Patents

Literature

796 results about "Track gauge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In rail transport, track gauge or track gage is the spacing of the rails on a railway track and is measured between the inner faces of the load-bearing rails. All vehicles on a rail network must have running gear that is compatible with the track gauge, and in the earliest days of railways the selection of a proposed railway's gauge was a key issue. As the dominant parameter determining interoperability, it is still frequently used as a descriptor of a route or network.

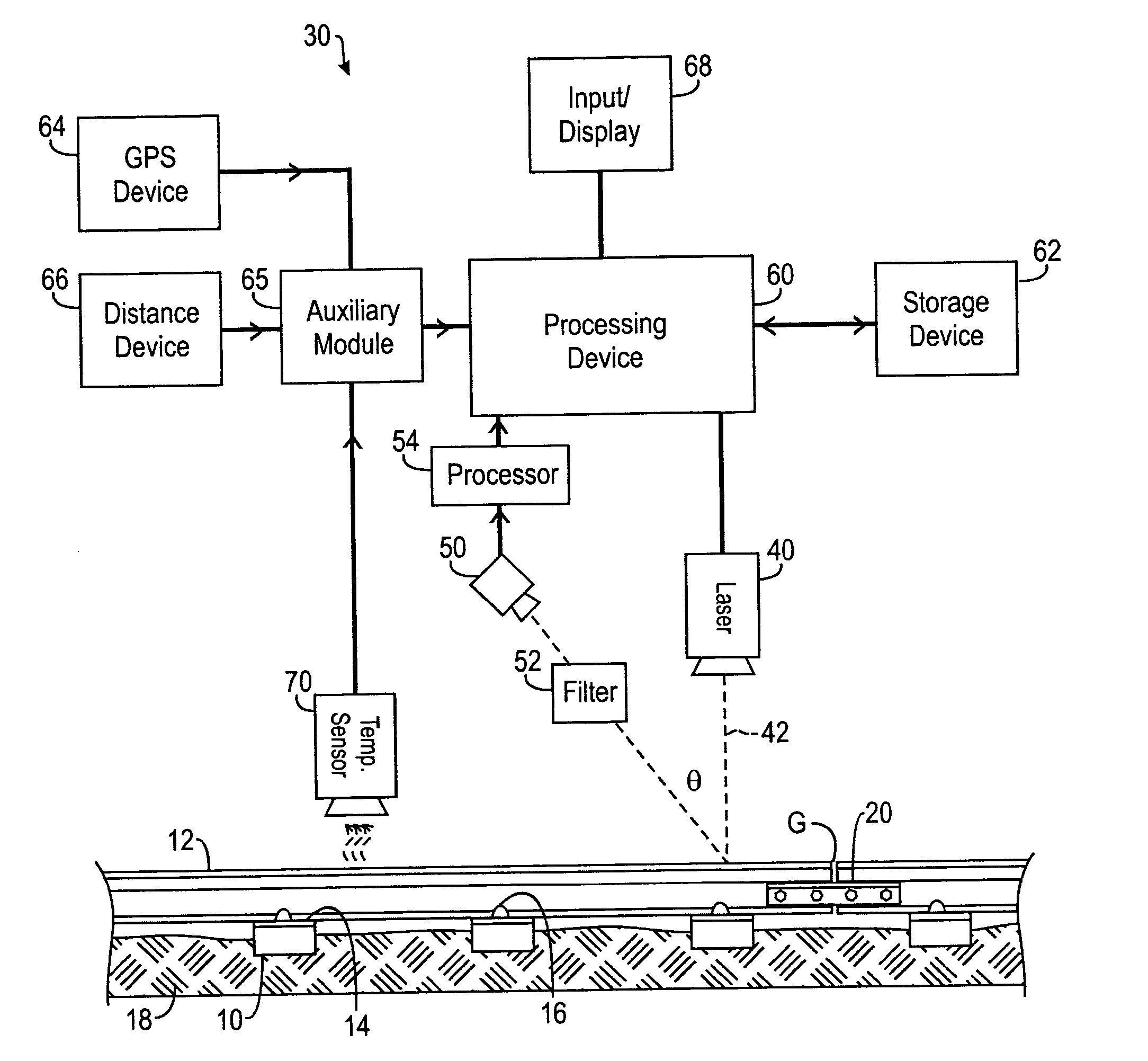

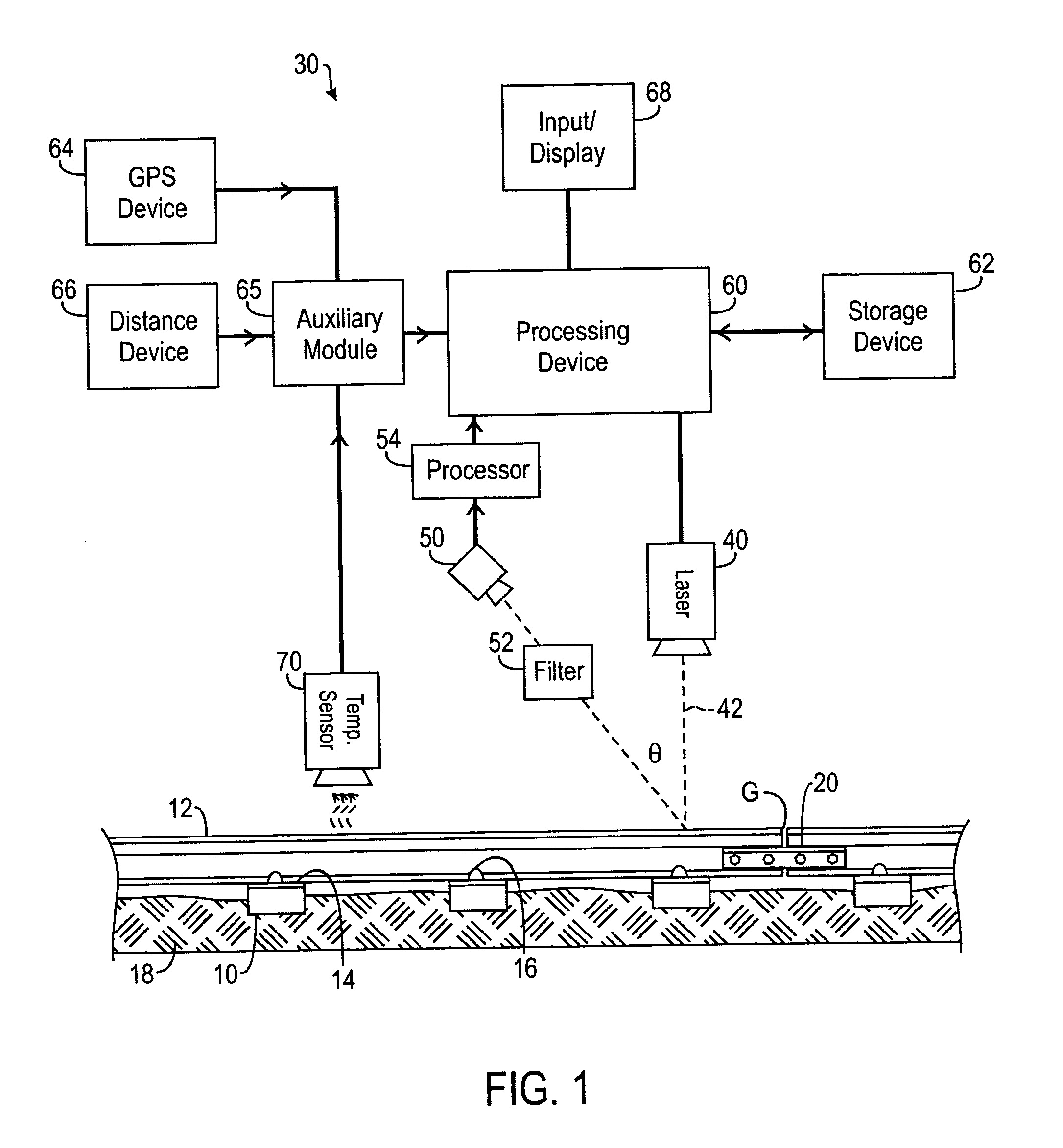

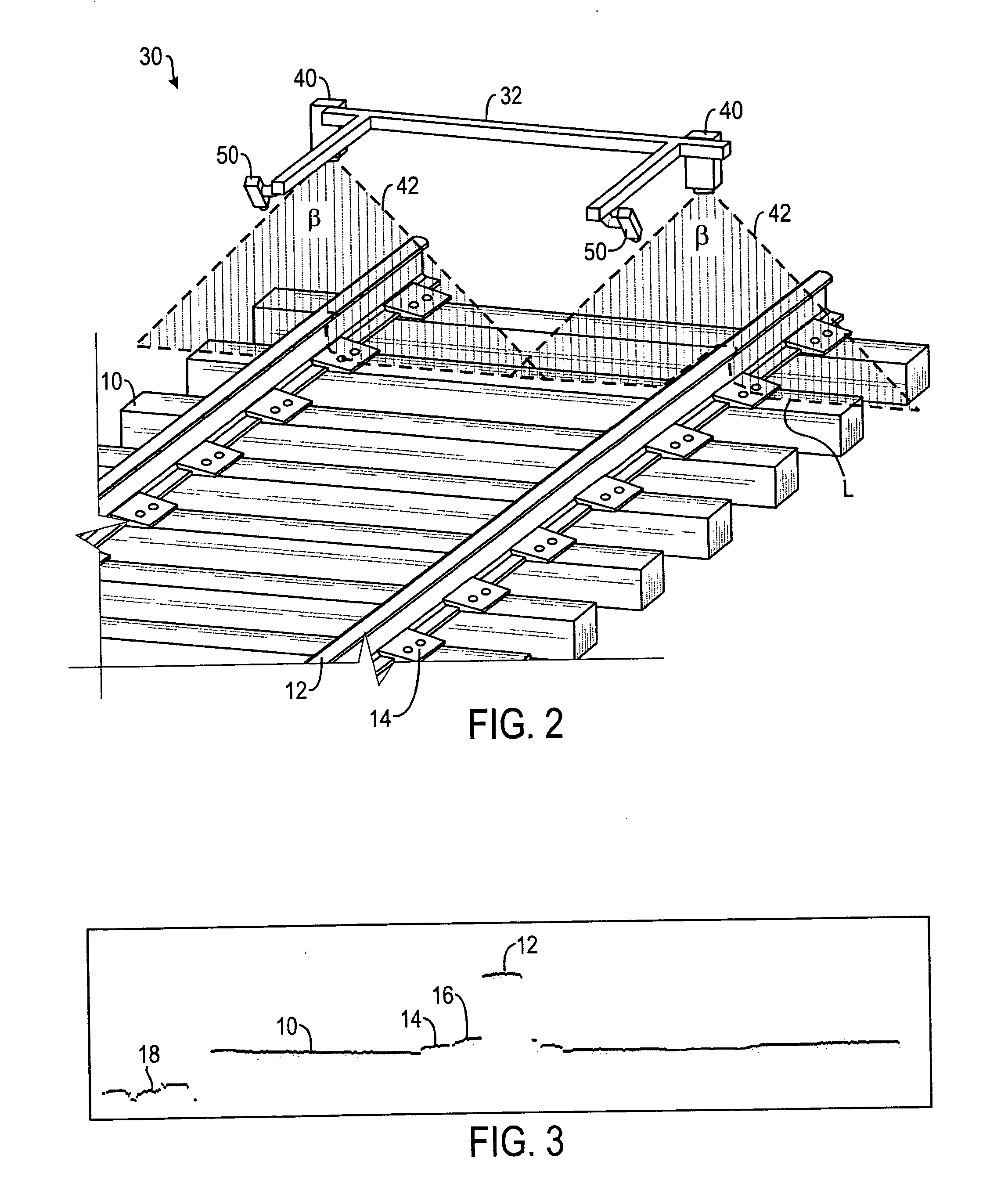

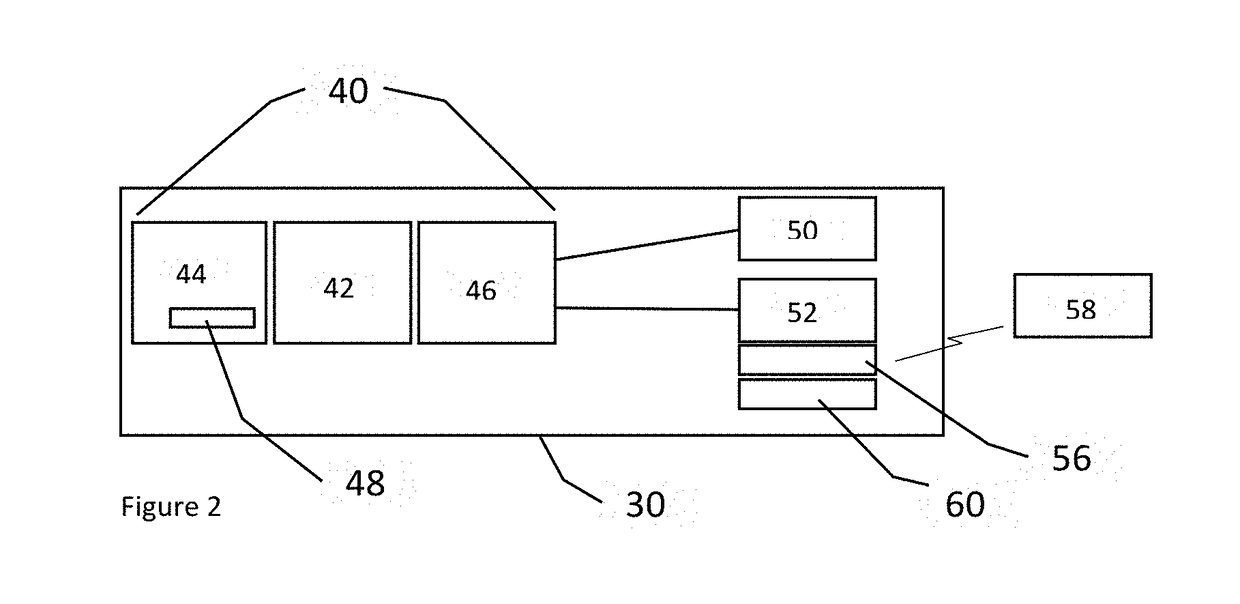

System and method for inspecting railroad track

A system and method for inspecting railroad track is disclosed. The disclosed system includes lasers, cameras, and a processor. The lasers are positioned adjacent the track. The laser emits a beam of light across the railroad track, and the camera captures images of the railroad track having the beam of light emitted thereon. The processor formats the images so that they can be analyzed to determine various measurable aspects of the railroad track. The disclosed system can include a GPS receiver or a distance device for determining location data. The measurable aspects that can be determined by the disclosed system include but are not limited to the spacing between crossties, the angle of ties with respect to rail, cracks and defects in surface of ties, missing fastener components, misaligned fastener components, sunken tie plates, raised spikes, rail wear, gage of rail, ballast height relative to ties, size of ballast stones, and break or separation in the rail. The system includes one or more algorithms for determining these measurable aspects of the railroad track.

Owner:LORAM TECH INC

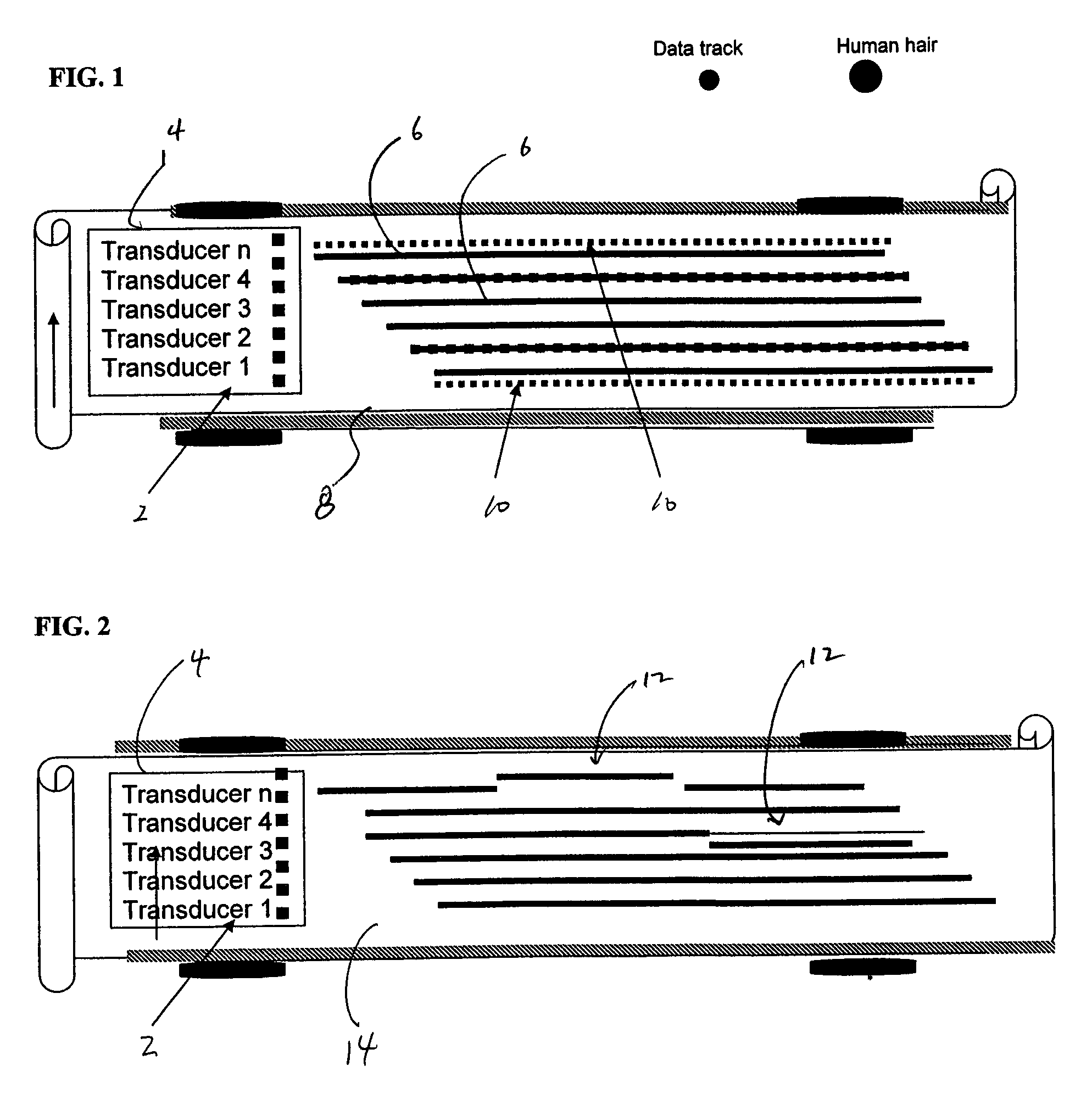

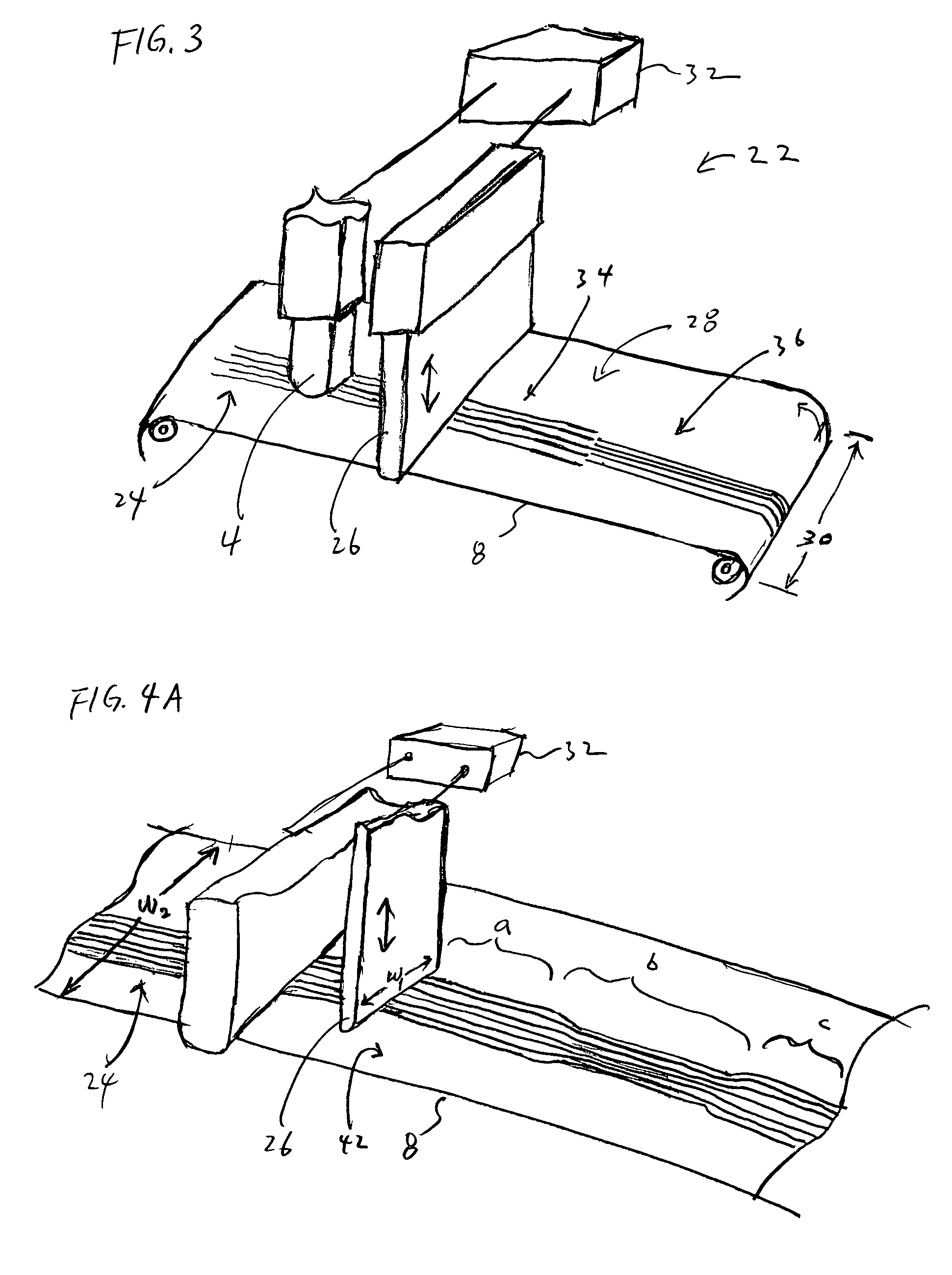

Ultra high track density adaptive head core track pitch control

ActiveUS7486464B2Filamentary/web record carriersAlignment for track following on tapesTrack densityMagnetic tape

Apparatuses and methods for adjusting the track pitches of the tracks on a data storage tape. In one variation, the method comprises adjusting the observed pitch between the tracks by applying variable amounts of pressure on the surface of the tape. In another variation, the pressure is applied to a localized region on the tape. The pressure can be modulated to induces a change in the physical characteristic of the tape in and around the area where pressure is applied. In another aspect, an apparatus is configured with a magnetic read-head for detecting written tracks on a magnetic tape, and an actuator is provided to apply pressure on the tape to control the track pitch of the written tracks.

Owner:QUANTUM CORP

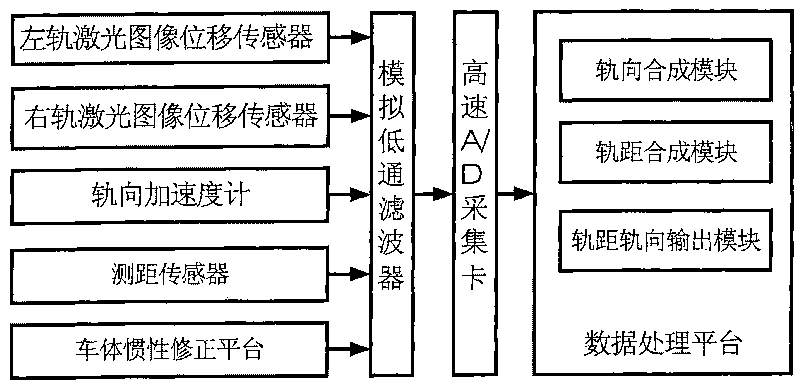

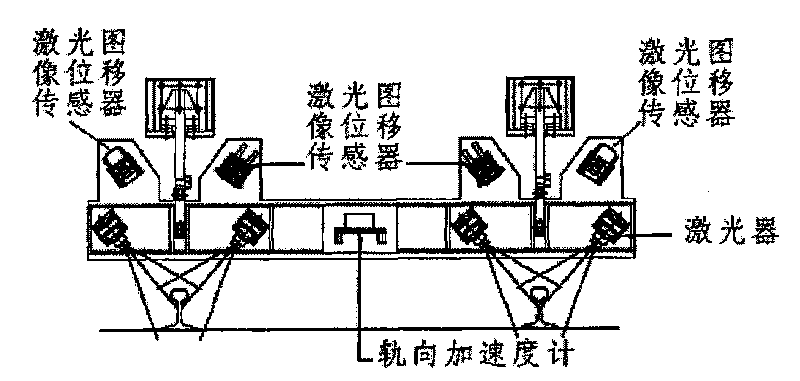

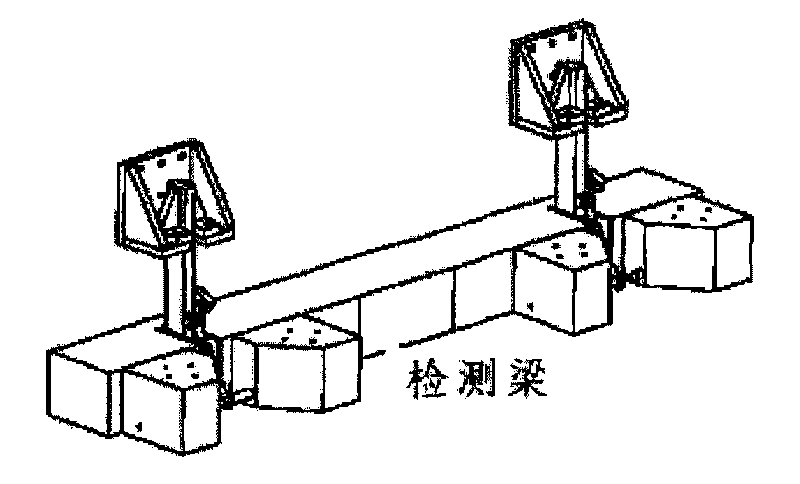

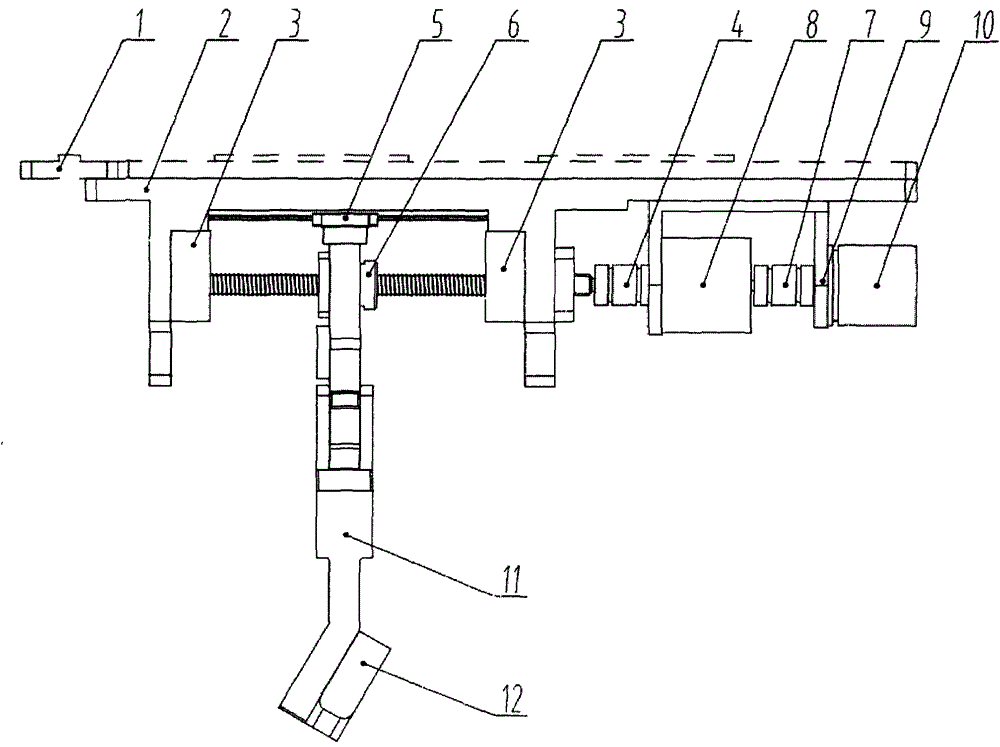

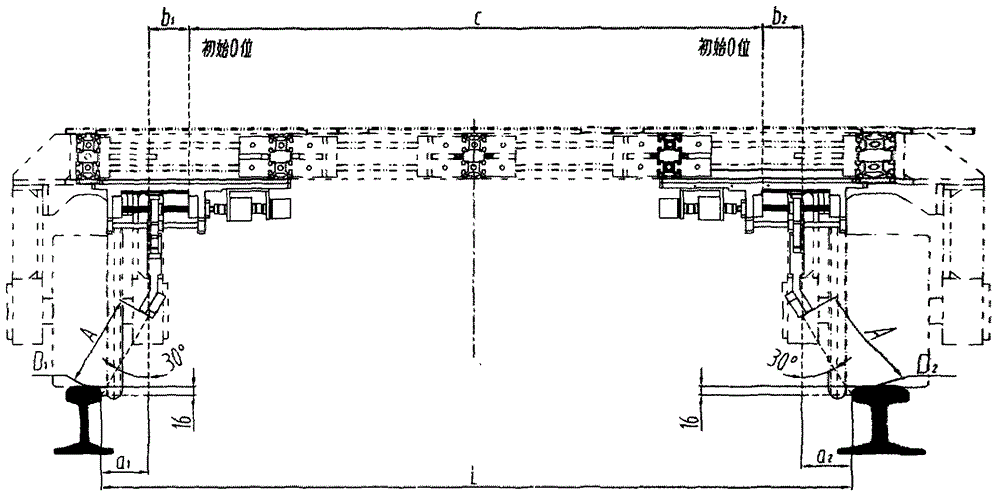

Framework type track gauge and track direction measuring device

InactiveCN101758835AAvoid safety hazardsSolve the unmeasurableRailway inspection trolleysUsing optical meansMeasurement deviceAccelerometer

The invention provides a framework type track gauge and track direction measuring device, comprising a detection beam which is arranged on a track detector car framework; two groups of laser image displacement sensors which are respectively arranged at two ends of the detection beam for detecting the displacement of the track relative to the detection beam; a track direction accelerometer which is used for measuring the displacement of the central point of the detection beam relative to inertial space; a car body inertia correction platform which is used for measuring the posture of the detection beam and correcting the effect of the posture of the detection beam to the measurement data; a distance measurement sensor which is arranged at the countershaft end of a track detector car wheel for measuring the driving distance and driving speed of the track detector car and providing distance sampling time interval; and a data processing platform which is arranged on the detection car for processing the detection data to obtain the track gauge and the track direction detection results; the device solves the safety hidden troubles of an axle box track gauge detection beam and the problem that the track gauge and the track direction can not be measured under high speed.

