Patents

Literature

158results about How to "Meet drying needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air source heat pump drying house with air inlet of evaporator as fresh air inlet of drying house

InactiveCN104359290AReduce the amount of entryIncrease temperatureHeat pumpsDrying gas arrangementsCold airBusiness efficiency

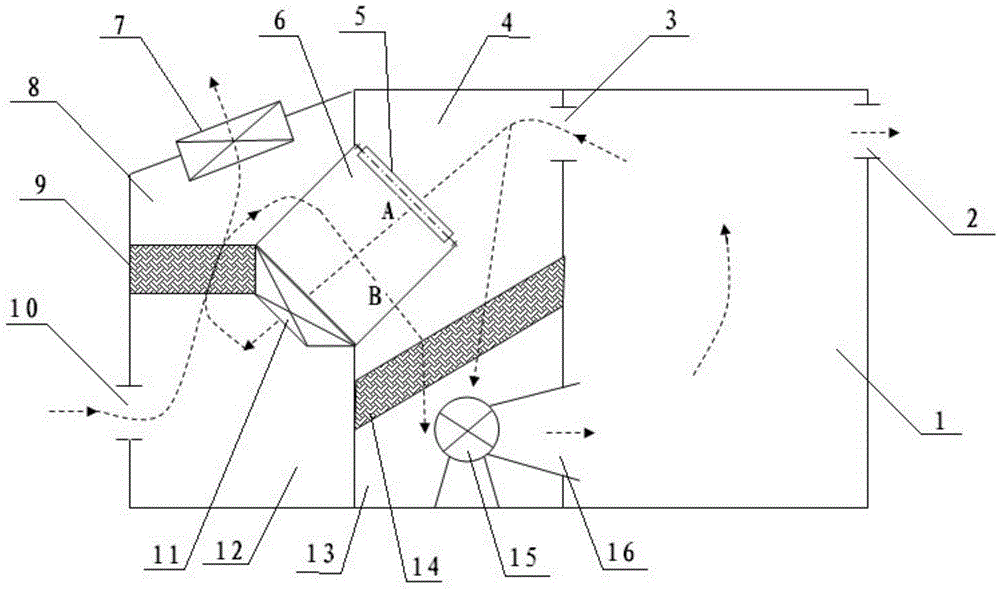

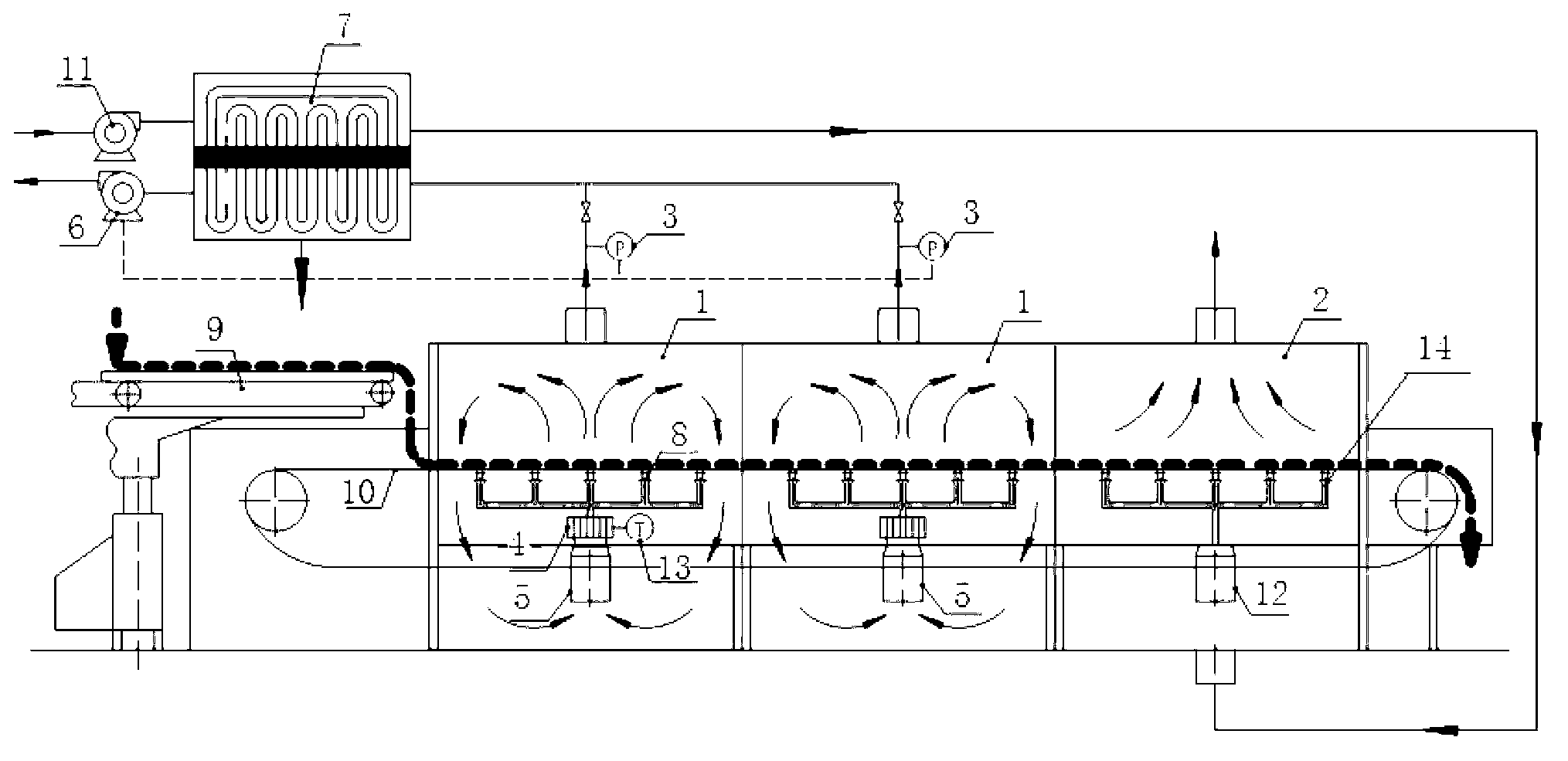

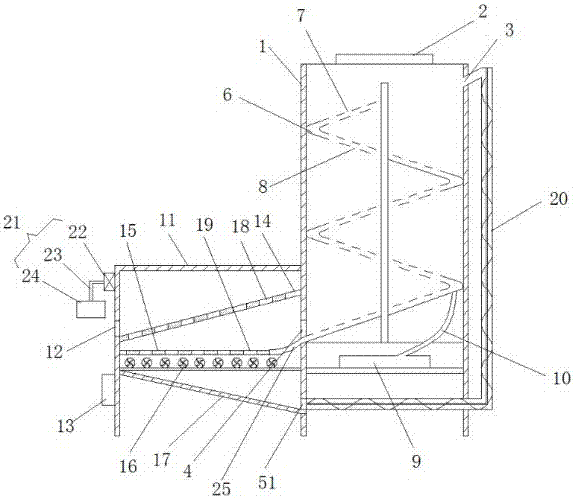

The invention discloses an air source heat pump drying house with the air inlet of an evaporator as the fresh air inlet of a drying house. The air source heat pump drying house comprises an air source heat pump, the drying house and an air-to-air total heat exchanger, and the housing of the air source heat pump is divided into a first chamber and a second chamber. When an automatic air door is closed, under the function of a condenser fan, relatively closed circulating air is generated to heat the drying house; when the temperature of material in the drying house is increased to certain temperature and humidity is increased, the automatic air door is opened, so that the air inlet of the evaporator serves as the fresh air inlet of the drying house. With the overall system structure configuration and the utilization of cold air after the heat exchange of the evaporator as a basis and the opening and closing of the automatic air door as a switching condition, the material drying method in which dehumidification and moisture removal are carried out at the same time is innovated, thus realizing the organic combination of a variety of operating modes; the overall functional trend of the system can be automatically, flexibly and conveniently changed to meet the different and even contradictory requirements of all material drying stages; the great increases of both energy efficiency ratio and material drying speed can be taken into consideration; equipment investment is saved.

