Patents

Literature

129results about How to "Uniform drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing instant noodles dried by hot air stream at high temperature

ActiveUS20110229613A1Moreish tasteMoreish textureFood preservationFood ingredient as taste affecting agentCaloric valuesFried noodles

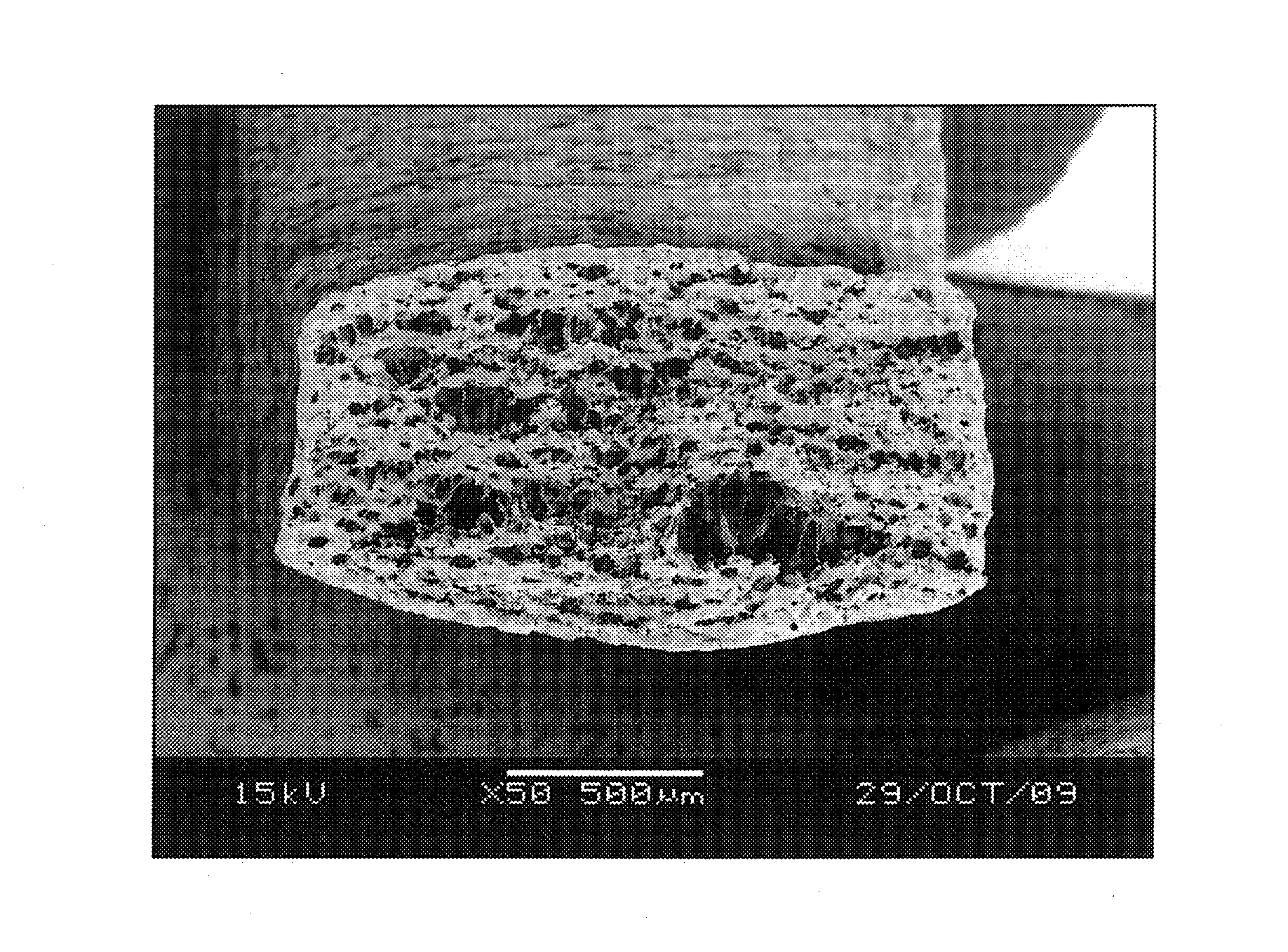

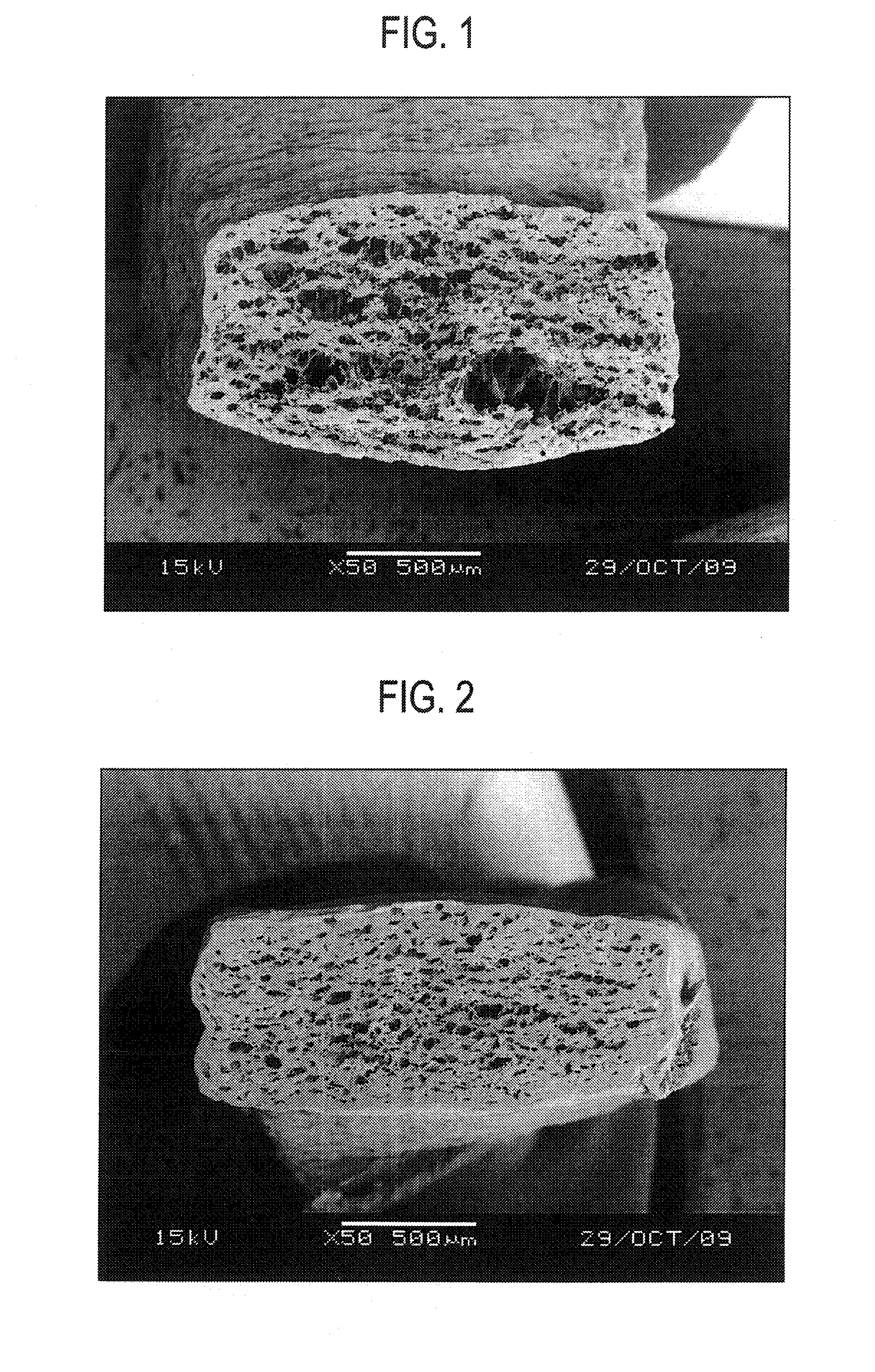

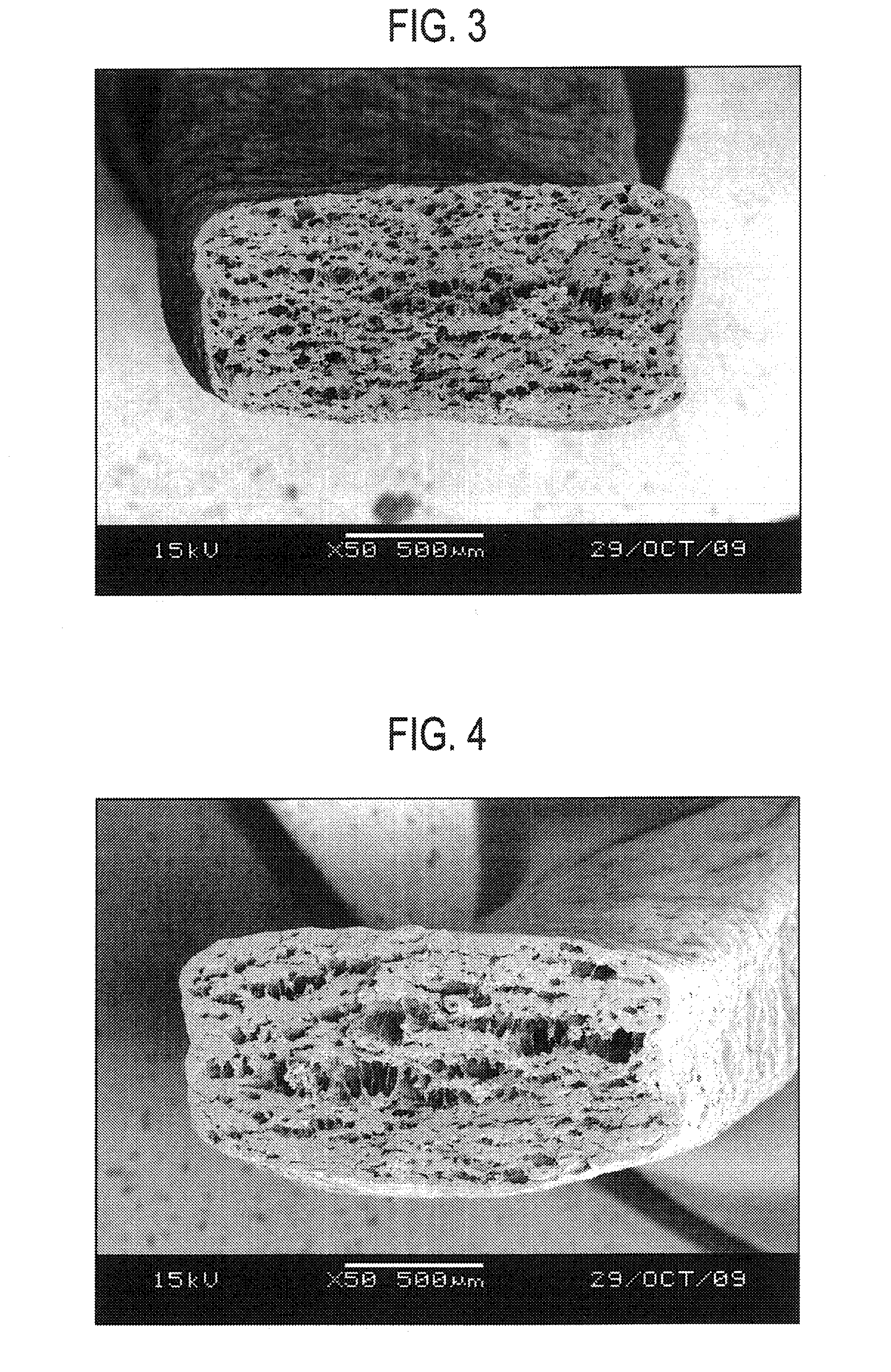

A method for producing instant noodles dried by a high-temperature hot air stream, wherein the noodles have a moreish taste and texture similar to fried noodles and yet have a low caloric value. The method for producing instant noodles dried by a high-temperature hot air stream comprises: step (a) producing a noodle band from a noodle dough prepared by adding an edible oil to a noodle dough material containing a raw material flour, and then producing raw noodle strands from the noodle band, step (b) adhering an edible oil to the raw noodle strands, and then steaming the raw noodle strands to produce steamed noodles, step (c) forming a noodle block by packing a predetermined amount of the steamed noodles into a retainer, and step (d) swelling and drying the noodle block by blowing a hot air stream at a temperature of 120° C. to 160° C. onto the noodle block from above and below the retainer at a stream speed of 30 m / s to 70 m / s for a period of 3 to 15 minutes.

Owner:NISSIN YORK

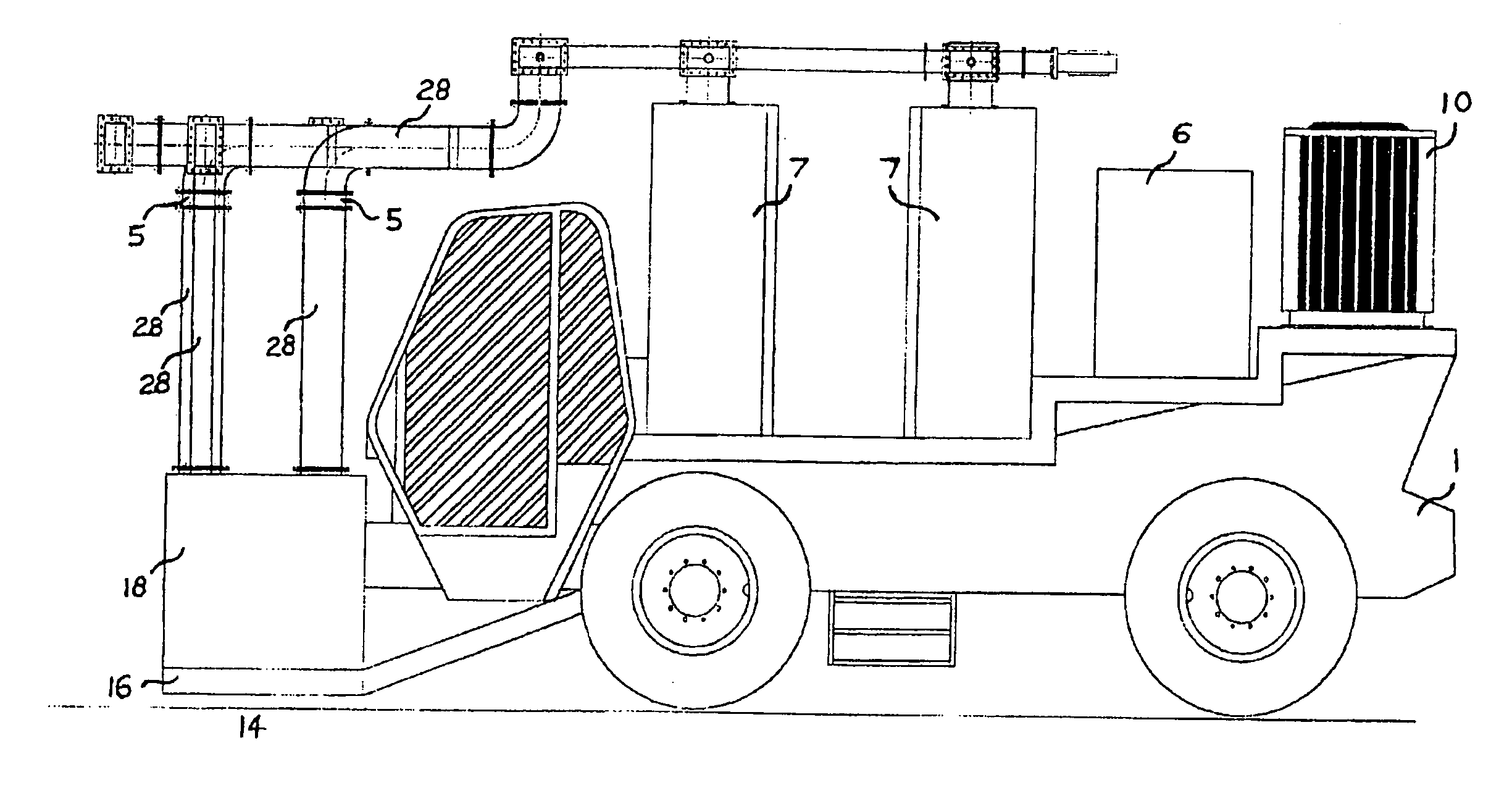

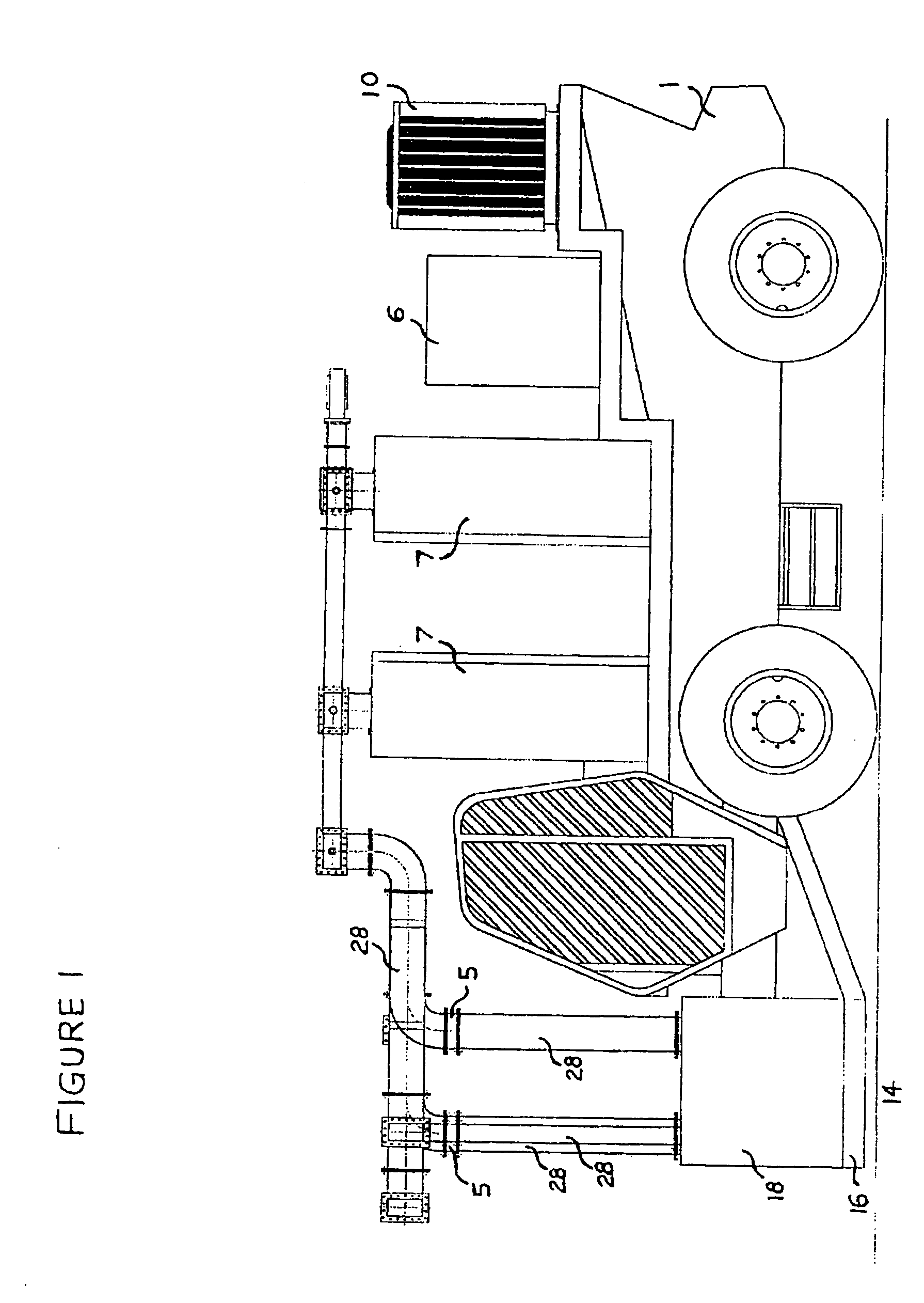

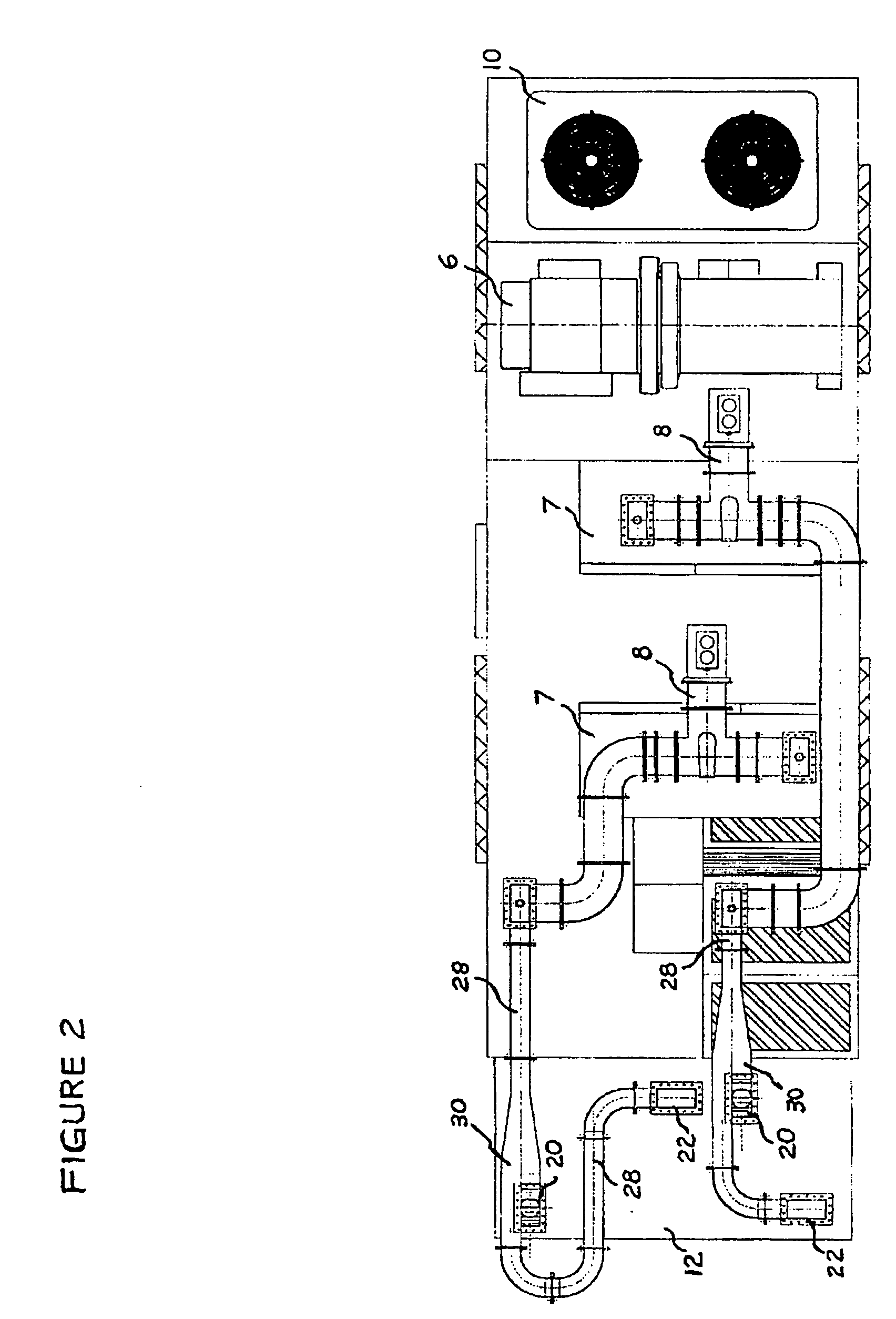

Continuous method and apparatus for microwave-based dryer

ActiveUS20060078383A1Efficiently and economically produceReduce moisture contentIn situ pavingsDrying solid materials with heatEngineeringMicrowave electromagnetic radiation