Owner:RAILWAY INFRASTRUCTURE TESTING RES INST CHINA ACAD OF RAILWAY SCI

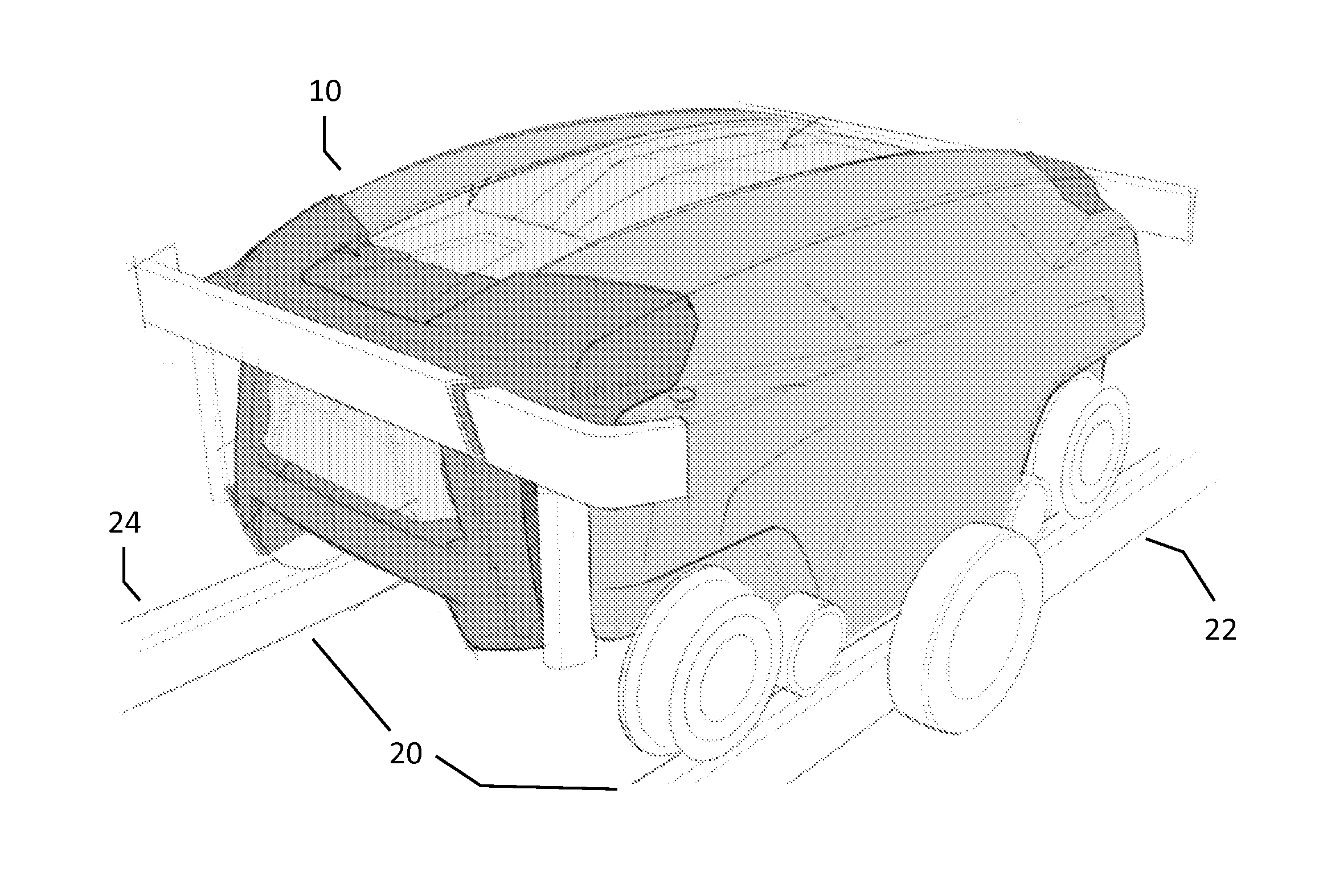

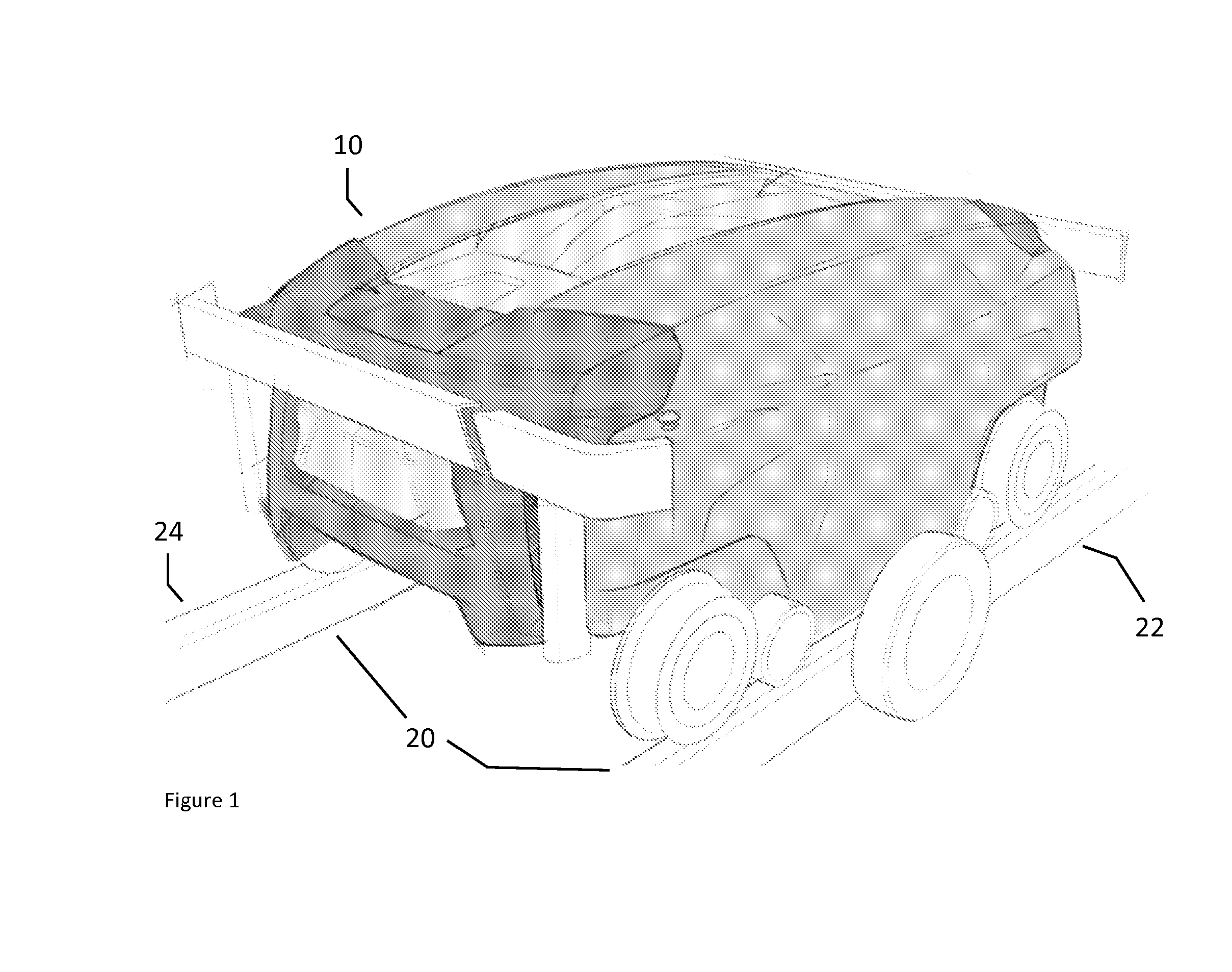

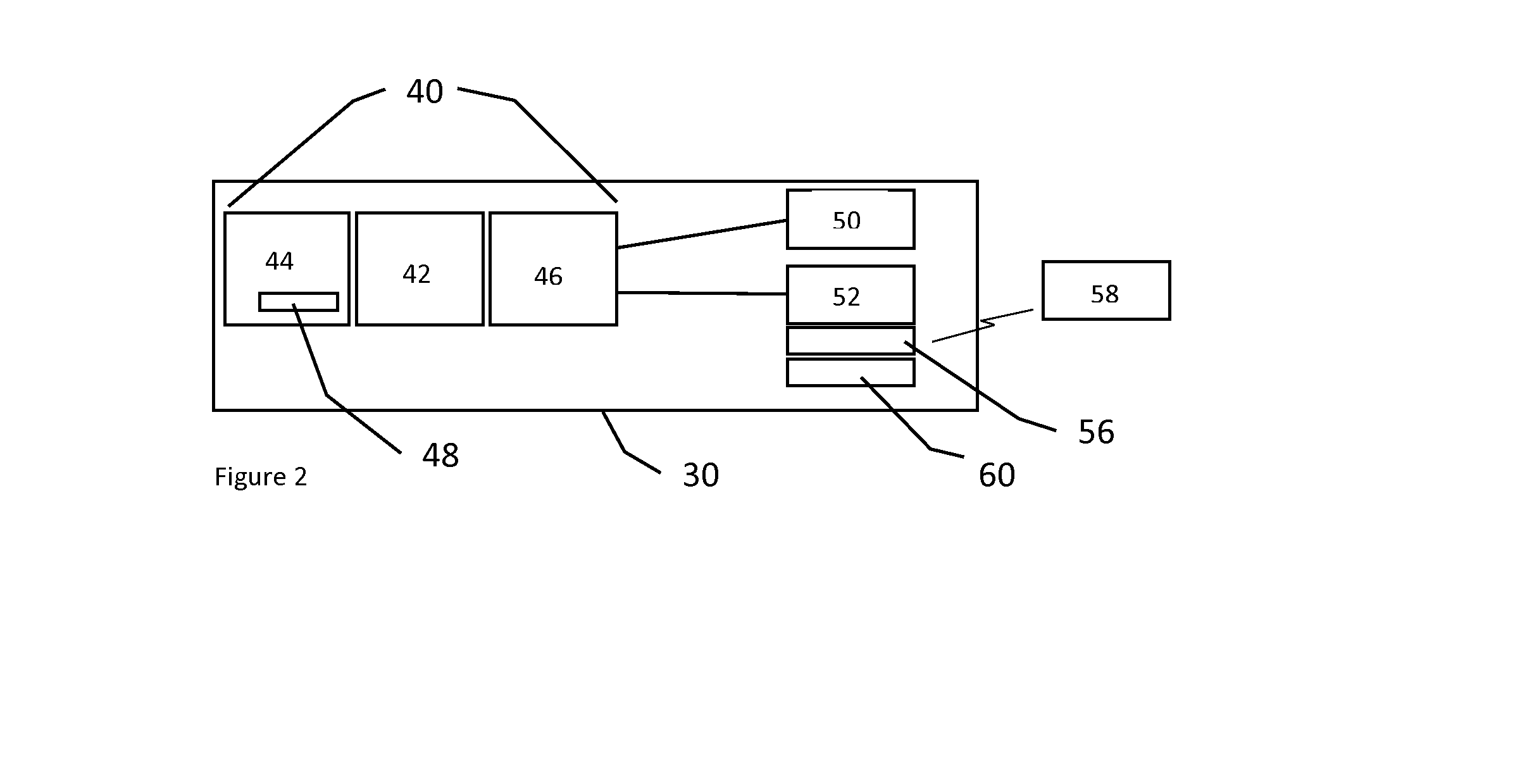

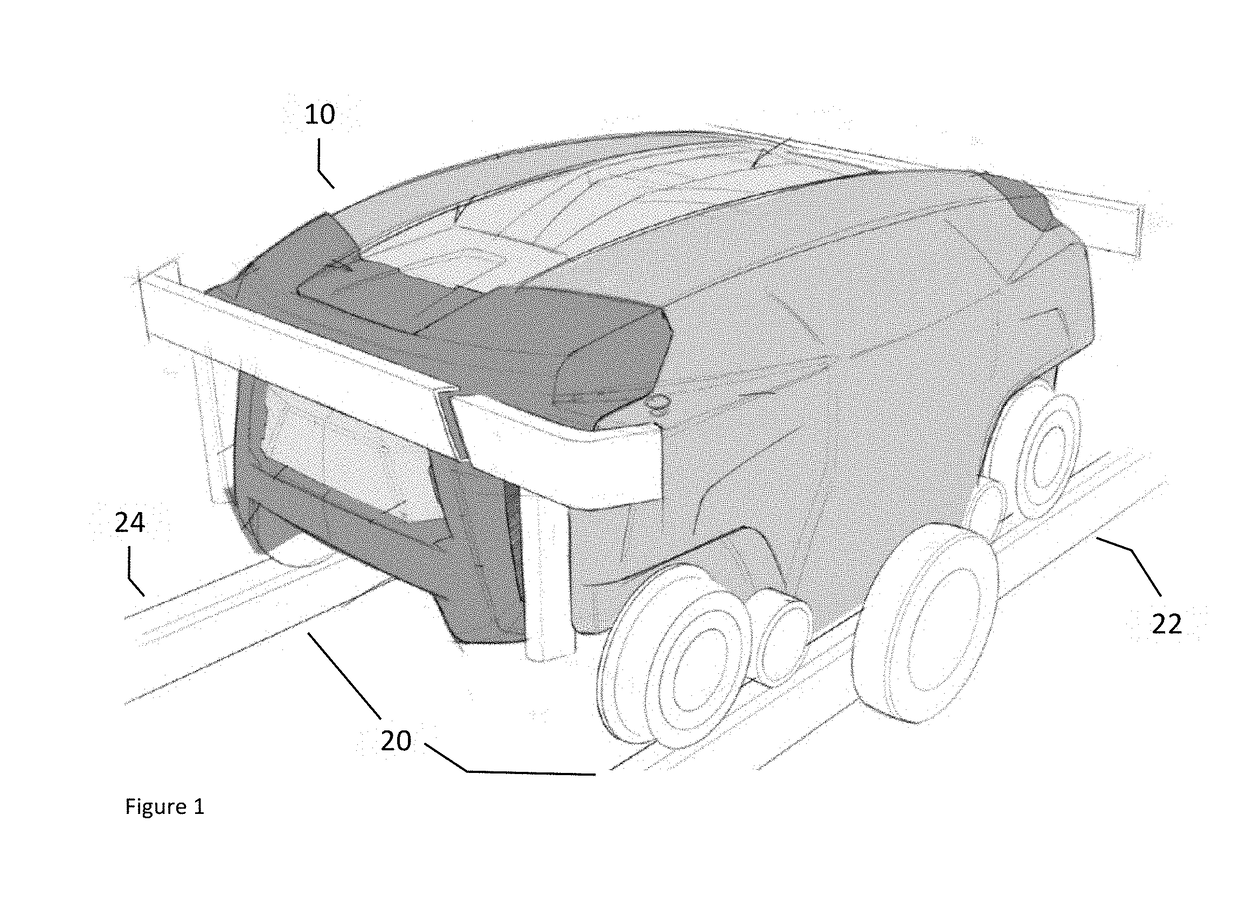

Automated track inspection system

ActiveUS20160002865A1High frequencyReduce riskMaterial analysis by optical meansLocomotive transmissionsDrive wheelMultiple sensor

An autonomous device for rail track inspection includes a drive wheel system propelling the device via a drive wheel system, an automatic track loading fixture for and applying a load on rails, and sensors for taking track gauge measurement. Different automatic track loading fixtures may require stopping for load and measurement, or loading and measuring while still in motion. A switch agnostic system for operation with devices on a conventional railroad track system includes a linear slider movably mounted along a linear sliding support; multiple sensors mounted to the linear slider, the sensors operable to identify a rail of a track junction; and multiple roller bearings operable to engage the rail of the track junction and control the device across the track junction in response to movement of the linear slider along the linear sliding support.

