Patents

Literature

98results about How to "Realize quantitative feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for quantitatively mixing double chemical liquid reagents

PendingCN107511100ARealize interval feedingChange direction of agitationMixing methodsTransportation and packagingGear wheelDrive motor

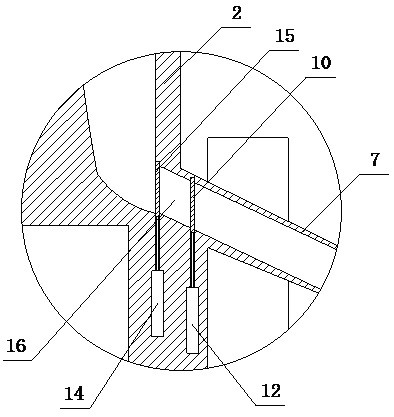

The invention discloses a device for quantitatively mixing double chemical liquid reagents. The device comprises a mixing box, a material adding motor, a feeding turnplate, a first drive motor, a cam, a second drive motor and a ripple spoiler, wherein the upper side of a support post is fixedly provided with the mixing box, the lower end of an output shaft of the material adding motor is fixedly connected with the feeding turnplate, a stirring shaft is also fixedly provided with a gear, the rear side of the gear is meshed with a rack, the left and right sides of the rack are provided with pothooks, the pothook is connected with a connecting rope, a housing of the left side of the mixing box is further slidingly provided with a connecting rod, and the connecting rod extends into the mixing box and is fixedly connected with the ripple spoiler. By adopting the liquid mixing device, material adding at intervals can be realized, and quantitative material adding can be realized by controlling the rotary speed of the material adding motor; spoiling can be performed inside the mixing box by the ripple spoiler, so that a layering phenomenon appearing during mixing can be effectively avoided, and the mixing effect is improved to the greatest extent.

Owner:ZHENGZHOU UNIV

Cast-welding method for lead-acid storage battery tabs

InactiveCN105290378ARealize quantitative feedingSave solderEnvironmental resistanceElectrical battery

The invention discloses a cast-welding method for lead-acid storage battery tabs. The cast-welding method comprises the following steps that a storage battery pole plate is placed on a cast-welding mold which is at least provided with a mold cavity; a certain amount V of molten lead liquid is injected to the side face or the bottom of the mold cavity through a communicating tube, and the lead liquid amount V is the lead liquid amount needed for tab welding in the cast-welding mold; a lead rod and an induction heating device are arranged at an inlet of the communicating tube; the induction heating device quickly heats a section of lead rod to form lead liquid, and the lead liquid drops into the communicating tube and injected into the mold cavity; and then tab cast-welding operation is conducted. According to the cast-welding method for the lead-acid storage battery tabs, cast-welding lead liquid is supplied quantitatively through pipeline lead supplying, and the requirement for the lead liquid amount for cast-welding of a set of battery tabs in the mold is met; lead rod induction heating is used for lead liquid conveying, and quantitative material supply is achieved, so that the method has the advantages of power saving, environmental protection, welding material saving and the like.

Owner:厦门华海大正电池装备有限公司

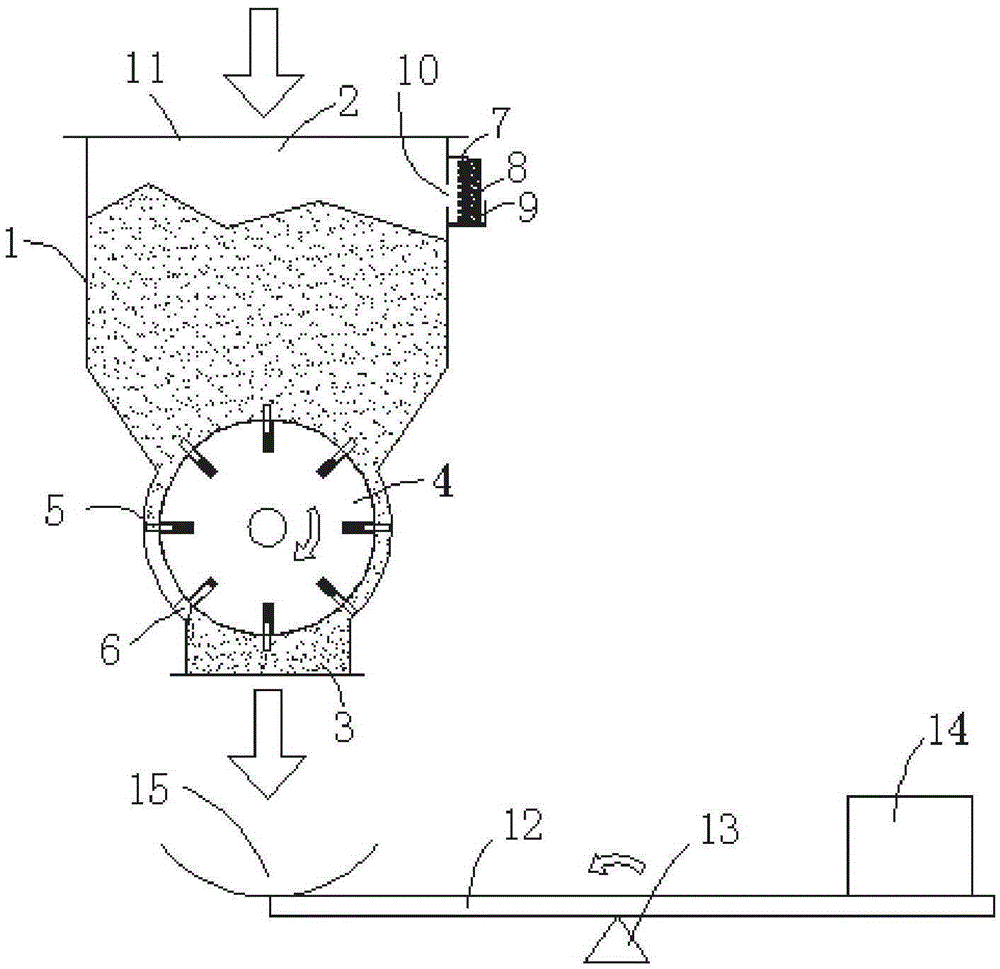

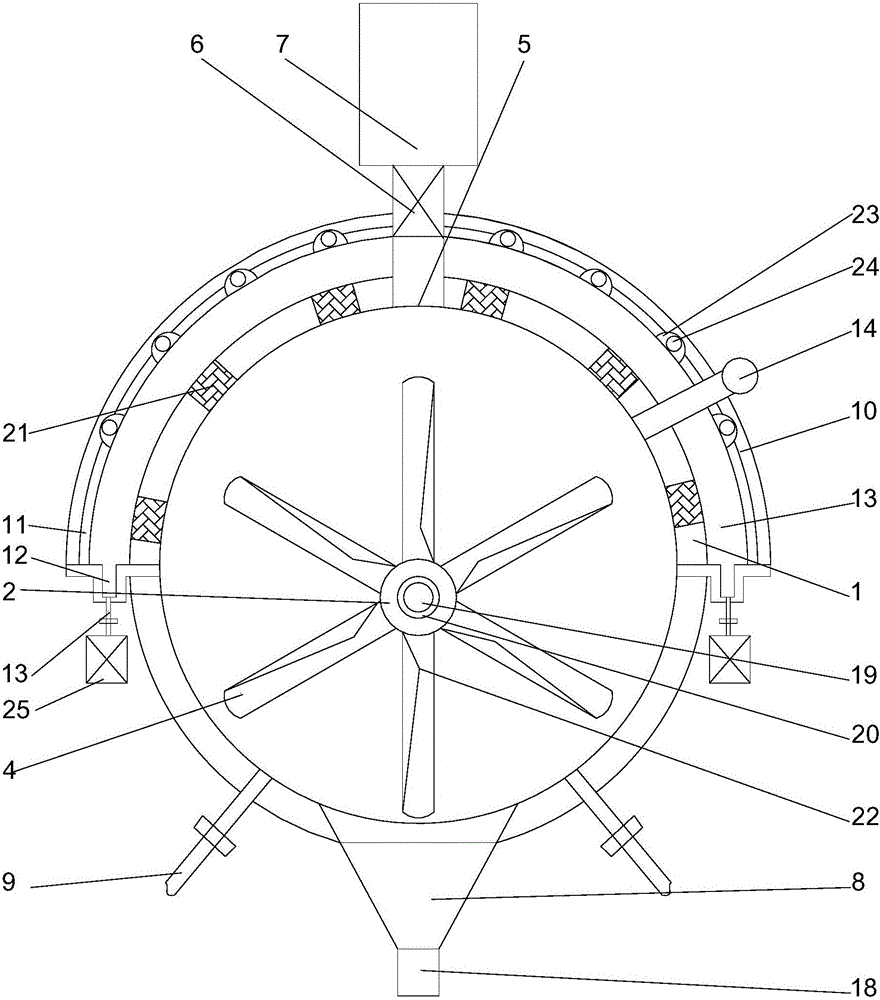

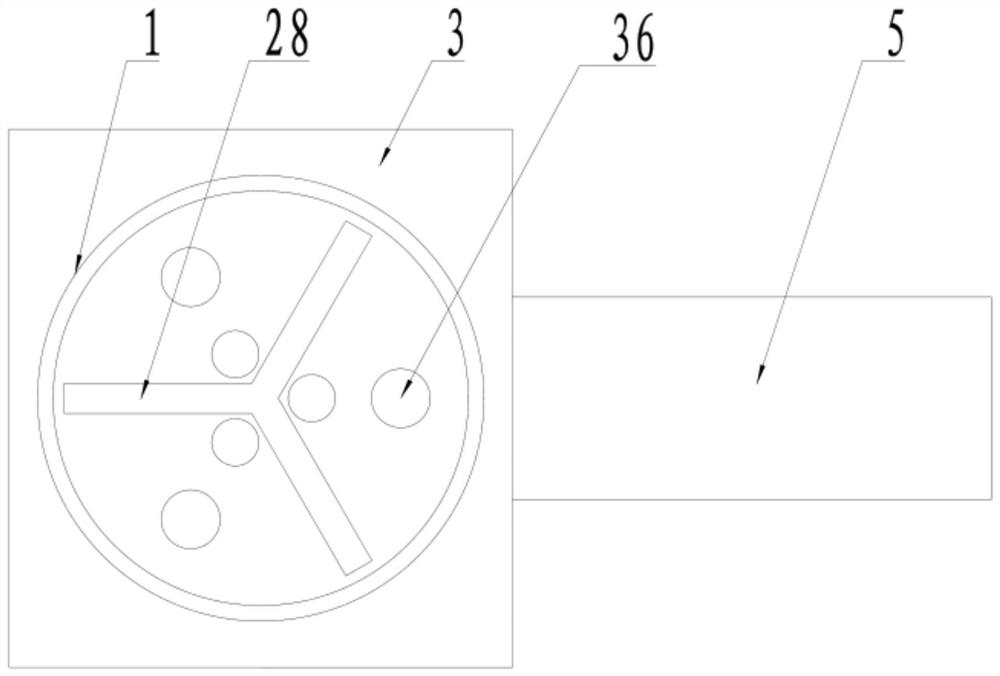

Flocculant feeding device

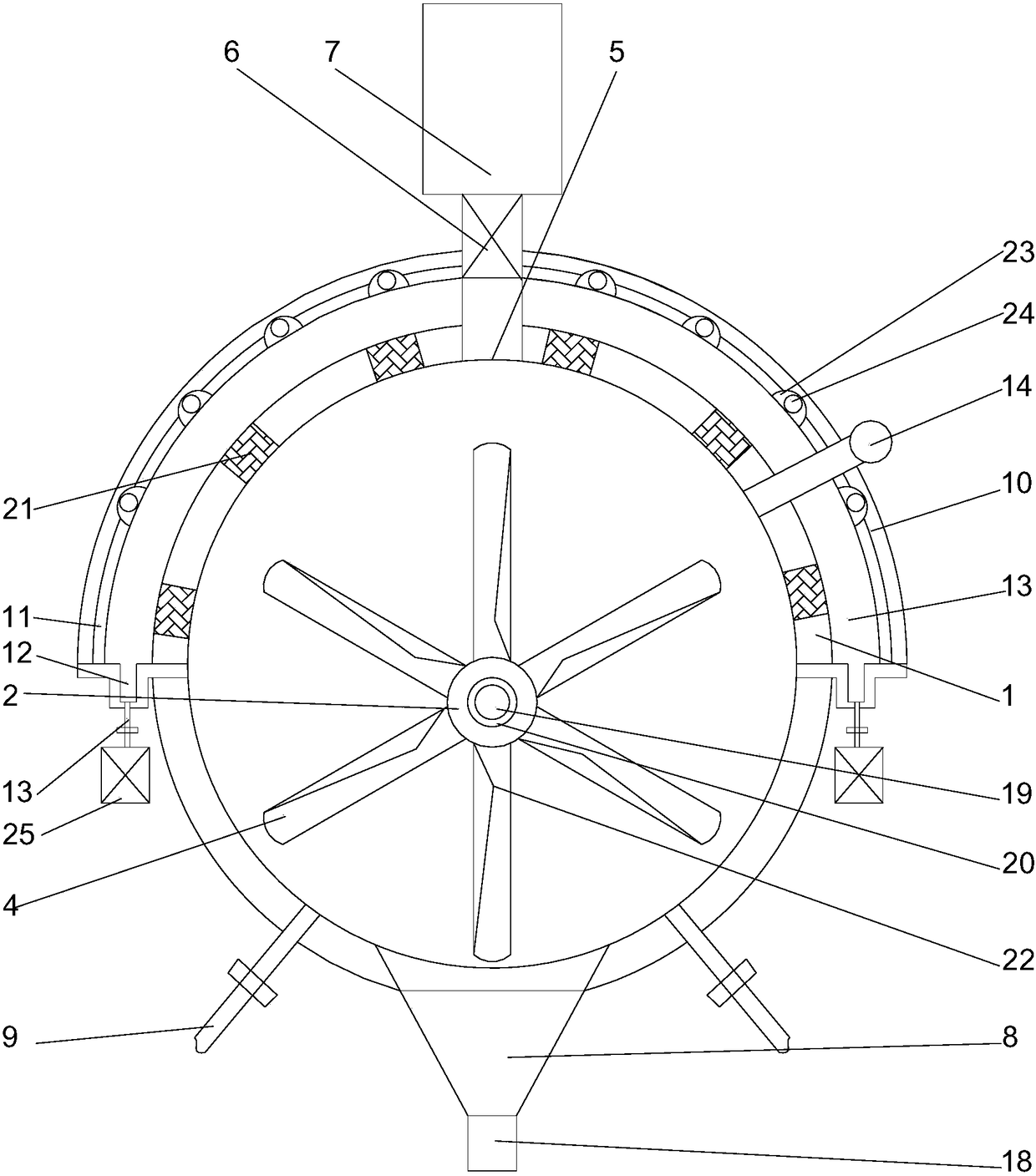

ActiveCN105346877AImprove sealingNot susceptible to moistureLarge containersTank wagonsImpellerEngineering

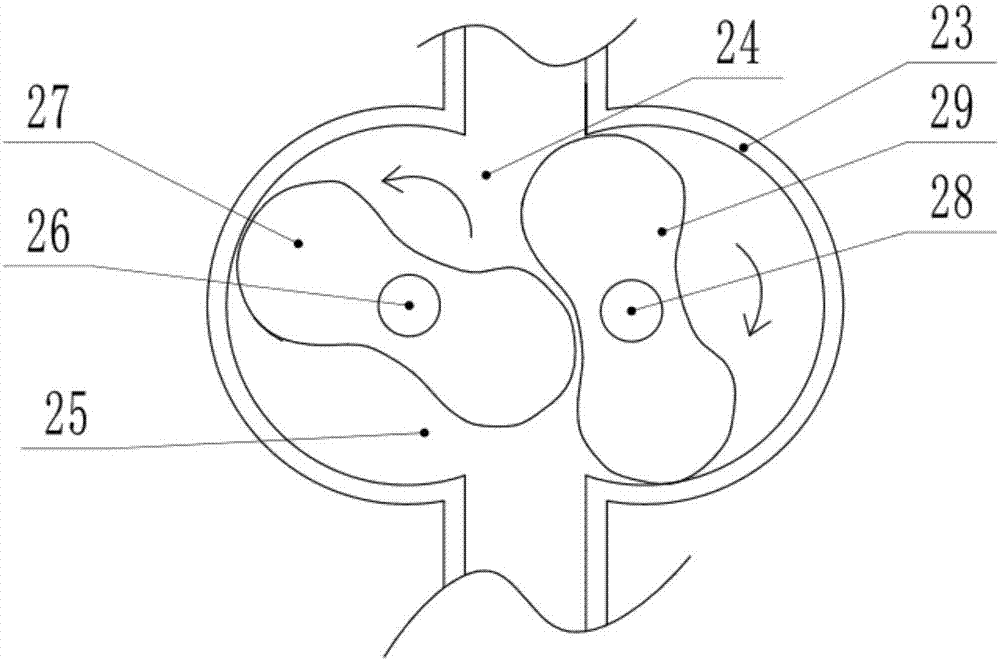

The invention discloses a flocculant feeding device which includes a bin, an impeller rotor and a cooling dehumidification device, wherein a feeding hole is formed in the top of the bin; a discharge outlet is formed in the bottom of the bin; the impeller rotor is arranged in the bin, and when the impeller rotor does not rotate, the discharging outlet is blocked by the impeller rotor, and when the impeller rotor rotates, the impeller rotor drives the material to be discharged; the cooling dehumidification device is installed on the side wall, close to the feeding hole, of the bin and comprises an evaporator, a refrigeration chip and a water absorption layer. The refrigeration chip cools the air in the bin via the evaporator, and the water absorbing layer adsorbs the cooled water and discharges the water out of the bin. The flocculant feeding device has good seal performance, ensures the drying of a flocculant, reduces the agglomeration phenomenon caused by damp, can still run normally after affected with damp to further guarantee the accuracy of the dose of the flocculant, and is simple and reliable in structure.

