Patents

Literature

300 results about "Solar drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

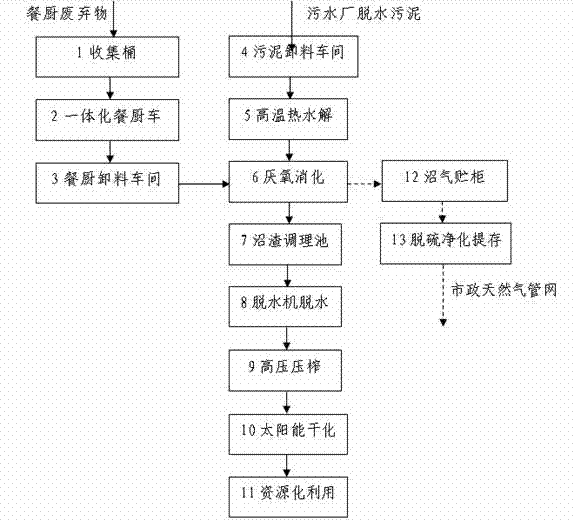

Cooperative treating method of kitchen waste and sludge of sewage plant

InactiveCN106964633AReduce the impactAvoid pollutionSludge treatment by de-watering/drying/thickeningWaste processingSolar dryingSewage

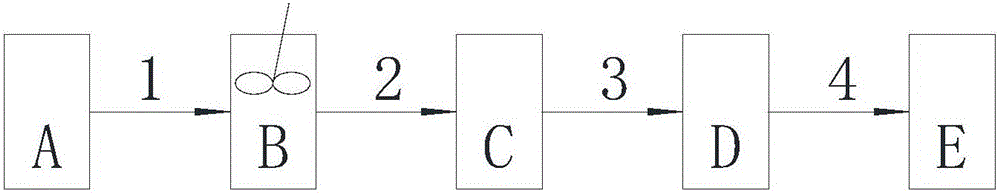

The invention discloses a cooperative treating method of kitchen waste and sludge of a sewage plant. The method comprises the following steps that A, a kitchen waste source is pretreated; B, the sludge is subjected to high-temperature hydrolysis cooperating with anaerobic digestion; C, biogas residues are dehydrated and pressed; and D, drying treatment is conducted to obtain finished products. The cooperative treating method has the advantages that after the comprehensive treating processes that the kitchen waste source is pretreated, the sludge is subjected to high-temperature hydrolysis cooperating with anaerobic digestion, the biogas residues are dehydrated through a dehydrator and pressed directly through a high-pressure filter press and subjected to solar drying, stabilization, harmlessness and reduction of the sludge can be achieved, and meanwhile waste is changed into treasures, specifically, available biogas and garden greening soil and forest land are produced.

Owner:江苏泓润生物质能科技有限公司

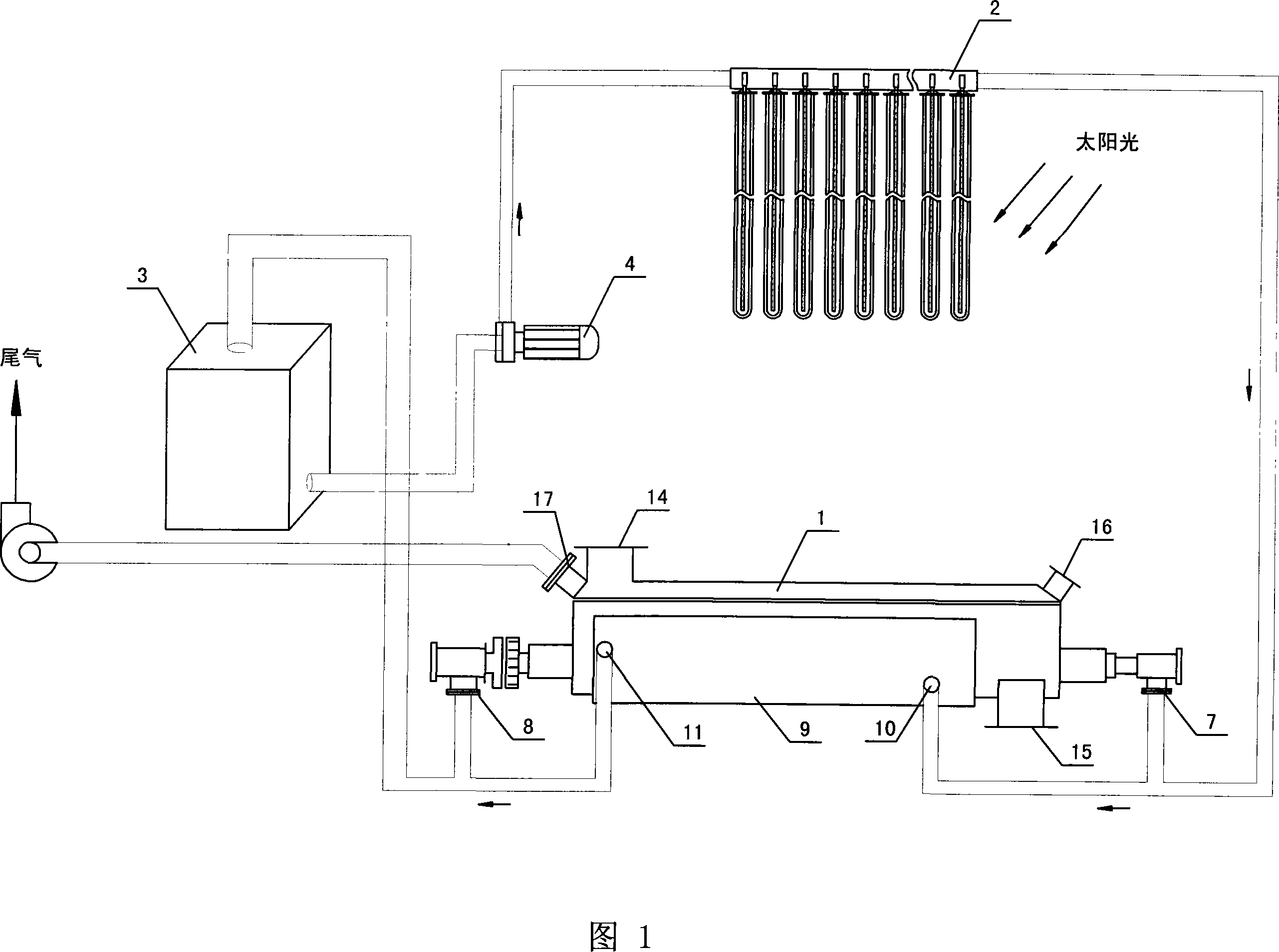

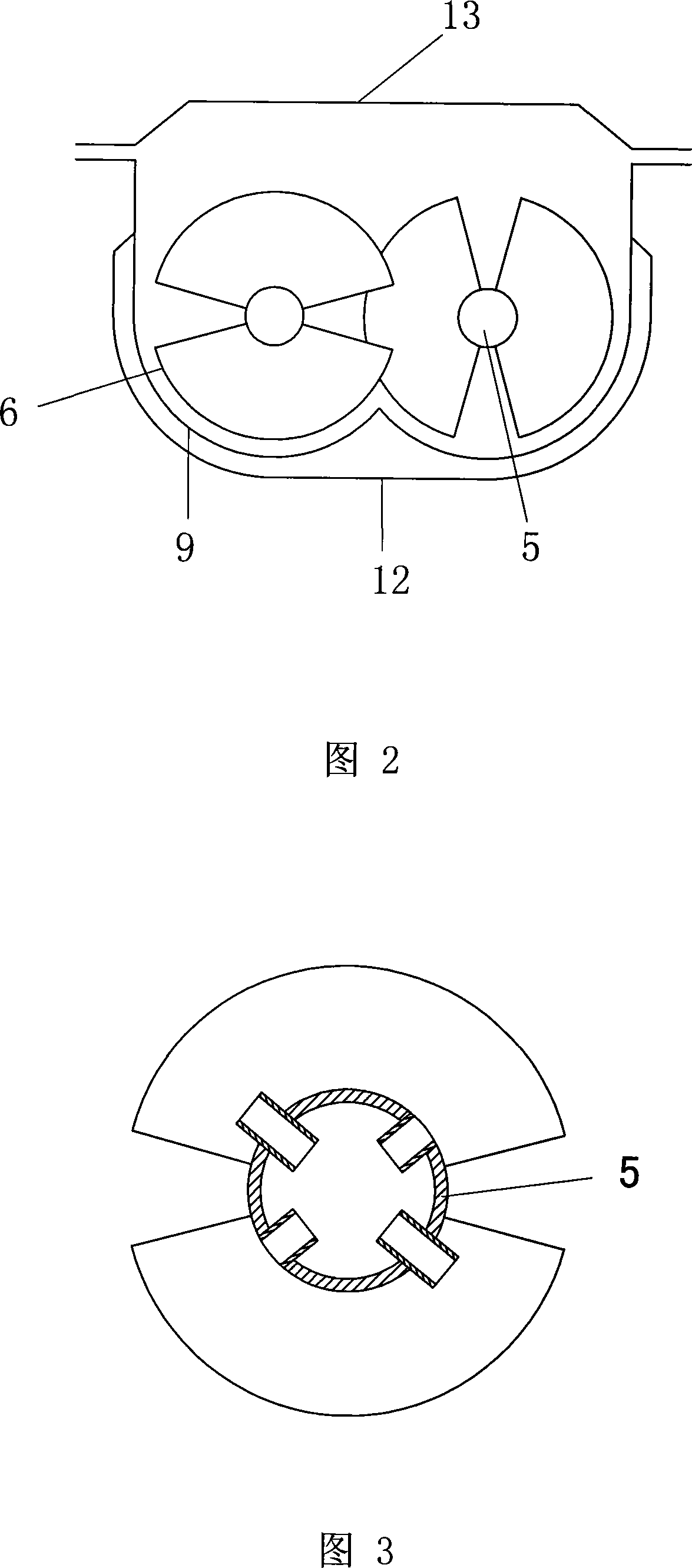

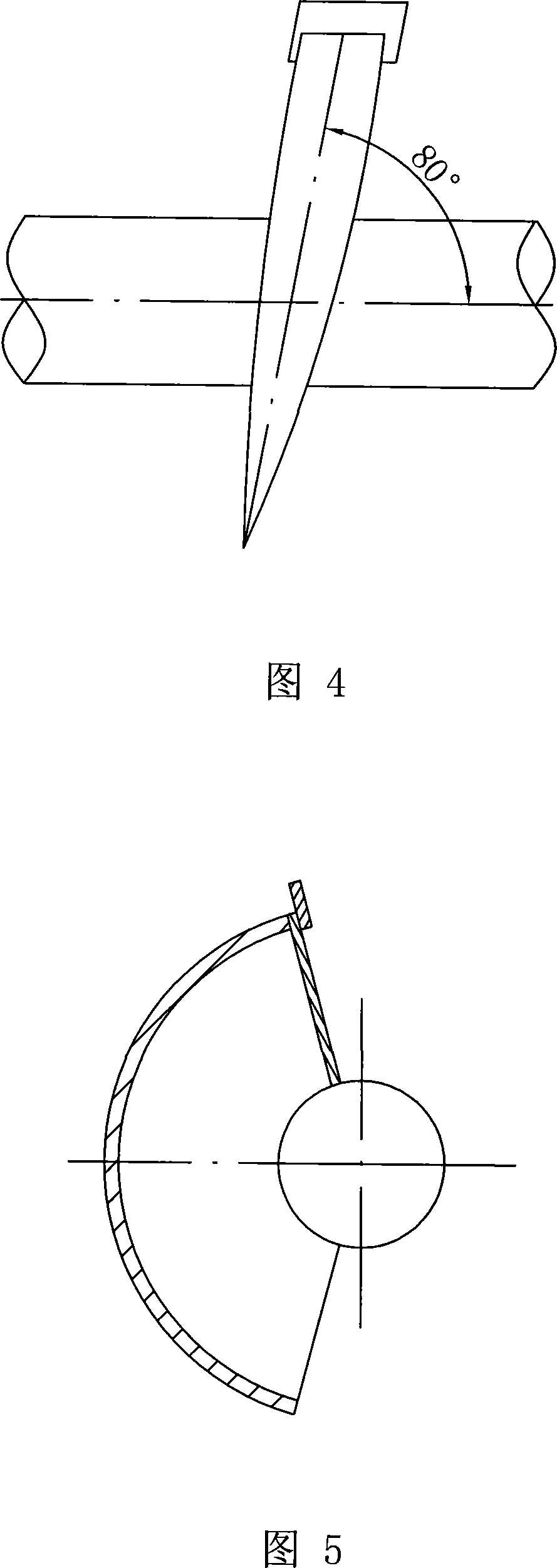

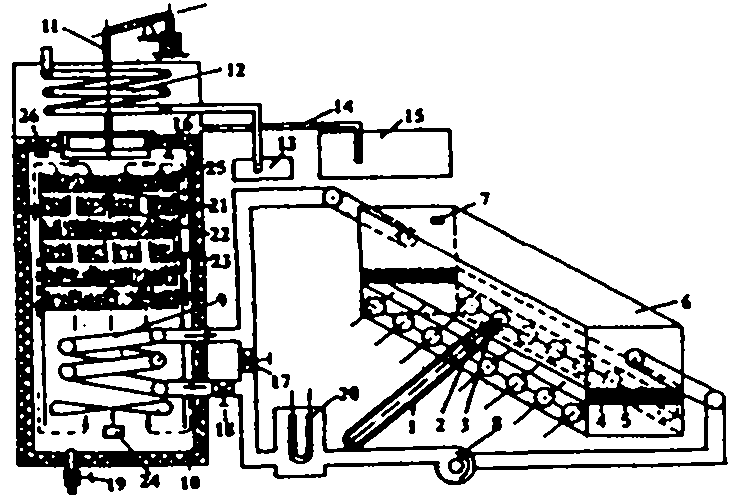

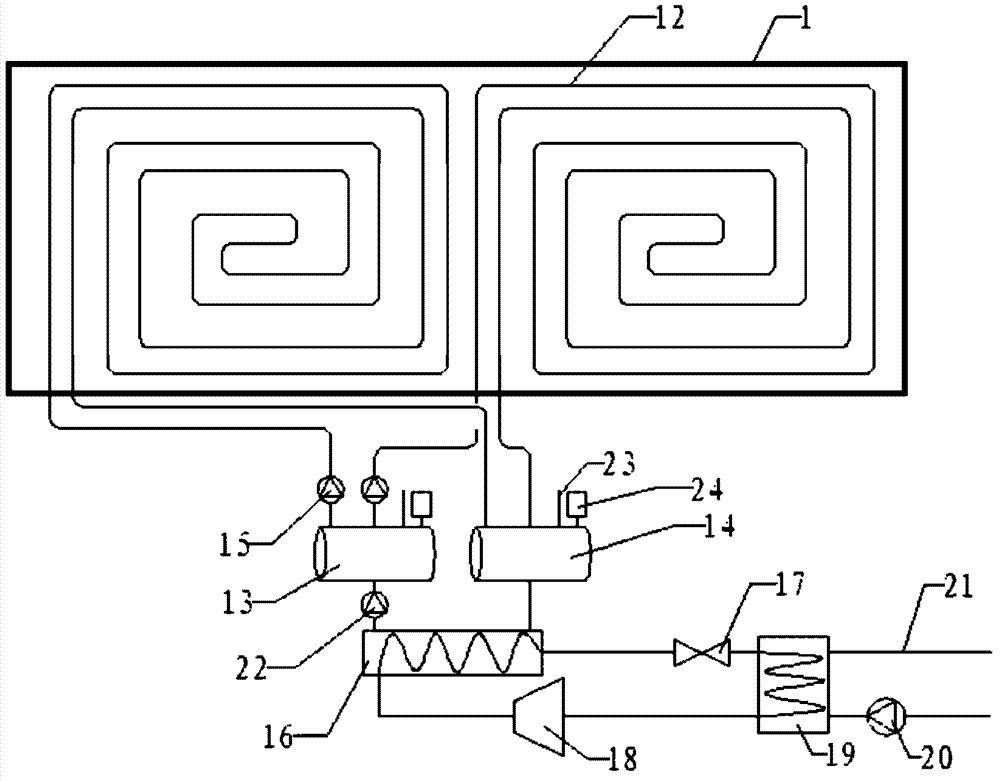

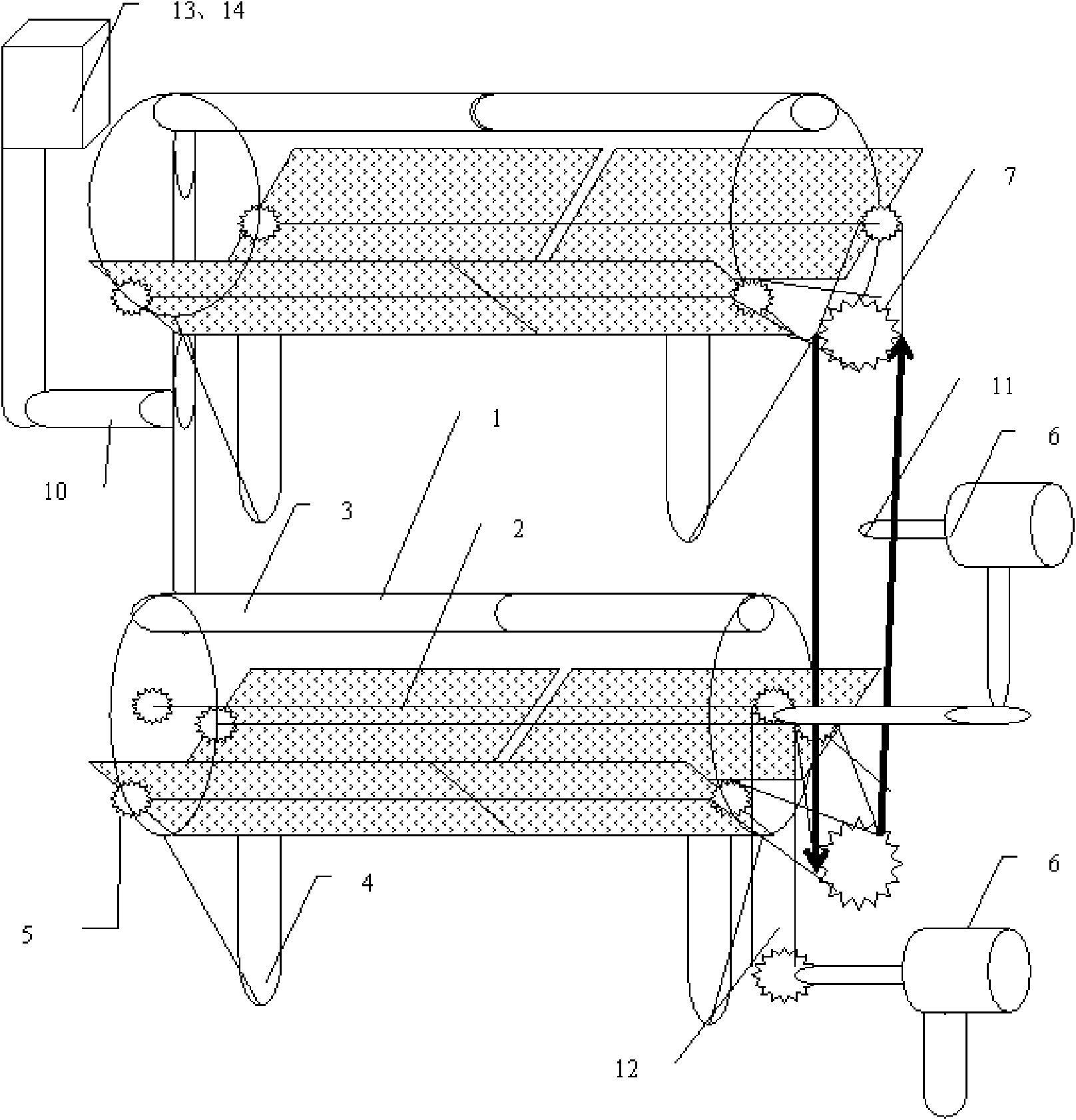

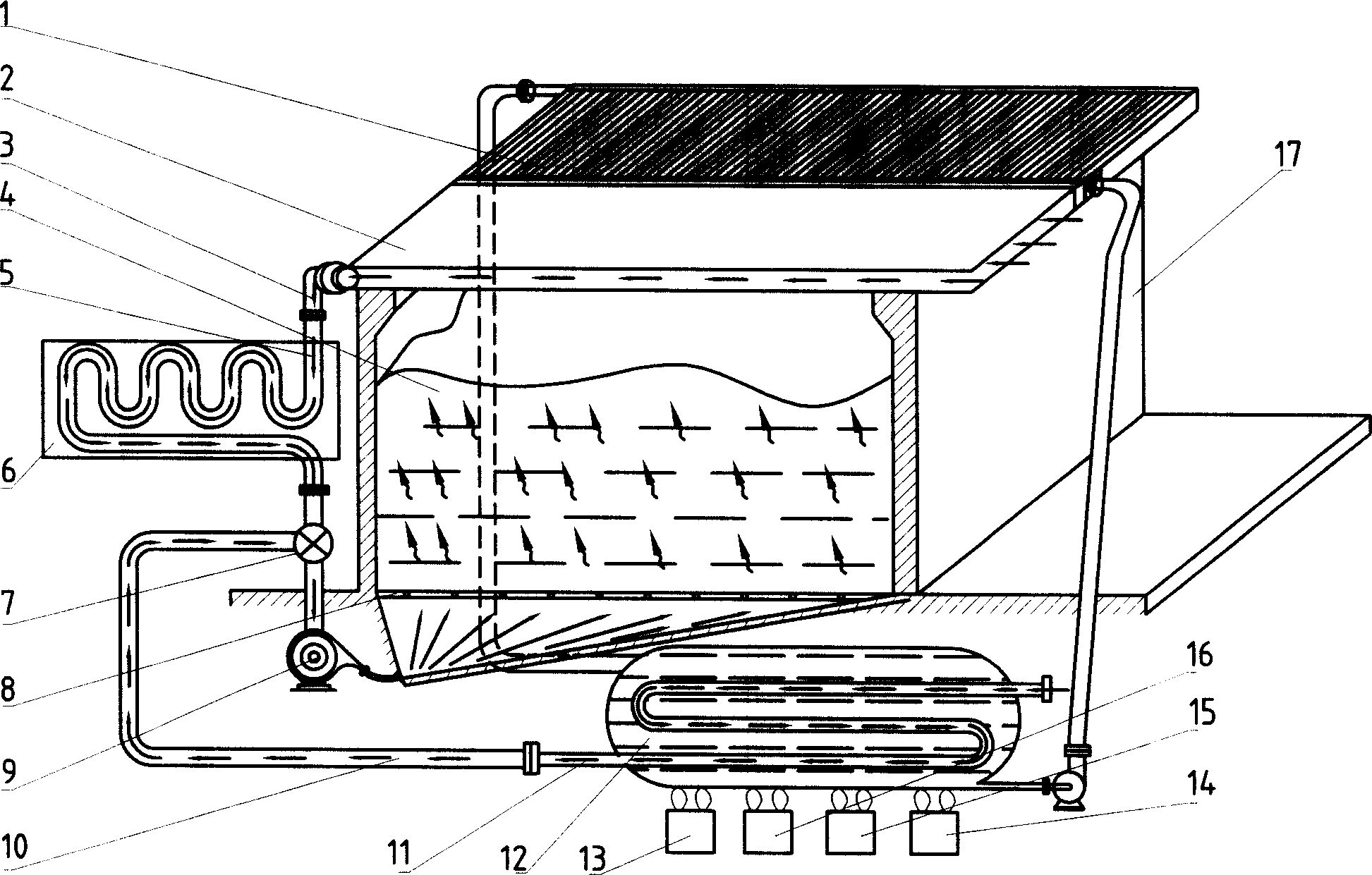

System for drying sludge by solar energy

The invention relates to a harmlessness and resource utilization technique of solid waste, aiming to provide a system for drying sludge using solar energy. The system comprises a rotary screw sludge drying and shaping machine, wherein at least one hollow thermal shaft is disposed inside the machine body and connected with a transmission mechanism, a plurality of hollow blades are disposed on the hollow thermal shaft, the heat-conducting oil outlets of the hollow thermal shaft and the shell are all connected with a heat-conducting oil tank via pipelines, the heat-conducting oil inlets of the hollow thermal shaft and the shell are all connected with a solar heat collector via pipelines, and the heat-conducting oil tank, a heat-conducting oil pump and the solar heat collector are connected with pipelines. The invention realizes sludge drying using solar energy, so as to remarkably the energy consumption during sludge drying process; uses heat-conducting oil as the heat transfer medium of the solar heat collector, so as to improve the heat transfer effect of the system; and makes the sludge particles into fuel, so as to take full advantages of the heat in the sludge and be in favor of further grinding and incineration.