Owner:NOVAK JUDITH

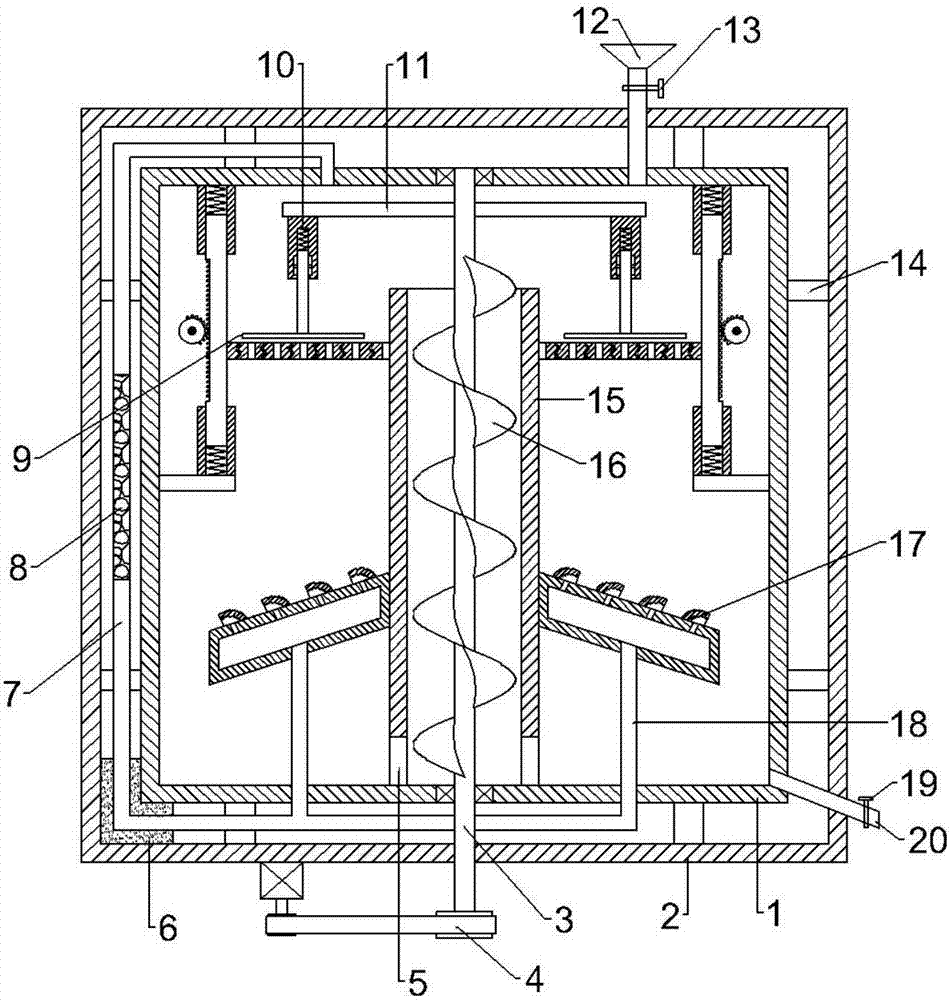

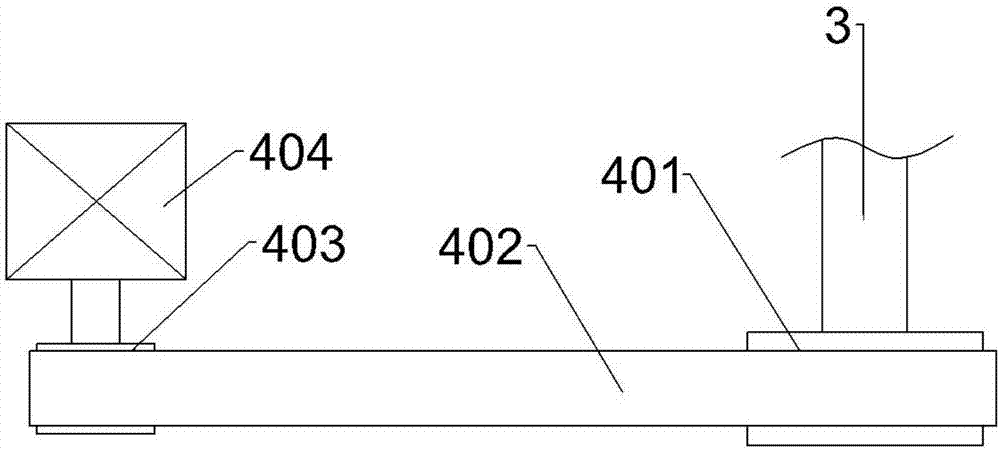

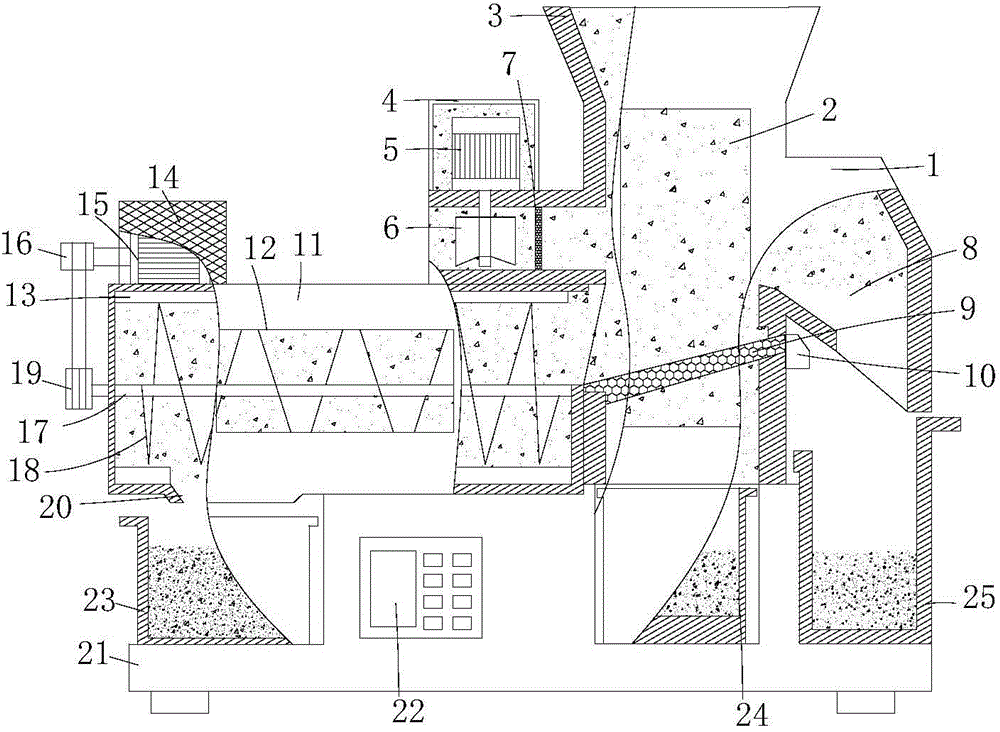

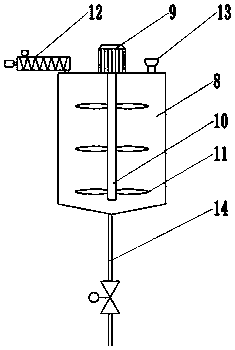

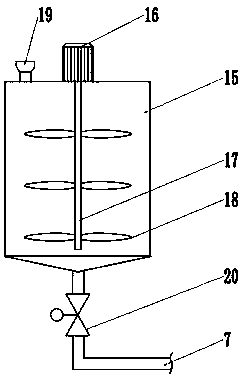

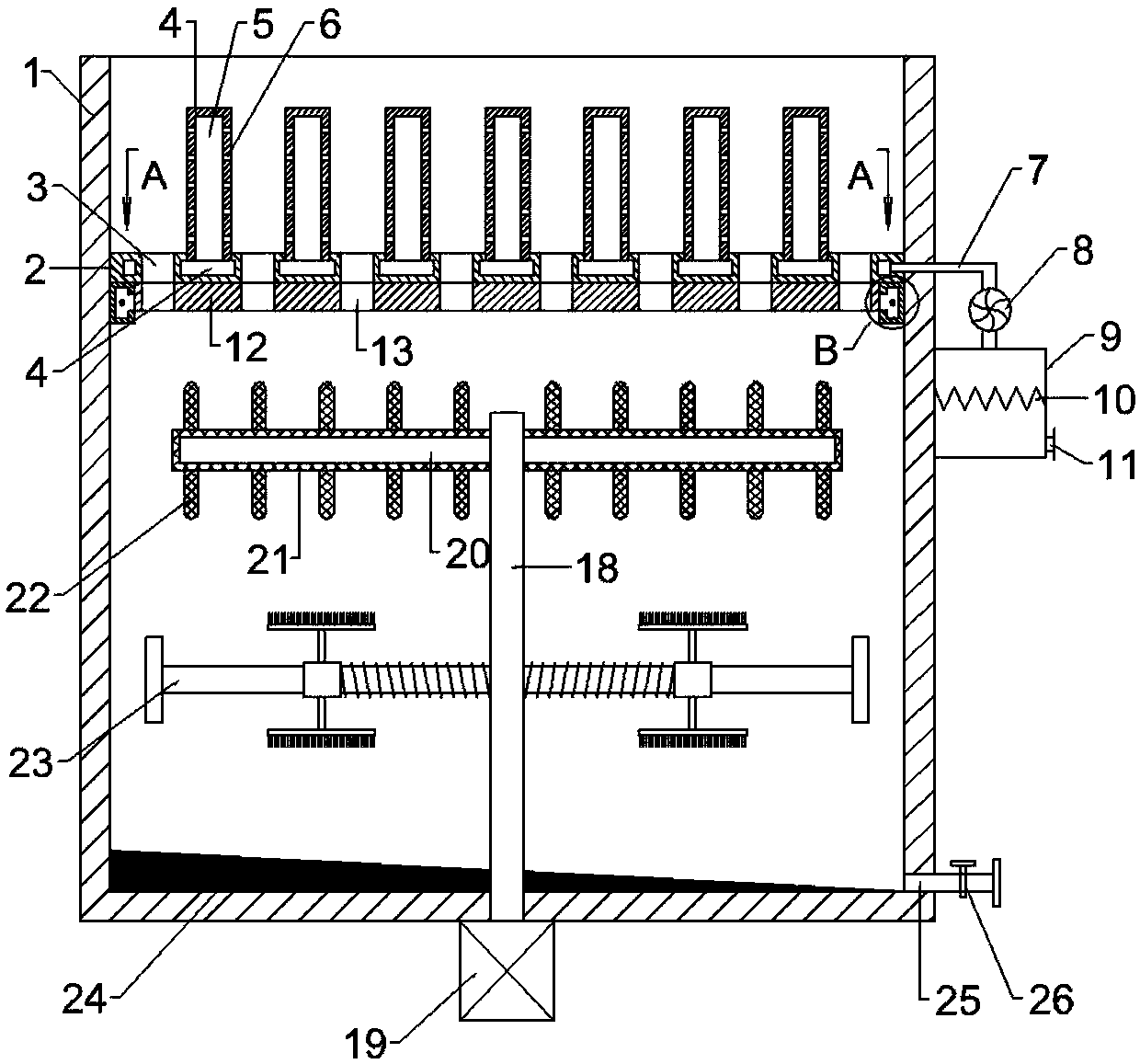

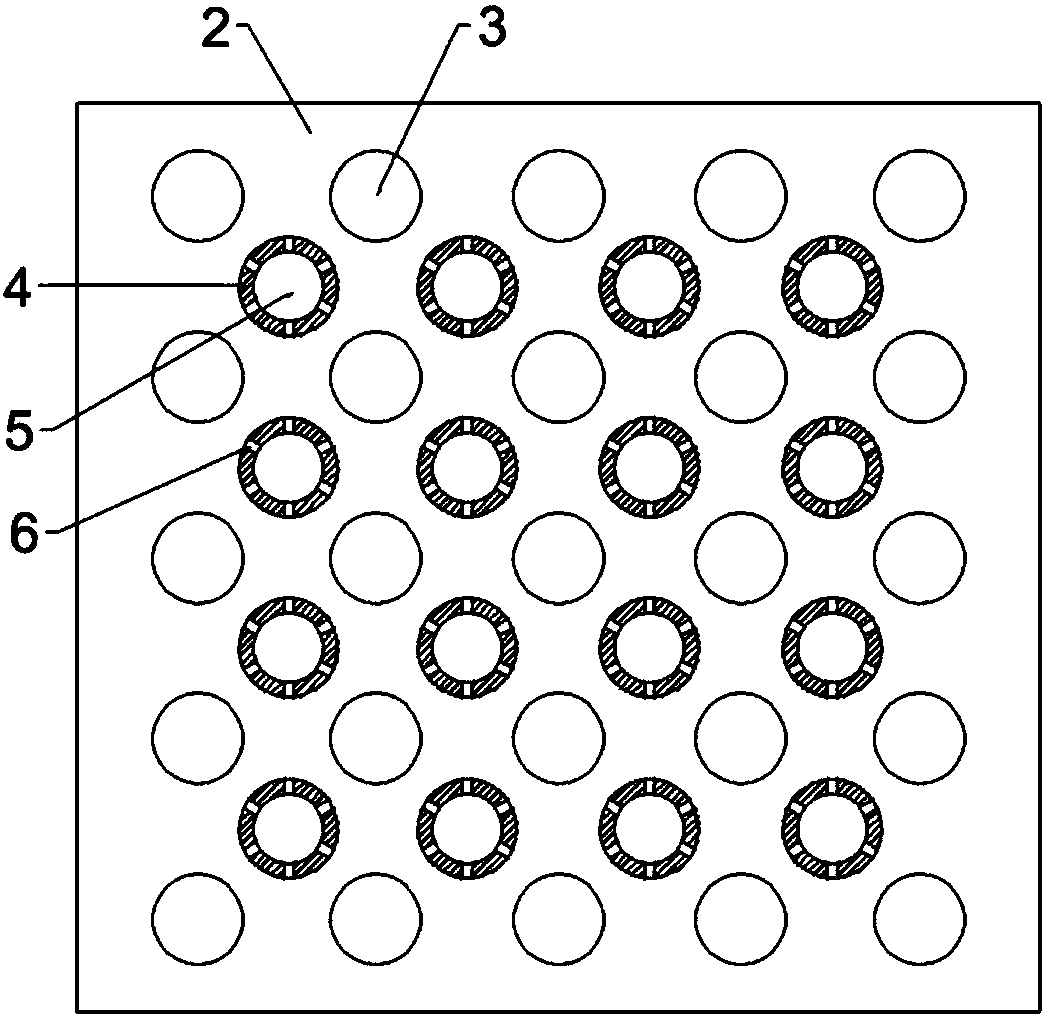

Energy-saving environment-friendly material drying equipment with disturbance drying function

ActiveCN107328190AKeep drySave energyDrying gas arrangementsDrying machines with non-progressive movementsEngineeringMechanical engineering

The invention provides energy-saving environment-friendly material drying equipment with a disturbance drying function. The energy-saving environment-friendly material drying equipment comprises an inner shell. An outer shell covers the inner shell. The outer shell is fixedly connected with the inner shell through a plurality of fixing blocks. The center of the bottom in the inner shell is fixedly connected with a first sleeve. A plurality of through holes are uniformly formed in the side wall of the bottom of the first sleeve. A first rotary shaft is arranged in the first sleeve. The bottom end of the first rotary shaft extends to the outside of the outer shell, and the bottom end of the first rotary shaft is connected with a driving device. A spiral auger is arranged on the side wall of the first rotary shaft. The energy-saving environment-friendly material drying equipment has the following beneficial effects that firstly, materials can be lifted through the spiral auger so that the materials can be dried circularly and repeatedly, and the drying effect is improved; and secondly, a vertical vibrating device drives the materials on a vibrating plate to be vibrated up and down, the situation that the materials are in contact with the vibrating plate for a long time, and consequently, the materials are excessively dried is avoided, and the drying effect is improved.

Owner:江苏龙鑫智能干燥科技有限公司

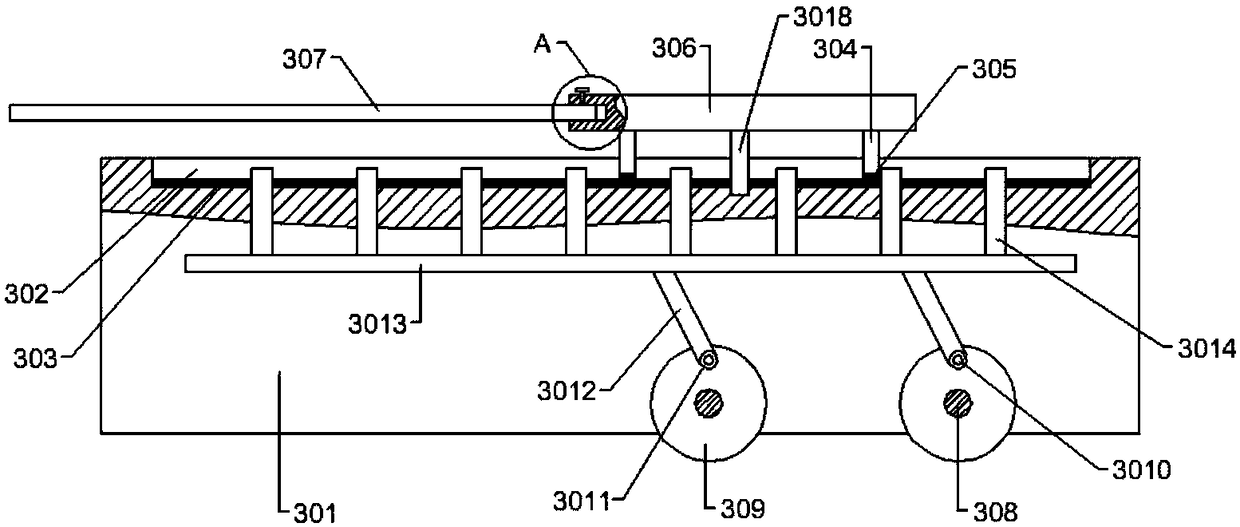

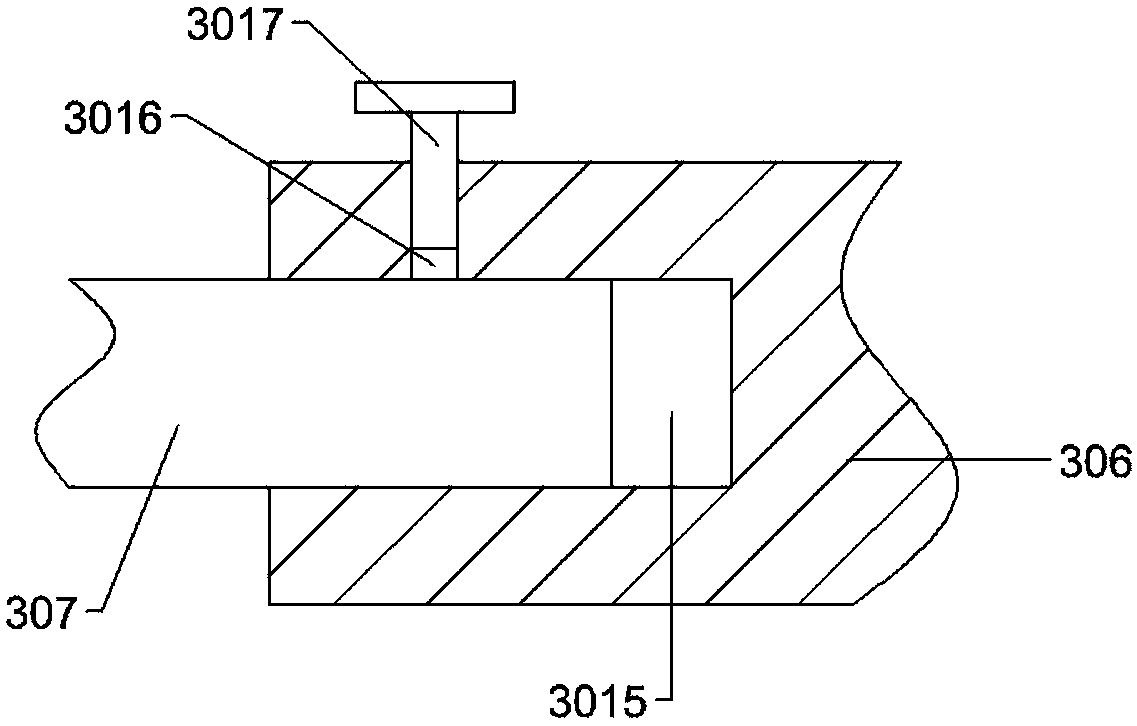

Coal powder drying device

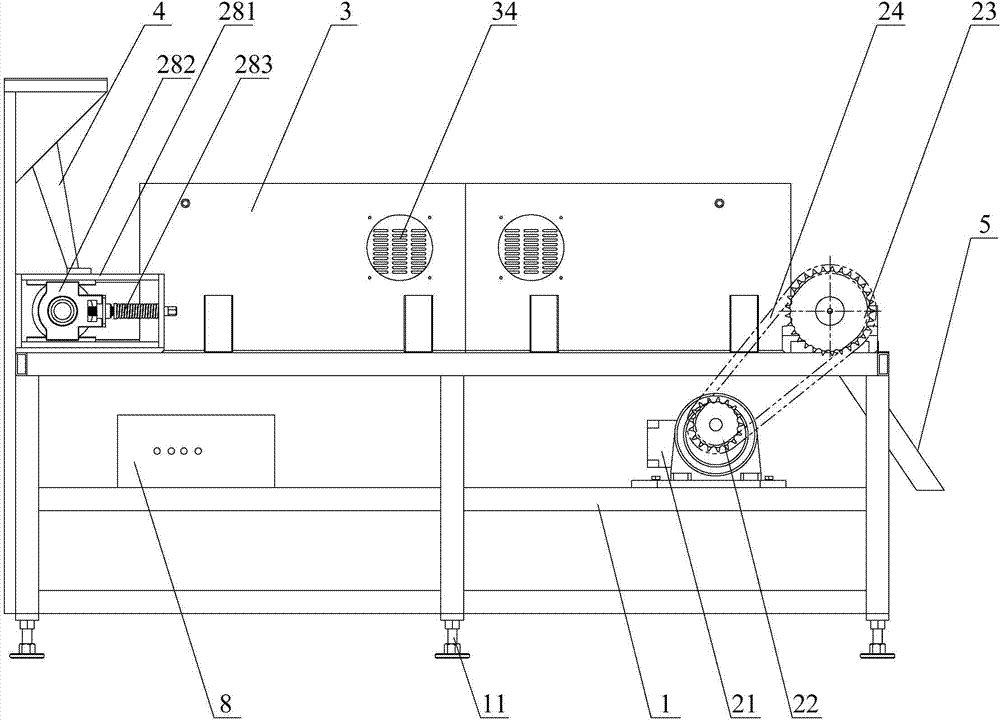

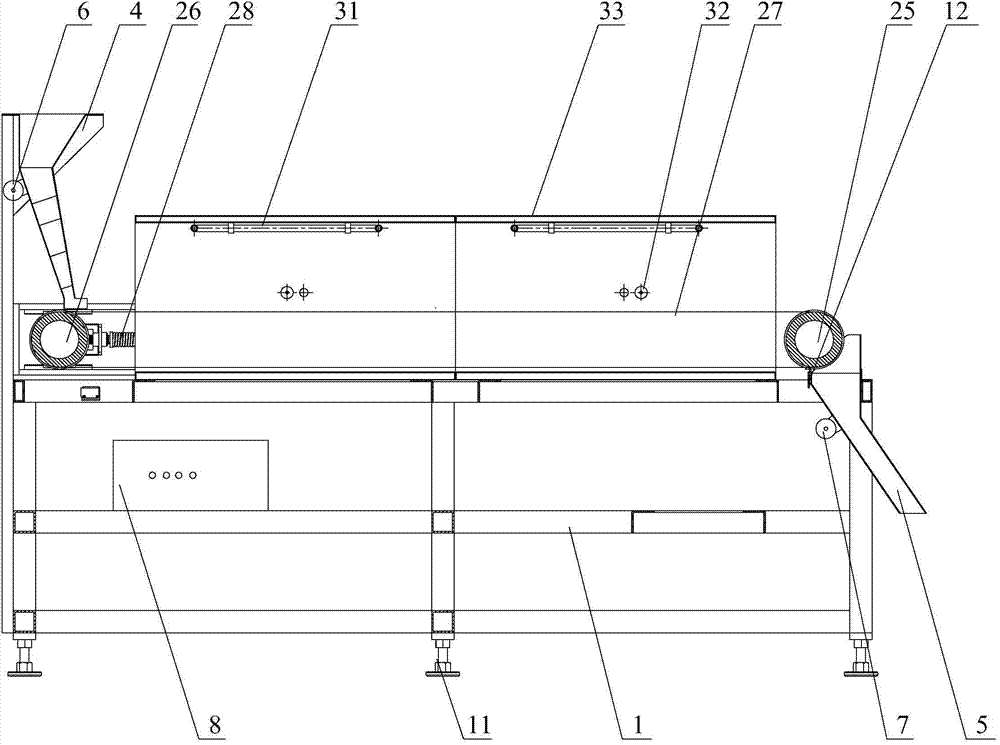

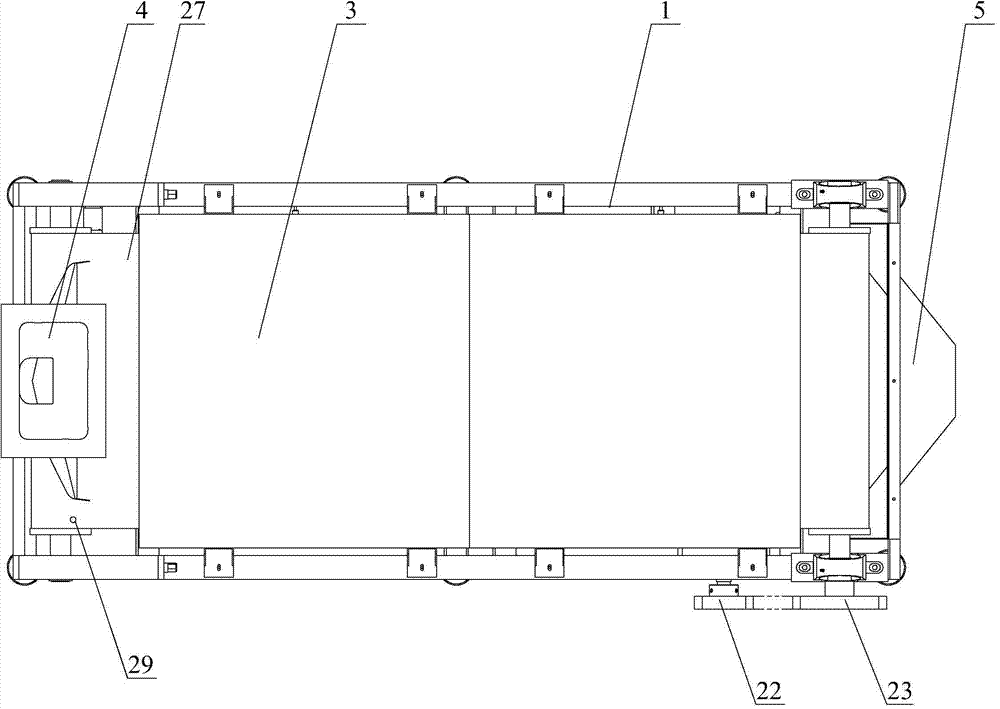

InactiveCN103542705ASolve online drying problemsUniform dryingDrying solid materialsHeating arrangementEngineeringDistributor

An embodiment of the invention discloses a coal powder drying device which comprises a rack, a conveying mechanism, a drying box, a material distributor and a material blanking machine. The conveying mechanism is arranged on the rack, the drying box is arranged on the rack and positioned above the conveying mechanism, infrared heating pipes are arranged in the drying box, the material distributor is positioned at a feeding end of the conveying mechanism, and the material blanking machine is positioned at a discharging end of the conveying mechanism. When the coal powder drying device works, coal powder is laid on the conveying mechanism through the material distributor, a laid coal layer is fed into the drying box by the conveying mechanism, the infrared heating pipes in the drying box work to dry the coal layer fed into the drying box, and the conveying mechanism feeds the coal layer after being dried into the material blanking machine after drying of the coal layer is finished. Infrared light is utilized to dry the coal layer and directly irradiates a laid material layer on a belt, the coal powder drying device is applicable to various coal samples, uniform in drying degree, extremely high in drying efficiency and capable of continuously drying the coal powder, and the problem of online drying of coal in the process of automatic sample preparation is solved.

