Patents

Literature

423 results about "Phased array ultrasonics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

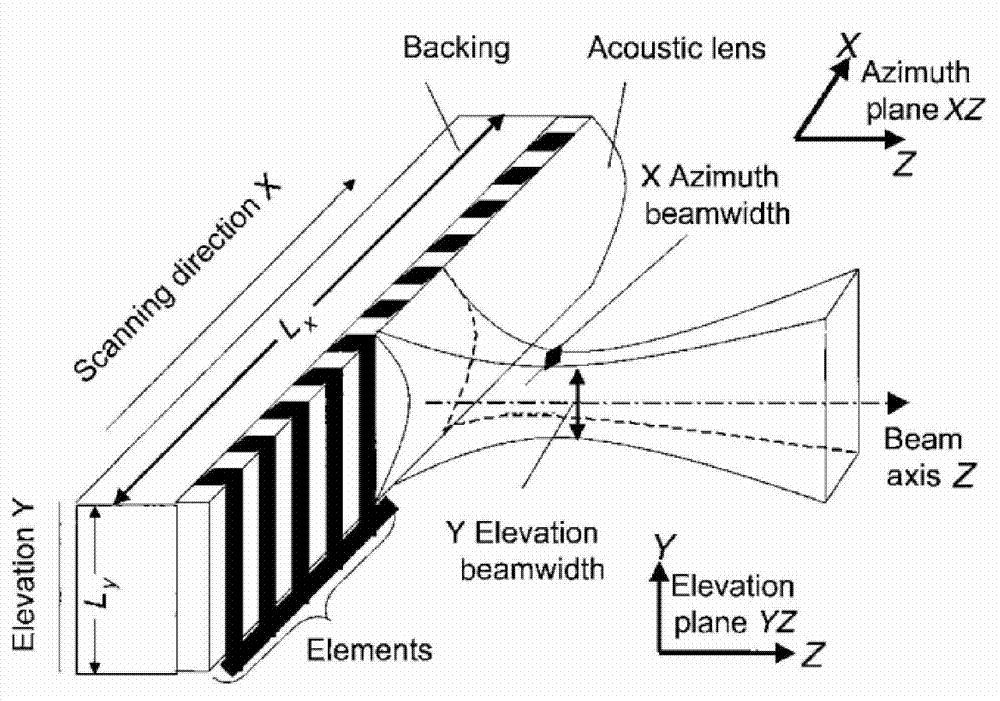

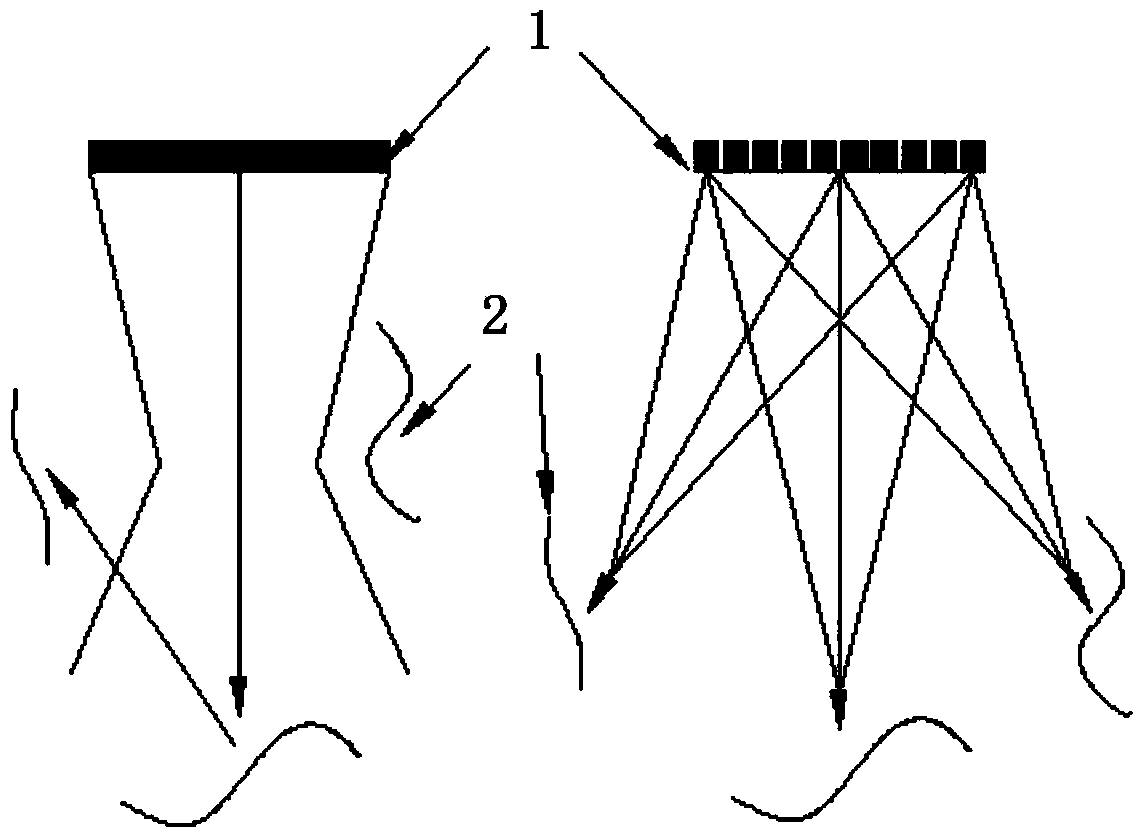

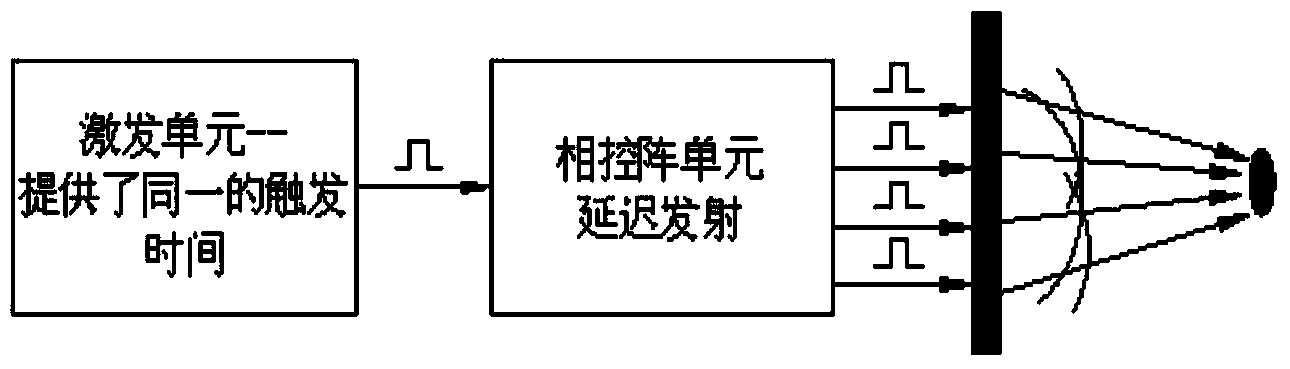

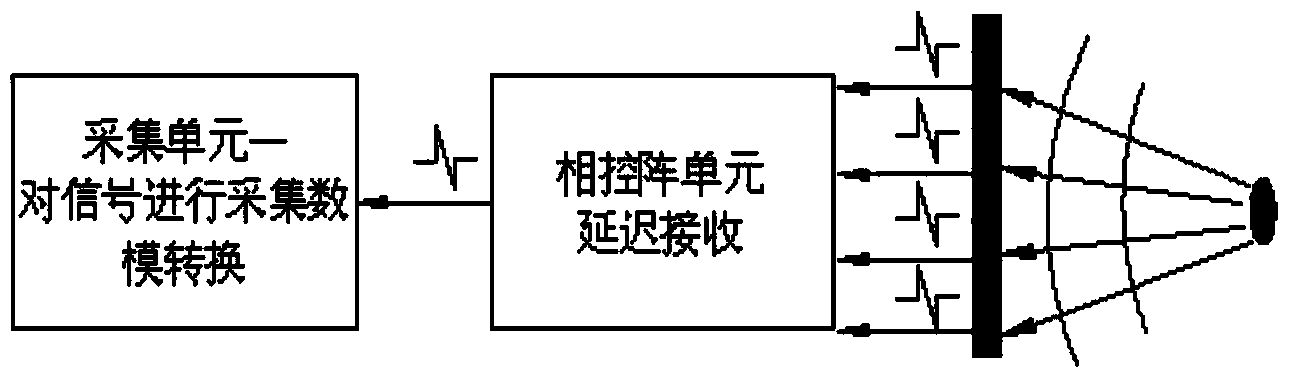

Phased array ultrasonics (PA) is an advanced method of ultrasonic testing that has applications in medical imaging and industrial nondestructive testing. Common applications are to noninvasively examine the heart or to find flaws in manufactured materials such as welds. Single-element (non-phased array) probes, known technically as monolithic probes, emit a beam in a fixed direction. To test or interrogate a large volume of material, a conventional probe must be physically scanned (moved or turned) to sweep the beam through the area of interest. In contrast, the beam from a phased array probe can be focused and swept electronically without moving the probe. The beam is controllable because a phased array probe is made up of multiple small elements, each of which can be pulsed individually at a computer-calculated timing. The term phased refers to the timing, and the term array refers to the multiple elements. Phased array ultrasonic testing is based on principles of wave physics, which also have applications in fields such as optics and electromagnetic antennae.

Phased ultrasound locating method and system of partial discharge of transformer

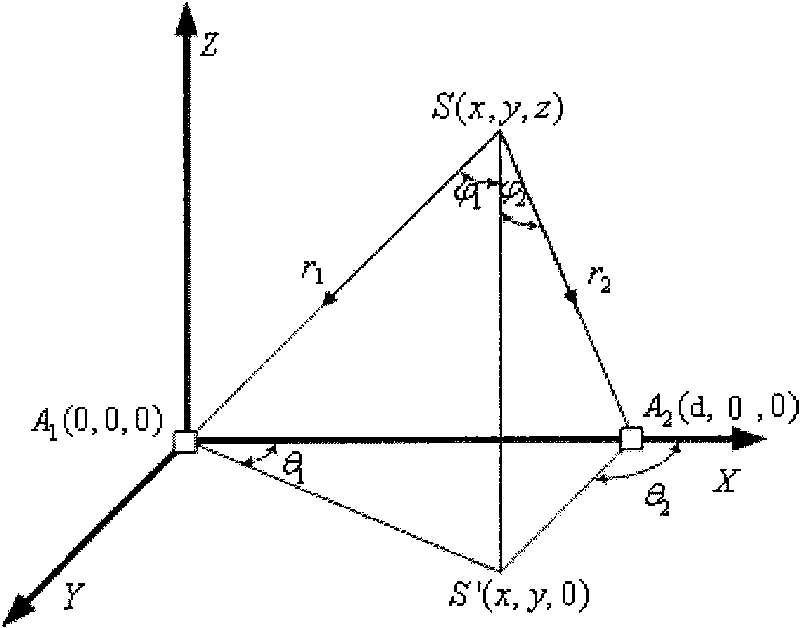

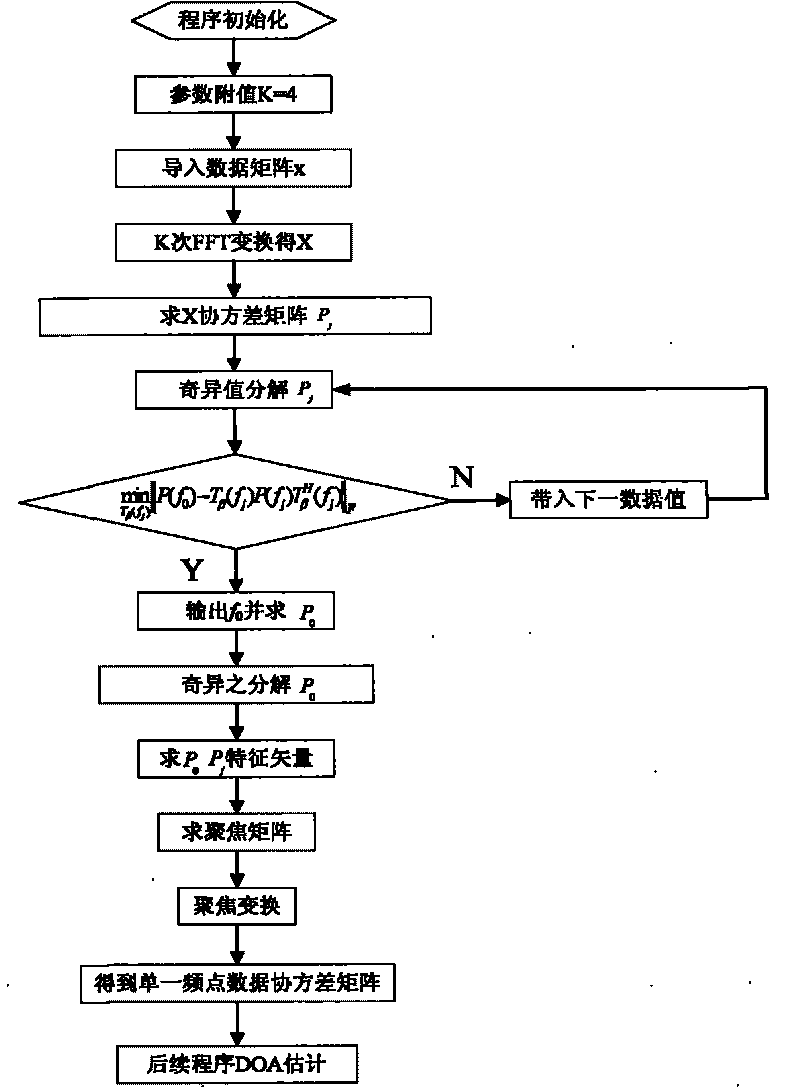

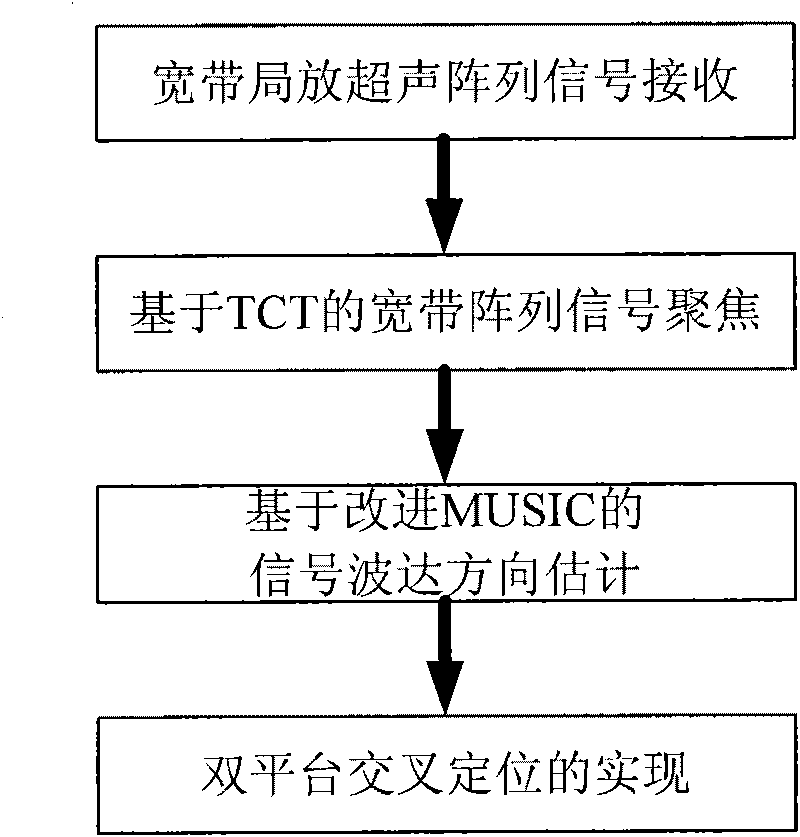

The invention relates to a phased ultrasound locating method of the partial discharge of a transformer, which is used for monitoring and locating partial discharge faults. Phased array ultrasound sensors arranged at two different positions of the transformer are adopted to receive ultrasound broadband signals sent out by a partial discharge source, and an array model is formed; then a broadband focus algorithm in a broad-ban array signal processing algorithm is applied to convert broadband signals received by the two phased array ultrasound sensors into narrow-band signals, then a narrow-band direction finding algorithm is applied to respectively carry out direction of arrival (DOA) estimation on the two narrow-band signals, and finally a cross locating algorithm is applied to determine the concrete position of the partial discharge. Meanwhile, the invention also discloses a locating system. The invention can carry out on-line accurate locating on the partial discharge in the transformer; moreover, the used locating system has simple structure, and the method is simple and easy to apply.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

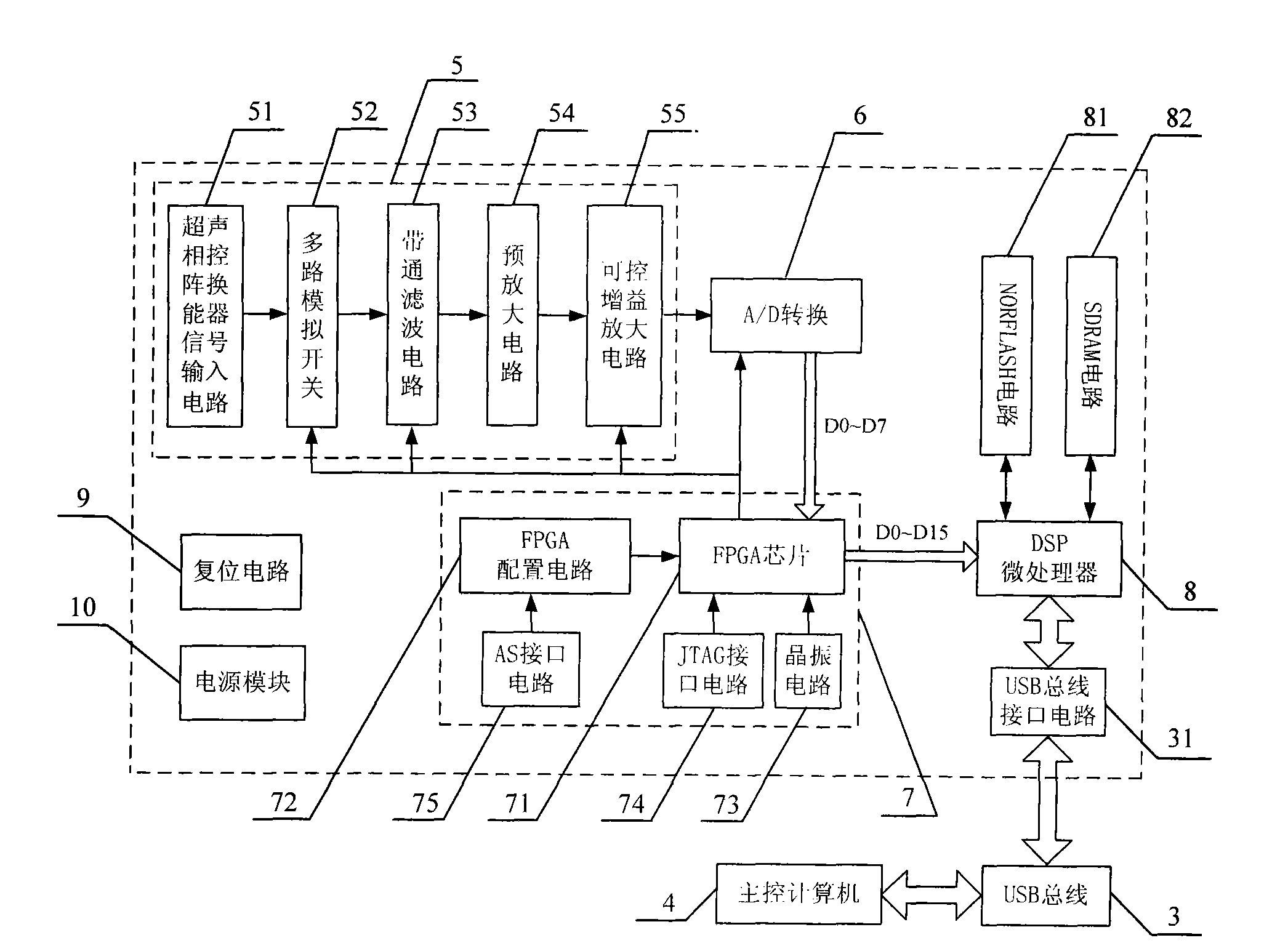

Phased array ultrasonic detection, data acquisition and process device

InactiveCN101493438ASimple structureReduce the number of response interruptionsAnalysing solids using sonic/ultrasonic/infrasonic wavesResponse signal detectionSonificationData acquisition

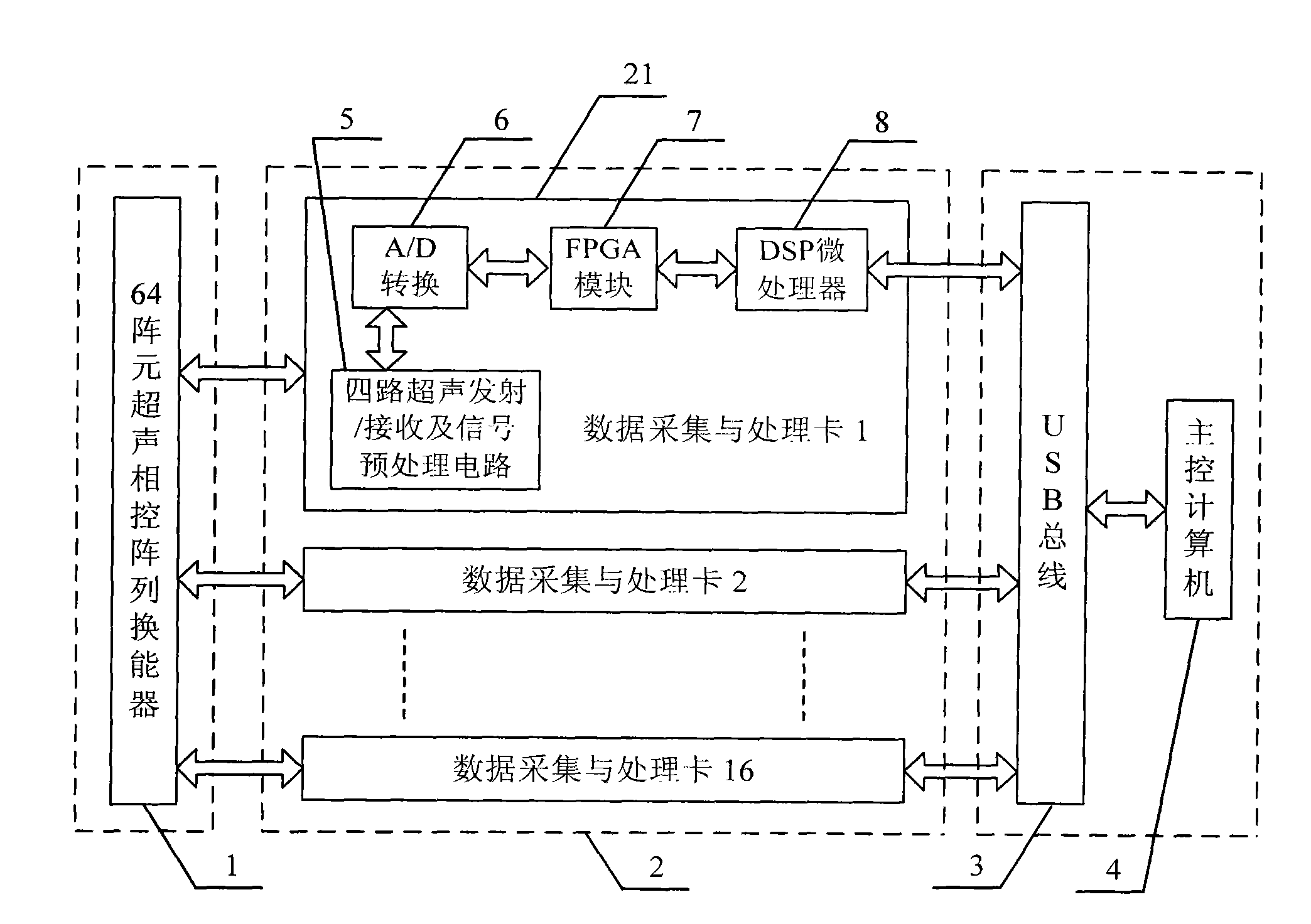

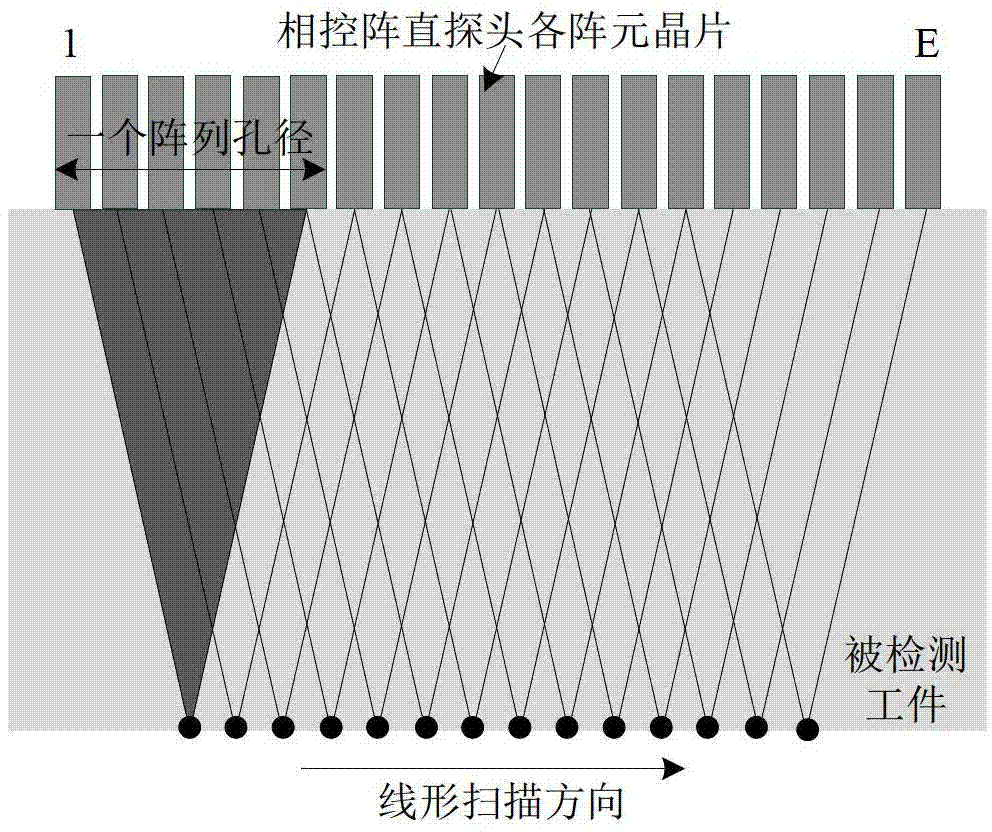

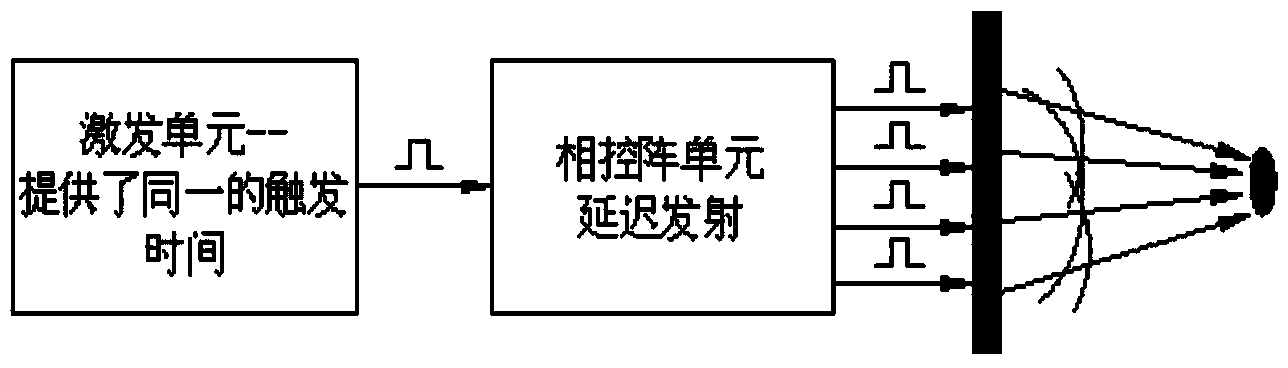

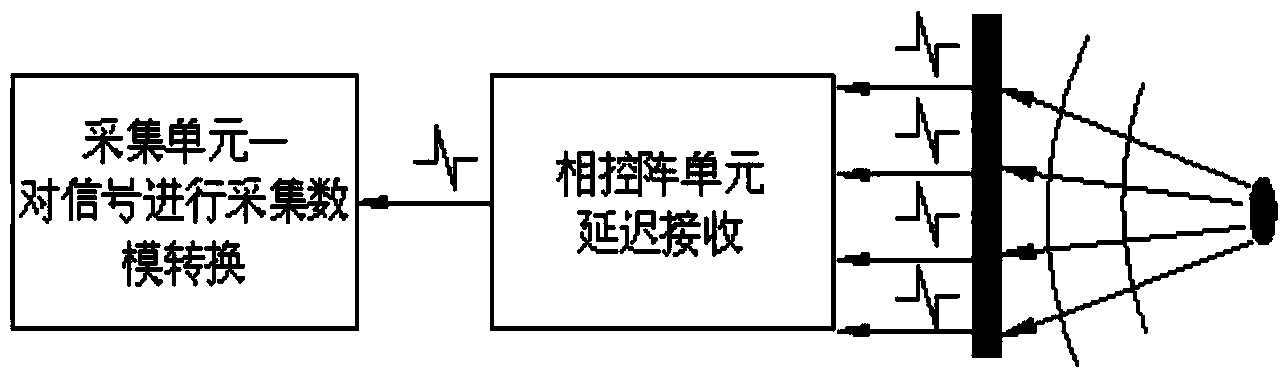

The invention discloses a phased array ultrasonic detection data acquisition and processing unit, comprising a USB bus and a main control computer; the USB bus communication is connected with a data acquisition and processing card component, and a 64 array element ultrasound phased array transducer in sequence; the data acquisition and processing card component comprises 16 completely same data acquisition and processing cards; the data acquisition and processing card comprises a four-way ultrasonic emission / reception and signal pretreatment circuit, an A / D conversion module, an FPGA module and a DSP microprocessor module, a reset circuit, and a power supply module, which are connected in a coordinating way; the data acquisition and processing card component has 64 input channels and 16 output channels, wherein every four input channels and one output channel have a data acquisition and processing card correspondingly; by controlling the time delaying of pulse excitating or receiving of each array element in a transducer array, and changing the phase relationship of sound wave emitted or received by each array element when reaching or coming from a cetain point in an object, the flexible deflection and focusing of the acoustic beam are achieved, and the transverse movement of the acoustic beam position can also be realized by selecting the needed array element group.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

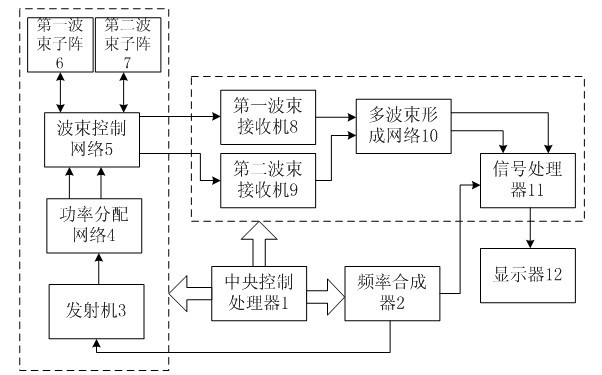

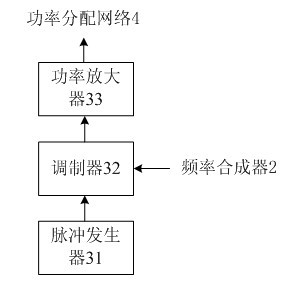

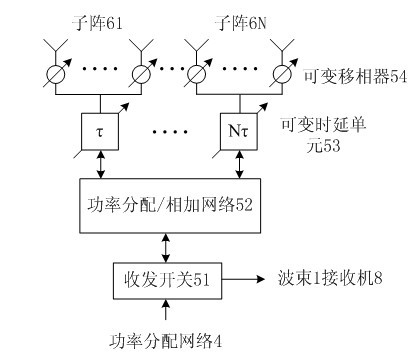

Multifrequency phased array ultrasonic Doppler flow detection system and method

InactiveCN101936756AReduce noiseHigh measurement accuracyVolume/mass flow measurementDisplay deviceBeam scanning

The invention discloses a multifrequency phased array ultrasonic Doppler flow detection system and a multifrequency phased array ultrasonic Doppler flow detection method. The system comprises a central control processor, a frequency synthesizer, a transmitting part, a receiving part and a display, wherein the transmitting part comprises a transmitter, a power distribution network, a beam control network, a first beam subarray and a second beam subarray; the receiving part comprises a first beam receiver, a second beam receiver, a multi-beam forming network and a signal processor. The system is characterized in that the central control processor is respectively connected with the frequency synthesizer, the transmitter, the power distribution network, the beam control network, the first beam receiver, the second beam receiver, the multi-beam forming network and the signal processor. In the detection method of the system, beam deflection and dynamic focusing are realized through the phased array technology, multi-directional and multi-depth positions can be measured on the cross section of an integral pipeline, and by a mode of adjusting beam scanning dynamically, the processing timeof the beam scanning is reduced, and the measuring accuracy is improved.