Owner:湖南省浏阳市择明热工器材有限公司

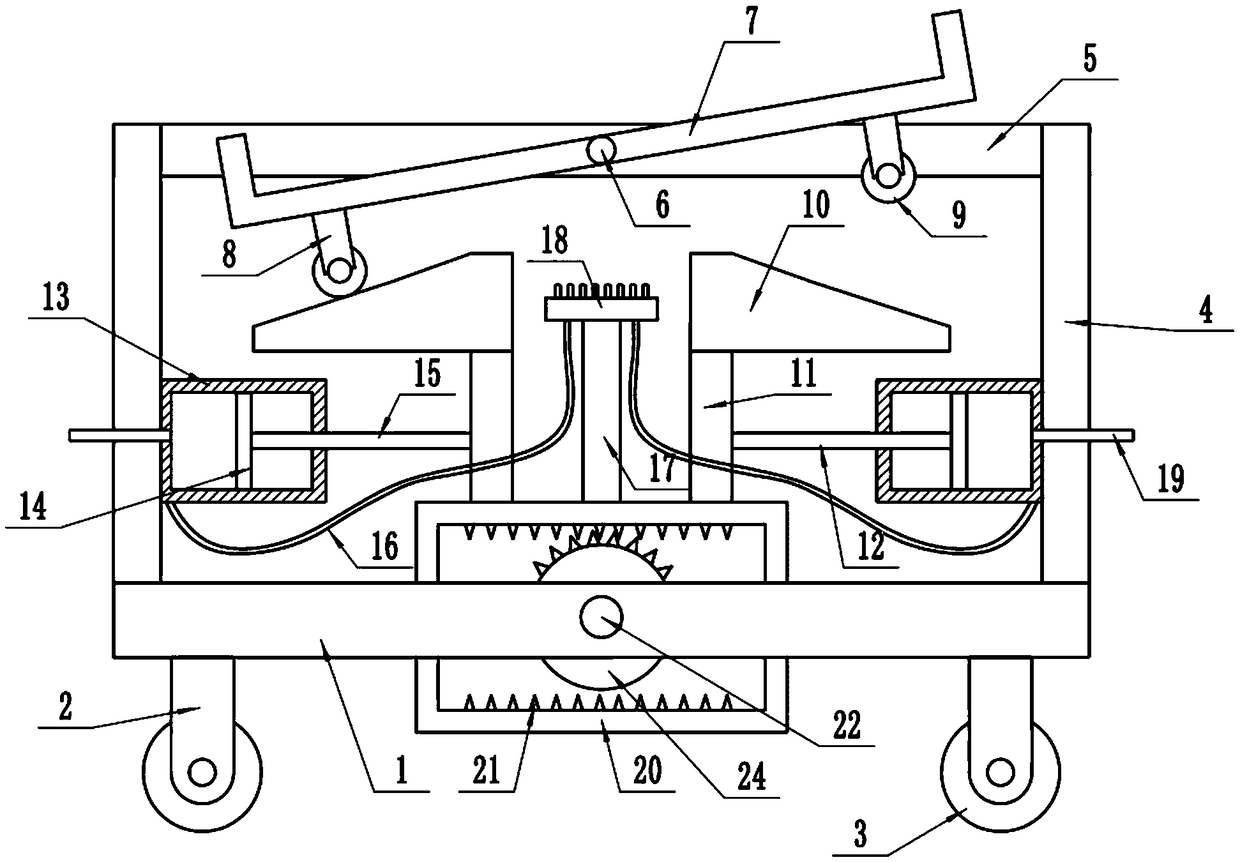

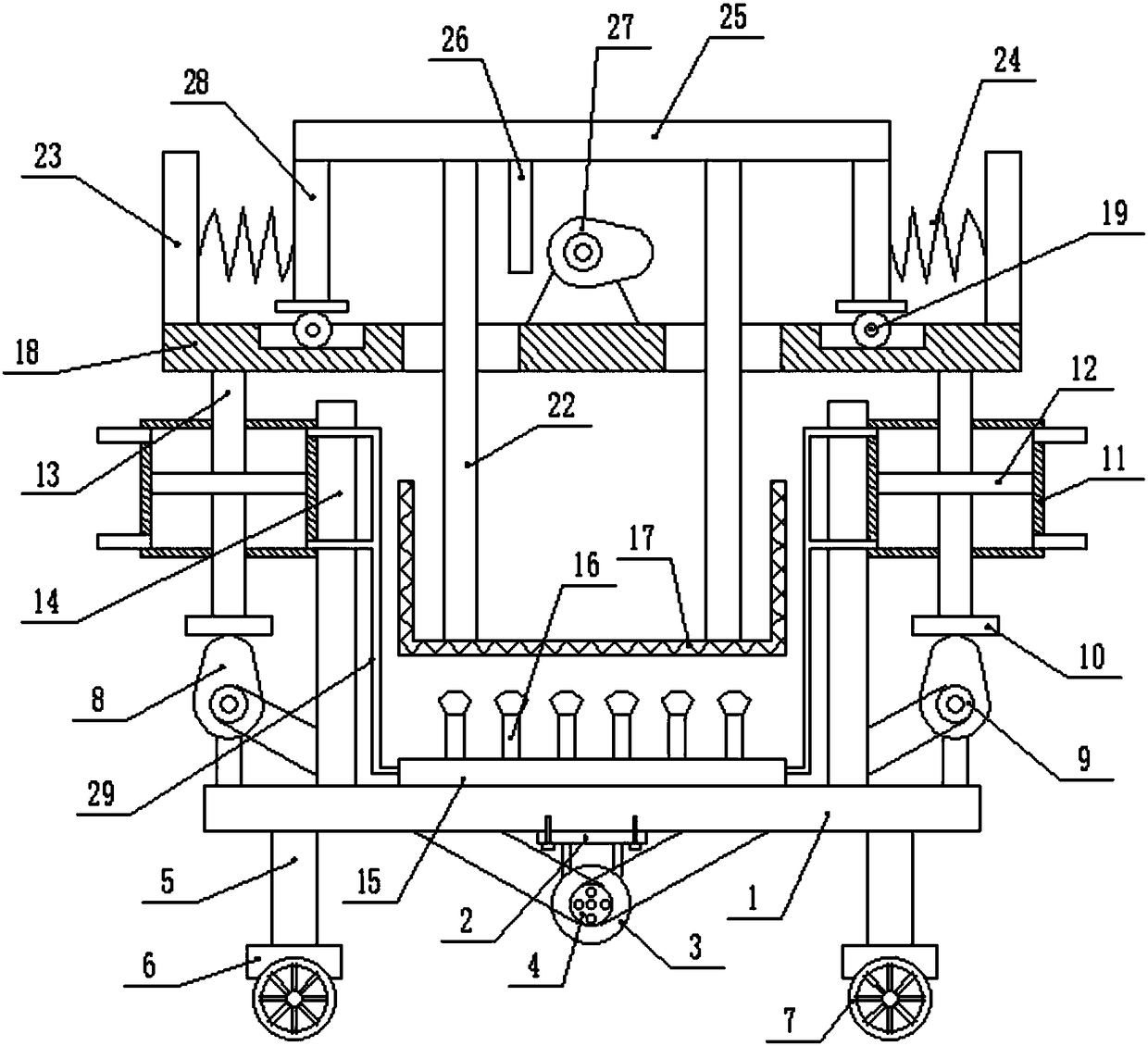

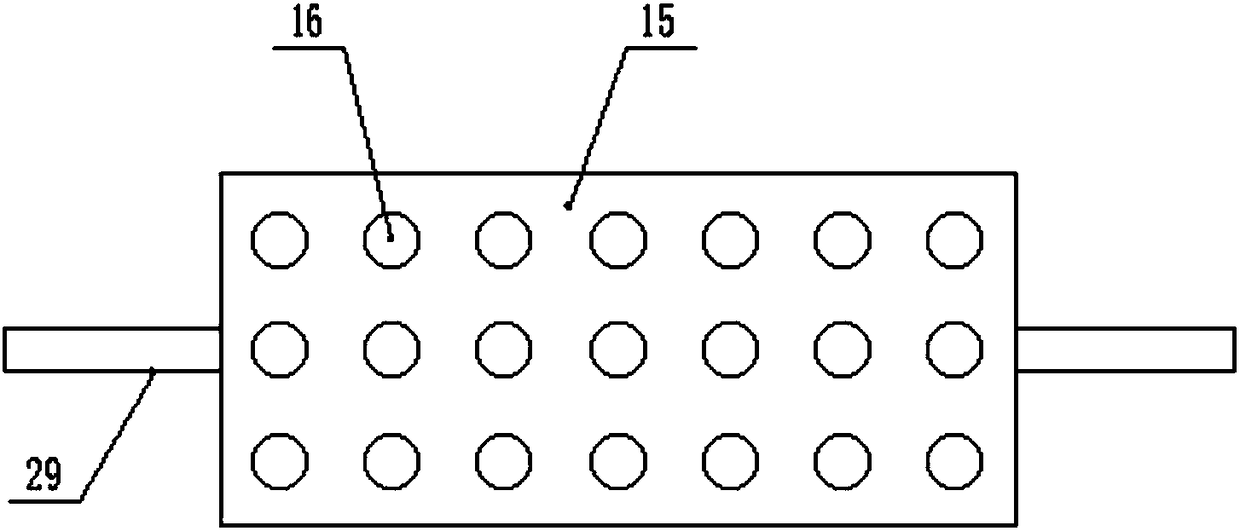

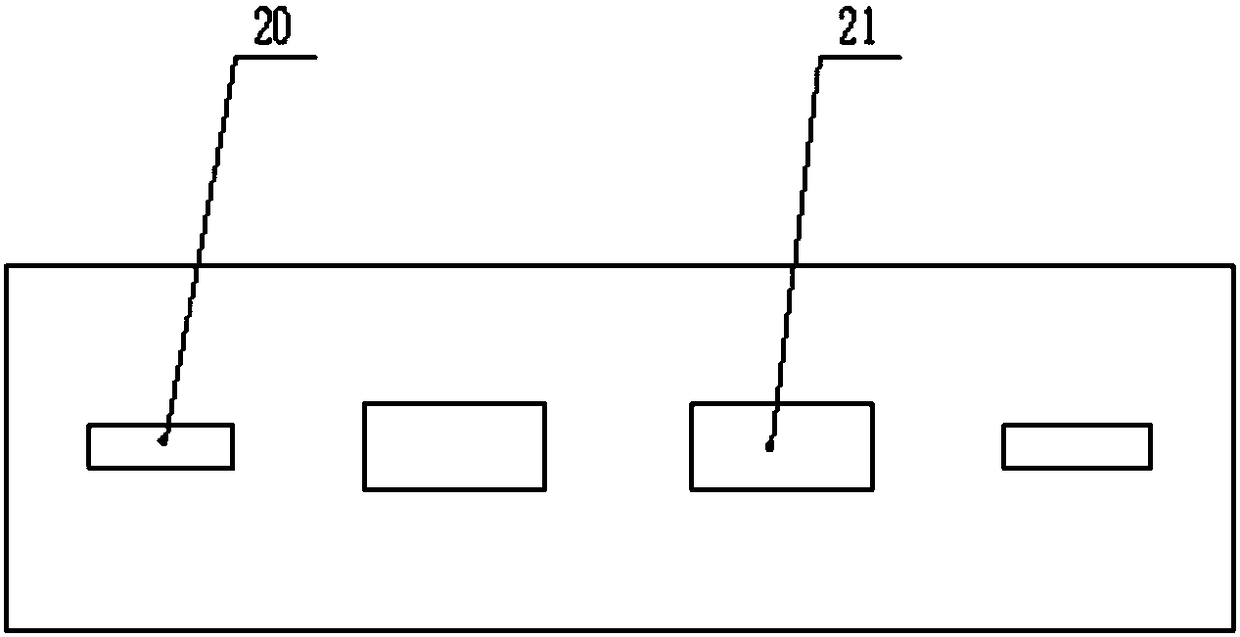

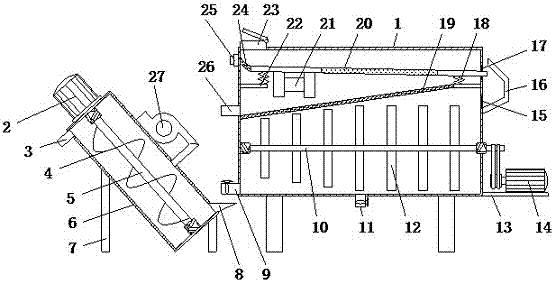

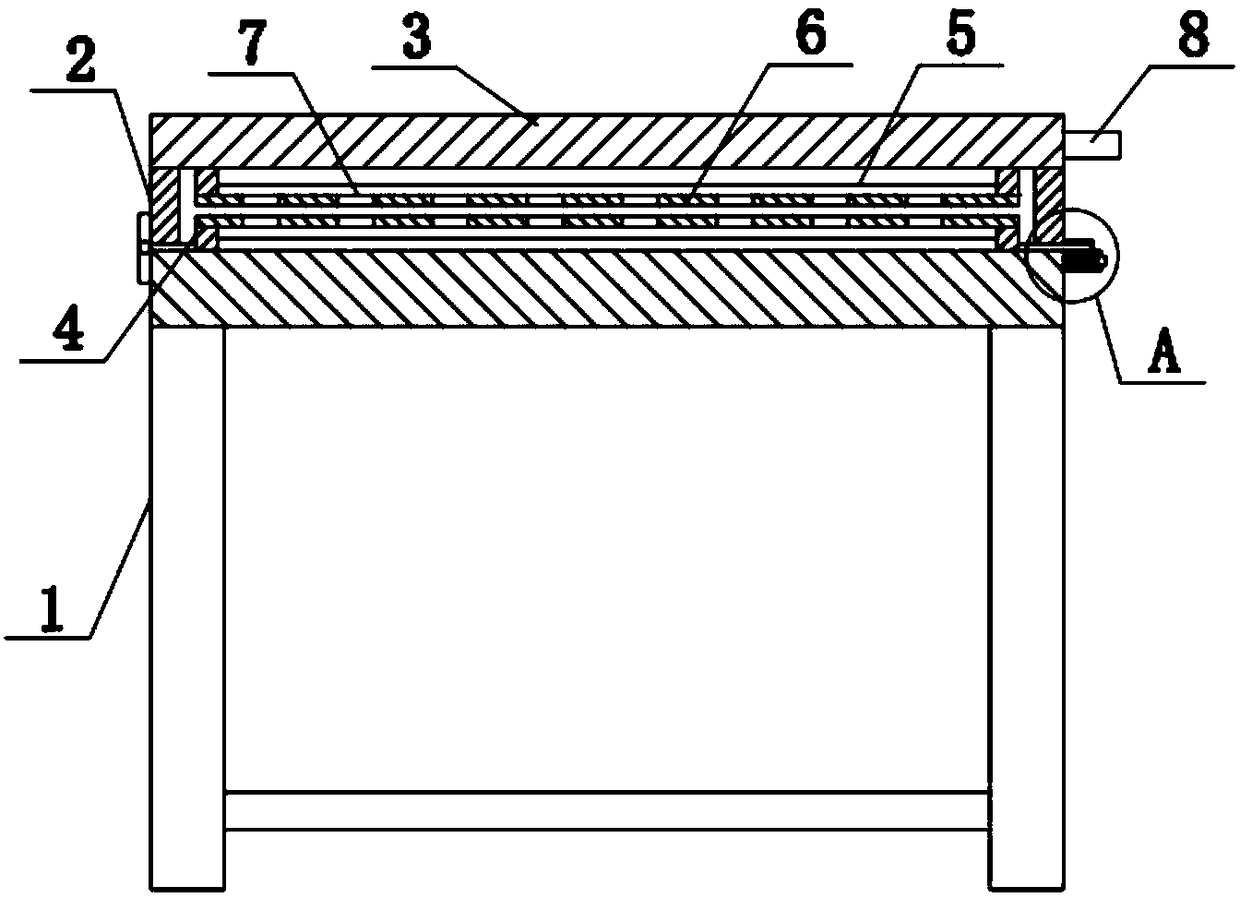

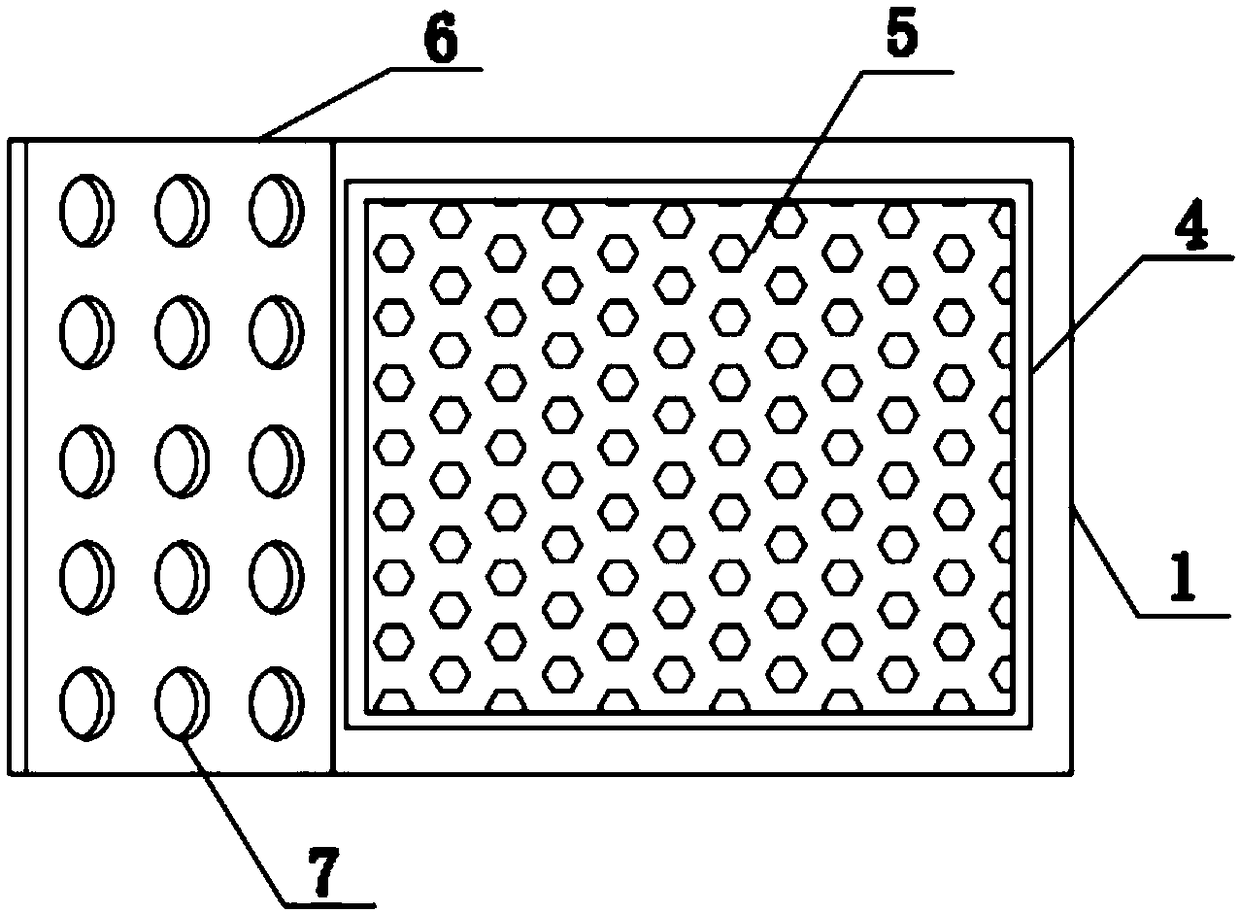

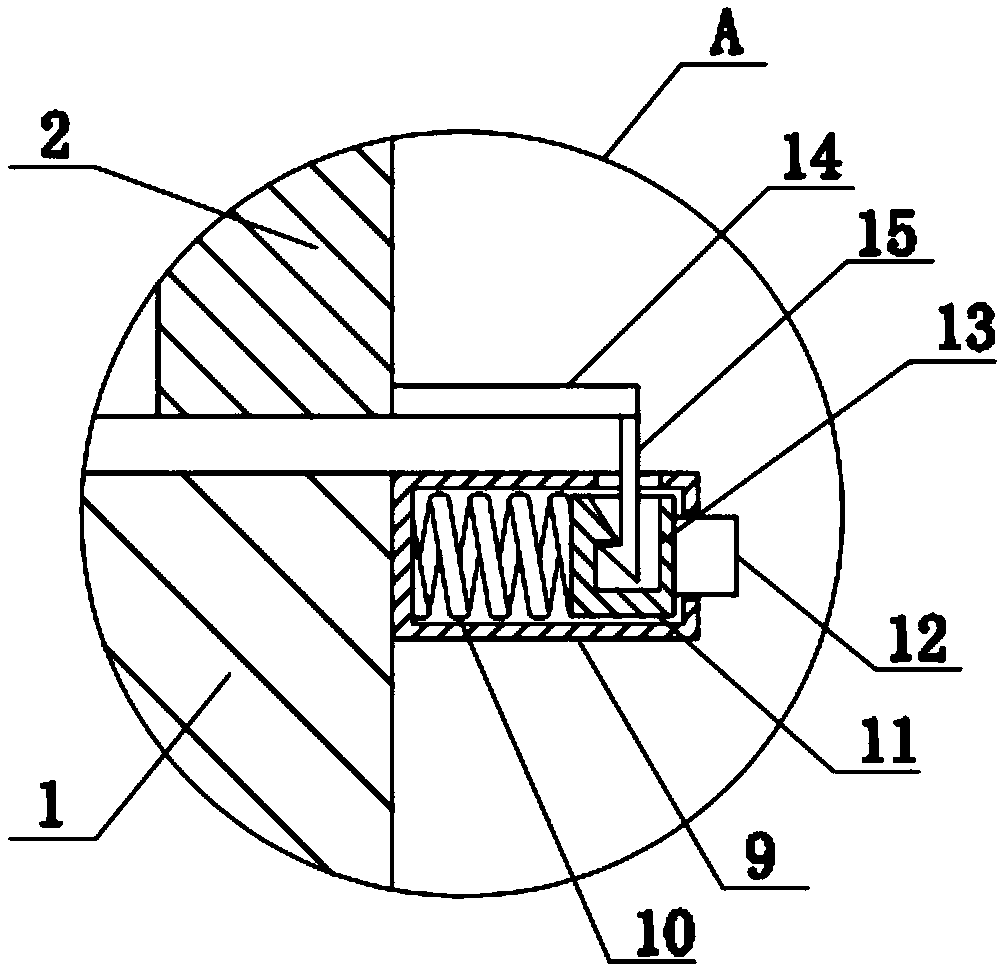

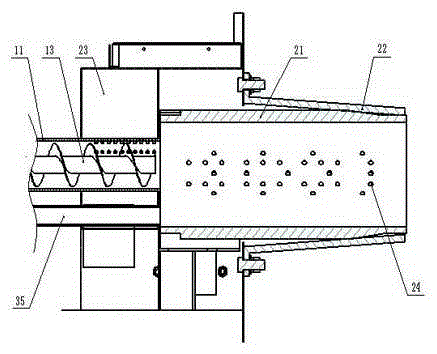

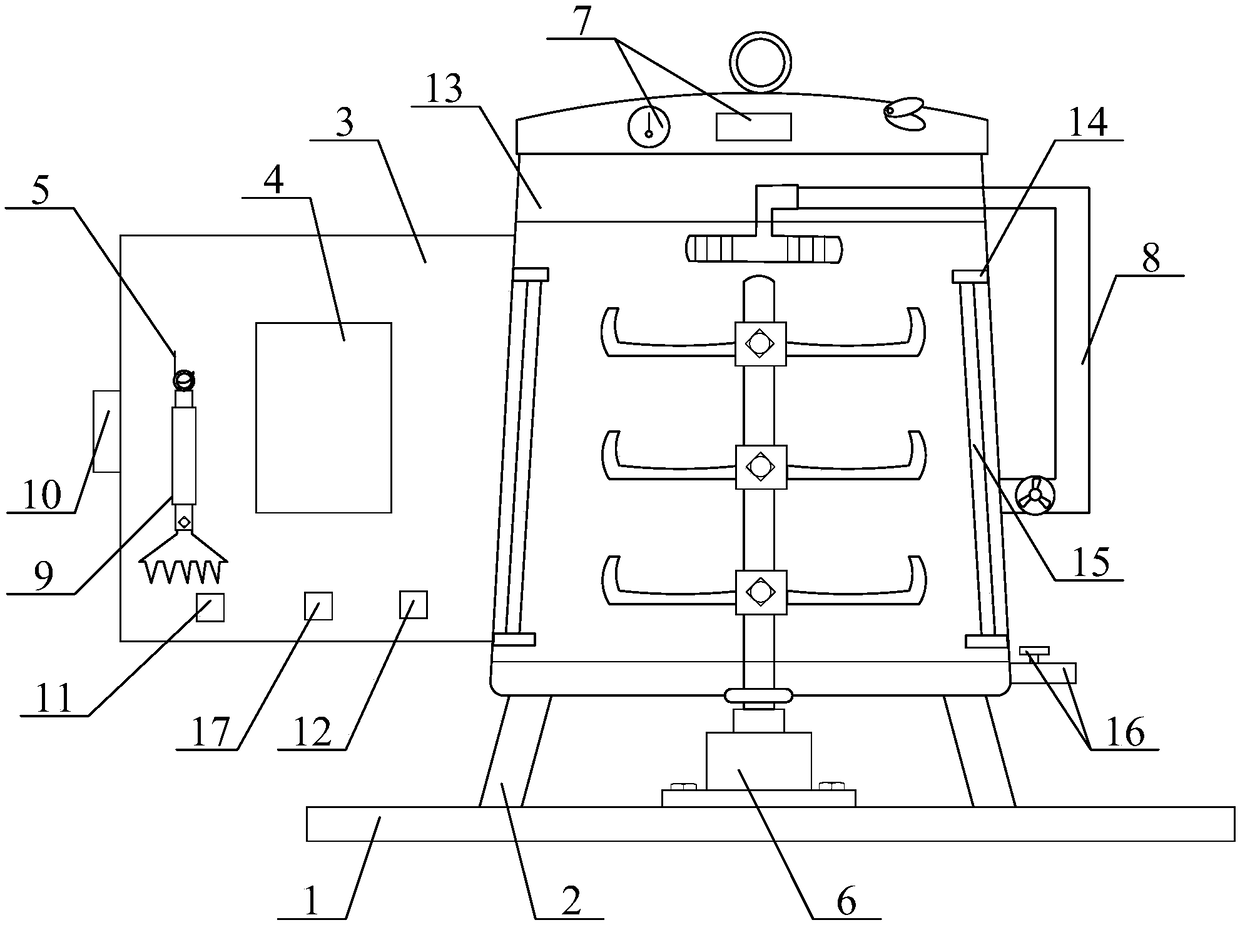

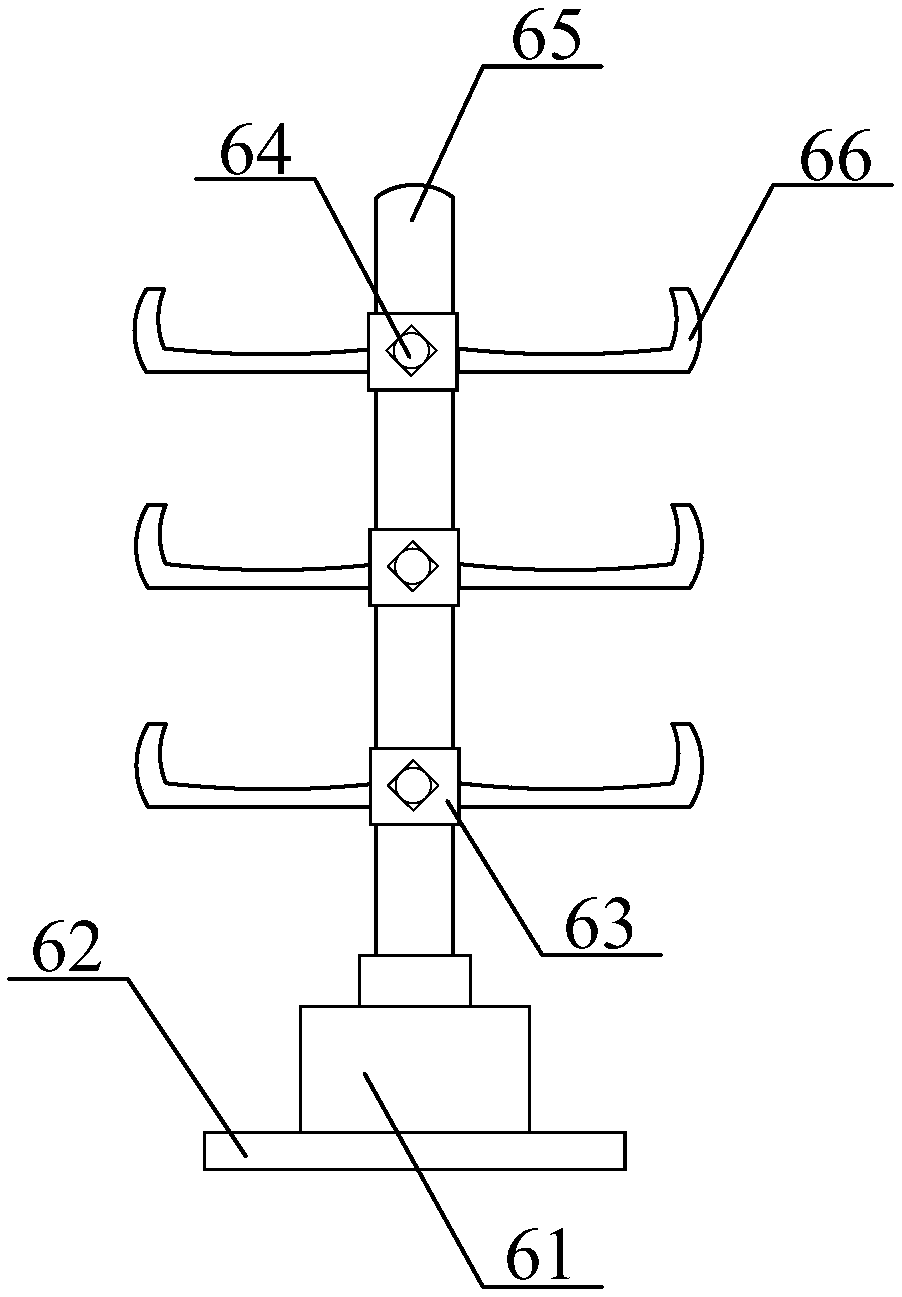

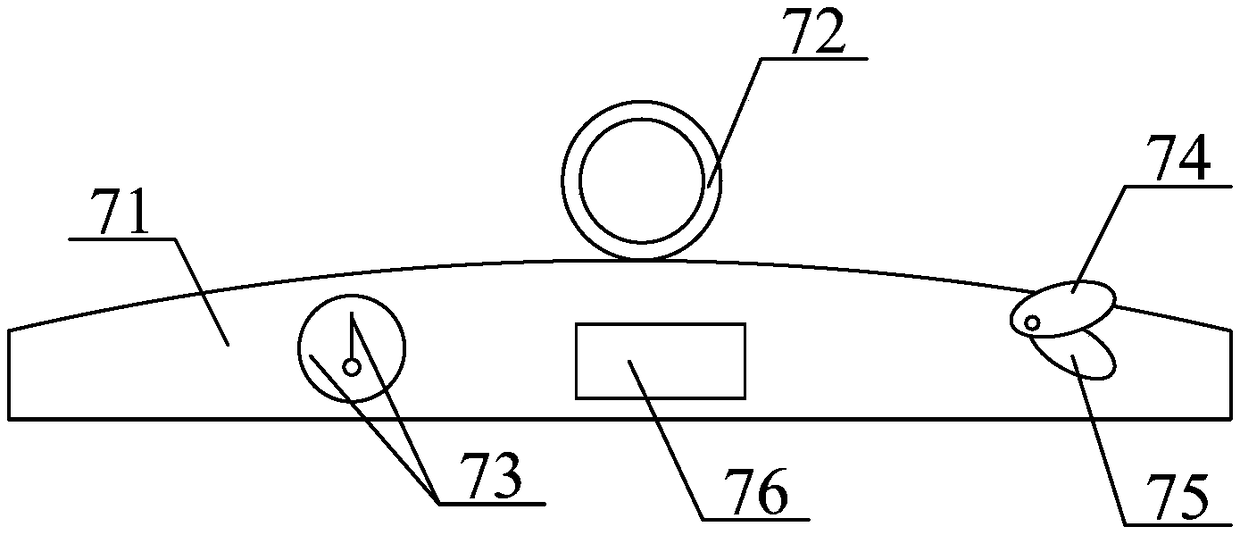

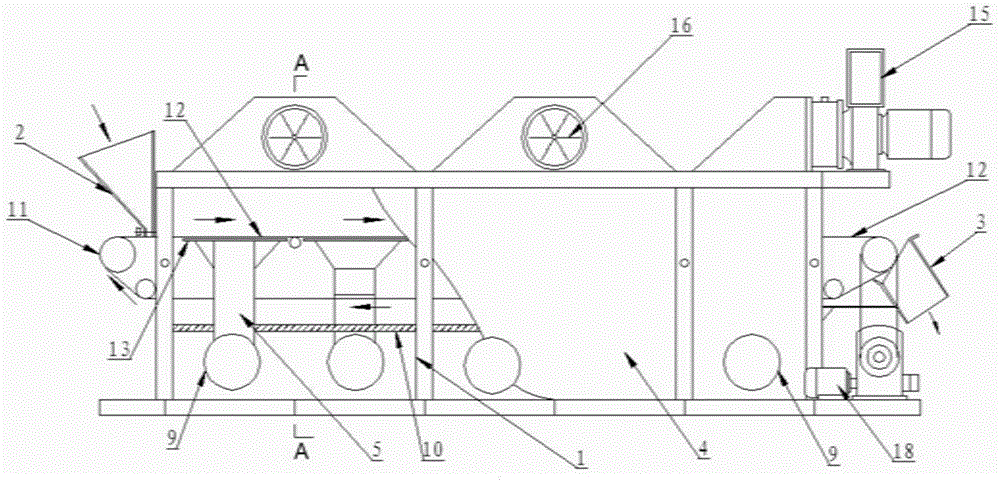

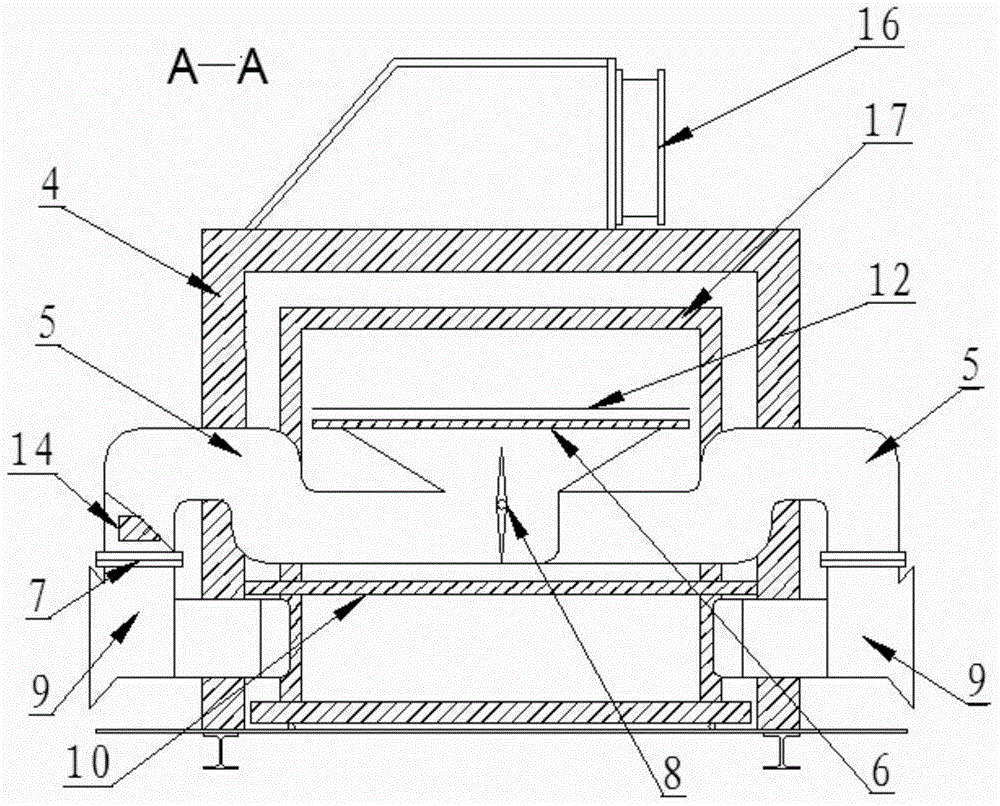

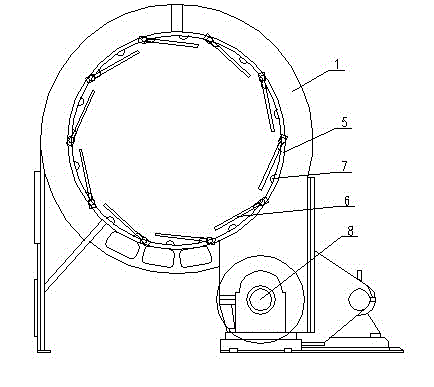

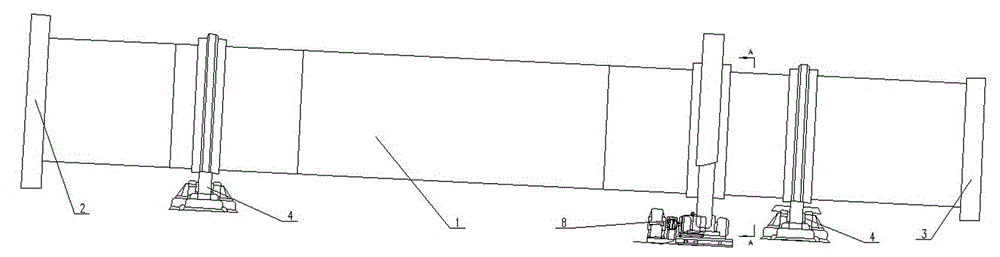

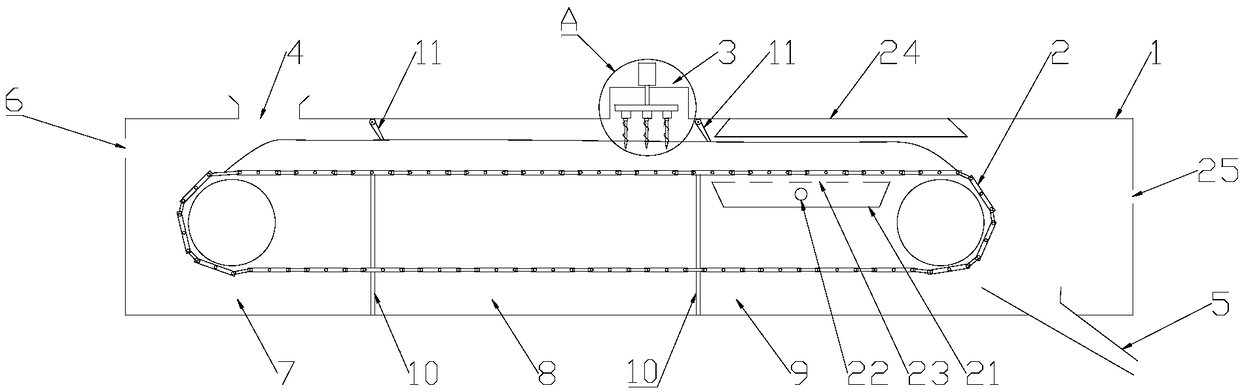

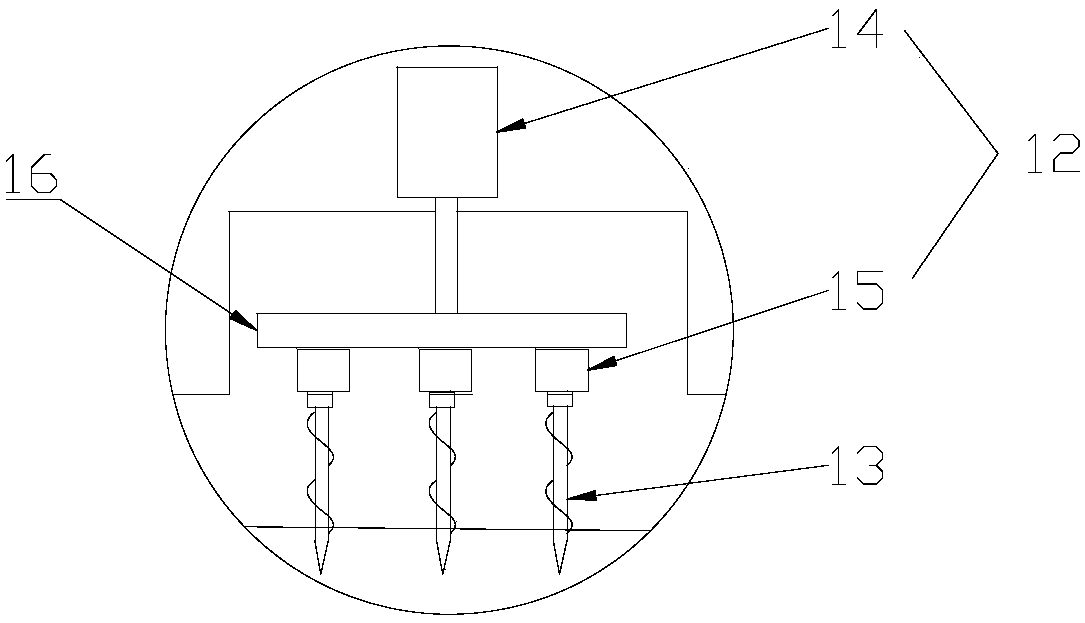

Pulsed gas jet impact drier

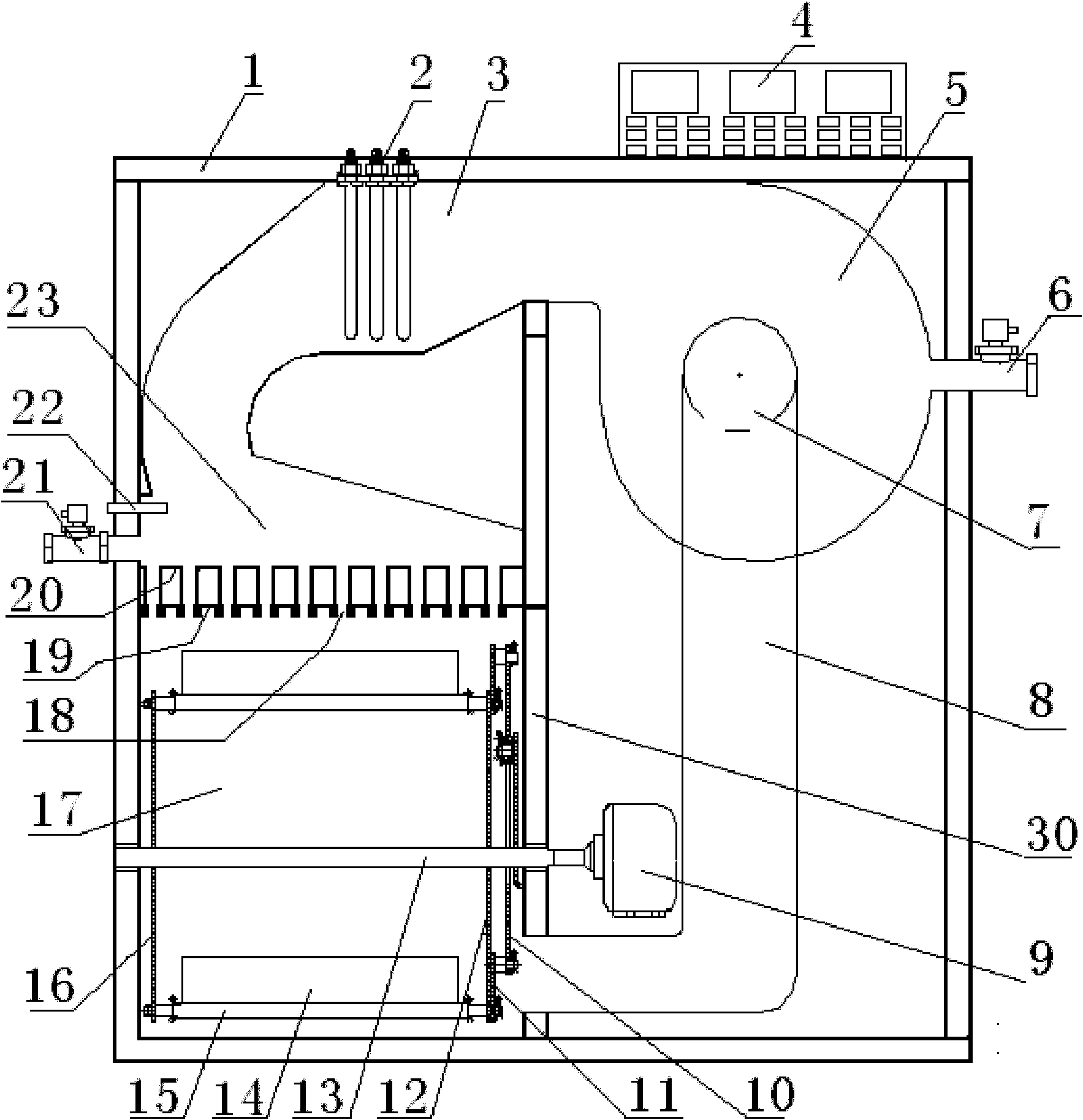

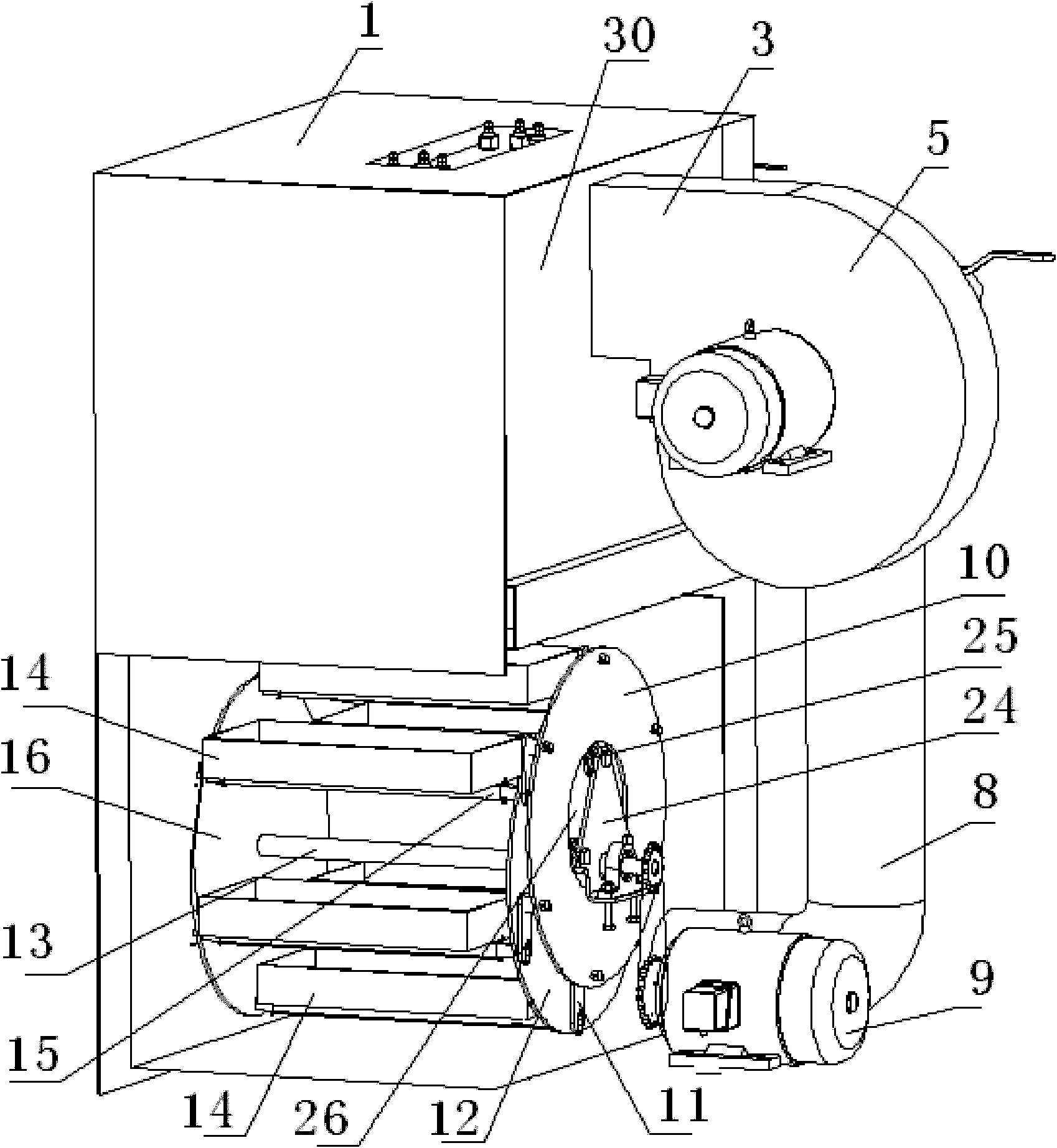

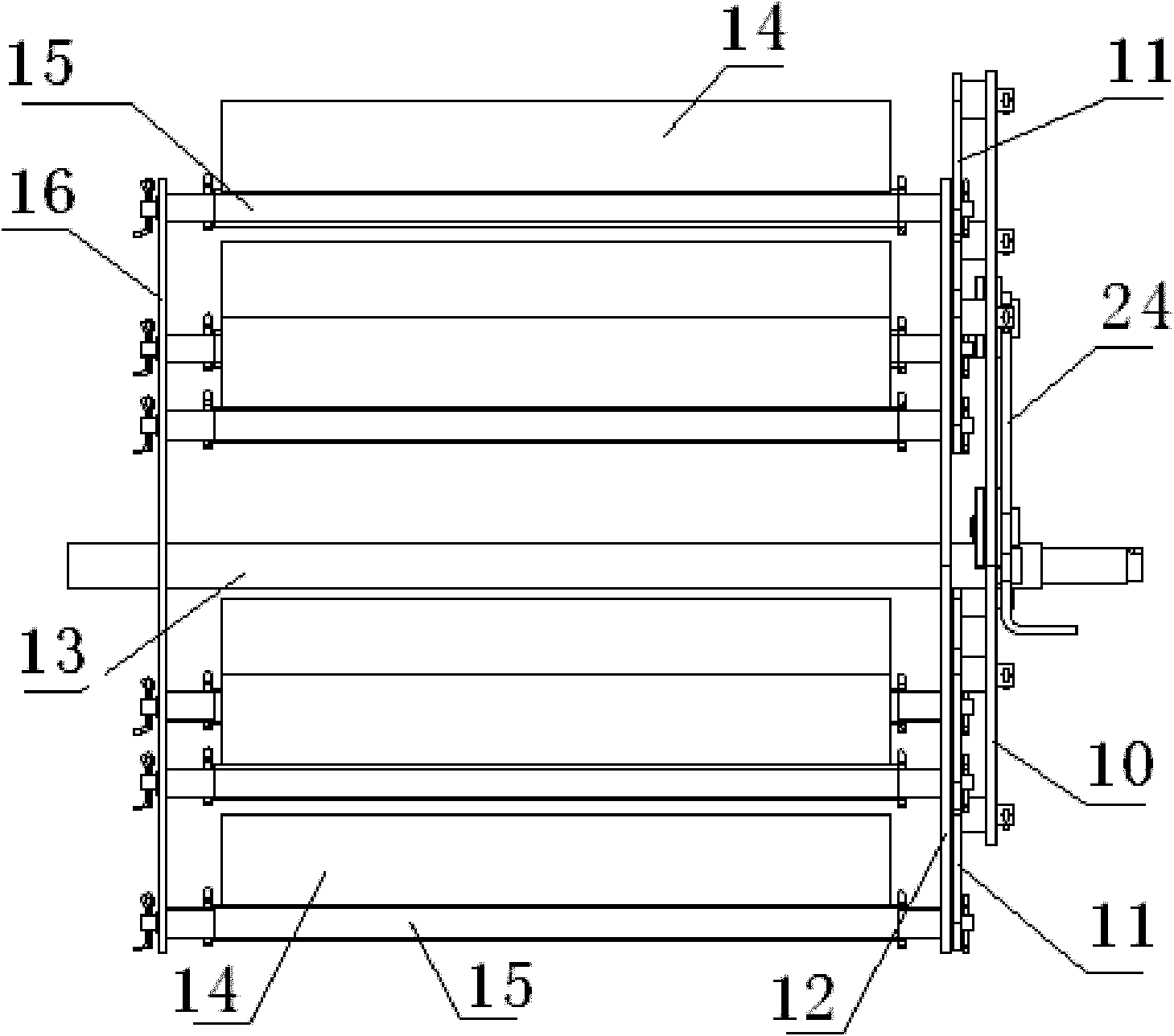

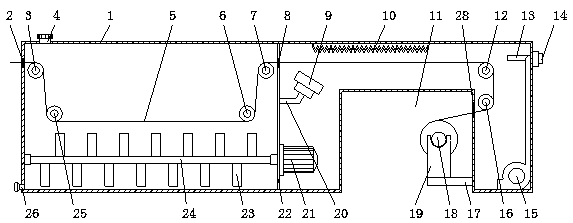

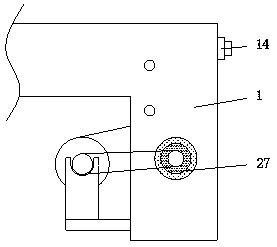

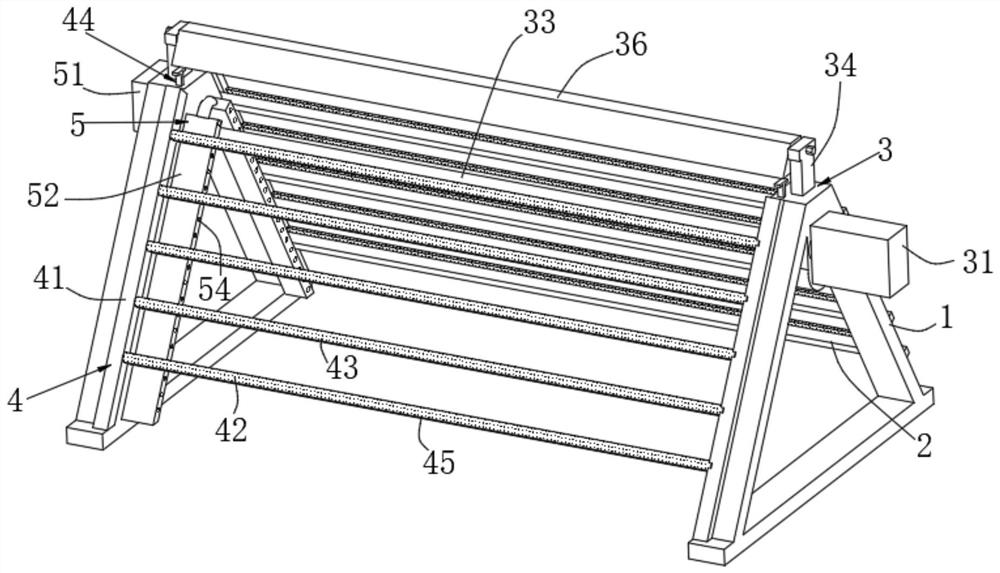

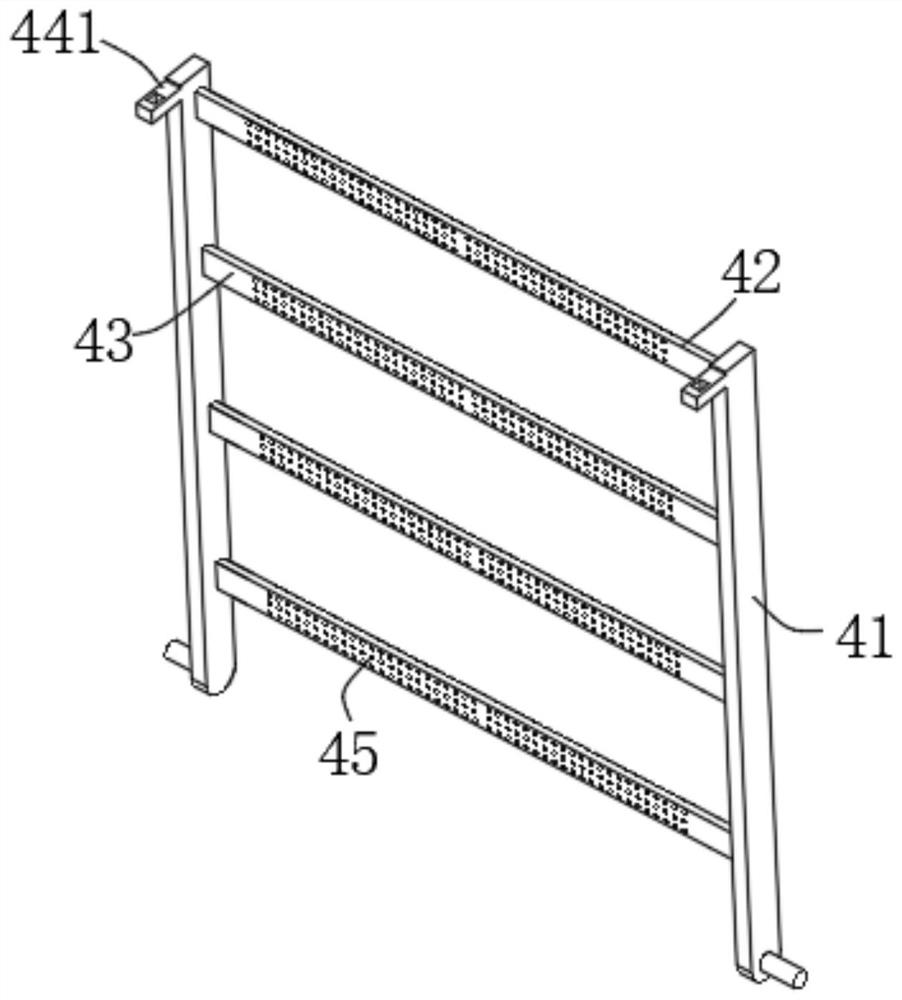

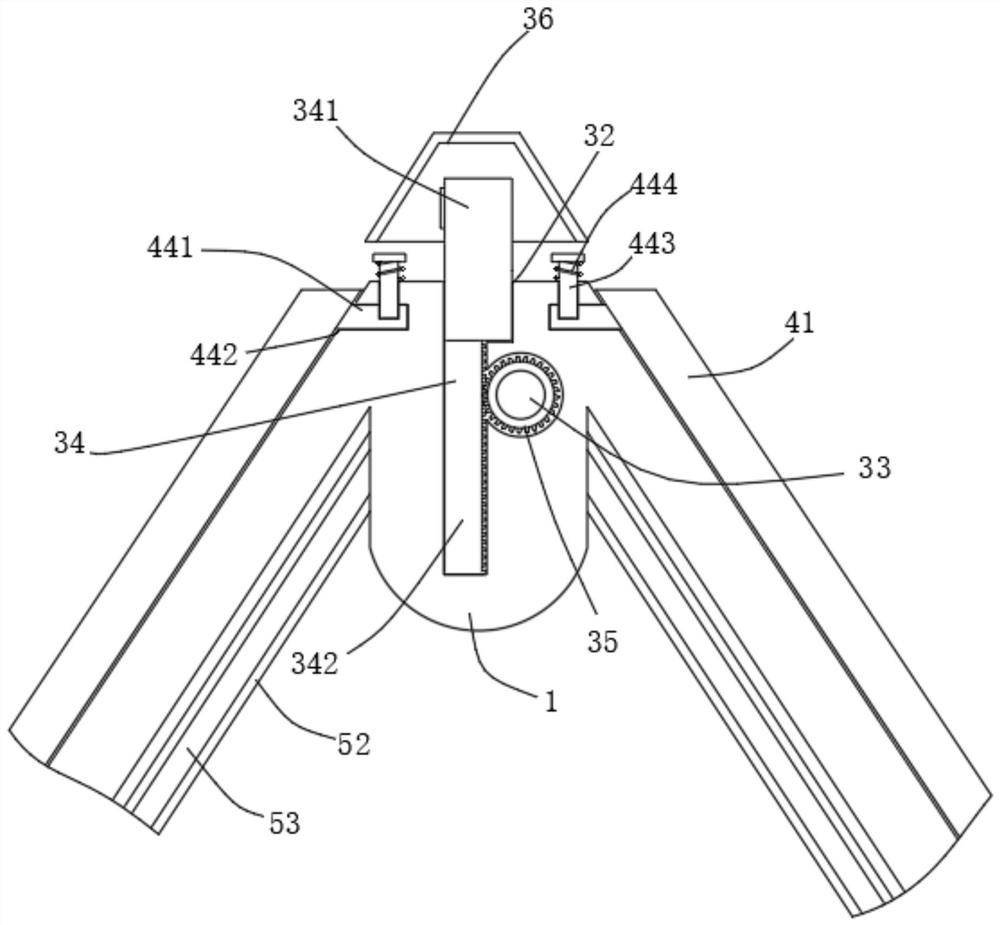

The invention belongs to the field of agricultural product processing machineries and relates to a pulsed gas jet impact drier. The pulsed gas jet impact drier consists of an air circulating system, a material drying system, a temperature and humidity control system and a case. A material frame of the drying system adopts a four-parallel rod mechanism; a material disc does horizontal rotary movement around a material frame shaft at a constant speed under the action of the four-parallel rod mechanism; and the bottom plane of the material disc is always vertical to the direction of the air flow jet by a jet plate. When the material disc is rotated to the top, the air flow impact applied to a material is maximum and then is gradually reduced; when the material disc is rotated to the bottom, the air flow impact applied to the material is minimum and then is gradually increased; and when the material disc is rotated to the top, the air flow impact applied to the material is maximum again and then the material is dried in a pulsing manner. Since a plurality of material discs do horizontal rotary movement around the material frame shaft at the same time, the loadage is increased and the phenomenon of uneven drying of the traditional gas jet impact drying device caused by relatively fixed positions of the material and a nozzle is avoided. The pulsed gas jet impact drier is applied to the drying of agricultural products, such as tomatoes, grapes, hot peppers and the like.

