Patents

Literature

246results about How to "Speed up the drying process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

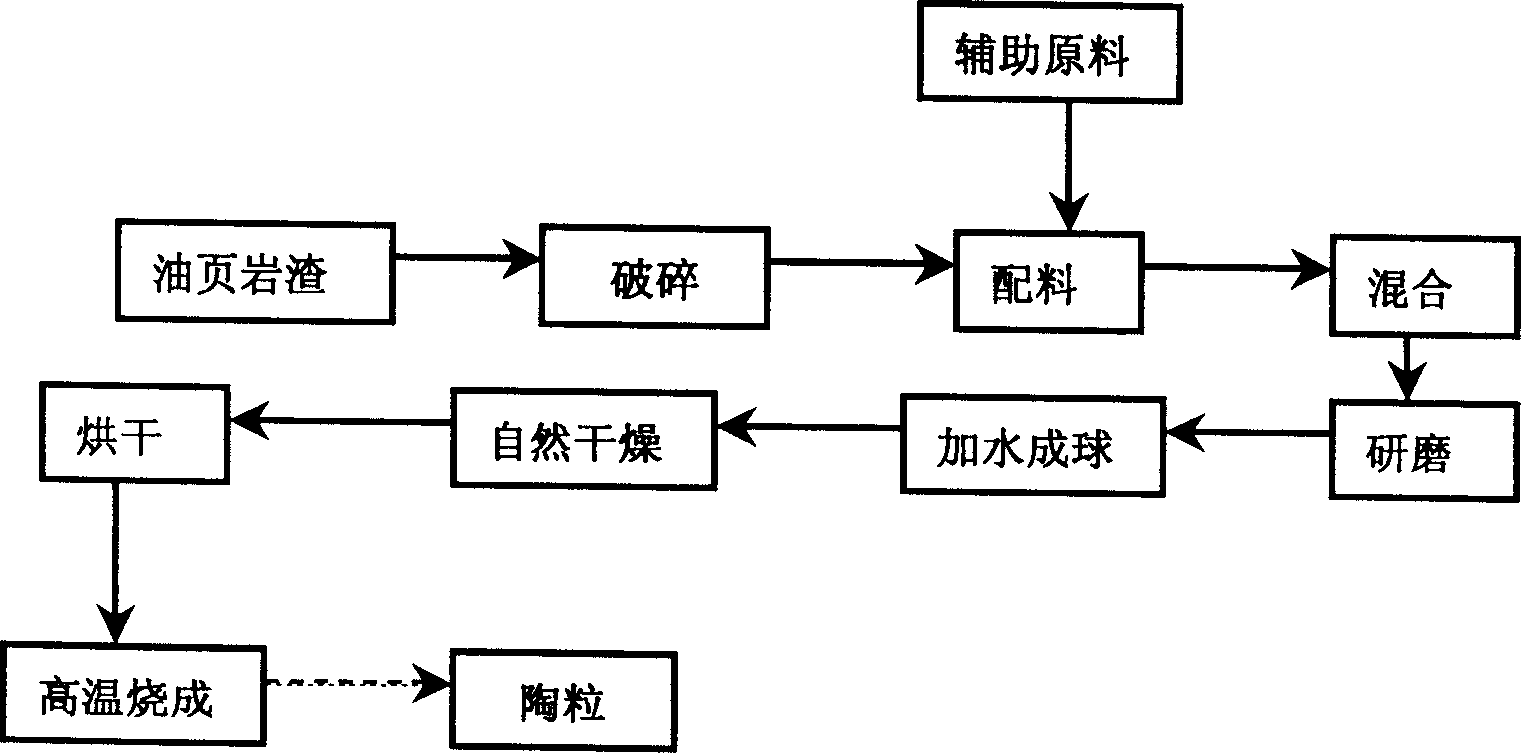

Haydite prepared from dregs of oil shale, and preparation method

InactiveCN1872782AWith added valueRegulatory plasticitySolid waste managementCeramicwareSlagExpanded clay aggregate

This invention relates to a method for manufacturing ceramic particles from oil shale slag. The method comprises: (1) grinding oil shale slag into particles; (2) drying; (3) sintering at 1000-1300 deg.C; (4) cooling to obtain the final product. The obtained porous ceramic particles have low water absorbency (lower than 3%), and high cylinder compressive strength (higher than 6.5 MPa).

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

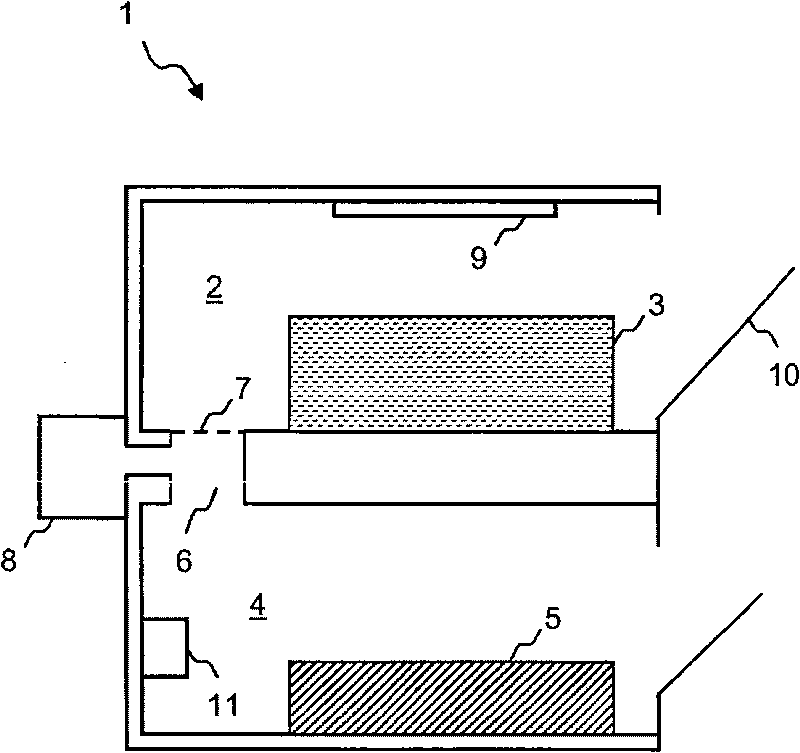

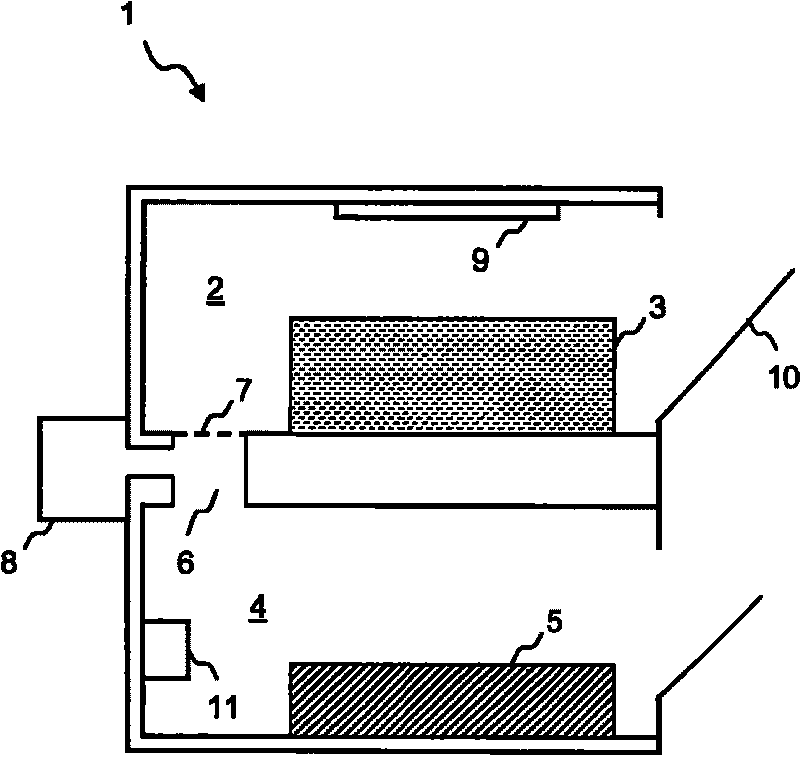

Adsorption dryer

InactiveCN101755088ANo apparent lossGood removal effectTableware washing/rinsing machinesTextiles and paperDesiccantEngineering

The invention relates to a dryer device having at least one receiving chamber for receiving textiles and drying agents, comprising a vacuum pump for creating a vacuum in the at least one receiving chamber. A drying method comprises introducing textiles and drying agents, particularly based on zeolite, into at least one receiving chamber, followed by a vacuum being created in the at least one receiving chamber.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

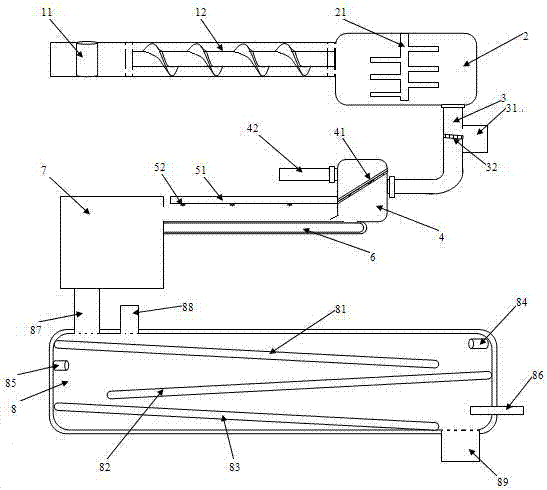

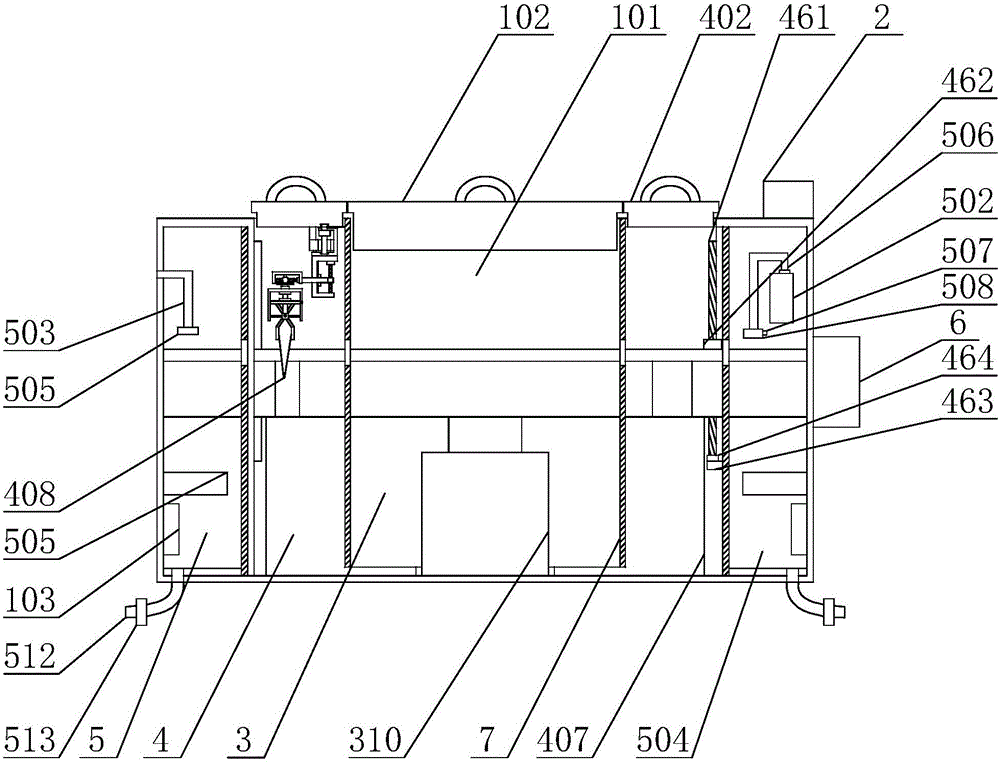

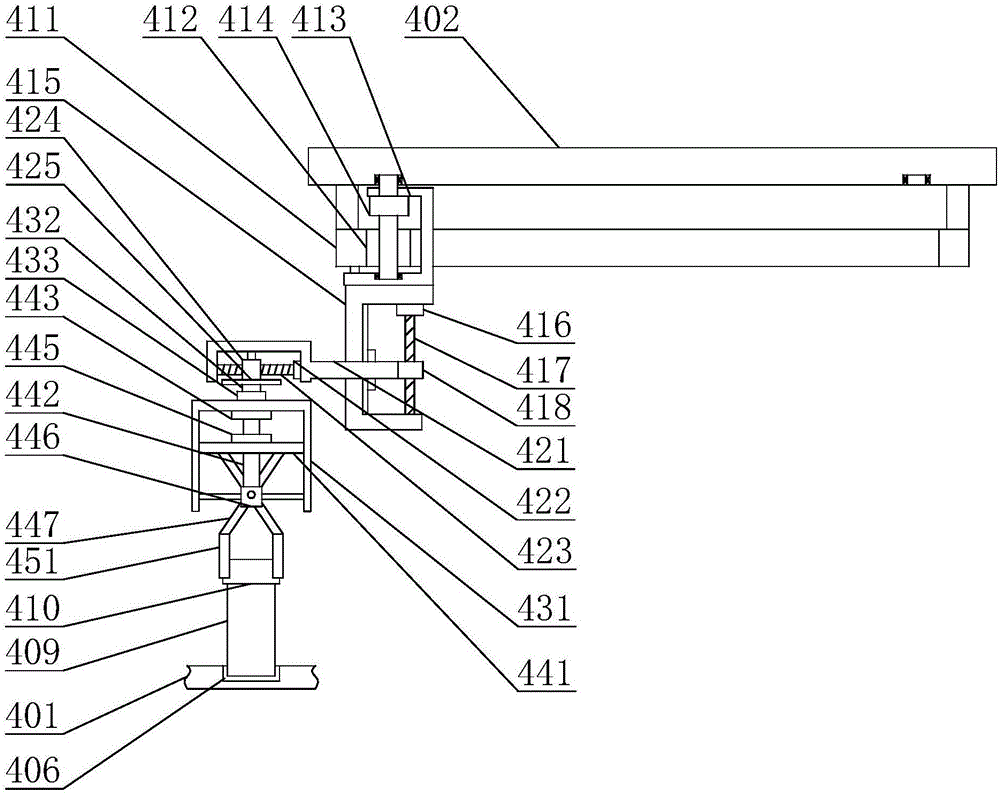

Sludge treatment apparatus for water conservancy project

ActiveCN107381987AAvoid damageAvoid the impact of product qualitySludge treatment by de-watering/drying/thickeningHydraulic engineering apparatusExpanded clay aggregateHydraulic engineering

The invention relates to a sludge treatment apparatus for a water conservancy project. The sludge treatment apparatus comprises a transport apparatus, a stirring chamber, a transport pipeline part, a sludge filter chamber, a sludge mixing and drying part, a mixing and granulating chamber and a ceramsite heating chamber. By arranging various parts, the sludge treatment, the ceramsite preparation from sludge and the ceramsite forming can be continuously carried out, so that not only can the sludge containing heavy metal be removed and the secondary pollution of the sludge to a water body be avoided, but also heavy metal elements are secondarily utilized for the ceramsite, and the harmful sludge can be actually turned into benefit.

Owner:畅庆环保科技(太仓)有限公司

Method for manufacturing qijing ham

InactiveCN101120794AImprove commoditySpeed up the drying processMeat/fish preservationFood preparationFlavorAnimal science

A production method of a Qijing ham consists of six technical processes of treatment of raw materials, preserving, fumigation, dry, hoarding fermentation and after-treatment. The raw material is the hind leg of local pig with 8-10 month-life. The hind leg needs to be expelled acid for 4-6 hours, and be finished. The preserving salt should be selected medium sized to meet green food salt standard, food salt, and the dosage should be within 15 percent. The hind leg need to be fumigated 3-5 days, and the smoke producing materials are leaves, roots and branches of cypress which is endemic to Qijing Mountain, which can make the ham have a special Chinese-bacon flavor. The dry mainly adds extrusion setting, drying or artificial drying procedures; and the target of extrusion is to extrude superfluous fat to make the ham oily but not greasy, and have good taste. The ham gives a series of flavor reaction by controlling temperature and humidity of hoarding fermentation, and so the ham has special taste and texture.

Owner:程玖瑛

Freeze drying preparation method of fruit and vegetable crisp slices

InactiveCN104222261AAccelerated sublimationSpeed up the drying processFruit and vegetables preservationFreeze-dryingProcess engineering

The invention discloses a preparation method for freeze-drying fruit and vegetable crisp slices. The preparation method comprises the following steps: blanching cleaned and split raw materials for enzyme deactivation, rapidly placing the raw materials after enzyme deactivation into a pre-cooling color-protecting liquid for cooling, pulping, homogenizing, paving material layers with thickness of 5-10mm in a metal material plate, inserting to an integrated metal grid mould, precooling at temperature of -30 DEG C, performing vacuum freeze drying according to the following process: when the temperature is lower than 10 DEG C, increasing temperature at the rate of 3-5 DEG C per hour, when the temperature reaches 10 DEG C, keeping the temperature for 1 hour, increasing temperature at the rate of 5-7 DEG C per hour, when the temperature reaches 40 DEG C, keeping for 2 hours, and then finishing the vacuum freeze drying. According to the invention, a proper amount of water is added into the raw materials for pulping and homogenizing, then curing is carried out, the integrated metal grid mould is used for accelerating the process that heat is conducted inside the material layers, the whole material plate is divided into a plurality of independent evaporation units, so that sublimation of water is greatly accelerated, obtained fruit and vegetable crisp slices are crisp and porous, good in reconstitution property, and the defect that the traditional freeze-drying fruit and vegetable crisp slices are poor in reconstitution property so as to stick teeth is overcome.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

Garage type biological drying method

ActiveCN104690073AIncrease temperatureSpeed up buildSolid waste disposalWater vaporResource utilization

The invention discloses a garage type biological drying method, belonging to the field of the household refuse disposal. The garage type biological drying method comprises the following steps: crushing household refuse to be with particle sizes not larger than 200mm, stacking the crushed life garbage in a garage, conveying hot air produced in other garages subjected to biological drying into the garage to help to establish an environment necessary for organisms in the garage quickly, compulsively ventilating a refuse dump after the heap temperature reaches 50-55 DEG C, feeding back and controlling oxygen concentration in ventilation quantity so as to make full use of heat evaporative water produced by aerobic microbial metabolism and take away the water vapor through the sufficient ventilation flow to quickly dry the refuse, sorting the dry refuse and carrying out resource utilization. A plurality of garage type drying cabins can be continuously arranged, and each cabin is provided with independent ventilation, deodorization and self control systems. According to the garage type biological drying method disclosed by the invention, weather influence is avoided, the refuse treatment capacity is large, the reaction period is short, the leachate production amount is low, the biological stability is good, the energy consumption and cost are low, the environmental pollution is effectively controlled, technological parameters can be adjusted online to monitor in real time, and the garage type biological drying method is safe and reliable.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD

