Patents

Literature

587 results about "Elasterell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Elasterell (officially "elasterell-p") is an alternative to the generic term "polyester" for a specific subgroup of inherently elastic, multicomponent textile fibers. The Federal Trade Commission (FTC) has issued a final rule which establishes the name. Elasterell was originally manufactured by E.I. du Pont de Nemours and Company and previously referred to as "T400". The FTC states that because this material is arguably comparable to other multicomponent polyester fibers, other companies that manufacture fibers satisfying the definition of "elasterell-p" may use that name in making required fiber content disclosures on labels.

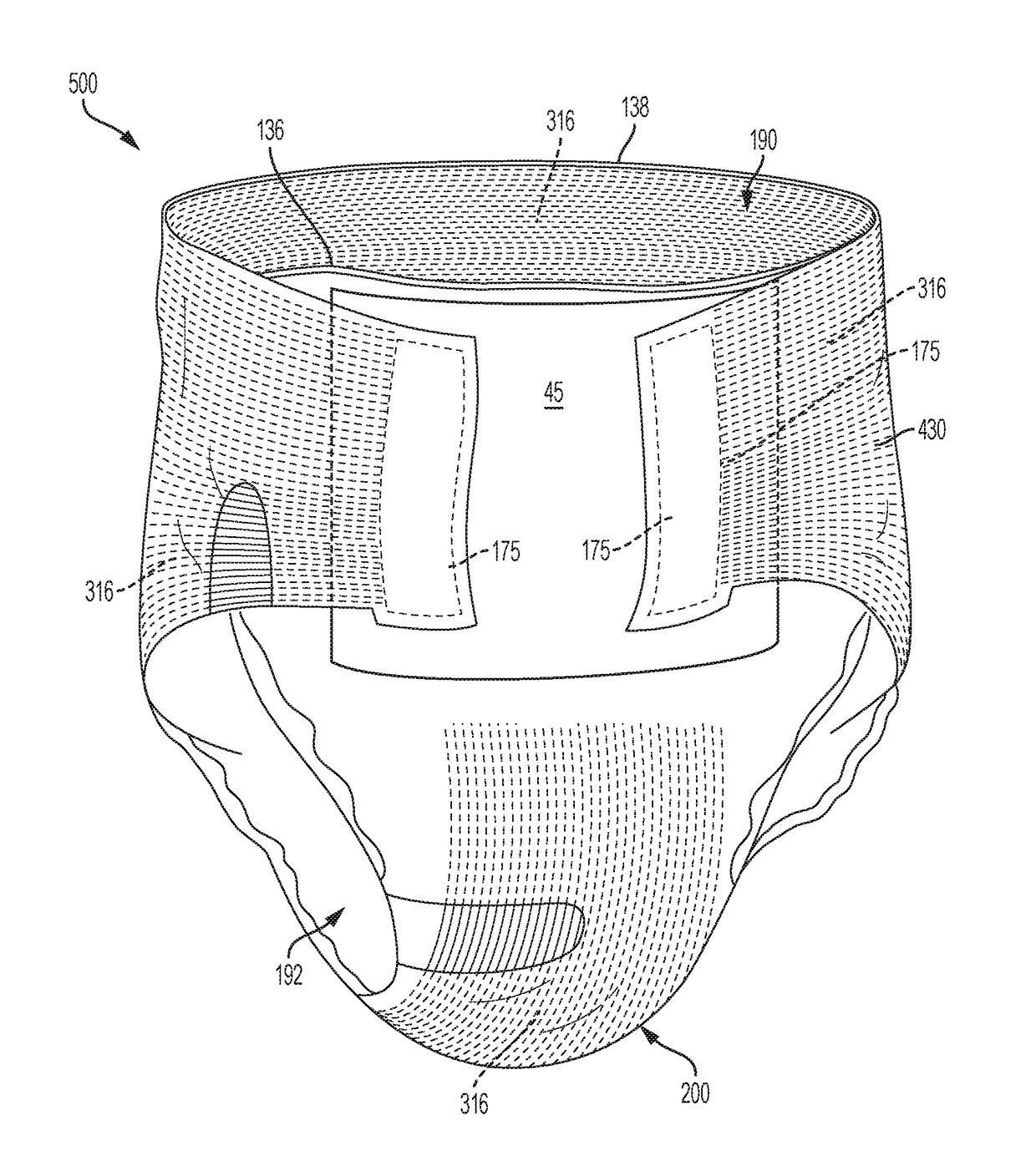

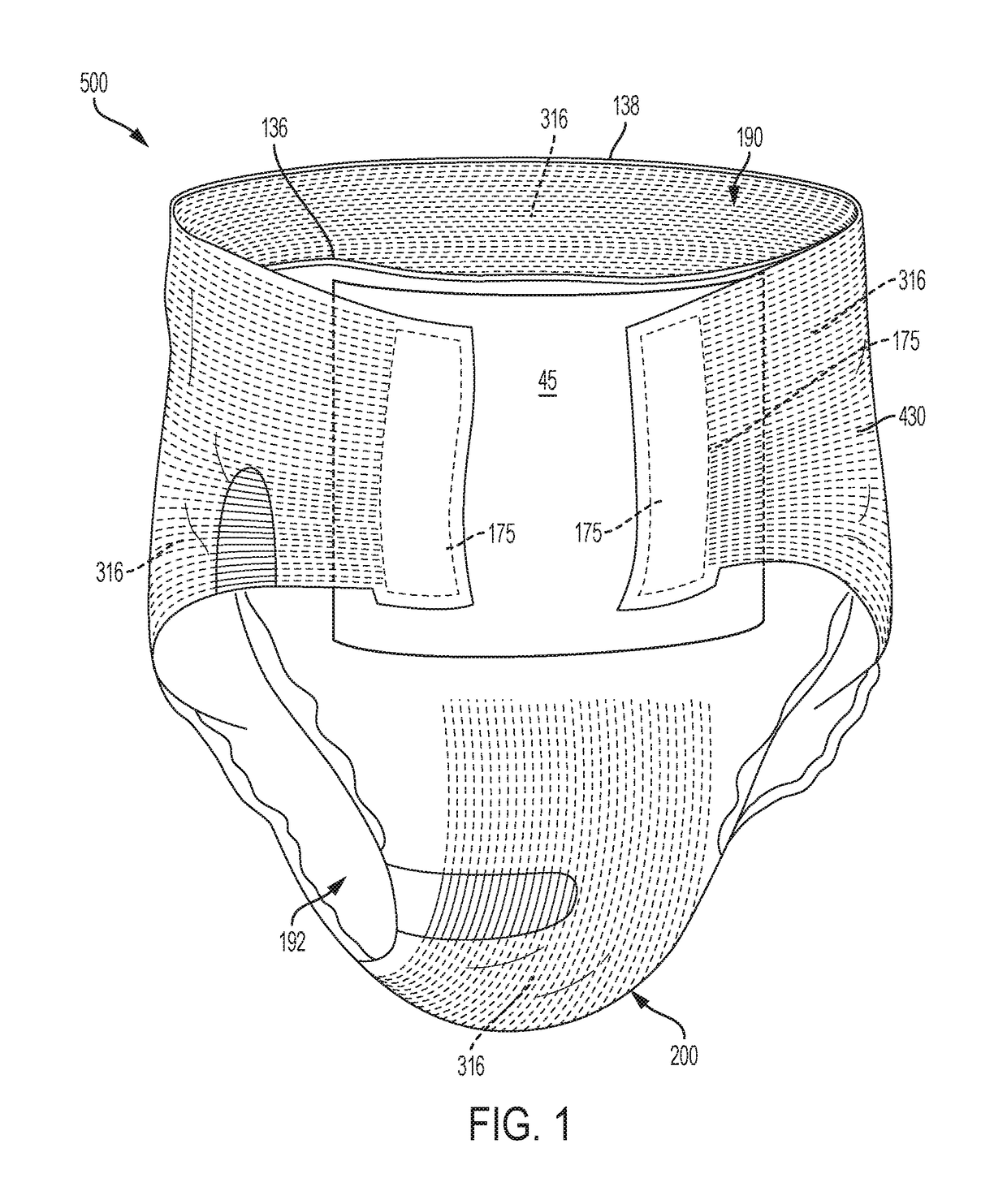

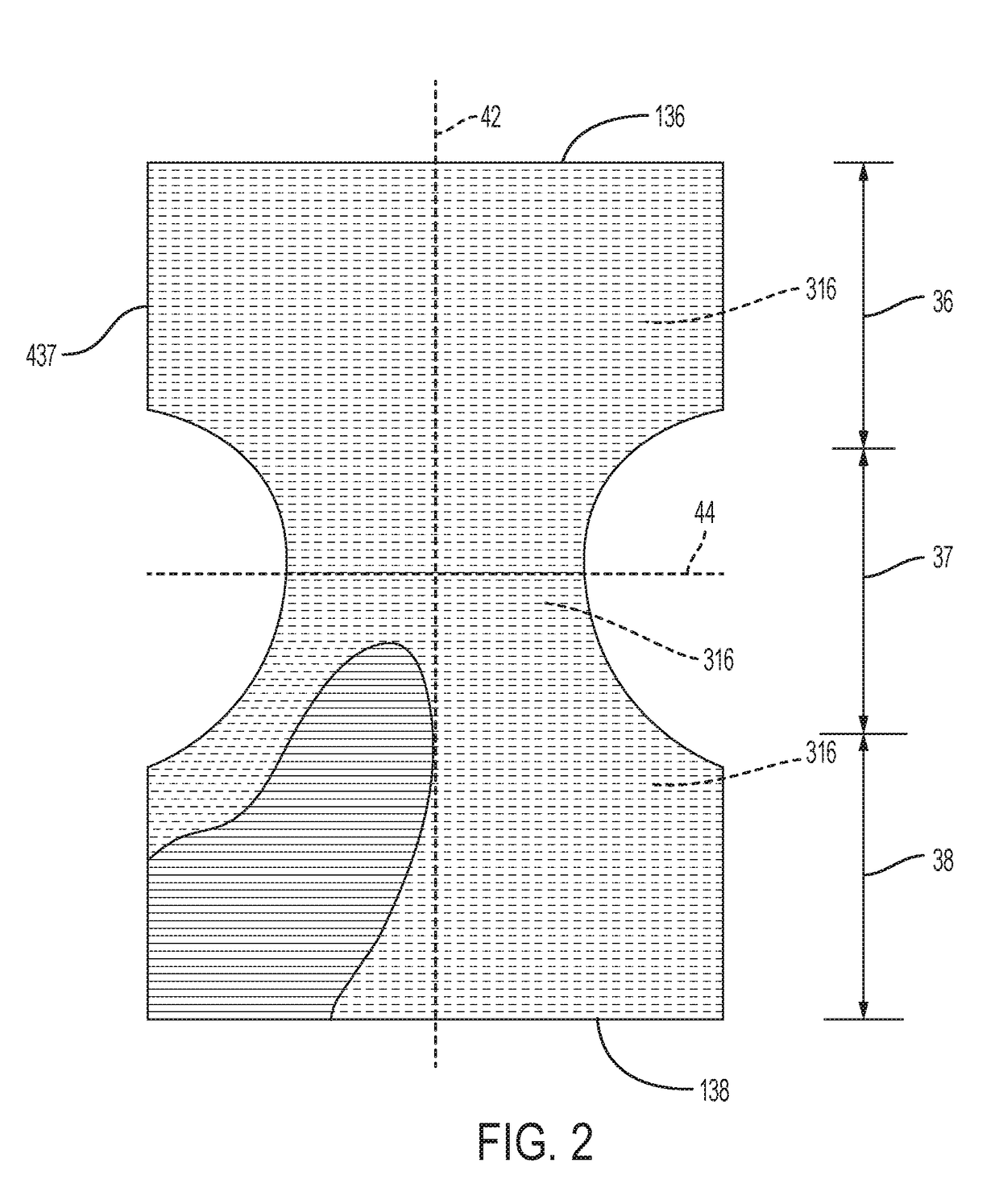

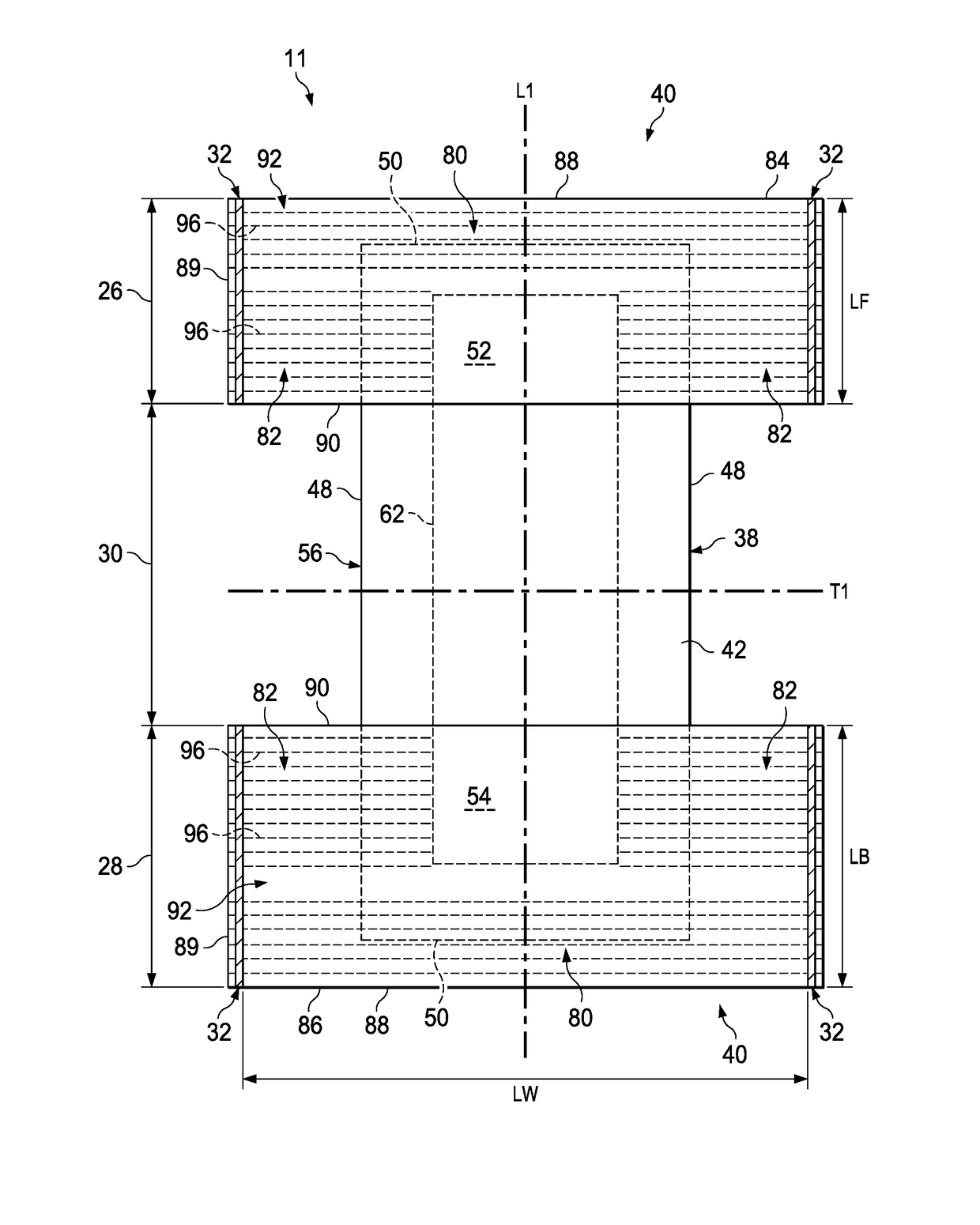

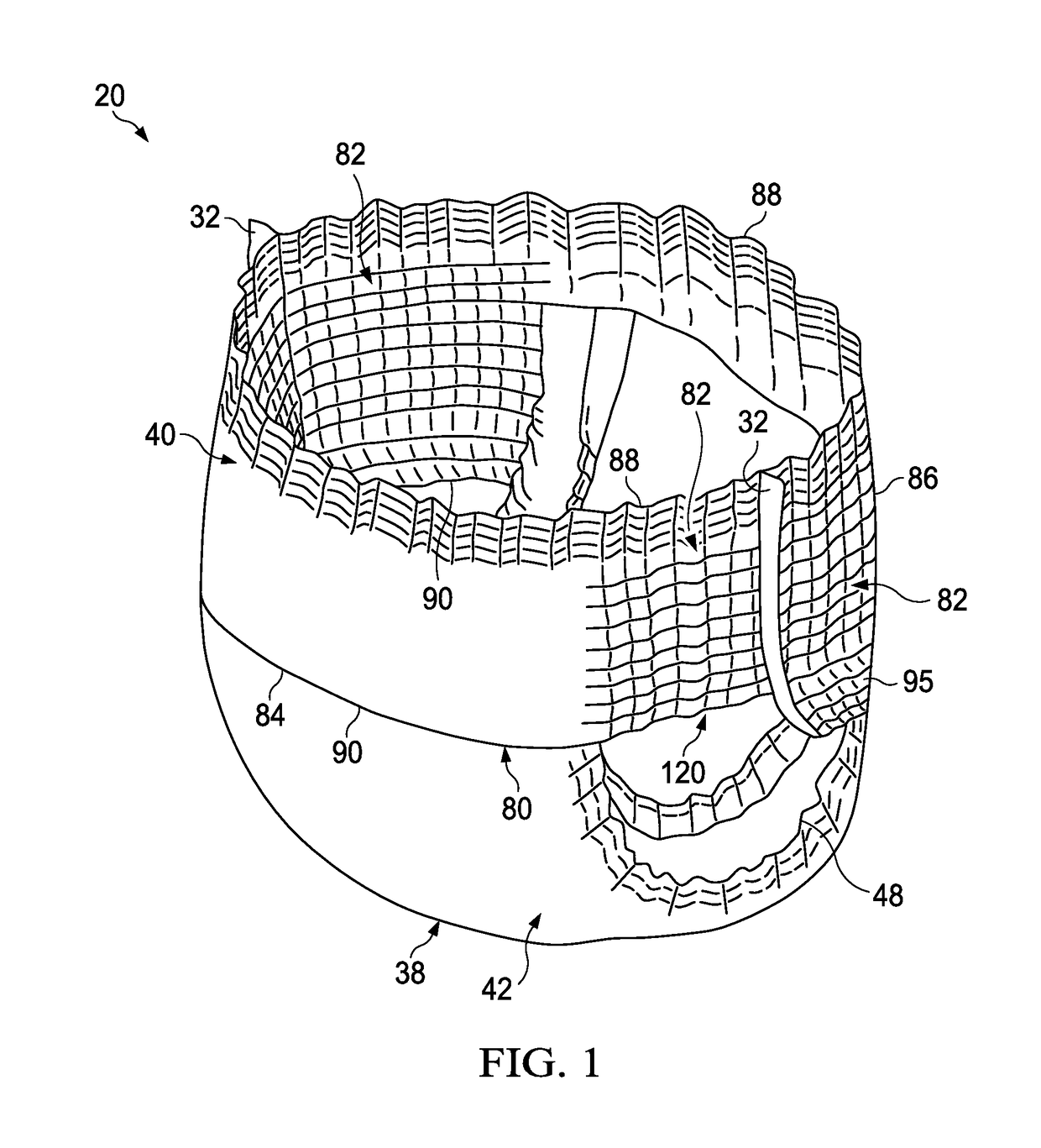

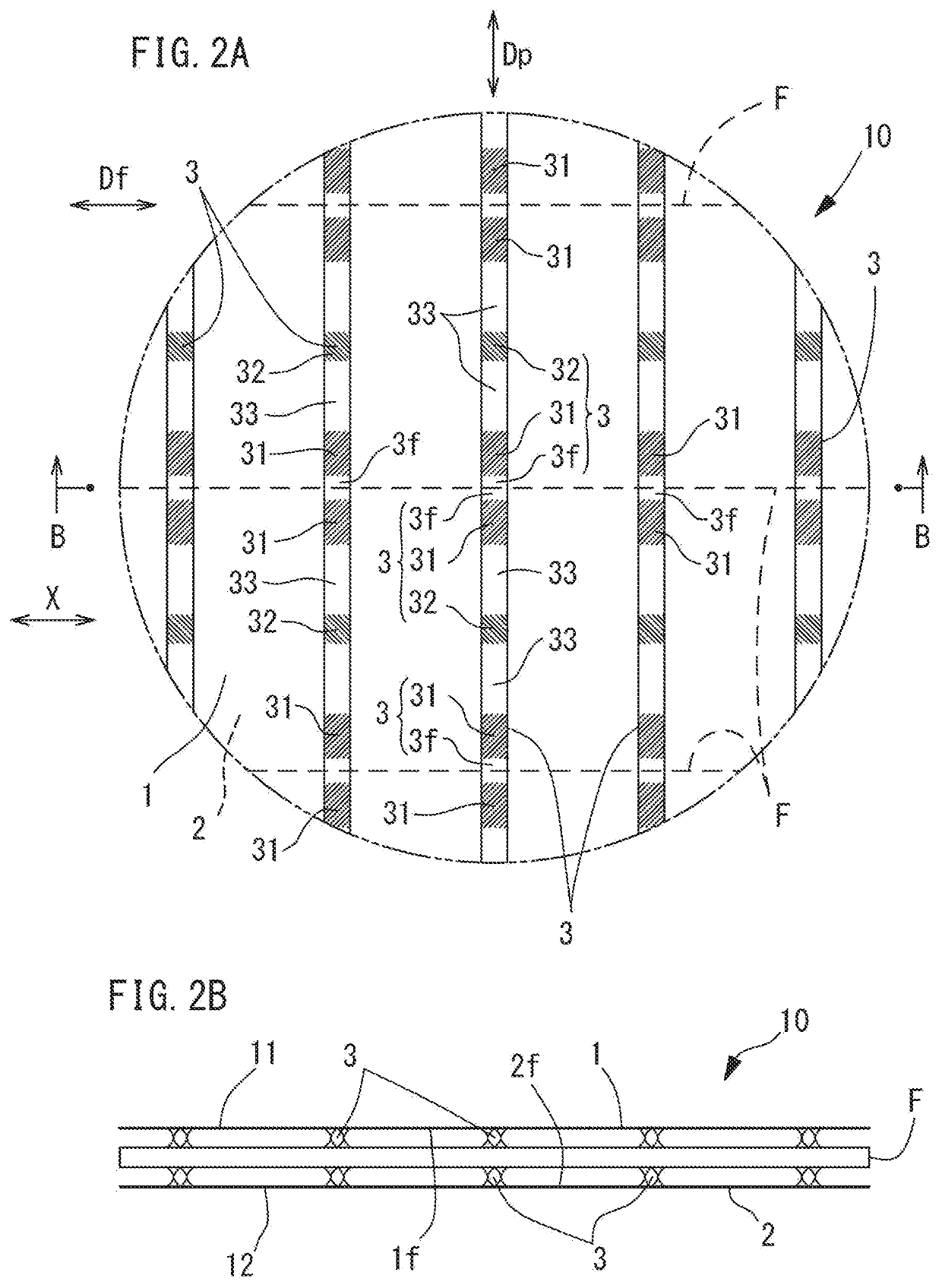

Absorbent article(s) chassis comprising beamed elastics

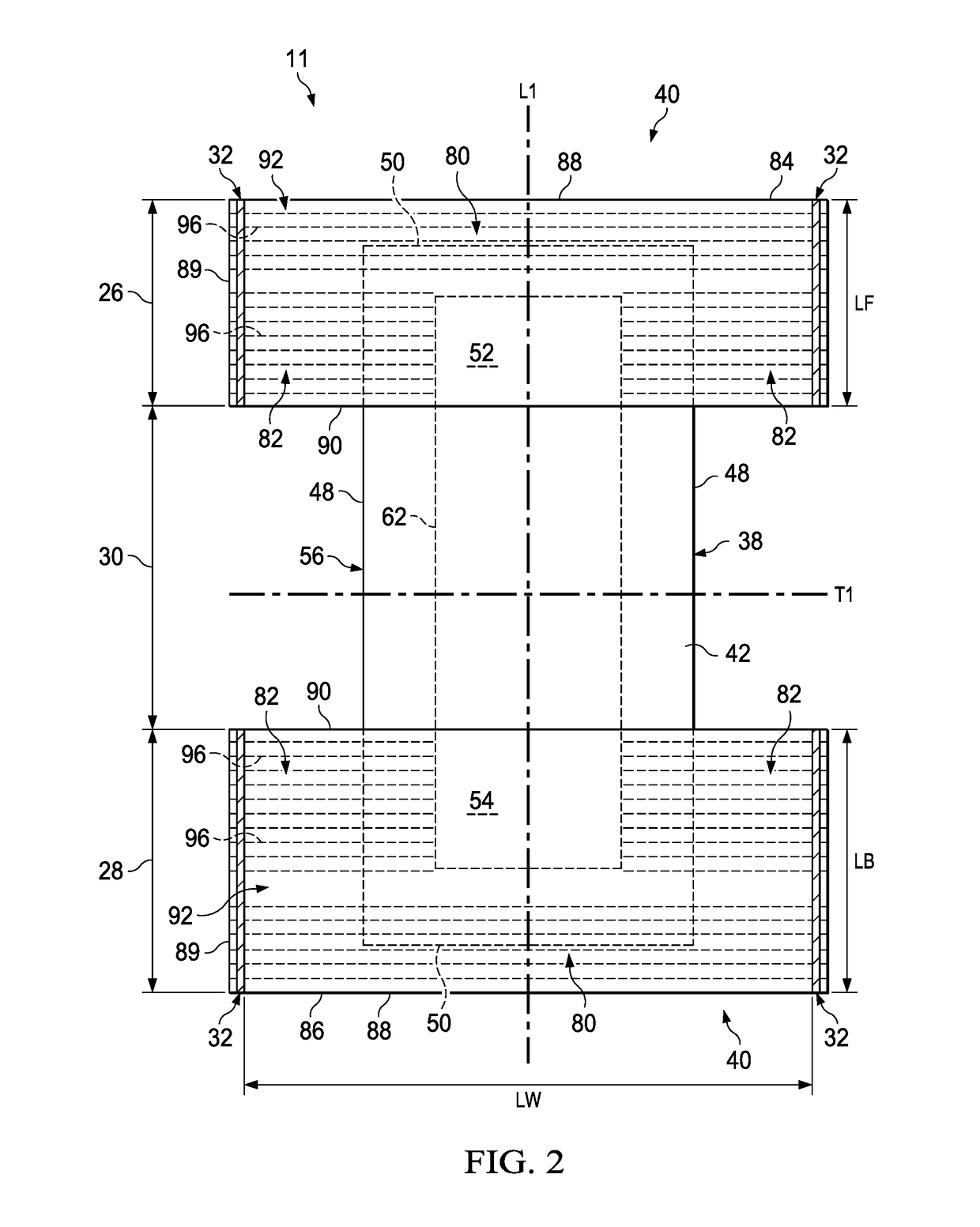

The present disclosure relates to absorbent article's chassis that may comprise one or more pluralities of tightly spaced (less than 4 mm, less than 3 mm, less than 2 mm, and less than 1 mm) and / or low decitex (less than 300, less than 200, less than 100 dtex) and / or low strain (less than 300%, less than 200%, less than 100%) elastics to deliver low pressure less than 1 psi (according to the conditions defined by the Pressure-Under-Strand Test in the Method below) under the elastics. The elastics in the chassis may be oriented parallel or transverse to the longitudinal axis.

Owner:THE PROCTER & GAMBLE COMPANY

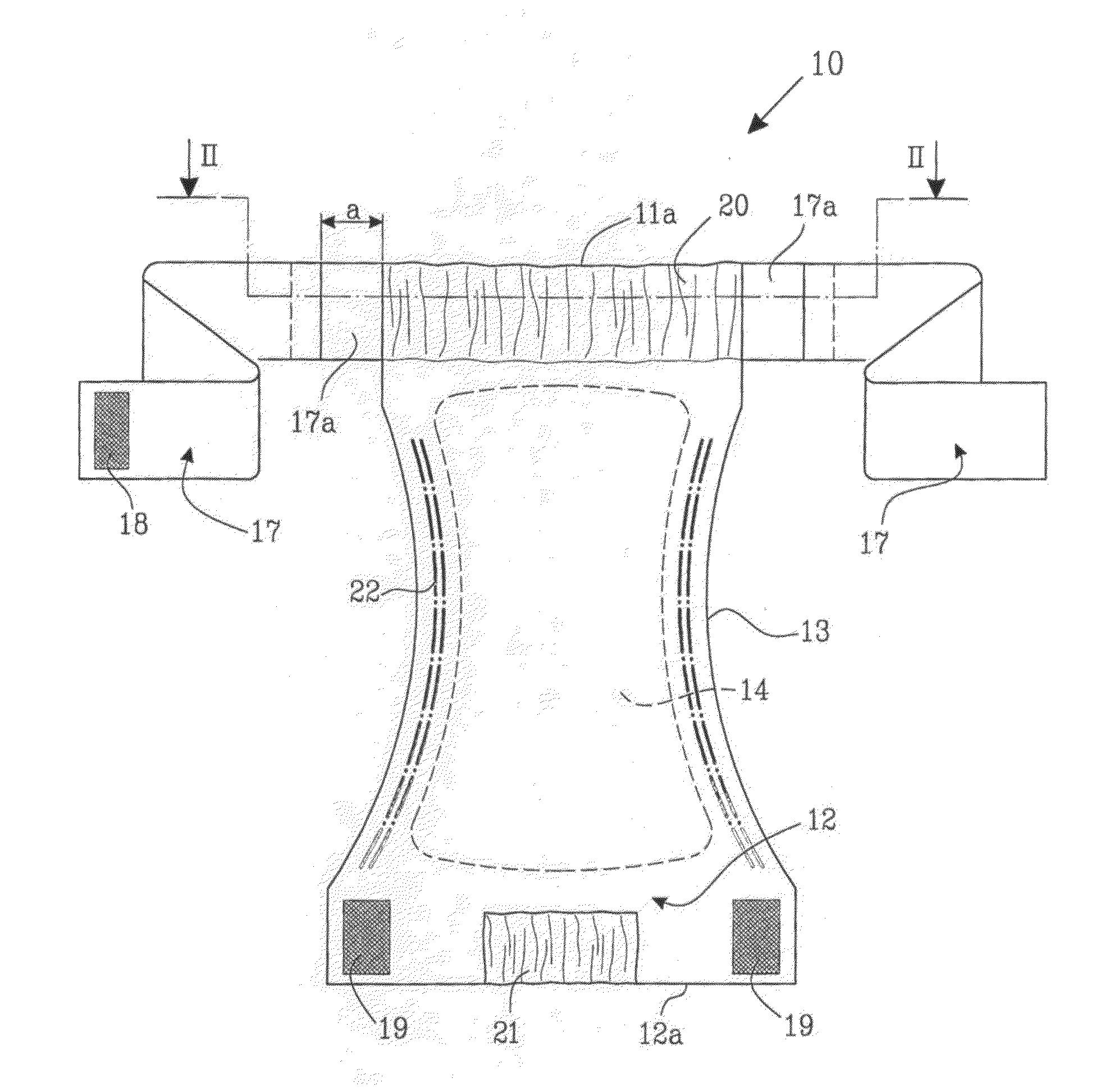

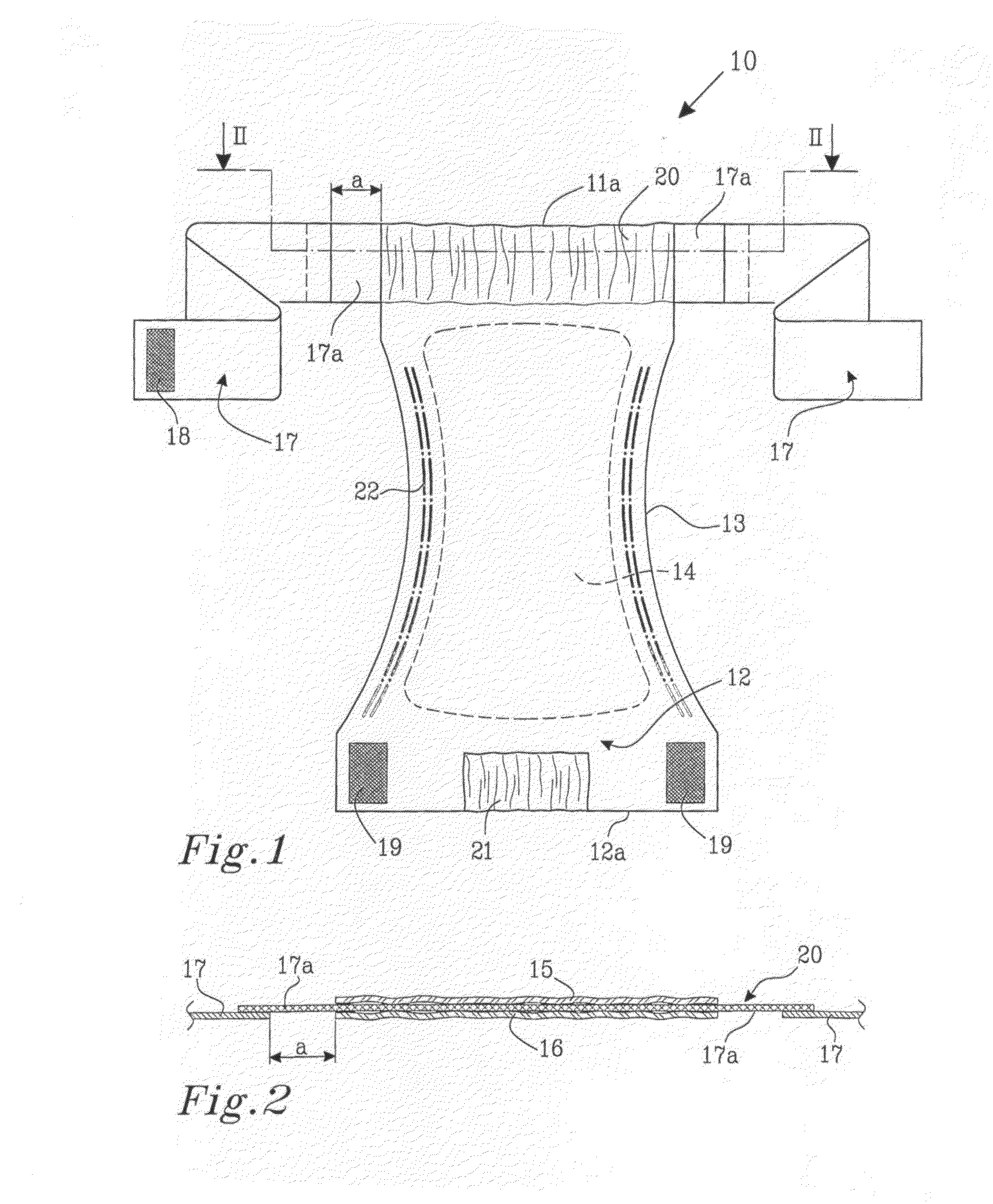

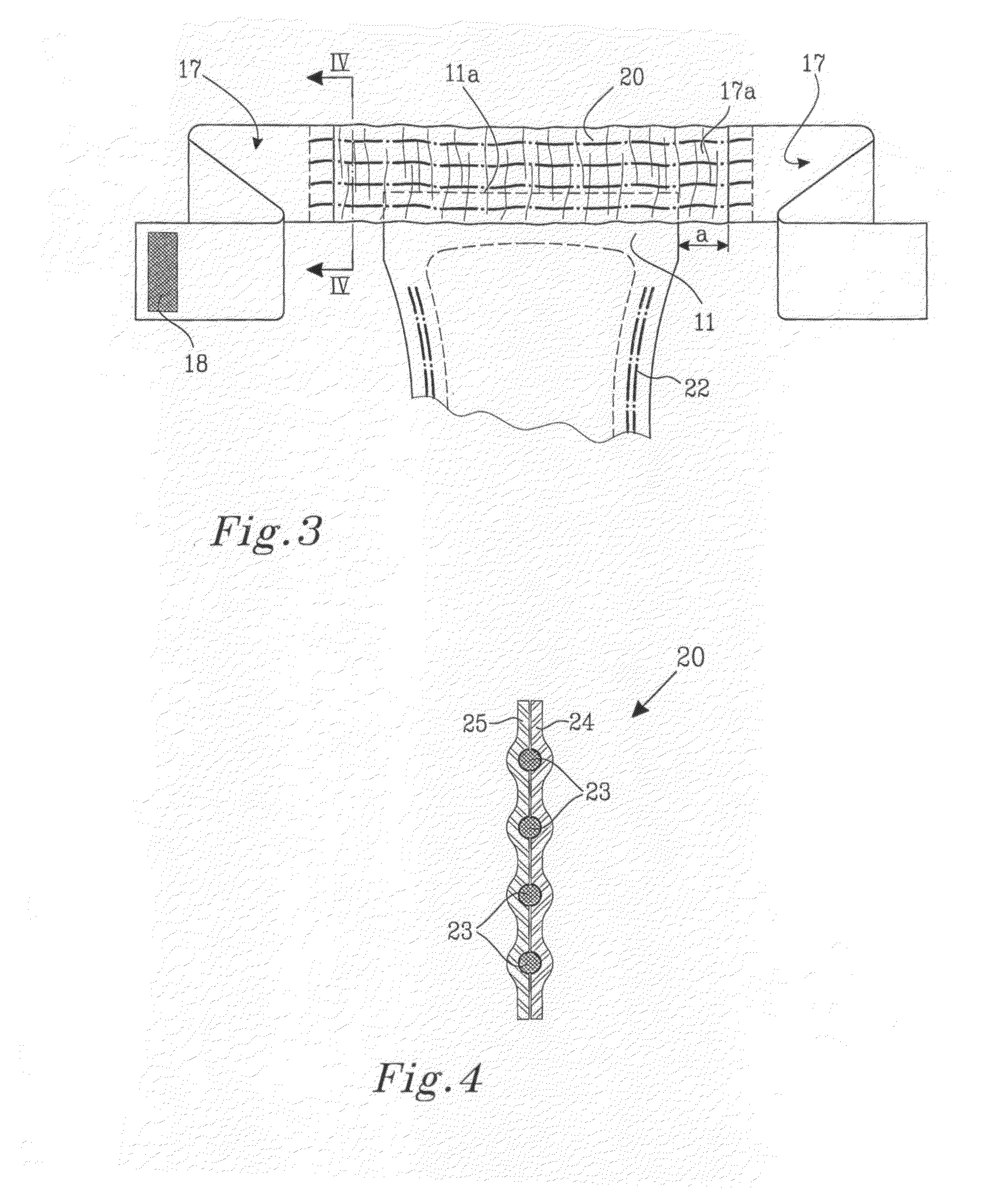

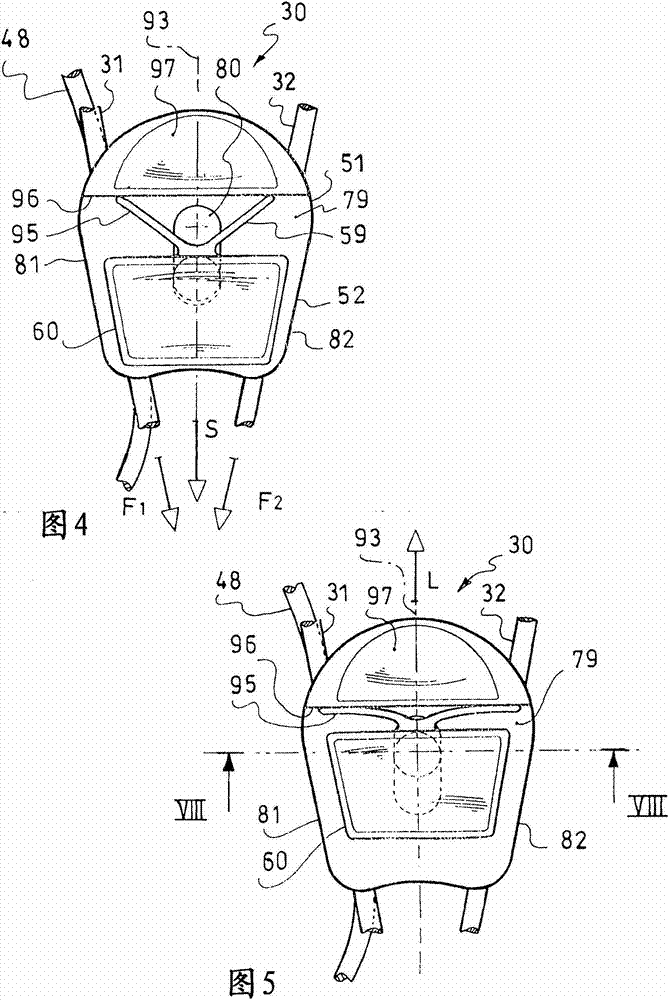

Belted absorbent garment

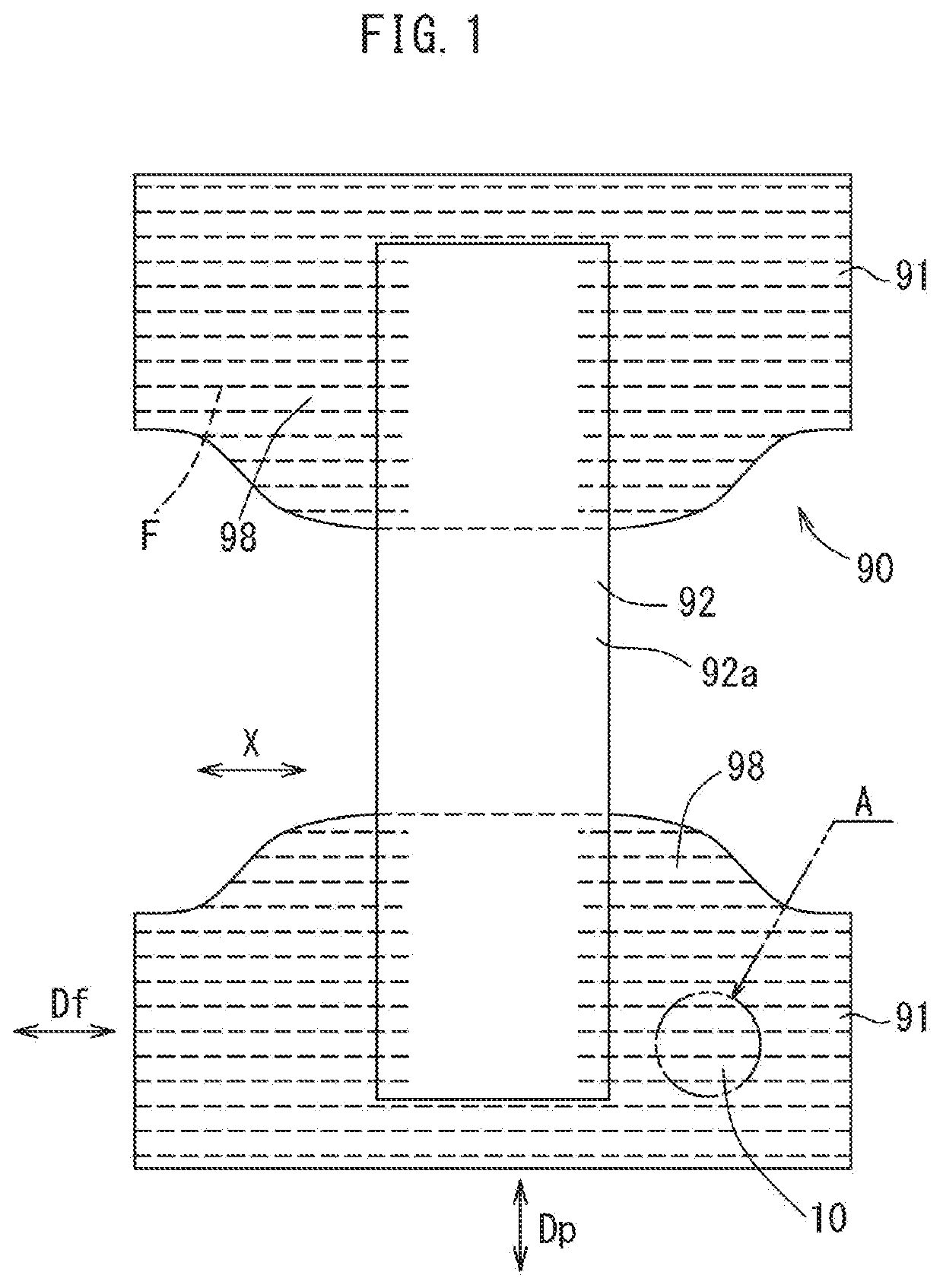

Absorbent garment such as a diaper and an incontinence guard, said garment comprises a first body panel (16), a second body panel (17) and a crotch portion (13) there between. The garment is provided with opposed laterally extending belt members (17) attached to the waist portion of the first body panel (11) and are adapted to be wrapped around the waist of the wearer of the garment and fastened together by means of first fastening means (18). The second body panel (12) at its waist portion is provided with second fastening means (19) adapted to be fastened to the belt members (17), in such a way that the garment will assume a pant-like shape. An elastic member (20) extends in transverse direction (x) along the waist portion (11a) of the first body panel (11) and extends into at least a portion of each belt member (17).

