Patents

Literature

81 results about "Interface waves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

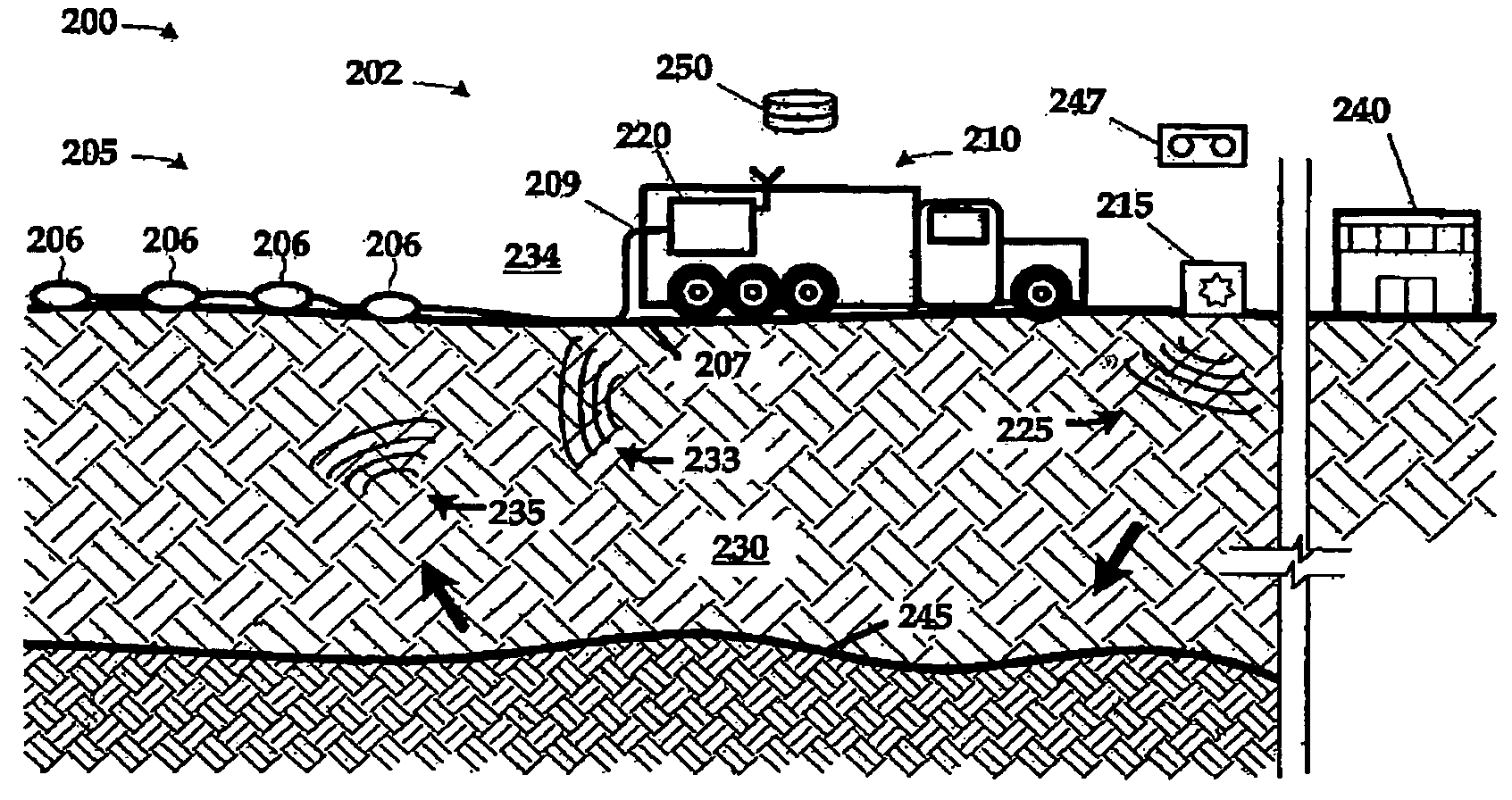

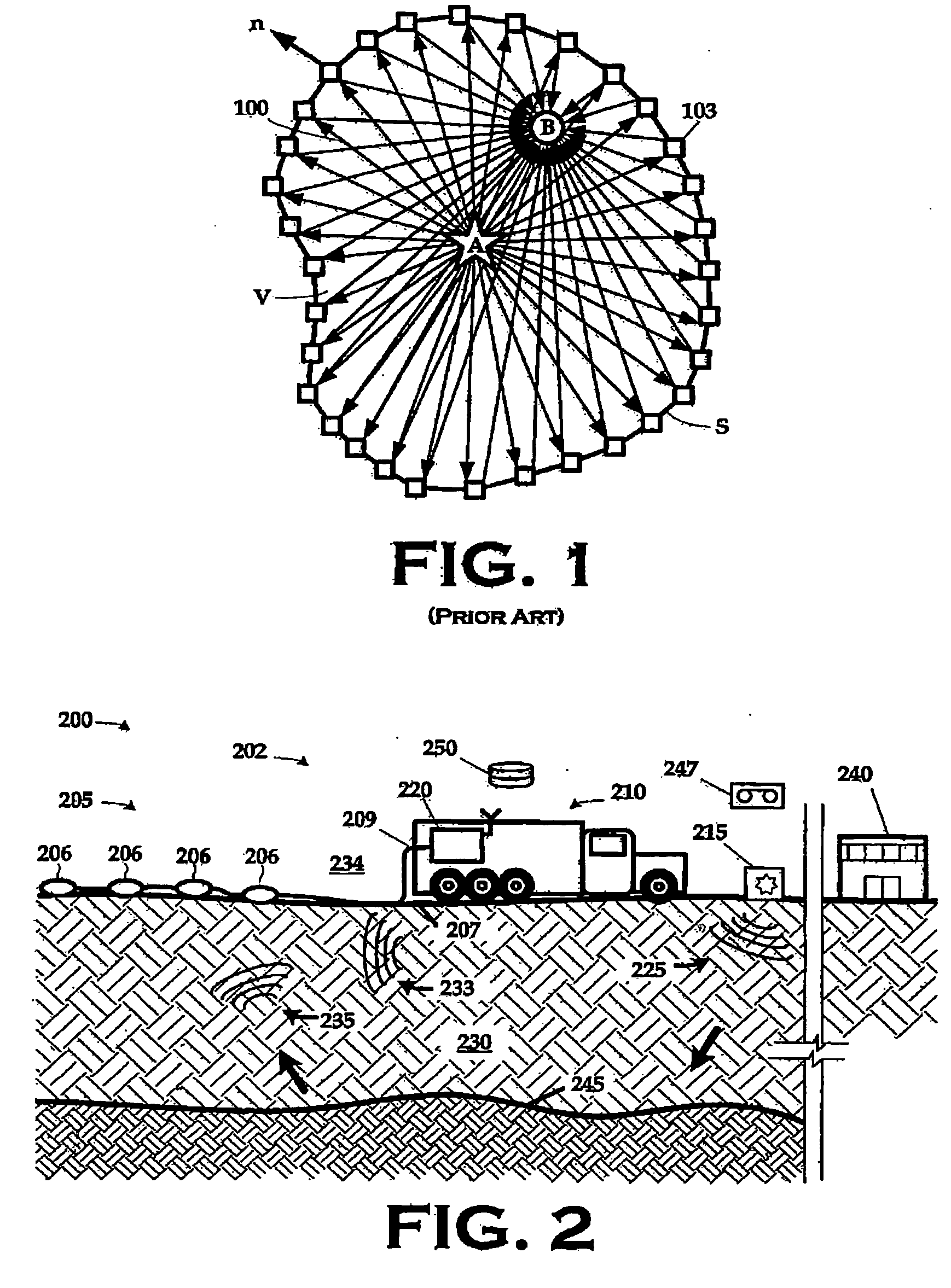

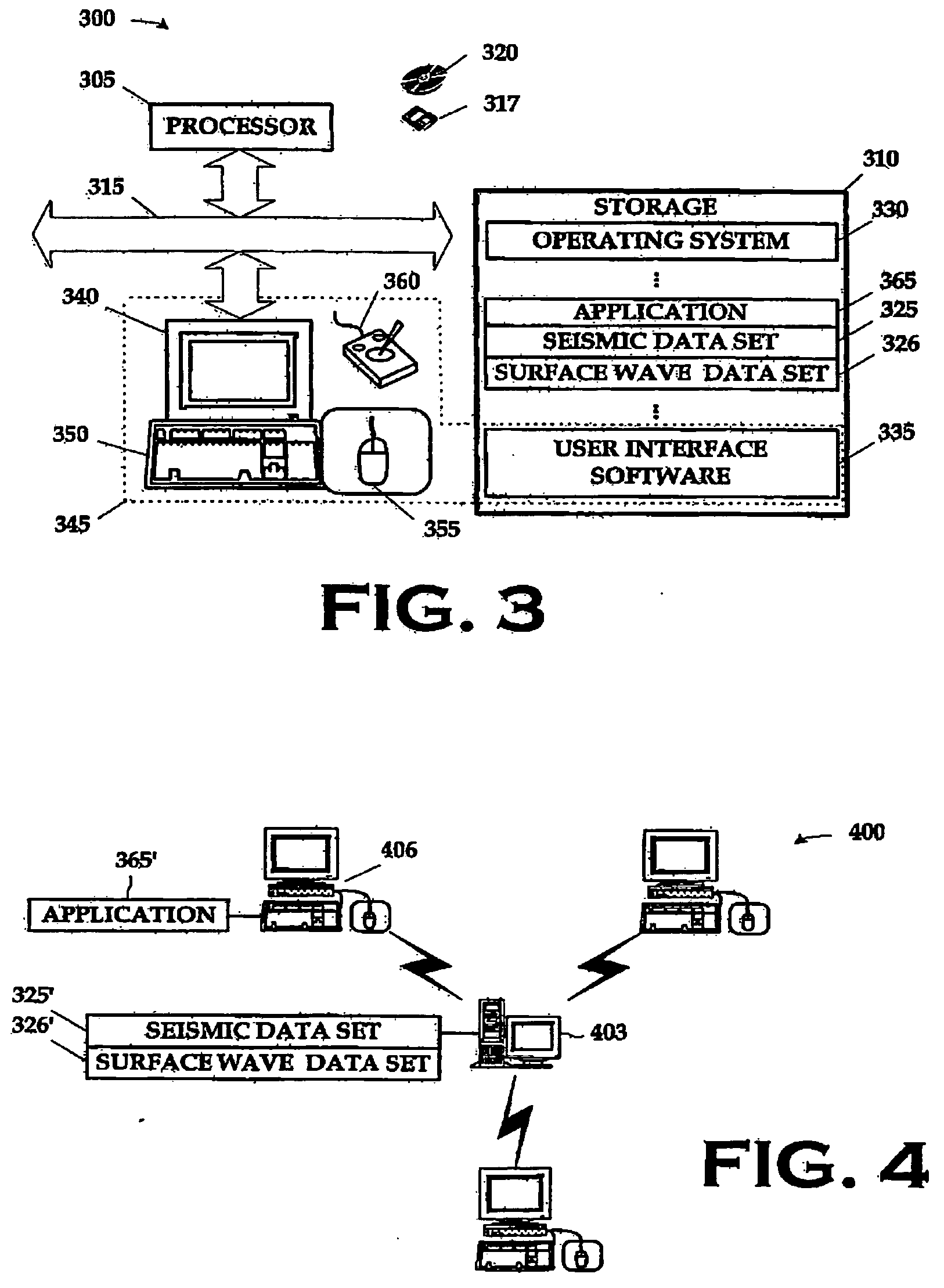

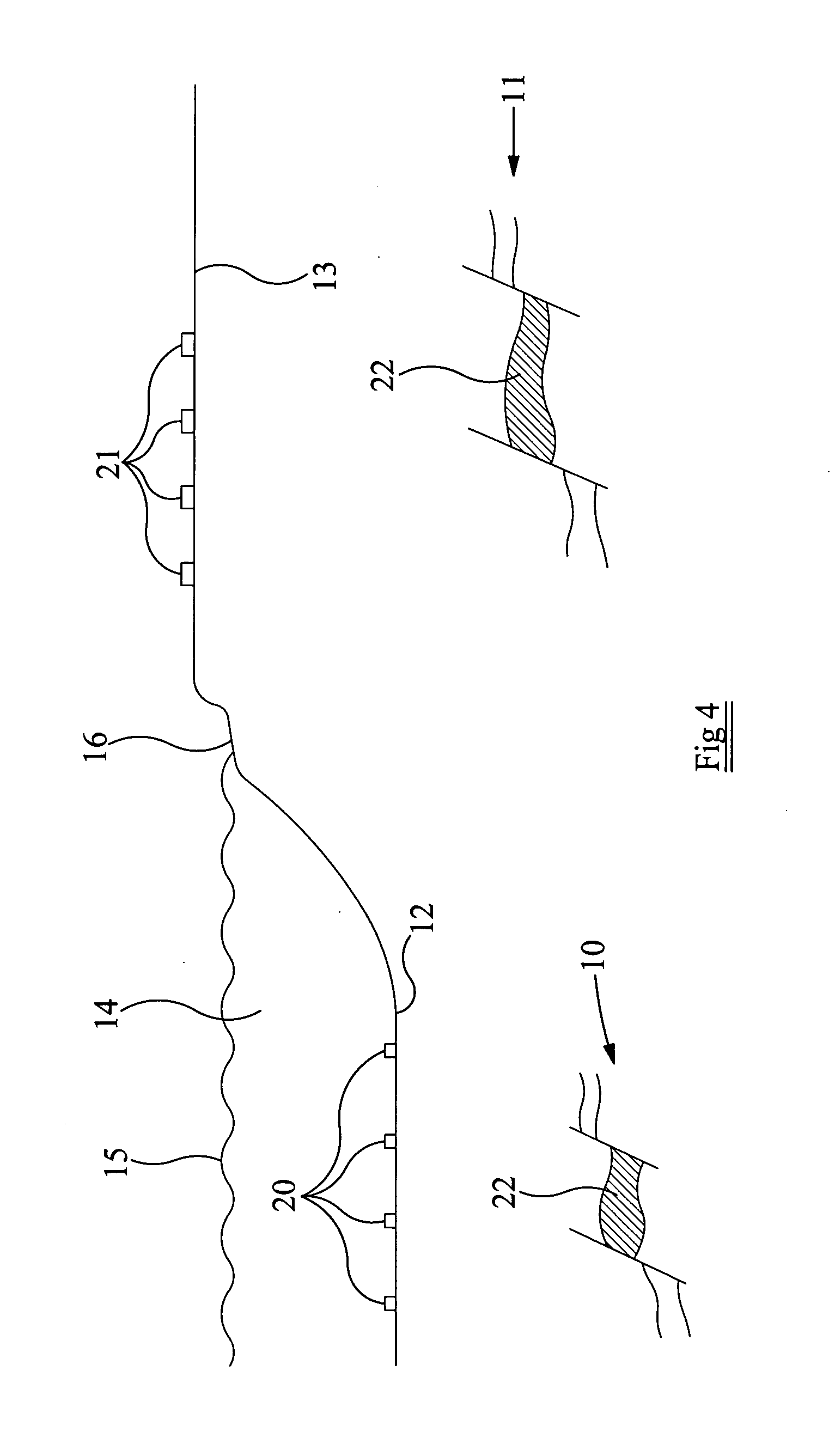

Construction and removal of scattered ground roll using interferometric methods

InactiveUS20070104028A1Interface is in effectSeismic data acquisitionSeismic signal processingData setWave field

A data set can be corrected for the effects of interface waves by interferometrically measuring an interface wavefield between each of a plurality of planned locations within a survey area; and correcting survey data acquired in the survey area for the interface waves. The interface wavefield may be interferometrically measured by receiving a wavefield including interface waves propagating within a survey area, the survey area including a plurality of planned survey locations therein; generating interface wave data representative of the received interface wavefield; and constructing a Green's function between each of the planned survey positions from the interface wave data. Other aspects include an apparatus by which the interface wavefield may be interferometrically measured and a computer apparatus programmed to correct the seismic data using the interferometrically measured interface wave data.