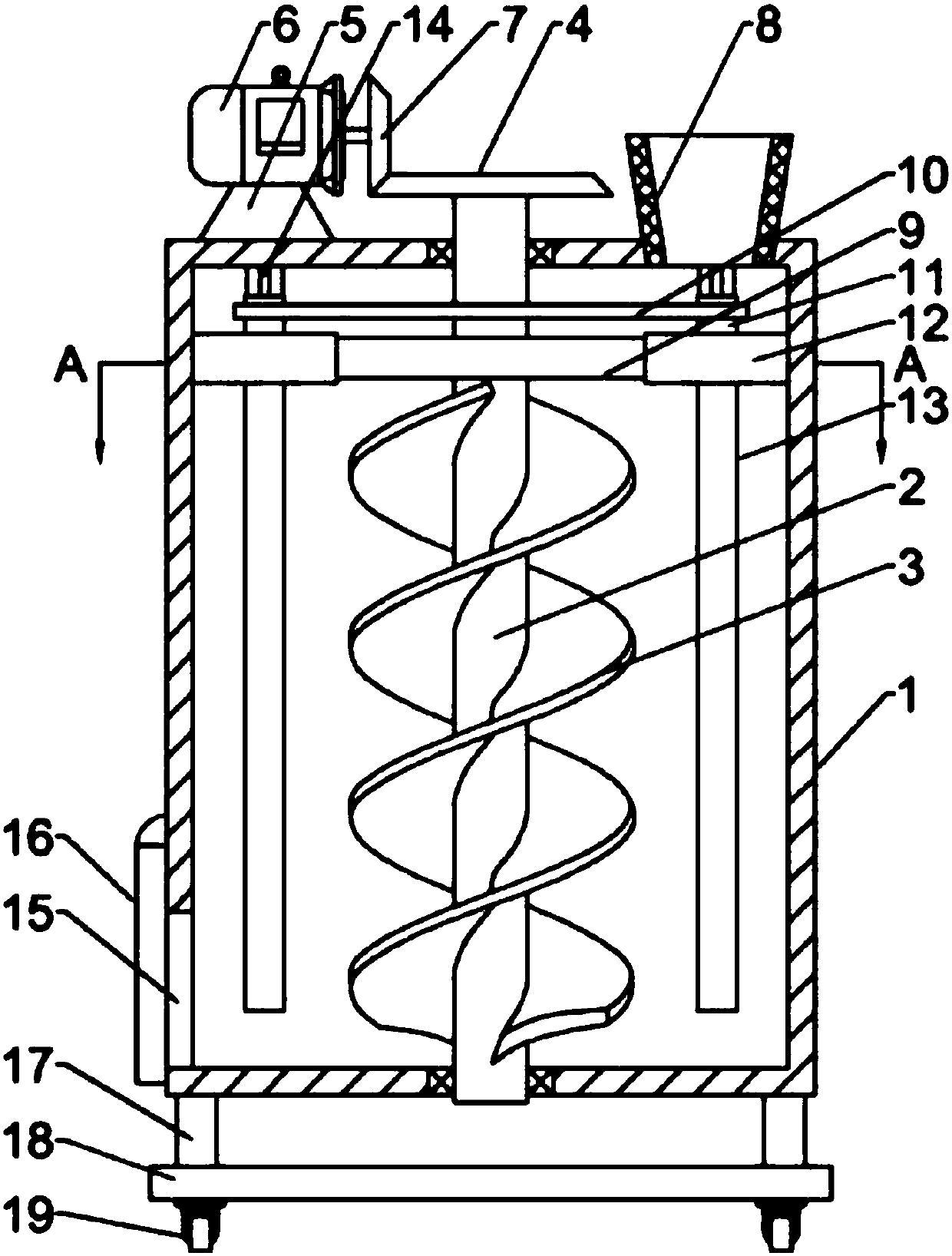

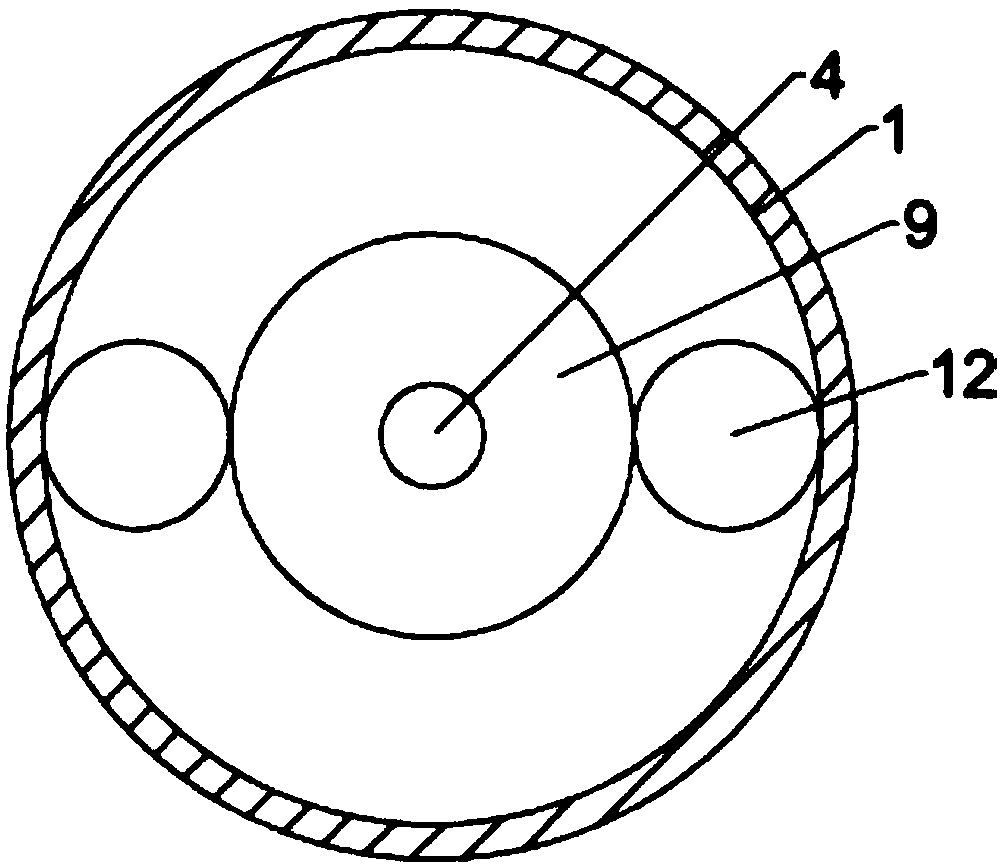

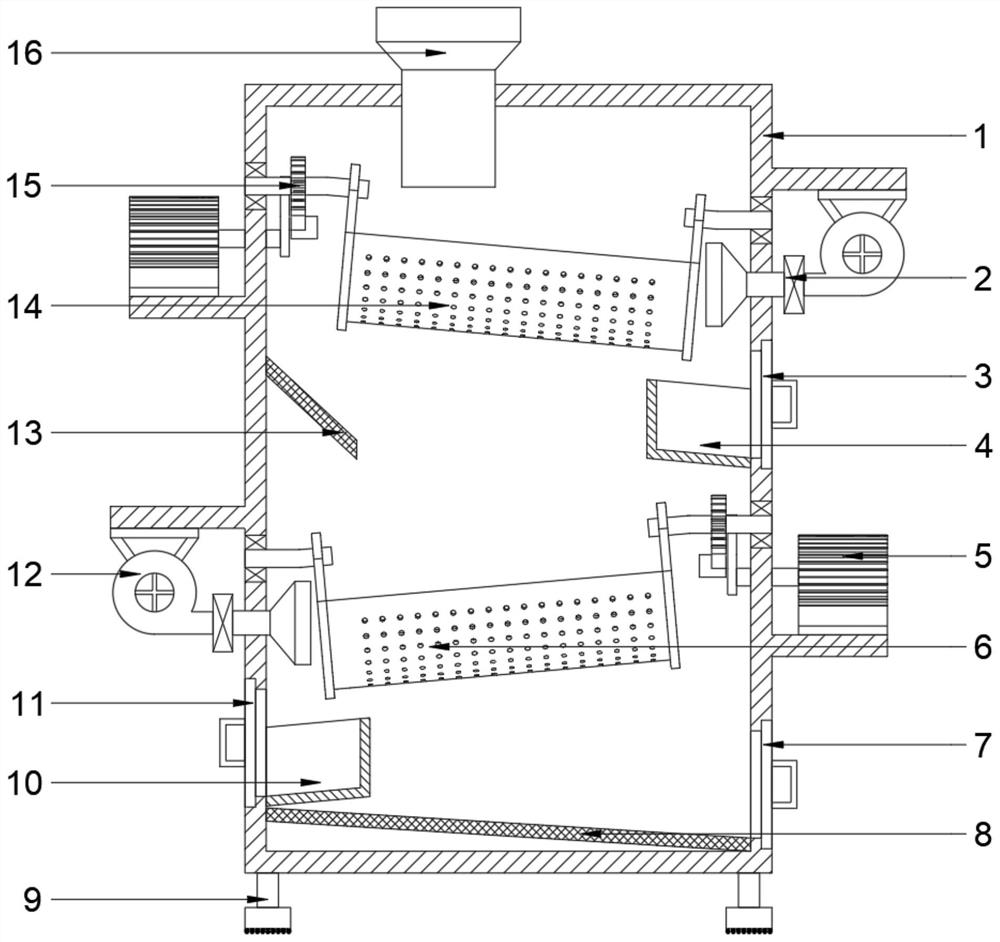

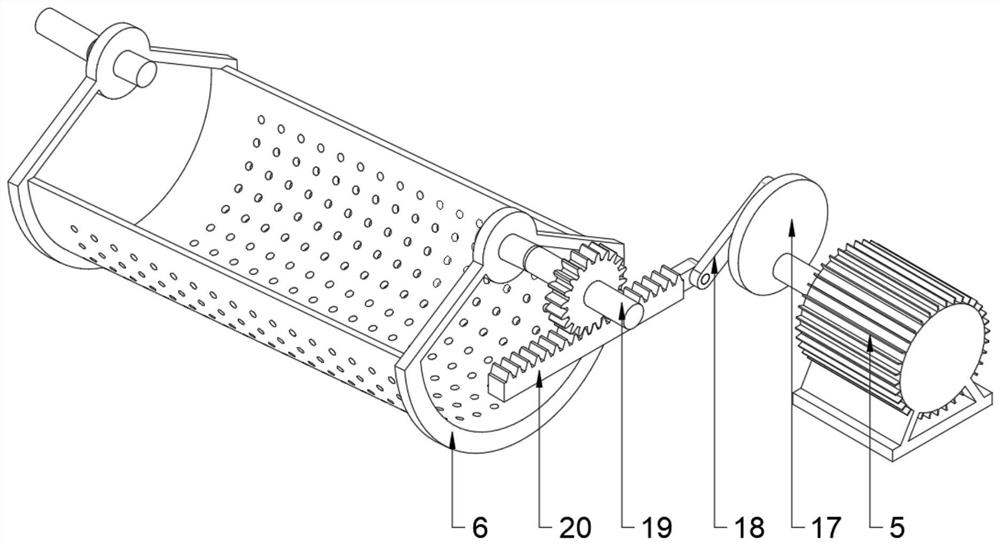

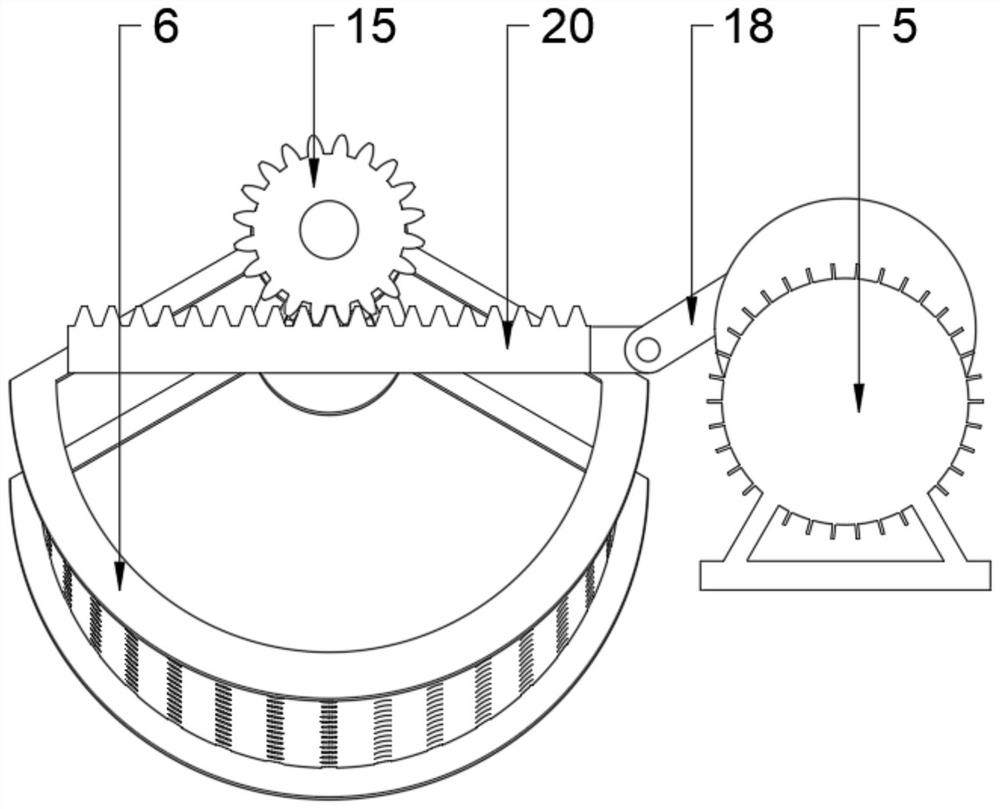

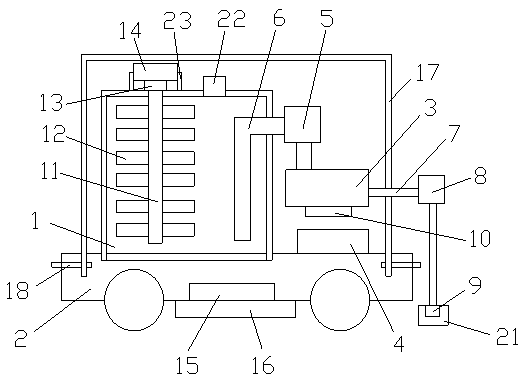

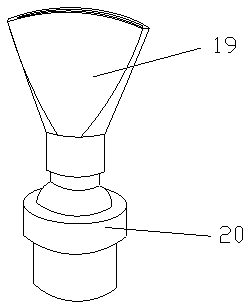

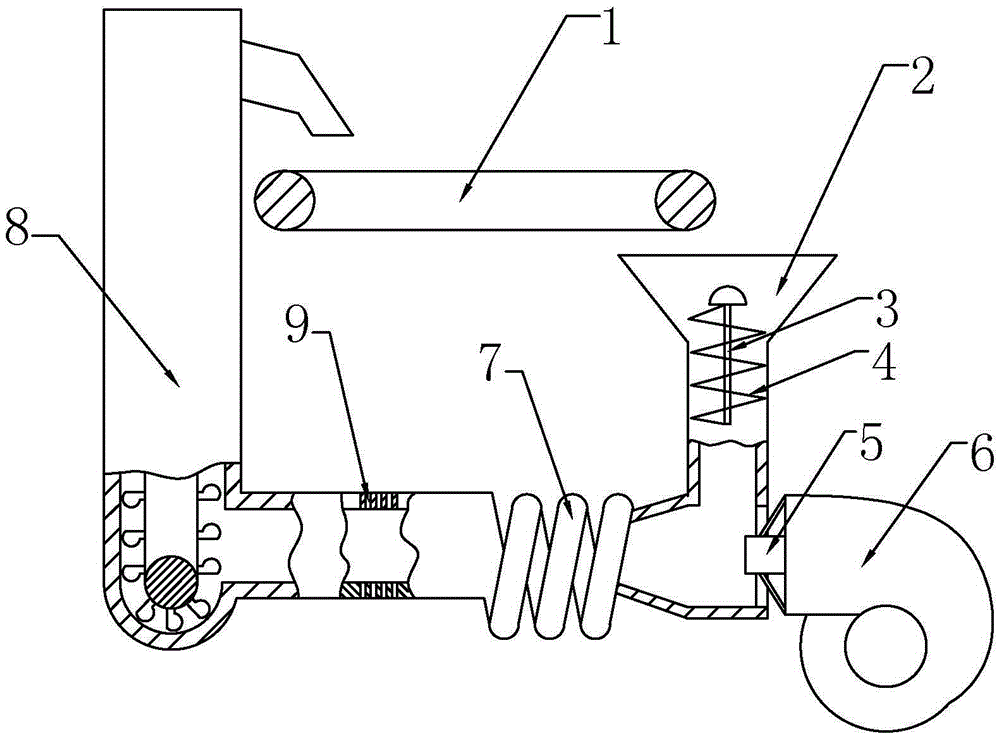

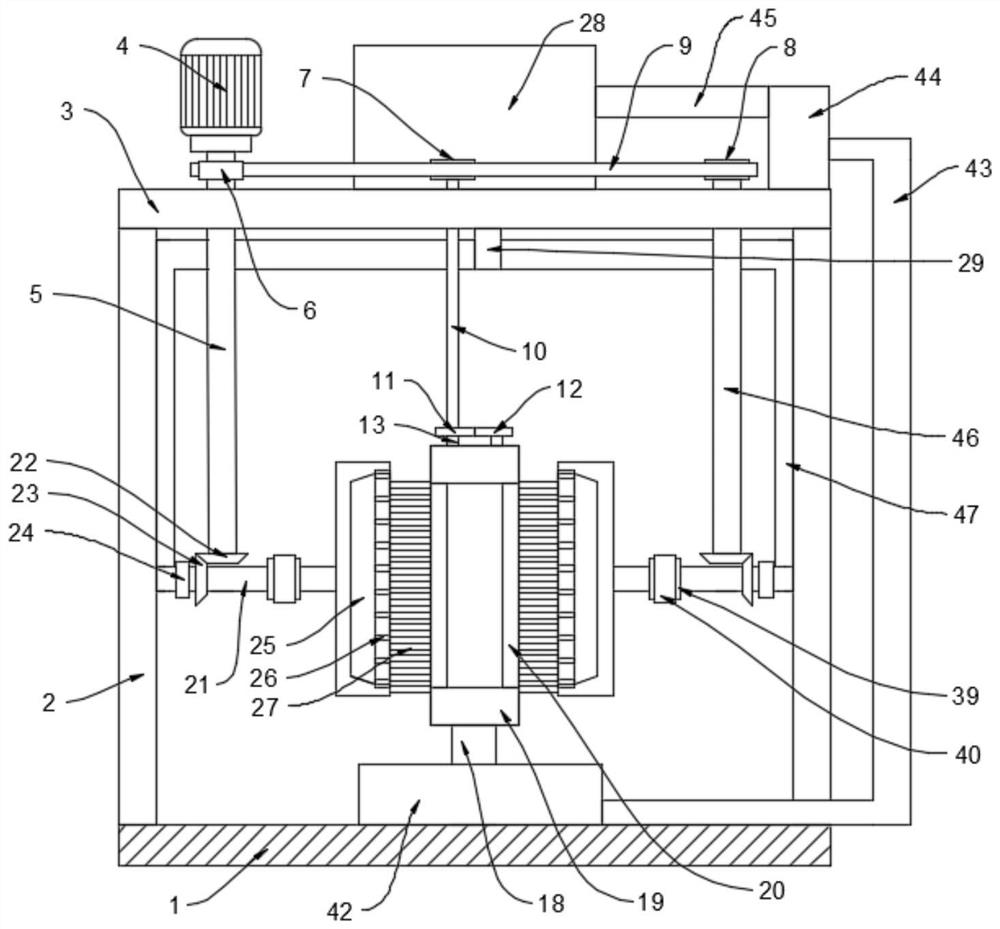

Chemical material drying equipment for preventing material accumulation

InactiveCN107631592AEfficient dryingAvoid accumulationDrying solid materialsDrying machines with non-progressive movementsEngineeringBevel gear

The invention discloses chemical material drying equipment for preventing material accumulation. The equipment comprises a shell. The middle of the shell is rotationally connected with a main rotary shaft through a bearing. The outer side of the main rotary shaft is fixedly connected with a spiral lifting blade. The top of the main rotary shaft is fixedly connected with a driven bevel gear. The upper left portion of the shell is fixedly connected with a motor base. The upper portion of the motor base is fixedly connected with a motor. The output end of the motor is fixedly connected with a drive bevel gear. The drive bevel gear is engaged with the driven bevel gear. The top of the main rotary shaft is fixedly connected with a drive gear. The upper portion of the drive gear is rotationallyconnected with a horizontal connecting rod. The lower portion of the outer end of the horizontal connecting rod is fixedly connected with longitudinal gear shafts. Compared with the prior art, the chemical material drying equipment provided by the invention has the beneficial effects that the equipment is simple in structure and convenient to use, chemical materials can be dried effectively, meanwhile, continuous stirring is performed during drying, so that material accumulation is prevented, drying can also be accelerated, and the equipment deserves to be popularized.

Owner:龙里县逸轩生产力促进中心

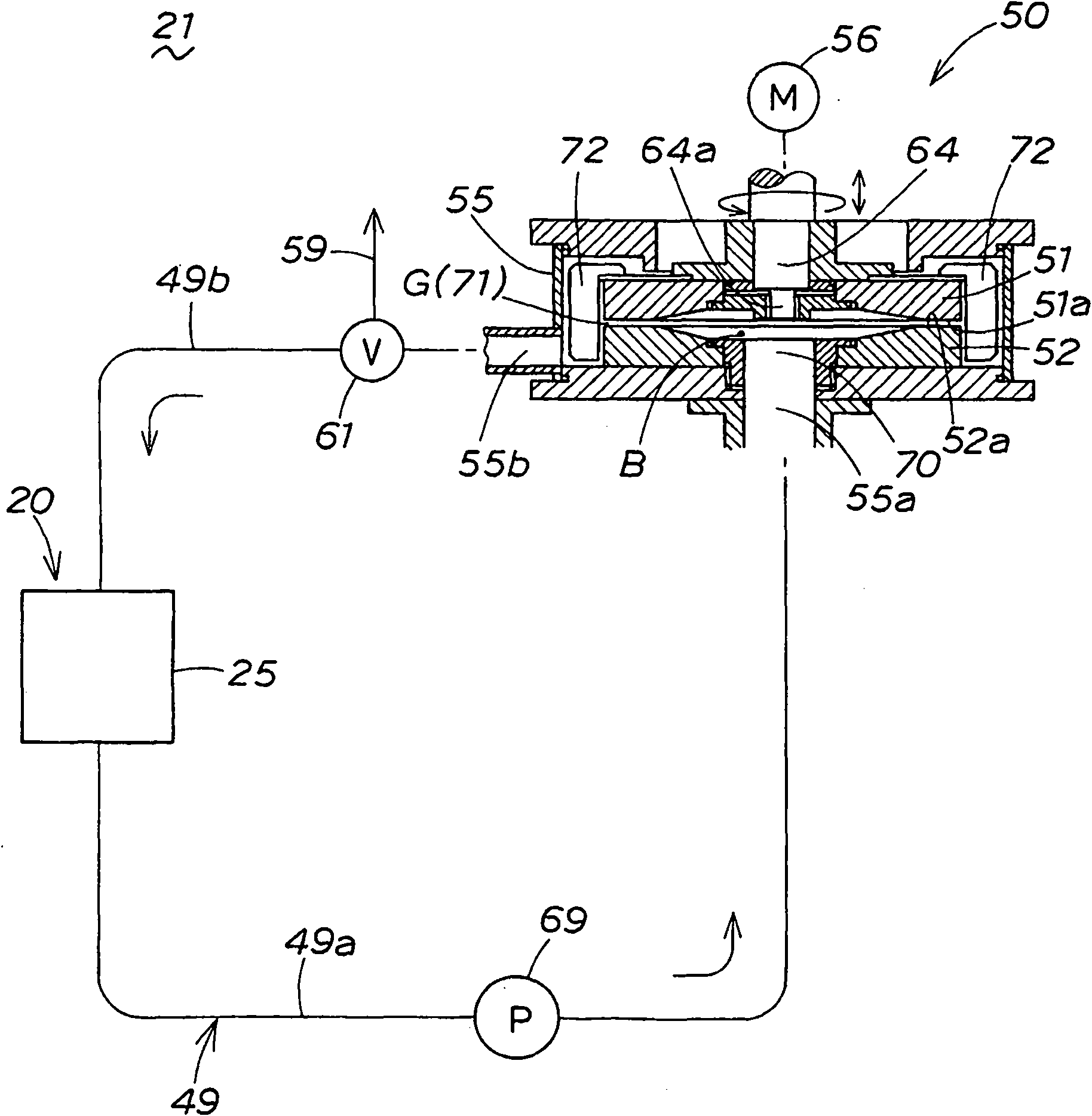

Overload protection control method and apparatus for heat pump type clothes dryer and clothes dryer equipped with the apparatus

InactiveCN101435150AGuaranteed operating conditionsControl loadHeat pumpsTextiles and paperDevice breakageMoisture sensor

The invention provides an overload protection control device of a heat pump type dry wardrobe, a control method of the device, and a dry wardrobe with the device, wherein, the control device comprises a temperature sensor used for measuring the temperature of circulated air in the dry wardrobe, a humidity sensor used for measuring the humidity of the circulated air in the dry wardrobe, a calculating device connected with the temperature sensor and the humidity sensor, and external forced draft ventilation equipment connected with and controlled by the calculating device. When the temperature-humidity of the circulated air in the wardrobe exceeds or is close to a safety range, the external forced draft ventilation equipment is started to reduce temperature, therefore, the damage to the equipment caused by the overload of a heat pump system can be avoided without stopping the operation of the heat pump system, the structure is simple and the drying efficiency is higher.

