Logistics mixing distribution system

A distribution system and logistics technology, which is applied in mixing methods, chemical/physical processes, dissolution, etc., can solve problems such as short residence time and mixing time, low catalyst utilization rate, and small logistics dispersion angle, so as to achieve uniform distribution and good mixing and distribution effect , space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

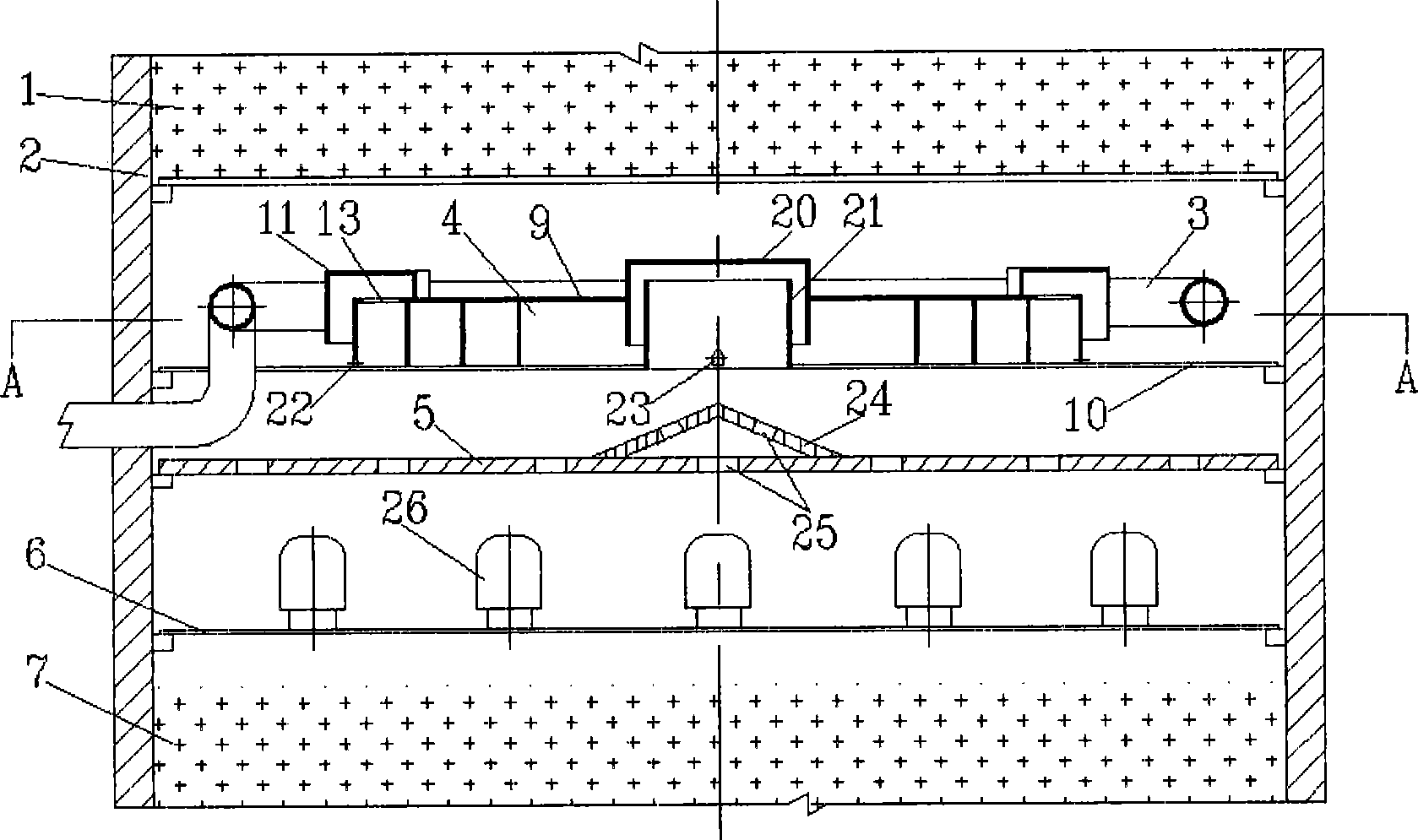

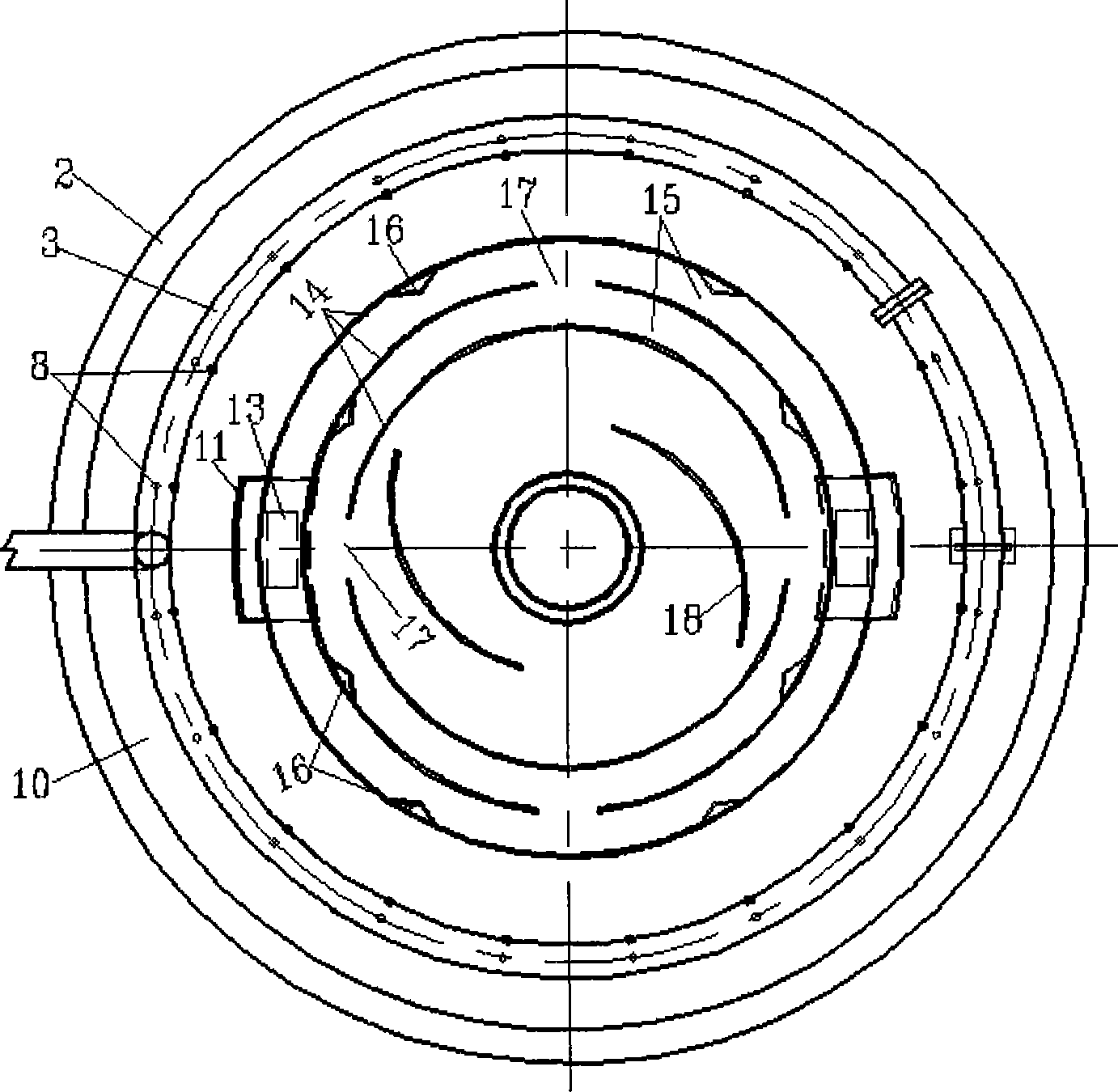

[0055] Example 1 illustrates the fluid mixing performance of the quench box in the material mixing distribution system provided by the present invention.

[0056] Adopt the quick cooling box provided by the invention, the structure is as figure 1 As shown, in the cold mold device with a diameter of 1000mm, the desorption efficiency of oxygen in oxygen-enriched water was measured with water and air as the simulated medium. The air and oxygen-enriched water are measured separately and introduced into the quench box for oxygen desorption, and the dissolved oxygen analyzer is used to detect the concentration of dissolved oxygen in the water at the inlet and outlet of the quench box online. 入 、C 出 , the oxygen desorption efficiency is calculated by the following formula:

[0057] Oxygen desorption efficiency:

[0058] C 入 ——Liquid phase oxygen concentration at the inlet of the quenching box, μg / ml

[0059] C 出 ——The liquid phase oxygen concentration at the outlet of the que...

