Dryer for refuse disposal

A garbage disposal and dryer technology, applied in the direction of dryers, drying, non-progressive dryers, etc., can solve the problems of difficult temperature control, poor drying effect, low drying efficiency, etc., to prevent scorching paste phenomenon, enhanced stirring effect, and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

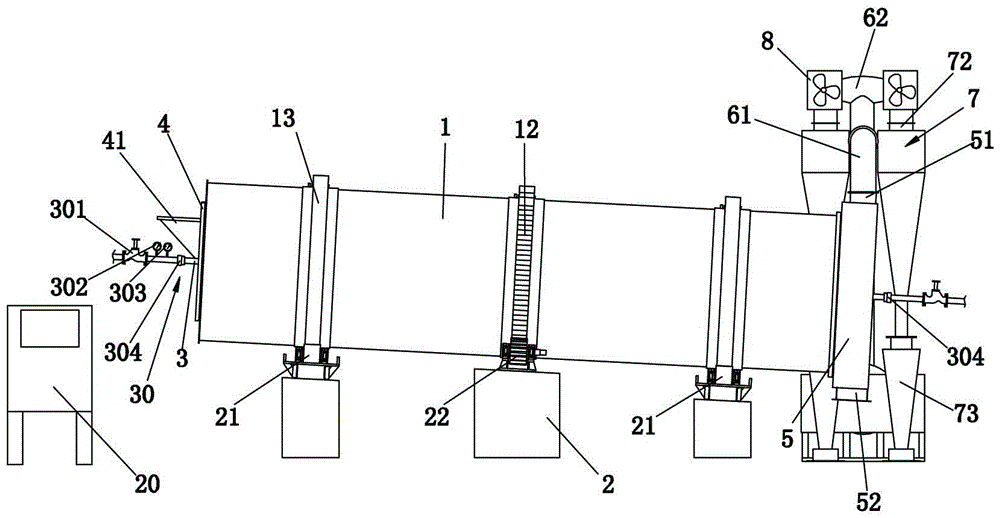

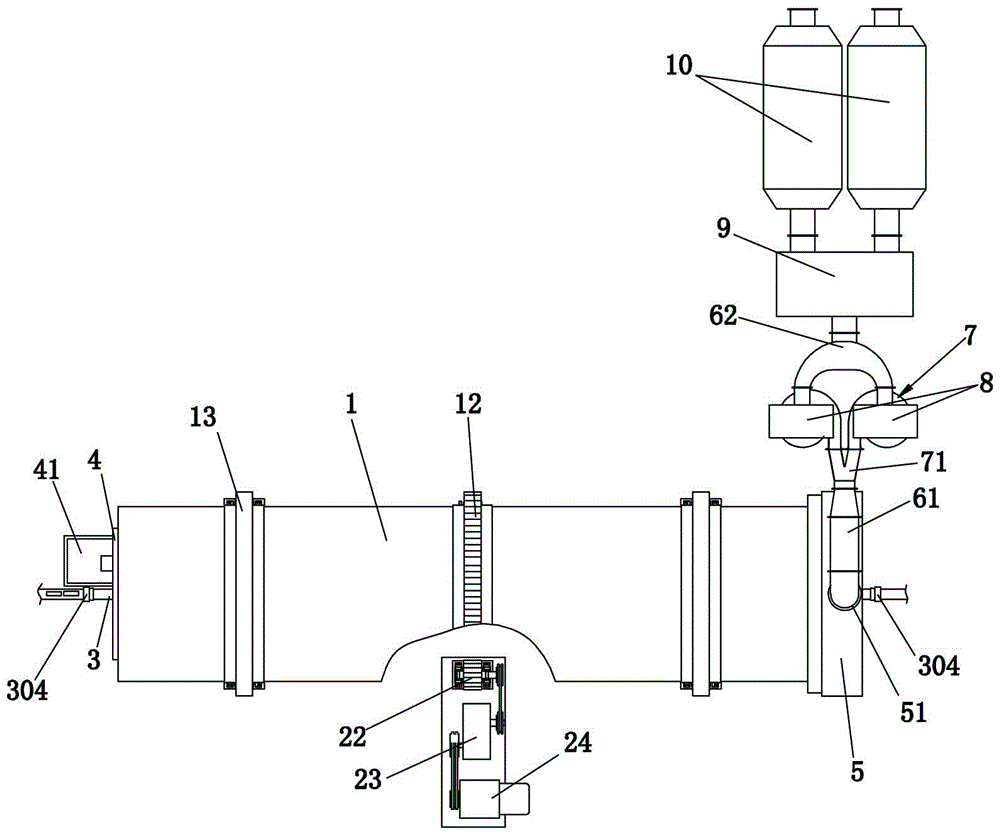

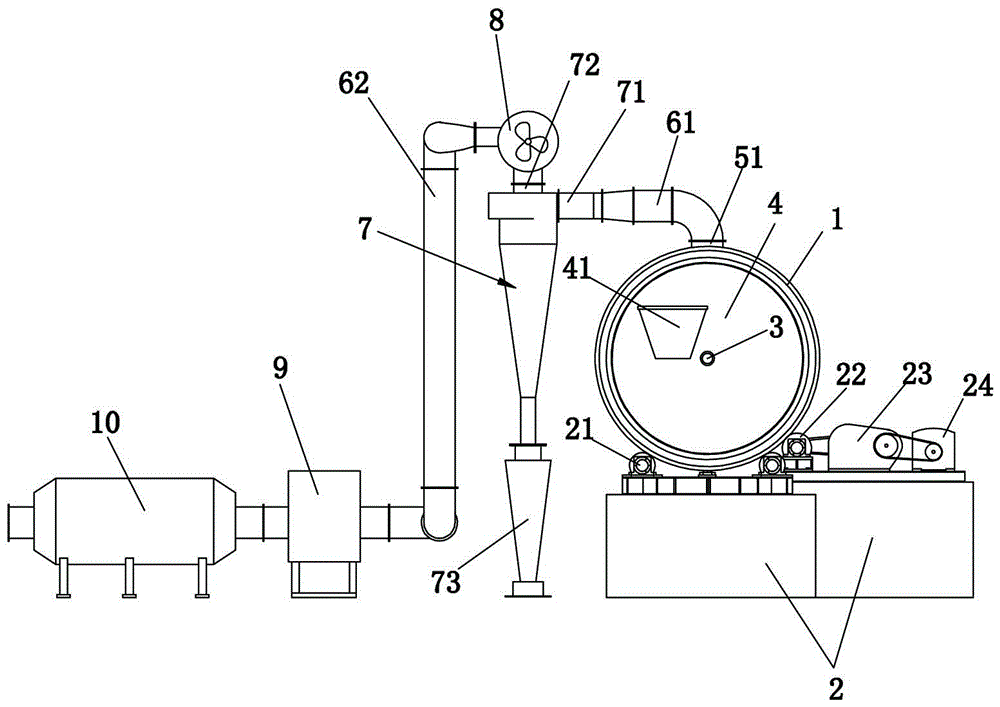

[0028] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0029] Such as figure 1 , figure 2 , image 3 and Figure 5 As shown, a dryer for garbage disposal includes a drum 1 and a support table 2, and the inner wall of the drum 1 is provided with a plurality of plates 11 for frying garbage. The outer surface of the drum 1 is provided with a large gear 12 and a support ring 13, and the upper surface of the support table 2 is provided with a support wheel 21 that cooperates with the support ring 13, a gear 22 that cooperates with the large gear 12, and a motor for driving the gear 22 to rotate. 24 and reducer 23. The roller 1 is rotatably and obliquely arranged on the support platform 2 through the supporting wheel 21 and the gear 22 . One end of the drum 1 at a higher position is the feed end, and a sealing cover 4 that is rotatably connected with the drum 1 is provided. The sealing cover 4 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com