Patents

Literature

91 results about "Dried peach" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biologic fresh-keeping method of peach and apricot

InactiveCN101228899AKeep the flavorLittle change in nutritional ingredients and active ingredientsFruit and vegetables preservationDried peachAdditive ingredient

The invention provides a biological preservation method for peach and apricot, which belongs to a field of biological preservation technology. The storage steps of the invention are that: (1) carrying out disinfection treatment to the storage environment of peach and apricot; (2) spraying a preservative solution with a concentration of 20mg-500mg / kg on the peaches and the apricots on trees one day before picking, and picking fruits after the preservative solution is dried with air; (3) packing the dried peaches and the apricots sprayed with preservative solution into membrane bags for storage or storing after dipping in a preservative solution with a concentration of 0.001mg-580mg / kg for 0.1-40min and drying. The components, proportioning and preparation method of the preservative solution is the technical core of the invention. The preservative solution is prepared by extraction, cineration, etc., vegetable chemistry methods. The method can extend the preservation time for 2-3 times, prolong the shelf life for 7-15 days and ensure that the original flavor of the stored peach and apricot is kept and a plurality of nutritional components are less changed, which is an important break through in the research field of storage and preservation.

Owner:李桂凤

Medicament for treating chronic obstructive emphysema and chronic pulmonary heart disease

InactiveCN101129660ANo drug resistanceNo dependencyPowder deliveryPill deliveryPolygonum fagopyrumDried peach

The invention relates to a Chinese medicament for treating chronic obstructive emphysema and pulmonary heart disease, which comprises the following crude herbal materials (by weight portion): chastetree fruit 15-25 parts, apricot kernel 5-15 parts, pinellia tuber 12-20 parts, schisandra fruit 10-35 parts, Sichuan fritillary bulb 8-35 parts, rhizome of Sichuan lovage 12-20 parts, red sage root 15-30 parts, root of balloonflower 5-15 parts, mulberry bark 8-30 parts, coltsfoot flower 10-18 parts, astragalus root 15-30 parts, pilose asiabell root 10-40 parts, ginkgo nut 12-20 parts, trichosanthes anguina 20-35 parts, white atractylodes rhizome 10-20 parts, Chinese angelica root 15-35 parts, poria cocos wolf 10-30 parts, honeysuckle flower 10-30 parts, coptis root 5-15 parts, golden buckwheat rhizome 10-30 parts, ledebouriella root 9-30 parts, licorice root 5-20 parts, dried peach 12-30 parts, wild or spiny jujuba seed 10-30 parts, pearl 6-15 parts.

