Ultrasonic detecting device and detecting method for interface corrugation of explosive welding composite material

A composite material and explosive welding technology, which is applied in the direction of analyzing solids and materials using sound waves/ultrasonic waves/infrasonic waves, and material analysis using sound waves/ultrasonic waves/infrasonic waves. It can solve the problems of high equipment cost, slow scanning speed, and the location of scanning devices Accuracy requirements are very high, to achieve the effect of high system reliability and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

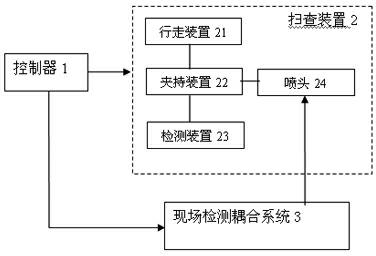

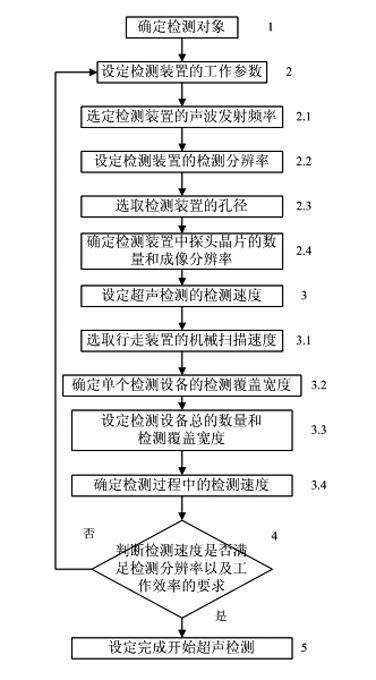

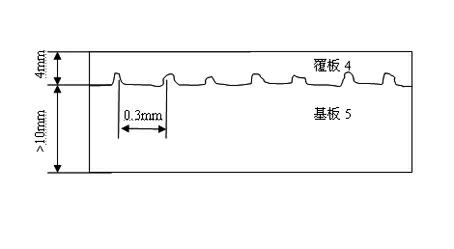

[0043] The invention discloses a high-frequency ultrasonic detection method for interface ripples of explosive welding composite materials. The detection technology adopted in the method is ultrasonic phased array technology, and the detection equipment adopts a phased array ultrasonic detection device. According to the thickness of the composite cladding and the resolution requirements of corrugated imaging, different excitation / receiving apertures and focusing laws are used to meet the requirements of different cladding thickness and detection resolution by controlling the focal depth and focal column diameter of the detection acoustic beam.

[0044] Ultrasonic phased array technology combines ultrasonic phased array technology and phased array ultrasonic detection technology.

[0045] According to the characteristics of various detection methods and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com