Owner:WESTERNGECO LLC

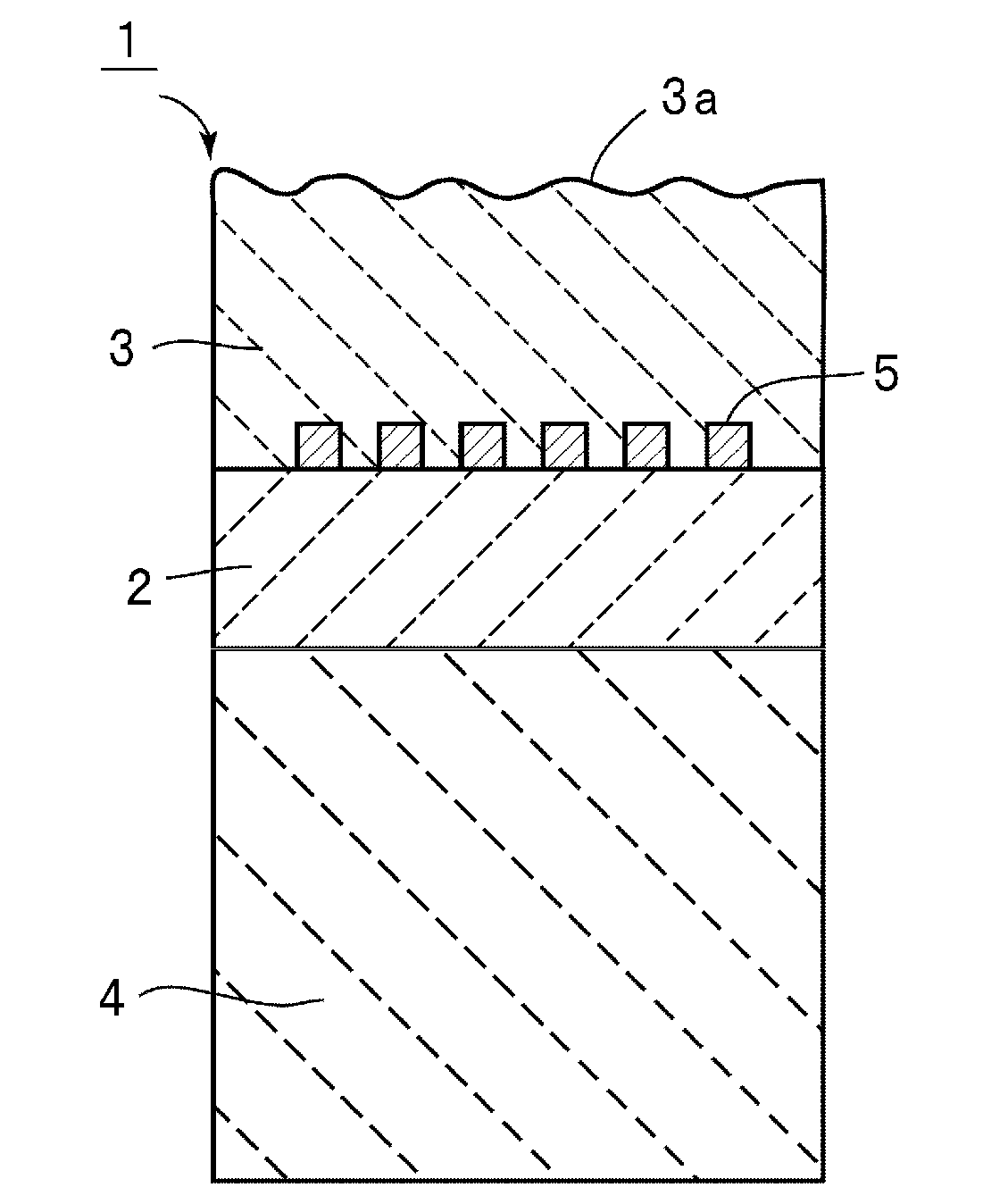

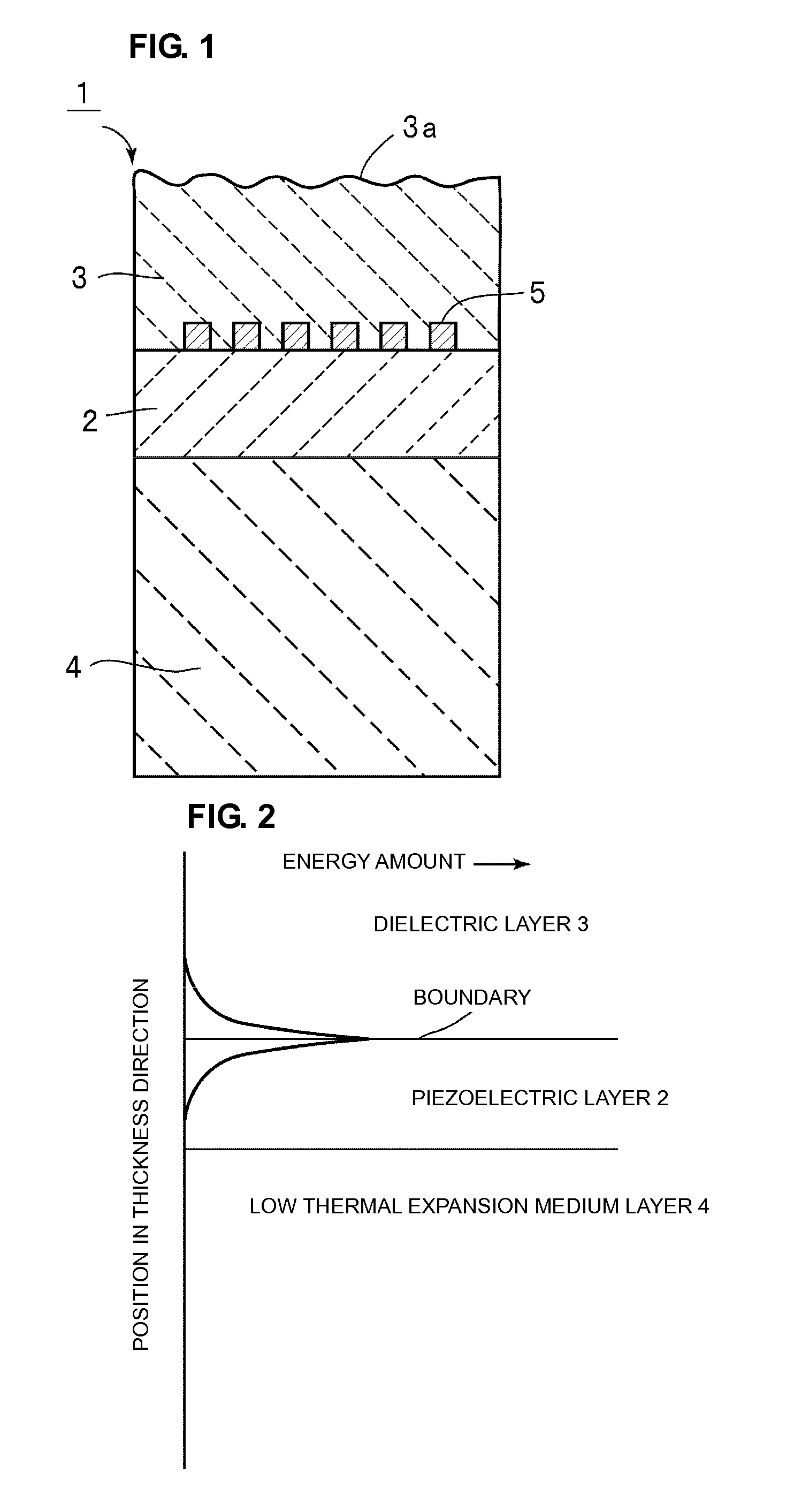

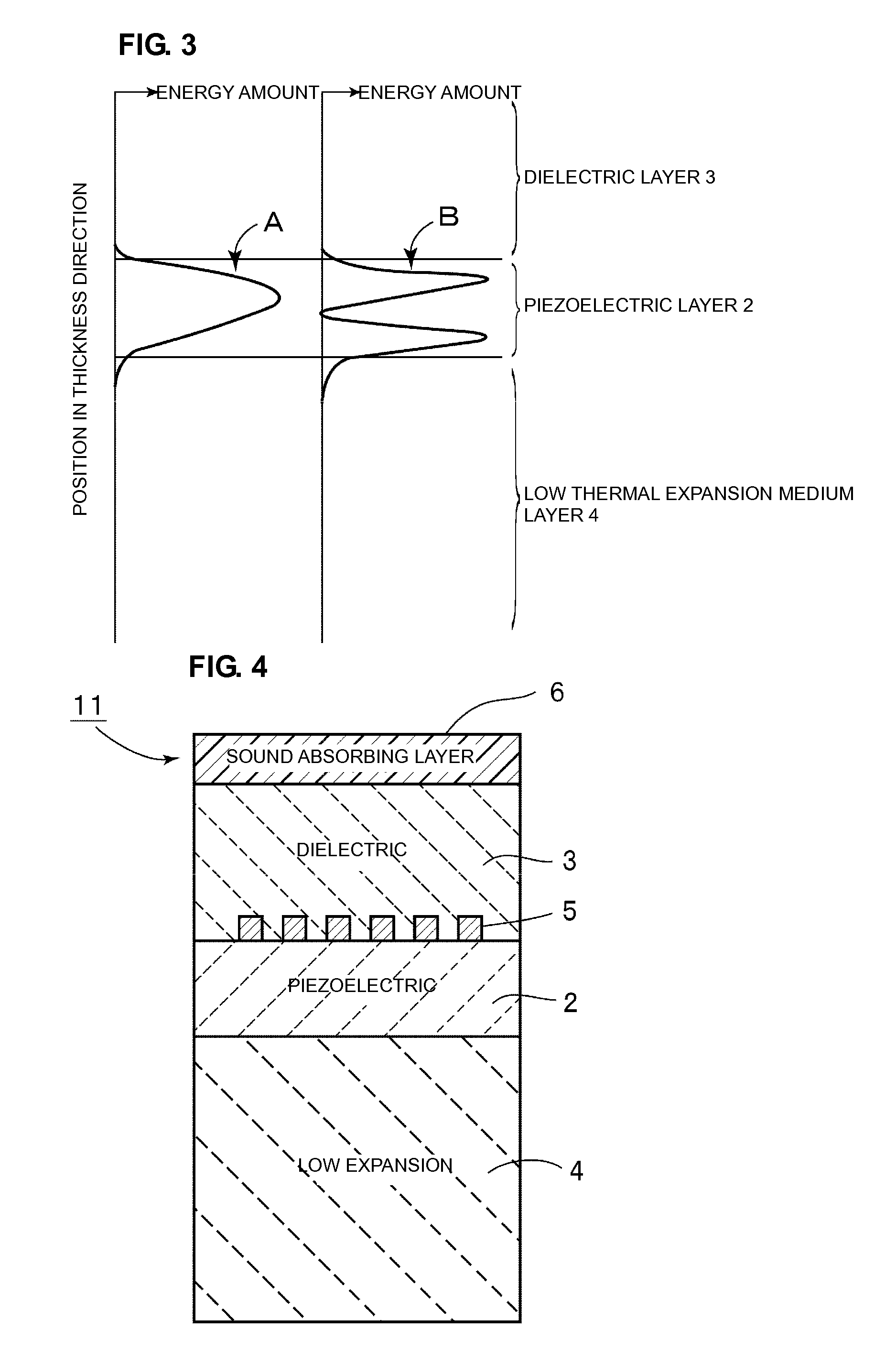

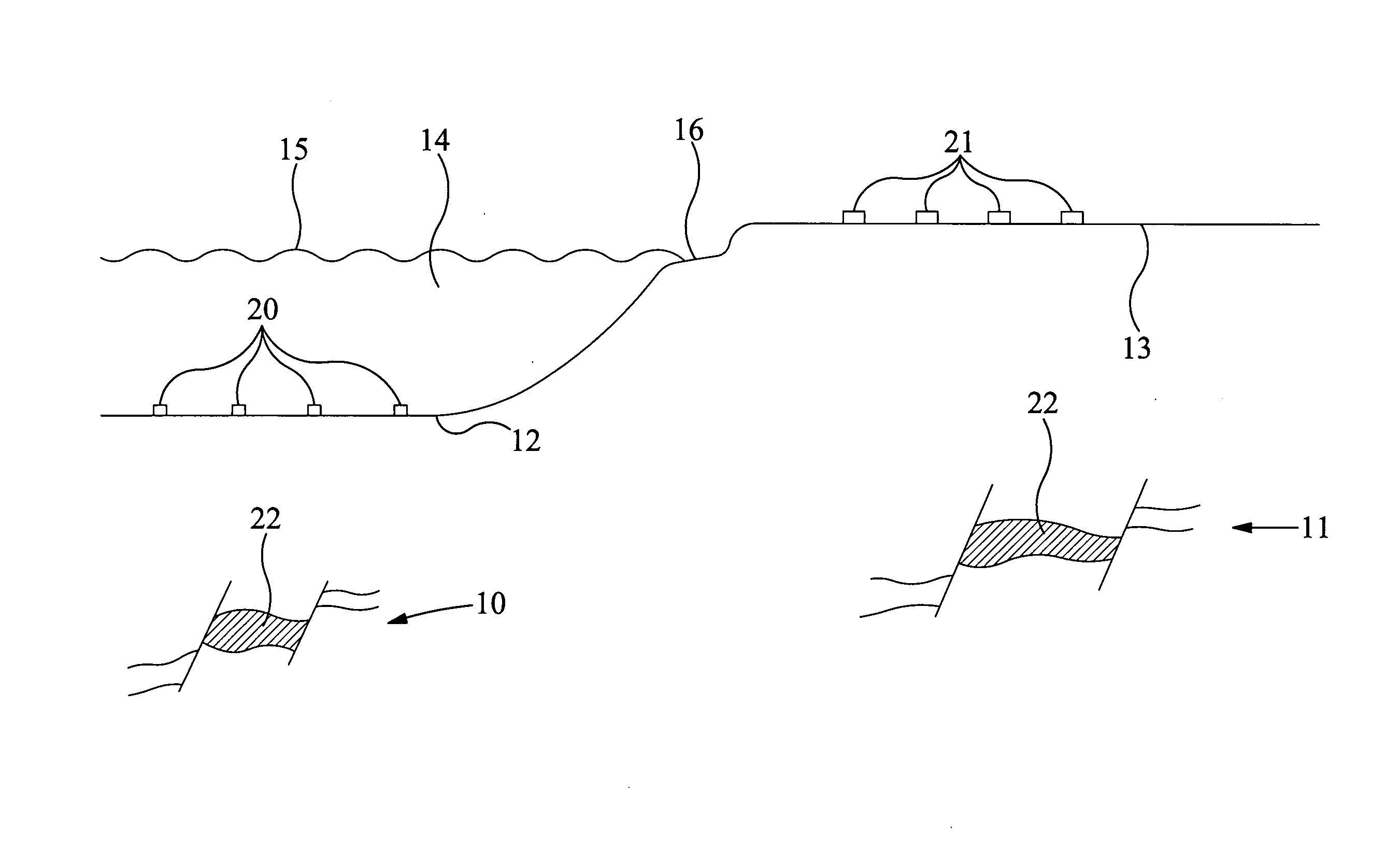

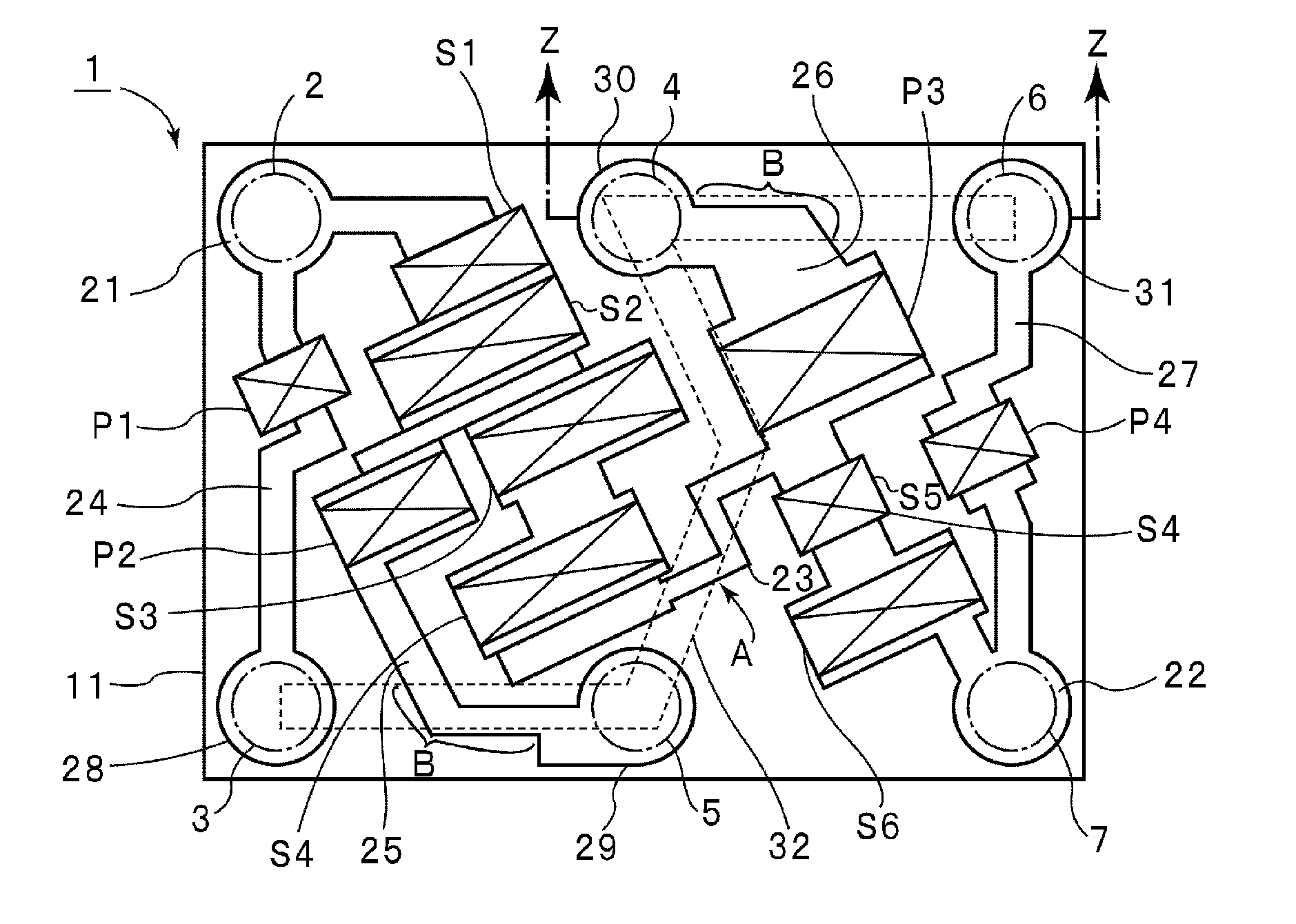

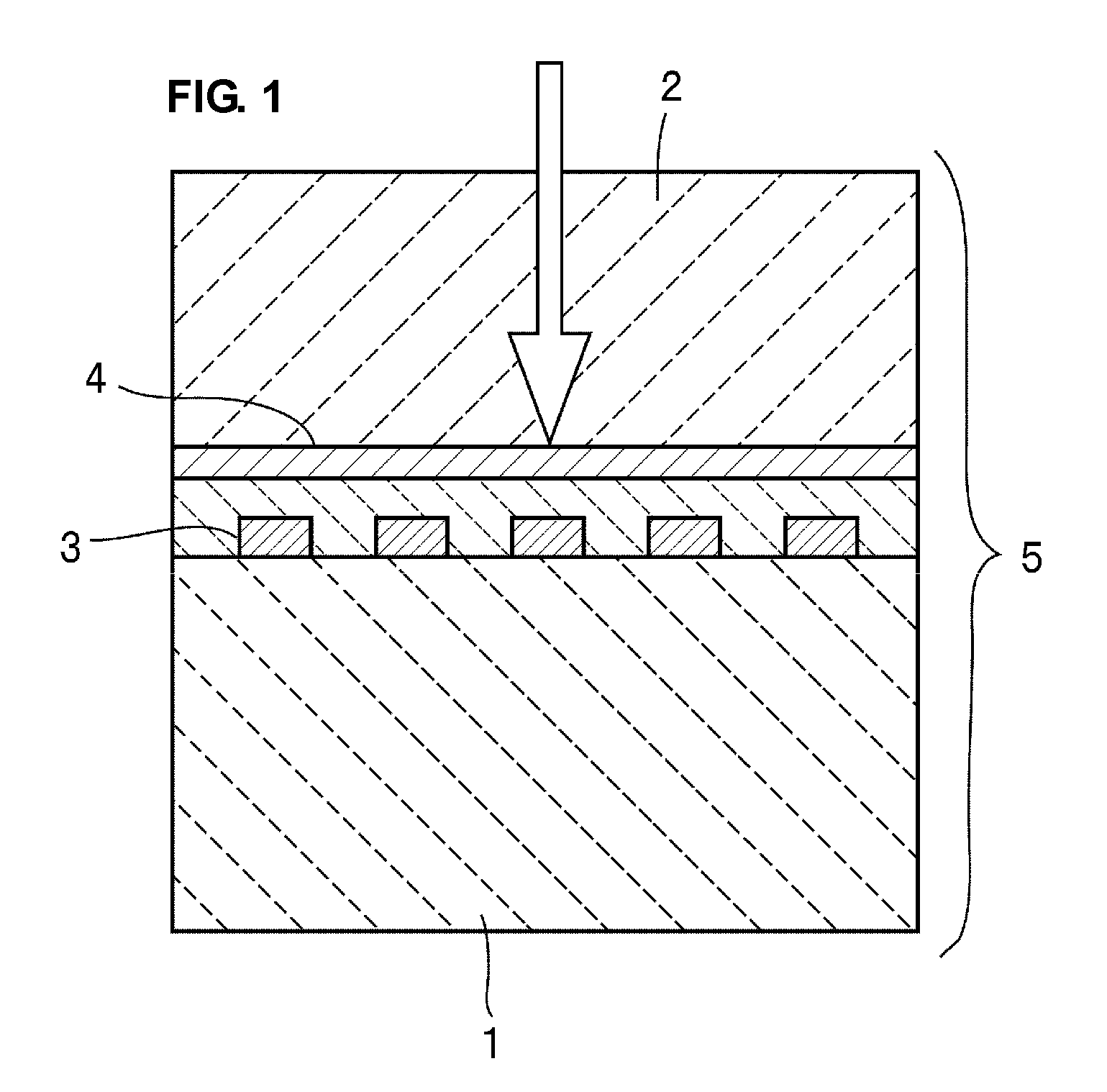

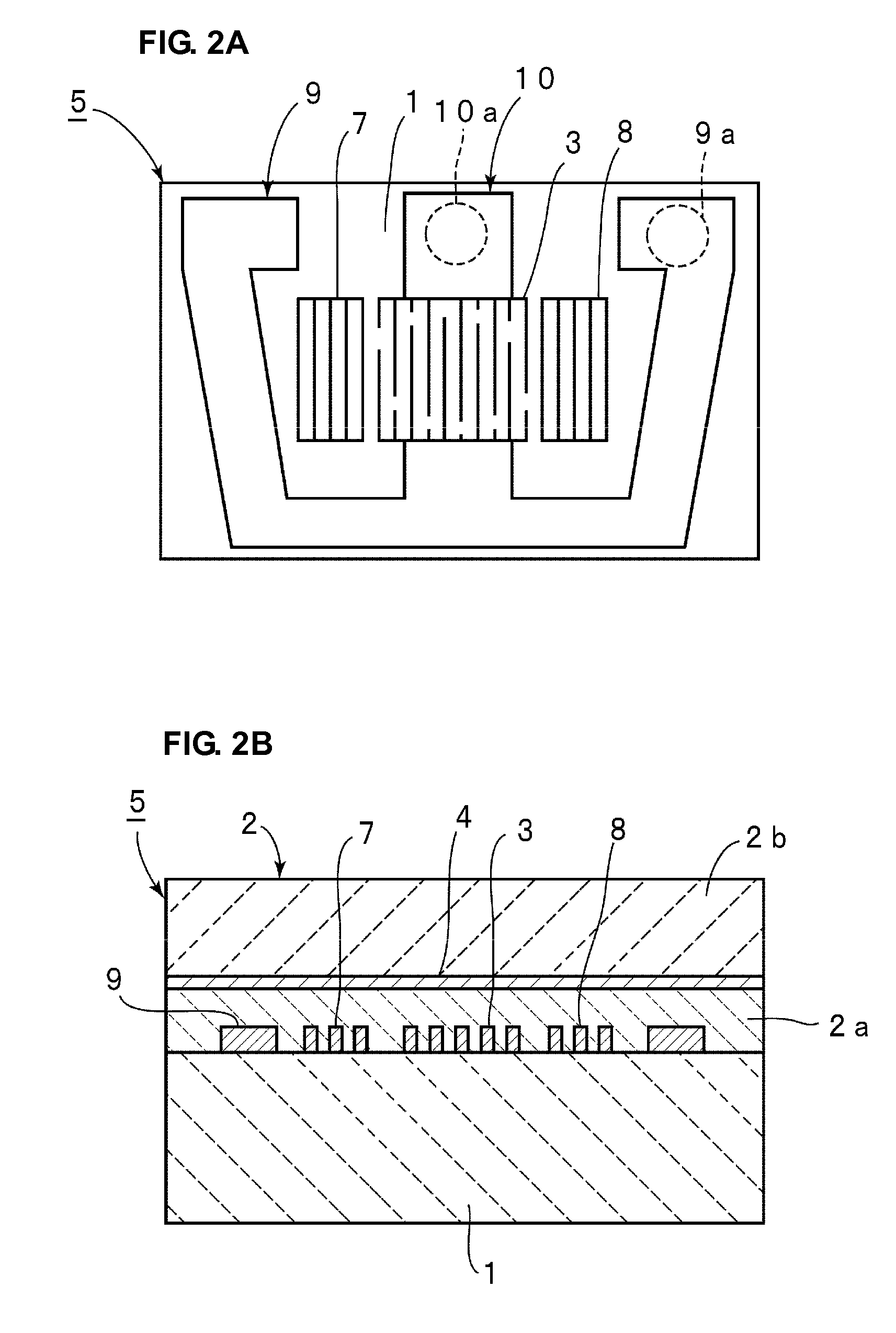

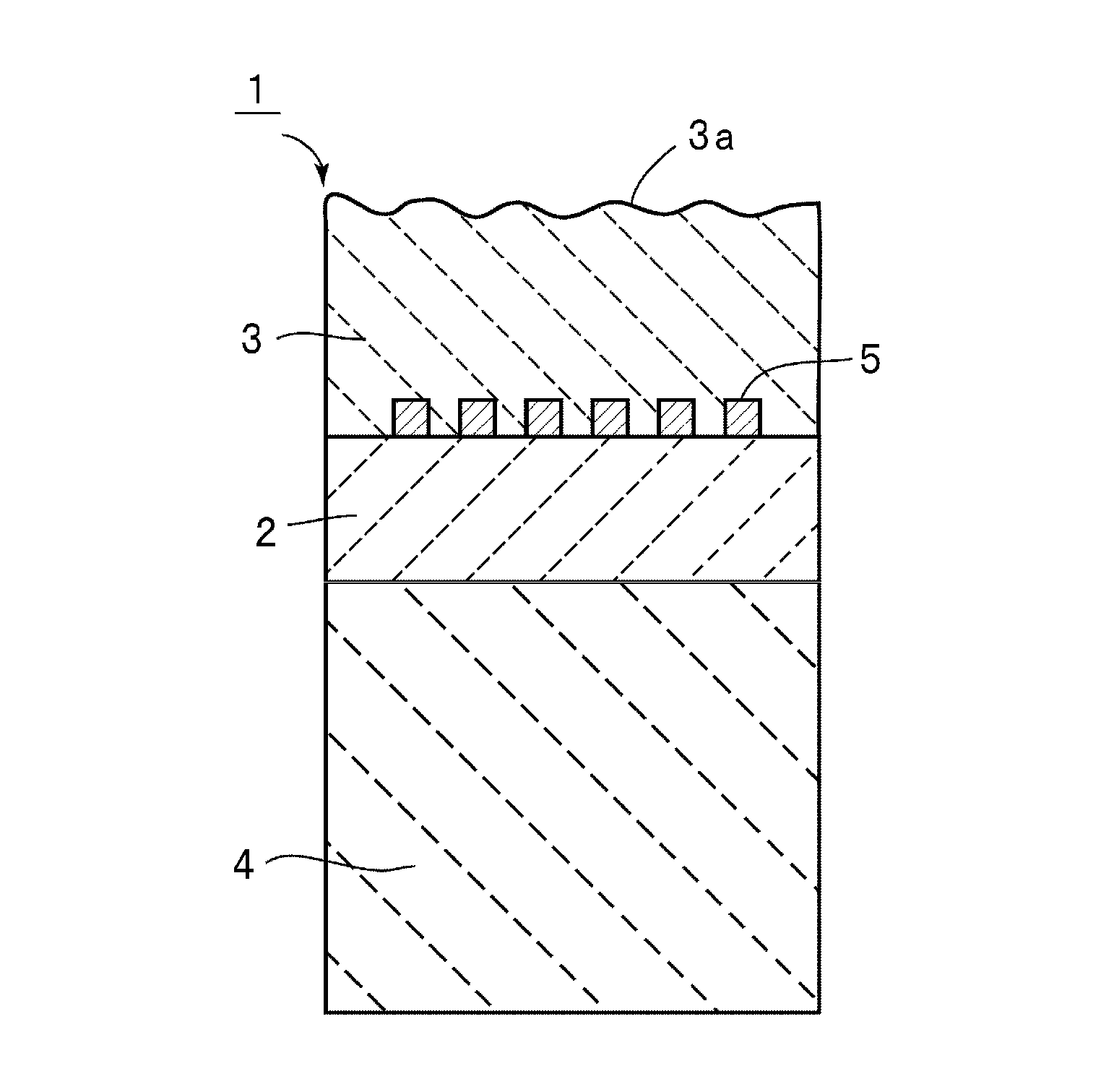

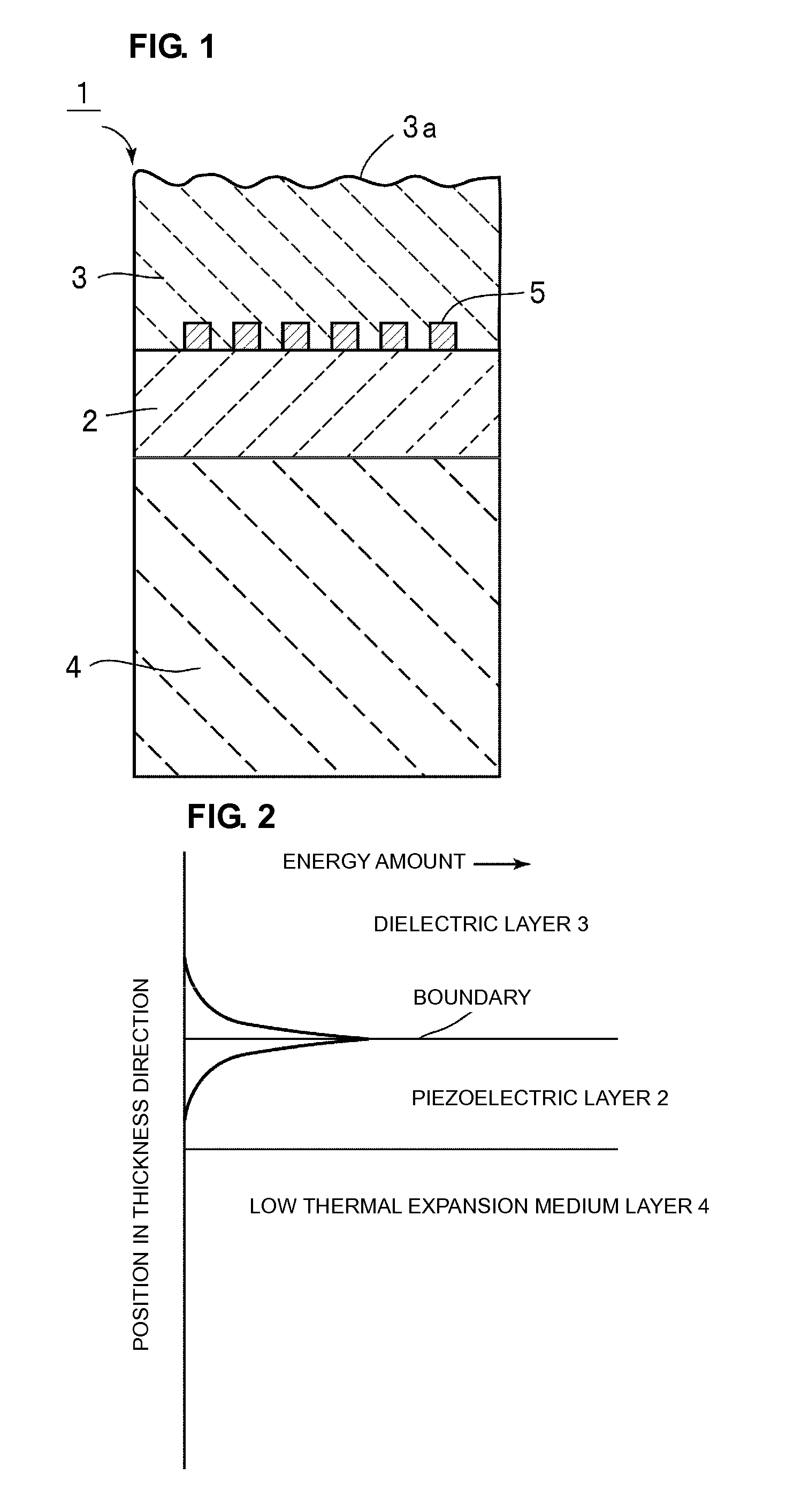

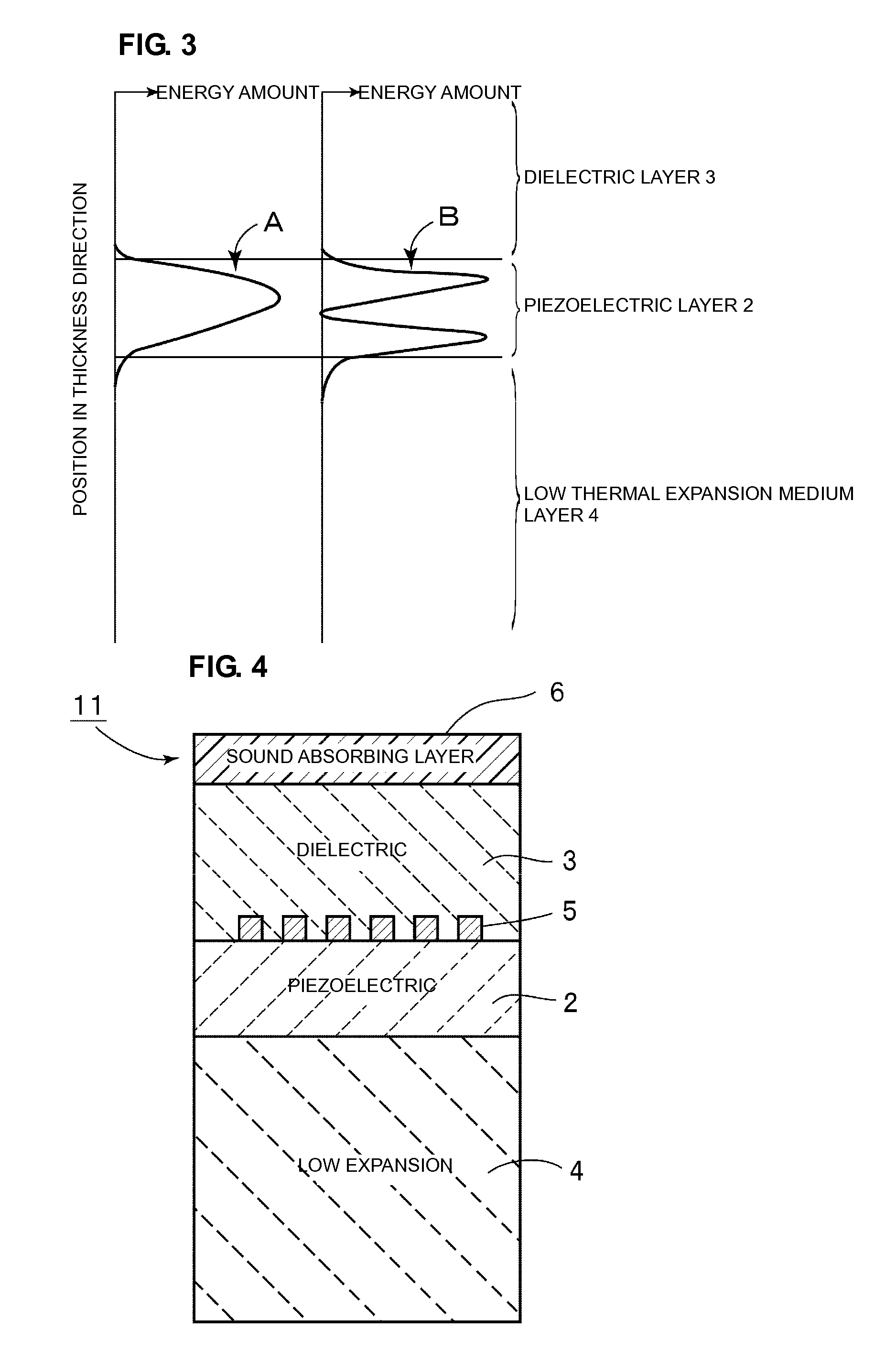

Boundary acoustic wave device

ActiveUS20090236935A1Reduce intensitySimple structurePiezoelectric/electrostriction/magnetostriction machinesImpedence networksResponse FrequencyMedia layer

A boundary acoustic wave device includes an IDT electrode between a piezoelectric layer and a dielectric layer. A low thermal expansion medium layer made of a material having a linear thermal expansion coefficient less than that of the piezoelectric layer is laminated on a surface of the piezoelectric layer opposite to the boundary. Acoustic velocities of transversal waves in a boundary acoustic wave propagation direction at the piezoelectric layer, the dielectric layer, and the low thermal expansion medium layer satisfy Expression (1), and when λ represents a wavelength of the IDT electrode, (an acoustic velocity of a transverse wave at the dielectric layer) / λ satisfies Expression (2) as follows:(acoustic velocity of transverse wave at dielectric layer)<(acoustic velocity of SH wave at piezoelectric layer)<(acoustic velocity of transverse wave at low thermal expansion medium layer) Expression (1), and(response frequency of boundary acoustic wave)<(acoustic velocity of transverse wave at dielectric layer) / λ<(response frequency of high order mode) Expression (2).