Owner:SOUTH CHINA UNIV OF TECH

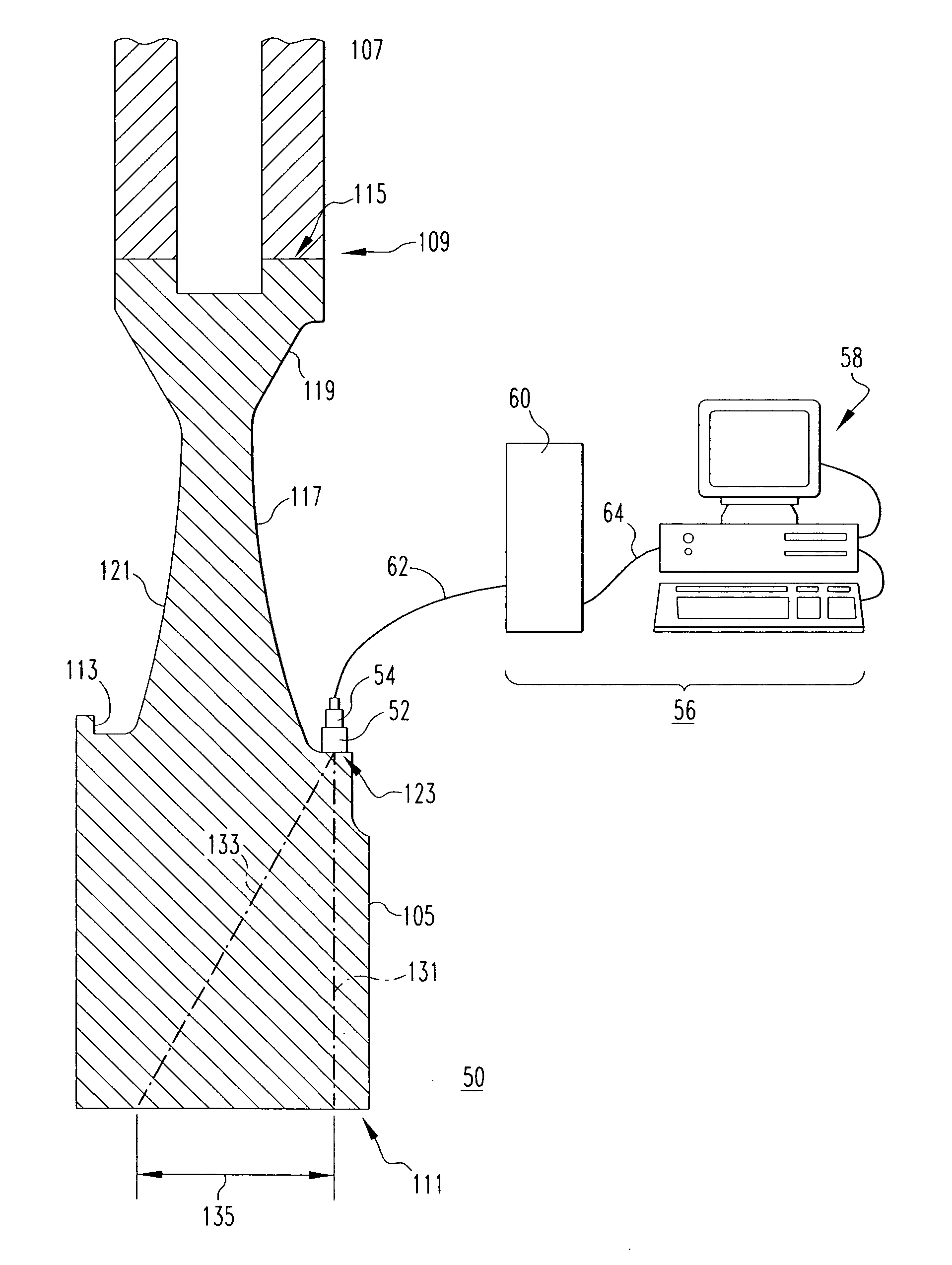

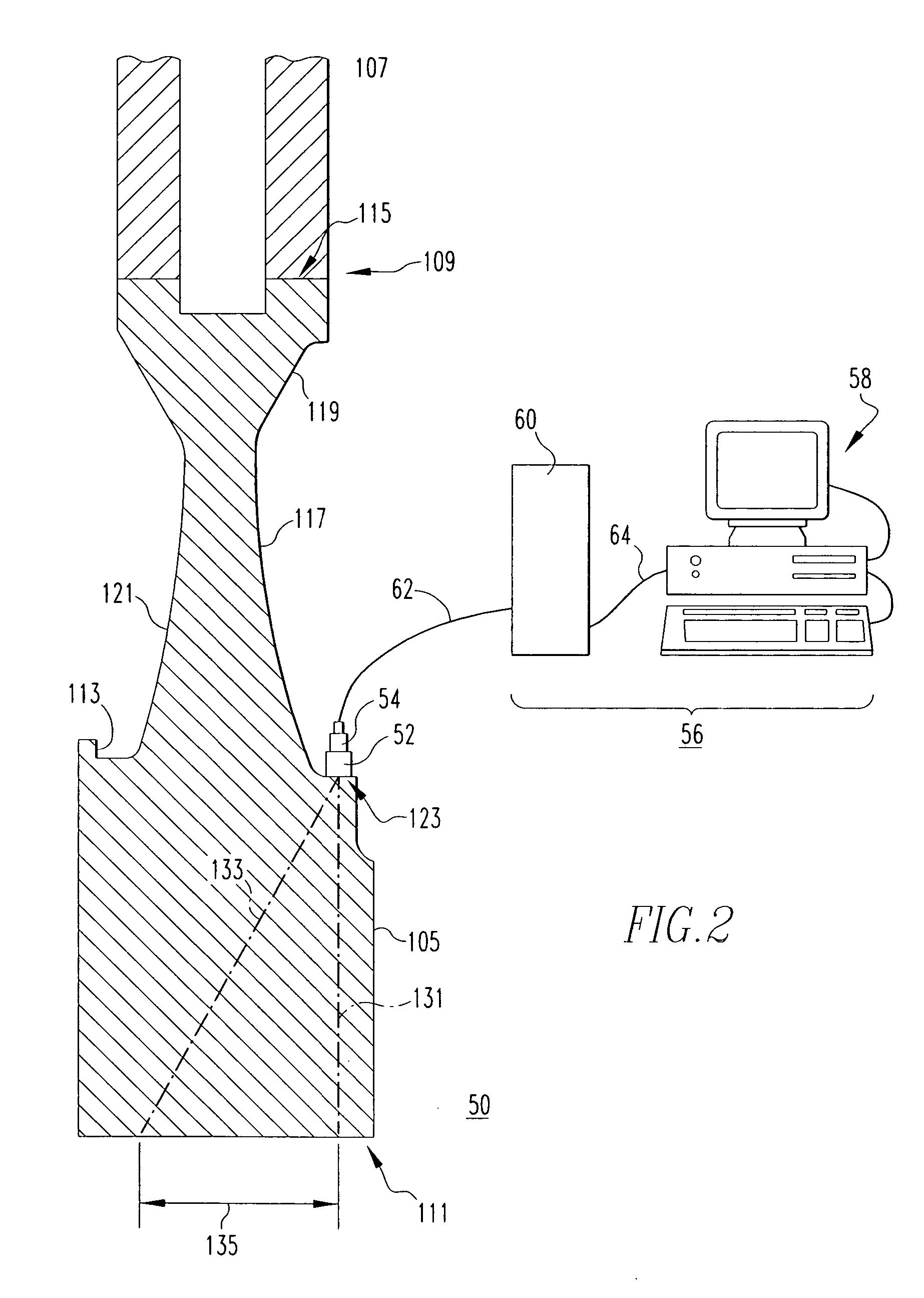

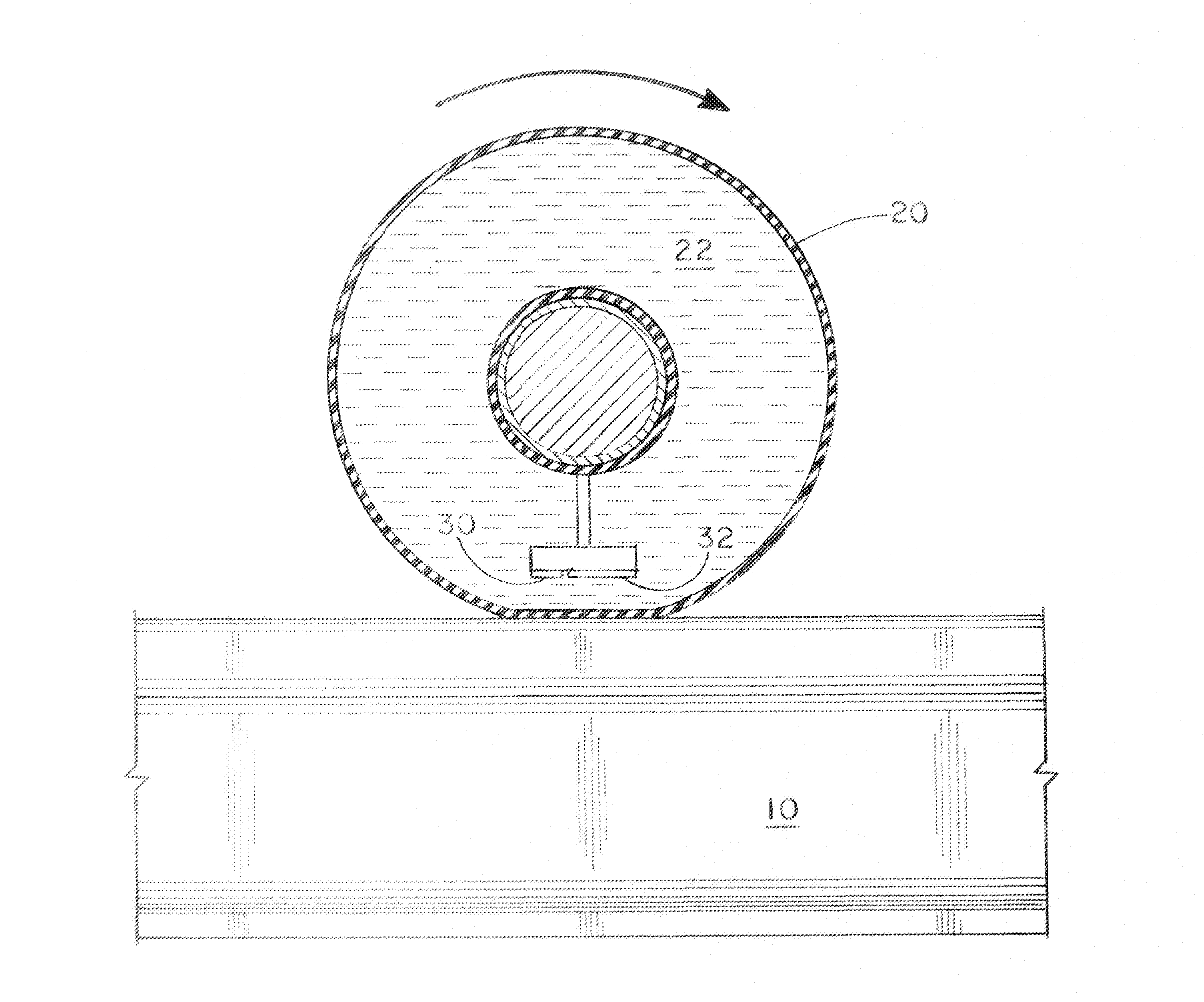

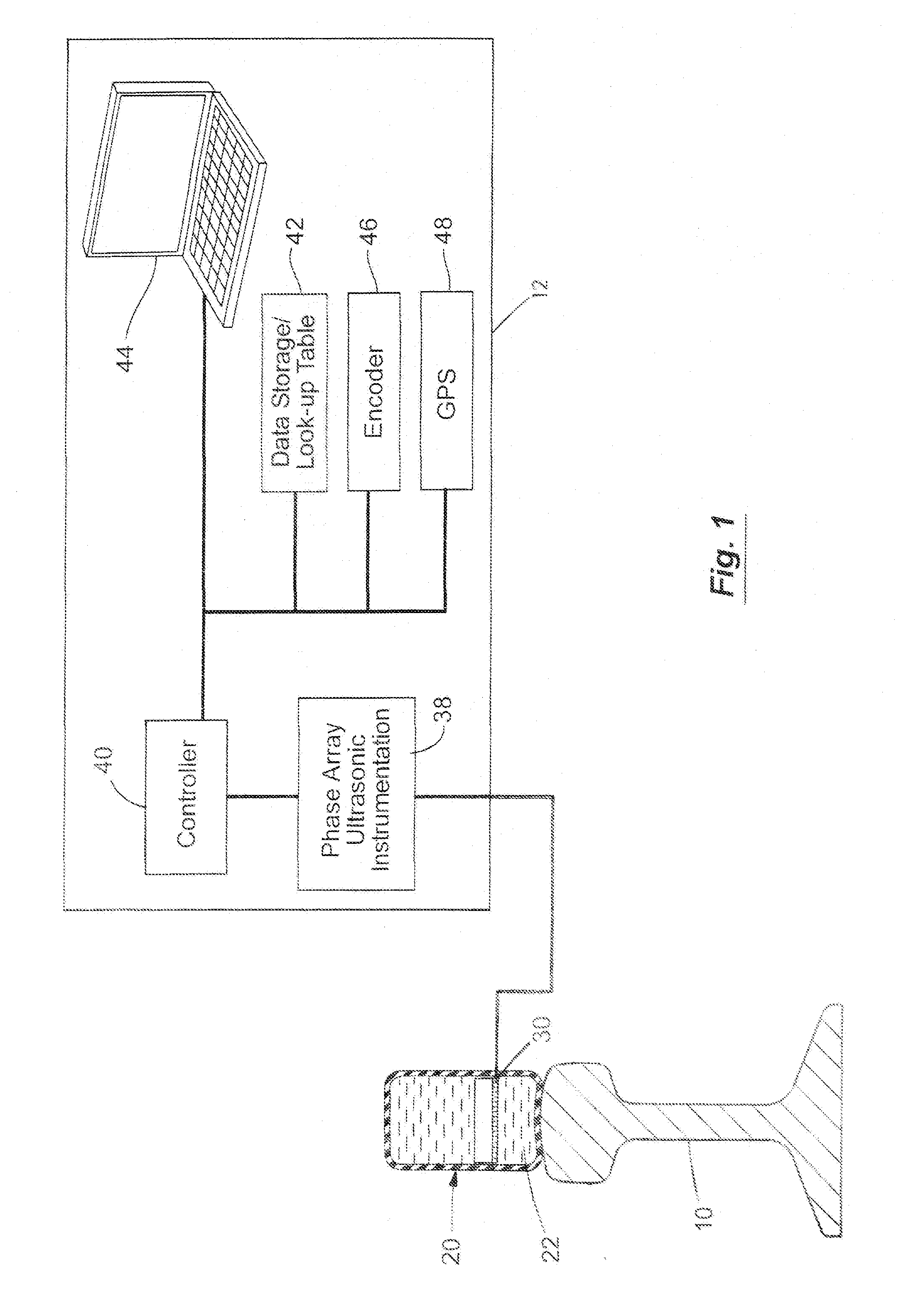

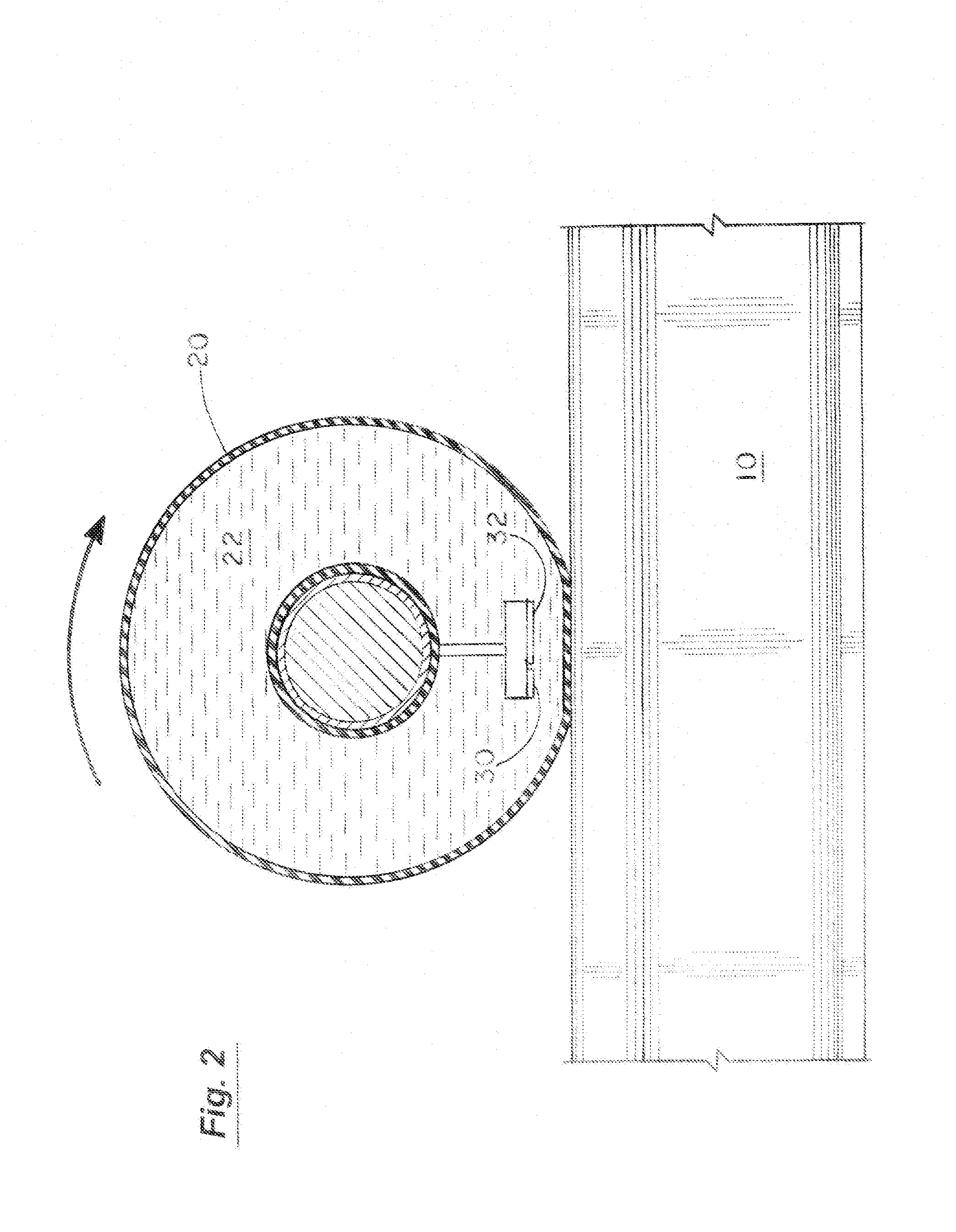

Phased array ultrasonic testing system and methods of examination and modeling employing the same

ActiveUS20060283250A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesCircular discSonification

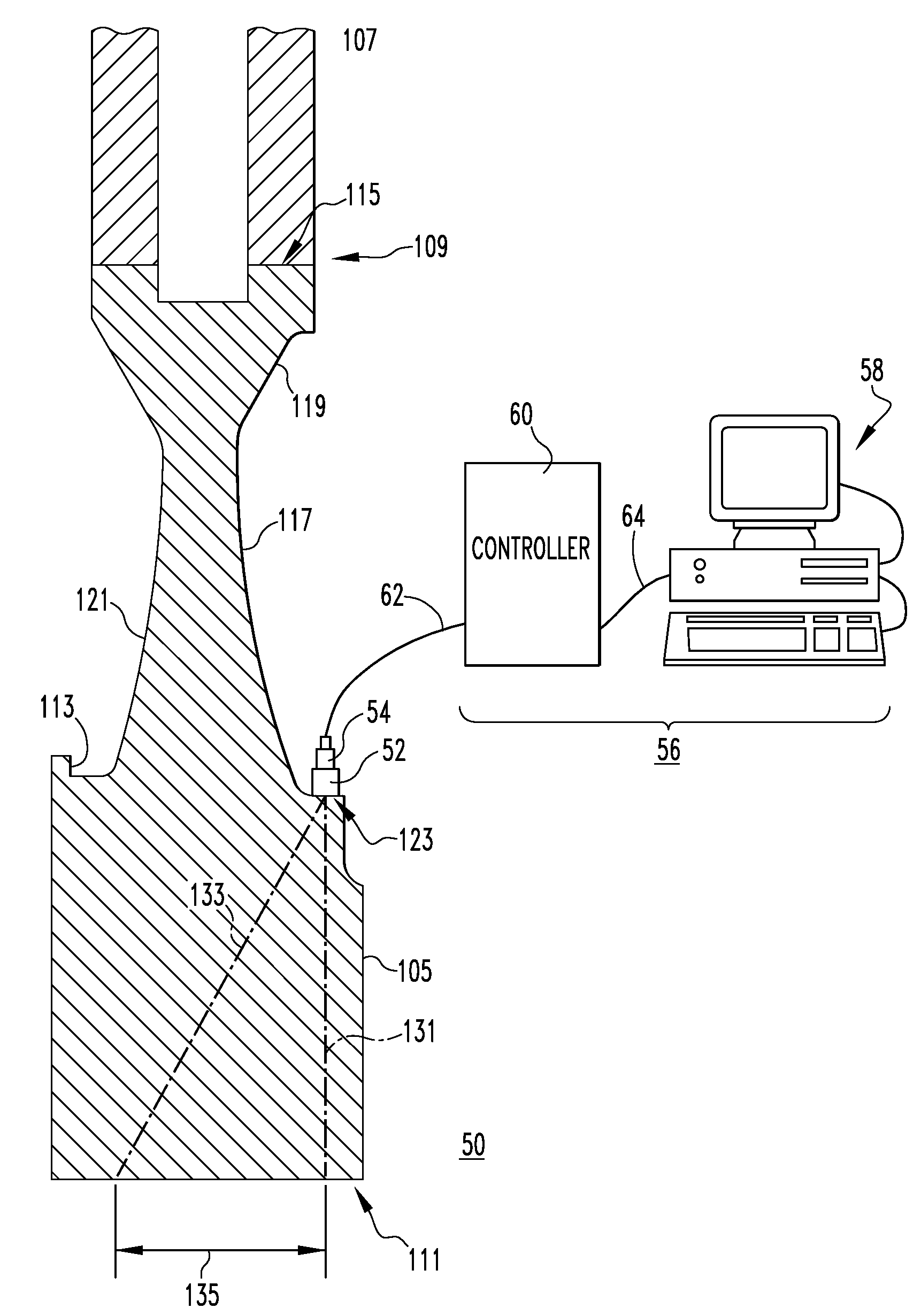

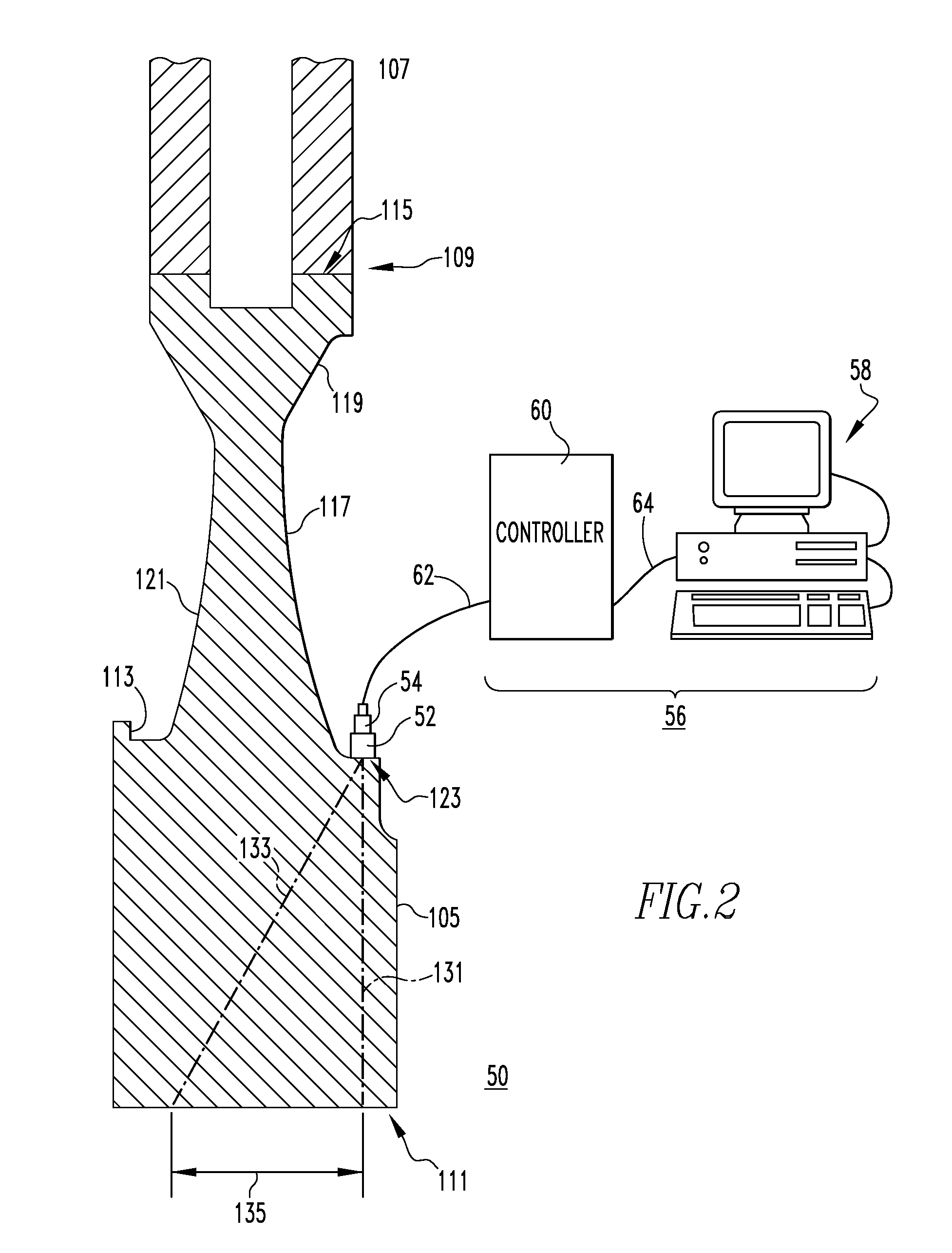

A phased array ultrasonic testing system is for examining turbine disc bores and blade attachments for discontinuities, such as stress corrosion cracking. The system is particularly suited to perform an accurate and efficient inspection of components despite their having a relatively complex geometry, such as axial entry blade attachments and bores of associated discs. The system includes a control system with a computer and a controller for programming, emitting, and steering an ultrasonic beam via at least one two-dimensional phased array probe, thereby precisely inspecting the area of interest while simultaneously accommodating the aforementioned complex geometry of the disc or blade attachment. Computer control of the beam permits the number of inspection locations and the number of different probe wedges to be reduced providing for an efficient, timely inspection. Methods of profiling and examining turbine components of known and unknown geometries, are also disclosed.

