Drier and its control method

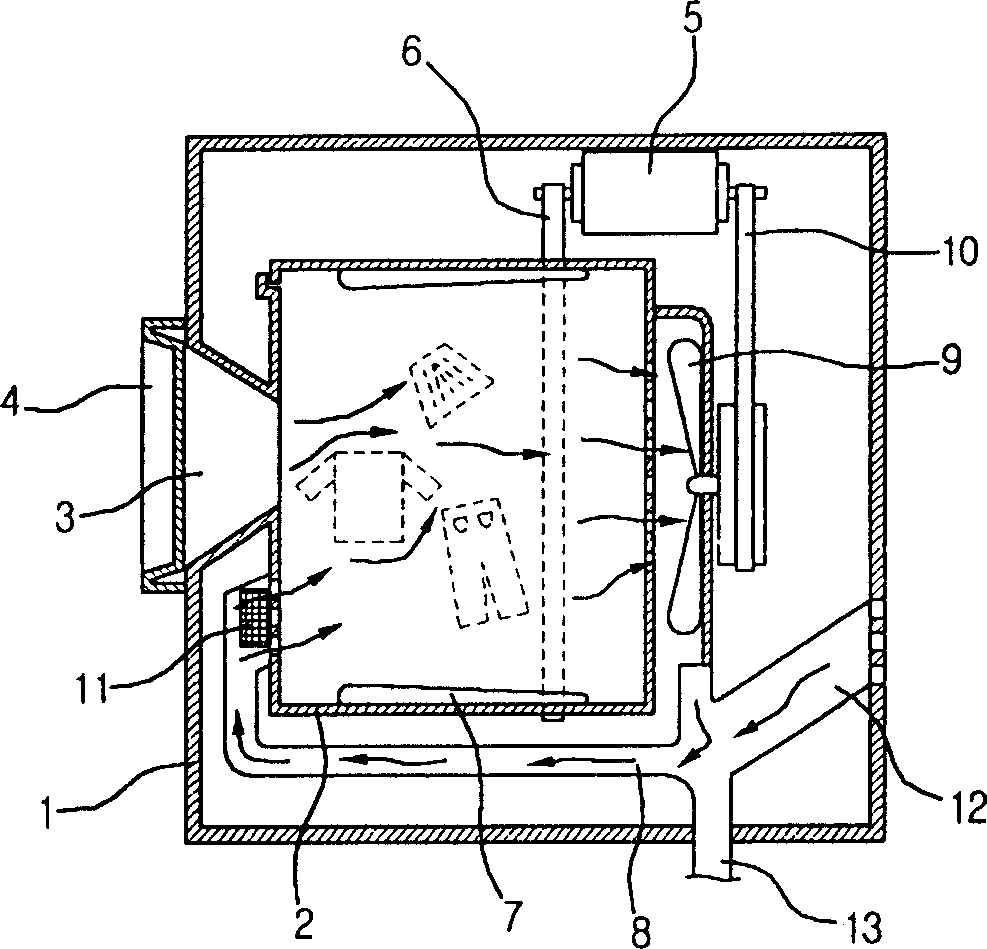

A control method and dryer technology, applied to household dryers, washing devices, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

