Patents

Literature

477results about How to "Guaranteed drying quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing charred wood by heat treatment

InactiveCN101069972AGuaranteed drying qualityShorten the timeWood treatment detailsWood charring/burningStrength lossMoisture

The invention relates to a preparation method of heat-treatment charred wood. It aims at providing the charred wood with short treatment cycle, small wood strength loss, industrialized and high maneuverability. It contains stages of preparing, preheating, heating, insulation and cooling. In the heating stage, heat the medium in the stove to 95-105 C degree with the speed of 10-18 C degree / h. Then, heat the materials to 120-130 C degree with the speed of 3-8 / C degree h for high temperature drying and reduce the inner moisture content of the woods to nearly 0. Finally, heat them to 185-220 C degree with the speed of 12-20 C degree / h. The intermittent steam-jet method is adopted to complete steam-jet treatment during the heating.

Owner:ZHEJIANG FORESTRY UNIVERSITY

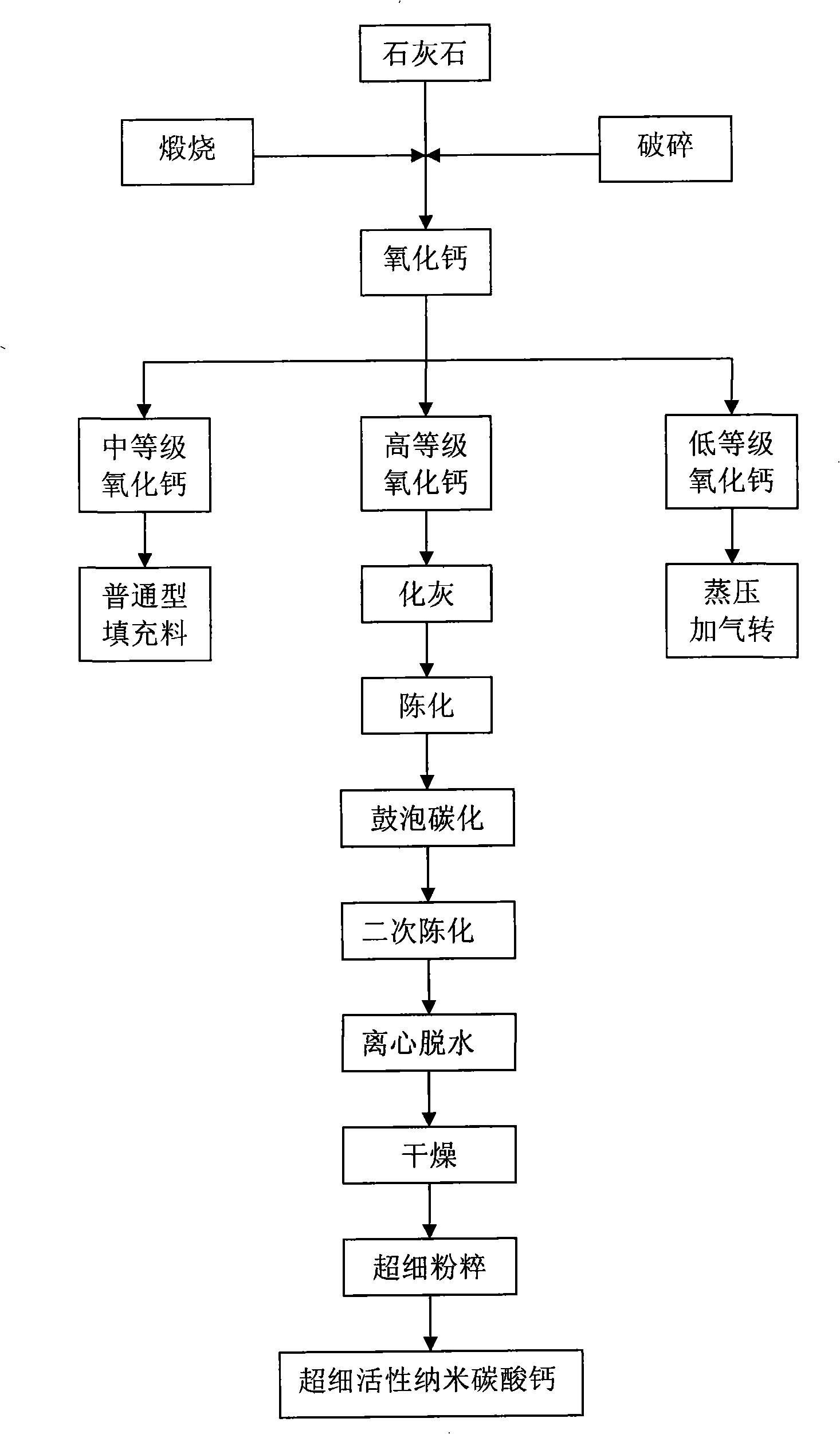

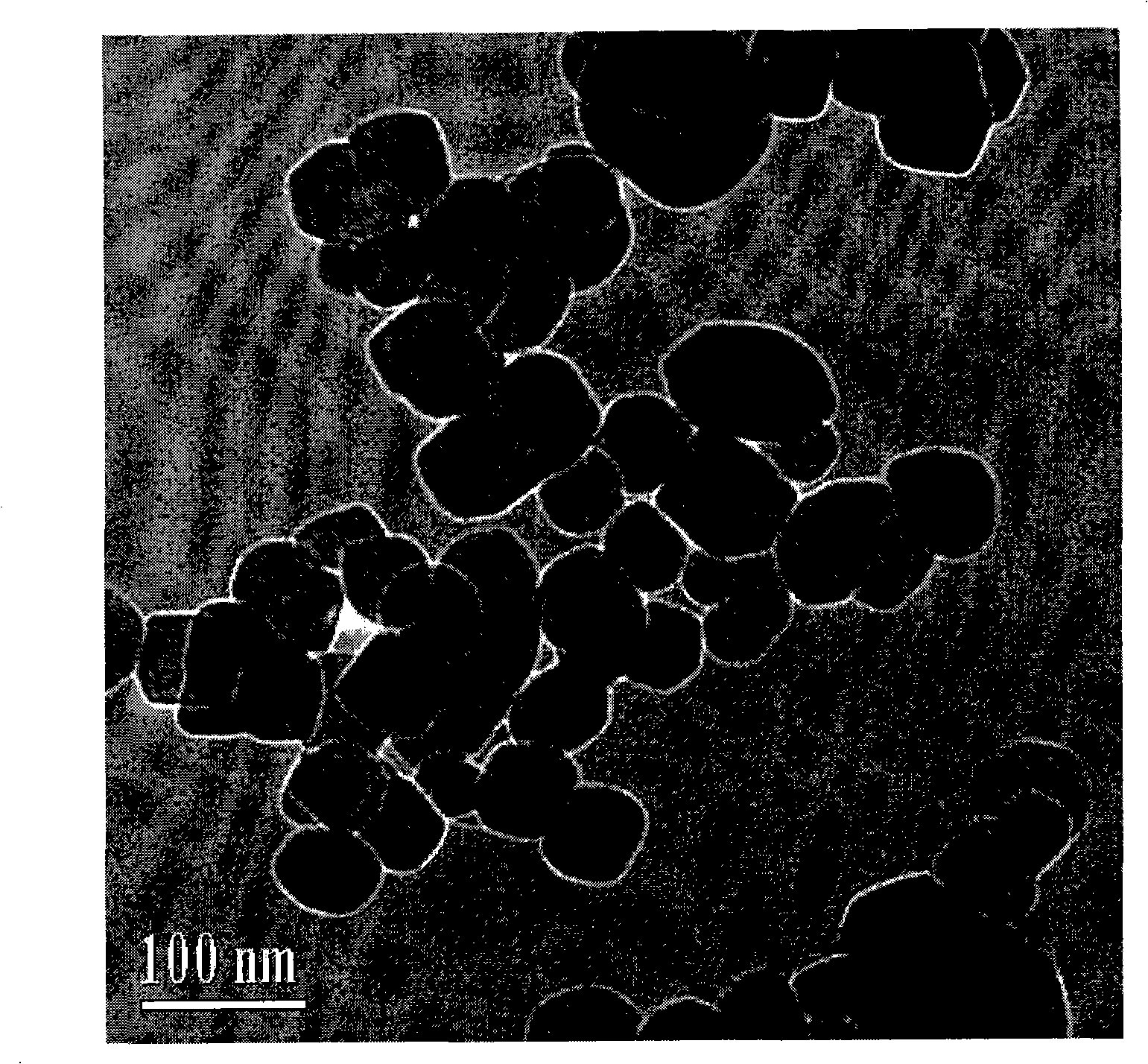

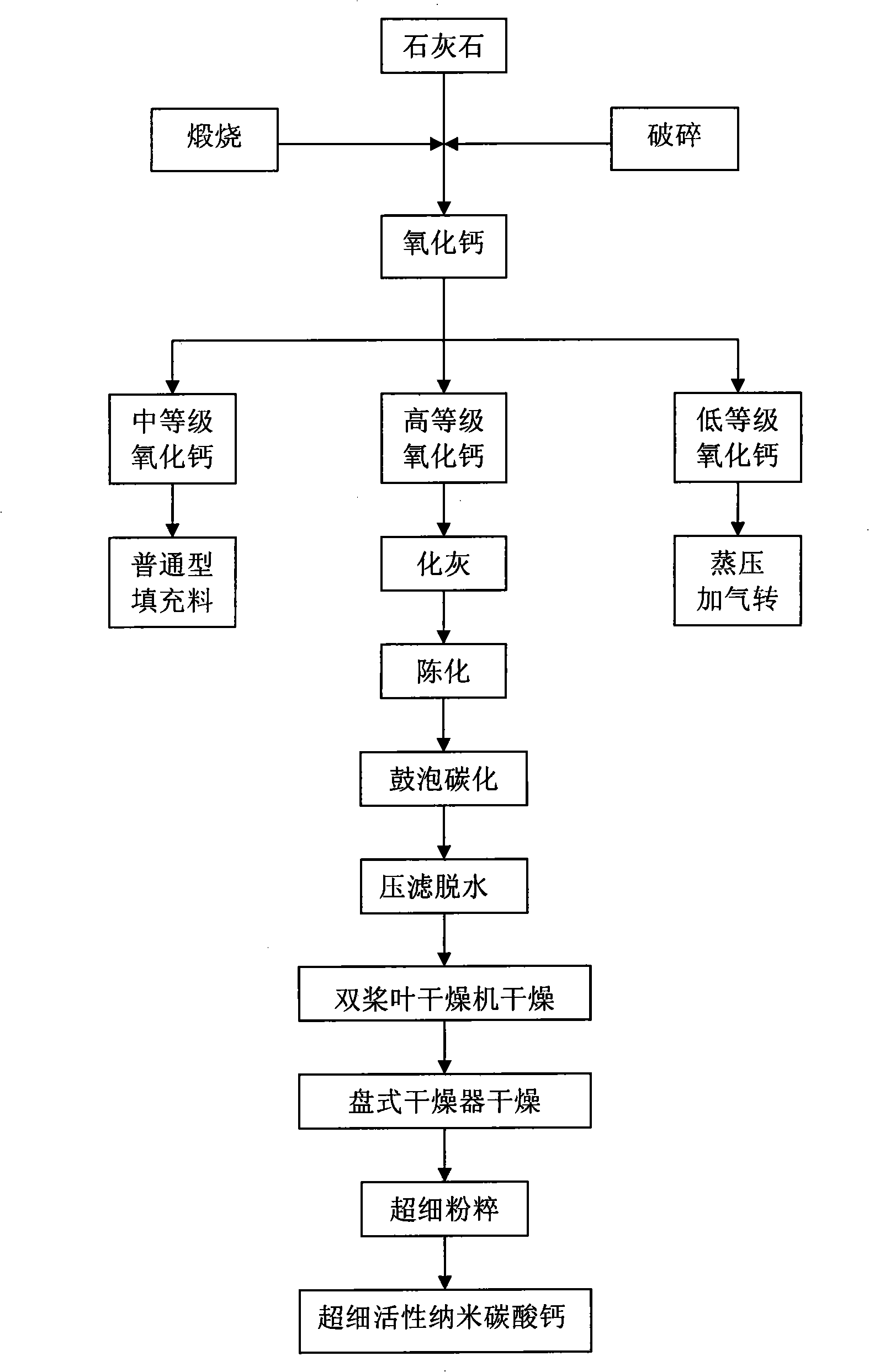

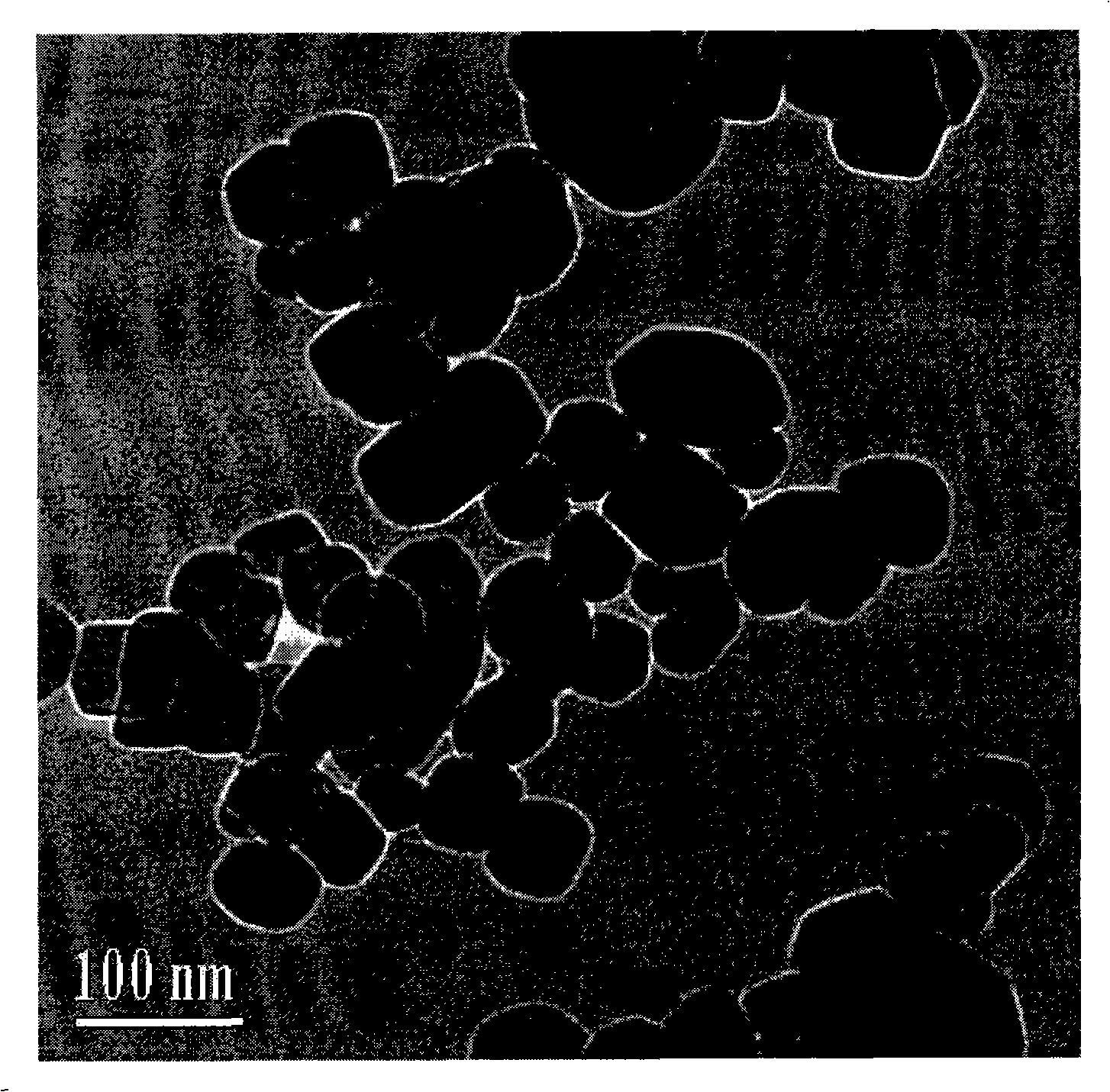

Method for preparing ultra-fine active nano-calcium carbonate with low-ore grade limestone wet-process activation

InactiveCN101318684AGuaranteed drying qualityGuaranteed stabilityCalcium/strontium/barium carbonatesChemistryCalcium hydroxide

The invention provides a method for preparing superfine activated nano calcium carbonate by utilization of low-grade lime. The method adopts the technical proposal that: firstly, the low-grade lime is calcined and crushed so as to prepare calcium oxide; secondly, staged sieving is performed, namely a part of high-quality calcium oxide enters into the next procedure for producing calcium hydroxide and calcium carbonate; and thirdly, the superfine activated nano calcium carbonate product is prepared after incineration through an incinerator, heat-insulated aging, bubbling carbonization, secondary aging, wet-way secondary activation, recarbonization, centrifugal dewatering, drying and superfine crushing of the high-quality calcium oxide. When the product is applied to plastics and rubber, the cost can be reduced and simultaneously the hardness, the toughness, the strength, the bending resistance and the abrasion resistance of polymer products can be improved; and when the product is applied to coating, performance parameters such as the insubmersibility, the storage stability, the thixotropy and so on can be effectively improved.

Owner:福建省万旗非金属材料有限公司

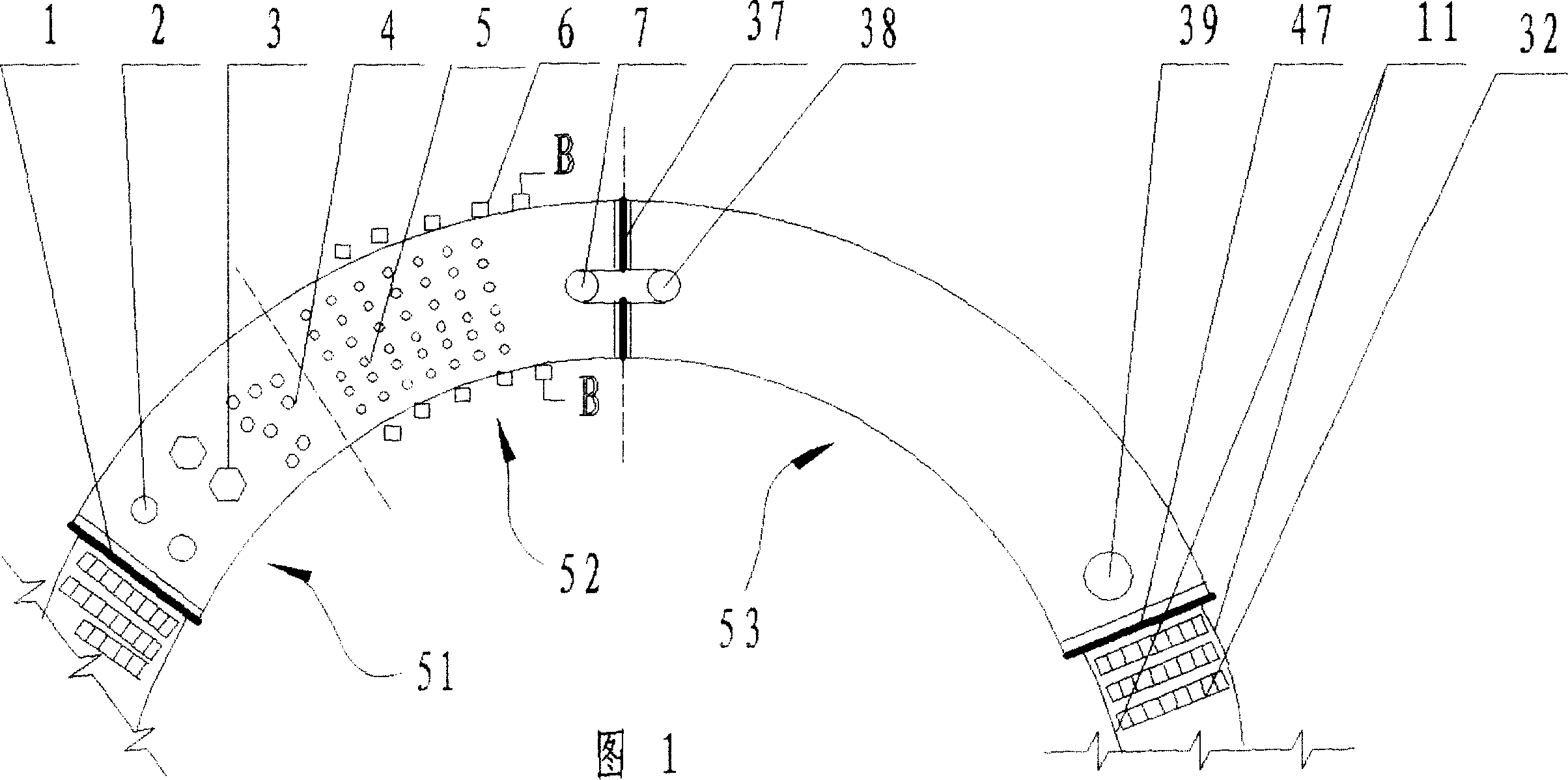

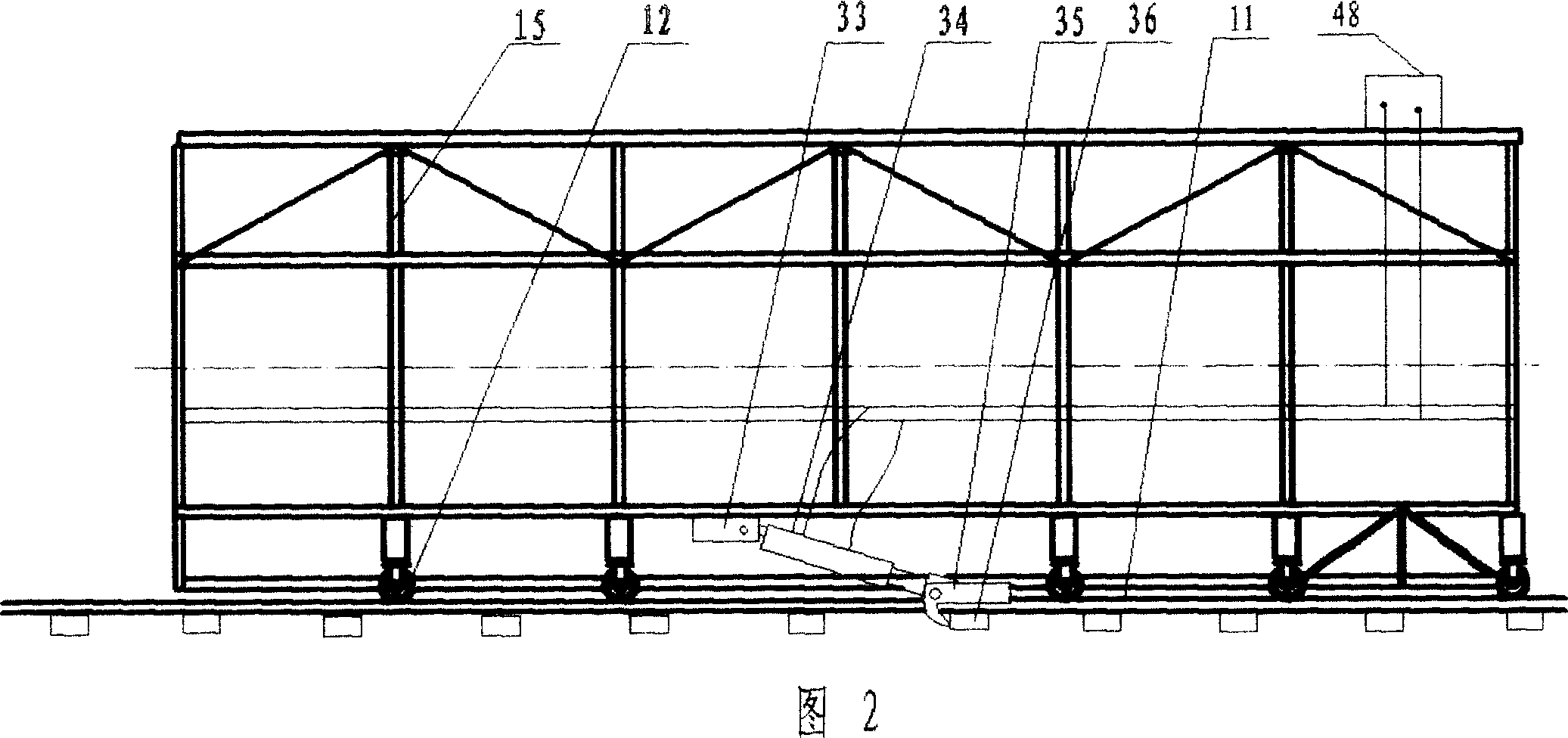

Mobile tunnel furnace

The invention relates to a mobile tunneling kiln, comprising kiln body; moving wheel set on the two side of kiln body, by which kiln body is set on the ground railway; and power equipment set on the kiln body. Kiln body can be controlled manually and move in any time by the power equipment set on the kiln body in the invention. It is simple structure, low cost and good efficiency when power equipment is hydraulic device. Several doors of said kiln body is sealed in segmentation so that temperature in kiln body is improved quickly and adjusted or controlled.