Owner:MURATA MFG CO LTD

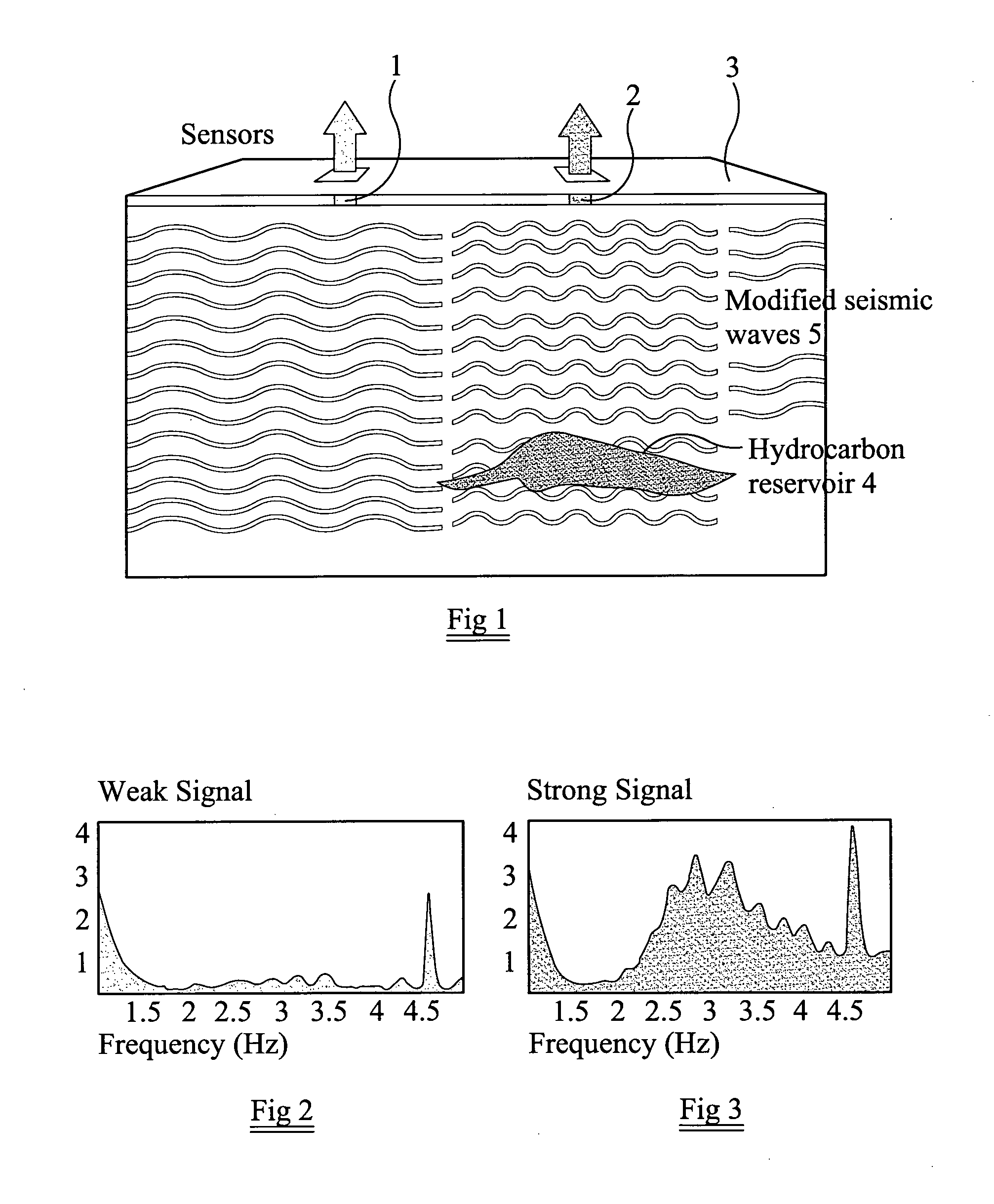

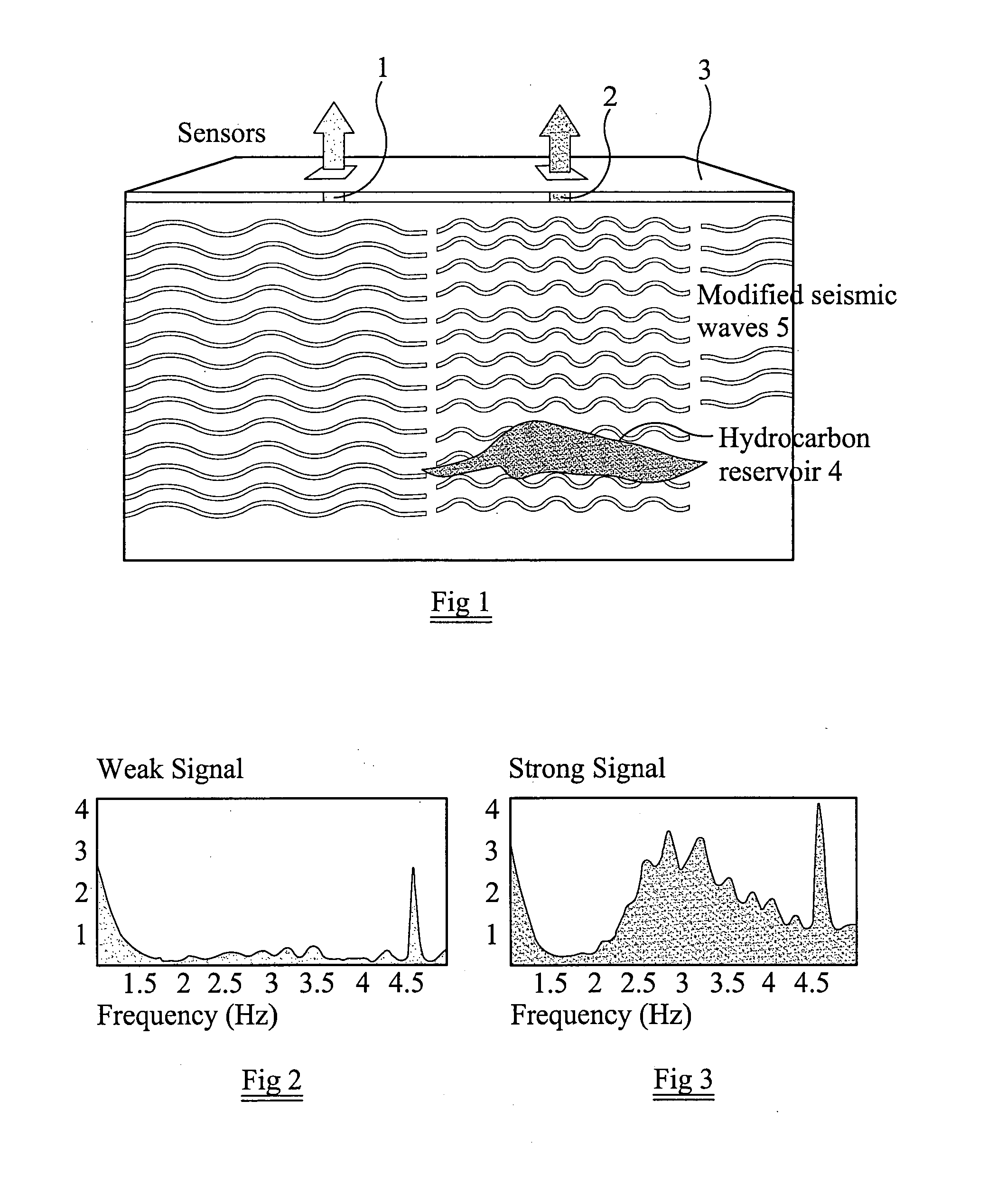

Method of and apparatus for exploring a region below a surface of the earth

ActiveUS20110046885A1Seismic signal processingSpecial data processing applicationsLower limitFrequency spectrum

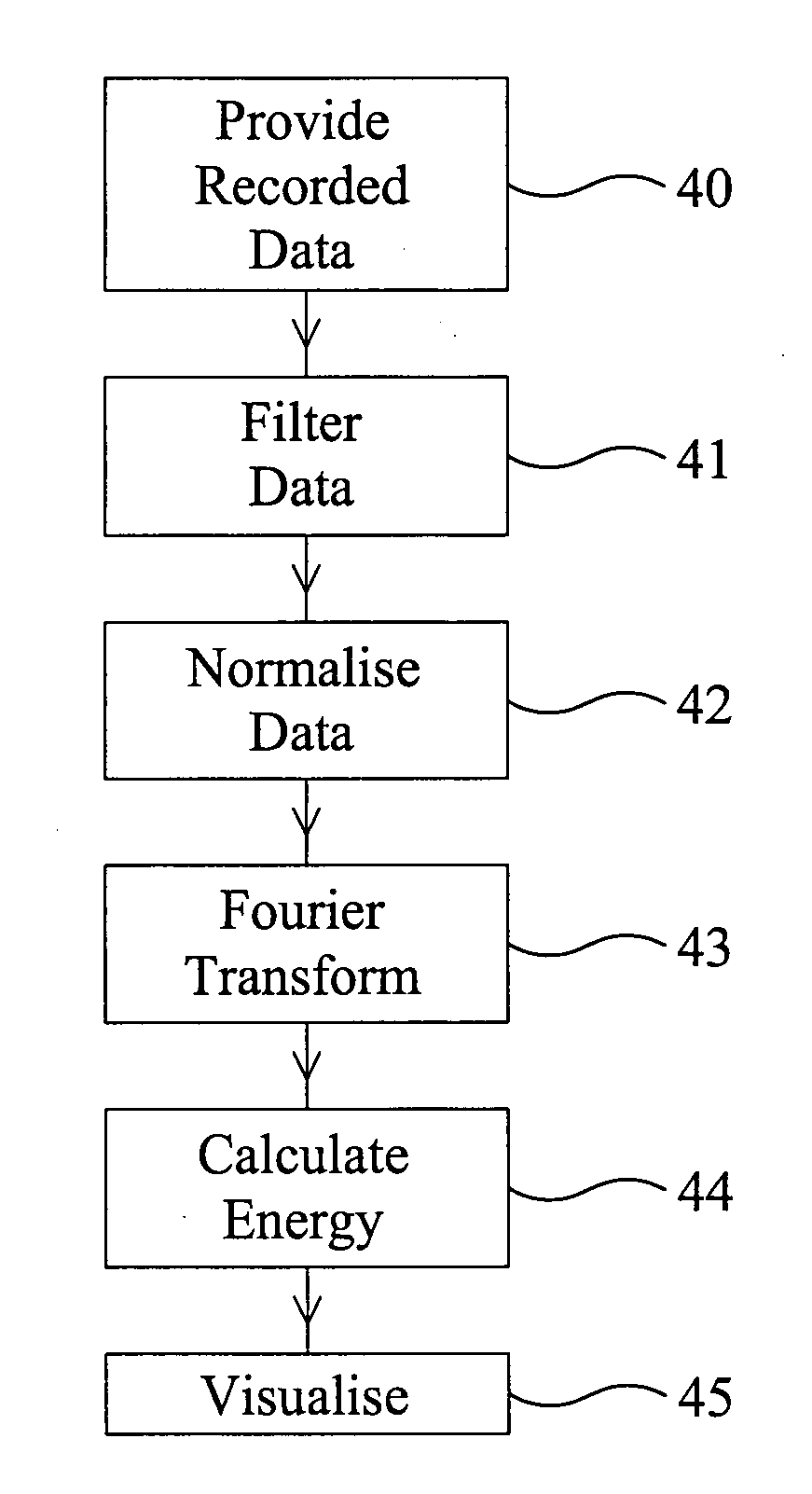

A passive method for exploring a region below the surface of the earth. The method comprises using a plurality of sensors to obtain seismic data obtained by recording ambient seismic interface waves in a frequency range whose lower limit is greater than 0 Hz, and whose upper limit is less than or equal to substantially 1 Hz. The sensors may be sensitive to three orthogonal components. Recordings may be made simultaneously by all sensors and normalization of data is unnecessary. The sensors may be moved and clean data may be selected. Local dispersion curves may be determined to improve vertical resolution. The data are processed so as to obtain a measure of the energy in a frequency band within the frequency range. The energy measure may be calculated by integrating the spectrum in the frequency domain over a desired frequency range. The resulting calculated energy provides information about the region of the earth being explored.

Owner:EQUINOR ENERGY AS

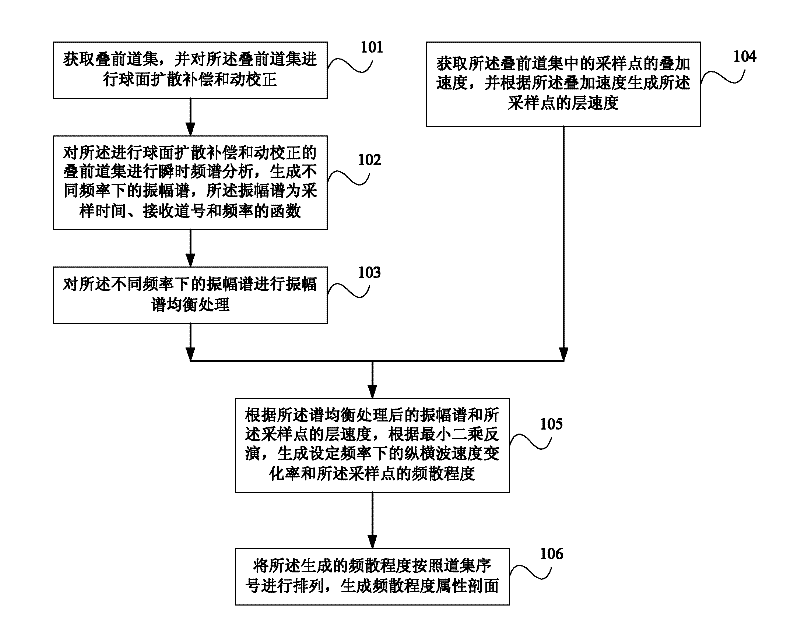

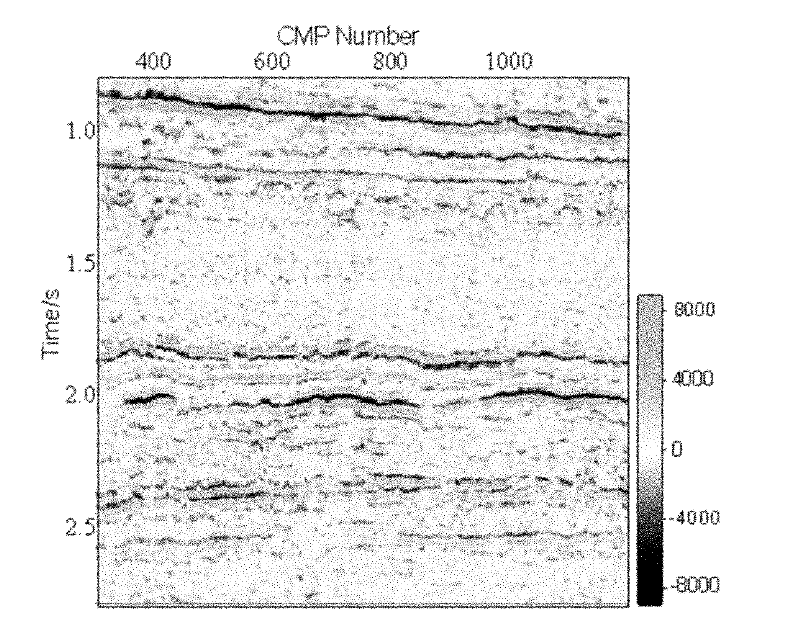

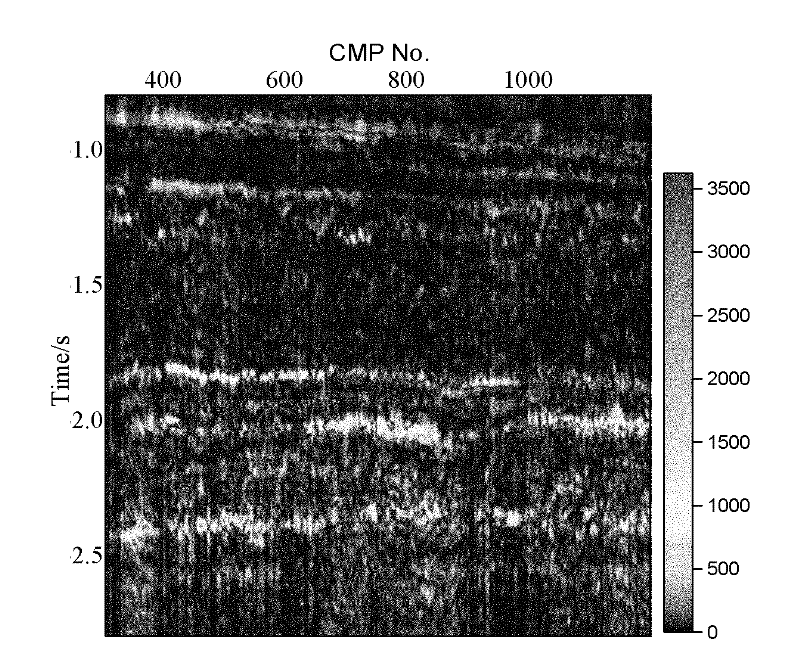

Inversion method of frequency dispersion amplitude versus offset (AVO)

ActiveCN102478667AEliminate the effects ofImprove mining efficiencySeismic signal processingFrequency spectrumInterface waves

The invention discloses an inversion method of frequency dispersion amplitude versus offset (AVO). The inversion method comprises the following steps: acquiring a pre-stack trace gather; carrying out spherical diffusion compensation and dynamic correction on the pre-stack trace gather, and carrying out instant spectrum analysis on the pre-stack trace gather, so as to generate amplitude spectra under different frequencies; carrying out amplitude spectrum balancing on the amplitude spectra; acquiring a stacking velocity of sampling points in the pre-stack trace gather; generating a layer velocity of the sampling points according to the stacking velocity; generating speed variation rate of the velocity of vertical and horizontal waves under a set frequency and frequency dispersion degree of the sampling points according to the amplitude spectra after amplitude spectrum balancing, the layer velocity of the sampling points, and least square inversion; and ranking the generated frequency dispersion degree according to the trace gather serial number, so as to generate an attribute section of the frequency dispersion degree. By utilizing the inversion method of frequency dispersion AVO provided by the embodiment of the invention, the influence of a strong amplitude energy group caused by impedance difference of an elastic interface wave can be eliminated, and the false 'frequency abnormality' caused by the stacking when post-stack seismic data spectrum is analyzed can be avoided, so that the obtained result is more reliable.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

