Patents

Literature

141results about How to "Non-polluting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

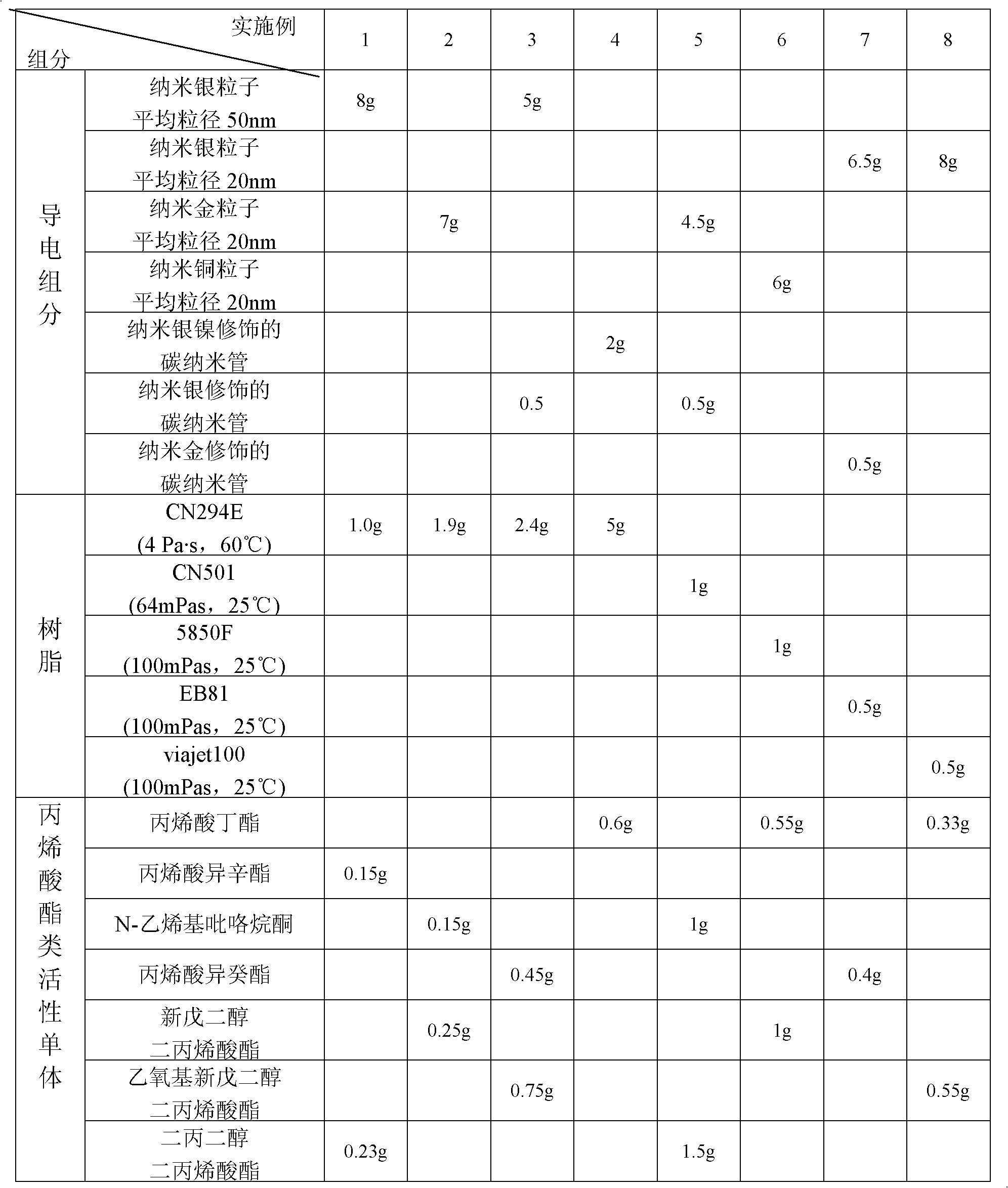

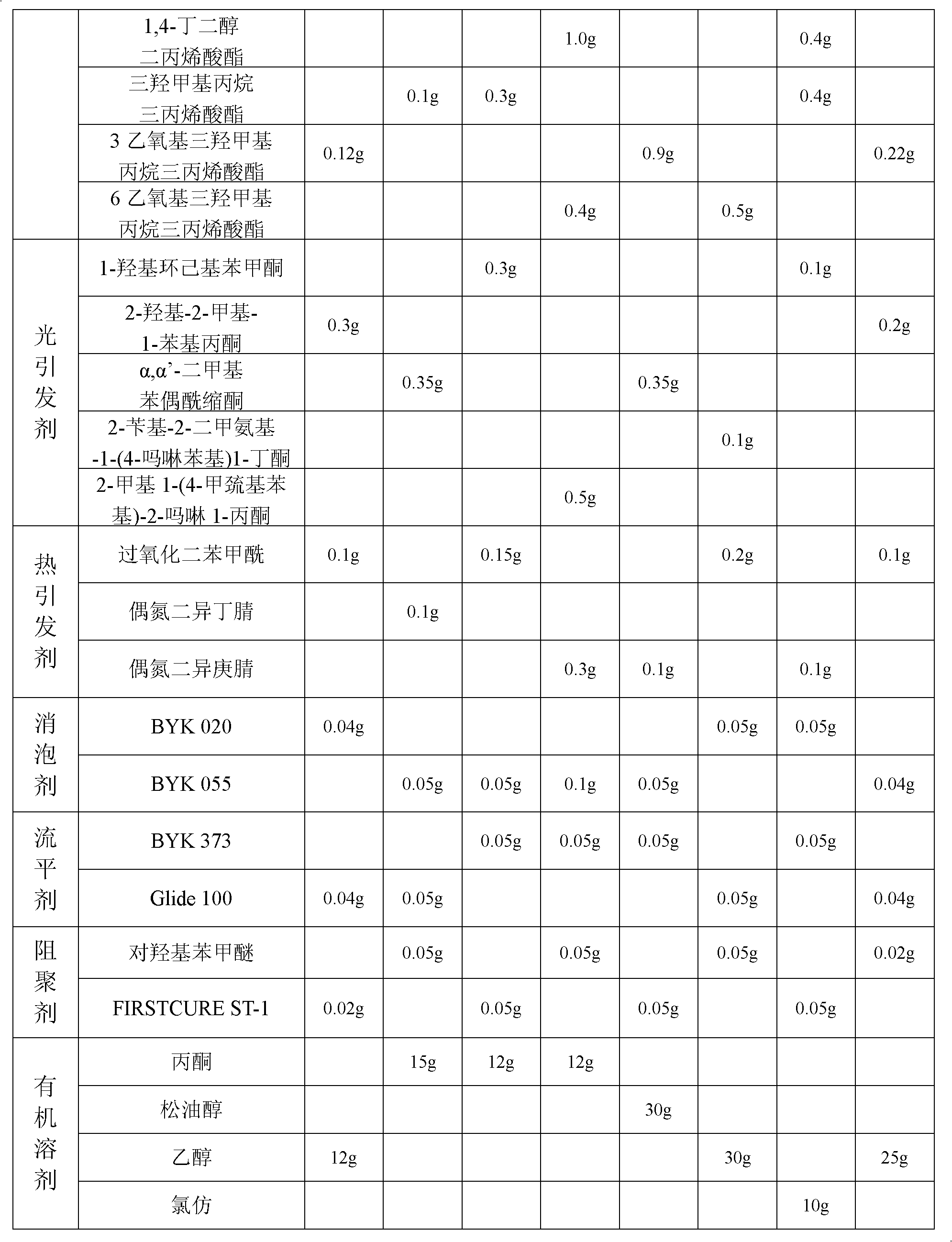

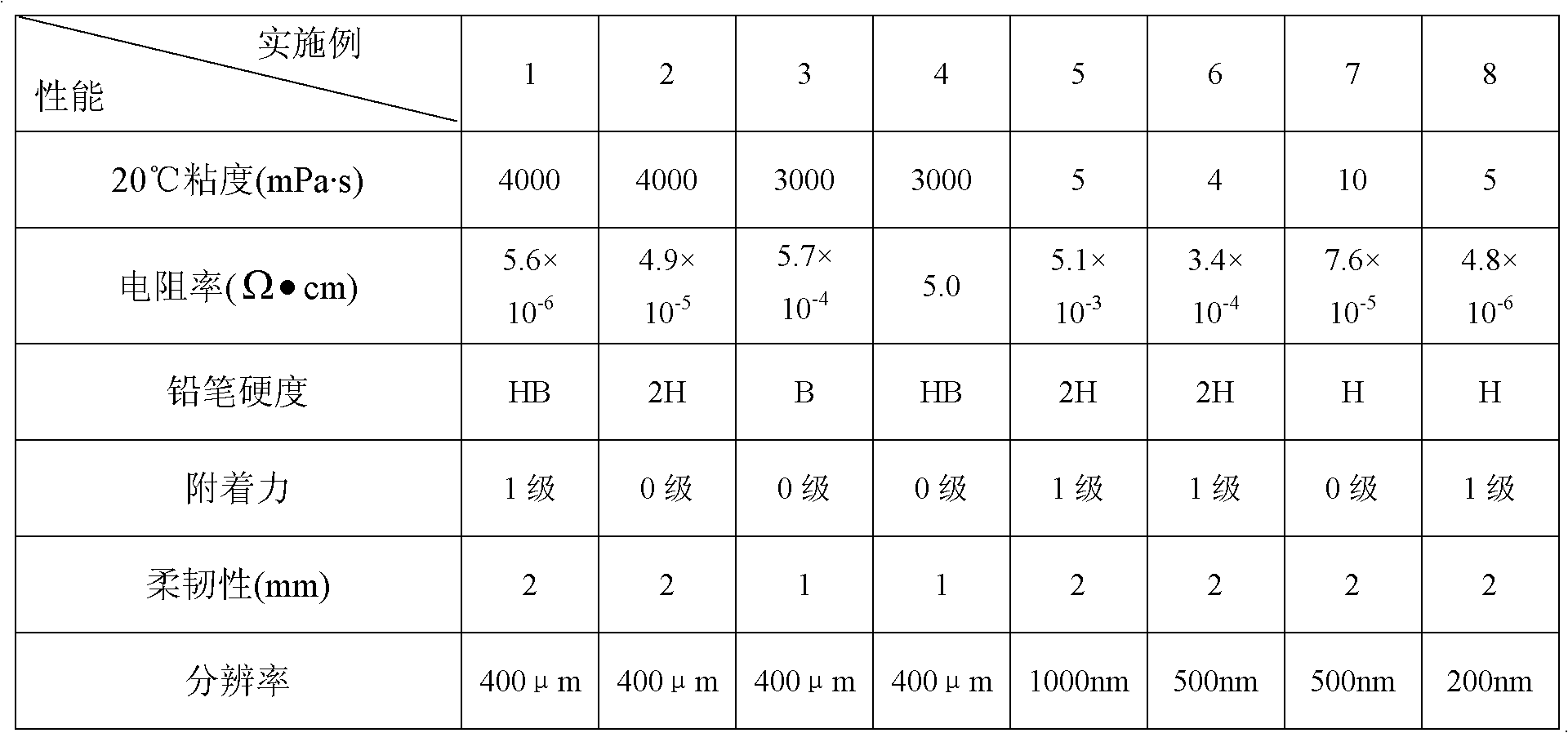

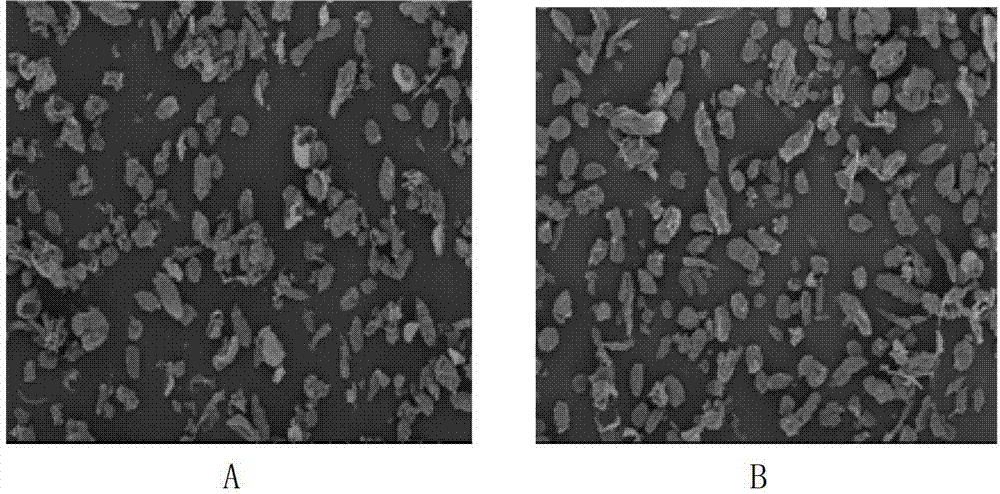

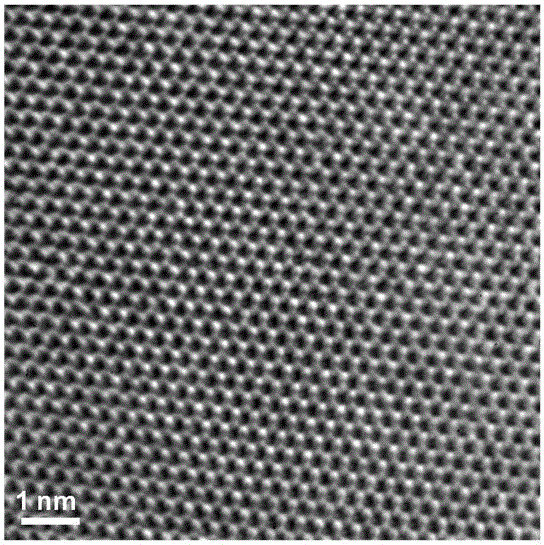

Flexible circuit conductive composition, preparation method and using method thereof

ActiveCN102212304AGuaranteed resistivityGuaranteed adhesionPhotomechanical apparatusPolyurea/polyurethane coatingsFlexible circuitsFlexible electronics

The invention relates to a flexible circuit conductive composition for a flexible printed circuit board (FPC), a preparation method and a using method thereof. The preparation method comprises the following steps of: adding photocurable resin and an optical activity monomer into a conductive nanometer material dispersion liquid and then preparing the composition by adopting a double-curing mode such as firstly photocuring and then thermal treatment. The photocuring leads the surface coating to be rapidly cured so as to achieve good mechanical property; and the thermal curing leads the coatingto be cured completely so as to reach the deep curing requirements. The thermal treatment leads nanometer metals to be sintered together so as to achieve good conductive performance. The prepared conductive system obtains a predesigned pattern in the specific area of a base material in a screen printing or nanometer impressing mode; the conductive pathway is obtained after the double curing and has the advantages of short curing time, low curing temperature, good electrical conductivity, high resolution ratio; and the prepared conductive film has the advantages of good adhesiveness, high hardness and good flexibility.

Owner:BEIJING UNIV OF CHEM TECH

Puffed glutinous rice purple sweet potato crisp chip and production method thereof

InactiveCN102726689AAdvantages of preparation processOutstanding aromaFood preparationBiotechnologySupersonic waves