Owner:江景秀

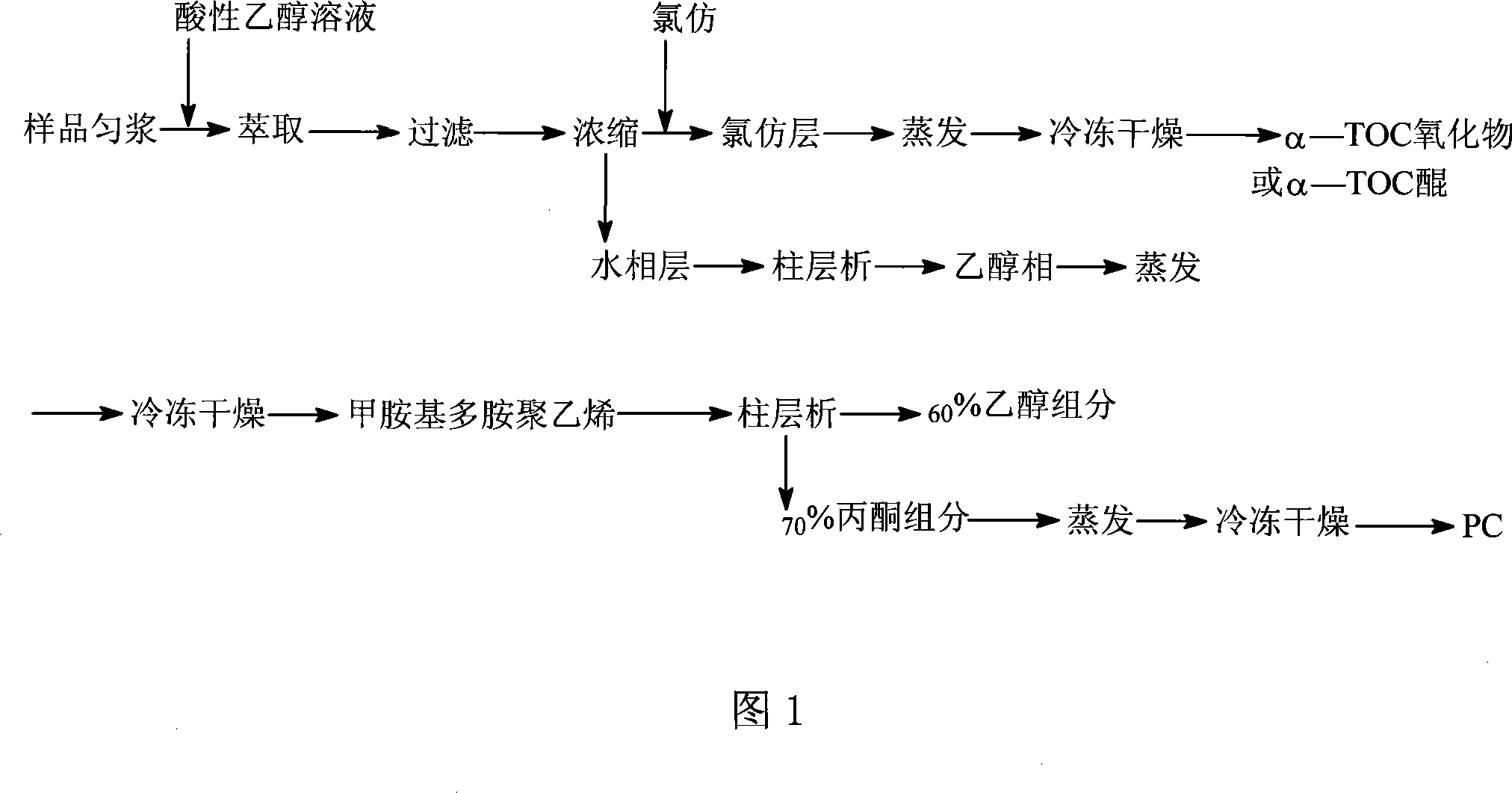

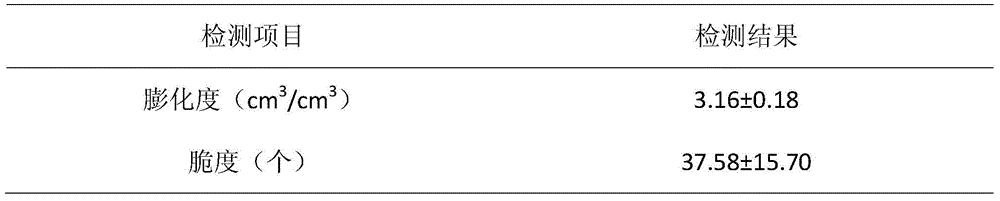

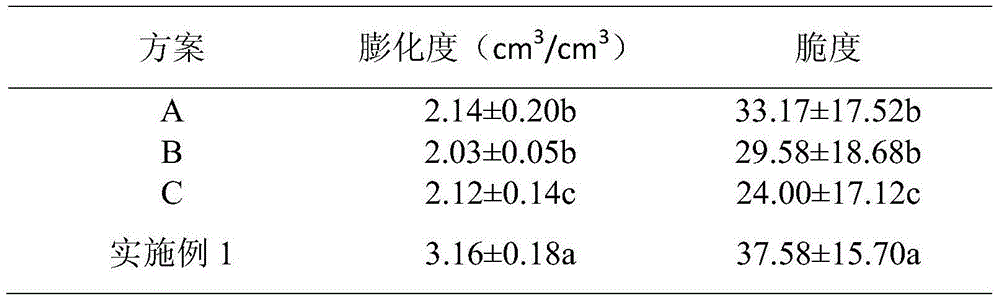

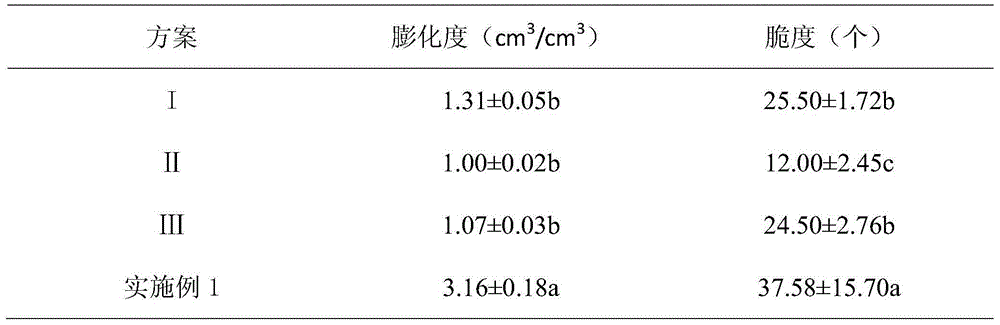

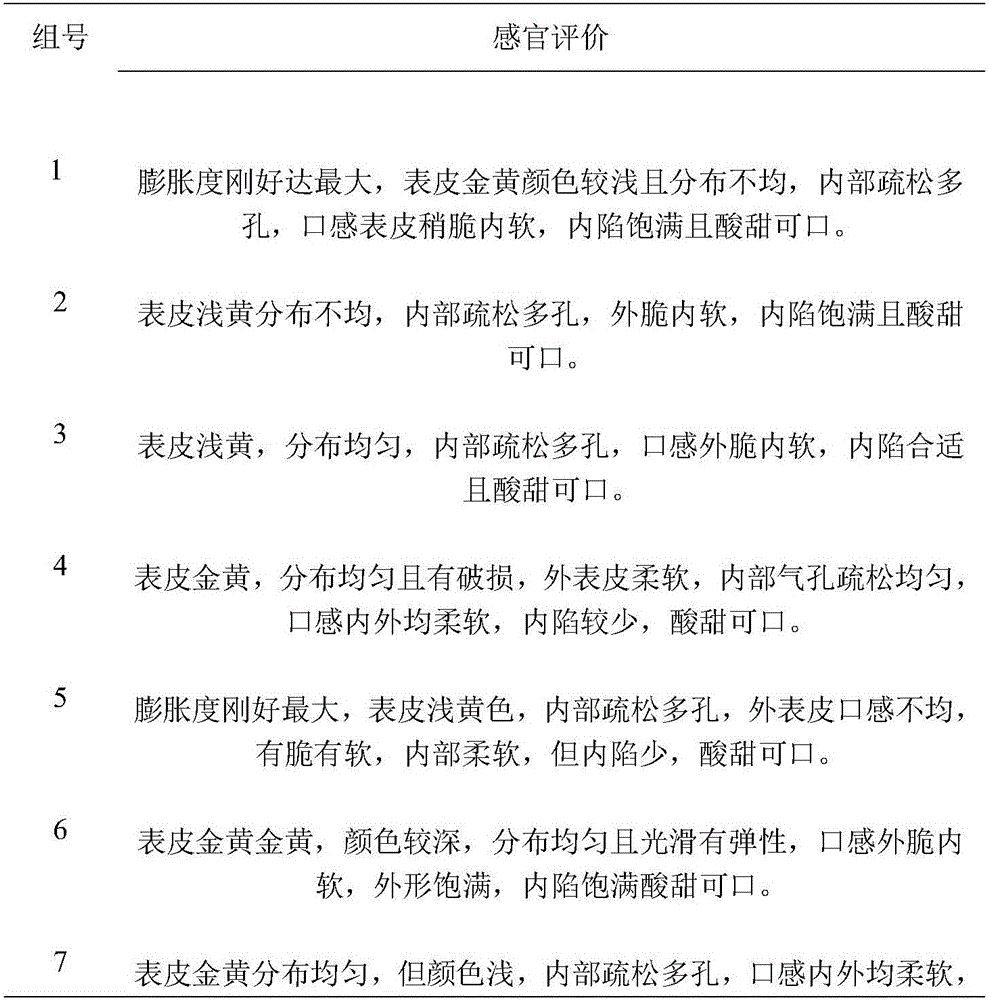

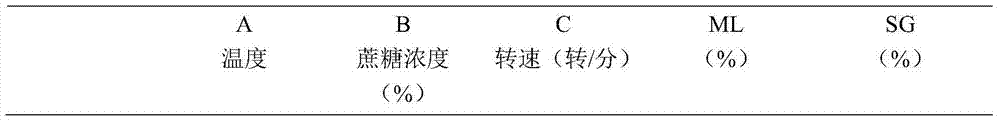

Preparation method of crisp peach chips

ActiveCN104543290AHigh degree of puffingImprove crispnessConfectionerySweetmeatsFood additiveDried peach

The invention discloses a preparation method of crisp peach chips. The preparation method comprises the following steps: (1) slicing peaches and soaking in a penetrating fluid to carry out osmotic dehydration so as to obtain osmotic dehydrated peach chips; (2) pre-drying the osmotic dehydrated peach chips to obtain pre-dried peach chips; (3) putting the pre-dried peach chips in a heated puffing tank to carry out pulsation differential pressure expansion drying, namely, pressurizing the puffing tank, maintaining the pressure and then releasing the pressure of the puffing tank, carrying out pulsation differential pressure expansion drying for at least one time to obtain puffed peach chips; (4) carrying out vacuum drying on the puffed peach chips in the puffing tank to obtain the crisp peach chips. The preparation method of the crisp peach chips has the following advantages: the crisp peach chips are high in puffing degree, high in crispness and proper in sweetness; by using a maltose fluid for osmotic dehydration, the color and the luster of the peach chips can be maintained and no food additives are added; the method is simple to operate, easy to control and low in cost.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Peach flower beauty tea

InactiveCN1853493APromote blood circulationImprove beauty effectPre-extraction tea treatmentDrug compositionsDried peachGreen tea

A face-beautifying peach flower tea is proportionally prepared from dried peach flower, green tea, Chinese angelica root, yam and peach kernel through choosing raw materials, crushing, mixing, packing and sterilizing. It is suitable for the adult women.

Owner:蒋佃水

Medicine which is used for treating acnes of young people and has skin whitening effect and preparation method thereof

InactiveCN102552642AAnti-inflammatoryAnti-inflammatory reachAnthropod material medical ingredientsHydroxy compound active ingredientsLiver and kidneyDried peach

The invention relates to a medicine which is used for treating acnes of young people and has a skin whitening effect and a preparation method thereof. The medicine comprises the following raw materials by weight: 40 to 60 grams of dry peach flower, 5 to 15 grams of angelica dahurica, 10 to 30 grams of tuckahoe, 20 to 40 grams of wax gourd seed, 20 to 40 grams of bitter almond kernel, 10 to 30 grams of fresh aloe gel, 5 to 15 grams of honey, 4 to 6 grams of pure glycerol, 5 to 15 grams of pure milk and 40 to 60 grams of vanishing cream. The preparation method comprises the following steps of: crushing the dry peach flower, the angelica dahurica, the tuckahoe, the wax gourd seed and the bitter almond kernel into 200-mesh fine powder, stirring to form paste by using the vanishing cream, adding the fresh aloe gel, the pure glycerol, the honey and the pure milk, and stirring to form paste. The medicine has the effects of cleaning skin dirt, clearing away heat, easing paining, relieving itching, resisting inflammation, removing vivotoxin, improving local blood circulation, promoting cell regeneration, softening skin stratum corneum, astringing, preserving moisture, moistening and nourishing, and is absorbed by local mucous membranes without the supersession of liver and kidney, so that medicinal potency reaches lesion sites directly to achieve the effects of easing pain, resisting inflammation, expelling toxin, fading black spots and scars and beautifying.

Owner:屈广花

Extraction method for peach gum polysaccharide

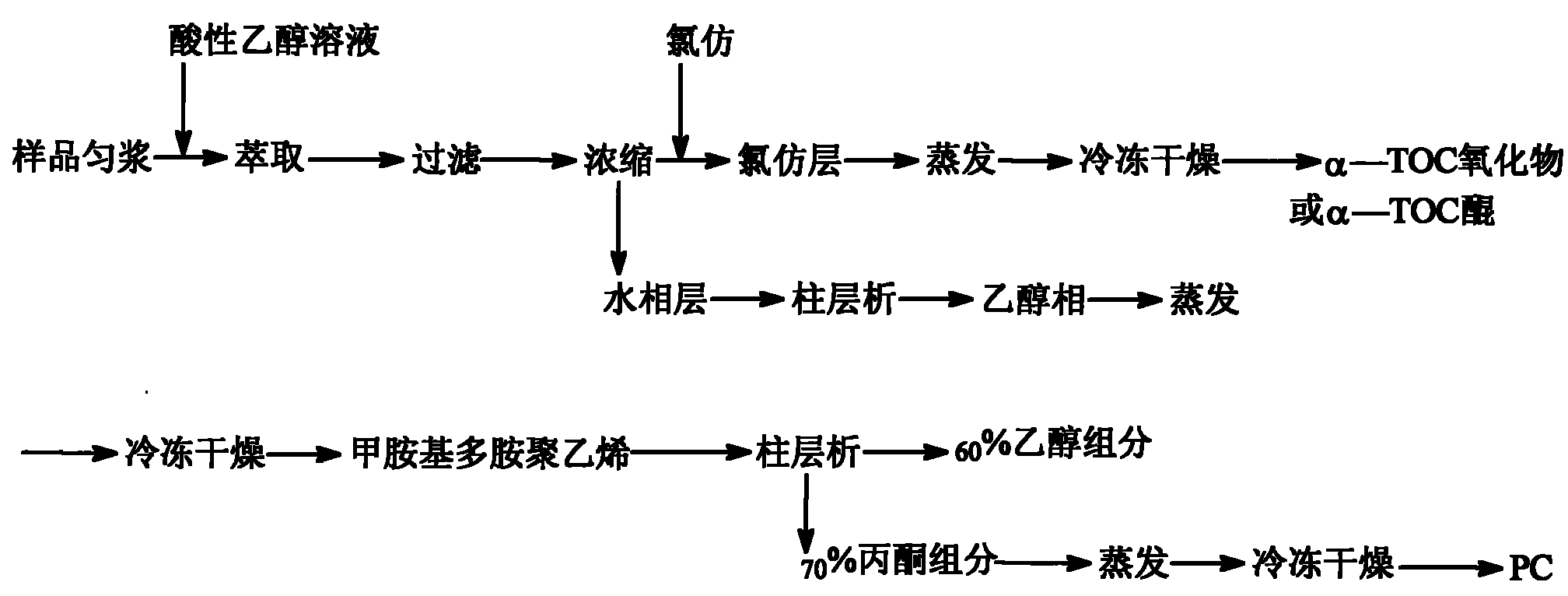

The invention specifically relates to an extraction method for peach gum polysaccharide, belonging to the technical field of extraction of natural active components. The extraction method comprises the following steps: subjecting dried peach gum to impurity removal and crushing and carrying out treatment at 60 to 65 DEG C; then mixing the treated peach gum with distilled water under stirring for extraction; carrying out centrifugation with a high-speed centrifuge so as to obtain a supernatant; subjecting the supernatant to vacuum concentration; then adding liquid nitrogen into a concentrate obtained in the previous step; storing the concentrate at 2 to 3 DEG C and removing a precipitate; adding absolute ethyl alcohol into the concentrate without the precipitate; and subjecting another precipitate obtained in the previous step to vacuum drying and grinding so as to obtain the peach gum polysaccharide. Unlike conventional methods where proteins in peach gum are removed through a Sevage process, the extraction method provided by the invention realizes removal of proteins in the peach gum by adding liquid nitrogen into the concentrate according to a volume ratio of the concentrate to the liquid nitrogen of 10: 1-2, and the removal rate of proteins reaches 99.5%; moreover, the process of removal poses no pollution to the peach gum polysaccharide; and thus, the high-quality peach gum polysaccharide is finally obtained.

