Patents

Literature

253results about How to "Guaranteed grinding accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

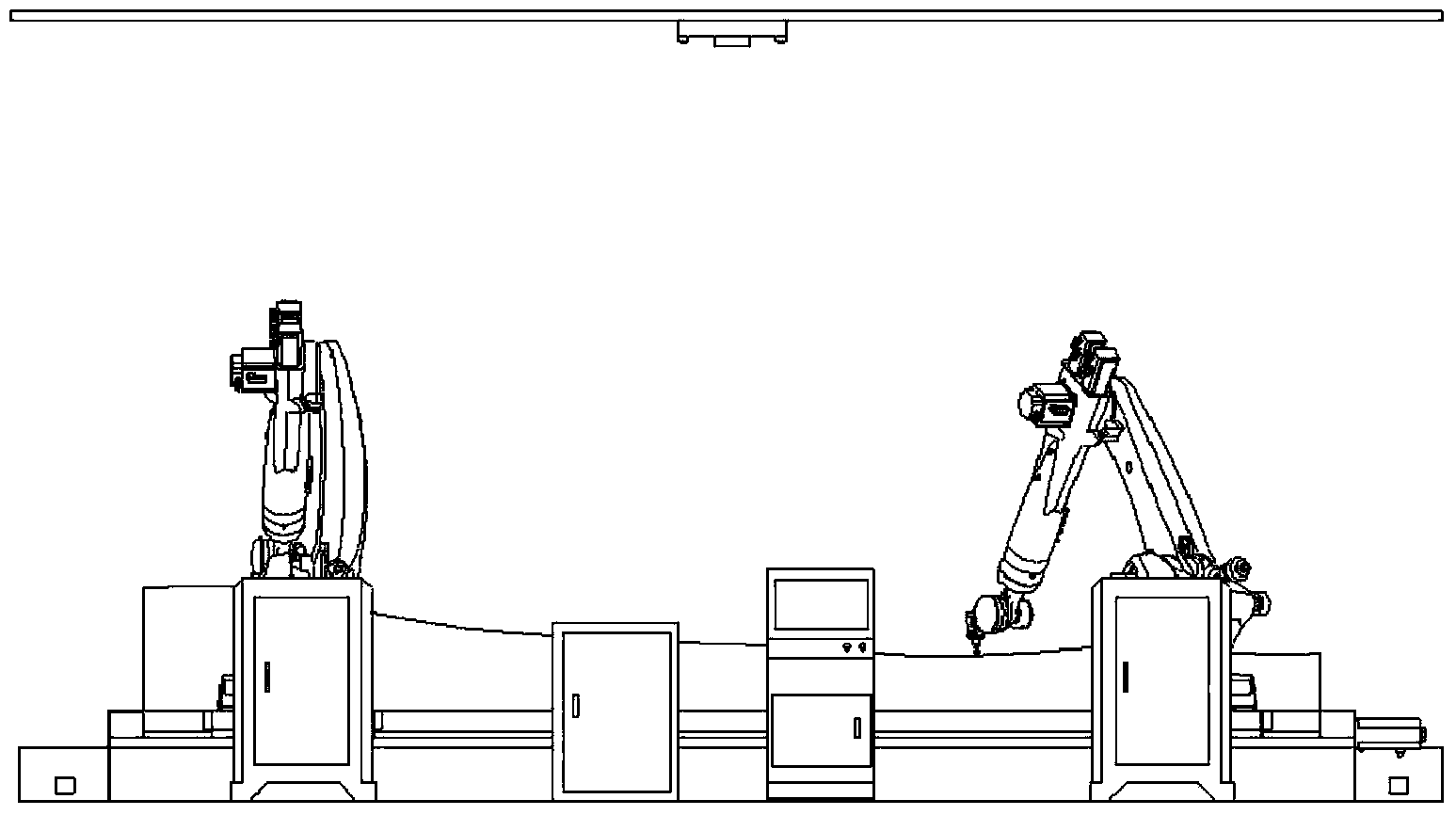

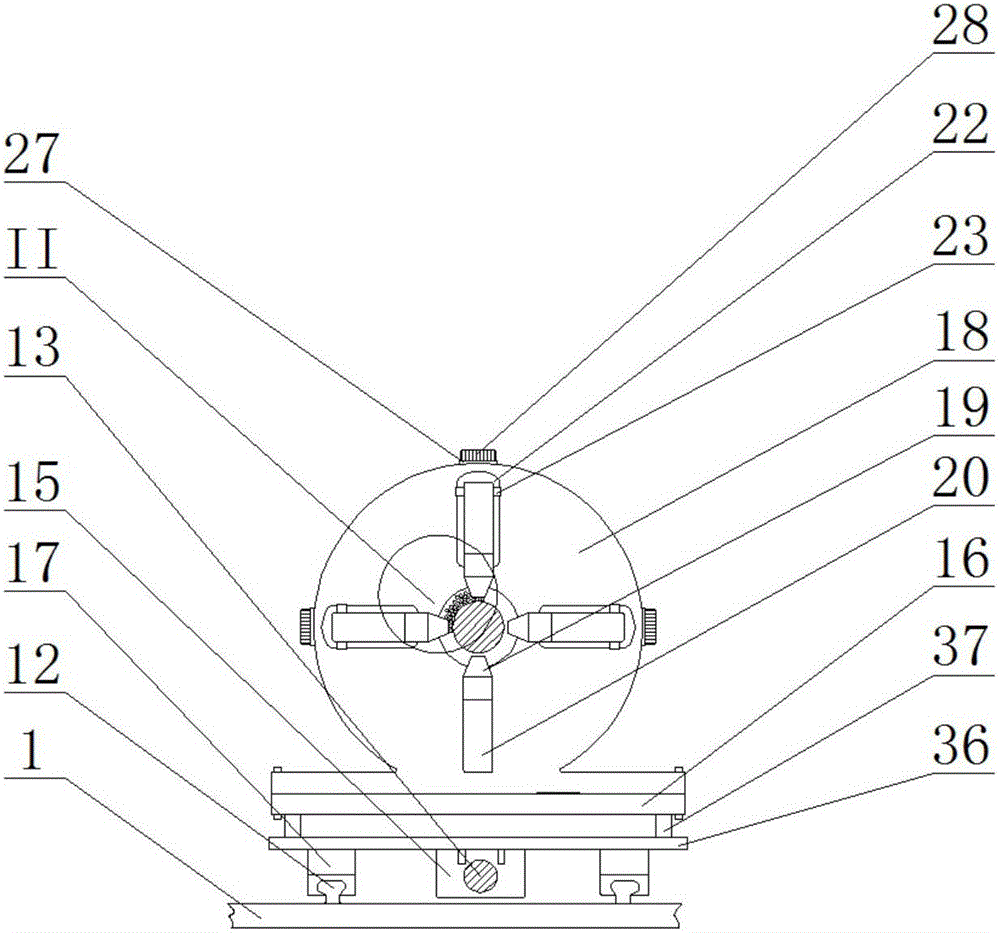

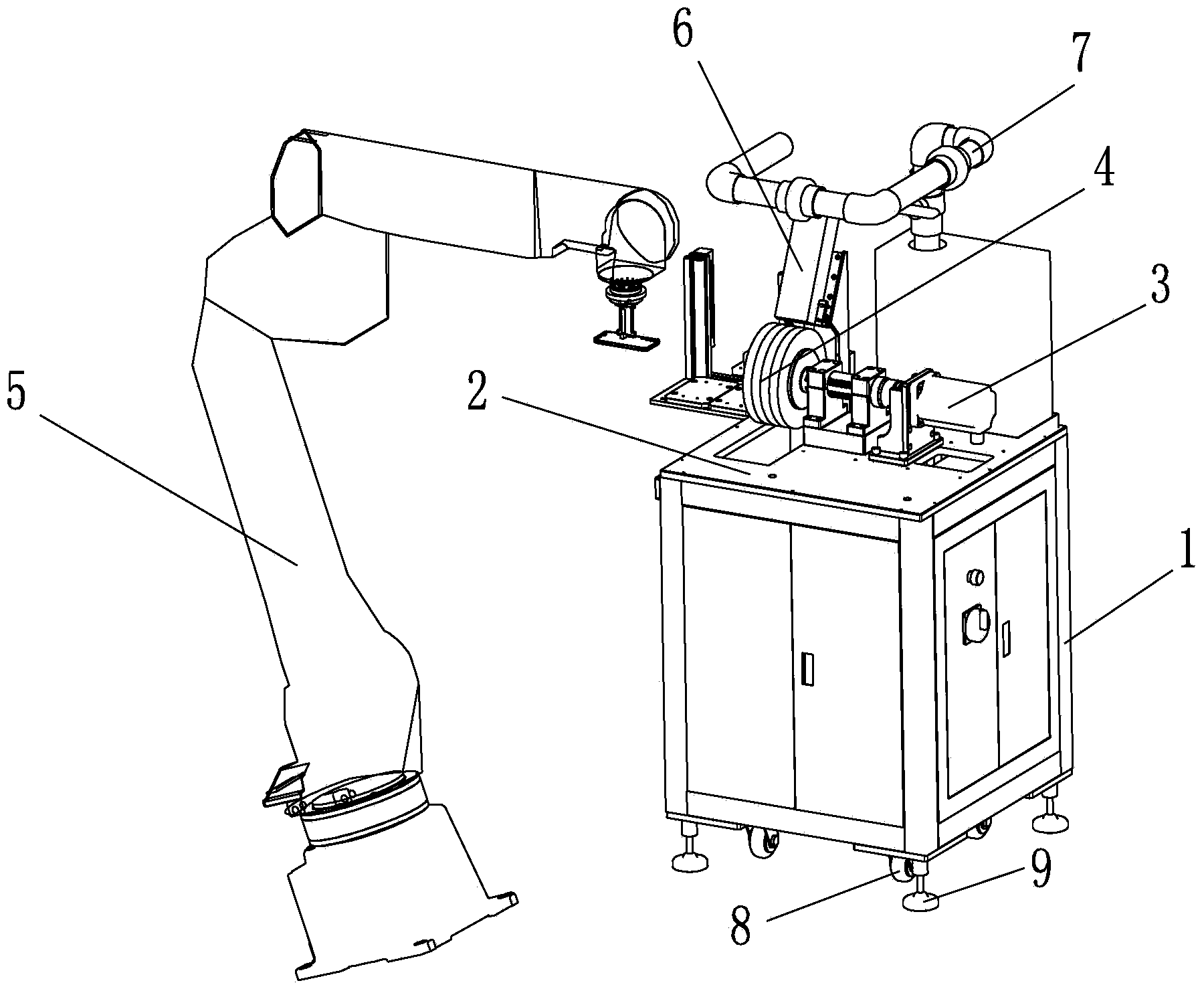

Automatic robot device for grinding air feeding and discharging edges of blade

ActiveCN104858748AGuaranteed machining accuracyGuaranteed grinding accuracyGrinding feed controlAutomatic grinding controlMeasurement deviceEngineering

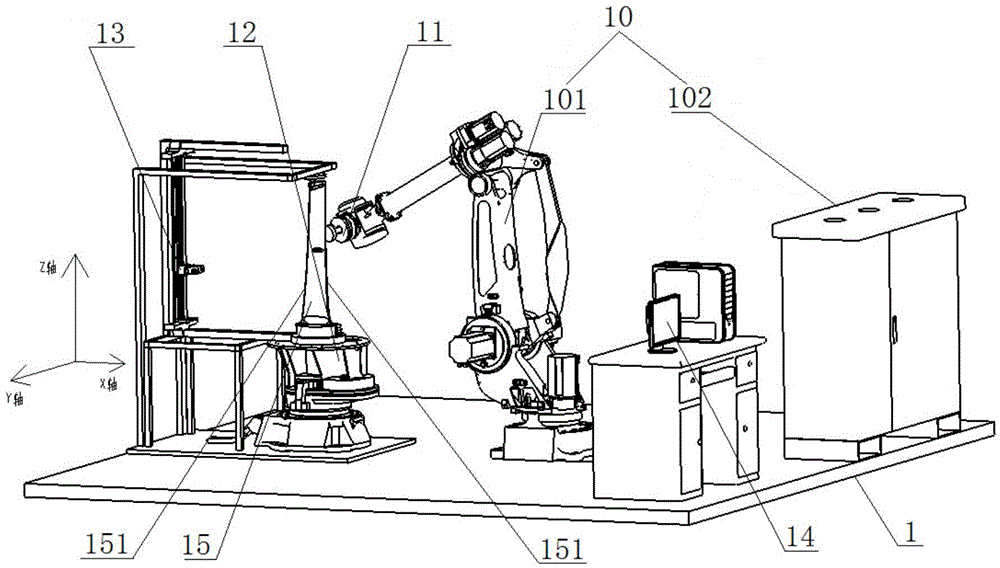

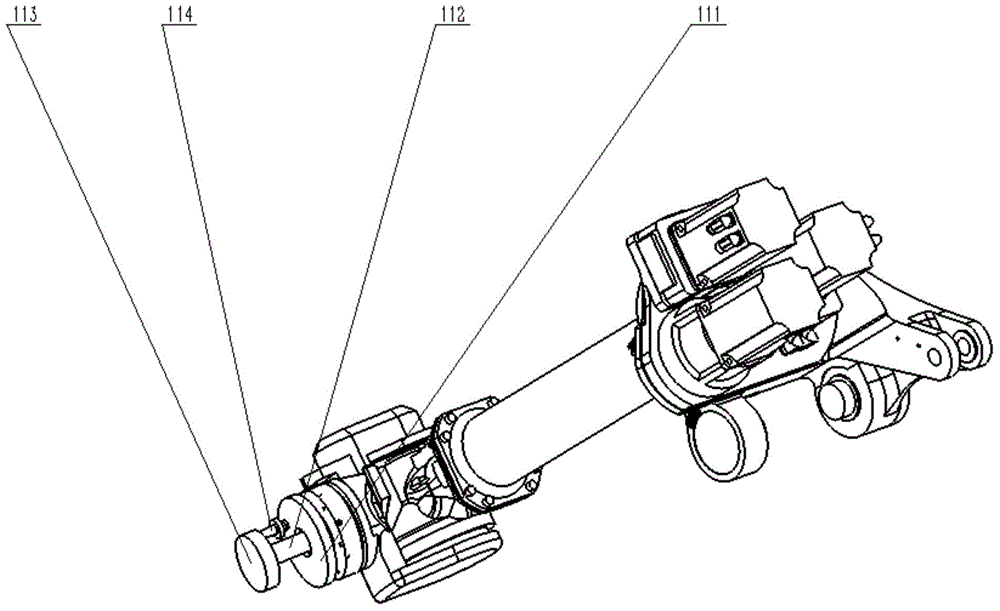

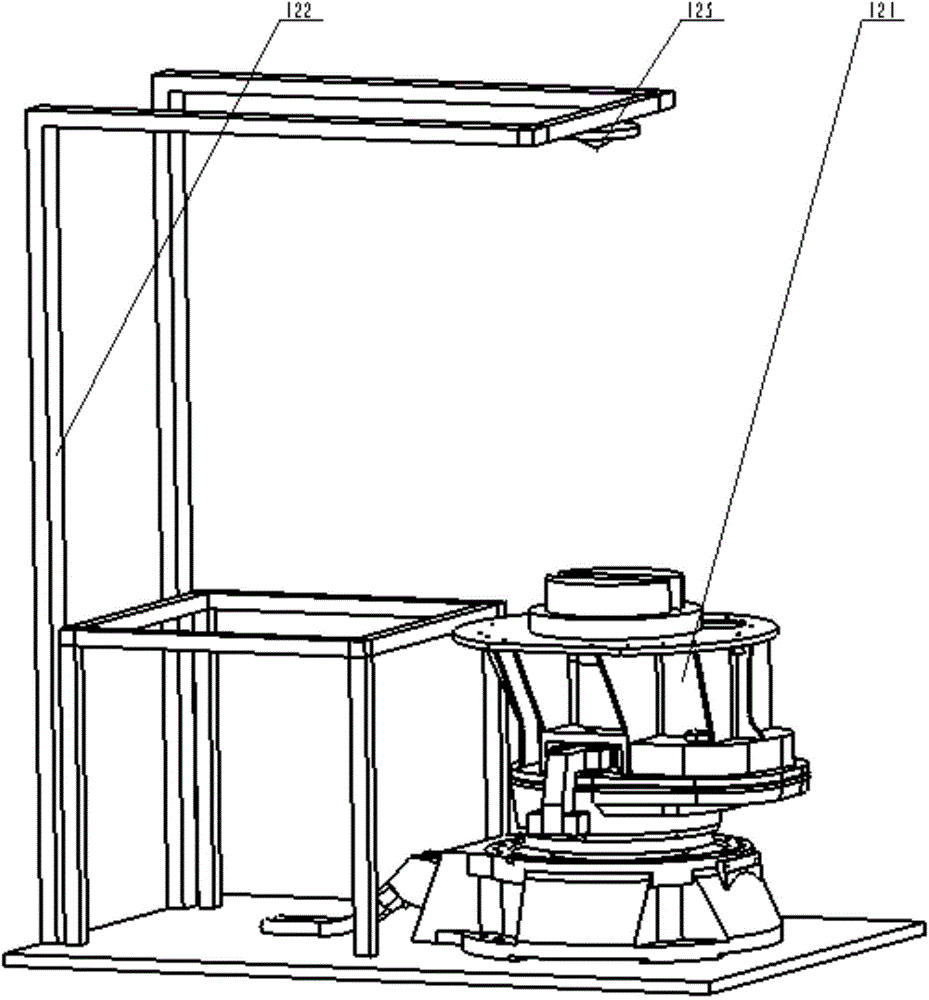

The invention discloses an automatic robot device for grinding air feeding and discharging edges of a blade. The automatic robot device comprises a base station, a six-freedom-degree robot, a grinding device, a position changing machine, a three-dimensional laser measurement device and a system control host. The six-freedom-degree robot is arranged on the base station. The grinding device is used for grinding the air feeding and discharging edges of the blade. The position changing machine is arranged on the base station. The three-dimensional laser measurement device is arranged on the position changing machine and comprises a triaxial movement platform and a three-dimensional laser measurement device body. The three-dimensional laser measurement device body comprises two three-dimensional laser outline scanners. The system control host is connected with the six-freedom-degree robot and the three-dimensional laser measurement device. The system control host is used for planning the machining path of the grinding device and a moving path of the three-dimensional laser measurement device and sending the paths and commands to the six-freedom-degree robot to be executed. The automatic robot device integrates self-adaptive grinding and measurement functions, and can guarantee the machining precision of the outlines of the air feeding and discharging edges of the blade.