Owner:魏胜英

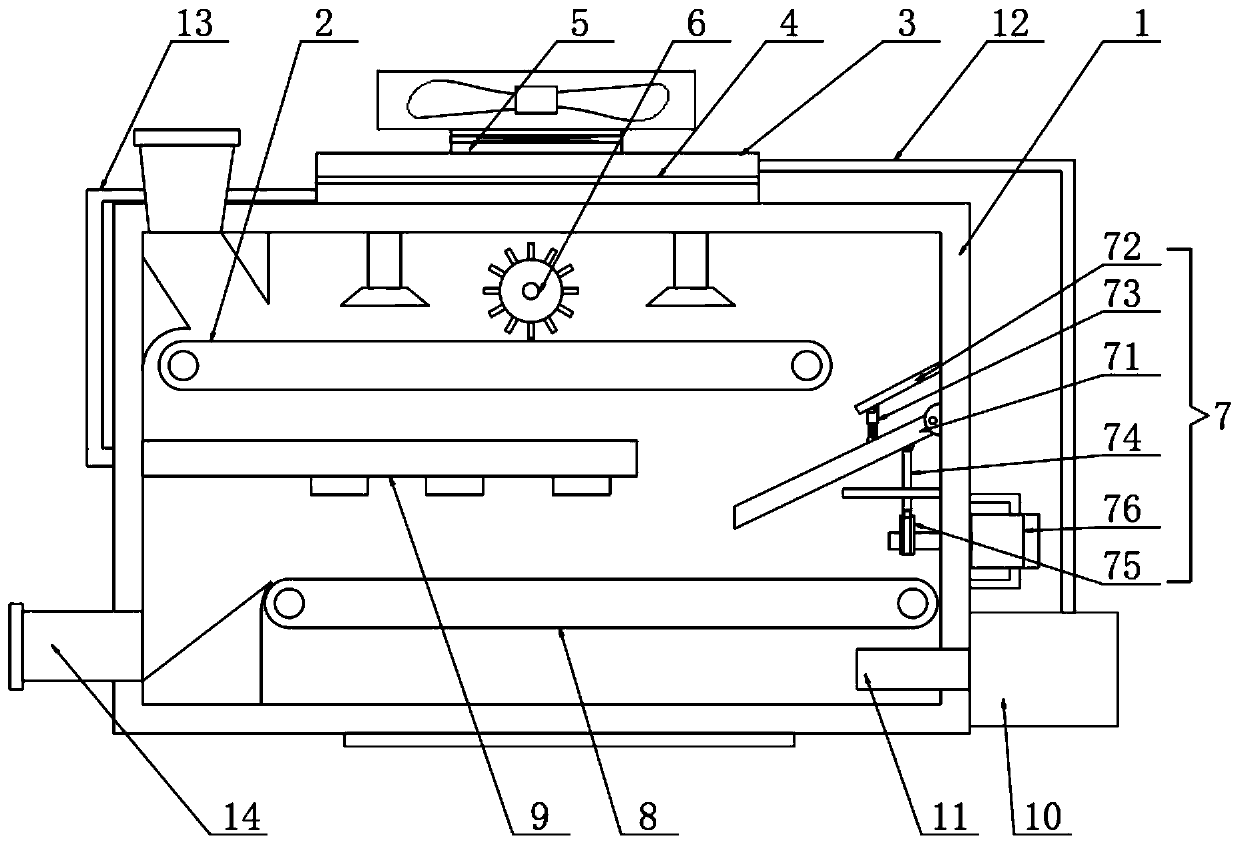

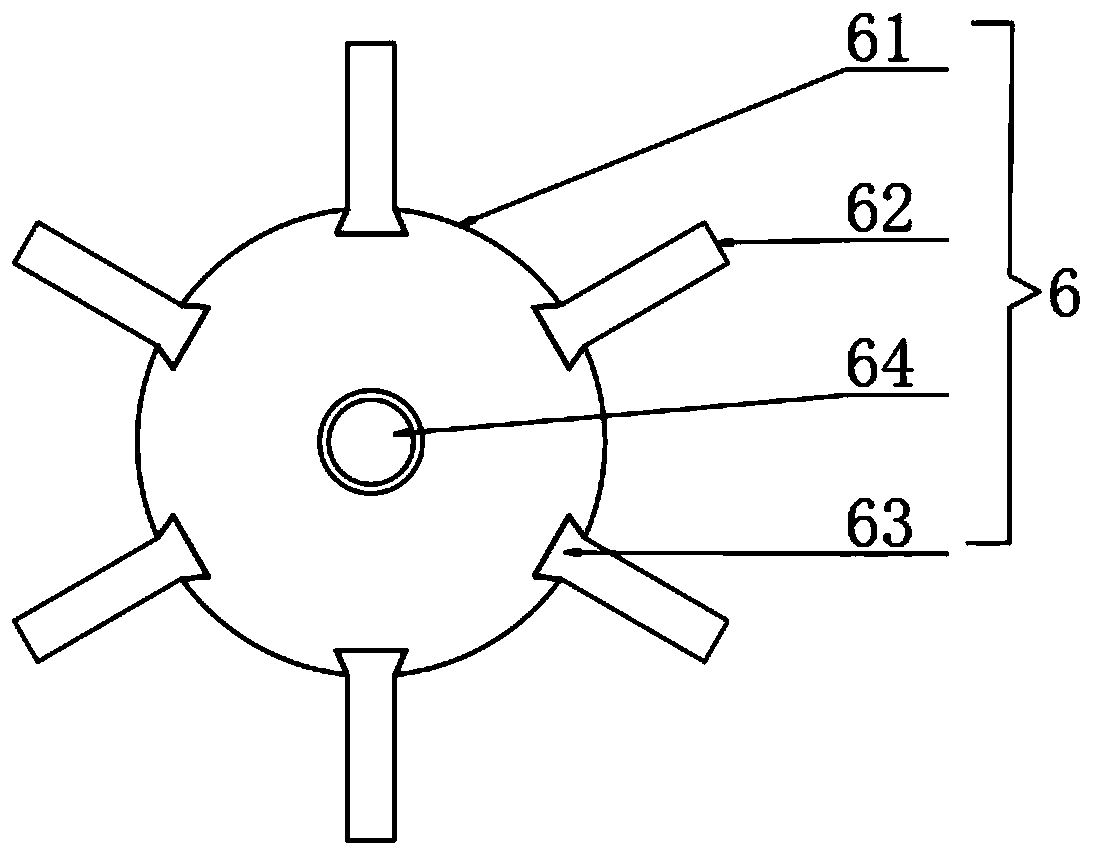

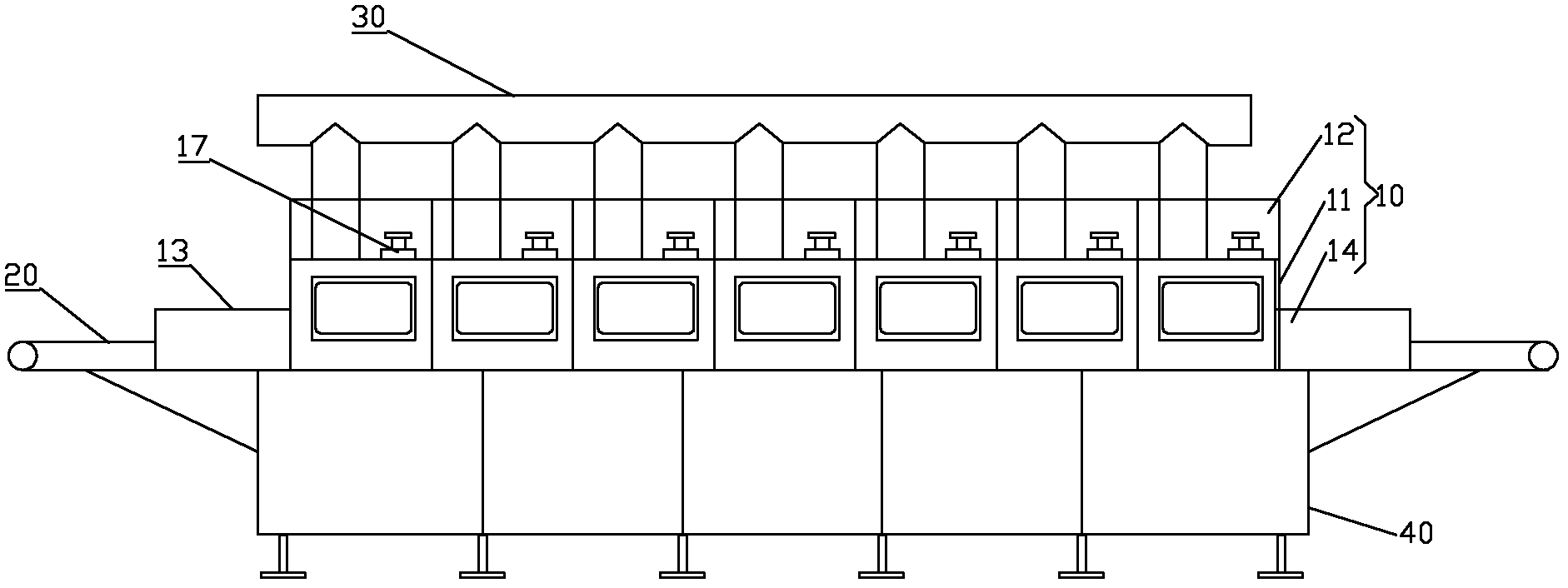

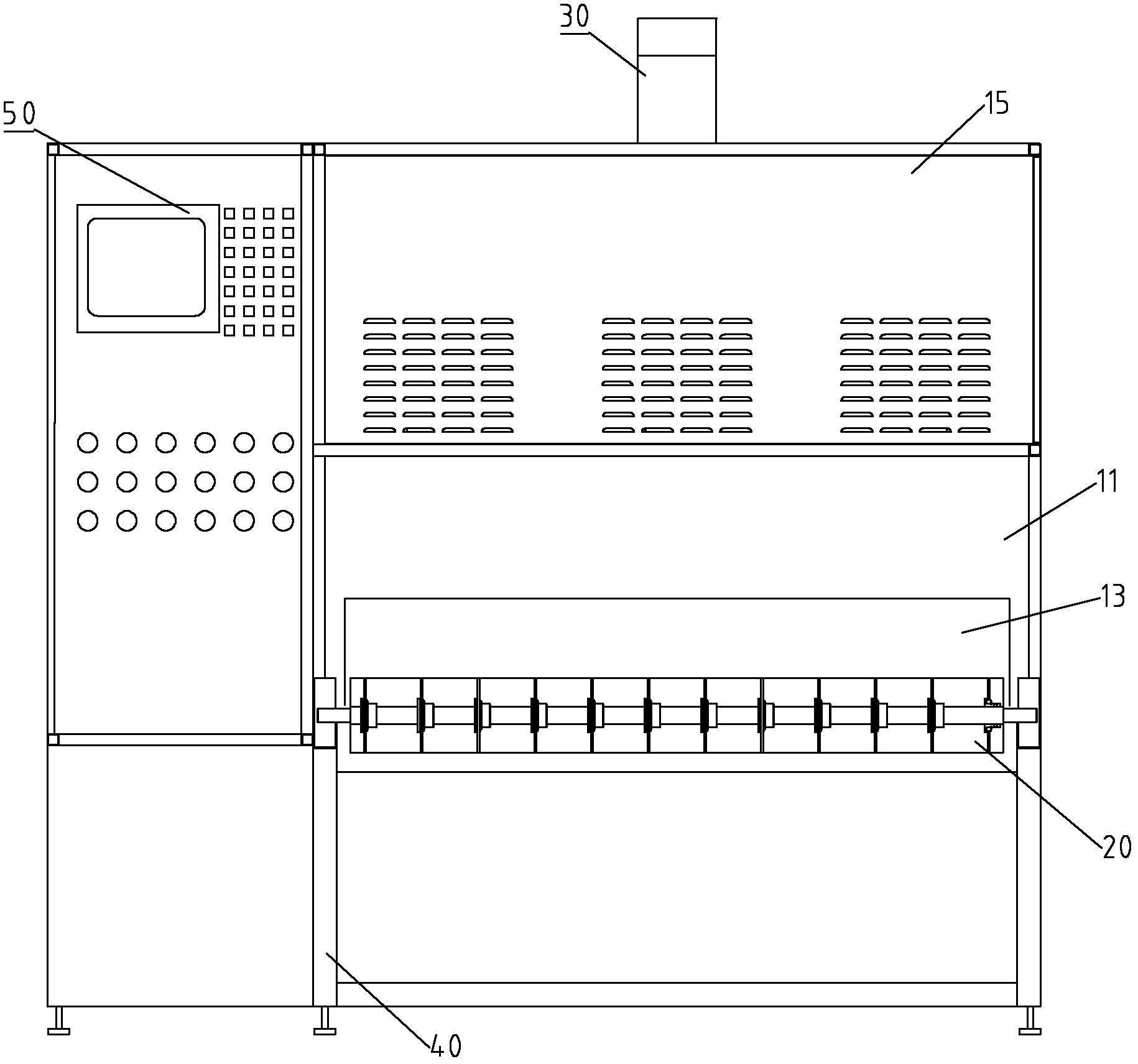

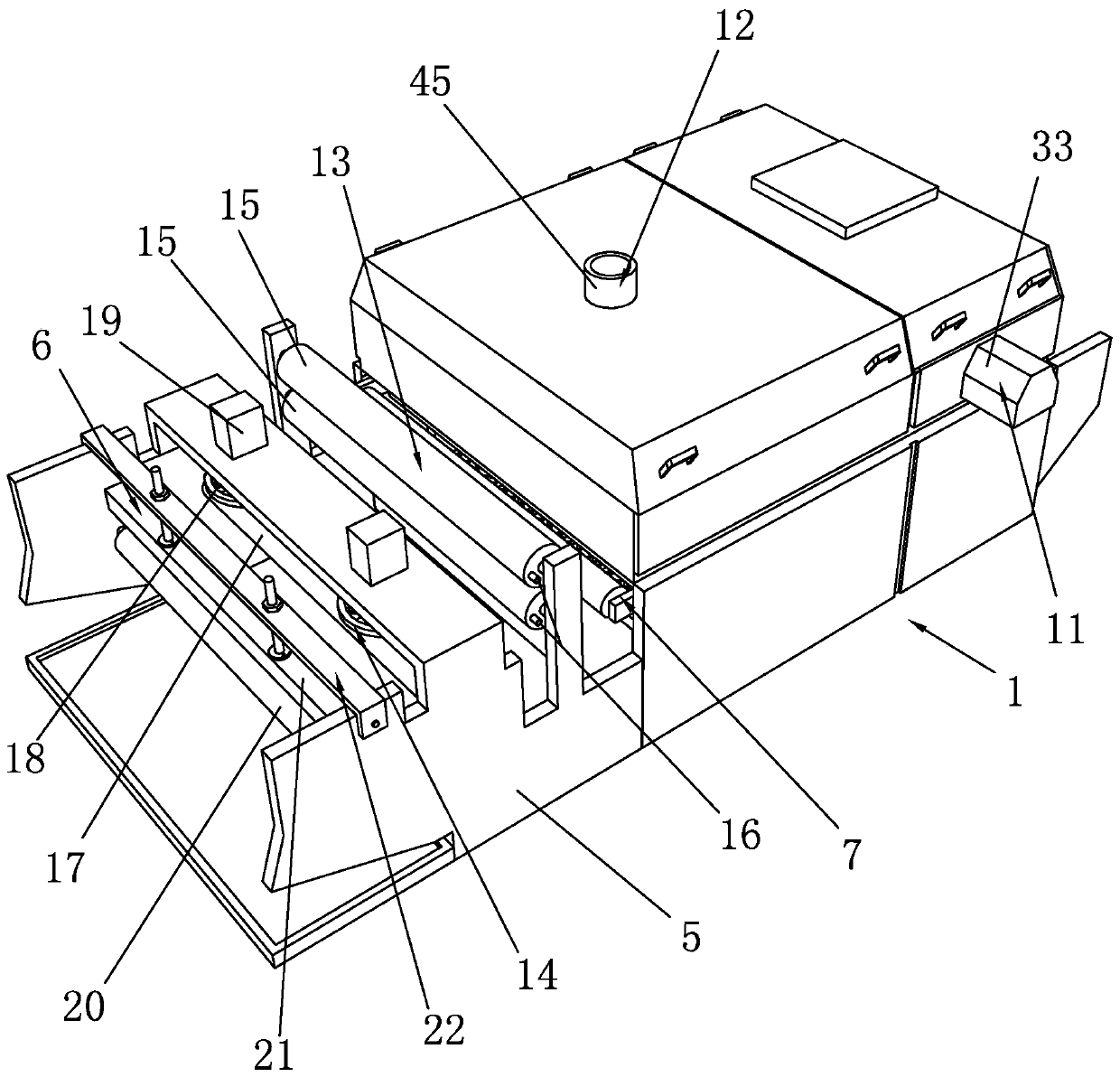

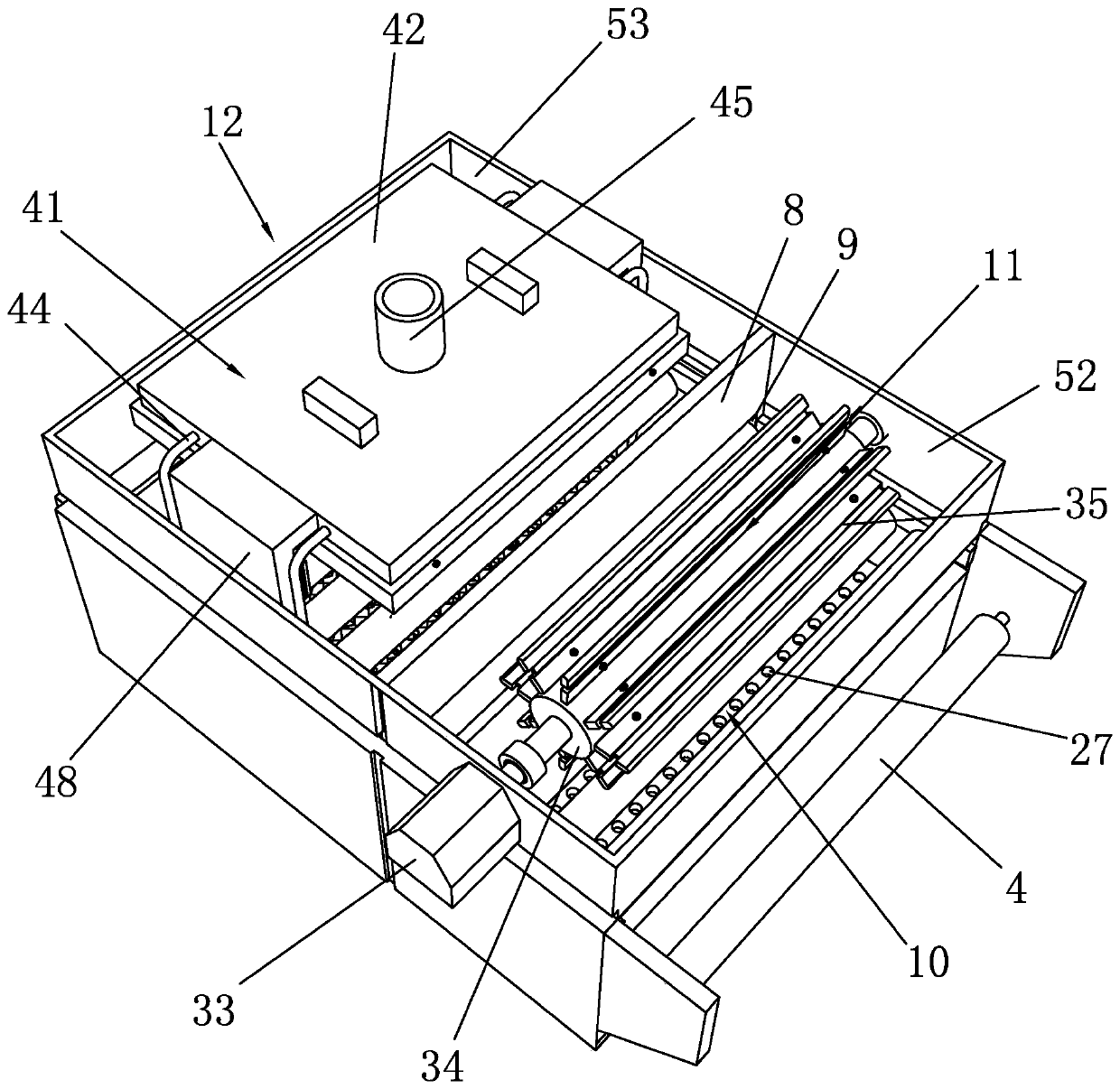

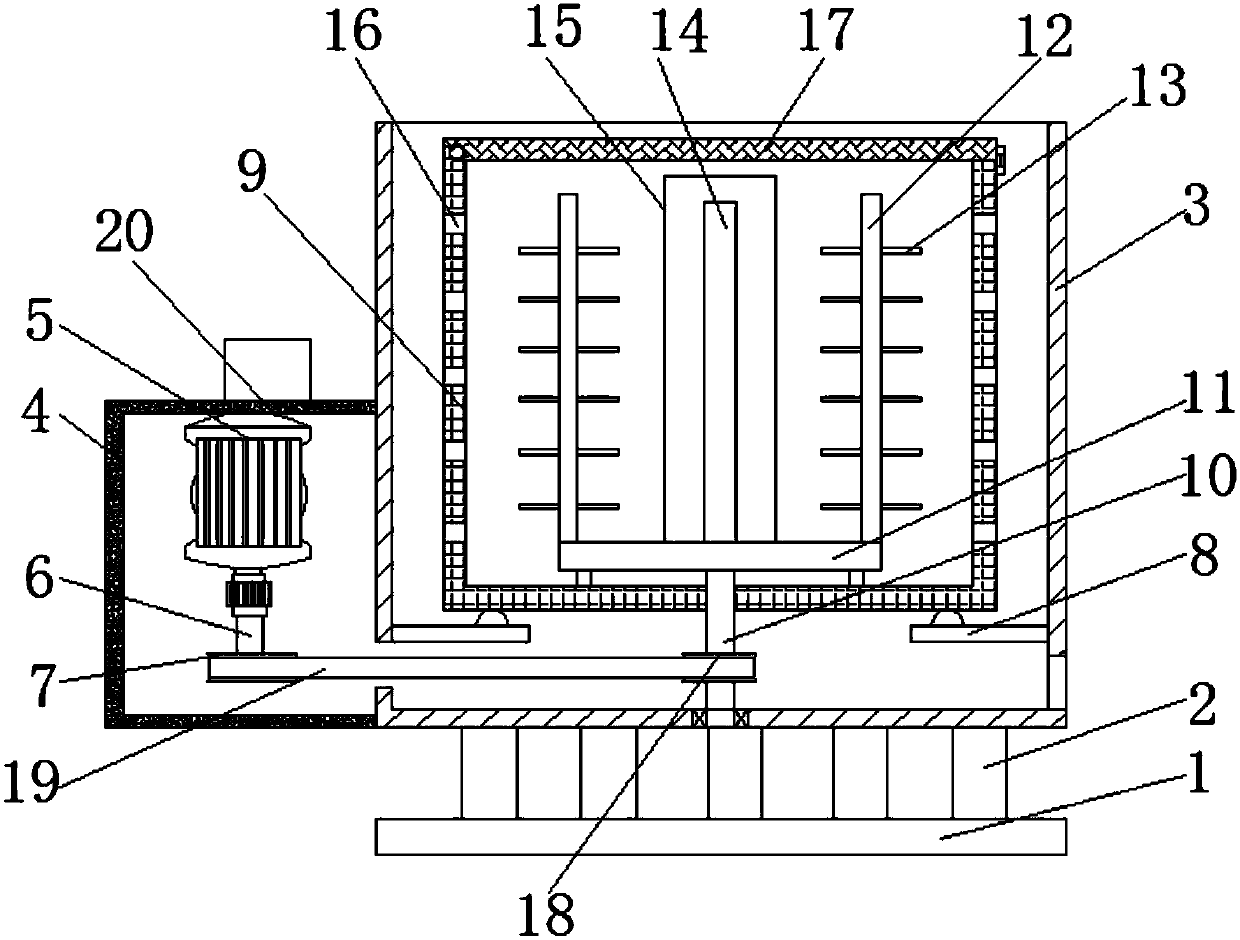

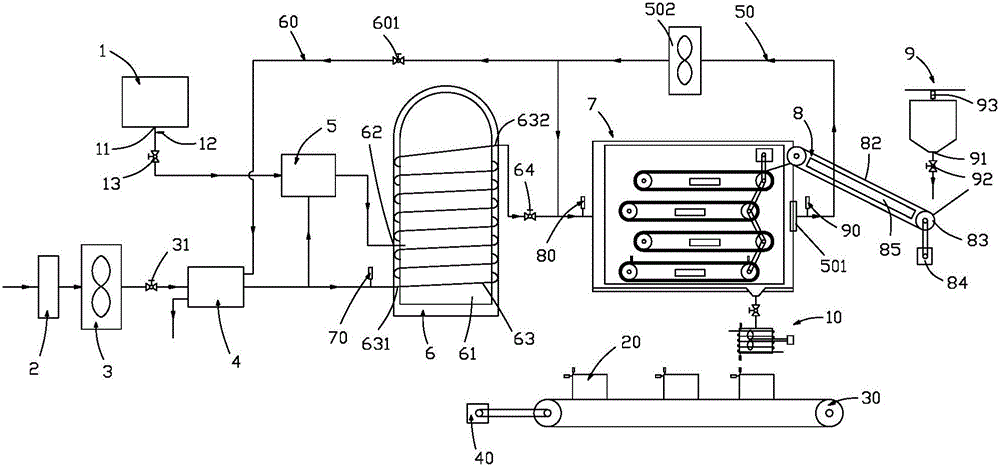

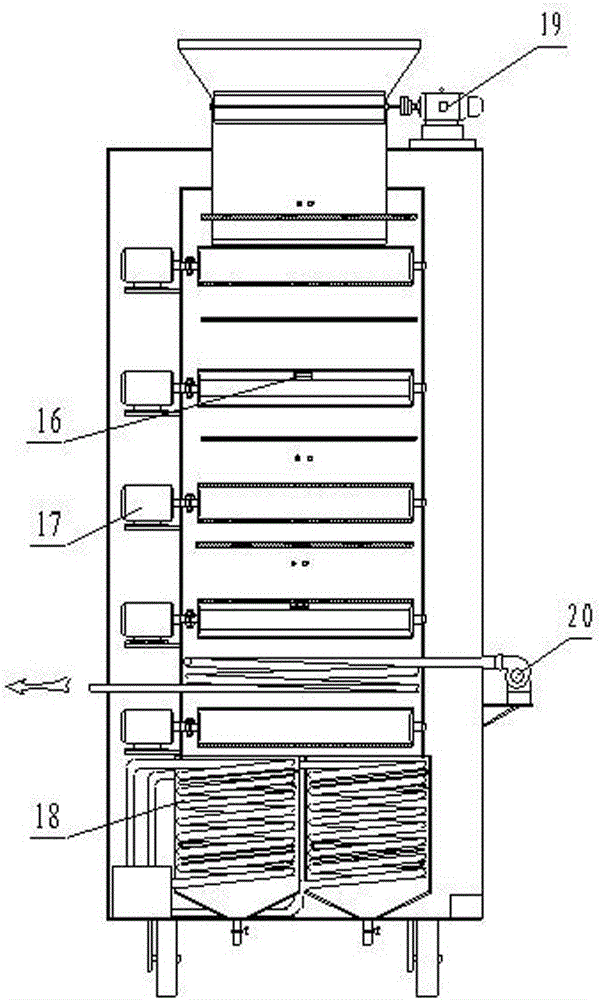

Chemical industry production drying equipment with poking device

InactiveCN109724391AImprove primary drying qualityImprove drying qualityDrying gas arrangementsDrying solid materialsChemical industrySprayer

The invention discloses chemical industry production drying equipment with a poking device in the technical field of chemical industry production. The chemical industry production drying equipment with the poking device comprises a drying box, a first horizontal conveyer belt and a second horizontal conveyer belt; a feeding hopper corresponding to the first horizontal conveyer belt is arranged onthe left side of the top of the drying box; the left side and the right side of the bottom of a heating shell are each provided with an air outlet pipe, and a material poking device is arranged between the two groups of air outlet pipes; and a material shaking and scattering device is obliquely arranged in the middle of the inner wall of the right side of the drying box. According to the chemicalindustry production drying equipment with the poking device, the material poking device is arranged, after materials pass through the first air outlet pipe, the materials are poked by turning claws tobe turned over, and then preliminary drying work is completed through the second air outlet pipe; meanwhile, the material shaking and scattering device is arranged, the materials are shaken and scattered, therefore, the subsequent material drying quality can be greatly improved, and the condition that part of the materials are adhered together is avoided; and secondary drying is conducted throughhot air sprayed by sprayer heads arranged at the bottom of an air distribution pipe, therefore, the drying quality is greatly improved, the drying time is shortened, and the working efficiency is improved.