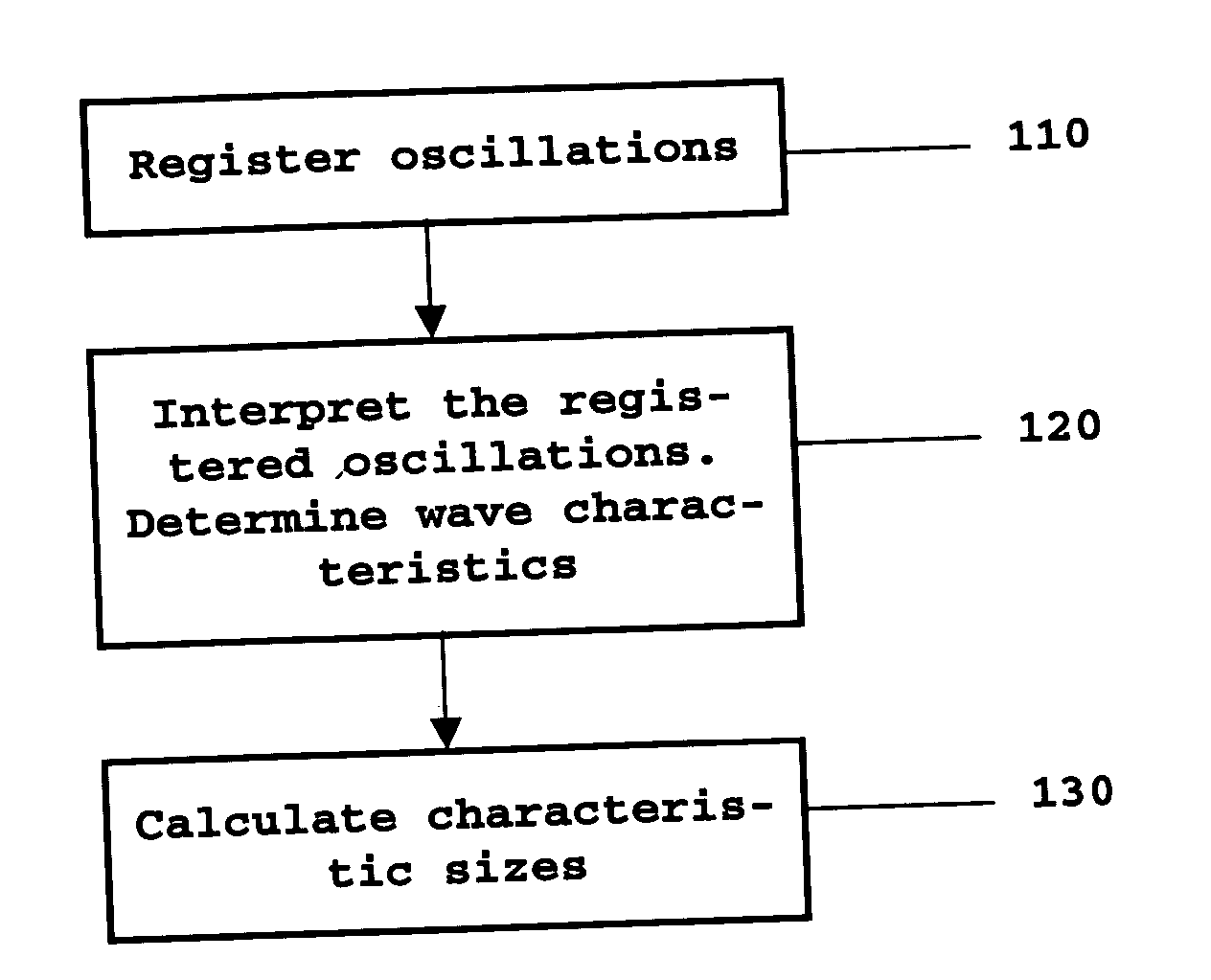

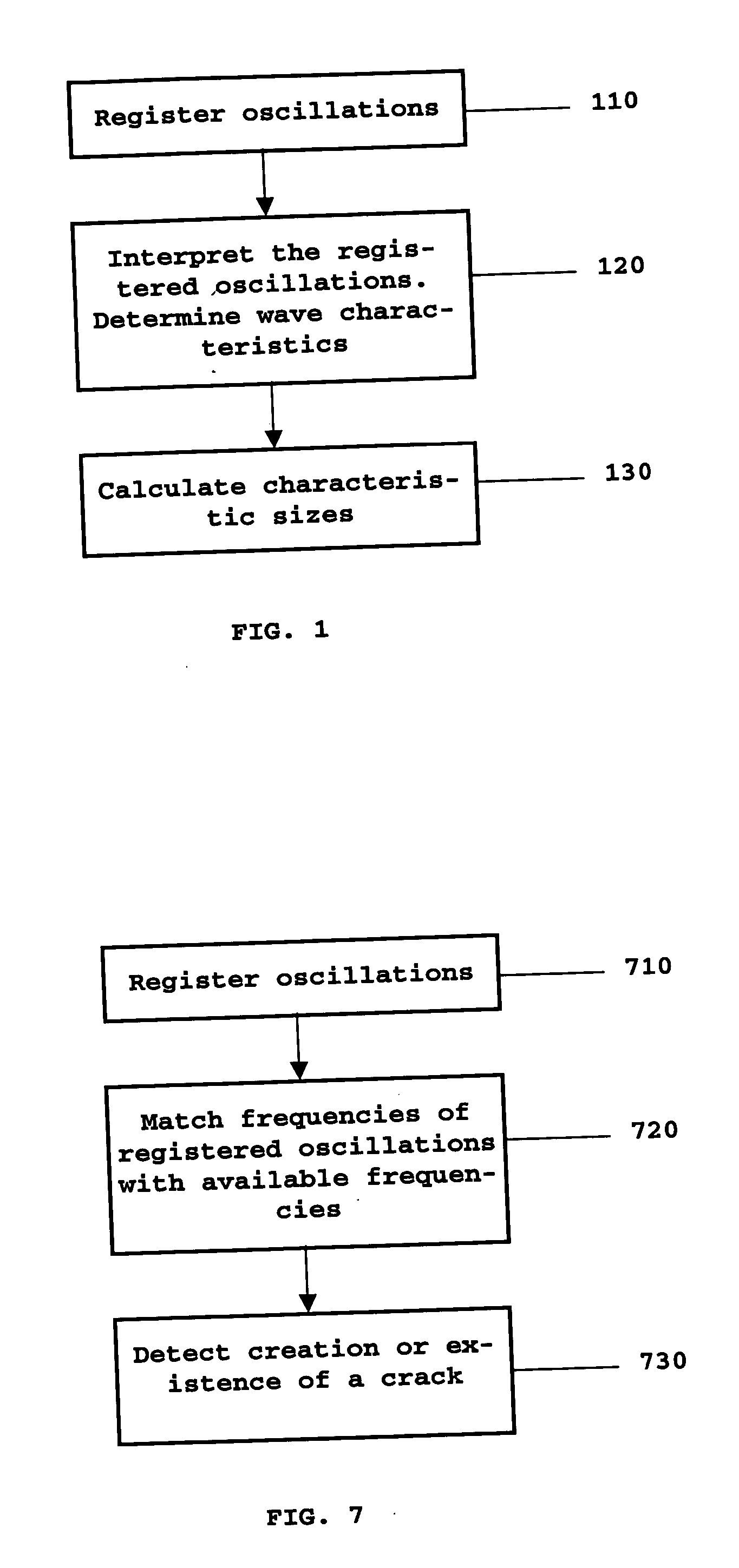

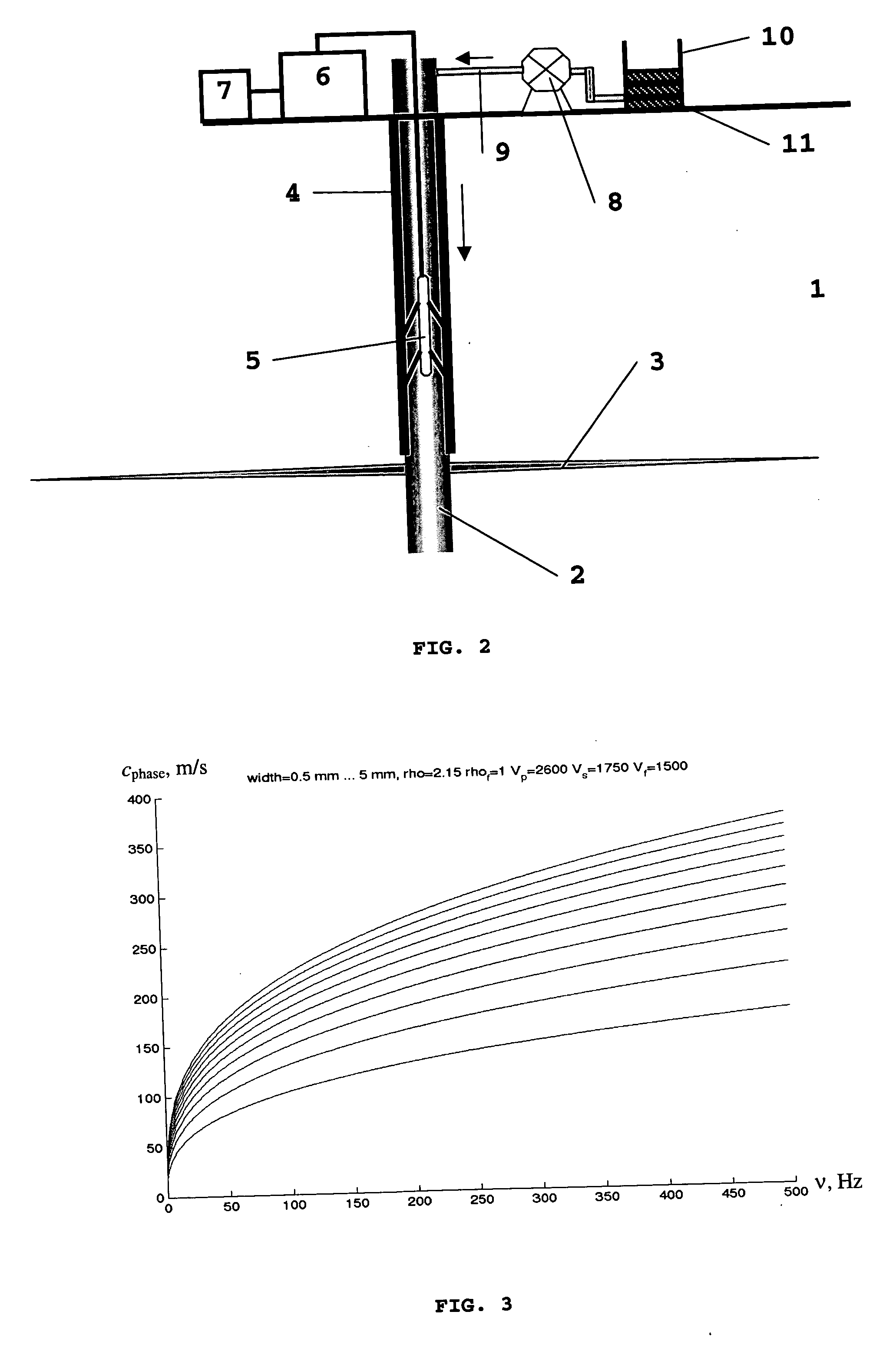

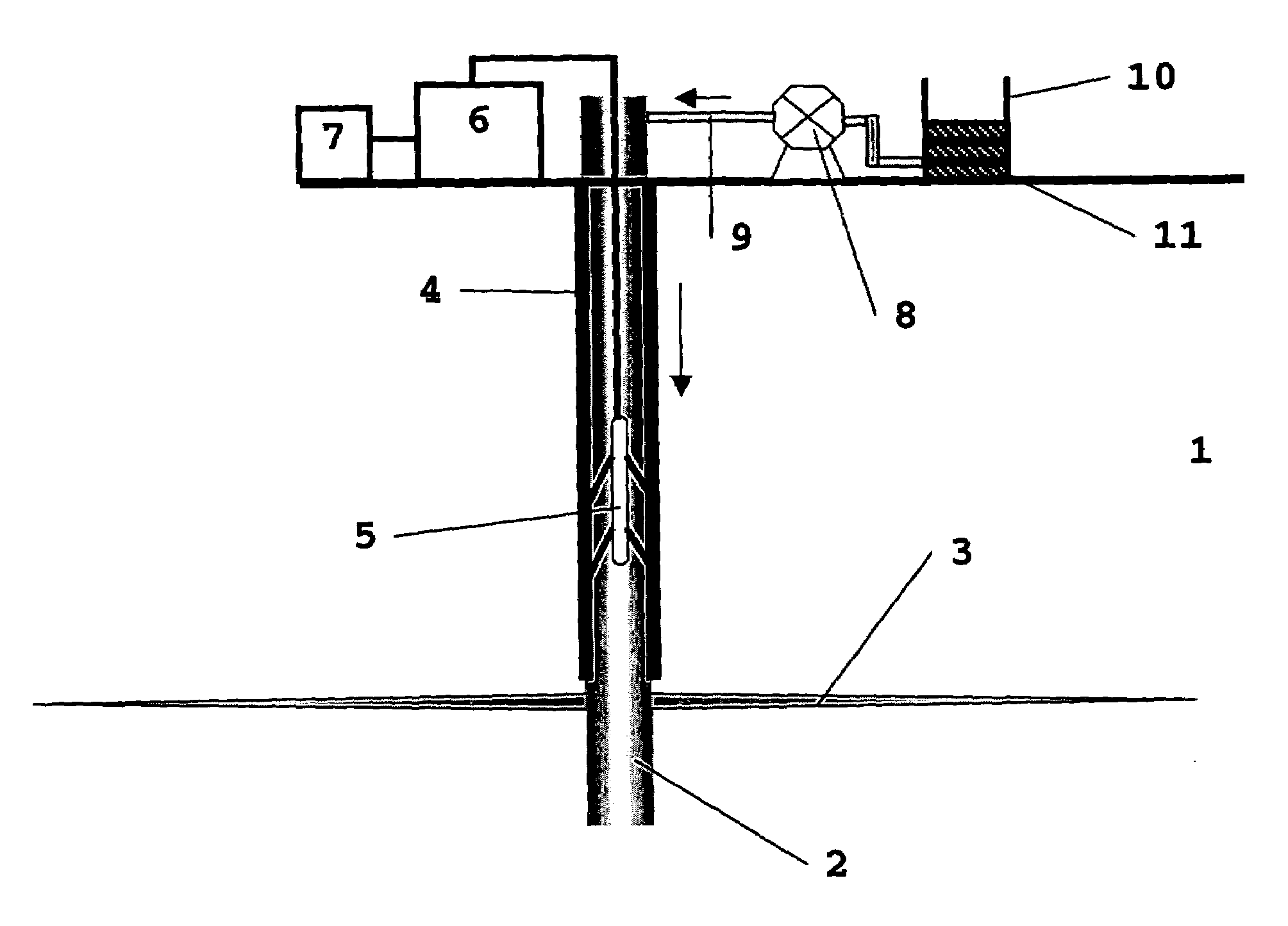

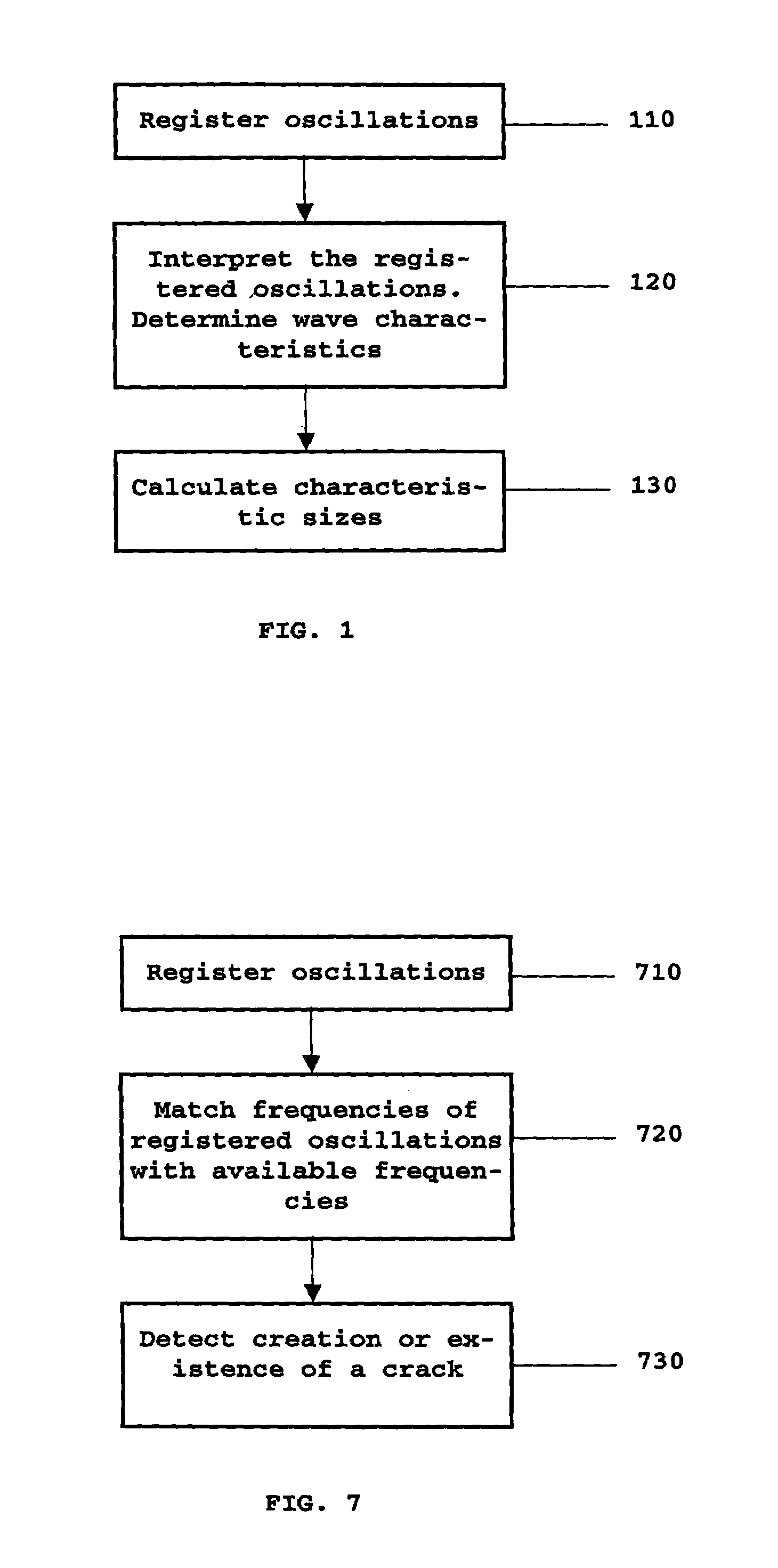

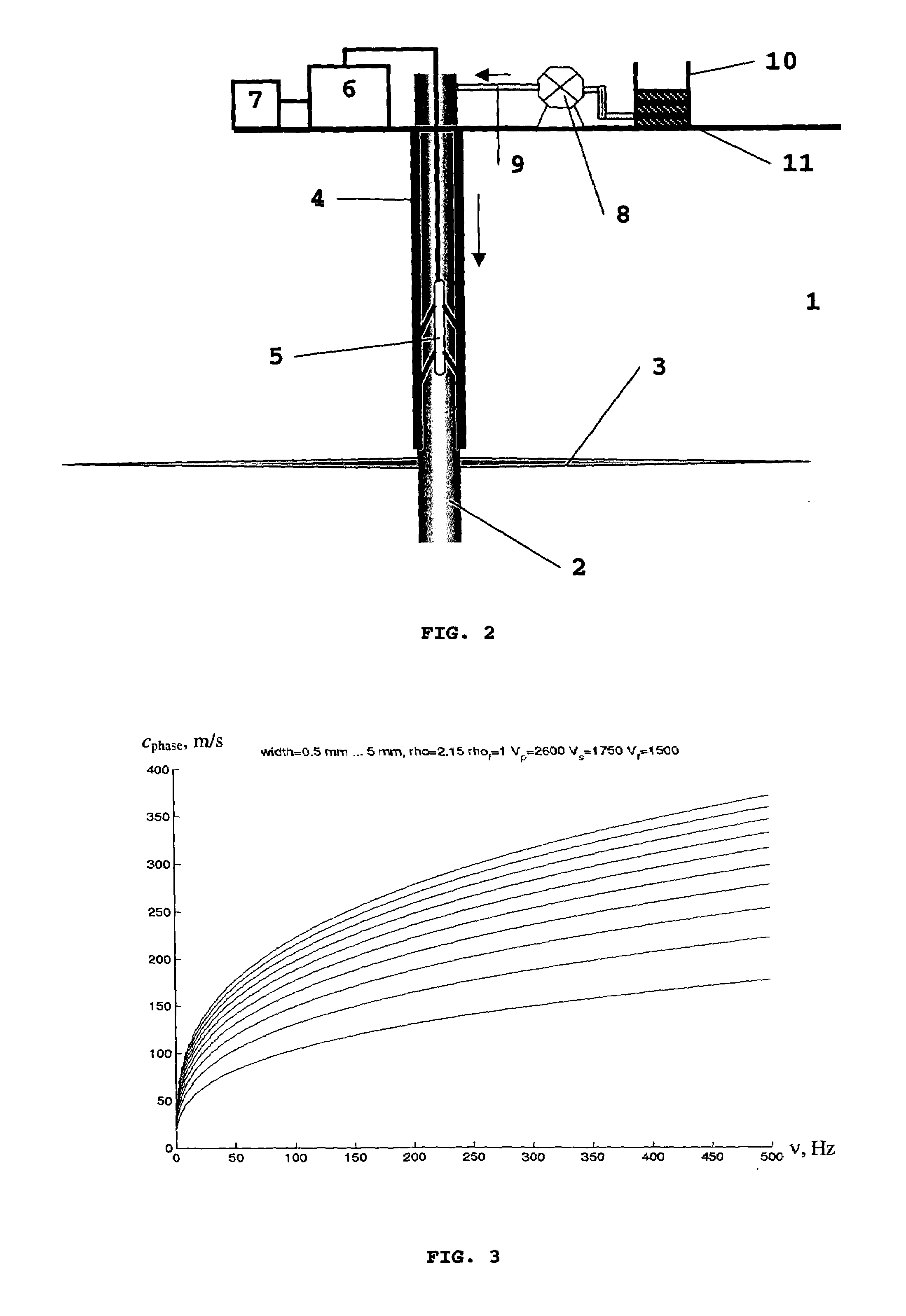

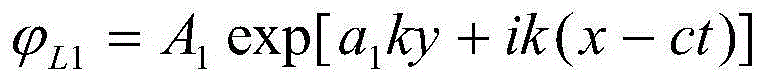

Method and system for monitoring of fluid-filled domains in a medium based on interface waves propagating along their surfaces

ActiveUS20050246131A1Efficient and reliable calculationImprove efficiencyMagnetic property measurementsVelocity propogationEngineeringHydraulic fracturing

The invention relates to monitoring of fluid-filled domains in various media including, for example, subterranean formations, construction elements, bones. Claimed are a method for determining characteristic sizes of a fluid-filled crack in a medium and a system for implementation thereof. In accordance with this method, oscillations of the fluid-filled crack are registered. Wave characteristics of standing interface waves propagating along the fluid-filled crack surfaces are determined based on the registered oscillations taking medium and fluid properties into account. The fluid-filled crack characteristic sizes are calculated based on the determined wave characteristics of the standing interface waves. Also claimed are methods for detecting creation or existence of a fluid-filled crack in a medium, for hydraulic fracturing in a subterranean formation, for detecting cessation of propagation of a fluid-filled crack in a medium, as well as a method for determining properties of a fluid filling a layer in a medium, of the medium and of the layer. Analysis of oscillations of fluid-filled domains based on interface waves propagating along their surfaces underlies all the methods listed above. The proposed methods, by virtue of the simplicity of data processing inherent thereto, can be implemented in real time.

Owner:SCHLUMBERGER TECH CORP

Method of and apparatus for exploring a region below a surface of the earth

A passive method for exploring a region below the surface of the earth. The method comprises using a single sensor located in turn at a plurality of locations to obtain seismic data obtained by recording ambient seismic interface waves in a frequency range whose lower limit is greater than 0 Hz, and whose upper limit is less than or equal to substantially 1 Hz. The data are processed so as to obtain a measure of the energy in a frequency band within the frequency range. For example, the seismic data may be filtered and may be subjected to amplitude normalization before being transformed into the frequency domain. The energy measure may then be calculated by integrating the spectrum in the frequency domain over a desired frequency range. The resulting calculated energy provides information about the region of the earth being explored.

Owner:EQUINOR ENERGY AS

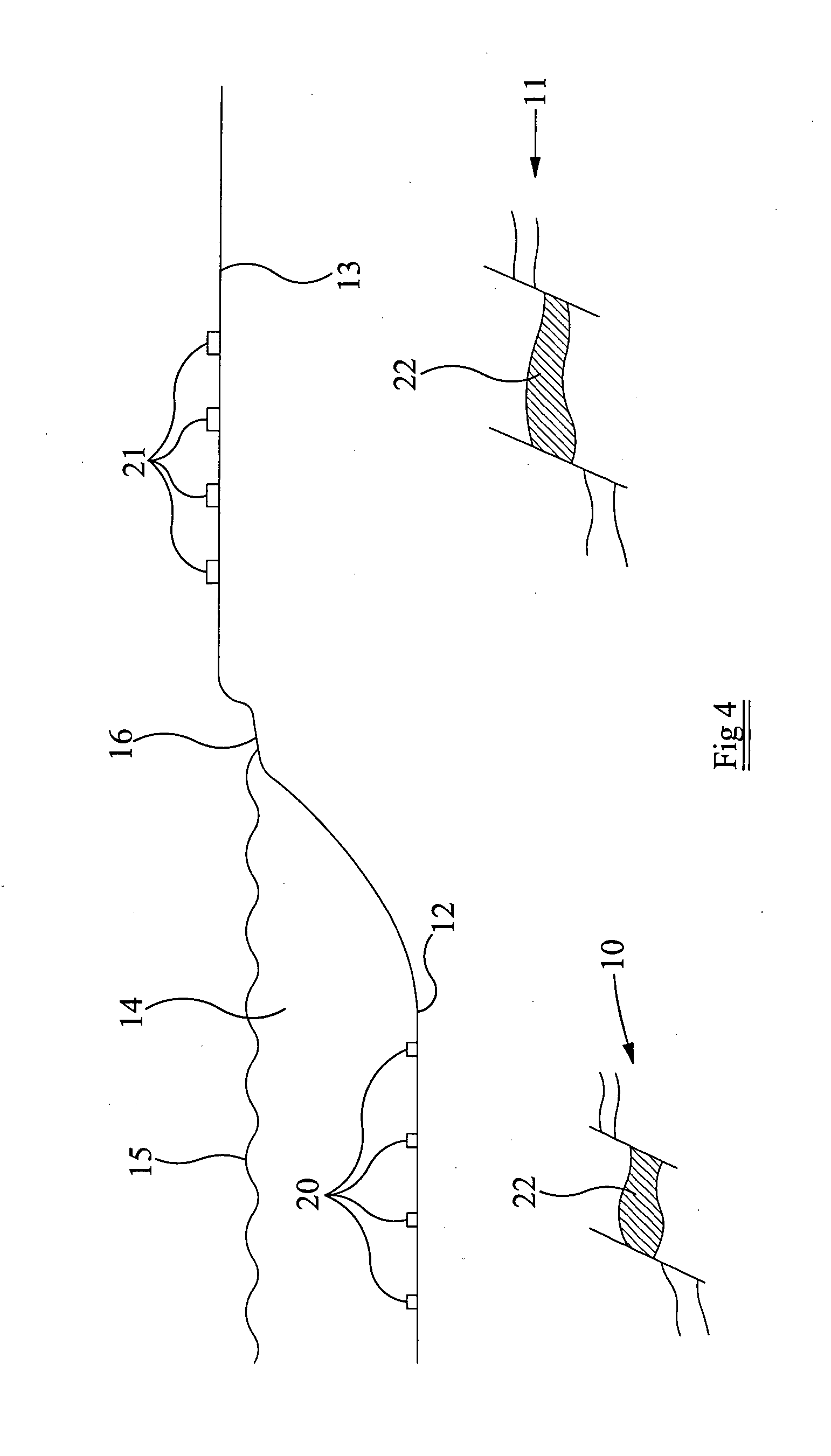

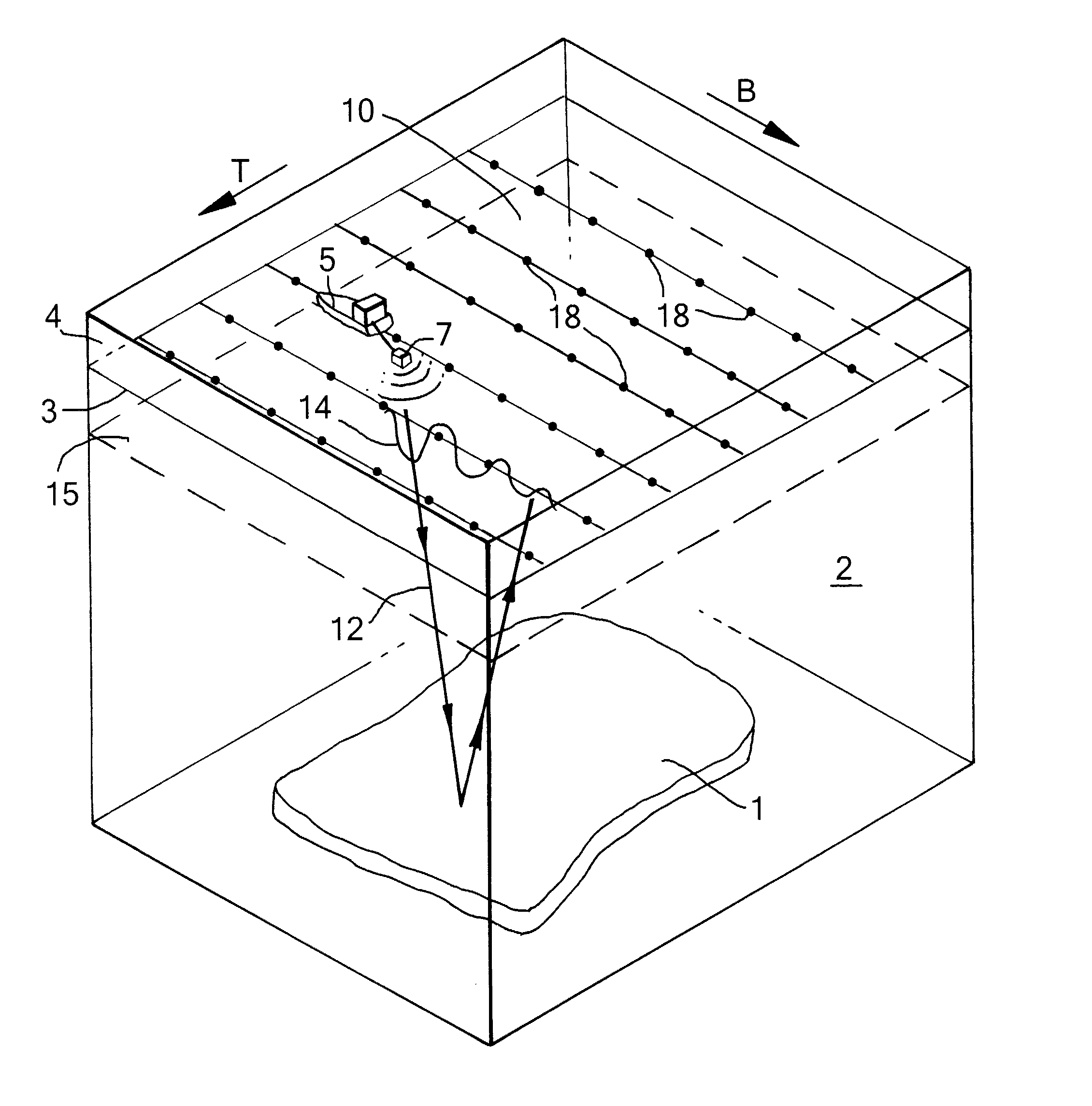

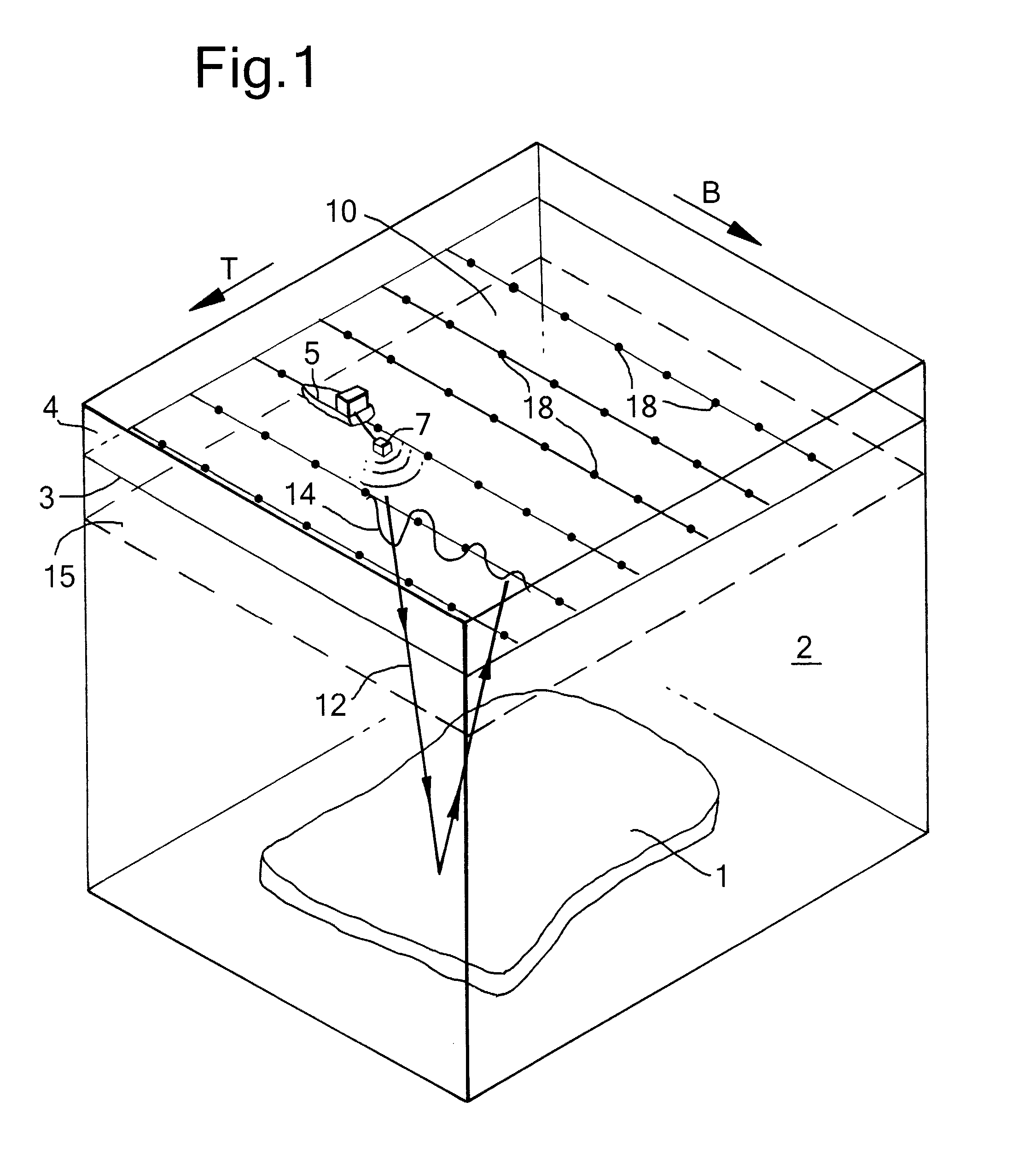

Monitoring a region of interest in a subsurface formation

InactiveUS20110046934A1Modifies temperatureSeismic signal processingAnalogue computers for fluid flowInterface wavesEarth surface

A method of monitoring a subsurface formation (2) including a region of interest (1), below a surface region, which method comprises the steps of exciting seismic interface waves (14), in the surface region over an area of the earth's surface at a first and a second moment in time; detecting seismic interface waves signals for a plurality of locations in the area; determining, from the detected seismic interface wave signals, an areal distribution of a parameter related to seismic interface wave velocity change between the first and second moments in time; and inferring, from the areal distribution, an indication of a volume change of the region of interest between the first and second moments in time.

Owner:SHELL OIL CO

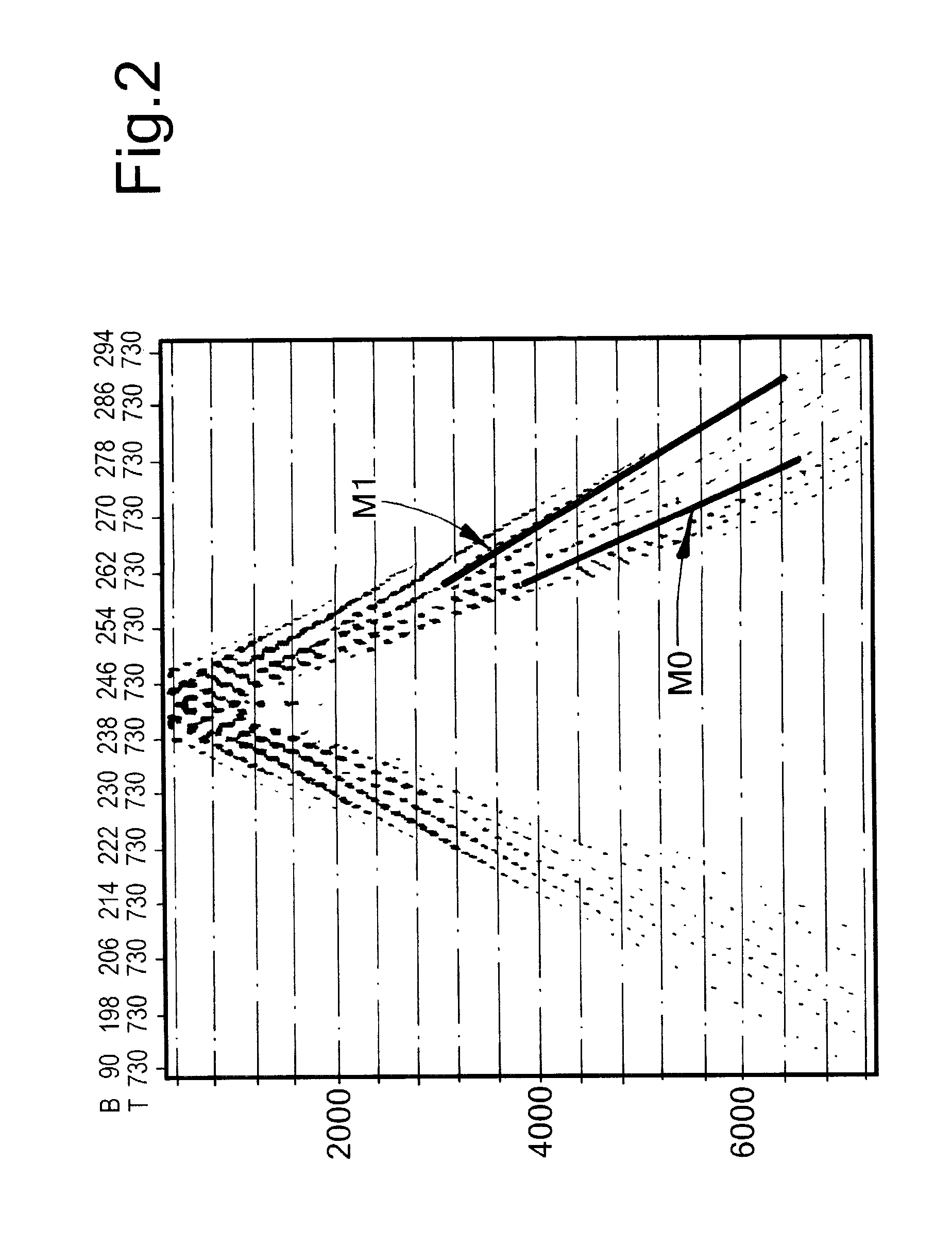

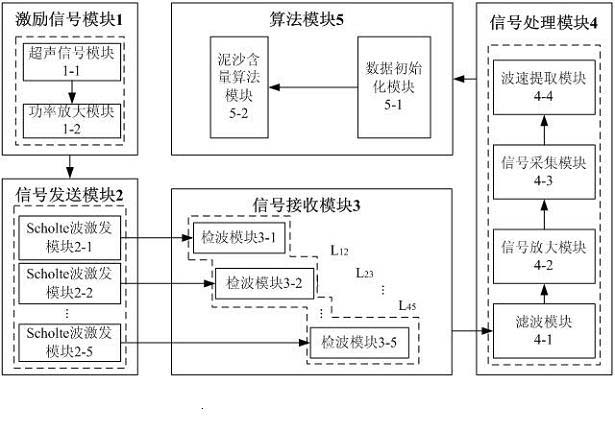

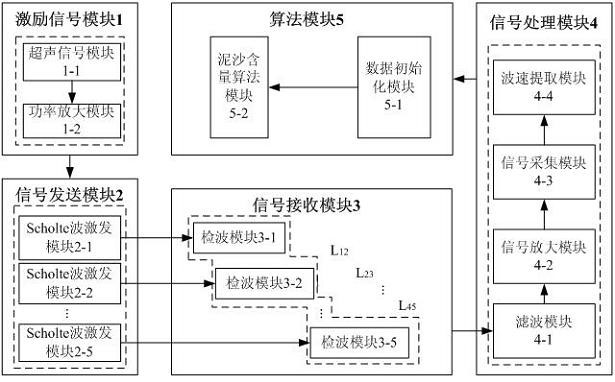

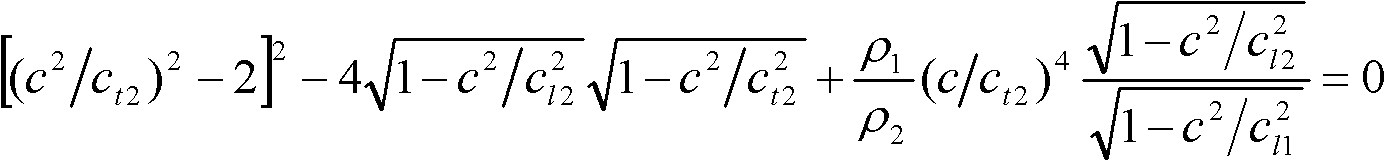

Fluid-solid interface wave based sediment concentration detection device and detection method

InactiveCN102323333AHigh measurement accuracyLong distanceMaterial analysis using sonic/ultrasonic/infrasonic wavesSonificationScholte wave

The invention discloses a fluid-solid interface wave based sediment concentration detection device and a detection method, and belongs to the technical field of ultrasonic detection and analysis. Fluid-solid Schotle waves are generated by a signal sending module at an excitation measurement side of an excitation signal module and are propagated along a bed, and fluid-solid Schotle wave signals are received by a signal receiving module; the received signals pass through a signal processing module, and then the average velocity of the Scholte waves is extracted and is processed by an algorithmmodule to obtain the average sediment concentration in a measurement range of the bottom of the detected river. The detection method provided by the invention has a large one-time detection range, and an average effect in a wave propagation range is detected by the fluid-solid Schotle waves because the sediment concentration of small regions is possibly different, accordingly, the overall macro detection and analysis are favorable; the method provided by the invention is favorable for real-time detection without sampling for re-detecting; and the relative amplitude of fluid-solid interface waves is large, so that the measurement accuracy of ultrasound can be relatively improved.