Owner:HUST WUXI RES INST

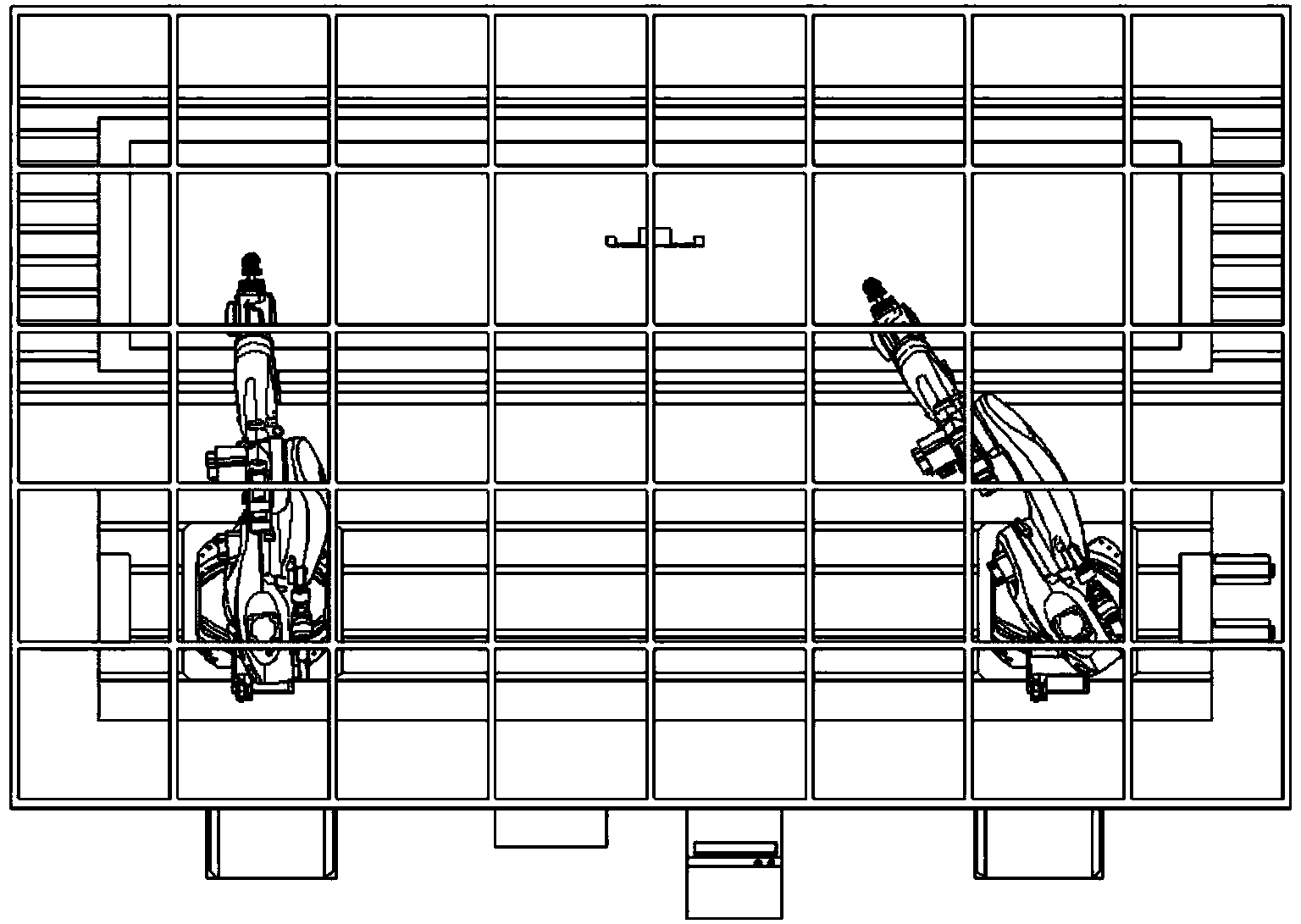

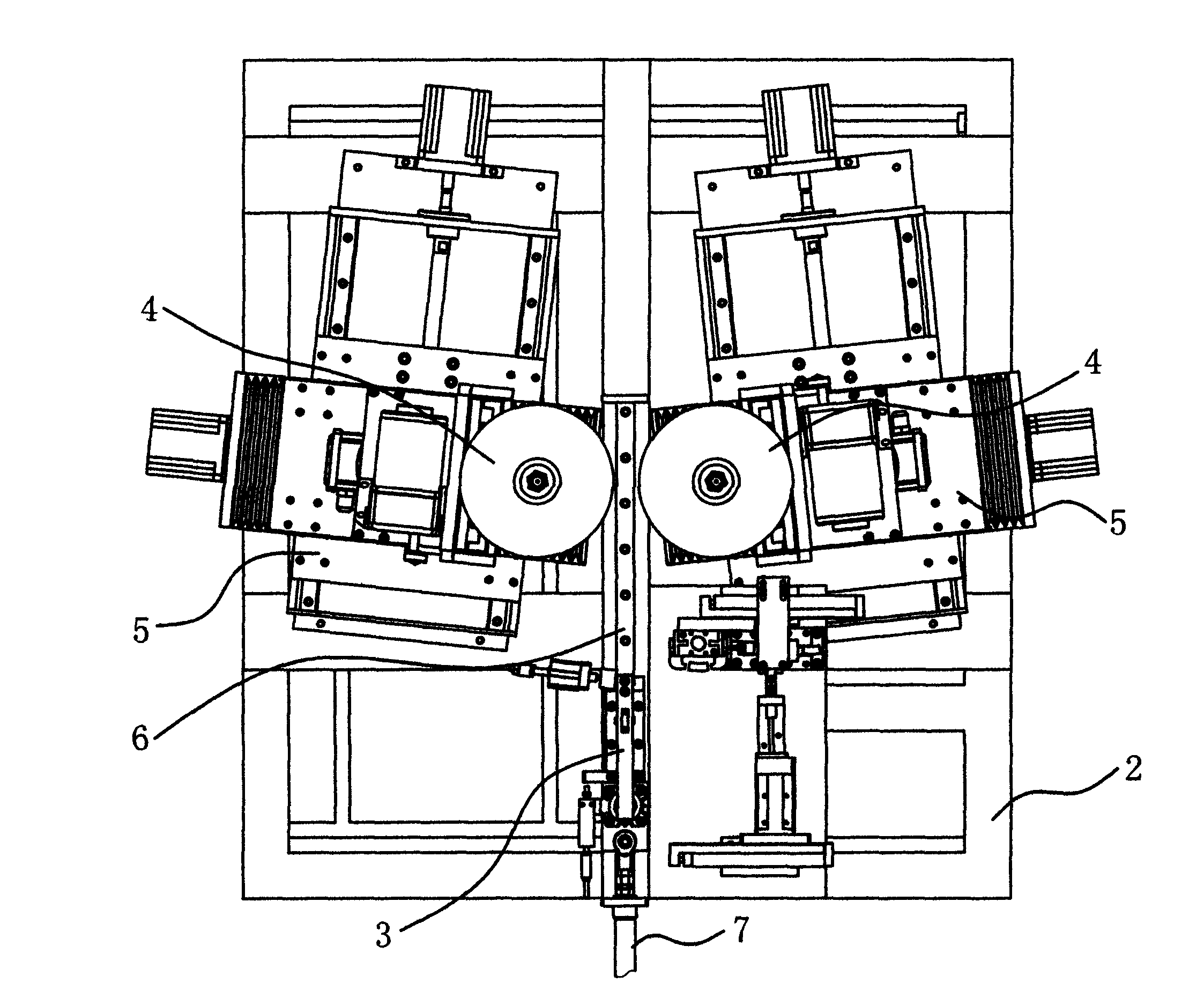

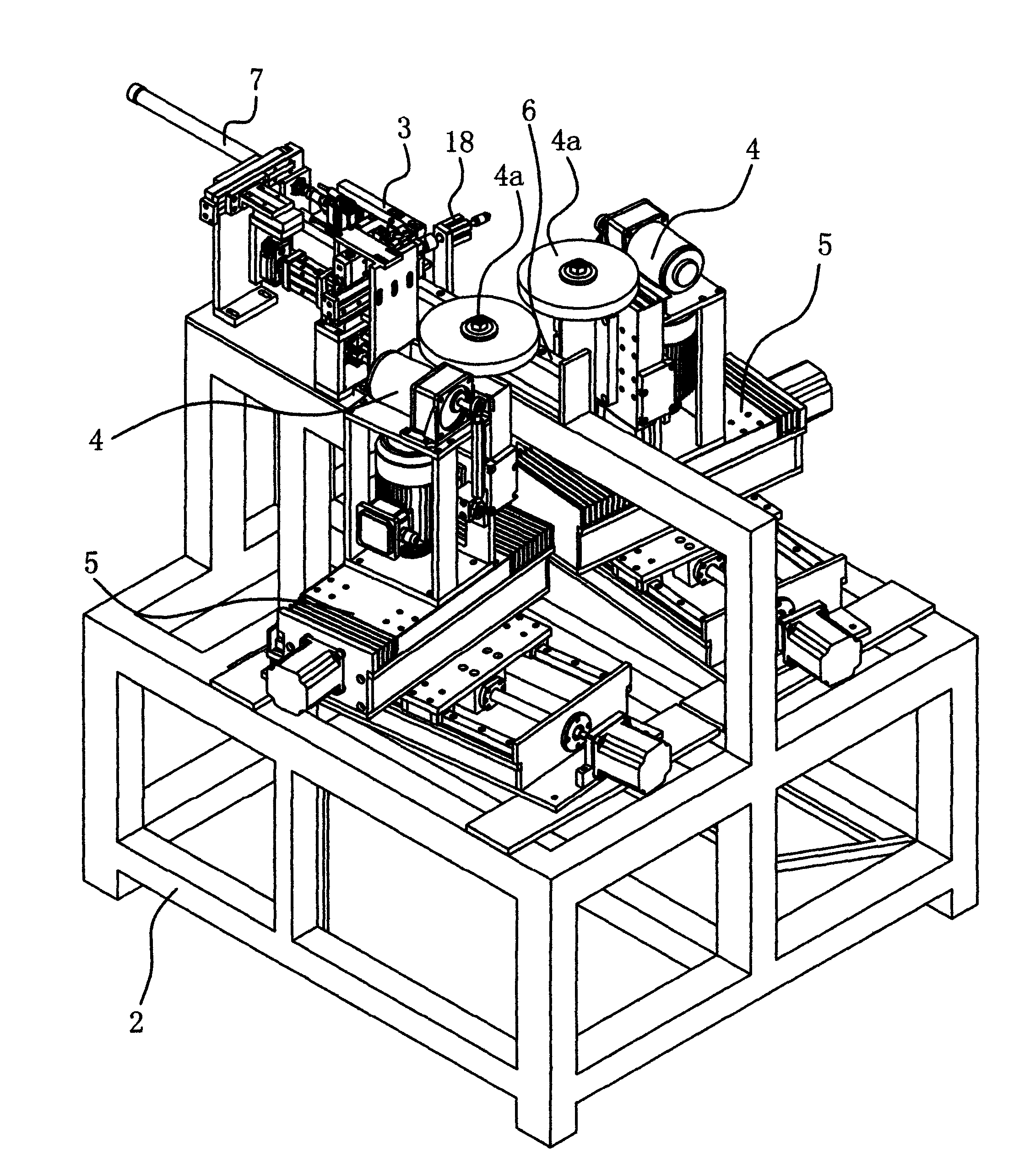

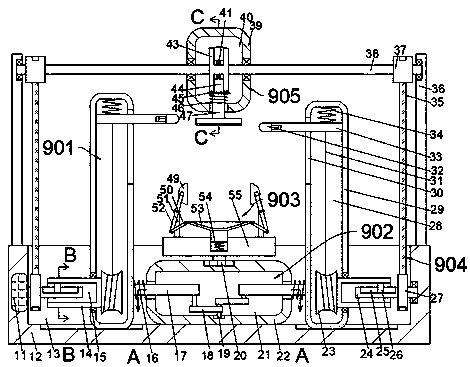

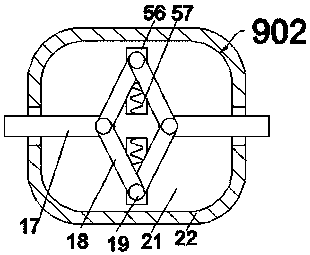

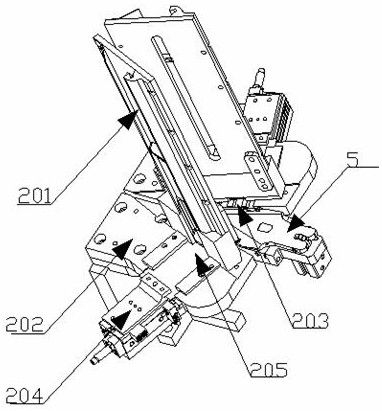

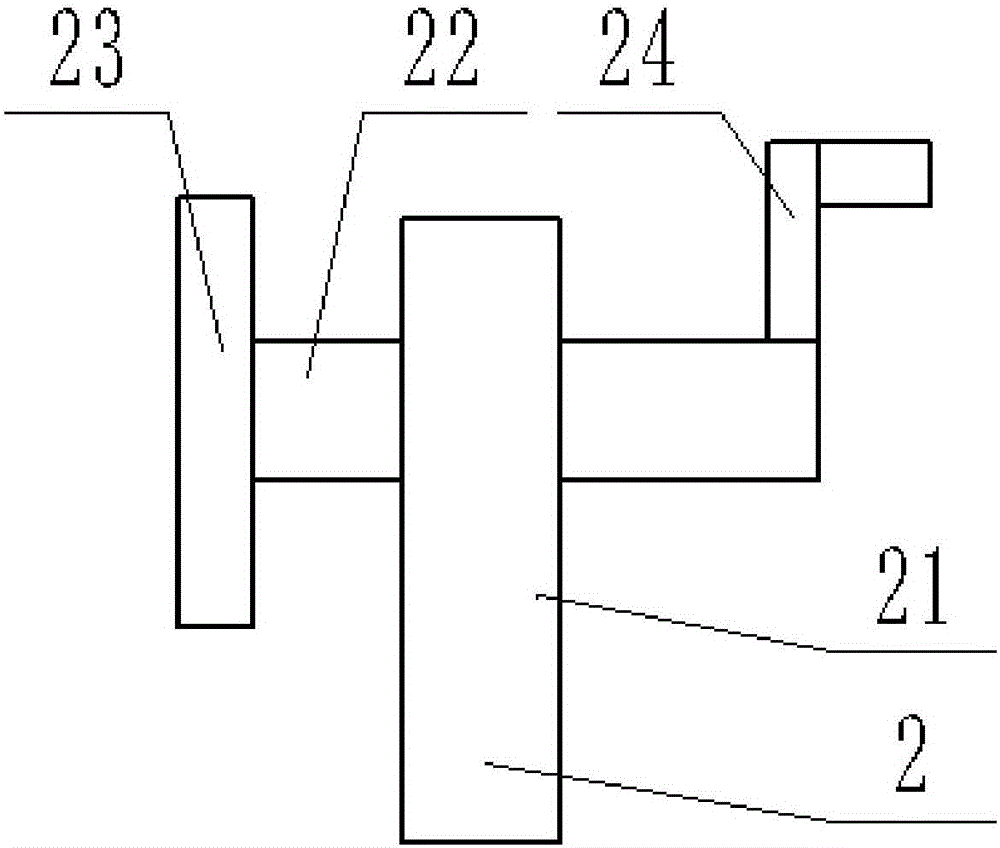

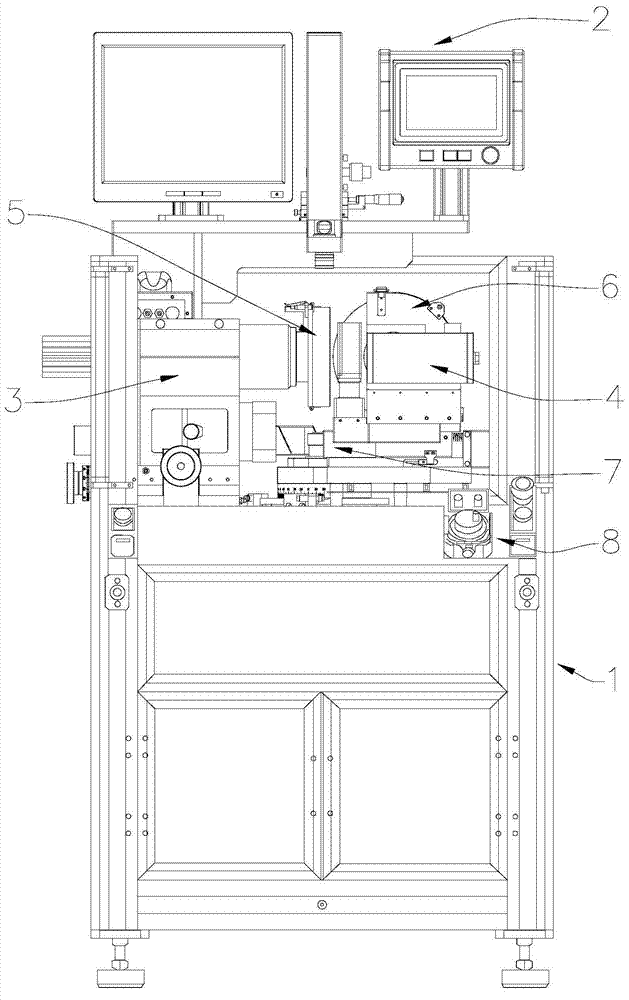

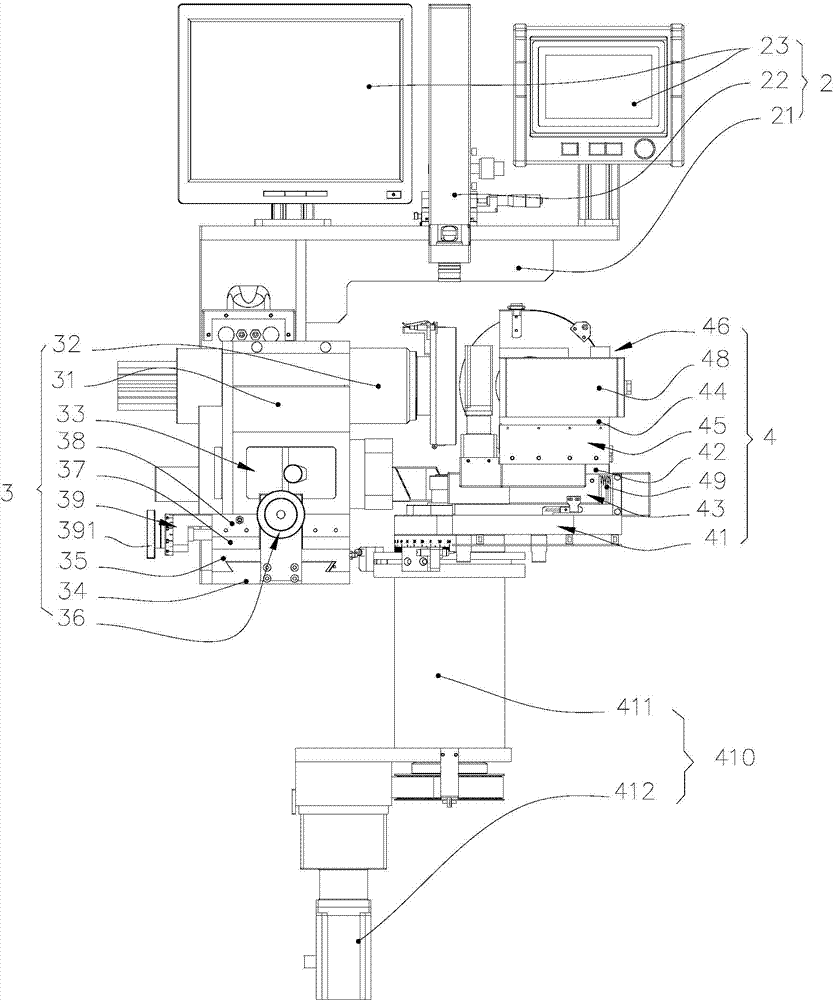

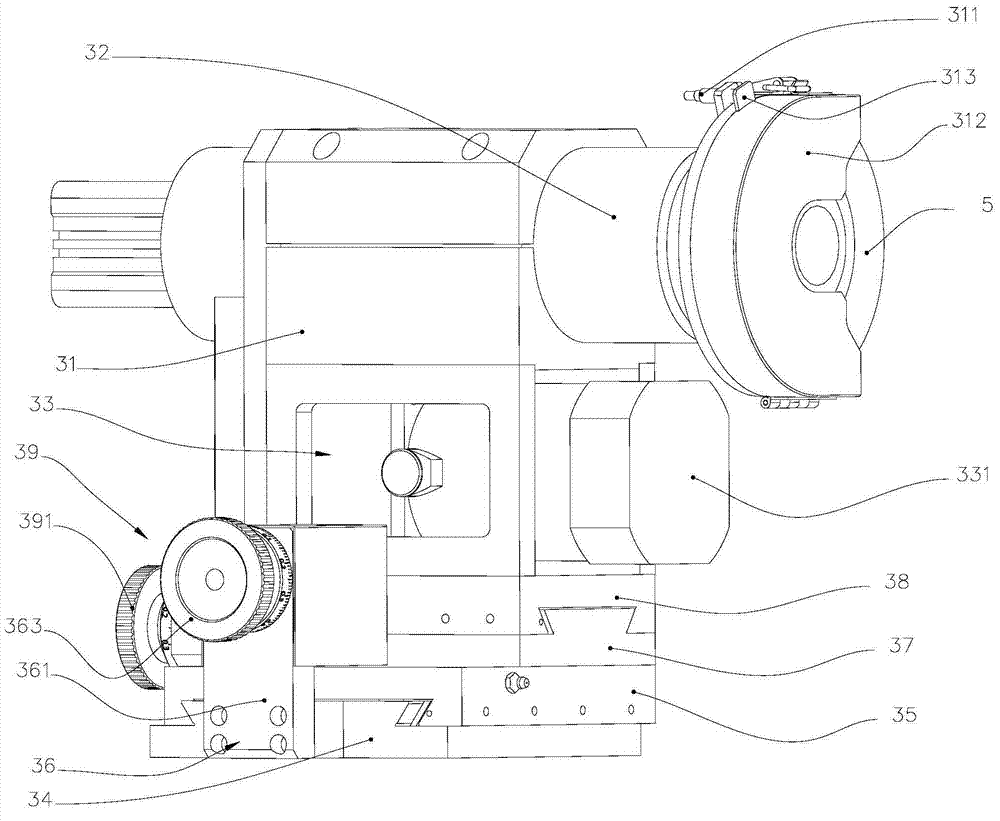

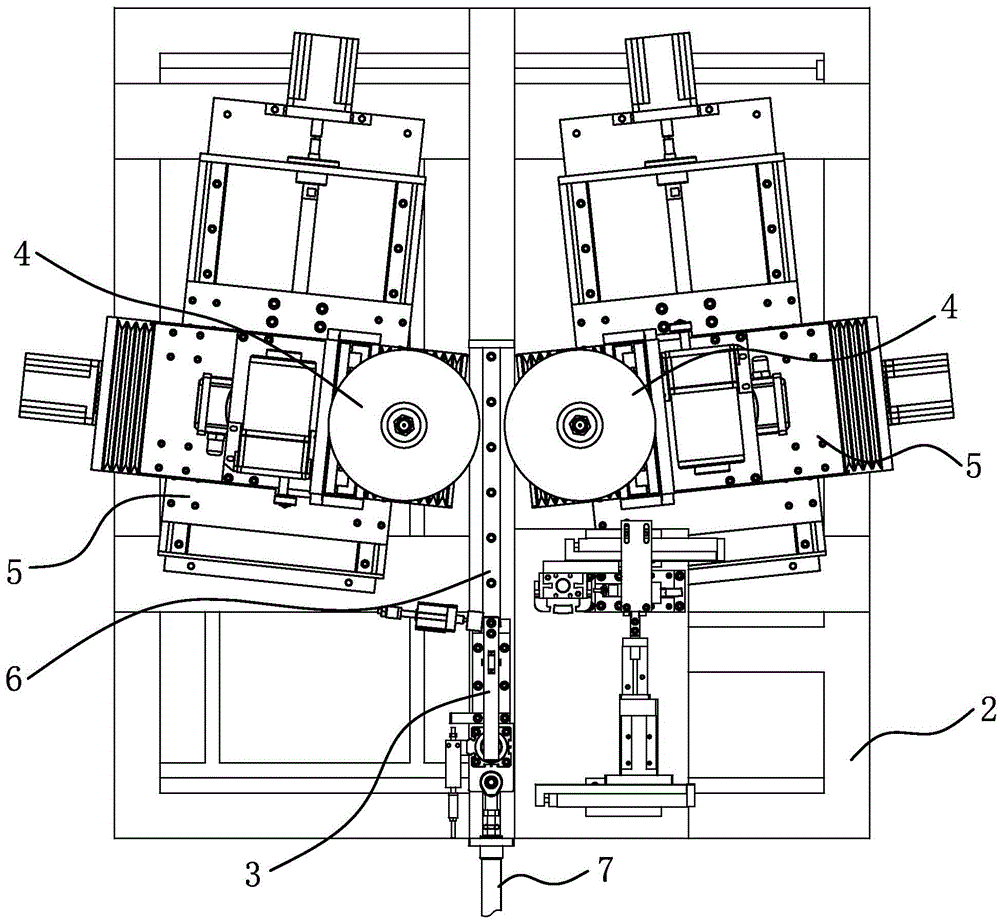

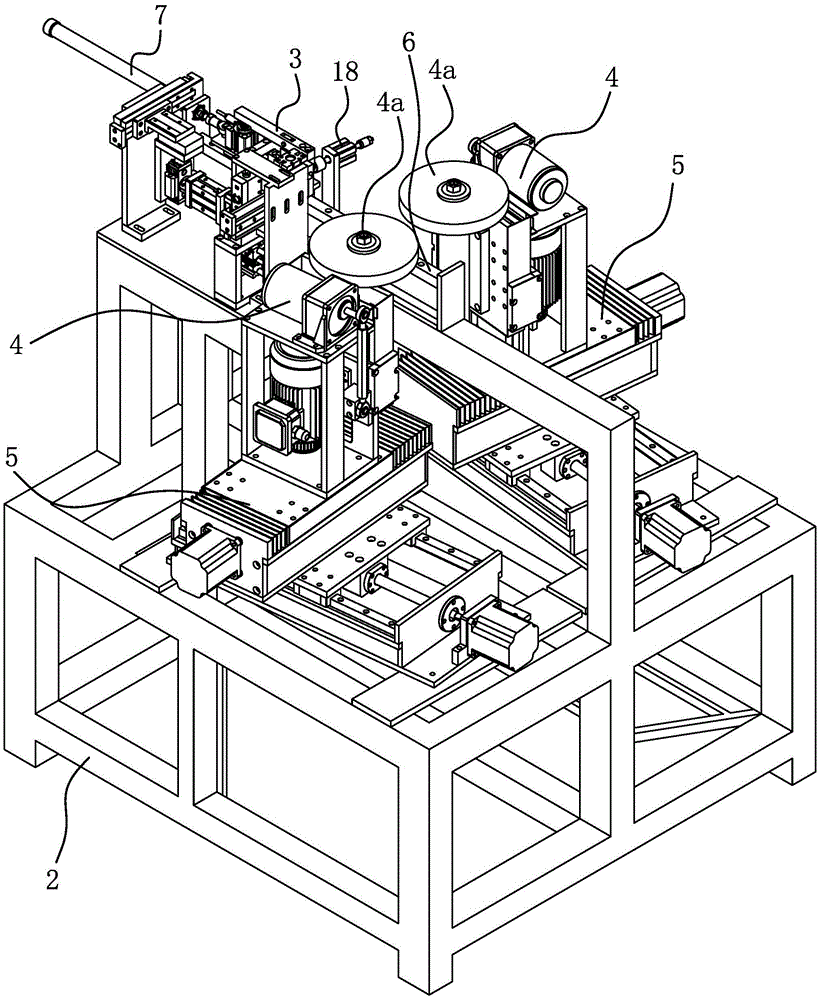

Robot parallel polishing system

ActiveCN103862340APressure controllableGuaranteed grinding removalEdge grinding machinesGrinding drivesSimulationSelf positioning

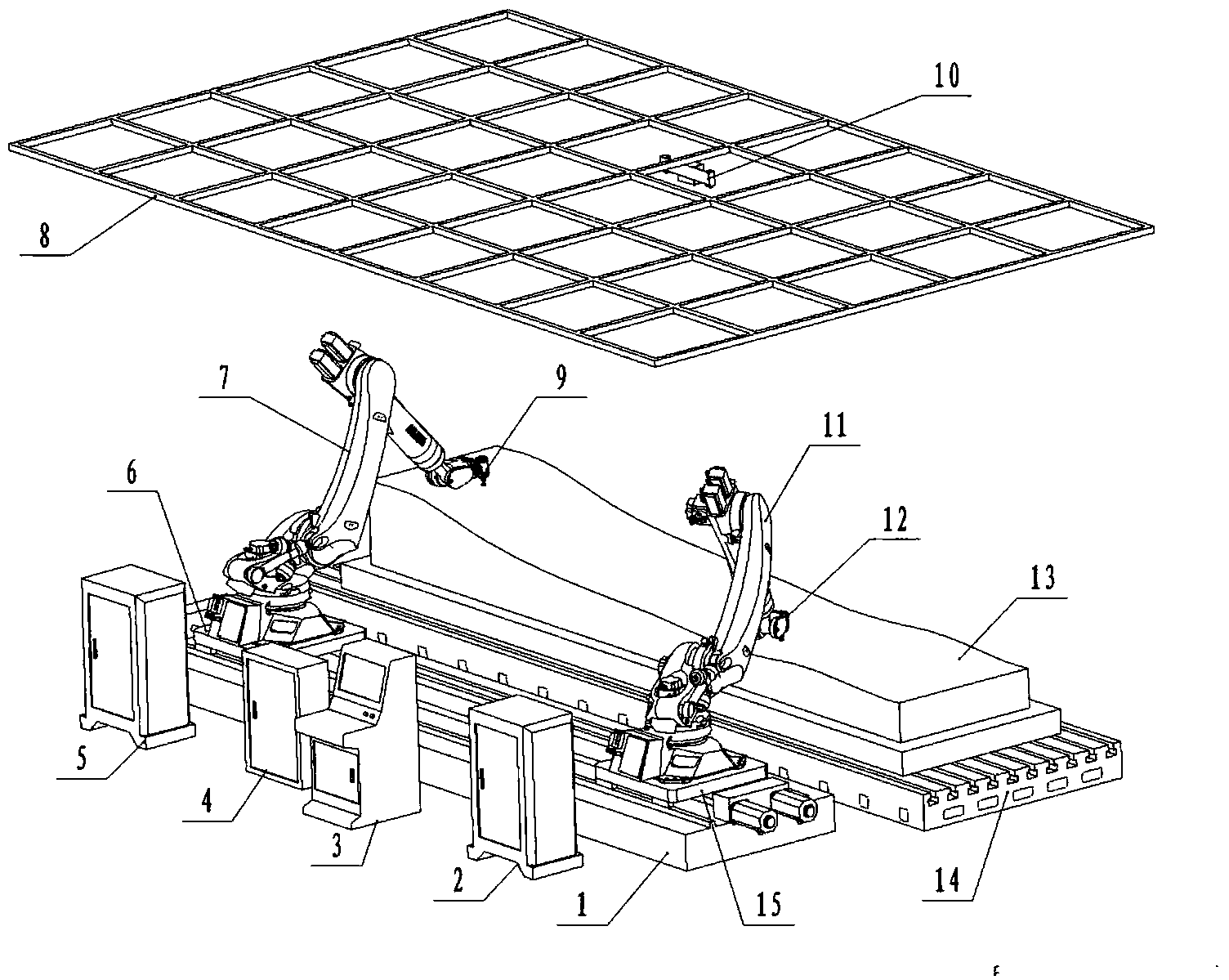

The invention discloses a robot parallel polishing system which comprises a coarse polishing system, a refined polishing system, a base component, a system control cabinet, a pneumatic control cabinet, a robot vision self-positioning system, workpieces and a working table. The workpieces with large free curved faces can be coarsely and finely polished through the polishing systems at the same time, simultaneous polishing on the two same workpieces can be achieved, the polishing accuracy can be effectively guaranteed, and the polishing efficiency is improved. Before the robot parallel polishing system works, the polishing areas are divided by path generative software according to three-dimensional models of the workpieces, the polishing paths are generated, standards of the workpieces are rapidly and accurately demarcated through the robot vision self-positioning system, two industrial robots drive a pneumatic polishing head to conduct coarse polishing and refined polishing on the polishing areas according to the planed paths, the pneumatic mild force control technology, the normal polishing force control technology and the path real-time calibration compensation technology are adopted in the polishing process, and the polishing accuracy and the coincidence of the polishing quality are effectively guaranteed.

Owner:中科君胜(深圳)智能数据科技发展有限公司

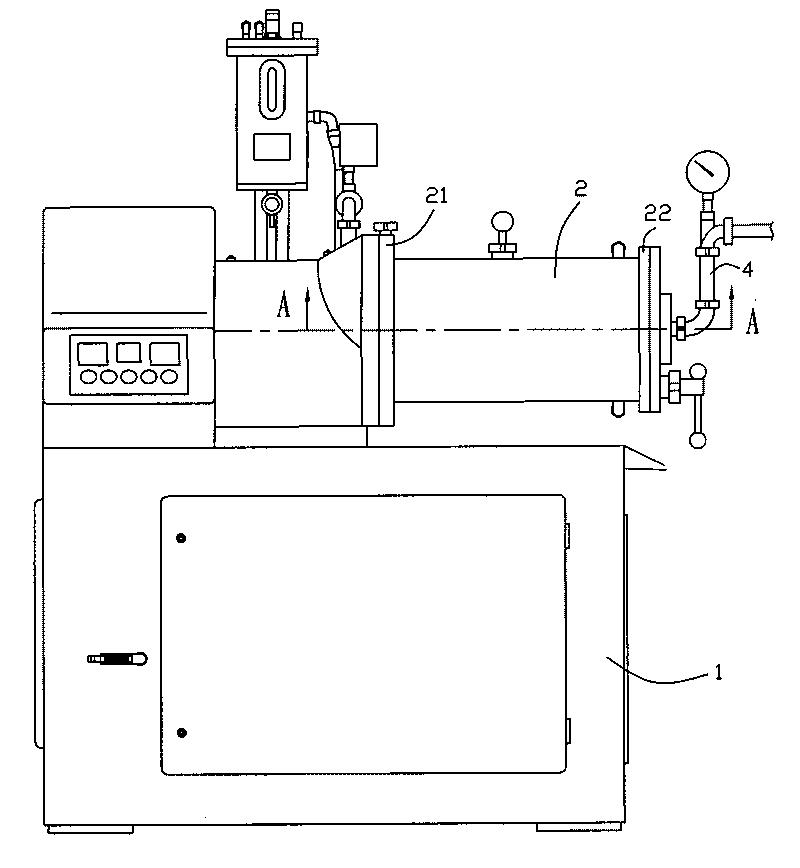

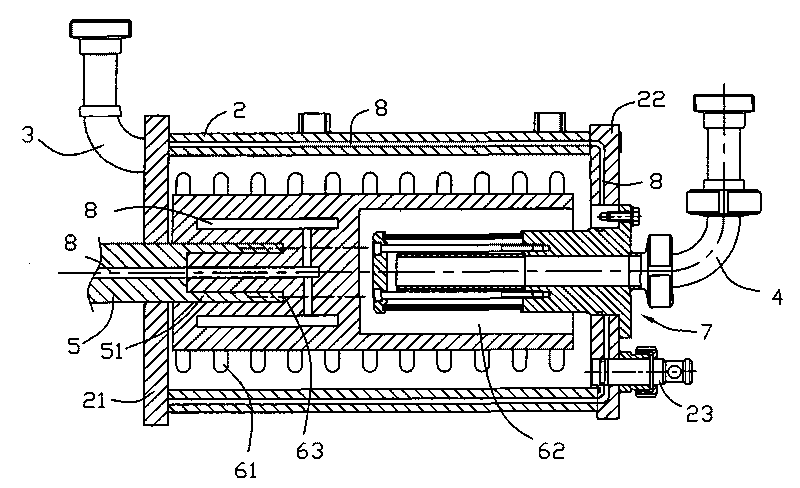

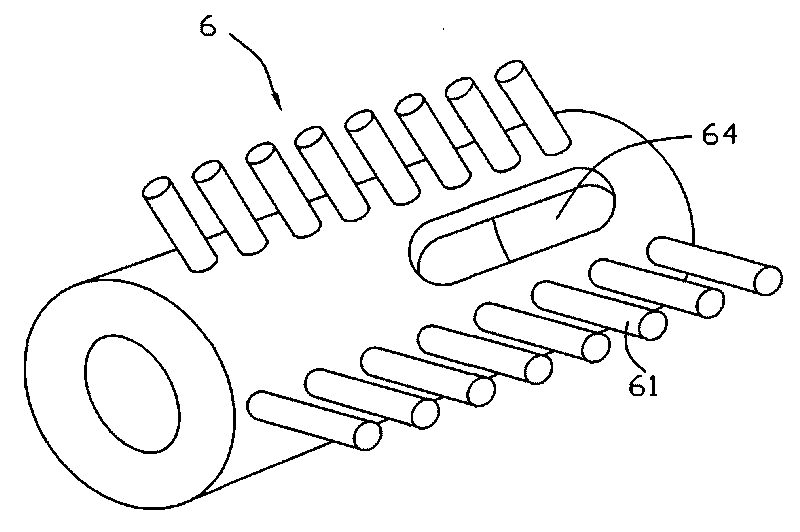

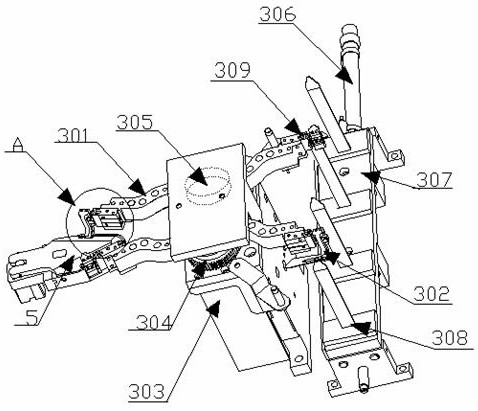

Nanoscale high-flow pin-type sand mill

The invention relates to a nanoscale high-flow pin-type sand mill comprising a rack and a sand cylinder which is arranged on the rack and is sealed by a left cover and a right cover, wherein a feed pipe and a discharging pipe are respectively arranged on the two sides of the sand cylinder; a spindle passes through the left end cover to extend into the sand cylinder and is fixedly provided with a rotor; the surrounding wall of the rotor is axially provided with a plurality of rows of pins; a separator is installed on the sand cylinder and is communicated with the discharging pipe; one end of the rotor is installed on the spindle, and the other end of the rotor is axially provided with a groove; one end of the separator is fixed on the right end cover; and the other end of the separator passes through the right end cover to extend into the groove. In this way, the length of the sand cylinder can be effectively shortened to increase the diameter thereof, thus the spindle can be designed to be short and thick so as to improve the rotational speed of the spindle and increase the linear speed of the material and grinding medium in the sand cylinder; and the material is fully dispersed and ground to ensure grinding precision and improve grinding efficiency.

