Patents

Literature

99results about How to "Measurement applicable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

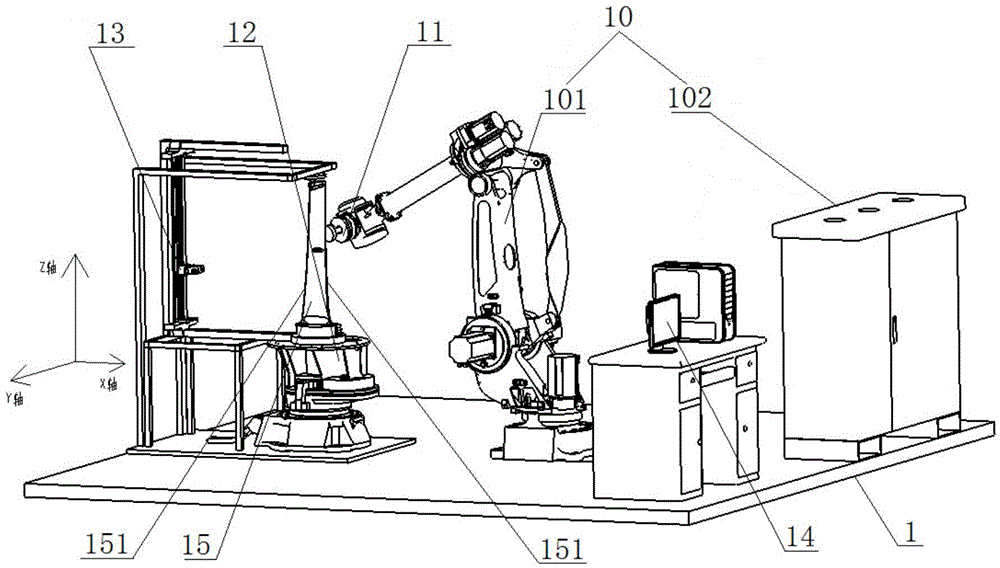

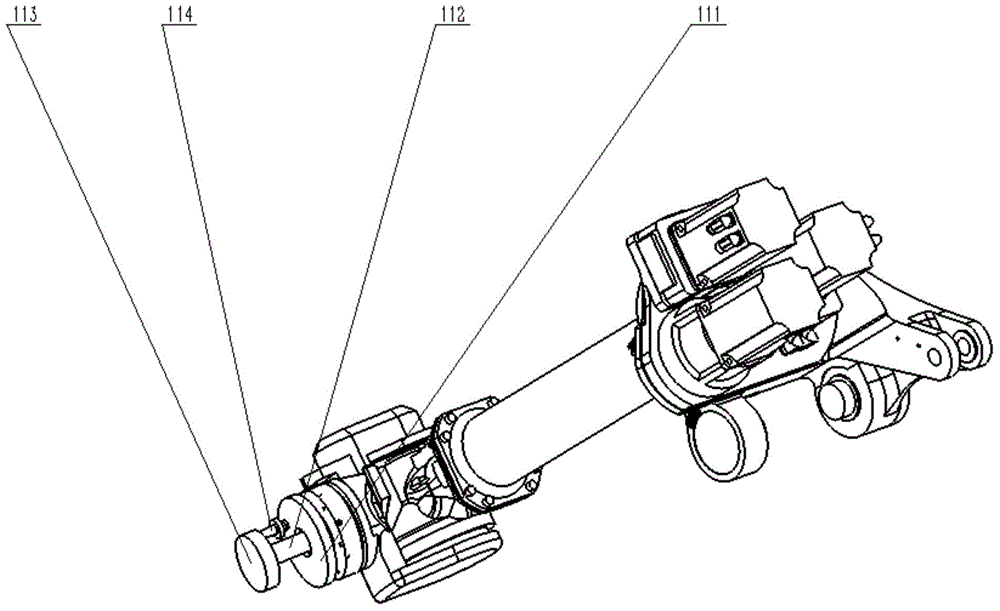

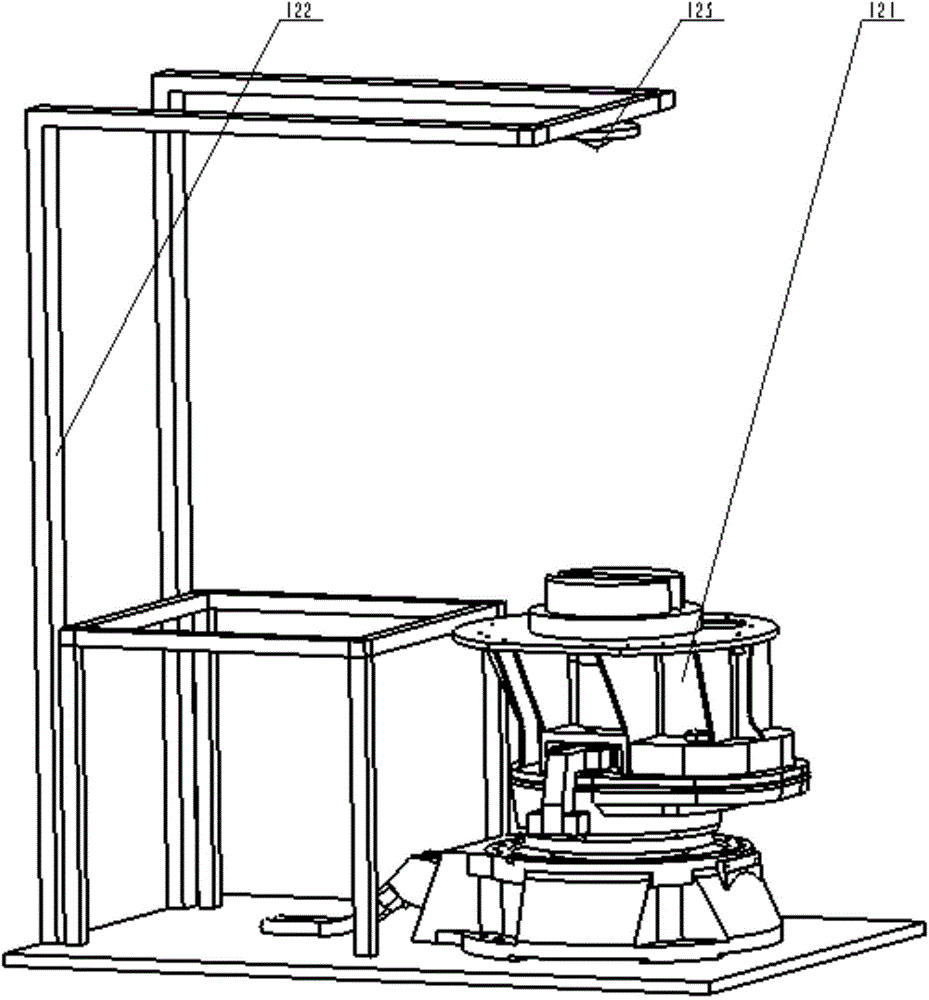

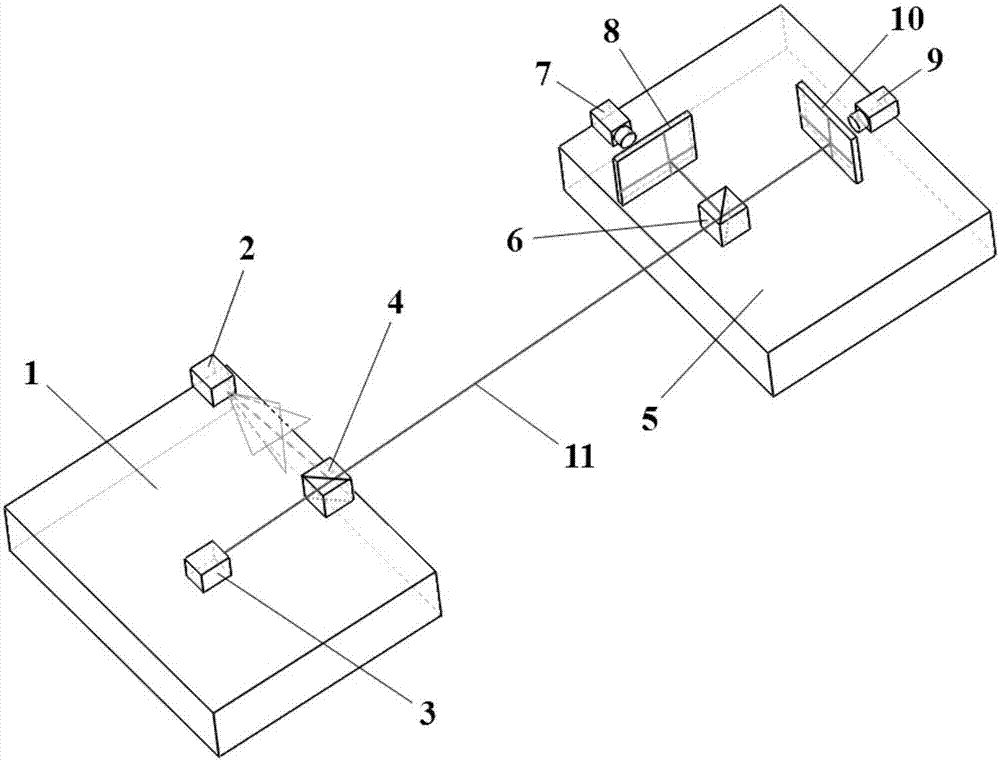

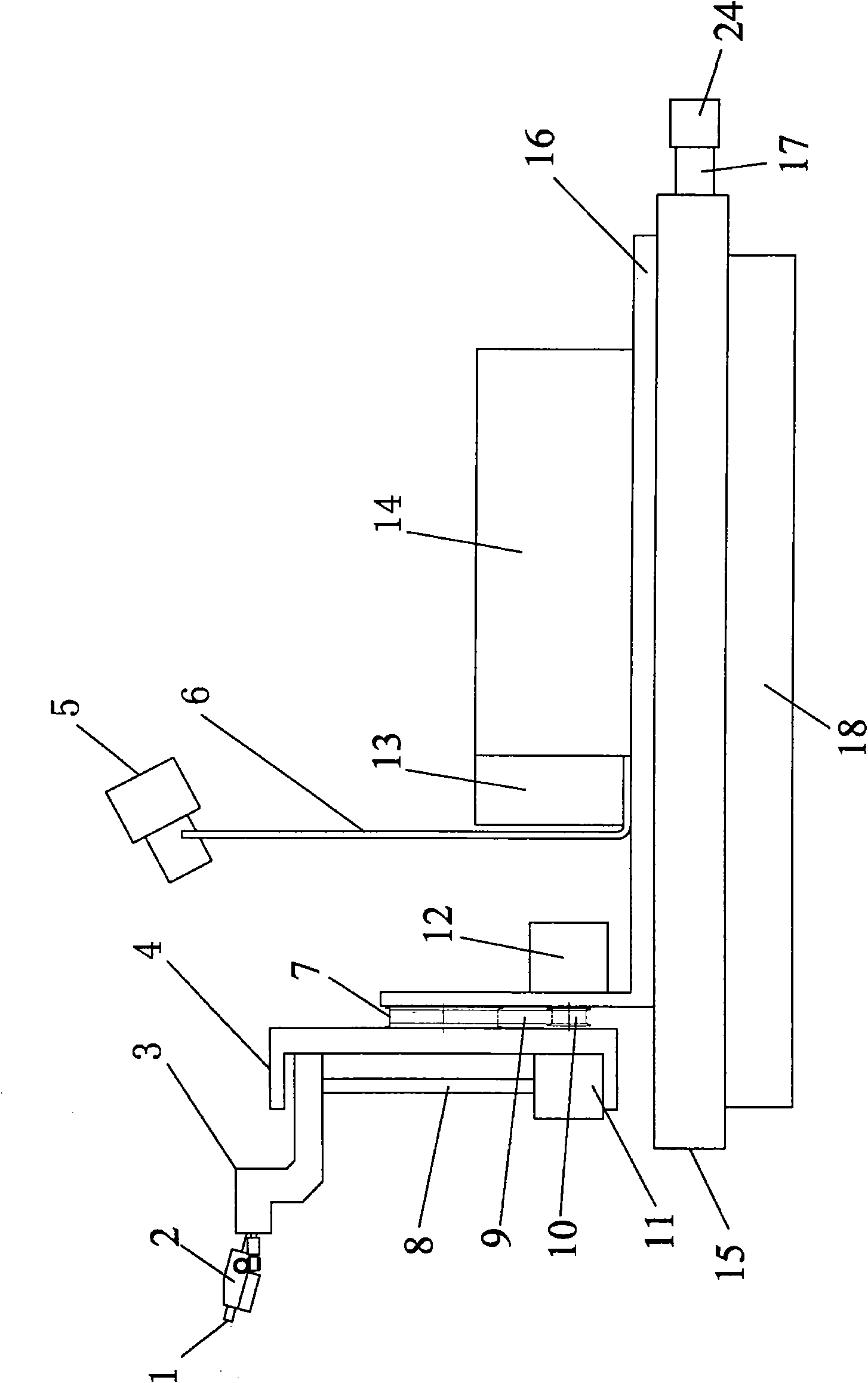

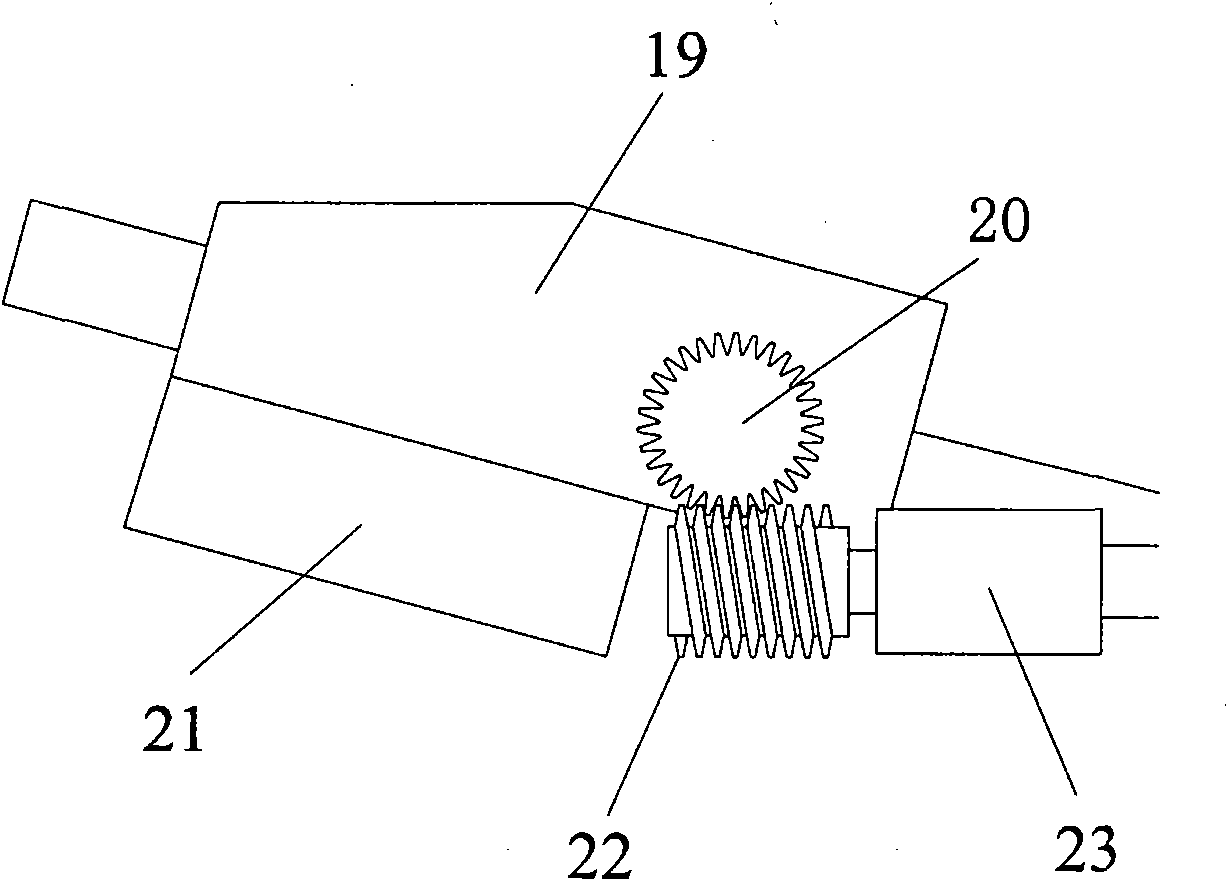

Automatic robot device for grinding air feeding and discharging edges of blade

ActiveCN104858748AGuaranteed machining accuracyGuaranteed grinding accuracyGrinding feed controlAutomatic grinding controlMeasurement deviceEngineering

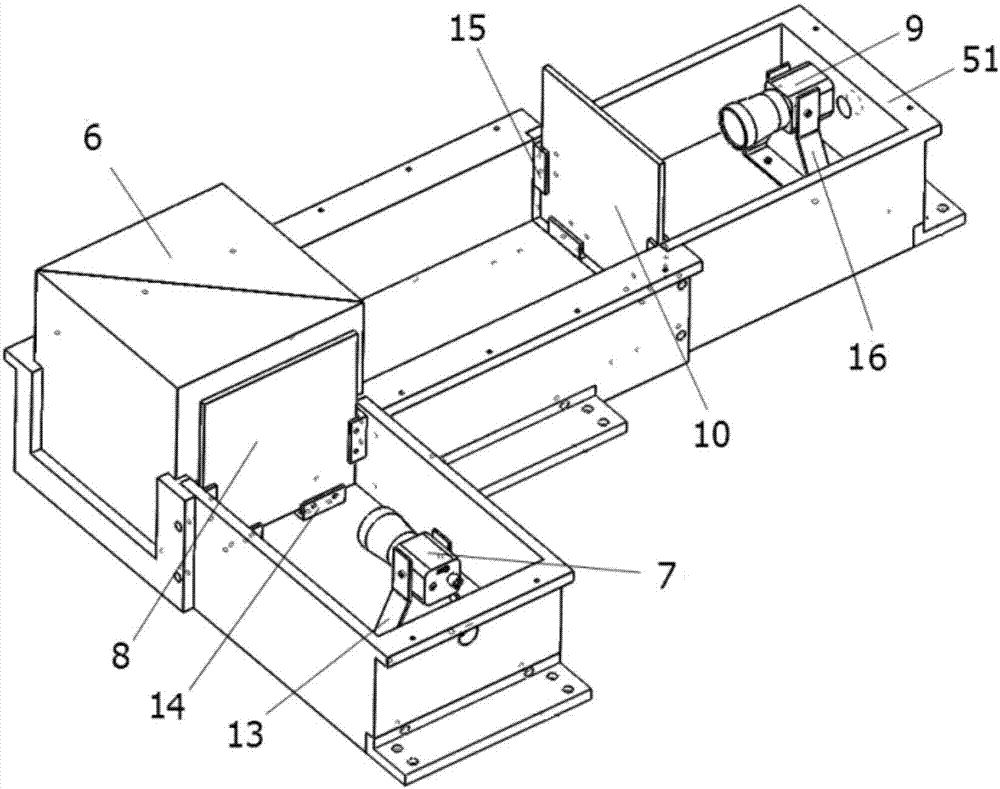

The invention discloses an automatic robot device for grinding air feeding and discharging edges of a blade. The automatic robot device comprises a base station, a six-freedom-degree robot, a grinding device, a position changing machine, a three-dimensional laser measurement device and a system control host. The six-freedom-degree robot is arranged on the base station. The grinding device is used for grinding the air feeding and discharging edges of the blade. The position changing machine is arranged on the base station. The three-dimensional laser measurement device is arranged on the position changing machine and comprises a triaxial movement platform and a three-dimensional laser measurement device body. The three-dimensional laser measurement device body comprises two three-dimensional laser outline scanners. The system control host is connected with the six-freedom-degree robot and the three-dimensional laser measurement device. The system control host is used for planning the machining path of the grinding device and a moving path of the three-dimensional laser measurement device and sending the paths and commands to the six-freedom-degree robot to be executed. The automatic robot device integrates self-adaptive grinding and measurement functions, and can guarantee the machining precision of the outlines of the air feeding and discharging edges of the blade.

Owner:HUST WUXI RES INST

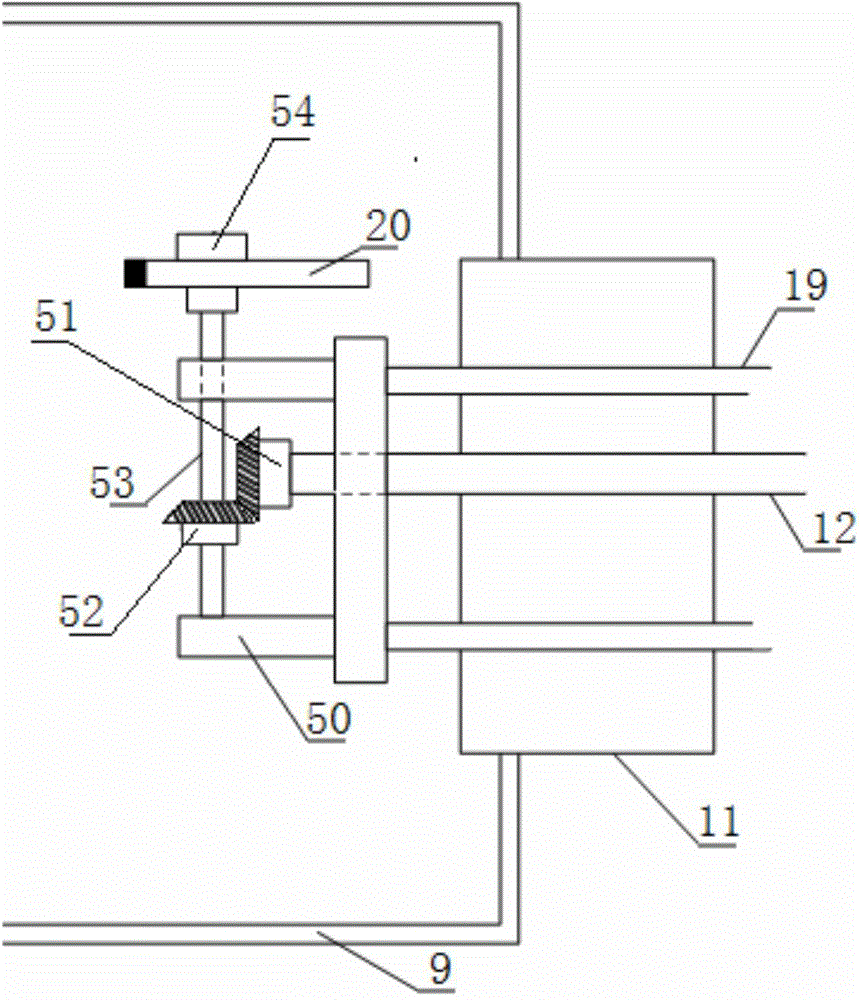

Surface charge measuring system with external motion control mechanism and measuring method

InactiveCN103954850ASmall sizeReduce SF

<sub>6</sub>

quantityElectrical measurementsParallel plateMotion controller

The invention discloses a surface charge measuring system with an external motion control mechanism and a measuring method. The surface charge measuring system and the measuring method aim to solve the problem that under a high-voltage SF6 environment, the surface charge of a component such as an insulator in a complex shape is difficult to measure. The surface charge measuring system mainly comprises a main shell, a side shell, an upper parallel-plate electrode, a lower parallel-plate electrode, an electrostatic measuring probe and a high-speed high-voltage electrostatic potential meter. According to a surface charge measuring device provided in the surface charge measuring system and the measurement method, the operation that one of the electrostatic measuring probe and the insulator rotates and the other one of the electrostatic measuring probe and the insulator moves horizontally can be achieved simultaneously by using equipment such as a multifunctional motion controller and a stepping motor, and it is ensured that the electrostatic measuring probe can scan and measure all parts of the surface of the insulator to be measured step by step.