Owner:HOHAI UNIV CHANGZHOU

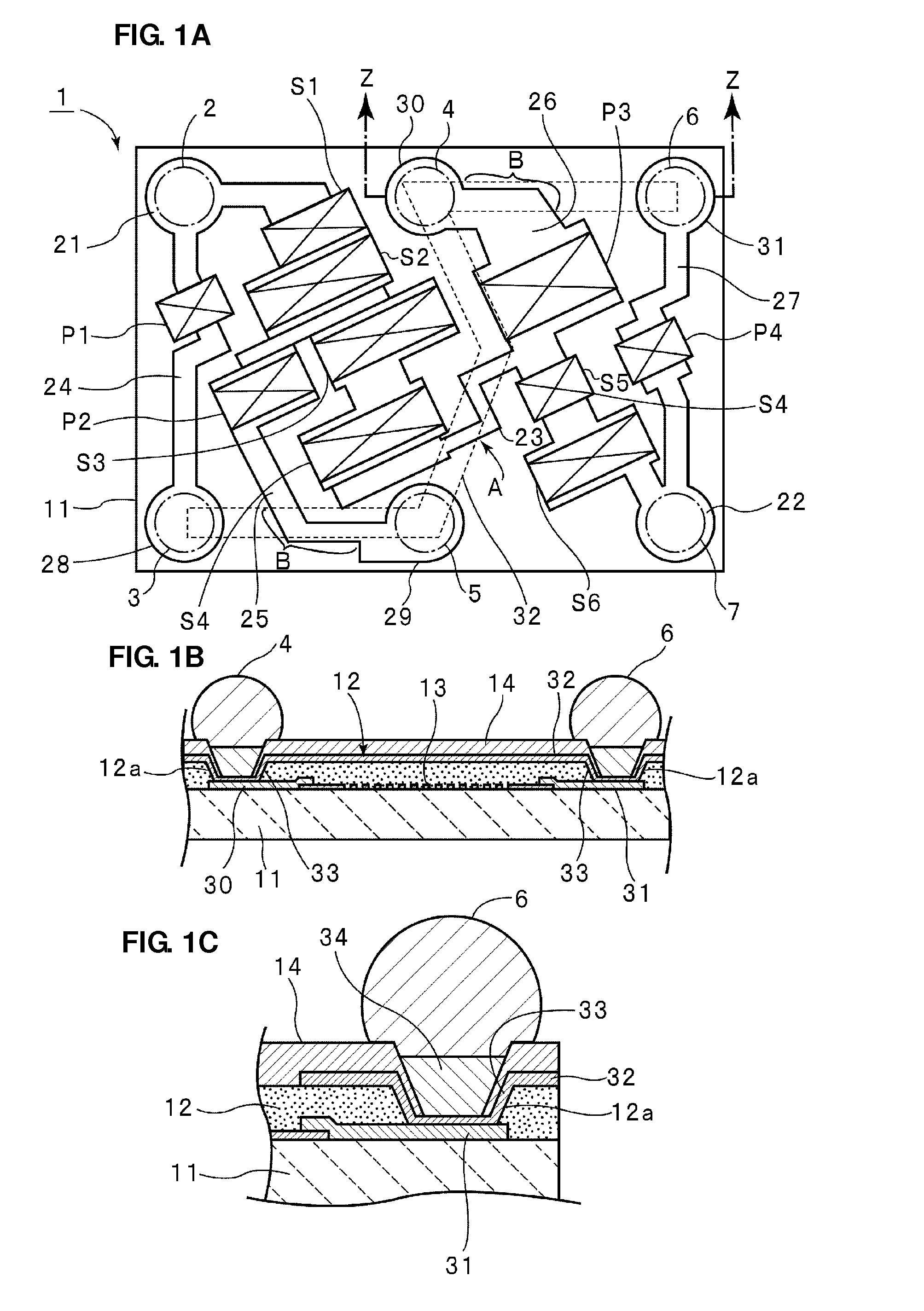

Boundary acoustic wave device

ActiveUS20110080234A1Grounding be strengthenAttenuation outside be increaseImpedence networksSolid-state devicesElectrical conductorPiezoelectric substrate

A boundary acoustic wave device includes an electrode structure that is provided at the interface between a piezoelectric substrate and a dielectric layer. The electrode structure defines a ladder filter in which at least two ground pads of a plurality of ground pads, to be connected to a ground potential, provided on the piezoelectric substrate are electrically connected by a connection conductor provided on the dielectric layer, and all of the ground pads are electrically connected.

Owner:MURATA MFG CO LTD

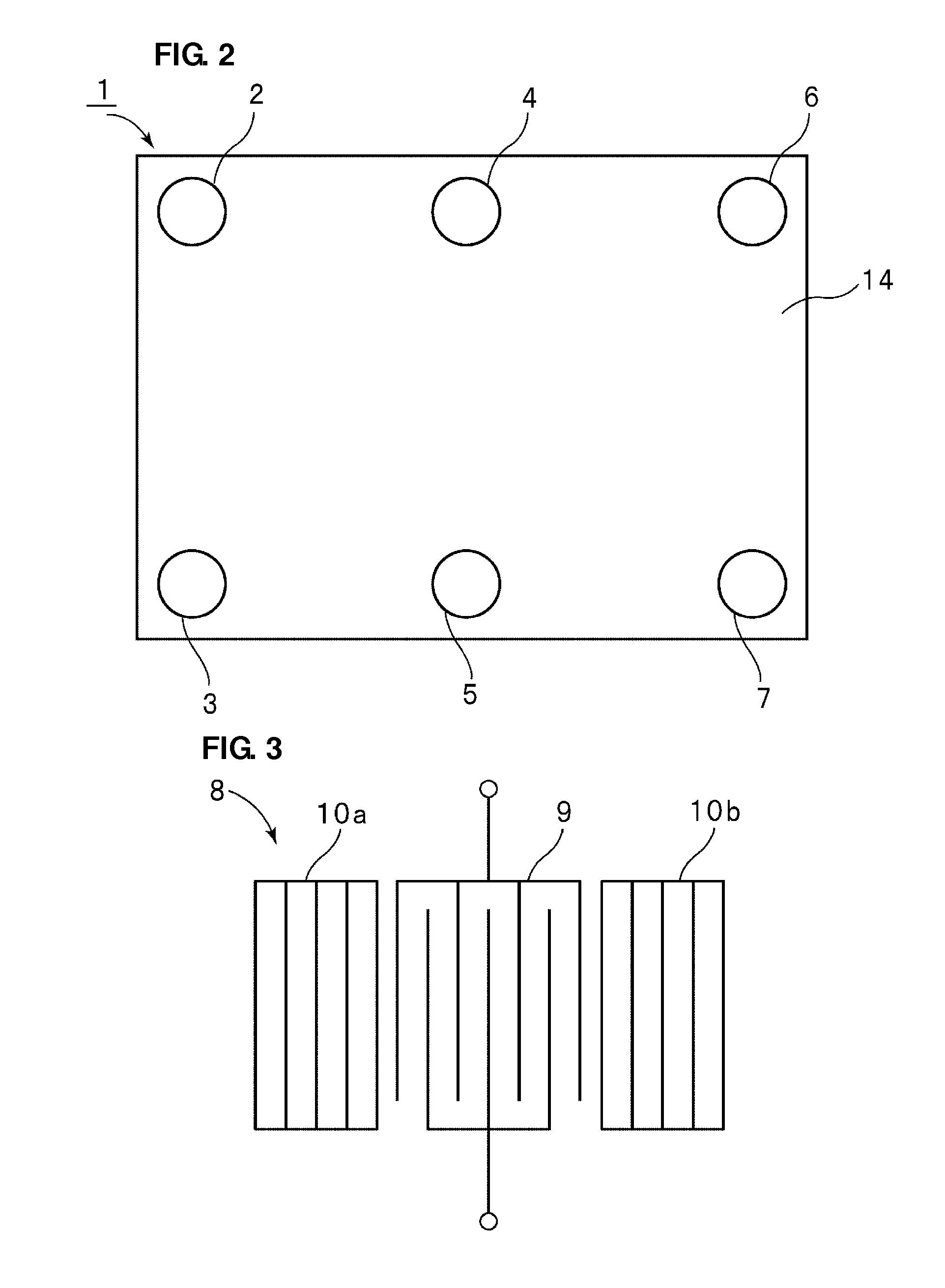

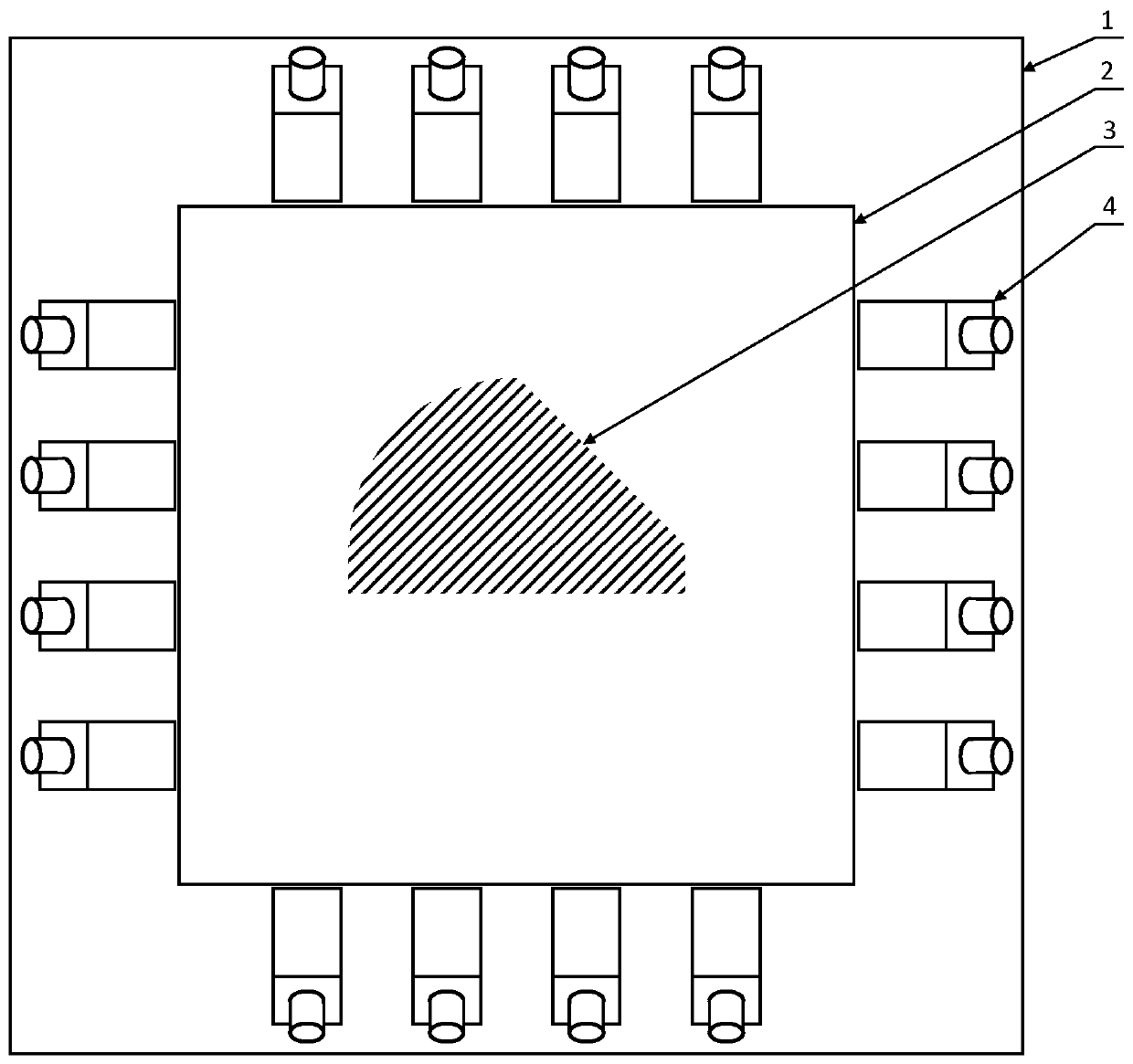

Ultrasonic damage-free checking focusing probe device

InactiveCN101339164AFocus on solvingReduce use costAnalysing solids using sonic/ultrasonic/infrasonic wavesLiquid mediumImage resolution

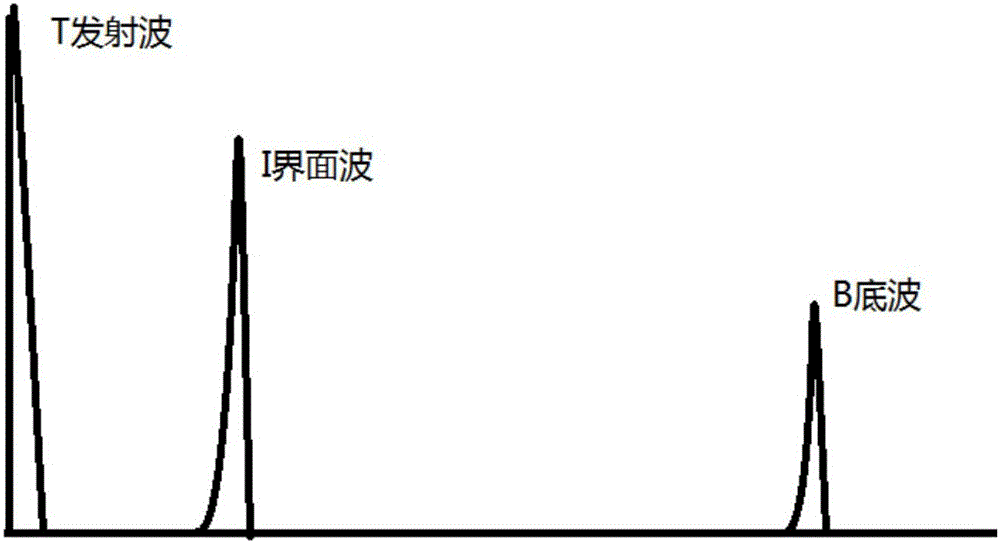

The invention discloses a focusing probe device of ultrasonic nondestructive detection used for detecting the defect of a detected sample, comprising a cylinder used for fixing the ultrasonic focusing probe; the ultrasonic focusing probe is connected with the big end of an inner cylinder in a sealing mode; the bottom end of the inner cylinder is encapsulated with a sound transmission film; a liquid medium used for transmission of the ultrasonic wave is arranged in the cylinder container of the inner cylinder; the inner cylinder provided with the probe is connected into a whole with an outer cylinder by thread in an adjustable mode; under the conditions of the same gain, the capability of detecting the defect of the sample is much better than a general straight probe; the water distance of the device leads the display distance of an initial wave, an interface wave, a defect wave and a bottom wave in the screen of a flaw detector to be pulled open and leads the area of the detected sample to be outside a triple near-field area of the ultrasonic wave on a beam axis, thus improving the resolution of waveform display and the detection sensitivity, leading the operation of finding and judging the defect wave in the process of detecting the defect to be convenient, saving a water tank and a water supply device and realizing field detection.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Method and system for monitoring of fluid-filled domains in a medium based on interface waves propagating along their surfaces

ActiveUS7302849B2Improve efficiencyEfficient and reliable calculationMagnetic property measurementsVelocity propogationEngineeringHydraulic fracturing

Owner:SCHLUMBERGER TECH CORP

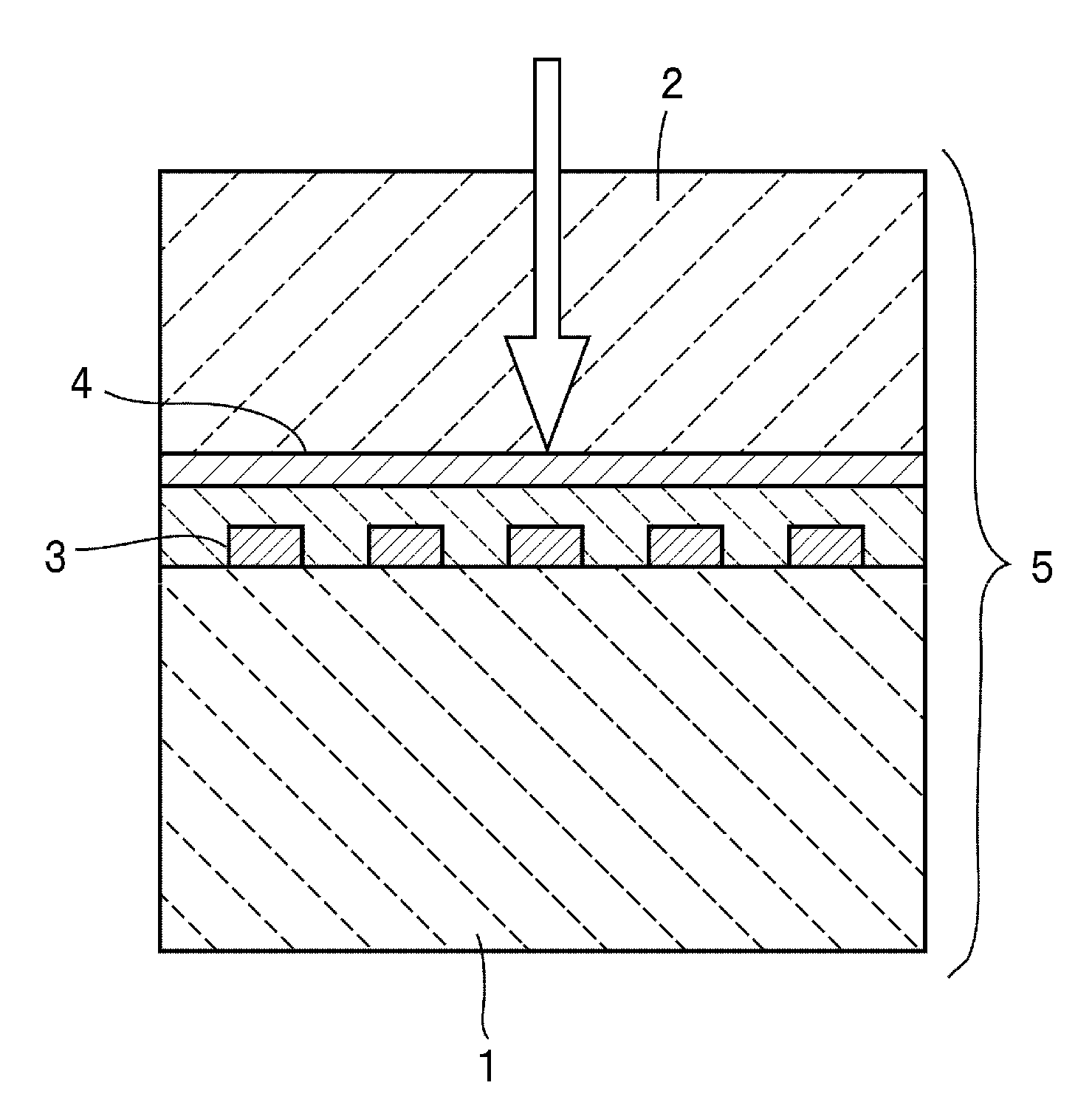

Boundary acoustic wave device manufacturing method and boundary acoustic wave device

ActiveUS20090200894A1Improve accuracyPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcousticsAcoustic wave

A method for manufacturing a boundary acoustic wave device includes the steps of preparing a laminated structure in which an IDT electrode is disposed at an interface between first and second solid media and reforming the first medium and / or the second medium by externally providing the laminated structure with energy capable of reaching the inside of the first medium and / or the second medium and thus adjusting a frequency of the boundary acoustic wave device. The above provides a boundary acoustic wave device manufacturing method that enables frequency adjustment to be readily performed with high accuracy.

Owner:MURATA MFG CO LTD

Nondestructive testing method for peel-off of oxidation layer on inner wall of boiler tube

InactiveCN104792876ACause harmMonitor growth rateAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansInterface wavesEngineering

The invention discloses a nondestructive testing method for peel-off of an oxidation layer on the inner wall of a boiler tube. The method comprises the following steps: coating a polished point with a coupling agent, using a high frequency probe to be in contact with a to-be-detected point, catching an interface wave between the oxidation layer on the inner wall of the boiler tube and a metal layer, displaying the thickness transmission sonic path distance of an oxide skin on the inner wall of the boiler tube of the detected point by an oscilloscope, and after the testing, converting the measured sonic path distance by the oscilloscope into the thickness value of the oxide skin on the inner wall. If the measurement result differences of the thickness values of the oxide skin on the inner wall are larger when the probe is moved within a small range near the to-be-detected point, the oxidation layer of the point is indicated to be peeled off.