Owner:RAILPOD

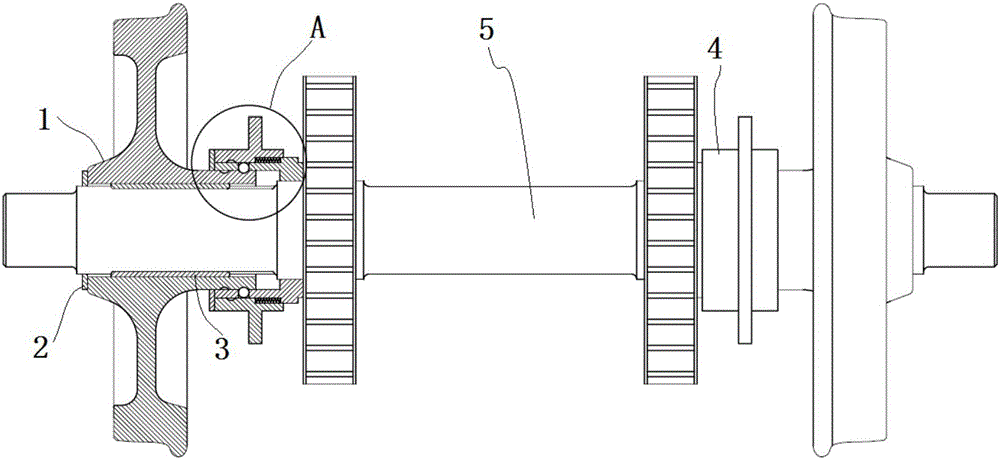

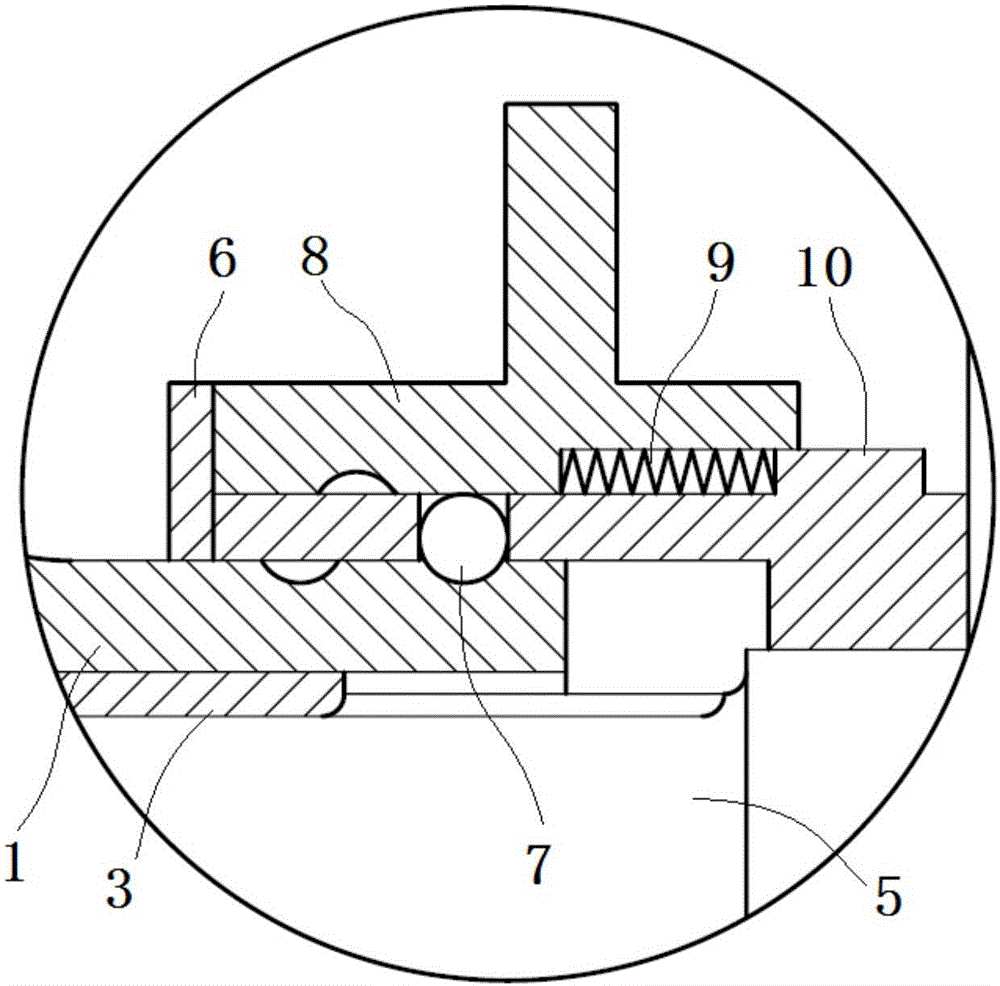

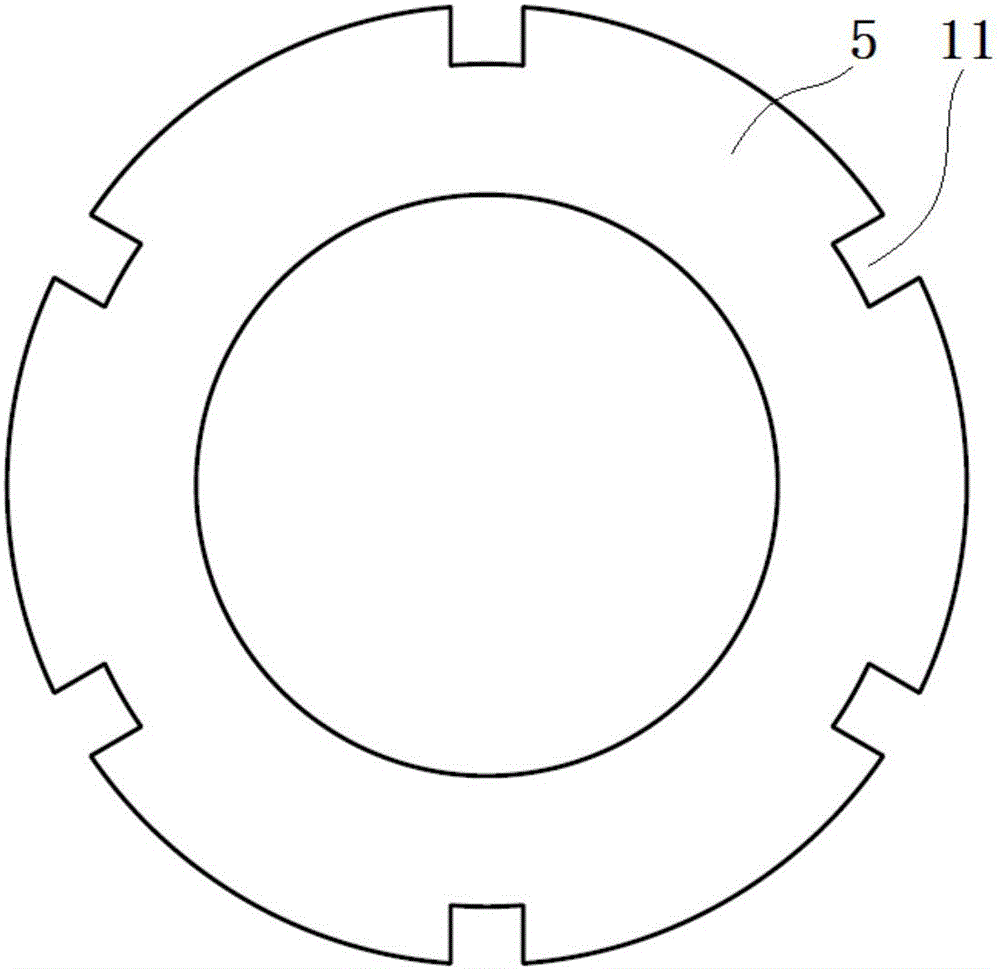

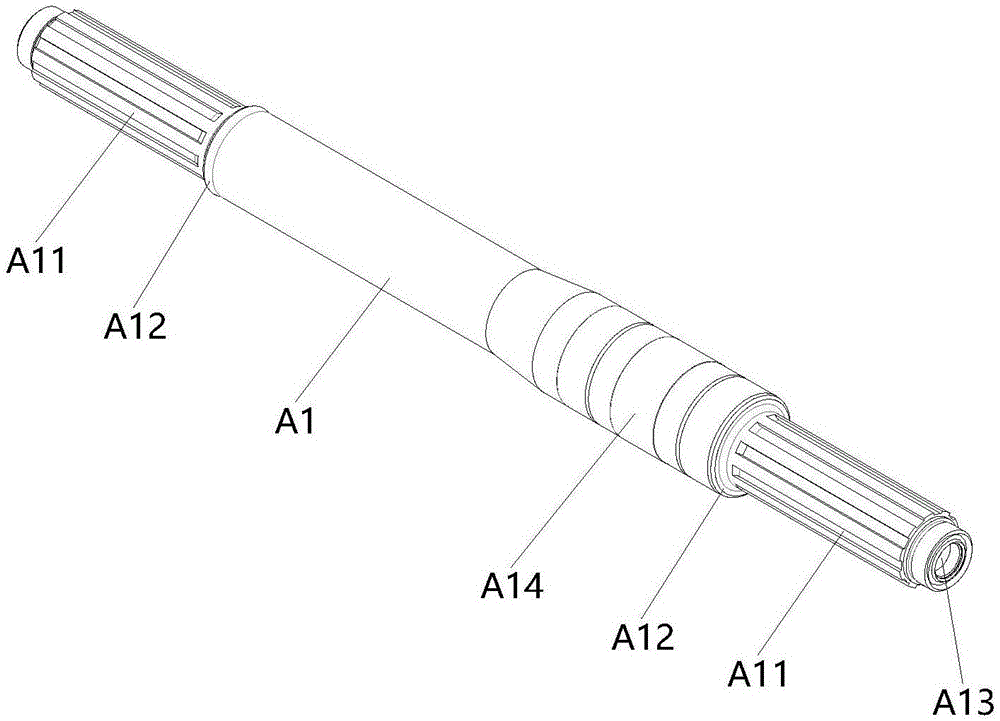

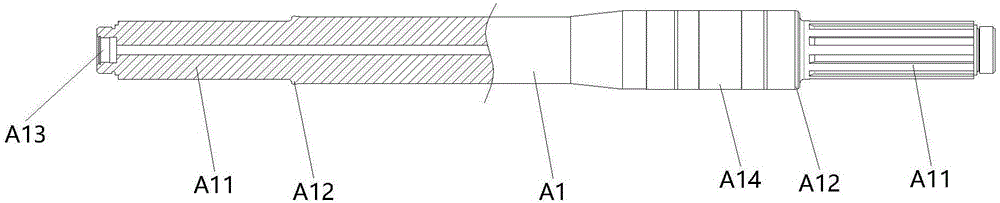

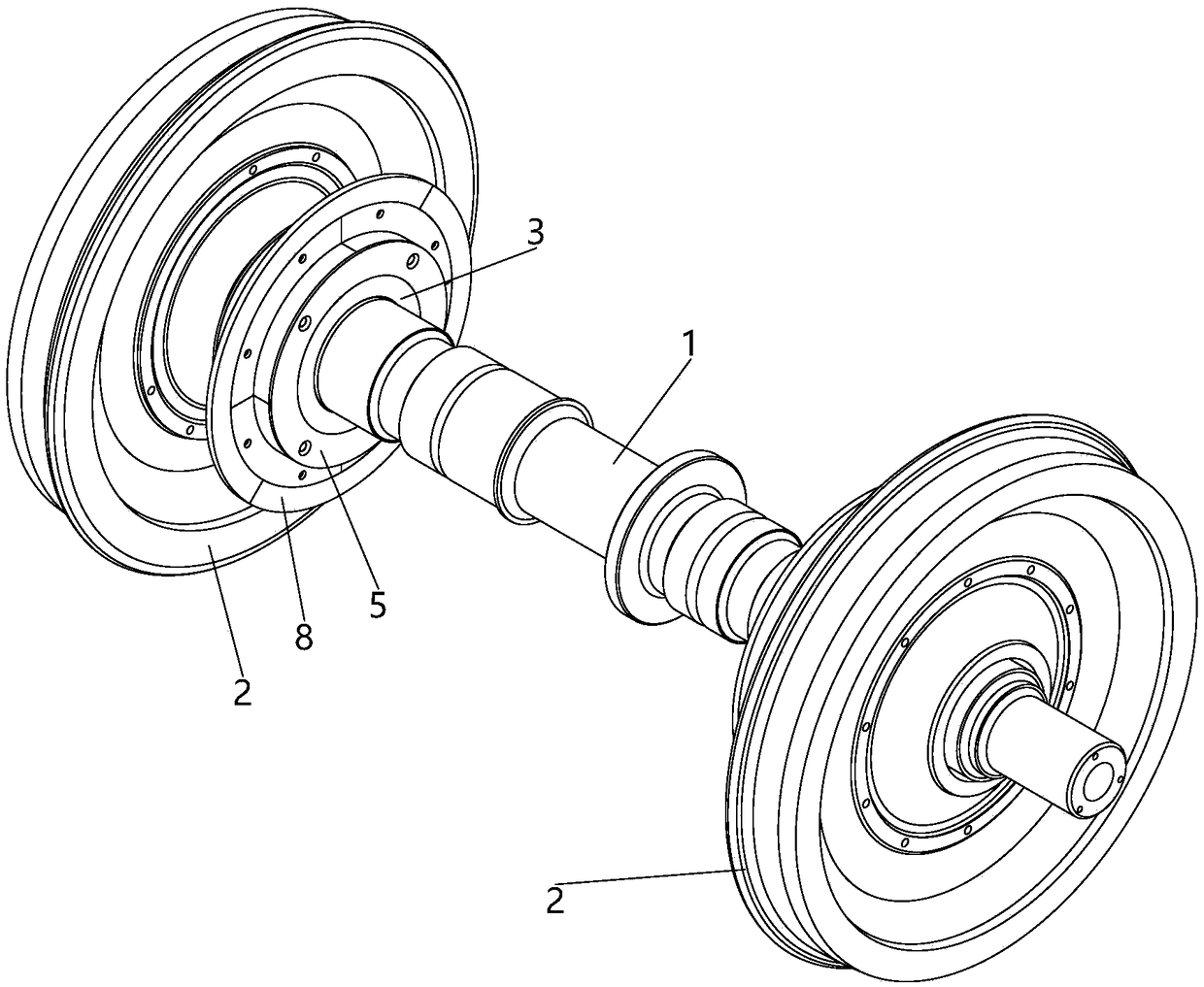

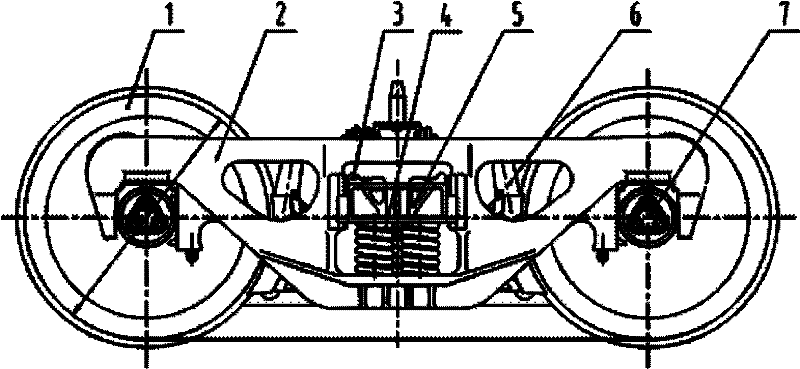

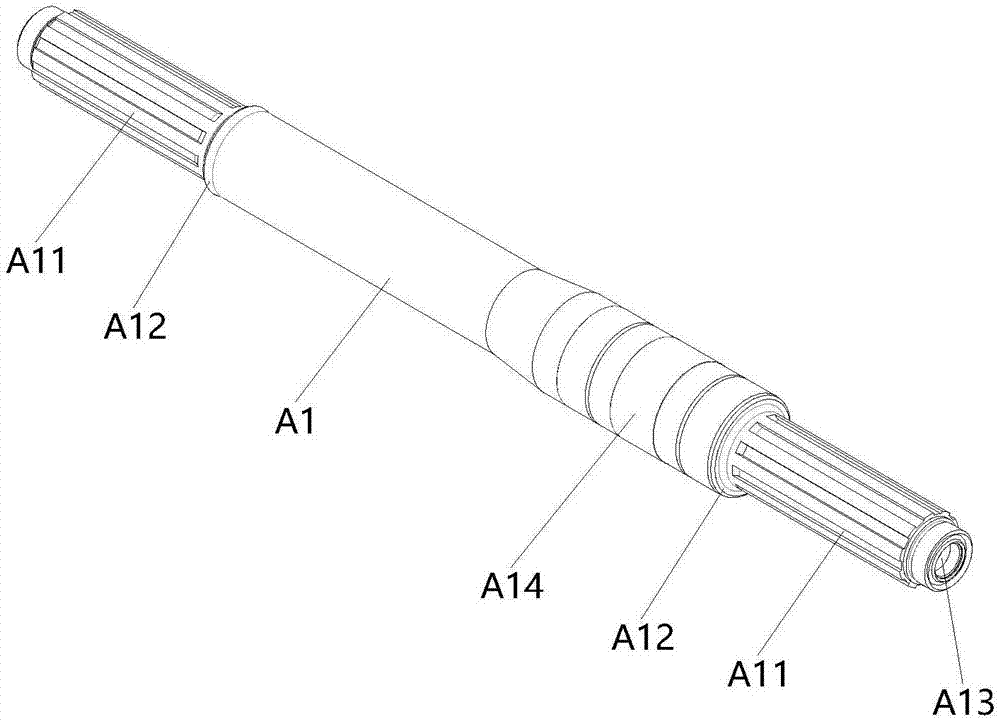

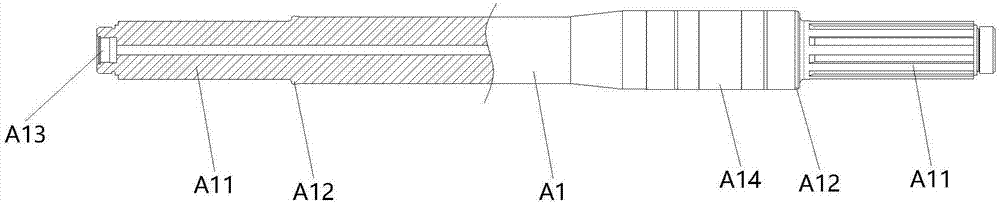

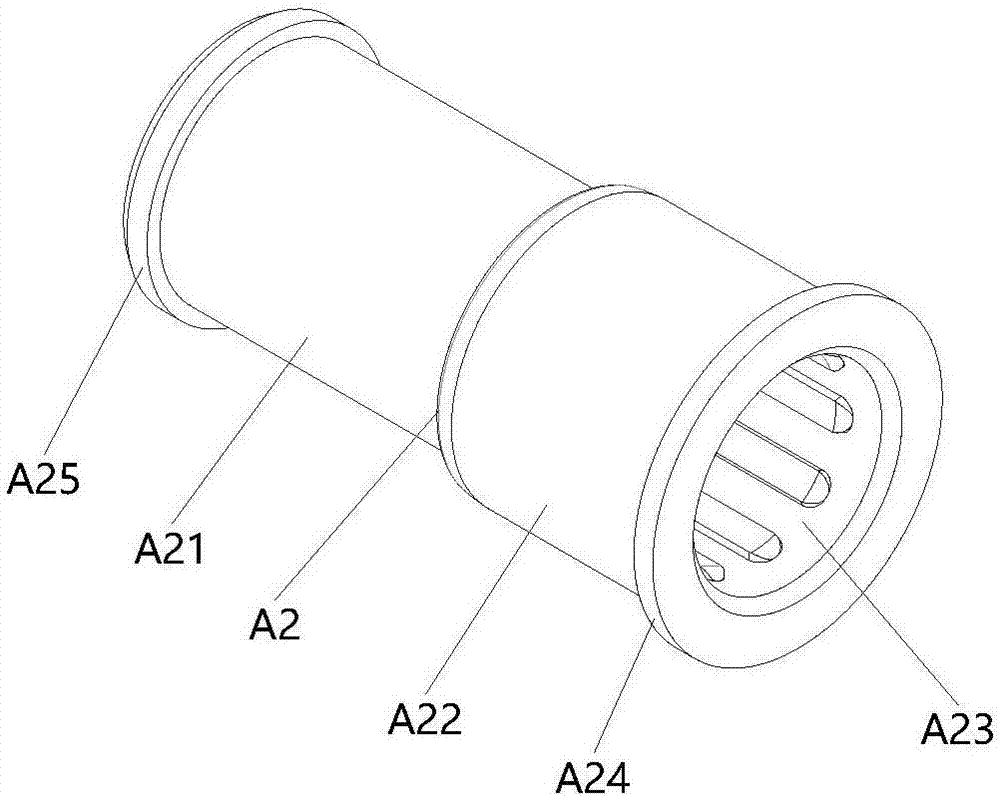

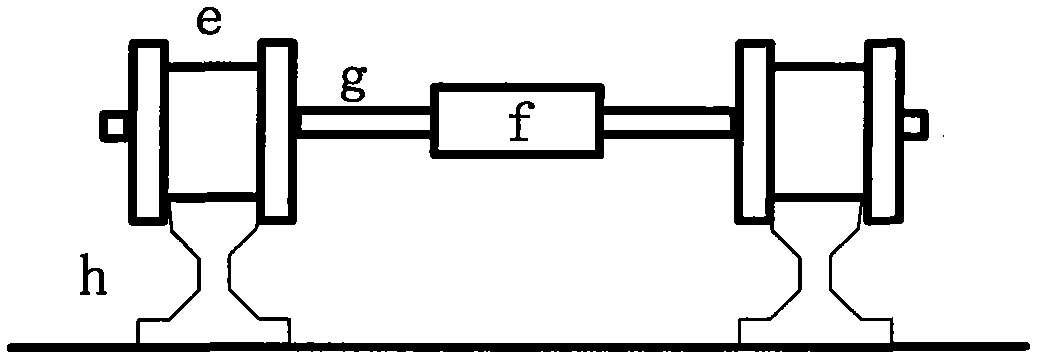

Variable-track-gauge wheel set and locking mechanism thereof

ActiveCN106740964AFlexible enoughSufficient reliabilityRail-engaging wheelsBogiesLocking mechanismEngineering

The invention discloses a variable-track-gauge wheel set and a locking mechanism thereof. The locking mechanism of the variable-track-gauge wheel set is arranged between a wheel hub and a wheel axle and used for locking wheels at different positions of the wheel axle to adjust the distance between the two wheels. A guiding structure for guiding the wheels to move axially is arranged on the wheel axle, and the locking mechanism adjusts the wheels to designated positions and then locks the wheels at the designated positions. On the premise that a variable track gauge is achieved, it is ensured that the wheel set has enough flexibility, reliability and accuracy.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

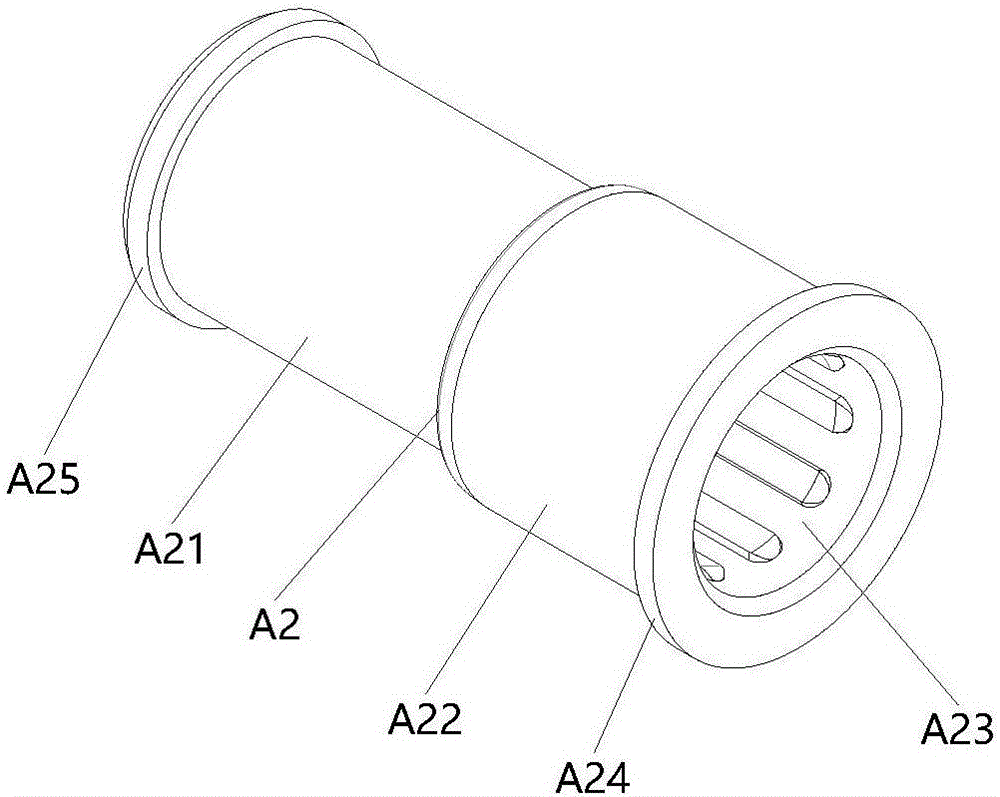

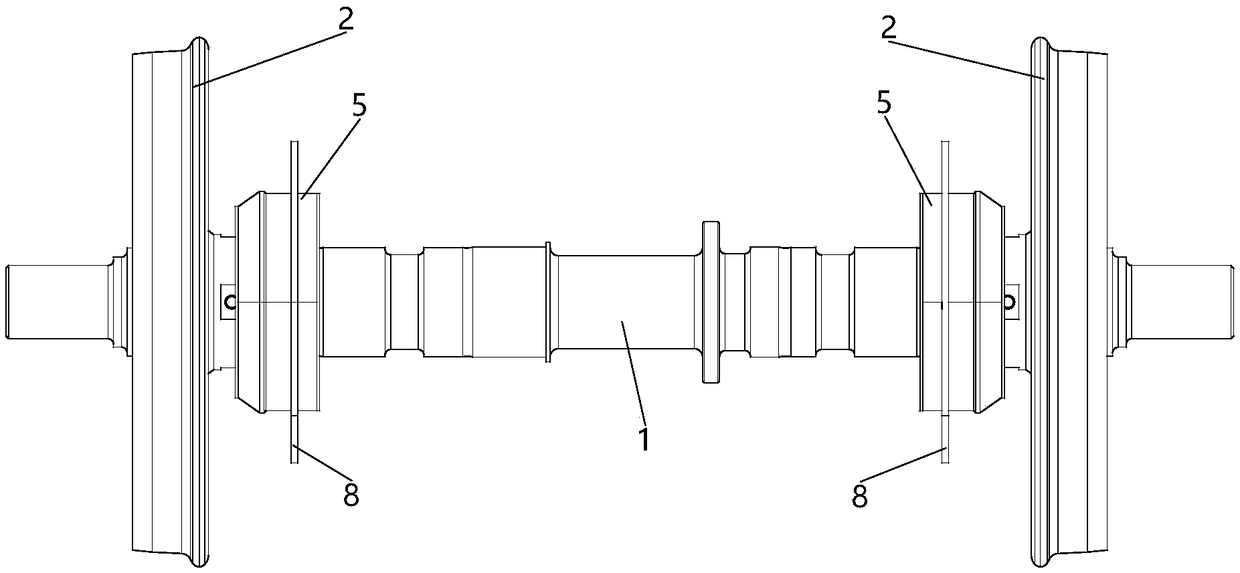

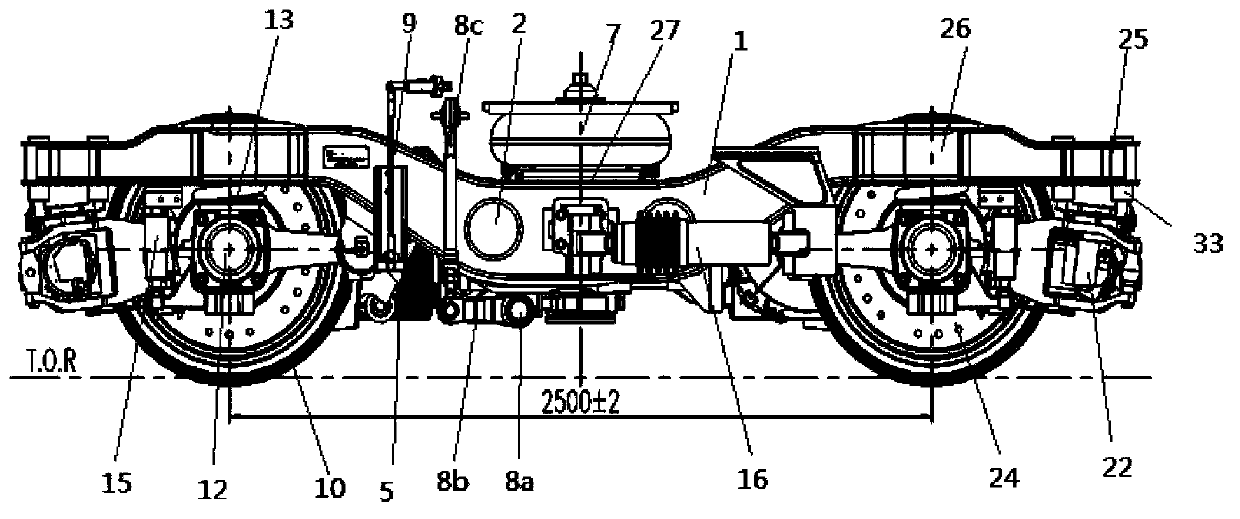

Variable gauge bogie

The invention belongs to the technical field of bogie systems, and particularly relates to a variable gauge bogie. The variable gauge bogie comprises an axle assembly, a sliding key assembly and an axle box assembly. The axle assembly comprises an axle and a bearing and wheel integrated mounting seat. The sliding key assembly comprises a sliding part. The axle box assembly comprises an axle box and a bearing. The position from a wheel seat to the end part of the axle is provided with a moving pair connecting part. The bearing and wheel integrated mounting seat comprises a bearing mounting seat and a wheel mounting seat which are mutually connected and further comprises a moving pair junction part. The moving pair junction part and the moving pair connecting part form an axial moving pair. The sliding part is of a cylindrical body. The outer side wall of the cylindrical body is in axial slidable connection with the axle box. The inner side wall of the cylindrical body is in axial fixed connection with the bearing mounting seat through the bearing. The wheel axial direction of the variable gauge bogie is adjustable to be adapted to different gauges, railway transportation of ''Silk Road Economic Belt'' is developed, and the problem that railway gauges are not uniform must be solved, therefore, it is very important and far-reaching to carry out design of the variable gauge bogie.

Owner:SOUTHWEST JIAOTONG UNIV +1

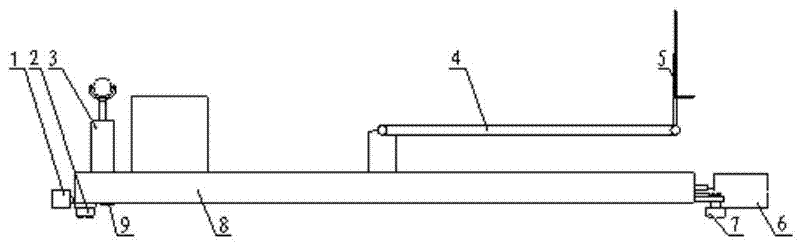

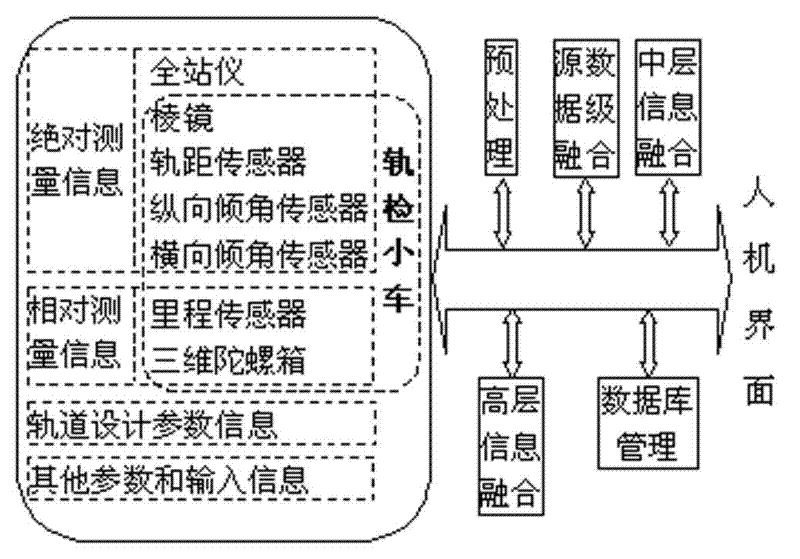

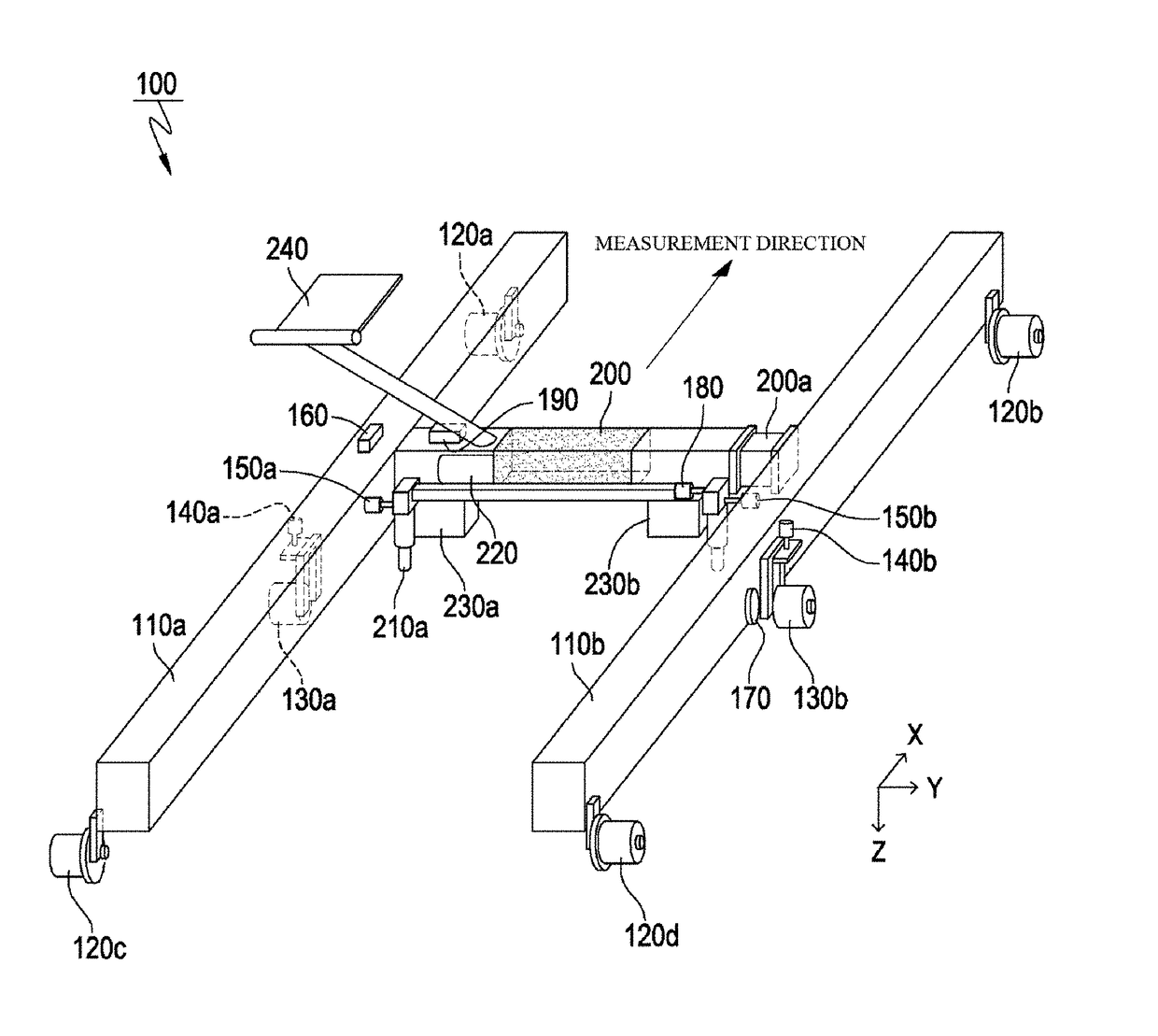

Track geometric state measurement system and method based on multisource information fusion technology

InactiveCN102251451AUniform push speedPushing for a uniform speedMeasuring apparatusTrackwayEngineering

The invention discloses a track geometric state measurement system based on a multisource information fusion technology and a track geometric state measurement method based on the multisource information fusion technology. The track geometric state measurement system comprises a track detection trolley and a total station, wherein the track detection trolley is provided with a computer with measurement software, a track gauge sensor, a longitudinal inclination angle sensor, a transverse inclination angle sensor, a mileage sensor and a three-dimensional top box. The invention also discloses the track geometric state measurement method. The invention has the advantages of high measurement precision and wide application range, integrates the advantage of absolute measurement of the total station and the advantage of locus measurement of the three-dimensional top box, and has remarkably higher measurement efficiency.

Owner:CHANGSHA HIGH TECH DEV ZONE RUIZHI ELECTROMECHANICAL TECH

Monitoring system and dynamic detection equipment thereof for medium-low magnetic suspension train contact rail

The invention discloses a monitoring system and dynamic detection equipment thereof for a medium-low magnetic suspension train contact rail. The dynamic detection equipment disclosed by the invention comprises a left displacement detection device, a right displacement detection device and a fixing rack, wherein the left displacement detection device and the right displacement detection device are respectively used for detecting parameters of a left train gauge and parameters of a right train gauge so as to obtain the left gauge and the right gauge; both ends of the fixing rack are respectively used for mounting the left displacement detection device and the right displacement detection device and respectively rotationally connected as well as hinged with both sides of a bogie, the rotational axis lines in a vertical plane, and the hinge axis extends along a running direction; and one end of the fixing rack is in slip connection with the bogie along a track span direction. The dynamic detection equipment can be better suitable for a special bogie structure of a medium-low magnetic suspension train and can be correspondingly changed along with the dynamic working conditions of the bogie so as to truly react the working states of the contact rail in the running process of a train.

