Patents

Literature

75results about How to "Improve polysaccharide yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

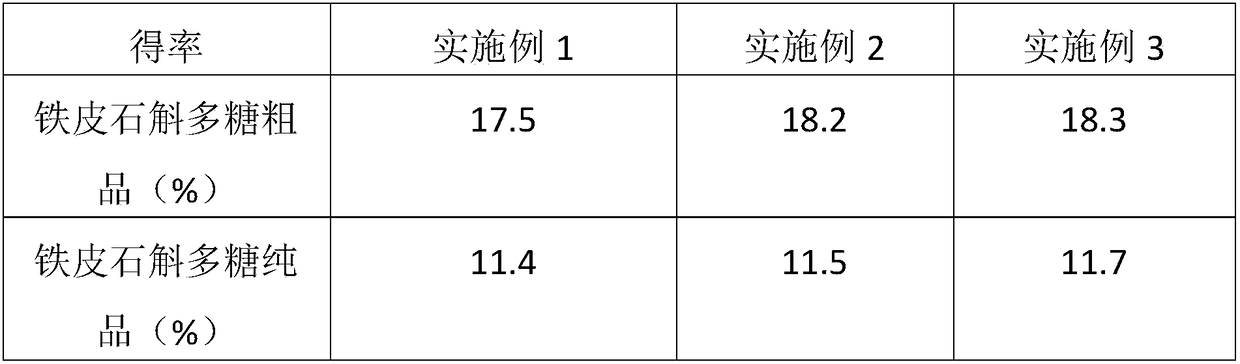

Extraction and purification method of bioactive polysaccharides in dendrobium huoshanense

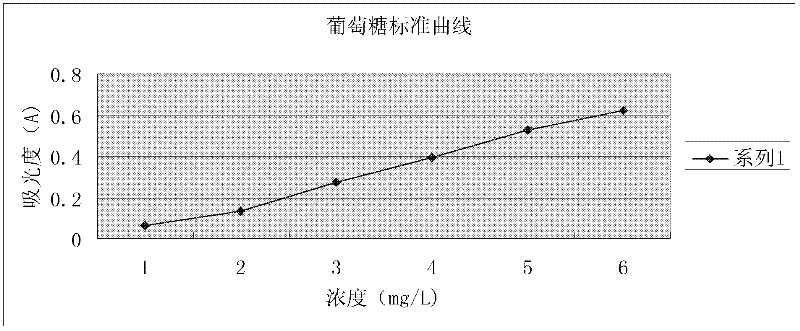

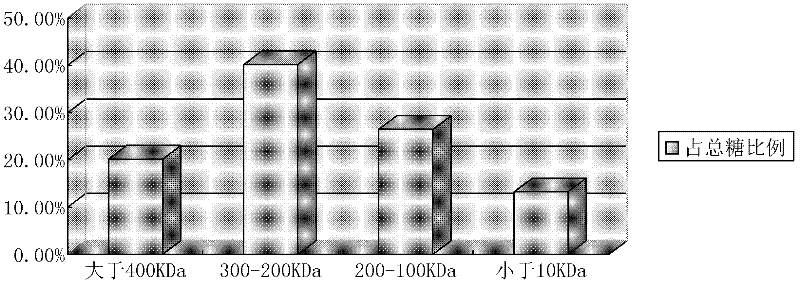

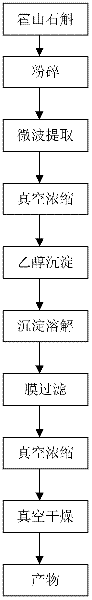

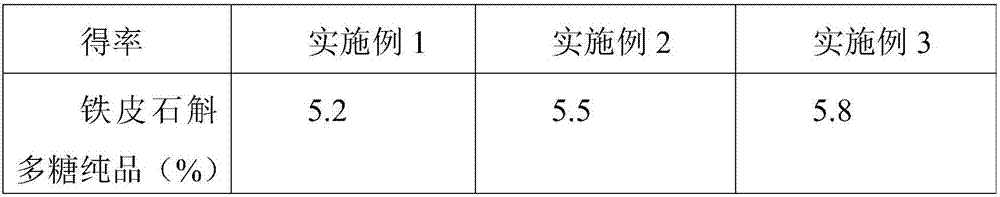

The invention discloses an extraction and purification method of bioactive polysaccharides in dendrobium huoshanense. The method comprises the following steps: crushing the dendrobium huoshanense, then adding water, performing microwave constant-temperature extraction, and performing vacuum concentration on extract solution till the relative density is 110-1.30 so as to get concentrated solution;adding ethanol into the concentrated solution, standing, and further performing centrifugation to get precipitate; adding the water into the precipitate for dissolution, enabling the solution to passthrough an ultrafiltration membrane in the molecular weight of 100KD under the pressure of 0.35MPa, collecting trapped fluid, then enabling the trapped fluid to pass through the ultrafiltration membrane in the molecular weight of 300KD under the pressure of 0.35MPa, and collecting passing fluid; and performing the vacuum concentration on the collected passing fluid, and drying to get a polysaccharide extract from the dendrobium huoshanense. By adopting the method, the extraction time can be shorted, and the yield of a crude extract can be improved from 20% to about 35% under the same extraction times; and the yield of the polysaccharides from the dendrobium huoshanense after purification can be improved from about 5% to 10-15%, and the content of the polysaccharides from the dendrobium huoshanense can be improved from 40% to above 60%.

Owner:JIUXIANZUN HUOSHAN DENDROBIUM CO LTD

Process for extracting polysaccharide from dendrobium officinale leaf according to enzymatic degradation method

The invention discloses a process for extracting polysaccharide from a dendrobium officinale leaf according to an enzymatic degradation method. According to the process, a pure product of the dendrobium officinale polysaccharide is obtained by drying the dendrobium officinale leaf, crushing, backflowing with an organic solvent, collecting a dreg of a decoction, drying the dreg of the decoction, adding distilled water to dissolve, conducting ultrasonic treatment, conducting enzymolysis by using cellulase, pectinase and papain, heating to denature the enzyme, centrifuging, filtering, decoloringa filtrate by using an activated carbon, filtering and collecting the filtrate again, concentrating in vacuum, adding an organic solvent to conduct alcoholysis, filtering and collecting a precipitateagain, airing to obtain a crude product of the dendrobium officinale polysaccharide, adding distilled water to dissolve, dialyzing with a nanofilm, adding the organic solvent to conduct alcoholysis, filtering and collecting a precipitate again, and finally freeze-drying. The yield of the prepared dendrobium officinale polysaccharide is high, the operation condition of the enzymatic method is relatively mild, and the process has the advantages of high efficiency, energy saving, low pollution and the like.

Owner:贺州市星辉科技有限公司

Ganoderma lucidum polysaccharide extracting method

InactiveCN108341890AImprove extraction efficiencyConducive to dissolutionChemistryLiquid temperature

The invention discloses a ganoderma lucidum polysaccharide extracting method. The extracting method comprises the steps: firstly, smashing ganoderma lucidum sporocarp and sieving by a 80-mesh sieve; then putting into a steam explosion device to be exploded, adding into water to be soaked for 1.5h according to a solid to liquid ratio as 1 to (10 to 20) and then heating to 30 to 50 DEG C to performultrasonic treatment; adjusting a material liquid temperature, a pH value, protease and cellulase; after enzymolysis finishes, warming to denaturalize enzyme, centrifuging, decoloring resin, deproteinizing, filtering, vacuum concentrating and vacuum drying under a lower temperature to obtain high-activity and high-purity ganoderma lucidum polysaccharide solid powder. Therefore, a polysaccharide extracting rate and a polysaccharide production efficiency are improved, a space structure of polysaccharide is prevented from being damaged, biological activity of the polysaccharide is prevented frombeing reduced, and the ganoderma lucidum polysaccharide extracting method is more suitable for industrial production.

Owner:四川岚晟生物科技股份有限公司

Preparation method of Caulis Lonicerae polysaccharide

InactiveCN102603914AHigh purityImprove biological activityAntinoxious agentsImmunological disordersWater bathsAnhydrous ethanol

The invention relates to a preparation method of Caulis Lonicerae polysaccharide, effectively solving the preparation problem of the Caulis Lonicerae polysaccharide. The preparation method comprises the following technical scheme: drying and crushing Caulis Lonicerae for later use; adding water to enzyme, dissolving, activating by a water bath to obtain an activated enzyme solution for later use; mixing Caulis Lonicerae powder with water, carrying out water bath, soaking, adjusting the pH to be 4.0-5.5, uniformly shaking, heating with water bath, adding the activated enzyme solution, mixing uniformly, carrying out enzymolysis, reflowing by water bath and extracting, filtering, condensing, adding ethanol till the ethanol content reaches 80%, standing, and centrifuging to remove supernate to obtain a polysaccharide precipitate; and sequentially adding anhydrous ethanol, acetone and aether to the polysaccharide precipitate, washing, centrifuging to remove supernate, drying the precipitate in vacuum to obtain the Caulis Lonicerae polysaccharide. The preparation method disclosed by the invention is simple, convenient and quick to operate and high in polysaccharide yield; initial reactants are available and low in price; and the preparation cost is greatly reduced, and the extracted Caulis Lonicerae polysaccharide is high in purity, keeps high biological activity and has remarkable economic and social values.

Owner:HENAN UNIV OF CHINESE MEDICINE

Method for preparing high-purity lucid ganoderma hyphostroma powder through liquid submerged fermentation

InactiveCN104082038AShorten the production cycleSmall footprintFood preparationHorticultureBiotechnologyFood industry

The invention provides a method for preparing high-purity lucid ganoderma hyphostroma powder through liquid submerged fermentation. The method solves the problems that the existing solid fermentation period of lucid ganoderma hyphostroma is long, the lucid ganoderma hyphostroma is prone to being contaminated by bacteria, the quality of the final product is unstable, and the content of active ingredients is low. The method includes the steps of culture medium preparation, strain activation, inoculation and culture, fermentation expansion, concentration, homogenization, spray drying and the like. The culture medium preparation step includes the procedures of A, agar slant culture medium preparation, B, shake flask culture medium preparation, C, seeding tank culture medium preparation and D, fermentation tank culture medium preparation. The method is widely used for processing lucid ganoderma hyphostroma powder in the food industry.

