Method for treating white mud produced by papermaking and use of the white mud treated by the method in removal of CO2 in tail flue gas from coal-fired boiler

A technology of papermaking white mud and treatment process, applied in sludge treatment, water/sludge/sewage treatment, energy wastewater treatment, etc., can solve problems such as low carbonation conversion rate, improve safety and economy, Easy to achieve, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Example The papermaking lime mud is treated, and the treated papermaking lime mud is used to measure the CO concentration in the tail flue gas of the coal-fired boiler. 2 removal of

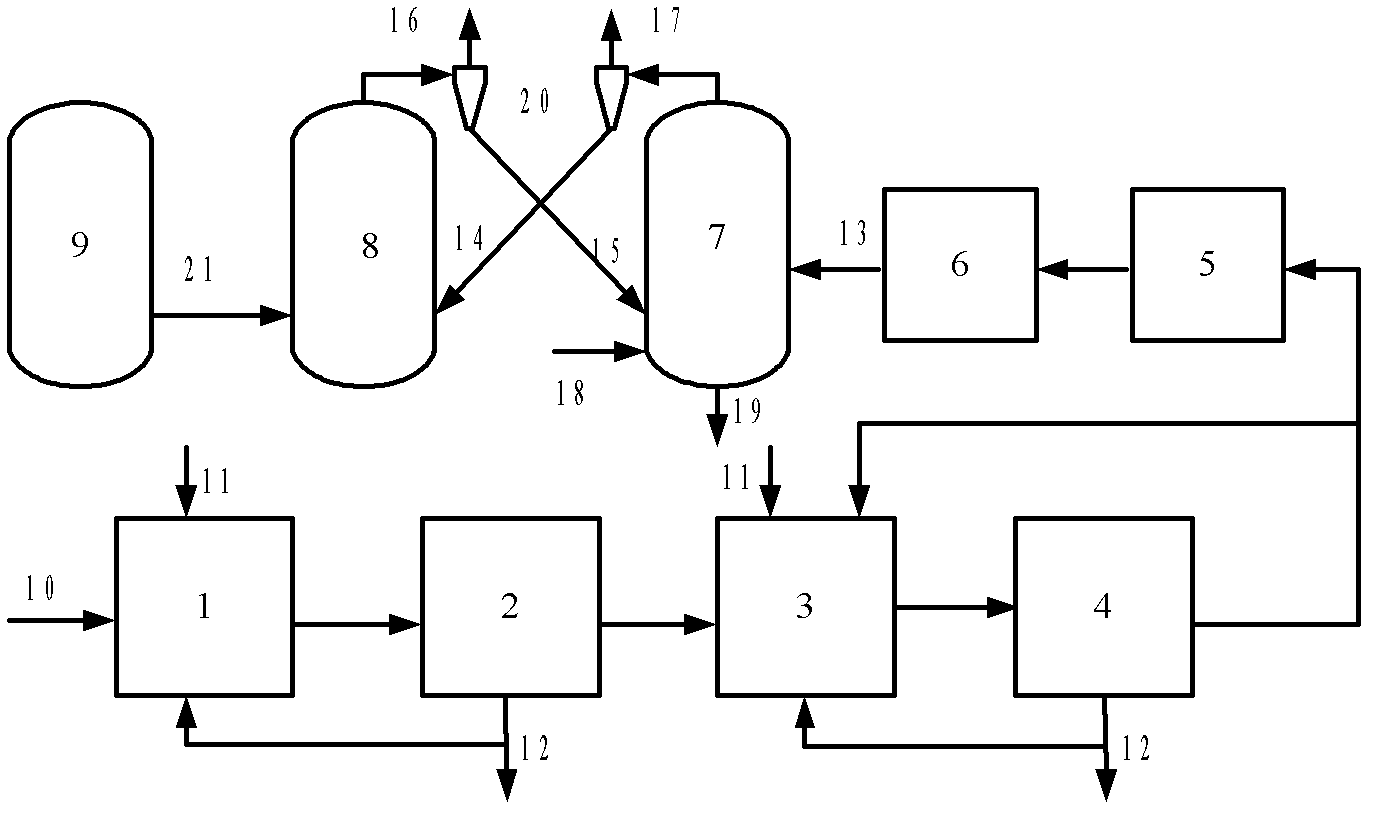

[0026] figure 1 For the coal-fired boiler mentioned in the present invention, the papermaking lime mud is used to circulate and remove CO in the tail flue gas. 2 The process flow of the method.

