Solar continuous drying system and method

A drying system, solar energy technology, applied in the field of life and production machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

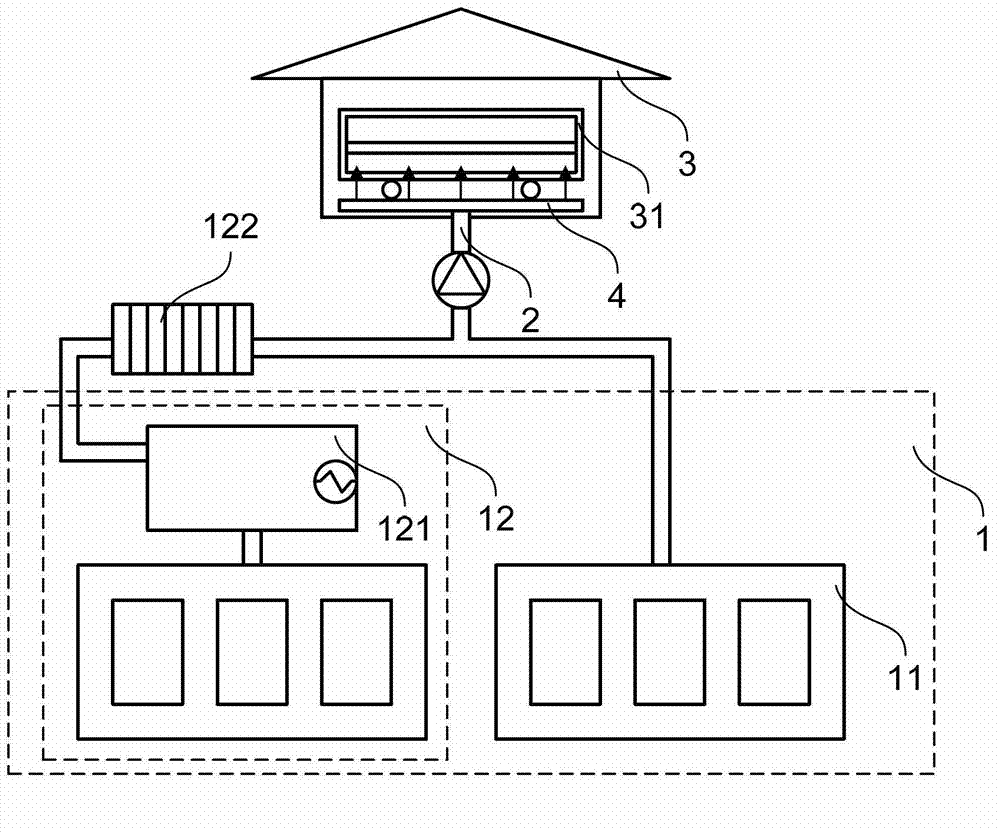

[0057] like Figure 1 to Figure 4 As shown, design and process a solar continuous drying system.