Owner:CHONGQING UNIV +1

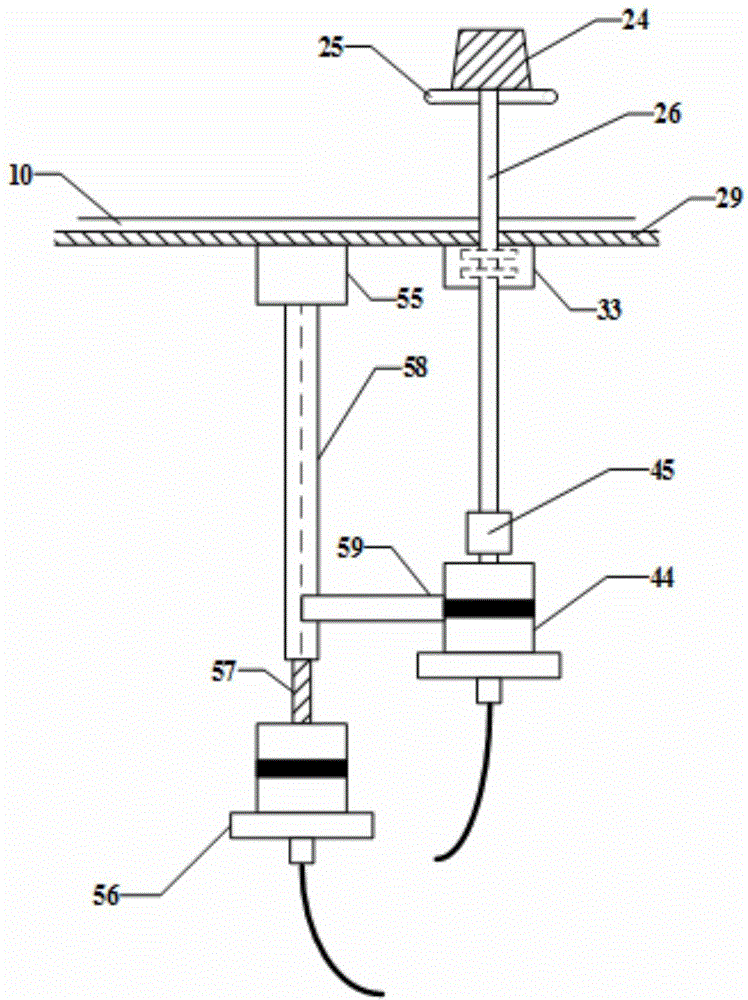

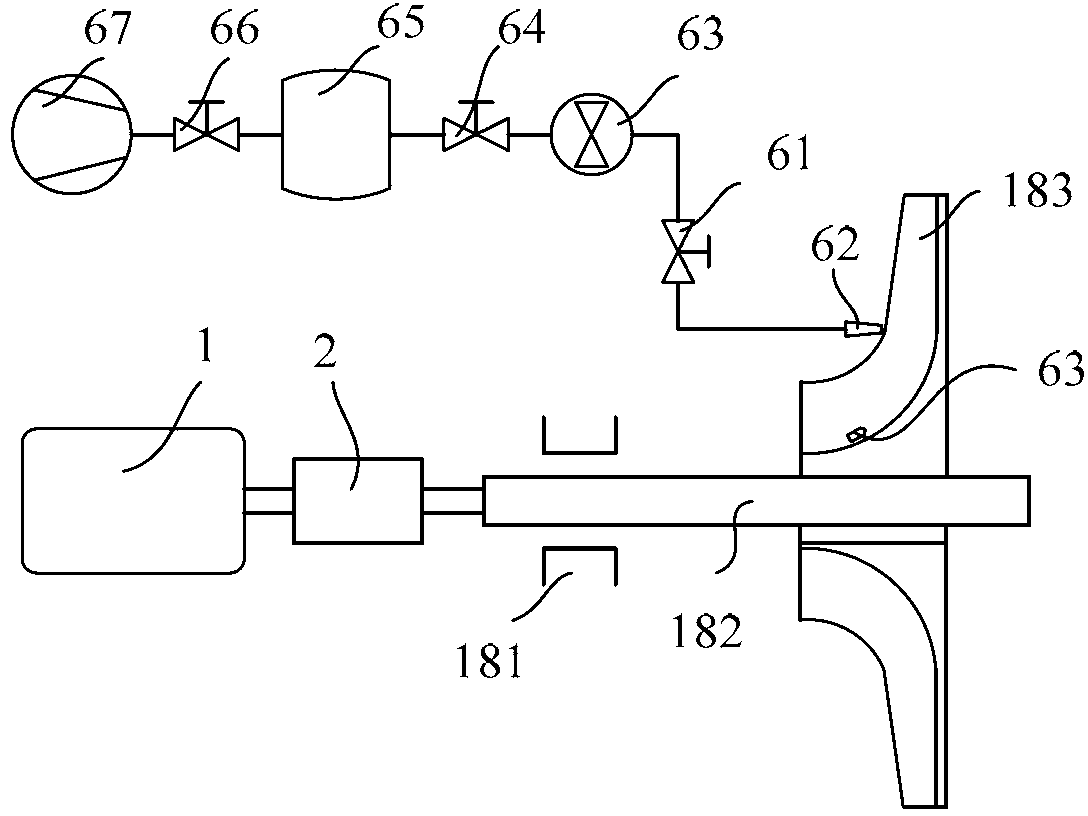

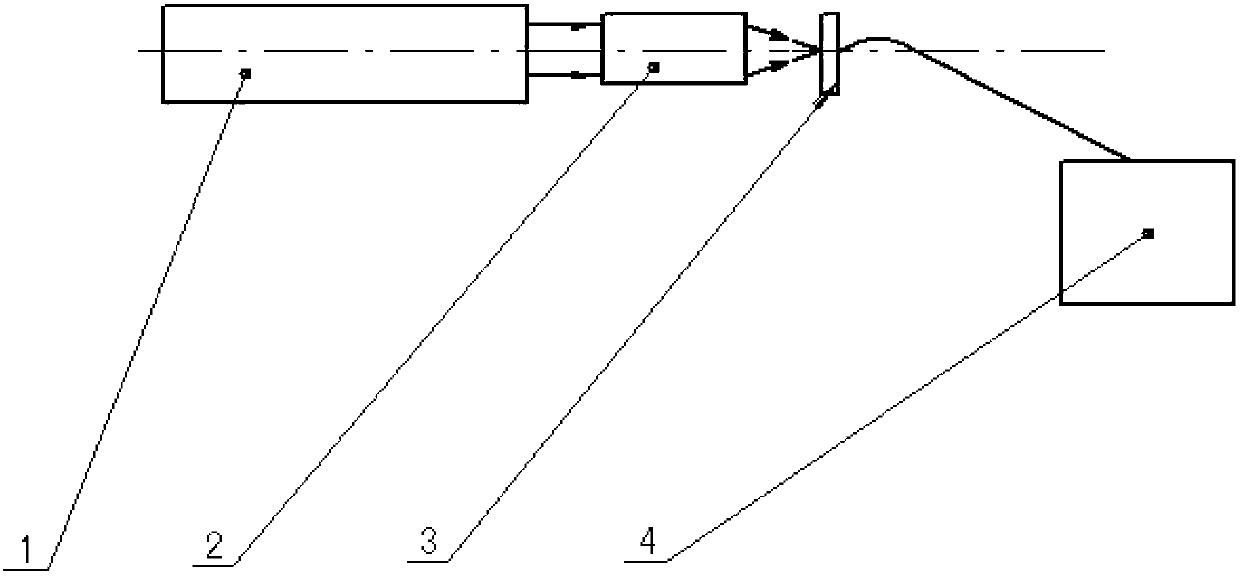

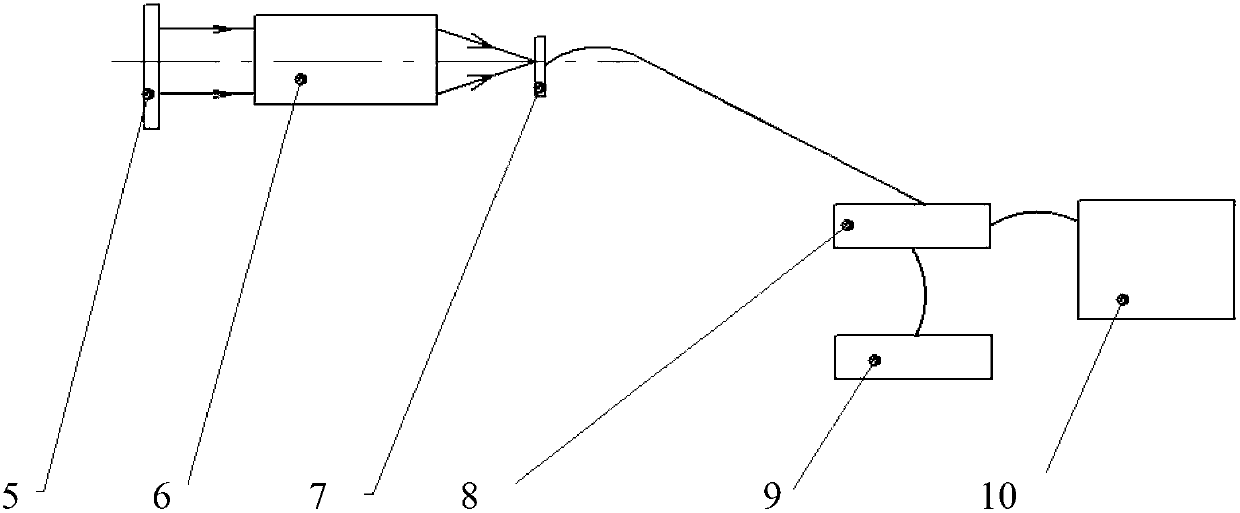

Real-time measurement device and method for dynamic positions and poses

ActiveCN107356236AAdjustable rangeAccuracy adjustableOptical rangefindersActive open surveying meansData processing systemData information

The invention discloses a real-time measurement device for dynamic positions and poses. The real-time measurement device for the dynamic positions and poses can be applied to real-time accurate position and pose measurement of a to-be-measured object in a dynamic environment and comprises a datum emission and transmission system, a dual-screen laser imaging system, a binocular visual inspection system and a data processing system, wherein the datum emission and transmission system provides three-dimensional angle datum for position and pose measurement by utilizing cross-line laser and a distance between a measured object and the measurement datum is obtained through combination with a distance measurement function; the dual-screen laser imaging system receives the cross-line laser and performs imaging on receiving screens; the binocular visual inspection system shoots cross-line laser images on the two receiving screens in real time and extracts position information of the cross-line laser center under the image coordinate system and an included angle between the cross horizontal line and a horizontal axis of the image coordinate system; the data processing system comprehensively processes data information of each system and calculates real-time positions and poses of the measured object relative to the measurement datum. The real-time measurement device is high in measurement precision, adjustable in measuring range and precision and suitable for measuring object positions and poses in a vibration environment.

Owner:TIANJIN UNIV

Gas particle concentration measurement method and device on basis of broadband linear frequency modulation ultrasound

InactiveCN102879309AHigh measurement accuracyLow costParticle suspension analysisPhysicsMeasurement device

Owner:SOUTH CHINA UNIV OF TECH

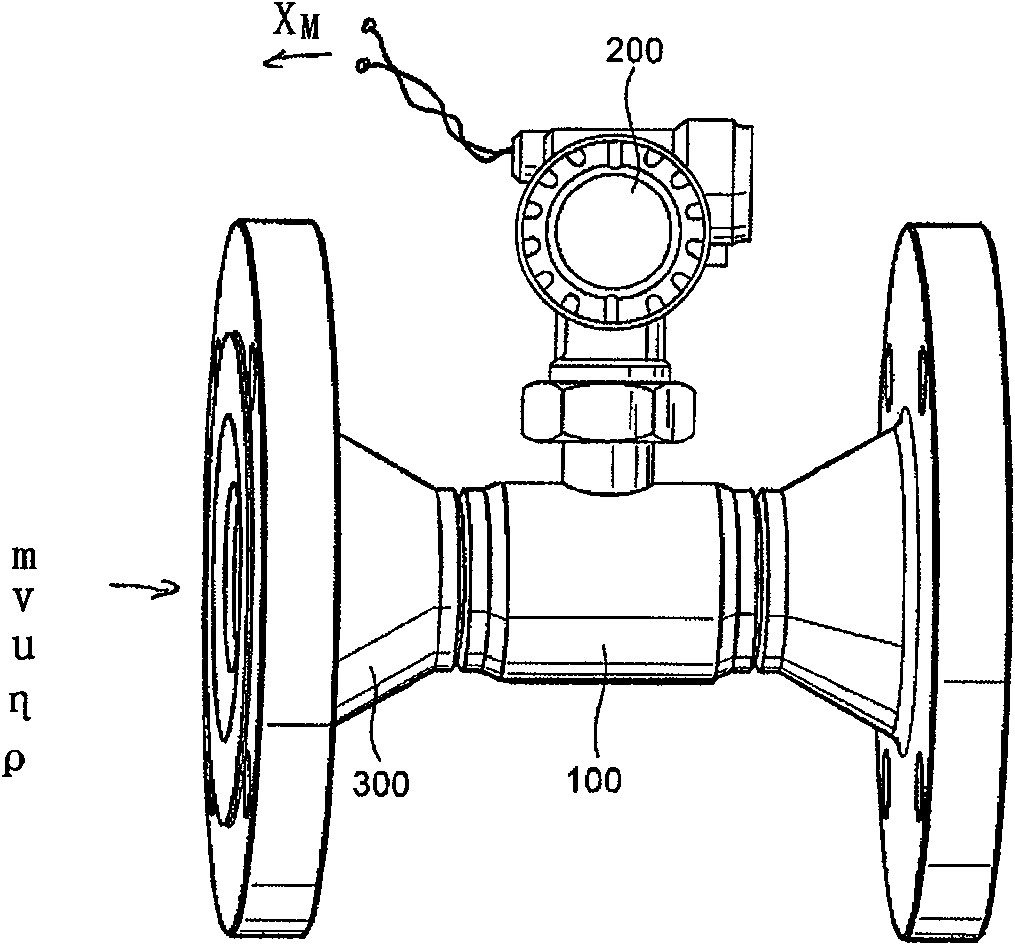

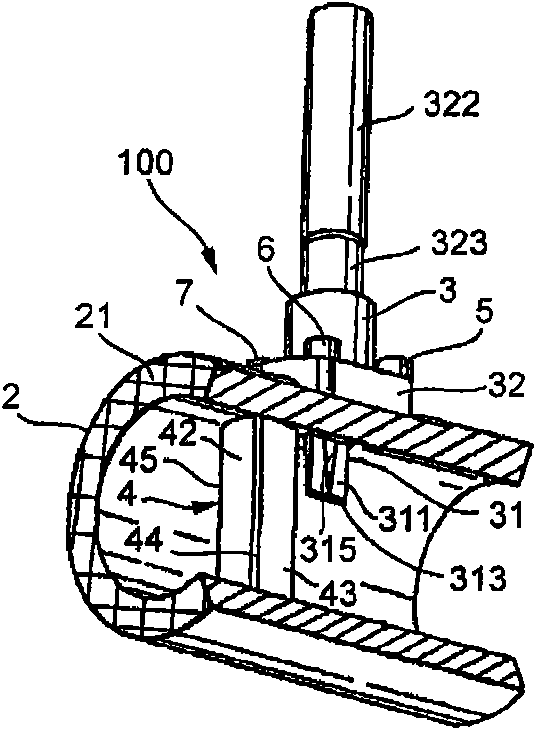

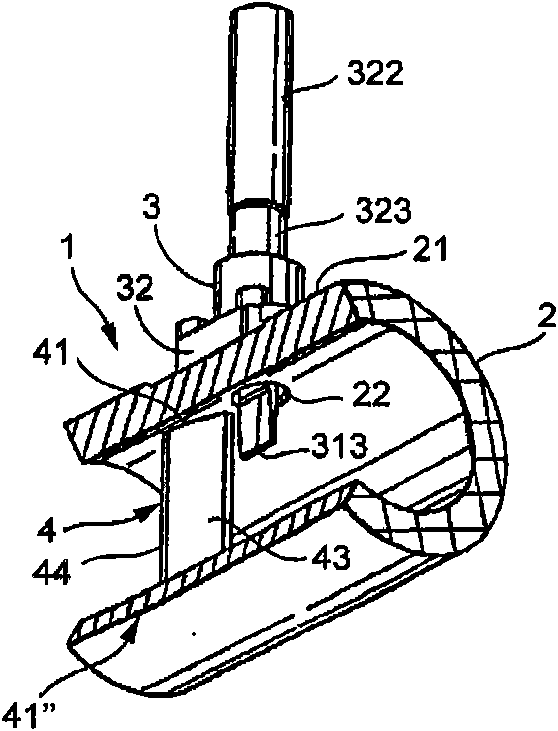

Measuring system for a medium flowing in a process line

ActiveCN101553714AEliminate disturbanceEasy to captureVolume meteringVolume/mass flow by dynamic fluid flow effectLine tubingEngineering

The measuring system is placed in the course of a process line and is used to detect at least one measurement variable of a medium flowing in the process line. The system comprises a measuring sensor for this purpose with a measuring tube that conducts the medium to be measured and a sensor assembly which has at least one sensor element that reacts primarily to the measurement variable to be detected and which supplies at least one measurement signal that is influenced by the measurement variable by means of the sensor element or elements. In addition, the measuring system comprises measuringelectronics that communicate with the measuring sensor and that use the measurement signal(s) to generate, at least intermittently, at least one measured value that represents the current measurementvariable. The measuring tube of said measuring system has a smaller flow cross-section than a supply segment of the process line that is connected to the inlet side of the measuring system. The measuring system therefore also has a flow conditioner that is situated on the inlet side of the measuring tube, extends between said tube and the supply segment of the process line and has a lumen which tapers towards the measuring tube and through which the medium flows during operation. The flow conditioner has at least one baffle which is situated upstream of the outlet end of said conditioner, projects into the lumen of the latter and against which the medium in the conditioner flows.