Owner:PUHLER GUANGDONG SMART NANO TECH CO LTD

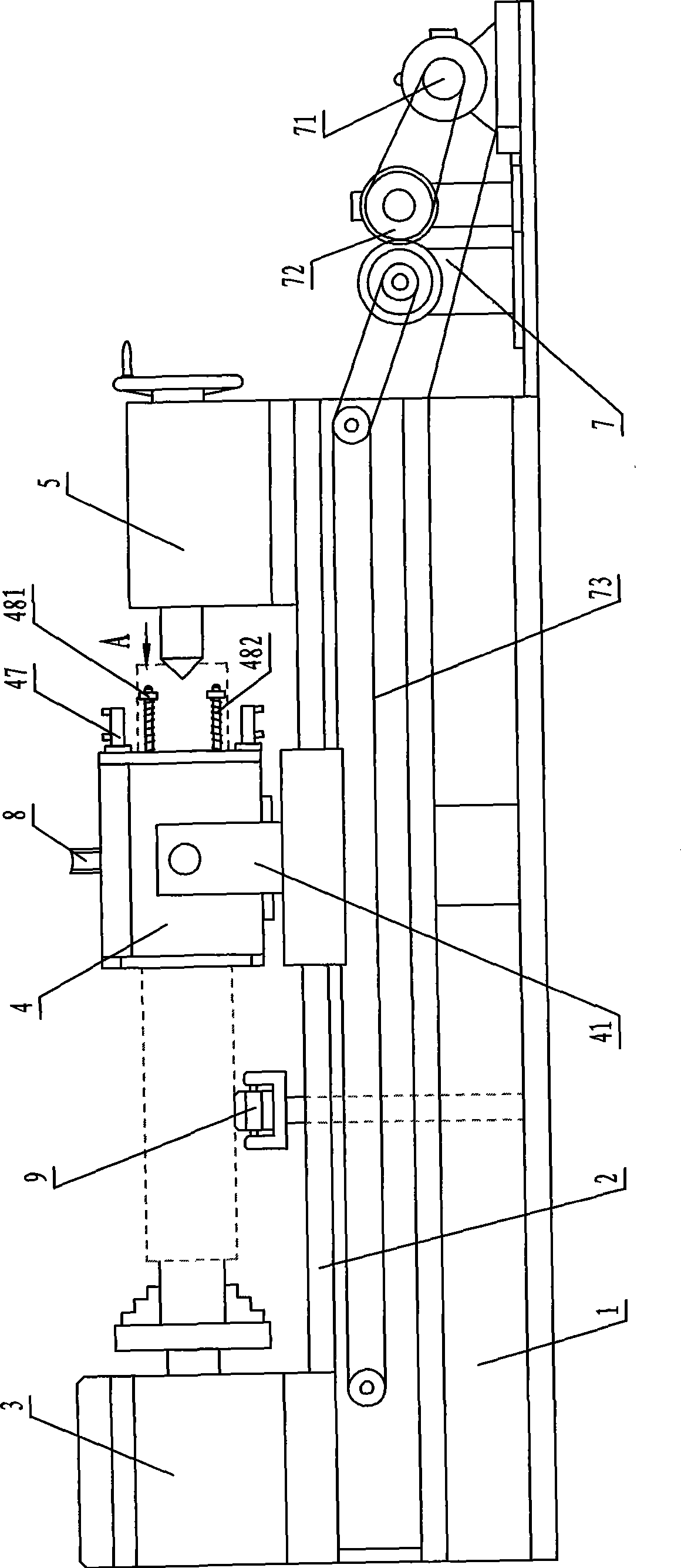

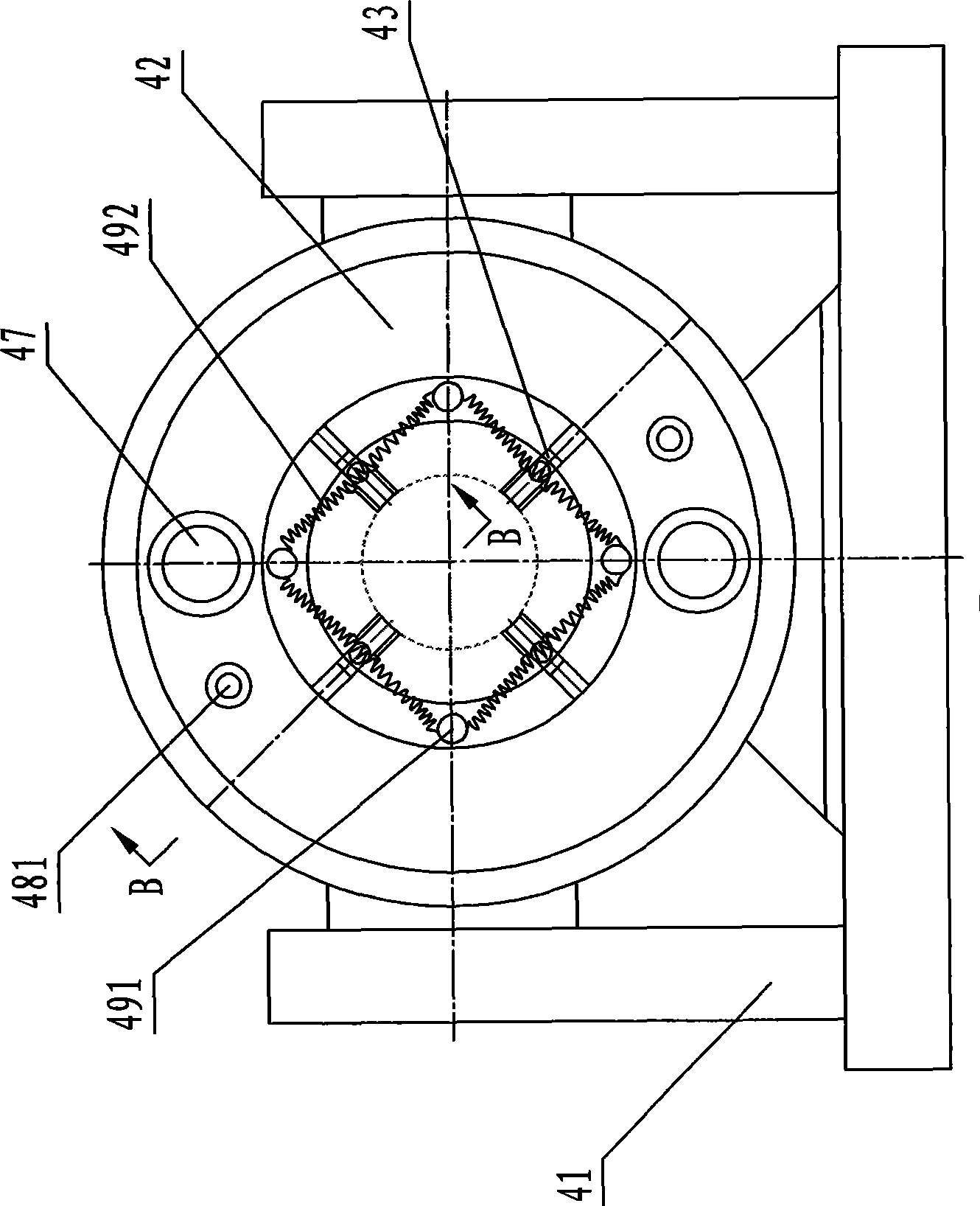

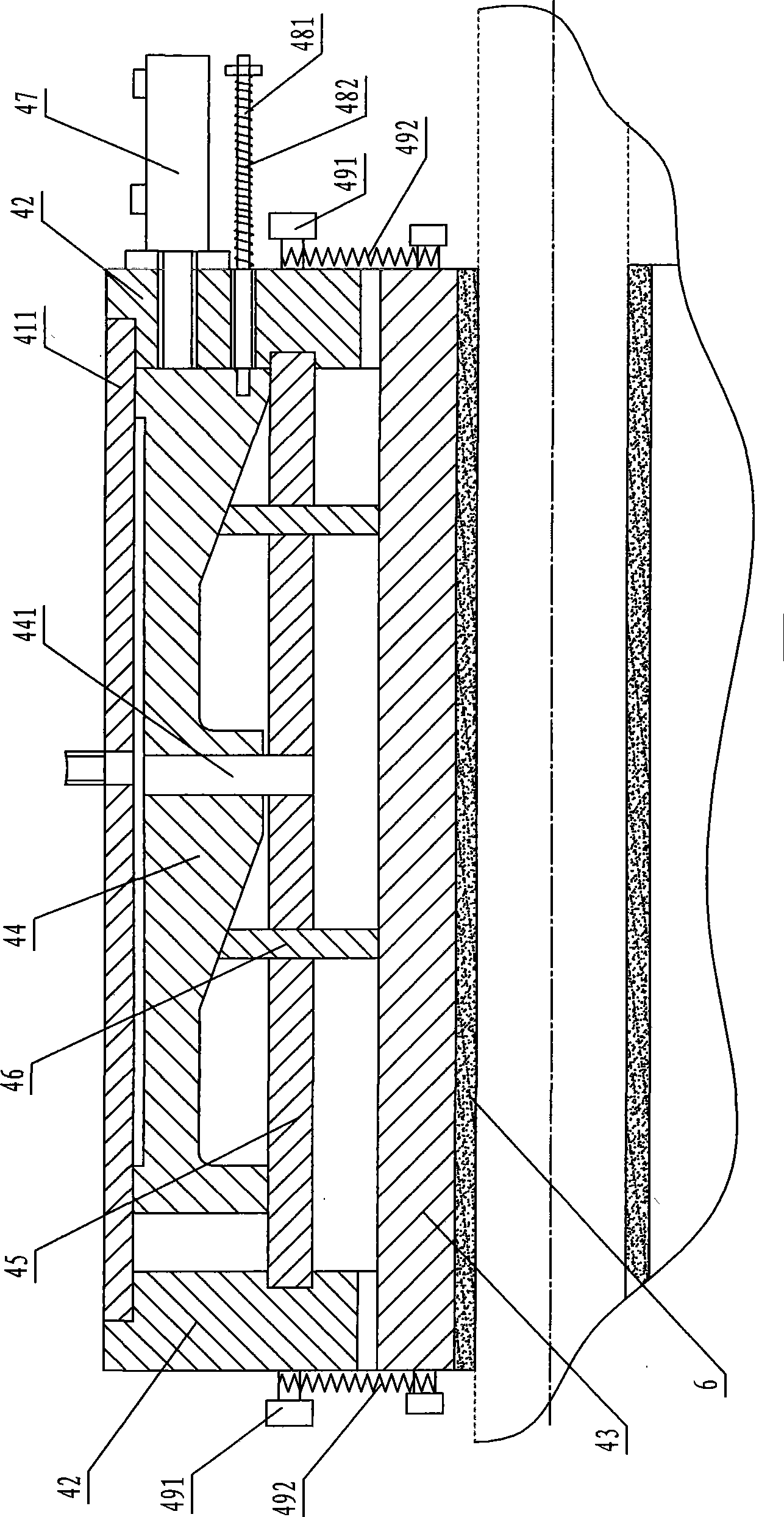

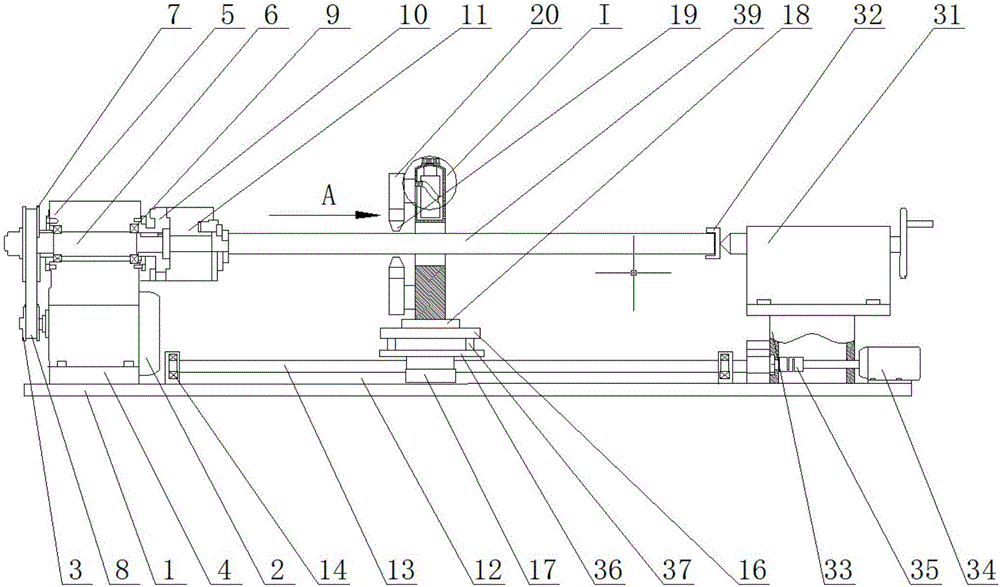

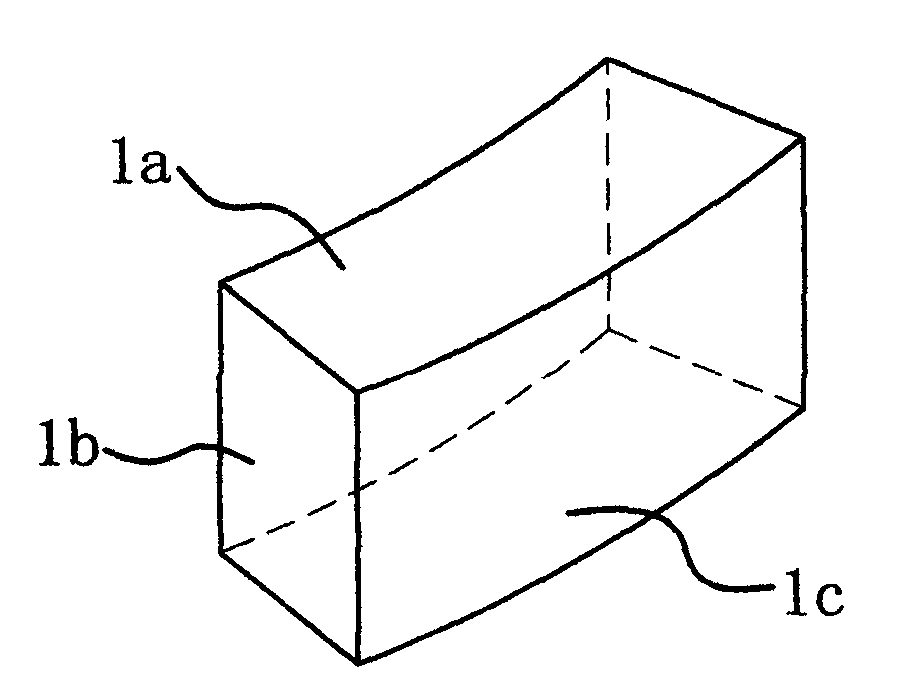

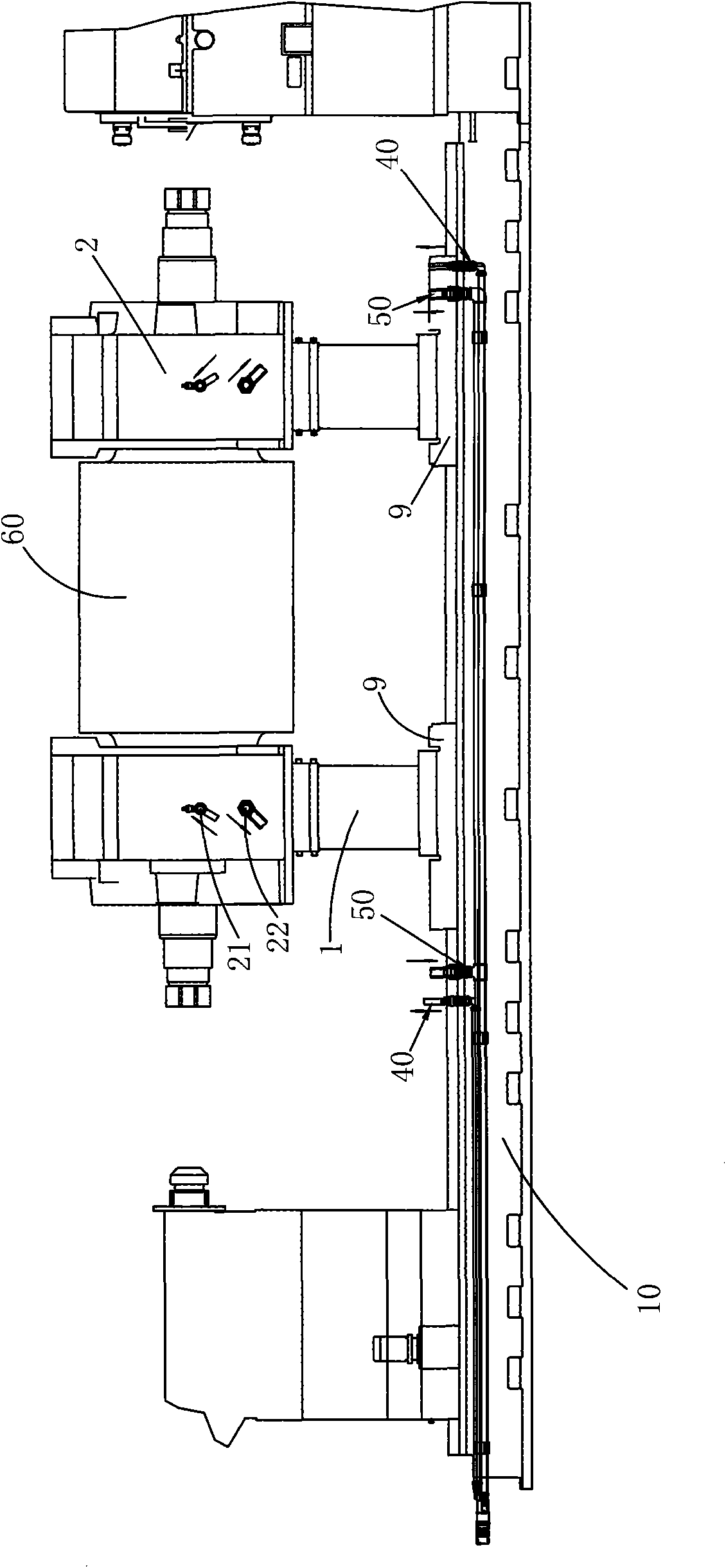

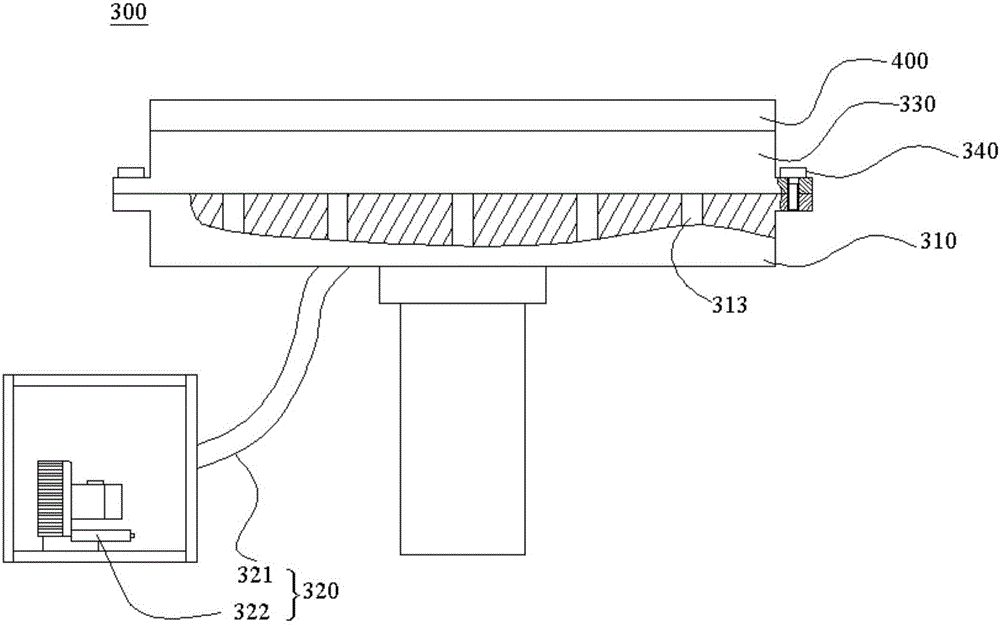

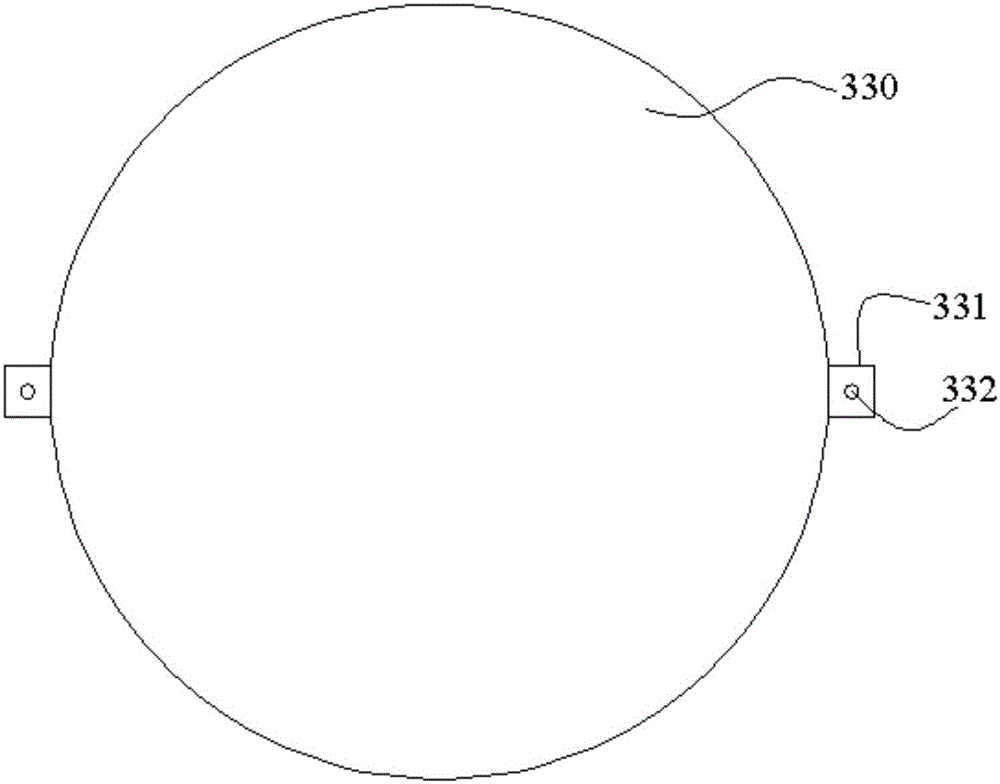

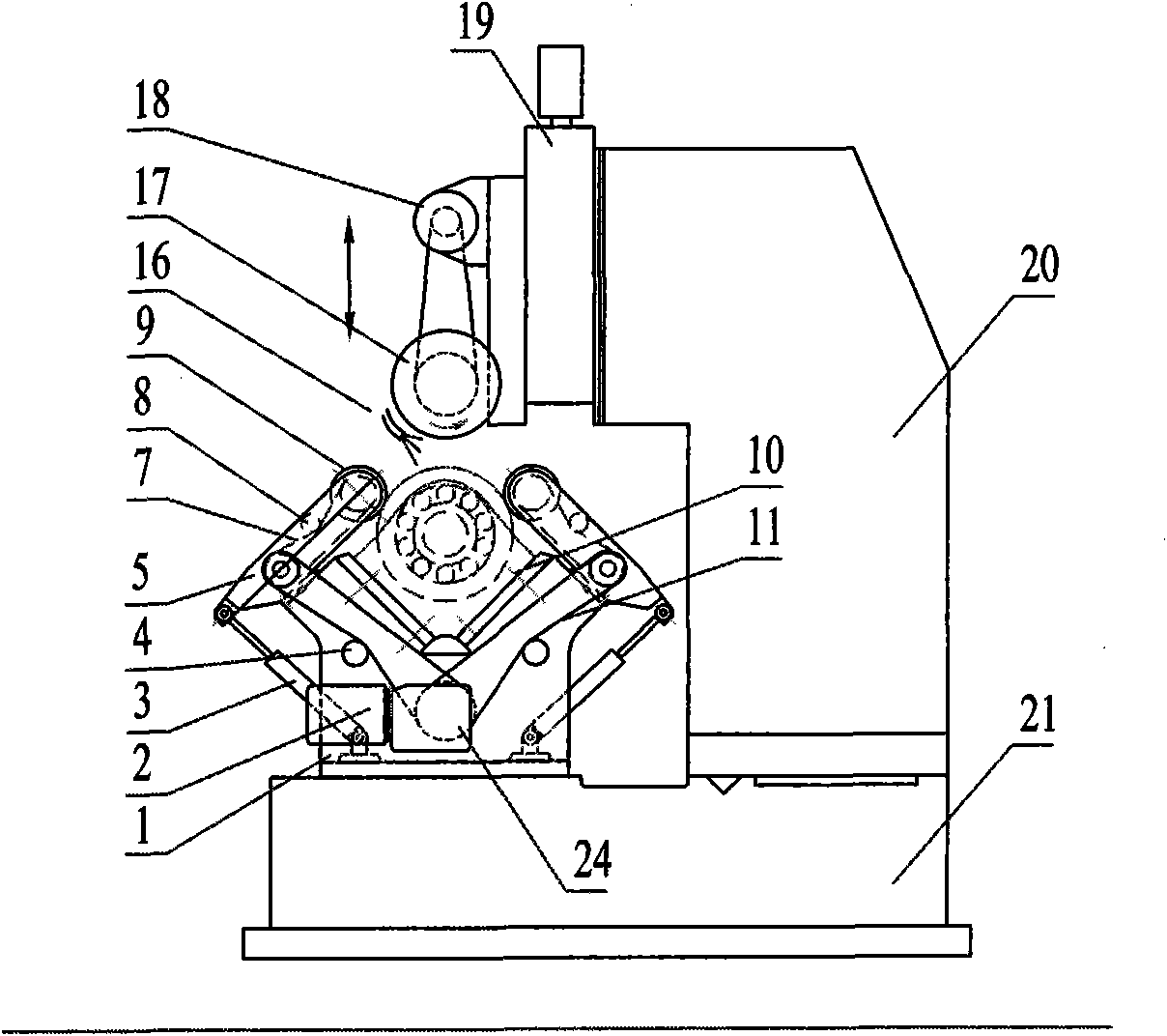

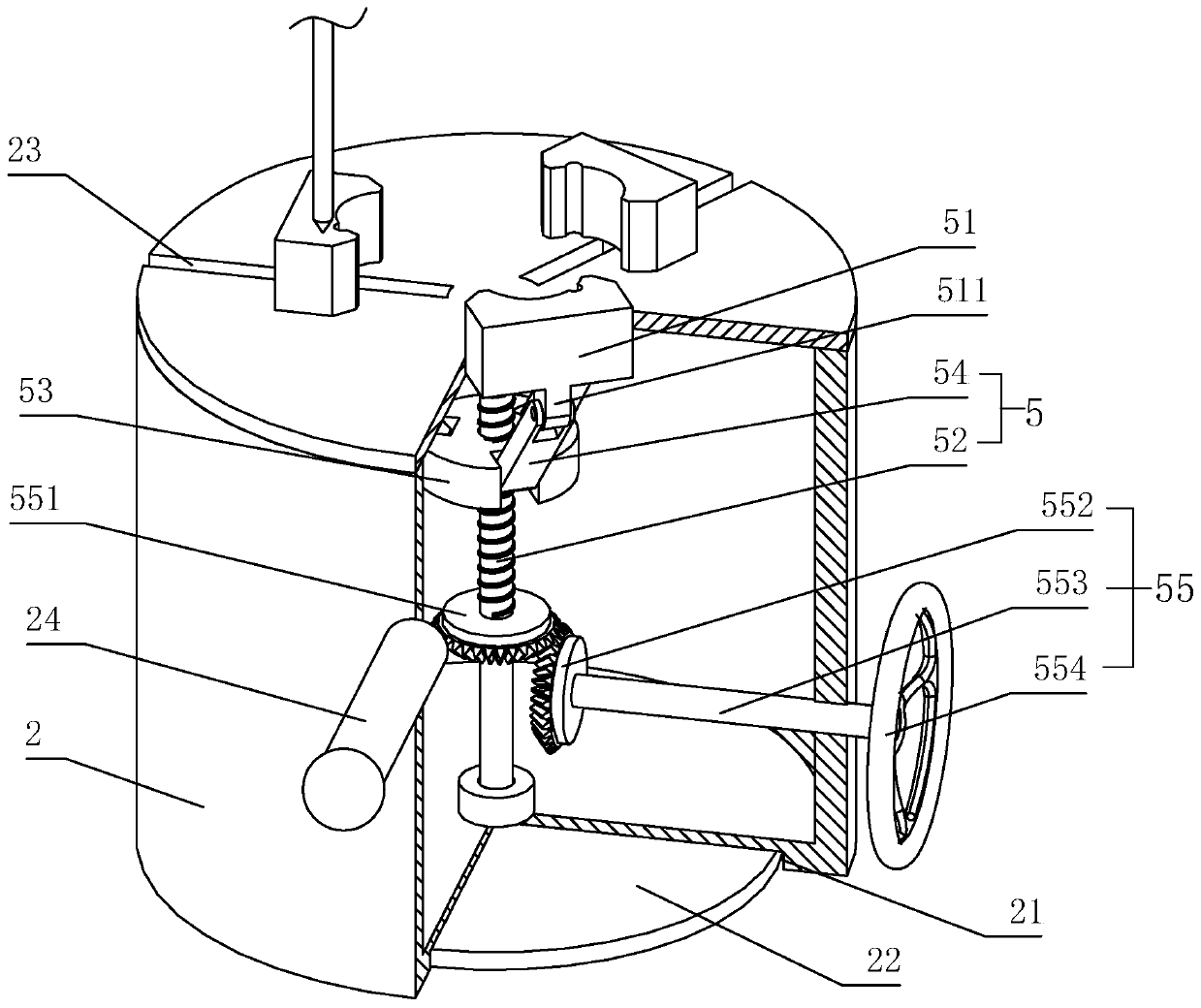

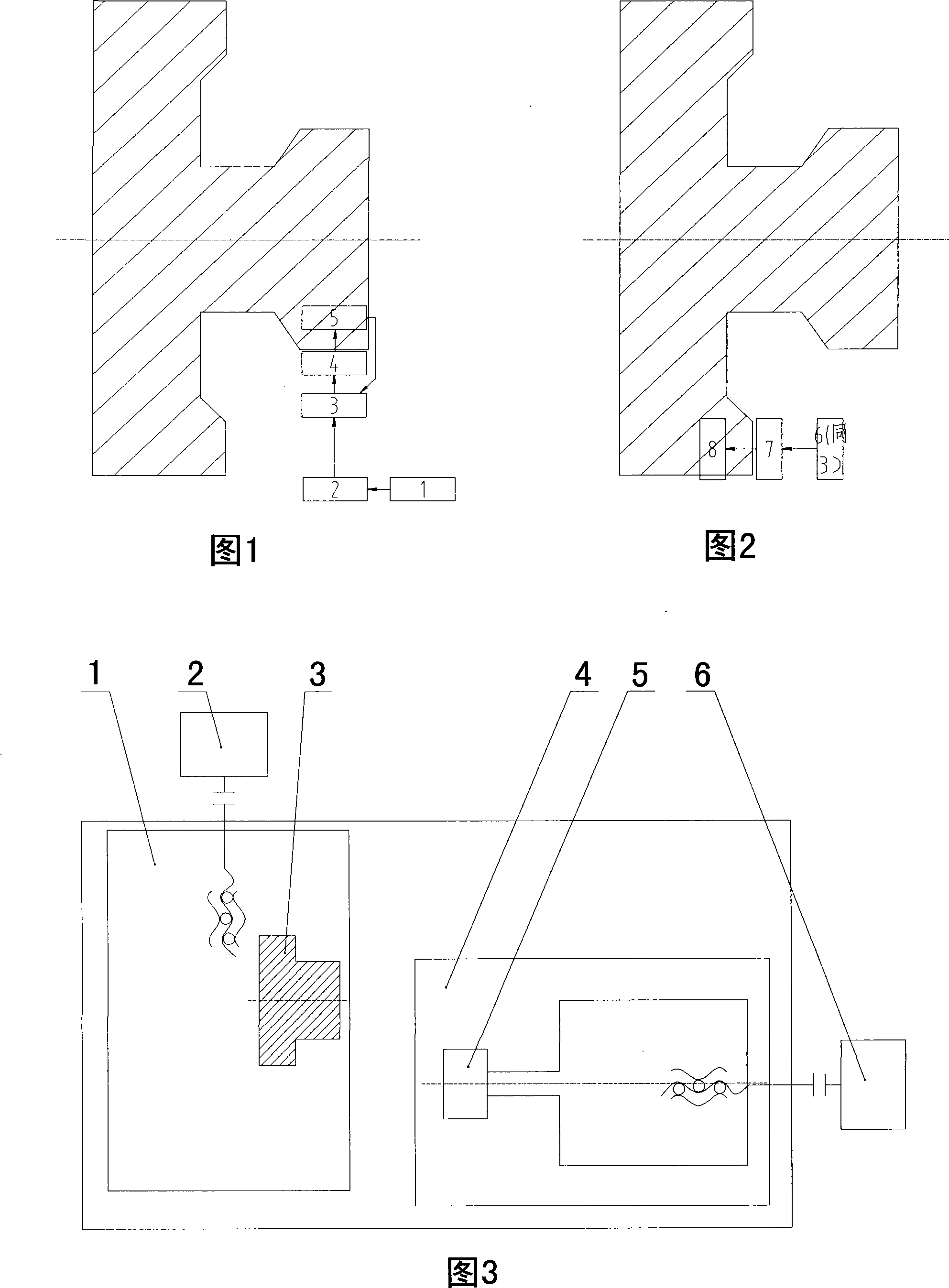

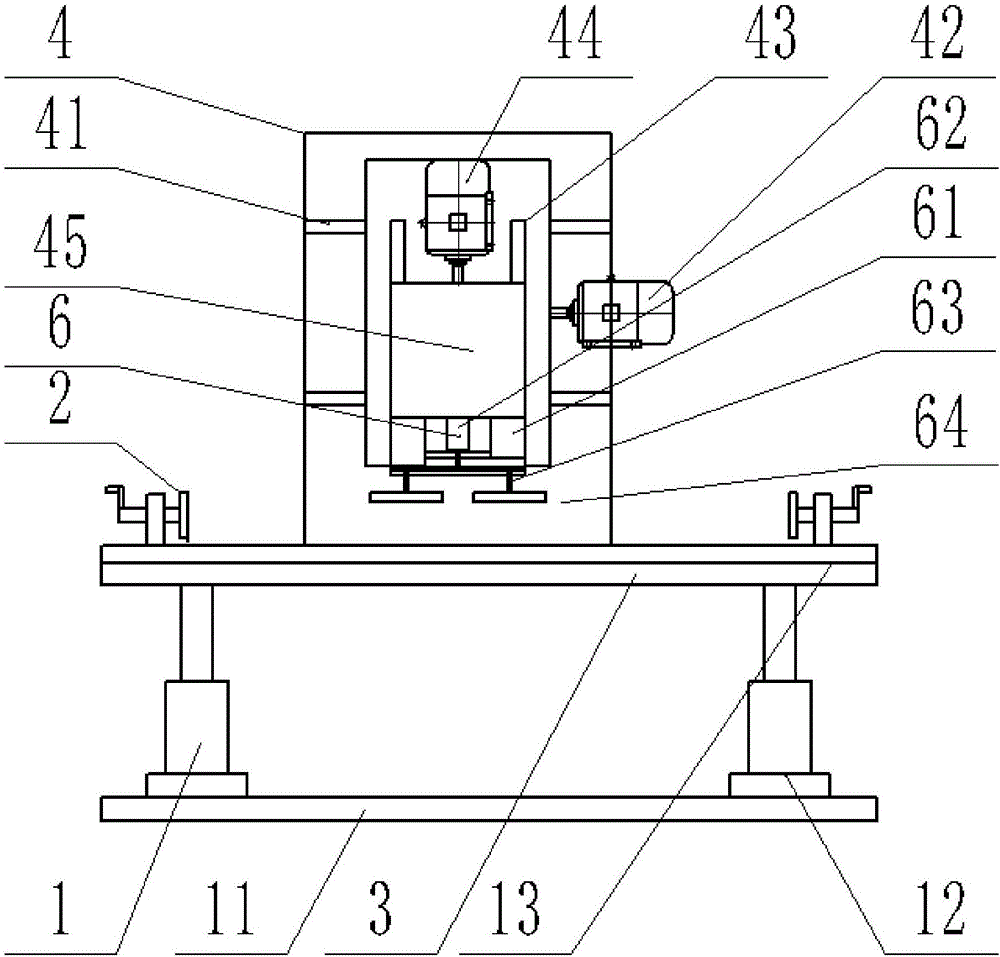

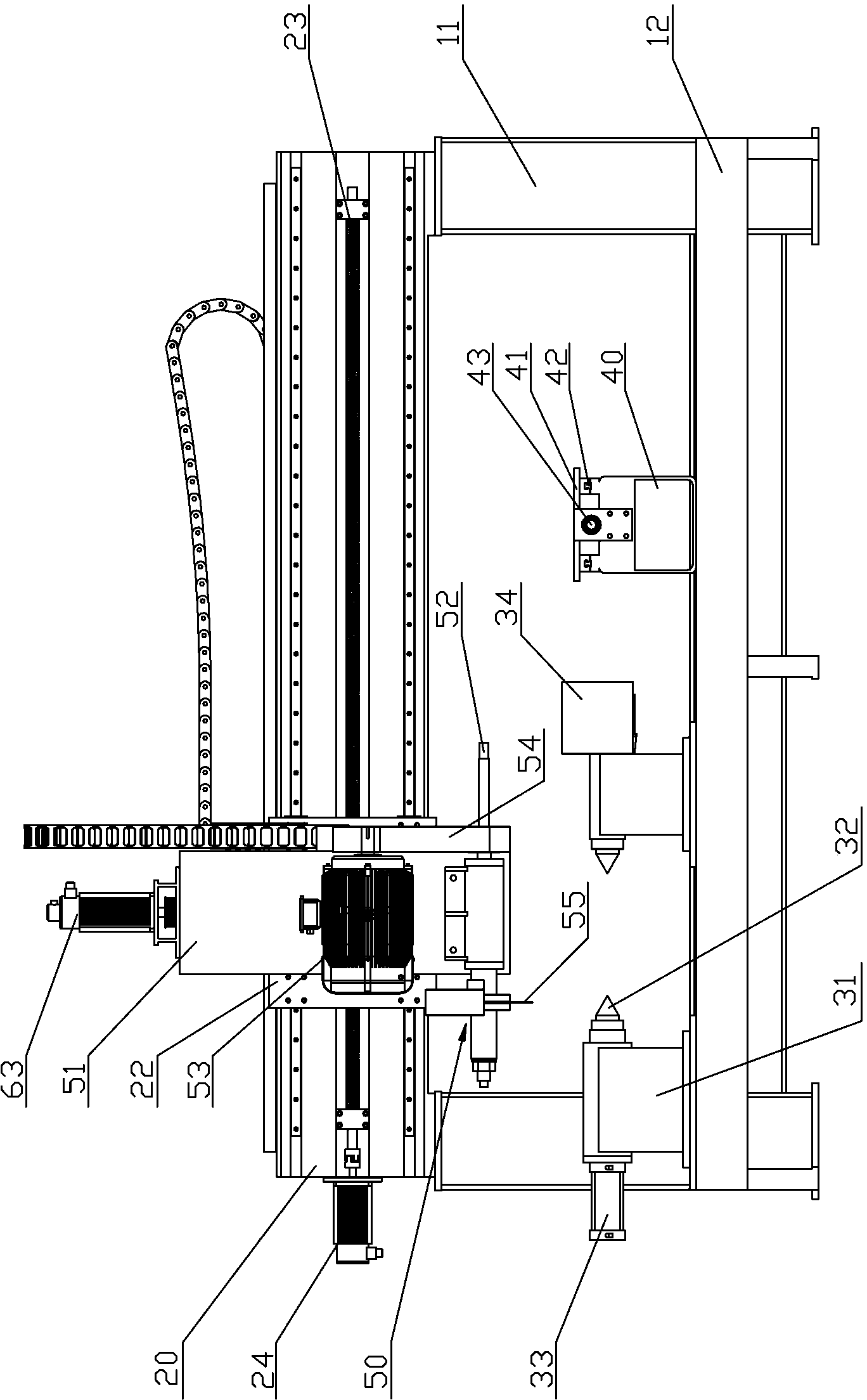

Equipment for grinding surface of long shaft workpiece

InactiveCN101462244AGuaranteed grinding accuracySolve the problem that the processing quality cannot meet the design requirementsGrinding carriagesRevolution surface grinding machinesCircular surfaceLong axis

The invention discloses a device for grinding the surface of a long-shaft type workpiece, which comprises a guide rail arranged on a lathe bed, wherein the guide rail is provided with a grinding head sleeved on the workpiece annularly; the grinding head is equivalently provided with at least two grinding strips annularly; the grinding head is also provided with a structure to drive all the grinding strips to perform radial motions so as to enclasp or break away from the workpiece; and the grinding head is driven to perform axial reciprocating movement on the guide rail by a driving device, and achieves the processing of grinding the outer circular surface of the workpiece through the rotary motion of the workpiece and the axial reciprocating movement of the grinding head. The grinding head of the device is sleeved on the workpiece annularly and performs axial reciprocating movement along the guide rail simultaneously so as to ensure the straightness of the motion and the grinding precision of the workpiece surface in the grinding process, and solve the difficult problem that the processing quality cannot reach the design requirement in the process of the one-step grinding of the long-shaft kind workpiece, thus the workpiece roundness, the cylindricity and the surface roughness can achieve the designed specified value, and the product quality and the working efficiency are improved.

Owner:CHANGZHOU TENT HYDRAULIC MACHINERY

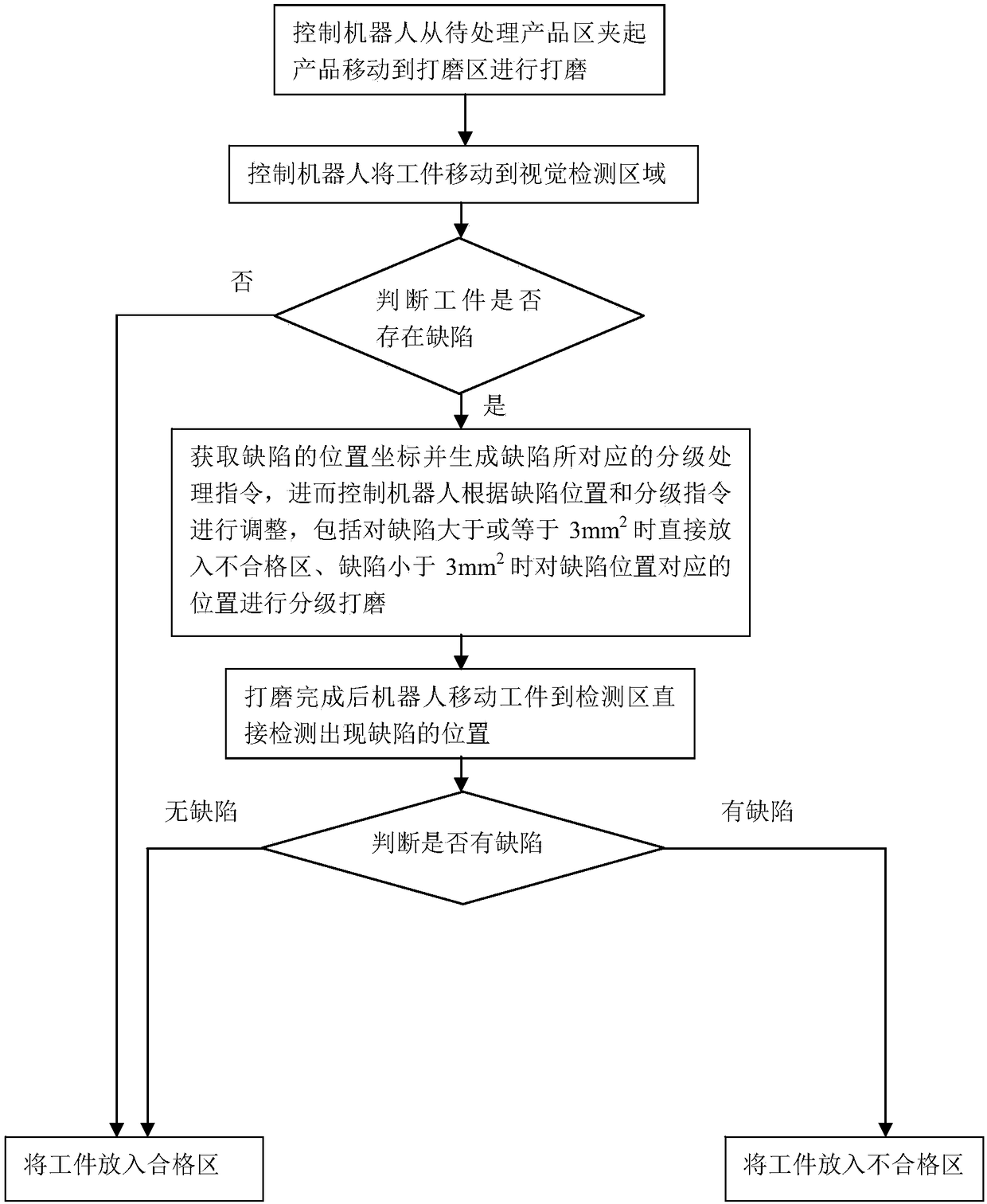

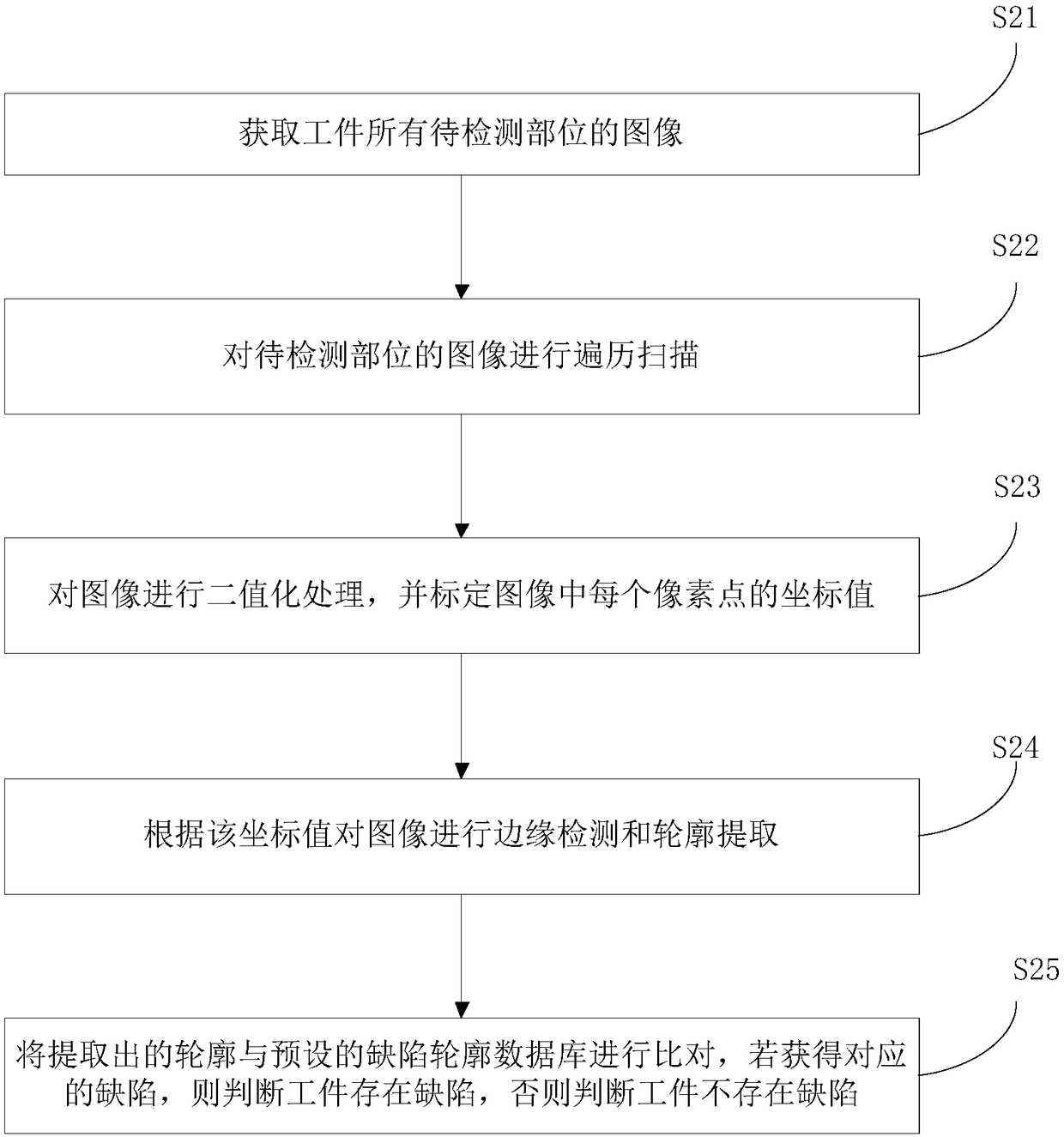

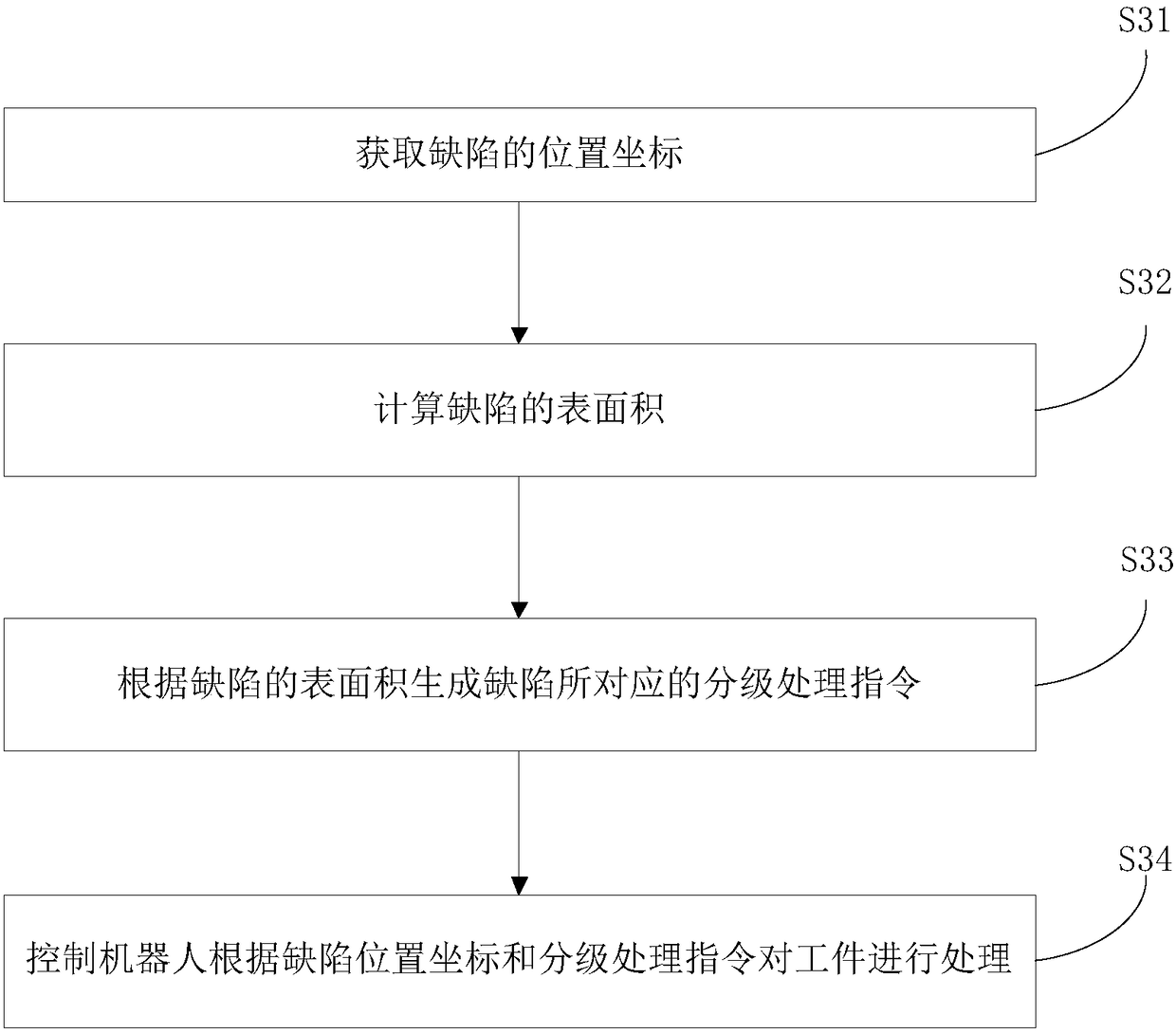

Robot polishing method and system based on visual inspection

ActiveCN108226164AIncrease productivityGuaranteed accuracyBelt grinding machinesGrinding feed controlSanderSimulation

The invention discloses a robot polishing method and system based on visual inspection. The system comprises a robot, a shielding case, a polishing belt sander, a computer, an end fixture for clampinga workpiece, and a camera for acquiring images. The camera is arranged in the shielding case; the robot is connected with the end fixture; the computer is connected with the robot, the camera and thepolishing belt sander; the computer comprises a workpiece moving module, a defect detecting module and a defect processing module. According to the robot polishing method and the system based on visual inspection provided by the invention, through integrating workpiece defect detection and workpiece polishing, the production efficiency is greatly improved. The robot polishing method and the system based on visual inspection provided by the invention is excellent in performance and can be widely applied to the technical field of workpiece processing.

Owner:深圳市智能机器人研究院

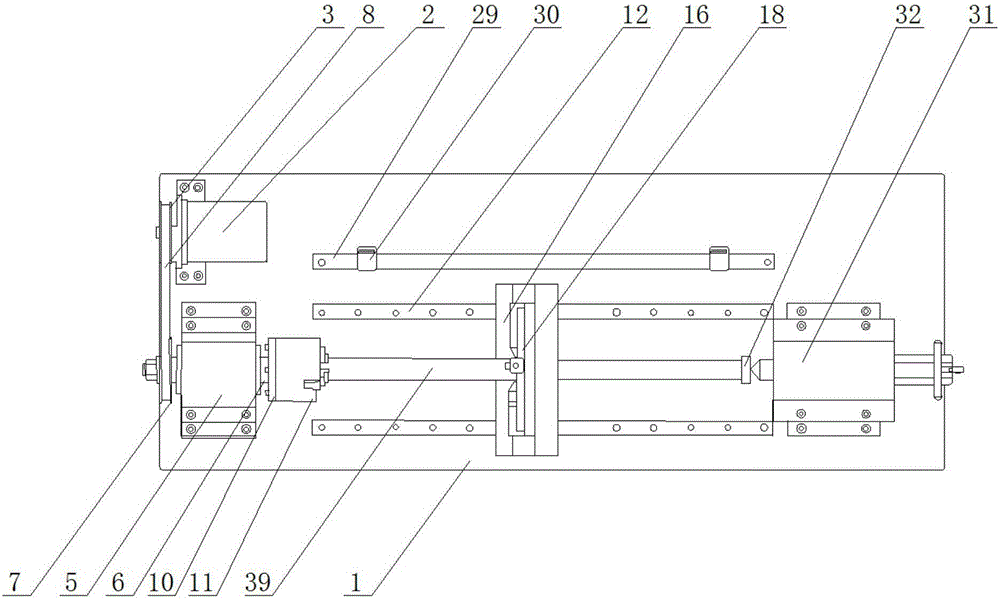

Automatic precision grinding device for outer surfaces of shaft type workpieces

InactiveCN106826403AEasy to operateLow costRevolution surface grinding machinesGrinding drivesDrive wheelCoupling