Owner:CHINA AGRI UNIV

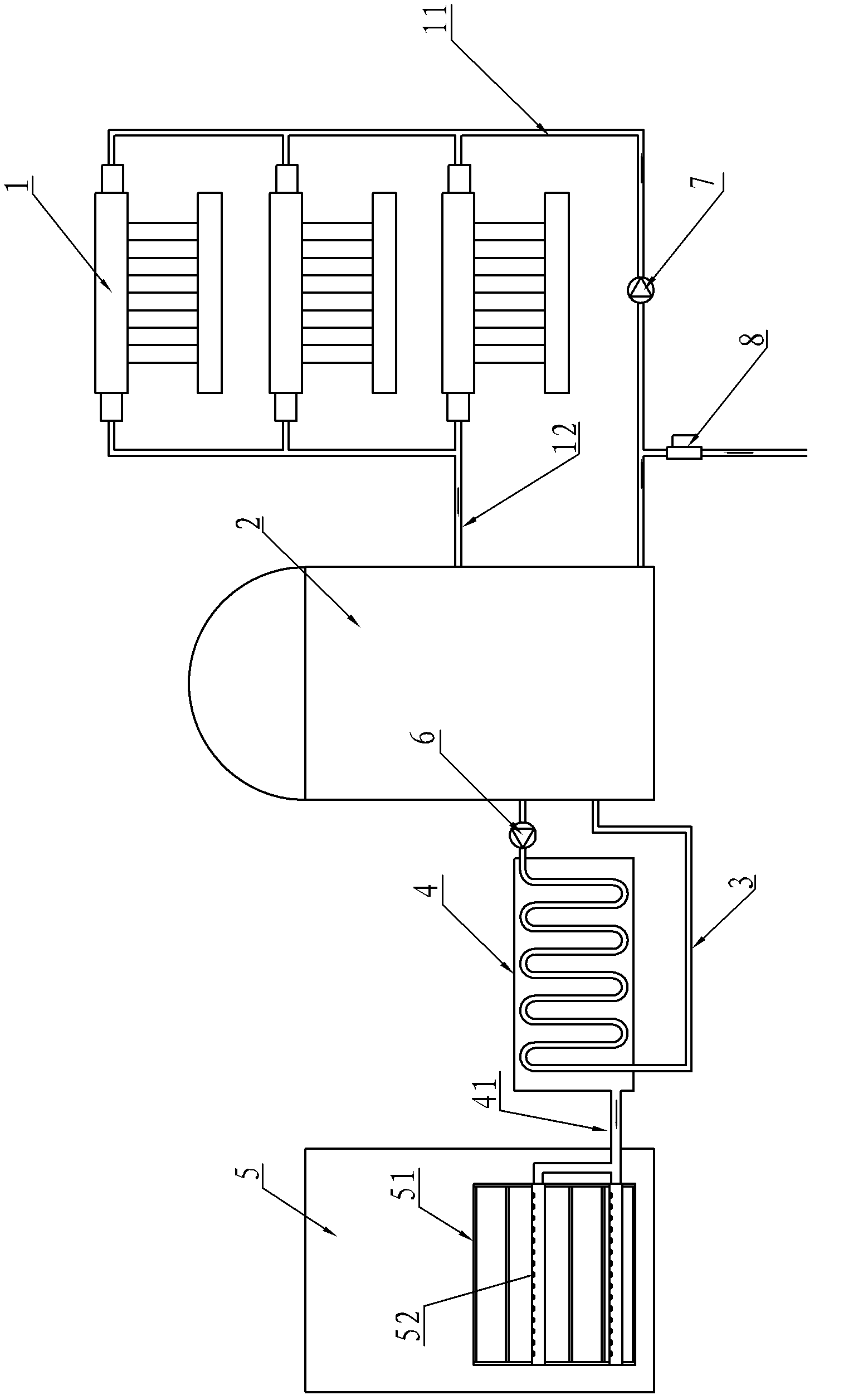

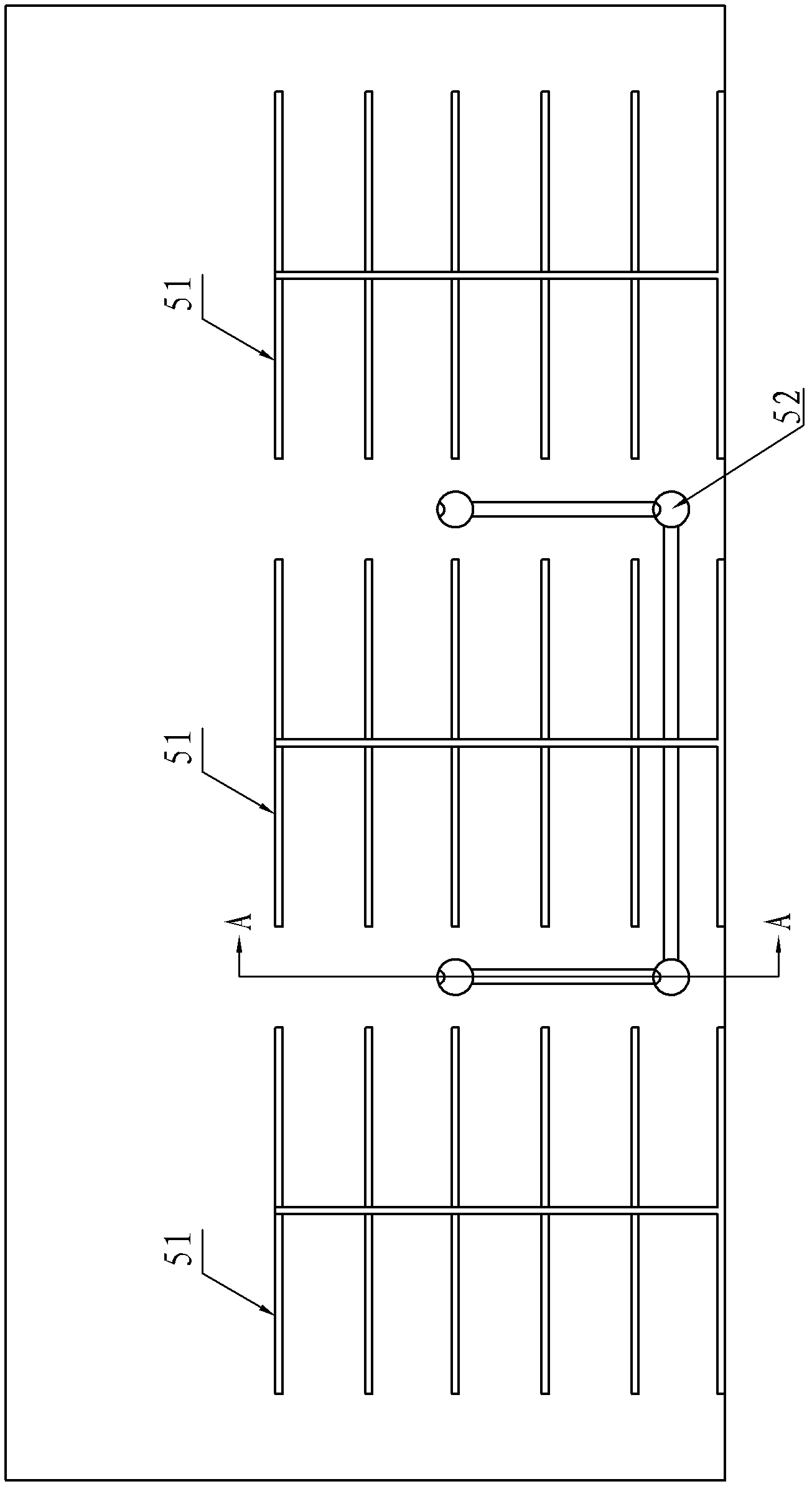

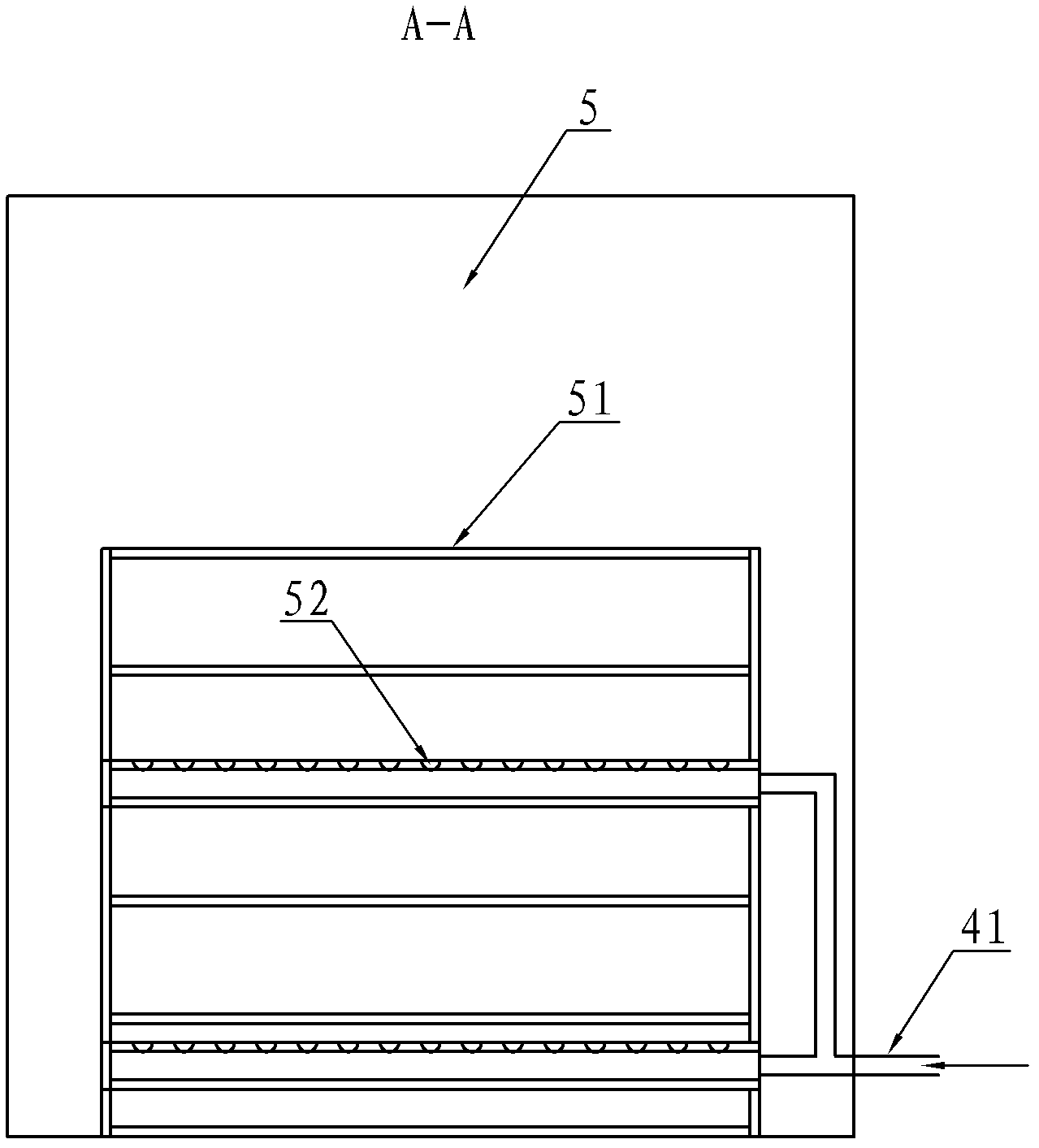

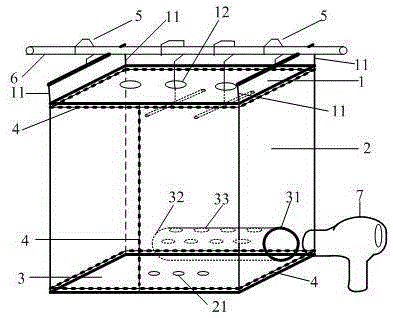

Heat collector system of multifunctional solar drying room

InactiveCN102564097AMeet drying needsReduce electricity consumptionSolar heat devicesDrying gas arrangementsThermal energySolar drying

A heat collector system of a multifunctional solar drying room comprises a solar heat collector, a heat-insulation water tank, a circulating water return pipe, a heat converter, a drying room, a heat exchange pump, a circulating water supply pump and a water replenishment valve. The solar heat collector acquires solar heat, forced circulation between the solar heat collector and the heat-insulation water tank is realized by the aid of the circulating water supply pump, accordingly, the solar heat acquired by the solar heat collector is continuously transmitted to the heat-insulation water tank, then hot water in the heat-insulation is delivered to the heat converter via the heat exchange pump, and is converted into hot air by the aid of circulation of the heat converter, and the hot air is delivered into the drying room via a heat supply pipe. Accordingly, an existing conventional heating mode is replaced, the temperature of water in the heat-insulation water tank can reach about 80 DEG C as long as illumination time reaches 8 hours, the temperature of the inside of the drying room can range from 50 DEG C to 60 DEG C, and conventional drying requirements can be met. Tests show that power consumption of the heat collector system can be saved by 60% to 75% as compared with the existing conventional heating drying mode.

Owner:JIANGSU PLET PLASTIC PACKING

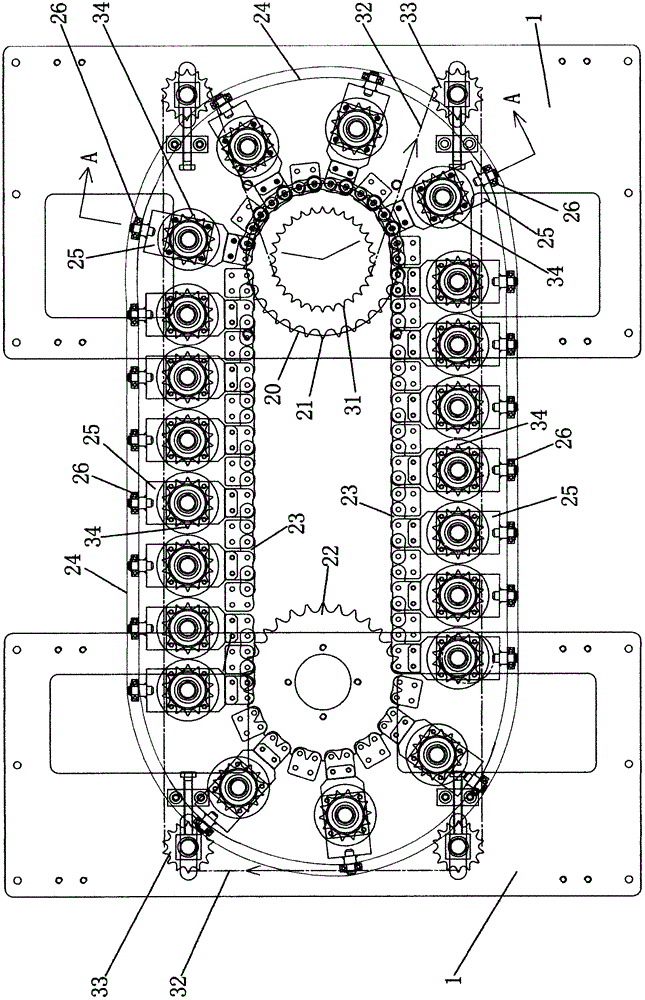

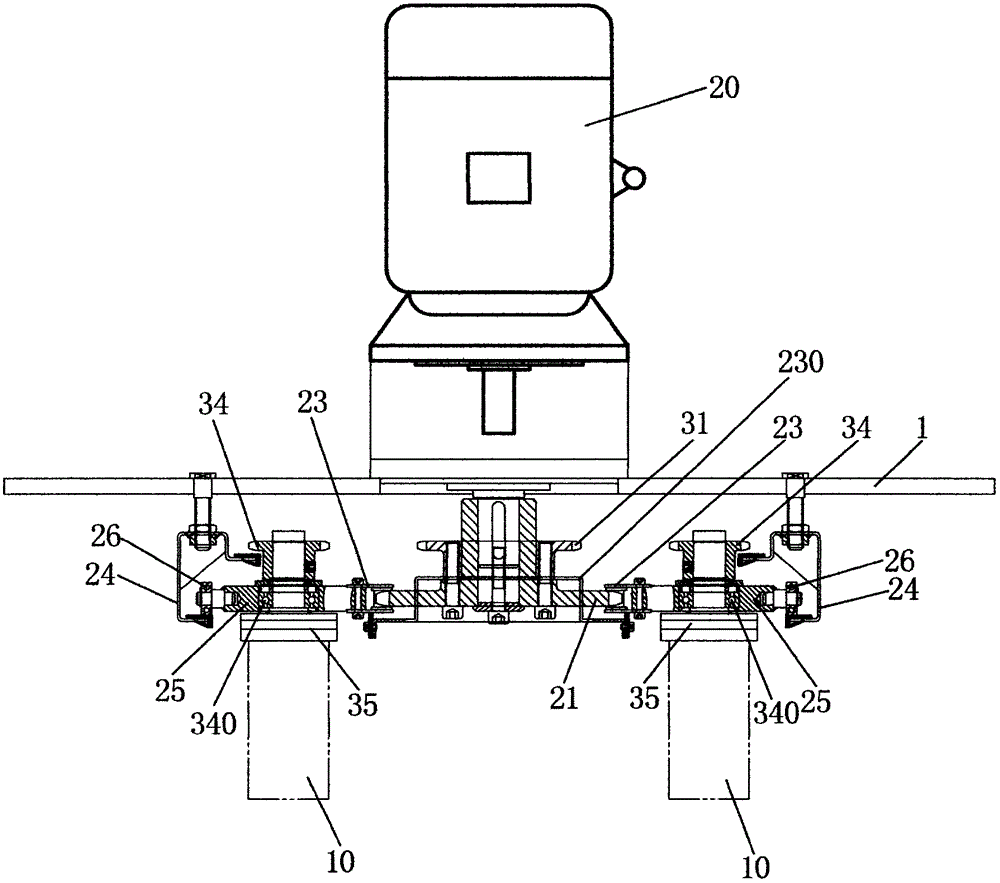

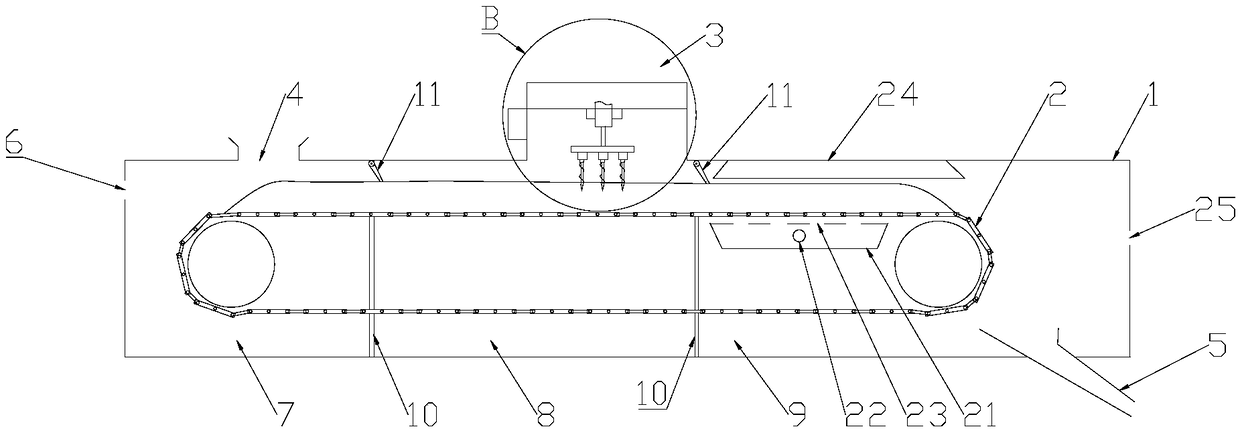

Packaging container conveying device

InactiveCN102976039AEvenly heatedImprove drying effectConveyorsDrying solid materialsEngineeringMechanical engineering

The invention discloses a packaging container conveying device, which is characterized by comprising a rack, a packaging container revolution conveying mechanism and a packaging container rotation mechanism, wherein the packaging container revolution conveying mechanism is arranged on the rack; the packaging container rotation mechanism is arranged on the packaging container revolution conveying mechanism and is in transmission connection with the packaging container revolution conveying mechanism. When the packaging container revolution conveying mechanism operates, the packaging container rotation mechanism revolves along with the packaging container revolution conveying mechanism, and meanwhile, the packaging container rotation mechanism rotates under the driving of the packaging container revolution conveying mechanism, so that the packaging container conveying device realizes that a packaging container can rotate during revolution to be uniformly heated, the drying effect of the packaging container is improved, the requirement of drying of the packaging container is met, and particularly the requirement of electromagnetic drying of a metal can is met.