Owner:ZHEJIANG UNIV

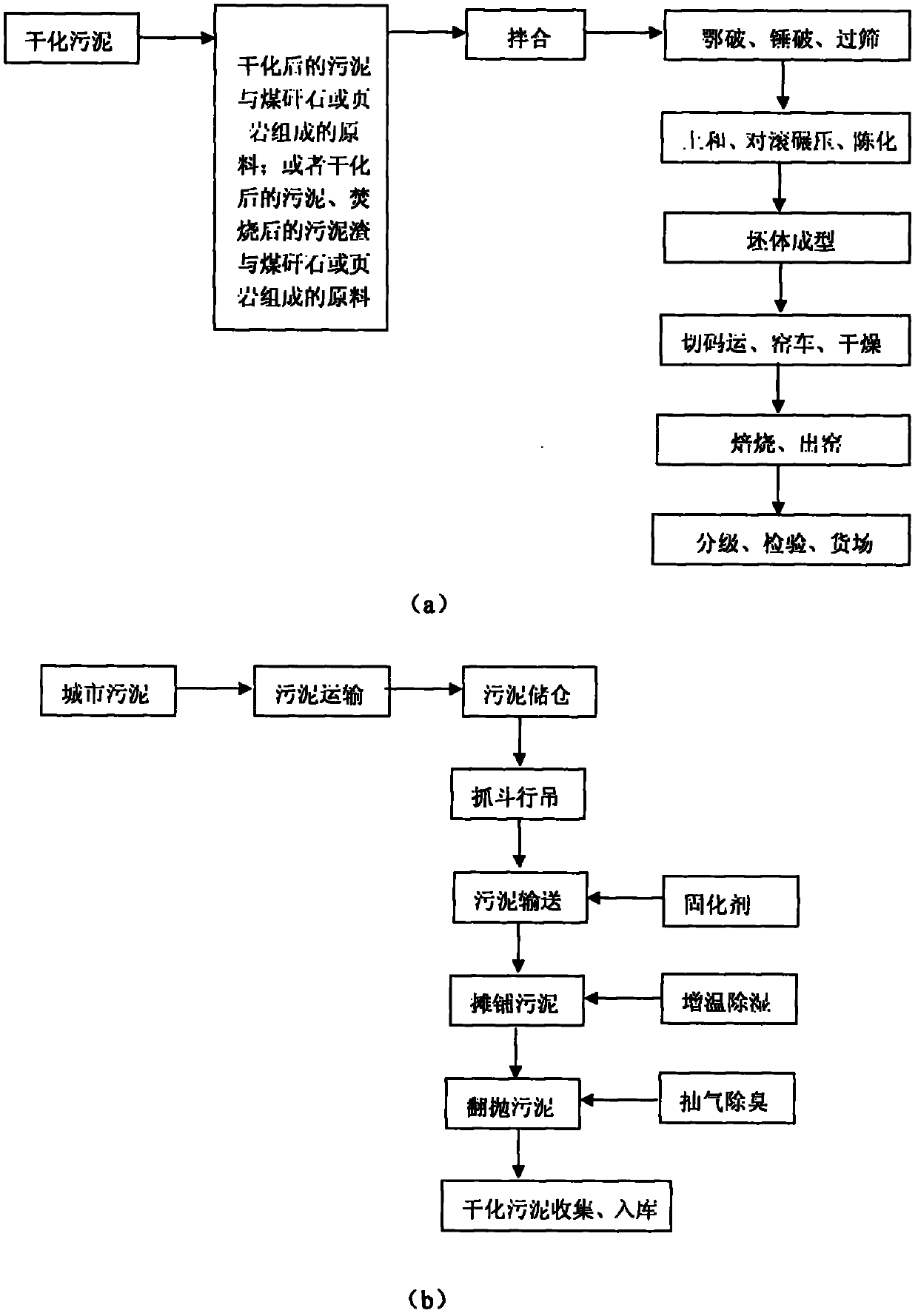

Method for brickmaking by comprehensive utilization of desiccated sludge

ActiveCN102381877AReduce moisture contentCrushed fullySludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentBrickSolar drying

The invention discloses a method for brickmaking by comprehensive utilization of desiccated sludge; sludge is desiccated and is used as a raw material for brickmaking; the method comprises the following steps: firstly transporting municipal sludge with water content of 80-85% to a sludge warehouse for sealing storage, grabbing the sludge in the sludge warehouse by controlling a grab bucket traveling boom through a PLC system, transferring the sludge to a feed hopper of a sludge feeding device, adding a curing agent into the feed hopper, fully stirring, transporting the sludge to a desiccationchamber of a desiccation device, performing desiccation in the desiccation chamber by solar energy and waste heat of a tunnel furnace so as to obtain sludge which is used as a material for brickmaking. The invention performs desiccation by using brickkiln waste heat and solar energy; the physical heat at a brick-baking tail part of the tunnel furnace is made full use of, which increases self heat, and saves a lot of energy; sludge is added into various raw materials, and no clay is used; with respect to baked brick production by using municipal sludge with a high mixing amount, the highest mixing amount of municipal sludge is up to 50%.

Owner:南京鑫翔环保产业有限公司

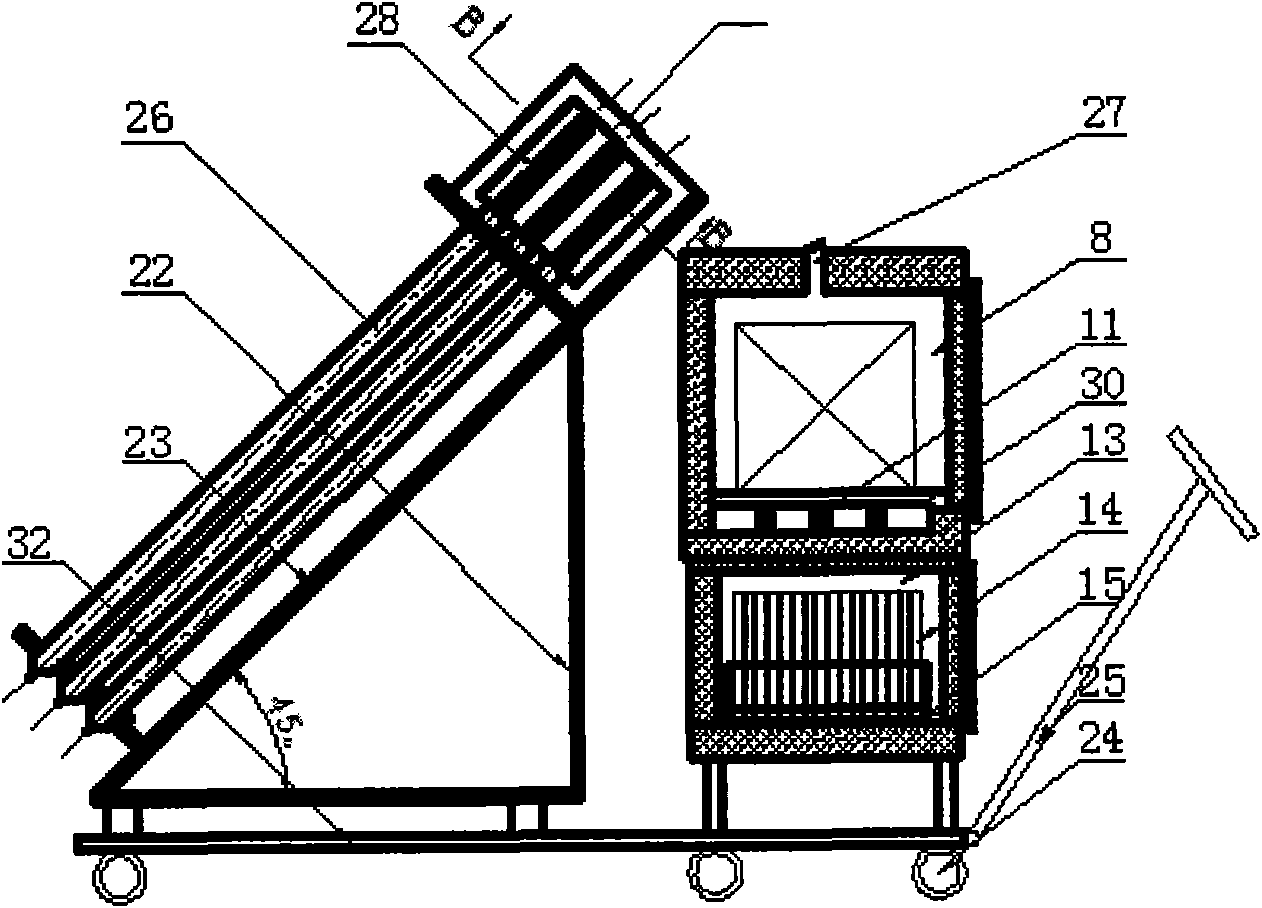

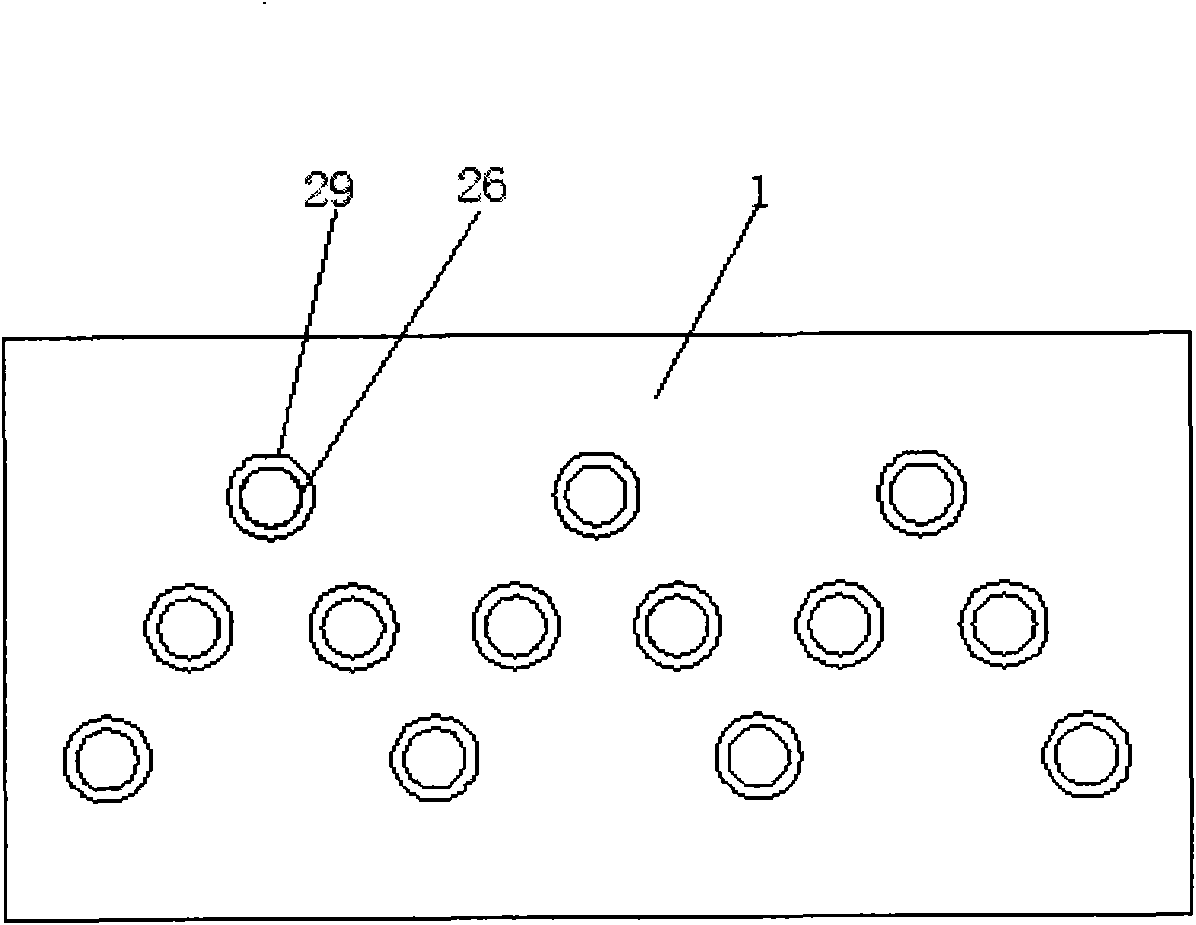

Drying method by using solar energy and device thereof

ActiveCN101776377AImprove drying efficiencyQuality improvementDrying solid materials with heatSolar heat devicesSolar dryingSolar energy conversion efficiency

The present invention discloses a wood drying method by using solar energy, comprising the steps of: putting the wood to be dried in a drying cabinet (8); supplying heat to the drying cabinet; and stopping the supply of heat when the temperature T2 of the drying cabinet (8) is higher than the setting drying temperature of the wood to dry the wood under the setting drying temperature. The movable drying device by using solar energy has stable running, constant drying temperature and continuous drying function with lower power consumption, higher solar energy conversion efficiency and good drying quality, thereby reducing the drying cost.

Owner:潍坊恒远新材料科技有限公司

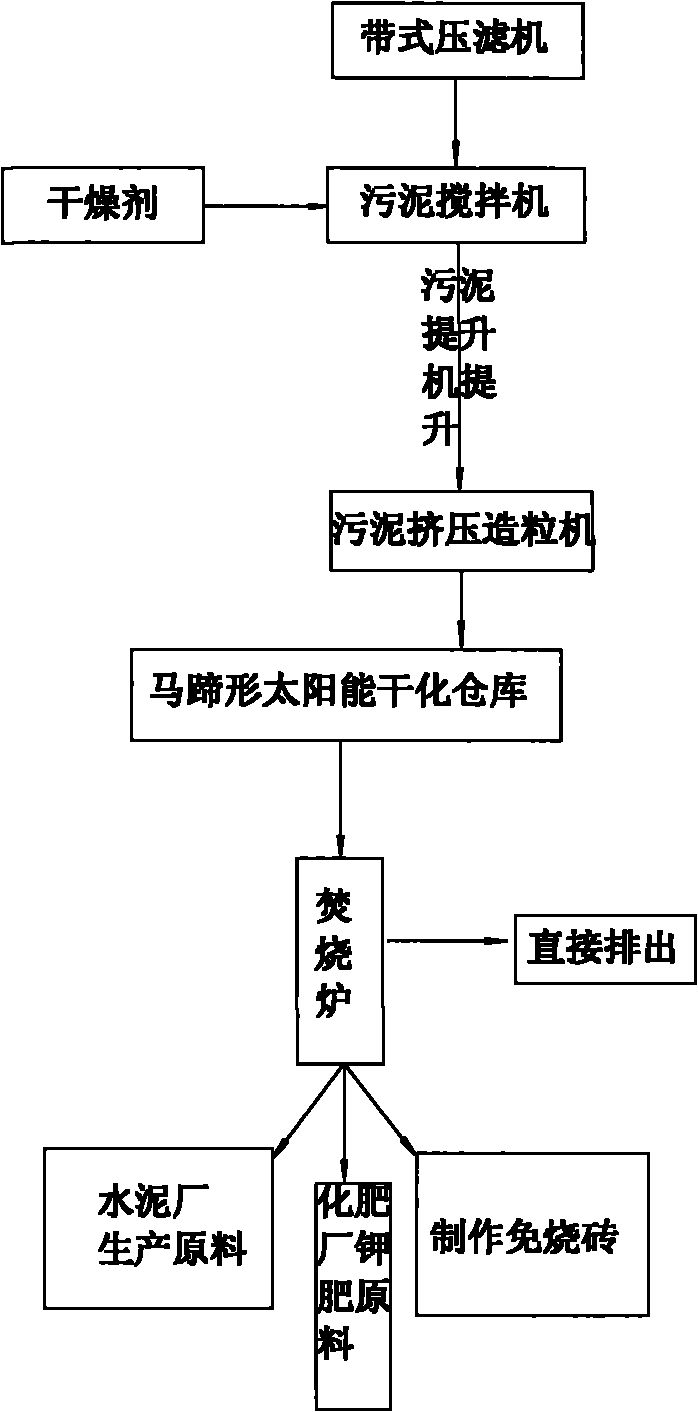

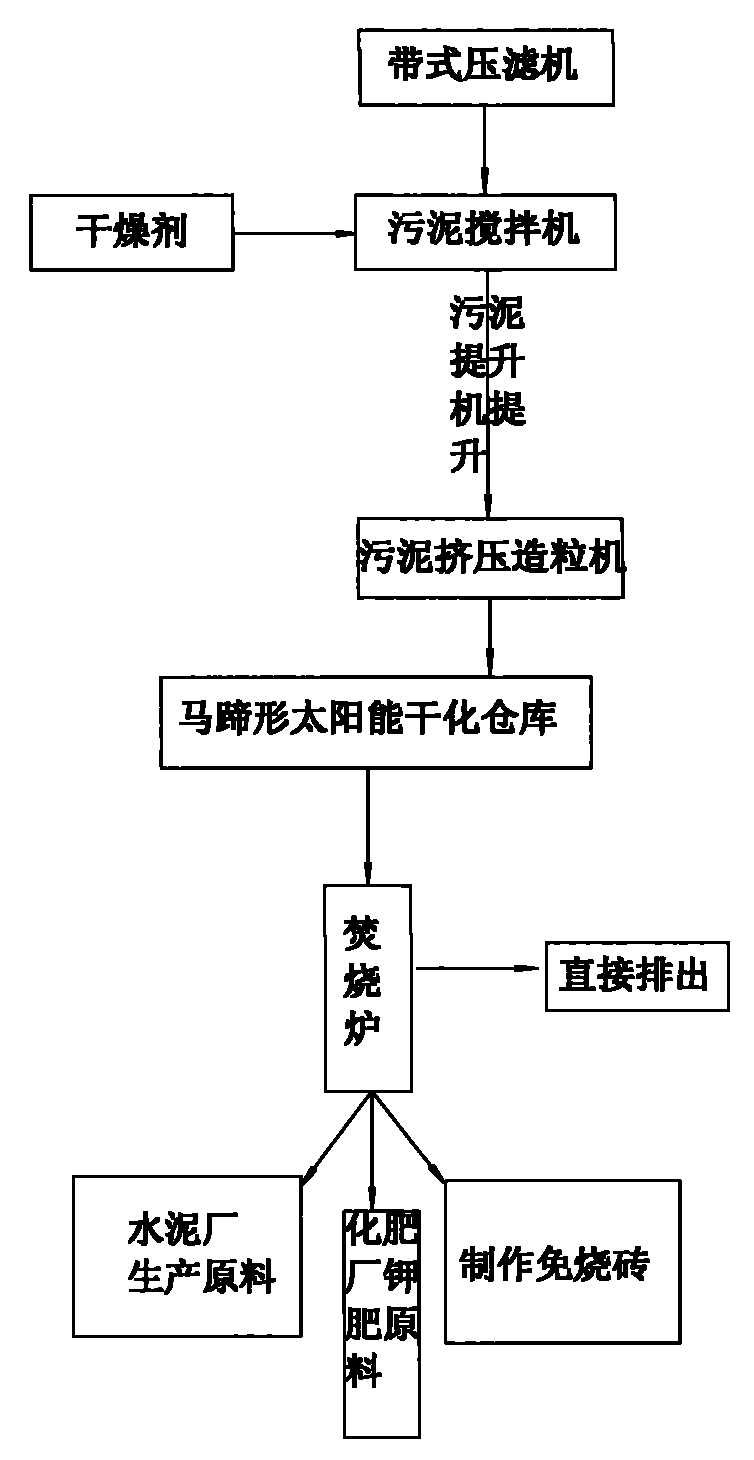

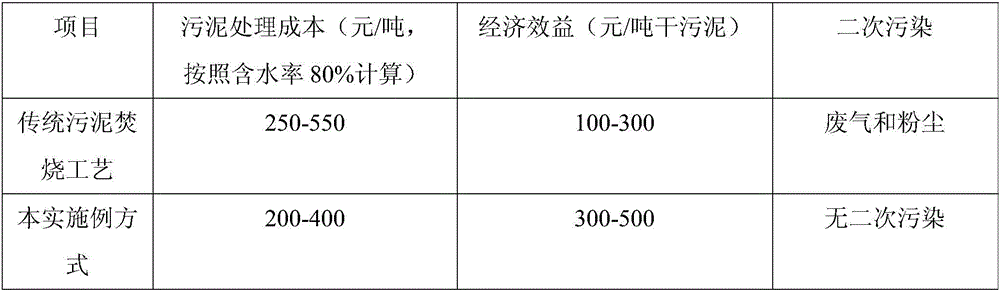

Sludge treatment method

InactiveCN101805105AAvoid secondary pollutionAchieve reductionSludge treatment by pyrolysisEnergy based wastewater treatmentSocial benefitsSolar drying

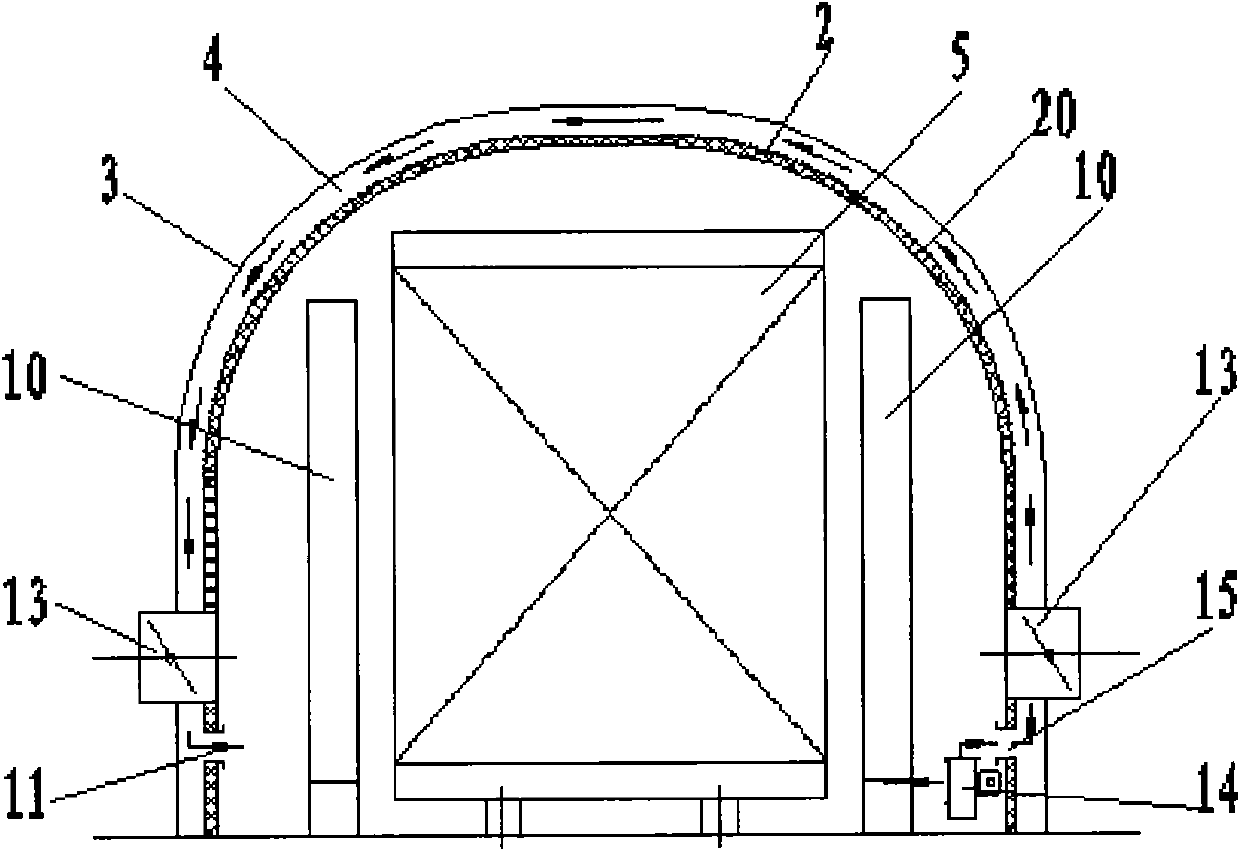

The invention relates to a sludge treatment method. Firstly, sludge with moisture content of 75-82% is conveyed into a sludge stirring machine by a belt press filter; secondly, drying agent is added into the sludge stirring machine, and stirring mixing is carried out; a hoisting machine is utilized to hoist mixture into a sludge pellet extruder, the sludge pellet extruder carries out extrusion conveying on the mixture, thus forming strip cylindrical sludge particles with moisture content of 50-60%; then the sludge particles are collected into a horseshoe shape solar drying storehouse, ammonia gas is guided in, deodorization drying is carried out at the temperature of 40-60 DEG C, so that moisture content of sludge particle is reduced to 20-30%; and finally the treated sludge particle is conveyed into an incinerator to be fully combusted, combustion temperature can reach 500-800 DEG C, and the residue after combustion is discharged. The sludge treatment method disclosed by the invention realizes reduction, harmlessness, stabilization and reclamation of sludge treatment and can obtain higher social benefit and economic benefit.