Owner:乳山市华隆生物科技股份有限公司

Tremella polysaccharide extracting method

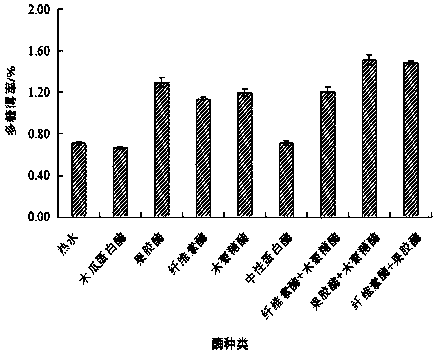

InactiveCN105481993AIncrease the added value of deep processingImprove polysaccharide yieldPectinaseProteinase activity

The invention discloses a tremella polysaccharide extracting method, and belongs to the technical field of edible fungus deep processing. The method comprises the steps of smashing, enzyme-extraction, alkaline extraction, primary concentration, protein removing, secondary concentration and drying, wherein an enzyme used in the step of enzyme-extraction is a compound enzyme which is obtained by mixing protease, cellulase and pectinase according to the mass ratio of 0.5 to 1 to 2-4. According to the tremella polysaccharide extracting method, by means of the matching design of the compound enzyme and adding the step of alkaline extraction, the yield of polysaccharide is greatly increased, and therefore the economic benefit of an edible fungus deep processing industry is improved.

Owner:赵志鑫

Preparation method and application of small-molecule panax notoginseng polysaccharide extract

InactiveCN106749731AResidue reductionHigh yieldOrganic active ingredientsImmunological disordersFreeze-dryingEthanol precipitation

The invention discloses a preparation method of small-molecule panax notoginseng polysaccharide extract. The preparation method includes: using panax notoginseng as the raw material, crushing the raw material, extracting with an ethanol solution, extracting panax notoginseng residues with water obtain crude panax notoginseng polysaccharide extract, performing ethanol precipitation, dissolving precipitate with water, and then adding trifluoroacetic acid or lysozyme to perform hydrolysis to obtain crude small-molecule polysaccharide liquid; using a cation-anion exchange column to remove the protein, pigment and the like of the crude small-molecule polysaccharide liquid, using activated carbon powder for decoloring, filtering with a titanium-bar filter to obtain a colorless low-viscosity small-molecule polysaccharide solution, concentrating, and performing freeze drying to obtain the small-molecule panax notoginseng polysaccharide extract. The preparation method has the advantages that the method is simple to operate, low in cost and high in industrialization degree; the small-molecule panax notoginseng polysaccharide extract can promote macrophage proliferation, further differentiation and maturation of macrophage can be achieved to obtain activated macrophage, and the phagocytic ability of the macrophage can be evidently enhanced; fast increasing of cell immunity during a cell culture immunity test can be achieved; the extract has application prospect in immunological disease treatment, and the preparation method is suitable for industrial production.

Owner:YUNNAN YUNKE PHARMA

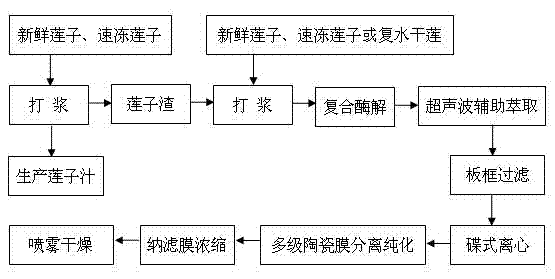

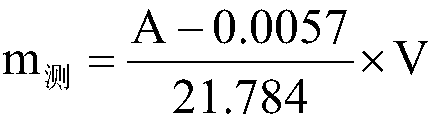

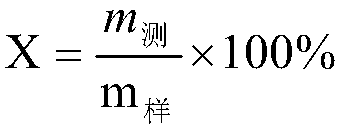

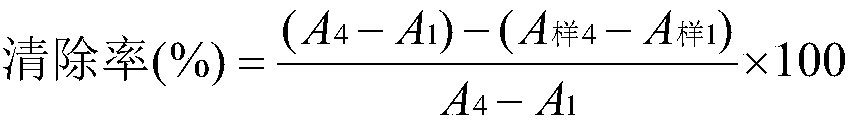

High-efficiency extraction process for polysaccharide of lotus seeds

The invention provides a high-efficiency extraction process for polysaccharide of lotus seeds. The high-efficiency extraction process includes steps of cleaning the lotus seeds, adding distilled water to the lotus seeds for making juice, mixing amylase, pedinase and acidic cellulase for complex enzymolysis at the temperature ranging from 25 DEG C to 35 DEG C, and then producing lotus seed polysaccharide powder after ultrasonic auxiliary extracting, filtering, alcohol precipitating, inorganic ceramic membrane separating and purifying, nanofiltration membrane concentrating and drying. The high-efficiency polysaccharide extraction process is applied to polysaccharide extraction for the lotus seeds by integrating with multiple technologies including complex enzymolysis, ultrasonic auxiliary extraction, multi-grade inorganic ceramic membrane separation and purification and nanofiltration membrane concentration, is easy to operate, pollution-free, low in energy consumption, high in efficiency, fine in healthcare effect and suitable for mass production of polysaccharide of the lotus seeds, and has evident economic benefits, the extraction rate of polysaccharide of the lotus seeds is increased to 3.5% from 1 %, finished-product purity reaches 40%, and produced polysaccharide of the lotus seeds is high in purity.

Owner:福建闽江源绿田实业投资发展有限公司

Auricularia auricular polysaccharide extraction method based on puffing treatment and preparation and application thereof

InactiveCN109265574AImprove polysaccharide yieldHigh yieldOrganic active ingredientsAntinoxious agentsAuriculariaPolysaccharide

The invention provides an auricularia auricular polysaccharide extraction method based on puffing treatment and a preparation and application thereof, which belong to the technical field of biology. According to the auricularia auricular polysaccharide extraction method based on puffing treatment provided by the invention, auricularia auricular polysaccharide is obtained by dry auricularia auricular grinding, extrusion, extraction in water and centrifuging. The invention further provides the application of the auricularia auricular polysaccharide and the preparation thereof in the preparationof food, food for special medical purpose, health-care food and medicines in terms of oxidation resistance and immunity enhancement. Compared with the prior art, the auricularia auricular polysaccharide prepared by utilizing the technical solution provided by the invention is remarkably improved in terms of yield, oxidation resistance and immunity enhancement.

Owner:INST OF MICROBIOLOGY HEILONGJIANG ACADEMY OF SCI

Method for preparing pure polysaccharose from alfalfa hay

InactiveCN102212144AReduce extraction timeReduce investmentAnimal feeding stuffAccessory food factorsAlfalfa hayCellulose

The invention relates to a method for preparing a pure polysaccharose from alfalfa hay and provides the method for preparing the pure alfalfa polysaccharose, which can be subject to mass production and is simple in process, low in cost and high in efficiency. The method comprises the following steps of: crushing aired or dried alfalfa; soaking the powder in a certain amount of water, wherein the ratio of the powder to the water is 1:20-1:45; heating the mixture at the temperature of 55 to 85 DEG C for 10 to 35 minutes under the action of 40 to 60kHz ultrasonic wave of which the power is 240 to 400W; filtering the mixture and collecting the filtrate; concentrating the obtained filtrate until the volume of the filtrate is reduced to one third; removing proteins from the filtrate with n-butyl alcohol-trichloromethane solution, wherein the volume ratio of n-butyl alcohol to hloromethane is 1 to 4; performing alcohol precipitation on the filtrate with ethanol of which the volume is 2 to 4.5 times that of the filtrate; after standing the filtrate, centrifugating the filtrate at the speed of 3,000 to 5,000 rpm for 10 to 20 minutes; freezing and drying the lower layer of precipitate at the temperature of -70 to -50 DEG C to obtain the e polysaccharose; and separating and purifying the polysaccharose through two kinds of cellulose column chromatography to obtain the high-purity polysaccharose. When the method is compared with the traditional method, the cost is reduced; the production efficiency is greatly improved; and the purity of the obtained polysaccharose product can be up to over 96 percent.

Owner:辽宁德宝农牧集团有限公司

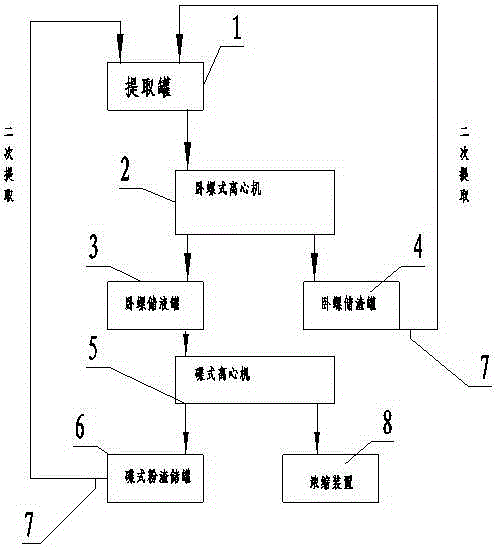

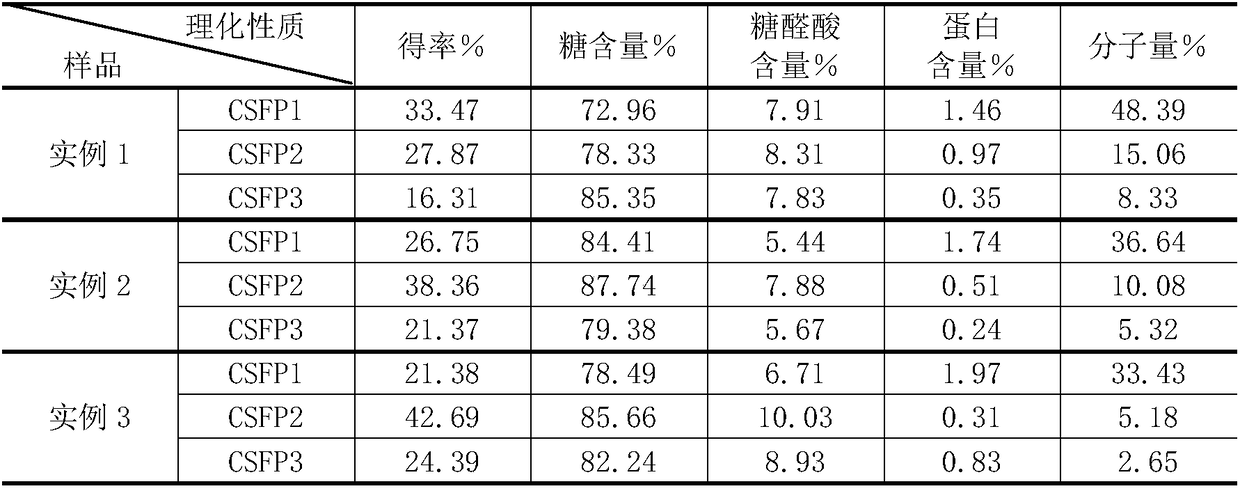

Industrial extraction and separation method of ganoderma spore polysaccharide and separation device

An industrial extraction and separation method of ganoderma spore polysaccharide comprises the following steps: (1) placing spore powder into an extraction device, adding water with a weight 8 to 12 times of that of spore powder, heating until a slight boiling state is reached, and maintaining the temperature to carry out extraction for 2 hours; (2) delivering the obtained extract in a suspension state to a separation device to carry out solid-liquid separation, returning the solid phase to the extraction tank, extracting the solid phase for a second time, adding water with a weight 8 to 12 times of that of solid phase, heating until a slight boiling state is reached, maintaining the temperature to carry out extraction for 2 hours, separating solid and liquid, merging the two liquid phases, and condensing the merge liquid phase to obtain ganoderma spore polysaccharide extract. The separation device used in the step (2) is a circulation system, which is prepared by serially connecting a horizontal screw type centrifuge and a butterfly type centrifuge. The separation device can effectively remove spore residues from ganoderma spore water, and separates solids and liquid to obtain high-purity ganoderma spore polysaccharide in a high yield. The provided extraction and separation method has the advantages of short time and high polysaccharide yield, reduces the labor intensity, and can be applied to the industrial massive production of ganoderma spore polysaccharide.