Owner:南通市金宏电化设备有限公司

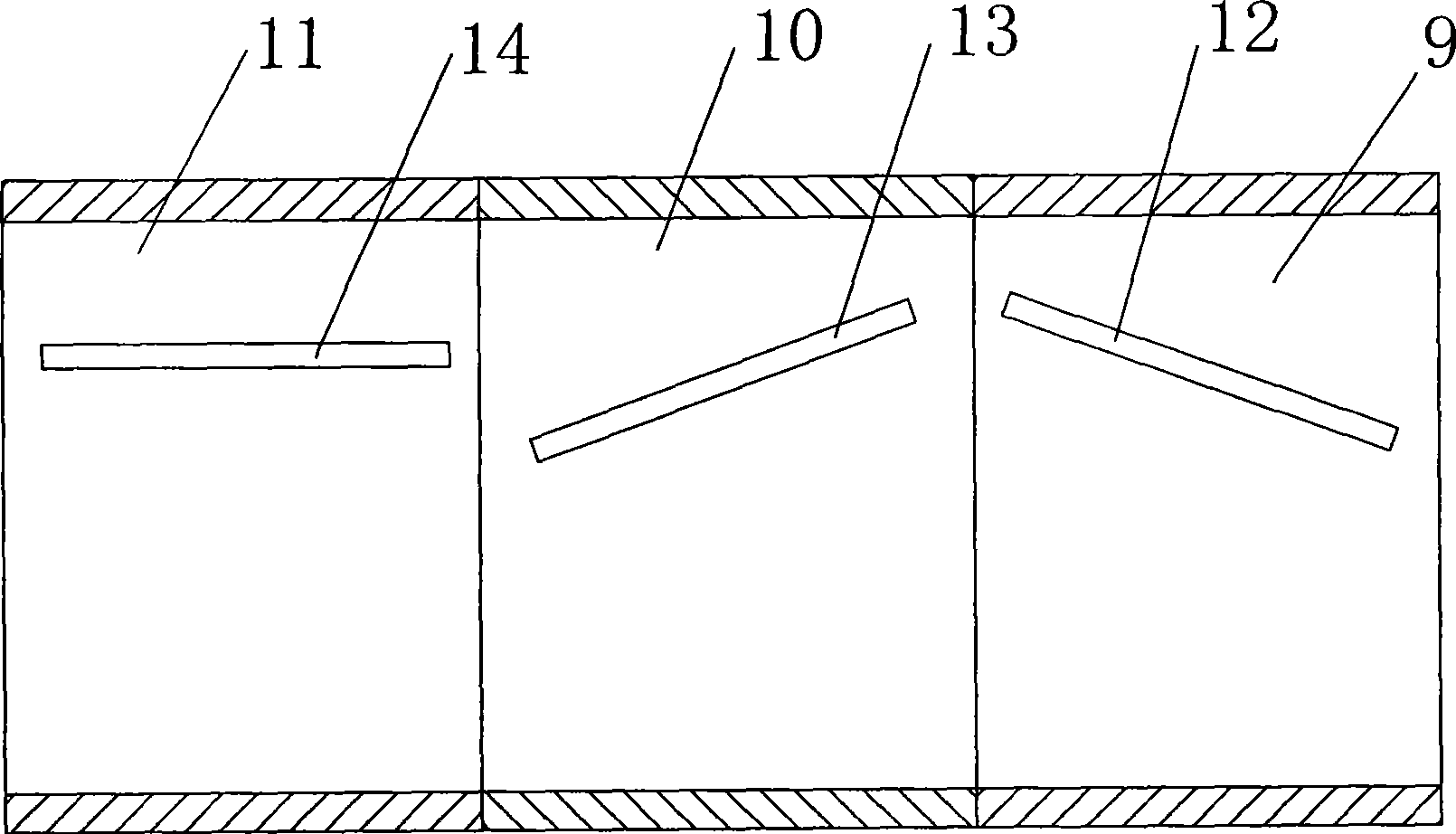

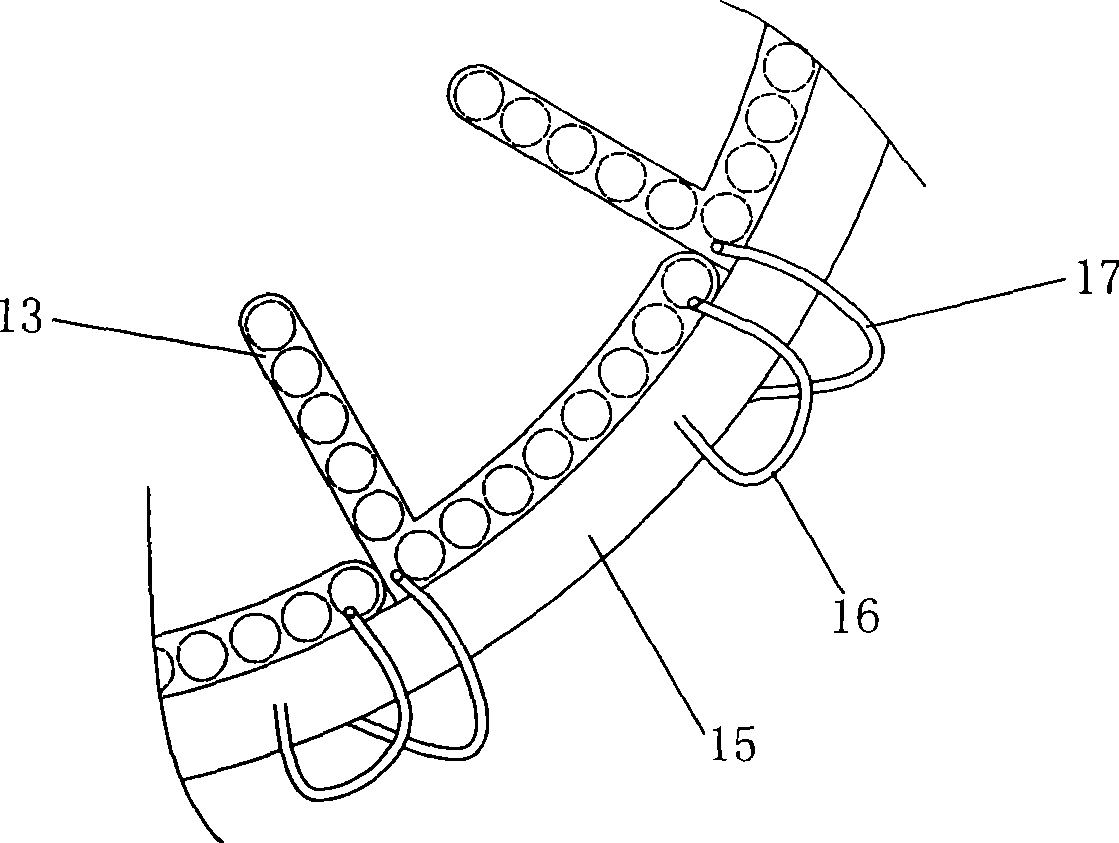

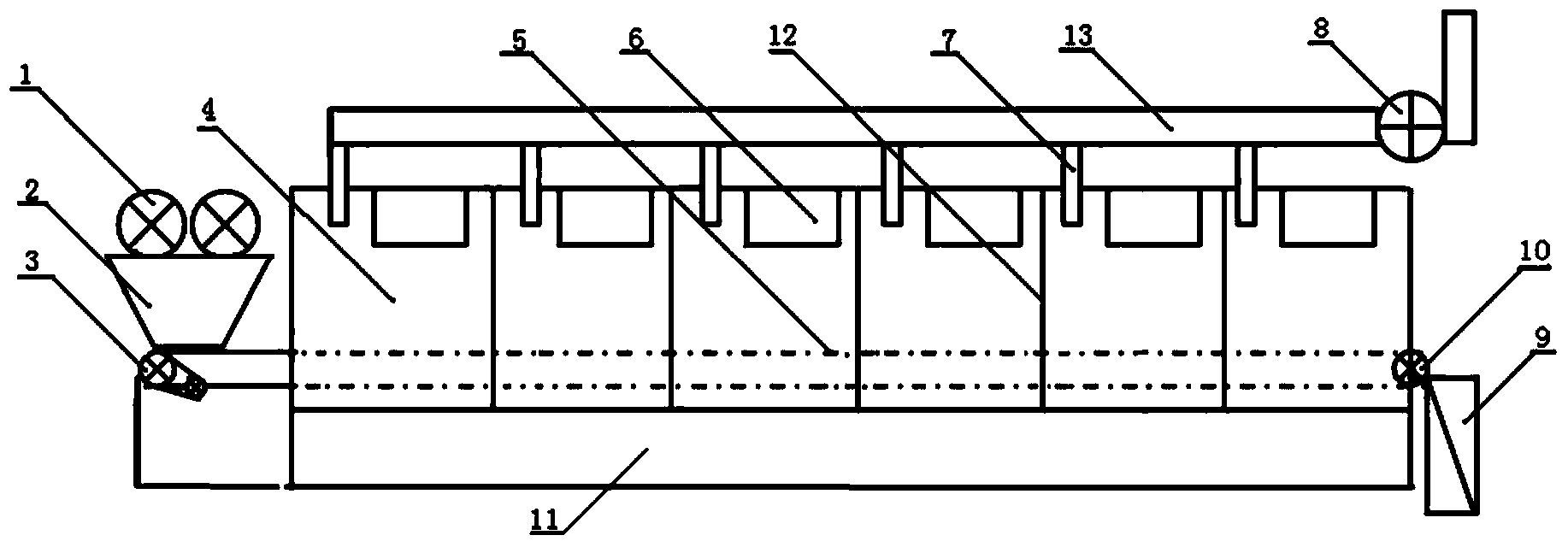

Three stage type tobacco shred drying technique and tobacco dryer

The invention provides a three-section tobacco shred drying process and a tobacco shred drying machine. In the three-section tobacco shred drying process, tobacco shreds are dried over three sections, wherein the heating temperature of the middle section is higher than that of the front section; the material flow rate and cylinder rotation speed of the middle section are higher than those of the front section; and the rear section has humidifying function. The three-section tobacco shred drying machine comprises a cylinder body, a heating pipeline and a hot wind pipeline, wherein the cylinder body consists of a front section, a middle section and a rear section, each section is connected with a rotating device and communicated with the hot wind pipeline; the interior of the front section is provided with a guiding plate forming a positive angle with the axial direction of the cylinder body; the interior wall surface of the middle section is provided with a heat exchange thin plate forming a negative angle with the axial direction of the cylinder body; the heat exchange thin plate communicates with the heating pipeline; the interior of the rear section is provided with a humidifying device and a guiding plate which parallels to the axis of the cylinder body. The invention dries tobacco shreds through three sections with different temperature and flow rates, reducing the occurrence of problems that the dried tobacco shreds may be charred on the outside and tender on the inside or only heads and ends are dried, preventing loss of nice smelling producing substances in the tobacco and ensuring the tobacco shred drying quality.

Owner:CHINA TOBACCO SHANDONG IND

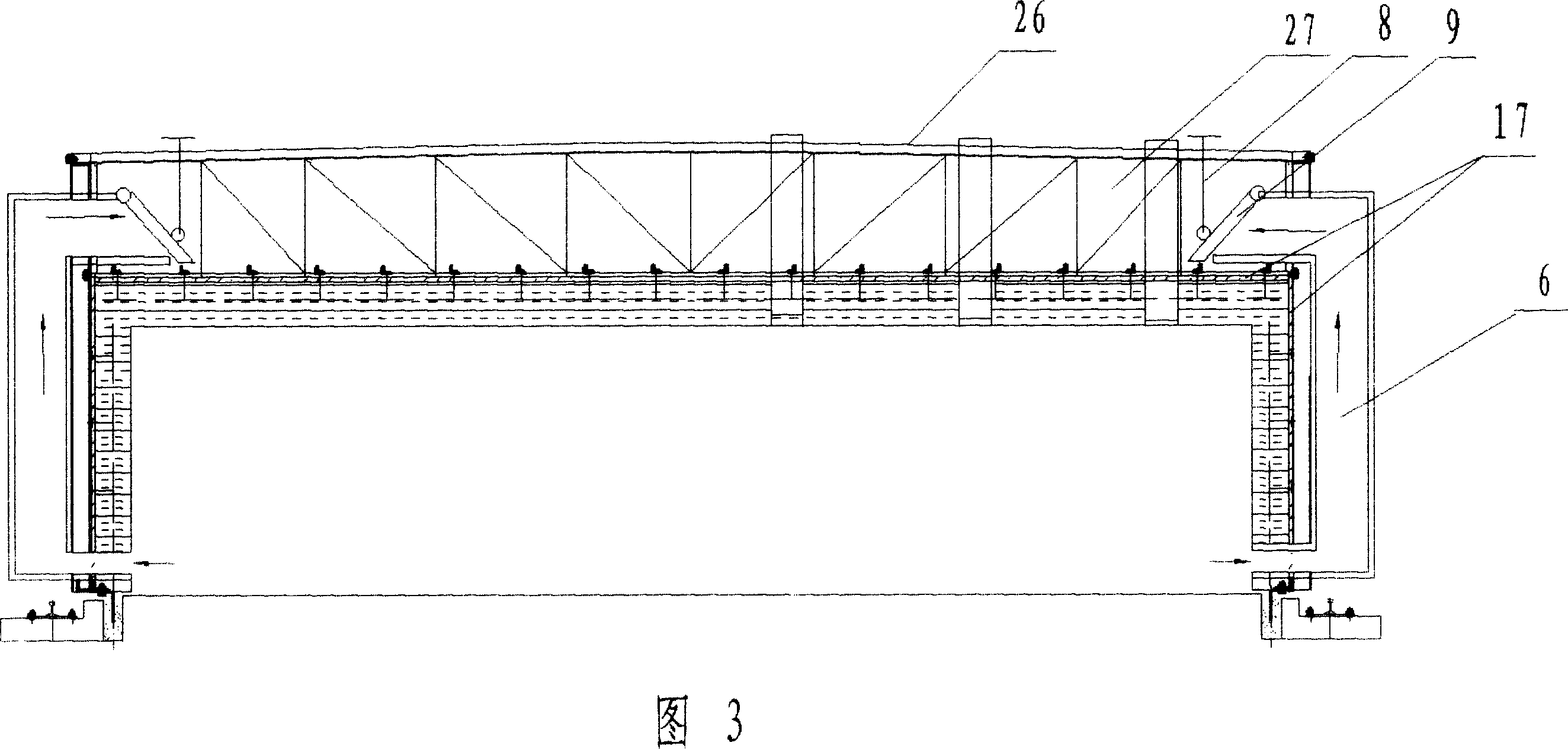

Equipment and method for drying gypsum boards

ActiveCN102538435AIncrease profitImprove efficiencyDrying gas arrangementsHeating arrangementResonant cavityElectricity

The invention provides equipment and a method for drying gypsum boards. The drying equipment comprises a drying device, a conveying device, a humidity discharging device and a control device, wherein the drying device comprises a resonant cavity and a microwave source; the resonant cavity comprises a drying channel; the microwave source is arranged above the resonant cavity; at least one part of the conveying device is arranged in the drying channel; the humidity discharging device is communicated with the resonant cavity; and the control device comprises a temperature and humidity detection unit for detecting temperature and humidity in the resonant cavity, and a control unit which is electrically connected with the temperature and humidity detection unit, the microwave source and the conveying device and controls the power of the microwave source and / or the speed of the conveying device according to the temperature and the humidity. By the equipment and the method for drying the gypsum boards, the gypsum boards to be dried are uniformly put into and pass through the resonant cavity; and meanwhile, the drying temperature and humidity can be monitored, and the humidity-discharging speed of the resonant cavity can be controlled, thus the use ratio of microwaves is improved, drying quality is guaranteed, and the equipment and the method have the characteristics of high drying speed, high efficiency, energy saving, environment friendliness and low cost.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Shaping machine for after-finishing of fabrics

ActiveCN109944006AGuaranteed cooling rateConsistent cooling rateSucessive textile treatmentsHeating/cooling textile fabricsEngineeringMechanical engineering

The invention discloses a shaping machine for after-finishing of fabrics. The shaping machine comprises a box body, wherein a bracket is arranged on the left side of the box body; a cooling assembly and a static electricity removing assembly are sequentially arranged on the bracket from left to right; a conveying roller platform penetrates through the box body; the interior of the box body is divided into a preheating cavity and a drying cavity by a partition plate; a through groove is formed in the partition plate; a steam spraying disc and a flapping assembly are arranged in the preheating cavity, and a drying assembly is arranged in the drying cavity. The provided shaping machine for after-finishing of fabrics is ingenious and reasonable in structural design; fabrics are subjected to steam humidification and heating treatment through the steam spraying disc in the preheating cavity; the surfaces of the fabrics are humidified more uniformly through the cooperation of the flapping assembly; the fabrics are better loosened and softened and then enter the drying cavity to be dried by the drying assembly at the optimal temperature; after the fabrics are cooled through the cooling assembly, the fabrics are subjected to static electricity removal treatment through the static electricity removing assembly, so that winding and treatment of the fabrics are more convenient.

Owner:绍兴柯桥如川纺织科技有限公司

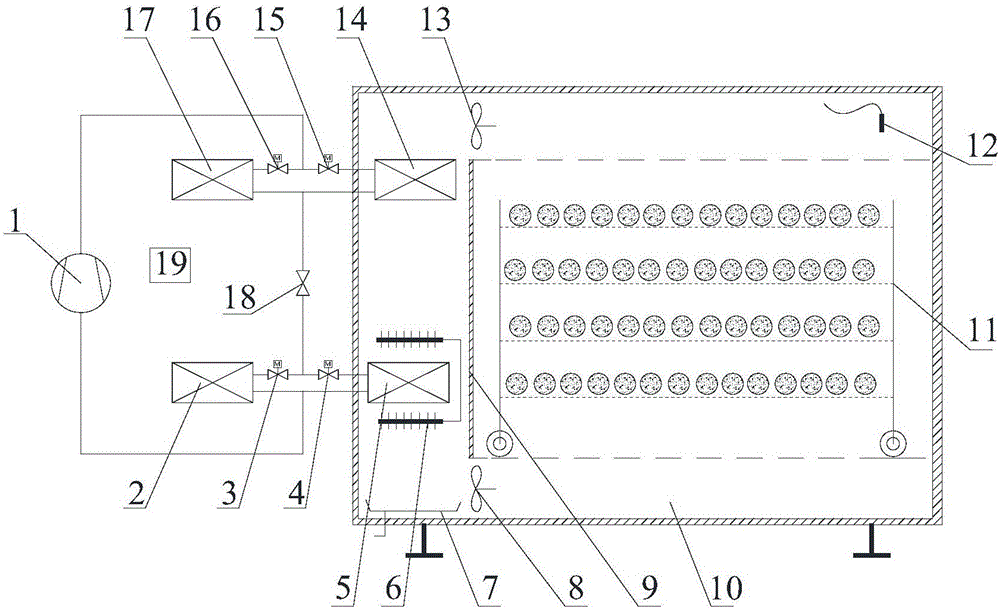

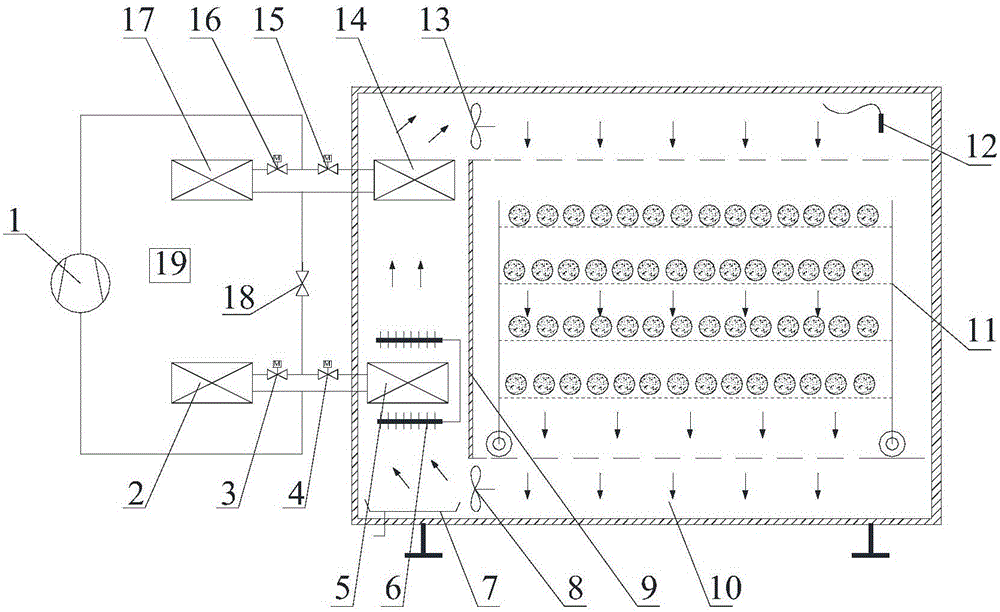

Energy-saving type garden staff heat pump drying device

InactiveCN105029655AHeating up fastGuaranteed drying qualityFood processingDrying machines with local agitationEngineeringMoisture sensor

The invention discloses an energy-saving type garden staff heat pump drying device. The energy-saving type garden staff heat pump drying device is composed of a compressor, a first evaporator, a first electromagnetic stop valve, a second electromagnetic stop valve, a second evaporator, heat pipes, a water pan, a return fan, a partition plate, a drying box, a garden staff rack, a temperature and humidity sensor, an air feeder, a first condenser, a third electromagnetic stop valve, a fourth electromagnetic stop valve, a second condenser, a throttling valve and a controller. The energy-saving type garden staff heat pump drying device has the advantages that heat can be absorbed from the environment in the drying starting stage, inlet air sensible heat of the evaporators in the drying box is directly used for heating circulating air, and excessive heat in the drying box in the drying later stage can be discharged out of the drying box; starting heating is quick, the temperature is controllable, the heat efficiency is high, the drying quality is good, and environmental friendliness and sanitation are achieved.

