Process for extracting polysaccharide from dendrobium officinale leaf according to enzymatic degradation method

A Dendrobium officinale polysaccharide and Dendrobium officinale technology, which is applied in fermentation and other directions, can solve the problem of low polysaccharide yield and achieve the effect of mild operating conditions and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

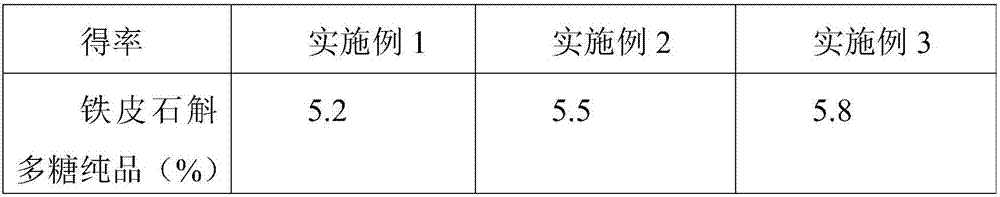

Examples

Embodiment 1

[0028] (1) Get the leaves of Dendrobium officinale and dry them at a temperature of 50°C to a moisture content of <20%;

[0029] (2) Get 100g of dried Dendrobium officinale leaves and pulverize it, reflux 2 times with 95% ethanol solution with volume solubility of 10 times the weight, and merge the medicinal residues;

[0030] (3) Dry the above-mentioned combined medicinal residues, add distilled water according to the solid-liquid weight ratio of 1 / 30, and ultrasonically treat for 20 minutes at a power of 300W;

[0031] (4) Adjust the pH value to 6, then raise the temperature to 40°C in a water bath, then add cellulase and pectinase equivalent to 2% of the mass of medicinal residues respectively, and perform enzymatic hydrolysis for 2 hours, wherein the cellulose The enzyme is 500U / g, and the pectinase is 500U / g, which can destroy all kinds of cellulose in the cell tissue;

[0032] (5) The temperature of the water bath is raised to 50° C., the pH value is adjusted to 6.5, pa...

Embodiment 2

[0041] (1) Get the leaves of Dendrobium officinale and dry them at a temperature of 65°C to a moisture content of <20%;

[0042] (2) Get 500g of dried Dendrobium officinale leaves and pulverize it, reflux 3 times with 15 times the volume solubility of the weight of the ethanol solution of 95%, and merge the medicinal residues;

[0043] (3) Dry the above-mentioned combined medicinal residues, add distilled water according to the solid-liquid weight ratio of 1 / 25, and ultrasonically treat for 25 minutes at a power of 400W;

[0044] (4) Adjust the pH value to 6.5, then raise the temperature to 45°C in a water bath, then add cellulase equivalent to 2.5% of the mass of the dregs and pectinase equivalent to 2.5% of the mass of the dregs, and perform enzymatic hydrolysis for 2.5 hours, wherein the fiber Sulfase is 500U / g, pectinase is 500U / g, which can destroy all kinds of cellulose in cell tissue;

[0045] (5) The temperature of the water bath is raised to 55°C, the pH value is adj...

Embodiment 3

[0054] (1) Get the leaves of Dendrobium officinale and dry them at a temperature of 50-80°C to a moisture content of <20%;

[0055] (2) Get 1000g of dried Dendrobium officinale leaves and pulverize it, reflux 4 times with 20 times the volume solubility of the weight of the ethanol solution of 95%, and merge the medicinal residues;

[0056] (3) Dry the above-mentioned combined medicinal residues, add distilled water according to the solid-liquid weight ratio of 1 / 20, and ultrasonically treat for 30 minutes at a power of 500W;

[0057] (4) Adjust the pH value to 7, then raise the temperature to 50°C in a water bath, then add cellulase equivalent to 3% of the mass of medicinal residues and pectinase equivalent to 3% of the mass of medicinal residues, and perform enzymatic hydrolysis for 3 hours, wherein the cellulose The enzyme is 500U / g, and the pectinase is 500U / g, which can destroy all kinds of cellulose in the cell tissue;

[0058] (5) The temperature of the water bath is rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com