Owner:苏州依斯倍环保装备科技有限公司

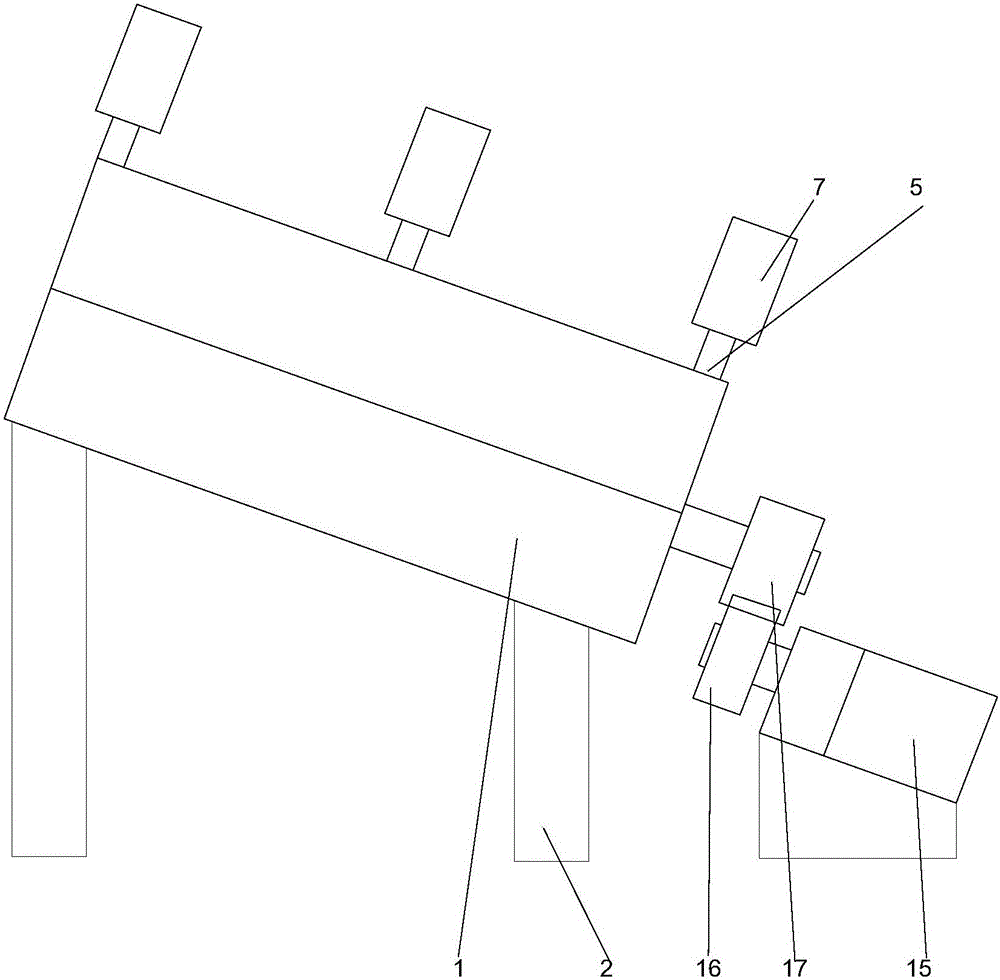

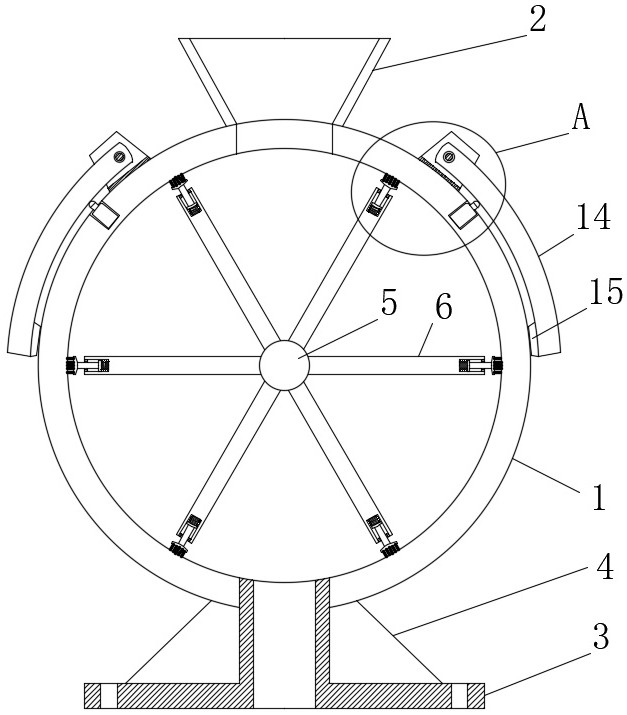

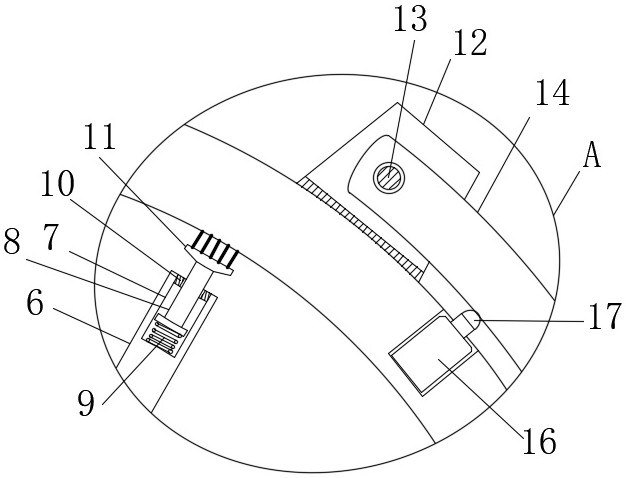

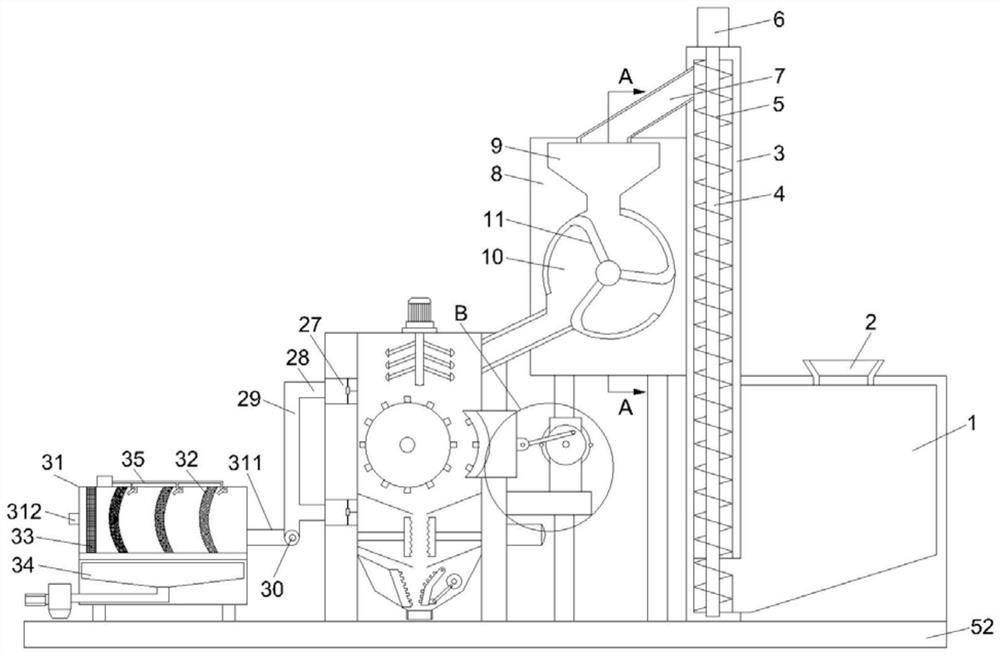

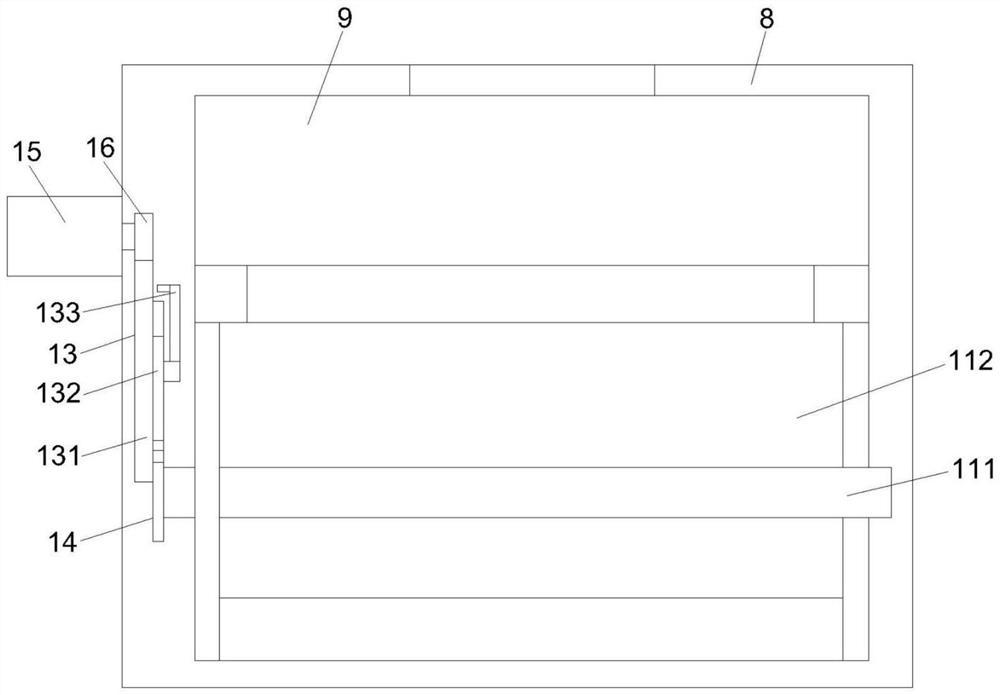

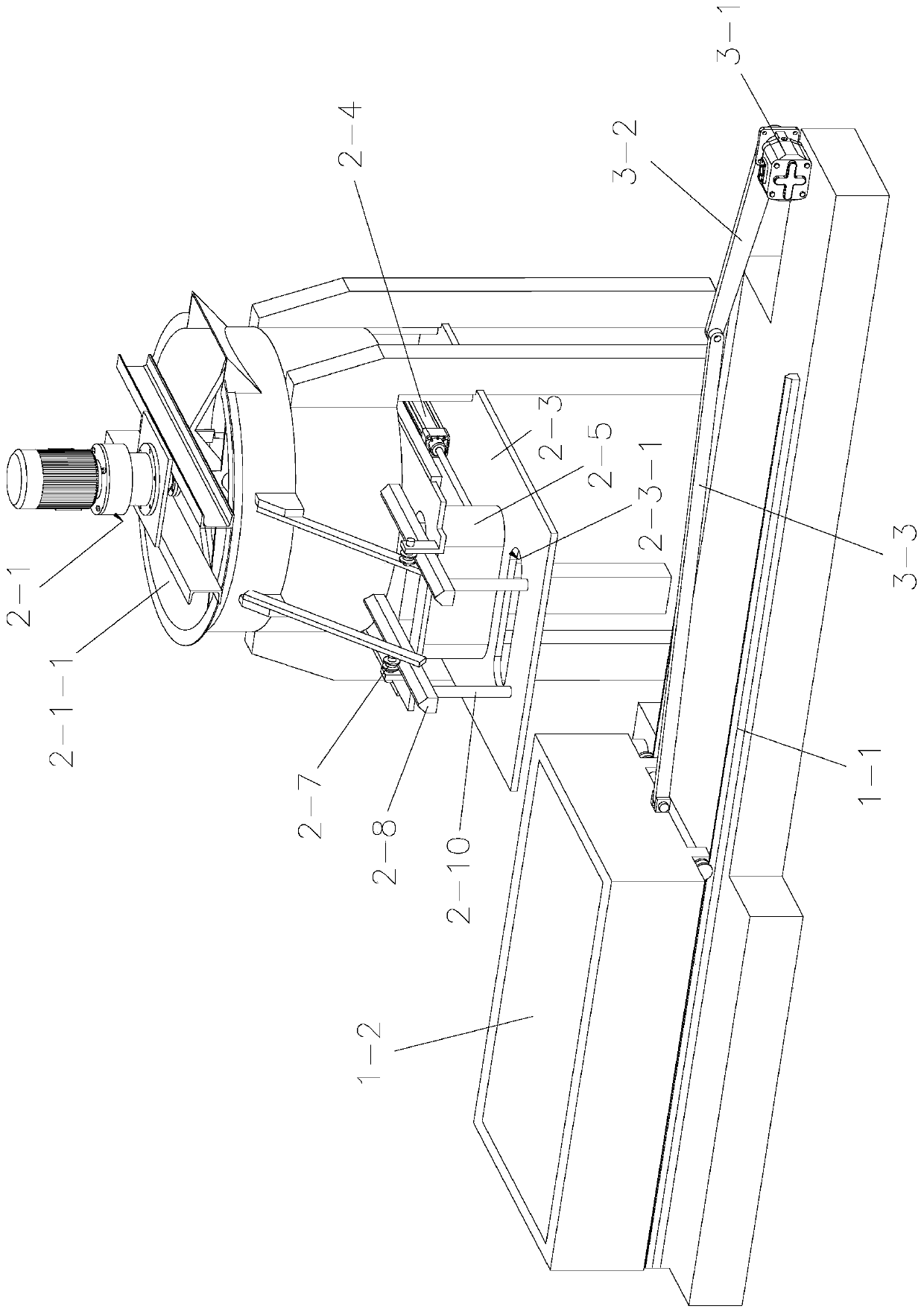

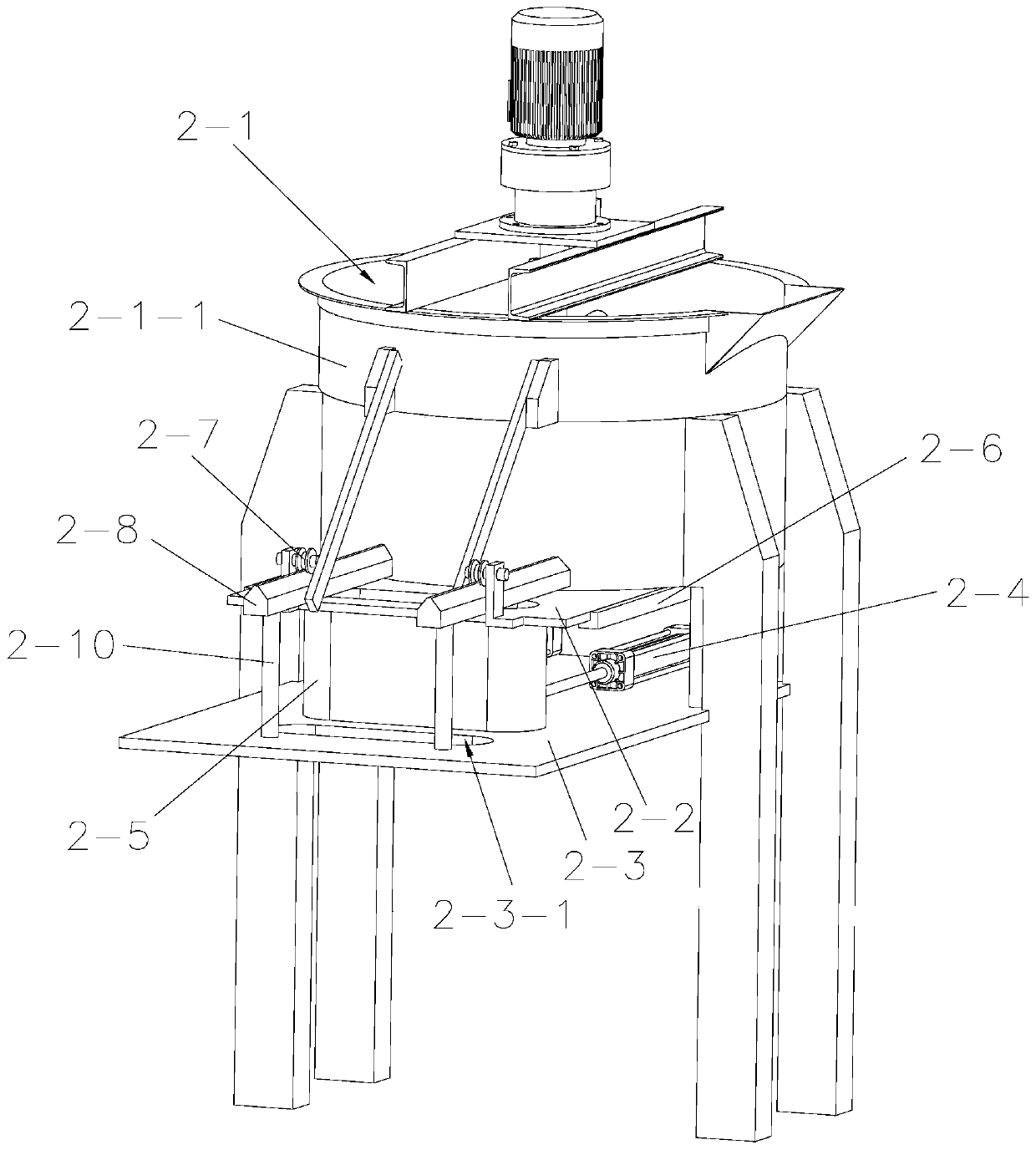

Particle material drying and mixing equipment

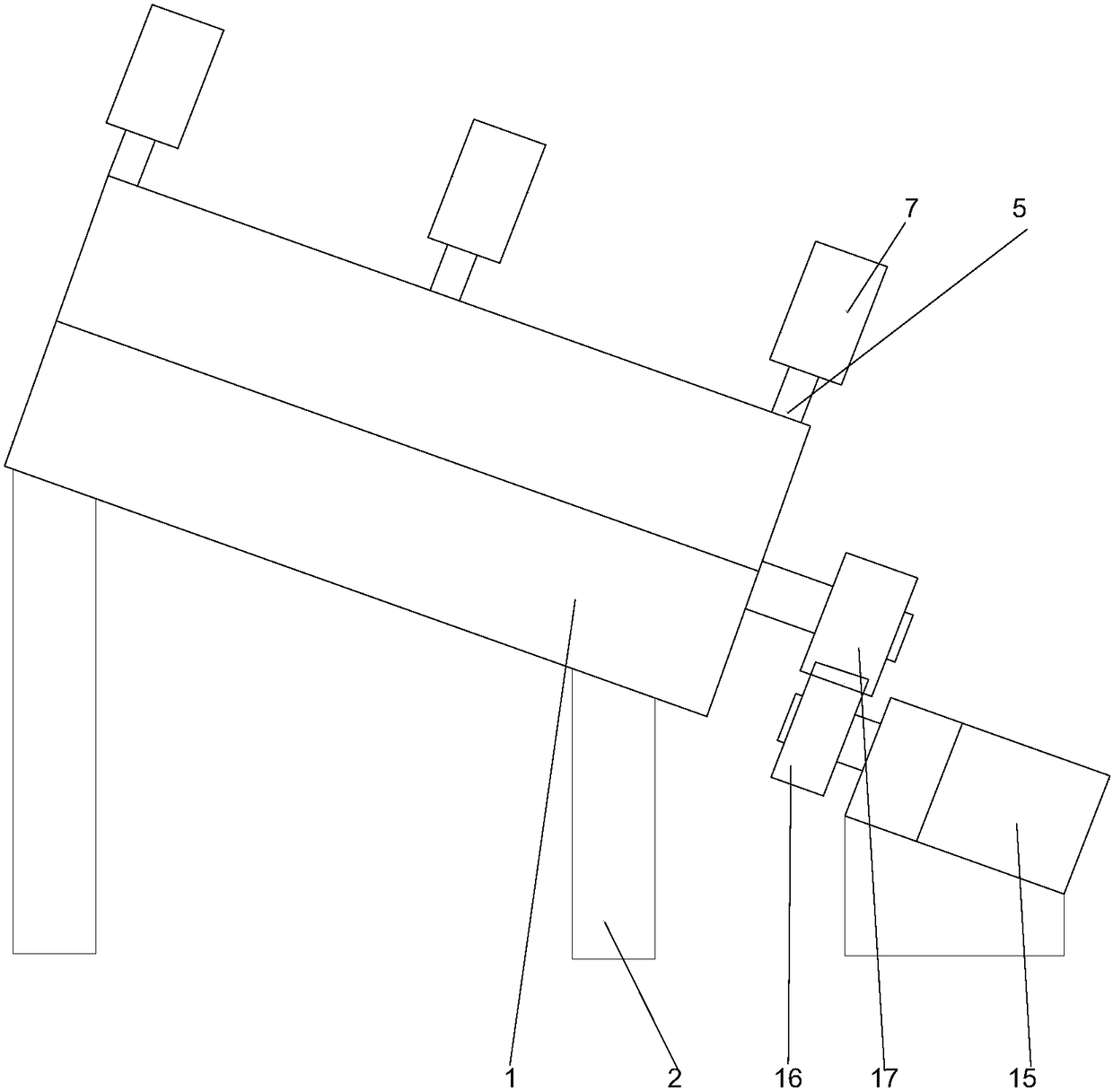

ActiveCN105806059AIncrease temperatureSpeed up the drying processDrying machines with non-progressive movementsDrying solid materialsParticle materialPulp and paper industry

The invention discloses particle material drying and mixing equipment. The equipment comprises a hollow cylindrical drying bin, and a bracket arranged below the drying bin; a rotating shaft is arranged on the inner side of the drying bin; the axis of the rotating shaft and the axis of the drying bin form an eccentric structure; at least four blades are arranged on the rotating shaft; in the rotating process of the blades, the outer side edges of the blades can be bonded on the inner wall of the lower end of the drying bin; and a feed port is formed in the upper end of the drying bin. As the rotating shaft and the drying bin are eccentrically arranged, in the rotating process of the blades, materials at the bottom of the drying bin can be totally driven to one side of an isolation cover at the upper part when passing through the bottom of the drying bin, and water in particle materials with water is output by a water collecting tank in the isolation cover in a concentrated manner; and the equipment is simple in structure and more uniform in drying of the materials.

Owner:山东艾克赛尔机械制造有限公司

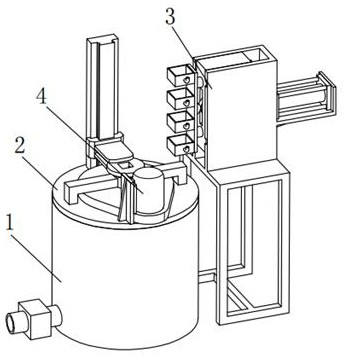

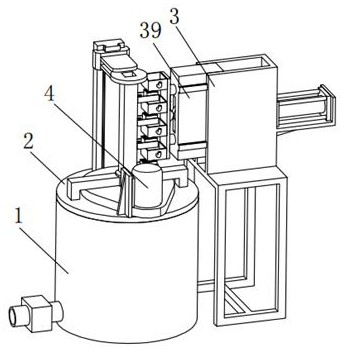

Particle material drying robot

InactiveCN106802066AAchieve conversionAchieve recyclingDrying solid materials with heatGranular material dryingEngineeringMechanical engineering

The invention provides a particle material drying robot which comprises a feeding mechanism, a stoving mechanism arranged on the rear portion of the feeding mechanism, a drying mechanism arranged on the upper portion of the drying mechanism, a discharging mechanism arranged on the rear portion of the stoving mechanism, and a control mechanism in signal connection with the feeding mechanism, the stoving mechanism, the drying mechanism and the discharging mechanism. To avoid the phenomena that in the prior art, drying efficiency is low and energy consumption is high during drying, the stoving mechanism is used for stoving materials, the feeing mechanism and the discharging mechanism are used for feeding and outputting the materials, the drying mechanism is used for rapidly recovering moisture in the materials, energy conversion and recovery are achieved while moisture is condensed and falls through a heat exchanger, and the drying effect is guaranteed while rapid drying is achieved.

Owner:ZHONGZHOU UNIV

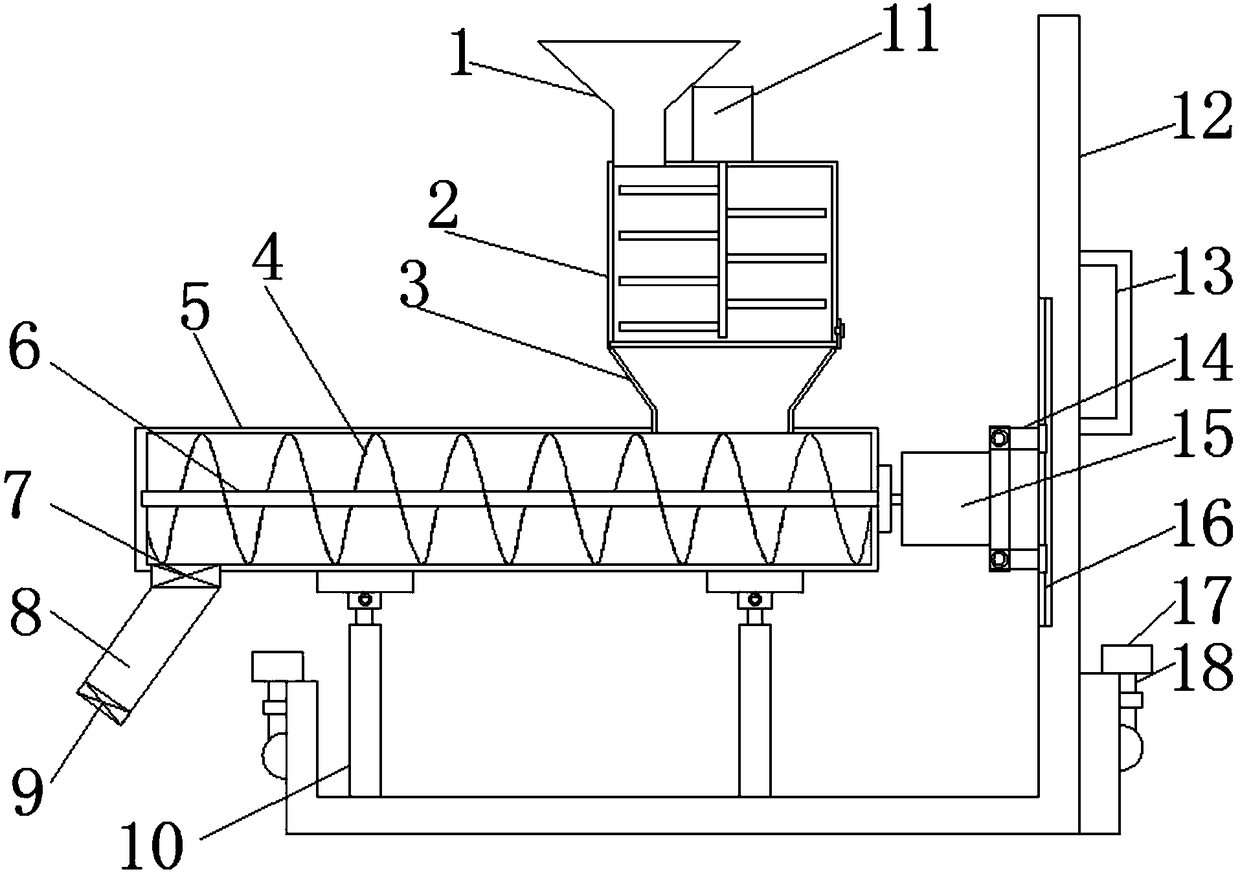

Movable charging machine

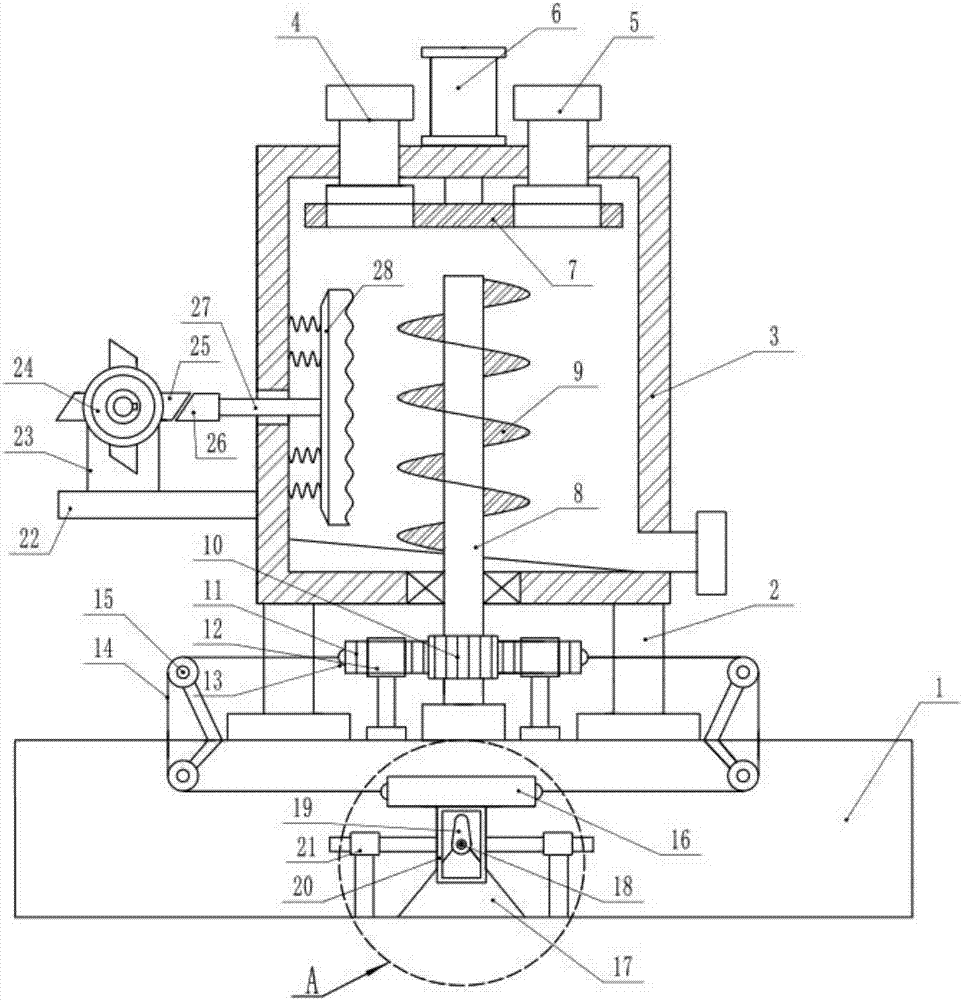

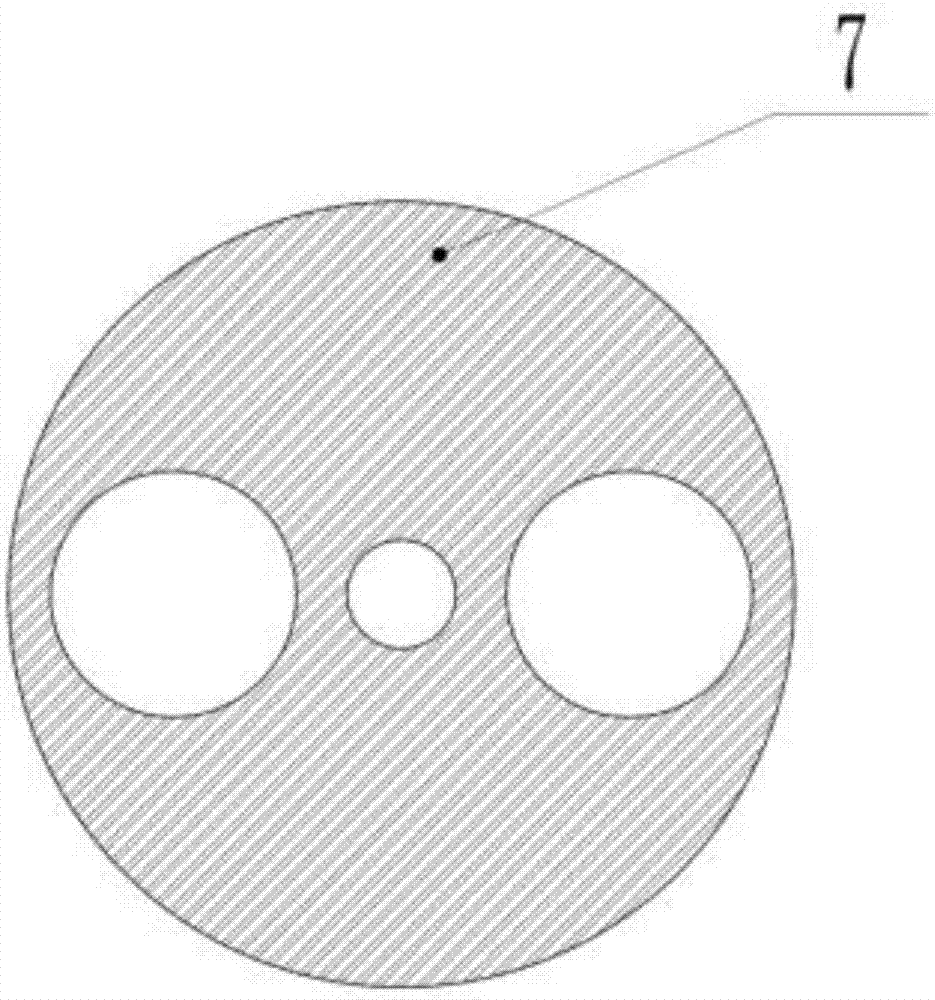

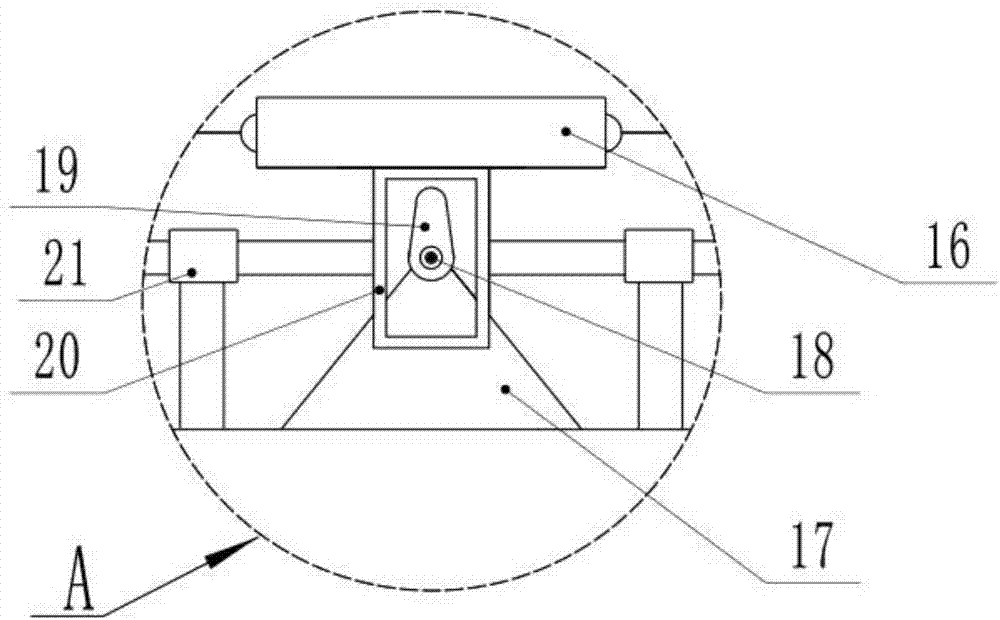

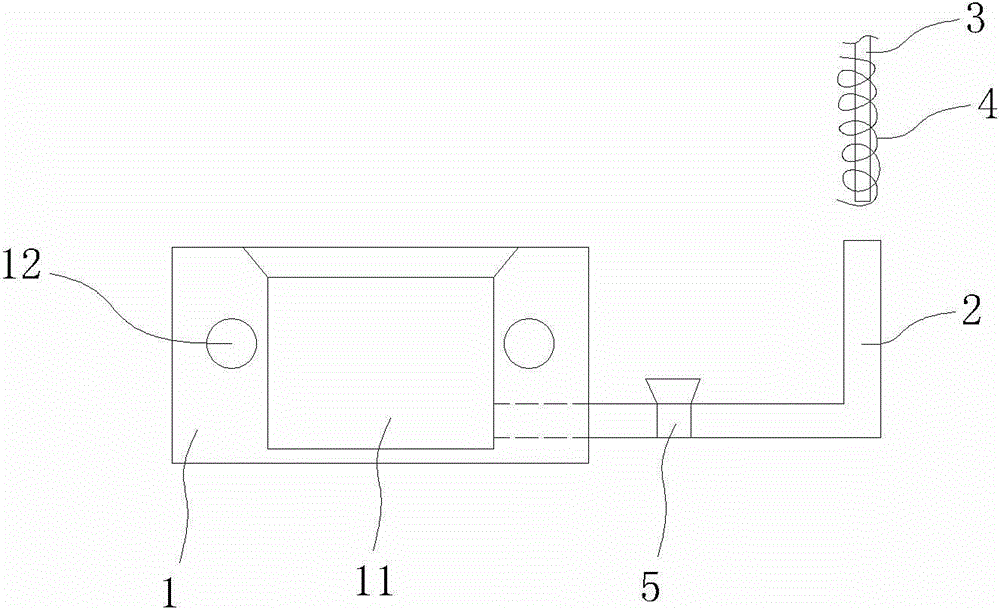

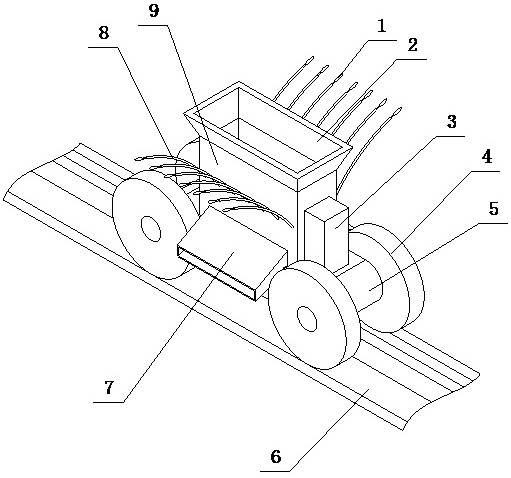

PendingCN108313759AAvoid accumulationAvoid cakingConveyorsAnimal feeding devicesHydraulic cylinderSpiral blade

The invention discloses a movable charging machine which comprises a feeding hopper, a stirring box, a guide hopper, a spiral blade, a main shaft, a guide box, a feeding valve, a guide pipe, a discharge valve, a hydraulic cylinder, a first motor, a support, a handrail, a connection rod, a second connection rod, a guide rail, moving wheels, a supporting rod, a fixed base, a fixed portion, a baffle,a supporting plate, a sealing plug plate, a fixing pin, a pull plate and a sealing slot. The material adding amount is controlled through the feeding valve, the guide pipe and the discharge valve, quantitative charging is achieved, the hydraulic cylinder and the fixed base are hinged, the inclination angle of the guide box and the guide pipe is flexibly adjusted, materials can be guided out moreeasily, and device moving is convenient through the moving wheels. Moving is convenient, fixing is stable, quantitative charging can be achieved, material conveying is more uniform, operation is easy,the work intensity is lowered, personnel loss is reduced, the cost is saved, and practicability is good.