Owner:北京科力康技贸有限公司

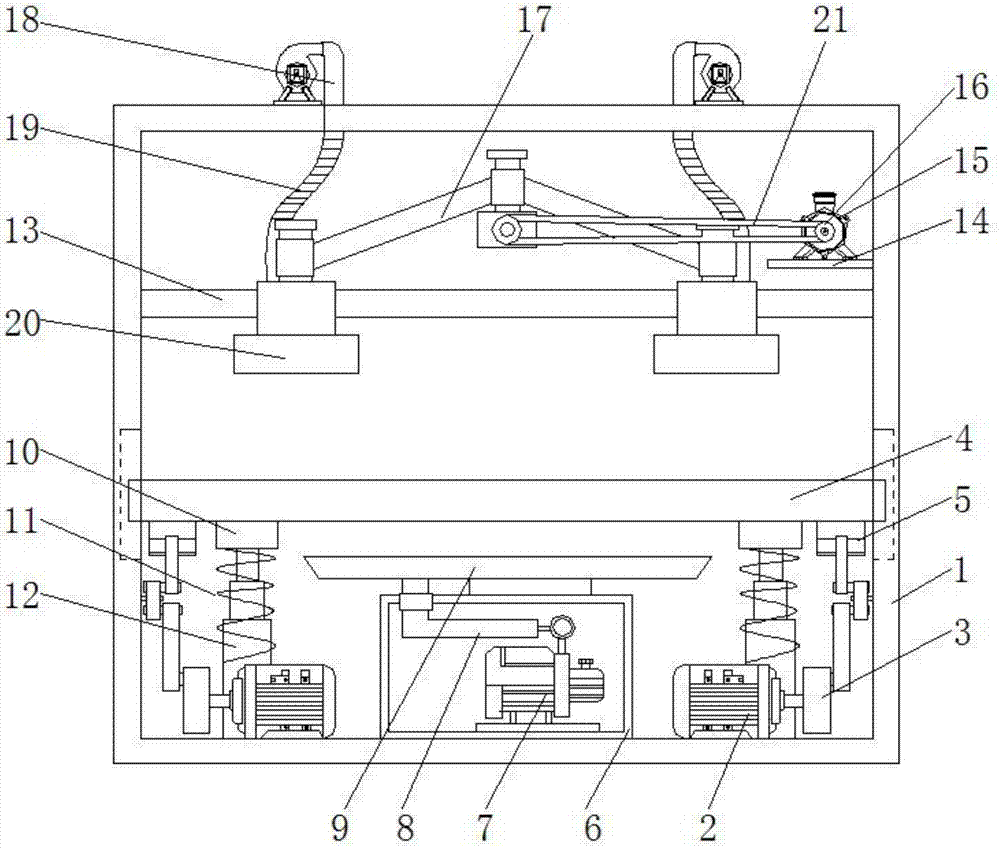

Uniform drying device for agricultural products

InactiveCN107543385AFlip in timeDry evenlyDrying gas arrangementsDrying chambers/containersAgricultural engineeringAir blower

The invention discloses a uniform drying device for agricultural products. The uniform drying device comprises a box body, wherein first motors are fixedly connected to two sides of the bottom of theinner wall of the box body; an output shaft end of each first motor is fixedly connected with a mobile device; a supporting plate is rotationally connected to one side of each mobile device; a bottombox is fixedly connected to the bottom of the inner wall of the box body; the bottom of the inner wall of the bottom box is fixedly connected with an air pump; a gas outlet of the air pump communicates with an air plate through the air pipe; a sliding rod is fixedly connected between the two sides of the upper portion of the inner wall of the box body; the right side of the inner wall of the box body is fixedly connected with a second motor through a motor fixing plate; an output shaft end of the second motor is in transmission connection with a sliding device through a belt; the top of the box body is fixedly connected with air blowers; and drying devices are fixedly connected with the bottom of the sliding device. The invention relates to the technical field of agricultural machinery. The uniform drying device for the agricultural products solves the problem that existing drying is affected by weather and the safety problem in the drying process, the drying speed is accelerated, andthe drying quality is guaranteed.

Owner:湖州桑农生态农业有限公司

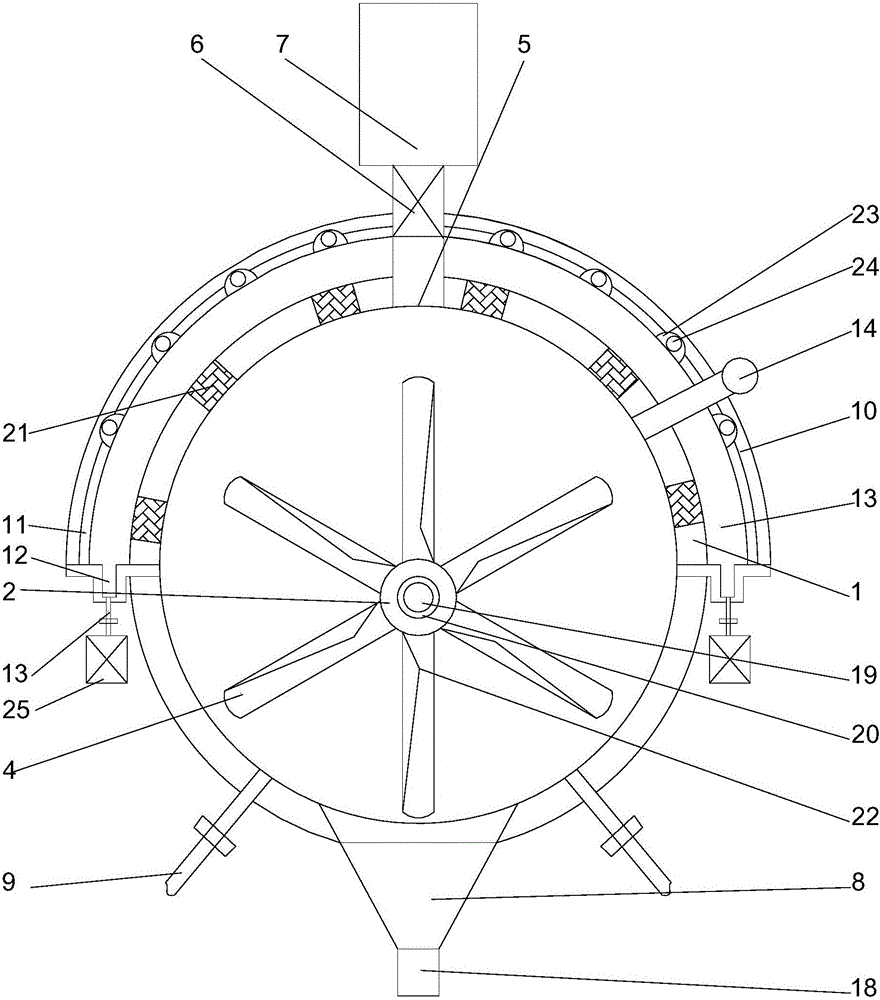

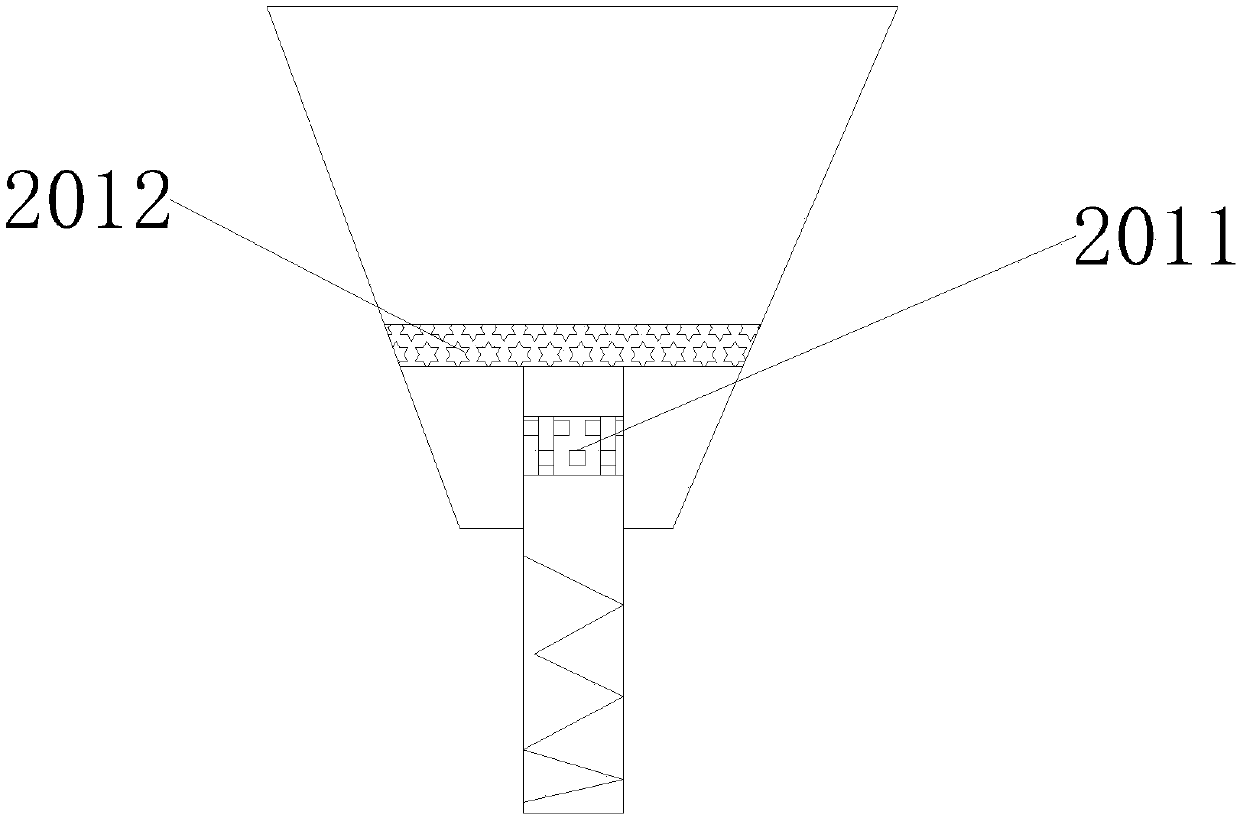

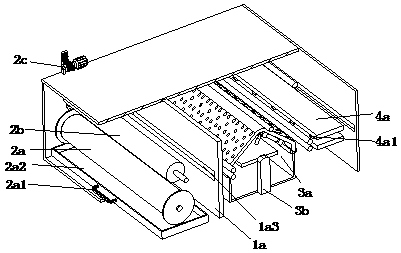

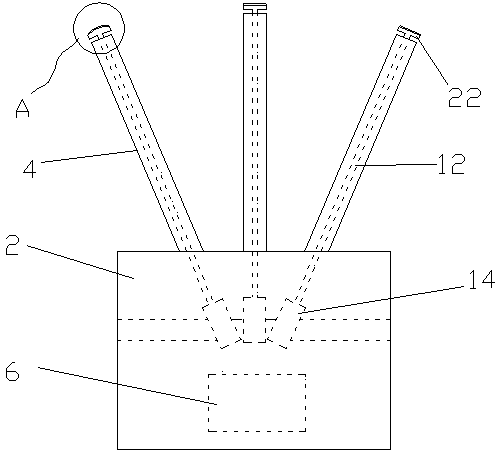

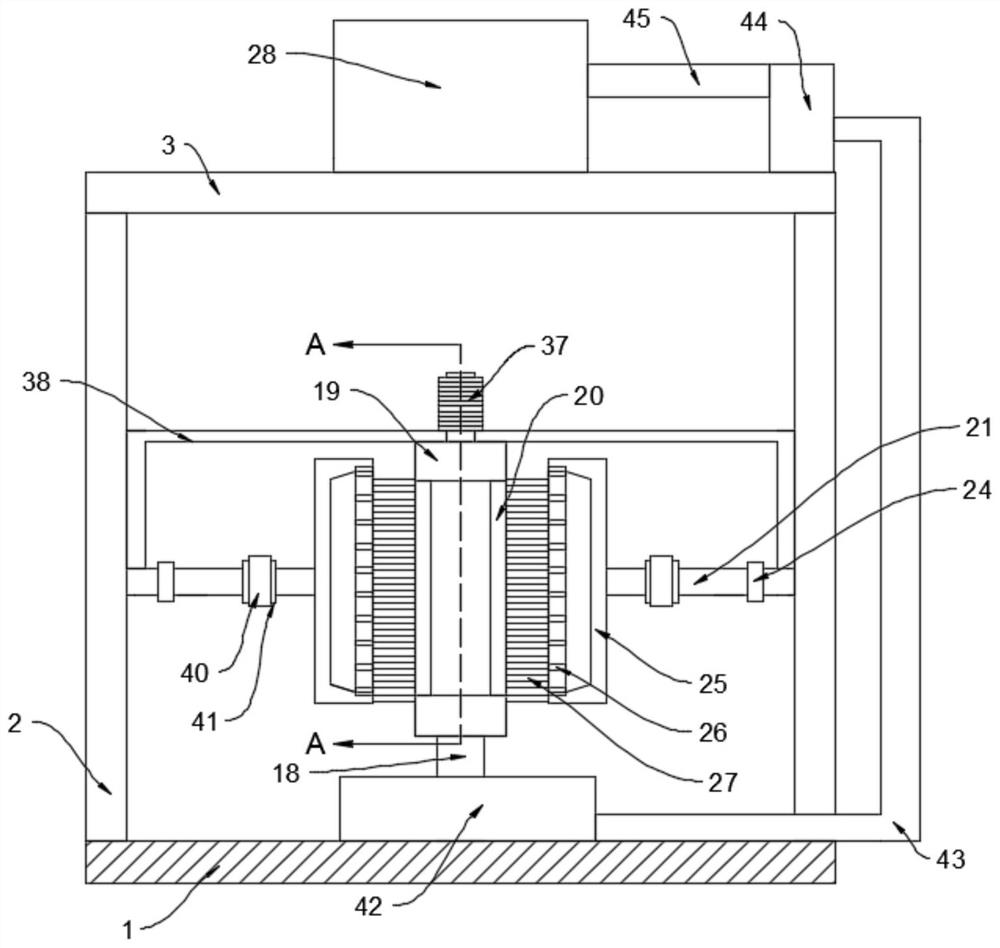

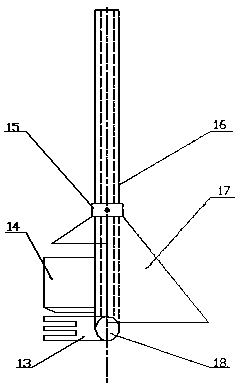

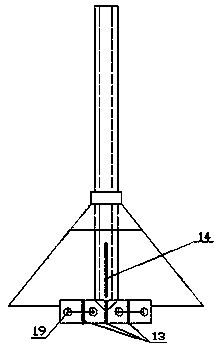

Particle material drying and mixing equipment

ActiveCN105806059AIncrease temperatureSpeed up the drying processDrying machines with non-progressive movementsDrying solid materialsParticle materialPulp and paper industry

The invention discloses particle material drying and mixing equipment. The equipment comprises a hollow cylindrical drying bin, and a bracket arranged below the drying bin; a rotating shaft is arranged on the inner side of the drying bin; the axis of the rotating shaft and the axis of the drying bin form an eccentric structure; at least four blades are arranged on the rotating shaft; in the rotating process of the blades, the outer side edges of the blades can be bonded on the inner wall of the lower end of the drying bin; and a feed port is formed in the upper end of the drying bin. As the rotating shaft and the drying bin are eccentrically arranged, in the rotating process of the blades, materials at the bottom of the drying bin can be totally driven to one side of an isolation cover at the upper part when passing through the bottom of the drying bin, and water in particle materials with water is output by a water collecting tank in the isolation cover in a concentrated manner; and the equipment is simple in structure and more uniform in drying of the materials.

Owner:山东艾克赛尔机械制造有限公司

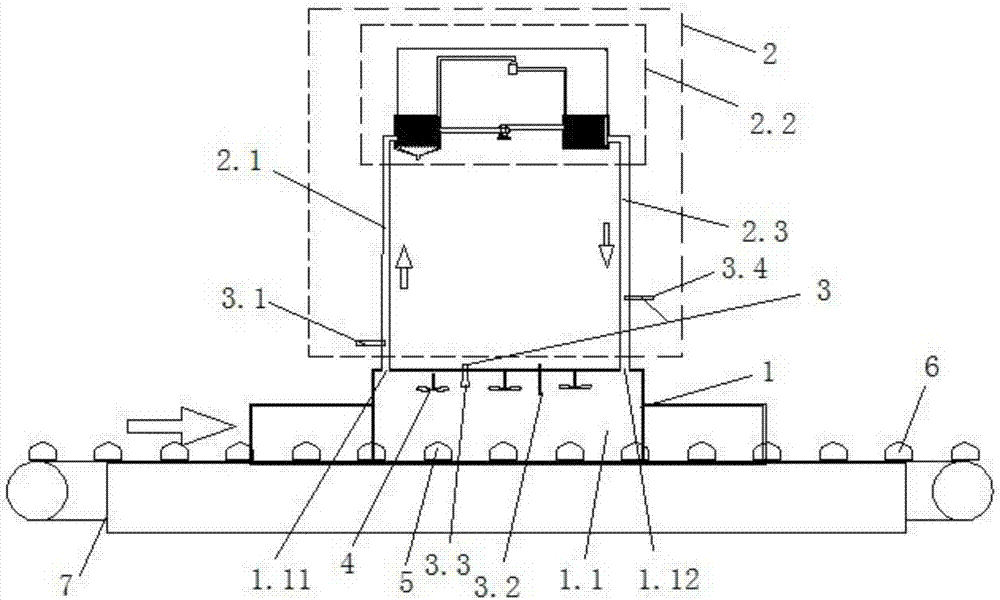

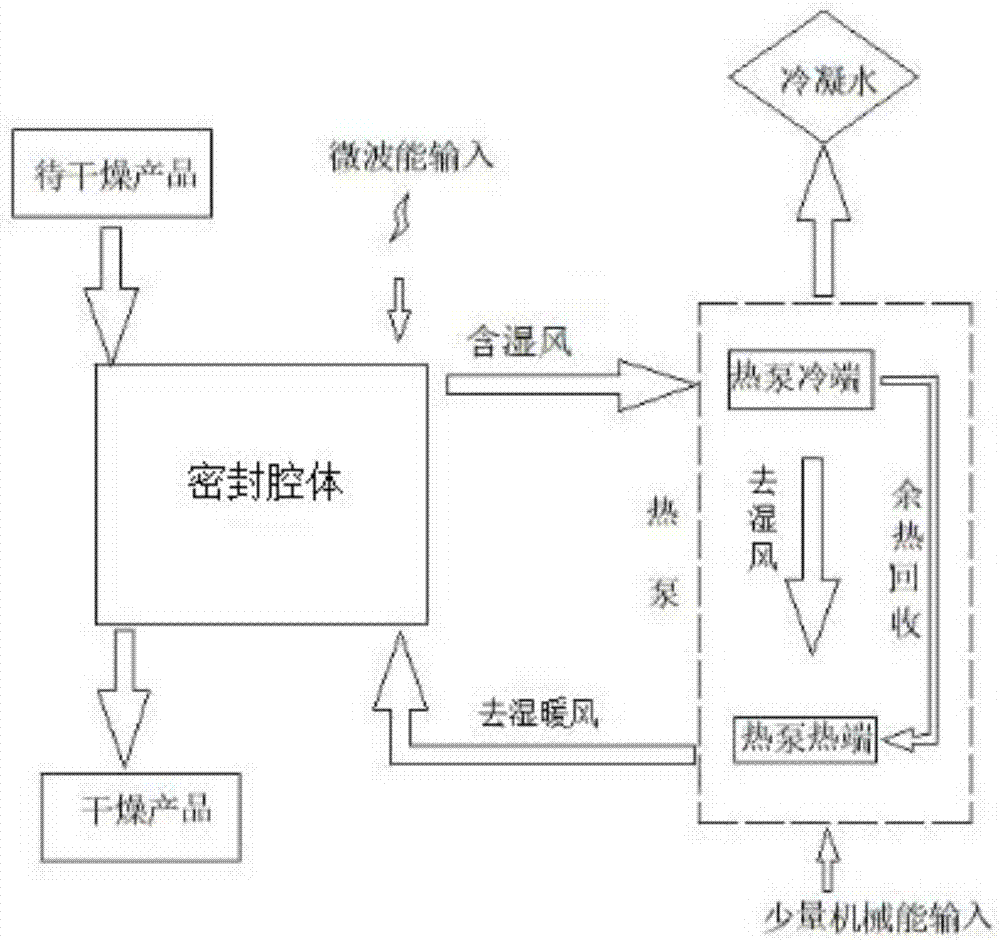

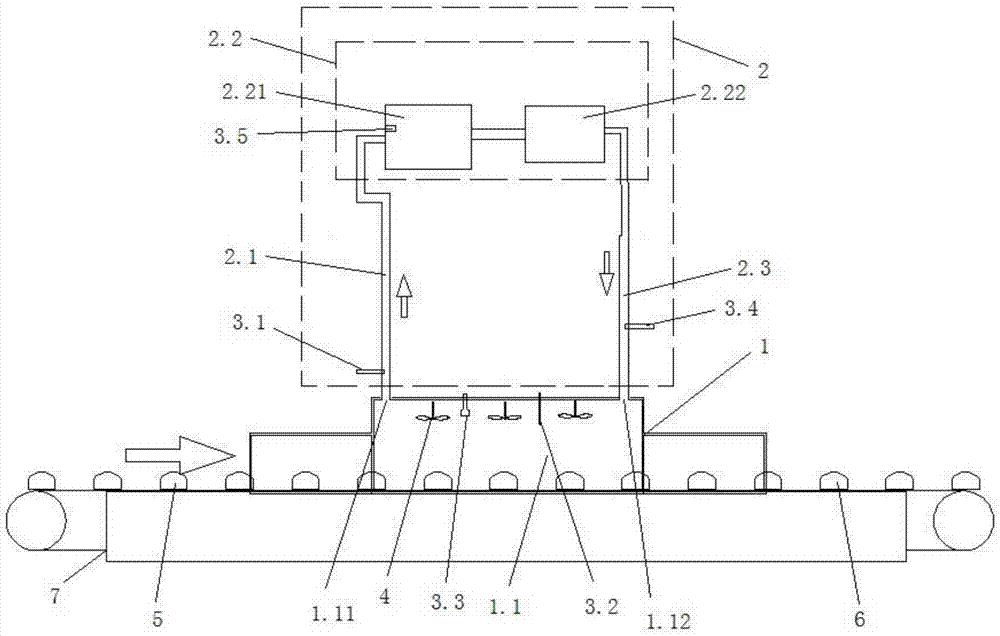

Microwave drying method and device adopted by same

PendingCN107314621ATemperature controlMaintain evaporation rateDrying solid materials with heatDrying gas arrangementsForce convectionProcess engineering

The invention provides a microwave drying method. The microwave drying method comprises the following steps: placing a product to be dried in a sealing cavity of microwave drying equipment; performing microwave drying through the microwave drying equipment emitting microwaves and meanwhile performing forced convection on a gas in the sealing cavity; and monitoring the temperature of the gas in the sealing cavity and the surface temperature of the product to be dried, and at the same time performing post-treatment on the gas in the sealing cavity and enabling the gas after post-treatment to return to the sealing cavity in a cyclic manner. According to the microwave drying method and the device adopted by the same, the temperature and humidity of the gas medium in the sealing cavity are controlled on the basis of the conventional microwave drying technology, meanwhile the essence of the material drying principle is well utilized, so that the purpose of performing microwave drying by efficiently utilizing microwaves is achieved, and technological problems that materials are excessively dried, deformed, burned and denatured during the microwave drying process are effectively avoided; meanwhile, the microwave drying process is enhanced in an energy-saving manner through approaches such as complete moisture circulation and reutilization and cavity heat preservation. The invention further discloses the device adopted by the method, parts are easy to obtain, and the implementation is easy to realize.

