Patents

Literature

101 results about "Rail wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

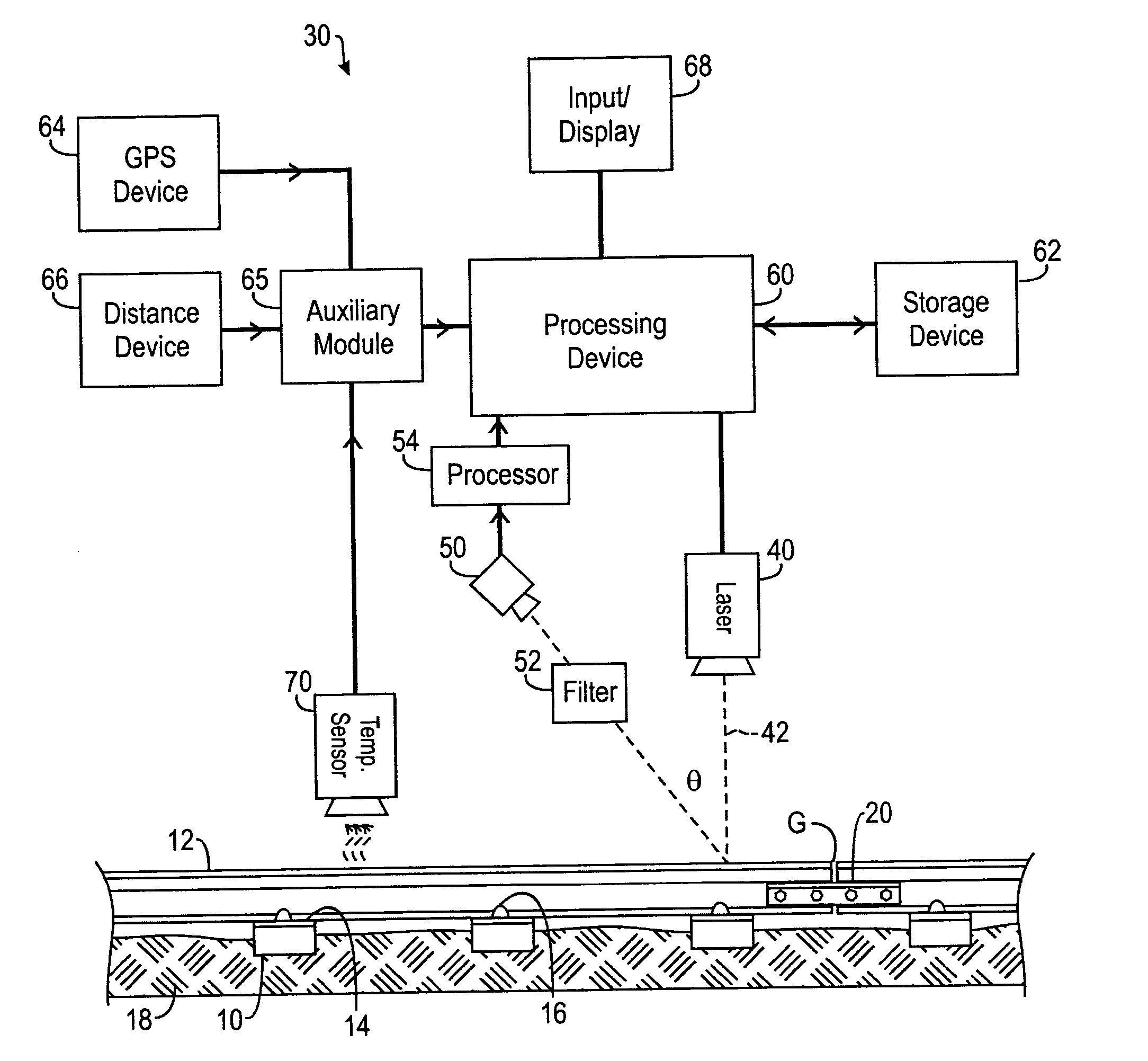

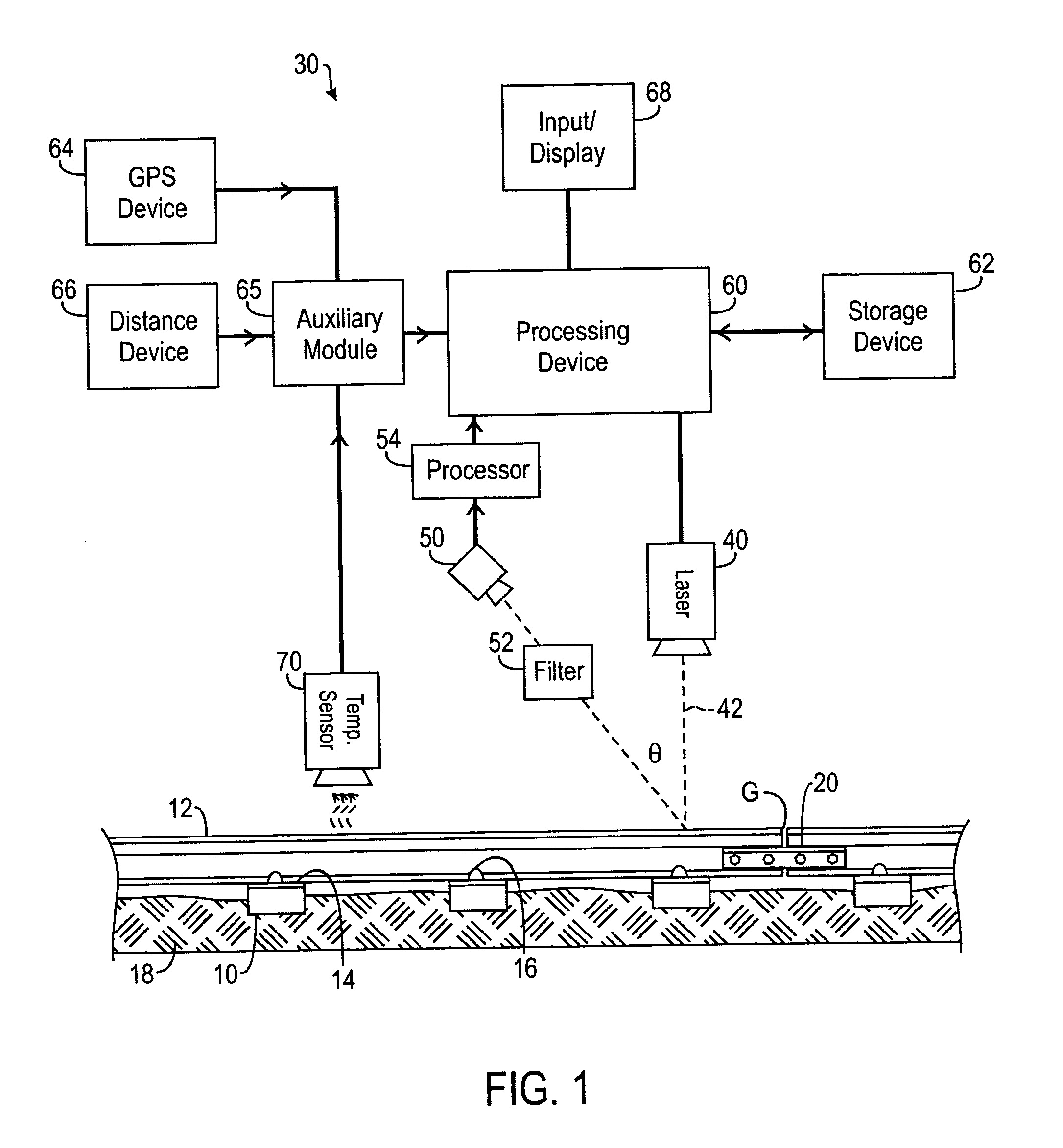

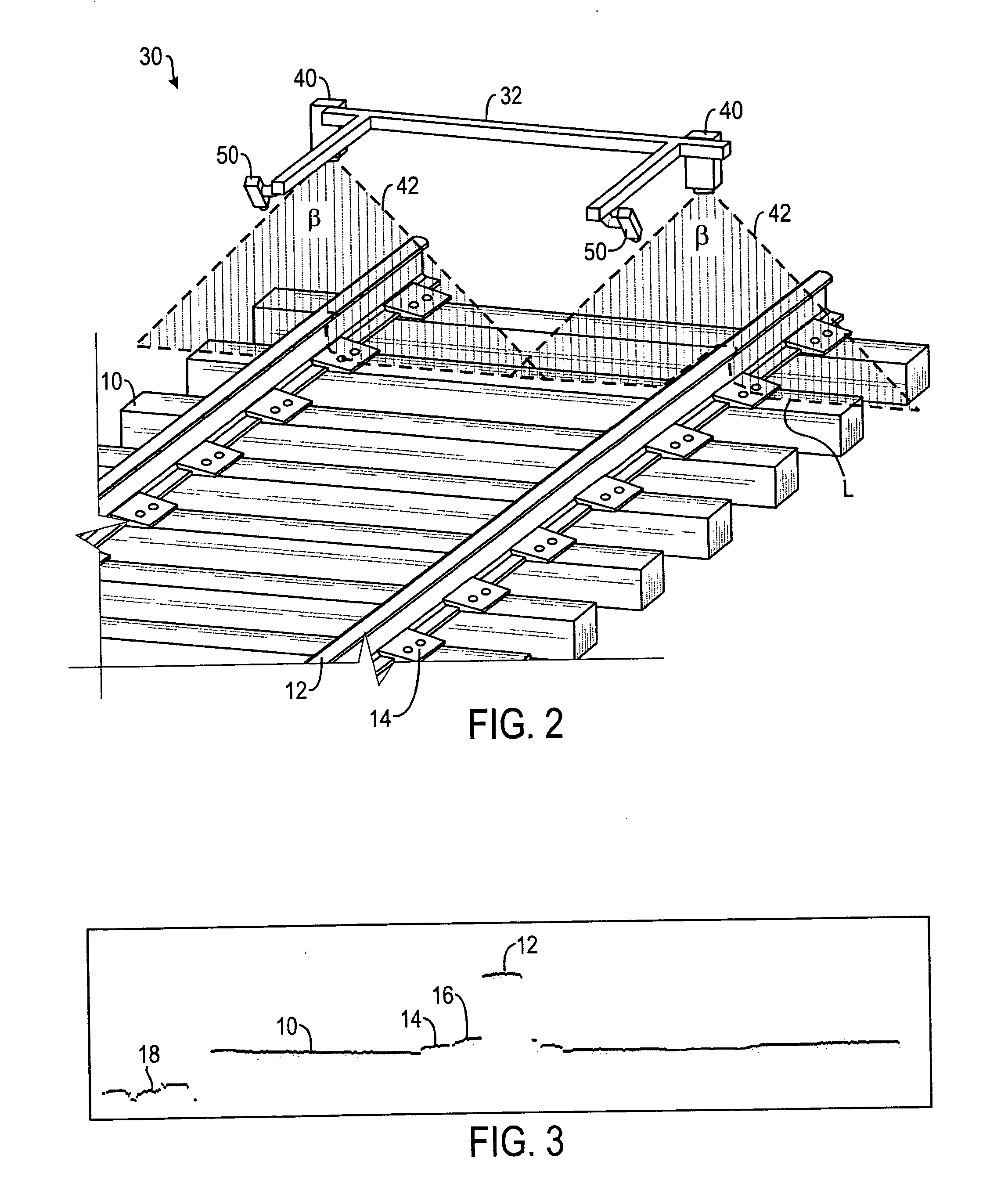

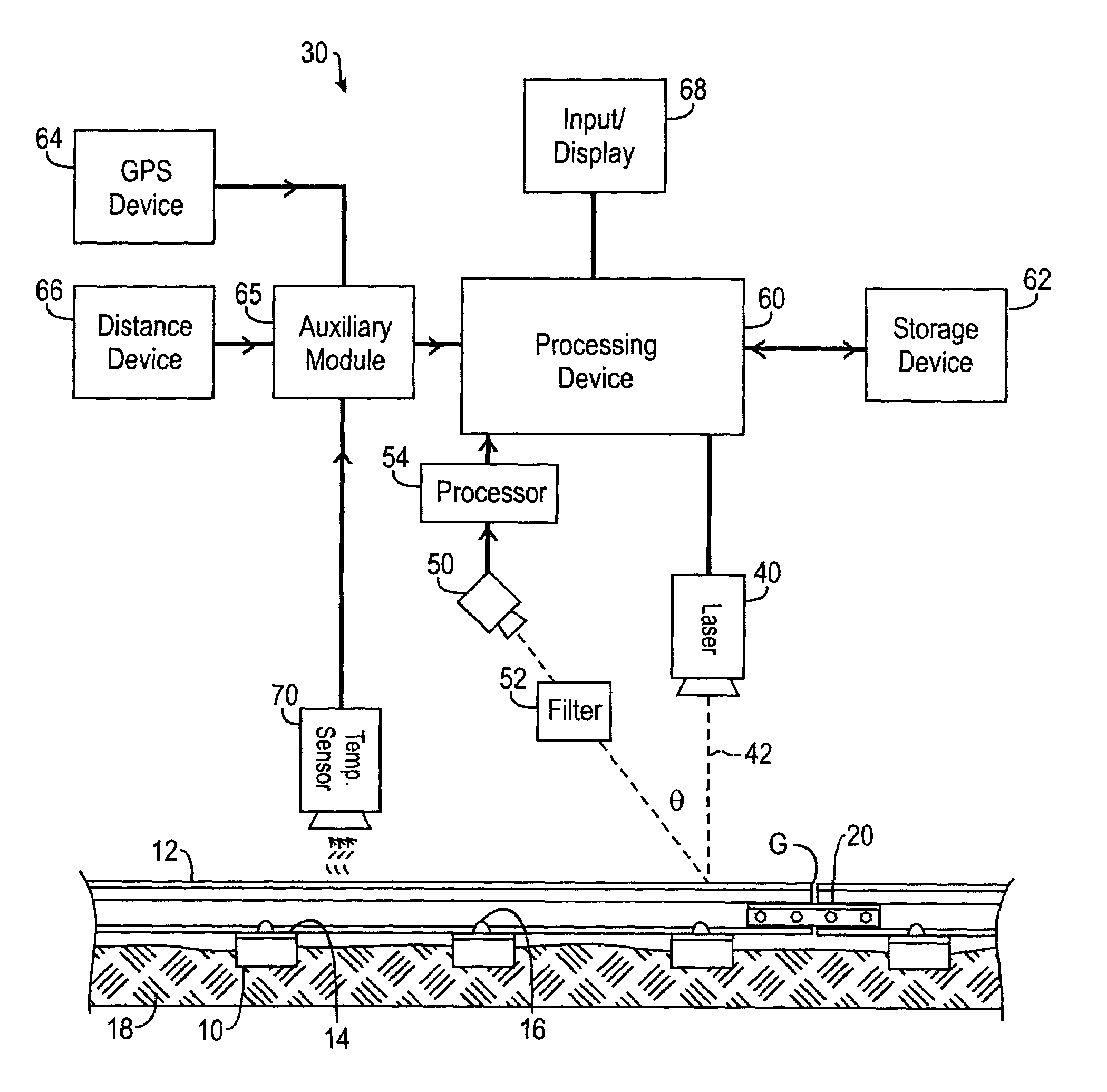

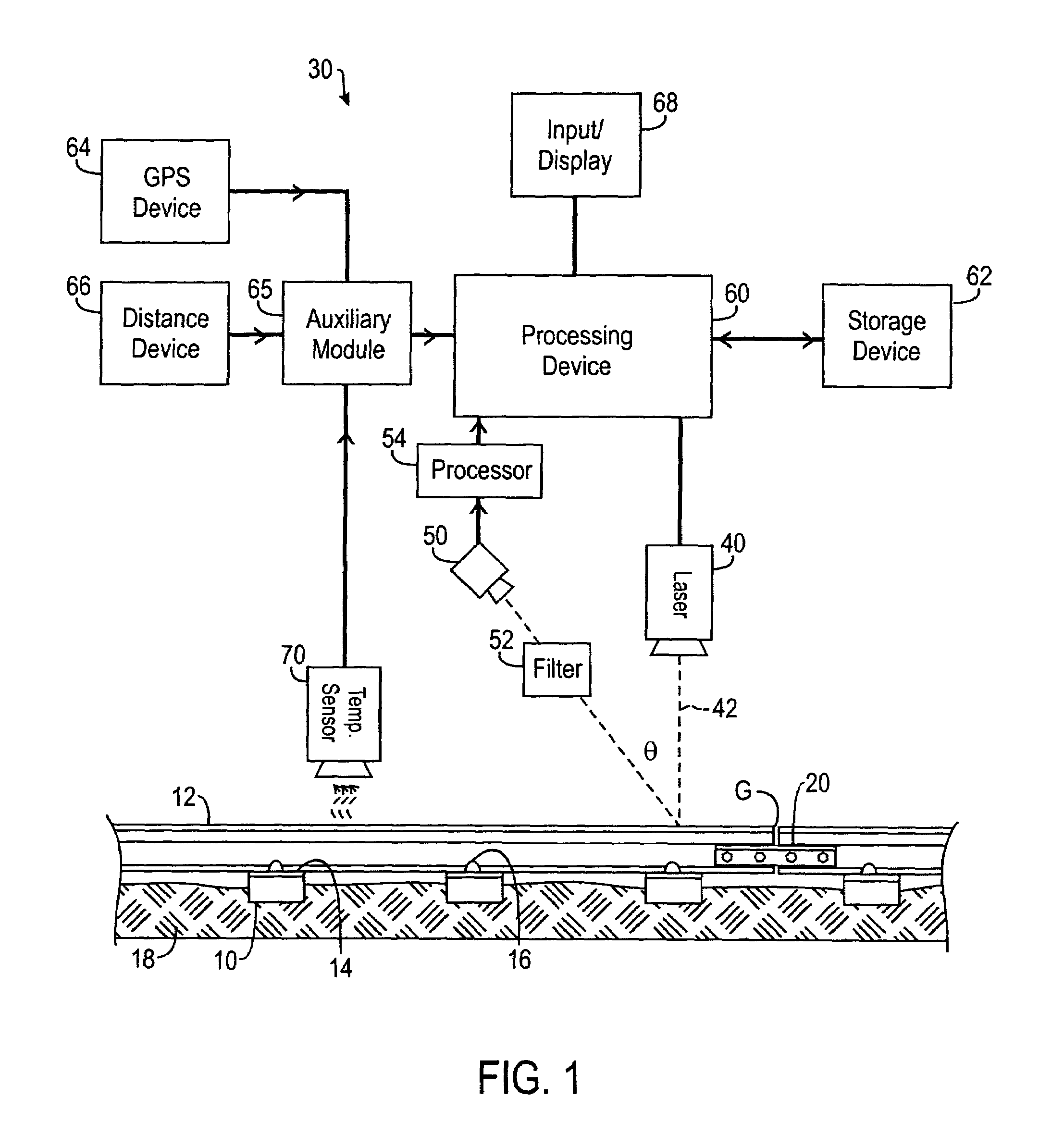

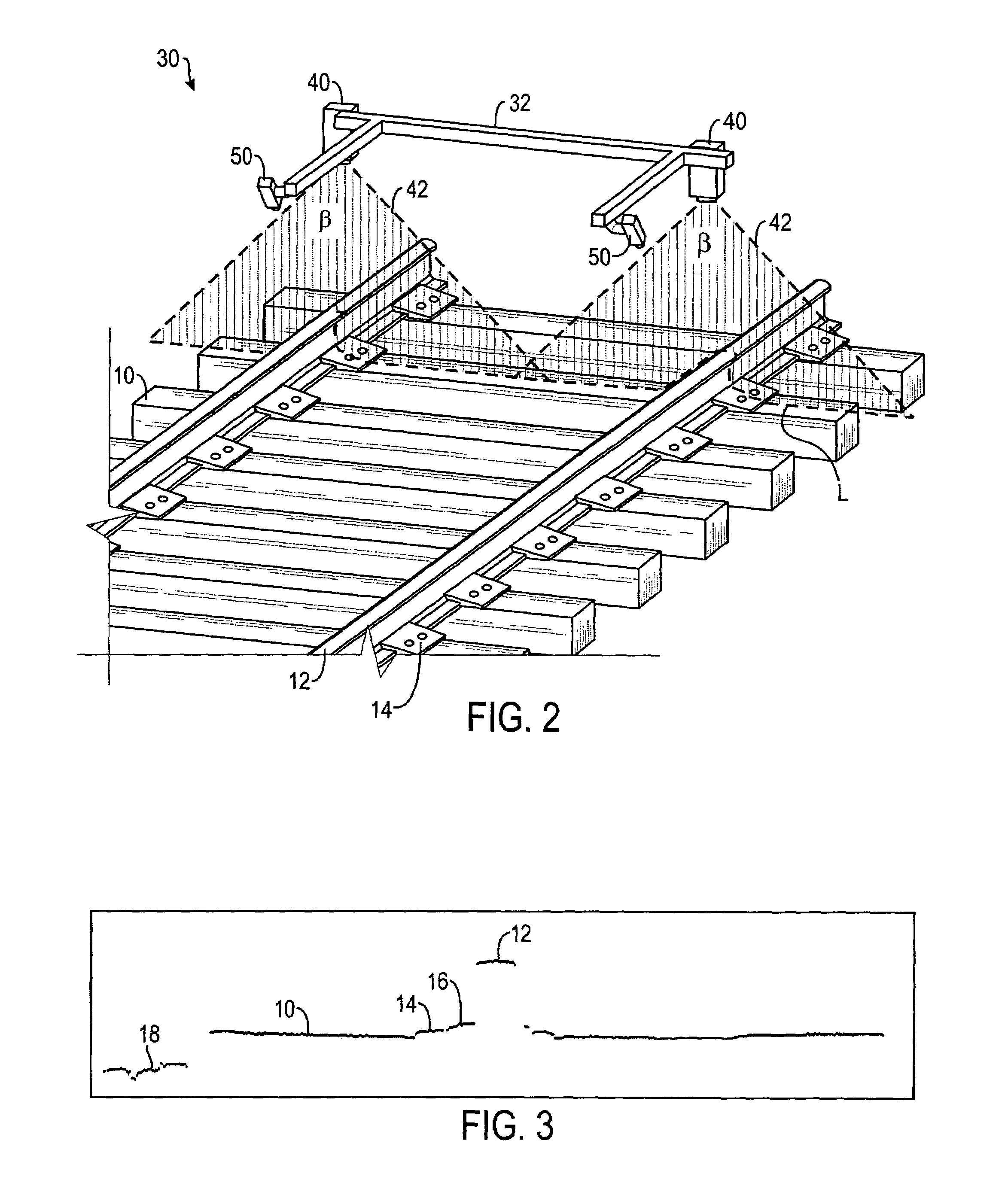

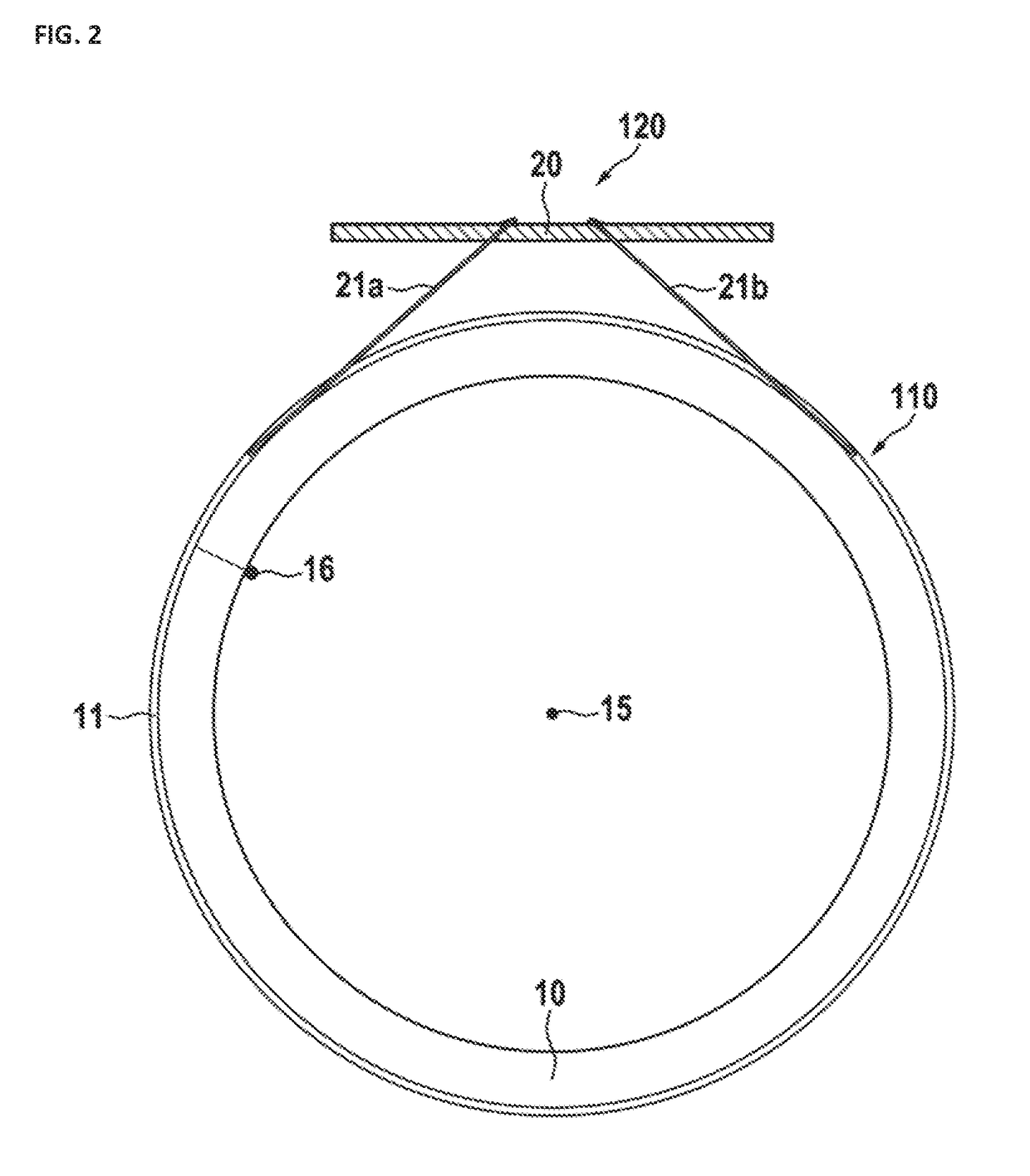

System and method for inspecting railroad track

A system and method for inspecting railroad track is disclosed. The disclosed system includes lasers, cameras, and a processor. The lasers are positioned adjacent the track. The laser emits a beam of light across the railroad track, and the camera captures images of the railroad track having the beam of light emitted thereon. The processor formats the images so that they can be analyzed to determine various measurable aspects of the railroad track. The disclosed system can include a GPS receiver or a distance device for determining location data. The measurable aspects that can be determined by the disclosed system include but are not limited to the spacing between crossties, the angle of ties with respect to rail, cracks and defects in surface of ties, missing fastener components, misaligned fastener components, sunken tie plates, raised spikes, rail wear, gage of rail, ballast height relative to ties, size of ballast stones, and break or separation in the rail. The system includes one or more algorithms for determining these measurable aspects of the railroad track.