Owner:CHANGSHA KAIYUAN INSTR

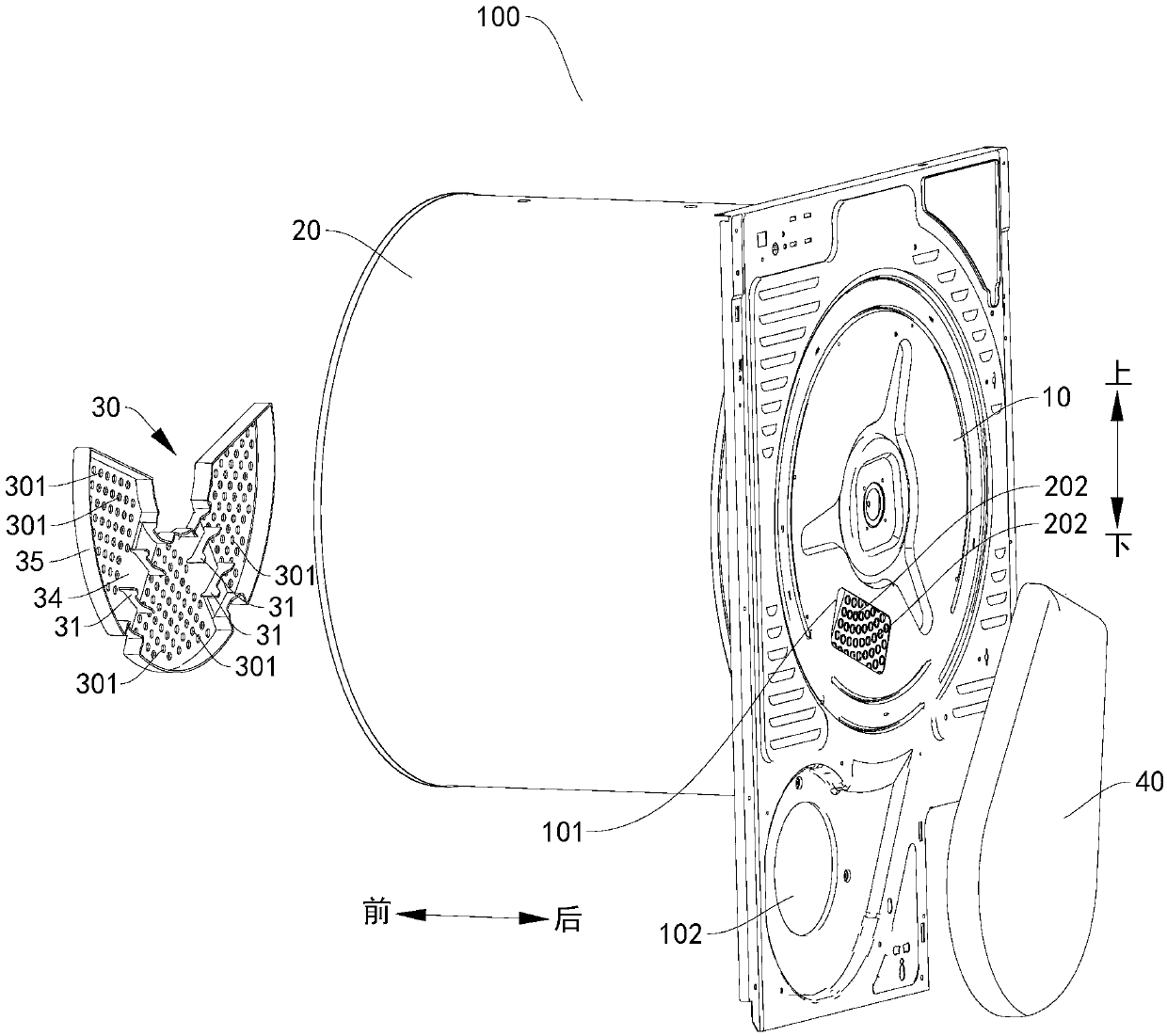

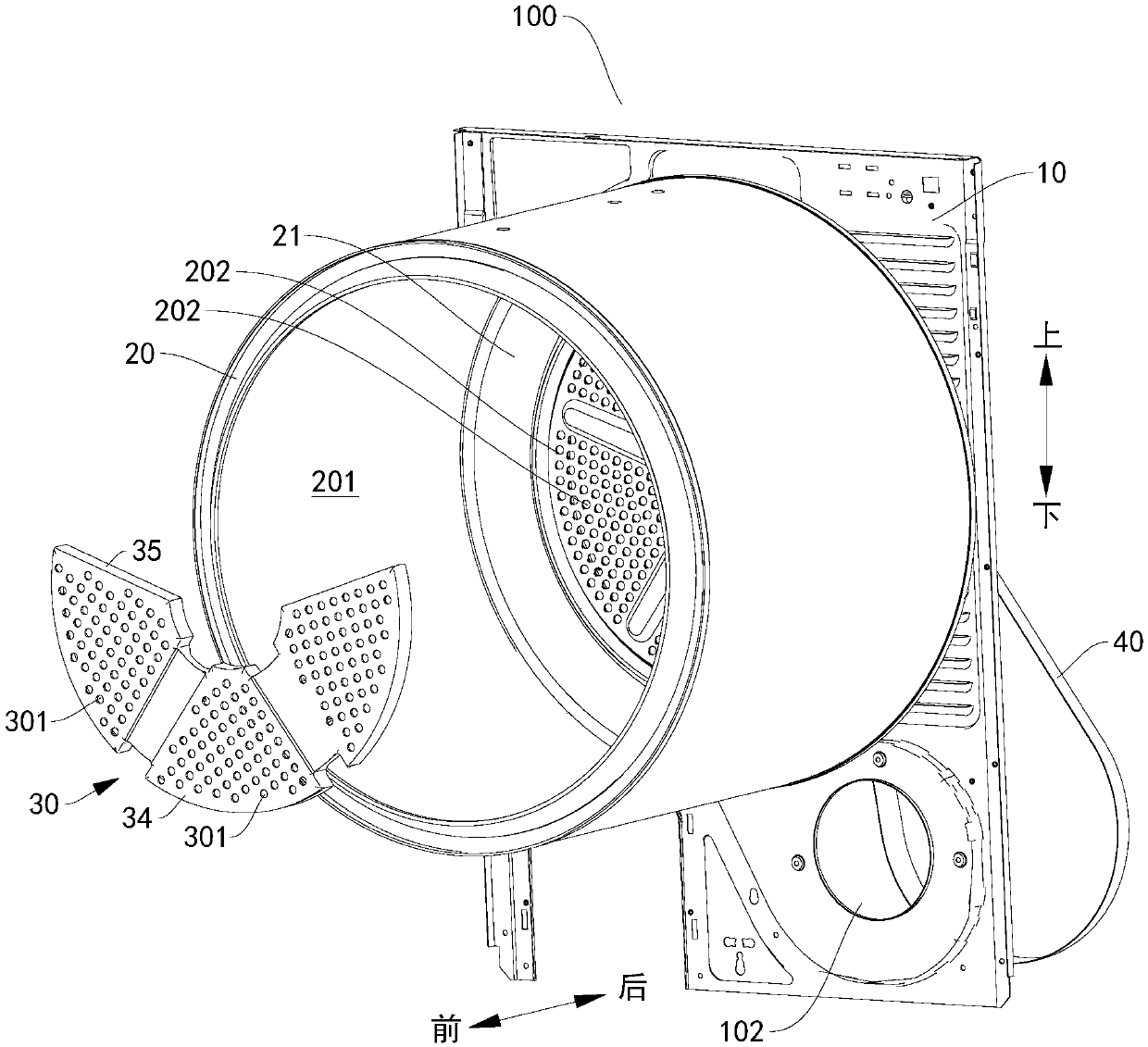

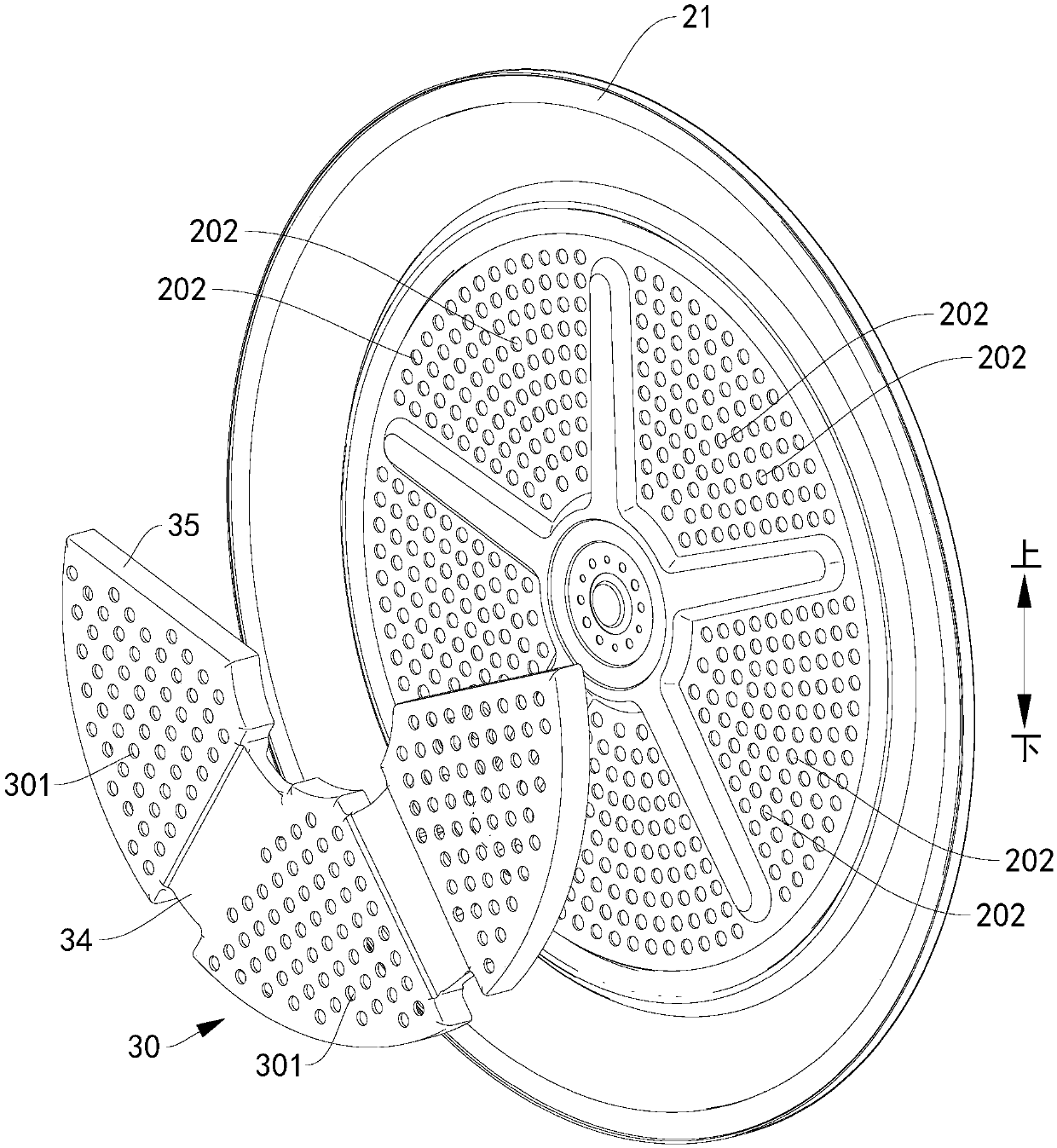

Clothes treatment device and inner cylinder assembly of clothes treatment device

ActiveCN111041764AUniform dryingImprove drying effectWashing machine with receptaclesTextiles and paperEngineeringMechanical engineering

The invention discloses a clothes treatment device and an inner cylinder assembly of the clothes treatment device. The clothes treatment device is provided with an air inlet duct. The inner cylinder assembly comprises a mounting plate, an inner cylinder and a wind guide part, wherein an air duct inlet of the air inlet duct is formed in the mounting plate; the inner cylinder is rotatably mounted onthe mounting plate, the inner cylinder is provided with a clothes containing cavity, and the inner cylinder is provided with an air inlet area communicating with the air duct inlet; and the wind guide part is located in the clothes containing cavity, a wind guide space is formed between the wind guide part and the inner cylinder, the air inlet area communicates with the wind guide space and the air duct inlet, the wind guide part is provided with a wind passing area communicating with the wind guide space and the clothes containing cavity, and the area of the wind passing area is larger thanthe area of the air duct inlet. According to the inner cylinder assembly in the embodiment of the invention, the dispersion degree of wind blown into the clothes containing cavity can be improved, sothat the uniformity of the temperature in the clothes containing cavity is improved, the drying degree of clothes is more uniform, and the drying performance is better.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

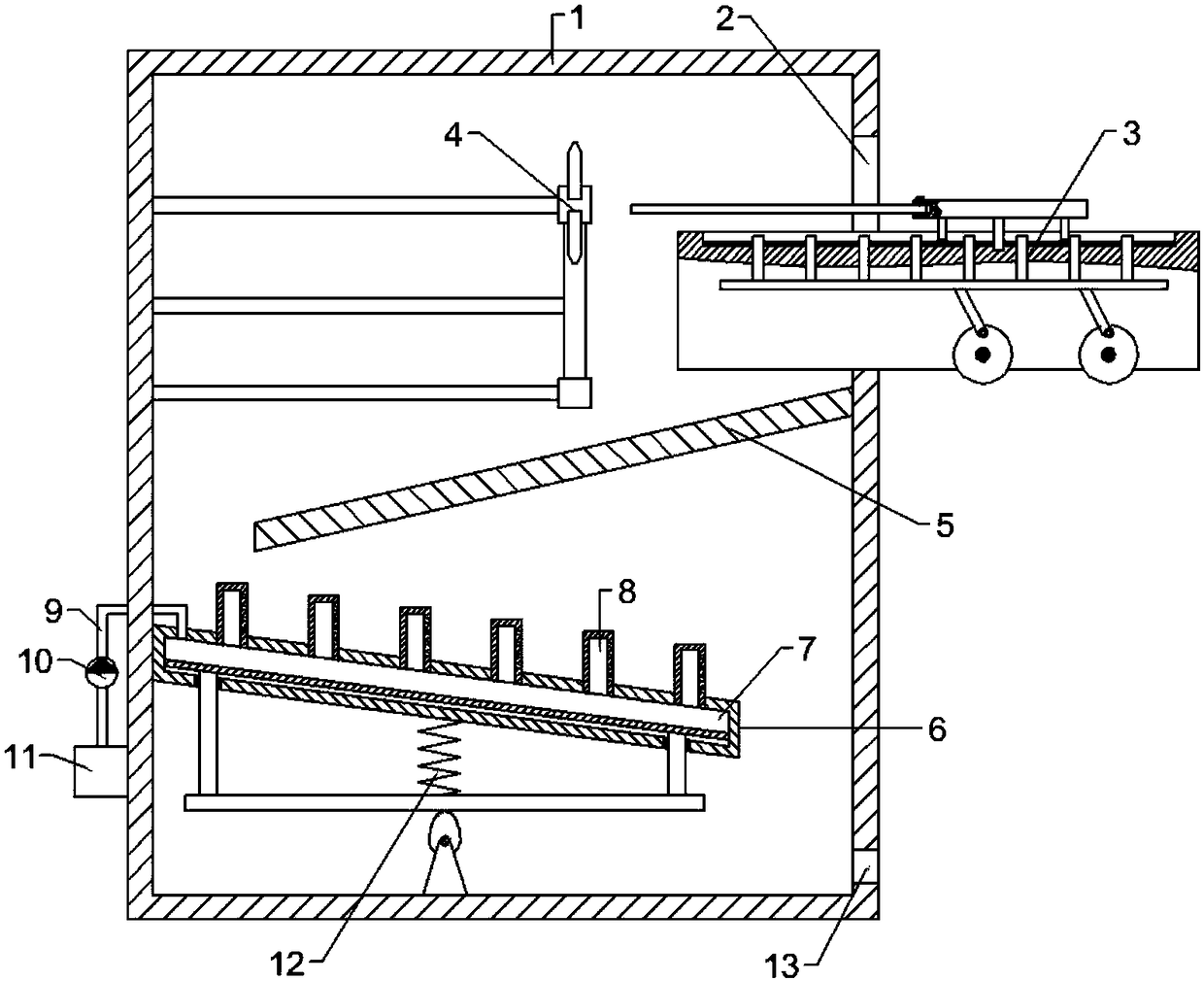

Cereal sorting device with drying effect

The invention discloses a cereal sorting device with drying effect. The cereal sorting device comprises a material cylinder and a drying cylinder body. A feeding table is arranged at the top of the material cylinder. A fan blade and a heating screen plate are arranged from left to right of an inner cavity of the material cylinder respectively. A screening net is arranged at the inner cavity of the material cylinder. A vibration exciter is arranged on the right side of the screening net. The drying cylinder body is arranged on the left side of the material cylinder. The inner wall of the drying cylinder body adheres to a heat conducting pipe. A main shaft is arranged in the middle of the inner cavity of the drying cylinder. Spiral blades are arranged on the periphery of the middle portion of the main shaft. A discharging opening is formed in the bottom of the left side of the drying cylinder body. A base is arranged at the bottom of the drying cylinder body. A control panel is arranged on the front face of the base. The cereal sorting device with the drying effect is good in sorting effect, during sorting, cereal is subjected to drying processing, using is convenient, and working efficiency is high.

Owner:HUBEI JIALIANG MACHINERY

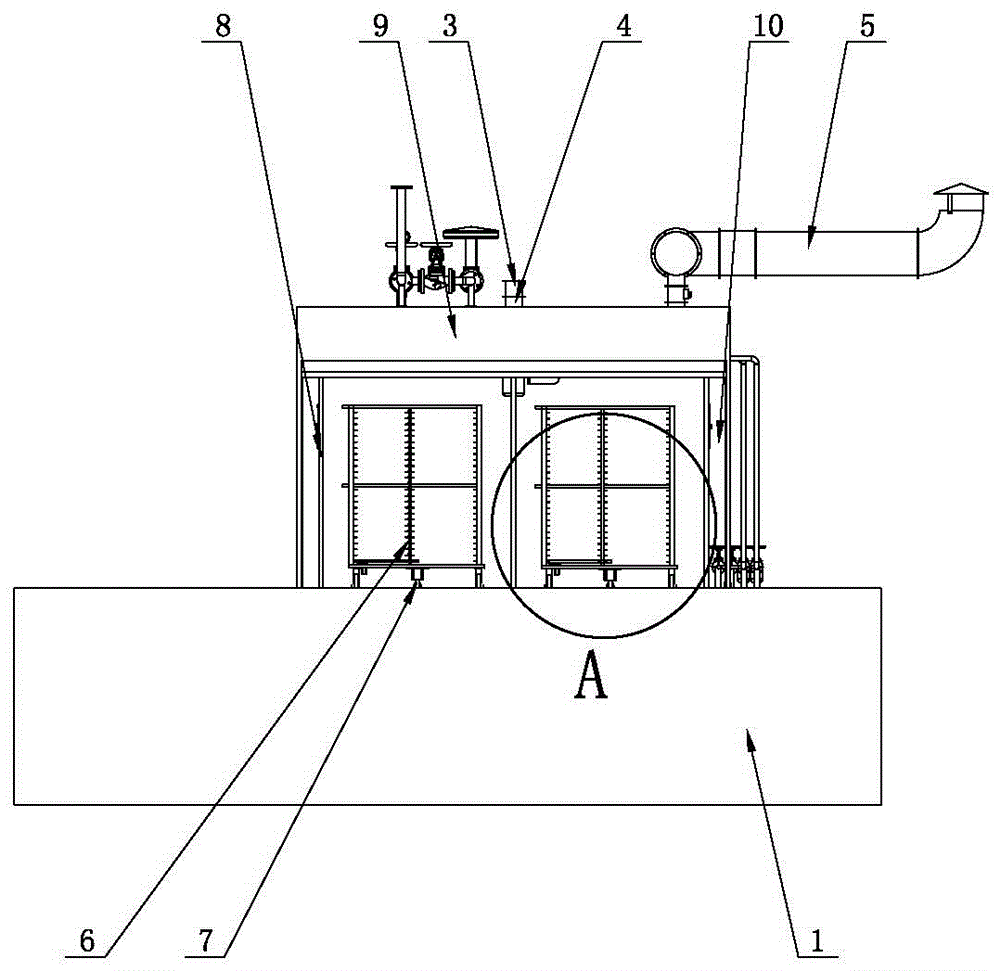

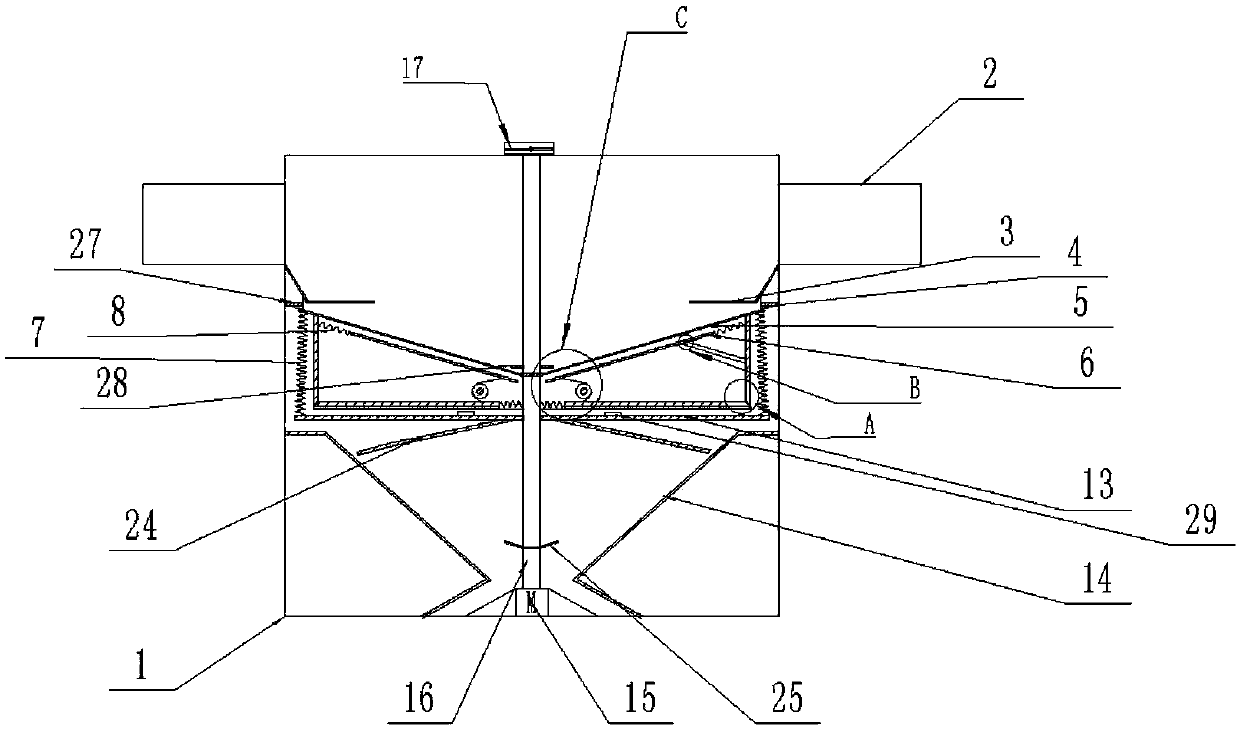

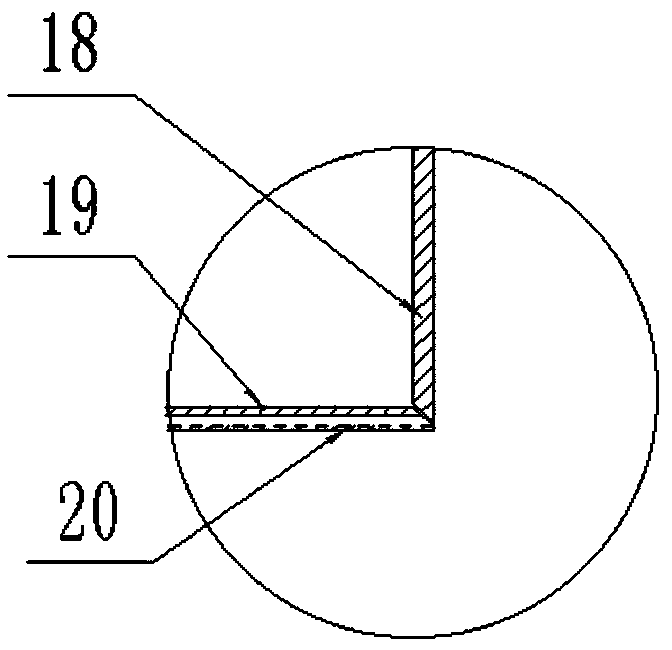

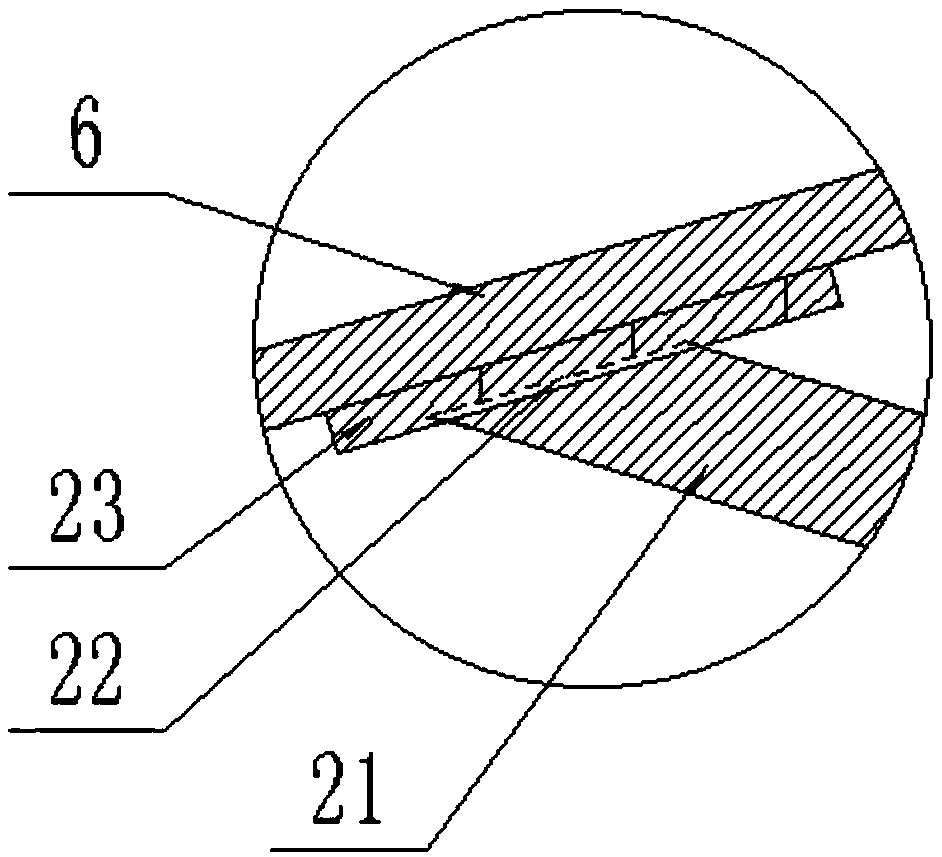

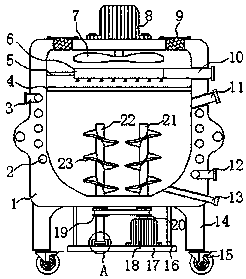

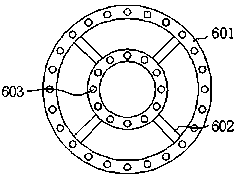

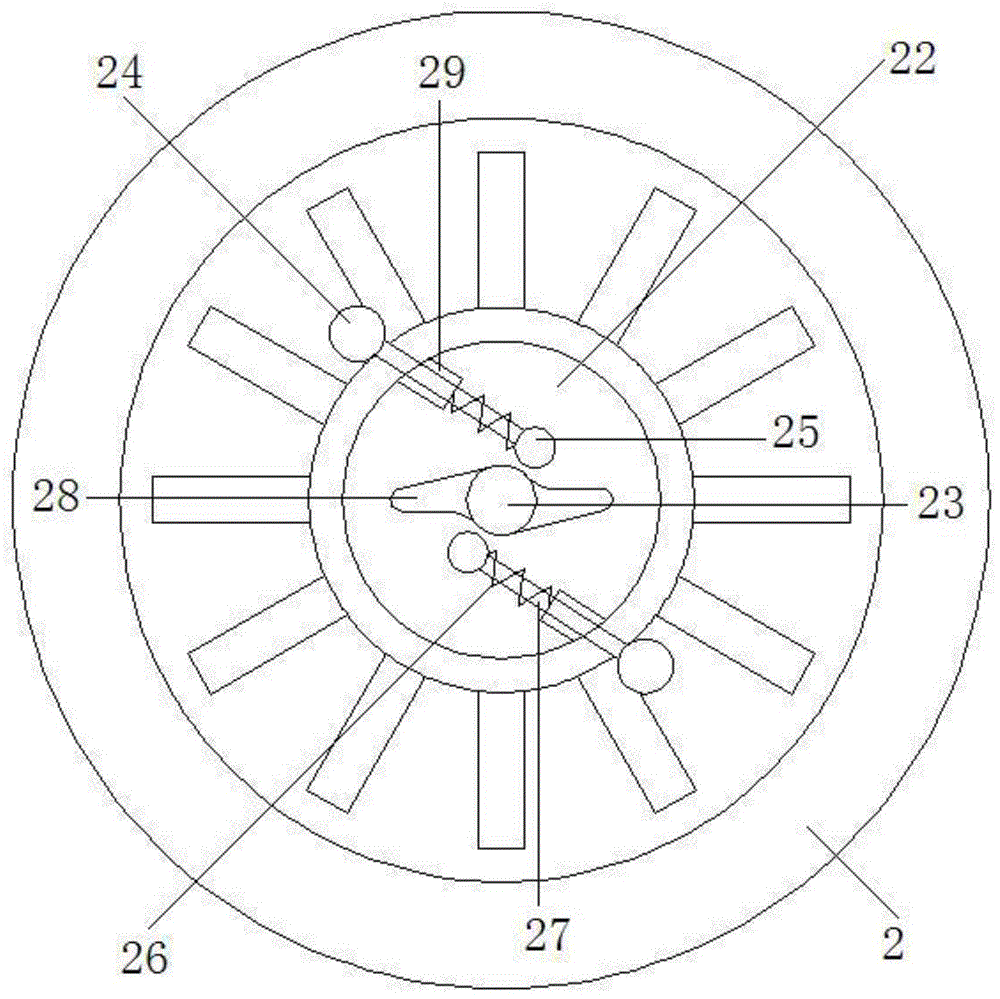

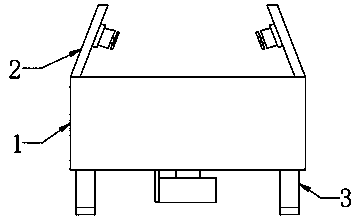

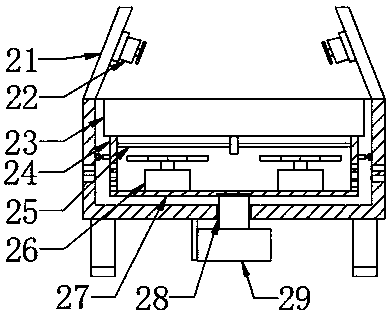

Central bidirectional-circulating temperature control and humidity control drier

ActiveCN104776694AIncreased installation flexibilityImprove insulation effectDrying gas arrangementsDrying chambers/containersTemperature controlAutomatic train control

The invention discloses a central bidirectional-circulating temperature control and humidity control drier. The central bidirectional-circulating temperature control and humidity control drier comprises a box body (2), a central heating system, a bidirectional hot air circulating system, a skip car and skip tray system, an automatic control system and a humidity discharging system, wherein the central heating system, the bidirectional hot air circulating system, the skip car and skip tray system and the automatic control system are mounted inside the box body (2); the humidity discharging system is mounted on the box body (2). The central bidirectional-circulating temperature control and humidity control drier disclosed by the invention is reasonable in structural design, convenient to operate, high in automation degree, high in work efficiency, capable of realizing small appearance and color difference of a dried medicinal material, uniform in drying degree, energy-saving, environment-friendly, applicable to drying of different medicinal materials and high in practicability.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

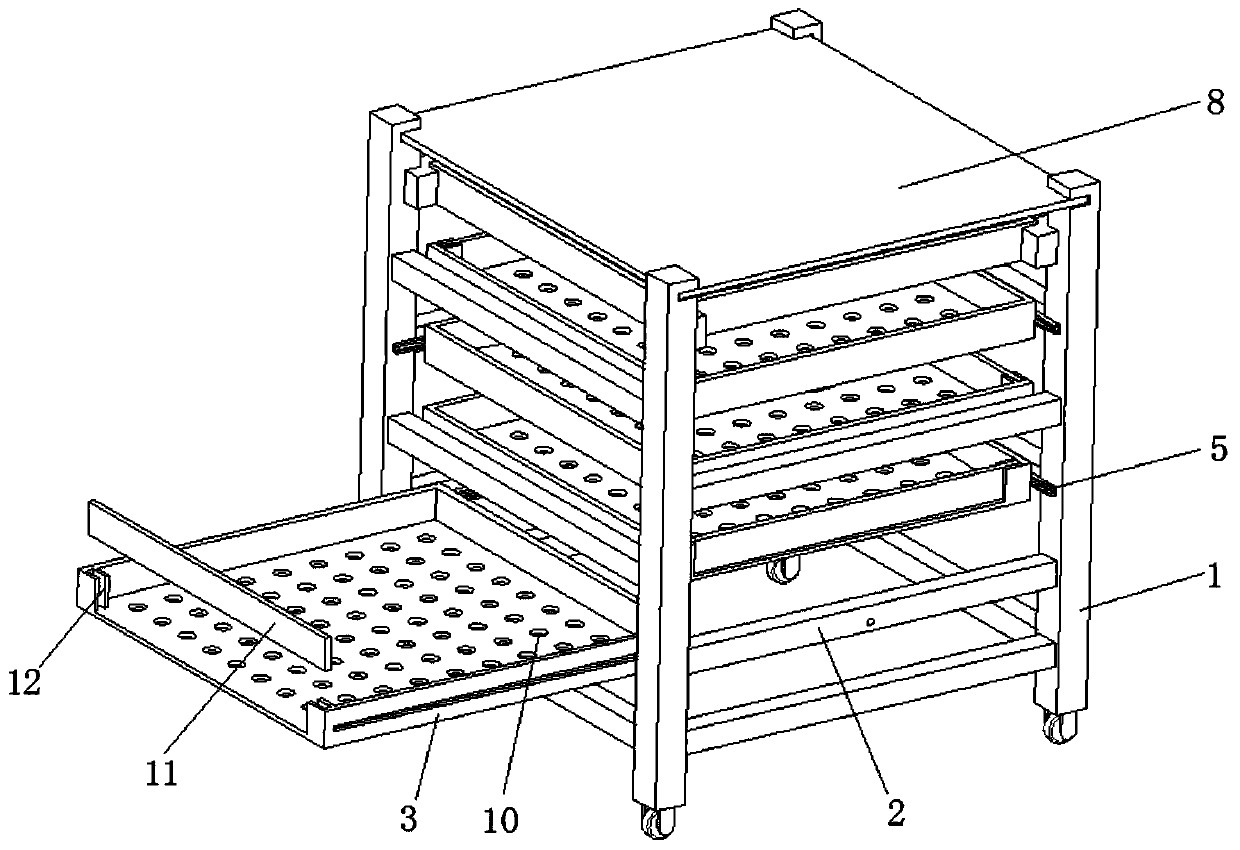

Agricultural and sideline product airing device

InactiveCN111306908AUniform dryingStrong emergency response capabilityDrying chambers/containersDrying solid materialsAgricultural engineeringEngineering

The invention provides an agricultural and sideline product airing device, and relates to the field of agriculture. The agricultural and sideline product airing device comprises four supporting columns, a plurality of transverse columns and four movable airing grooves, wherein the four supporting columns are vertically enclosed into a rectangular frame body, the supporting columns are connected through the transverse columns, the two sides of each movable airing groove are connected with the supporting columns through sliding rails, the four movable airing grooves are sequentially arranged from bottom to top, the four movable airing grooves can slide out of the frame body towards the four directions of north, south, east and west, and a shielding cover is arranged between the four supporting columns and located above the four movable airing grooves. During airing, the four movable airing grooves are removed in the four different directions, and the four movable airing grooves and fixedairing grooves jointly form a downward two-dimensional cross-shaped airing shape, so that crops in each movable airing groove and each fixed airing groove can receive enough sunlight, and the airingdegree of the crops is relatively uniform. In addition, moisture spilled from each layer of movable airing groove and each layer of fixed airing groove does not fall in the lower layer of airing grooves, so that the airing grooves do not affect each other.