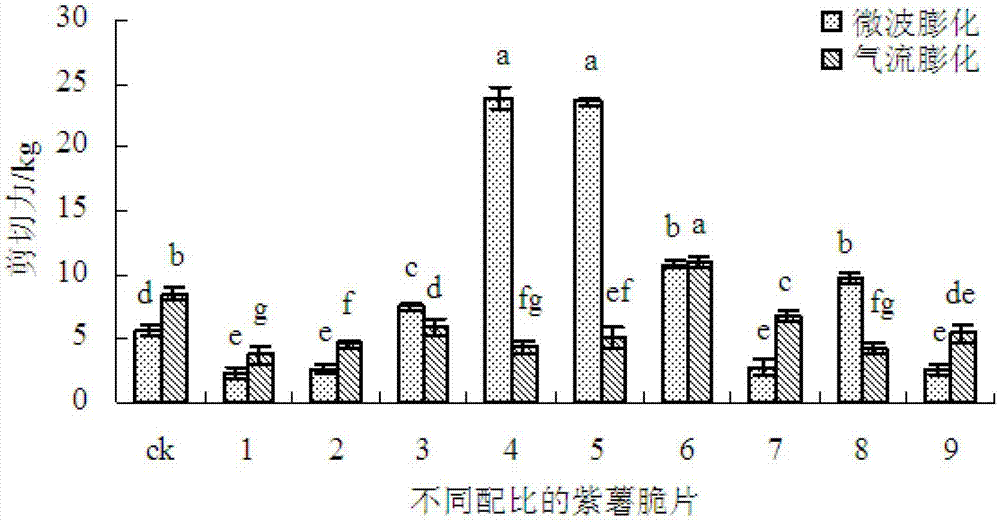

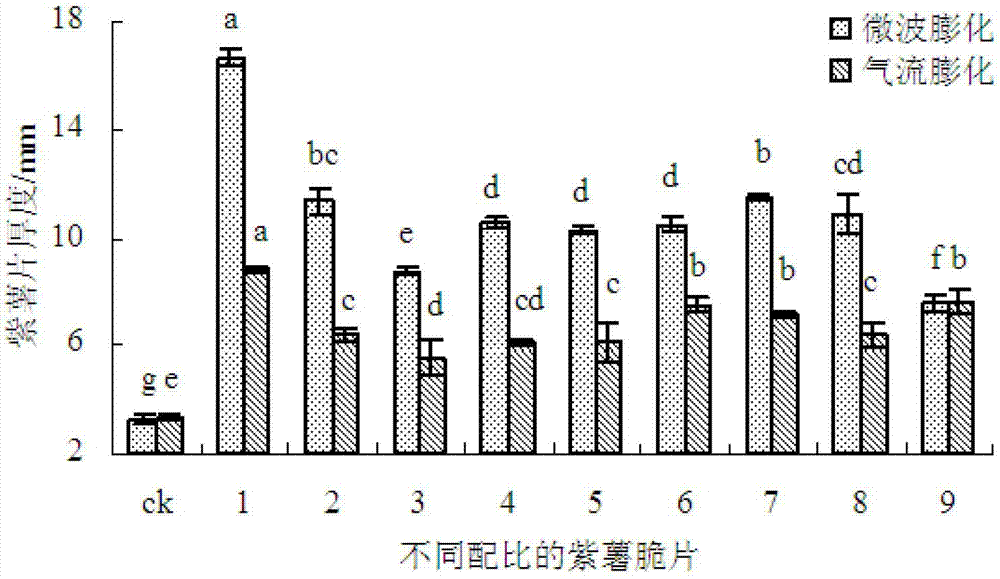

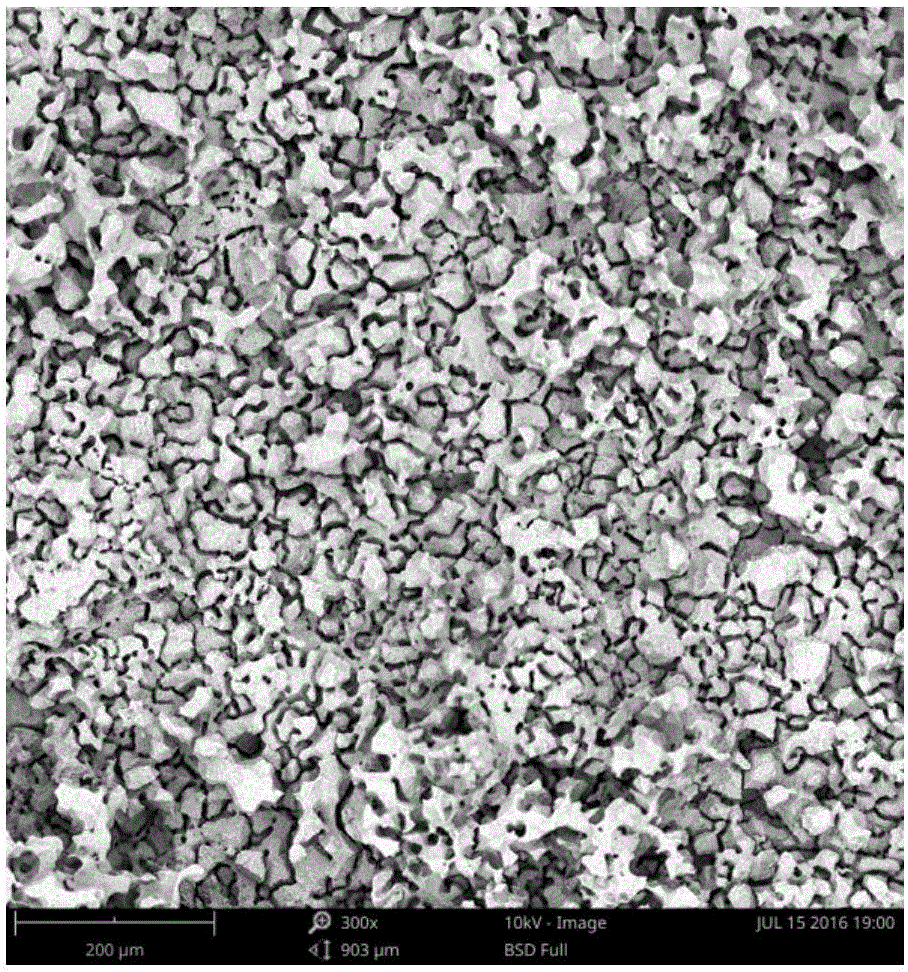

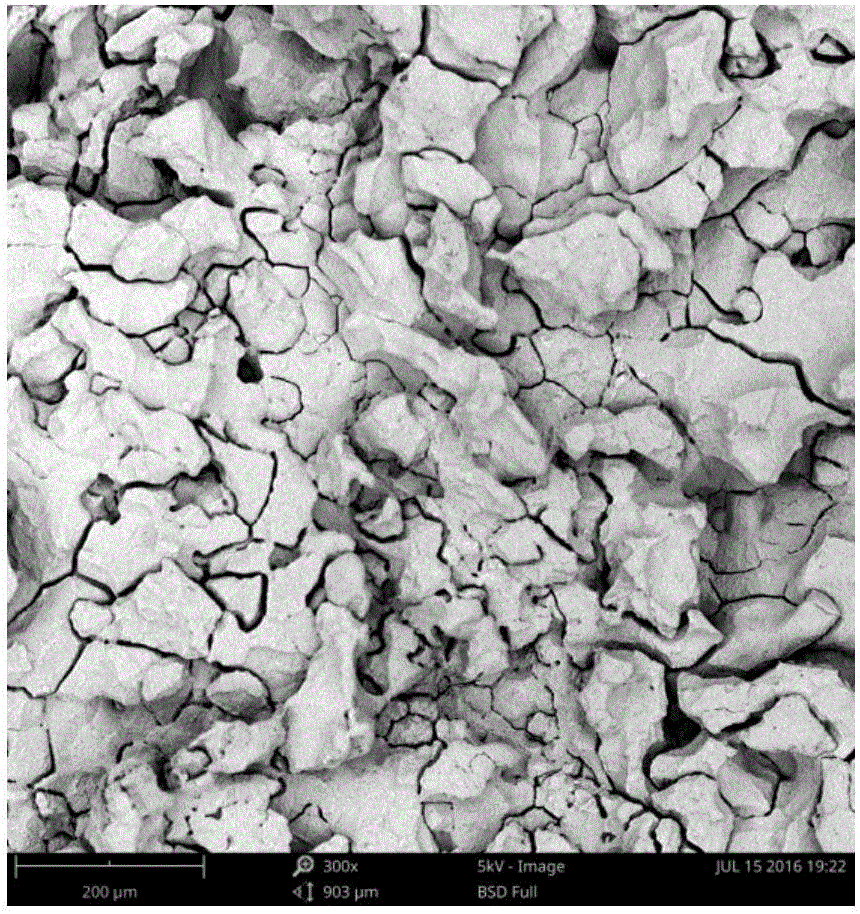

The invention discloses a puffed glutinous rice purple sweet potato crisp chip and a production method thereof. The production method for the puffed glutinous rice purple sweet potato crisp chip comprises the following steps: pre-cooking and stewing cleaned and sliced purple sweet potatoes and then dispersing cells of the purple sweet potatoes by using pectinex or supersonic waves so as to prepare unicellularized purple sweet potato mash; uniformly mixing the materials of water, potato mash, the purple sweet potato mash, glutinous rice flour, white sugar, salt and a swelling agent to obtain mixed batter, drying the batter, slicing the dried batter and carrying out air-flow differential puffing or microwave puffing so as to obtain the puffed glutinous rice purple sweet potato crisp chip. The puffed glutinous rice purple sweet potato crisp chip produced by using the production method highlights the unique fragrance of purple sweet potatoes and the fragrance of glutinous rice and is rich in nutritional components like proteins, cellulose, starch, anthocyanin and phenol substances; the product of the crisp chip has crisp taste, a high puffing rate, excellent flavor, a beautiful color, high content of anthocyanin and abundant nutritional components, and the product is very popular among people and is a novel non-fried health-care puffed purple sweet potato crisp chip.

Owner:NANJING AGRICULTURAL UNIVERSITY

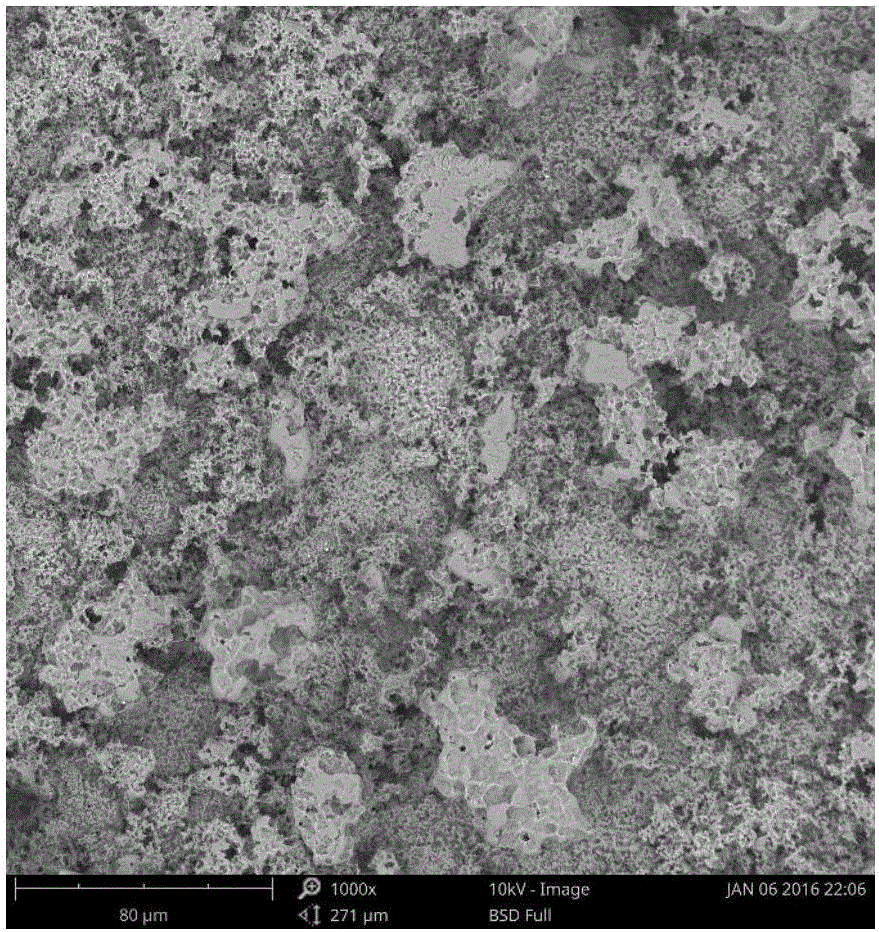

Aluminum alloy electrode material and preparation method and application of aluminum alloy electrode material

ActiveCN106191571AUniform corrosionReduce corrosion rateFuel and primary cellsCell electrodesRare-earth elementCrystallite

The invention provides an aluminum alloy electrode material. The aluminum alloy electrode material comprises 0.1-3 wt% of Mg, 0.05-1 wt% of Sn, 0.01-0.5 wt% of Ga, 0.02-0.1 wt% of RE and the balance Al. According to the aluminum alloy electrode material, an aluminum substrate is doped with a certain amount of magnesium, stannum, gallium and the rare earth element, on the basis of improving the activity of an aluminum anode, through the refining function of the rear earth element on grains, corrosion of the aluminum anode is evener, and the corrosion rate is lowered; meanwhile on the one hand, due to addition of the elements, the electrochemical performance of the aluminum alloy is good; on the other hand, the added elements are free of contamination; and the rare earth element is added in the form of an aluminum rare earth master alloy, and the price is low. The invention further provides a preparation method of the aluminum alloy electrode material and application of the aluminum alloy electrode material in air batteries.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

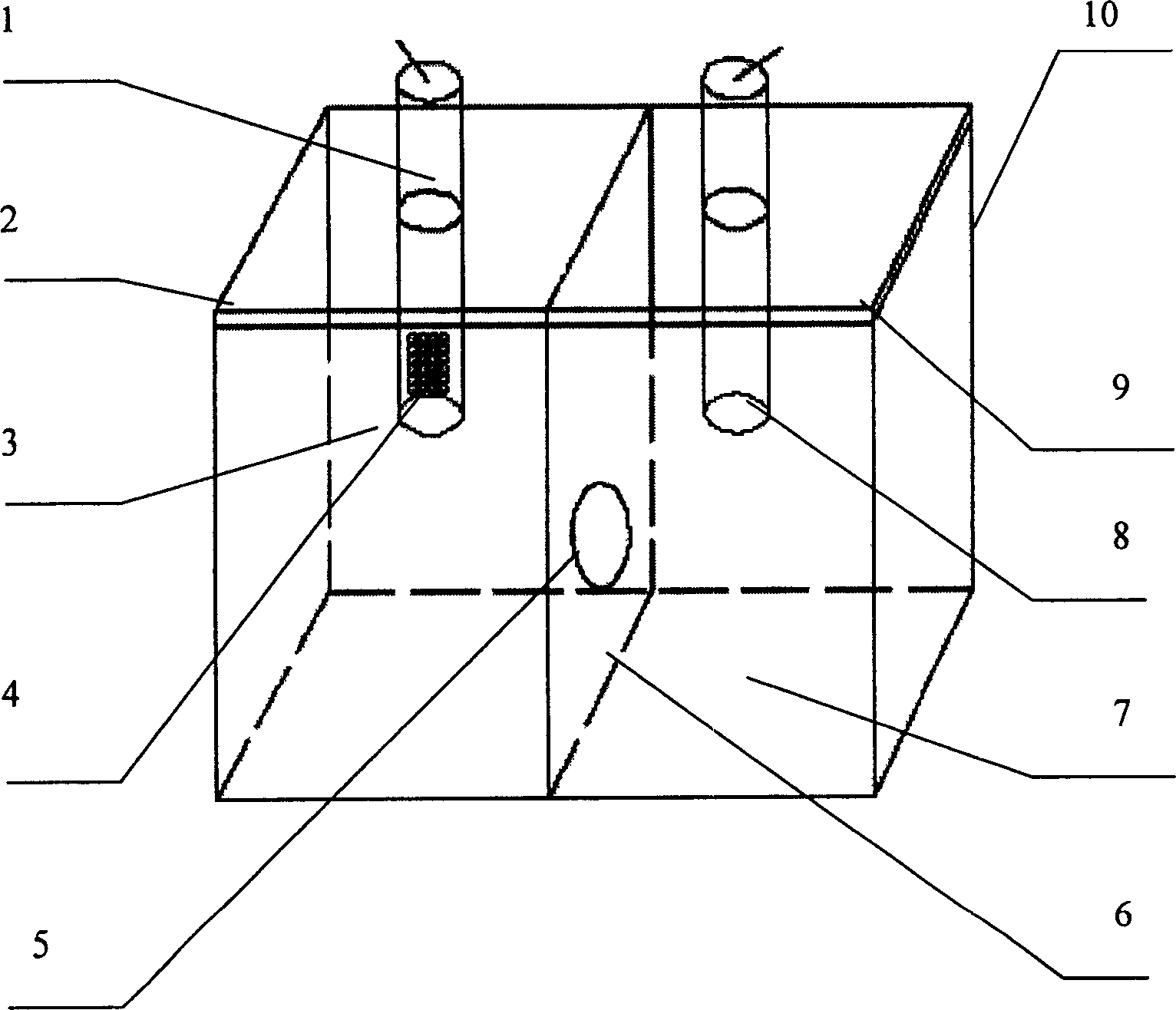

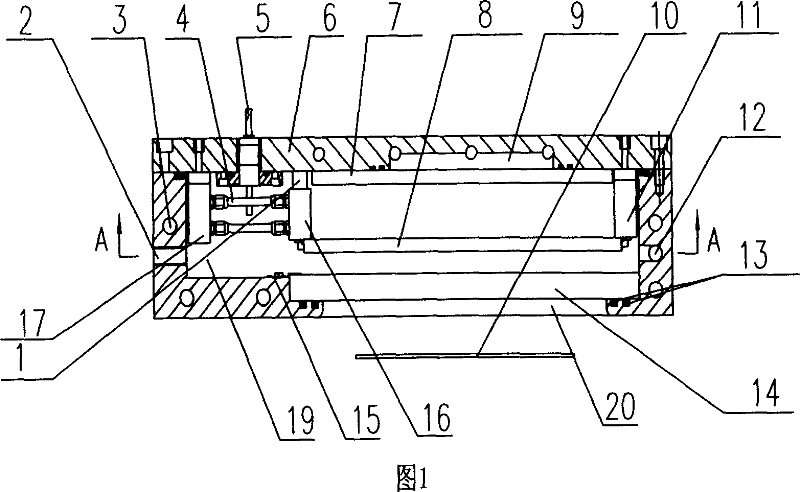

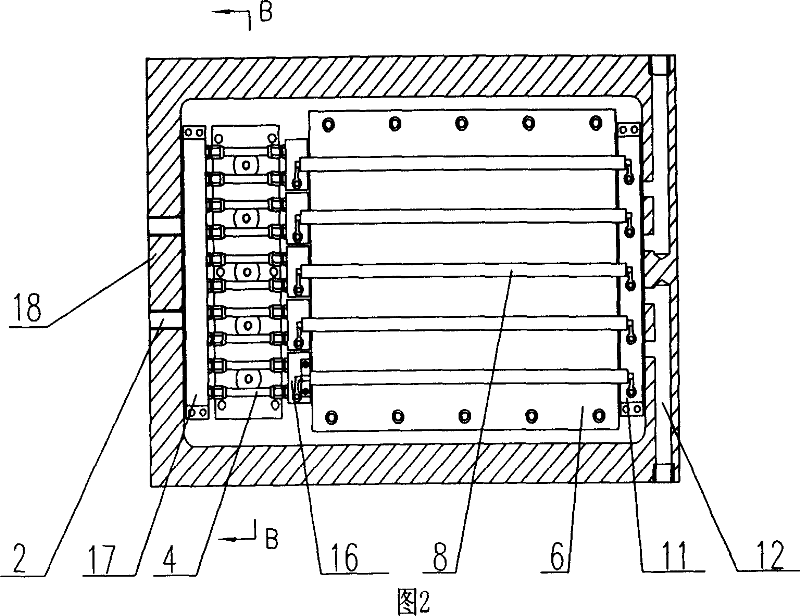

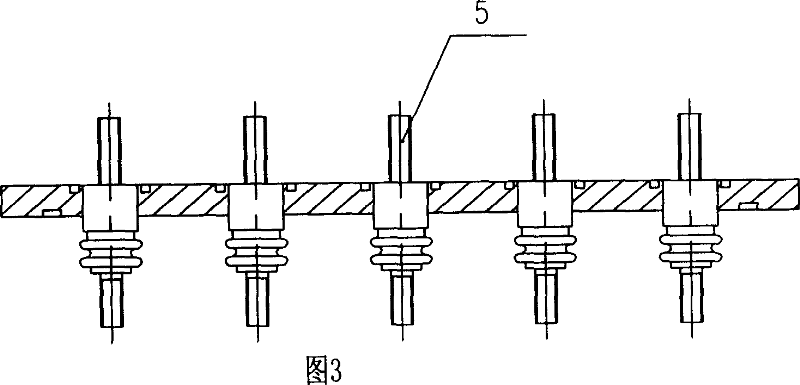

Microbial fuel cell

InactiveCN1588683AGuaranteed survivalNon-pollutingBiochemical fuel cellsPotassium ferricyanideEngineering

The invention microbe fuel cell consists of box, separating plate dividing the box to positive pole cavity and negative pole cavity, there is a hole on the separating plate, hydrogen selecting film is fit on the hole. In positive pole cavity, there is solution compounded by amylaceum, sodium dithydrogen phosphate and methylene blue, a sealine lid is covered on the positive pole cavity, a positive pole graphite rod is fit on the sealing lid, one end of the positive pole grahpite rod with honeycomb small holes rod is soaked in the solution in positive pole cavity, beer saccharomycetes and the substratum are in the honeycomb small holes. In negative pole cavity, there is solution compounded by potassium ferricyanide and fumaric and ferrous, an end lid is covered on the negative pole cavity, a negative pole graphite rod is fit on the end lid, one end of the negative pole graphite rod is soaked in the solution in negative pole cavity.