Owner:LORAM TECH INC

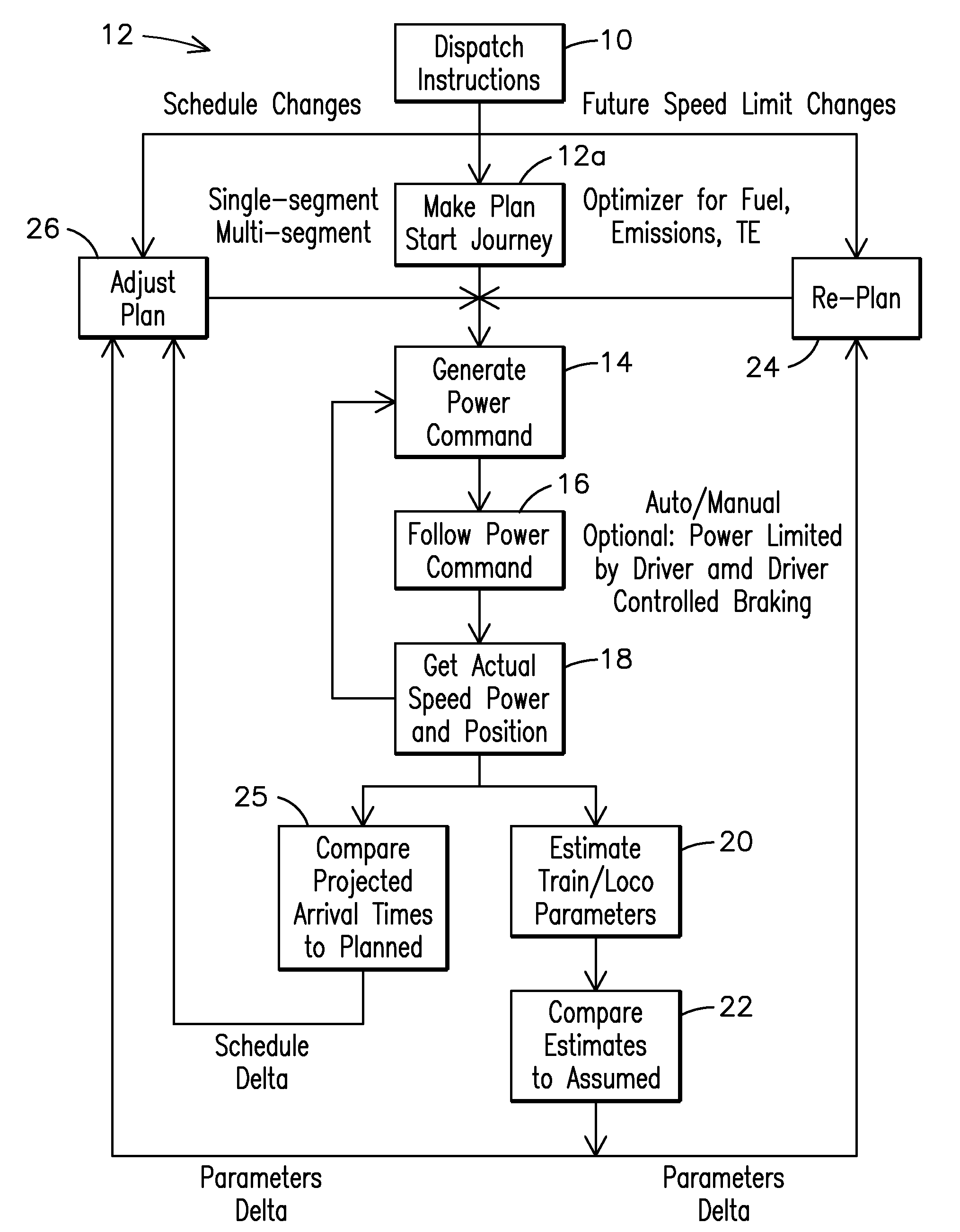

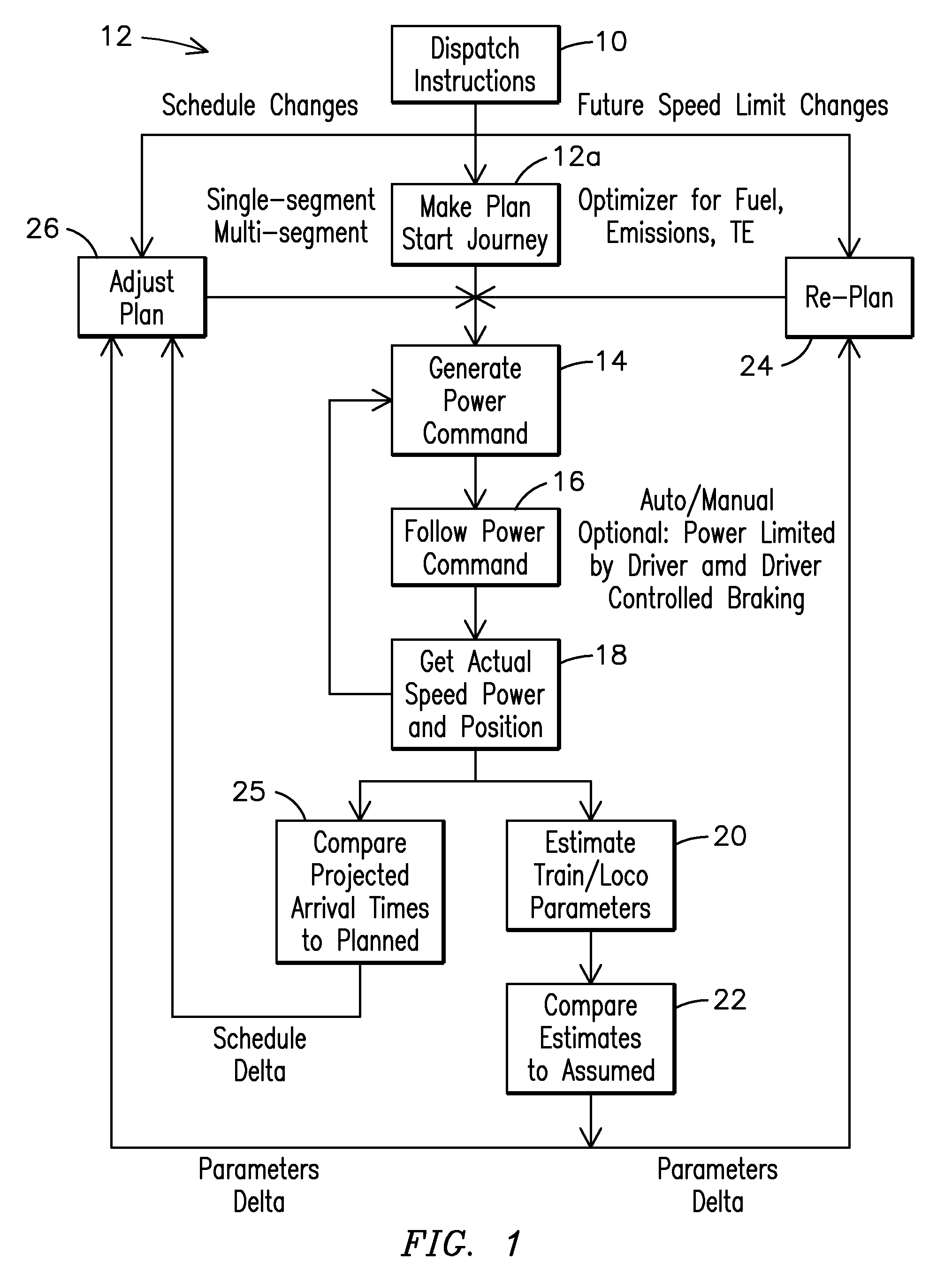

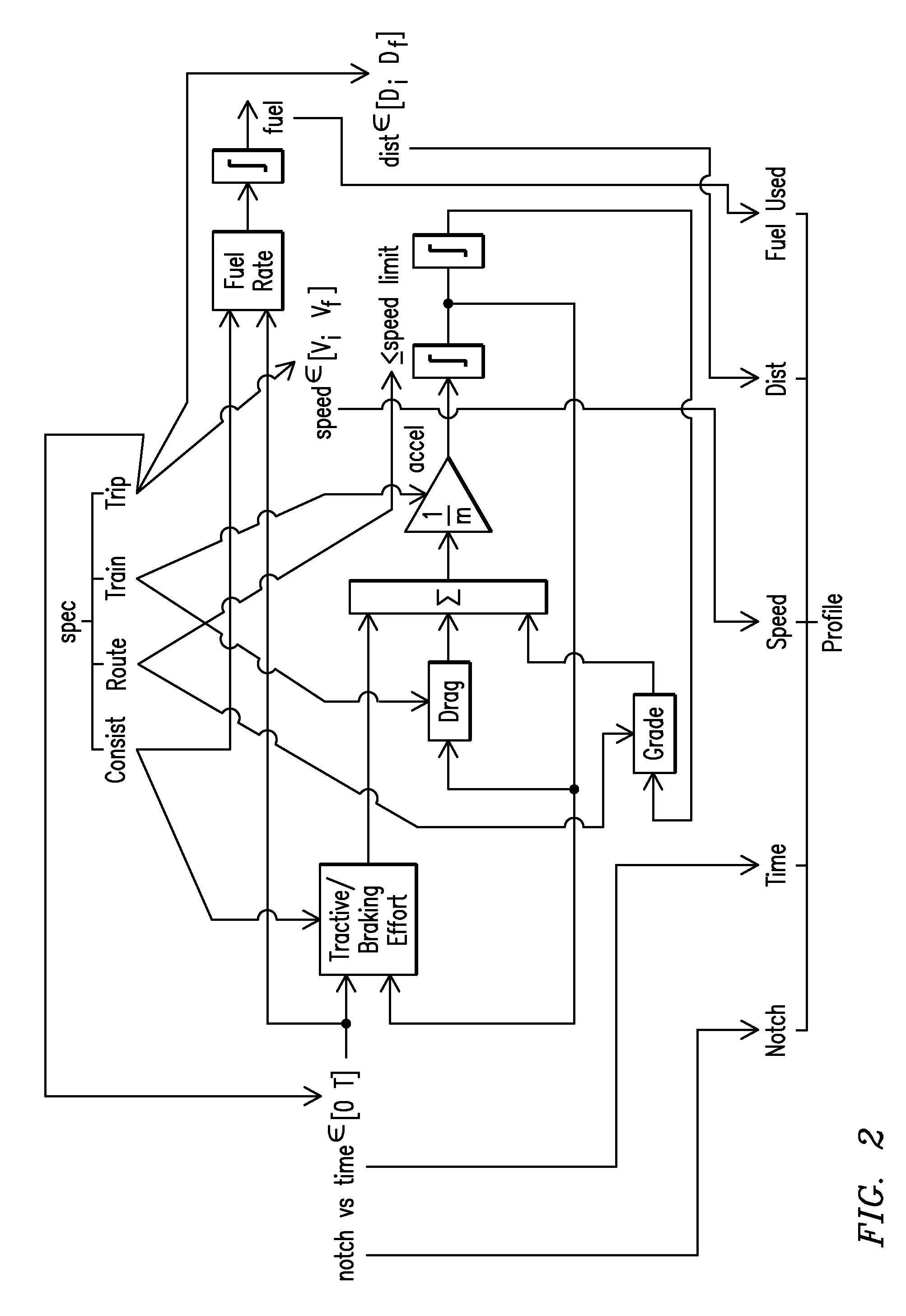

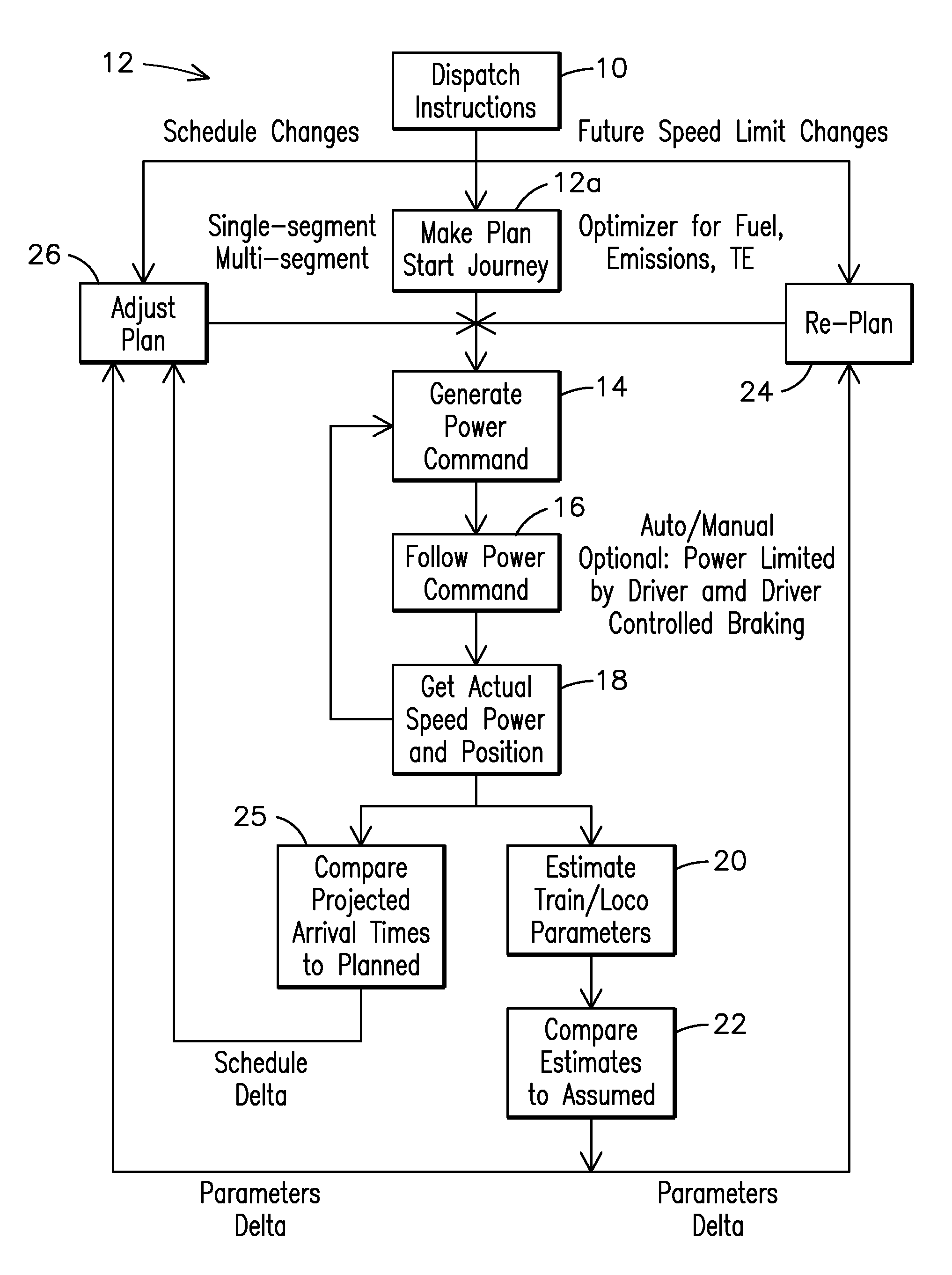

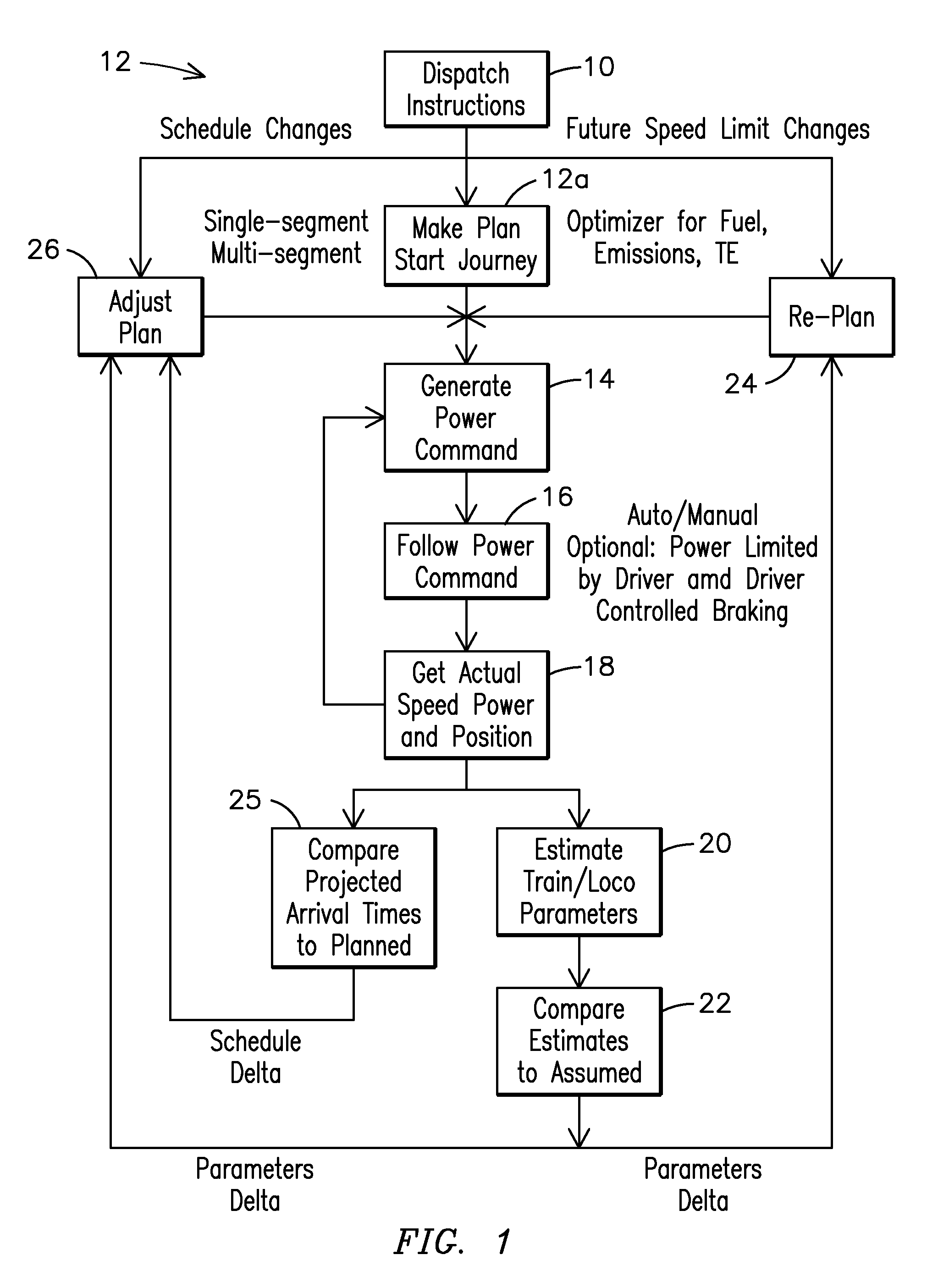

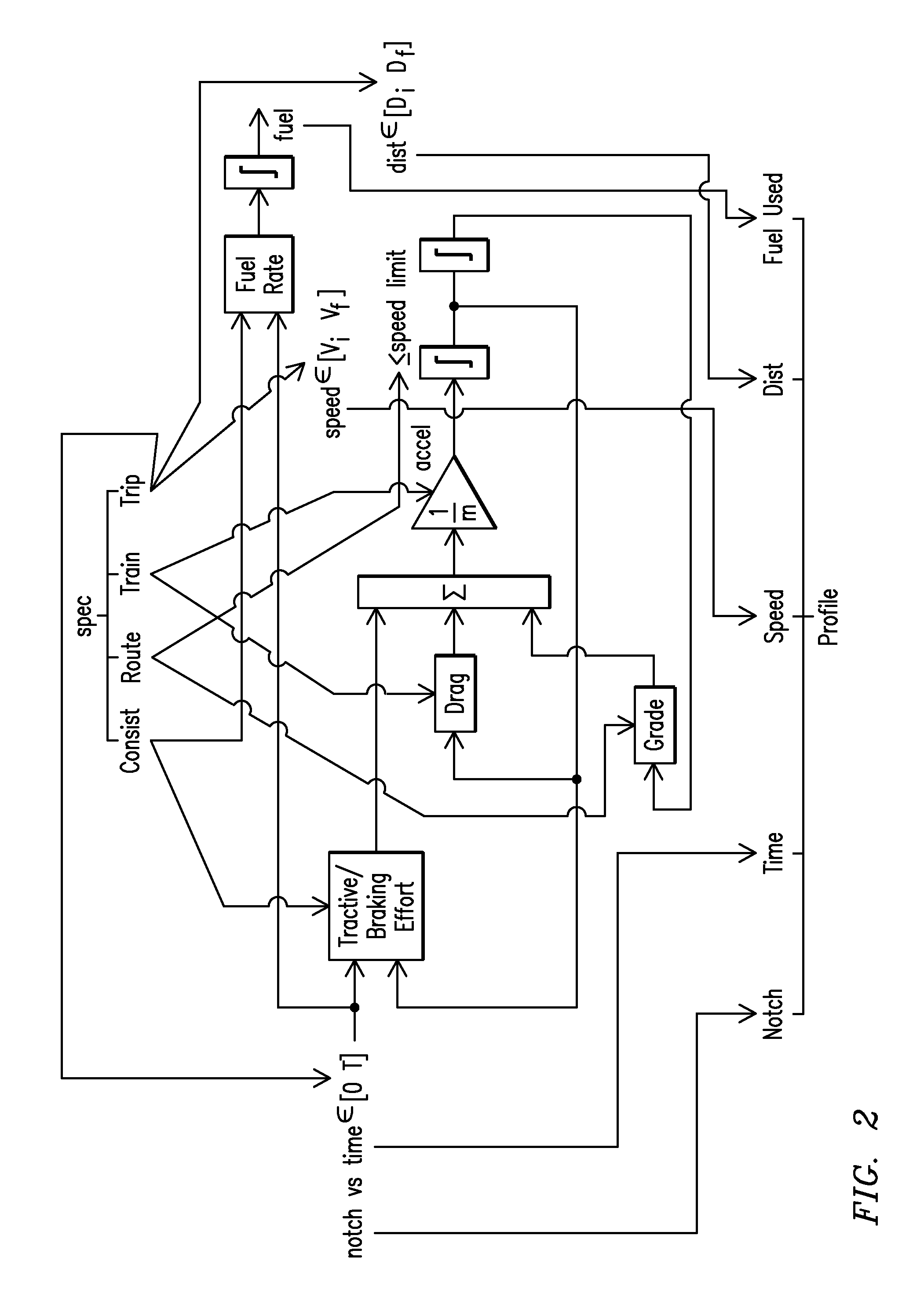

Trip optimizer method, system and computer software code for operating a railroad train to minimize wheel and track wear

ActiveUS20100023190A1Reduce the overall heightShorten speedDigital data processing detailsTrack side maintainanceWheel wearComputer software

A system for controlling a railroad train over a segment of track. The system comprises a first element for determining a location of the train on the segment of track; a second element for providing track characterization information for the segment of track; the track characterization information related to physical conditions of the segment of track; and a processor for controlling applied tractive forces and braking forces of the train responsive to the location of the train and the track characterization information to reduce at least one of wheel wear and / or track wear during operation of the train over the segment of track.

Owner:GE GLOBAL SOURCING LLC

System and method for inspecting railroad track

A system and method for inspecting railroad track is disclosed. The disclosed system includes lasers, cameras, and a processor. The lasers are positioned adjacent the track. The laser emits a beam of light across the railroad track, and the camera captures images of the railroad track having the beam of light emitted thereon. The processor formats the images so that they can be analyzed to determine various measurable aspects of the railroad track. The disclosed system can include a GPS receiver or a distance device for determining location data. The measurable aspects that can be determined by the disclosed system include but are not limited to the spacing between crossties, the angle of ties with respect to rail, cracks and defects in surface of ties, missing fastener components, misaligned fastener components, sunken tie plates, raised spikes, rail wear, gage of rail, ballast height relative to ties, size of ballast stones, and break or separation in the rail. The system includes one or more algorithms for determining these measurable aspects of the railroad track.

Owner:LORAM TECH INC

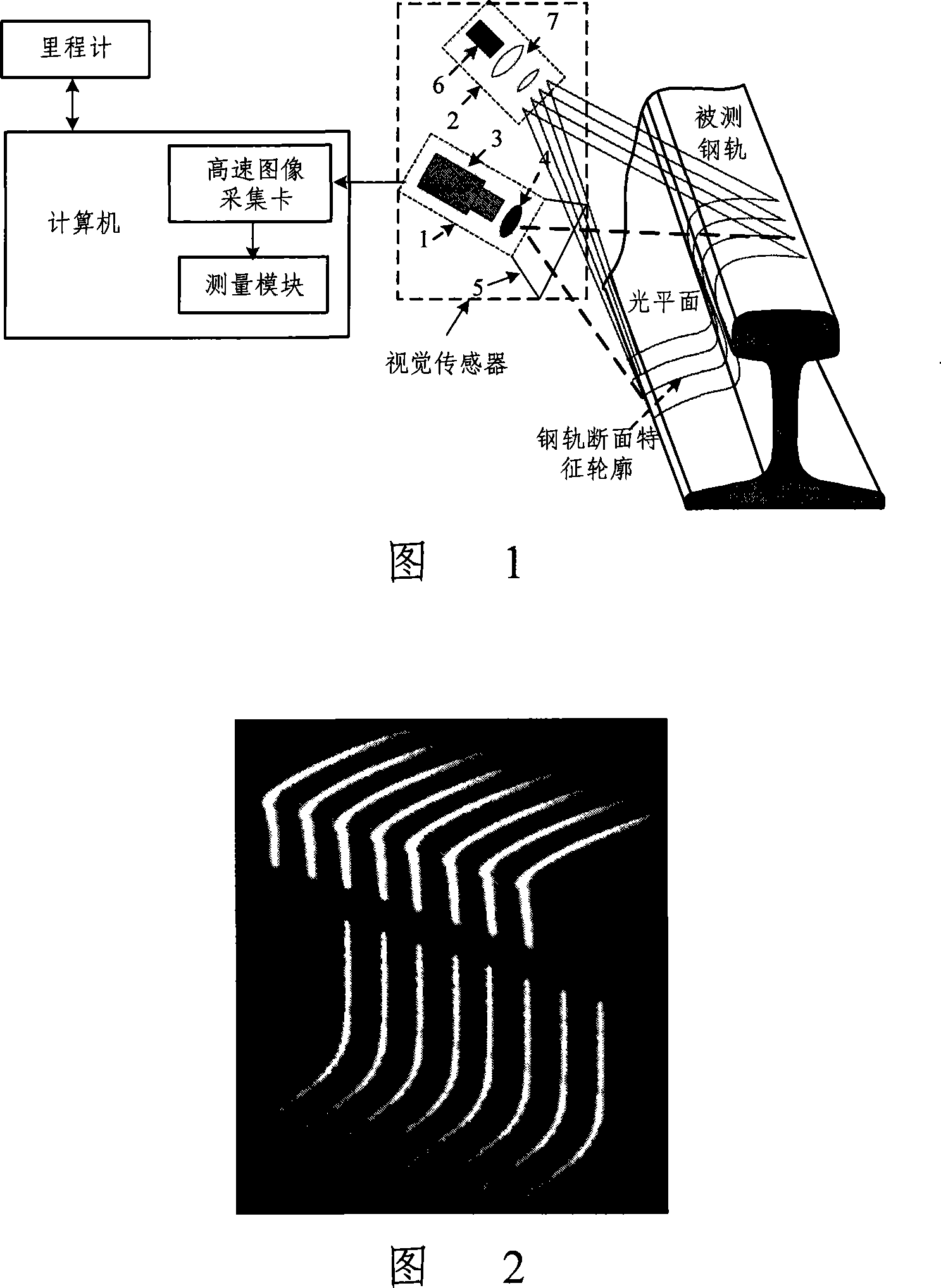

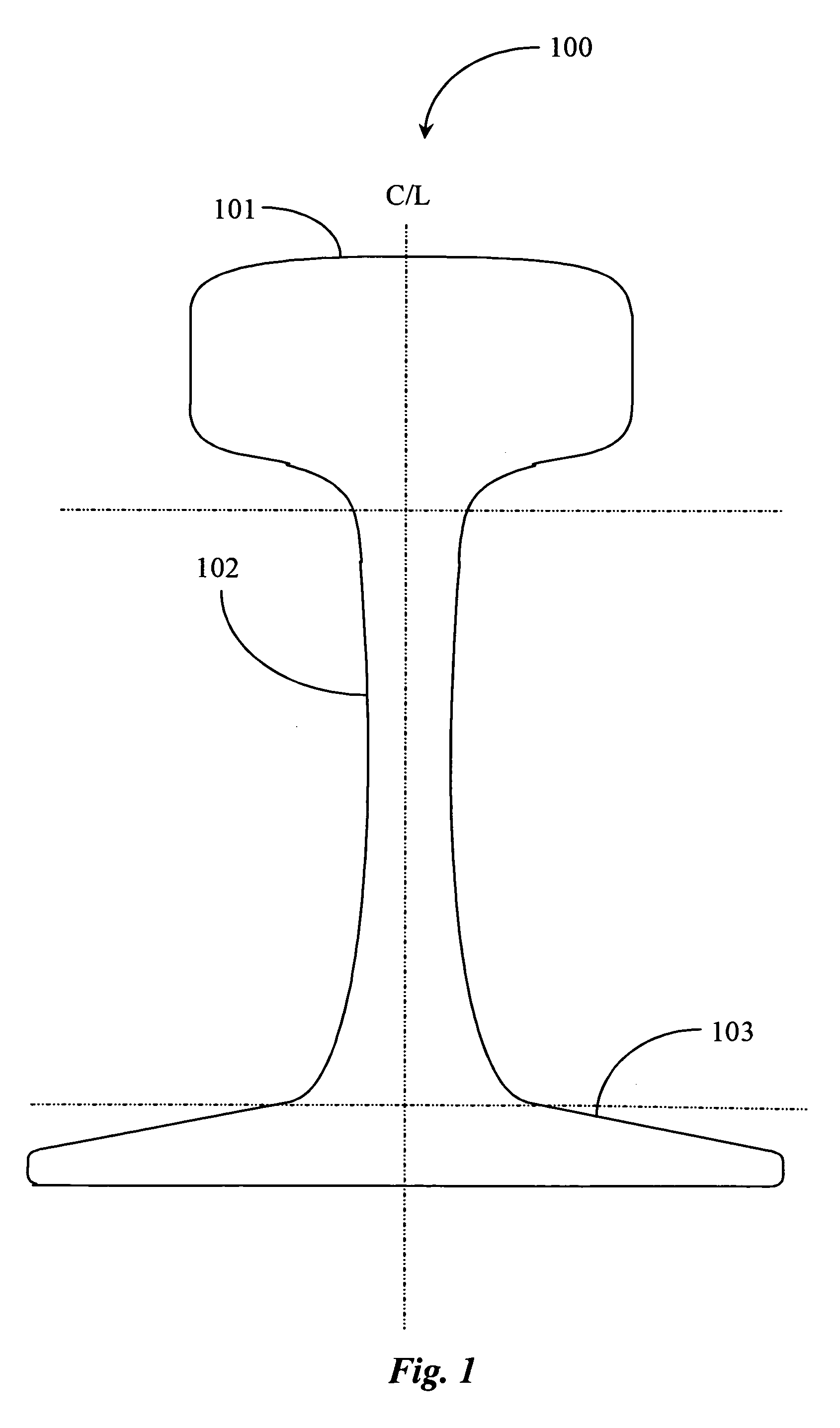

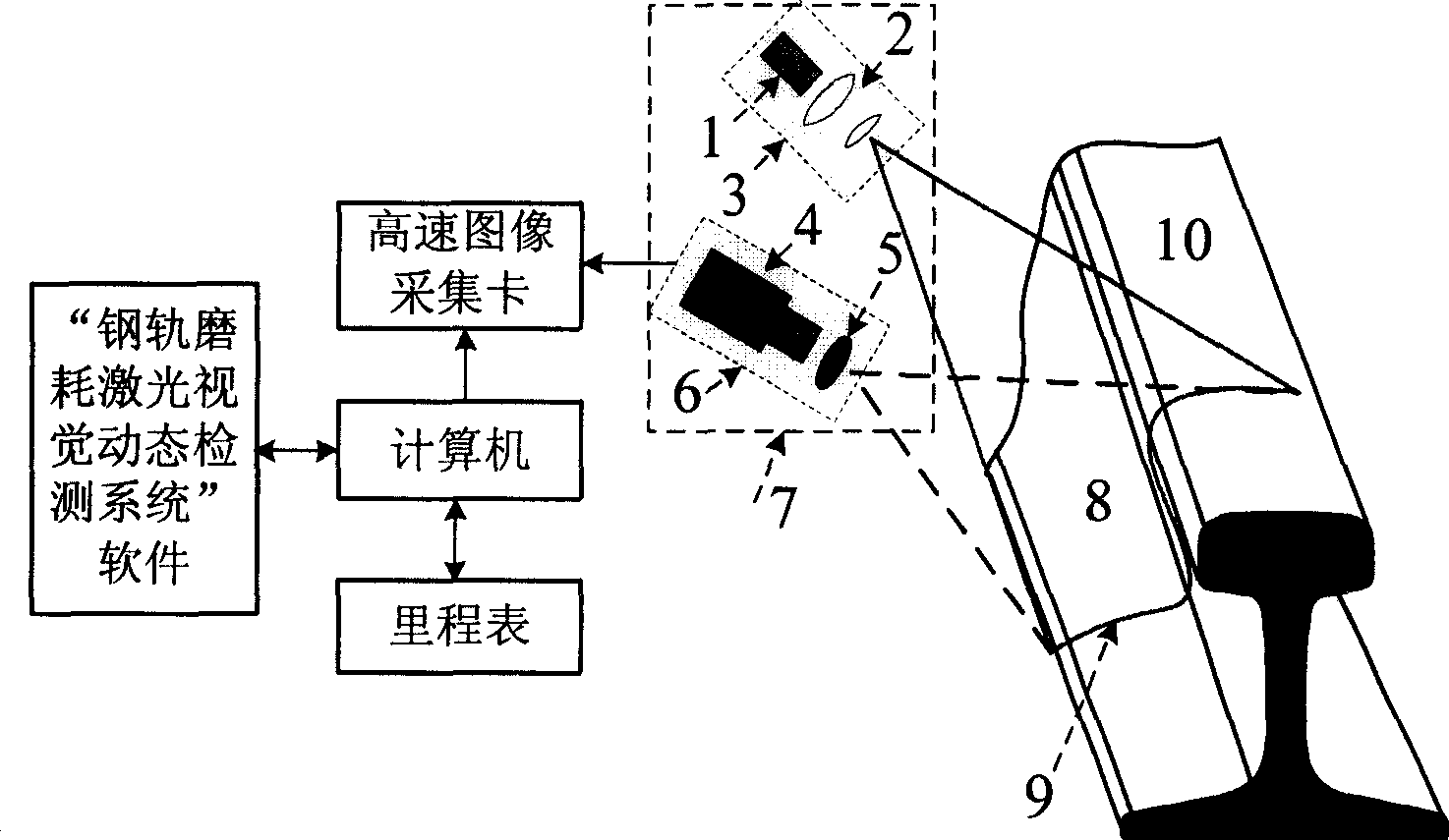

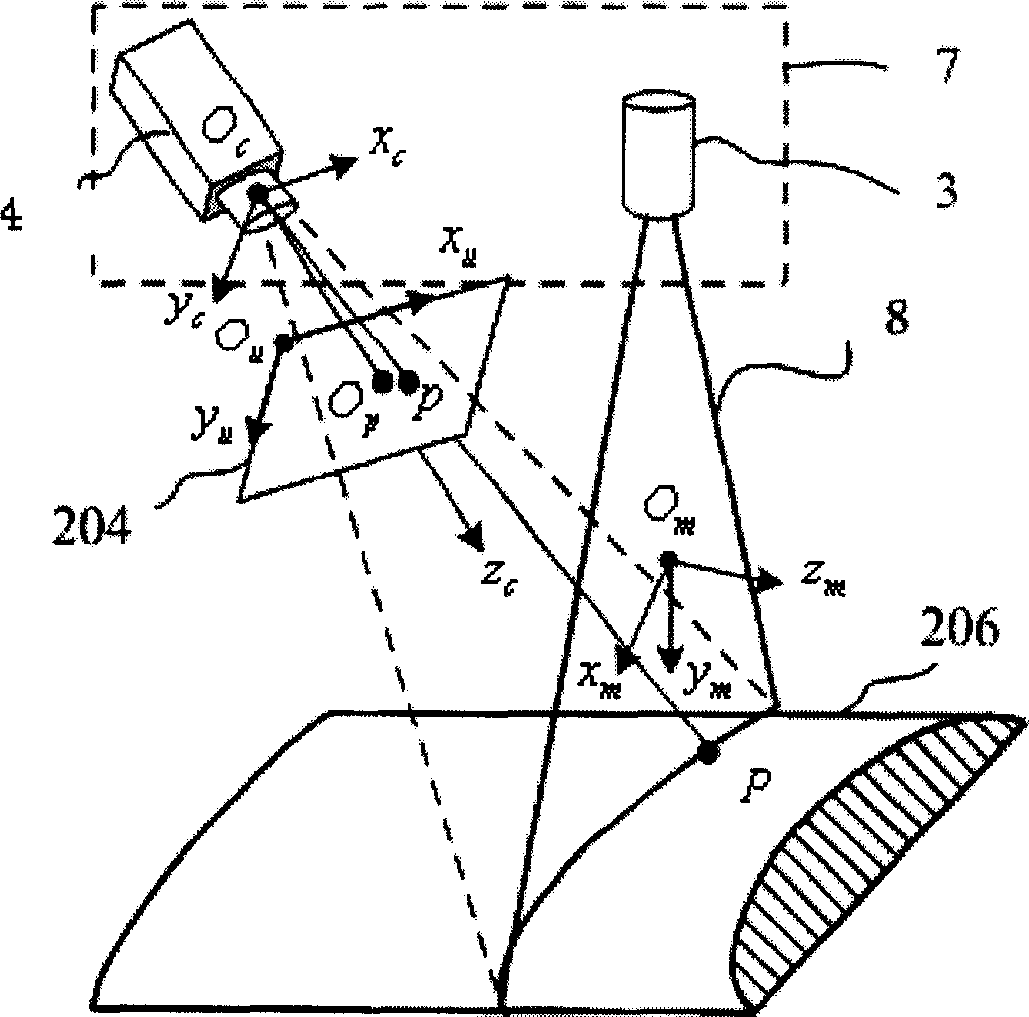

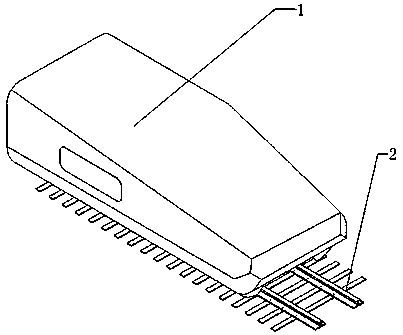

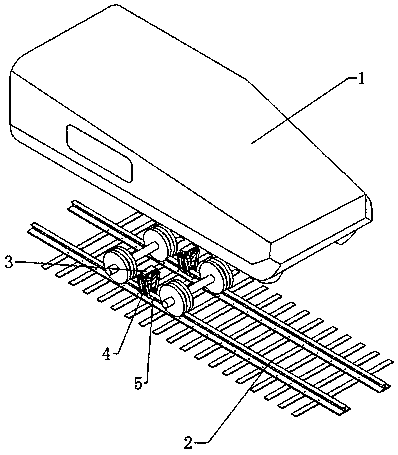

Steel rail wearing integrative parameter vehicle-mounted dynamic measuring device and method