Owner:SCA HYGIENE PROD AB

Array of wearable articles

Owner:THE PROCTER & GAMBLE COMPANY

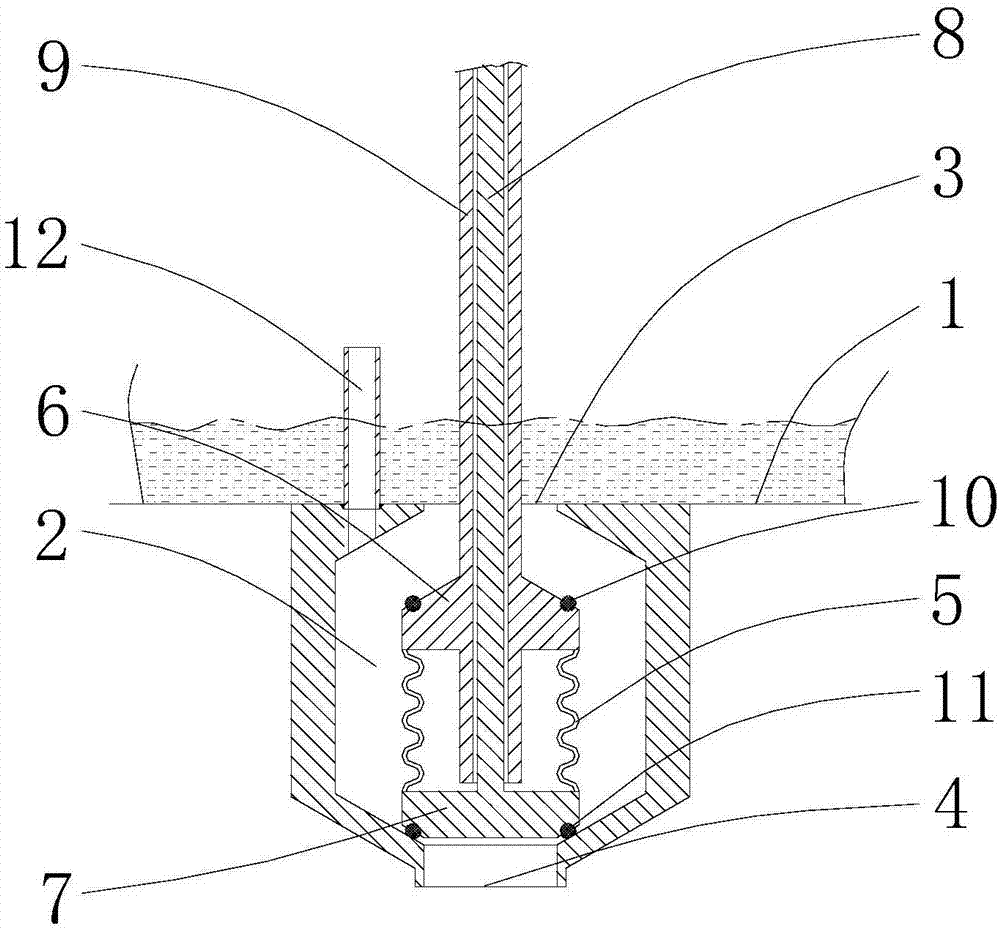

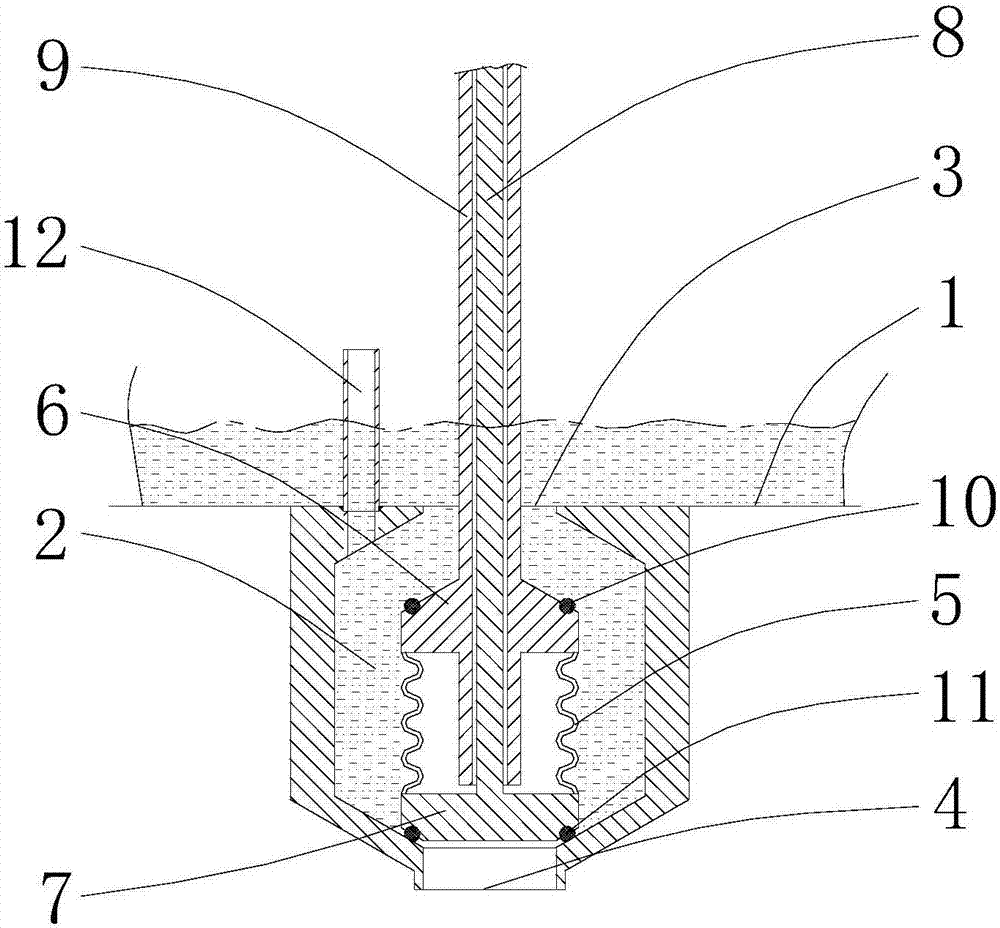

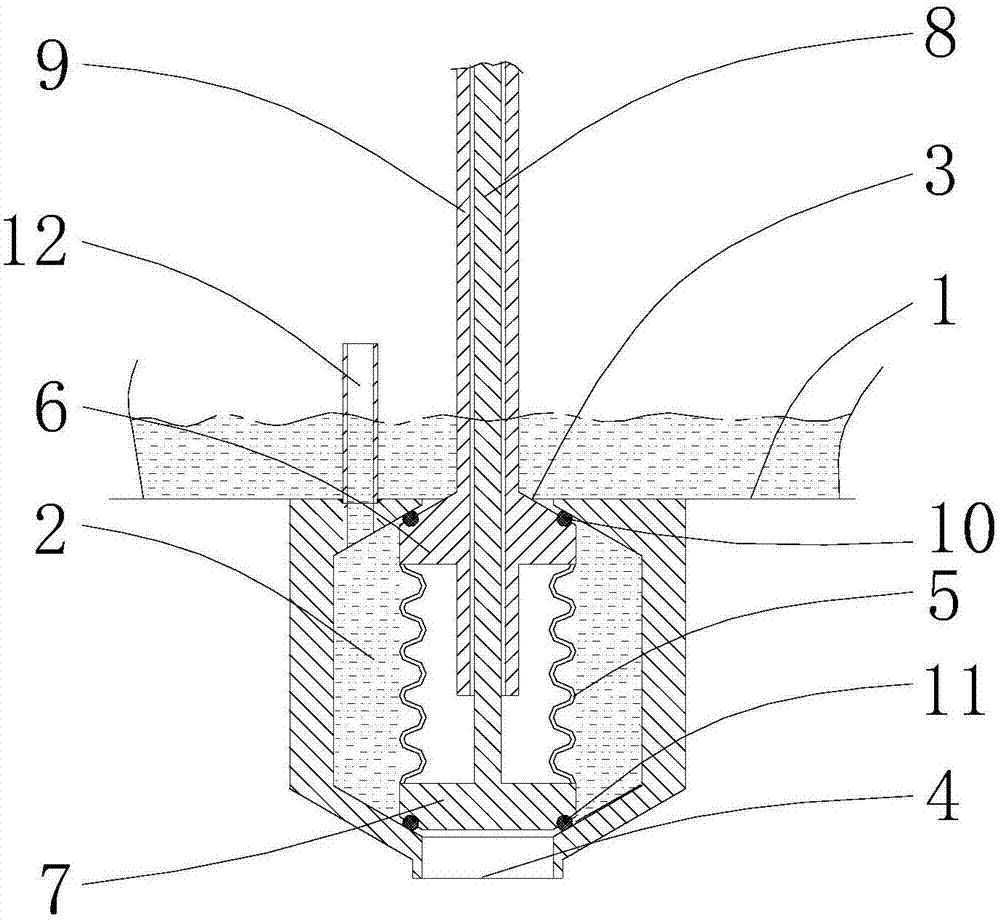

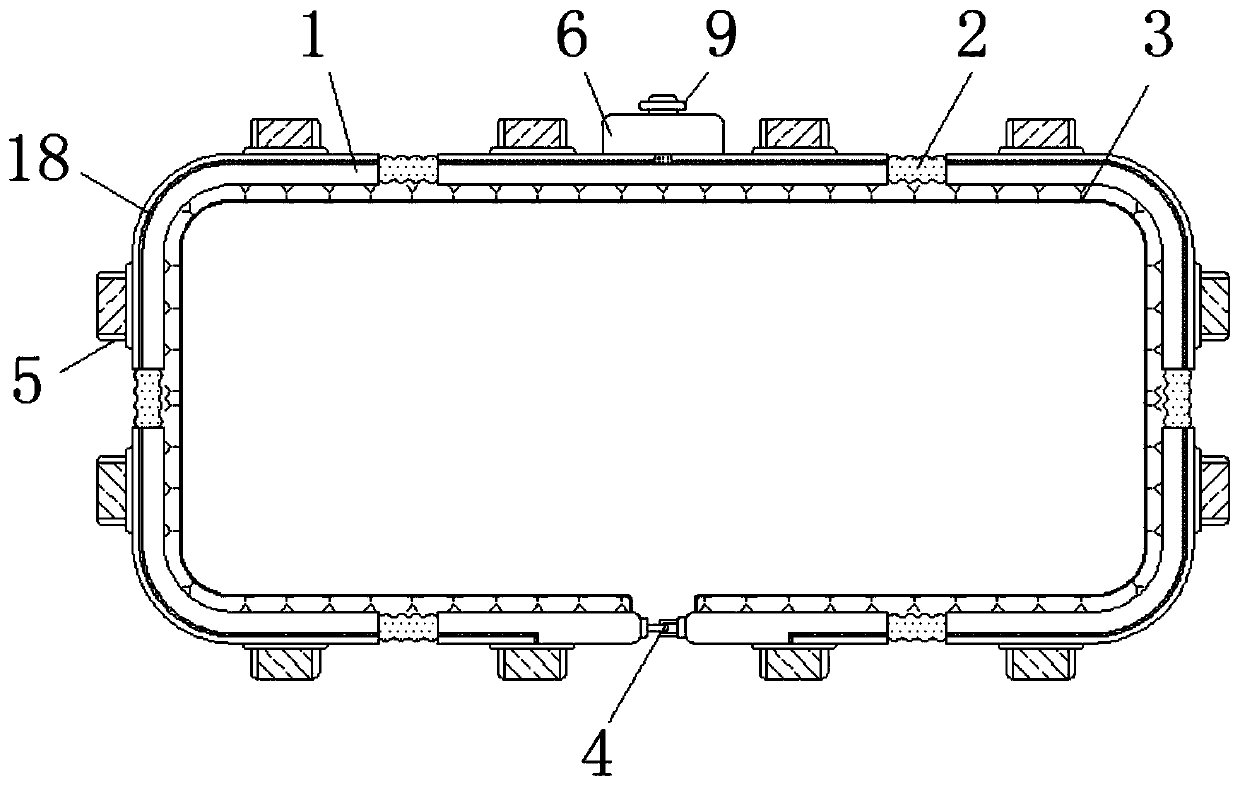

Sensor For Detecting Pressure Waves In A Fluid, Provided With Static Pressure Compensation

ActiveUS20160299026A1Reduce sensitivityVibration measurement in fluidSubsonic/sonic/ultrasonic wave measurementFiberGrating

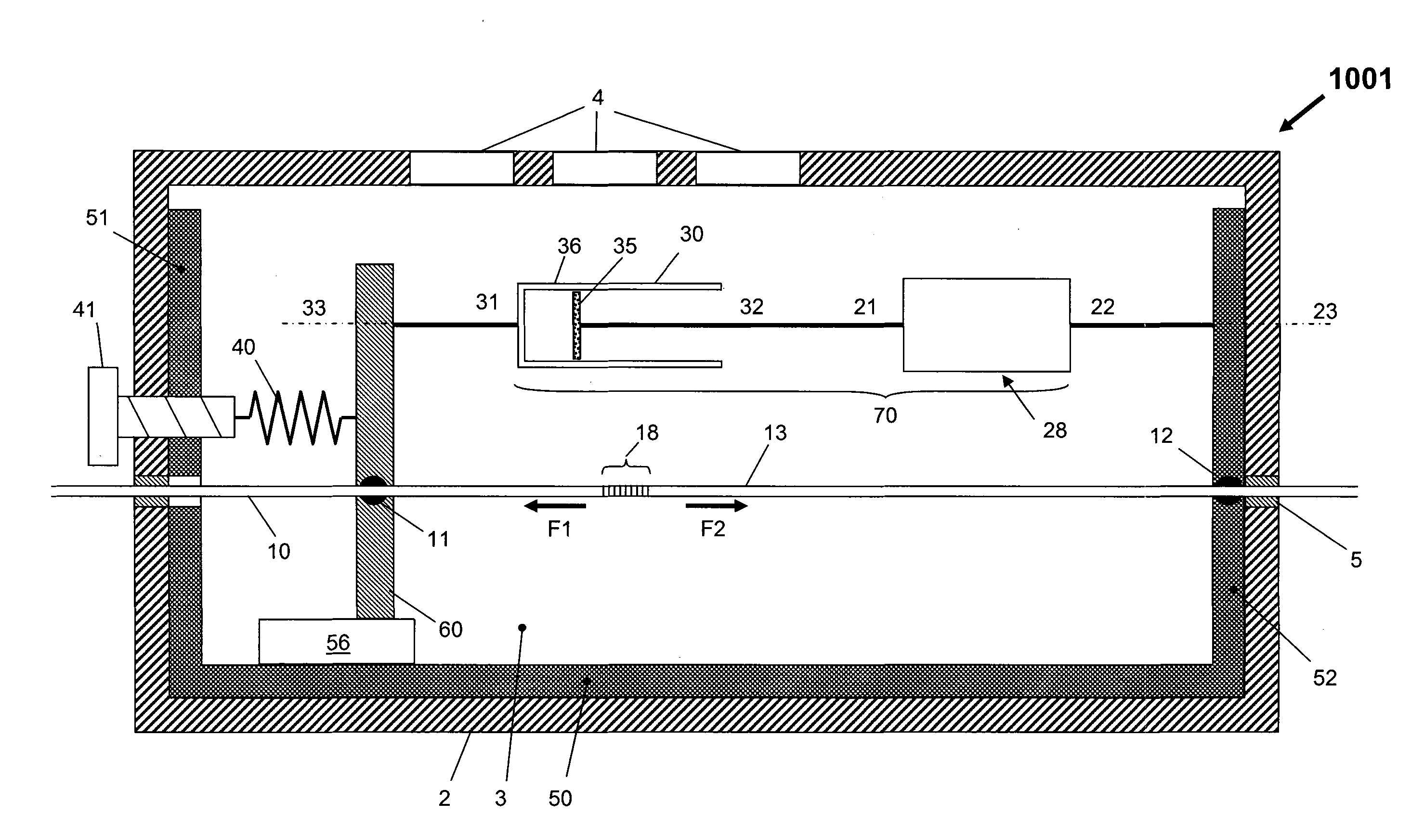

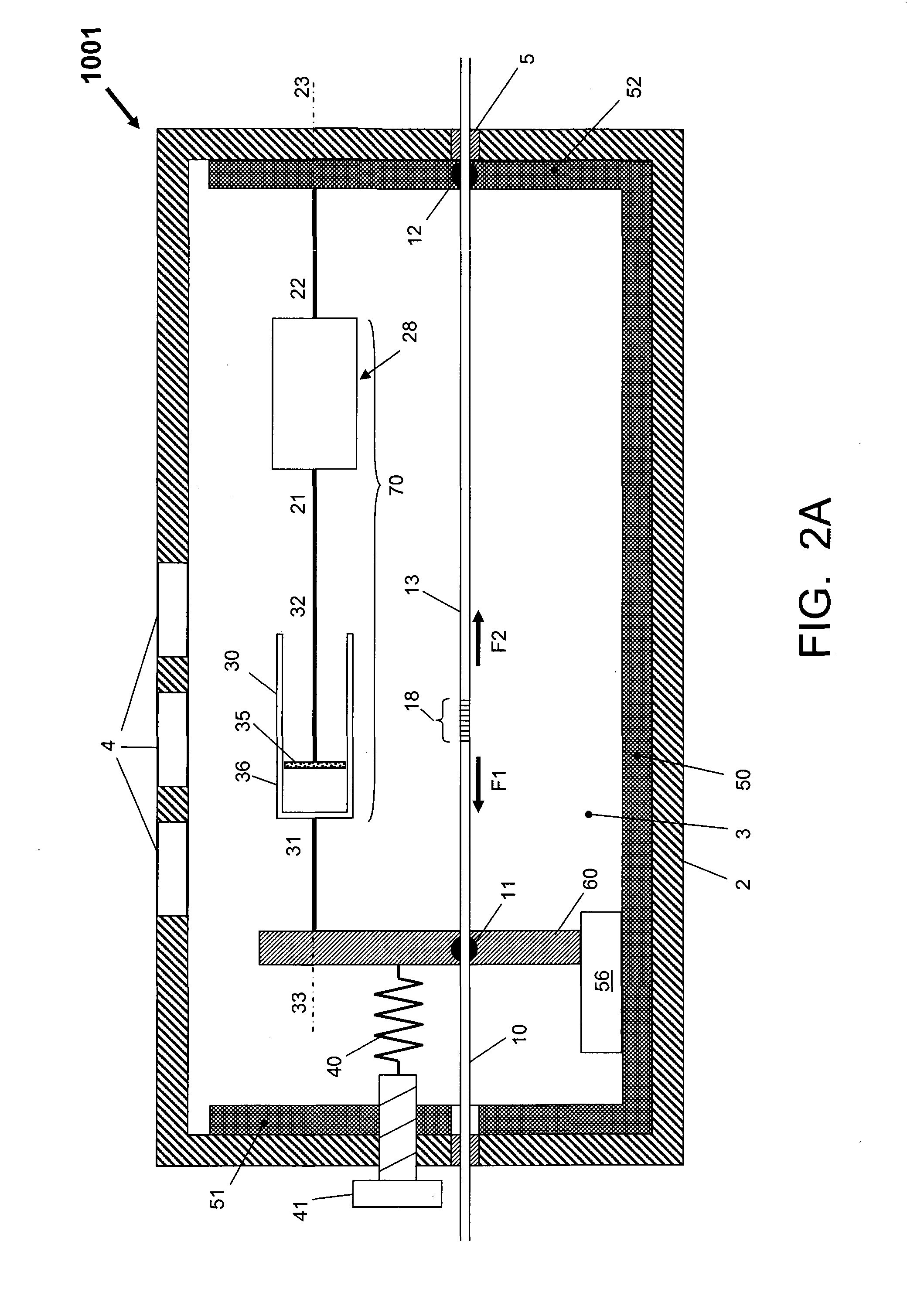

A pressure sensor device having a chamber filled with a pressure transfer medium, the chamber having at least one window that at least partly transfers pressure waves in a fluid; an optical fiber extending longitudinally through the chamber, the optical fiber including a Fiber Bragg Grating and two mounting spots at opposite sides of the Fiber Bragg Grating; a frame having a first frame end and a longitudinally opposite second frame end; a pressure response assembly connected in parallel to a fiber portion between the two mounting spots, the pressure response assembly including a series arrangement of a pressure response means and a movement damper; and a resilient member connected in series to the fiber portion and the frame.