Owner:ZHEJIANG UNIV

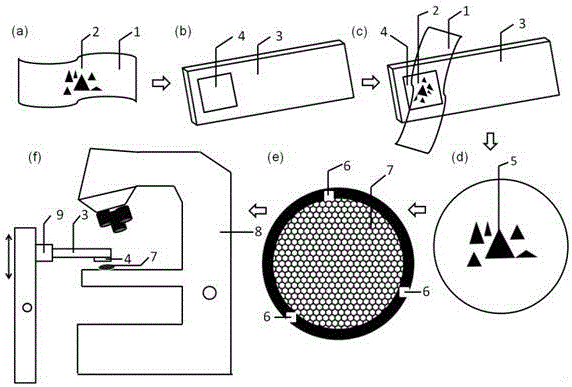

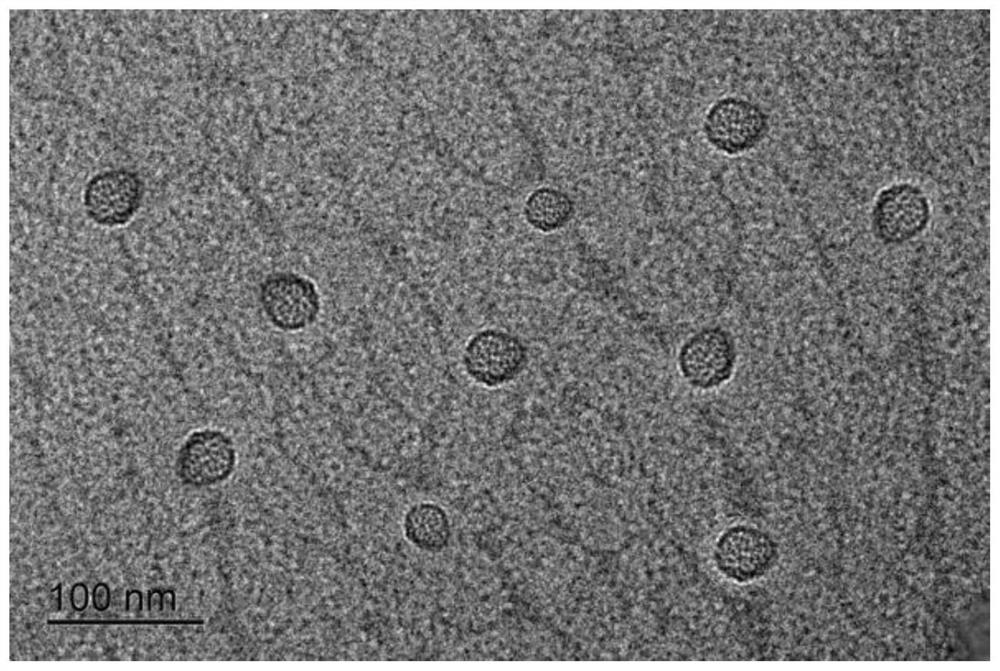

Dry method for preparing TEM (Transmission Electron Microscope) sample of two-dimensional material

ActiveCN106769326AGet efficientlyEasy to operatePreparing sample for investigationMicroscope slideElectron microscope

The invention discloses a dry method for preparing a TEM sample of a two-dimensional material. The method comprises the following steps: peeling a two-dimensional material sheet from the surface of the two-dimensional material by an adhesive tape, repeatedly adhering and separating until the sheet presents a dense sample area, and adhering a glass slide and PDMS (Polydimethylsiloxane) gel tablet, so that the PDMS gel surface is adhered to the adhesive tape dense sample surface, and the adhesive tape is peeled; and taking a micro grid, and transferring the sample on the PDMS gel tablet onto the micro grid under an optical microscope, thereby obtaining the TEM sample of the two-dimensional material. According to the method disclosed by the invention, any pollutant is not introduced in the operating process, the topographic characteristics and structural properties of the two-dimensional material are not damaged, and the method has the characteristics of flexibility, simple operation and capacity of efficiently obtaining the TEM sample of the sheet two-dimensional material.

Owner:EAST CHINA NORMAL UNIV

Laser cladding printer and manufacturing method of circuit board

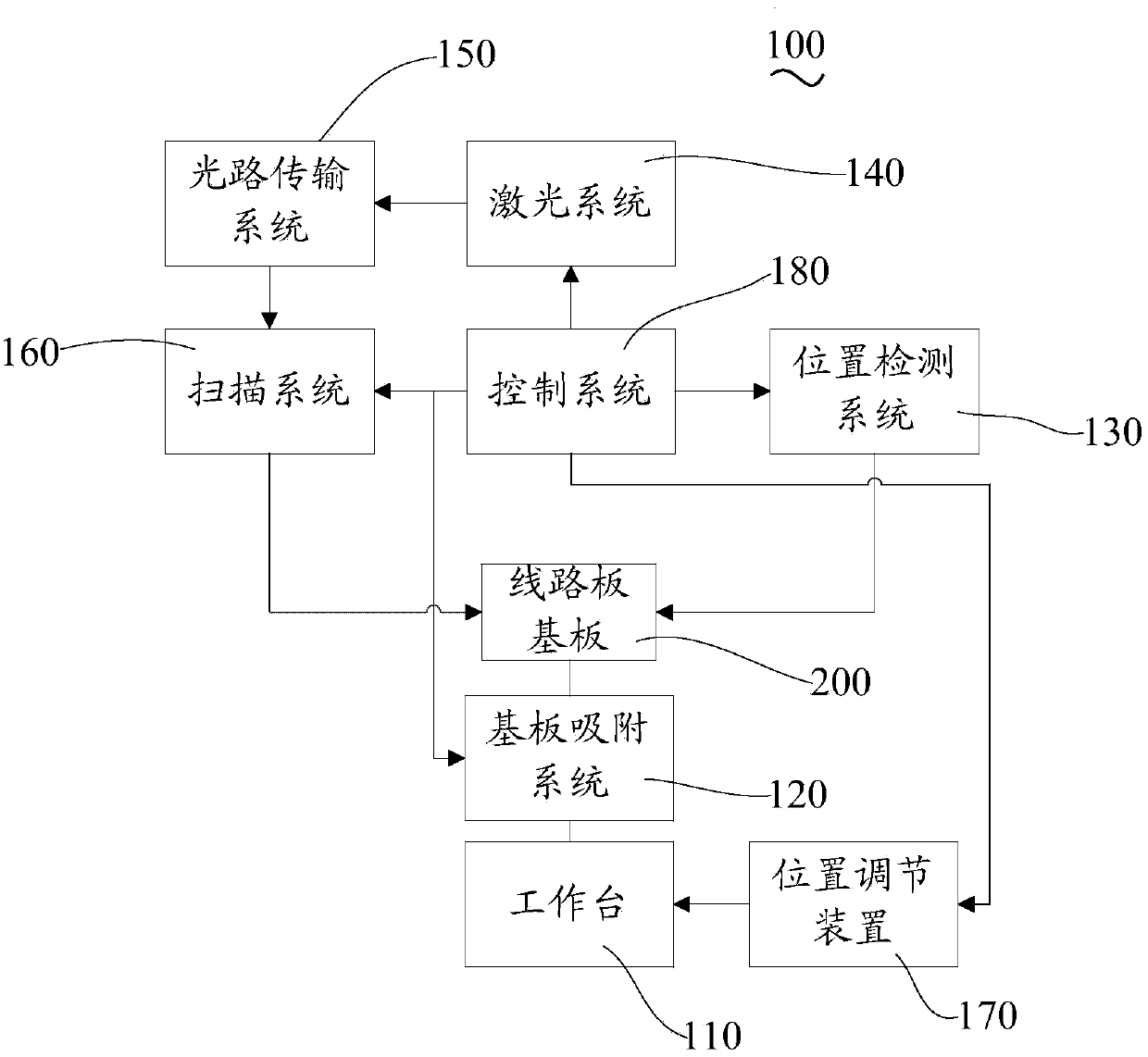

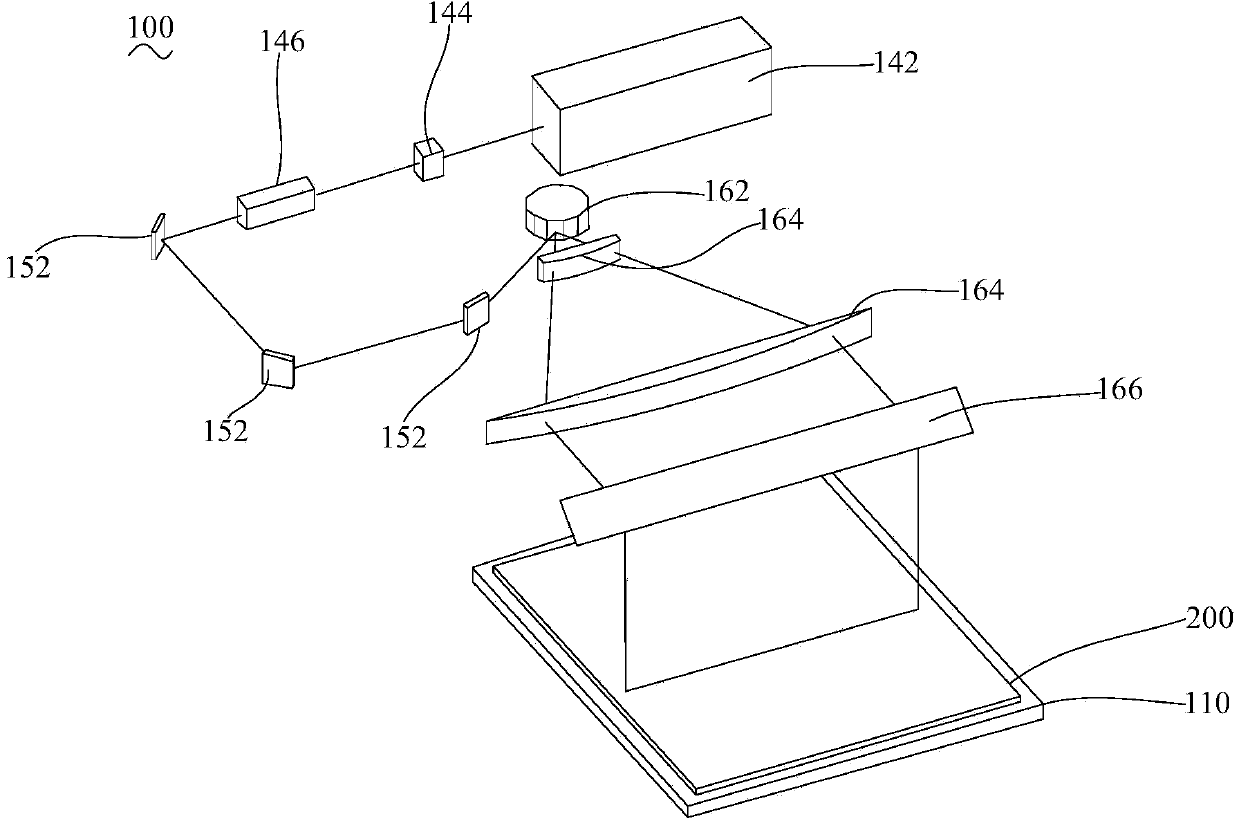

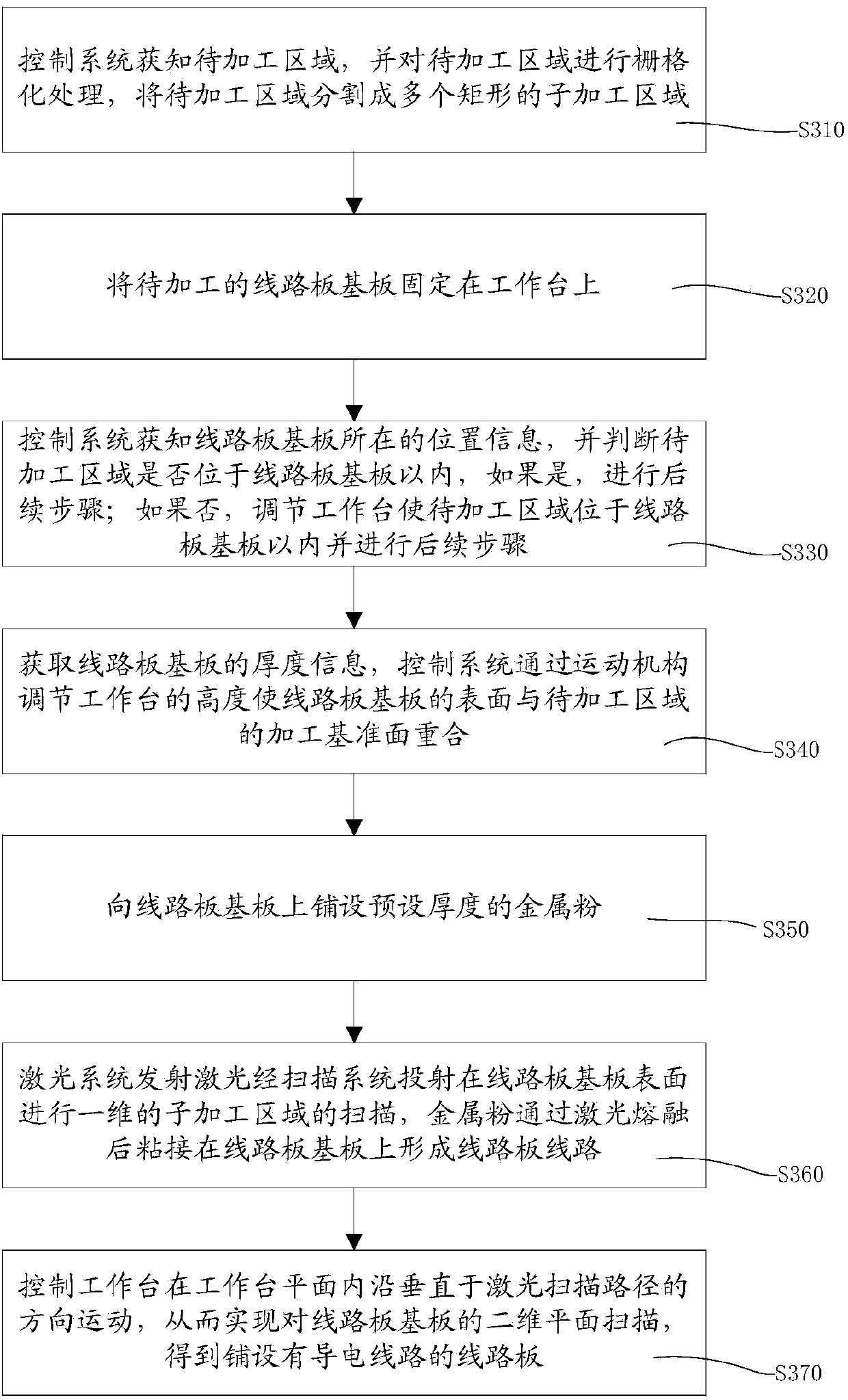

ActiveCN103433619AEasy to makeLow costConductive pattern formationLaser beam welding apparatusControl systemEngineering

The invention relates to a laser cladding printer. The laser cladding printer comprises a worktable, a position detection system, a laser system, a scanning system, a position regulation device and a control system. According to the laser cladding printer, manufacturing procedures of existing partial circuit boards can be replaced, an effect for directly manufacturing circuits of the circuit board through printing the circuit board on high-temperature-resistant substrates such as ceramics, high polymer materials and the like is achieved, the manufacturing process of the circuit board is simple and pollution-free and is low in cost. Besides, the invention further relates to a manufacturing method of the circuit board by utilizing the laser cladding printer.

Owner:HANS CNC SCI & TECH

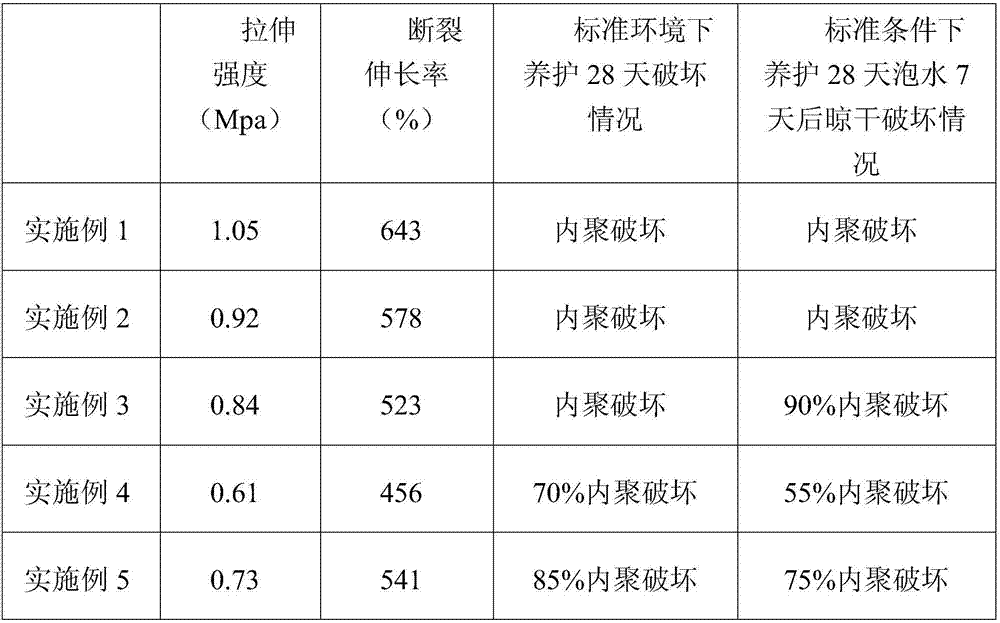

Patching material for building tear and construction process thereof

InactiveCN101402518AImprove adhesionStrong stress resistanceSolid waste managementBuilding repairsWater immersionShock resistance

The invention discloses a patching material for processing building cracks, which is prepared from powders of group A, liquid materials of group B through mixing, wherein the weight proportion of the powders of the group A to the liquid materials of the group B is between 0.8 and 2 to 1. The content range of each composition of the powders of the group A is as follows: 30 to 80 percent of 425 Portland cement, 10 to 50 percent of quartz powders, 5 to 30 percent of nano-size calcium carbonate, 1 to 5 percent of polypropylene short fiber, 1 to 10 percent of wood fiber, 1 to 10 percent of methyl cellulose, and 1 to 10 percent of calcium formate; and the content range of each composition of the liquid materials of the group B is as follows: 10 to 80 percent of pure acrylic resin copolymer emulsion, 0.1 to 1 percent of defoamer, 1 to 11 percent of bactericidal preservative, 1 to 12 percent of alkaline swelling thickener, 0.5 to 12 percent of pH modifier, 5 to 20 percent of talc powders, and 10 to 40 percent of water. The construction process of the patching material is performed according to the following steps: base course processing, patching material scraping, and surface layer brushing. A product of the patching material has the advantages of strong cohesive force, high mechanical strength, impact resistance, shock resistance, insolation resistance, water immersion resistance, chemical corrosion resistance, no pollution, excellent physical and chemical properties of the product, strong stress resistance, and certain waterproof effect.