Owner:ZHANGZHOU TIANYANG MACHINERY

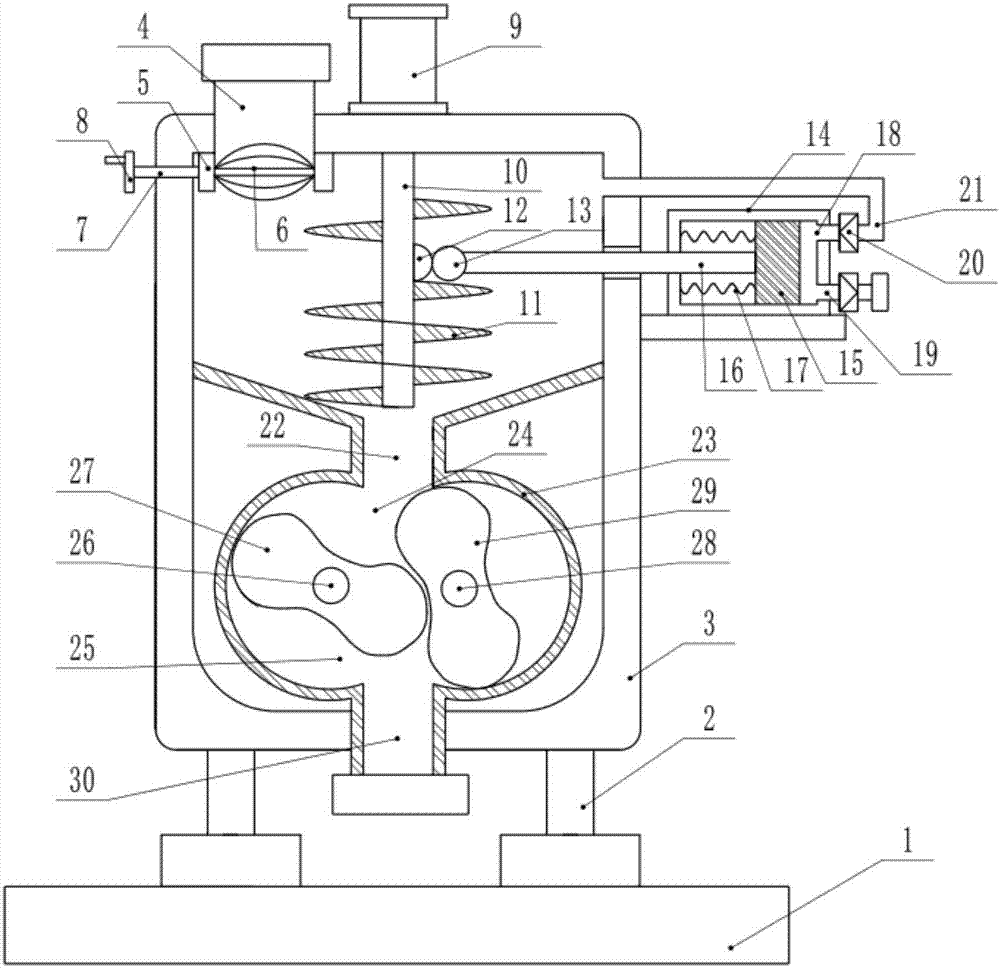

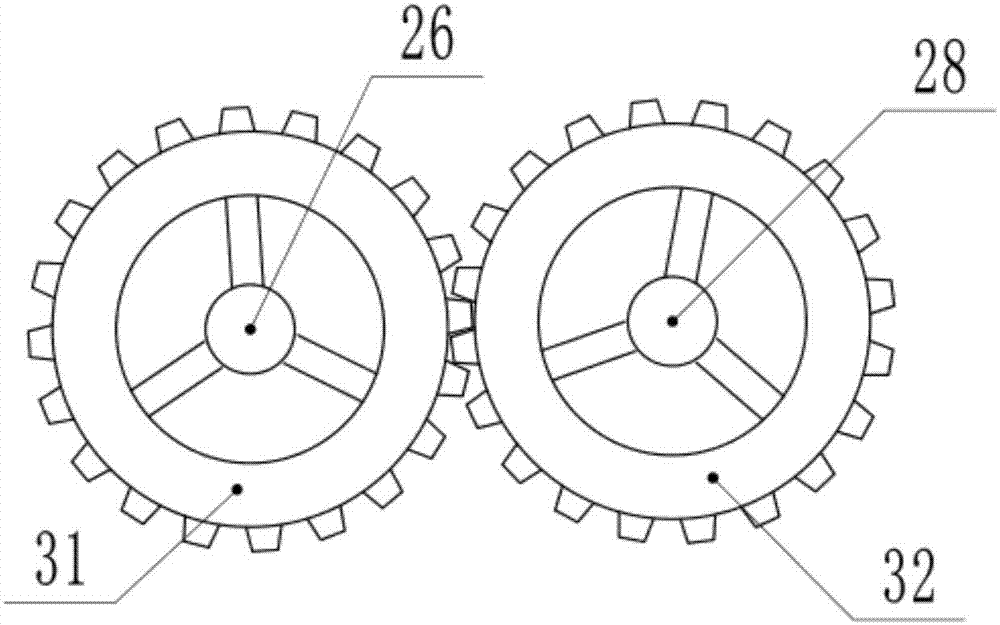

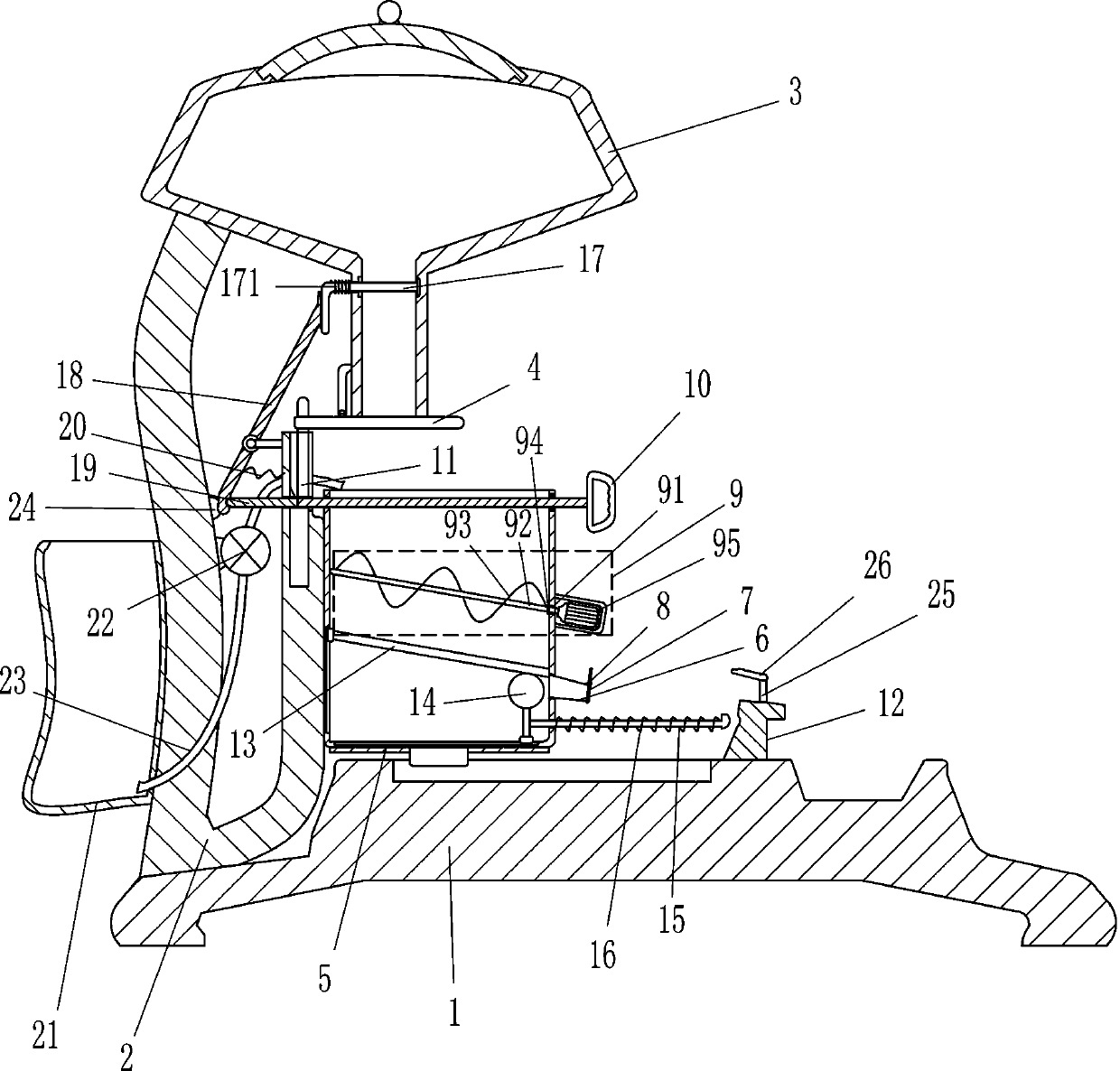

Lead-acid storage battery coloring paste stirring device for preventing blowhole

InactiveCN107537370AAvoid it happening againNovel structureRotary stirring mixersFoam dispersion/preventionPorosityPlastic materials

The invention discloses a lead-acid storage battery color glue stirring device for preventing pores, which comprises a stirring box, a feeding wheel, a stirring motor, an air extraction device and an extruding device. The upper end of the support column is fixedly welded with a stirring box. There is a feed runner below the feed inlet; the output shaft of the stirring motor is fixedly connected to the stirring shaft inside the stirring box, and the stirring blade is spirally installed on the stirring shaft, and there is also a protrusion on the stirring shaft. An air extraction device is also fixedly installed on the side, and an extruding device is also provided inside the mixing box. During the stirring process, the air pumping device is driven to pump and exhaust air, thereby exhausting the gas inside the mixing box to the greatest extent, effectively preventing the gas from entering the inside of the color glue, thereby generating pores during curing, and reducing the rate of defective appearance of the product; at the same time, the color glue After stirring, it enters the extrusion device to realize the extrusion of the stirred color glue raw material, further avoiding the occurrence of pores in the color glue raw material, thereby effectively improving the pass rate of the product concept.

Owner:黄思宜

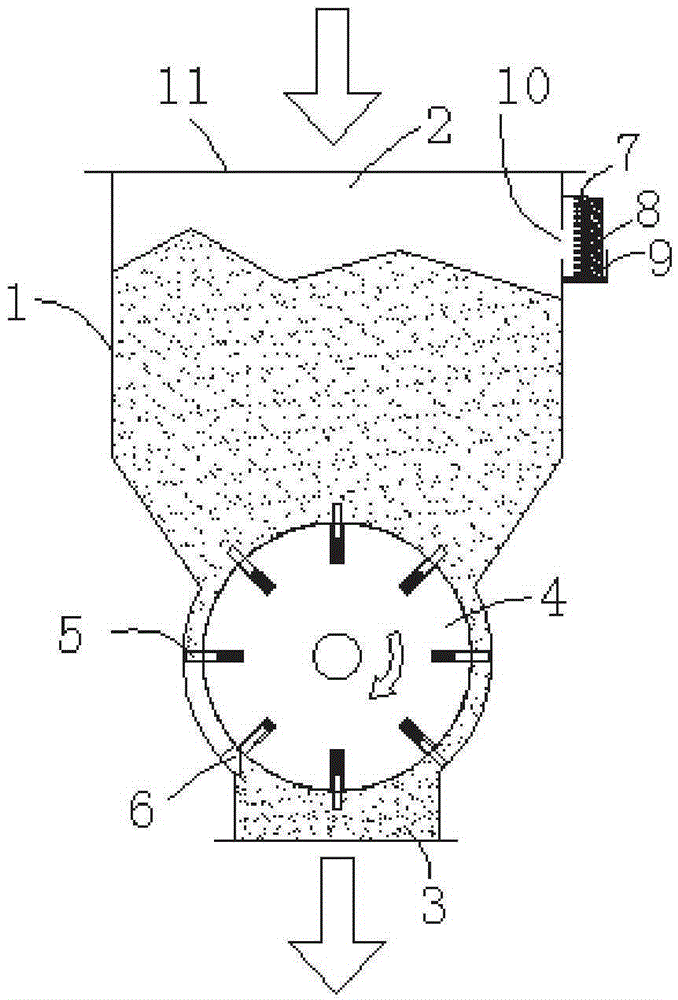

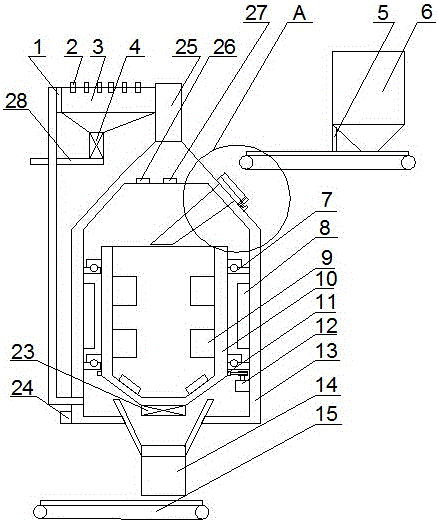

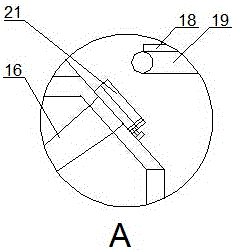

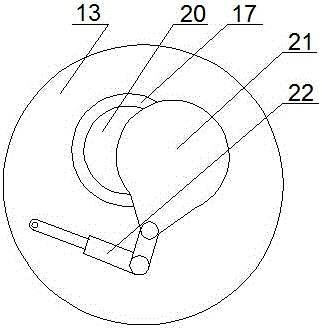

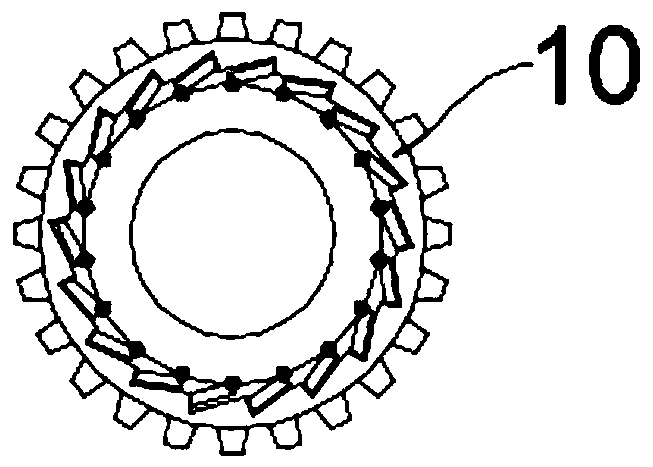

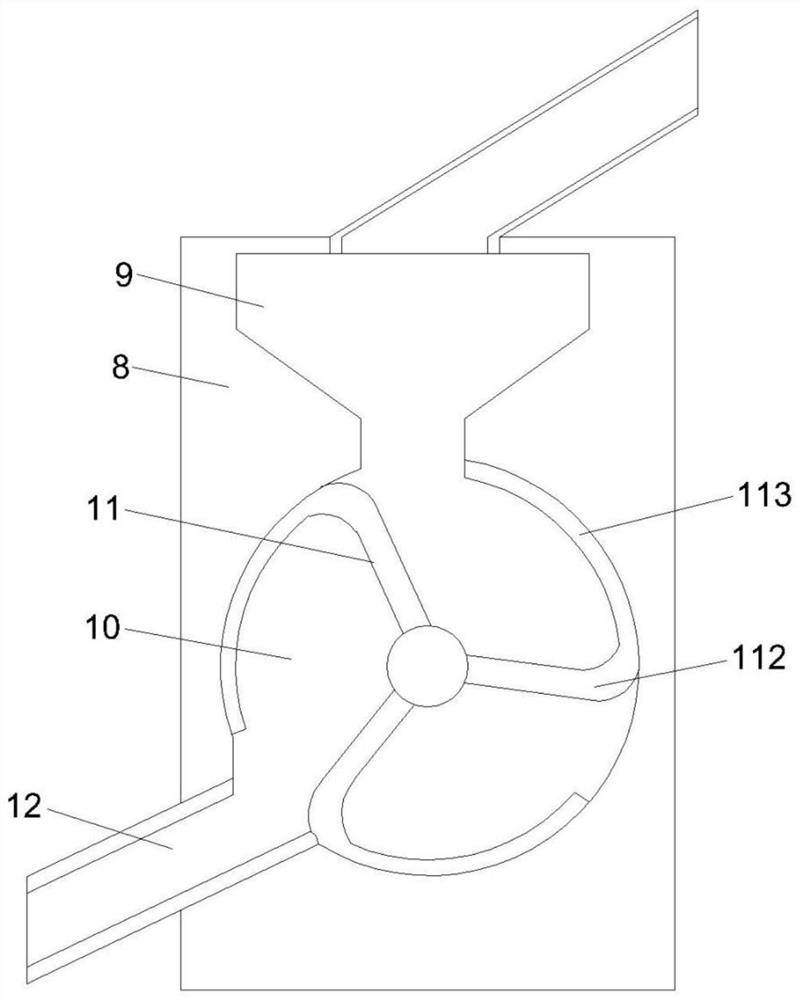

Rotating-unloading-type air-lock controllable unloading machine

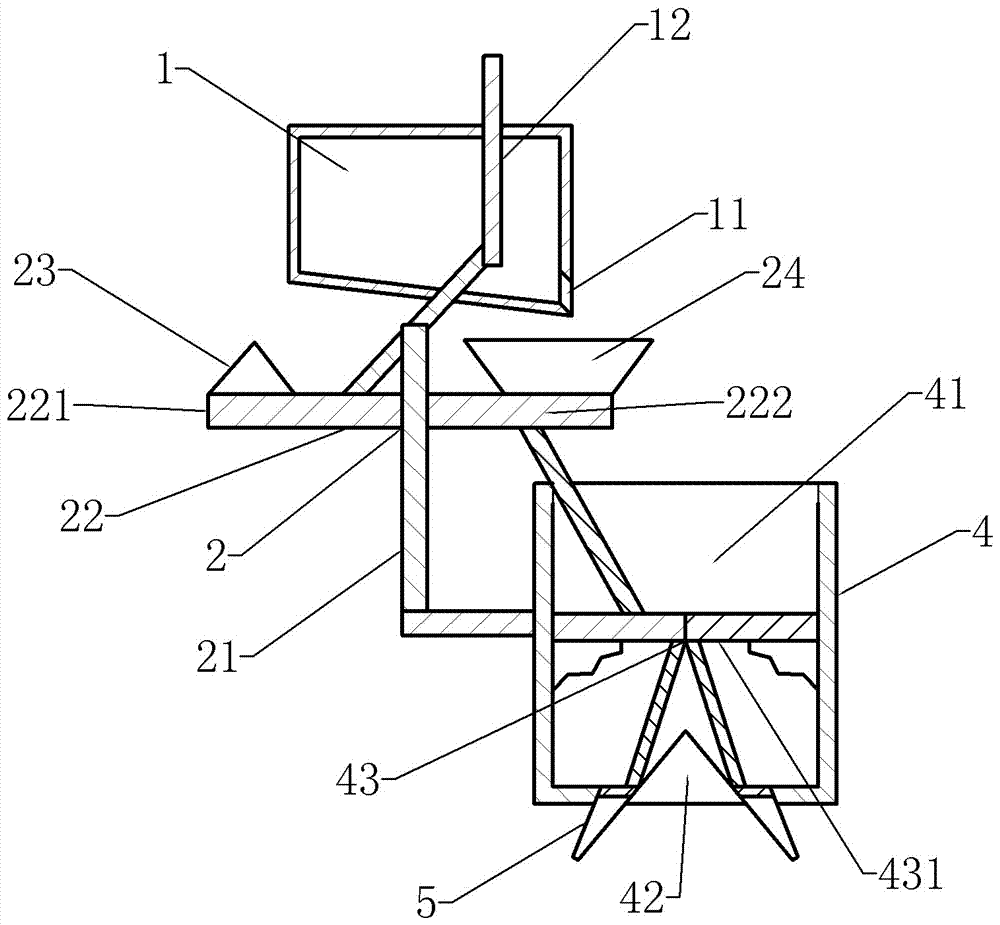

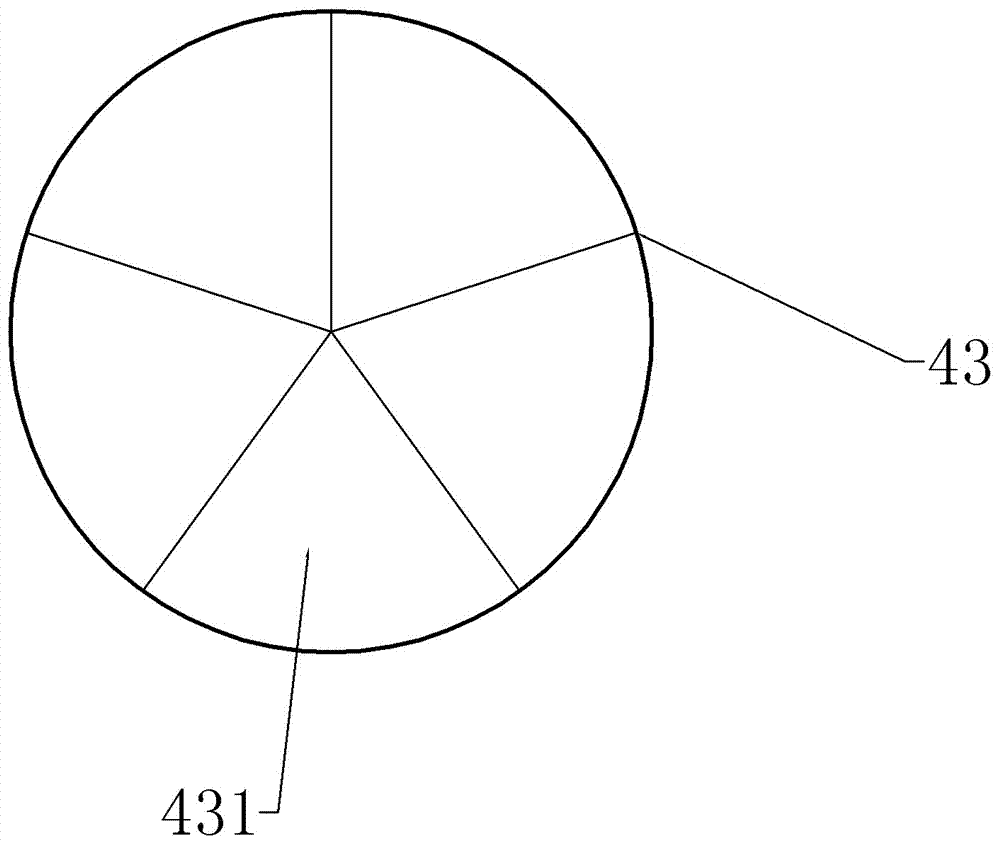

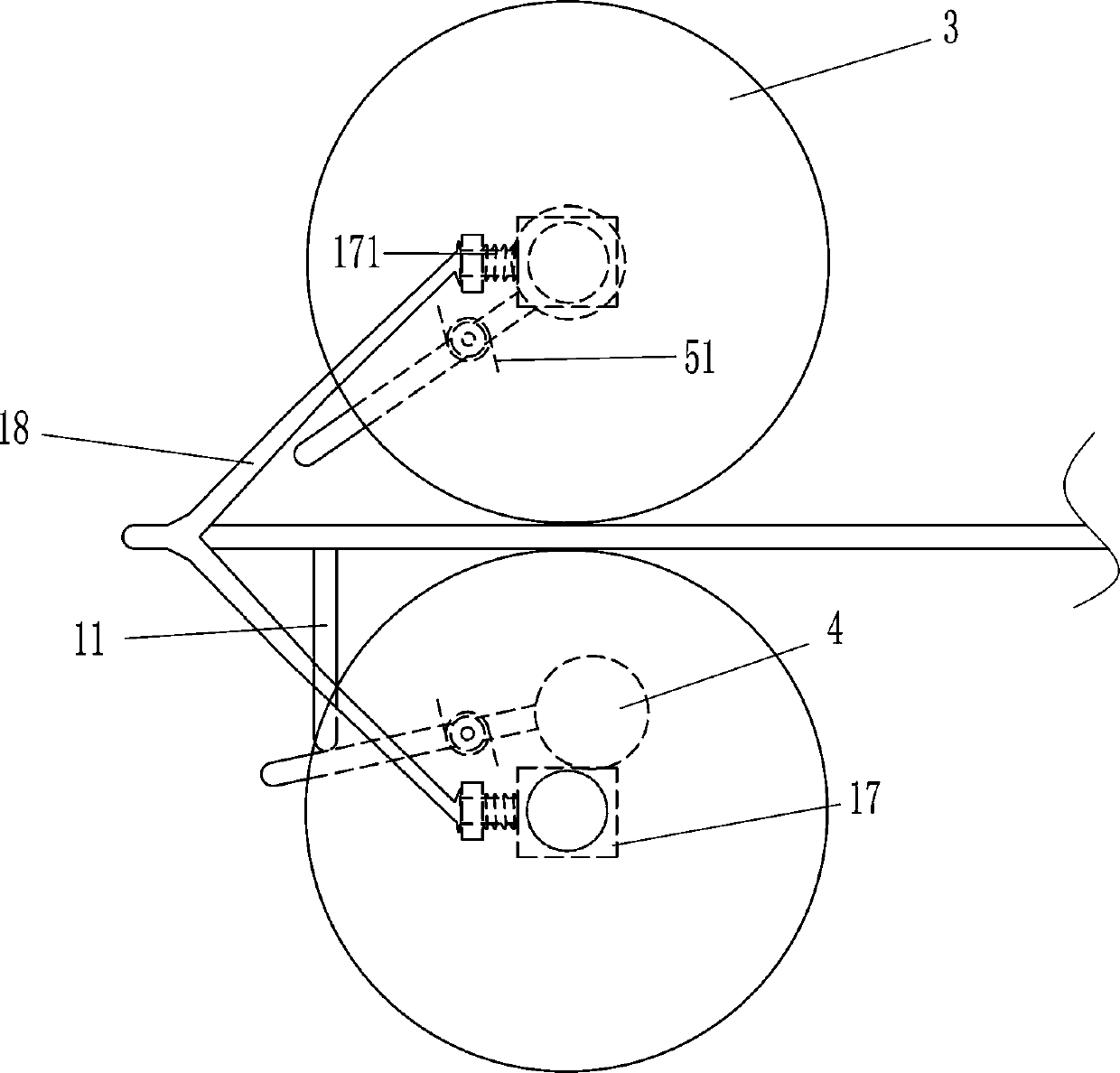

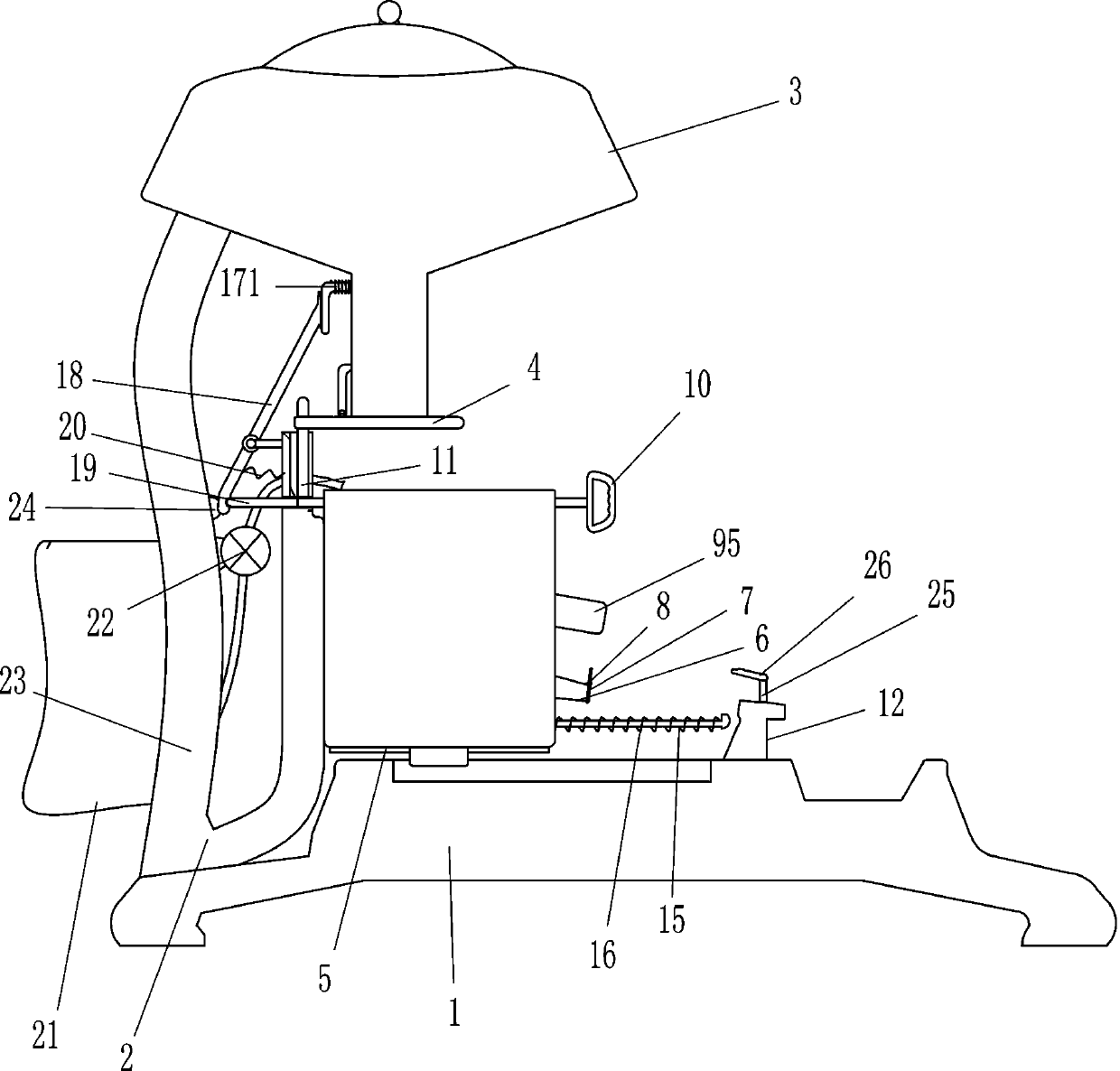

InactiveCN103662869AAccurately realize and control the distribution and unloading statusRealize quantitative feedingLoading/unloadingImpellerCrankshaft

The invention discloses a material separation loading and unloading device, and particularly relates to a rotating-unloading-type air-lock controllable unloading machine which can effectively and accurately achieve and control material separation and unloading states. The rotating-unloading-type air-lock controllable unloading machine comprises a separation mechanism, an unloading mechanism and a power mechanism. The separation mechanism comprises a separation box and a pushing device; a feeding port is formed in the top of one side of the separation box, and a discharging port is formed in the bottom of the other side of the separation box; the pushing device comprises a front push plate, a push rod, a connecting rod, an eccentric wheel, a crankshaft and a first chain wheel, wherein the front push plate, the push rod, the connecting rod, the eccentric wheel, the crankshaft and the first chain wheel are mutually connected, and rollers are arranged at the two ends of the back side of the front push plate. The unloading mechanism comprises an unloading box, a second chain wheel, a main shaft and impeller blades, wherein a receiving port is formed in the top of the unloading box, an outlet is formed in the bottom of the unloading box, the receiving port is connected to the bottom of the discharging port, the second chain wheel is fixed to the end of the main shaft and is in transmission connection with the power mechanism, and the impeller blades are symmetrically and fixedly arranged on the main shaft.

