Grinding pad fixing device and chemical machinery grinder

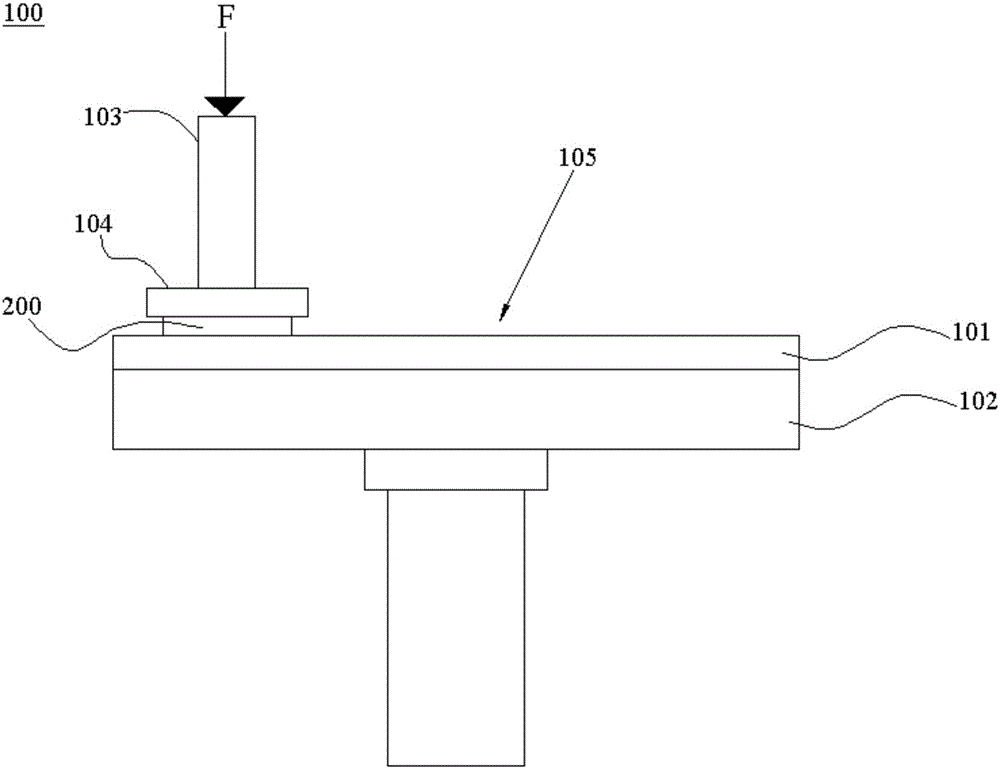

A technology of fixing device and grinding pad, applied in the direction of grinding tools, etc., can solve the problems of high scrap rate of grinding pads, reduce production costs, etc., and achieve the effect of ensuring service life, preventing deformation, and ensuring grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