Owner:MAANSHAN TIANJINYUN PAINT IND

Nano cellulose glass fiber composite filter material as well as preparation method and application thereof

InactiveCN111467875AHigh precisionImprove breathabilitySynthetic cellulose/non-cellulose material pulp/paperMembrane filtersGlass fiberPlant fibre

The invention belongs to the field of filtration, and particularly relates to a nano cellulose glass fiber composite filter material and a preparation method and application thereof. The method comprises the following steps: (1) defibering fibrillable plant fibers by a defibering machine, and dispersing in water to obtain slurry; (2) performing treatment by a physical or chemical method to obtainnanocellulose, and washing and ultrasonically treating to obtain a nanocellulose solution; (3) adding water and a dispersing agent into the glass fiber raw material, uniformly dispersing to obtain slurry, and sequentially deslagging, diluting, forming and dehydrating to form wet paper sheets with uniform thickness; (4) coating the surface of glass fiber paper with the nano-cellulose solution in acoating manner to form a nano-fiber coating; (5) drying and forming. The nano cellulose solution prepared from the plant fibers is compounded with the glass fiber base material in a coating manner, sothat the obtained fiber material has the advantages of high precision, high air permeability, low resistance, long service lifetime and the like, and is particularly suitable for the field of filtering of air, water and the like.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

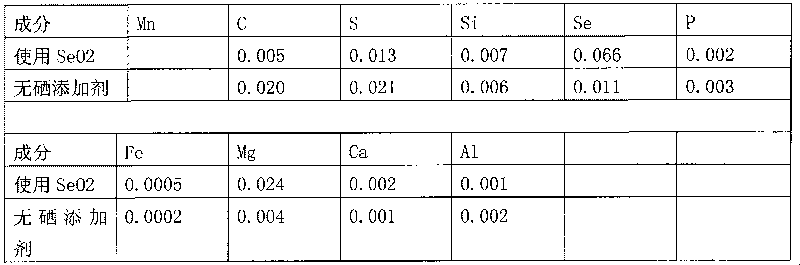

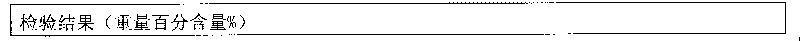

Organic additive for production of electrolytic manganese and preparation method thereof

ActiveCN101717957ANon-pollutingNot corrosivePhotography auxillary processesOrganic sulfide compoundManganese

The invention relates to an electrolytic additive free of selenium dioxide for production of electrolytic manganese and a preparation method thereof. The organic additive for production of the electrolytic manganese is characterized by being prepared from the following raw materials in percent by weight: 2-5% of organic sulfide, 6-10% of surfactant, 15-20% of polyethylene glycol and 65-77% of water, wherein the sum of the weight percent of the raw materials is 100%. The organic additive of the invention can be used for replacing the traditional selenium dioxide for the production of the electrolytic manganese, has the characteristics of environmental protection, no toxicity, simple processes and the like, and has higher electrolytic efficiency, low content of selenium impurities in products and high product quality.

Owner:WUHAN SUNEN TECH

Method for preparing 5-hydroxymethylfurfural from acidic iron liquids

InactiveCN102199136AIncrease polarityImprove stabilityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsDistillationReaction temperature

The invention discloses a method for preparing 5-hydroxymethylfurfural from acidic iron liquids. The 5-hydroxymethylfurfural is prepared by catalyzing fructose by directly taking the acidic iron liquids, i.e., [BMim]TS and [BPy]TSO, as a solvent and a catalyst. When a reaction is carried out at the temperature of 80 DEG C and the speed of 150r / min for 30min, the conversion rate of the fructose can reach 100%, and the yield of the 5-hydroxymethylfurfural can reach 94.5%. The acidic iron liquids not only can dissolve the fructose and the 5-hydroxymethylfurfural under the action of static electricity, but also can generate hydrogen ions to be in bronsted acidity and can form a hydrogen bond with the fructose to activate a reaction bond, thereby lowering the reaction temperature and shortening the reaction time. The separation of the 5-hydroxymethylfurfural from an ionic liquid can be realized in a way of organic solvent extraction or distillation, the ionic liquid can be recovered, a volatile organic solvent is avoided being used in the reaction process and during later separation, and the pollution to the environment is reduced.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

Organic additive for electrolytic manganese production and preparation method thereof

The invention relates to an organic additive without selenium dioxide for electrolytic manganese production and a preparation method thereof. The organic additive for electrolytic manganese production is characterized by being prepared from the following raw materials by the weight percentage: 1%-2% of polyacrylamide, 2%-5% of acetate, 5%-13% of auxiliary agent and 80%-92% of water, and the sum of the weight percentage of each raw material is 100%. The organic additive does not contain selenium dioxide, can replace the existing selenium dioxide to be used for electrolytic manganese production, and has the advantages of environment protection, no poison, simple technology and the like. By using the additive, the electrolytic efficiency is high. The content of selenium impurities in the product is low, and the product quality is high.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

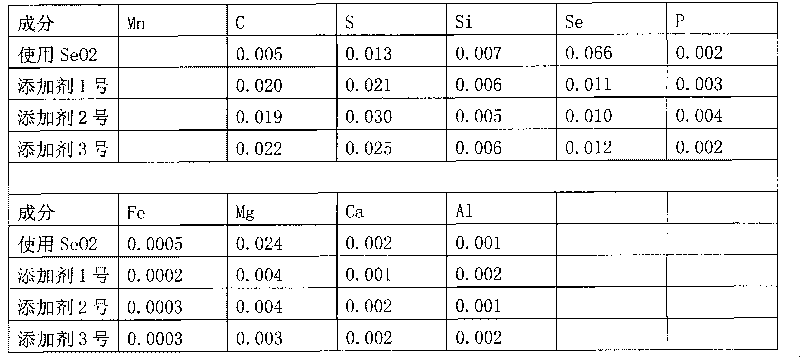

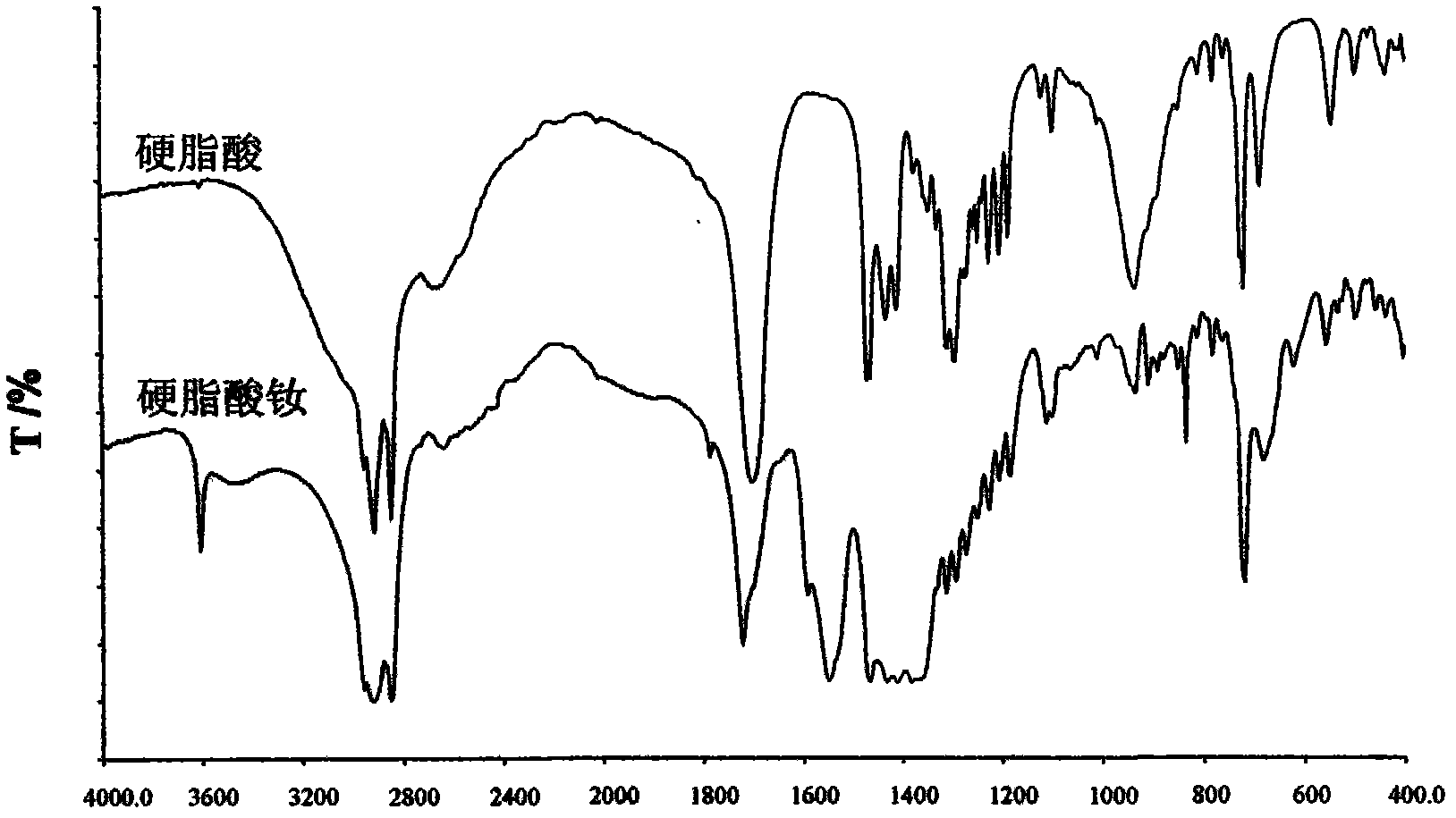

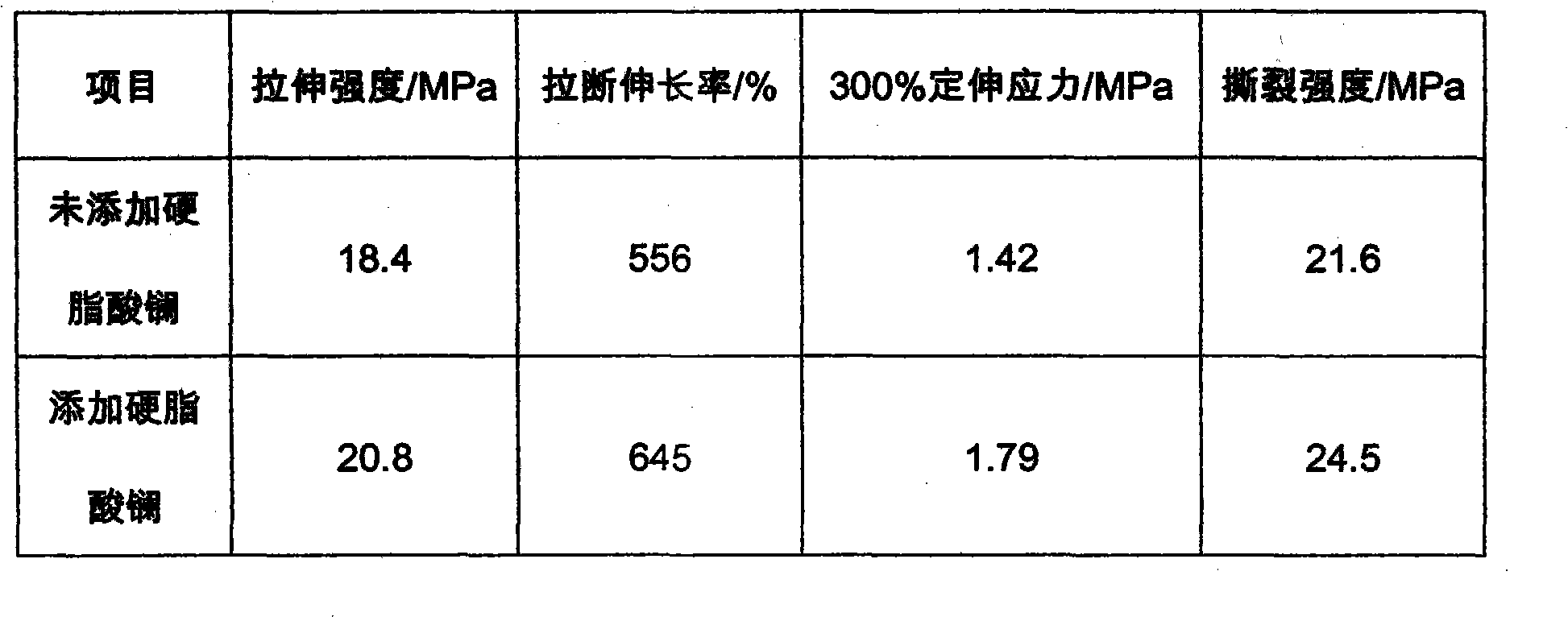

Method for improving aging performance of epoxidized natural rubber

The invention discloses a method for improving aging performance of epoxidized natural rubber. The method comprises adding 0.5-6 parts of rare earth stearate to a complexing system of epoxidized natural rubber, wherein rare earth ion with special electron structure in the rare earth stearate can maintain epoxy group stable in the aging process of the epoxidized natural rubber, reduce ring openingof the epoxy group and catch free radicals generated in the aging process of the epoxidized natural rubber, thus the aging resisting performance of the epoxidized natural rubber is improved. The method has the advantages that used rare earth stearate has no toxicity or pollution and simple preparation method, the cost is low, and mass production can be realized easily.

Owner:ZHANJIANG KANGNIAN RUBBER PROD CO LTD

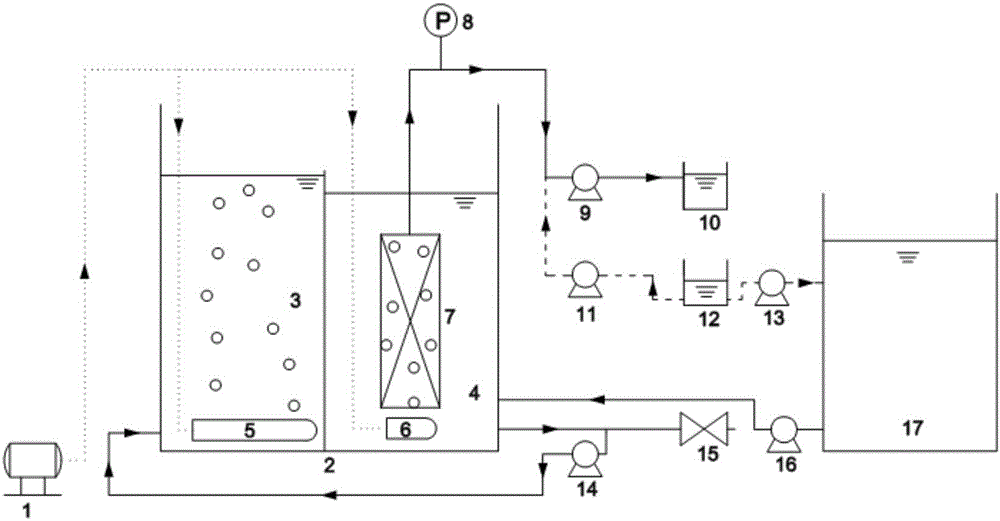

Ceramic membrane chemical cleaning system and method

InactiveCN106542631AEasy to cleanImprove oxidation efficiencySemi-permeable membranesSpecific water treatment objectivesWater treatment systemCeramic membrane

The invention relates to a ceramic membrane chemical cleaning system and method which are used for cleaning a ceramic membrane in a water treatment system. The chemical cleaning system comprises an online cleaning part, wherein the online cleaning part comprises a dosing pump and a sucking pump; the dosing pump is coupled onto the ceramic membrane arranged in a membrane pool by virtue of a pipeline, so as to inject a cleaning liquid into the ceramic membrane; the sucking pump is coupled onto the ceramic membrane by virtue of a pipeline, so as to discharge water from a back absorption membrane of the ceramic membrane; and the cleaning liquid on the ceramic membrane is discharged into the membrane pool in a sucking process. The system and method which are provided by the invention can be used for solving the problems of pollution of the ceramic membrane in a water treatment process, production of secondary pollutants by the cleaning liquid in a membrane cleaning process, secondary treatment of the membrane cleaning liquid, and the like.