Owner:HUANGGANG WEISI MACHINERY

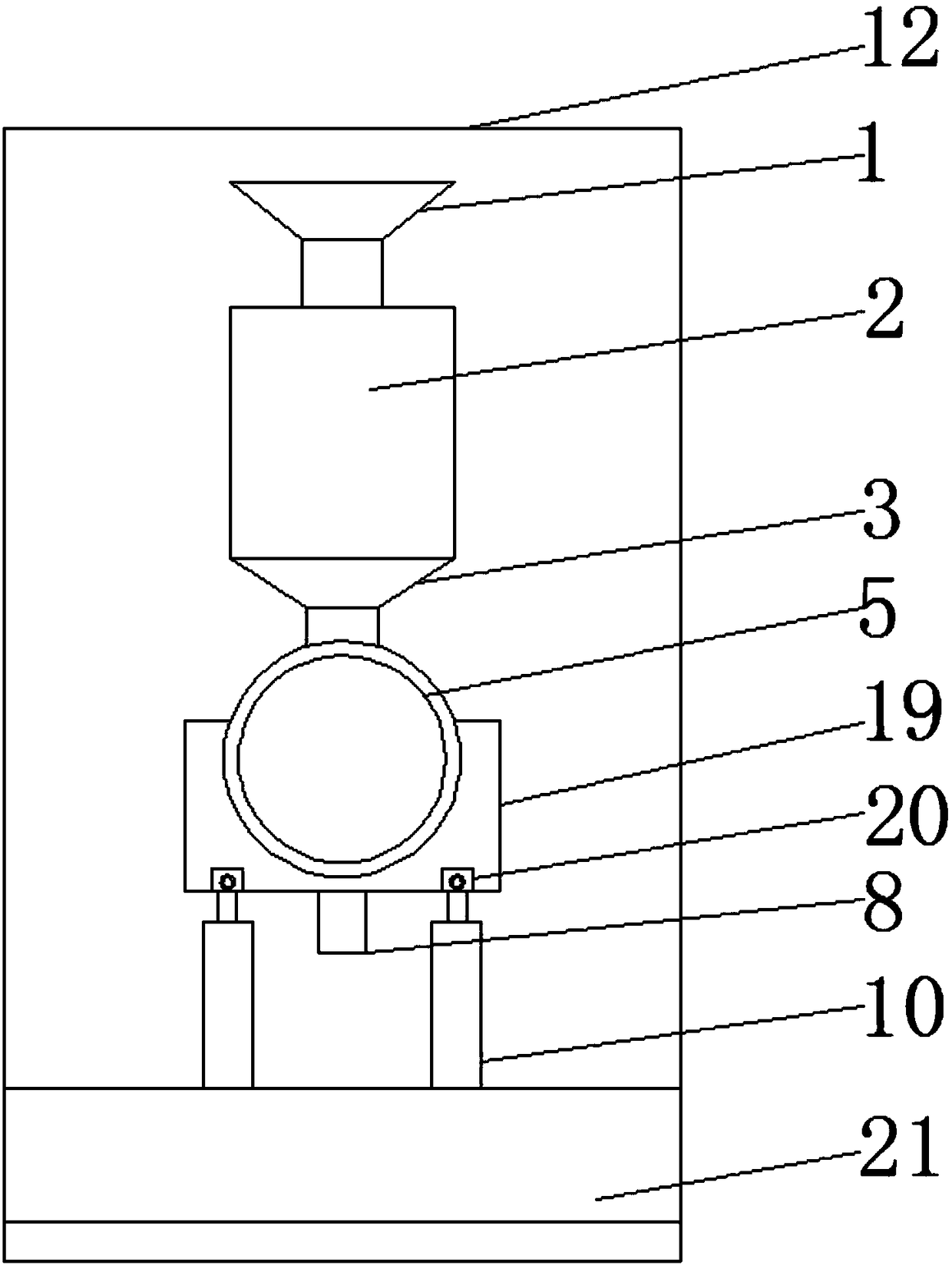

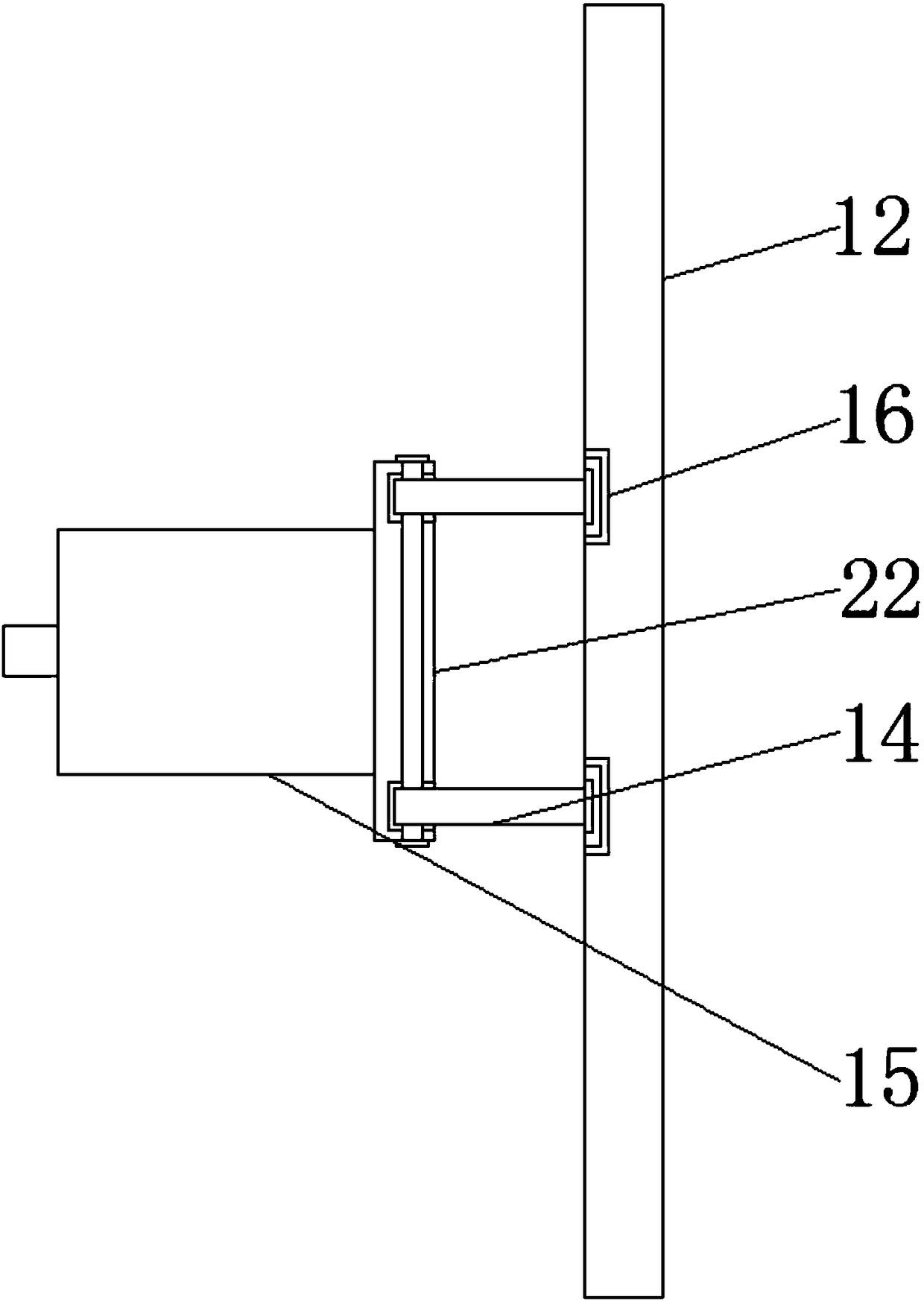

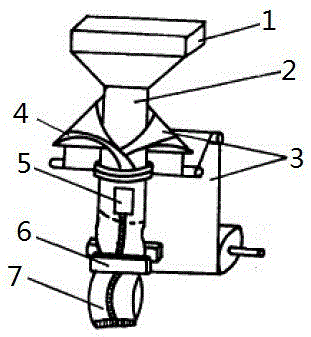

Powder grinder for strontium carbonate processing

PendingCN111889216ARealize quantitative feedingAvoid troubleHollow article cleaningGrain treatmentsStrontium carbonatePhysical chemistry

The invention relates to the technical field of grinding devices, in particular to a powder grinder for strontium carbonate processing. The powder grinder comprises a grinding device feeding frame, afeeding port is formed in the top end of the grinding device feeding frame, a discharging frame is arranged at the bottom end of the grinding device feeding frame, and a reinforcing rib plate is additionally arranged between the discharging frame and the grinding device feeding frame; a driving shaft penetrates through the surface of the grinding device feeding frame, a plurality of material stirring plates are arranged on the surface of the driving shaft, and a telescopic groove is formed in the surface of the material stirring plate. The powder grinder for strontium carbonate processing hasbeneficial effects that the powder grinding device for strontium carbonate processing is additionally provided with the grinding device feeding frame, the driving shaft is additionally arranged in thegrinding device feeding frame for mounting material stirring plates, a plurality of charging spaces are formed by the plurality of material stirring plates, quantitative feeding of the discharging frame is achieved, a series of troubles caused by one-time continuous feeding are avoided, and a telescopic structure is additionally arranged at the end part of the material stirring plate to pull a cleaning plate to clean residual materials on the inner wall of the grinding device feeding frame.

Owner:GUIZHOU HONGKAI CHEM CO LTD

Mixing equipment for plastic additive processing

ActiveCN113320041ARealization of quantitative additionImprove mixing efficiencyRotary stirring mixersTransportation and packagingProcess engineeringPipe

The invention discloses mixing equipment for plastic additive processing, and belongs to the technical field of mixing devices. The mixing equipment for plastic additive processing comprises a stirring barrel and a barrel cover, and further comprises a loading component and a stirring component, wherein the barrel cover is arranged at the top of the stirring barrel, the loading component is arranged at one side of the stirring barrel, and the stirring component is arranged in the stirring barrel. According to the invention, a vibration assembly works to drive a loading shell to transversely vibrate, materials in the loading shell continuously fall into a material storage part in the process, after vibration is carried out for a period of time, the material storage part is full of the materials, quantitative adding for the materials is completed, then the loading pipe continues to move downwards till the materials enter the stirring barrel, and at the moment, mixed liquid is injected through the top of the loading pipe; and the mixed liquid enters the material storage part through a water inlet hole to be mixed with the materials, the materials are taken out of the material storage part through the mixed liquid and enter the stirring barrel, at the moment, the stirring component works to carry out material mixing operation, quantitative adding for the materials is realized, and preliminary mixing for the materials is completed in the process that the materials are taken out of the material storage part through the mixed liquid, so that the material mixing efficiency is increased.

Owner:LAIZHOU GLASS FIBER REINFORCED PLASTICS PRODS

Quantitative feeding device for agricultural breeding

PendingCN111492990AHigh degree of automationGood feeding effectAnimal feeding devicesLivestockAnimal science

The invention discloses a quantitative feeding device for agricultural breeding, and relates to the technical field of agricultural breeding. The quantitative feeding device mainly aims at solving theproblem that in existing agricultural breeding, the feeding amount is difficult to control by manually adding feed. The quantitative feeding device comprises a bottom plate, a trough and a feeding unit, wherein the trough is fixedly installed on the upper surface of the bottom plate; the feeding unit comprises a material cylinder, partition plates and a driving mechanism for driving the partitionplates to rotate; the driving mechanism comprises a standing plate, a spring, an arc-shaped rack, a single-stage flywheel, a bevel gear pair, a worm and a worm gear; and air bags for adjusting the volume are installed on the two side walls of each partition plate. The feeding unit is arranged, quantitative feeding is achieved through the weight of livestock, the automation degree is high, and thebreeding effect is good; and the air bags are arranged, the purpose of adjusting the volume of the space between the adjacent partition plates is achieved by adjusting the size of the air bags, and therefore the feeding amount is adjusted to meet the breeding requirements in different periods.

Owner:滕锐

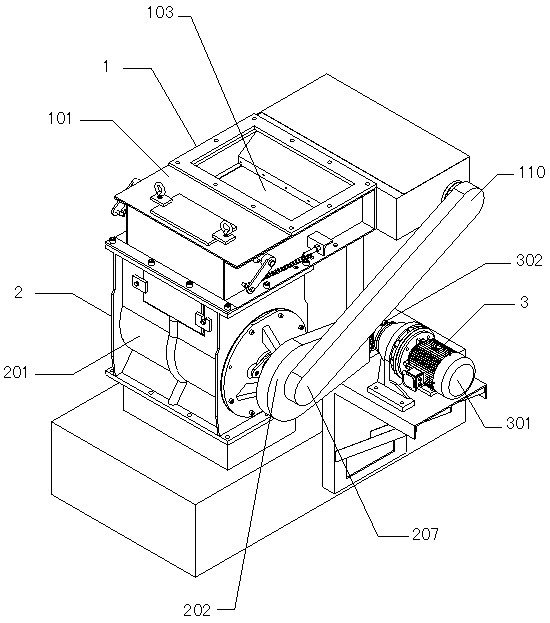

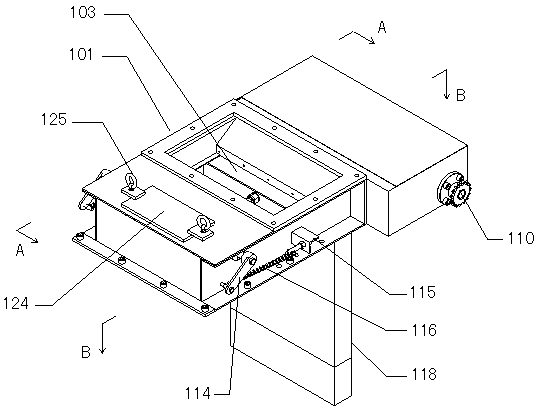

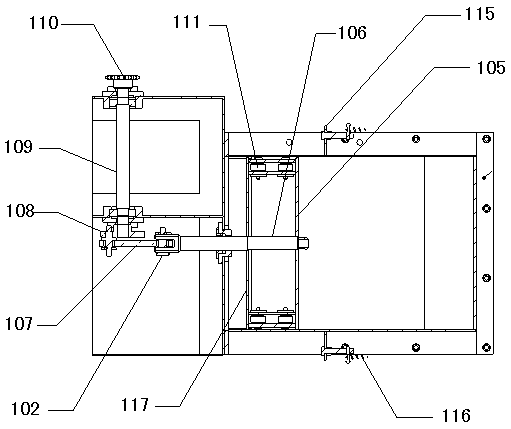

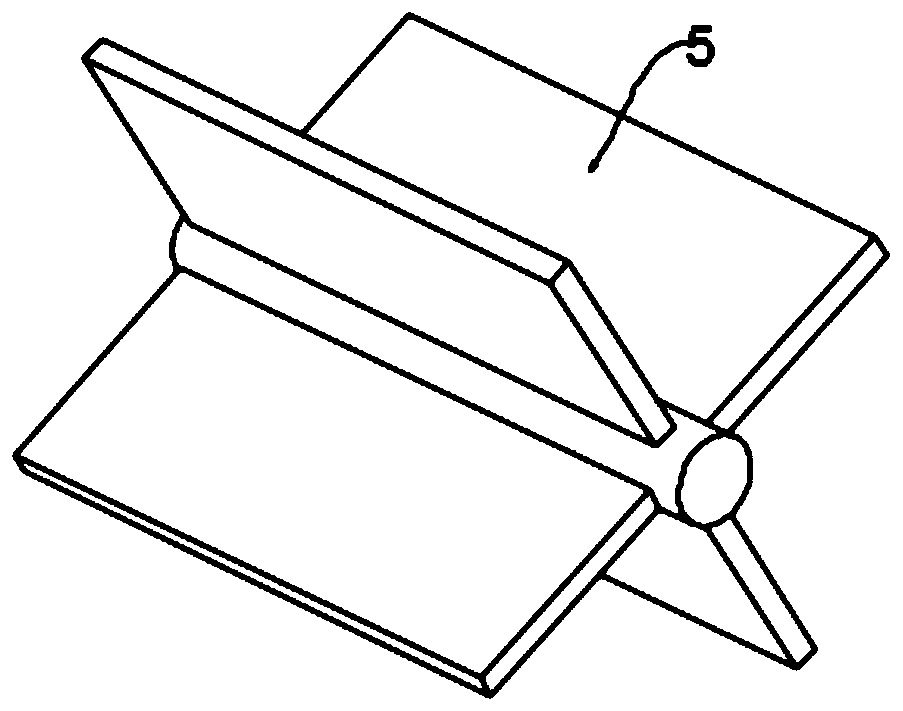

Crusher with multi-stage crushing function

PendingCN112871410ARealize quantitative feedingAvoid accumulationDispersed particle filtrationTransportation and packagingRotational axisElectric machine

The invention discloses a crusher with a multi-stage crushing function. The crusher comprises a storage box, a conveying rod, a conduction channel, a feeding box, a box body and a bottom plate; the box body is fixed to the bottom plate; a rotating motor is arranged in the center of the outer side wall of the top of the box body; the output end of the rotating motor is connected with a rotating shaft; the rotating shaft vertically extends into an inner cavity of the box body; a plurality of groups of crushing rods are uniformly arranged on the rotating shaft; first crushing rollers are arranged in the box body; first guide plates which are inclined downwards are arranged below the first crushing rollers; a vertical rotary grinding disc and a telescopic grinding disc are arranged below the first material guide plates; two second material guide plates are arranged below the rotary grinding disc and the telescopic grinding disc; a static crushing plate and a swing crushing plate are arranged on the two sides of the upper portion of s discharging port respectively; and air suction fans are arranged at the upper end and the lower end of the box body respectively. According to the crusher with the multi-stage crushing function, dust generated in the crushing process can be collected, and the situation that the dust flies to harm the health of constructors and pollute the environment is avoided.

Owner:SUZHOU INST OF INDAL TECH

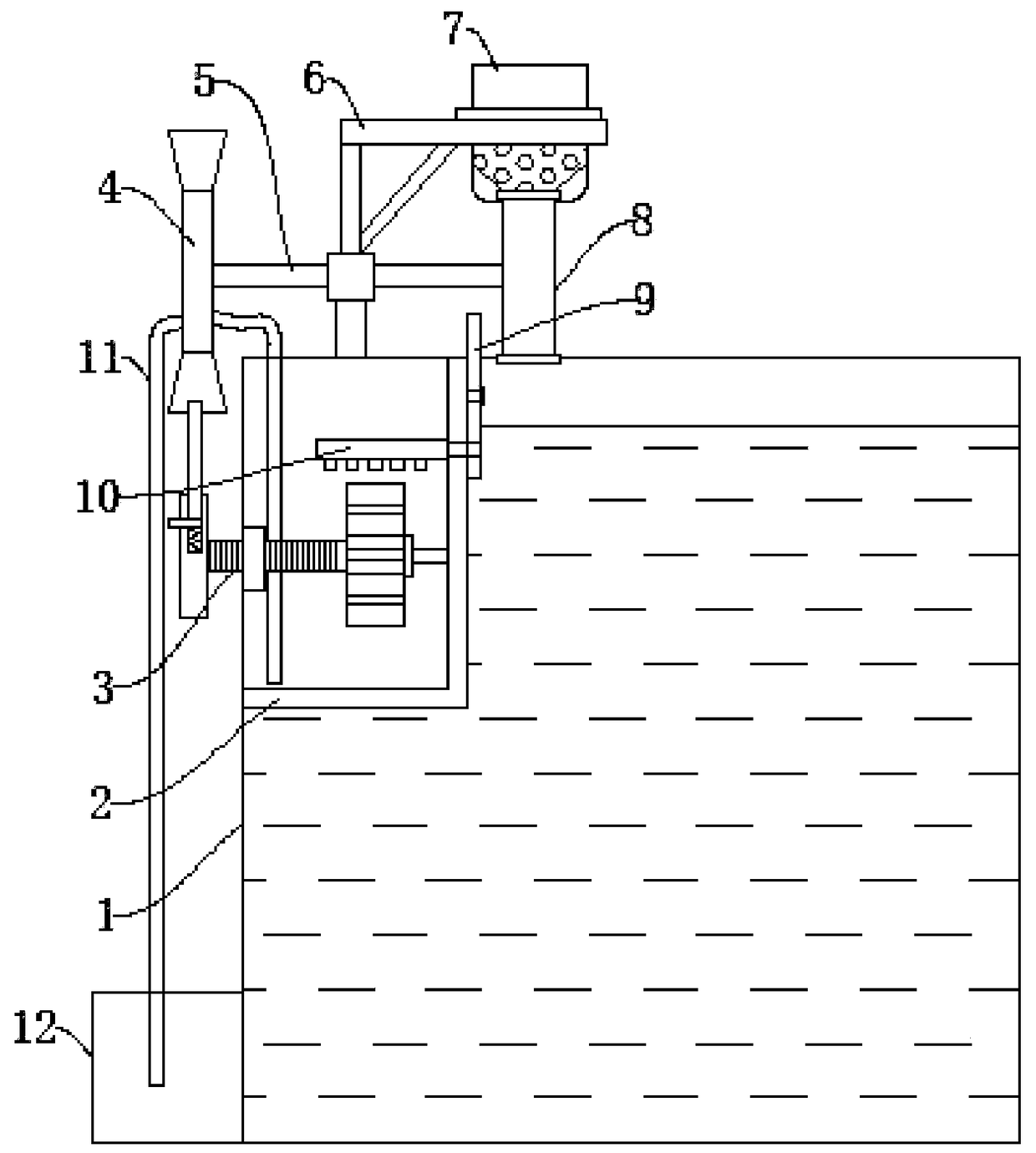

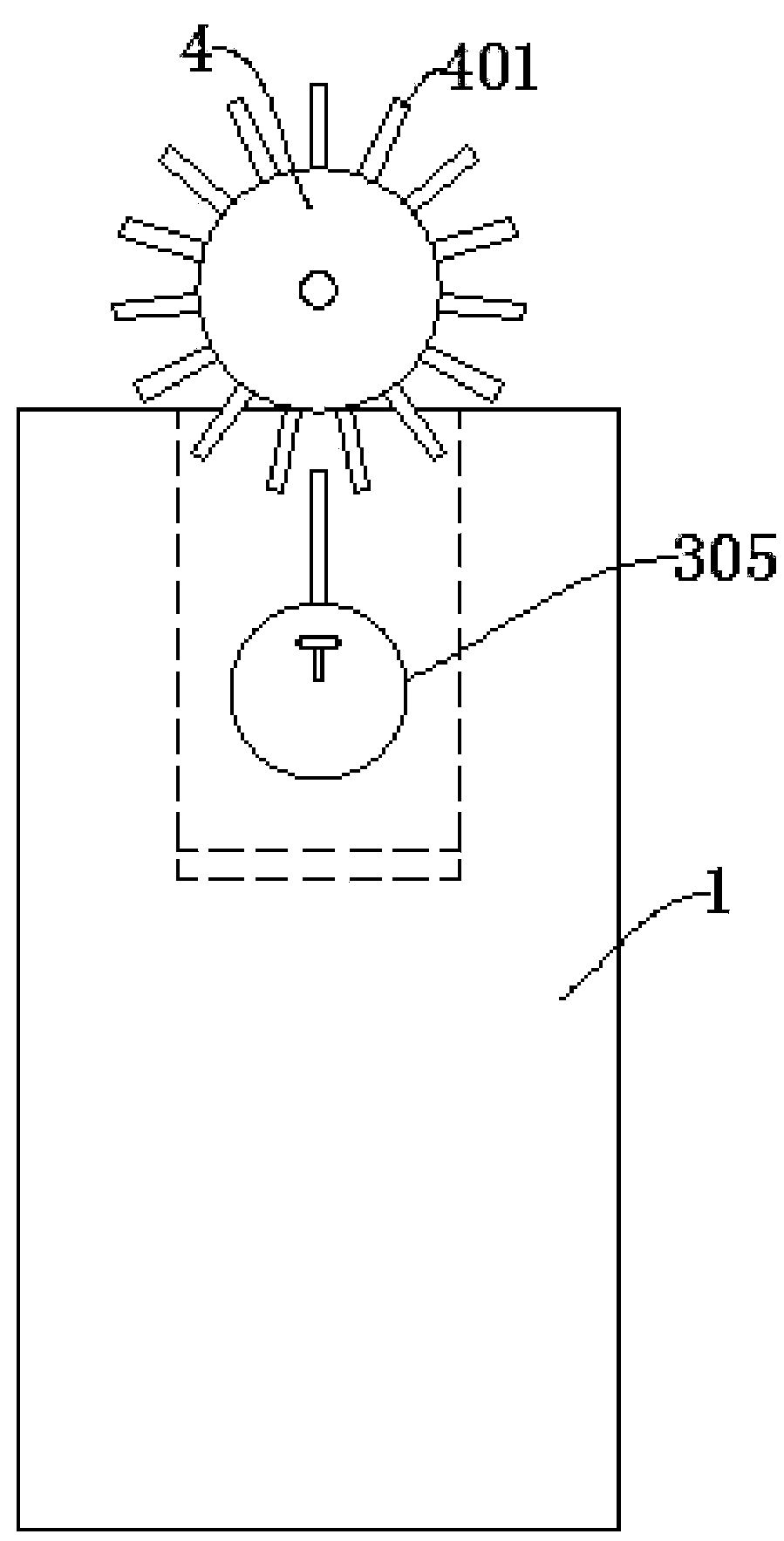

Automatic quantitative feeding fish tank

ActiveCN108834997AEasy to operateRealize quantitative feedingClimate change adaptationPisciculture and aquariaPipingEngineering

The invention discloses an automatic quantitative feeding fish tank which comprises a fish tank body. A separated cavity is formed in the fish tank body and consists of a base plate and a side wall, the side wall is provided with a water guiding pipe, the water guiding pipe horizontally extends into the separated cavity, the side wall is provided with a water inlet hole, the water inlet hole is communicated with the water guiding pipe, and the outer side of the side wall is provided with a rotatable water baffle capable of blocking the water inlet hole. The automatic quantitative feeding fishtank has the advantages that a driving mechanism is driven to act by diverting water in the fish tank body and utilizing the impact force of water flow, finally a quantitative feeding wheel is drivento rotate, and fish feed is quantitatively put in the fish tank body. Quantitative fish feed putting can be achieved without power connection, and meanwhile the fish tank is more attractive.