Owner:仙芝科技(福建)股份有限公司 +1

Method for increasing polysaccharide content of morel submerged fermentation mycelium through astragalus extract solution

InactiveCN103952451AImprove polysaccharide yieldReduce ecological damageMicroorganism based processesFermentationMetaboliteSubmerged fermentation

The invention discloses a method for increasing polysaccharide content of morel submerged fermentation mycelium through astragalus extract solution. The method is characterized in that the astragalus extract solution is added to morel submerged fermentation culture solution to promote the growth of morel mycelium so as to increase the morel polysaccharide content. According to the method, active ingredients (alkaloid, saponin, flavones and the like) of astragalus can promote or inhibit the growth of medical fungal mycelium and the growth of metabolite.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

Purification method of low-molecular-weight sargassum fusiforme polysaccharides

InactiveCN108117609AImprove polysaccharide yieldUniform molecular weightPurification methodsFreeze-drying

The invention discloses a purification method of low-molecular-weight sargassum fusiforme polysaccharides. The purification method comprises the following steps of (1): ultrafiltration classification:enabling an argassum fusiforme polysaccharide solution containing different molecular weights to pass through ultrafiltration systems, the molecular weight cutoffs of which are 10kDa, 5kDa and 1kDa respectively and which are further sequentially connected in series, and enabling primary tail liquid of the 10kDa ultrafiltration system to flow into a circulation cup of the 5kDa ultrafiltration system to carry out water circulation ultrafiltration, wherein the weight-average molecular weight of the primary tail liquid is smaller than and equal to 10kDa; enabling secondary tail liquid of the 5kDaultrafiltration system to flow into a circulation cup of the 1kDa ultrafiltration system to carry out the water circulation ultrafiltration until tertiary tail liquid of the 1kDa ultrafiltration system does not contain polysaccharide, wherein the weight-average molecular weight of the secondary tail liquid is smaller than and equal to 5kDa; afterwards, rinsing the polysaccharide solution in pipelines of the ultrafiltration systems by using water and collecting respectively; (2), concentration and freeze-drying: collecting the polysaccharide solution of each interval section, carrying out reduced pressure concentration, and then carrying out reduced pressure freezing-drying, so that the low-molecular-weight sargassum fusiforme polysaccharides of intervals of the corresponding molecular weights can be obtained.

Owner:温州大学苍南研究院

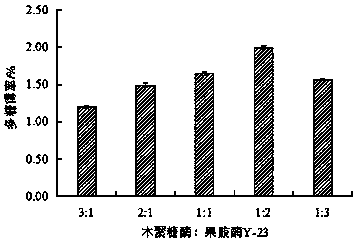

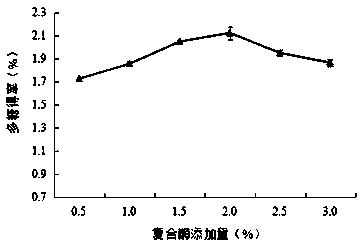

Method for extracting polysaccharide of pineapple pomace

The invention discloses a method for extracting polysaccharide of pineapple pomace. The method for extracting the polysaccharide of the pineapple pomace comprises the following steps of pretreatment,degreasing, enzymolysis of a raw material, water extraction of filter residues, concentration, alcohol precipitation, deproteinization, depigmentation, drying and the like, wherein the extraction rateof the polysaccharide of the pineapple pomace can be improved effectively by adopting xylanase and pectinase Y-23 as a mixed enzyme preparation, then a trichloroacetic acid-butanol mixed solution isadded for deproteinization of crude polysaccharide, X-5 macroporous adsorption resin is added for the depigmentation of the deproteinized polysaccharide solution, and the purity of the polysaccharideof the pineapple pomace can be improved by controlling the conditions of the steps. The method for extracting the polysaccharide of the pineapple pomace is simple and rapid, and compared with a hot water extraction method, an ultrasonic wave-assisted extraction method and a cellulase extraction method, the obtained polysaccharide of the pineapple pomace has a high extraction rate, high purity andgood antioxidant activity, and can be used for preparing functional food, cosmetics and the like.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI

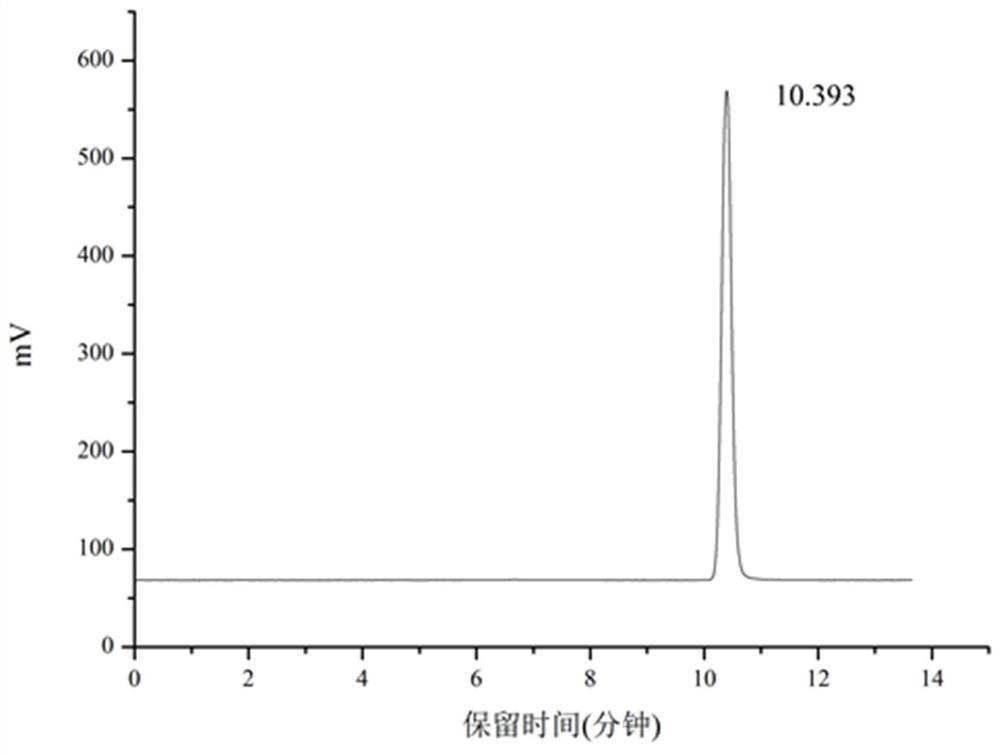

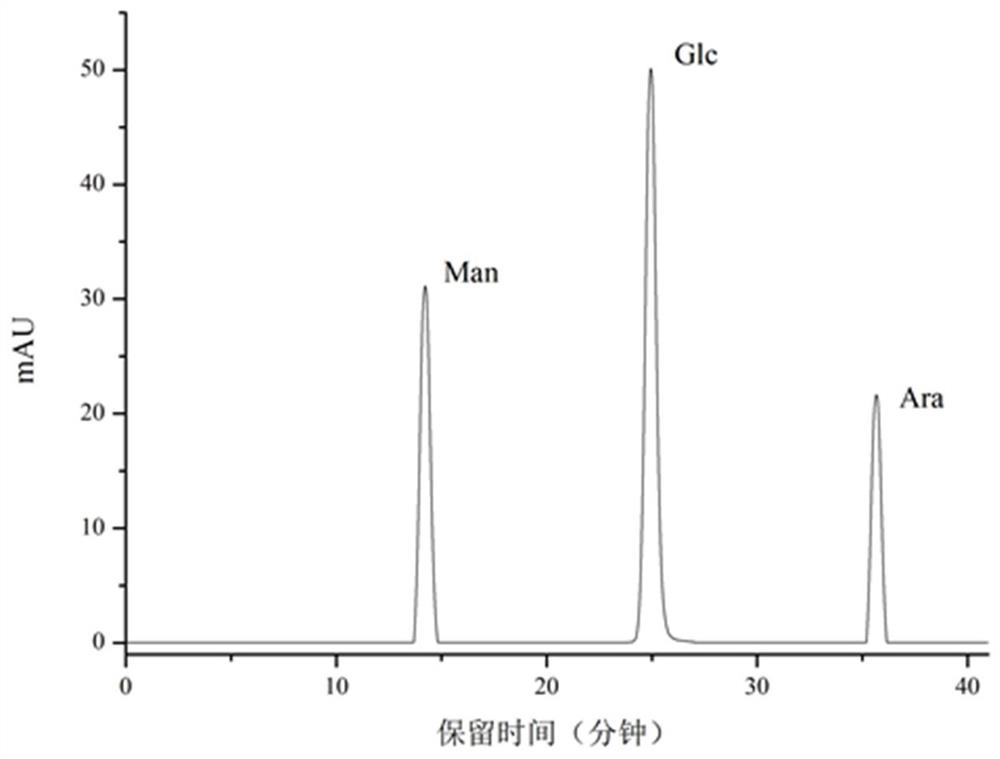

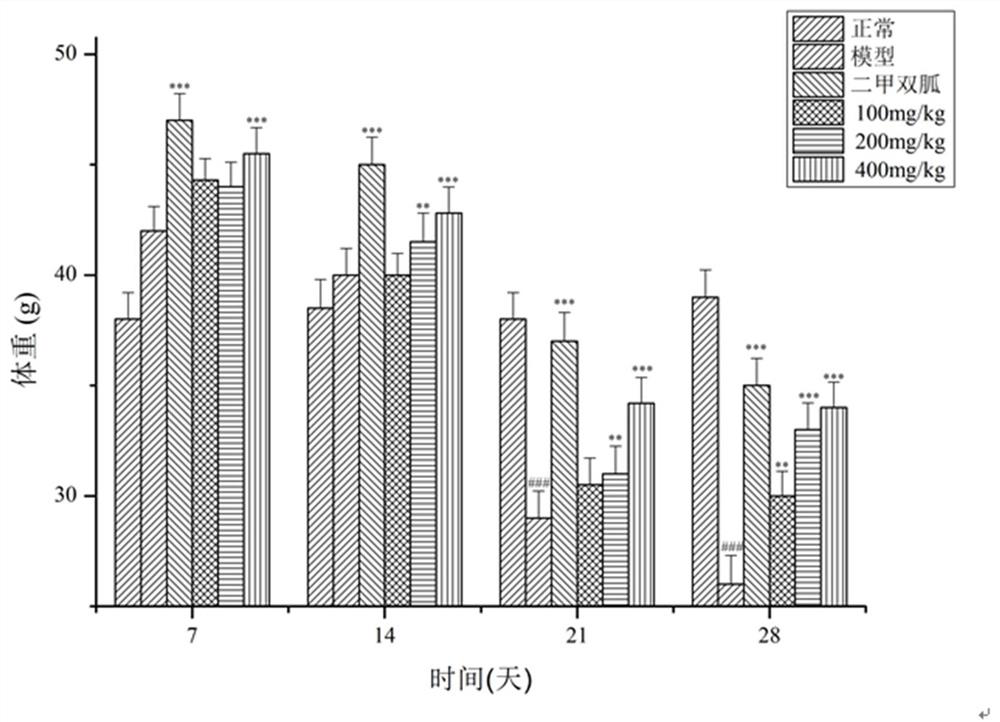

Large-leaf yellow tea polysaccharide with blood sugar reducing effect

InactiveCN111793660AImprove polysaccharide yieldImprove biological activityMetabolism disorderFermentationBiotechnologyMonosaccharide composition

The invention discloses a preparation method of large-leaf yellow tea polysaccharide with a blood sugar reducing effect. The preparation method is characterized in that large-leaf yellow tea polysaccharide LYT-2 is prepared by taking large-leaf yellow tea produced from Huoshan as a raw material, performing solid-state fermentation through EM bacteria and carrying out extracting by utilizing a deepeutectic solvent technology; the molecular weight of the polysaccharide compound is 4.38x104 Da, the polysaccharide compound contains 4.98% of binding protein, and the molar ratio of mannose to glucose to arabinose is 2.16:4.83:1 in monosaccharide composition. In-vivo experimental data shows that LYT-2 can obviously reduce the weight and blood sugar level of high-sugar and high-fat mice. The result shows that LYT-2 has good application prospects in the aspects of food, medicine, health care and the like.

Owner:ANHUI UNIVERSITY

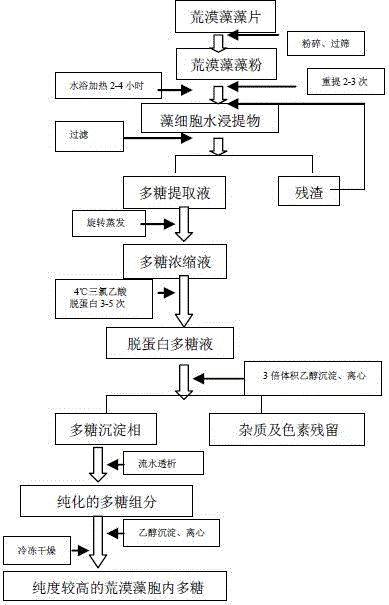

Extraction method of microcoleus vaginatus intracellular polysaccharide

The invention discloses an extraction method of microcoleus vaginatus intracellular polysaccharide. The steps include: (1) subjecting microcoleus vaginatus to large-scale culture, then collecting the algal liquid, filtering the algal liquid to obtain an algal piece, and performing air-drying; (2) crushing the algal sheet to obtain algal powder; (3) mixing the algal powder with sterile water to obtain an extracted solution; (4) concentrating the polysaccharide extracted solution to obtain a polysaccharide concentrated solution; (5) using a trichloroacetic acid solution to precipitate protein, performing centrifugation and taking the supernatant; (6) using ethanol to precipitate polysaccharide, and staying the product overnight, conducting centrifugation, retaining the precipitate, dissolving ethanol precipitated crude polysaccharide in distilled water, carrying out running water dialysis, collecting polysaccharide (high molecular weight); (7) after dialysis, adding the dialysate into ethanol; (8) evaporating the ethanol in the precipitated phase to obtain polysaccharide, and conducting freeze drying. The method has the advantages of simple operation, low cost, simple equipment, high extraction rate, good product purity, and safety and reliability, reaches a multi-stage separation and extraction effect, and is suitable for industrial large-scale production.

Owner:XINYANG NORMAL UNIVERSITY

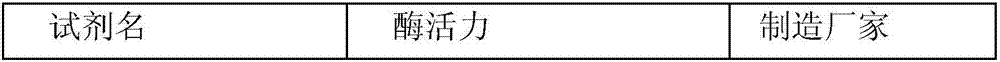

Complex enzymatic extraction method for laminarin and obtained laminarin

The invention discloses a complex enzymatic extraction method for laminarin and the obtained laminarin. The method comprises the following steps: taking kelp processing waste as a raw material, drying and crushing the kelp processing waste first, extracting and adding a proper amount of kelp powder into a fully-automatic hydrolysis reactor, adding a buffer solution with pH 6.0 for uniform stirring according to a solid-liquid ratio of 1:(35-45)ml, and adding complex enzymes, the additions of cellulase, hemicellulase, pectinase and protease being 0.004 to 0.006 grams, 0.006 to 0.008 grams, 0.004 to 0.006 grams and 0.001 to 0.014 grams based on the mass of 1 gram of the kelp powder; regulating the pH value to be 5.5 to 6.5, performing enzymatic hydrolysis for 3 to 4h at 45 to 55 DEG C, raising the temperature for enzyme deactivation, extracting hydrolysate, performing suction filtration to remove precipitates and insoluble substances, adding ethanol into supernatant until the volume fraction of the ethanol of the system is 65 to 75 percent, and performing cold storage overnight in a refrigerator of 4 DEG C; performing centrifugation for 20min at 3,000 to 4,000g / min, and performing freeze-drying on precipitates to obtain crude laminarin. According to the method and the laminarin, the yield and purity of the laminarin can be effectively improved under a mild condition, the structure and bioactivity of the laminarin can be completely preserved, and toxic substances and environmental pollution in a process are avoided.

Owner:YANTAI UNIV

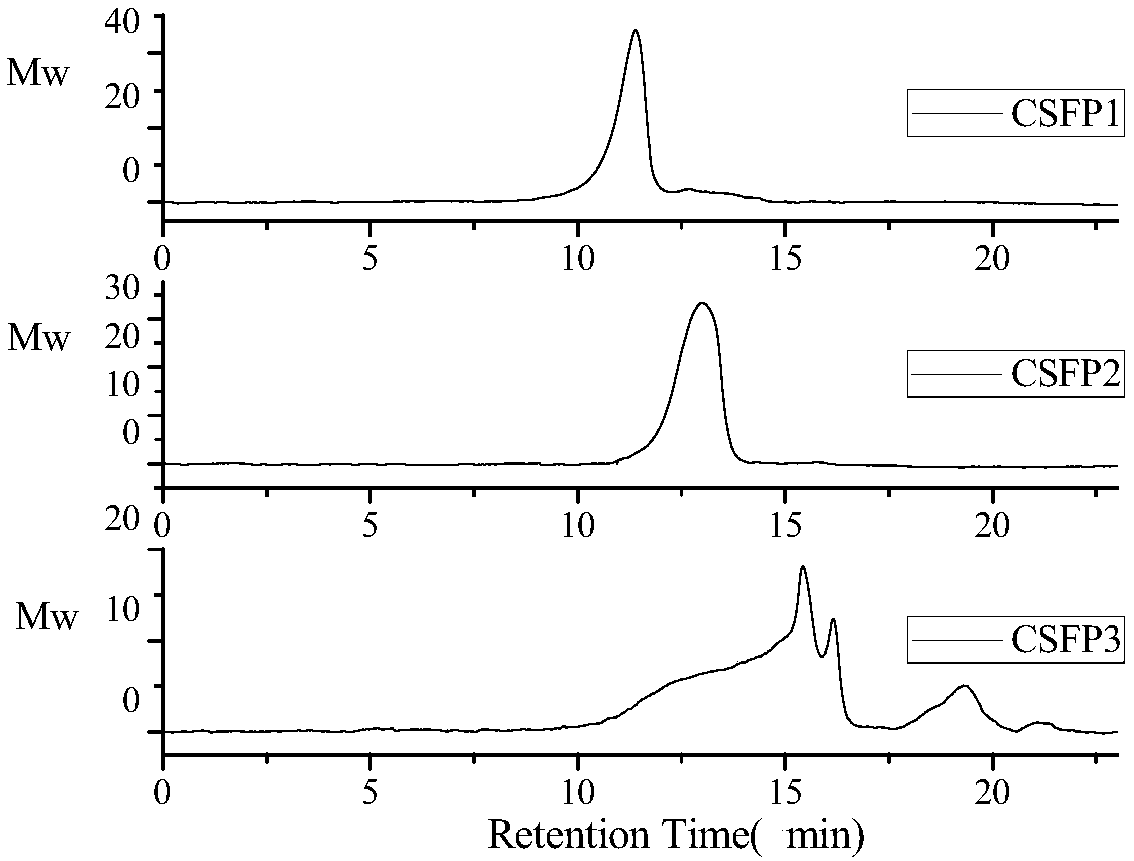

Preparation method of low molecular glossy ganoderma polysaccharide

InactiveCN101704903AHigh extraction rateIncrease contentAntineoplastic agentsPolysaccharideGanoderma lucidum

The invention mainly relates to a preparation method of low molecular glossy ganoderma polysaccharide, in particular to the preparation method of low molecular ganoderma lucidum polysaccharide. The method comprises the steps of grinding, water extracting, concentrating, grading acetone sinking and centrifugal drying. The preparation method of the low molecular glossy ganoderma polysaccharide is simple, convenient, speedy and efficient, has low cost, few steps, no pollution, and high polysaccharide purity and is suitable for industrialization production.