Owner:江苏展宏环保科技有限公司

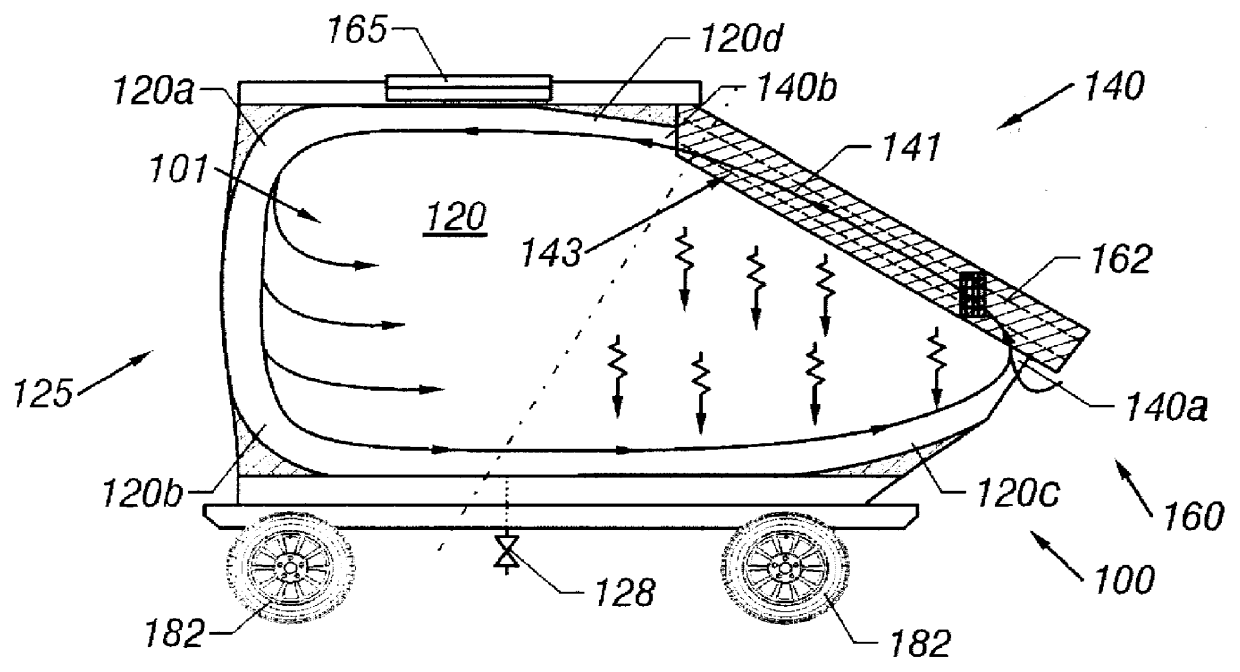

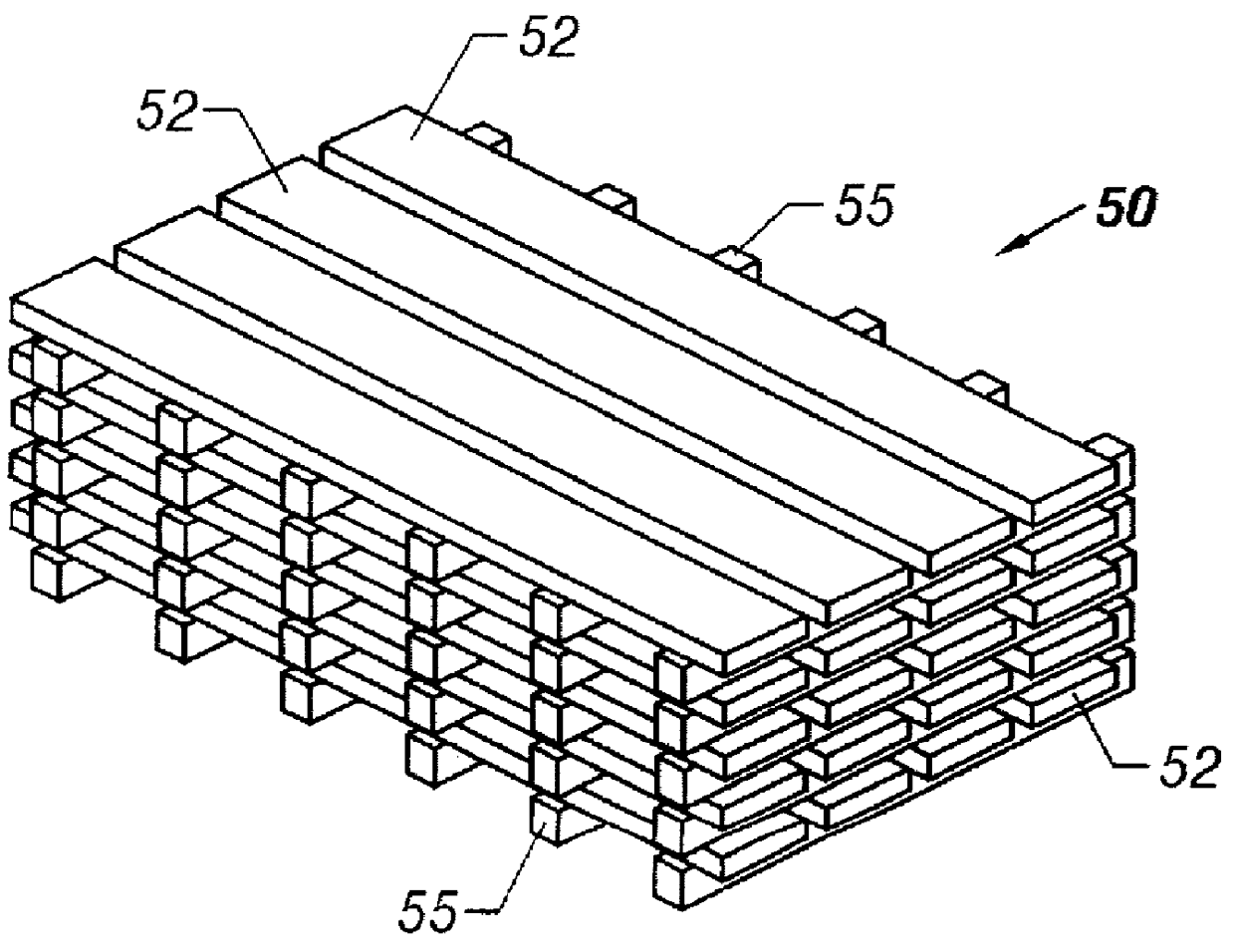

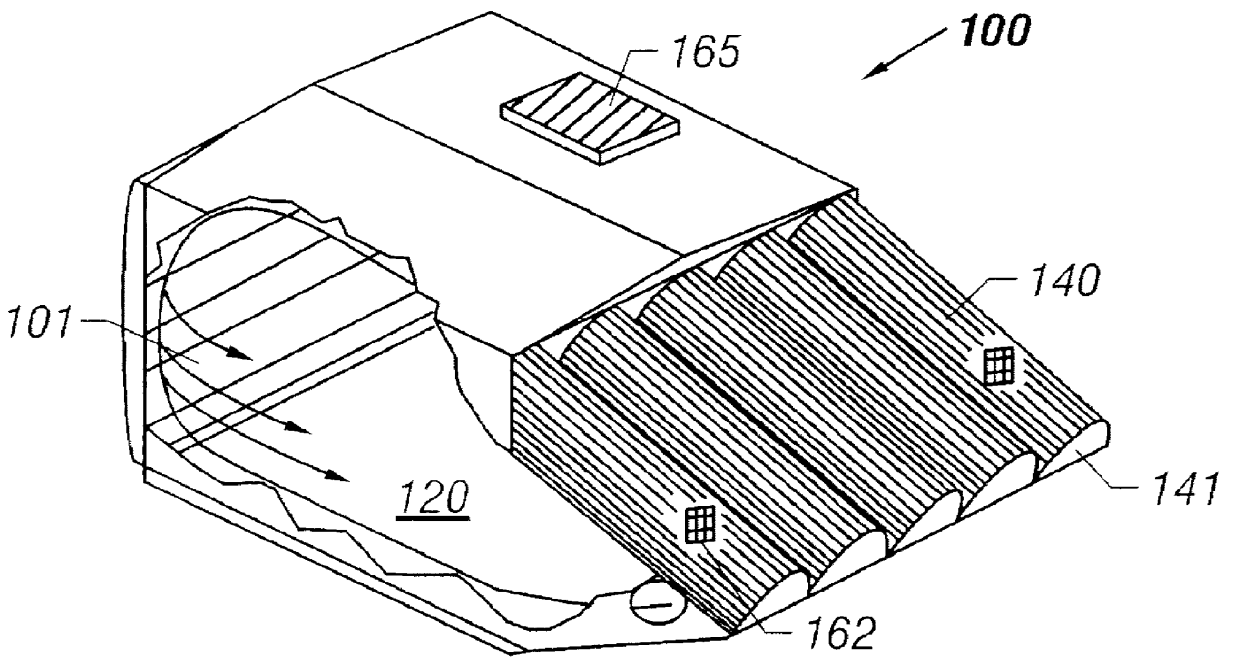

Solar drying process

InactiveUS6138379ADrying using combination processesDrying solid materials with heatSolar dryingMechanical engineering

A drier with a curvalinear chamber having a heat transfer surface at one end and baffles at the other end. A fan is provided to circulate air within the chamber. In the process for drying, the product to be dried is positioned within the chamber and air circulated across the heat transfer surface, toward the baffle, past the product, and back to the heat transfer surface.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

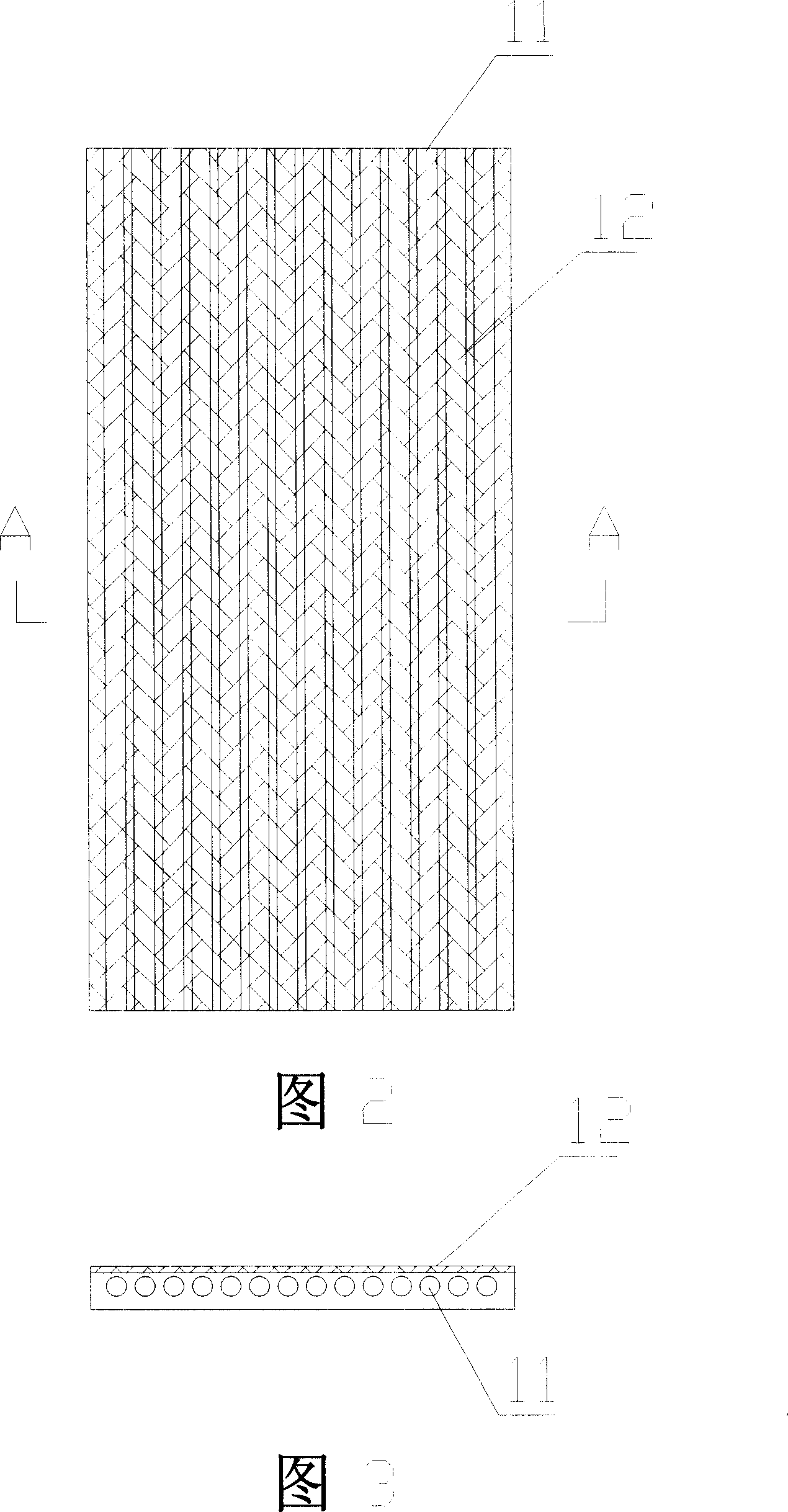

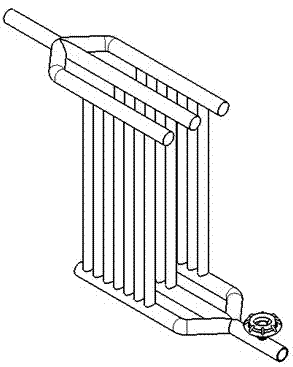

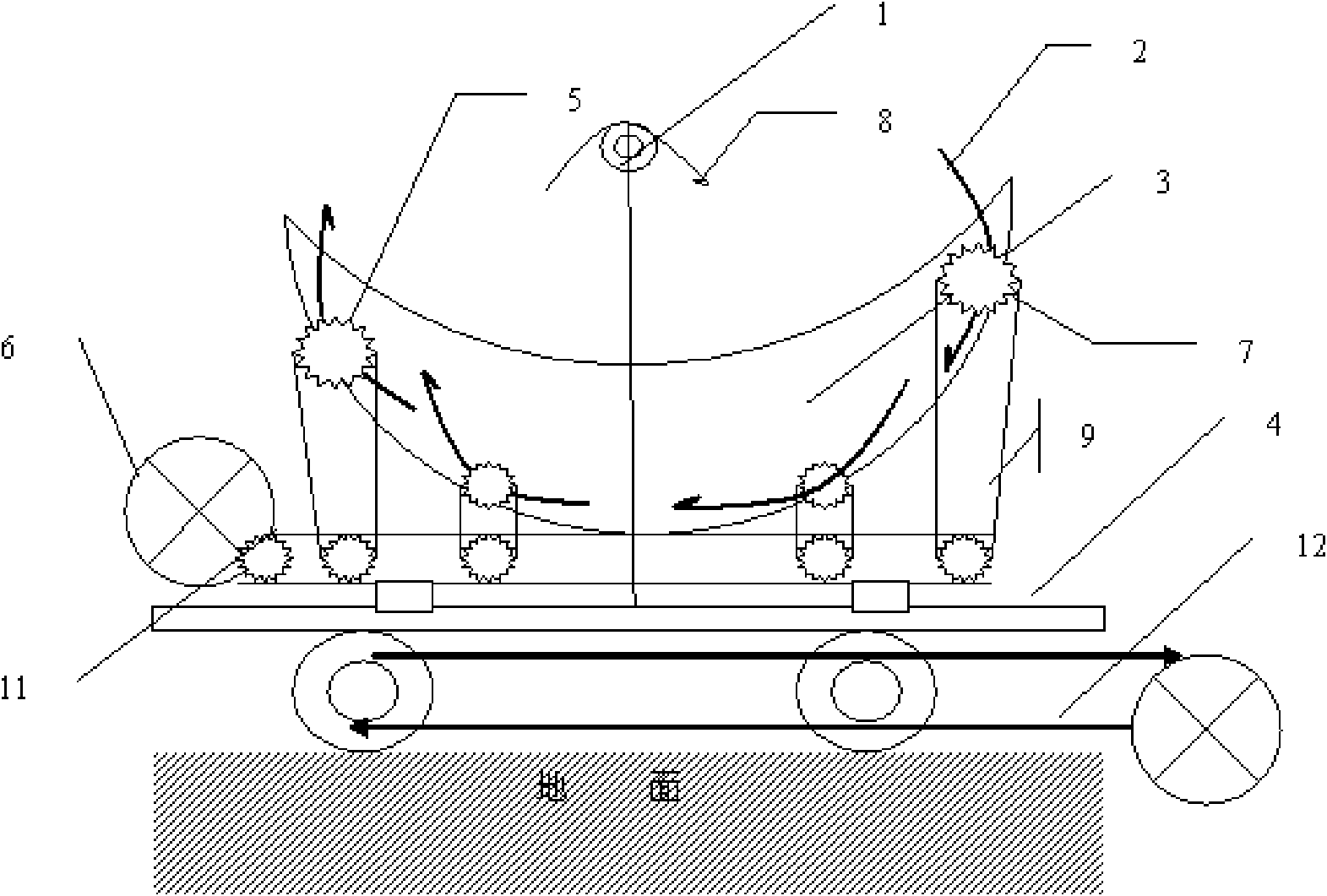

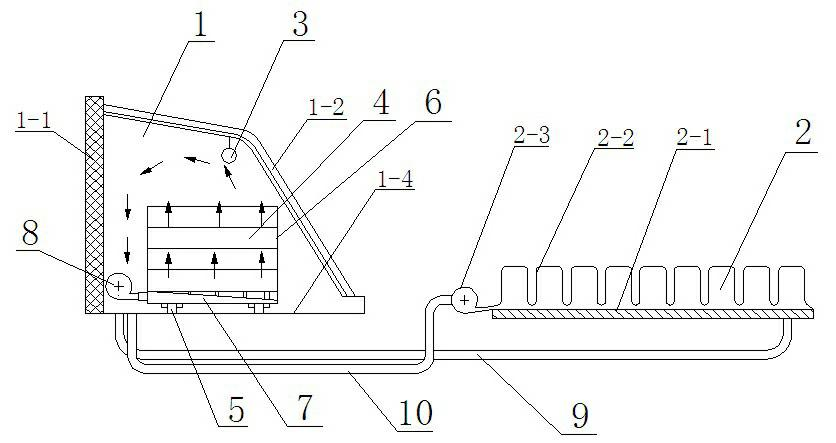

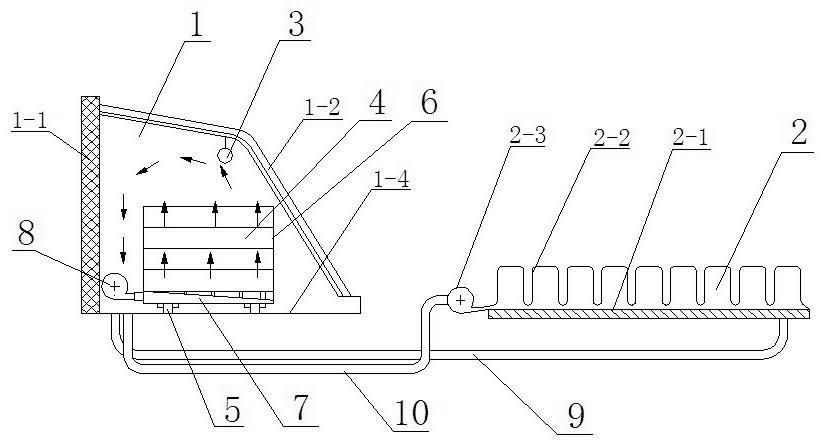

Recovery type solar drying device

InactiveCN101839616AIncrease the heat collecting areaIncrease profitSolar heating energyDrying solid materials with heatElectricitySolar drying

The invention relates to a recovery type solar drying device, comprising: 1. a hot air flow heat-collecting and heat-storing circulating system implemented by components such as an all-glass vacuum heat-collecting tube, a heat tube (2), a heat-dissipating piece (3), a metal net layer (4), a pebble heat-storing device (5), a heat exchange device (9), a variable-frequency speed-regulating fan (8) and the like; 2. a material drying system implemented by components such as a material drying insulating box (10), a netty material drying box (21), a fan (24), a material (25) to be dried and the like; 3. a dried material water recovery system implemented by components such as a dried material steam discharge device (11), a condensing device (12), a dried material water recovery pipeline (14) and the like; and 4. components including a valve, an electric auxiliary heating device, a sensor and the like. The recovery type solar drying device has wide application range, can dry different types of materials and form series of products of the solar drying device.

Owner:沈晓莉

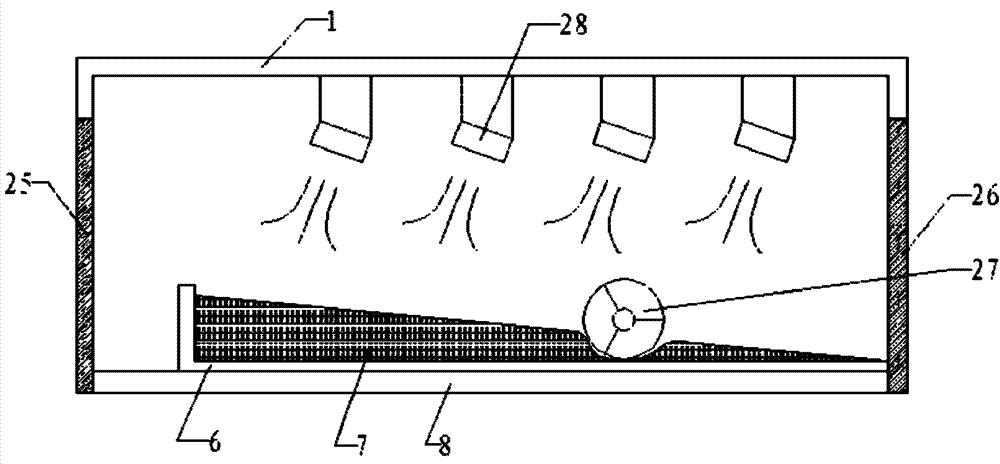

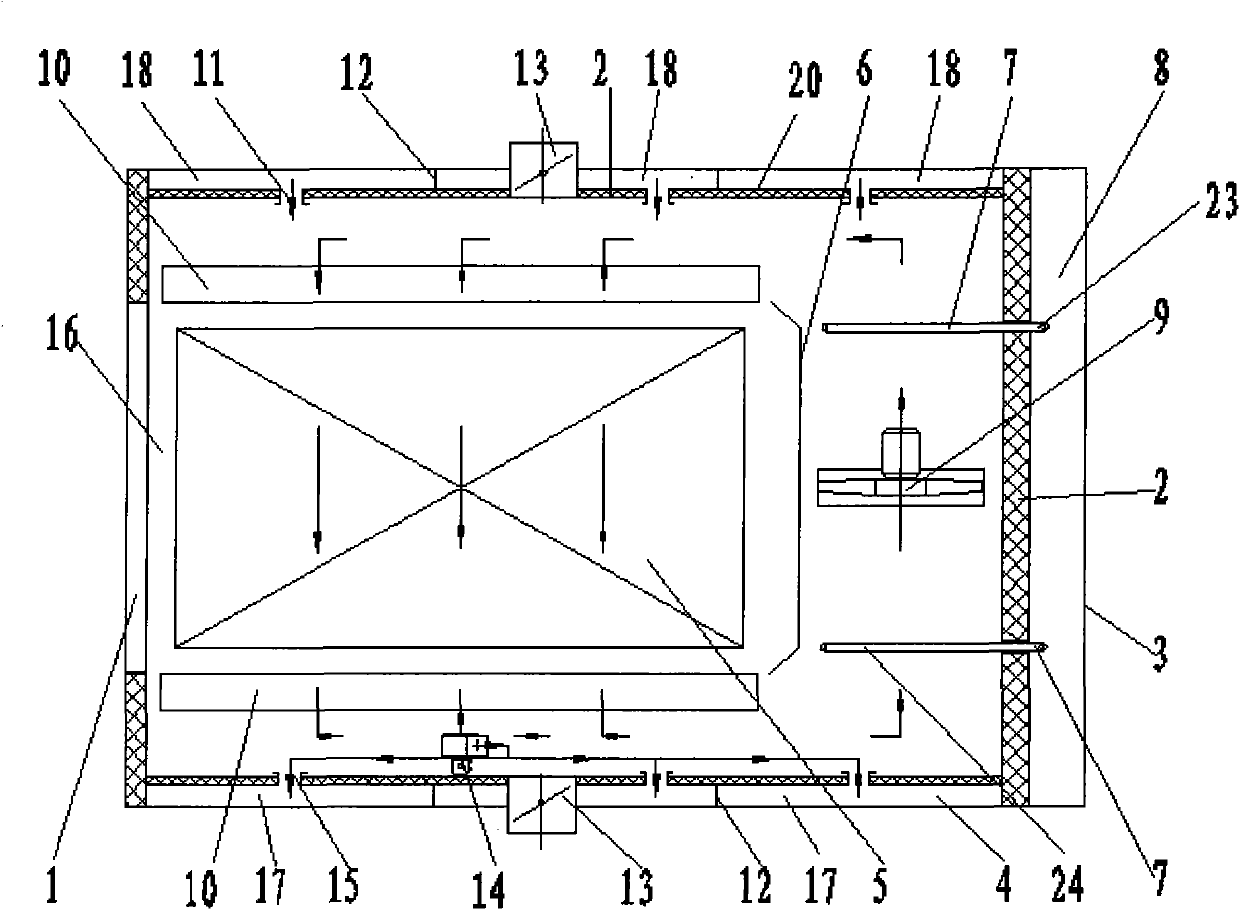

Greenhouse-type solar heat pump combination drying device and method thereof

ActiveCN102767937AMeet the area requirements for collecting solar energyPlay the role of sludge storageSludge treatment by de-watering/drying/thickeningDrying solid materials with heatSolar dryingGreenhouse

The invention relates to solar drying devices, and particularly discloses a greenhouse-type solar heat pump combination drying device and a method thereof. The device comprises a greenhouse, an air return fan, a fresh air fan, a drying bed and a control center, wherein the air return fan is arranged inside the greenhouse, one end of the air return fan is an air return port, the other end of the air return fan is an exhaust port and penetrates through the side wall of the greenhouse to extend out of the greenhouse through an air return pipe, the fresh air fan is positioned outside the greenhouse, one end of the fresh air fan is a fresh air port, the other end of the fresh air fan is an air supply port and penetrates through the side wall of the greenhouse to extend into the greenhouse through an air supply pipe, the drying bed is arranged inside the greenhouse, and the control center is connected with the air return fan and the fresh air fan. By the greenhouse-type solar heat pump combination drying device and the method thereof, heat of solar energy can be utilized to heat and dry materials in the greenhouse in an energy-saving and high-efficiency manner.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Solar energy drying shed

InactiveCN1916545AOvercoming the open airOvercoming heatingDrying solid materials with heatDrying machines with local agitationBrickSolar drying

A drying shed of solar energy is prepared as forming shed roof by framework and light transmittance as well as heat insulation layer, opening air-vent on top of shed and air inlet at bottom of shed, arranging door on wall of shed for sending in and moving out material to be dried and dried material as well as paving ground in shed by bricks.