Owner:绍兴市上虞区凤茗茶果专业合作社

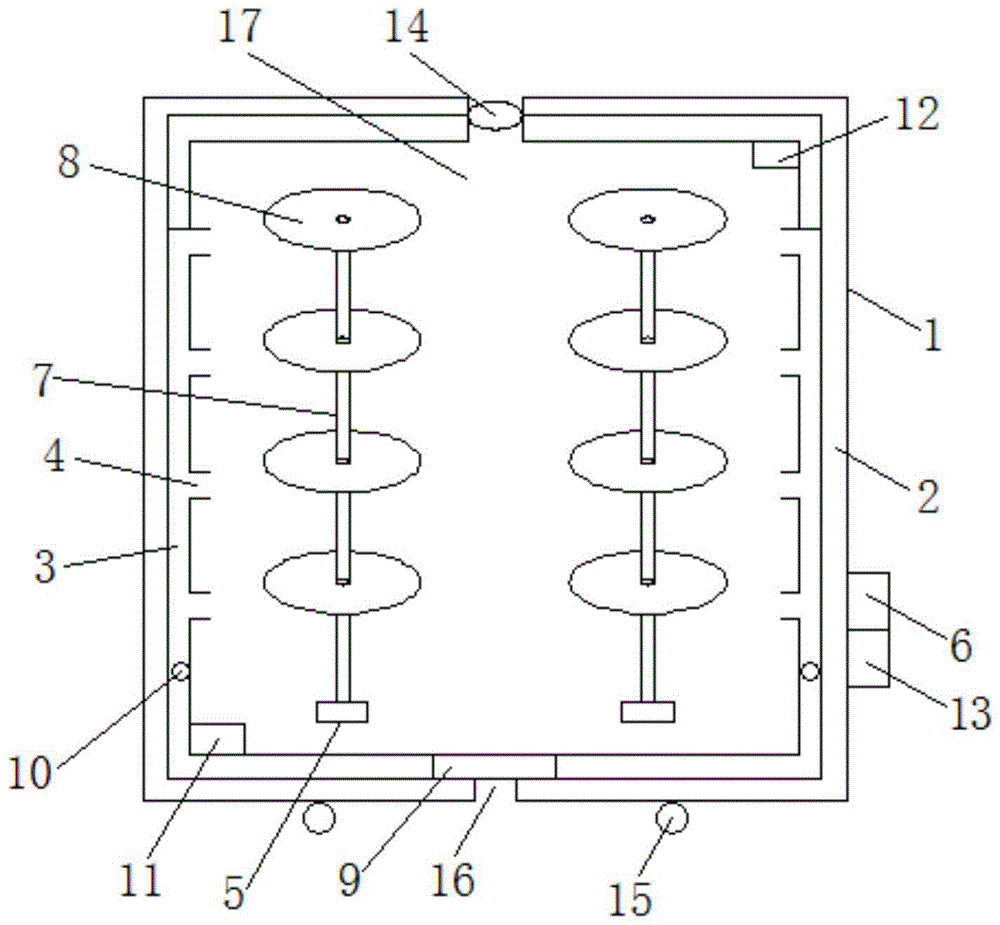

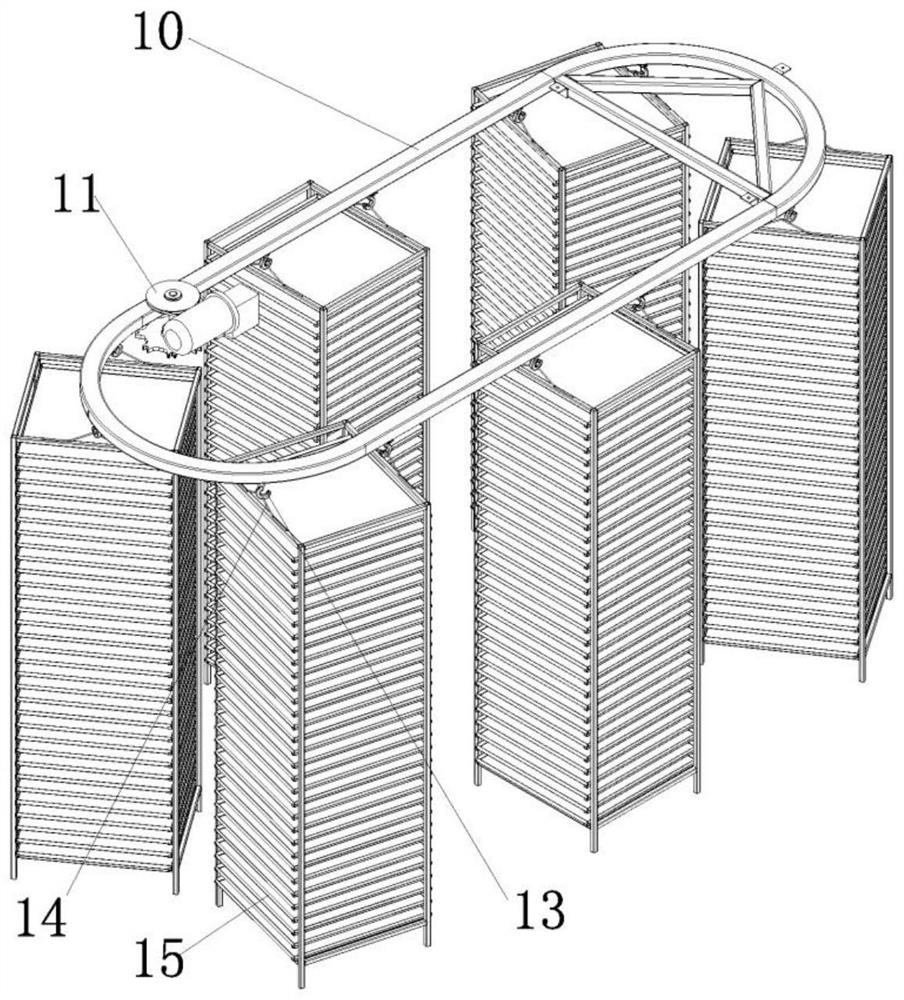

Drying system for dark green tea

InactiveCN104654757AImprove drying qualityMellow tasteDrying gas arrangementsDrying machines with non-progressive movementsAgricultural engineeringFood flavor

The invention discloses a drying system for dark green tea. A drying room is arranged in a shell; the inner side of the shell is provided with an air duct; an insulating layer is arranged between the shell and the air duct; air outlets are formed in the upper end of the air duct; an air intake fan is arranged in the air duct; the lower end of the air duct is provided with an infrared heating device; an air inlet is formed in the bottom part of the infrared heating device; a driving device is arranged at the bottom part of the drying room; the driving device is provided with a revolving shaft; the revolving shaft is provided with turnplates; an exhaust fan is arranged at the top part of the drying room; a first temperature sensor is arranged at the corner of the bottom face and the side face of the drying room; a second temperature sensor is arranged at the corner of the top face and the side face of the drying room; the outer side of the shell is provided with a display screen and a controller; the bottom part of the shell is provided with castors. The drying system for the dark green tea has the advantages that components in the tea are fully decomposed, the tea is heated and dried evenly, the drying speed is fast, the drying efficiency is high, the drying quality of the dark green tea is good, and the tea does not have a smoky flavor.

Owner:HUNAN AGRICULTURAL UNIV

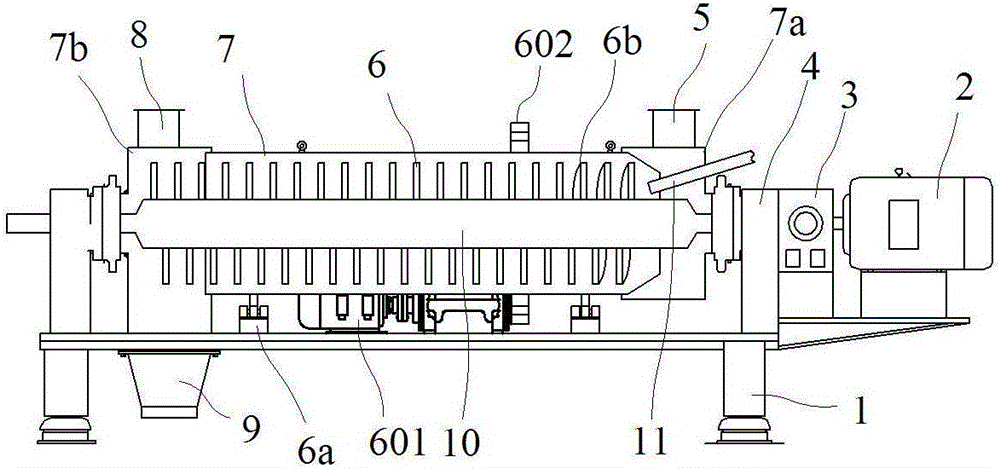

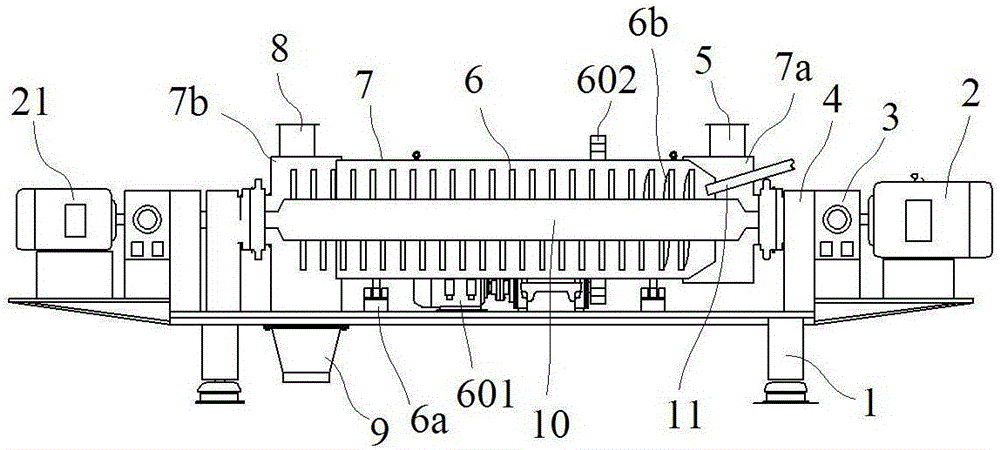

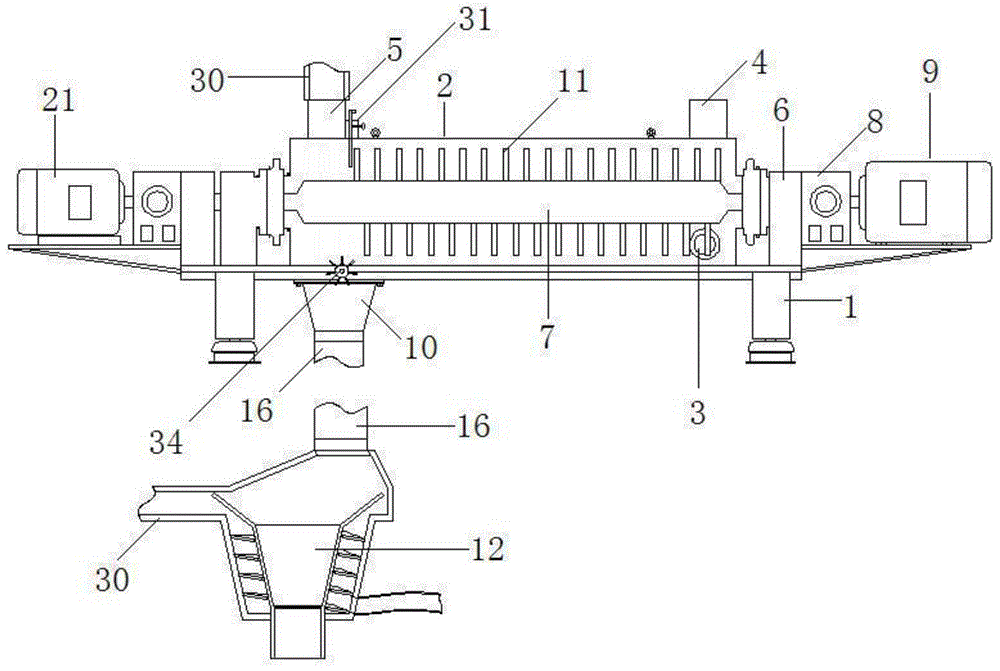

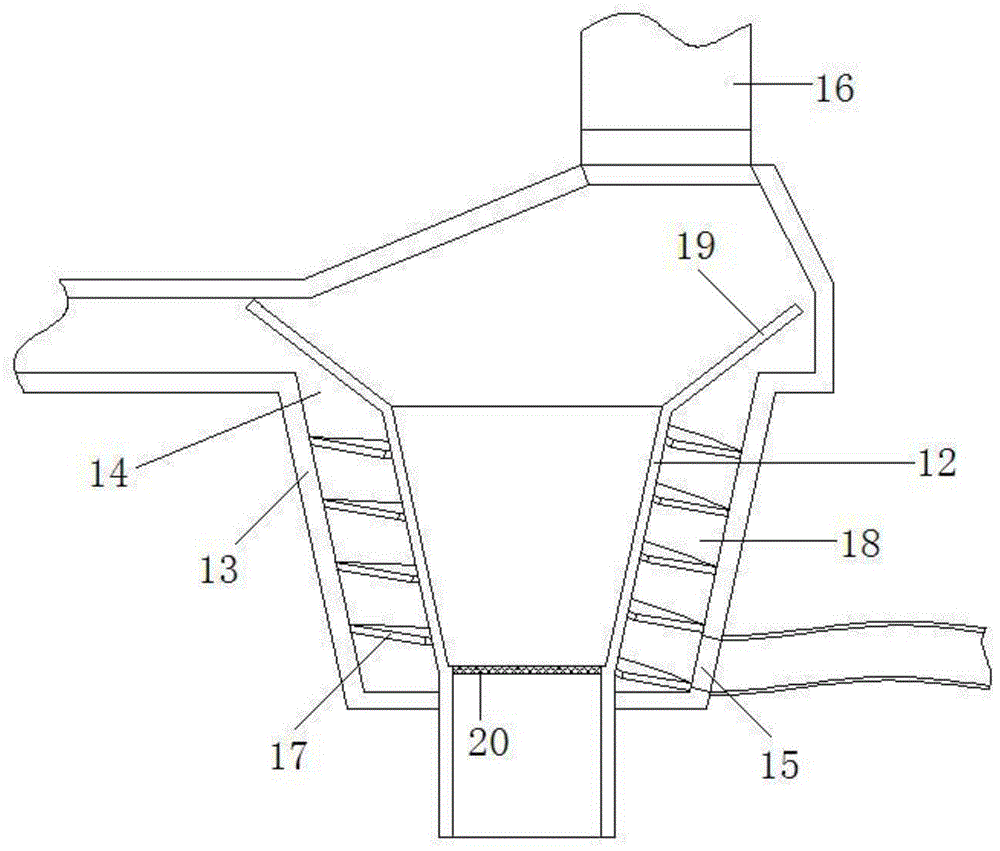

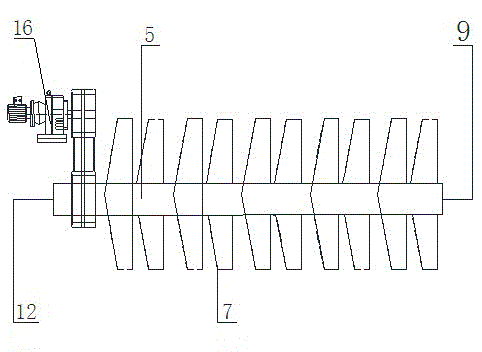

A sludge crushing and drying equipment

ActiveCN105084707BReasonable useFully contactedSludge treatment by de-watering/drying/thickeningFlue gasSludge

The invention discloses a sludge fragmentation-type drying device. The sludge fragmentation-type drying device comprises a transverse drying main cylinder, a frame for positioning the drying main cylinder and a rotor main shaft. One end of the drying main cylinder is provided with a feeding end and the other end is provided with a discharge end. The drying main cylinder can rotate relatively to the feeding end and the discharge end. The top of the feeding end is provided with a heat flue gas inlet and the top of the discharge end is provided with a wet flue gas outlet. The rotor main shaft is arranged in the drying main cylinder. The frame is provided with a bearing pedestal for positioning the rotor main shaft. The frame is provided with a main shaft driving motor for driving the rotor main shaft to rotate and a main cylinder driving motor for driving the drying main cylinder to rotate. Rotation directions of the rotor main shaft and the drying main cylinder are opposite. The rotor main shaft is provided with multiple stirring pushing rods. The sludge fragmentation-type drying device can effectively dry high-water content sludge, has a continuous and stable drying process, has high drying efficiency, has high integral drying uniformity and has good drying effects.

Owner:ZHEJIANG SANLIAN ENVIRONMENT MACHINERY EQUIP

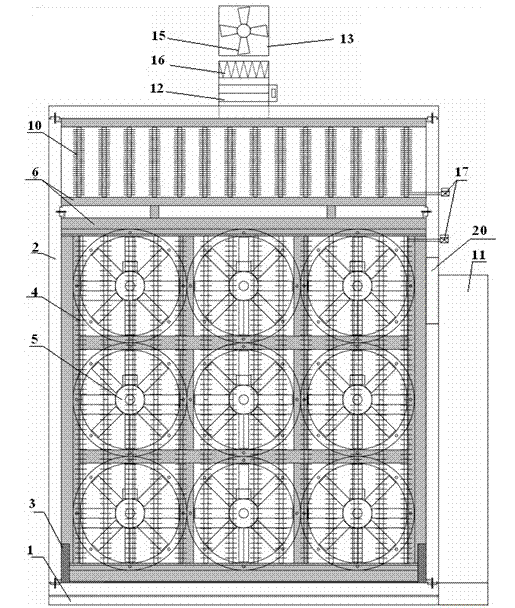

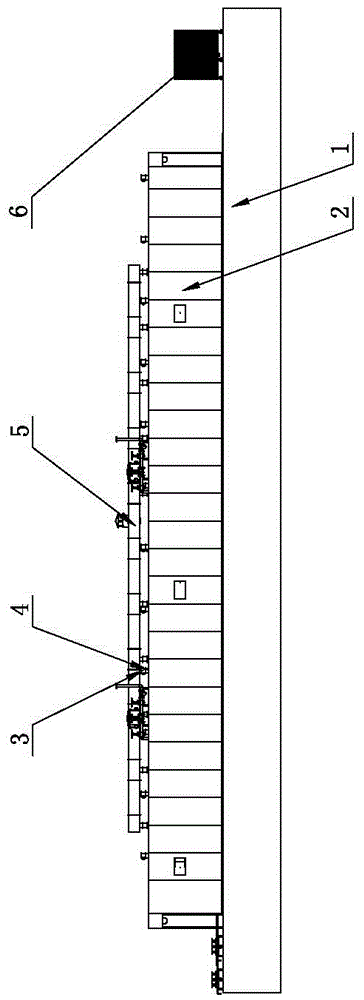

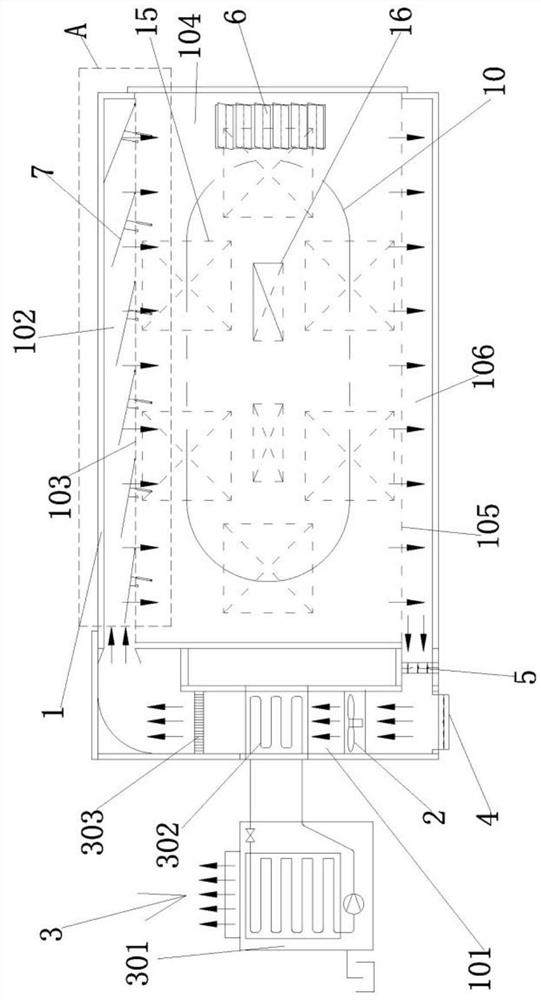

Tunnel type fruit and vegetable drying chamber and fruit and vegetable drying method

ActiveCN106196968AUniform dryingImprove qualityDrying gas arrangementsDrying machines with progressive movementsComing outAgricultural engineering

The invention provides a tunnel type fruit and vegetable drying chamber and a fruit and vegetable drying method in the technical field of drying. The tunnel type fruit and vegetable drying chamber comprises a drying chamber arranged on a base, wherein driving mechanisms used for driving a drying vehicle to enter and come out of the drying chamber are arranged on the base; the drying chamber comprises an outer box body and an inner box body; a circulating air duct is reserved between the outer box body and the inner box body; a plurality of circulating fans are arranged in the positions, at the top of the inner box body, inside the circulating air duct; heaters are arranged corresponding to the circulating fans; a plurality of circulating air holes are formed in the side wall of the inner box body; an air supplementation pipe is arranged on the inner box body to communicate with the external air; an air supplementation valve is arranged on the air supplementation pipe; a wet air discharge device is further arranged on the inner box body or the outer box body; the integral driving mechanisms are positioned inside the drying chamber; and openable and closable doors are arranged at the two ends of the drying chamber. According to the tunnel type fruit and vegetable drying chamber, the thermal loss is low, energy is saved, the fruit and vegetable drying degree is uniform, and the quality of dried fruits and vegetables is good.