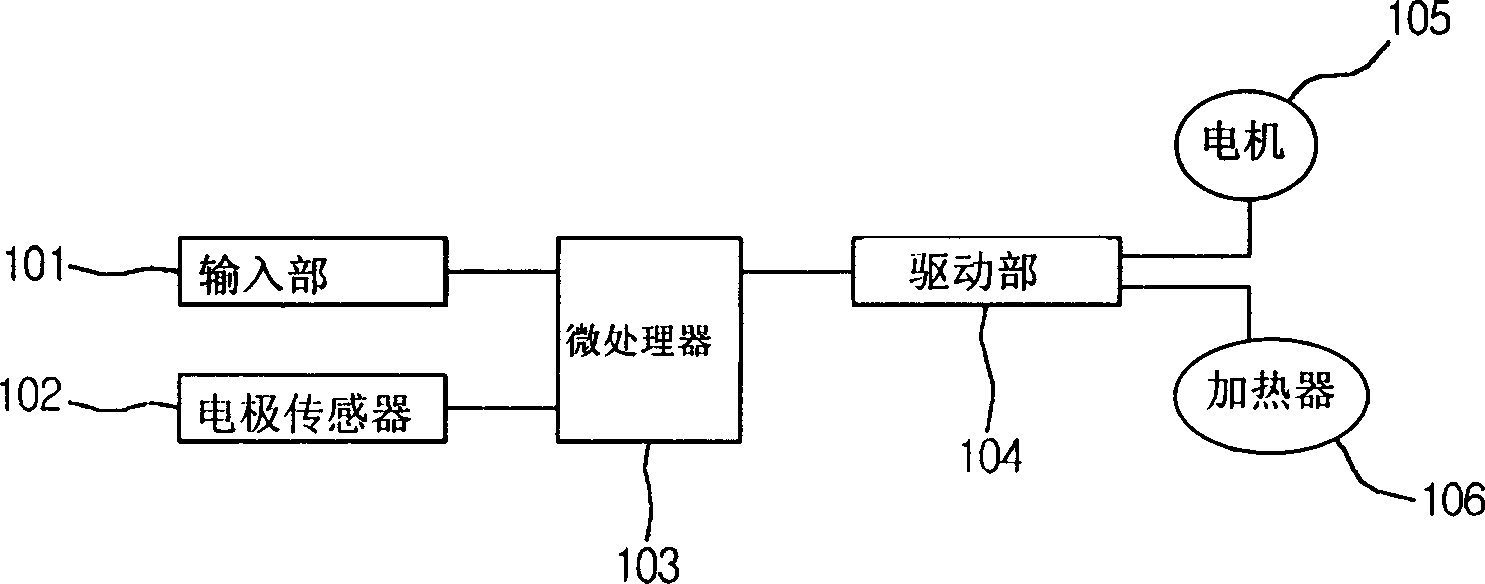

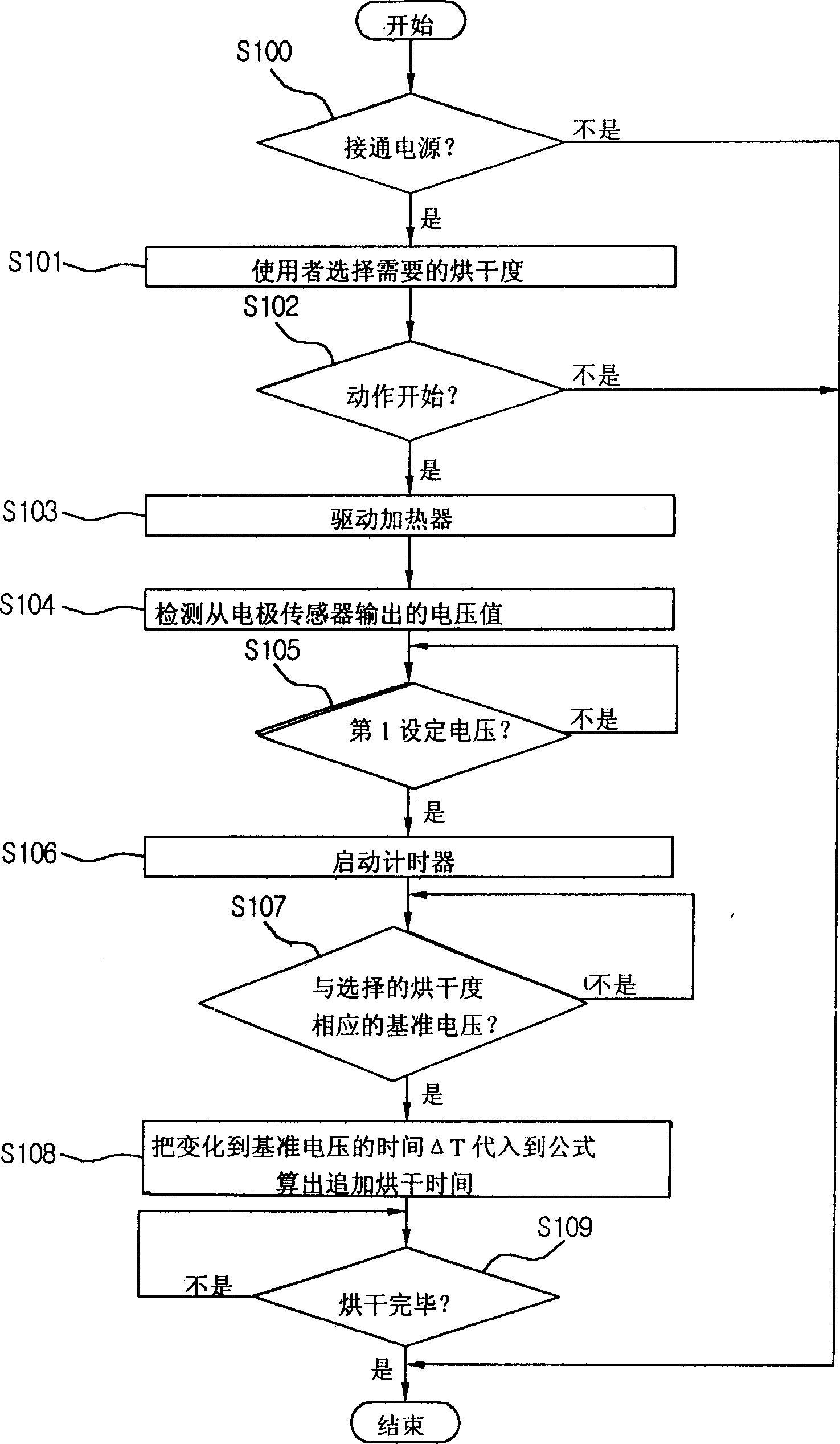

[0024] The drying machine of the present invention is provided with a heater, and is provided with an input unit, an electrode sensor, a microprocessor, and a drive unit; the input unit is used to input the user's order and the selection of the drying degree, and the electrode sensor detects the humidity state of the article After the user's work start command is input through the input unit, the microprocessor detects the voltage value output by the electrode sensor in a certain period. Calculate the additional drying time based on the time taken to change to the reference voltage, and change the drying conditions according to the additional drying time. The drive unit controls the operation of the heater and other components according to the control signal of the microprocessor.

[0025] The control method of the present invention for a dryer with an electrode sensor, a motor and a heater includes the following stages: the stage where the user selects the degree of drying as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com