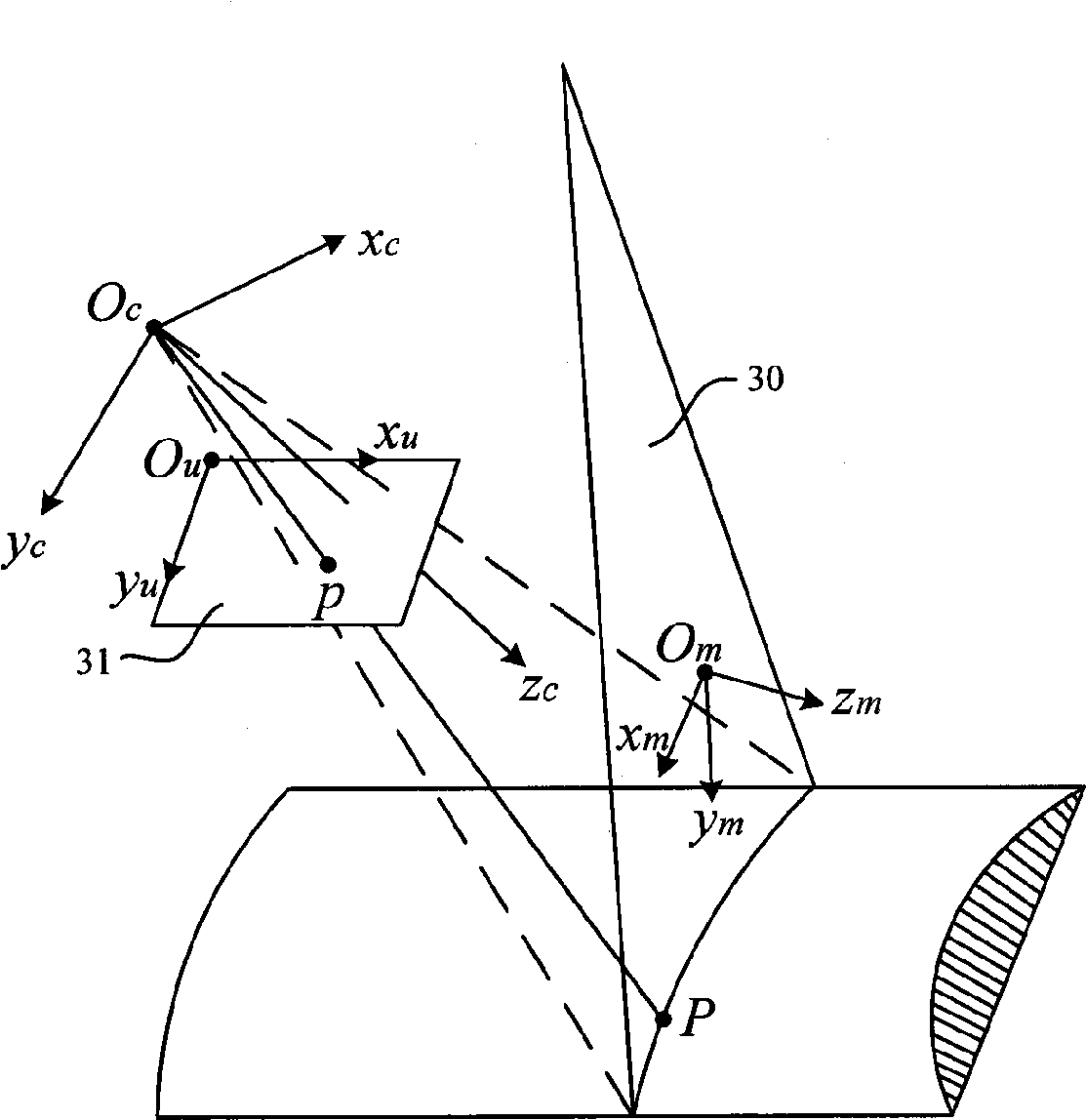

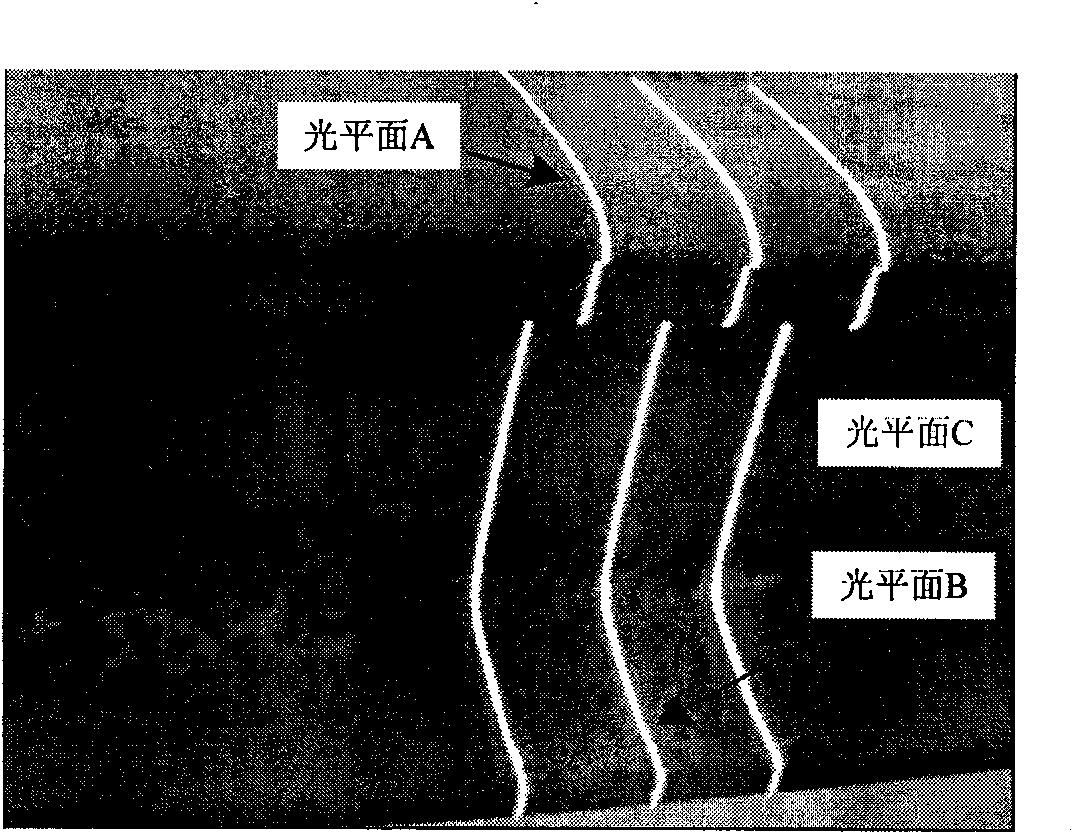

InactiveCN101144714AIncrease sampling intensityMeet the requirements of high-speed online dynamic measurementUsing optical meansRailway auxillary equipmentVehicle dynamicsMeasurement device

The invention discloses a vehicle dynamic measuring device of a steel rail abrasion integrated parameter, and the vehicle dynamic measuring device comprises a visual sensor, a computer and a mileometer, wherein, a high speed image acquisition card and a measuring module are installed in the computer, the visual sensor comprises a steel rail section image system and an optical grating projector, the optical grating projector can project out more than one light planes vertical to a measured steel rail, the measuring module is used for obtaining the vertical abrasion of the steel rail, the lateral surface abrasion, the wave depth and the wave length of the wave abrasion; the invention also discloses a vehicle dynamic measuring method of a steel rail abrasion integrated parameter. The adoption of the device and the method described in the invention can improve a sampling intensity under the condition of not improving the performance of the image sensing and an acquisition hardware equipment, thereby meeting the high speed online dynamic measurement requirement of the wave abrasion, and obtaining the exact wave depth and the wave length of the wave abrasion.

Owner:BEIHANG UNIV

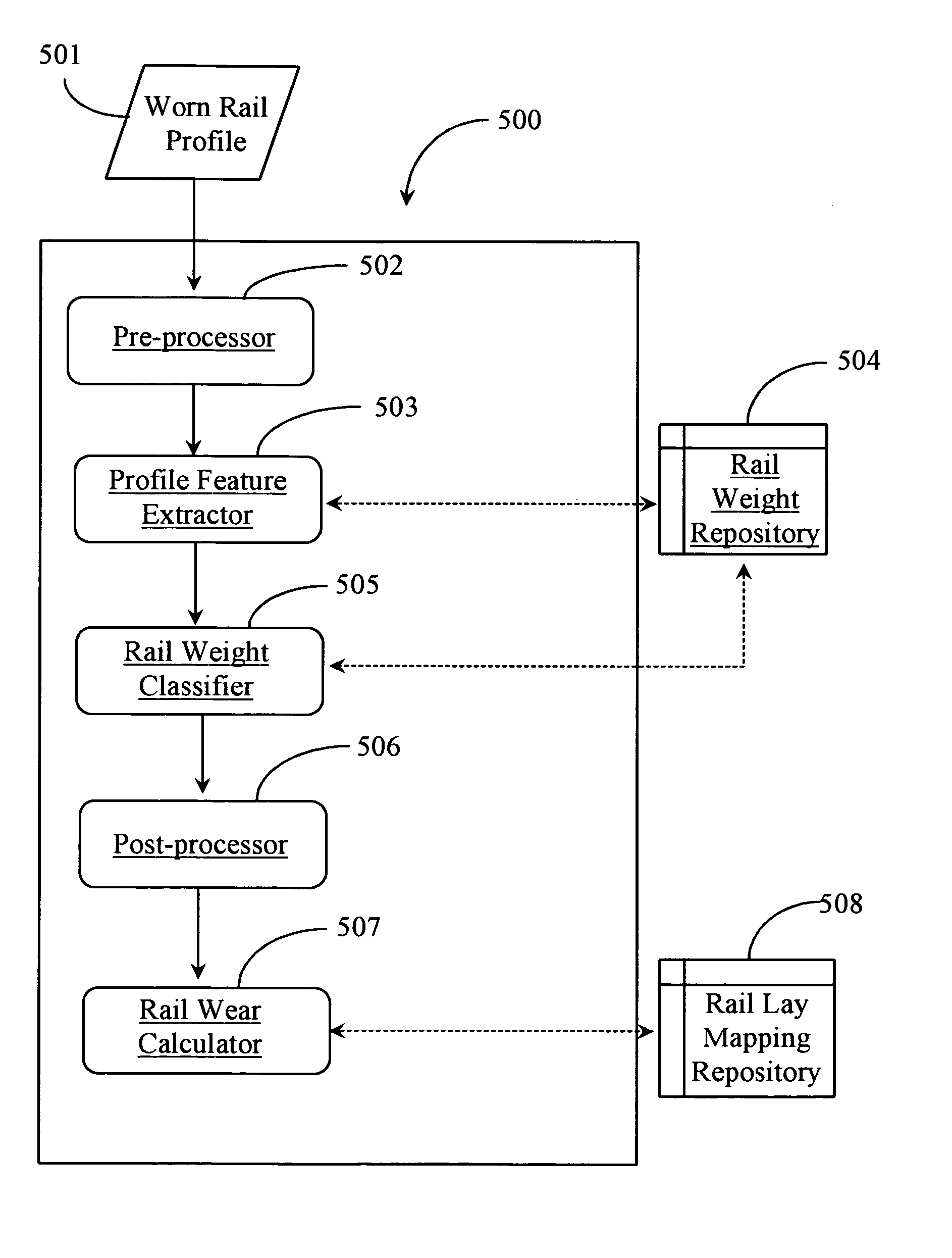

Enhanced method and apparatus for deducing a correct rail weight for use in rail wear analysis of worn railroad rails

InactiveUS20050279240A1Easy selectionBroaden applicationBallastwayTrain hauling devicesMeasurement deviceEngineering

A system for identifying rail weights applicable to worn railroad rails measured along a railroad track system includes at least one track measurement device for recording at least a portion of a profile shape of the worn rails, and, a data processor running a software implement for accepting recorded data as input data from the at least one track measurement device and for processing the input data against known unworn railroad rail data to facilitate selection and application of the appropriate rail weights equated thereto to the worn railroad rails.

Owner:TATA CONSULTANCY SERVICES LTD

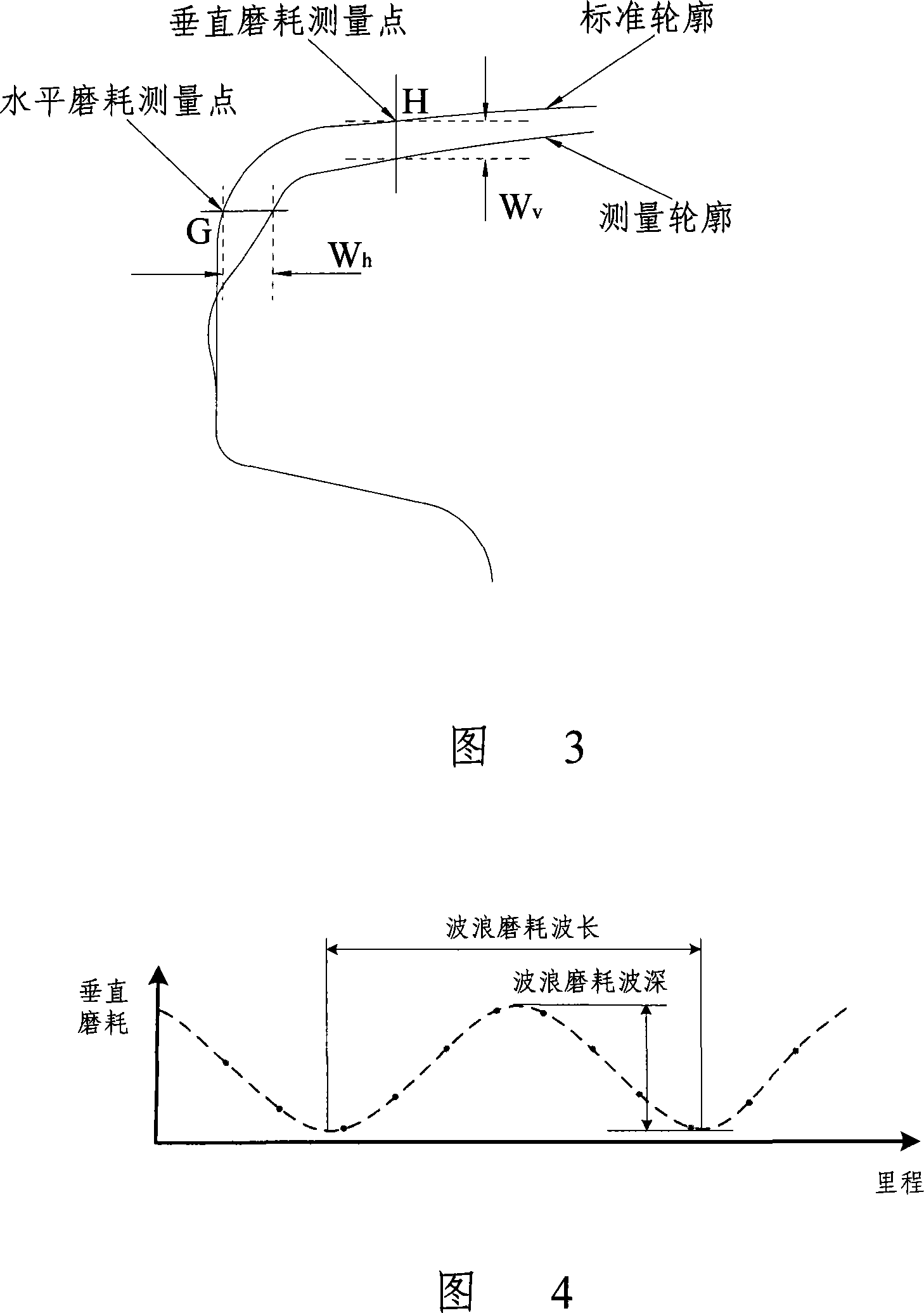

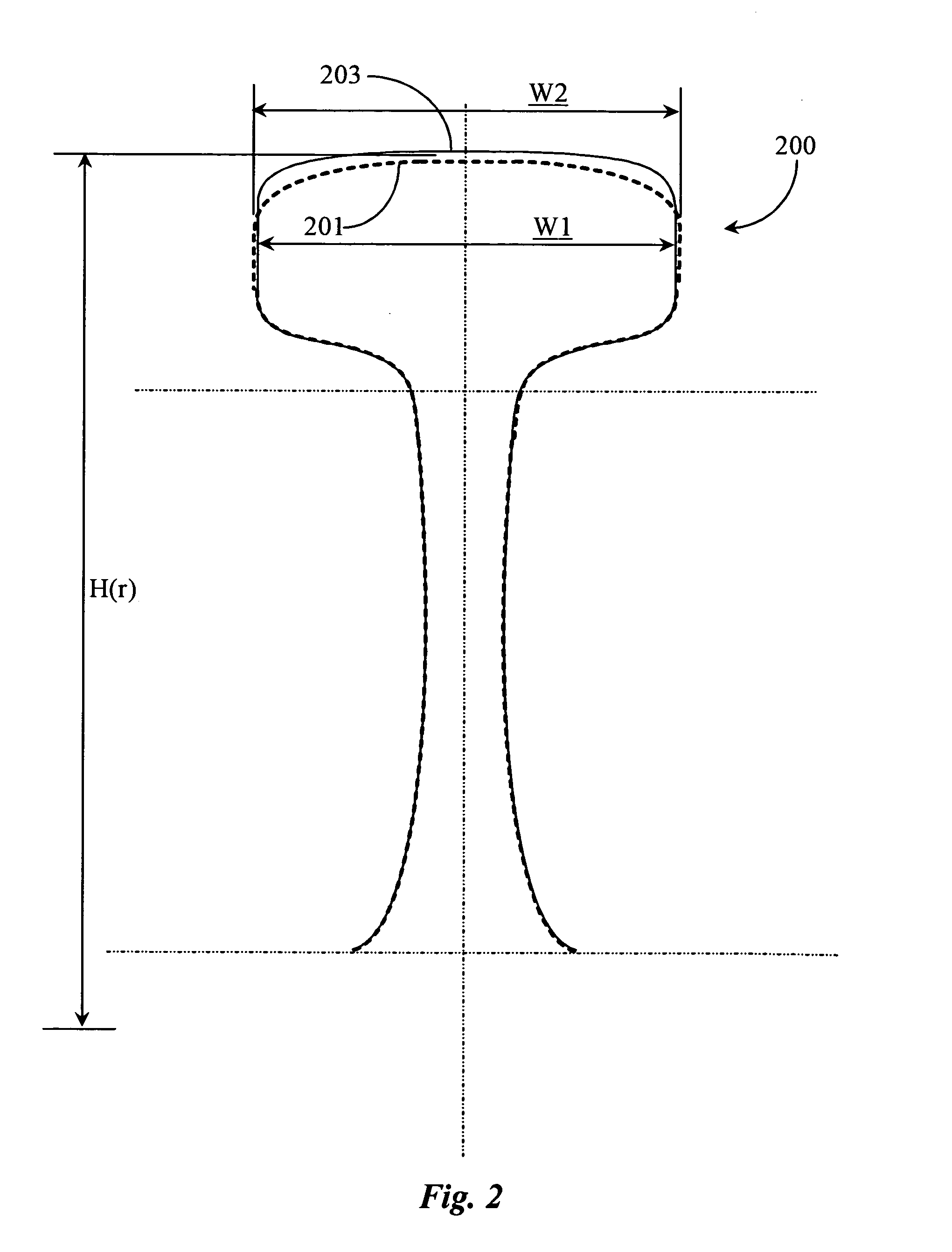

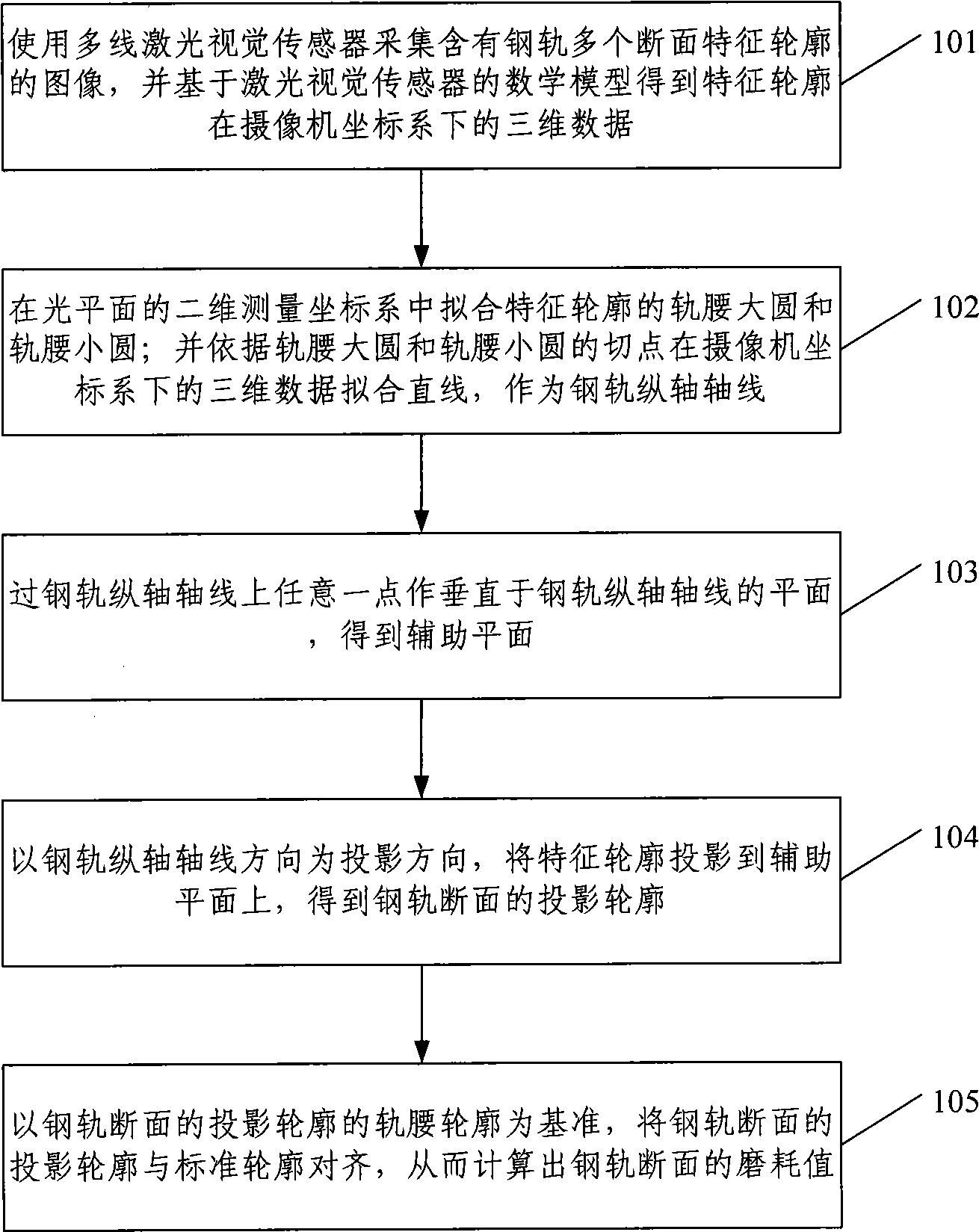

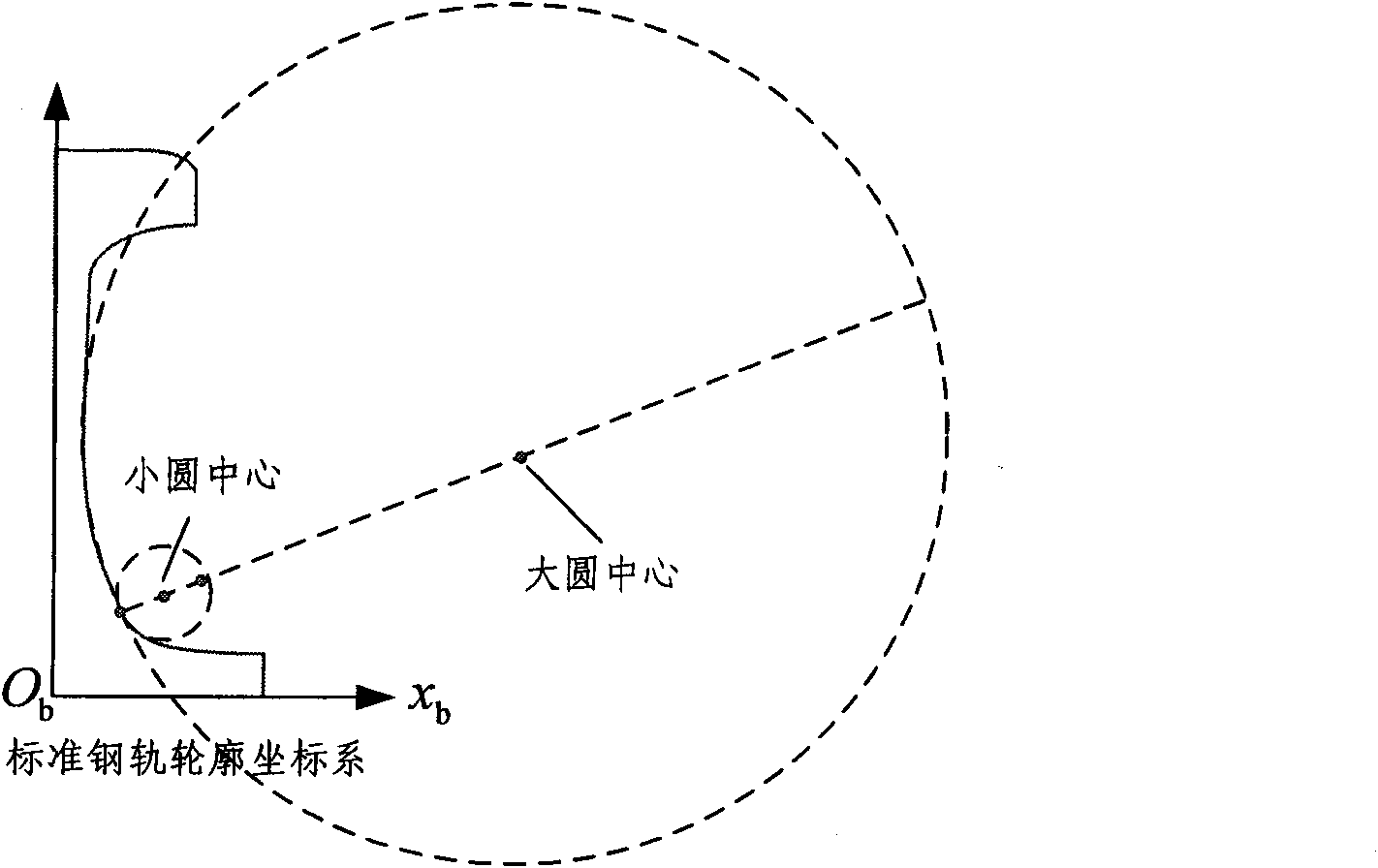

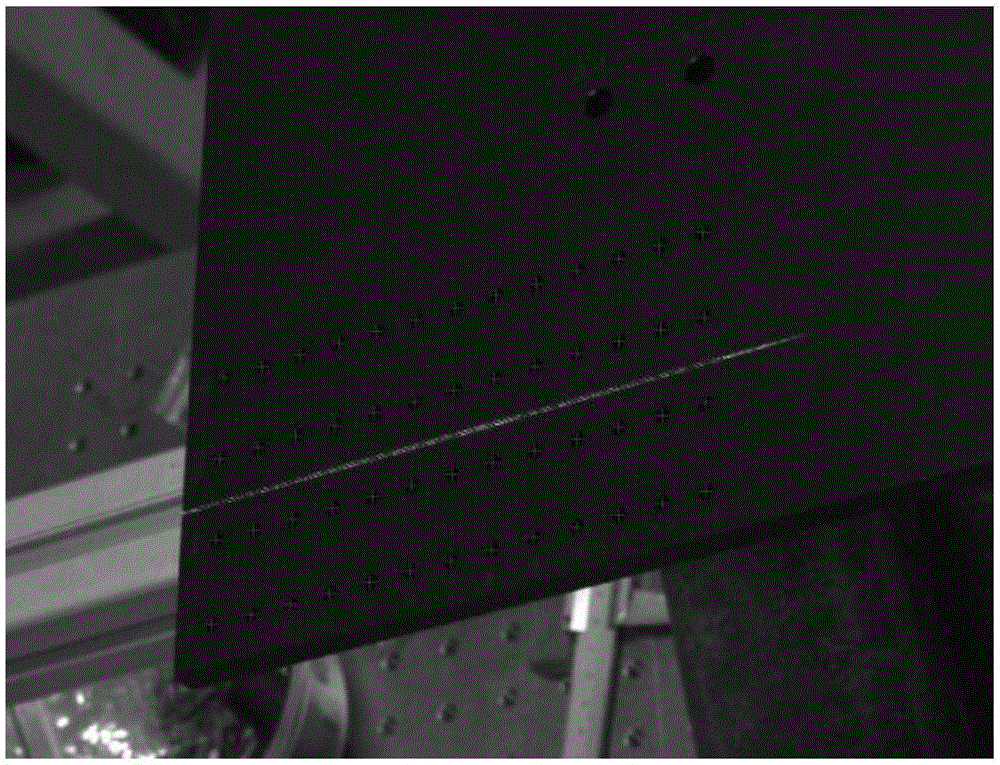

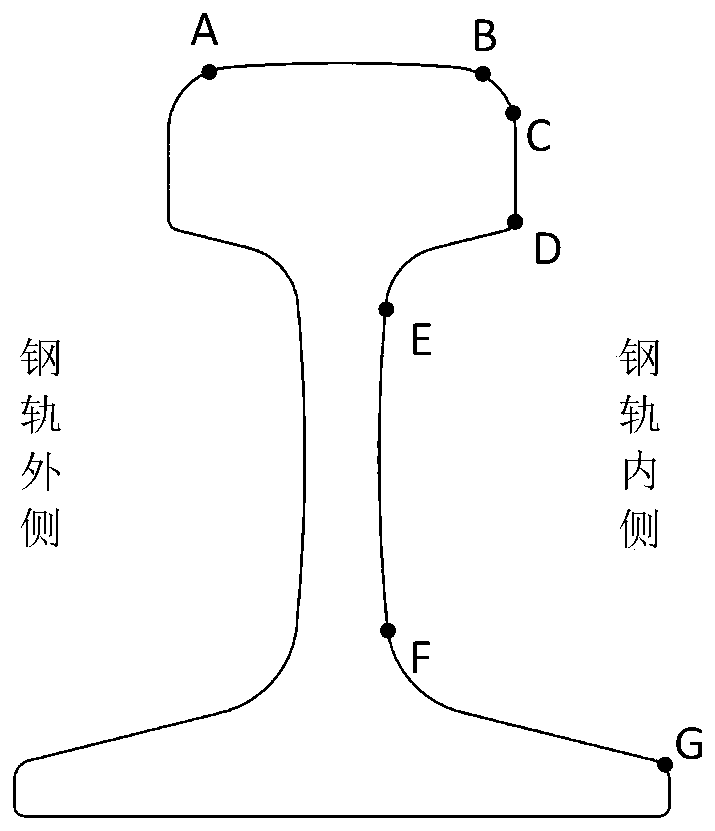

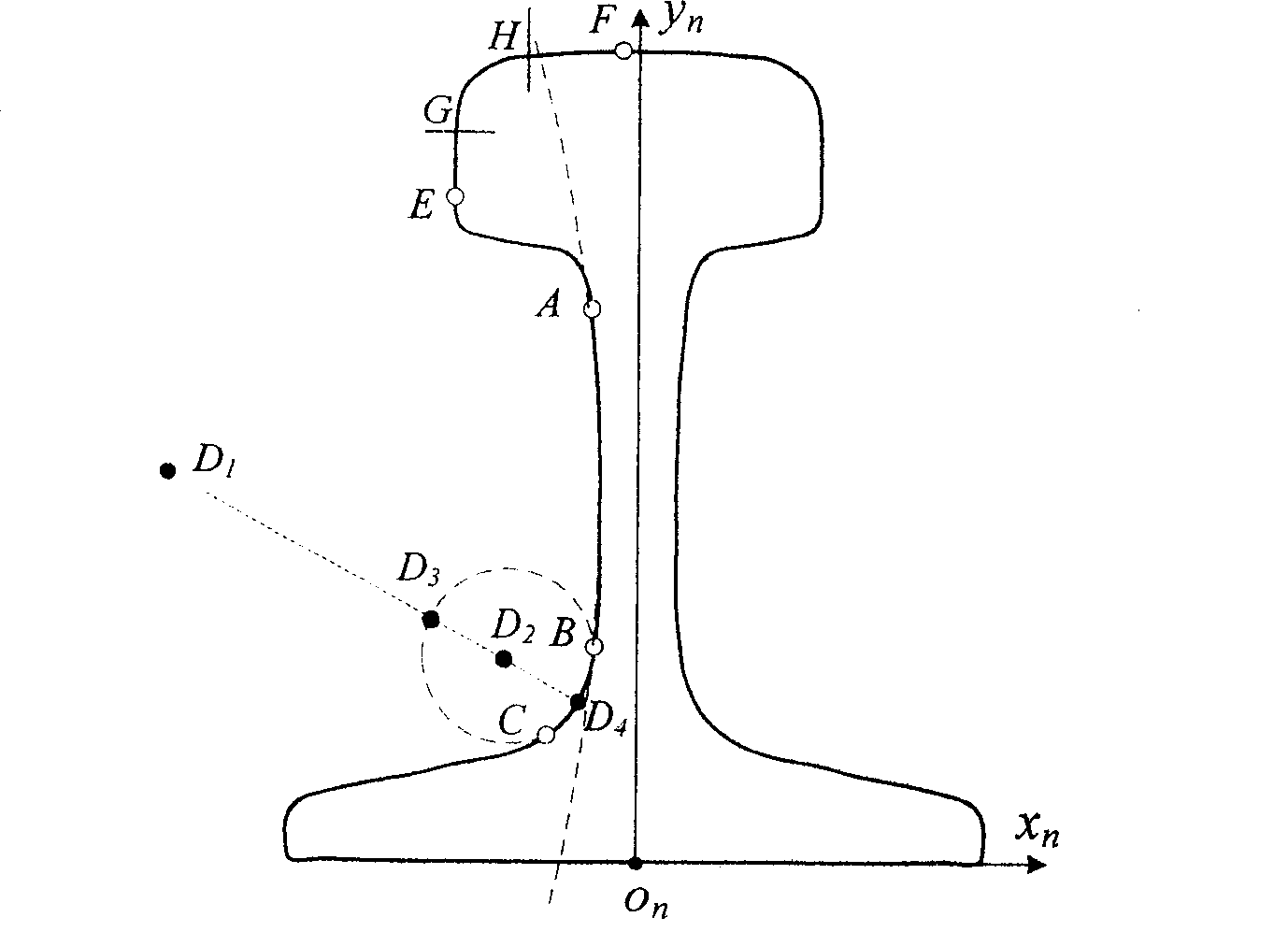

Deviation correction method for measurement of rail wear based on laser vision

InactiveCN101532827AIncrease profitEliminate Wear Measurement ErrorsUsing optical meansObservational errorEngineering

The invention discloses a deviation correction method for measurement of rail wear based on laser vision, comprising the steps of dividing a rail waist profile of a characteristic profile of dividing a cross section of a rail obtained by the measurement by a laser vision sensor into a rail waist big circle and a rail waist small circle; fitting a rail longitudinal shaft line according to a tangent point of the rail waist big circle and the rail waist small circle; projecting the characteristic profile to an auxiliary plane which is vertical to the rail longitudinal shaft line to obtain a projection profile of the cross section of the rail; and calculating the wear value of the cross section of the rail by aligning a standard profile of the cross section of the rail with the projection profile. The measurement error of the rail wear caused by that a light plane projected by the laser vision sensor is not vertical to the rail longitudinal shaft line can be eliminated based on the method.

