Aeration drying device and method

A kind of ventilation drying and drying technology, applied in the direction of drying gas arrangement, progressive dryer, drying solid materials, etc., can solve problems such as low drying efficiency of materials, reduce drying cost, improve drying efficiency, and ensure the effect of drying amount of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

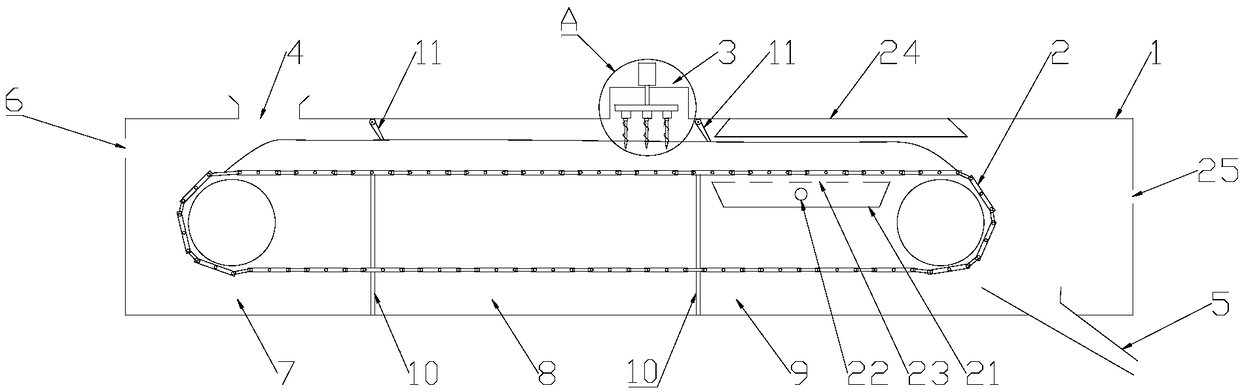

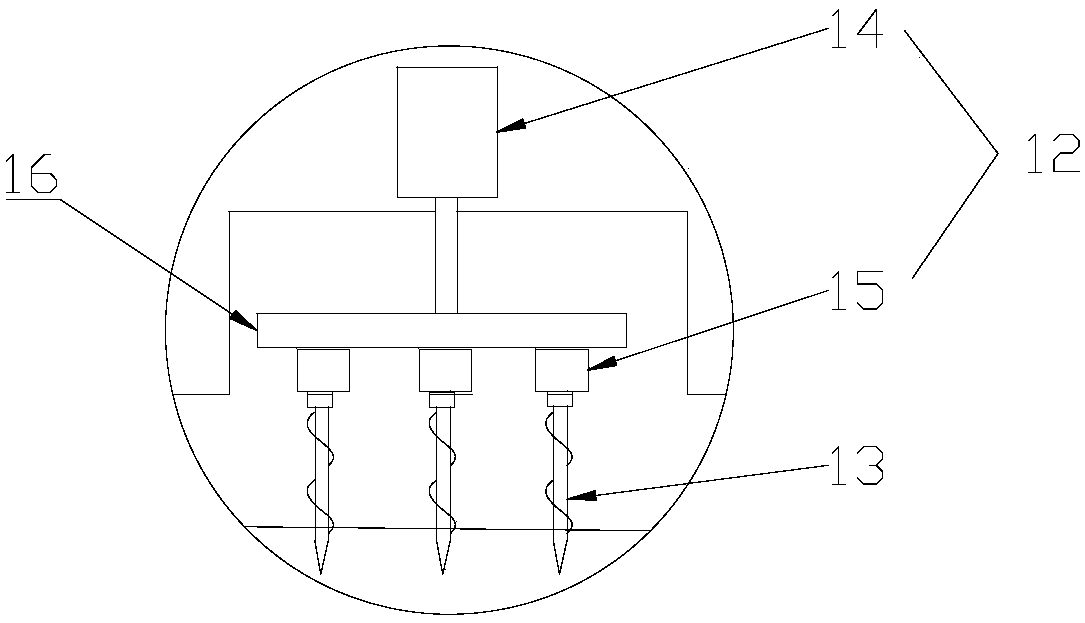

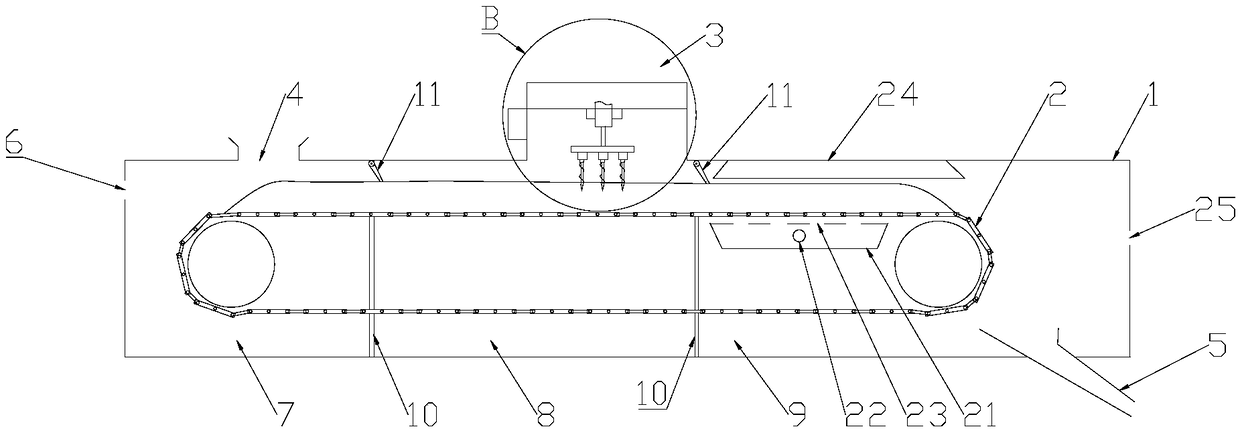

[0031] Embodiment 1 of the present invention provides a ventilating and drying device. The ventilation and drying device includes a shell 1, a conveying plate chain 2 and a punching part 3. The shell 1 is provided with a feed port 4, a discharge port 5, and a first blowing port 6. The inside of the shell 1 is sequentially separated for preheating. Section 7, heat preservation section 8 and drying section 9; the conveyor plate chain 2 is set in the housing 1 and the material is transported from the feed port 4 to the discharge port 5 through the preheating section 7, heat preservation section 8 and drying section 9; The hole part 3 is arranged at the end of the heat preservation section 8 and punches the material.

[0032] The ventilating and drying device provided by Embodiment 1 of the present invention can input materials from the feeding port 4 by setting the feeding port 4 and the discharging port 5 on the casing 1 and setting the conveying plate chain 2 in the casing 1, a...

Embodiment 2

[0064] like Image 6 As shown, Embodiment 2 of the present invention provides a ventilation drying method, and the ventilation drying method uses the ventilation drying device in Embodiment 1. The ventilated drying method includes the following steps: S01, put the material into the shell 1, the shell 1 has a drying channel for drying the material, the drying channel includes a preheating section 7, a heat preservation section 8 and a drying section 9, and the material is in the drying channel S02, the material is preheated in the preheating section 7 to reach the growth temperature of the microorganisms in the material; S03, the microorganisms generate heat in the heat preservation section 8, and the material is punched and / or dried before the material enters the drying section 9 Or turn the material; S04, dry the material in the drying section 9 and discharge the material out of the drying channel.

[0065] Specifically, the operator can put materials into the interior of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com