Method for decoloring mesona chinensis benth acid polysaccharide

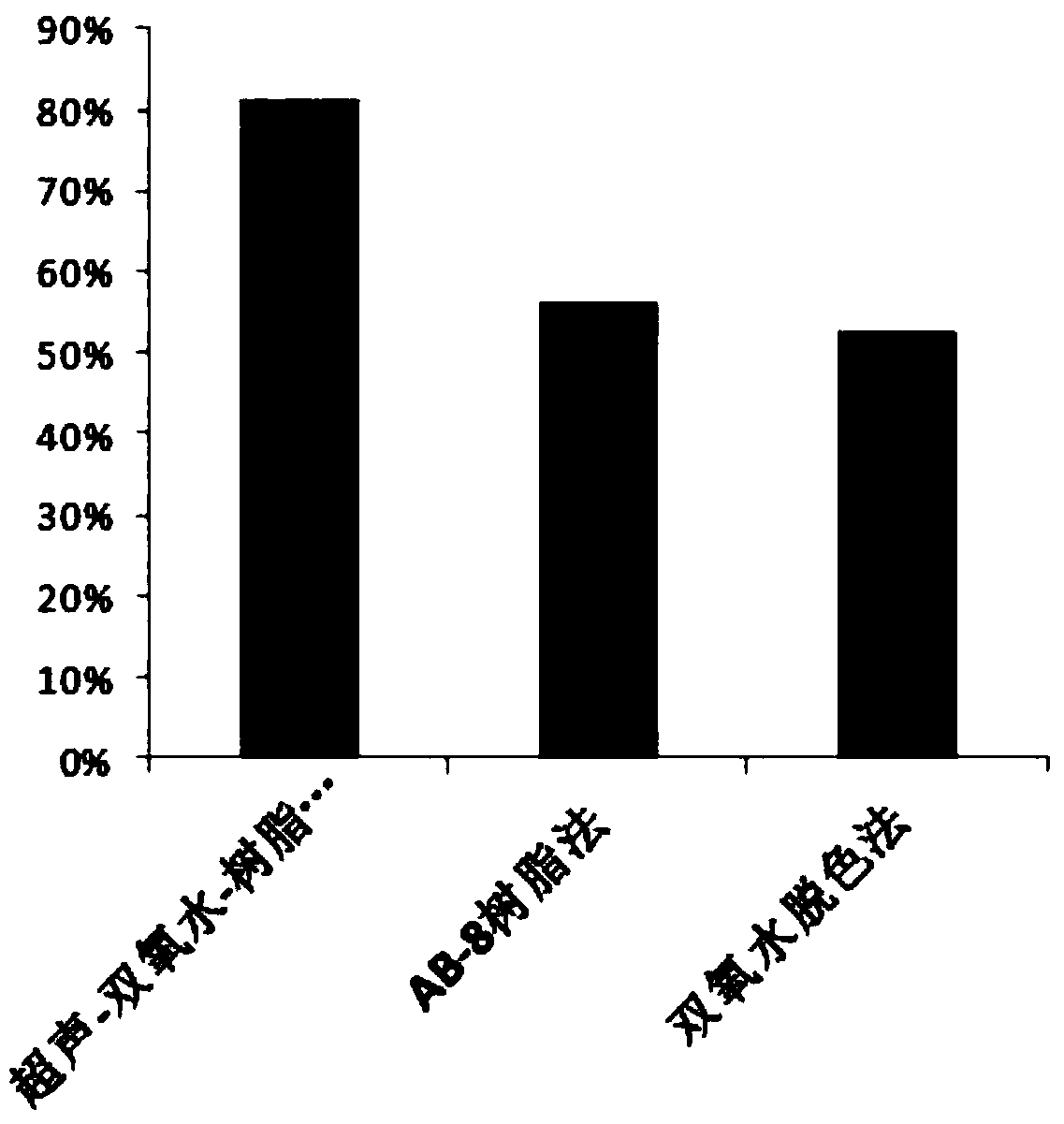

The technology of acid polysaccharide and jelly grass is applied in the field of extraction, separation and purification of biological active substances of natural products, and can solve the problems of complicated operation, low polysaccharide yield, large loss of active polysaccharide components, etc., and achieves mild operating conditions and high polysaccharide yield. , the effect of short decolorization period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