Owner:BEIHANG UNIV

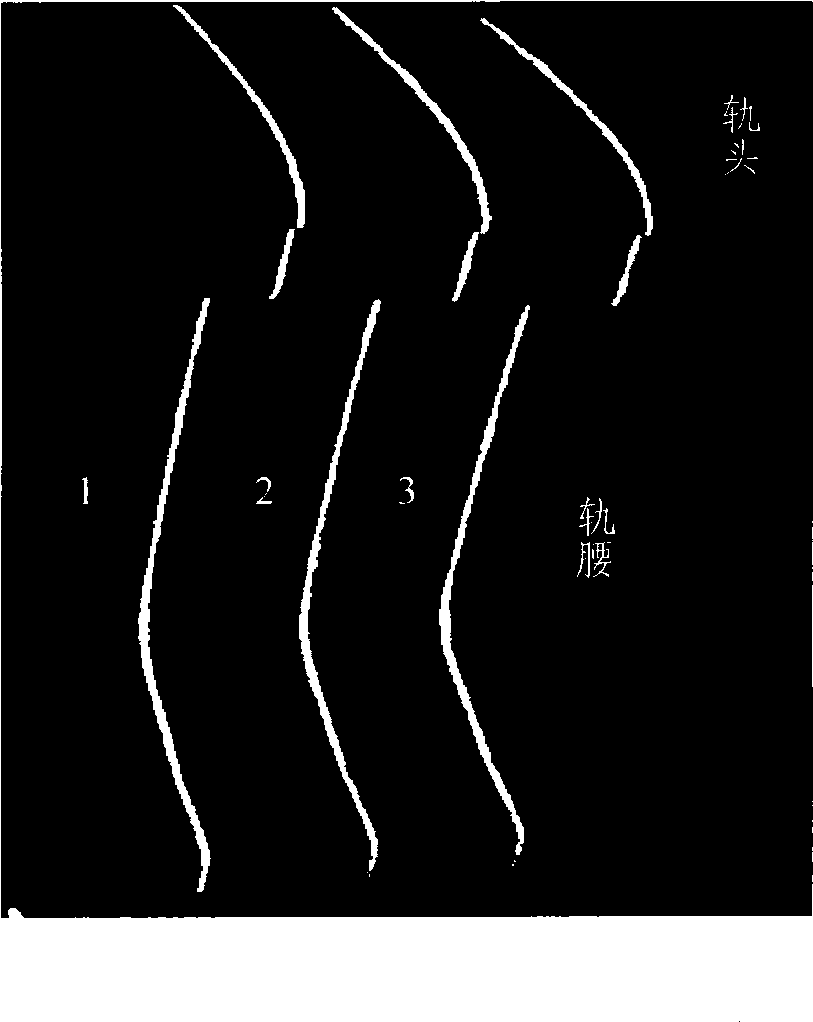

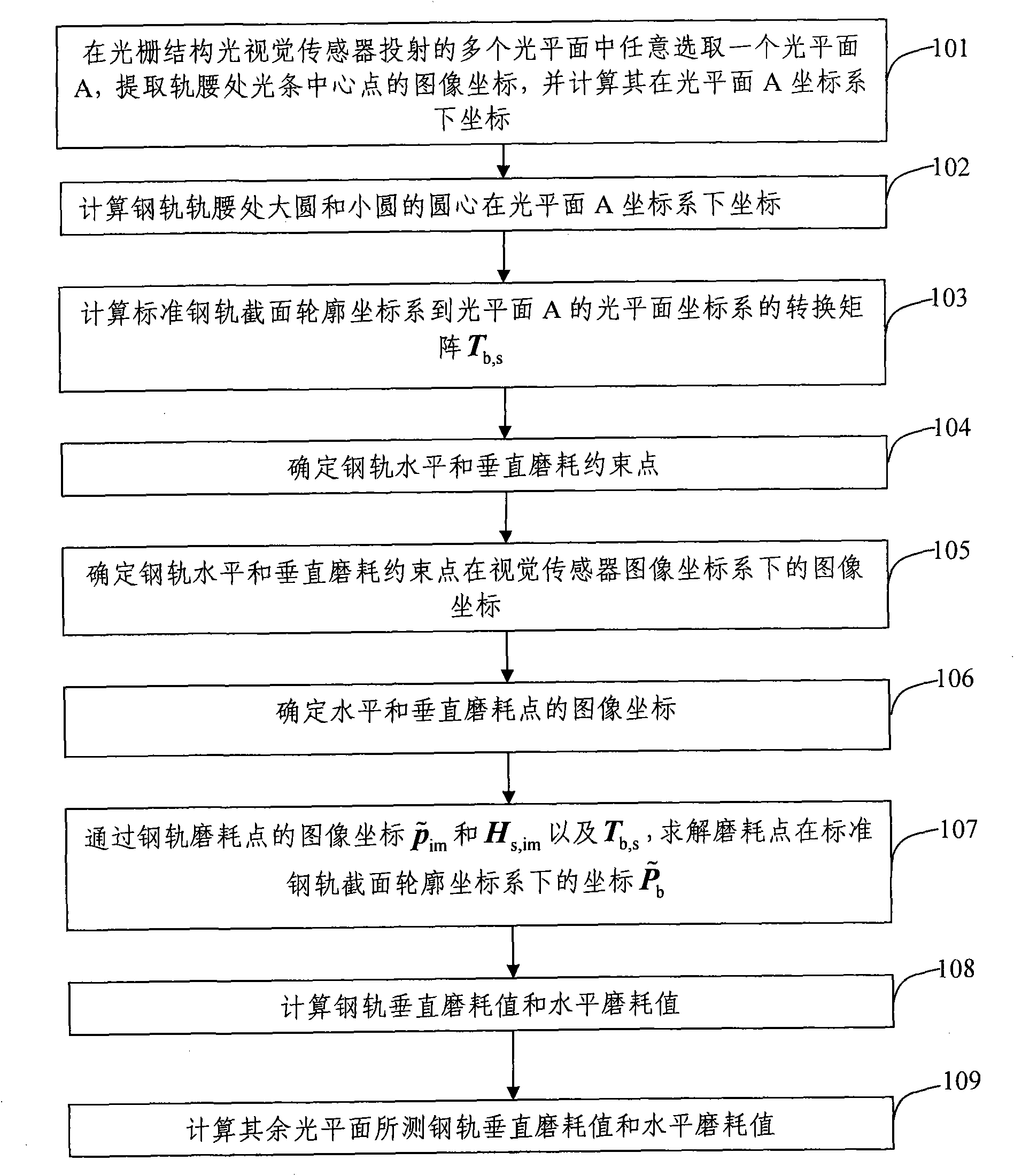

Fast processing method of laser vision image of steel rail wear

InactiveCN101576375ASmall amount of calculationRealize wear value calculationUsing optical meansRailway auxillary equipmentVideo sensorsGreat circle

The invention discloses a fast processing method of a laser vision image of steel rail wear, comprising the following steps of: projecting more than two optical planes which are mutually parallel and vertical to the axial direction of the steel rail, selecting one optical plane and projecting the optical plane to images of the rail waist of the steel rail and an optical strip of the rail head, calculating a coordinate of the center of the optical strip at the rail waist in a coordinate system of the optical plane, and calculating circle center coordinates of large circles and small circles of the rail waist in the coordinate system of the optical plane; calculating a transformation matrix between the coordinate system of the selected optical plane and a profile coordinate system of the section of the standard steel rail; respectively determining intersection points of line segment and the optical strip of the rail head between the constraint points of vertical wear and the constraint points of horizontal wear in the image plane of a video sensor; carrying out inverse transformation on the image coordinate of the vertical wear point and horizontal wear point to the profile coordinate system of the section of the standard steel rail, and determining the coordinate of the vertical wear point and horizontal wear point of the steel rail in the profile coordinate system of the section of the standard steel rail, and the vertical distance and horizontal distance between the vertical wear point and the horizontal wear point of the steel rail and the profile of the standard steel rail, namely the wear value of the measured steel rail. The detection efficiency of the wear value of the steel rail is improved greatly.

Owner:BEIHANG UNIV

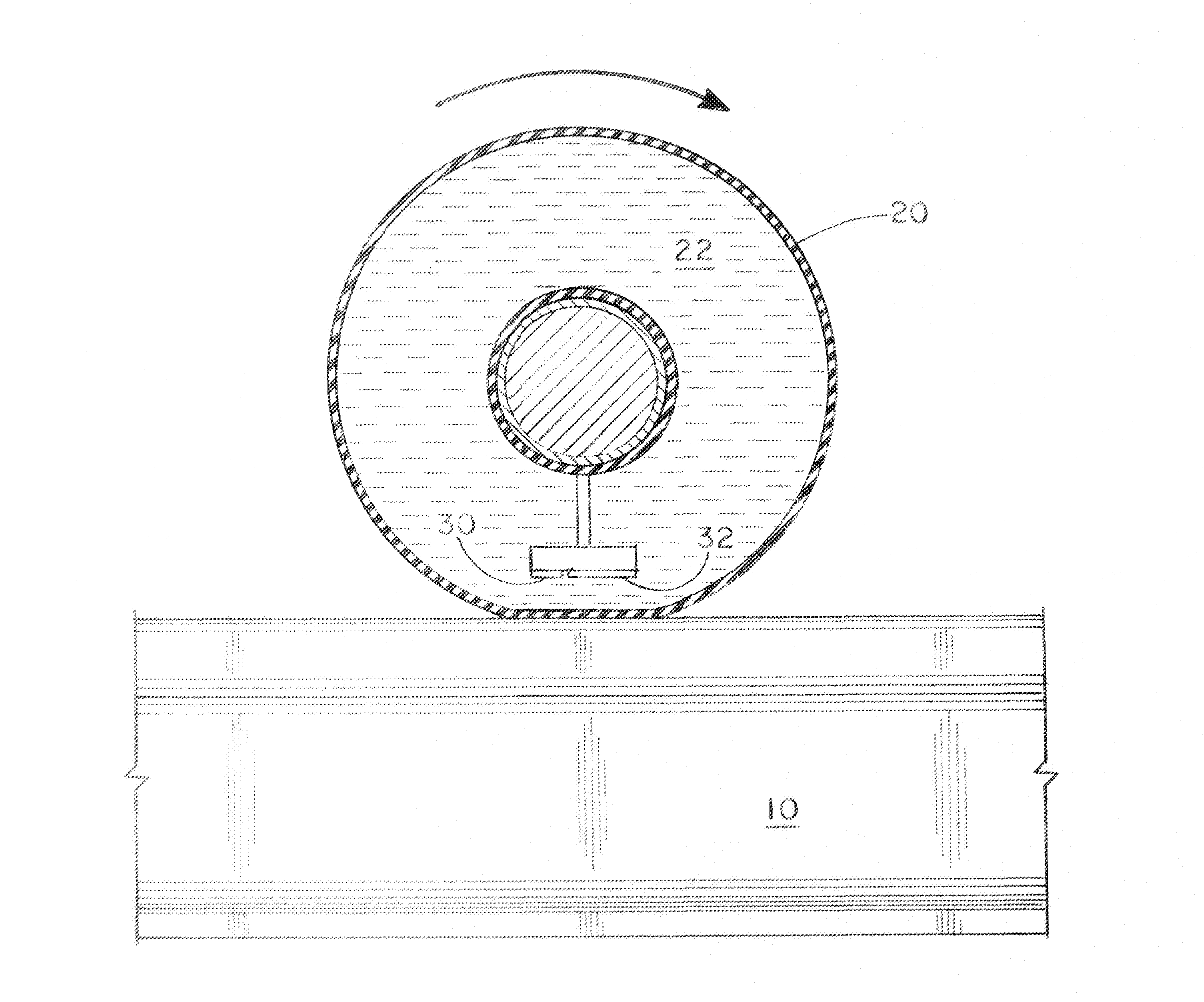

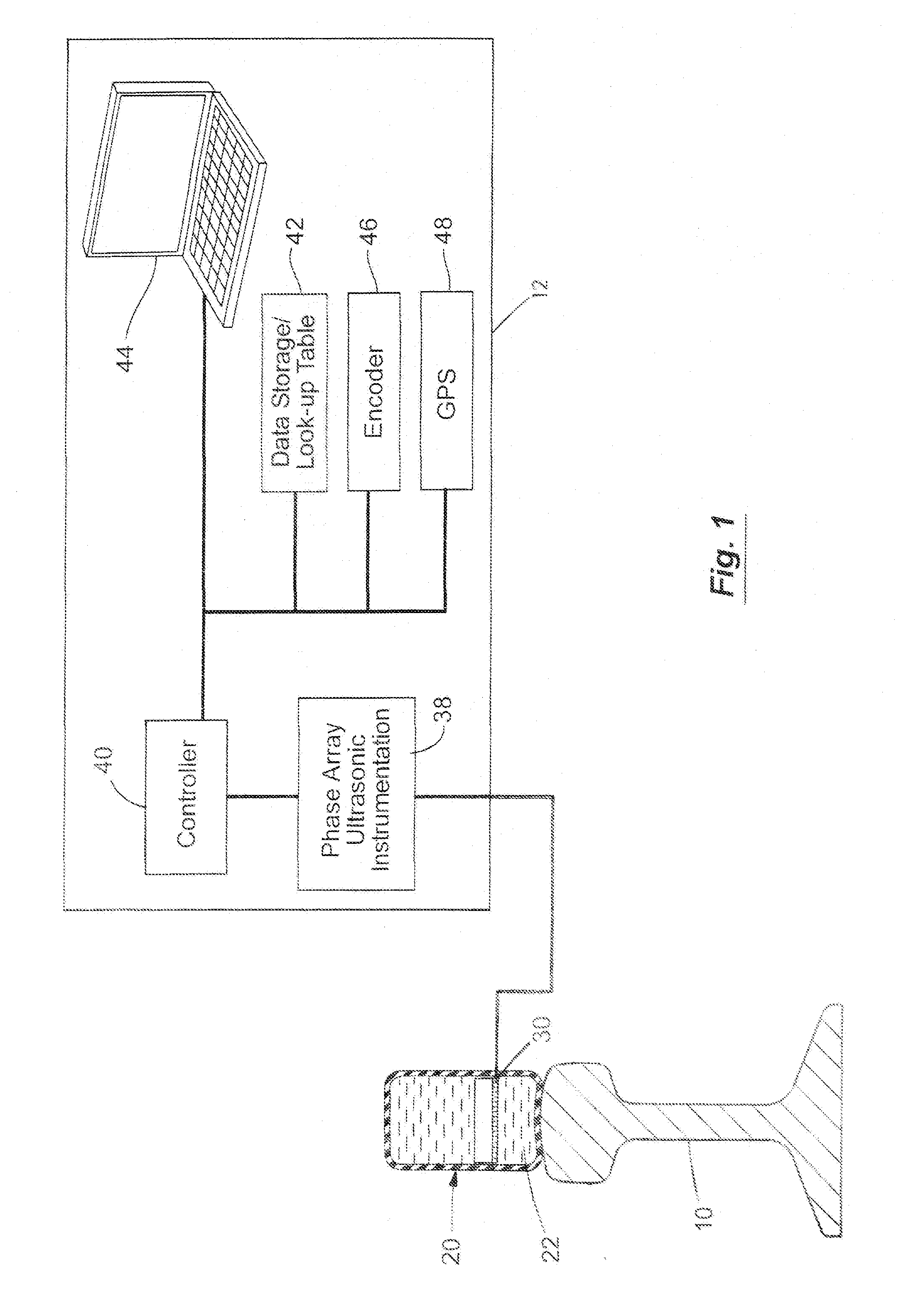

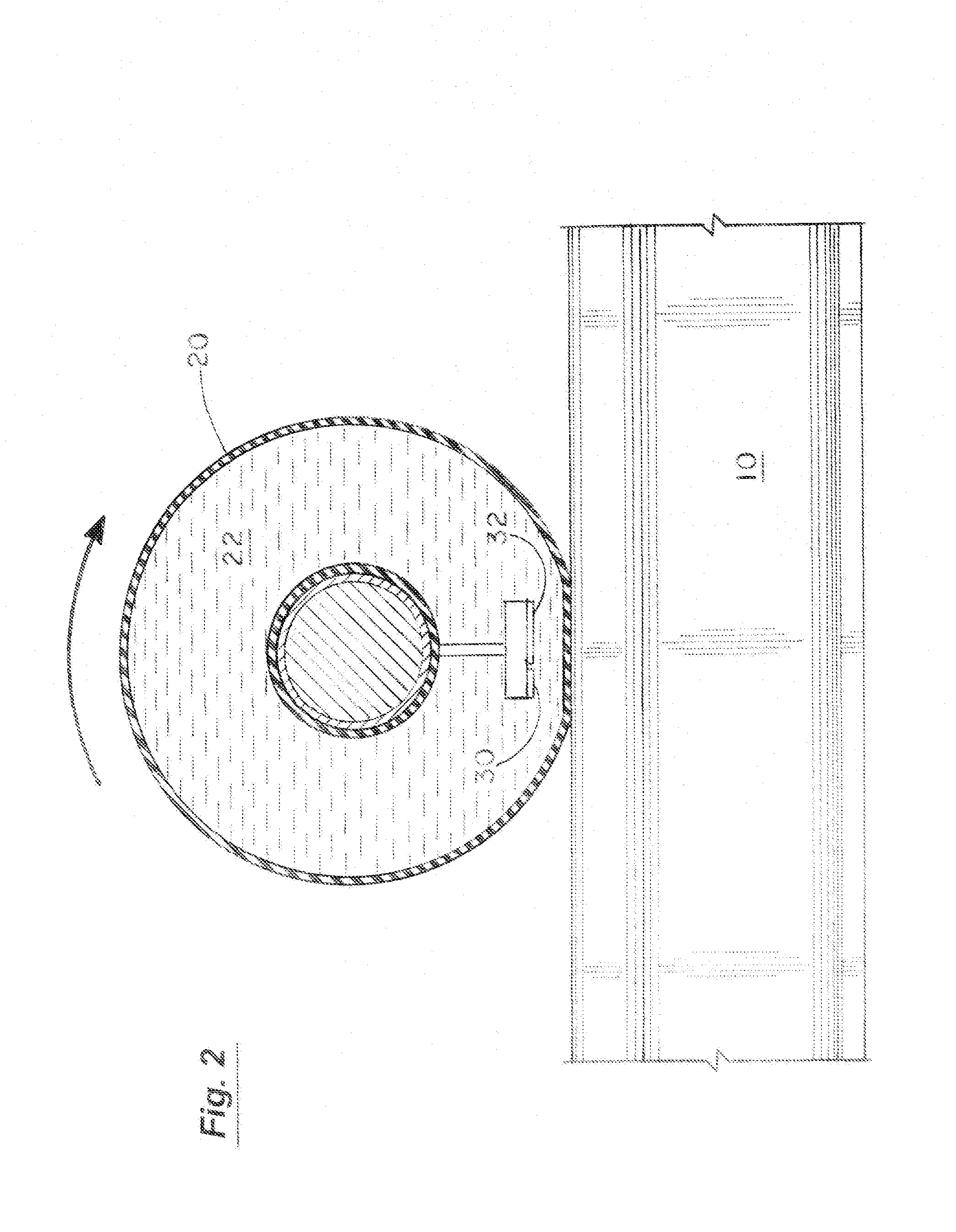

System for inspecting rail with phased array ultrasonics

InactiveUS20160304104A1Make up for deficienciesCompensation effectAnalysing solids using sonic/ultrasonic/infrasonic wavesSignalling indicators on vehicleRail profileEngineering

A system for inspecting railroad rail using phased array ultrasonic technology measures the time of flight of ultrasonic signals at locations across the rail head to determine the wear profile of the rail. The rail wear profile is then used to adjust the focal laws of the phased array ultrasonic probes to dynamically compensate for changes in the rail profile as the inspection vehicle moves along the rails.

Owner:TRANSPORTATION TECH CENT

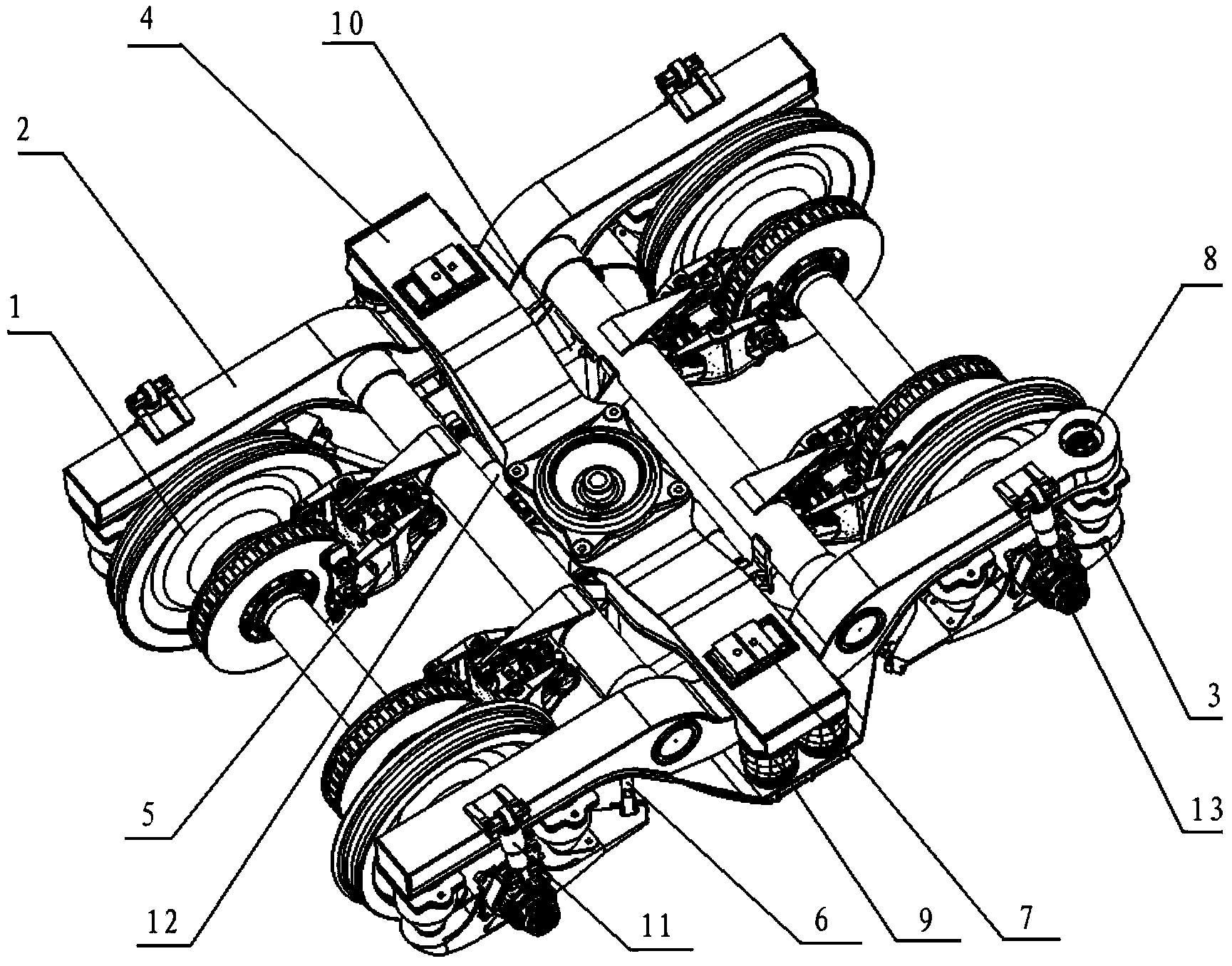

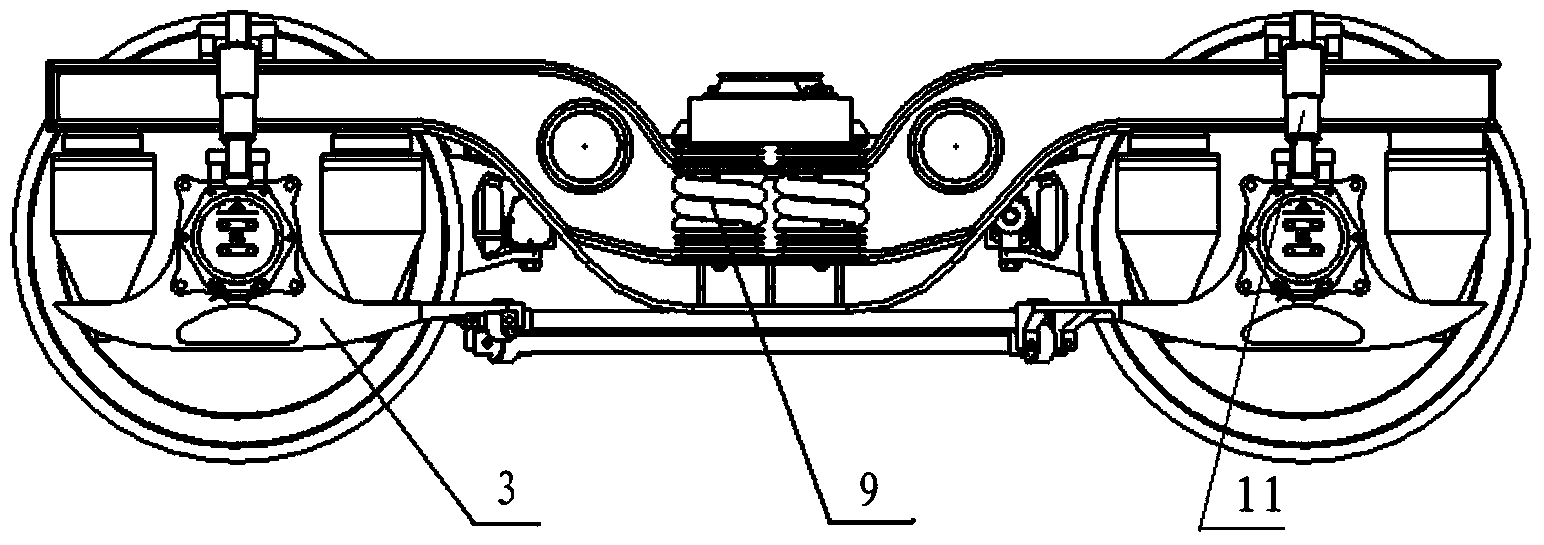

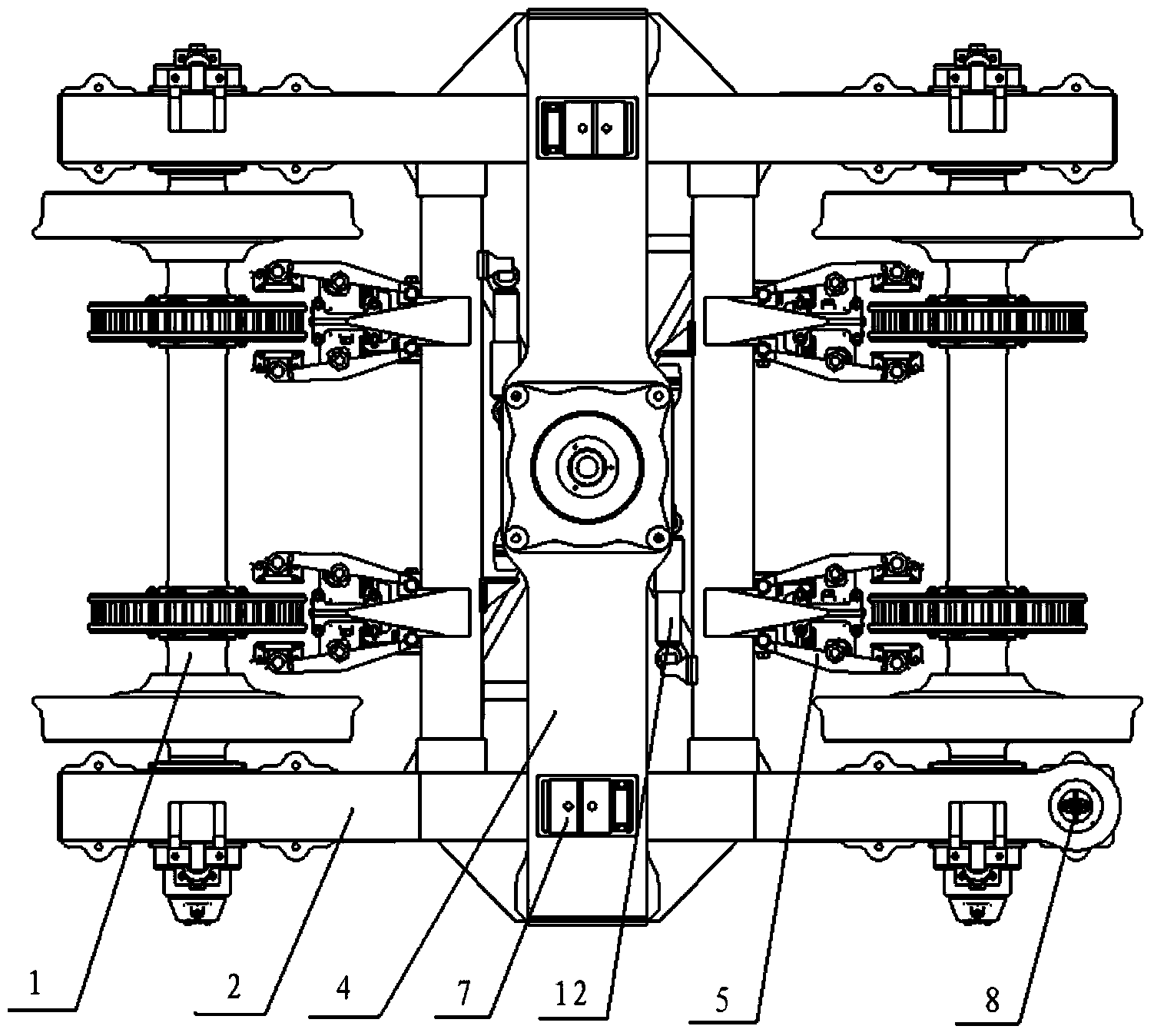

Rapid freight car radial bogie

InactiveCN103661464AReduce forceReduce lateral vibration accelerationBogie-underframe connectionsAxle-boxes mountingBogieTruck

The invention discloses a rapid freight car radial bogie. The rapid freight car radial bogie comprises an axle assembly, a frame, a swing bolster, a braking device, central suspension devices, a radial device, a side bearing device arranged on the swing bolster and an axle box suspension device, wherein the frame is installed on the axle assembly through the axle box suspension device, the two ends of the swing bolster are fixedly installed in the middle of the frame respectively through the central suspension devices, the frame is composed of two side beams and parallel cross beams connected with the side beams, and bearing platforms where the central suspension devices are installed are arranged outside the middle portions of the side beams. The rapid freight car radial bogie structure obviously reduces wheel-rail wear and wheel-rail noise, reduces wheel-rail acting force, reduces vehicle transverse vibration acceleration and improves vehicle operation lateral stability, straight line stability and curve line negotiating capacity. The unsprung mass of the bogie is reduced, the speed of the bogie is high, vehicle braking performance is improved, wheel-rail wear and wheel-rail noise are small, vehicle operation stability is good, and stability and safety are high.