Owner:TIANJIN AOLV AGRI & SIDELINE PROD GRP

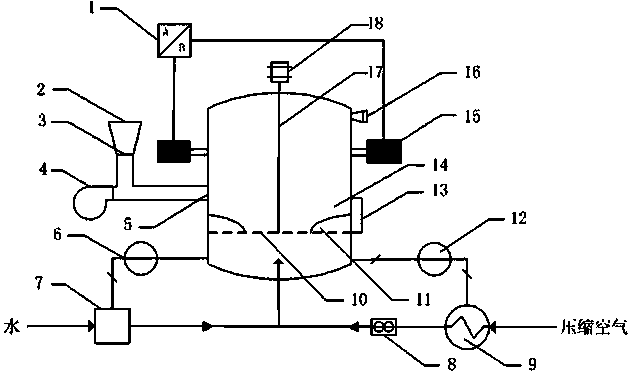

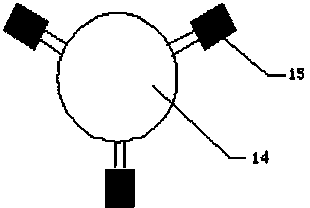

Microwave-hot air combined fluidized bed drying experiment device

ActiveCN104034127AEvenly distributedHeating evenlyDrying solid materials with heatDrying gas arrangementsFluidized bed dryingEnergy absorption

A microwave-hot air combined fluidized bed drying experiment device is characterized by comprising a tower type fluidized bed, a microwave drying device disposed on the lateral wall of the tower type fluidized bed and a hot air drying system connected to the bottom of the tower type fluidized bed. The microwave drying device comprises a microwave generator and a microwave controller. The hot air drying system comprises a hot air heater, a temperature controller, a steam generator, a humidity detector and a compressed air source. By the microwave-hot air combined fluidized bed drying experiment device which is high in automation level, small in floor space and simple and safe to operate, fast temperature rise of materials can be achieved in a short time, even heating is achieved, and evenness of microwave energy absorption is increased; during drying, microwaves can stimulate polar molecules to change orientations constantly to generate a non-thermal effect by high-speed molecule vibration so as to accelerate drying, materials (such as tobacco) with the effective components mostly being glycoside, terpene lactone and volatile oil can be well protected, and quality of dried materials is guaranteed.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Method for preparing sludge and mud sintered brick

InactiveCN106938914AImprove dehydration efficiencyEffective dispersionCeramic materials productionClaywaresBrickFiltration

The invention belongs to the technical field of building materials, and discloses a method for preparing a sludge and mud sintered brick, and the method is as follows: adding a dehydrating agent and a filtration aid agent into wet sludge, stirring and dewatering to obtain a mixture mud cake; adding dry river lake mud powder into the mixture mud cake, stirring and aging to obtain a blank forming material; pressing and forming the blank forming material to obtain a to-be-died brick blank; in turn drying the to-be-died brick blank at room temperature and drying in a drying room to obtain a to-be-burnt brick blank; and firing the to-be-burnt brick blank at 950 to 1050 DEG C. The method for preparing the sludge and mud sintered brick achieves the effects of improving finished product yield and quality, reducing energy consumption and realizing recycling of resources.

Owner:JIANGSU ZHONGYI ECOLOGICAL SOIL INST +1

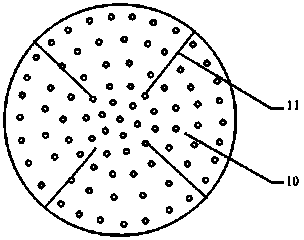

Method for preparing ultra-fine active nano-calcium carbonate with low-ore grade limestone activation of activation tank

InactiveCN101318685AIncrease productivitySolving Lime Burning and OverburningCalcium/strontium/barium carbonatesPoor qualityCalcium hydroxide

The invention provides a method for preparing superfine activated nano calcium carbonate by utilization of low-grade lime. The method adopts the technical proposal that: firstly, the low-grade lime is calcined and crushed so as to prepare calcium oxide; secondly, staged sieving is performed, namely a part of low-quality calcium oxide is grinded into intermediate-grade calcium oxide products through a high-speed kneader or a ring roll, another part of high-quality calcium oxide enters into the next procedure for producing calcium hydroxide and calcium carbonate, and finally calcium oxide with poor quality is used for producing green building materials - aerated concrete blocks; and thirdly, the superfine activated nano calcium carbonate product is prepared after incineration through an incinerator, heat-insulated aging, bubbling carbonization, secondary aging, wet-way secondary activation, recarbonization, centrifugal dewatering, drying and superfine crushing of the high-quality calcium oxide. The method utilizes the low-grade lime to the utmost extent to prepare superfine functional calcium inorganic powder materials.

Owner:福建省万旗非金属材料有限公司

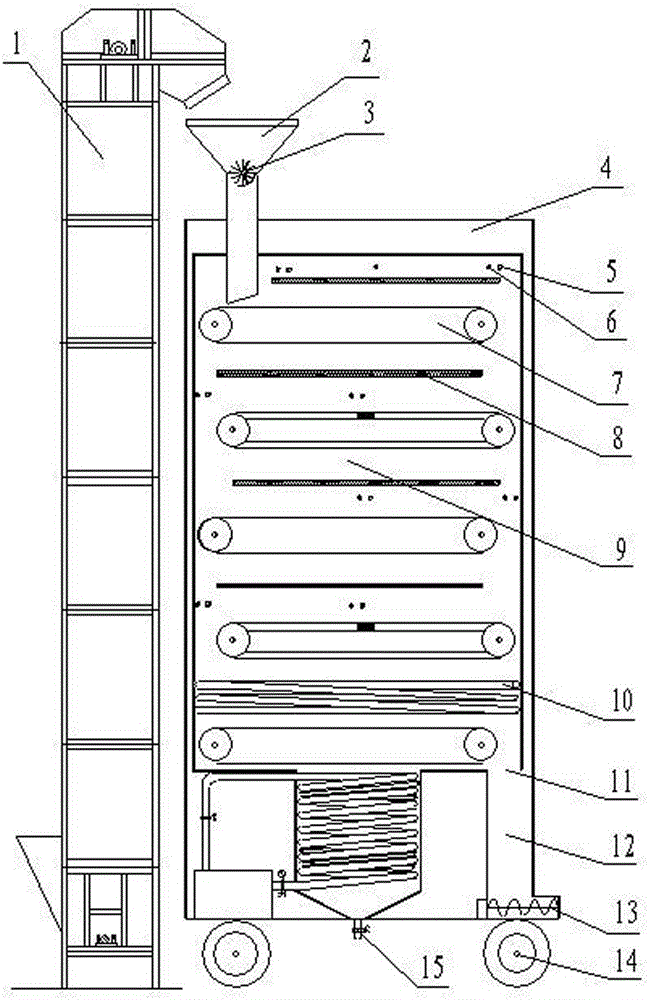

Agricultural byproduct dewatering drying machine

InactiveCN107621142AEvenly heatedSpeed up dryingDrying solid materialsDrying machines with non-progressive movementsAgricultural engineeringEngineering

The invention discloses an agricultural byproduct dewatering drying machine which comprises a base. A damper is fixedly connected to the top of the base. The damper comprises a damping plate. A damping spring is fixedly connected to the top of an inner cavity of the damping plate. The end, away from the top of the inner cavity, of the damping spring is fixedly connected with a damping rod. The bottom end of the damping rod penetrates the bottom of the damping plate and extends to the outer portion of the damping plate. A box body is fixedly connected to the top of the damping plate. The left side of the box body is fixedly connected with a motor box, and a motor is fixedly connected to the top of an inner cavity of the motor box. By means of the agricultural byproduct dewatering drying machine, due to use of a roller, water on the surfaces of humid agricultural byproducts can be rapidly removed, and the baking time is shortened; and due to use of a stirring rod, the phenomenon that thesurface layer is dry and the inner layer is humid is avoided, the drying quality is ensured, the service life of the machine is prolonged, the production cost is reduced, and the production efficiency is improved.

Owner:重庆市六方格农业综合开发有限公司

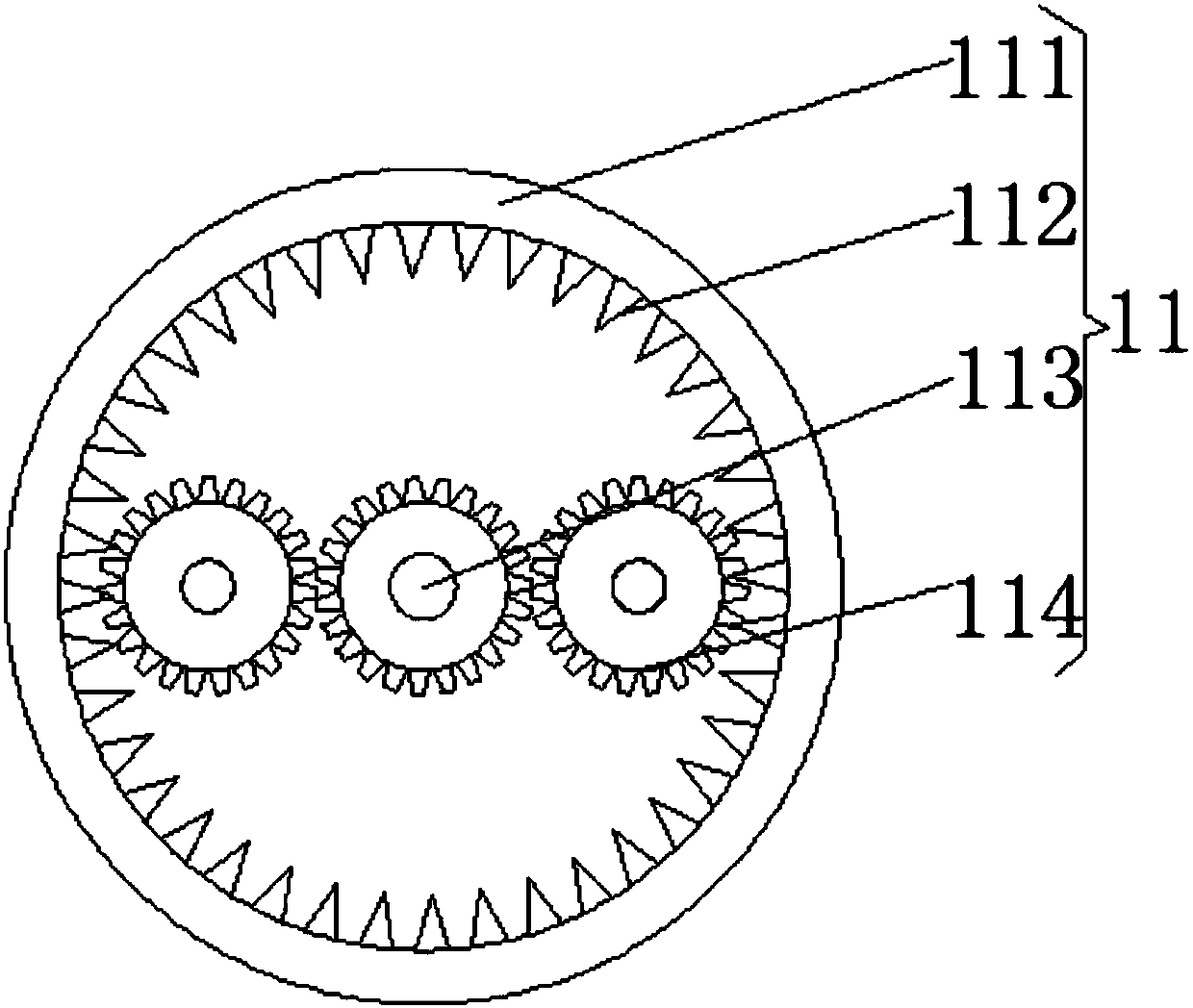

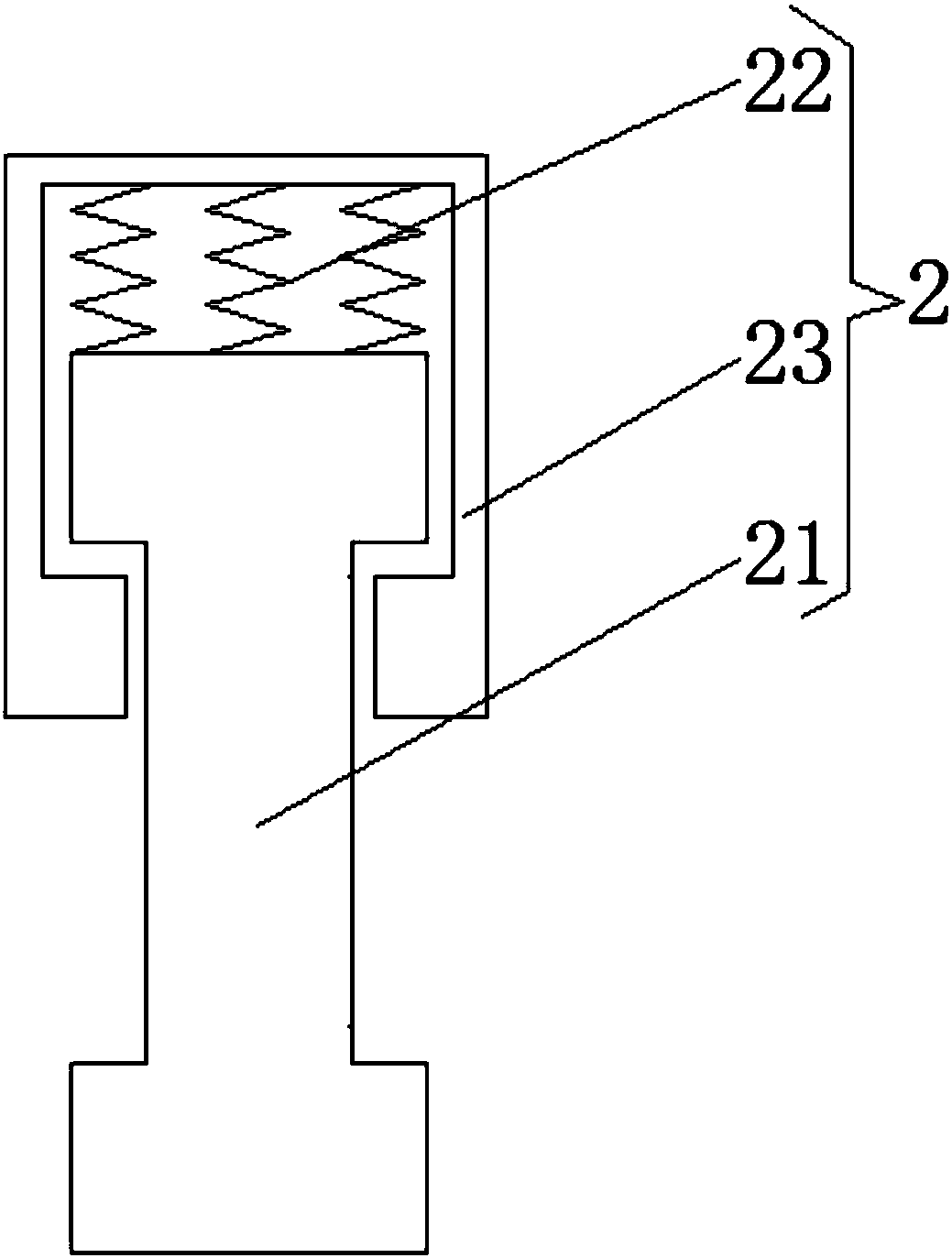

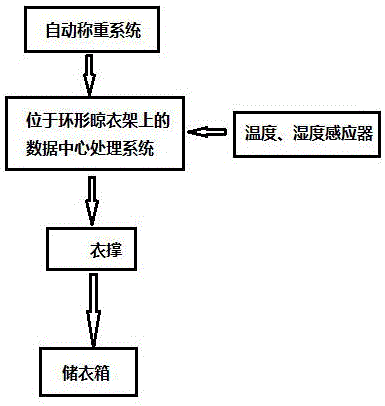

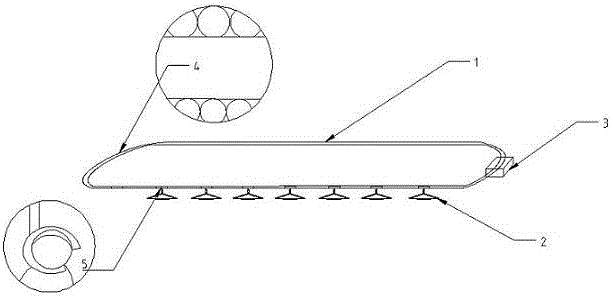

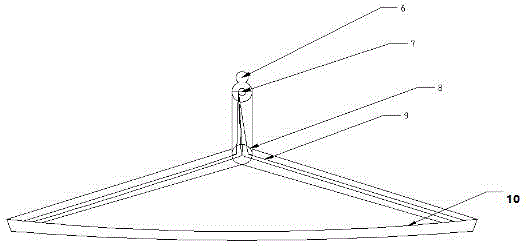

Automatic clothes airing system

ActiveCN105821630ASimple structureInnovative designApparel holdersTextiles and paperRound barClothes hanger

The invention provides an automatic clothes airing system. The automatic clothes airing system comprises an automatic clothes weighing system, a clothes hanger, an annular drying rack and a clothes storage box. The automatic weighing system is arranged in a washing machine and further comprises a data storage module, an information transmission module and a display screen for reading the weight of clothes. The clothes hanger comprises a round bar type hook, an upper clothes hanger rod and a lower clothes hanger rod. A rotating device is arranged above the upper clothes hanger rod, and a suspending device is arranged above the rotating device. The annular drying rack comprises a main rod, a connecting device is arranged on the lower side of the main rod, the suspending device is matched with the connecting device, a guide rail is arranged in the main rod, and a conveying belt is arranged in the guide rail. The clothes storage box comprises multiple supporting rods and a clothes storage box cover. A pressure responsive device is arranged in the clothes storage box. The clothes airing quality can be guaranteed, the influences of human factors are avoided, the clothes can be collected in time to guarantee the quality of the clothes, and the characteristic of intelligence can be shown.

Owner:NANJING INST OF TECH

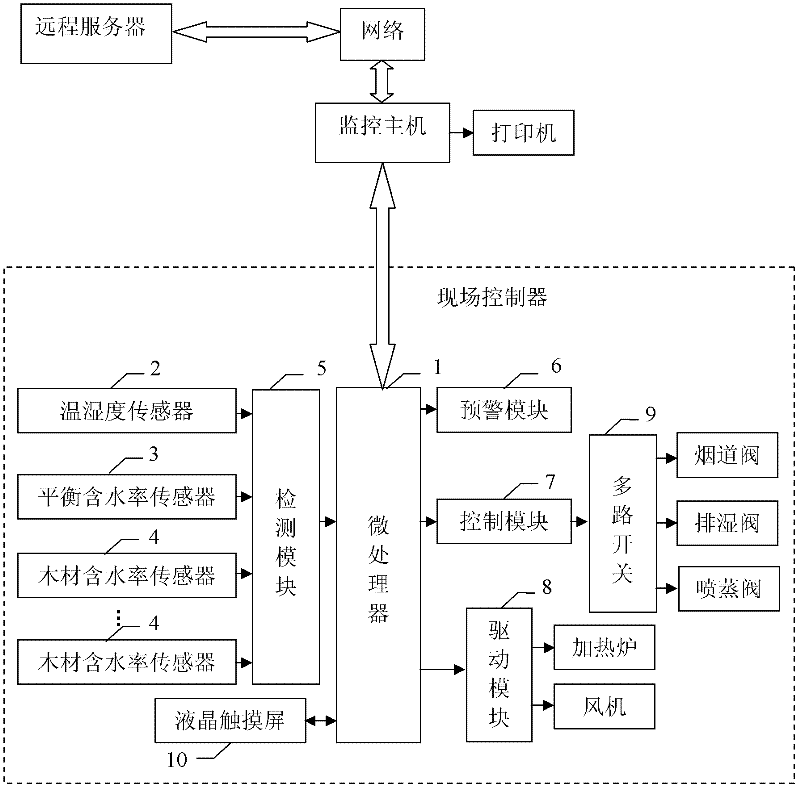

Wood drying remote monitoring system based on DSP (digital signal processor)

InactiveCN102564106AShort drying cycleImprove efficiencyDrying solid materialsDigital signal processingThe Internet

The invention discloses a wood drying remote monitoring system based on a DSP (digital signal processor), which relates to a wood drying remote monitoring system and solves problems of low drying efficiency and complication in operation of an existing wood drying remote monitoring system. The wood drying remote monitoring system comprises a remote server, a monitoring host and a field controller. The monitoring host and the field controller are in data transmission by a serial bus, the monitoring host and the remote server are in data transmission via an Internet according to the TCP (transmission control protocol), and the field controller can run independently, can also receive various commands from the remote server and the monitoring host via a network bus and the serial bus and feeds data back to the monitoring host after the commands are executed. The wood drying remote monitoring system is applicable to automatic wood drying places with middle and large-size drying kilns.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for establishing moisture content gradient of shaving board

ActiveCN103950085AReduce drying energy consumptionGuaranteed drying qualityWood working apparatusFlat articlesWood shavingsSurface layer

The invention discloses a method for establishing a moisture content gradient of a shaving board. The method consists of three technological links, namely drying in levels, respective glue mixing and respective paving. The drying in levels is characterized in that two levels of drying systems are established and a shaving sorting procedure is set up between the first-level drying system and the second-level drying system; the shavings subjected to drying in levels are respectively stored, metered and mixed with glue, and the moisture content difference between shavings in a core layer and shavings on a surface layer are stabilized; after the shavings are metered, the shavings are respectively paved, and the moisture content gradient is finally established on a cross section of a blank of the shaving board. By the moisture content gradient, the moisture on the surface of the blank is quickly vaporized in the heating process, a steam impact effect is generated, the heat transfer speed is improved, the temperature rise speed of the core layer is improved and the aims of shortening hot-pressing time and improving hot-pressing efficiency are finally fulfilled; in addition, by establishing the moisture content gradient of the blank, the performance and the surface quality of the finished shaving board can be obviously improved, the static bending intensity of the board is improved, the made shaving board is more smooth in surface, and the sanding loss of the shaving board is reduced.