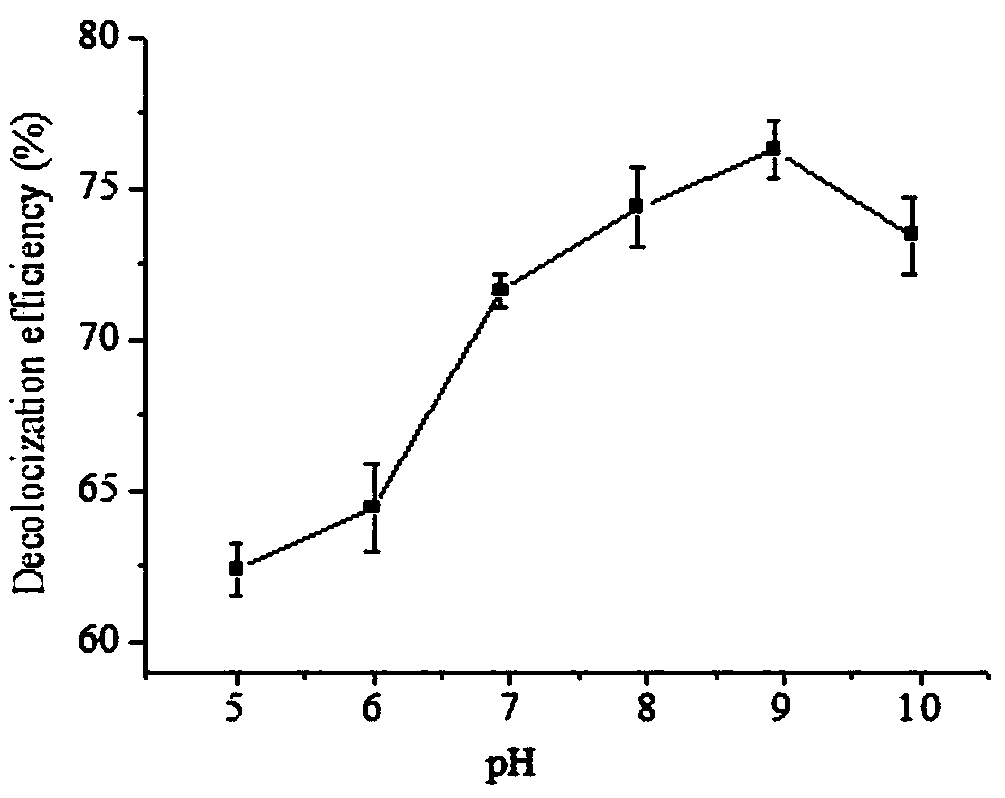

[0026] Decolorization:

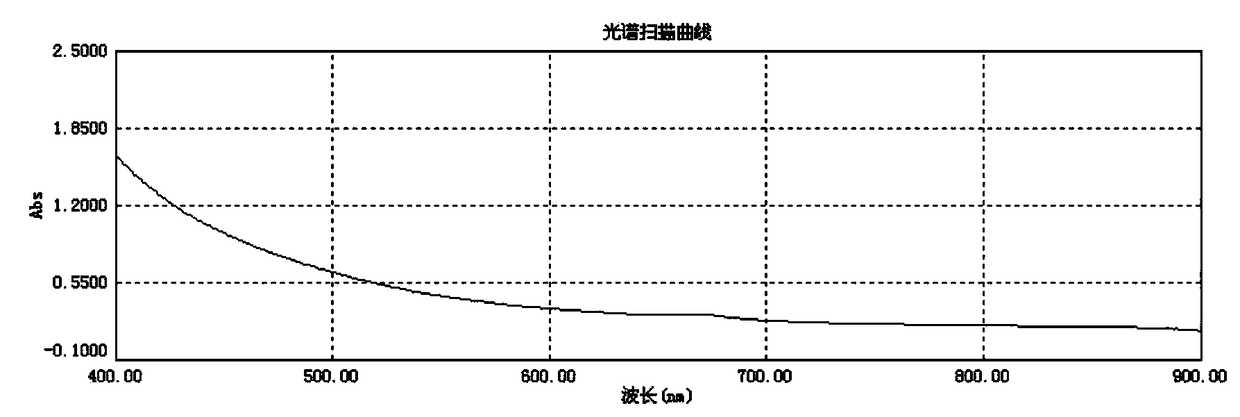

[0027] Clean the jelly grass, remove weeds, rotting leaves, etc., crush the raw jelly jelly to 20 meshes for use, take 100g jelly jelly, add 80% ethanol that is 8 times the weight of the jelly jelly for the first time, soak for 12 hours, and then soak for 12 hours for the second time Soak in 5 times the amount of 80% alcohol for 6 hours, put the jelly jelly in a fume hood, wait for the ethanol to volatilize completely, and then move it to a 40°C oven for drying to obtain the defatted jelly jelly powder. Extract the jelly jelly above with 0.5% sodium carbonate aqueous solution with a solid-liquid ratio of 1:20 at 80°C for 2 hours, cool slightly after leaching, filter with gauze while it is hot, centrifuge the filtrate, and collect The filtrate and the filter residue were repeatedly extracted twice, and the filtrates were combined. The extract was concentrated in vacuo with a rotary evaporator, reduced in pressure and reduced in temperature to 1 / 3 volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com