Owner:黄坤勇

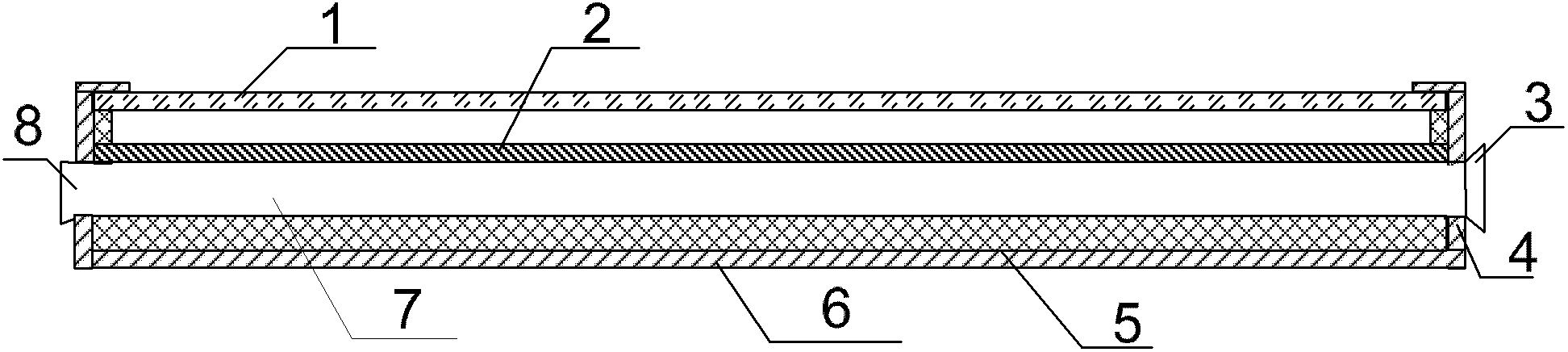

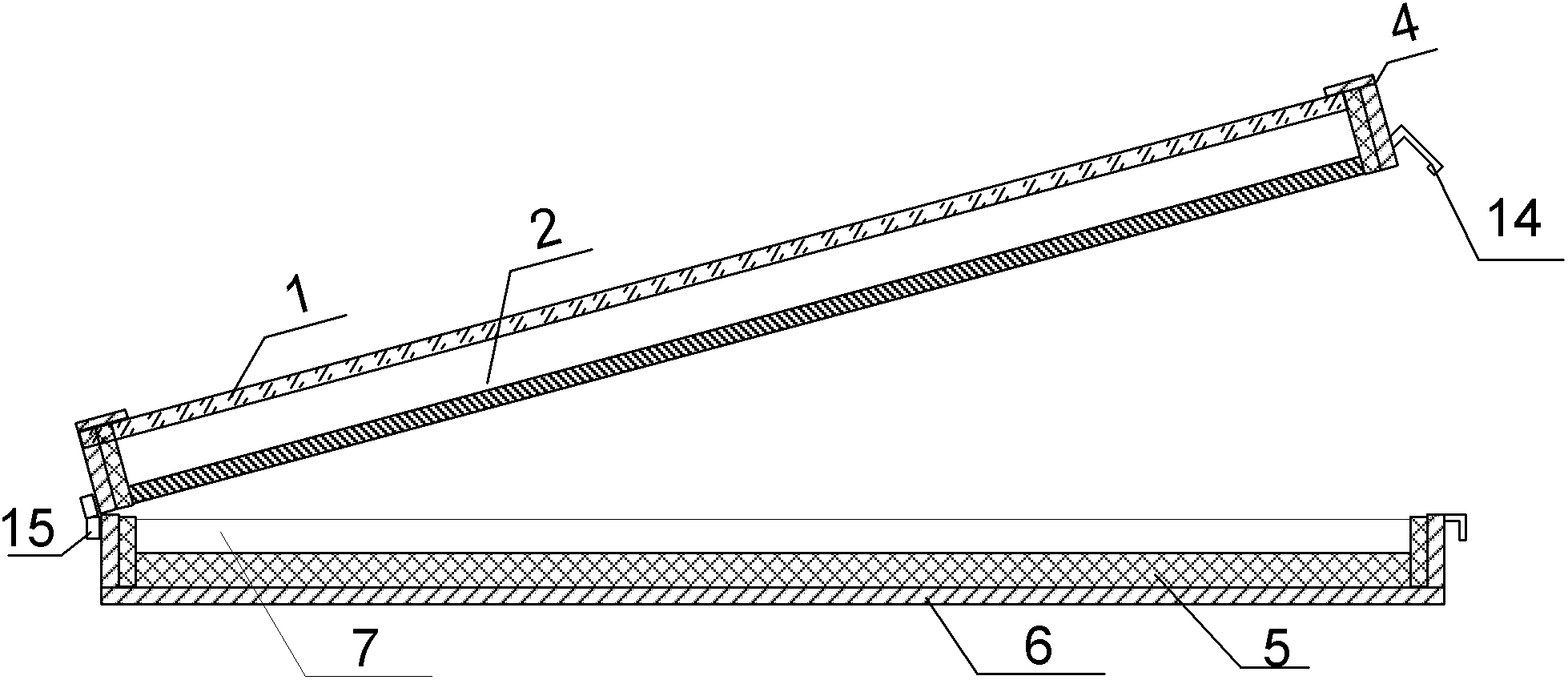

Panel-type solar drying machine based on heat conduction

InactiveCN102353242AKeep the pressureMaintain concentrationSolar heating energySolar heat devicesSolar dryingInsulation layer

The invention discloses a panel-type solar drying machine based on heat conduction. The panel-type solar drying machine comprises a photic cover plate (1), a heat absorption plate (2), borders (4), a heat insulation layer (5), a bottom plate (6) and an object drying chamber (7); the photic cover plate (1) is arranged on an uppermost layer, and the heat absorption plate (2), the heat insulation layer (5) and the bottom plate (6) are sequentially arranged below the photic cover plate (1); the borders are (4) are arranged on the peripheries of the photic cover plate (1), the heat absorption plate (2), the heat insulation layer (5) and the bottom plate (6) for fixation; and a space between the heat absorption plate (2) and the heat insulation layer (5) is the object drying chamber (7). When sunlight radiates to the heat absorption plate (2), the heat absorption plate (2) is used for transferring heat to an object which is to be dried and ins close contact with the heat absorption plate (2) through temperature-difference drive, so that moisture inside the object is heated and evaporated and escapes from the drying machine, and thus, the object is dewatered and dried.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

Solar collector-oven combined clothes drying device

InactiveCN102268806AEliminate the phenomenon of good imageImprove availabilityLaundry dryer apparatusTextiles and paperSocial benefitsAromatherapy

The invention relates to a solar heat collector-oven combined clothes drying device, comprising a solar drying box, the solar drying box includes a heat transfer pipe, a temperature and humidity meter, an incubator, a movable glass door, a fan and a regulating valve, and the heat preservation There are three rows of heat transfer pipes in the box, and regulating valves are installed on the heat transfer pipes. There are movable glass doors on the front and back of the incubator, fans are installed on the rear movable glass doors, and a temperature and humidity instrument is installed on the side. Inside the incubator. Compared with the prior art, the present invention occupies a small area, can be used indoors under the condition of completely imitating the "natural environment", and is equipped with an ultraviolet disinfection lamp and a hollowed-out aromatherapy box, which can dry clothes while drying them. Sterilization and fresh air achieve better results than outdoor drying. The invention can be effectively applied to various families, hotels, schools, etc., and has high practical value and economic and social benefits.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

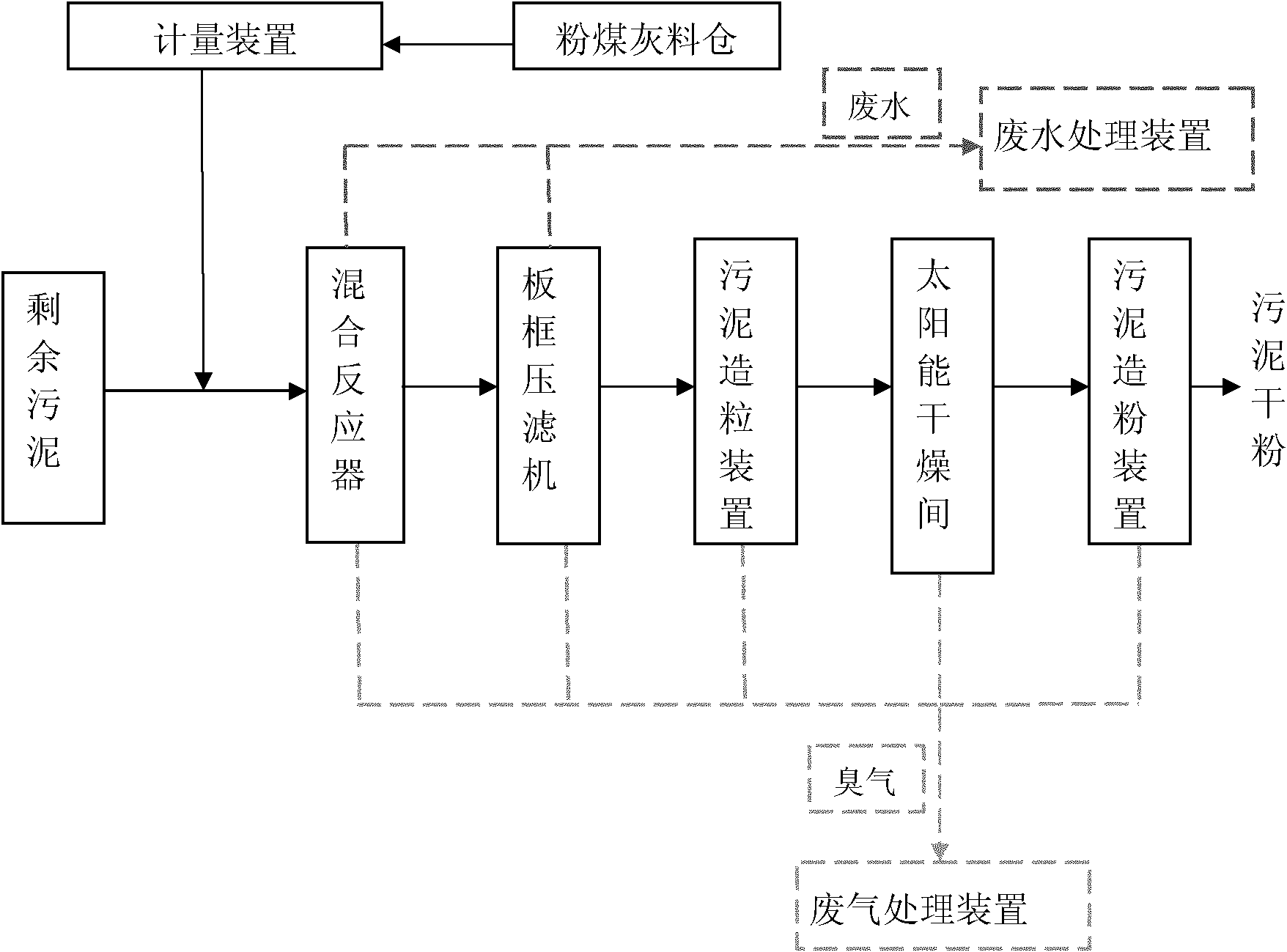

Process for treating excess sludge by utilizing fly ash

ActiveCN102161562ALoose textureWell-developed poresSludge treatment by de-watering/drying/thickeningWaste processingBound waterSolar drying

The invention relates to a process for treating excess sludge by utilizing fly ash. The method specifically comprises the following steps of: 1, feeding excess sludge to be treated which has the water content of between 80 and 90 percent, and fly ash in an amount which is 20 to 50 percent based on the mass of the excess sludge into a mixing agitator; fully mixing and reacting for 5 to 15min; feeding into a plate and frame dehydrator for dehydration to obtain sludge of which the water content is reduced to be between 35 and 45 percent; crushing the sludge into coarse particles with the particle size of between 3 and 5mm by using a sludge granulation device; feeding the sludge particles into a solar drying room, and drying for 24 to 48h at the temperature of above 40 DEG C and under the humidity of below 15 percent to ensure that the water content of the sludge is reduced to between 8 and 15 percent; and treating by sludge pulverization equipment and a high-speed airflow collision technology, wherein the particle size of sludge powder is 150 to 300 meshes and the water content is 5 to 10 percent after the treatment. The method has the advantages that: interstitial water, adsorbed water and capillary bound water in the excess sludge are absorbed into the fly ash; due to the characteristic of high permeability coefficient of the fly ash, the water in the fly ash is easily discharged; and the secondary pollution to the environment is avoided by appropriately treating the excess sludge.

Owner:北京方兴科创环境科技有限公司

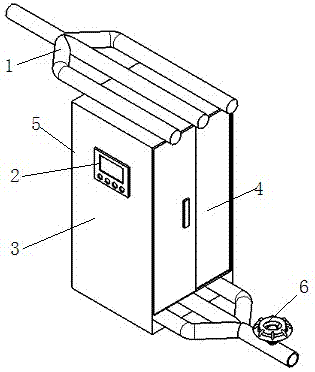

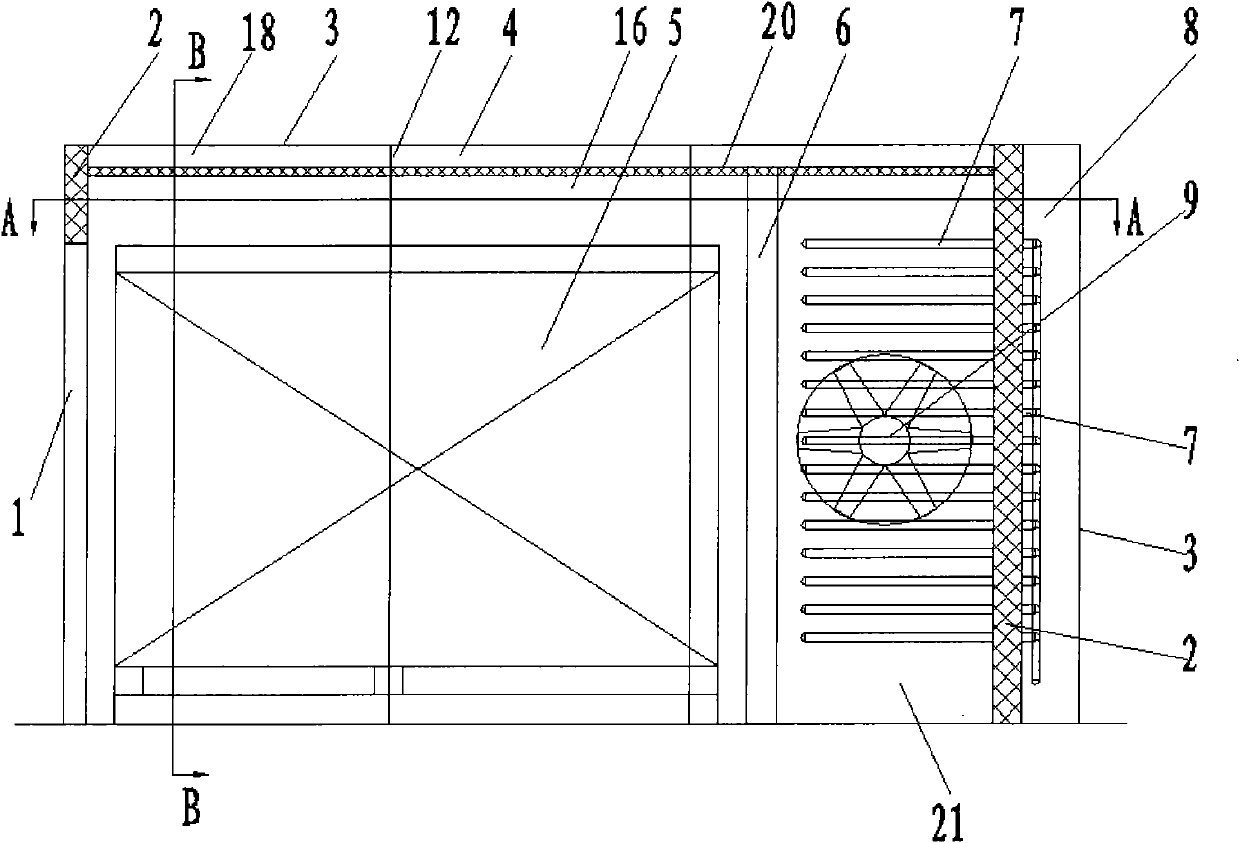

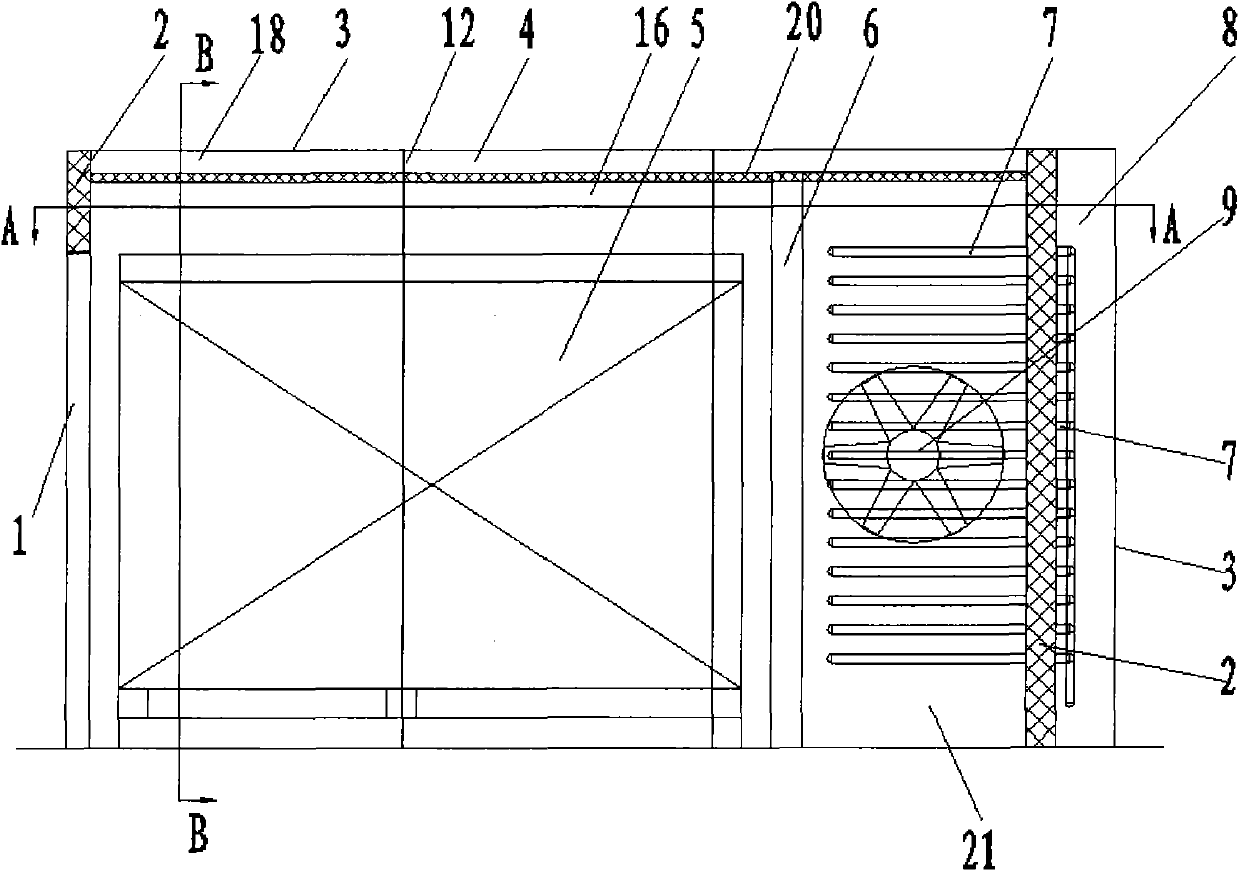

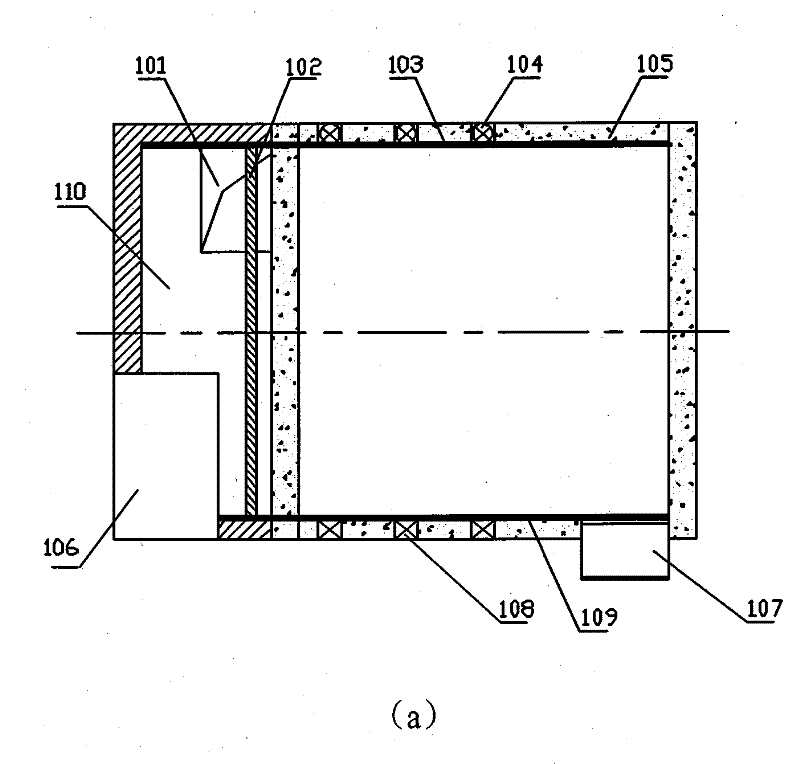

Solar drying device

InactiveCN101907384AIncrease the areaImprove thermal efficiencySolar heating energySolar heat devicesTemperature controlSolar drying

The invention relates to a wood solar drying device. The drying device adopts an integral end-fan structure of a greenhouse and a heat collector and combines the advantages of the greenhouse and the heat collector. The heat sources of the drying device comprise a heat-pipe solar heat collector located on a south-end wall and an integral arched solar heat collector, and the heat collectors have large area and high heat efficiency. The two heat collecting systems can be used independently or cooperatively according to required drying temperature, and temperature control is flexible and stable. A heat-accumulation air-guiding wall is arranged inside the drying device so as to ensure the continuity and the uniformity of drying. A technical method of the wood solar drying device is as follows: when solar energy is sufficient in the daytime, the drying device is in a heating and drying stage, and when solar energy is insufficient in the night or on cloudy days, the drying device is in a heat preservation stage. The solar drying device has stable operation, high solar conversion efficiency and obviously reduced drying energy consumption, thereby having low drying cost and high drying quality.