Owner:BEIJING ENTERPRISES HLDG MAGLEV TECH DEV +1

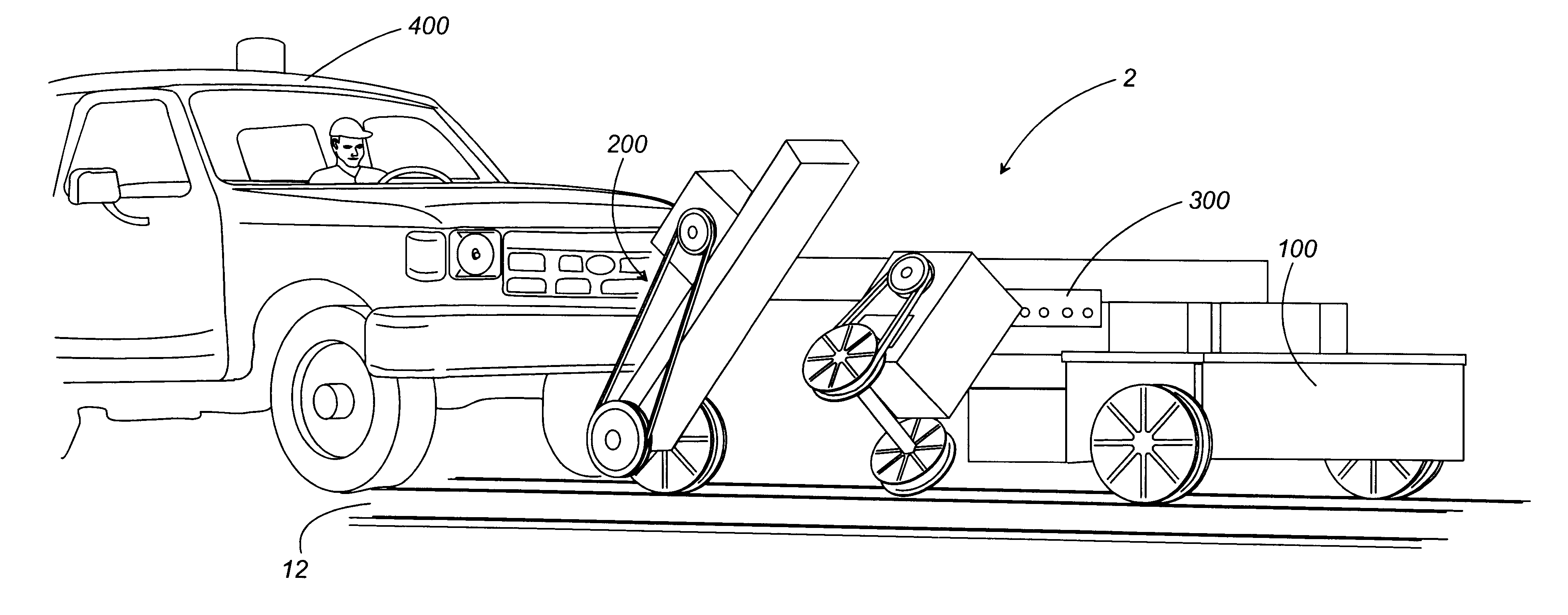

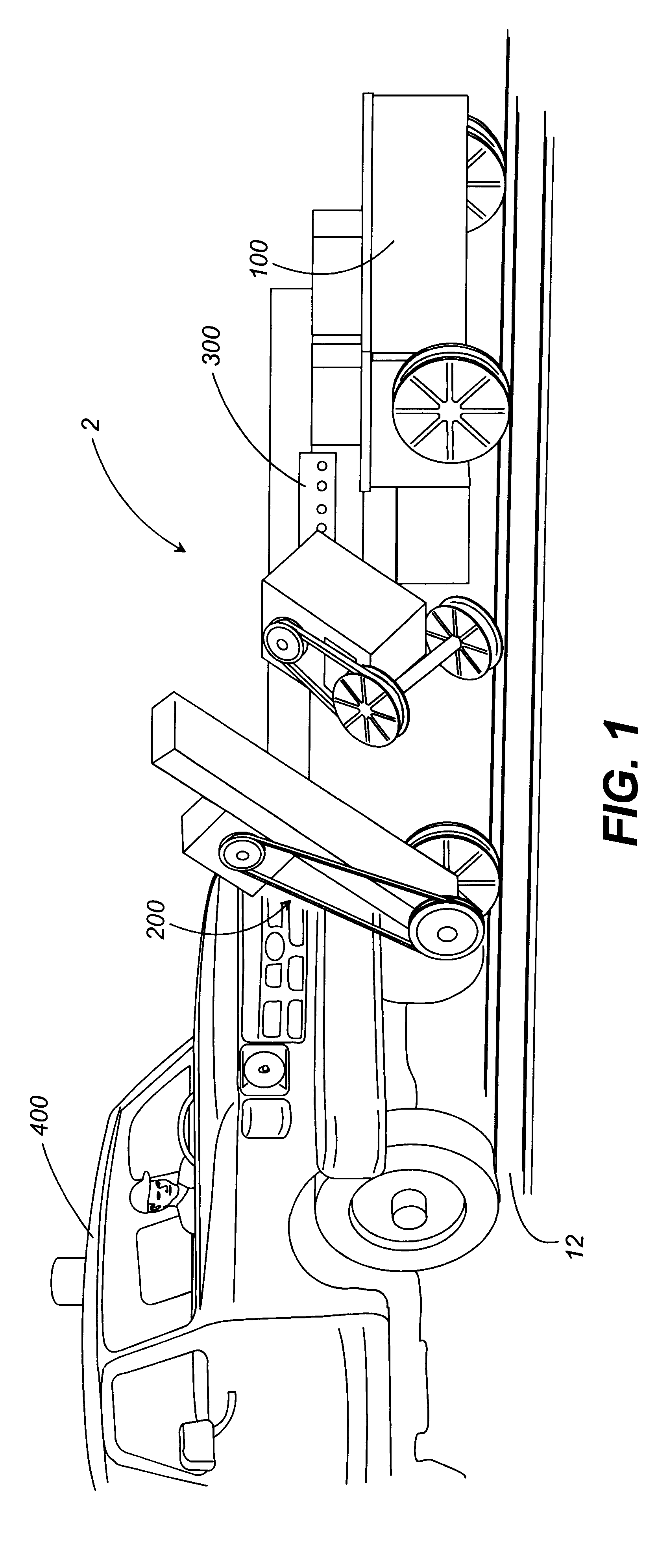

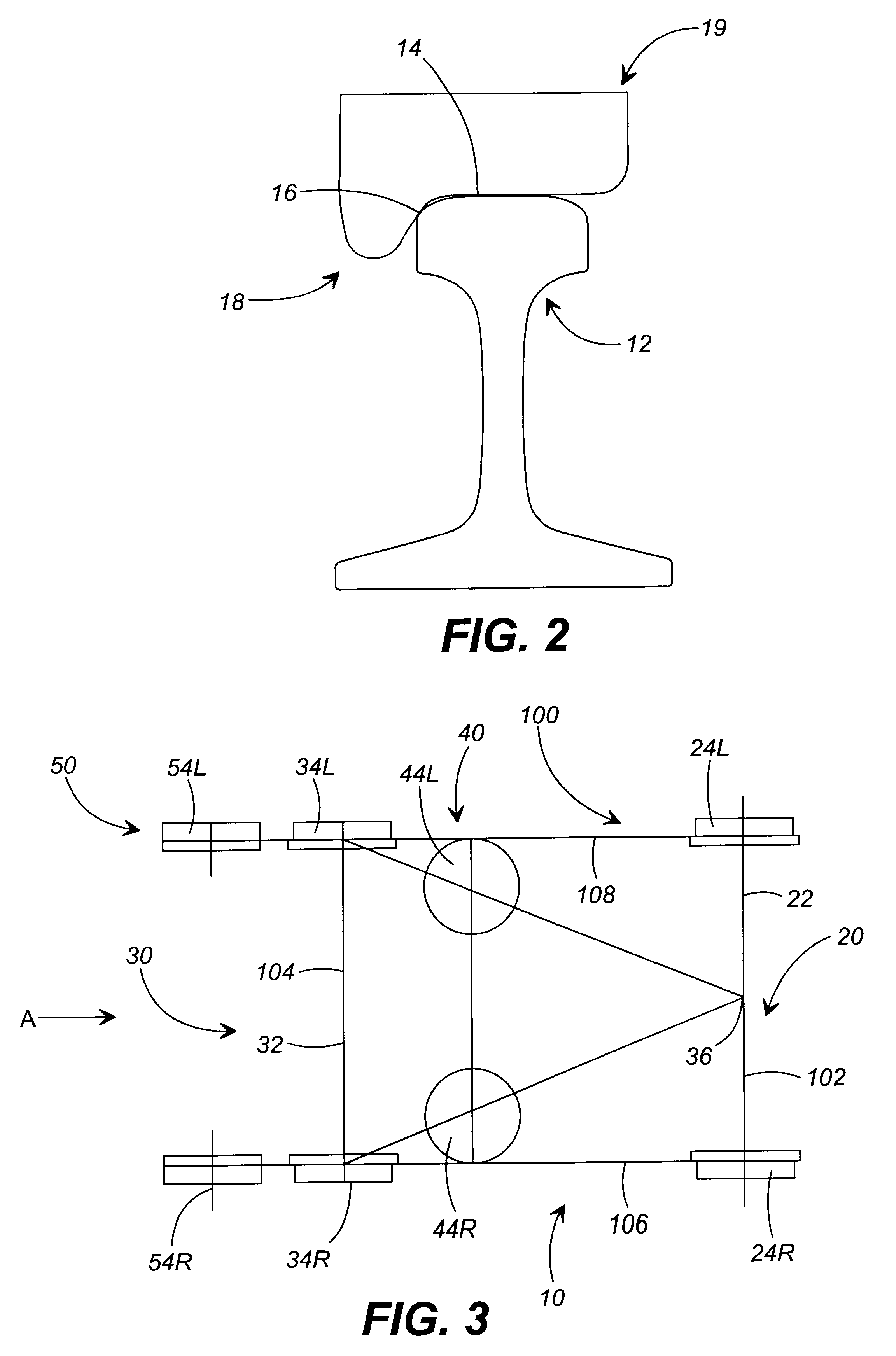

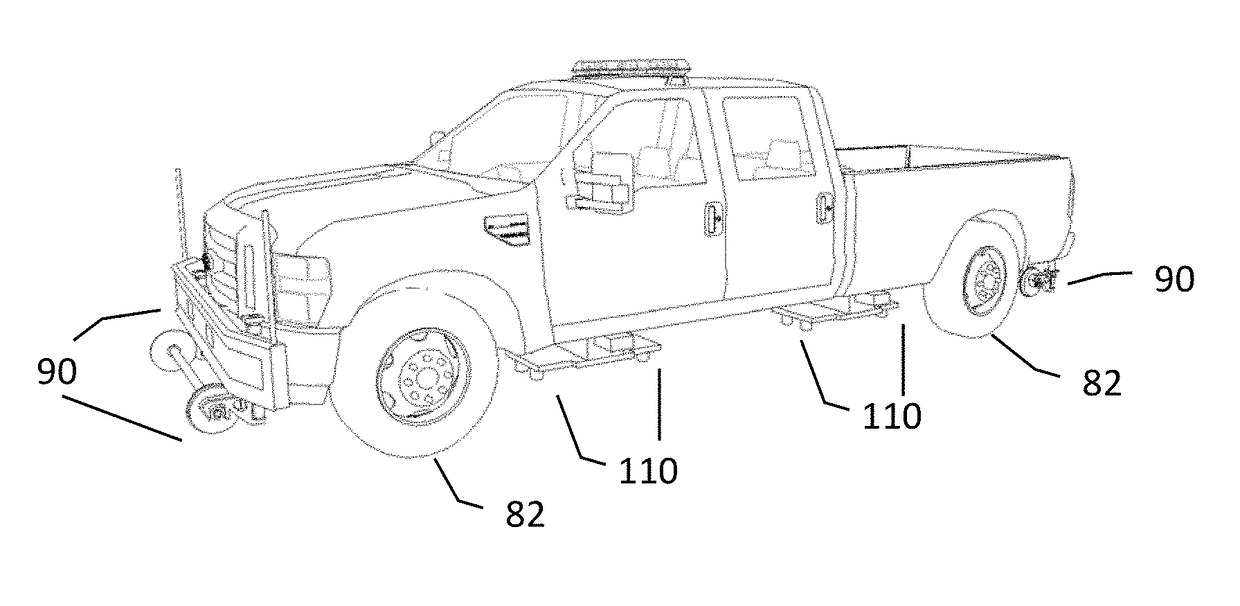

Tribometer for testing the efficiency of lubrication upon a railroad track surface

InactiveUS6192736B1Reduce capacityReduce frictionMeasurement/indication equipmentsRailway auxillary equipmentMechanical engineeringLubrication

An automated tribometer for measuring the coefficient of friction of the tread and gauge surfaces of railroad rail is disclosed. A tribometer is provided that is pushed in front of a high-rail vehicle, wherein during operation, the tribometer extends a rail test assembly to contact the surfaces of the rail. The rail test assembly has a rail testing wheel that is urged towards contact with the rail to be tested, and eventually contacts the rail, and lastly applies a known load to the rail. The testing wheel is then dynamically braked to slow the testing wheel to the point of creepage. The automated tribometer then can calculate the coefficient of friction of the rail.

Owner:DIVERSIFIED METAL FABTORS

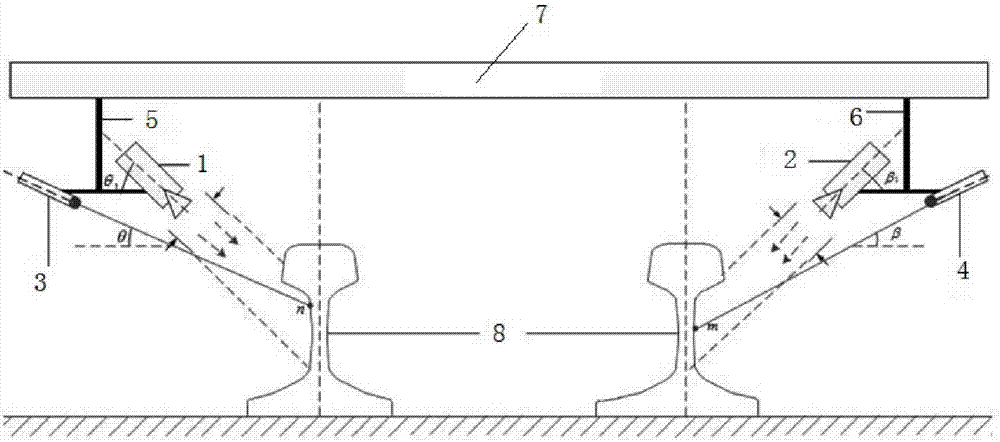

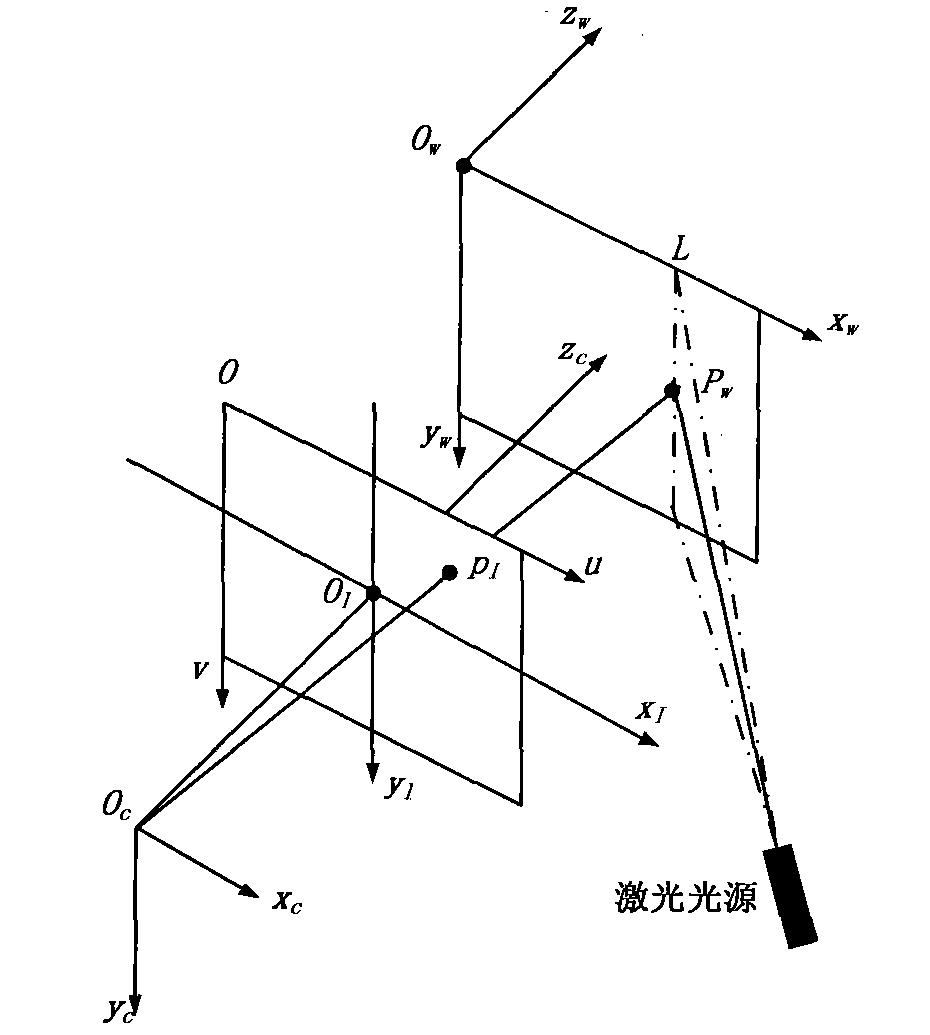

Vehicle-mounted rail gauge measurement system and measurement method

ActiveCN106871805AReduce distractionsHigh-resolutionUsing optical meansHardware structureEngineering

The present invention discloses a vehicle-mounted rail gauge measurement system and measurement method and belongs to the technical field of metering equipment characterized by using optical methods. According to the method, two sets of laser sources and cameras are combined together to obtain the lateral displacement change quantities of a locomotive relative to a left rail and a right rail respectively; the difference value of the lateral displacement change quantities of the locomotive relative to the left rail and the right rail is utilized to reflect the change of the lateral movement quantity between wheel tracks; and therefore, indirect measurement of the rail gauge of the rails can be realized. The rail gauge measurement method has the advantages of simple hardware structure, small data computation amount and high precision measurement, and can realize the non-contact dynamic measurement of rail gauge parameters.

