Oyster mushroom galactomannan as well as preparation method and application thereof

A technology of Pleurotus ostreatus galactomanna and mannaglucose, which is applied in the fields of application, pharmaceutical formulations, polysaccharide/gum-containing food ingredients, etc., and can solve the large demand that cannot meet the industrial development and production of such products, and the extraction time is long , large amount of solvent, etc., to achieve the effect of protecting myoblasts from oxidative damage, shortening the extraction time, and reducing the amount of reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Pulverize the dried fruiting bodies of flat mushrooms and pass through a 40-mesh sieve to form dry fruiting body powders of flat mushrooms. The dried fruiting bodies of flat mushrooms are packed into a wall breaking machine, and deionized water is added according to a material-to-liquid ratio of 1:40. The wall was broken for 10 minutes, and a single-screw extruder was used for extrusion and filtration. The diameter of the die hole of the single-screw extruder was 16 mm, the temperature of the sleeve of the extruder was 58° C., and the screw speed was 220 r / min. Concentrate the extract at 70°C to 1 / 3 of its original volume, cool to room temperature, add 3 times the volume of absolute ethanol, let stand at 4°C for 12 hours, centrifuge at 10,000 r / min for 5 minutes, volatilize the residual ethanol, freeze-dry, and the dry powder is flat Mushroom fruiting body crude polysaccharide.