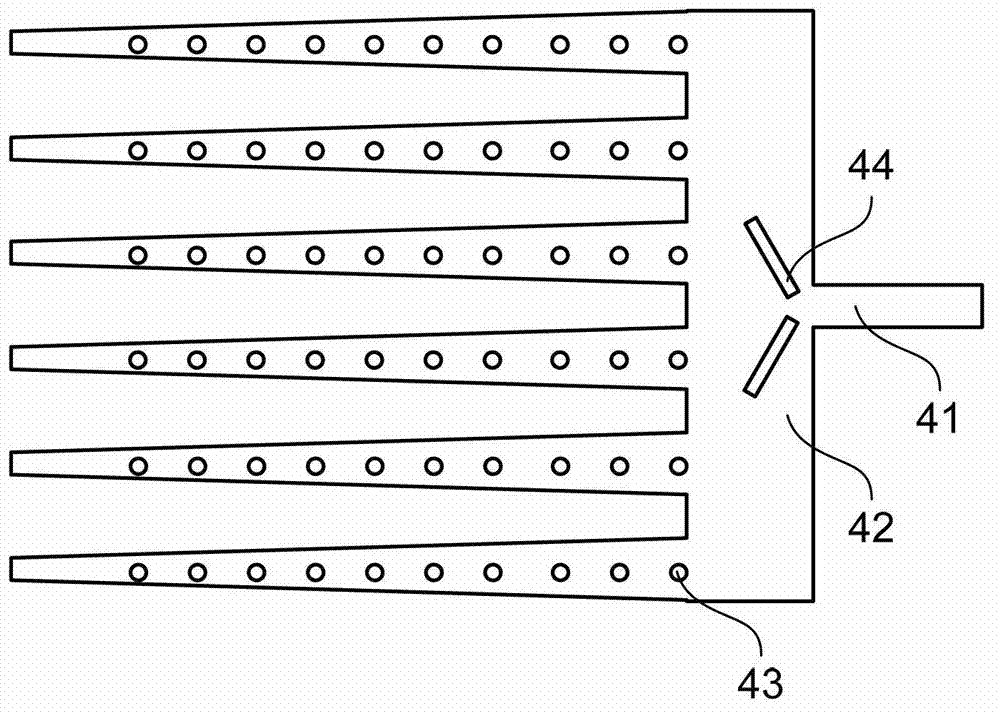

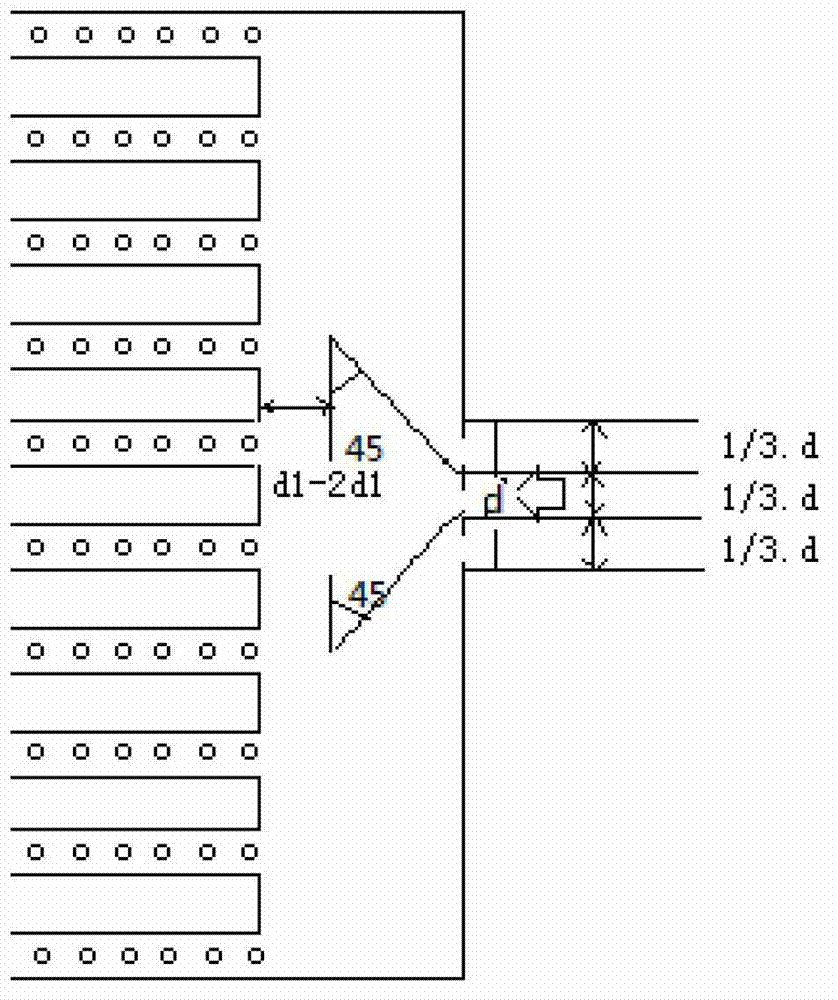

[0058] figure 1 It is a schematic diagram of the structure of the solar continuous drying system. The solar energy continuous drying system, the heating system 1 blows hot air into the drying chamber 3 through the air pipeline through the main air outlet 2 to dry the items in the drying chamber 3, and the heating system 1 includes solar air as a source of hot air Heat collector 11 and solar water heat collector 12. The air heated by the solar air heat collector 11 is blown into the drying chamber 3 through the first air pipeline, and the water heated by the solar water heat collector 12 is stored in the water tank 121, and then the hot air is obtained through heat exchange along the second air pipeline. Drum into drying chamber 3. The supplementary air pipeline is connected to the main air outlet 2, and the supplementary air pipeline is controlled by the supplementary air sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com