Owner:XIAN THERMAL POWER RES INST CO LTD

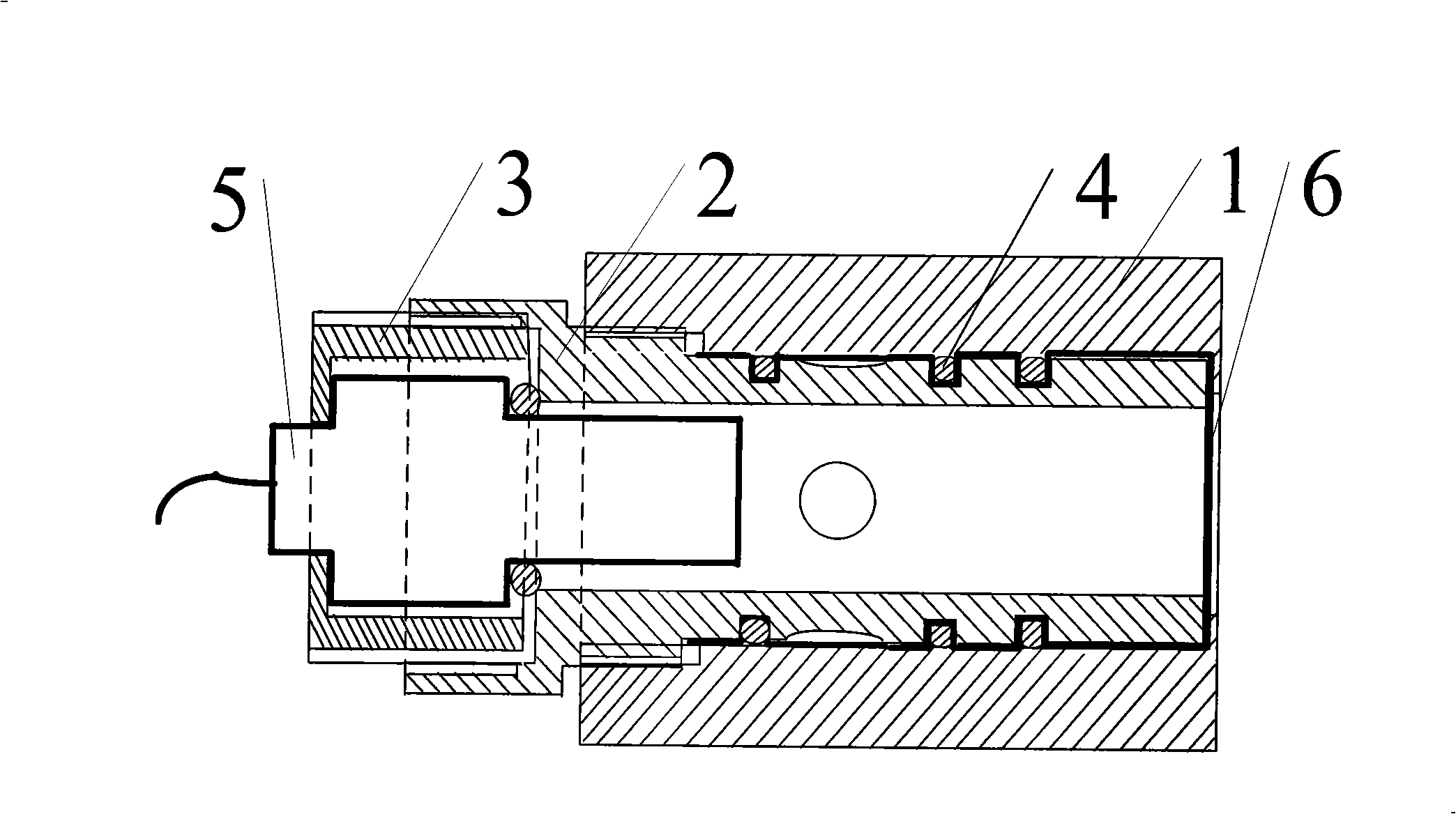

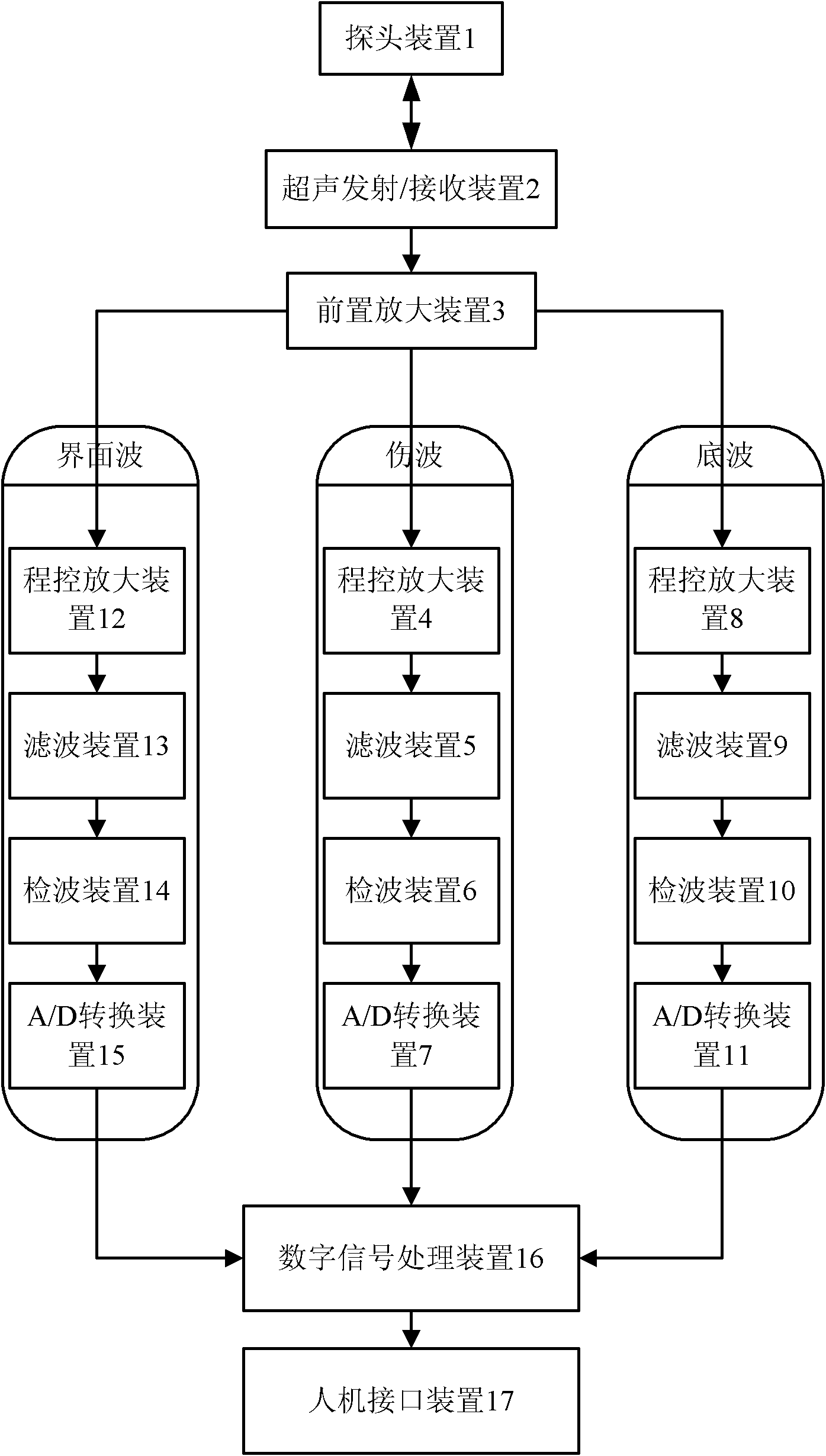

Novel digital ultrasonic flaw detection system and method

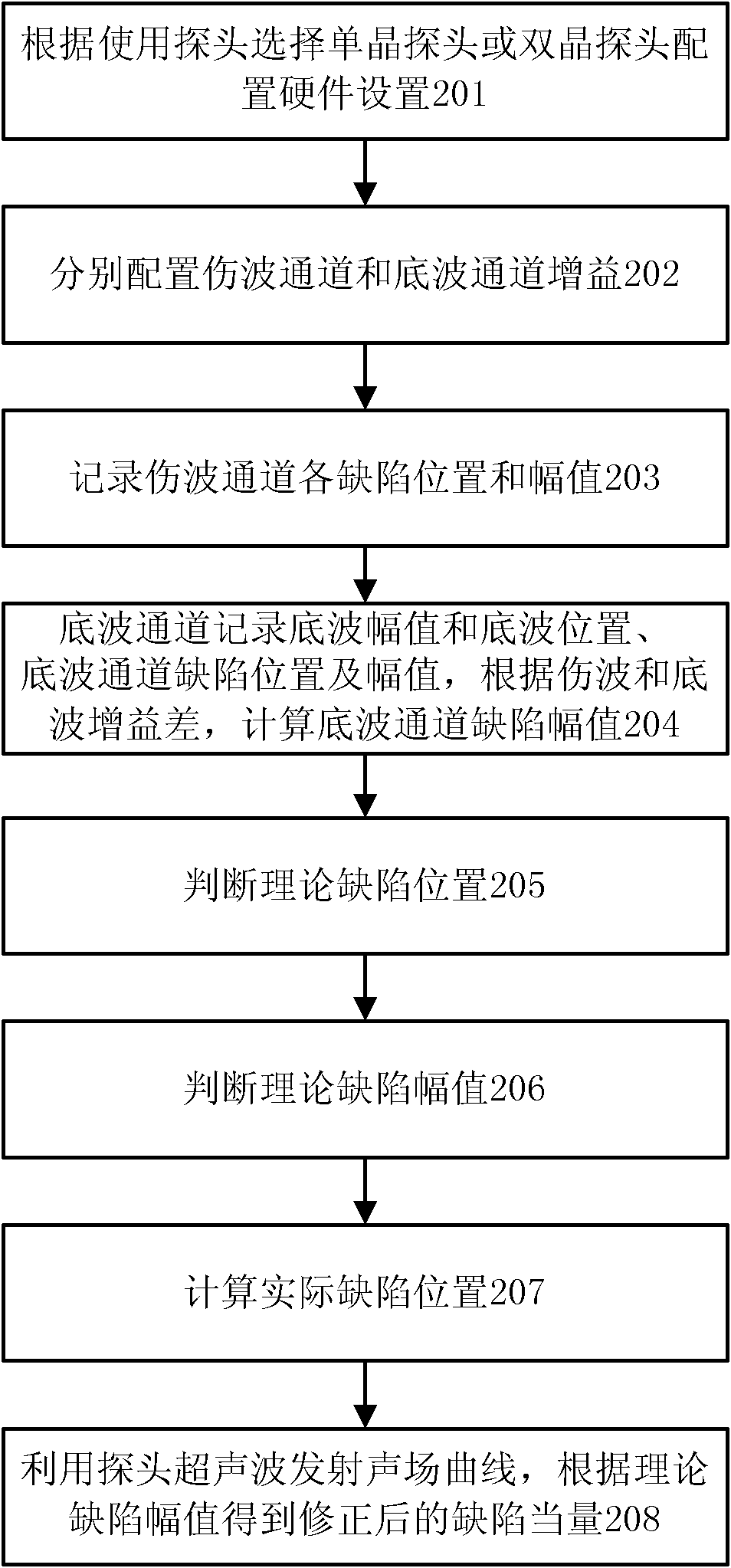

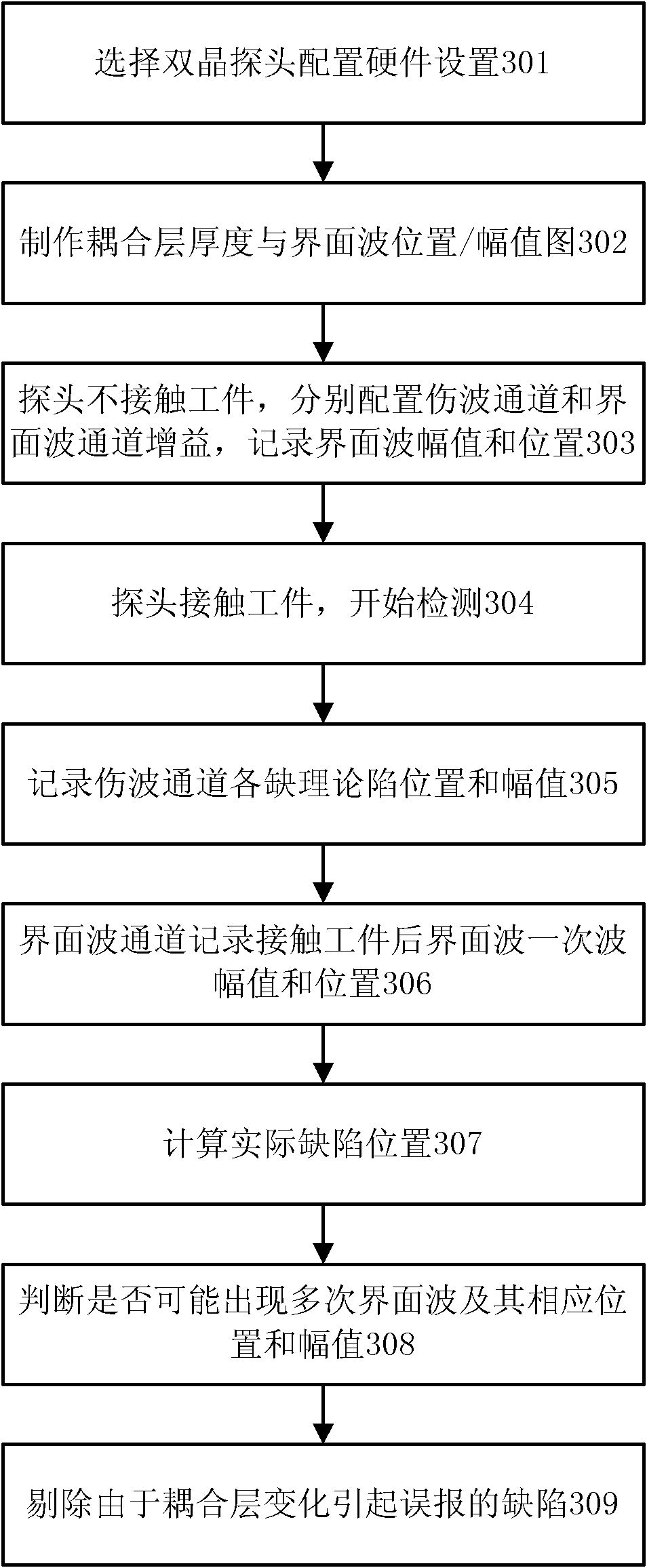

ActiveCN101839894AReduce the impactReduce high dependencyAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalDigital signal processingSonification

The invention discloses a novel digital ultrasonic flow detection system and a method. The novel digital ultrasonic flow detection system comprises a probe device, an ultrasonic transmitting / receiving device and a preposed amplifying device which are connected with a flaw echo programmed control amplifying device, a flaw echo filter device and a flaw echo A / D conversion device of the preposed amplifying device, a bottom echo programmed control amplifying device, a bottom echo filter device, a bottom echo wave detection device and a bottom echo A / D conversion device, and an interface wave programmed control amplifying device, an interface wave filter device, an interface wave detection device, and an interface wave A / D conversion device in turn, and are connected with digital signal processors of the flaw echo A / D conversion device, the bottom echo A / D conversion device and the interface wave A / D conversion device, wherein the signal processors are connected with a man-machine interface device. The system adopts a bottom echo correction method and an interface wave and bottom echo unified correction method. So, the novel digital ultrasonic flaw detection system and the method for reducing influences, caused by coupling layer changes in the flaw detection process, on a detection result, reducing the high dependency of the detection result to inspectors, and improving the accuracy and the reliability of the detection result are provided by the invention.

Owner:ALLRISING BEIJING TECH

Ultrasonic detecting device and detecting method for interface corrugation of explosive welding composite material

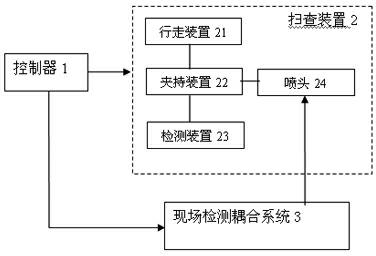

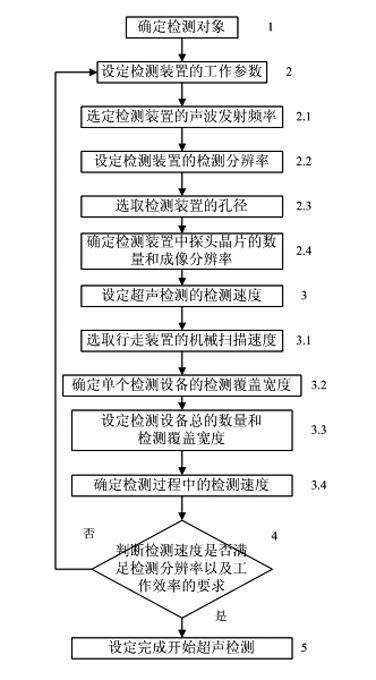

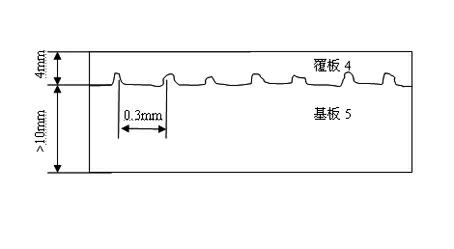

ActiveCN102608209AHigh resolutionImprove reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesImage resolutionEngineering

The invention discloses a detecting method for an ultrasonic detecting device for interface corrugations of an explosive welding composite material. The method comprises the following steps of 1. determining a detected object, wherein the detected object is a composite material and comprises a coating plate and a base plate which are composited together; 2. setting working parameters of the detecting device; 3. setting detecting speed of ultrasonic detection on the interface corrugations of the explosive welding composite material; 4. judging whether set detecting speed meets requirements on detection resolution ratio and work efficiency; and 5. carrying out the ultrasonic detection on the interface corrugations of the explosive welding composite material after a technique design is finished. The detecting method provided by the invention uses a high-frequency phased array ultrasonic detection technology so as to obtain detection images with high resolution ratio, and only high-precision mechanical scanning in the one-dimensional direction is required, so that the reliability of a system is high; a phased array probe is used to flexibly adjust the depth of focusing and the focusing column diameter of a detected wave beam through implementing different focusing rules; and therefore, flexible detection techniques on products with different parameters can be formulated.

Owner:上海斌瑞检测技术服务有限公司

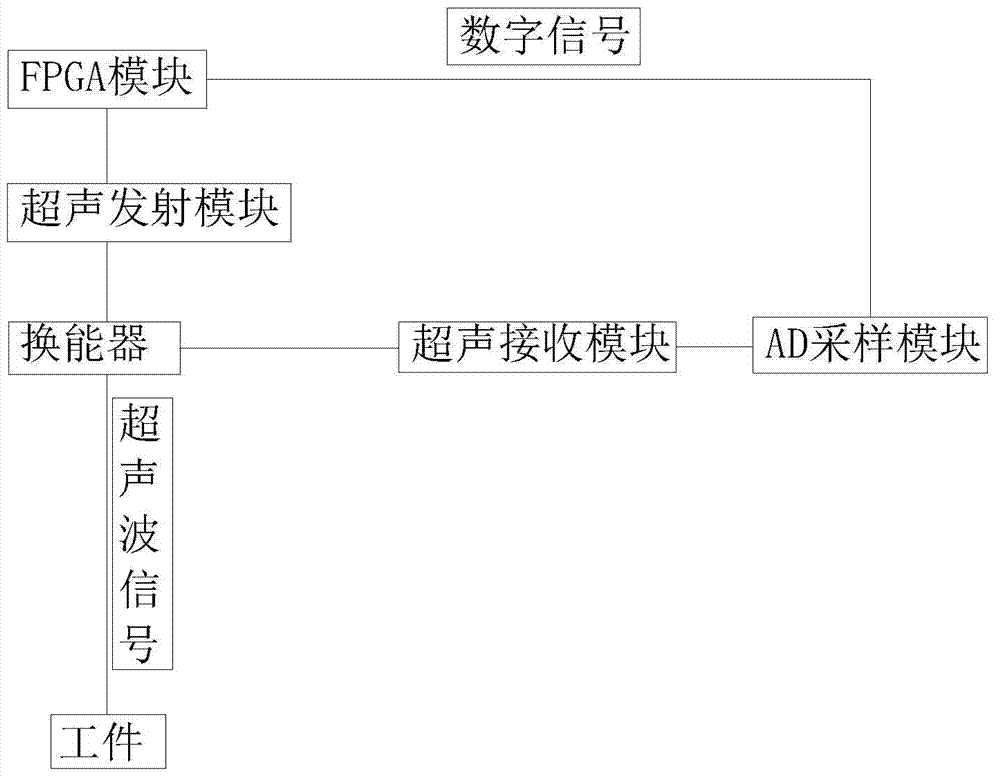

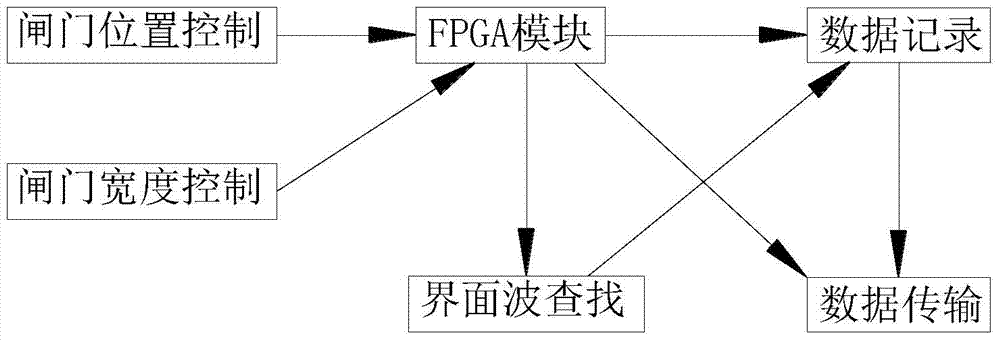

Ultrasonic tracking system and method of pipeline interface waves

ActiveCN104237377AReduce data volumeLower requirementAnalysing solids using sonic/ultrasonic/infrasonic wavesPipeline systemsSonificationEngineering

The invention aims at providing a system and a method for tracking interface waves which are echoes generated between water and workpieces and also called as water layer waves. The system comprises an FPGA module, an ultrasonic transmission module, an ultrasonic reception module, an AD sampling module, a gate position control assembly and a gate width control assembly, wherein the ultrasonic transmission module is used for generating high voltage and transmitting a high-voltage signal to a transducer; the ultrasonic reception module is used for receiving an ultrasonic signal converted electric signal in the transducer; the AD sampling module is used for sampling the received electric signal into a digital signal and sending the digital signal to the FPGA module; the gate position control assembly is used for determining the effective starting position of the sampling; the gate width control assembly is used for determining the range of the effective starting position of the sampling. The system and the method for tracking interface waves are specifically capable of realizing the following functions: (1) exciting an ultrasonic probe and sampling the echoes; (2) tracking the interface waves; (3) simplifying the original ultrasonic data and retaining the data effective to the workpiece detection.

Owner:NANTONG UNION DIGITAL TECH DEV

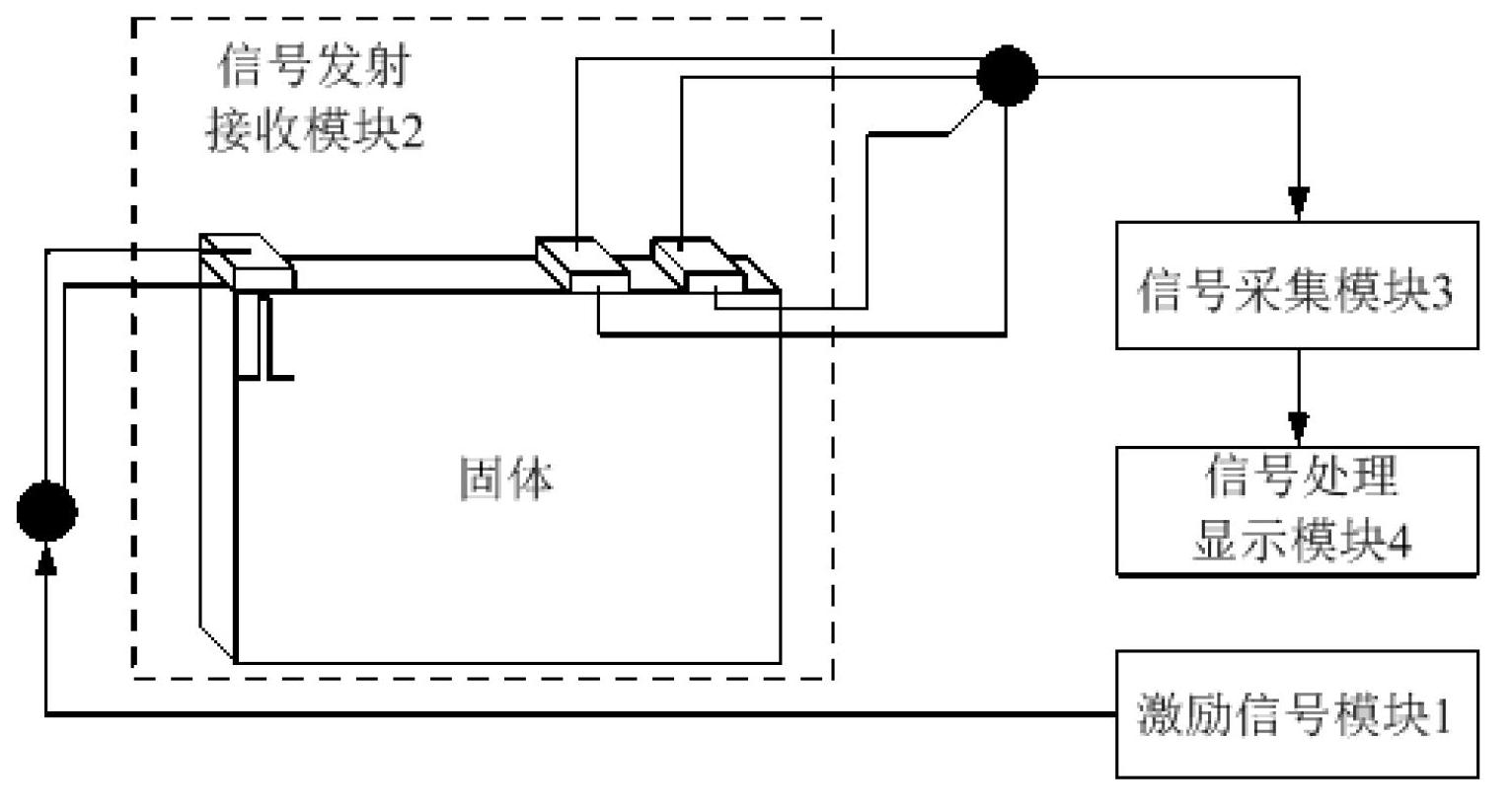

Detection device and detection method for interface wave

InactiveCN102680576AReduce radiationAvoid conducting electricityAnalysing solids using sonic/ultrasonic/infrasonic wavesEpoxyElectricity

The invention discloses a detection device and a detection method for an interface wave, belonging to the technical field of ultrasonic detection and analysis. Piezoelectric ceramic sheets are produced into narrow-band cuboid shapes and are used as signal emitting modules and signal receiving modules, the signal emitting modules and the signal receiving modules are fixed at both ends of a solid side of an interface and then wrapped by epoxy resin, and effects of insulating and reducing energy radiation can be realized by using the epoxy resin. The detection method comprises the following steps: a required square-wave pulse signal is generated by an excitation signal module and is used for exciting the signal emitting modules to generate an interface wave, the interface wave is spread along the interface and received by an ultrasonic signal receiving module, and then acquired waveform data are transmitted to a computer terminal via an acquisition module to be subjected to data processing and be displayed. Only the interface wave spread forwards along the interface is generated via using the method disclosed by the invention, thus being good for reducing interference and improving detection accuracy.

Owner:HOHAI UNIV CHANGZHOU

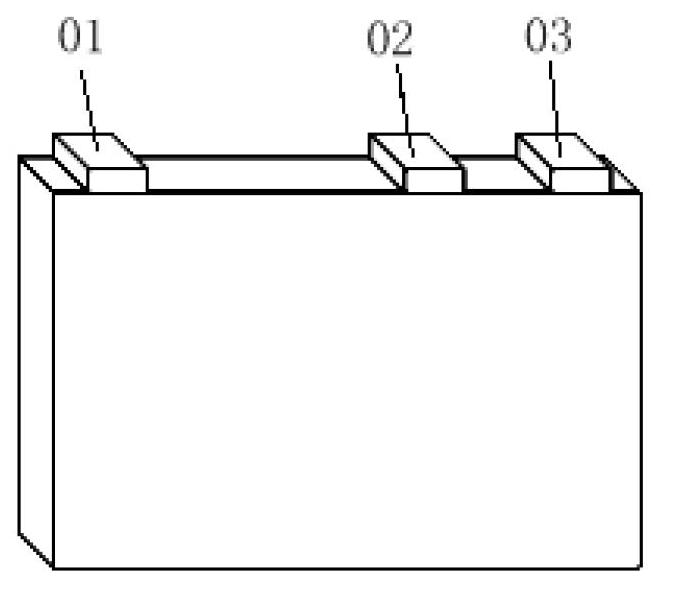

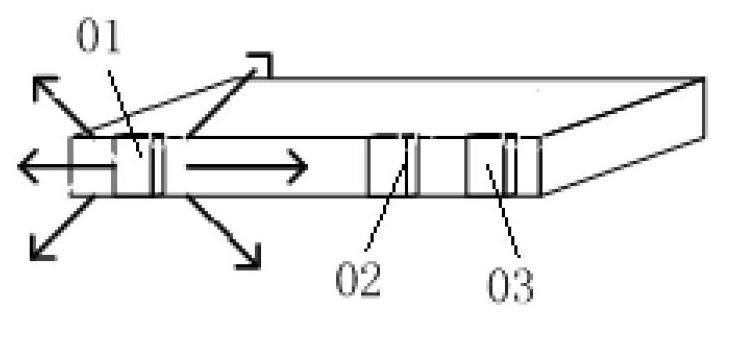

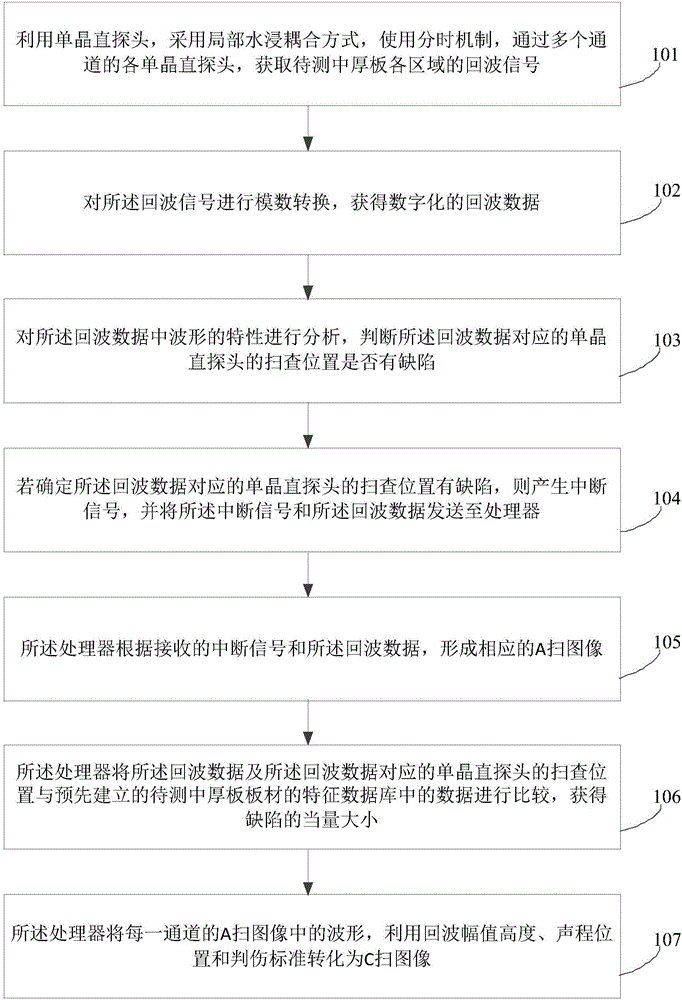

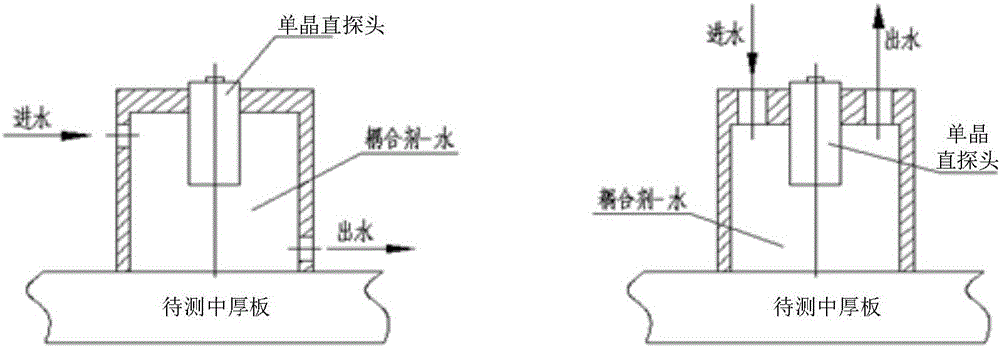

Local water leaching coupling manner based medium plate ultrasonic testing method employing single crystal straight probes

ActiveCN105806948AReduce wearSatisfy defect requirementsAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationCoupling

The invention provides a local water leaching coupling manner based medium plate ultrasonic testing method employing single crystal straight probes. By the single crystal straight probes, and in a local water leaching coupling manner and a real-time interface wave gate tracking manner, ultrasonic testing is carried out on defects of medium plates through a multi-channel automatic plate detection technology for evaluating the defects through a first flaw wave and a first bottom wave under different sensitivity conditions. The method comprises the following steps: by the single crystal straight probes and a time sharing mechanism, and in the local water leaching coupling manner, obtaining echo signals from each region of a medium plate through the multi-channel single crystal straight probes and carrying out analogue-to-digital conversion; judging whether defects exist or not according to converted echo data; if so, generating an interrupt signal, and transmitting the interrupt signal and the echo data to a processor; and forming an A scanning image by the processor and obtaining the equivalent size of the defect according to the interrupt signal and the echo data, and converting the A scanning image into a C scanning image according to an echo amplitude height, a sonic path distance position and a flaw judgment standard. According to the method provided by the invention, the requirements for detecting the defects of the medium plates can be effectively met; the probe abrasion is reduced; and the practicability is relatively high.

Owner:ALLRISING BEIJING TECH

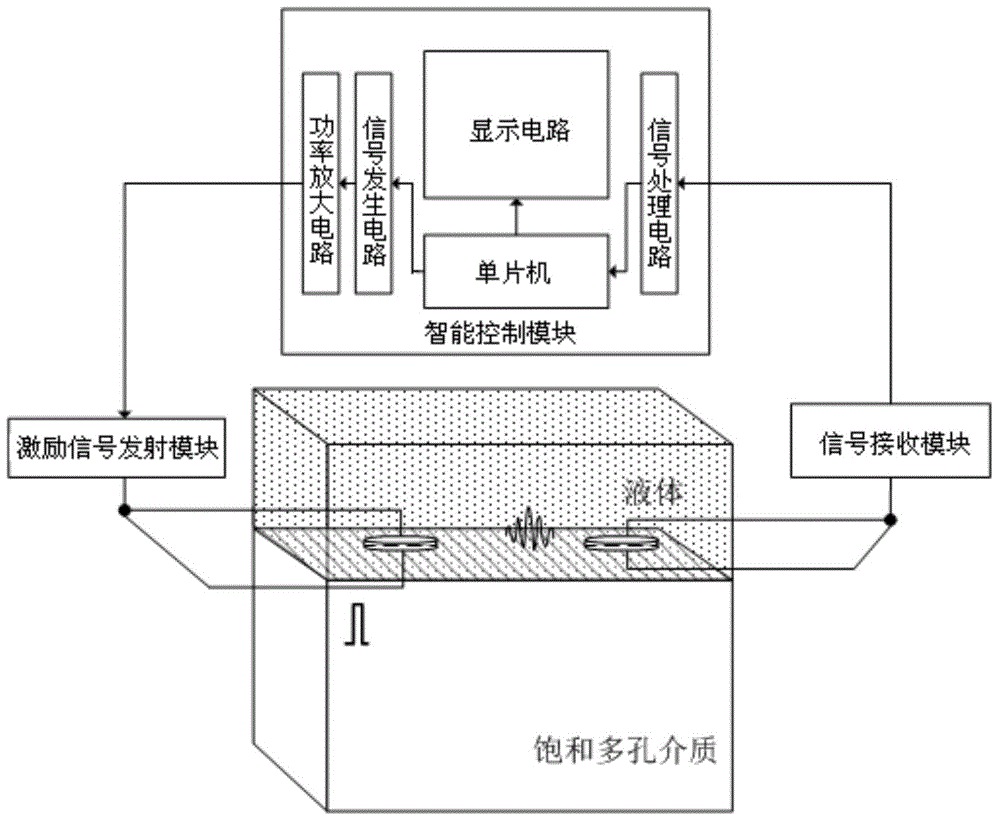

Sand grain diameter detection device and method based on fluid/solid interface wave

InactiveCN103604728ABig-amplitudeSmall dispersionParticle size analysisRelation graphMicrocontroller

The invention discloses sand grain diameter detection device and method based on a fluid / solid interface wave. Ultrasonic detection is applied to the detection of river sand grain diameter, Scholte wave energy is mainly focused in a fluid near a fluid / solid interface, and has the characteristics of largest amplitude, small frequency dispersion and high detection precision, the detection device is characterized in that a singlechip intelligent control module generates a pulse signal, an excitation signal generating module transmits the pulse signal in multiple paths of Scholte waves, a receiving module receives the corresponding Scholte waves, the signal is transmitted to the singlechip intelligent control module for performing calculation to obtain a relation graph between a number of the Scholte waves and the grain diameter, and a defect in existing grain diameter detection is well made up; the detection device has the advantages of small size, convenience in use, wide detection range to the grain diameter and high reliability, is easy to carry, is suitable for detection of the field river sand grain diameter detection, and is beneficial to the actual popularization and use.