Owner:ENDRESS HAUSER FLOWTEC AG

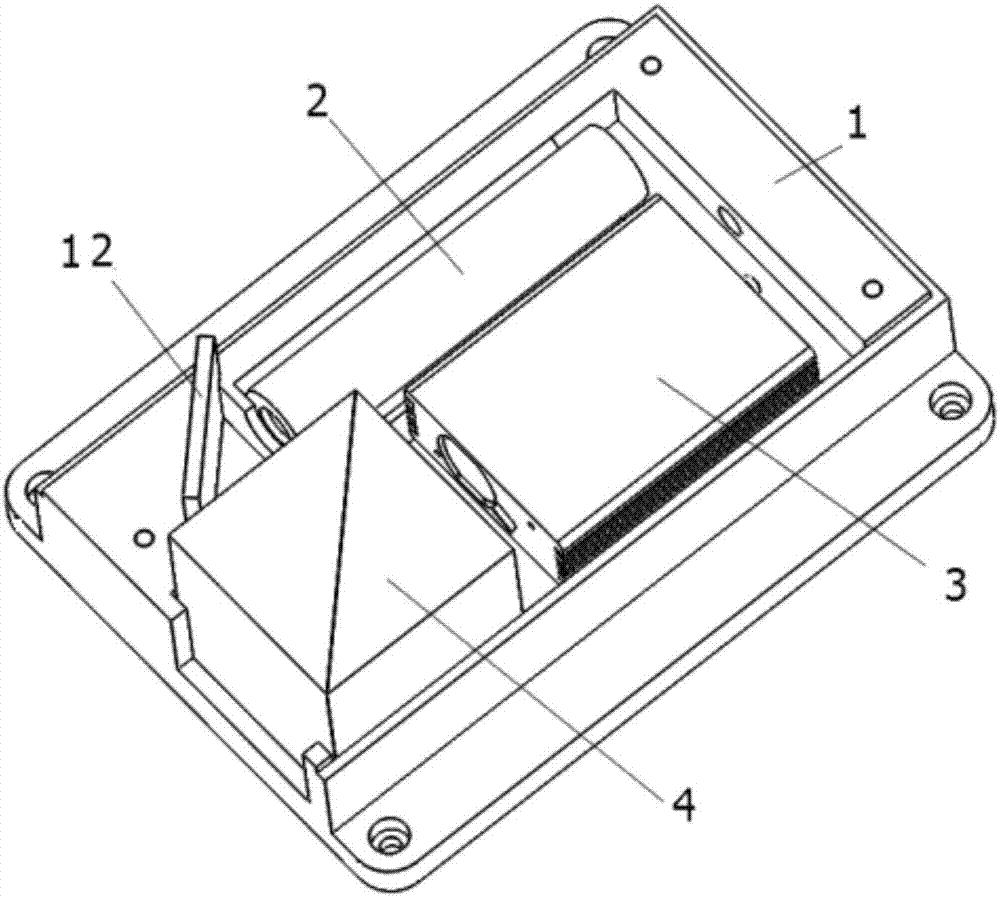

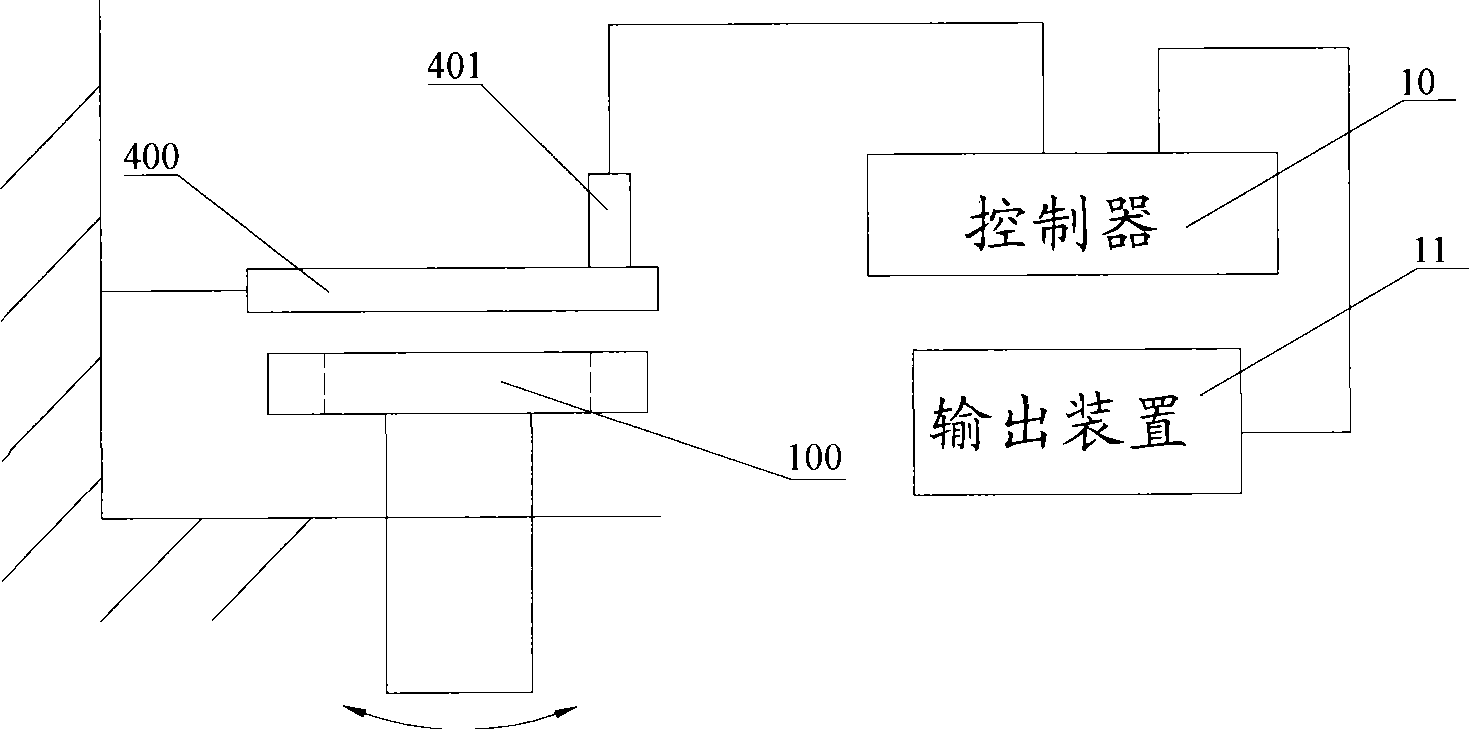

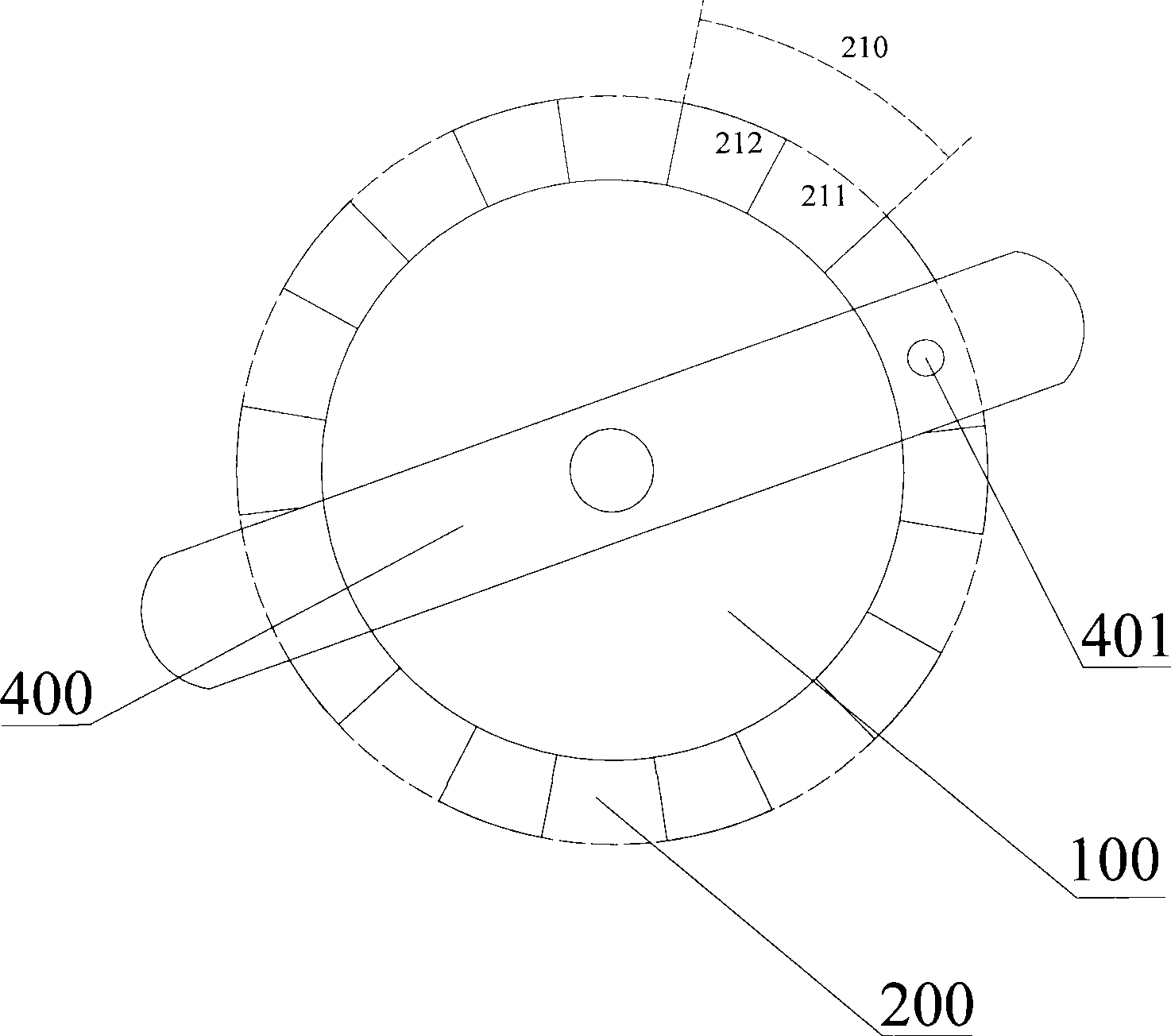

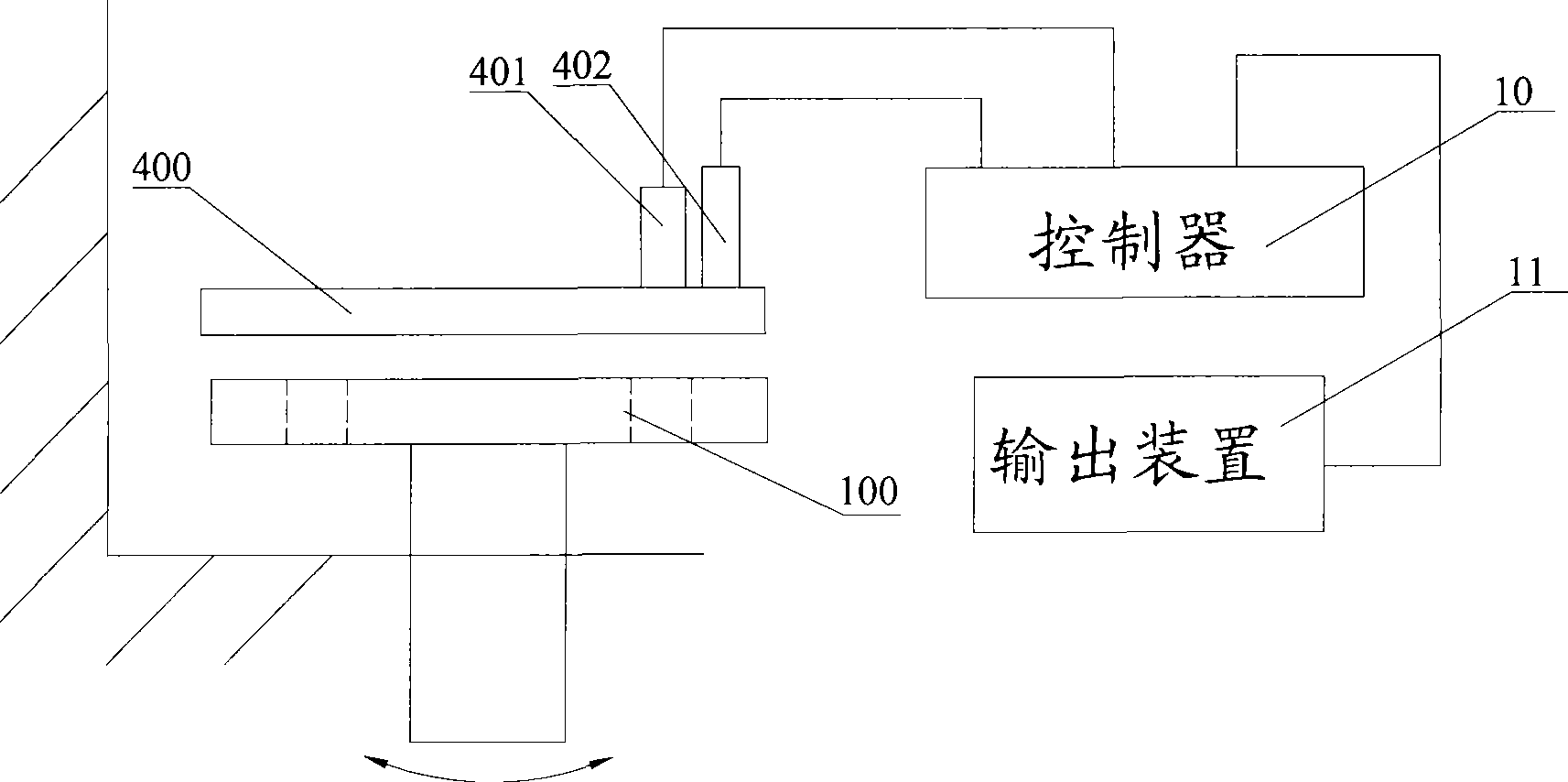

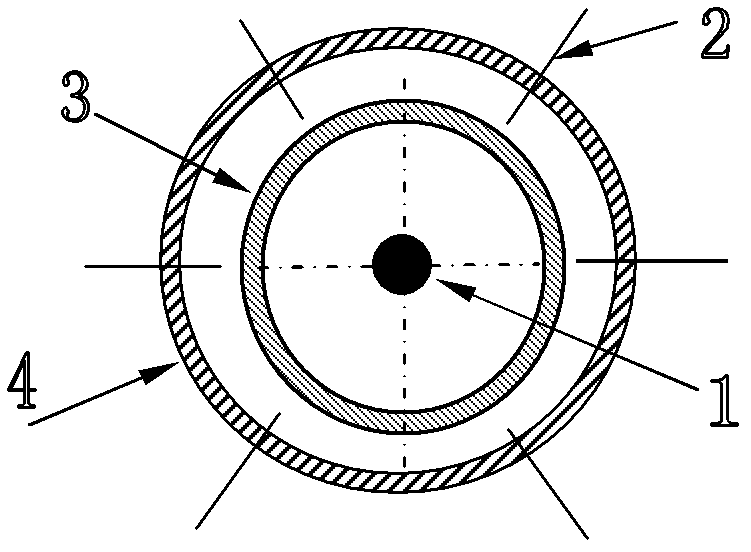

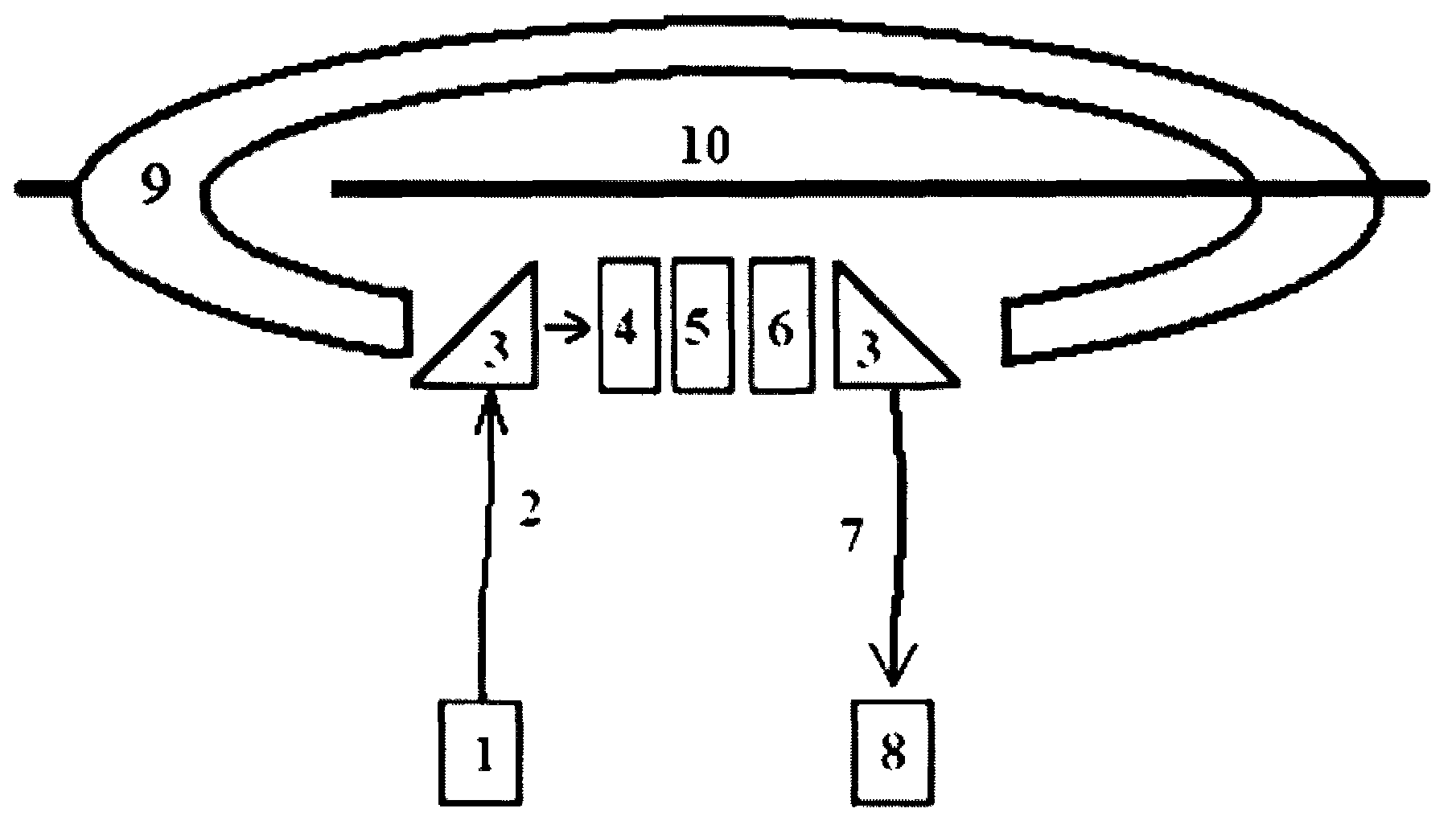

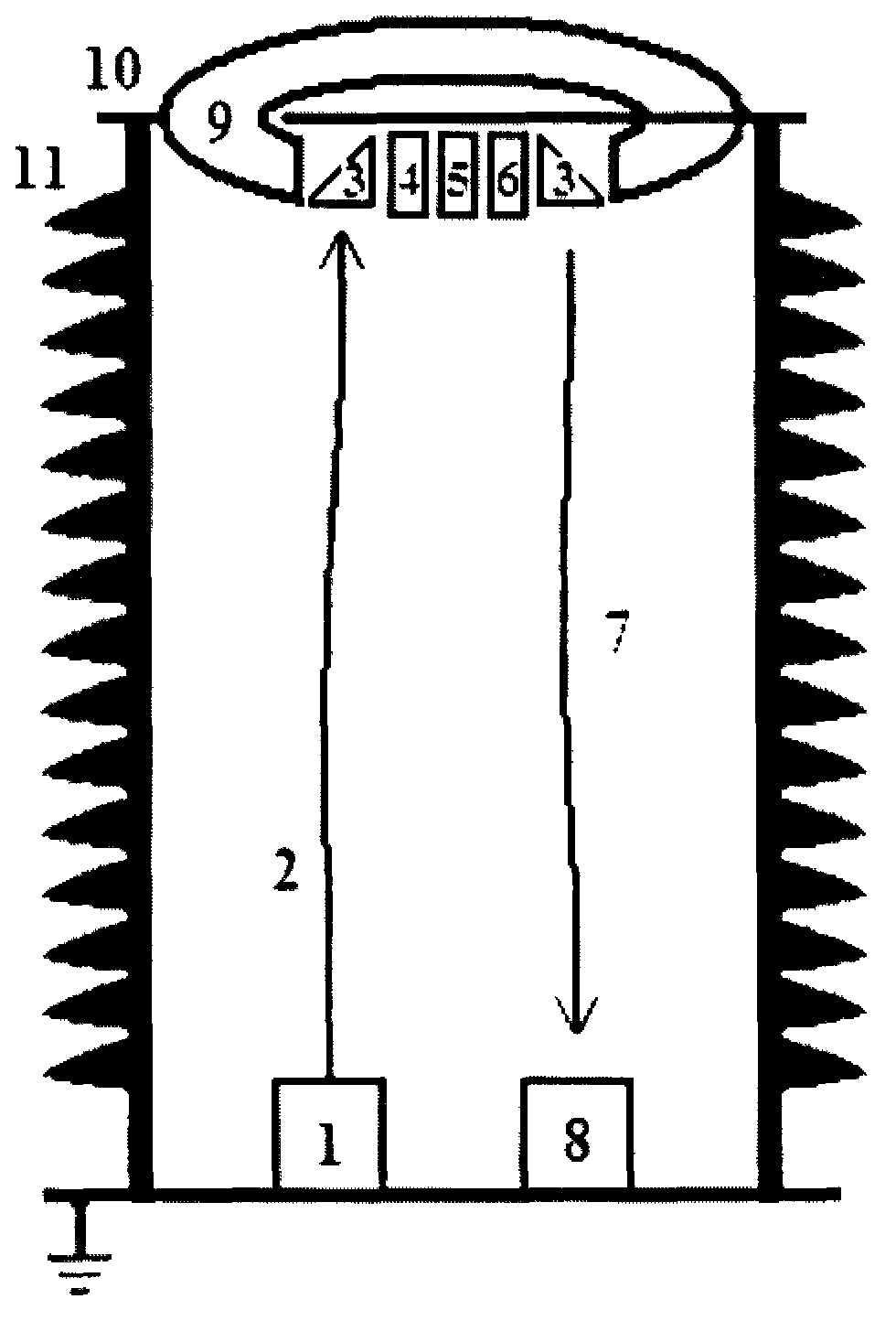

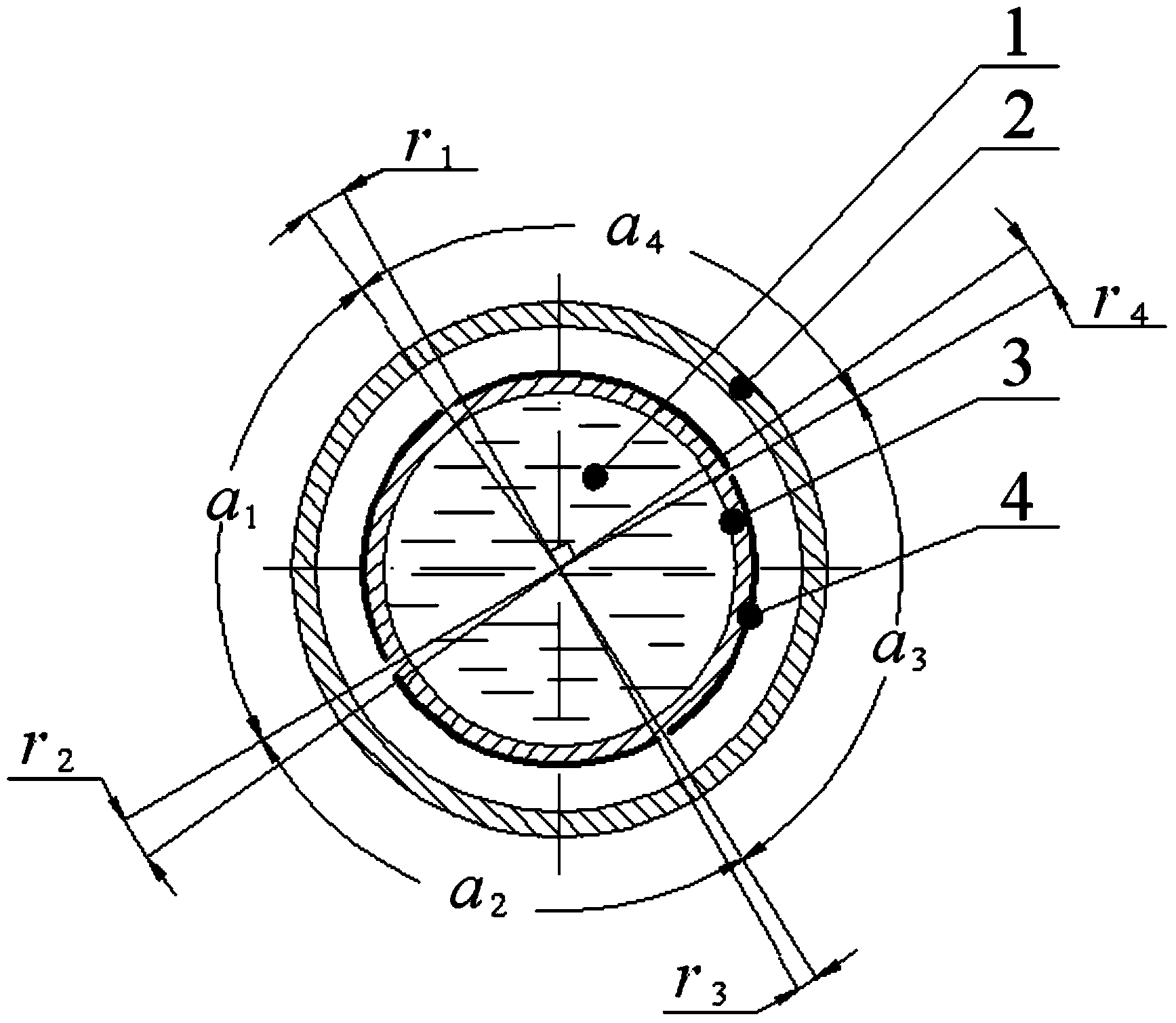

Four-dimensional self-adaptive insulation piece surface charge measuring device

InactiveCN101788613AMeasured close toMeasurement applicableElectrical measurementsMeasurement deviceImage resolution

The invention relates to a four-dimensional self-adaptive insulation piece surface charge measuring device, which belongs to the technical field of the high-voltage device and the electron. The measuring device comprises a measuring probe, a probe control mechanism, a rotation disc, a camera, a power source, a controller infrared distance meter and the like. A distance signal is received by the infrared distance meter, the distance and the angle between the probe and the measured surface are automatically adjusted through a plurality of motors, the probe is maintained to be vertical to the surface, and the distance between the probe and the measured surface is constant, so the measurement of the surface charge of the insulation piece is realized. The measuring device can be arranged inside a sealing cavity which can bear the air pressure, measures the surface charge of the insulation piece in the high-air-pressure environment, realizes two translation motions and rotations of the probe, is applicable to the measurement of the insulation pieces with different shapes, and has high space resolution ratio.