Owner:湖南源创高科工业技术有限公司

Blueberry cleaning machine with drying effect

InactiveCN107912786AGood for fallingImprove work efficiencyFood treatmentAgricultural engineeringSmall hole

The invention discloses a blueberry cleaning machine with drying effect, which comprises a body, a water tank and a blower arranged above the body in sequence, and a rough washing room, a spraying room and a drying room are arranged in the body along the blueberry moving direction in sequence, An electric heating chamber, an air duct, a filter screen and a water receiving plate are sequentially arranged in the drying chamber from top to bottom, the electric heating chamber is connected with a blower, and a number of ventilation holes are provided on the side of the air duct close to the filter screen. A baffle coated with a sponge layer to limit the passage of blueberries is provided at the junction of the spray chamber and the drying chamber. The solution provided by the invention can effectively dry the washed blueberries, which is beneficial to the storage of the blueberries.

Owner:雅安雅莓种植专业合作社

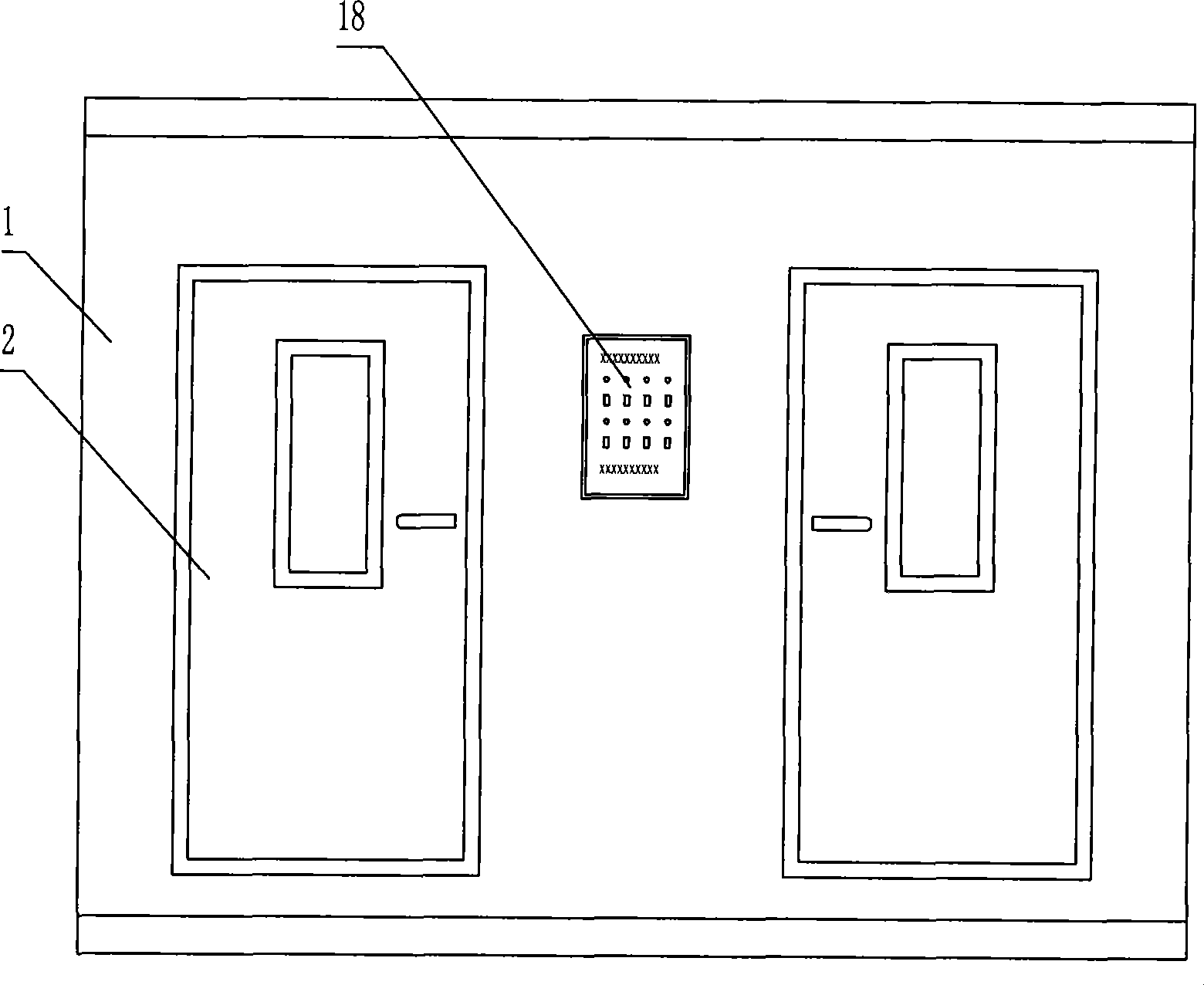

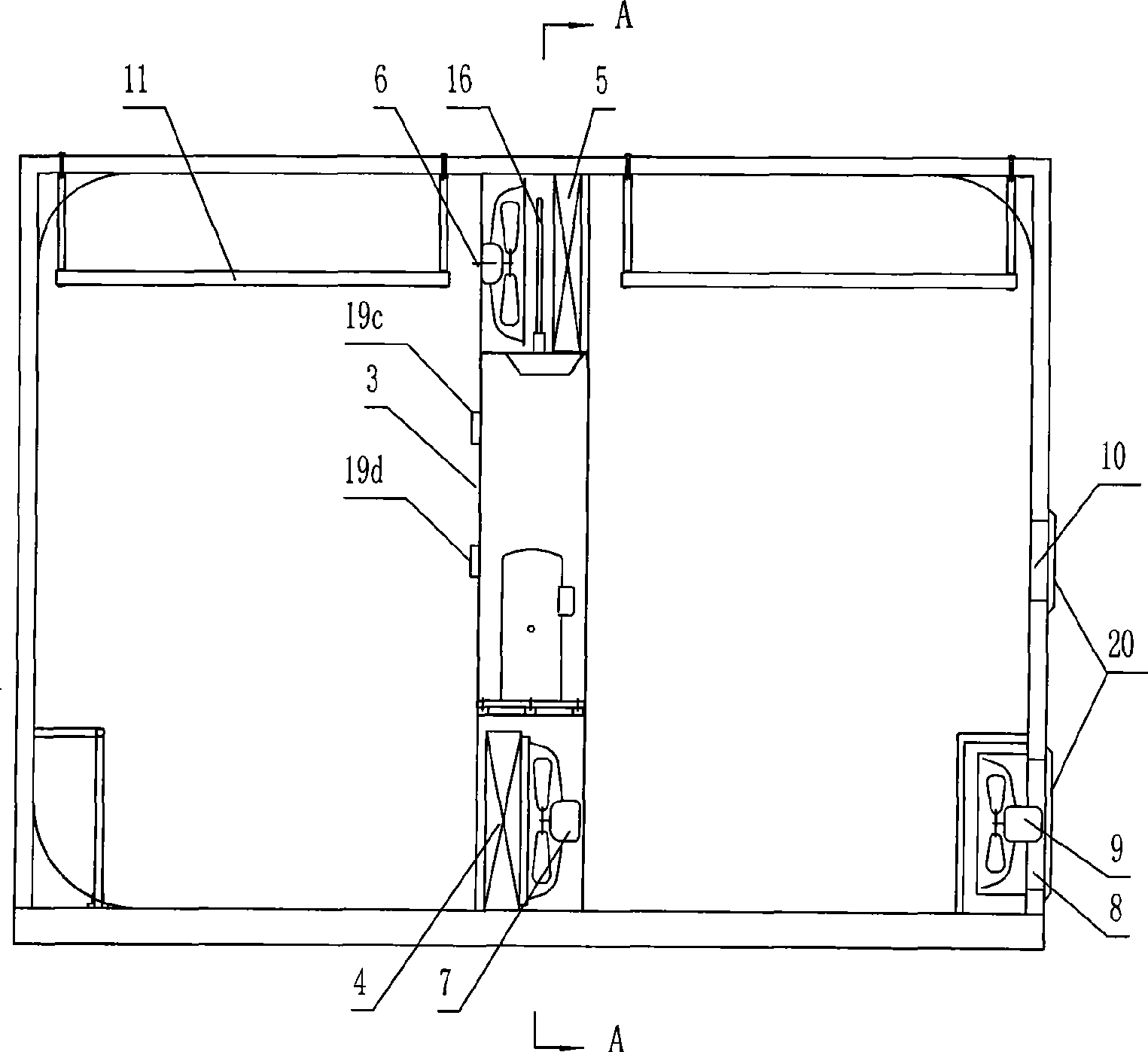

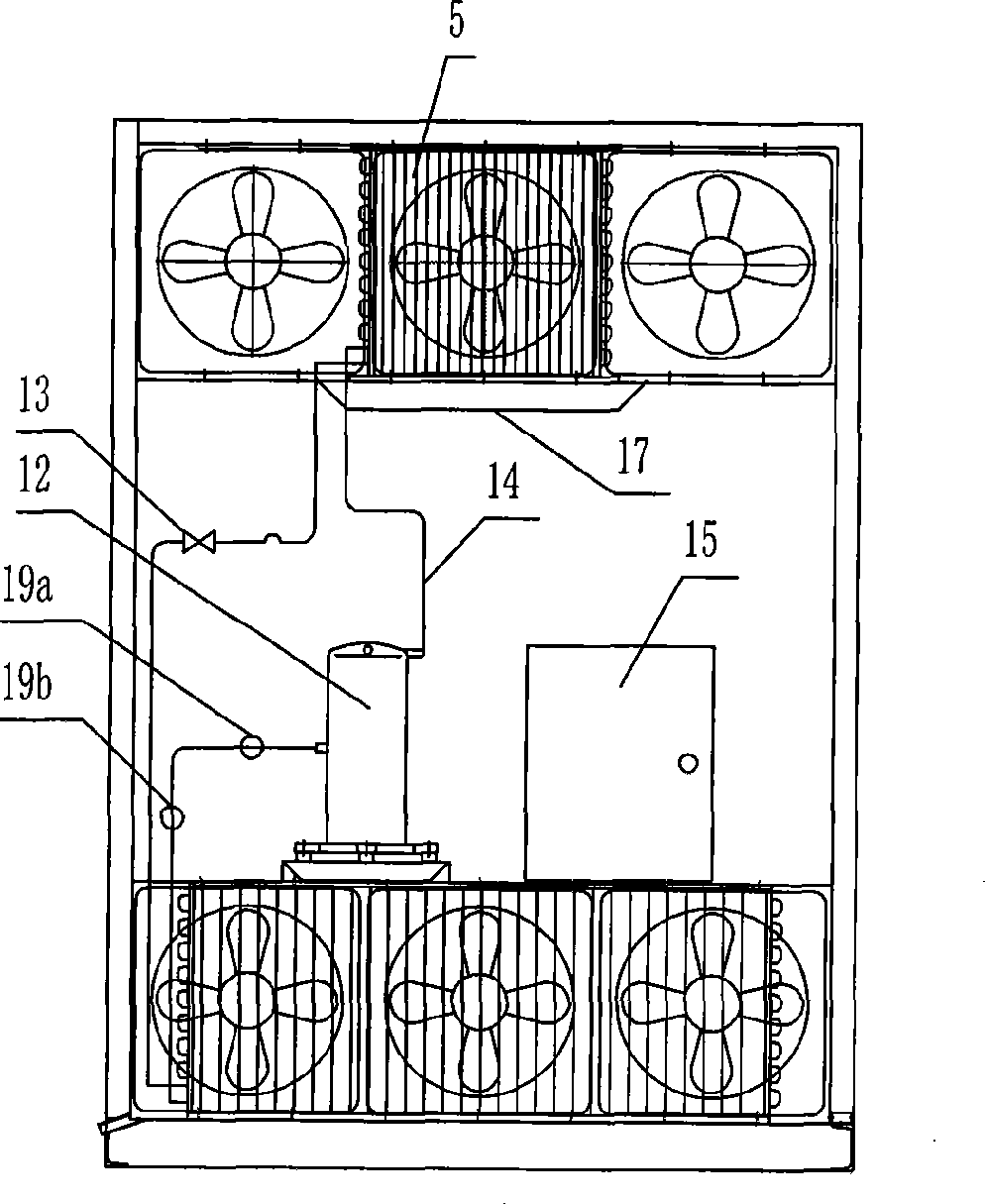