Owner:SHANTOU XINQING CANNERY MACHINERY

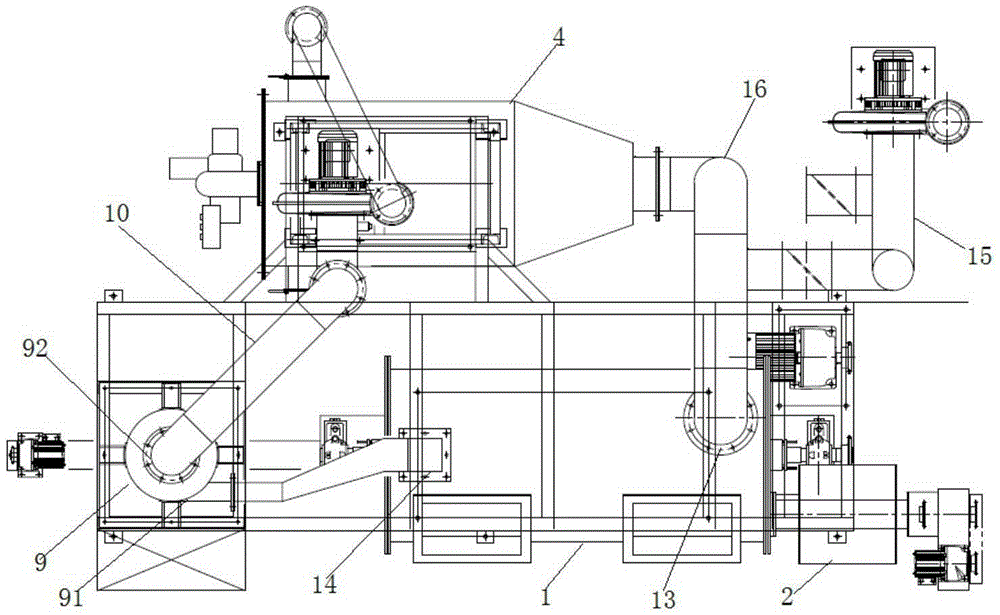

Drying and adjusting process and device for viscose fibers

ActiveCN102797064AImprove heat transfer efficiencyFlexible formArtificial filament washing/dryingTextile/flexible product manufactureWater vaporOscillating flow

The invention discloses a drying and adjusting process for viscose fibers. The process comprises the following steps of: 1) feeding the viscose fibers into a superheated vapor drier in a front area by a feeder; feeding a drying medium heated by a vapor coil into a drying chamber of the superheated vapor drier in the front area; drying the viscose fibers; evaporating water of the viscose fibers during drying; increasing pressure; and discharging out excessive water vapor to an oscillating-flow heat pipe heat exchanger through the linkage of a pressure controller and an induced draft fan; 2) under an effect of a chain conveying device, conveying the viscose fibers to a superheated vapor drier in a middle area, wherein the drying process in the middle area is similar to that in the front area; meanwhile, discharging out the excessive water vapor to the oscillating-flow heat pipe heat exchanger; and 3) heating the recycled water vapor in the oscillating-flow heat pipe heat exchanger into fresh air; feeding the fresh air into a hot air drier in a back area, so as to finish deep drying and adjusting of the viscose fibers; obtaining the dried viscose fibers; and emptying tail gas. The invention further discloses a device of the process. The viscose fibers with high qualities can be obtained; and energy consumption is reduced by 35-40%.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

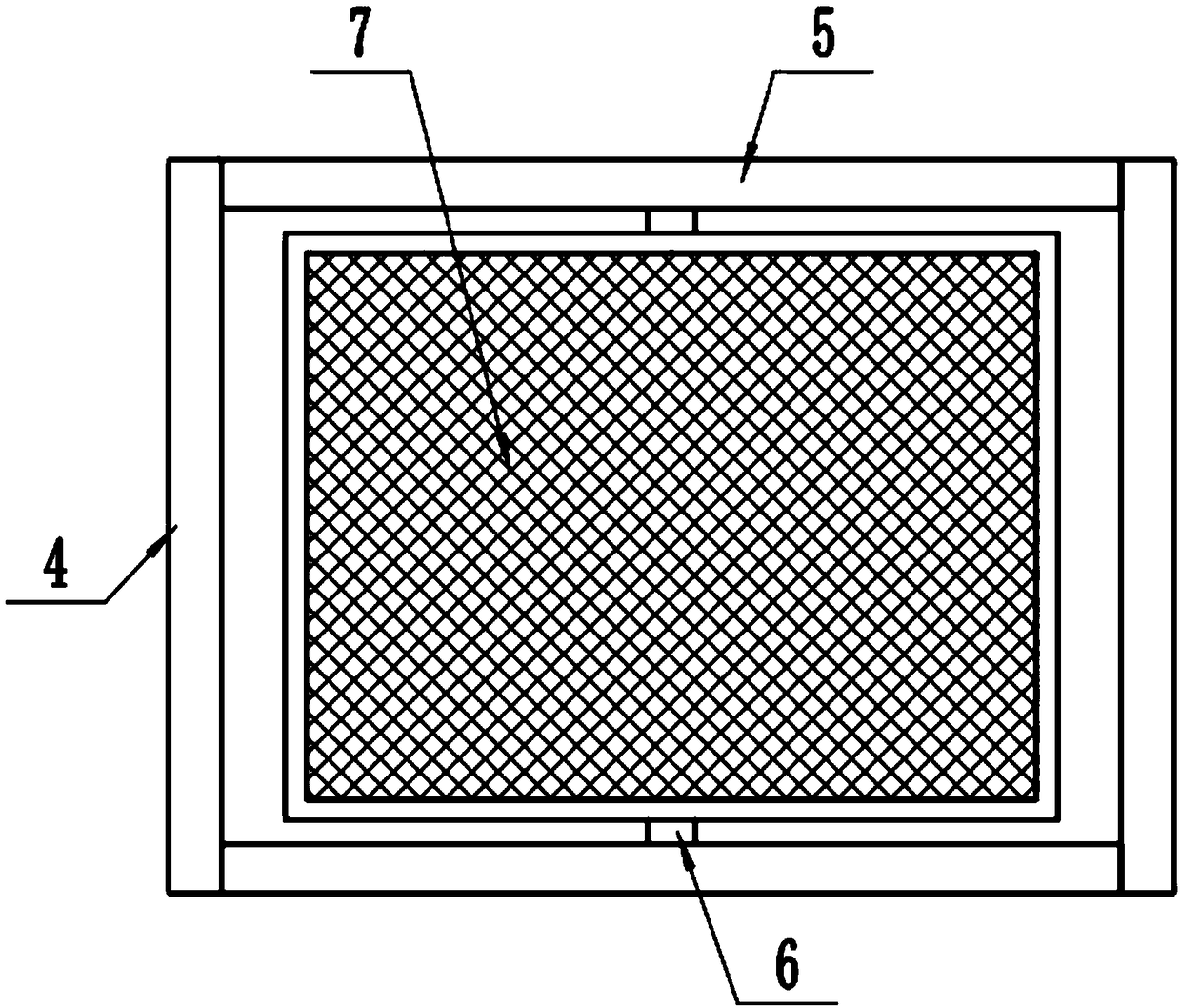

Swing type chrysanthemum natural drying and impurity removing device

InactiveCN109470038AReasonable structureInnovative designPre-extraction tea treatmentTea dryingDrive shaftPulp and paper industry

The invention discloses a swing type chrysanthemum natural drying and impurity removing device, which belongs to the technical field of chrysanthemum processing, and comprises a bottom plate, whereinsupport frames are arranged on two sides of the upper end of the bottom plate; a top frame is arranged between the top ends of the support frames; a swing shaft is arranged in the middle of the top frame; a screen is arranged in the middle of the swing shaft; guide posts are arranged on two sides of the lower end of the screen; guide wheels are arranged at the lower ends of the guide posts; a hollow groove is formed in the middle of the bottom plate; a drive shaft is arranged in the hollow groove; a drive wheel is arranged in the middle of the drive shaft; limiting grooves are arranged at twoends of the hollow groove; limiting springs are arranged in the limiting grooves; limiting rods are arranged at the other ends of the limiting springs; a swing frame is connected to the limiting rods;the upper end and the lower end of the swing frame are provided with swing teeth; the two sides of the upper end of the swing frame are provided with swing columns; and wedge blocks are arranged at the upper ends of the swing columns. The swing type chrysanthemum natural drying and impurity removing device realizes left-right swing of the swing frame, so that chrysanthemum is dried more uniformlywhen being dried naturally, and meanwhile, the effect of removing dust and impurities on the screen by an air injection cavity is also realized.

Owner:临泉县同鑫达农业有限公司

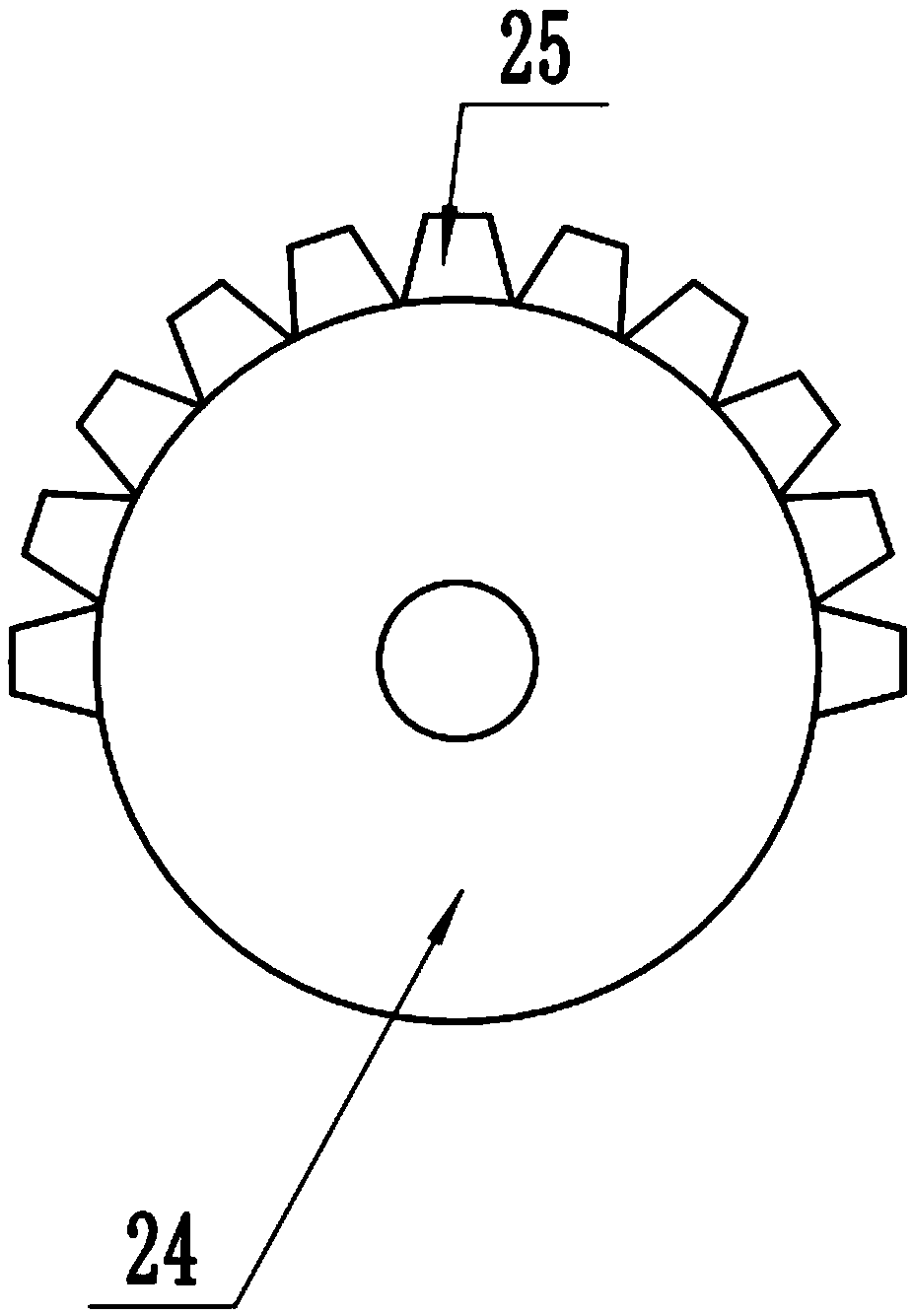

Cam rotary type bamboo shoot fast and efficient drying device

InactiveCN108224961AReasonable structureInnovative designDrying gas arrangementsDrying machines with non-progressive movementsReciprocating motionAgricultural engineering

The invention discloses a cam rotary type bamboo shoot fast and efficient drying device comprising a support seat. A base is connected to the middle of the lower end of the support seat. A rotary motor is connected to the middle of the lower end of the base. A rotary belt wheel is installed at the front end of the rotary motor. A driving belt wheel is connected to the rotary belt wheel through a belt. A driving cam is installed in the coaxial position at the rear end of the driving belt wheel. A lifting column makes contact with the upper end of the driving cam. A piston plate is installed inthe middle of the lifting column. A fixed plate is connected to the upper end of the lifting column. A chute is installed in the middle of the upper end of the fixed plate and is internally provided with a pulley. A movable column is connected to the upper end of the pulley. A movable plate is installed at the upper end of the movable column. A rotary cam is installed in the middle of the upper end of the fixed plate. A baffle matched with the rotary cam is arranged in the middle of the lower end of the movable plate. According to the cam rotary type bamboo shoot fast and efficient drying device, up-down and left-right reciprocating motion of a drying sieve is achieved, thus bamboo shoots on the drying sieve can be fully dried, drying cost is lowered, and the drying needs of a large numberof bamboo shoots are met.

Owner:丁文海

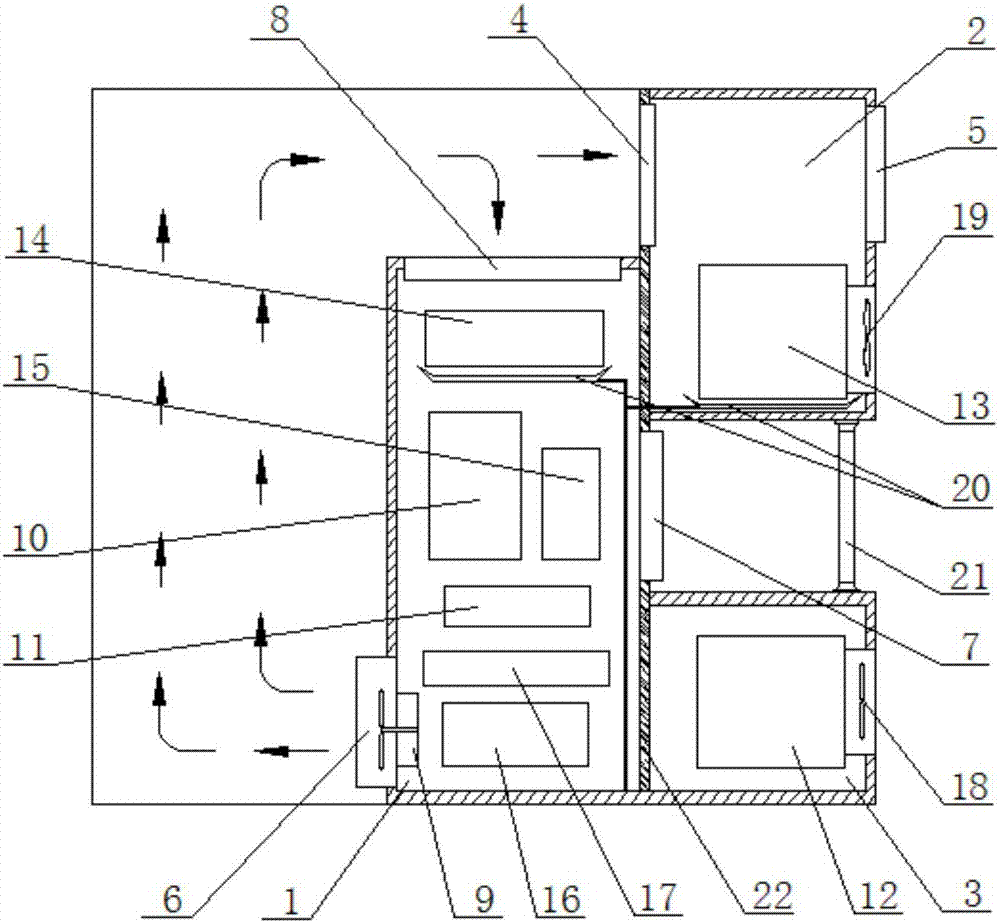

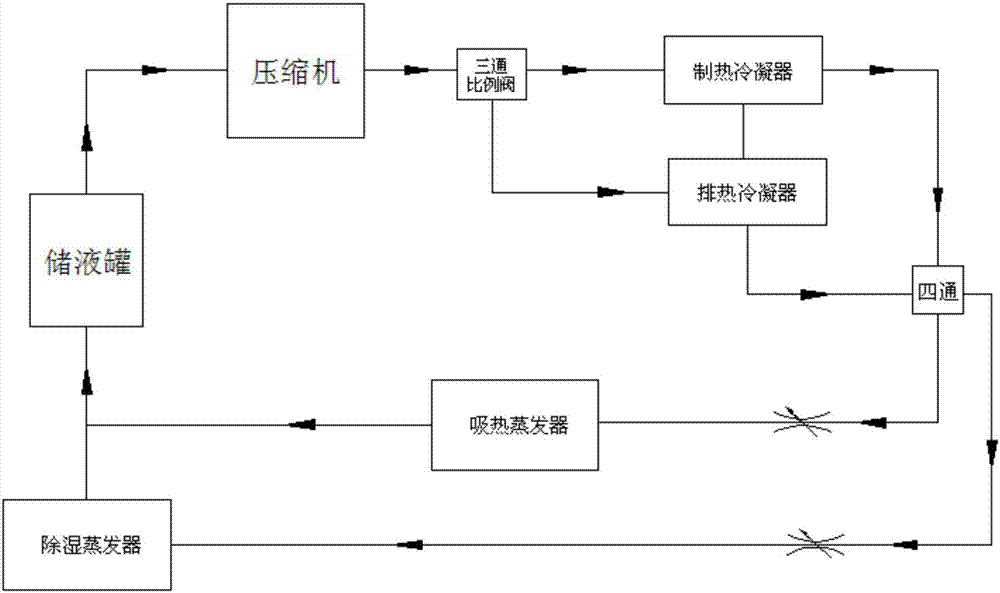

Air source heat pump drying system

PendingCN107202475APrevent moisture returnIncrease heating capacityHeat pumpsDrying gas arrangementsModularityLiquid storage tank

The invention relates to an air source heat pump drying system, which belongs to the technical field of drying systems. The invention mainly solves the technical problems of low drying efficiency, large energy consumption, poor drying effect, unreasonable structural design and easiness in moisture regain phenomenon of the existing heat pump drying systems. The technical solution of the invention is that an air source heat pump drying system comprises an indoor cavity body, an outdoor upper cavity body and an outdoor lower cavity body; the indoor cavity body is arranged in a drying room, and the outdoor upper cavity body and the outdoor lower cavity body are both arranged outside the drying room; the air source heat pump drying system further comprises a compressor, a heating condenser, a heat removal condenser, a heat absorbing evaporator, a dehumidifying evaporator, a condensed water collecting disc and a liquid storage tank. The air source heat pump drying system has the advantages of compact structure, high drying efficiency, high finished product quality, wide application range, modularized design, compatibility for auxiliary heat sources, simple operation, reasonable structural design, no influence from environment temperature and humidity, and the like.

Owner:刘贵平

Rice cleaning device

The invention discloses a rice cleaning device. The rice cleaning device comprises a housing and a drying box, wherein the upper ends at the two sides of an inner cavity of the housing are fixedly connected with supporting plates; the top ends of the supporting plates are movably connected with a vibrating screen; the left end of the bottom of the vibrating screen is fixedly equipped with a vibrating motor; the middle end at the left side of the inner cavity of the housing is fixedly connected with a first baffle plate; the lower end of the inner cavity of the housing is movably equipped with a first rotary shaft; the outer surface of the first rotary shaft is fixedly connected with a stirring blade; a water outlet is formed in the middle end of the bottom of the housing; and the bottom at the right side of the housing is fixedly equipped with a motor supporting base. According to the rice cleaning device disclosed by the invention, the top end of the supporting plate is connected with the vibrating screen through a spring, and screening needs, on impurities in rice, of people can be met through the action of the vibrating motor and the first baffle plate, so that the problem that an existing rice cleaning device only has a single cleaning effect and cannot screen the impurities in the rice is solved.