Owner:TSINGHUA UNIV

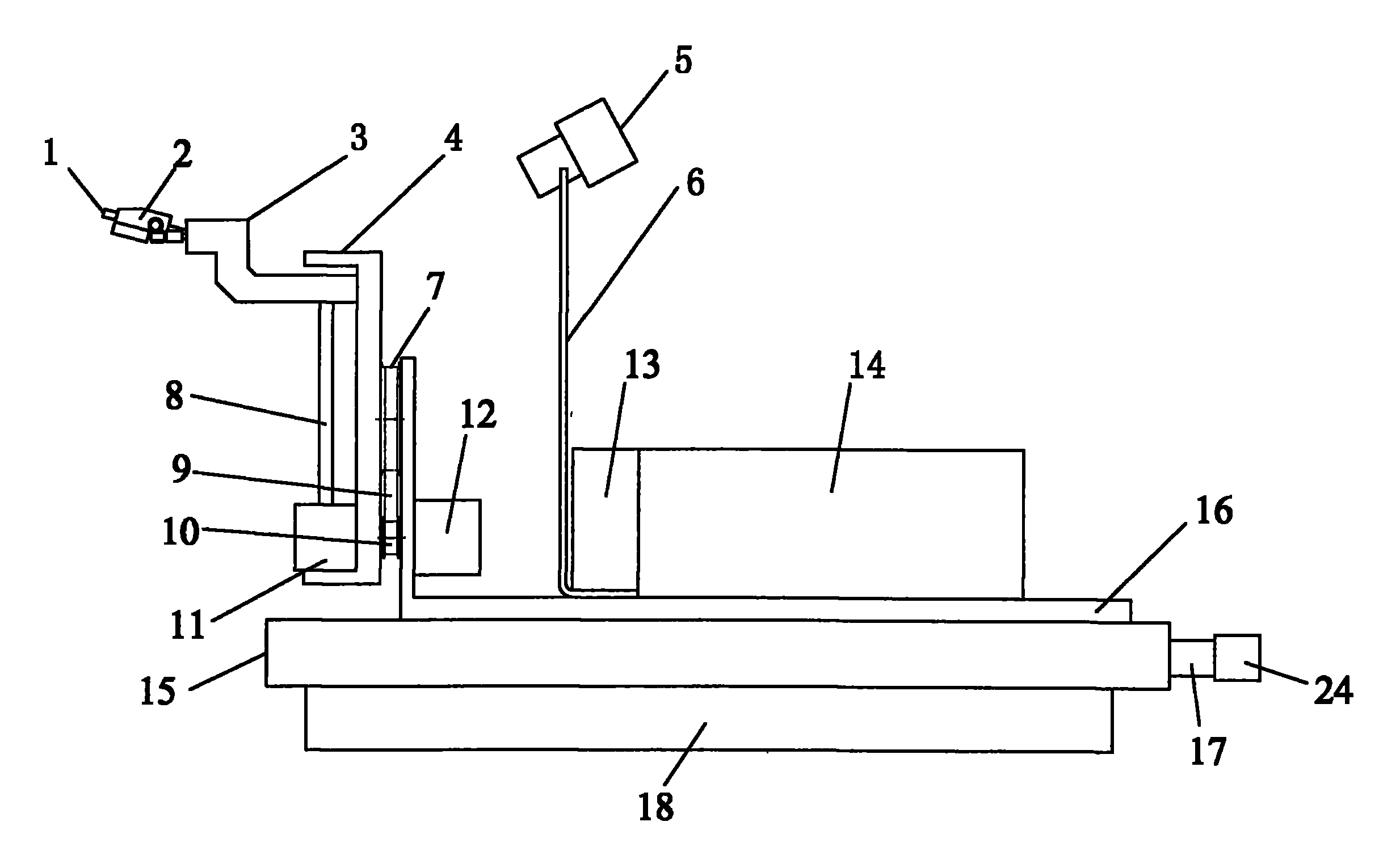

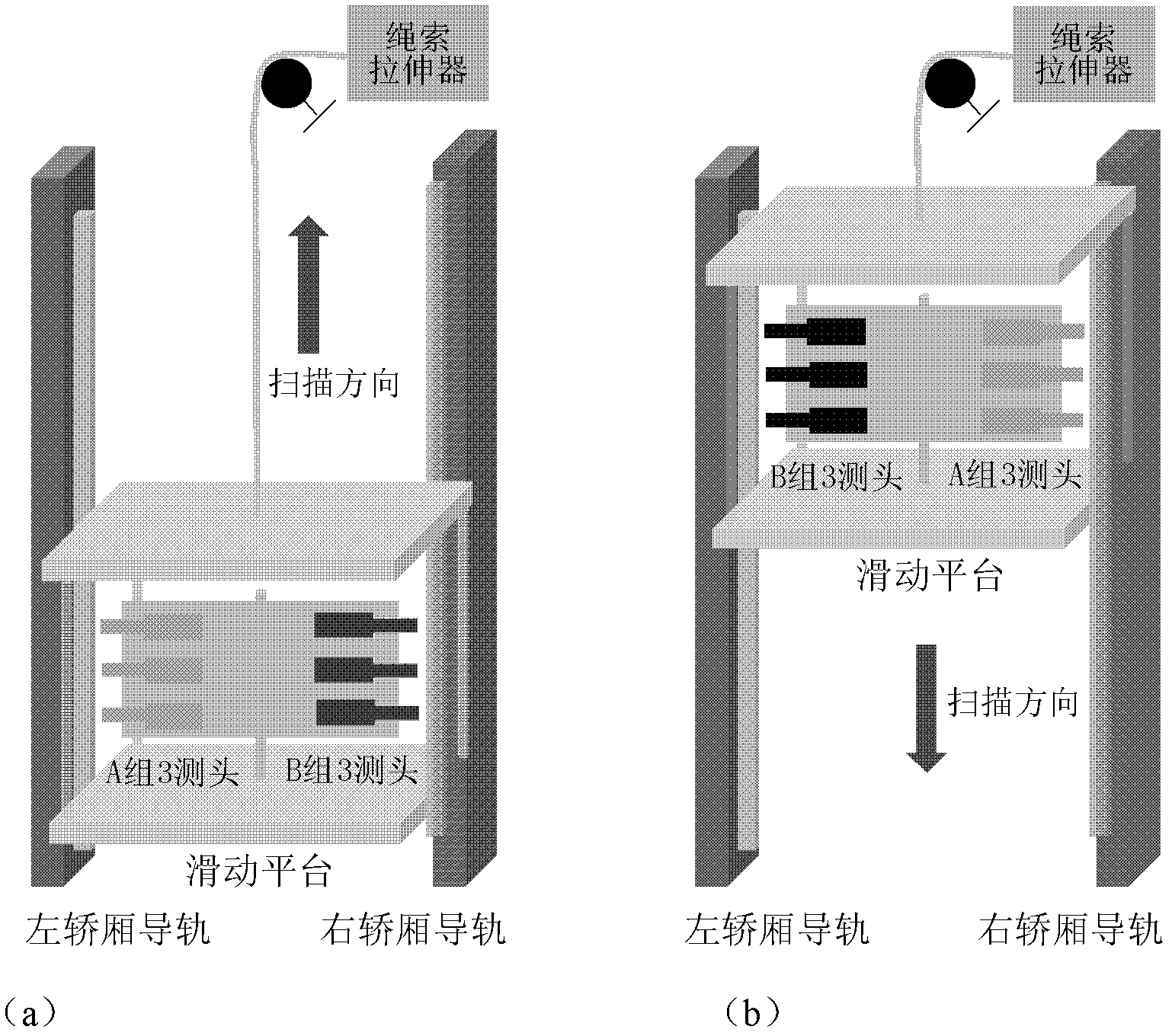

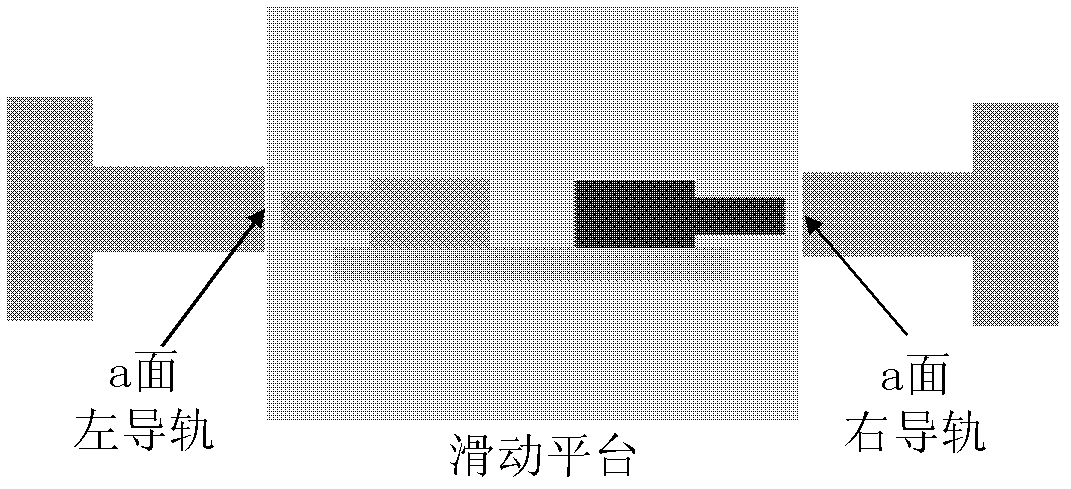

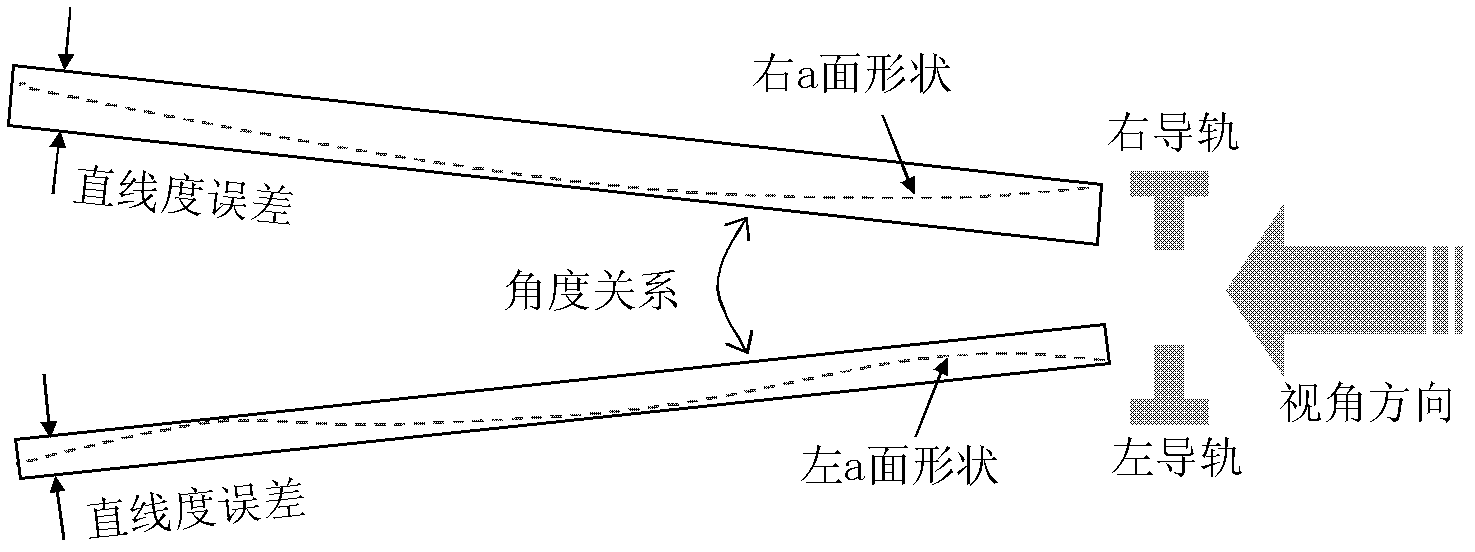

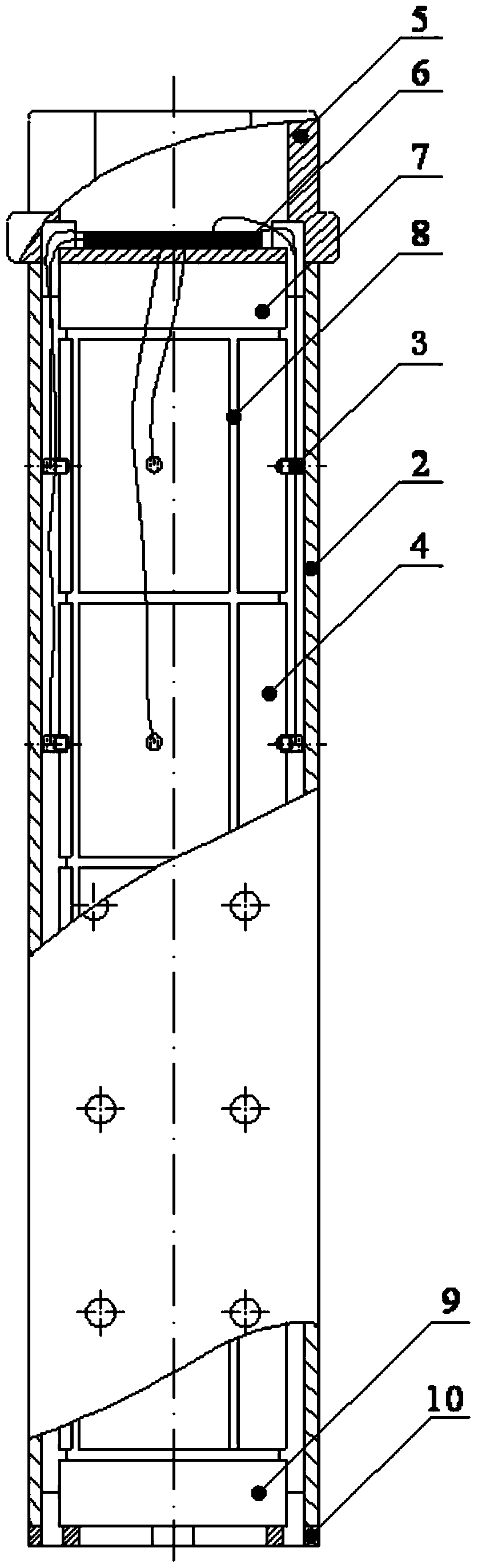

Device and method of guide rail straightness measuring

InactiveCN103033161AUnlimited lengthMeasurement applicableMeasurement devicesTraction systemMeasurement device

The invention discloses a device and a method of a guide rail straightness measuring. The device of the guide rail straightness measuring comprises displacement sensor installation arms, a data acquisition system, a slide platform and an upper computer control system, wherein each array of the displacement sensor installation arms are provided with a plurality of displacement sensor assemblies which are arranged at the roughly same intervals, and sensor measuring faces are basically in the same plane. Compared with the background technology of a guide rail straightness measuring device, scan guide rails do not need to be additionally and specially arranged, and the existing lift car and the traction system are only needed to be borrowed. The length of each measured guide rail is not limited, three faces of a single guide rail can be respectively measured, and spatial position relationship between two guide rails can be measured. By adopting the guide rail straightness measuring device, guide rail straightness and the spatial position relationship of the guide rails can be on-position high-accurately measured, the device and the method of the guide rail straightness measuring particularly has no limit on the length of each installed measured lift guide rail and is suitable for measuring the installed lift guide rails.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

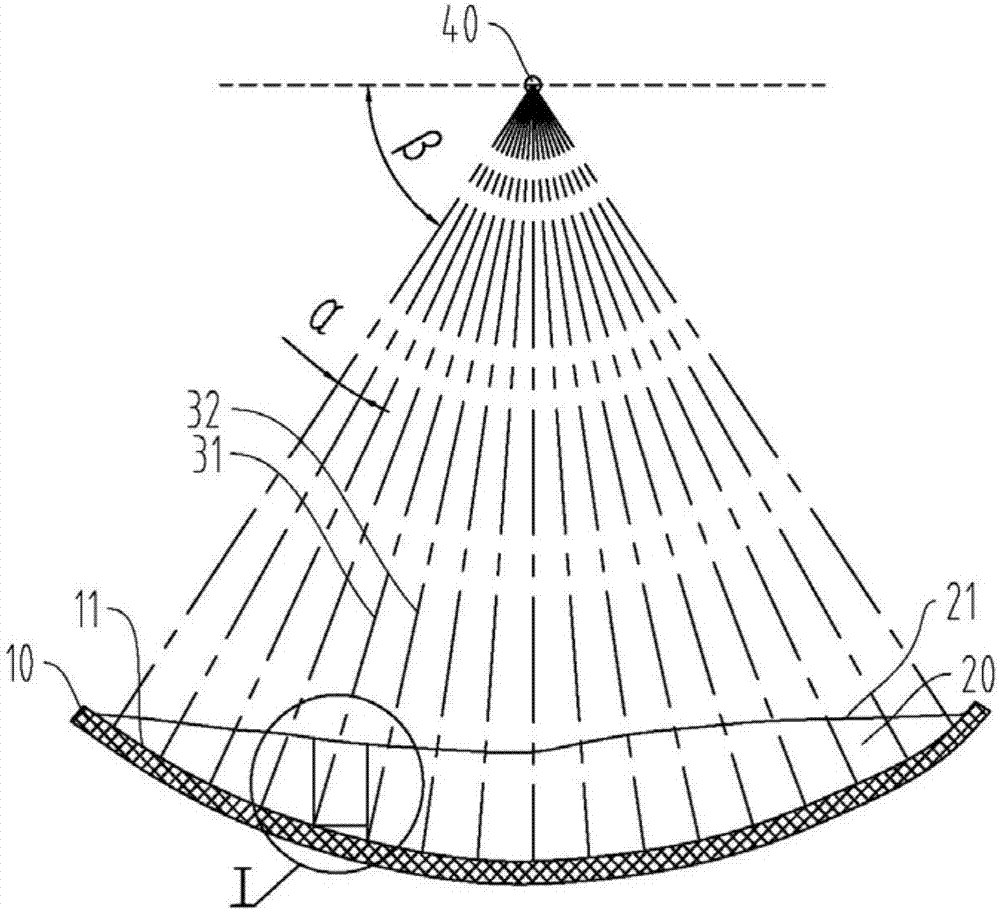

Structural fault detection method and system for measuring relative deformation of wind turbine blade

ActiveCN109099852AOvercoming the technical difficulty of matchingMeasurement applicableUsing optical meansCorrelation coefficientReference Region

The invention discloses a structural fault detection method and a system for measuring the relative deformation of a wind turbine blade, wherein the method comprises: calculating a rotation angle of adeformation region relative to a reference region; generating a deformation region parameter; updating pixel coordinates of the deformation region after rotating the angle; calculating a pixel pointmatching correlation coefficient of the reference region and the updated deformation region; updating the deformation region parameter; updating the pixel coordinates; calculating the pixel point matching correlation coefficient of the reference region and the deformation region after the second update; comparing the pixel point matching correlation coefficient of the deformation region after thesecondary update with a preset threshold value; and calculating three-dimensional coordinates of the pixel in the deformation region and the strain of the blade to determine and locate the structuralfailure of the blade. According to the structural fault detection method and the system for measuring the relative deformation of the wind turbine blade, the technical difficulty of the traditional digital image correlation technology method in matching the large rotation angle can be overcome, and it is suitable for the measurement of the rotating blade.

Owner:SHANGHAI UNIV +1

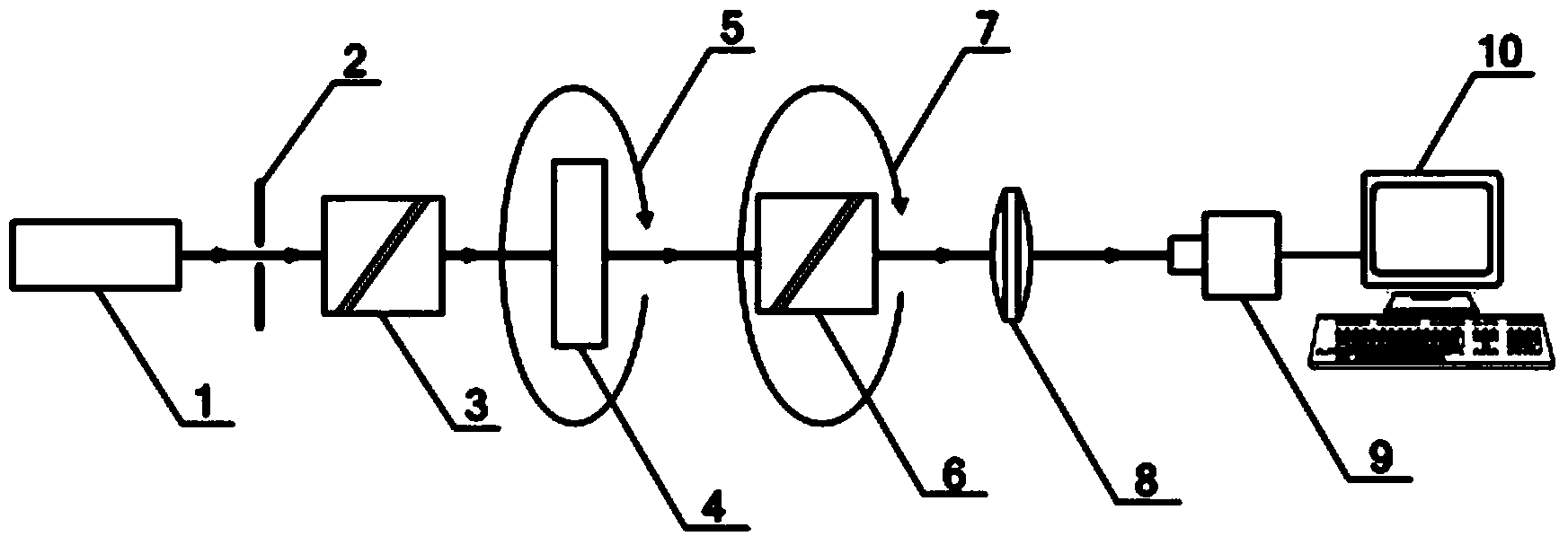

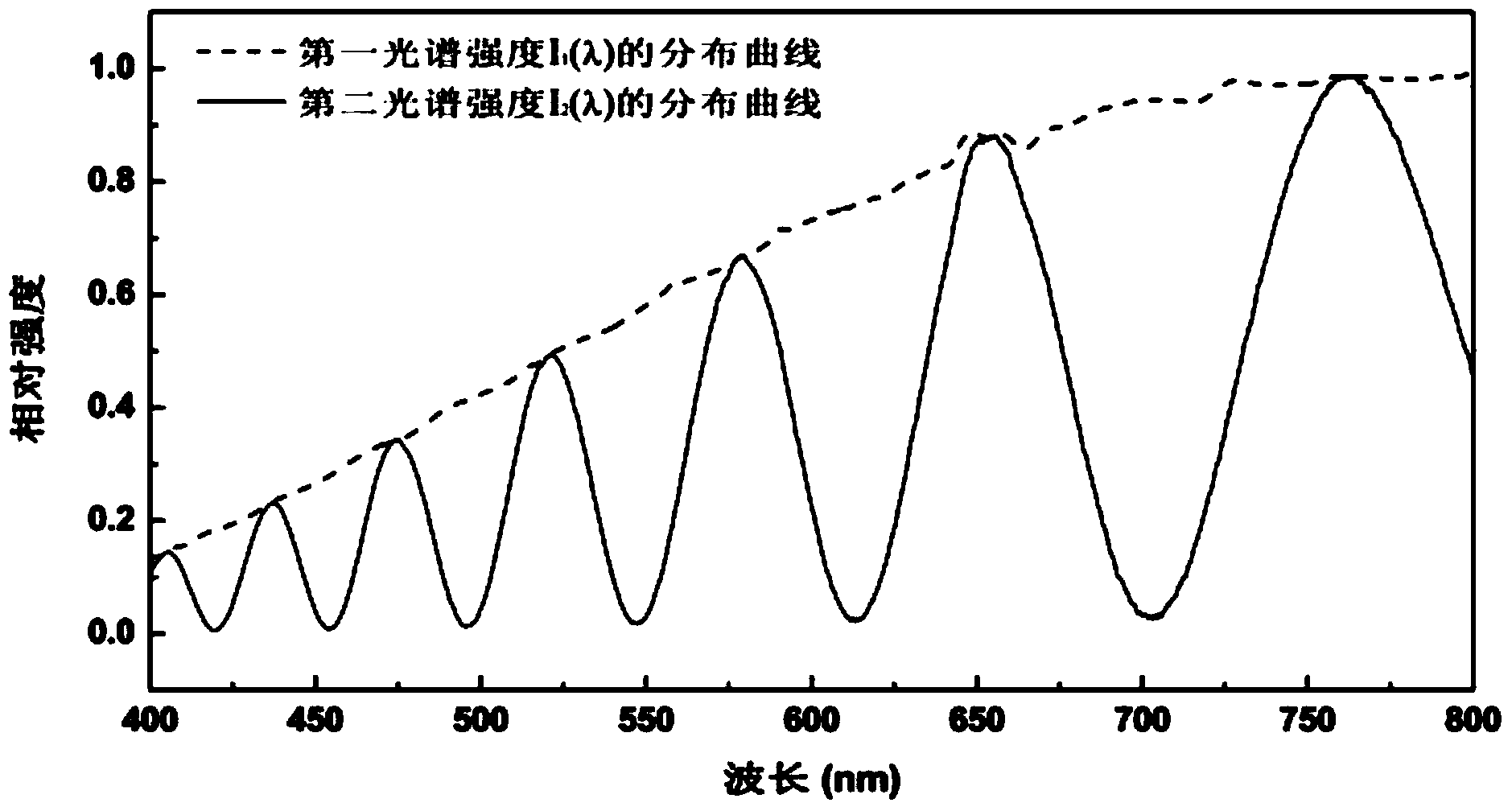

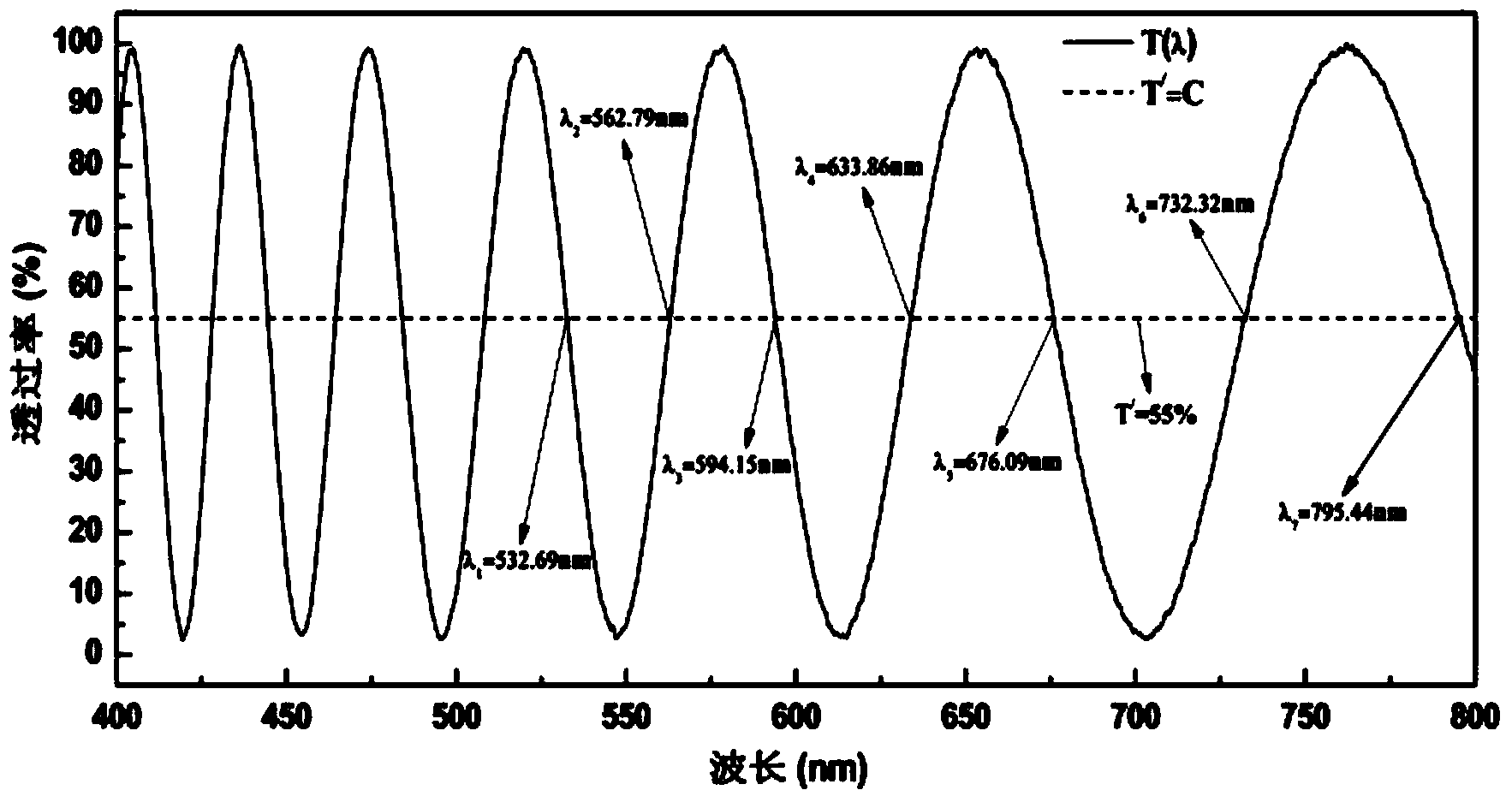

Method capable of accurately measuring phase delay quantity of wave plate

InactiveCN103411756AGuaranteed to proceed normallyMeasurement applicableTesting optical propertiesPhase retardationTransmittance

A method capable of accurately measuring the phase delay quantity of a wave plate belongs to the technical field of parameter measurement of the wave plate. A device comprises a light source, a diaphragm, a polarizer, the wave plate to be detected, a polarization analyzer, a spectrometer and a computer. A uniformization spectrum transmittance T (lambda) curve can be obtained by measuring a first spectrum intensity I1 (lambda) distribution curve and a second spectrum intensity I2 (lambda) distribution curve. The computer is utilized to calculate the phase delay quantity and other a plurality of physical parameters of the wave plate to be detected according to the wave length of the intersection point between a line with the transmittance as a fixed value and the uniformization spectrum transmittance T (lambda) curve. The method is a non-contact nondestructive measurement technique and can acquire the plurality of physical parameters of the absolute phase delay quantity, the effective phase delay quantity, the thickness, the level and the like of the wave plate to be detected in a wide spectrum range. The method is high in measuring accuracy, a measuring device is easy to adjust, requirements for the position of the polarizer, the position of the wave plate to be detect and the position of the polarization analyzer are not strict, and the method is suitable for measuring a non-compound crystalline wave plate.