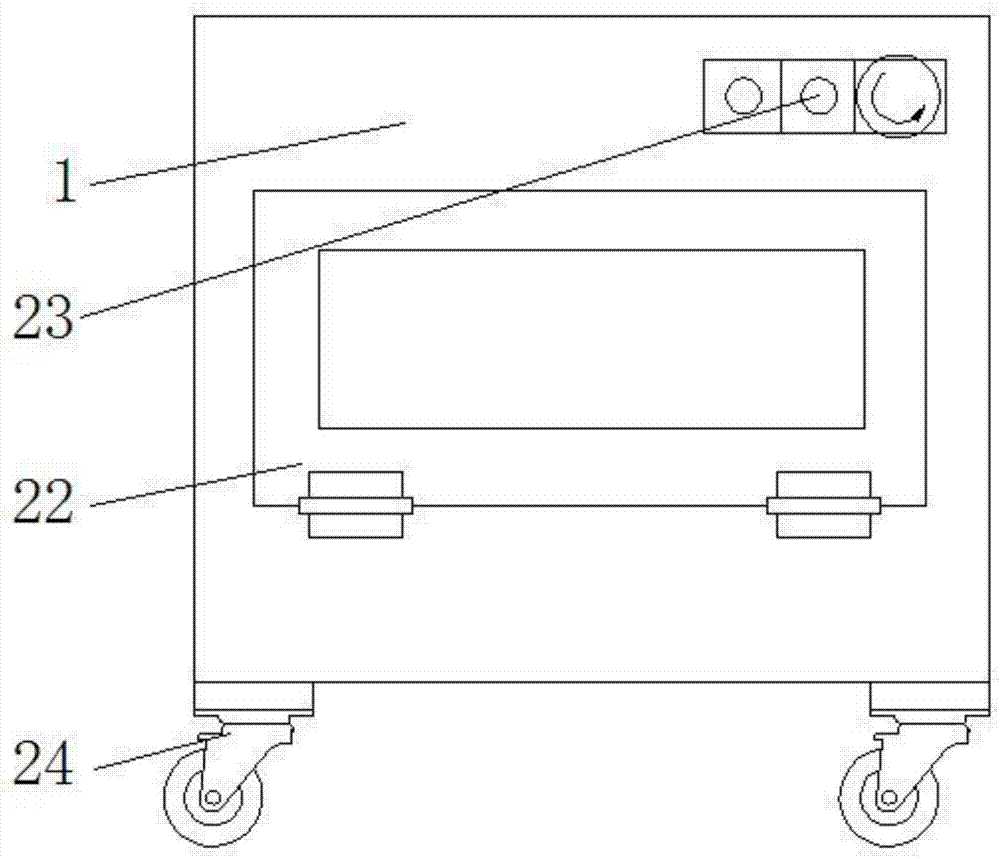

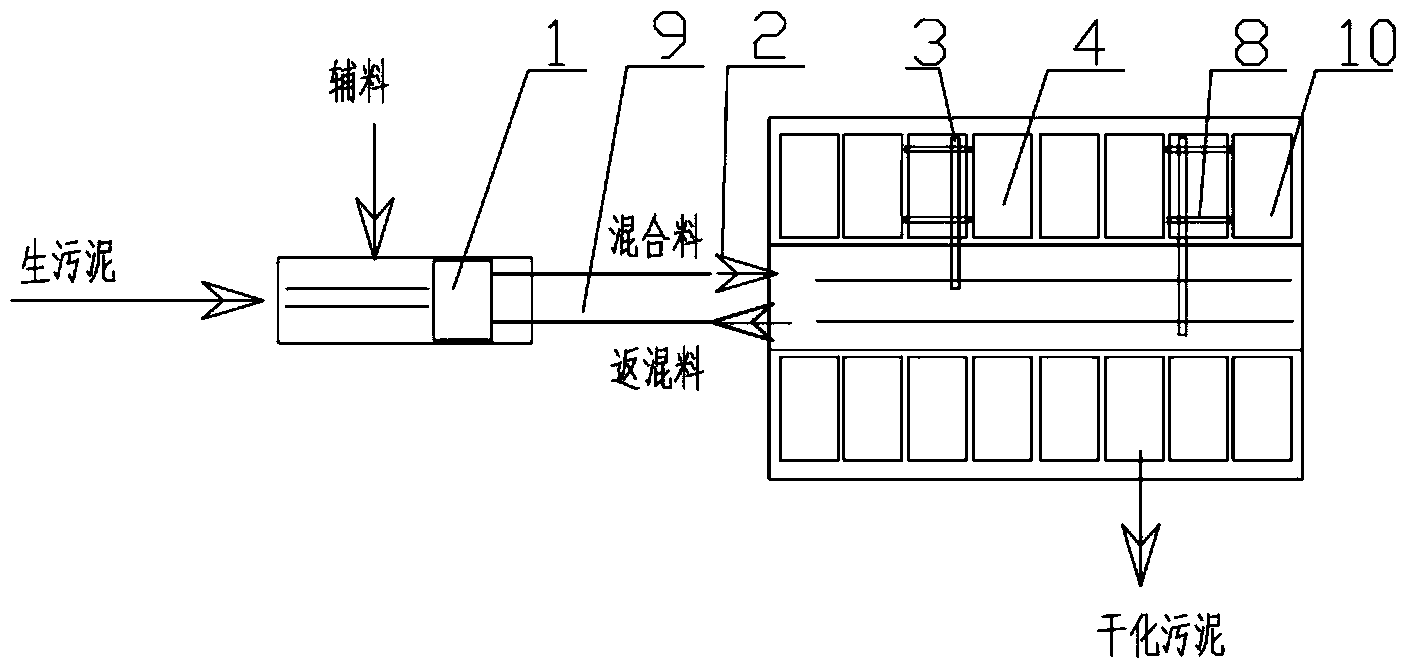

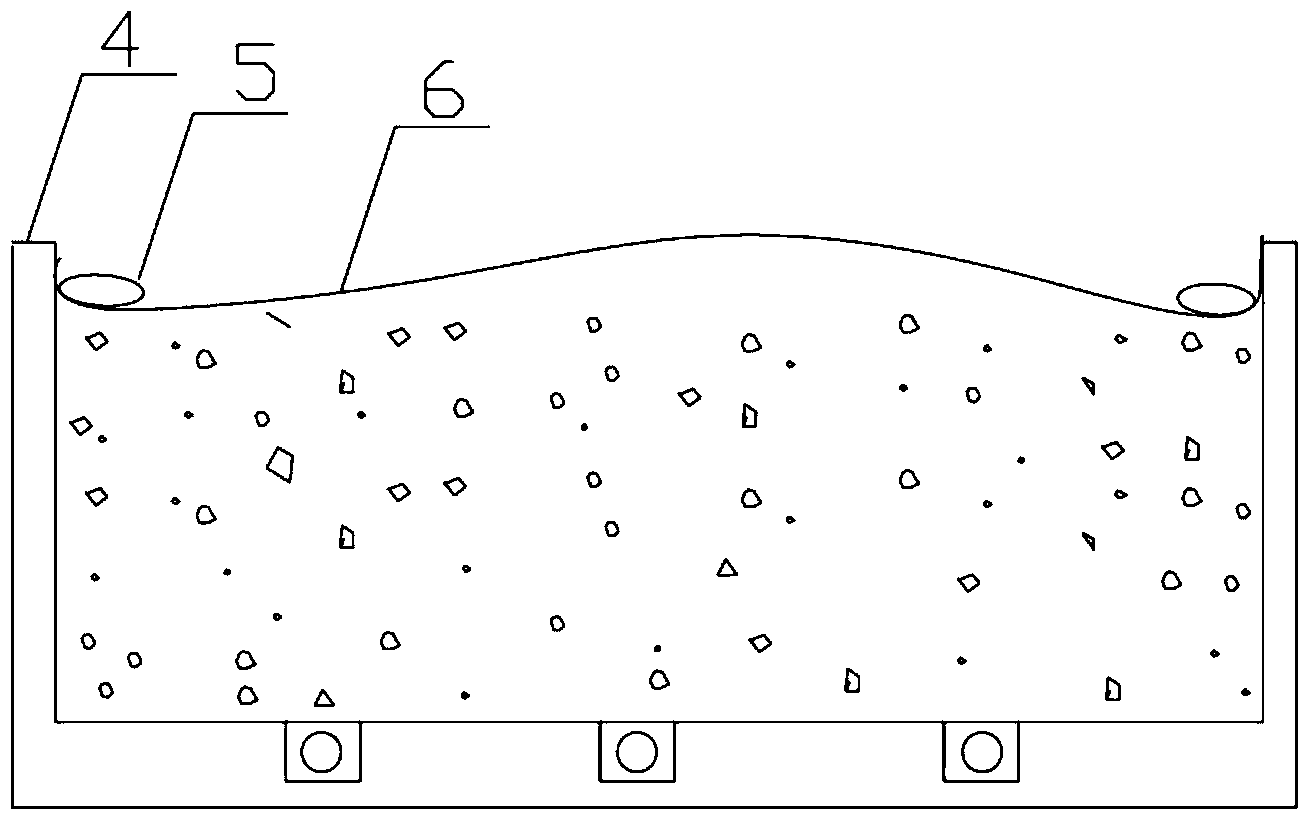

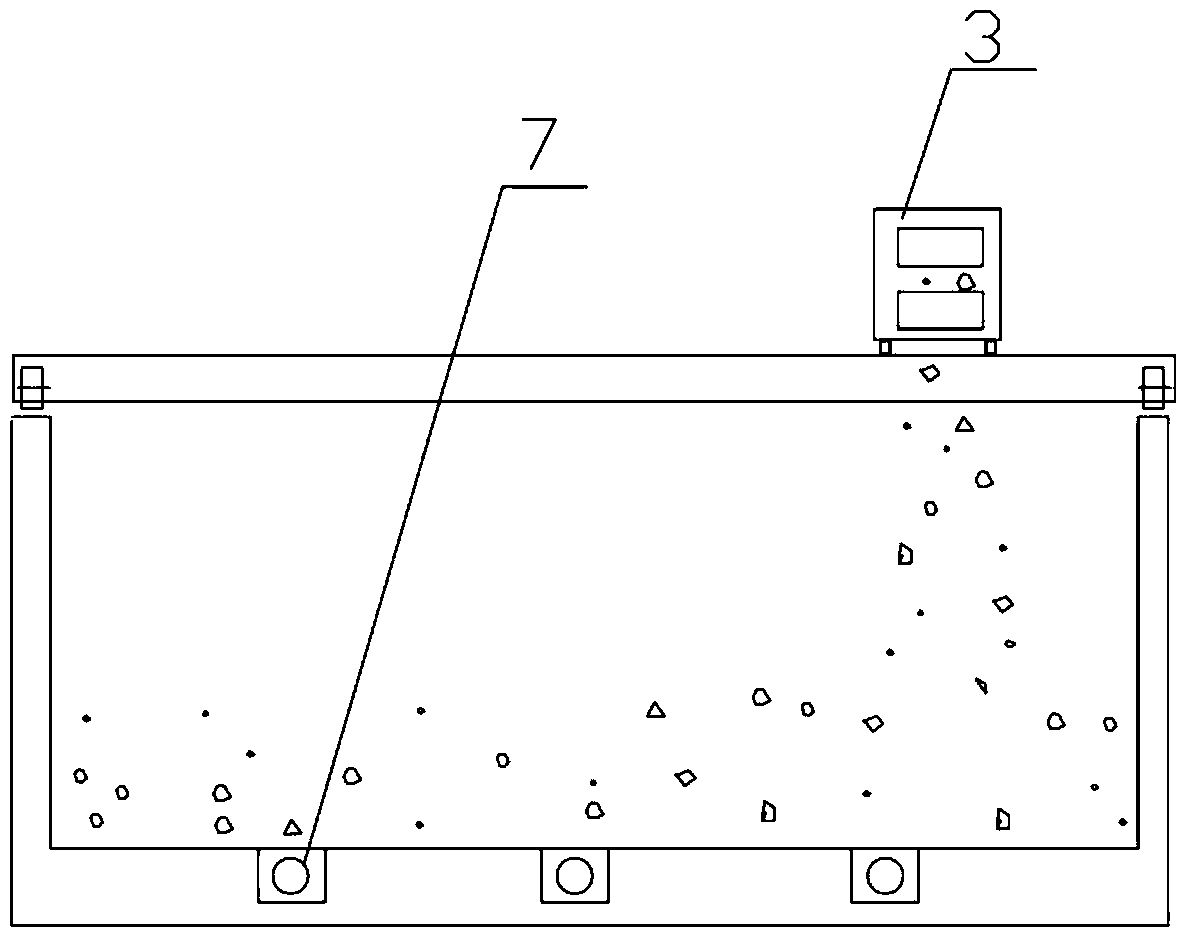

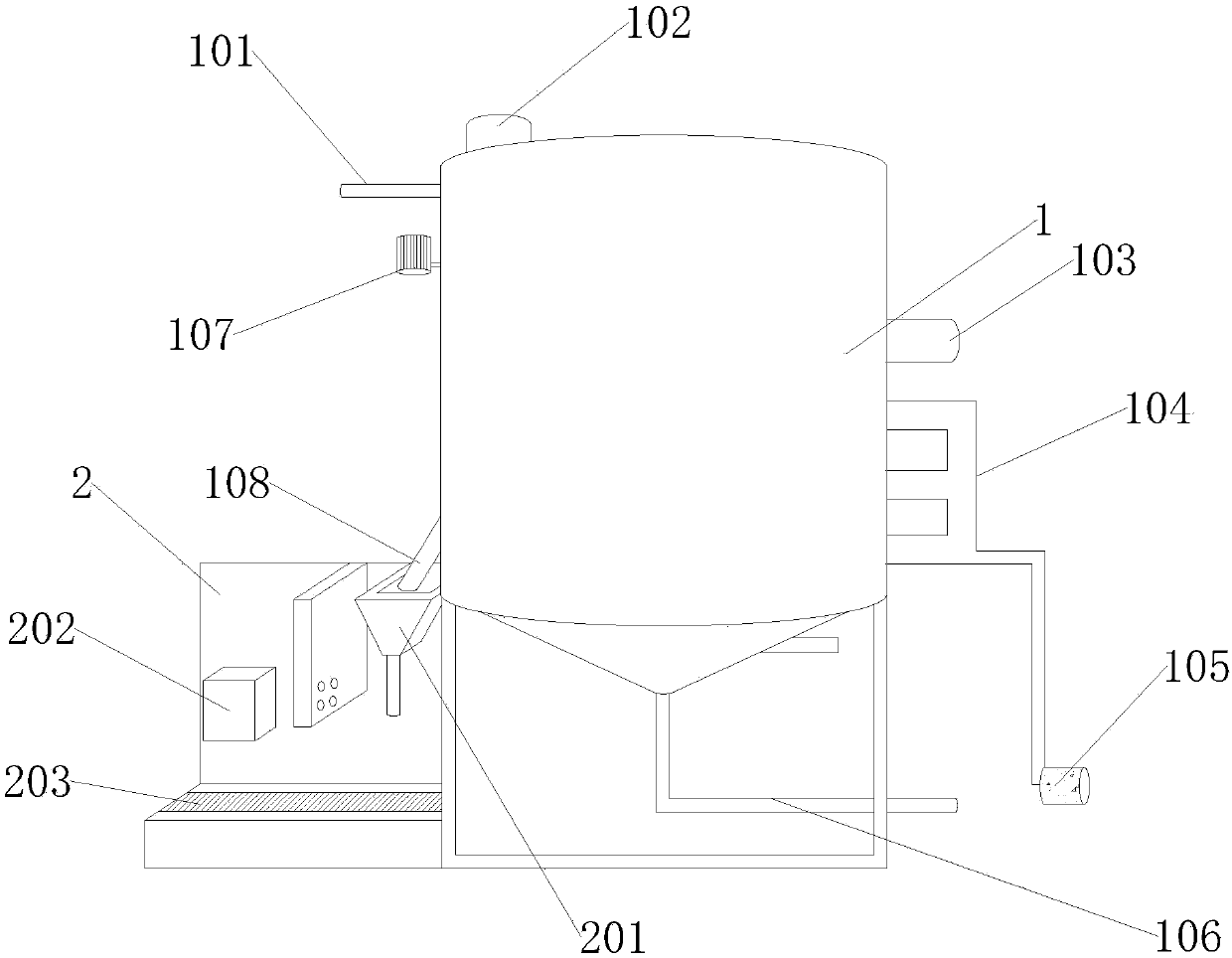

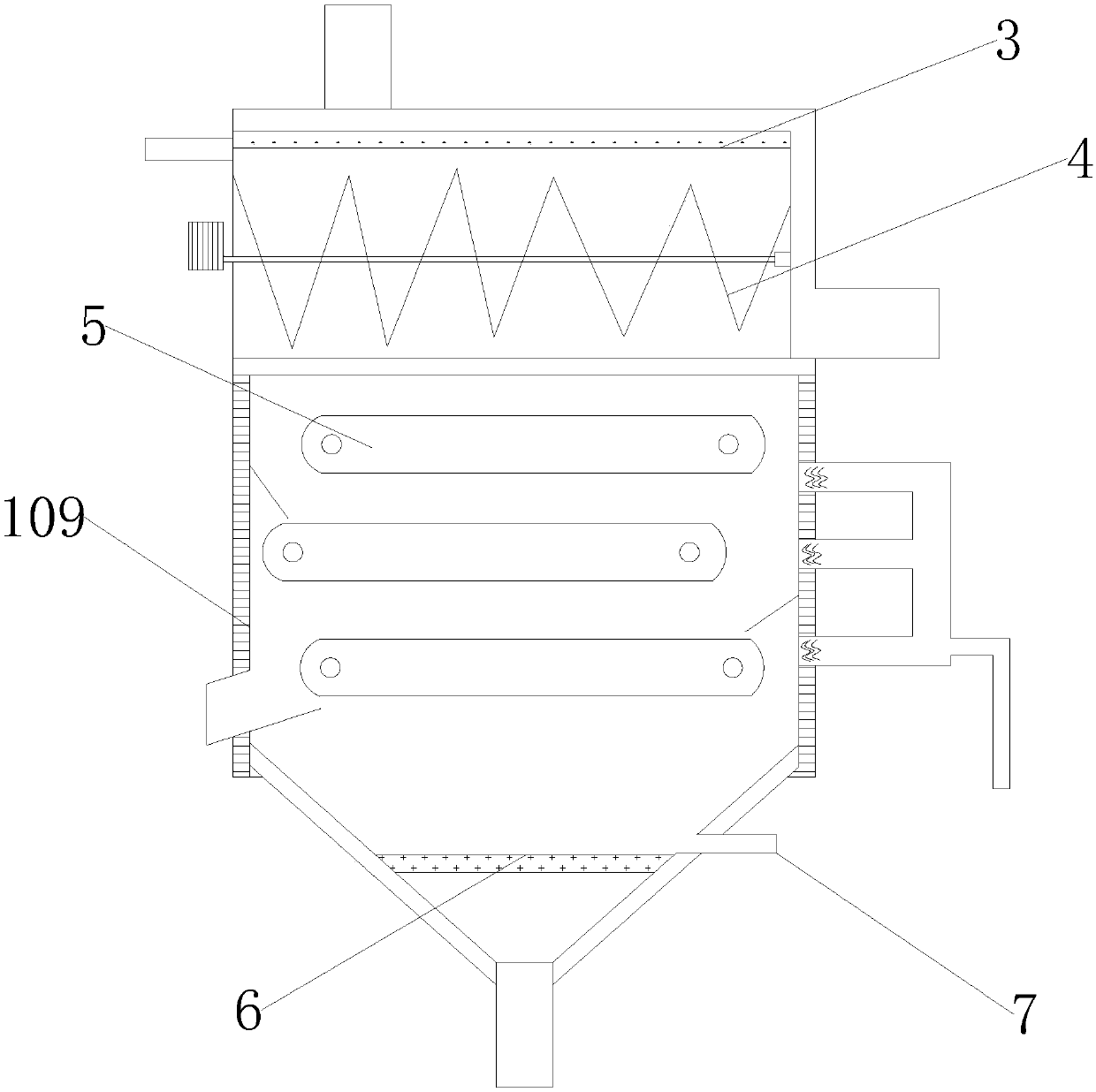

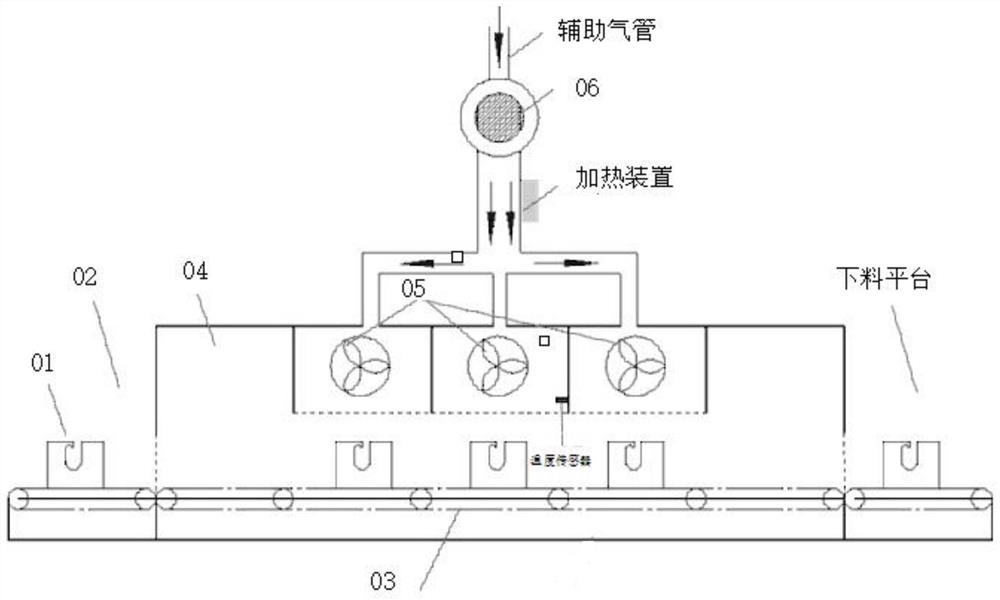

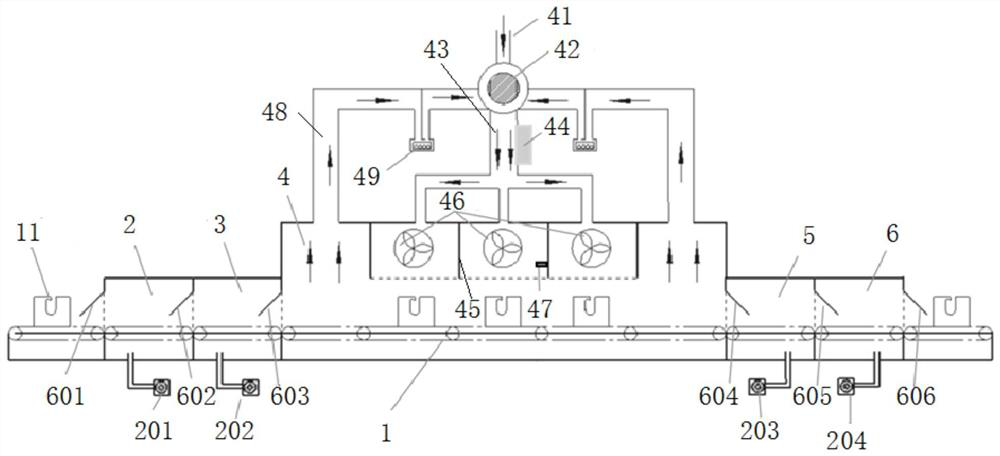

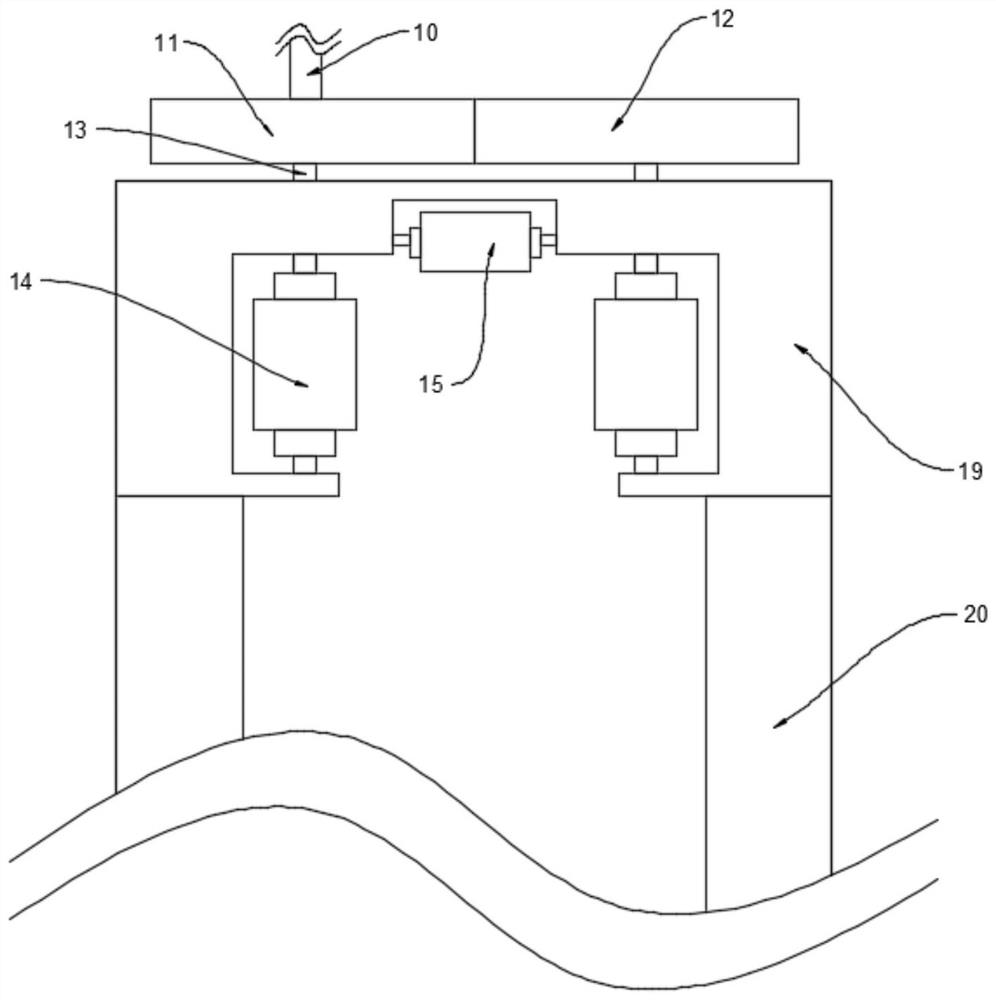

Dewatered sludge aerobic fermentation device and technique

ActiveCN104230133ASave engineering investmentEffective lossSludge processingBiological sludge treatmentWorking environmentAgricultural engineering

The invention relates to a dewatered sludge aerobic fermentation device and technique. The device comprises a mixing crusher and a fermentation unit, wherein the fermentation unit is composed of two rows of fermentation tank sets; and two conveyer belts, and an automatic distributor and an automatic reclaimer which are arranged on the conveyer belts, are arranged between the fermentation tanks. The dewatered sludge aerobic fermentation device and technique effectively prevent the odor from dispersion in the fermentation process, improve the ground work environment of the site, and increase the fermentation rate of the materials.