Owner:CRRC MEISHAN

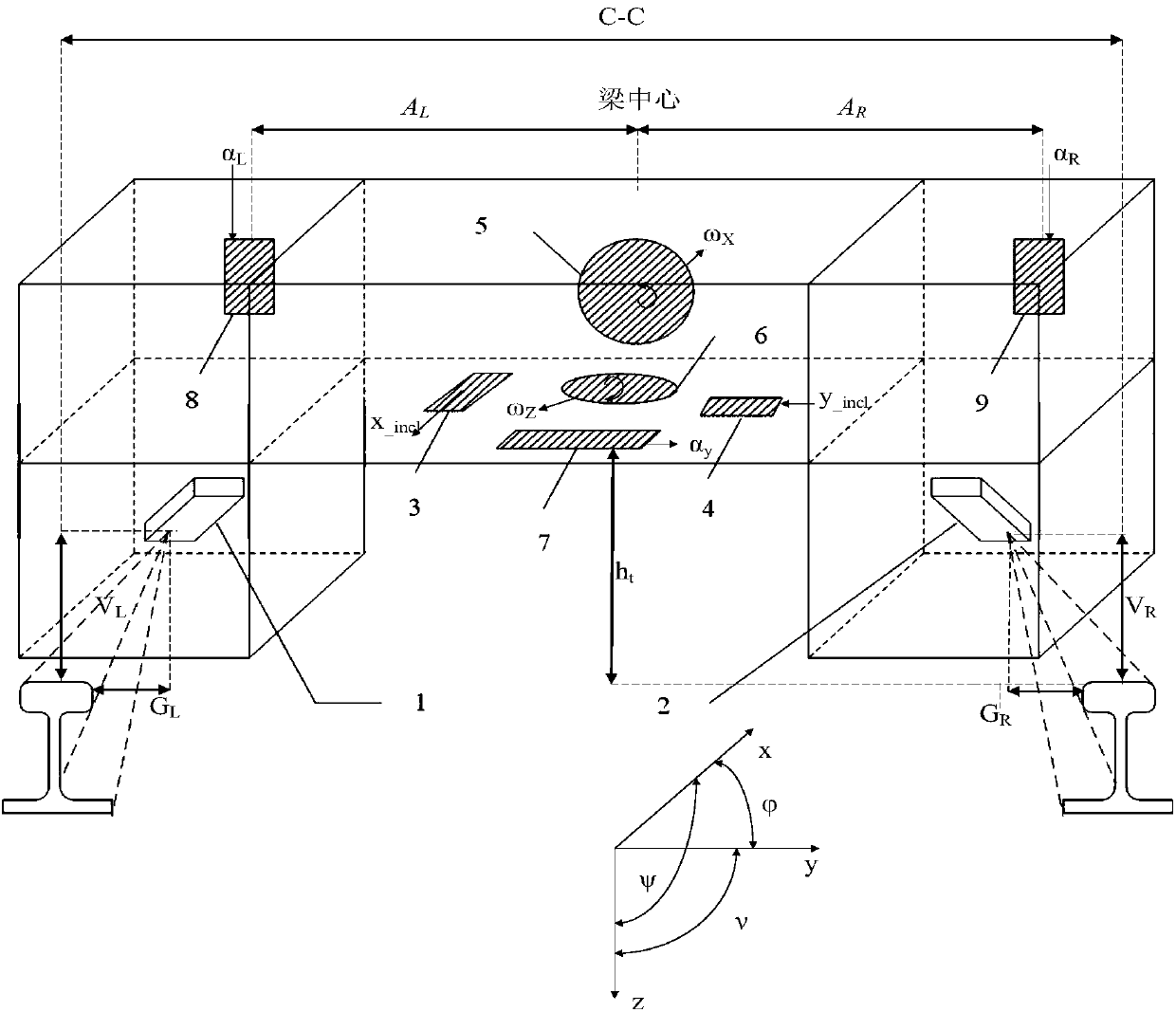

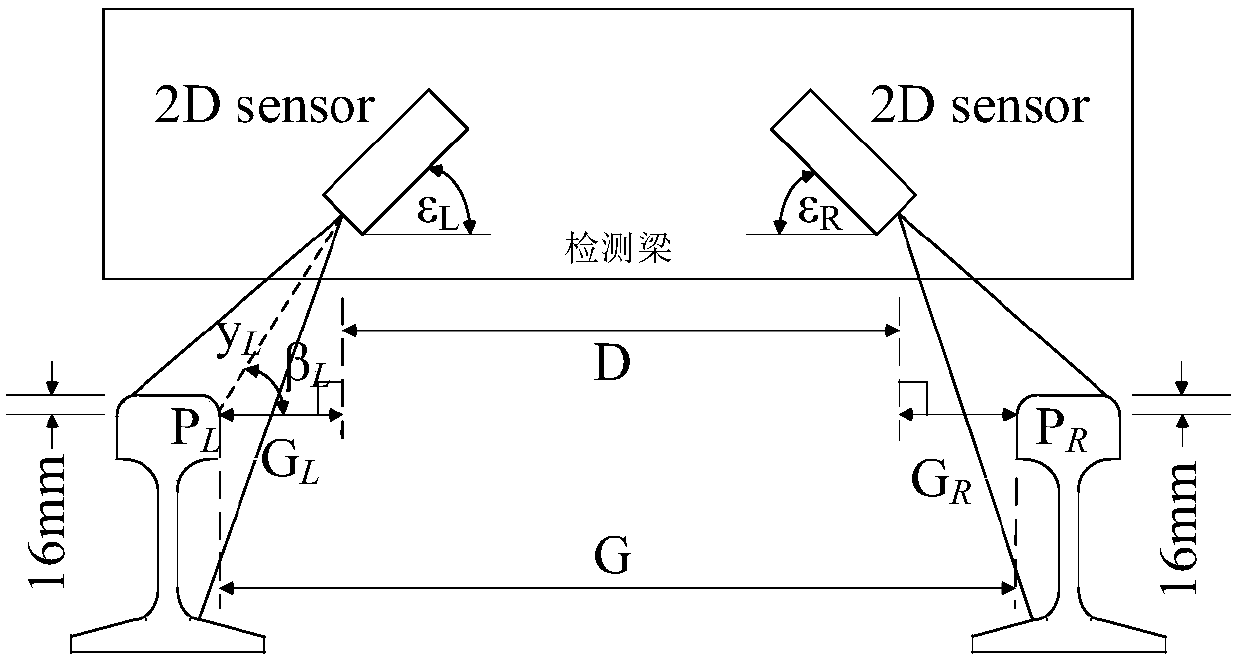

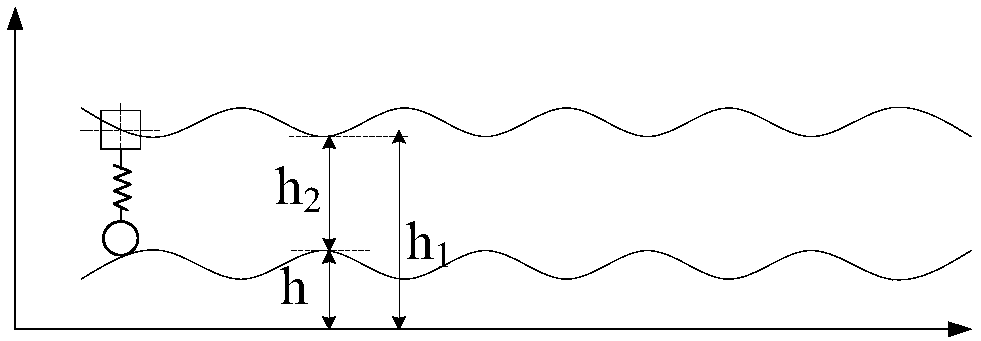

Track geometric irregularity inspection method based on two-dimensional laser displacement sensors

ActiveCN107554553AImprove anti-interference abilityEasy to handleUsing optical meansRailway auxillary equipmentGyroscopeAccelerometer

The invention discloses a detection method for track geometric irregularity based on a two-dimensional laser displacement sensor. A left laser sensor, a right laser sensor, a longitudinal inclinometer, a lateral inclination meter, a gyroscope, a lateral accelerometer, and a left vertical acceleration are installed on the detection beam. meter, right vertical accelerometer, the left laser sensor and the right laser sensor are two-dimensional laser sensors; perform the following measurements: track gauge detection, height detection, rail direction detection, horizontal superhigh detection, twist detection, curvature detection, Rail vertical as well as side wear measurements. The present invention adopts a high-speed two-dimensional laser displacement sensor, which has strong anti-interference ability. Based on the two-dimensional sensor, there is no complicated image processing step, and with simple and effective back-end algorithm processing, it has higher detection and calculation speed. It can effectively eliminate the influence of vehicle body vibration on the detection result, the detection result has high repeatability, can compensate the detection result, and has higher detection accuracy.

Owner:CHANGZHOU LUHANG RAILWAY TRANSPORTATION TECH

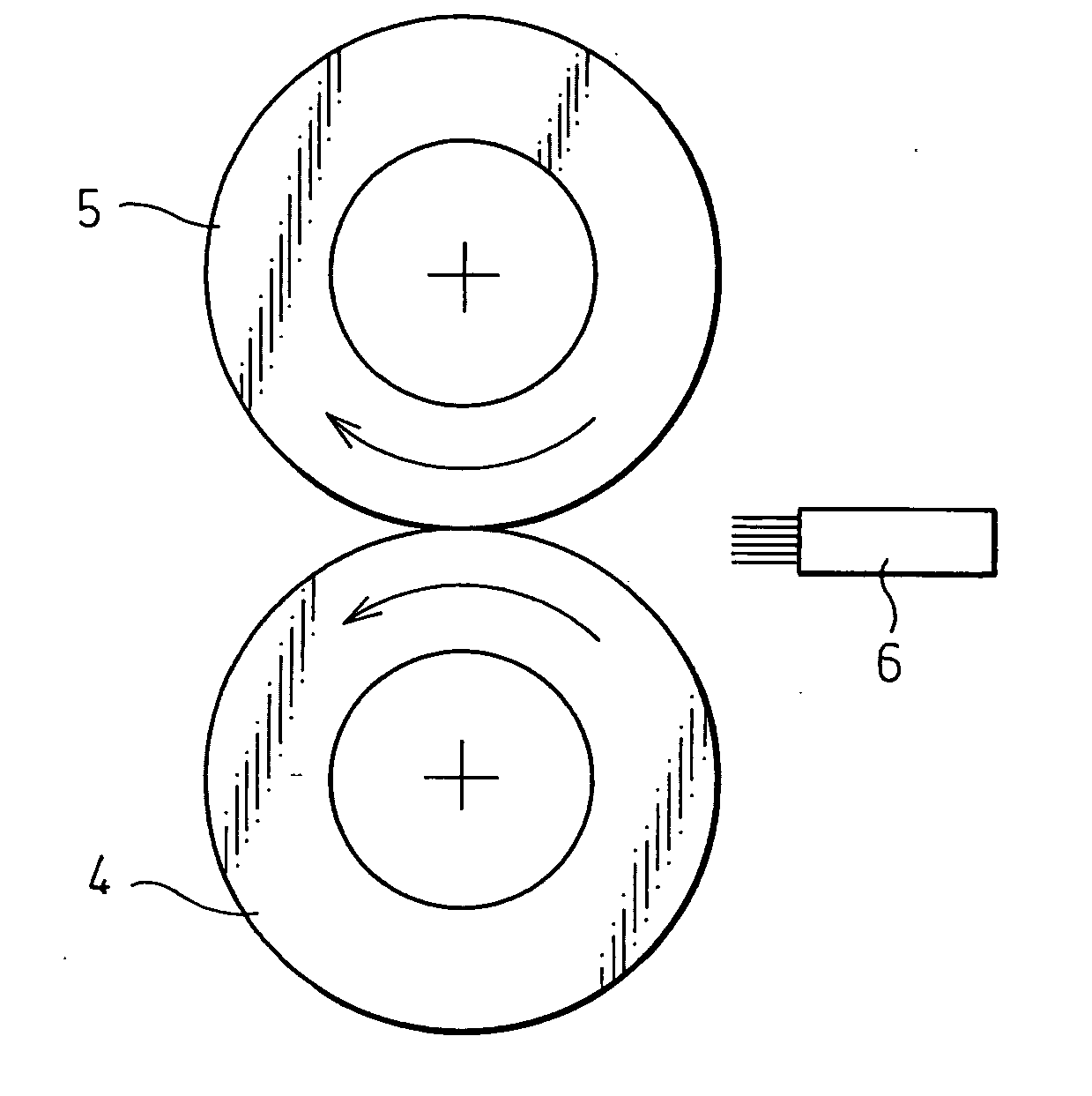

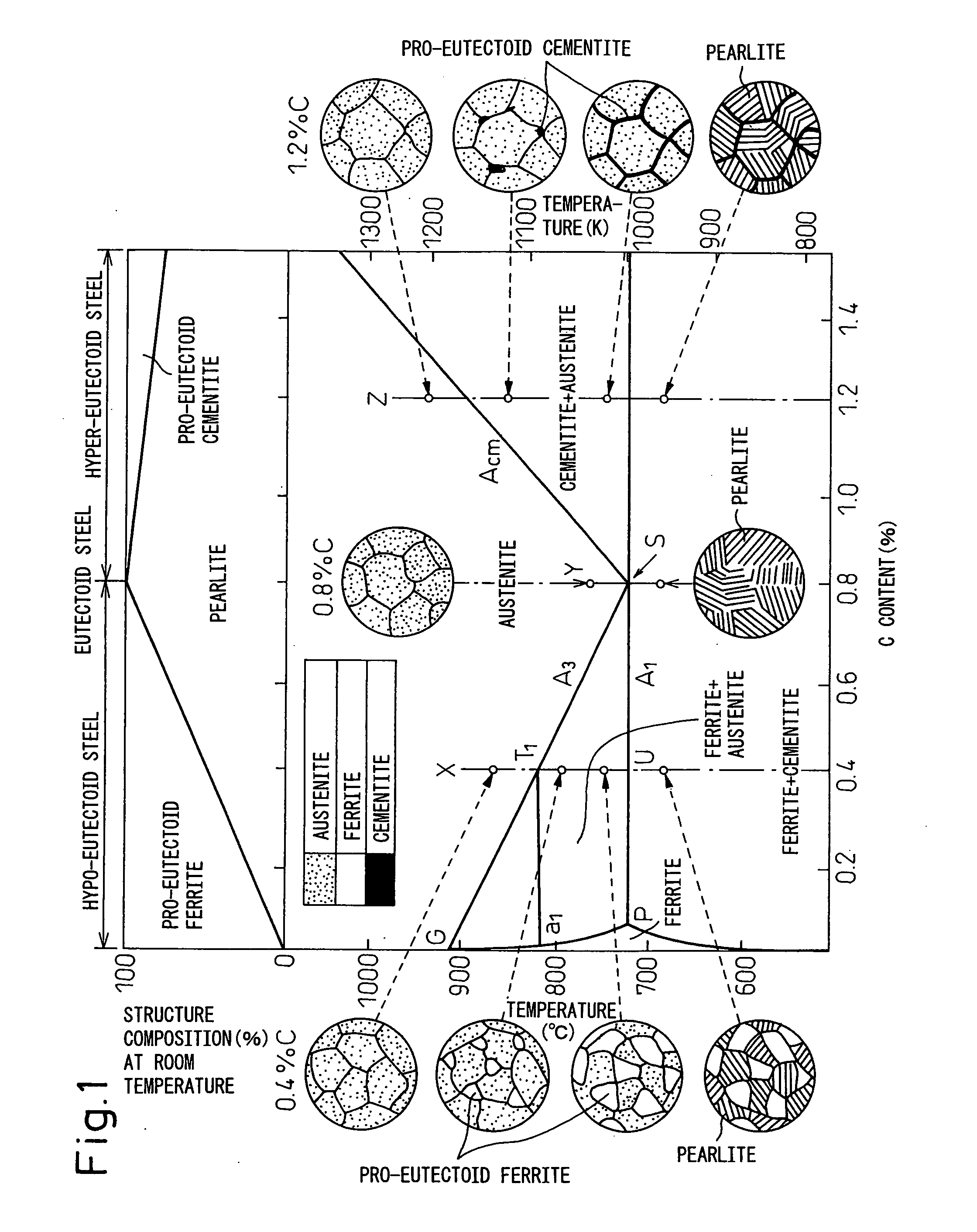

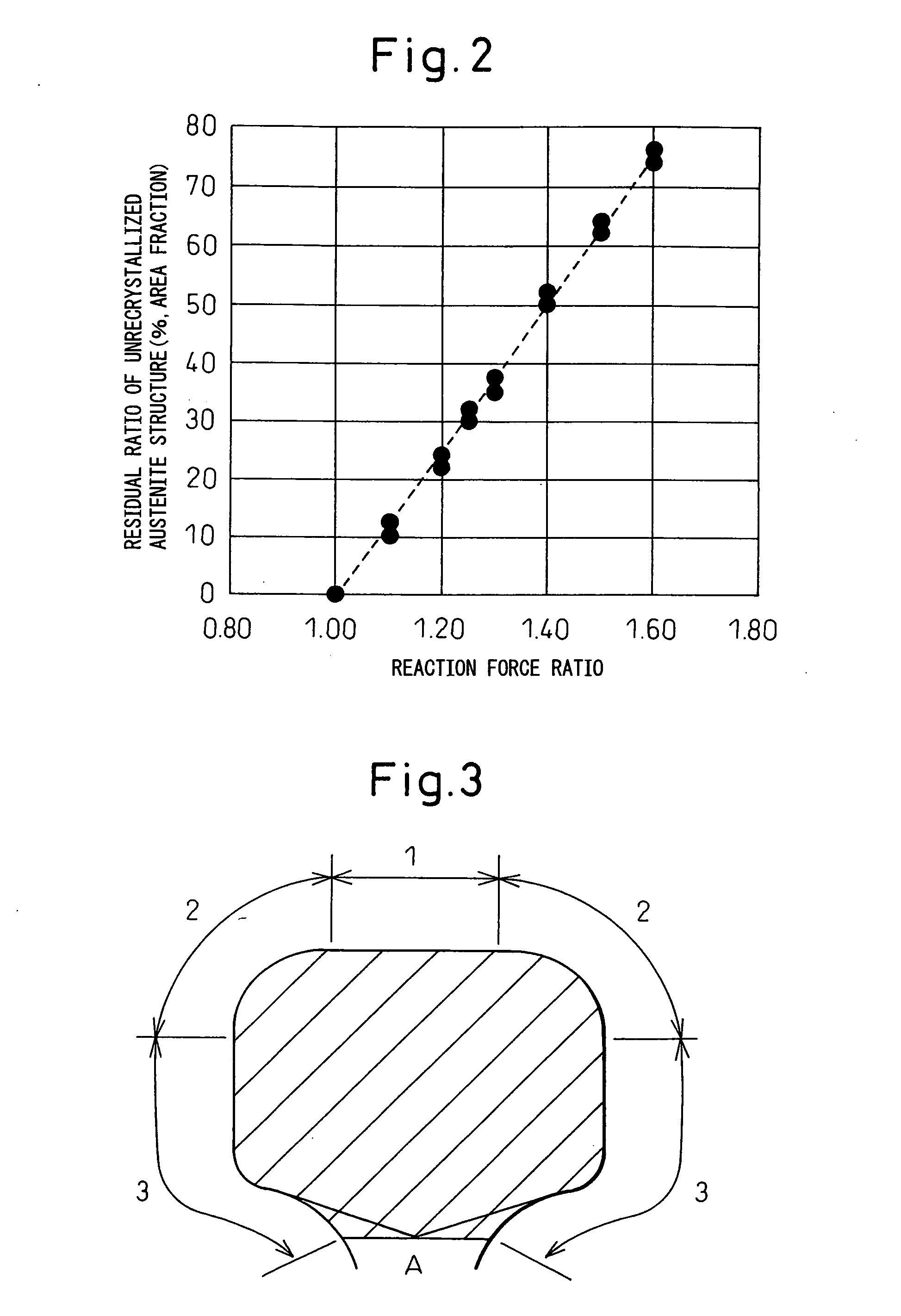

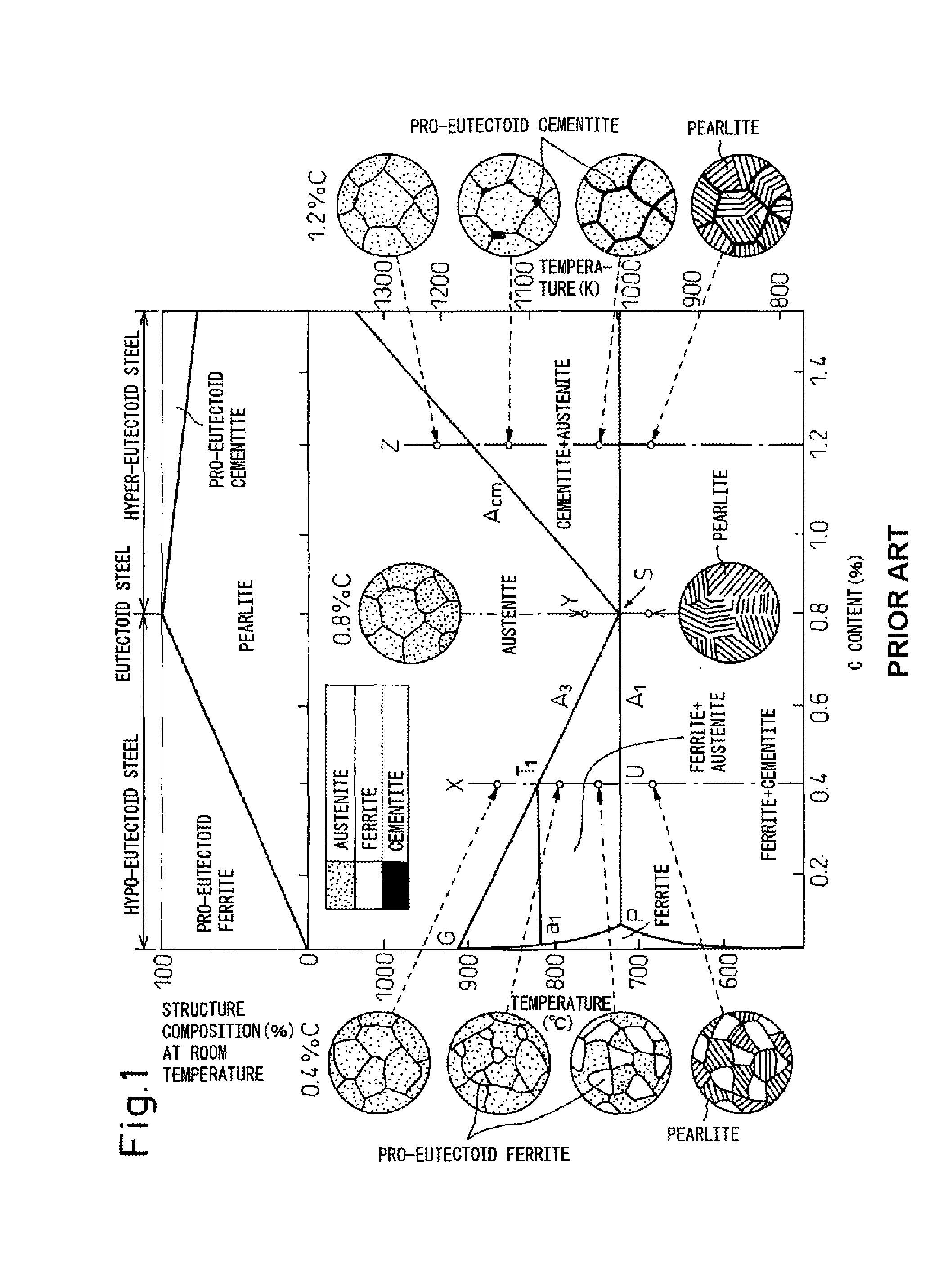

Method for producing pearlitic rail excellent in wear resistance and ductility

ActiveUS20090314049A1Improve ductilityImprove wear resistanceShaping toolsFurnace typesHardnessPearlite

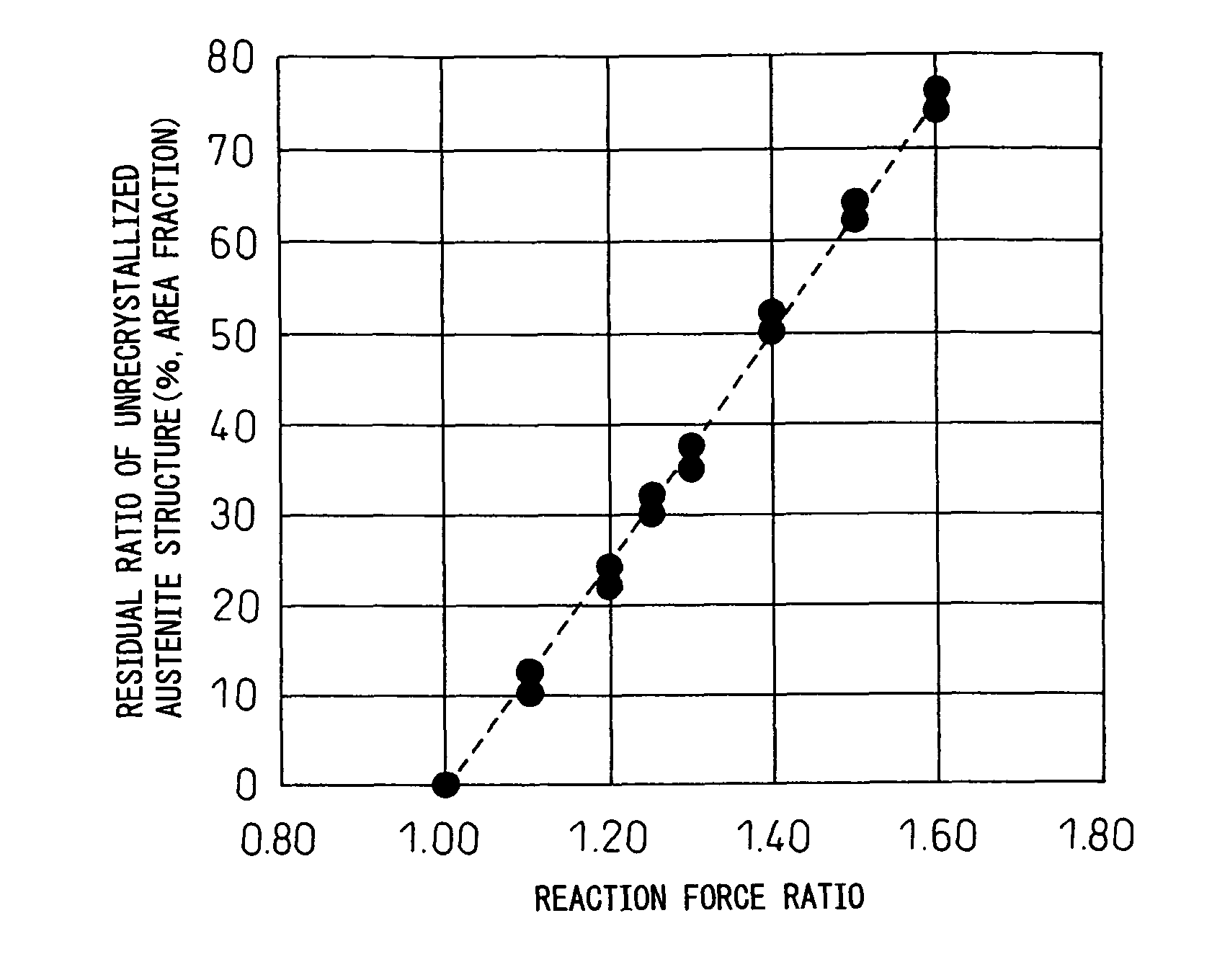

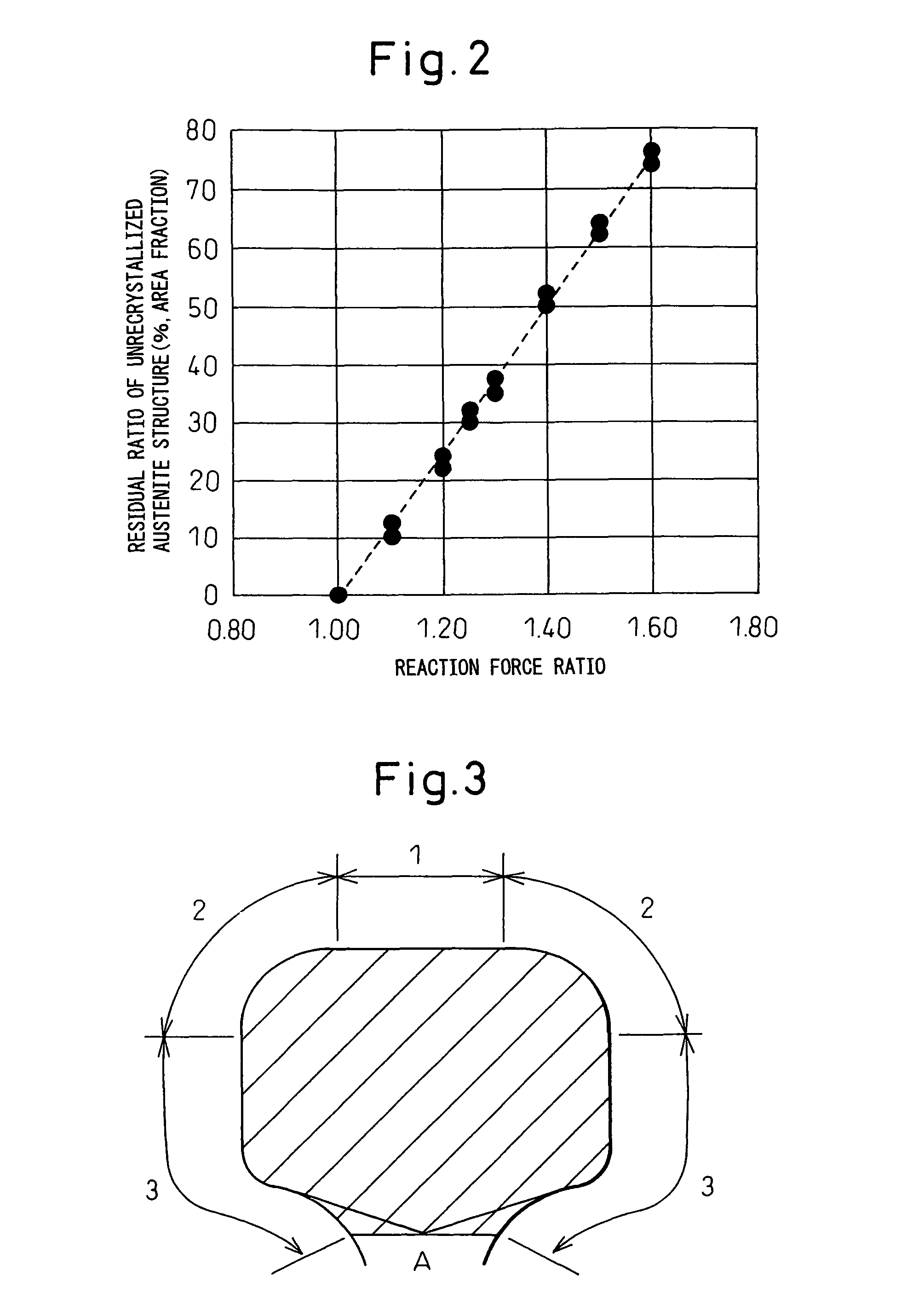

The invention provides a method for producing a pearlitic rail by subjecting to at least rough hot rolling and finish hot rolling a billet comprising, in mass %, C: 0.65-1.20%, Si: 0.05-2.00%, Mn: 0.05-2.00%, and a remainder of iron an unavoidable impurities, wherein the finish hot rolling is conducted by rolling at a rail head surface temperature in a range of not higher than 900° C. to not lower than Ar3 transformation point or Arcm transformation point to produce a head cumulative reduction of area of not less than 20% and a reaction force ratio of not less than 1.25, and the finish hot rolled rail head surface is subjected to accelerated cooling or spontaneous cooling to at least 550° C. at a cooling rate of 2 to 30° C. / sec, thereby refining the rail head structure to attain a hardness within a predetermined range and improving rail wear resistance and ductility.

Owner:NIPPON STEEL CORP

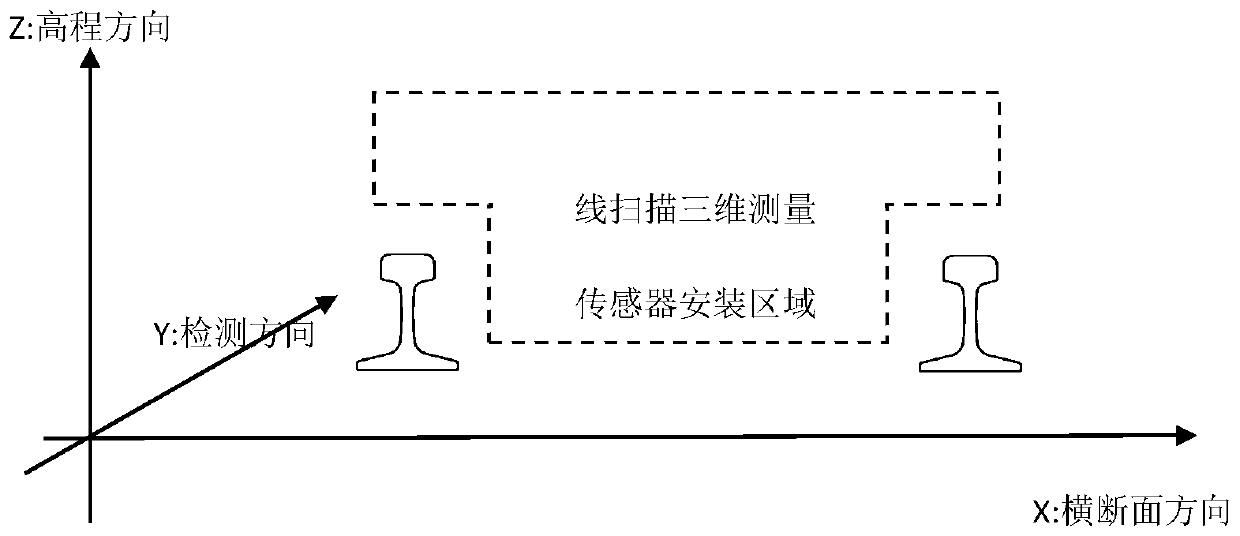

Method for high precisely detecting geometric outline of rail

InactiveCN106885532AEasy and flexible installationImprove detection accuracyUsing optical meansComputer visionIntegrated processing

The invention belongs to the technical field of photoelectric detection and relates to a method for high precisely detecting the geometric outline of a rail. The method is suitable for analysis of rail gauge and rail wear. A plurality of lasers and a plurality of cameras are used to construct a joint measurement system. By means of the joint calibration of the measurement system and the comprehensive processing of acquired data, the geometric outline feature points of the rail in two non-overlapped dynamic three-dimensional coordinate systems are obtained with high precision. A detection device is simple and flexible to install and high in detection precision, can simultaneously calibrate the world coordinates of the bilateral rails, and completes the three-dimensional detection of the geometric outline of the rails. The detection device is simple and flexible to install and high in detection precision, and can simultaneously calibrate the world coordinates of the bilateral rails.

Owner:WUHAN BINHU ELECTRONICS

Trip optimizer method, system and computer software code for operating a railroad train to minimize wheel and track wear

ActiveUS9233696B2Reduce problemsReduce wearDigital data processing detailsTrack side maintainanceWheel wearComputer software

A system for controlling a railroad train over a segment of track. The system comprises a first element for determining a location of the train on the segment of track; a second element for providing track characterization information for the segment of track; the track characterization information related to physical conditions of the segment of track; and a processor for controlling applied tractive forces and braking forces of the train responsive to the location of the train and the track characterization information to reduce at least one of wheel wear and / or track wear during operation of the train over the segment of track.