Owner:CHINA PHARM UNIV

Extraction method for peach gum polysaccharide

The invention specifically relates to an extraction method for peach gum polysaccharide, belonging to the technical field of extraction of natural active components. The extraction method comprises the following steps: subjecting dried peach gum to impurity removal and crushing and carrying out treatment at 60 to 65 DEG C; then mixing the treated peach gum with distilled water under stirring for extraction; carrying out centrifugation with a high-speed centrifuge so as to obtain a supernatant; subjecting the supernatant to vacuum concentration; then adding liquid nitrogen into a concentrate obtained in the previous step; storing the concentrate at 2 to 3 DEG C and removing a precipitate; adding absolute ethyl alcohol into the concentrate without the precipitate; and subjecting another precipitate obtained in the previous step to vacuum drying and grinding so as to obtain the peach gum polysaccharide. Unlike conventional methods where proteins in peach gum are removed through a Sevage process, the extraction method provided by the invention realizes removal of proteins in the peach gum by adding liquid nitrogen into the concentrate according to a volume ratio of the concentrate to the liquid nitrogen of 10: 1-2, and the removal rate of proteins reaches 99.5%; moreover, the process of removal poses no pollution to the peach gum polysaccharide; and thus, the high-quality peach gum polysaccharide is finally obtained.

Owner:杨俊

Extracting method for pleurotus eryngii polysaccharide

The invention discloses an extracting method for pleurotus eryngii polysaccharide, and belongs to the technical field of plant active ingredient extraction. The extracting method comprises the following steps: firstly, separating micromolecule components to the greatest extent by taking a low-concentration alcohol solution as a solvent, and supplementing with ultrasonic treatment; and then, extracting by taking water as a solvent and adopting an ultrasonic-inner boiling method and precipitating pleurotus eryngii polysaccharide from the high-concentration alcohol solution. Compared with conventional methods such as a water extraction method and an alcohol extraction method, the extracting speed and the extracting rate are obviously increased; the pleurotus eryngii polysaccharide yield is higher than or equal to 11% which is improved by 17-59% in comparison with that of the conventional method; and moreover, the activity of the pleurotus eryngii polysaccharide is kept to the greatest extent, so that the whole extracting process is short in consumed time, is high in yield, is less in impurities and is low in cost.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Method for extracting polysaccharide from auricularia

The invention discloses a method for extracting polysaccharide from auricularia. The method comprises the following steps of selecting dried auricularia as a raw material, soaking, cleaning, crushing, adding cellulase, controlling enzymolysis conditions, and hydrolyzing by enzyme, thus breaking down cell walls; extracting auricularia residues, subjected to enzyme hydrolysis, by hot water; combining an auricularia enzyme hydrolysis solution and an auricularia extracting solution, filtering, adding a tannic acid solution, removing protein out of filtrate, and performing alcohol settling on a centrifugally collected polysaccharide solution by an ethanol solution; finally, vacuum-drying to obtain a polysaccharide product. The extraction method has the advantages that a technology is reasonable, the operation is simple, components are comprehensively reserved, the a yield rate and maturity of the polysaccharide are high, and the safety of the product is good.

Owner:昭平县科学技术指导站

Preparation method of inonotus obliquus polysaccharides

The invention discloses a preparation method of inonotus obliquus polysaccharides. The method comprises the following steps: firstly, carrying out superfine grinding on inonotus obliquus, then breaking walls, extracting with hot water and performing centrifugation to obtain an extracting solution, and carrying out the steps of microfiltration and ultrafiltration on the extracting solution, aqueoustwo-phase extraction, macroporous adsorption resin decolorization, nanofiltration desalting and concentration, freeze-drying and the like to obtain an inonotus obliquus polysaccharide product. The preparation method of the inonotus obliquus polysaccharides disclosed by the invention has the advantages that 1, the release of polysaccharide substances in the inonotus obliquus is obviously improvedby using a low-temperature micro-nano wall breaking technology to destroy the cell walls, 2, most of proteins can be separated from the polysaccharides by using an aqueous two-phase extraction technology, to avoid causing influence on the polysaccharides, 3, depigmentation is performed by using macroporous adsorption resin to make the color of the polysaccharide finished product lighter, 4, sodiumcitrate and other inorganic salts mixed in a polysaccharide solution can be removed by using a nanofiltration membrane technology, and the polysaccharide solution is concentrated to avoid the effectof high temperature on polysaccharide activity, and 5, the solvent is safe and pollution-free, the yield is high, and the preparation method is convenient to operate and low in cost.

Owner:DAXINGANLING PERFECTION NOBILITY FRIGID ZONE BIO TECH CO LTD

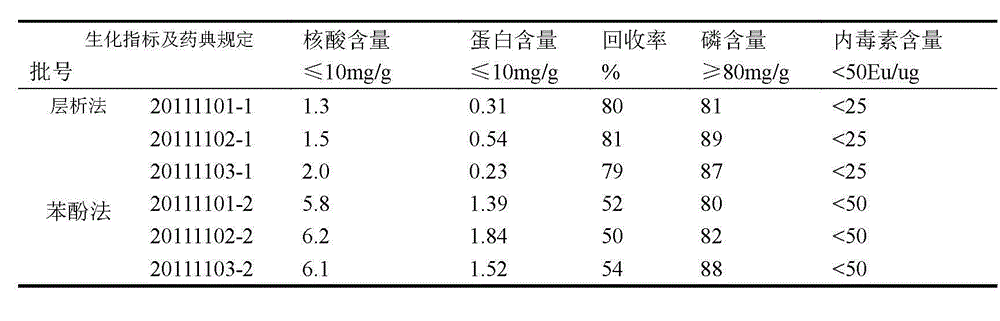

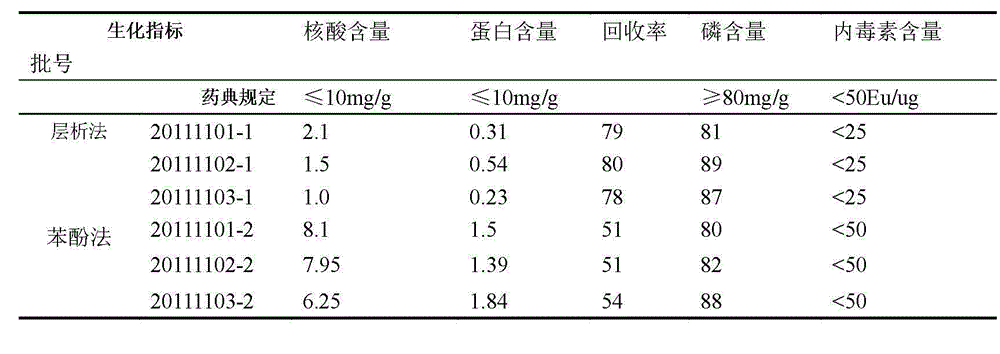

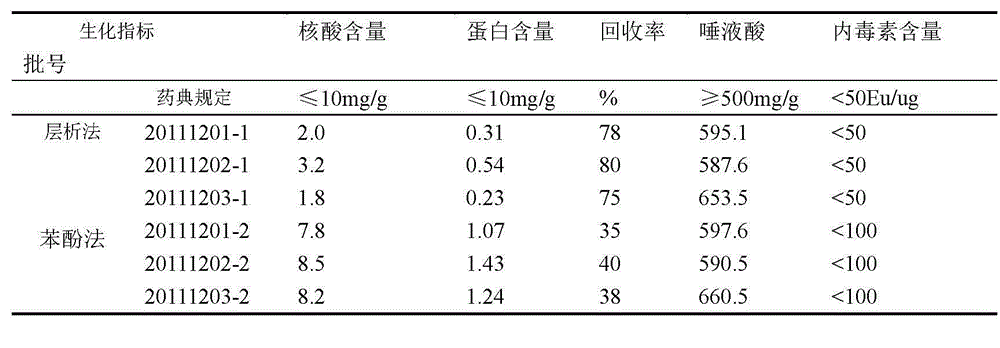

Process for refining group C/Y/W135 meningococcal polysaccharides

ActiveCN102911285AProtein content controlLow in proteinAntibacterial agentsAntibody medical ingredientsMeningococcal carriageMENINGOCOCCAL POLYSACCHARIDE

The invention discloses a process for refining group C / Y / W135 meningococcal polysaccharides. The process includes dissolving one of a coarse group C meningococcal polysaccharide, a coarse group Y meningococcal polysaccharide and a coarse group W135 meningococcal polysaccharide, displacing the polysaccharide into an equilibration buffer solution, feeding a collected polysaccharide to an anion exchange column, using an eluant to elute absorption substances from the anion exchange column, piecewise collecting absorption peaks with wavelength smaller than 206 according to different elution peaks and using a desalting method to remove micromolecule materials. According to the process for refining the group C / Y / W135 meningococcal polysaccharides, protein contents can be effectively controlled, so that the polysaccharide protein content is far lower than the polysaccharide protein content in a cold phenol method, the recovery rate can reach around 80%, and the process is applicable to mass production with 100g of coarse polysaccharide yield per batch.

Owner:罗益(无锡)生物制药有限公司

Lentinan beverage and preparation method thereof

ActiveCN103960736AImprove polysaccharide yieldPromote development and utilizationFood ingredient functionsFood preparationHigh-fructose corn syrupAdditive ingredient

The invention provides a lentinan beverage which is prepared from the following raw materials by weight parts: 10-40 parts of lentinus edodes fruiting body extracting liquid, 10-20 parts of xylitol, 5-10 parts of white granulated sugar, 5-10 parts of high fructose corn syrup, 0.13-2 parts of citric acid, 6-10 parts of stevioside and 20-30 parts of water, wherein the content of crude polysaccharides in the lentinus edodes fruiting body extracting liquid is controlled to be more than 0.250-0.256g / 100ml. The lentinan beverage has a plurality of health functions of improving body immunity, resisting tumors, viruses and infection, reducing blood sugar and blood fat and the like, and serves as a health beverage suitable for most of people.

Owner:GUANGDONG LINZHONGBAO BIOTECH CO LTD

Method for extracting dendrobium officinate kimura et migo polysaccharide by using ultrasonic method

The invention discloses a method for extracting dendrobium officinate kimura et migo polysaccharide by using an ultrasonic method. The method comprises the following steps: on the basis of a traditional water extraction method, heating and extracting a sizing agent of the dendrobium officinate kimura et migo through an ultrasonic water bath, determining proper technical parameters and extracting pure dendrobium officinate kimura et migo polysaccharide. Compared with the traditional water extraction method, the method disclosed by the invention has the advantage of low water consumption, environment friendliness and high yield of the dendrobium officinate kimura et migo polysaccharide.