Owner:杨俊

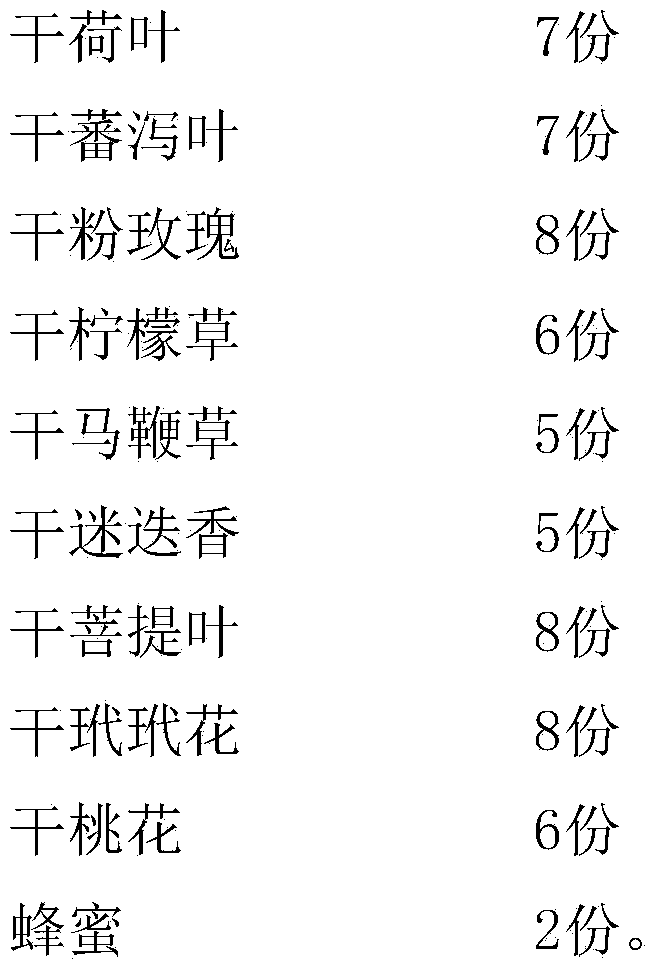

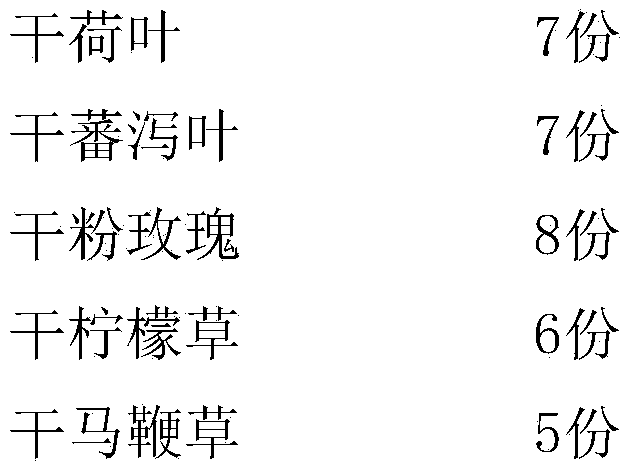

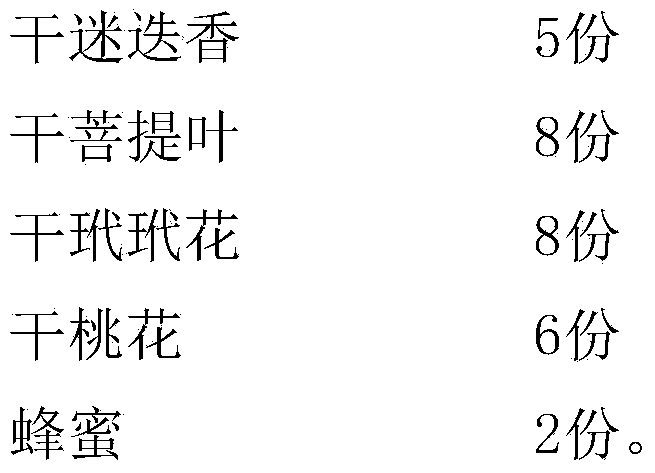

Weight loss herb tea bag and preparation method thereof

The invention discloses a weight loss herb tea bag and relates to the technical field of tea production and processing. The weight loss herb tea bag is characterized in that a seasoning bag consists of bagged seasonings, wherein the bagged seasonings consist of the following components in parts by weight: 7 parts of dried lotus leaf, 7 parts of dried cassia angustifolia, 8 parts of dried pink rose, 6 parts of dried lemon-grass, 5 parts of dried verbena officinalis, 5 parts of dried rosmarinus officinalis, 8 parts of dried linden leaves, 8 parts of dried seville orange flower, 6 parts of dried peach blossom and 2 parts of honey. The method comprises the following steps: (1) selecting the dried lotus leaf, dried cassia angustifolia, dried pink rose, dried lemon-grass, dried verbena officinalis, dried rosmarinus officinalis, dried linden leaves, dried seville orange flower and dried peach blossom which are collected in mountains and are cleaned and naturally aired for later use; (2) preparing the honey into granules; and (3) bagging and sterilizing the aired dried lotus leaf, dried cassia angustifolia, dried pink rose, dried lemon-grass, dried verbena officinalis, dried rosmarinus officinalis, dried linden leaves, dried seville orange flower, dried peach blossom and granular honey, thereby obtaining the product. The weight loss herb tea bag is diversified in components, good in weight loss effect and good in taste and has the effects of reducing fat, diminishing inflammation and losing weight.

Owner:郎溪县雪瓯茶业有限公司

Peach-Bamboo tea compound and preparing method

InactiveCN1528159ATreat constipationTreatment of amenorrheaPre-extraction tea treatmentDiseaseTree root

The present invention discloses a peach bamboo tea using fruit tree plant as main raw material. Its composition comprises dried peach fruit, dried peach leaf, dried peach flower, dried tree root, bamboo leaf and green tea. Said invention can be used for directly curing diabetes (insulin dependence and chronic complicating disease), at the same time can be used for curing the diseases of hypertension, amenorrhea, constipation, senile dementia and cerebral thrombosis, etc. and can be used for regulating immunity of human body and activating immune interferon of human body self-body complement system to attain the goal of implementing synchronous health-care and therapy.