Owner:GE GLOBAL SOURCING LLC

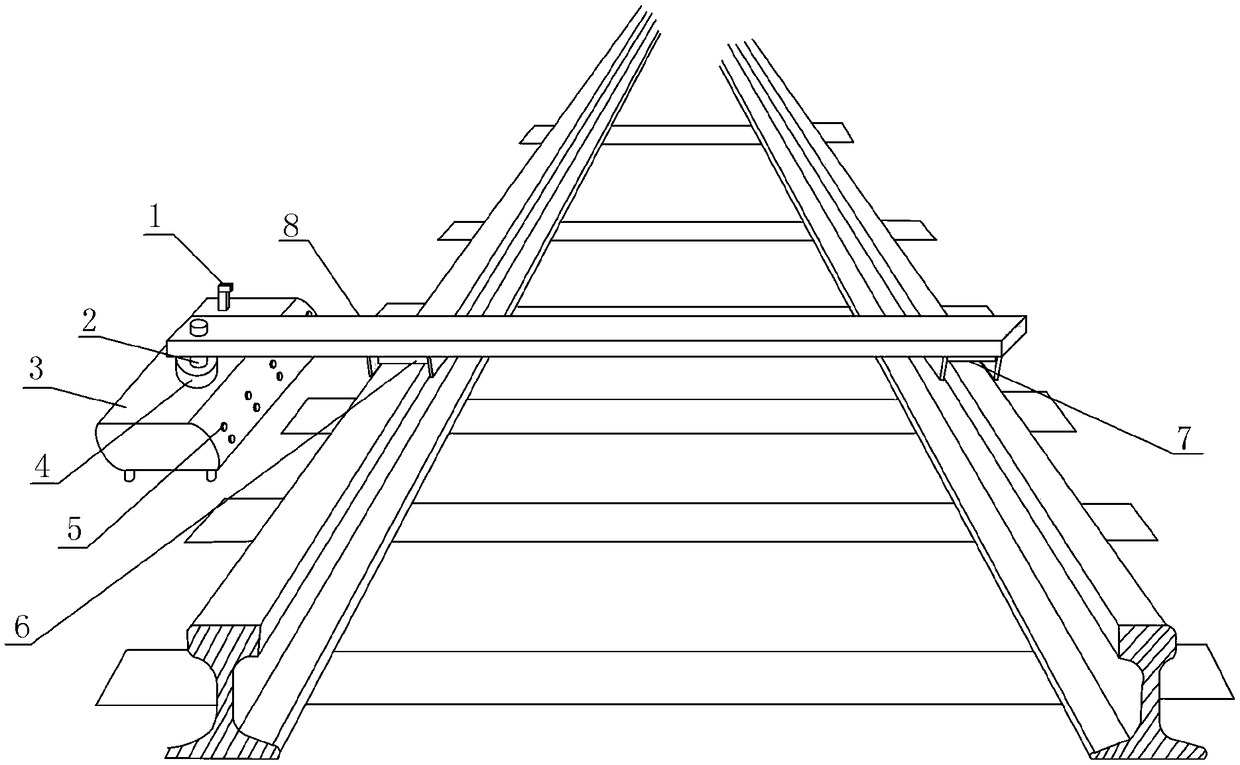

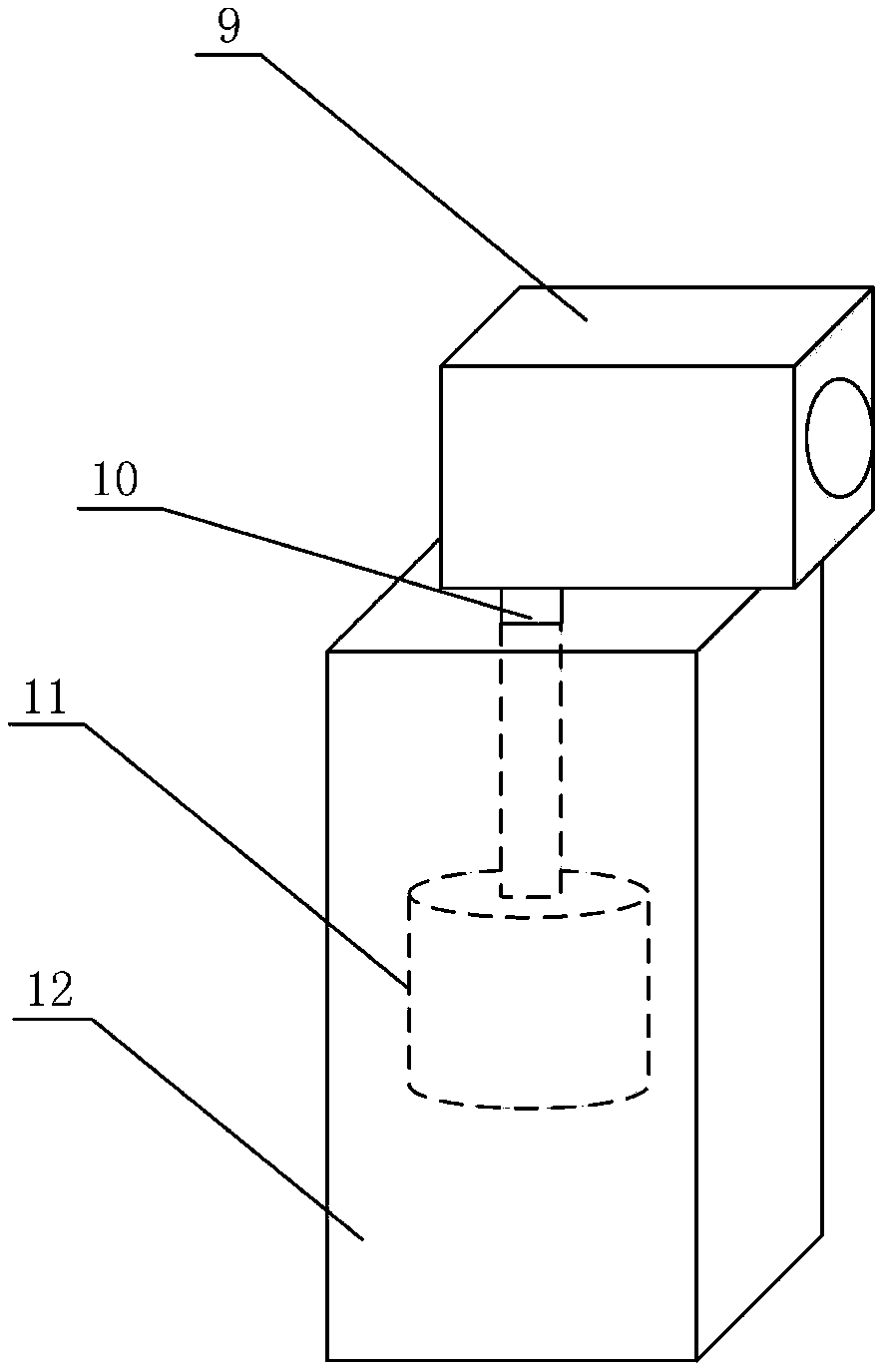

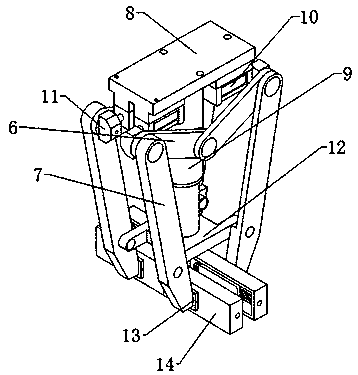

Steel rail wearing detecting device

ActiveCN109373907AAffect drivingDoes not affect operationUsing optical meansRailway auxillary equipmentComputer moduleDistance detection

The invention discloses a steel rail wearing detecting device comprising an image collecting device, a first telescopic motor, a walking device, a servo motor, an ultrasonic range finder, a left wearing detector, a right wearing detector and a cross bar. The detecting device walks along the rail by using the walking device, wherein the distance between the walking device and the outer side of thesteel rail is consistent all the same. The left wearing detector and the right wearing detector are installed at the walking device to carry out synchronous wearing detection and rail distance detection of the two steel rails at the same track. The image collecting device guides the walking device to move forward and guides the cross bar to stretch the left wearing detector and the right wearing detector to the steel rails for detection. A GSM module transmits departure information of a dispatch center to the walking device; and when a train enters the zone, the walking device rotates the cross bar to the outer side of the track, thereby preventing the cross bar from affecting driving of the train.

Owner:EAST CHINA JIAOTONG UNIVERSITY

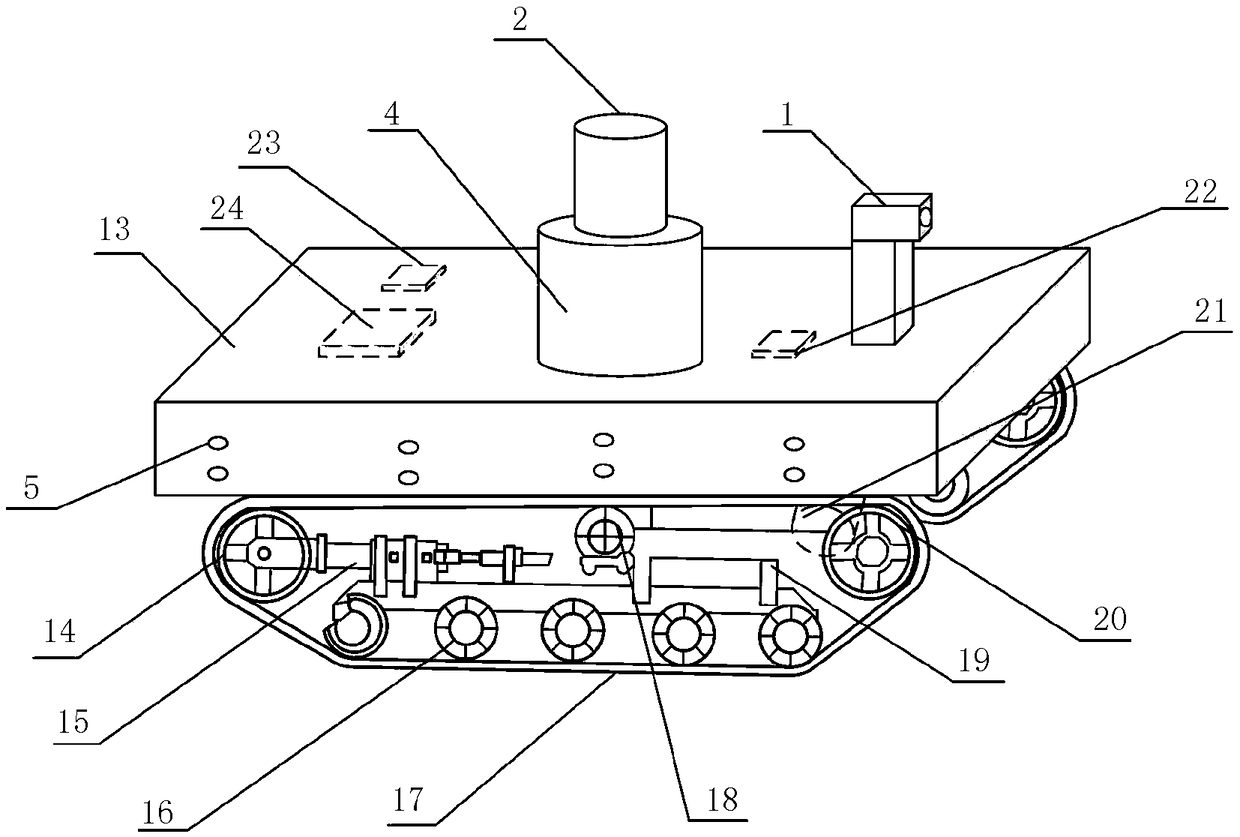

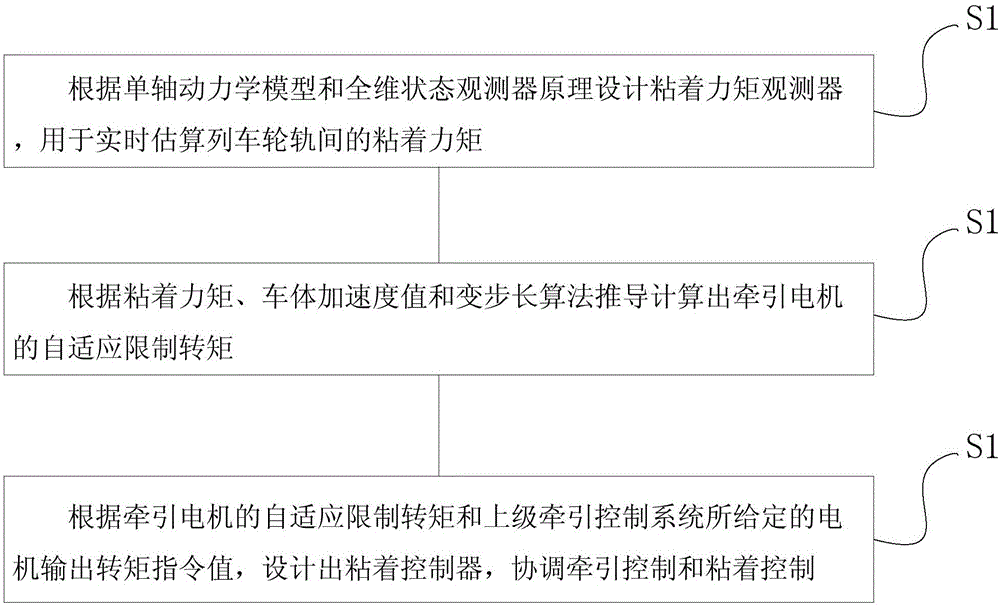

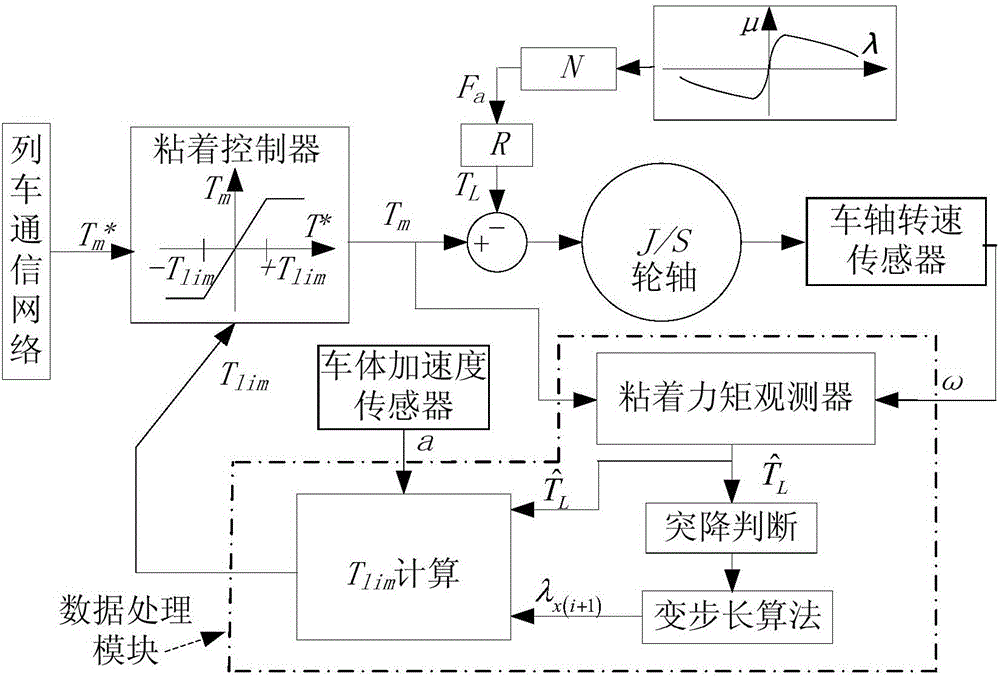

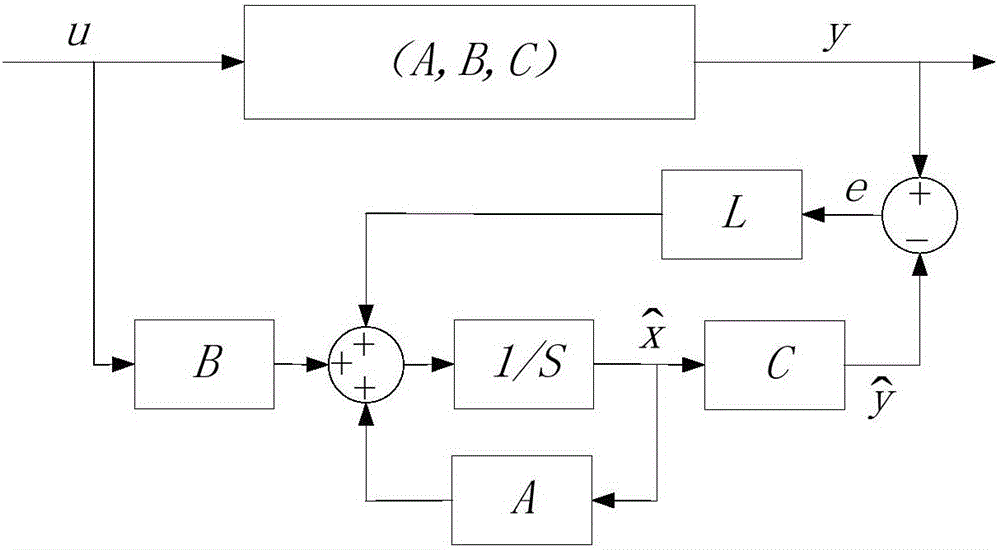

Safe and efficient operation active adhesion controlling method and system for motor train unit

InactiveCN106444373AReduce wearExtended service lifeAdaptive controlTraction control systemState observer

The invention relates to a safe and efficient operation active adhesion controlling method for a motor train unit. The method comprises the following steps: S1, designing an adhesion torque observer for estimating an adhesion torque il between train wheels and a rail in real time according to a single-axis dynamical model and the full-dimensional state observer principle; S2, deriving an adaptive limiting torque Tlim of a traction motor according to the adhesion torque il, a body acceleration value a and a variable step length algorithm; and S3, designing an adhesion controller according to the daptive limiting torque Tlim of the traction motor and a motor output torque index value Tm* given by a superior traction control system, to coordinate traction control and adhesion control. The method effectively improves the traction braking efficiency of a train, reduces wheel-rail wear, strengthens safe and stable operation of the train, prolongs the service lives of wheels and rails, improves the comfort of passengers and reduces energy consumption of the train.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

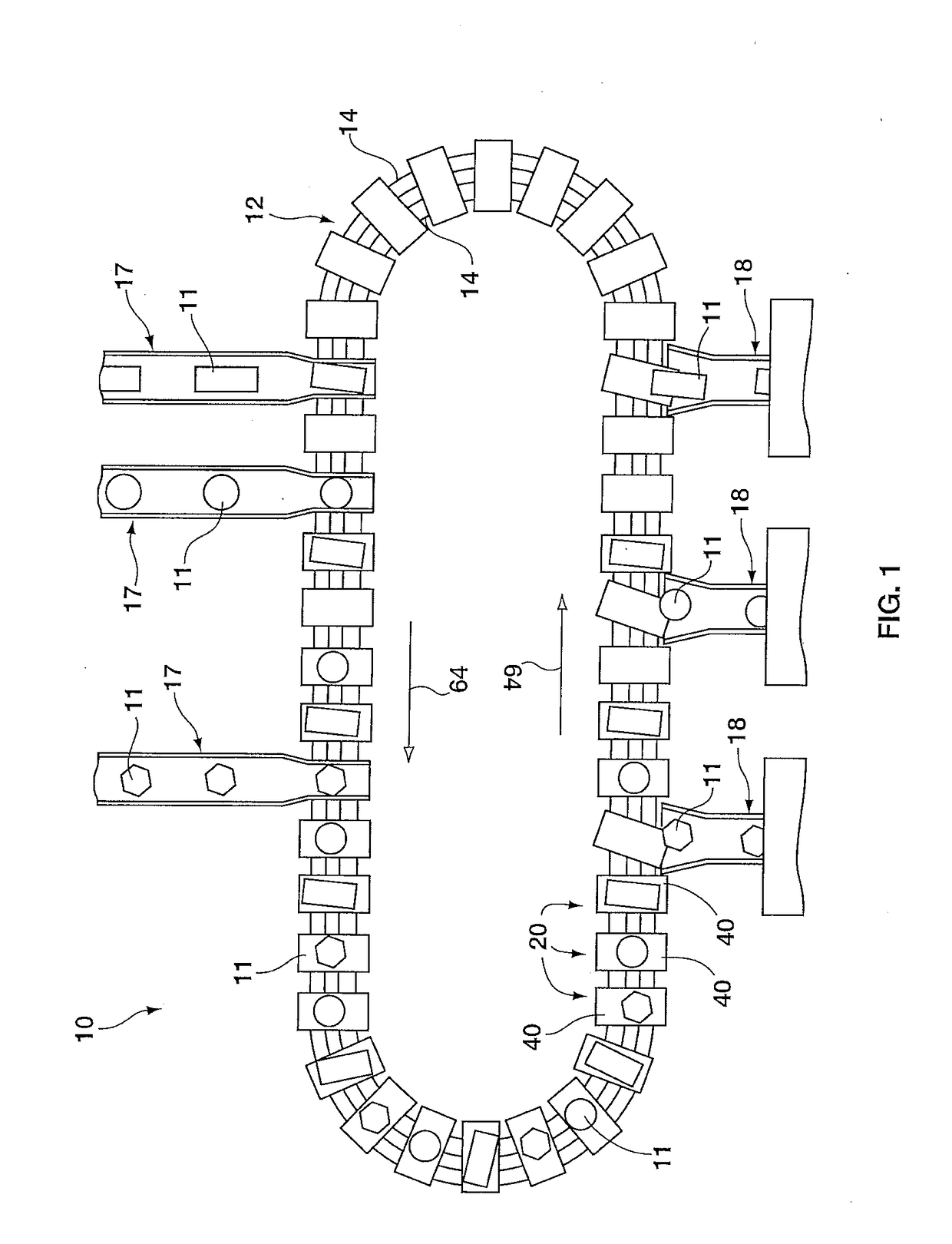

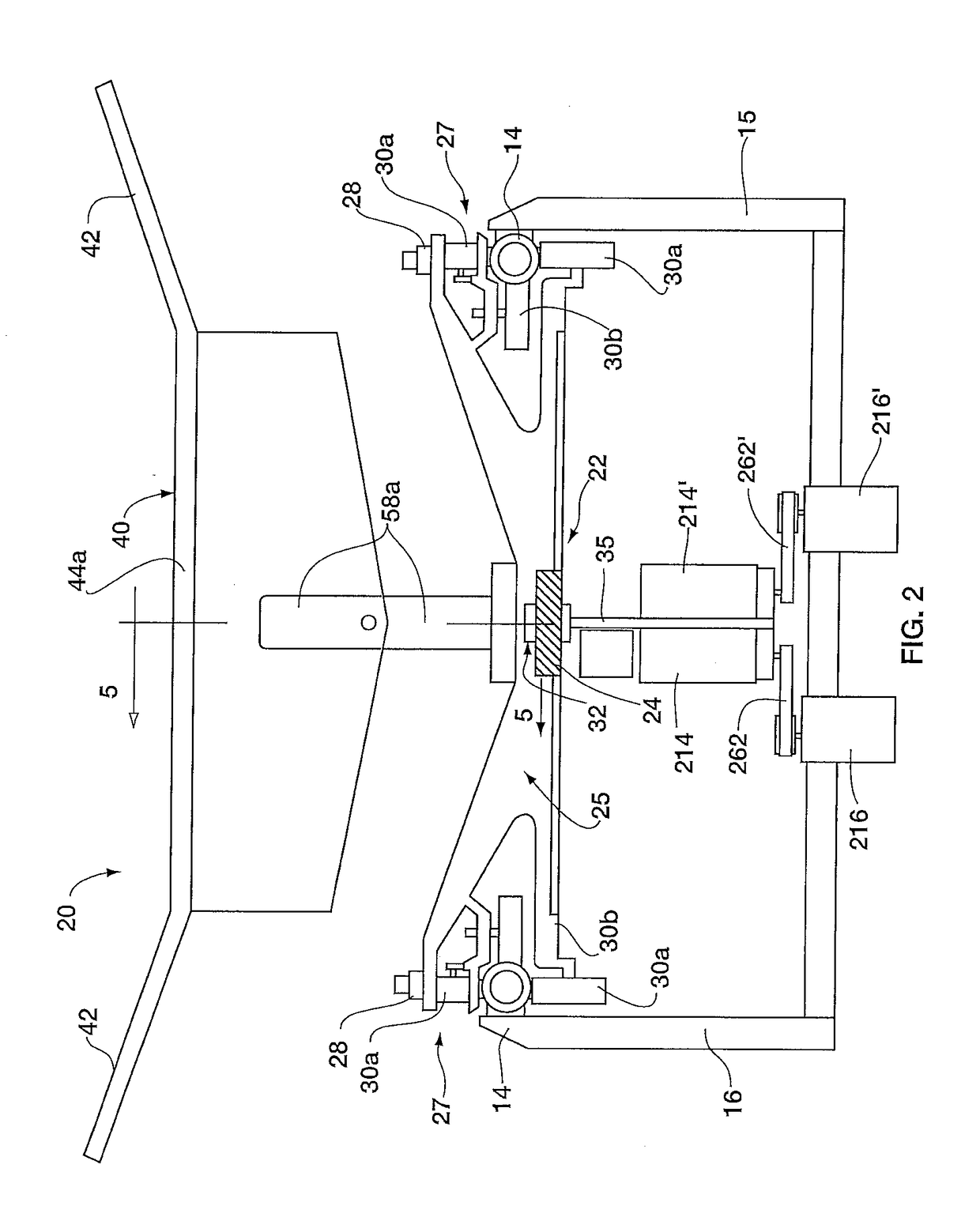

Conveyor system wheel failure detection and remediation

ActiveUS20170283183A1Preventing track wearInhibits track wearConveyorsControl devices for conveyorsRail wearConveyor system

A sorting conveyor for transporting objects and unloading objects at one or more unloading stations adjacent the conveyor. The sorting conveyor includes a conveyor track and a train of conveyor carts connected end-to-end. At least one of the conveyor carts may include a frame base for engaging the conveyer track; a conveyor surface for holding the objects; and a conveyor support for supporting the conveyor surface above the frame base. A wear guard associated with the axle support prevents track wear. A track wear prevention system includes a wear guard and a height detection module. Systems and methods for track wear prevention are also disclosed.

Owner:MANTISSA CORP

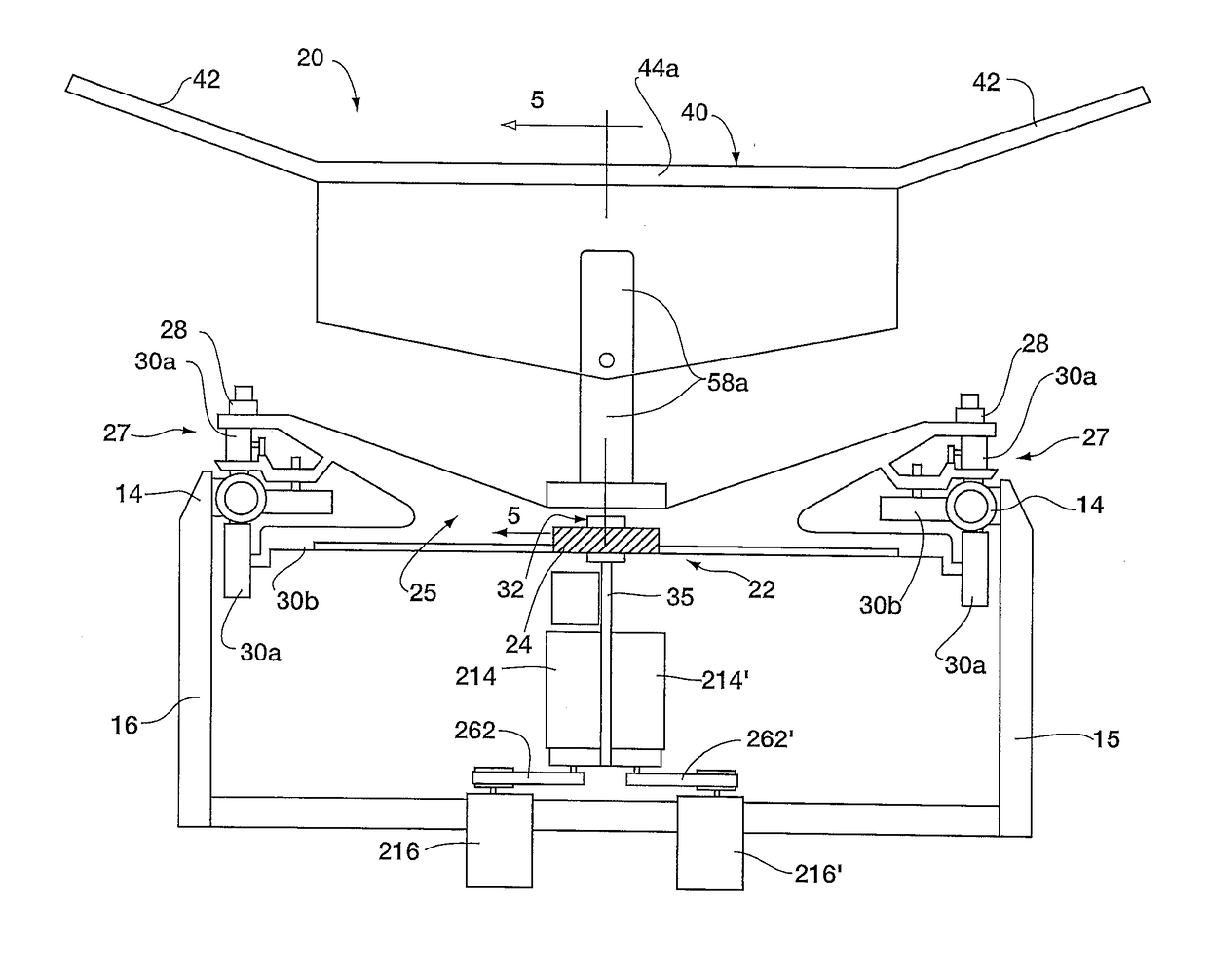

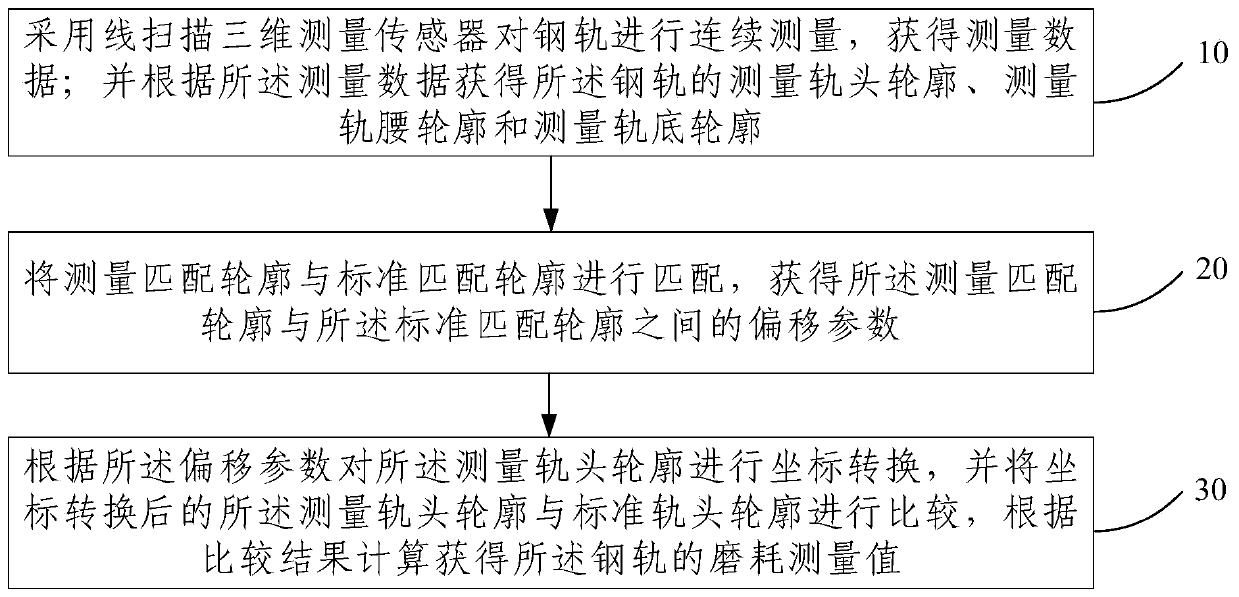

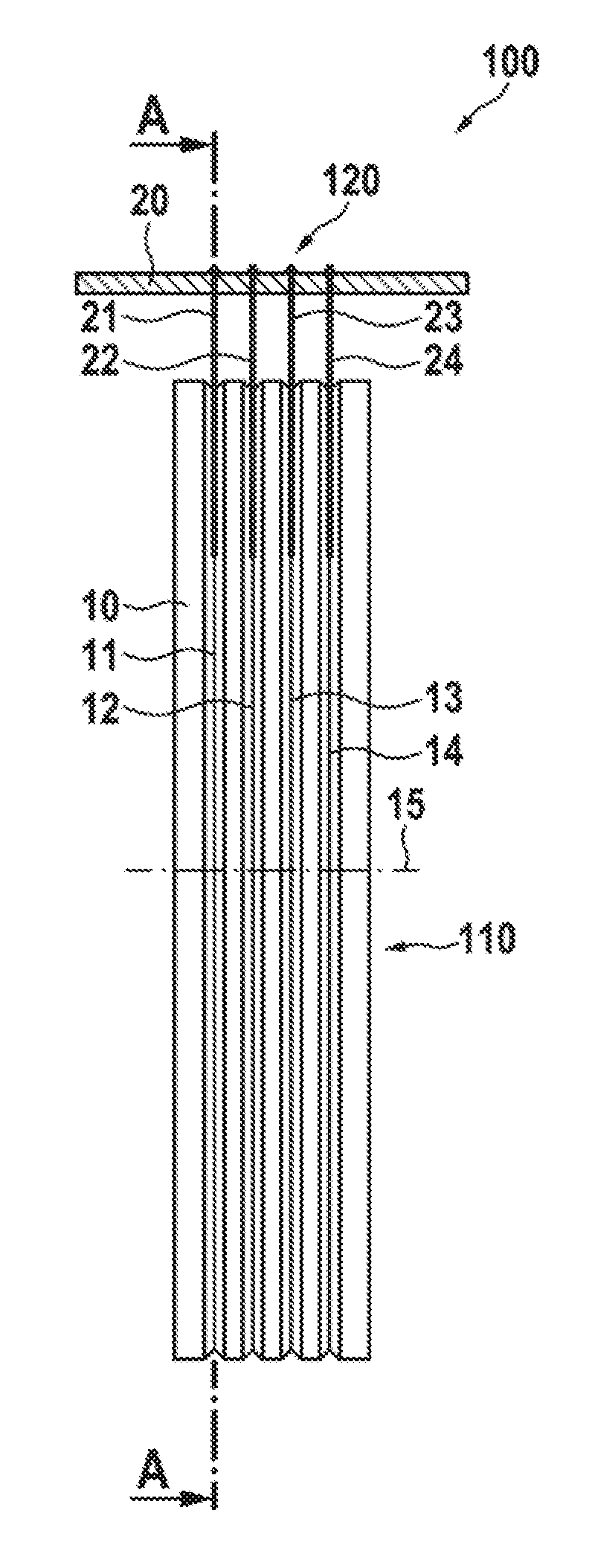

Steel rail wear measurement method and device

The embodiments of the present invention provide a steel rail wear measurement method and device. The method includes the following steps that: a line scanning three-dimensional measuring sensor is adopted to continuously measure a steel rail, so that measurement data can be obtained; the measurement railhead contour, measurement rail web contour and measurement rail base contour of the steel railare obtained according to the measurement data; the measurement matching contours are matched with standard matching contours, so that the deviation parameters of the measurement matching contours and the standard matching contours are obtained; and coordinate transformation is performed on the measurement rail head contour according to the deviation parameters, the measurement rail head contourwhich has been subjected to the coordinate transformation is compared with a standard rail head contour, and the wear measurement value of the steel rail is calculated based on a comparison result. According to the steel rail wear measurement method and device provided by the embodiments of the present invention, the line scanning three-dimensional measuring sensor can quickly obtain the high-precision steel rail contours, that is, the measurement points of the steel rail contours in a cross-sectional direction and a measurement moving direction are relatively dense, and therefore, the influence of steel rail surface undulating texture on measurement results can be decreased; and the accuracy of the measurement results can be improved.