Owner:SHIJIAZHUANG TIEDAO UNIV

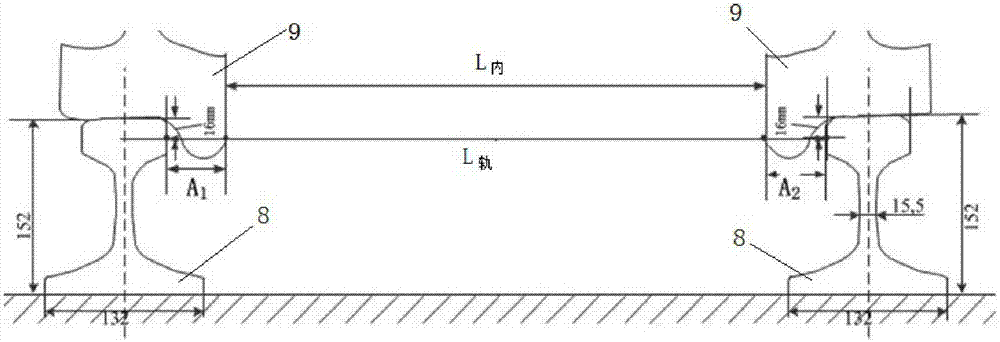

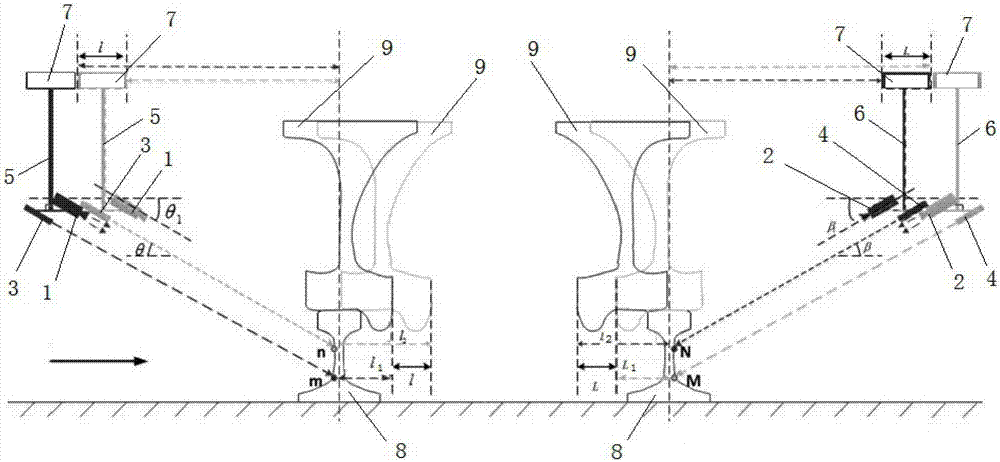

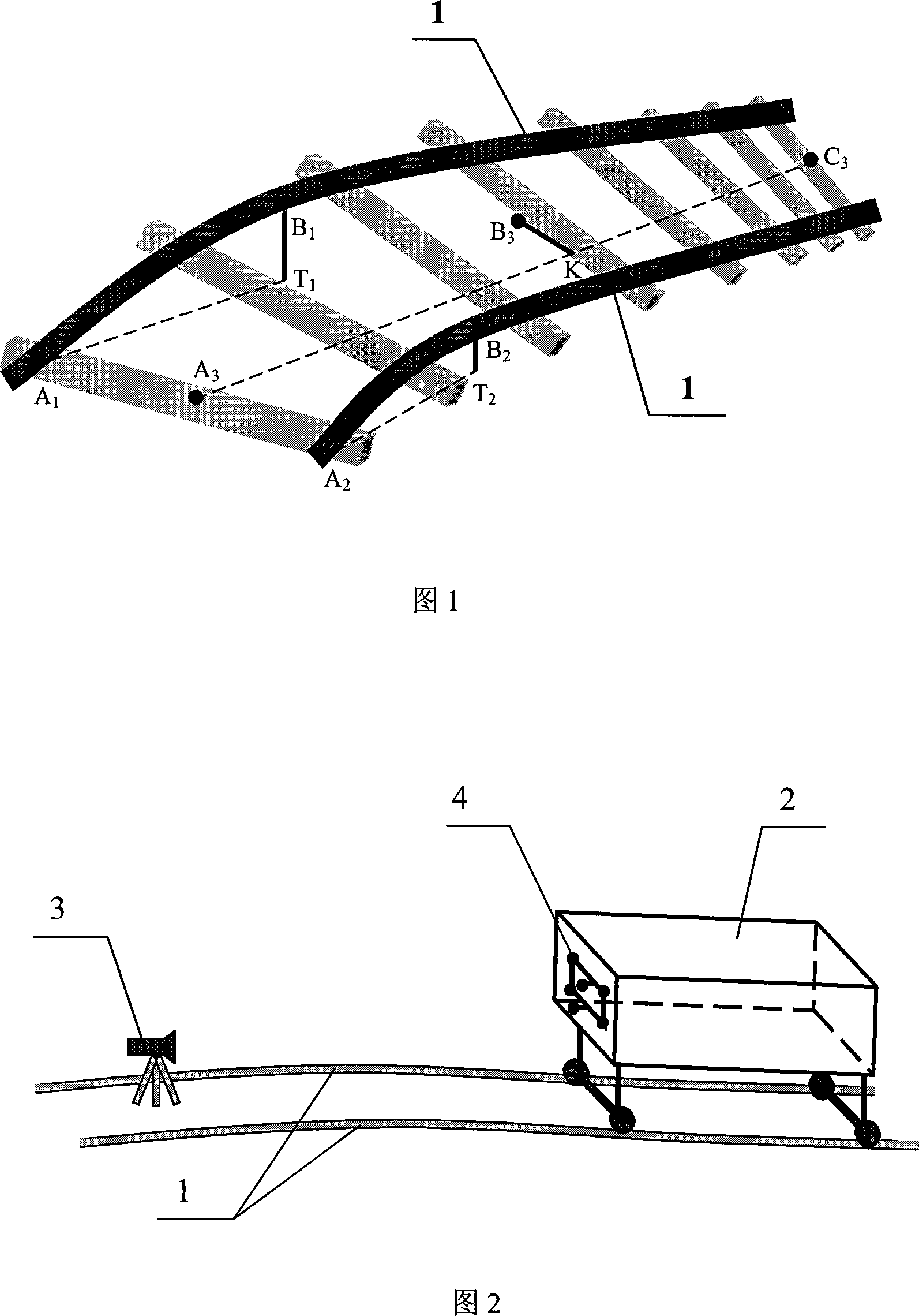

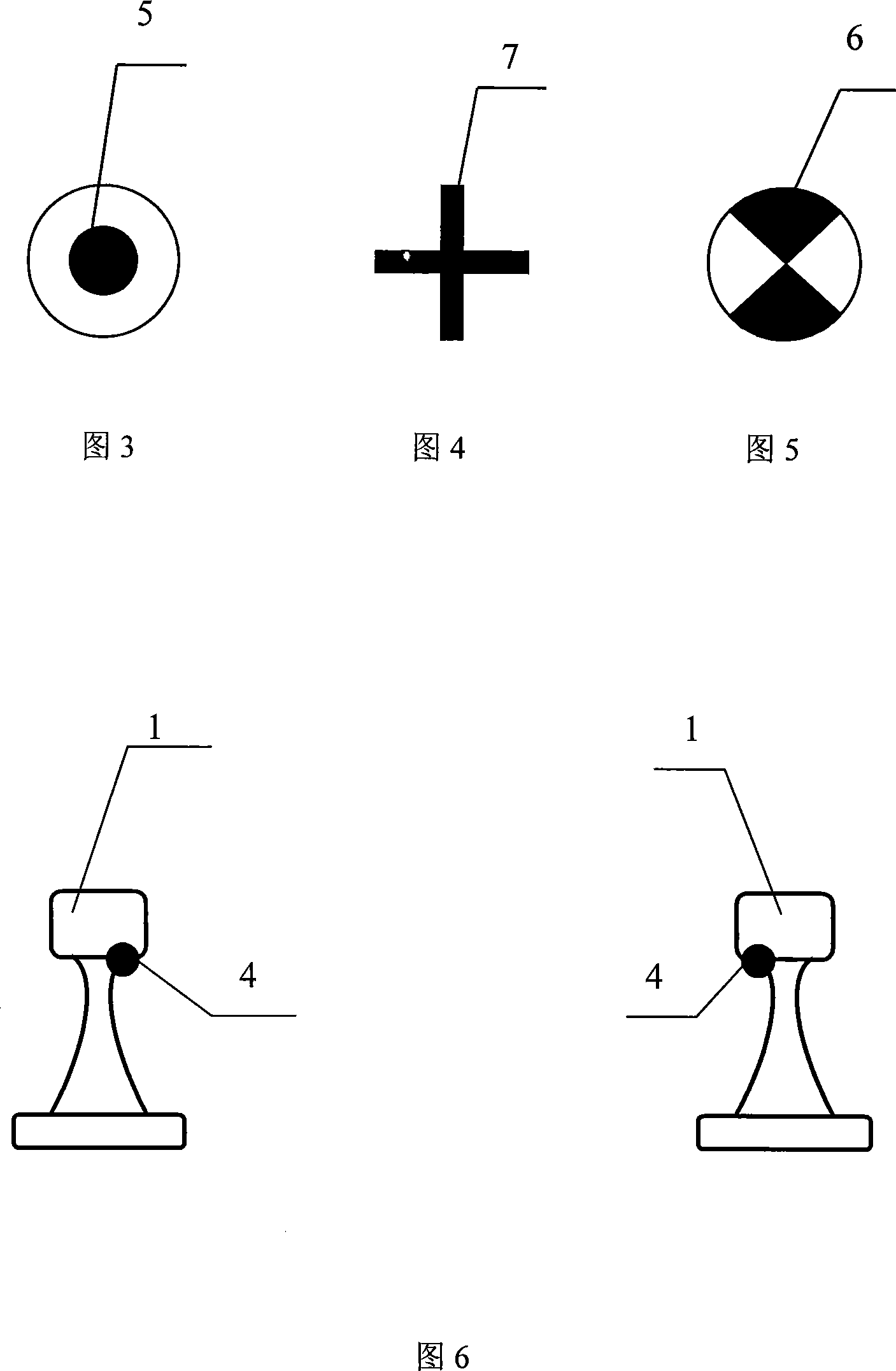

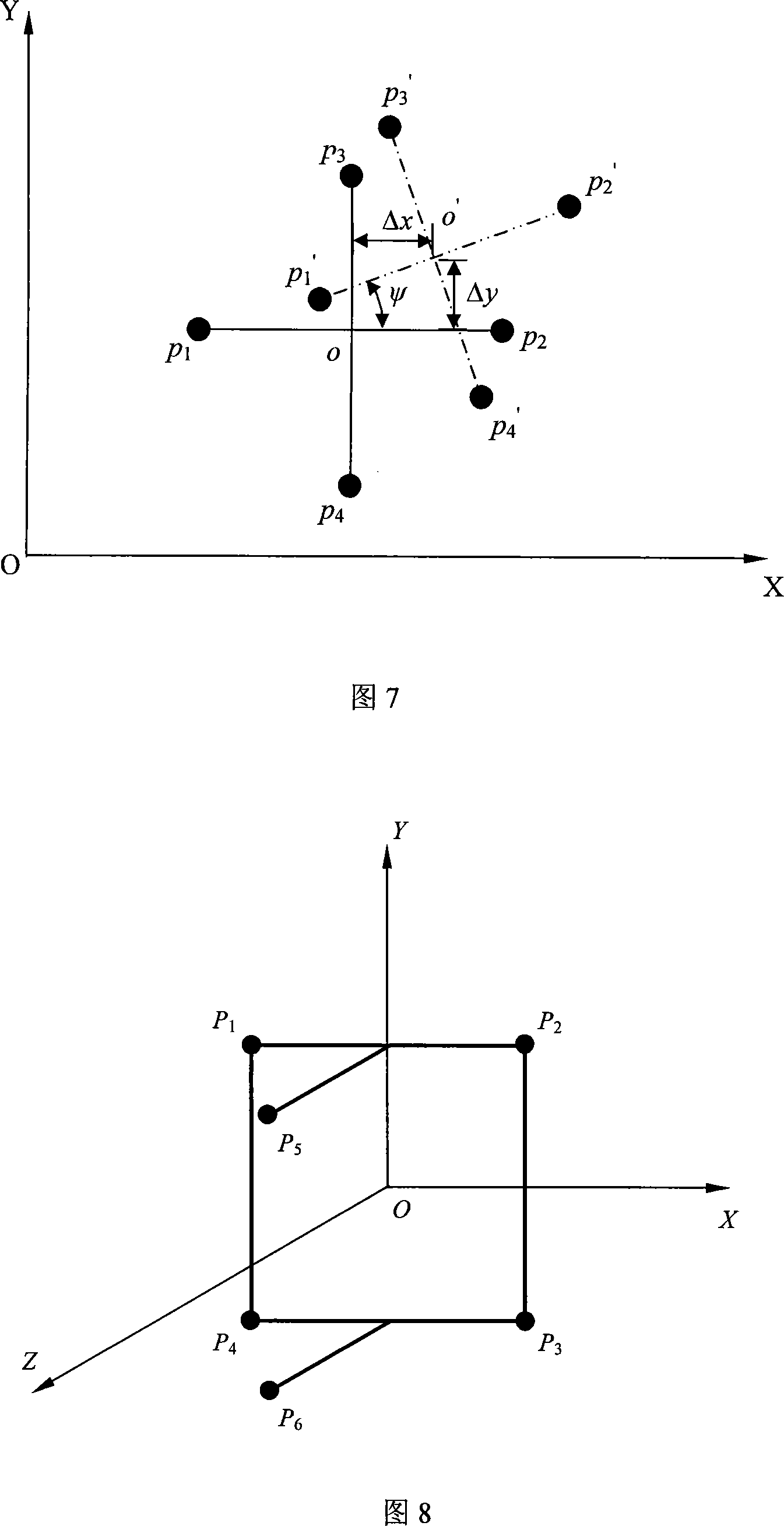

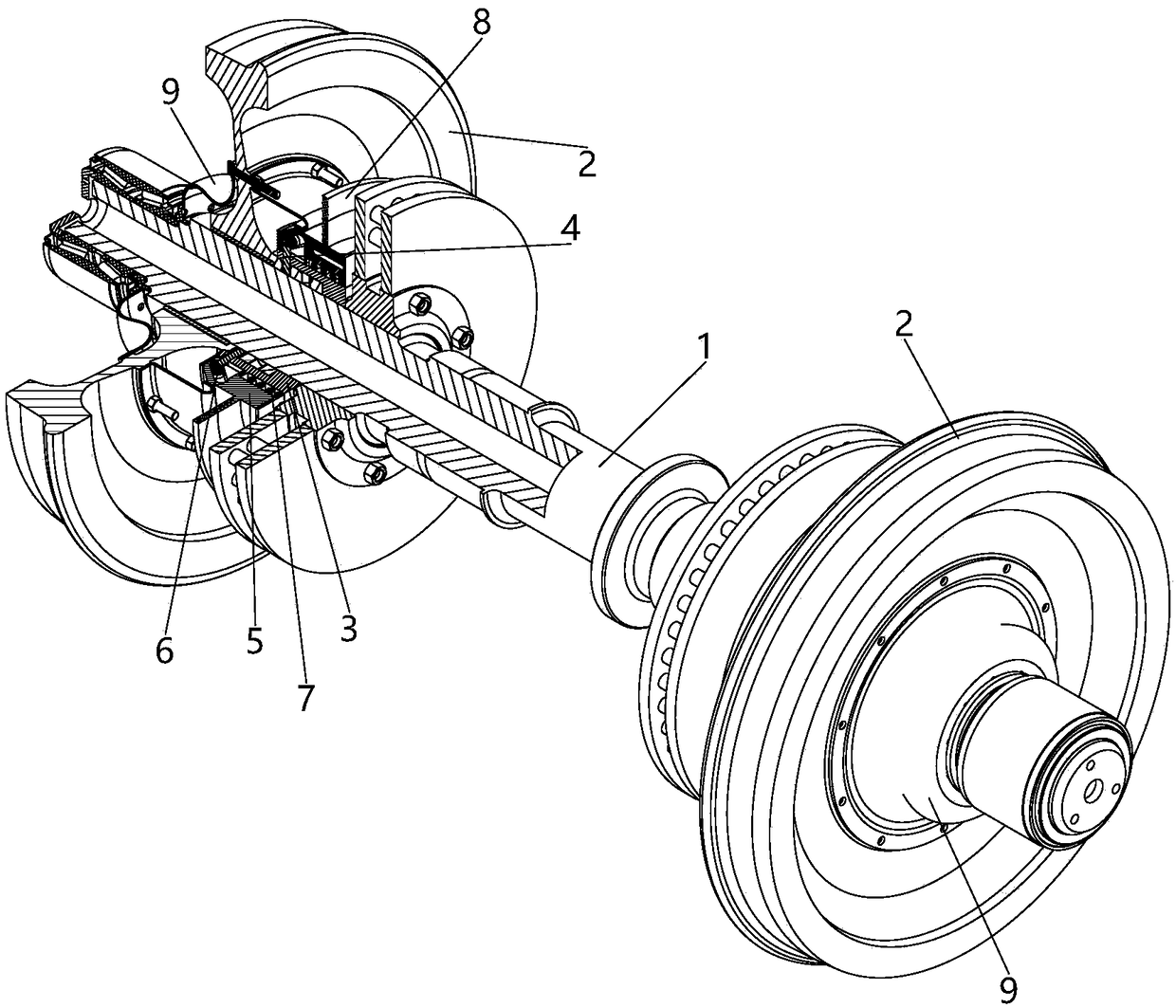

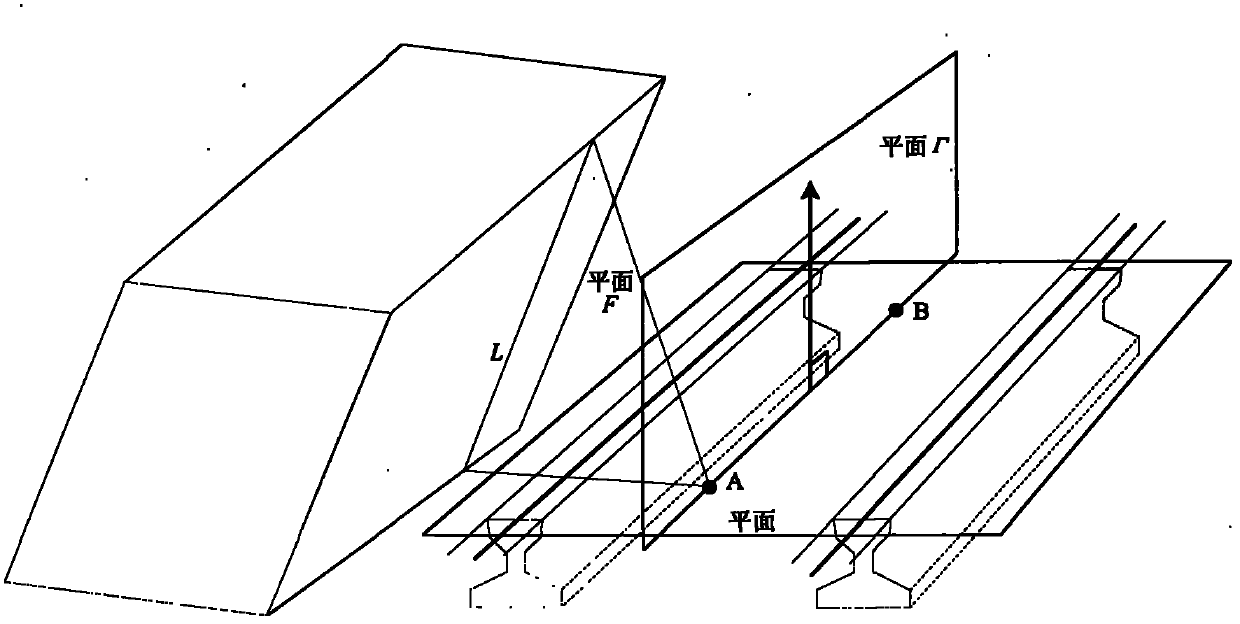

Long straight rail geometric parameter photogrammetry

InactiveCN101021417AAchieve precise positioningEasy to operatePhotogrammetry/videogrammetryImaging processingDigital image

A camera measuring method of long-straight track geometric parameter belongs to digital camera measuring and digital image disposing technique of railway contribution. It is: fix cooperate symbol on circuit detecting vehicle head moving on long-straight track, install camera before the vehicle. When vehicle moving along the track, at least two images at different time of the symbol moving as track waving and deflecting are shoot. Achieve geometric parameter (at least one of gage, cant, longitudinal deviation and versed sine) of the track by image processing. The invention efficiently meets high-speed railway requirements of high precision, reliability and automatic degree detecting, greatly improves geometric parameter level of track, which can be applied directly in geometric parameter detecting system of tamping vehicle and be as a core to design multiform track detecting vehicles.

Owner:于起峰 +3

Wheel set for variable gauge bogie and bogie

The invention relates to the field of variable gauges for rail vehicles, and discloses a wheel set for a variable gauge bogie and the bogie. The wheel set comprises wheels, an axle and variable gaugemechanisms, and the variable gauge mechanism comprises a fixed sleeve, a locking pin, a mitigation sleeve and an unlocking disc. The wheels are slidably disposed at two ends of the axle, and the variable gauge mechanisms are respectively disposed on the inner side axle of the wheel, and by pushing the unlocking disc to drive the locking pin to move upwards, the fixed sleeve is unlocked with the mitigation sleeve. Therefore, the wheels are locked or unlocked conveniently, to achieve the variable gauge. The wheel set variable gauge process is convenient and reliable.

Owner:CRRC QINGDAO SIFANG CO LTD

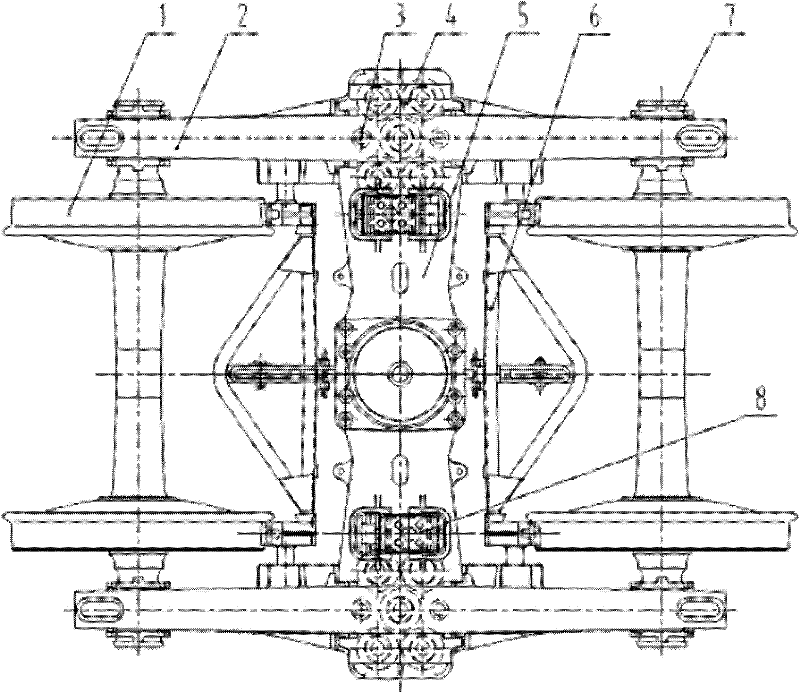

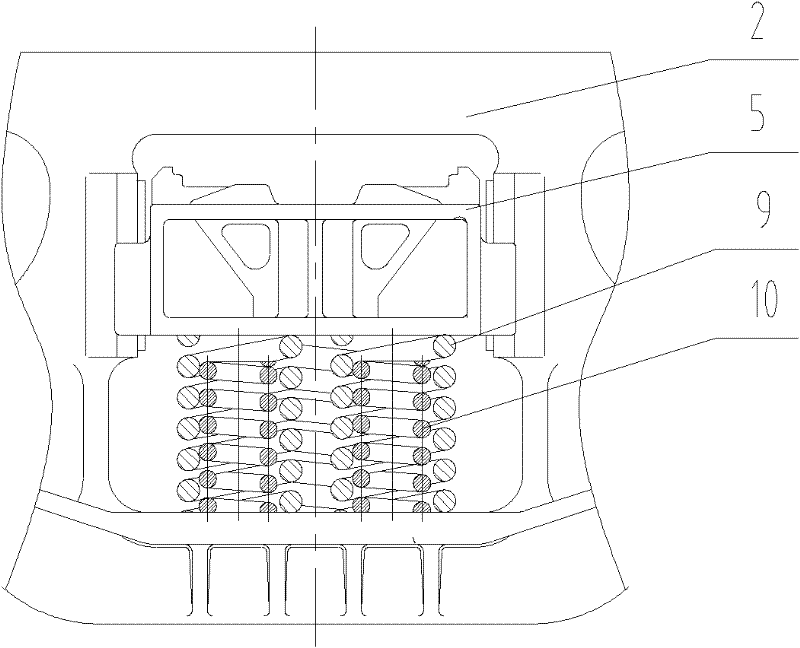

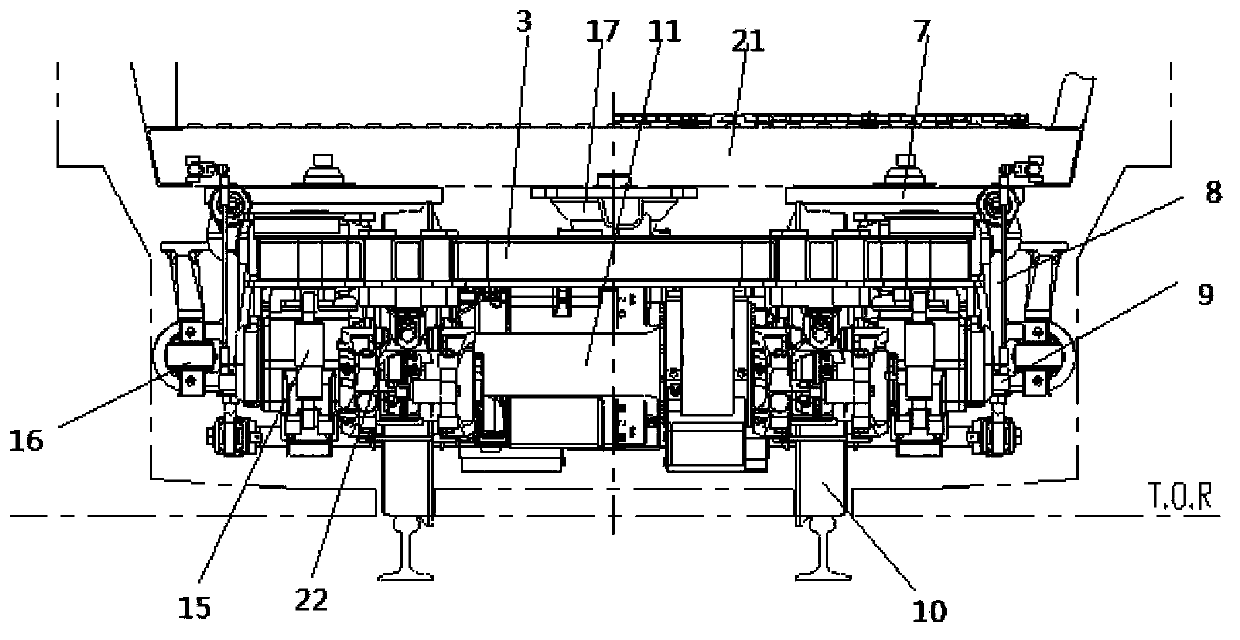

Bogie of narrow gauge railway vehicle

InactiveCN102514584AImprove diamond stiffnessIncrease static deflectionBogiesBogie-underframe connectionsVariable stiffnessBogie

The invention discloses a bogie of narrow gauge railway vehicle, which comprises a wheel pair, a side frame, a vibration absorber, a swing bolster and a braking device. The wheel pair is connected with the side frame in a rolling way through a rolling bearing device; the side frame and the swing bolster form a bogie body structure through central mounting; a dual-acting elastic side bearer is laid in a swing bolster side bearer box; and the swing bolster side bearer box and the swing bolster are cast into a whole body. The invention optimizes structures of the wheel pair, a vehicle axle, the swing bolster and the side frame, and ensures that the wheel pair meets running requirements of narrow gauge (especially 1067mm gauge), and the structural strength of main bearing structures, such as the swing bolster and the side frame, meets bearing requirements of an 18t axle load bogie. The central mounting adopts a dual-stage variable stiffness spring, increases the empty natural bow, and meets different requirements on the central mounting in different operating conditions. By adopting the frictional vibration absorber of the control type bogie, the diamond resistant rigidity of the bogie is improved. By adopting the dual-acting elastic side bearer, stable turning drag torque is provided for the running of a vehicle, and the running speed of the vehicle is increased.

Owner:CRRC MEISHAN

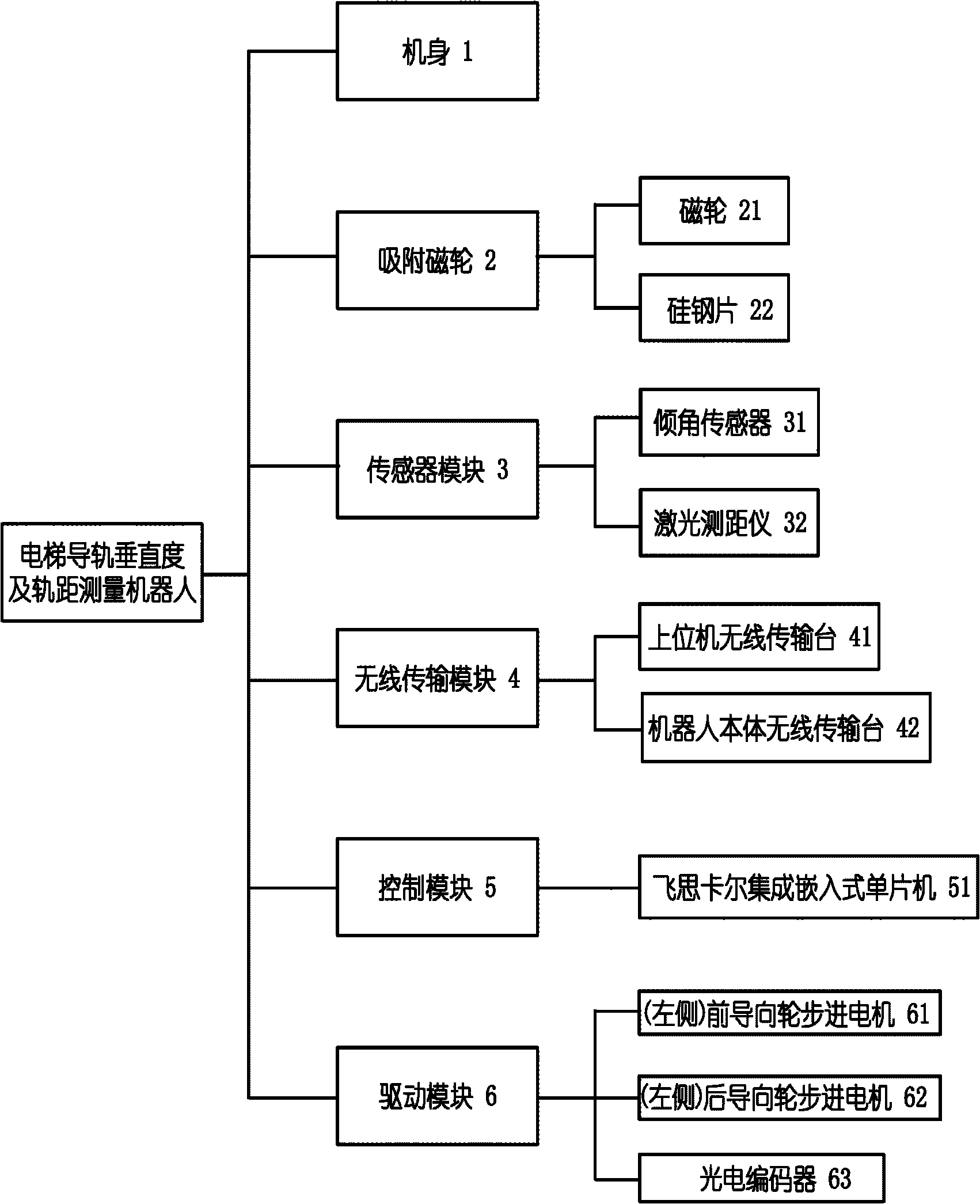

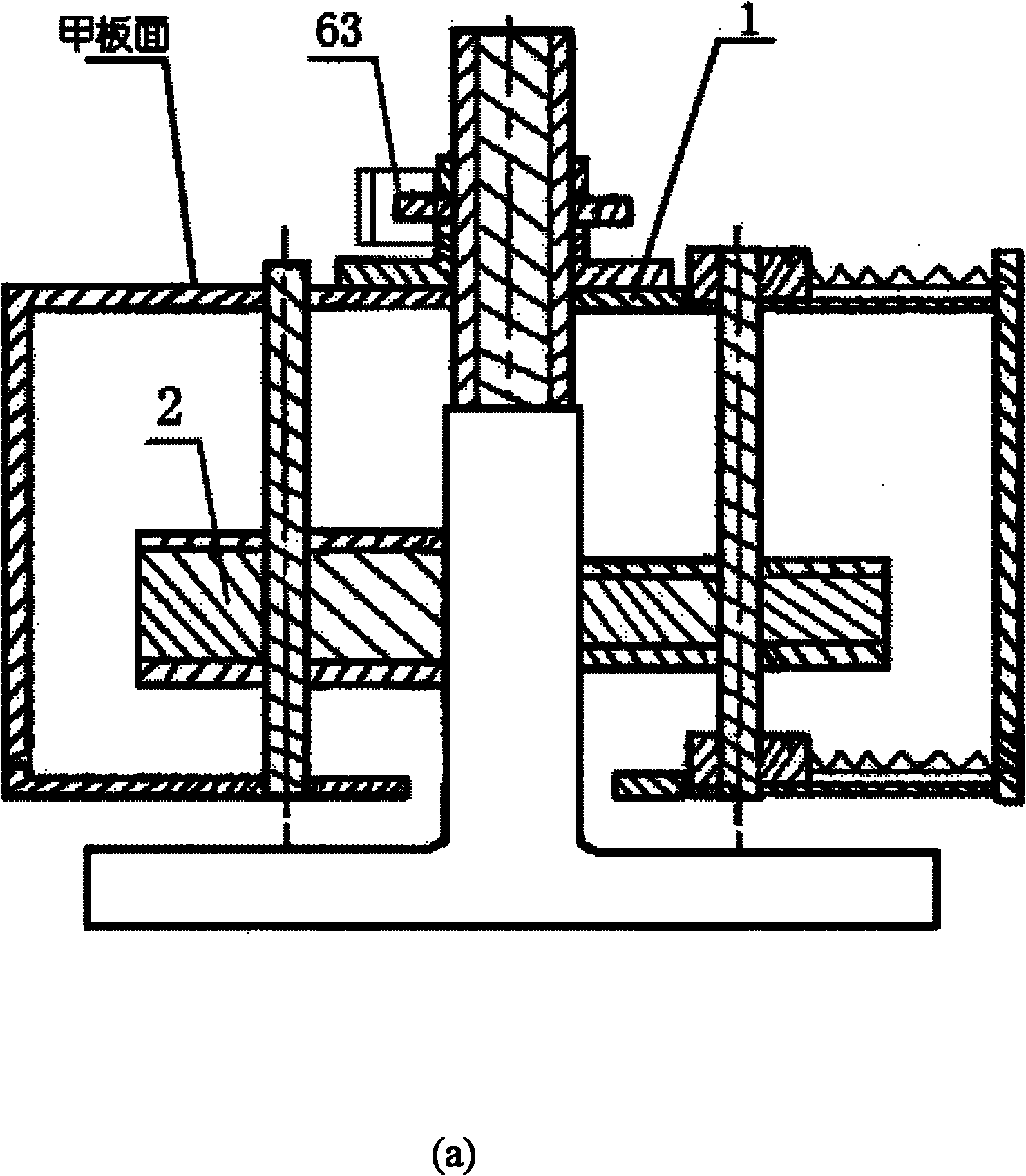

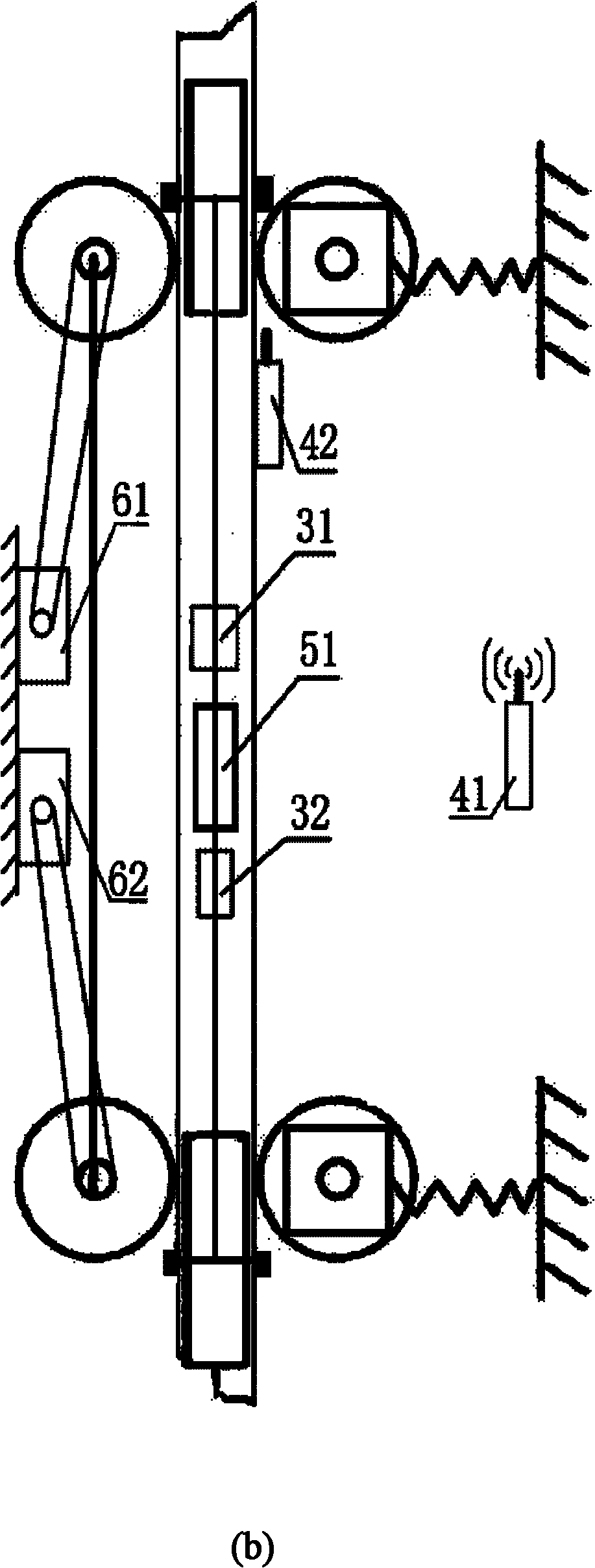

A robot for measuring verticality and gauge of elevator guide rails

ActiveCN102278956ARealize measurementReduce manufacturing costUsing optical meansMicrocontrollerLaser ranging

The invention discloses an elevator guide rail verticality and gauge measuring robot which comprises a robot body, an adsorption magnetic wheel, a sensor module, a wireless transmission module, a control module and a driving module. The adsorption magnetic wheel comprises a magnetic wheel and silicon steel plates, the silicon steel plates are attached on two end faces of the magnetic wheel respectively and are fixed on the robot body through a bearing embedded in a body wall. The sensor module comprises an inclination angle sensor and a laser range finder which are installed on a deck surfaceof the robot body, the inclination angle sensor and the laser range finder are above and under a one-chip microcomputer respectively, and both are in bidirectional connection with the one-chip microcomputer. The wireless transmission module comprises a host computer wireless transmission bench and a robot body wireless transmission bench. The control module comprises the one-chip microcomputer and control program. The driving module comprises a front directive wheel stepping motor, a rear directive wheel stepping motor and an encoder.