Owner:HOHAI UNIV CHANGZHOU

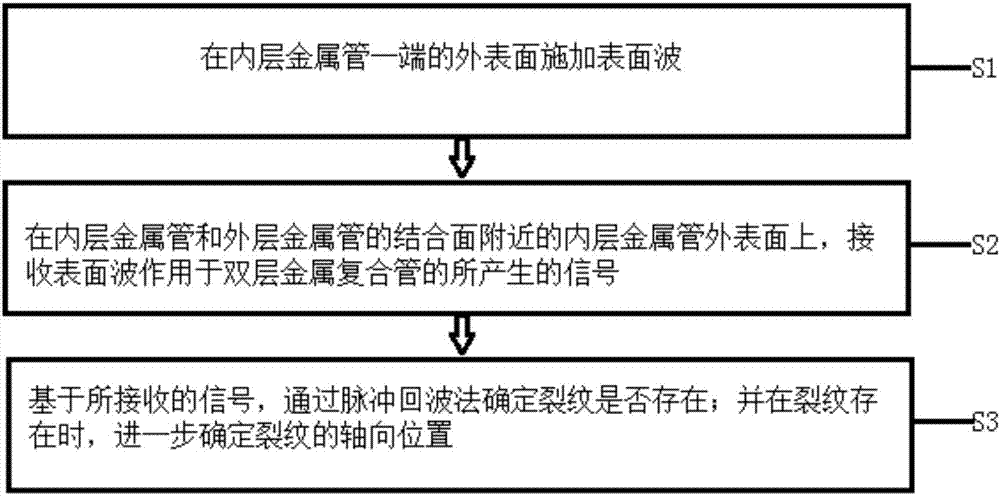

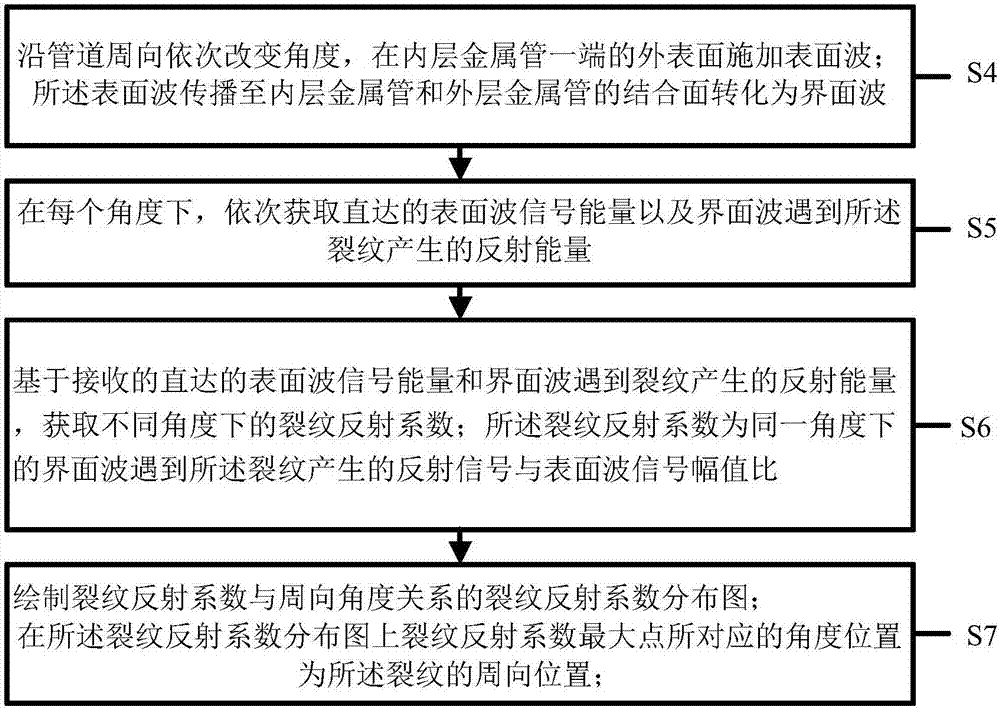

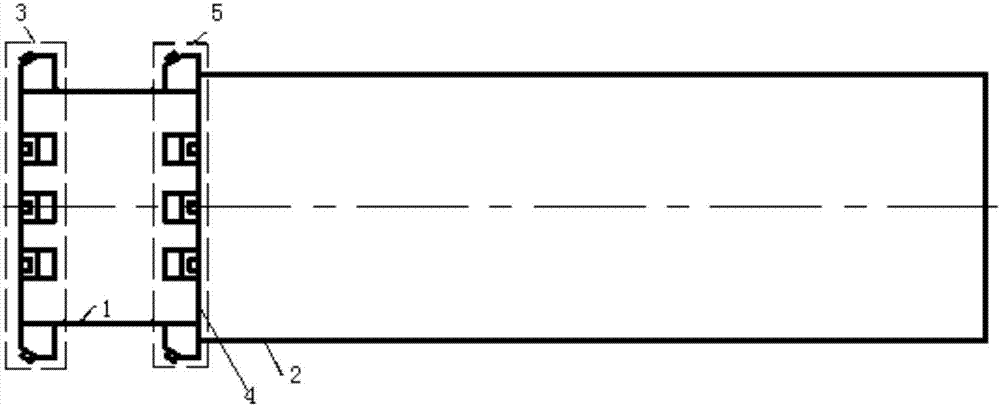

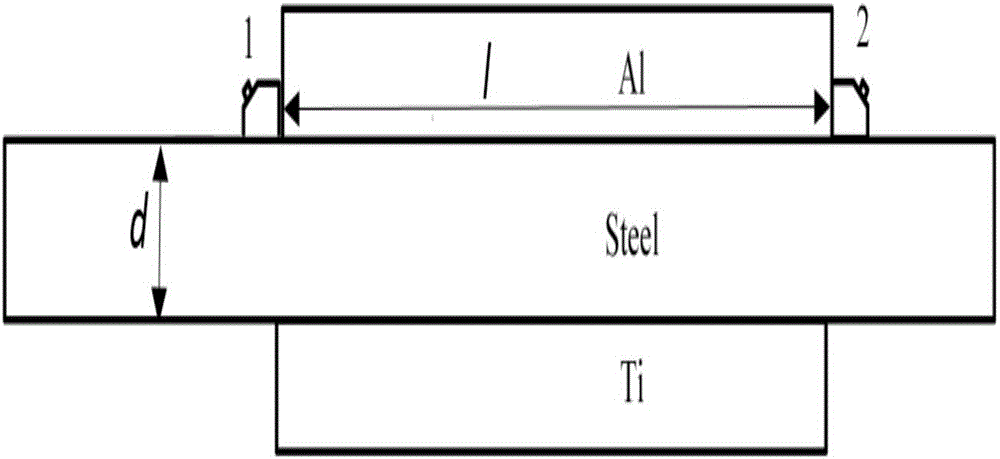

Crack detection method for double-layer metal compound pipe based on interface wave

ActiveCN107271548AImprove effectivenessLow number of patternsAnalysing solids using sonic/ultrasonic/infrasonic wavesInterface wavesFrequency dispersion

The invention relates to a crack detection method for a double-layer metal compound pipe based on an interface wave. The method comprises the following steps: analyzing a signal which is generated by a surface wave acting on the double-layer metal compound pipe, thereby confirming if a crack exists, and if the crack exists, and further confirming an axial position and a circumferential position of the crack by utilizing the surface wave which is converted into the interface wave on a joint surface of an inner layer metal pipe and an outer layer metal pipe. The interface wave is free from frequency dispersion in the diffusing process on the joint surface of the metal compound pipe, the energy is concentrated on the interface, the interface wave is sensitive to the damages, such as, cracks, on the interface, the model number of the interface wave in the metal compound pipe is less and the recognition for a crack reflected signal in the signal processing process is benefited, so that the validity and accuracy of the crack recognition and positioning can be increased. According to the invention, the detection operation is convenient, the recognition for the damage on the interface of the whole compound pipe can be realized by stimulating and receiving the signal at one end of the pipe and the crack detection efficiency is increased.

Owner:XI AN JIAOTONG UNIV

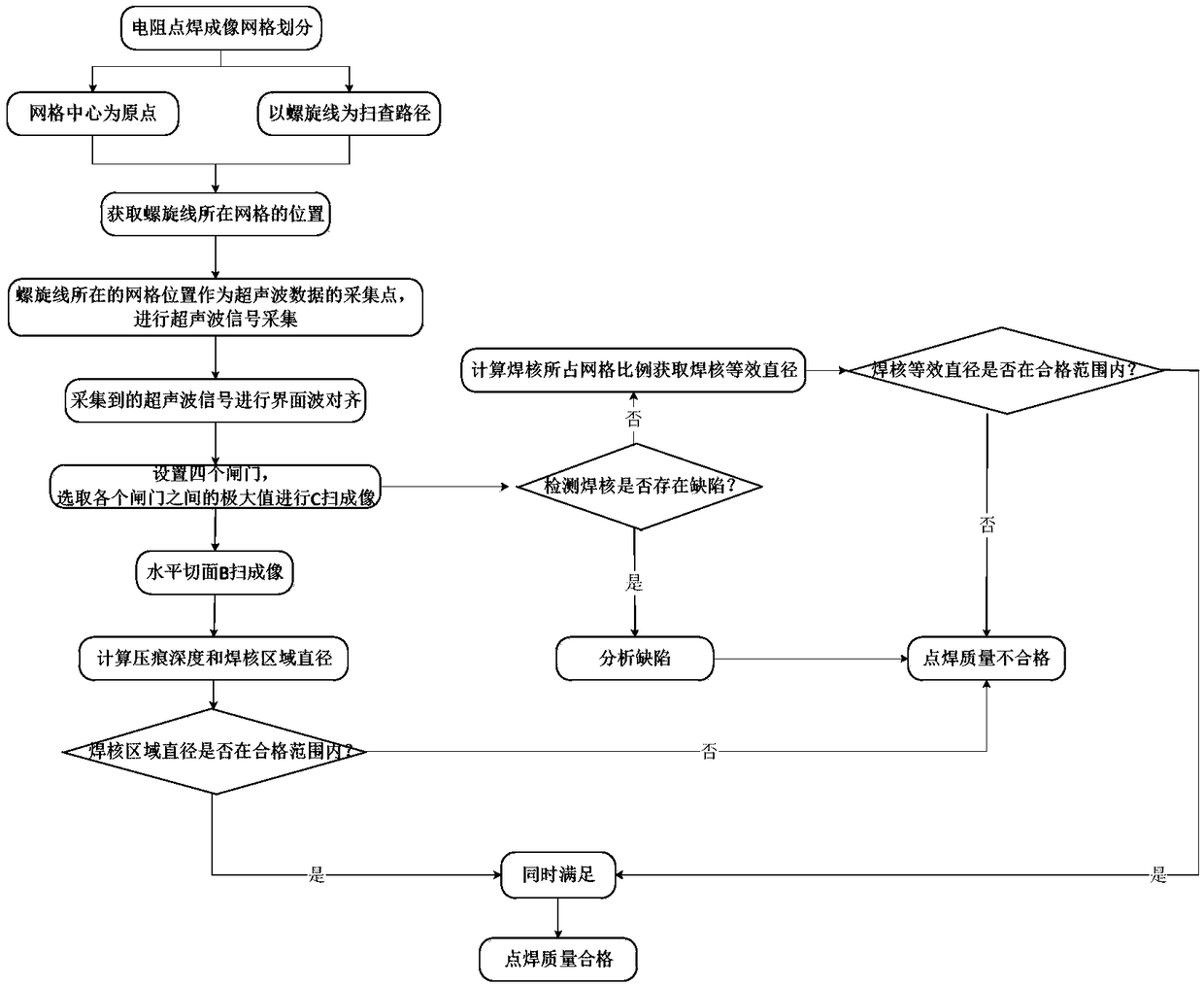

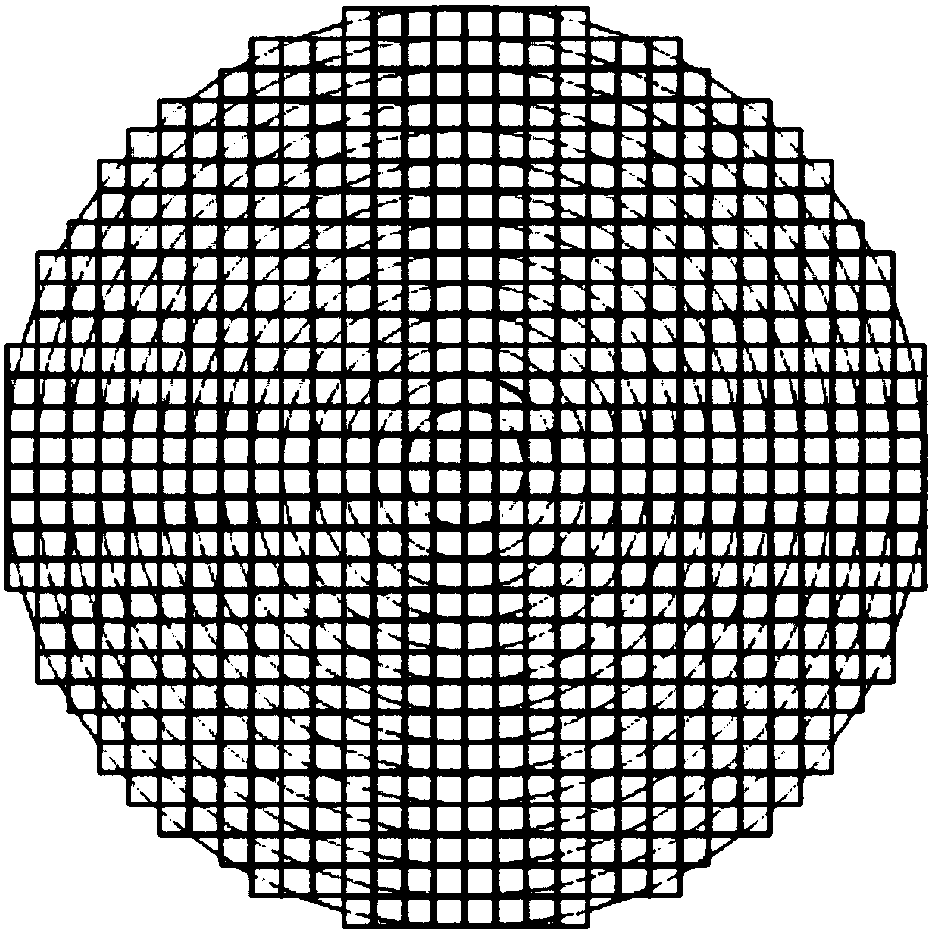

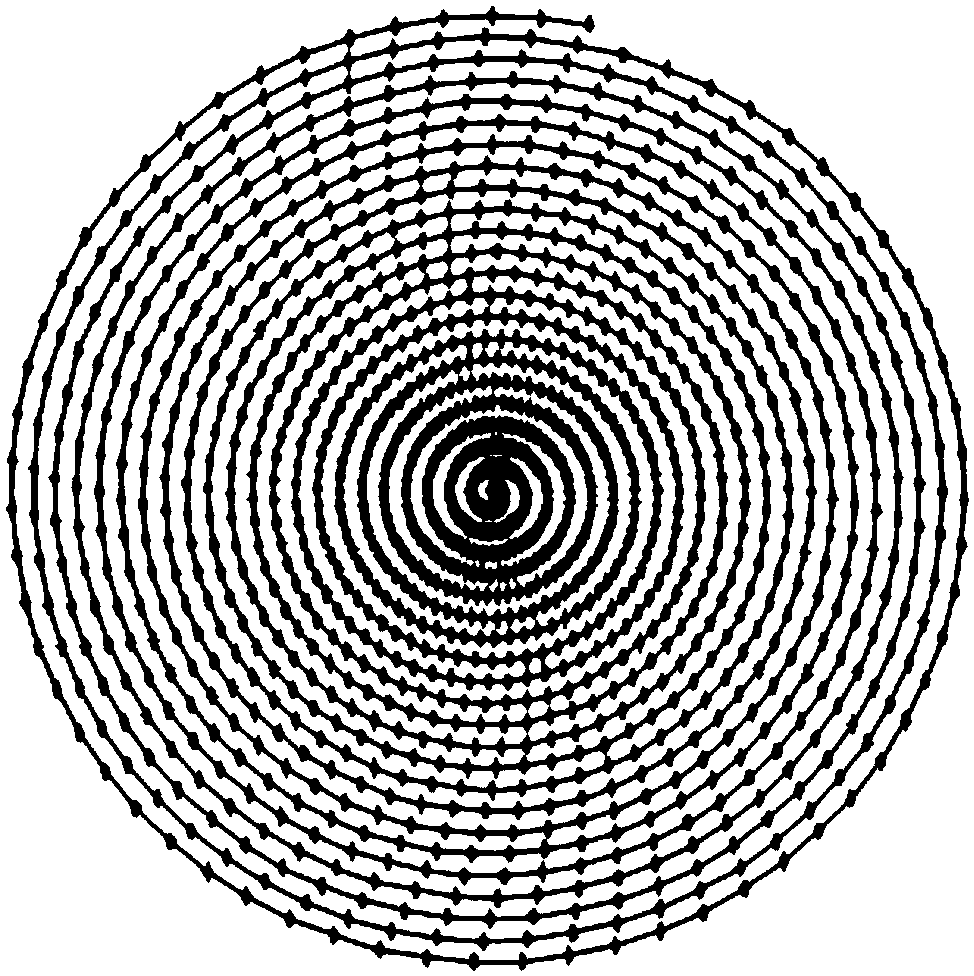

Resistance spot welding quality evaluation method based on ultrasonic scanning imaging

ActiveCN108414623AReduce data volumeImproving Imaging EfficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesElectrical resistance and conductanceUltrasonic imaging

The invention relates to the field of resistance spot welding ultrasonic imaging, and discloses a resistance spot welding quality evaluation method based on ultrasonic scanning imaging, and the resistance spot welding quality evaluation method comprises the following steps: dividing resistance spot welding imaging grids; acquiring the position of a grid where a spiral line is located; collecting ultrasonic signals; performing interface wave aligning on the acquired ultrasonic signals; setting multiple gates, and selecting the maximum values of the gates for C-scan imaging; and performing horizontal-section B-scan imaging; if resistance spot welding has defects, determining that the quality of the spot welding is unqualified; if the equivalent diameter of a welding core is not within an acceptable range, determining that the quality of the spot welding is unqualified; if the depth of indentation or the region diameter of the welding core is not within an acceptable range, determining that the quality of the spot welding is unqualified; if the welding core has no defect, the equivalent diameter of the welding core is within the acceptable range, the depth of indentation and the region diameter of the welding core are within the acceptable range, determining that the quality of the spot welding is qualified. The resistance spot welding quality evaluation method has simple operation, large scanning diameter and high efficiency, and obtained results are more realistic.

Owner:CRRC QINGDAO SIFANG CO LTD

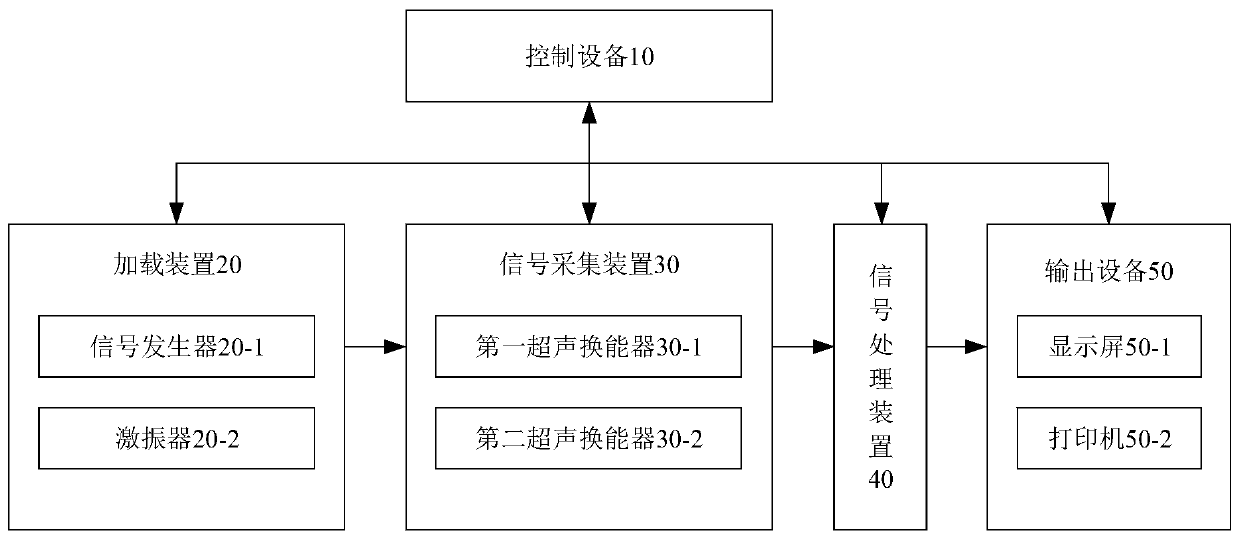

Method, device and system for measuring material mechanical property information

ActiveCN110849970AMeasurement applicableAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalTransducerThin membrane

The invention discloses a method, device and system for measuring material mechanical property information. The method includes the steps that excitation signals of different frequencies are loaded toa material to be measured; motion information of surface wave signals or interface wave signals of the material to be measured under different frequency excitation signals are measured, wherein the motion information includes wave velocity and dispersion information, and the surface wave signals or the interface wave signals are ultrasonic signals of the surface or internal interface of the material to be measured and collected by at least two ultrasonic transducers; the mechanical property information of the material to be measured is determined according to the motion information of the surface wave signals or the interface wave signals of the material to be measured under different frequency excitation signals; and the mechanical property information of the material to be measured is output. Based on the fact that the ultrasonic transducers measure the motion information of surface waves or interface waves of the material, the inversion of the mechanical property information of a thin film wrapping material or other wrapping materials or materials in a special environment is realized.

Owner:北京曦健科技有限公司

Ultrasonic detection method of babbit metal bearing

ActiveCN101750453AEasy to detectQuick checkAnalysing solids using sonic/ultrasonic/infrasonic wavesSignal waveWave form

The invention discloses an ultrasonic detection method of a babbit metal bearing. A proper flaw detector is selected, a soft-faced probe with high frequency and small diameter is combined with the selected flaw detector, the sensitivity of the flaw detector is adjusted by taking a defect-free part at the bottom of a bearing bush as a reference, the probe makes regular parallel-shift scanning on the concave cambered surface of the bearing, and a fluorescent screen of the flaw detector is monitored to display the wave form. When abnormal signal wave form appears on the fluorescent screen, defect is judged to exist in the bonding between the babbit metal and steel bearing bush at the position of the probe, and when bottom wave of the flaw detector completely disappears, and only interface wave appears, the babit metal and the steel bearing bush are judged not to be bound. By using the method, the binding layer of the babbit metal bearing can be conveniently and quickly detected, the pollution to the environment by using a traditional detection method is avoided, and the detection efficiency is improved.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

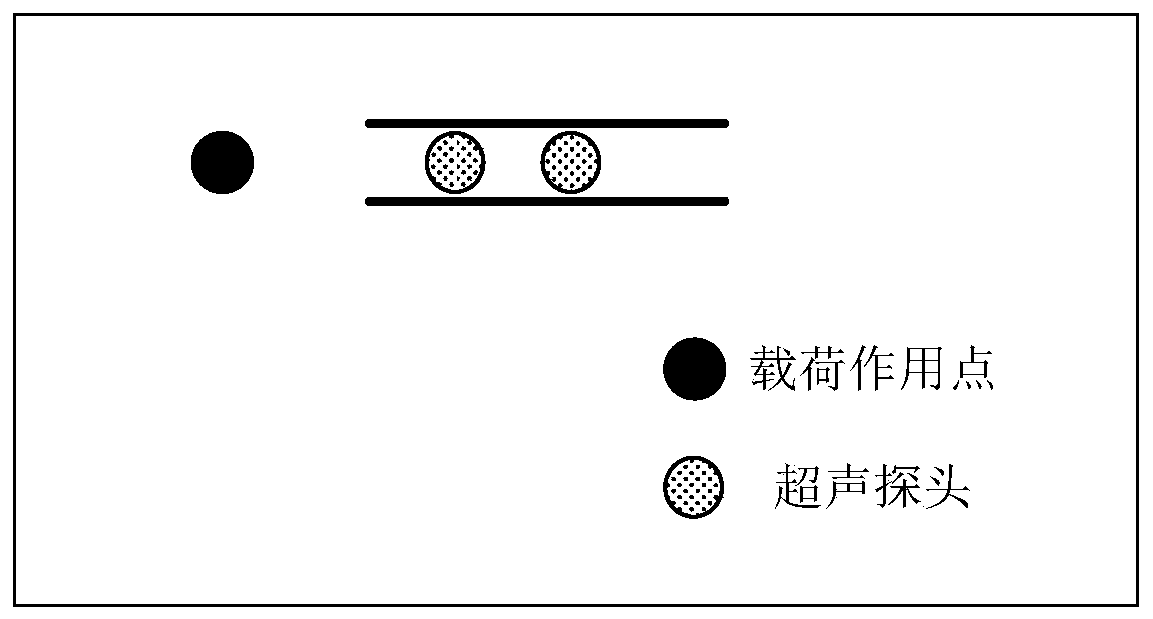

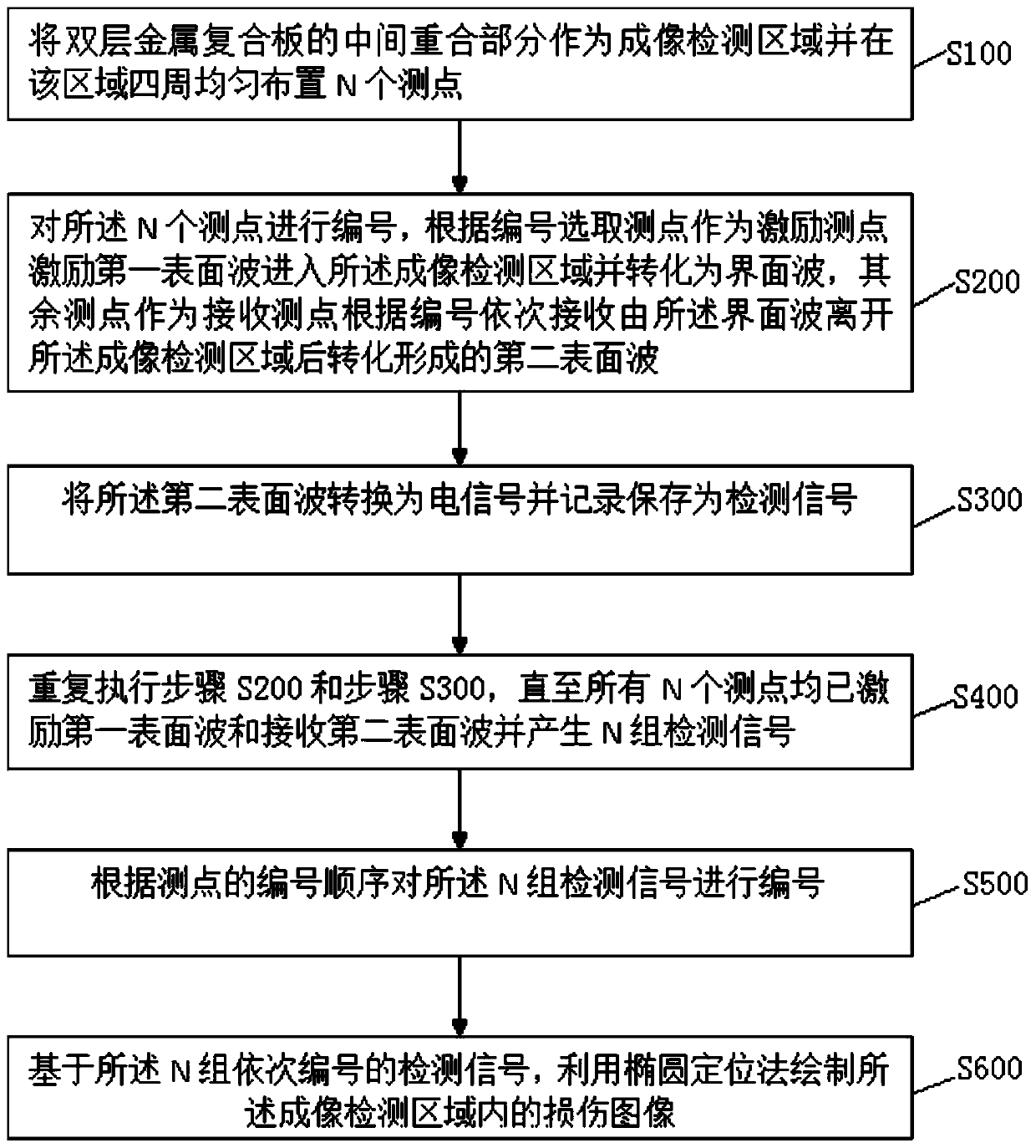

Delamination damage imaging method based on interface waves and used for a double-layer metal composite board

InactiveCN110333288AImprove effectivenessReduce labor costsAnalysing solids using sonic/ultrasonic/infrasonic wavesImage detectionInterface waves

The invention discloses a delamination damage imaging method based on an interface wave and used for a double-layer metal composite board. The method comprises the following steps: taking a coincidedpart of the metal composite board as an imaging detection region and arranging N measuring points; numbering the N measuring points, sequentially selecting each measuring point to be stimulated to generate a surface wave according to numbers, and enabling the other measuring points to sequentially receive the surface wave and convert the received surface wave into a detection signal; repetitivelyexecuting the steps 1 and 2 until the N measuring points are respectively stimulated to generate the surface waves, receive the surface waves and generate N groups of detection signals; according to anumber sequence of the measuring points, numbering the N groups of detection signals; and based on the N groups of numbered detection signals, drawing an image of damage in the imaging detection region by utilizing an elliptical localization process. The invention also discloses a device used for stimulating the surface waves. The method disclosed by the invention utilizes the characteristics that the interface wave does not result in frequency dispersion when being propagated at a combined part of the metal composite board and energy can be concentrated on an interface, and effectiveness ofdetecting delimitation damage on the interface can be improved.