Owner:WUHAN WUDA ZOYON SCI & TECH

Rail and special vehicle for rail

ActiveCN103806351ASimple structureSimple electromechanical structureRailsRail switchesChinese charactersEngineering

The invention discloses a rail and a special vehicle for the rail. By aiming at the condition that a turnout technology of an automatic traffic system cannot meet requirements of an automatic vehicle on high-efficiency and reliable steering, the characteristics of arranging guide wheel passages which are shaped like a Chinese character 'tu' and are matched up and down and high-and-low-position guide surfaces at interaction panel points of rail bars of various turnout zones of the rail are provided, so that the vehicle can smoothly, reliably and automatically transfer to a different rail and turn in various turnout zones only by action of ascending and descending in advance of guide wheels without any maneuvering control of the rail, and the aim of a fixed turnout which has higher practicality and is not provided with moving components is fulfilled. Moreover, a safer guide wheel shaft bracket, a guide wheel assembly and a bearing wheel assembly are arranged for the guide wheels of the vehicle, the safer guide wheel shaft bracket is of a vertical plate shape, and the guide wheel assembly and the bearing wheel assembly have a lifting-turning transposition function, so that the vehicle can reliably turn at a right angle at a crossing rail switch.

Owner:上海云街智能科技中心

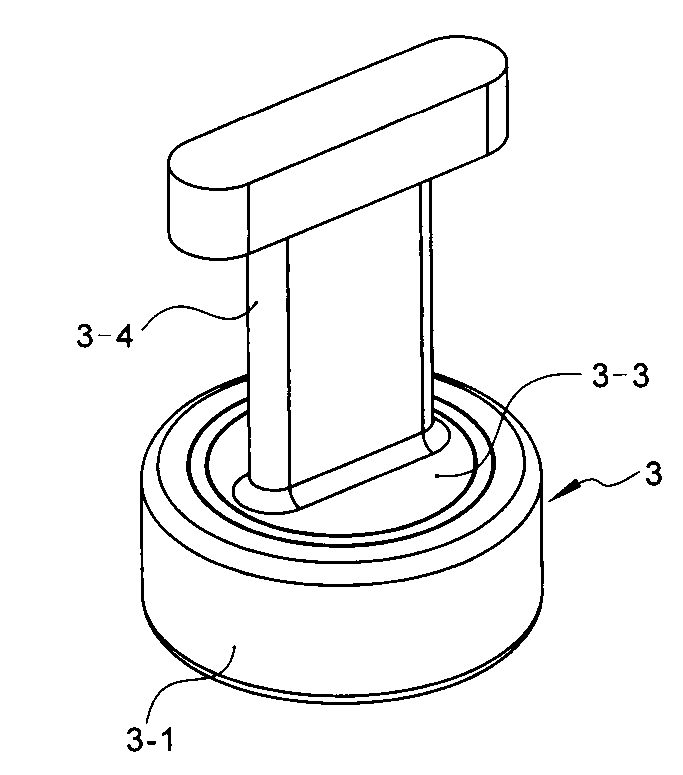

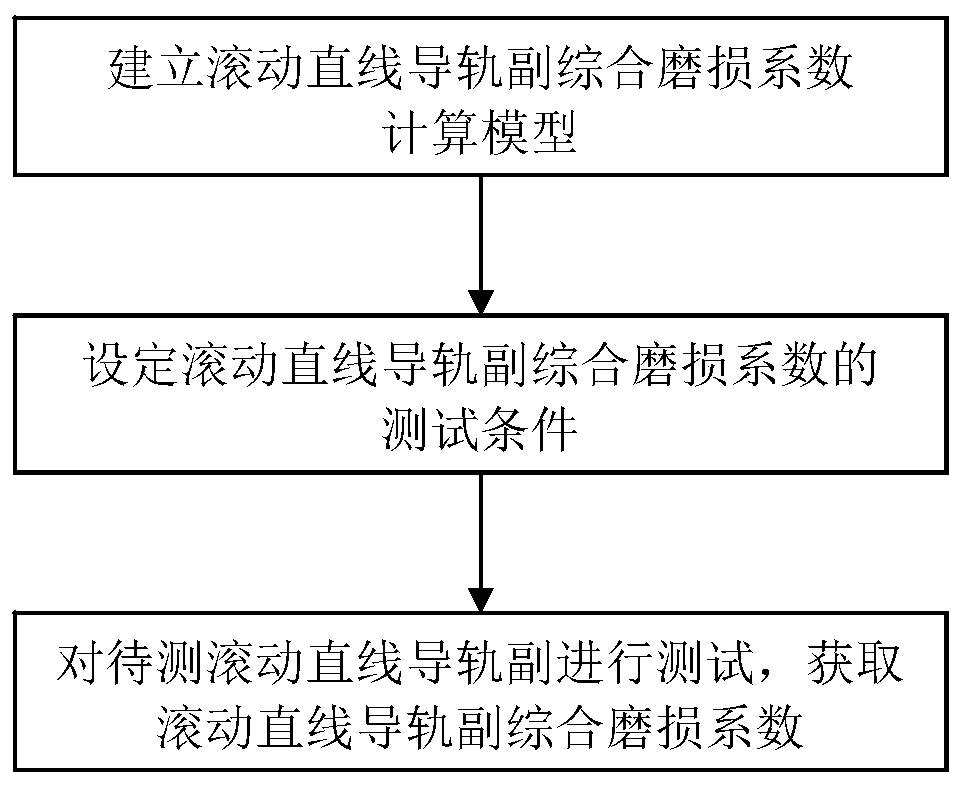

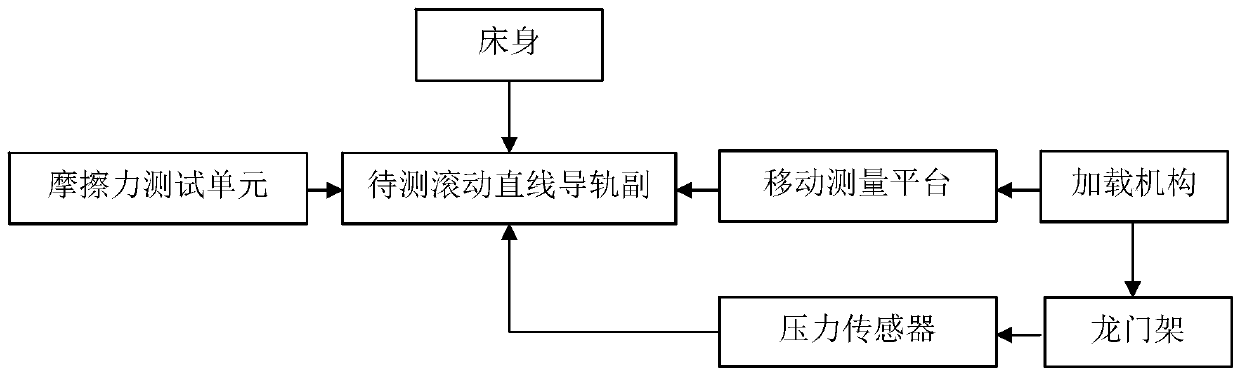

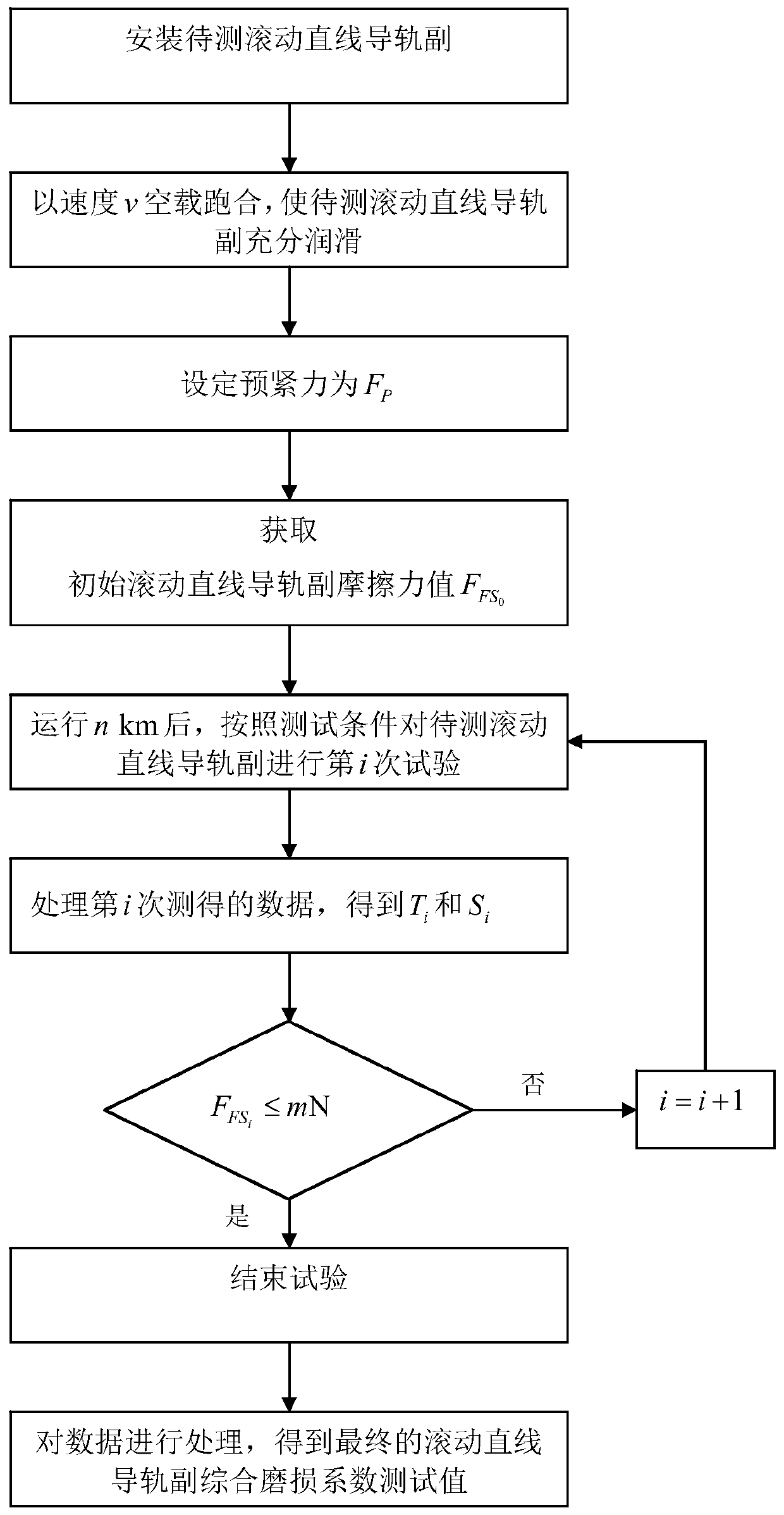

Rolling linear guide rail pair integration wear coefficient test method

ActiveCN110095280AHigh numerical precisionCoincidence analysisMachine gearing/transmission testingInvestigating abrasion/wear resistanceWear coefficientMechanical engineering

The invention discloses a rolling linear guide rail pair integration wear coefficient test method and belongs to the rolling linear guide rail pair performance test field. A rolling linear guide railpair integration wear coefficient refers to the wear coefficient which comprehensively considers guide rail wear and slide block wear, and the integration wear coefficient directly reflects a degradation speed of a preload and other performance degradation speeds caused by the degradation of the preload. The method comprises the following steps of establishing a rolling linear guide rail pair integration wear coefficient calculation model; setting a test condition of the rolling linear guide rail pair integration wear coefficient; and testing the rolling linear guide rail pair to be tested soas to obtain the rolling linear guide rail pair integration wear coefficient. In the invention, theoretical and experimental methods for measuring the rolling linear guide rail pair integration wear coefficient are provided so as to fill the blank in the field. By using the method, a measuring speed is fast, precision is high, and theoretical support and experimental verification are provided fora performance degradation model of a rolling linear guide rail pair.

Owner:NANJING UNIV OF SCI & TECH

Method for producing pearlitic rail excellent in wear resistance and ductility

The invention provides a method for producing a pearlitic rail by rough hot rolling and finish hot rolling a billet. In the finish hot rolling, the billet is rolled at a rail head surface temperature in a range of not higher than 900° C. to not lower than the Ar3 transformation point or Arcm transformation point to produce a head cumulative reduction of area of not less than 20%, where the reaction force ratio of the finish rolling is not less than 1.25. The finish hot rolled rail head surface is subjected to accelerated cooling or spontaneous cooling to a temperature of 550° C. or less at a cooling rate of 2 to 30° C. / seconds, thereby refining the rail head structure to attain a hardness within a predetermined range, and improving rail wear resistance and ductility.

Owner:NIPPON STEEL CORP

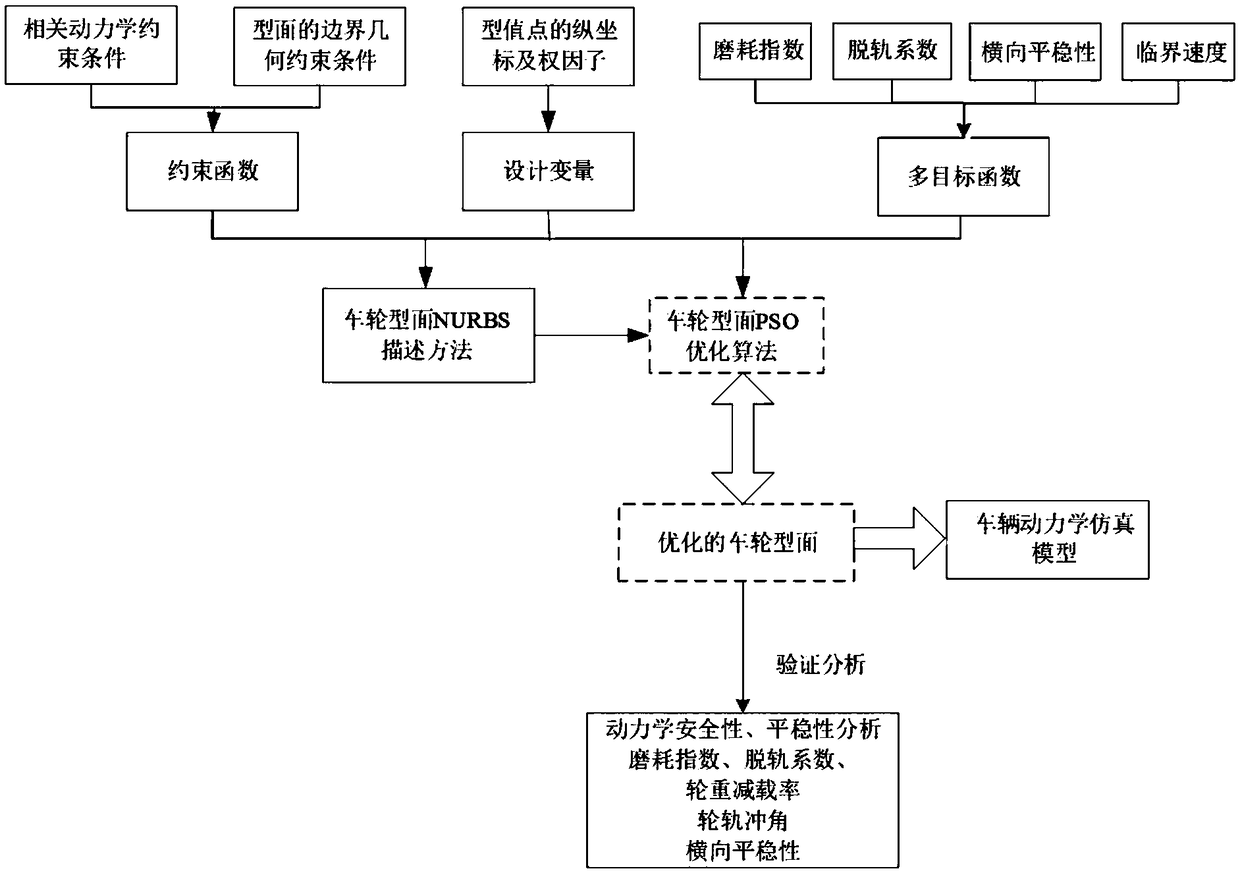

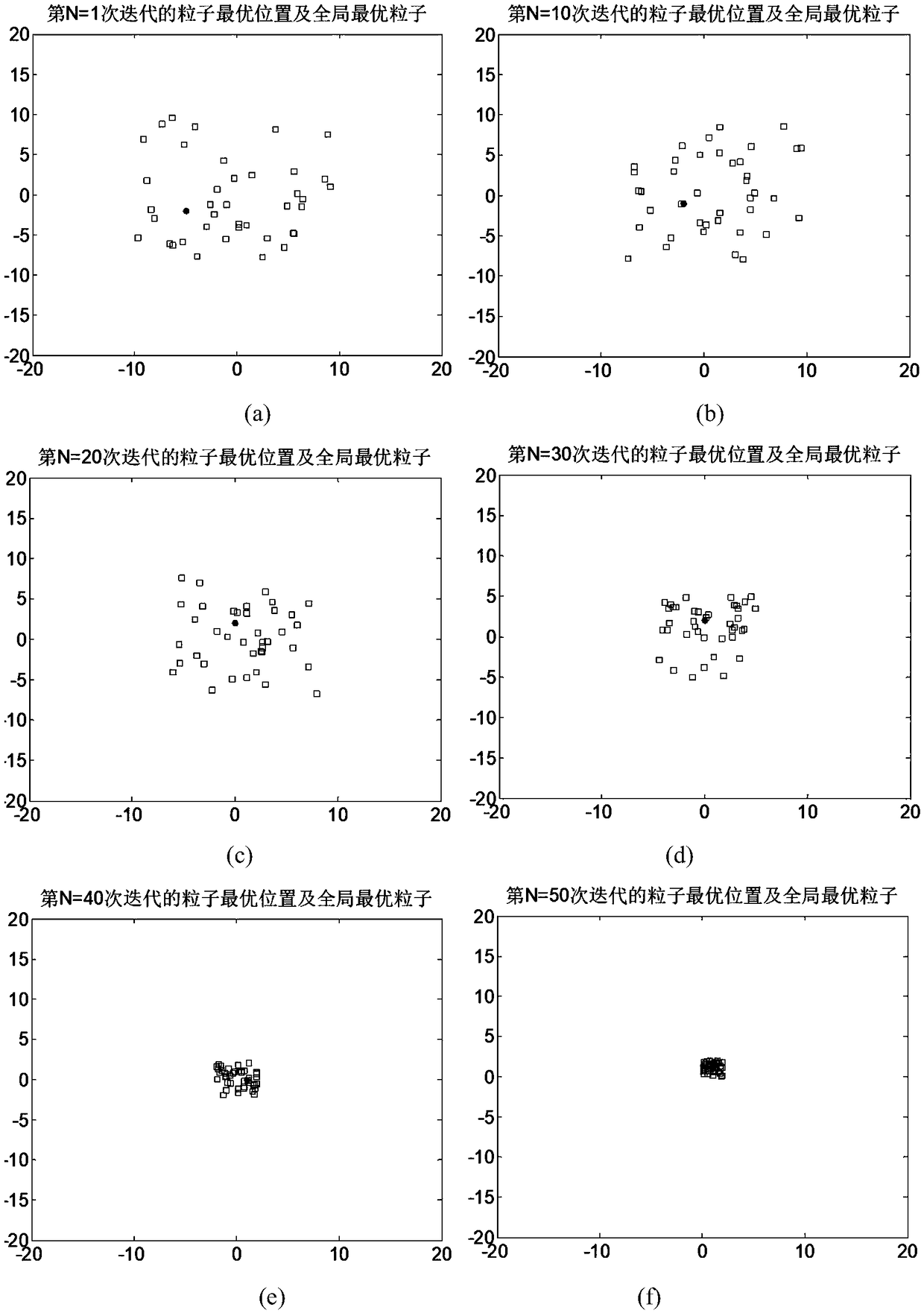

A wheel profile multi-objective optimization method based on improved particle swarm optimization algorithm

InactiveCN109408854AExtended service lifeReduce maintenance costsGeometric CADInternal combustion piston enginesReduction rateDerailment

The invention discloses a wheel profile multi-objective optimization method based on an improved particle swarm algorithm. The methods are as follows: firstly, a multi-objective optimization model ofwheel profile based on NURBS theory is established; then wear index, derailment coefficient, lateral stationarity index and critical velocity are selected as optimization objective functions. Secondly, the multi-objective optimization model is established with the wheel-rail lateral force, wheel-axle lateral force and wheel load reduction rate as the dynamic constraint conditions, and the concavity, convexity, continuity and smoothness of the optimized profile curve as the geometrical constraint conditions. Finally, the improved particle swarm optimization algorithm is used to solve the multi-objective optimization model iteratively, and the optimized wheel profile with low wear is obtained. The invention is based on an improved particle swarm algorithm, and the optimized profile has goodvehicle running safety, running stability, curve passing performance and wheel / rail wear is reduced at the same time.

Owner:NANJING UNIV OF SCI & TECH

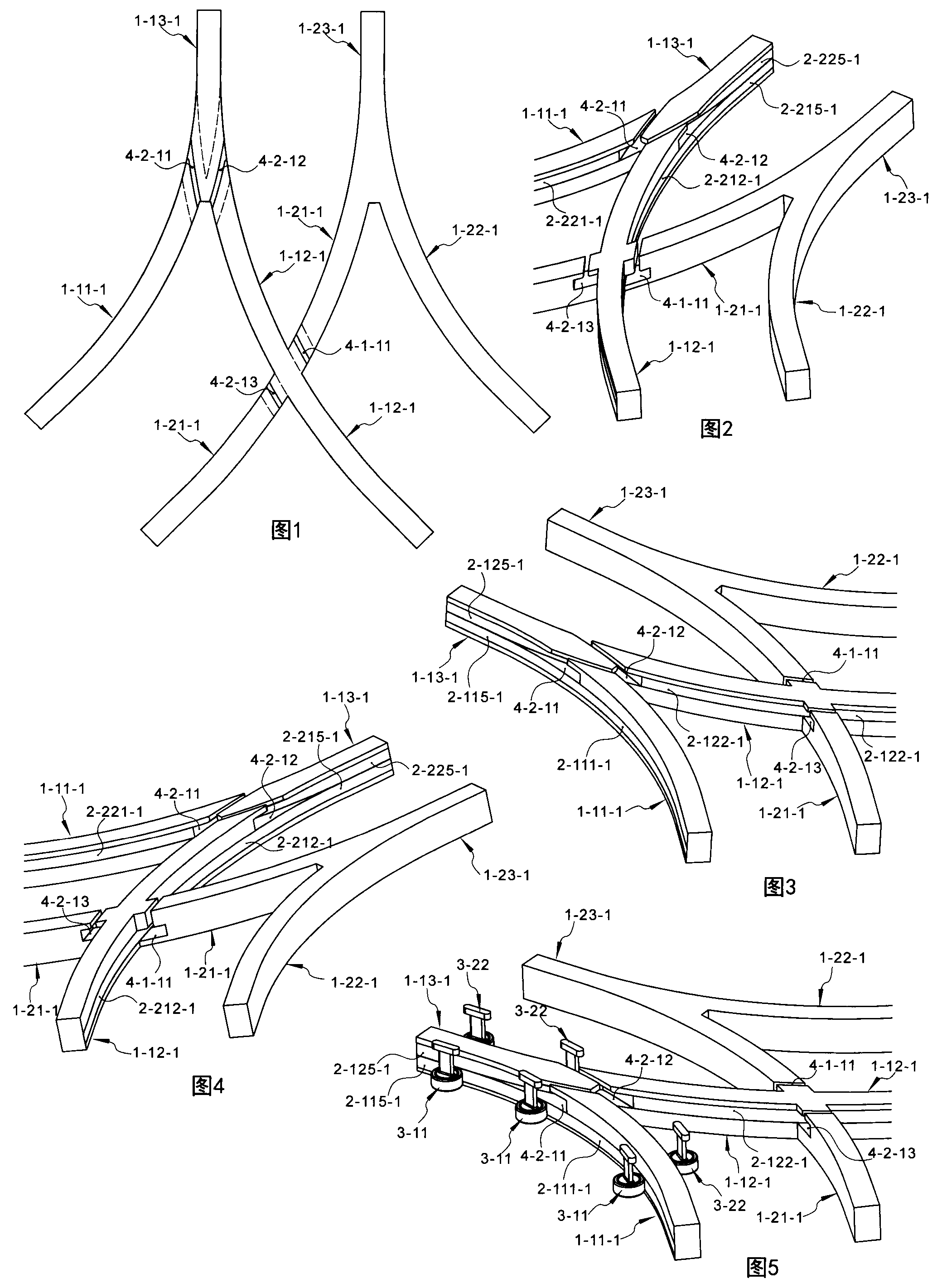

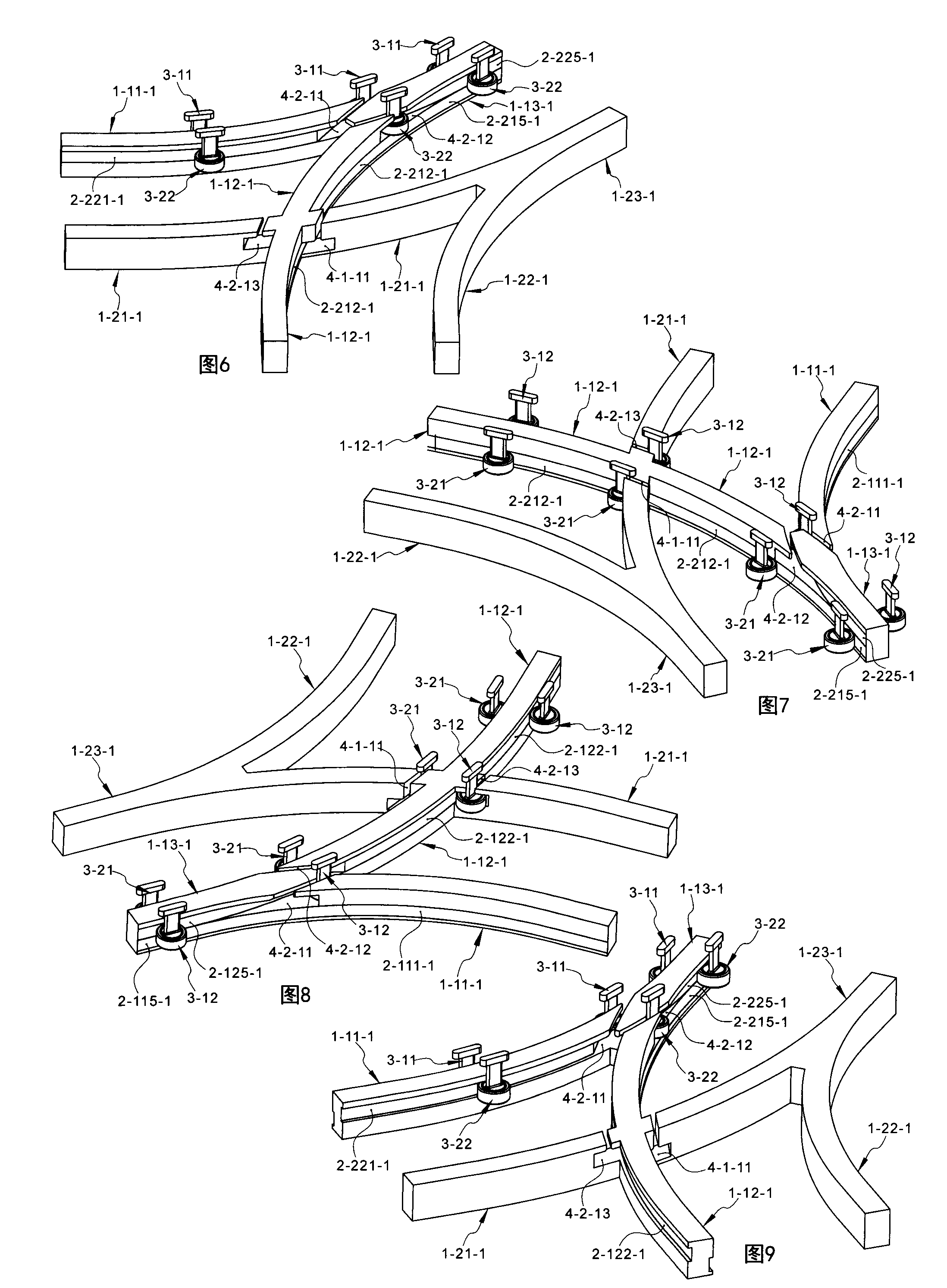

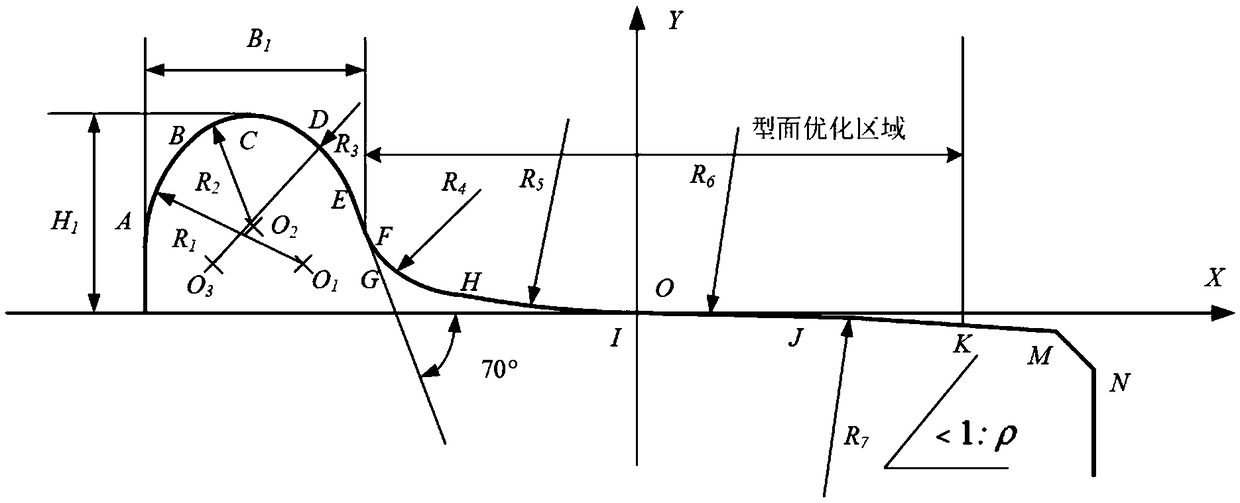

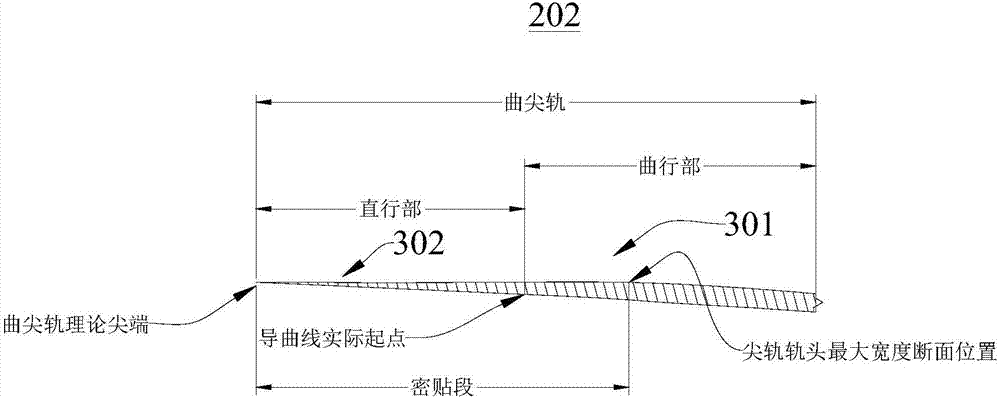

Curved switch rail, switch and turnout

InactiveCN107237221AImprove performanceSolution to short lifeRail switchesEngineeringWear resistance

The utility model relates to a curved point rail, a switch and a turnout, which belong to the field of rail transportation. The switch rail includes a straight section and a curved section connected to each other. The line type of the separation half tangent of the curved point rail with a large separation value. By extending the length of the straight section at the front end of the curved point rail, the position of the maximum wear of the wheel rail is moved to the thick section of the point rail. The curved point rail with the above design structure can reduce the wear effect of the train, thereby increasing the service life of the curved point rail. In addition, the impact angle of the curved point rail is small, which can reduce the impact of the train and improve the safety of driving. It has the advantages of good wear resistance, long service life and good comfort.

