Intelligent cloth drying device

An intelligent technology for fabric drying, applied in drying, dryers, heating devices, etc., can solve problems such as low drying efficiency, secondary wetting of fabrics, and failure to control the drying effect in time, and achieve Improve drying efficiency, ensure drying quality, and ensure smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

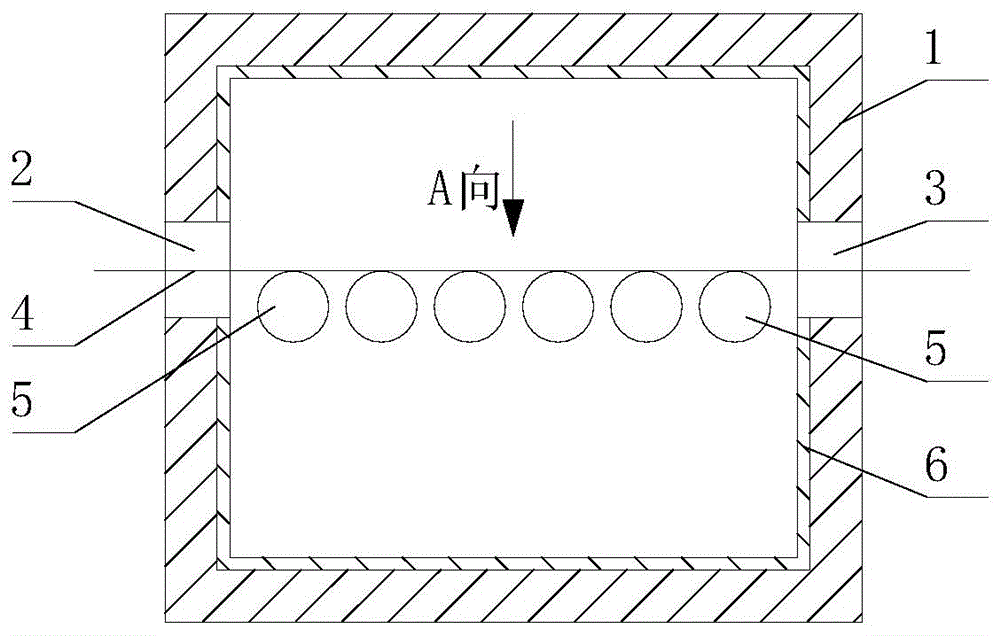

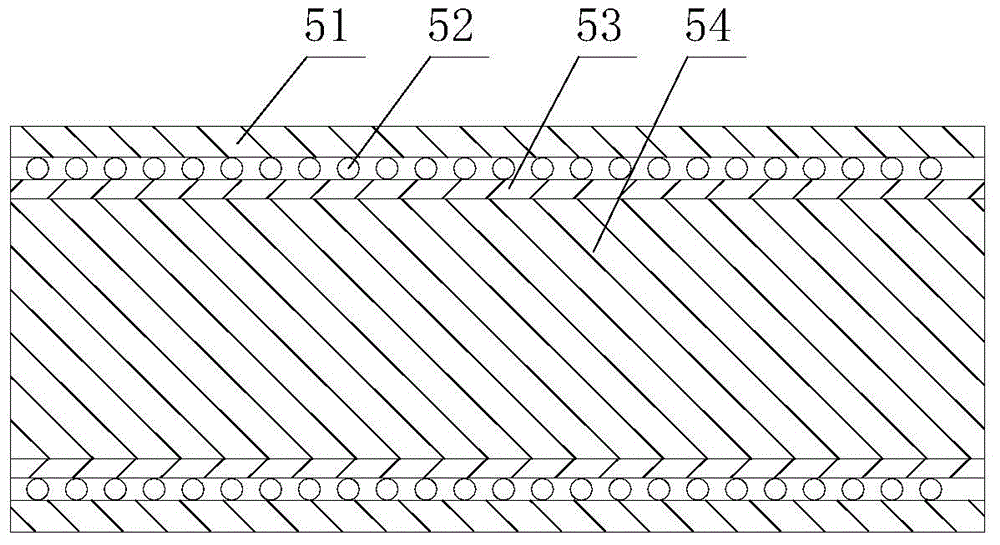

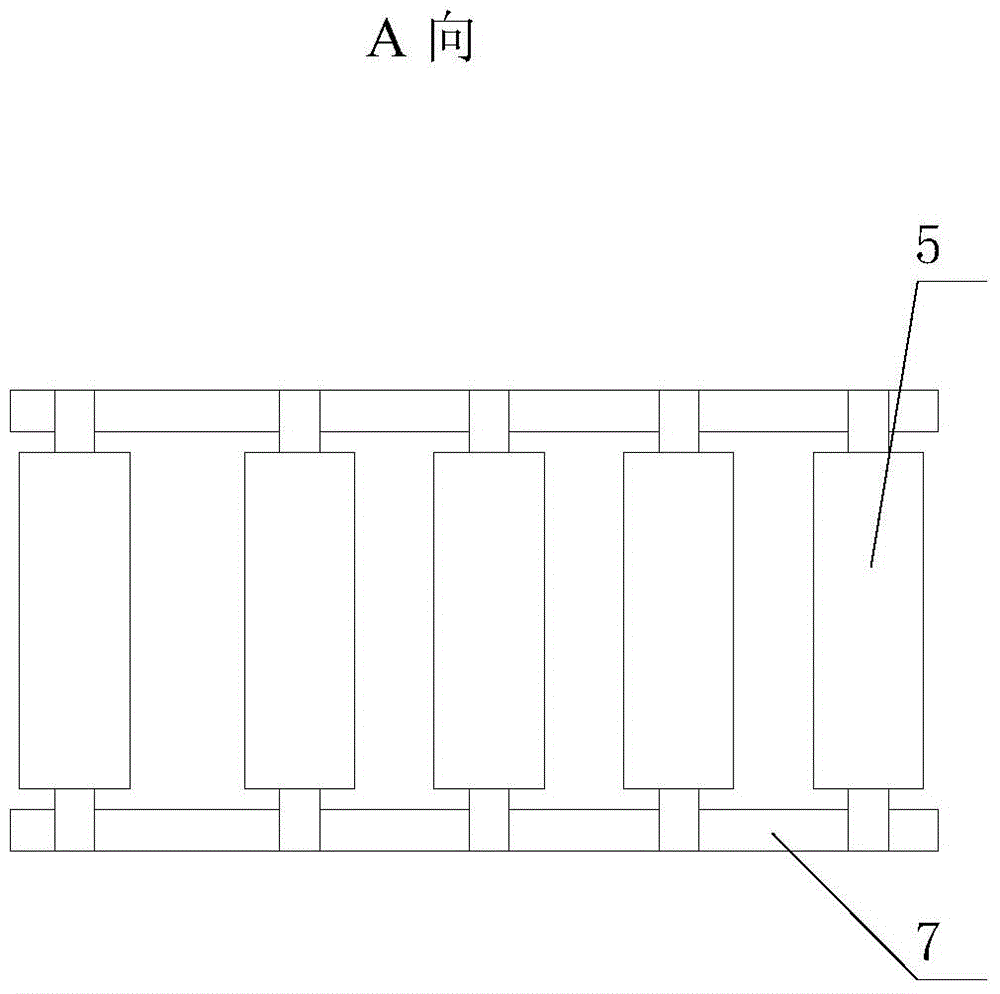

[0020] Such as Figures 1 to 3 As shown, an intelligent cloth drying device includes a housing 1 with an inner cavity, one side of the housing 1 is provided with a cloth inlet 2, and the other side of the housing 1 is provided with a cloth outlet 3, and in the inner cavity of the housing 1 A conveying device for conveying the cloth 4 and drying the cloth 4 is provided, the conveying device includes a plurality of heating rollers 5 rotating around its own axis, the plurality of heating rollers 5 rotate in the same direction and are arranged side by side at intervals, and the plurality of heating rollers 5 are connected to the feeder. The cloth opening 2 and the cloth outlet 3 are compatible; the heating roller 5 is provided with a temperature sensor for real-time monitoring of the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com