Owner:THUNIP CORP LTD

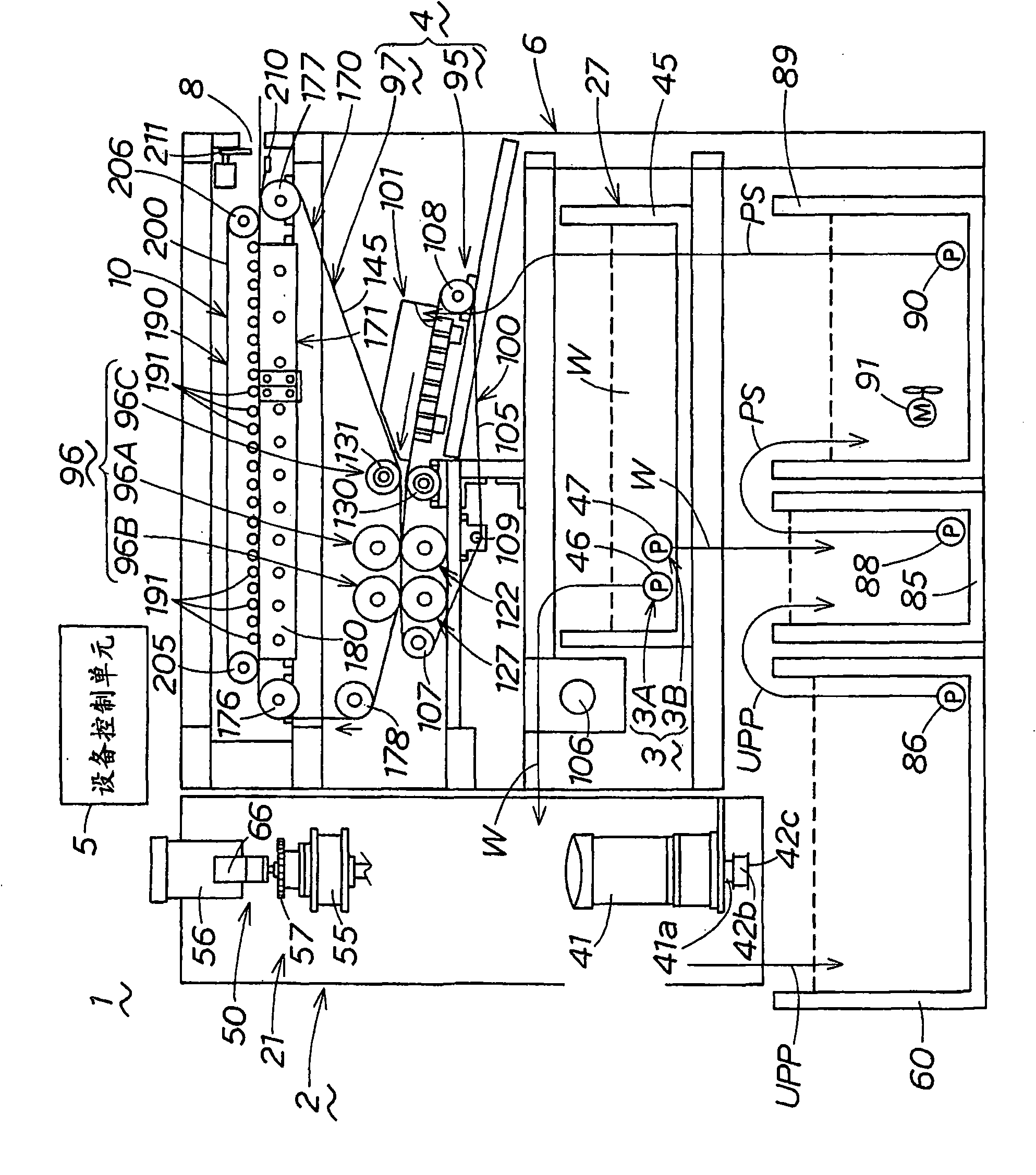

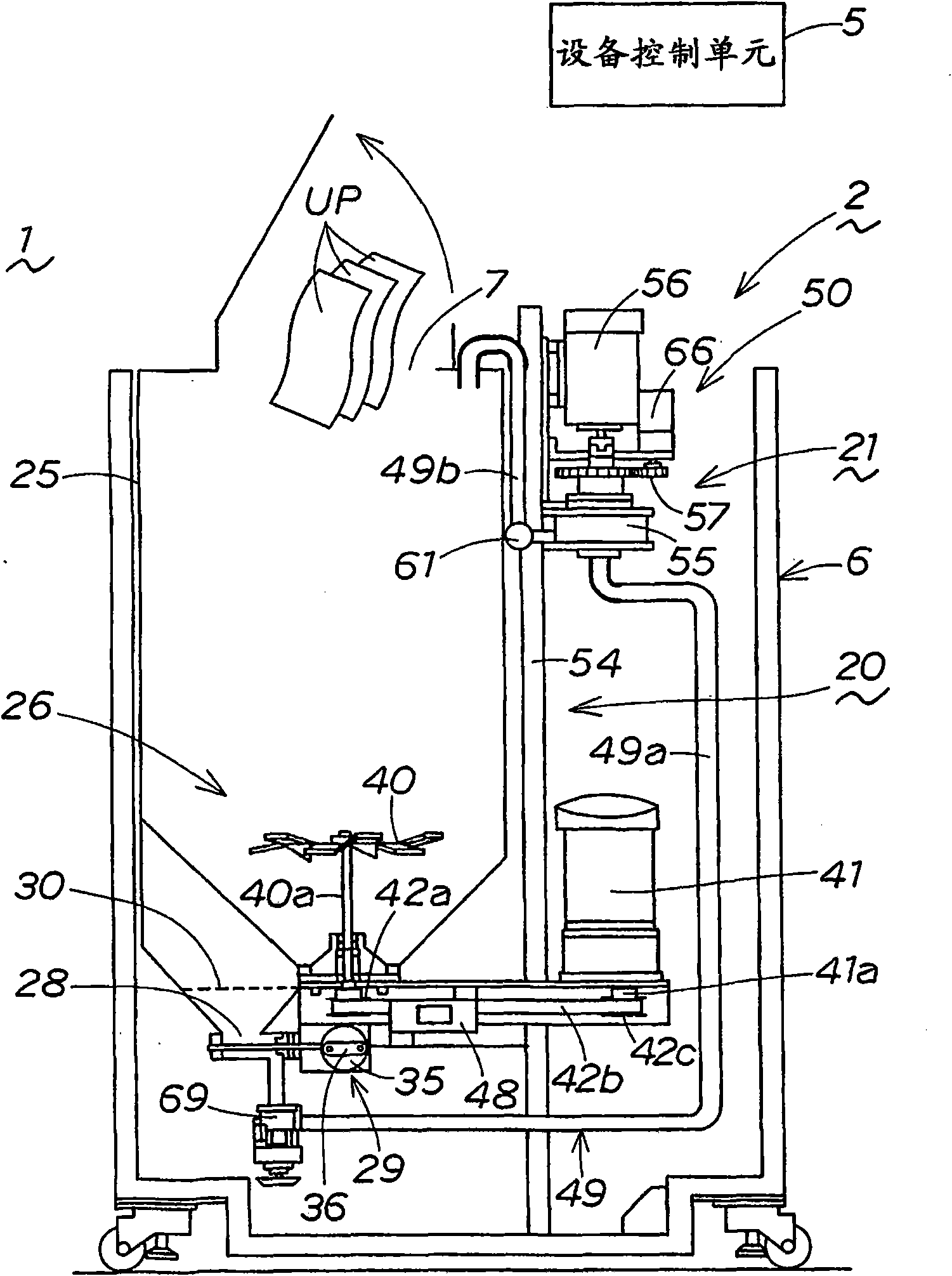

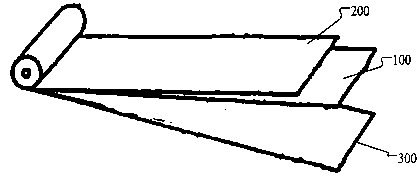

Regenerated paper smoothing device of used paper recycling apparatus, paper making device, and used paper recycling apparatus

InactiveCN101988275AWrinkle freeUniform pressureCalendersRaw material divisionWrinkle skinPaper recycling

The invention relates to a regenerated paper smoothing device of used paper recycling apparatus, a paper making device, and an used paper recycling apparatus. In a very narrow used paper processing space of a used paper recycling apparatus of furniture size, the present invention presents a recycled paper smoothing technology for manufacturing securely into a wrinkle-free and smooth recycled paper from wet paper made and formed in a paper making processing unit of a paper making unit. The recycled paper smoothing processing unit is formed as pressing means for pressing the entire wet paper conveyed on a smooth surface belt with a uniform pressure from the upper side in a heating and drying unit, and includes a covering belt conveyor having a covering belt running while covering the entire wet paper on the smooth surface belt in an enclosed state together with the smooth surface belt, and a plurality of pressing rollers disposed at specified intervals in the running direction of the covering belt for pressing this covering belt from the upper side, and therefore the wet paper made and formed in the paper making net conveyor is securely reproduced as a wrinkle-free and smooth recycled paper.

Owner:SEED RUBBER CO LTD

Drying kiln for ceramic products

InactiveCN107747862AConsistent temperatureUniform temperatureDrying gas arrangementsDrying chambers/containersAgricultural engineeringDrying time

The invention discloses a drying kiln for ceramic products. The drying kiln comprises a drying chamber, a drying preparation chamber, a conveying device and a control device; the conveying device penetrates through the drying chamber and the drying preparation chamber; a separating plate is arranged in the drying chamber; a first heating box is arranged above the separating plate; a first exhaustfan is arranged on the right side of the separating plate; a first placing rack is located below the separating plate; a second heating box is arranged below the first placing rack; an air blower is arranged on the left side of the first placing rack; a temperature sensor is arranged in the drying chamber; a communicating pipe is arranged at the upper end of the drying chamber; the other end of the communicating pipe communicates with the upper end of the drying preparation chamber; a second exhaust fan is arranged at the end opening of the communicating pipe; and a valve is arranged on the communicating pipe. Preliminary heat can be discharged into a drying preparation box by the aid of the communicating pipe after a drying procedure is completed, so that the drying time of the drying chamber is effectively shortened; the temperature of the drying chamber can be monitored by the aid of the temperature sensor, and the temperature of the drying chamber can be closest to the optimal drying temperature through adjustment and control by the aid of the control device.

Owner:耒阳市井阳陶瓷有限公司

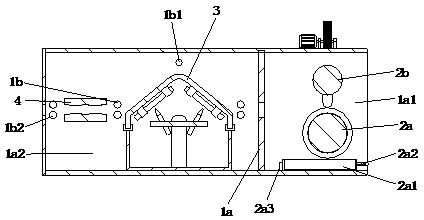

Automatic sputum specimen smearing instrument

InactiveCN105890955AEasy to observeSpeed up the drying processPreparing sample for investigationBottleWater pipe

The invention discloses an automatic sputum specimen smearing instrument. The automatic sputum specimen smearing instrument comprises a shell and a controller, wherein a glass slide accommodating chamber, a smearing chamber and a staining chamber are arranged inside the shell from the center to the edge in sequence, a slide outlet chamber is arranged outside the shell, a glass slide accommodating disc is arranged in the glass slide accommodating chamber, and a first lifting device is arranged between the bottom of the glass slide accommodating disc and the shell; an annular accommodating disc and a smearing device are arranged in the smearing chamber, a staining fluid bottle, a water pipe, a staining fluid collecting box and a drying device are arranged in the staining chamber, and a first pair of sliding rails, a second pair of sliding rails, a third pair of sliding rails and a fourth pair of sliding rails matched with one another are arranged in the glass slide accommodating chamber, the smearing chamber, the staining chamber and the slide outlet chamber respectively. By the adoption of the automatic sputum specimen smearing instrument, smearing, staining, drying and cleaning of a sputum specimen can be achieved automatically, operation is easy and convenient, and time is saved; opening and closing of a bottle cap and smearing are achieved through a smearing device, operation is easy and convenient, and cost is saved.

Owner:李源

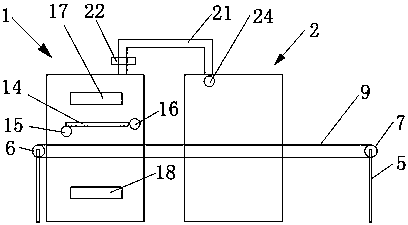

Rice cleaning and packaging equipment

InactiveCN107824538AIncrease transport distanceSpeed up the flowSievingScreeningEvaporationDrive motor

The invention discloses a rice cleaning and packaging equipment, which consists of a cleaning machine and a packaging machine. A packaging machine is arranged on the left side of the cleaning machine. The packaging machine is fixedly connected in the cleaning machine through bolts. The port is connected to the washing machine by welding. The left side of the washing machine is equipped with a water inlet pipe, which is embedded in the washing machine. The left side of the washing machine is equipped with a drive motor. There is a rice outlet on the lower side, and the rice outlet is embedded in the washing machine. In order to speed up the air flow and drive the evaporation of water, there is an air supply pipe on the side of the drying area, and the outside side of the air supply pipe is provided by a fan, and at the same time, the wind is heated by the electric heating wire at the outlet of the drying area, so as to speed up the drying process. The purpose of the internal air flow can also increase the air temperature, which solves the problem that the air in the traditional device does not circulate during drying, and the moisture in the air is not easy to evaporate.

Owner:WUXI KING MO MACHINERY

Rice cleaning device for energy-saving food processing

The invention discloses a rice cleaning device for energy-saving food processing, and belongs to the field of food processing equipment. The rice cleaning device is characterized in that a controlleris fixed to the top of a workbench; a first motor is fixed to the tail end of a fourth bracket; a humidity sensor is fixed to the left side of a fifth bracket; an air heater is fixed to the top end ofa sixth bracket; a drying device is fixed to the top end of a seventh bracket; and a water purification device is positioned at the left lower corner in a water purification tank. According to the rice cleaning device, water is sprayed to rice in a roller through action of a water pump, the first motor drives the roller to rotate to drive rice to move upwards, rice mixed with impurities and immature grains falls into the water purification tank through circular holes of a roller outer shell, and screening and cleaning operation of rice is achieved; hot air is blown to a rotation box through the air heater, a second motor drives the rotation box to rotate, rice is uniformly heated, and drying operation of rice is achieved; and the manual rice screening and cleaning process is replaced, andproduction efficiency is improved.

Owner:湖北国宝桥米有限公司

Drying device and drying method for textile yarns

InactiveCN109974423ASpeed up the drying processSolve wasteful technical problemsDrying solid materials with heatDrying solid materials without heatTextile yarnEngineering

The invention discloses a drying device for textile yarns, and belongs to the technical field of textile yarns. The drying device comprises a box body, a rolling assembly, a drying assembly and a sterilization assembly, wherein a dummy plate is arranged in the box body, the rolling assembly is fixedly connected with the box body, the drying assembly is fixedly connected with the inner wall of thebox body, the sterilization assembly is located beside the drying assembly and fixedly connected with the box body, and a through groove for the yarn to pass through is formed in the dummy plate. According to the invention, one end of the to-be-dried yarn moves in the direction of the two lamp bases sequentially through one set of wire rollers, the wire drawing roller and the other set of wire guide rollers, the heating pipe is used for heating the second drying space, the plurality of blowing nozzles work to convey the heated air into the yarn direction through the blowing nozzle, when the heating tube begins to work, heat emitted by the heating tube can be conveyed to the yarn through the plurality of blowing nozzles, the blowing nozzle can convey the heat to the yarn more uniformly, sothat the drying operation of the yarn is accelerated, and the heat emitted by the heating tube is fully utilized.

Owner:王楠

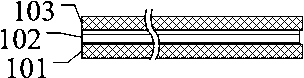

Ceramic diaphragm with good bonding property, preparation method thereof and lithium ion battery containing ceramic diaphragm

PendingCN111244368AImprove adhesionLarge specific surface areaSecondary cellsCell component detailsSlurry coatingLithium-ion battery

The invention discloses a ceramic diaphragm. A diaphragm base material is coated with a first aqueous slurry coating, and the surface of the first aqueous slurry coating is coated with a second aqueous slurry coating. The thickness of the second aqueous slurry coating is greater than that of the first aqueous slurry coating. The compactness of the first aqueous slurry coating is greater than thatof the second aqueous slurry coating. The invention further discloses a lithium ion battery containing the ceramic diaphragm. The ceramic diaphragm disclosed by the invention has the characteristics of strong cohesiveness, good drying effect and excellent electrochemical performance.

Owner:SHENZHEN HONCELL ENERGY CO LTD

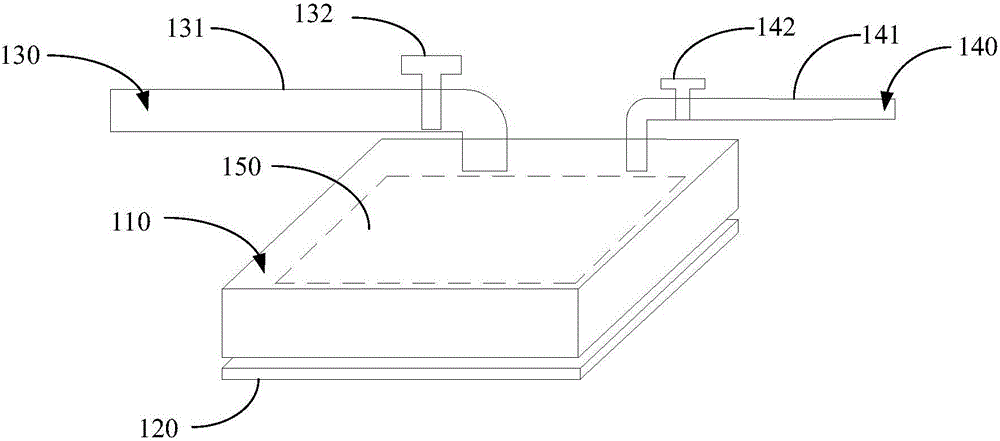

Silicon wafer drying device and method

PendingCN112460971AReduce pollutionReduce humidityDrying gas arrangementsDrying chambers/containersControl systemSurface oxidation

The invention discloses a silicon wafer drying device and method. The silicon wafer drying device comprises a texturing basket conveying device, a first buffering cavity, a first low-pressure cavity,a drying cavity, a second low-pressure cavity and a second buffering cavity; the texturing basket conveying device is used for conveying texturing baskets which load silicon wafers and are arranged atequal intervals, the texturing basket conveying device is sequentially provided with the first buffering cavity, the first low-pressure cavity, the drying cavity, the second low-pressure cavity and the second buffering cavity in the conveying direction, the cavities are separated into closed spaces through double side doors, the buffering cavities and the low-pressure cavities are connected witha vacuum system, and a gas filtering reduction system, a heating temperature control system, a gas purging system and a water vapor condensation circulating system are arranged in the drying cavity. By means of the above manner, the textured silicon wafers and the texturing baskets can be dried, silicon wafer surface oxidation caused by water vapor and oxidizing atmosphere in the drying process isavoided, and poor product manufacturing procedures are reduced.