Owner:单仲琢

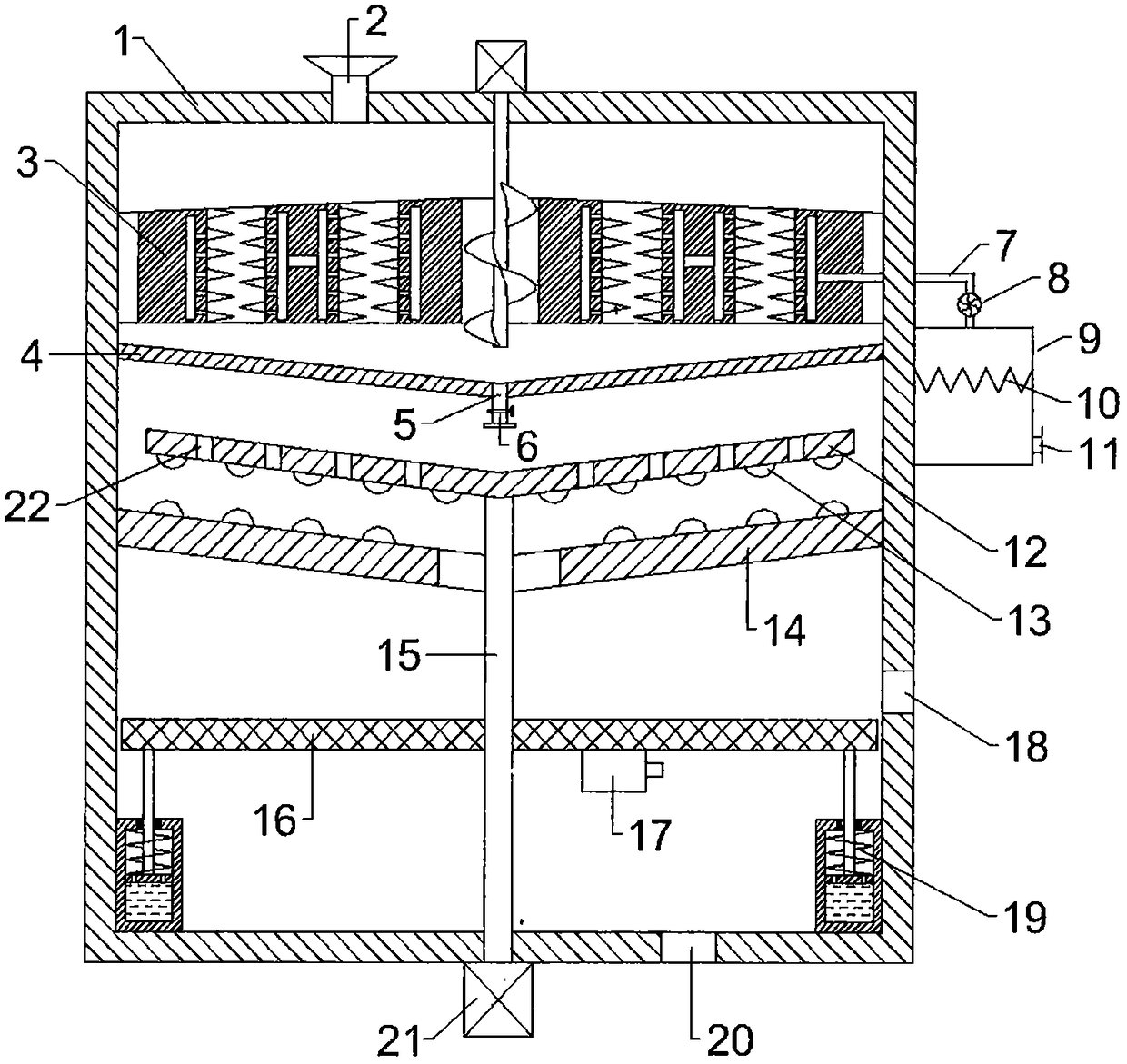

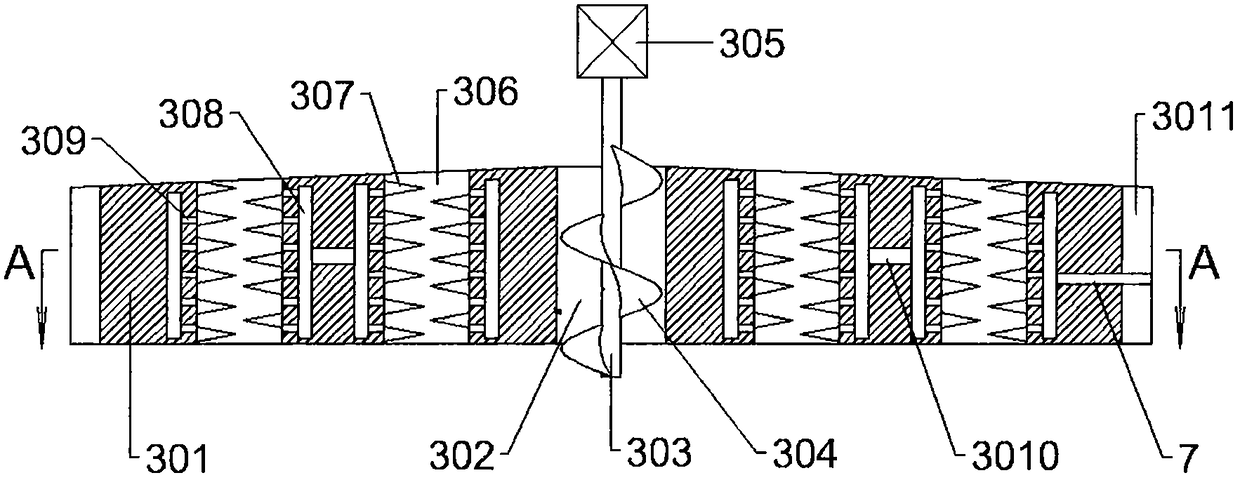

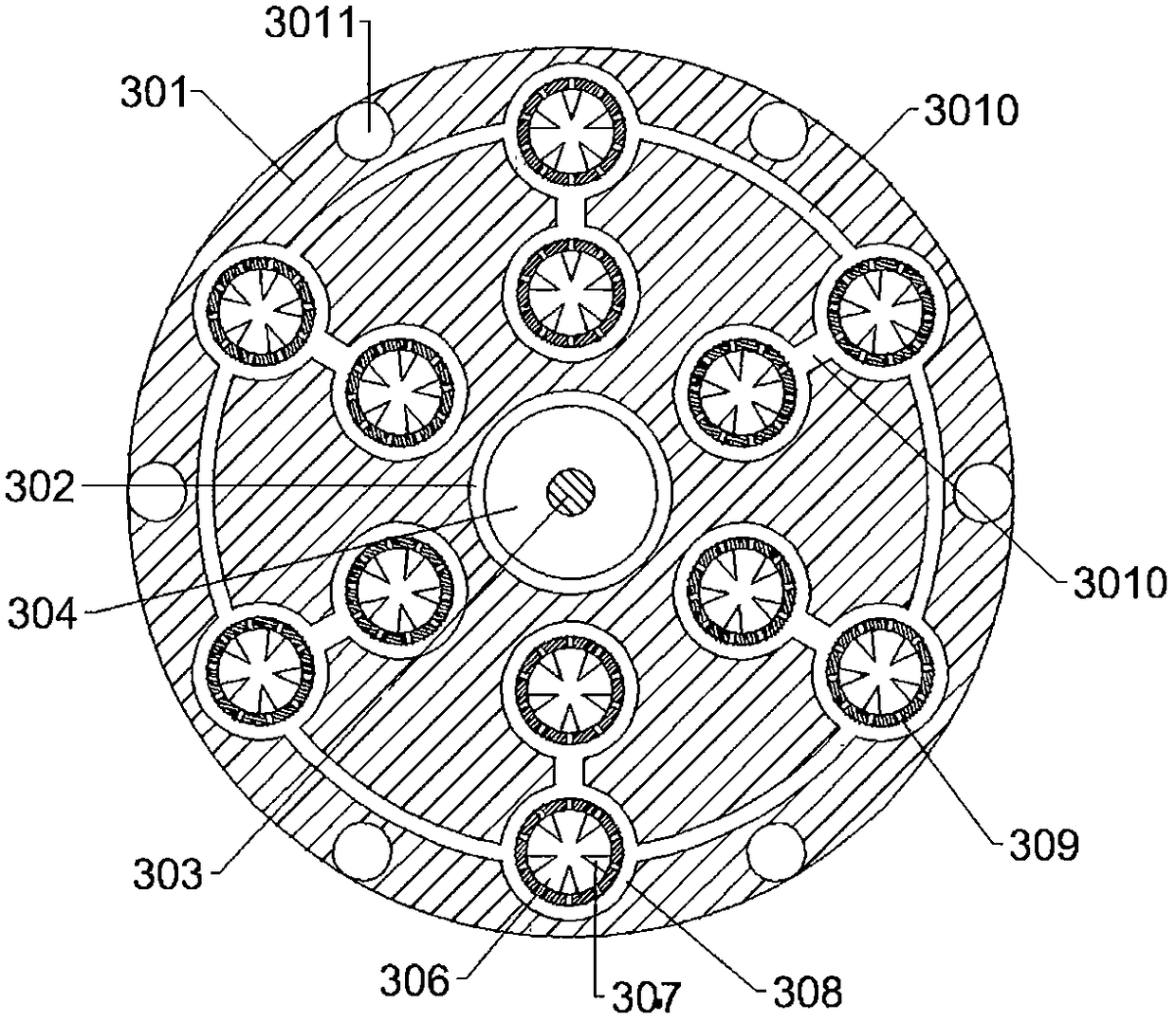

Integrated drying and smashing equipment with uniform drying function for peach gum production

InactiveCN108387101AUniform dryingWell mixedDrying gas arrangementsDrying solid materialsDried peachControl valves

The invention provides integrated drying and smashing equipment with a uniform drying function for peach gum production. The integrated drying and smashing equipment with the uniform drying function for peach gum production comprises a shell, wherein a clapboard is fixedly connected onto inner side walls of the shell; a cross section of the clapboard is in a V shape; a discharging channel is arranged in the middle of the clapboard; an electronic control valve is arranged on the discharging channel; a drying device is arranged between the upper side of the clapboard and the inner top part of the shell; a second rotary shaft is arranged at the position, under the clapboard, in the shell, and is vertically arranged; and the bottom end of the second rotary shaft penetrates through the shell soas to downwards extend. The integrated drying and smashing equipment with the uniform drying function for peach gum production provided by the invention has the following beneficial effects that firstly, hot air produced by a hot air generating device enters air distribution cavities through a pipeline, then uniformly enters each air distribution cavity through a connecting channel, and then uniformly enters circulation through holes through air outlet holes so as to uniformly and effectively dry peach gum; and the peach gum is disturbed through disturbance bulges arranged on inner side wallsof the circulation through holes, so that a mixing effect of the peach gum and the hot air is better.

Owner:刘奇美

Cosmetic compound capable of preserving moisture, moistening skin and delaying senescence

InactiveCN102973461AEasy to lockSimple ingredientsCosmetic preparationsToilet preparationsSide effectDried peach

The invention relates to a cosmetic compound capable of preserving moisture, moistening skin and delaying senescence, and a preparation method of the cosmetic compound. The cosmetic compound is prepared from the following Chinese herbal medicines, raw materials and water in parts by weight: 100-200 parts of Job tears, 30-50 parts of astragalus membranaceus, 50-80 parts of aloes, 40-60 parts of winter melon kernel, 20-40 parts of siberian cocklebur, 15-35 parts of peach blossoms, 20-40 parts of asarum, 1-5 part(s) of glycolic acid, 5-15 parts of nicotinamide and 100-300 parts of deionized water. The preparation method comprises the following steps of: weighing the raw materials in proportion; grinding the Job tears, performing extraction on the astragalus membranaceus, the siberian cocklebur, and the winter melon kernel and the asarum to which the water and ethanol are added, thus obtaining mixed extracting solution; performing extraction on the dry peach blossoms by supercritical CO2 fluid, thus obtaining peach blossom oil; and performing ethanol extraction on the aloes to which ethanol solution is added, thus obtaining aloe extracting solution, etc. The cosmetic compound has high safety performance, few side effects and a good cosmetic effect.

Owner:汤燕

Manufacturing method of acne-removing moisturizing tea

InactiveCN103125654AEasy to operateEffective in moisturizing acneTea substituesDried peachWarm water

The invention discloses a manufacturing method of acne-removing moisturizing tea, which comprises the following steps: step one, taking 20 g of fresh roses, performing cleaning, disinfection, airing to prepare dried roses; step two, taking 20 g of roselle buds, performing cleaning, disinfection, airing to prepare dried roselle; step three, taking 20 g of peach blossom petals, performing cleaning, disinfection, airing to prepare dried peach blossoms; step four, mixing the dried roses, dried roselle, and dried peach blossoms according to a ratio of 1:1:1, and grinding into powder; step five, infusing in warm water with a temperature of 80 DEG C. The method of the invention is simple and easy to operate, and the acne-removing moisturizing tea has good acne-removing and moisturizing effects.

