Phased-array ultrasonic detection method for interfacial de-bonding of composite material

A composite material and ultrasonic detection technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., to achieve the effect of high detection accuracy, high resolution and strong detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

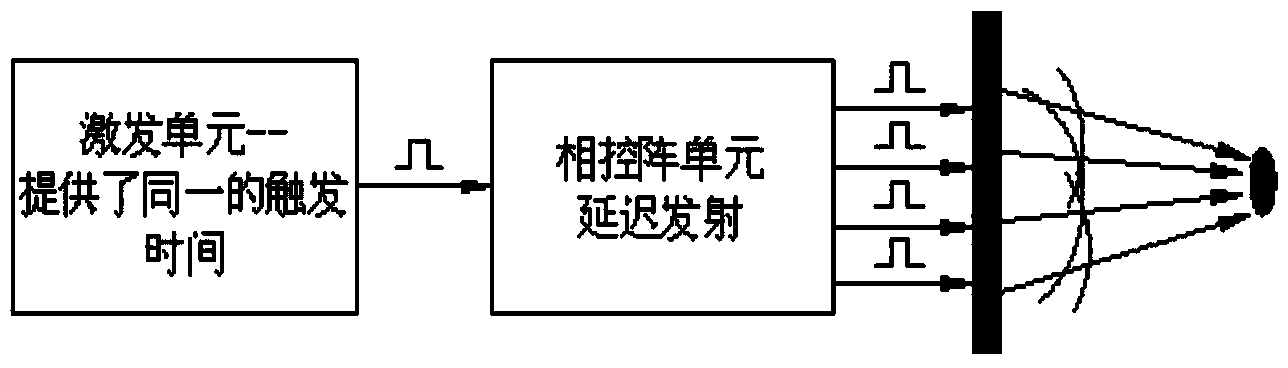

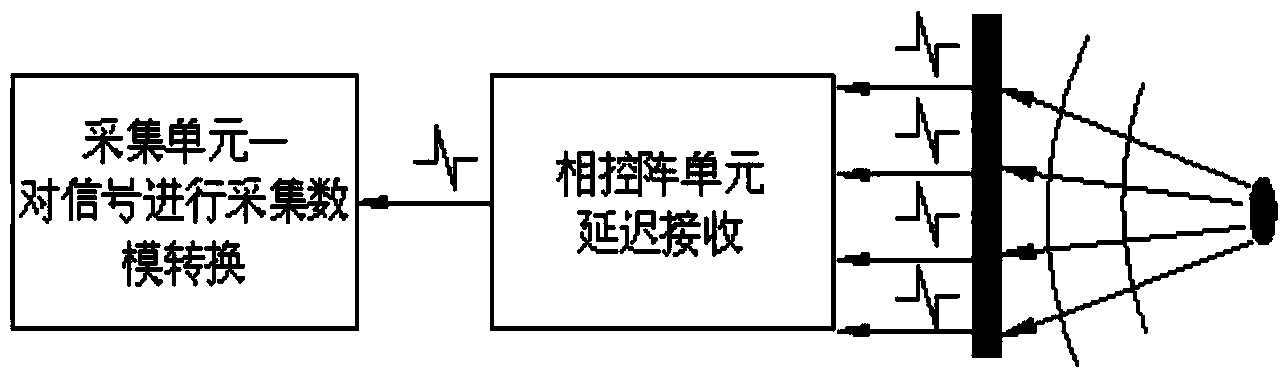

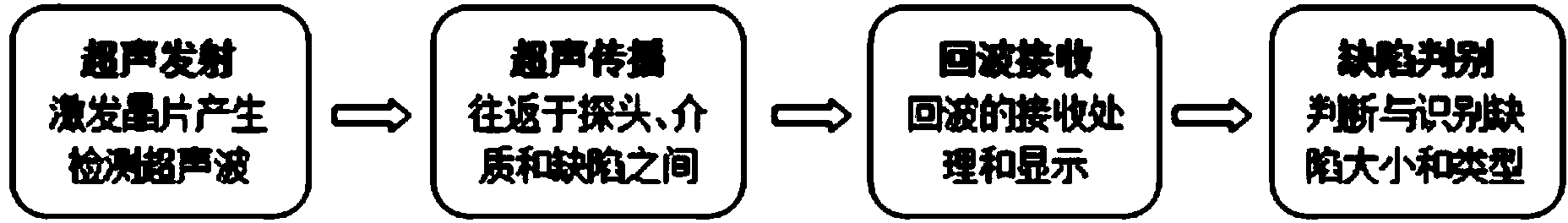

[0029] Such as Figure 3a , Figure 3b , Figure 4a , Figure 4b As shown, the present invention proposes a phased array ultrasonic detection method for interfacial debonding of composite materials, which uses the synthesis and focusing of ultrasonic beams to detect composite materials, and the detection process includes the following steps:

[0030] 1. Input the sound velocity of composite material 2 and composite material 3, deflection angle of sound velocity, probe frequency, focal length, number of activated wafers, scanning type, and scanning step on the phased array ultrasonic detector through the preset software as required. parameters such as angle of entry.

[0031] 2. After completing the parameter setting, remove the dirt on the surface of the object to be detected and the moving area of the probe, and apply a coupling agent on the surface of the composite material 2 and the moving area of the probe. The coupling agent is machine oil.

[0032] 3. Adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com