Owner:SIEMENS ENERGY INC

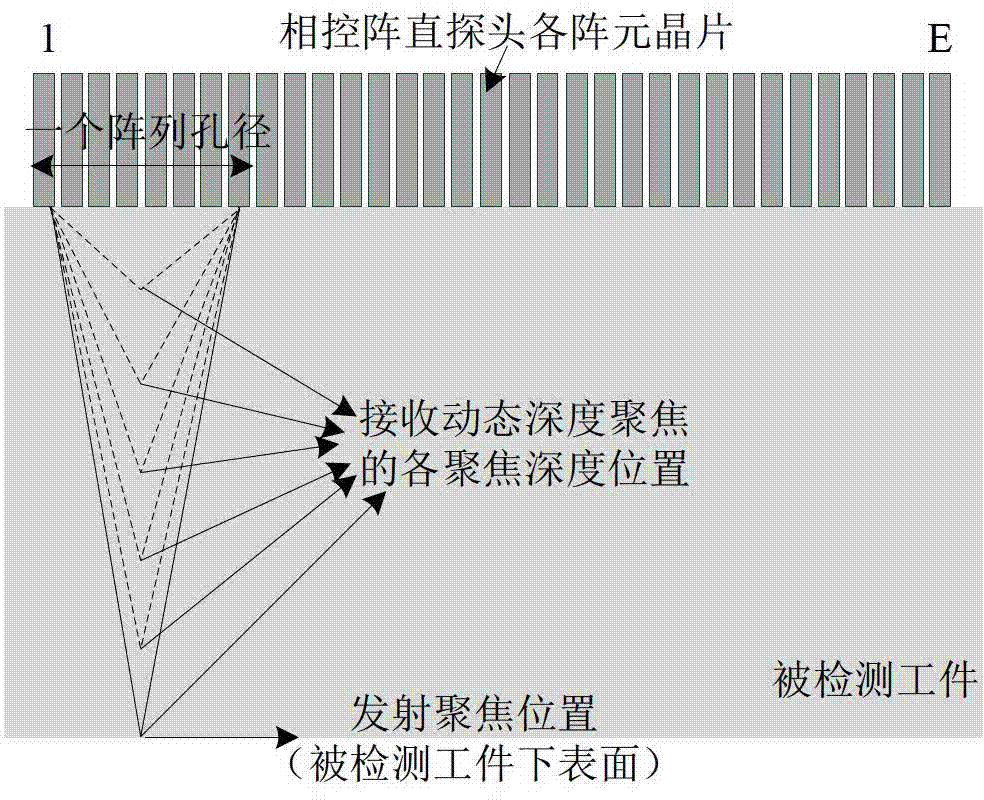

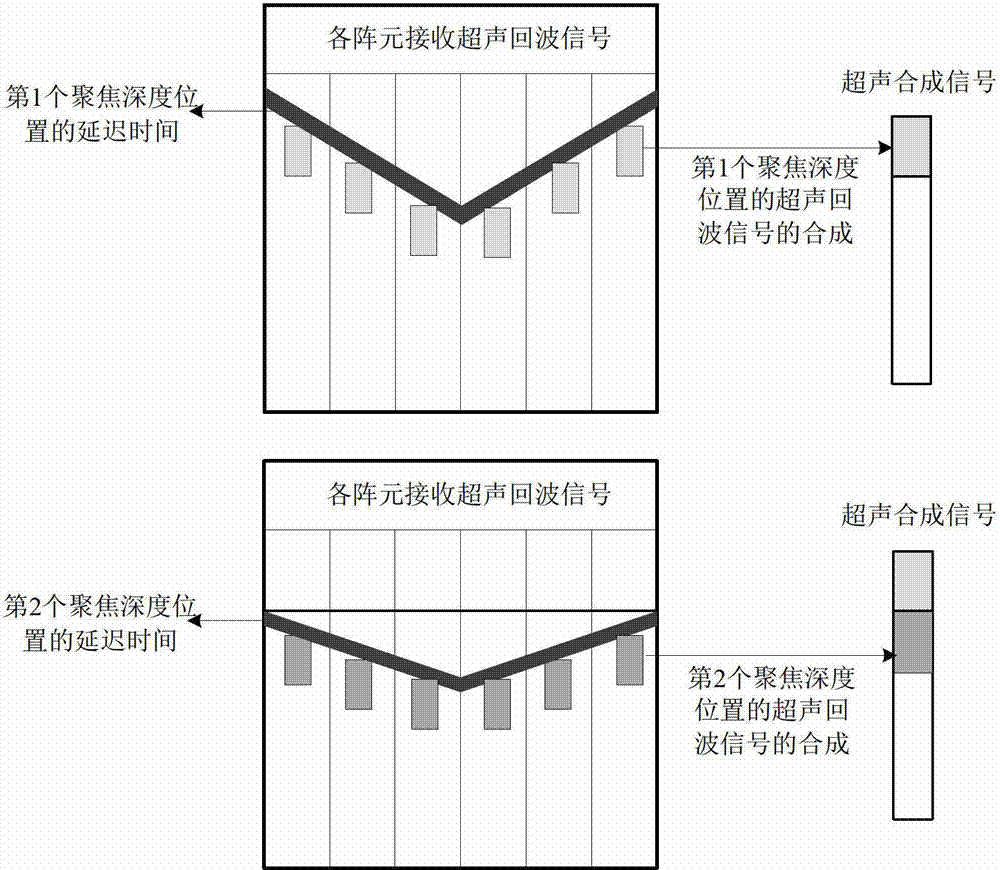

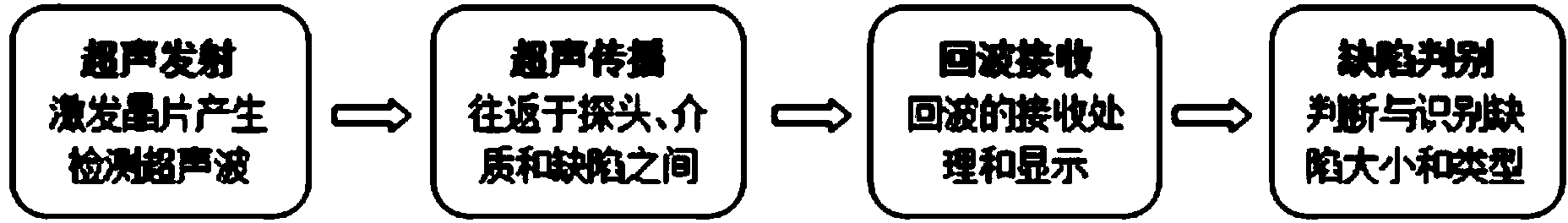

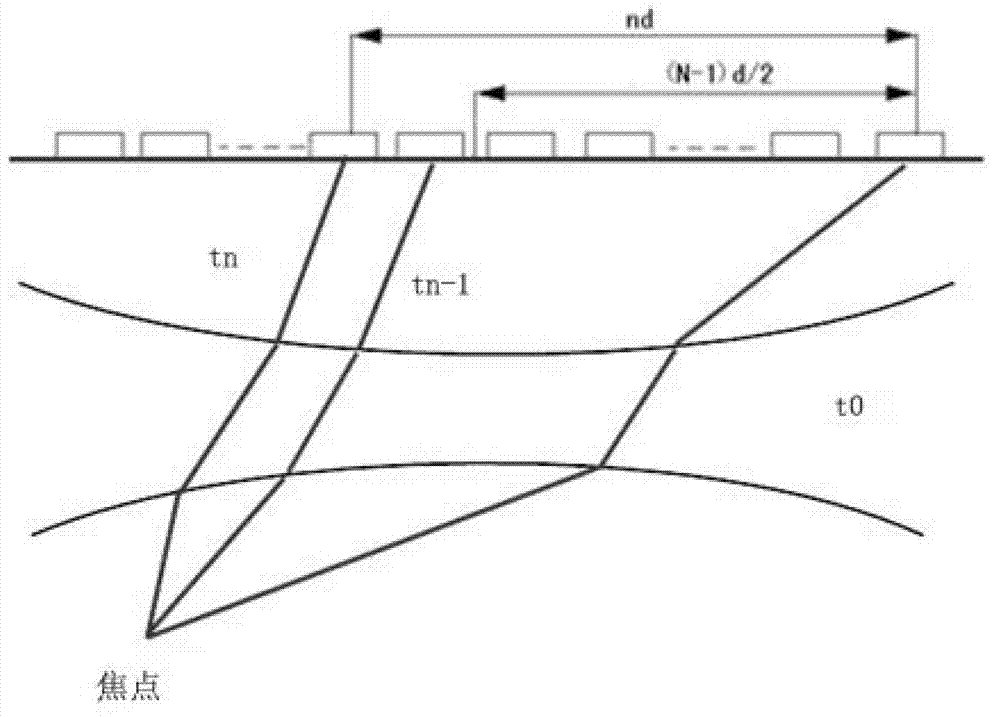

Phased array ultrasonic testing method based on improved dynamic depth focusing

InactiveCN102809610AAccurate focusSolve the problem of difficult defect identificationAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationUltrasonic transmission

The invention belongs to the technical field of non-destructive testing and particularly discloses a phased array ultrasonic testing method based on improved dynamic depth focusing. The method comprises the following five steps of: performing phased array ultrasonic transmission and reception, discriminating a defect, calculating delay time, post-processing echo signals and reconstructing a B type drawing. The ultrasonic echo signals are accurately focused to the position of the defect, so that the problem that the defect is difficult to identify when the signal-to-noise ratio of a reflection echo signal of the defect is too low can be solved; by the method, the problem that the deviation exists between an ideal focus and an actual focus because a material of a tested workpiece is nonuniform can be effectively solved, and the testing resolution of phased array ultrasonic testing of layered media and anisotropic media can be effectively improved; and by the method, the problems that ultrasonic imaging results are fuzzy and distorted due to errors of hardware systems such as phased array flaw detectors can also be solved, and the quality of phased array ultrasonic imaging can also be improved.

Owner:BEIHANG UNIV

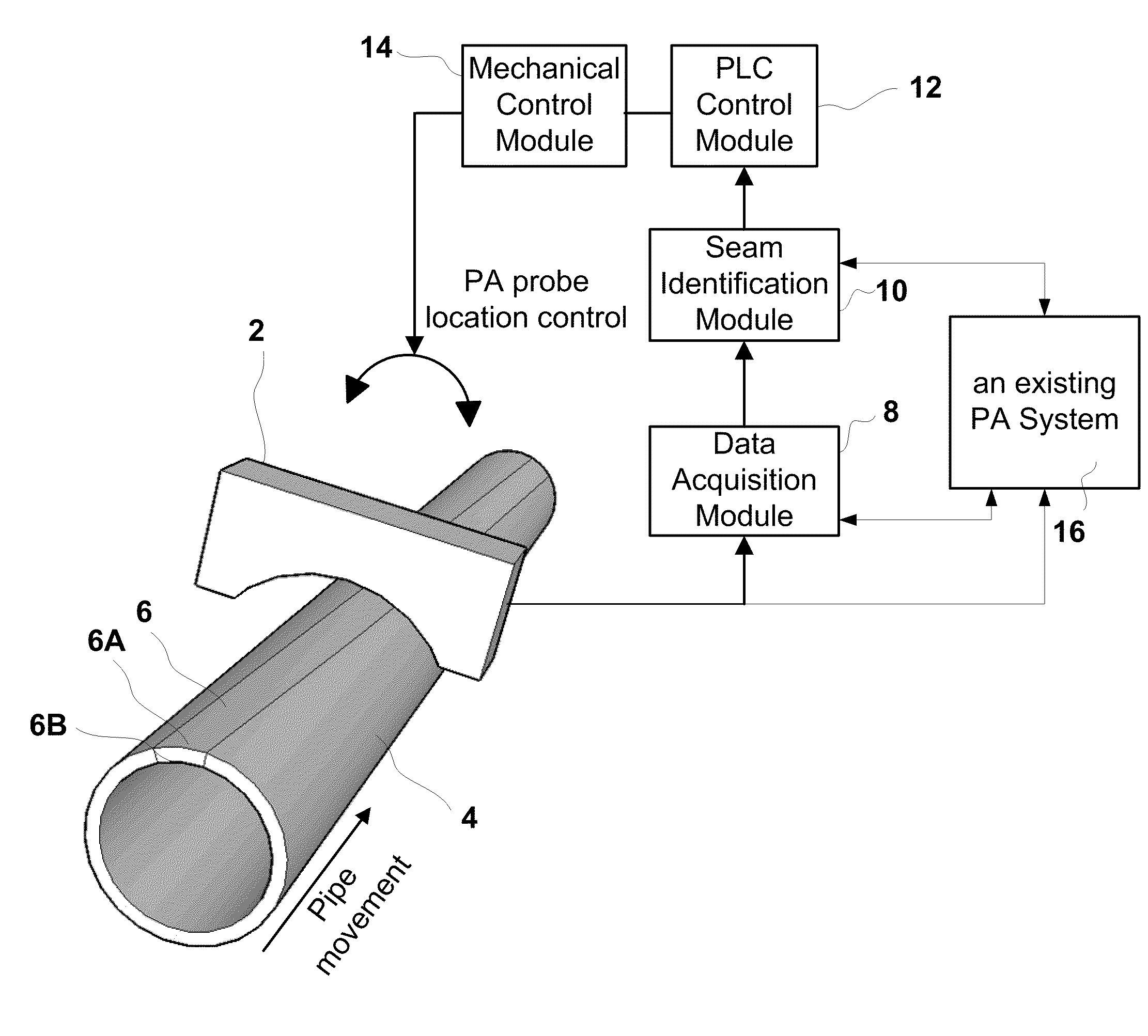

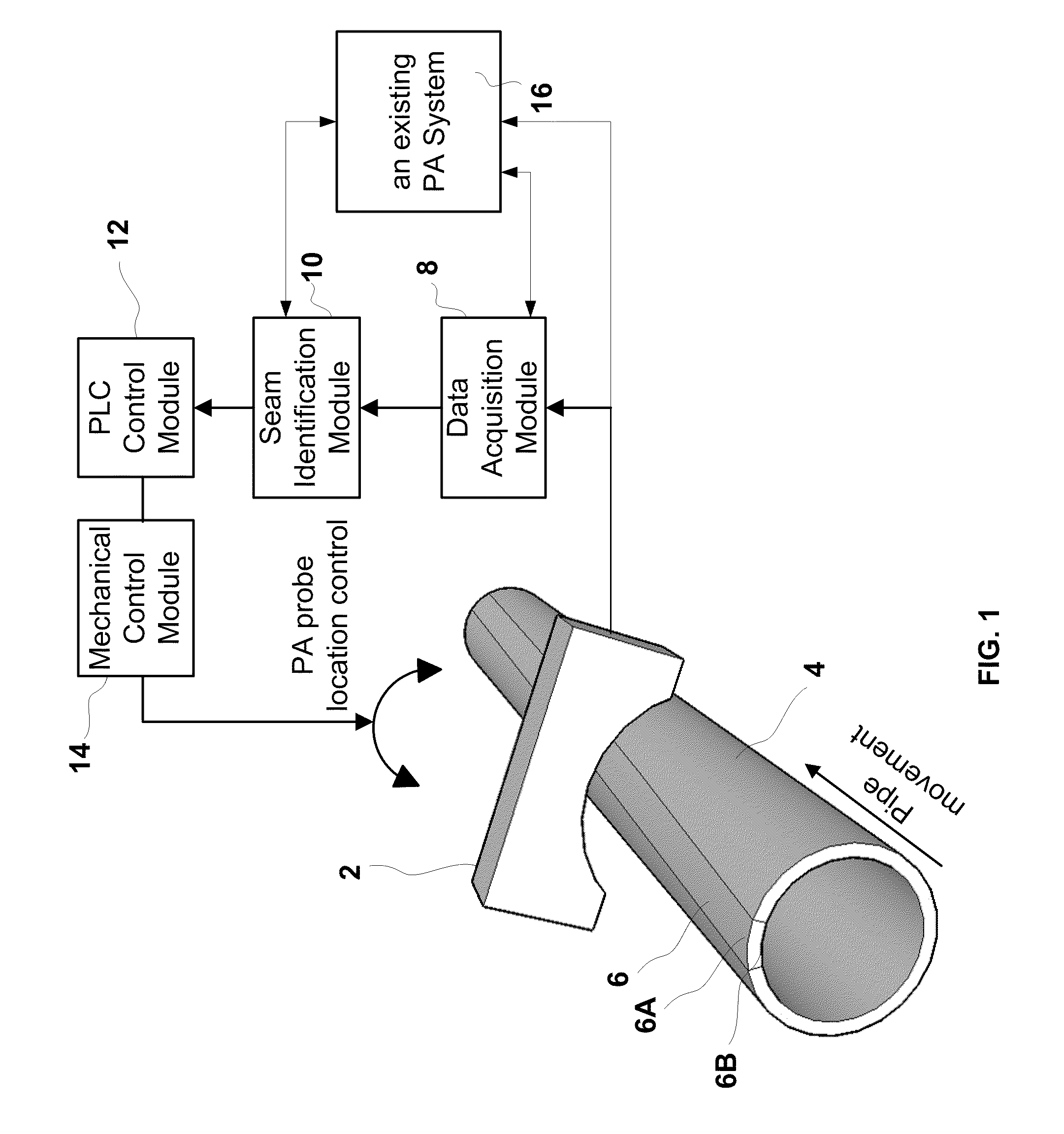

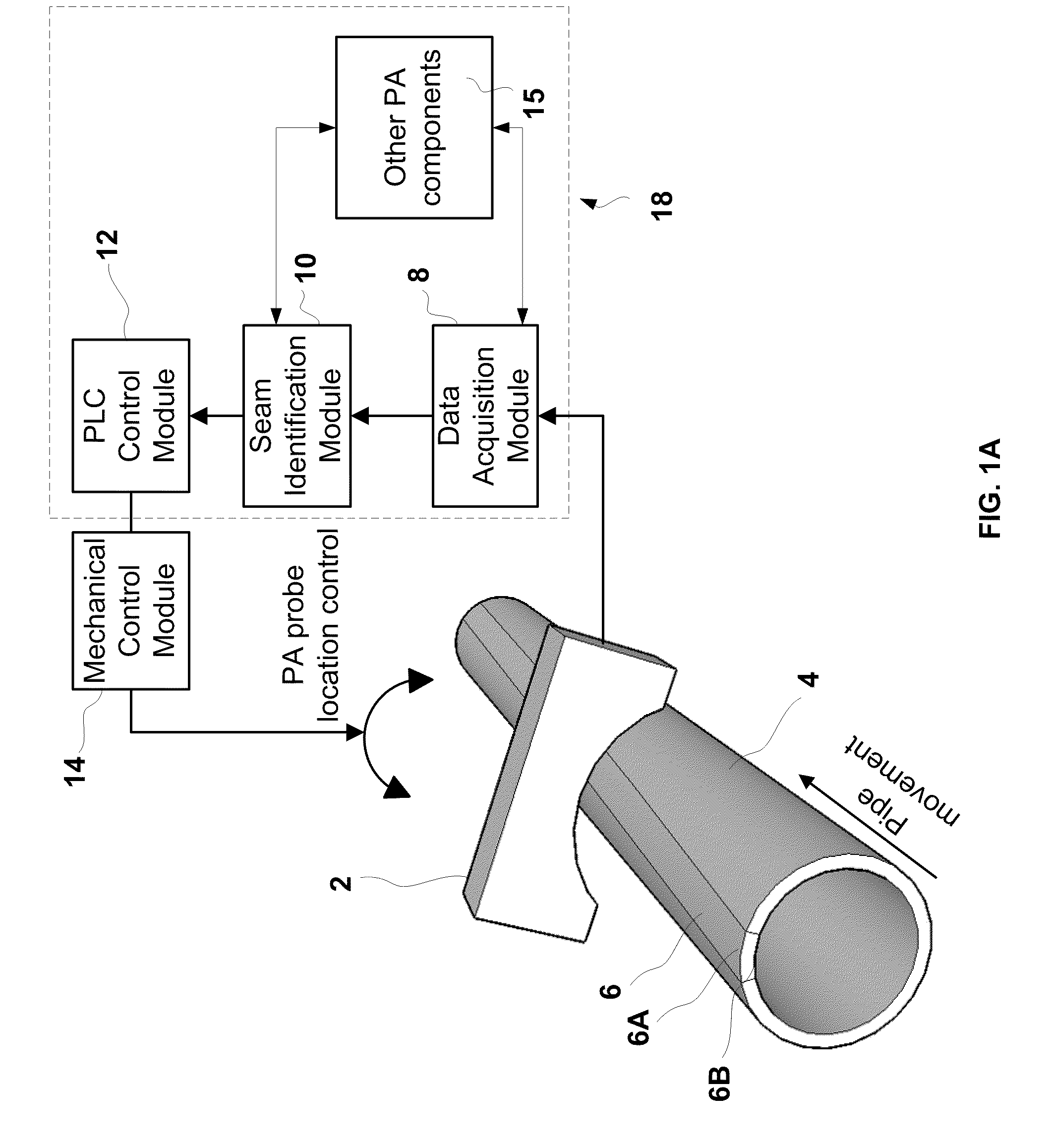

Weld seam tracking system using phased array ultrasonic devices

ActiveUS20110083512A1Low costSmoothly doneAnalysing solids using sonic/ultrasonic/infrasonic wavesWelding apparatusEngineeringWeld seam

A weld seam tracking device for tracking weld seams on pipes or the like uses NDT / NDI sensor(s) in conjunction with an NDT / NDI operation, such as an ultrasonic phased array (PA) inspection. Processing of the weld seam tracking data is integrated or combined with the existing data processing element of the existing NDT / NDI inspection devices. Wide scanning areas of phased array probes allow weld seam tracking and inspection to be performed using a single set of probe and data processing elements to achieve both fault scanning and seam tracking with a single run of the PA scan.

Owner:OLYMPUS AMERICA

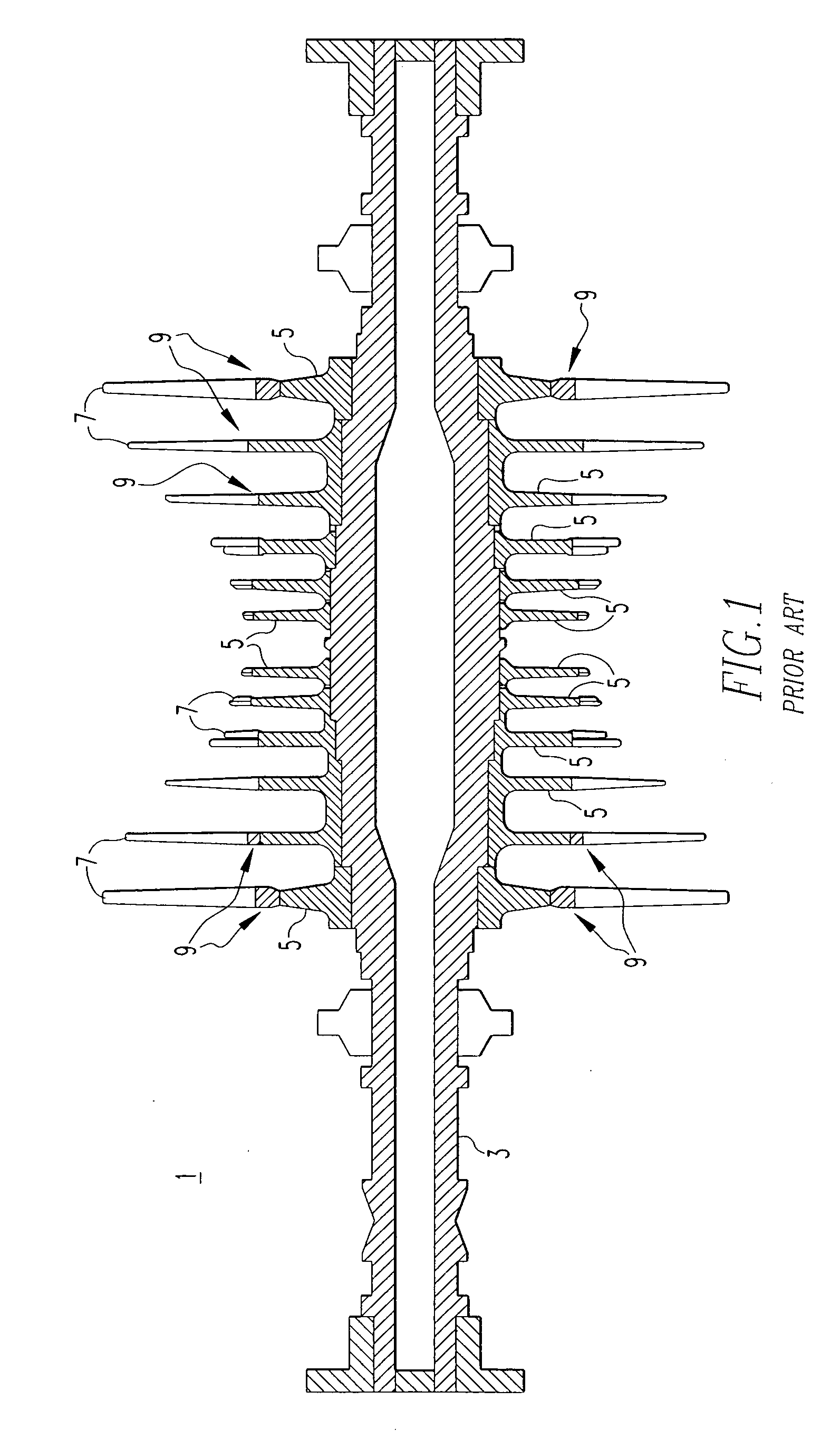

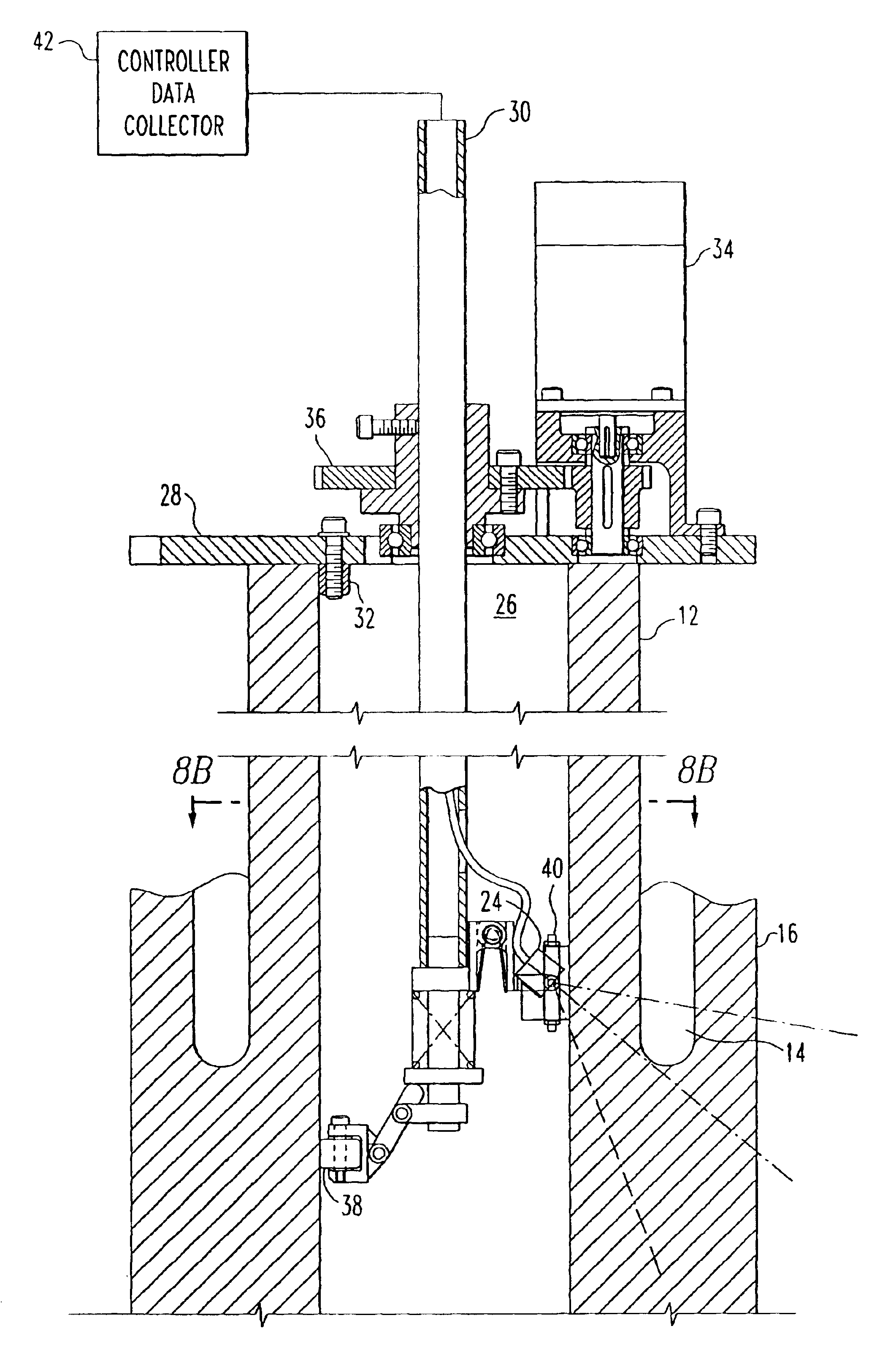

Nondestructive examination of high pressure turbine cylinders

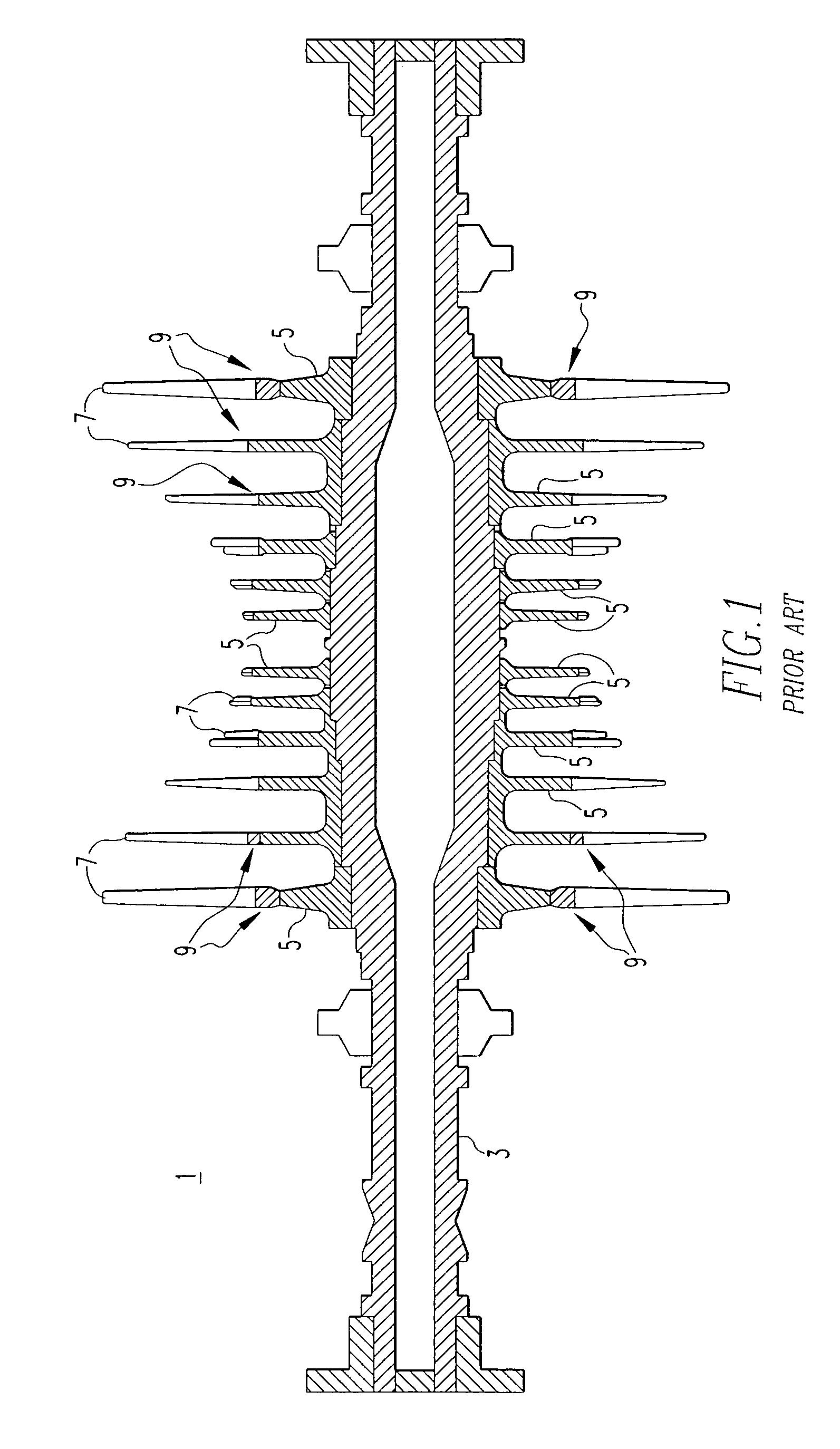

ActiveUS6886407B1ConfidenceSave inspection timeMaterial analysis using sonic/ultrasonic/infrasonic wavesSpecific gravity measurementEngineeringHigh pressure

A method of inspecting the steam inlet sleeves on high pressure outer cylinders and the nozzle chamber to cylinder welds on the high pressure steam turbines using linear phased array ultrasonic transducers. The transducers are supported on the surface of the component to be monitored. The transducers are then move axially while monitoring the transducer's output to identify the location to be monitored. The axial extent of the transducers are then fixed and the transducers are moved circumferentially around the surface of the component at least 360° while noting outputs of the transducers indicative of fatigue-induced flaws. The transducers are then routed to the location on the wall of the component where the most significant flaw was noted. Then the transducers are successively focused at different depths in the wall where the most significant flaw was identified to further characterize the depth and size of the flaw.

