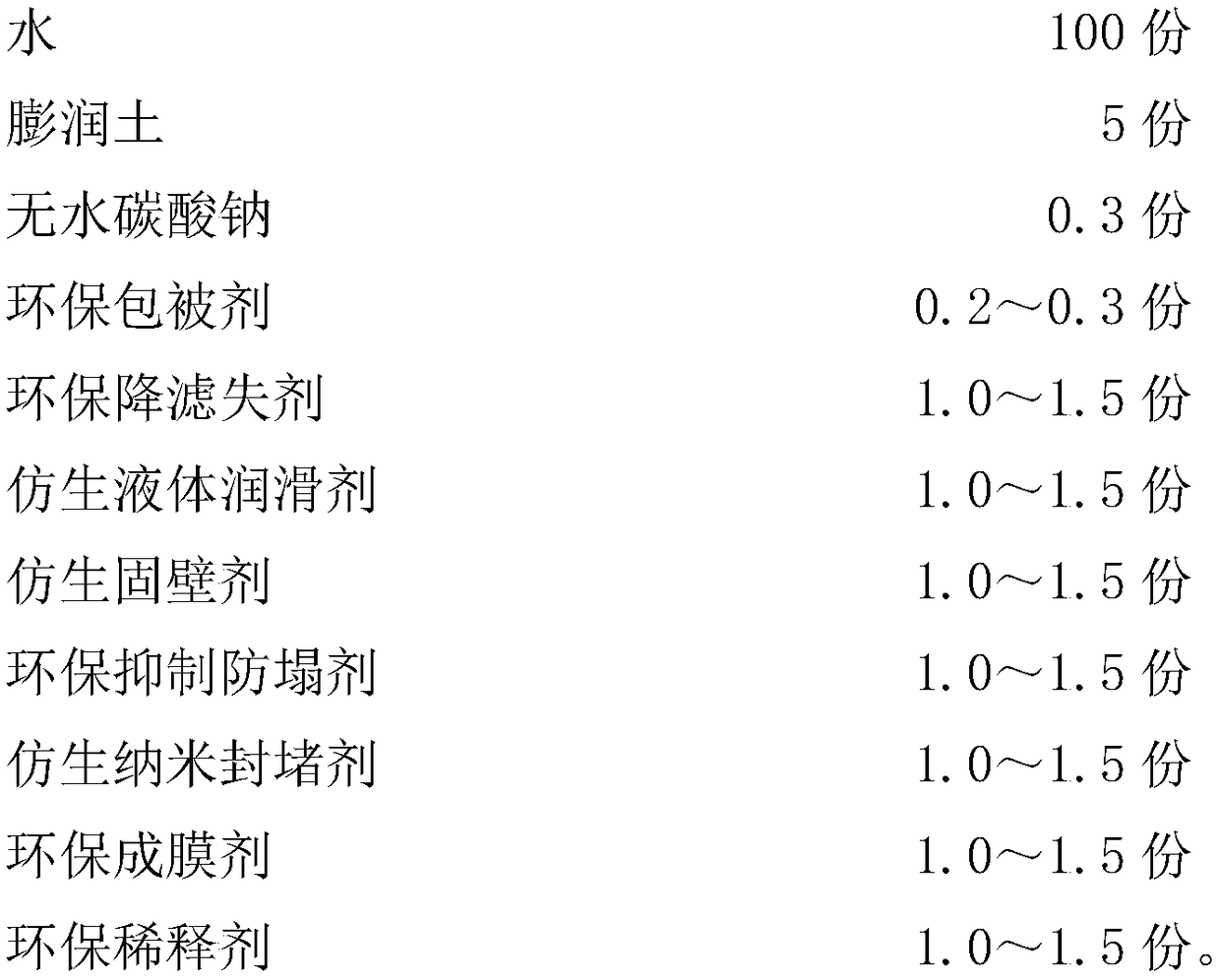

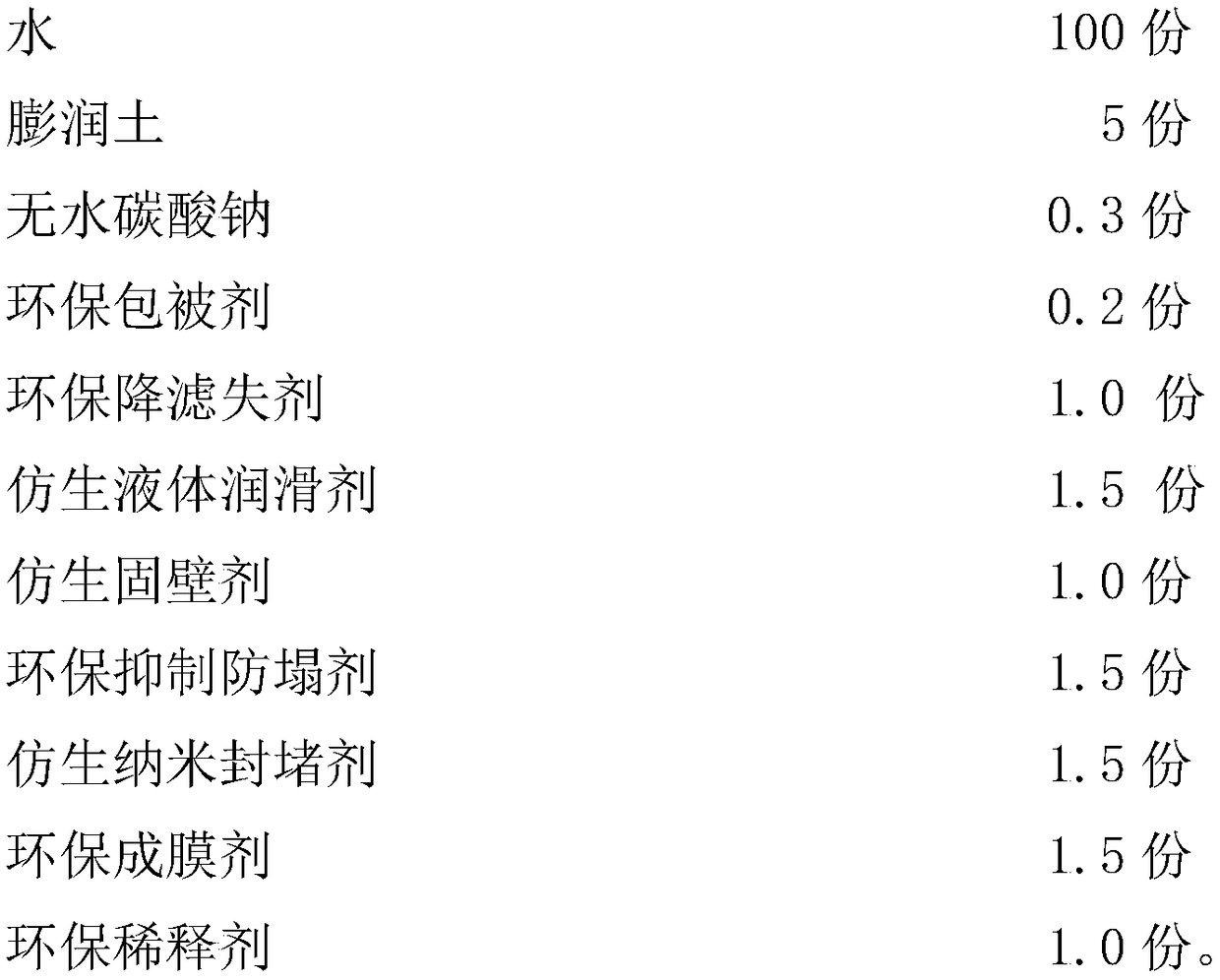

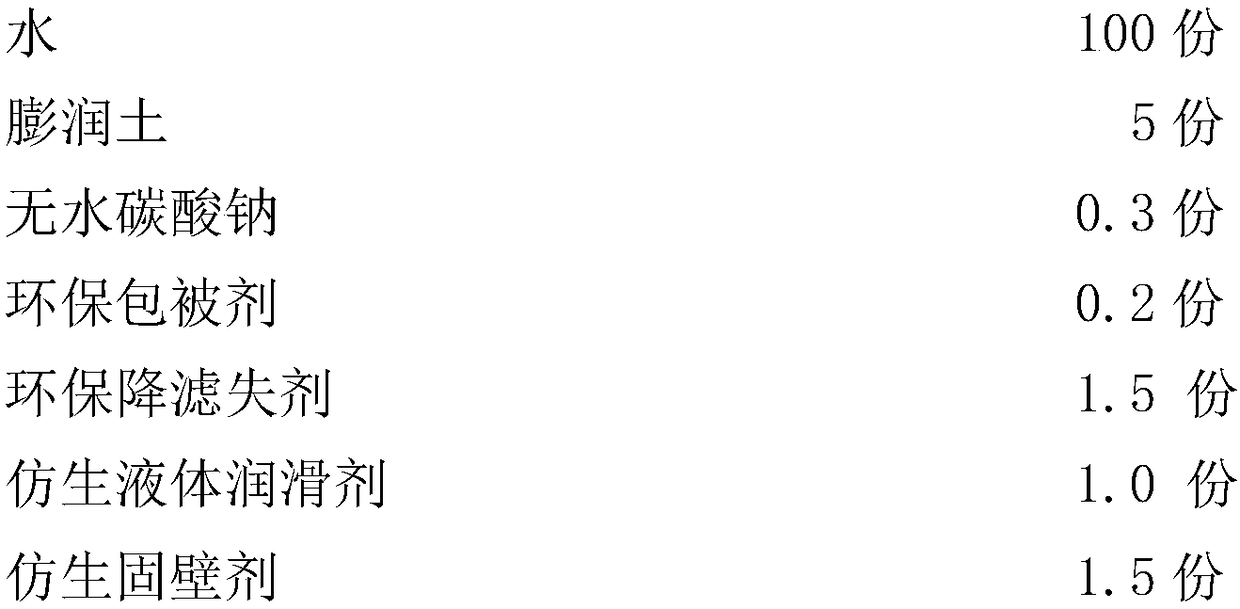

Embodiment 1

[0038] Embodiment 1: The (HL-FFQH) environment-friendly drilling fluid system of the present invention is made of raw materials according to the weight ratio described in Table 1. Described environment-friendly coating agent is: coating agent multi-polymer HLBE-1 for drilling fluid (coating agent terpolymer HLBE-1 for drilling fluid); described environment-friendly fluid loss reducer is: used for drilling fluid Filtrate reducer natural modified glucoside HLJ-6; the biomimetic liquid lubricant is: liquid lubricant biomimetic amino acid ester HLR-2 for drilling fluid; the biomimetic wall-solidifying agent is: wall-solidifying agent for drilling fluid Modified resin polymer HLGB-3; the environmental protection inhibition and anti-slump agent is: inhibitor biomimetic amino acid polymer HLY-1 for drilling fluid; the biomimetic nano plugging agent is: biomimetic plugging agent for drilling fluid Lactic acid resin HLFD-1, nano-scale; the environmentally friendly film-forming agent is...

Embodiment 2

[0040] Embodiment 2: The HL-FFQH environment-friendly drilling fluid system of the present invention is made of raw materials according to the weight ratio described in Table 1. Refer to Example 1 for the preparation method of the HL-FFQH environment-friendly drilling fluid system.

Embodiment 3

[0041] Embodiment 3: The HL-FFQH environment-friendly drilling fluid system of the present invention is made of raw materials according to the weight ratio described in Table 1. Refer to Example 1 for the preparation method of the HL-FFQH environment-friendly drilling fluid system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com