Owner:HEBEI UNIV OF TECH

Online detection method for crane tracks

InactiveCN105651221AGuaranteed uptimeReal-time measurementUsing optical meansLoad-engaging elementsHeight differenceElevation data

The invention discloses an online detection method for crane tracks. The method comprises that the track at the triboelectric side of a crane is provided with a laser collimator and a fixed laser reception target to establish a collimation reference system; and the crane is provided with a mileage sensor, a mobile laser reception target, a laser displacement sensor and a one-dimensional inclination sensor to measure mileage data, real-time displacement data, data of distance between the tracks, the track linearity data, relative elevation data of the tacks and relative height difference data of the tracks in real time, and thus, the crane tracks are detected in real time. The crane and the tracks are provided with the corresponding measuring components, the movement locus of the crane and the relative relation between the crane and the tracks are measured to obtain track parameters, the production order is not interfered, the measuring efficiency is improved, and safe and reliable operation of the crane is ensured.

Owner:SHANGHAI JINYI INSPECTION TECH

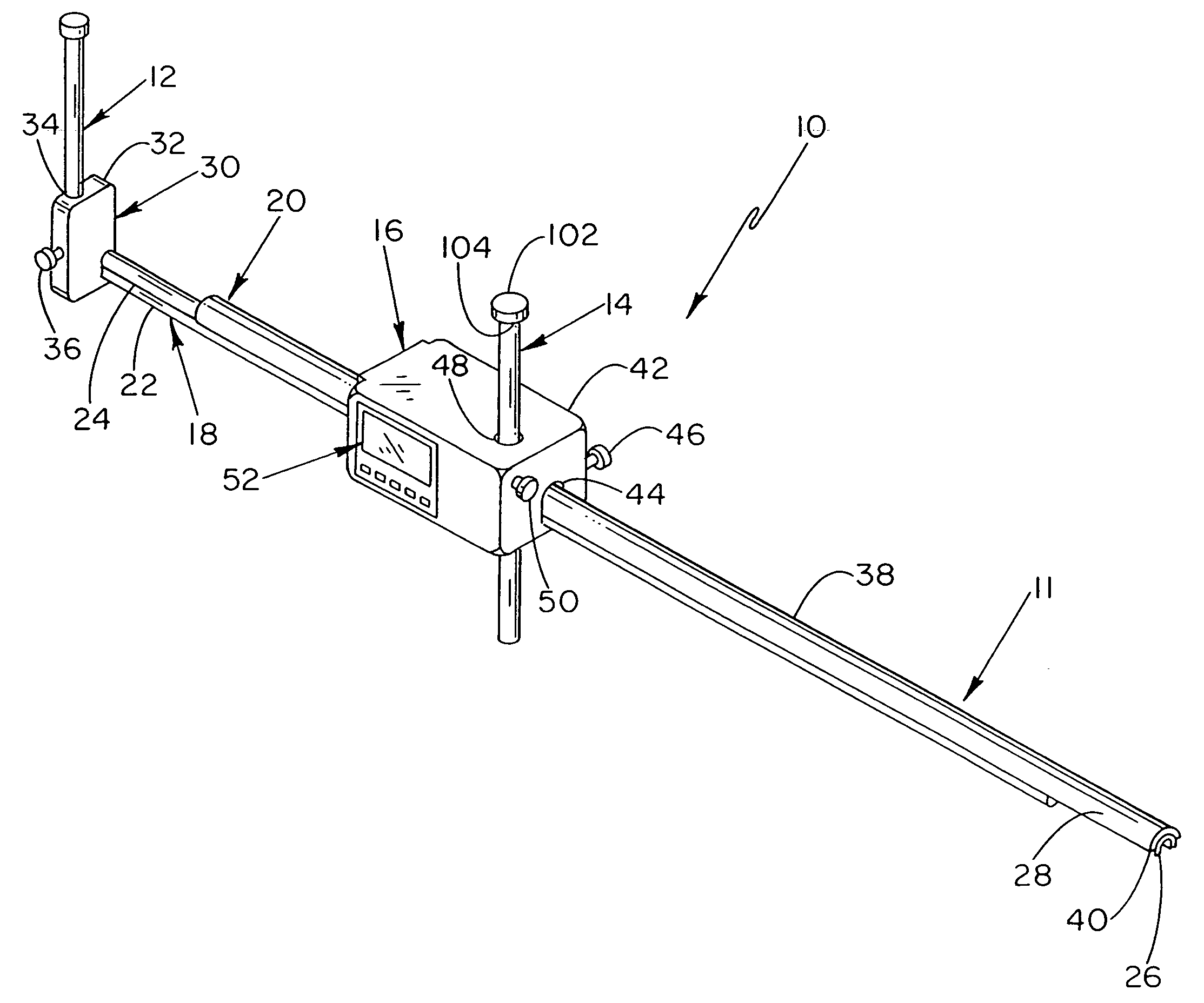

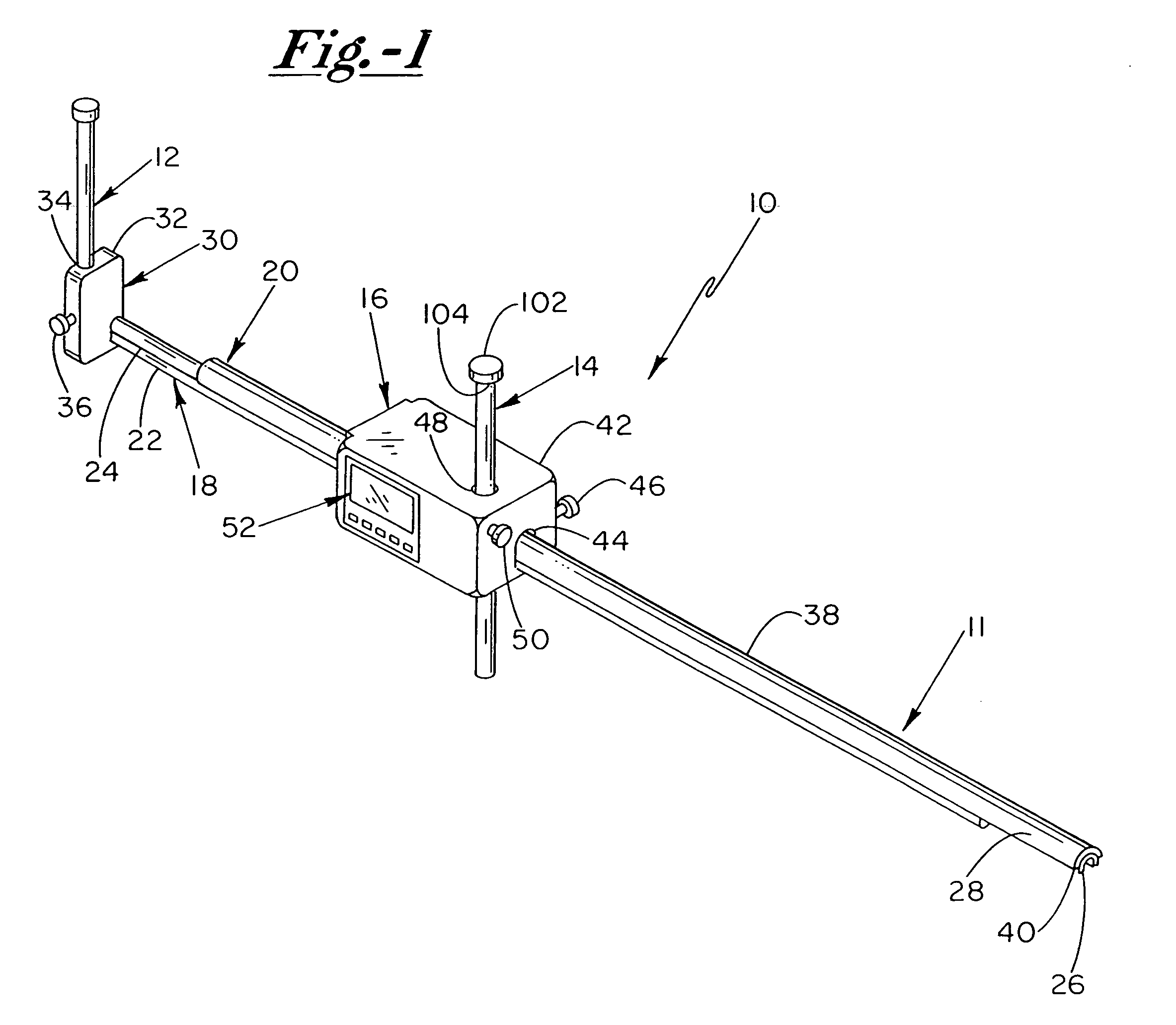

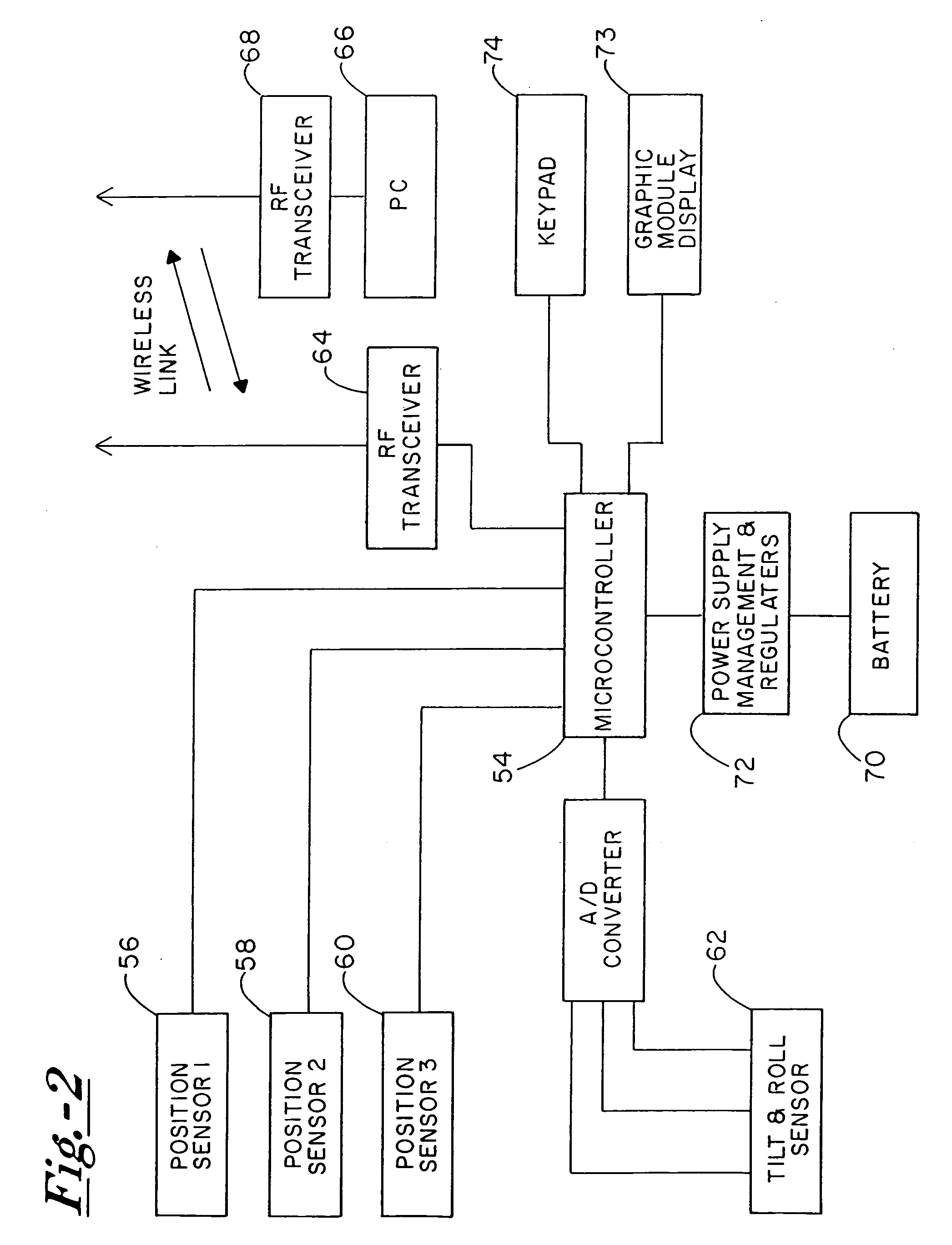

Wireless tram gauge assembly

ActiveUS7275335B2Reliable and accurate measurementAngles/taper measurementsUsing electrical meansWireless transmissionLevel sensor

The present invention relates to a digital tram gauge assembly having an extendible elongate tram bar having a first height rod at a first end and a second height rod at a second end. A digital measuring device is positionable about the tram bar and is capable of digitally sensing, displaying and wirelessly transmitting measurement data from the digital tram gauge. The digital measuring device further includes a digital level sensor that functions as a digital level comparator to indicate whether the tram gauge assembly is oriented substantially parallel to a user-defined reference datum plane.

Owner:CHASSIS LINER

Precision measurement control method of metro track structure construction

ActiveCN102953304ARealize high-precision adjustmentGuaranteed smoothnessMeasuring apparatusObservational errorTotal station

The invention specifically relates to a precision measurement control method of a metro track structure construction, which solves the problems of poor safety, smoothness and comfort of a line and high equipment abrasion and noise vibration in the operation process because the existing measurement control method of the track structure construction has multiple steps and the control benchmarks for measurement can not be reused. According to the precision measurement control method, precision measurement control is performed on the track structure by utilizing a method of establishing a track basic control network in combination with a total station and a track geometrical state measurement instrument, thereby realizing high-precision adjustment on the track; and the track geometrical state measurement instrument is applied so that the precision requirements on points in the metro track measurement are improved to be requirements on the overall smoothness of the line, thereby guaranteeing that the indexes of track gauge, high-low rate of change, track orientation, high and low smoothness and the like of the track are capable of meeting higher requirements; and besides, digitization and automation are realized.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +3

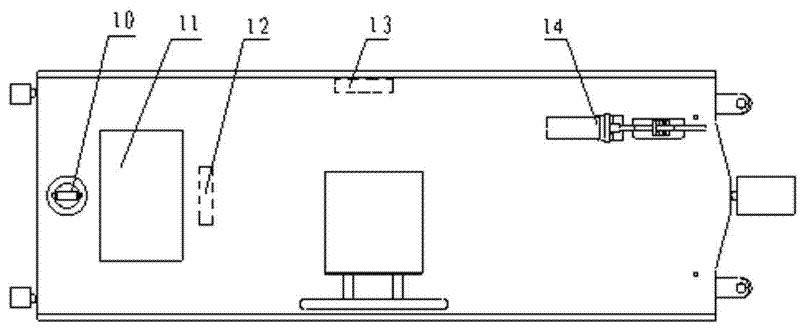

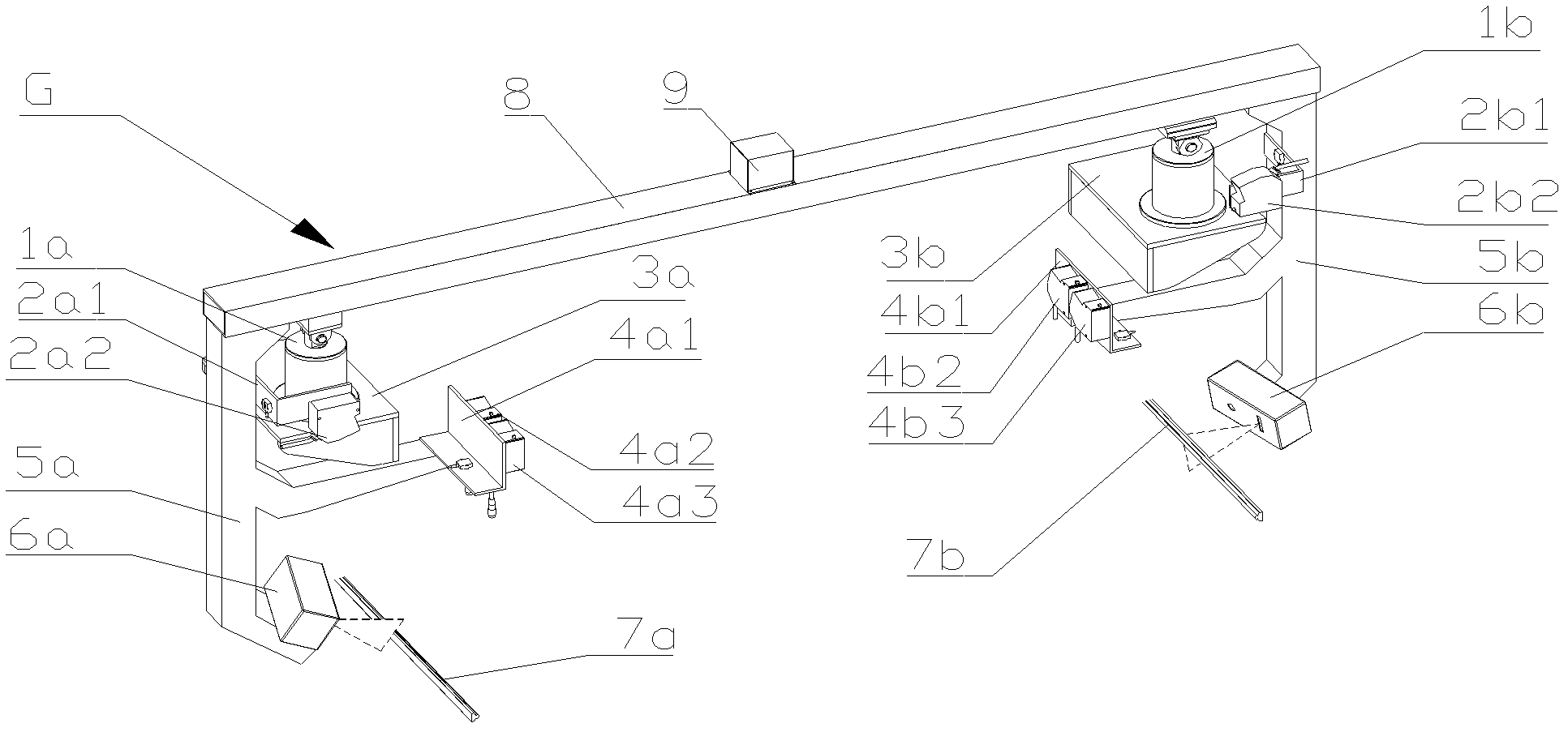

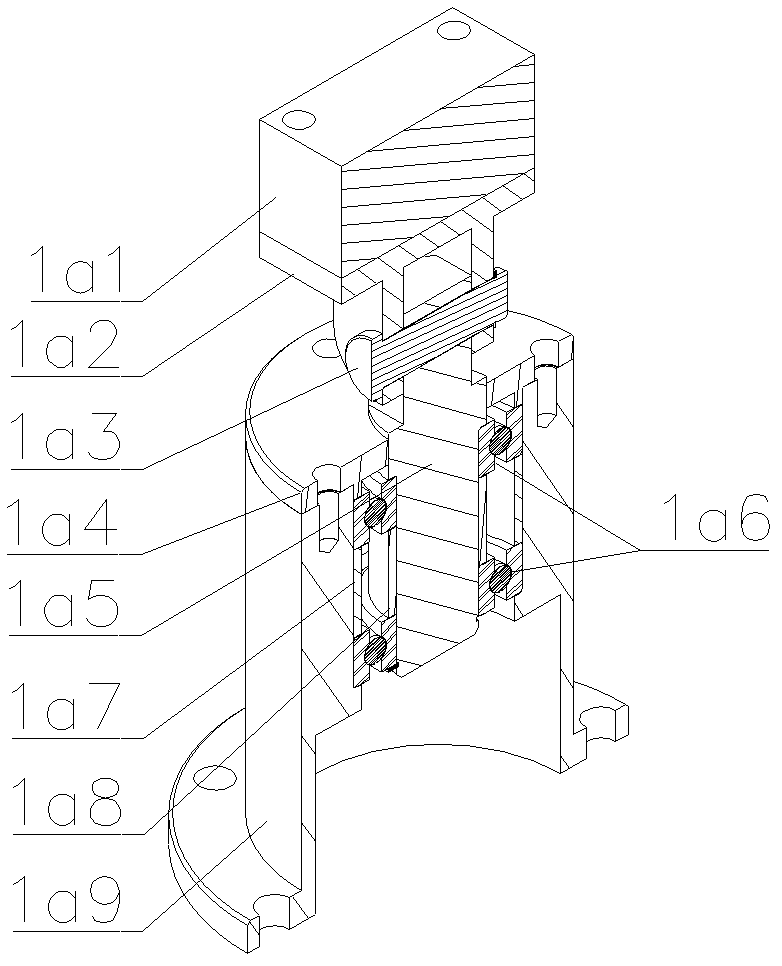

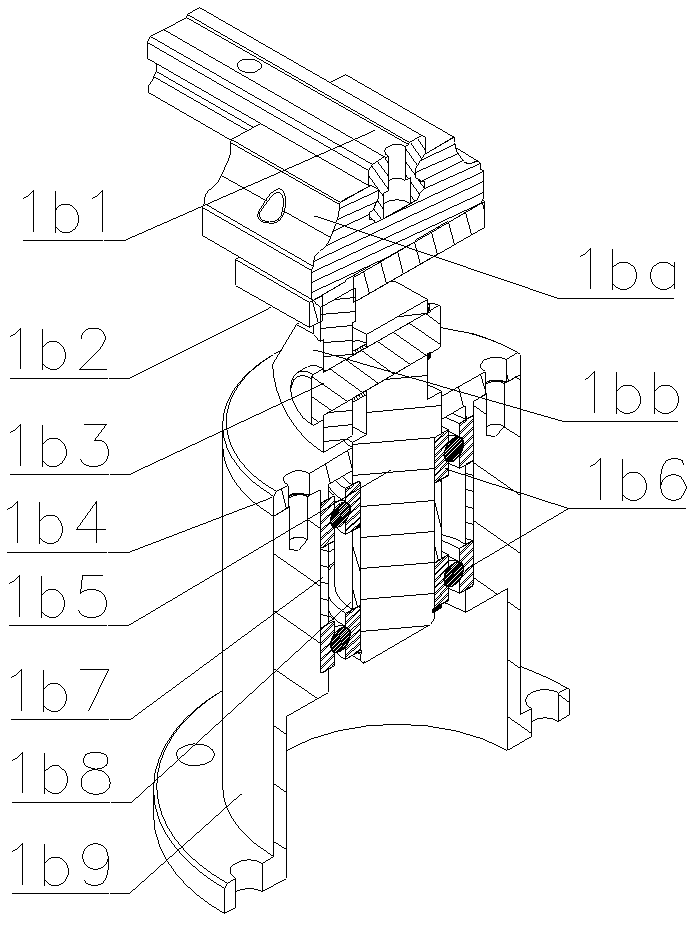

Track detector

ActiveCN104890699AImprove integrityNot easy to vibrateRailway auxillary equipmentRailway profile gaugesElastic componentData acquisition

The invention discloses a track detector. The track detector comprises a machine frame, a gauge measuring device and a geometric parameter measuring device for an F-shaped track, wherein the machine frame consists of a horizontal beam, a vertical beam and a running device, and one end of the horizontal beam is connected with the vertical beam; the gauge measuring device comprises a first pressing device and a gauge measuring sensor, the first pressing device is connected with the other end of the horizontal beam through an elastic component, and the gauge measuring sensor is mounted at one end, connected with the elastic component, of the horizontal beam; the geometric parameter measuring device for the F-shaped track is arranged on the vertical beam and comprises second pressing devices, a data collecting sensor and one or more brackets allowing the data collecting sensor to be mounted, and during the operation, the first pressing device, the second pressing devices and the elastic component are matched to fasten the track detector on the F-shaped track. The main body of the machine frame consists of the horizontal beam and the vertical beam, so that the track detector is good in wholeness, not prone to vibrate, simple in structure and convenient to assemble, disassemble and carry.