Owner:贺州市星辉科技有限公司

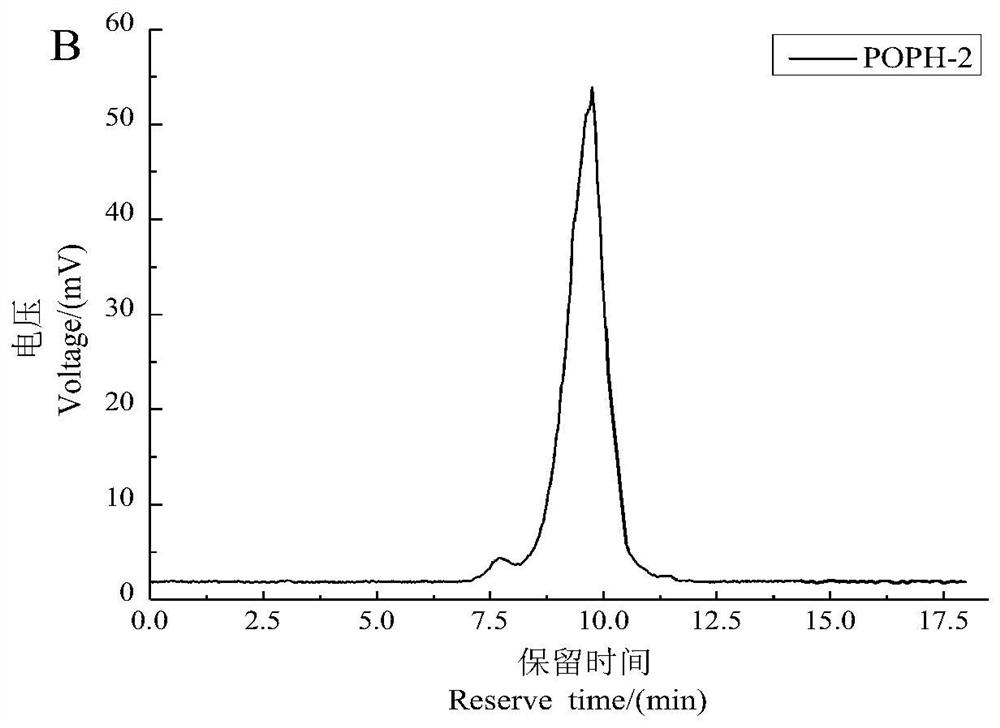

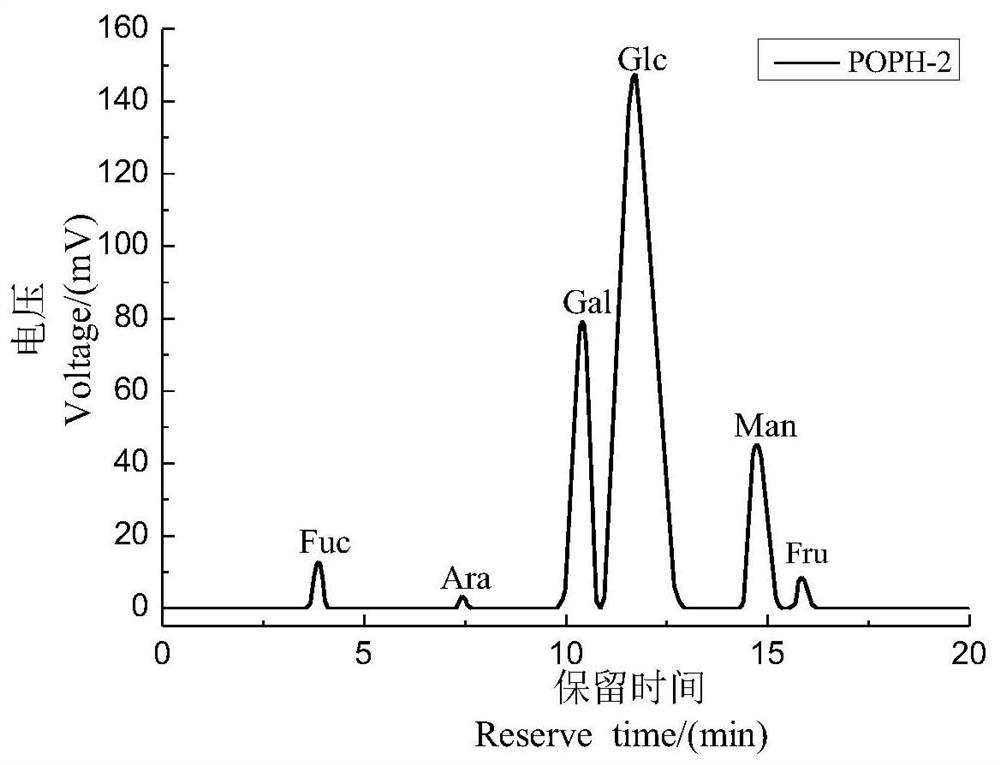

Oyster mushroom galactomannan as well as preparation method and application thereof

ActiveCN111704678AReduce dosageProtects against oxidative damageOrganic active ingredientsAntinoxious agentsBiotechnologyMyogenic cell

The invention relates to oyster mushroom galactomannan as well as a preparation method and an application thereof, and belongs to the field of preparation of effective components of edible mushrooms.The pleurotus ostreatus galactomannan is obtained by performing normal-temperature wall-breaking extraction on dried fruiting bodies of pleurotus ostreatus, and combining extrusion separation, proteinremoval and ion exchange chromatography. According to the wall breaking in combination with extrusion filtration, in the preparation method, the extraction time is shortened, the reagent consumptionis reduced, the energy is saved, and the polysaccharide yield is improved; and an adopted extrusion filtration technology is suitable for separation of a viscous solution, and the obtained oyster mushroom galactomannan has the functional activity of protecting myocyte oxidative damage, and can be used for preparing auxiliary medicines and health foods for protecting myocyte oxidative damage.