Owner:汤汉忠

Process for preparing peach blossom wine

InactiveCN101260359AAdjust endocrinePromote circulationAlcoholic beverage preparationCassia abbreviataHuman body

The invention discloses a method for producing a peach blossom liquor, including preparation, extraction, blending and packaging. The invention is characterized in that the preparation of the invention is as follows: 20 to 30 portions by weight of dried peach blossoms, 20 to 40 portions by weight of cassia seeds, 10 to 30 portions by weight of peach seeds, 10 to 30 portions by weight of angelicas, 20 to 40 portions by weight of aloes, 40 to 60 portions by weight of rock candies, 100 portions by weight of water and 100 portions by weight of distilled spirits between 50 and 60 degrees are mixed; after mixing, the dried peach blossoms, cassia seeds, peach seeds and angelicas are ground into particles or powder, put in distilled spirits together with aloes, kept at a temperature of between 60 and 100 DEG C for 30 to 60 minutes, and filtered for collecting water extracting solutions; water extracting solutions and the liquid extracts of distilled spirits are mixed, blended and packaged. The production method does not damage active ingredients contained in peach blossoms, which are beneficial to human bodies, and can effectively extract active ingredients and make active ingredients combined and mutually dissolved, nurse internal secretions of human bodies, promote the blood circulation and improve the blood supply of peripheral nerves of human skins, and further facilitate the skin care and the body health.

Owner:贾冀升

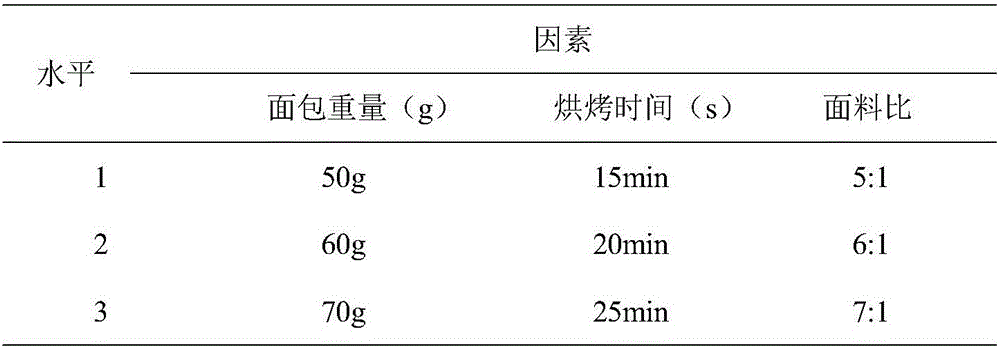

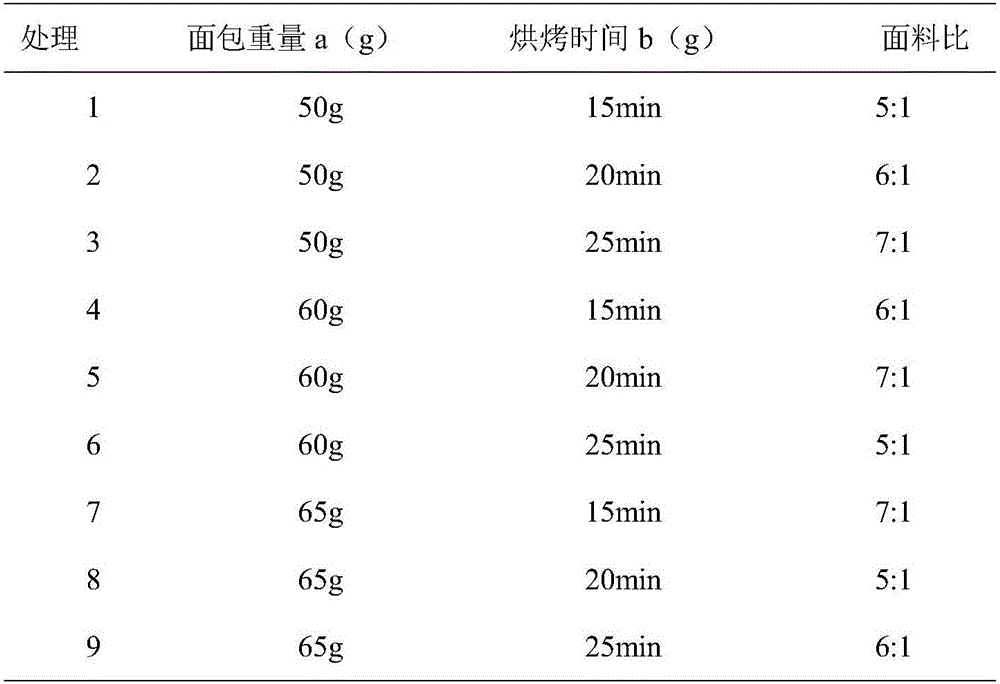

Dried peach pulp bread and preparation method thereof

InactiveCN105961516AHigh in ironMake up for cognitionDough treatmentModified nutritive productsIcing sugarYeast

The invention discloses dried peach pulp bread and a preparation method thereof. The dried peach pulp bread contains dried fruits and dough, the dried fruits comprise dried peach pulp, dried kiwi fruits and raisins, the weight ratio of the dried peach pulp to the dried kiwi fruits to the raisins is 2:1:1, the mass ratio of the dough to the dried fruits is 5:1-7:1, and the dough is prepared from 350-550 g of high-gluten flour, 40-60 g of eggs, 80-120 g of powdered sugar, 1-5 g of baking powder, 2-8 g of yeast, 30-50 g of butter, 150-300 g of water and 2-8 g of salt. The dried peach pulp bread overcomes the defects that the bread varieties are single and the nutrients are insufficient and develops a novel way for peach pulp utilization; the preparation method is simple and suitable for scale production and has the great usage and popularization value.

Owner:HUNAN UNIV OF ARTS & SCI

Preparation method of nanometer solid-phase coated lithium battery cathode material

ActiveCN106058242ARaw materials are easy to getSimple reactivityCell electrodesNanotechnologyEnvironmental resistanceDried peach

The invention discloses a preparation method of a nanometer solid-phase coated lithium battery cathode material, and belongs to the technical field of preparation of a lithium battery cathode material. In preparation of a coated lithium battery cathode material in the prior art, through liquid-phase compounding, the problem that materials are prone to aggregate in a liquid phase, resulting in affecting electrochemical performance of the lithium battery cathode material is solved. Provided is the preparation method comprising, stirring and mixing potassium permanganate and lithium hydroxide and performing precipitation to prepare nanometer lithium manganate, stirring and mixing nanometer lithium manganate powder and dried peach gum and performing solid-phase coating, and performing roasting and carbonization to prepare the solid-phase coated lithium battery cathode material. Through solid-phase coating, lithium manganate powder is effectively prevented from agglomeration during dispersion in a liquid phase. A lithium battery prepared from the lithium battery cathode material has the first discharge capacity being 130 mAh / g, the electric capacity being 125 mAh / g after charging and discharging for 50 times, and the capacity retention ratio being as high as 96.2%. The preparation method is available in raw materials, mild in reaction, and simple in preparation process, is green and eco-friendly, and is free of pollution.

Owner:YINGDE KEHENG NEW ENERGY TECH CO LTD

Beautifying and spot-removing medicinal liquor

InactiveCN104127592AEasy to prepareEasy accessNervous disorderDigestive systemCutaneous microcirculationDried peach

Owner:SUZHOU JIETIAN AGRI DEV

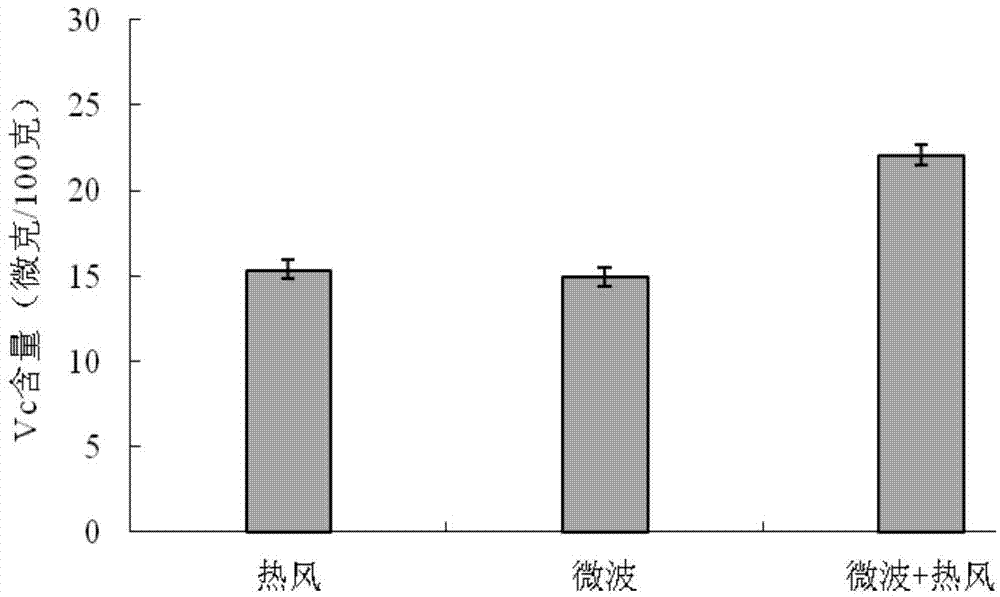

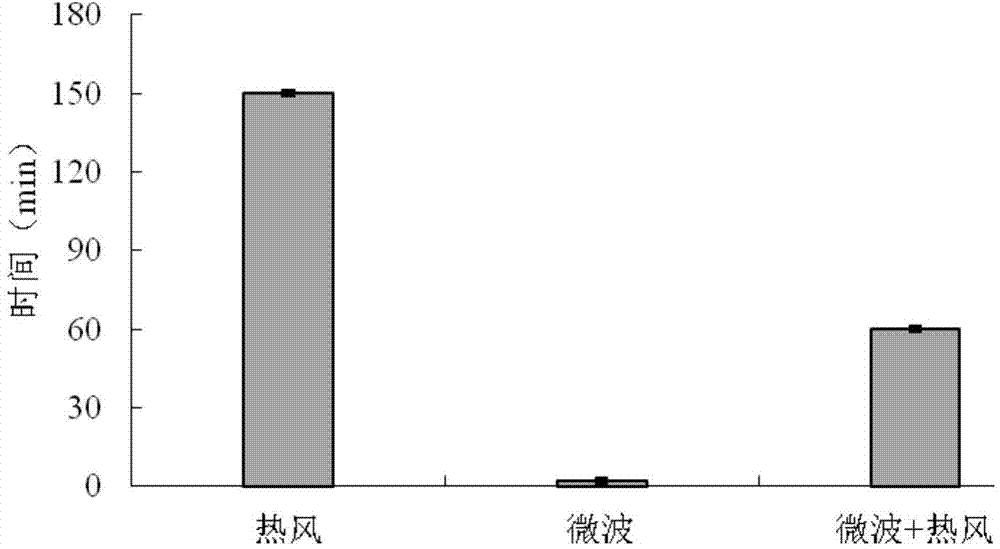

Dried peach slices and making technique thereof

ActiveCN104770556ARetain Vc contentShorten drying timeConfectionerySweetmeatsDried peachDistilled water