Owner:SUZHOU SHENGCHENG SOLAR EQUIP

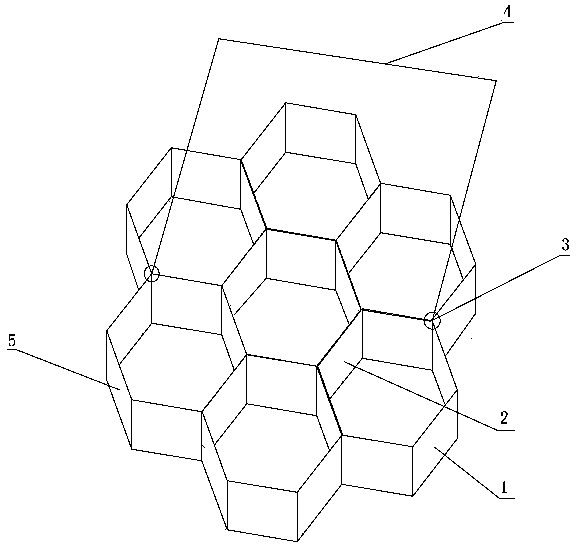

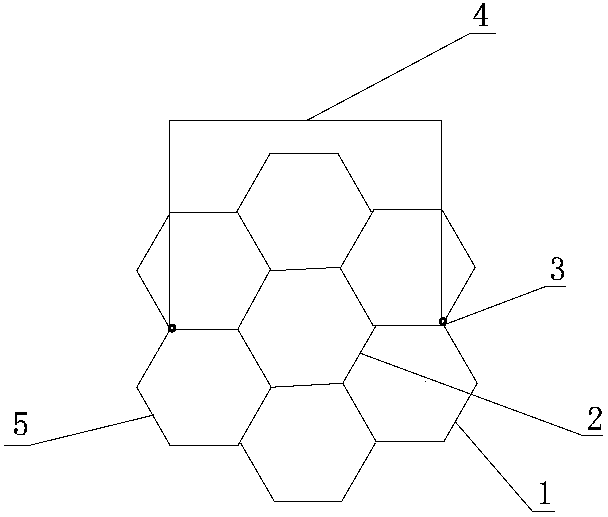

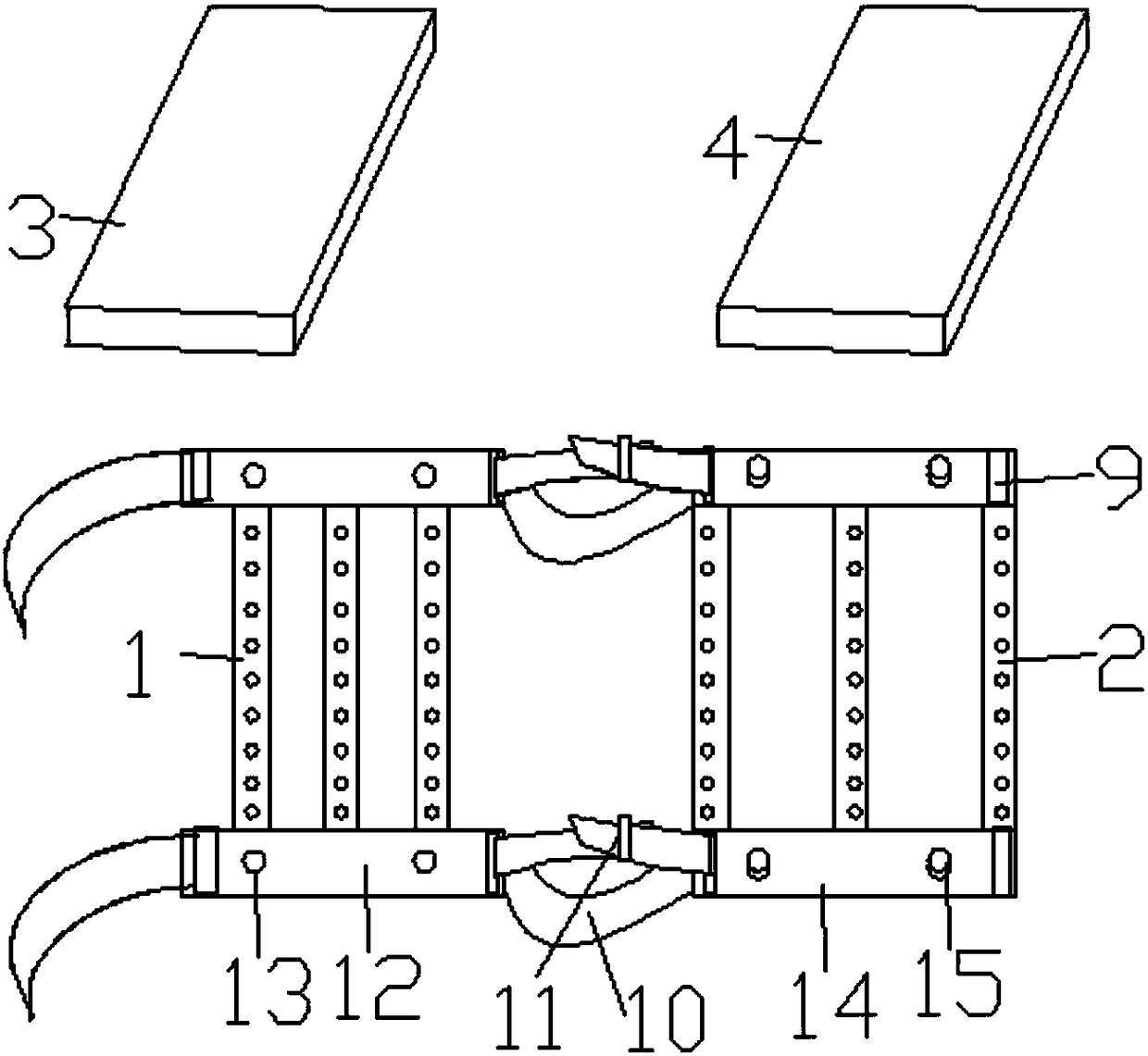

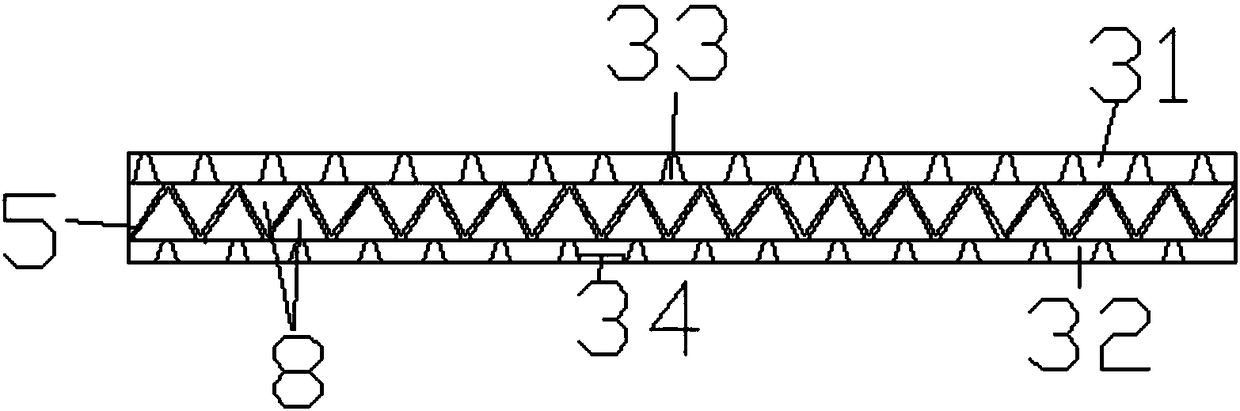

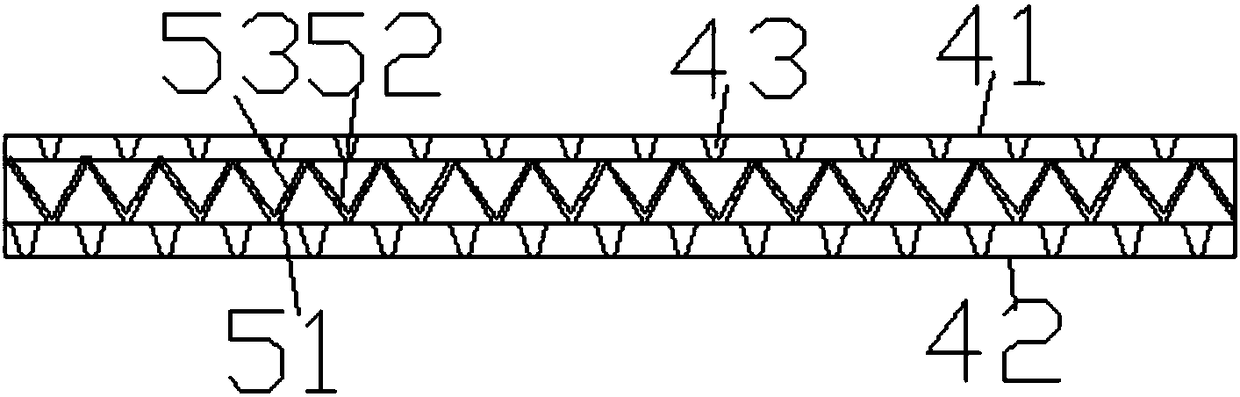

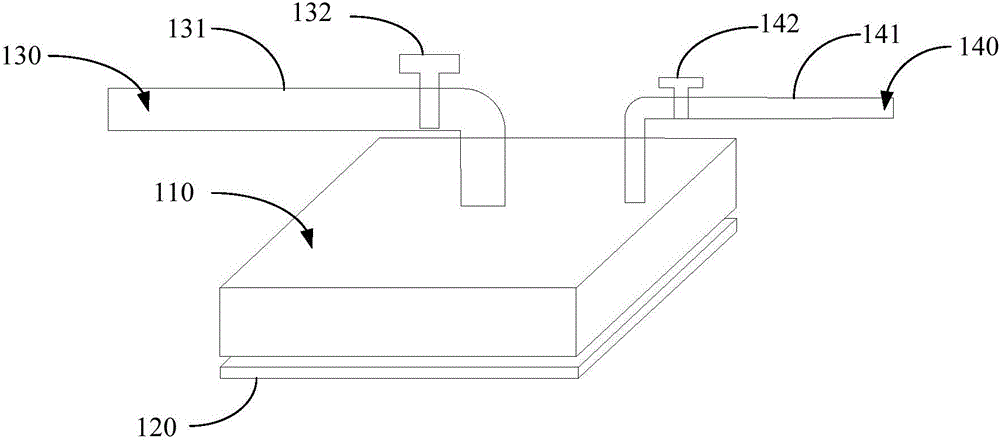

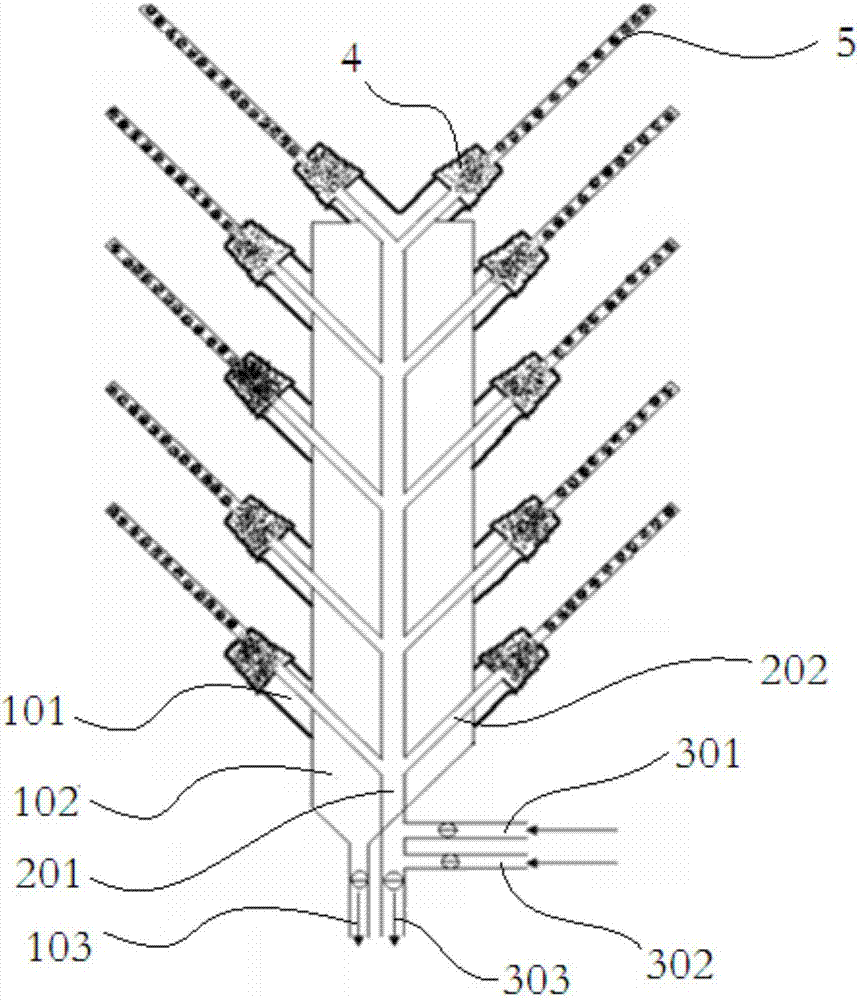

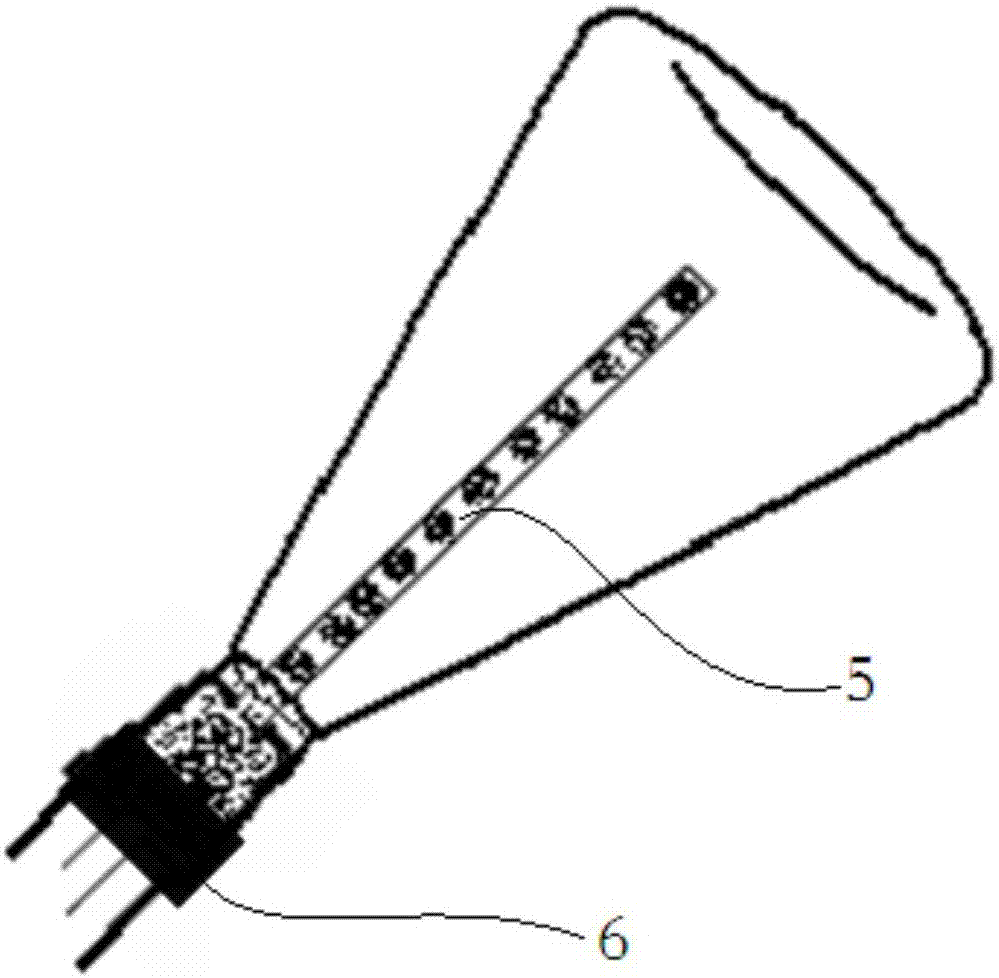

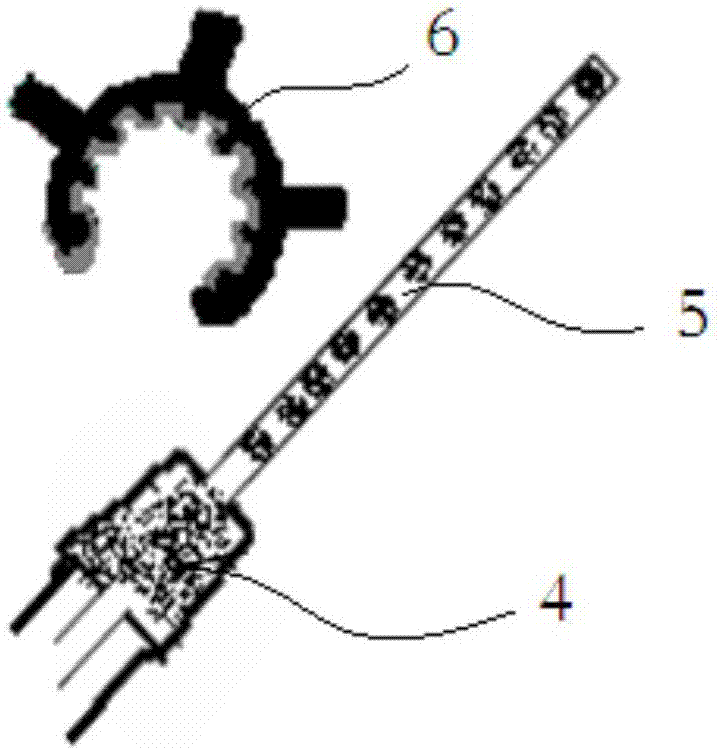

Plant specimen holder, specimen cabinet for fixing specimen holder, and fixing method for specimen holder

ActiveCN108184820ASpeed up the flowSpeed up the drying processDead plant preservationAir cycleBiochemical engineering

The invention discloses a plant specimen holder, a specimen cabinet for fixing the specimen holder, and a fixing method for the specimen holder. The plant specimen holder comprises clamping plates which are composed of a left clamping plate and a right clamping plate, wherein a left fixing plate is arranged in the left clamping plate and the a right fixing plate is arranged in the right clamping plate; an upper clamping piece and a lower clamping piece are arranged between the left clamping plate and the right clamping plate, and are internally provided with a V-shaped supporting plate separately; one side of the upper clamping piece and / or the lower clamping piece is provided with a moisture sensor; a controller is connected with the moisture sensor and an alarm; and the data detected bythe moisture sensor is transmitted to the controller, and the controller controls the operation of the alarm. The plant specimen holder of the invention can remind the related staff to replace absorbent paper; the upper clamping piece and the lower clamping piece are internally provided with the V-shaped support plates and vent holes, so the flowing of air is enhanced, and the drying process of aspecimen is accelerated; the specimen cabinet can simultaneously fix two sides and two ends of a plurality of specimen holders to prevent the occurrence of overturning and the like; and the specimen cabinet is provided with an air circulation device which quickly dehumidifies air in the cabinet to accelerate the flowing of the air and prevent specimens from mildew.

Owner:BEIJING FORESTRY UNIVERSITY

Drying device for chemical raw material processing

InactiveCN111854408AGuaranteed drying qualityAvoid accumulationDrying gas arrangementsDrying chambers/containersProcess engineeringDry box

The invention discloses a drying device for chemical raw material processing. The drying device comprises a drying box, a screening assembly and an air blowing assembly, wherein the screening assemblyand the air blowing assembly are arranged in the drying box; the screening assembly comprises a first swing screen and a second swing screen, each of the first swing screen and the second swing screen is provided with multiple sets of swing screen holes, and the hole of each swing screen hole on the first swing screen is greater than that of each swing screen hole on a second swing screen; the air blowing assembly comprises a dryer, the screening assembly further comprises two sets of driving device for driving the first swing screen and the second swing screen to swing. The first swing screen and the second swing screen with different swing screen hole diameters are adopted to drive raw materials falling on the first swing screen and the second swing screen to shake back and forth through mutual cooperation of an eccentric wheel, a gear and a rack; the raw materials are dried in a dispersion mode and collected in a classified mode, thereby guaranteeing the drying quality of the raw materials; by adopting the dryer and a horn mouth, the air is blown in the screening process in cooperating with a heating device, the contact area of the raw material and air is increased, the raw material can be heated evenly, the drying effect is improved, and the working efficiency is improved.

Owner:马恒

Road and bridge construction surface spraying device and spraying method thereof

InactiveCN108787220ASpeed up the drying processSpray evenlySpray nozzlesPretreated surfacesEngineeringBolt connection

The invention discloses a road and bridge construction surface spraying device. The road and bridge construction surface spraying device comprises a storage box for loading paint, a remote control vehicle for loading the storage box, a discharge cavity and a control device, wherein the control device is connected with the remote control vehicle in a bolted mode; the storage box is located above the remote control car, and the remote control vehicle is provided with a groove; the storage box is placed in the groove, and the storage box is fixedly connected with the groove; the storage box is detachably connected with the remote control vehicle through the groove, a material pumping pump is arranged on the right side of the storage box, and feed delivery pipes are connected to a feeding portand a discharging port of the material pumping pump; the feeding port and the discharging port of the material pumping pump are all connected with the corresponding feed delivery pipes on the feedingport and the discharging port in a bolted mode, the feed delivery pipes communicate with the discharge cavity, the feed delivery pipes are connected to the discharge cavity in a bolted mode, and thedischarge cavity is connected with a spraying pipe; and the spraying pipe is connected with the discharge cavity in a bolted mode, and the spraying pipe is provided with a spraying pump. The road andbridge construction surface spraying device can effectively spray uniformly.

Owner:芜湖薰衣草知识产权运营有限公司

Pressure-reducing heating and drying device

ActiveCN105783438AReduce the temperatureShorten the timeDrying solid materials with heatOptical filtersAtmospheric pressureElectrical and Electronics engineering

The invention discloses a pressure-reducing heating and drying device. The pressure-reducing heating and drying device comprises a cavity, a bearing mechanism, a heating mechanism, a pressure reducing mechanism and an air pressure adjusting mechanism; the bearing mechanism and the heating mechanism are arranged in the cavity; the pressure reducing mechanism and the air pressure adjusting mechanism communicate with the cavity; the cavity is used for covering the periphery of a substrate; the bearing mechanism is used for bearing the substrate in the state that the main face of the substrate faces upwards; the heating mechanism is used for heating the substrate; the pressure reducing mechanism is used for reducing pressure in the cavity when the heating mechanism heats the substrate; and the air pressure adjusting mechanism is used for adjusting the intensity of the pressure in the cavity when the intensity of the pressure in the cavity and the temperature of the substrate meet preset requirements, and therefore the intensity of pressure inside and outside the cavity can be balanced. In this way, the pressure-reducing heating and drying device can effectively accelerate the drying process, shortens the production process and saves the production cost.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Washing and blowing type washing rack

PendingCN107262470ASave human effortSave moneyHollow article cleaningDrying gas arrangementsEngineeringProcess engineering

The invention discloses a washing and blowing type washing rack. The rack is characterized by comprising a rack body, a built-in pipeline, an external pipeline, external grinding ports and hollow pipes; the rack body is composed of a plurality of body branches, a body and a waste liquid discharging pipeline provided with a valve. The numbers and positions of branch pipelines of the built-in pipeline correspond to those of the body branches. The branch pipelines penetrate through the corresponding body branches. The external pipeline is composed of a gas-liquid conveying pipeline provided with a valve, a cleaning fluid conveying pipeline provided with a valve, and a cleaning fluid discharging pipeline provided with a valve. The external grinding ports are mounted at the tops of the corresponding body branches. The hollow pipes are inserted into the corresponding external grinding ports and connected with the corresponding body branches. A plurality of spray holes are formed in the outer wall of each hollow pipe.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

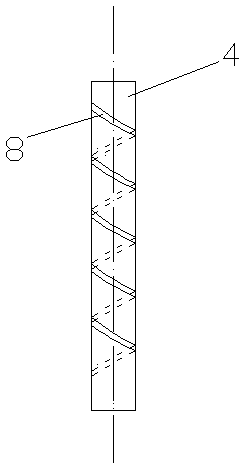

Laboratory pneumatic dryer

InactiveCN103629911AReduce drying blind spotsShorten drying timeDrying gas arrangementsHelical lineBlind zone

The invention relates to a laboratory pneumatic dryer which comprises a hollow cylindrical main body and a plurality of air outlet pipes arranged on the main body, wherein the main body contains an air supply device communicated with the air outlet pipes. The laboratory pneumatic dryer is characterized in that the side wall of each air outlet pipe is provided with a slit-like air outlet; and the air outlet represents a helical line shape around the air outlet pipe, and the axial line of the air outlet coincides with the axial line of the air outlet pipe. According to the pneumatic dryer provided by the invention, different from the traditional hole shape, the air outlet represents a helical line shape around the air outlet pipe, thereby reducing blind zones during vessel drying, shortening the fully drying time and realizing more thorough drying.

Owner:YIFENG CLEAN SCI & TECH JIANGSU

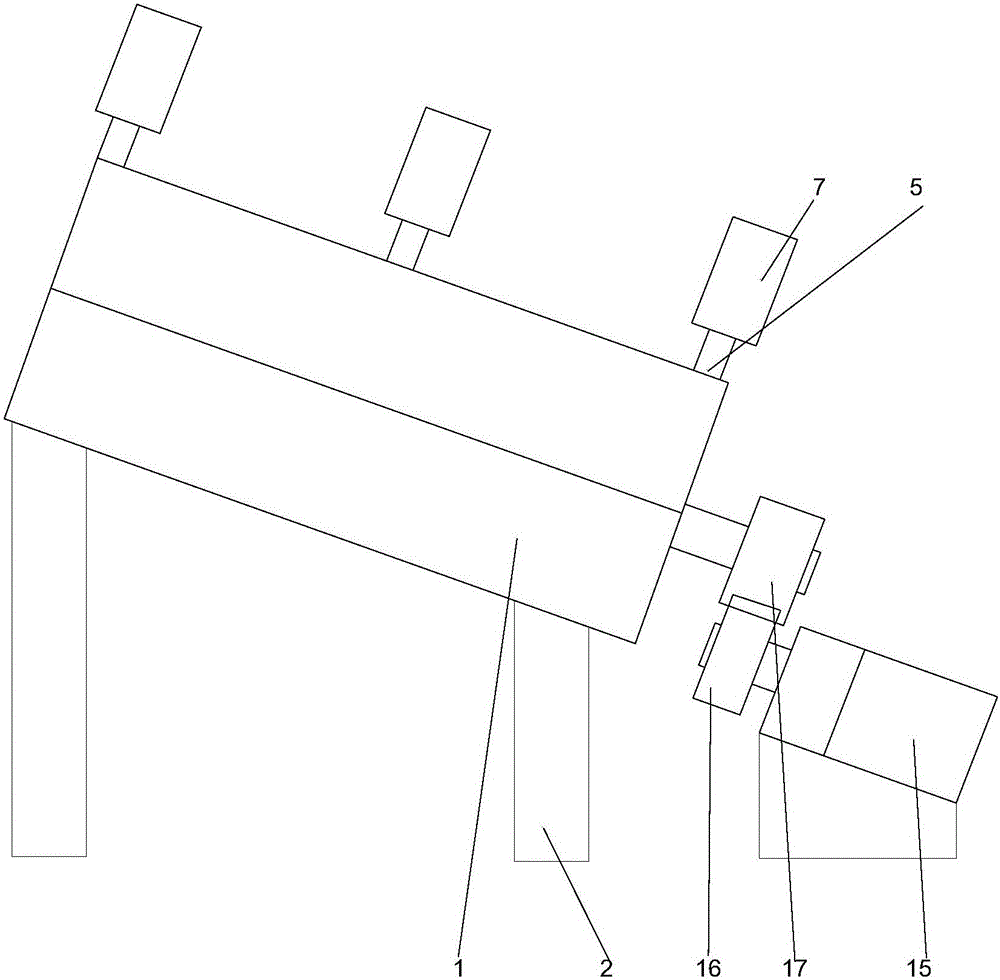

Drying device for manufacturing flour

InactiveCN105248628AIncrease the drying areaSpeed up the drying processSeed preservation by dryingGrain millingEngineeringSpiral blade

The application of the invention relates to a drying device, and discloses a drying device for manufacturing flour. The drying device comprises a conveyer, wherein a drying belt is arranged on the conveyer, a feeding hopper is arranged below the conveyer, a main shaft is arranged in the feeding hopper, a spiral blade is fixedly connected on the main shaft, a spiral pipe is communicated with an exit of the feeding hopper, a first electrical heating wire is arranged on the pipe wall of the spiral pipe, an opening is formed in a feeding hopper wall on a relative side of the spiral pipe, a fan is arranged in the opening, a ventilating hole is formed in the spiral pipe, a lifter is connected with one end, far away the feeding hopper, of the spiral pipe, and a discharge hole of the lifter is arranged on one side close to the conveyer. Compared with the prior art, the drying device provided by the application of the invention dries wheat without airing depending on weather and spreading, so that the wheat drying time is largely shortened, the labor intensity of farmers is reduced, and the drying efficiency is improved.