Owner:BEIJING FORESTRY UNIVERSITY

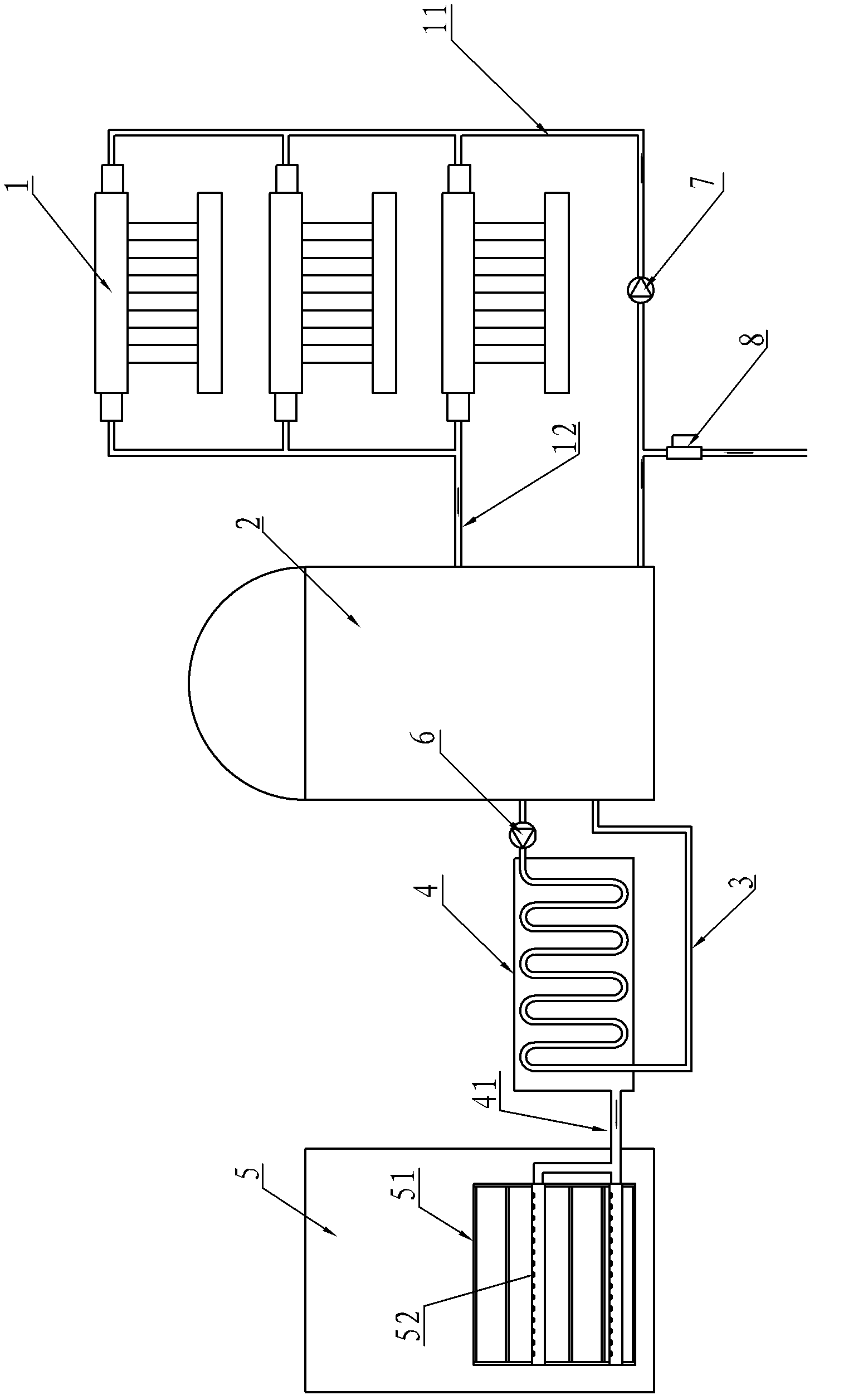

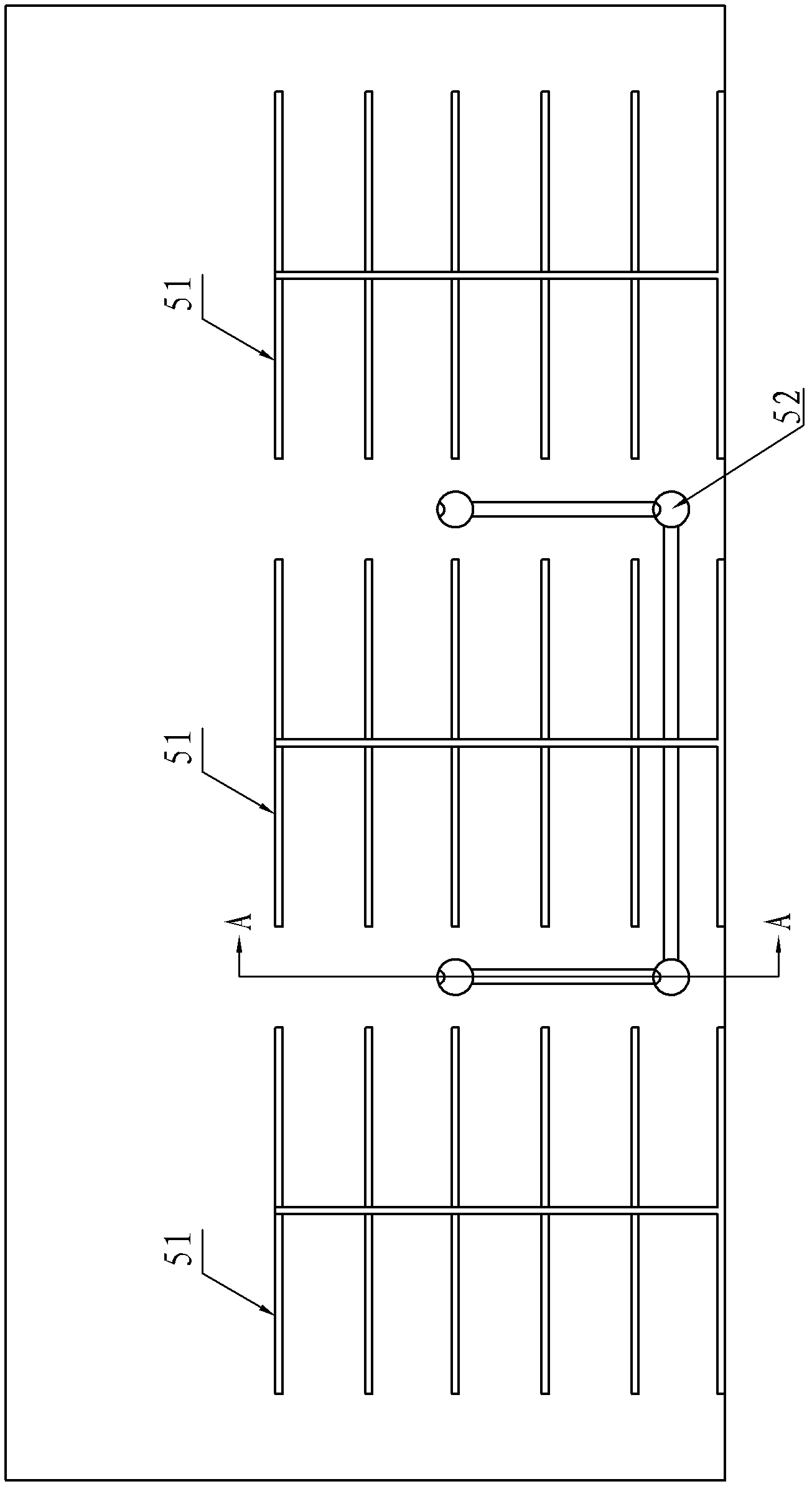

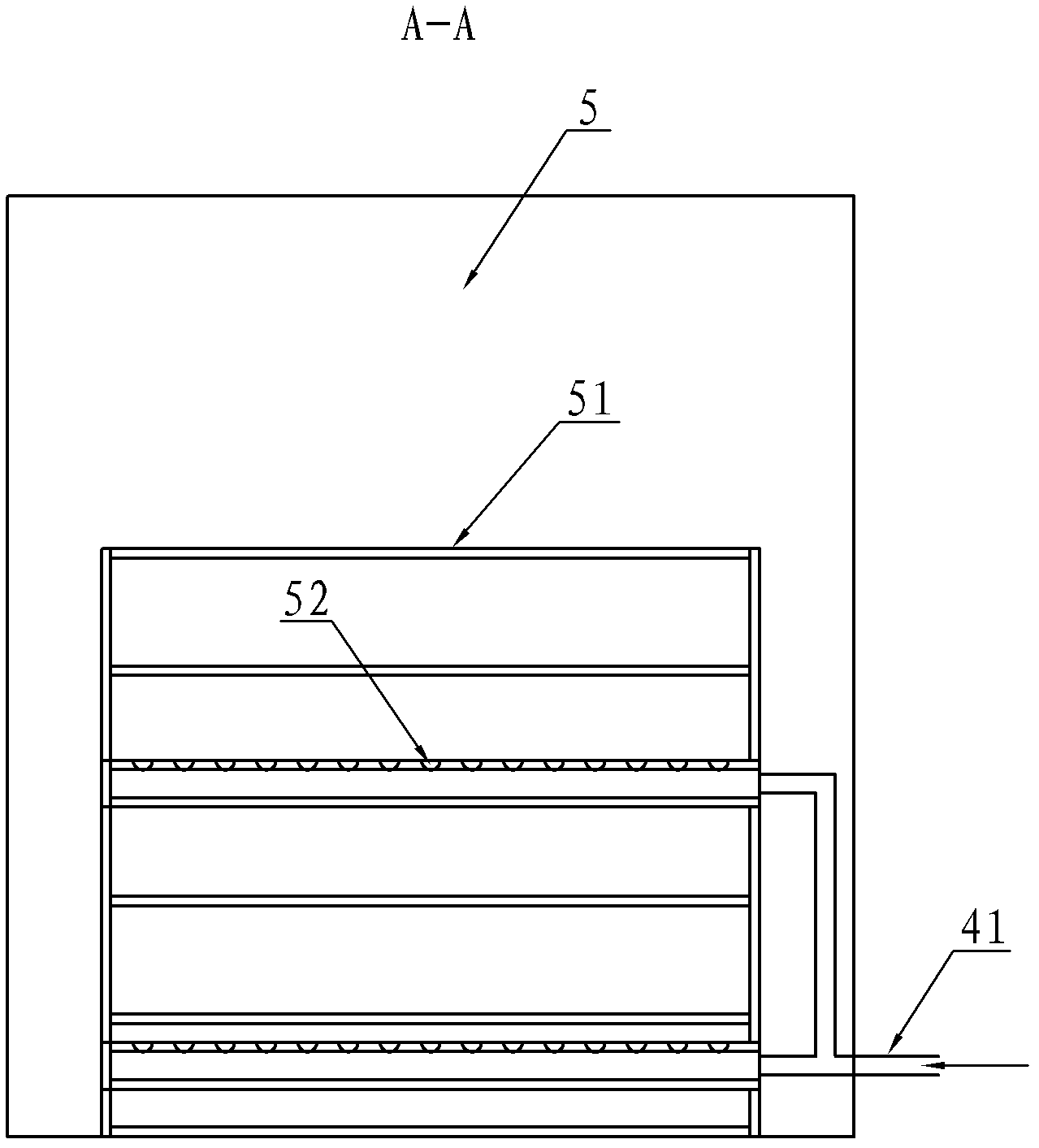

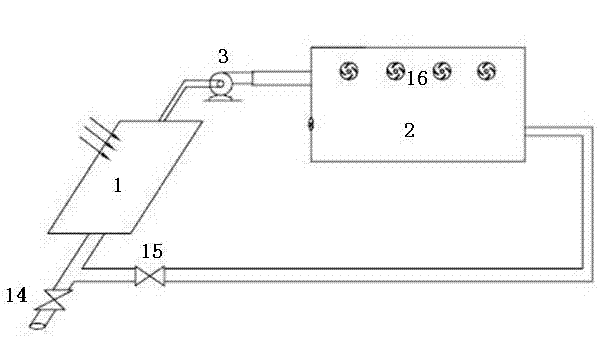

Heat collector system of multifunctional solar drying room

InactiveCN102564097AMeet drying needsReduce electricity consumptionSolar heat devicesDrying gas arrangementsThermal energySolar drying

A heat collector system of a multifunctional solar drying room comprises a solar heat collector, a heat-insulation water tank, a circulating water return pipe, a heat converter, a drying room, a heat exchange pump, a circulating water supply pump and a water replenishment valve. The solar heat collector acquires solar heat, forced circulation between the solar heat collector and the heat-insulation water tank is realized by the aid of the circulating water supply pump, accordingly, the solar heat acquired by the solar heat collector is continuously transmitted to the heat-insulation water tank, then hot water in the heat-insulation is delivered to the heat converter via the heat exchange pump, and is converted into hot air by the aid of circulation of the heat converter, and the hot air is delivered into the drying room via a heat supply pipe. Accordingly, an existing conventional heating mode is replaced, the temperature of water in the heat-insulation water tank can reach about 80 DEG C as long as illumination time reaches 8 hours, the temperature of the inside of the drying room can range from 50 DEG C to 60 DEG C, and conventional drying requirements can be met. Tests show that power consumption of the heat collector system can be saved by 60% to 75% as compared with the existing conventional heating drying mode.

Owner:JIANGSU PLET PLASTIC PACKING

Greenhouse-type drying device combining solar and sewage sources with heat pump and method

InactiveCN102765864AMeet the area requirements for collecting solar energyPlay the role of sludge storageSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentSolar dryingGreenhouse

The invention relates to the technical field of solar drying devices, and specifically discloses a greenhouse-type drying device combining solar and sewage sources with a heat pump and a method. The device comprises: a greenhouse gas having an air inlet and an air outlet; a drying bed arranged in the greenhouse; the heat pump, arranged outside the greenhouse, for absorbing heat of external mediums, and making use of the heat to heat liquid working mediums; a ground radiation mechanism arranged under the drying bed, connected with the heat pump unit, and used for heating the material and air in the greenhouse by using the liquid working mediums; and a control center connected with the heat pump unit for controlling the heat pump unit based on solar intensity. The drying device can be energy-saving and efficient in making use of the heat of solar and sewage to heat and dry the materials in the greenhouse.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

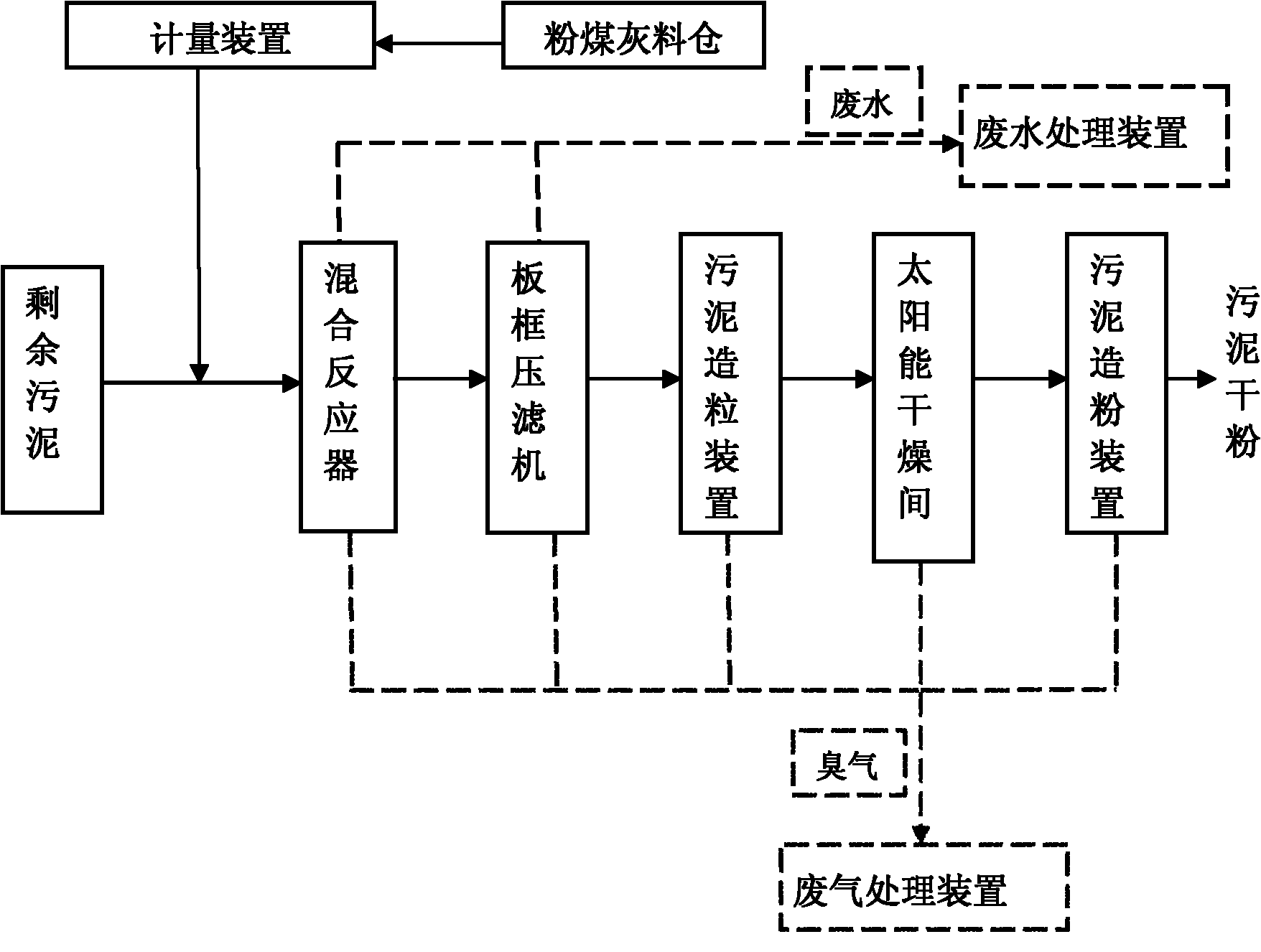

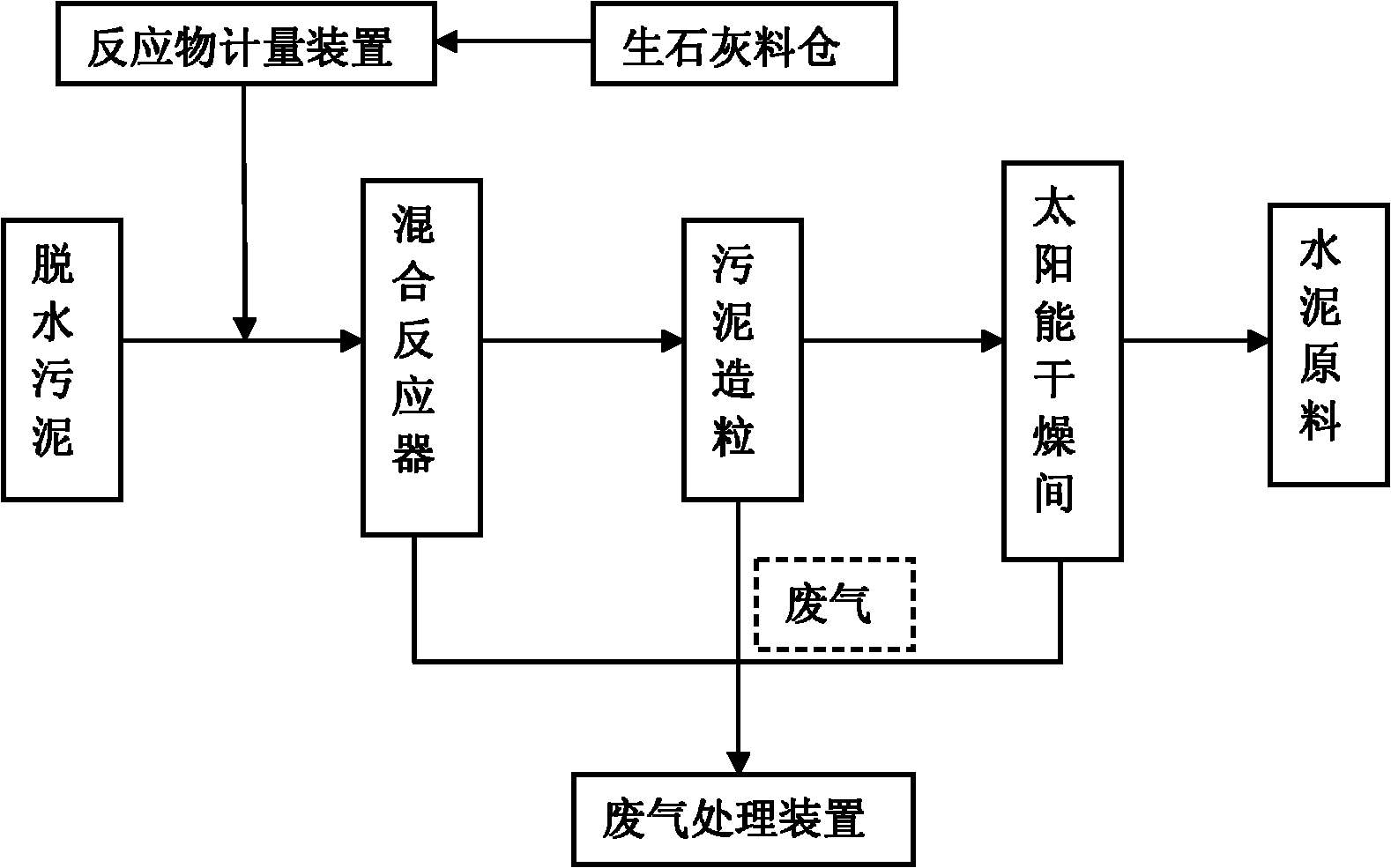

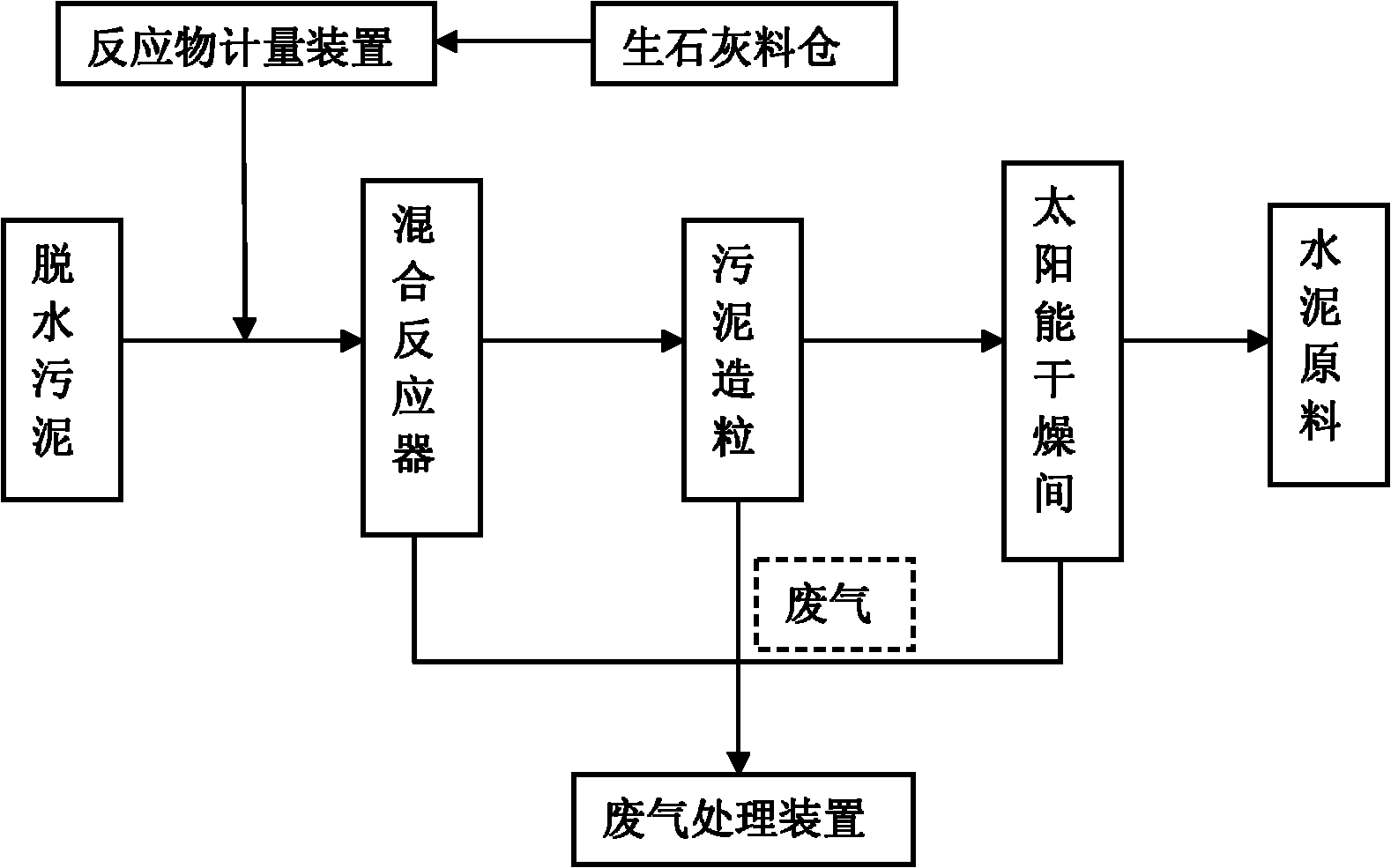

Method for treating low-heating value excess sludge

ActiveCN102173557AReduce usageNo secondary pollutionSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentSolar dryingSludge

The invention provides a method for treating low-heating value excess sludge, which comprises the following steps of: storing calcined lime in a calcined lime storage bin, and conveying different amounts of calcined lime in an amount which is 20 to 50 percent of the mass of the excess sludge into a mixed reactor by using a reactant metering device according to requirements; conveying excess sludge to be treated with the moisture content of between 80 and 90 percent and the calcined lime into the mixed reactor, and mixing uniformly for reaction to prepare half-dried sludge; and feeding the half-dried sludge into a sludge granulating device, crushing to form sludge granules, guiding the granules into a solar drying room, drying for 24 to 48 hours to obtain dried sludge with the moisture content of between 5 and 10 percent, and introducing generated stench into a waste gas treatment device. The method has the advantages that: the aims of the innocuity and minimization of the excess sludge are fulfilled by lower energy consumption without generation of secondary pollution; and compared with that of a mode of treating the excess sludge by using the calcined lime merely, the using amount of the calcined lime can be reduced by the method.