Owner:BEIJING ENTERPRISES HLDG MAGLEV TECH DEV +1

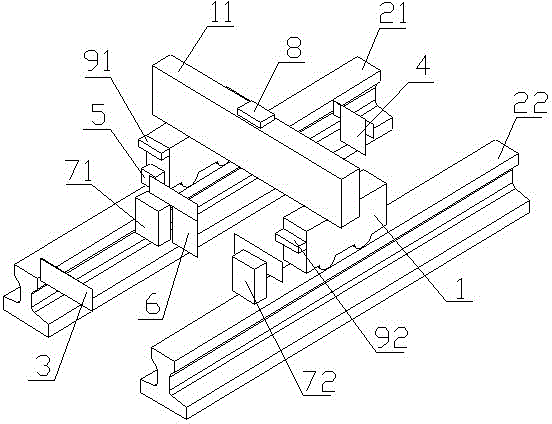

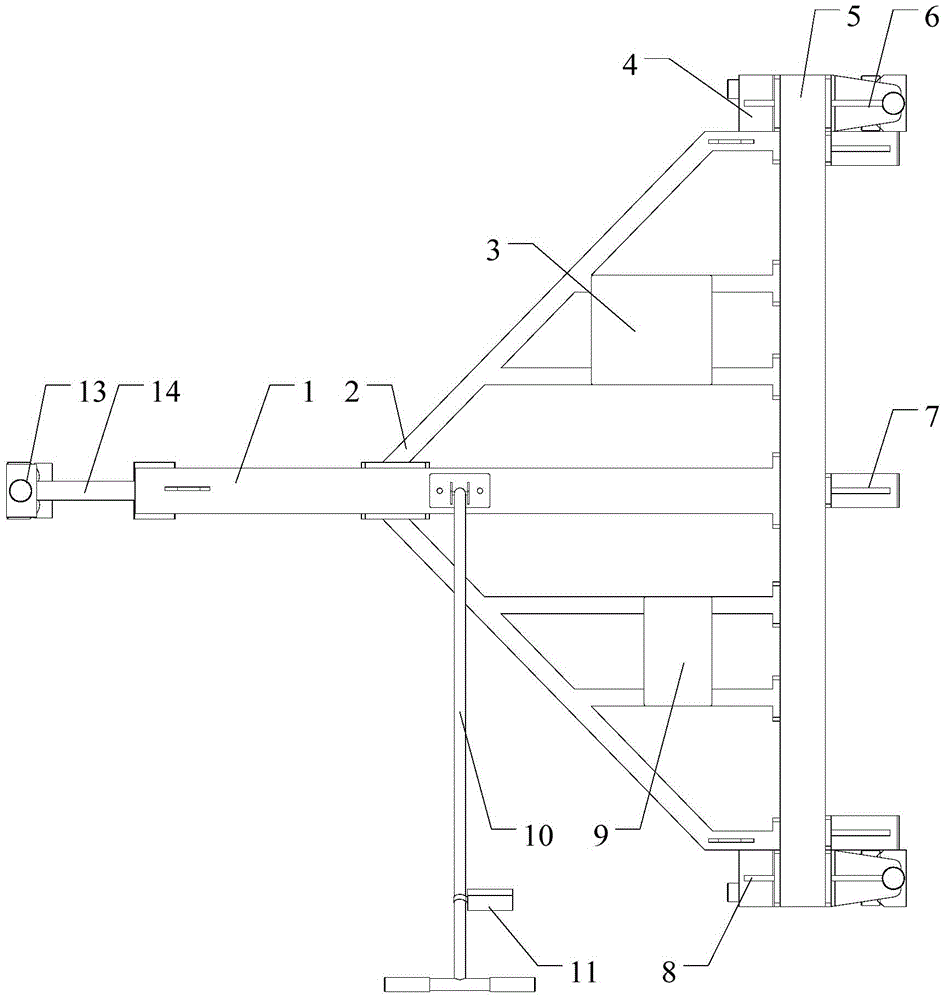

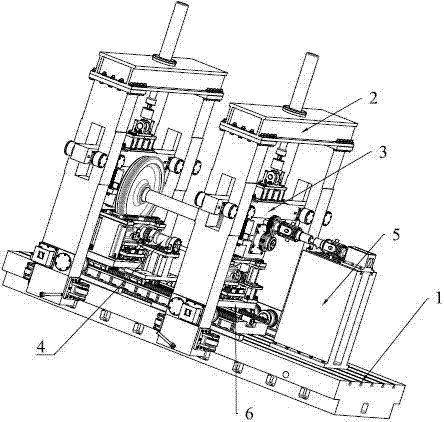

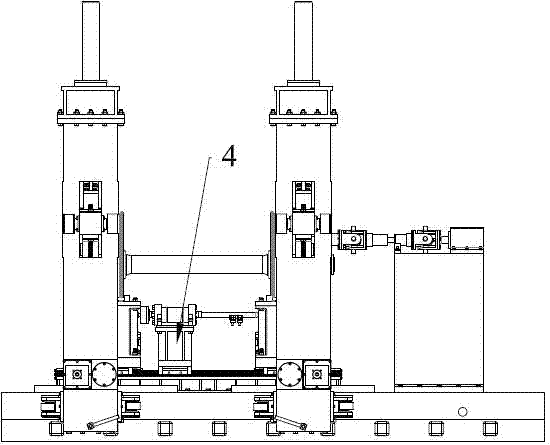

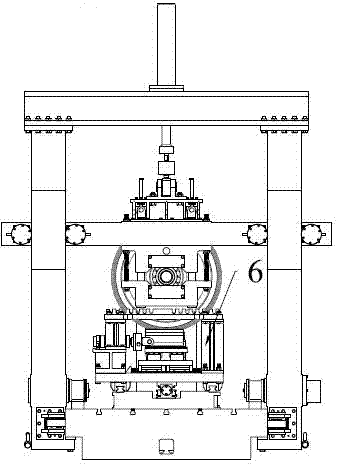

Force measurement wheel set calibration test stand

ActiveCN103759885AEasy to operateHigh precisionForce/torque/work measurement apparatus calibration/testingTransverse forceEngineering

A force measurement wheel set calibration test stand comprises a T-shaped stand base, portal systems and a transverse loading system. The force measurement wheel set calibration test stand is characterized in that perpendicular guide systems are installed on the portal systems and used for fixing a wheel set and achieving perpendicular loading; a bottom plate system is arranged at the position, below two portal top beams of the two portal systems, of the T-shaped stand base and used for adjusting track gauge, provides a platform for applying longitudinal force and transversely limiting the wheel set; a wheel set rotating indexing system is arranged at one end of the T-shaped stand base and used for achieving loading of any automatic rotating angle of the wheel set. According to the force measurement wheel set calibration test stand, perpendicular force and transverse force are independently loaded on the wheel set, and combined loading of loads in three directions can also be conducted on the wheel set; the force measurement wheel set calibration test stand has the wide track gauge calibration capacity, and meets the requirement for calibrating force measurement wheel sets of railway vehicles with the meter gauge, railway vehicles with the standard track gauge, railway vehicles with the wide gauge and other different railway vehicles; the force measurement wheel set calibration test stand has the capacity for adjusting lateral moving amount of wheel track contact points, and provides required perpendicular, transverse and longitudinal loads in a hydraulic loading mode.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

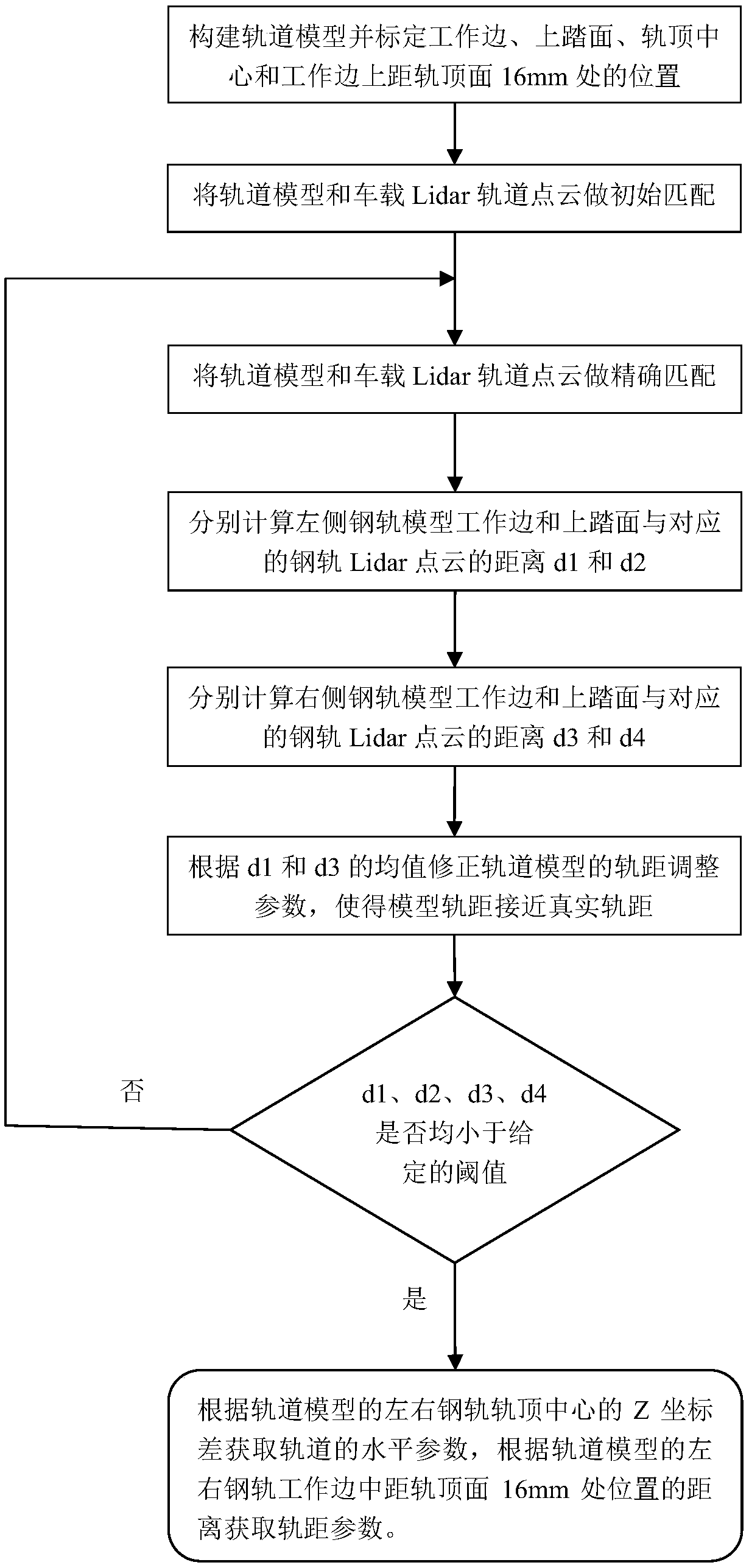

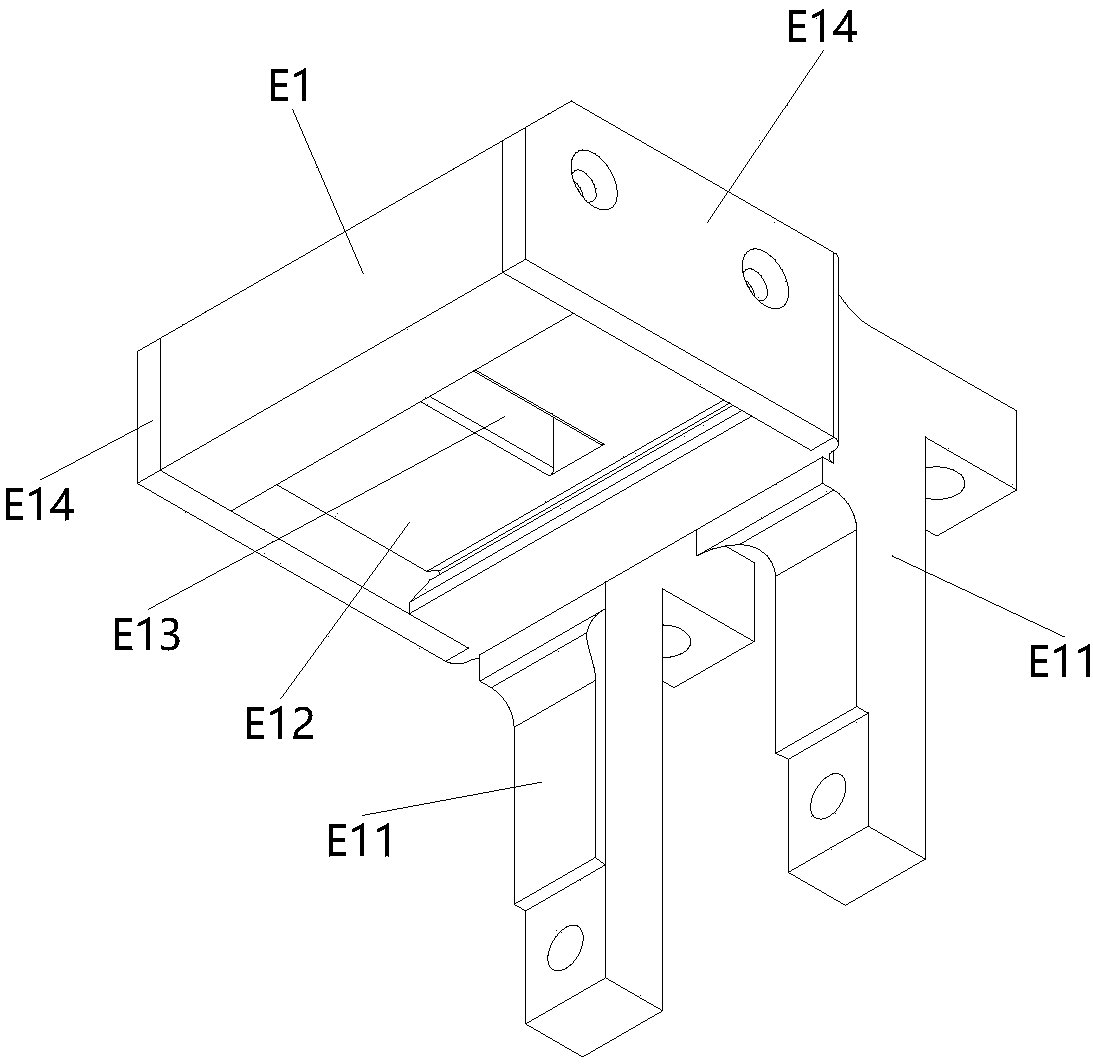

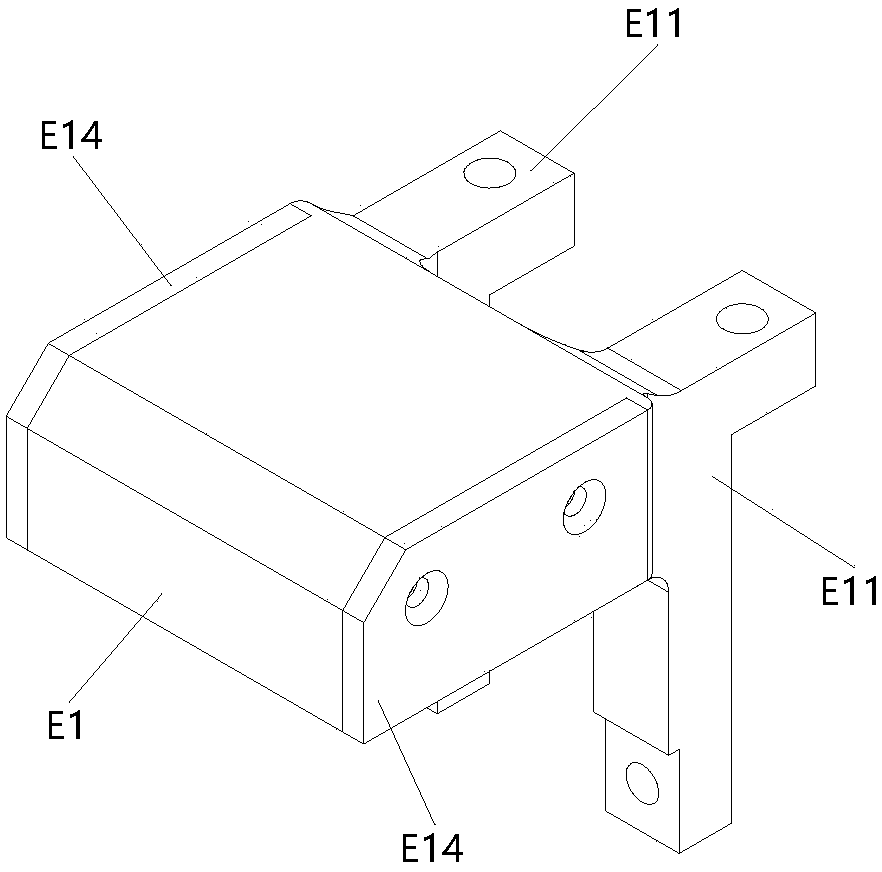

Railway track gauge and horizontal parameter measuring method based on vehicle-mounted Lidar point cloud

ActiveCN108657222ASolve the non-parallelSolve gaugeImage analysisRailway auxillary equipmentPoint cloudTracking model

The invention discloses a railway track gauge and horizontal parameter measuring method based on vehicle-mounted Lidar point cloud. The method includes the following steps that S1, a track model is established; S2, the track model and the vehicle-mounted Lidar track point cloud are initially matched; S3, the track model and the vehicle-mounted Lidar track point cloud are precisely matched, the distances from left and right working edges and an upper tread surface of the steel track model to the corresponding vehicle-mounted Lidar point cloud are calculated separately, and the gauge is adjustedaccording to the distances from the working edges of the steel track model to the vehicle-mounted Lidar point cloud; and S4, the step S3 is repeated iteratively until the distances from the working edges and the upper tread surface of the steel track model to the vehicle-mounted Lidar point cloud are smaller than a preset threshold value. The method realizes high-precision measurement of geometric parameters of a railway track, realizes matching of the track model considering the gauge and horizontal parameters with the vehicle-mounted Lidar track point cloud, and the gauge and the horizontalparameters of a railway track are measured based on the track model, so that technical support is provided for railway track measurement by using the vehicle-mounted Lidar technology.

Owner:SOUTHWEST JIAOTONG UNIV

Braking device for gauge-changeable bogie

ActiveCN107628059AAchieve brakingRailway transportBrake arrangement with pressed braking surfaceBogieEngineering

The invention belongs to the technical field of braking devices, and particularly relates to a braking device for a gauge-changeable bogie. The braking device comprises a braking lifting seat and a braking clamp mounting seat, the braking lifting seat comprises a sliding joint, the braking clamp mounting seat comprises a sliding connector, and the sliding joint and the sliding connector form an axial sliding pair. The invention aims to provide a braking device for the gauge-changeable bogie to solve the problem that the gauge-changeable bogie cannot adopt a wheel disc braking mode, and the braking device can move along with a wheel disc braking disc on a wheel, so that wheel disc braking of the gauge-changeable bogie is achieved. Railway transportation of a 'silk road economic belt' is implemented, the problem of non-uniform railway gauges needs to be solved, and axial adjustment of a shaft disc braking device of the gauge-changeable bogie is an important link, so that design of a shaft disc braking mode of changeable rail gauges has quite important and profound significance.

Owner:CRRC TANGSHAN CO LTD +1

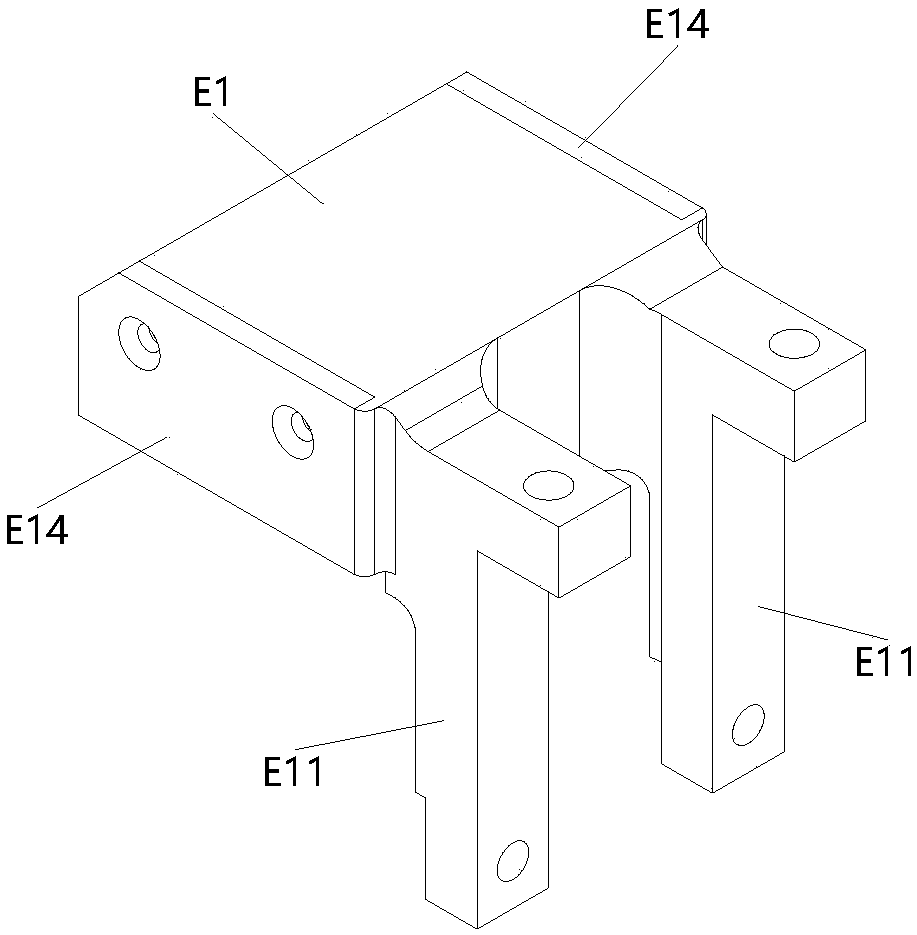

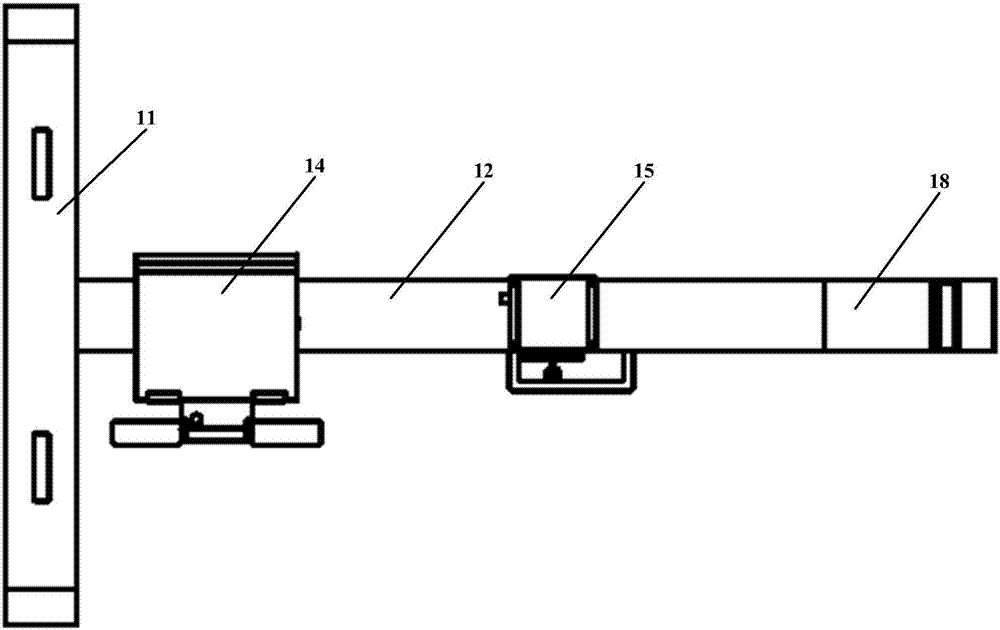

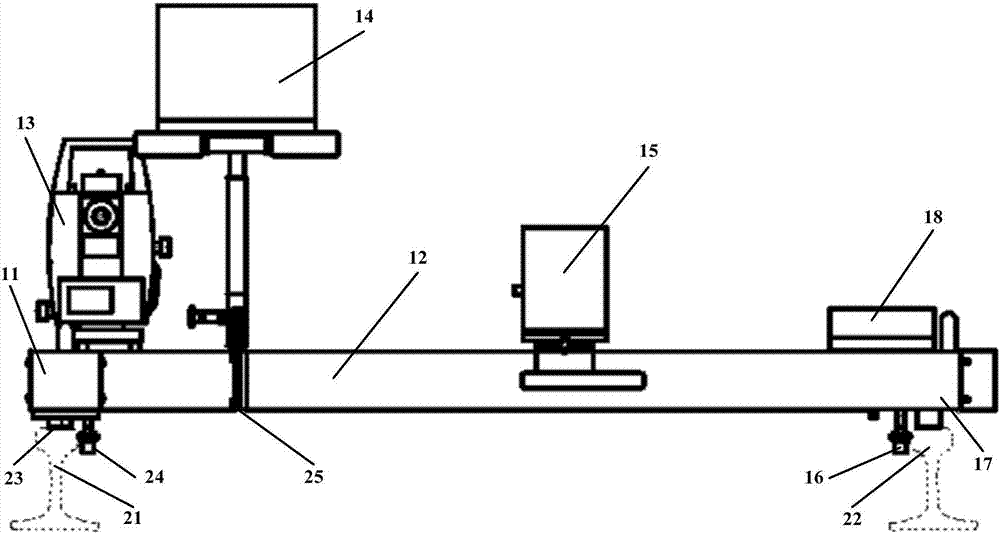

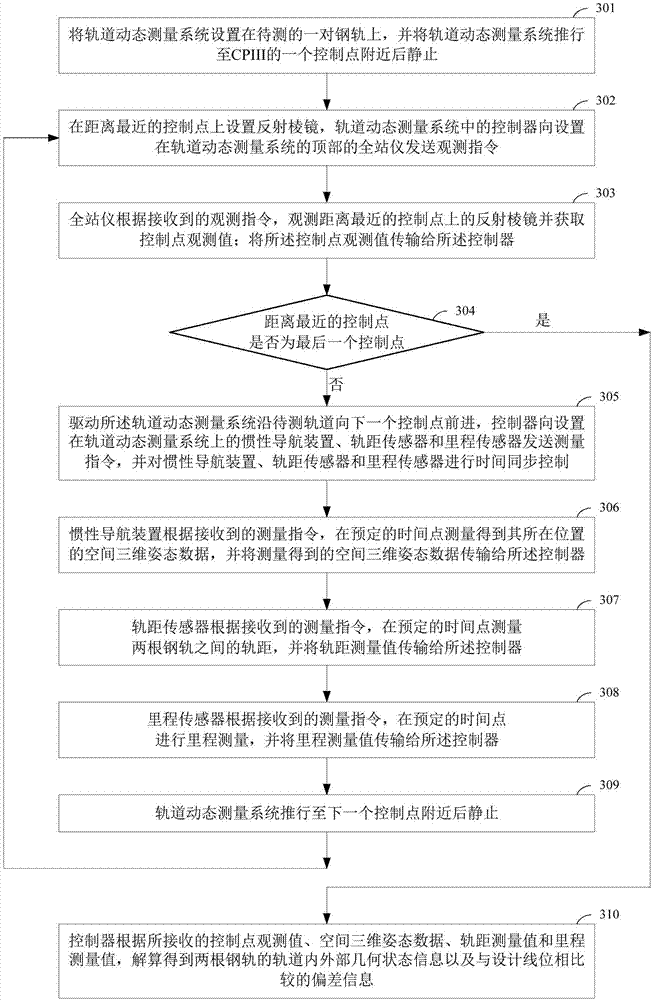

Track dynamic measuring system and method

PendingCN107299568ARealize dynamic measurementExcellent absolute measurement accuracyMeasuring apparatusTrackwaySimulation

The invention provides a track dynamic measuring system and method. The track dynamic measuring system comprises a longitudinal beam, a transverse beam, a total station instrument, a controller, an inertial navigation device, track gauge sensors and a mileage sensor. By using the track dynamic measuring system and method, the track measuring efficiency can be greatly enhanced on the premise of guaranteeing the absolute measuring accuracy of the track, can avoid problems that GNSS signals are missing in long and bid tunnels and the measuring accuracy does not satisfy the use requirement and can realize the balance between the track dynamic measuring accuracy and the track dynamic measuring efficiency.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

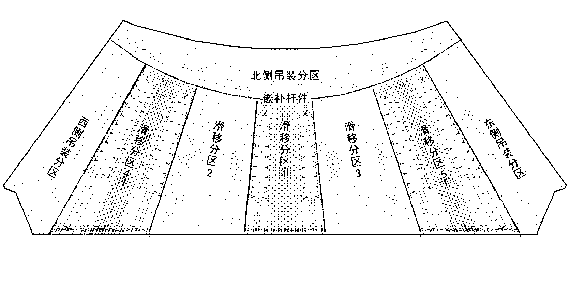

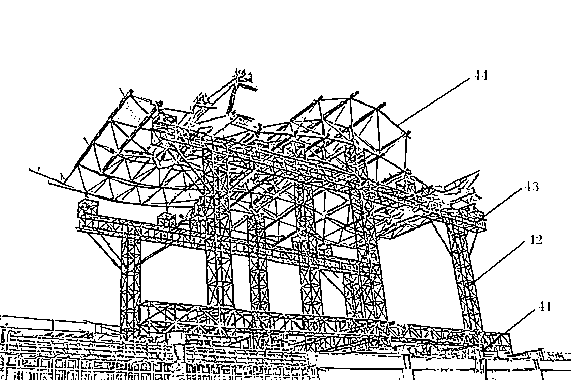

Construction method of track gauge variation block slippage of long span spatial composite roof truss

ActiveCN103216109ASolve the problem that cannot be hoisted and constructedReduce the impactBuilding material handlingLong spanTon

The invention discloses a construction method of track gauge variation block slippage of a long span spatial composite roof truss, namely, the roof is divided into a plurality of slippage zones in the radial direction, the slippage zones are assembled on a hall hollow side and are mounted through a radial accumulation slippage method, and lastly the remained lifting zones are lifted and mounted through a combined installation method of slippage and lifting. The construction method of track gauge variation block slippage of the long span spatial composite roof truss can be applied to the construction of the long span spatial composite roof truss which weights more than 10000 tons, the problem that oversized profile steel pillars can not be lifted and mounted is solved, and the construction method can be widely used in the field of long-span construction of a steel structure and has wide popularization and application prospects.