Owner:WESTINGHOUSE ELECTRIC CORP

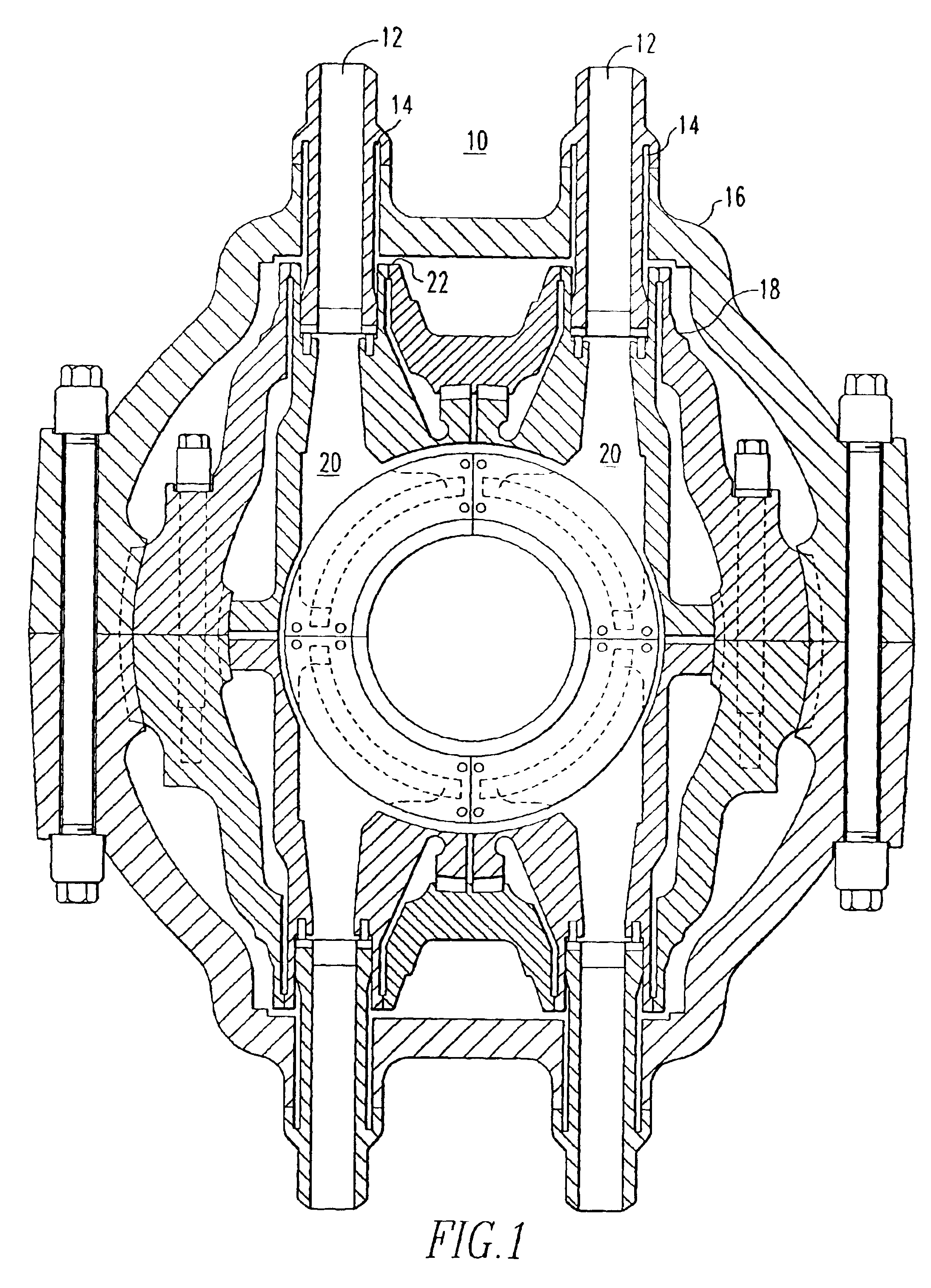

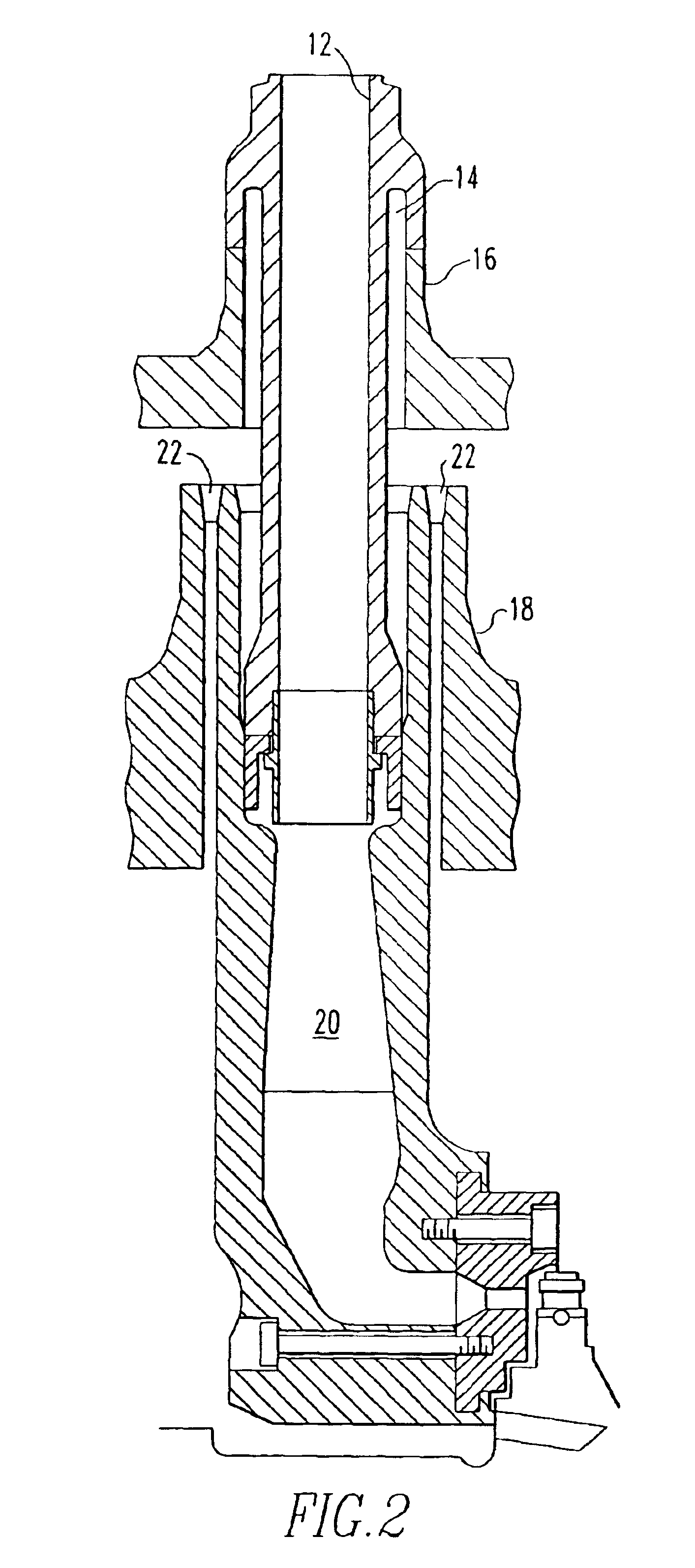

Phased array ultrasonic testing system and methods of examination and modeling employing the same

ActiveUS7428842B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationEngineering

A phased array ultrasonic testing system is for examining turbine disc bores and blade attachments for discontinuities, such as stress corrosion cracking. The system is particularly suited to perform an accurate and efficient inspection of components despite their having a relatively complex geometry, such as axial entry blade attachments and bores of associated discs. The system includes a control system with a computer and a controller for programming, emitting, and steering an ultrasonic beam via at least one two-dimensional phased array probe, thereby precisely inspecting the area of interest while simultaneously accommodating the aforementioned complex geometry of the disc or blade attachment. Computer control of the beam permits the number of inspection locations and the number of different probe wedges to be reduced providing for an efficient, timely inspection. Methods of profiling and examining turbine components of known and unknown geometries, are also disclosed.

Owner:SIEMENS ENERGY INC

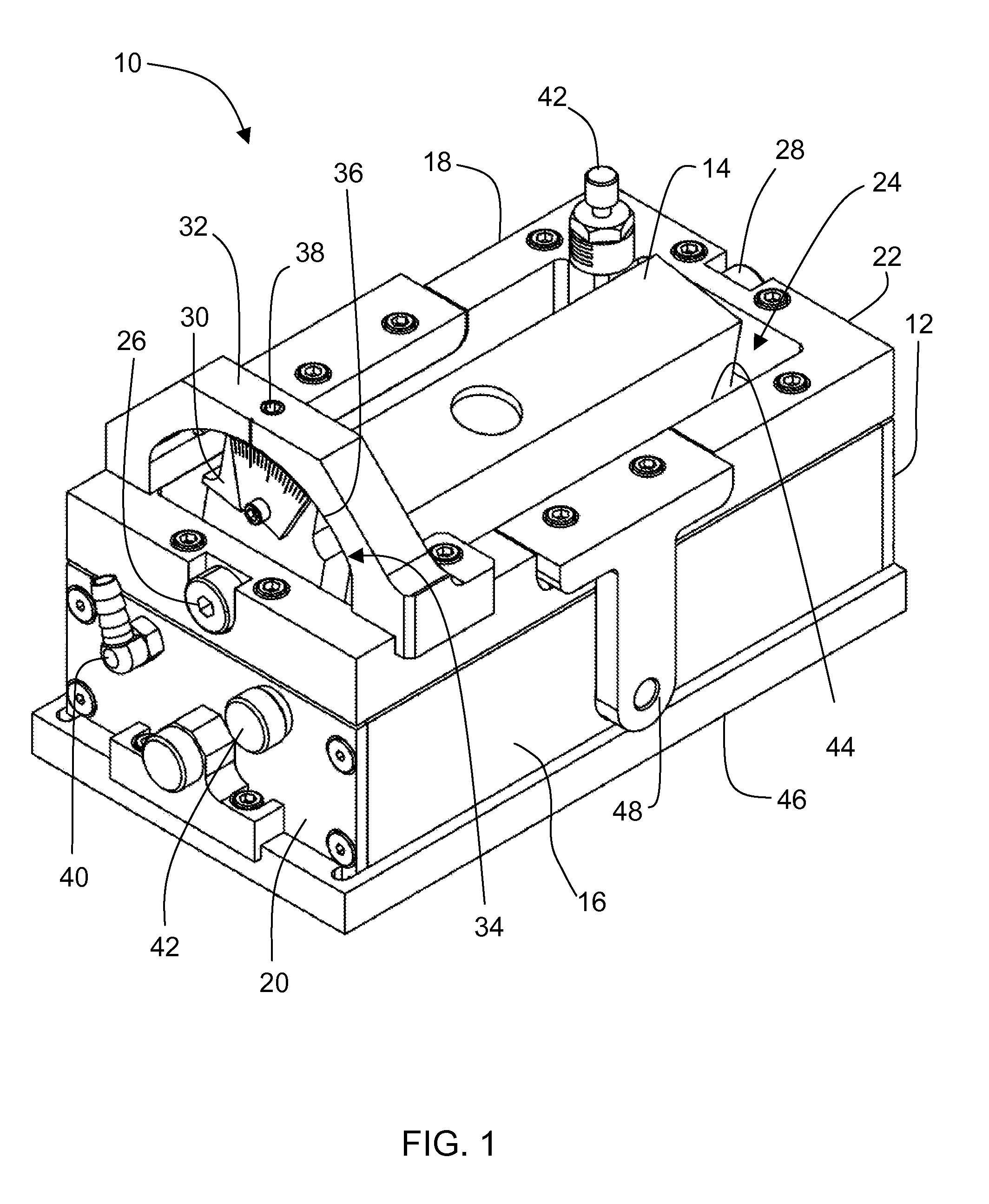

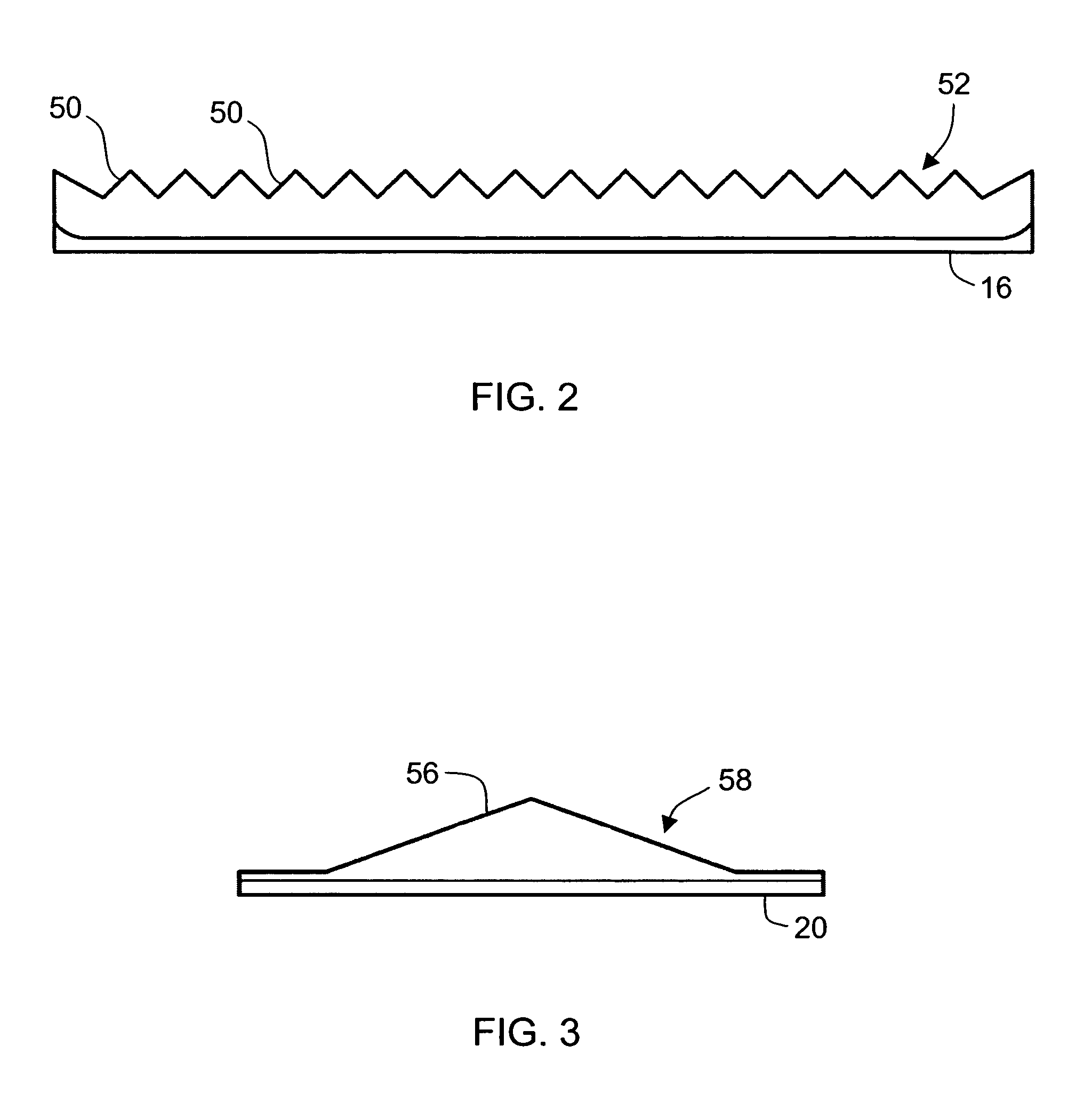

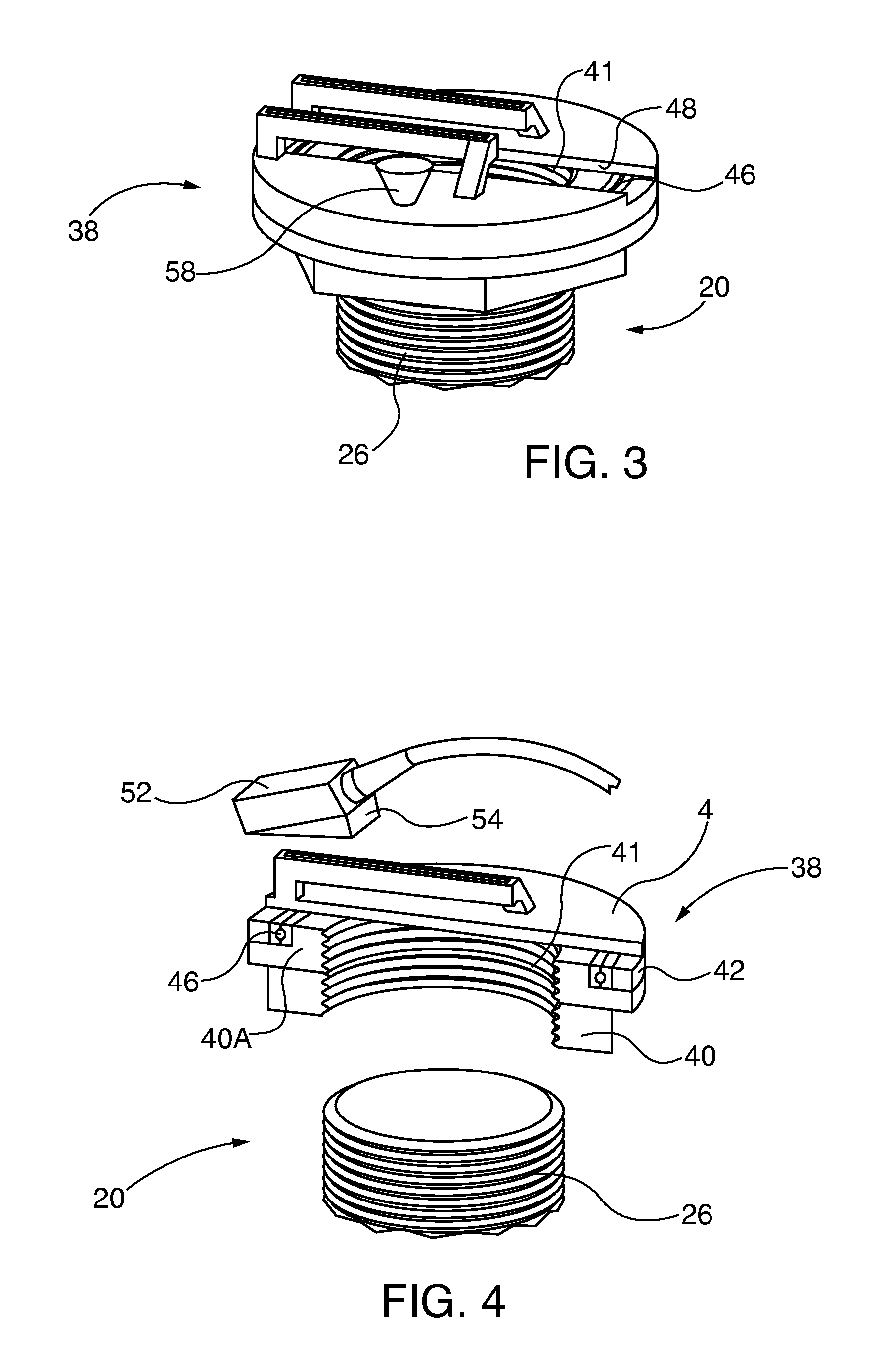

Phased array ultrasonic water wedge apparatus

InactiveUS7694569B2Analysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsEngineeringPhased array transducer

A phased array ultrasonic probe assembly includes, in an exemplary embodiment, a housing and a phased array transducer supported inside the housing. The housing includes a first side wall and an opposing second side wall, and a first end wall and an opposing second end wall. The first and second side walls and the first and second end walls define a housing cavity in which the phased array transducer is positioned. The first and second side walls each have an inside surface that include a plurality of projections.

Owner:GENERAL ELECTRIC CO

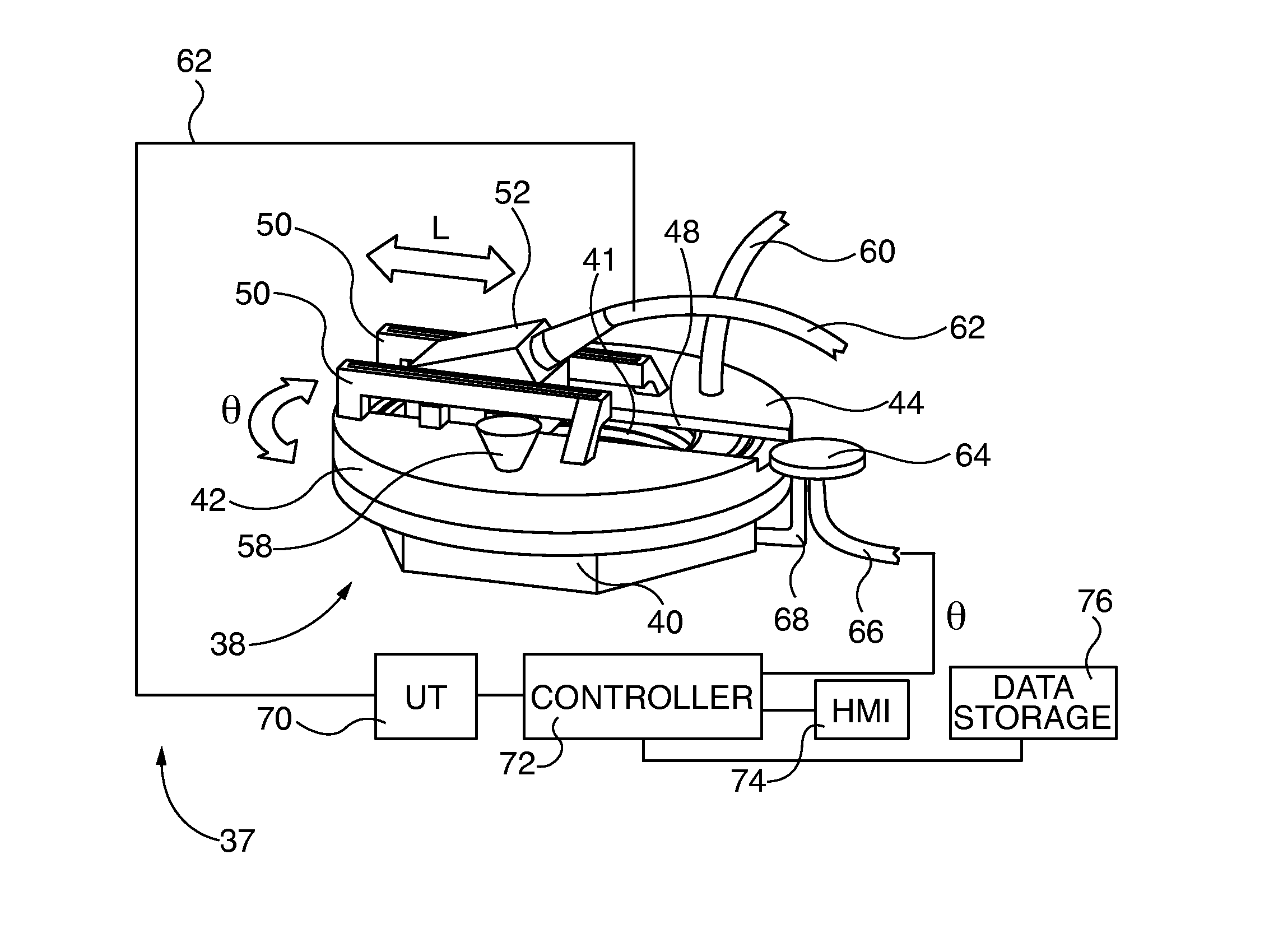

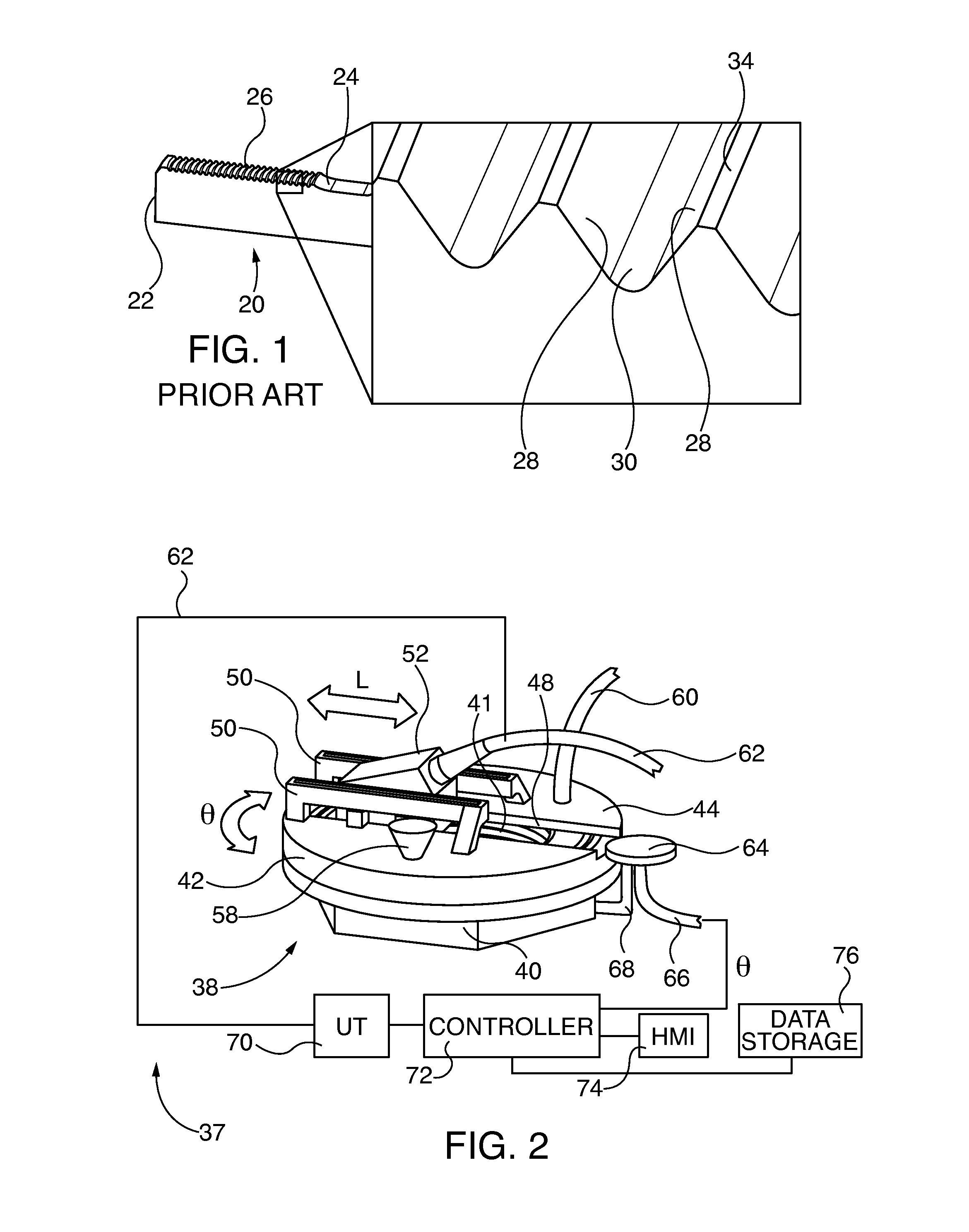

Phased array ultrasonic bolt inspection apparatus and method

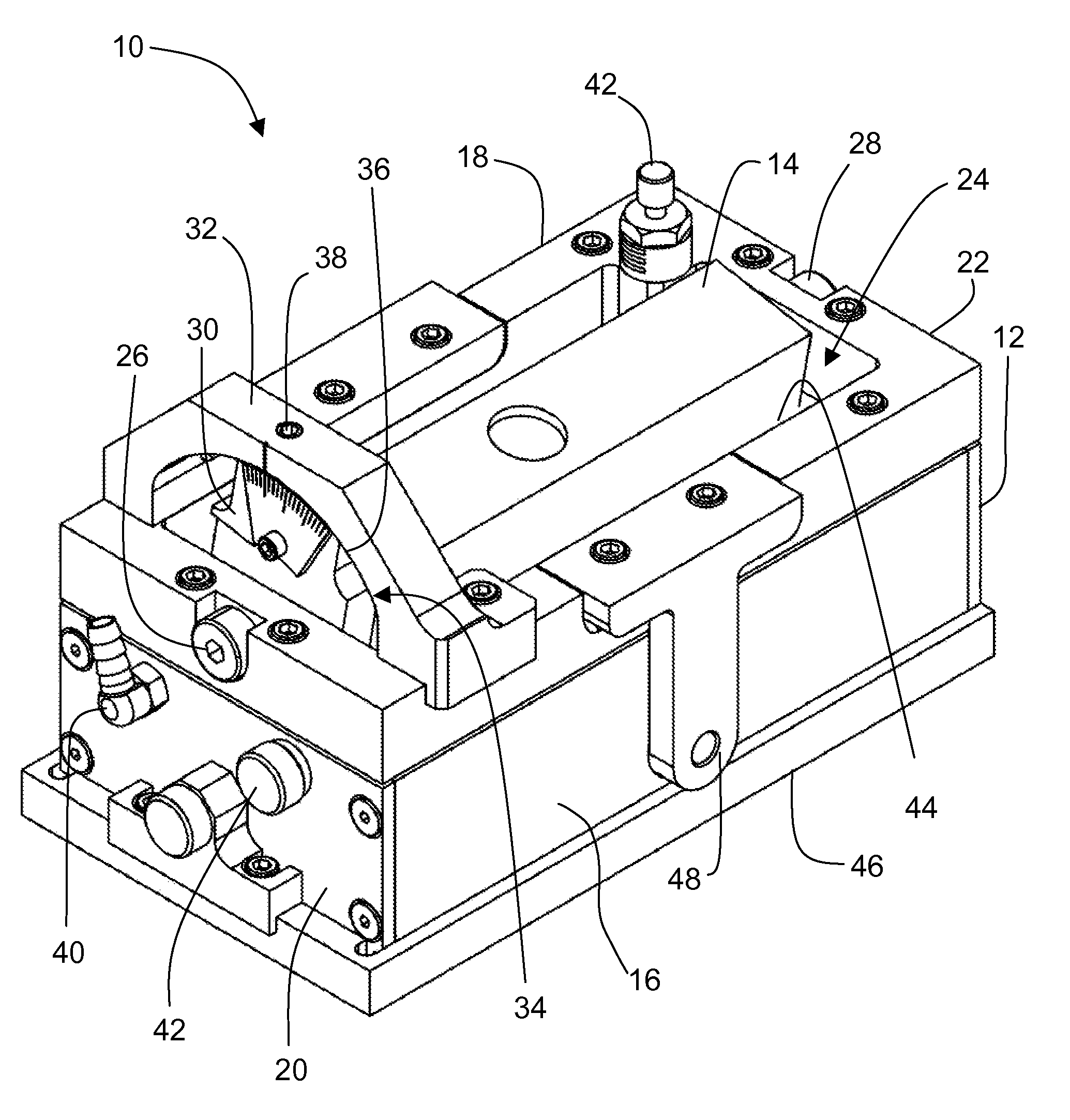

ActiveUS20140283612A1Easy to checkFacilitate in situAnalysing solids using sonic/ultrasonic/infrasonic wavesThermometers using physical/chemical changesNon destructiveEngineering

Ultrasonic bolt inspection apparatus and methods facilitate in situ as well as bench non-destructive evaluation (NDE) inspection of fastening bolt distal ends and their mating nuts. The apparatus is coupled to an exposed end of a fastener bolt head, its exposed thread tip or to a mating nut. The apparatus retains a phased array ultrasonic probe that generates inspection scan data and a rotational position encoder that generates rotational position data. The probe is coupled to an ultrasonic inspection system analyzer, which converts scan data into inspection data that characterizes possible defects in the inspected bolt. A system controller is coupled to the analyzer and the rotational position encoder, correlating rotation position data and inspection data, in order to identify location and characteristics of possible defects in the inspected bolt end.