Owner:北京方兴科创环境科技有限公司

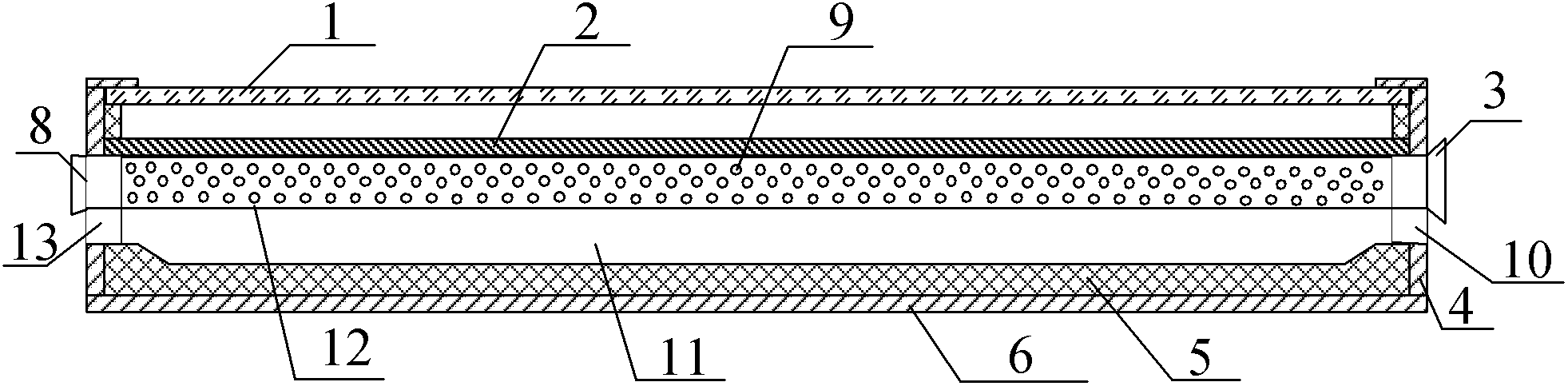

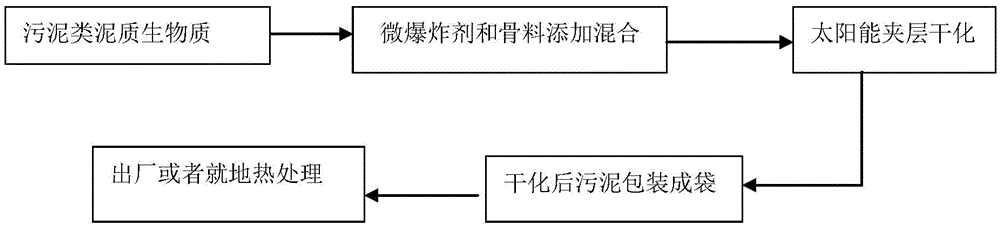

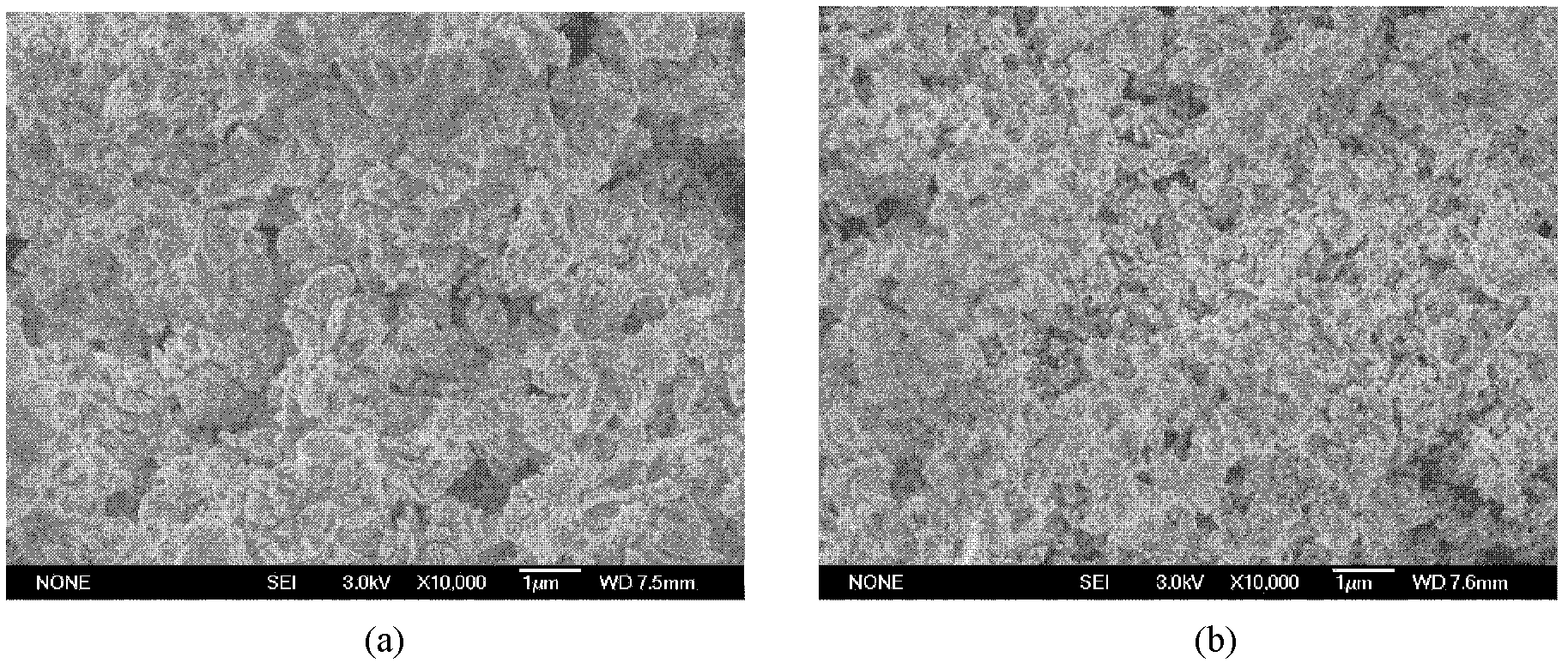

Activated carbon preparation method of sludge type argillaceous biomass

ActiveCN105523555APromote formationGood removal effectSludge treatment by de-watering/drying/thickeningCarbon compoundsSolar dryingWater vapor

The invention discloses an activated carbon preparation method of a sludge type argillaceous biomass. The method comprises: carrying out a process of constructing and conditioning micro-explosion agent / aggregate, a process of solar sandwich drying and a process of activation two-stage pyrolysis; uniformly mixing the sludge obtained after dehydration of the sludge type argillaceous biomass, the micro-explosion agent and the aggregate in a mass ratio of 8.5:0.5:1.0-6:2:2 of a dry basis, then carrying out distribution, carrying out drying in a solar sandwich drying system, then carrying out two-stage pyrolysis in a pyrolysis furnace, controlling the temperature of the initial carbonization stage at 230 DEG C for 20 minutes, then raising the temperature to 400 DEG C at a rate of 20-40 DEG C / min, making a stop for 30-60minutes, and introducing water vapor into a water vapor activation stage at a flow rate of 0.1-1L / (min.G), wherein the pyrolysis final temperature is 550-650 DEG C, the residence time is 20-60 minutes, the EET of the formed activated carbon is 200-500m2 / g, and the particle size is less than 20mm; and the micro-explosion agent is one or more of ammonium nitrate, potassium ammonium nitrate and calcium ammonium nitrate, and the aggregate is a waste circuit board. The preparation method disclosed by the invention comprehensively uses solar drying, micro-explosion agent swelling pore-forming and waste resin to construct a framework, and thereby improving the solar drying efficiency of the sludge and the quality of the activated carbon.

Owner:SHANGHAI JIAO TONG UNIV

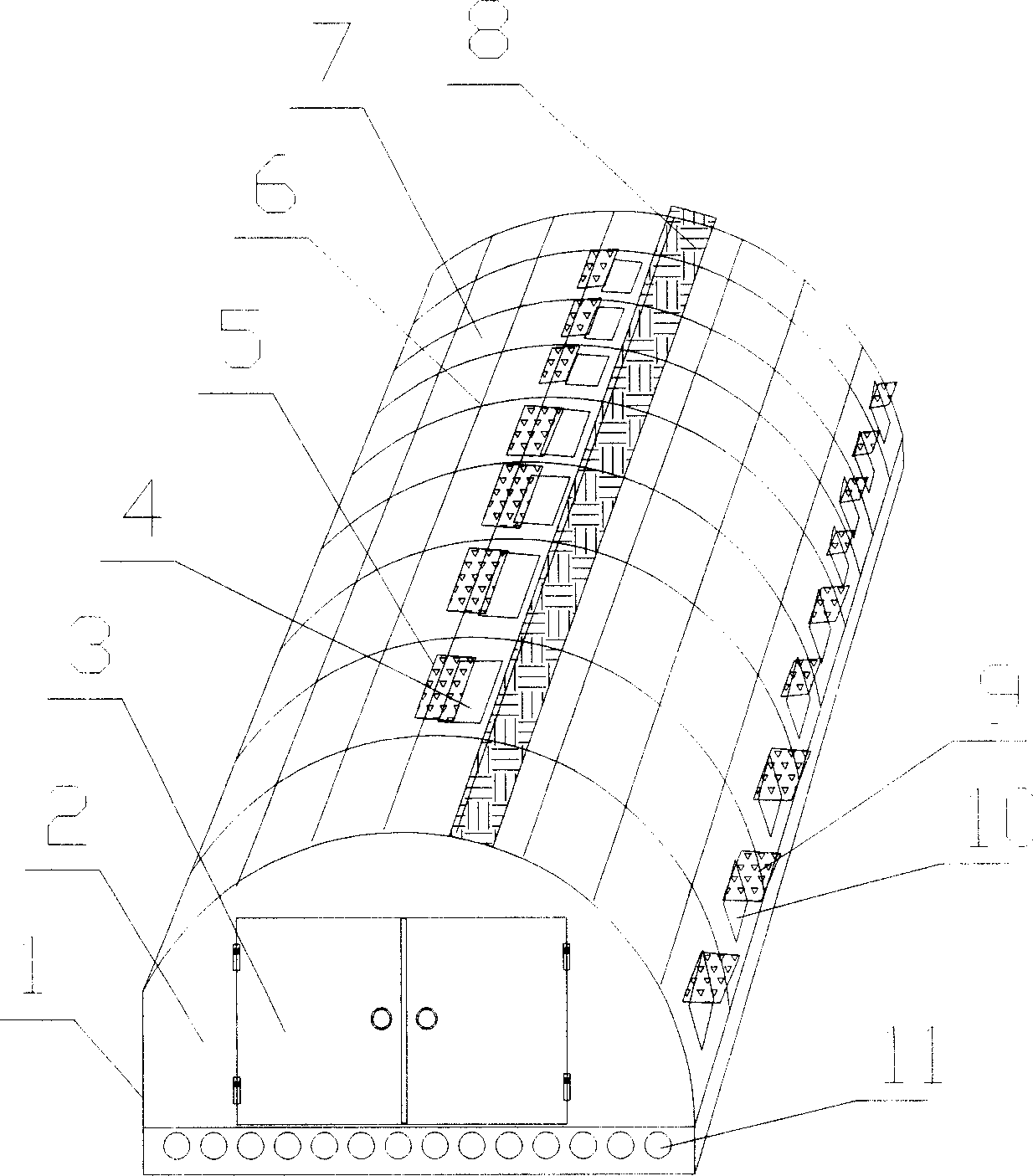

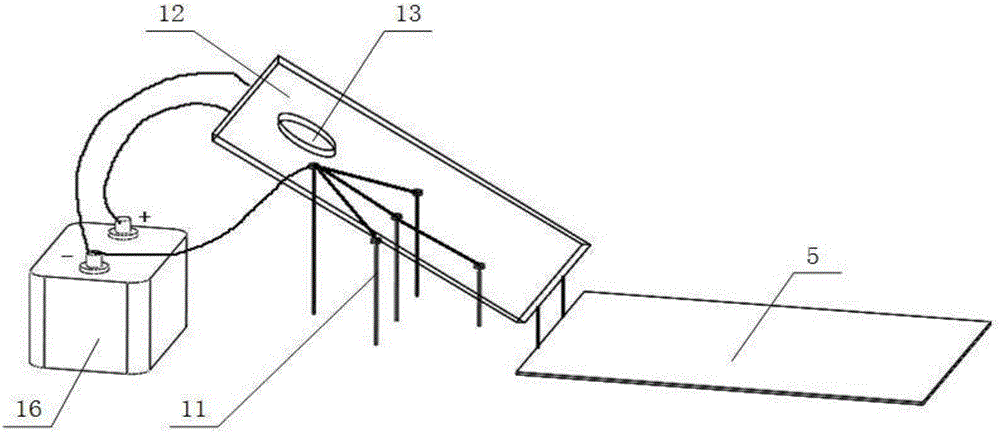

Solar multi-directional tracking solar energy drying equipment

InactiveCN101839617AReduced range of motionReduce energy consumptionSolar heating energyDrying solid materials with heatSolar dryingPlane mirror

The invention discloses solar multi-directional tracking solar energy drying equipment. In the equipment, one or a group of solar linear focusing optical mirrors comprising a plurality of reflecting mirrors, a Fresnel mirror, a plane mirror and the like is / are adopted; a revolving shaft of each mirror is arranged on a solar linear focusing optical mirror support; each solar optical mirror can rotate around the shaft, and meanwhile moves together with the solar mirror support, so that the tracking of the solar energy can be realized by the multi-directional tracking consisting of rotating around the shaft and moving together with the solar mirror support; and as the solar energy drying equipment is arranged in a cylinder interval on ground or a building, when the solar mirror moves, the solar energy drying equipment can keep still, the focal length is variable zooming and tracking, and the solar energy drying equipment realizes the drying utilization of the focused and tracked solar energy in a cylinder. The invention provides an array structure of the equipment, which is suitable for systems of different scales, and simultaneously suitable for large-scale utilization of the solar energy drying equipment.

Owner:BEIJING WISWORD HI TECH

Solar drying technique for apricot

InactiveCN101171975AGolden colorSave energyFood processingFood preservationThermal energySolar drying

The invention provides a novel technology for drying apricot by combining the solar energy heating and the vapor heat energy heating, and combining the solar radiation drying and the hot blast convection drying. The drying processing of the apricot is divided into three steps, and the parameter such as dying temperature, humidness, etc. of each step is provided. The drying process cycle of the drying process is short, the energy is saved, and the dried apricot has the advantages that the color is golden, the taste is pure, and the quality product rate is high.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