Owner:SOUTHWEST FORESTRY UNIVERSITY

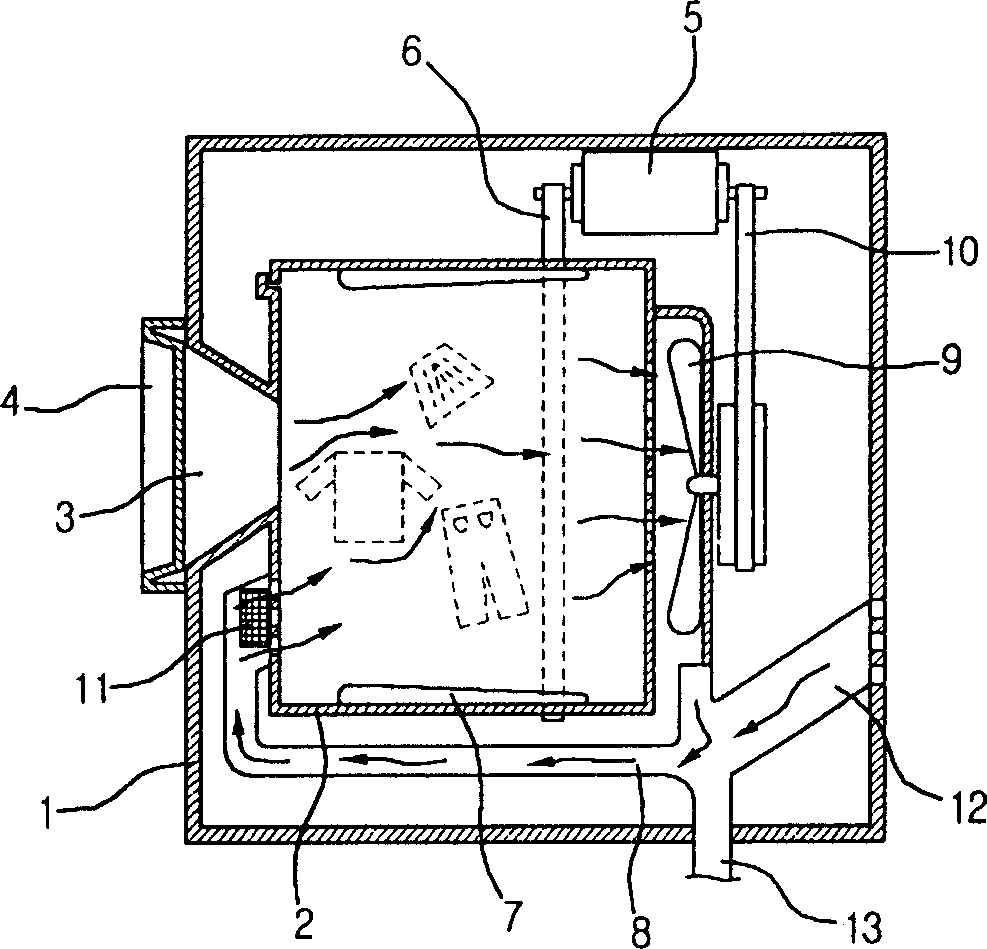

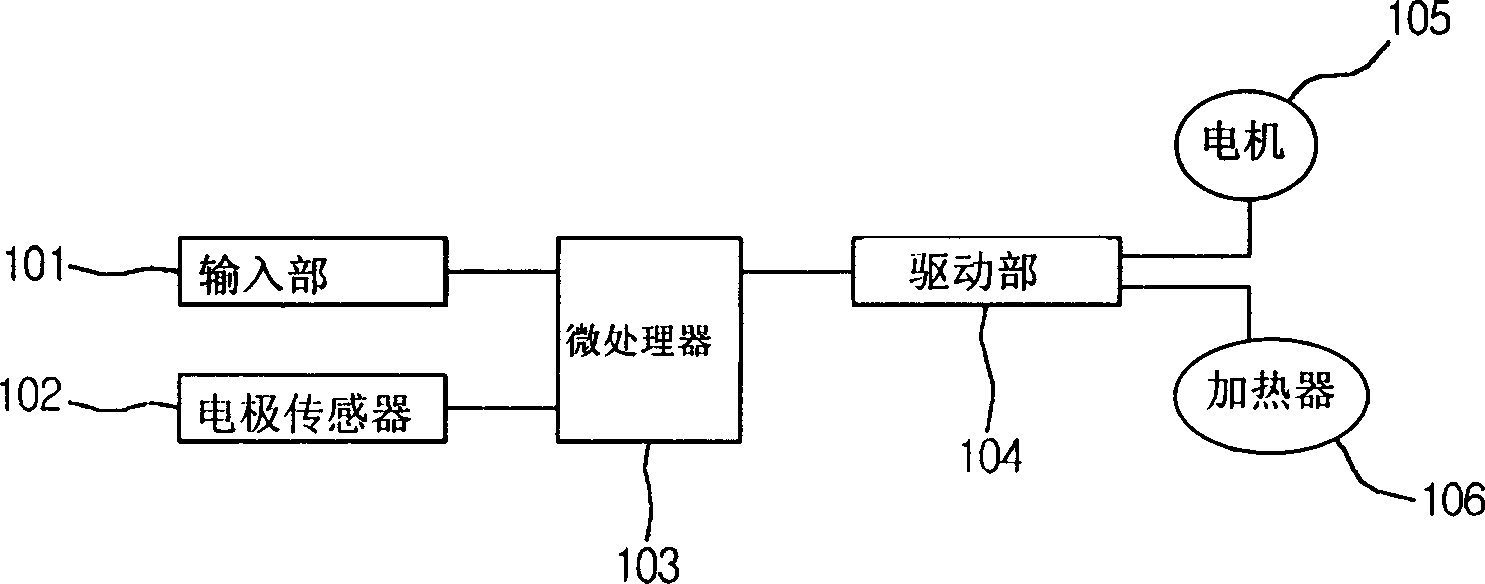

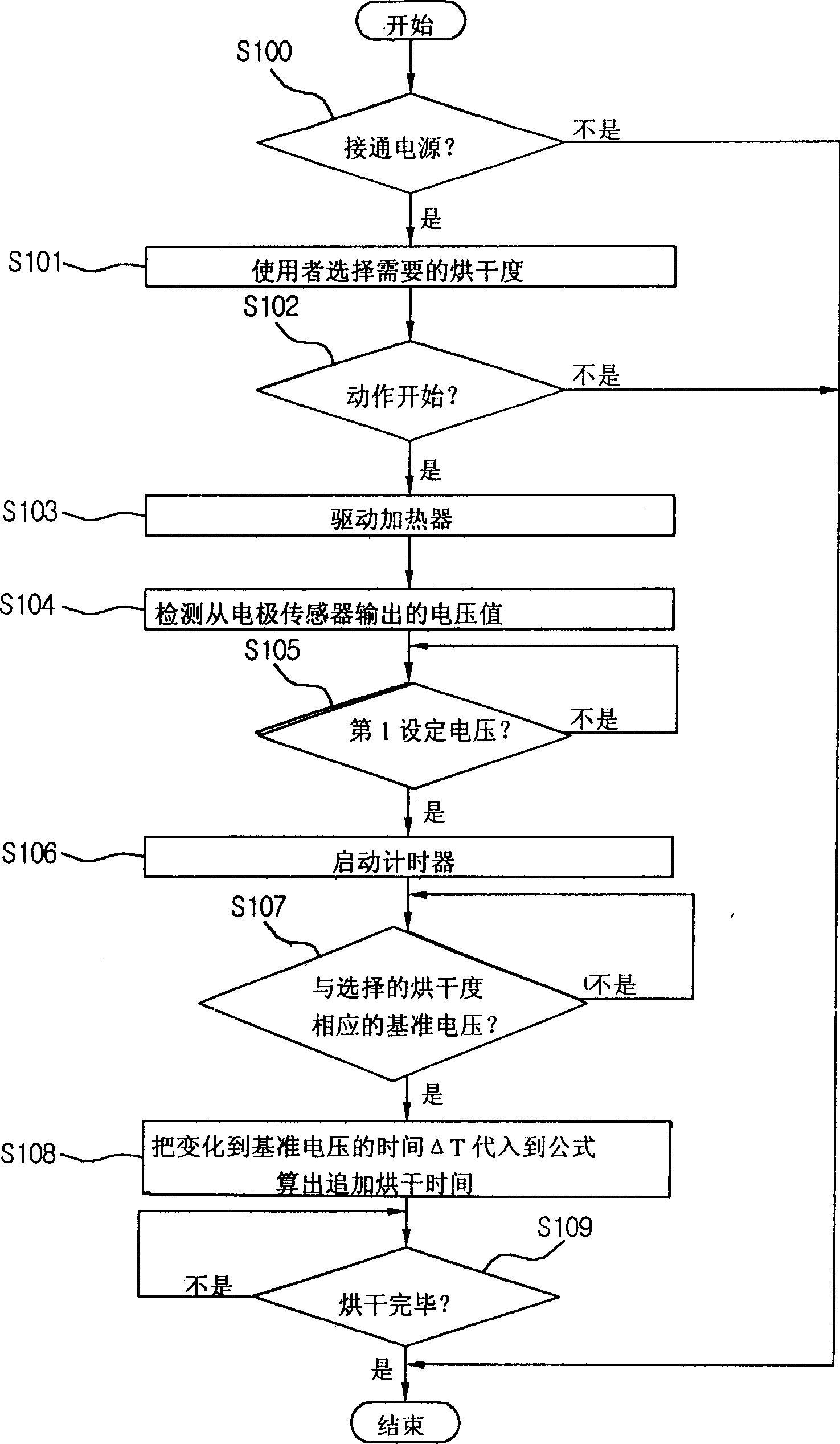

Drier and its control method

InactiveCN1715547AChange drying conditionsGuaranteed drying qualityTextiles and paperLaundry driersControl signalEngineering

The drier control method is to change the stoving operation end point based on the user selected stoving grade, slight moist, sub-dry, dry, complete dry, etc. The drier of the present invention is provided with heater, input unit, electrode sensor, microprocessor, and driving unit. After the stoving command and the stoving grade are input in the input unit, the electrode sensor detects the humidity of the article, the microprocessor detects the voltage value the electrode outputs in certain period until reaching the set reference voltage, detects the time from the first voltage value to the second voltage value to calculate the additional stoving time and alters the stoving condition based on the additional time, and the driving unit controls the operation of the heater and other parts based on the control signal from the microprocessor. The present invention can maintain the optimal stoving state.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

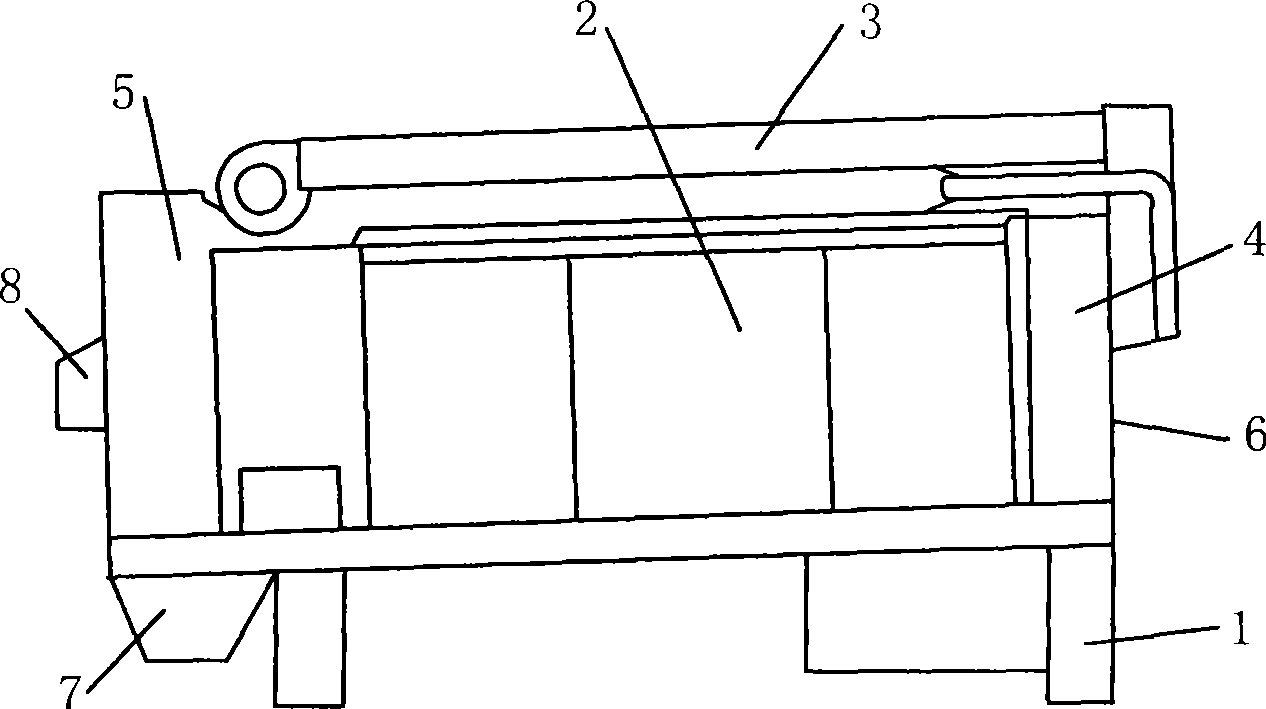

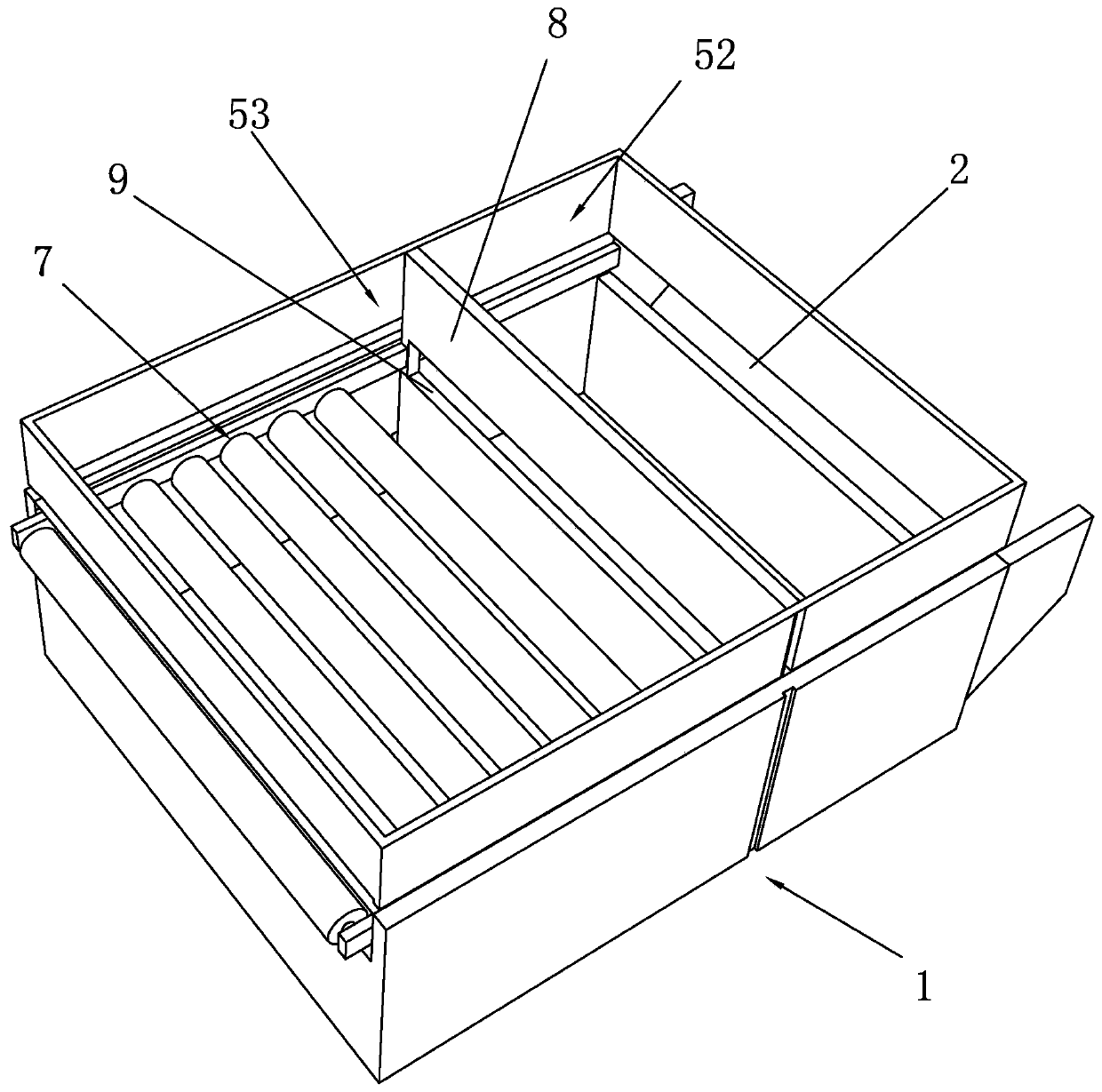

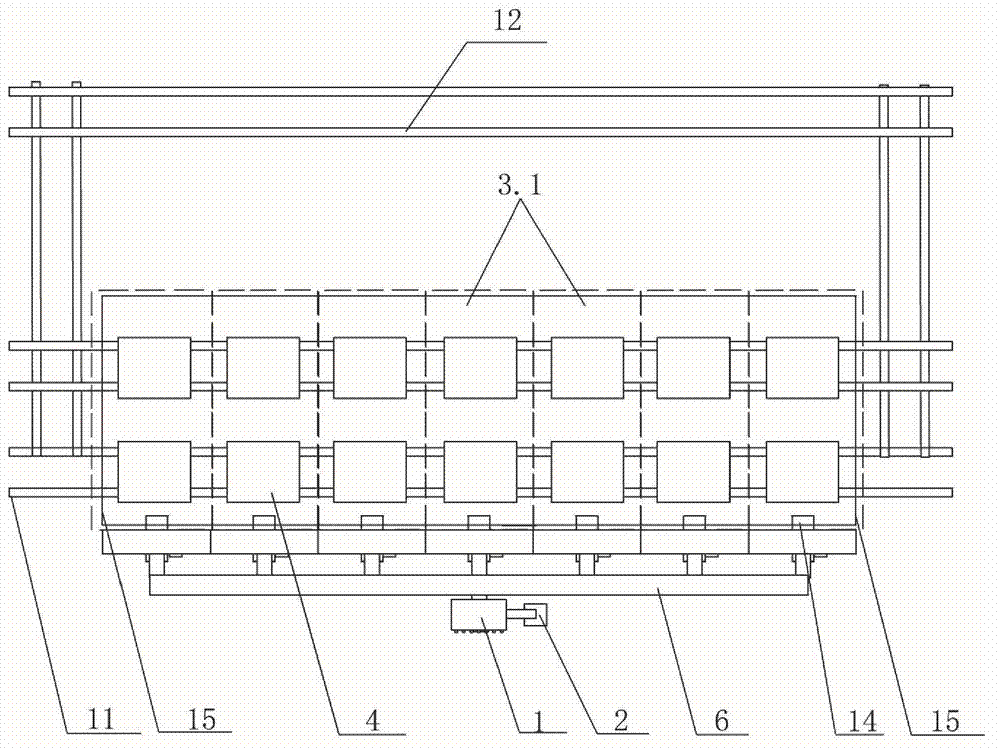

Wood chip drying device

InactiveCN102901329AEven airflowGuaranteed drying qualityDrying gas arrangementsDrying chambers/containersCombustionHeat exchanger

The invention discloses a wood chip drying device, which comprises a combustion furnace (1), a blower (2), a dryer tunnel (3) and a dryer trolley (4), wherein the combustion furnace (1) is connected with the blower (2); the wood chip drying device is characterized by comprising at least two heat exchangers (5), wherein the combustion furnace (1) is connected with the heat exchangers (5) through a heat pass pipe (6); the upper parts and the lower parts of the heat exchangers (5) are provided with exhaust fans (7) and flow fans (8) respectively; the heat exchangers (5) are connected with the dryer tunnel (3) through air flow passages (14); and the dryer tunnel (3) corresponding to the heat exchangers is divided into drying units (3.1) by the heat exchangers (5). The wood chip drying device has the advantages that the drying tunnel is divided into a plurality of drying units by the heat exchangers to realize a multi-point execution and multi-point air draft mode, and the wood chip drying effect is good.

Owner:DAYUAN ENVIRONMENTAL PROTECTION ENG NANNING CITY

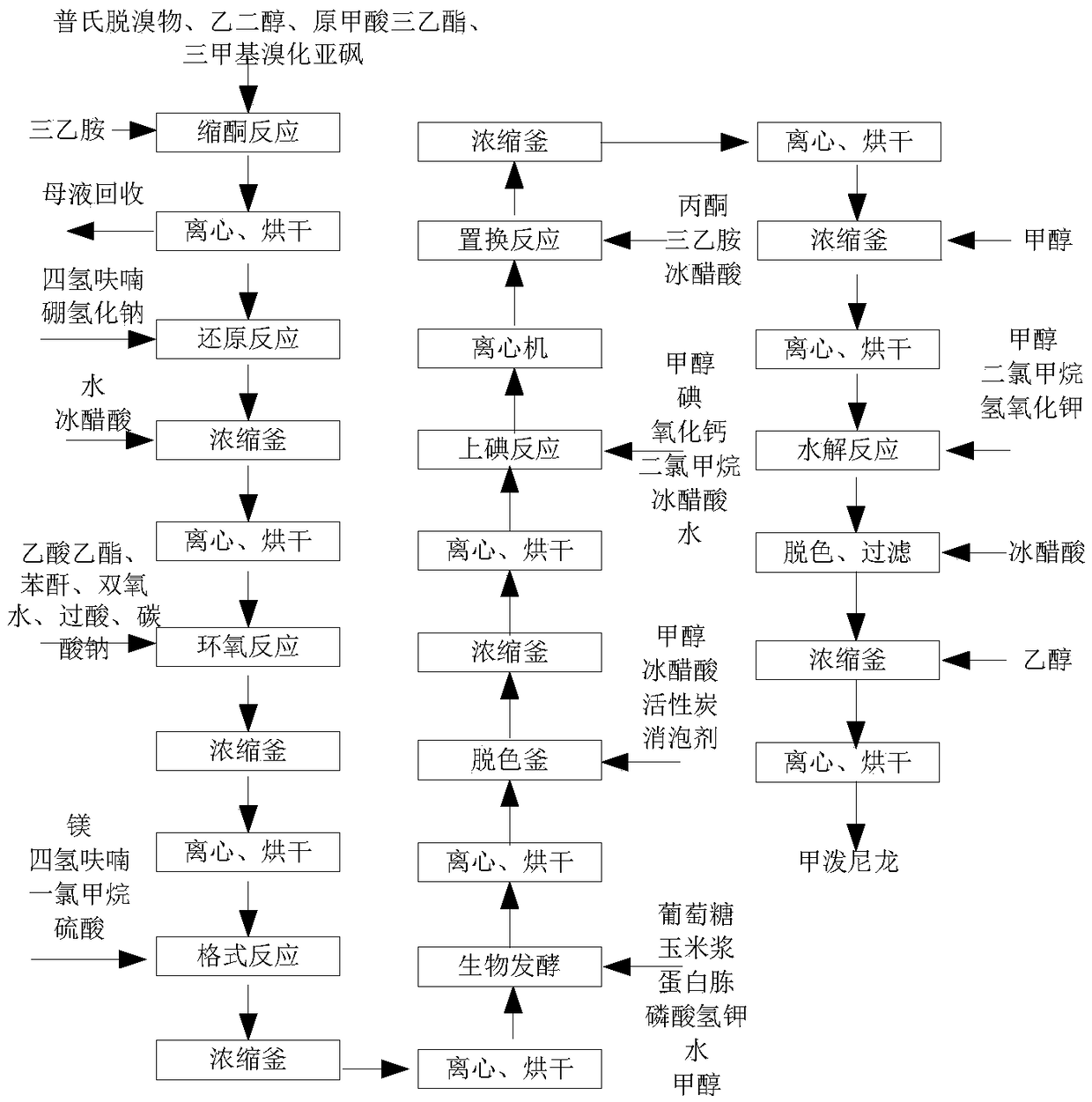

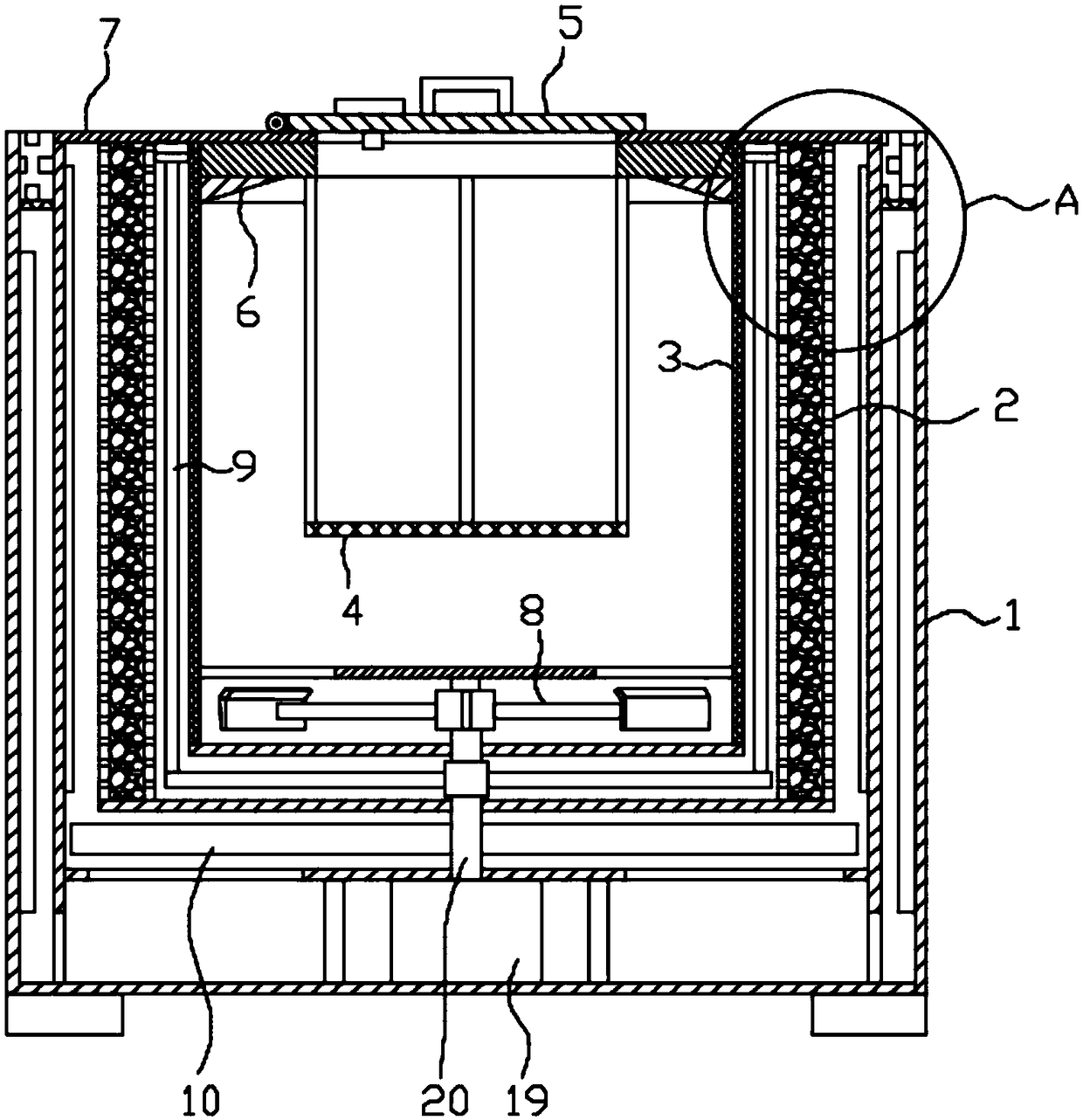

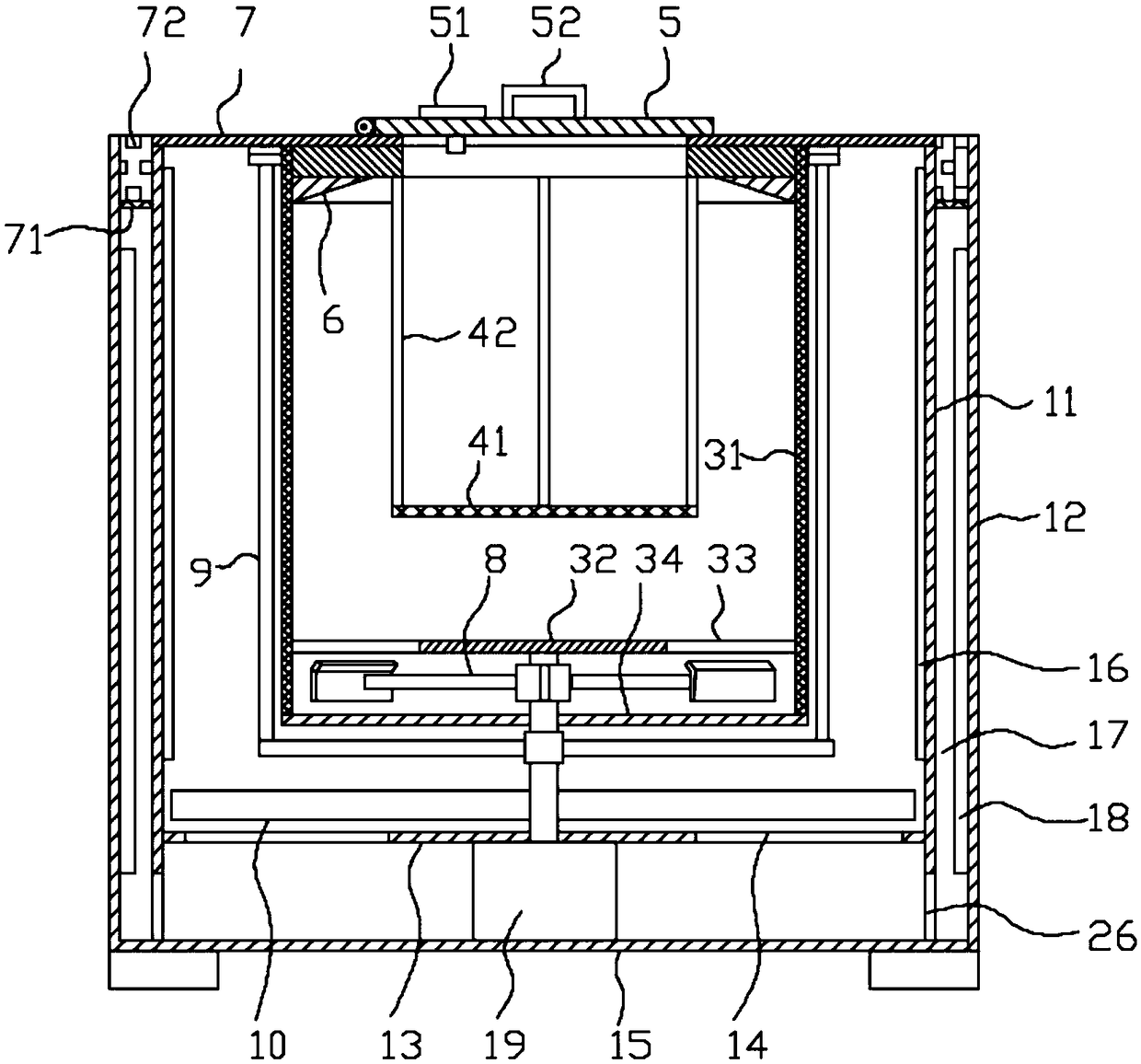

Methylprednisolone production method and production device

ActiveCN108912192AGuaranteed purityQuality assuranceDrying gas arrangementsSteroidsMethylprednisoloneElectric machinery

The invention discloses a methylprednisolone production device, which comprises a reaction kettle, an elutriation kettle, a centrifugal filtration device, a concentration kettle, a decoloration kettle, a biological fermentation tank and a drying device which are connected in sequence, wherein the drying device comprises an outer cylinder, a drying cylinder and an inner cylinder; a motor is arranged on the bottom surface of the outer cylinder; an exhaust fan blade, a cylinder type impeller and a vortex impeller are arranged on a motor rotating shaft; the exhaust fan blade is arranged between the drying cylinder and the bottom surface of the outer cylinder; the cylinder type impeller is arranged between the drying cylinder and the inner cylinder; the vortex impeller is arranged at the bottomof the inner cylinder; an infrared heating pipe is arranged on the top surface of the inner cylinder; a feeding port is formed in the center of the upper end of the inner cylinder; the side wall of the outer cylinder comprises an inner layer wall and an outer layer wall; an annular interlayer cavity is formed between the inner layer wall and the outer layer wall; an annular baffle is arranged atthe outlet of the upper end of the interlayer cavity, a vent is formed in the baffle, and a rotatable air purification ring is arranged at the upper end of the baffle. According to the method, the preparation time of intermediate products in the production process of the methylprednisolone can be reduced, and rapid and high-quality production of the methylprednisolone can be realized.