Owner:SHANDONG JIAOTONG UNIV

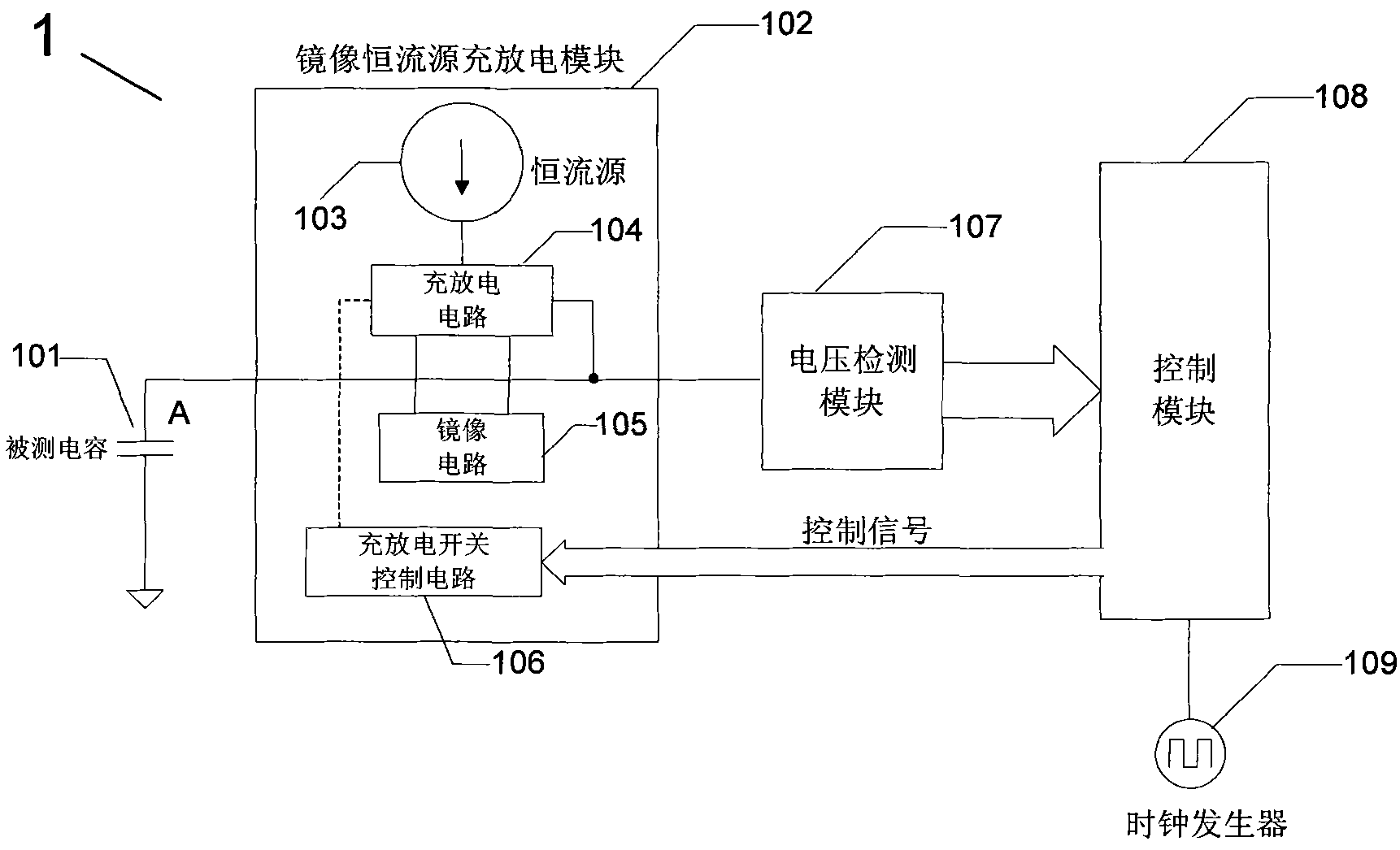

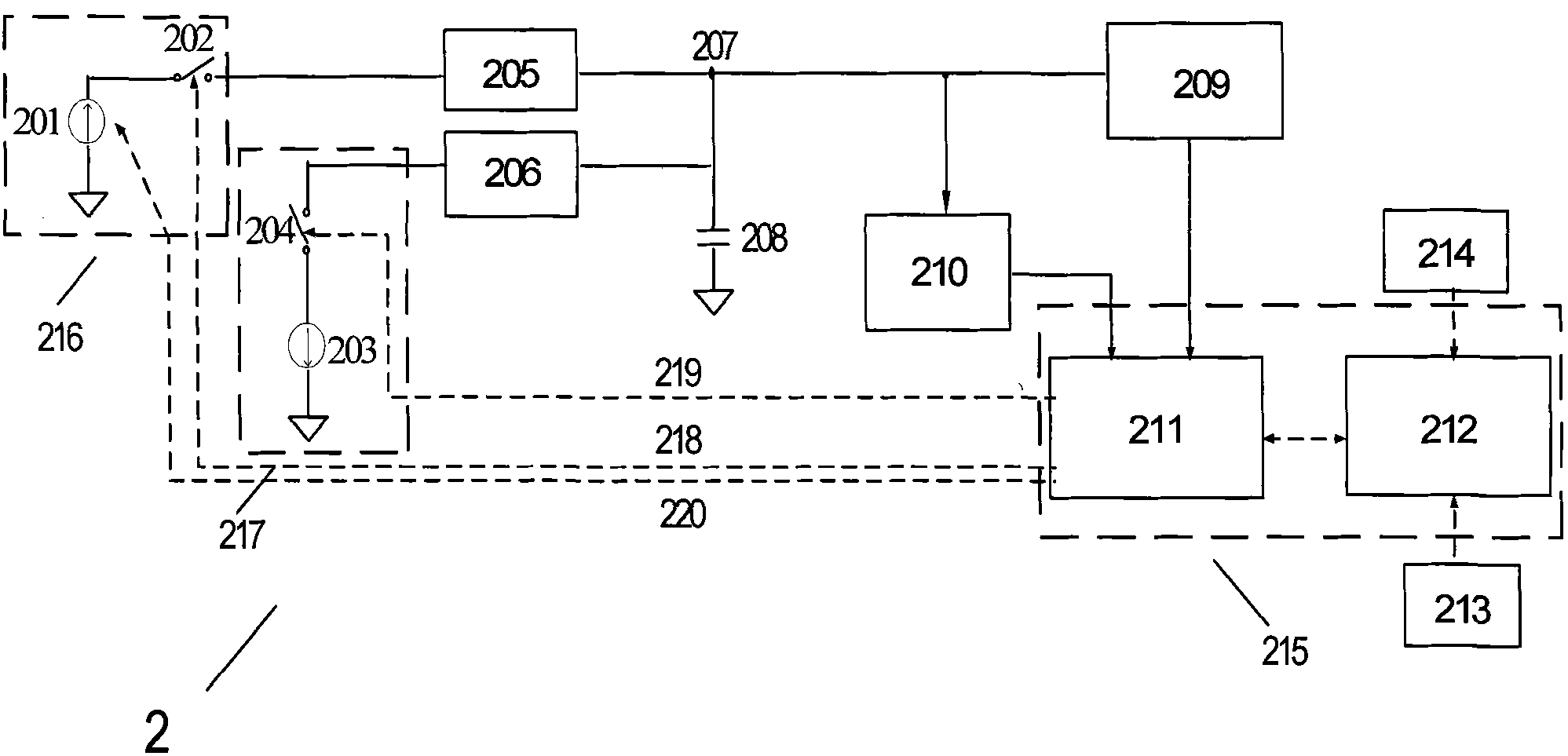

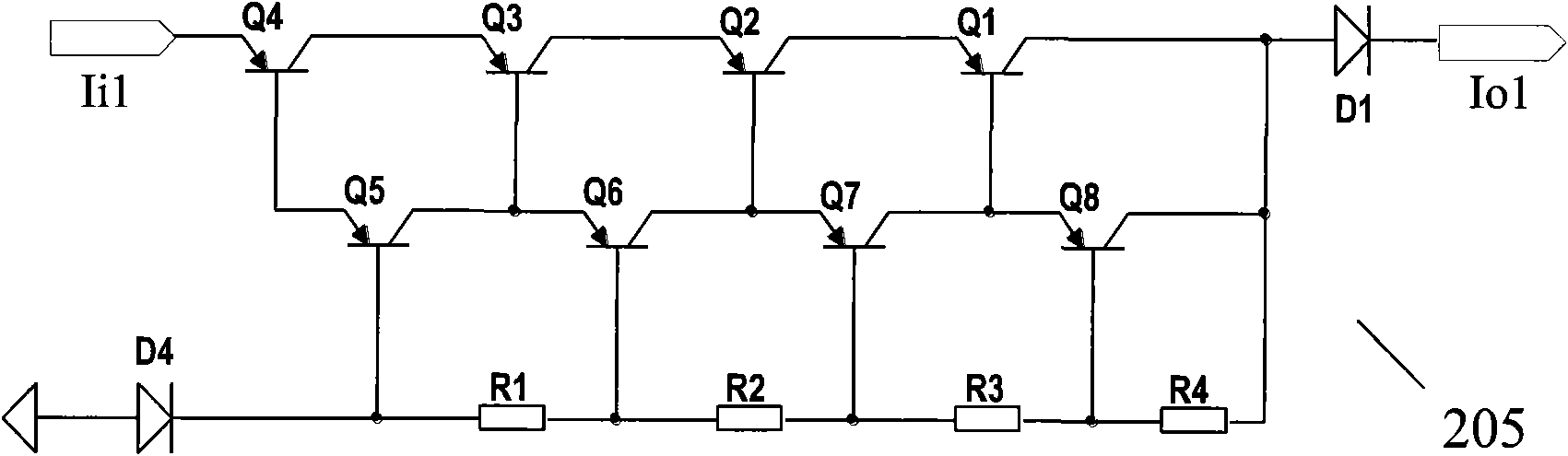

Measurement device with function of measuring capacitance

ActiveCN102072989AMeasurement applicableSimple control methodResistance/reactance/impedenceMeasurement deviceDelta-v

The present invention provides a measurement device with a function of measuring capacitance, which comprises a capacitance measurement end (207), a charging module (216), a discharging module (217), an A / D (analog / digital) conversion module (209), a double-limit comparator (210), a control processing module (215), a first voltage division circuit (205) and a second voltage division circuit (206). The charging timer of the control processing module (215) has two charging ending conditions: the maximum charging time and the first threshold voltage VH. When the charging ending conditions are satisfied, the charging timer stops timing, and the A / D conversion module (209) is controlled to measure the voltage. By adopting the method, the charging time delta t and the voltage delta V in the formula C = Ic delta t / delta V can be obtained, and the capacitance of a capacitor (208) to be measured can be calculated. The measurement device solves the problem of the prior art that the existing measurement device can not automatically adapt to measurement of small capacitance and large capacitance.

Owner:RIGOL

Rotating angle measurement apparatus and rotating angle measurement method

InactiveCN101387491AEasy to installEasy maintenanceUsing electrical meansConverting sensor outputMeasurement deviceClassical mechanics

Owner:SANY HEAVY IND CO LTD (CN)

Method for measuring deformation of metal cylinders under internal explosion effect and device

InactiveCN102519352AMeasurement method directReliable measurement resultsUsing electrical meansElectrical/magnetic solid deformation measurementMetal cylinderEngineering

Disclosed are a method for measuring deformation of metal cylinders under an internal explosion effect and a device. The device consists of an exploder, a priming device, a plurality of electric probes, a multichannel detonation velocity meter and signal recording equipment. The exploder is arranged on an axis of a metal cylinder, the priming device detonates the exploder and outputs a priming time signal, the electric probes are arranged outside the metal cylinder, by the aid of the multichannel detonation velocity meter, pulse response is generated when measuring points of the electric probes contact with the wall of the metal cylinder, the signal recording equipment is used for recording output pulses of the multichannel detonation velocity meter and the priming time signal, gap values among the measuring points of the electric probes and the wall of the metal cylinder form a non-equivalence sequence, and when one of the electric probes contacts with the wall surface of the metal cylinder, a deformation value measured at the position of the corresponding measuring point of the electric probe corresponds to radial deformation of the metal cylinder. The method and the device have the advantages of simplicity, directness, reliable measurement results, easiness in operation and the like, measurement of deformation of different ranges is realized by means of changing mounting positions of the measuring points of the electric probes, and the method and the device are particularly applicable to measuring large-deformation parameters.

Owner:NORTHWEST INST OF NUCLEAR TECH

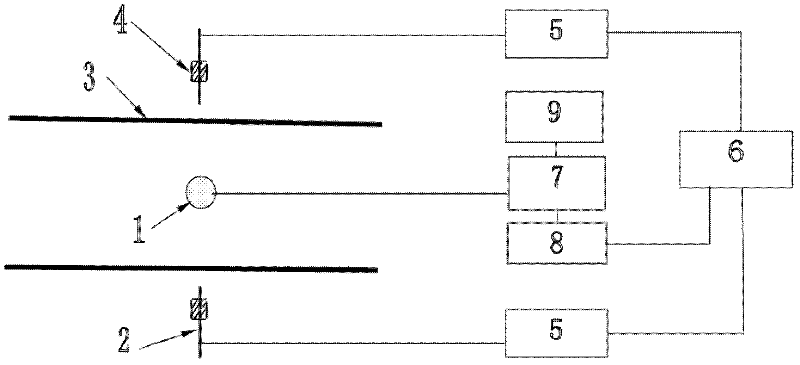

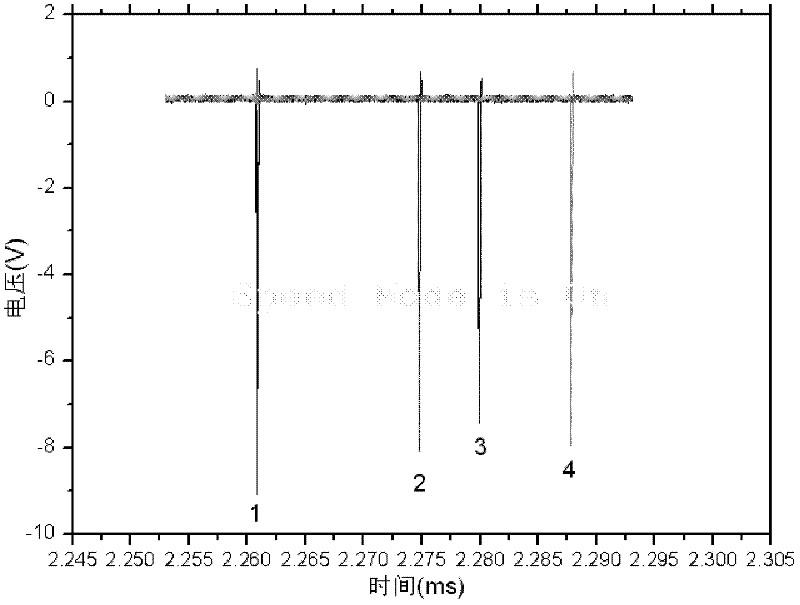

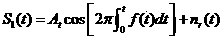

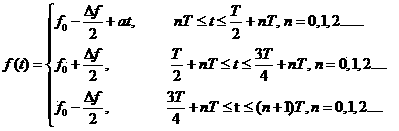

Automotive anti-collision radar system and multi-target identification algorithm utilizing same

ActiveCN105301592ALow costReduce the amount of calculationRadio wave reradiation/reflectionRF front endRadar systems

The invention discloses an automotive anti-collision radar system and a multi-target identification algorithm utilizing same. The automotive anti-collision radar system comprises the components of a modulating circuit, a modulating mode controller, an FMCW / FSK double-function radar, a radar system switching unit, an RF front-end, an intermediate frequency processing module and a data processing module. The multi-target identification algorithm comprises six steps. The automotive anti-collision radar system and the multi-target identification algorithm are technologically advantageous in that on condition that calculation amount and hardware cost are not increased, clear multi-target detection matching can be realized in comparing the automotive anti-collision radar system with a system in which FM continuous wave radar modulation is singly used; and parameters of targets in a stationary state and a moving state can be simultaneously measured in comparing the automotive anti-collision radar system with the system in which frequency shift keying modulation is singly used, so that the radar system can simultaneously and effectively identify and detect one or a plurality of targets in the stationary state and the moving state.

Owner:HEFEI UNIV OF TECH

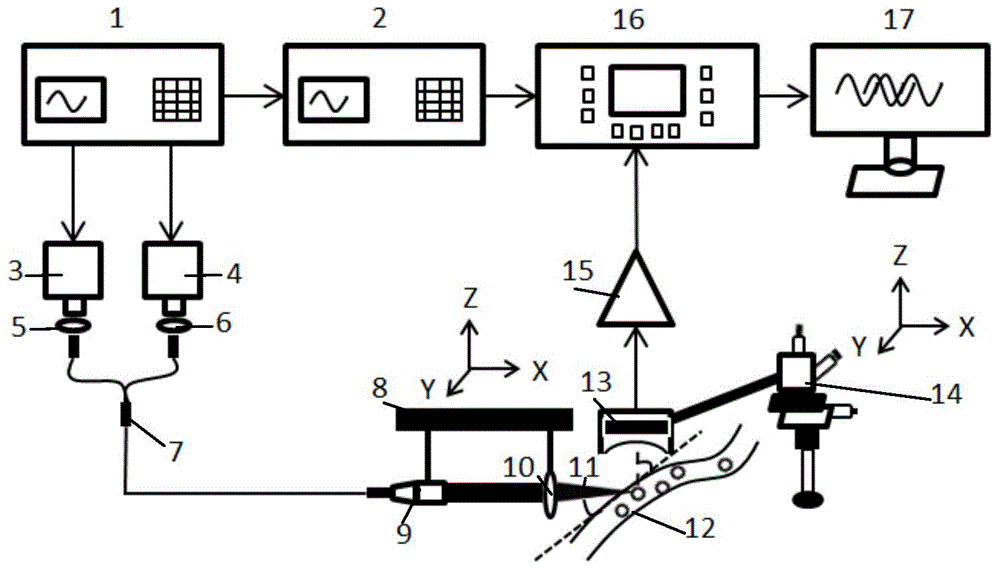

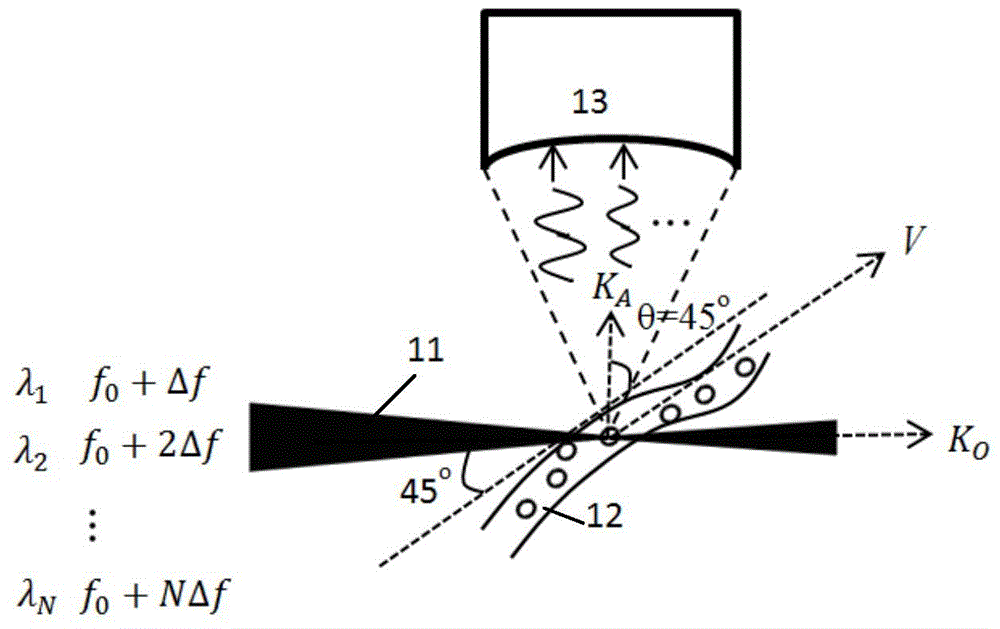

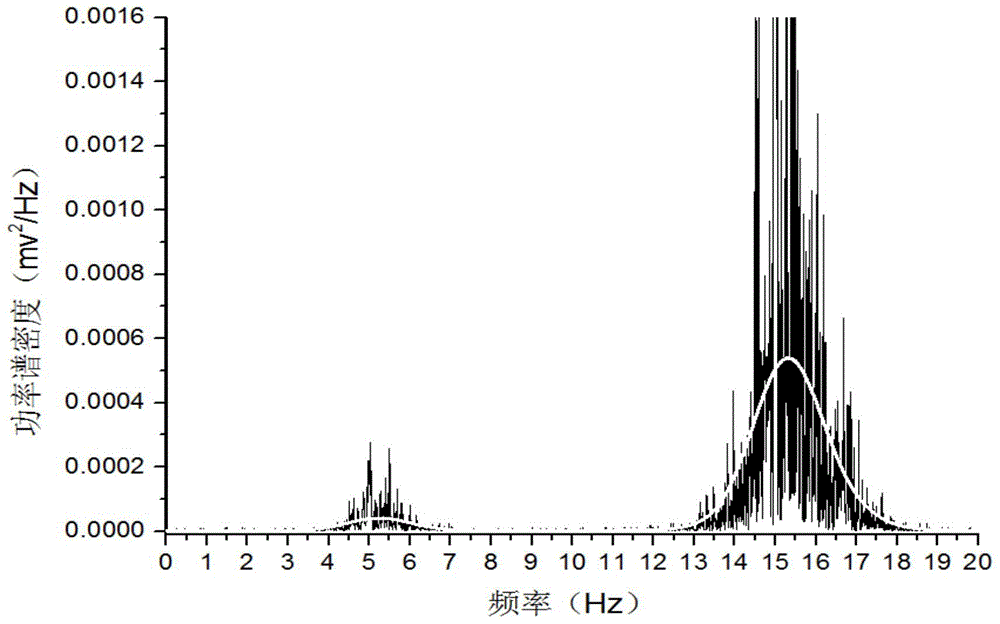

Opto-acoustic Doppler blood flow rate measurement method and system for determining oxygen content of red blood cells

InactiveCN105030223AMeasurement applicableLarge detection depthDiagnostic recording/measuringSensorsFrequency spectrumUltrasonic sensor

The invention discloses an opto-acoustic Doppler blood flow rate measurement method and a measurement system for determining oxygen content of red blood cells. According to the measurement system, multiple paths of laser beams coded by intensity modulation frequency and with different wavelengths focus and illuminate the same area of a blood vessel, and a lock-in amplifier is adopted for demodulating to obtain opto-acoustic Doppler frequency spectrum signals obtained by an ultrasonic transducer and positioned at different center frequencies. The measurement method and the measurement system have the characteristics that photoacoustic spectrometry of red blood cells change along with oxygen content, the flow rate and the flow direction of blood can be accurately determined, the oxygen content of blood also can be determined, so that arterial blood and venous blood can be distinguished. The measurement method and the measurement system can be used for researching blood microcirculation, and through the simultaneous detection on the flow rate of the blood and the oxygen content of the blood, the metabolism condition of the local tissue is obtained.