Owner:OPTICS11 BV

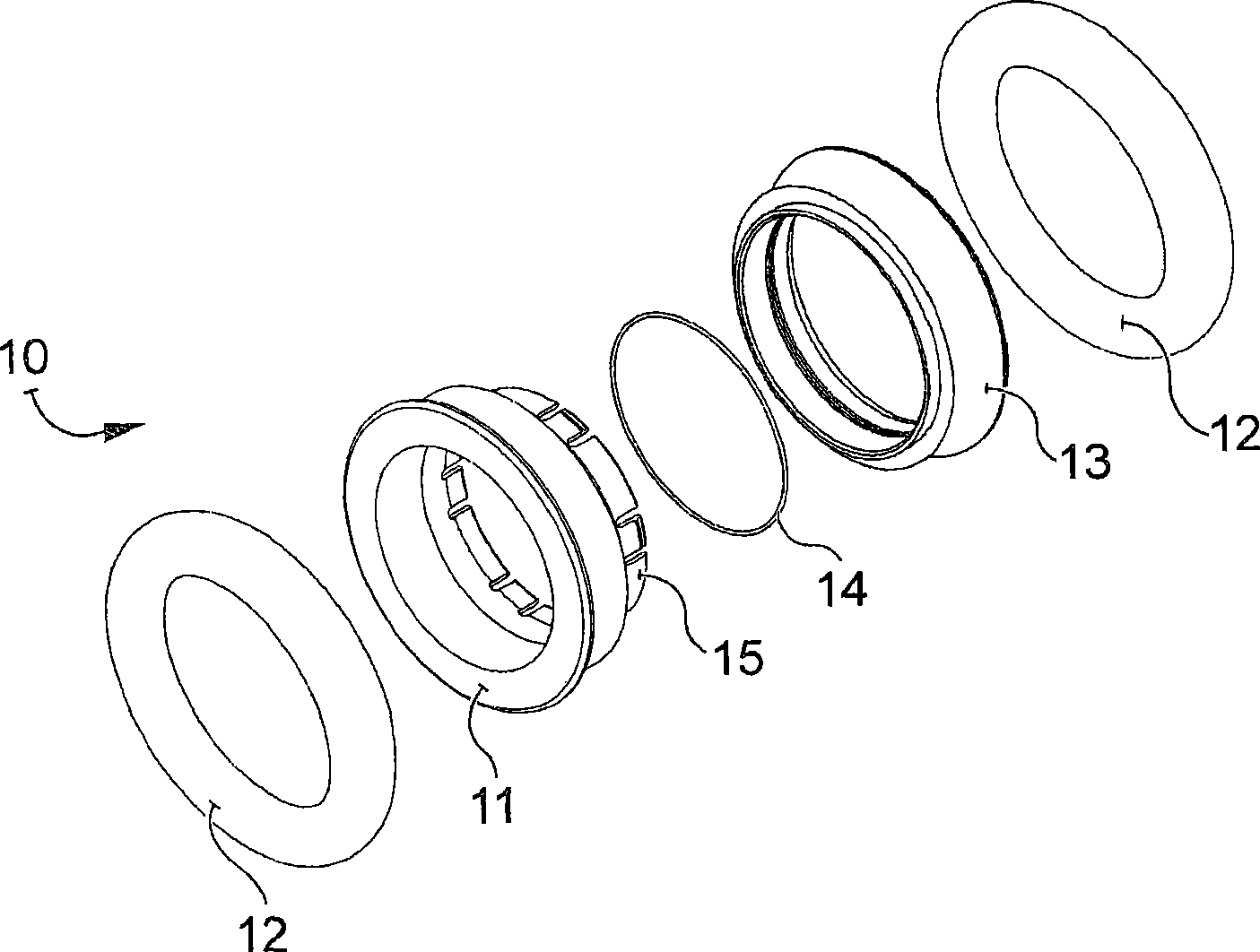

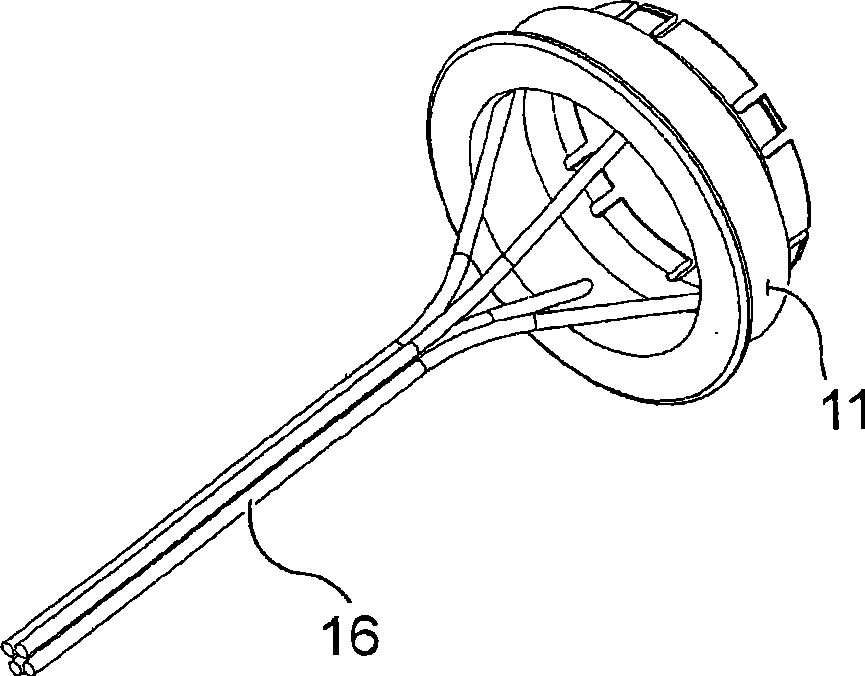

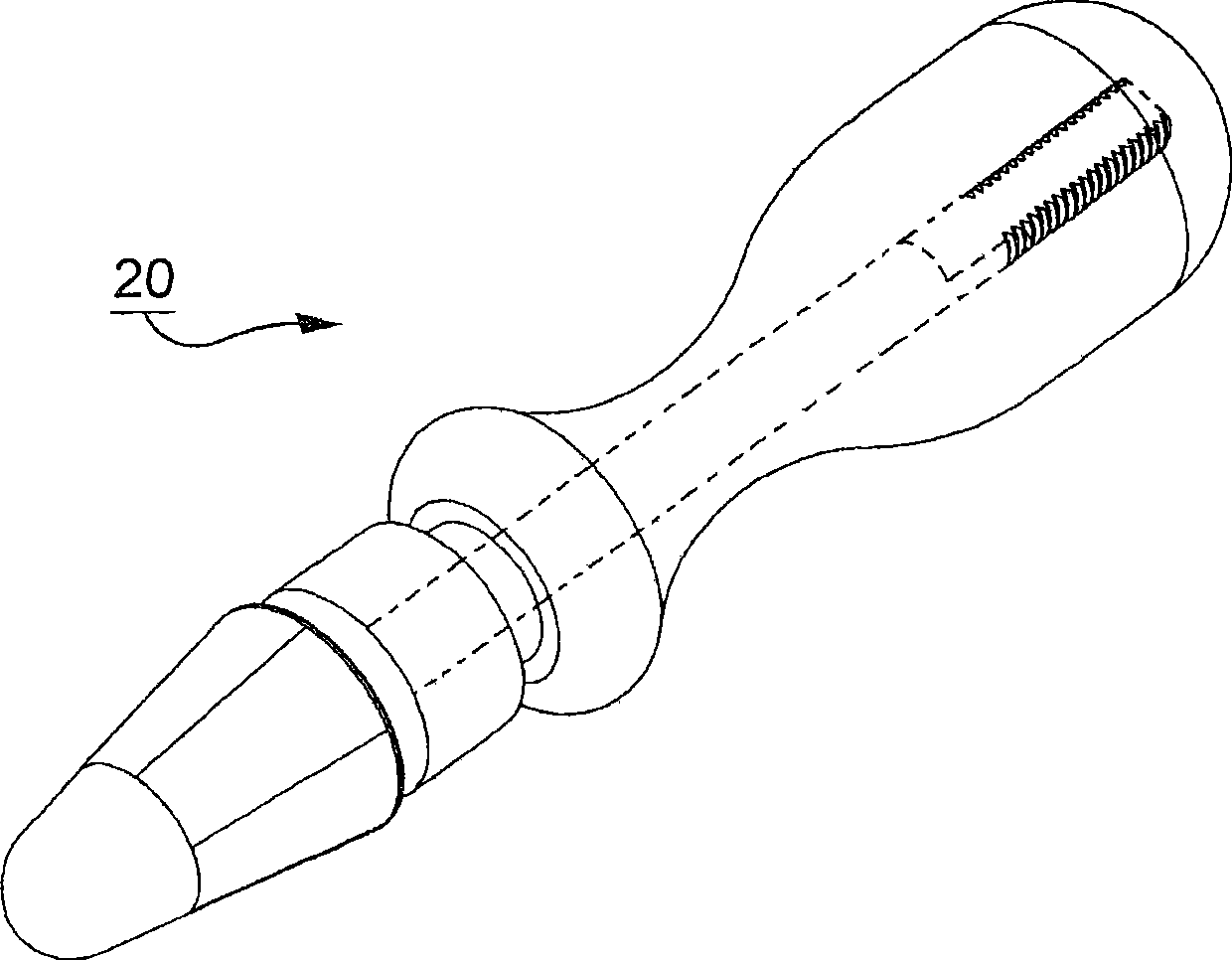

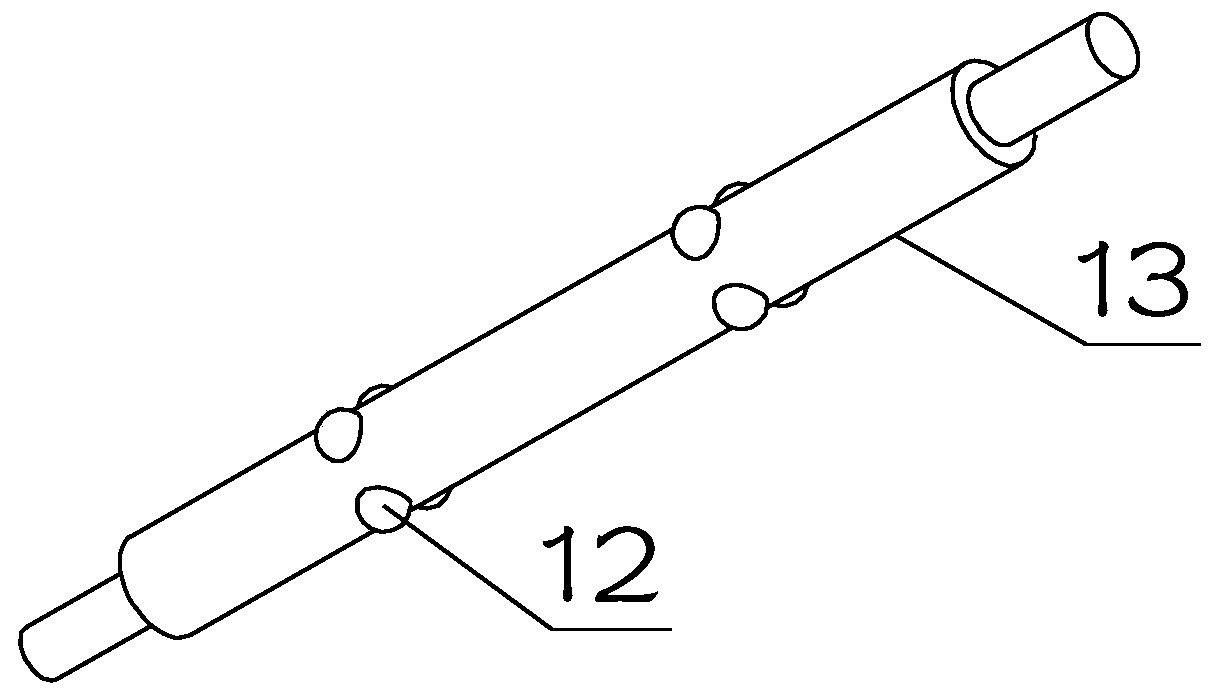

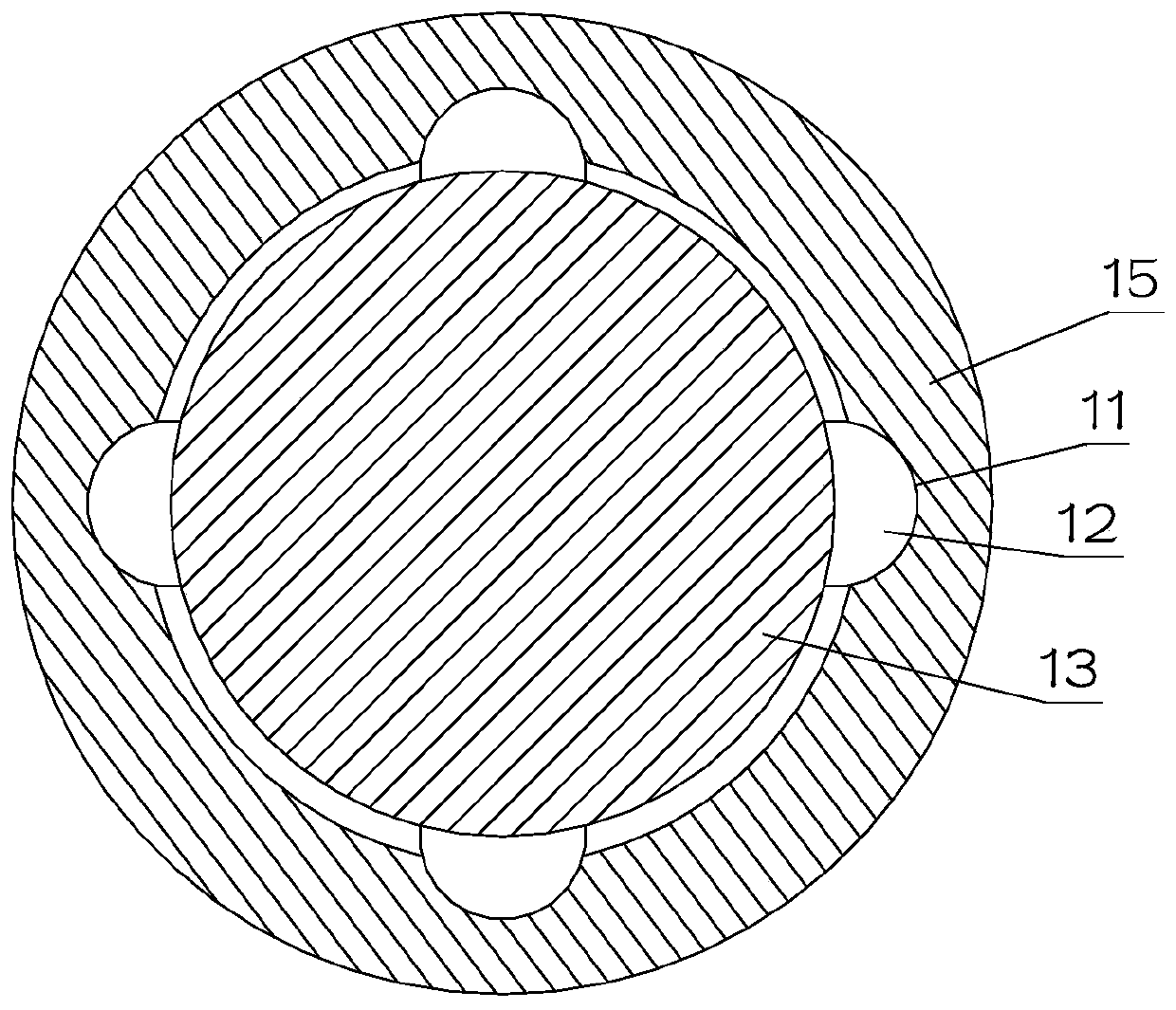

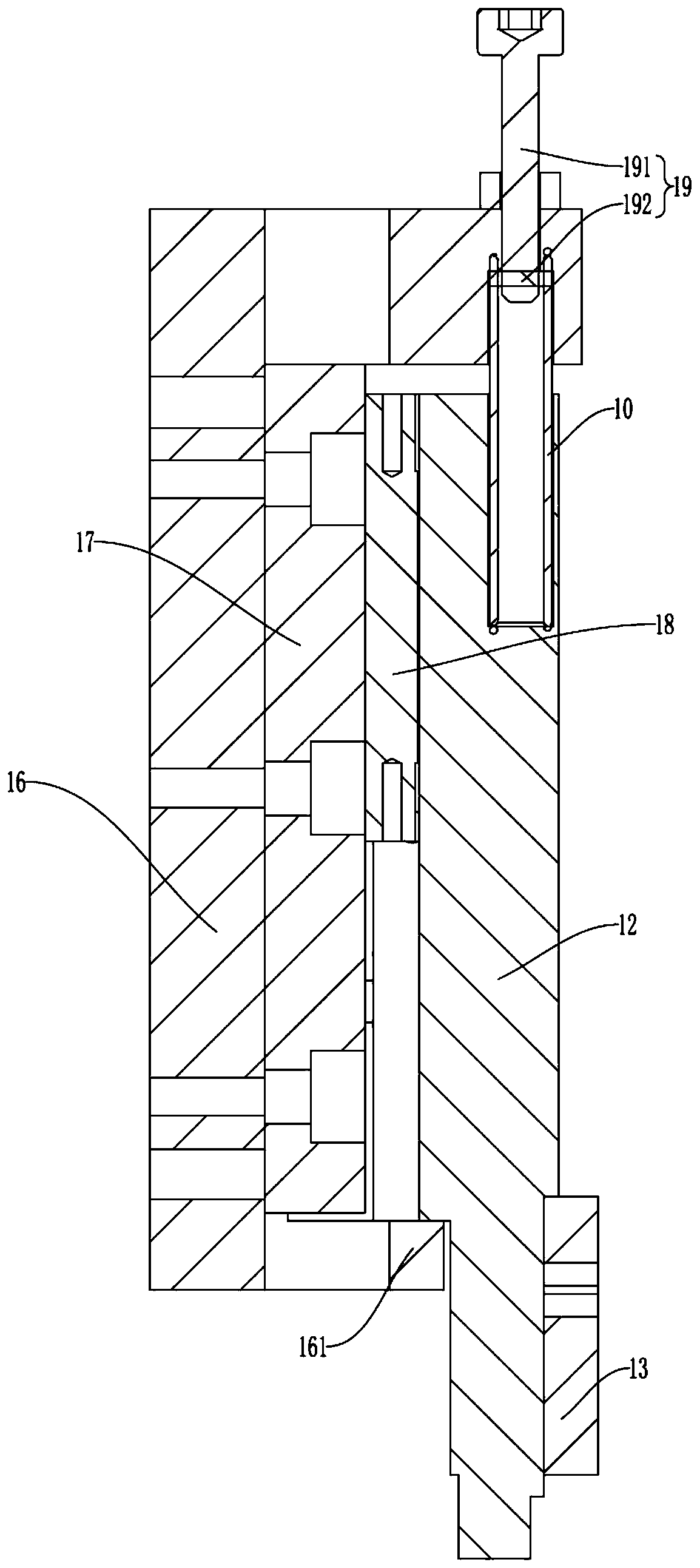

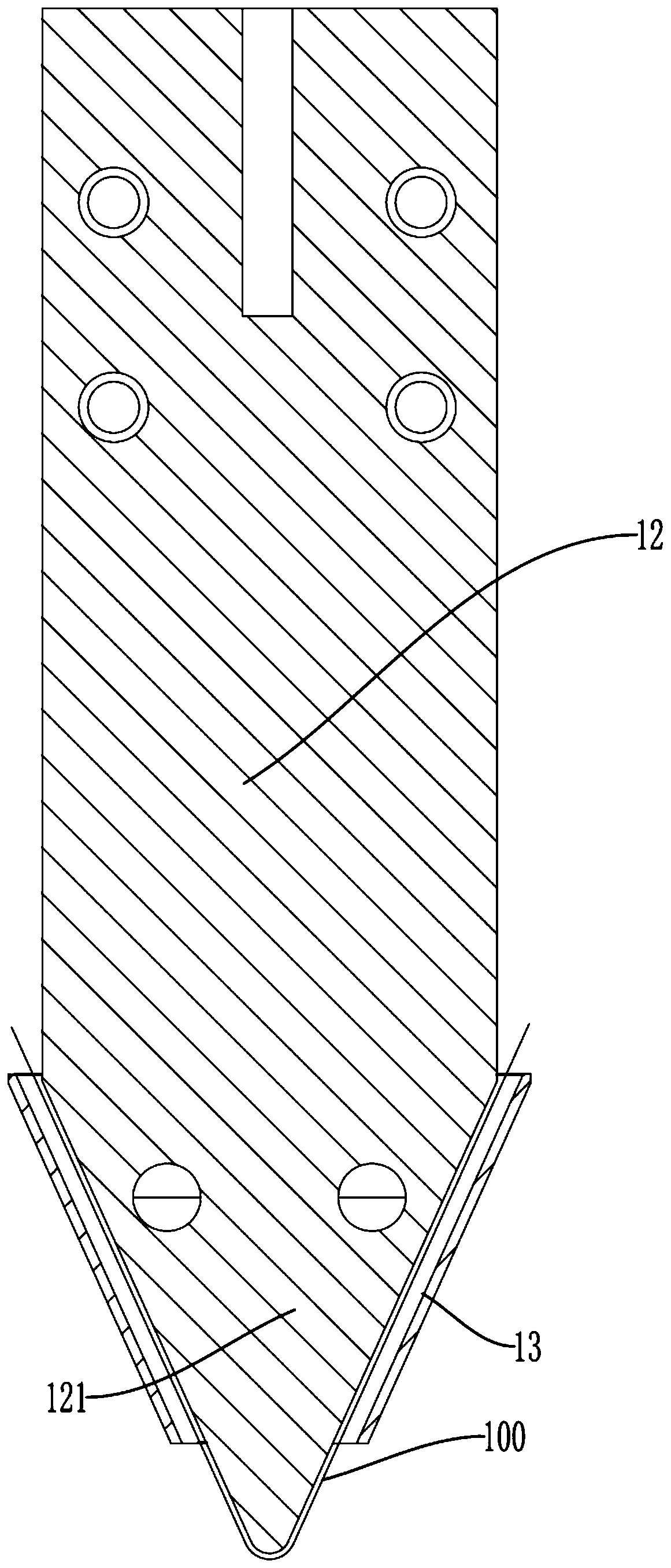

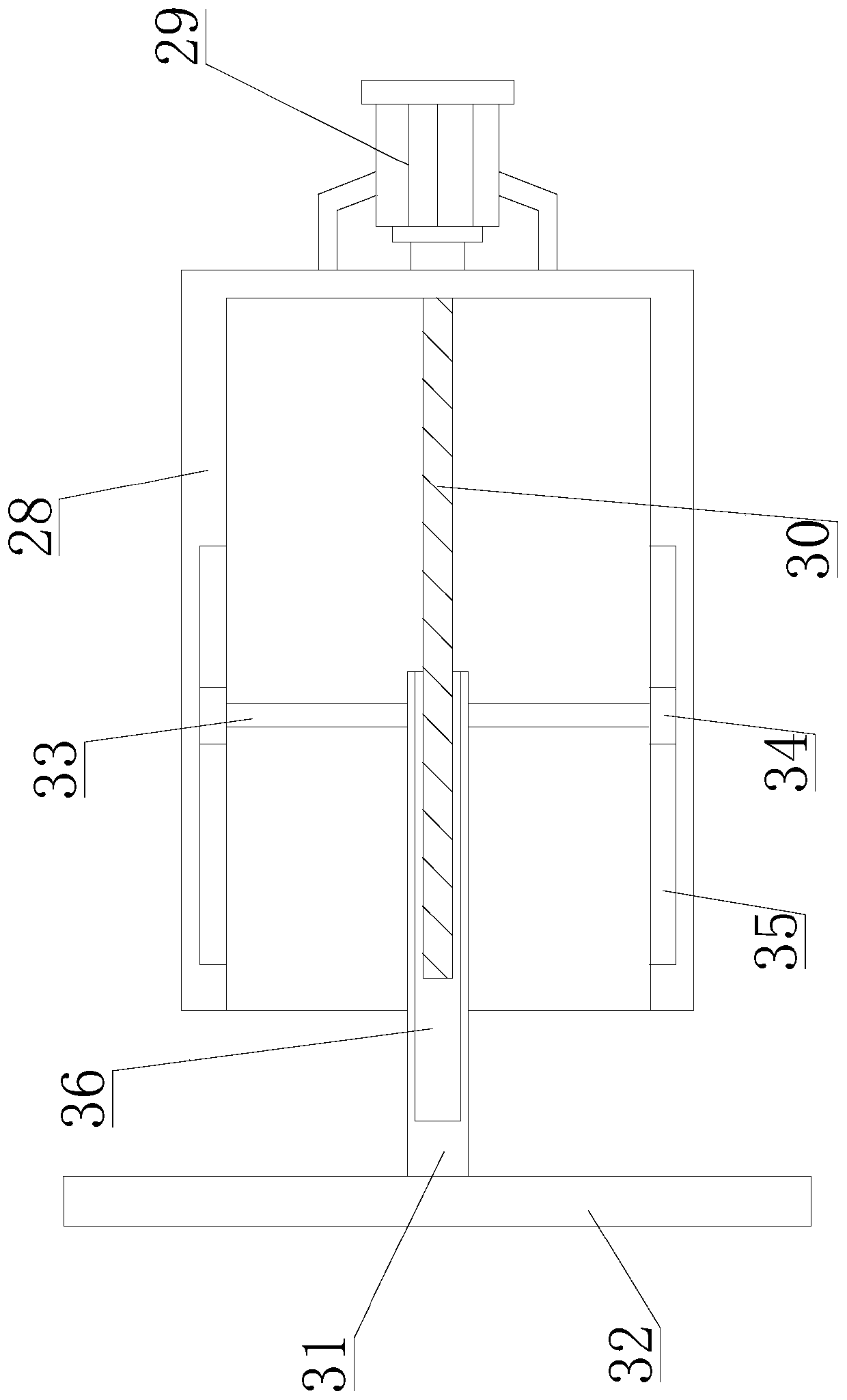

Method for a device for anastomosis

A device (10, 200) for anastomosis of a tubular structure (90) comprises a first and a second member of a generally hollow open configuration, which each includes a rigid part (11, 13) and an elastic part (12), and a connection member (15, 160) for interlocking the first and second members. According to a first embodiment the connection member (15) is integral with the rigid part (11) of the first member, and has longitudinal slits (37) forming tongues (38) there between, of which at least one has an outward protrusion (39) at its free end. ). In an alternate embodiment of the first embodiment, the connection member (15) has at least one circumferential groove (192) around the outer periphery, and the second rigid part (193) has a protrusion (194) arranged around the inner periphery. According to a second embodiment (200) the connection member (160) is arranged as a member separated from the first rigid part (11). The elastic parts (12) are essentially circular rings, and are made of a polymeric, a biocompatible and / or biodegradable material. The rigid parts (11, 13) have an outer surface that is partly semi-circular in cross section, wherein the diameter at a non-connecting end (30, 40) is larger than or equal to the diameter at a connecting end (31, 41), which ends in an edge (36, 46). The first and second members are connected to each other so that a distance is formed between the elastic parts (12). A cavity (203) is formed between the rigid parts (13) and the connection member and the tubular structure (90), when arranged in the device (200).

Owner:CARPONOVUM AB

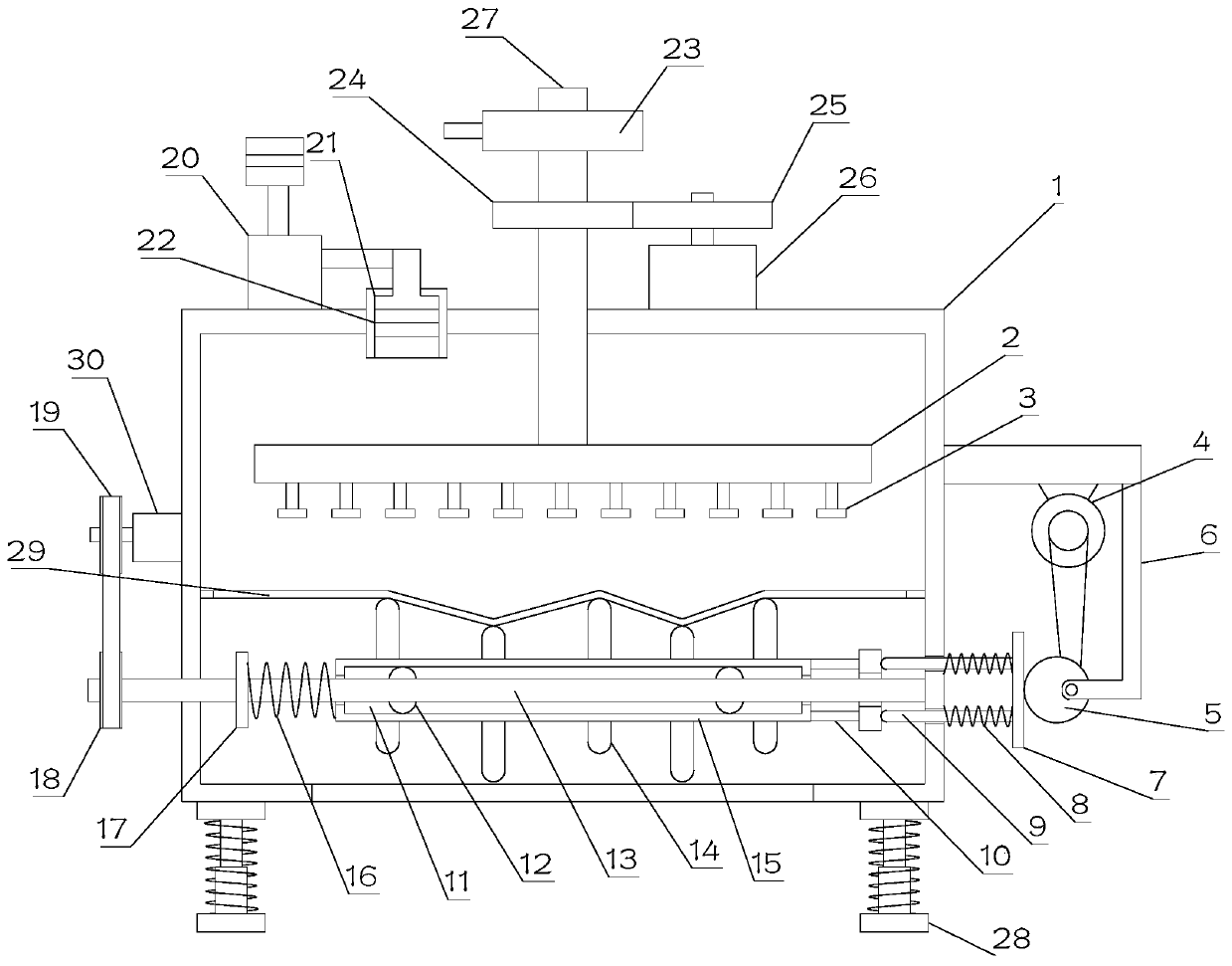

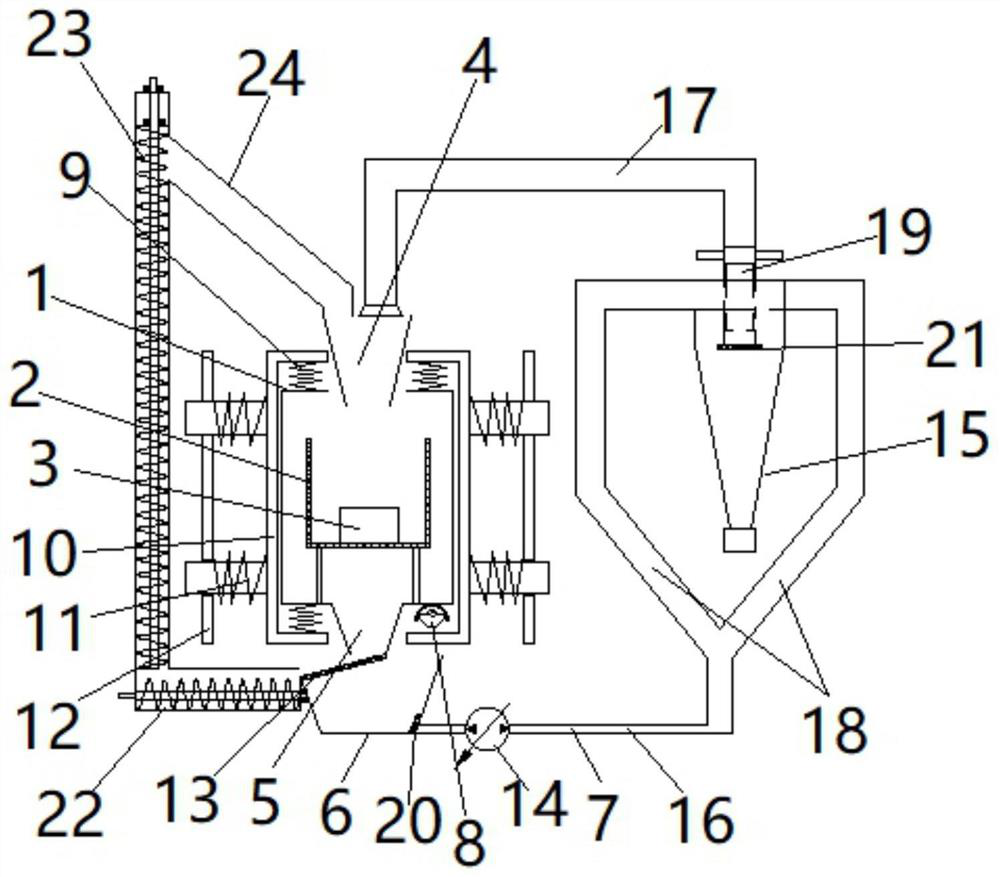

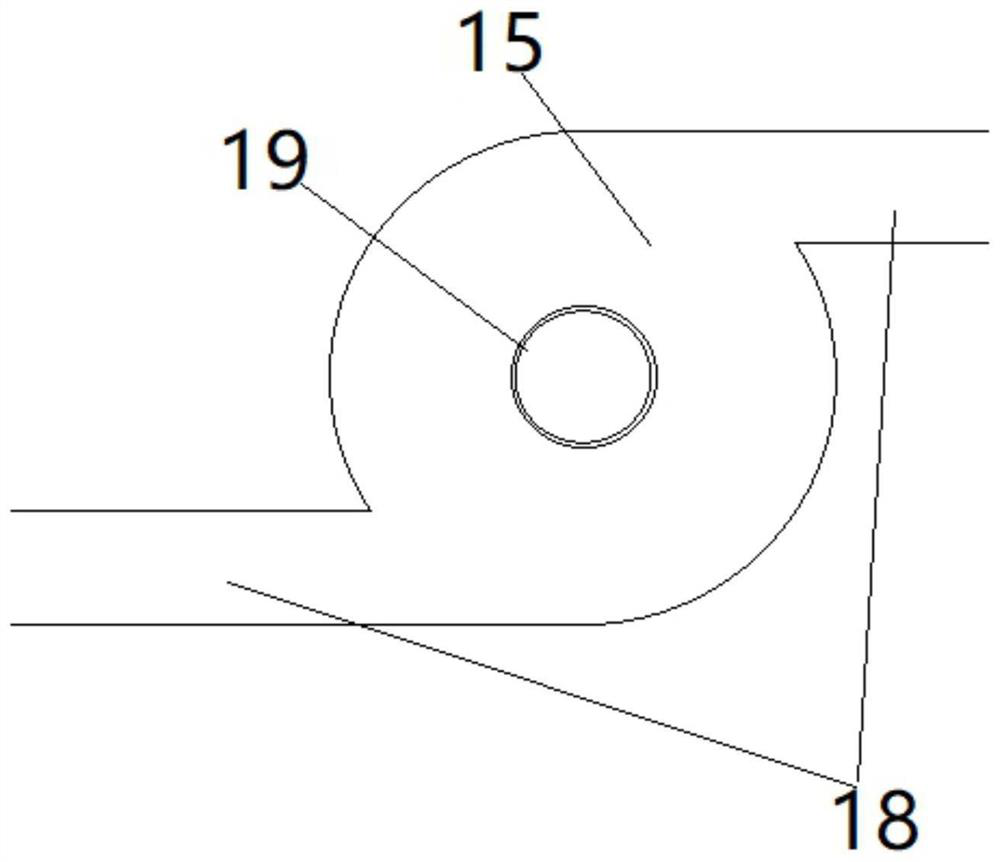

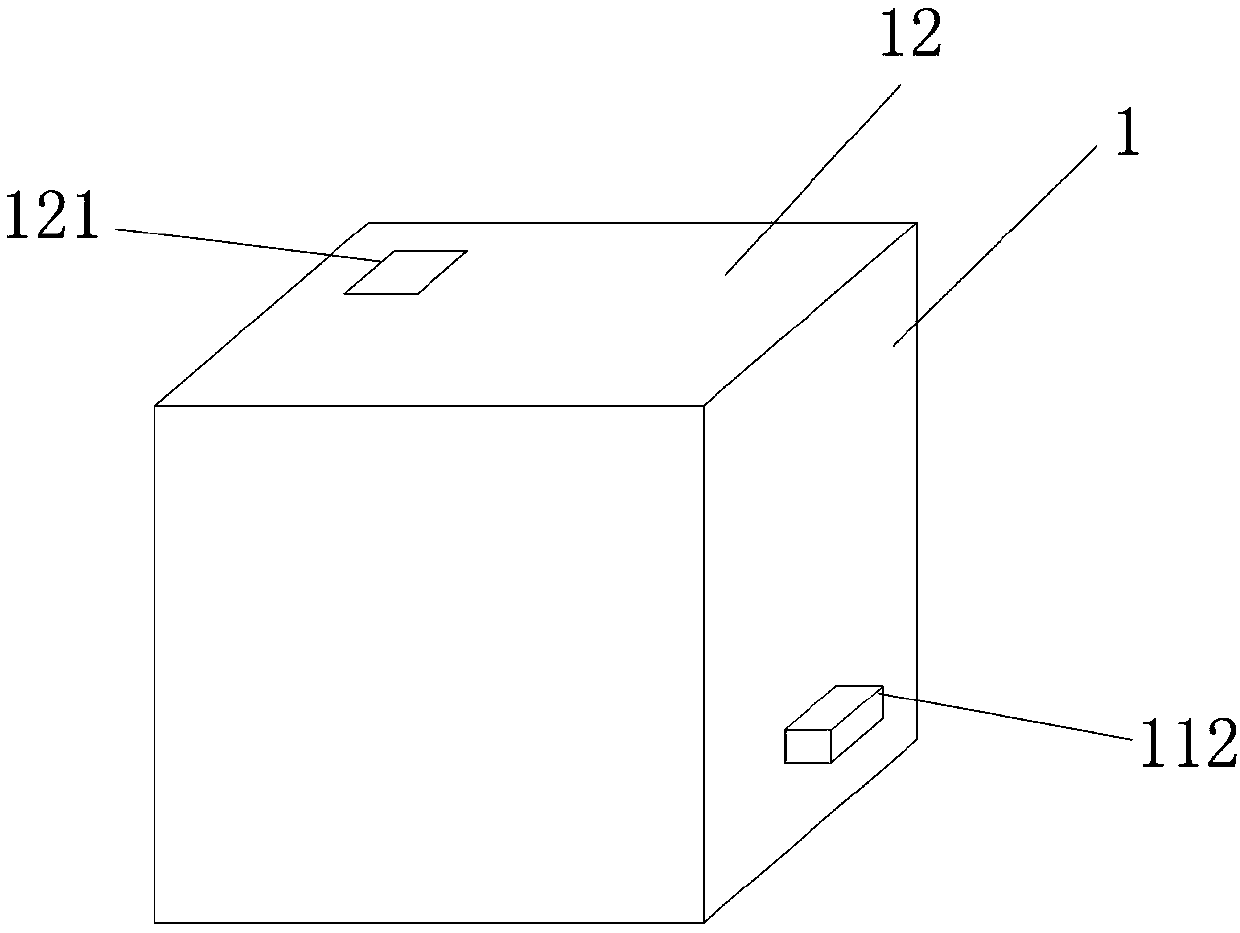

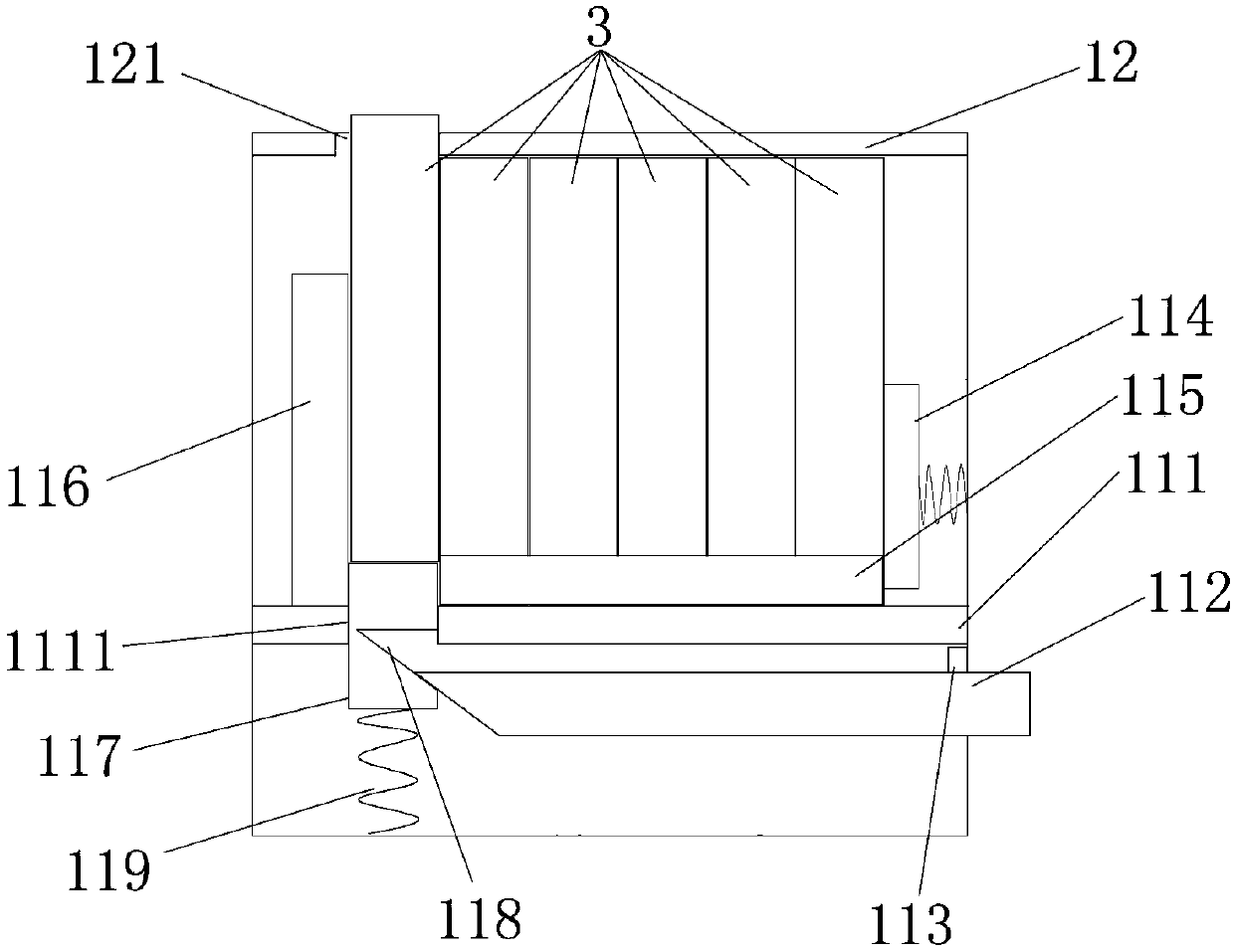

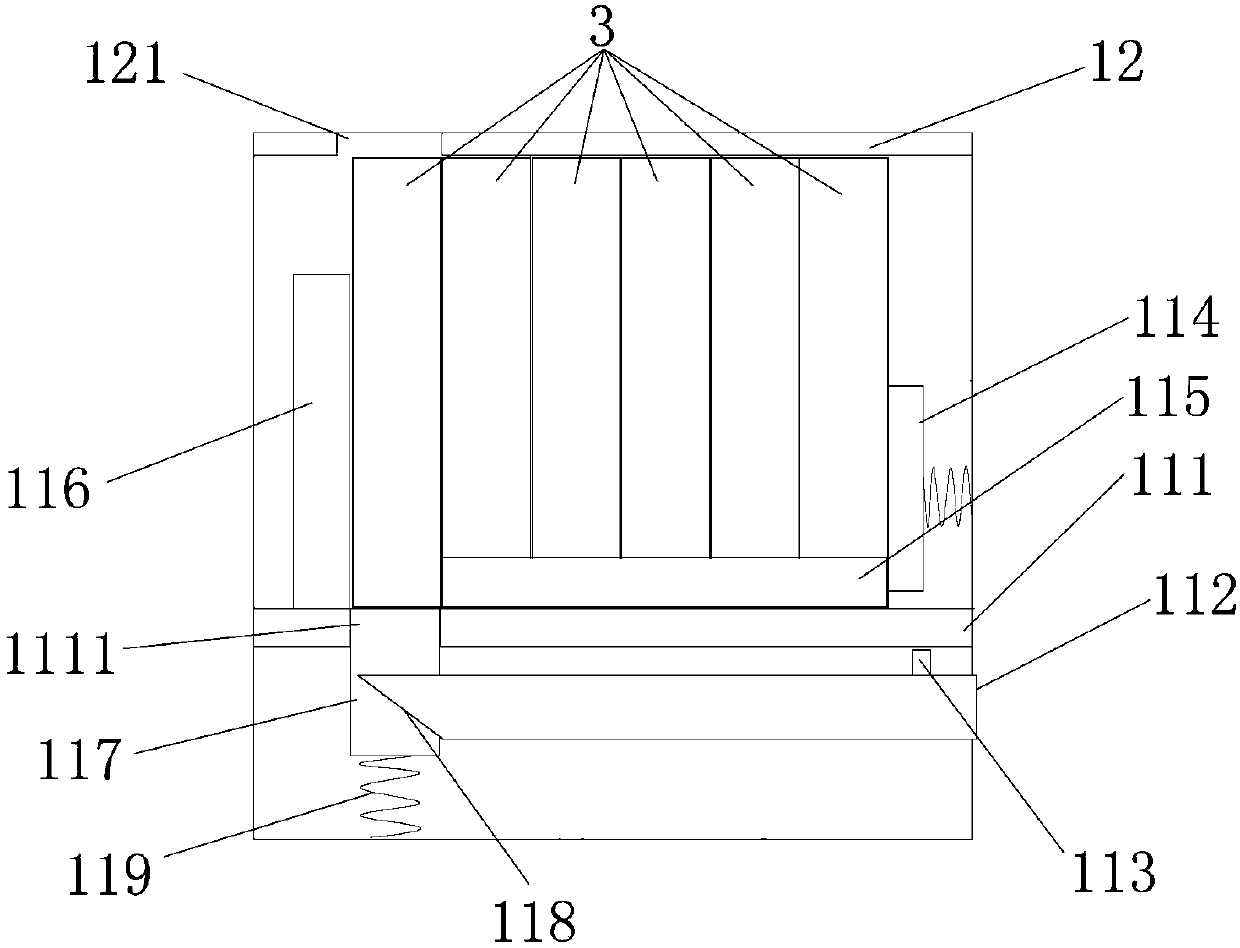

Efficient feed drying device

ActiveCN110763000AEfficient dryingAchieve recyclingDrying gas arrangementsDrying chambers/containersReciprocating motionStructural engineering

The invention discloses an efficient feed drying device, and relates to the technical field of feed processing. The drying device comprises a drying main body internally provided with a drying cavity,an elastic drying film is arranged in the drying main body, a plurality of cams with different mounting angles are arranged on the outer side of a sliding sleeve, and the upper ends of the cams abutagainst the bottom of the elastic drying film; the sliding sleeve is sleeved on a rotating shaft which is rotatably mounted on the drying main body, a protrusion is arranged on the outer side of the rotating shaft, the protrusion is arranged in a sliding groove of the sliding sleeve in a left-right sliding mode, the two ends of a B elastic part sleeved on the rotating shaft are fixed to one end ofthe sliding sleeve and a supporting block correspondingly, and the supporting block is fixedly installed on the sliding sleeve; a reciprocating assembly for driving the sliding sleeve to reciprocateleft and right is arranged at the other end of the sliding sleeve; a rotating assembly for driving the rotating shaft to rotate is arranged on the rotating shaft; and a rotating air injection assemblyis arranged above the elastic drying film. According to the efficient feed drying device, efficient drying of the feed and energy conservation are realized.

Owner:沈阳美神农牧科技有限公司

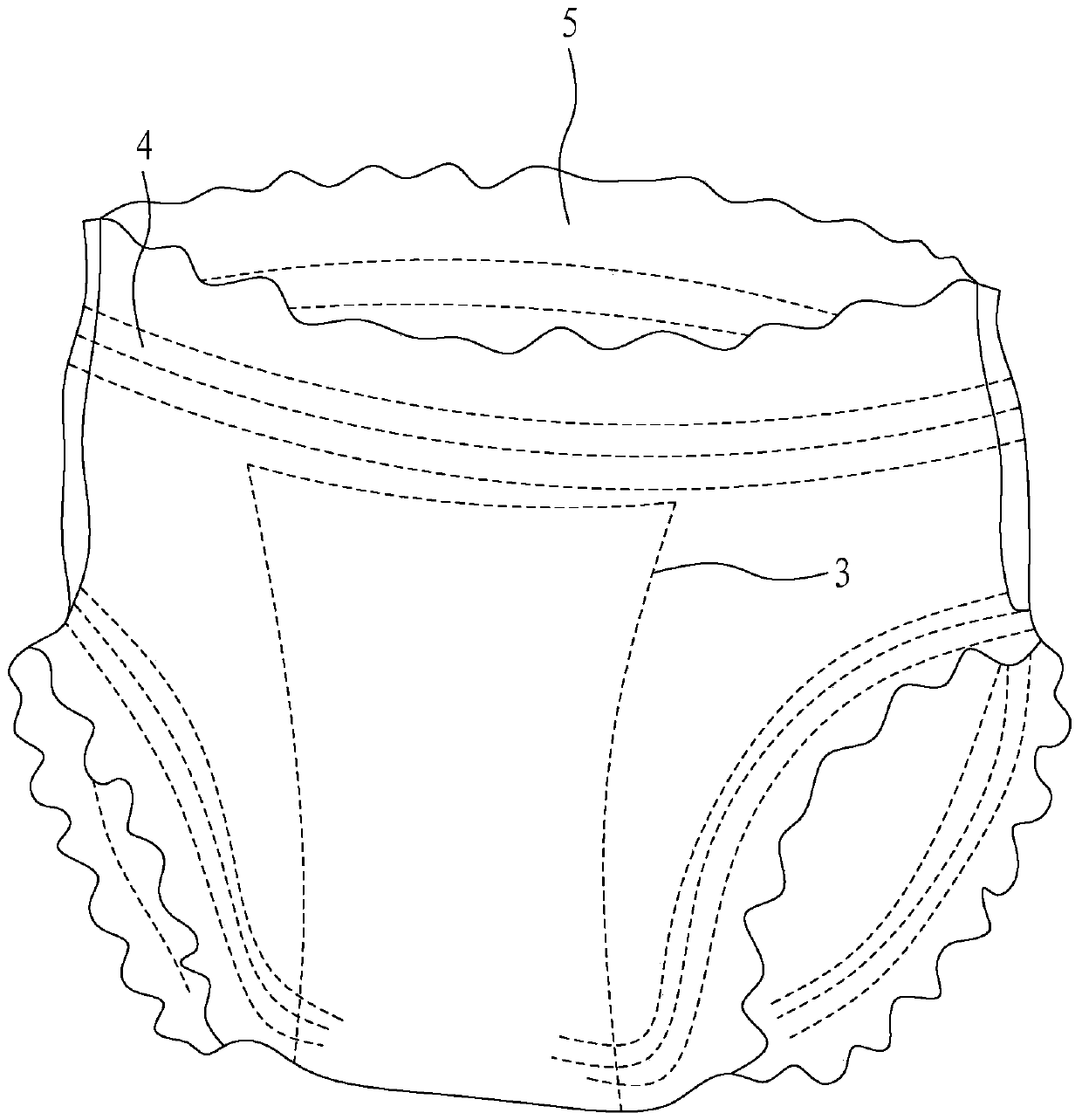

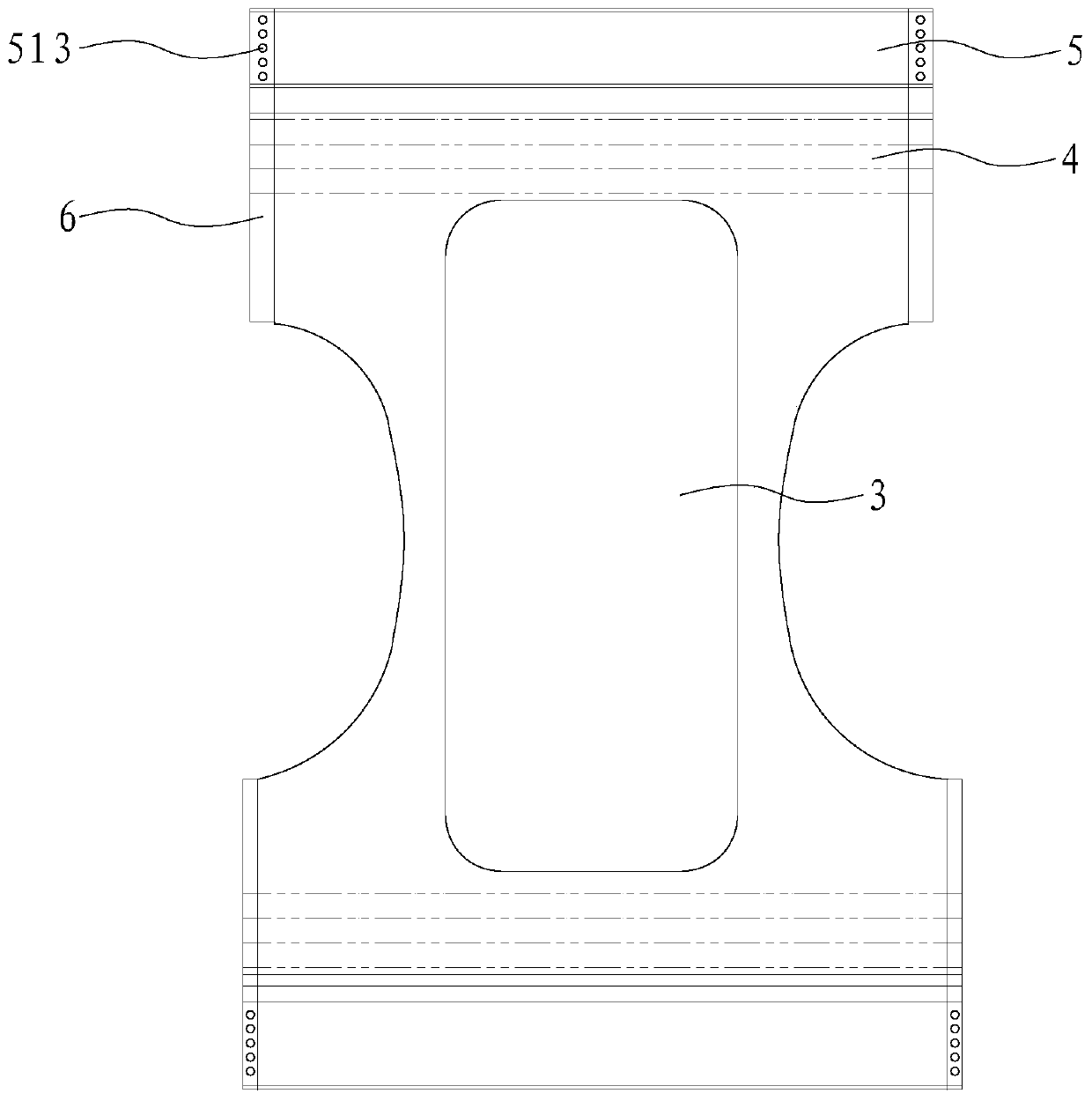

Composite elastic waistline pull up diaper and manufacturing technology thereof

PendingCN110613554APrevent looseningReduce strangulationAdhesive articlesAbsorbent padsManufacturing technologyEngineering

The invention relates to the field of disposable sanitary products, in particular to a composite elastic waistline pull up diaper. The composite elastic waistline pull up diaper comprises an outer covering layer, an inner covering layer and an absorption body, the two ends in the length direction of the inner covering layer and the outer covering layer both exceed the absorption body, a lower waistline part is formed by the areas, exceeding the absorption body and overlapped, of the inner covering layer and the outer covering layer, an upper waistline part is arranged on one side of the lowerwaistline part in a connected mode, a lower elastic part is arranged in the lower waistline part, the upper waistline part comprises an upper elastic part and waist non-woven fabric, the lower elasticpart and the upper elastic part are combined to form a composite elastic waistline, the lower elastic part comprises a plurality of elastic rubber bands, and the two ends, on one side of the absorption body, of the lower waistline part and the upper waistline part are fixedly connected with the parts, on the other side of the absorption body, of the lower waistline part and the upper waistline part to form a connecting part. The invention further provides a manufacturing technology of the composite elastic waistline pull up diaper. The technical problems that existing pull up diapers are likely to produce a bounding feeling and a tying trace are solved.