Owner:扬州福尔喜果蔬汁机械有限公司

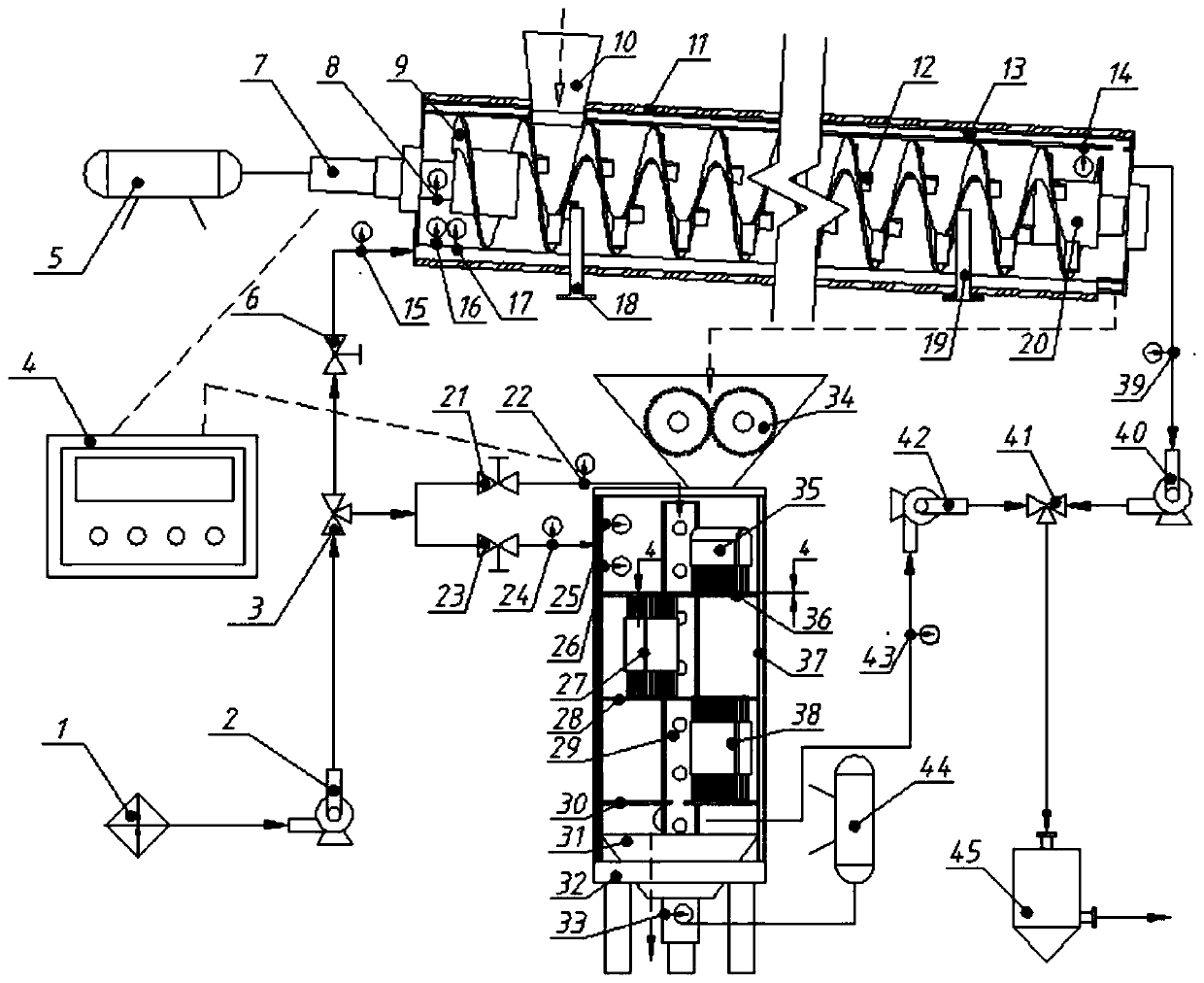

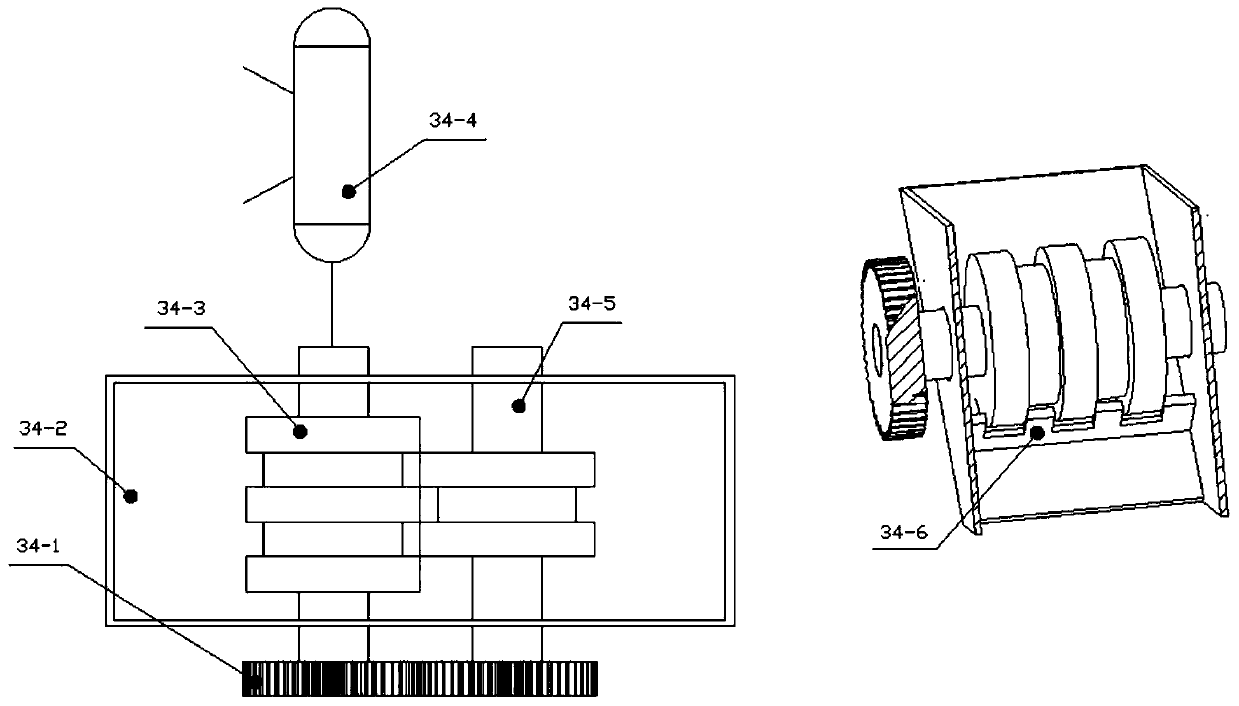

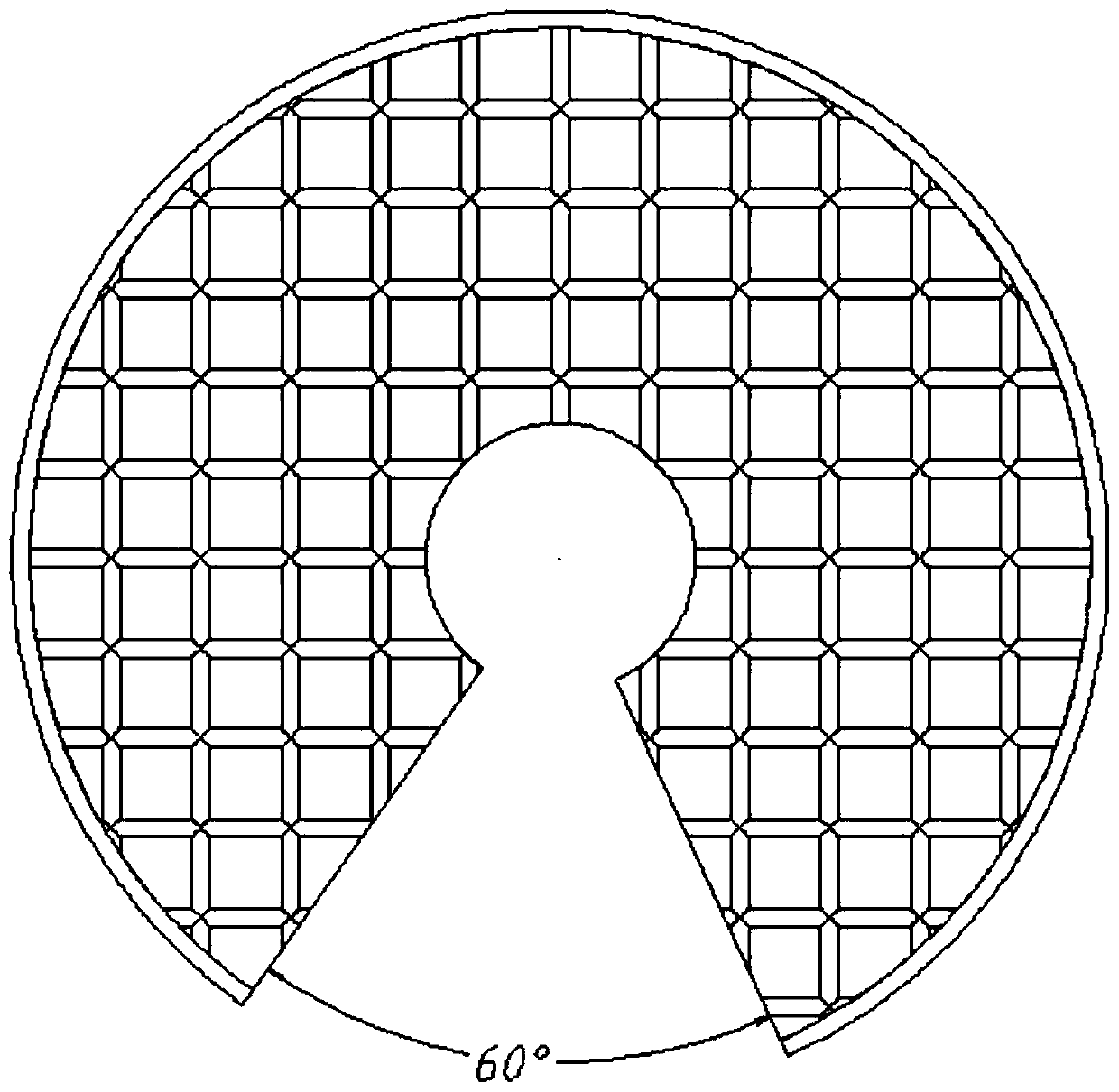

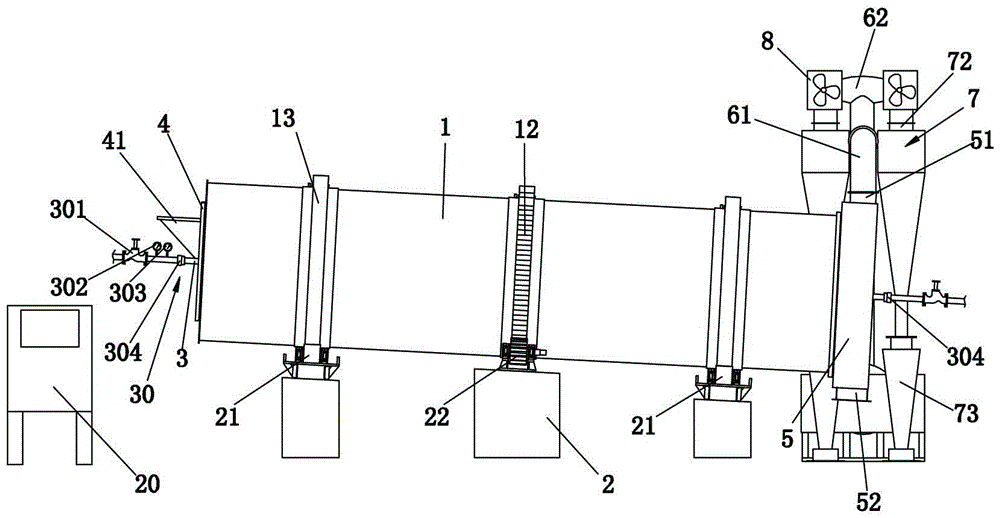

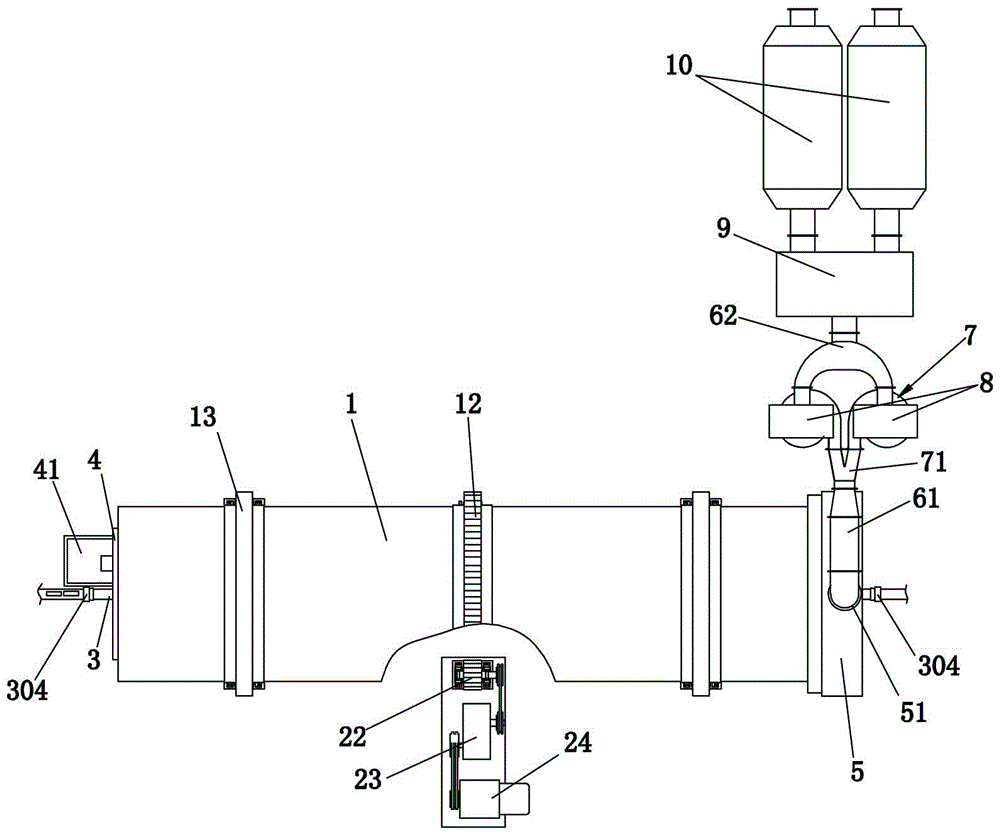

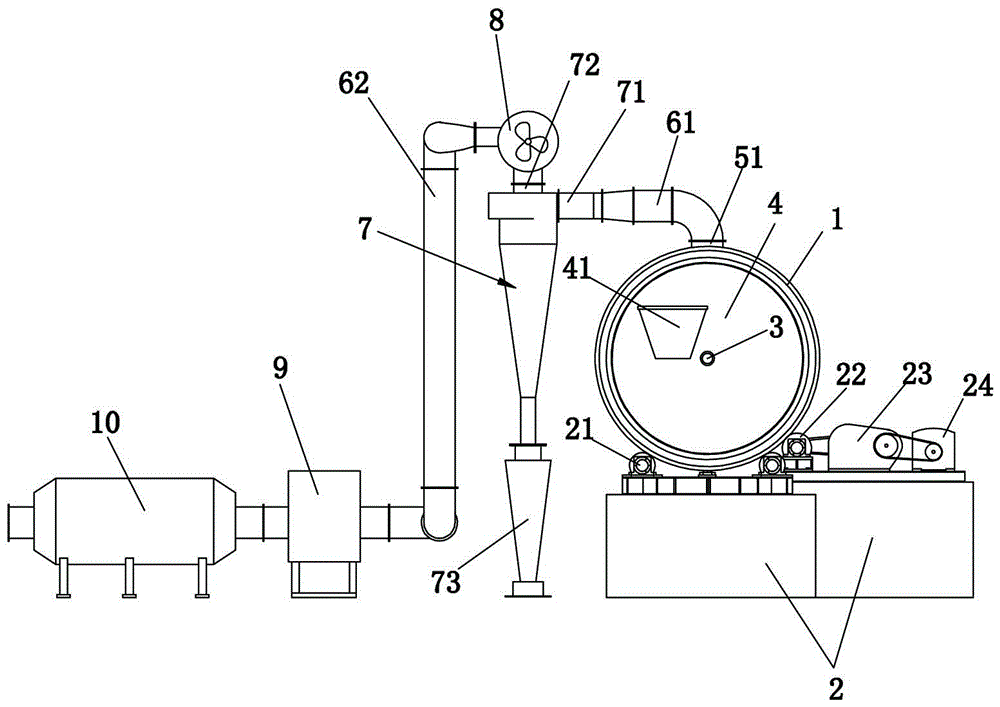

Two-stage sludge drying equipment system

PendingCN110002715AImprove drying rateUniform dryingSludge treatment by de-watering/drying/thickeningWater treatment multistage treatmentsActivated carbonSludge

The invention relates to a two-stage sludge drying equipment system. A sludge filler module is mounted at the rotating shaft end of the upper left side of a first-stage spiral drying module; the first-stage spiral drying module comprises an inclined drying cylinder and a built-in spiral feeding device, and an interlayer is formed in the wall of the drying cylinder; a strip extruding module is located below the first-stage spiral drying module, a second-stage tower-type cleaning drying module is installed below the strip extruding module, and a discharge port of the strip extruding module is the feed port of the second-stage tower-type cleaning drying module; the second-stage tower-type cleaning drying module comprises a vertical metal cylinder, an internal cleaning device and an upper hotair inlet; a tail gas purification module comprises a purification chamber as well as a sprayer, activated carbon and a UV ultraviolet light source which are located in the purification chamber, and two induced draft fans introduce waste gas of the first stage and the second stage into the purification chamber respectively. The system has higher drying rate and lower energy consumption.

Owner:ZHEJIANG UNIV OF TECH

Environment-friendly sludge conditioning and drying treatment device

InactiveCN108191203AAccurate measurementPrevent overloadSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFlue gasChemical preparation

The invention discloses an environment-friendly sludge conditioning and drying treatment device and belongs to the technical field of sludge treatment equipment. The environment-friendly sludge conditioning and drying treatment device comprise a chemical preparation device, a conditioning device, a dehydration drying device and a control device. The amount of sludge entering a drying drum can be metered precisely, and overload of the dehydration drying device is avoided; meanwhile, drying is performed by means of hot flue gas, and energy is used reasonably; the sludge is smashed uniformly by astirring push rod in a drying process and is pushed to advance, the drying process is uniform, the hot flue gas makes full contact with the sludge, the drying effect is good, the drying process is continuous and efficient, a secondary drying device is arranged, heat of wet flue gas is fully used, the energy use rate is high, and the drying effect is obvious.

Owner:陕西专壹知识产权运营有限公司

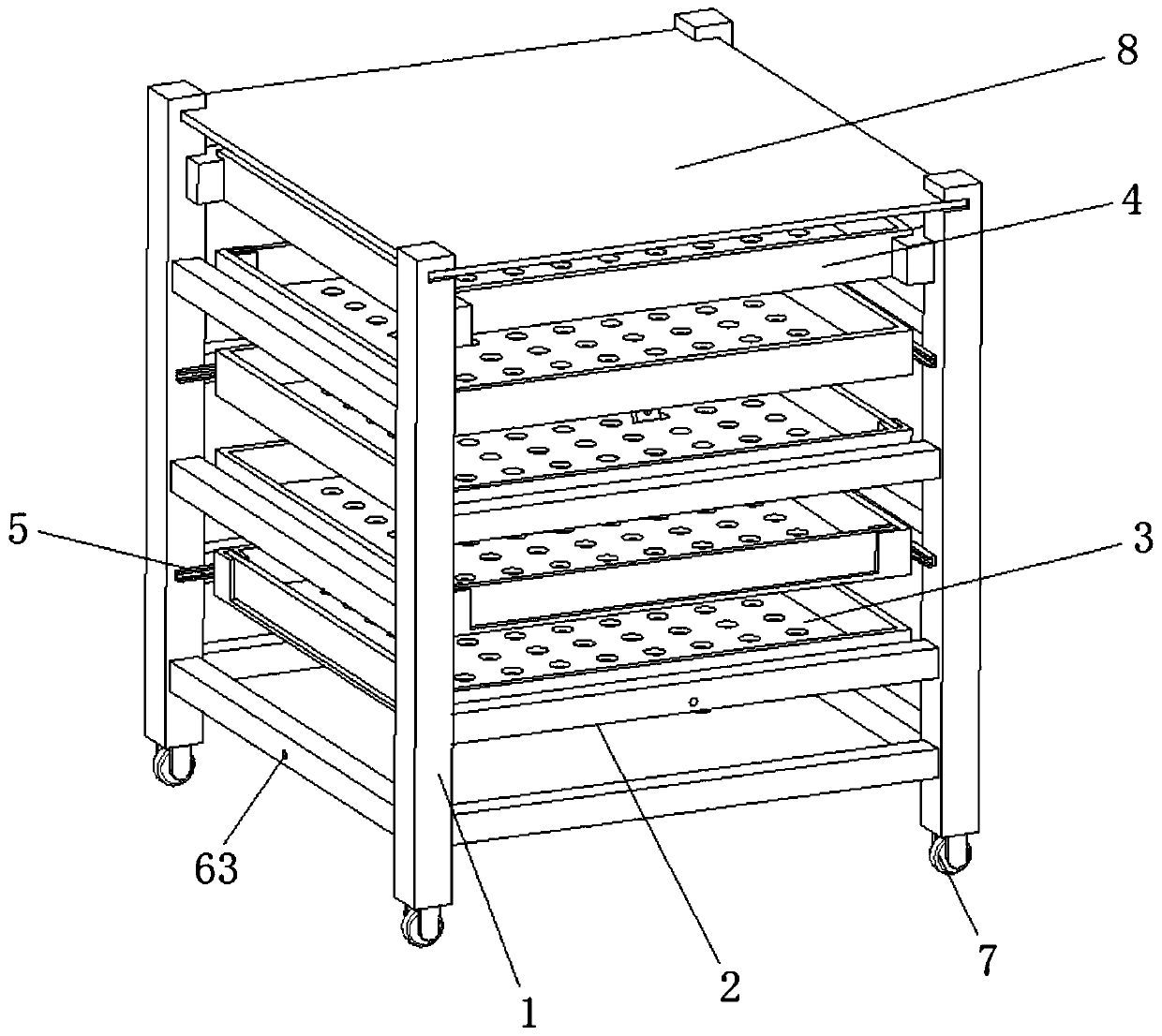

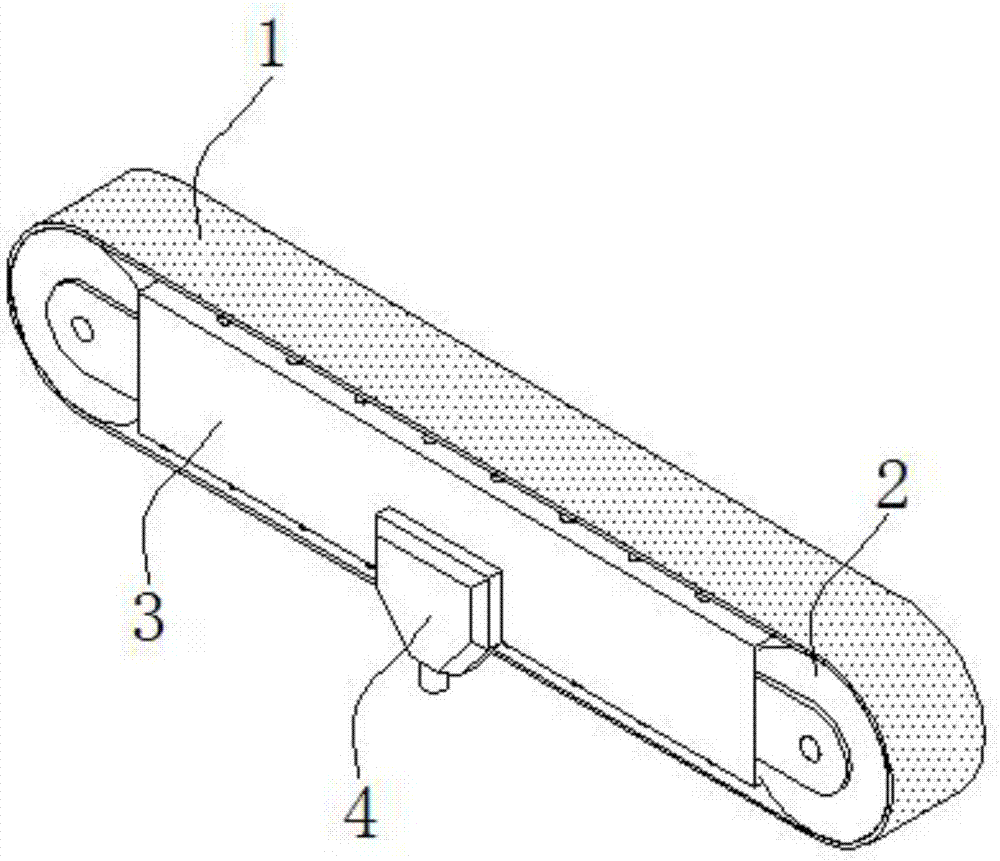

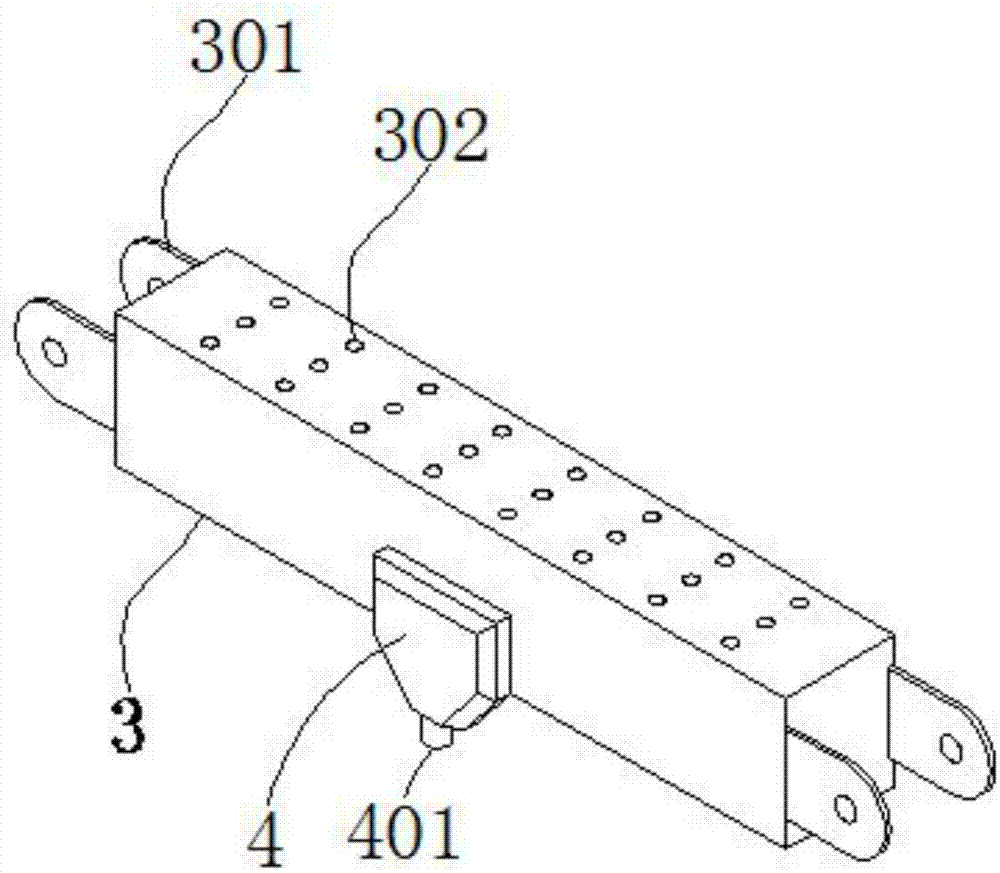

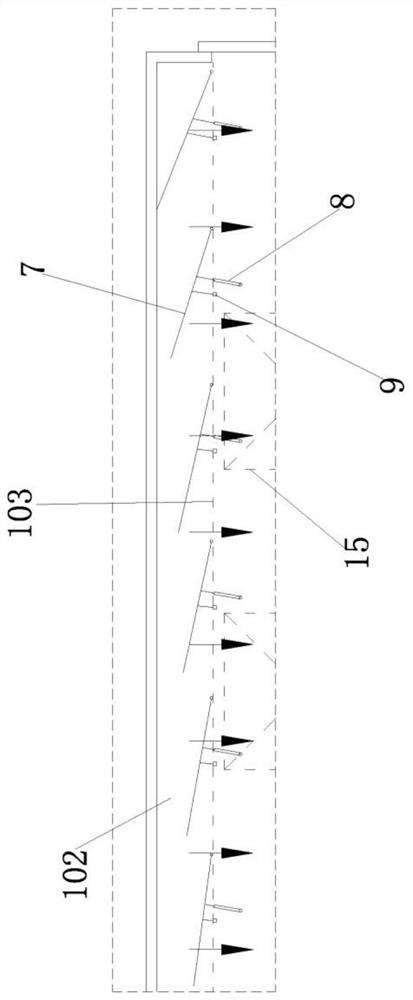

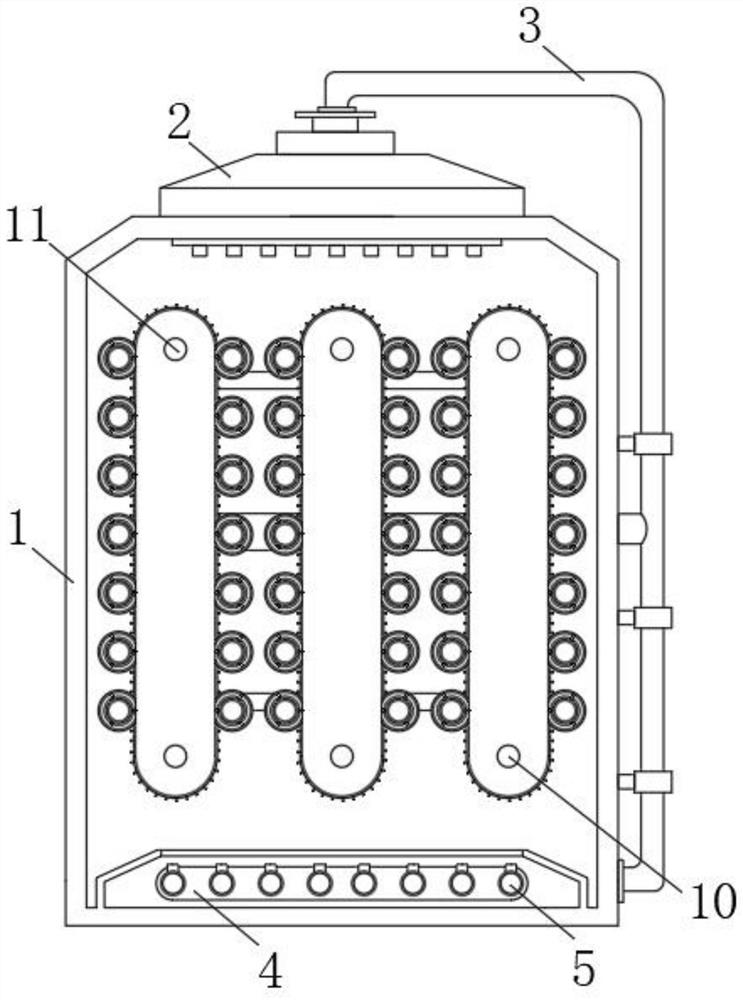

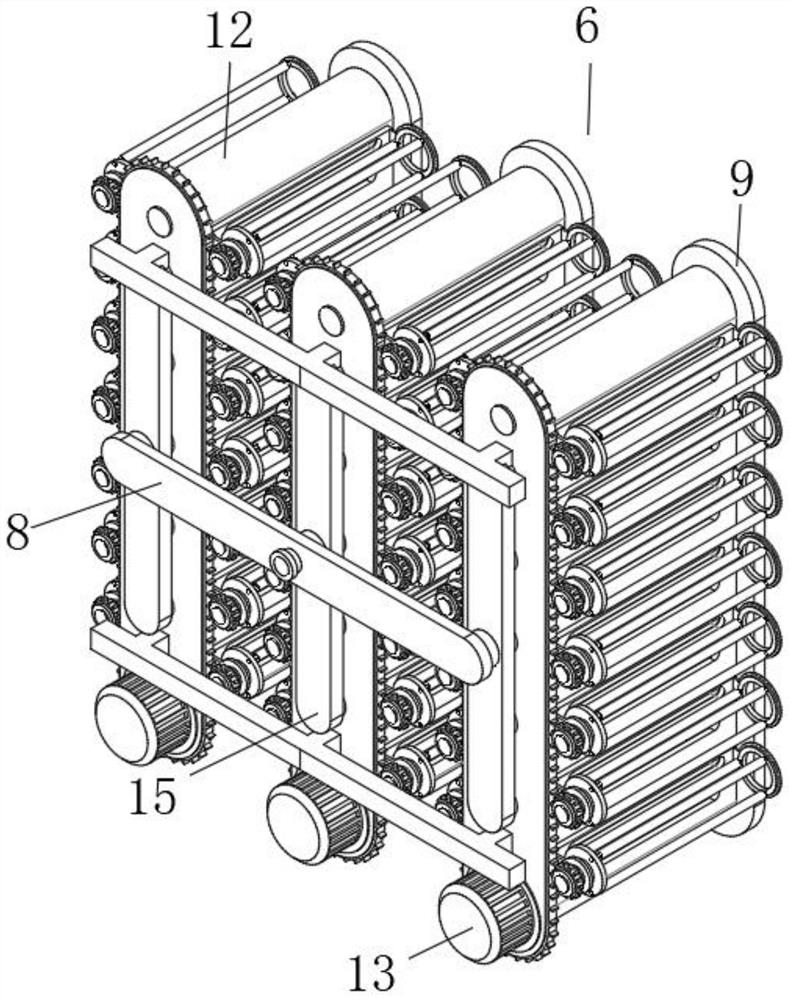

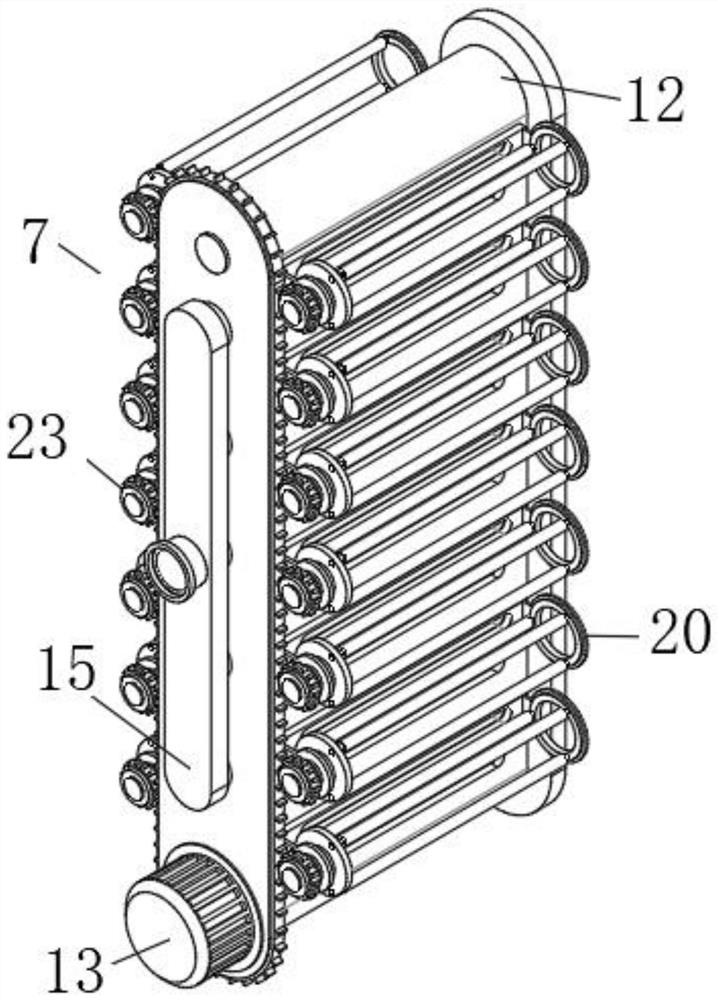

Conveying and drying device for grain drying machine

InactiveCN107490284APrevent mildewUniform dryingDrying gas arrangementsSeed preservation by dryingAtmospheric pressureGrain drying