The invention discloses an automatic precision grinding device for the outer surfaces of shaft type workpieces and relates to the technical field of magnetic grinding. The device comprises a baseplate, a heel block, a driving wheel, a driven wheel, a transmission belt, a main shaft end cover, a first transmission box, a positioning seat, a flange plate, a three-jaws self-centering chuck, a grinding device, a connecting block, a grinding support base, a workpiece positioning base, a tailstock, a second motor, a coupling, a screw positioning seat, a screw, a supporting plate, a nut, a sensor positioning seat, a limit sensor, a slide way, the nut and a sliding block. A punched hole is formed in the top and / or the side of the grinding support base, a cylindrical cam is arranged on a connecting rod, the cylindrical cam is provided with a rotating rod, the grinding support base is provided with an arc block, a rotary knob is installed on the arc block, and the rotating rod is sleeved with the rotary knob. The automatic precision grinding device for the outer surface of shaft type workpieces has the beneficial effects that the device is simple in operation, low in cost, capable of adapting to shaft type workpieces of different specifications , capable of improving the machining efficiency and capable of improving the precision and quality of the outer surface of the shaft workpieces.

Owner:NANJING INST OF RAILWAY TECH

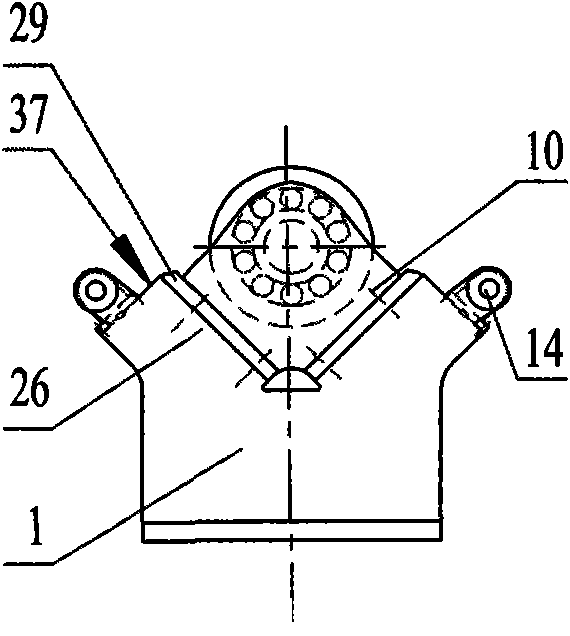

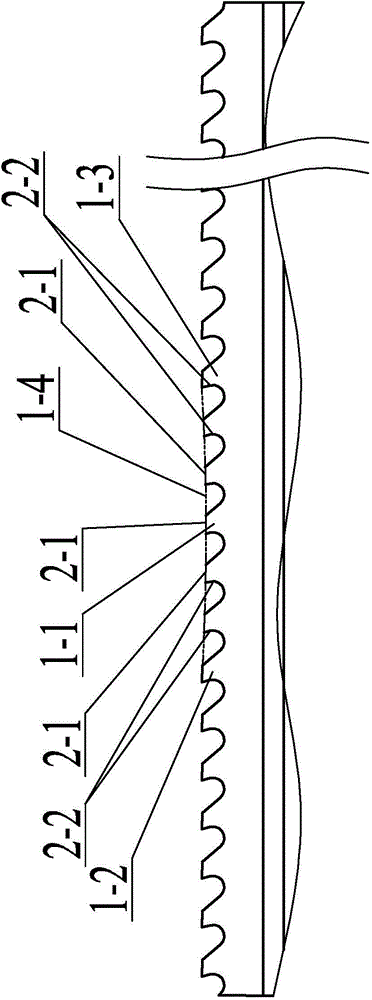

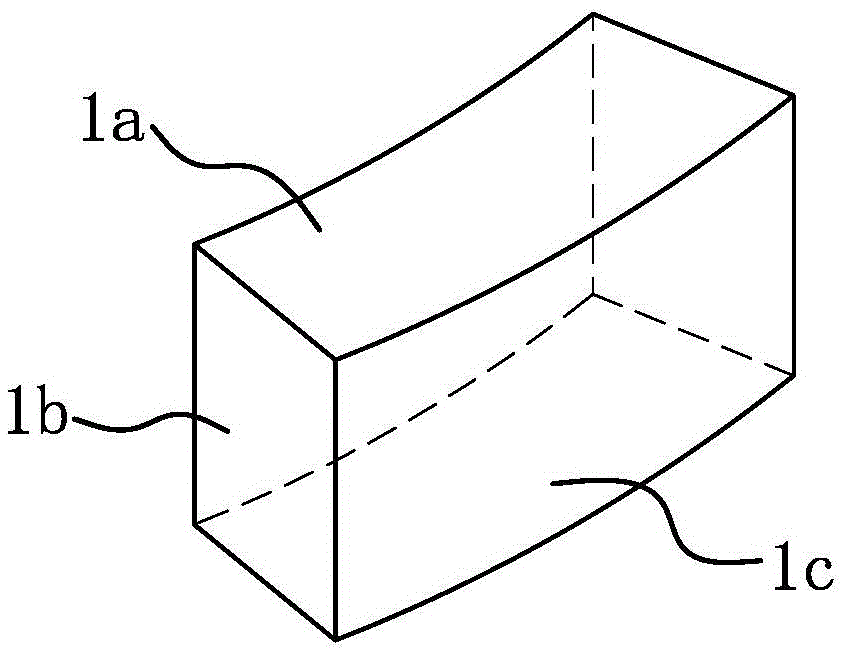

Diamond tool bit slope grinding device

ActiveCN103317407AIncrease productivityGuaranteed grinding accuracyEdge grinding machinesGrinding drivesTool bitGeneral purpose

The invention provides a diamond tool bit slope grinding device, belongs to the technical field of operations and solves the problem of low production efficiency due to the fact that presently, diamond tool bit slopes are grinded through the general-purpose machine tool. The diamond tool bit slope grinding device comprises a machine frame and a clamp arranged on the machine frame and used for clamping a diamond tool bit. The clamp is provided with a group of grinding mechanisms with grinding wheels relative to the outer sides of two slopes of the clamped diamond tool bit, and feeding mechanisms capable of feeding the grinding wheels along the corresponding target slopes in parallel are arranged between the grinding mechanisms and the machine frame. The diamond tool bit slope grinding device automatically feeds and grinds the slopes of the diamond tool bit and the two slopes are processed simultaneously, and therefore the diamond tool bit slope grinding device has the advantage of high production efficiency. The grinding wheels of the diamond tool bit slope grinding device can be automatically supplemented after being decreased gradually through grinding, and therefore the diamond tool bit slope grinding device has the advantages of being high in production efficiency and ensuring grinding accuracy.

Owner:HEBEI XINGLONG ELEVATORING EQUIP CO LTD

Robot polisher

InactiveCN103639867AGuaranteed grinding accuracyHigh degree of automationEdge grinding machinesElectric machineryManipulator

The invention discloses a robot polisher used for polishing the surface of a workpiece. The robot polisher comprises a rack and a worktable arranged on the top of the rack; a six-shaft mechanical arm, a servo motor and a polishing wheel are installed on the worktable, wherein the six-shaft mechanical arm is used for grasping the workpiece to be polished, and the polishing wheel is in transmission connection with the servo motor. According to the polisher, based on the technology of adopting a six-shaft robot to simulate the track of a product and adopting the servo motor to control the polishing wheel and based on the automatic wax supply and automatic wetting functions, product polishing precision is improved, the degree of automation is high, and product polishing cost is reduced.