Owner:FUJIAN HENGAN HLDG CO LTD +2

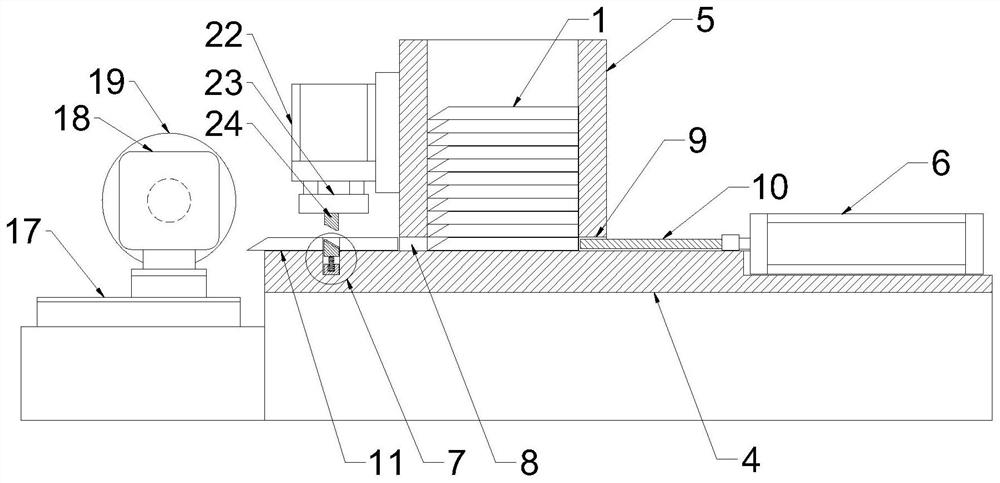

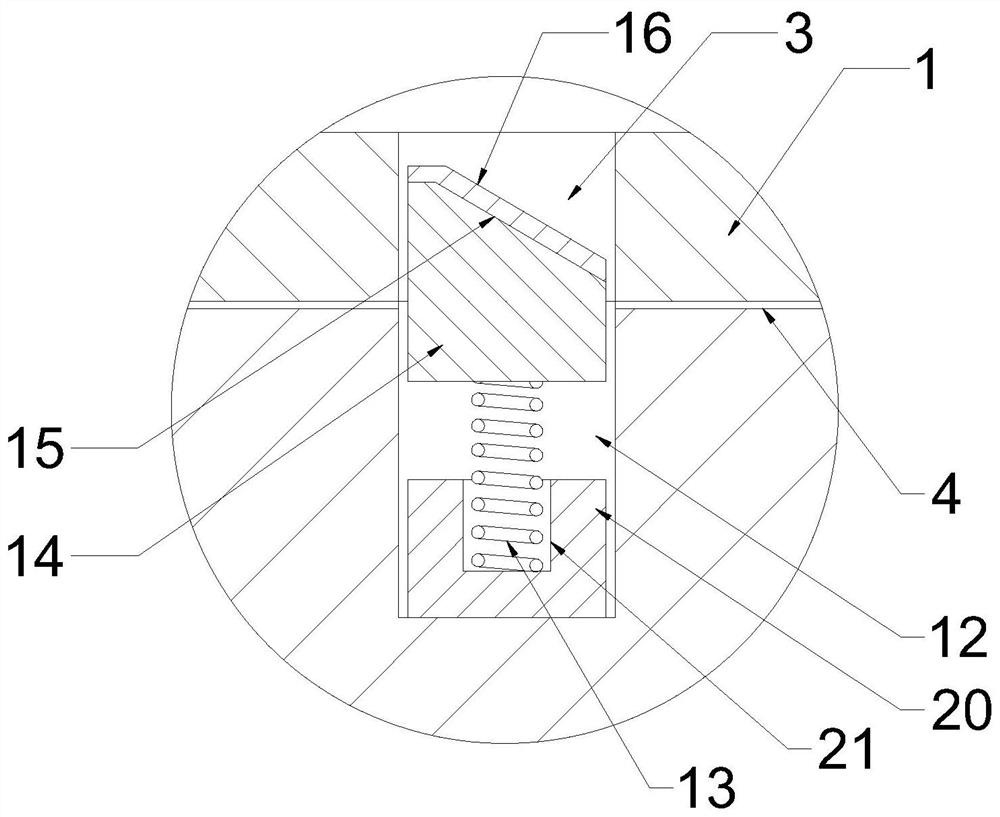

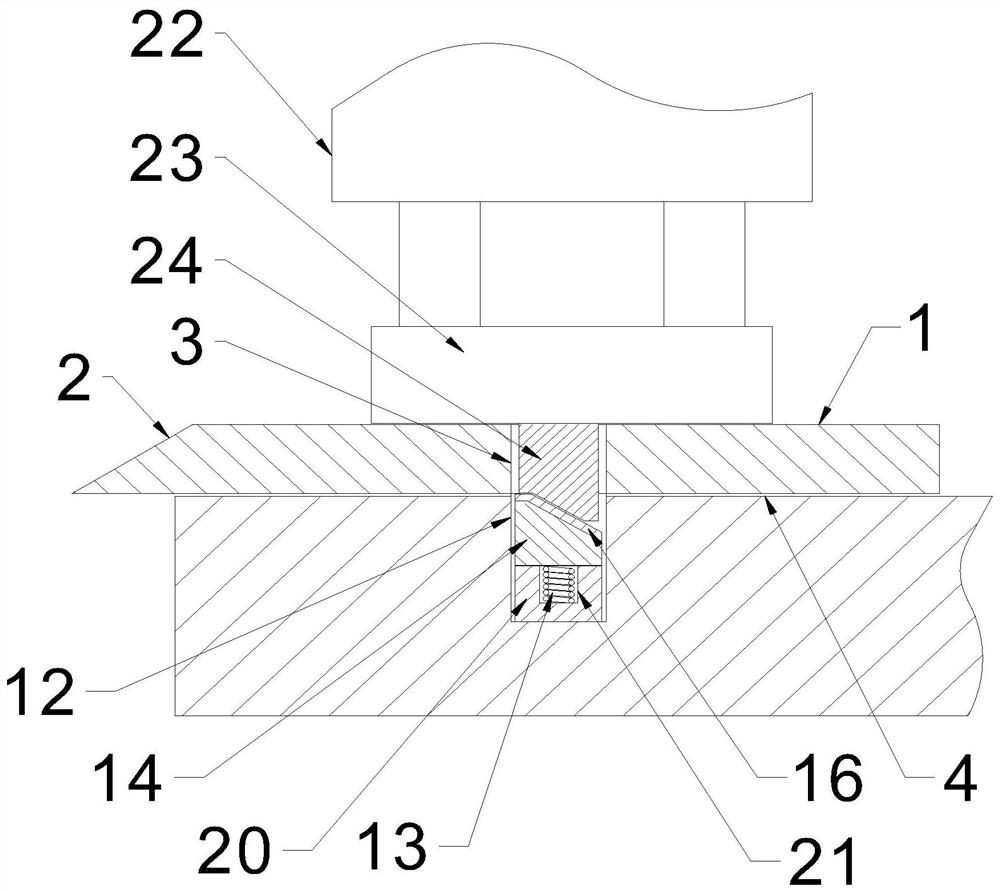

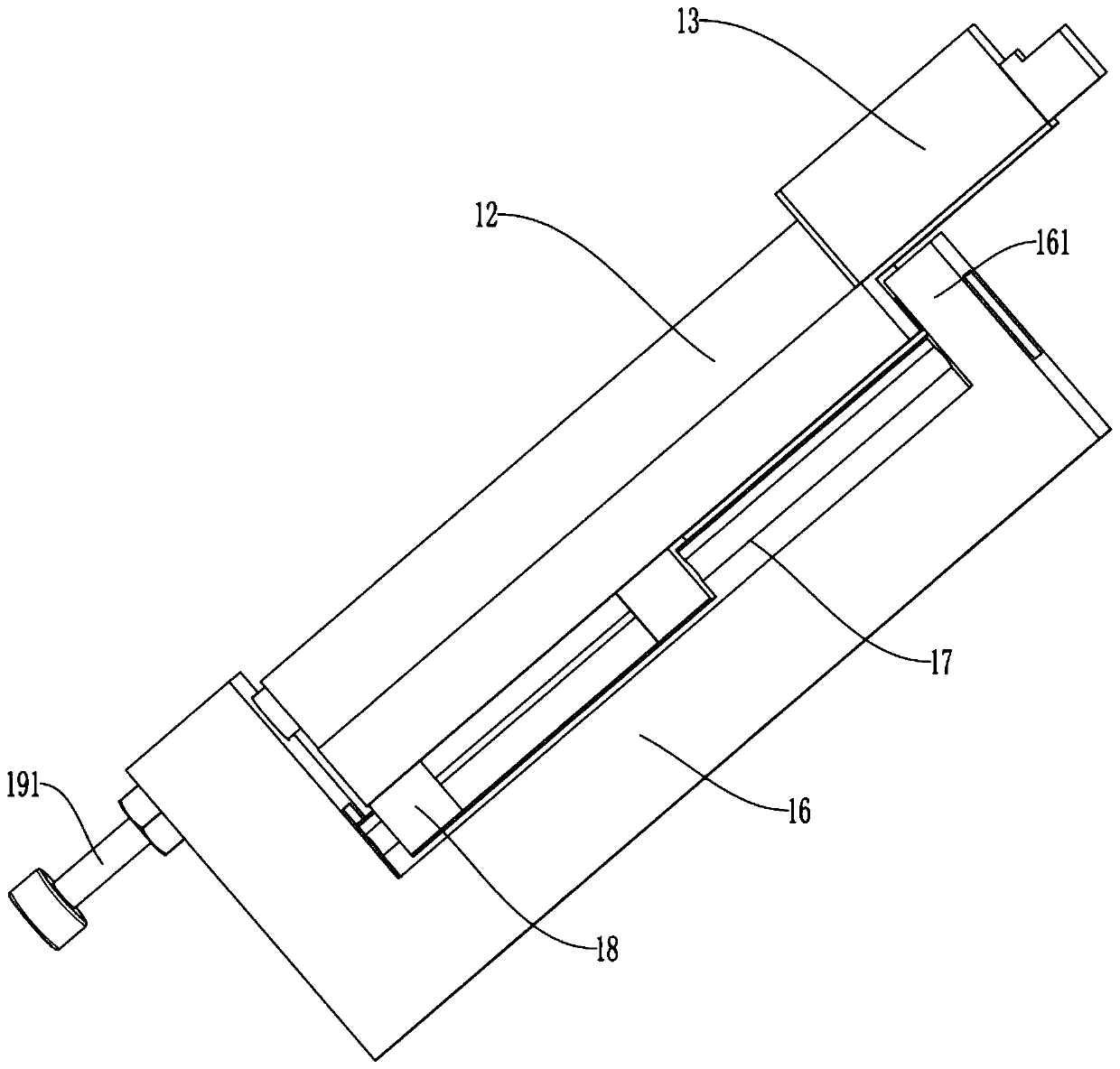

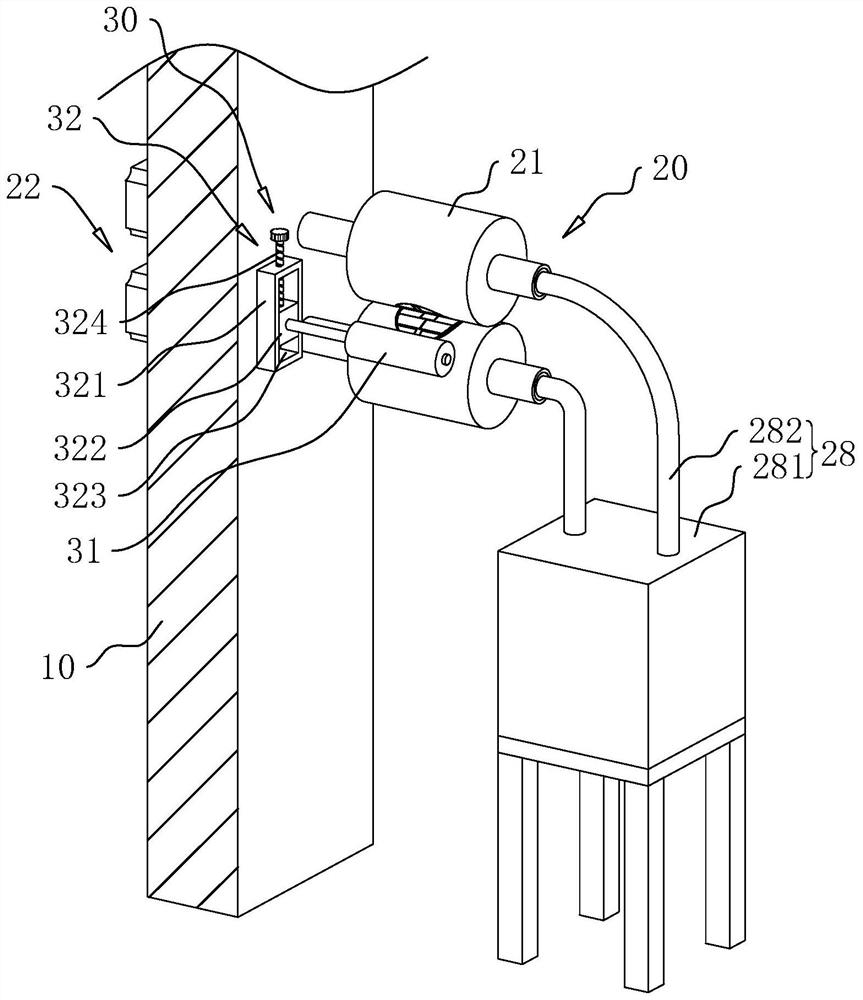

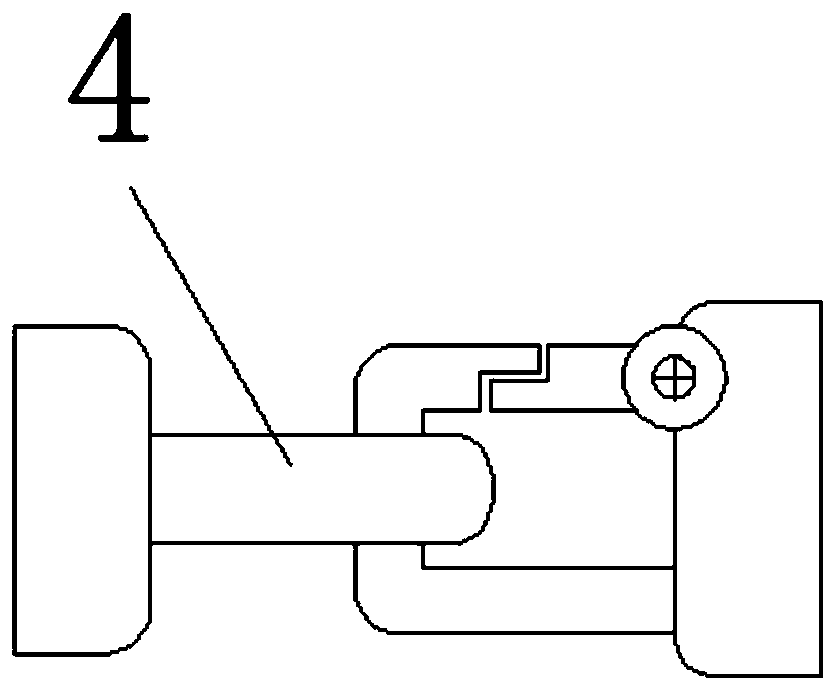

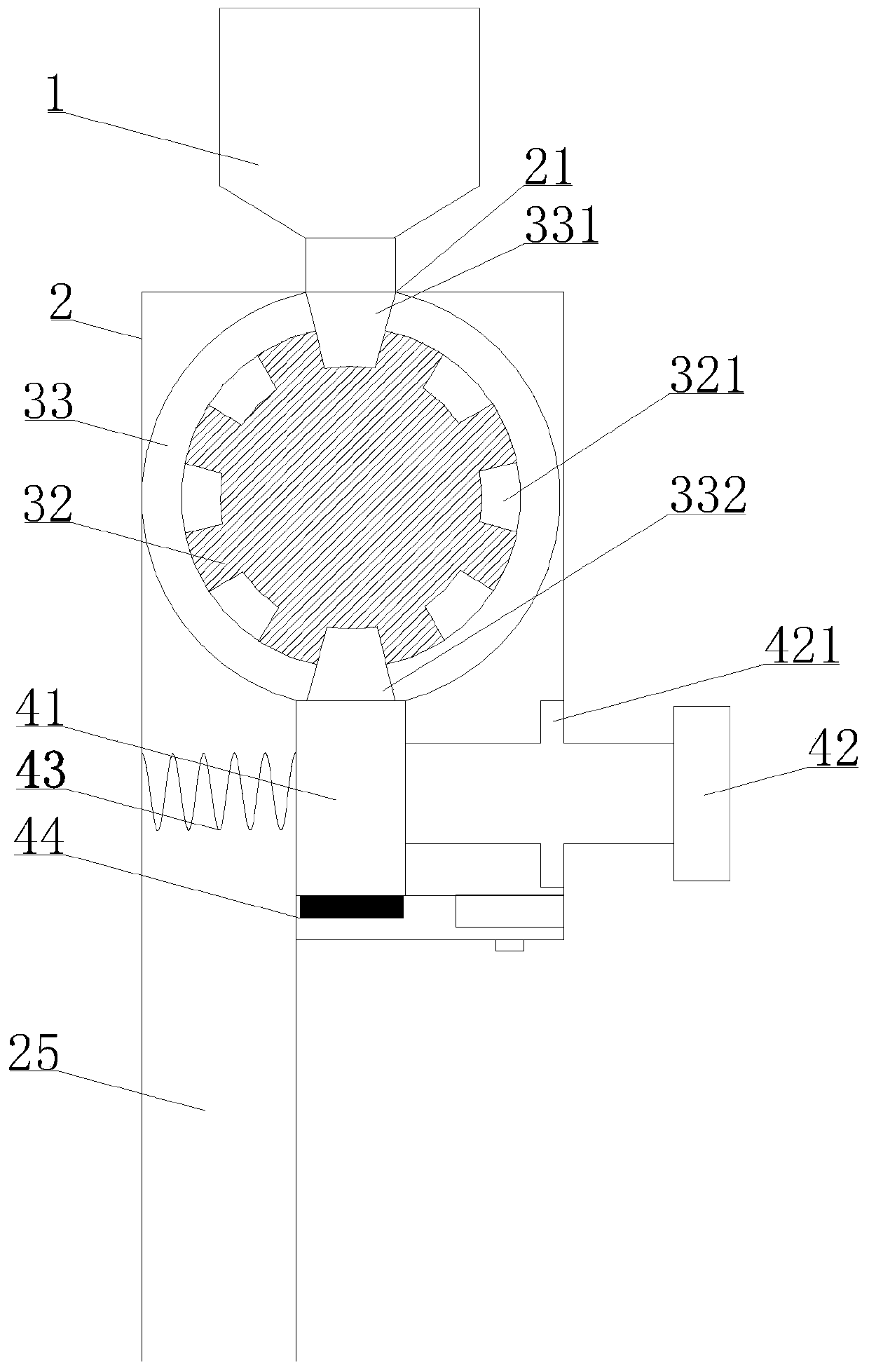

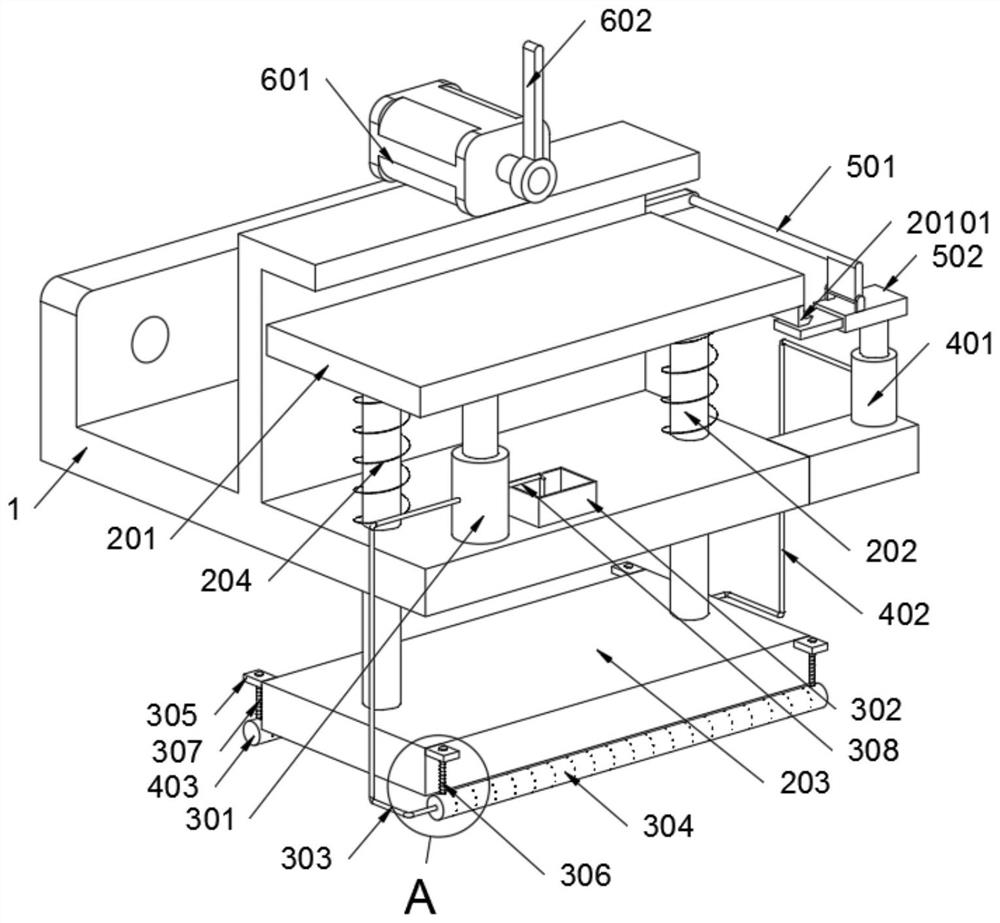

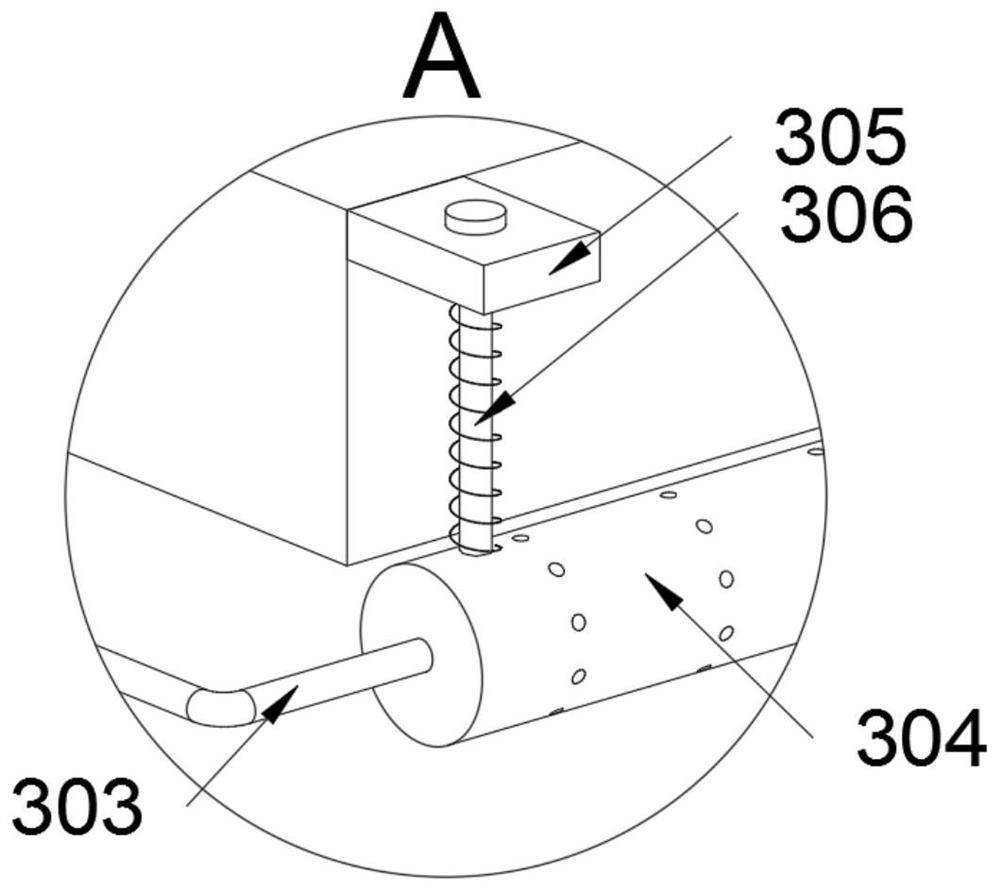

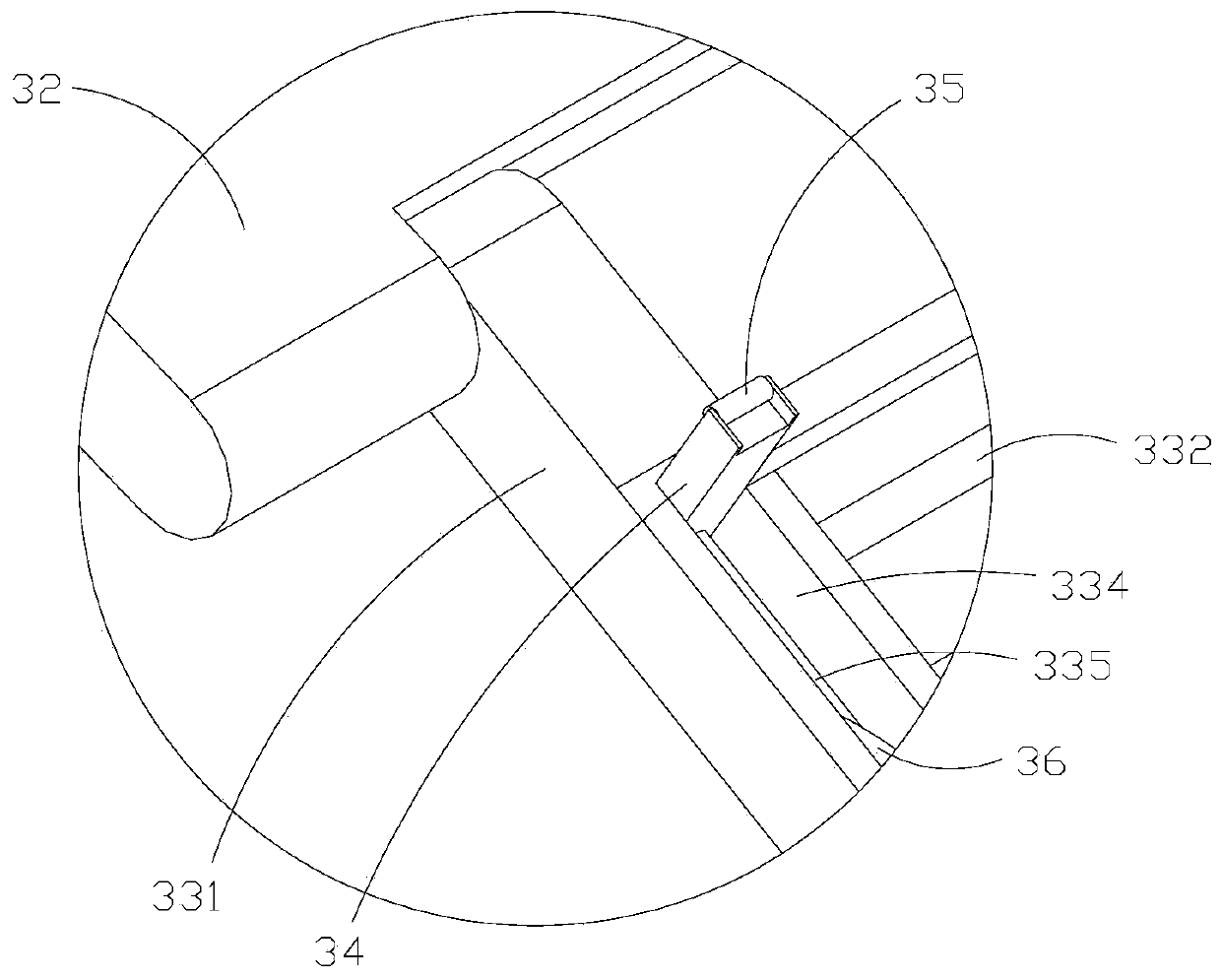

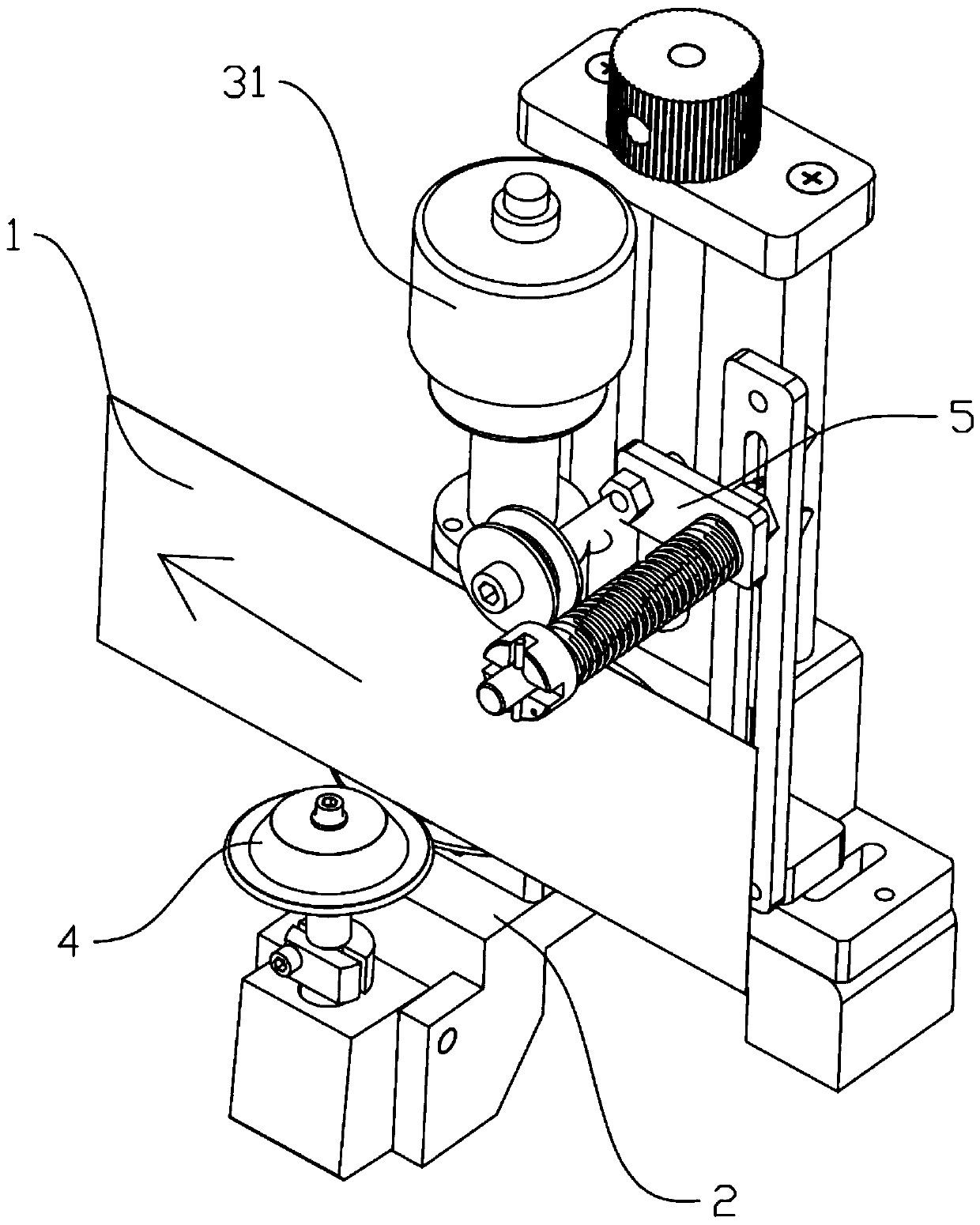

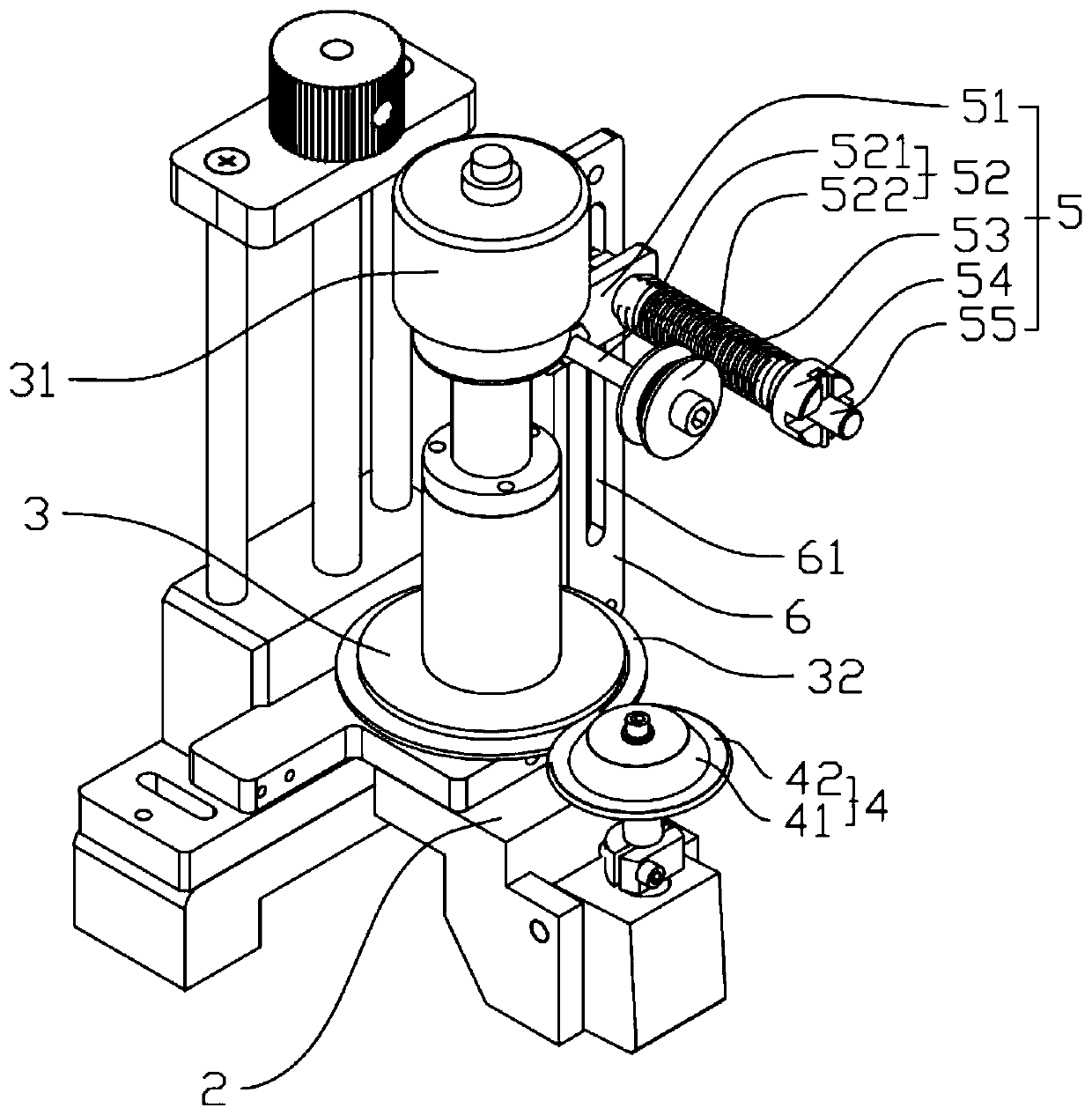

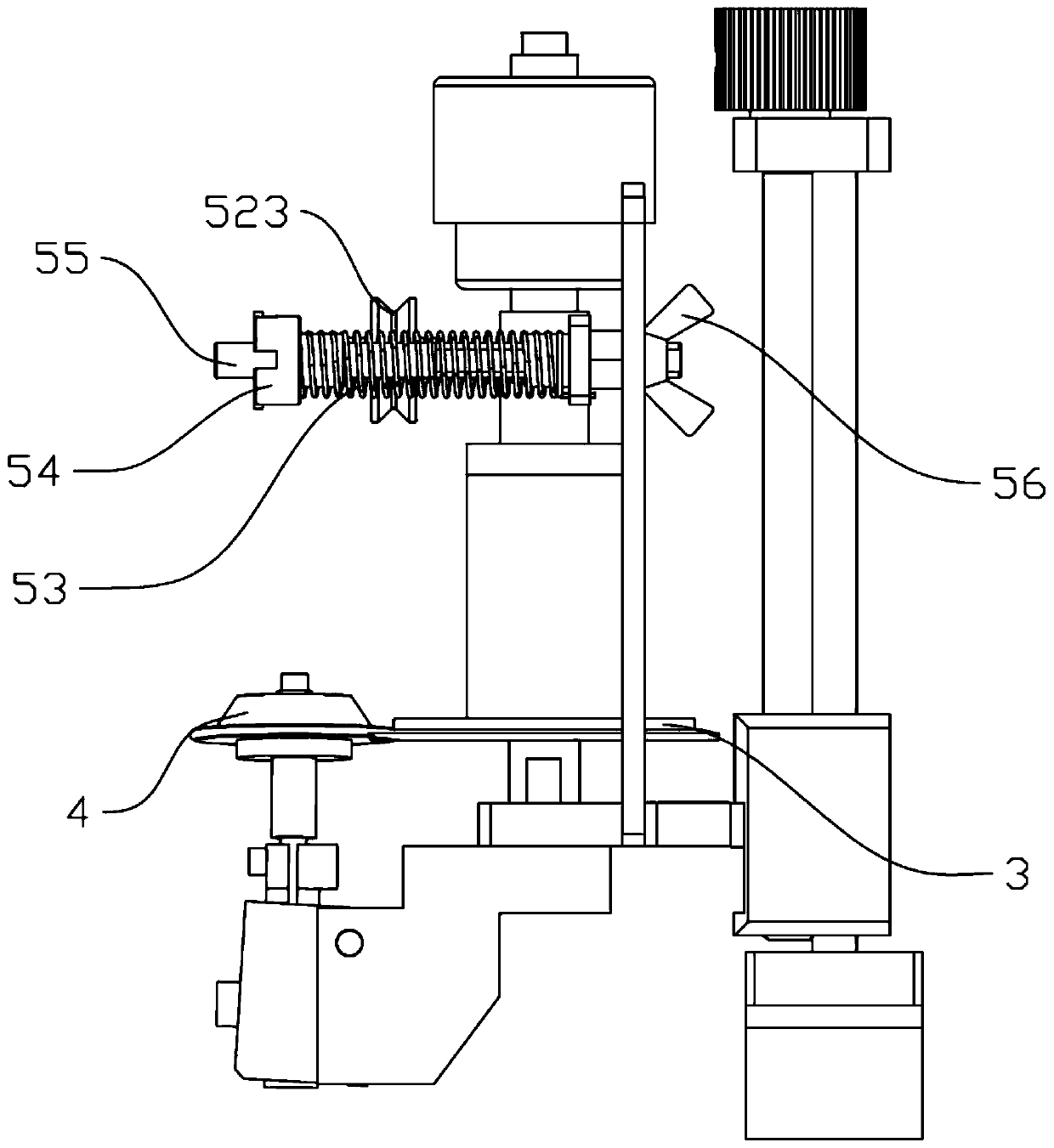

Cutting edge grinding device of transverse scissors and feeding method of cutting edge grinding device

