Steel rail wearing detecting device

A technology for detecting device and rail wear, which is applied in the directions of measuring device, optical device, transportation and packaging, etc., which can solve problems such as caliper wear, high worker ability requirements, and decreased measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

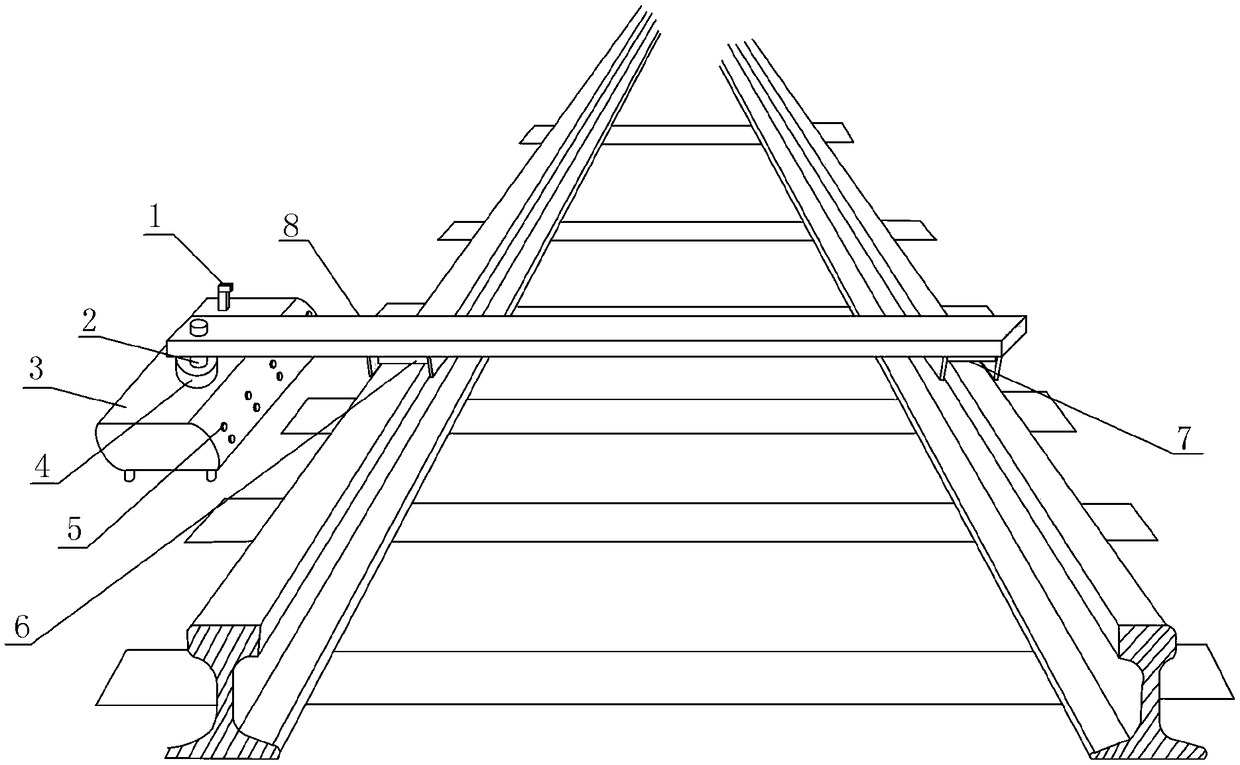

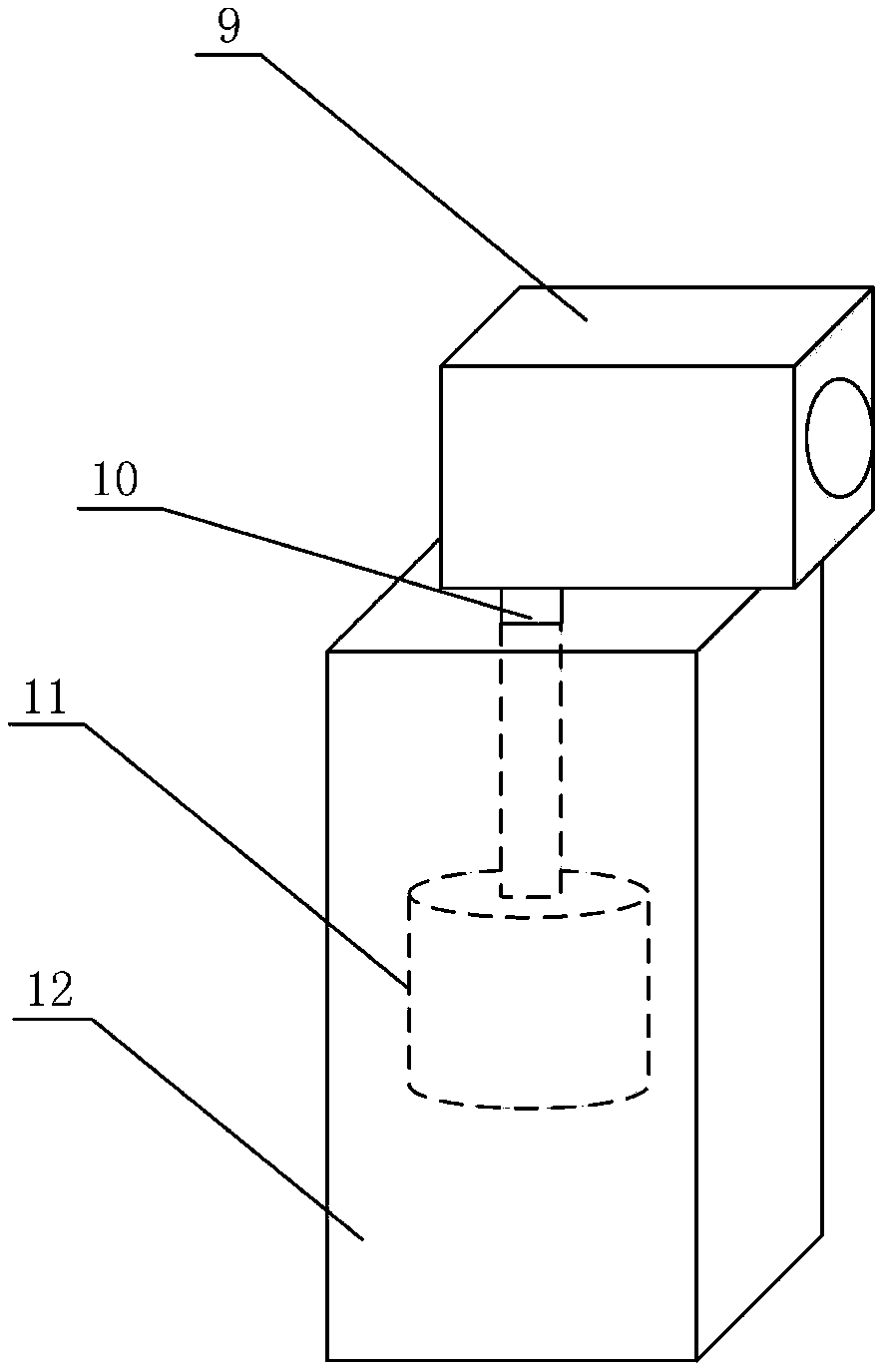

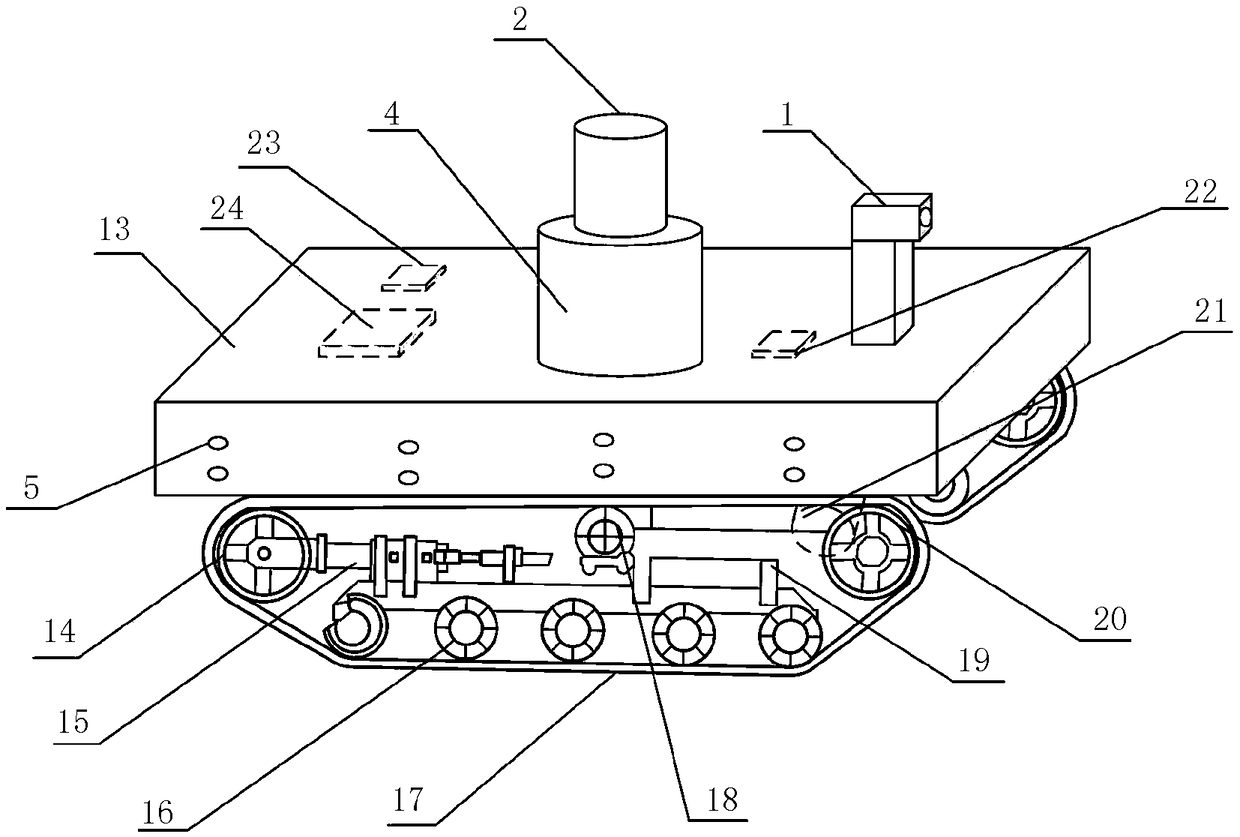

[0039] see Figures 1 to 10 , shows a rail wear detection device in the present invention, including an image acquisition device 1, a first telescopic motor 2, a traveling device 3, a servo motor 4, an ultrasonic rangefinder 5, a left wear detector 6, a right wear detection Instrument 7, crossbar 8.

[0040] like figure 1 As shown, the walking device 3 is used to move the crossbar 8, and moves along the outer side of the track with the assistance of the image acquisition device 1 and the ultrasonic range finder 5, so that the left wear detector 6 and the right wear detector 7 To detect along the rail, the image acquisition device 1 and the servo motor 4 are installed on the top of the traveling device 3, the image acquisition device 1 is used to guide the traveling device 3 to move forward, and at the same time guide th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com