Owner:SIEMENS ENERGY INC

Phased-array ultrasonic detection method for interfacial de-bonding of composite material

InactiveCN103901108AEnables real-time non-destructive testingImprove detection accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesInterfacial bondingUltrasound

The invention discloses a phased-array ultrasonic detection method for interfacial de-bonding of a composite material. The method comprises the following steps: (1) sequentially triggering each wafer of a phased-array probe to generate ultrasonic signals, superposing the ultrasonic signals, propagating the ultrasonic signals inside the composite material, and reflecting the ultrasonic signals during the interface de-bonding or interfacial de-bonding of the composite material; (2) superposing the reflected ultrasonic signals, receiving the ultrasonic signals by using the phased-array probe, performing data processing, and then outputting a phased-array scanning image through a phased-array display instrument; (3) comparing an ultrasonic detection image during the good interfacial bonding of the composite material with an ultrasonic detection image during the interfacial de-bonding of the composite material to judge whether the composite material has a de-bonding defect. The method has the advantages of high detection accuracy, simple operation process and the like.

Owner:SOUTH CHINA UNIV OF TECH

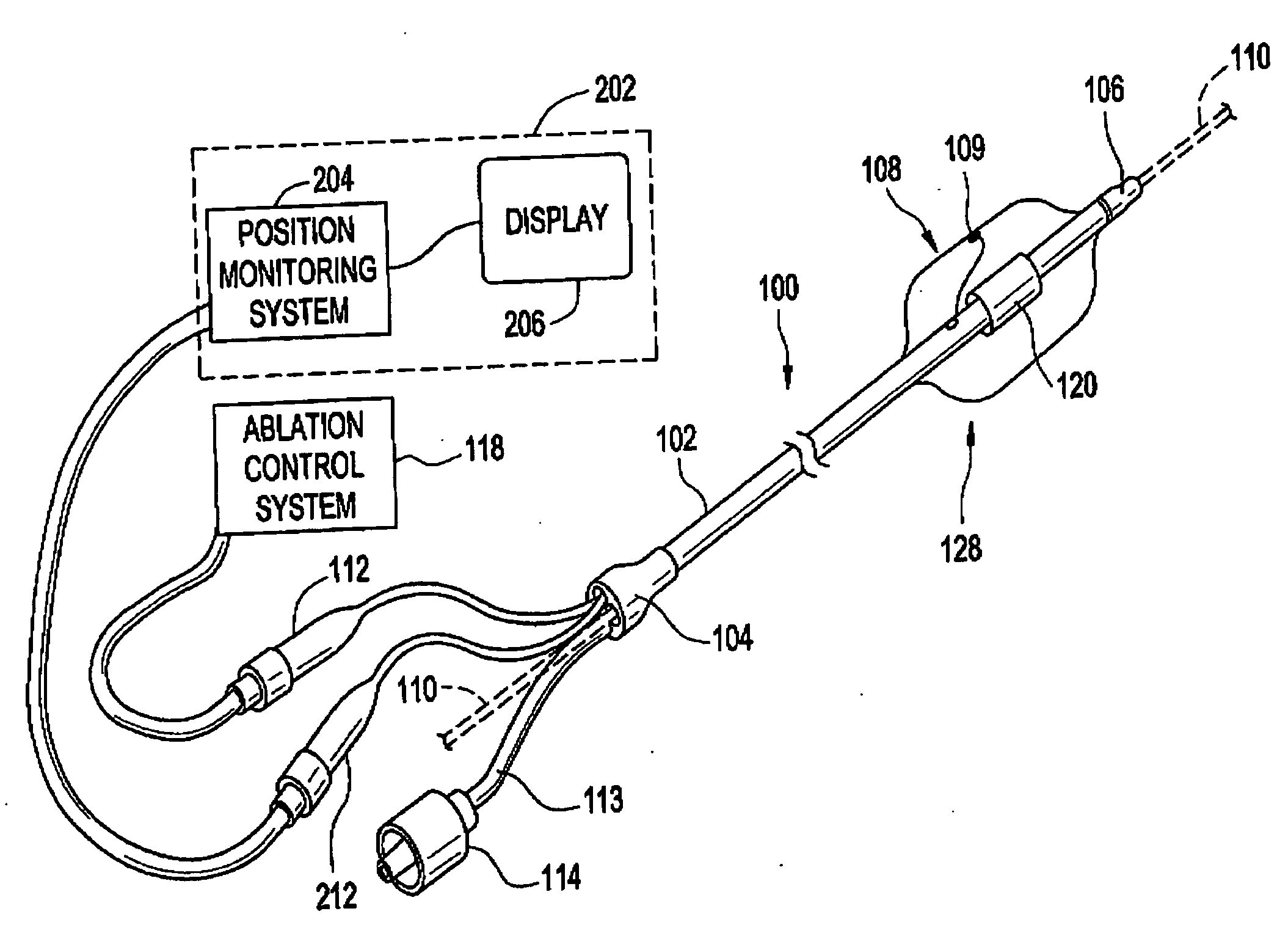

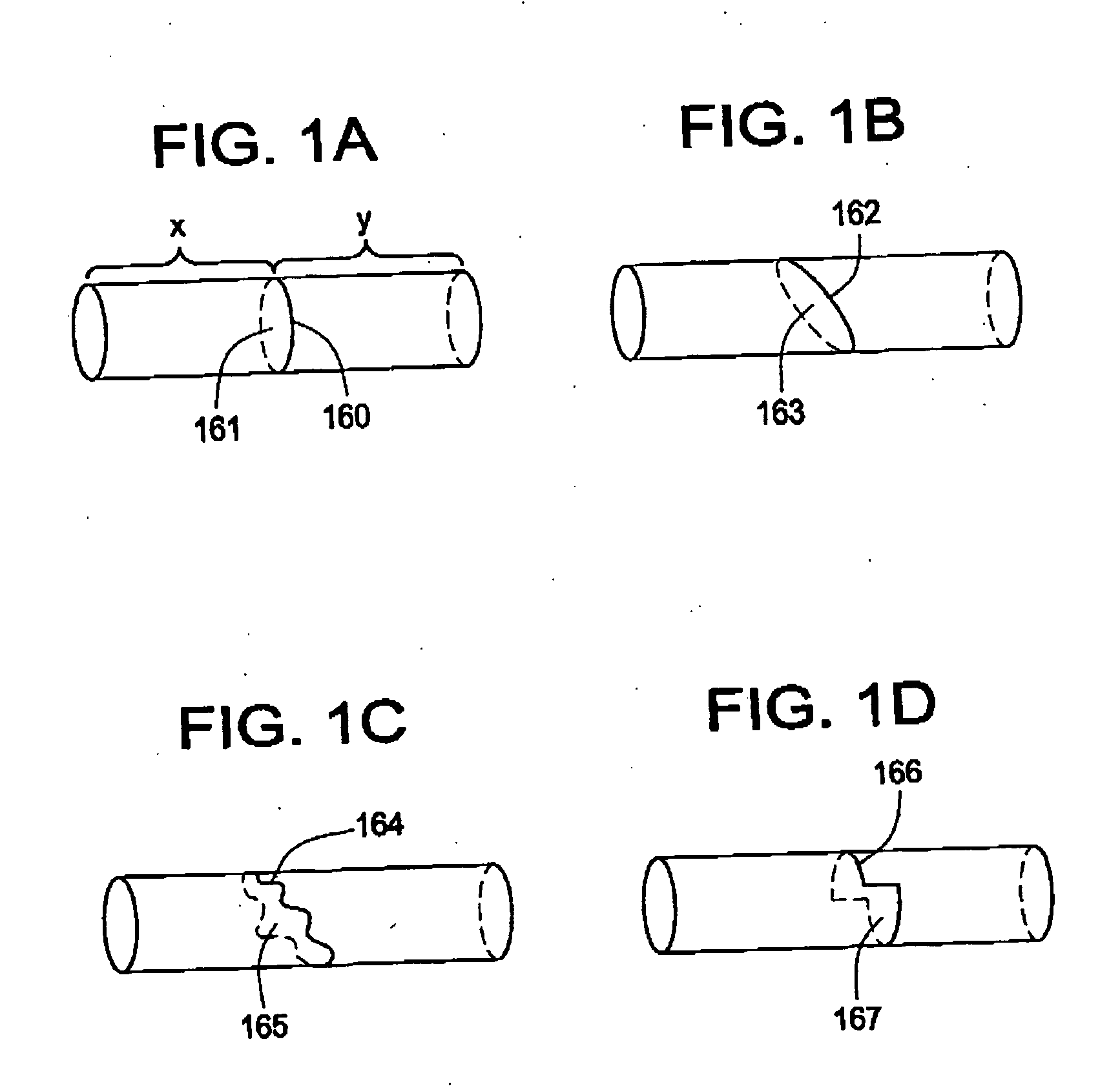

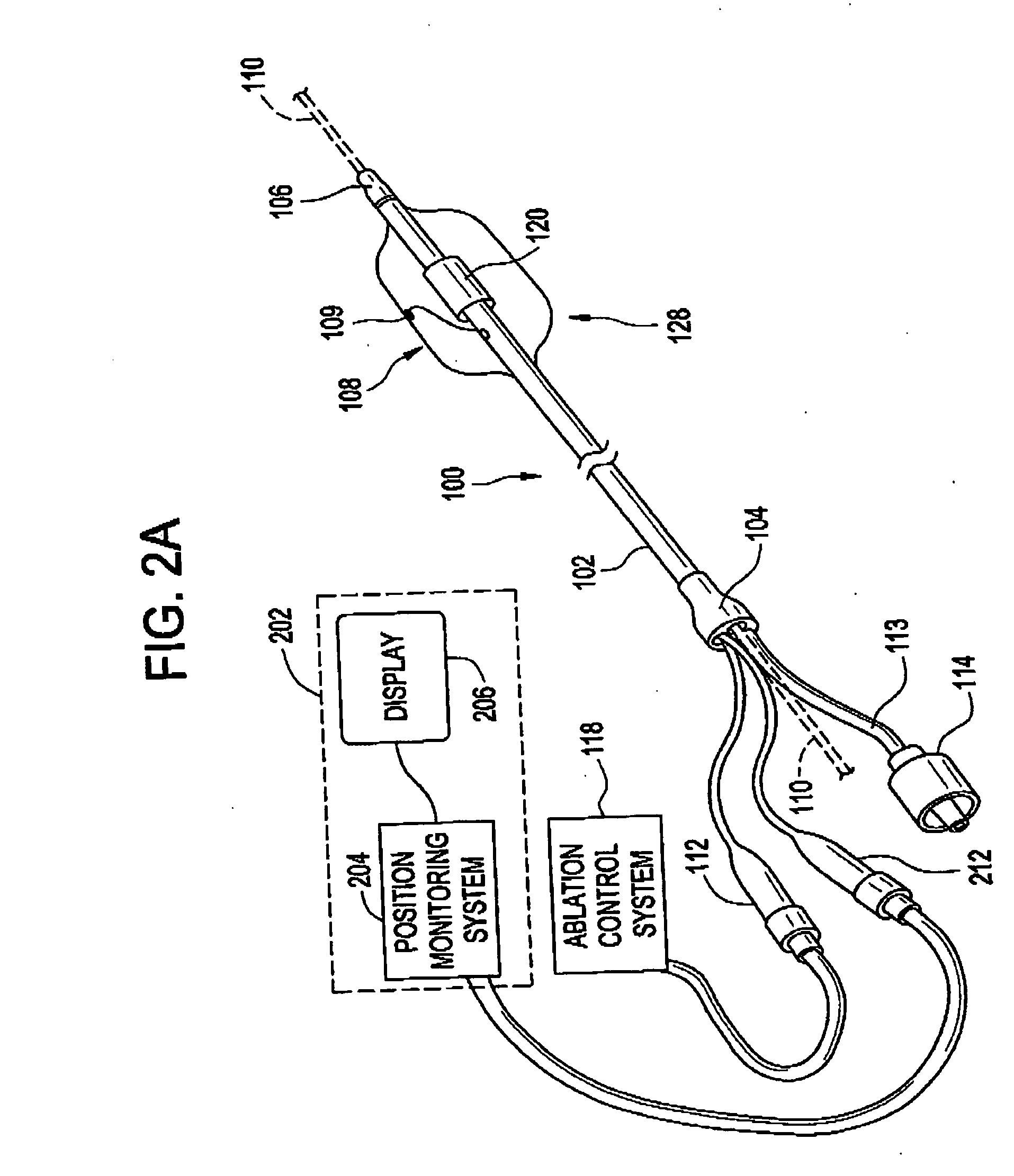

Ablation device with phased array ultrasound transducer

InactiveUS20060064081A1Eliminates arrhythmogenic conductionUltrasound therapyExcision instrumentsAcoustic energyEngineering

The present invention relates to a tissue ablation device having a plurality of transducer elements that can be operated out of phase to orient the acoustical energy beam forward or backward in the longitudinal direction. The transducer elements may also be driven by a signal that has a common frequency, but where each element has a phase that is chosen to provide an acoustic energy beam that has an additive effect at a predetermined distance from the transducers. The transducers include a cylindrical inner electrode, a cylindrical piezoelectric material disposed over the inner electrode, and a cylindrical outer electrode disposed over the cylindrical piezoelectric material. In one embodiment, circumferential grooves are cut through at least the outer electrode separating the transducer into a plurality of functionally discrete serially arranged transducer segments. The transducer segments can be operated independent from one another.

Owner:ROSINKO MICHAEL

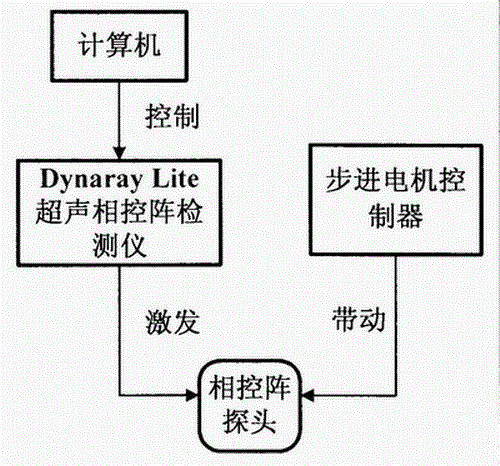

Method for ultrasonically detecting weld quality of main loop pipeline of nuclear power plant by phased array

ActiveCN103336055AHigh-precision detectionEasy to adjustAnalysing solids using sonic/ultrasonic/infrasonic wavesOperational systemNuclear power

The invention discloses a method for ultrasonically detecting the weld quality of a main loop pipeline of a nuclear power plant by a phased array and belongs to the technical field of ultrasonic non-destructive detection and evaluation. According to the method, a phased array ultrasonic test system composed of a Dynaray Lite ultrasonic phased array tester, an integrated UltraVision3.2R9 phased array operation system, a scanning device and a calibration block is adopted. Aiming at the main pipeline having a thickness of 66-99 mm, a proper area array probe is selected, and a focusing principle parameter, an ultrasonic parameter and a mechanical parameter are matched, so as to perform layered detection on a weld of the main pipeline and the peripheral region. Layered permeation in the existing means for detecting the main pipeline is only capable of detecting the surface open defects of the weld; radiographic detection is incapable of quantifying defect depths and insensitive to area defects such as cracks and incomplete fusion; and the conventional ultrasonic detection technology has the defects of being low in detection efficiency, high in cost, low in imaging capacity and the like. The method disclosed by the invention overcomes the defects is good in quantifying accuracy and high in efficiency in field detection, and has great economic benefits and social benefits.

Owner:DALIAN UNIV OF TECH +2

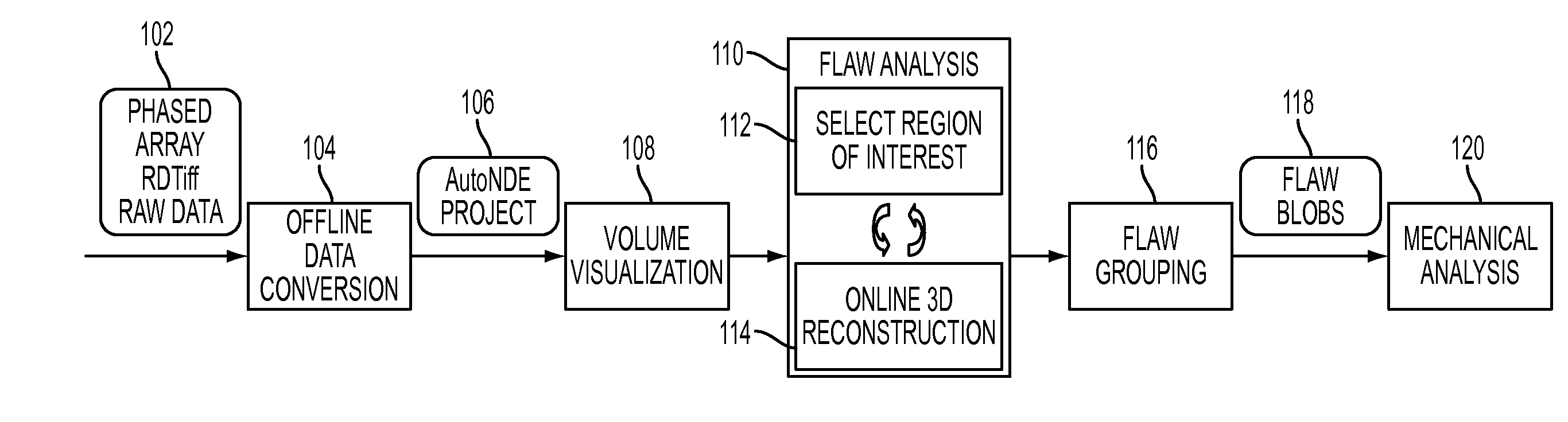

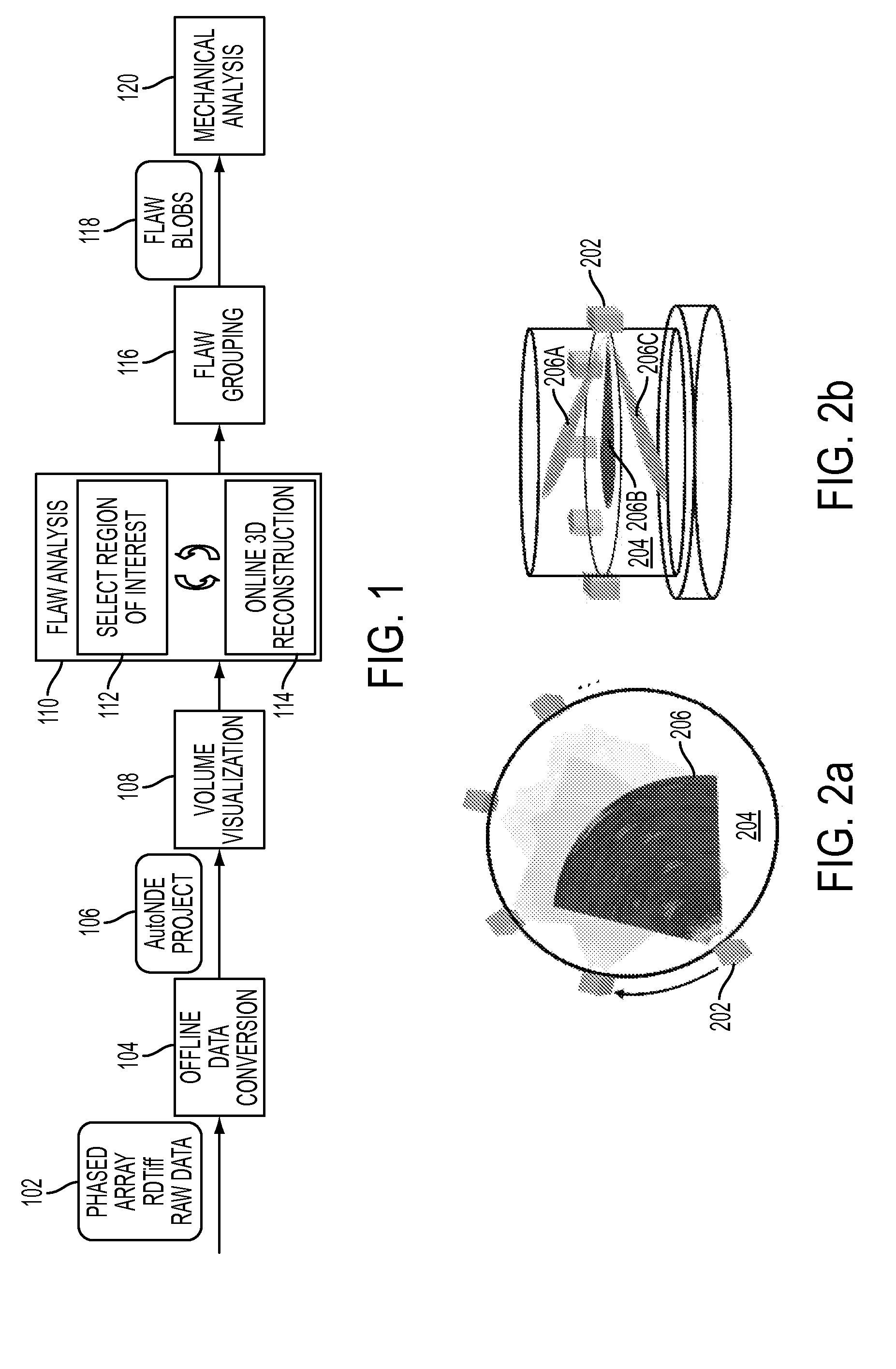

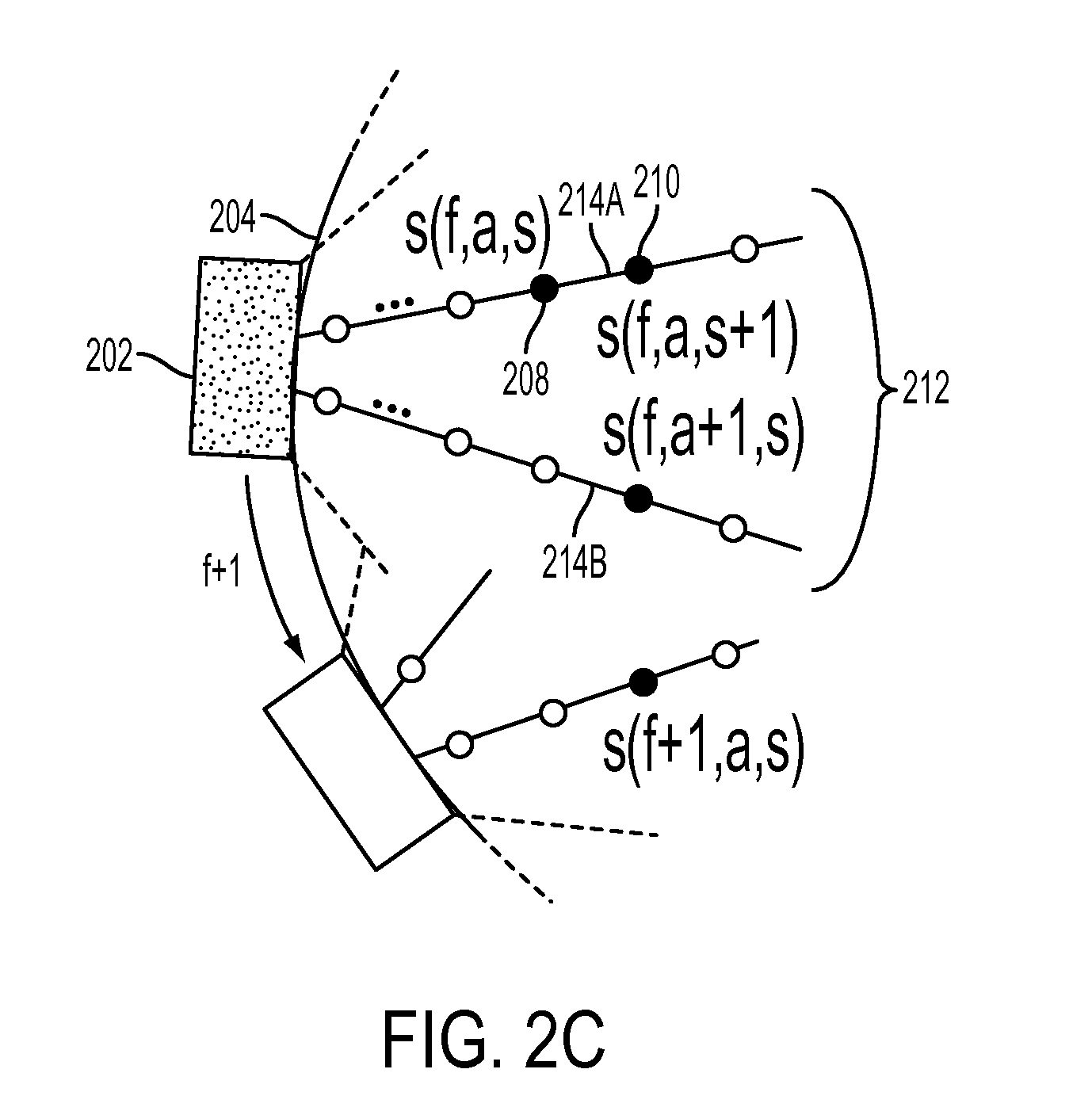

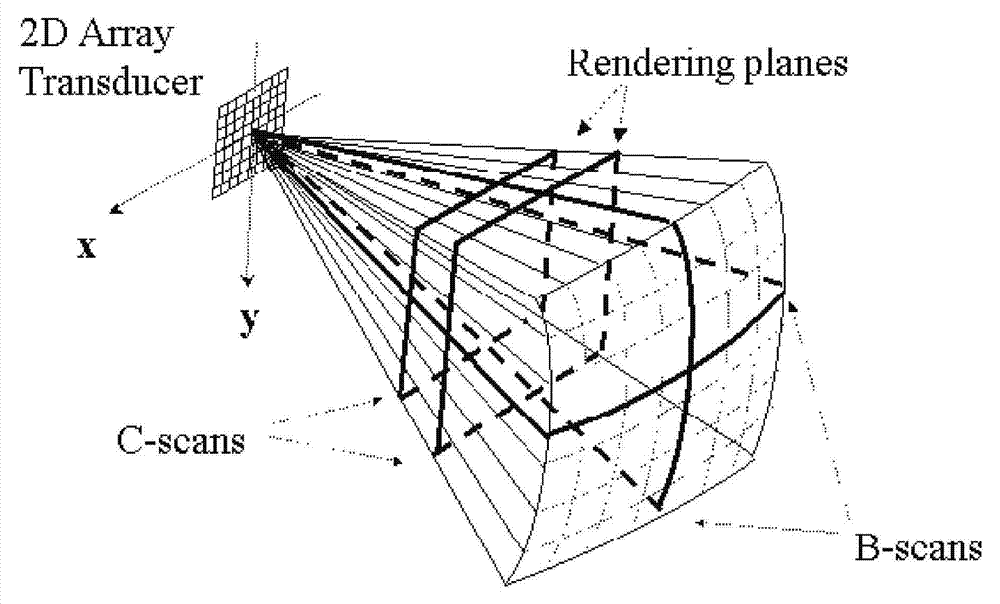

Method and Apparatus for Three-Dimensional Visualization and Analysis for Automatic Non-Destructive Examination of a Solid Rotor using Ultrasonic Phased Array

ActiveUS20110109627A1Details involving processing stepsAnalysing solids using sonic/ultrasonic/infrasonic wavesRegular gridNon destructive

A method and apparatus for three-dimensional visualization and analysis for automatic non-destructive examination of a solid Rotor using ultrasonic phased array is disclosed. Data is acquired by scanning a solid rotor with a phased array ultrasound transducer producing a plurality of two dimensional ultrasound scans. Each of a plurality of sample points of a plurality of two dimensional ultrasound scans are associated with a corresponding 3D image point of a regular grid. A kernel function for each of the plurality of sample points defining a size and shape of a kernel located at the corresponding image point is determined. A weight is assigned to each kernel which, in one embodiment, is based on the sample point value. A value for each image point of the regular 3D grid is determined based on kernels overlapping each image point. A three-dimensional volume representing the solid rotor is then visualized.