ActiveCN113263362AIncrease weightThe feeding action is stable and reliableGrinding drivesGrinding feed controlEngineeringElasterell

The invention discloses a cutting edge grinding device of transverse scissors. A feeding mechanism of the cutting edge grinding device comprises a workbench, a material bin, a material pushing air cylinder and a blocking piece, multiple transverse scissors are stacked in the material bin, a discharging groove and a material pushing groove are oppositely formed in the bottom of the material bin, a pushing plate is installed on the material pushing air cylinder, and the material pushing air cylinder can drive the pushing plate to push the bottommost transverse scissors out of the material bin from the discharging groove. A clamping groove used for containing the blocking piece is formed in the workbench, the blocking piece comprises an elastic piece and a clamping block, the wedge-shaped face of the top of the clamping block faces one side of the material bin, the transverse scissors press the clamping block into the clamping groove through the wedge-shaped face till an assembling hole moves to the position above the clamping groove, and the clamping block is jacked into the assembling hole through the elastic piece so that the transverse scissors can be positioned on a grinding station. A grinding mechanism comprises a three-axis sliding table, a driving device and a grinding wheel, the driving device is in driving connection with the grinding wheel, and the three-axis sliding table can move the grinding wheel till the grinding wheel is in abutting connection with cutting edges of the transverse scissors on the grinding station. The cutting edge grinding device is labor-saving and flexible in transverse scissors feeding, compact in equipment structure, small in occupied space and high in grinding precision.

Owner:南京凯斯特机械设备科技有限公司

Cleaning device

Owner:KUNSHAN XUNTAO PRECISION MACHINERY

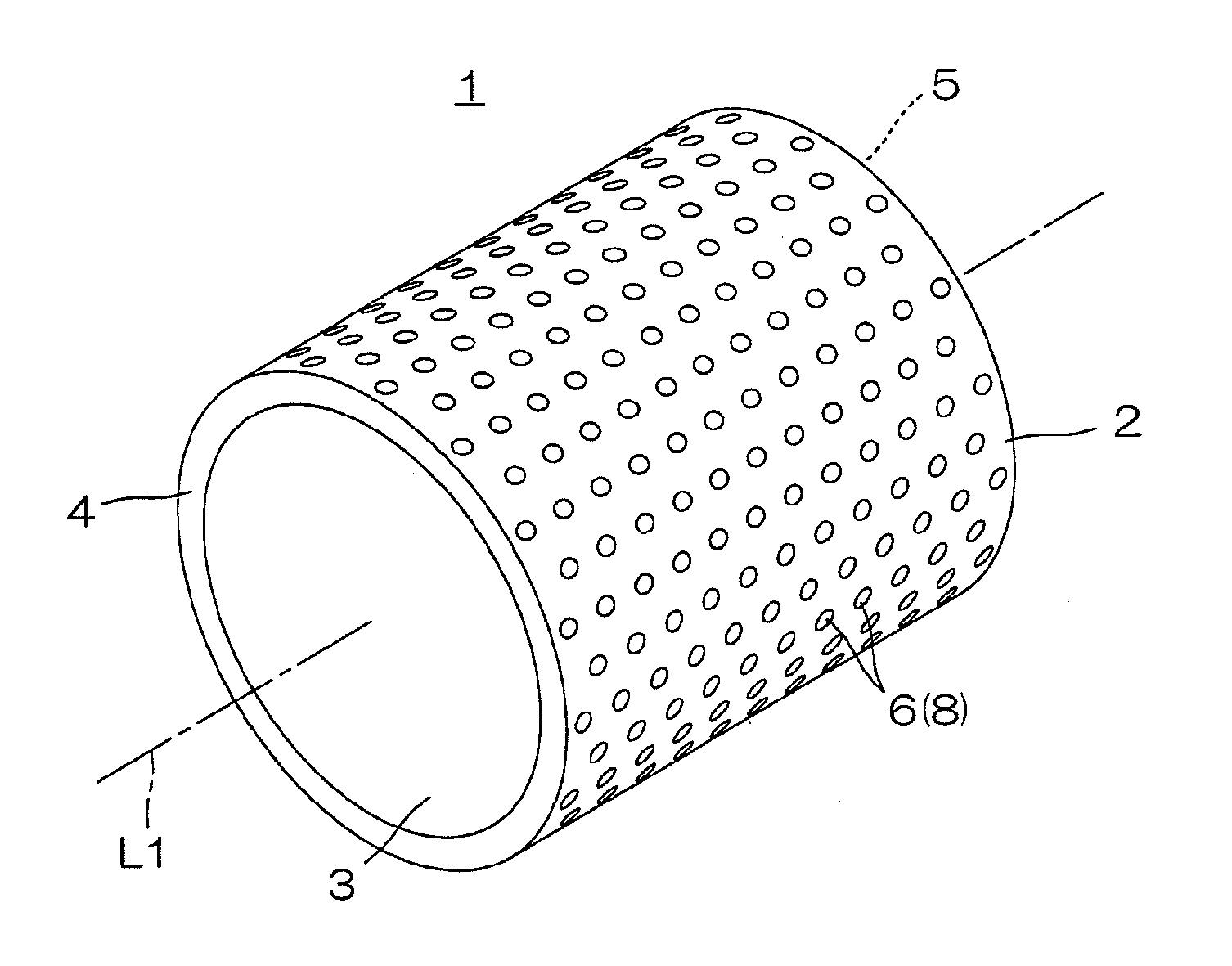

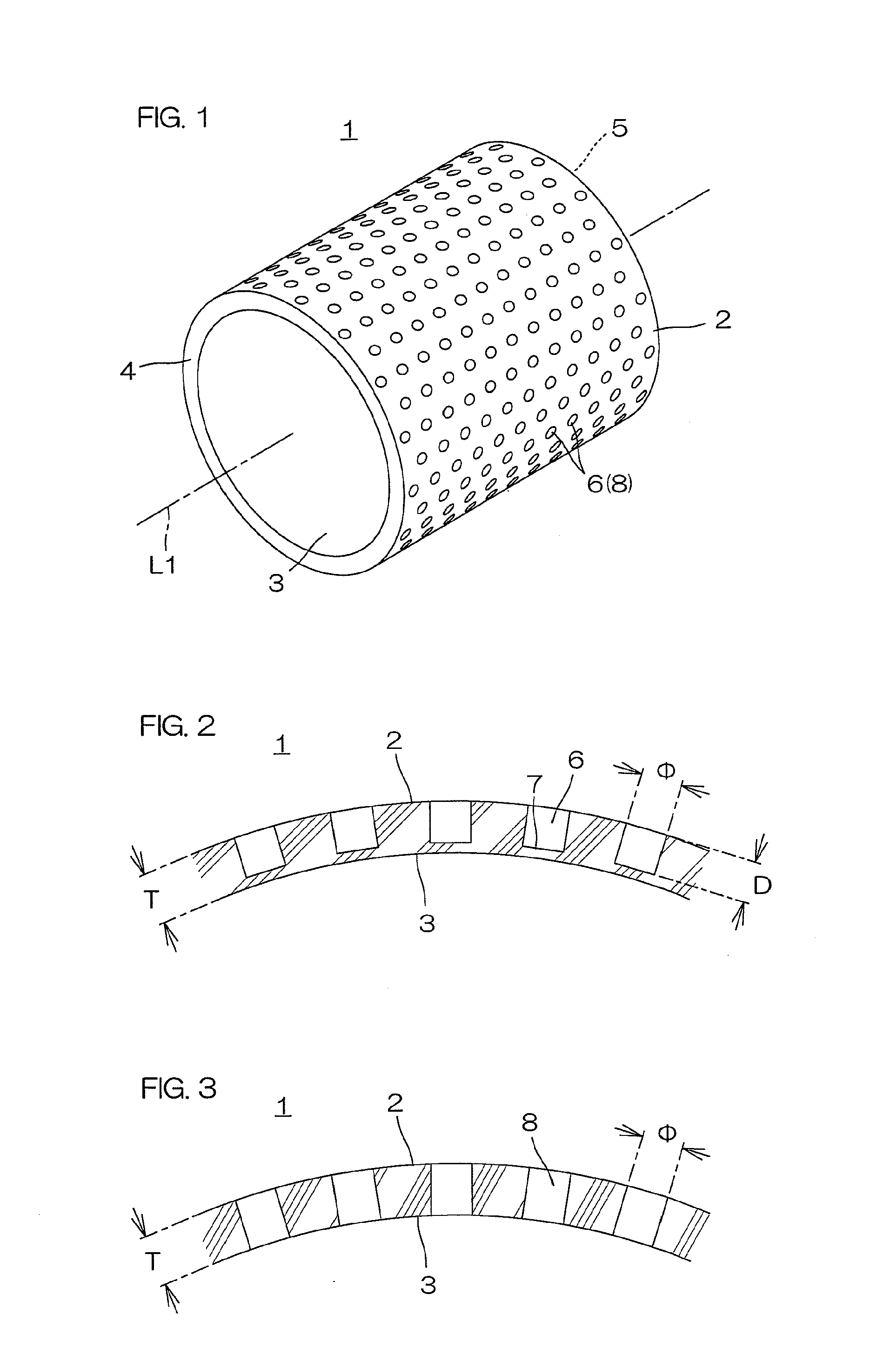

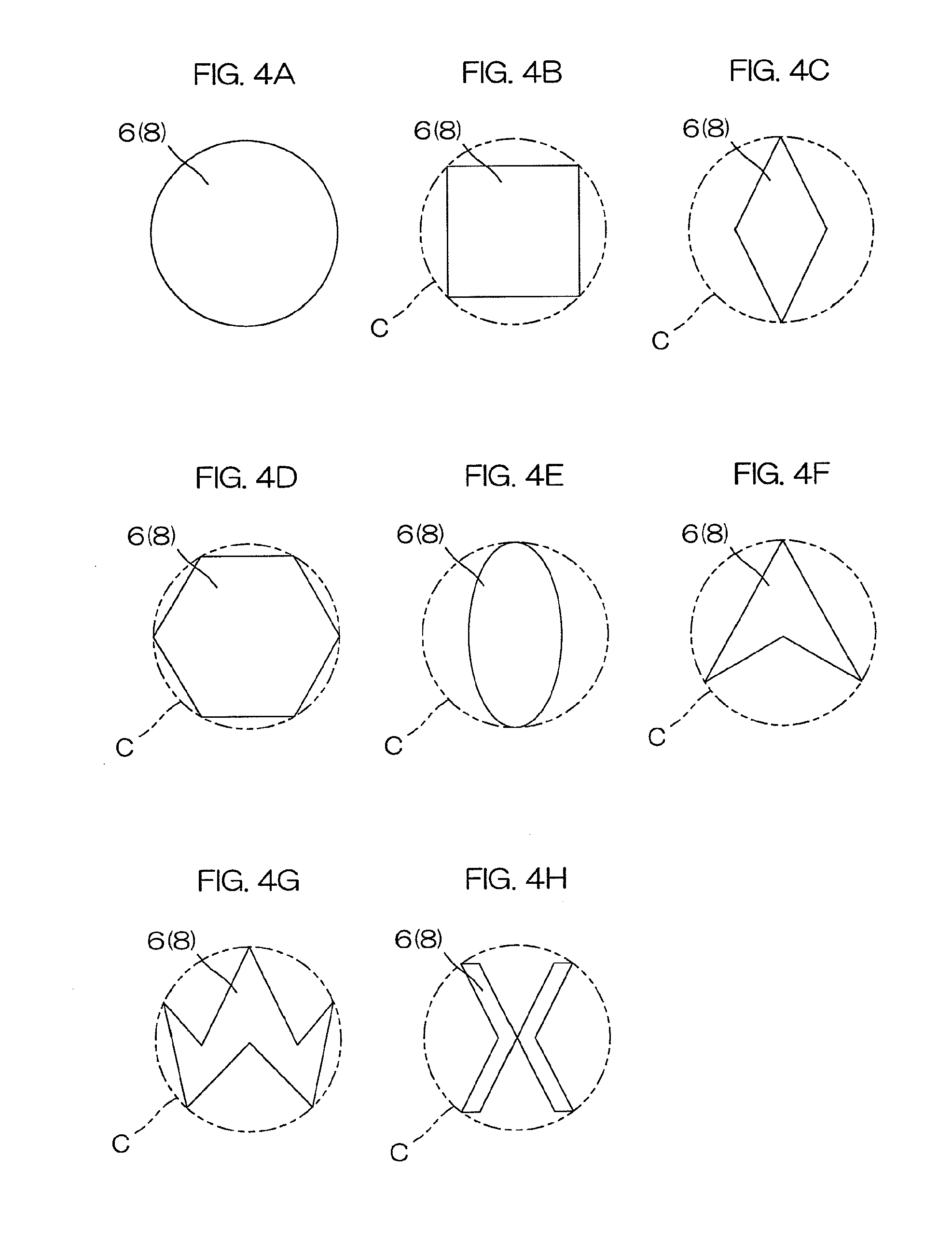

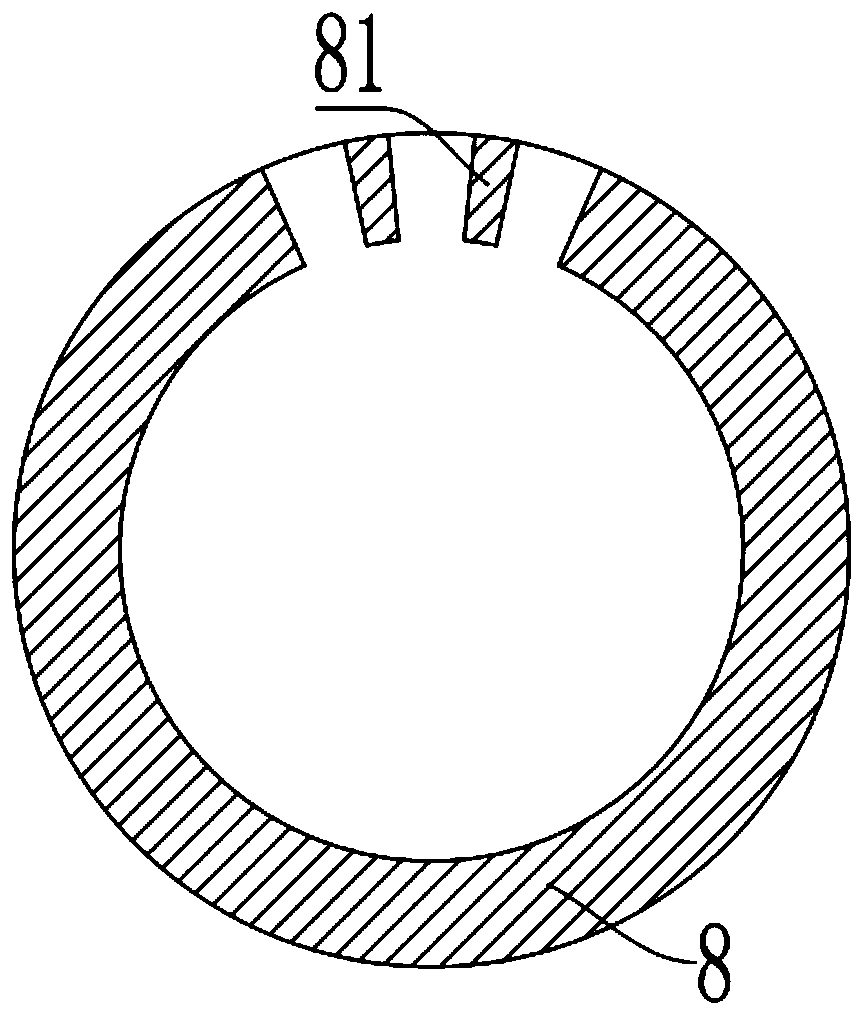

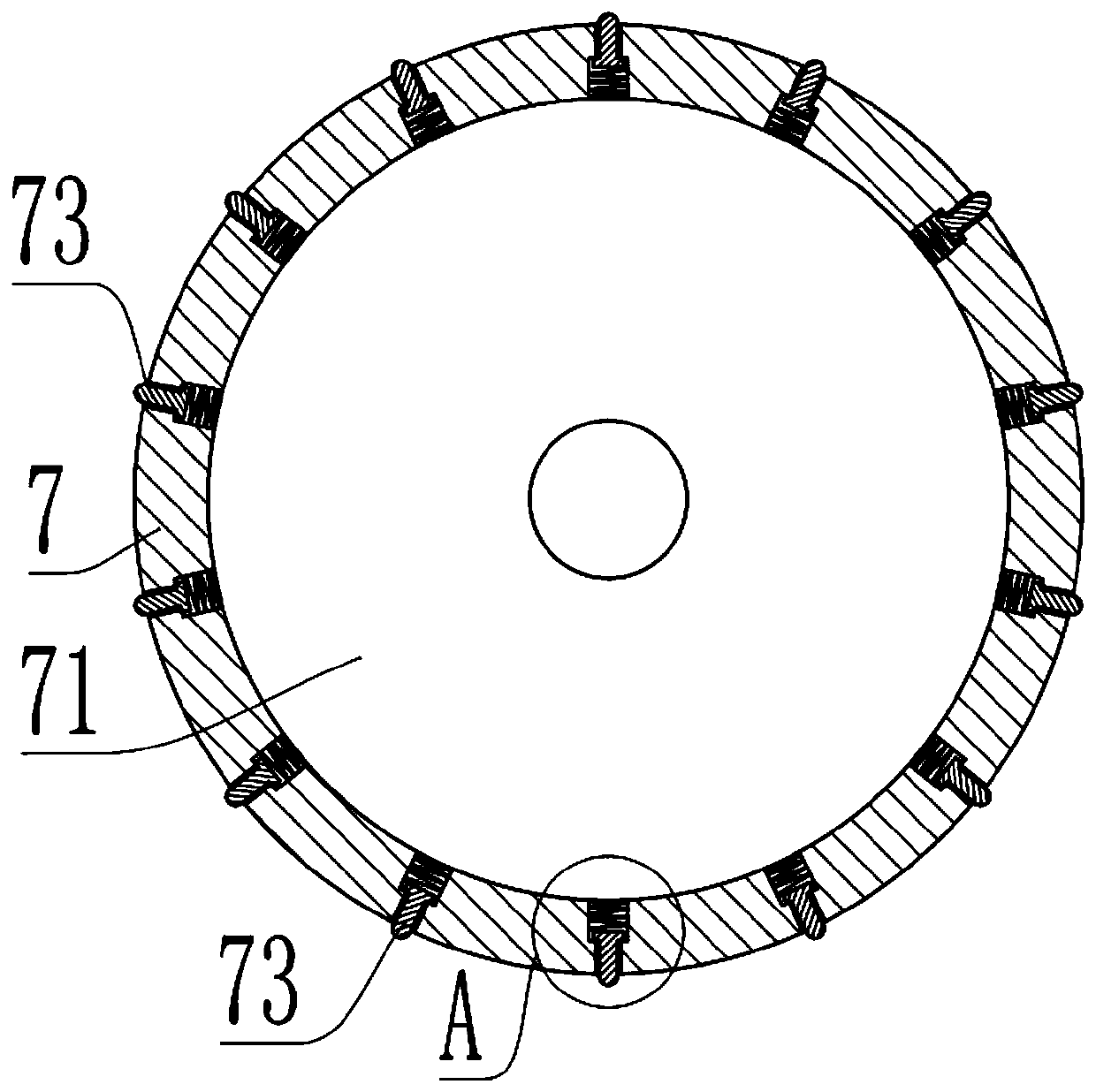

Sheet conveying roller and production method therefor

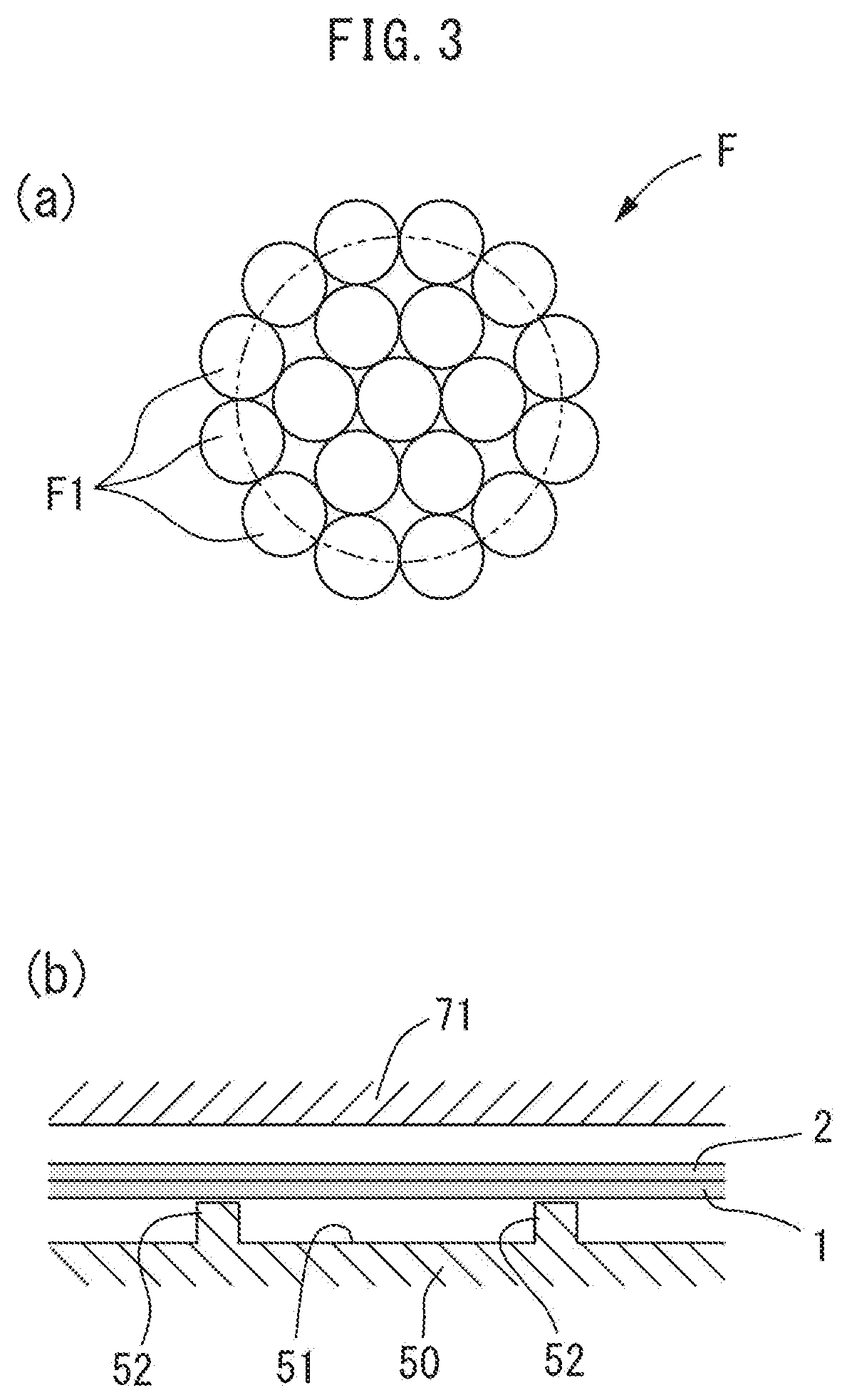

InactiveUS20130217554A1Reduce the amount requiredSuppress sheet transportation failureAuxillary shaping apparatusAgricultural rollersVulcanizationPaper dust

The present invention provides a sheet conveying roller, which effectively reduces the amount of paper dust accumulated on its outer peripheral surface to thereby suppress sheet transportation failure. The sheet conveying roller includes a nonporous tubular elastic member (1). The elastic member (1) has a plurality of recesses (6) or a plurality of through-holes (8) equidistantly arranged in a center axis (L1) direction thereof and equidistantly arranged in a circumferential direction thereof, and each having an opening having a round plan shape in an outer peripheral surface (2) thereof, wherein the recesses (6) each have a constant depth as measured thicknesswise of the elastic member (1), wherein the through-holes (8) each extend thicknesswise through the elastic member (1). A production method includes forming the elastic member by vulcanizing a rubber composition in a vulcanization mold having projections corresponding to the recesses or the through-holes.

Owner:SUMITOMO RUBBER IND LTD

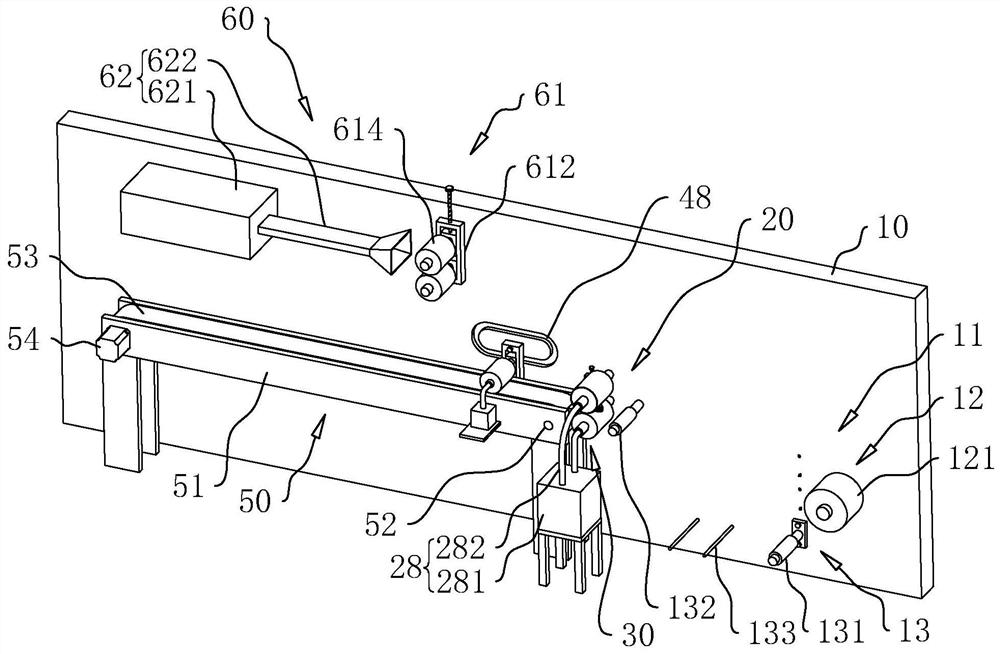

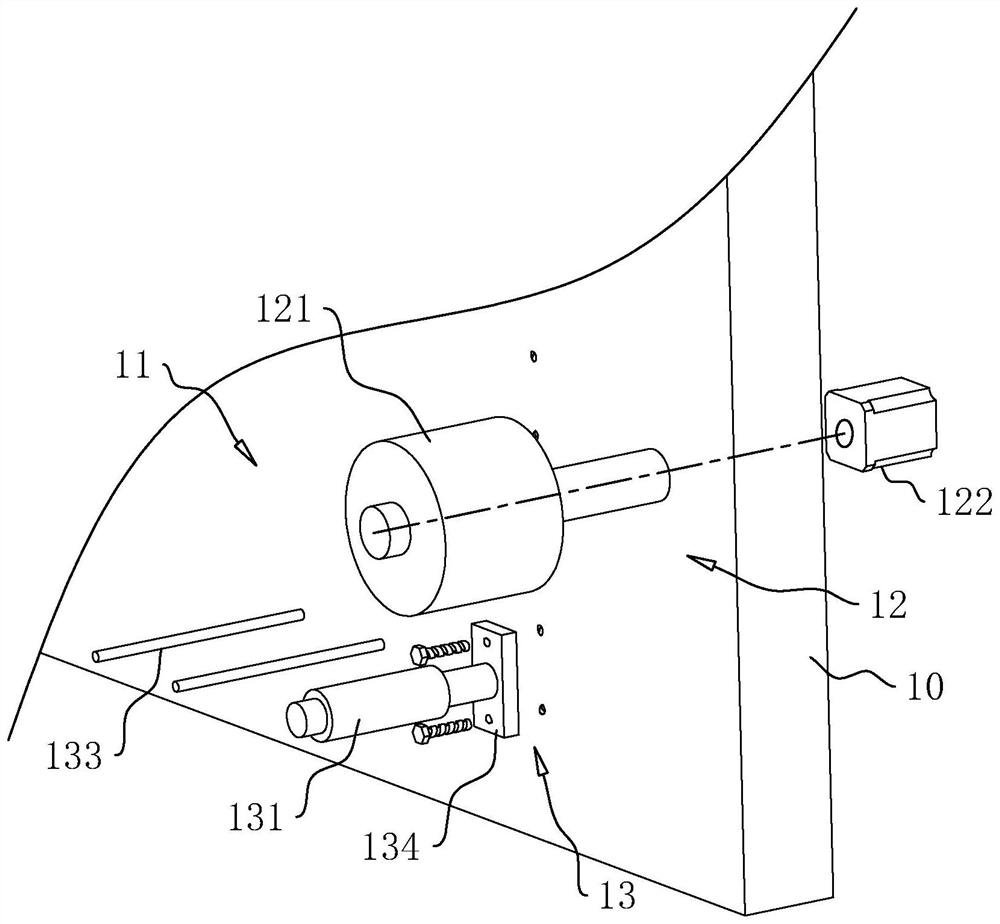

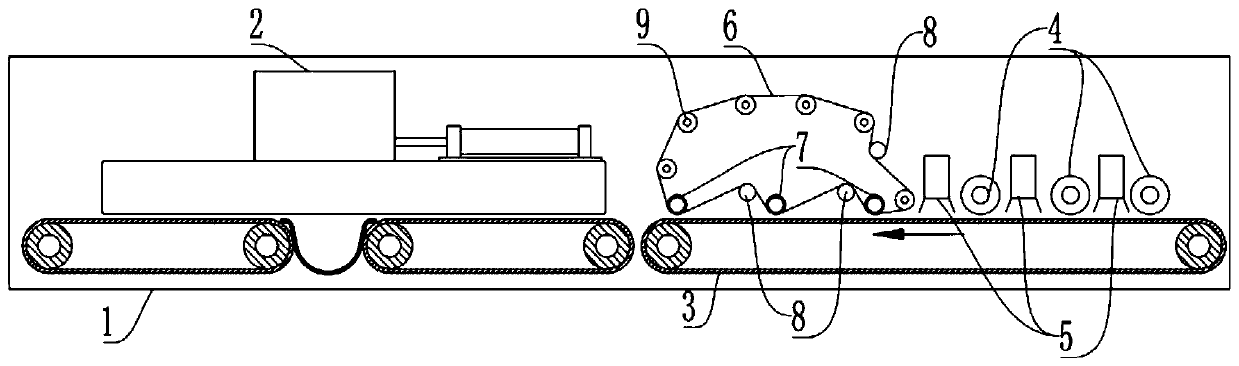

Non-woven fabric facial mask paper production equipment and process

ActiveCN113047025AReduce wasteEasy to separateSevering textilesMetal working apparatusPaper productionStructural engineering

The invention relates to non-woven fabric facial mask paper production equipment and process. The non-woven fabric facial mask paper production equipment comprises a base plate, and an unwinding mechanism, a cutting mechanism and a material receiving mechanism are sequentially mounted on one side of the base plate in the material guiding direction. The cutting mechanism comprises two knife rollers arranged in a spaced mode and a first driving part for driving the two knife rollers to rotate reversely, cutting dies are mounted on the surfaces of the two knife rollers, cutting areas are formed by the cutting dies in a surrounding mode and used for cutting and separating a non-woven fabric into surface films and waste materials, when the knife rollers rotate to a certain position, the cutting dies on the two knife rollers abut against each other, and a plurality of elastic pieces are movably mounted in the cutting areas of the two knife rollers and protrude out of the surfaces of the cutting dies for applying force to the facial masks, so that the facial masks are separated from the waste materials. According to the non-woven fabric facial mask paper production equipment and process, adhesion between the cut facial masks and the waste materials is reduced.

