Particle material drying and mixing equipment

A technology for mixing equipment and granular materials, which is applied in drying solid materials, dry cargo handling, non-progressive dryers, etc. It can solve the problems of product quality impact and insufficient drying of materials, and achieve the effect of increasing temperature and accelerating drying process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

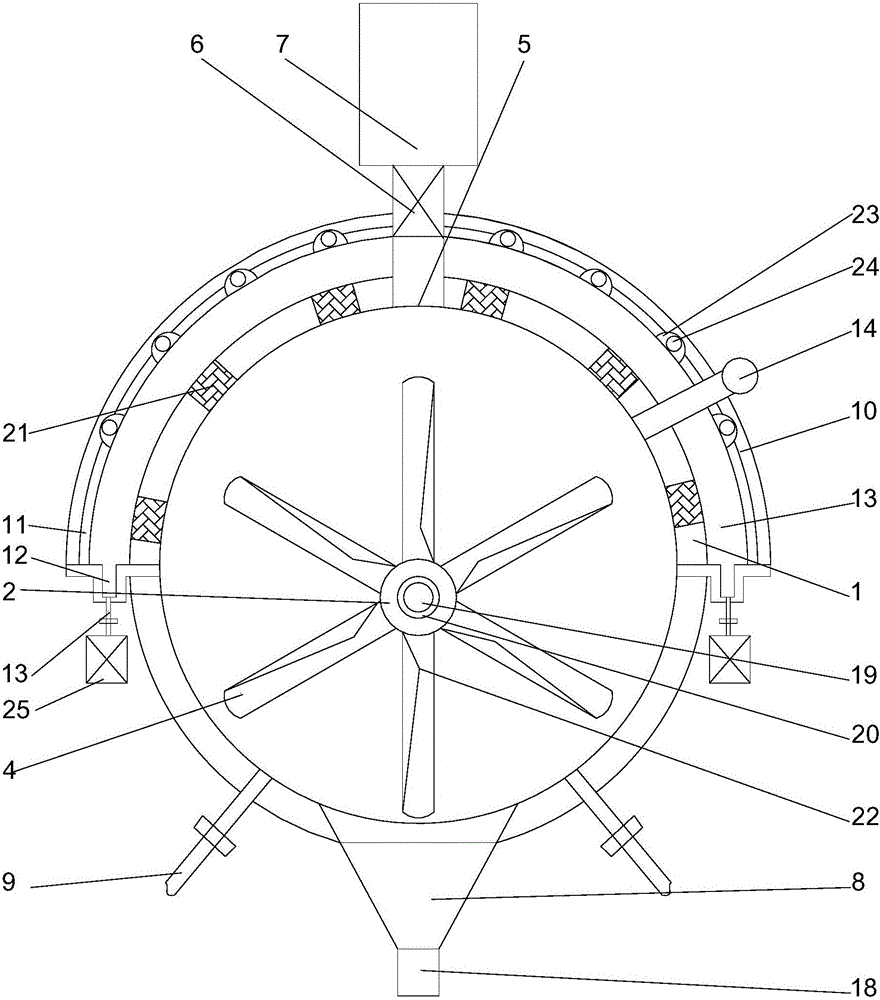

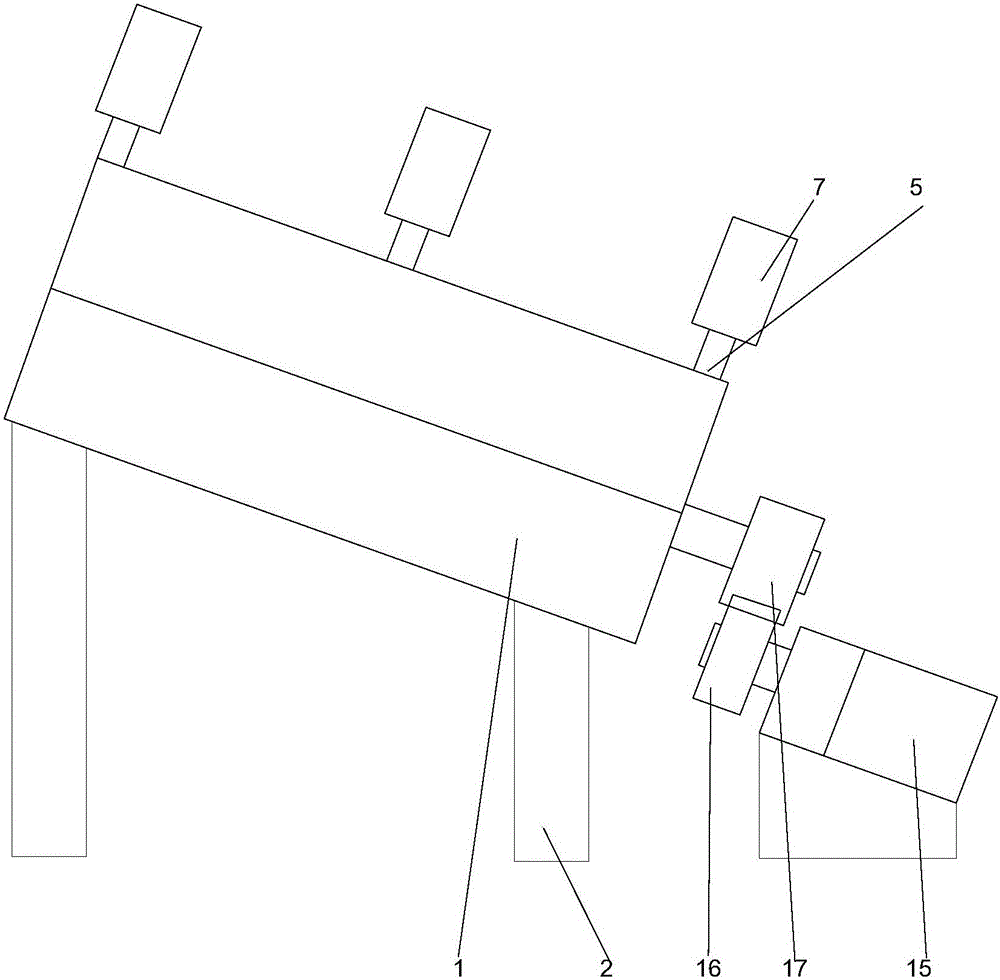

[0022] like figure 1 As shown, 1. A granular material drying and mixing equipment, comprising a hollow cylindrical drying bin and a bracket 2 arranged below the drying bin, a rotating shaft 3 is arranged inside the drying bin, and the The axis of the rotating shaft and the axis of the drying bin form an eccentric structure, and at least four blades 4 are arranged on the rotating shaft. During the rotation of the blades, the outer edges of the blades can be attached to the On the inner wall of the lower end of the drying bin, the upper end of the drying bin is provided with a feeding port 5, and the feeding port is at least 2 arranged at equal intervals along the length direction of the outer wall of the drying bin. The inside of the feed inlet is provided with a star valve 6, a vibrating feeder 7 is arranged on the feed inlet, and a discharge port 8 is arranged below the drying bin. A discharge valve 18 is arranged on the top, an air inlet is arranged on the side of the disch...

Embodiment 2

[0025] This embodiment is based on Embodiment 1, in order to speed up the drying speed, in this embodiment, preferably, a cavity 20 is provided in the middle of the rotating shaft, and an electric heater 19 is provided in the cavity. The rotating shaft is heated by an electric heater, so that the particulate matter can exchange heat during contact with the rotating shaft, and at the same time help to increase the internal temperature of the drying cylinder and accelerate the drying process.

[0026] In this embodiment, in order to avoid easy wear of a single blade due to uneven material distribution between adjacent blades, preferably, through holes are provided on the blades. The drying efficiency can be improved by making the material flow between the adjacent blades through the through holes.

[0027] In order to make the materials move relative to each other when the blades are in contact with each other, and accelerate the sufficient mixing and collision between the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com