Owner:SIEMENS ENERGY INC +1

System for inspecting rail with phased array ultrasonics

InactiveUS20160304104A1Make up for deficienciesCompensation effectAnalysing solids using sonic/ultrasonic/infrasonic wavesSignalling indicators on vehicleRail profileEngineering

A system for inspecting railroad rail using phased array ultrasonic technology measures the time of flight of ultrasonic signals at locations across the rail head to determine the wear profile of the rail. The rail wear profile is then used to adjust the focal laws of the phased array ultrasonic probes to dynamically compensate for changes in the rail profile as the inspection vehicle moves along the rails.

Owner:TRANSPORTATION TECH CENT

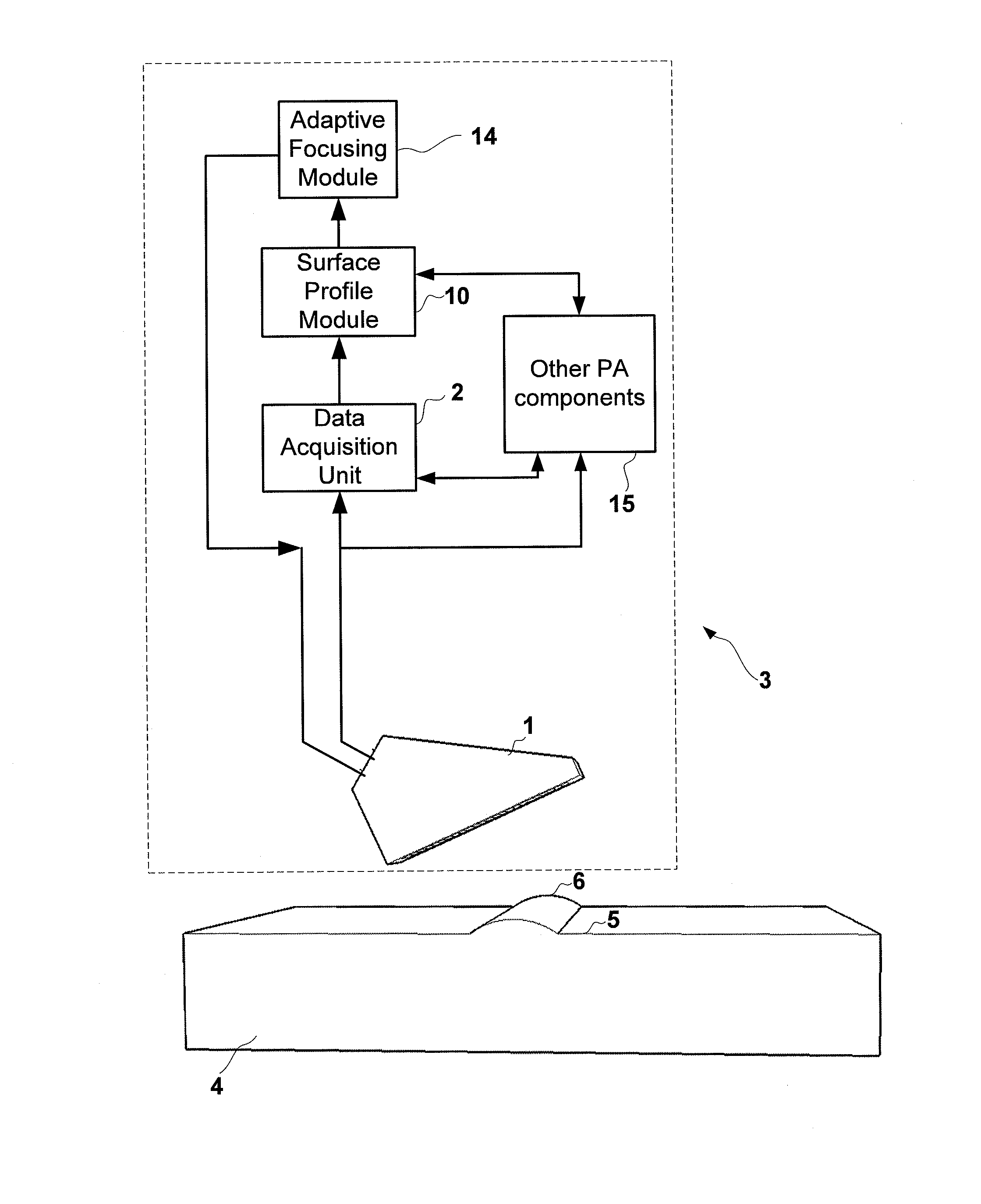

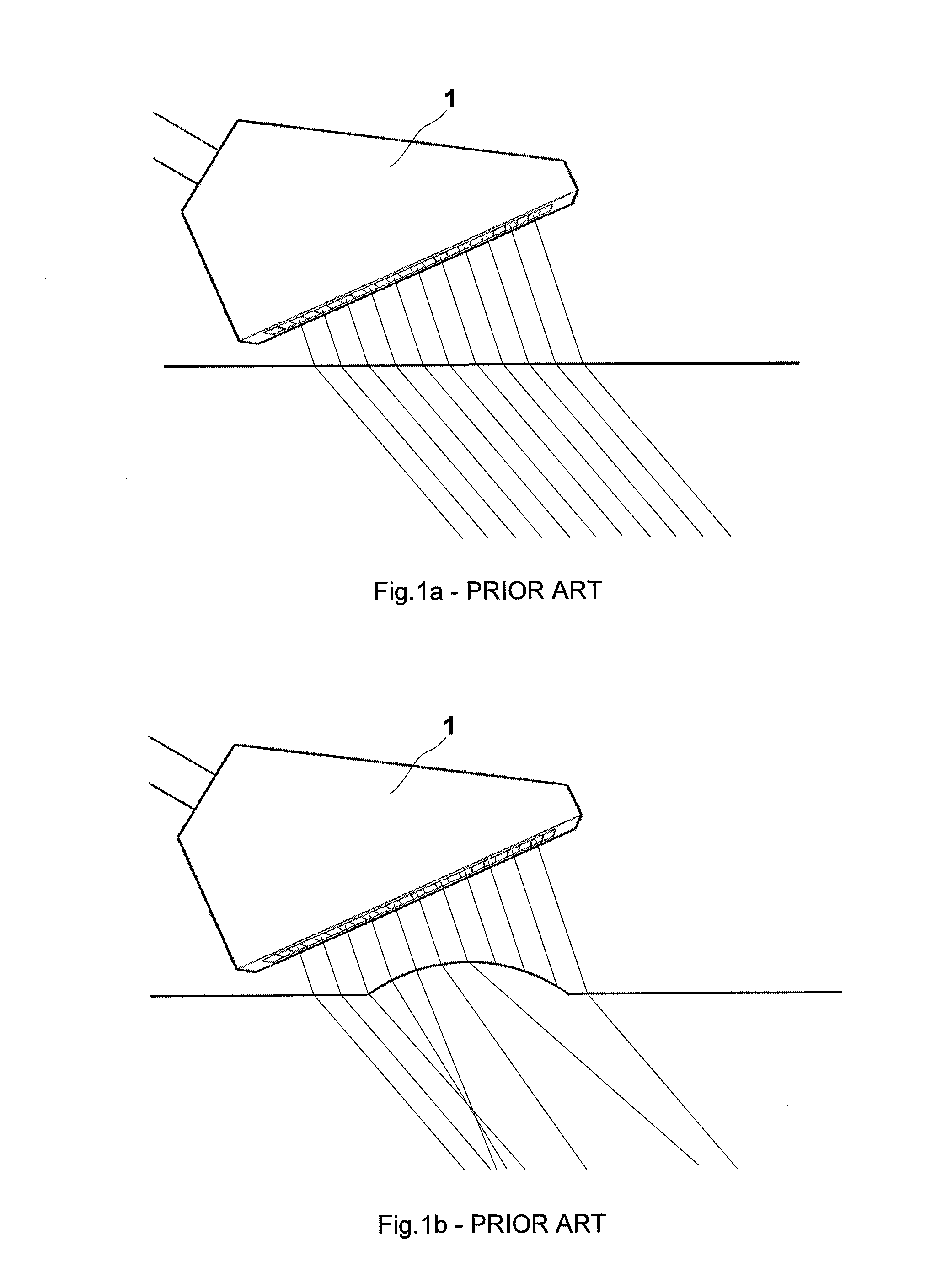

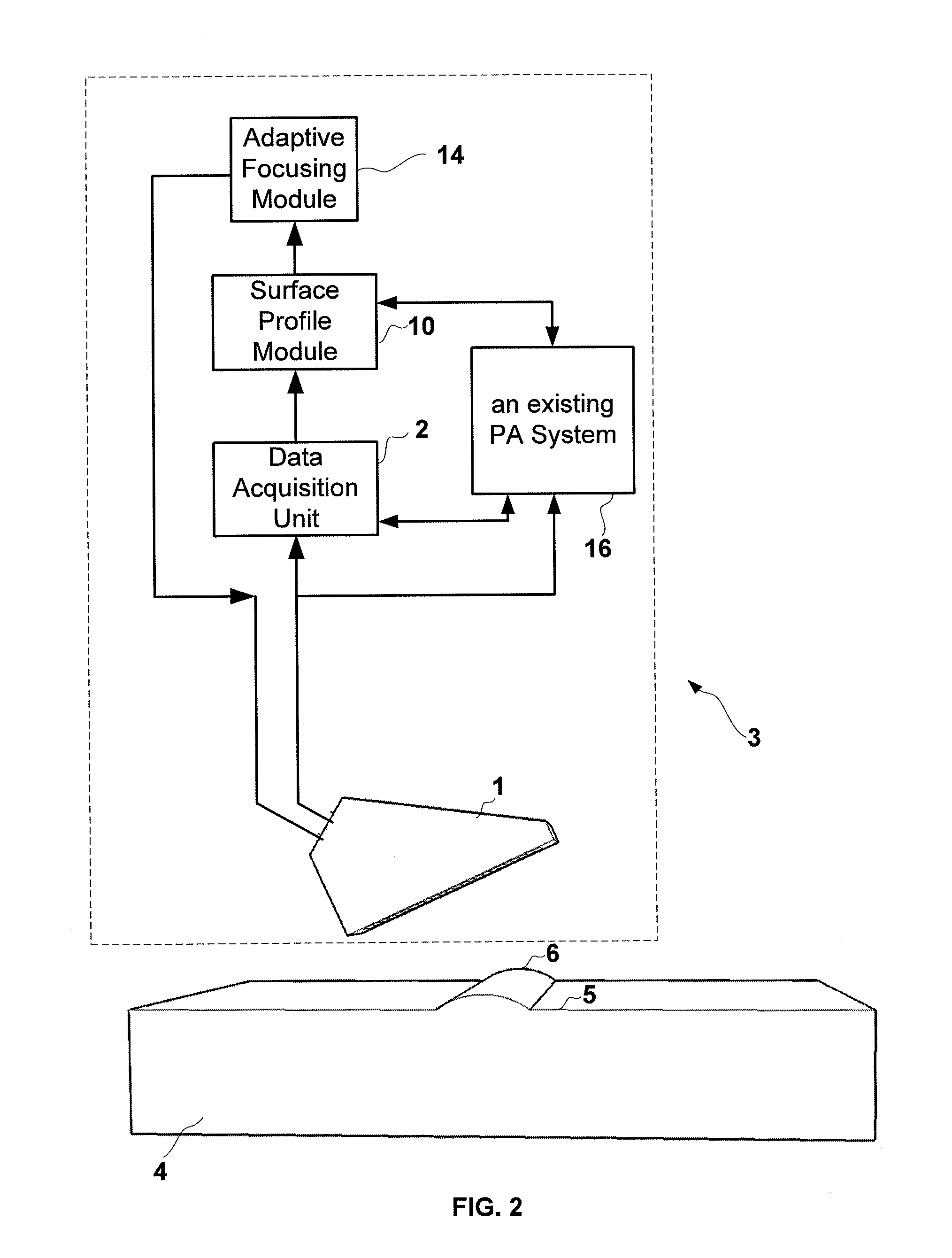

System and a method of adaptive focusing in a phased array ultrasonic system

InactiveUS20140283611A1Analysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansSonificationUltrasound sonography

Disclosed in the present disclosure is a phased array system configured to ultrasonically inspect test targets complex surfaces while employing the surface profiling capability of phased-array linear and sectorial scans. Adaptive focusing is employed for inspecting the test target by using customized apertures according to the surface profiles to generate a plurality of beams that are evenly and thoroughly spaced along a scan line inside the test target.

Owner:OLYMPUS NDT

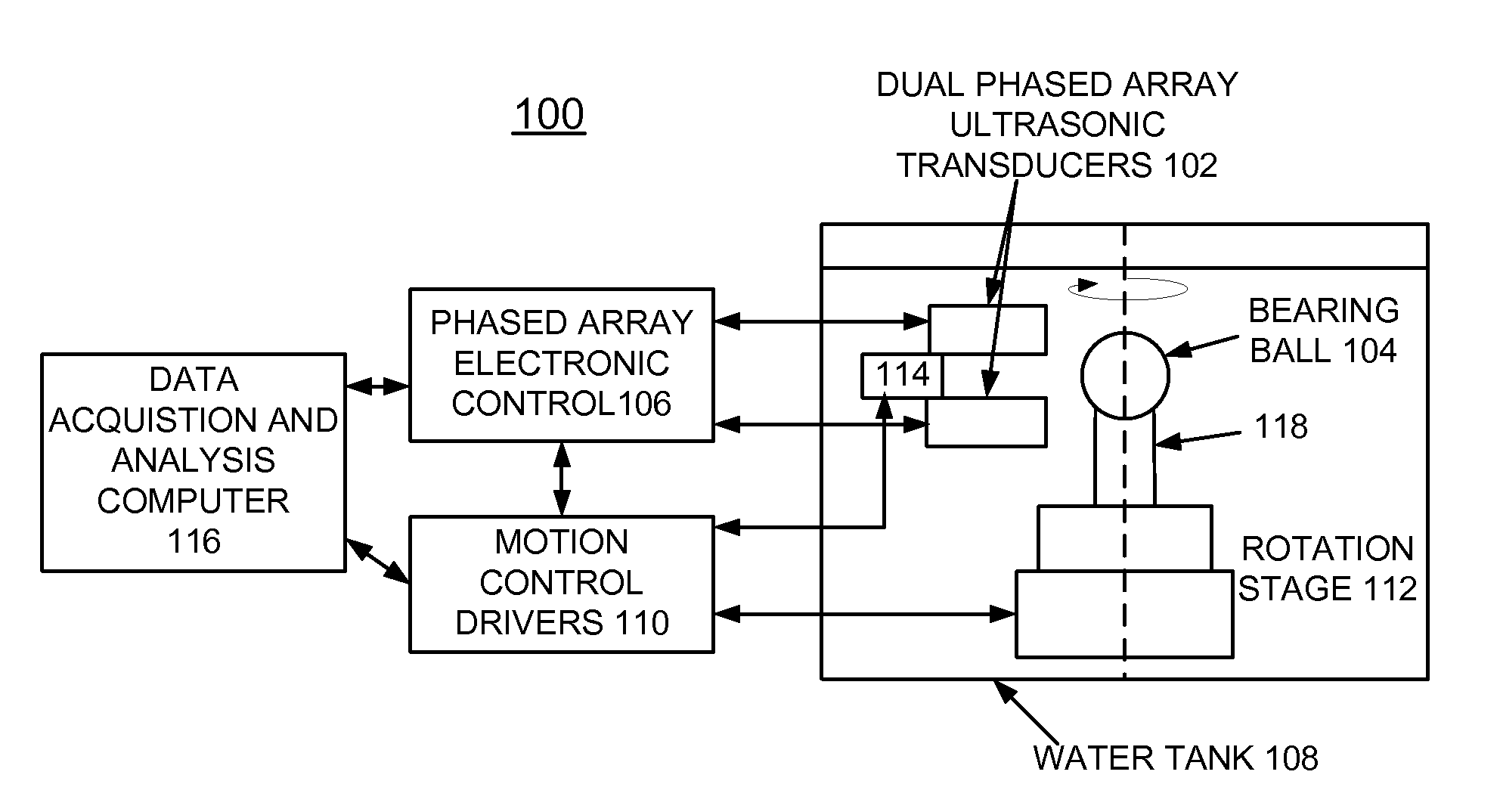

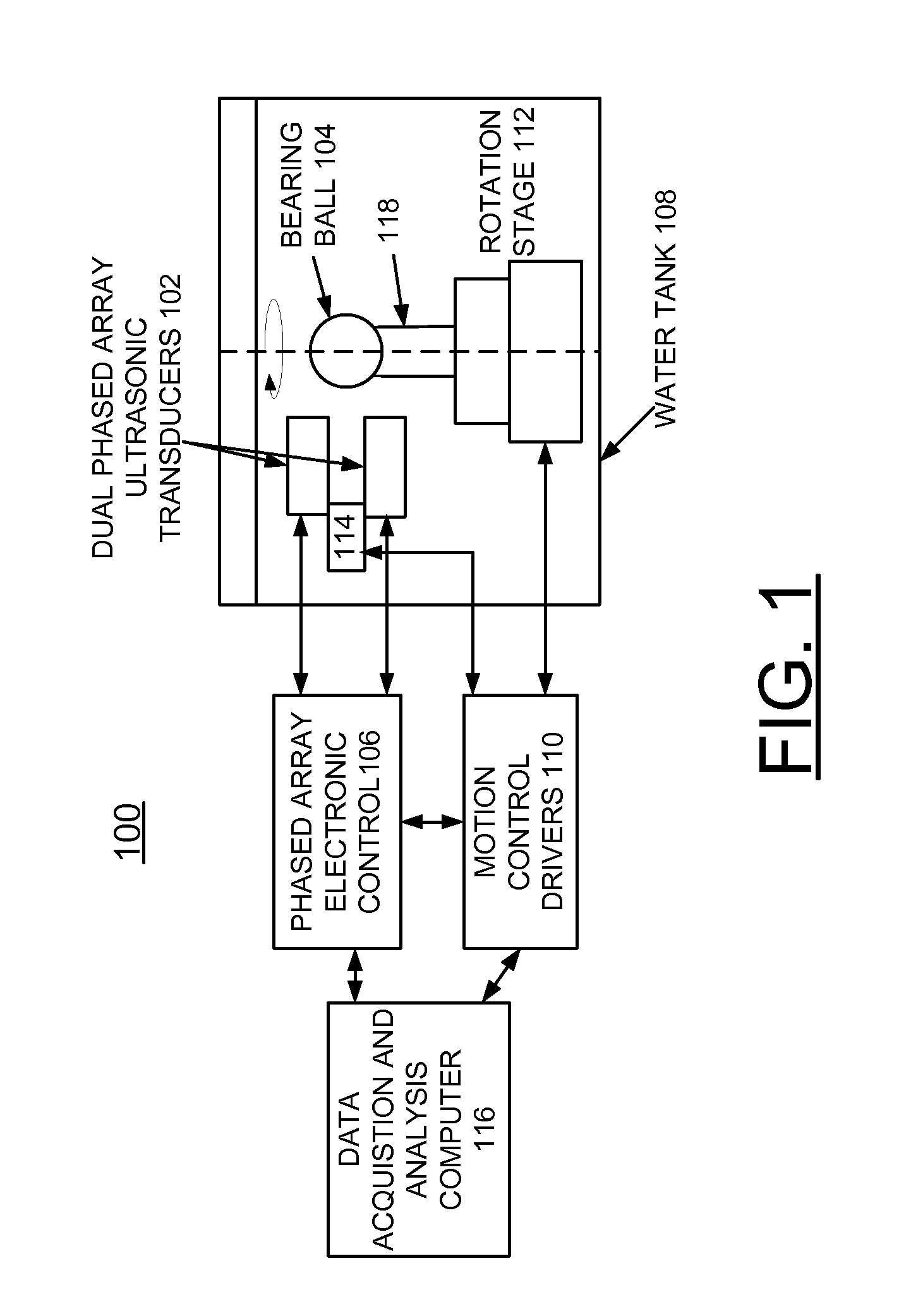

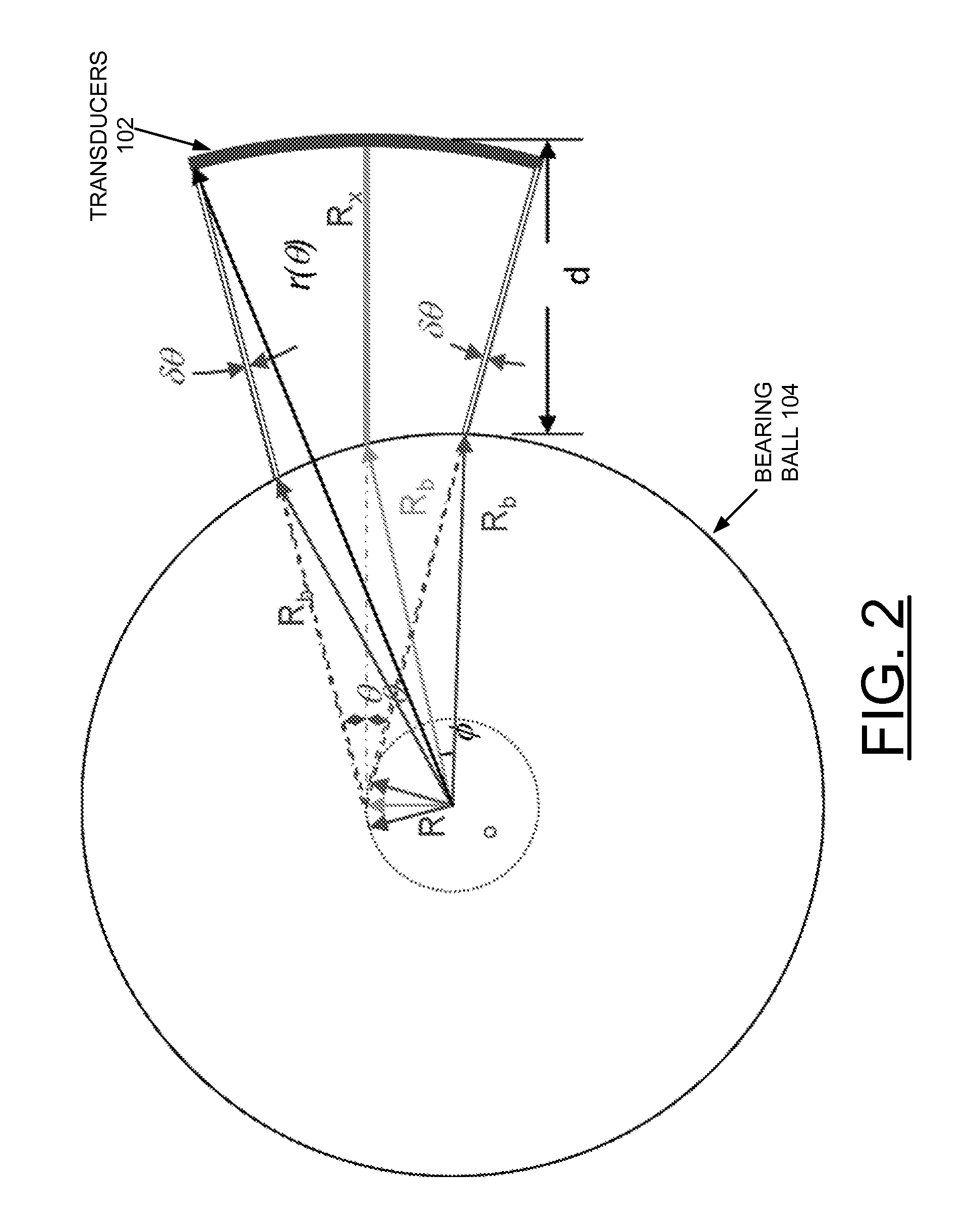

Method and apparatus for ultrasound phased array testing of bearing balls

InactiveUS20090019937A1Rapid and low-cost detectionRapid surfaceVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveSonification

Owner:UCHICAGO ARGONNE LLC

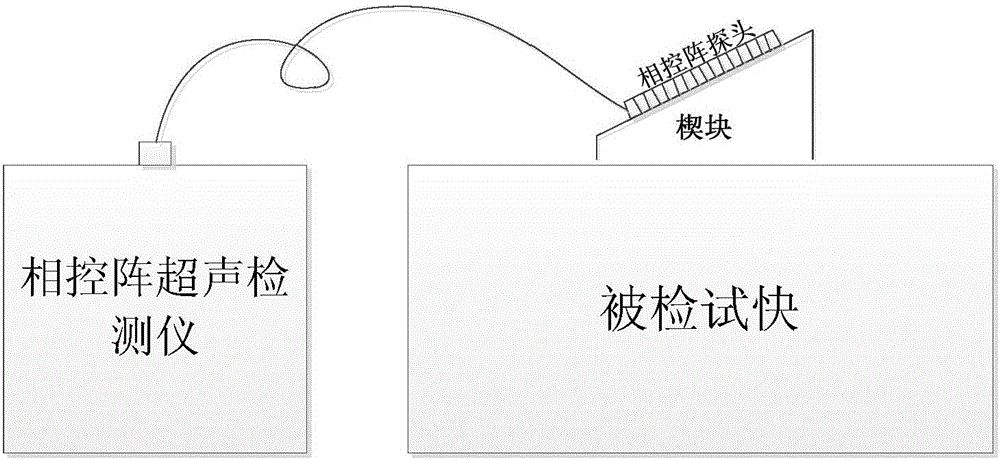

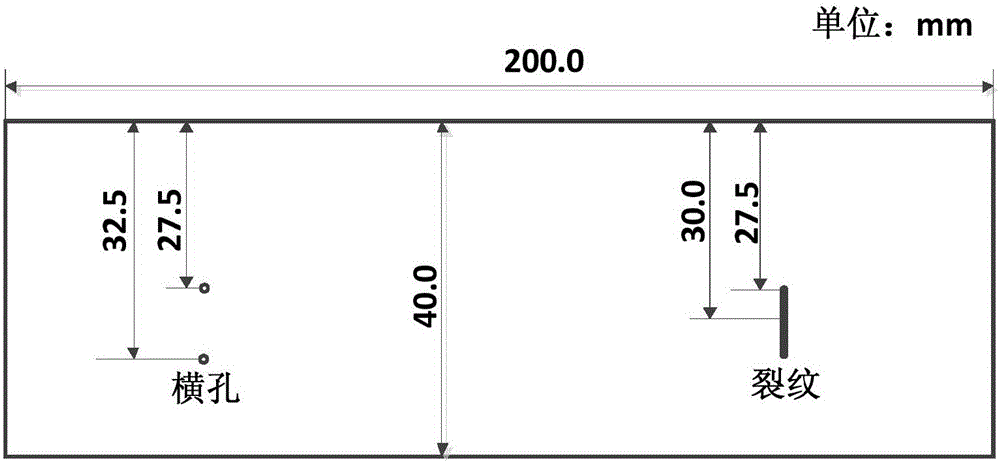

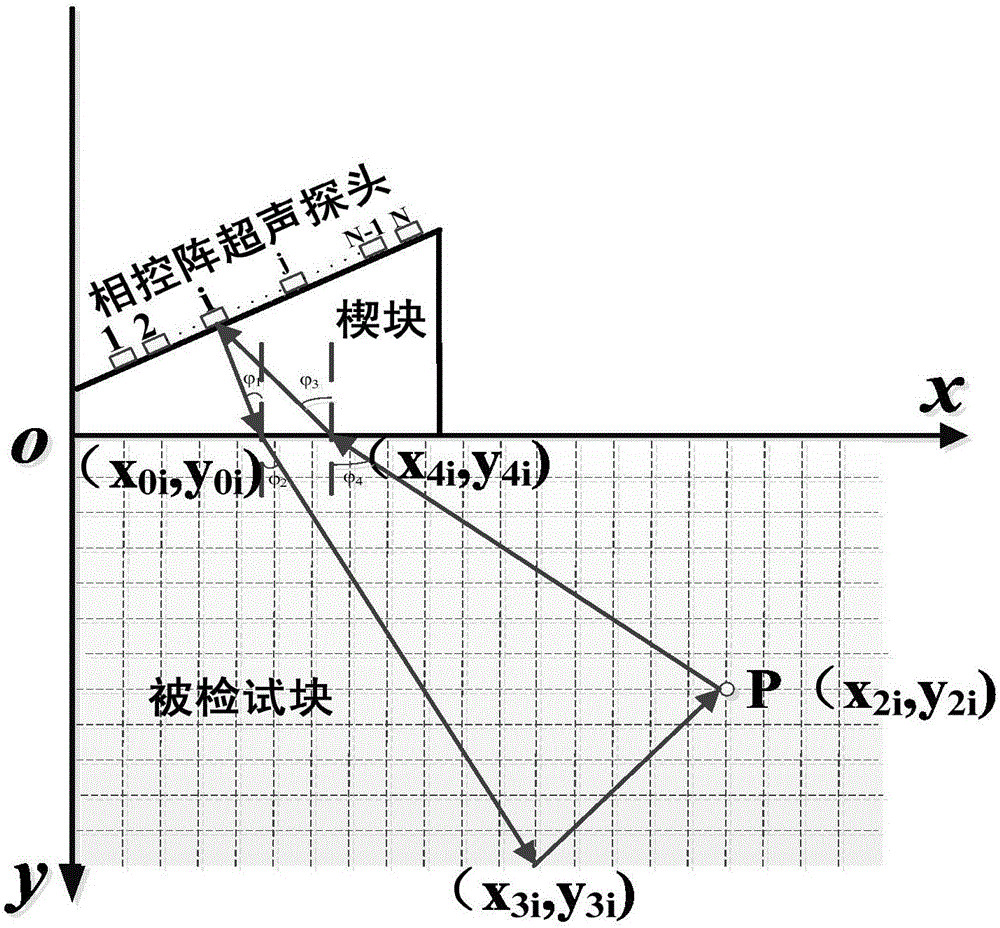

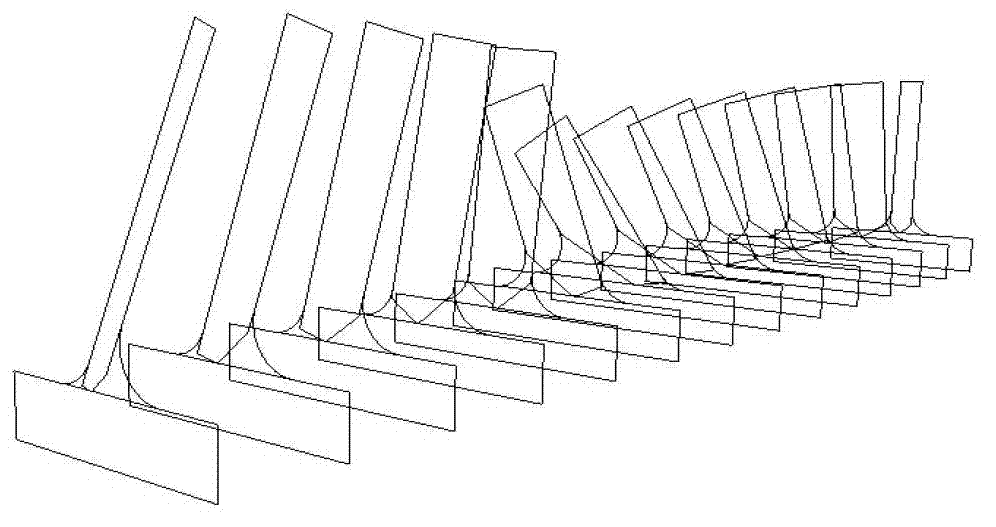

Defect two-dimensional morphology imaging detection method based on multi-mode acoustic beam synthetic aperture focusing

ActiveCN106770669ARealize automatic real-time imagingHigh engineering applicationAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationElectron

The invention discloses a defect two-dimensional morphology imaging detection method based on multi-mode acoustic beam synthetic aperture focusing, belonging to the technical field of nondestructive testing. According to the method, a phased array ultrasonic detector, a phased array ultrasonic probe and a phased array ultrasonic detection system of an oblique wedge block are adopted; and signal acquisition of a detected test block is performed by the electronic scanning function of the phased array ultrasonic detector to obtain A-scanning signal of each aperture of the phased array ultrasonic probe. According to different mode conversion types of excitation acoustic beam of each aperture on the interface between the wedge block and test block, at the bottom of the test block and on the defect surface, proper multi-mode acoustic beam is selected from 8 acoustic beam transmission modes. Based on SAFT imaging principle and Fermat's theorem, the transmission delay of the multi-mode acoustic beam of each aperture is calculated, and amplitudes are overlapped to obtain a reconstructed SAFT image, thus realizing complete representation of defect two-dimensional morphology features. The invention can realize correct recognition of volume type and area type defects so as to realize accurate quantification of defect length, depth and orientation, and has relatively high engineering application value.