Owner:HANGZHOU XUYUAN NONWOVEN PROD

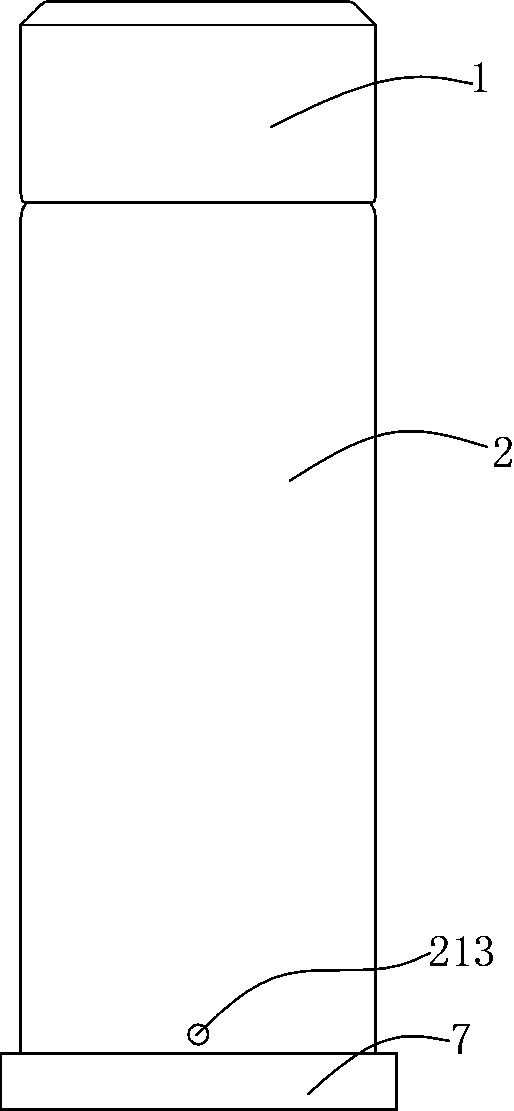

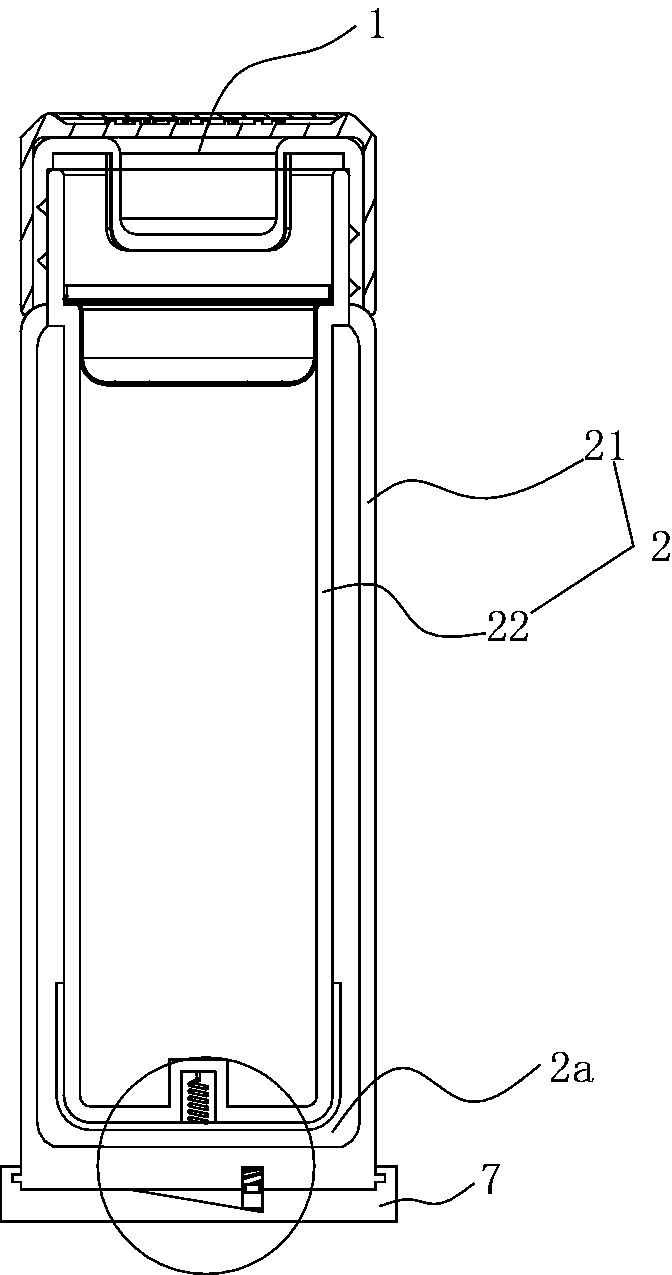

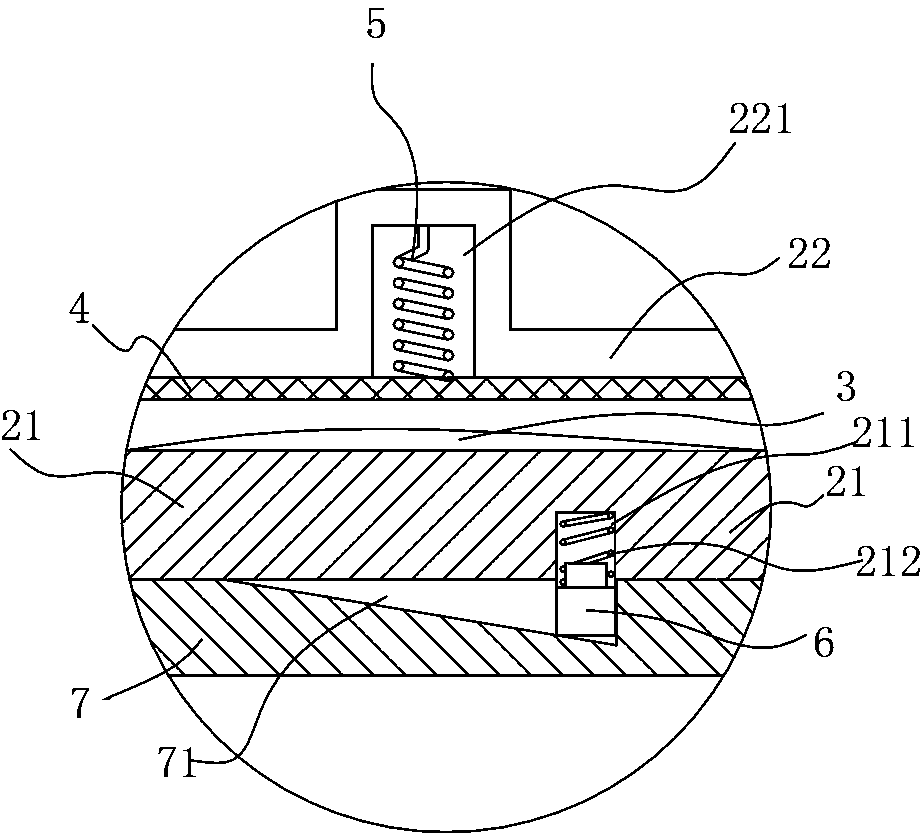

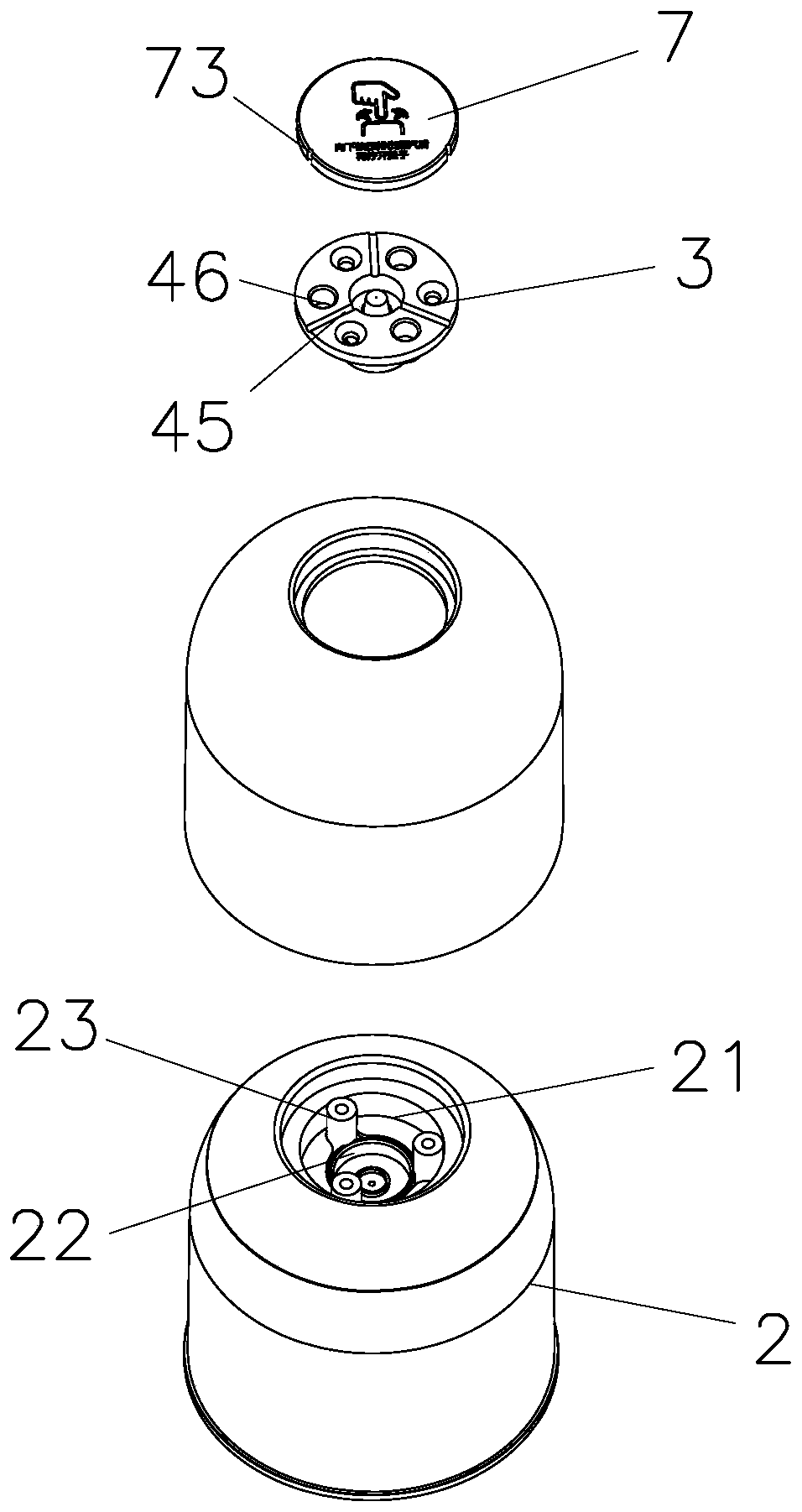

Multipurpose vacuum cup

The invention discloses a multipurpose vacuum cup. The cup comprises a cup cover and a cup body, the cup body is divided into a shell and an inner container, a closed space is formed between the shelland the inner container, and the closed space is vacuumized to form a vacuum layer. The cup is characterized in that iodine powder is arranged in the vacuum layer; the outer ring of the bottom of theinner container is sleeved with a heat conduction shell, and the heat conduction shell is connected to the outer ring of the inner container in a sliding mode; an elastic piece is arranged at the bottom of the inner container, one end of the elastic piece is in contact with the bottom of the inner container, and the other end of the elastic piece is fixed to the heat conduction shell; the heat conduction shell is spaced apart from the shell by certain distance under the action of the elastic piece; a chamber is formed in the bottom of the shell, a magnet is connected into the chamber in a sliding mode, and a base is connected to the outer ring of the bottom of the shell in a rotating mode; and a cavity is formed in the base, one end of the magnet is located in the cavity, and the bottom of the cavity is an inclined face with one high side and one low side.

Owner:永康市华格工业产品设计有限公司

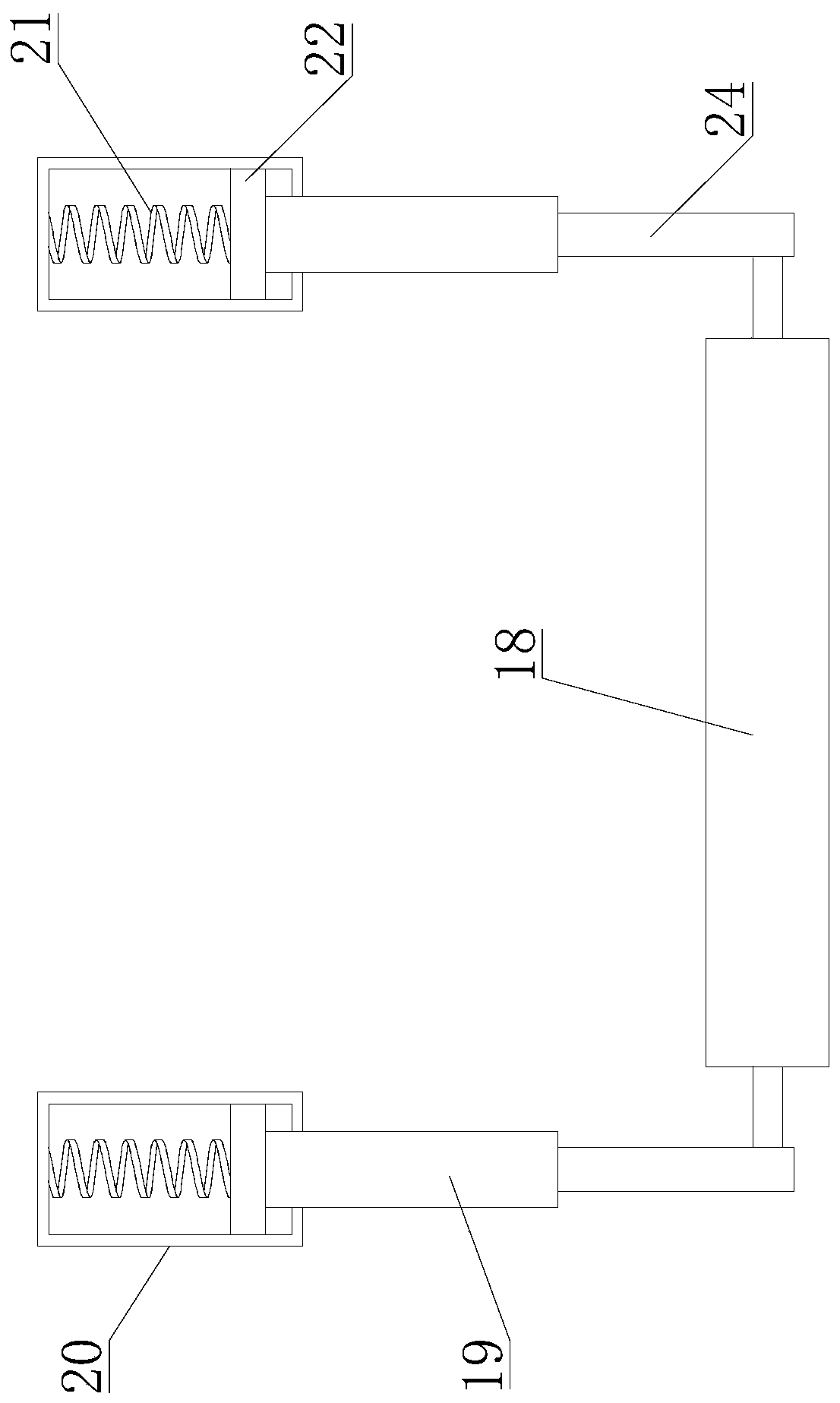

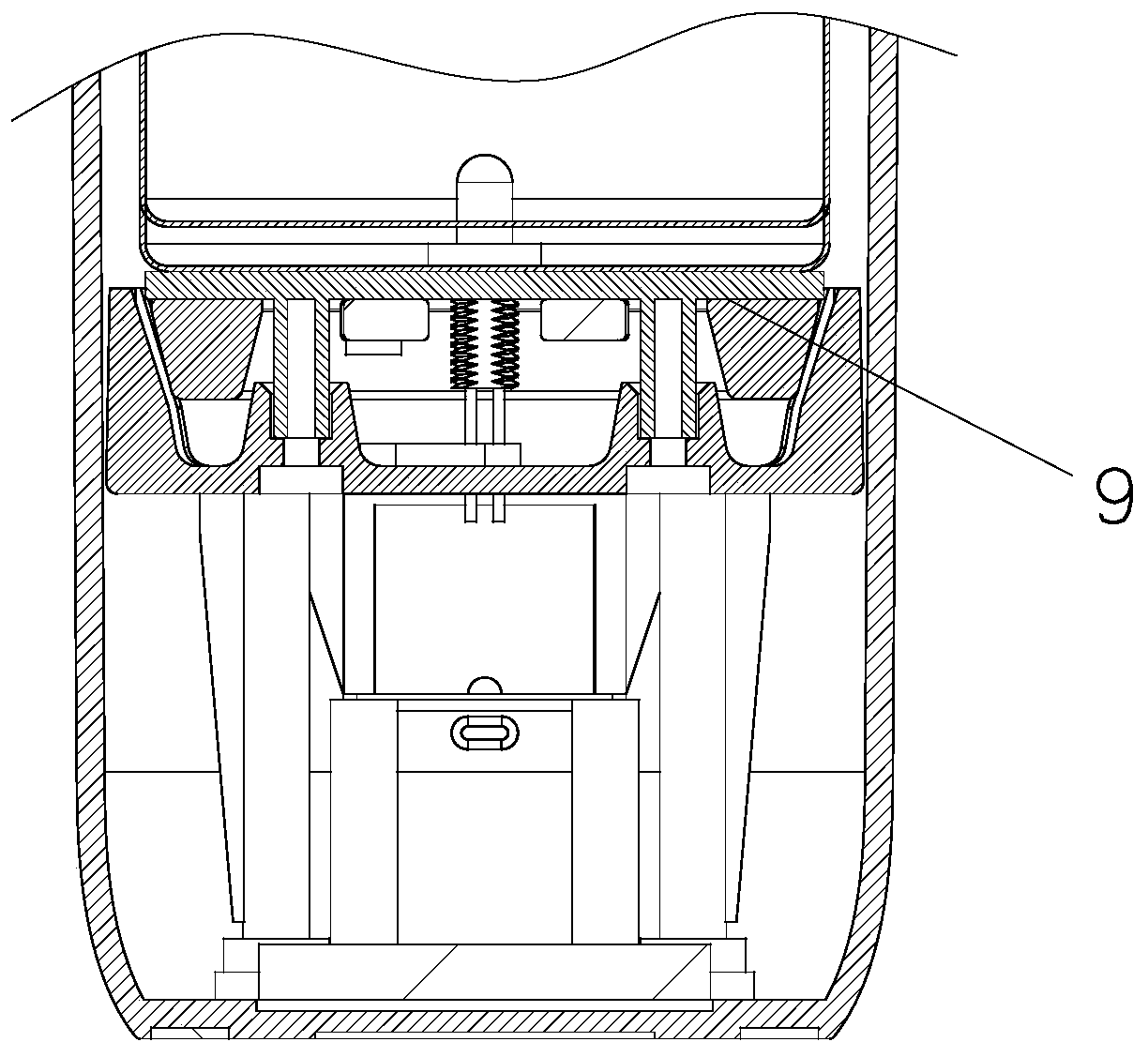

Constant volume valve

The invention discloses a constant volume valve which communicates with a storage tank used for storing materials. The constant volume valve comprises a valve cavity, a feeding port, a discharging port, elastic parts, a first valve seat, a second valve seat, a first driving mechanism and a second driving mechanism, wherein the feeding port is formed in the valve cavity and communicates with the storage tank, the discharging port is formed in the valve cavity, the elastic parts are arranged between the feeding port and the discharging port and extend and contract in the extending direction of the length of the elastic parts, the first valve seat is arranged at the ends, close to the feeding port, of the elastic parts, the second valve seat is arranged at the ends, close to the discharging port, of the elastic parts, the first driving mechanism is used for driving the first valve seat to move along the elastic extension and contraction direction of the elastic parts to plug or get far away from the feeding port, and the second driving mechanism is used for driving the second valve seat to move along the elastic extension and contraction direction of the elastic parts to plug or get away from the discharging port. According to the constant volume valve, the elastic parts are arranged between the feeding port and the discharging port, the first valve seat and the second valve seat are arranged on the two ends of the elastic parts, the first driving mechanism and the second driving mechanism are arranged to be used for driving the first valve seat and the second valve seat respectively, and therefore the precise volume fixing and the sterile filling of the materials are realized.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

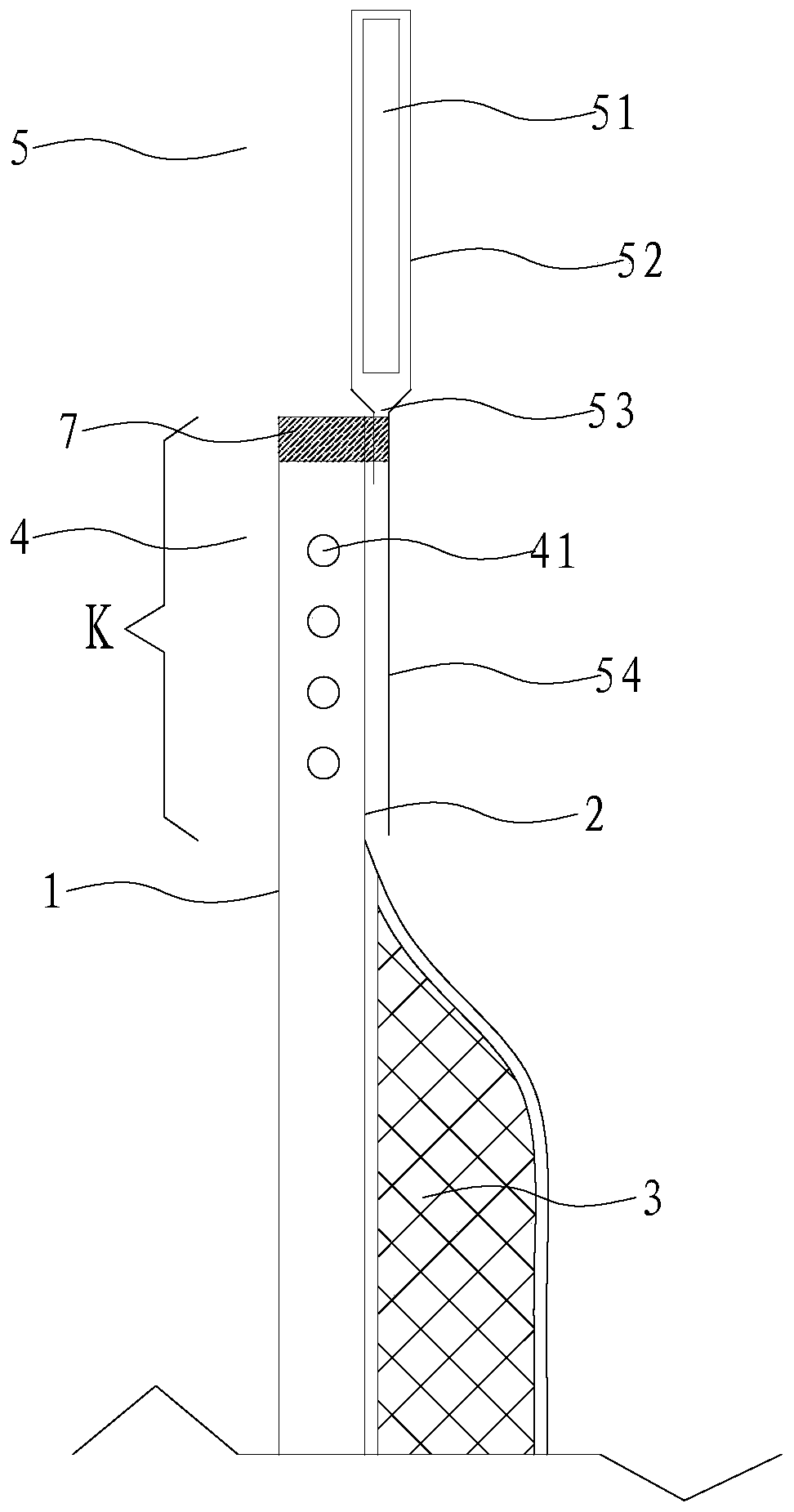

Building outer wall construction waistband type air bag type anti-falling protection tool

ActiveCN111119506AWill not affect normal workReduce personal safety hazardsSafety beltsBuilding material handlingArchitectural engineeringFall protection

The invention discloses a building outer wall construction waistband type air bag type anti-falling protection tool. The tool comprises waistband leather, a storage battery, an igniter and trace gunpowder. An elastic cloth belt is fixedly connected between the waistband leather, a sealing pipe and a positioning pipe are fixedly installed on the outer wall of the waistband leather, the positioningpipe is located in the middle of the waistband leather, the storage battery is movably installed in the positioning pipe, a first elastic piece is fixedly connected between the positioning pipe and apositioning piece, a positioning rod is installed in the middle of a connecting piece in a penetrating mode, and one end of a fine nylon rope is fixed to the inner wall of the sealing pipe. The building outer wall construction waistband type air bag type anti-falling protection tool is directly worn on the waist of a constructor and does not affect normal work of the constructor; and meanwhile, when an emergency accident happens, the constructor can be quickly positioned between constructed scaffolds, so that personal safety hazards caused by falling and repeated collision are reduced.

Owner:嘉兴巨腾信息科技有限公司

Multi-function waste pile classified treatment recycling device for garment processing plant

InactiveCN111472118AAchieve recyclingKeep dryLiquid/gas/vapor removal by squeezing rollersTreatment involving filtrationSprayerEnvironmental engineering

A multi-function waste pile classified treatment recycling device for a garment processing plant comprises a treatment recycling device body. The treatment recycling device body is internally providedwith a spray cleaning chamber, a water squeezing chamber, a drying chamber and a recycling chamber. A driving roller is longitudinally arranged in the spray cleaning chamber, a driven roller is longitudinally arranged in the recycling chamber, and a conveying belt is in transmission connection with the driving roller and the driven roller. A water storage chamber is arranged in the treatment recycling device body. A conveying pipe is arranged on the treatment recycling device body and communicates with the spray cleaning chamber, and sprayers are arranged at the bottom of a water collecting part. A water pumping pipe and a water conveying pipe are arranged on a water pump, the water pumping pipe is vertically inserted into a filtering device, and the water conveying pipe communicates withthe water collecting part. The water squeezing device comprises a water squeezing roller, movable rods, connecting cylinders, elastic parts and limiting blocks, and electric heating pipes are arranged in the drying chamber. The device integrates spray cleaning, water squeezing, drying, recycling and compression functions, has various functions, is simple to operate, saves time and labor in the operation process, can realize effective recycling of waste pile, and is excellent in use effect.