The invention discloses dried peach slices and a making technique thereof. The making technique of the dried peach slices specifically comprises the following steps that firstly, selected peaches are peeled, washed and sliced and then are placed in a color fixative for color protection, the surfaces of peach slices are washed with distilled water, and water on the surfaces of the peach slices is removed through absorption; secondly, the peach slices are placed in a constant-temperature table for oscillation, sugar infusion and dewatering, the surfaces of the peach slices are washed with distilled water, and water on the surfaces of the peach slices is removed through absorption; thirdly, microwave-assisted drying is conducted, so that semi-finished products are obtained, and then the dried peach slices are obtained by conducting drying with hot air. According to the dried peach slices and the making technique thereof, by the adoption of the penetration, dewatering and assisting microwave and hot air combined drying method, drying time can be shortened, production cost is reduced, Vc in the peach slices is effectively reserved, and the texture quality of the peach slices is good. According to the method, operation is easy and effective, cost is low, efficiency is high, application and popularization are facilitated, the method is suitable for large-scale production and application, and the application prospect is broad.

Owner:YANGZHOU UNIV

Heat-clearing tasty and refreshing chenopodium quinoa drink and preparing method thereof

InactiveCN106173676AComprehensive and balanced nutritionNutrition and healthSugar food ingredientsYeast food ingredientsDried peachAdditive ingredient

The invention discloses a heat-clearing tasty and refreshing chenopodium quinoa drink. The chenopodium quinoa drink is prepared from, by weight, 300-310 parts of chenopodium quinoa, 42-44 parts of cucumbers, 20-21 parts of green apples, 17-18 parts of aloe, 25-26 parts of malabar spinach, 12-13 parts of yellow peaches, 20-21 parts of ginseng fruits, 27-28 parts of corn juice, 9-10 parts of Chinese yam flour, 2-3 parts of poria cocos, 1-2 parts of dried peach blossoms, and an appropriate amount of water. The chenopodium quinoa drink has the advantages that chenopodium quinoa is used as the main raw material, multiple cool, tasty and refreshing healthy food materials are combined, and the prepared drink has strong fragrance and unique flavor and is smooth, rich in nutritional ingredients such as plant protein, essential amino acids, mineral substances and vitamins, low in sugar and sodium content, nutrient and healthy.

Owner:陆伟

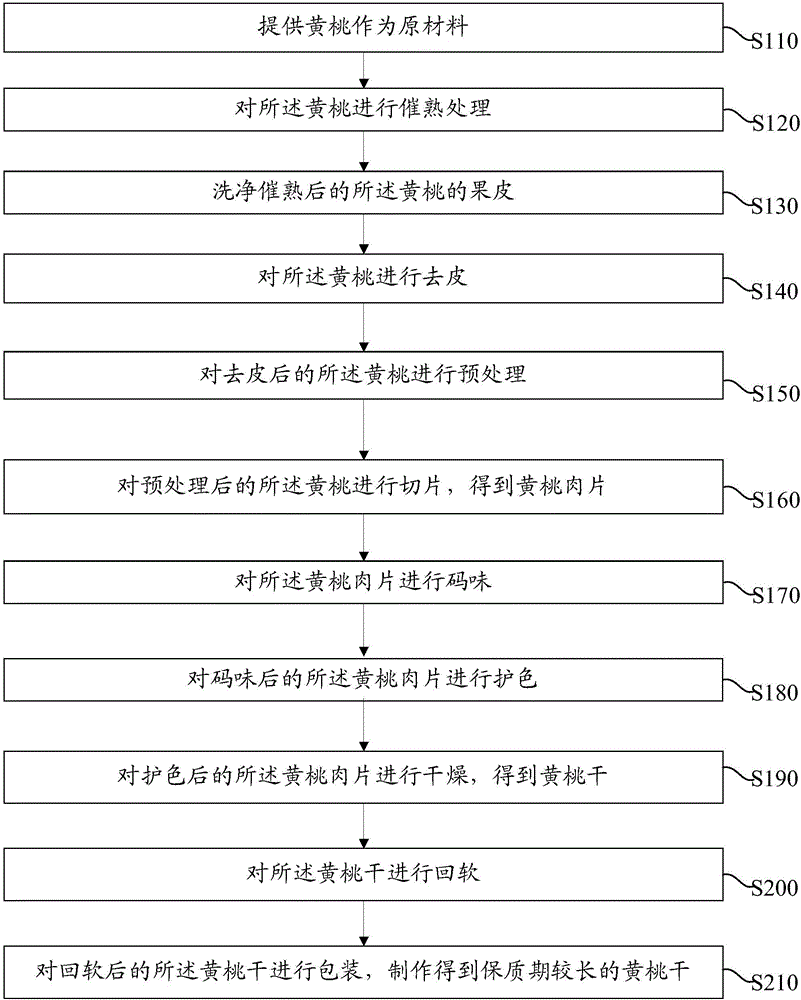

Making method for dried yellow peaches

InactiveCN106107683AExtended shelf lifeFruits/vegetable preservation by dehydrationDried peachChemistry

The invention provides a method for making dried yellow peach, which specifically includes the following steps: providing yellow peach as a raw material; washing the peel of the yellow peach; peeling the yellow peach; slicing the yellow peach to obtain yellow peach Peach slices; drying the yellow peach slices to obtain dried yellow peaches; softening the dried yellow peaches; packaging the softened dried yellow peaches to obtain dried yellow peaches with a longer shelf life.