Owner:DALIAN UNIV OF TECH

Ultrasonic phased array detecting and monitoring method

InactiveCN103076395AClosed tightlyReduce misjudgmentAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationDisplay device

The invention relates to an ultrasonic phased array detecting and monitoring method, and belongs to the metal welding nondestructive detection field. The method is characterized in that an ultrasonic phased array probe moves at a uniform speed in a direction paralleling to a weld direction, an image and a waveform displaying the echo signal in the weld of a test piece in a phased array ultrasonic instrument display are simultaneously observed while moving the probe, and whether the thin plate weld has a known defect or not can be judged through comparing with a defective etch image and a defective etch signal which are previously stored. The image formed by the ultrasonic echo signal in the thin plate weld can be seen in real time in the detection process, and the image comprises the information comprising the position, the length and the like of the defect, so compared with methods for simply judging the probe quality through the waveform, the ultrasonic phased array detecting and monitoring method has the advantages of accuracy, misjudgment reduction, and improvement of the accuracy and the working efficiency.

Owner:CHINA AIRPLANT STRENGTH RES INST

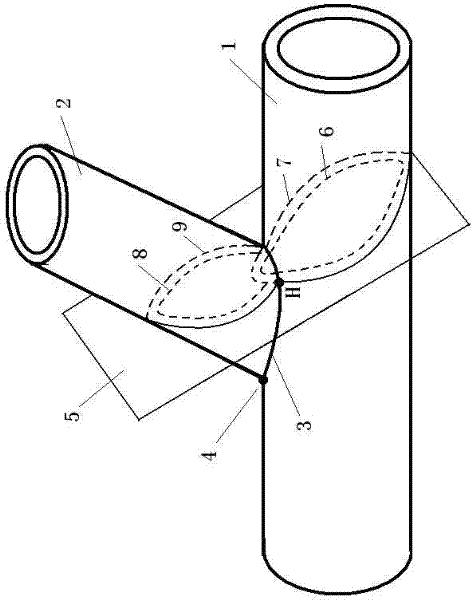

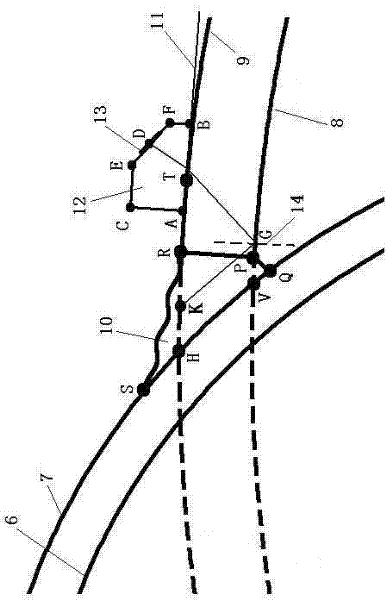

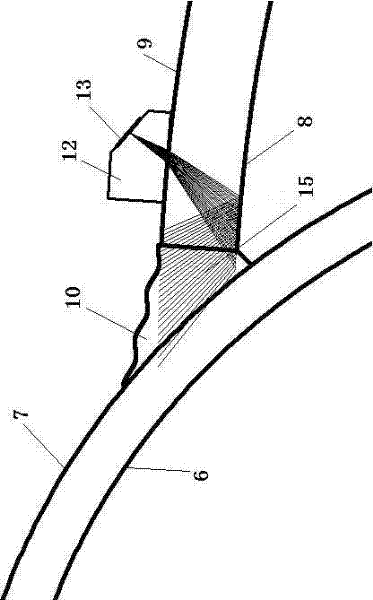

A Phased Array Ultrasonic Beam Covering Method for tky Pipe Joint Welds

InactiveCN102288681AReduce missed detectionReduce false positive rateMaterial analysis using sonic/ultrasonic/infrasonic wavesLeading edgeUltrasonic beam

The invention discloses a TKY pipe joint welding seam phased array ultrasonic beam covering method, the steps are as follows: according to the physical size of the pipe joint welding seam, the section figure at the specific position of the pipe joint is obtained; the weld joint outline is drawn in the obtained section picture; Obtain the phased array probe length, front length, height, inclination angle, and array element center height; select the incident point of the main sound beam of the array element on the ellipse of the outer wall of the branch pipe of the obtained graphic, and make the tangent line of the ellipse of the outer wall of the branch pipe at this point; the determined incidence The point is the elliptical contact point between the outline of the phased array probe and the outer wall of the branch pipe, and the tangent direction is the length direction of the phased array probe. Draw the outline of the phased array probe and draw the position of the array element; select the sound beam drawing method to draw the sound beam line. The invention contributes to the evaluation of the blind area of TKY pipe joint weld ultrasonic detection, determines the coverage state of the ultrasonic beam on the pipe joint welding joint, effectively reduces the probability of missed detection or misjudgment of pipe joint detection, and contributes to the phase control of the TKY pipe joint weld Process design and defect assessment for array ultrasonic testing.

Owner:NANCHANG HANGKONG UNIVERSITY

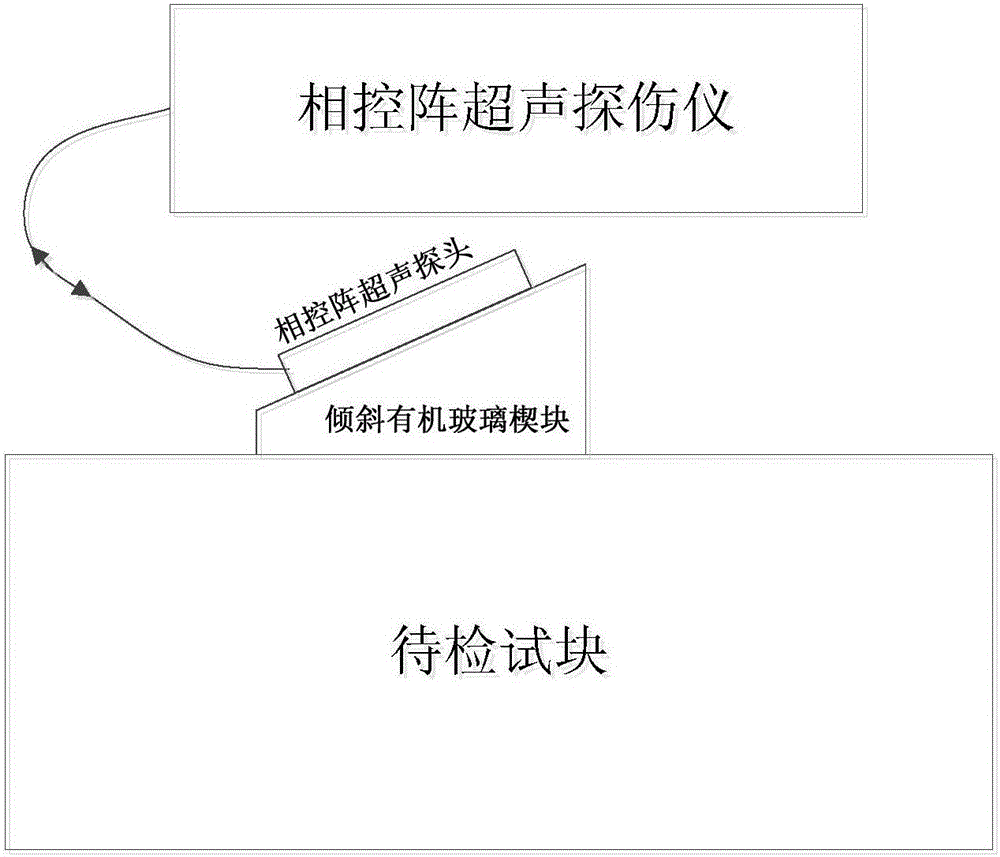

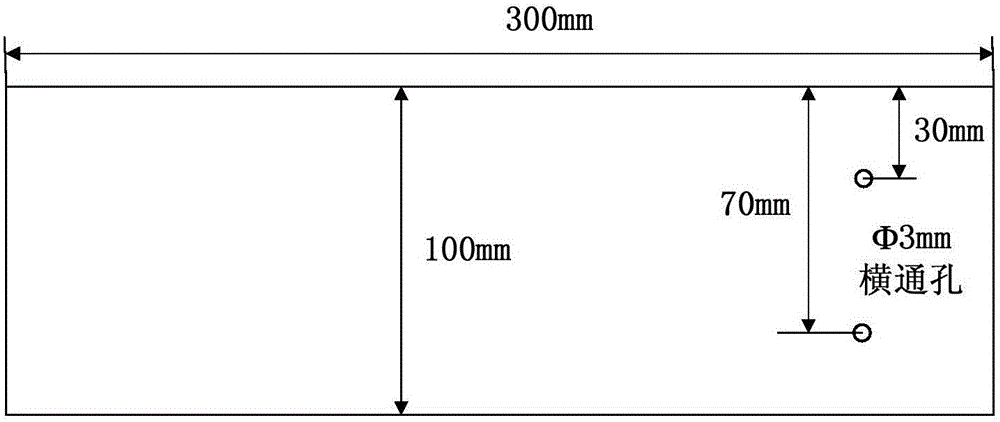

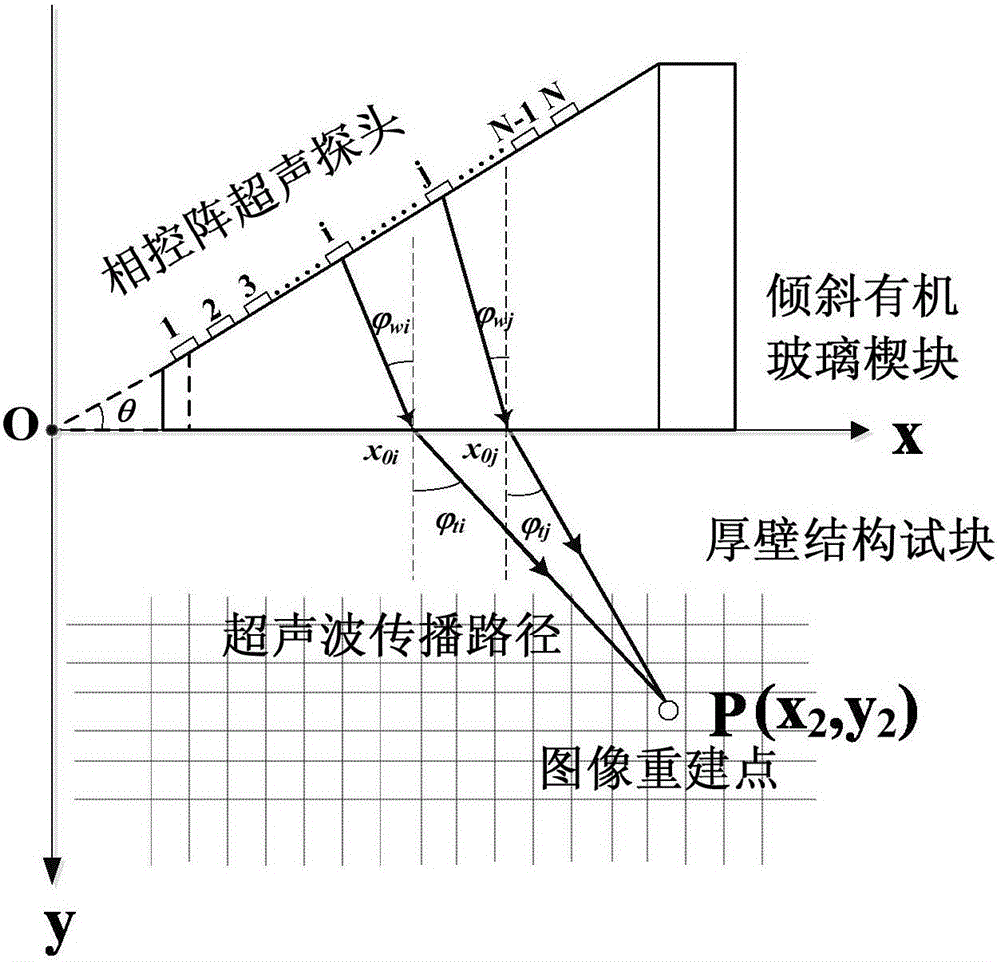

Oblique incident ultrasonic synthetic aperture focusing-based thick wall structure defect detection method

ActiveCN106093205ALarge energy coverageImprove defect detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic attenuationThick wall

The invention discloses an oblique incident ultrasonic synthetic aperture focusing-based thick wall structure defect detection method, and belongs to the technical field of nondestructive detection. The method comprises the following steps: a thick wall structure test block is detected through using a phased array electron scanning function by using an ultrasonic detection system comprising a phased array ultrasonic flaw detector, a phased array ultrasonic probe and an oblique organic glass wedge in order to obtain the A scanning signal set of all phased array elements; the Fermat's theorem is used to solve the emission point positions of all the phased array elements and image reconstruction points in the wedge / test block interface, and all A scanning signals undergo time delaying and amplitude superposing processing; and the processed A scanning signals undergo Hilbert transformation, and a difference function is used to obtain a reconstructed ultrasonic detection B scanning image. The method has the advantages of high defect detection resolution, large detection range, detection efficiency increase, and provision of an effective solving technology for the nondestructive detection problem of the defect of a thick wall structure. The method also can be embedded to the flaw detector to realize automatic real-time imaging, and has high engineering application values.

Owner:DALIAN UNIV OF TECH

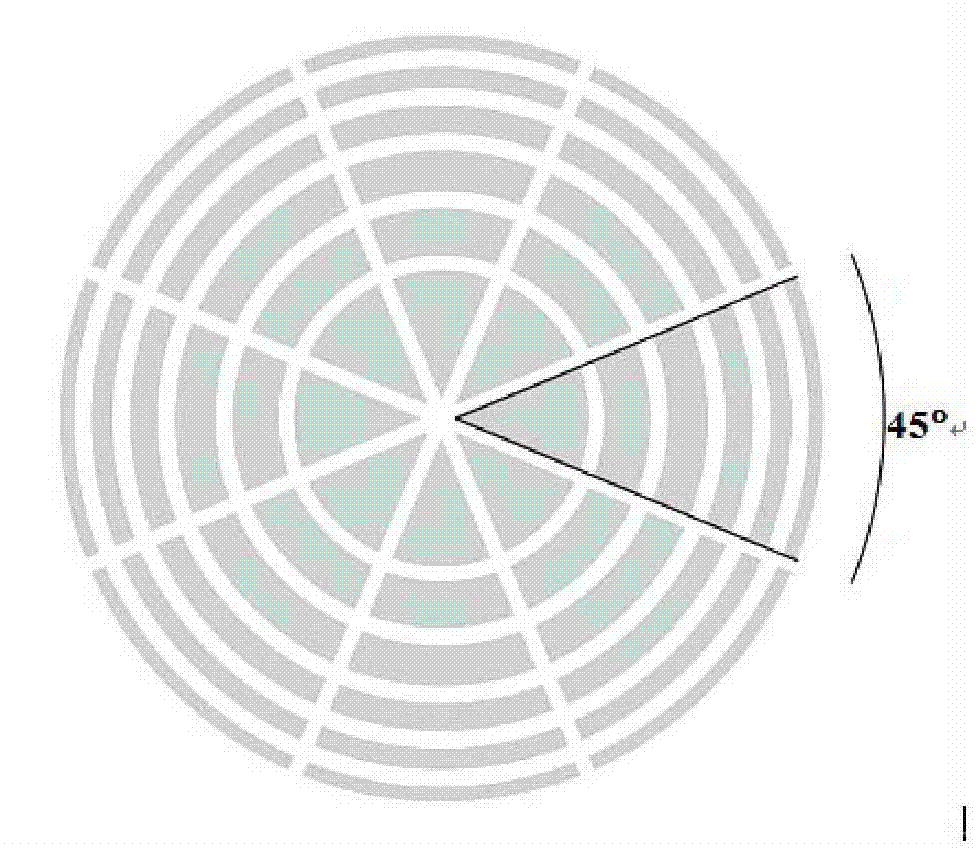

Two-dimensional annular phased array ultrasonic transducer structure

ActiveCN102824190AAvoid difficultyAvoid SNRUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSignal-to-noise ratio (imaging)Ultrasonic imaging

The invention discloses a two-dimensional annular phased array ultrasonic transducer structure for three-dimensional ultrasonic imaging. The transducer structurally comprises more than one array element ring which is annularly distributed in a concentric circle way, and each array element ring comprises more than two array elements, and the area of each array element is the same. According to the two-dimensional annular phased array ultrasonic transducer structure, the defect of signal to noise ratio caused by high technical process difficulty and small array element size of a two-dimensional area array transducer can be overcome, and the limit that a one-dimensional array and a phased array are in geometric focusing fixing, and a wave beam cannot be effectively narrowed can be overcome, so that the lateral resolution can be comprehensively improved, the signal to noise ratio can be effectively increased, and real-time three-dimensional ultrasonic imaging can be realized by electronic phased scanning.

Owner:SHENZHEN UNIV

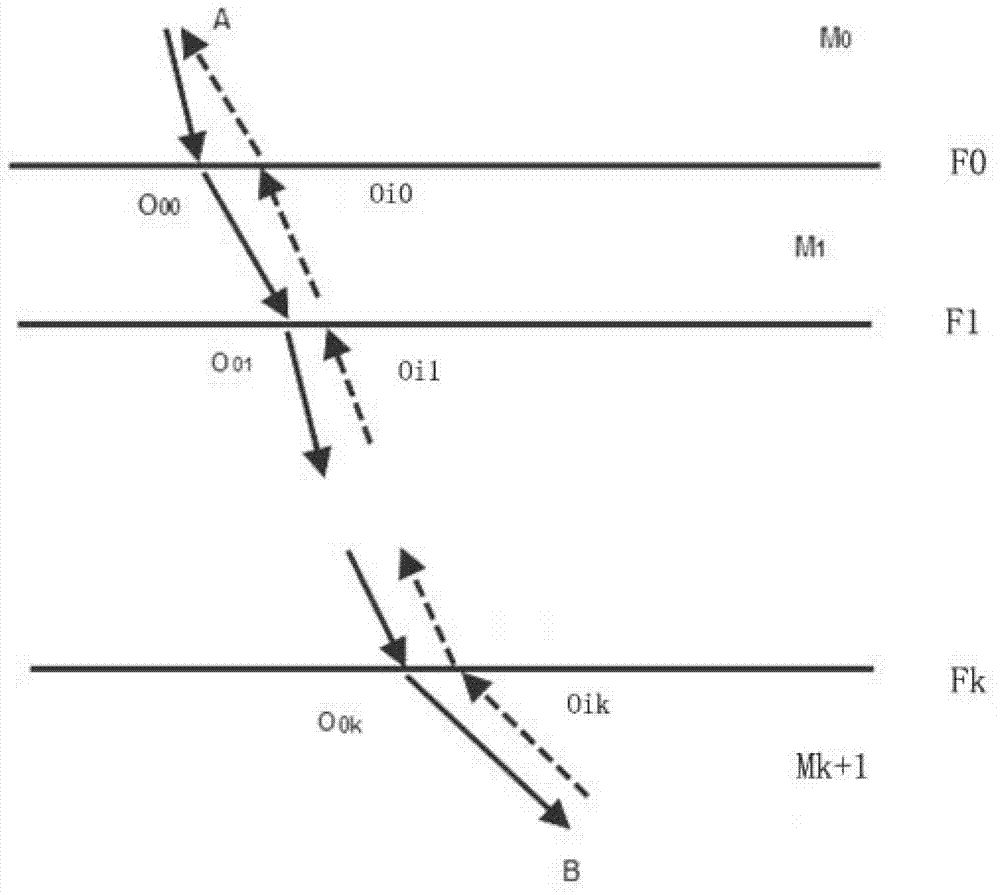

Calculation method of sound field distribution of phased array ultrasonic probe in flaw detection in multilayer medium

A calculation method of sound field distribution of a phased array ultrasonic probe in flaw detection in a multilayer medium. The method comprises the steps of: S1, modifying a Rayleigh integral expression to obtain an expression of phased array sound field transmission; S2, establishing a fast algorithm of path in an arbitrary multilayer medium; and S3, calculating chip delay time and excitation delay time: S3-1, establishing a three-dimensional system of coordinates comprising a probe wafer, a wedge and a work piece; S3-2, conducting Fourier transform on a drive signal; S3-3, forming a path matrix; S3-4, calculating a point source delay time, diffusion attenuation, and reflection and transmission through each section; S3-5, calculating sound field amplitude and phase transformation generated from a target signal, and conducting inverse transformation to obtain sound field from each point source drive signal transmitting to the target calculation point; S3-6, superimposing to obtain sound field value at the target point; and S3-7, dividing units and sequentially calculating to obtain sound field distribution in the target area. The invention can effectively assist process design and defect evaluation phased array detection of complex multilayer structure.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

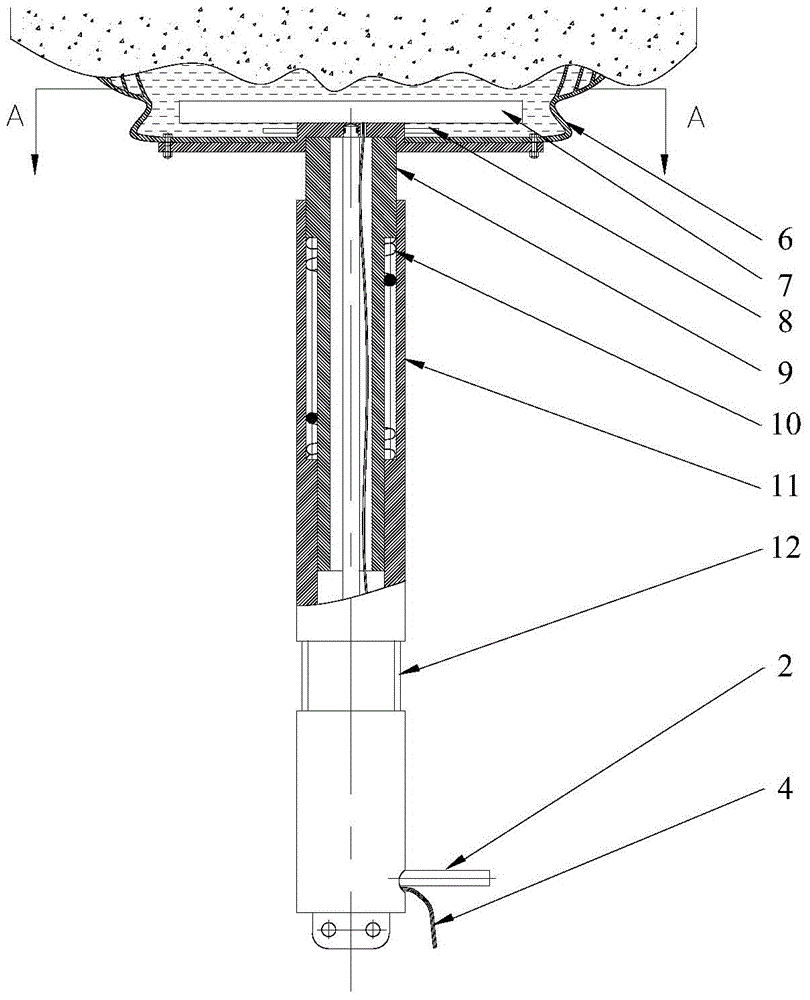

Phased array ultrasonic detection device and method for inner defects of composite insulator

InactiveCN103901109ADestructiveHigh detection requirementsAnalysing solids using sonic/ultrasonic/infrasonic wavesComposite insulatorsData transmission

The invention discloses a phased array ultrasonic detection device for inner defects of a composite insulator. The phased array ultrasonic detection device comprises a phased array probe, a phased array displayer, a phased array system unit and a system main control computer. The invention also discloses a detection method applicable to the phased array ultrasonic detection device for the inner defects of the composite insulator. The detection method comprises the following steps: 1, generating an ultrasonic signal by the phased array probe and generating a reflected ultrasonic signal when the ultrasonic signal meets the defects of the composite insulator; 2, transmitting the reflected ultrasonic signal to the phased array system unit and the system main control computer, and then transmitting data to the phased array system unit and the system main control computer; 3, processing data with the phased array system unit and the system main control computer, and then outputting a phased array scanning image with the phased array displayer; 4, determining sizes, types and positions of the inner defects of the composite insulator. The detection device and the detection method have the advantage of being capable of quickly, accurately and nondestructively detecting the inner defects of the composite insulator.

Owner:SOUTH CHINA UNIV OF TECH

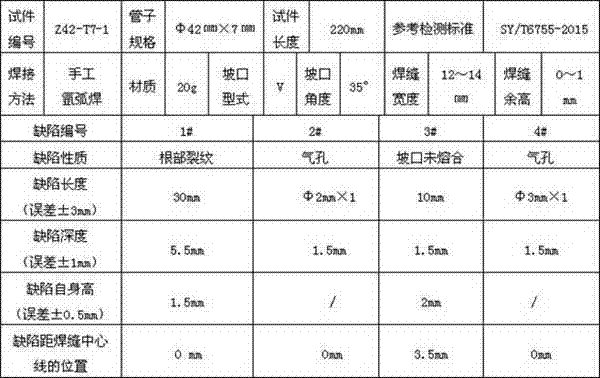

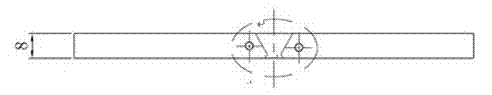

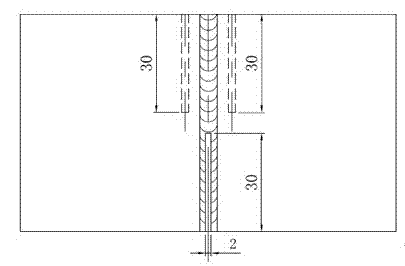

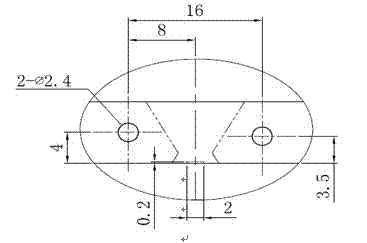

Method for detecting weld seam of thin-wall small diameter tube by adopting phased array ultrasonic combination technology

ActiveCN104849349AEasy to operatePractical operationAnalysing solids using sonic/ultrasonic/infrasonic wavesVisibilityWeld seam

The invention provides a method for detecting a weld seam of a thin-wall small diameter tube by adopting a phased array ultrasonic combination technology. The method for detecting the weld seam of the thin-wall small diameter tube with the wall thickness of more than or equal to 3.5mm and smaller than or equal to 7mm by adopting the phased array ultrasonic combination technology is characterized in that the setting of a test block passing a phased array ultrasonic system is subjected to field detection by adopting phased array ultrasonic equipment through a phased array probe; the detection result is obtained by the flow of evaluating and issuing a detecting report. The method disclosed by the invention has the advantages of simplicity and practicality in operation, no radiation, no pollution, high detection efficiency, high quantitative precision, small influence from human factors and low possibilities of missing evaluation and misjudgment; the detection result is displayed in a three-dimensional image form, so the visibility and the understandability are realized. The method is suitably applied for detecting the weld seam of the thin-wall small diameter tube.