Embodiment 2

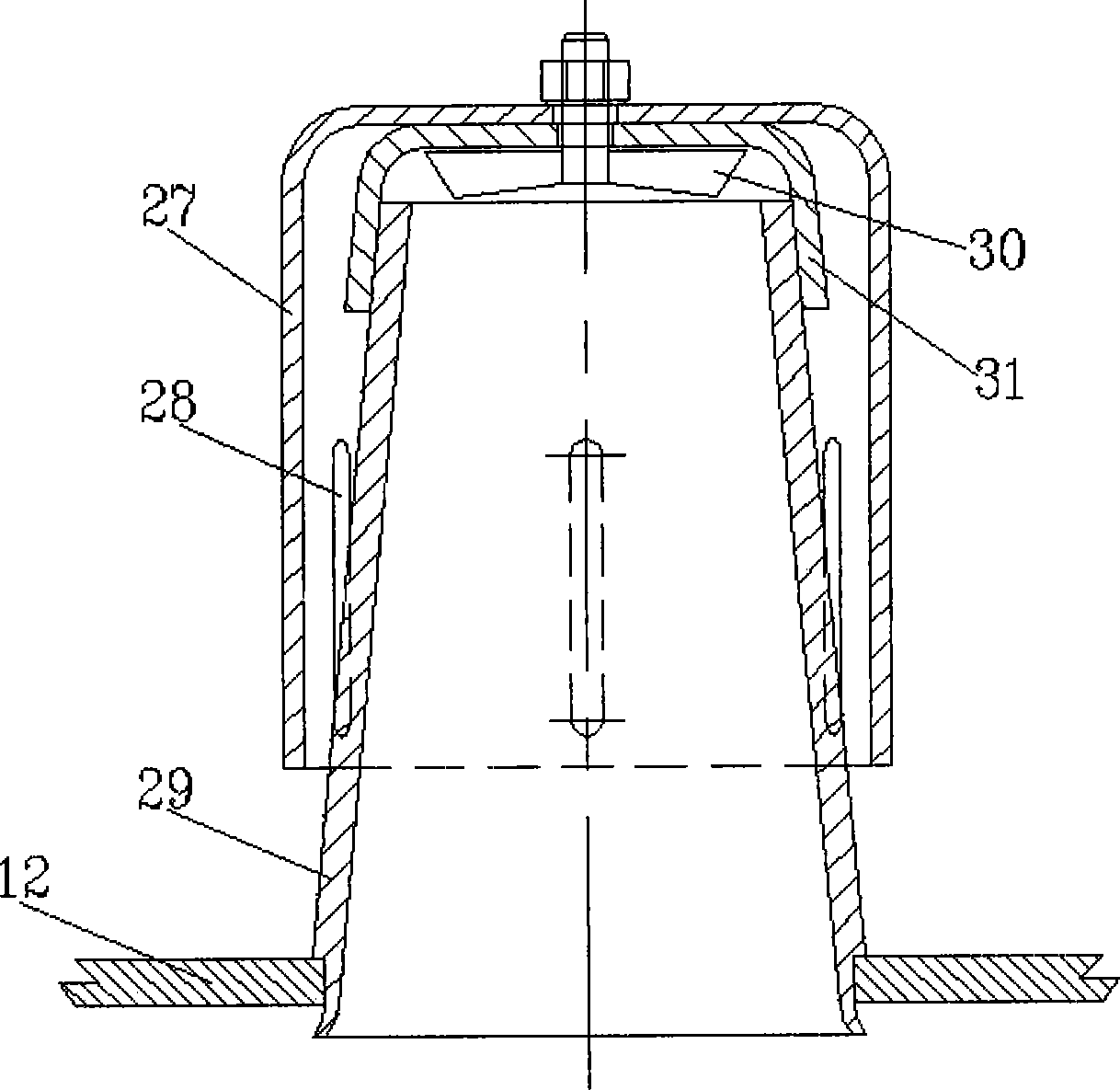

[0068] The allocator structure is like image 3 As shown, the swirl structure is arranged at the nozzle on the central tube. In the cold model test device with a diameter of 500mm, 3 distributors are set on the distribution plate, and the swirl structure of the distributor is composed of 4 swirl sheets. The liquid phase distribution curve is measured with water and air as the simulated medium, and the flow rate is 1.5m 3 / h of water, the flow rate is 180Nm 3 After the two phases of the / h air are mixed and flow into the distributor to distribute the fluid, the liquid phase is sampled and measured under the distributor, and the liquid distribution curve is obtained. The results are shown in Figure 9 Curve B in.

Embodiment 3

[0070] The allocator structure is like Figure 4 As shown, the swirl structure is arranged at the lower nozzle of the central tube. Test method is with embodiment 2, and liquid phase distribution curve sees Figure 9 Curve C in.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com