Owner:SUZHOU YIMEIDE TECH CO LTD

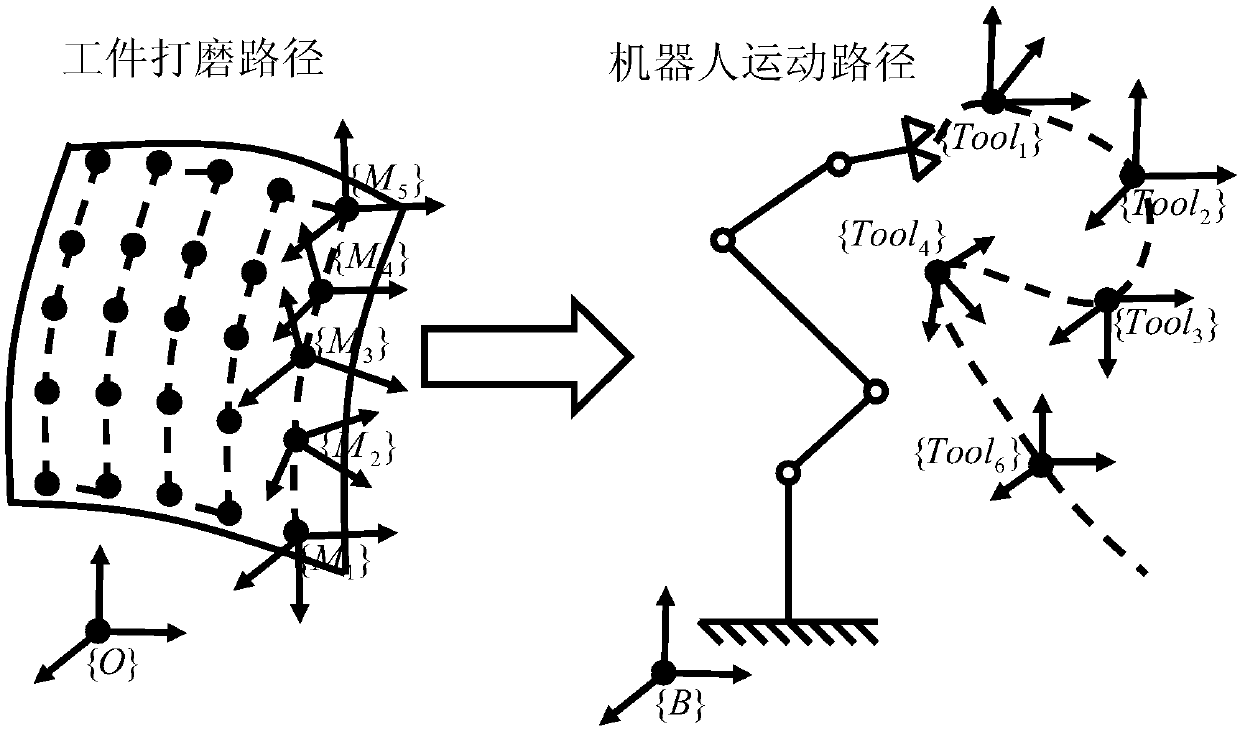

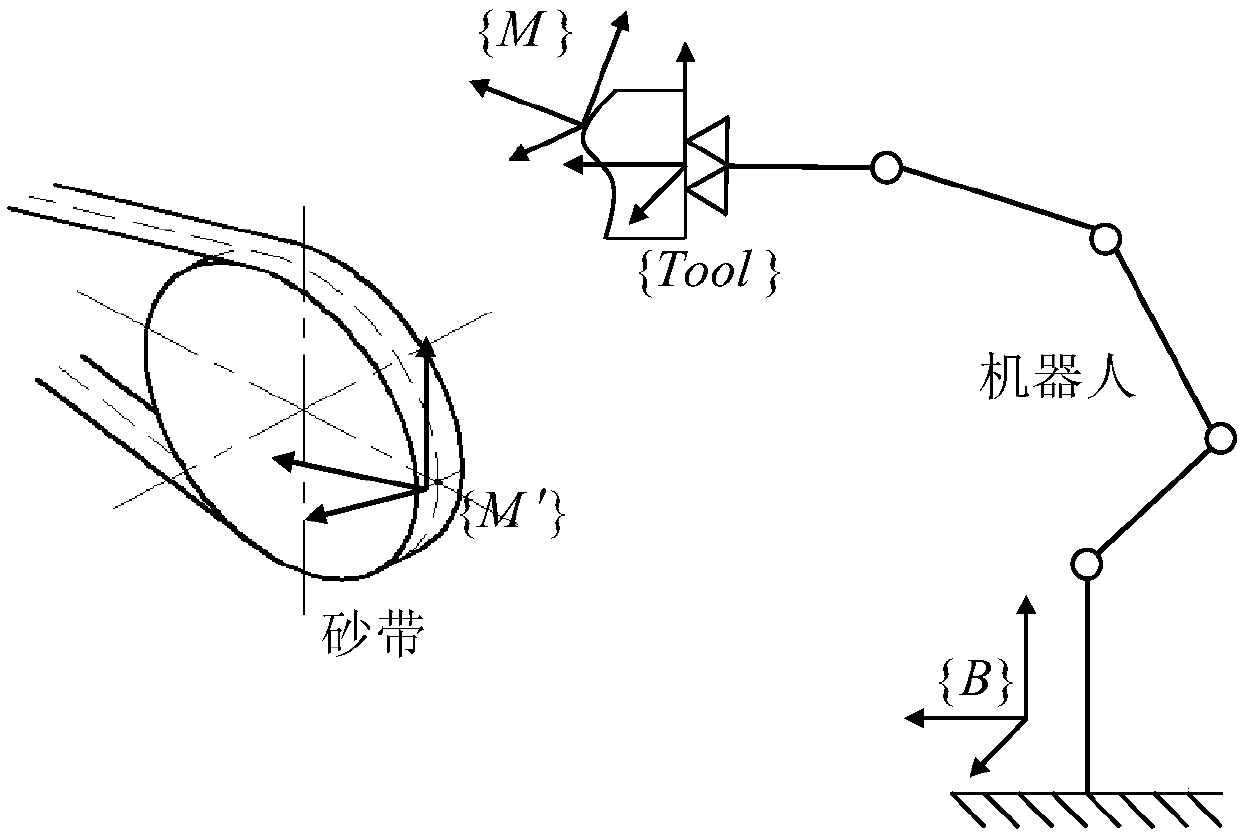

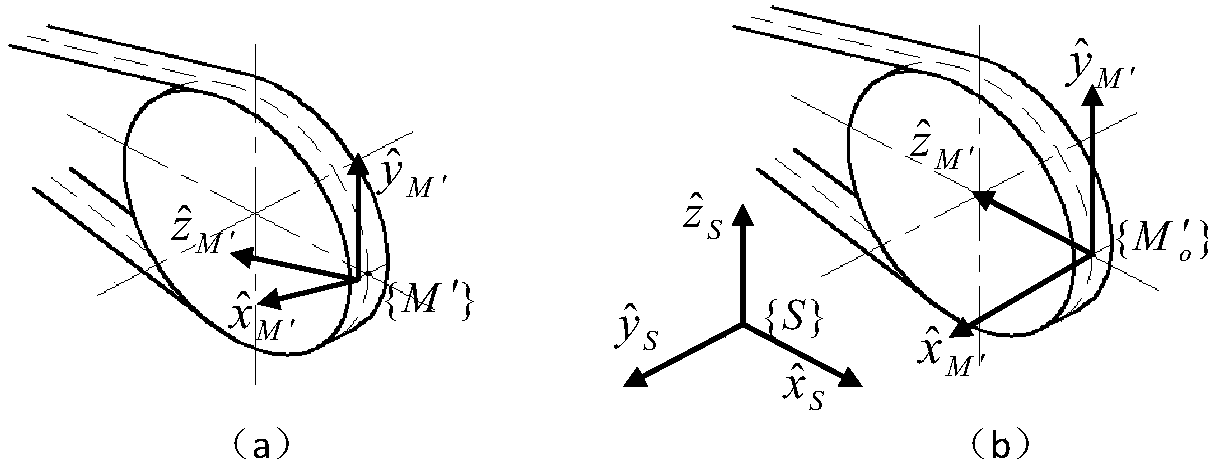

Motion path anticollision adjustment method for grinding of robot belt

ActiveCN107414860AAvoid collisionGuaranteed grinding accuracyProgramme-controlled manipulatorSimulationMachining process

The invention discloses a motion path anticollision adjustment method for grinding of a robot belt. The motion path anticollision adjustment method comprises the steps of (1) generating a robot motion path: converting a workpiece grinding path into the robot motion path; (2) adjusting the anticollision of the robot motion path: changing the position and posture of each cutter contact point on the motion path when grinding is performed by a robot, so that the robot is prevented from colliding during machining. The motion path anticollision adjustment method has the characteristics of flexibility and practicability, a three-dimensional problem is simplified into a two-dimensional problem for searching an optimized curve in a reliable area in a collision layer, the robot can be effectively prevented from colliding when a workpiece is ground by the belt, and additionally, the grinding accuracy and efficiency can be guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

Composite plating manufacturing method of high-precision irregular grinding wheel

ActiveCN106584299AImprove wear resistanceHigh hardnessLiquid/solution decomposition chemical coatingGrinding devicesChemical platingGrinding wheel

The invention discloses a composite plating manufacturing method of a high-precision irregular grinding wheel. The manufacturing method comprises the following steps of preparing of a substrate and abrasives, treating before plating of the abrasives, preparing of a plating solution, treating before plating and preplating of the substrate, mould cavity abrasive grain dispensing, chemical plating thickening, passivating treatment after plating, testing and packing. The manufacturing method has the advantages that the compositely-plated grinding wheel has the characteristic of high profiling, and the consistency of abrasive molding surfaces reaches up to 95% or above; the height uniformity of the abrasives subjected to plating solidification is high, the abrasives can be used for grinding simultaneously to the largest extent, and machining efficiency is improved; and the shape preserving property is good, and the shape of the grinding wheel curve surface almost does not change under the continuous grinding condition, so that the grinding efficiency and the machining precision of the grinding wheel are guaranteed, and the service life of the grinding wheel is prolonged greatly.

Owner:郑州众邦超硬工具有限公司

Polishing device used for curvy neck of ceramic bottle

ActiveCN110625757AGuaranteed grinding accuracyIntegrity guaranteedGrinding carriagesGrinding drivesSlide plateEngineering

Owner:景德镇当歌雅酒文化有限公司

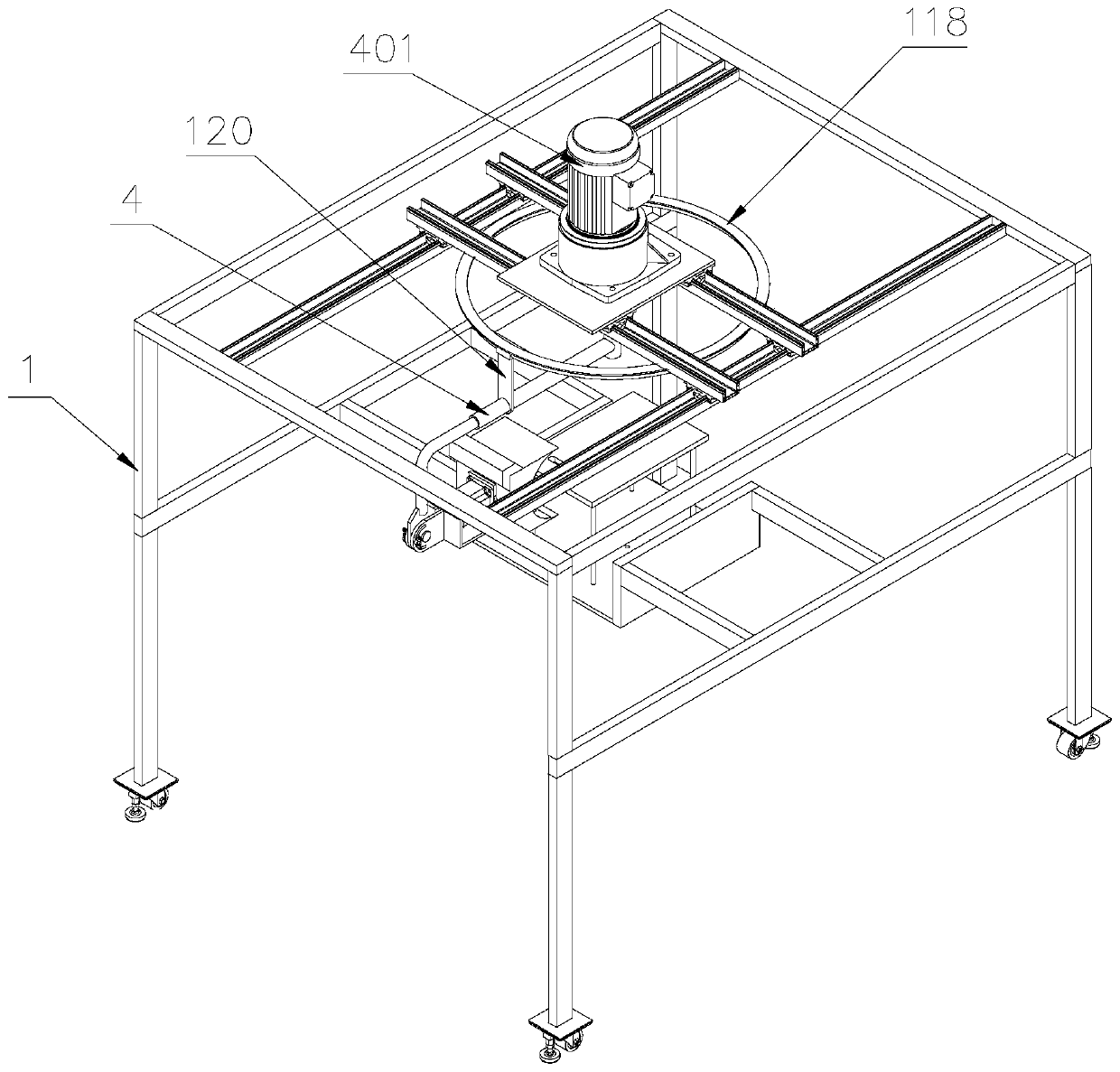

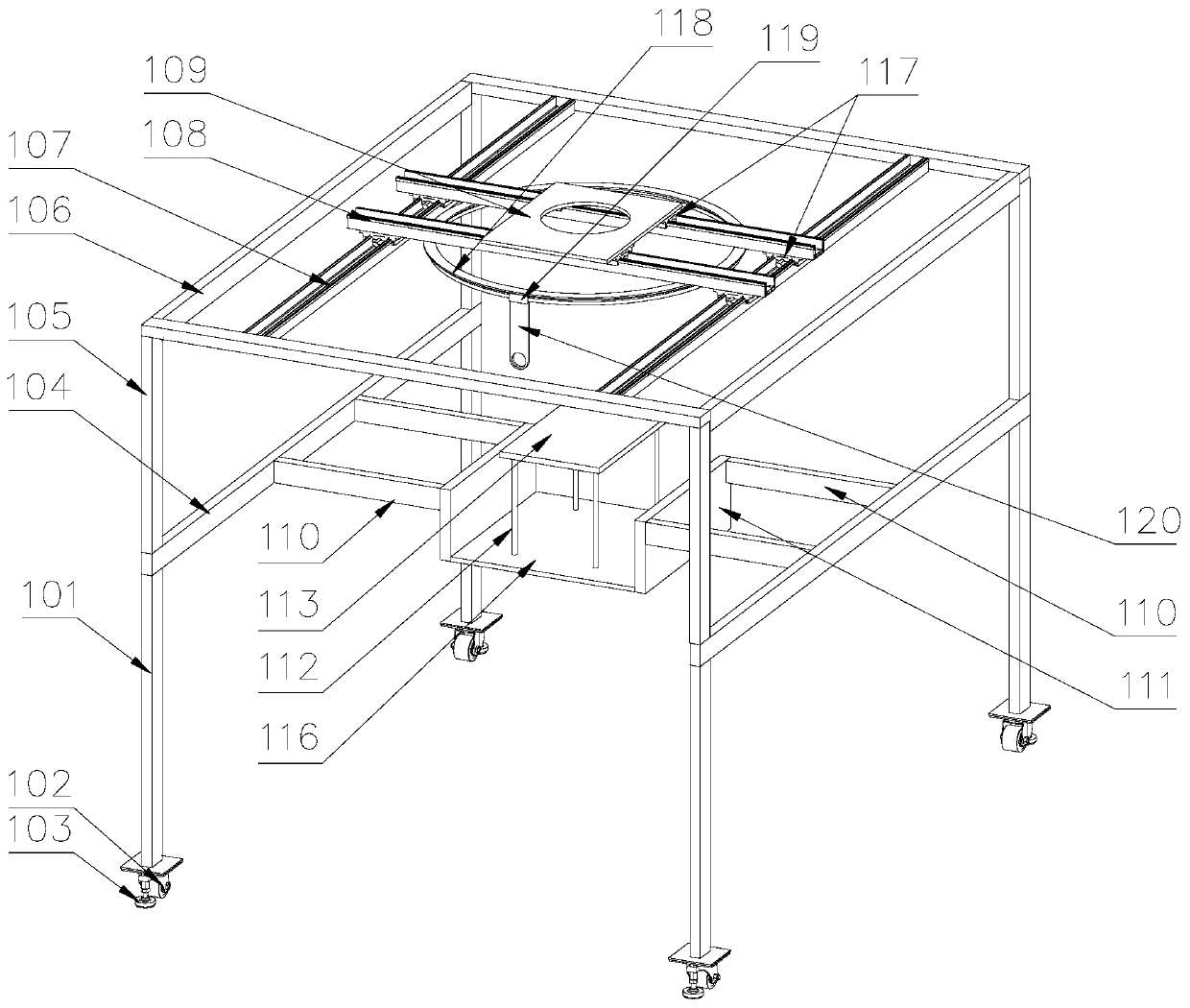

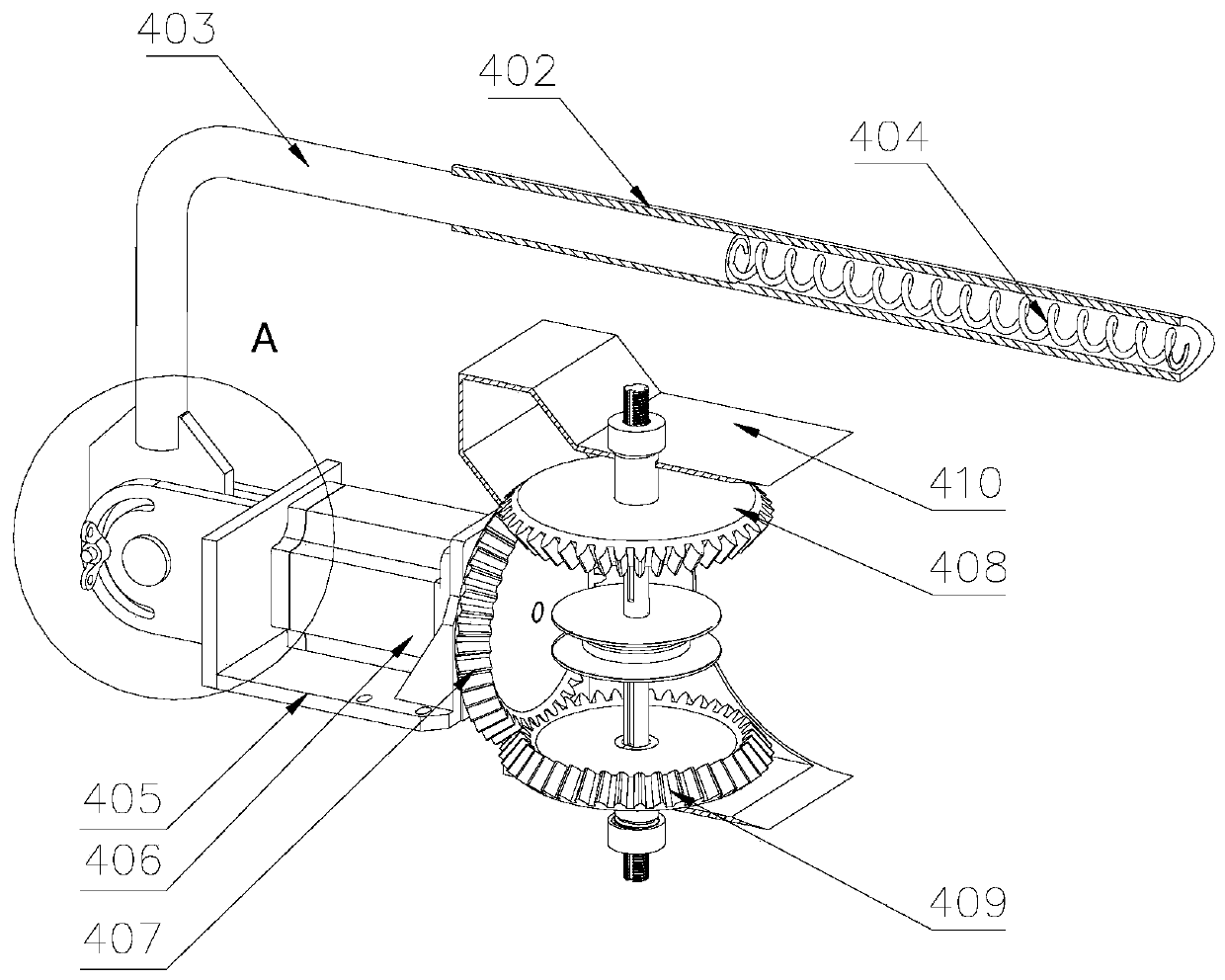

Automatic edge finding and grinding device for specially shaped metal part

ActiveCN111015415AGuaranteed grinding accuracyGuaranteed accuracyEdge grinding machinesGrinding carriagesCrankGear wheel

The invention discloses an automatic edge finding and grinding device for a specially shaped metal part. The automatic edge finding and grinding device comprises a support frame and a driving device;the support frame comprises a plurality of support legs, first cross beams connected with the upper ends of the support legs, vertical columns arranged at the upper parts of the first cross beams, andsecond cross beams connected with the upper parts of the vertical columns; the driving device comprises a first motor installed at the upper part of a first motor base, a sleeve connected with an output shaft of the first motor, and a crank arm arranged in the sleeve, and the sleeve is internally provided with a tension spring; one side of a driving gear is provided with a first driven gear, andthe other side of the driving gear is provided with a second driven gear; and one end of a first rotating shaft is provided with grinding wheels, and one side of each grinding wheel is provided with atop wheel. According to the automatic edge finding and grinding device, the grinding wheels are arranged on the upper and lower side faces of a workpiece, and used for grinding the both sides of theworkpiece; one side of each grinding wheel is provided with the top wheel, and the top wheels are traveled around the contour of a specially shaped workpiece, so that the edge grinding device is usedfor automatically finding an edge around the specially shaped workpiece for grinding; and the grinding accuracy of the specially shaped workpiece is ensured, and the grinding efficiency of the specially shaped workpiece is improved.

Owner:济南工程职业技术学院

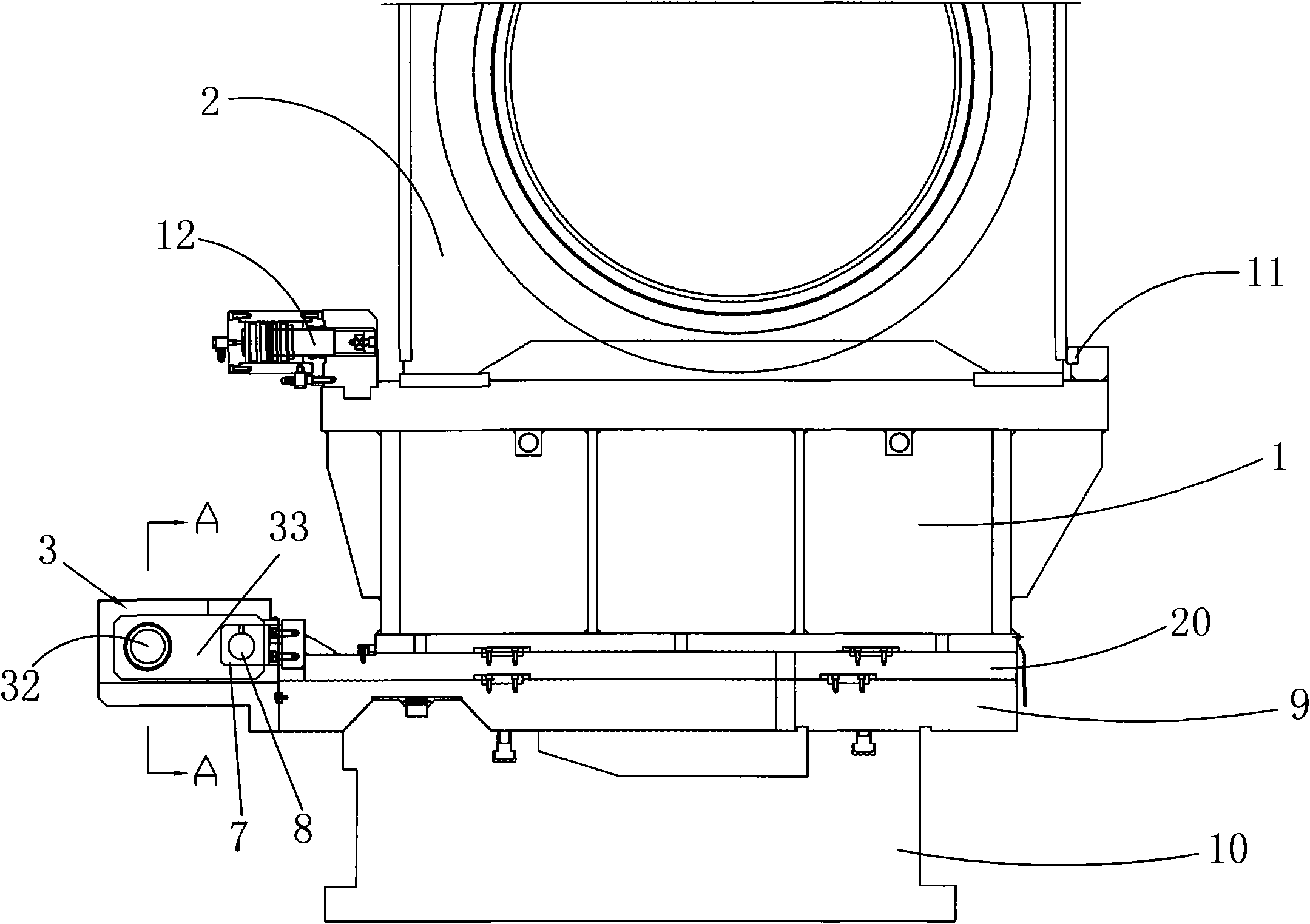

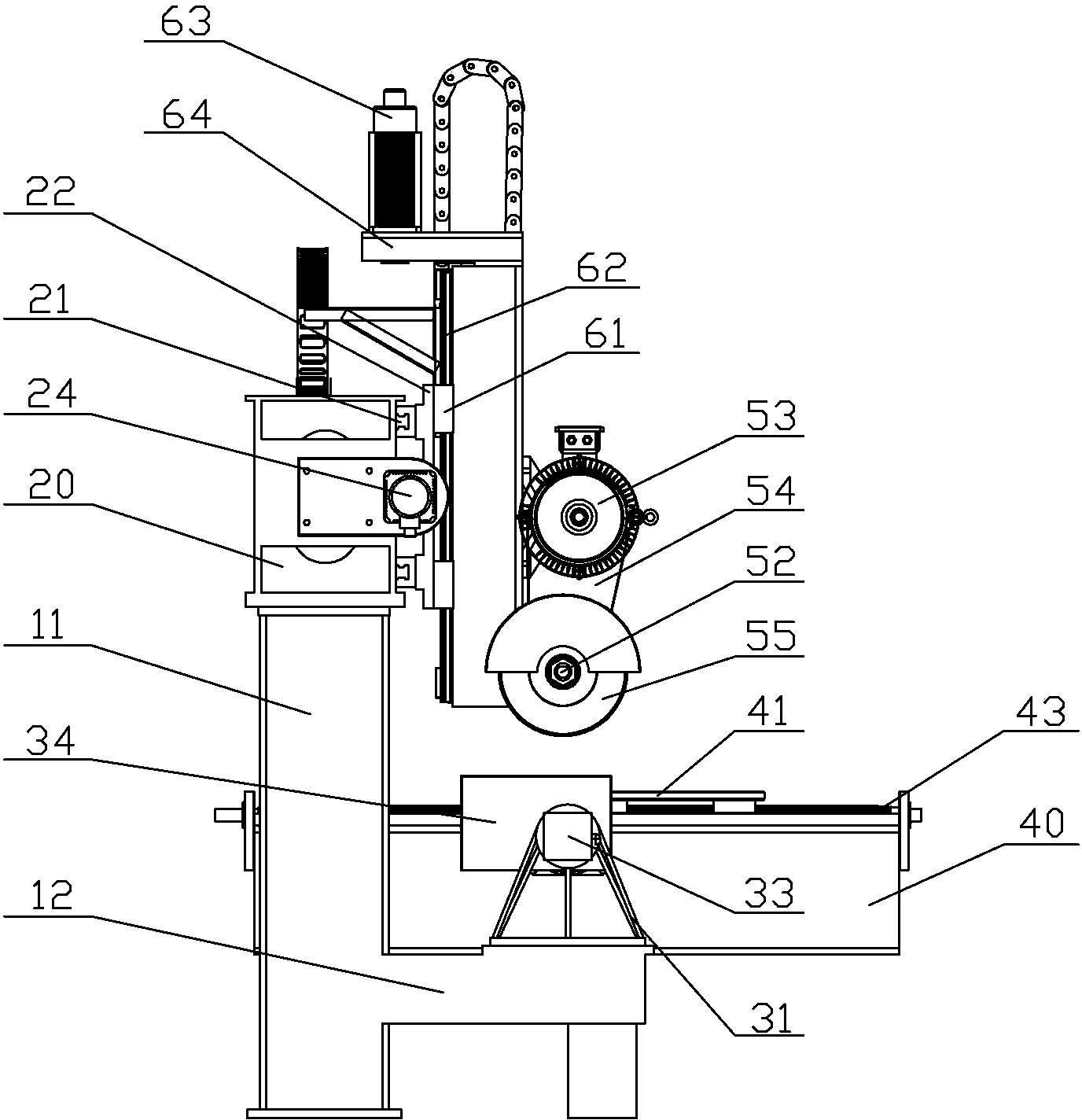

Full-automatic digital control roll grinder backup roll belt box grinding device

ActiveCN101856795AAvoid injury hazardGuaranteed grinding accuracyRevolution surface grinding machinesRadial positionFuel tank

The invention discloses a full-automatic digital control roll grinder backup roll belt box grinding device, comprising an installation precision regulating device, an oil supplying device and an oil temperature controlling device, wherein the installation precision regulating device comprises a bearing box pushing cylinder, limit blocks, an inching device and a clamping plate, the bearing box pushing cylinder and the limit blocks are arranged on the box seat and used for locating the position of the bearing box relative to the box seat, the clamping plate is used for driving the box seat to slide in a radial direction relative to a bed body of a workpiece, and the inching device and the lamping plate are used for regulating the radial position of the box seat at one end of the bed body of the workpiece so as to parallel a space axial line between the two box seats with the axial line of a grinding wheel, thereby ensuring grinding precision; the oil temperature controlling device comprises a temperature sensor and an oil temperature controller, which is used for ensuring that the temperature of the supplied oil in the oil supplying device is proper; and the oil supplying device comprises an oil inlet pipeline, a cylinder and an oil outlet pipeline with an overflow valve and a throttle valve, which is used for supplying the oil meeting the requirements of temperature, oil pressure and flow to a bearing box so as to ensure that a oil film bearing forms an effective dynamic pressure, thereby effectively avoiding hidden troubles of damaging a bearing and ensuring grinding efficiency. In all, the invention ensures grinding, and can be convenient and reliable in use.