Owner:田国良

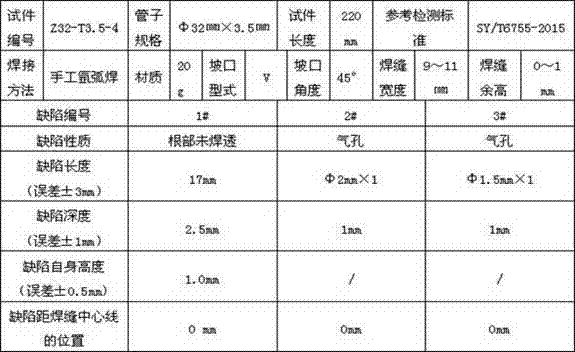

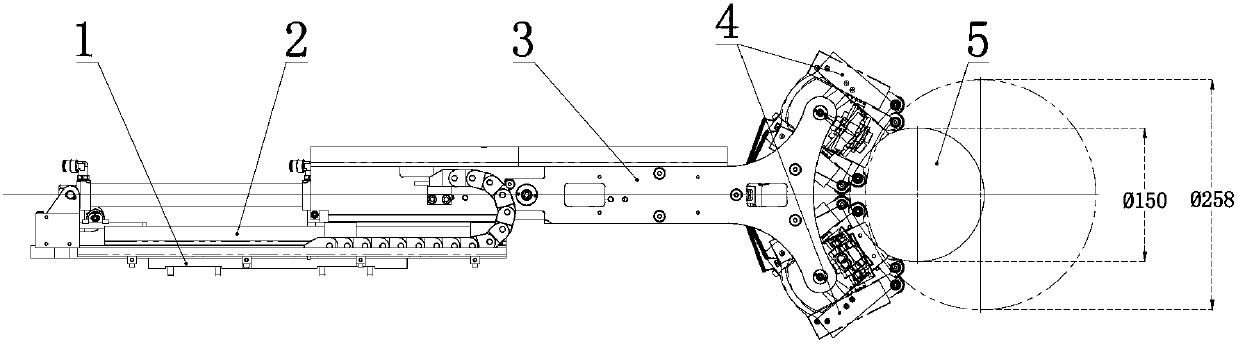

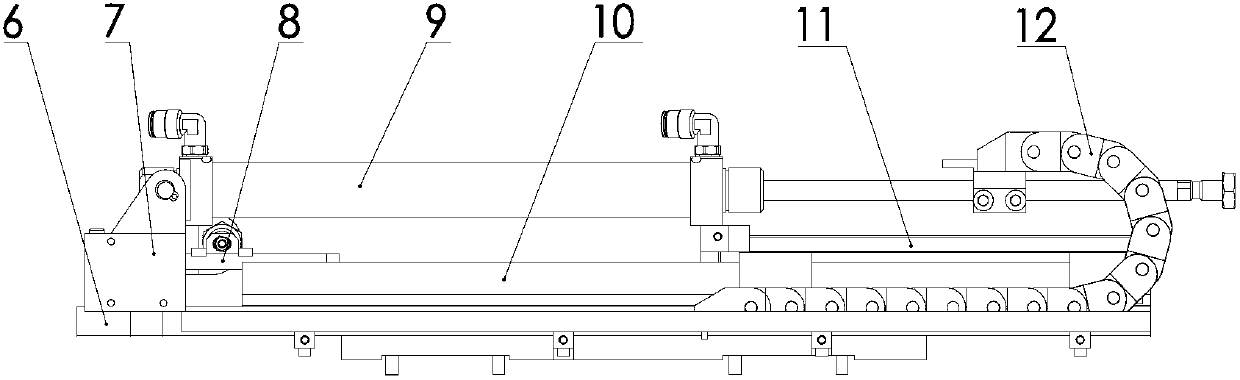

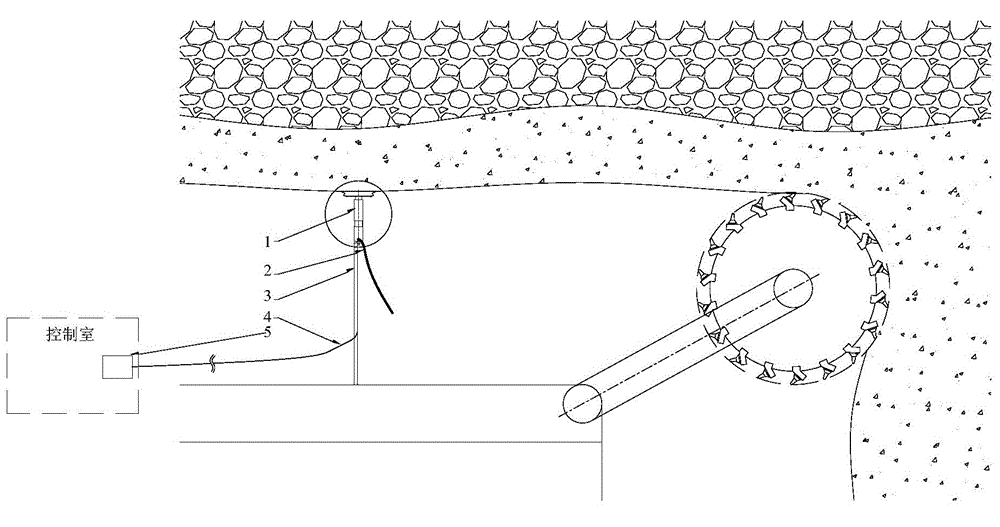

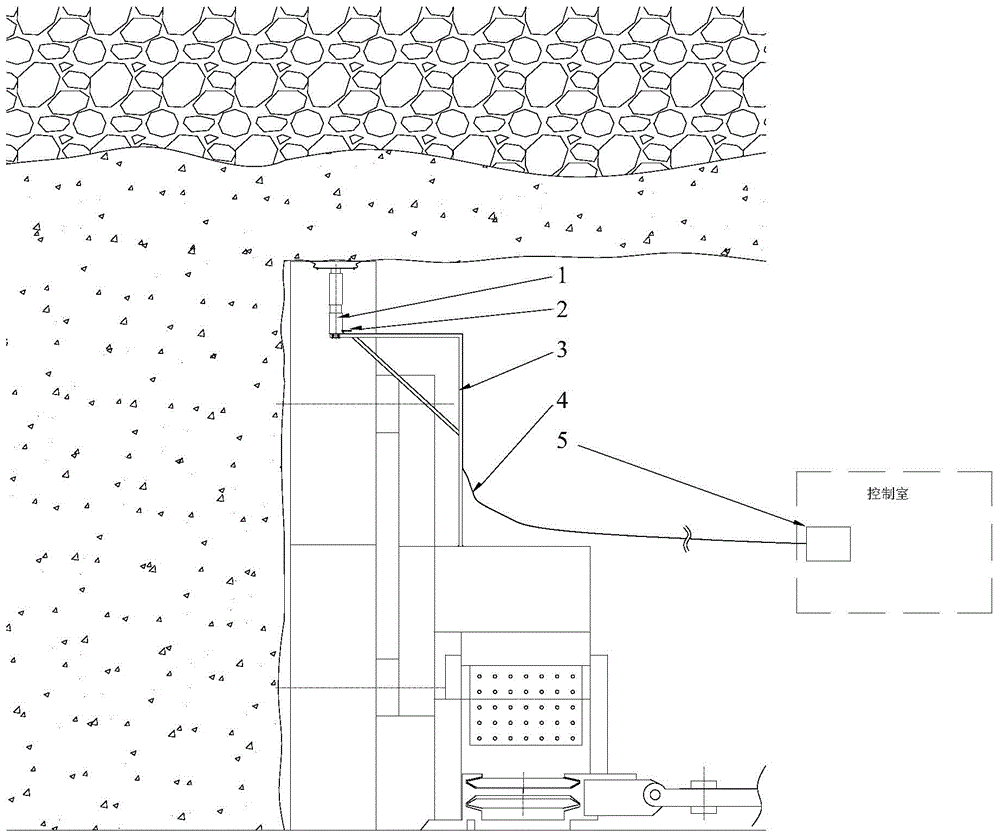

Railway axle phased array ultrasonic flaw detection self-adaptive scanning device

ActiveCN102998373AGuaranteed stabilityEnsure safetyMaterial analysis using sonic/ultrasonic/infrasonic wavesAir compressionCoupling

The invention discloses a railway axle phased array ultrasonic flaw detection self-adaptive scanning device. Air compression force is adopted for driving an ultrasonic probe clamp, the gas flow rate and pressure can be regulated, the pressure is positioned in a floating manner, the clamp and the probe can be prevented from being damaged by excessive pressure, and the safety of detection equipment can be further protected; during the positioning process of the probe, according to the detected axle diameter, the single-axle rotational angle of the probe can be regulated in a self-adaptive manner for meeting the flaw detection requirements of railroad car axles with different diameters; and during the flaw detection process, the probe can move along a telescopic guide pole, the joint pressure between the probe and the surface of the axle can be regulated by extension and contraction of a pressure spring, the friction force between the surfaces of the probe and the axle can be reduced along with the rotation of rolling wheels, and the stability in coupling of the probe can be further ensured. The railway axle phased array ultrasonic flaw detection self-adaptive scanning device disclosed by the invention has the advantages of convenience in operation and strong applicability, and can ensure the safety and stability in probe positioning and improve the ultrasonic axle flaw detection efficiency.

Owner:王黎 +5

Method for detecting coal-rock interface by phased-array ultrasonic imaging

InactiveCN104820021ADirectionalLong distanceAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationHigh energy

The invention relates to a coal-rock interface identification method, and particularly relates to a method for detecting a coal-rock interface by phased-array ultrasonic imaging. The method is realized by adopting a system for detecting the coal-rock interface on the basis of phased-array ultrasonic imaging. The system consists of a supporting device, a coupling device, an ultrasonic phased-array transducer and an imaging device. The phased-array transducer in water transmits ultrasonic waves to a coal bed, the ultrasonic waves enter the coal bed after being transmitted to a water and coal interface, then the ultrasonic waves are transmitted to the coal-rock interface and returned to the coal bed, and then the ultrasonic waves are returned to the water and received by the phased-array transducer. The thickness of the coal bed is calculated according to parameters such as the transmitting and receiving time difference of the phased-array transducer, and the coal-rock interface can be judged. By utilizing the advantages of the phased-array ultrasonic wave such as good directivity, high energy, high measurement precision and deflection focusing as well as the characteristic of the ultrasonic wave of no scattering in the water, the coal-rock interface can be precisely identified in real time, the method can be used for adjusting the cutting depth of a coal mining machine roller and reducing the residual coal bed, thereby reducing the coal loss to increase the coal exploitation quantity.

Owner:CENT SOUTH UNIV

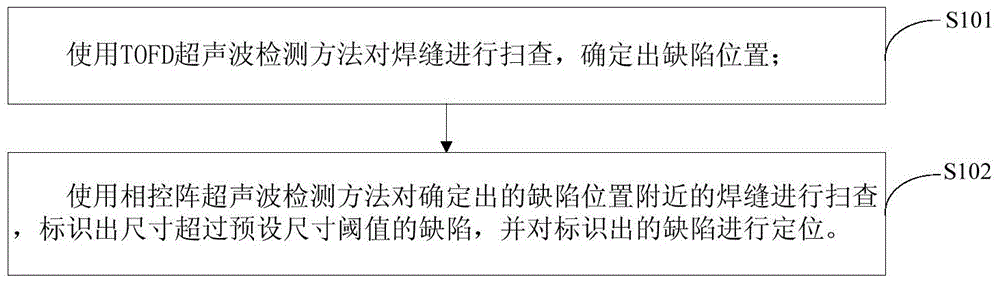

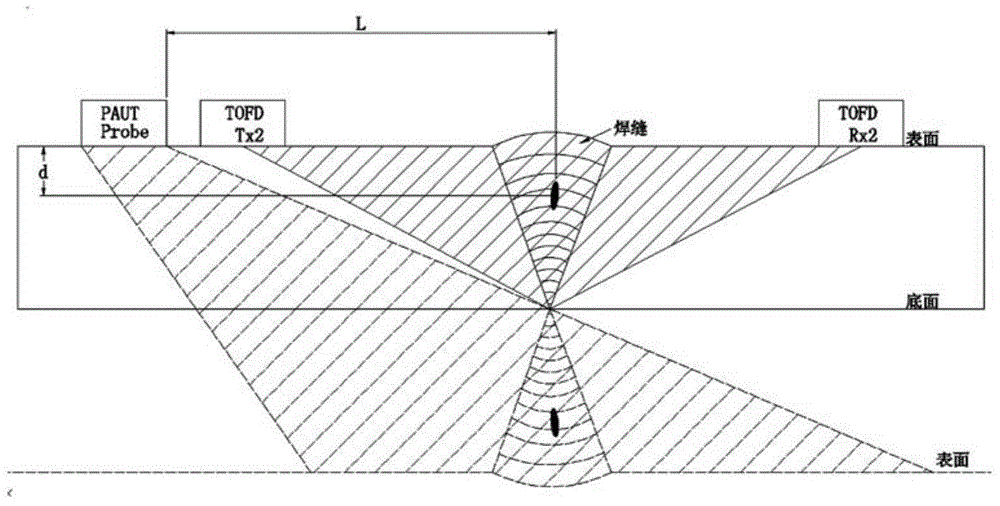

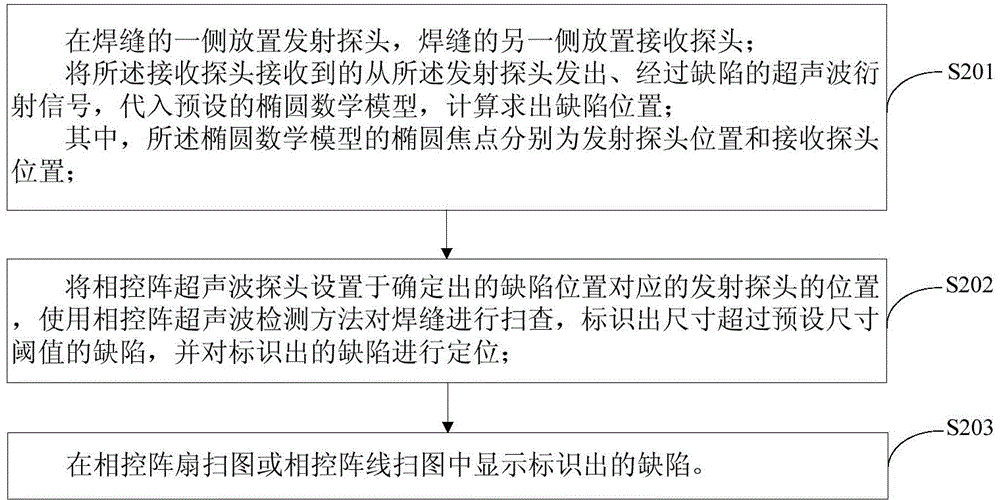

Ultrasonic detecting and positioning method and device based on TOFD (time of flight diffraction) and phased array

InactiveCN104792866AAnalysing solids using sonic/ultrasonic/infrasonic wavesDepth directionTime of flight

The invention relates to an ultrasonic detecting and positioning method and device based on TOFD (time of flight diffraction) and a phased array. The device comprises a TOFD detection unit and a phased array detection unit, wherein the TOFD detection unit is used for scanning weld joints with a TOFD-based ultrasonic detection method to determine positions of defects; the phased array detection unit is used for scanning weld joints nearby the determined defect positions with a phased-array-based ultrasonic detection method, identifying defects with sizes exceeding a preset size threshold and positioning the identified defects. Position information of the defects in horizontal and depth directions can be determined accurately through phased-array-based ultrasonic detection, during positioning in cooperation with TOFD detection, the defects of the weld joints are accurately positioned with TOFD scanning serving as a main method and phased array scanning serving as an auxiliary method, and problems that the positioning accuracy of TOFD scanning is poor and transverse defects cannot be detected during non-parallel scanning are solved.

Owner:SENSE ENG SERVICES

Ultrasonic flaw detection method of austenitic stainless steel sheet weld joint

InactiveCN103115959AApparent scatter attenuationOvercome the inability to assessAnalysing solids using sonic/ultrasonic/infrasonic wavesAusteniteMaterials science

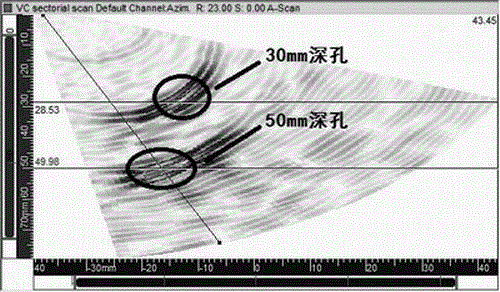

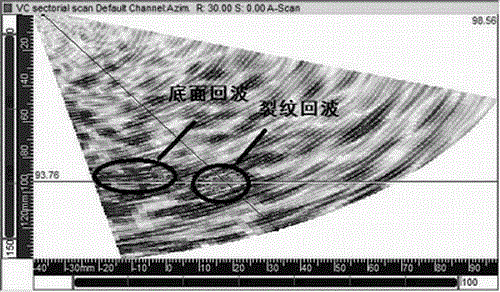

The invention discloses an ultrasonic flaw detection method of an austenitic stainless steel sheet weld joint. The ultrasonic flaw detection method comprises the following steps of: 1, selecting a phased array ultrasonic flaw detection device; 2, making a reference block by adopting the same material, and determining a material, a shape and a size of the reference block; 3, detecting and debugging the reference block by using the phased array ultrasonic flaw detection device, and screening artificial flaw detection echoes and noise waves; and 4, carrying out sector-scanning on a workpiece by using the phased array ultrasonic flaw detection device, accurately positioning and quantitatively screening doubtful echoes so as to confirm whether the doubtful echoes are flaw echoes. According to the ultrasonic flaw detection method of the austenitic stainless steel sheet weld joint, various flaws in the stainless steel sheet weld joint can be rapidly and effectively detected.

Owner:HUDONG HEAVY MACHINERY

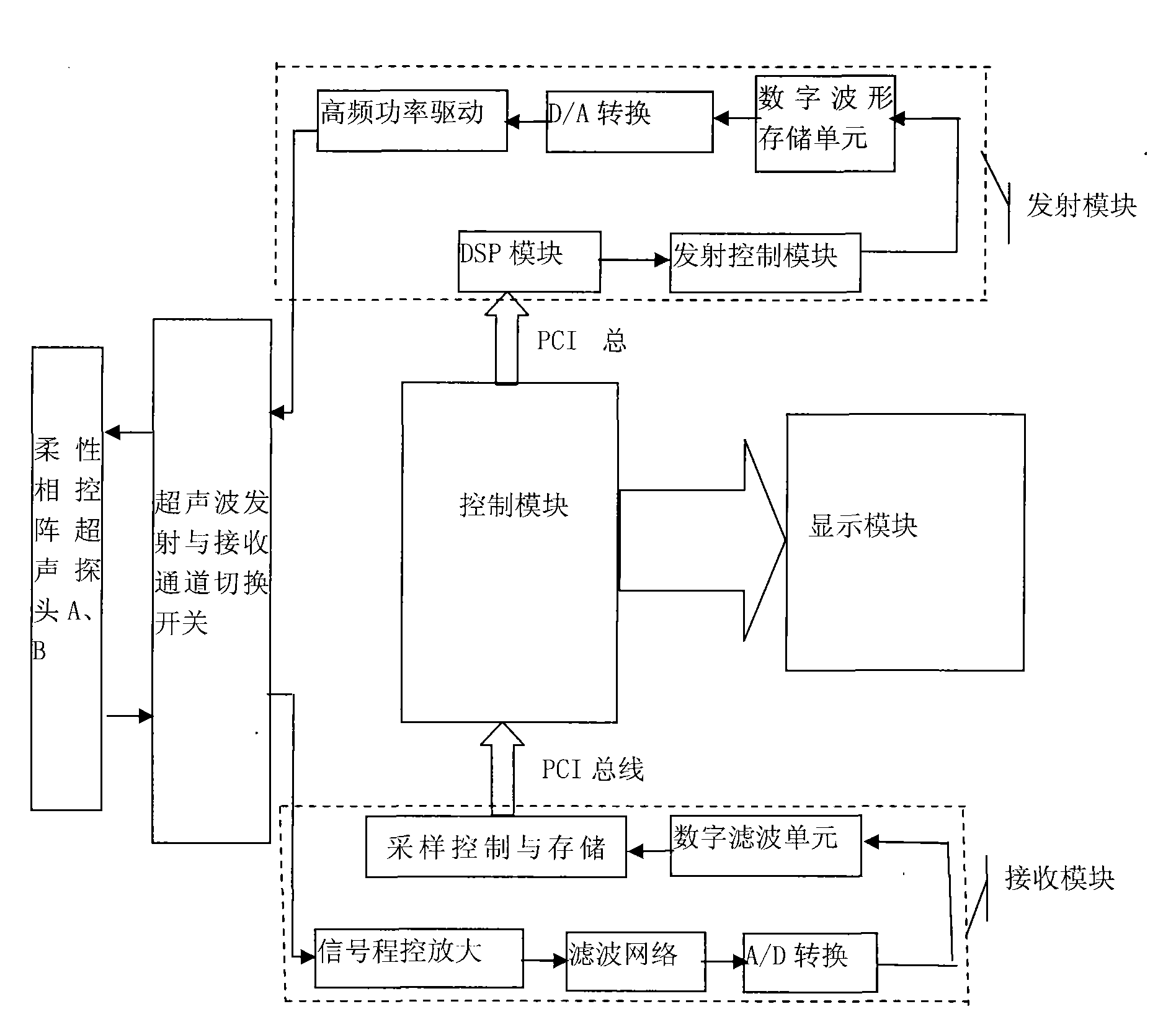

Oral cavity comprehensive detecting method and apparatus based on flexible phase controlled ultrasonic array

InactiveCN101966088AOvercoming detectionOvercome the costUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsUltrasound attenuationMedicine

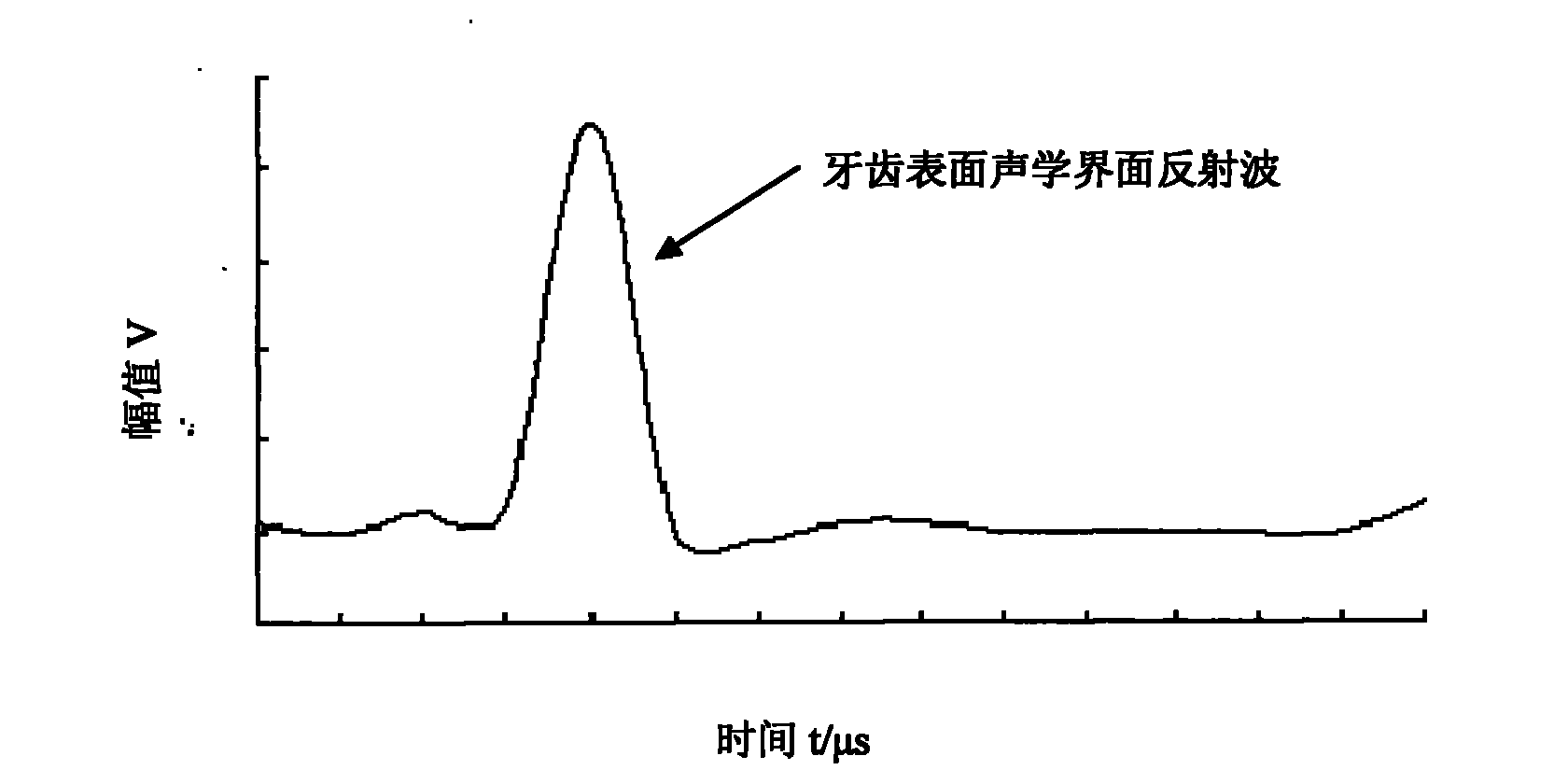

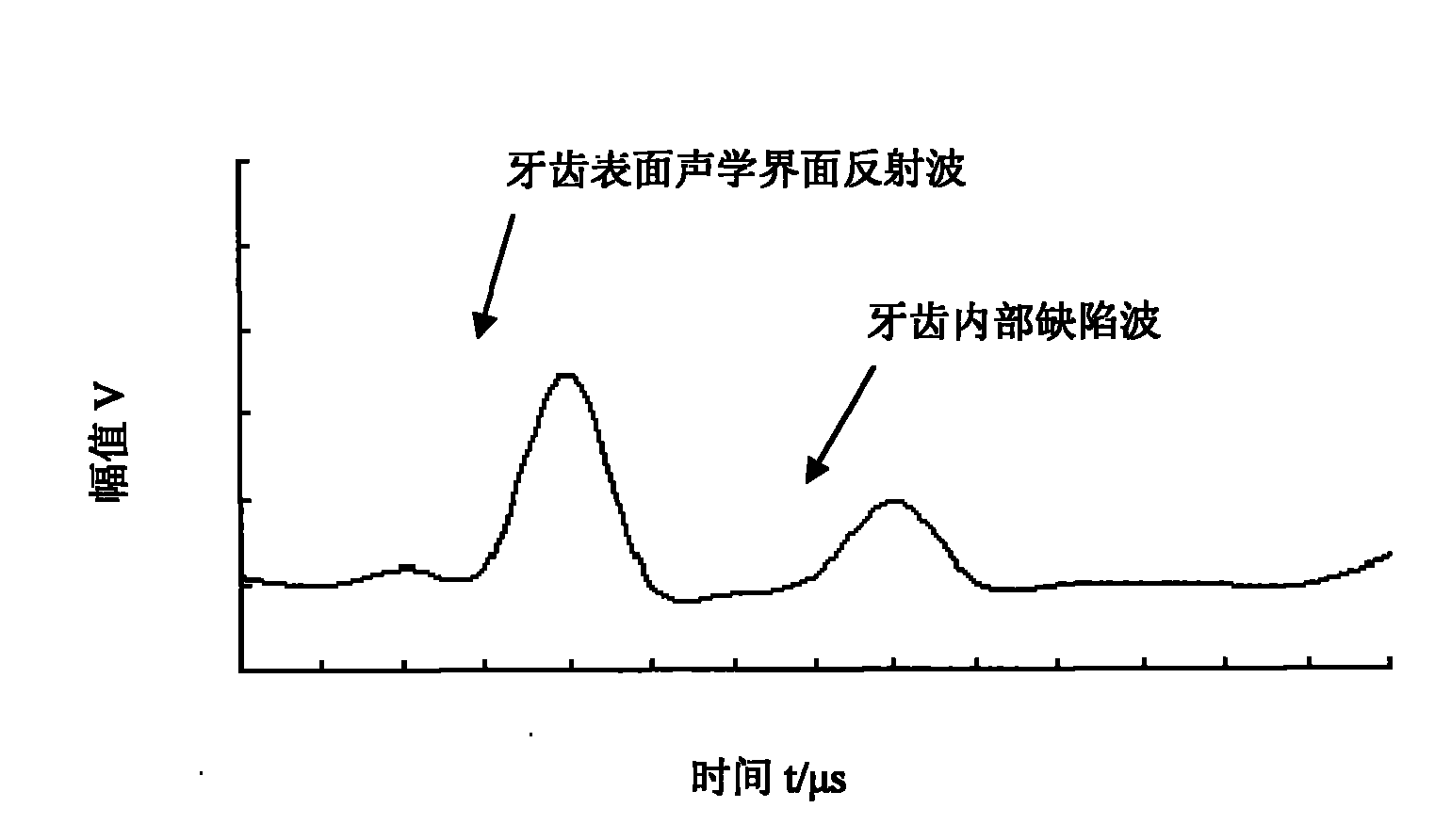

The invention discloses oral cavity comprehensive detecting method and apparatus based on a flexible phase controlled ultrasonic array. The apparatus comprises a display module, a phase controlled ultrasonic transmitting module and a phase controlled ultrasonic receiving module connected with a control module, respectively. The phase controlled ultrasonic transmitting module and the receiving module are further connected with a flexible phased array ultrasonic transducer array. The method comprises the following steps of: performing ultrasonic scanning to detect teeth facing outwards skin in periphery of the oral cavity on the face or in all directions of other soft tissues of the oral cavity through the flexible phased array ultrasonic transducer array; transmitting ultrasonic waves with set frequency to detection points through the phased array focused ultrasound when detecting the teeth so as to detect the amplitude of the reflected wave and detect whether defect waves exist in the reflected wave; and transmitting ultrasounds with different frequencies to the detection points through the phased array focused ultrasound and detecting the attenuation of the transmitted wave with different frequencies at the other end when detecting the soft tissues of the oral cavity so as to obtain broadband ultrasonic attenuation parameters. Therefore, health states of the soft tissues of oral cavity can be obtained rapidly.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com