Complex enzymatic extraction method for laminarin and obtained laminarin

A technology of laminar polysaccharides and extraction methods, which is applied in the field of compound enzyme extraction methods and obtained laminar polysaccharides, can solve the problems of long time consumption, extraction rate, low purity and activity, and pollute the environment, and achieve the effect of improving the yield of polysaccharides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

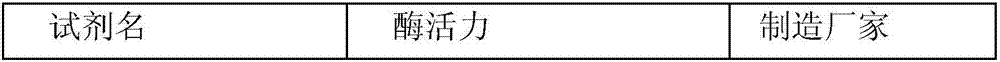

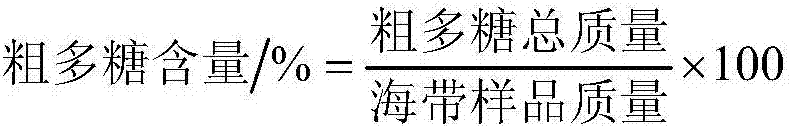

[0045] Kelp processing leftovers are used as raw materials, first dried and crushed, take an appropriate amount of kelp powder, add it to a fully automatic hydrolysis reactor, add a certain volume (solid-liquid ratio 1g: 35ml) of 0.1mol / L, pH6.0 citric acid-sodium citrate Buffer solution, stir well and then add compound enzyme. According to the mass of kelp powder is 1g, the amount of cellulase added is 0.004g, hemicellulase 0.006g, pectinase 0.004g and protease 0.01g;

[0046] Adjust the pH value to 5.5, 45°C, enzymatic hydrolysis for 3 hours, heat up to inactivate the enzyme, take out the hydrolyzate, filter to remove precipitates and insoluble matter, add ethanol to the supernatant until the volume fraction of ethanol in the system is 60%, refrigerate at 4°C overnight . Centrifuge at 3000g / min for 20min, and freeze-dry the precipitate to obtain kelp crude polysaccharide. The crude polysaccharide was formulated into a 25% aqueous solution, and ethanol was added until the et...

Embodiment 2

[0048] Kelp processing leftovers are used as raw materials, first dried and crushed, take an appropriate amount of kelp powder, add it to a fully automatic hydrolysis reactor, add a certain volume (solid-liquid ratio 1g: 40ml) of 0.1mol / L, pH6.0 citric acid-sodium citrate Buffer solution, stir well and then add compound enzyme. According to the mass of kelp powder is 1g, the amount of cellulase added is 0.005g, hemicellulase 0.007g, pectinase 0.005g and protease 0.012g;

[0049] Adjust the pH value to 6.0, 50°C, enzymatic hydrolysis for 3.5h, increase the temperature to inactivate the enzyme, take out the hydrolyzate, remove the precipitate and insoluble matter by suction filtration, add ethanol to the supernatant until the volume fraction of ethanol in the system is 65%, refrigerate at 4°C, overnight. Centrifuge at 3500g / min for 20min, and freeze-dry the precipitate to obtain kelp crude polysaccharide. Prepare a 30% aqueous solution of the crude polysaccharide, add ethanol u...

Embodiment 3

[0051] Kelp processing leftovers are used as raw materials, first dried and crushed, take an appropriate amount of kelp powder, add it to a fully automatic hydrolysis reactor, add a certain volume (solid-liquid ratio 1g: 45ml) of 0.1mol / L, pH6.0 citric acid-sodium citrate Buffer solution, stir well and then add compound enzyme. According to the mass of kelp powder is 1g, the amount of cellulase added is 0.006g, hemicellulase 0.008g, pectinase 0.006g and protease 0.014g;

[0052] Adjust the pH value to 6.5, 55°C, enzymatic hydrolysis for 4 hours, increase the temperature to inactivate the enzyme, take out the hydrolyzate, remove the precipitate and insoluble matter by suction filtration, add ethanol to the supernatant until the volume fraction of ethanol in the system is 70%, refrigerate at 4°C overnight . Centrifuge at 4000g / min for 20min, and freeze-dry the precipitate to obtain kelp crude polysaccharide. Prepare a 35% aqueous solution of the crude polysaccharide, add ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com