Owner:深圳市康源环境纳米科技有限公司 +1

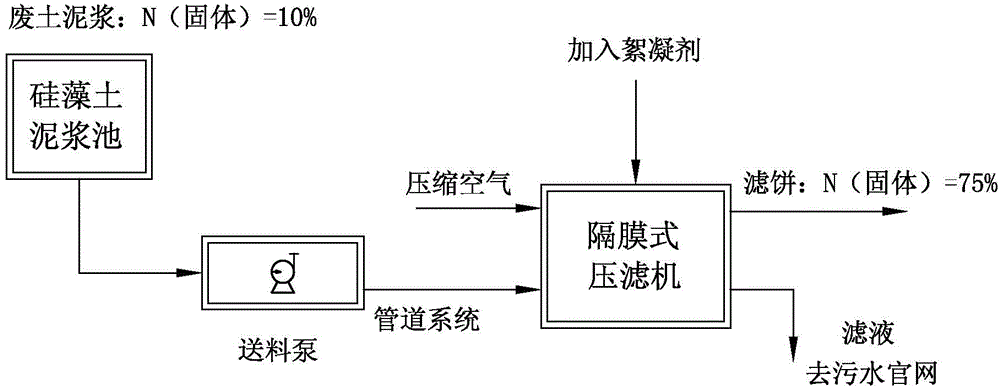

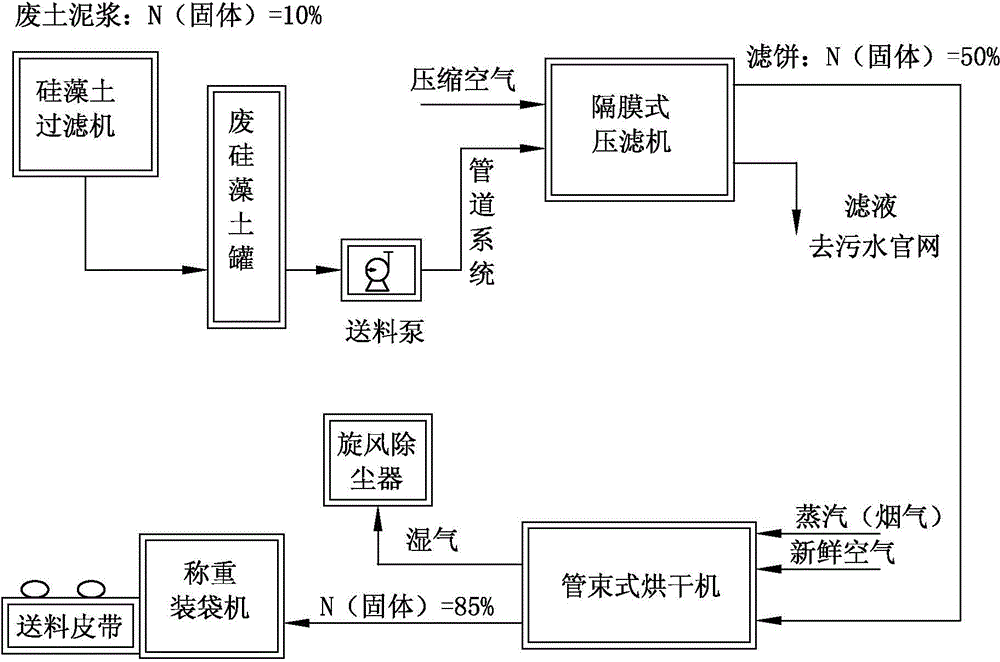

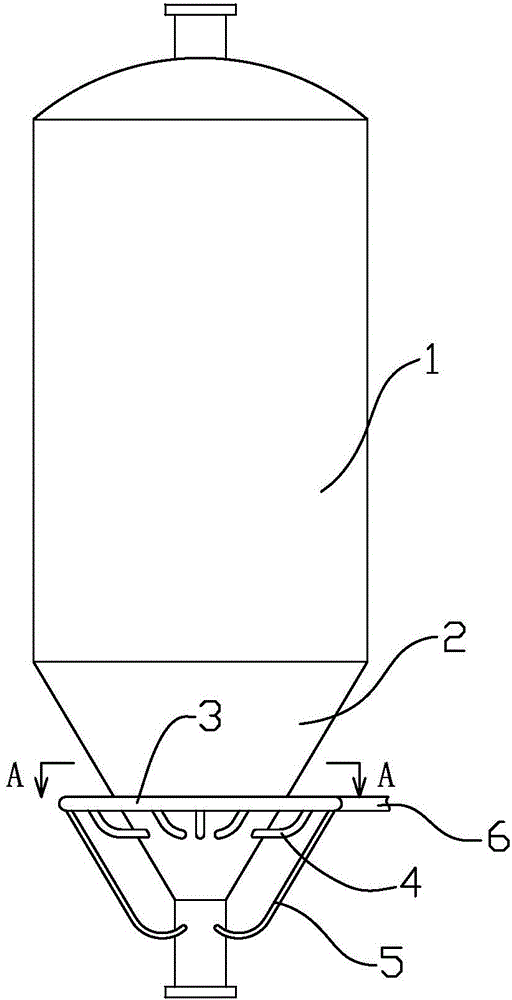

Waste diatomite processing system and waste diatomite processing technique

InactiveCN104824380AReduce moisture contentReduce power consumptionSolid waste disposalAnimal feeding stuffSewageHandling system

The invention discloses a waste diatomite processing system and a waste diatomite processing technique. The waste diatomite processing system comprises a diatomite temporary storage device and dewatering equipment, wherein a feeding pump is arranged on a pipeline system between the diatomite temporary storage device and the dewatering equipment, a discharge hole and a liquid outlet are formed on the dewatering equipment, the liquid outlet is connected with a sewage pipe network, the discharge hole of the dewatering equipment is connected with drying equipment by a belt conveyer, a wet gas outlet of the drying equipment is connected with a dust collection device, the discharge hole of the drying equipment is connected with packaging equipment by a screw conveyer, and the packaging equipment is provided with a finished product conveying device. The waste diatomite processing technique sequentially comprises the steps of conveying, storing temporarily, dewatering, drying, packaging and the like. According to the waste diatomite processing system and the waste diatomite processing technique, the investment is low, the energy consumption is low, the effect is rapid, the pollution problem of waste diatomite is solved and waste reutilization can be realized.

Owner:QILU UNIV OF TECH

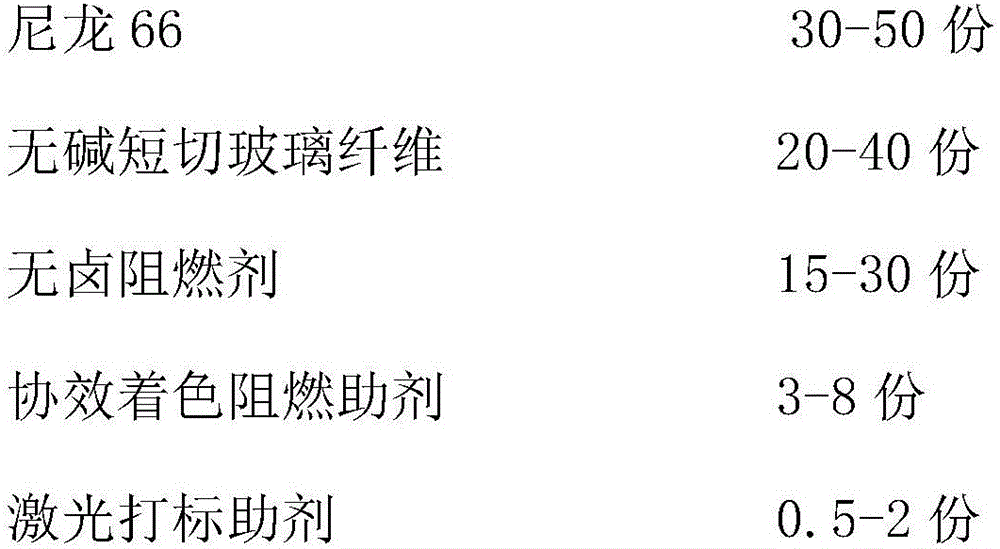

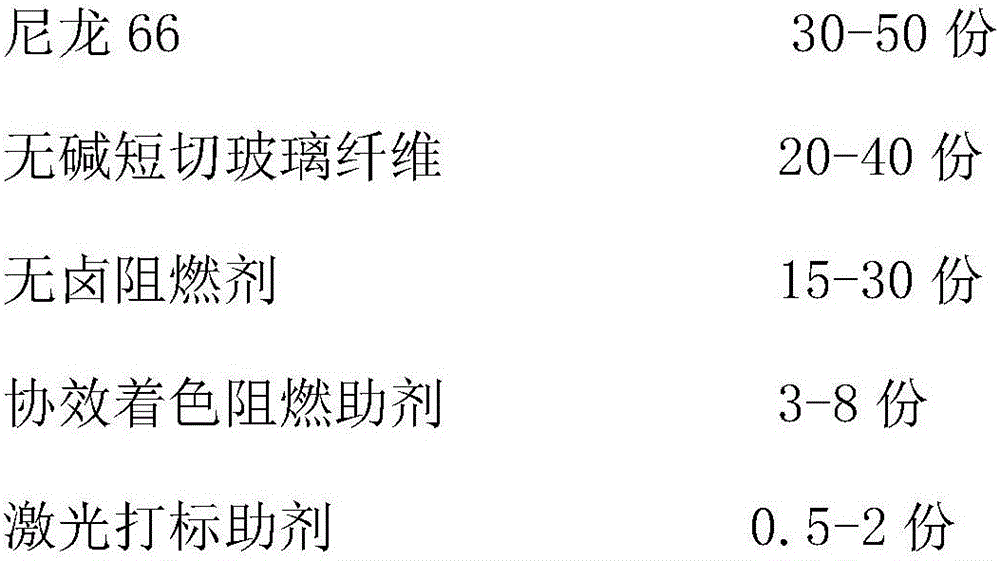

Glass fiber reinforced environment-friendly nylon composite material and preparation method thereof

Belonging to the technical field of modified polyamide, the invention relates to a glass fiber reinforced, easy dyeing, laser marking, halogen-free, environment-friendly and flame retardant nylon 66 composite material and a preparation method thereof. The composite material comprises the following raw materials by weight: 30-50 parts of nylon 66, 20-40 parts of alkali-free short glass fiber, 15-30 parts of a halogen-free flame retardant, 3-8 parts of a synergistic coloring flame-retardant additive, 0.5-2 parts of a laser marking additive, and 0.5-1.5 parts of other additives, i.e. a compound of a silane coupling agent, an antioxidant and a dispersant. The composite material is mainly used in bearing covers, electrical junction boxes, row plug-in pieces and the like in automobiles, machinery, electrical and electronic appliances and other industries, and can be applied to components and parts with high requirements for environmental protection and safety, flame retardance, laser marking, intensity and color.

Owner:NANJING JULONG SCI&TECH CO LTD

Enclosed infrared heating device for semiconductor chip

InactiveCN101038856ANon-pollutingSemiconductor/solid-state device manufacturingOhmic-resistance heatingWater channelSemiconductor chip

The invention provides a closed infrared heater for semiconductor wafer, which includes an infrared generating chamber disposed at the inner of a shell having seal cover, a transmission window seal by transmission glass is arranged on one side of the shell, wherein, the two ends of the chamber respectively has lamp holders for mounting at least two lamps, and a reflection plate is disposed on one side of the lamps, and each lamp holder is mounted on the cover plate by insulation pillars and is connected to the power supply base, sub water inlets and sub water back ports arranged at the two ends of cooling water channel of each lamp holder are respectively connected to corresponding water back ports and water inlets of the water diversion bus, cooling water channel of the water diversion bus is connected to the same of the cover plate, and some cooling water channels of the shell are connected to the same of the cover plate, and air inlets and air outlets are respectively arranged on both sides of the shell. The invention is fit for radiation heating the movable wafer or fixed wafer of the semiconductor device, and has no pollution, can work in vacuum condition, and is fit for heating material such as silicon wafer which requires high cleanliness.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

High-temperature-resistant organic/inorganic hybrid polymer filtrate reducer and preparation method thereof

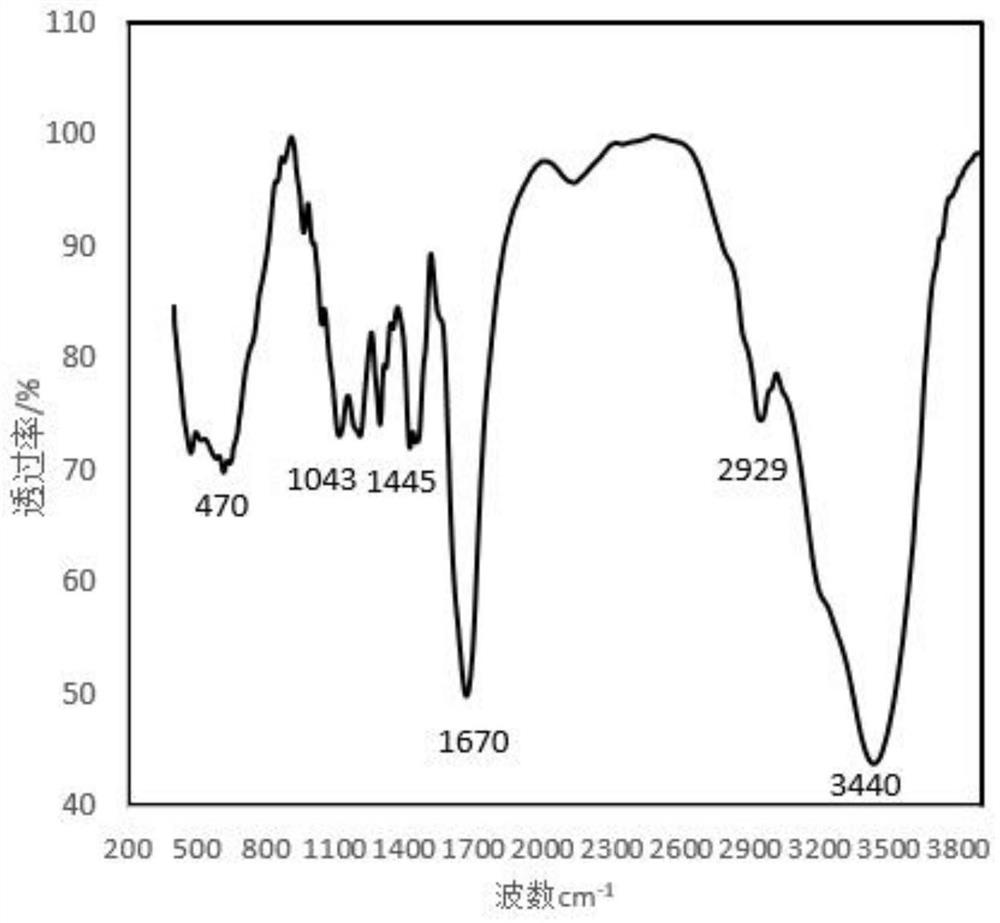

PendingCN112457454AEasy to prepareNon pollutingDrilling compositionPyrrolidinonesUltrasonic dispersion

The invention discloses a water-based drilling fluid high-temperature-resistant organic / inorganic hybrid polymer filtrate reducer and a preparation method thereof. The preparation method comprises thefolloiwng steps: uniformly mixing three organic monomers including acrylamide, dimethyl diallyl ammonium chloride and N-vinyl pyrrolidone in proportion, adjusting the pH value to 9, transferring themixture into a three-neck flask, adding inorganic monomer modified nano silicon dioxide while introducing nitrogen, performing ultrasonic dispersion for 25 minutes by an ultrasonic dispersion instrument, transferring the mixture into the three-neck flask, heating to 70 DEG C, adding an initiator, reacting for 7 hours under stirring to obtain milk white viscous liquid, cooling, drying, grinding andcrushing to obtain the organic / inorganic hybrid quaternary graft copolymer. In the invention, the four reaction monomers do not contain sulfonation groups, and the filtrate loss reduction effect of the four reaction monomers at 150-210 DEG C is better than that of a common sulfonation type high-temperature-resistant filtrate loss reducer for an oil field, so that the filtrate loss reducer is environment-friendly and has good filtrate loss reduction property, and the temperature resistance can reach 210 DEG C.

Owner:SOUTHWEST PETROLEUM UNIV

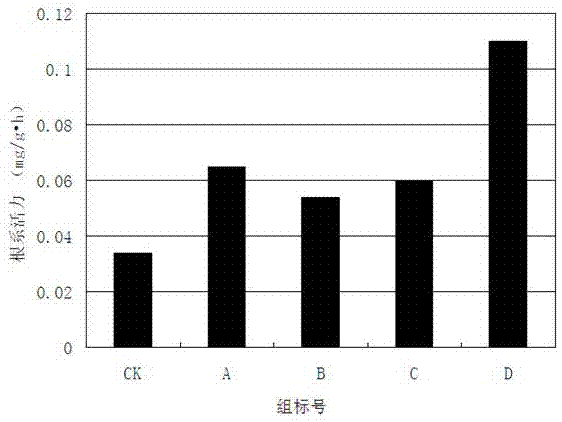

Method and reagent set for preventing citrusyellowshoot

The invention provides a method and a reagent set for preventing citrusyellowshoot, and belongs to the field of agricultural plant cultivation. The technical scheme is that the method for preventing citrusyellowshoot comprises the following steps: A, applying quick lime to soil of a citrus orchard according to usage amount of 50-150 kg / mu; B, applying organic fertilizer containing microorganism bacteria to the soil of the citrus orchard according to usage amount of 100-250 kg / mu; C, every 30-40 days, spraying a plant immunity inducer on citrus plants or irrigating the plant immunity inducer on roots, usage dosage being 100-150 g / mu, and continuously using 3-5 times. The quick lime is used to adjust soil acidity, and an organic biological bacterial fertilizer is used in a cooperated manner, to improve soil structure and quality. The biological bacteria is cooperated with the plant immunity inducer to promote root activity of the citrus plants, improve citrus disease resistance, so as to efficiently prevent citrusyellowshoot in a green manner, and promote healthy growth of the citrus plants.

