Real-time aluminum profile surface defect detection system based on machine vision

A machine vision, real-time detection technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of difficult to detect small, slow detection, fatigue intensity and other subjective factors, so as to improve the overall product quality and reduce defective products. The effect of producing, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

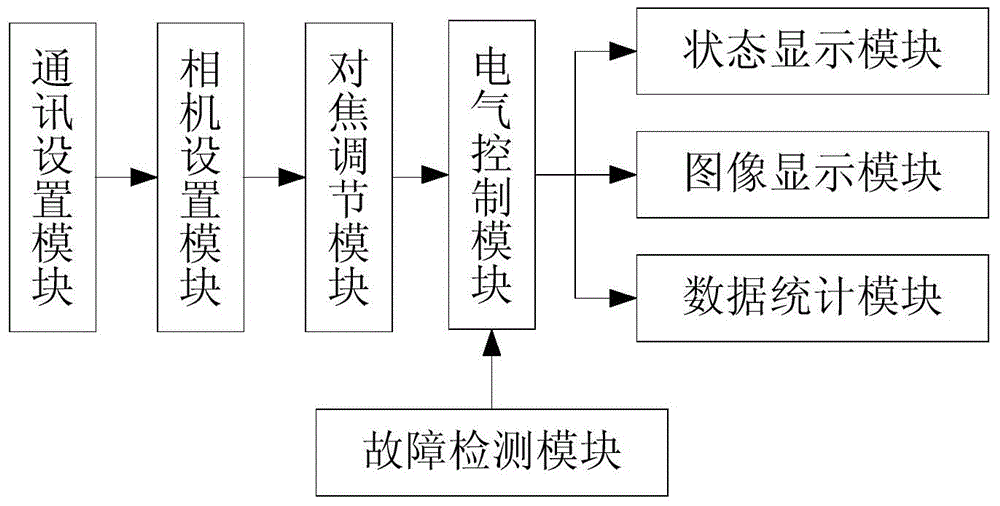

[0029] The machine vision-based real-time detection system for surface defects of aluminum profiles of the present invention includes a communication setting module, a camera setting module, a focus adjustment module, an electrical control module, a state display module, an image display module, a data statistics module and a fault detection module. Such as figure 1 shown.

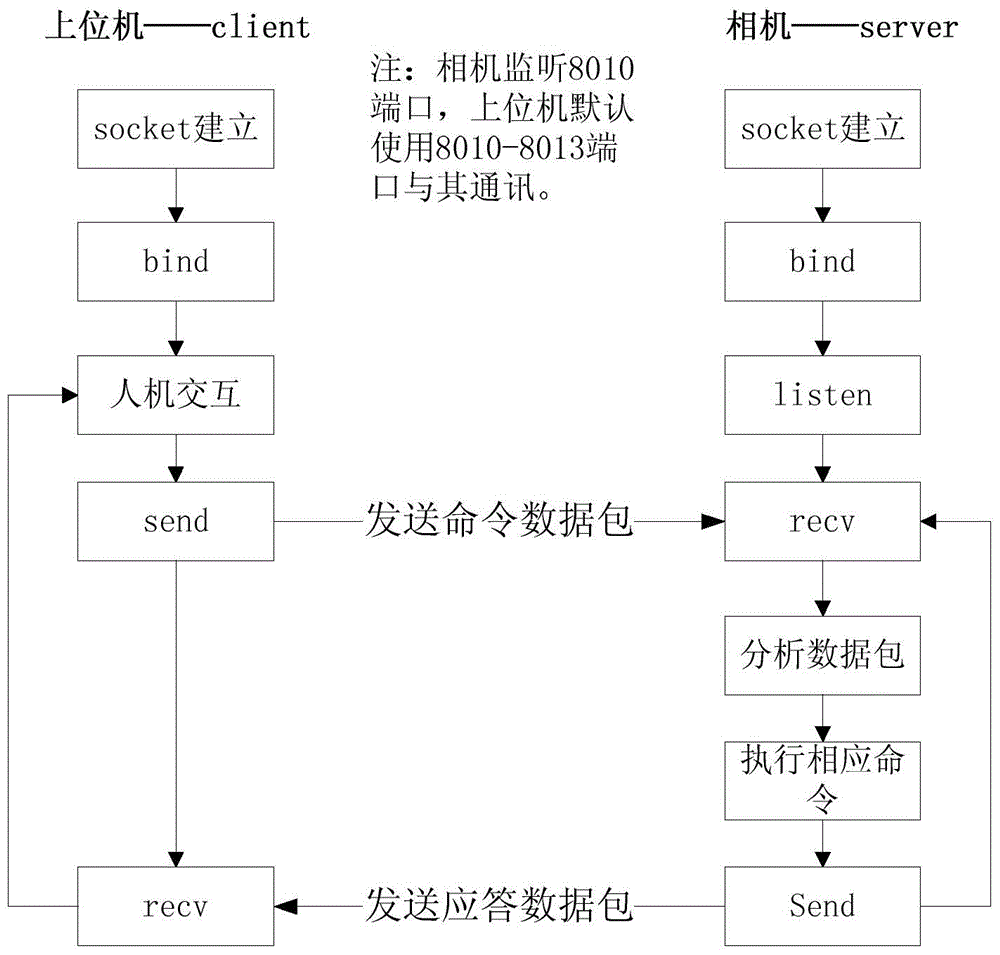

[0030] The communication setting module is used to set the IP address, the UDP listening port number and the TCP listening port number of each camera communicating with the upper computer, the UDP listening port number and the TCP listening port number of the upper computer, which are the communication between the upper computer and the camera. Communication provides guarantee; UDP protocol: The host computer sends control commands to a camera with a specified IP address and port number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com