Owner:NANKAI UNIV

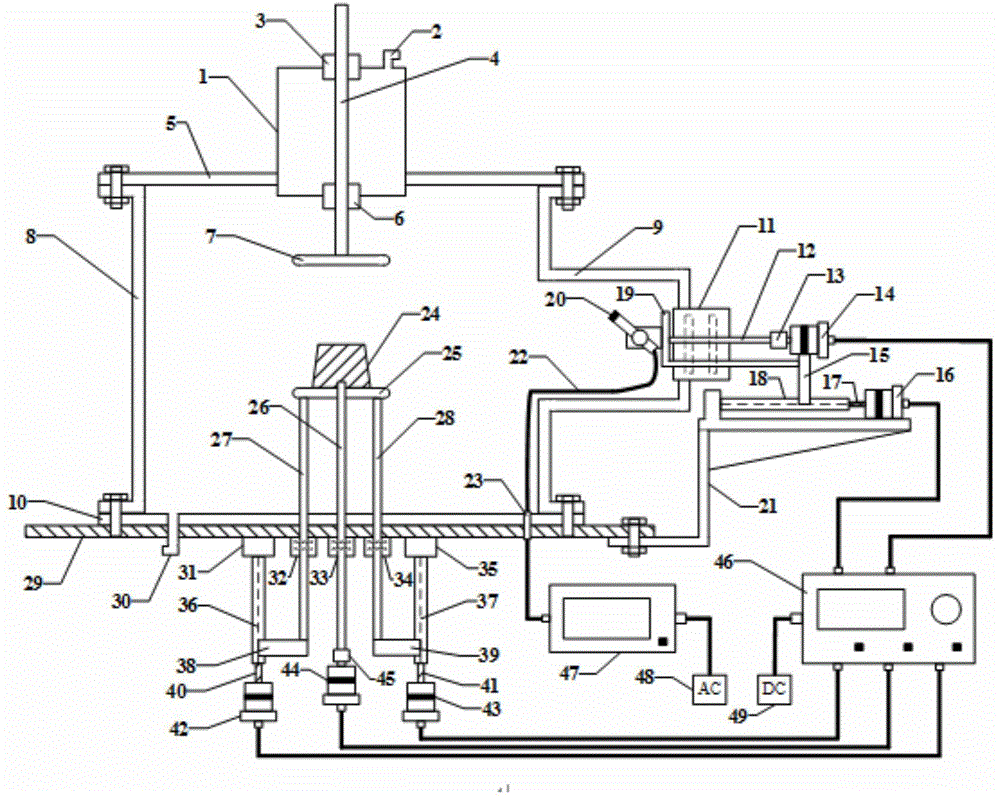

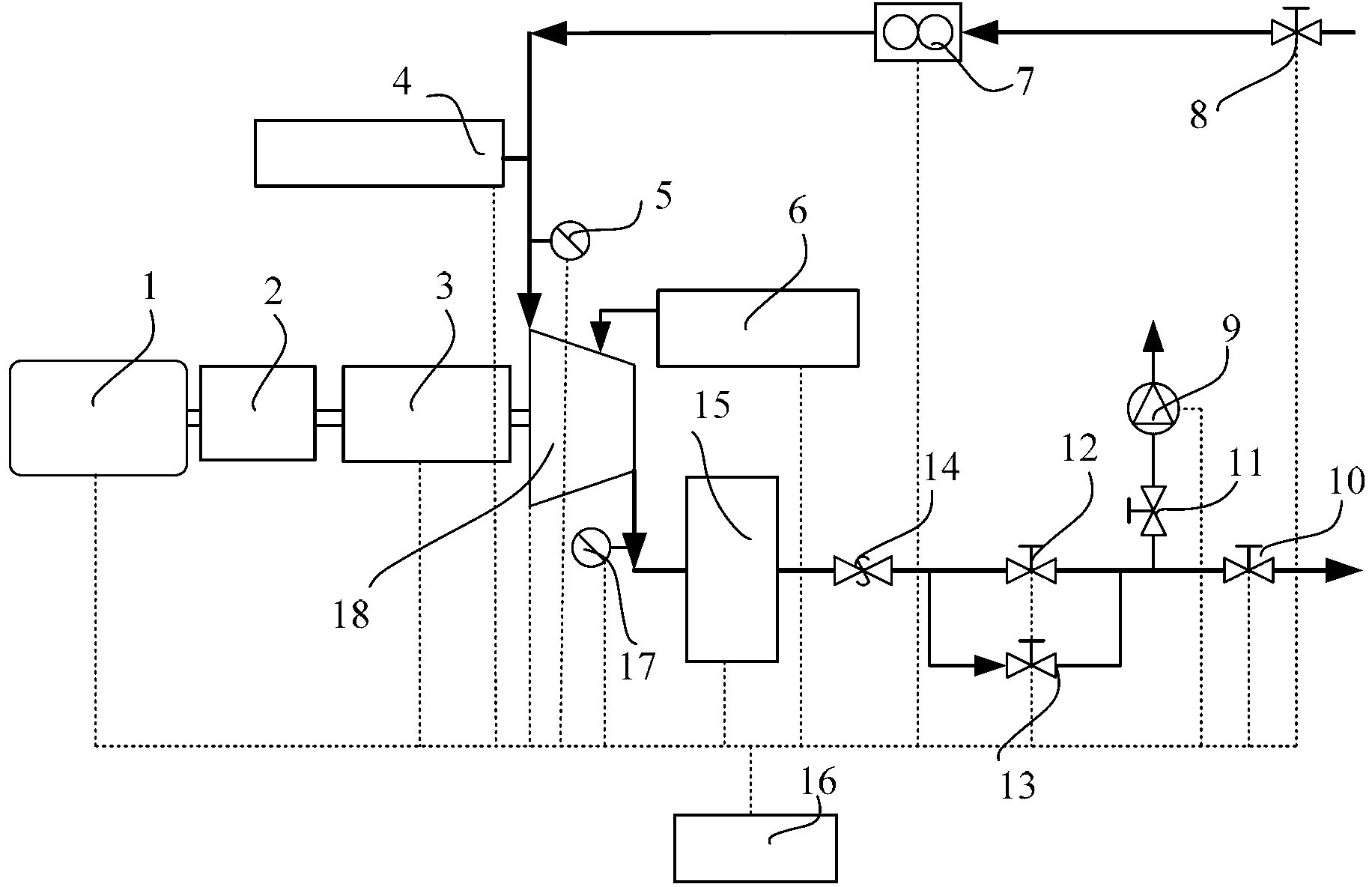

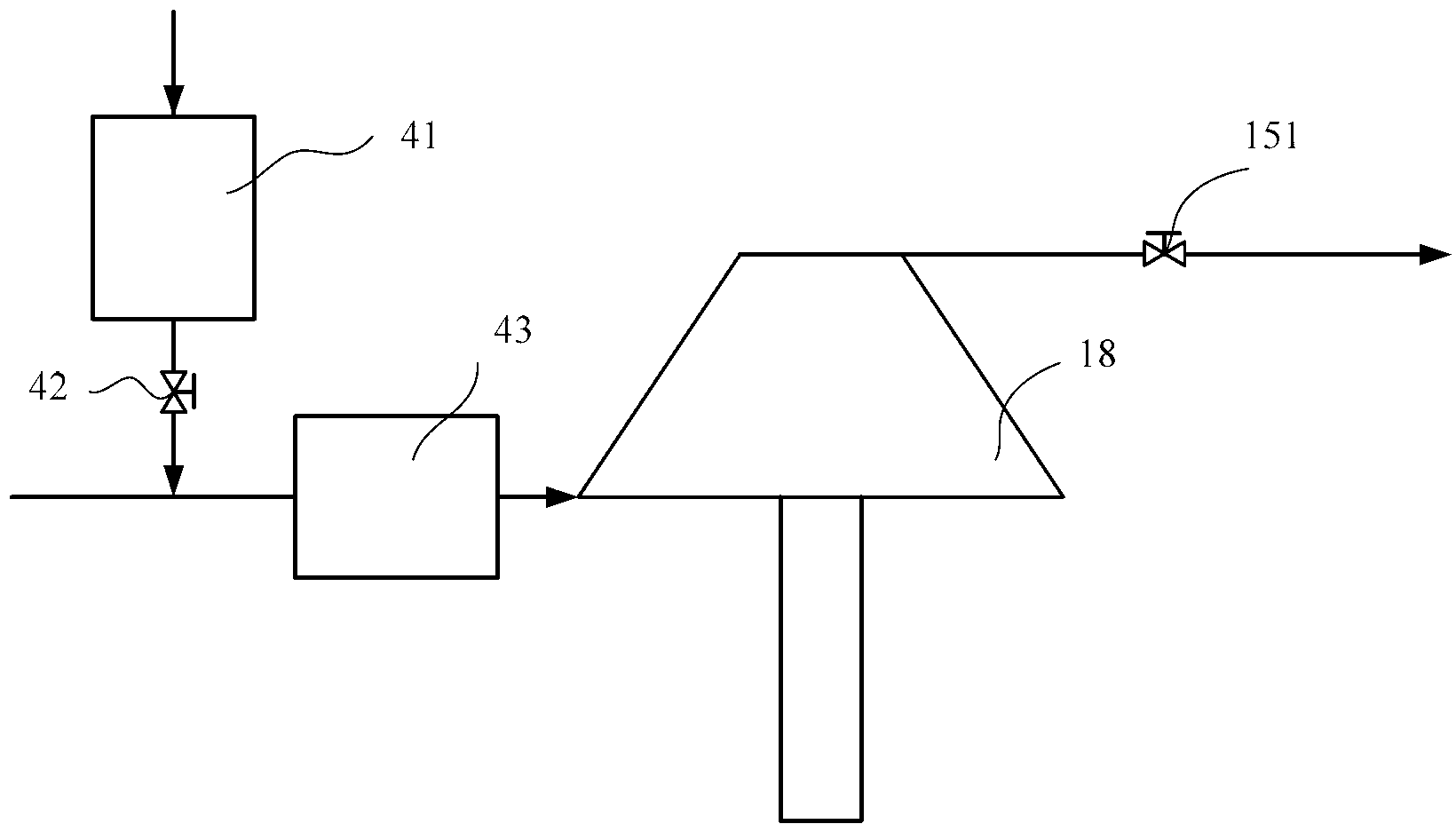

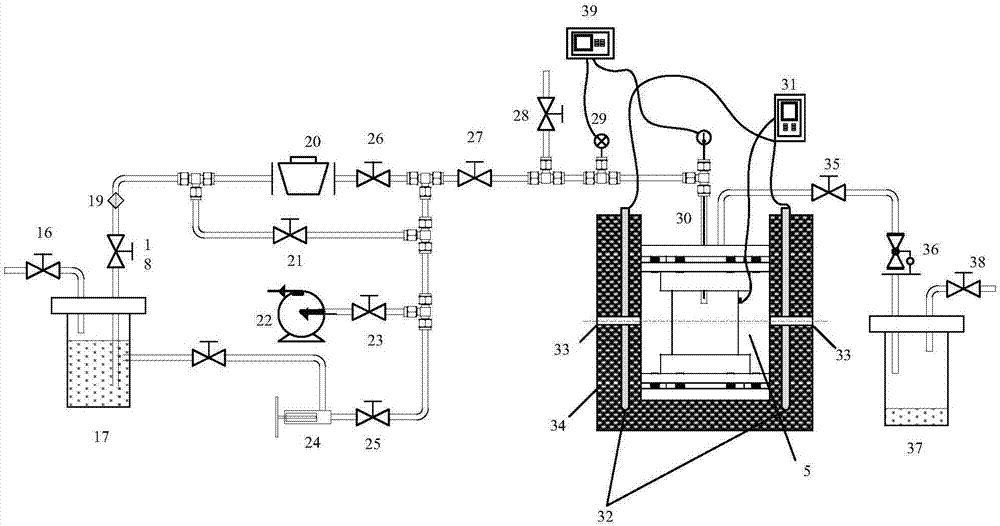

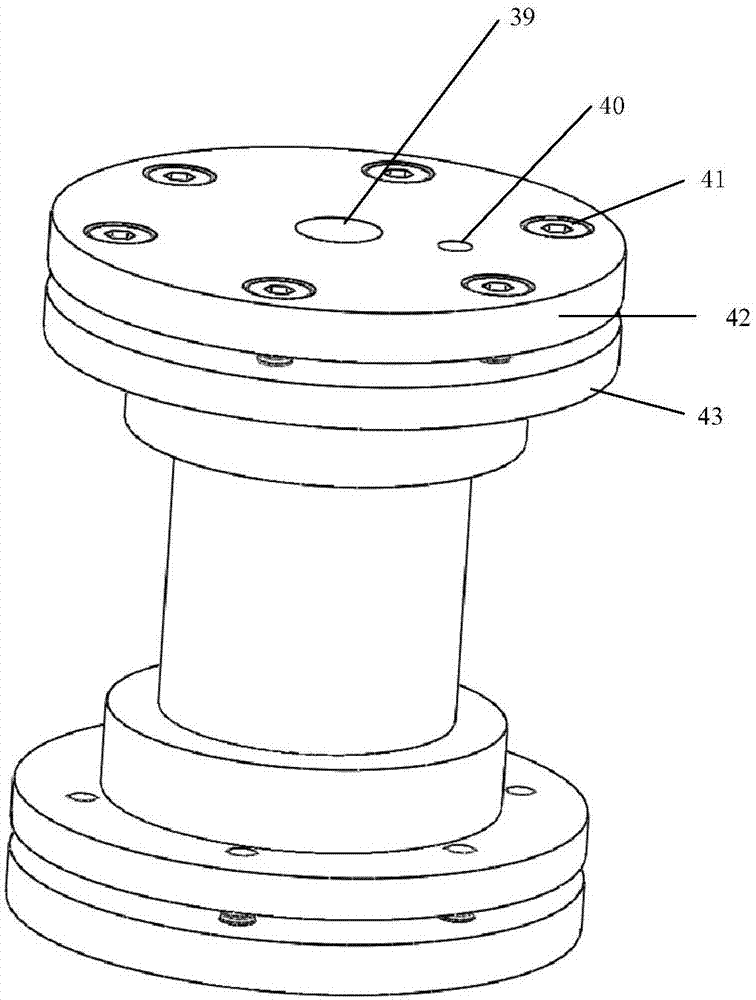

Turbine compressor test system

InactiveCN102937104AEnhanced airflow excitationReduce power consumptionPump controlNon-positive displacement fluid enginesTorque sensorAutomotive engineering

The invention discloses a turbine compressor test system. The turbine compressor test system is characterized in that rotation output of a motor is driven to a turbine compressor main shaft of a turbine compressor through a transmission case and a torque sensor so as to form a test main engine, an air inlet disturbance unit, an exhaust disturbance unit, an airflow actuating device and a measure and control unit are respectively arranged aiming at the test main engine. The turbine compressor test system provided by the invention can test properties of the turbine compressor under various working conditions such as different air inlet condition saltations, air inlet distortion and exhaust conditional mutation, simulate the excitation of airflow to blades under different work conditions through an experimental method, and measure the parameters including stress and vibration frequency of the blades under situations with different excitation of airflow.

Owner:HEFEI GENERAL MACHINERY RES INST

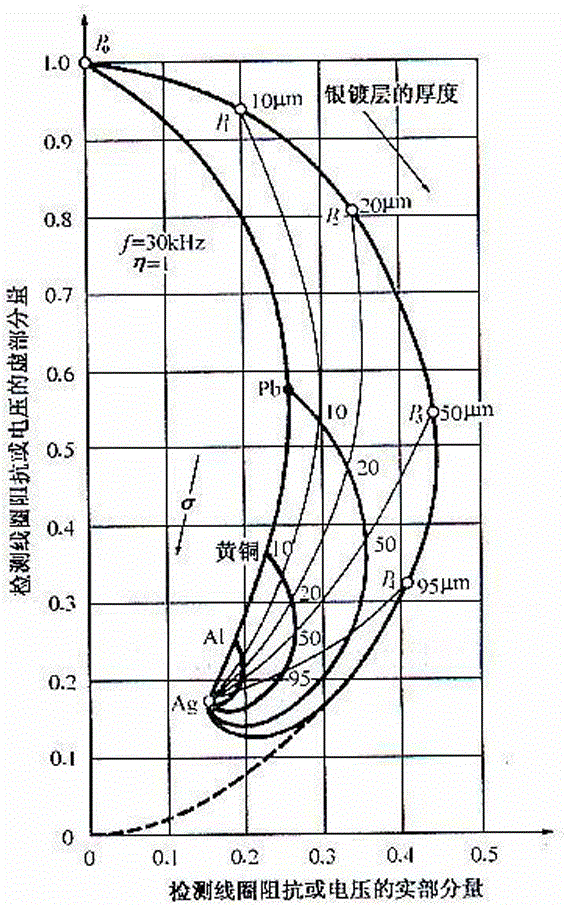

Measurement method of nonferromagnetic metal coating layer thickness on nonferromagnetic metal

ActiveCN106500581AMeasurement applicableUsing electrical meansElectrical/magnetic thickness measurementsMetal coatingEddy current

The invention discloses a measurement method of a nonferromagnetic metal coating layer thickness on nonferromagnetic metal. The method comprises the following steps of (a) a calibration step: using an eddy current phase method to measure calibration phases corresponding to different known coating layer thicknesses of different calibration test pieces and establishing a corresponding relation of the calibration phases and the coating layer thicknesses; (b) an actual measurement step: using a eddy current phase method which is the same with the method in the step (a) to measure a tested phase corresponding to a coating layer of an object to be measured, and according to the corresponding relation of the calibration phases and the coating layers, which is acquired from the step (a), calculating a coating layer thickness of the object to be measured. A measurement demand when a current conductivity difference is small and a matrix metal conductivity is changed in a certain range is satisfied.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for imaging quality degradation amount of photoelectric platform in motion by using optical transfer function

InactiveCN103217272AMeasurement applicableTelevision systemsTesting optical propertiesOptical axisImaging quality

The invention relates to a method for imaging quality degradation amount of a photoelectric platform in motion by using an optical transfer function. The method comprises the following steps of fixing the photoelectric platform on a swing table, aligning an optical axis of the photoelectric platform at a white noise random target pattern when the swing table is static, using a random target method to measure an optical transfer function value when the swing table is static, starting the swing table to enable the swing table to move along pitching and azimuth directions at certain frequency and certain swing amplitude, aligning the optical axis of the photoelectric platform at the white noise random target pattern, using the random target method to measure the optical transfer function value of the photoelectric platform subjected to servo control, comparing the optical transfer function value in a motion state and the optical transfer function value in a static state and obtaining the imaging quality degradation amount of the photoelectric platform in motion. The evaluation of imaging quality degradation of the photoelectric platform in motion is obtained by calculating the difference of the optical transfer function values in static and moving states by means of the method.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

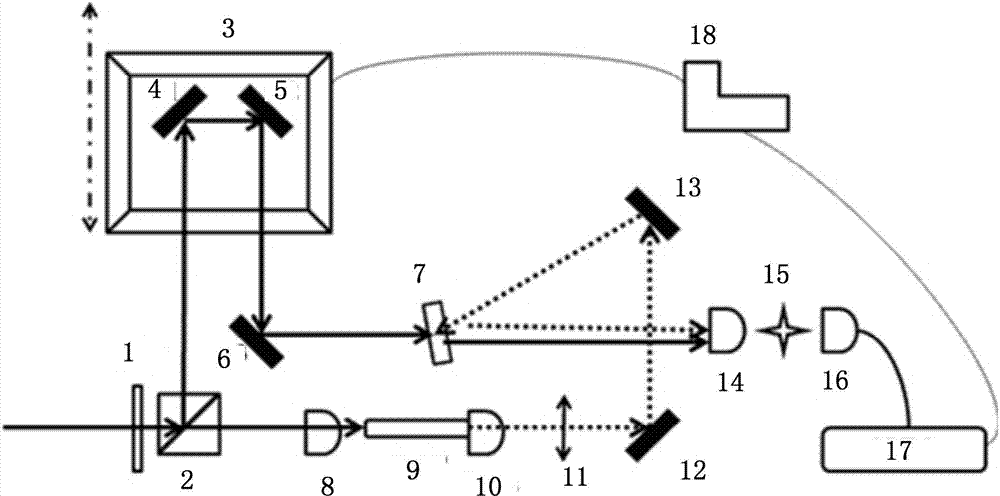

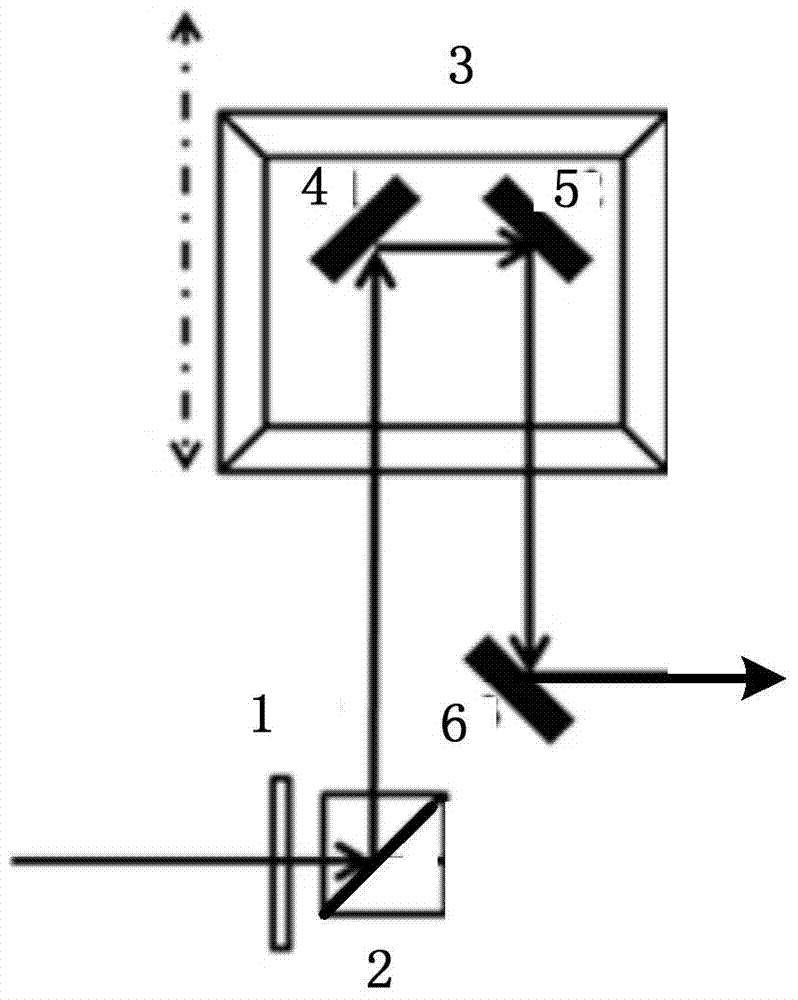

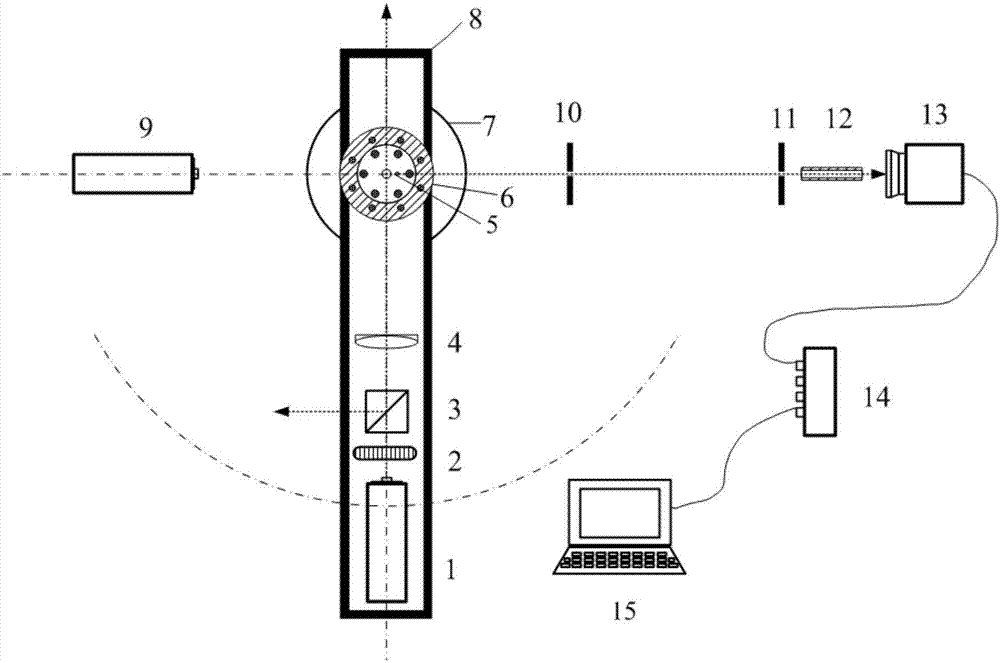

Supercontinuum pulse laser measurement device based on nonlinear nano material and method

The invention discloses a supercontinuum pulse laser measurement device based on a nonlinear nano material and a method. According to the invention, a 1 / 2 waveplate, a polarized light splitting device, an electric stepping motor, a first high reflection mirror, a second high reflection mirror, a third high reflection mirror, a laser line light filter, a focusing lens, a photonic crystal optical fiber, a collimating lens, a light filter, a fourth high reflection mirror, a fifth high reflection mirror, an achromatic focusing lens, the nonlinear nano material, a collection focusing lens, a spectrometer and a PC; the optical distance of a detection optical path is changed by an optical delay system, and an excitation optical path transmits supercontinuum pulse laser; through the laser line light filter, excitation-detection optical paths are integrated and are converged to the nano material through a focusing system, so as to excite sum frequency spectrums; and through a mobile stepping motor, the sum frequency spectrums are synchronously detected, and the characteristics of a supercontinuum laser pulse are completely detected.