Owner:湘潭中微科生物工程有限公司

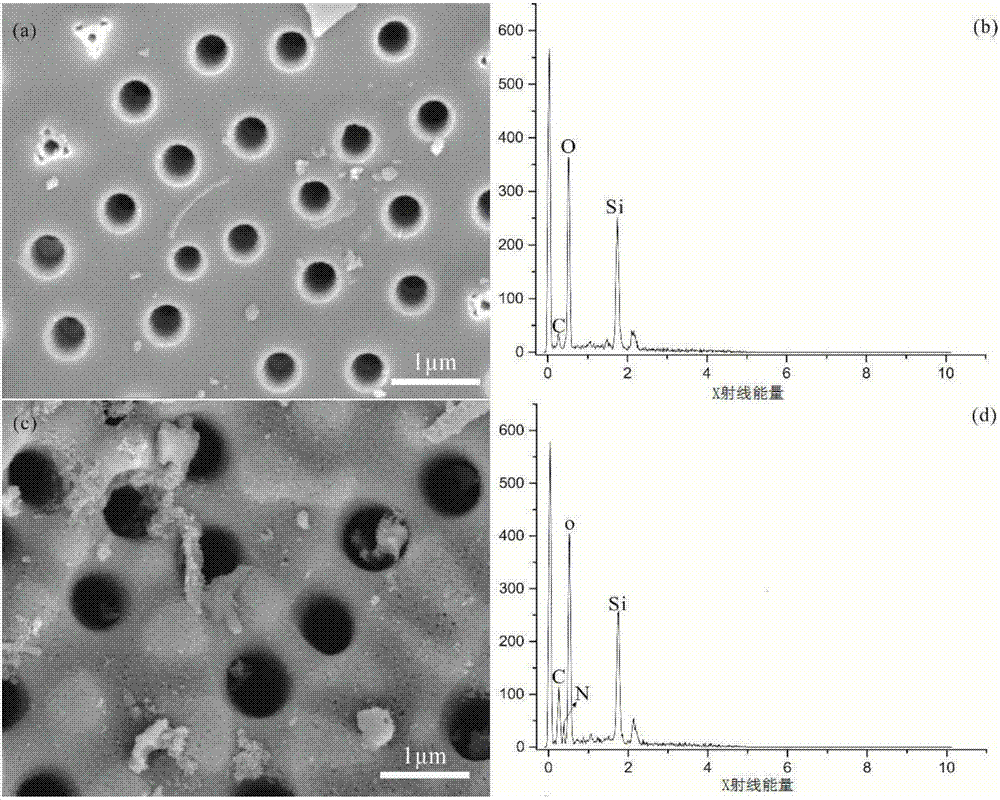

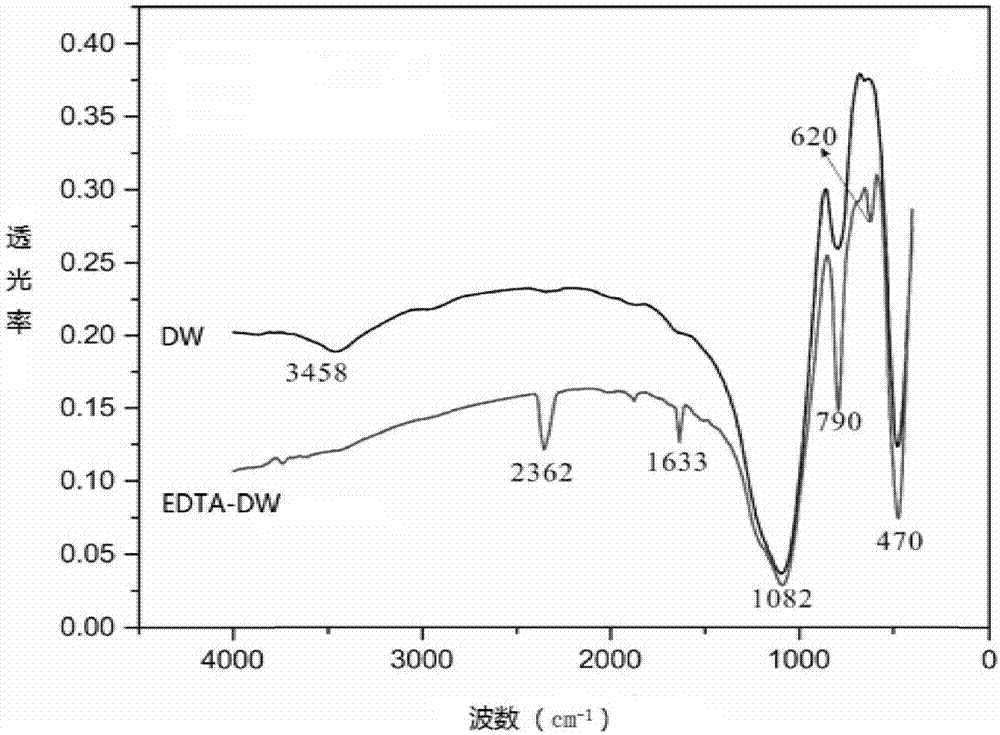

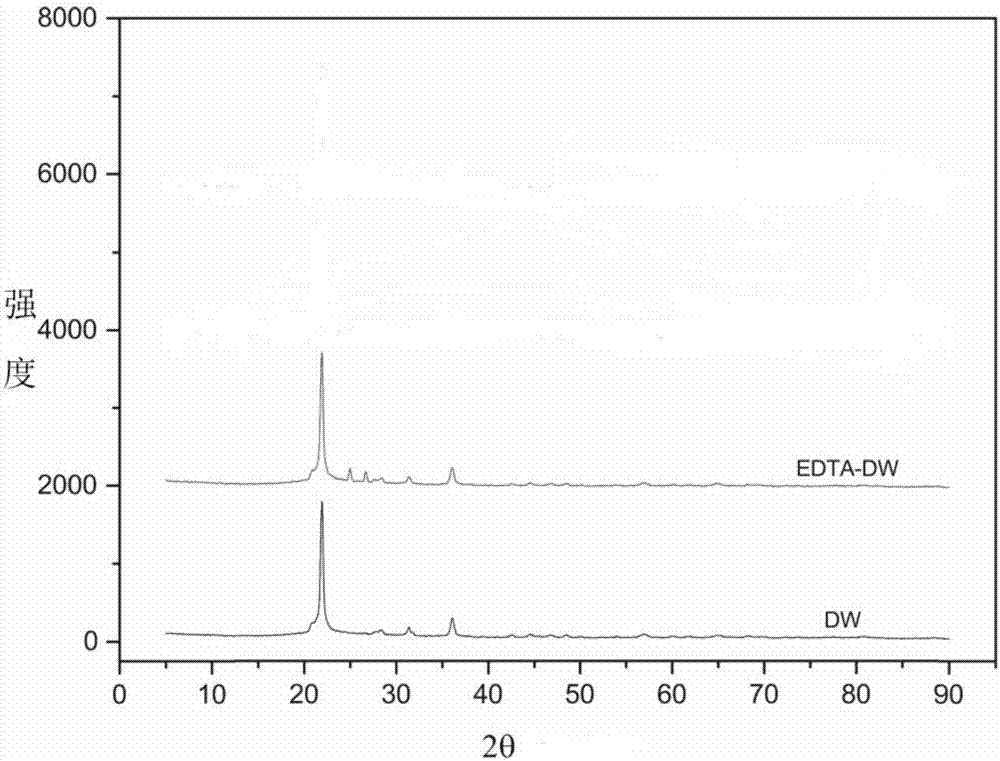

Ethylenediamine tetraacetic acid modified diatomite adsorbent as well as preparation method and application thereof to treatment of heavy metal ions in wastewater

ActiveCN107376849AHigh porosityEasy accessOther chemical processesWater contaminantsEthylenediamineSorbent

The invention discloses a preparation method of a modified diatomite adsorbent. The preparation method comprises the following steps: 1) pre-treating diatomite: immersing the diatomite into an alkali solution and an acid solution respectively and carrying out stirring treatment; then washing the diatomite with water until the diatomite is neutral, drying; 2) mixing urea, ethylenediamine tetraacetic acid and the diatomite treated by step 1) in an organic solvent; stirring at 40 DEG C to 60 DEG C for 20min to 30min; then putting an obtained mixture into a reaction kettle and carrying out heating reaction at 160 DEG C to 200 DEG C for 6h to 8h; cooling to room temperature, washing and drying. The invention further discloses the ethylenediamine tetraacetic acid modified diatomite adsorbent and application thereof to adsorption of heavy metal ions in wastewater. The ethylenediamine tetraacetic acid modified diatomite adsorbent takes waste diatomite of a beer factory as a raw material; the price is low and the raw material is convenient to obtain; a modified material has no dangers and no pollution; a whole operation process is simple and the obtained adsorbent has a strong adsorption capability and has relatively high adsorption and removal efficiency on hexavalent chromium and divalent nickel in the wastewater; no other pollutants are produced in a whole adsorption and removal process.

Owner:HOHAI UNIV

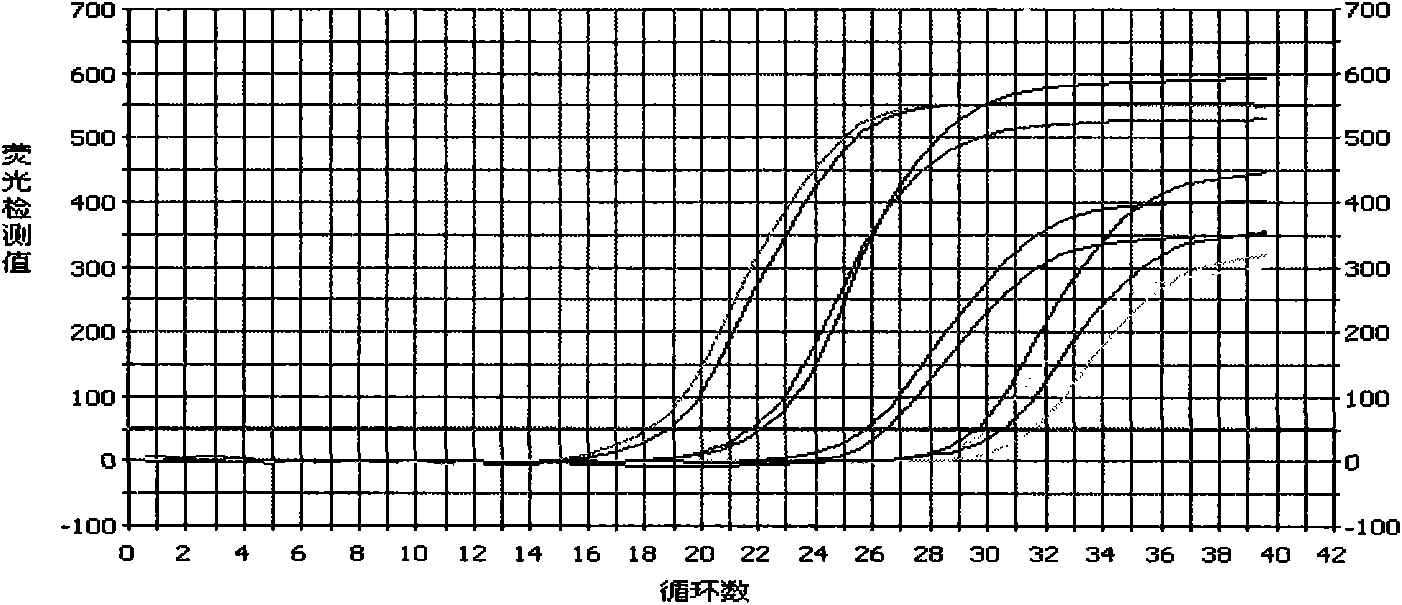

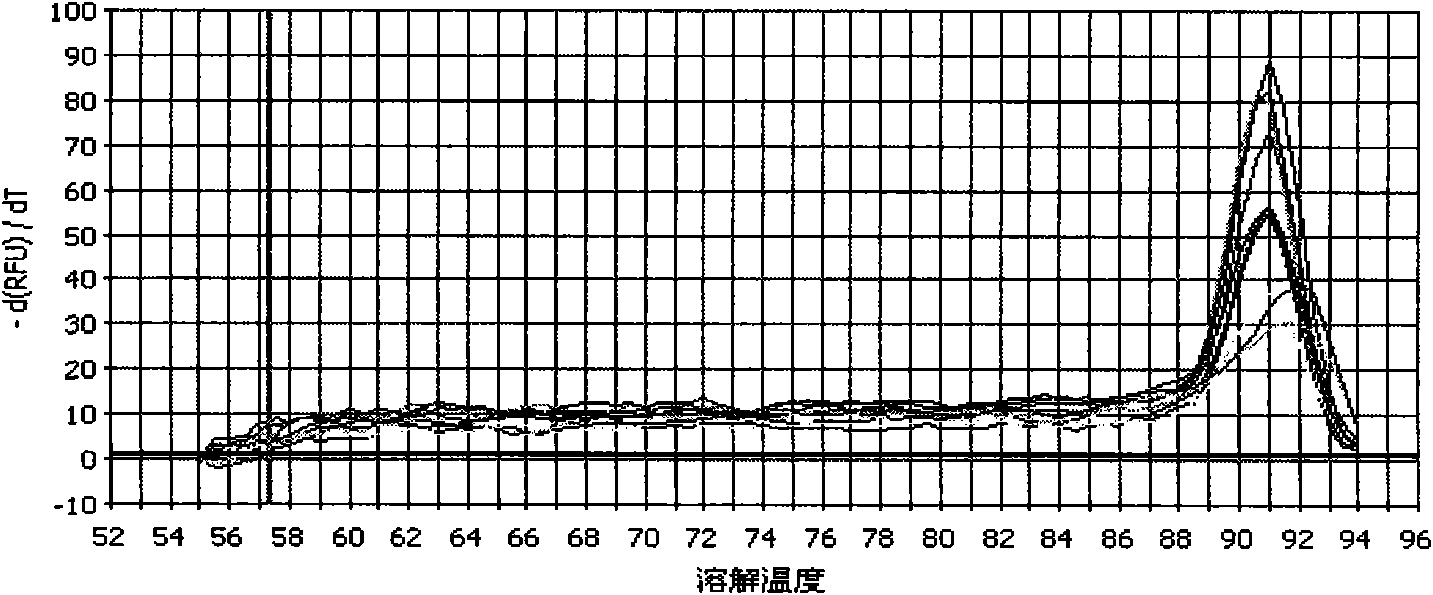

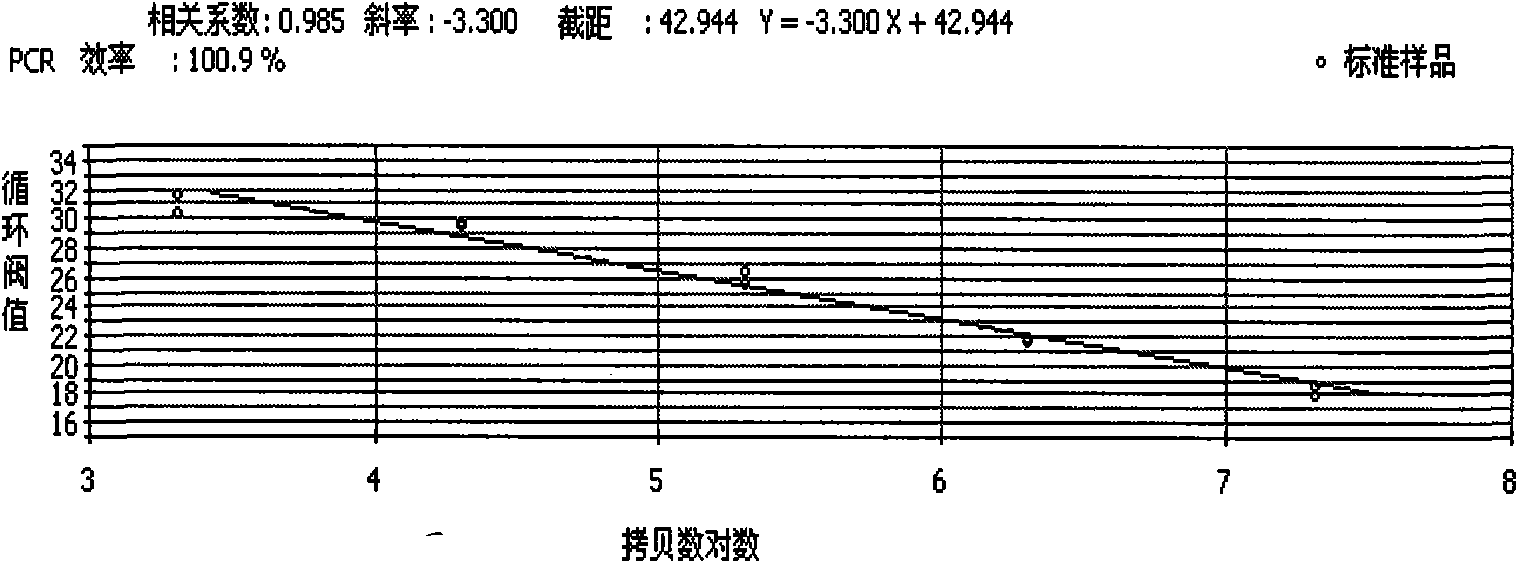

Method for counting archenteric flora of aquatic animals and special primer thereof

InactiveCN101591710AQuantitatively accurateAvoid background distractionsMicrobiological testing/measurementMicroorganism based processesEcological environmentAquatic animal

The invention discloses a method for counting archenteric flora of aquatic animals and a special primer thereof. The special primer provided by the invention is a primer pair consisting of nucleotide shown in a sequence 1 of a sequence table and nucleotide shown in a sequence 2 of the sequence table. The special primer can be applied to preparation of kit counting the archenteric flora of the aquatic animals or used for carrying out counting of the archenteric flora of the aquatic animals. The special primer and the method can avoid background interference, can make accurate quantification on the number of total flora in a complex micro-ecological environment, and has the characteristics of high sensitivity, stronger specificity and reliability, multiple reaction realization, high automation degree, non pollution, real time, accuracy and the like.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