Owner:王玲芝

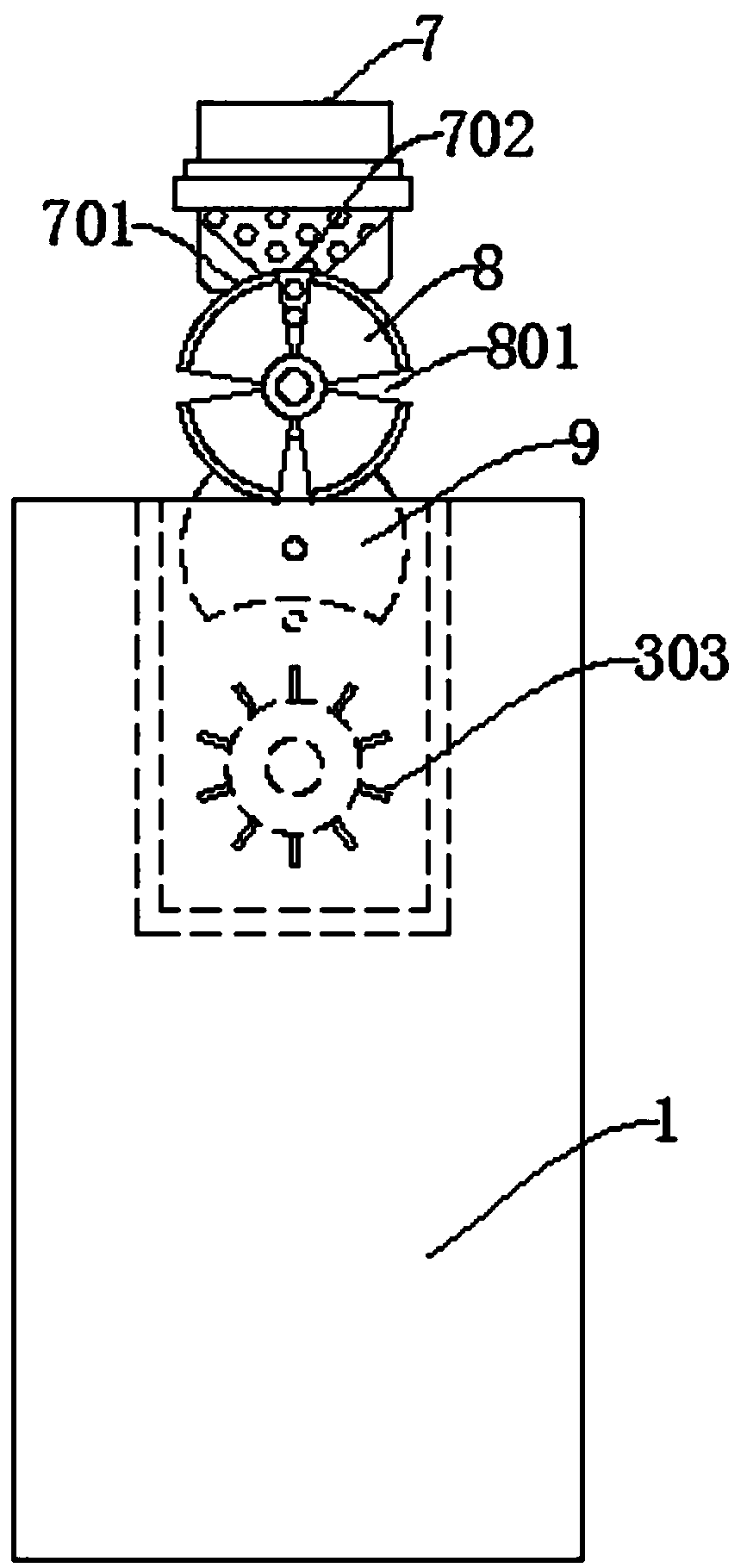

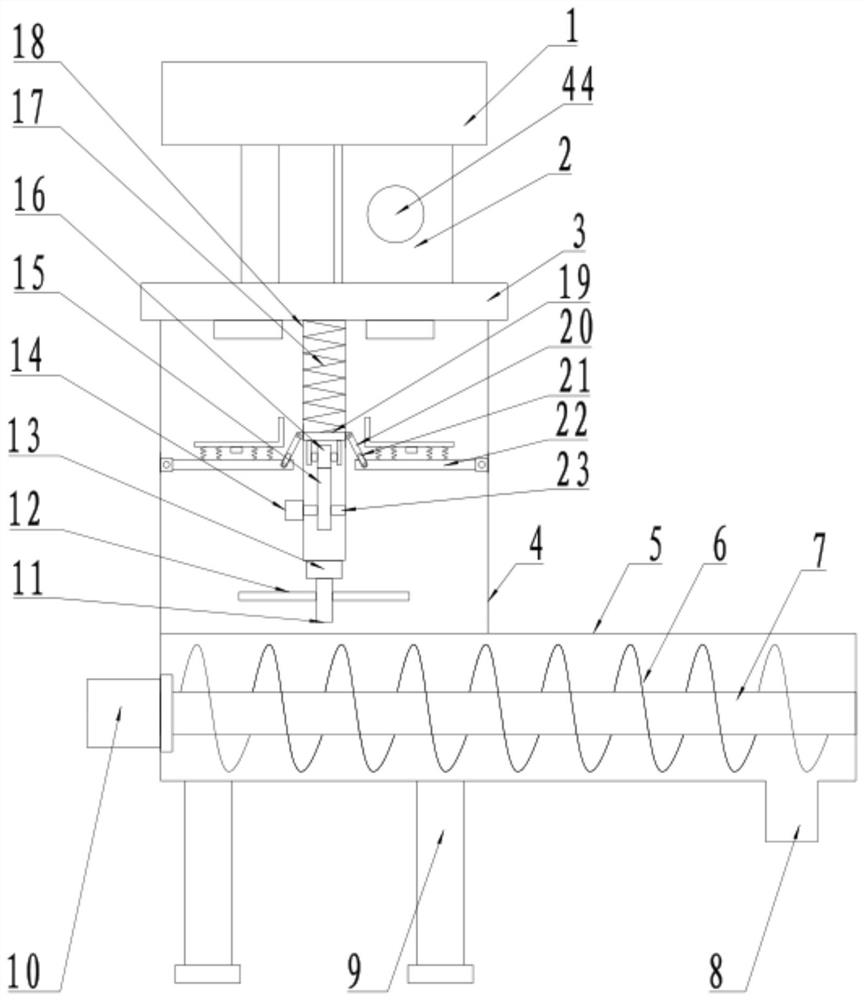

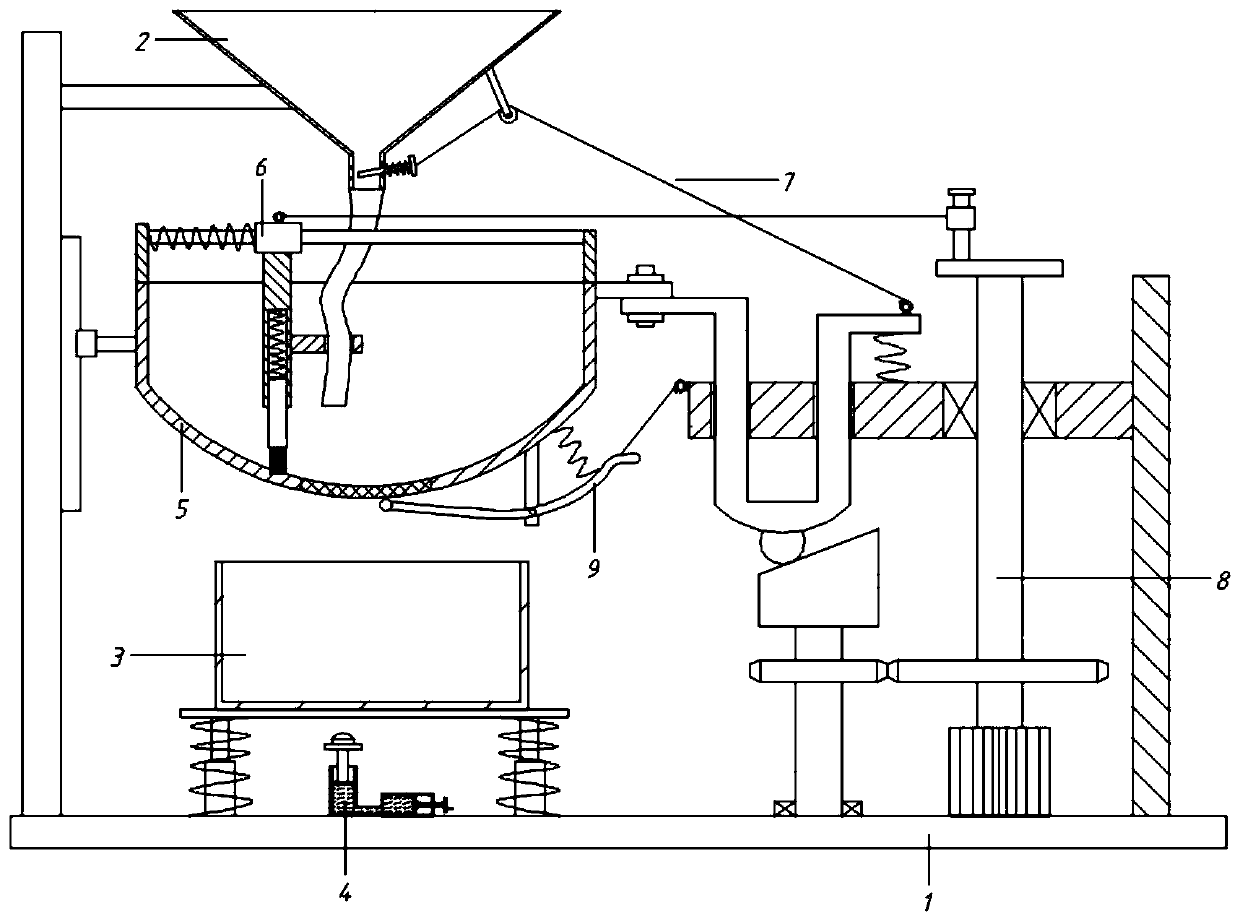

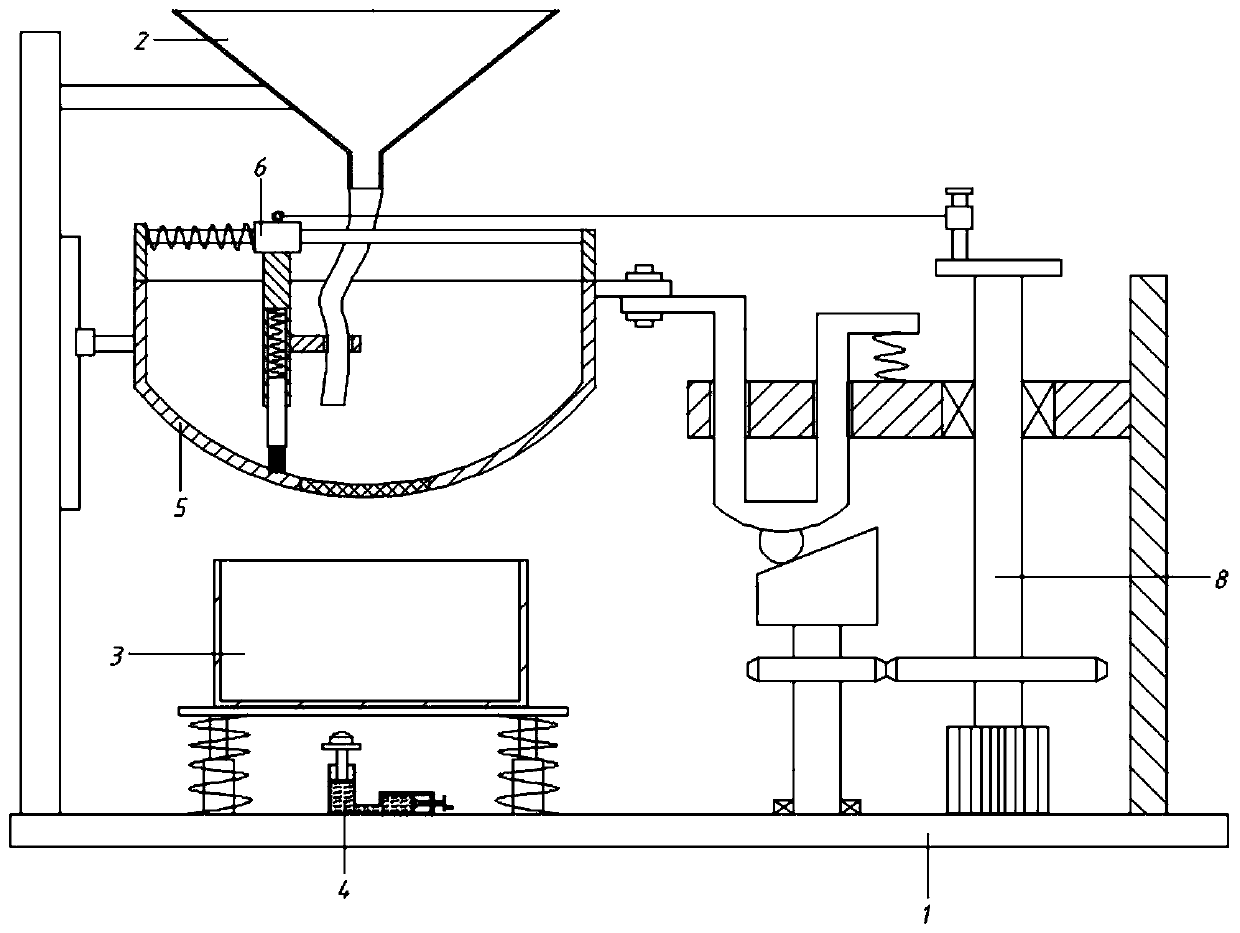

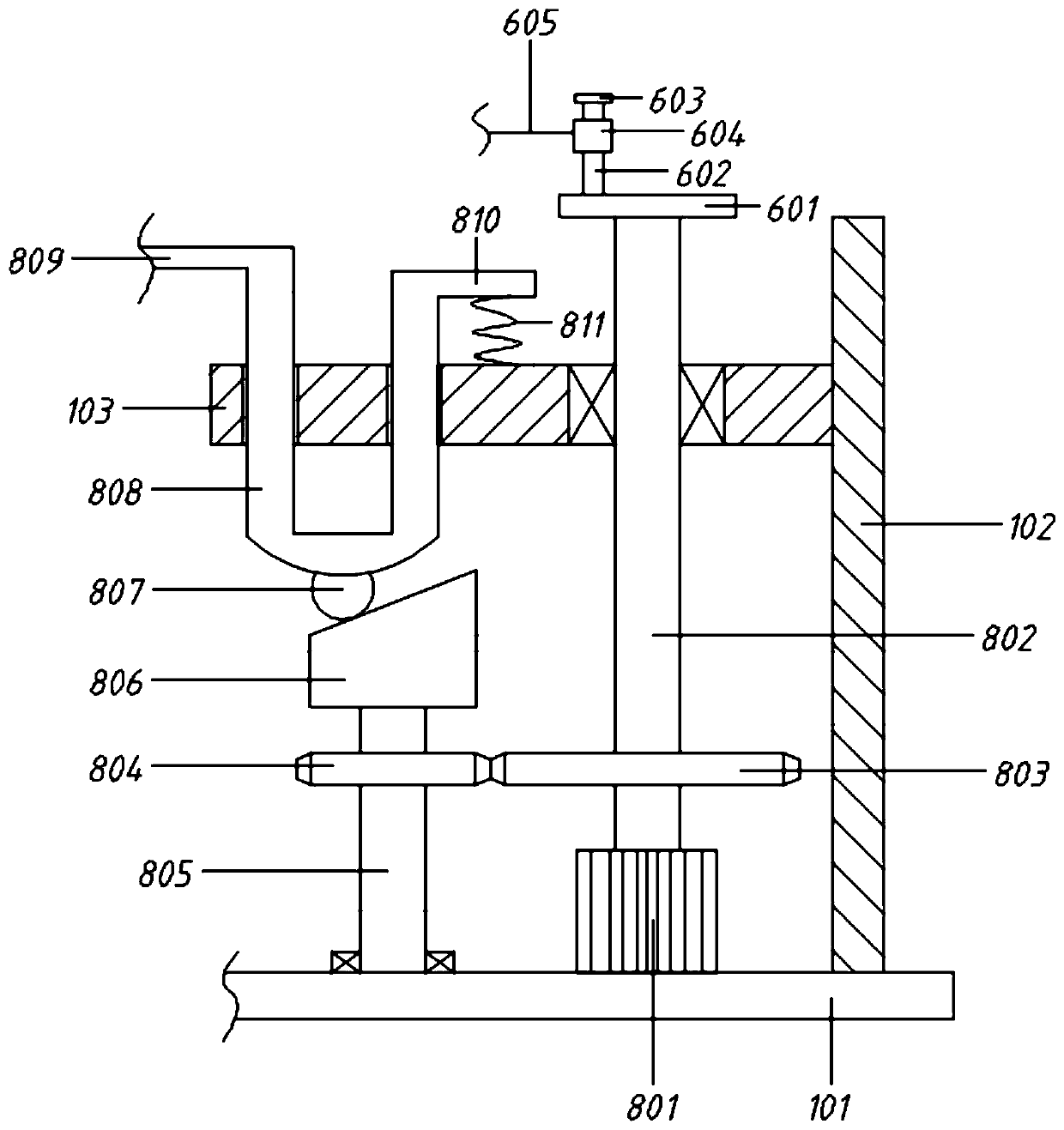

Quantitative conveying and stirring device for cement-based stone-imitating type curbs

PendingCN110843113AImprove molding efficiencyReduce labor intensityDischarging apparatusFeeding arrangmentsStructural engineeringProcess engineering

The invention relates to a quantitative conveying and stirring device for cement-based stone-imitating type curbs, and belongs to the technical field of artificial stones. The quantitative conveying and stirring device for the cement-based stone-imitating type curbs comprises a stirring mechanism, a quantitative conveying mechanism and a material moving mechanism; the stirring mechanism is used for stirring and uniformly mixing concrete mixed wet materials; the quantitative conveying mechanism is used for quantitatively conveying the concrete mixed wet materials stirred by the stirring device;the material moving mechanism is used for receiving and moving the concrete mixed wet materials conveyed by the quantitative conveying mechanism; the volume of a material moving cylinder in the material moving mechanism is definite, and then quantitative feeding on a material moving cart is achieved; and the quantitative materials in the material moving cart can be directly loaded into a mold, and then quantitative feeding is achieved. According to the quantitative conveying and stirring device for the cement-based stone-imitating type curbs, stirring, quantitative conveying and material moving of the concrete mixed wet materials are mechanically and sequentially completed, the mechanization degree is high, the labor intensity of workers is reduced, and the molding efficiency of the curbsis improved.