Owner:ZHEJIANG UNIV

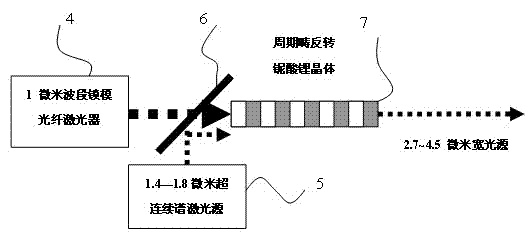

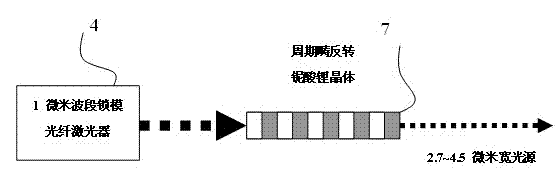

Super-high spectral resolution gas medium wave infrared spectrum measurement system

InactiveCN103091283AMeasurement applicableDuring the measurement, the measurement appliesColor/spectral properties measurementsSpectrometerLongitudinal mode

The invention discloses a super-high spectral resolution gas medium wave infrared spectrum measurement system which is composed of a no-longitudinal mode broadband medium wave infrared laser source, a gas absorption tank and a super-high resolution spectrograph, wherein the no-longitudinal mode broadband medium wave infrared laser source directly spatially enters the gas absorption tank by virtue of an optical system and enters the super-high resolution spectrograph to obtain a to-be-measured gas absorption spectrum after exiting from the gas absorption tank. By adopting the no-longitudinal mode broadband medium wave infrared laser source, an incident light source has the characteristics that spectral components are continuous and spectrum is stable among different laser pulses, and spectrum measurement of the super-high resolution spectrograph can not be affected by mode jump. Therefore, the super-high spectral resolution gas medium wave infrared spectrum measurement system has sky-high spectral resolution, can be used for measuring slight change of the gas absorption spectrum, and is suitable for measurement of a trace gas.

Owner:ZHEJIANG UNIV

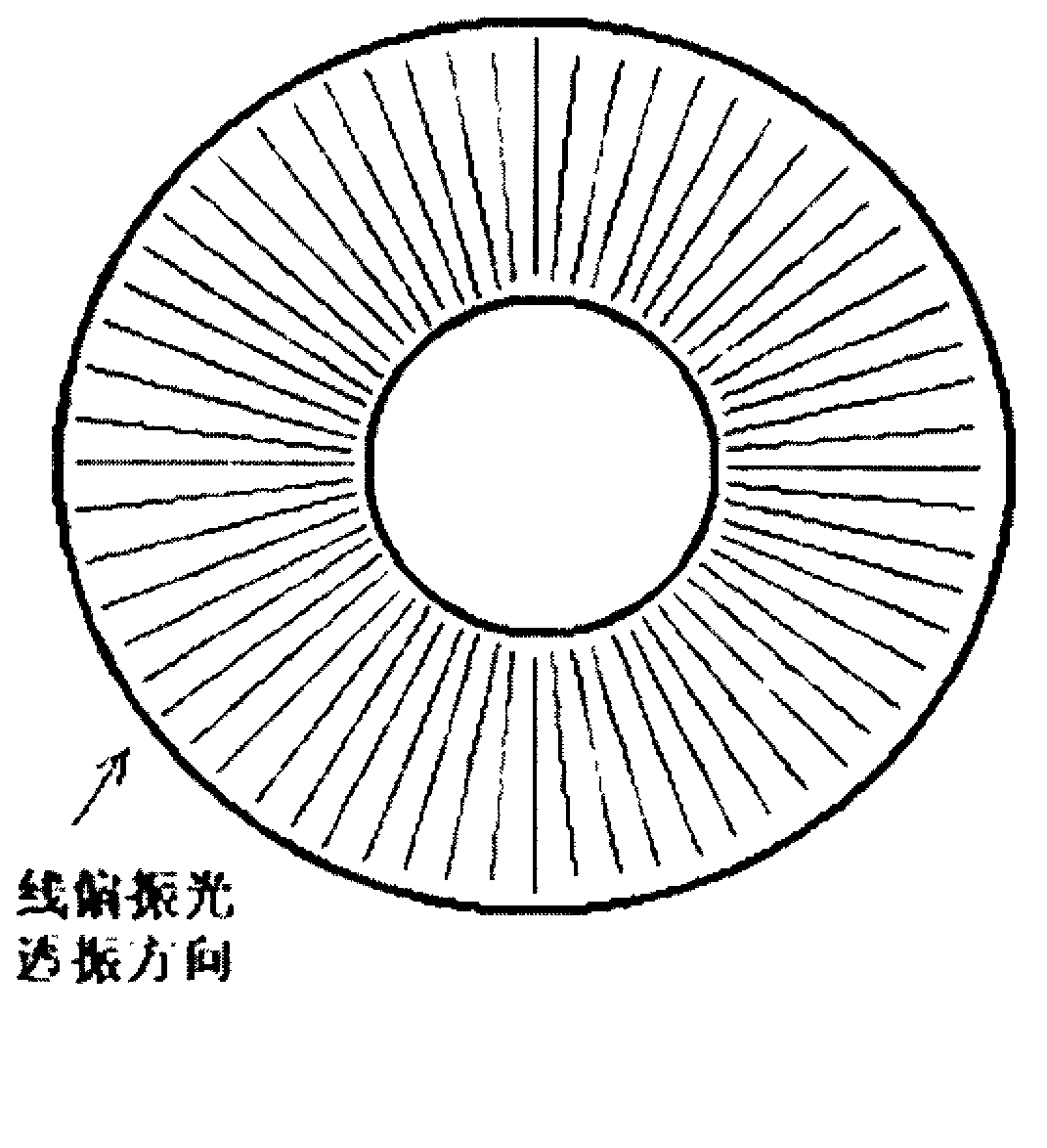

Radial analyzer type magneto-optical film current sensor

InactiveCN103675390AMeasurement applicableVoltage/current isolationMeasurement using digital techniquesElectric power systemCurrent sensor

The invention relates to a radial analyzer type magneto-optical film current sensor. A fundamental principle adopted is the Faraday magneto optical effect based on which the plane of polarization of a magneto-optical film can rotate under the action of a current magnetic field when linearly polarized light permeates the magneto-optical film, a radial analyzer is adopted for demodulation, an image transmission rod or an image transmission optical fiber bundle is adopted for image transmission, and a digital image positioning method is adopted for directly measuring the rotation angle of the plane of polarization, so that the real-time digital current signals can be obtained. The current sensor is suitable for measuring AC / DC of electric power systems.

Owner:徐启峰

Method for measuring accumulated thickness of MOS (metal oxide semiconductor) tube gate oxide layer

InactiveCN102176421AAccurate capacitance valueAccurate accumulation of thickness valuesSemiconductor/solid-state device testing/measurementElectrical/magnetic thickness measurementsCapacitanceVacuum permittivity

The invention discloses a method for measuring the accumulated thickness of an MOS (metal oxide semiconductor) tube gate oxide layer, comprising the following steps: S1, regulating a test voltage to be close to a breakdown voltage between a grid and a substrate; S2, measuring the capacitance of a gate oxide layer in accordance with the test voltage in the S1; and S3, calculating the accumulated thickness of the gate oxide layer in accordance with the capacitance in the S2. The calculation formula of the accumulated thickness of the gate oxide layer is as follows: Tox=epsilon*epsilon0*A / Cox, wherein Tox represents the accumulated thickness of the gate oxide layer, Cox represents the capacitance of the gate oxide layer, epsilon represents a vacuum permittivity, epsilon0 represents a dielectric constant and A represents a capacitance area. The method provided by the invention is applied to measuring the thinner MOS tube gate oxide layers.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Measuring device and method for pulsed ion beam cross section image

InactiveCN104965217AMeasurement applicableMeasurement is not limitedNeutron radiation measurementLatent imageHigh pressure

The invention provides a measuring device and method for a pulsed ion beam cross section image, and especially provides a measuring device and method for a pulsed ion beam cross section image with a continuous adjustable acceleration voltage, and with a single pulse or an adjustable pulse frequency. An imaging plate is installed in a target position of the measuring device. High vacuum inside the measuring device is achieved by utilization of a vacuum unit. When the pulse ion source of the measuring device discharges, a cathode material is ionized, and plasma is generated. When a high-voltage pulse is applied at a guiding-out electrode, a pulse ion beam is guided out and hits on the imaging plate. After the imaging plate receives the pulse ion beam, a sensitive layer is excited and carries the ion beam distribution latent image. After the imaging plate is taken out from the pulse ion beam cross section image measuring device, an imaging analyzer releases hard light and thus de-excitation of the sensitive layer is carried out, the latent image is converted into an optical image, then the optical image is converted into a digital image, and then the digital image is transmitted to a computer. The shape of the image can be observed conveniently, and transverse dimension and vertical dimension of a beam spot can be measured quantificationally.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

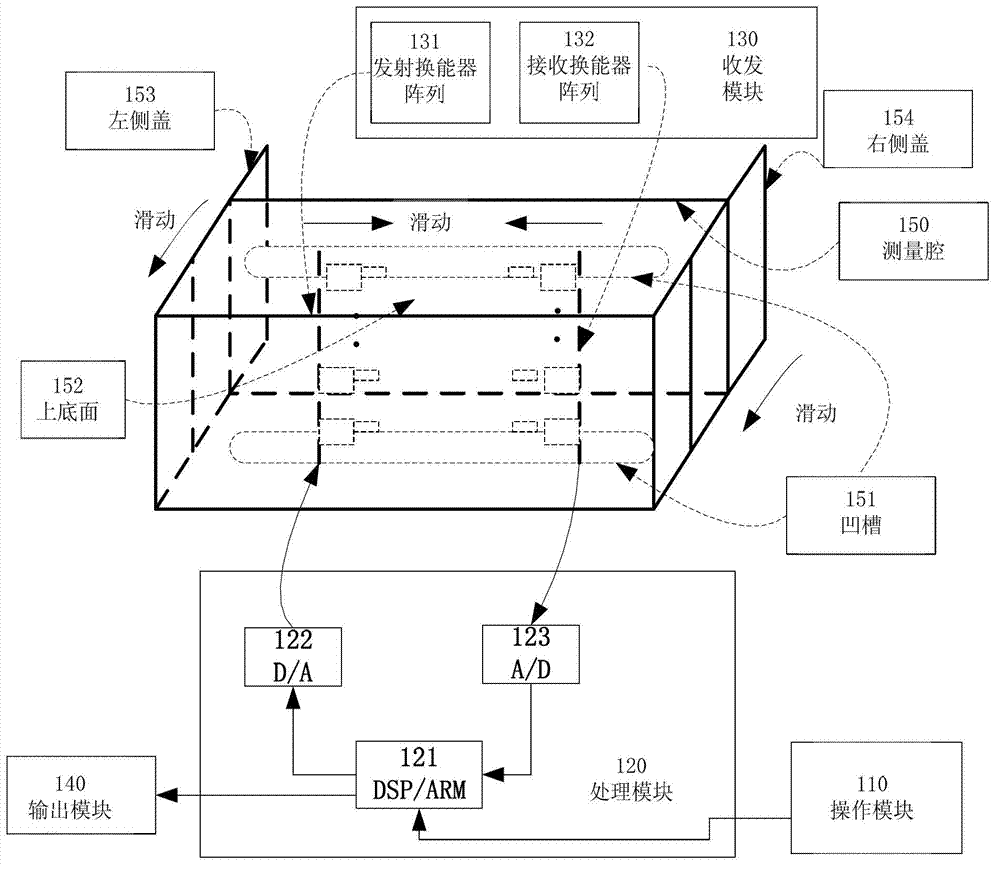

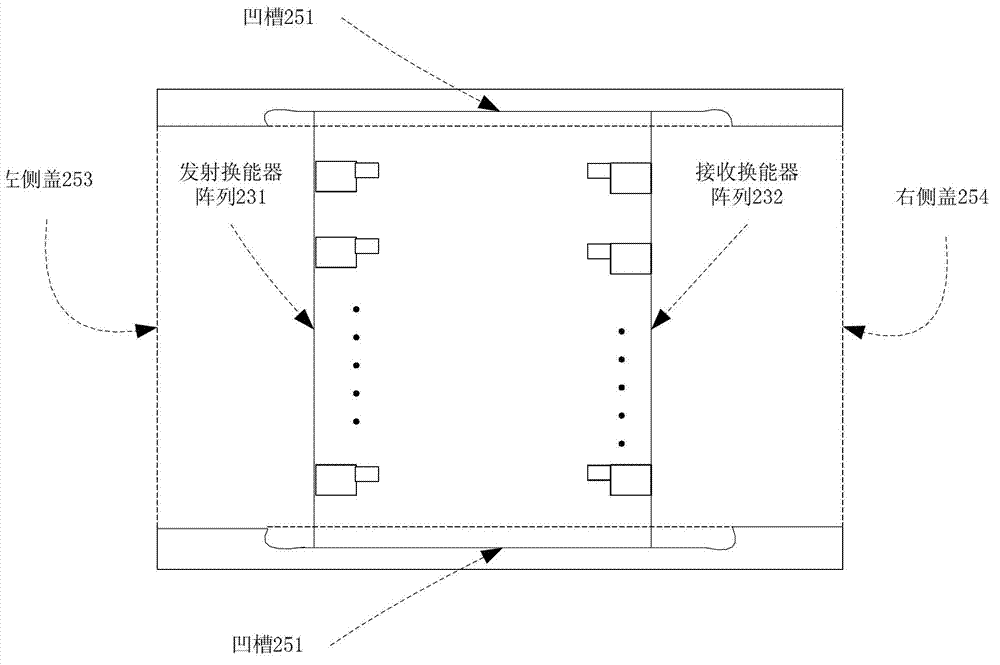

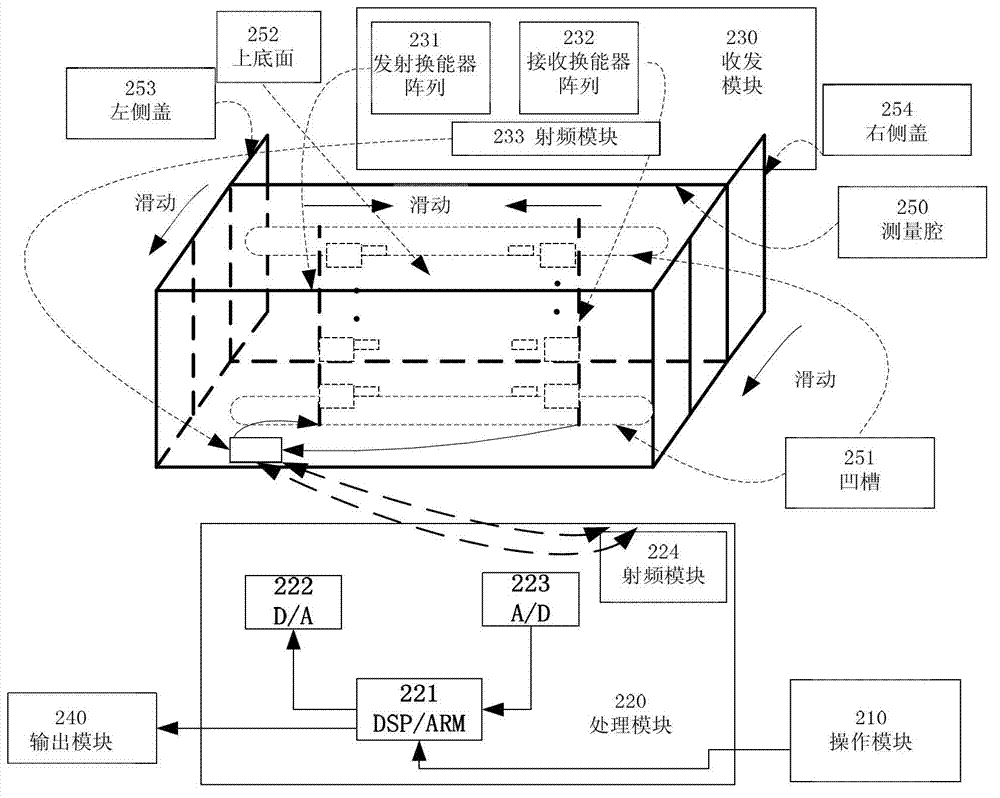

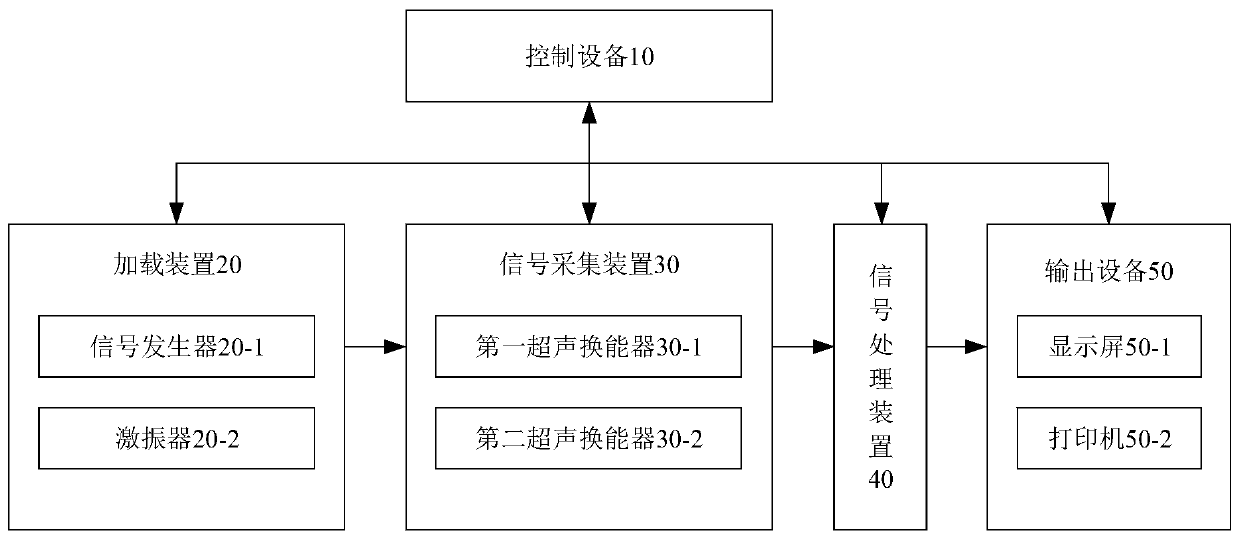

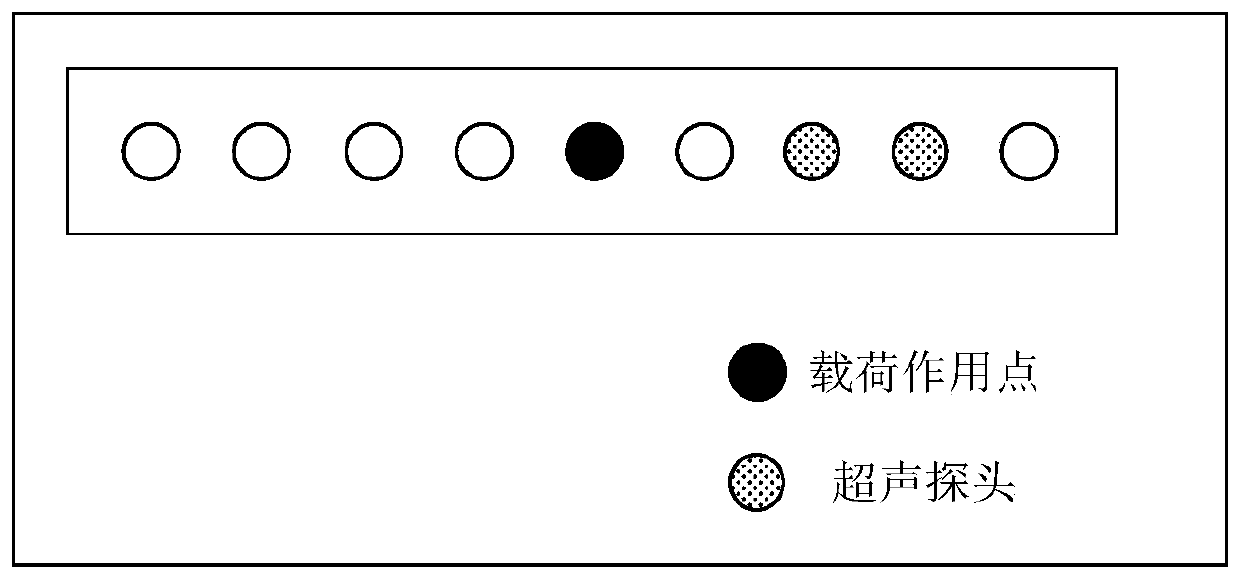

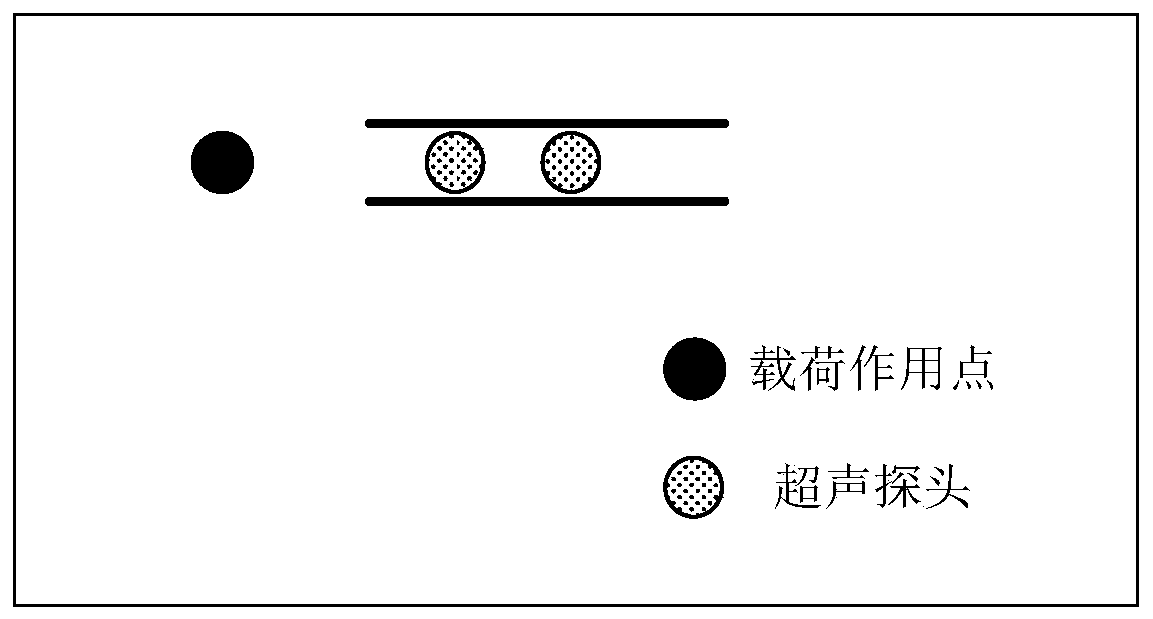

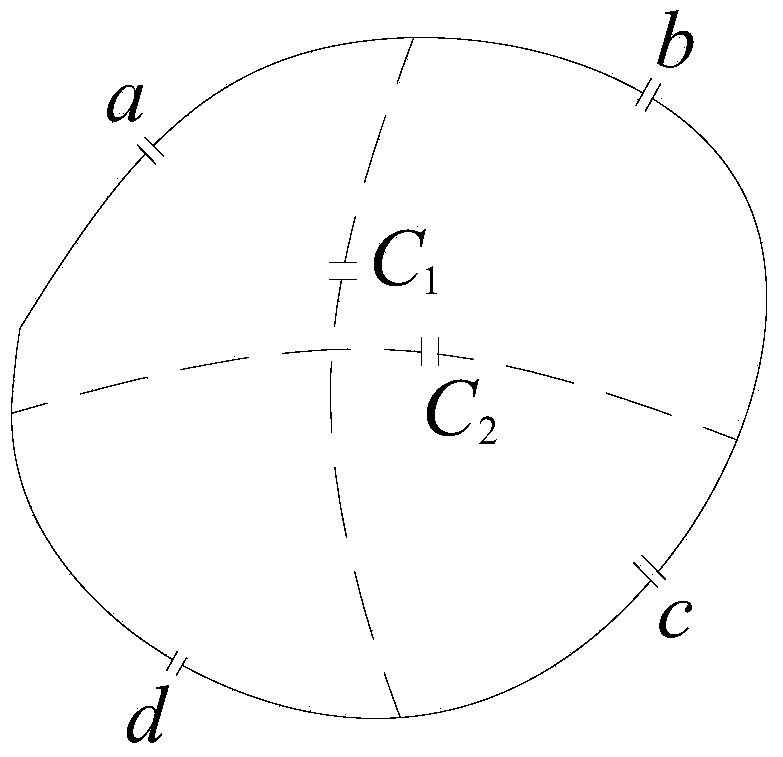

Method, device and system for measuring material mechanical property information

ActiveCN110849970AMeasurement applicableAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalTransducerThin membrane

The invention discloses a method, device and system for measuring material mechanical property information. The method includes the steps that excitation signals of different frequencies are loaded toa material to be measured; motion information of surface wave signals or interface wave signals of the material to be measured under different frequency excitation signals are measured, wherein the motion information includes wave velocity and dispersion information, and the surface wave signals or the interface wave signals are ultrasonic signals of the surface or internal interface of the material to be measured and collected by at least two ultrasonic transducers; the mechanical property information of the material to be measured is determined according to the motion information of the surface wave signals or the interface wave signals of the material to be measured under different frequency excitation signals; and the mechanical property information of the material to be measured is output. Based on the fact that the ultrasonic transducers measure the motion information of surface waves or interface waves of the material, the inversion of the mechanical property information of a thin film wrapping material or other wrapping materials or materials in a special environment is realized.