Owner:XUCHANG TONGXING MODERN AGRI SCI & TECH

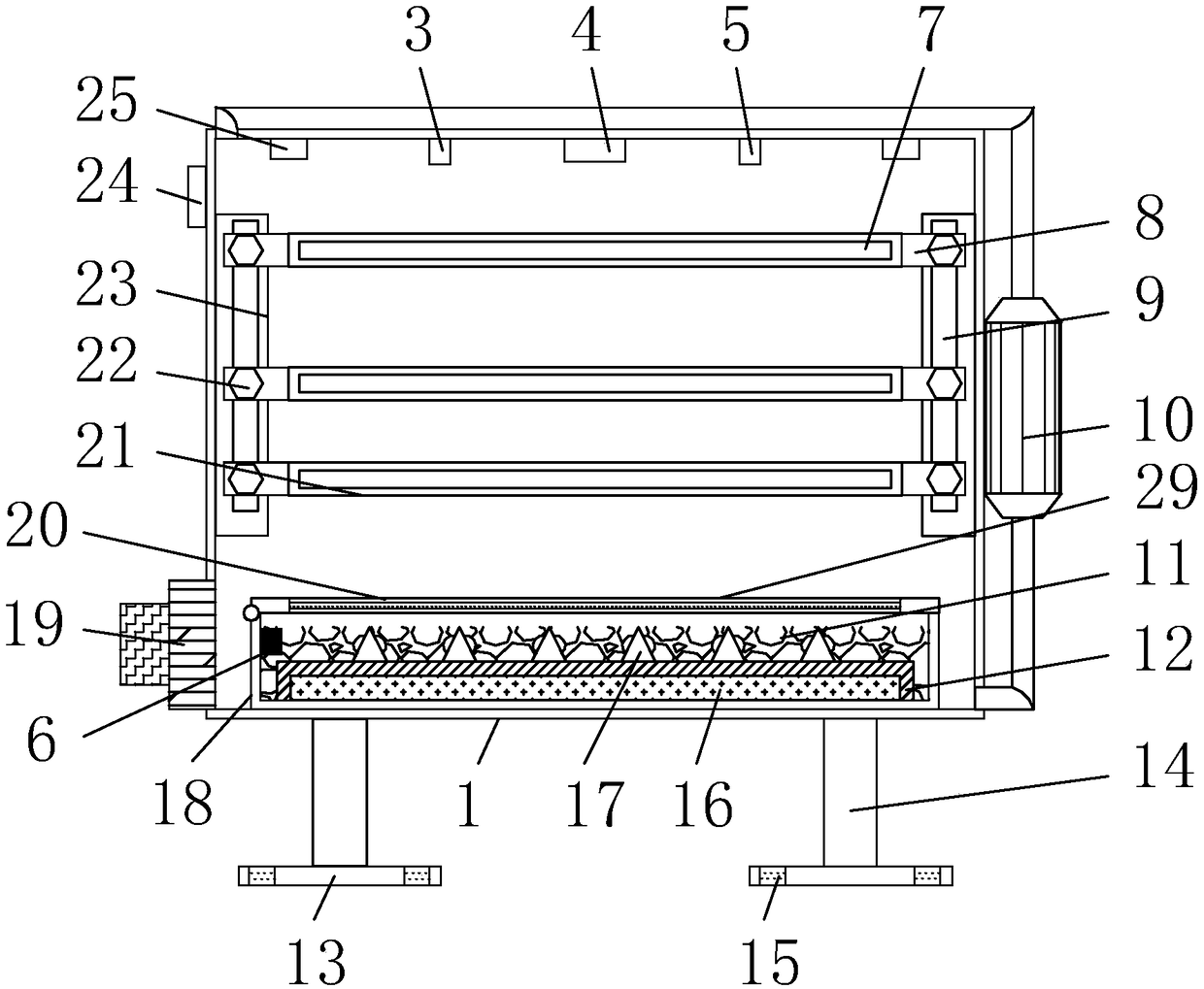

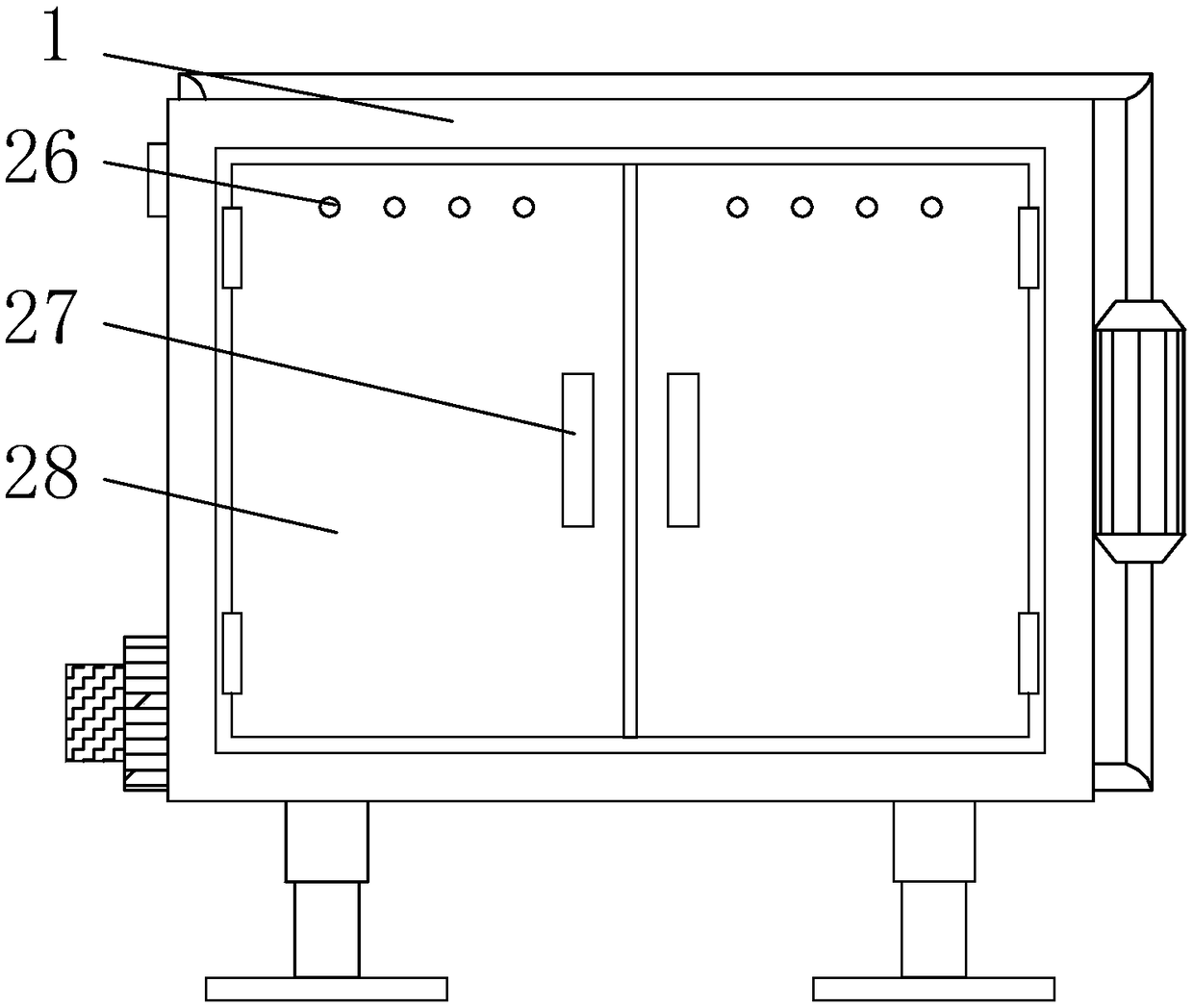

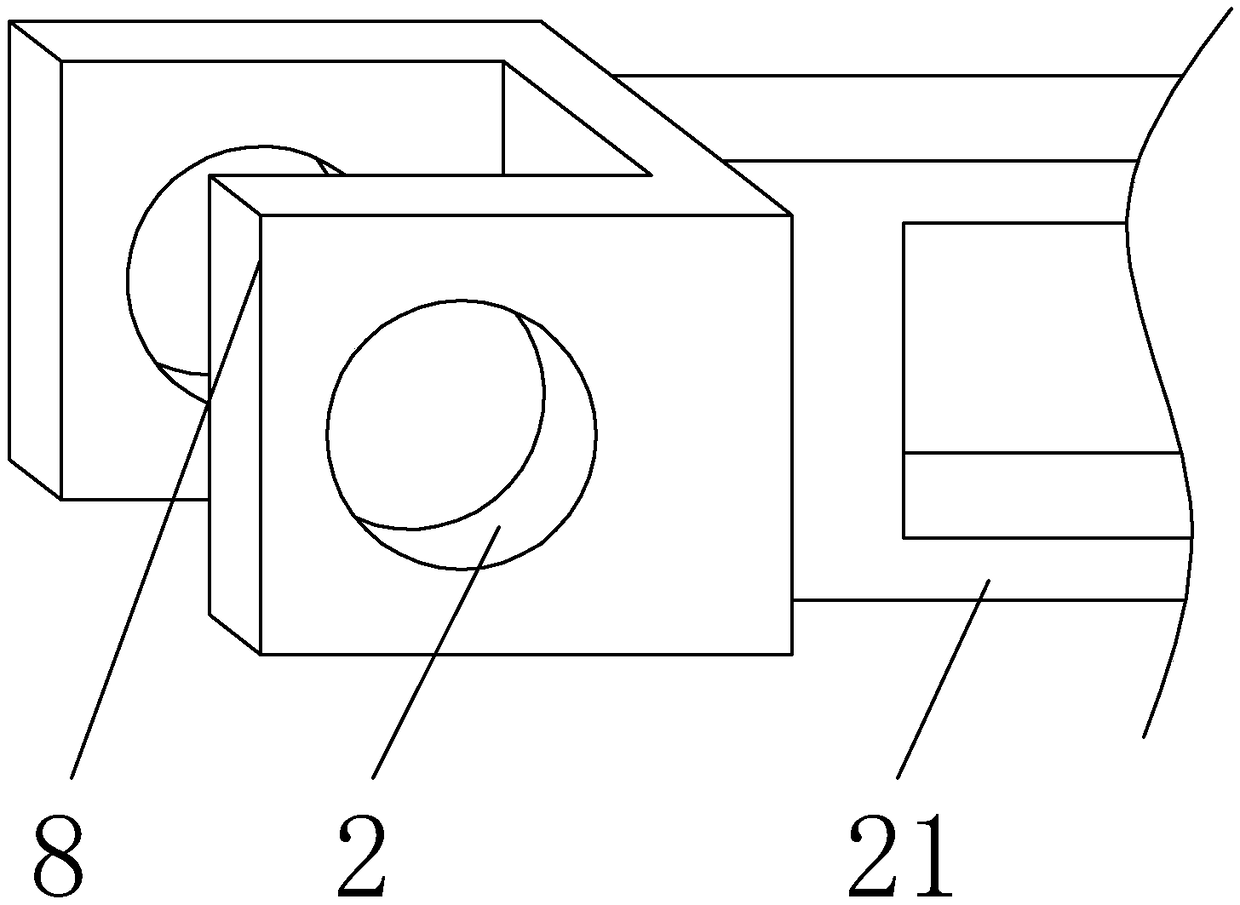

A dehumidification switch cabinet

InactiveCN109066348AMeet installation needsMeet the needs of dryingSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDesiccantEngineering

The invention discloses a dehumidification switch cabinet, which includes a housing, A left and right ends of the top of the inn cavity of thehousing are fixedly connected with a refrigeration plate,4G communication module are fixedly connected with the middle end of the top of the inner cavity of the housing, A first humidity sensor is fixedly connected to the left side of the 4G communication module at the top of the housing internal cavity, A temperature sensor is fixedly connected with the top of the housing inner cavity and located on the right side of the 4G communication module, the left and right sides of the housing inner cavity are fixedly connected with a third mounting plate, the inner surface of the third mounting plate is provided with a first sliding groove, and the outer surface of the third mounting plate is slidably connected with a card plate. The invention fixedly connects the dryer placing box at the middle end of the shell inner cavity bottom, and effectively improves the dehumidification effect of the switch cabinet and guarantees the safety of the switch cabinet through the functions of a heating plate, a heat conduction plate, a desiccant, a second humidity sensor, a circulating fan, a first humidity sensor and a dehumidification fan.

Owner:浙江瑞腾电力发展有限公司

Grain drying machine

InactiveCN107120949AExtend the path of descentEvenly heatedDrying gas arrangementsDrying solid materialsEngineeringAir blower

The invention discloses a grain drying machine. The grain drying machine comprises a drying machine body, a first feeding inlet, a second feeding inlet, a first discharging outlet, a second discharging outlet and a third discharging outlet. The drying machine body has a hollow cavity, and a screw propulsion plate is arranged at the center of the inside of the drying machine body. A hollow chamber is formed in the screw propulsion plate. First exhaust outlets and second exhaust outlets are formed in the upper surface and the lower surface of the screw propulsion plate separately. A hot-air blower is arranged at the bottom of the drying machine body and further communicates with the screw propulsion plate through a hot-air pipeline. An analysis room is arranged at the left side of the drying machine body. The analysis room comprises an L-shaped support, a second discharging outlet and a PLC. A first tilted baffle, a material receiving plate, air blowers and a second tilted baffle are sequentially arranged inside the L-shaped support from top to bottom. The air blowers and the hot-air blower are electrically connected to the PLC. The grain drying machine has the advantages of being small in size, low in weight, convenient to transport, capable of achieving grain circulation drying, uniform in heating, high in drying efficiency and free of pollution.

Owner:HEFEI HUIZHI NEW MACHINERY TECH CO LTD

Textile-fabric printing and dyeing device

InactiveCN107904839AMeet drying needsMeet mixing needsTextile treatment containersTextile treatment machine arrangementsEngineeringDyeing

The invention discloses a textile fabric printing and dyeing device, which comprises a casing, and the inner cavity of the casing is sequentially provided with a first conveying roller, a second conveying roller, a third conveying roller, a fourth conveying roller, a partition plate, the fifth conveying roller and the sixth conveying roller, the upper end on the right side of the partition is fixedly connected with a hot air blower through the first support rod, the lower end on the right side of the partition is fixedly installed with a first motor, and the output of the first motor The shaft is fixedly connected with a stirring shaft, and the outer surface of the stirring shaft is fixedly connected with a stirring blade. In the present invention, a hot air blower is fixedly connected to the upper end of the right side of the partition through a first support rod, and a heating wire is fixedly connected to the right end of the top of the inner cavity of the casing, and through the function of the fan and the pipeline, it can satisfy people's requirements for the surface of the cloth after printing and dyeing. The need for drying solves the problem that the existing printing and dyeing devices only have a single printing and dyeing ability, which leads to low overall processing efficiency of fabrics and does not conform to the self-interest of the enterprise.

Owner:苏州旺谦纺织科技有限公司

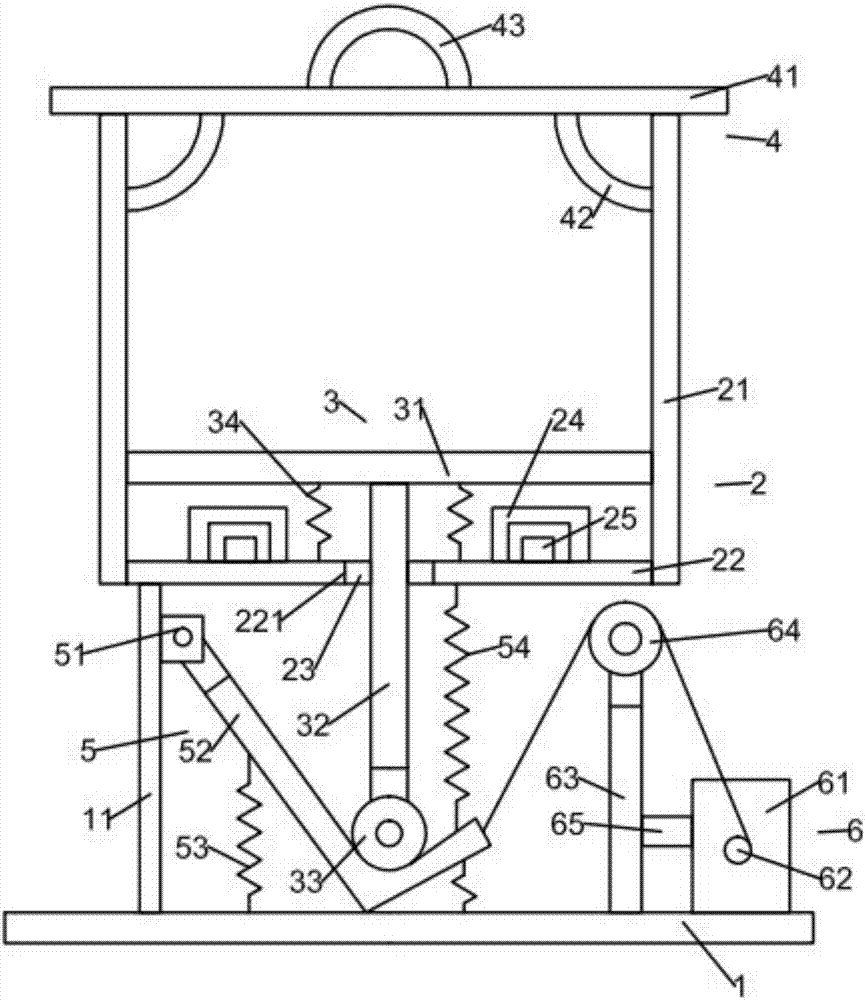

Drying device for cleaning electronic instrument part

InactiveCN106989581AFully dry treatmentMeet the needs of dryingDrying gas arrangementsDrying solid materialsElectronic instrumentEngineering

A drying device for cleaning electronic meter parts, the drying device for cleaning electronic meter parts includes a base plate, a frame device located above the base plate, a lifting device arranged on the frame device, a The cover device above the body device, the push device below the frame device, and the drive device on the right side of the push device. The drying equipment for cleaning electronic instrument parts of the present invention can realize sufficient contact between hot air and electronic instrument parts, and then can perform sufficient drying treatment on electronic instrument parts, with high drying efficiency and uniform drying, which can meet the requirements for electronic instrument parts. The need for instrument parts drying.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

Electric heating table with function of drying clothes

InactiveCN109330204AShorten drying timeMeet the needs of dryingHeating fuelLighting and heating apparatusEngineeringDrying time

The invention discloses an electric heating table with a function of drying clothes. The electric heating table comprises a heating table body, the top on the left side of the heating table is connected with a first plate shaped like the Chinese character 'hui' through a hinge, the top of the first plate shaped like the Chinese character 'hui' is in screw connection with a table board, and the opposite faces of the table board and the heating table body are in screw connection with second plates shaped like the Chinese character 'hui' respectively. The centers of the inner walls of the secondplates shaped like the Chinese character 'hui' are in screw connection with net plates, cover plates are hinged to the left sides on the surfaces of the two opposite second plates shaped like the Chinese character 'hui' respectively, vertically through holes are uniformly formed in the surfaces of the cover plates, and a handle is in screw connection with the center on the right side of the tableboard. Through the cooperation of a push plate, a rectangular block, a clamping groove, a clamping rod, the first plate shaped like the Chinese character 'hui' and the net plates, the heat emitted from the heating table body and the table board can be used for drying the clothes, the clothes drying time is shortened, convenience is brought to wear and travel of people, the electric heating table is more flexible to use, and the clothes drying requirements are greatly met.

Owner:CHANGSHA BAOZHEN ELECTRICAL APPLIANCE

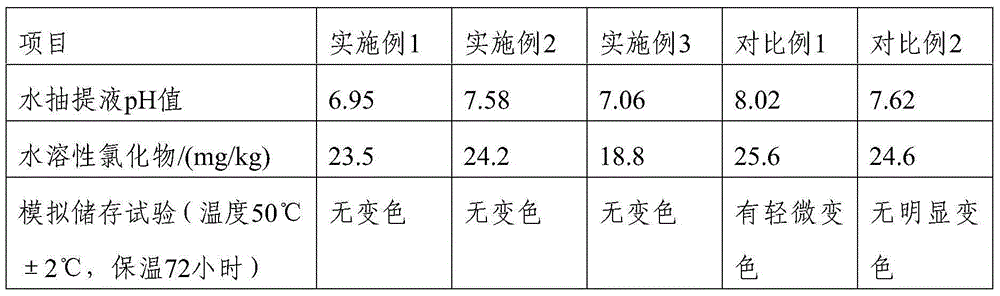

Preparation method of special neutral packaging paperboard for preventing copper product from color change

The invention relates to the technical field of a papermaking process and particularly relates to a preparation method of a special neutral packaging paperboard for preventing a copper product from color change. The preparation method comprises the following steps: crushing sulfate wood pulp, and washing with treated water until the content of residual drugs in the sulfate wood pulp is reduced to be lower than 120mg / L; controlling the concentration of the pulp to be 3.6-4.0% and the pH to be 5.0-8.0; carrying out primary grinding and secondary grinding on the pulp respectively; then diluting with water to obtain a pulp-water mixture; carrying out impurity removal, water filtering and molding on the pulp-water mixture to obtain a wet paper blank; and then, calendering to obtain a product. By virtue of the preparation method provided by the invention, the prepared special neutral packaging paperboard for preventing the copper product from the color change has high cleanliness and strong anti-oxidization; and the color and luster of the packaged copper material have no abnormal response, so that the special neutral packaging paperboard is particularly suitable for packaging the copper product with a relatively long storage period.

Owner:XINSHAO GUANGXIN ELECTRICAL INSULATING MATERIALS

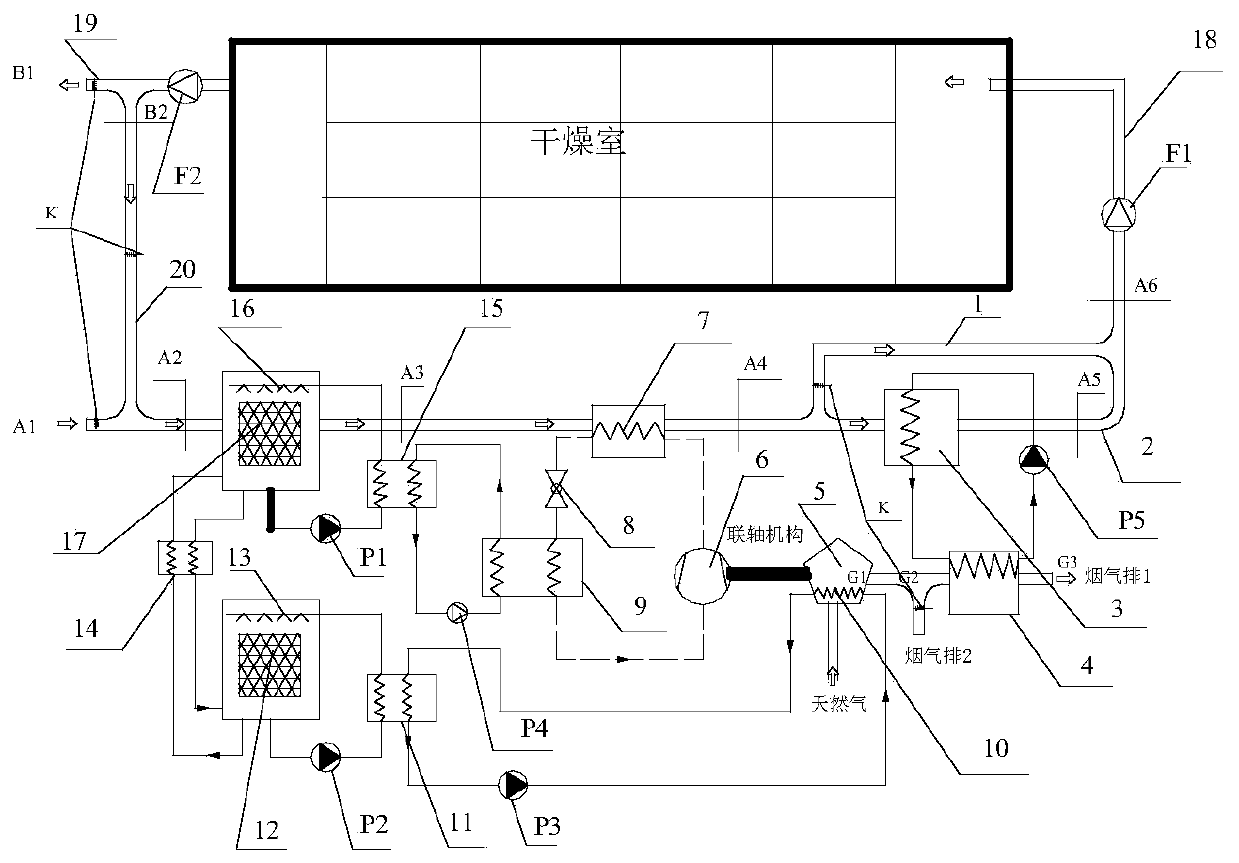

Fuel gas pump type drying device

PendingCN110094962ANo frostMeet drying needsFluid heatersDrying gas arrangementsTemperature conditioningEngineering

The invention discloses a fuel gas pump type drying device. The drying device includes a dehumidifier, a condenser and a drying chamber which form a loop through pipelines in order. The pipeline of one end, being close to the condenser, of the drying chamber is an air supply pipe, and the pipelines of the other end are an air exhaust pipe and an air return pipe. The end of the exhaust pipe communicates with the outside for exhausting air. The middle section of the exhaust pipe communicates with the air return pipe. The air return pipe is provided with an external air access port. Dry air in the air return pipe and outside air are mixed and then enter the dehumidifier. The device uses an internal combustion engine to drive a heat pump cycle, and waste heat of the internal combustion enginecan be utilized so as to realize a width range change of drying temperature and overcome the defect of a narrow conventional adjustment range of drying temperature of a heat pump.

Owner:ZHEJIANG OCEAN UNIV

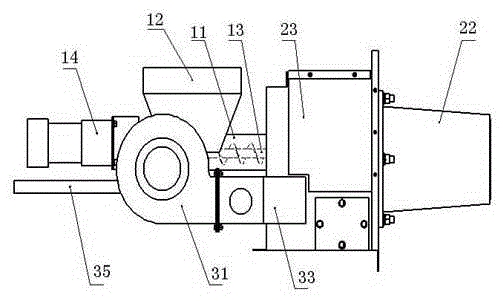

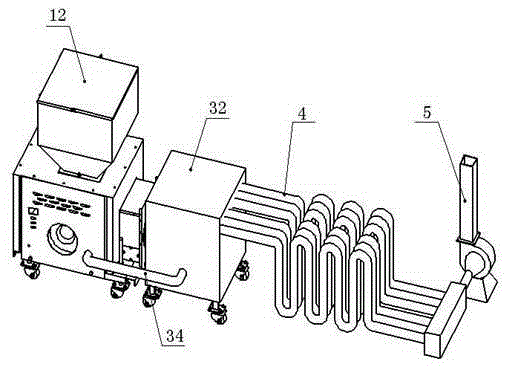

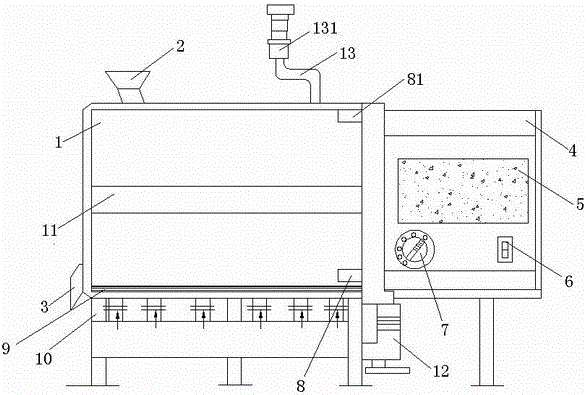

Biomass particle combustion drying equipment

InactiveCN105241212ABurn completelySufficient oxygen supplyDrying gas arrangementsAir heatersCombustion systemEngineering

The invention discloses biomass particle combustion drying equipment. The biomass particle combustion drying equipment comprises a feeding system and a combustion system. The feeding system comprises a feeding pipe. The combustion system comprises a flame outlet pipe, a flame outlet guiding pipe and a bellows. The flame outlet pipe penetrates through the bellows to be communicated with the feeding pipe. Air holes are formed in the portion, located in the bellows, of the flame outlet pipe. The flame outlet pipe is sleeved with the flame outlet guiding pipe. A gap is reserved between the flame outlet guiding pipe and the flame outlet pipe. The gap is communicated with the bellows. The biomass particle combustion drying equipment is simple in structure, low in manufacturing cost, capable of saving energy, efficient, environmentally friendly and suitable for industrial drying.

Owner:广西节得乐生物质能源科技有限公司

Improved traditional Chinese medicine drying device convenient to maintain

InactiveCN108645165AImprove efficiencyEasy maintenanceDrying gas arrangementsDrying machines with non-progressive movementsRotary switchEngineering

The invention provides an improved traditional Chinese medicine drying device convenient to maintain. The drying device comprises a drying device base, supporting frames, a protection door, an observing window, hooks, a rotary medicine bracket structure, a conveniently-dismounted drying barrel cover structure, a hot air circulation spraying pipe structure, an adjustable traditional Chinese medicine stirring structure, a mechanical lock, a rotary switch, a circulation switch, a drying barrel, a fixing base, a heating bar, a liquid discharge faucet and a heating switch; and the upper ends of thesupporting frames are in bolted connection to the left and right sides of the lower surface of the drying barrel, and the lower ends of the supporting frames are in bolted connection to the left andright sides of the upper surface of the drying device base. According to the improved traditional Chinese medicine drying device, a rotary motor, a rotary rod and the medicine bracket are arranged, traditional Chinese medicines placed on the medicine bracket can be better rotated, it is guaranteed that the medicines can be evenly heated, and the drying efficiency is improved; and the conveniently-dismounted drying barrel cover and a lifting dismounting ring are arranged, and therefore the conveniently-dismounted drying barrel cover can be conveniently dismounted from the drying barrel, and maintenance of the drying device is facilitated.