Owner:JILIN AGRICULTURAL UNIV

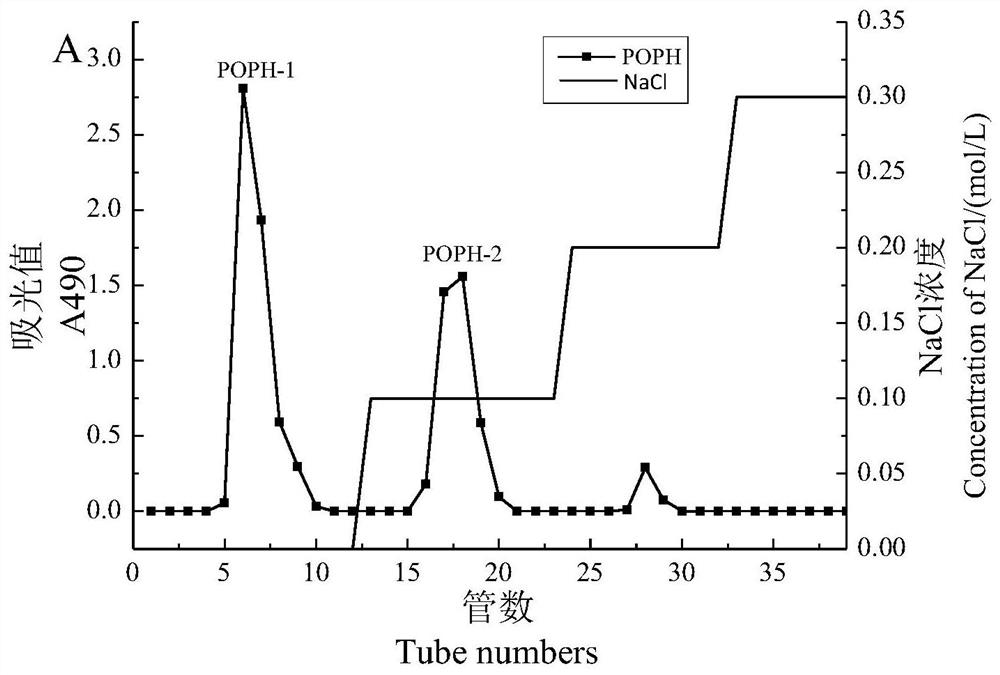

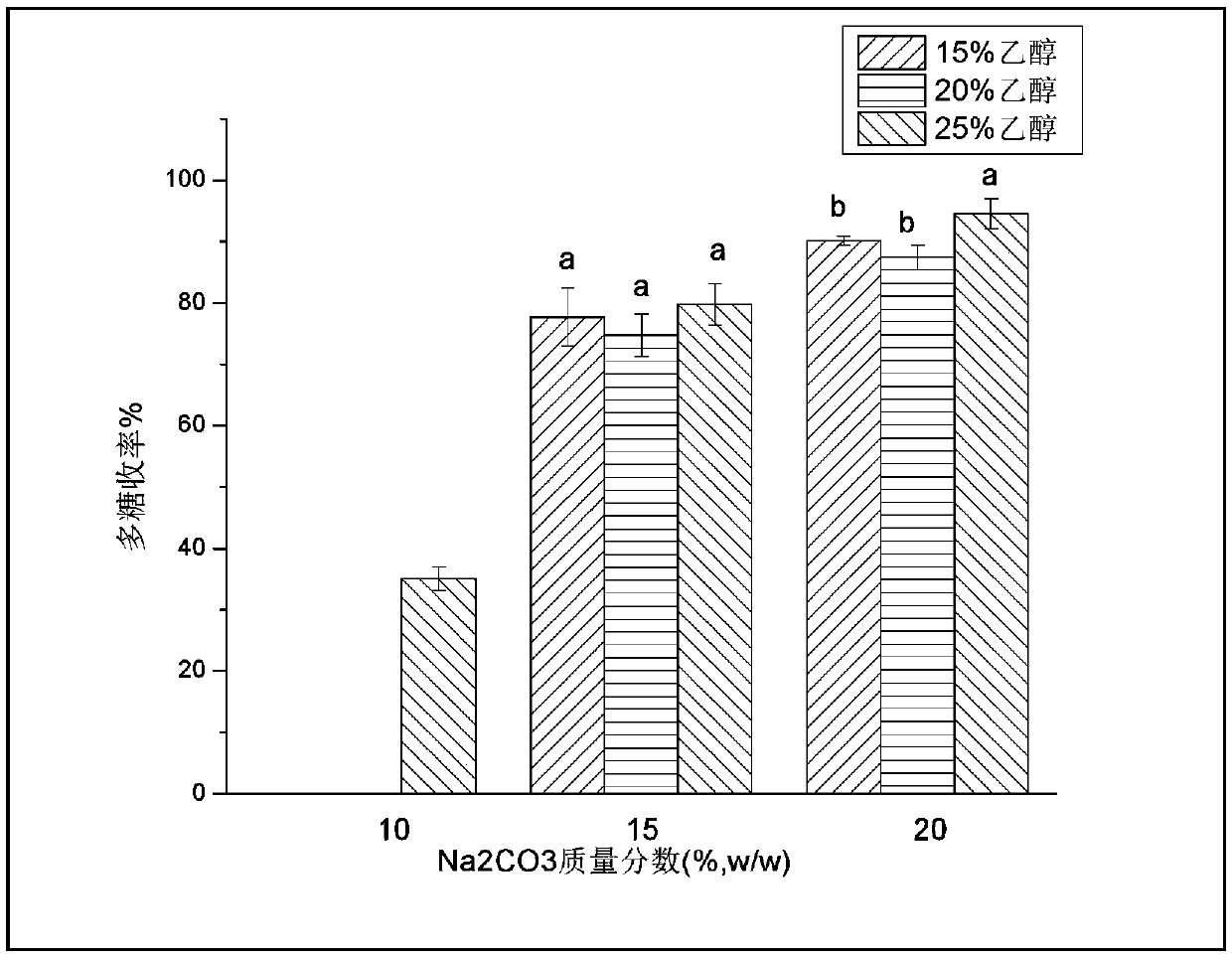

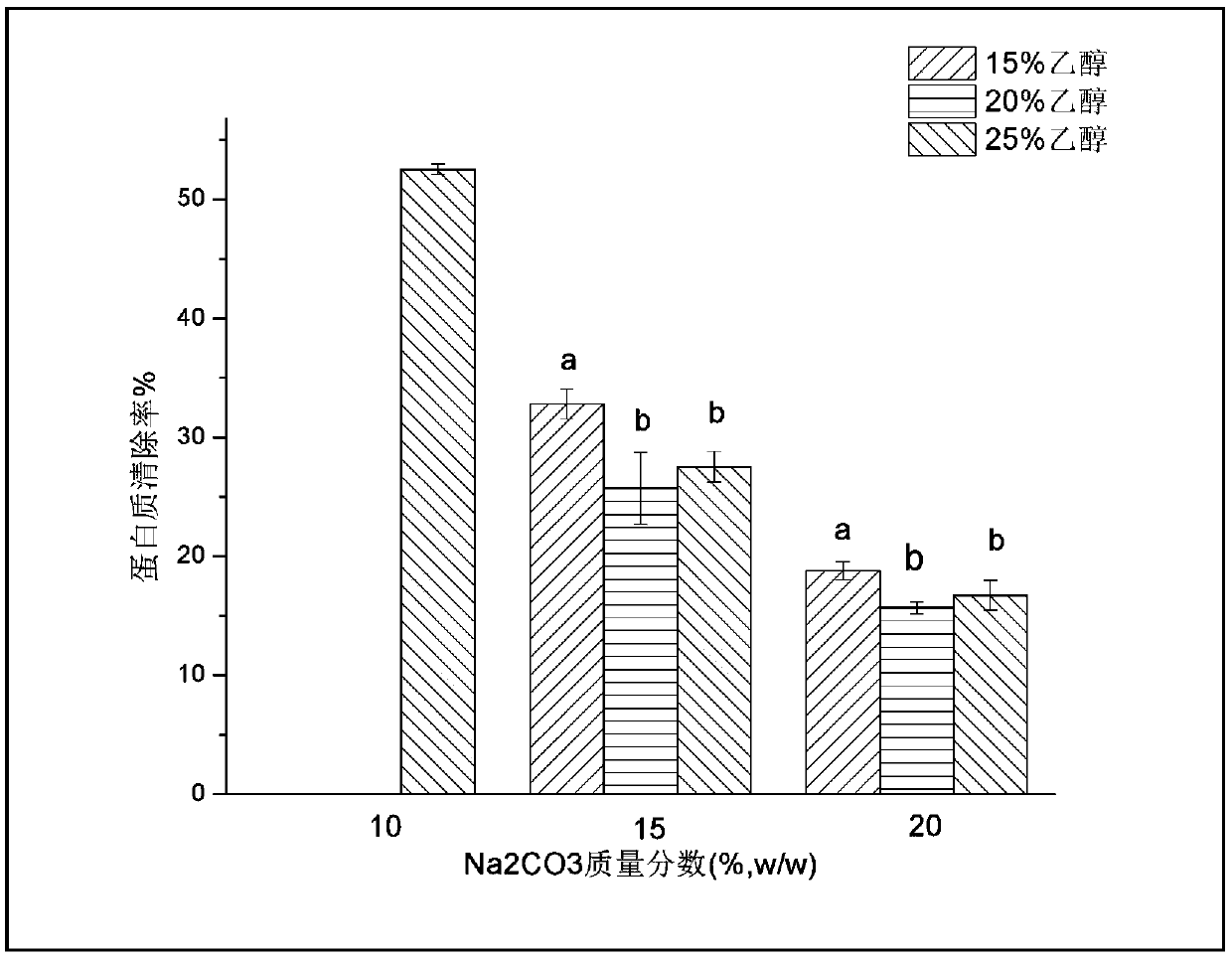

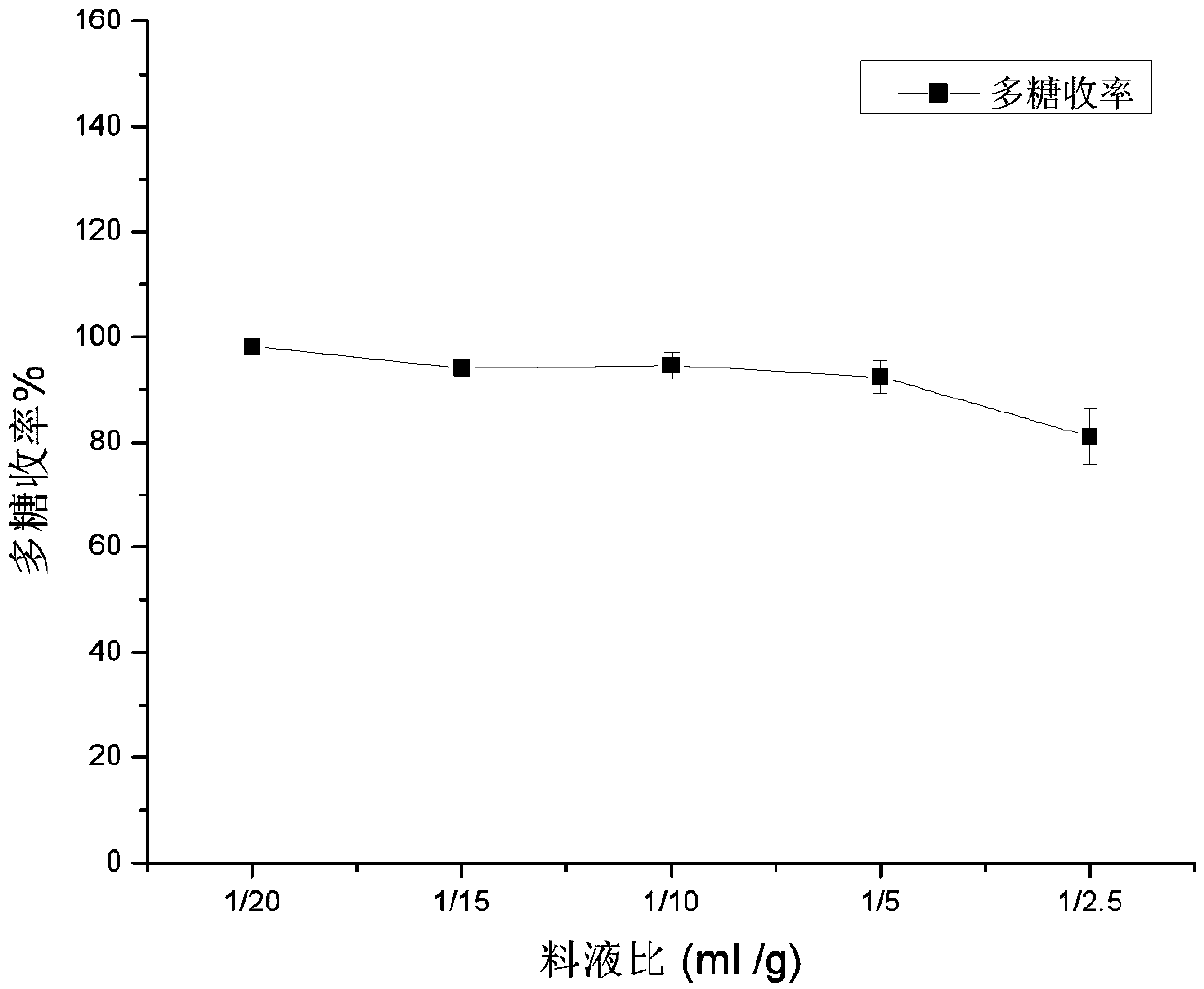

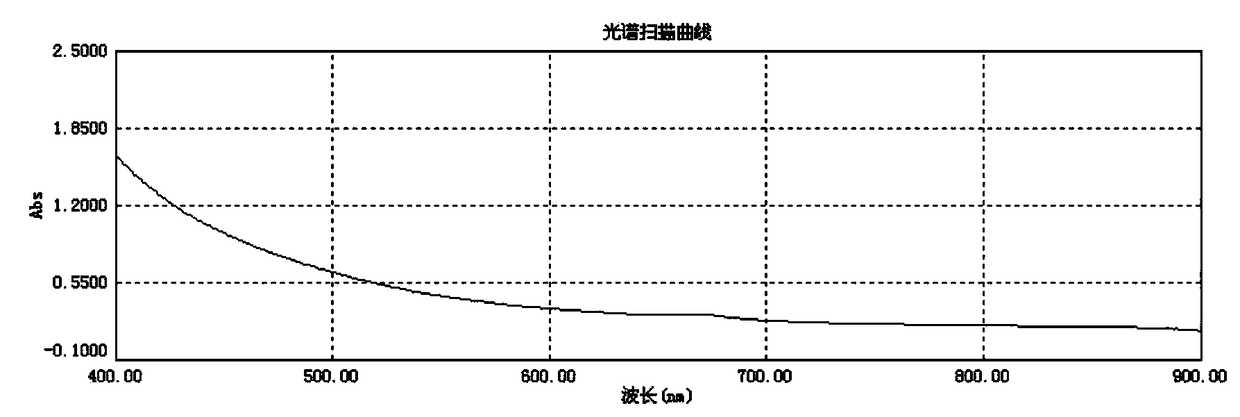

Method for separating and purifying schizophyllan by two aqueous phase extraction

The invention relates to the technical field of schizophyllan extraction, and discloses a method for separating and purifying schizophyllan by two aqueous phase extraction. The method comprises the following steps of preparing schizophyllum fermentation solution and performing extraction by using a sodium carbonate / ethyl alcohol dual water phase extraction system. The schizophyllan extracted by the method has the advantages that the structure is complete; the schizophyllan yield is high; the protein removal rate is high; the operation is simple and convenient; the toxicity is low; the safety is realized and the industrial scale preparation is easy.