Owner:JIHUA 3536 PROFESSIONAL CLOTHING

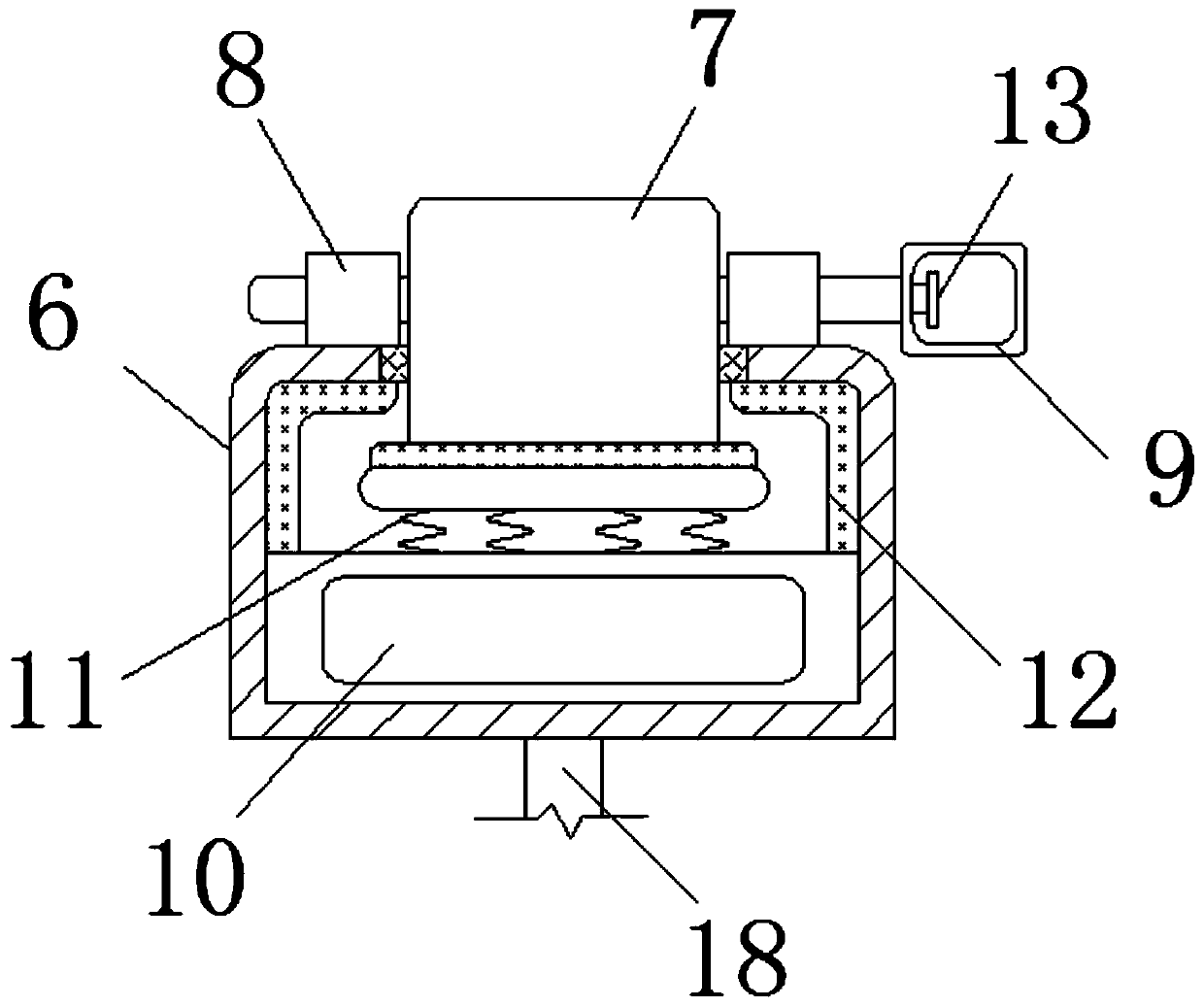

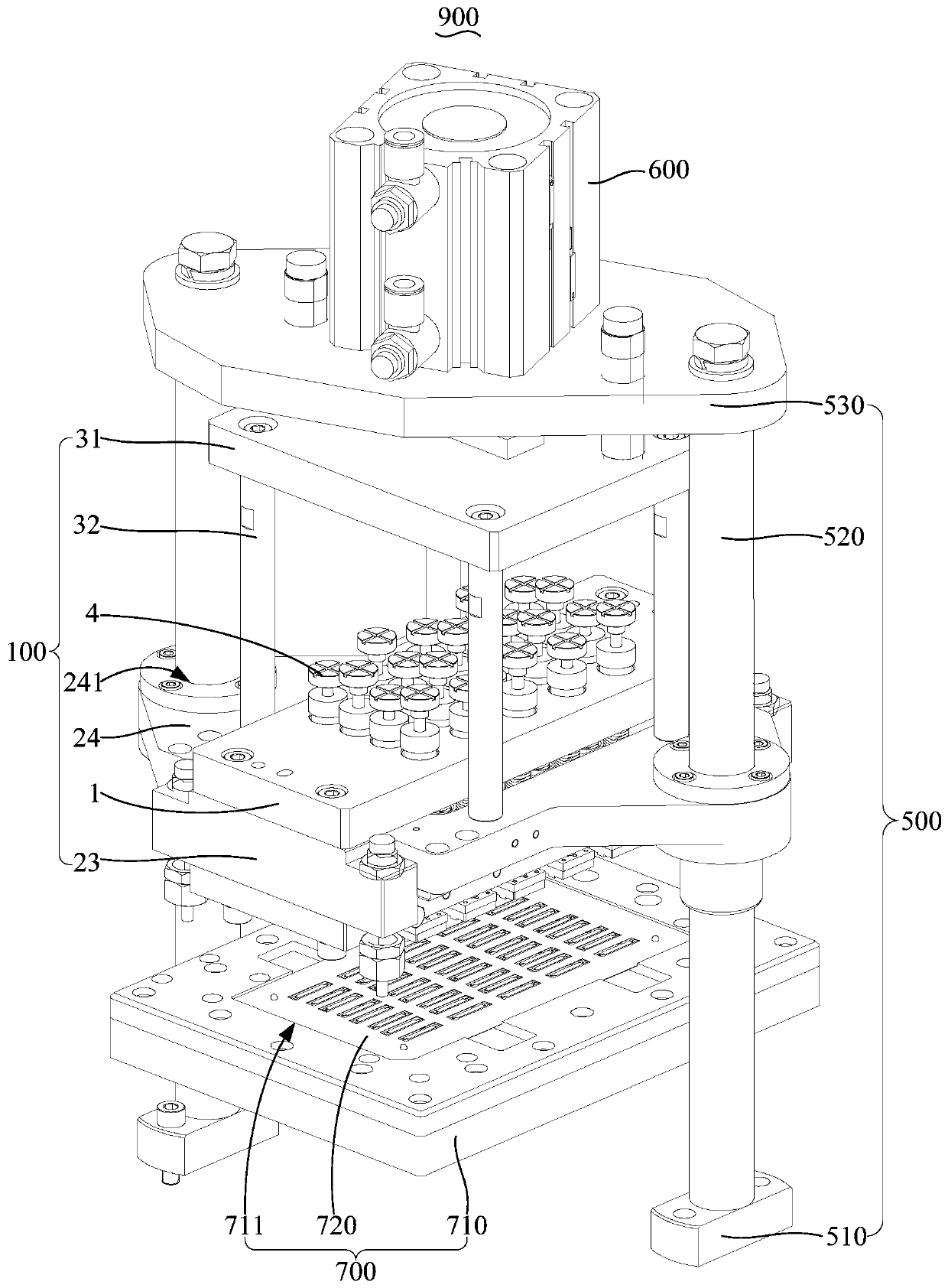

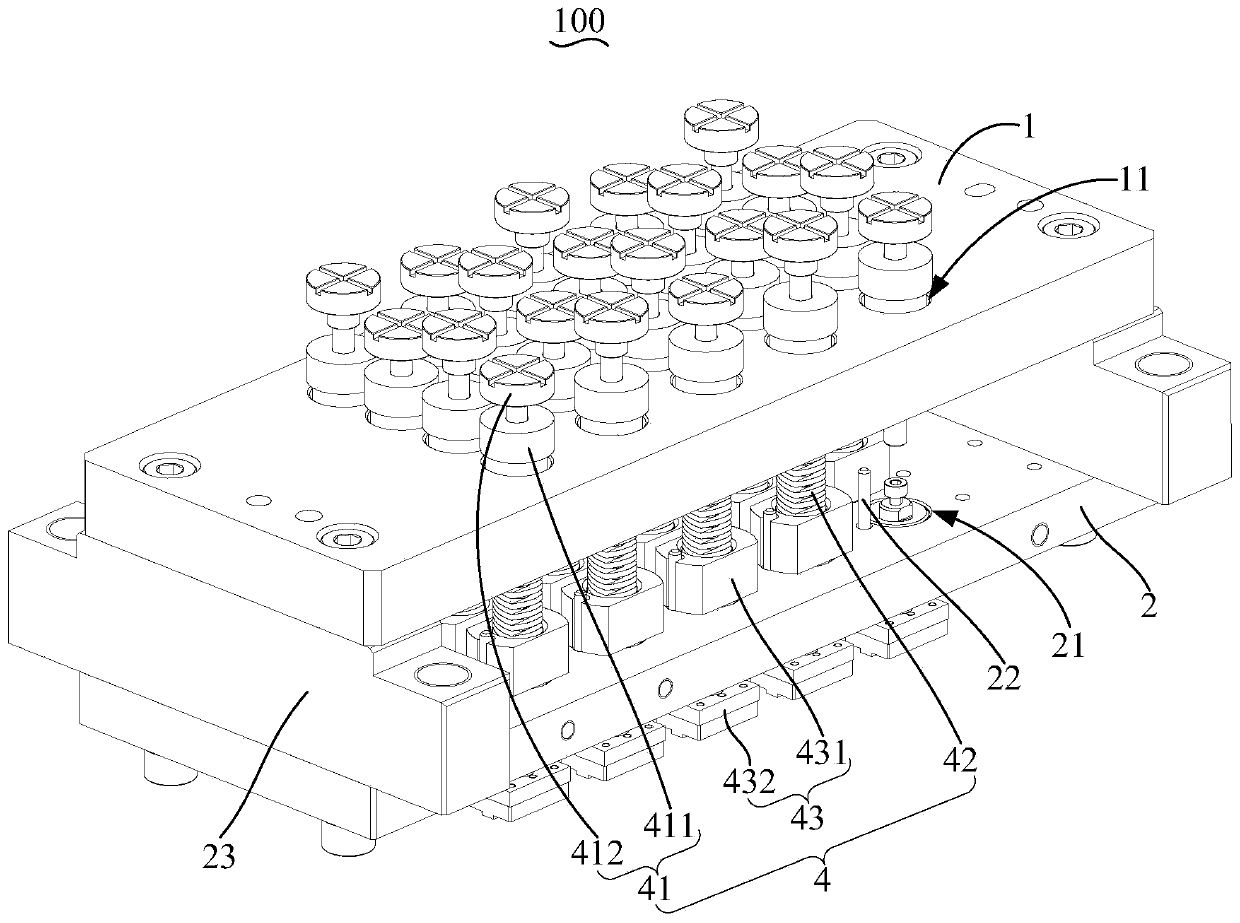

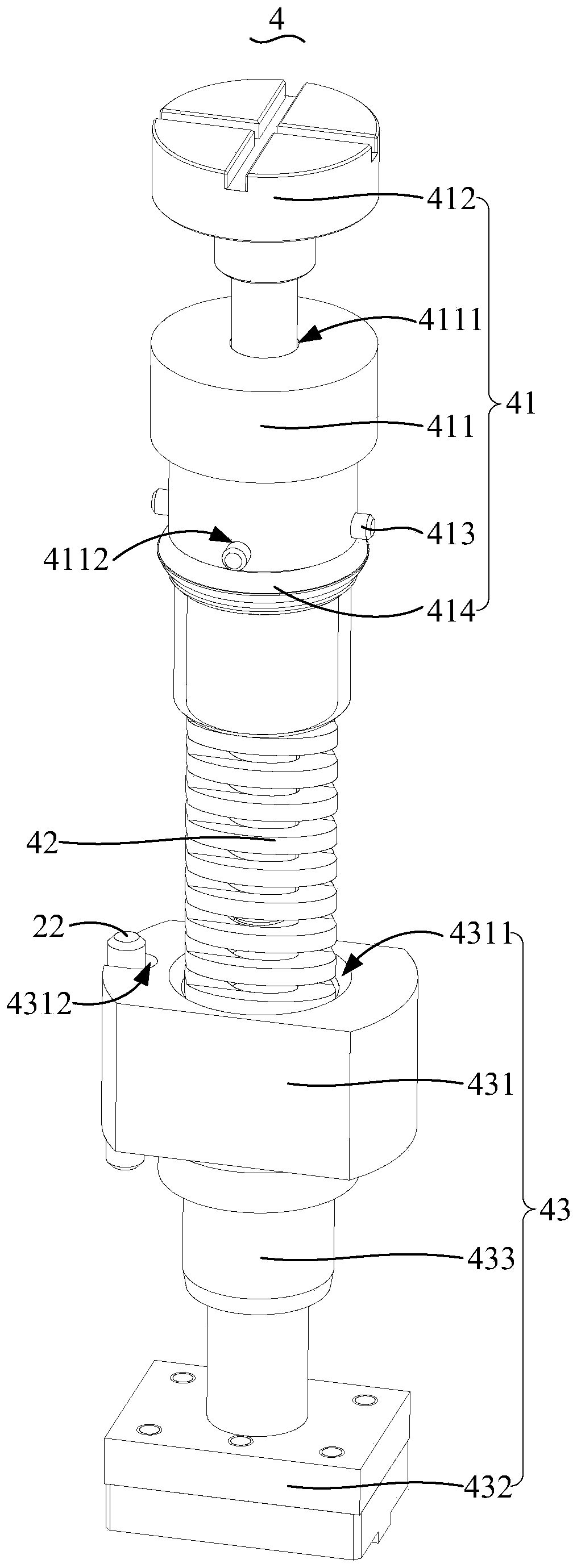

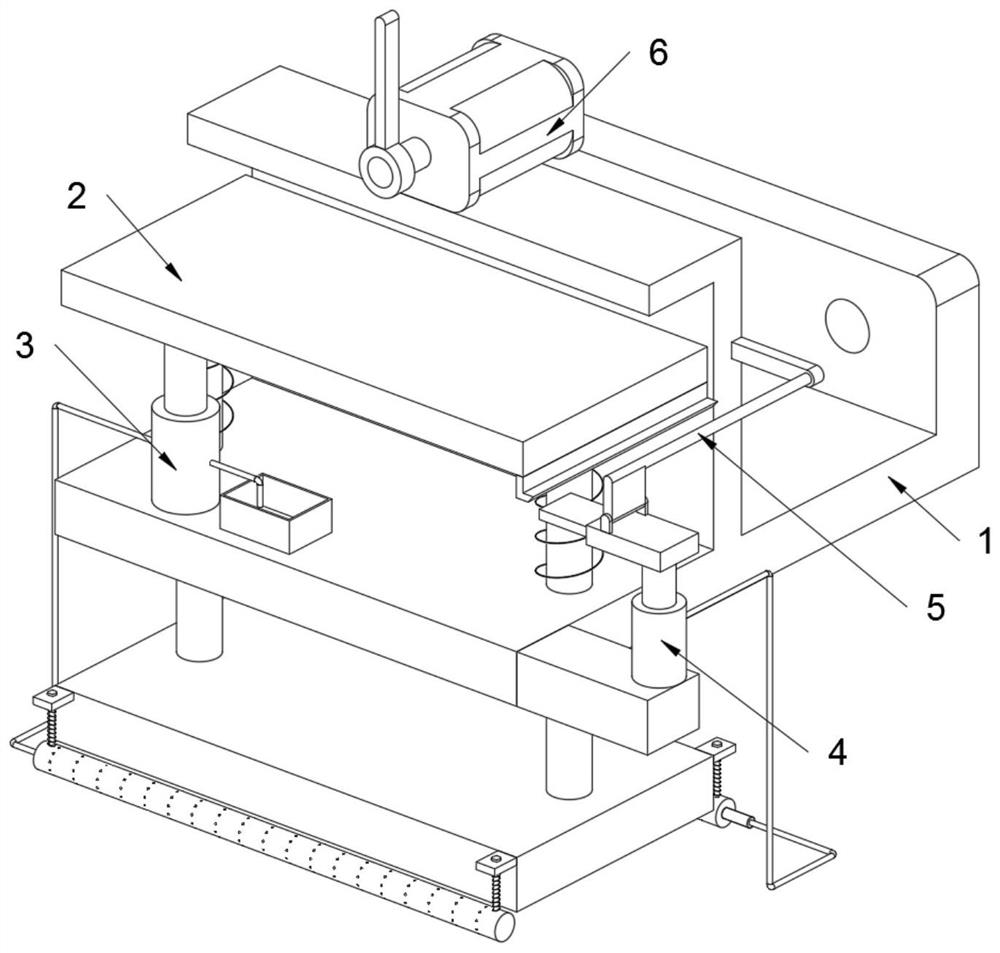

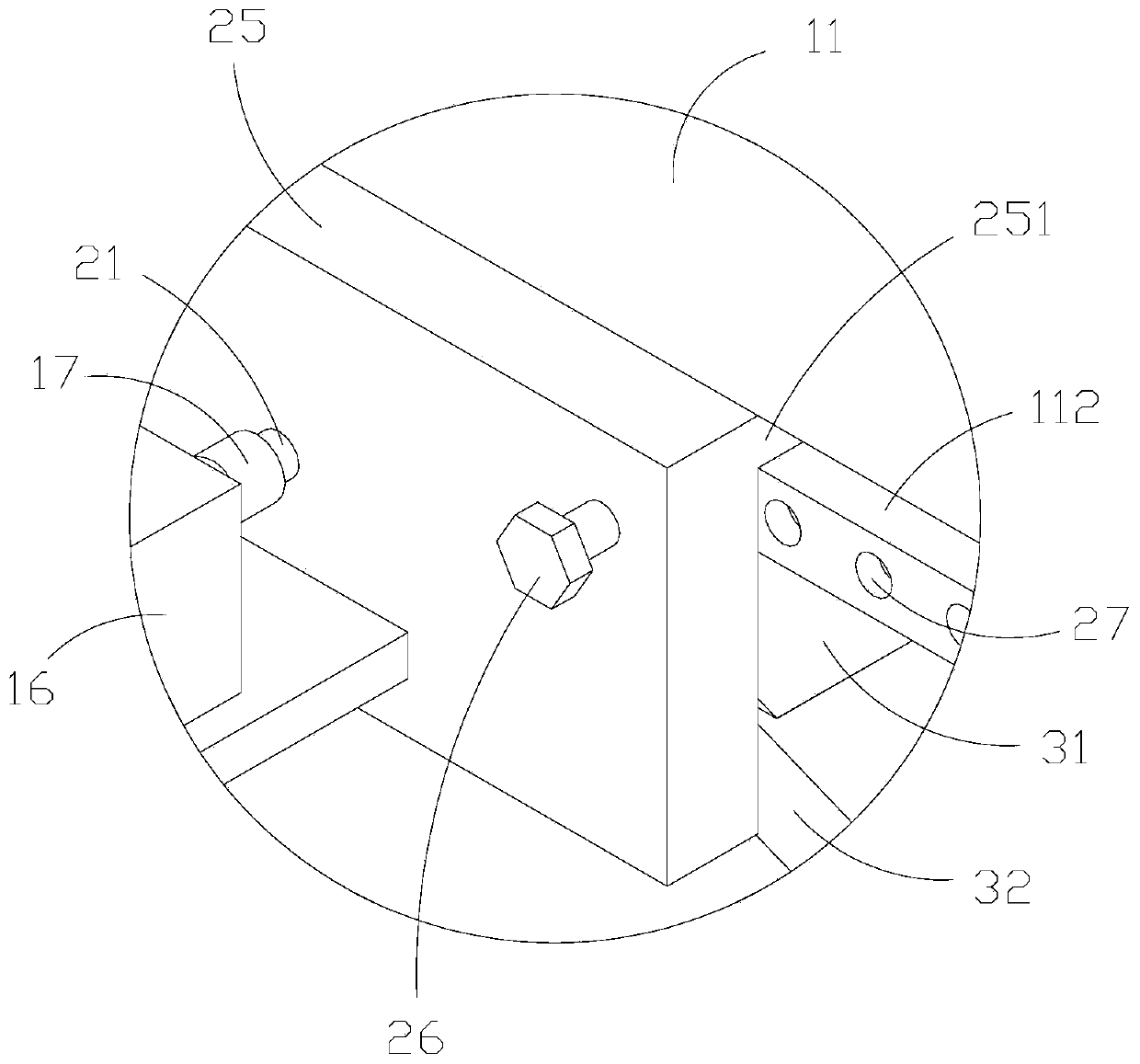

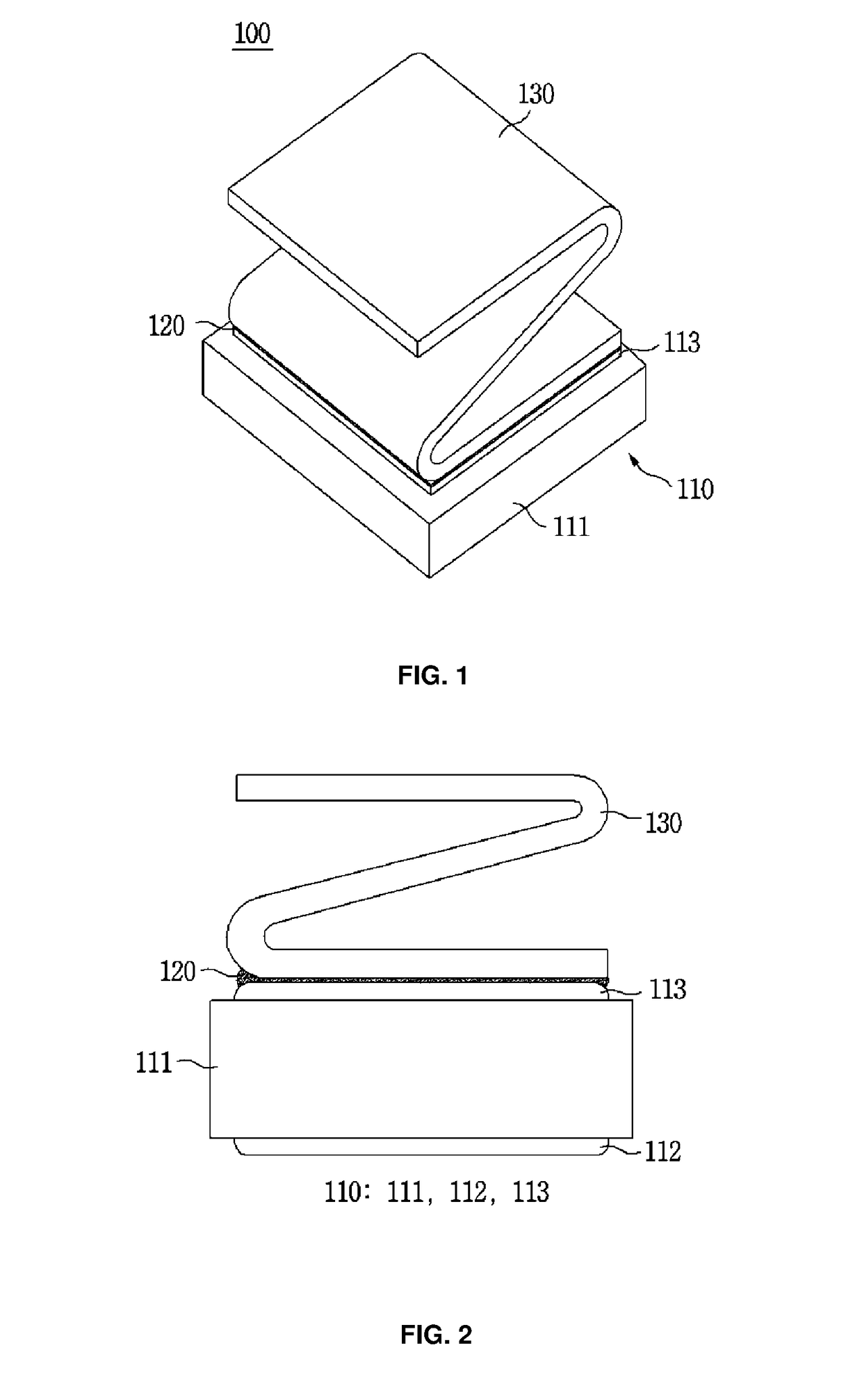

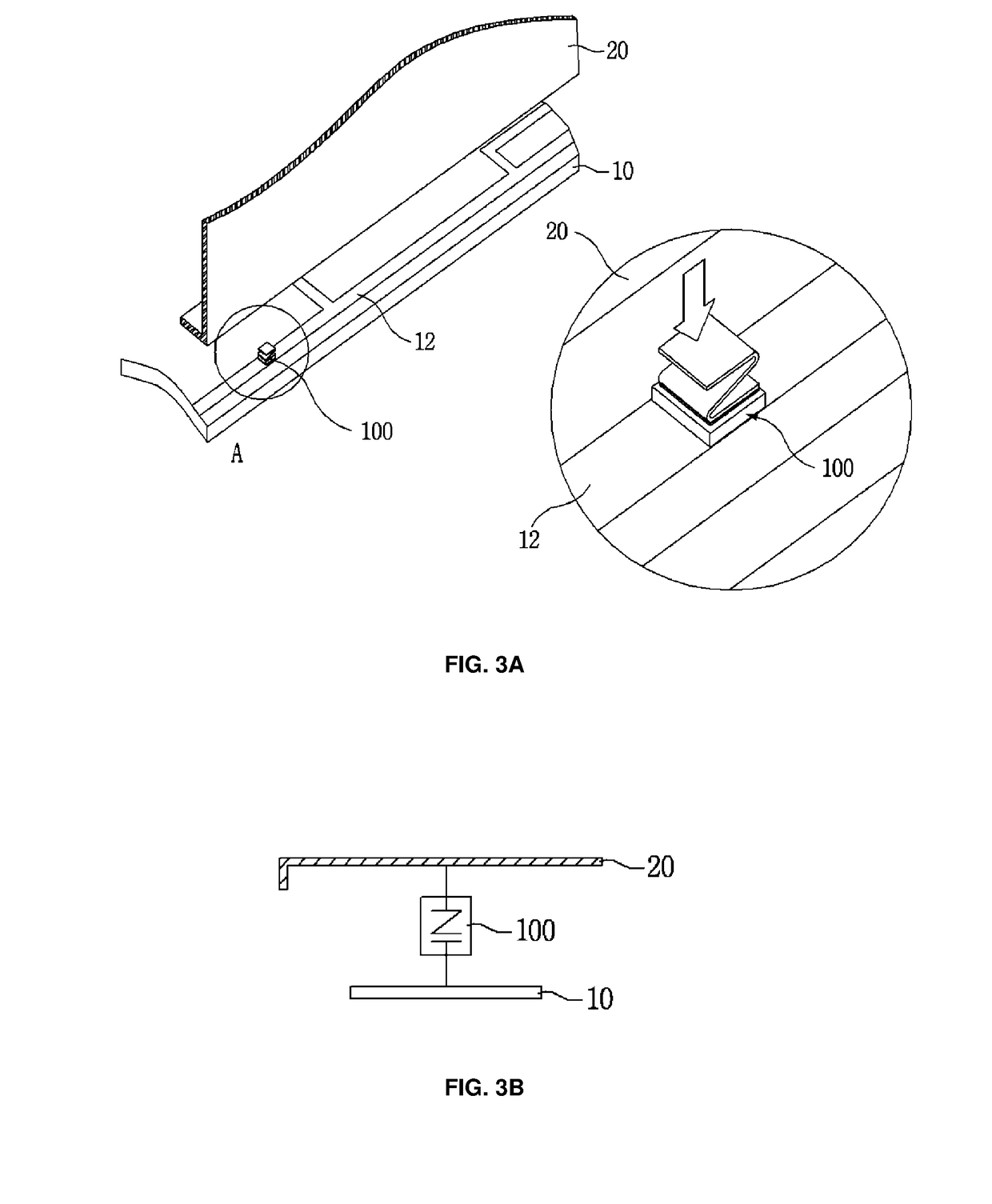

Pressure head structure, pressure head device and pressure maintaining equipment

ActiveCN110913589ARegulating pressureAdjustable pressureMaterial gluingPrinted circuit manufactureElasterellPhysics

The invention discloses a pressure head structure, a pressure head device and pressure maintaining equipment. The pressure head structure is applied to the pressure head device. The pressure head device comprises a mounting plate and a supporting plate which are oppositely arranged, and the pressure head structure comprises a pressure adjusting assembly which is rotatably connected with the mounting plate; an elastic piece, located between the mounting plate and the supporting plate, and one end of the elastic piece being connected with the pressure regulating assembly; a pressing head piece,arranged on the supporting plate in a sliding and penetrating mode, and the other end of the elastic piece being connected with the pressing head piece. The pressure adjusting assembly rotates relative to the mounting plate so as to adjust the elastic compression amount of the elastic piece. The invention aims to provide the pressure maintaining structure capable of adjusting the pressure, so thatthe pressure maintaining structure can maintain the pressure of different products, and meanwhile, the pressure maintaining structure is applied to the pressure head device, so that the pressure headdevice is provided with a plurality of pressure maintaining structures at the same time, the pressure head device maintains the pressure of a plurality of materials at the same time, and the efficiency is improved.

Owner:GOERTEK INC

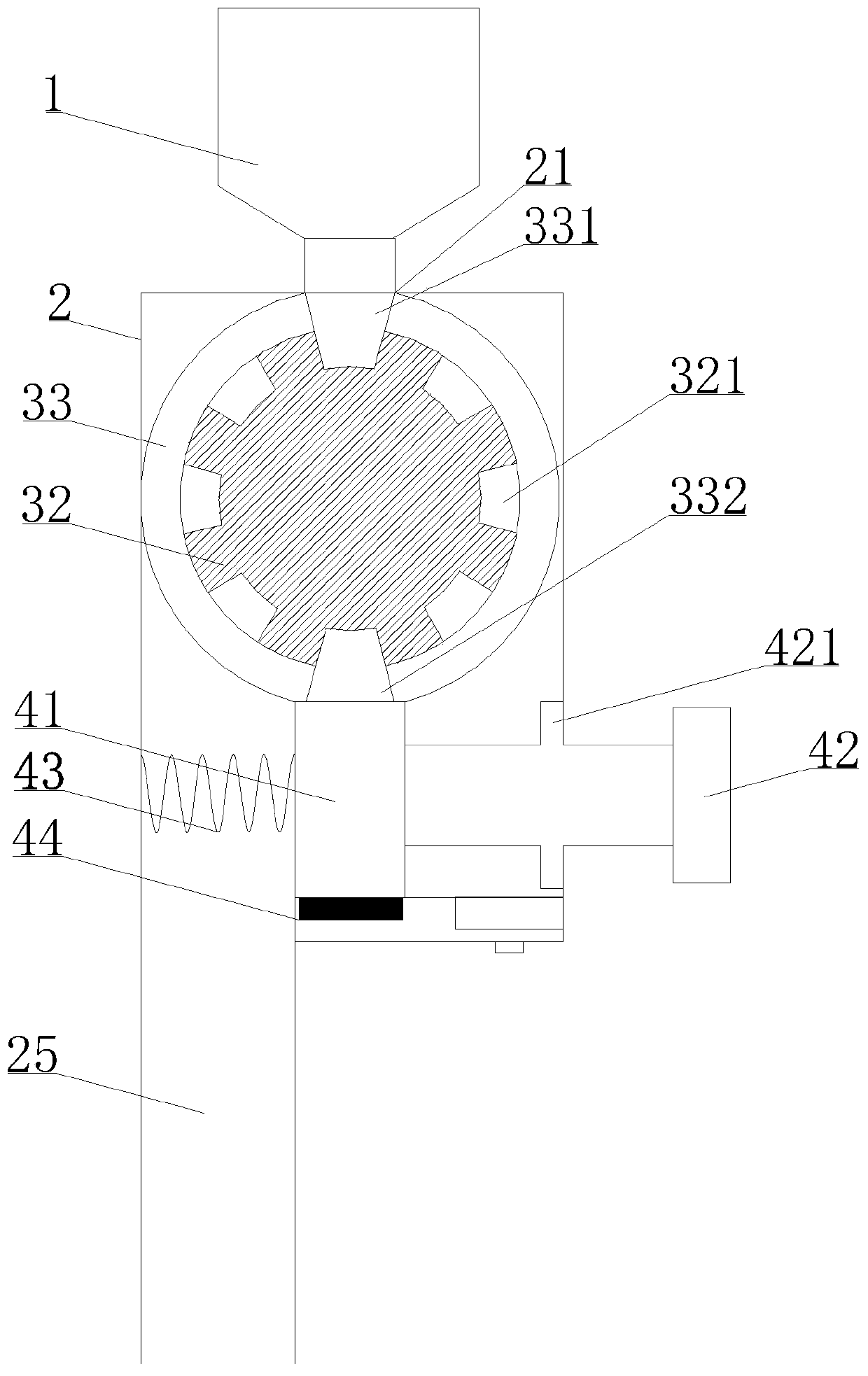

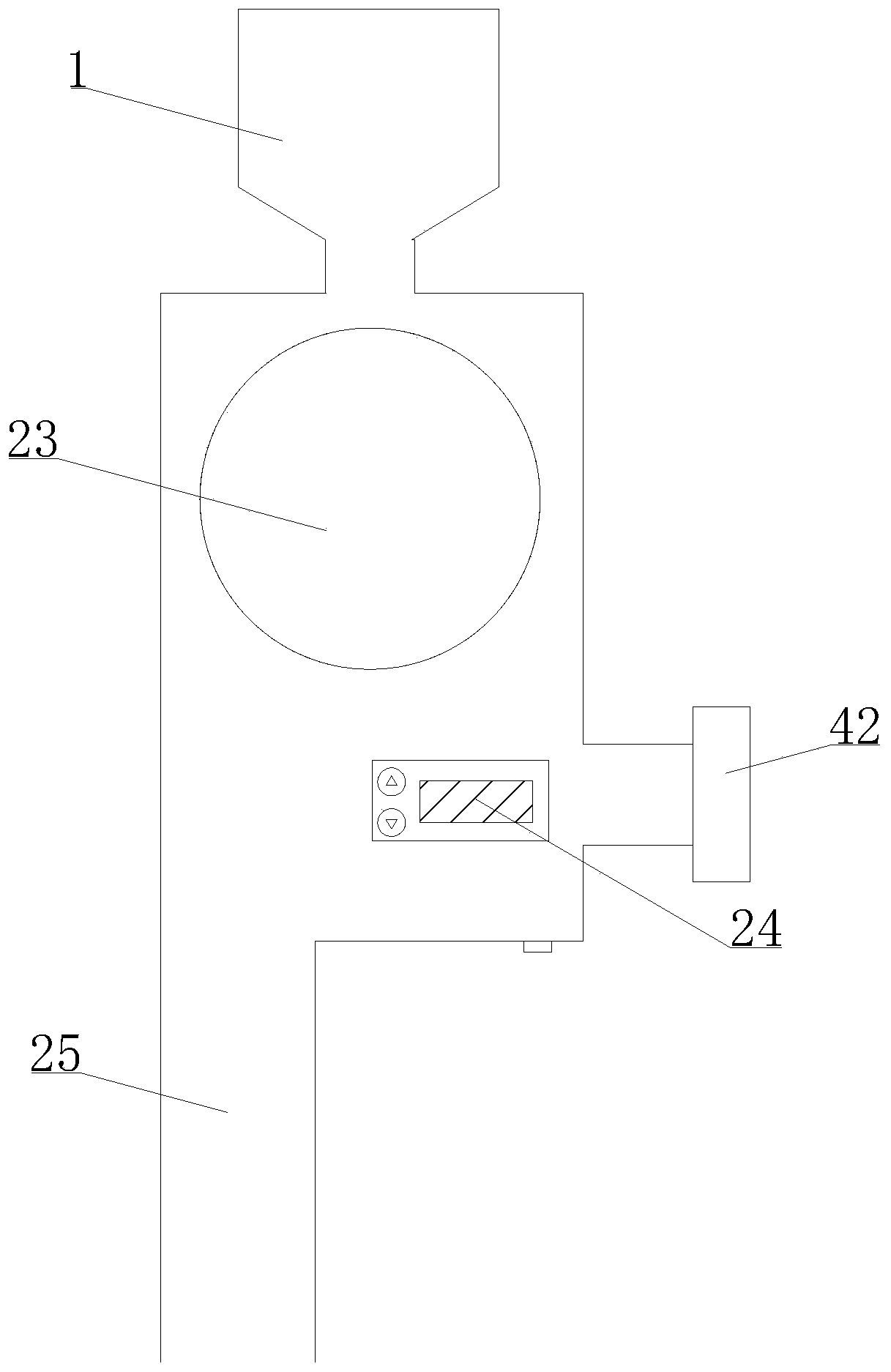

Laboratory solid powder quantitative taking device

InactiveCN111238611AReduce wasteIncrease weightWeighing apparatus for materials with special property/formElasterellForce sensor

The invention relates to a laboratory solid powder quantitative taking device which comprises a reagent bottle, a shell, a sampling assembly and a push rod assembly, wherein a connecting opening matched with the bottle opening of the reagent bottle is formed in the upper part of the shell; the sampling assembly comprises a power part, an inner disc and an outer disc, the inner disc is of a cylindrical structure with grooves evenly formed in the circumferential direction, the outer disc is of a hollow cylindrical structure with a feeding port and a discharging port formed in the side face, theinner disc is arranged in the outer disc in a sleeved mode, and the output end of the power part is connected with the center of the inner disc and used for driving the inner disc to rotate; the pushrod assembly comprises a material storage cavity, a push rod, an elastic piece and a film pressure sensor, the material storage cavity is of a hollow structure with openings formed in the upper end and the lower end, and the opening in the upper end of the material storage cavity corresponds to the outer disc discharging opening. The laboratory solid powder quantitative taking device is simple, convenient and efficient in weighing process and can effectively reduce metering errors and reduces waste of solid samples in the transferring process and thus improves experiment efficiency.

Owner:FUJIAN NORMAL UNIV

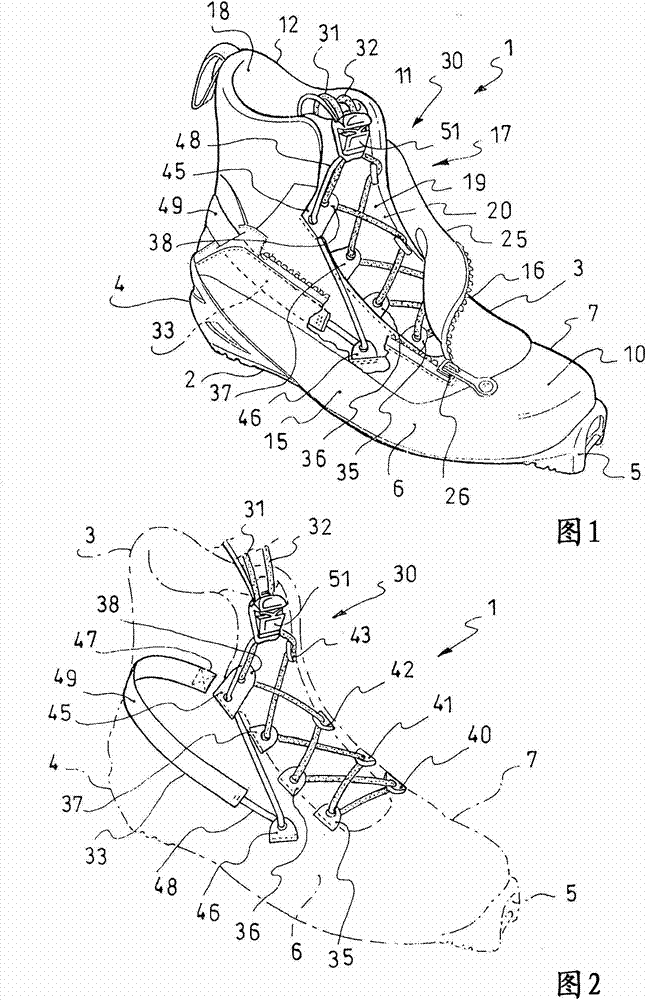

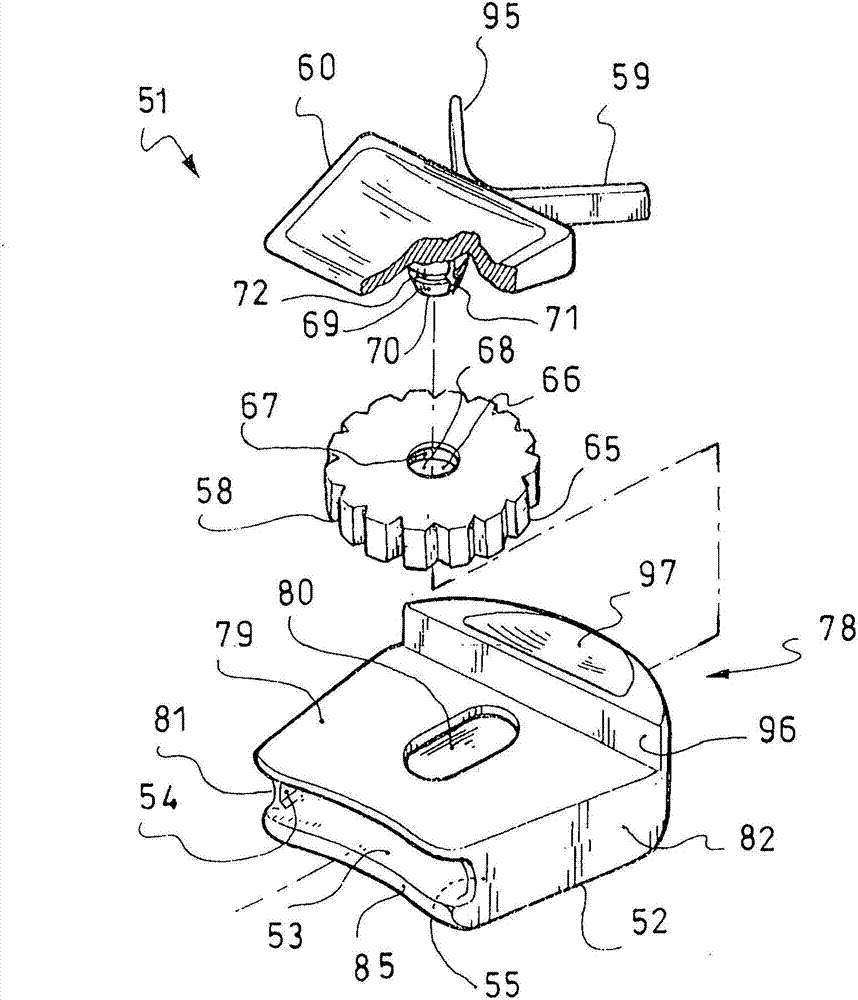

Device for blocking strands of yarn

InactiveCN102783764AStay lockedSimple structureRopes and cables for vehicles/pulleyShoe lace fasteningsYarnClassical mechanics

Owner:SALOMON SA

Printing and dyeing equipment

ActiveCN111993759AAchieve purificationAchieve extrusionPlaten pressesOther printing apparatusPolymer scienceEngineering

The invention provides printing and dyeing equipment, and relates to the technical field of garment mark printing. The problems are solved that linkage absorption and filtration of harmful gas duringprinting cannot be achieved in a linkage manner in the up-and-down printing process, the wind power drying of pigment on a clothing mark cannot be achieved in a linkage manner in the up-and-down printing process, and a purification structure and a drying structure cannot be organically combined with a fixing structure of the clothing mark. The printing and dyeing equipment comprises a main body seat and a rectangular plate, wherein a printing and dyeing structure is mounted on the main body seat, a purification structure is mounted on the main body seat, and a drying structure is further mounted on the main body seat. As the outer wall of a spray head is slidably connected with two sliding rods B on the rear side, the two sliding rods B on the rear side are sleeved with two elastic piecesB, the two elastic pieces B jointly form an elastic reset structure of the spray head, the spray head is in an elastic contraction state when a printing and dyeing base conducts printing and dyeing, and normal printing and dyeing are not affected.

Owner:常州京江源纺织有限公司

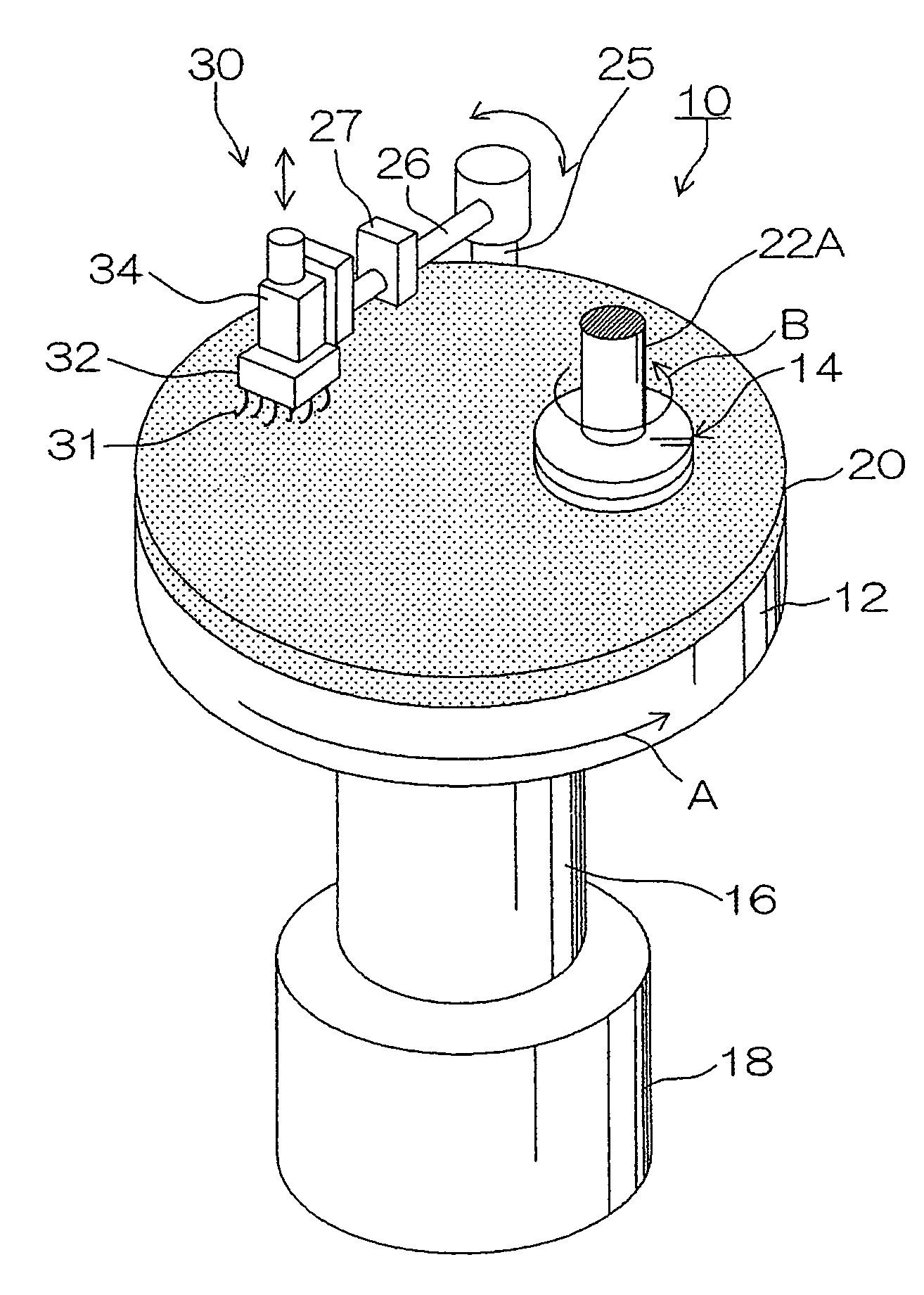

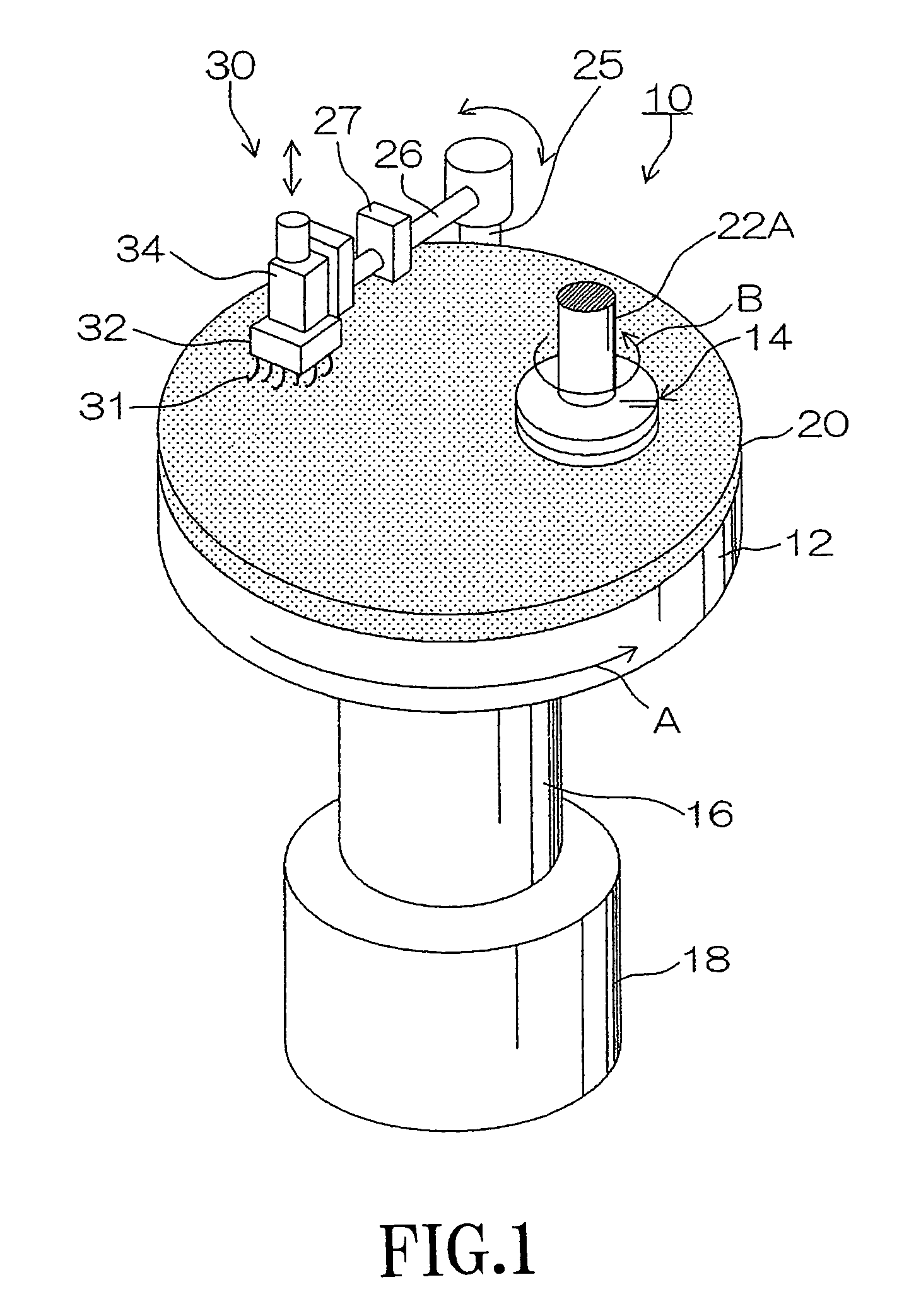

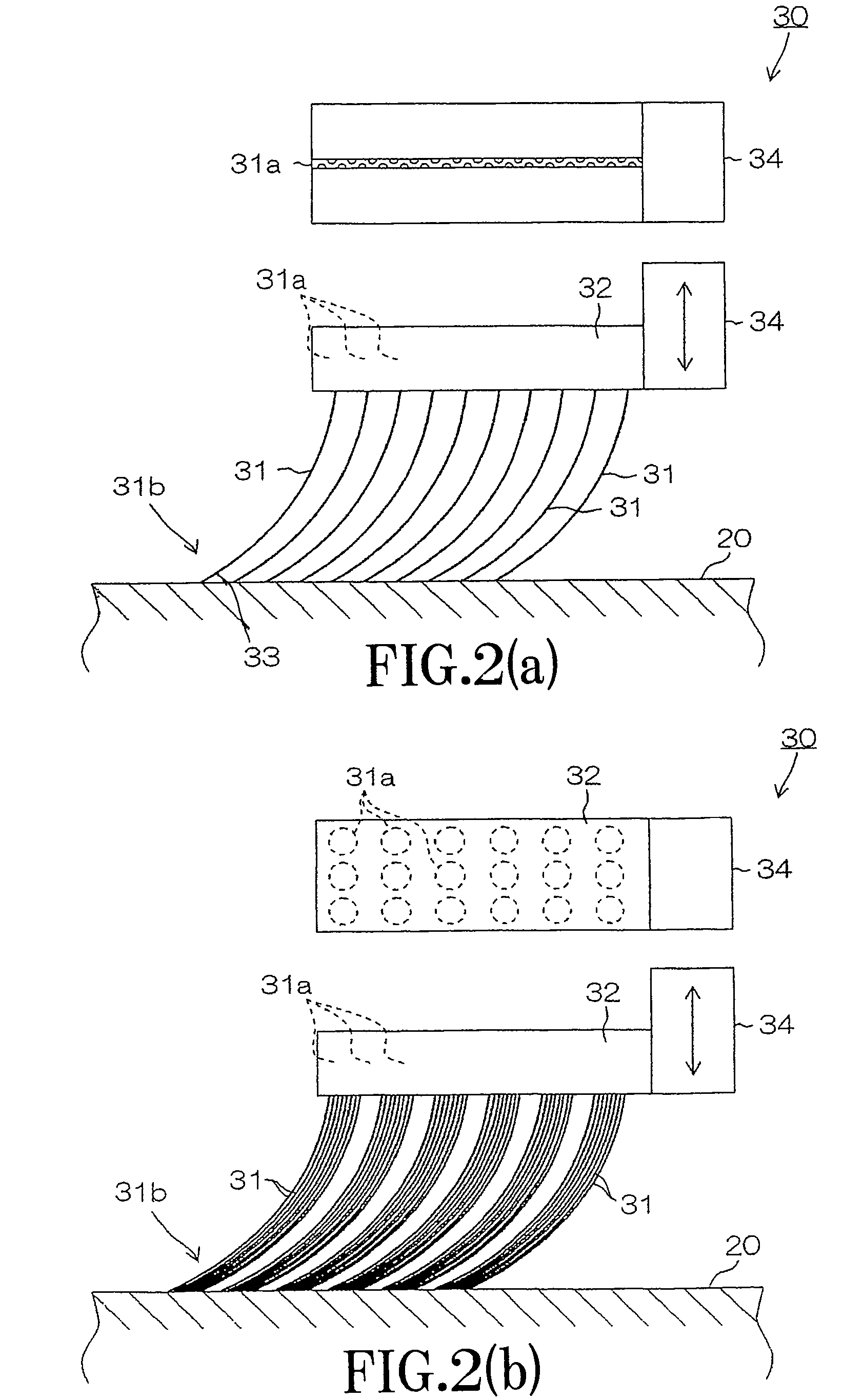

Pad dresser, polishing device, and pad dressing method

InactiveUS8257150B2Improve uniformityEasy to processEdge grinding machinesGrinding drivesBiomedical engineeringDressing method