Owner:XI AN JIAOTONG UNIV

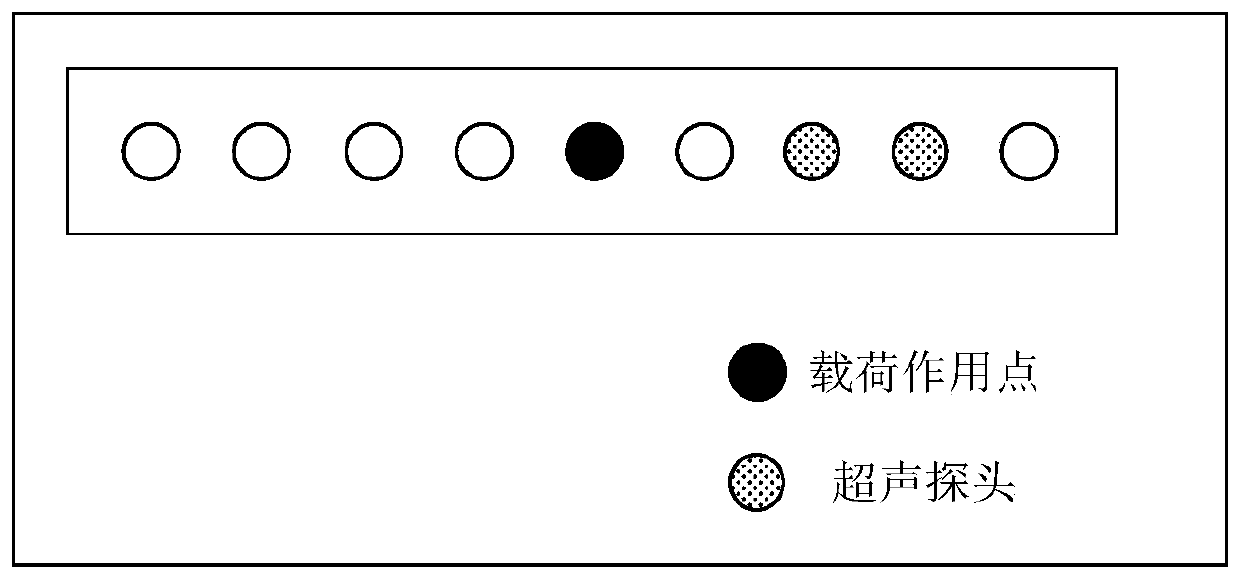

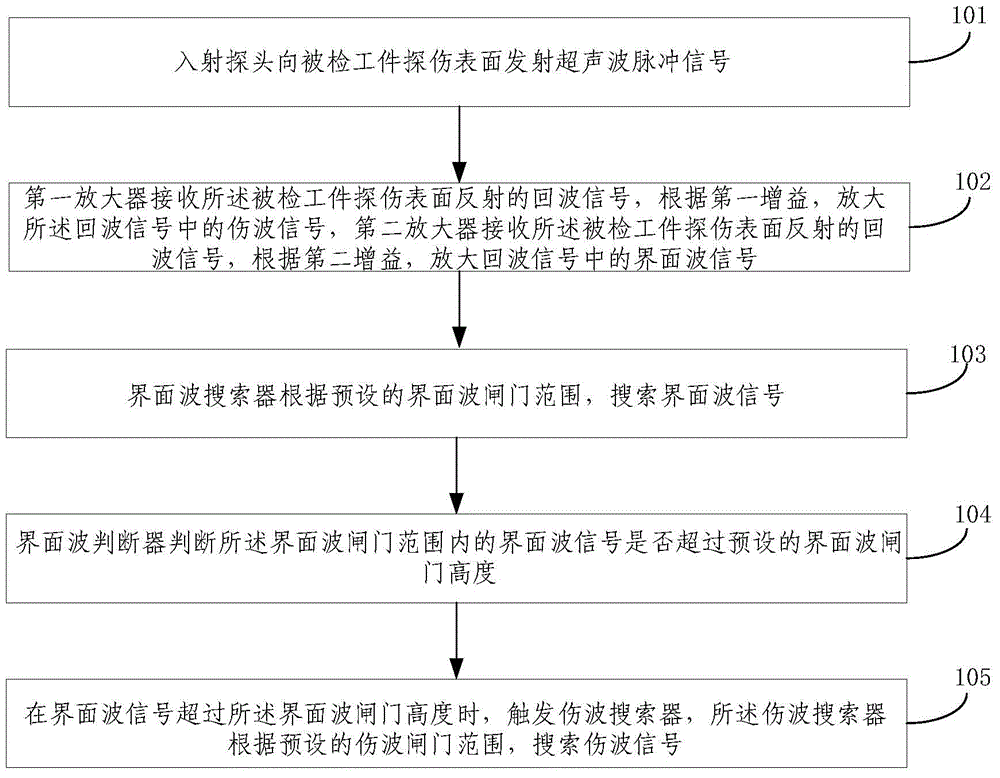

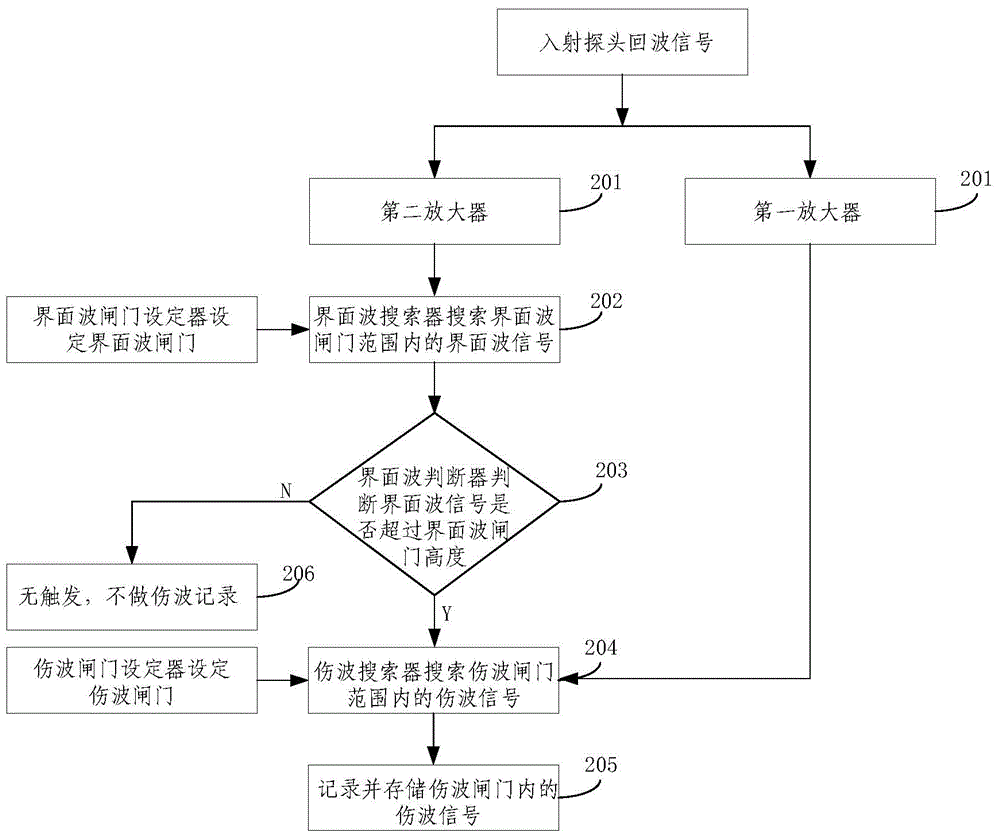

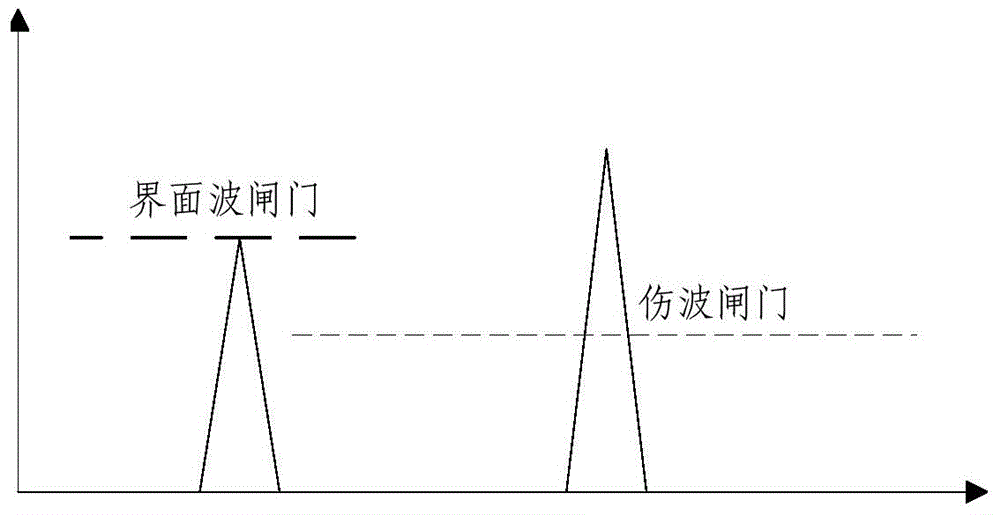

Ultrasonic detection method and system used for wheels of railway vehicle and based on interface wave correlation detection

InactiveCN104569152AGuaranteed triggerAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationAudio power amplifier

The invention provides an ultrasonic detection method and system used for wheels of a railway vehicle and based on interface wave correlation detection. The method comprises the following steps: an incident probe transmits an ultrasonic pulse signal to a flaw detection surface of a detected workpiece; a first amplifier receives an echo signal reflected by the flaw detection surface of the detected workpiece and amplifies a flaw wave signal in the echo signal, and a second amplifier receives the echo signal reflected by the flaw detection surface of the detected workpiece and amplifies an interface wave signal in the echo signal; an interface wave searcher searches an interface wave according to a preset interface wave gate range; an interface wave judger judges whether the interface wave within the interface wave gate range exceeds a preset interface wave gate height or not; when the interface wave exceeds the interface wave gate height, a flaw wave searcher is triggered and searches flaw wave information according to a preset flaw wave gate range. The ultrasonic detection method and system provided by the invention can guarantee triggering of the interface wave on the premise of not generating a false alarm, and is accurate and reliable.

Owner:ALLRISING BEIJING TECH

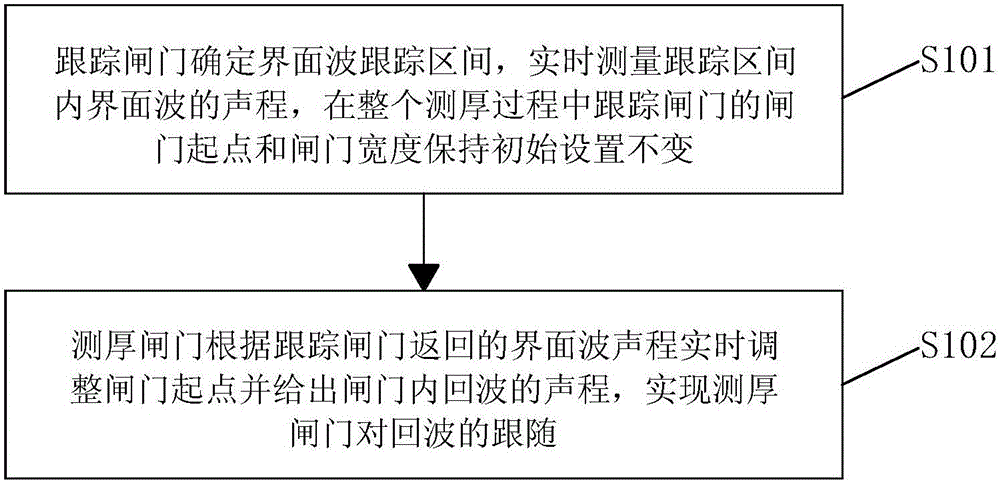

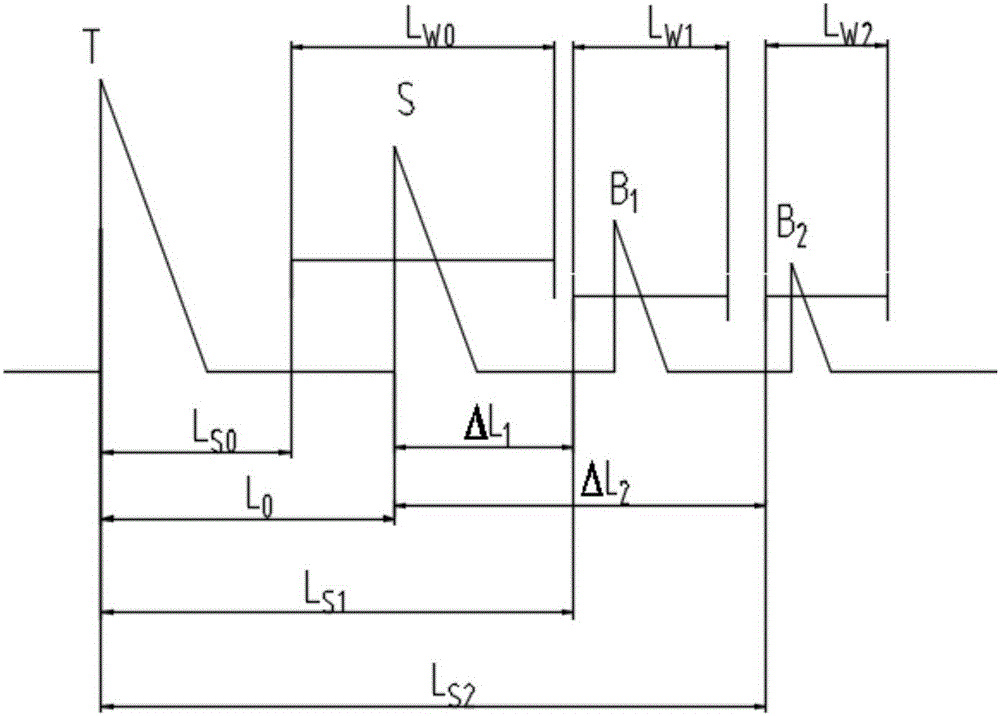

Method for real-time following echo of ultrasonic thickness measuring gate

ActiveCN106289124AGood followabilitySolve the problem of inaccurate wall thickness measurementUsing subsonic/sonic/ultrasonic vibration meansSonificationInterface waves

The invention discloses a method for real-time following echo of an ultrasonic thickness measuring gate. The method comprises the following steps: confirming an interface echo tracking section by a tracking gate; measuring the sonic path distance of the interface wave in the tracking section at real time; maintaining the initial setting of the gate starting point and the gate width of the tracking grate in the whole thickness measuring process; adjusting the gate starting point according to the sonic path distance of the interface wave fed back by the tracking gate at real time and giving an echo sonic path distance in the gate by the thickness measuring gate, thereby realizing the echo following of the thickness measuring gate. According to the method provided by the invention, the problem of inaccurate thickness measurement for a steel pipe wall caused by echo swinging in the thickness measurement process is solved; the adverse effect of workpiece motion on the thickness measurement is eliminated; the following property of the thickness measuring gate of the ultrasonic thickness measuring method is increased; the accurate measurement for the steel pipe thickness in the motion process is realized; the reliability of the ultrasonic measurement for the steel pipe thickness is ensured.

Owner:HUST WUXI RES INST

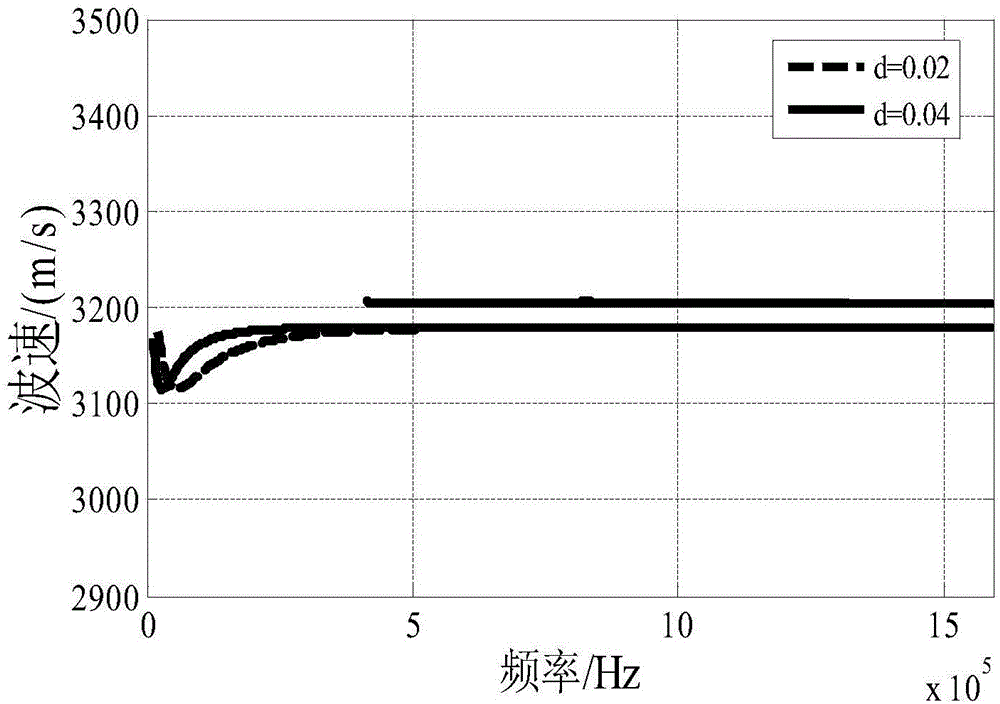

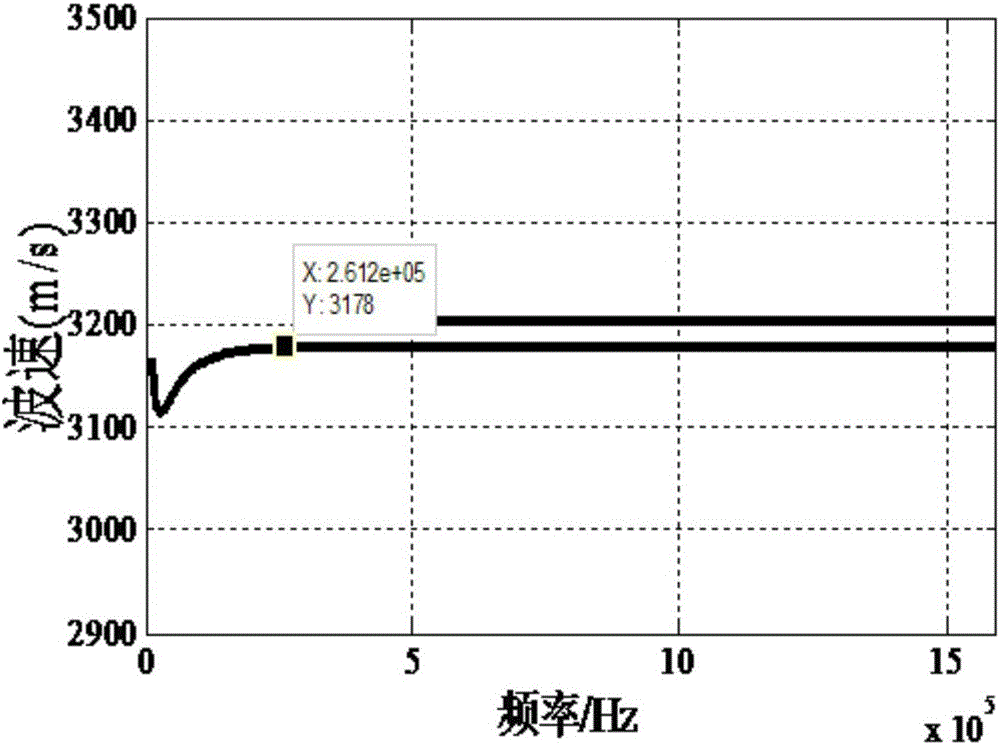

Method and apparatus for measuring thickness of intermediate layer of three-layer composite plate

InactiveCN106643592ASolve the problem that the thickness cannot be measuredImprove Thickness Measurement EfficiencyUsing subsonic/sonic/ultrasonic vibration meansDispersion curveInter layer

The invention relates to a method and apparatus for measuring the thickness of the intermediate layer of a three-layer composite plate. By means of the interface wave transmitted between the interfaces, the intermediate layer of the three-layer composite plate is excited to generate and receive a guided wave signal, and by means of the guided wave signal, the interface wave velocity is measured, and by changing the frequency of the excitation signal several times, the dispersion curve of the interface wave transmitting in the composite plate can be obtained, and the group velocity stable corner frequency can be found; By means of the consistence of the interface wave group velocity and the phase velocity stable corner frequency, by taking the product (namely frequency thickness product) of the phase velocity stable corner frequency and the thickness of the intermediate layer of the three-layer composite plate as a constant value, and by means of the principle that the phase velocity stable corner frequency is related to the thickness of the intermediate layer, in the case of known stable corner frequency, the frequency thickness product is divided by the stable corner frequency to obtain the accurate thickness of the intermediate layer of the three-layer composite plate The measurement method is simple and easy, high in measurement precision, and reliable in measurement result, and is suitable for the accurate measurement of the intermediate layer of the three-layer composite plate.

Owner:XI AN JIAOTONG UNIV

Boundary acoustic wave device

ActiveUS8049395B2Reduce the intensity of the reactionSimple structureImpedence networksPiezoelectric/electrostriction/magnetostriction machinesThermal dilatationAcoustic wave

A boundary acoustic wave device includes an IDT electrode between a piezoelectric layer and a dielectric layer. A low thermal expansion medium layer having a linear thermal expansion coefficient less than that of the piezoelectric layer is laminated on the piezoelectric layer opposite to the boundary. Acoustic velocities of transversal waves at the piezoelectric layer, the dielectric layer, and the low thermal expansion medium layer satisfy Expression (1), and (an acoustic velocity of a transverse wave at the dielectric layer) / λ satisfies Expression (2) as follows:(acoustic velocity of transverse wave at dielectric layer)<(acoustic velocity of SH wave at piezoelectric layer)<(acoustic velocity of transverse wave at low thermal expansion medium layer) Expression (1), and(response frequency of boundary acoustic wave)<(acoustic velocity of transverse wave at dielectric layer) / λ<(response frequency of high order mode) Expression (2).

Owner:MURATA MFG CO LTD

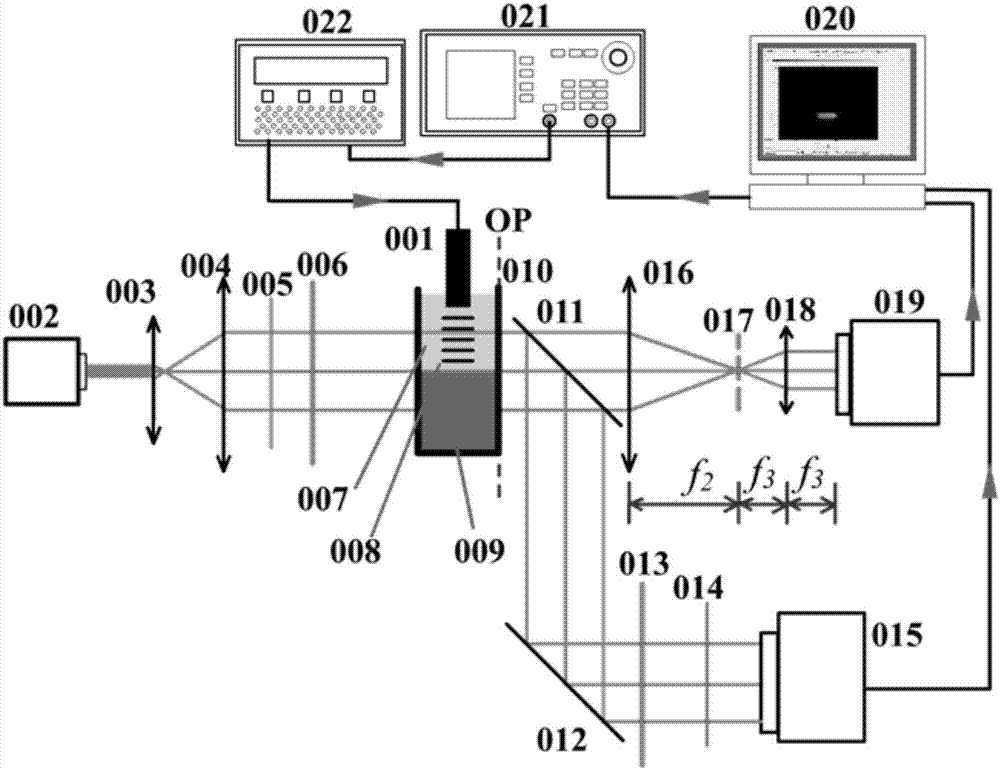

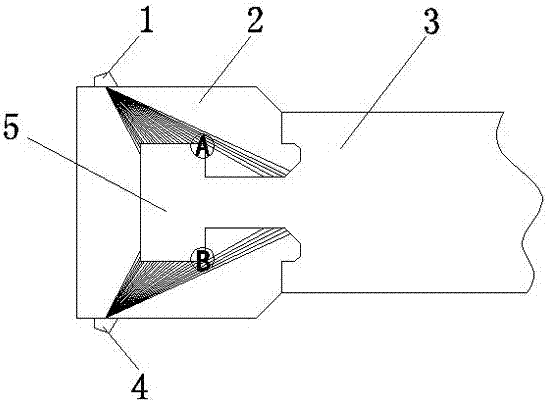

Optical device and method for simultaneous observation of internal sound fields of transparent fluid and transparent solid

ActiveCN106970157AObserving dynamic propagation propertiesWon't interfereAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesPolarizerInterface waves

The invention discloses an optical device and a method for simultaneous observation of internal sound fields of a transparent fluid and a transparent solid. Circular polarized light is formed by a polarizer and a 1 / 4 slide to pass through the sound fields, and light with information of the internal sound fields of the transparent fluid and the transparent solid is split into two beams by an optical light splitter, wherein one of the beams passes through a convergent lens to be subjected to spatial filtering and imaging and is used for observing the sound field in the fluid, and the other beam passes through the 1 / 4 slide and a polarization analyzer to obtain an image of the sound field in the solid by imaging. Therefore, non-invasive imaging of the internal sound fields of the transparent fluid and the transparent solid can be realized at the same time, and observation of the internal sound fields of the transparent fluid and the transparent solid is realized. Instantaneous sound field states as well as continuous sound field dynamic changes can be obtained, more accurate and comprehensive information of the internal sound fields of the transparent fluid and the transparent solid are provided, propagation characteristics of the sound fields in liquid and solid interfaces can be observed, and the optical device and the method can be applied to acoustic method based liquid and solid interface wave detection for further research and teaching of material characteristics.

Owner:HOHAI UNIV CHANGZHOU

Method for detecting T-shaped groove in rotor rim of steam turbine

InactiveCN107247090ARealize real-time imaging detectionAchieve positioningAnalysing solids using sonic/ultrasonic/infrasonic wavesImpellerSonification

The invention relates to a method for detecting a T-shaped groove in a rotor rim of a steam turbine. The method disclosed by the invention comprises the following steps: performing cover scanning on a to-be-detected position by adopting an ultrasonic phased array inspection device, performing time synchronization on interface waves and impulse transmission waves of the T-shaped groove, and compiling imaging software so as to realize ultrasonic phased array real-time imaging detection, so that the detection of the T-shaped groove in the rim is reliable and convenient, and misjudgment and missing detection can be avoided. Compared with the conventional ultrasonic detection method, the method disclosed by the invention has the advantages that the T-shaped groove of the impeller is subjected to flaw detection by adopting the ultrasonic phased array real-time imaging detection technology, full-coverage scanning of a reverse T-shaped groove can be completed under the conditions that the scanning range is wide, the defect waves are easily identified and a probe does not need to move back and forth, the detection efficiency is improved, and location and quantification of crack defects can be realized.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com