The invention discloses a conveying and drying device for a grain drying machine, and relates to the technical field of conveying equipment. The conveying and drying device comprises a conveying belt, belt wheels and a diversion box; a group of suspension loops is arranged on each of the opposite end faces of the diversion box; a plurality of through holes are formed in one side surface of the diversion box; an air inlet disc is arranged on the other side surface of the diversion box; an air inlet is formed in one side surface of the air inlet disc; each belt wheel is arranged between the corresponding suspension loops; the conveying belt is arranged on the outer sides of the belt wheels and the diversion box; the diversion box comprises partition plates and a guide plate; the partition plates are fixed between the inner wall of the diversion box and the guide plate, thus first cavities are formed; and a second cavity is formed between the inner wall of the diversion box and the guide plate. Hot air is conveyed for drying through the diversion box arranged between the two belt wheels, so that the discharge amounts of the hot air of the through holes in different positions are the same, and the cross section of the guide plate is V-shaped, so that air pressure of different diversion holes is the same, and mildewing caused by the fact that the degree of drying of grain is not consistent is avoided.

Owner:合肥横冲机械科技有限公司

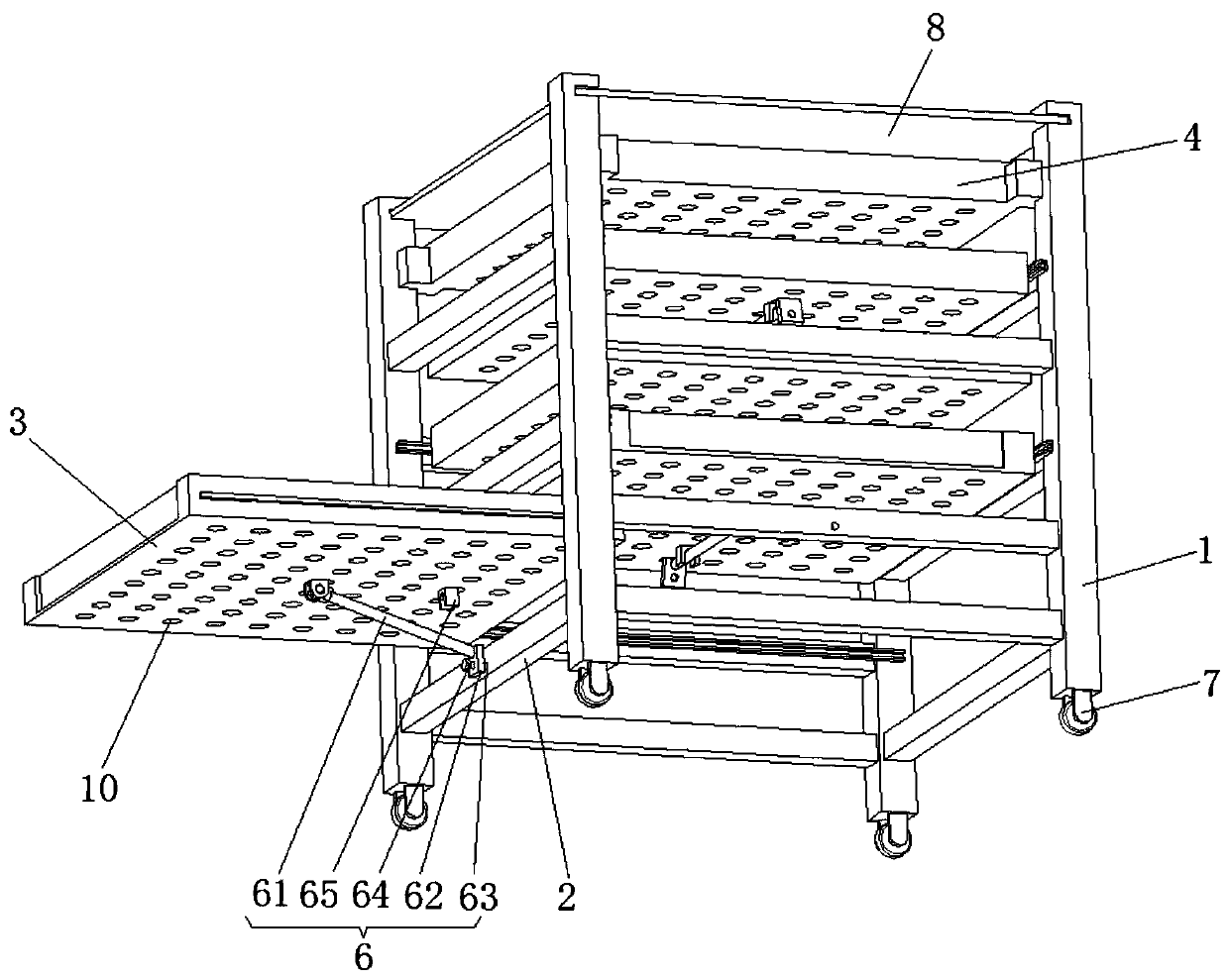

Powder heating and drying device

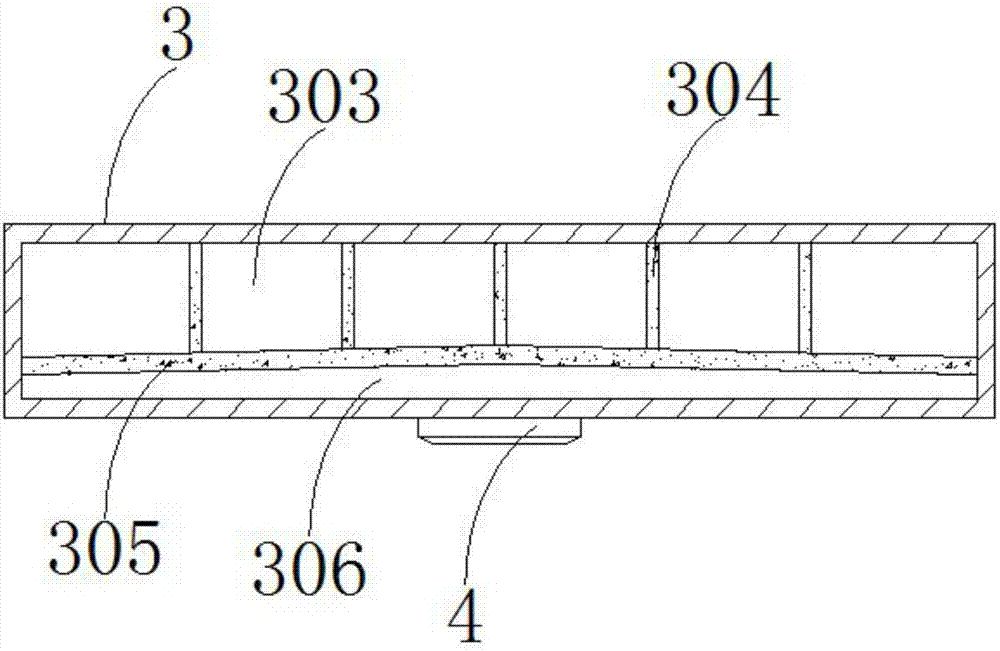

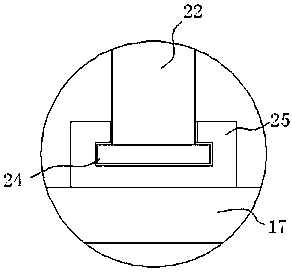

PendingCN111412727AImprove heating uniformityGuaranteed performance consistencyDrying solid materials with heatDrying solid materials without heatVacuum dryingBattery cell

The invention discloses a powder heating and drying device. The powder heating and drying device comprises a drying furnace, a material conveying mechanism, and a heating mechanism, wherein a vacuum drying cavity is formed inside the drying furnace; the material conveying mechanism comprises a material conveying vehicle, material boxes and a first driving assembly, the material boxes are arrangedon the material conveying vehicle, and the first driving assembly is used for driving the material conveying vehicle to enter and exit the vacuum drying cavity in the material conveying direction; andthe heating mechanism comprises heating plates and a second driving assembly, the heating plates are contained in the vacuum drying cavity, and the second driving assembly is used for driving the heating plates to make contact with or be separated from the material boxes. The powder heating and drying device has the advantages of being fast in heating speed, high in heating efficiency and high inheat effective value utilization, and the rapid and effective drying treatment process of battery powder or medicine powder and the like in the material boxes is achieved; and moreover, a contact type heating and heat radiation heating dual-heating mode is adopted, and the material boxes are uniformly heated favorably, so that the heating uniformity of materials such as the battery powder or themedicine powder is improved, the performance consistency of batteries or medicines and the like is maintained favorably, and the product yield is improved.

Owner:SHENZHEN TIME HIGH TECH EQUIP

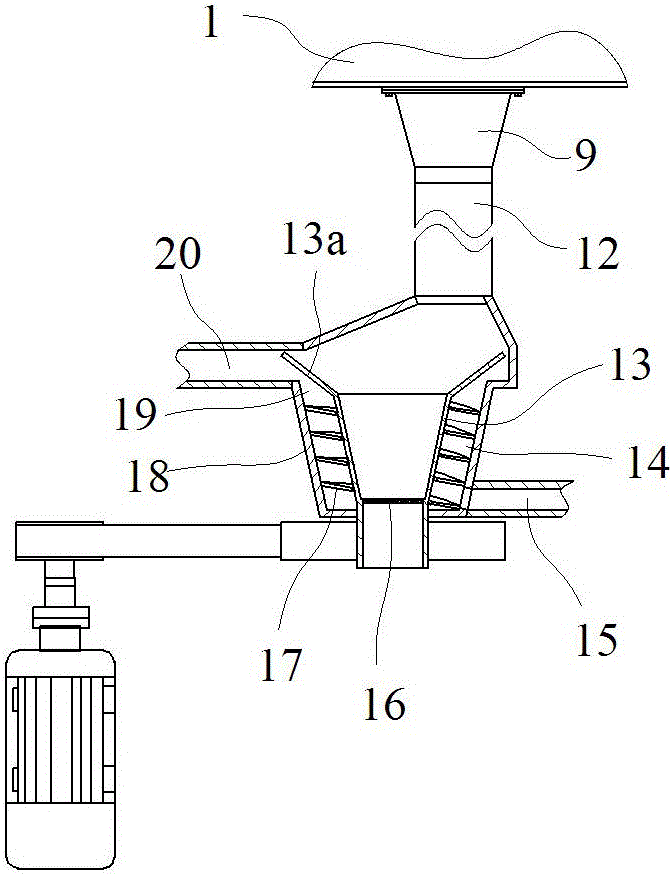

Rice drying device

ActiveCN109631536ADry evenly and fullyEasy to control moisture contentDrying gas arrangementsSeed preservation by dryingCircular coneAgricultural engineering

The invention belongs to the field of agricultural equipment, and particularly discloses a rice drying device. The rice drying device comprises a machine shell, a motor and a feeding box, the motor ismounted on the machine shell, the feeding box communicates with the inner part of the machine shell, the rice drying device further comprises a first leaking plate with a leaking hole, a second leaking plate with a leaking hole, a receiving plate, a limiting part and an adjusting unit, the first leaking plate and the second leaking plate are both mounted on a rotating shaft of the motor, the first leaking plate and the second leaking plate are adjacently distributed in the length direction of the rotating shaft, the first leaking plate is slidably arranged on the rotating shaft in the lengthdirection of the rotating shaft, one side of the receiving plate is hinged to the first leaking plate through an elastic reset part, the first leaking plate is in a circular cone plate shape, the second leaking plate comprises two arc-shaped plates, a circular cone shape is defined by the two arc-shaped plates, and the rotating shaft is positioned between the two arc-shaped plates. After the ricedrying device is adopted, dried rice is automatically separated from the leaking plates due to the weight change before and after rice drying in the rice drying process.