Owner:广西全创投资有限公司

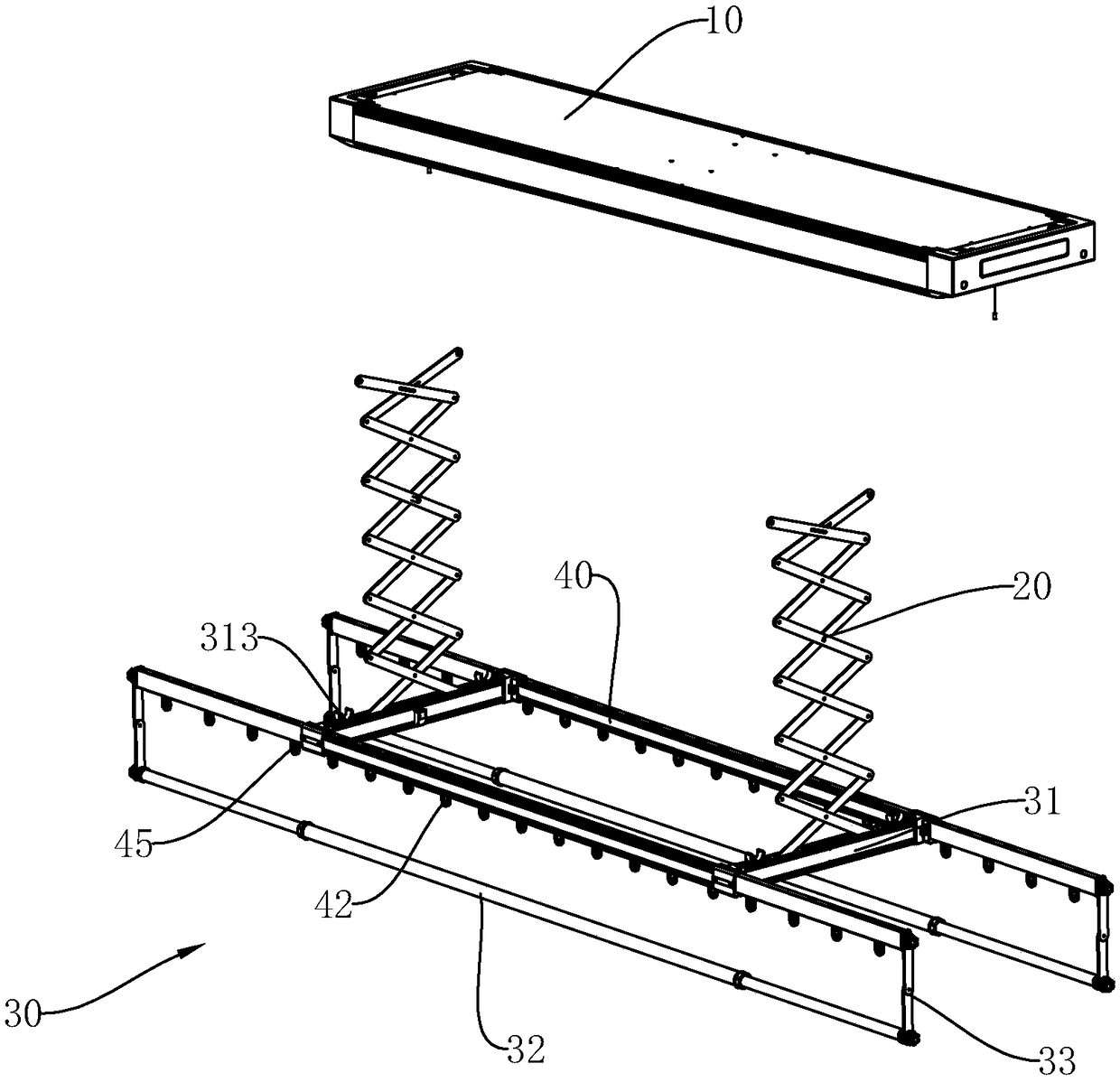

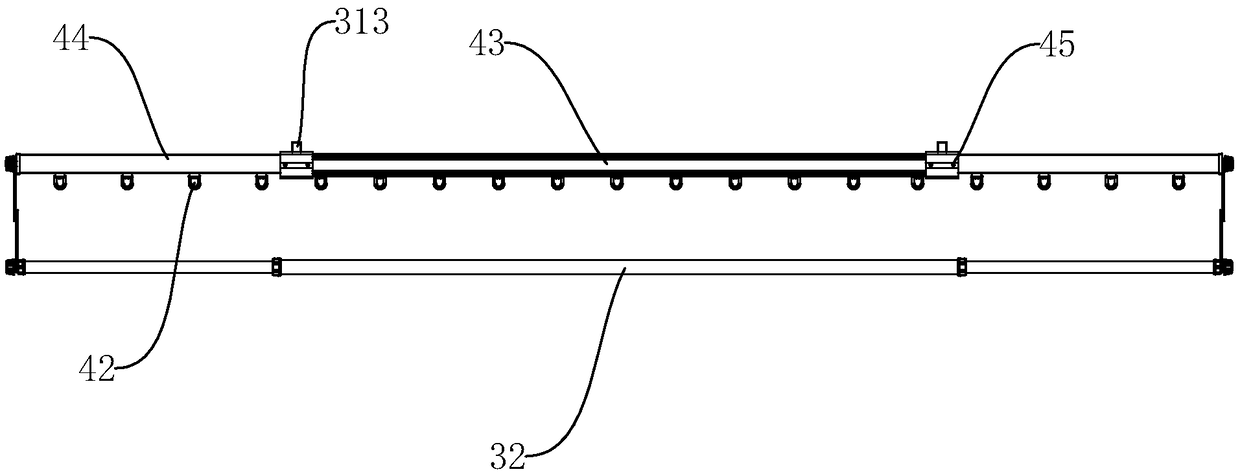

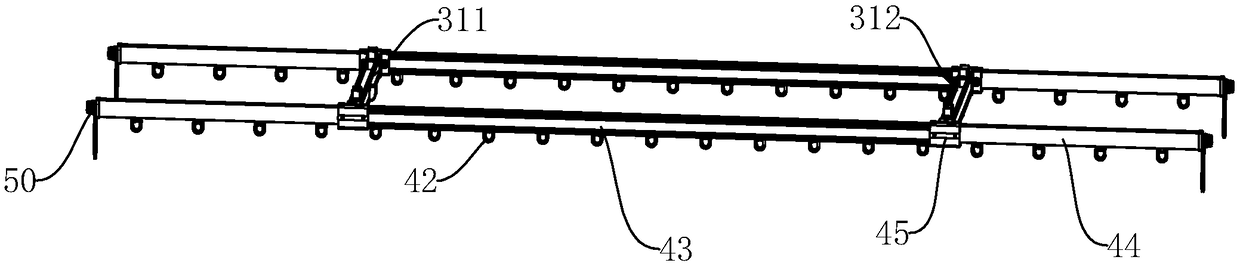

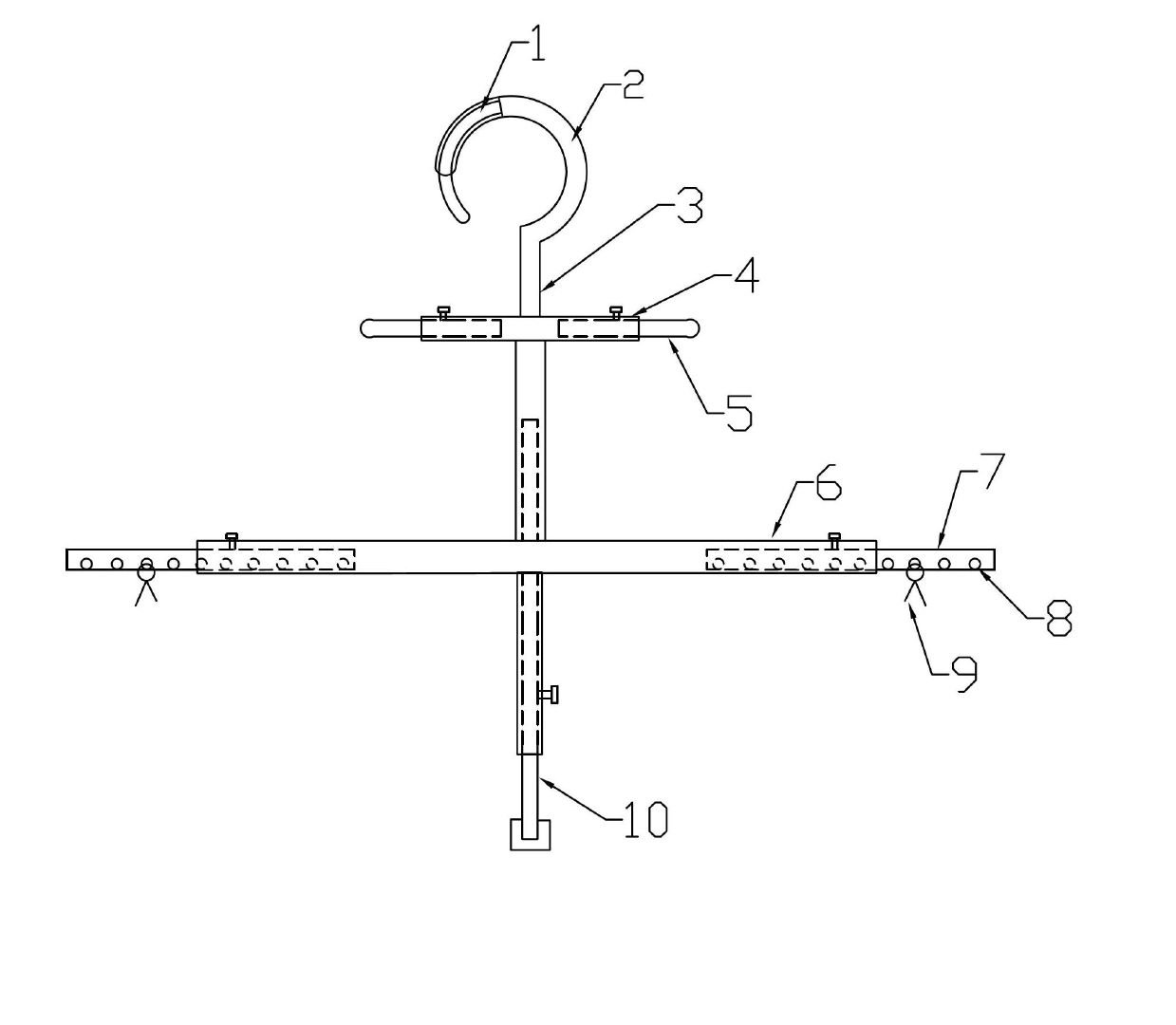

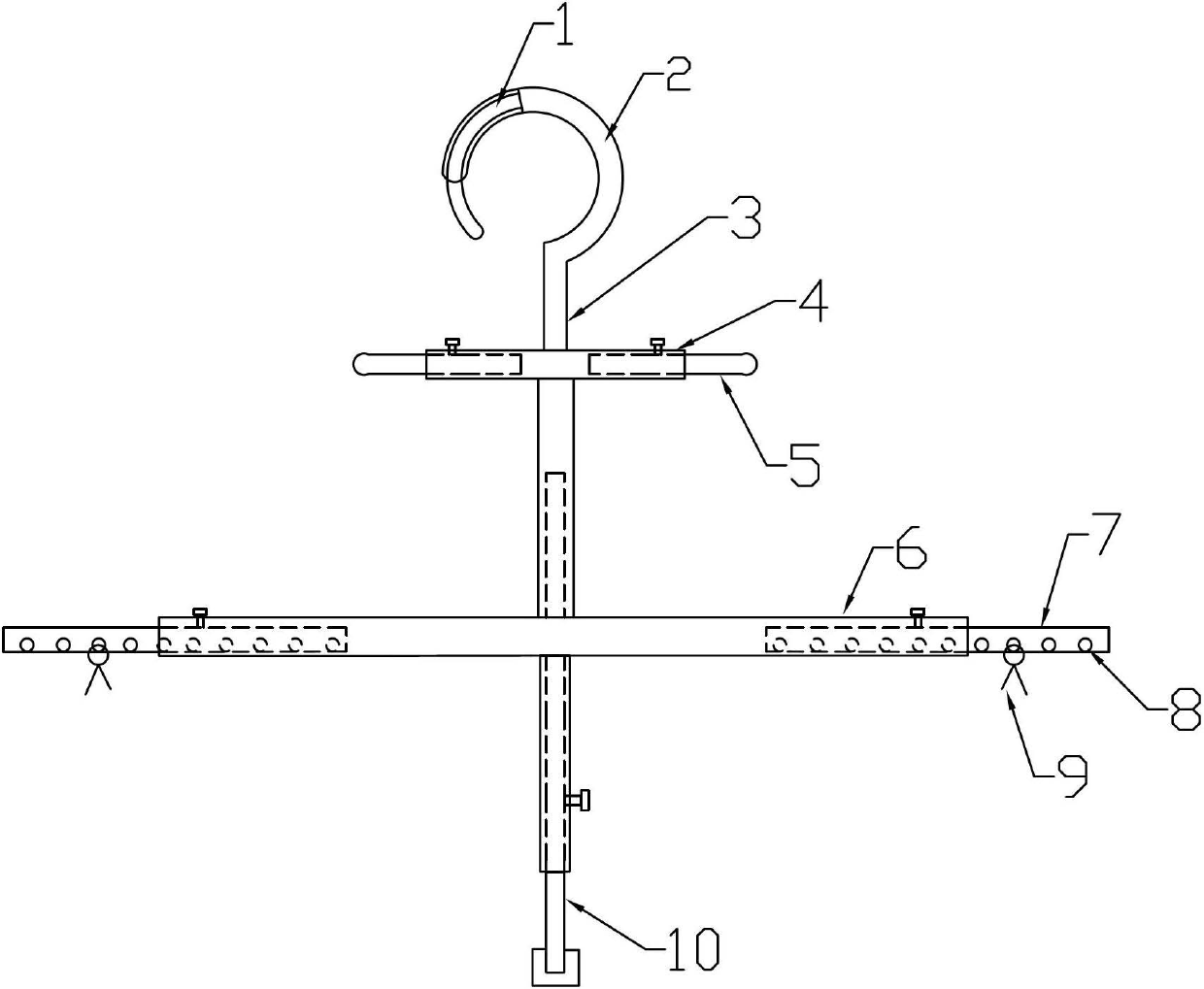

Novel automatic clothes hanger and assembling method thereof

PendingCN108914509AReduce volumeSave shipping spaceOther drying apparatusTextiles and paperEngineeringClothes hanger

The invention provides a novel automatic clothes hanger and an assembling method thereof. The clothes hanger comprises a mainframe, a folding frame, and an airing rod frame. The folding frame is connected with the mainframe and the airing rod frame in a liftable manner. The mainframe is used to control the folding frame to automatically lift. The airing rod frame comprises a pair of fixed supportsand a pair of clothesline poles. The fixed support is detachably connected with the clothesline pole. The lower end of the folding frame is connected with the fixed support. Each clothesline pole isprovided with a main rod, a pair of slave rods, a holding groove, and a plurality of suspension loops. The slave rod is connected with two sides of the main rod in an extension manner. The holding groove is arranged on the bottom surfaces of the main rod and the slave rod in a horizontal manner. The suspension loop is detachably connected with the holding groove, so as to adjust the distance between the suspension loops. Thus, the detachable suspension loops replace hanging supports, volume of the clothesline pole is greatly reduced, transportation space is saved, and transportation cost is reduced.

Owner:宁波斯洛曼智能科技有限公司

Portable clothes drying rack

InactiveCN105316922AMeet the needs of dryingSimple structureTextiles and paperLaundry driersEngineeringClothes hanger

The invention provides a portable clothes drying rack. The portable clothes drying rack comprises an upper cover, a lower cover and an enclosure curtain. The enclosure curtain is connected with the edge of the upper cover and the edge of the lower cover and encloses the space between the upper cover and the lower cover. Zippers are arranged at the edge of the upper cover, the edge of the lower cover and the edge of the enclosure curtain, connect the upper cover and the lower cover with the upper end and the lower end of the enclosure curtain respectively and seal the connecting portions. Four hanging ropes are arranged on the edge of the upper cover, and the clothes drying rack can be hung through the hanging ropes. An air inlet and an air guide bag communicated with the air inlet and arranged in the enclosure curtain are arranged at the lower end of the enclosure curtain. Outside hot air is blown into the enclosure curtain through the air inlet and the air guide bag. Air outlets are formed in the upper cover, and clothes hangers can be hung on an external fixing device through the air outlets or directly hung on the air outlets. The portable clothes drying rack is simple in structure, convenient to carry and capable of meeting the requirement of a traveler staying at a hotel for air-drying clothes.

Owner:任万坤

Textile airing device with clamping structure and using method of textile airing device

InactiveCN112815648AMeet drying needsImprove drying effectDrying solid materials with heatDrying gas arrangementsMechanical engineeringIndustrial engineering

The invention discloses a textile airing device with a clamping structure and a using method of the textile airing device. The textile airing device comprises two airing supporting columns; the airing supporting columns are of trapezoidal structures; a plurality of airing supporting rods are arranged between the two airing supporting columns; and the plurality of airing supporting rods form a V-shaped airing surface between the two airing supporting columns. According to the textile airing device with the clamping structure and the using method of the textile airing device, textile cloth is aired in a V shape, and meanwhile, an airing ejector rod is driven to ascend and descend through the transmission cooperation between a gear and a lifting plate, so that the airing requirements of the textile cloth with different lengths are met, and the application range of the device is effectively expanded; meanwhile, a clamping mechanism is further arranged, a plurality of clamping supporting rods are used for synchronously clamping all parts of the textile cloth, and air holes are further formed while the good clamping effect is ensured, so that the airing effect of the parts, at the clamping positions, of the textile cloth is improved, and the possibility that the textile cloth is blown away in the weather with the high wind speed is further reduced; and the clamping is convenient, and the actual use is facilitated.

Owner:肖勇

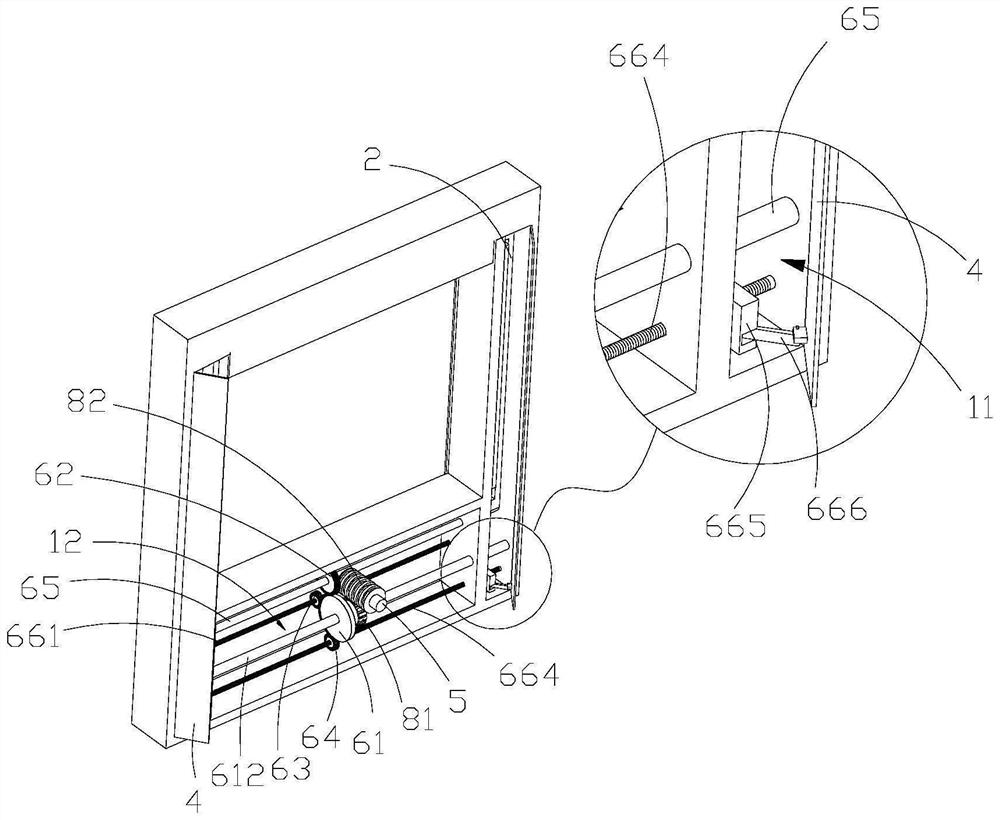

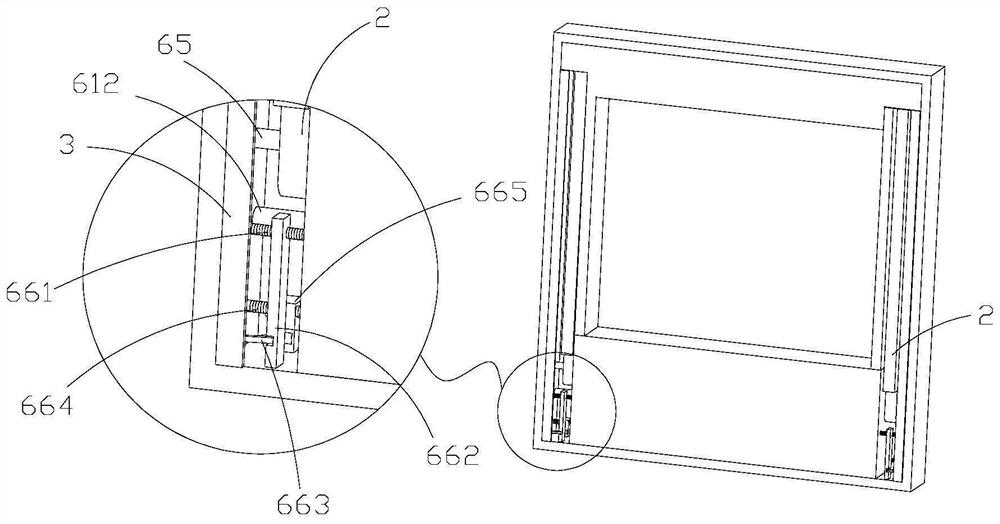

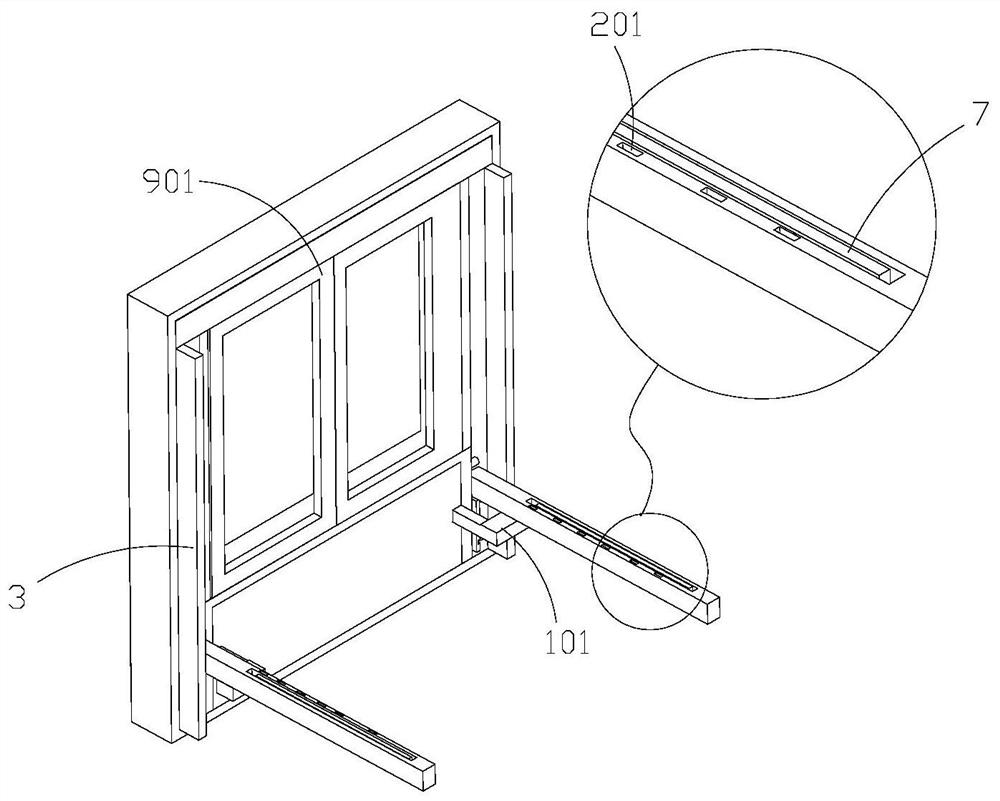

Window frame based on multifunctional movable rod capable of rotating inwards and outwards and intelligent aluminum alloy window

ActiveCN111706236AMeet the needs of dryingRich use functionOther drying apparatusSuspended tablesEngineeringStructural engineering

The invention discloses a window frame based on a multifunctional movable rod capable of rotating inwards and outwards. A rotating rod is rotatably connected with the interior of a storage groove, outer door leaf plates are hinged to the left and right ends of the front side respectively, and inner door leaf plates are hinged to the left and right ends of the back side respectively; and a bracketis movably connected with the interior of the rotating rod. The rotating rod rotates outwards and inwards to be in linkage with opening and closing of the outer door leaf plates, and the rotating rodrotates inwards and outwards to be in linkage with opening and closing of the inner door leaf plates. The invention also discloses an intelligent aluminum alloy window. The window frame has the advantages of being high in functional integration, compact in structure and good in function integration effect.