Owner:CHANGZHOU INST OF LIGHT IND TECH

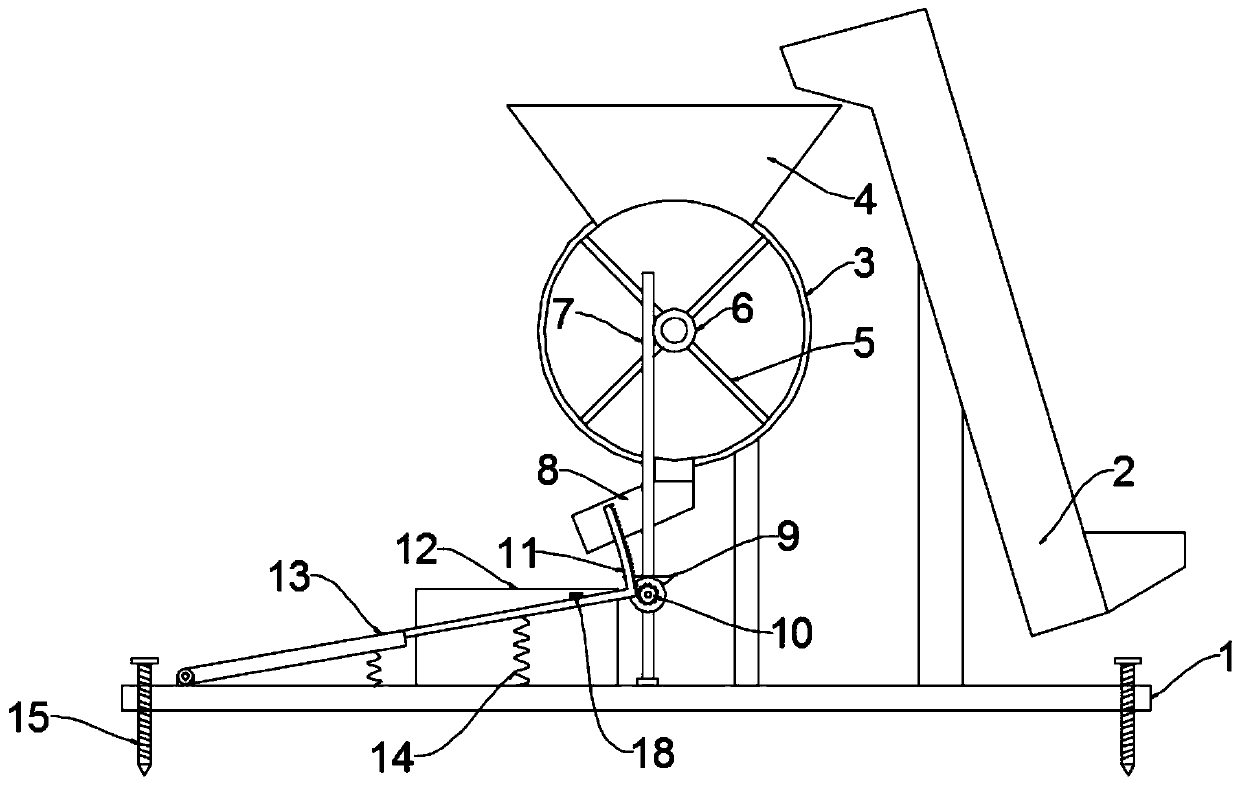

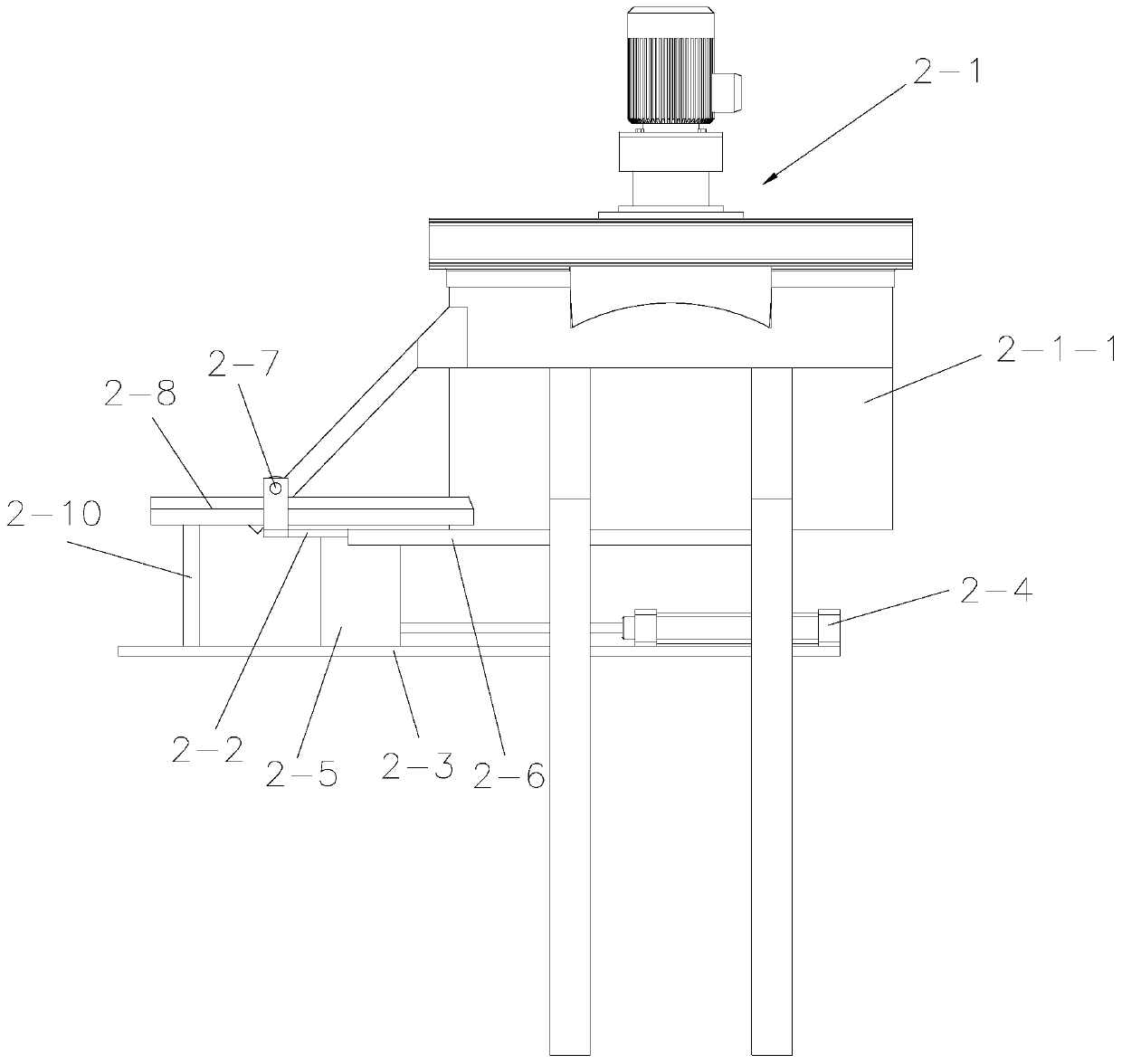

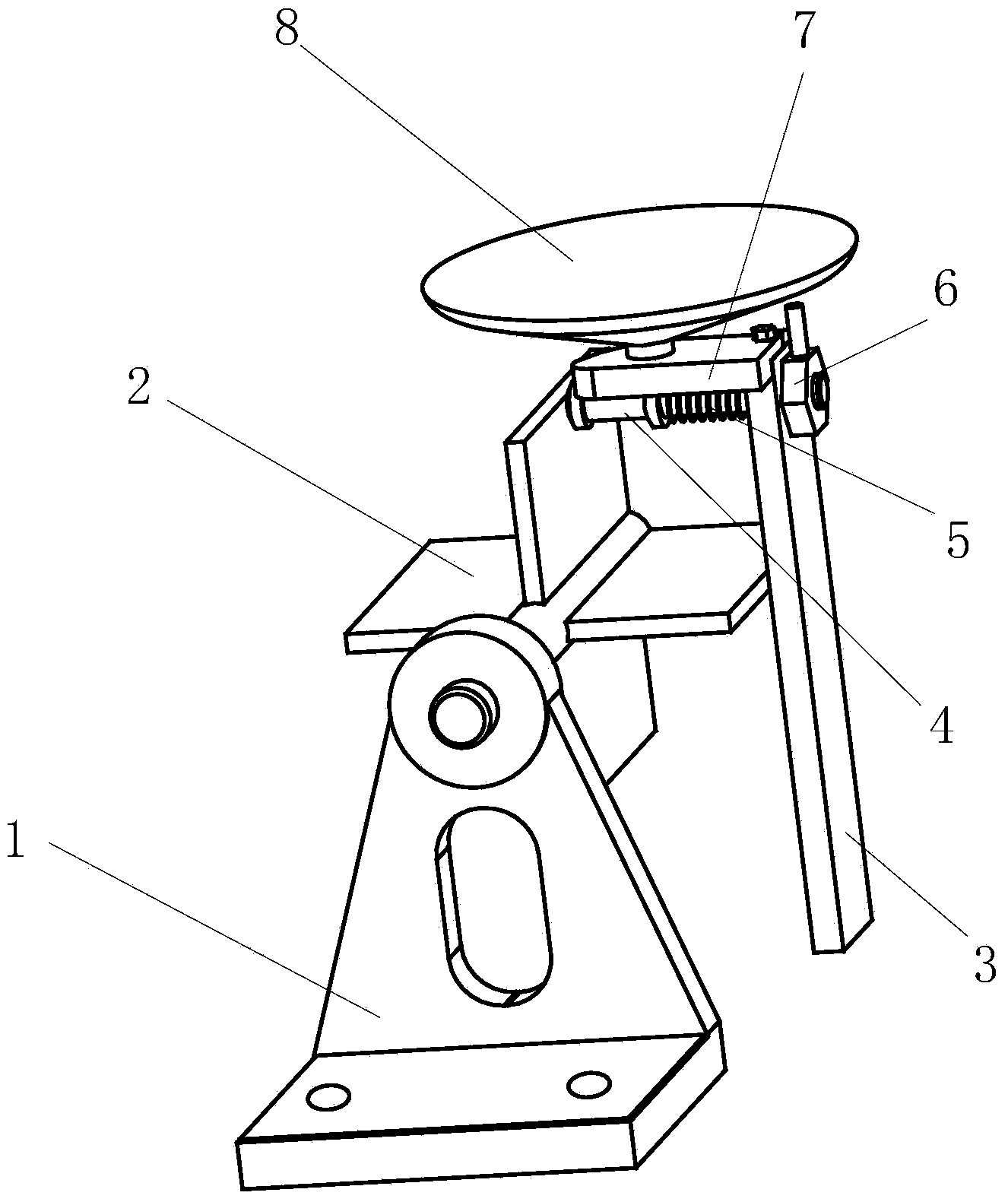

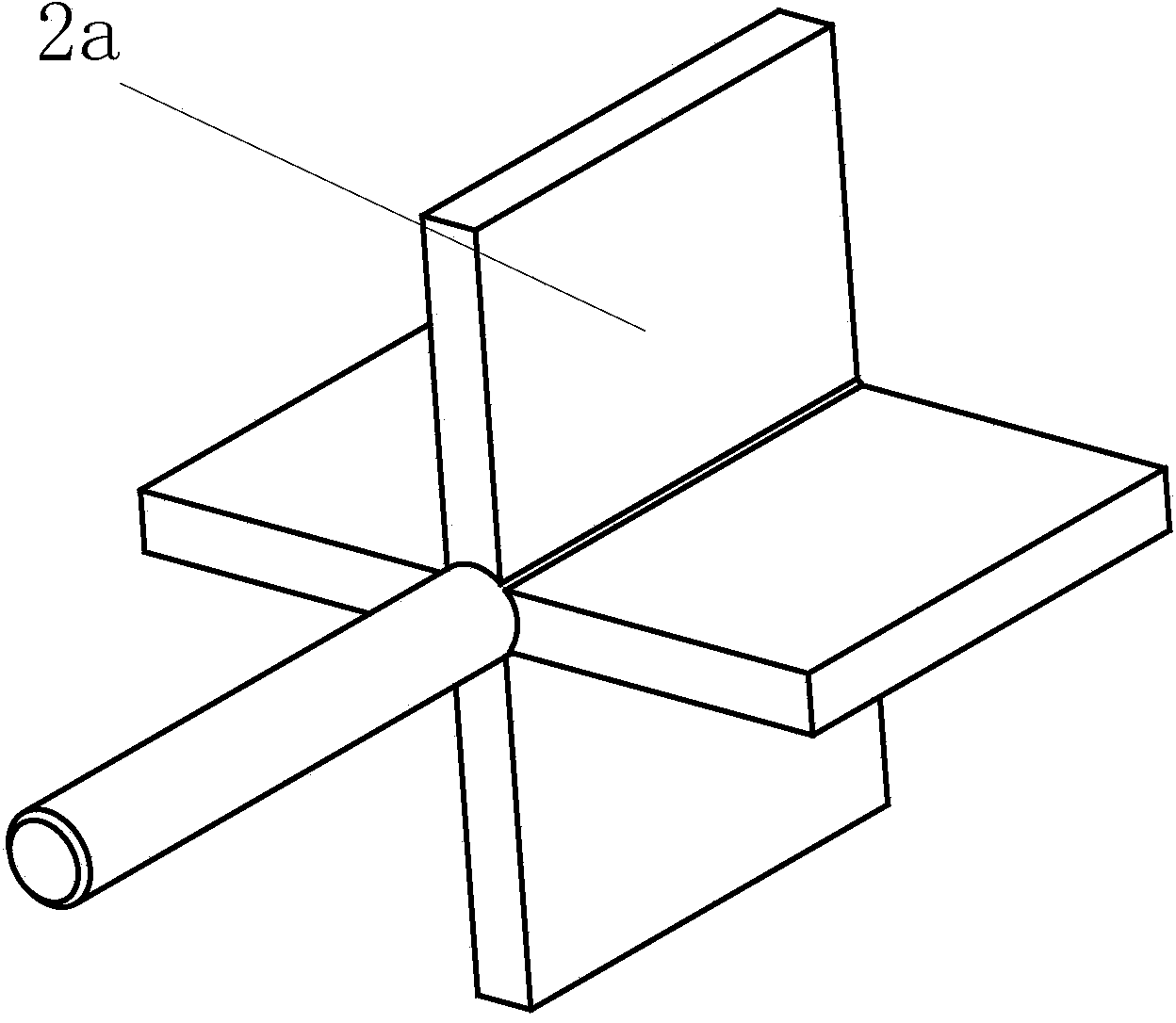

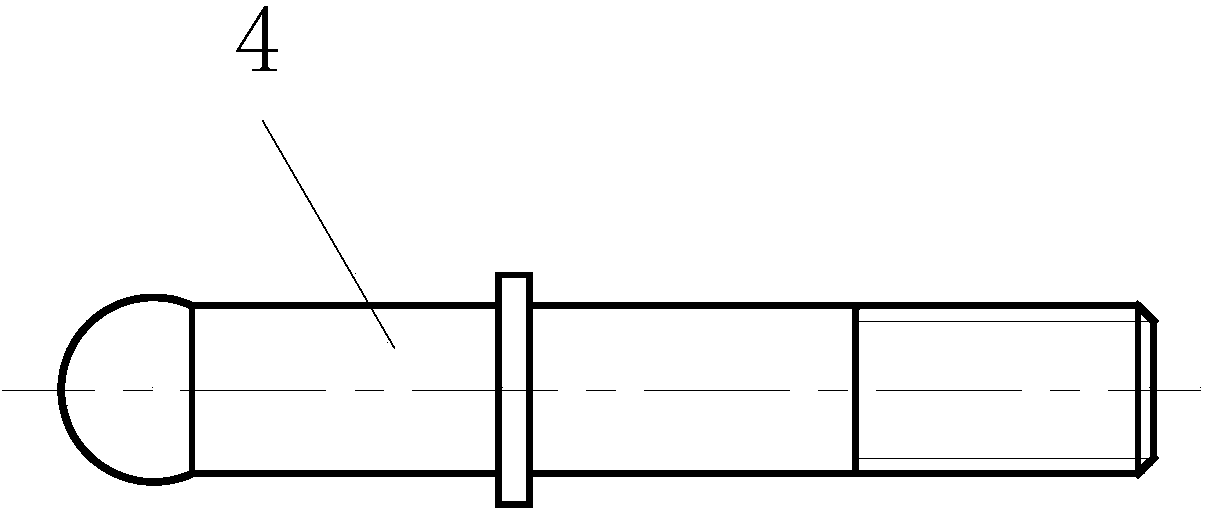

Quantified feed device of feed system

The invention relates to a quantified feed device of a feed system. The quantified feed device comprises a support rack, a quantified feed fan, a support rod, a spring lock shaft, a spring, a spring locking fastening nut, a rotary plate and a material leaking plate. The quantified feed fan is mounted on the support rack. The quantified feed fan can rotate on the support rack and used for feeding a stirring tank. A through hole is formed in the upper portion of the support rod. One end of the spring lock shaft is provided with threads. The middle portion of the spring lock shaft is provided with a step. The spring lock shaft penetrates the through hole of the support rod. One end of the spring lock shaft is screwed to the spring lock fastening nut. The spring is mounted on the spring lock shaft. The rotary shaft is hinged to the upper portion of the support rod. The material leaking plate is mounted on the middle portion of the rotary plate. The quantified feed device is reasonable in design, low in cost, firm in structure, less prone to damage and capable of achieving quantified feeding.

Owner:中嘉卫华(固安)新材料科技有限公司

Ceramic cigarette holder automatic glaze dipping method

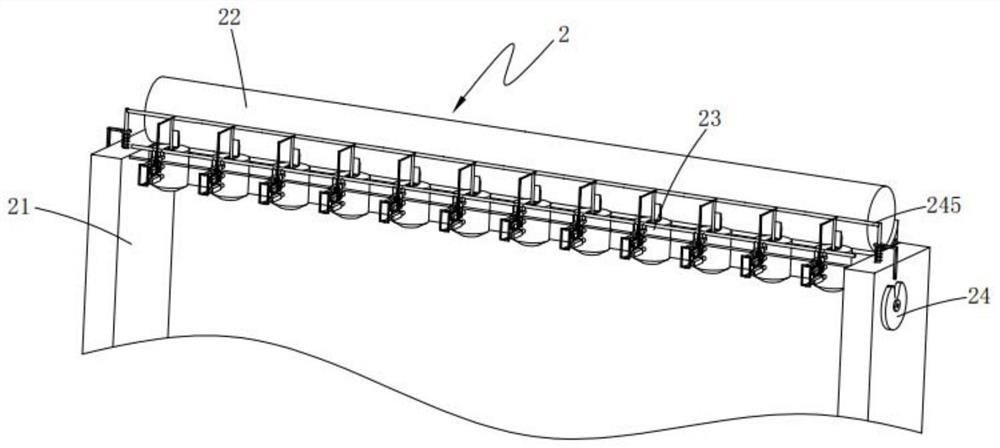

ActiveCN109733839AAvoid adjustmentEliminate pollutionCeramic shaping apparatusConveyor partsMouth pieceMetallurgy

The invention provides a ceramic cigarette holder automatic glaze dipping method. The ceramic cigarette holder automatic glaze dipping method comprises the steps of automatic material feeding and sequencing, specifically, ceramic cigarette holders are placed inside an intelligent storage, and a PLC controller controls the intelligent storage to quantificationally place the ceramic cigarette holders into multiple layers of material discharging passages at the bottom of the intelligent storage; material falling control, specifically, the PLC controller controls the material falling takt time; automatic circulation material receiving, specifically, material receiving discs are firstly placed to corresponding stations to perform material waiting through horizontal driving air cylinders, and after the material receiving discs are full of materials, the material receiving discs full of the materials are fed to corresponding material fetching stations; automatic material fetching, specifically, the PLC controller controls an automatic material fetching device to fetch the materials after the material receiving discs run to the corresponding material fetching stations; automatic glaze dipping; automatic drying; and material outputting. By means of the ceramic cigarette holder automatic glaze dipping method, the problems in the prior art that manual assist is needed to complete glaze dipping treatment and large amount of dust is generated in the glaze dipping process to do harm to the human body are solved.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Bread surface layer uniform material scattering device

The invention relates to the technical field of food processing equipment, in particular to a bread surface layer uniform material scattering device which comprises a conveying mechanism which uniformly conveys a bearing part in the conveying direction of the conveying mechanism; a material scattering mechanism which is arranged in the middle of the conveying mechanism and comprises a base, a storage barrel, an oiling assembly and a linkage assembly, wherein the oiling assembly comprises an oiling piece, a first air suction piece, a powder blowing piece, a second air suction piece, a pushing piece and a linkage unit; and a baking mechanism which is used for baking the bread; through step-by-step arrangement of the first air suction part, the powder blowing part and the second air suction part in the material scattering mechanism, the periphery of slurry pushed out by the pushing part is lengthened under the first air suction part, the surface area of the slurry is increased, after theslurry passes through the powder blowing part, auxiliary materials are uniformly sprayed, and after the slurry passes through the second air suction part, the unfirm auxiliary materials on the pulp are recycled, the utilization rate of the auxiliary materials is increased, and meanwhile the production quality of bread is improved.

Owner:东台市汉源食品机械制造有限公司

Discharging device for mechanical equipment

InactiveCN111703914AAchieve unblockingThere will be no residue phenomenonLarge containersLoading/unloadingElectric machineryEngineering

The invention discloses a discharging device for mechanical equipment, and relates to the technical field of mechanical equipment. The discharging device includes a collecting tank, a mounting columnis connected with the collecting tank in a rotating mode, a first motor is fixedly connected with the bottom of the collecting tank on one axial side of the mounting column, bearing rods are fixedly connected with one side of the top end of the mounting column at equal intervals, scrapers are fixedly connected with two sides of the bottom of the bearing rods, and two rotating rollers are connectedwith the bottom of the bearing rods between the scrapers in a rotating mode. Feeding holes are opened at the bottom of the collecting tank and corresponds to the lower parts of the scrapers on two sides of the bottom of the bearing rods respectively, a sending shell is fixedly connected with the bottom of the collecting tank below the feeding holes, a mounting plate is fixedly connected with thebottom of the sending shell, a mounting box is fixedly connected with the bottom of the mounting plate, a sending drum is fixedly connected with the bottom of the mounting tank, a transmission columnis connected with the sending drum in a rotating mode, a second motor is fixedly connected with an outside wall of the sending drum on one axial side of the transmission column, and a spiral sending blade is fixedly connected with the transmission column. The device is reasonable in structural principle design, convenient for operation and use, and high in practicability.

Owner:孟正明

Fruit and vegetable beverage reverse bagging, filling and sealing machine

InactiveCN105480451AImprove packaging efficiencyLow costWrapper twisting/gatheringSuccessive articlesButt jointThin membrane

The invention discloses a fruit and vegetable beverage reverse bagging, filling and sealing machine capable of once finishing bagging, filling and sealing. The machine comprises a storer and a feeding pipe arranged at the lower part of the storer; a discharge port is formed in the lower part of the feeding pipe; a drum capable of rotating is arranged in the side direction of the feeding pipe; a plastic film is arranged on the drum; multiple parallel guide rollers are arranged between the drum and the feeding pipe; a reverse former is arranged on the feeding pipe; the feeding pipe is provided with a longitudinal sealing heater below the reverse former; the plastic film bypasses through all the guide rollers in sequence, can be wound at the outer periphery of the feeding pipe through the reverse former, and are in longitudinal butt joint to form a cylindrical bag through the longitudinal sealing heater; a transverse sealing heater for sealing the upper part and the lower part of the cylindrical bag is arranged below the feeding pipe; and a shearing structure is arranged on the transverse sealing heater.