Owner:TOKYO SEIMITSU

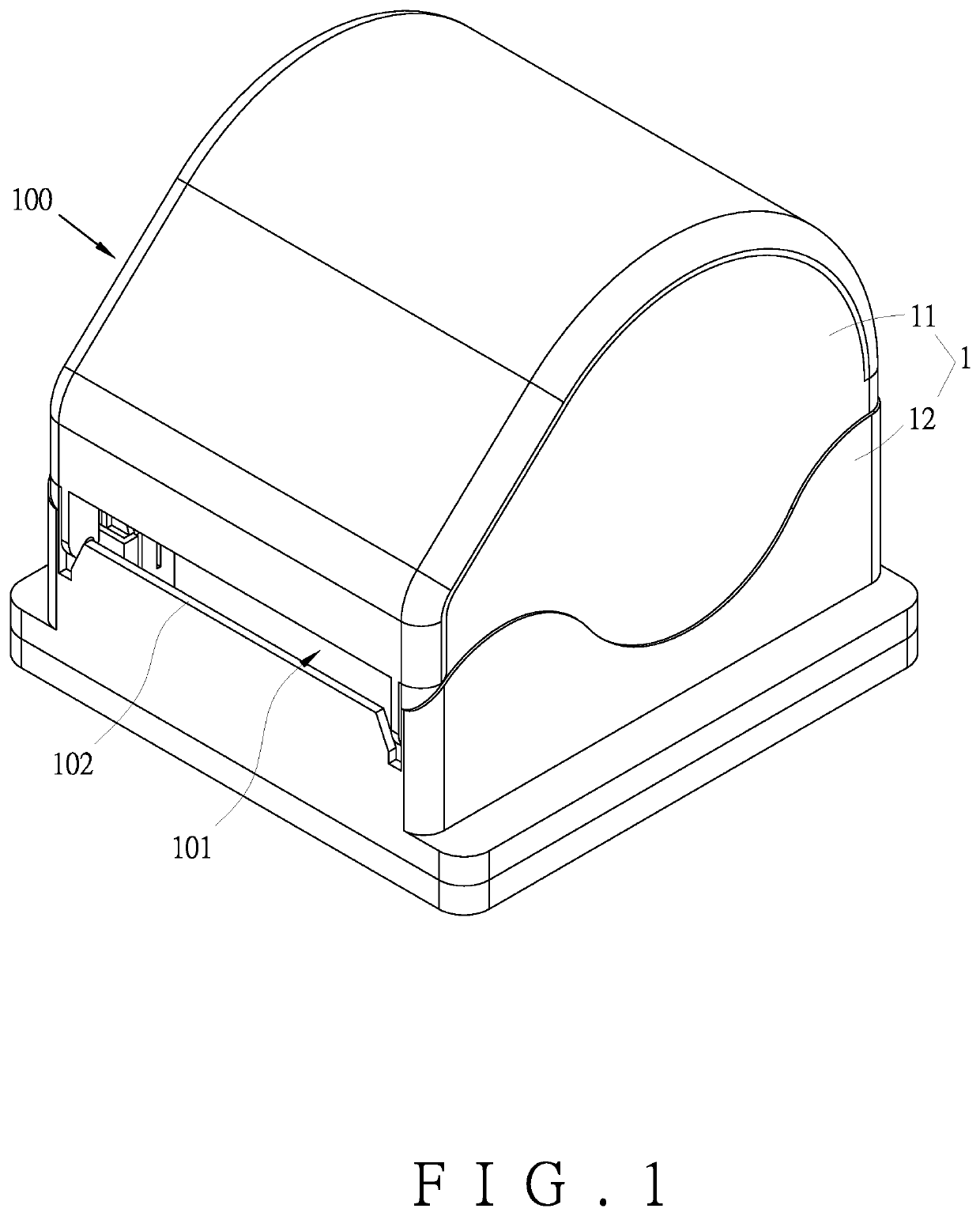

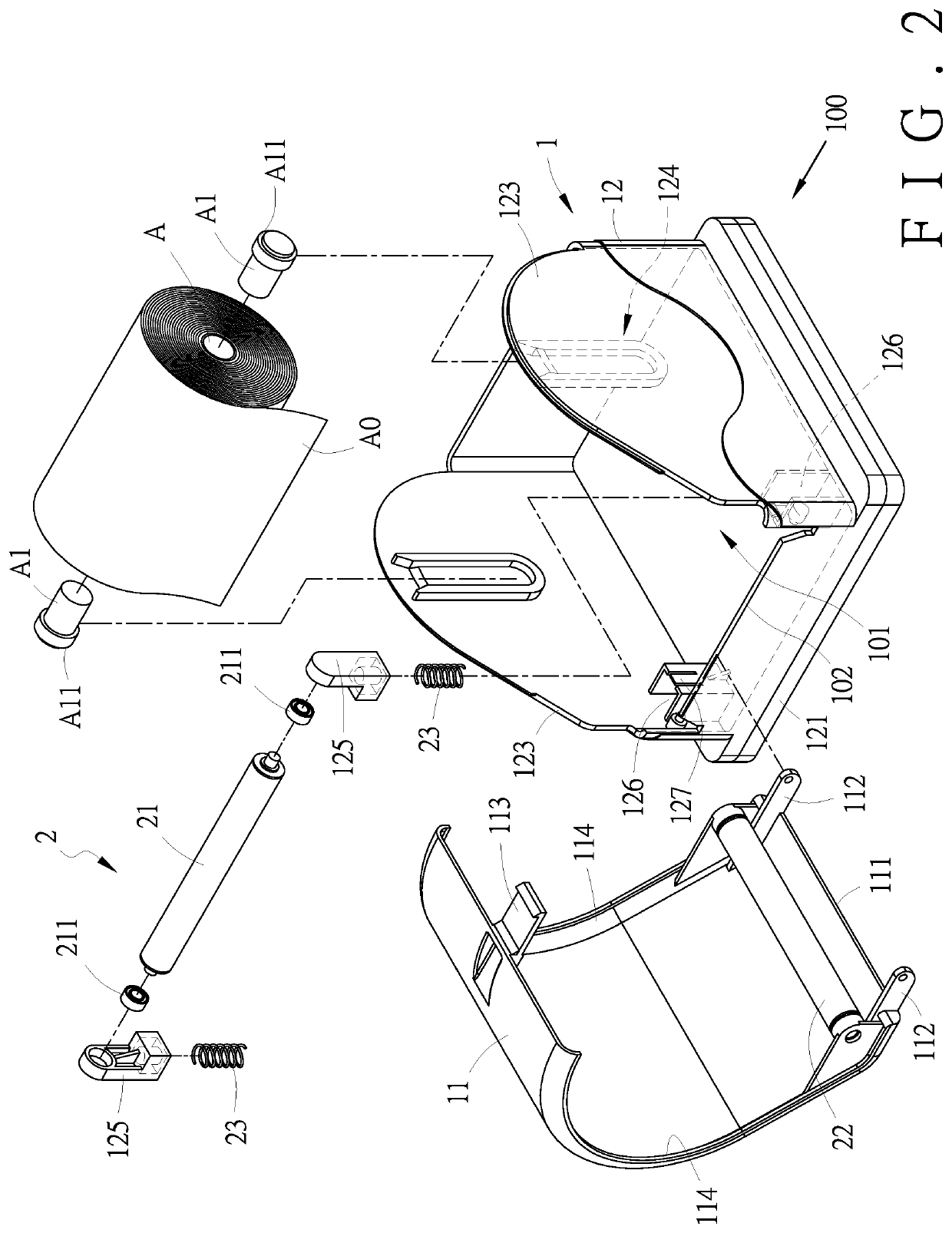

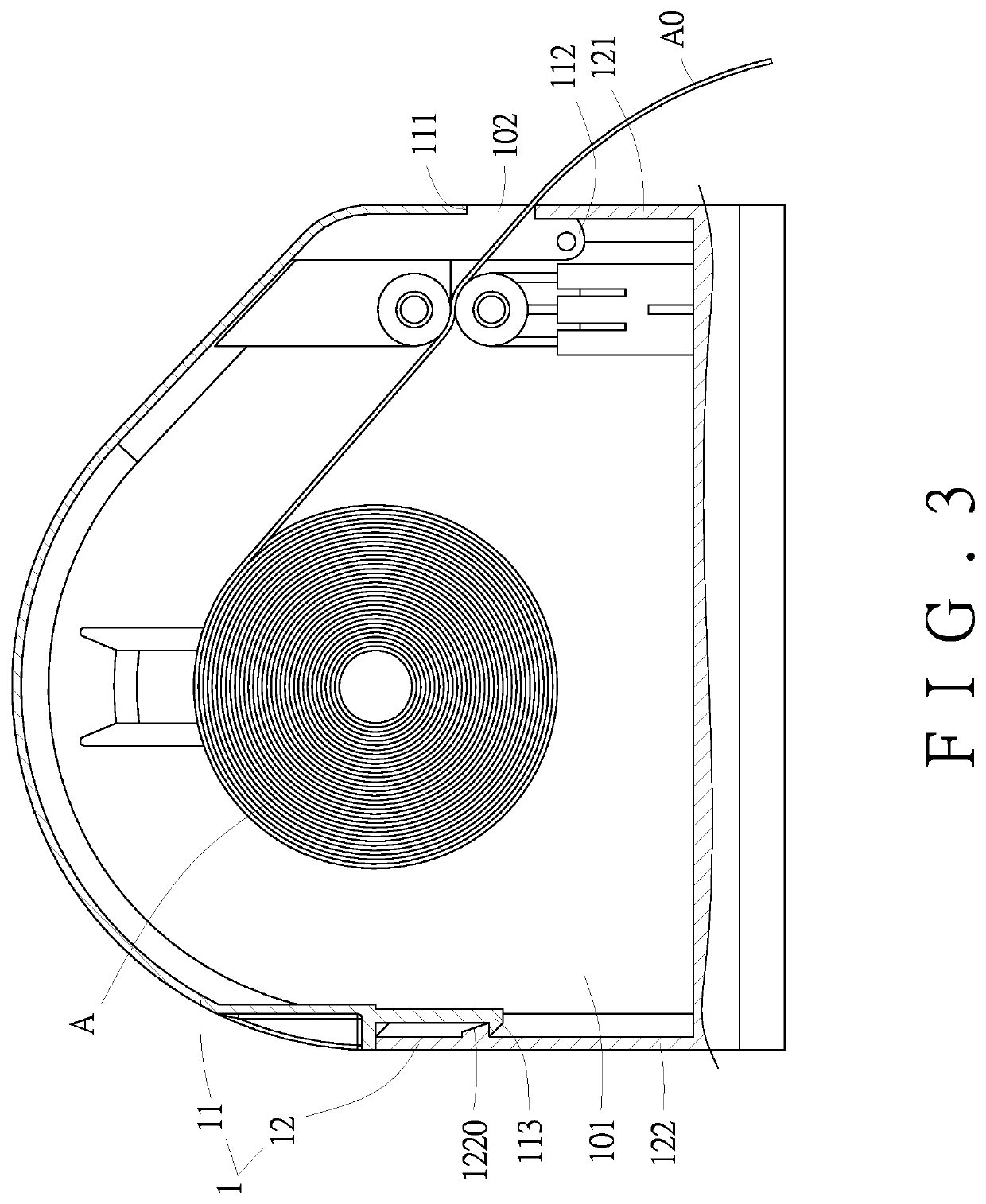

Rolled sheet material dispenser

ActiveUS11051665B2Light weightAppropriate structural strengthDomestic applicationsWebs handlingRolling-element bearingEngineering

A rolled sheet material dispenser, used for dispensing a sheet material on a reel, includes a box and a clamping assembly. The clamping assembly includes a first clamping member, a second clamping member and at least one elastic member. The first clamping member or / and the second clamping member may be a roller. The roller is pivotally connected to the box through a pair of rolling bearings and adjacent to a dispensing opening. The roller is connected with the elastic member so that the roller can be displaced by an elastic force of the elastic member to a clamping position and can be supported by the rolling bearings to clamp the sheet material stably.

Owner:CHIN CHEN JAY

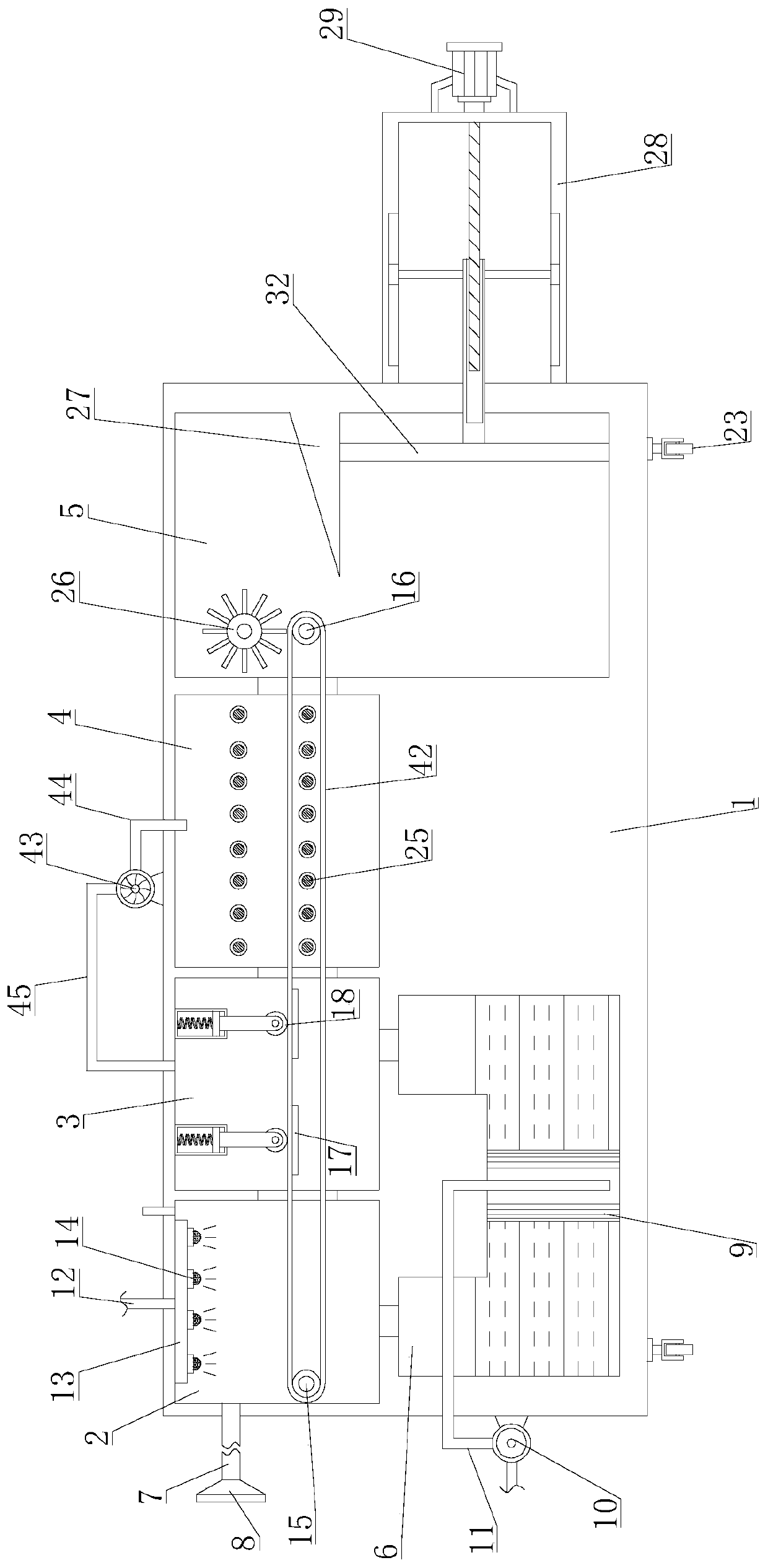

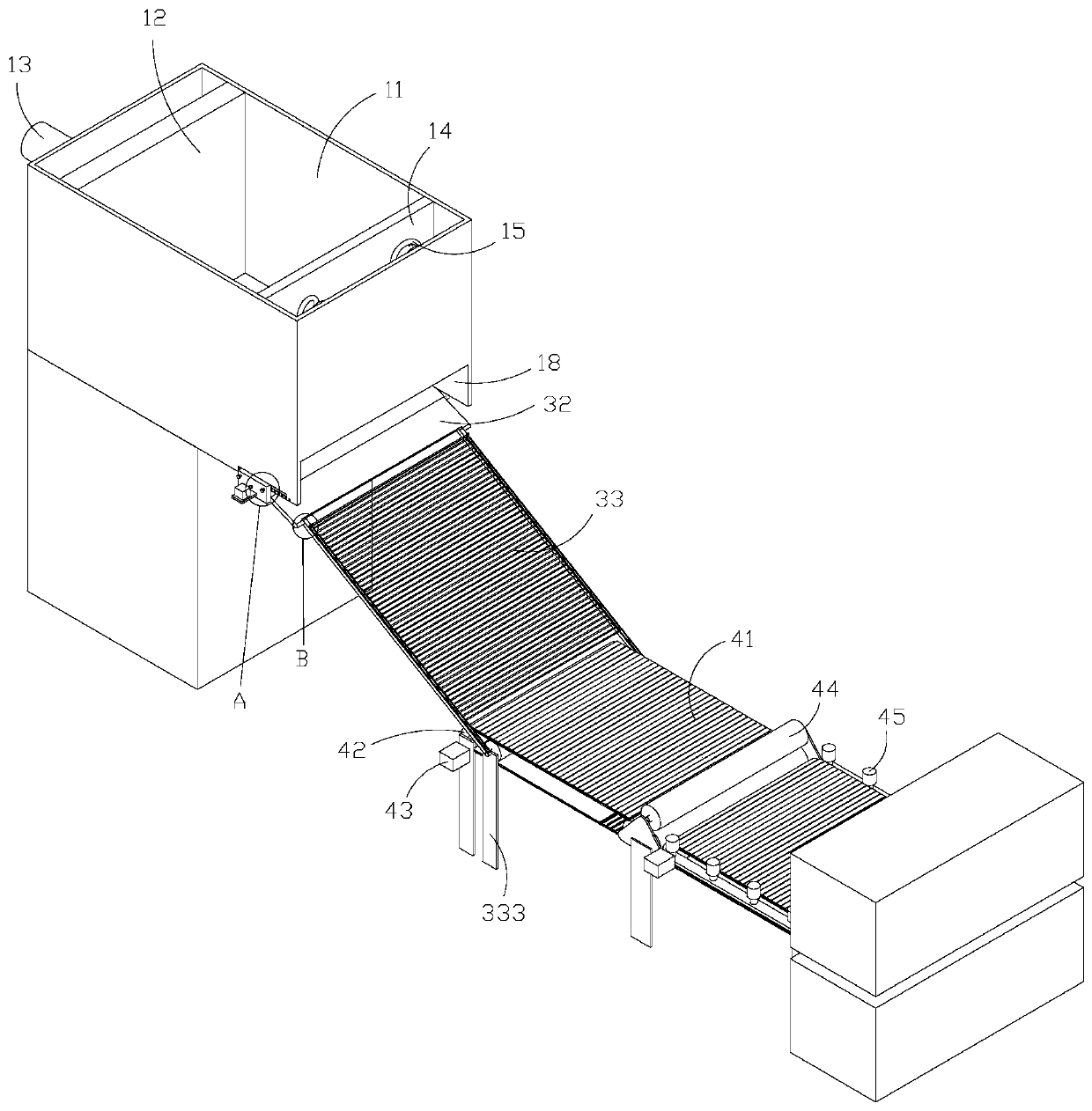

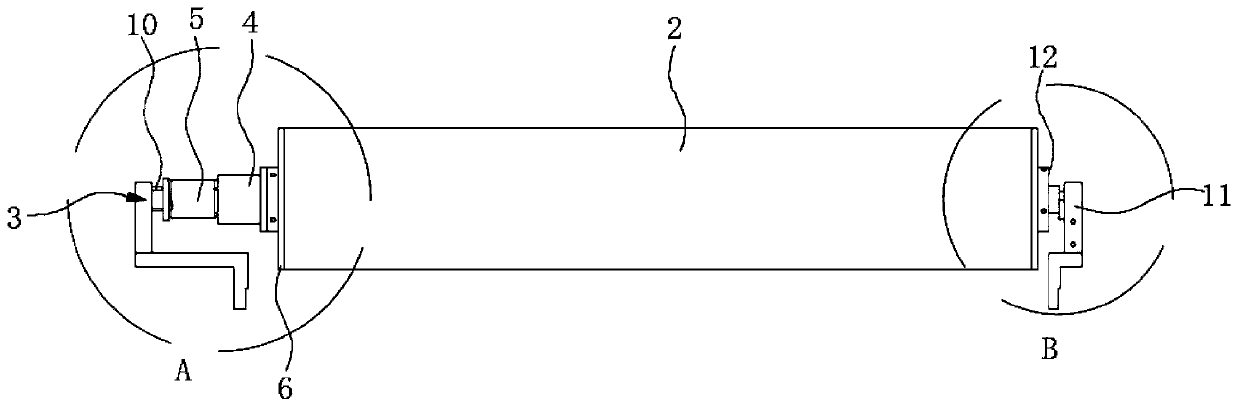

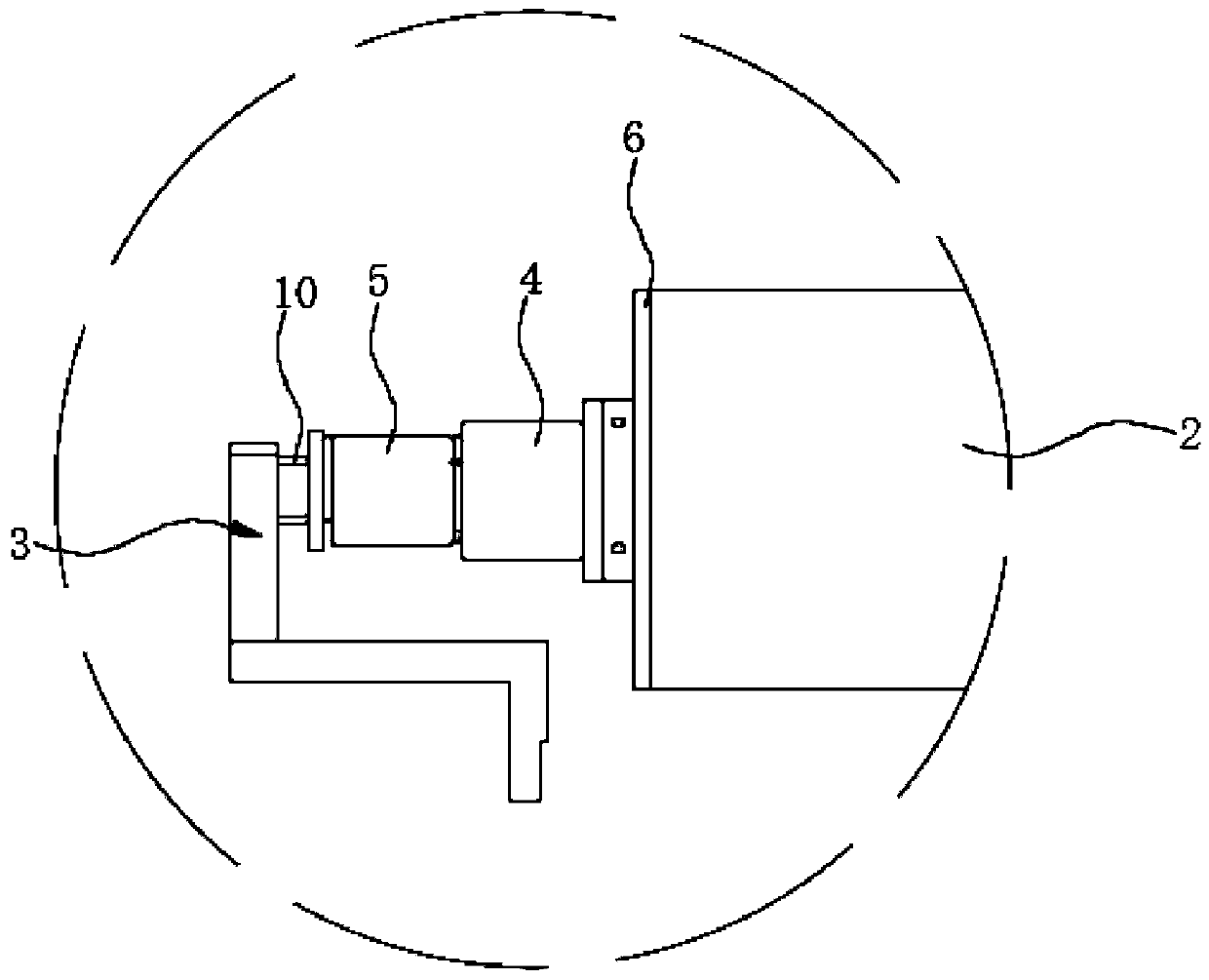

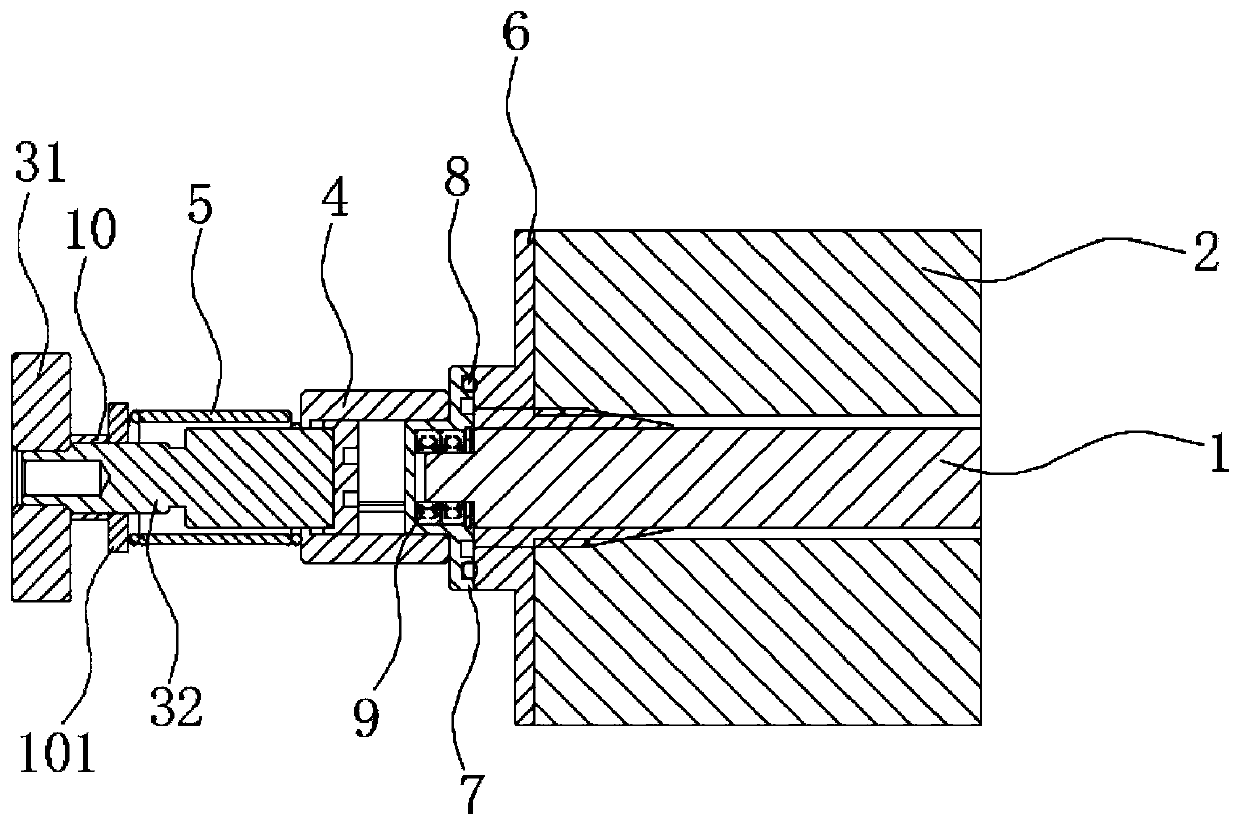

Production system for heat exchanger processing

ActiveCN111250615AIncrease contactStable apartMetal-working feeding devicesHeat exchange apparatusProcess engineeringElasterell

The present invention discloses a production system for heat exchanger processing. The production system comprises a hydraulic device, an automatic discharging device and a conveying device, wherein the automatic discharging device comprises a discharging hopper, a material pushing plate capable of moving back and forth, a material pushing driving part used for driving the material pushing plate to move back and forth, a material abutting plate arranged in the discharging hopper, an elastic part used for connecting the material abutting plate and the discharging hopper, a material separating structure used for separating materials and a material guide structure used for guiding the materials to the conveying device; and the material separating structure comprises a separating roller capable of moving back and forth, a material separating driving part used for driving the material separating roller to move back and forth, a transmission sleeve used for transmission connection between the material separating roller and the material separating driving part, and a position adjusting structure used for adjusting the position of the material separating roller. By the arrangement of the material separating structure, single-piece discharging is realized, convenience and quickness are achieved, time and labor are saved, the labor intensity of workers is greatly reduced, and the processing efficiency is improved.

Owner:浙江舜特机械设备有限公司

Polishing and deburring device

PendingCN112828776AAchieve cycleAvoid scratchesAbrasive feedersAbrasive machine appurtenancesPolishingReciprocating motion

The invention discloses a polishing and deburring device. The polishing and deburring device comprises a working chamber, a conveying assembly, an oil tank mechanism, a first movement assembly, a second movement assembly and a limiting assembly. The working chamber is driven by an eccentric wheel to swing, so that a workpiece is ground and polished by an abrasive material; through buffering andresetting of a first elastic piece, the abrasive material can make full contact with the workpiece conveniently, and the surface wall of the workpiece is effectively polished; the limiting assembly can guarantee that a frame reciprocates in the horizontal direction; through arrangement of a second elastic piece, the frame is buffered and reset; the first elastic piece is arranged between the frame and the working chamber, the second elastic piece is arranged between a positioning plate and the frame, and thus interference between the first elastic piece and the second elastic piece can be effectively avoided; through the oil tank mechanism, lubrication between the abrasive material and the workpiece is facilitated, and excessive friction and scratching of the workpiece are prevented; and the abrasive material at a discharging outlet can be conveyed to a feeding inlet through the conveying assembly by a conveying mechanism, the abrasive material circulates in the working chamber, and the practicability is good.

Owner:CHANGSHA AERONAUTICAL VACATIONAL AND TECHNICAL COLLEGE

Safe heating vacuum cup

The invention discloses a safe heating vacuum cup. The cup comprises a cup body and a cup cover. A heating device is arranged in the cup body. A pressure relief device is arranged at the top of the cup cover. A pressure relief hole corresponding to the pressure relief device is formed in the bottom surface of the cup cover. The pressure relief device comprises a base. The inner cavity of the baseis communicated with the pressure relief hole, a silica gel sealing piece moving up and down through an elastic piece is further arranged in the inner cavity of the base, the silica gel sealing piecemoves up and down to be separated from or attached to the wall face of the inner cavity of the base to achieve unblocking of the pressure relief hole and the outside atmosphere, the inside and the outside of the cup are communicated, air pressure is balanced, and the cup cover is opened easily. The silica gel sealing piece is provided with an exhaust hole which can be elastically opened under theaction of air pressure, when the air pressure in the cup is too large, the exhaust hole can be expanded to exhaust air in the cup, and the safety problem caused by overpressure is prevented.

Owner:广东顺德奇伟电器科技有限公司

Elastic composite filter

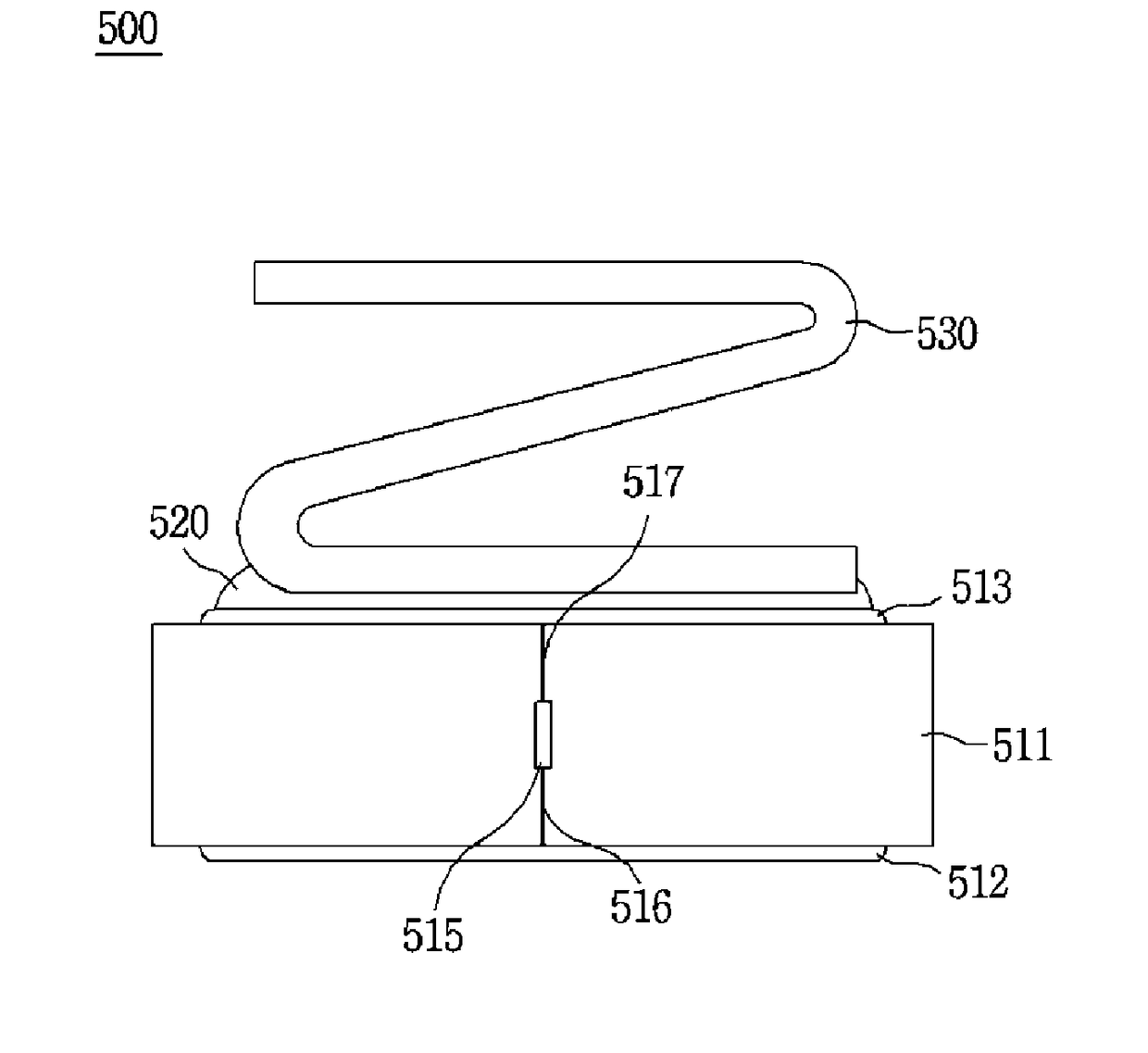

ActiveUS20170077891A1Prevent and attenuate electric shockPrevent and attenuate and noiseMultiple-port networksStructural fixed capacitor combinationsElasterellComposite filter

Disclosed is a technology that enables an elastic composite filter to have a capacitor to remove noise. The elastic composite includes a functional material layer; electrode patterns disposed on top and bottom surfaces of the material layer, respectively; and a conductive elastic member adhered onto the top electrode pattern, wherein the elastic member is coupled electrically and mechanically to the top electrode pattern to be used as an electrode, and the elastic member is in direct contact with a conductive object to provide elasticity.

Owner:JOINSET

Coiled material feeding device

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Ejection type storage box

The invention relates to an ejection type storage box structurally comprising a box body. A bearing layer, a blocking layer and a first ejection mechanism are arranged in the box body. The first ejection mechanism is arranged below the bearing layer. Articles in the storage box are stored between the bearing layer and the blocking layer. The bearing layer is connected to the box body and is provided with an ejection opening matched with the first ejection mechanism. The first ejection mechanism comprises an elastic part, an ejection block and a control rod. A control hole is formed in the ejection block. The control rod is matched with the control hole through a bevel, and the control rod makes contact with the control hole all the time. Part of the control rod is arranged outside the boxbody. The blocking layer is provided with an article outlet. The position of the article outlet is matched with that of the first ejection mechanism. According to the storage box provided by the invention, stored articles can be taken out from a storage space simply and separately, and the space in the storage box is used as far as possible for storing the articles.

Owner:浙江中赢包装有限公司

Anti-jumping conductive jig

PendingCN111041537AAvoid offsetAvoid skippingElectrolysis componentsEngineeringStructural engineering

The invention discloses an anti-jumping conductive jig comprising a fixed bottom plate and a conductive wheel. The fixed bottom plate further comprises a guide wheel parallel to the conductive wheel and an anti-jumping assembly for pressing the strip-shaped material. A gap for a strip-shaped material to penetrate through is formed between the guide wheel and the conductive wheel, the anti-jumpingassembly and the guide wheel are oppositely arranged on the two sides of the strip-shaped material, the anti-jumping assembly comprises a rotating shaft and an adjusting plate rotationally arranged onthe rotating shaft, a material pressing block is arranged on the side, away from the rotating shaft, of the adjusting plate, and an elastic piece is arranged on the other side. The anti-jumping assembly enables the strip-shaped material to have a movement trend towards one side of the guide wheel, the strip-shaped material can be positioned in the gap between the guide wheel and the conductive wheel, the strip-shaped material is prevented from jumping in the axis direction of the conductive wheel, the strip-shaped material and the conductive guide wheel are fully kept in contact through the guide wheel and the anti-jumping assembly, deviation and poor contact of the transverse working position of the strip-shaped material can be avoided and thus the surface of the strip-shaped material isensured to be evenly deposited.

Owner:KUNSHAN SOKAY AUTOMATION TECH CO LTD

Door plate lacquering curtain coating production line

ActiveCN110694821AWipe cleanWipe is beneficialSpraying apparatusDirt cleaningAdhesion beltElasterell

The invention relates to the technical field of curtain coating equipment, and particularly discloses a door plate lacquering curtain coating production line. The door plate lacquering curtain coatingproduction line comprises a rack, a conveying belt, a grinding unit, a negative pressure unit and a curtain coating unit. An adhesion unit is arranged between the negative pressure unit and the curtain coating unit, and comprises a driver, an adhesion belt and multiple liquid conveying rollers, the driver drives the liquid conveying rollers to rotate, the adhesion belt is made of fabric, the liquid conveying rollers are sleeved with the adhesion belt, a cavity is formed in each liquid conveying roller, a solution is arranged in the cavities, a circulation channel is arranged on the liquid conveying rollers, the circulation channel communicates with the cavities, plugging blocks are in sliding connection to the circulation channel, and elastic parts are connected between the other ends ofthe plugging blocks and the corresponding inner wall of the circulation channel. Circulation grooves enabling the exterior to communicate with the cavities are formed in the circulation channel, and the circulation grooves can be blocked by the plugging blocks. The problems that in the prior art, the negative pressure absorbing manner is adopted for absorbing ground-down saw dust, absorbing is notthorough, the saw dust is adhered to a door plate, and the door plate appearance quality is affected are solved.

Owner:重庆市佳禾家具制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com