Owner:HIECISE PRECISION EQUIP (KUNSHAN) CO LTD

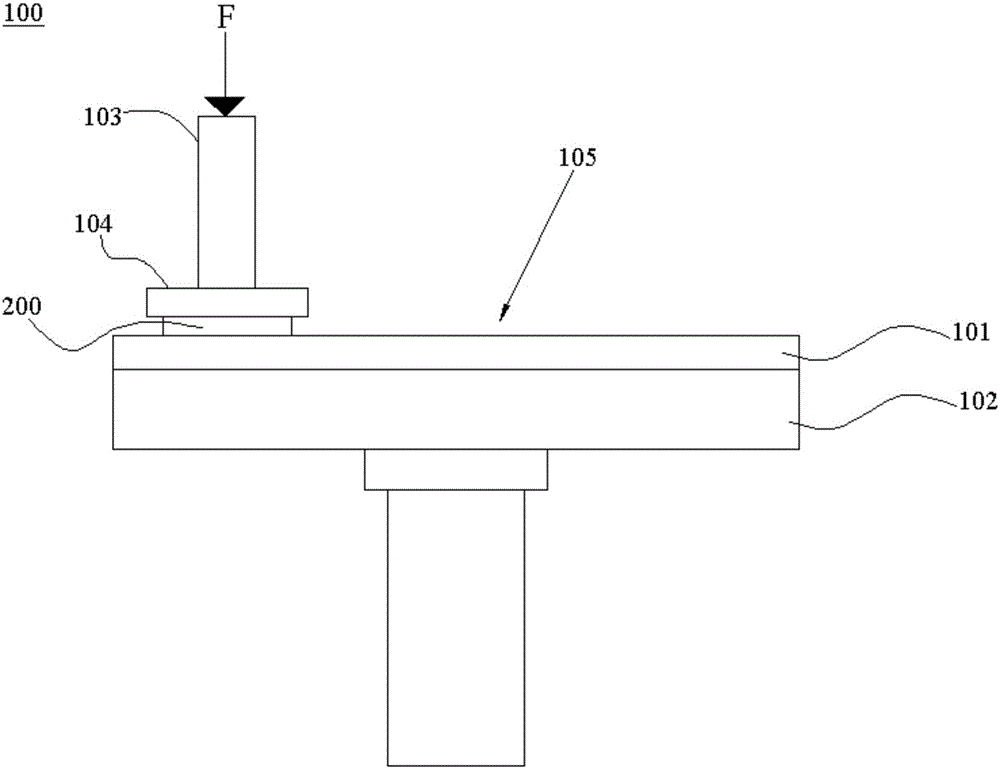

Grinding pad fixing device and chemical machinery grinder

The invention provides a grinding pad fixing device and a chemical machinery grinder; the grinding pad fixing device comprises a vacuum system connected with a grinding platform and a substrate absorbed on the grinding platform in a vacuum manner; the grinding pad is fixed on the substrate. The grinding pad fixing device uses the grinding platform connected with the vacuum system, so a vacuum absorption surface is formed on the top surface of the grinding platform; the substrate adsorbed on the grinding platform through vacuum can fix the grinding pad on the grinding platform; when the grinding pad needs to be replaced, the substrate and the grinding pad can be integratedly dismounted from the grinding platform without damaging the grinding pad, thus ensuring the lift of the grinding pad; when the grinding pad is fixed, the grinding pad can be fixed without having deformation caused by improper fixation, thus ensuring grinding precision.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

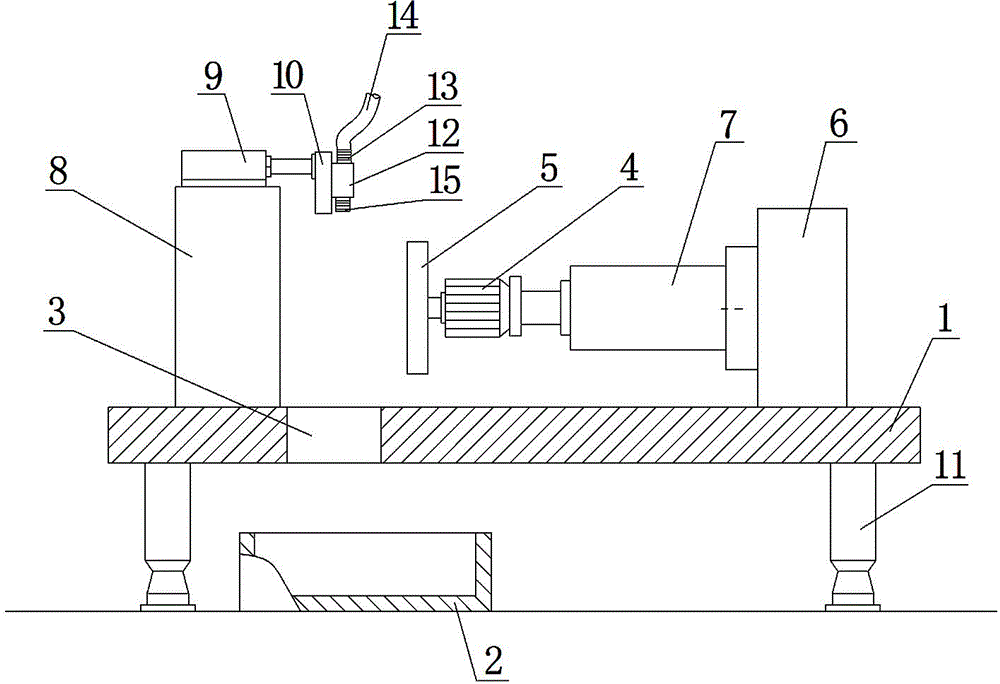

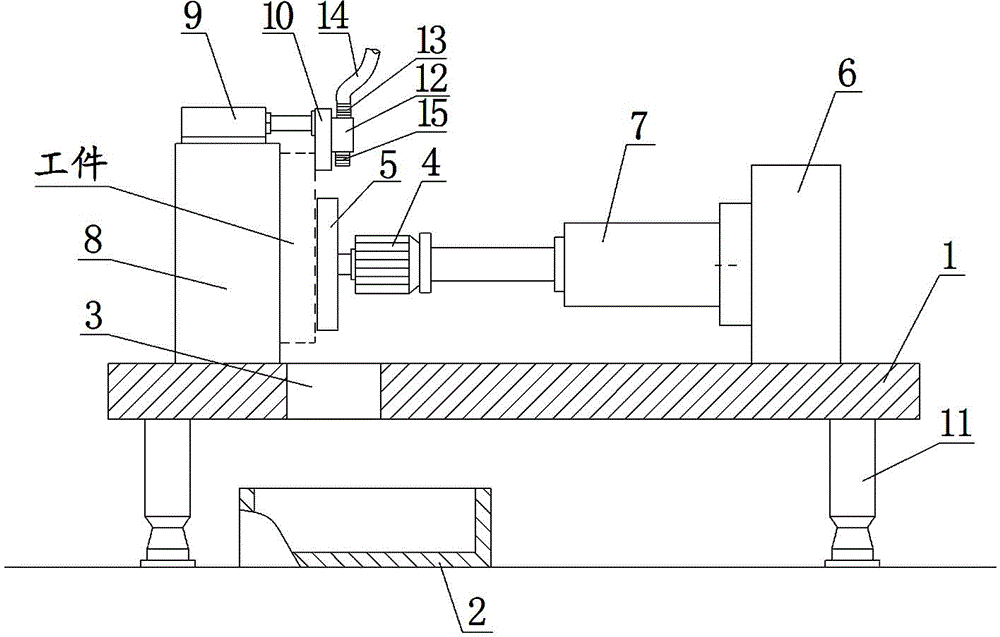

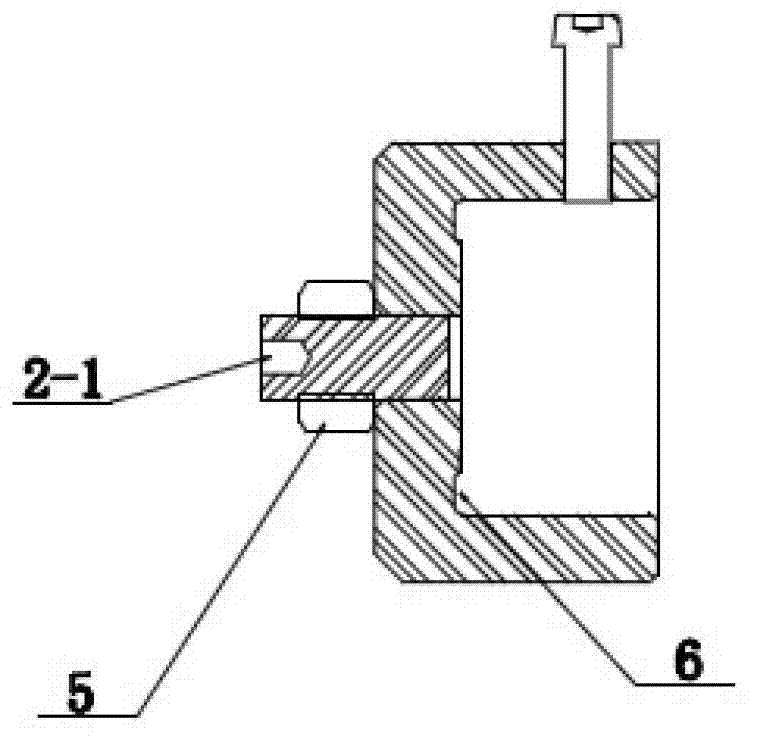

Grinding miller provided with chip blowing device

InactiveCN104400620AQuick fixPrevent deviationLapping machinesWork carriersEngineeringMechanical engineering

The invention discloses a grinding miller provided with a chip blowing device. The grinding miller comprises a workbench (1), a chip collection box (2), a hold-down gear and a grinding device, wherein the grinding device is formed by a servo motor (4), a grinding disc (5), a fixed block (6) and an oil cylinder (7), the oil cylinder (7) is vertical to the lateral surface of the fixed block (6) and is fixedly arranged on the fixed block (6), the servo motor (4) which is vertical to the lateral surface of the fixed block (6) is arranged on a piston rod of the oil cylinder (7), a support table (8) is parallel to the grinding disc (5) and is arranged on the workbench (1), a pressure plate (10) is arranged on the piston rod of a cylinder (9), the pressure plate (10) is parallel to the grinding disc (5) and is arranged between the support table (8) and the grinding disc (5), and an air outlet (15) of a reversing valve (12) is downwards formed above the grinding disc (5). The grinding miller has the following beneficial effects of simplicity in operation, high grinding precision and capabilities of reducing the labor intensity of workers and quickly implementing clamping of disc type work pieces.

Owner:CHENGDU TIMEMAKER CRYSTAL TECH

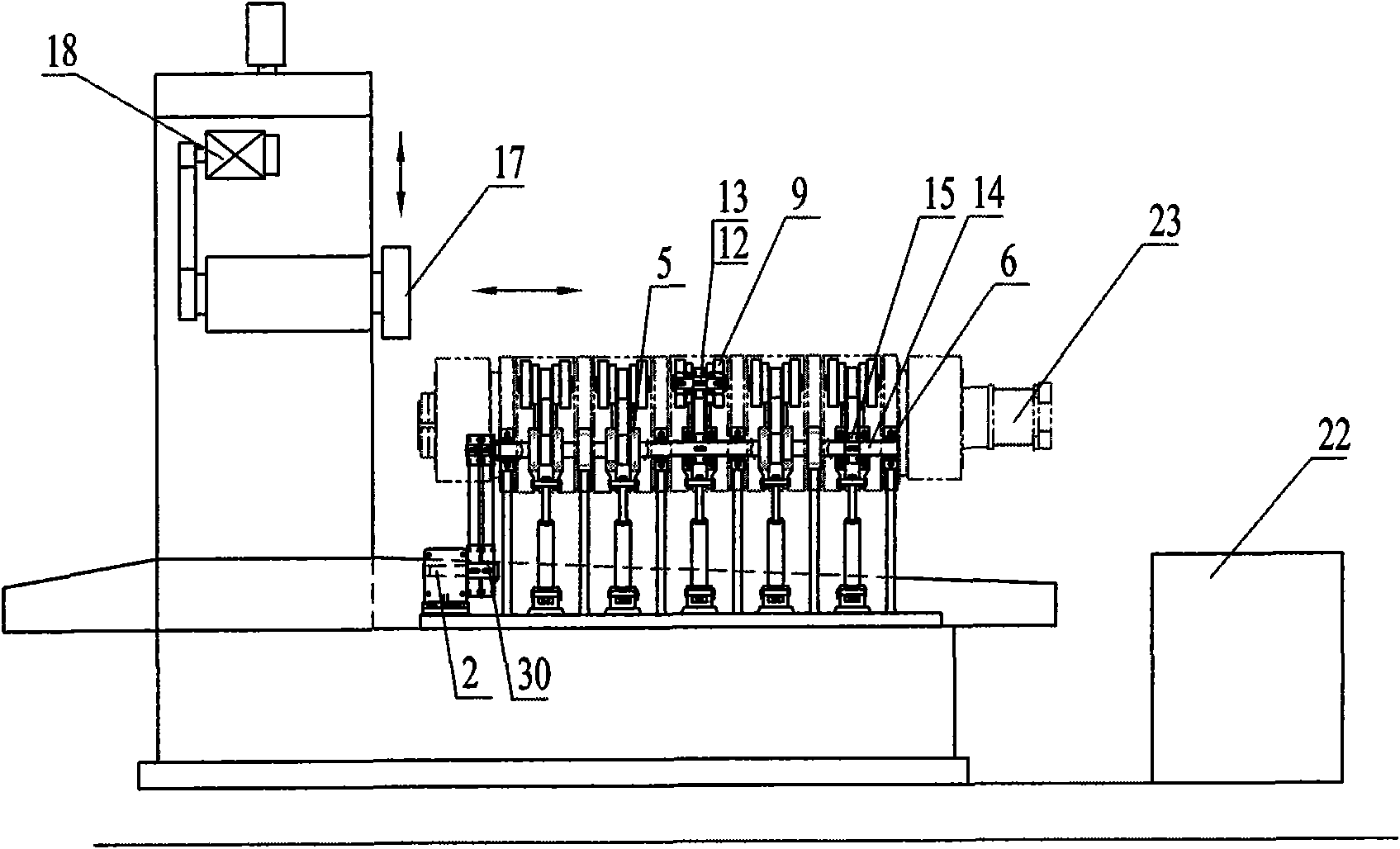

Multi-roller mill backing roller integral gapless repairing method and repairing device thereof

The invention relates to a multi-roller mill backing roller integral repairing method, which includes steps of: selecting, assembling and grinding, wherein bottom surface of a base plate (26) of a backing roller is used as installation standard, the backing roller to be repaired is integrally installed on a grinding processing standard surface of a reconditioning mold. The invention also relates to a multi-roller mill backing roller integral repairing device, which includes a mold arranged on a workbench (21). The mold comprises a fixed base (1) for supporting the backing roller to be repaired, the fixed base is provided with a compaction roller driving device with a power machine and a transmission mechanism and compaction devices which has same number with bearing roller on the backing roller and are arranged at one side or two sides of the backing roller to be repaired, a groove (29) which is adapted with shape of the base plate of the backing roller is arranged at upper end of the fixed base (1), and the groove is in V shape or circular arc shape. The invention can carry out integral gapless grinding for the backing roller to be repaired, realizes integral moulding grinding, and has advantages of simple process, high precision and low cost.

Owner:CERI TECH

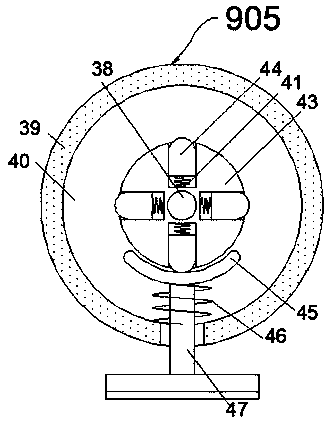

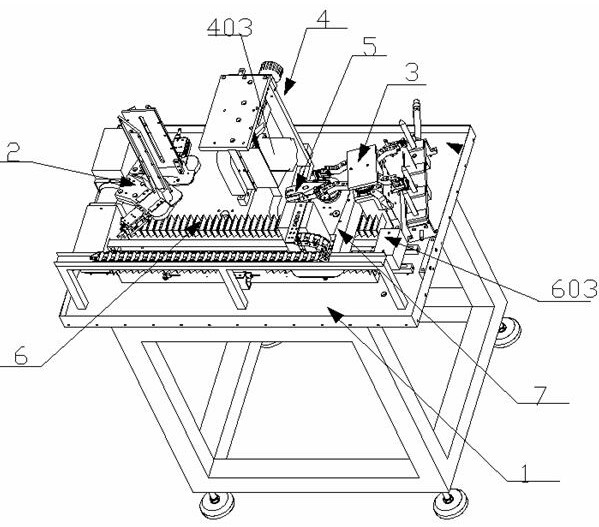

Blade grinding device

PendingCN111805311AReduce scrap rateGuaranteed grinding accuracyOther manufacturing equipments/toolsGrinding feedersKnife bladesStructural engineering

The invention relates to the technical field of knife grinding, and discloses a blade grinding device. The blade grinding device comprises a rack, a feeding assembly, a discharging assembly, a grinding abrasion wheel assembly and a clamping hand fixed seat moving along with a conveying belt. The clamping hand fixed seat is fixed to the conveying belt and is rotationally connected with a clamping hand. At least one blade trough used for fixing to-be-ground blades is arranged at one end of the clamping hand. The clamping hand fixed seat can do reciprocating motion along with the conveying belt,and the clamping hand can rotate on the clamping hand fixed seat by a preset angle. When the clamping hand fixed seat moves to the feeding station, the clamping hand fixed seat cooperates with the feeding assembly to feed blades. When the clamping hand fixed seat moves to the grinding station, the clamping hand fixed seat cooperates with the grinding abrasion wheel assembly to grind blades. When the clamping hand fixed seat moves to the discharging station, the clamping hand fixed seat cooperates with the discharging assembly to discharge blades. Compared with the prior art, single-face grinding is carried out on blades, the problem that cutting edges ground through traditional mechanical knife grinding are prone to being broken is solved, multiple blades can be fed at a time, and one-timefeeding and single-face grinding of multiple blades are achieved through clamping hand rotating and moving.

Owner:HUAIAN TIANDA MEDICAL INSTR

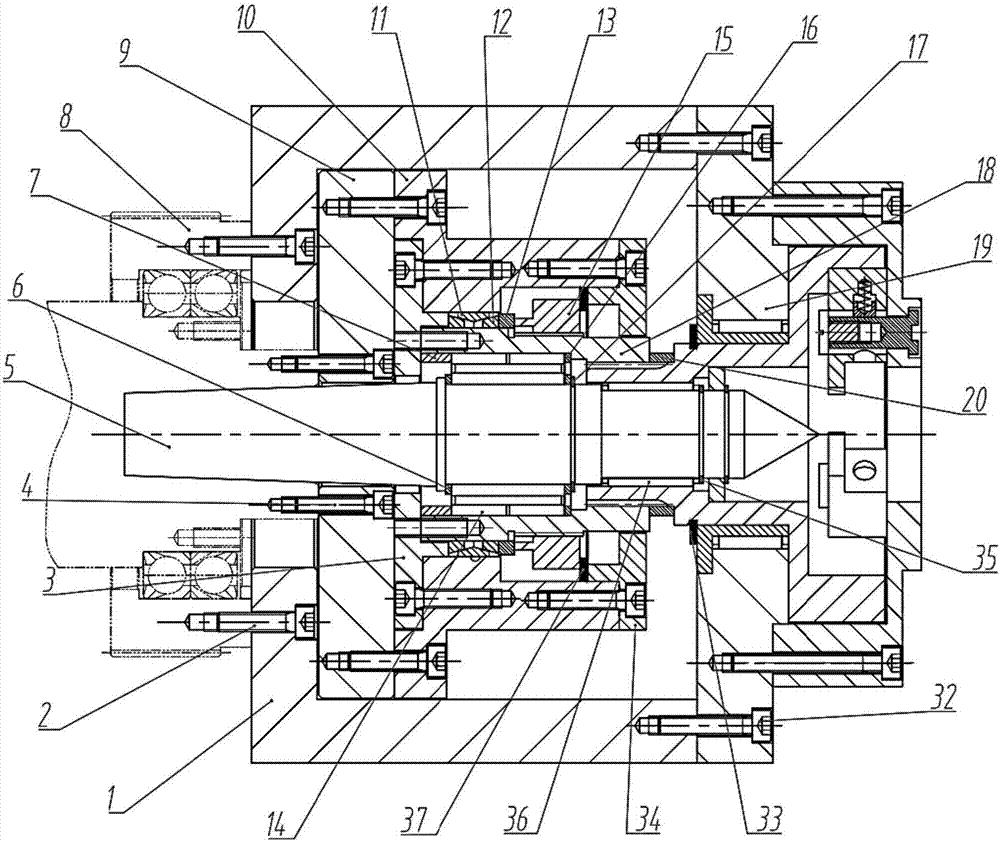

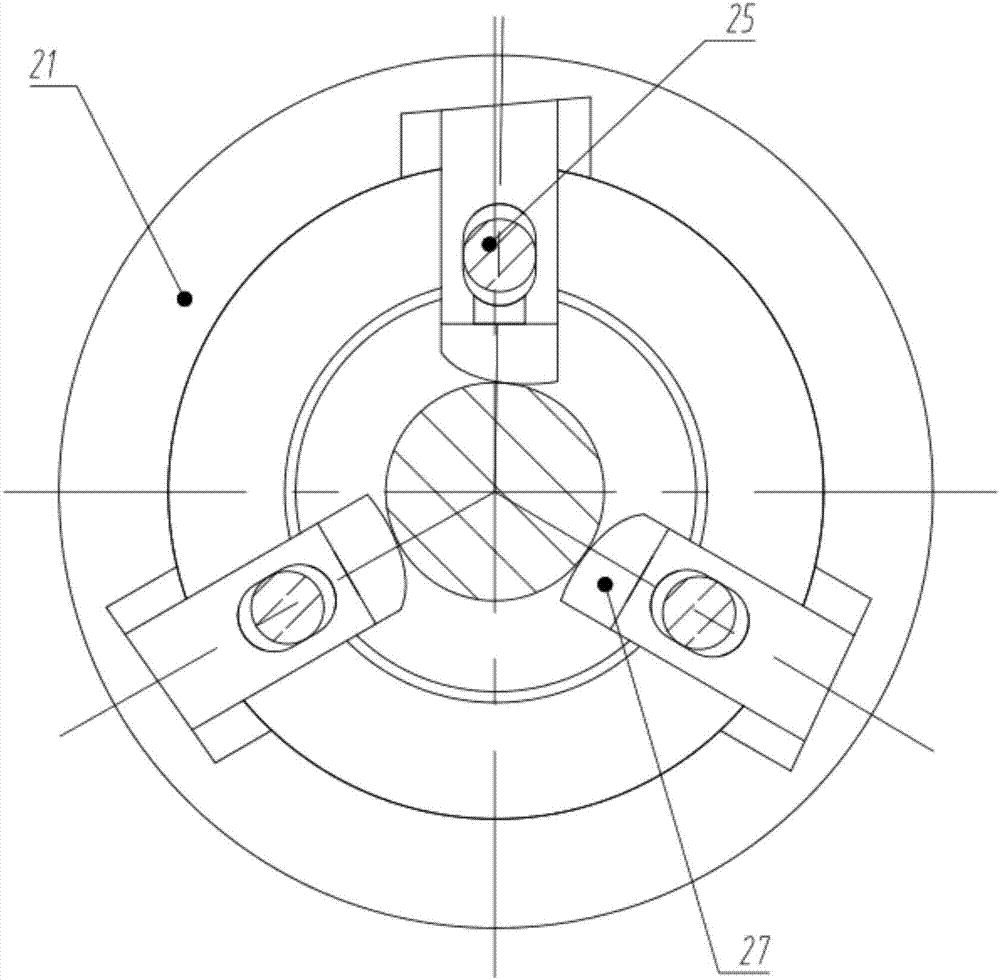

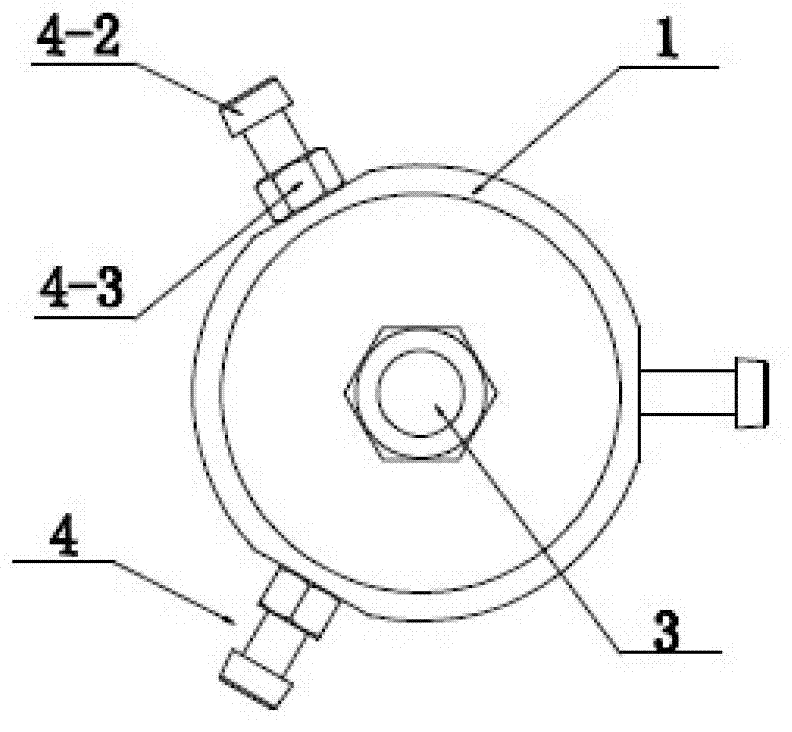

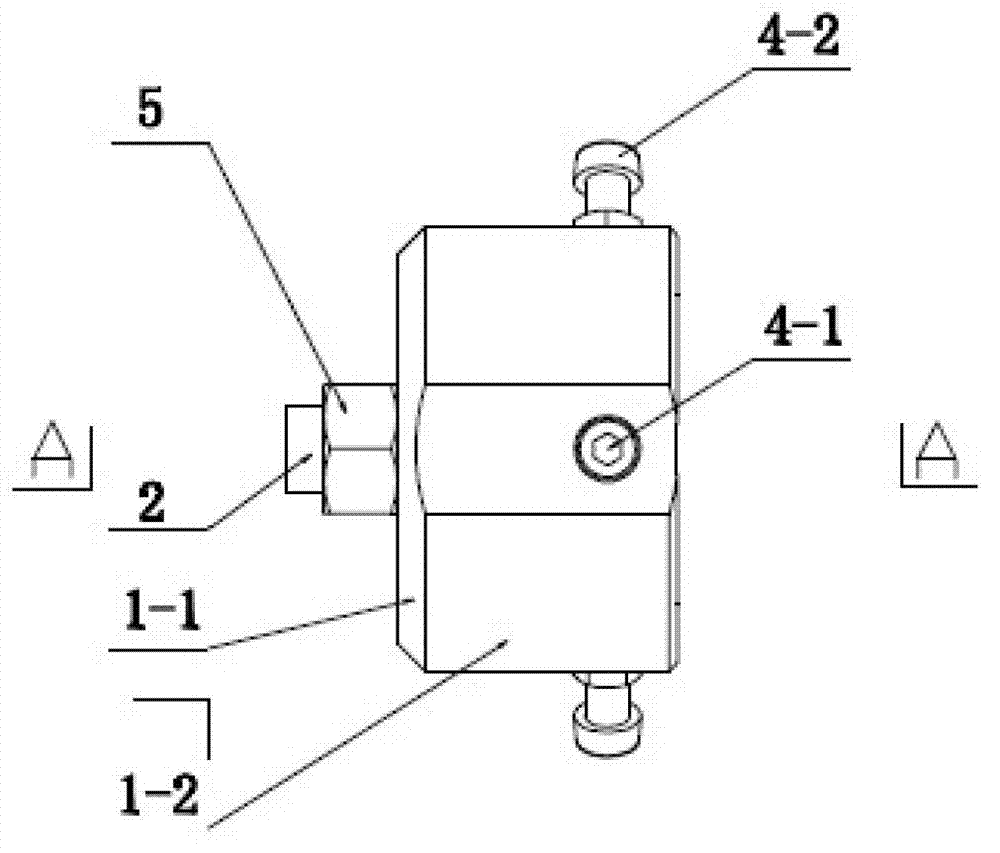

Friction wedge type automatic clamp for cylindrical grinding and application method thereof

ActiveCN106965087AGuaranteed coaxialityRealize automatic clampingGrinding work supportsNeedle roller bearingGear wheel

The invention discloses a friction wedge type automatic clamp for cylindrical grinding and an application method thereof. The friction wedge type automatic clamp for cylindrical grinding comprises a connecting flange, a left end cover, a head rack tip, a positioning flange, an intermediate sleeve, a hexagonal nut, a spline inner sleeve, a supporting ring, a wedge ring, a shifting ring, wedges, a supporting ring positioning sleeve, a needle bearing and a right end cover, wherein the connecting flange is mounted onto a gear of a head rack through a screw; the connecting flange, the supporting ring and the shifting ring are sequentially fixed through the screws; the shifting ring is connected with three wedges through three uniformly-distributed shifting pins; the three wedges are correspondingly embedded into three bevel grooves of the wedge ring; the positioning flange is fixed to a machine body of the head rack and is fixedly connected with the intermediate sleeve; the spline inner sleeve is connected with the wedge ring; a pre-tensioned inner conical spring and a pre-tensioned outer conical spring are mounted between the intermediate sleeve and the spline inner sleeve. According to the friction wedge type automatic clamp for the cylindrical grinding, an automatic wedge clamping manner is used for replacing an existing general manual chuck and a hydraulic driving chuck, so that the structure is simplified, and meanwhile, the automatic clamping function is achieved; in addition, the grinding precision is ensured.

Owner:QUZHOU COLLEGE OF TECH

Polishing device and technology for false tooth machining

ActiveCN111251143APrevent overthrowUndershootGrinding drivesLapping machinesPolishingFixed prosthodontic

The invention relates to a polishing device for false tooth machining. The polishing device comprises a base, an installation seat which is placed on the base and is used for fixing a false tooth in the polishing process, a support fixed to the base and a grinding tool which is installed at the end, away from the base, of the support and is used for grinding the false tooth. The polishing device is characterized in that a magnetic worktable is arranged on the upper end face of the base; multiple concentric ring-shaped grooves are formed in the lower end face of the installation seat; magnets are arranged in the ring-shaped grooves; and a clamping mechanism used for clamping and fixing the false tooth is arranged on the installation seat. The polishing device has the effects that the relative position between the installation seat and the base is conveniently adjusted, and therefore the grinding process is more convenient.