Owner:GUANGDONG PHARMA UNIV

Preparation method of honey raisin tree polysaccharide

The invention discloses a preparation method of honey raisin tree polysaccharide. The method comprises the following steps: (1) drying, crushing and degreasing honey raisin tree pulp; (2) extracting honey raisin tree polysaccharide in a vacuum pulsing manner by adopting a complex enzyme preparation, extracting twice, merging extracting solutions, and concentrating in vacuum for later use; (3) carrying out alcohol precipitation on the concentrated honey raisin tree polysaccharide extracting solution, centrifugally separating and drying in vacuum, so as to obtain a honey raisin tree polysaccharide product. The honey raisin tree polysaccharide is extracted by adopting a complex enzyme method, so that the method has the characteristics of short extraction time, high polysaccharide yield, and good storage of active ingredients. Mass transfer is reinforced by vacuum pulsing in the polysaccharide extracting process, so that the efficiency is further improved, and the extraction time is shortened.

Owner:JISHOU UNIVERSITY

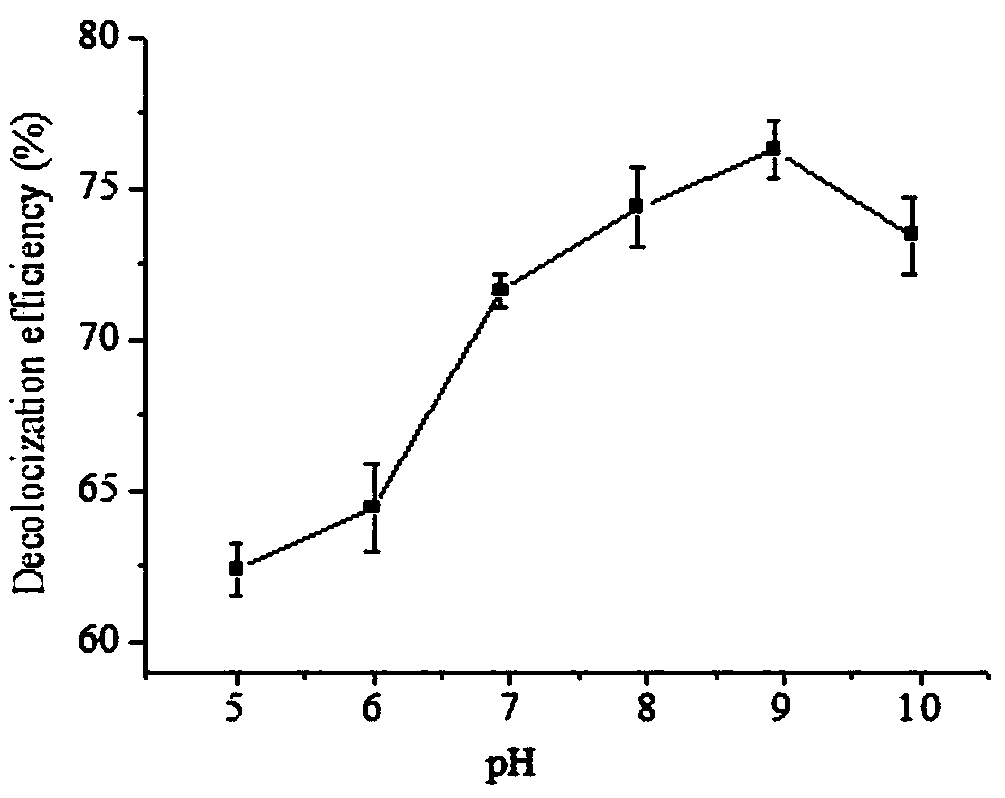

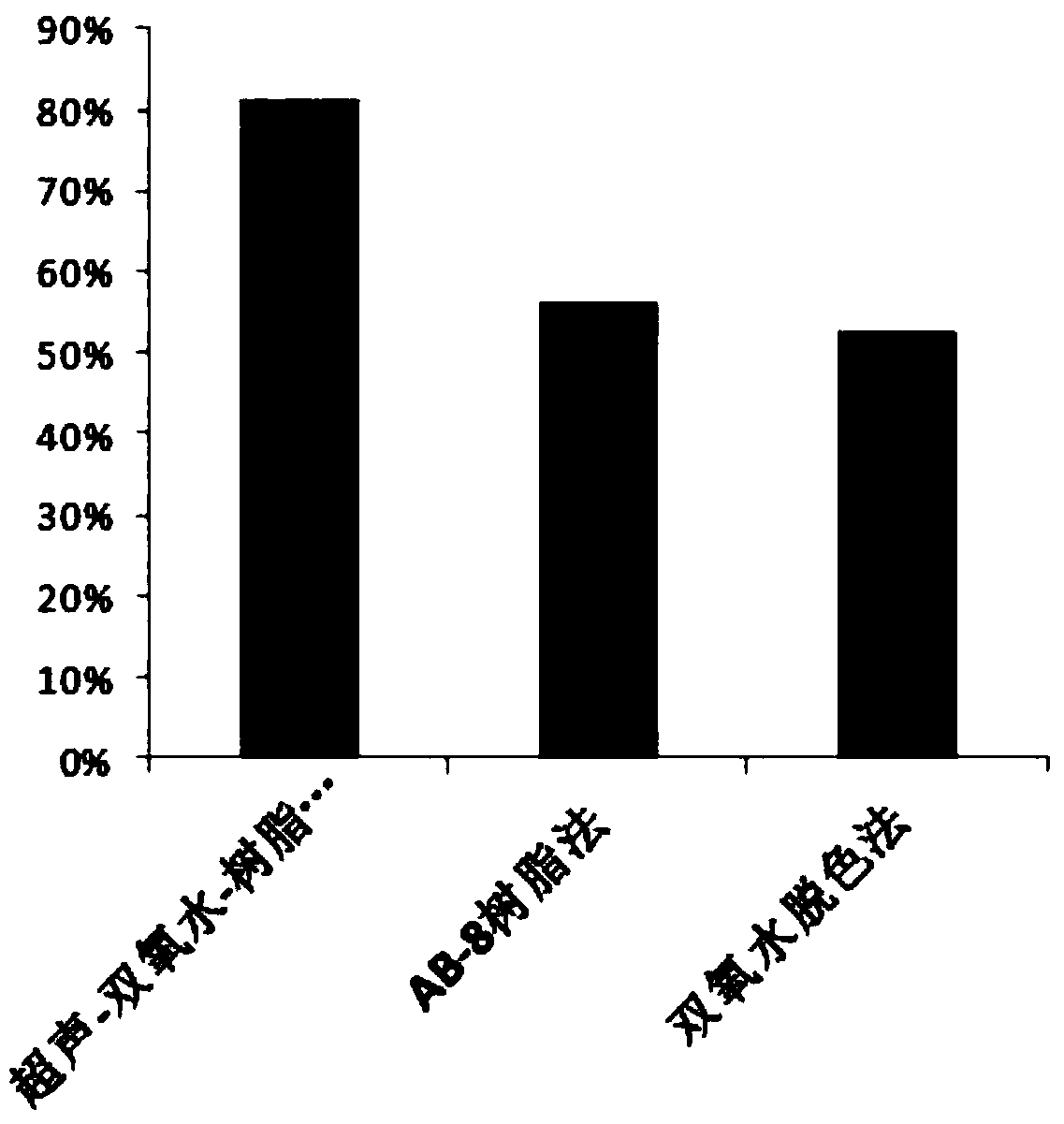

Method for decoloring mesona chinensis benth acid polysaccharide

The invention discloses a method for decoloring mesona chinensis benth acid polysaccharide by combining ultrasound-hydrogen peroxide with macroporous resin. The method comprises the following nine steps: pretreating raw materials, removing impurities by ethanol, carrying out water extraction by weak alkali, carrying out enzymolysis on crude polysaccharide, carrying out ultrasound-hydrogen peroxidedecolorization on a mesona chinensis benth polysaccharide concentrated solution, carrying out decolorization by an AKTA-macroporous resin chromatographic system, dialysing, centrifuging and thus obtaining the polysaccharide. The method for decoloring the mesona chinensis benth acid polysaccharide, disclosed by the invention, has the beneficial effects of being simple and convenient to operate, mild in operating conditions, short in decolorization period, high in polysaccharide yield and low in comprehensive cost.

Owner:NANCHANG UNIV

Preparation method and use of polysaccharide of radix millettiae speciosae

InactiveCN110343186APromote dissolutionGood removal effectOrganic active ingredientsRespiratory disorderNatural productProteinase activity

The invention discloses a preparation method and use of polysaccharide of radix millettiae speciosae, relates to a natural product polysaccharide, and aims to solve the problems of low yields and unsatisfied purities as required for drugs and health care product additives for extraction processes of polysaccharide of radix millettiae speciosae in the prior art. The preparation method comprises thefollowing steps: (1) subjecting radix millettiae speciosae powder to supercritical CO2 extraction to obtain a radix millettiae speciosae extract; (2) soaking the extract in water of equal weight, wherein a complex enzyme accounting for 0.5-1.0% of the raw materials by mass is added to the water, and proportions of the components in the complex enzyme are as follows: cellulase:xylanase:protease =(1-3):(3-1):(2-4); (3) subjecting the enzymolysis mixture from the step (2) to continuous countercurrent extraction with water to obtain an extract; (4) after filtering the extract to remove impurities, adsorbing the extract by using a macroporous resin, filtering the extract, retaining the entrapped liquid, and concentrating the entrapped liquid in vacuum to 10-20% of the original volume; and (5)drying: drying the entrapped concentrate, thereby obtaining the polysaccharide of radix millettiae speciosae. The polysaccharide of radix millettiae speciosae obtained by the preparation method can used in production of medicaments for treating acute lung injury.

Owner:YULIN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com