Owner:长沙万众农业发展有限公司

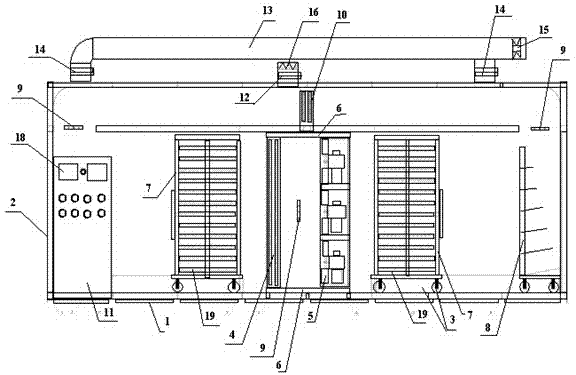

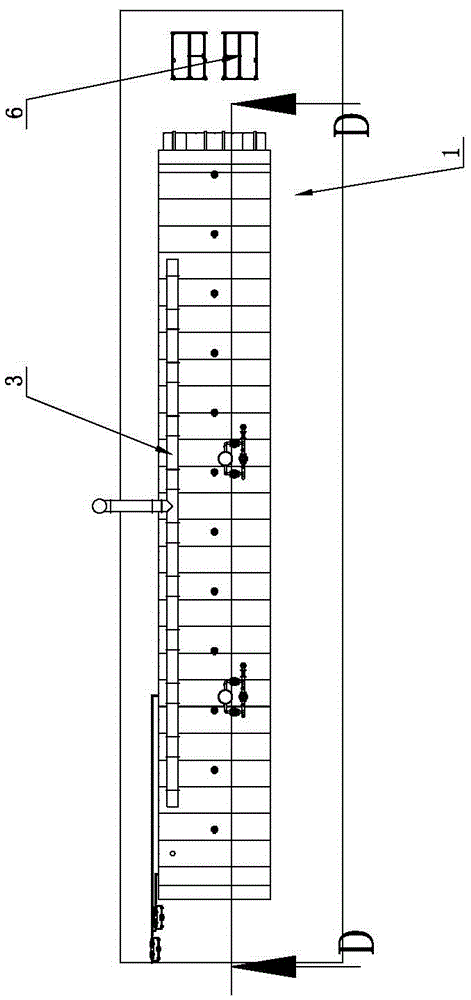

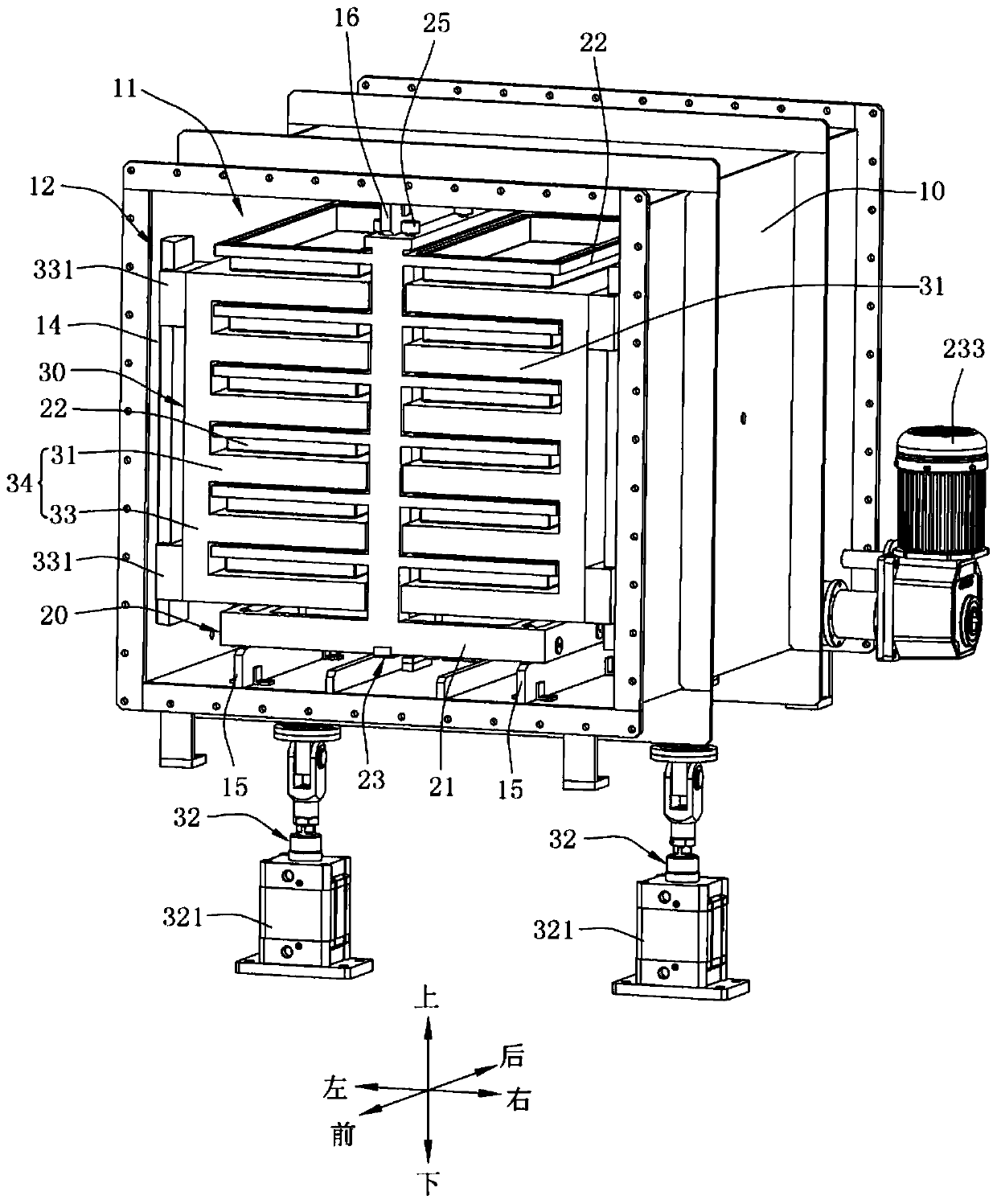

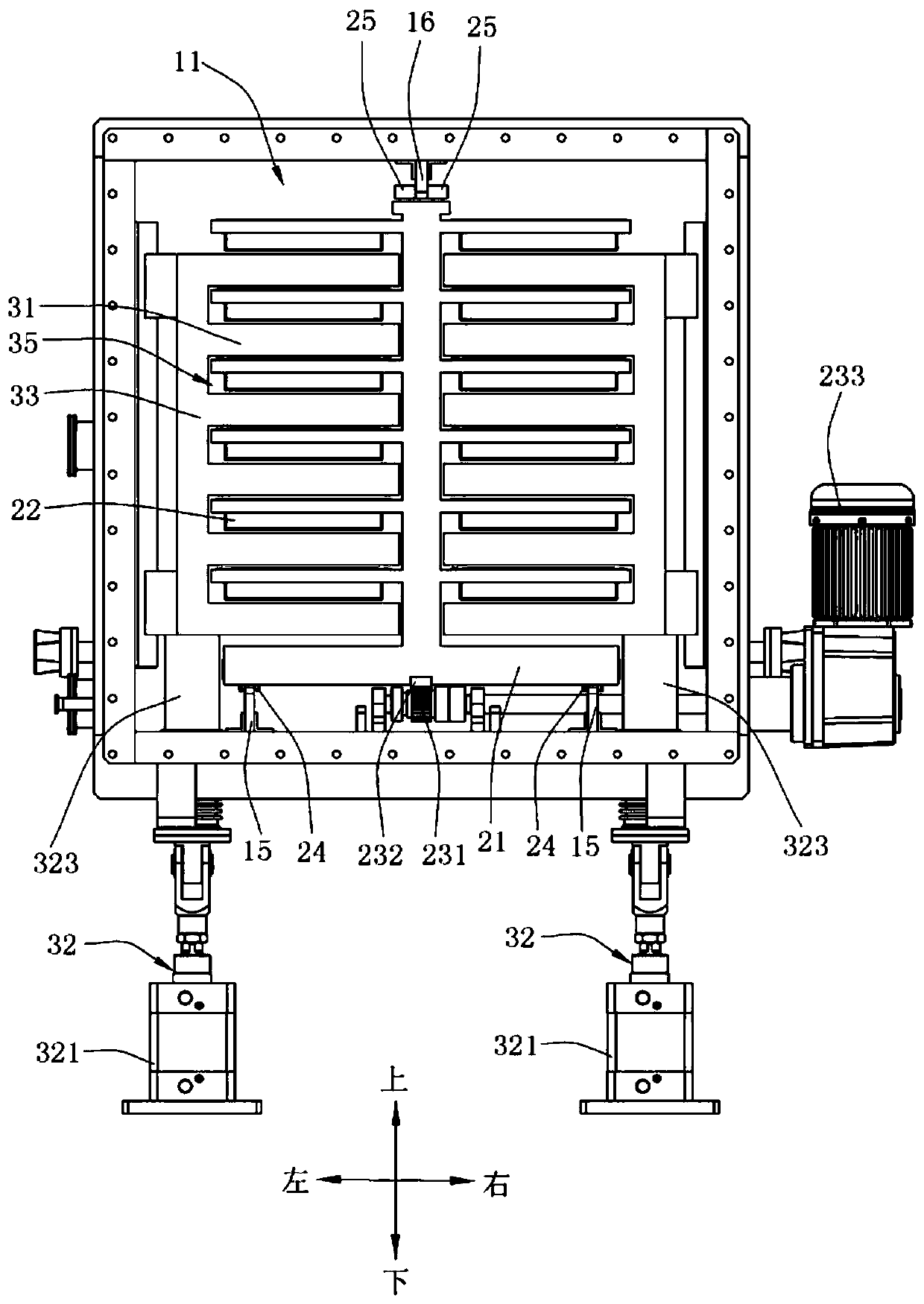

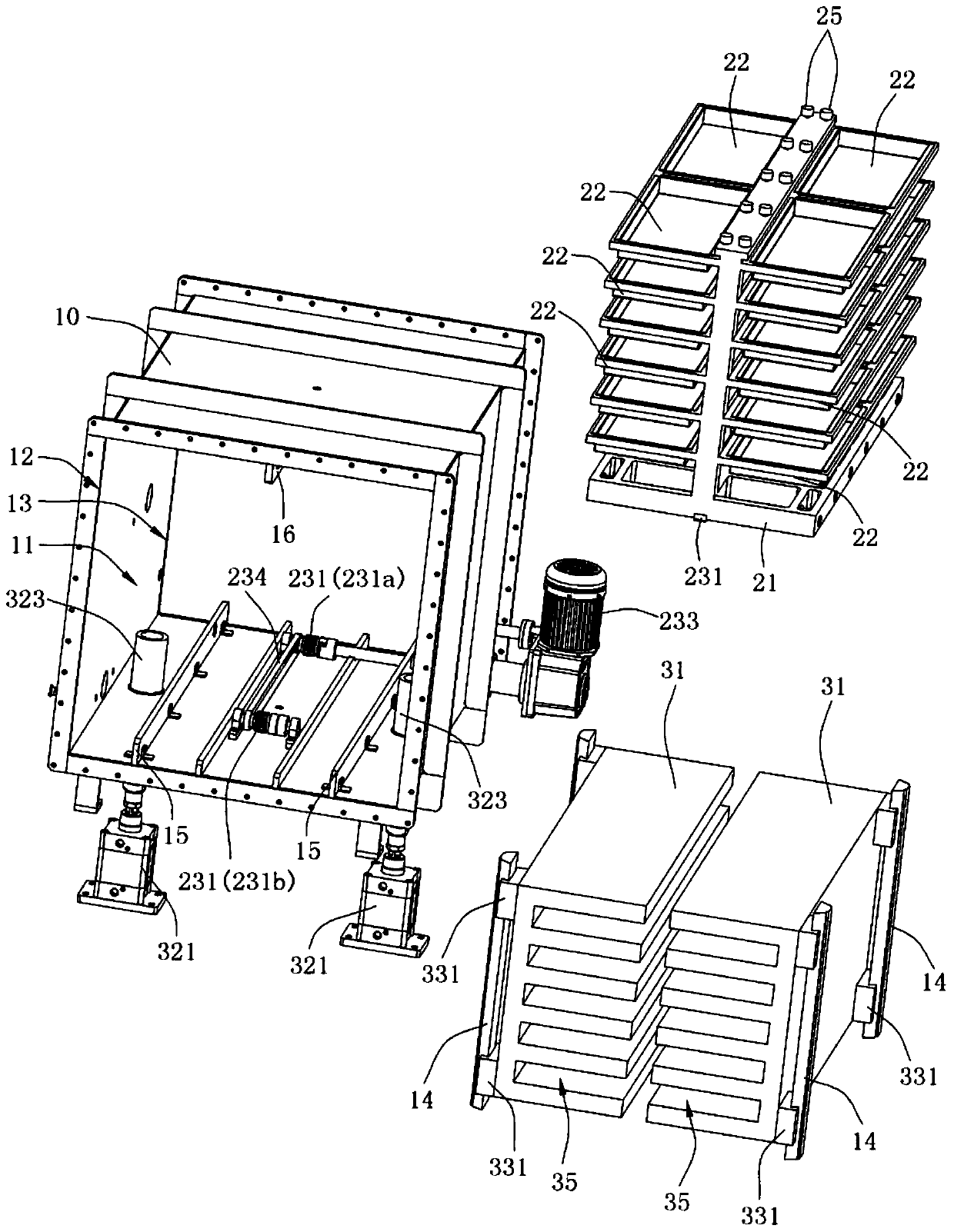

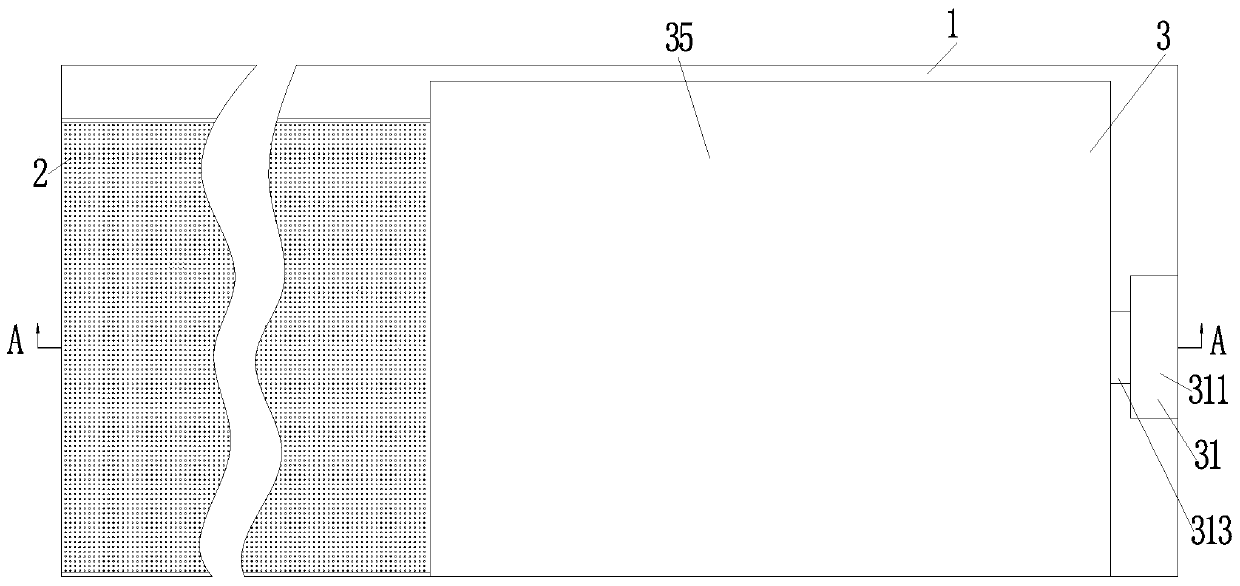

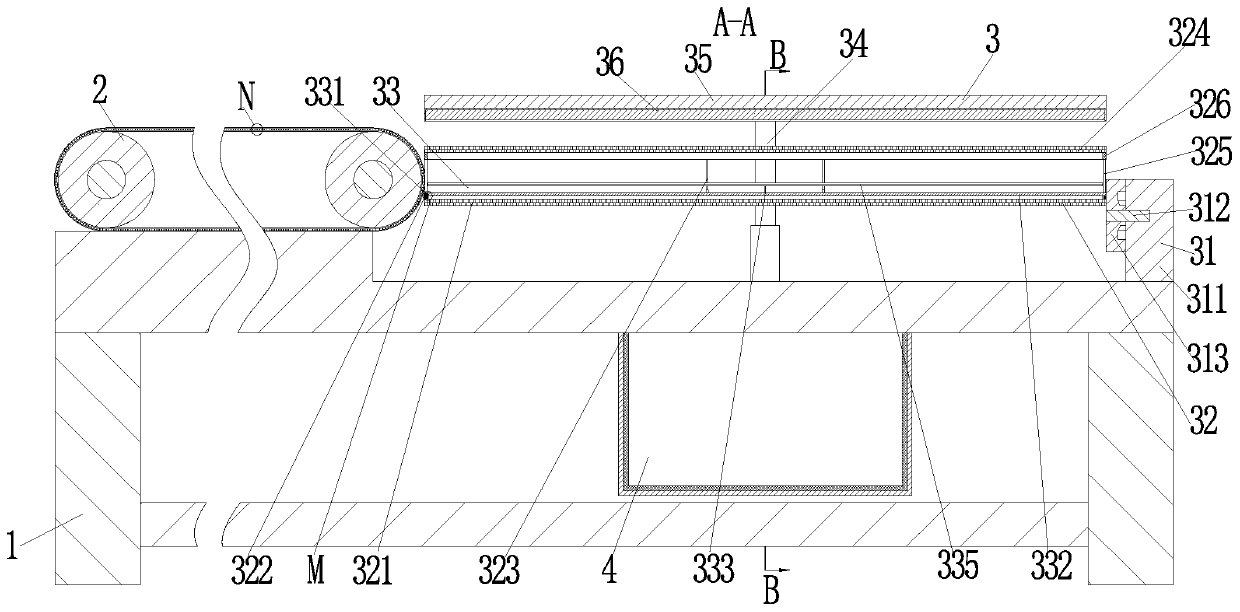

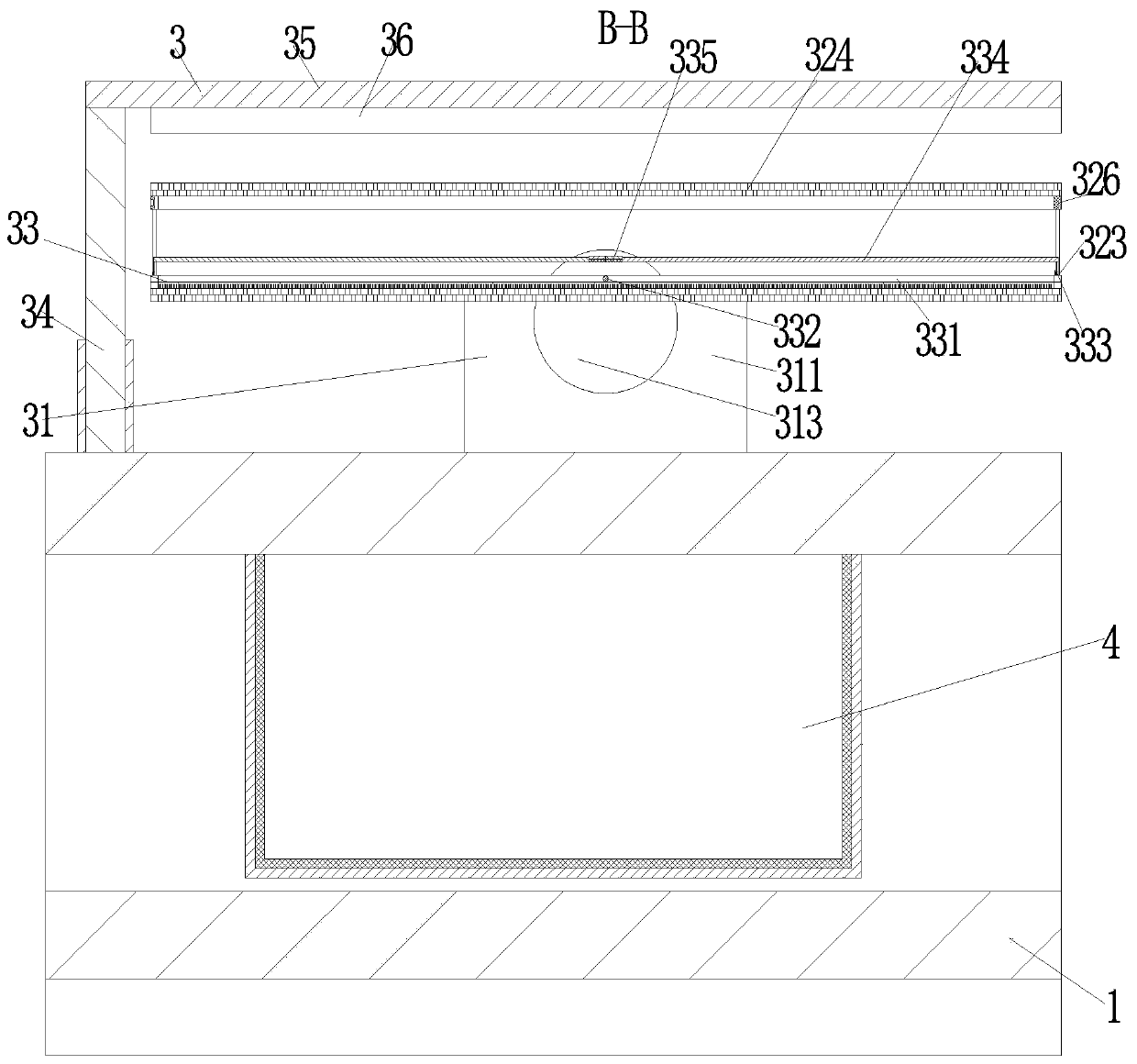

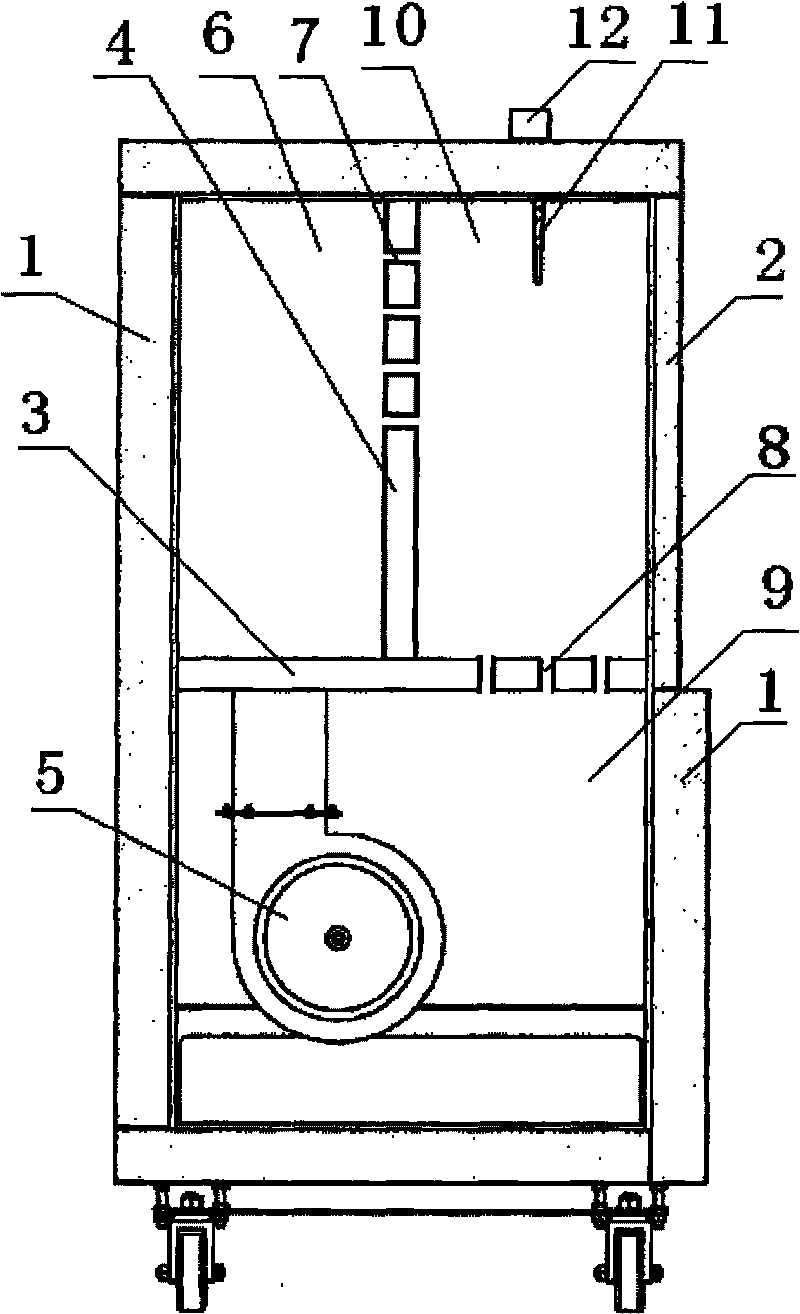

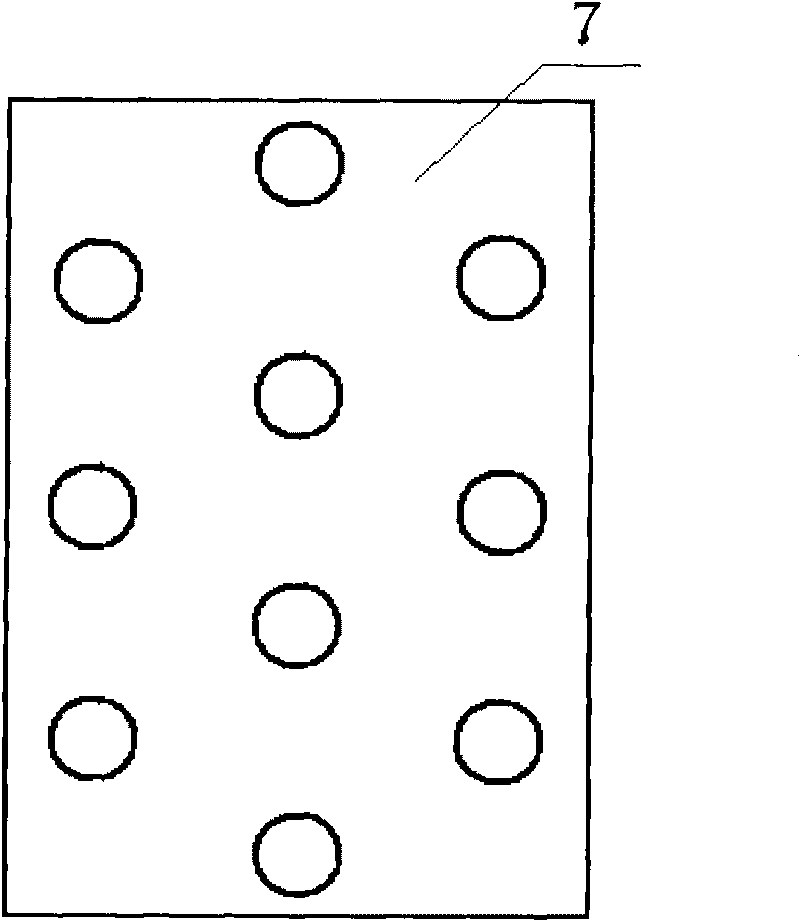

Tray frame fixed rail moving dryer based on side ventilation structure

PendingCN111780534AEvenly distributedSolve the problem of uneven dryingDrying gas arrangementsDrying chambers/containersAgricultural engineeringStructural engineering

The invention relates to a tray frame fixed rail moving dryer based on a side ventilation structure in the technical field of agricultural product drying. A fan chamber, an air inlet chamber, a dryingchamber and an air return chamber communicate according to a circulating airflow sequence; an intake air side punching plate is arranged between the air inlet chamber and the drying chamber; an exhaust air side punching plate is arranged between the drying chamber and the air return chamber; multiple air guide plates with automatically adjusted opening angles are uniformly distributed in the horizontal direction of the intake air side punching plate, so that drying airflow can reach a relatively uniform state in the horizontal direction; and as the vertical section structure of the fan chamber is a rectangular structure, all fans are arranged as a vertical column in the height direction of the fan chamber at equal intervals, and the drying airflow can keep a relatively uniform state in the vertical direction. Such schemes as vertical ventilation of an axial flow fan set, air distribution and homogenization of multi-grade air guide plate combination and movement of a tray frame along aguide rail are adopted to solve the problems of nonuniform ventilation and drying in the vertical direction and the horizontal direction.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Garlic bulb treating equipment with earth drying function

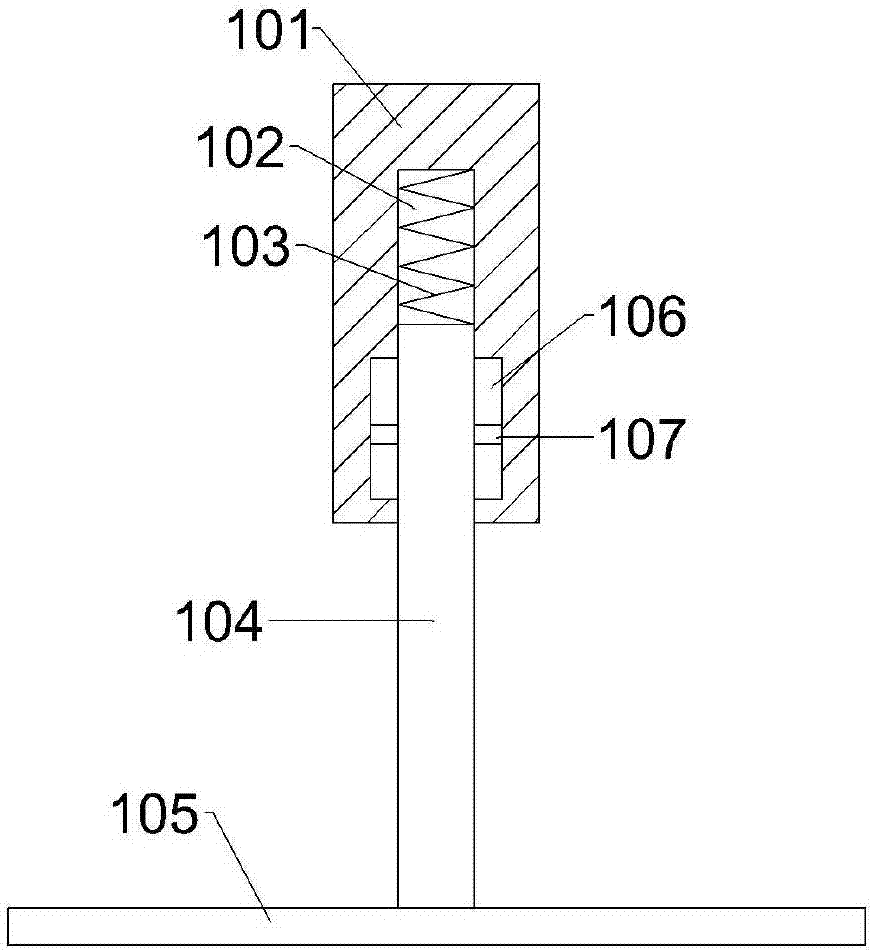

The invention provides garlic bulb treating equipment with an earth drying function. The garlic bulb treating equipment comprises a shell, wherein the inner side wall of the shell is fixedly connectedwith a first partition plate, a plurality of first vertical through holes are formed uniformly in the first partition plate, first cavities are formed in the first partition plate, the first cavitiesare communicated with a hot air generating device on the outer side wall of the shell through a flexible pipe, and an induced draft fan is arranged on the flexible pipe; and a plurality of vertical columns are uniformly arranged on the upper side of the first partition plate, and second cavities are formed in the vertical columns. The garlic bulb treating equipment has the beneficial effects: because the vertical columns and air outlets are uniformly arranged, drying treatment can be uniformly and effectively carried out on the garlic bulbs, thereby greatly improving the drying effect and being convenient for subsequent treatment; a first motor drives a threaded rod to rotate, a shifting block matched with the threaded rod shifts in a shifting chute, so the first vertical through holes are superposed with the second vertical through holes, and the garlic bulbs can pass through the first vertical through holes and the second vertical through holes to continue falling.

Owner:睢宁秋歌农业发展有限公司

Wood drying method

InactiveCN105222534AAbsorb in timeGentle absorptionDrying using combination processesWood treatment detailsWaxHeating furnace

The invention relates to the field of wood storage, and discloses a wood drying method. The method comprises the following steps of a, placing wood into liquid to be stewed, b, burying the stewed wood into high-temperature sand, c, taking out the wood from the sand and placing the wood into a heating furnace to be heated and dried under a vacuum condition, d, taking out the wood from the heating furnace and placing the wood outdoors to be naturally air-dried, and e, immersing the wood into liquid wax to form a wax film on the surface of the wood. Different from an existing drying method, the wood is dried through the high-temperature sand before being heated and dried, water is absorbed more evenly and mildly, and the drying degree in the wood is made more even, so that the fracturing phenomenon on the surface of the wood is effectively prevented, and material waste is avoided.

Owner:重庆雨帝建材有限公司

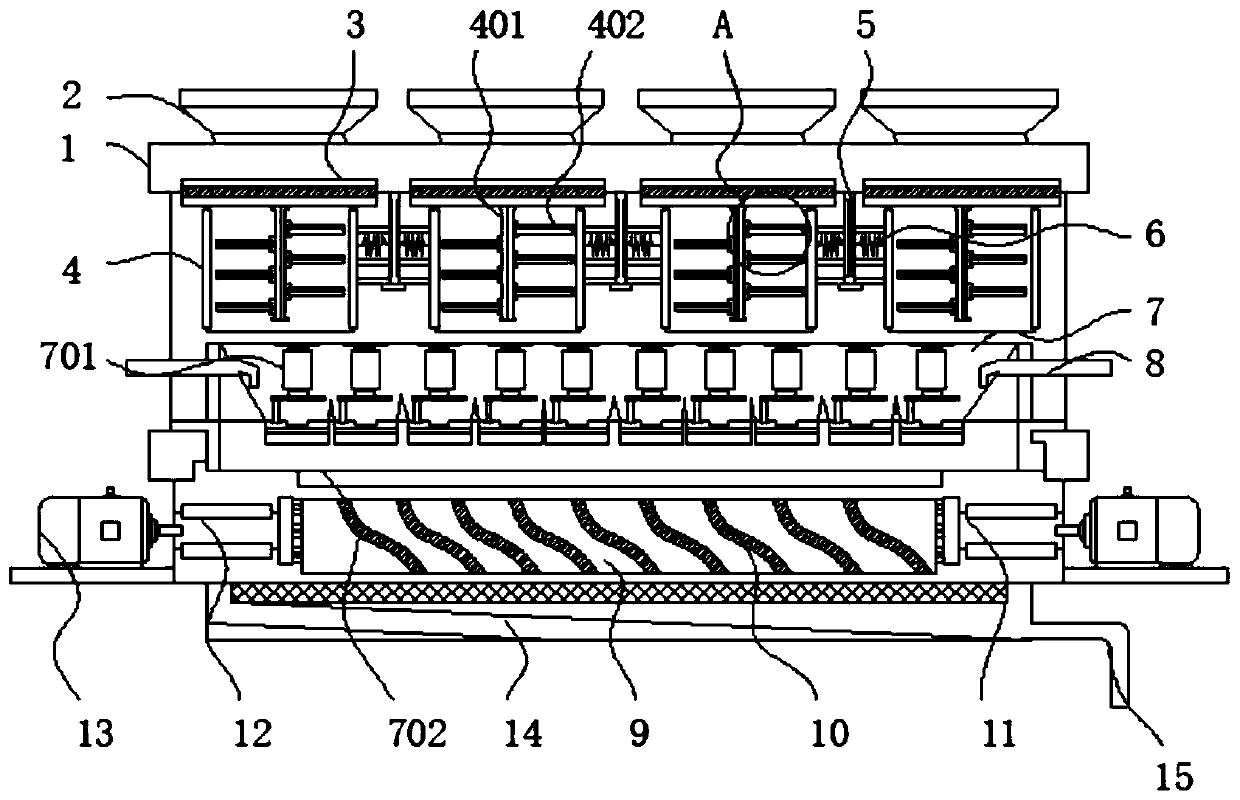

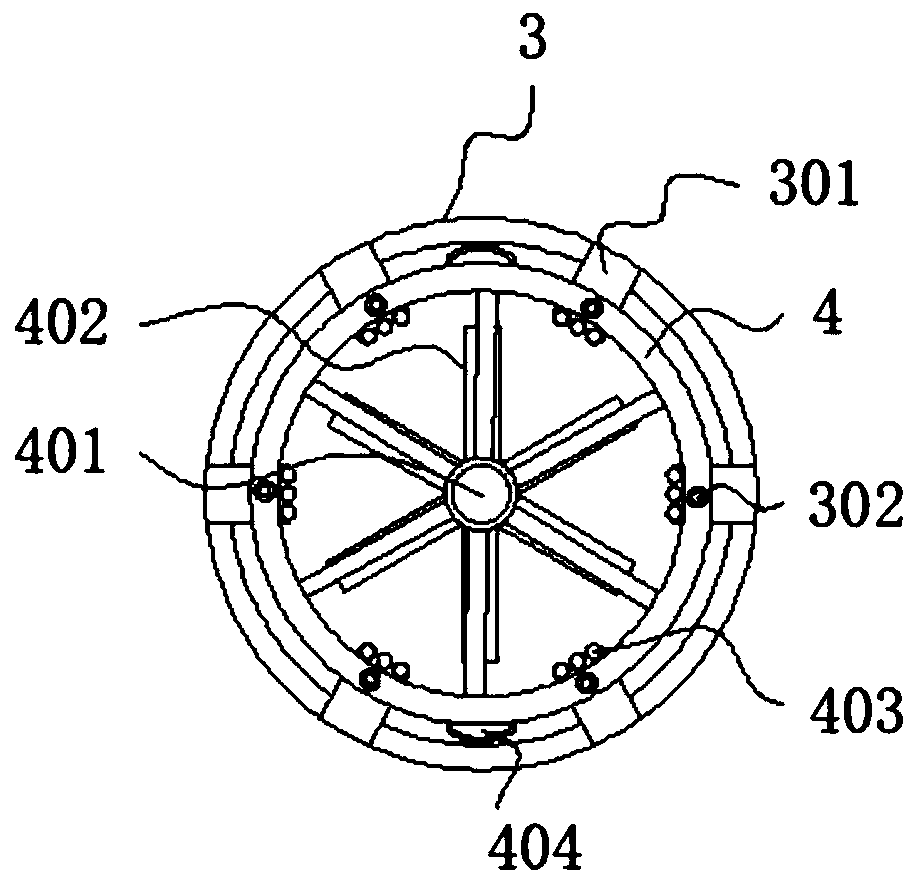

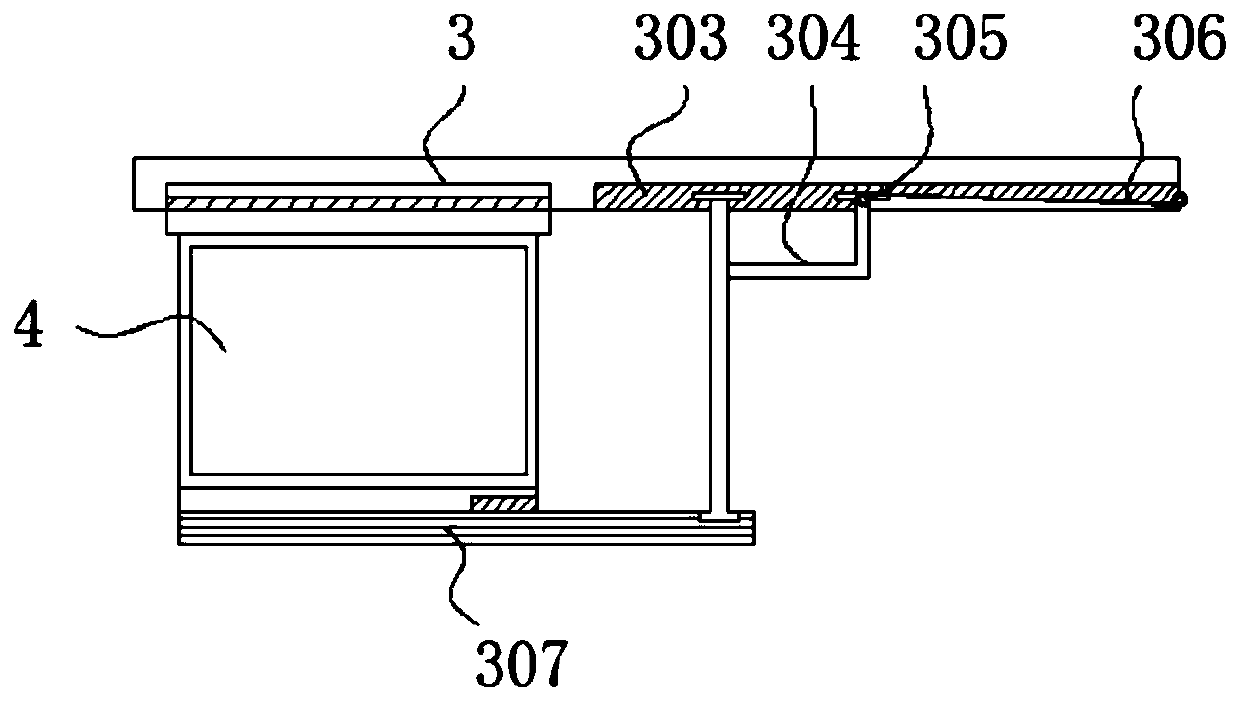

Production method and production equipment of special compound fertilizer for lotus roots.