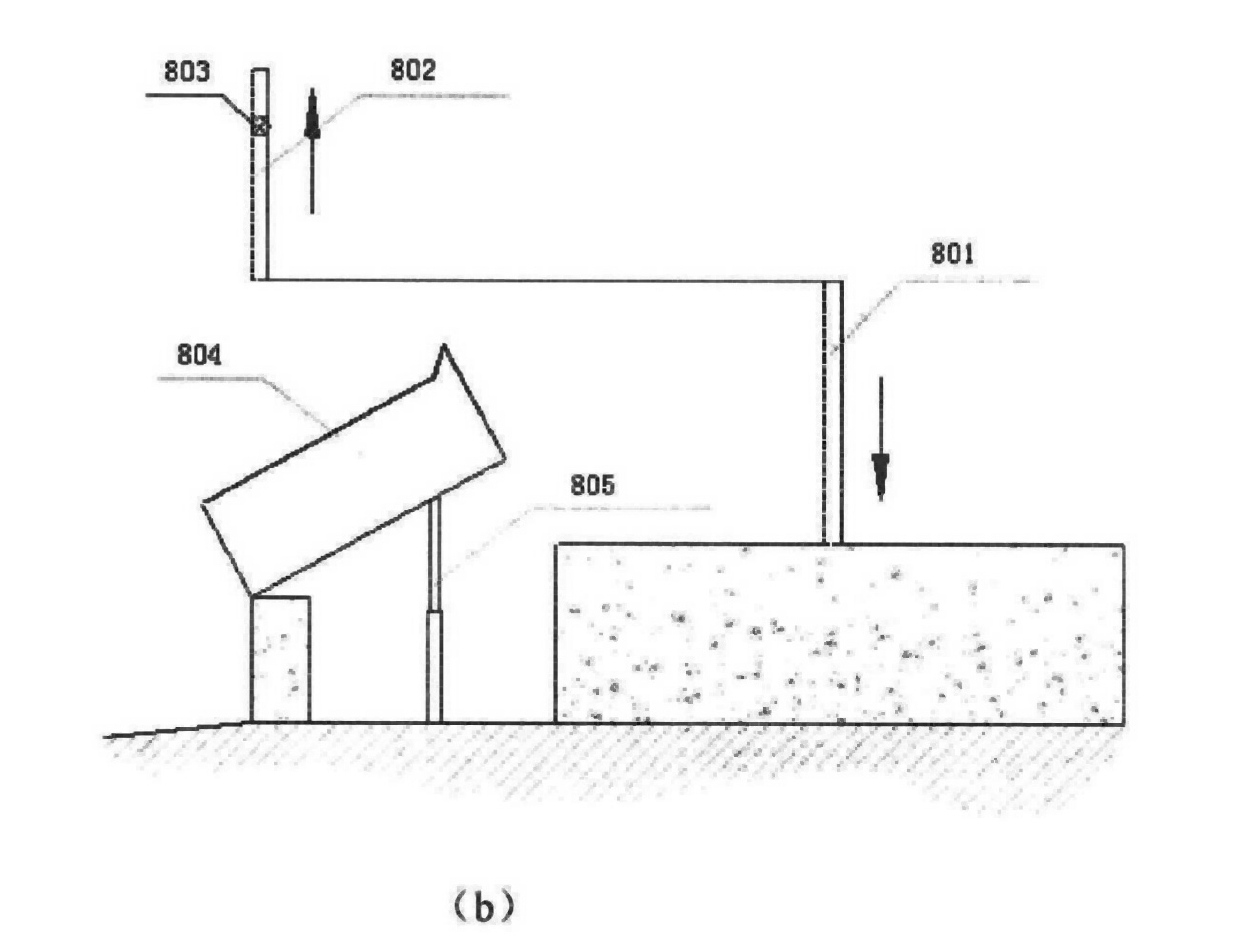

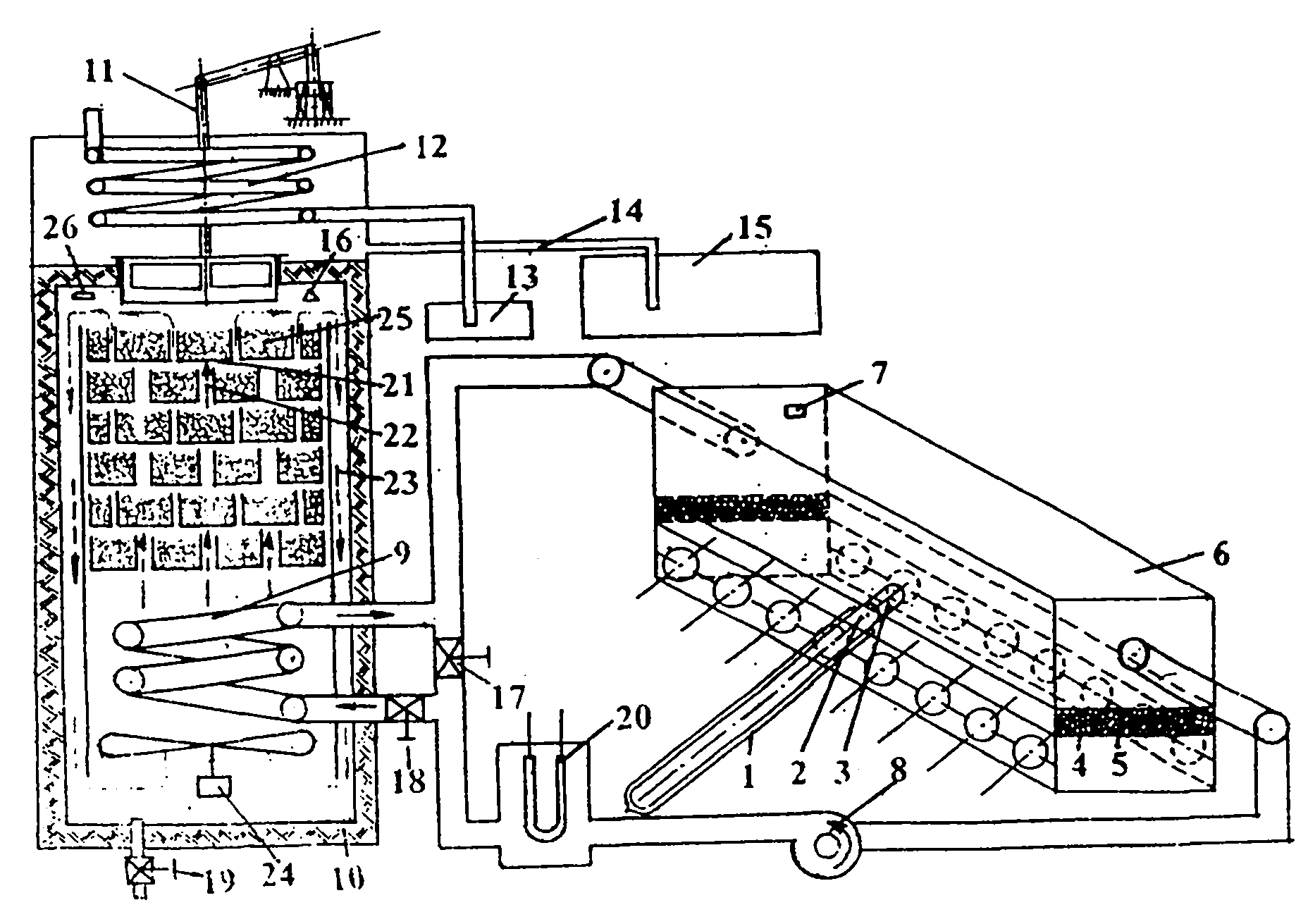

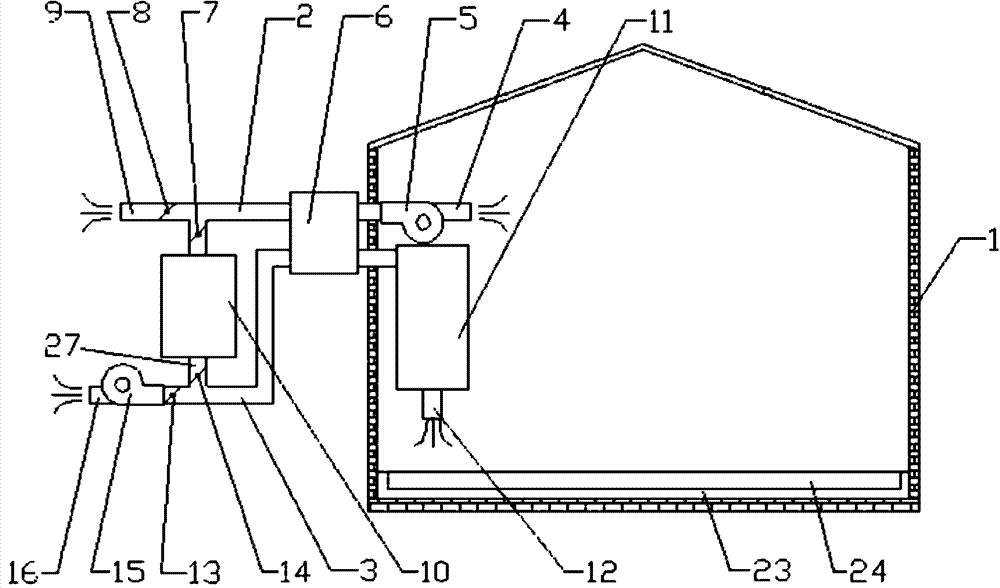

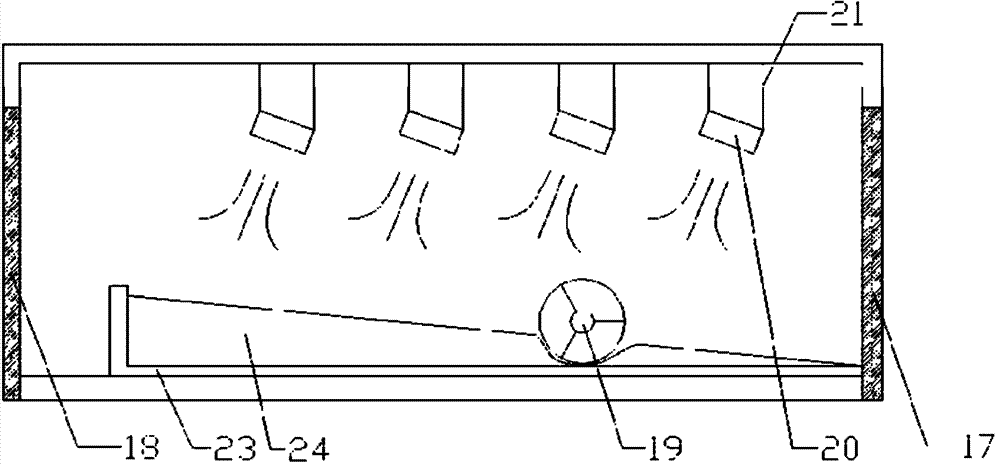

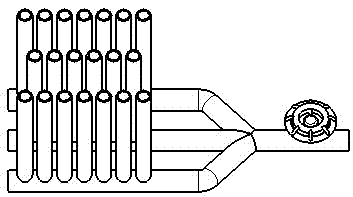

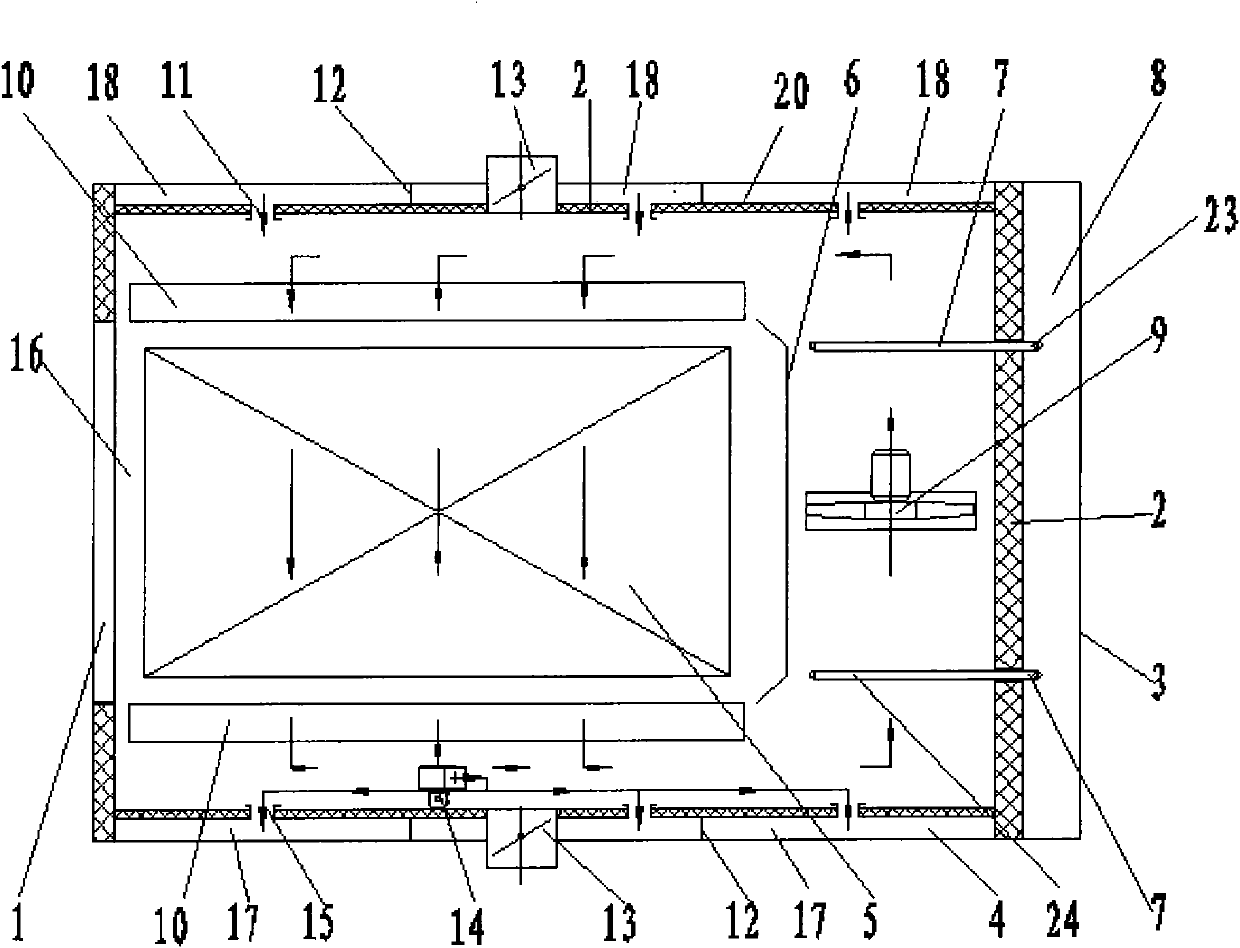

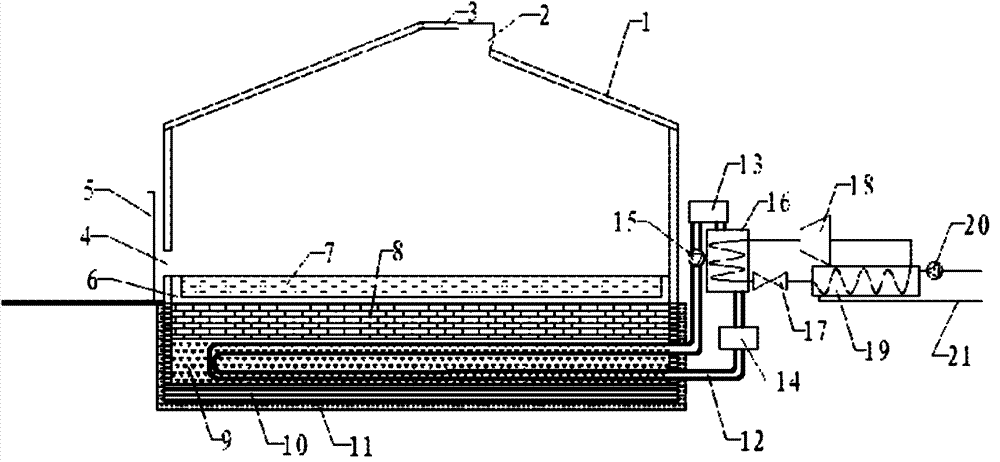

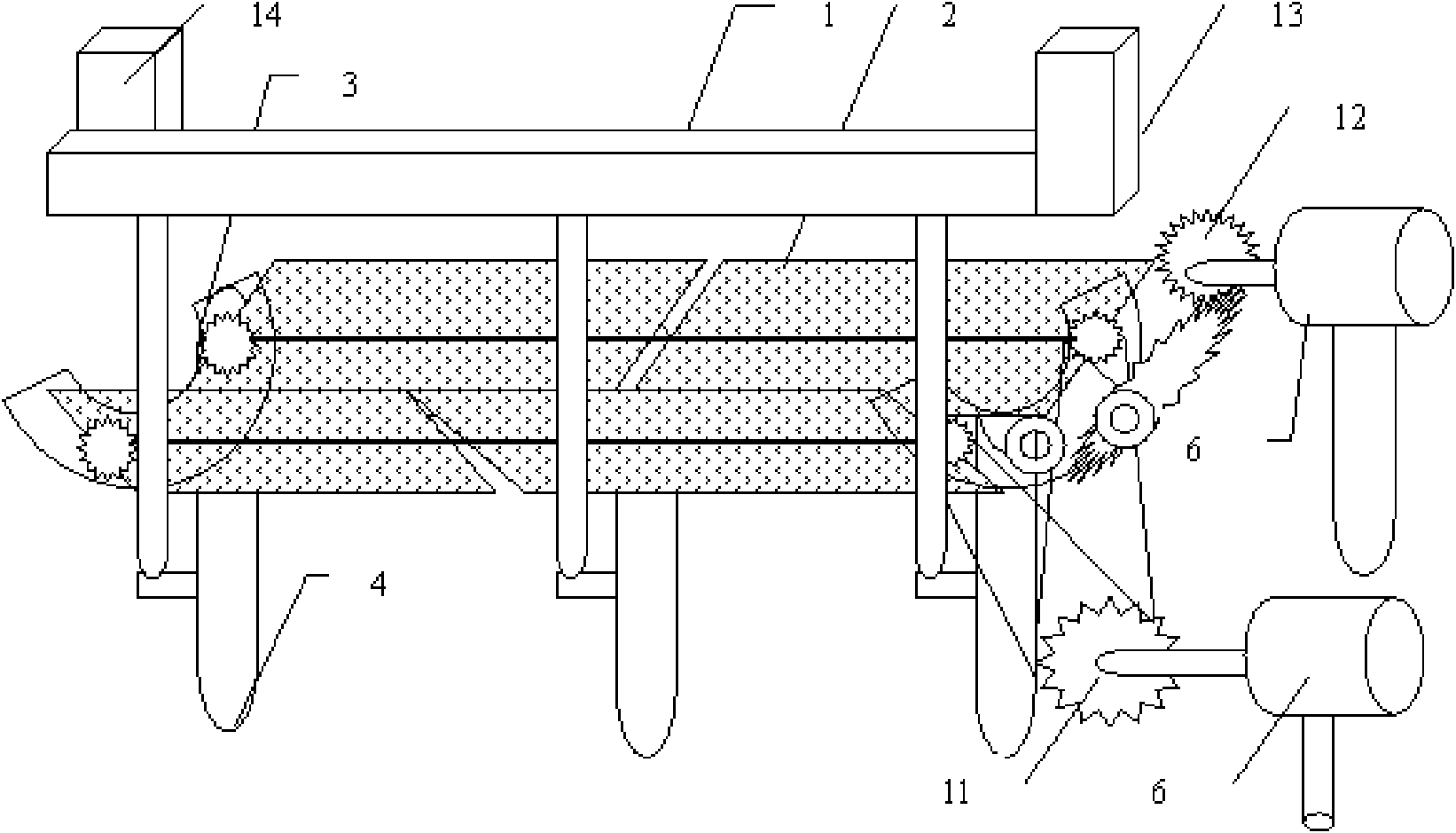

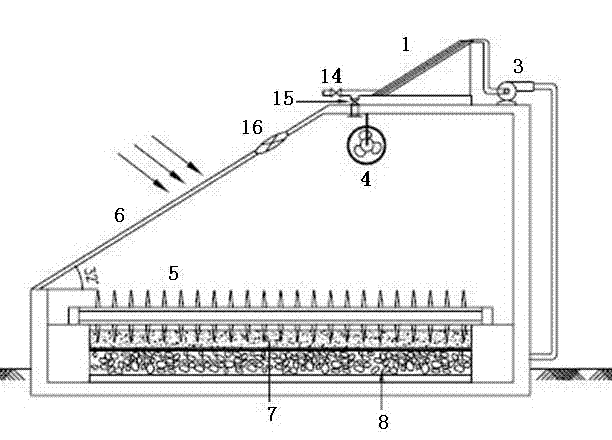

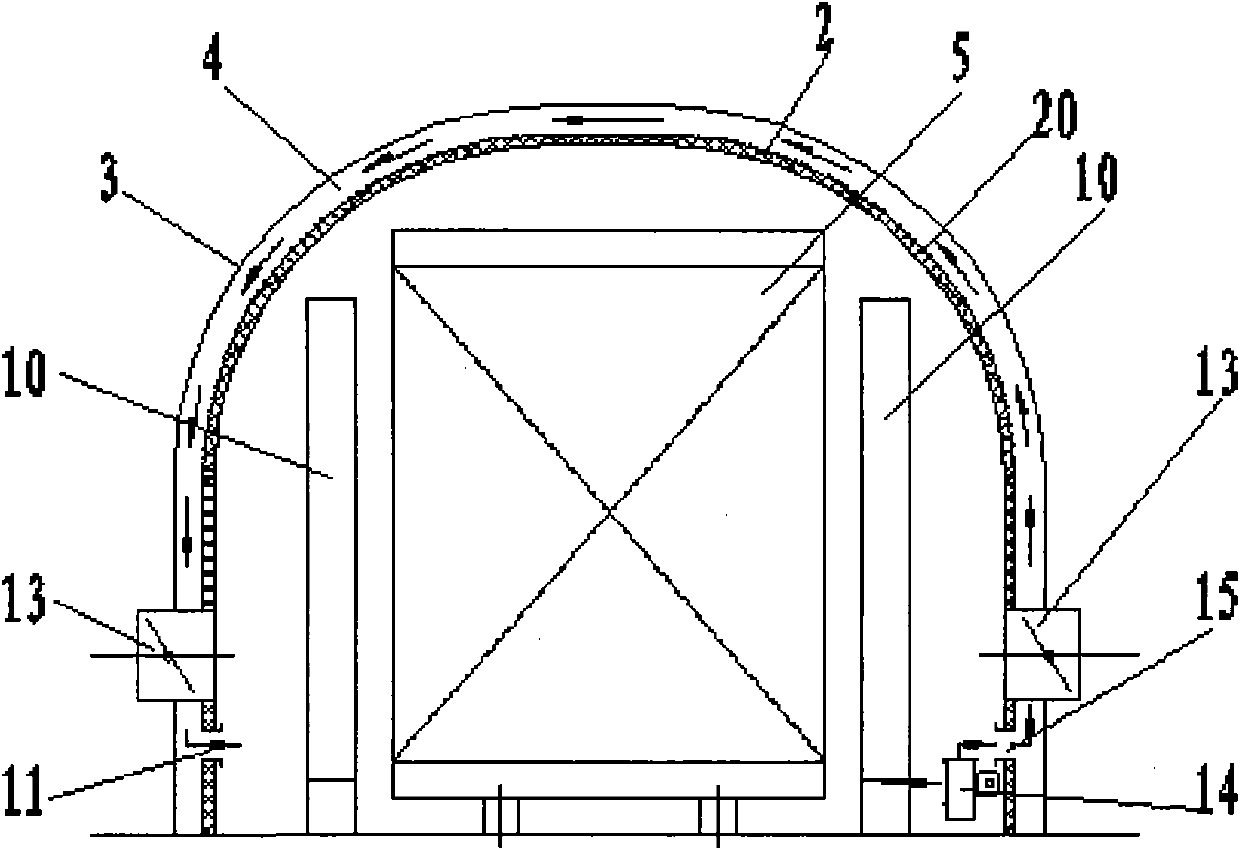

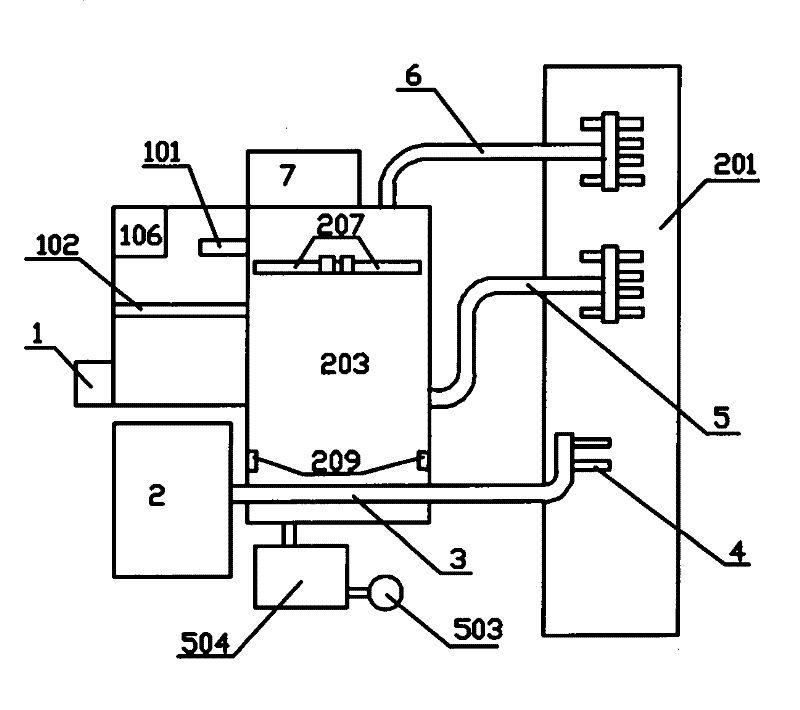

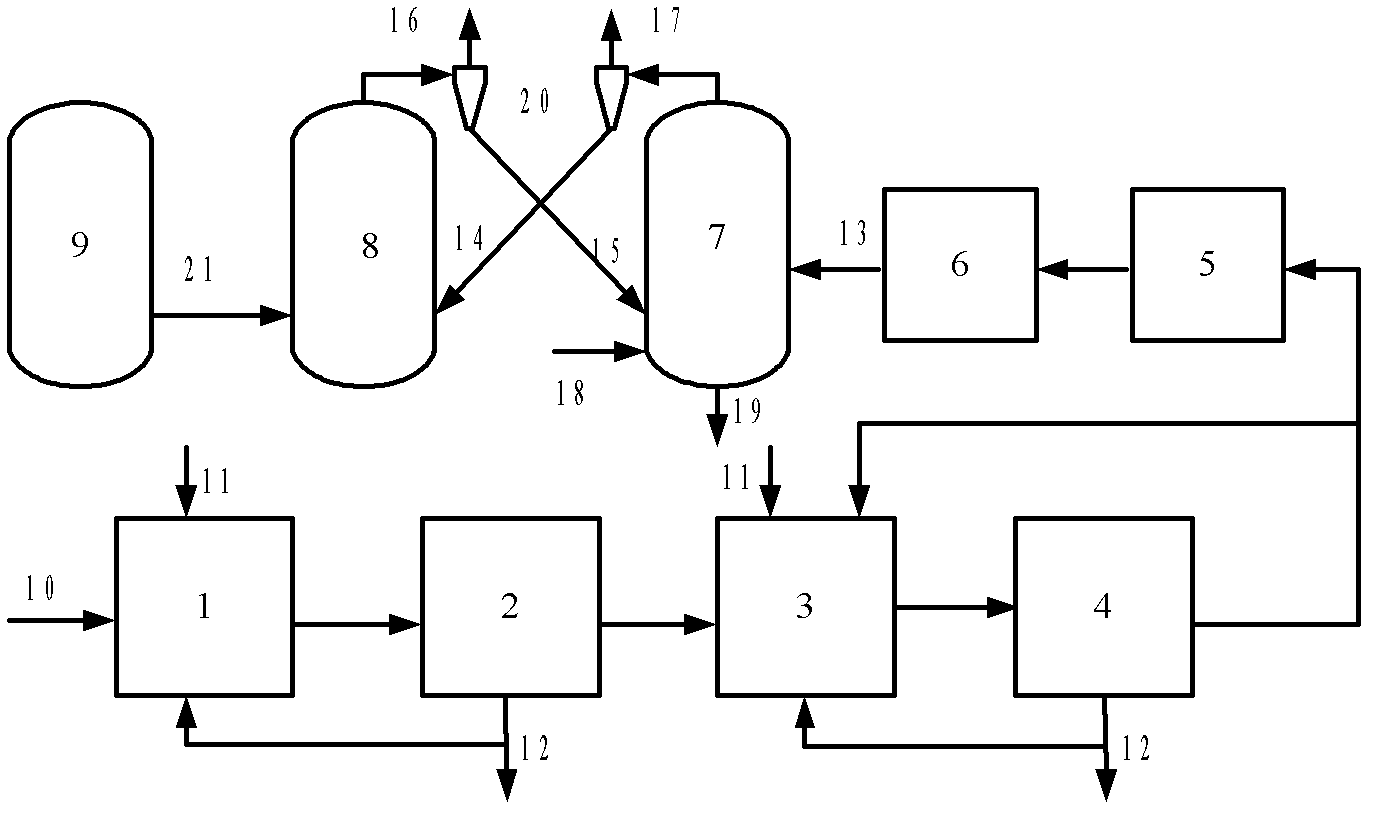

Greenhouse-heat collector-type solar sludge drying system and method

InactiveCN102381826AShorten drying timeImprove energy savingSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentSolar air collectorSolar drying

The invention relates to a greenhouse-heat collector-type solar sludge drying system and method. The system comprises a feed bin (11), a solar greenhouse (2), a solar air collector (1), a duct fan (3), ventilation equipment and a three-way pipe, wherein a first end of the three-way pipe is communicated with outside atmospheric air through a first valve (14), a second end of the three-way pipe is communicated with the solar greenhouse (2) through a second valve (15), and a third end of the three-way pipe is communicated with the hot air inlet of the solar air collector (1); the hot air outlet of the solar air collector (1) is communicated with the hot air inlet of the solar greenhouse through the duct fan (3); a heat storage layer is laid on the bottom surface of the solar greenhouse; and a spreader and sludge turning equipment are also arranged in the solar greenhouse. The greenhouse-heat collector-type solar sludge drying system has the advantages of low operating cost, zero discharge, good technical effect and capability of industrial automated operation, thus playing a positive role in supporting reduction and resource utilization of sludge.

Owner:JIANGSU LONG LEAPING ENG DESIGN +2

Preparation method of paraffin phase-change microcapsule

InactiveCN107722943AIncrease coverageNot easy to break emulsionHeat-exchange elementsMicroballoon preparationSolar dryingThermal insulation

The invention provides a preparation method of a paraffin phase-change microcapsule applicable to the phase change energy storage field. The preparation method comprises the following steps: preparinga melamine modified urea resin prepolymer solution; adding paraffin and an emulsifier solution into the prepolymer solution, so as to obtain a paraffin emulsion; and adjusting the pH value of the paraffin emulsion to 3, and stirring at a constant temperature to generate in situ polymerization, so as to obtain the paraffin phase-change microcapsule adopting melamine modified urea resin as a wall material. The paraffin phase-change microcapsule prepared by virtue of the preparation method has the advantages of small particle size, excellent phase-change performance, good stability and the likeand can be directly applied to the fields of building thermal insulation, solar drying, textiles and the like.

Owner:BEIJING FORESTRY UNIVERSITY

Blue-green algae and excess sludge resourceful treatment method

InactiveCN105800892AAchieving processing powerImplement resourcesSludge treatment by de-watering/drying/thickeningSewage/sludge fertilisersSludge cakeSolar drying

The invention discloses a blue-green algae and excess sludge resourceful treatment method.Blue-green algae with water content of 95-98% and excess sludge are mixed according to the mass ratio of 1:100 to 1:5, dry solid flocculant is added according to the mass percentage of 1%o to 8%o, the materials are sent into a plate frame pressure filter, and sludge cakes with water content of 70-80% is obtained after dewatering.Then, the mud cakes are sent to a storage yard, sludge drying is further achieved through solar drying and air blowing measures, mud cakes are sent into a sludge granulating device to prepare granules with granularity of 2-4 mm and water content of 5-15%.The method has the advantages that blue-green algae and excess sludge can be effectively used as raw materials, nitrogen phosphorus and potassium organic fertilizer contained in blue-green algae and excess sludge is sufficiently used for preparing garden greening and biological agriculture organic slow-release fertilizer, and harmless treatment and resource utilization of blue-green algae and excess sludge are achieved.

Owner:ANHUI JINNONG HUIMIN BIOTECH CO LTD

Additional energy drying device of solar energy drying apparatus

InactiveCN101086423AOvercome the problem that the drying operation cannot be carried outGuaranteed drying qualityHeating arrangementCold airSolar drying

The invention discloses a solar energy drying equipment and an energy drying device for drying the herbage, the herbage seed or the like in the agricultural product and the Chinese herbal medicine in the rain, which is characterized by the following: installing the electric heat section which comprises a curved blast pipe and an electric heater at the blast pipe lower of the plate collector; increasing a plurality of heaters which burn with the coal or the fuel oil or the fuel gas or the agronomic crop stem separately at the storage calorifier lower of the vacuum tube collector hot air drying system. When it rains, the electric heater is stared and the cold air from the blast pipe of the plate collector which is heated by the electric heater through the bend blast pipe blows in the drying storage for drying the material, or the heater which burn with the coal or the fuel oil or the fuel gas or the agronomic crop stem is started, the water in the storage calorifier is heated and the snakelike blast pipe is heated, the internal hot air is used for drying the material in the storage. The invention achieves the drying operation in the rain, which achieves all-weather continuous drying operation, and keeps the drying quality of the drying material.

Owner:HUHHOT BRANCH OF CHINESE ACAD OF AGRI MECHANIZATION SCI

Method for drying wood by using solar energy

InactiveCN101907381AIncrease the areaImprove thermal efficiencySolar heating energyDrying solid materials with heatThermodynamicsSolar drying

The invention relates to a method for drying wood by using solar energy. The method comprises the following steps of: placing a wood to be dried in a drying chamber (16); supplying heat to the drying chamber, and when the temperature T3 of the drying chamber (16) rises and is 2 DEG C higher than the set drying temperature of the wood, stopping the heat supplying of a greenhouse-type heat collector (4) to the drying chamber (16) in order to dry the wood at the set drying temperature. The method for drying wood by using solar energy of the invention is convenient to run and flexible to control the temperature; the drying temperature can be constant and the continuous drying is realized; moreover, the drying energy consumption is reduced remarkably, the drying cost is reduced and the better drying quality is obtained; in addition, the solar heat collector in the method of the invention has large area, high heat efficiency and high conversion efficiency.

Owner:BEIJING FORESTRY UNIVERSITY

Energy-collecting-type solar drying system

InactiveCN102353239AImprove the phenomenon of dry materialsGuaranteed time to drySolar heat devicesDrying gas arrangementsSolar dryingEngineering

The invention relates to an energy-collecting-type solar drying system, relates to a solar heat utilization technology, and also relates to the technical field of material and grain drying. The drying system mainly consists of a drying house the top of which is diaphanous, and a solar energy collecting chamber, wherein the air outlet of the solar energy collecting chamber is connected with an air supply pipe, and the other end of the air supply pipe is connected to the air inlet of the drying house. The drying system provided by the invention has the advantages of simple and reasonable structure and low manufacturing cost; and moreover, as dry high-temperature gas is transferred from the solar energy collecting chamber to the drying house through the air supply pipe, materials in the drying house can be dried. Furthermore, by using the drying system disclosed by the invention, a renewable energy source (solar energy) can be fully utilized to dry the materials according to different humidities of the materials and grains, thus the current phenomenon of drying materials completely dependent upon natural climate conditions can be effectively improved, and the system is suitable for drying materials and grain in overcast and rainy climate and can be used for ensuring the time for drying materials and grains and improving the quality.