Owner:北京曦健科技有限公司

Novel capacitive liquid level sensor based on capacitance calculation principle and application thereof

ActiveCN103940493ASuitable for measurementMeasurement applicableLevel indicators by physical variable measurementCapacitanceDielectric

The invention discloses a novel capacitive liquid level sensor based on the capacitance calculation principle and the application thereof. The novel capacitive liquid level sensor comprises a shielding cover, an insulator, a metal layer, an upper packaging piece, a circuit board, a special metal pin and a lower packaging piece. The insulator is shaped like a barrel, and the outer surface of the insulator is plated with the metal layer. The shielding cover is coaxial with the insulator and located on the periphery of the insulator, and the insulator and the shielding cover are assembled together through the upper packaging piece and the lower packaging piece. A positioning and clamping surface is arranged outside the upper packaging piece, and the signal processing circuit board is arranged inside the positioning and clamping surface. Small holes through which liquid can flow are evenly distributed in the shielding cover. Based on the capacitance calculation principle, the precision of the capacitive liquid level sensor is only influenced by the relative dielectric constant of the liquid to be measured and the relative dielectric constant of air and is expected to be improved than that of a traditional capacitive liquid level sensor, and the novel capacitive liquid level sensor is also suitable for measurement of the level of ultralow-temperature liquid.

Owner:CHINA JILIANG UNIV

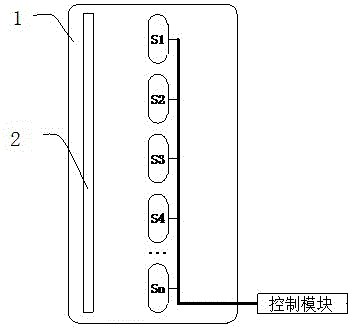

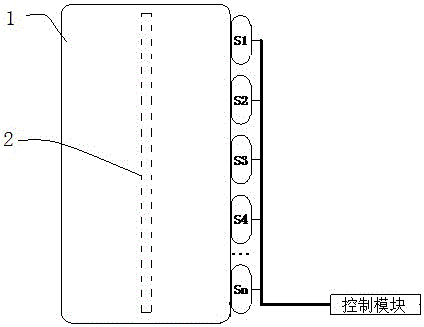

In-vessel layered interface measurement device and method

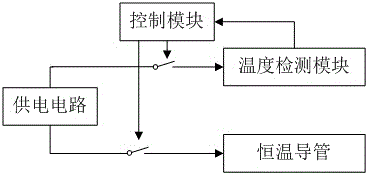

InactiveCN106197606AAccurate measurementMeasurement applicableLevel indicators by physical variable measurementSpecific gravity measurementMeasurement deviceLayer interface

The invention relates to an in-vessel layered interface measurement device and method. The device comprises a vessel, a constant temperature guide tube, a temperature detection module and a control module; the vessel is used for containing solid and liquid or stratified liquid; the constant temperature guide tube is located inside the vessel or outside the vessel, the arrangement direction of the constant temperature guide tube is in the height direction of the vessel, the height of the constant temperature guide tube is at least the same as that of the solid and liquid or the stratified liquid which is contained in the vessel, and the constant temperature guide tube is used for releasing heat to the solid and liquid or the stratified liquid which is contained in the vessel; the temperature detection module is located on the outer wall of the vessel and comprises multiple temperature detection points which are arranged in the height direction of the vessel and used for detecting temperature signals and transmitting the temperature signals to the control module, and the distances between the temperature detection points and the constant temperature guide tube are the same; the control module is used for receiving the temperature of the constant temperature guide tube and the temperature signals of the temperature detection module and outputting densities corresponding to all the temperature detection point positions, and layered interfaces are obtained according to the densities. According to the in-vessel layered interface measurement device and method, real-time non-contact measurement can be conducted, and the measurement result is precise.

Owner:冯正民

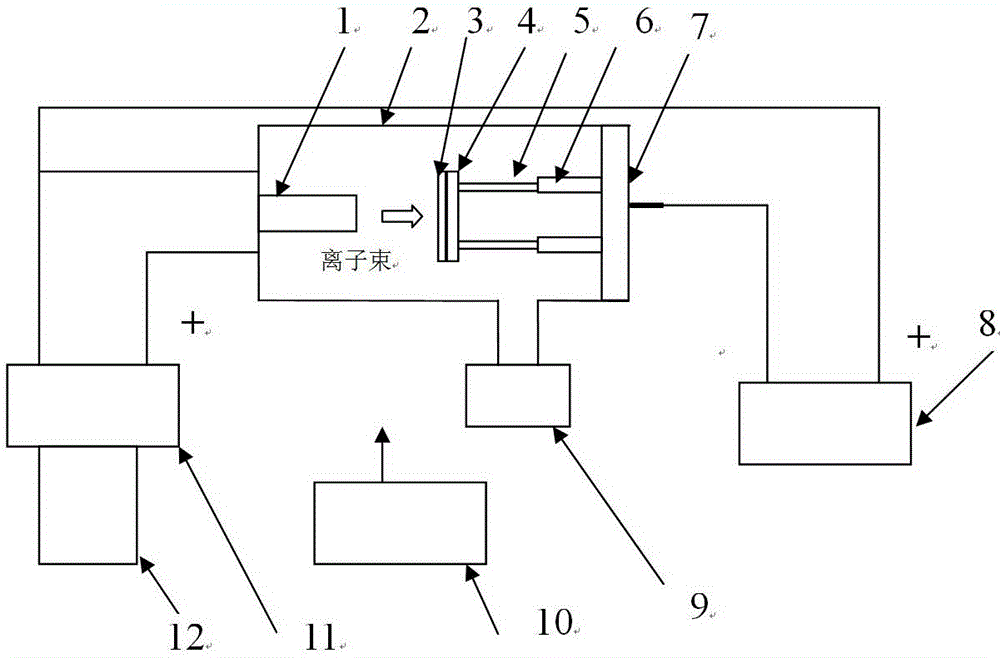

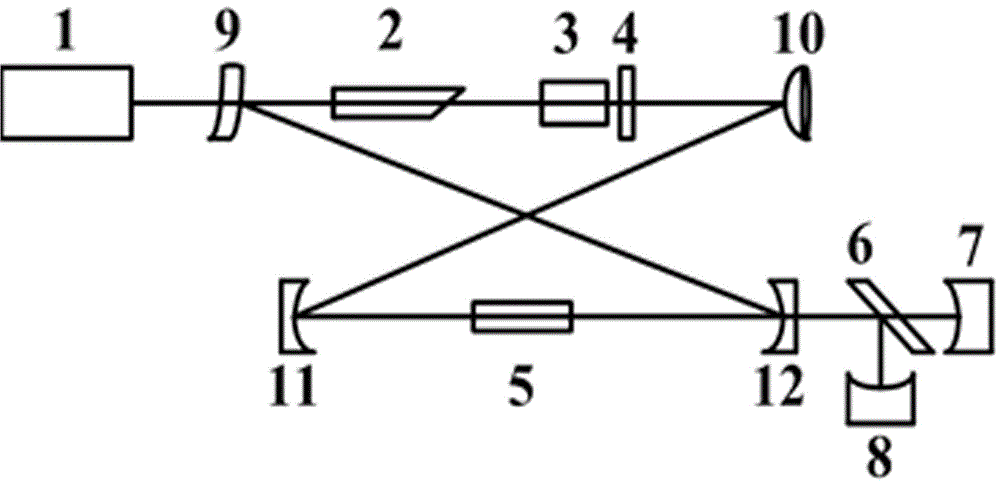

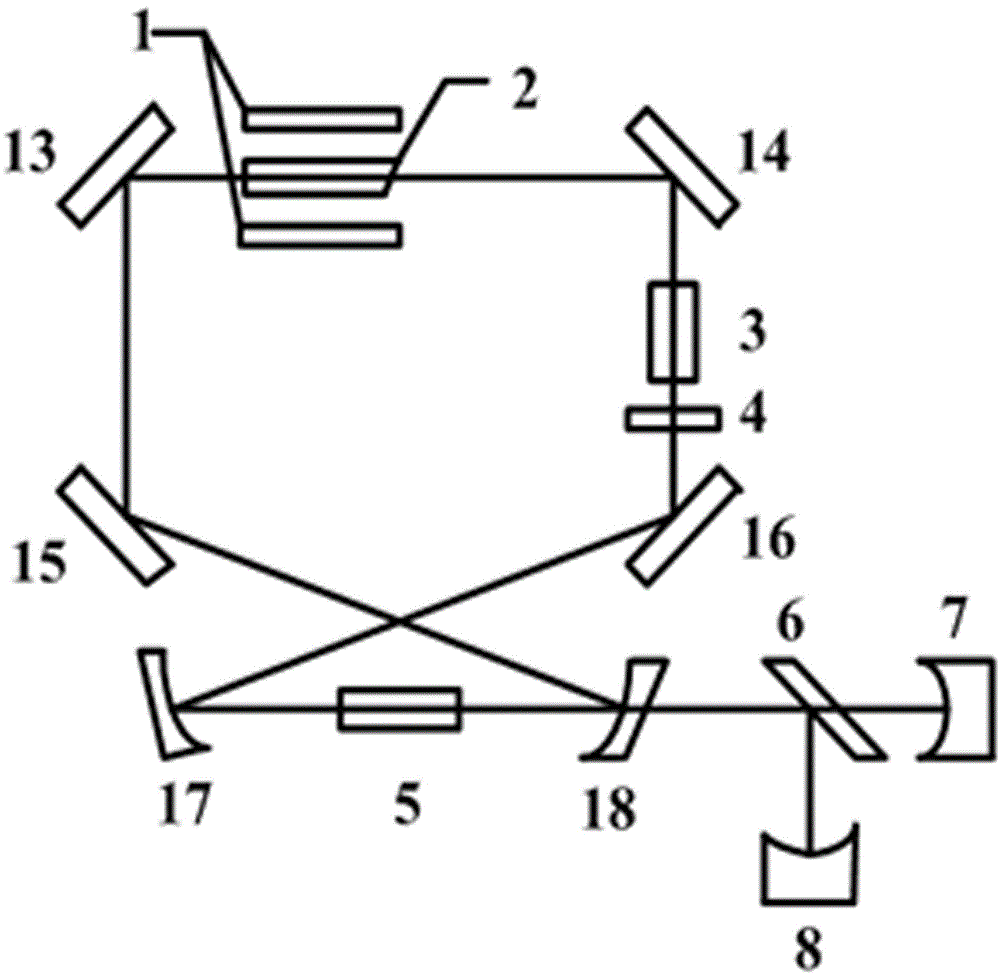

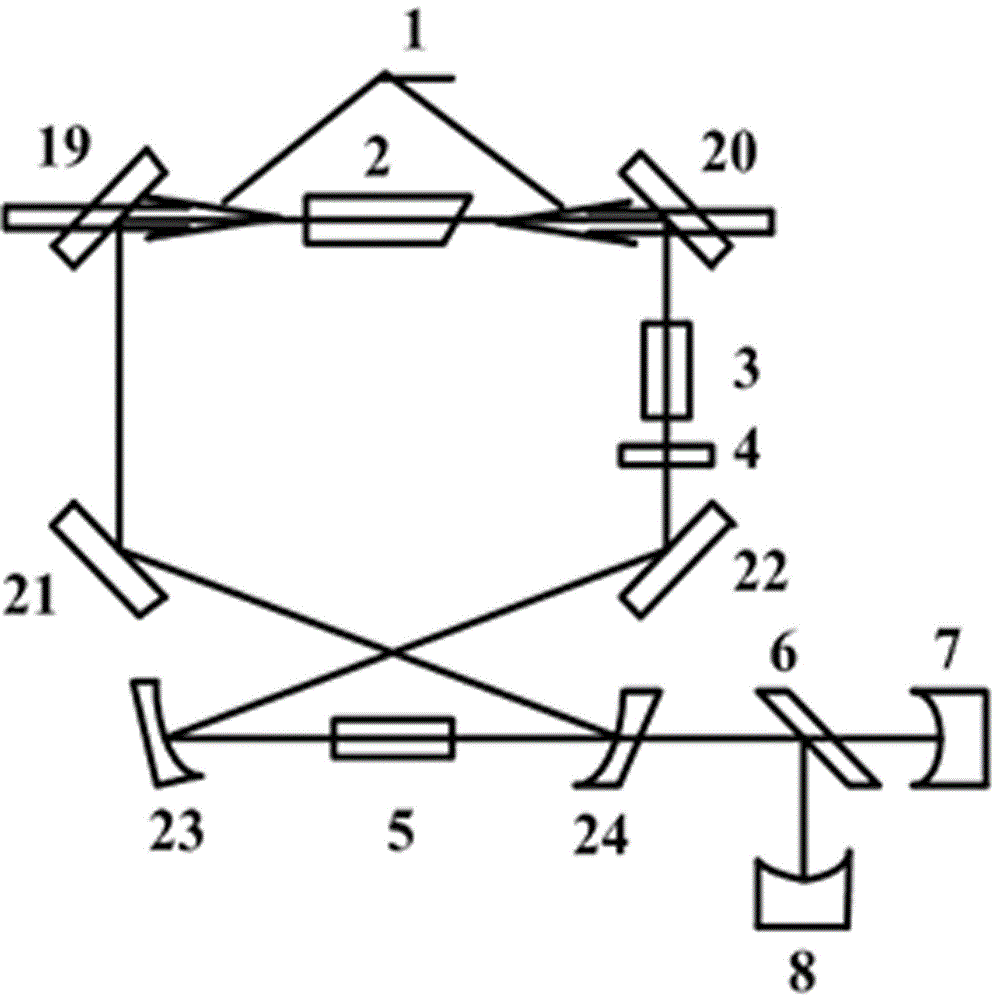

Measuring method for linear losses inside cavity of all-solid-state laser

ActiveCN105973573AEnable interference-free measurementsAccurate measurementTesting optical propertiesBeam splitterHalf wave

The invention relates to a measuring method for linear losses inside a cavity of an all-solid-state laser. A pumping source (1), a gain crystal (2), ring resonant cavity, an isolator, a beam splitter (6), a first power meter (7),and a second power meter (8) are arranged, wherein the isolator is formed by a magneto-optical media (3) and a half-wave plate (4) that are arranged in a permanent magnet. The measuring method is characterized in that a frequency multiplication crystal (5) having a non-linear effect is introduced into the resonant cavity, wherein a phase matching way of the frequency multiplication crystal (5) is an I type or II type non-critical phase matching way; output values of corresponding fundamental waves and second harmonics of any two working temperature points of the frequency multiplication crystal (5) are measured in a single frequency area; and then the two groups of numerical values are substituted into a linear loss expression inside a cavity to carry out calculation, so that a linear loss value inside the cavity of the laser as well as a numerical value of a pumping factor is obtained. The linear loss expression includes a non-linear transformation factor of the frequency multiplication crystal (5), a fundamental wave output power, a second harmonic output power, and a pumping factor.

Owner:北京泰和浩天科技有限公司

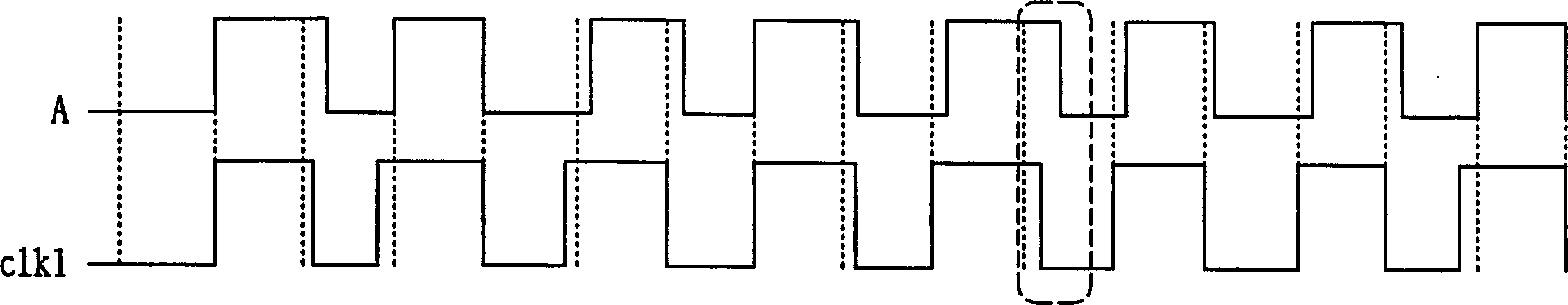

Signal dithering measuring method and device

InactiveCN1838584AMeasurement applicableError detection/prevention using signal quality detectorData signalComputer science

The invention relates to a signal dither measuring method which comprises the following steps: first providing a first data signal and making the first data signal as a second data signal of another equivalent, wherein the frequency of the first data signal is multiply with the frequency of the second data signal and the up and down of the second data signal is as the same of the first data signal. Doing statistic to the high and low location width of the second data signal to generate a prediction shake flow, wherein it comprises the prediction shake value of the up and down of the second data signal. Then it computes an eye opening breadth by the shake distributing picture of the up and down rim.

Owner:NASOFORM INC

Device and method for measuring viscosity of fluid near-critical area

ActiveCN107328690AMeasurement applicableNo interferenceIndirect flow property measurementTemperature stressUltrasound attenuation

The invention provides a device and a method for measuring viscosity of a fluid near-critical area. The device comprises a polarized light path, an experiment unit, a diffracted light path and a detection and analyzing unit, wherein the laser emitted by a laser device can be subject to attention by an adjustable attenuation sheet, polarizing and light dividing by a polarizing and light dividing prism, gathering by a lens, and transmitting into an experiment body; the diffracted light produced by the experiment unit passes through a light diaphragm and a light shielding cylinder, and is detected by a photo counter, and the detecting result is transmitted to an analyzer by a digital correlator; the analyzer is used for calculating to obtain the viscosity of the near-critical area of the to-be-measured fluid according to the detecting result; the experiment unit comprises the experiment body and a temperature and pressure control system, the experiment body is used for carrying the to-be-measured fluid, and the temperature and pressure control system is used for enabling the to-be-measured fluid to reach the temperature and pressure of the near-critical area; an electric heater and a temperature controller are used for controlling the temperature of the to-be-measured fluid, the to-be-measured fluid is pressurized and pumped into the device for controlling the pressure of the to-be-measured fluid, and a measuring circuit is used for detecting the pressure and temperature of the to-be-measured fluid.

Owner:XI AN JIAOTONG UNIV

Method and system for measuring volume flow of material on conveying belt

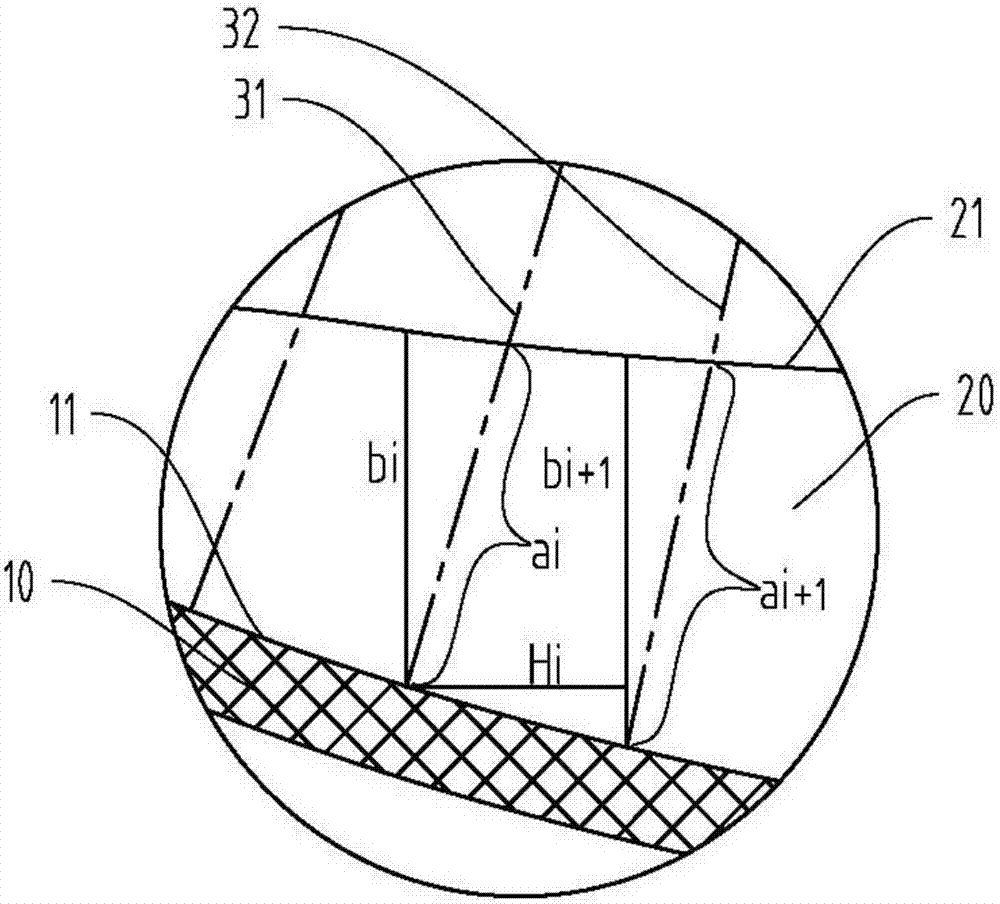

The invention discloses a method and system for measuring the volume flow of a material on a conveying belt, which can measure the volume flow of a solid material having an irregular surface on the conveying belt. The measurement method includes: a, acquiring first position information of a plurality of points of a surface of thee conveying belt, wherein the plurality of points are positioned in the same section; b, acquiring second position information of a plurality of points of a material surface in each section of a plurality of sections of the material, wherein the plurality of points of the material surface in each section are corresponding to the plurality of points of the step a in a one-to-one manner; c, acquiring a distance between every two corresponding points in each section of the plurality of sections of the material according o the first position information and the second position information; d, drawing up a plurality of class trapezoids according to the distance between every two corresponding points, calculating the areas of the plurality of class trapezoids, and calculating the sum of the area of each section of the material; and e, calculating the volume flow of the material according to the area of each section and the speed of the conveying belt.

Owner:BEIJING UNIV OF TECH +2

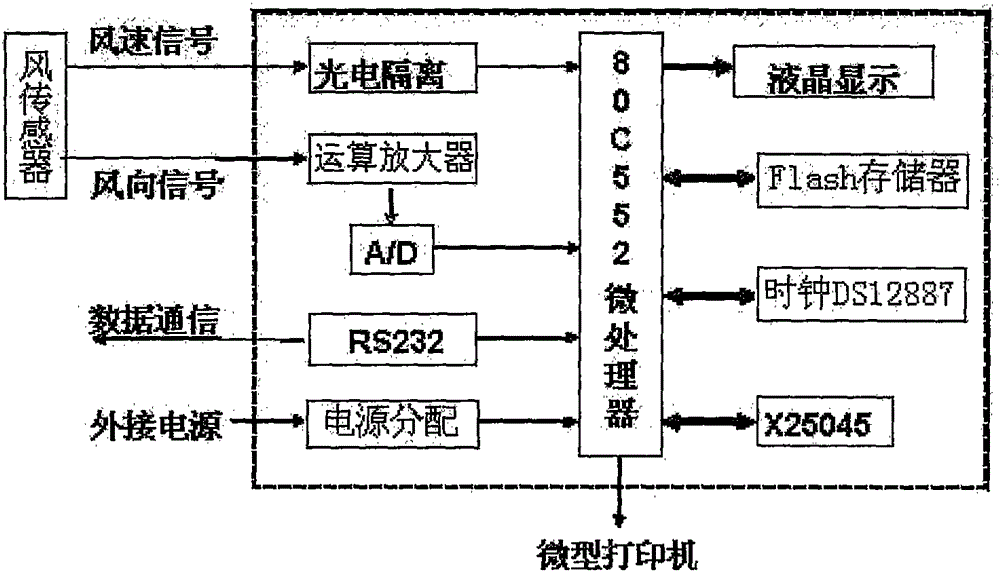

Wind speed and direction measurement instrument

InactiveCN105259369AMeasurement applicableAccurate measurement dataIndication/recording movementSpeed/acceleration/shock instrument detailsAudio power amplifierMeasurement device

The invention discloses a wind speed and direction measurement instrument, and relates to the technical field of wind speed and direction measurement devices. The wind speed and direction measurement instrument comprises a microprocessor. The wind speed frequency signal output end of a wind sensor is connected with one signal input end of the microprocessor after passing through a photoelectric isolation module. The wind direction voltage signal output end of the wind sensor is connected with the input end of an A / D conversion module after passing through an operational amplifier module. The output end of the A / D conversion module is connected with one signal input end of the microprocessor. A communication module and the microprocessor are connected in a two-way mode. A clock module and the microprocessor are connected in a two-way mode. A display module is connected with the signal output end of the microprocessor. A memory module and the microprocessor are connected in a two-way mode. A watchdog module and the microprocessor are connected in a two-way mode. A power supply module is connected with the power input ends of the modules needing power supply in the measurement instrument. The measurement instrument can be used for measuring both the speed and direction of wind, has the advantages of wireless communication function, small size and the like, and is especially suitable for outdoor wind energy measurement.

Owner:STATE OCEAN TECH CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com