InactiveCN112250504AImprove decomposition abilityImprove toughnessSievingBio-organic fraction processingAgricultural engineeringPoultry manure

The invention discloses a production method of a special compound fertilizer for lotus roots. The method comprises the following steps: S1, uniformly mixing livestock and poultry manure and crushed straw according to a mass ratio of 2: 1 to obtain an organic matter mixture; placing microbial strains into a culture medium and comprising saccharomycetes, photosynthetic bacteria, rhizobium and sporebacteria, wherein the content of microorganisms in lotus root growth sludge is supplemented, the decomposition capacity of nutrient substances is improved, absorption of lotus roots is facilitated, and phosphorus-potassium fertilizer, urea, microelements, hexaurea ferric trinitrate and plant ash are mixed into a fermentation product; fully stirring and mixing the raw materials, then adding the radix puerariae powder and the tapioca flour, and fully and uniformly stirring to obtain a viscous mixed material, so that the toughness of the fertilizer can be improved, the loose texture of the fertilizer can be avoided, and slowly decomposing the fertilizer, continuously and efficiently providing nutrients for lotus roots, bysetting the extrusion granulation components, it is possible to push thefertilizer after molding, preparing fertilizer particles with uniform texture and balanced compactness , and realizing high-quality production of the fertilizer.

Owner:ANHUI SIERTE FERTILIZER IND

Drying device used after cleaning of flour preparation raw materials

ActiveCN111457706AImprove drying speed and drying qualityUniform thicknessDrying solid materials with heatDrying solid materials without heatProcess engineeringRaw material

The invention relates to a drying device used after the cleaning of flour preparation raw materials. The drying device comprises a workbench, a belt conveyor, a drying device body and a collecting device, wherein the belt conveyor is mounted on the left side of the workbench; the drying device body is mounted at the right end of the workbench; the collecting device is mounted at the right end of the drying device body; and the drying device body comprises a rotating frame, a containing plate, a scraper frame, a first telescopic bracket, a supporting plate and a drying lamp. According to the drying device, wheat is subjected to draining while being conveyed by the belt conveyor, so that the drying speed and quality of the drying device are improved; the accumulated wheat is uniformly spreadby the drying device, so that the thickness of the wheat is uniform, and the drying degree is uniform; and at the same time, the wheat is overturned, so that the upper surface and lower surface of the wheat are both subjected to drying treatment, and the aim of completely drying the wheat is achieved.

Owner:汪峤

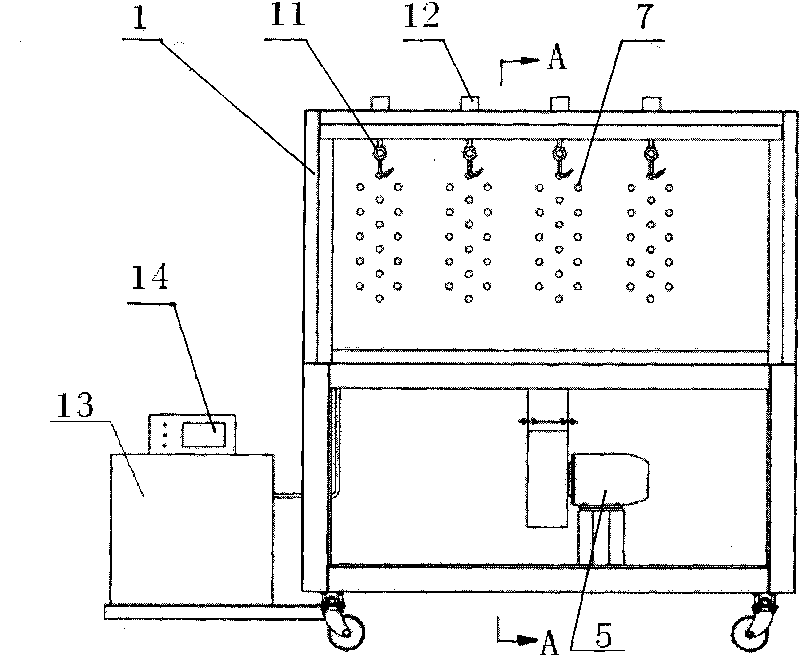

Semi-finished roast duck airing device

InactiveCN101692910AAchieve mechanical propertiesAchieve standardizationMeat/fish preservation by freezing/coolingFood preparationEngineeringRoast duck

The invention discloses a semi-finished roast duck airing device which belongs to the technical field of food processing and is used for unfreezing and dewatering semi-finished roast ducks by airing. The device comprises a box body, an airflow circulation system, a refrigeration system, a hanging system and a control system. A semi-finished roast duck airing room is isolated from the outside by the movable box body with favorable heat-insulating property, a line of semi-finished roast duck hanging hooks are arranged on the top board of the box body in the semi-finished roast duck airing room for hanging the semi-finished roast ducks, and the semi-finished roast ducks are rotated for being aired and dewatered uniformly. The airflow circulation system forces the air in the box to blow onto the semi-finished roast ducks at certain airflow speed, the refrigeration system is used for controlling the airing temperature and ensuring the temperature required for unfreezing and dewatering the semi-finished roast ducks by airing, and the control system controls and adjusts the airing temperature, the airing speed and the rotary speed of the semi-finished roast ducks. The device can set the semi-finished roast duck airing temperature, the airing speed and the rotary speed of the semi-finished roast ducks, prevent the semi-finished roast ducks from being polluted by flies and dust, overcome the influence of weather change and single-direction airflow on the semi-finished roast duck quality, and realizes the mechanization and standardization of unfreezing and dewatering the semi-finished roast ducks by airing.

Owner:CHINA AGRI UNIV

Organic fertilizer drying device for methane combustion energy conservation

PendingCN110285661ASpeed up the flowEasy to dryManure dryingDrying gas arrangementsDrive motorAgricultural engineering

The invention discloses an organic fertilizer drying device for methane combustion energy conservation. The organic fertilizer drying device comprises a drying oven, wherein a partition is welded to theposition, close to the top, in the drying oven; reversed-V-shaped vent holes are uniformly formed in the partition; and a first driving motor is fixed at the center of the top of the drying oven through bolts. Gas outlet spray heads spray hot air to organic fertilizer; the arranged first driving motor drives fan blades to rotate to accelerate flow of the hot air; cyclic hot water is supplied into a spiral groove, so that a wall of the drying oven performs secondary drying on the organic fertilizer,a multilayer drying effect is achieved,the drying efficiency of the organic fertilizer is improved, andthe manpower is saved; a second driving motor drives spiral blades to rotate to stir the organic fertilizer; the organic fertilizer can be dispersed and drop continuously in the drying oven under the action of the spiral blades rotating at a high speed; the hot air can dry the organic fertilizer uniformly; the drying effect is guaranteed; the rotating spiral blades can also crush the organic fertilizer; caking of the organic fertilizer is avoided; and the organic fertilizer is dried completely.

Owner:东营市延旭环保科技有限公司

Drying device for wood processing and treatment

InactiveCN111664692AAvoid wind blind spotsUniform dryingDrying gas arrangementsDrying chambers/containersWood dryingEnvironmental geology

The invention discloses a drying device for wood processing and treatment, and relates to the technical field of wood processing. The drying device comprises a shell; the bottom face of the shell fixedly communicates with a hot air supplying assembly; one end of an air outlet of the hot air supplying assembly fixedly communicates with an air supplying main pipe; the bottom face of the shell is fixedly connected with a set of main hot air spraying pipes which mutually communicate through a first branch air pipe; one end of the air supplying main pipe fixedly communicates with the first branch air pipe; the interior of the shell is fixedly connected with a drying mechanism; the drying mechanism comprises a set of loading units which are mutually connected through a connecting pipe; and the drying mechanism further comprises a second branch air pipe. Through the design of an annular conveying net in the drying mechanism, static drying of a traditional wood drying mechanism is switched into dynamic drying, during working, the annular conveying net can drive to-be-dried wood to annularly rotate, and through annular rotation, the air bearing strength and air bearing angle of the wood arechanged repeatedly.

Owner:合肥念萍电子商务有限公司

Edible oil processing oil press capable of preventing oil leakage and convenient to clean

ActiveCN109910346AEasy to cleanPrevent oil spillsRotary stirring mixersHollow article cleaningSurface mountingEdible oil

The invention discloses an edible oil processing oil press capable of preventing oil leakage and convenient to clean and relates to the technical field of oil press equipment. The edible oil processing oil press specifically comprises a main body and a woven cloth bag. Hoppers are welded above the main body, and a locating frame is mounted at the bottom of each hopper. An agitating vessel is put below each locating frame. A fixing rod is mounted on the surface of each agitating vessel. Treatment boxes are mounted below the agitating vessels. A first clamping rod is connected to the right sideof the woven cloth bag, and a second clamping rod is connected to the left side of the woven cloth bag. A first motor is mounted at the outer side of the second clamping rod. An oil chute is mounted below the woven cloth bag. According to the edible oil processing oil press capable of preventing oil leakage and convenient to clean, the locating frames are located below the hoppers and meanwhile fixed to the main body, and the number of the locating frames is the same as that of the agitating vessels; and the locating frames are mainly arranged for fixedly storing the agitating vessels.

Owner:山东矬草峪农业科技有限公司

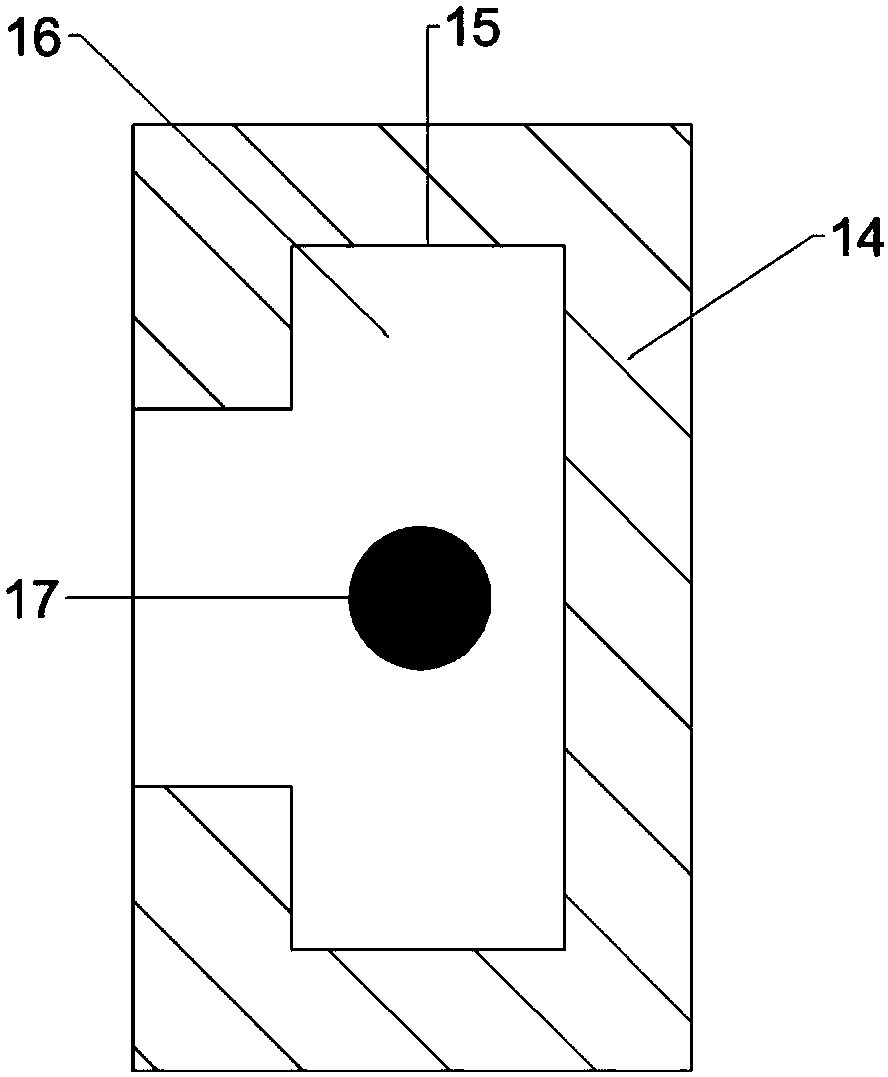

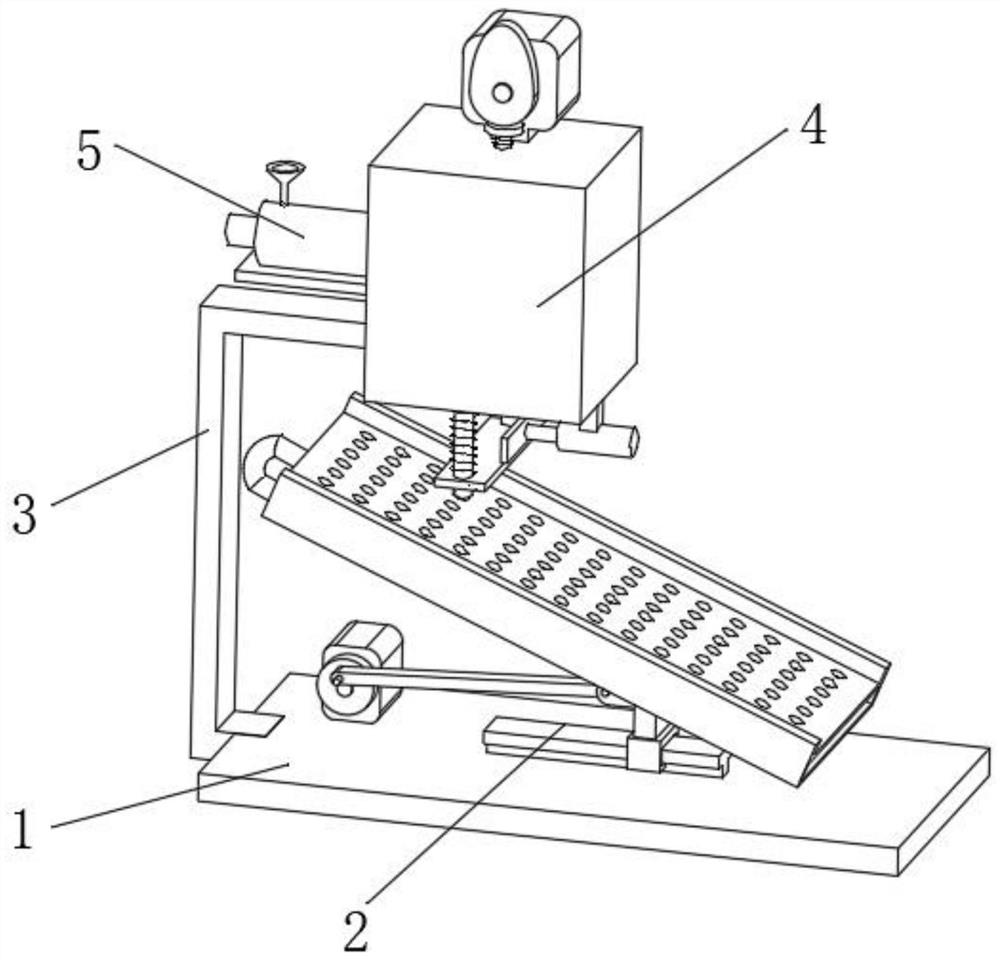

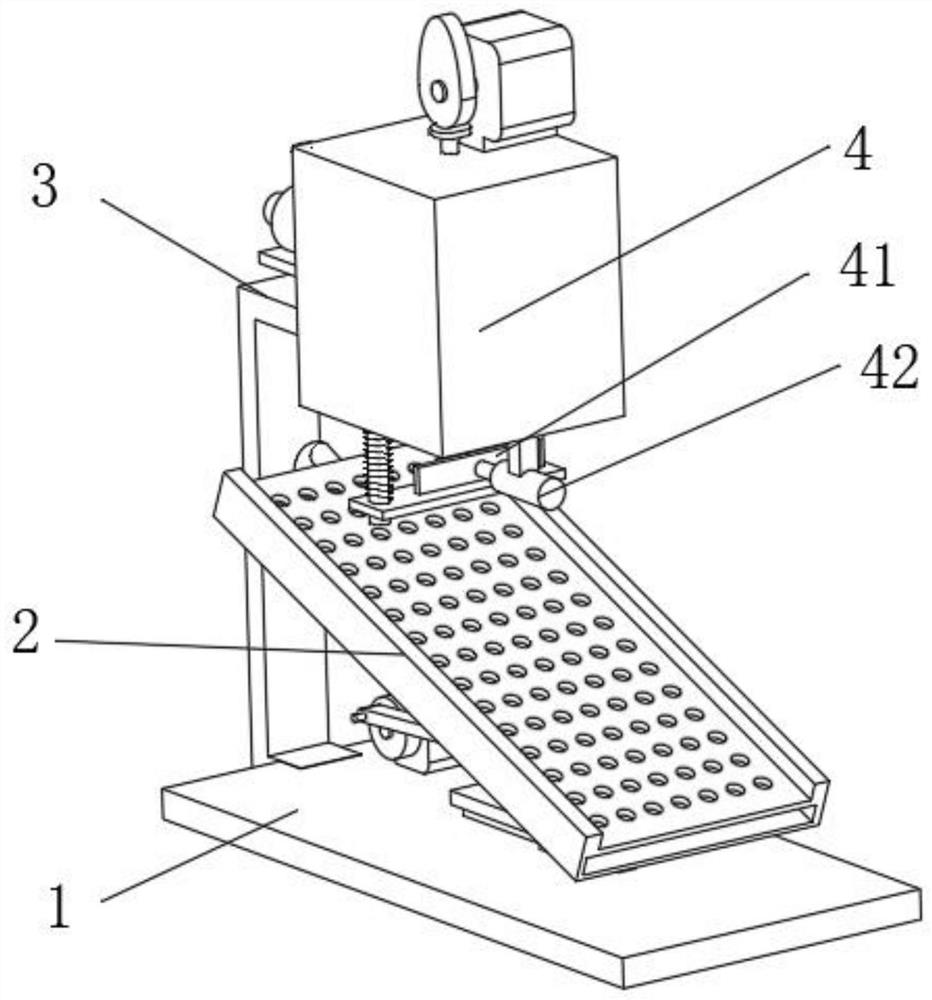

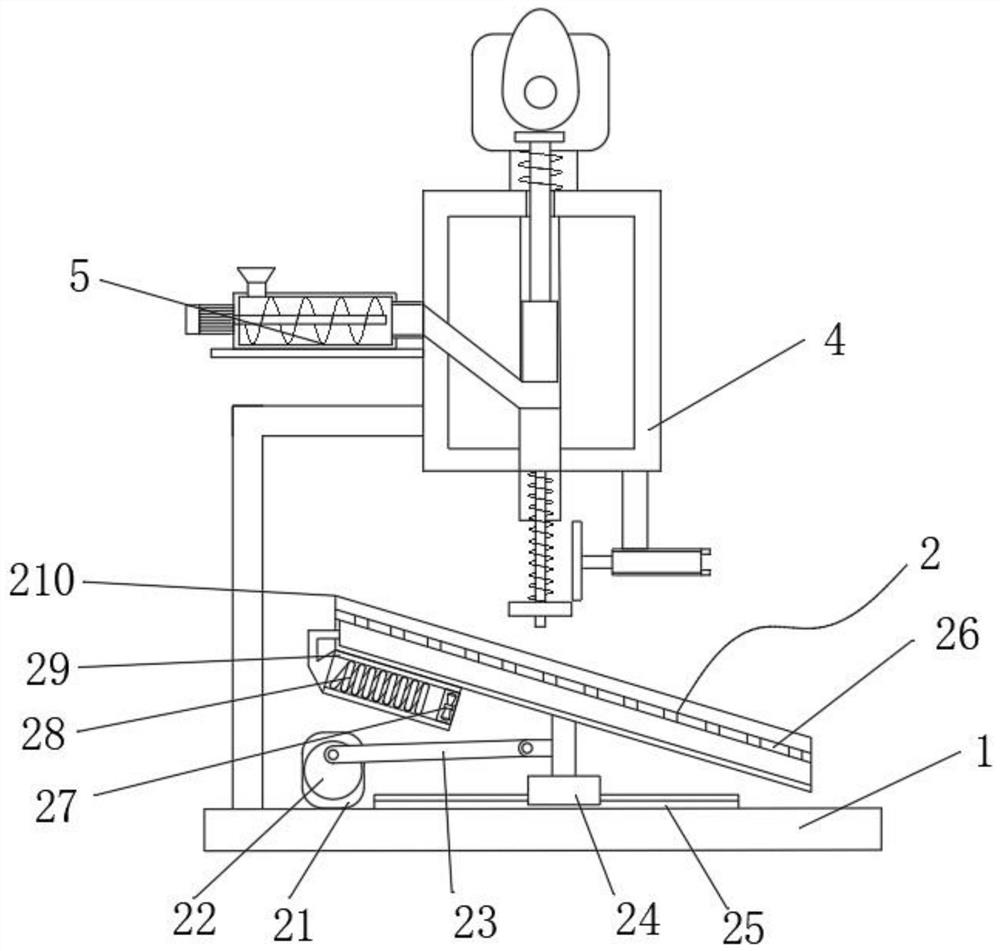

Equal-length cutting equipment for medicine processing based on parallel feeding principle

InactiveCN108326921ARealize equidistant movementGuaranteed equally spaced truncationDrying gas arrangementsMetal working apparatusEngineeringCircular disc

The invention provides equal-length cutting equipment for medicine processing based on a parallel feeding principle. The equal-length cutting equipment comprises a shell, wherein an opening is formedin the right side wall of the shell, a parallel feeding device is arranged at the opening part, and the left part of the parallel feeding device penetrates through the opening and enters the shell; acutting device is arranged in the shell; the lower side of the cutting device is provided with a guide plate, the guide plate is obliquely arranged towards the left lower part, and a drying device isarranged below the guide plate; and the drying device comprises an oblique plate. The equal-length cutting equipment has the beneficial effects that first, a moving plate is driven to make circular path movement by a disc through a support column; when one pushing plate acts on a baffle, the baffle is driven to move towards the left side for a certain length, the pushing plate is then separated from the baffle, the next pushing plate acts on the baffle, and the baffle is driven to move leftwards; and through repeated operation in this way, the equal-distance movement of a mounting plate can berealized, and the equal-length cutting of medicines can be ensured.

Owner:葛润生

Sludge heating and drying device

ActiveCN105016598AUniform dryingReduce wasteSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeFlue gas

The invention discloses a sludge heating and drying device, and aims to the sludge heating and drying device which is capable of carrying out drying treatment on sludge with high moisture content, continuous and stable in drying process, high in drying efficiency, high in integral drying uniformity, and good in drying effect. The sludge heating and drying device comprises a rack, a transverse drying main barrel and a dried sludge receiving part, wherein a a sludge feeding hole, a hot flue gas inlet and a wet flue gas inlet are formed in the drying main barrel; a bearing base is arranged on the rack; a matched rotor main shaft is arranged on the bearing base; a main shaft drive motor which is connected with the rotor main shaft by a speed reducer is arranged on a base frame; a sludge discharge hole is formed in the lower part, far from one end of the sludge feeding hole, of the drying main barrel; and a plurality of stirring and pushing rods are arranged on the rotor main shaft. The sludge heating and drying device has the beneficial effects that: energy resources are reasonably utilized; the drying process is uniform, continuous and efficient; the drying effect is obvious as a secondary drying device is provided; and the working effect in the future can be guaranteed and the service life can be prolonged as a clearing structure is provided.

Owner:ZHEJIANG SANLIAN ENVIRONMENT MACHINERY EQUIP

Thick broad-bean sauce drying device

InactiveCN109631539AKeep drySolve the problem of insufficient drying effectDrying gas arrangementsDrying chambers/containersPulp and paper industryBroad beans

The invention provides a thick broad-bean sauce drying device. The thick broad-bean sauce drying device comprises a drying box body, inclined plates, first motors, a drying groove, supporting plates,resistance wires, second motors, a bottom plate, a rotating shaft and a rotating motor. The inclined plates are installed on the left and right sides of the end surface of the drying box body; the first motors are arranged on the left and right end surfaces of the corresponding inclined plates; the drying groove is formed in the upper side of the interior of the drying box body; the supporting plates are connected to the lower end surface of the drying groove; the bottom plate is connected to the lower end surfaces of the supporting plates; and second motors are arranged on the left and rightsides of the upper end surface of the bottom plate; the rotating shaft is arranged on the lower side of the interior of the drying box body, the rotating motor is connected to the lower end surface ofthe rotating shaft, and the resistance wires are assembled at the upper sides of the second motors and are arranged on the lower end surface of the drying groove. The thick broad-bean sauce drying device solves the problem of insufficient drying effect of thick broad-bean sauce drying devices. The thick broad-bean sauce drying device has a reasonable structure, uniform drying, good stability andhigh reliability.

Owner:巫溪县众悦调味品有限公司

Dryer for refuse disposal

InactiveCN105180609AImprove the mixing effectGuaranteed dryingDrying gas arrangementsDrying machines with non-progressive movementsLitterControl system

The invention discloses a dryer for refuse disposal, and relates to the field of refuse disposal. The dryer comprises a roller, a supporting table and a heating pipeline. The roller is obliquely arranged on the supporting table in a rotatable manner through supporting wheels. The heating pipeline is rotationally arranged in the roller. The dryer further comprises a dust removal system and a control system used for controlling the drying temperature. The dryer has the beneficial effects that heat inside the heating pipeline dries refuse in the roller through a main pipe body and bifurcated pipe bodies in a dispersed manner, the drying effect can be improved by rotating the heating pipeline, and therefore the charring phenomenon is avoided; no polluted air is produced by the dryer through the dust removal system, and the working environment is improved; and the controllability and accuracy of the drying temperature inside the roller are improved through the control system, so that the drying effect is improved, and drying efficiency is improved.

Owner:DATIAN WEST ENVIRONMENTAL PROTECTION TECH CO LTD

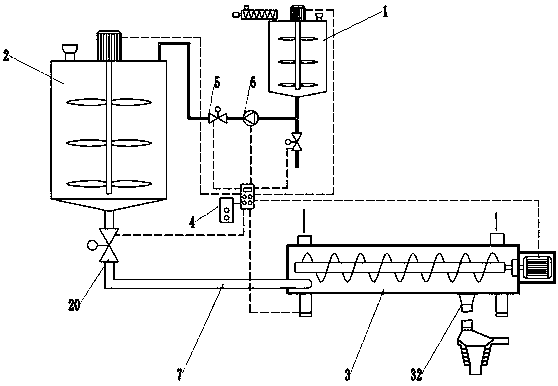

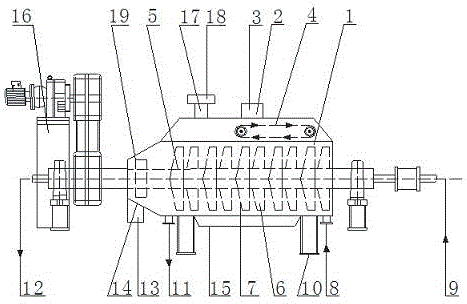

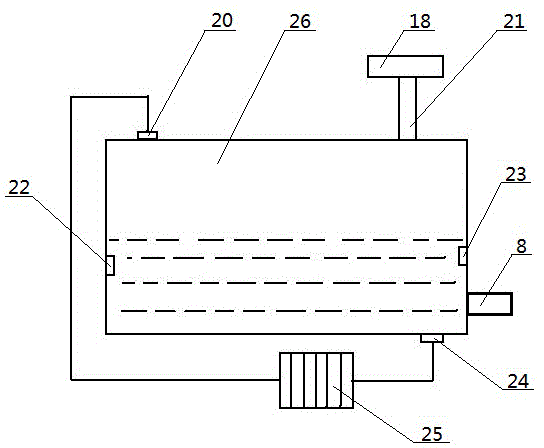

A sludge drying integrated machine

InactiveCN104649540ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningTemperature controlSludge

The invention relates to the field of environment protection equipment, and particularly relates to a sludge drying integrated machine. The sludge drying integrated machine comprises a machine body, gear type spiral push shafts, a bracket, a condensate water circulating device, a drive system, an air cleaning system and an automatic temperature control system. The air cleaning system is arranged on the machine body. The two gear type spiral push shafts parallel to each other and the automatic temperature control system are arranged in the machine body. Two ends of the machine body are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet, and two ends of the gear type spiral push shafts are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet. The machine body is horizontally arranged on the bracket. The condensate water circulating device is arranged below the bracket. The drive system is arranged at one end of the gear type spiral push shafts. The sludge drying integrated machine achieves an integrated process of sludge drying, achieves low energy consumption and high efficiencies in the operation process, and adopts a fully-automatic operation mode without the need of a specially-assigned person for watching.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com