Owner:YUEYANG HUANYU PHARMA +6

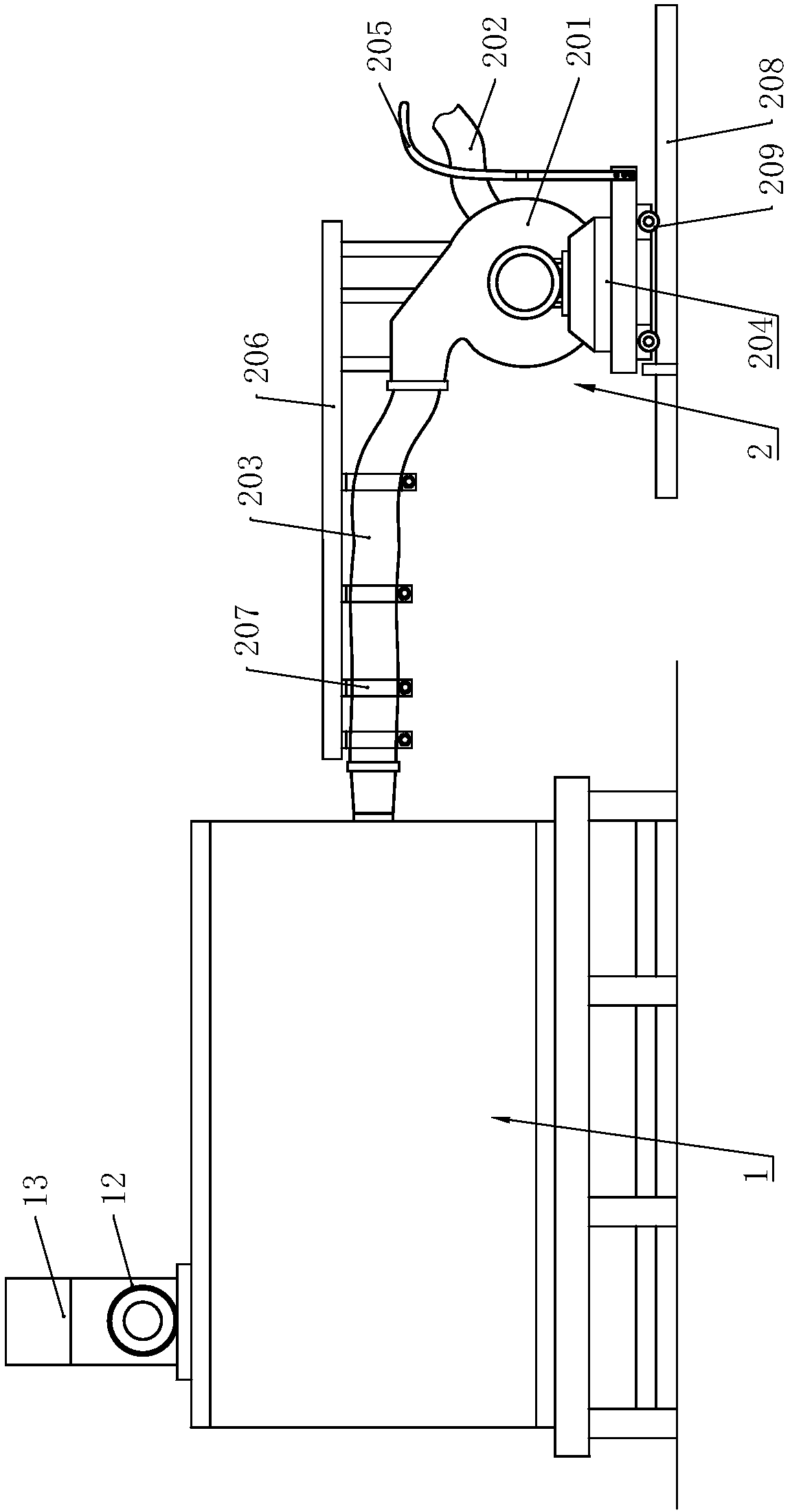

Full-automatic tea leaf drying device

ActiveCN106288727ASolve pollutionAvoid moisture returnTea dryingDrying gas arrangementsMechanical equipmentEngineering

The invention provides a full-automatic tea leaf drying device, and belongs to the field of tea leaf processing mechanical equipment. The full-automatic tea leaf drying device comprises a fuel storage bin, a first draught fan, a boiler, a drying box, a feeding device and a leaf storage bin. The fuel storage bin and the first draught fan are connected with the boiler, and the boiler is then connected with the drying box. The leaf storage bin is sequentially connected with the feeding device and the drying box. A heat exchange pipe is arranged on the inner wall of the boiler and provided with a heat exchange pipe opening end and a heat exchange pipe outlet end which are connected with the first draught fan and the drying box correspondingly. The drying box is provided with a hot air inlet end and a hot air outlet end which are connected with each other through a hot air circulation pipe. The hot air circulation pipe is provided with a second draught fan and a hot air extension pipe which is provided with a first electromagnetic valve in a penetrating manner. The full-automatic tea leaf drying device can achieve automatic feeding, drying, discharging and cooling of the tea leaf drying process and can accurately control the drying degree of tea leaves and improve the tea leaf drying quality and drying efficiency, and the device is easy and convenient to operate.