Owner:YANGZHOU UNIV

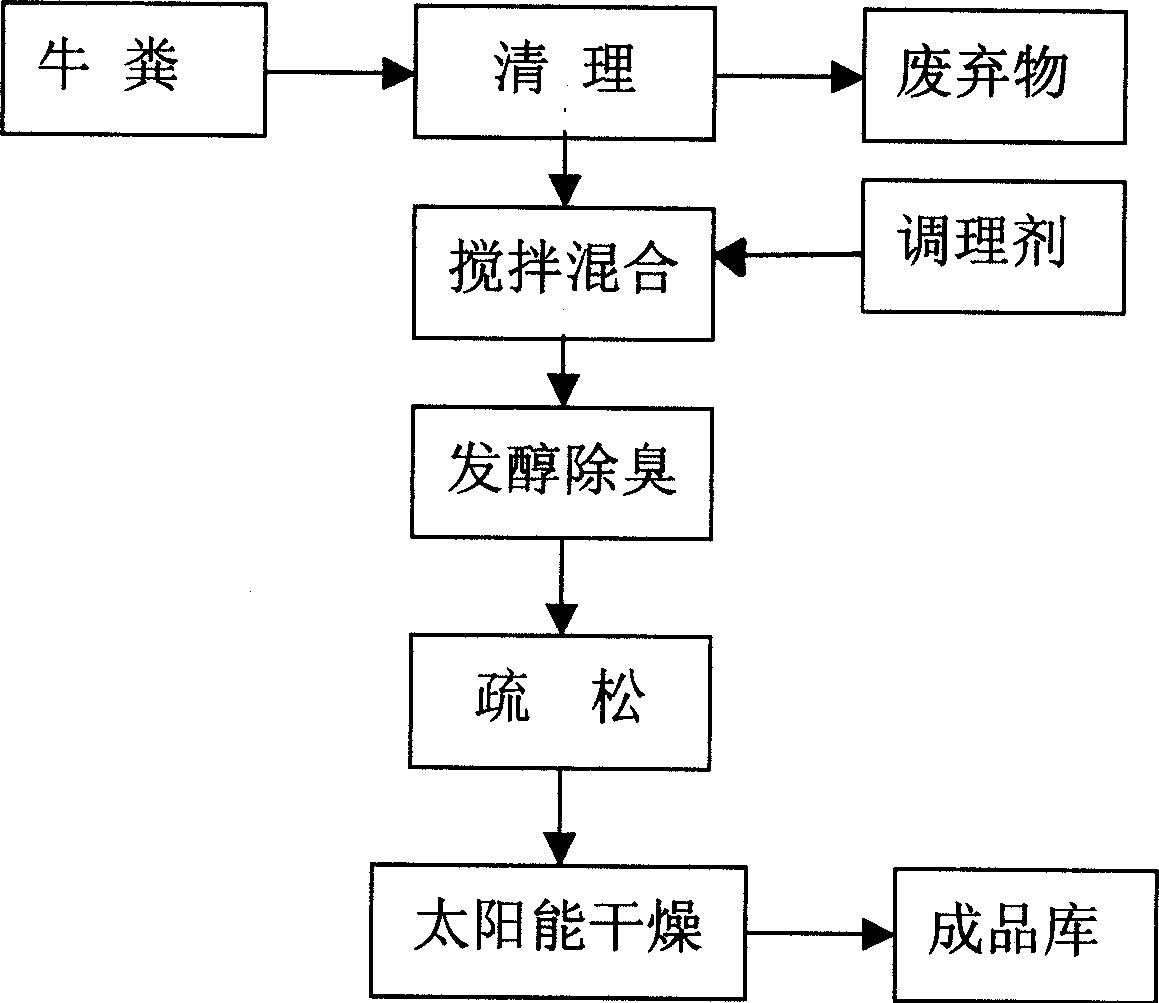

Artificial turf and preparing method thereof

InactiveCN1742552ASolve environmental problemsIncrease incomeAgriculture gas emission reductionCultivating equipmentsFiberSolar drying

The invented man-made turf is made up by mixing cattle dung and amendment, the water content of cattle dung is 60%-70%, and the amendment is formed from wheat straw or fiber-flax stalk, calcium perphosphate and raw soil. Said invention also provides their mixing ratio. Its preparation process includes the following steps: (a). cleaning cattle dung and making water content of cattle dung be reduced to 60%-70%; (b). preparing amendment; (c). mixing and stirring them; (d). fermentation and deodorization; (e). loosening; (f). solar drying; and (g). checking finished product and putting in storage.

Owner:甘肃省花卉工程技术研究中心

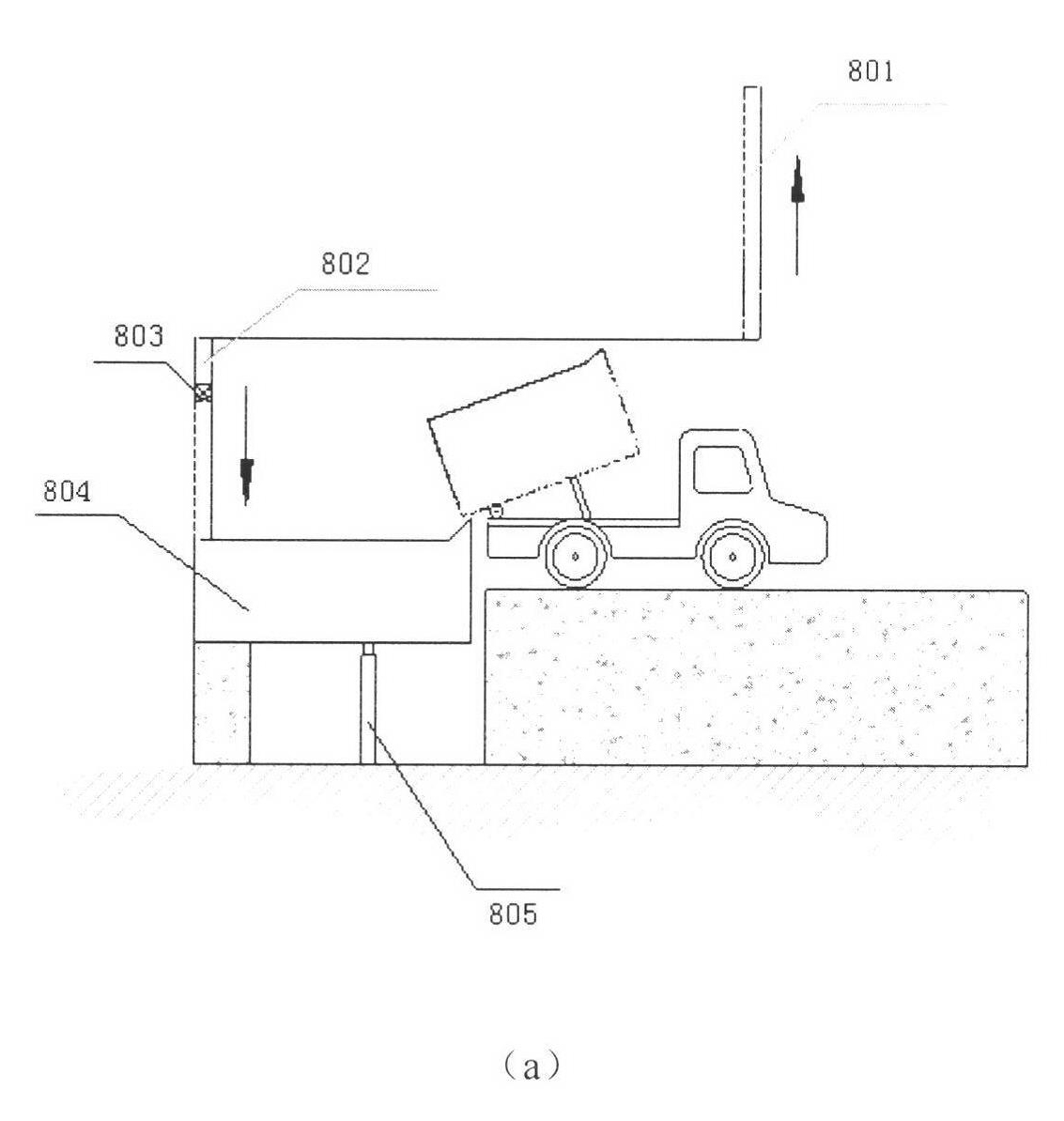

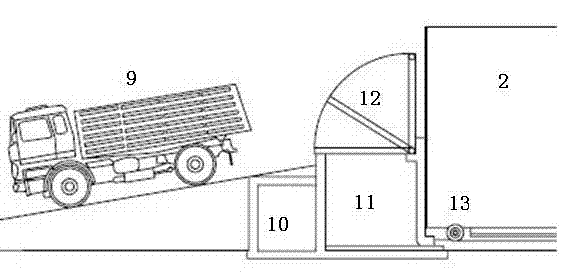

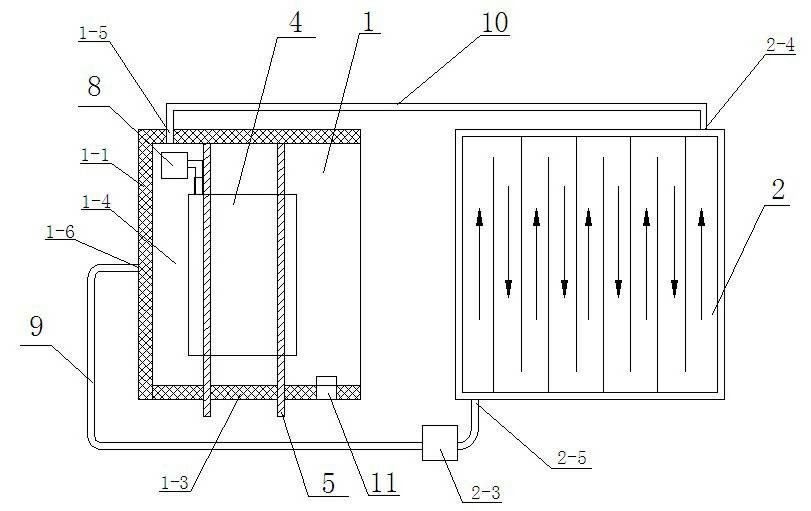

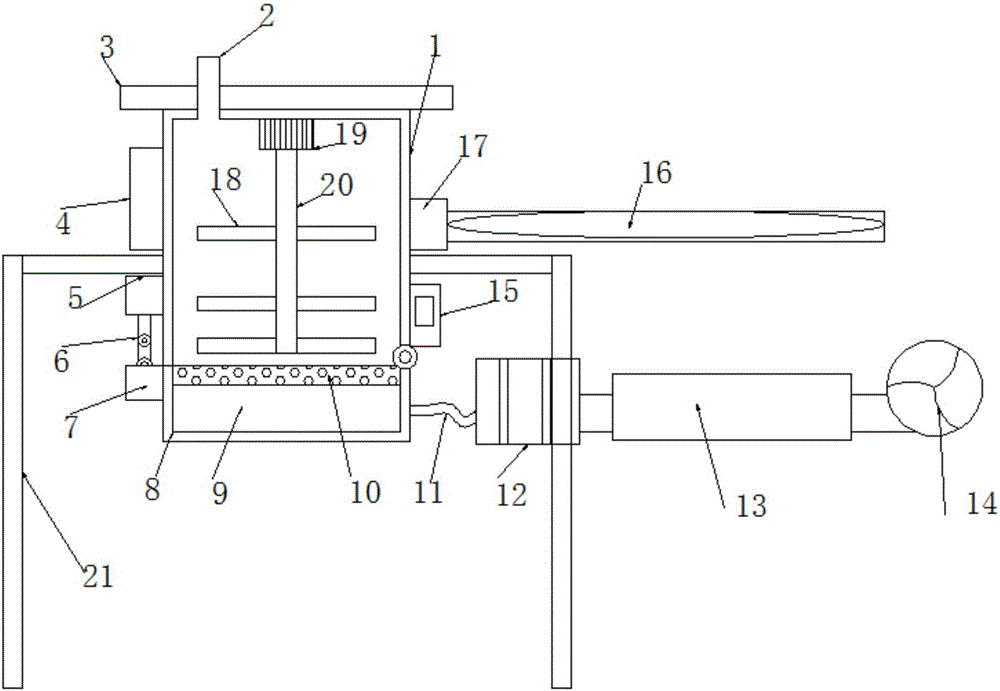

Sludge drying system

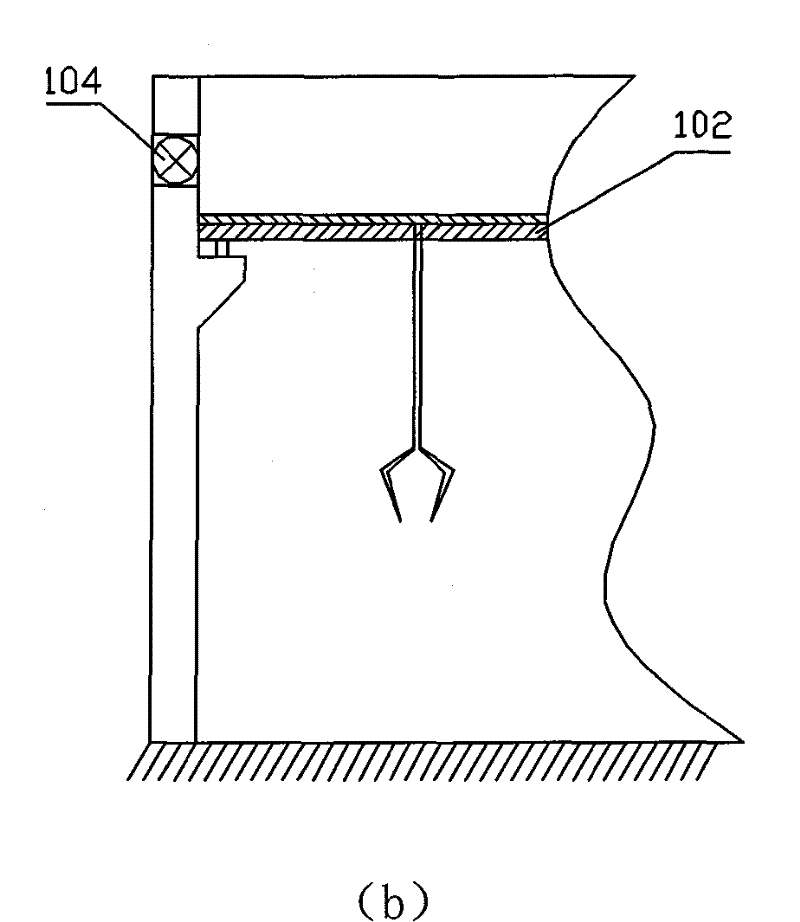

ActiveCN102531317AReduce moisture contentProtection securitySludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentSolar dryingSludge

The invention discloses a sludge drying system, which comprises a sealed sludge storage cabin and a drying device. Sludge in the sealed sludge storage cabin is fed into the drying device for drying the sludge through a material feeding mode. The sealed sludge storage cabin comprises a sludge feeding device, a grab bucket crane, a grab bucket crane track, a sludge tank barrier, a feeding port and a control chamber. The grab bucket crane grabs the sludge in the sealed sludge storage cabin and sends the sludge to a feeding hopper of the sludge feeding device which transmits the sludge to the drying device. The drying device comprises a roof, a wall body, a material table and a sludge paver. The sludge paver paves and throws the sludge, and then the sludge is performed with warming for dehumidification and drying by waste heat from a flue and solar energy, and the dried sludge is conveyed outside the drying chamber through a material conveying machine. By means of the sludge drying system, the sludge is placed in a sealed environment, polluted gas generated by the sludge is prevented from being directly discharged into the air, waste heat of a brick kiln and the solar energy are used for drying the sludge, and physical heat on the tail portions of fired bricks in a tunnel brick kiln can be used fully, so that a large amount of energy can be saved.

Owner:南京鑫翔环保产业有限公司

Simple solar drying device

InactiveCN106196948AIncrease light intensityGuaranteed work performanceSolar heating energySolar heat devicesSolar dryingAgricultural engineering

The invention discloses a simple solar drying device. The simple solar drying device comprises a drying box and a charging port. Supporting legs are symmetrically arranged on the two sides of the lower end of the drying box. A storage battery is arranged on the upper left side of the drying box and electrically connected with a solar power generation plate located on the top of the drying box. The charging port is formed in the top of the drying box. The lower end of the drying box is rotationally provided with an overturning base plate. A connecting block is arranged at the left end of the overturning base plate. A telescopic air cylinder is further arranged on the left side face of the drying box. The output end of the telescopic air cylinder is connected with the connecting block through a connecting rod. The telescopic air cylinder is electrically connected with a control panel located on the right side of the drying box. A partition screen plate is arranged at the upper end of the overturning base plate. Ventilation holes are evenly distributed in the surface of the partition screen plate. A stirring motor is arranged on the top in the drying box and electrically connected with the control panel. A stirring shaft is arranged at the output end of the stirring motor. The simple solar drying device is simple and reasonable in structure, good in material overturning effect and drying effect and high in efficiency and practicality, and discharging is facilitated.

Owner:成都锦汇绿源环保技术有限公司

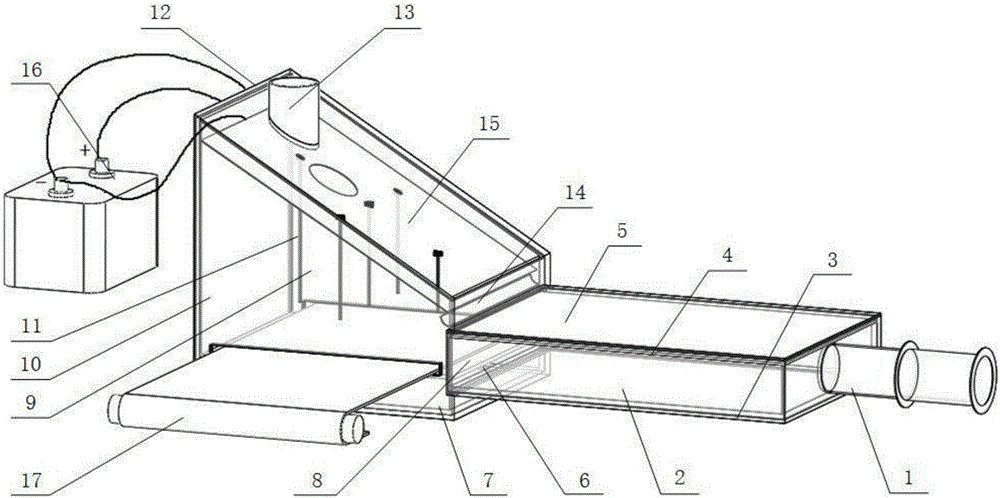

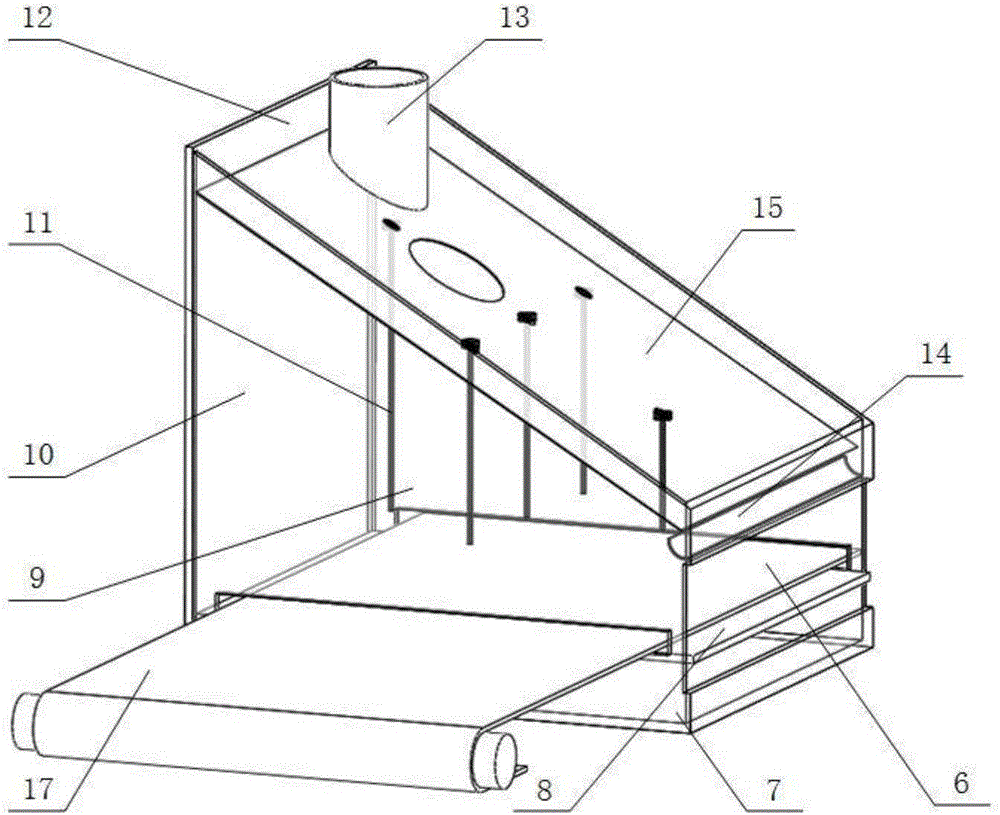

High voltage auxiliary solar drying device and method

ActiveCN106277704AEffective combinationImprove drying rateSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentElectricitySolar drying

The invention relates to a high voltage auxiliary solar drying device and method. A heat collecting chamber heat preservation layer is arranged on the inner side of a solar heat collecting chamber, an air inlet is formed in the right side of the solar heat collecting chamber, an air port formed in the left side of the solar heat collecting chamber is communicated with a solar drying chamber, and a thin film solar cell panel A and a heat collecting panel A are arranged on the upper portion of the solar heat collecting chamber. A drying chamber heat preservation layer is arranged on the inner side of the solar drying chamber, a water tank is arranged on the right side of the solar drying chamber, a reflector is arranged on the left side of the solar drying chamber, and an air outlet, a thin film solar cell panel B, a heat collecting panel B, a high-voltage electrode pin and a high-voltage electrode plate are arranged from top to bottom. Dry air is heated to 40 DEG C to 50 DEG C through the thin film solar cell panel A and solar energy obtained after heat collection through the heat collecting panel A, matter input by a conveying mechanism and needing to be dried is dried through the dry air and an auxiliary high-voltage electric field, and solar energy is fully utilized by a thin film solar cell panel coupling storage battery energy storage system. Solar energy and high voltage are combined, the drying rate is increased, drying efficiency is improved, a good drying effect is achieved, and the high voltage auxiliary solar drying device and method are clean, efficient and free of pollution and have wide application prospects.

Owner:ZHEJIANG UNIV

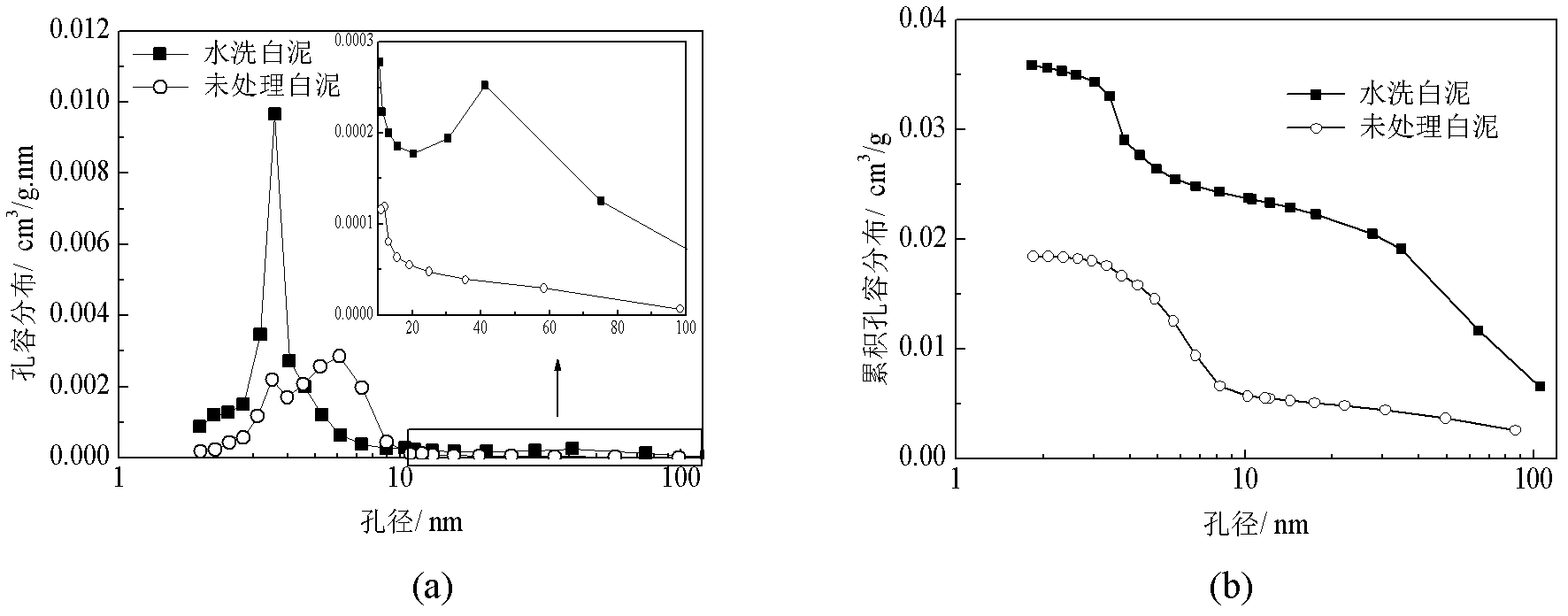

Method for treating white mud produced by papermaking and use of the white mud treated by the method in removal of CO2 in tail flue gas from coal-fired boiler

InactiveCN102718373ARealize resource utilizationEfficient removalSludge treatmentDispersed particle separationSolar dryingTrapping

The invention discloses a method for treating white mud produced by papermaking. The method is characterized in that through multistage washing filtration and solar energy drying of white mud produced by papermaking, impurity ions such as Na, K and Cl producing adverse effects on white mud carbonation are removed and the white mud produced by papermaking and treated by the method can be used as a CO2 absorbent. A research result shows that through multistage washing filtration and solar energy drying, the CO2 cyclic-trapping performance of the white mud treated by the method is greatly improved. The method provided by the invention realizes a process route combining recycling application of white mud produced by papermaking, and removal of CO2 discharged by a coal-fired boiler. The method provided by the invention has simple and convenient processes, a small investment, a low cost and good industrial application prospects.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com