Owner:CHONGQING YUXI FLOUR PROD

Automatic dust removal equipment for electronic glass

InactiveCN112355011AImprove cleaning efficiencyEasy to cleanDrying solid materials without heatDrying gas arrangementsDust controlWater resources

The invention discloses automatic dust removal equipment for electronic glass. The automatic dust removal equipment comprises a base; two support plates are fixedly connected to the base; the tops ofthe two support plates are jointly and fixedly connected with a fixed plate; the top of the fixed plate is fixedly connected with a motor; a conveying mechanism is fixedly connected to the base; a cleaning mechanism is arranged between a transmission rod and the support plates; a drying mechanism fixedly connected with the support plates is arranged on the rear side of the cleaning mechanism; anda water circulation mechanism is arranged between the base and the fixed plate. The automatic dust removal equipment for the electronic glass provided by the invention is reasonable in structure, theto-be-dedusted circular electronic glass with different radiuses can be conveyed through the conveying mechanism, and the dedusting efficiency is improved; the whole outer wall of the electronic glasscan be cleaned through the cleaning mechanism, and the cleaning range is wide; liquid on the electronic glass can be dried through the drying mechanism, so that the next procedure can be convenientlycarried out; and water after cleaning can be collected and recycled through the water circulation mechanism, so that water resources are saved.

Owner:德清县诚达金属材料有限公司

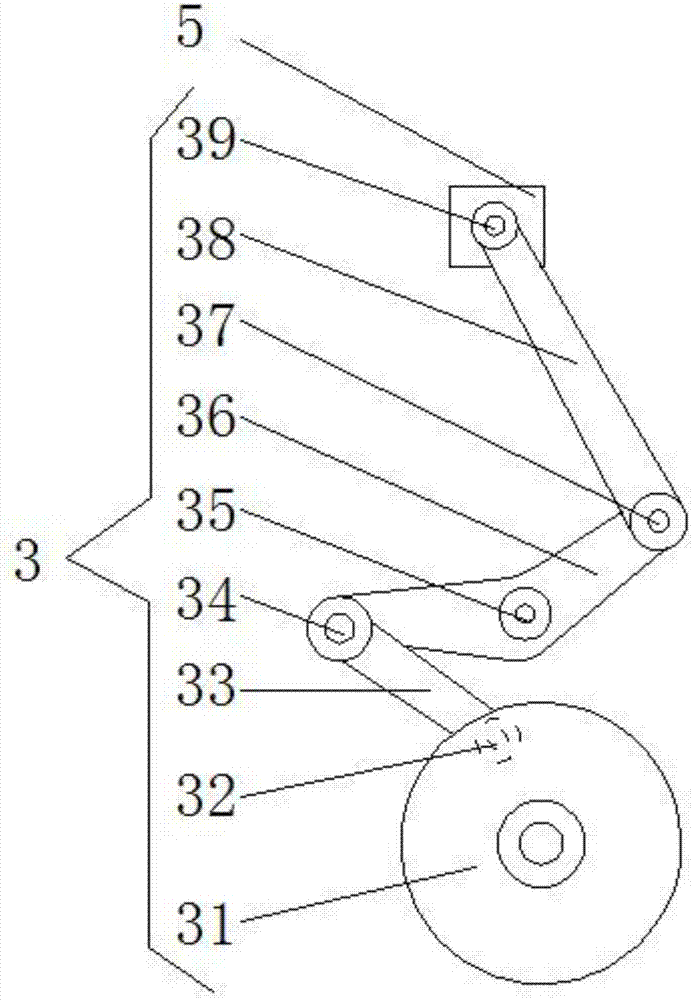

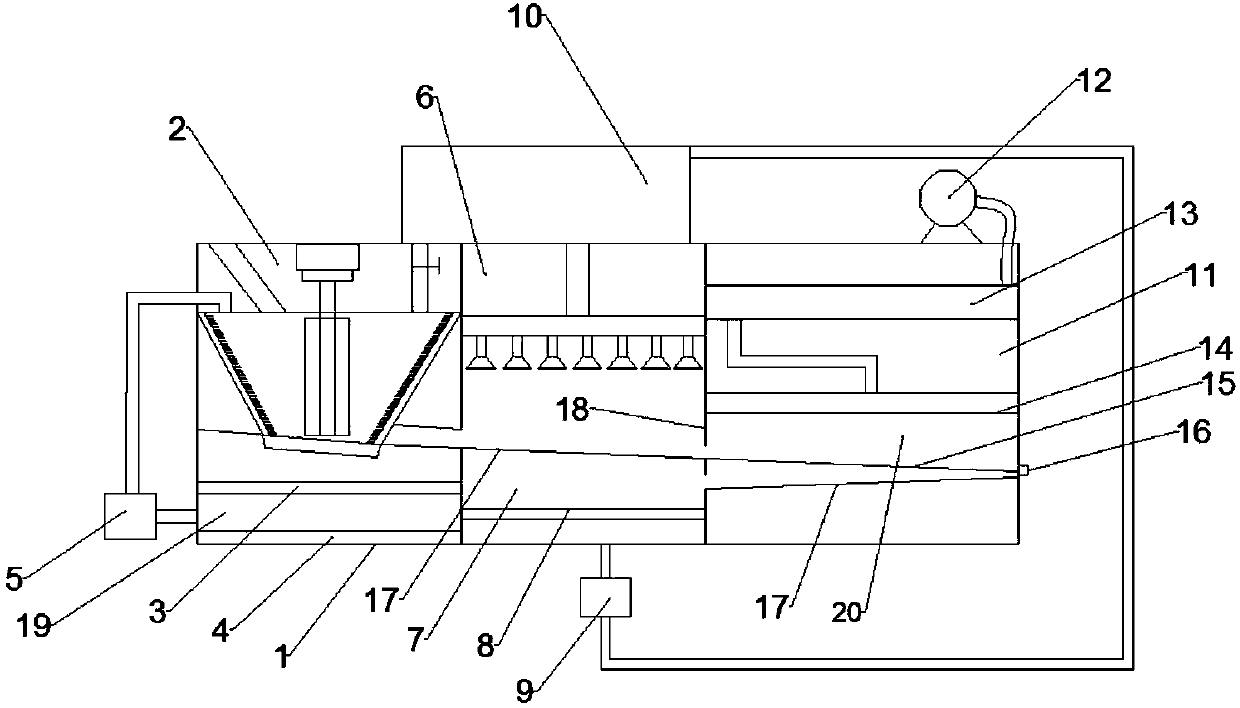

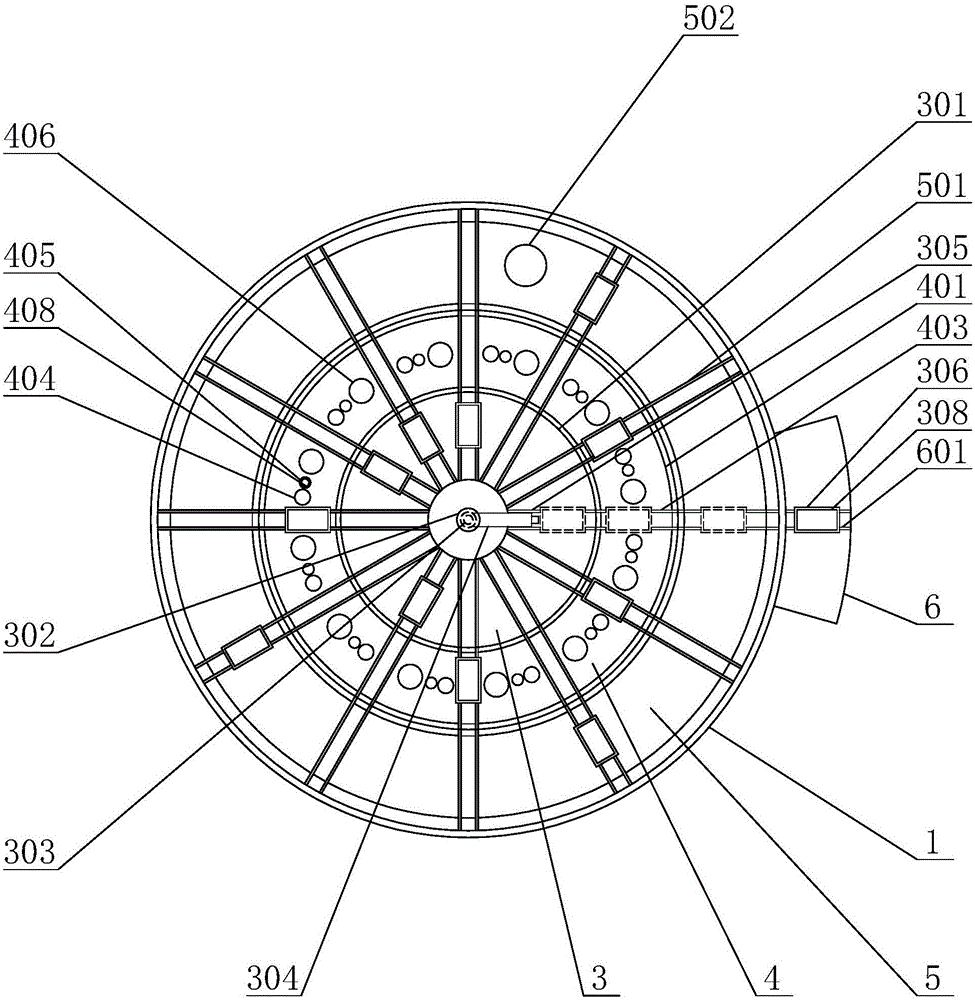

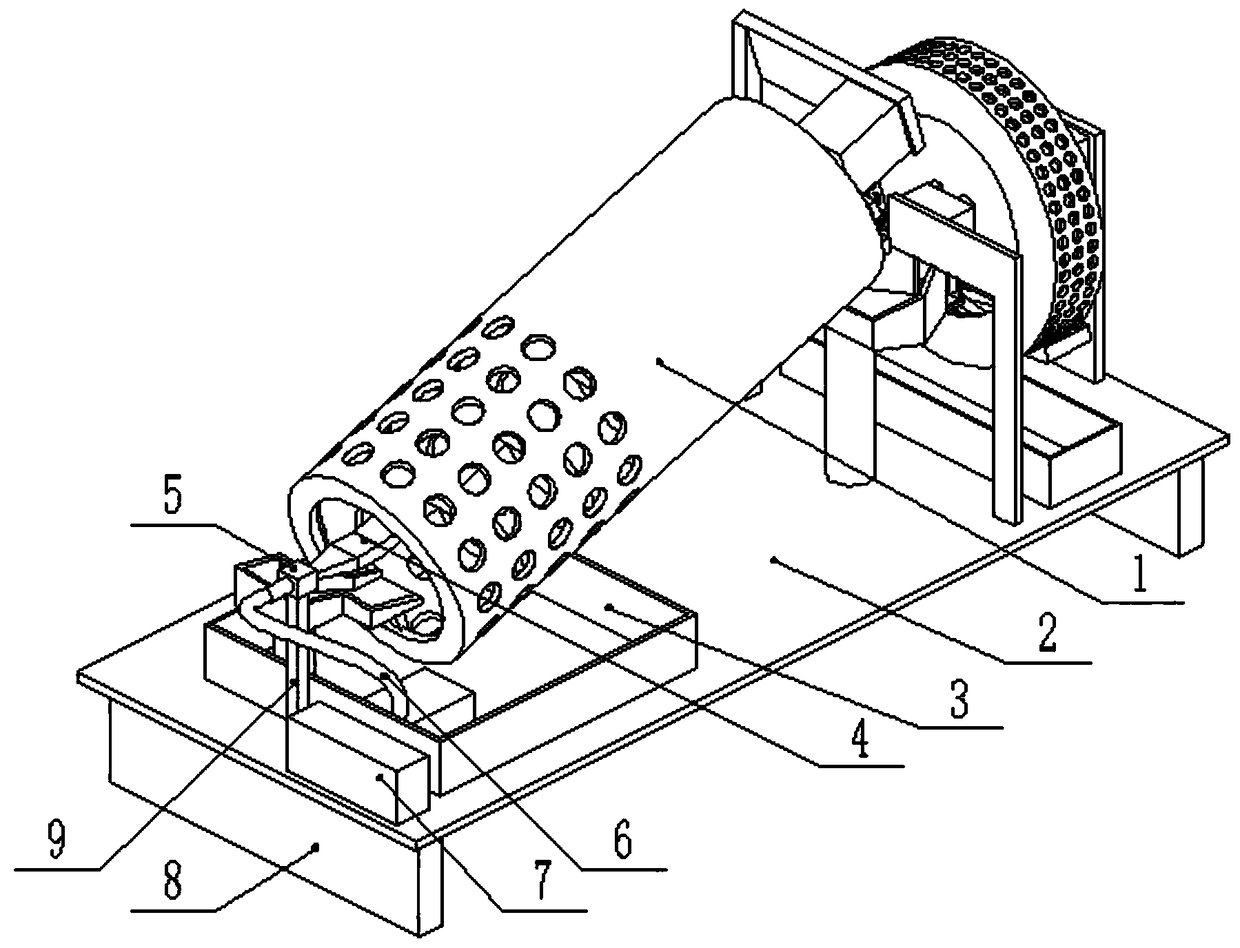

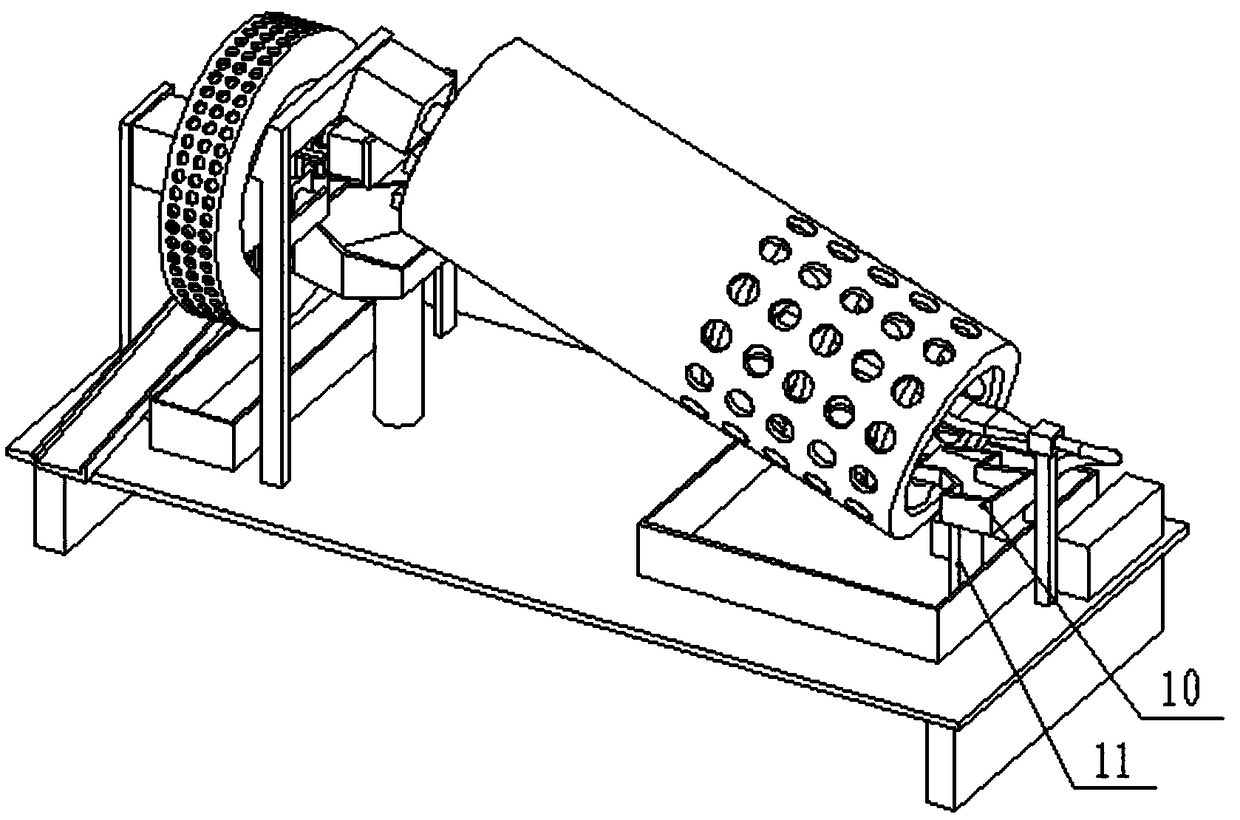

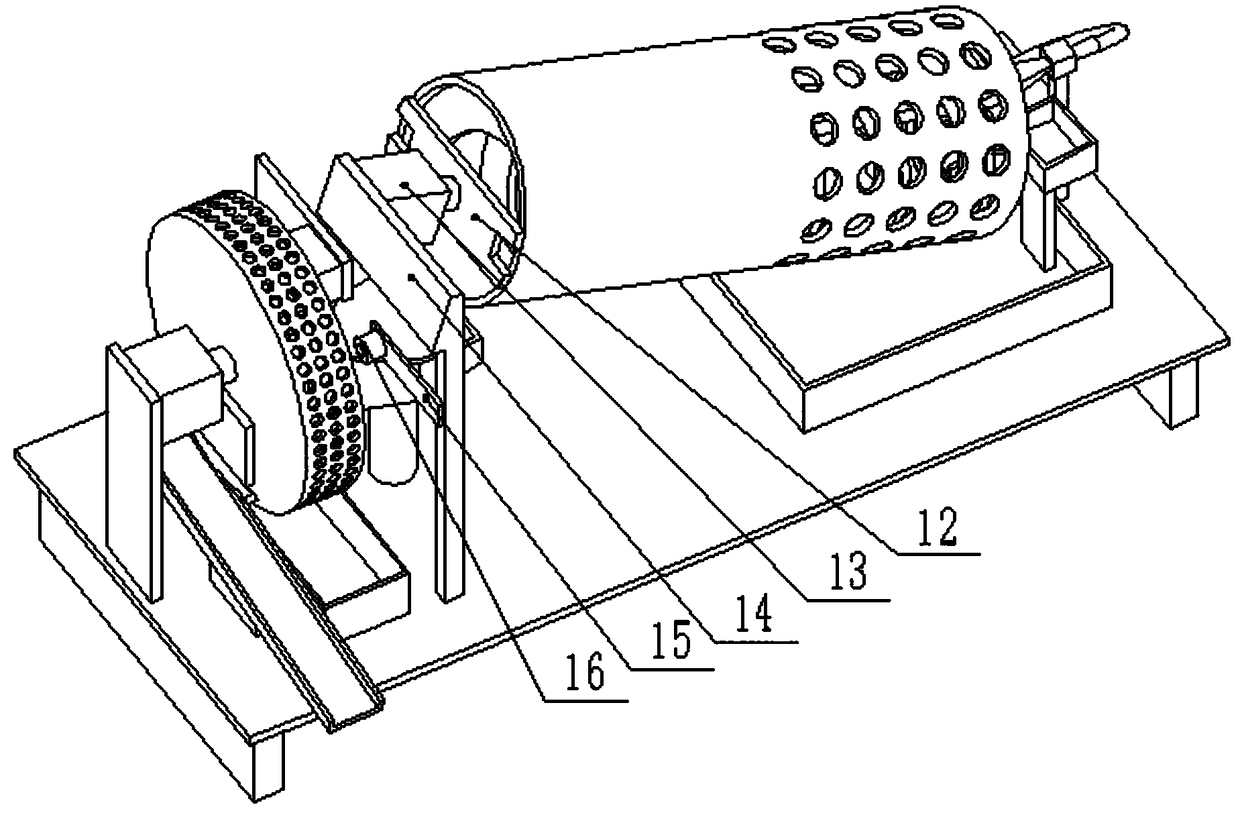

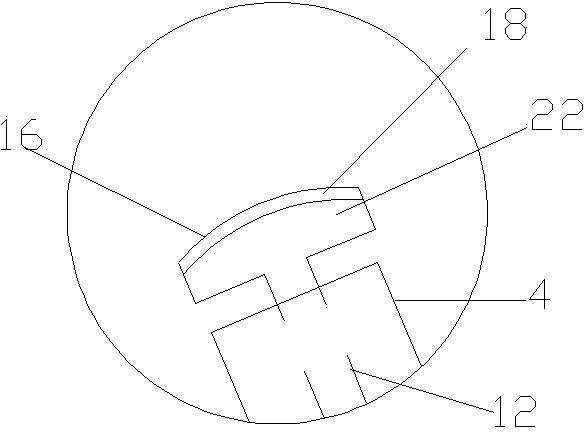

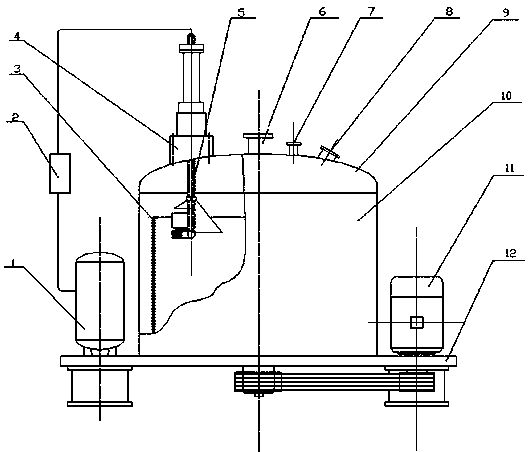

Efficient filtering centrifuge capable of conducting air blowing

ActiveCN107262297AEasy to separateIncrease evaporation areaRotary centrifugesFilter mediaEvaporation

The invention discloses an efficient filtering centrifuge capable of conducting air blowing, and relates to a centrifuge. The filtering centrifuge comprises a centrifuge base (12), a centrifuge shell (10), a centrifuge cover (9), a rotary drum assembly (3), a power mechanism (11) and an air blowing system. The centrifuge cover (9) is provided with a feeding inlet (6), an air outlet (7), a viewport (8) and a scraper blade seat (4). A scraper blade rod (16) is arranged on the scraper blade seat, a mechanical transmission mechanism or a hydraulic transmission mechanism is arranged in the scraper blade seat, the scraper blade rod is a hollow pipe and is connected with a heater and an air compressor through hoses, and an umbrella-shaped baffle (17) is installed on the lower portion of the scraper blade rod (16). According to the efficient filtering centrifuge, a block-shaped filter cake is scraped off from a filtering medium through a scraper blade and then stirred to be loosened through a blade body, meanwhile, air is blown into a rotary drum through the air compressor, thus, surface liquid and capillary liquid are released, the moisture evaporation area is increased, and the drying process is accelerated. After air blowing, centrifugal filtering operation is repeated again, efficient filtering is achieved, and the product moisture content is decreased.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com