Owner:江西浮梁贡茶叶有限公司

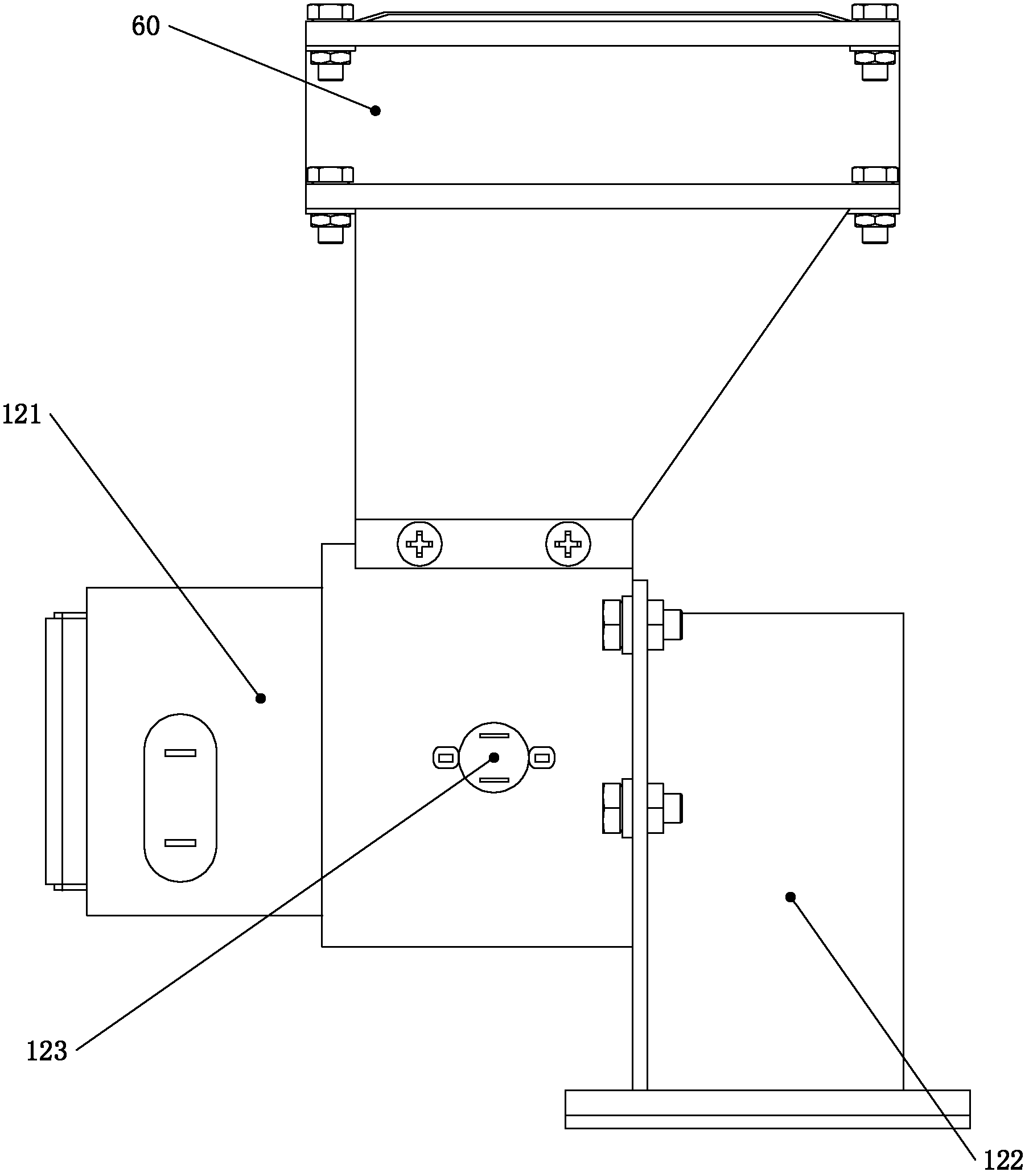

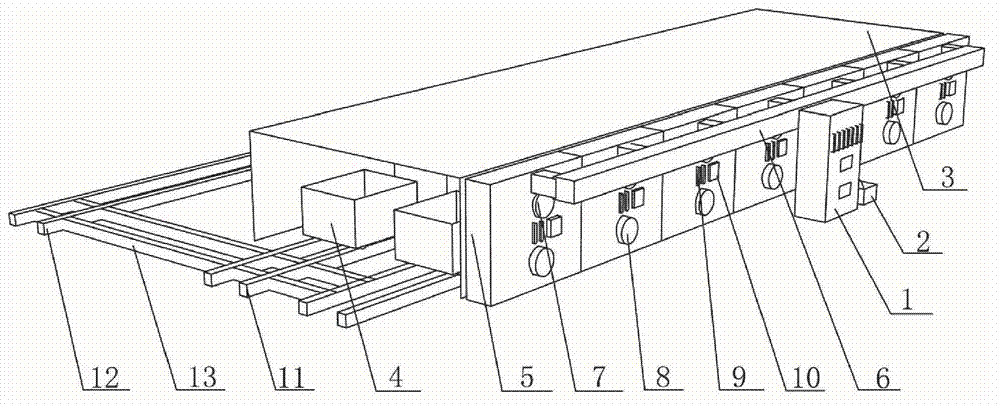

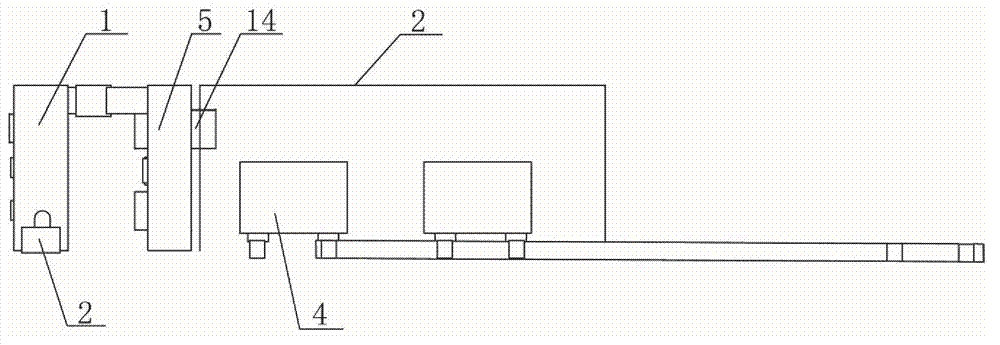

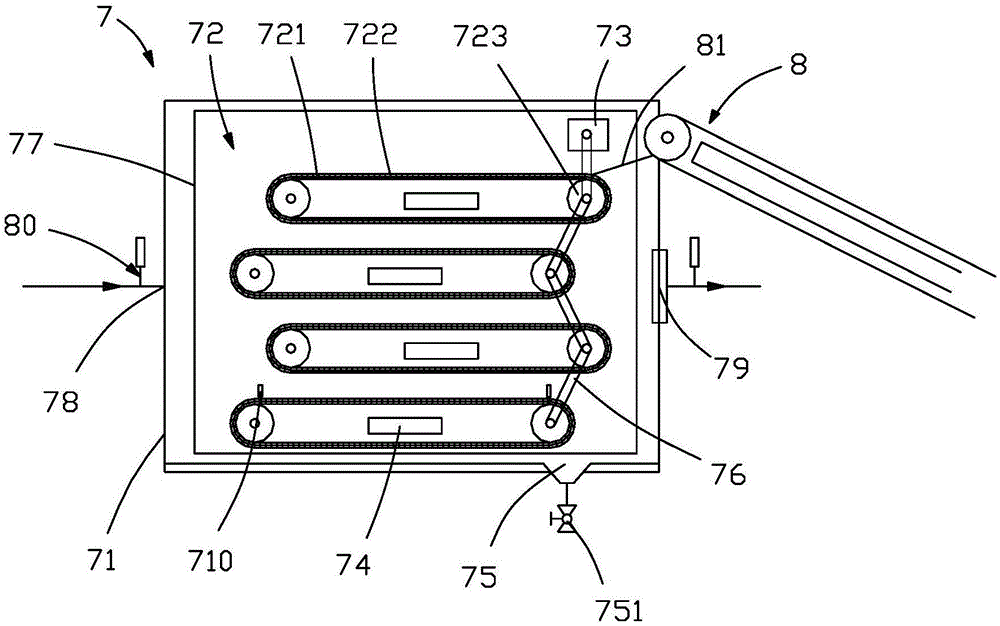

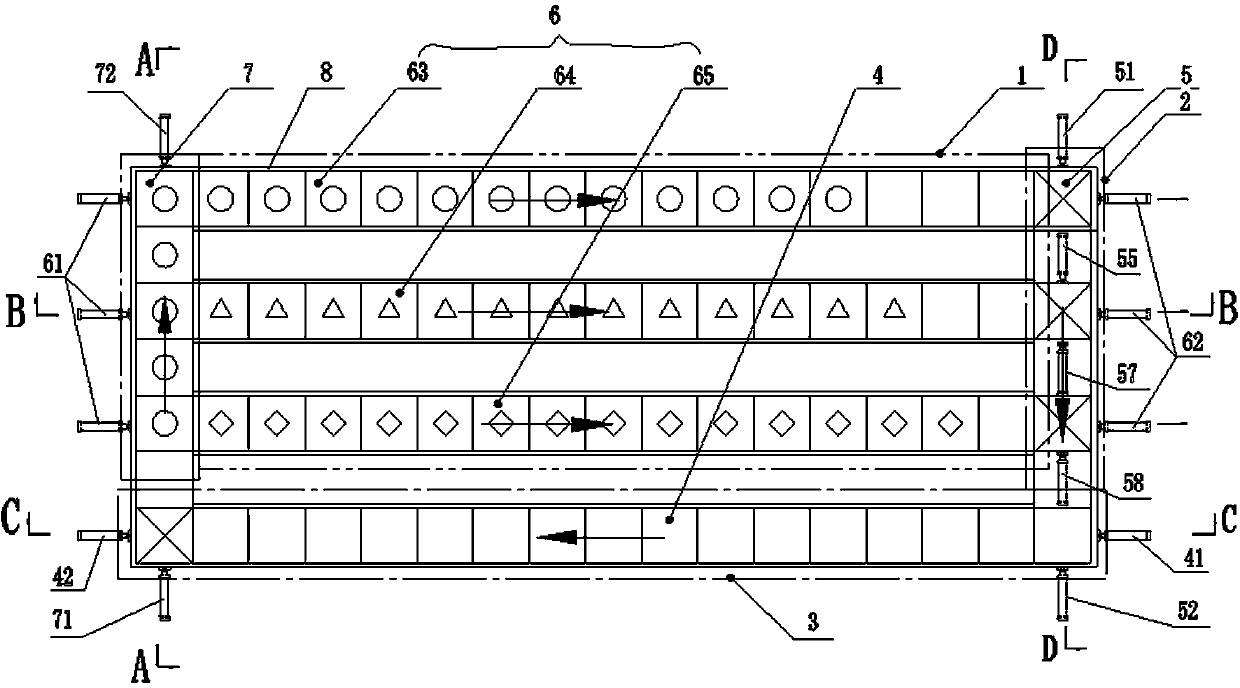

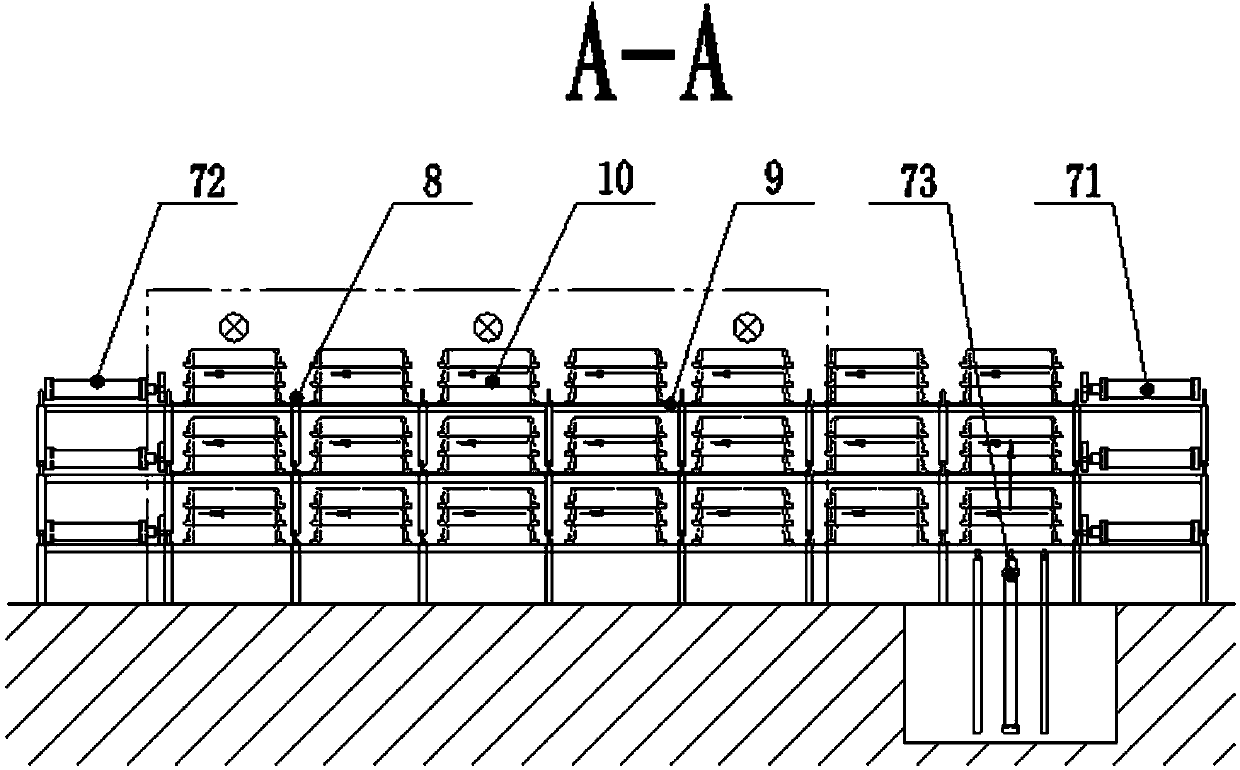

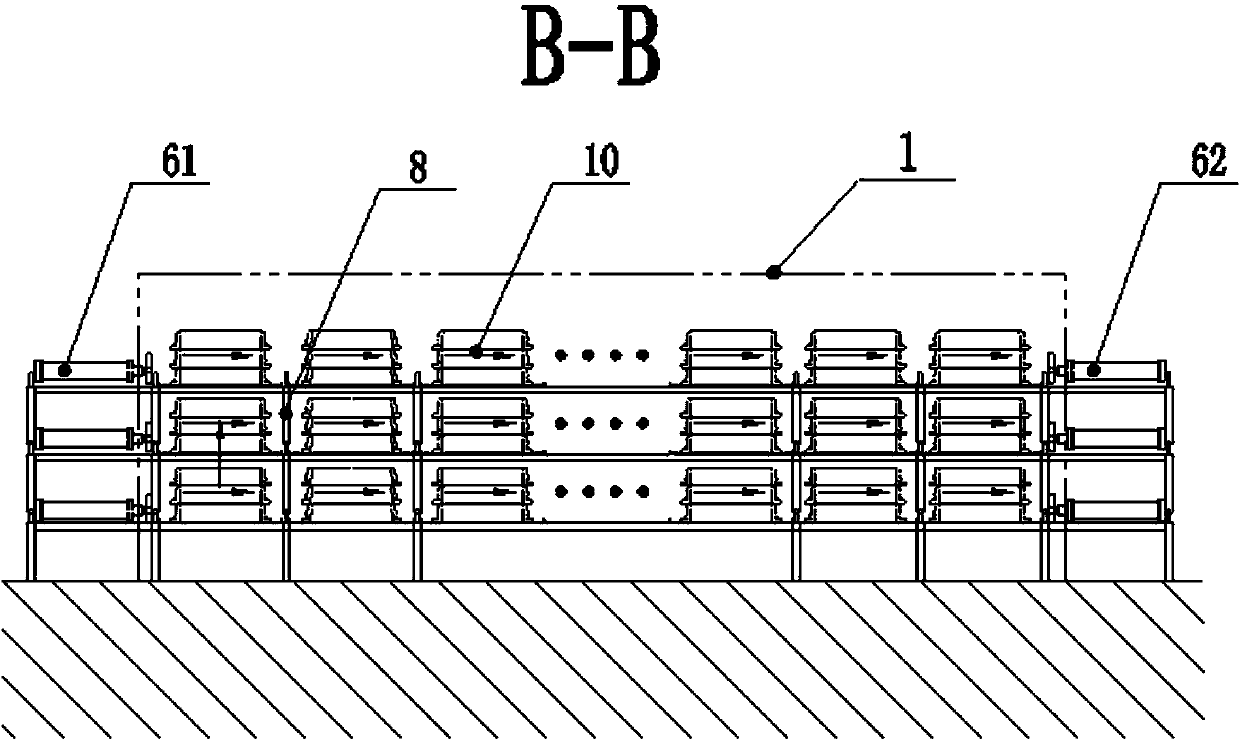

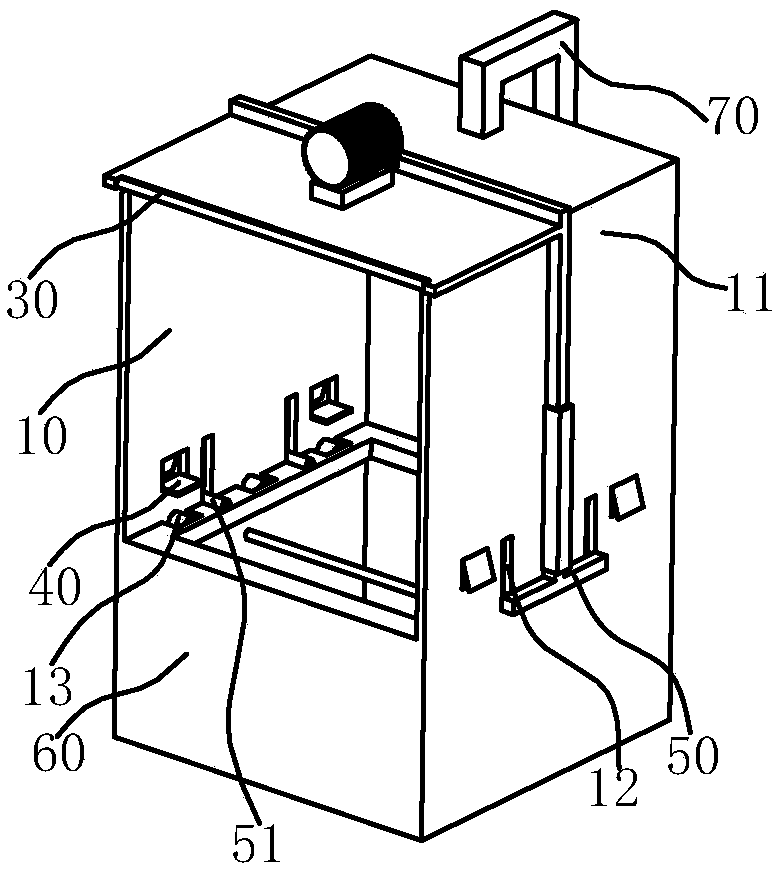

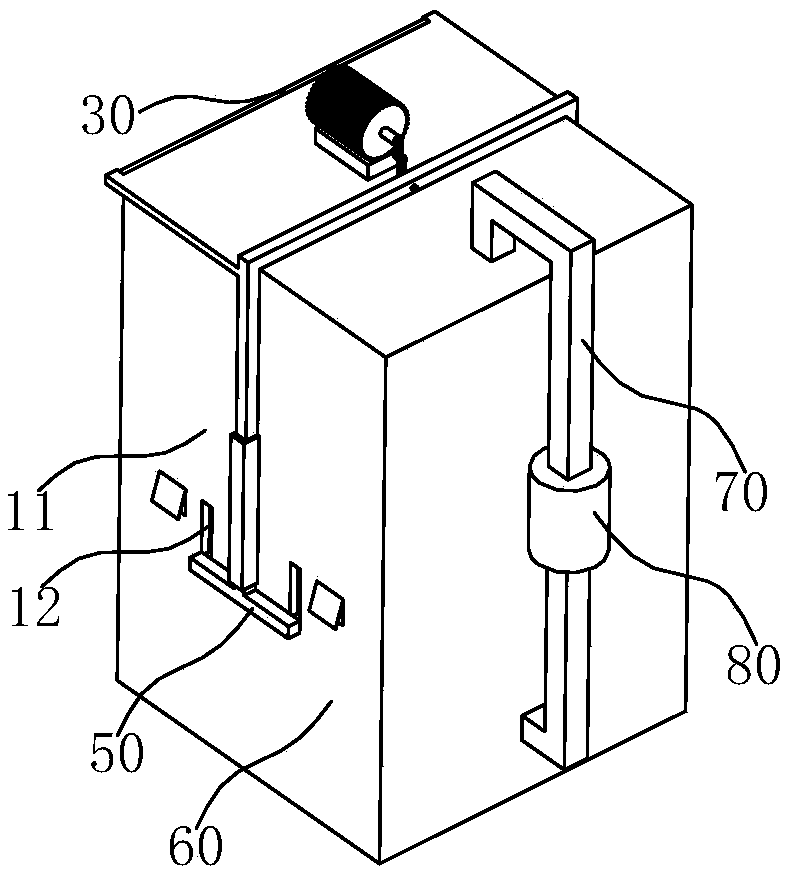

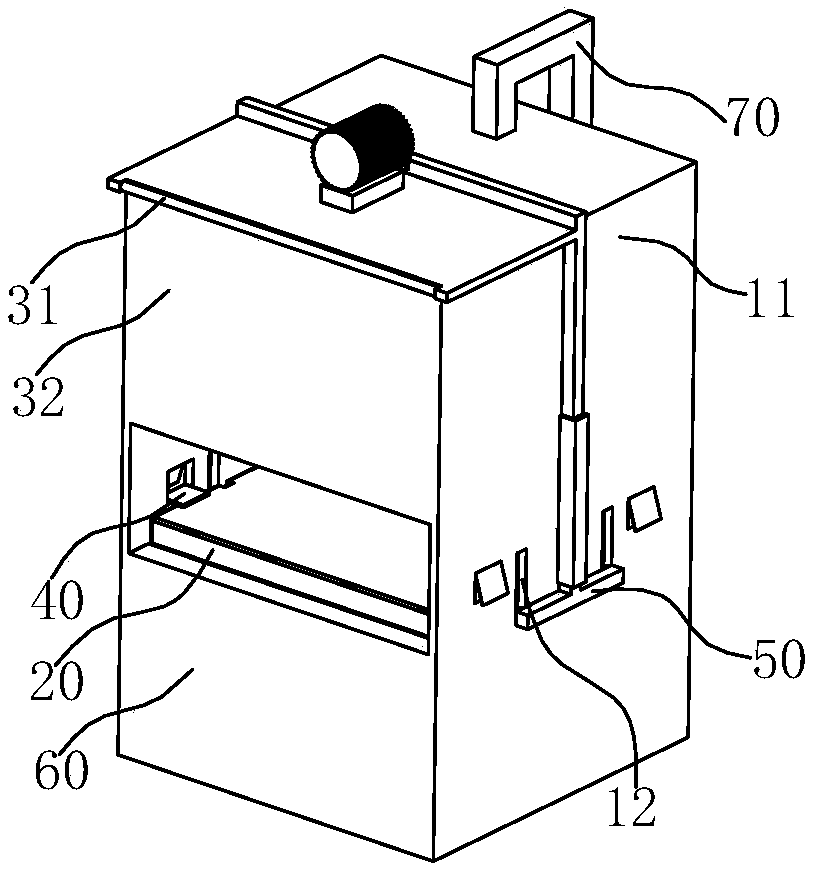

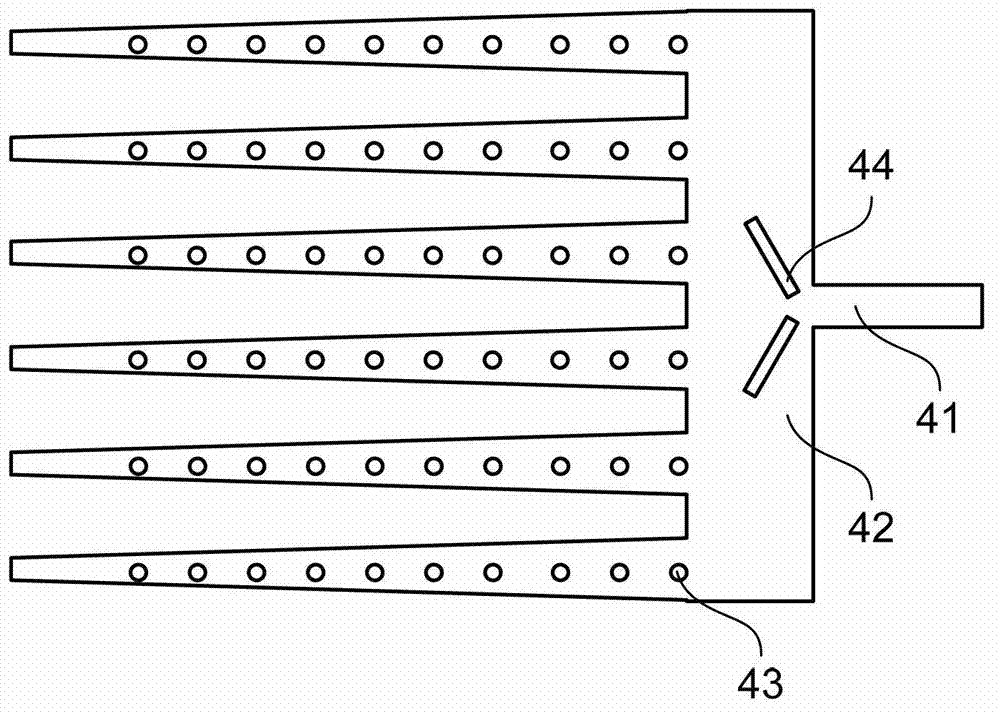

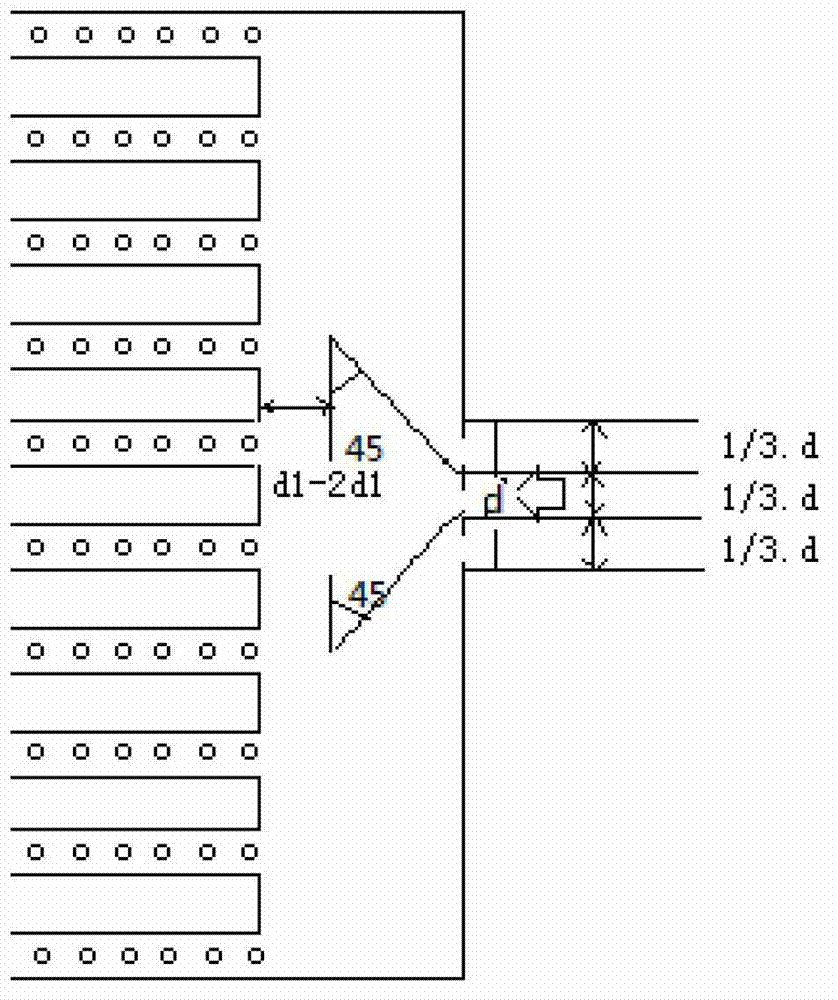

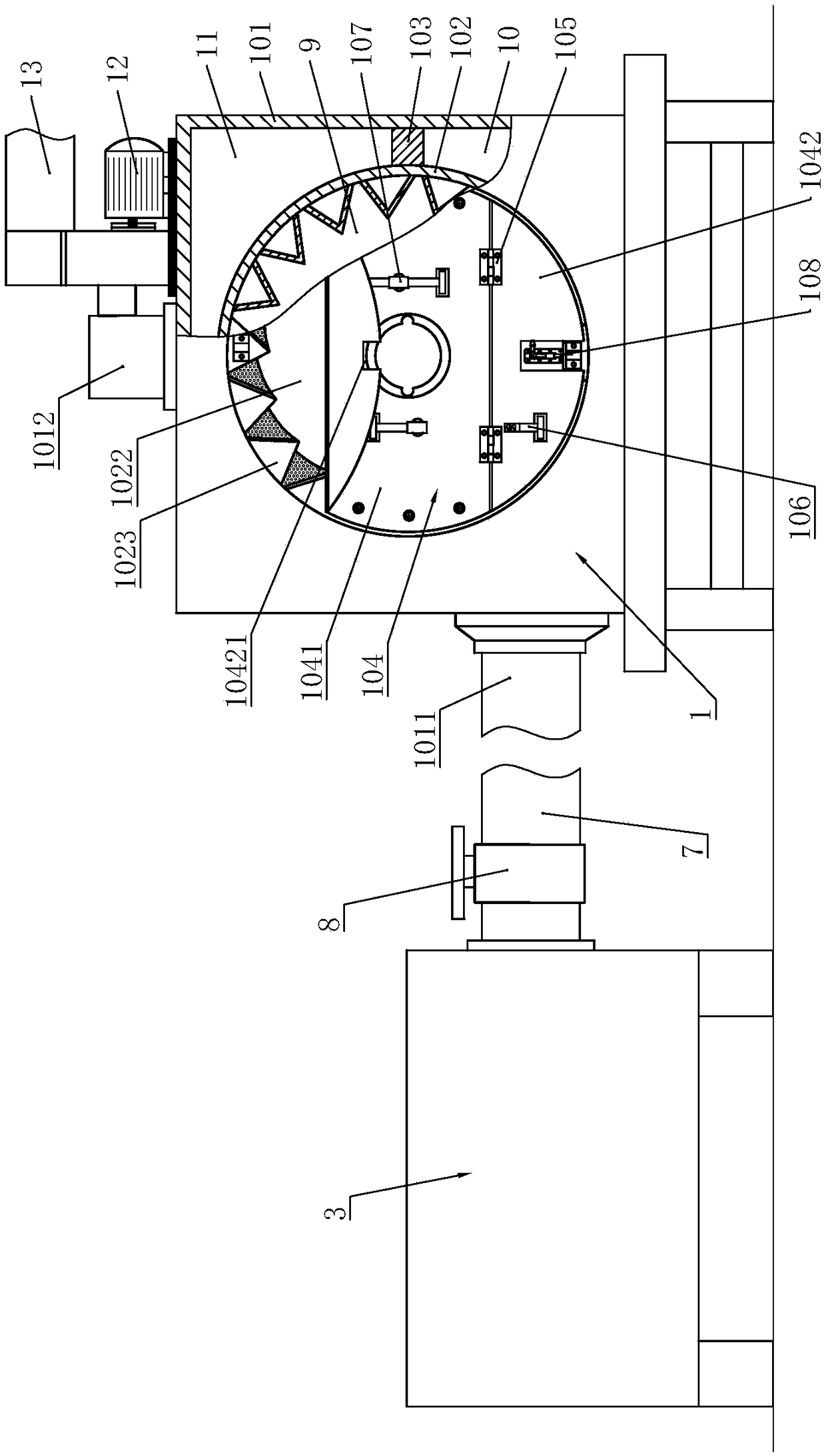

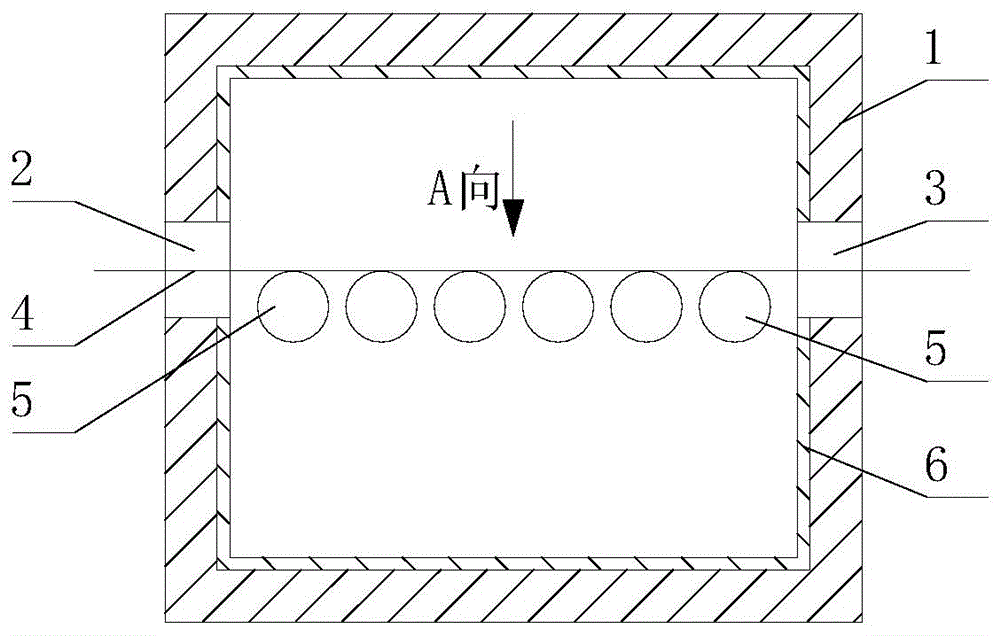

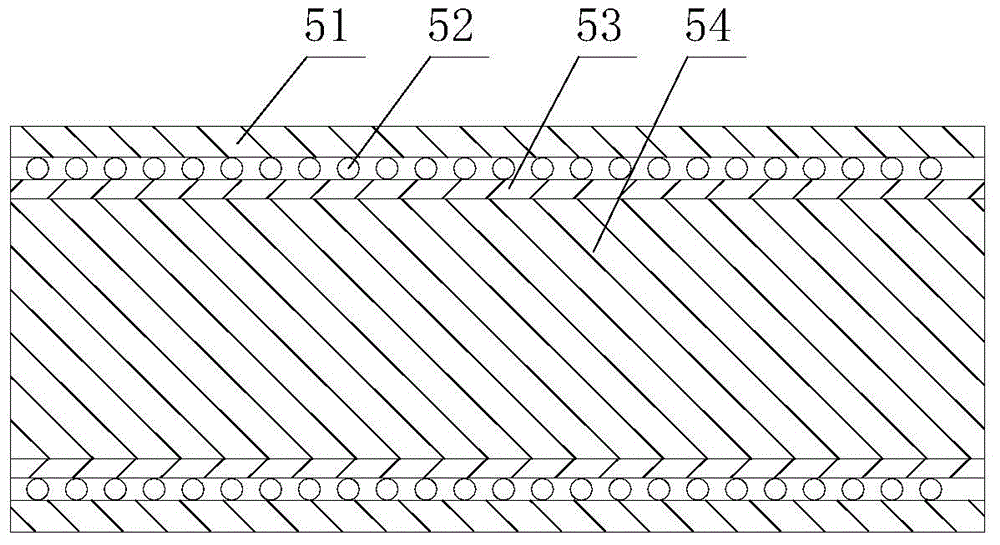

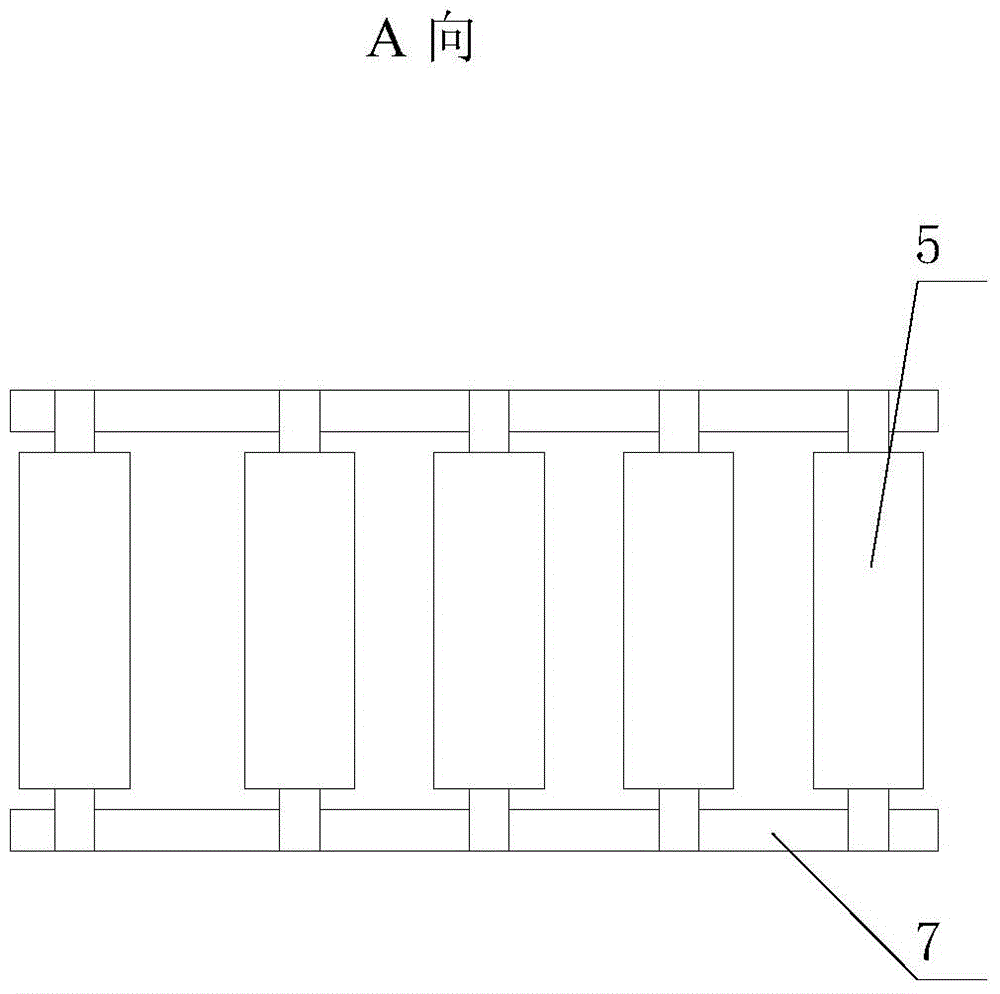

Integrated sand core feeding and discharging device for drying room

ActiveCN103736934ARealize in and outRealize automatic circulationFoundry mouldsFoundry coresNuclear engineering

The invention discloses an integrated sand core feeding and discharging device for a drying room, and relates to the technical field of cast molding core treatment. The device comprises more than two core storing channels which are formed in parallel, and flowing and rotating channels which are connected with core feeding channels, wherein two ends of each core storing channel are respectively connected with the core feeding channels and core discharging channels; the flowing and rotating channels are parallel to the core storing channels; the flowing and rotating channels, the core feeding channels, the core storing channels and the core discharging channels are the same in the structure and respectively comprise brackets; tracks are arranged on the brackets; sand core trays are arranged on the tracks; sand core tray jacking mechanisms are respectively arranged at the inlet ends of the flowing and rotating channels, the core feeding channels, the core storing channels and the core discharging channels; the sand core trays in which sand cores are placed are promoted by the sand core tray jacking mechanisms to sequentially enter the flowing and rotating channels, the core feeding channels and the core storing channels, then the sand cores are taken out from the core discharging channels, and the empty trays are pushed to the flowing and rotating channels. The device is simple in structure, convenient to operate and high in working efficiency, and can be used for guaranteeing the drying quality and lightening the working intensity of a worker.