Owner:CHONGQING XIUCAI BAY FRUIT & VEGETABLE PROFESSIONAL COOP

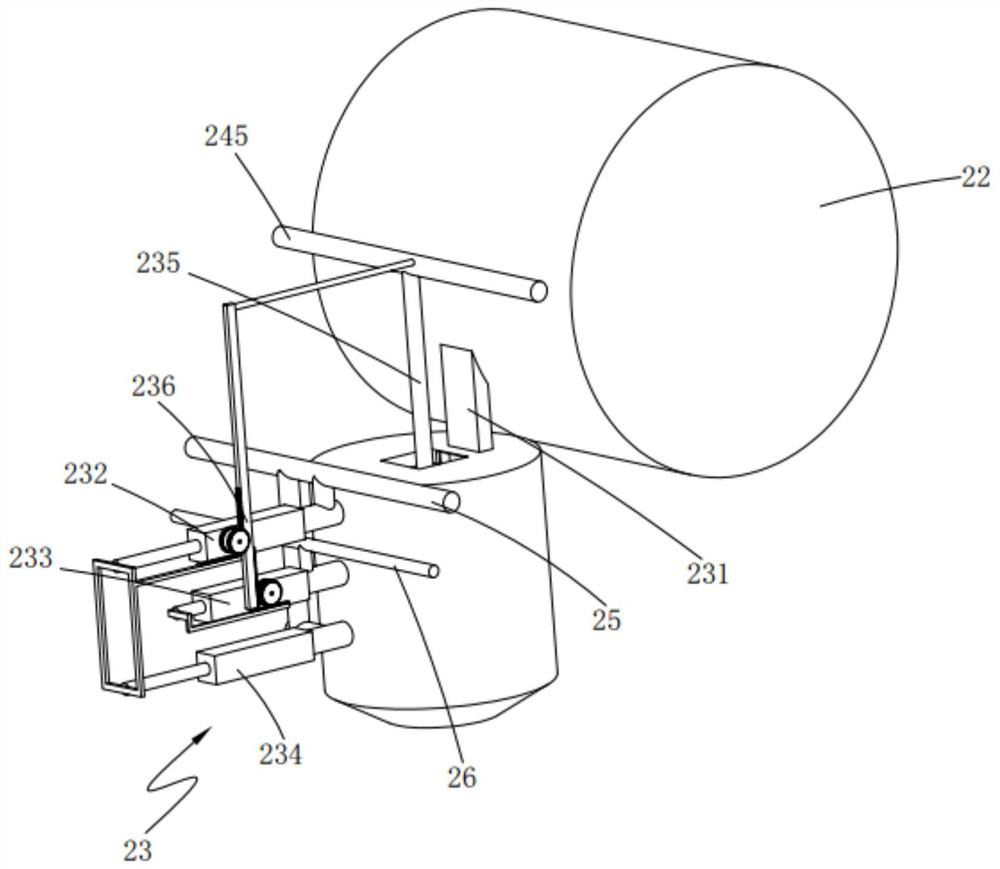

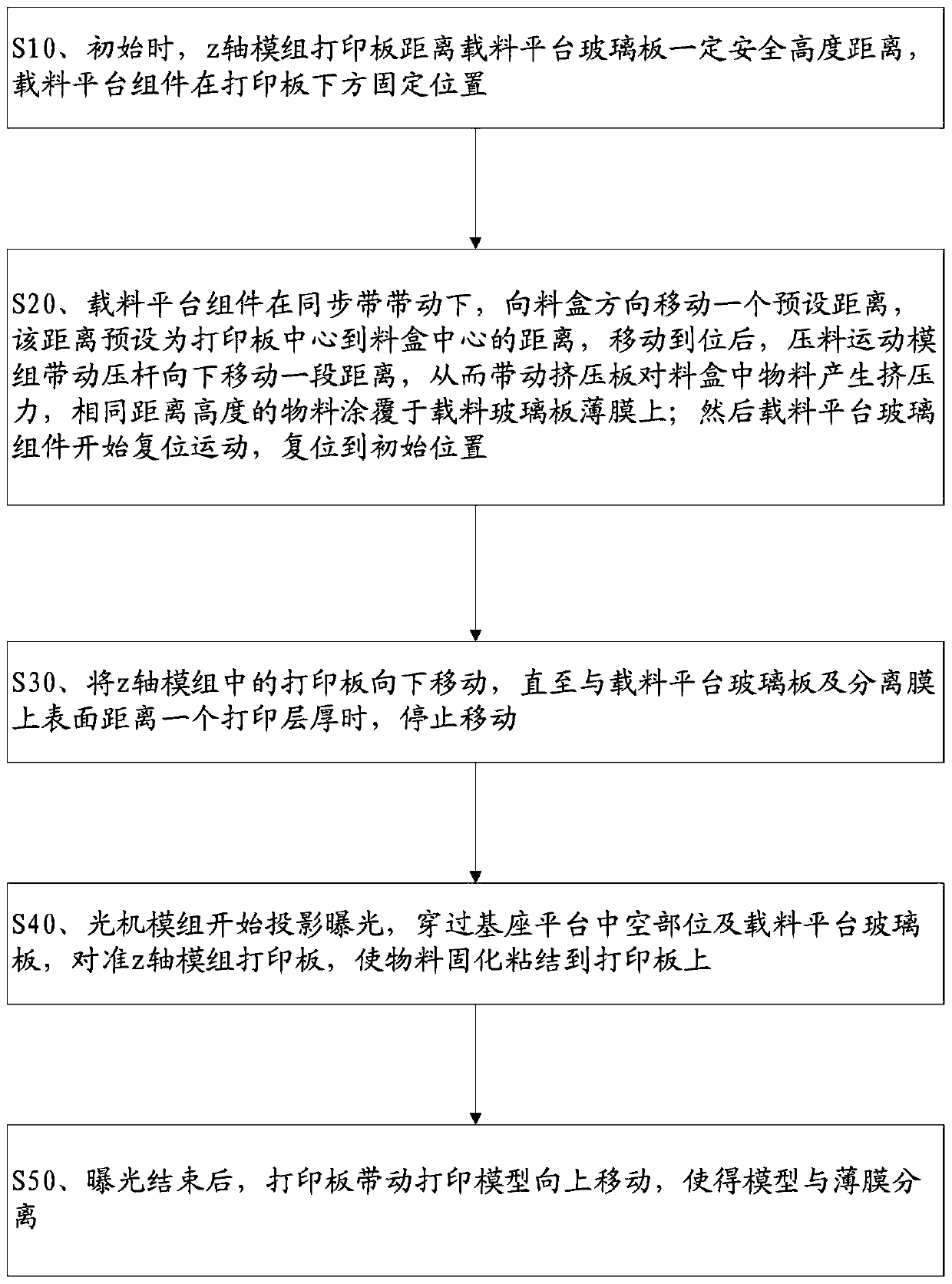

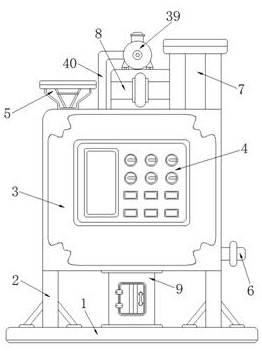

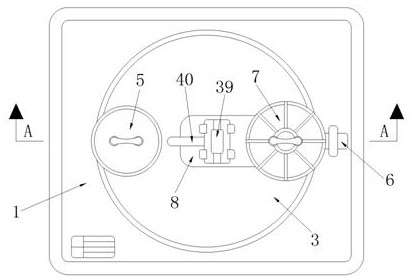

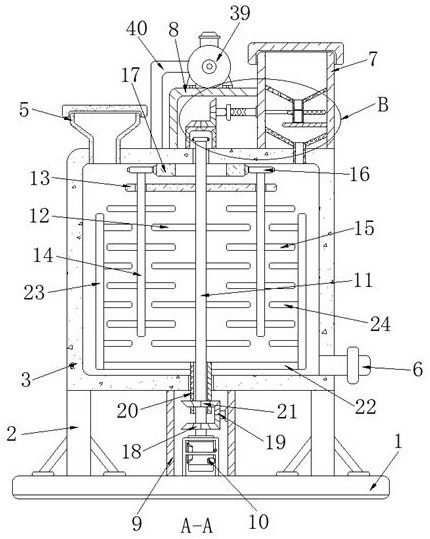

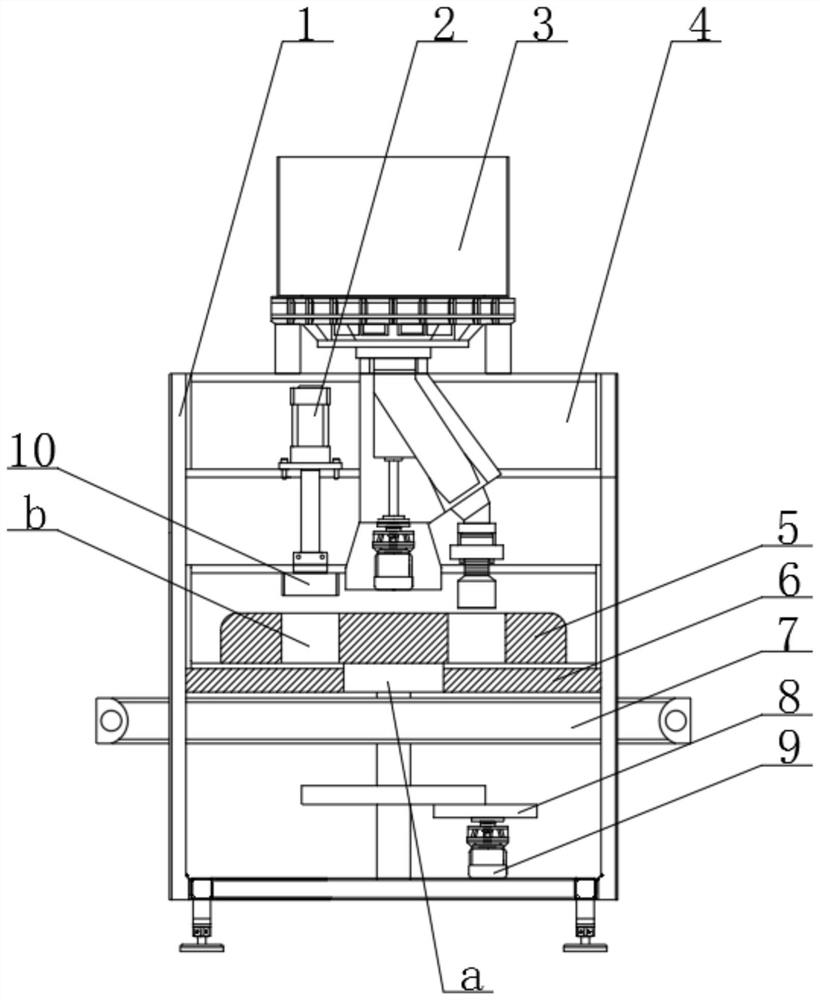

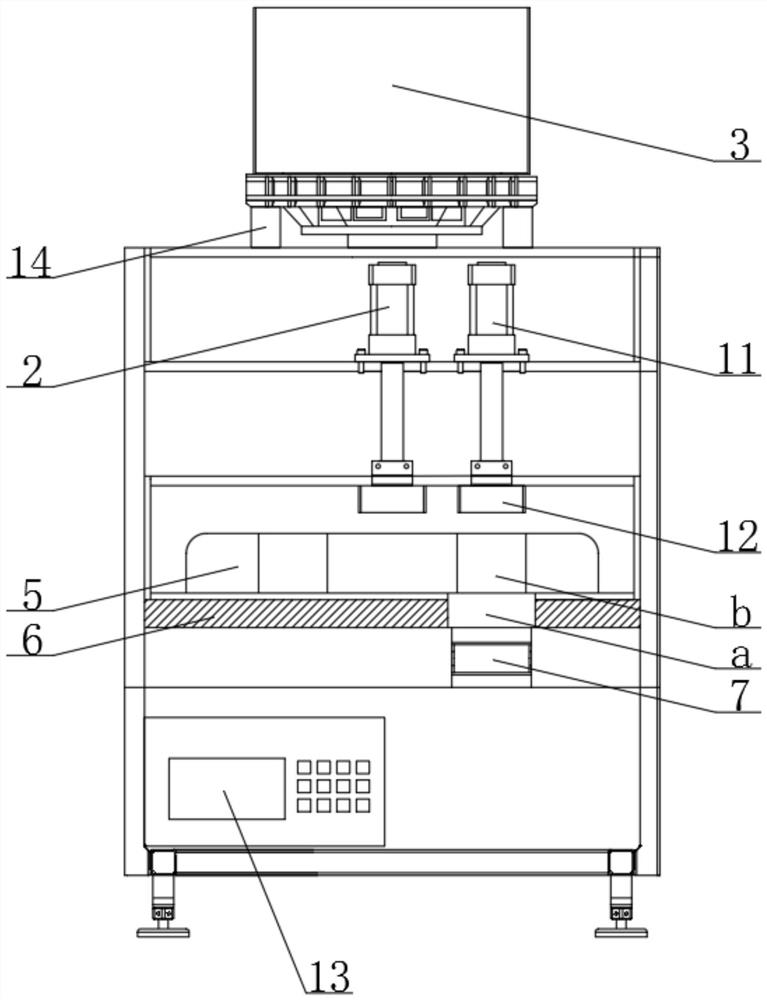

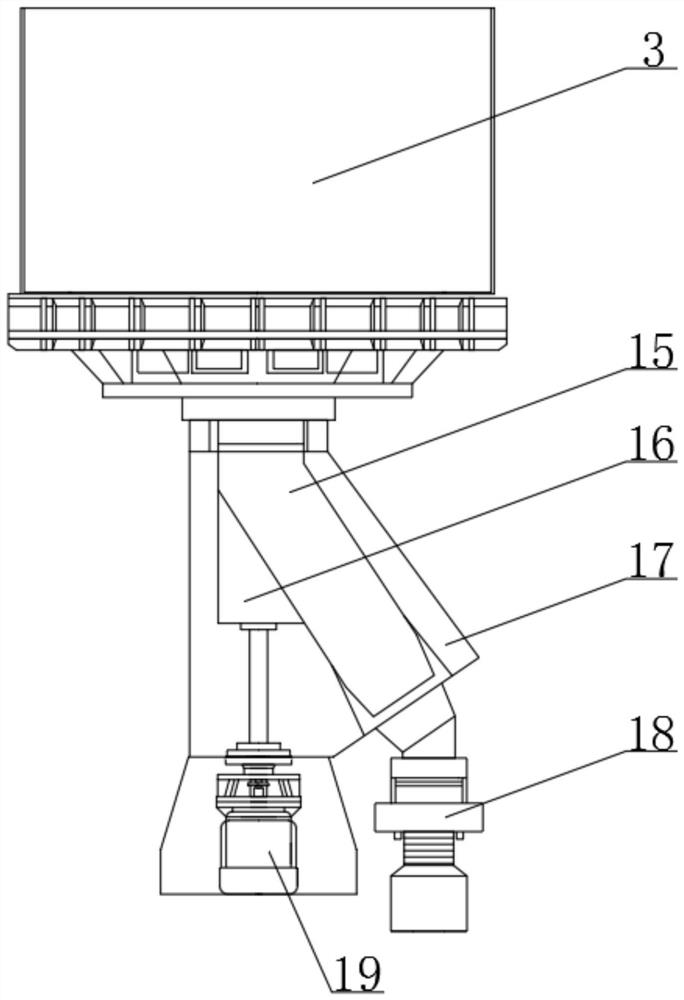

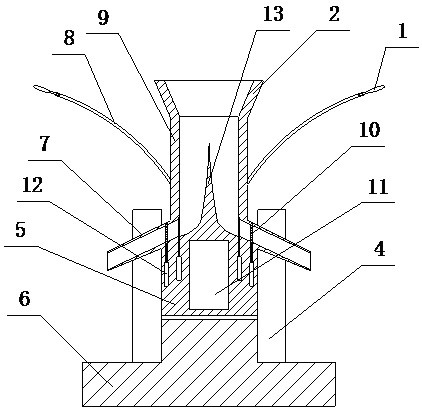

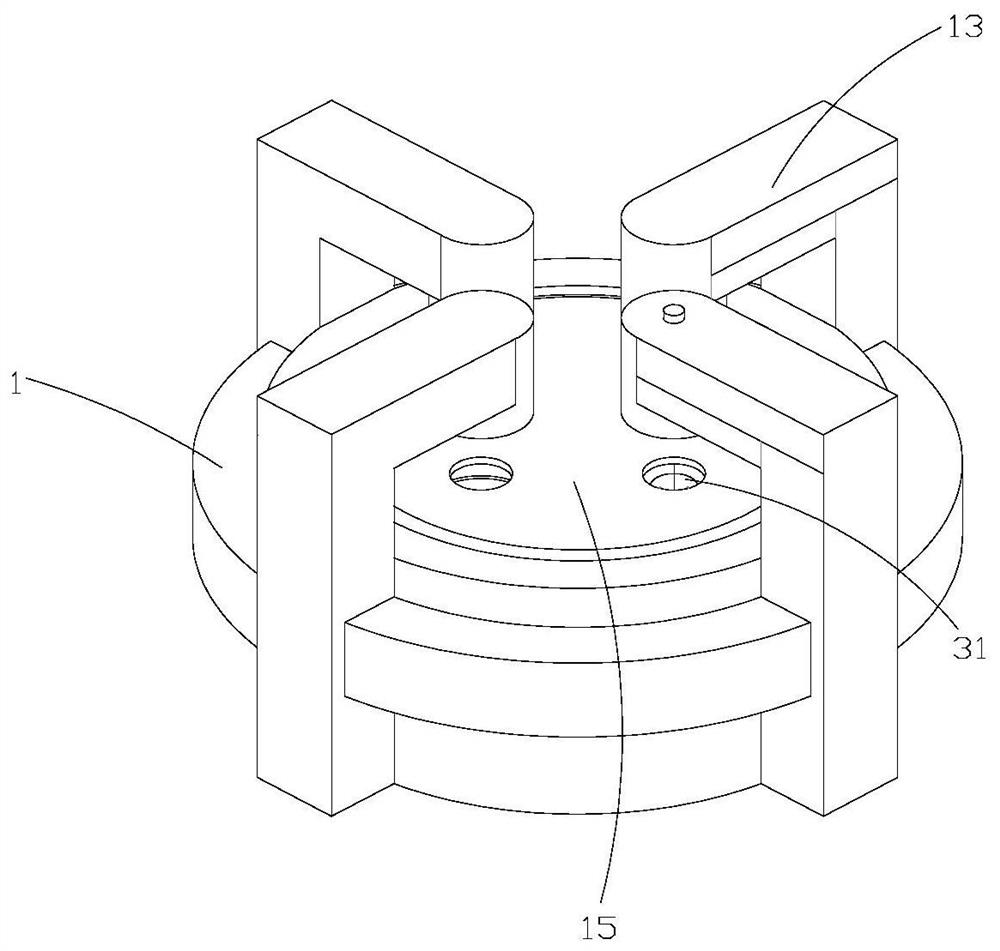

3D printing quantitative feeding device, 3D printer and 3D printing method

ActiveCN111136912ASolving 3D printing problemsRealize quantitative feedingManufacturing platforms/substratesCeramic shaping apparatus3d printComputer printing

The invention discloses a 3D printing feeding device, a 3D printer and a 3D printing method. The 3D printing feeding device comprises a base, a feeding component, a loading platform and a platform driving component, wherein the feeding component, the loading platform and the platform driving component are fixed above the base; the loading platform is positioned at the lower part of the feeding component; the platform driving component is positioned on one side of the loading platform and the feeding component; one end of the platform driving component is connected with the feeding component and the loading platform separately; and the platform driving component drives the loading platform to feed the material to a working area in a directional manner. A magazine extrudes in a quantitativemanner, the platform moves back and forth, the problem about 3D printing of viscous and difficult-to-flow resin is solved, and the 3D printing feeding device can be particularly applied to ceramic 3Dprinting, and 3D printing manufacturing of a dental wainscot and inlay, can realize quantitative feeding and saves the material; the magazine adopts magnetic attraction and a pin hole for positioningand can be conveniently detached and changed; and application of an optical coupler, an photoelectric separation blade and a linear guide rail is precise in positioning and improves the precision.

Owner:HANS LASER TECH IND GRP CO LTD

Cold-pressed tea oil grease deacidification equipment convenient for adding auxiliary materials and deacidification method

ActiveCN114806709AStir wellEasy to add quantitativelyRotary stirring mixersTransportation and packagingProcess engineeringMechanical engineering

The invention discloses cold-pressed tea oil grease deacidification equipment facilitating auxiliary material adding and a deacidification method. The cold-pressed tea oil grease deacidification equipment comprises a bottom plate and a supporting column, and the supporting column is fixedly and vertically installed on the top face of the bottom plate; the box body is fixedly mounted on the top surface of the supporting column; the control panel is embedded in the front side surface of the box body; the feeding hopper penetrates through the left side of the top surface of the box body; the discharging pipe is arranged in a manner of penetrating through the lower end of the right side wall of the box body, and a valve is mounted on the discharging pipe; the material adding cylinder is fixedly mounted on the right side of the top surface of the box body; and the protective shell is mounted on the top surface of the box body. According to the cold-pressed tea oil grease deacidification equipment convenient for adding the auxiliary materials, materials can be quickly, effectively and uniformly stirred, the working efficiency is improved, meanwhile, quantitative adding can be conveniently carried out, the adding precision is guaranteed, time and labor are saved, the efficiency is high, and the practicability is high.

Owner:GUIZHOU NORMAL UNIVERSITY

Adjustable quantitative filtering and screening machine for flour

ActiveCN111167706AEasy to adjust and fixRealize quantitative feedingSievingScreeningGear driveGear wheel

The invention relates to the technical field of quantitative screening equipment for flour, in particular to an adjustable quantitative filtering and screening machine for flour. A servo motor is usedfor driving a first rotating shaft to rotate, so that a first gear drives a second gear to enable a second rotating shaft to rotate, and a rotating block at the top end rotates; because the eccentricposition of the inclined surface of the top end of the rotating block is matched with a roller, when the rotating block rotates, the roller drives a U-shaped frame to move up and down, a screening basket moves up and down along with the U-shaped frame to generate oscillation, and the flour is filtered through a sieve screen and falls into a material collecting box; the weight of the material collecting box is gradually increased, and a supporting plate is pressed to vertically move down until a braking switch is pressed down, a servo motor is braked, and oscillation discharging is stopped; and at the moment, the material collecting box can be replaced for collecting materials again. The position of the braking switch keeps unchanged, i.e., correspondence to the same flour amount is realized, and quantitative material collection is realized; and the position of the braking switch is convenient to regulate and fix, and can adapt to flour collection weight of different requirements.

Owner:浙江冯源科技有限公司

Cattle breeding method

InactiveCN107232141AStop slippingImprove cleanlinessFood processingAnimal feeding devicesDiseaseMaterials preparation

The invention belongs to the technical field of livestock breeding and discloses a cattle breeding method. The method comprises the steps of site building, a calf raising period, an adult cattle developing period and an adult cattle growing stage. A feeding device is arranged in a calf breeding room, and the feeding device comprises a material storage chamber, a material preparation part and a discharging part; the bottom of the material storage chamber is aslant arranged, and a discharging opening is formed in the bottom of one side of the material storage chamber; the material preparation part comprises a support pillar and a balance bar, the balance bar is hinged to the support pillar, the balance bar comprises a quantitative end and a material preparation end, a quantitative block is arranged on the quantitative end, and a material preparation box is arranged at the material preparation end; the discharging part comprises a discharging barrel and a diverter which is located on the bottom of the discharging barrel, a circular material baffle is arranged above the diverter in the discharging barrel, and a reset elastic part is arranged between the bottom of the material baffle and the side wall of the discharging barrel; material splitting grooves are formed in the bottom of the discharging barrel, and automatic suction machines are arranged on the bottoms of the discharging grooves. The cattle breeding method solves the problems that in the cattle breeding process of the prior art, the calf is low in immunity and easy to infect diseases, so that the survival rate is low.

Owner:桐梓县华美乐享养殖有限公司

Automatic preparation equipment for building putty

ActiveCN110787682ASimple structureEasy to operateRotary stirring mixersTransportation and packagingTorsion springElasterell

The invention belongs to the technical field of building equipment, and particularly relates to automatic preparation equipment for building putty. The technical problem to be solved by the inventionis how to provide the building putty automatic preparation equipment which is uniform in stirring and capable of automatically preparing materials. The automatic preparation equipment comprises a support, a rack, two material tanks, material baffles, a mixing tank, torsion springs, a discharging pipe, a shielding plate, a first elastic piece, a stirring device, a pull rod, a stirring block and thelike, wherein the rack is arranged on the support, the two material tanks are arranged at the top of the support, the material baffles are rotatably arranged on discharge ports of the material tanks;each torsion spring is arranged between each material baffle and the corresponding discharge port. The effects of uniform stirring and automatic batching are achieved. Through driving the pull rod tomove leftwards, the mixing tank is located on the lower side of the material tanks; the pull rod abuts against a special-shaped rod, then the stirring block is driven to rotate, and quantitative feeding can be achieved.

Owner:CHINA NUCLEAR IND ZHONGYUAN CONSTR

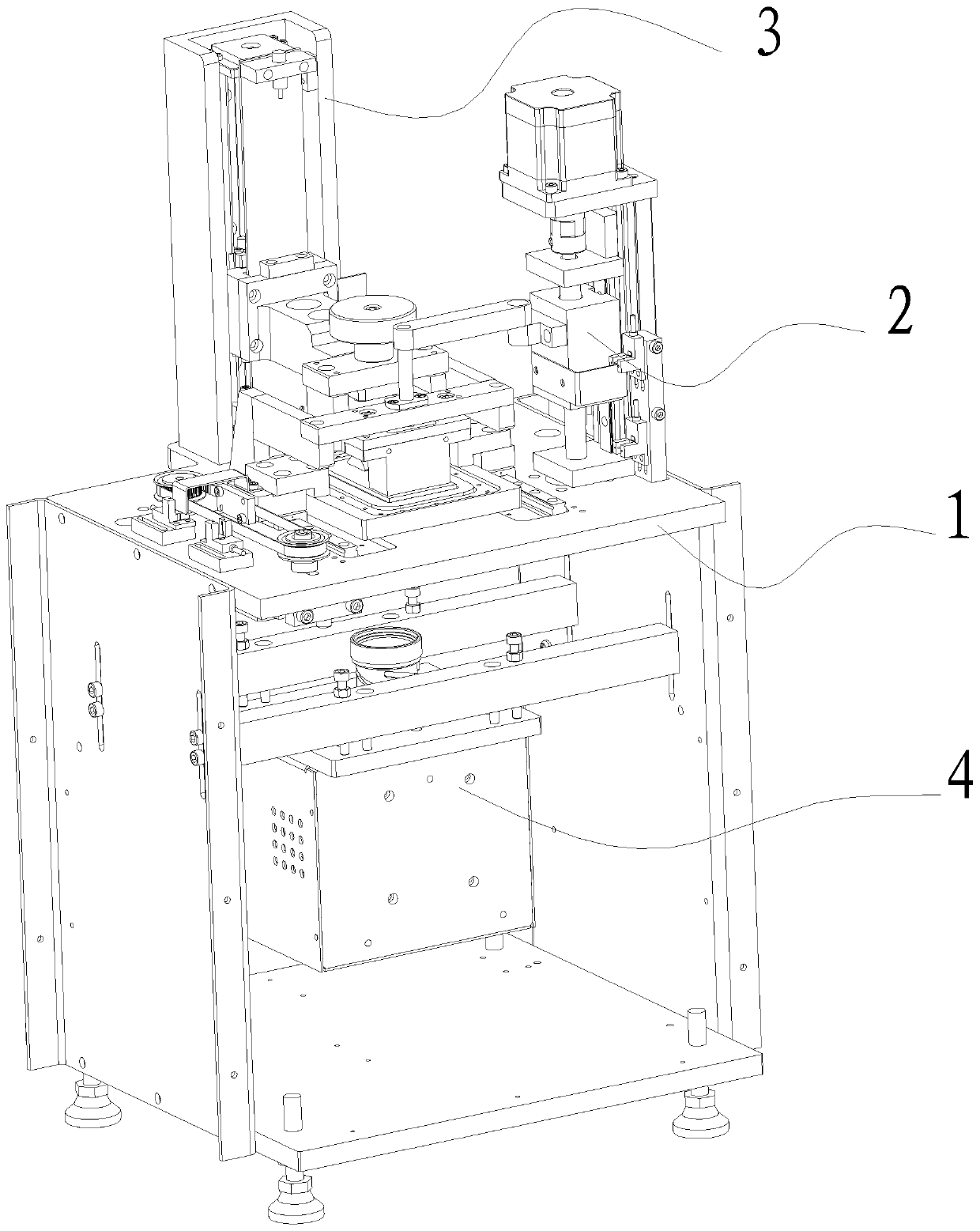

Tabletting device for producing health foods

InactiveCN112848478AGuaranteed stabilityGuaranteed uptimeFood shapingShaping pressEngineeringTableting

The invention relates to the technical field of processing of health foods and particularly relates to a tabletting device for producing health foods. The tabletting device comprises a mounting frame, a storage barrel, a tabletting round mold, a mounting plate and a semi-conical shell, wherein a supporting plate is mounted at the upper end of the mounting frame; the storage barrel is mounted in the middle of the upper surface of the supporting plate; the semi-conical shell is mounted on the mounting frame; a pipe frame is mounted in the middle of the interior of the semi-conical shell; the mounting plate is mounted on the mounting frame below the semi-conical shell; the tabletting round mold is mounted on the mounting plate; the tabletting round mold is rotatably connected with the mounting plate through a rotating shaft; four mold grooves are evenly formed in the outer circumferential surface of the tabletting round mold; and a discharging electric cylinder is mounted in the middle of the front of the mounting frame. According to the tabletting device for producing the health foods, the tabletting round mold and the semi-conical shell are arranged; the automation level of the device is increased; the machining quality of the device is improved; and the device is capable of achieving quantitative feeding.

Owner:陕西优民惠科技有限公司

A dry mixing equipment for granular materials

InactiveCN105806059BIncrease temperatureSpeed up the drying processDrying solid materialsDrying machines with non-progressive movementsPulp and paper industryGranular material

The invention discloses particle material drying and mixing equipment. The equipment comprises a hollow cylindrical drying bin, and a bracket arranged below the drying bin; a rotating shaft is arranged on the inner side of the drying bin; the axis of the rotating shaft and the axis of the drying bin form an eccentric structure; at least four blades are arranged on the rotating shaft; in the rotating process of the blades, the outer side edges of the blades can be bonded on the inner wall of the lower end of the drying bin; and a feed port is formed in the upper end of the drying bin. As the rotating shaft and the drying bin are eccentrically arranged, in the rotating process of the blades, materials at the bottom of the drying bin can be totally driven to one side of an isolation cover at the upper part when passing through the bottom of the drying bin, and water in particle materials with water is output by a water collecting tank in the isolation cover in a concentrated manner; and the equipment is simple in structure and more uniform in drying of the materials.

Owner:山东艾克赛尔机械制造有限公司

Automatic feeding device for free-range chickens

PendingCN111972319AImprove meat qualityRealize quantitative feedingAvicultureTaming and training devicesEngineeringMechanical engineering

The invention discloses an automatic feeding device for free-range chickens, which can move on a given track in a circulating manner and carry out timed feeding through a feeder by using the alimentative instincts of the free-range chickens to drive the free-range chickens to continuously move, so as to improve the meat quality of the free-range chickens. The automatic feeding device is characterized in that a storage tank is located above a track; power boxes are separately arranged at the positions, close to the bottom, at two ends of the storage tank; road wheels are separately arranged attwo ends of each power box; the road wheels at two ends of each power box are attached to two sides of the track; the storage tank is divided into an upper tank body and a lower tank body; the upper tank body is of a hollow structure; a placement groove is formed in the lower tank body; a battery pack is arranged in the placement groove; a splitter plate is arranged in the upper tank body; the bottom of the splitter plate extends downwards to be connected with the top of the lower tank body; the thickness of the splitter plate is gradually increased from top to bottom; a control box is arranged at the top of each power box and fixed to the storage tank; and a feeding hopper is arranged at an opening of the storage tank and communicates with the inside of the storage tank.

Owner:王元夫

Cell sap glucose content detection method

InactiveCN113624699AImprove feeding efficiencySimplify detection stepsMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsBiotechnologyCentrifugation

The invention discloses a cell sap glucose content detection method. The method comprises the following steps: a, adding a buffer agent, a cell sap sample and a standard substance into a dilution plate; b, preparing a glucose detection reaction solution; c, adding a glucose detection reaction solution into the detection plate; d, detecting the glucose concentration of the cell sap sample by a microplate reader, and calculating the glucose content of the cell sap sample, wherein the mixing machine comprises a main body, a motor, a rotating frame, a bracket, a feeding device, a rotating roller, a rotating disc and a mixing device; according to the method, glucose content detection can be completed by using a small amount of cell sap sample in the cell culture process, pretreatment work such as centrifugation is not needed, and detection steps are simplified; the determination can be completed by the microplate reader, and the operation is simple; meanwhile, the mixing device is adopted when the glucose detection reaction solution is prepared so that the mixing efficiency can be improved; and quantitative feeding can be realized by adopting the feeding device, so that the preparation effect is improved.

Owner:杭州皓阳生物技术有限公司

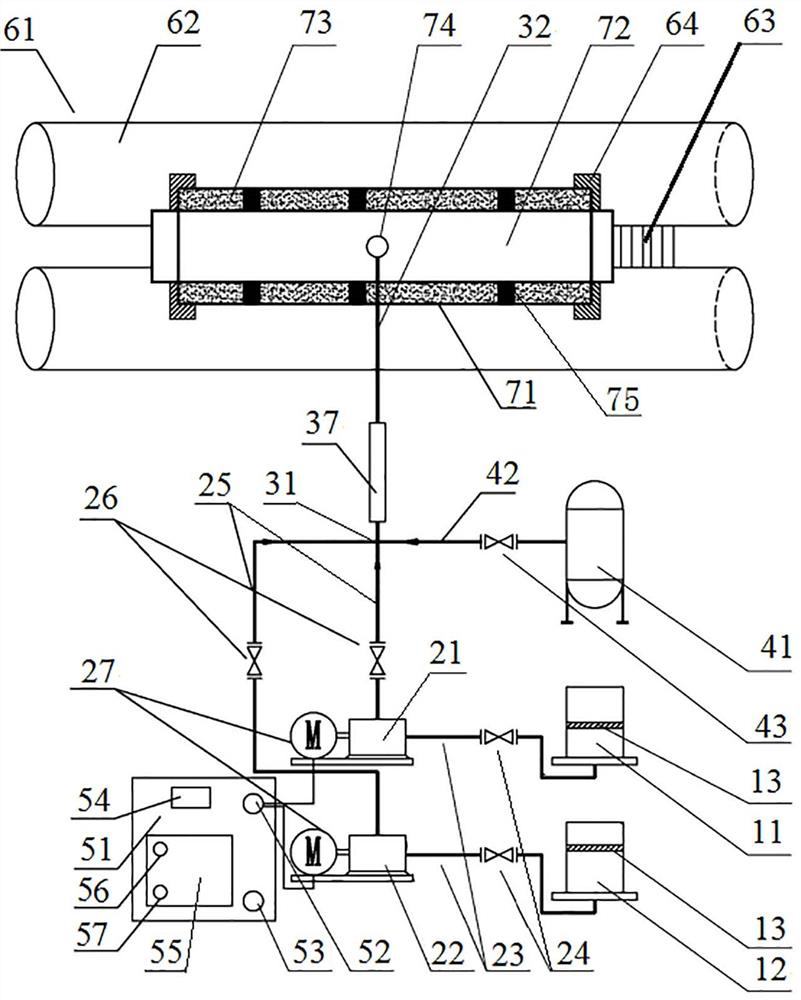

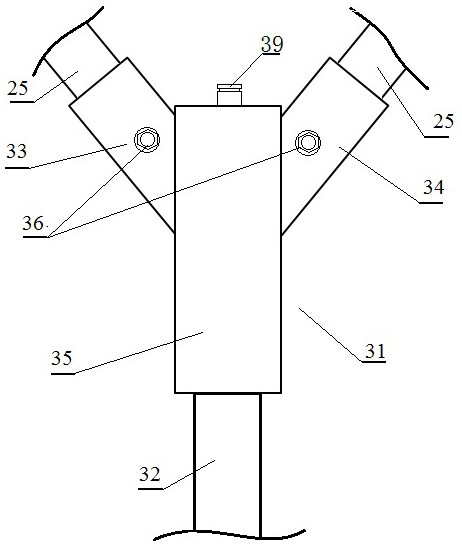

Foaming method for thermal insulation layer of polyurethane foaming thermal insulation pipe

The invention belongs to the field of manufacturing of polyurethane foaming thermal insulation pipes, and particularly relates to a foaming method for a thermal insulation layer of a polyurethane foaming thermal insulation pipe. The foaming method for the heat preservation layer of the polyurethane foaming heat preservation pipe comprises the following steps that firstly, compressed gas is introduced into a material injection pipe, and the material injection pipe is used for injecting a foaming material into an inter-pipe annular space between an inner pipe body and an outer pipe body of the polyurethane foaming heat preservation pipe; 2, two foaming components needed by polyurethane foaming are pumped into the material injection pipe, and the foaming material is pushed into the inter-pipe annular space through compressed gas. The problems that in the prior art, when a polyurethane foaming heat preservation pipe is manufactured, a heat preservation layer is prone to cavities, and operation efficiency is low can be solved.