Owner:泉州市超维医疗科技有限公司

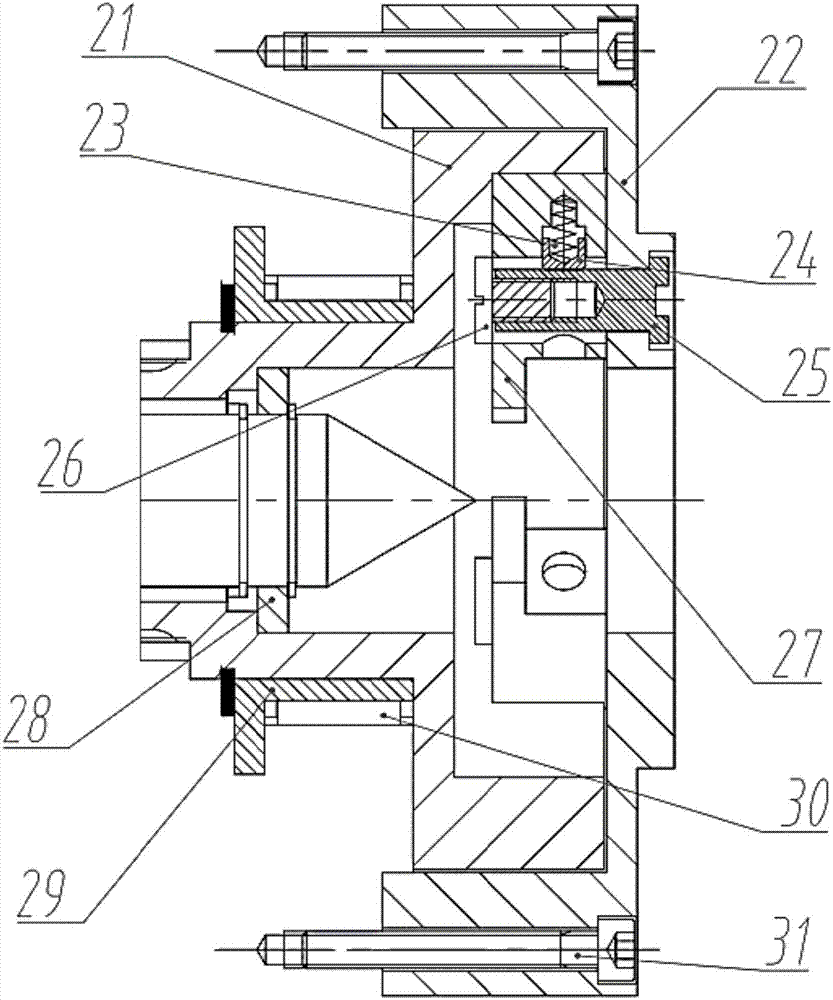

Method for abrasively processing flange bearing top circle and end plane

InactiveCN101219522AGuaranteed grinding accuracyImprove processing qualityRevolution surface grinding machinesGrinding wheelFlange

The invention relates to a grinding processing method for the outer circle and the end face of a flange. A flange bearing (3) to be processed is located on a feed trailing bar (1) and a grinding wheel (5) is fixed on a reciprocating trailing bar (4); the axial work station is changed by a reciprocating step motor (6) to drive the reciprocating trailing bar while the radial work station is changed by a feed step motor (2) to drive the feed trailing bar, and the position kept unchanged is the initial work station a; the grinding of the flange bearing outer circle starts from the initial work station a, then is axially changed to a work station b, radially to a work station c, and radially again and quickly changed to a work station d and finally the outer circle grinding is executed at a work station e. After the grinding of the flange bearing outer circle is finished, the flange returns from the work station e to a work station f which is coincided with the work station c, and the end surface is grinded at the work station f. At this moment, the flange at the work station f axially and quickly closes to a work station g to carry out the grinding to the end surface of the flange baring (3) at a work station h. After the grinding of the end surface of the flange bearing is completed, the flange withdraws directly from the work station h to the initial work station a, thereby, the whole grinding processing of the flange bearing outer circle and the end face thereof is completed.

Owner:LUOYANG BEARING SCI & TECH CO LTD

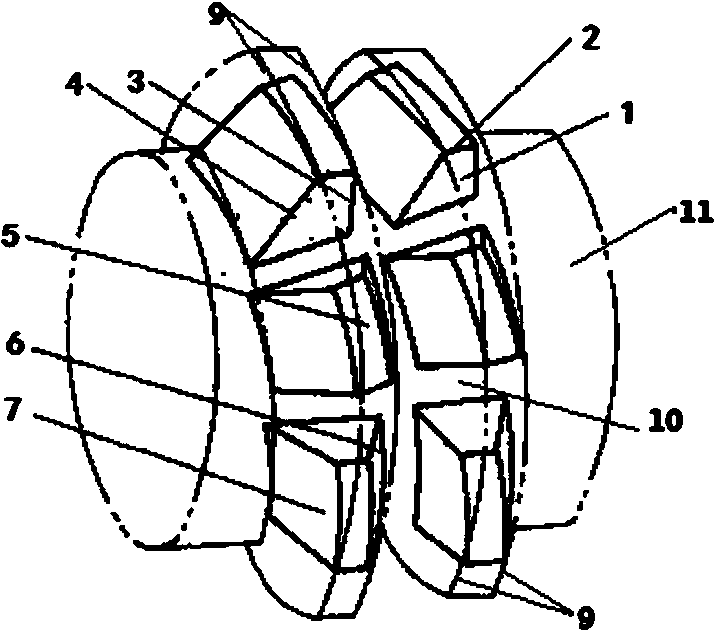

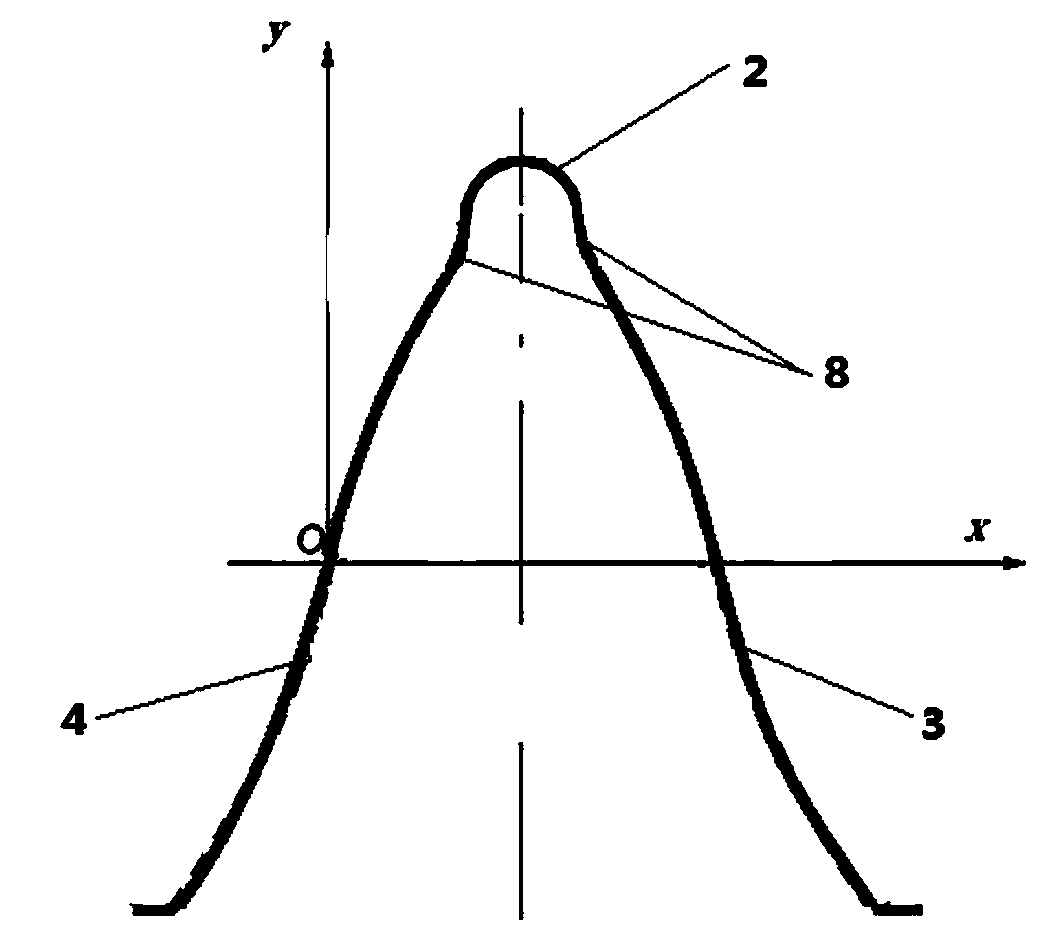

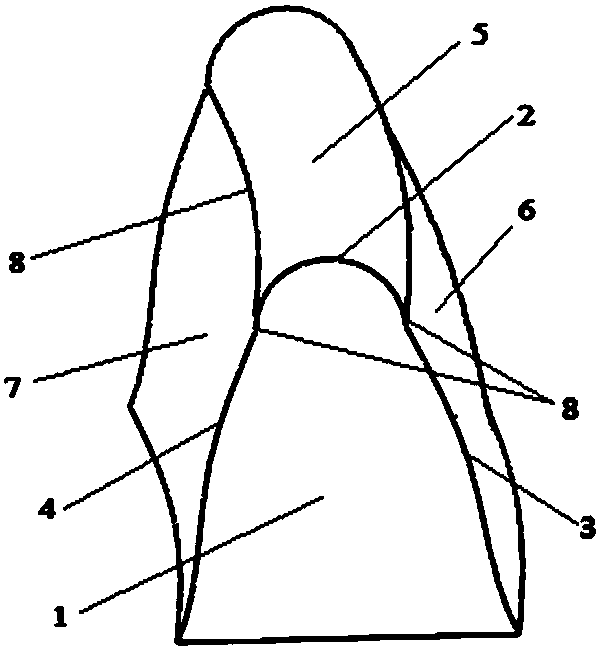

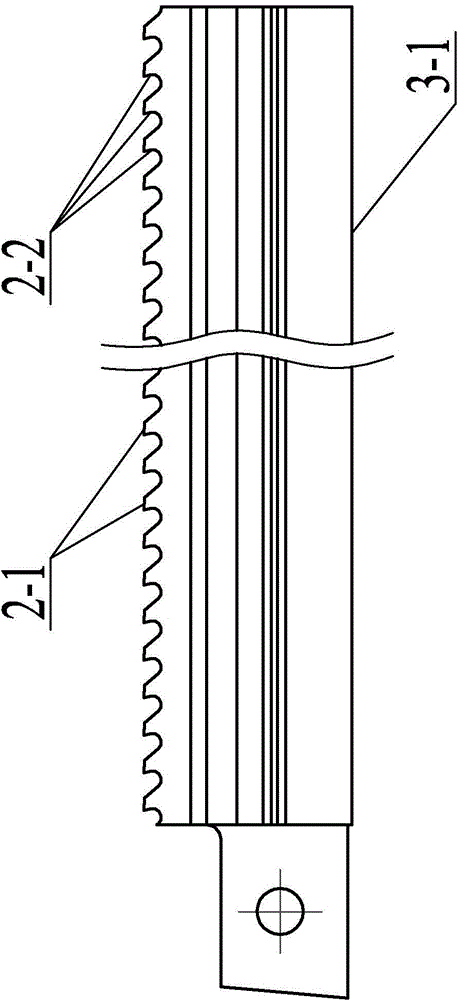

Pre-grinding hob for machining micro-segment gears

InactiveCN103551674AIncrease production capacityAchieve preparationGear teeth manufacturing toolsGear teethEdge segmentLine segment

The invention relates to a pre-grinding hob for machining micro-segment gears. A cutting edge normal tooth profile of the pre-grinding hob comprises a main cutting edge segment, an addendum arc segment and a characteristic curve connecting segment, the main cutting edge segment is a normal engagement contacting tooth profile curve segment for machining the micro-segment gears, micro-segment curved lines or micro-segment straight lines are smoothly connected to form the main cutting edge segment, the length of the main cutting edge segment is not larger than 1 micrometer, the characteristic curve connecting segment is a connecting curve segment of a pre-grinding hob tooth addendum arc segment and a micro-segment tooth profile segment, and the trend and the length of the characteristic curve connecting segment are related to the modulus, the initial pressure angle, the pressure angle increment, the grinding allowance, the distribution form of the grinding allowance and the like of the micro-segment gears to be machined. The high-precision micro-segment gears can meet specific use requirements and mass production conditions as far as possible according to theoretical calculation and experience of the trends and the lengths of an undercutting arc segment and a characteristic transition curve segment.

Owner:HEFEI UNIV OF TECH

Polishing device for optical lens production

PendingCN111002151AAvoid damageAvoid scrappingEdge grinding machinesGrinding drivesEngineeringOptic lens

The invention relates to the technical field of optical lens production and especially relates to a polishing device for optical lens production. The device comprises a base. A fixing mechanism for fixing an optical lens is arranged at a top of the base. Edge grinding mechanisms are arranged on a left side and a right side of the fixing mechanism. A dedusting mechanism is arranged inside the base. In the invention, the fixing mechanism is arranged, movement of two side clamping plates is used, the lens positioned at a top end of a placing disc is always located in a center of the placing disc, and a pressing block is used for stably fixing the lens so that product scrap caused by clamping deviation of the lens to be processed is avoided, and positioning precision is high; positions of polishing wheels on two sides can be rapidly adjusted by arranging a first motor, and polishing precision is guaranteed by arranging a third motor and finely adjusting the positions of the polishing wheels; and polishing quality can be improved, and pollution to the environment can be reduced by arranging the dedusting mechanism.

Owner:江苏新事通光电科技有限公司

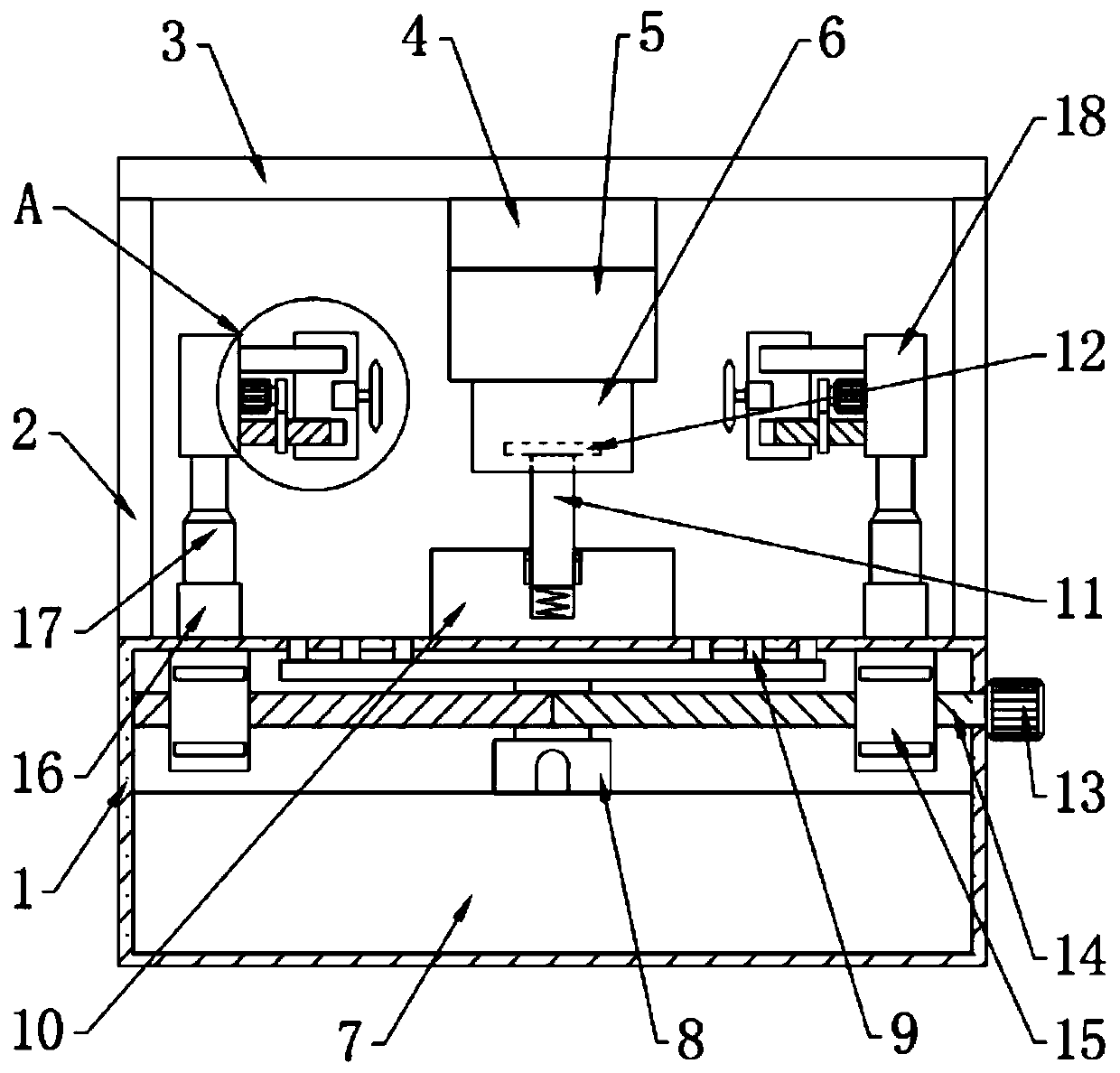

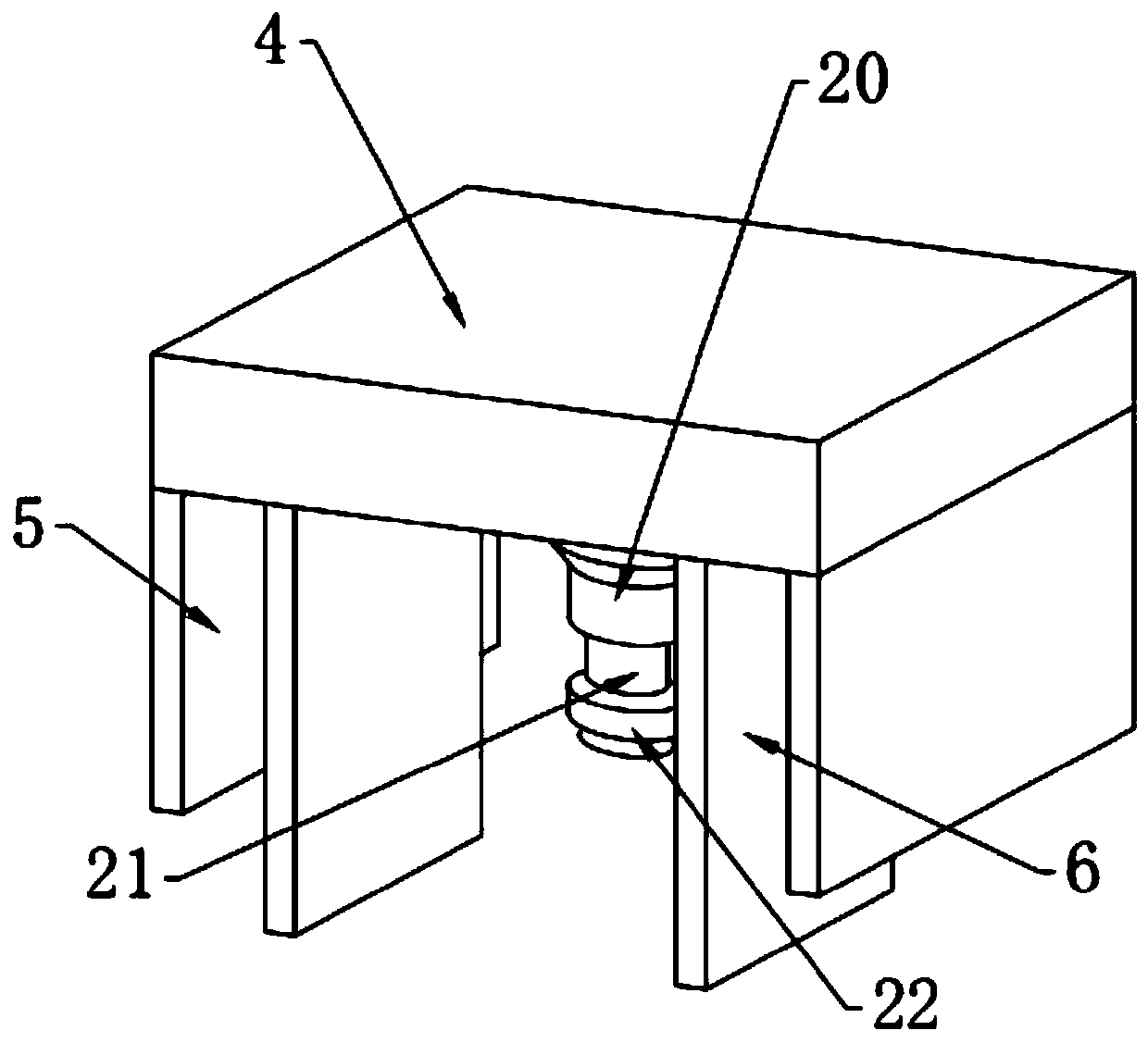

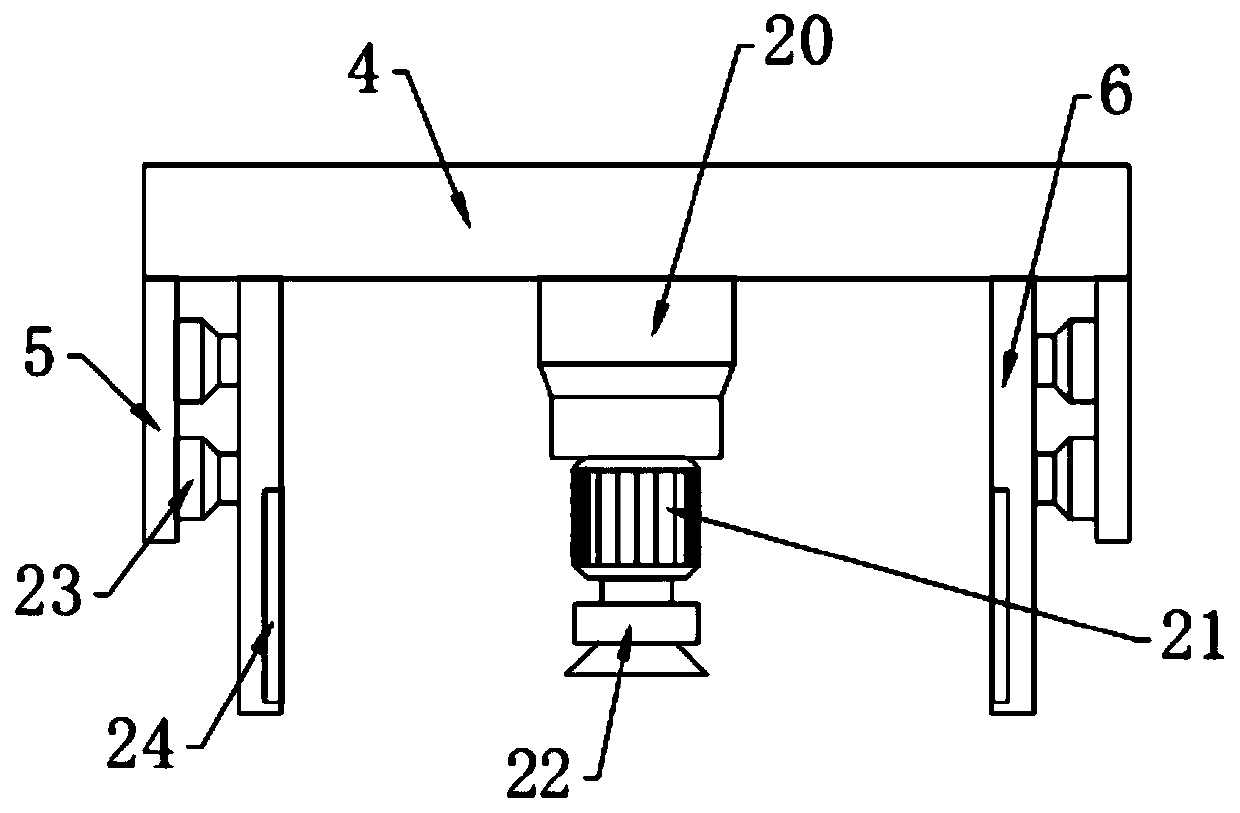

Vertical double-shaft numerical control grinder

InactiveCN106737150AImprove work efficiencyGuaranteed grinding accuracyGrinding carriagesGrinding bedsNumerical controlHydraulic cylinder

The invention discloses a vertical double-shaft numerical control grinder. The vertical double-shaft numerical control grinder comprises a bracket, a lateral locking device, a workbench, a driving mechanism and a polishing device, wherein the bracket comprises a base, four hydraulic cylinders and cam seats, the cam seats are arranged on the left and right sides of the base, mounting holes are formed in the cam seats, the four hydraulic cylinders are respectively symmetrically mounted on four sides of the base, the bottom ends of the hydraulic cylinders are fixedly connected with the base, and the top ends of the hydraulic cylinders are connected with the workbench through bolts; the driving mechanism is arranged behind the bracket and comprises a horizontal transverse guide rail and a transverse servo motor which are arranged on the workbench along a front-back direction, and a horizontal longitudinal guide rail is connected to the horizontal transverse guide rail in a sliding manner. According to the vertical double-shaft numerical control grinder, the adjustment of the overall height is realized, the grinding precision is guaranteed, the structure is novel, the machining speed is high, the machining number is large, the working efficiency is high, the cost is low, and the machining quality is uniform and stable.