Owner:JIANGSU HUNING STEEL MECHANISM

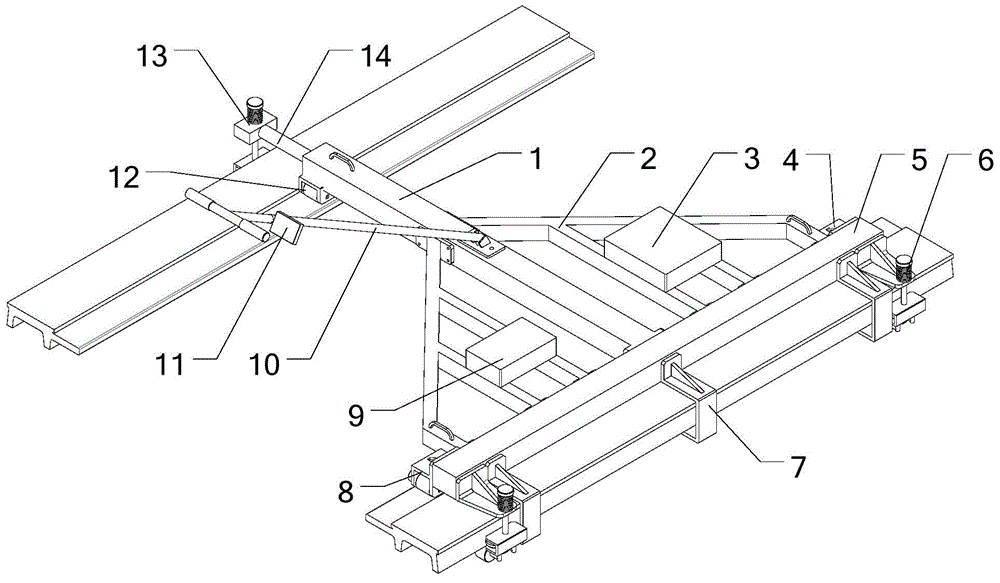

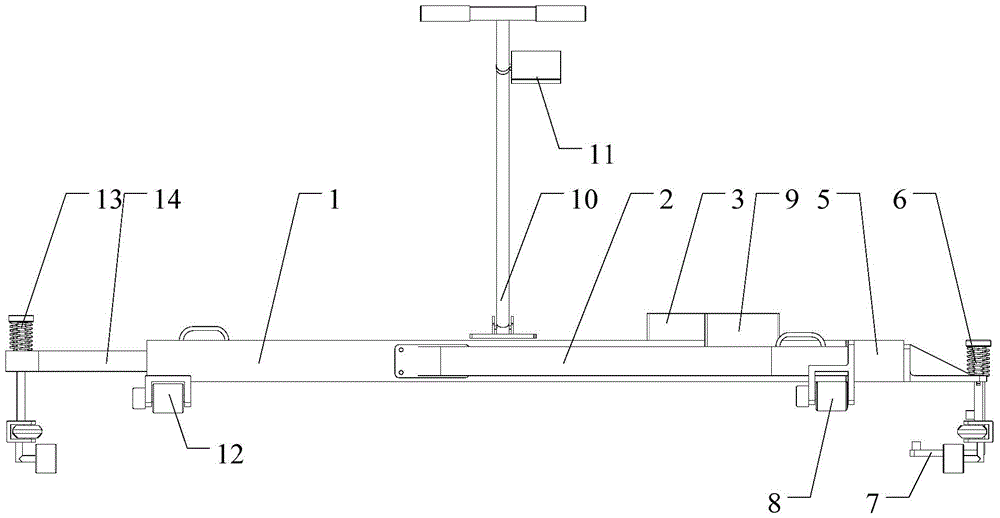

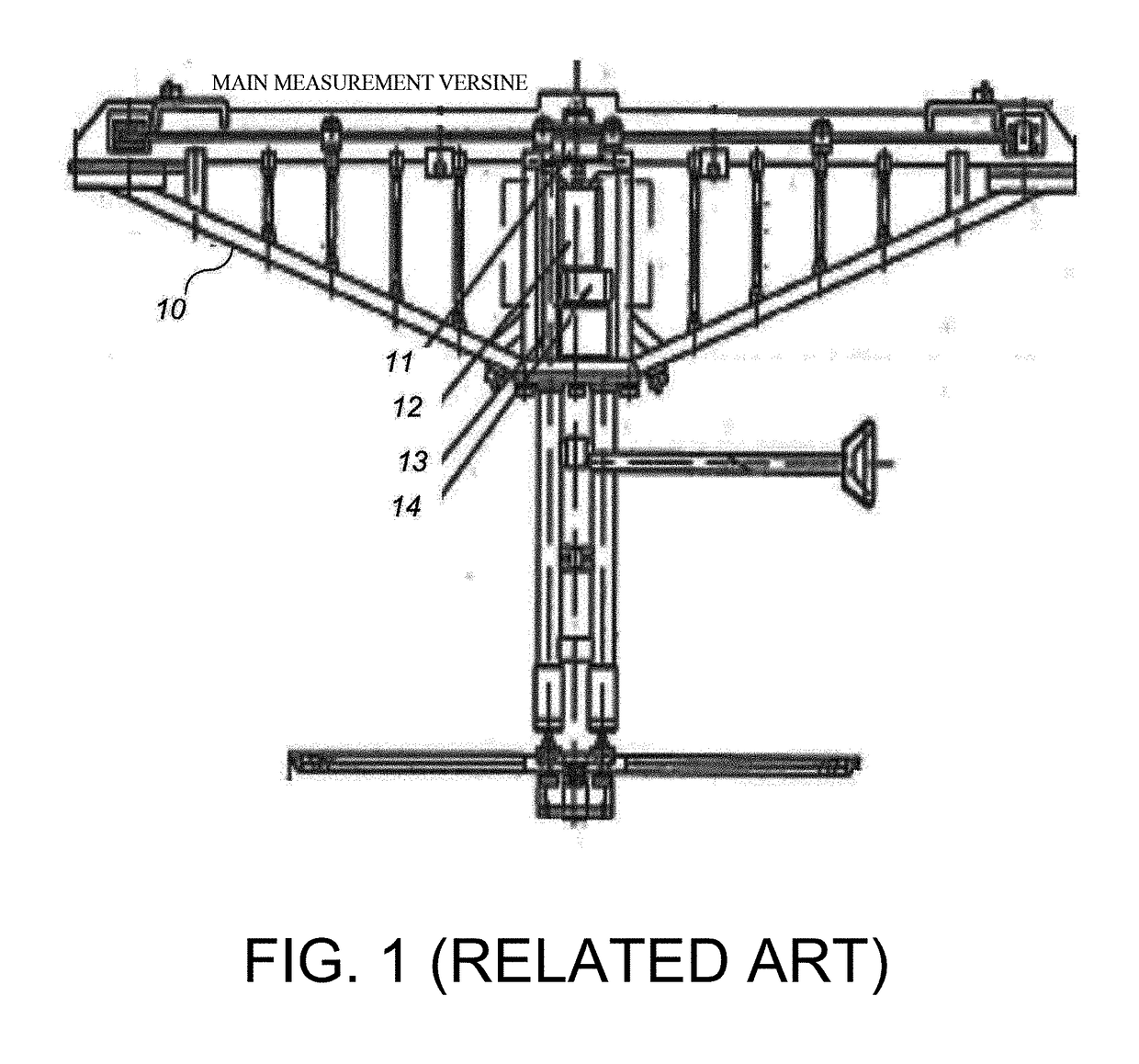

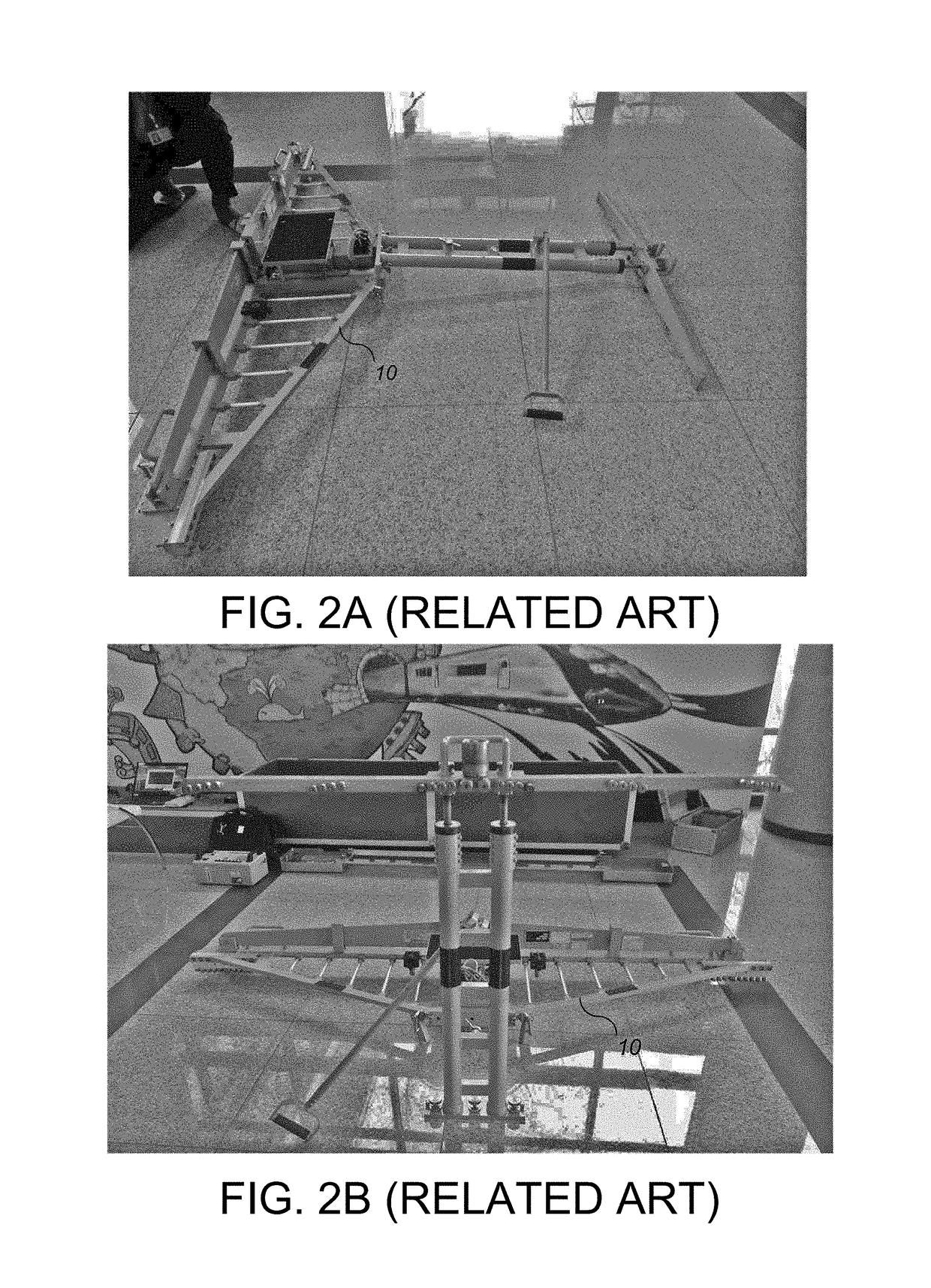

Versine trolley-type equipment for inspecting track irregularity

ActiveUS20180143017A1Reduced measurement timeEasily height differenceRailway inspection trolleysLinear/angular speed measurementHeight differenceEngineering

Provided is versine trolley-type equipment for inspecting a track irregularity, having sensors respectively provided to a trolley so as to measure a height difference, direction misalignment, gauge irregularity, rail longitudinal slope, cant and the like of railroad rails, and simultaneously measuring the height difference and direction misalignment of a left rail and a right rail so as to reduce a measurement time by half and, also, allowing left and right measurement frames to freely move in a vertical direction within a predetermined range, thereby bringing front and rear trolley wheels of the left and right measurement frames into close contact with the rails all the time even if the rails are warped.

Owner:KOREA RAILROAD RES INST

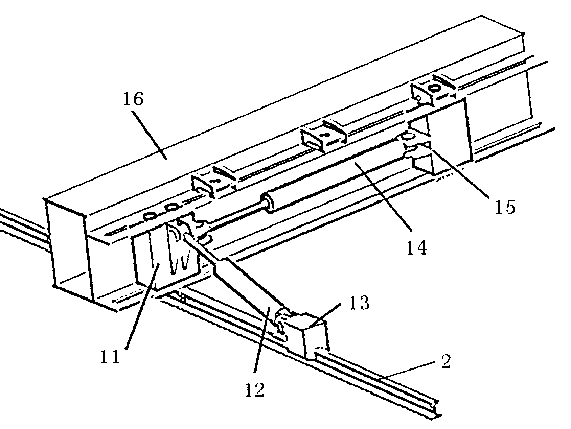

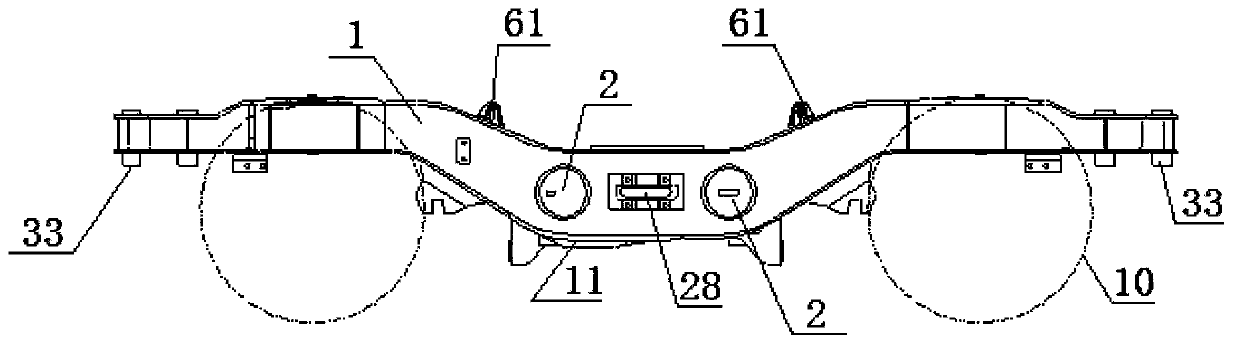

Gauge transforming device

PendingCN107574728AIncreased gauge change efficiencyTransformation is automatically implementedRailway tracksAxle unitsBogieEngineering

The invention belongs to the technical field of railway track devices, and particularly relates to a gauge transforming device. The gauge transforming device comprises a supporting rail, an unlockingrail and a guiding rail, the supporting rail comprises a supporting preparing rail and a supporting sustaining rail, and the unlocking rail comprises an unlocking preparing rail and an unlocking sustaining rail; the supporting preparing rail forms a supporting section; the supporting sustaining rail and the unlocking preparing rail form an unlocking section; and the supporting sustaining rail, theunlocking sustaining rail and the guiding rail form a guiding section. According to the gauge transforming device, the problem that the gauge transforming mode of a bogie is low in efficiency is solved, the gauge-changeable bogie can automatically achieve transforming of a gauge specification after passing through the gauge transforming device. To carry out railway transportation of 'silk road economic belt', the problem that the railway gauges are not uniform must be faced, and the ground gauge transforming device is essential equipment in the rail-changing link, therefore, carrying out of design of the ground gauge transforming device has very important and profound significance.

Owner:SOUTHWEST JIAOTONG UNIV +1

Narrow-gauge train bogie

The invention relates to a narrow-gauge train bogie which comprises a framework. Two wheel sets, a traction device, two traction motors, two gearboxes, a primary suspension device, a secondary suspension device and a foundation brake device are arranged on the framework. The primary suspension device is composed of a steel spring and a rocker arm type axle box, the rocker arm type axle box is connected with the framework through the steel spring, each wheel set comprises a wheel axle and wheels fixed to the two ends of the wheel axle, the wheel axles are connected with the rocker arm type axle box, the secondary suspension device comprises an air spring, a side rolling resisting torsion bar and a height control valve, the air spring, the side rolling resisting torsion bar and the height control valve are arranged on the framework, and the foundation brake device is a wheel-mounted disc brake device. The components are optimized and are combined in a matched mode, performance parameters are optimized, and therefore the performance of the bogie is greatly improved. As is proved by the experiment, according to the narrow-gauge train bogie, the operating speed of a train can be 160km / h on a narrow gauge of 1076mm, and the narrow-gauge train bogie has good stability, comfort and safety performance.

Owner:CRRC QINGDAO SIFANG CO LTD

Method and device for determining dynamic equivalent conicity of railway vehicle

InactiveCN107391911ASimple calculationSpecial data processing applicationsInformaticsRail profileEngineering

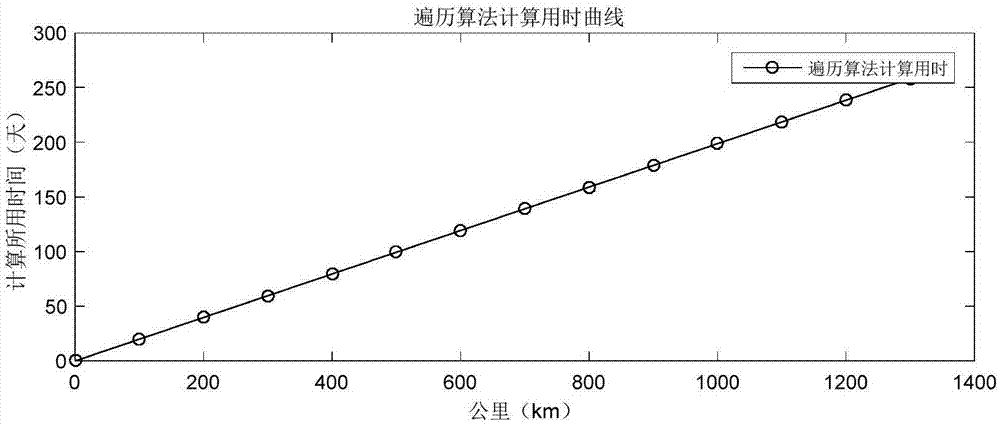

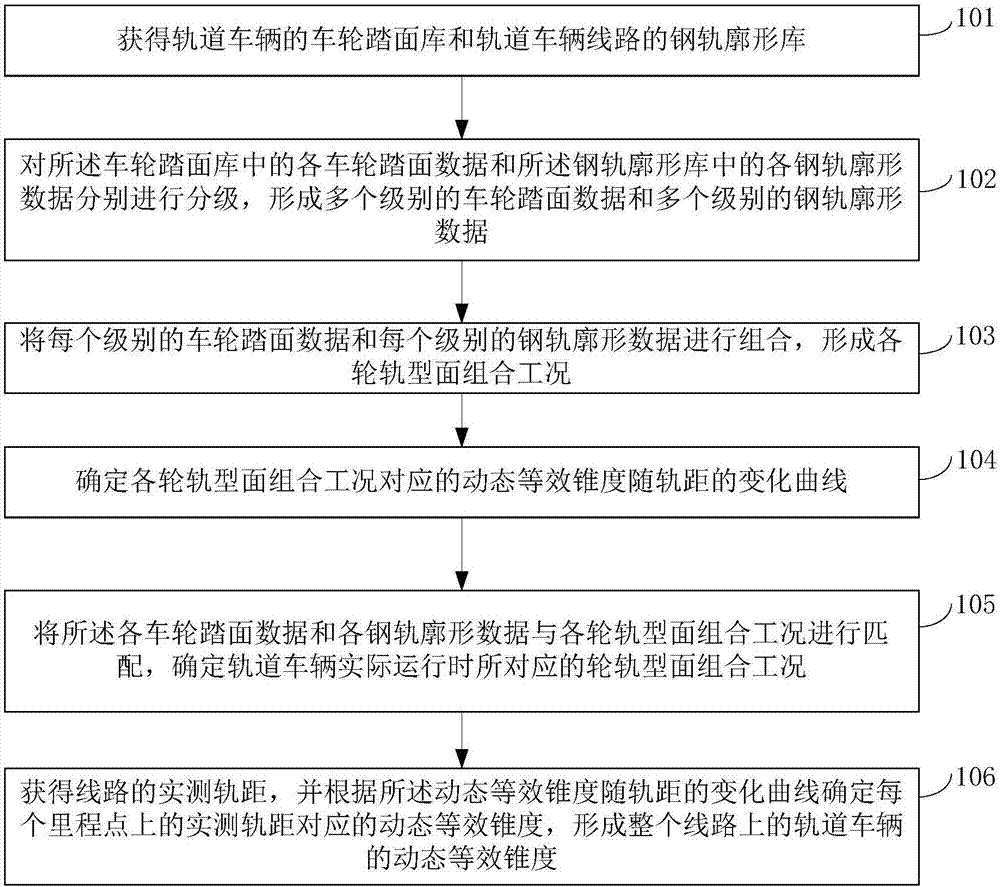

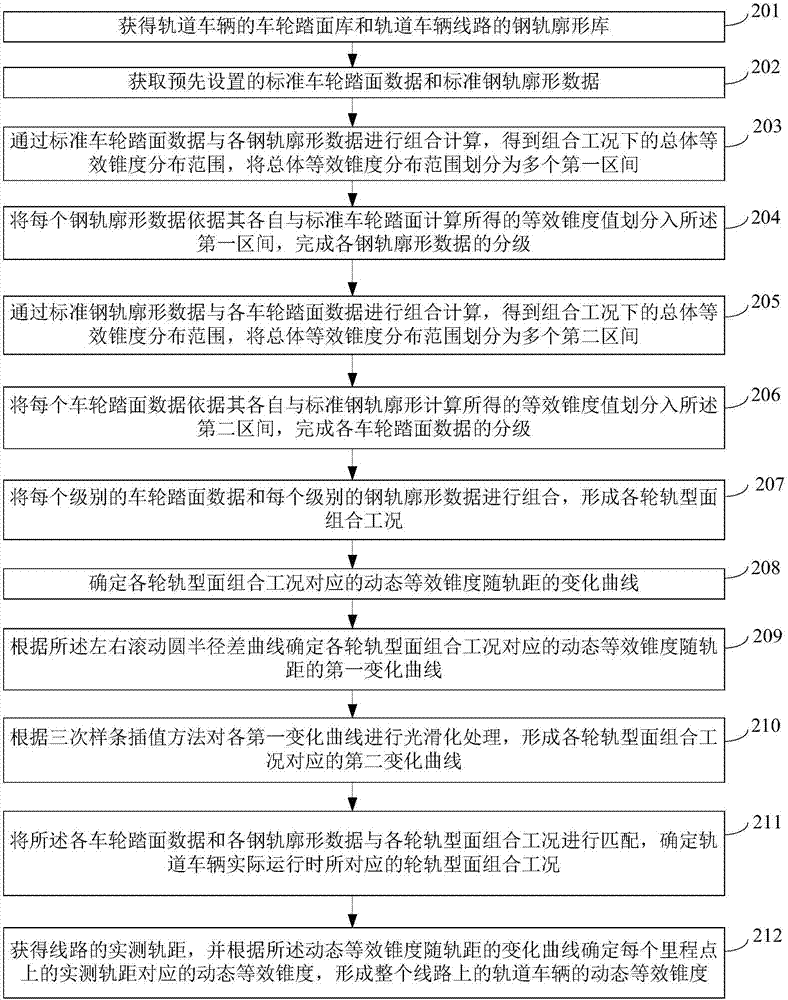

The invention provides a method and device for determining the dynamic equivalent conicity of a railway vehicle, and relates to the technical field of railway vehicle routes. The method comprises the steps that tread data of each wheel in a wheel tread library and profile data of each steel rail in a steel rail profile library are classified and combined respectively, and various wheel-rail molded surface combined working conditions are formed; the change curve of the equivalent conicity corresponding to the wheel-rail molded surface combined working conditions along with the gauge is determined; the tread data of each wheel and the profile data of each steel rail are matched with the wheel-rail molded surface combined working conditions, and the wheel-rail molded surface combined working conditions corresponding to actual operation of the railway vehicle are determined; the actually measured gauge of a route is obtained, the dynamic equivalent conicity corresponding to the actually measured rail gauge on each mileage point is determined according to the change curve of the dynamic equivalent conicity along with the gauge, and the dynamic equivalent conicity of the railway vehicle on the whole route is formed.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

Dynamic noncontact rail gauge measuring system and method thereof

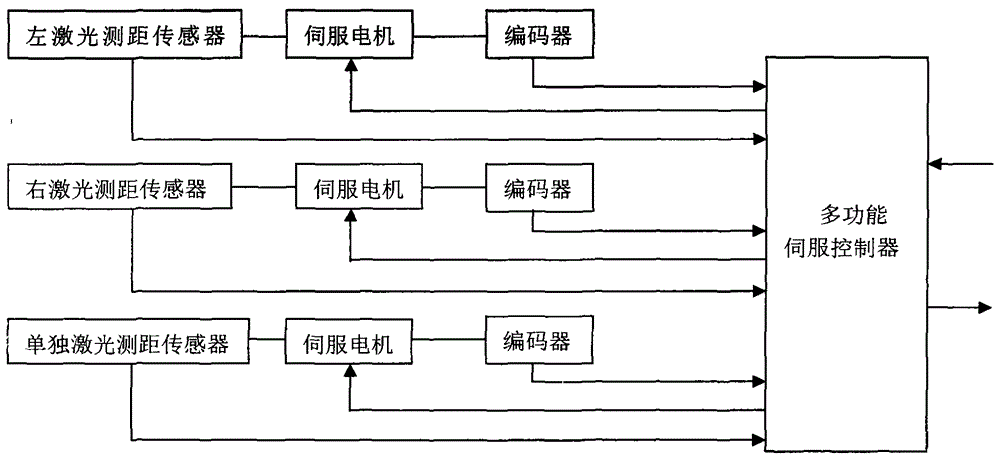

The invention discloses a dynamic noncontact rail gauge measuring system and a method thereof. The dynamic noncontact rail gauge measuring system based on a laser ranging sensor of the triangulation principle is composed of three identical gauge measuring components and a multifunctional servo controller component capable of controlling the three identical gauge measuring components simultaneously. The dynamic noncontact rail gauge measuring system and the method thereof are used for a rail parameter dynamic detection trolley to realize noncontact gauge measurement, the highest detection speed can be 60kg / h and measuring precision can be + / -0.2m so that the dynamic noncontact rail gauge measuring system and the method thereof have a function of correcting heading direction of a high-speed rail inspection trolley, and are simple in structure, high in stability of the measuring result and favorable for popularization and application on various rail inspection trolleys.

Owner:北京星网宇达科技股份有限公司

Automated track inspection system

ActiveUS9950716B2High frequencyReduce riskRailway auxillary equipmentRailway profile gaugesDrive wheelMultiple sensor

An autonomous device for rail track inspection includes a drive wheel system propelling the device via a drive wheel system, an automatic track loading fixture for and applying a load on rails, and sensors for taking track gauge measurement. Different automatic track loading fixtures may require stopping for load and measurement, or loading and measuring while still in motion. A switch agnostic system for operation with devices on a conventional railroad track system includes a linear slider movably mounted along a linear sliding support; multiple sensors mounted to the linear slider, the sensors operable to identify a rail of a track junction; and multiple roller bearings operable to engage the rail of the track junction and control the device across the track junction in response to movement of the linear slider along the linear sliding support.

Owner:RAILPOD

Rapid non-contact measuring method of railway intrusion boundary

InactiveCN101947962AAvoid defectsHigh speed measurementUsing optical meansRailway auxillary equipmentVisual perceptionStructure based

The invention provides a rapid non-contact measuring method of railway intrusion boundary, and specifically relates to the method of automatically measuring the distance between objects such as a railway station and the like and a gauge center and the height of the objects relative to a rail surface based on a structured light three-dimensional visual detection technology. In the method, on the basis of a principle of structured light three-dimensional visual measurement, a linear-structured laser and a camera are employed, wherein, the linear-structured laser emits a laser line which is vertical to the rail surface, the camera acquires an image illuminated by the laser line, and a microprocessor calculates the distance between the objects such as the railway station and the like and the gauge center and the height of the objects relative to the rail surface according to spatial three-dimensional relation, thus realizing non-contact, high-speed and high-precision measurement.

Owner:NANJING UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com