Owner:惠州市顺步科技有限公司

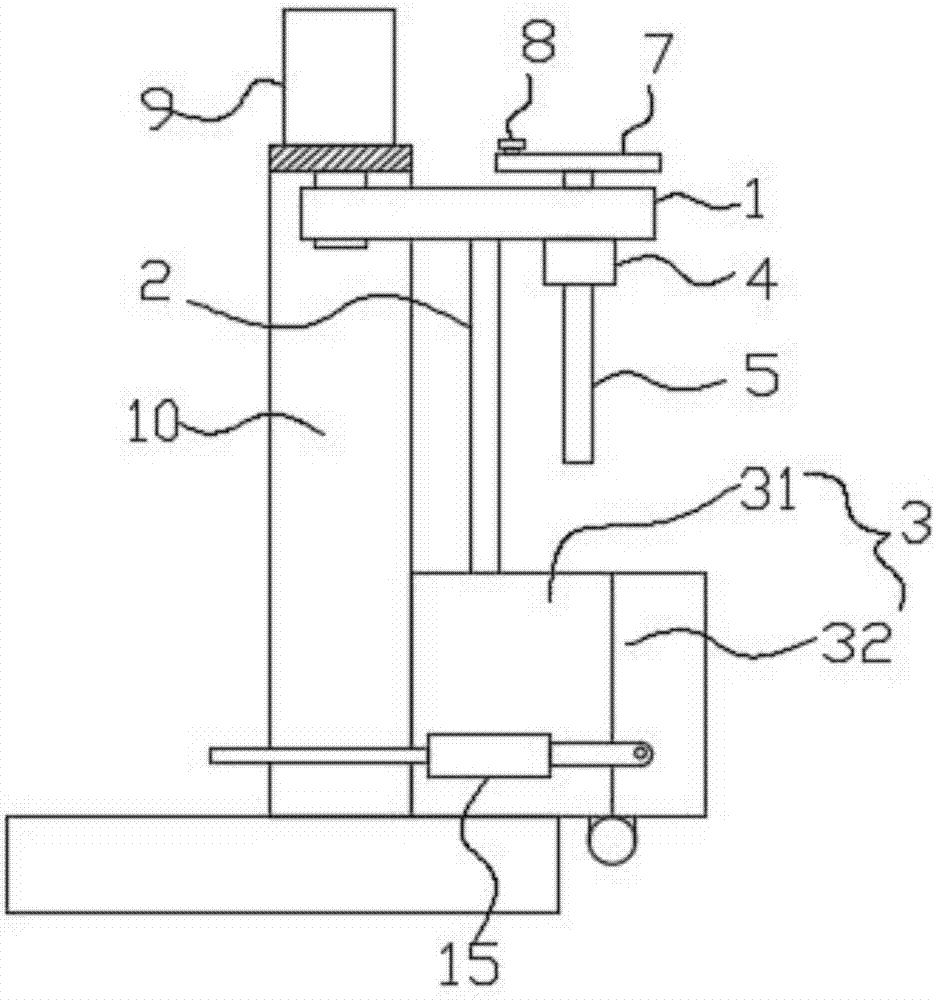

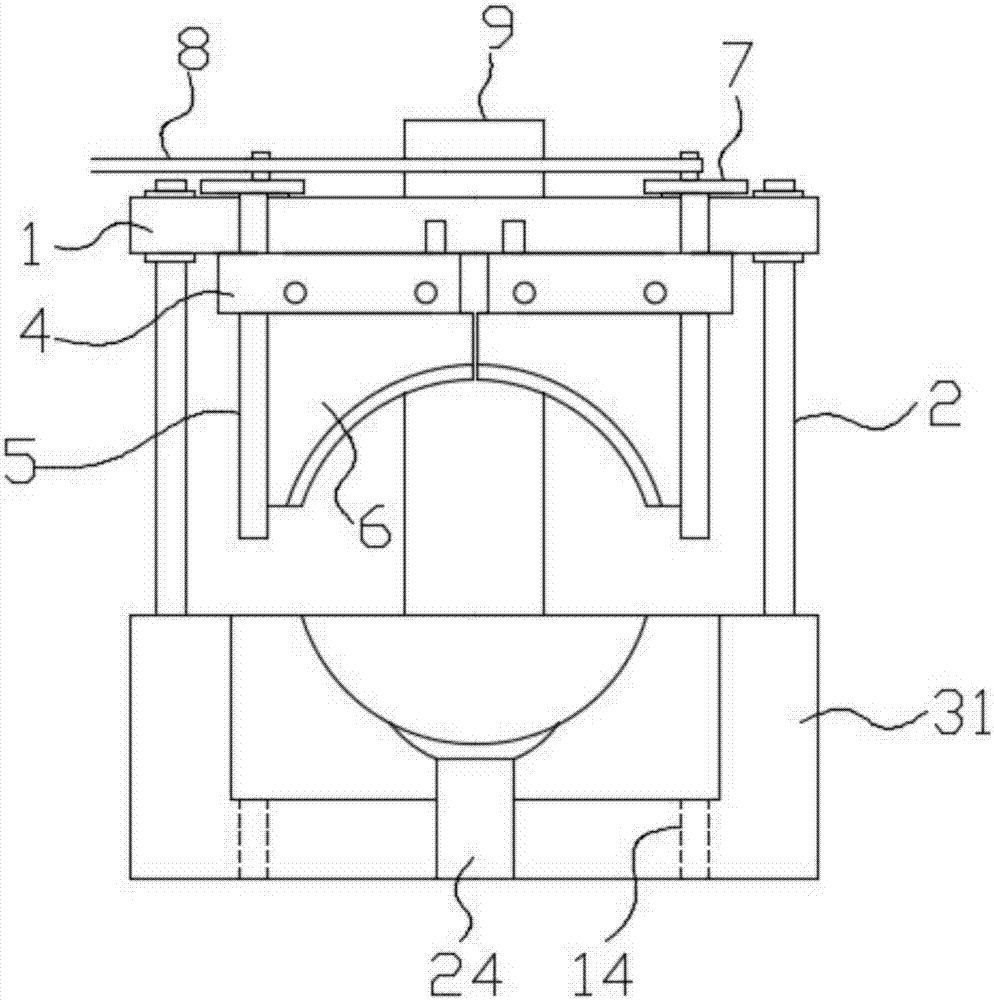

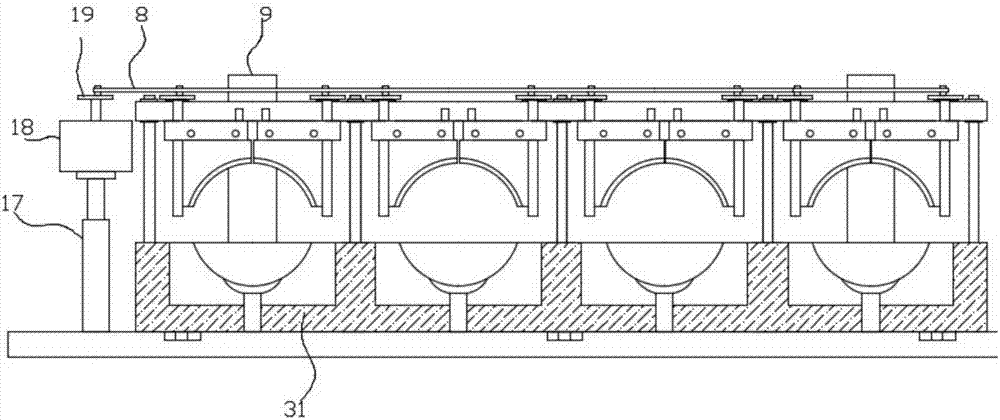

Device for fast and automatically separating peach flesh and peach pit and used for dried peach processing

ActiveCN107334162AIncrease productivityImprove resource utilizationFruit stoningDried peachElectric machinery

The invention discloses a device for fast and automatically separating peach flesh and a peach pit and used for dried peach processing. The device comprises an elevating beam connected to an elevating mechanism, and the elevating beam sleeves sliding shafts, and the lower end of the sliding shaft is arranged on a positioning mould; the lower end of the elevating beam is equipped with a knife rest set; a knife rest plate set comprises two knife rest poles which are symmetrically arranged, and a rotation shaft is vertically arranged at one end of each knife rest pole, and a locating shaft is vertically arranged at the upper end of the other end of each knife rest pole; the upper end of each rotation shaft passes through the elevating beam and is connected to a driven rotation disk; the lower end of each knife rest pole is equipped with a detachable cutter; the lower end of the elevating beam is provided with arc-shaped grooves used for cooperating with the locating shafts; the driven rotation disks are connected by a linkage rod; the linkage rod is connected to a rotary electric machine; the interior of the positioning mould is equipped with a peach flesh cavity and a swing cavity; and the interior of the peach flesh cavity is equipped with a peach pit cavity. The device can realize automatic flesh dissection and pit dissection of peaches in batches. The device can automatically separate the peach flesh and the peach pits with smooth and stable operation so as to greatly raise production efficiency of dried peaches.

Owner:HUNAN HAILIAN FOOD CO LTD

Dried peach fruit production method

InactiveCN104770549APrevent browningBright and clearConfectionerySweetmeatsDried peachAqueous sodium hydroxide

The present invention discloses a dried peach fruit production method which includes choosing well-ripen and freestone variety of fresh peaches, and washing and cleaning the peaches, and is characterized by the following steps: treating the washed and cleaned fresh peaches in boiled sodium hydroxide solution for 25-40 seconds, draining, rubbing, washing and peeling the soaked peaches, putting the peeled peaches into a color protecting liquid which is composed of D-sodium isoascorbate, citric acid and water, removing the fruit kernels, slicing the denucleated peaches into peach slices, blanching and scalding the peach slices in boiling water for 3 to 5 minutes, picking up the boiled peach slices to conduct draining and drying, stratifiedly adding powdered glucose to conduct sugar-soaking for 10-12 hours, spreading the sugar-soaked peach slices into a single layer at 60-70 DEG C to conduct drying for 10-12 hours, and placing the dried peach slices in an enclosed storage compartment for 12-36 hours, thereby preparing the finished products of the dried peach fruits. The dried peach fruit production method has a simple production process and is easy to operate, the technology is easy for promotion, the products are nutritious and have excellent sense and quality, and the production method can alleviate the fresh fruit storage and sale pressures for the majority of orchard workers, can also greatly enhance the added value of products, and has a strong practicability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Production method of nutrient honey

The invention discloses a production method of nutrient honey. The nutrient honey is made by mixing 75 parts of honey, 15 parts of rose flowers, 15 parts of haws, 15 parts of spina date seeds, 8 parts of longan pulp, 8 parts of black sesame seeds and 8 parts of Chinese wolfberry fruits. The production method comprises the following steps of firstly drying the peach kernels, the haws and the dried longan pulp, grinding the dried peach kernels, the dried haws and the dried longan pulp, putting the ground peach kernels, the ground haws, the ground longan pulp and the spina date seeds into a pot for heating to 90 DEG C, then performing decoction for 10 minutes with a small fire, cooling decocted products, pouring the honey, the black sesame seeds and the Chinese wolfberry fruits into the pot, and uniformly stirring the decoction products, the honey, the black sesame seeds and the Chinese wolfberry fruits so as to obtain the nutrient honey. The nutrient honey disclosed by the invention is simple to make, the characteristics and the efficacies of fresh ginger and longans are reserved, and the nutrient honey is convenient to eat and is a nutritional type food suitable for both old people and young people.

Owner:栾凤海

Peach wood degumming, insect-removing, cracking preventing and deformation preventing wood treatment technology process

The invention belongs to the technical field of peach wood processing, and particularly relates to a peach wood glue removing, insect removing, cracking preventing and deformation preventing wood treatment technology process. The method comprises the following steps: (1) material selection: selecting peach wood to remove bark; (2) soaking: conducting soaking in a soaking solution for 20 hours or more, wherein the soaking temperature is 30-40 DEG C; (3) boiling with water: putting the soaked peach wood into a clean water tank to be cleaned, adding the peach wood into boiling water to conduct boiling for 1-2 hours, then adding caustic soda into the boiling water, and then conducting boiling for 1-2 hours; (4) acid leaching: adding the boiled peach wood into an acid pool for soaking, and thenconducting cleaning with clear water to be neutral; and (5) preparing of a finished product: naturally drying the peach wood treated in the step (4) in air, spraying a chitosan solution and a sodiumalginate solution on the surface of the air-dried peach wood, and conducting drying in a drying oven after the peach wood is dried. The peach wood raw material is stewed to remove glue and then driedby the dryer to form the material of a peach wood craft product, so that the defects that the peach wood is easy to crack, deform and damage by worms can be overcome.