Owner:NANTONG ZHONGNAN NUMERICAL CONTROL MACHINE MADE

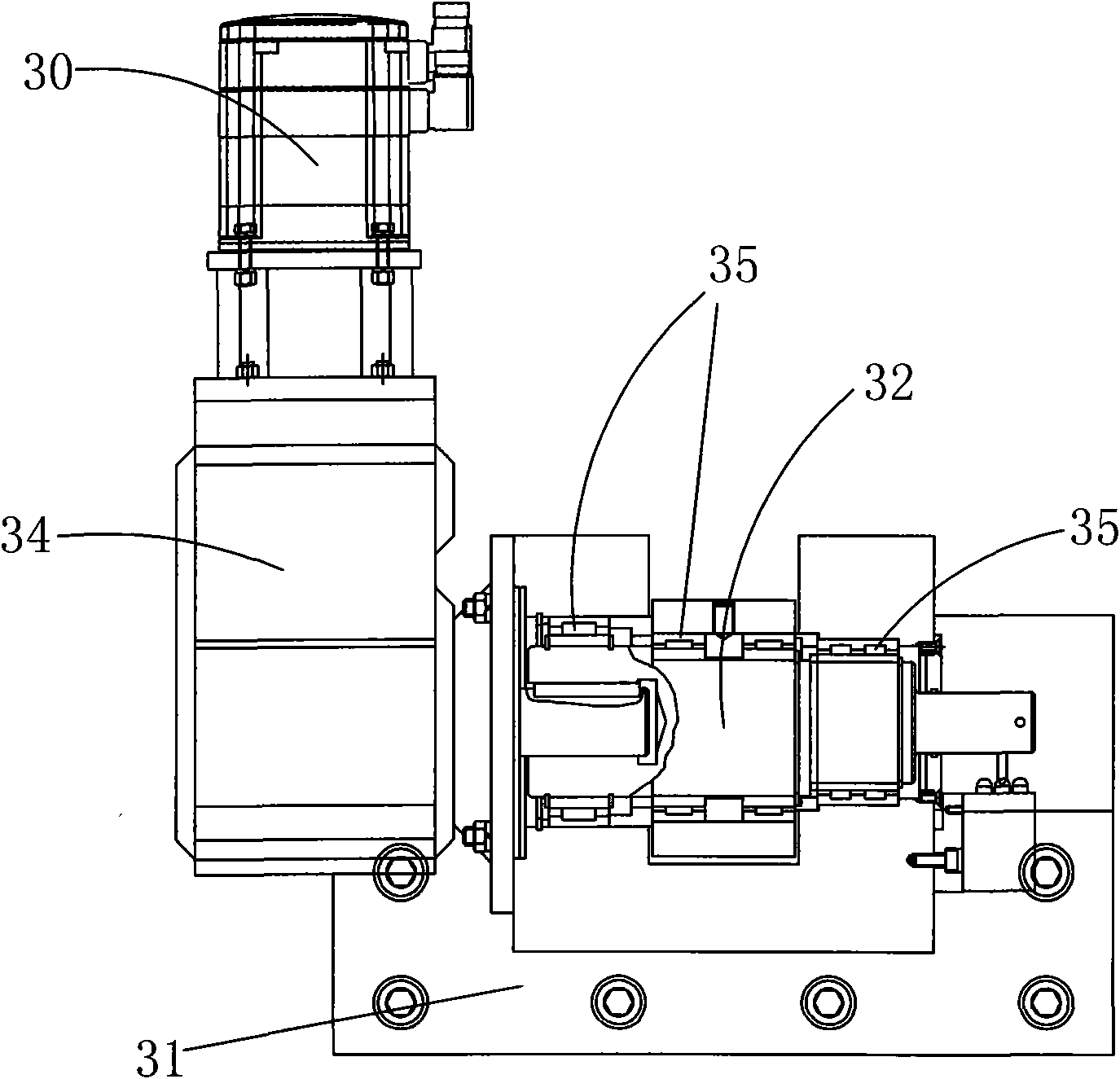

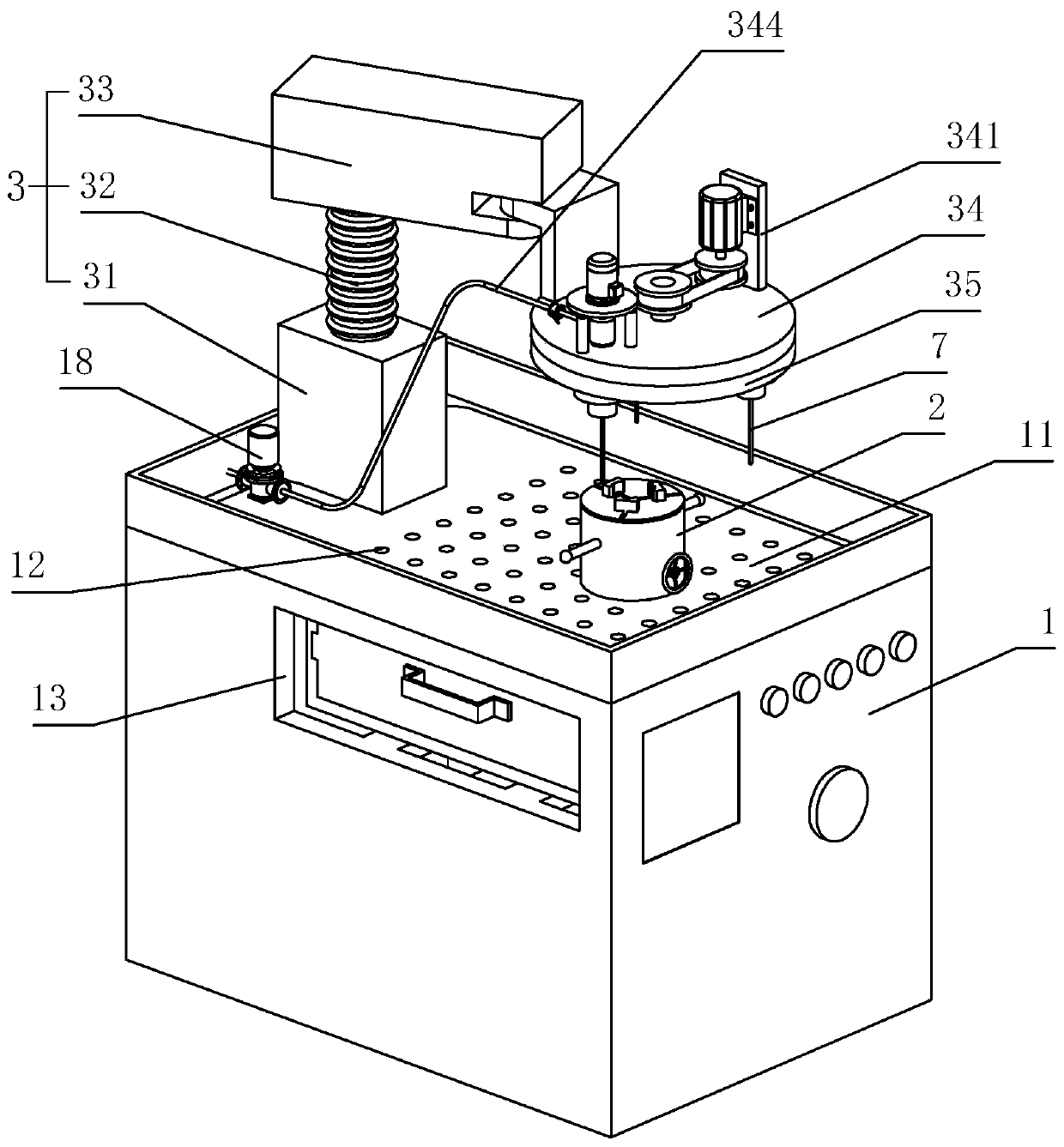

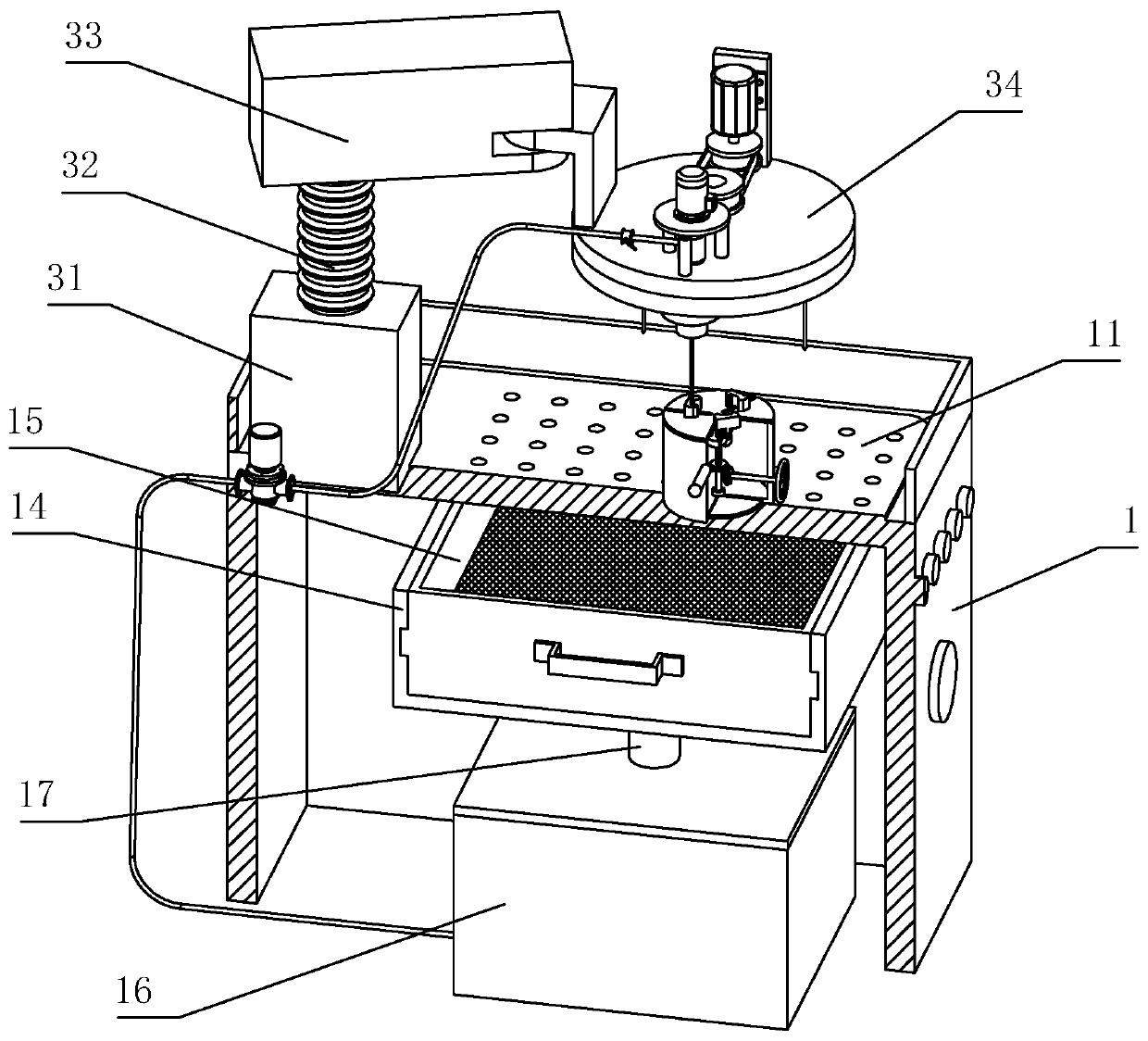

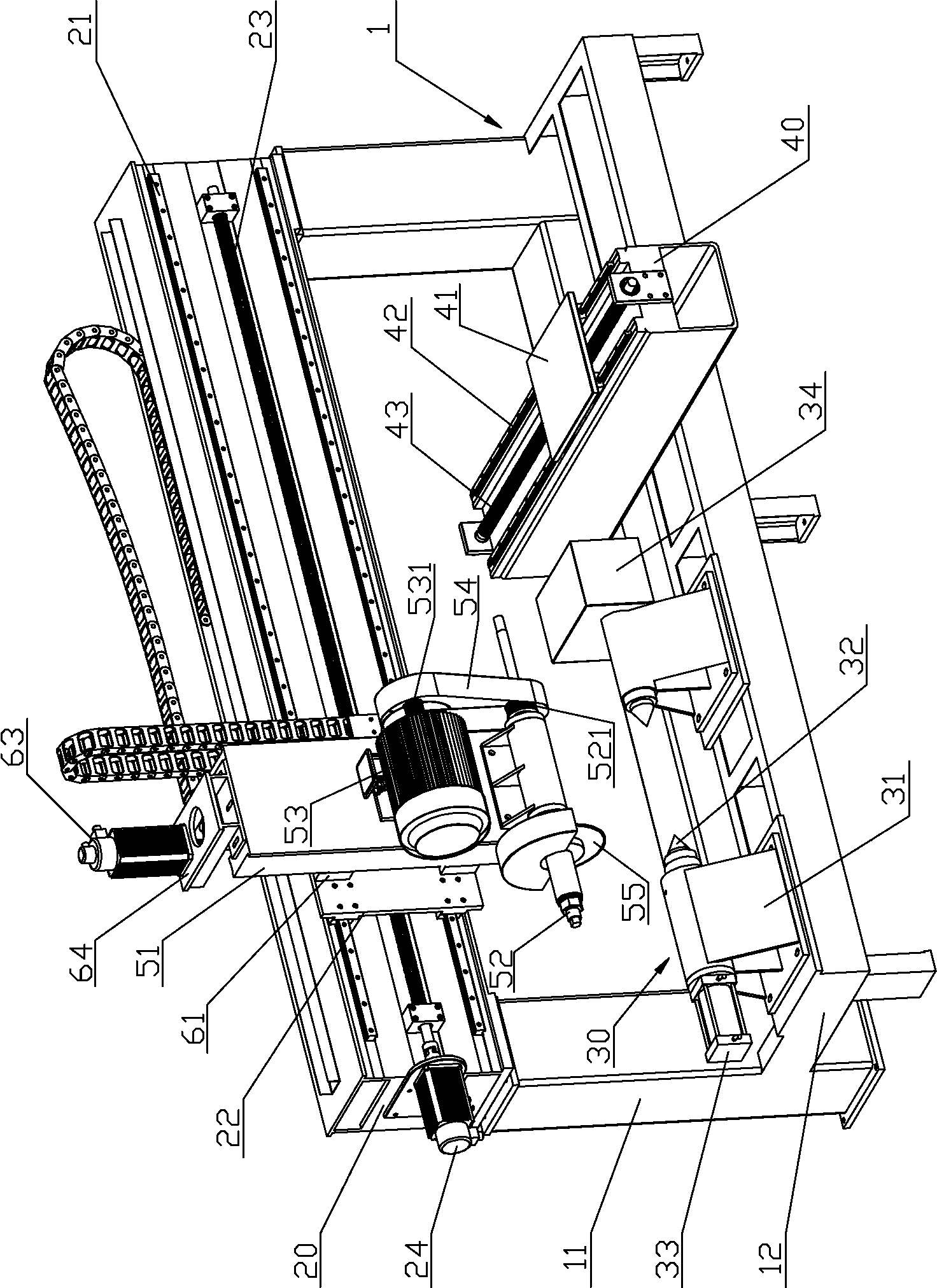

Full-automatic grinding wheel sharpening machine

ActiveCN104742019AGuaranteed grinding accuracyImprove processing efficiencyAbrasive surface conditioning devicesSlide plateSharpening

The invention relates to the technical field of grinding wheel sharpening and provides a full-automatic grinding wheel sharpening machine which comprises a machine frame, a control device, an image observing device, a to-be-ground piece fixing device and a grinding wheel sharpening device. The control device, the image observing device, the to-be-ground piece fixing device and the grinding wheel sharpening device are arranged on the machine frame. The grinding wheel sharpening device comprises a rotating table, a feeding sliding plate horizontally arranged on the rotating table, a feeding device for driving the feeding sliding plate to move, a reciprocating sliding plate arranged above the feeding sliding plate, a reciprocating device for driving the reciprocating sliding plate to move in a reciprocating mode relative to a grinding wheel to be ground, a second base arranged on the reciprocating sliding plate, a second main shaft arranged at a first base body and a second rotating mechanism for driving the second main shaft to rotate. The feeding direction of the feeding sliding plate is perpendicular to the reciprocating direction of the reciprocating sliding plate. A sharpening grinding wheel is arranged on the second main shaft. Compared with the prior art, according to the full-automatic grinding wheel sharpening machine, working efficiency is improved, and the sharpening accuracy of the grinding wheel to be ground can be well guaranteed.

Owner:湖北远蓝机器有限公司

Polishing equipment

InactiveCN111546156AQuality assuranceGuaranteed flatnessGrinding drivesGrinding feed controlPolishingEngineering

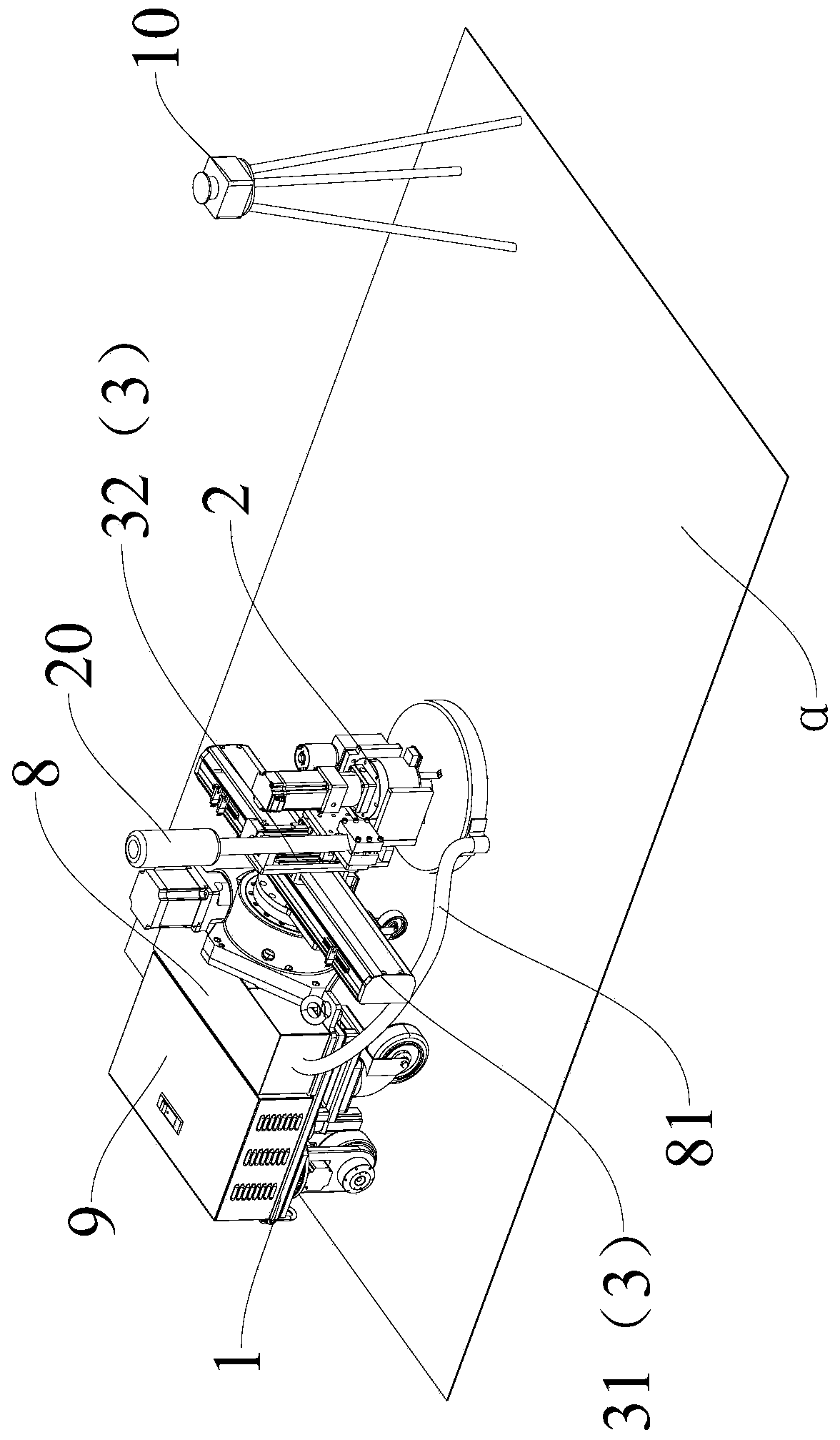

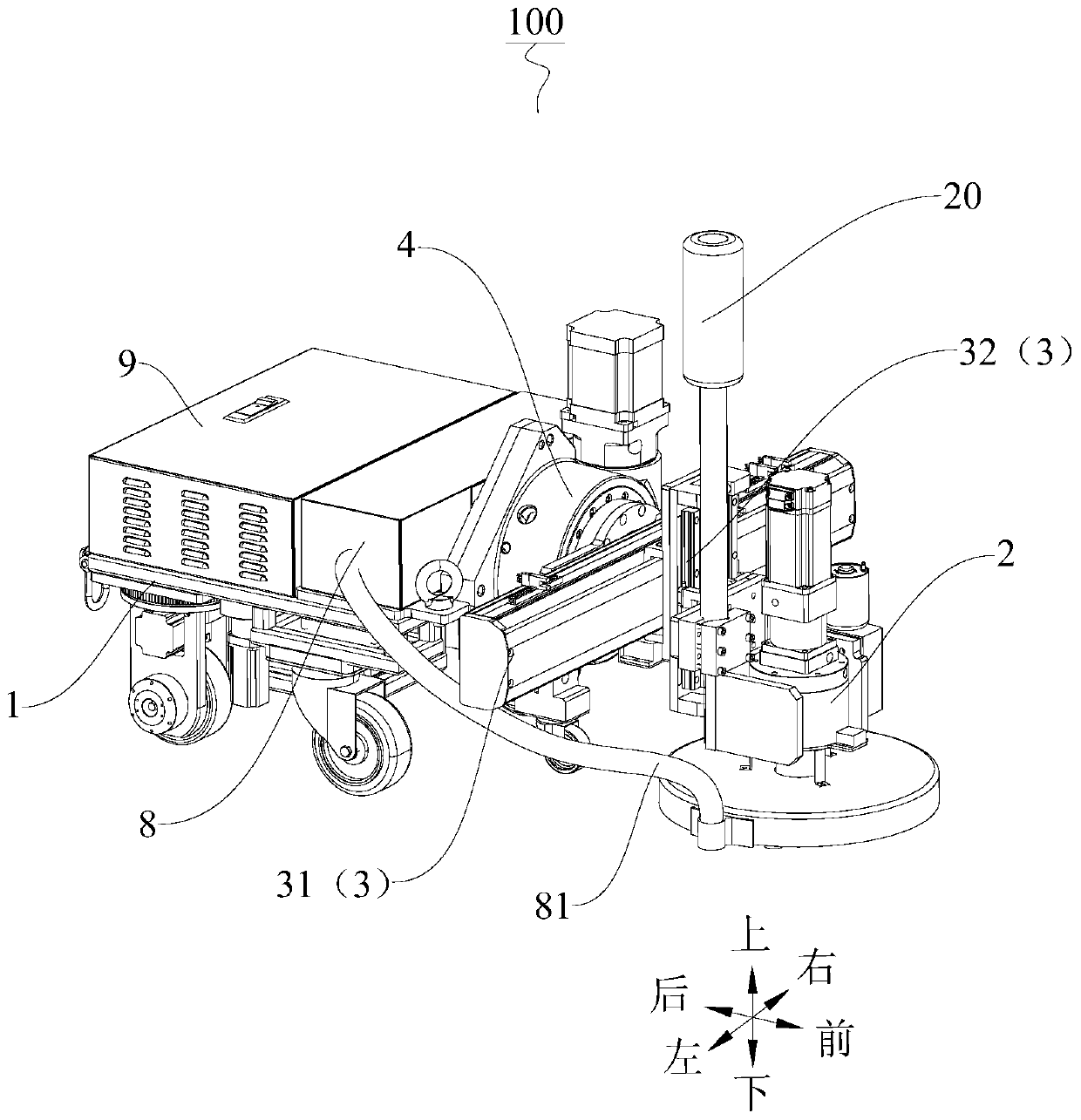

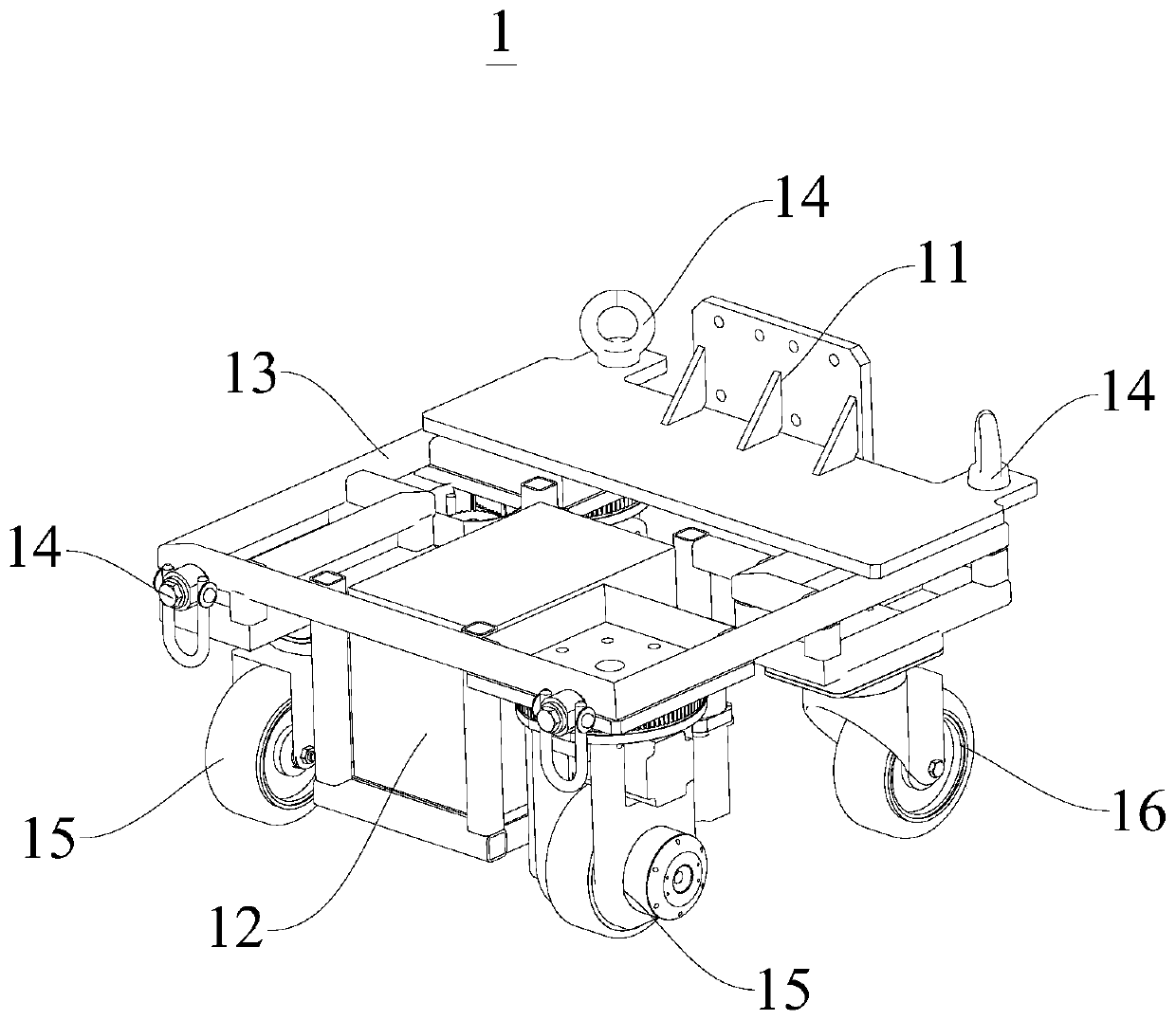

The invention discloses polishing equipment. The polishing equipment comprises a walking device, a polishing device, a linear driving device, a first angle adjusting device, and a second angle adjusting device, wherein the polishing device can rotate about a first axis so as to polish a base surface to be polished; the linear driving device is arranged on the walking device and is used for drivingthe polishing device to move in a horizontal direction and / or a vertical direction; the first angle adjusting device is used for adjusting the deflection angle of the polishing device relative to a first plane; the first plane is perpendicular to the first axis; the second angle adjusting device is used for adjusting the deflection angle of the polishing device relative to a second plane; and thesecond plane is perpendicular to the first plane and perpendicular to the forward direction of the walking device. The polishing equipment of the embodiment can automatically perform polishing; the overall automation degree of the polishing equipment is increased; and meanwhile the angle of the polishing device can be adjusted to ensure the polishing accuracy of the polishing device and the polishing flatness of the base surface to be polished.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Special equipment for forming and grinding abrasive wheels

ActiveCN103894930ALow costMeet the precision requirementsAbrasive surface conditioning devicesBrickEngineering

A set of special equipment for forming and grinding abrasive wheels comprises a supporting base, wherein a workpiece tool is arranged on the lower portion of the supporting base, a grinding mechanism capable of moving in the direction of the X axis and the direction of the Z axis of the supporting base is arranged on the upper portion of the supporting base and located above the workpiece tool, the grinding mechanism comprises a vertical plate capable of moving in the direction of the Z axis of the supporting base, a rotating shaft arranged in the direction of the X axis of the supporting base and a first motor for driving the rotating shaft to rotate are arranged on the vertical plate, a blade is fixed to one end of the rotating shaft, an extension segment is arranged at the other end of the rotating shaft, a corundum tool is detachably installed on the extension segment, an operating table board capable of moving in the direction of the Y axis of the supporting base is arranged beside the extension segment, and a pair of bath bricks for grinding the abrasive wheels are fixed to the operating table board. The equipment is low in manufacturing cost, the machining efficiency is substantially improved while forming and grinding can be achieved, meanwhile, tool setting and feeding is convenient to perform when the abrasive wheels are ground, the grinding accuracy is guaranteed, and the abrasive wheel forming and grinding time is effectively shortened.

Owner:环球石材(福建)有限公司

Method for sharpening broach for processing turbine wheel disc blade root groove

The invention relates to a method for sharpening a broach for processing a turbine wheel disc blade root groove, and relates to a method for sharpening the broach, for solving the problems that the working stability of a conventional sharpened broach of the turbine wheel disc blade root groove is degraded, the service life of the broach is shortened, and the precision of the processed turbine wheel disc blade root groove is degraded. The method comprises the following steps: 1, mounting the broach onto a broach grinding machine; 2, measuring a highest point of a rear cutter surface of a cutter tooth, grinding a front cutter surface of a cutter tooth of which the abrasion is smaller than 0.3 mm, wherein the feeding amount of a grinding wheel is 0.01 mm, the rotation speed of the grinding wheel is 3000rpm, and polishing the grinding wheel once after every 100 cutter teeth are polished; 3, firstly, confirming and calculating the grinding amount expected by the front cutter surface of the marked cutter tooth, and forming a concave surface between 2-3 first cutter teeth and a top point of the rear cutter surface from the cuter teeth to 2-3 second cutter teeth. The method is used for sharpening the broach for processing the turbine wheel disc blade root groove.

Owner:HARBIN TURBINE

Diamond tool bit bevel face grinding device

ActiveCN105619204AIncrease productivityGuaranteed grinding accuracyEdge grinding machinesGrinding drivesGeneral purposeTool bit

Owner:鄂州市通磊超硬材料有限公司

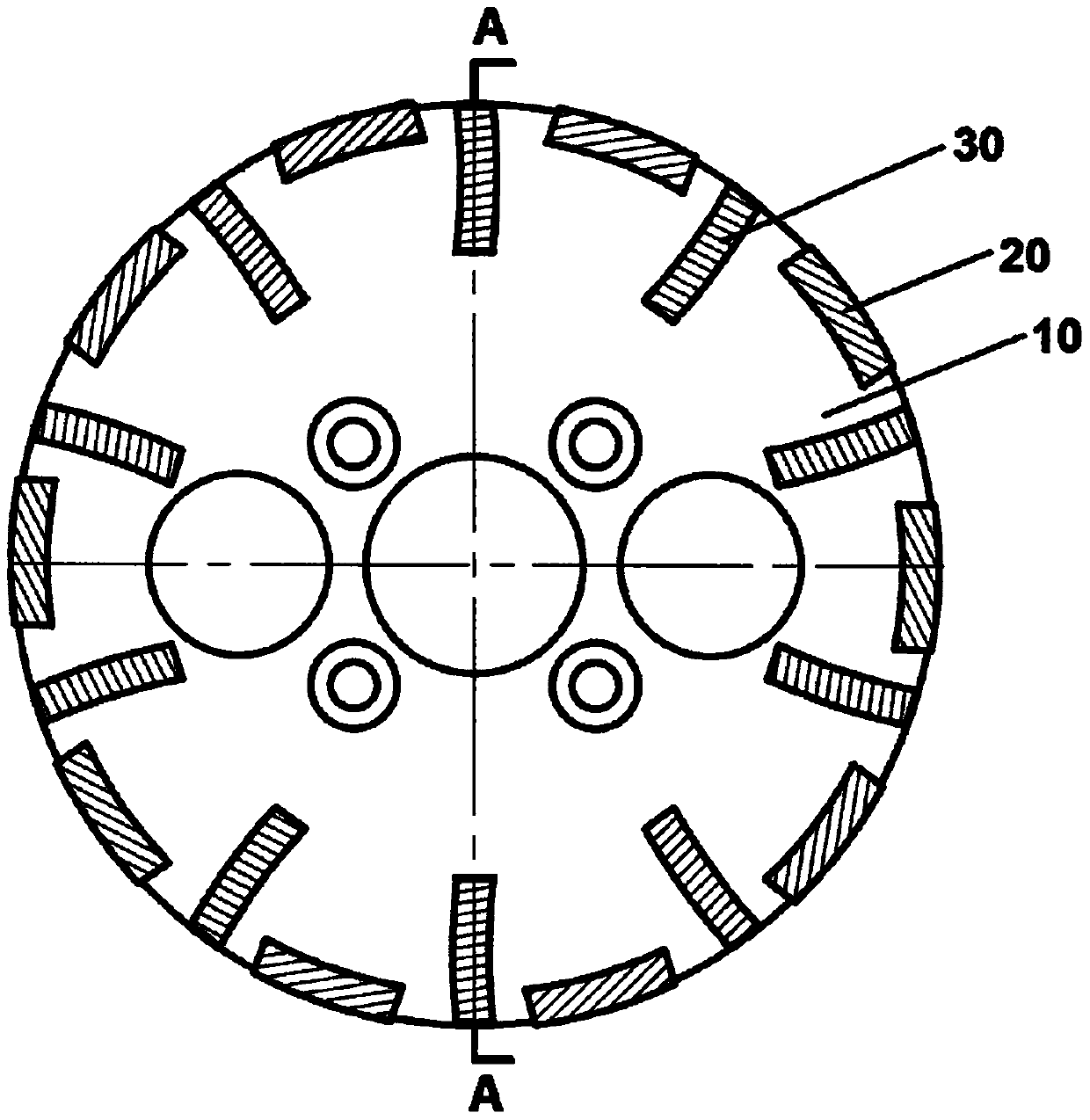

Diamond grinding disc and preparation method thereof

ActiveCN110125820AGood sharpnessGood stabilityBonded abrasive wheelsGrinding devicesDiamond grindingHorizontal projection

The invention relates to a diamond grinding disc and a preparation method thereof, and belongs to the technical field of diamond tools. The diamond grinding disc comprises a disc-shaped base body, first and second diamond tool bits are arranged on the surface of the disc-shaped base body in a spaced manner, the first and second diamond tool bits are in segment shapes, and horizontal projections are each in a shape formed by two parallel arc sides and two straight sides; the connecting line of the midpoints of the two straight sides form the length direction of the first and second diamond toolbits; the edge of one arc side of the first diamond tool bit extends along the outer edge of the base body; one straight side of the second diamond tool bit is arranged to be close to the outer edgeof the base body, and the length direction extends in the radial direction. The diamond grinding disc can be applied to an airport runway, a bridge project, a highway and application places, such as special reinforced concrete, with high requirements for concrete surface grinding smoothness and roughness.

Owner:江苏友美工具有限公司

Cylindrical work piece grinding and processing tooling and use method thereof

InactiveCN102814735ASolve the card loading problemGuaranteed grinding accuracyGrinding work supportsWear resistantLocking mechanism

The invention discloses a cylindrical work piece grinding and processing tooling which is characterized by consisting of a cylindrical tooling body and a process plug head; the tooling body comprises a cylindrical wall and a cylindrical bottom; a threaded through hole is arranged in the center of the cylindrical bottom; the process plug head is fixedly arranged in the threaded through hole; a central hole is arranged in the center of the process plug head; and three sets of work piece position adjusting and locking mechanisms are arranged on the cylindrical wall. The invention also discloses a use method of the tooling. According to the tooling and the use method, the work piece coarse and fine grinding and processing problems that the end of a similar piston is provided with no central hole are fully solved, i.e. the central hole can be removed before the surface of the work piece is strengthened, so that very good hardness and wear resistant performance are realized on the surface treatment on the end surface of the work piece.

Owner:YANTAI AIDI PRECISION MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com