Cutting edge grinding device of transverse scissors and feeding method of cutting edge grinding device

A grinding device and scissors technology, applied in the direction of grinding drive device, grinding machine, grinding feed movement, etc., can solve the problems of adverse effects on grinding accuracy, large space occupied by equipment, and easy shaking, etc. The feeding action is stable and reliable, and the effect of preventing forward and backward movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

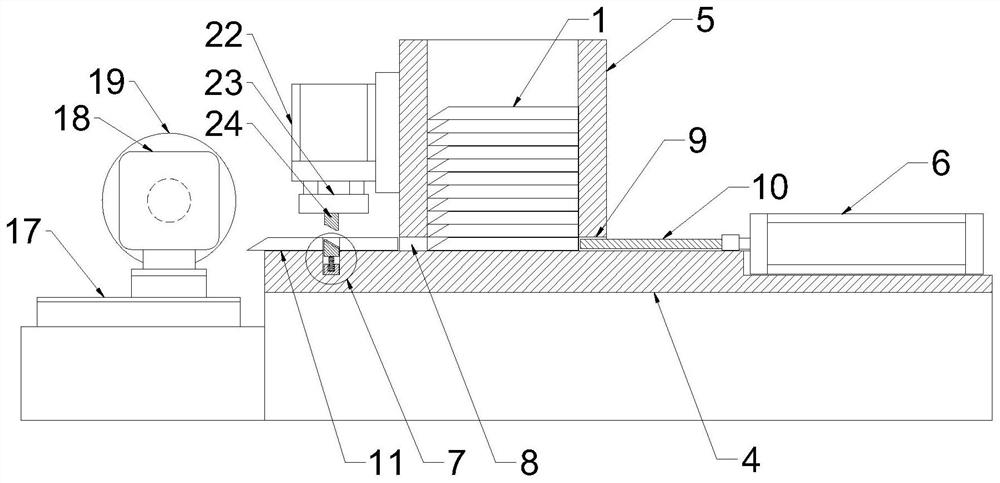

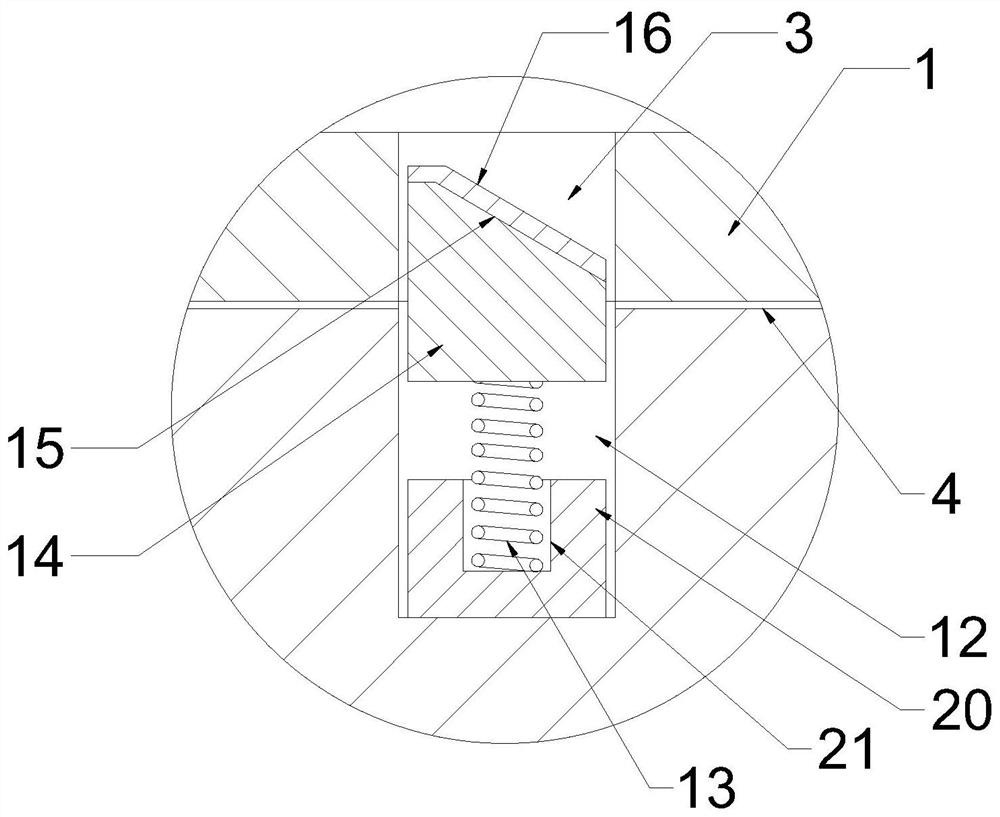

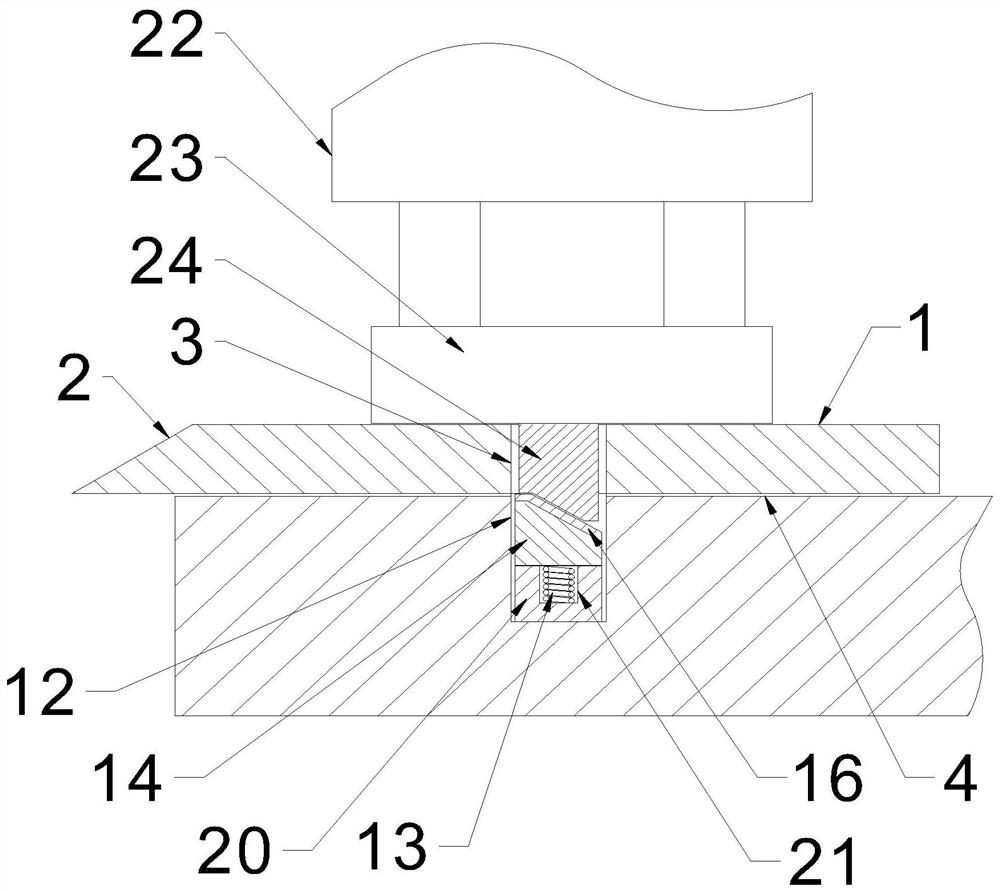

[0038] like figure 1 As shown in the figure, a blade grinding device for transverse scissors is used for grinding the blade of the transverse shears blank of the transverse shearing machine. As shown in Figure 4, the transverse shears 1 are provided with one or more assembly holes 3, and the assembly holes 3 The horizontal scissors 1 are assembled on the horizontal shearing machine. The device includes a feeding mechanism, a grinding mechanism and a pressing mechanism.

[0039] The feeding mechanism includes a workbench 4 , a bin 5 , a pushing cylinder 6 and a blocking member 7 .

[0040] The silo 5 is fixed on the worktable 4 by welding or screwing, and a plurality of horizontal scissors 1 can be stacked in the silo 5. The cross-sectional structure of the silo body of the silo 5 is similar to that of the horizontal scissors, and its top is open, and the horizontal scissors 1 It can be put into the silo from the top of the silo 5 . The bottom of the silo 5 is provided with ...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that, first, if Figure 4 As shown, the side wall of the silo 5 is provided with a window 27 for sorting materials. The window 27 penetrates the side wall of the silo 5 in the vertical direction and communicates with the pushing chute 9. Through the window 27, the material can be sorted manually and flexibly. The horizontal scissors in bin 5 prevent the horizontal scissors from being stacked unevenly.

[0061] Next, install the photoelectric sensor 28 on the side wall of the window 27. The detection head of the photoelectric sensor 28 faces the inside of the silo 5, and its installation height is located at the position of the second or third horizontal scissors from the bottom of the silo 5. The photoelectric sensor 28 It is used to detect whether there is no material in the silo 5, so as to remind the operator to replenish the material in time; the photoelectric sensor 28 is connected to the controller, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com