Owner:SHANDONG ARTS & CRAFTS INST

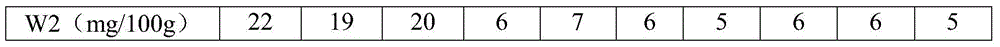

Application of peach flower extract to preparation of medicine for treating prostatitis

ActiveCN107485655AAbundant raw materialsEasy to prepareUrinary disorderPlant ingredientsAdditive ingredientDried peach

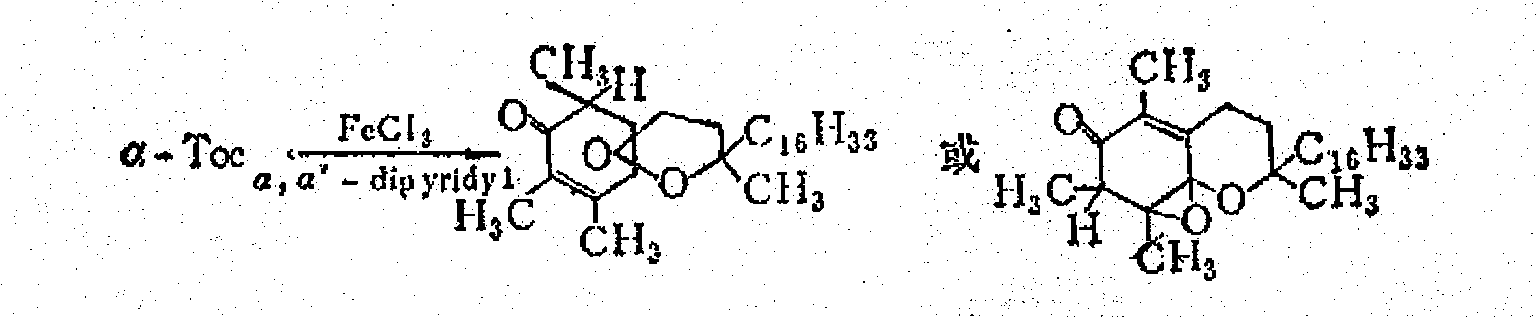

The invention aims to provide the application of a peach flower extract to preparation of a medicine for treating prostatitis. The peach flower extract serves as the only active component and can effectively solve the medication problem for treating prostatitis. According to the application of the peach flower extract to preparation of the medicine for treating prostatitis, the peach flower extract is prepared by the following steps: pulverizing dry peach flowers into crude powder, adding petroleum ether at first, performing flux extraction, degreasing, and discarding a petroleum ether extracting liquid; volatilizing the petroleum ether in the peach flower dreg, adding ethanol to soak, performing flux extraction, filtering twice, combining two filtrates, performing reduced-pressure recovery on ethanol until no alcohol odor exists, freeze-drying and pulverizing. The extract raw materials are rich, the preparation method is simple, the cost is low, the peach flower extract serving as the sole active component can be effectively used for treating prostatitis, the medicinal value of the peach flowers is exploited, and good economic and social benefits are achieved.

Owner:HENAN UNIV OF CHINESE MEDICINE

Traditional Chinese medicine dressing for eliminating lymphoma

InactiveCN104825583ANon-traumaticNo painMammal material medical ingredientsAntineoplastic agentsTree rootSide effect

The invention discloses a traditional Chinese medicine dressing for eliminating lymphoma which is characterized by comprising the following components in parts by weight: 40-60 parts of dried peach tree root and bark, 40-60 parts of dried masson pine root and bark, 40-60 parts of dried hibiscus mutabilis root and bark, 20-30 parts of root of dried sophora flavescens, 20-30 parts of scales of manis pentadactyla, and 10-20 parts of musk. The traditional Chinese medicine dressing disclosed by the invention has the advantages that no wound, no pain and no limitation are realized for a patient; no toxic or side effect exists; and lymphoma can be cured with low cost and high curative effect, and the patient is easy to recover and feels comfortable in the curing process.

Owner:陈菊元

Processing method of shrimp-flavored dried peach strips

InactiveCN107712712ASoft and umamiGood color protectionFood thermal treatmentFood ingredient as taste affecting agentShrimpDried peach

The invention discloses a processing method of shrimp-flavored dried peach strips. The processing method is characterized by comprising the following steps: (1) pretreatment: cleaning yellow peaches,then sterilizing the cleaned yellow peaches with an ultraviolet lamp, and putting the yellow peaches on a conveying belt of a spraying machine for performing alkaline spraying treatment; (2) pulping:putting the pulp of the yellow peaches into a pulping machine for stirring, and then adding aloe, a lotus extracting solution and other components for performing stirring and mixing; (3) forming: pouring the mixed fruit pulp into strip-shaped molds for performing ultrasonic oscillation treatment, and then performing baking in an oven; (4) fermentation: centrifuging fresh soybean milk, then takingand standing the supernatant liquor for 2-3 days, spraying the surfaces of yellow peach strips with the supernatant liquor and performing fermentation; (5) sterilization and baking: sterilizing the fermented yellow peach strips at high temperature, and then putting the yellow peach strips into the oven for performing baking treatment; and (6) packaging: standing the dried yellow peach strips at acondition of 35-38 DEG C, cooling the dried yellow peach strips to room temperature and performing sealed packaging to obtain the dried yellow peach strips.

Owner:陈玉海

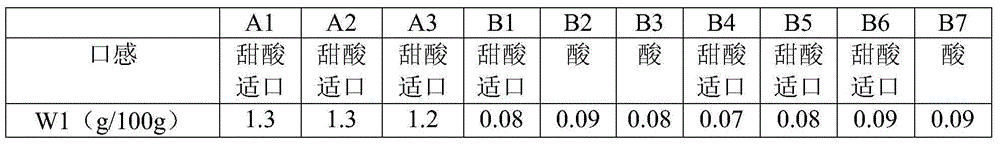

Dried peach fruit and preparation method thereof

InactiveCN104957343AAvoid churnRich in content and sweet and sourConfectionerySweetmeatsVitamin CDried peach

The invention discloses a dried peach fruit and a preparation method thereof. The preparation method comprises the following steps:(1) peeling peaches, and cutting the peeled peaches so as to prepare peach slices M1; (2) performing water removal on the peach slices M1 so as to prepare peach slices M2; (3) preserving the peach slices M2 with sugar so as to obtain peach slices M3; (4) mixing the peach slices M3, lemon juice, glucose sirup, honey, malic acid, vitamin C, potassium sorbate, aspartame and water so as to obtain a mixture, and cooking the mixture so as to obtain peach slices M4; (5) performing microwave drying on the peach slices M4 so as to obtain peach slices M5; and (6) airing the peach slices M5 so as to obtain the dried peach fruit. The dried peach fruit prepared by the preparation method is rich in dietary fibers and phosphorus content, and is palatable in sweet and acid degrees; the preparation method is simple and feasible, and is suitable for mass production.

Owner:ANHUI HEZHONG AGRI SCI & TECH

Peach blossom wine

InactiveCN108048288APromote absorptionReduce concentrationDigestive systemAlcoholic beverage preparationFlavorAlcohol

The invention discloses peach blossom wine which is composed of 20 g of wild peach blossom, 25 g of wild peach blossom honey, 20 g of fresh peach pulp, 15 g of peach kernel, 2 g of radix angelicae and800ml of Baijiu. A preparation method includes: putting 20 g of mature fresh peach pulp with skin and hair removed and plump flesh into 800ml of fen-flavor Baijiu of 45-55 degrees in concentration, maintaining for 1-1.5h at temperature of 50 DEG C, and grinding 15 g of peach kernel and 2 g of radix angelicae into powder; adding 20 g of dry peach blossom picked on 3th, March of lunar calendar andafter being washed and dried, 25 g of wild peach blossom, 25 g of wild peach blossom honey and ground peach kernel and radix angelicae powder together into the Baijiu soaked with the pulp, and sealing; burying underground for 25-30 days for drinking. The peach blossom wine can be drunk for twice each day, 15ml for each time. Or 20ml can be additionally drunk before sleep according to conditions ofepidemic disease. The peach blossom wine is convenient to process, low in alcohol concentration, faint in scent, capable of relaxing the bowels and excellent in face beautifying and nourishing effect.

Owner:明光市千里浓酒业有限公司

Dried peach white fruit wine and its production process

The invention discloses a dried peach white fruit wine and its production process, which consists of using peach fruit as raw material, making fruit pulp through disintegration, then charging fruit wine yeast EC1118 and type 900 isomaltose hypgather, fermenting at 15-18 deg. C, ageing then clarifying with gelatine and bentonite clay, filter-pressing with plates and frames, finally canning and sterilizing.

Owner:邱德忠

Jam peach blossom vinegar flavored sweet potato fruit and preparation method thereof

InactiveCN105029285AEdible sweet and sourNutritious propertiesLipidic food ingredientsNatural extract food ingredientsWater ChestnutsDried peach

The invention discloses a jam peach blossom vinegar flavored sweet potato fruit which is prepared from the following raw materials in parts by weight: 380-385 parts of sweet potatoes, 85-90 parts of water chestnut starches, 40-45 parts of walnut powder, 13-16 parts of dried peach blossoms, 30-35 parts of blueberry jam, 35-40 parts of lettuce, 13-15 parts of preserved apricot, 10-14 parts of tomato vinegar, 10-12 parts of oleum morrhuae, 25-30 parts of malt syrup, 3.1-3.5 parts of bamboo leaves, 2-2.5 parts of rabdosia lophanthide, 2.5-2.7 parts of corn stigma and a proper amount of oil and water. The sweet potato fruit is prepared by matching the raw materials such as the sweet potato powder, the dried peach blossoms, the tomato vinegar and the oleum morrhuae; in the preparing process, extracting solutions of various traditional Chinese herbs such as the bamboo leaves and the corn stigma are further provided; the raw materials are reasonably matched, so that the prepared sweet potato fruit has mellow peach blossom fragrance, tastes sour and sweet, is rich in nutrients, can enhance the immunity after long-time eating and is favorable for the health of people.

Owner:ANHUI HONGYUN FOOD

Biologic fresh-keeping method of peach and apricot

InactiveCN101228899BKeep the flavorLittle change in nutritional ingredients and active ingredientsFruit and vegetables preservationFlavorDried peach

The invention provides a biological preservation method for peach and apricot, which belongs to a field of biological preservation technology. The storage steps of the invention are that: (1) carrying out disinfection treatment to the storage environment of peach and apricot; (2) spraying a preservative solution with a concentration of 20mg-500mg / kg on the peaches and the apricots on trees one day before picking, and picking fruits after the preservative solution is dried with air; (3) packing the dried peaches and the apricots sprayed with preservative solution into membrane bags for storageor storing after dipping in a preservative solution with a concentration of 0.001mg-580mg / kg for 0.1-40min and drying. The components, proportioning and preparation method of the preservative solution is the technical core of the invention. The preservative solution is prepared by extraction, cineration, etc., vegetable chemistry methods. The method can extend the preservation time for 2-3 times,prolong the shelf life for 7-15 days and ensure that the original flavor of the stored peach and apricot is kept and a plurality of nutritional components are less changed, which is an important break through in the research field of storage and preservation.

Owner:李桂凤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com