Three stage type tobacco shred drying technique and tobacco dryer

A three-stage shred drying machine technology, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of loss of aromatizing substances, reduce processing precision of shredded tobacco, and reduce processing quality, so as to prevent the loss of aromatizing substances, reduce The effect of direct baking time and avoiding partial over-baking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

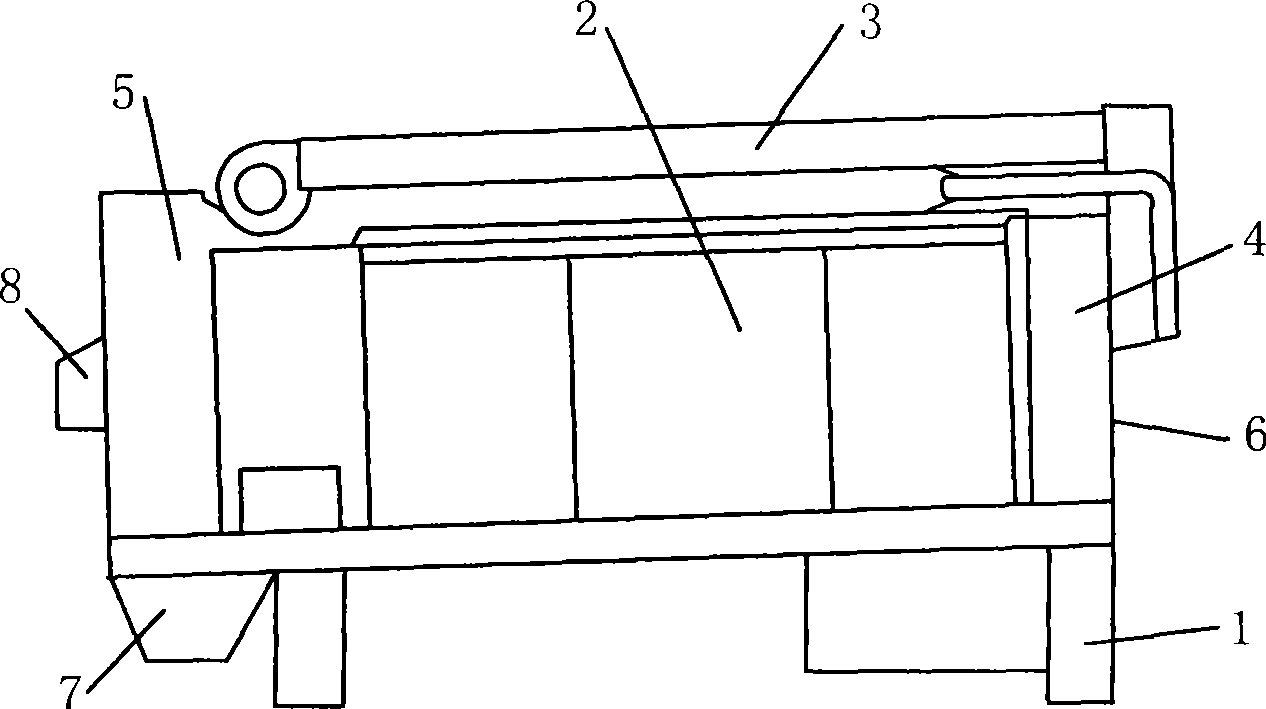

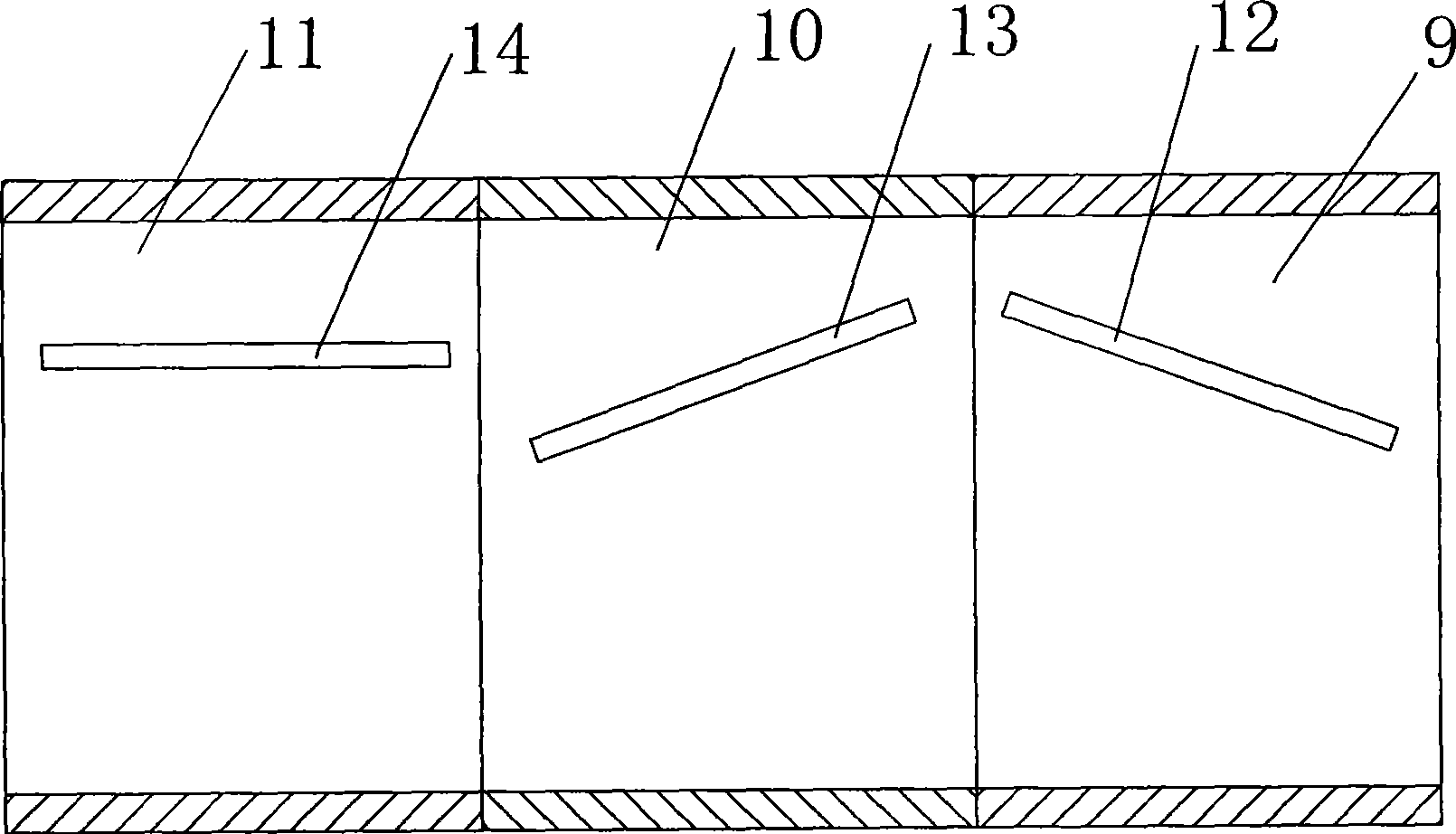

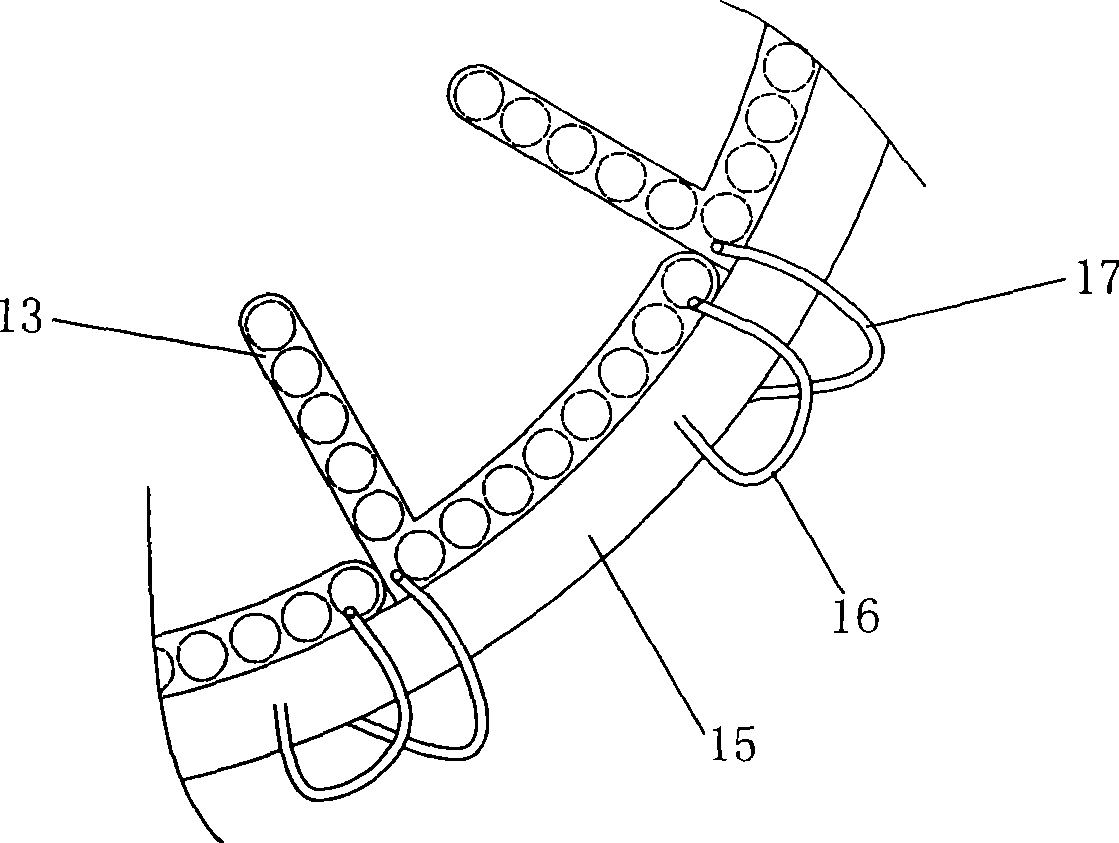

[0016] Such as figure 1 As shown, the three-stage silk drying machine of the present invention includes a frame 1 , a cylinder body 2 , a heating pipeline 15 , a hot air pipeline 3 , a front chamber 4 and a rear chamber 5 . The front chamber 4, cylinder body 2 and rear chamber 5 are installed on the frame 1 in sequence, the front chamber 4 is provided with a feed port 6, and the rear chamber 5 is provided with a discharge port 7. The exterior of the rear chamber 5 is provided with a rotary joint 8 communicating with the cylinder body 2 . The cylinder body 2 is divided into three sections from front to back, the three sections are connected by a feed port, and an insulation layer is provided at the joint to prevent the temperature of the three sections from tending to be the same. The length of the cylinder is larger than that of the drum of the existing shred drying machine, so as to adapt to the process of drying and dehydrating shredded tobacco at a lower temperature and me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com