Owner:XINXING HEBEI ENG & RES INC

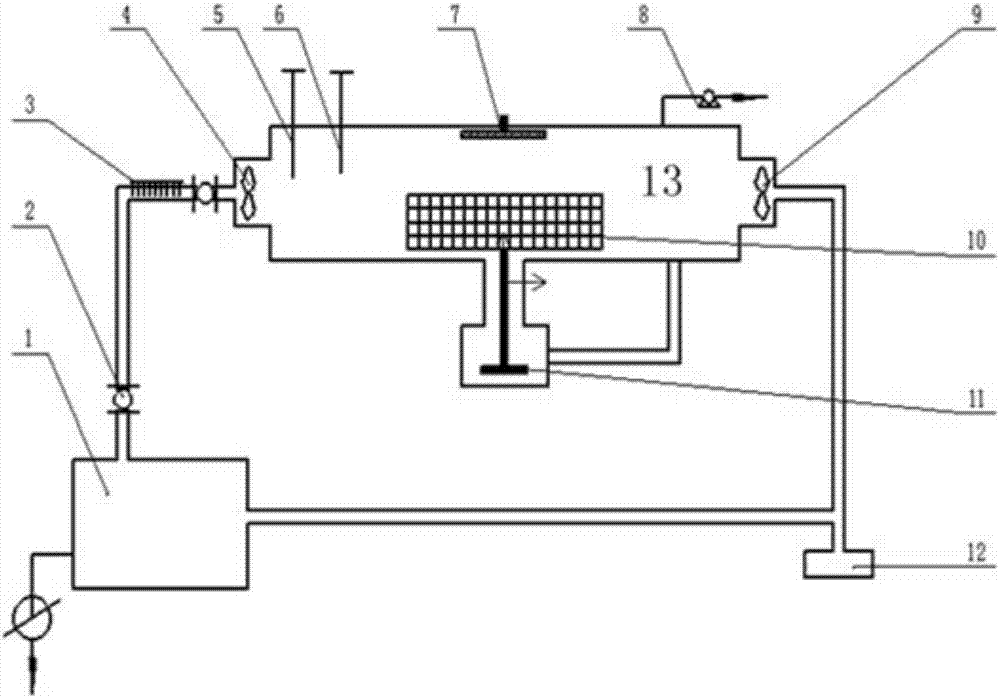

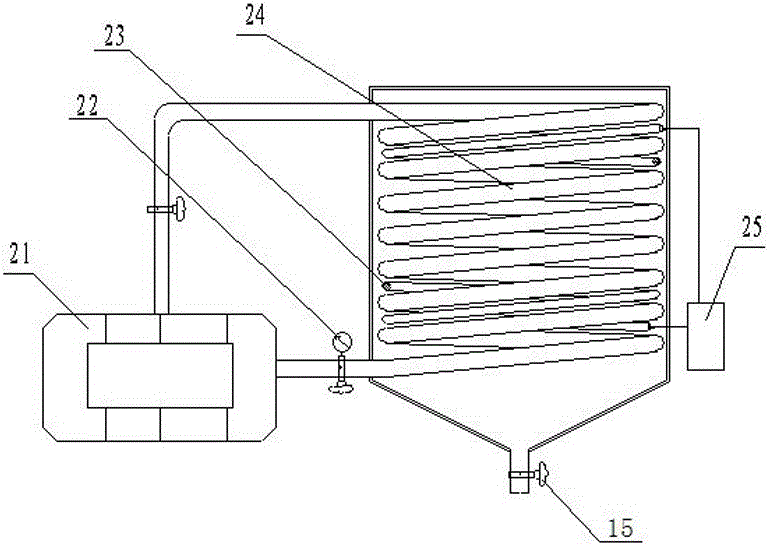

Microwave and low-pressure superheated steam combined drying test apparatus and drying method

InactiveCN106979669ADry fastReduce thermal stress cracksDrying using combination processesDrying solid materials with heatThermal energyAtmospheric air

The present invention belongs to the technical field of material drying, and discloses a microwave and low-pressure superheated steam combined drying test apparatus and a drying method. The combined drying test apparatus is composed of a steam generator, steam opening valves, a heater, an inlet fan, an air velocity transducer, a temperature sensor, a microwave generator, a vacuum pump, an outlet fan, a net-shaped material tray, a weighing sensor, a running water valve and a drying box. The drying method comprises that low-pressure superheated steam is used as a drying medium of a closed drying system, and materials are dried by the superheated steam and microwave together. The interiors of agricultural products are heated, inside moisture transfer speed of the agricultural products is raised, drying of the agricultural products is accelerated, temperature difference between the inside and the surface is reduced, generation of thermal stress cracks is reduced, and the drying quality and the drying uniformity of the agricultural products are ensured. No dust or volatile substances are discharged into the air in the drying process, the exhaust gas is saturated steam and can be recycled, the heat utilization rate is raised and total energy consumption of drying is lowered.

Owner:CHINA AGRI UNIV

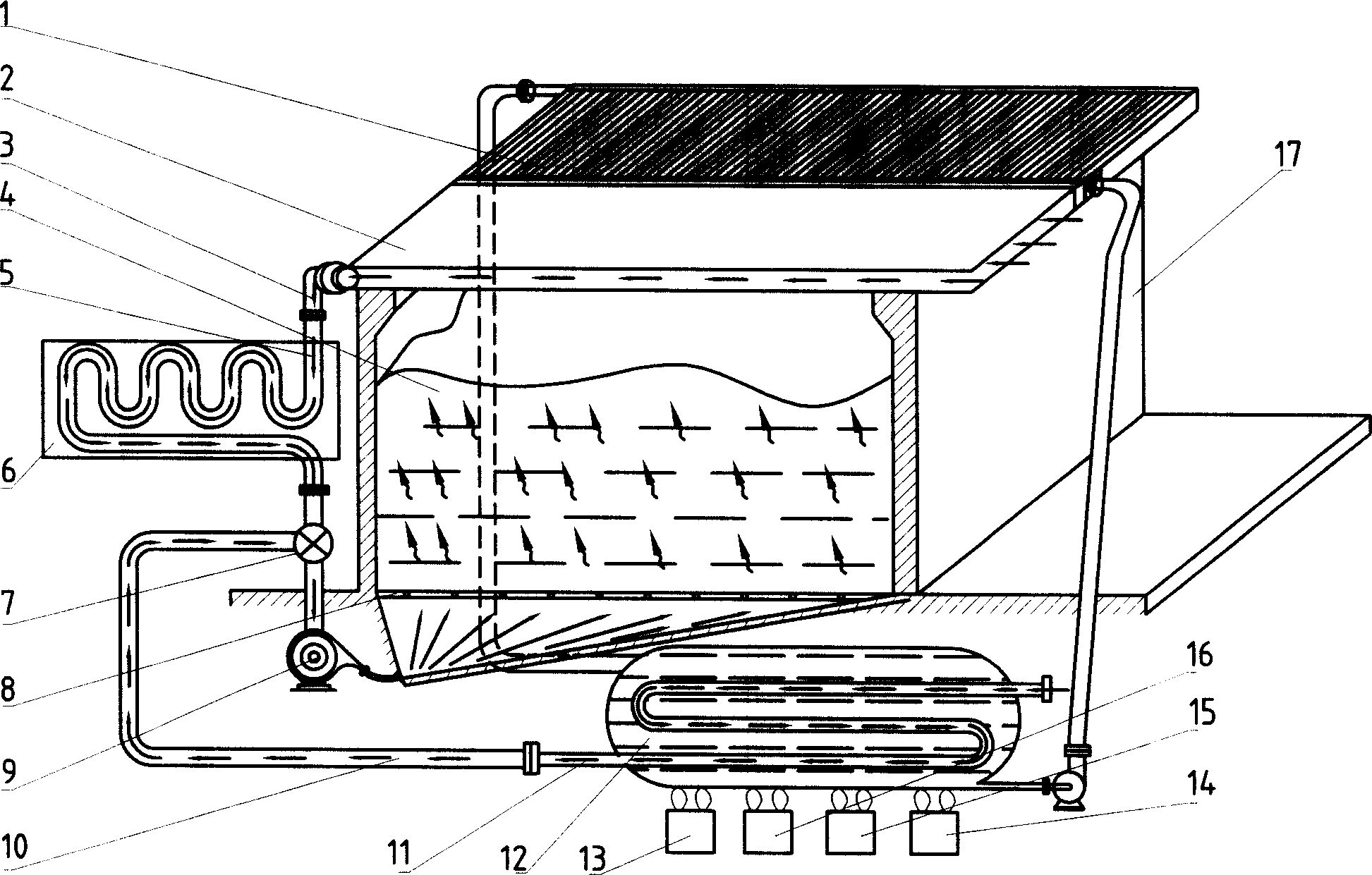

Additional energy drying device of solar energy drying apparatus

InactiveCN101086423AOvercome the problem that the drying operation cannot be carried outGuaranteed drying qualityHeating arrangementCold airSolar drying

The invention discloses a solar energy drying equipment and an energy drying device for drying the herbage, the herbage seed or the like in the agricultural product and the Chinese herbal medicine in the rain, which is characterized by the following: installing the electric heat section which comprises a curved blast pipe and an electric heater at the blast pipe lower of the plate collector; increasing a plurality of heaters which burn with the coal or the fuel oil or the fuel gas or the agronomic crop stem separately at the storage calorifier lower of the vacuum tube collector hot air drying system. When it rains, the electric heater is stared and the cold air from the blast pipe of the plate collector which is heated by the electric heater through the bend blast pipe blows in the drying storage for drying the material, or the heater which burn with the coal or the fuel oil or the fuel gas or the agronomic crop stem is started, the water in the storage calorifier is heated and the snakelike blast pipe is heated, the internal hot air is used for drying the material in the storage. The invention achieves the drying operation in the rain, which achieves all-weather continuous drying operation, and keeps the drying quality of the drying material.

Owner:HUHHOT BRANCH OF CHINESE ACAD OF AGRI MECHANIZATION SCI

Method and device for producing nano calcium carbonate by microwave drying

ActiveCN104229850AFast heatingAchieve heating effectCalcium/strontium/barium carbonatesMaterial nanotechnologyHeating timeMicrowave

The invention discloses a method for producing nano calcium carbonate by microwave drying. The method is carried out according to the following steps: (1) preparing Ca(OH)2 raw refined slurry; (2) preparing boiled calcium carbonate slurry; (3) preparing an activated calcium carbonate filter cake; (4) pelletizing; (5) carrying out microwave drying; and (6) crushing and sieving to prepare a nano calcium carbonate product. A device for producing nano calcium carbonate by microwave drying comprises a pelletizer, a feeding hopper, a conveyor belt, a transmission mechanism, a tunnel type microwave drying box, a microwave generator, a discharge hopper and a moisture removal mechanism. The method and the device are adopted to produce nano calcium carbonate, so that time of drying operation in a production process of the nano calcium carbonate can be greatly shortened, the energy consumption is lowered, the agglomeration of the nano calcium carbonate is weakened and the dispersion is improved, and thus, the quality of the nano calcium carbonate is improved; the prepared nano calcium carbonate has the advantages of small grain size, low agglomeration strength, a great specific surface area, small hardness and good dispersion; and moreover, the heating time is short, so that the whiteness of the nano calcium carbonate can be improved.

Owner:FUJIAN HONGFENG NANO TECH

Production method for spun-silk wool blended worsted fabrics

ActiveCN103774319AGood extensibilityGuaranteed smooth productionWoven fabricsYarnFiberAfter treatment

The invention relates to a production method for spun-silk wool blended worsted fabrics and relates to the technical field of textile manufacture. The method comprises top dyeing and recombing, spinning, weaving and after treatment to manufacture the fabrics successively. The mass percentage of wool in spinning raw materials accounts for 50% to 60%, the mass percent of spun silks ranges from 40% to 50%, the spun silk raw materials are machined and are broken through a breaking machine to be manufactured into spun silk velvet strips with the average length between 40mm and 50mm, the length discretion smaller than 50%, and the gram weight ranging from 5g / m to 8g / m. The spun silk velvet strips with the fiber length smaller than 30mm account for less than 30% of the total spun silk velvet number. According to the production method, the spun silk content is high, the spinnability is good, the yarn levelness quality is guaranteed effectively, and yarn faults are few.

Owner:江苏丹毛时装有限公司

Tea leaf drying oven

PendingCN107865129AAvoid churnChurn will notPre-extraction tea treatmentStructural engineeringLaboratory oven

The invention discloses a tea leaf drying oven. The tea leaf drying oven comprises an oven allowing tea leaf drying nets to be placed, wherein a chamber of the oven is connected with a heat source; one side surface of the oven is opened, and a curtain baffle is arranged at the opening; supporting brackets for supporting the tea leaf drying nets are arranged in the oven; space allowing the tea leafdrying nets to be inserted is formed between the supporting brackets and the bottom of the oven; and a lifting mechanism is driven by a driving unit to drive the tea leaf drying net arranged at the bottom of the oven to move upwards. According to the tea leaf drying oven disclosed by the invention, the curtain baffle is arranged, so that the opening of the oven is covered, and the situation thatheat quantity runs off is avoided; the tea leaf drying nets are inserted between the supporting brackets and the bottom of the oven, and are continuously overlapped and lifted to a top layer of the oven in a progression manner; in the overlapping process, the pulling-down length of the curtain baffle is adjusted, so that the lower edge of the curtain baffle is always level with the upper edge of the tea leaf drying net on the upmost layer, and the heat quantity is guaranteed not to run off always; and after the tea leaves are dried, the tea leaf drying nets are drawn from the top to the bottomof the oven layer by layer, so that the tea leaf drying oven is convenient and swift, and the drying quality of the tea leaves is guaranteed.

Owner:安徽宣城华阳茶叶机械股份有限公司

Intelligent normal-pressure far infrared drying method for frozen grains

ActiveCN105660847AReal-time control of radiation powerReal-time control of belt speedSeed preservation by dryingGrain storageProcess engineering

The invention relates to an intelligent normal-pressure far infrared drying method for frozen grains. The intelligent normal-pressure far infrared drying method for the frozen grains comprises steps as follows: real-time monitoring is performed by means of temperature sensors, humidity sensors and weight sensors in a drying machine in a multi-stage far infrared irradiation heating manner, and the radiation power of far infrared heating plates and the speed of material conveying belts are regulated in real time; the dried grains heated through multi-stage far infrared irradiation are cooled and stored in a grain storage chamber; a large amount of vapor generated in the grain drying process forms air flows downwards flowing smoothly under the joint action of an upper hot environment in a drying chamber, a lower precooling environment at condensation air pipes and a cold environment provided by vapor catchers; the drying machine comprises the drying chamber, the humidity sensors, the temperature sensors ad the far infrared irradiation heating plates are arranged in the drying chamber, the condensation air pipes are mounted at the material conveying belt on the fifth layer, and the lower side of the drying chamber is connected with the vapor catchers. With the adoption of the method, grain drying is intelligently and automatically controlled in the whole process, and cold sources are effectively utilized.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

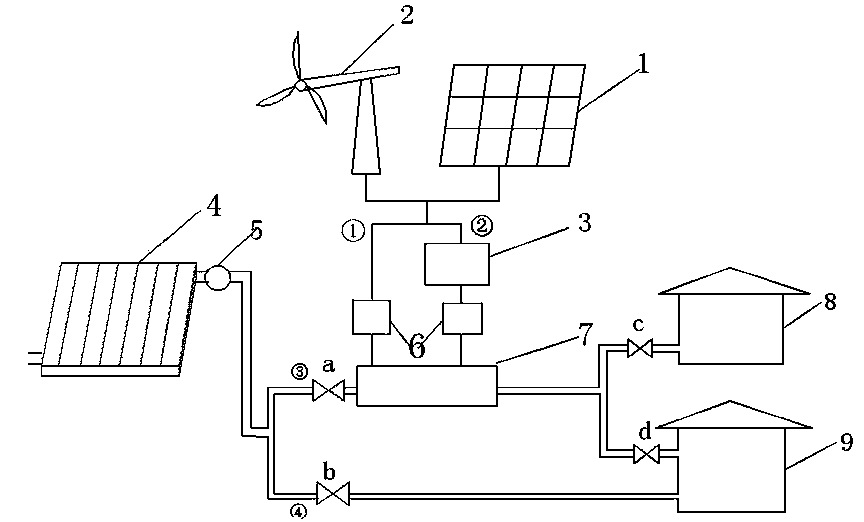

Heat pump drying and heating system powered by solar energy and wind energy in complementary mode

InactiveCN103727772AIncrease profitMeet electricity demandBatteries circuit arrangementsPV power plantsElectricityEngineering

A heat pump drying and heating system powered by solar energy and wind energy in a complementary mode comprises a solar photovoltaic module, a wind power generation system, a storage battery, an air heating collector, a draught fan, a heat pump, a controller, a drying chamber and a house, wherein the output end of the solar photovoltaic module and the wind power generation system is divided into two branches (I and II), the branch II is connected to the storage battery, the storage battery is connected with the heat pump through the controller, two branches of the heat pump are connected with the house and the drying chamber respectively, the branch I is directly connected with the heat pump through the controller, the air heating collector is divided into two branches (III and IV), the branch III is connected with the heat pump, and the branch IV is directly connected with the drying chamber. The heat pump drying and heating system powered by the solar energy and the wind energy in the complementary mode can generate electricity by combining the solar energy and the wind energy, effectively improve the comprehensive utilization rate of the solar energy and the wind energy, lower environmental pollution, achieve the purpose of continuously drying agricultural products, avoid the problem that the quality of the agricultural products is lowered due to manual airing, and provide a heat source for heat supply of the house.

Owner:YUNNAN NORMAL UNIV

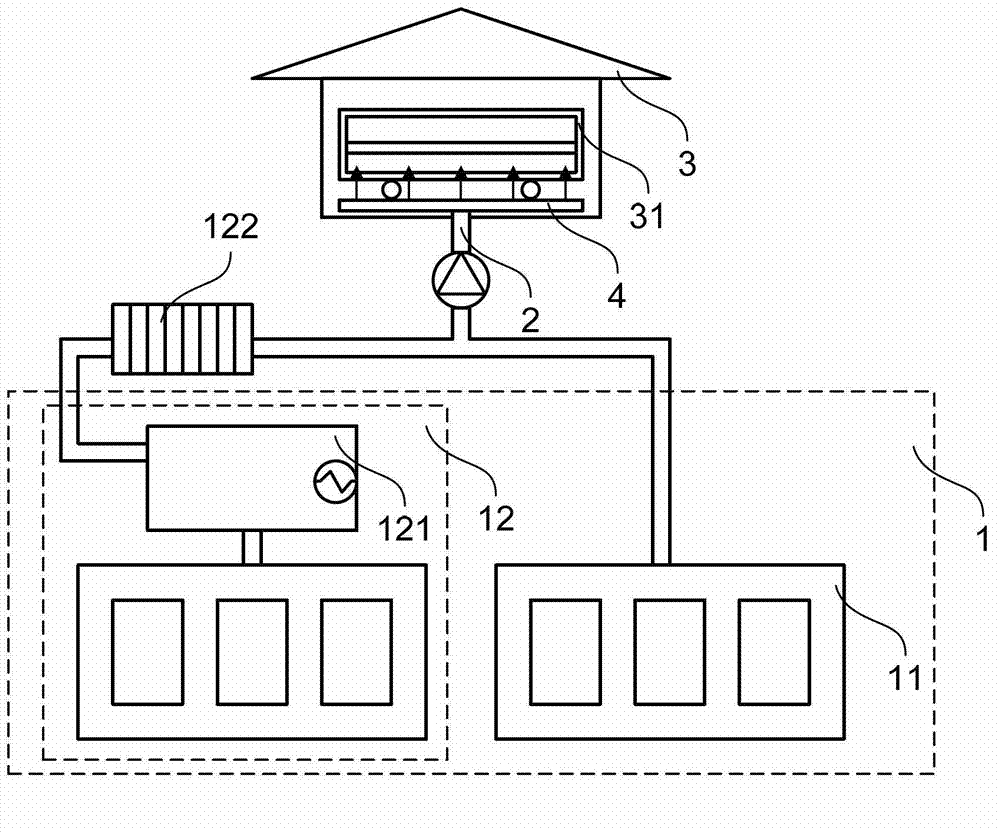

Solar continuous drying system and method

ActiveCN103033028ATake advantage ofGuaranteed drying effectSolar heating energyDrying solid materials with heatSolar dryingAutomatic control

The invention discloses a solar drying system and a solar drying method. Aiming at the defect that the solar drying system and the solar drying method in the prior art cannot perform continuous drying, the invention provides a solar continuous drying system and a solar continuous drying method. The drying system introduces hot air into a drying chamber through an air path pipeline; a heat supply system comprises a solar air heat collector and a solar water heat collector; air heated by the solar air heat collector is directly blown into the drying chamber; hot air is obtained through heat exchange of water heated by the solar water heat collector and then is blown into the drying chamber; and an automatic control system of the continuous drying system judges and selects the hot air source blown into the drying chamber and opens and closes the pipeline. Solar heat collectors with two heat exchange working mediums are adopted, so the time difference of utilizing the solar energy is generated, the technical problem that continuous drying operation cannot be realized caused by that the solar drying system or the solar drying method are limited by the sunshine duration condition is solved, electric energy can be saved greatly when large articles are subjected to solar drying operation, and an excellent drying effect is achieved.

Owner:拉萨市城关区地毯厂

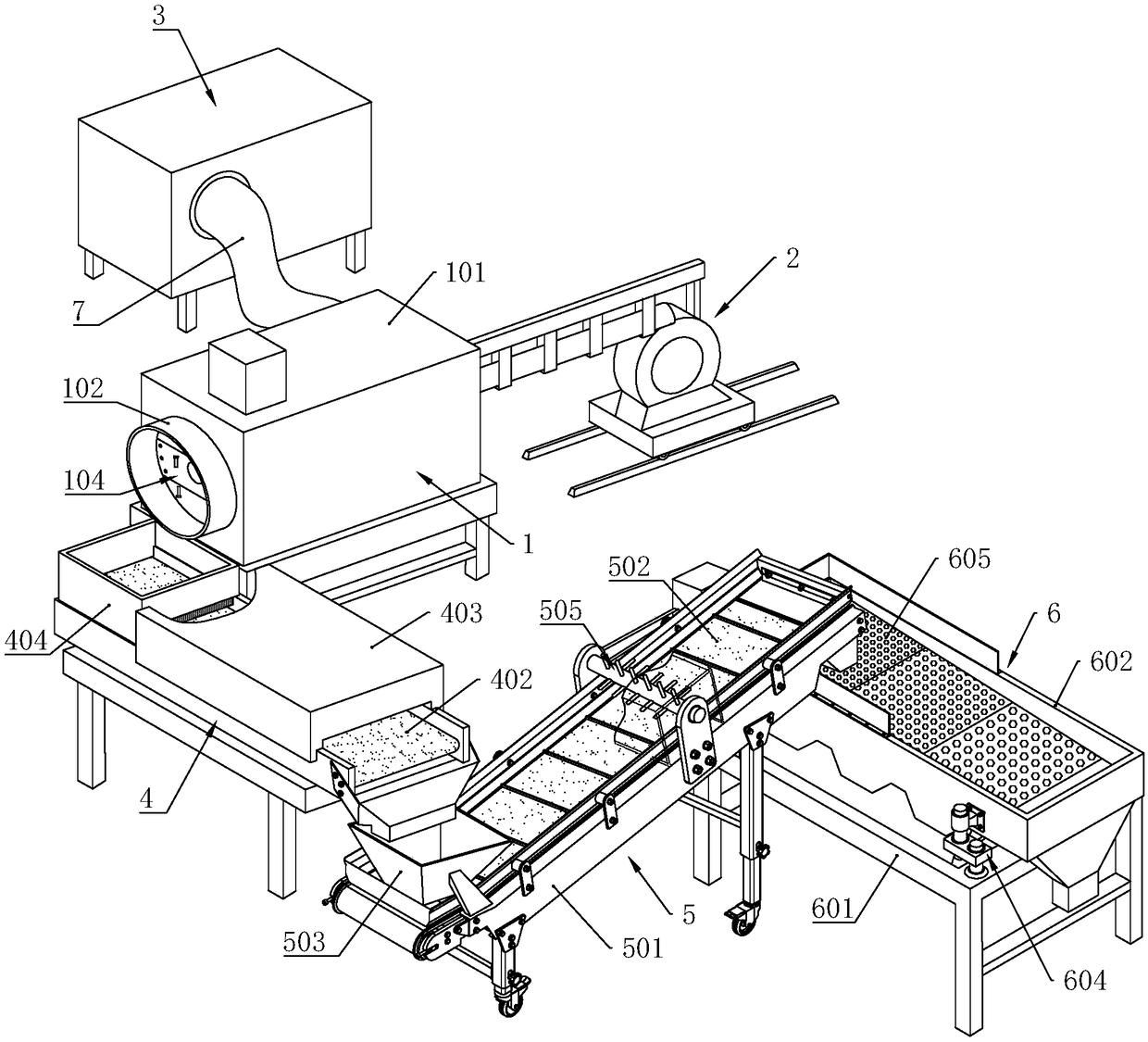

Drying and screening integrated production line

PendingCN108518967AImplement the sieving operationRealize automatic processingSievingScreeningProcess efficiencyEngineering

The invention belongs to the technical field of automated production and provides a drying and screening integrated production line. The drying and screening integrated production line comprises a feeding mechanism, a first dryer, a hot-blast stove, a second dryer, a material conveying machine and a material screening machine. The feeding mechanism and a feeding port of the first dryer are arranged in a corresponding manner. A temperature sensor is arranged in the first dryer. The hot-blast stove communicates with the first dryer through a hot air pipe. Additionally, the hot air pipe is equipped with an electromagnetic valve electrically connected with the temperature sensor. The downstream of the first dryer is provided with a second dryer. A feeding end of the second dryer and a discharge port of the first dryer are arranged in a corresponding manner. The downstream of the second dryer is provided with the material conveying machine. A feeding end of the material conveying machine and a discharge end of the material conveying machine are arranged in a corresponding manner. Integral automated processing such as material drying, conveying and screening is achieved. Therefore, processing efficiency and processing quality of material are increased.

Owner:青岛创高世纪信息科技有限公司

Intelligent cloth drying device

InactiveCN104422258AGuaranteed flatnessEfficient use ofDrying machines with progressive movementsHeating arrangementDisplay deviceEngineering

The invention discloses an intelligent cloth drying device. The intelligent cloth drying device comprises a shell with an inner cavity, wherein a cloth inlet is formed in one side of the shell and a cloth outlet is formed in the other side of the shell; the inner cavity of the shell is internally provided with a conveying device which is used for conveying cloth and drying the cloth; the conveying device comprises a plurality of heating rollers which rotate around self-axes; the plurality of heating rollers rotate in the same direction and are arrayed side by side at intervals; the plurality of heating rollers adapt to the cloth inlet and the cloth outlet; a temperature sensor is arranged on the heating rollers and a control panel is arranged at the outer part of the shell; the control panel is provided with a temperature display device, a temperature setting device and an alarm promoting lamp; the shell is internally provided with a controller for controlling the heating speeds and the rotary speeds of the heating rollers; the temperature display device, the temperature setting device, the alarm promoting lamp and the temperature sensor are connected with the controller. By virtue of the intelligent cloth drying device, the drying speed can be effectively controlled and the drying effect is guaranteed.

Owner:WUXI DANGKOU TONGHE TEXTILE MACHINERY PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com