[0027] The treatment methods for papermaking white mud are as follows:

[0028] Papermaking lime mud 10 and water 11 are mixed in the primary mixing tank 1, the mixing ratio is 1Kg lime mud and 4L of water, after stirring for 2-4 hours, the mixed slurry enters the primary filter 2 for filtration, and the filtered water 12 is discharged. After fully filtering, the obtained solid enters the secondary stirring tank 3 and mixes according to the ratio of 1Kg white mud to 2L water, and stirs for 2-4 hours. Then the mixed slurry enters the secondary filter 4 and is fully filtered, and the filtered wa...

experiment example

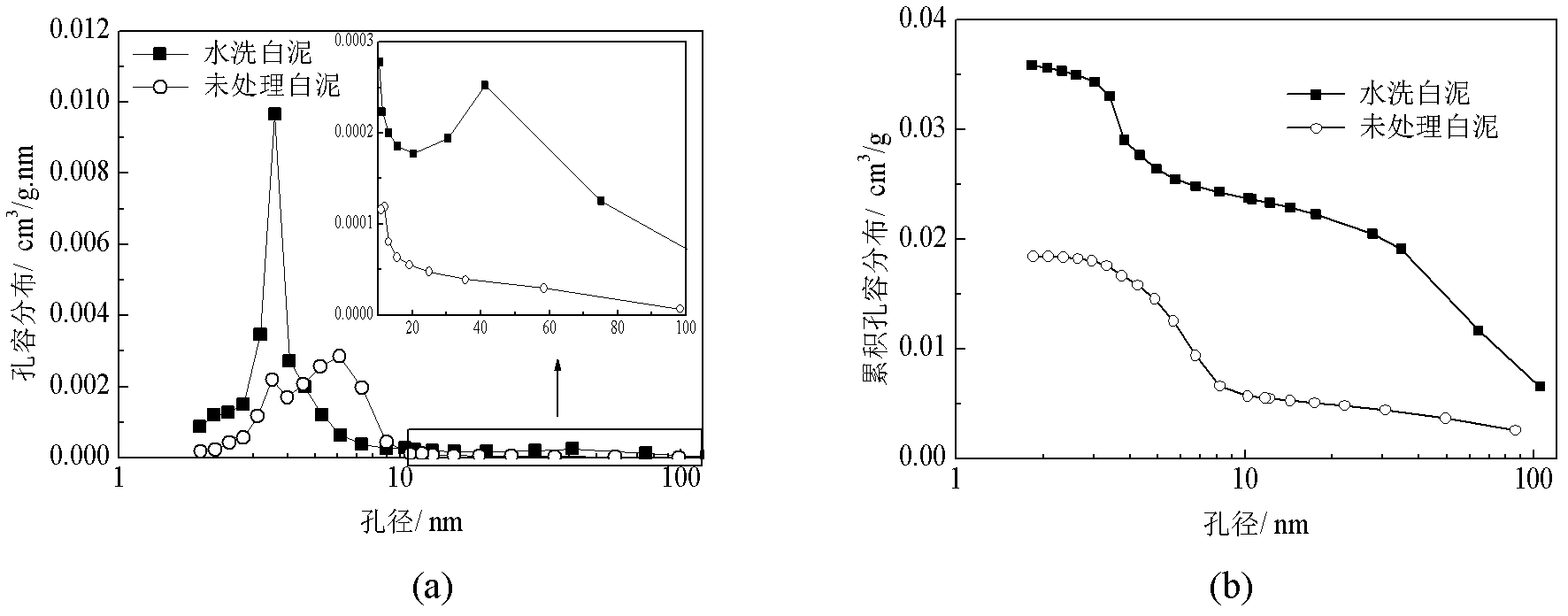

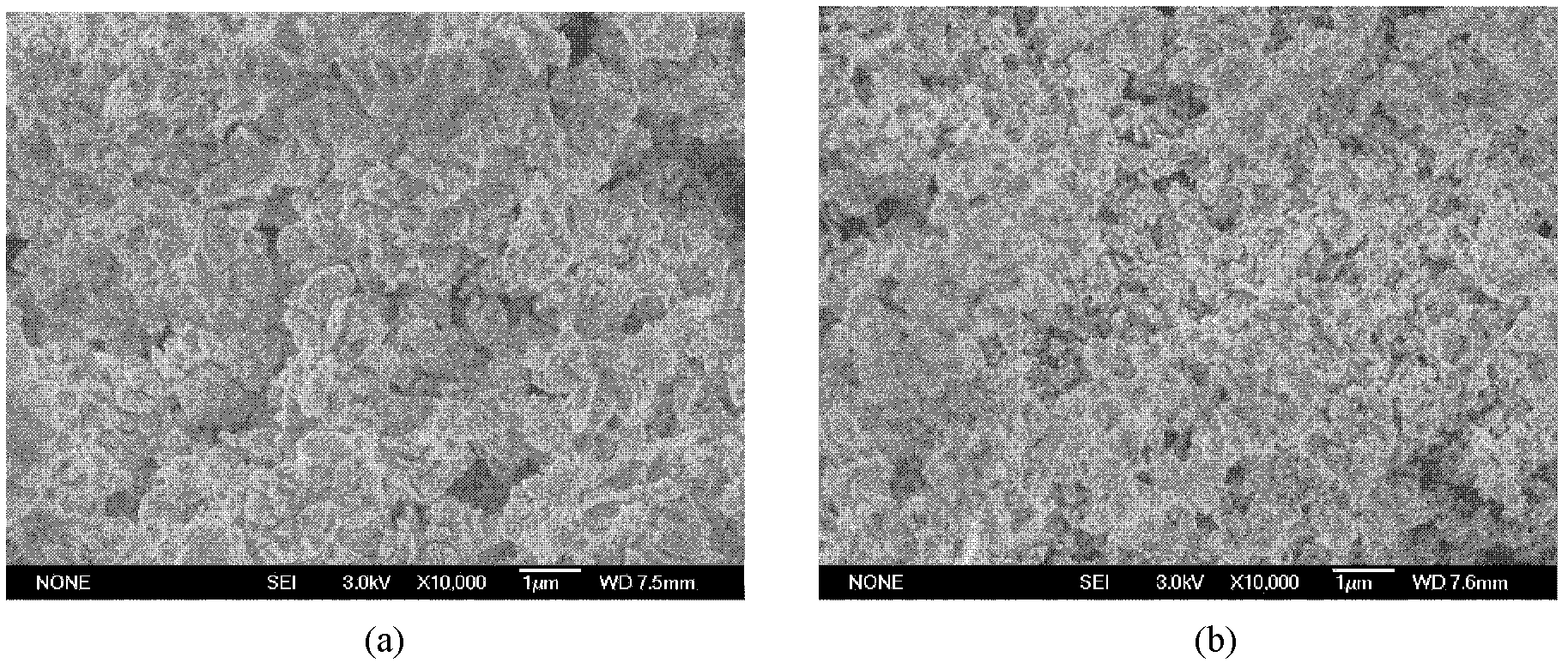

[0032] The carbonation conversion rate of untreated white mud and treated white mud (prepared in the example) of a paper mill was measured on a double fixed-bed reactor, and the carbonation conversion rate characterizes the CO captured by the absorbent. 2 ability. The absorbent is first calcined at high temperature in the calciner reactor, and the calcining atmosphere is pure N 2 , the calcination temperature is 850°C, and the calcination time is 10min; then the CaO obtained by calcination enters the carbonation reactor and CO 2 Carry out carbonation reaction, the carbonation atmosphere is 15% CO 2 and 85%N 2 , the carbonation temperature is 700°C, and the carbonation time is 40min. After calcination and carbonation, the sample was accurately weighed on a high-precision electronic balance, and the carbonation conversion rate of the absorbent was calculated according to the mass change before and after the carbonation reaction, as shown in formula (1).

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com