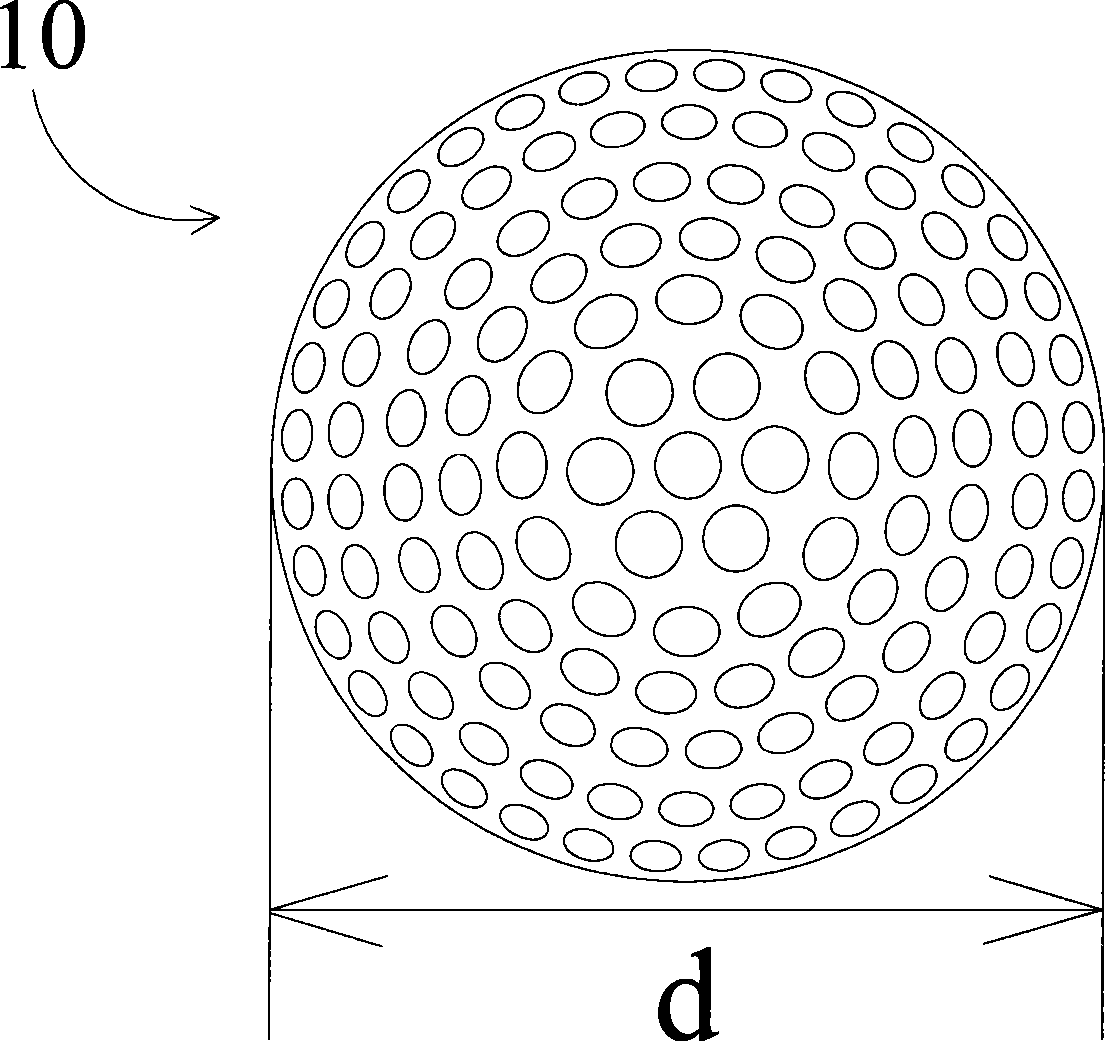

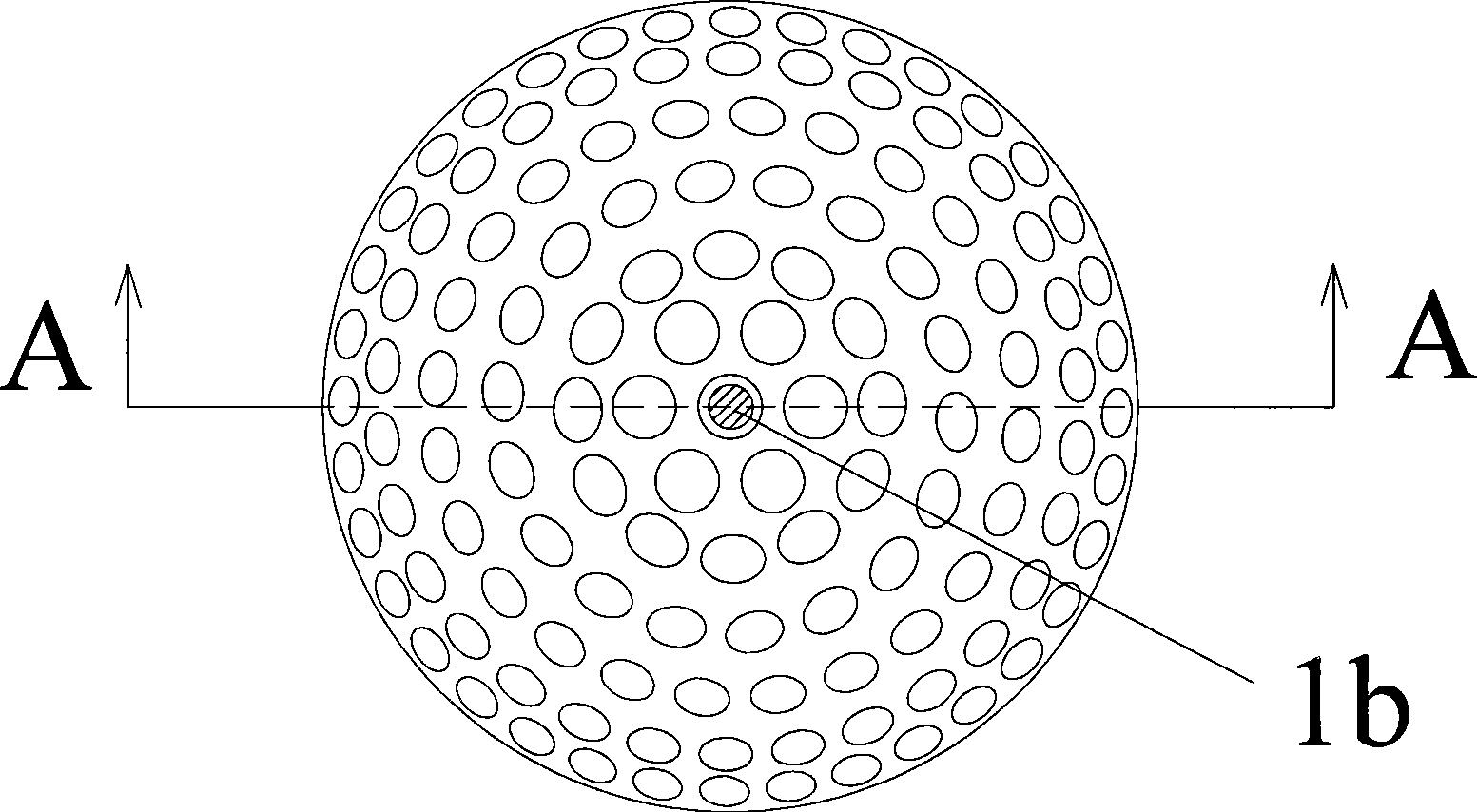

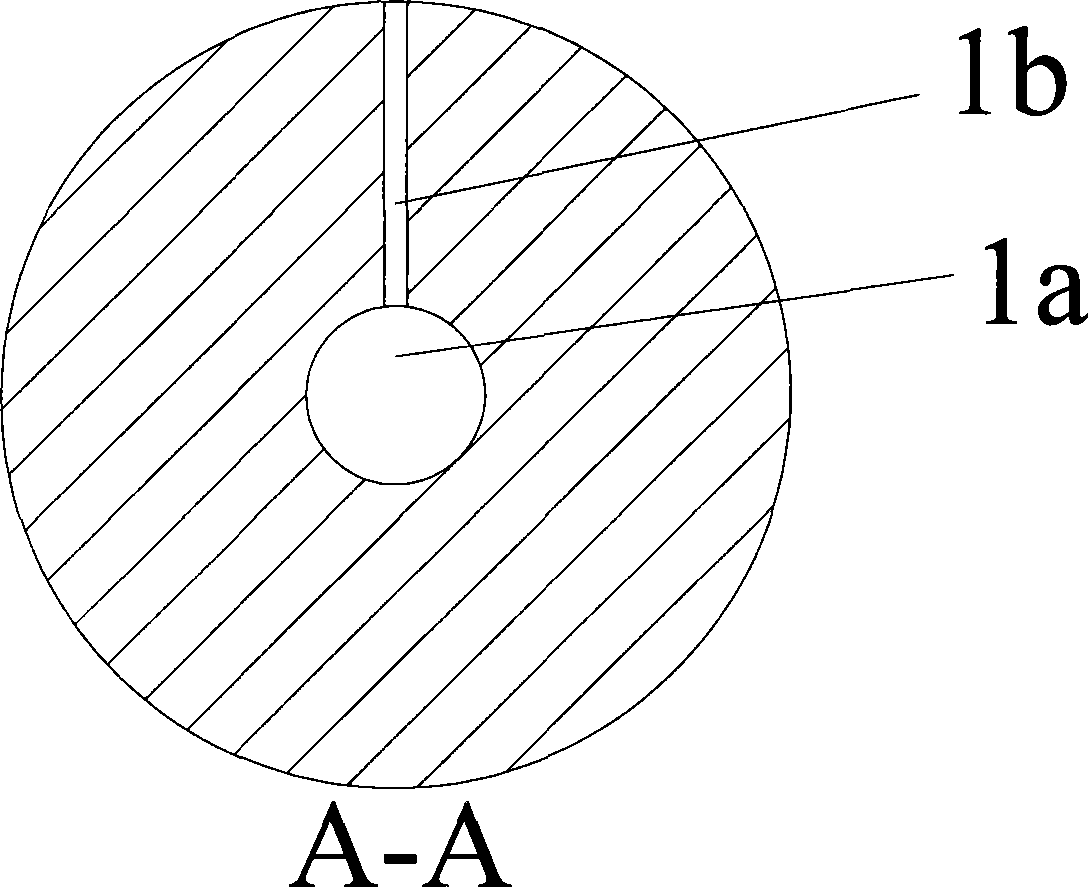

Water soluble biological degradation type golf balls and preparation method thereof

ActiveCN101396600AGood water solubilityImprove the speed of dissolution and degradationHollow non-inflatable ballsGolf ballsPolyvinyl alcoholPlasticizer

The invention provides a water-soluble biodegradation type golf ball and a manufacturing method thereof, and more particularly provides the golf ball which is made from the mixture of polyvinyl alcohol, fillers, natural polymer material, plasticizer and the like as well as is water-soluble and naturally biodegradable and the manufacturing method thereof. The water-soluble biodegradation type golf ball provided by the invention has a cavity structure, after the golf ball is batted into the water, the water comes into the cavity through via holes on the golf ball, so that the contact area between the water and the ball body is enlarged to accelerate the ball body to be dissolved, and finally the ball body can be completely biodegraded in the environment. The golf ball is especially applied for the overwater golf sports being gradually popular, and avoids the pollution to the environment while the people enjoy the sports.

Owner:JIANGMEN PROUDLY WATER SOLUBLE PLASTIC CO LTD

Thermo-oxidative ageing resistant epoxidized natural rubber composite material and preparation method thereof

The invention discloses a hydrotalcite / epoxidized natural rubber composite material and a preparation method thereof. The preparation method comprises the following steps: modifying hydrotalcite and dispersing the modified hydrotalcite by using deionized water; adding epoxidized natural rubber latex, continuously and ultrasonically stirring to obtain a hydrotalcite / epoxidized natural rubber composite material at a rubber latex state; and adding vulcanization processing aids, thereby obtaining an ageing-resistant epoxidized natural rubber composite material. The thermo-oxidative ageing resistant epoxidized natural rubber composite material with excellent performance, prepared by the invention, can be used for high-performance tires, medical rubber latex products, rubber tubes, shoe soles and other epoxidized natural rubber products.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

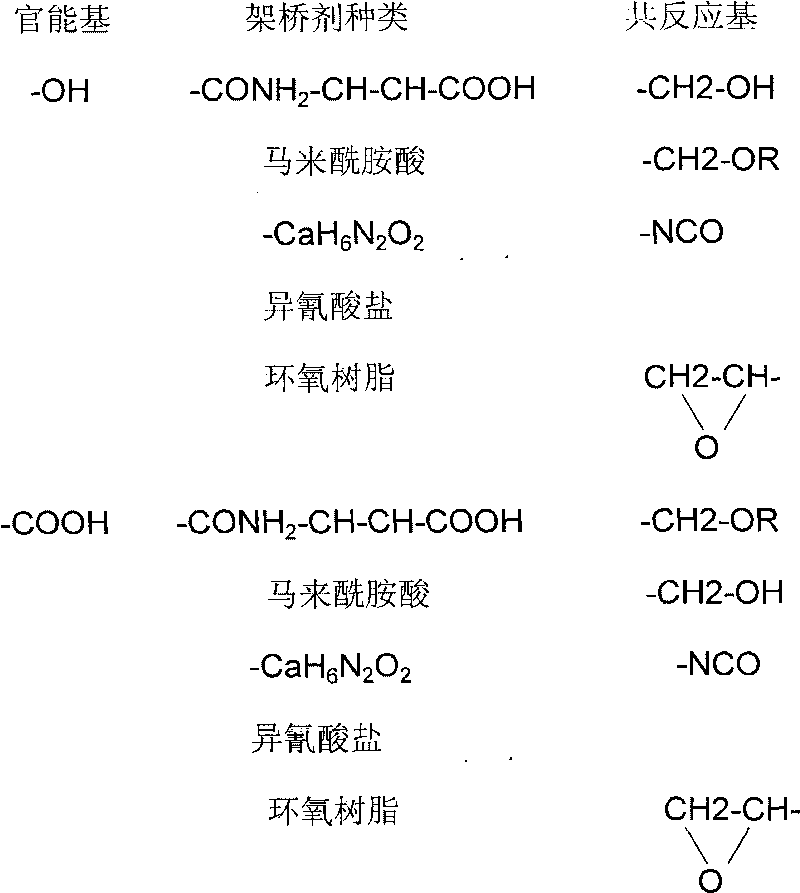

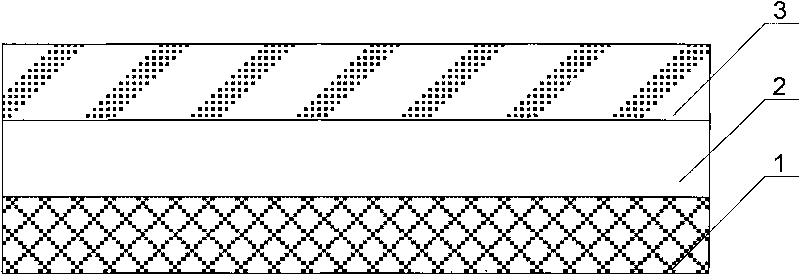

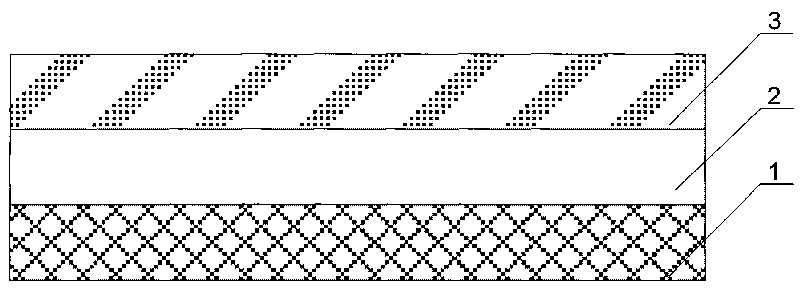

Building sealant for house industrialization and preparation method thereof

ActiveCN107057625ALow VOCGood construction performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesWeather resistancePlasticizer

A building sealant for house industrialization comprises the following components in parts by weight: 100 parts of silane-modified polyether resin, 30-100 parts of a plasticizer, 80-400 parts of nano calcium carbonate, 0-2 parts of an ultraviolet absorbent, 2-7 parts of a silane coupling agent, 3-8 parts of a silane cross-linking agent, and 1-7 parts of a catalyst. The building sealant of the invention has the following advantages that (1) the building sealant is environment-friendly, has no toxicity, low VOC, good constructability and no bubbling, and has no harm to environment and human body; (2) after curing, the building sealant has good weather resistance, surface paintability, and no pollution; and (3) the building sealant can bear a certain range of deformation, has good displacement resistance, has good bonding property to concrete, and can achieve the effects of no cracking and debonding.

Owner:广东长鹿新材料科技有限公司

Polyolefin masking tape for paint spraying and baking

InactiveCN101760146AExcellent adhesionNon-pollutingFilm/foil adhesivesSynthetic resin layered productsPolyolefinEngineering

The invention provides a polyolefin masking tape for paint spraying and baking with convenient operation and easy tear, and the masking tape has excellent high-temperature resistance and ultra-soft material, can be used according to pulling line forms of different angles and is beneficial to environmental protection. The upper surface of a glue layer of acrylic is added with a polyolefin copolymer layer, the upper surface of the polyolefin copolymer layer is added with an anti-adhering coating, and anti-adhering processing is carried out on the anti-adhering coating by a non-silicone oil series, and the polyolefin copolymer layer is co-polymerized by ethylene and propylene. The masking tape is characterized by ultra-softness, heat resistance and no pollution and can increase the adherence to the material, being especially suitable for paint spaying and baking in buildings or indoors or paint spraying and baking on pulling lines in automobile industry, and the masking tape accords with environmental protection requirements, has no pollution and has recycling ability.