Owner:SINOPEC SSC +1

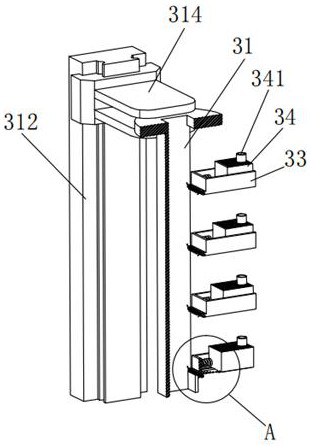

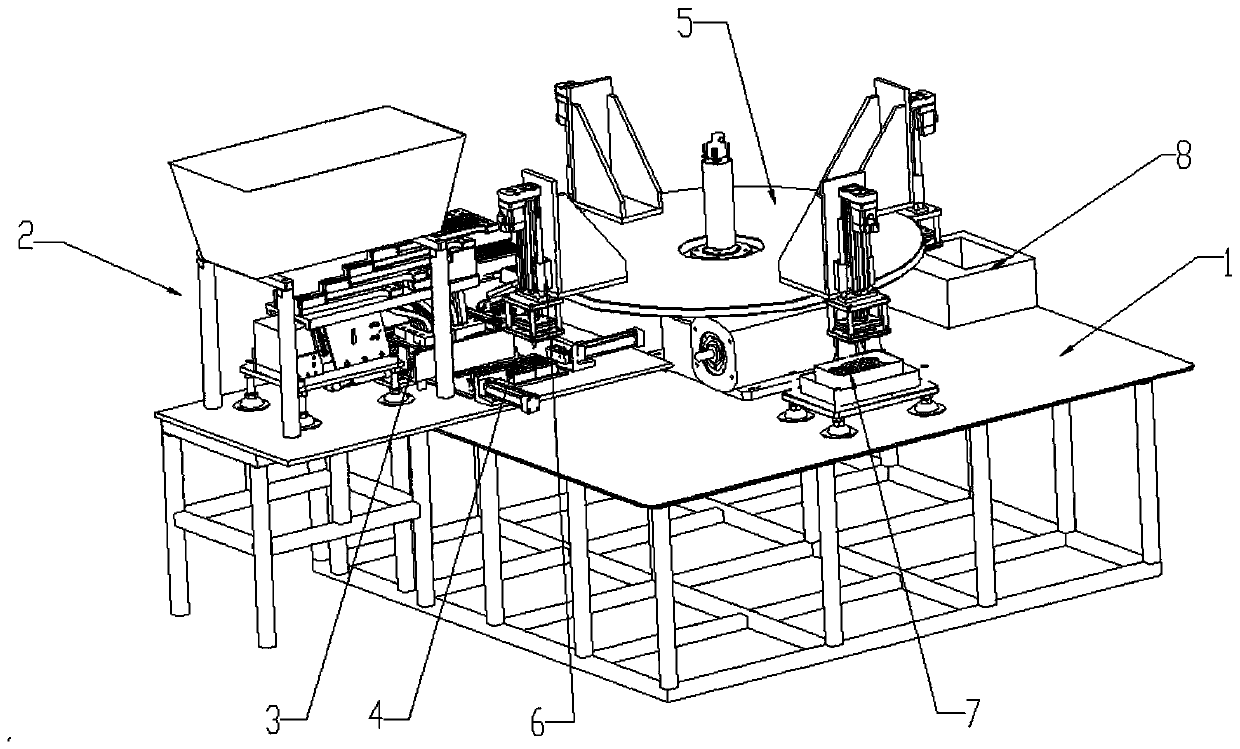

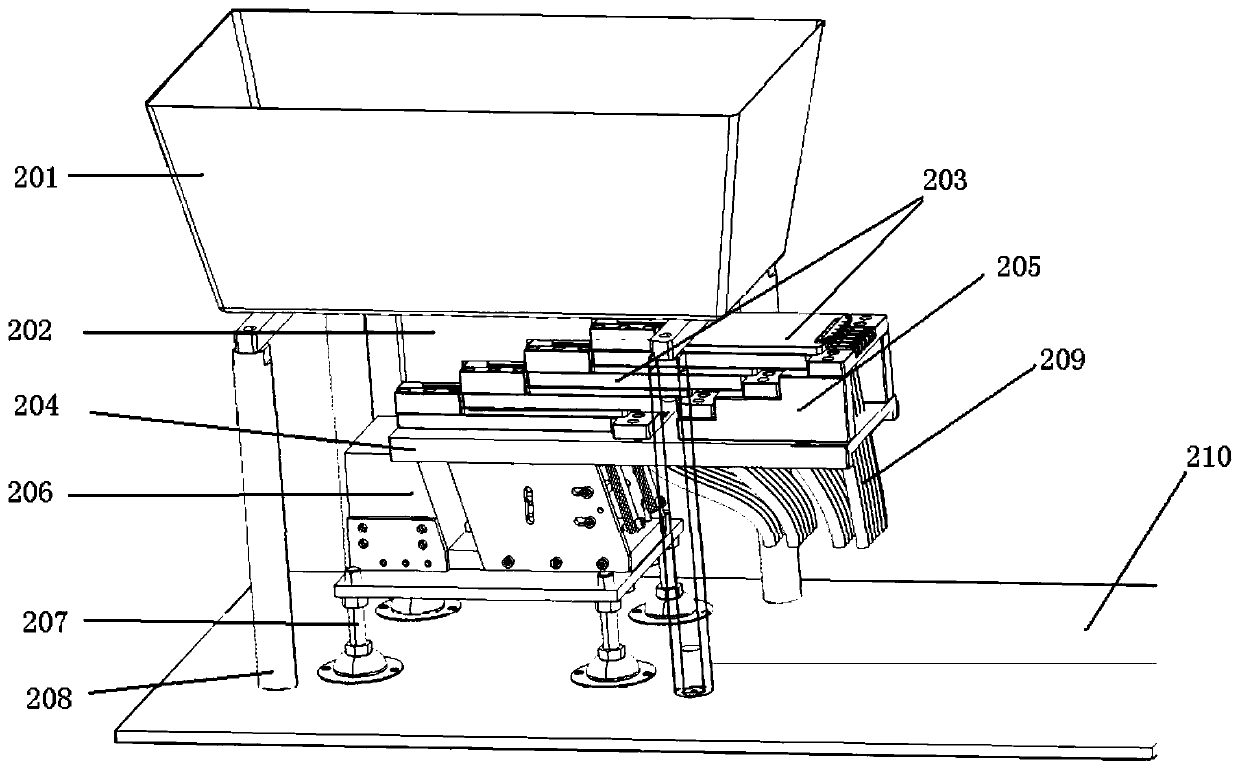

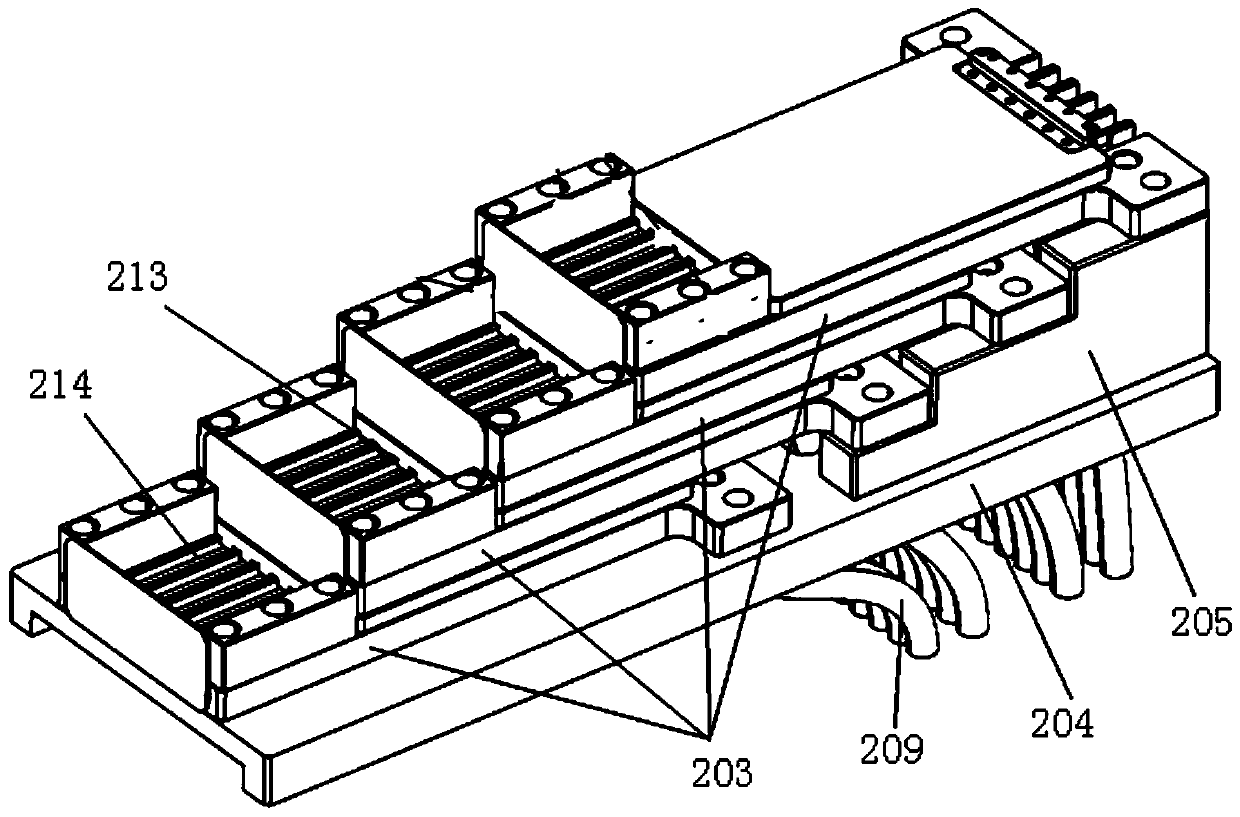

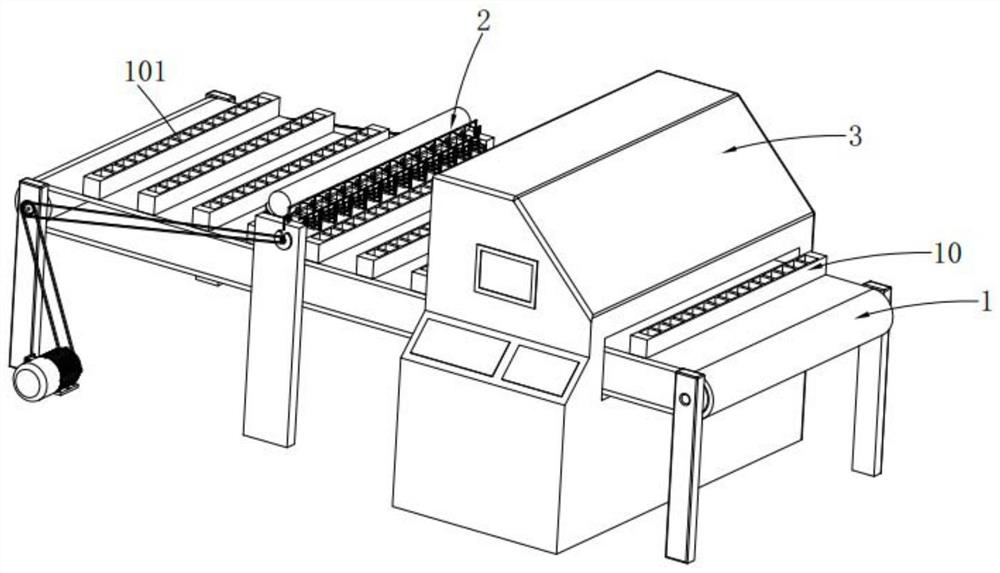

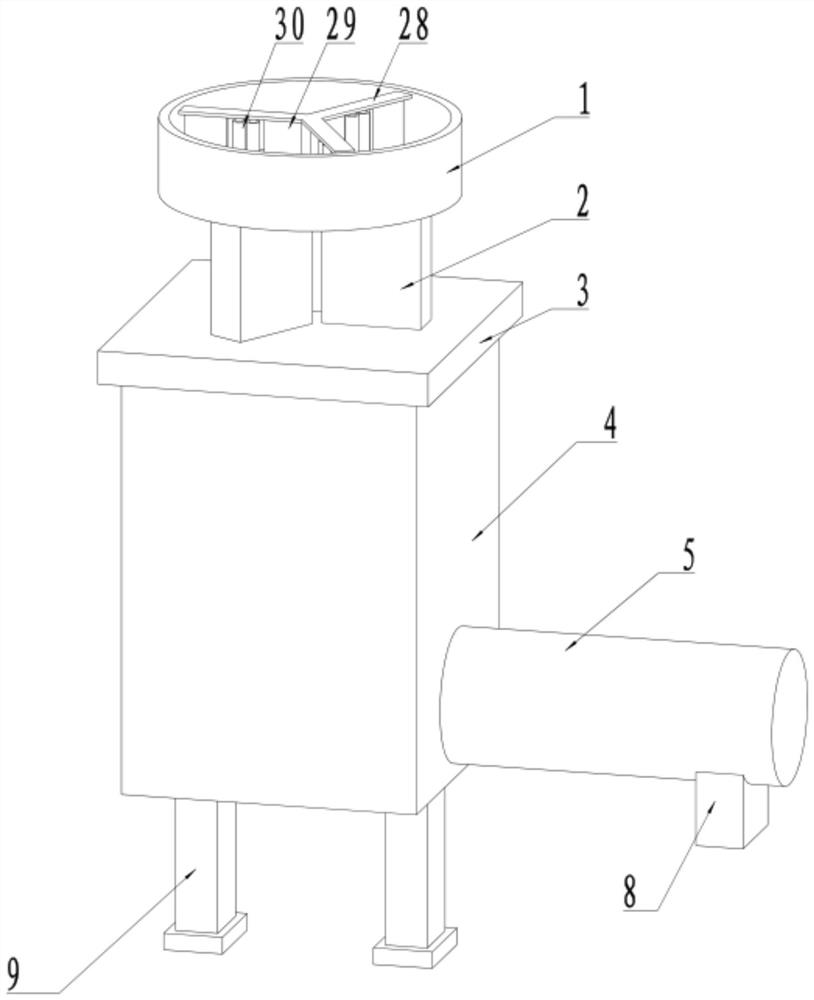

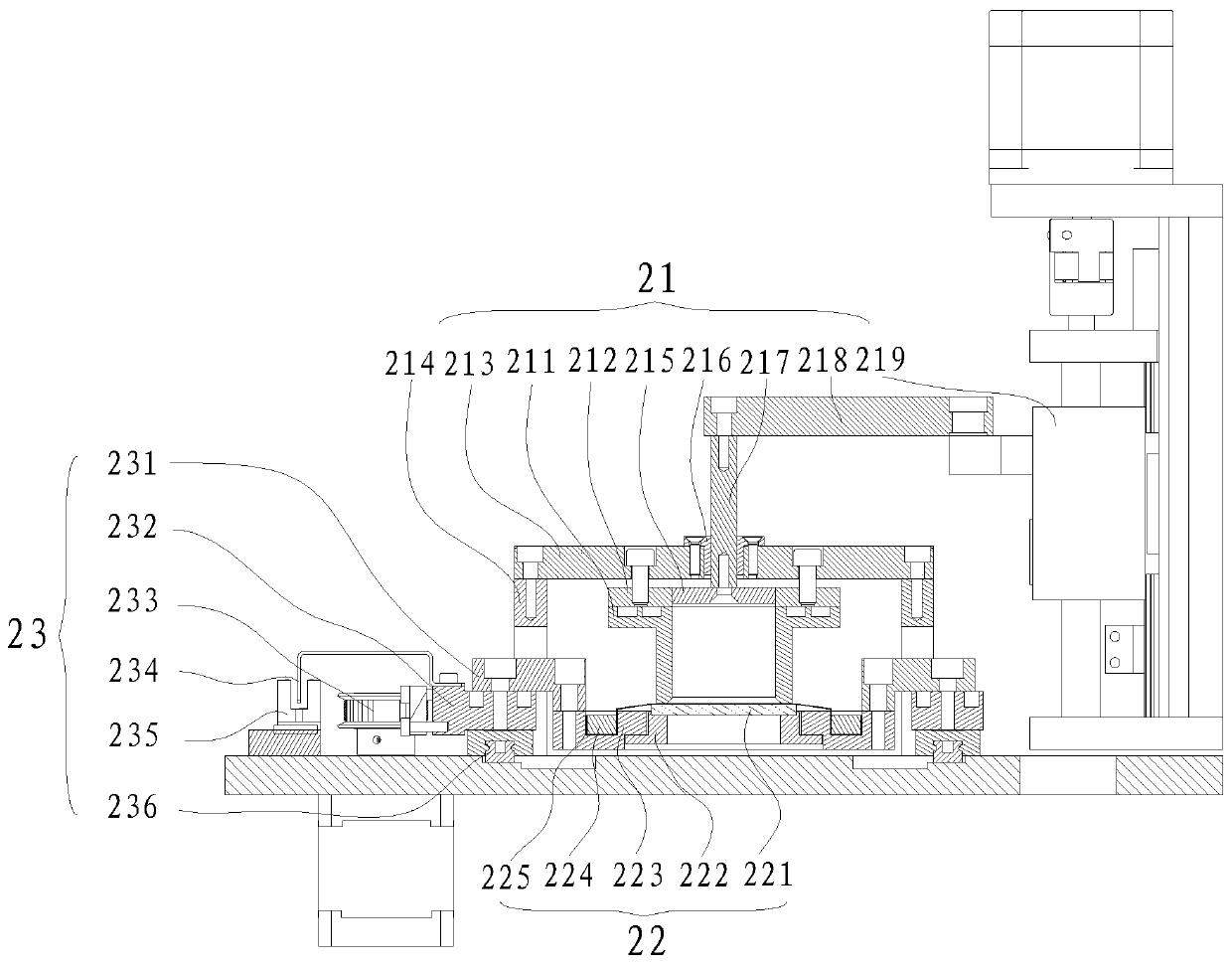

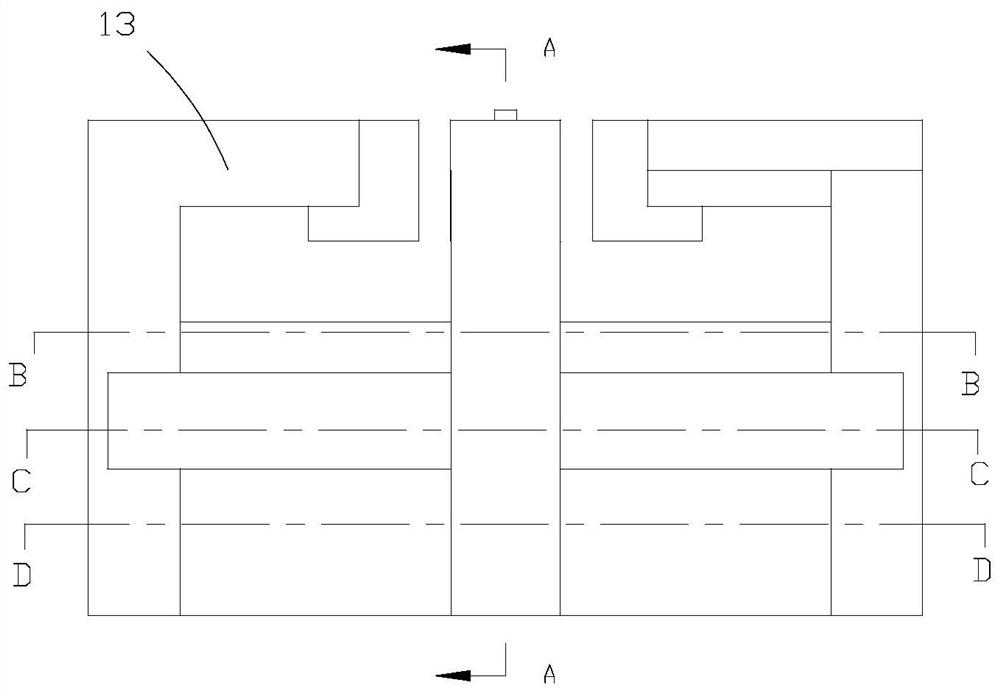

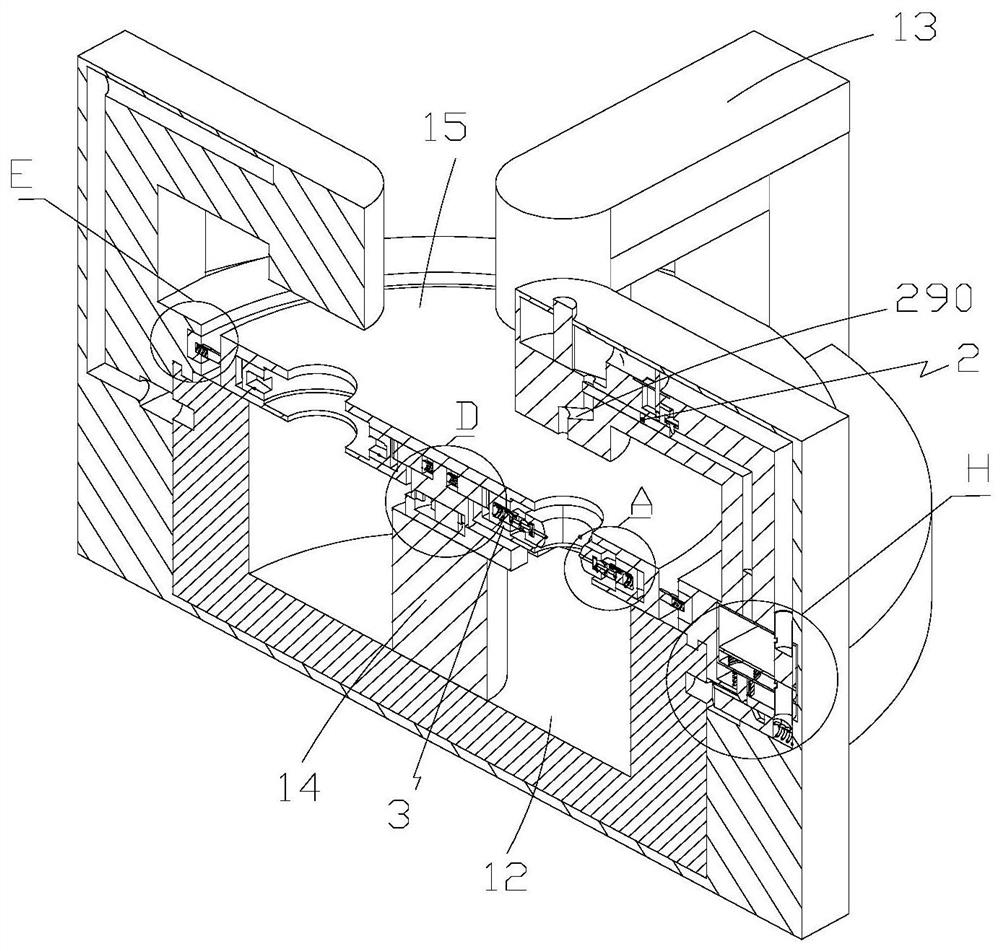

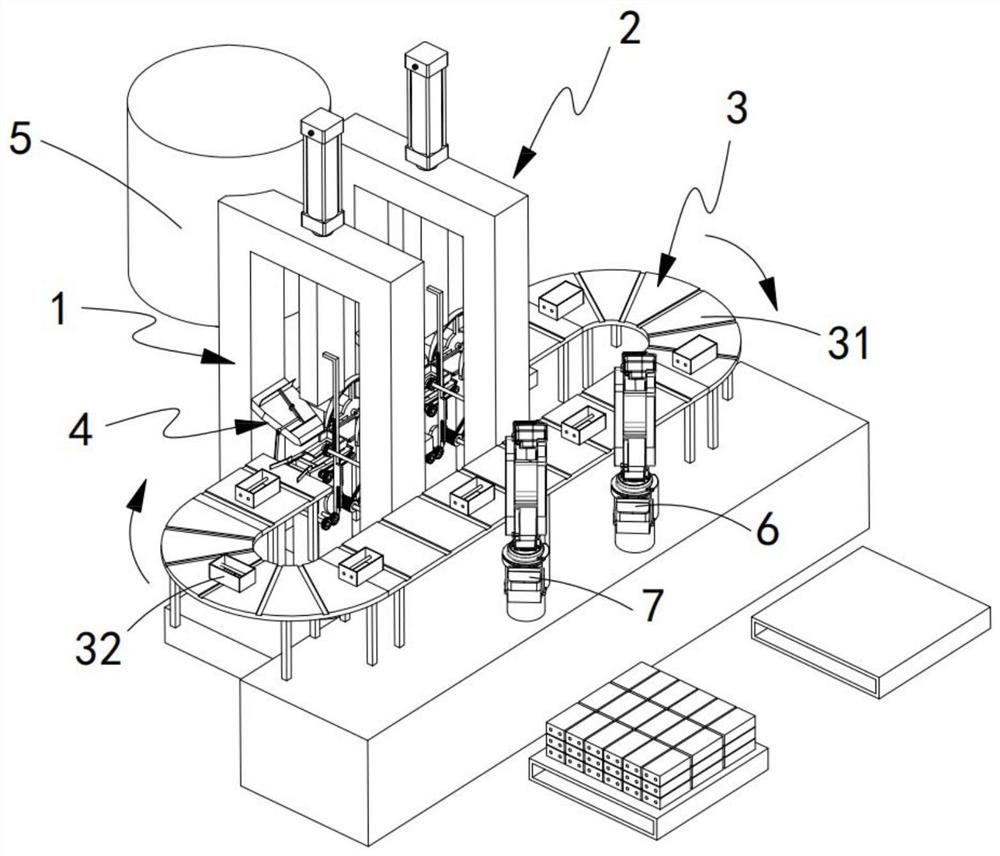

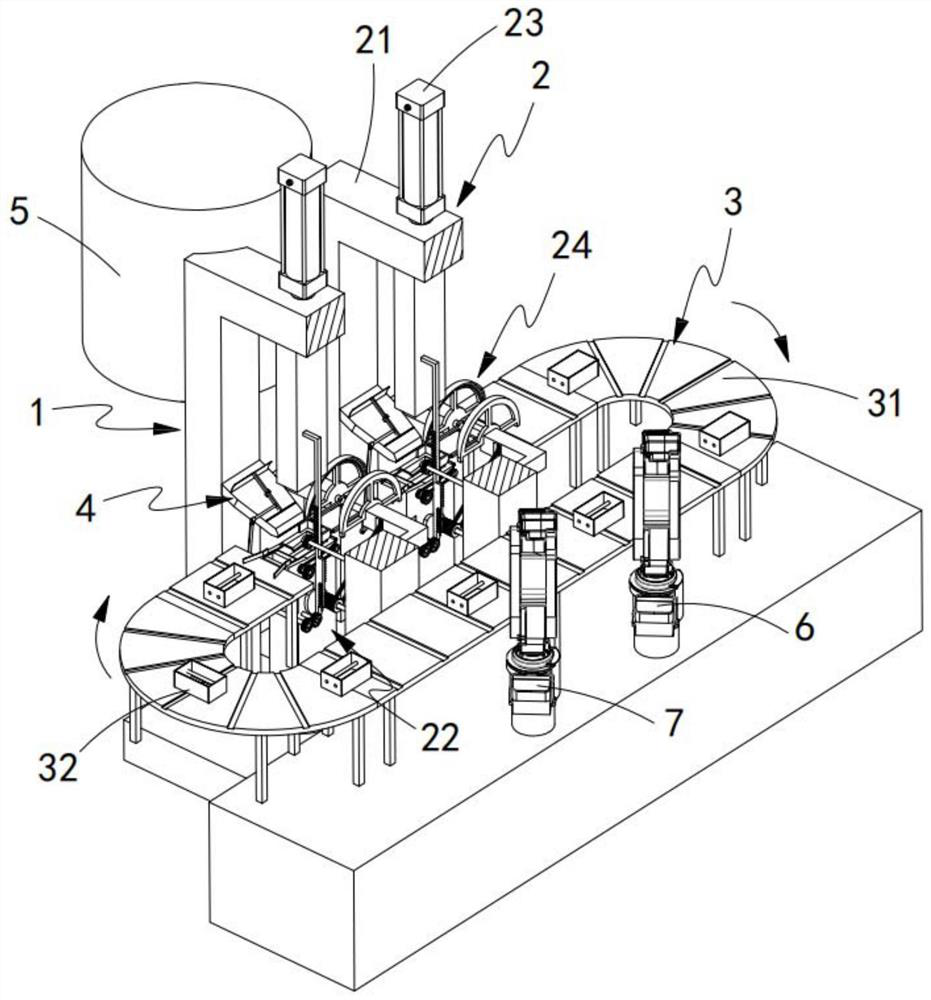

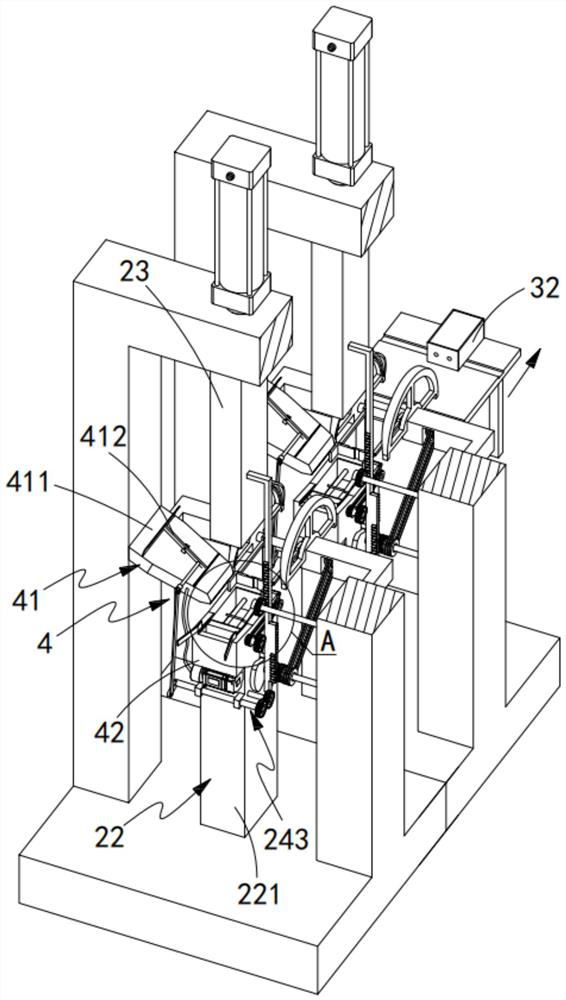

Preparation equipment and process of high-strength magnesia carbon brick for refining ladle

ActiveCN111844374AUniform densityRealize automated productionFeeding arrangmentsShaping conveyorsProcess equipmentFire brick

The invention relates to preparation equipment and process of a high-strength magnesia carbon brick for a refining ladle. The equipment comprises a first pressing device, a second pressing device which is arranged on one side of the first pressing device, a mold circulation device and a powder adding device, the first pressing device and the second pressing device each comprise a rack, a mold cavity assembly, a pressing mold assembly and a transmission assembly and further comprise a mold leading-in assembly; and the process comprises the procedures of mold feeding, primary pressing, secondarypressing, transferring and overturning, reverse side pressing and discharging. The first pressing device and the second pressing device are arranged to press and form the front face and the back faceof powder, transferring and overturning a mold is realized over between the first pressing device and the second pressing device through a second transmission unit, and automation of mold feeding, primary pressing, secondary pressing, transferring and overturning, reverse side pressing and discharging is matched, so that automatic production is achieved, forward and reverse pressing of bricks isachieved, pressure is balanced, and the compaction degree of refractory brick pressing is uniform.

Owner:CHANGXING FUZILING SPECIAL FIRE RESISTANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com