Owner:奋安铝业股份有限公司

Multifunctional hanger

Owner:张 智源

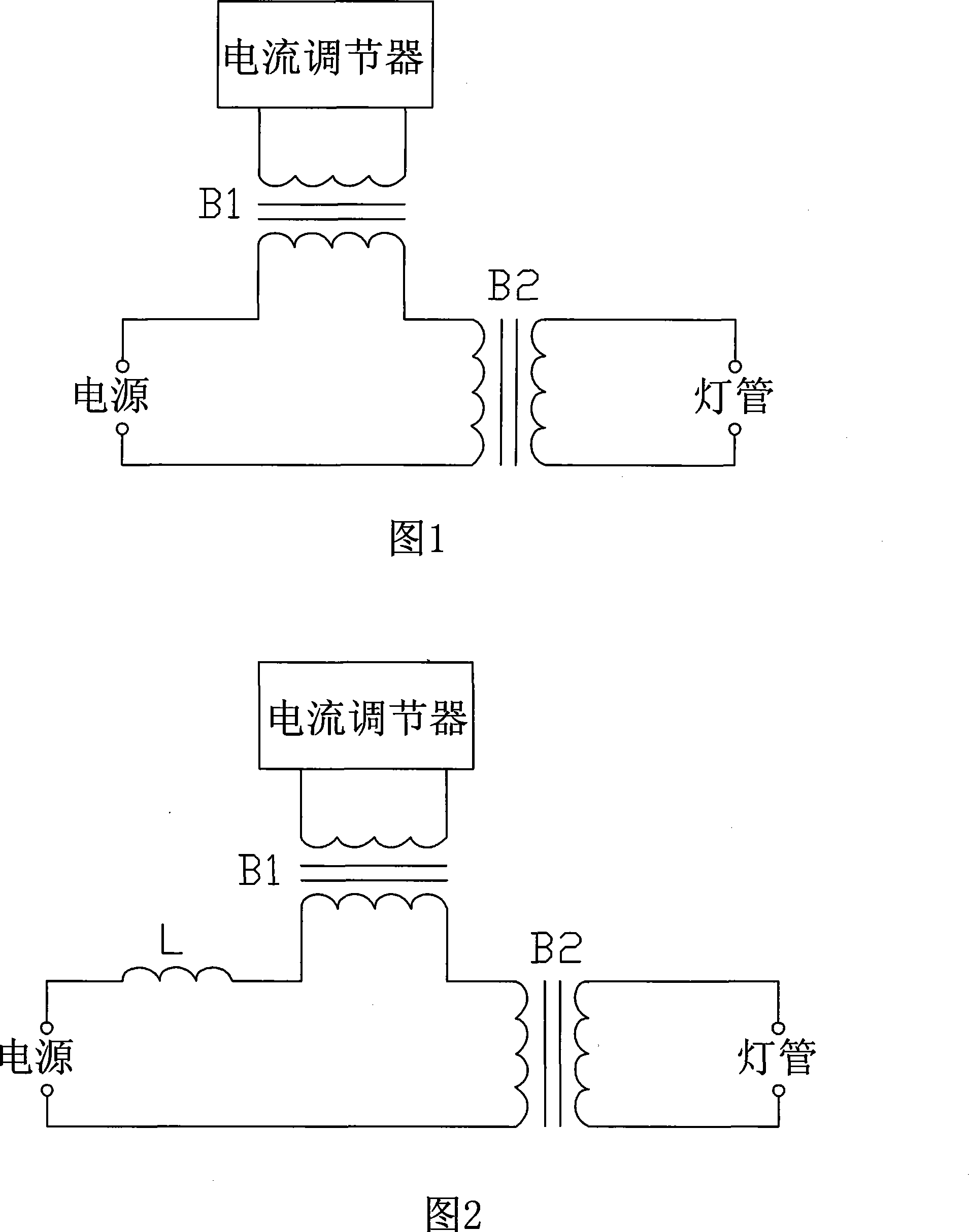

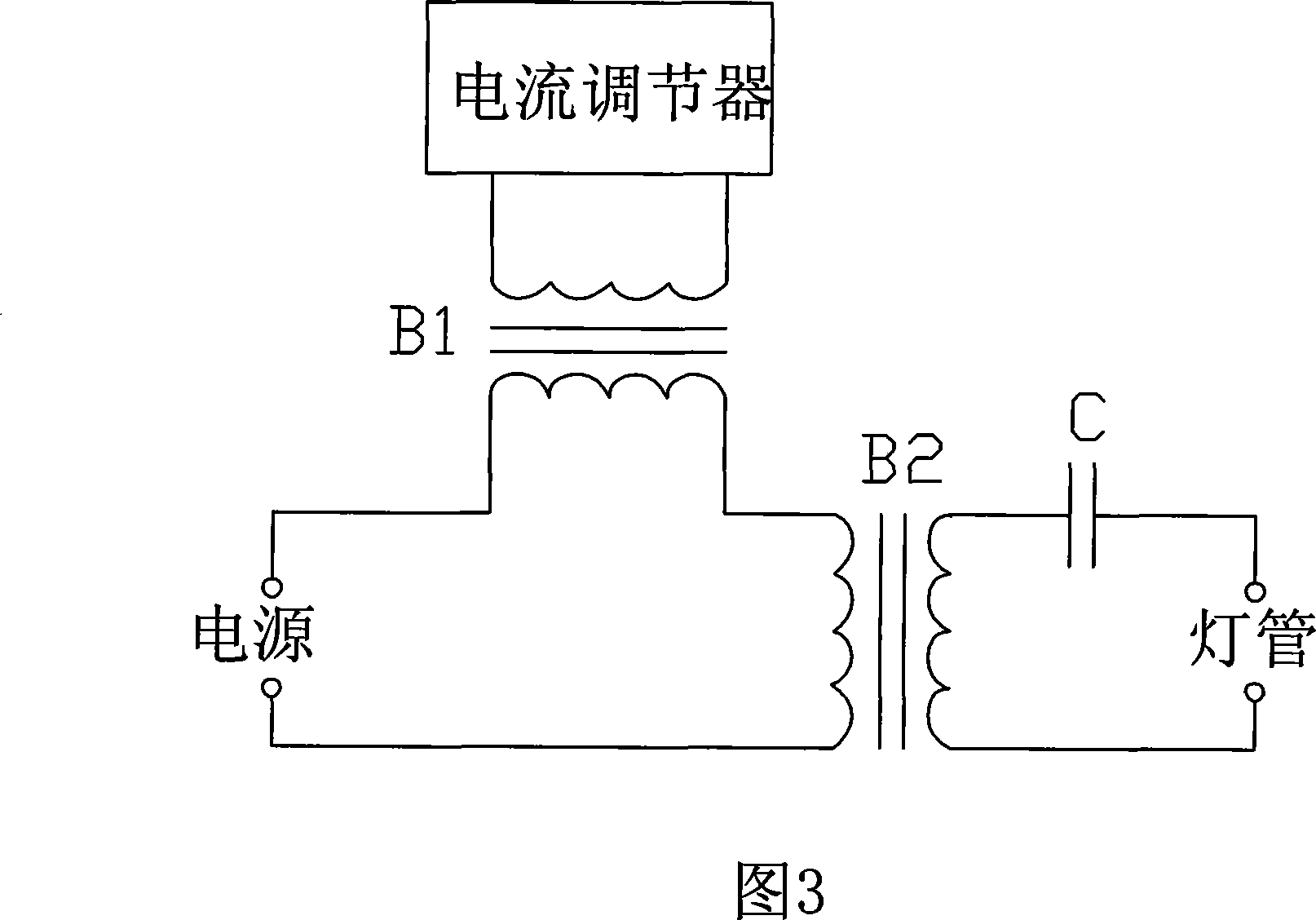

Ultraviolet ray light tube stepless power regulating eqiupment

InactiveCN101232766AChange light intensityMeet drying needsElectrical apparatusElectric lighting sourcesElectric power systemUltraviolet

The invention discloses a stepless power regulator of an ultraviolet lamp, which comprises a transformer booster. A primary side of the transformer booster is connected with an electric power source; a secondary side is connected with an ultraviolet lamp; the primary side or the secondary side of the transformer booster is connected with a voltage regulator which is used for continuously adjusting the output voltage. The user can continuously adjust the output voltage through the voltage regulator according to the condition of ink and paper, so that the illumination intensity of the ultraviolet lamp can be changed to satisfy the need of drying. As a result, not only the safety and the reliability of the product are strengthened, but also the energy consumption and the using cost are reduced. Furthermore, the invention is also suitable for application in other fields of ultraviolet lamp and has a broad market prospect.

Owner:刘洪生

Intelligent temperature controlled grain dryer

InactiveCN106720292AReal-time weight monitoringCorrected drying temperatureSeed preservation by dryingMoisture sensorTemperature control

The invention discloses an intelligent temperature controlled grain dryer, comprising a dryer body, a main control system, a temperature and humidity sensor, and a weighing sensor; the inner cavity of the dryer body is a drying silo; the lower side part of the drying silo is provided with the temperature and humidity sensor; the bottom part of the drying silo is provided with the weighing sensor, and the temperature and humidity sensor and the weighing sensor are in data connection with the main control system; the upper part of the dryer main body is provided with a feeding opening and an induced draught system; the left side part of the dryer body is provided with a discharging opening, the lower part of the dryer main body is provided with a hot air charging device; the hot air charging device is connected with an air outlet of the fan and the dryer main body; the heating air in the fan is introduced to the drying silo of the dryer main body. The intelligent temperature controlled grain dryer can meet the demand of differential drying of grains with different types and different weights; the drying automation degree is high.

Owner:赵恩崇

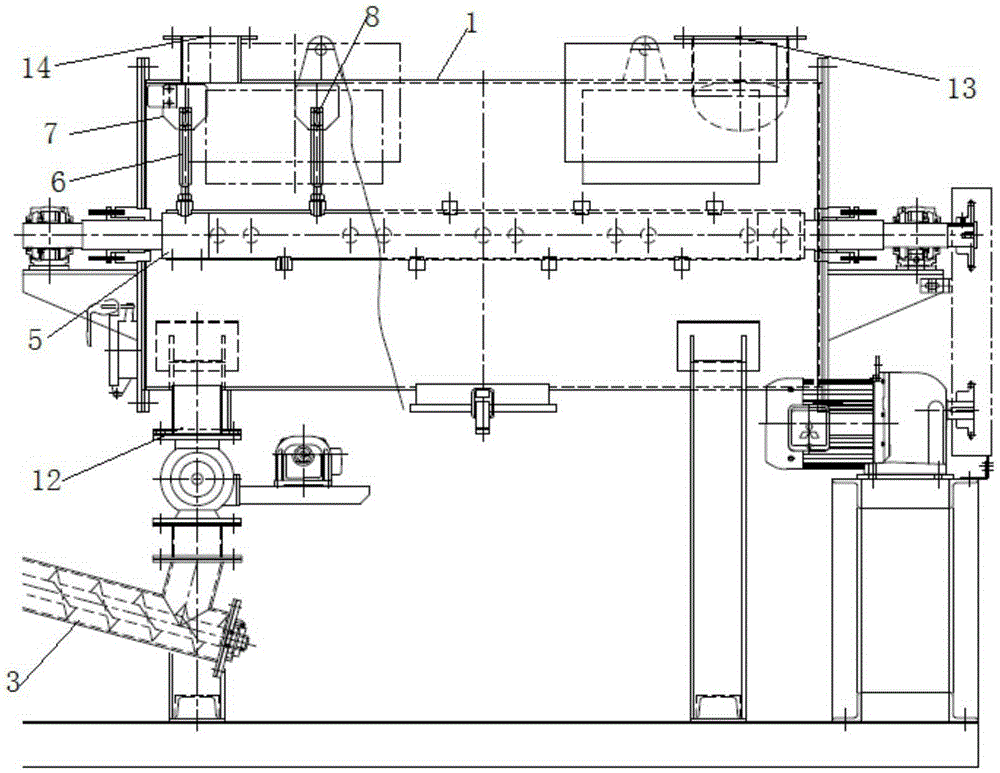

All-weather fluidized bed method grain drier

ActiveCN104126660APollution-free service lifeReduce wasteFood processingDrying gas arrangementsEngineeringFluidized bed

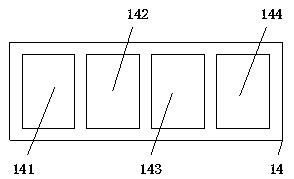

The invention provides an all-weather fluidized bed method grain drier. The all-weather fluidized bed method grain drier is characterized by comprising a bracket, a feed hopper, an outlet hopper, a transportation mechanism, at least one dehumidification segment, an air-drawing dust removing segment and a protective hood, wherein the feed hopper and the outlet hopper are arranged at the two ends of the bracket, the transportation mechanism is arranged between the feed hopper and the outlet hopper, the dehumidification segment and the air-drawing dust removing segment span over the transportation mechanism and are sequentially arranged, and the protective hood wraps outsides the dehumidification segment and the air-drawing dust removing segment. The all-weather fluidized bed method grain drier has the beneficial effects that standard unit module combination with one dehumidification segment as a unit is adopted, the amount of the dehumidification segment can be increased or reduced according to different actual processing capacities of users or different matters to be processed, and the length of the transportation mechanism as well as the sizes of the bracket and the protective hood are correspondingly increased or reduced, so that the drying needs of various users for different processing capacities and different matters to be processed are satisfied.

Owner:TIANJIN MESSCCOER TECH CONSULTING

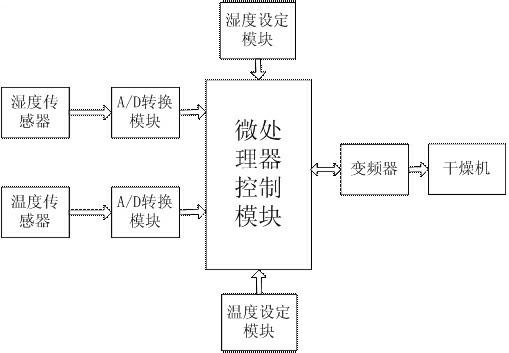

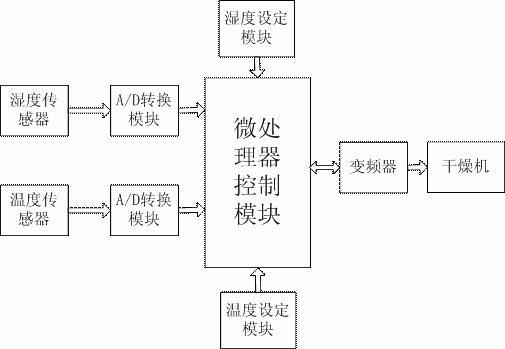

Automatic control system of drying machine

InactiveCN102679710ARealize automatic controlImprove drying qualityDrying solid materialsFrequency changerAutomatic control

The invention discloses an automatic control system of a drying machine. The automatic control system comprises a microprocessor control module, wherein a humidity sensor, a humidity setting module and the drying machine are respectively connected to the microprocessor control module; and a frequency converter is connected between the microprocessor control module and the drying machine. By the automatic control system, the problems that the drying machine is generally manually controlled by a worker by experience, and materials cannot be accurately dried in the prior art are solved; the temperature and humidity information of materials to be dried is acquired through a temperature and humidity sensor and is compared with a set value, and the microprocessor control module controls the operating frequency of the drying machine through a comparison result, so that the drying machine is automatically controlled, the drying quality is improved, and various different drying requirements can be met.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

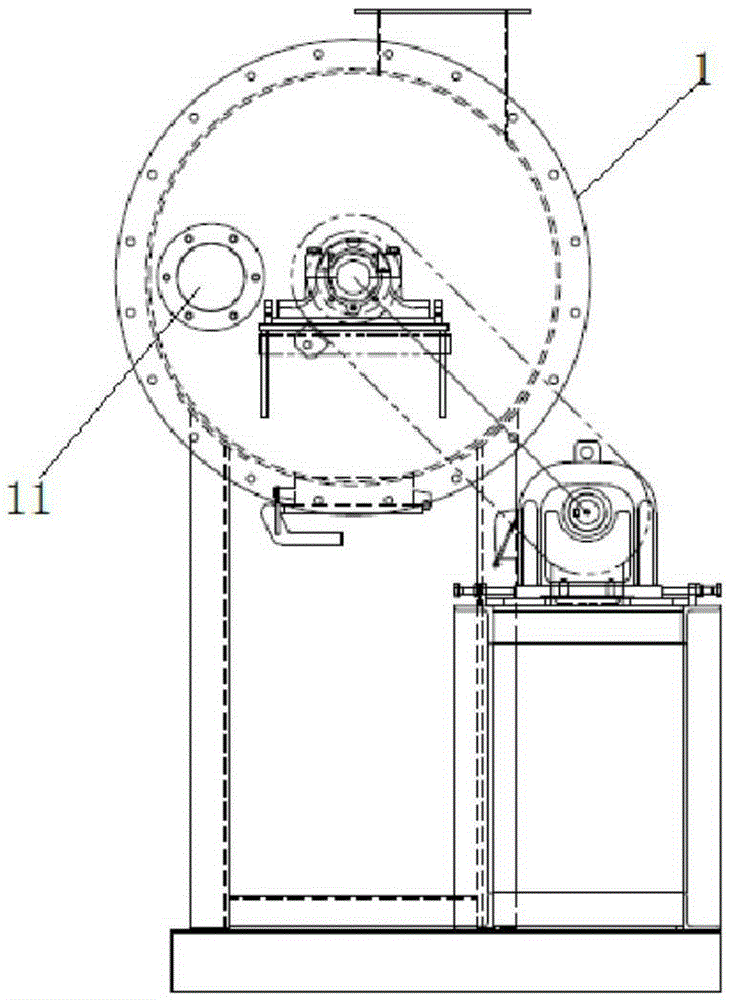

Rotary dryer

InactiveCN103148681AIncrease frictionMeet drying needsDrying machines with non-progressive movementsCoal slurryMechanical engineering

The invention discloses a rotary dryer with a good drying effect. The rotary dryer comprises a cylindrical barrel, a feed port formed at one end of the cylindrical barrel, and a discharge port formed at the other end of the cylindrical barrel, wherein the two ends of the cylindrical barrel are obliquely supported on ground by riding wheel devices; the feed port is higher while the discharge port is lower; the cylindrical barrel is internally provided with an inner rotating drum; the inner rotating drum is internally and uniformity provided with a plurality of roasting plates and semicircular bumps; and the inner rotating drum is connected with a conveyer arranged on the ground. The rotary dryer has the advantages that the roasting platesroastmaterials; the semicircular bumps can increase friction between the materials and the inner rotating drum; and the rotary dryer is good in drying effect, simple in structure and convenient to use, and can meet requirements on drying the clammy materials of coal slurry, sludge and chemical engineering tailings.

Owner:JIANGSU SINOMA ENVIRONMENTAL ENG

Aeration drying device and method

PendingCN108195179ASpeeds up the drying processEnsure the amount of drynessDrying gas arrangementsDrying machines with progressive movementsProduct gasMechanical engineering

The embodiment of the invention provides an aeration drying device and method. The aeration drying device comprises a shell, a conveying plate chain and a drilling component. The shell is provided with a feed port, a discharge port and a first blowing port. The interior of the shell is sequentially divided into a preheating section, a heat holding section and a drying section. The conveying platechain is arranged in the shell and conveys materials from the feed port to the discharge port through the preheating section, the heat holding section and the drying section. The drilling component isarranged at the tail end of the heat holding section and conducts drilling on the materials. According to the aeration drying device, the shell is divided into the preheating section, the heat holding section and the drying section; the materials are completely preheated at the preheating section to provide the proper growth temperature for microorganisms in the materials; the microorganisms react to generate heat to evaporate water in the materials at the heat holding section; the drilling component conducts drilling on the materials at the tail end of the heat holding section to guarantee inflowing of dry gas and outflowing of moist gas after the materials go into the drying section; it can be guaranteed that water in the materials is sped up to transfer the mass outwards; the drying process is accelerated, and the drying efficiency is improved.

Owner:SHANDONG QIQUAN ENERGY TECH CO LTD

Drying device

ActiveCN105387712AKeep dryStir wellSludge treatment by de-watering/drying/thickeningSludge dryingEngineeringProduct gas

The invention discloses a drying device. The drying device comprises a furnace body, a charging device for charging a material into the furnace body, a collecting device for collecting a dried material in the furnace body, an air supply device for inducing external hot gas into the furnace body by a first gas inlet, and a stirring device for stirring and pulverizing the material, wherein the stirring device comprises a rotary shaft which penetrates through a cavity of the furnace body, the rotary shaft is provided with a venting cavity provided with a plurality of gas nozzles, the gas spraying direction of the gas nozzles is misaligned and not parallel with the stirring direction of the stirring device and the stirring direction of blades, during material drying, the hot gas is induced into the cavity of the furnace body by the first gas inlet, and the rotary shaft rotates to drive a stirring assembly on the rotary shaft to continuously stir the material along the axial direction and radial direction of the rotary shaft, so that the material is turned over in the furnace body along the axial direction and radial direction of the rotary shaft, the stirring time of the material is prolonged, and a convection heat exchange area between the material and the hot gas is increased. In addition, the stirring assembly can pulverize the material to form a material of smaller particles, thus further increasing the convection heat exchange area between the material and the hot gas and improving the drying efficiency and drying effect of the material.

Owner:汪振朴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com