Owner:东莞市富邦科技应用材料有限公司

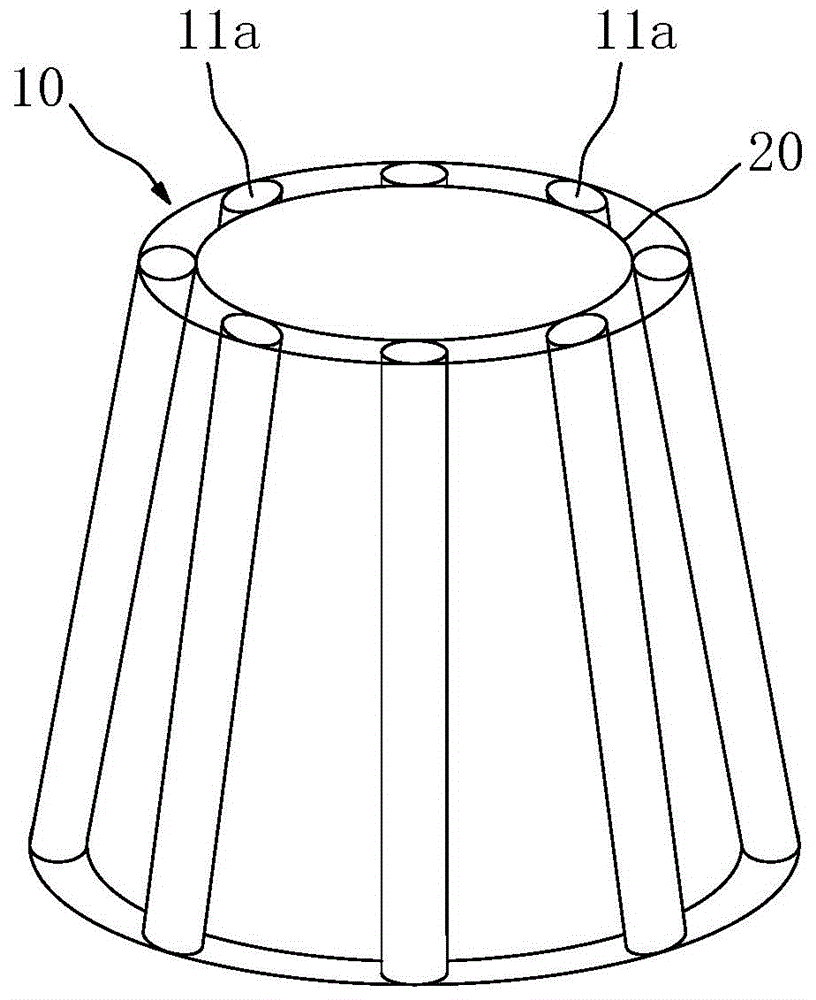

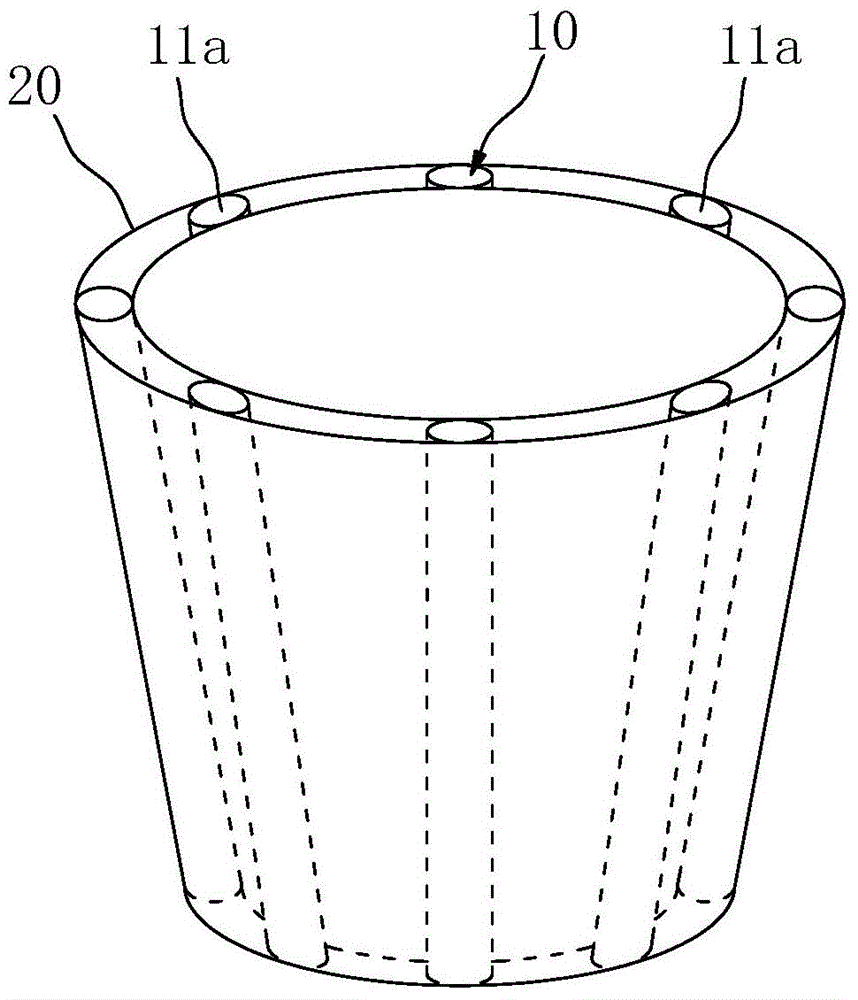

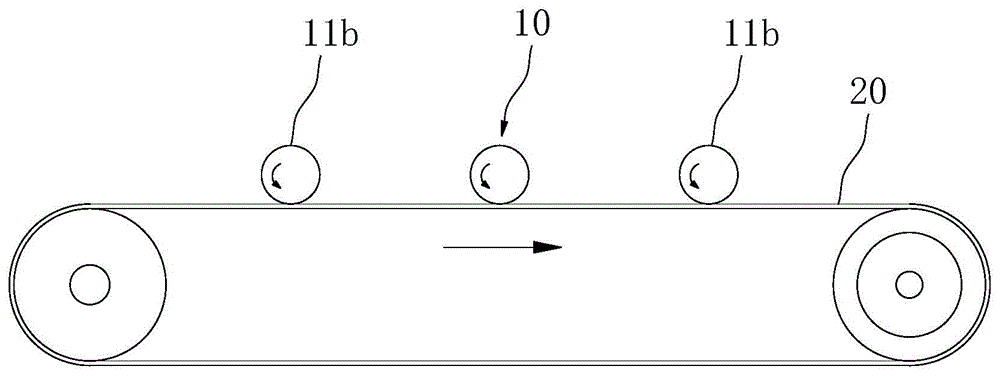

Blue-green algae extruding and crushing device

ActiveCN104959185AWith magnetic suction functionEasy to implementMagnetic separationGrain treatmentsTreatments proceduresBlue green algae

The invention belongs to the technical field of treatment of water surface blue-green algae, and in particular, relates to a blue-green algae extruding and crushing device. The device comprises a first extruding part and a second extruding part, wherein the contact surfaces of the first extruding part and the second extruding part are formed to an extruding and crushing area; the first extruding part and the second extruding part are respectively provided with magnetic sucking mechanisms on the contact surfaces thereof; and the device further comprises magnetic sucking particles absorbed by the magnetic sucking mechanisms to crush the blue-green algae. The device can effectively realize the purpose of convenient treatment of the blue-green algae so as to provide blue-green algae residues, lower in water content and easier to be treated, to subsequent treatment procedures, and is stable and reliable in operation and higher in treatment efficiency.

Owner:安徽东升农牧科技有限公司

Yak skin collagen sponge having rapid haemostasis effect, and production method and application thereof

PendingCN107126579ANon-pollutingIncrease added valueSurgical adhesivesPharmaceutical delivery mechanismSurgical operationWound healing

The invention discloses a yak skin collagen sponge having a rapid haemostasis effect, and a production method and an application thereof. The rapid haemostasis collagen sponge is a scaffold having a three-dimensional porous structure, obtained through freeze drying or direct drying of a yak skin extract I collagen and gelatin mixed solution. The rapid haemostasis collagen sponge can accelerate the haemostasis speed of wounds, promote the proliferation of wound cells, prevent adhesion and accelerate the healing of the wounds, and can be used as a filler. The yak skin collagen sponge has the advantages of good endophilicity, realization of uniform and close adherence to the wounds, promotion of the healing of the wounds, certain mechanical strength, softness, no deformation, and good biocompatibility. The rapid haemostasis collagen sponge has wide uses, can be applied to the haemostasis of epidermal hemorrhage and the haemostasis of excessive hemorrhage of internal organ tissues, and also can be applied to the neurosurgery department, the orthopaedics, the gynaecology, the general surgery, operating rooms and other fields in clinic medical science.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Food conveying belt

The invention provides a food conveying belt comprising a framework, a covering layer and a bonding layer, wherein the covering layer comprises the following components in parts by weight: 80-120 parts of natural rubber, 3-7 parts of zinc oxide, 0.3-0.7 part of sulfur, 2-4 parts of an accelerant, 1-3 parts of an anti-ageing agent, 1-4 parts of stearic acid, 30-40 parts of barium sulfate, 0.8-1.2 parts of paraffin wax and 15-25 parts of white carbon black. The food conveying belt disclosed by the invention has the functions of no toxin, no odor and no pollution.

Owner:JIANGSU FULAIOU IND TAPE PERPARATION

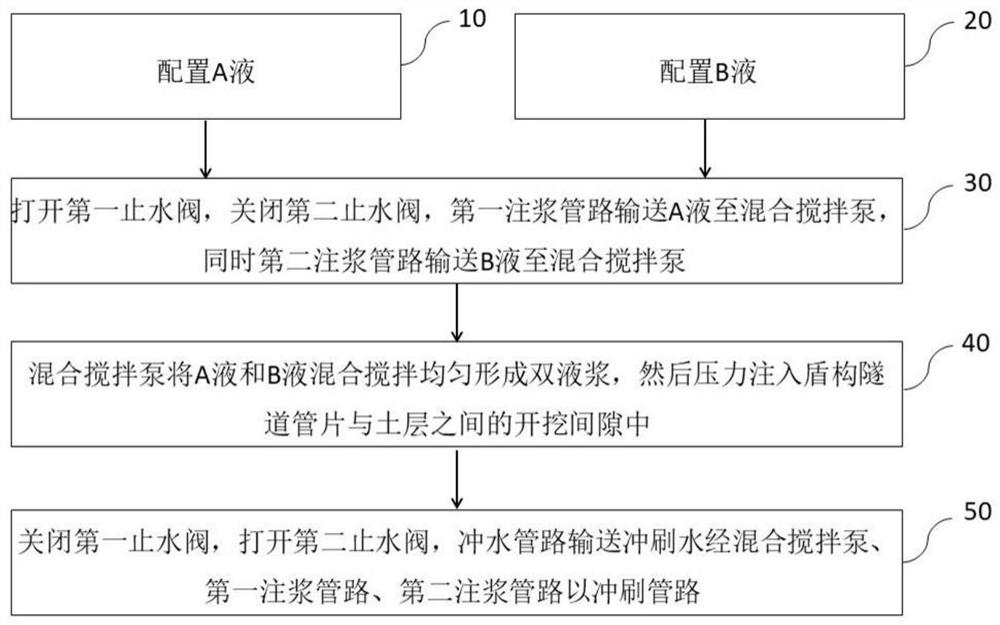

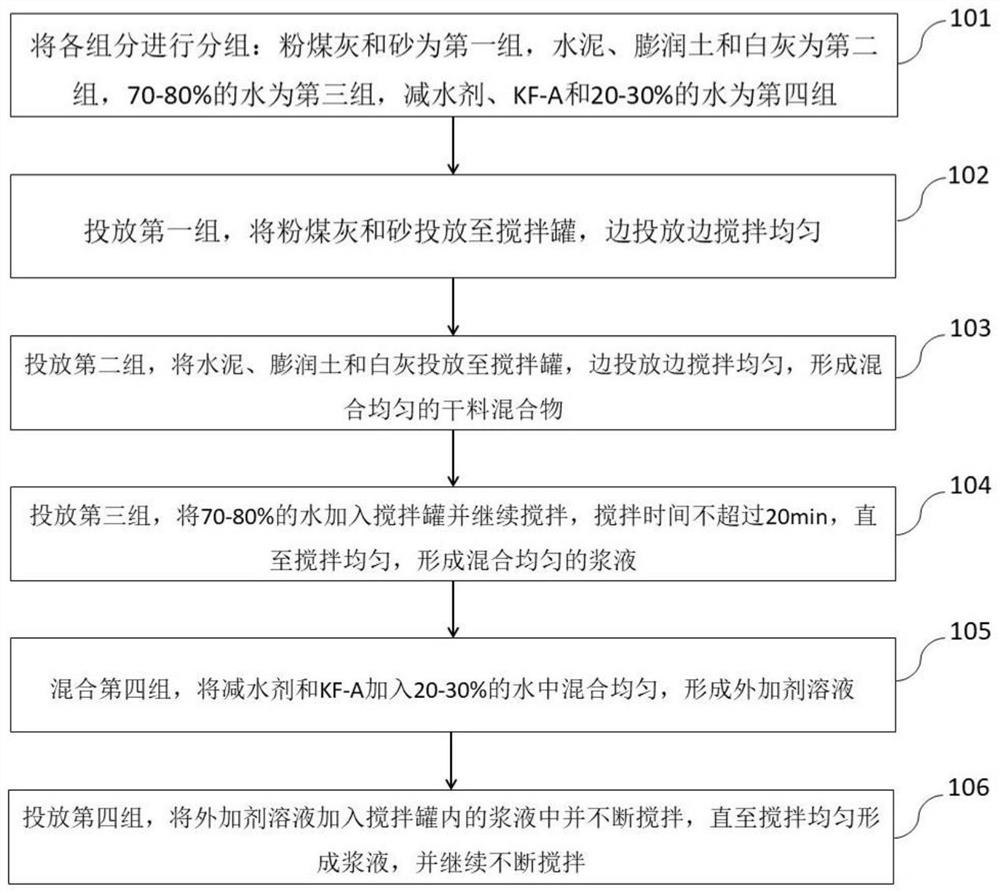

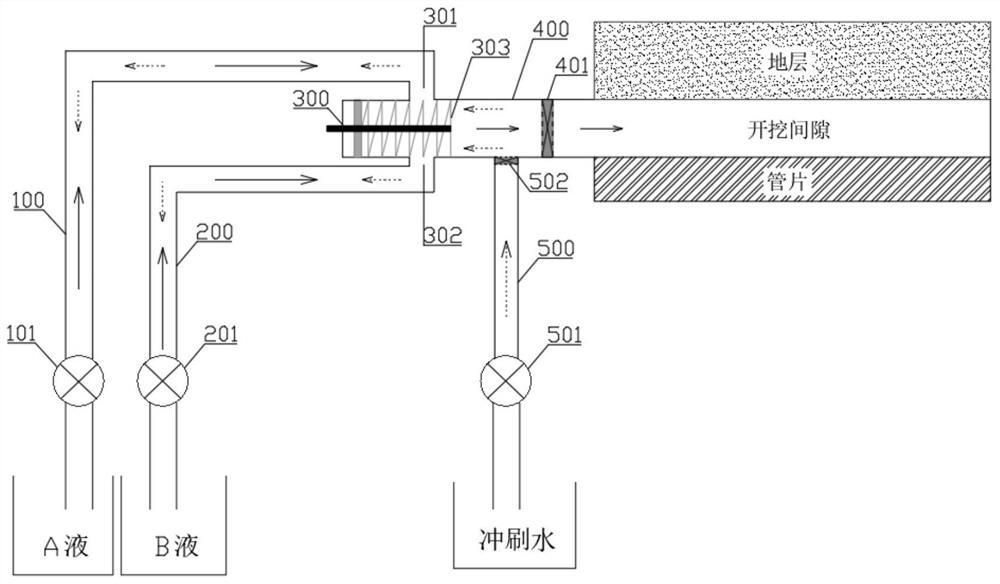

Shield excavation gap synchronous grouting slurry for water-rich powdery soil layer

The invention relates to a shield excavation gap synchronous grouting slurry for a water-rich powdery soil layer, the synchronous grouting slurry is a double-liquid slurry formed by mixing and stirring a liquid A and a liquid B. The liquid A comprises the following concrete components in terms of per cubic meter: 100 to 200 kg of cement; 400 to 600 kg of fly ash; 40 to 80 kg of bentonite; 600 to 800 kg of sand; 20 to 70 kg of lime; 400 to 550 kg of water; 6-9 kg of a water reducing agent; and 10 to 20 kg of KFA (potassium fluosilicate); wherein the solution B is a water glass solution, and the volume ratio of water glass to water is (3-4): 1; the liquid A and the liquid B are mixed and stirred according to the volume ratio of 10: 1. The synchronous grouting slurry disclosed by the invention can be widely applied to a powdery soil layer and is not limited to a pure sandy cobble layer and a pure clay layer, and double slurries can be gelled in an extremely short time, so a reinforcing effect of filling and solidifying is rapidly achieved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

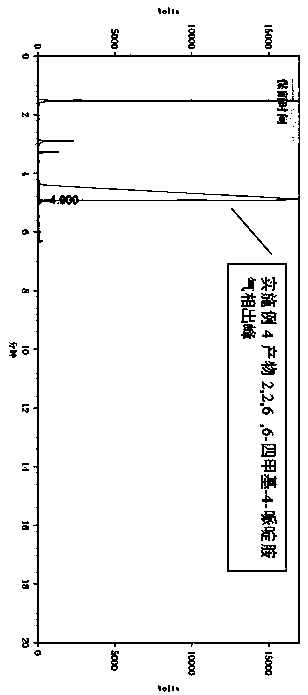

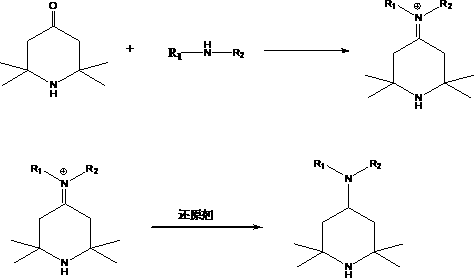

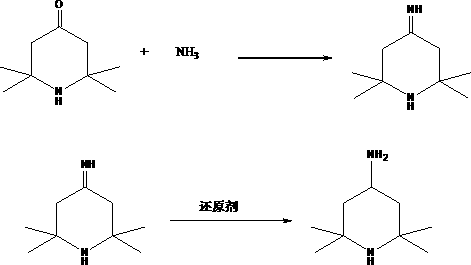

2,2,6,6-tetramethyl-4-piperidinamine preparation method

ActiveCN110845396AEliminate flammableEliminate potential safety hazardsOrganic chemistrySide productCarbonyl group

The invention relates to a 2,2,6,6-tetramethyl-4-piperidinamine preparation method, which comprises: adding a raw material 2,2,6,6-tetramethylpiperidone, an amine reactant and a solvent into a reaction kettle, stirring and premixing at 10-50 DEG C to form an imine intermediate, reducing the imine intermediate by using a reducing agent at a certain temperature under a certain pressure, and reactingfor a certain time to finally synthesize the target product 2,2,6,6-tetramethyl-4-piperidinamine compound. According to the invention, 2,2,6,6-tetramethyl-4-carbonyl piperidone reacts with an amine compound to generate an imine intermediate, and a reducing agent is used for replacing catalytic hydrogenation to perform reduction, so the product yield can reach more than 92%, the generation of the2,2,6,6-tetramethylpiperidone hydrogenation byproduct tetramethylpiperidinol is avoided, the hydrogenation process with a high risk coefficient is avoided, and the method is an ideal process for achieving industrialization.

Owner:宿迁联盛科技股份有限公司

Extraction method for peach gum polysaccharide

The invention specifically relates to an extraction method for peach gum polysaccharide, belonging to the technical field of extraction of natural active components. The extraction method comprises the following steps: subjecting dried peach gum to impurity removal and crushing and carrying out treatment at 60 to 65 DEG C; then mixing the treated peach gum with distilled water under stirring for extraction; carrying out centrifugation with a high-speed centrifuge so as to obtain a supernatant; subjecting the supernatant to vacuum concentration; then adding liquid nitrogen into a concentrate obtained in the previous step; storing the concentrate at 2 to 3 DEG C and removing a precipitate; adding absolute ethyl alcohol into the concentrate without the precipitate; and subjecting another precipitate obtained in the previous step to vacuum drying and grinding so as to obtain the peach gum polysaccharide. Unlike conventional methods where proteins in peach gum are removed through a Sevage process, the extraction method provided by the invention realizes removal of proteins in the peach gum by adding liquid nitrogen into the concentrate according to a volume ratio of the concentrate to the liquid nitrogen of 10: 1-2, and the removal rate of proteins reaches 99.5%; moreover, the process of removal poses no pollution to the peach gum polysaccharide; and thus, the high-quality peach gum polysaccharide is finally obtained.

Owner:杨俊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com