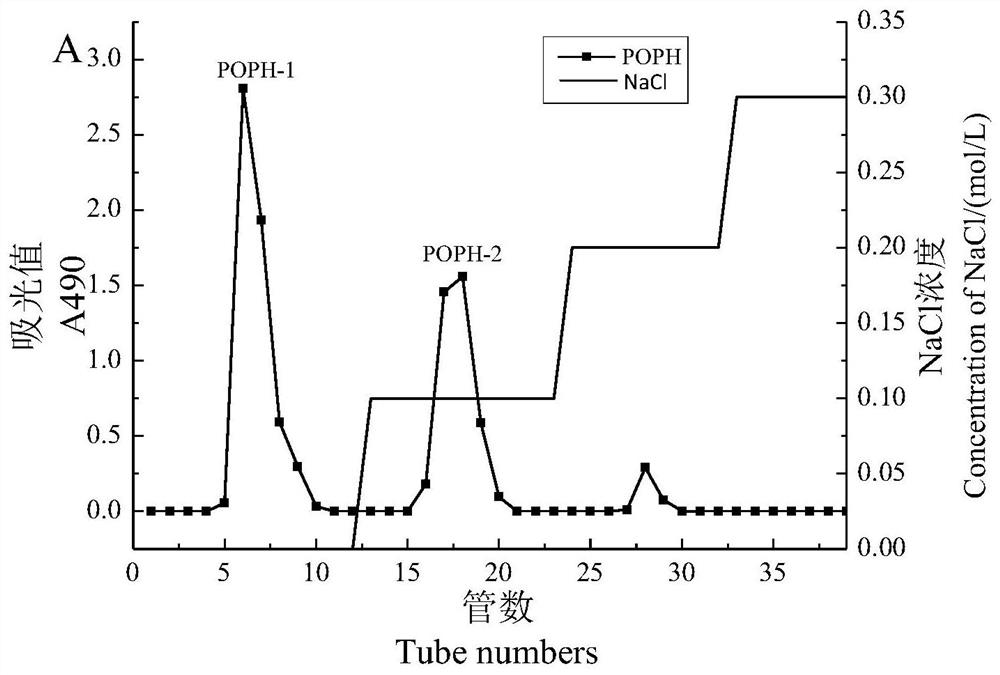

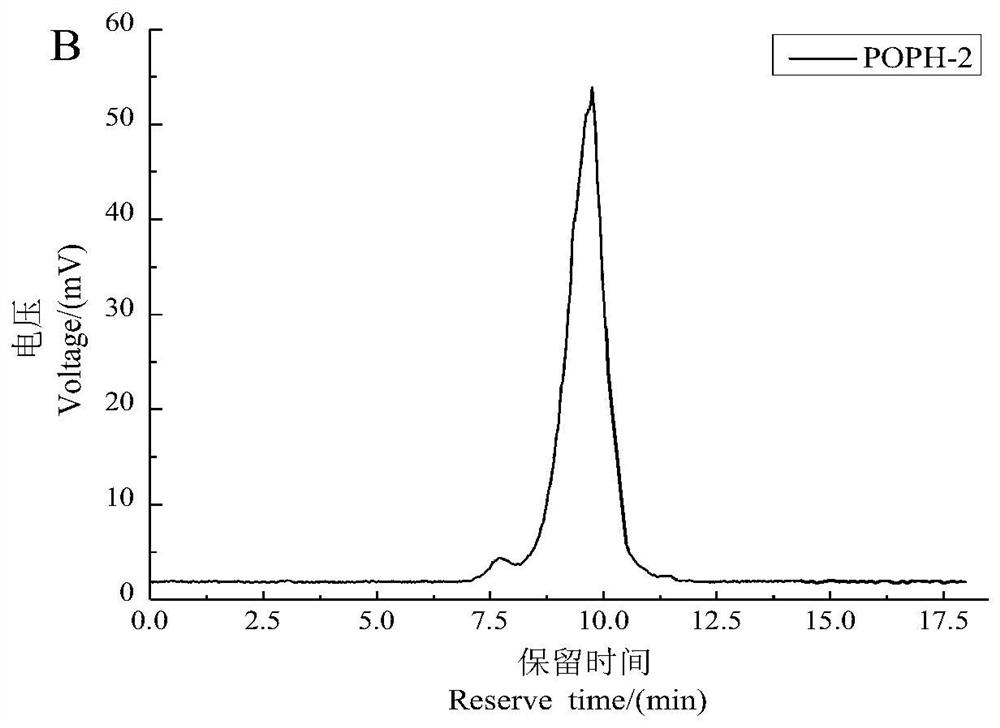

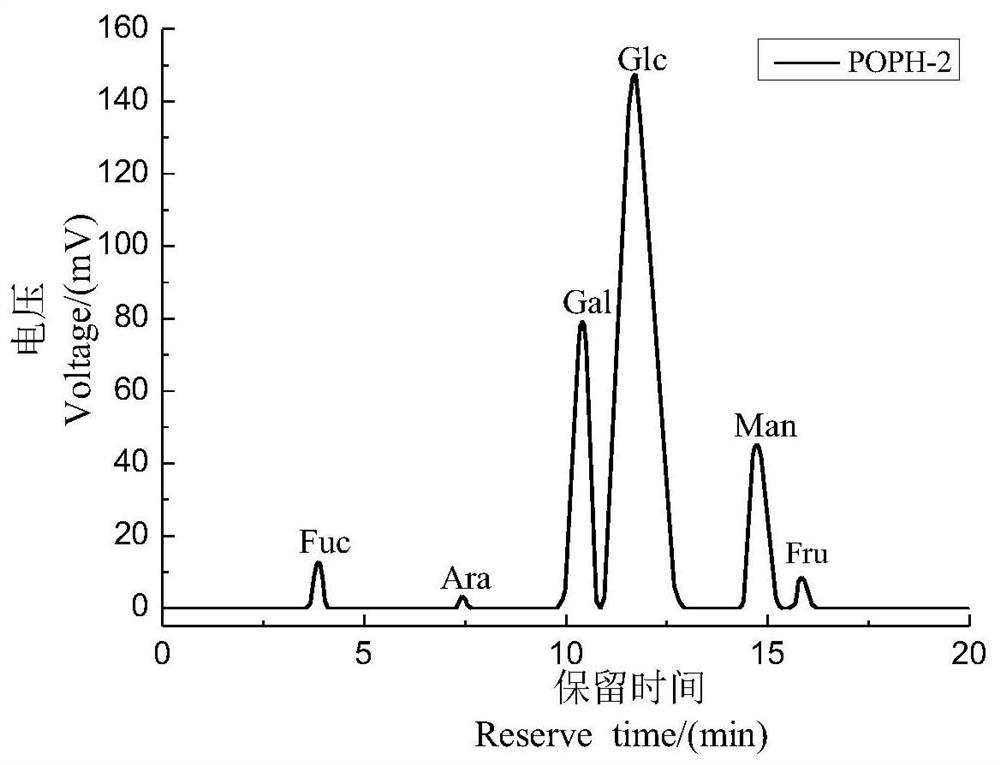

[0027] 2, Pleurotus ostreatus sporocarp crude polysaccharide is prepared into 5mg / ml sol...

Embodiment 2

[0030] 1. Pulverize the dried fruiting bodies of flat mushrooms and pass through a 40-mesh sieve to form dry fruiting body powders of flat mushrooms. Put the dried fruiting bodies powder of flat mushrooms into a wall breaking machine, add deionized water according to the ratio of material to liquid at 1:10, The wall was broken for 20 minutes, and a single-screw extruder was used for extrusion and filtration. The diameter of the die hole of the single-screw extruder was 8mm, the temperature of the extruder sleeve was 90°C, and the screw speed was 240r / min. Concentrate the extract at 90°C to 1 / 4 of its original volume, cool to room temperature, add 4 times the volume of absolute ethanol, let it stand at 4°C for 12 hours, centrifuge at 5000r / min for 10 minutes, volatilize the residual ethanol, freeze-dry, and the dry powder is flat Mushroom fruiting body crude polysaccharide.

[0031]2, Pleurotus ostreatus sporocarp crude polysaccharide is prepared into 5mg / ml solution, adds chlo...

Embodiment 3

[0034] 1. Pulverize the dried fruiting bodies of flat mushrooms and pass through a 40-mesh sieve to form dried fruiting bodies of flat mushrooms. The dried fruiting bodies of flat mushrooms are packed into a wall breaking machine, and deionized water is added according to a material-to-liquid ratio of 1:80. The wall was broken for 2 minutes, and a single-screw extruder was used for extrusion and filtration. The diameter of the die hole of the single-screw extruder was 16 mm, the temperature of the sleeve of the extruder was 40° C., and the screw speed was 160 r / min. Concentrate the extract at 80°C to 1 / 3 of its original volume, cool to room temperature, add 3 times the volume of absolute ethanol, let it stand at 4°C for 12 hours, centrifuge at 7000r / min for 8 minutes, volatilize the residual ethanol, freeze-dry, and the dry powder is flat Mushroom fruiting body crude polysaccharide.

[0035] 2, Pleurotus ostreatus sporocarp crude polysaccharide is prepared into 5mg / ml solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com