Tray frame fixed rail moving dryer based on side ventilation structure

A dryer and material tray technology, applied in the direction of progressive dryers, dryers, drying solid materials, etc., can solve problems such as uneven drying, and achieve the effect of precise regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

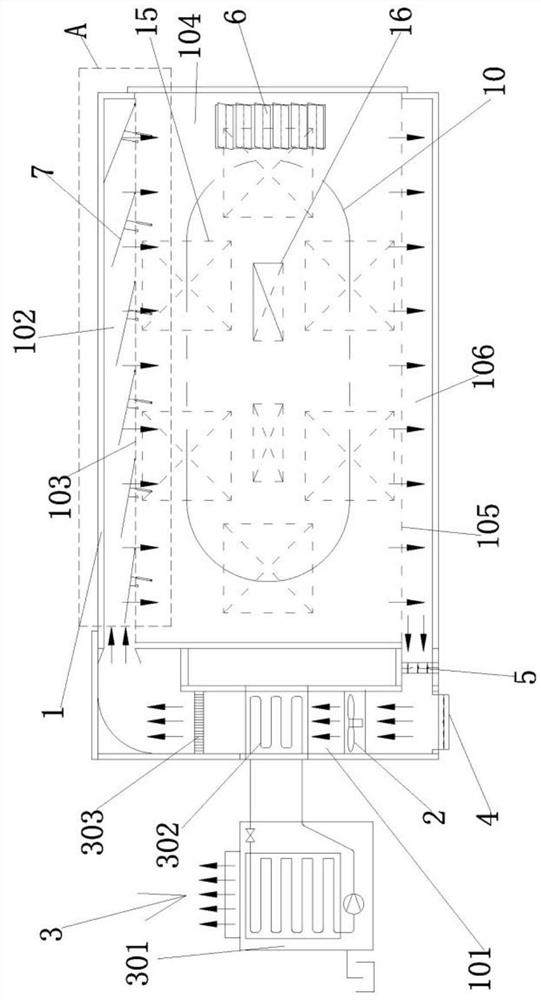

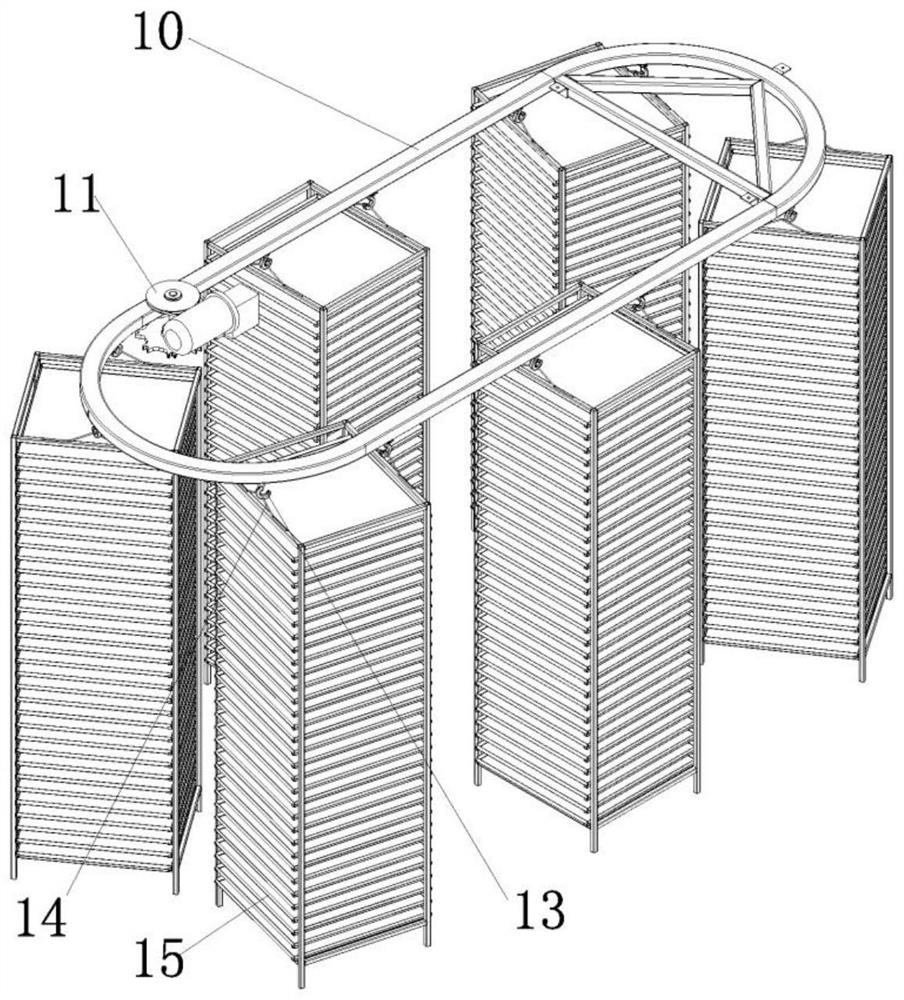

[0043] Attached below Figure 1-10 The present invention is further illustrated with specific examples.

[0044] Such as figure 1 As shown in the figure, a tray frame rail-fixed mobile dryer based on a side ventilation structure includes a main chamber 1 with a closed structure and an insulation layer. The main chamber 1 is provided with an air duct, and a fan is arranged in the air duct. The assembly is also provided with a heating device 3 corresponding to the air outlet side of the fan assembly.

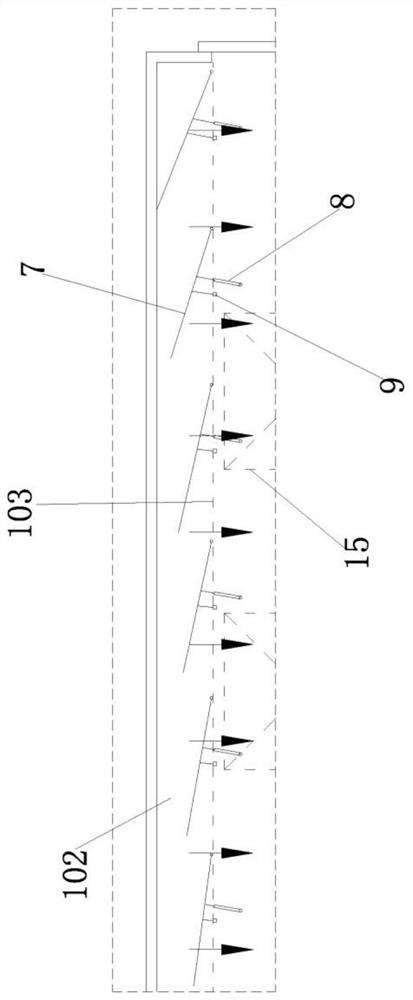

[0045] The air duct in the above-mentioned main warehouse body 1 is set as a circulation air duct structure that guides the dry air flow to carry out horizontal circulation movement. 1, the air inlet chamber 102, the drying chamber 104, and the air return chamber 106 are connected and arranged according to the order of the circulating air flow, and a vertical air inlet side punching plate with uniformly distributed air holes is set between the air inlet chamber 102 and the dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com