Owner:SOUTHWEST JIAOTONG UNIV +2

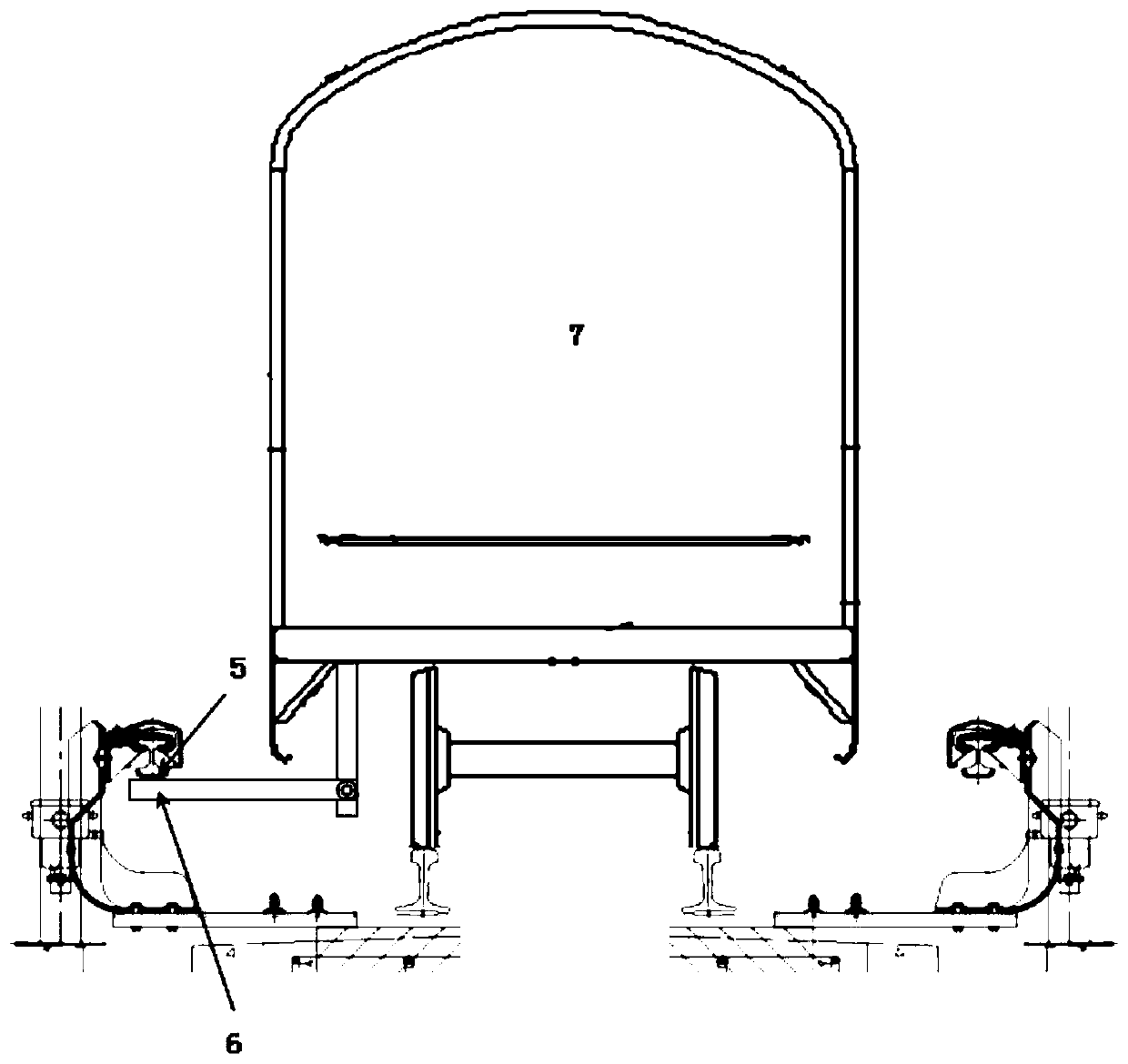

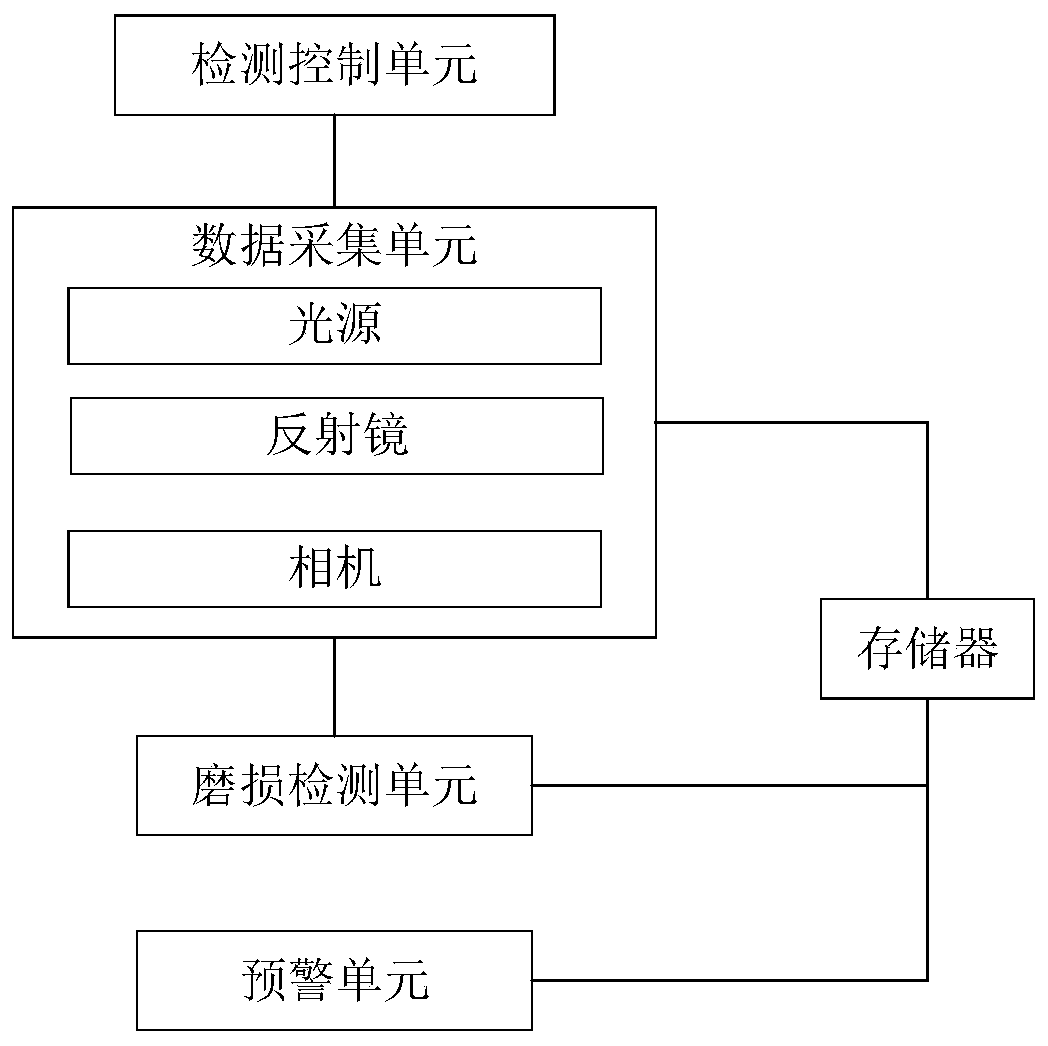

Steel-aluminum composite contact rail wear detection system and method

PendingCN110030960ANo need for manual inspectionThe detection process is fastUsing optical meansThermometer applicationsData acquisitionEngineering

The invention provides a steel-aluminum composite contact rail wear detection system and method. The system comprises: a detection controller connected with a data collector for transmitting a detection start signal and / or a detection stop signal to the data collector; the data collection installed at the bottom of a train and connected with a wear detector for starting or stopping the collectionof state data of a steel-aluminum composite contact rail according to the received detection start signal and / or the detection stop signal in a running process of the train, and sending the state dataof the steel-aluminum composite contact rail to the wear detector; and the wear detector for receiving the state data of the steel-aluminum composite contact rail and obtaining wear data of the steel-aluminum composite contact rail. By adoption of the steel-aluminum composite contact rail wear detection system and method provided by the invention, the wear of the steel-aluminum composite contactrail can be detected, the structure is simple, the detection speed is high, and the measurement precision is high.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

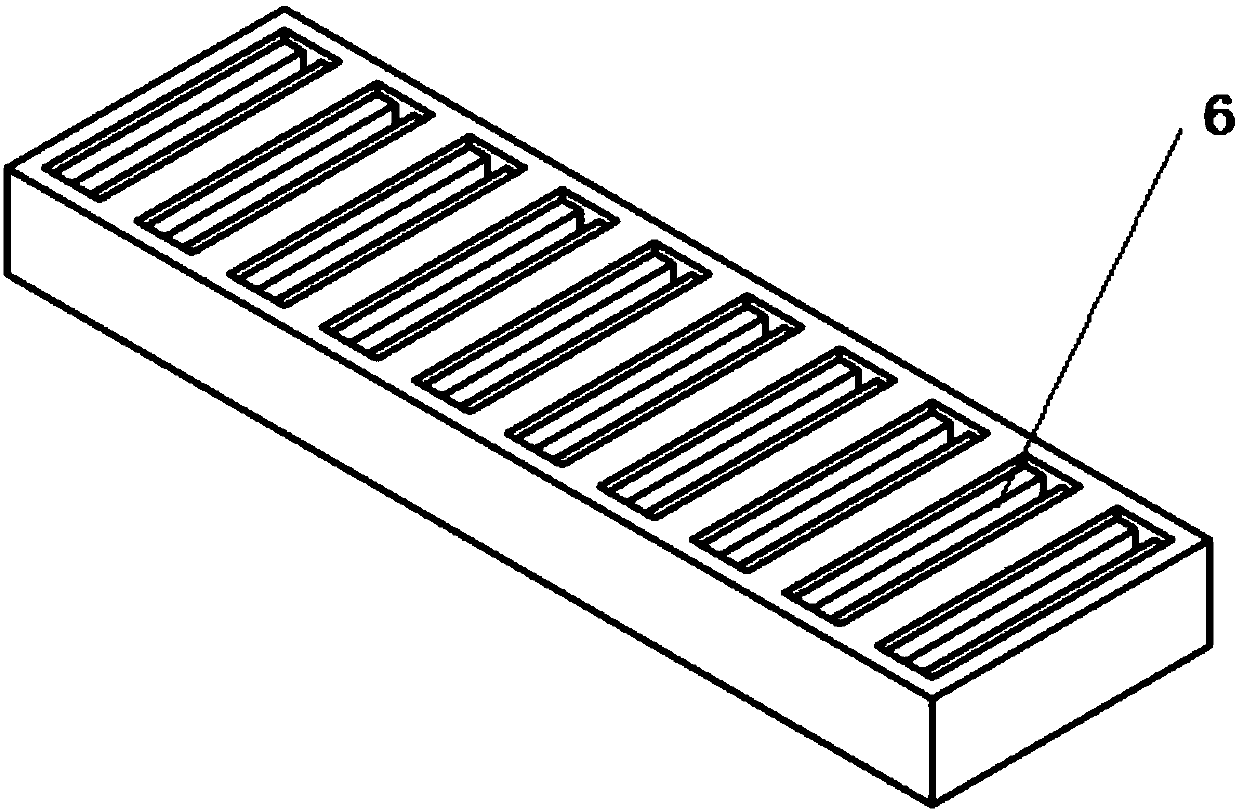

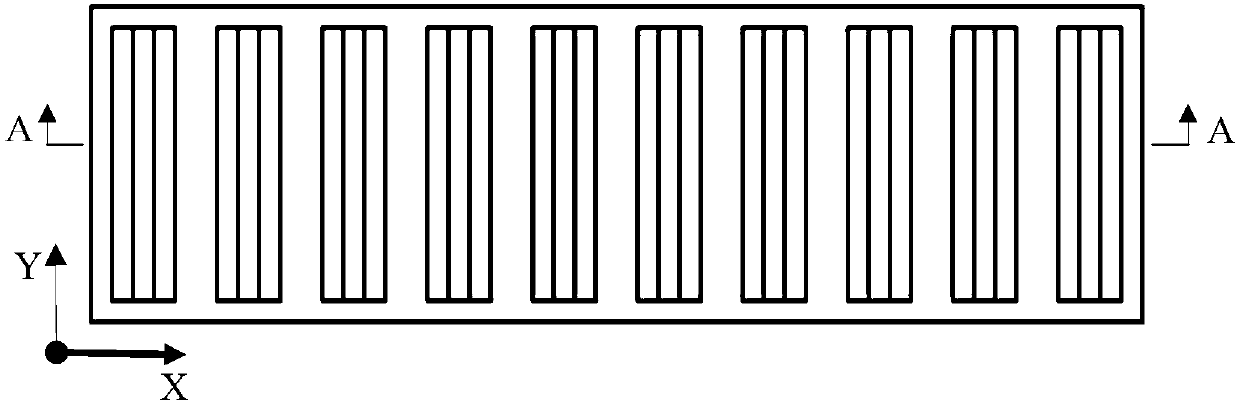

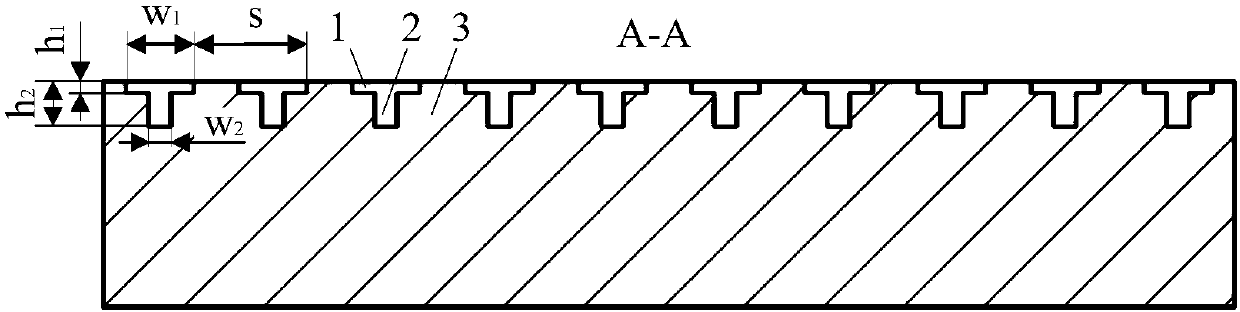

Surface texturing method for improving wear resistance of guiding rails of sand core moulding machine

ActiveCN107775285AImprove wear resistanceImprove bearing capacityMoulding machine componentsEngineeringWear resistance

Owner:SUZHOU FURUTA AUTOMATION TECH

Steel rail wear laser visual dynamic measuring method

InactiveCN100462678CLow costRealize on-site measurementUsing optical meansRailway auxillary equipmentMeasurement deviceLaser projector

The disclosed measuring device is composed of laser vision sensor, computer, image acquisition card in high speed, calibrating target drone and measuring software. The method includes steps: after imaging system for rail section images light plane projected from laser projector, the image acquisition card captures rail section images and sands them to computer. Processing the collected images, the computer picks up image coordinates of sectional feature contour, as well as calculates out vertical abrasion, side abrasion and total abrasion based on measured model. The invention is capable of measuring sectional contour of rail in single side, vertical abrasion, side abrasion and parameter of total abrasion through single laser vision sensor.

Owner:BEIHANG UNIV

Slipring with wear monitoring

PendingUS20170214202A1Protect from wearLengthen life timeRotary current collectorBrushes manufactureEngineeringSlip ring

A slipring with at least one slip ring module having at least one sliding track, and at least one wear indication track. A wear indication circuit is connected to the at least one wear indication track for monitoring electrical properties of the wear indication track and signaling an abnormal slipring condition. A wear indication track may be exposed to higher load, higher rotation speed, higher brush pressure force, or other lifetime-reducing influence as compared to a normal sliding track.

Owner:SCHLEIFRING GMBH

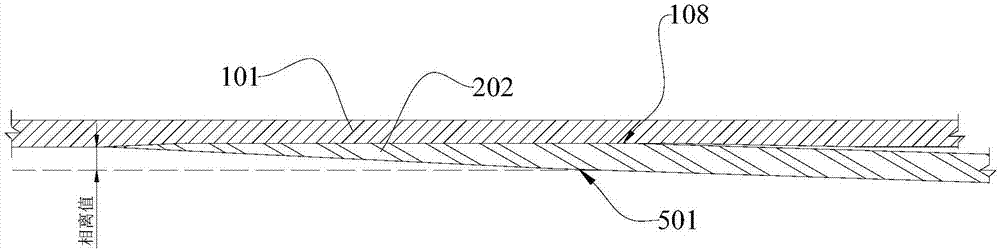

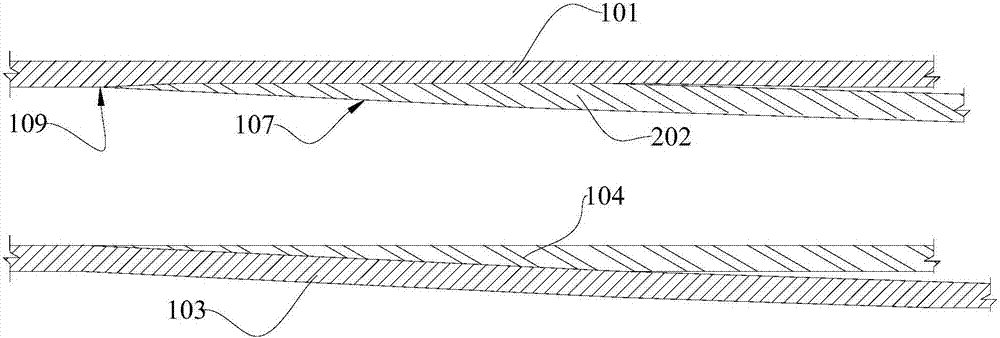

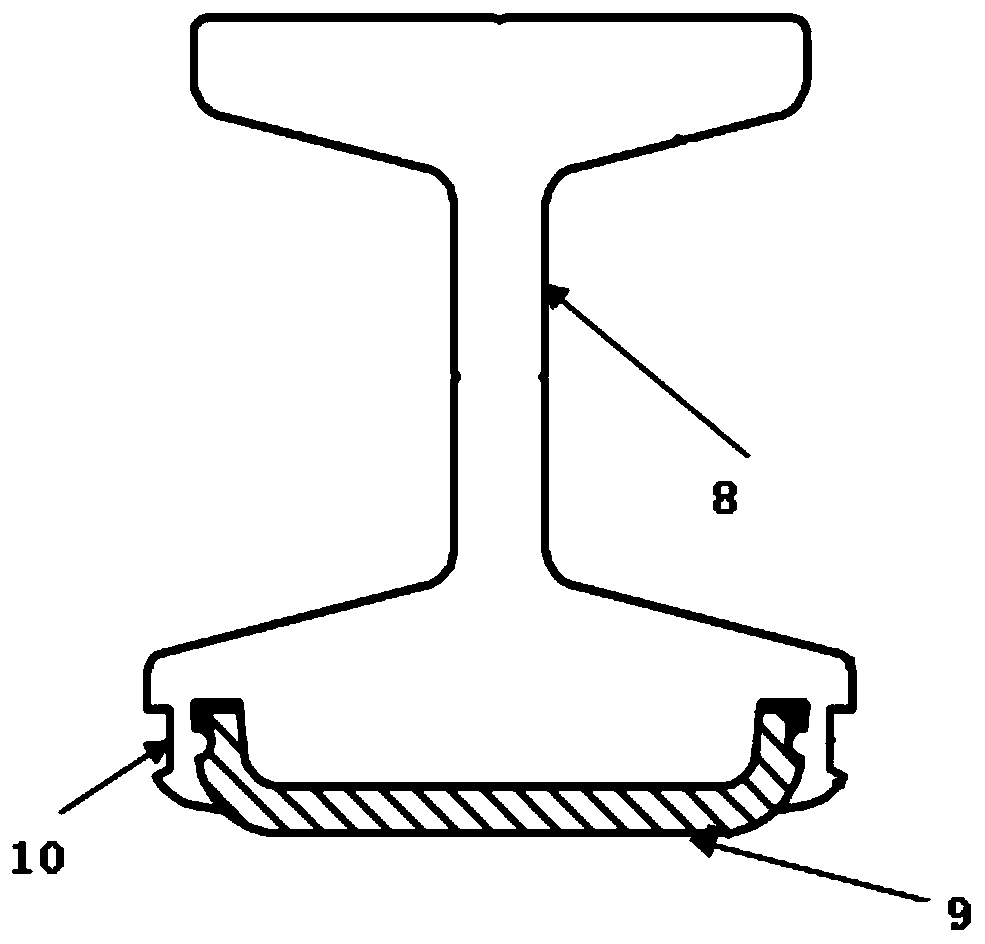

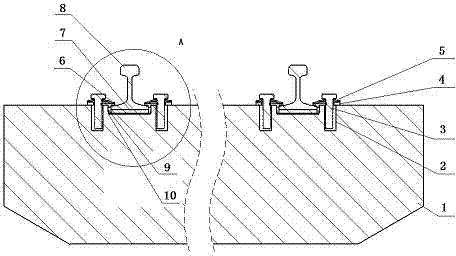

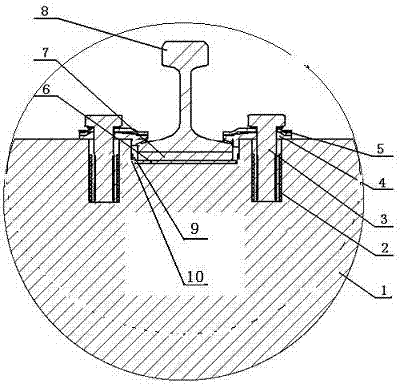

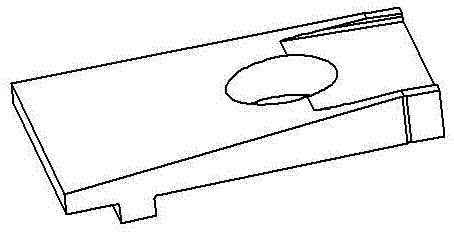

A Ballastless Track Vibration Damping Structure with Uniform and Continuous Rigidity

InactiveCN102296493AUniform continuous support stiffnessMeet development needsBallastwayRail fastenersEngineeringGauge block

The invention belongs to the technical field of ballastless track, and proposes a ballastless track with uniform rigidity and continuous vibration damping structure, which mainly includes steel rail (8), track bed plate (1), gauge block (4), and spring bars (5); There are two parallel grooves for laying steel rails (8) on the track bed plate (1), and a plurality of continuously laid steel rails (8) are located in the grooves; an elastic The under-rail pad (7) and the under-rail pad boots (6); the under-rail pad boots (6) are continuously laid in two longitudinally arranged grooves on the track bed, and the under-rail pad boots (6) are "U "shaped structure; the elastic under-rail pad (7) is continuously arranged along the laying direction of the rail and is located in the under-rail pad boot (6). The invention provides uniform and continuous support rigidity for the rail, improves the safety, stability and comfort of the train operation, reduces the waveform wear on the rail surface caused by the wheel-rail stage, and satisfies the development requirement of the ballastless track.

Owner:洛阳双瑞橡塑科技有限公司

Brake device for rail traffic

InactiveCN110435709ASolve the problem of more serious wear and tearReduce severityTrack-braking member co-operationEngineeringRail traffic

The invention relates to the field of rail brake, in particular to a brake device for rail traffic. The device comprises a bullet train and a rail, and further comprises a supporting assembly, a movable assembly and a friction assembly; the movable assembly comprises two symmetrically-arranged dual-connecting-rod mechanisms, each dual-connecting-rod mechanism comprises two symmetrically-arranged single-connecting-rod mechanism, each single-connecting-rod mechanism is composed of two short connecting rods and two long connecting rods, one ends of the short connecting rods are oppositely hingedto the middle of the outer side of the supporting assembly, one ends of the long connecting rods are oppositely hinged to the free ends of the two short connecting rods respectively, and the free endsof the long connecting rods are oppositely hinged to the lower half part of the supporting assembly separately. The problem that when the brake device brakes the bullet train, abrasion to wheels andrails are serious is solved, abrasion severity is lowered, and safety and stability are improved.

Owner:贾文康

Rail wheel tread wear degree detection method

InactiveCN106053277AAccurate detectionLow costRailway auxillary equipmentInvestigating abrasion/wear resistanceEngineeringCoal

The invention discloses a rail wheel tread wear degree detection method, and belongs to the technical field of rail detection. According to the present invention, analysis is performed, wherein concrete crossties are arranged under the bending paths having the bending angle of more than 4 DEG on the rail before more than 10 years, and most of trains are coal conveying trains or empty trains, and a plurality of grain conveying trains and passenger and freight mixed trains; worn pad plates, damaged or frayed insulation bodies, loose fasteners, cast and loose supporting materials, excessive rail wear, and broken crossties are detected; the goal is to evaluate the data of the existing track inspection car (TGC) and whether other detection system technologies can locate the position of the RSA; the purpose is to determine whether the output data of the TGC can be used for detect the RSA; and with the rail wheel tread wear degree detection method, the defect misjudgement rate and the miss of detection can be effectively reduced, the position, the size and the depth of the rail wheel tread defect can be exactly detected, and the rapid and effective new approach with the characteristics of low cost and high detection precision is provided for the rail wheel tread wear degree surface defect detection.

Owner:合肥德泰科通测控技术有限公司

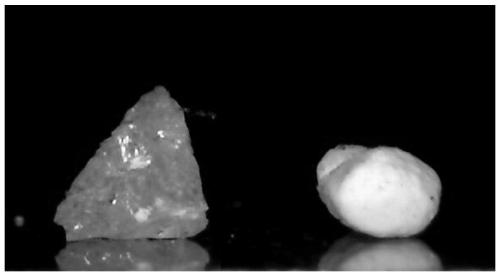

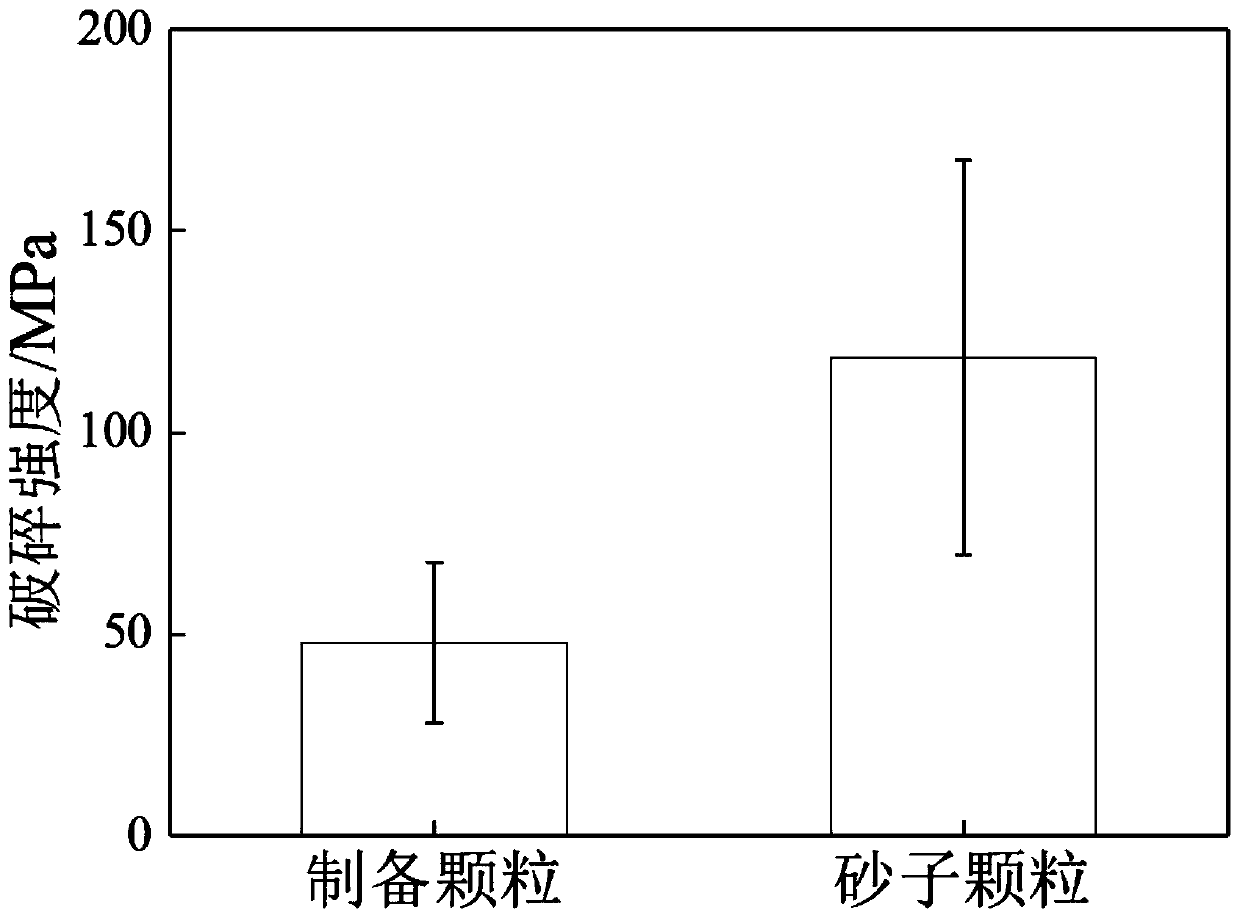

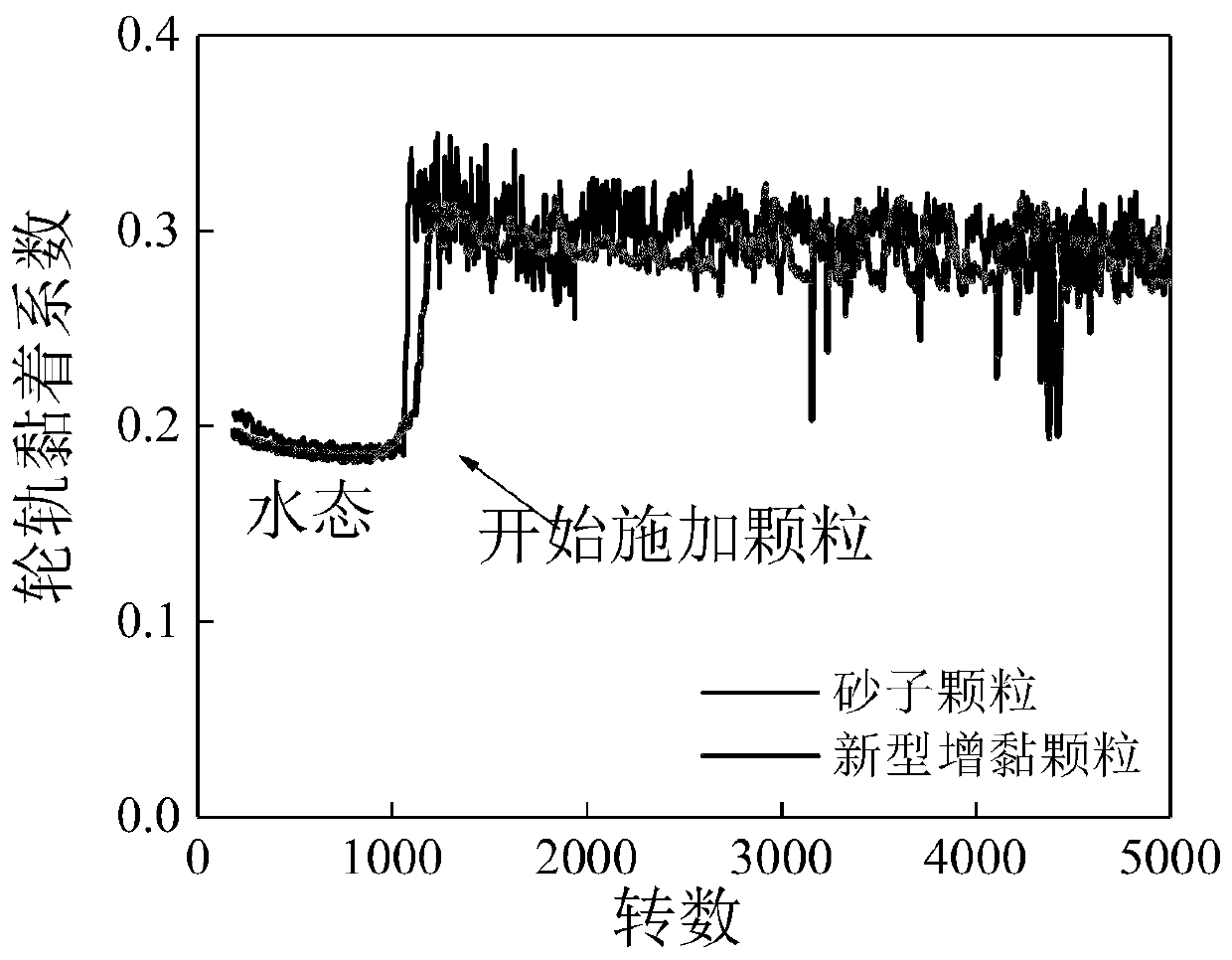

Tackifying particle for tackifying rail transit wheel-rail interface, and preparation method thereof

The invention discloses a tackifying particle for tackifying a rail transit wheel-rail interface, and a preparation method thereof. The preparation method comprises the following steps: 1, adding silica powder into water to form a premixed liquid; 2, carrying out spray drying on the premixed solution obtained in step 1 to form a particle green body; and 3, sintering the particle green body obtained in step 2 to obtain the finished product particle. The tackifying particle prepared by the invention can effectively avoid the problems of wheel rail wear and damage aggravation caused by hard particles in the tackifying process while meeting the wheel rail tackifying requirement; and tests show that the wear rate of the wheel rail material in the tackifying process is reduced by 70% compared with the traditional sand particle tackifying process, and the wheel rail sample has a smooth surface and has no obvious damage such as particle indentation and the like.

Owner:SOUTHWEST JIAOTONG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com