Green high-efficiency recyclable SO2 gas absorbent and preparation thereof

A technology of gas absorbent and absorbent, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve the problems of unfavorable industrialization and high cost of amino acid ionic liquids, achieve low equipment requirements, improve desulfurization effect, and reduce SO2 The effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

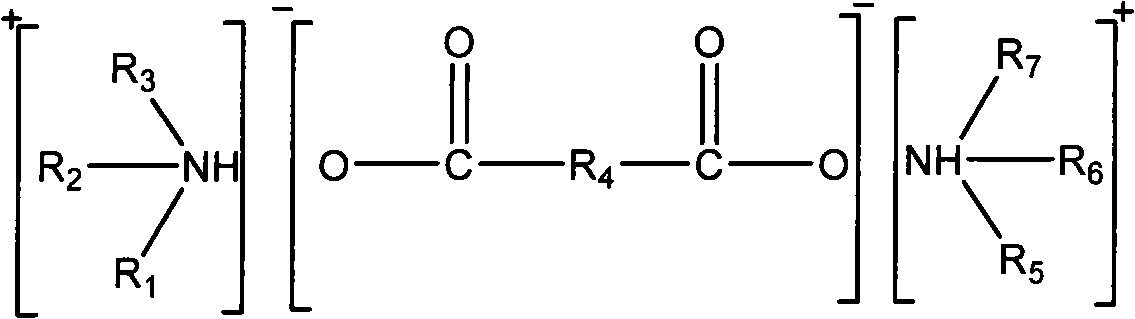

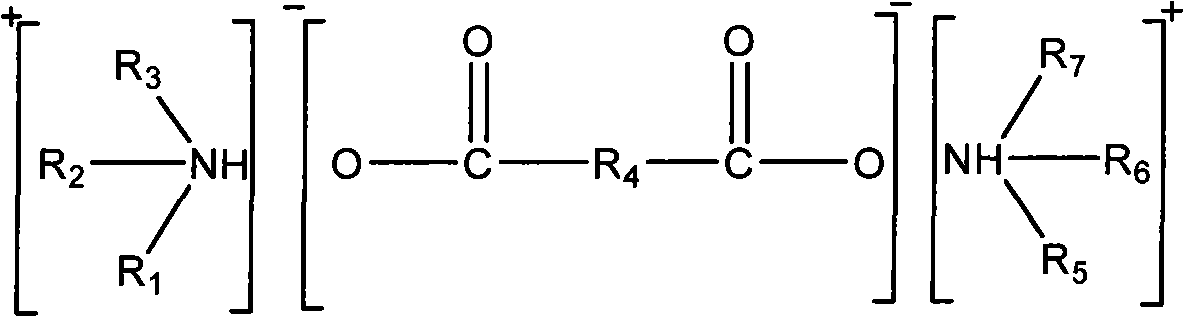

Method used

Image

Examples

Embodiment 1

[0030] The experimental device is mainly composed of a three-necked flask with a condensing reflux pipe on it, and is equipped with a sealed dropping funnel and a stirring device. The molar ratio of oxalic acid decrystallized water to triethylamine is 1:2, and ethanol is used as a solvent. The temperature was controlled at 25°C, triethylamine was added dropwise, and reacted at 25°C for 10 hours. The mixed liquid was rotatably distilled under reduced pressure at 70°C to remove unreacted raw materials and solvents, and finally a light yellow solid of triethylamine oxalic acid was obtained.

[0031] Accurately weigh the solid triethylamine oxalic acid, dissolve it in a small amount of ethanol, mix it with an equal amount of activated carbon, evaporate the solvent at 70°C, then put the mixture into the absorber, and pass sulfur dioxide gas into the absorber at room temperature for SO 2 Absorption; place the ionic liquid with absorption equilibrium in an environment of 80°C for SO...

Embodiment 2

[0033] Assemble the three-neck flask, condensing reflux tube, sealing dropping funnel and stirring device together. The molar ratio of malonic acid to triethylamine is 1:2, and ethanol is used as a solvent. The temperature was controlled at 10°C, triethylamine was added dropwise, and the reaction was carried out for 10 hours. The mixed liquid was rotatably distilled under reduced pressure at 70° C. to remove unreacted raw materials and solvents, and finally a colorless ionic liquid of triethylamine malonate was obtained with a yield of 86.5%.

[0034] Accurately weigh the triethylamine malonate ionic liquid and place it in the absorber, place the absorber in a constant temperature system at 25°C, and feed SO into the absorber 2 gas, the ionic liquid turns yellow and transparent, and the ionic liquid with absorption balance is placed in an environment of 90°C for SO 2 In the desorption test, the equilibrium absorption capacity reached 94.2% in 1 hour, and the desorption equil...

Embodiment 3

[0036] The experimental device is mainly composed of a three-necked flask with a condensing reflux pipe on it, and is equipped with a sealed dropping funnel and a stirring device. The molar ratio of succinic acid to triethylamine is 1:2, and distilled water is used as a solvent to react at 40° C. for 10 hours. Heating at 140° C. removes unreacted raw materials and solvents, and finally obtains a light yellow ionic liquid of triethylamine succinic acid.

[0037] Accurately weigh the triethylamine succinic acid ionic liquid and place it in the absorber, place the absorber in a constant temperature system at 10°C, and feed SO into the absorber 2 Gas, with crystals produced. The ionic liquid with absorption equilibrium was placed in an environment of 100 °C for SO 2 In the desorption test, the theoretical adsorption capacity can reach 93.4% in 3 hours, and it can be completely desorbed in 2 hours. SO absorption after 50 cycles 2 The molar ratio to triethylamine succinic acid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com