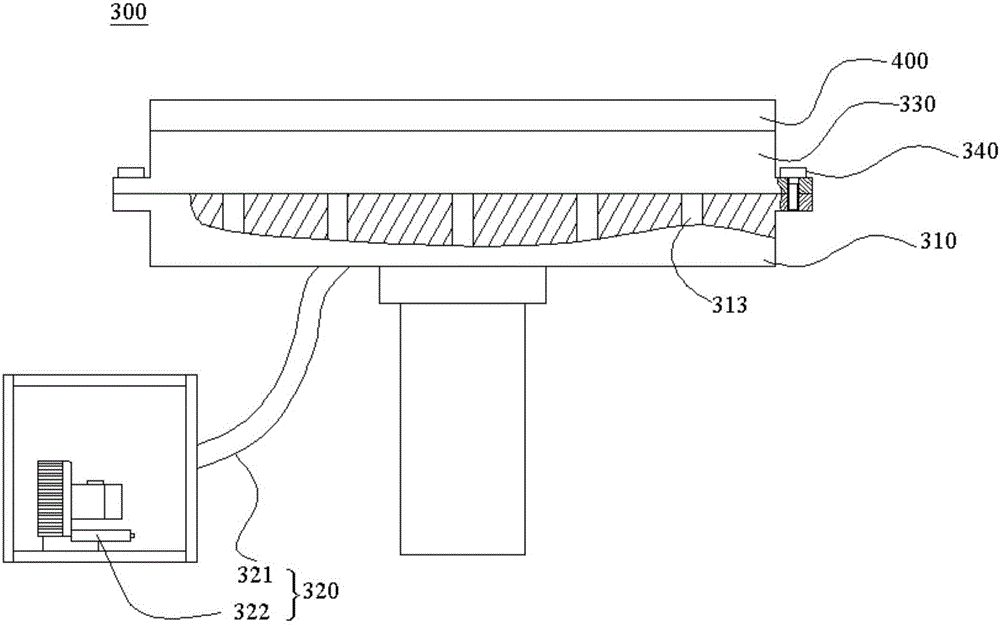

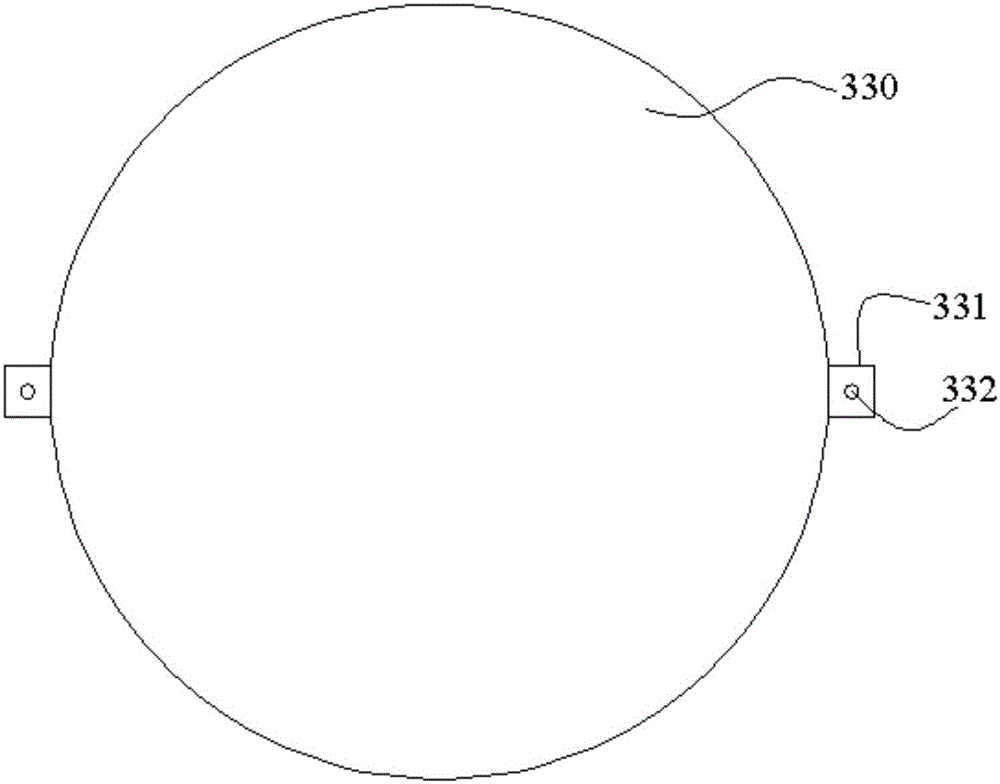

[0032] refer to figure 2 , the grinding pad fixing device 300 of the present embodiment includes a grinding platform 310, a vacuum system 320 and a substrate 330, wherein the vacuum system 320 is connected to the grinding platform 310, so that the upper surface of the grinding platform 310 is formed as a vacuum adsorption surface. , the bottom of the substrate 330 is vacuum-adsorbed on the upper surface of the polishing platform 310 , and the back surface of the polishing pad 400 is fixed on the upper portion of the substrate 330 . Then, when the grinding pad 400 needs to be replaced, it is only necessary to remove the substrate 330 and the grinding pad 400 from the grinding platform 310 as a whole, and then the substrate 330 and the grinding pad 400 can be placed as a whole and kept moist for use for Use it next time.

[0033] The inventor considers that the material of the grinding pad 400 is relatively soft. If the grinding pad 400 is directly vacuum-adsorbed on the grind...

Embodiment 2

[0051] This embodiment provides a chemical mechanical polishing device, including a polishing pad, a polishing head disposed above the polishing pad and used for grinding wafers, and the polishing pad fixing device described in Embodiment 1, the polishing pad fixing device can be used For fixed abrasive pads, see Figure 8 .

[0052] Such as Figure 8 As shown, the chemical mechanical polishing apparatus 500 of this embodiment includes a polishing pad 510 , a substrate 520 , a polishing platform 530 , a polishing head 540 and a vacuum system 550 . The vacuum system 550 includes a vacuum pipeline 551 connected to the grinding platform 530 and a vacuum pump 552 connected to the vacuum pipeline 551 . The substrate 520 is disposed between the polishing pad 510 and the polishing platform 530 , and is vacuum-adsorbed on the upper surface of the polishing platform 530 . The polishing pad 510 is fixed on the upper portion of the substrate 520 , and the polishing head 540 is dispose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com