Narrow-gauge train bogie

A technology for bogies and passenger cars, applied in the field of bogies, can solve problems such as poor performance, improve the overall anti-fatigue performance, simplify the structure of the traction beam, and achieve a small turning angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

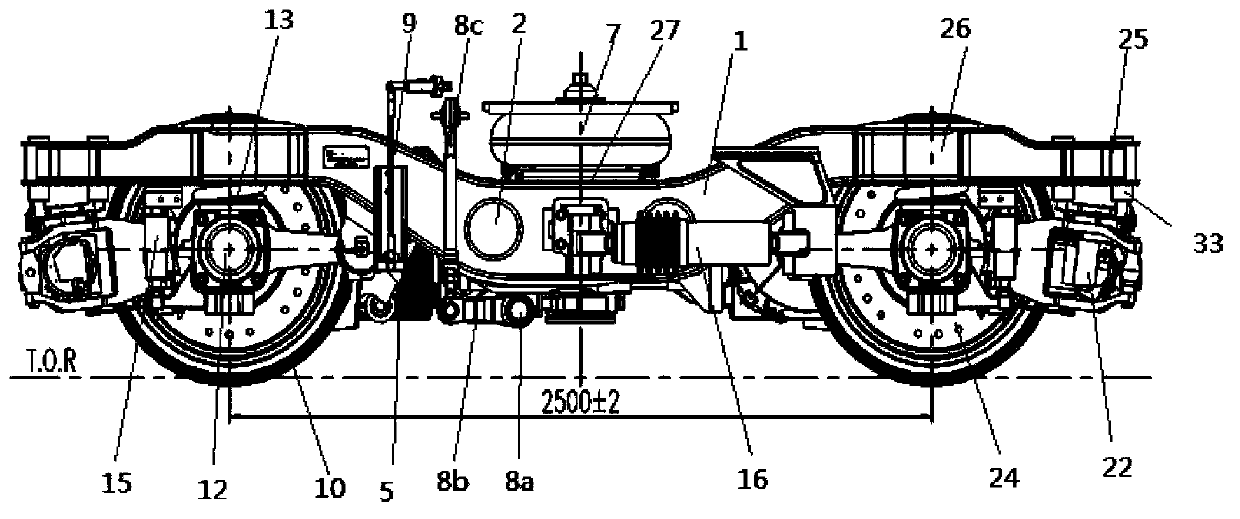

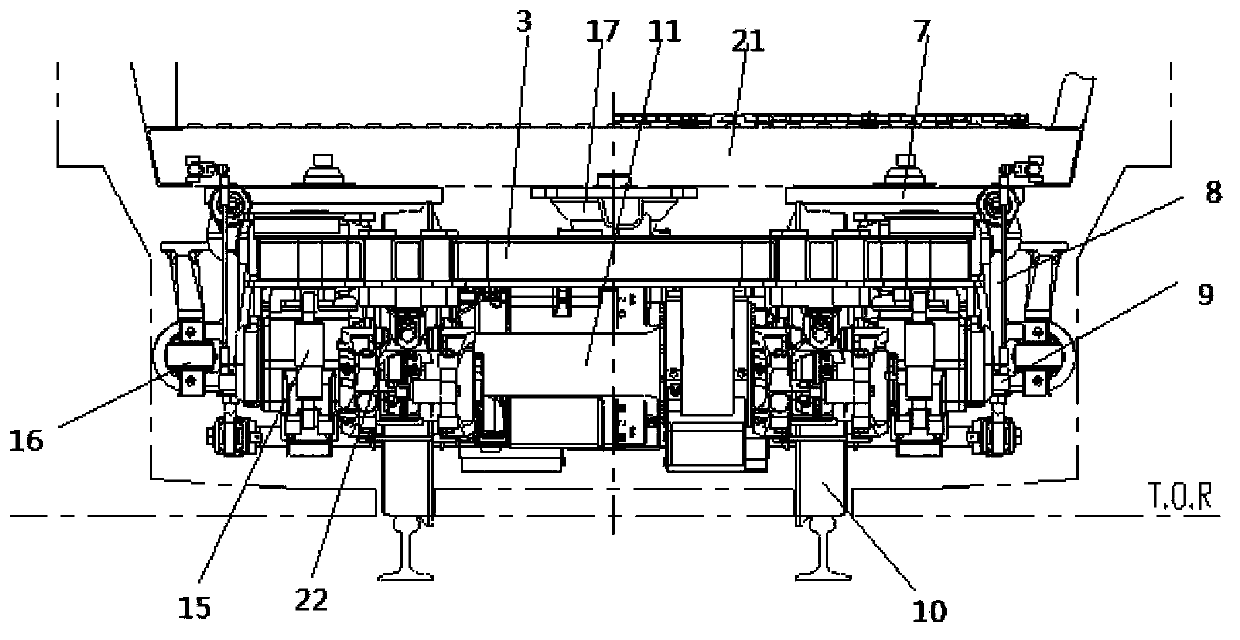

[0037] Such as Figure 1 to Figure 3 As shown, a narrow-gauge passenger car EMU bogie is used for narrow-gauge EMUs, and is suitable for 1067mm narrow-gauge EMUs. It includes a frame on which two wheelsets, a traction device, a traction motor 5, a gear box 6, a primary suspension device, a secondary suspension device and a foundation braking device are arranged. The wheelset is fixed on the frame through the primary suspension device, and the frame is connected with the vehicle body through the secondary suspension device. The primary suspension device includes a pivoting arm type axle box 12, steel spring 13 and vertical shock absorber 15, the secondary suspension device includes an air spring 7, an anti-roll torsion bar 8 and a height adjustment valve 9, and the wheel set includes wheels 10 and Axle 11.

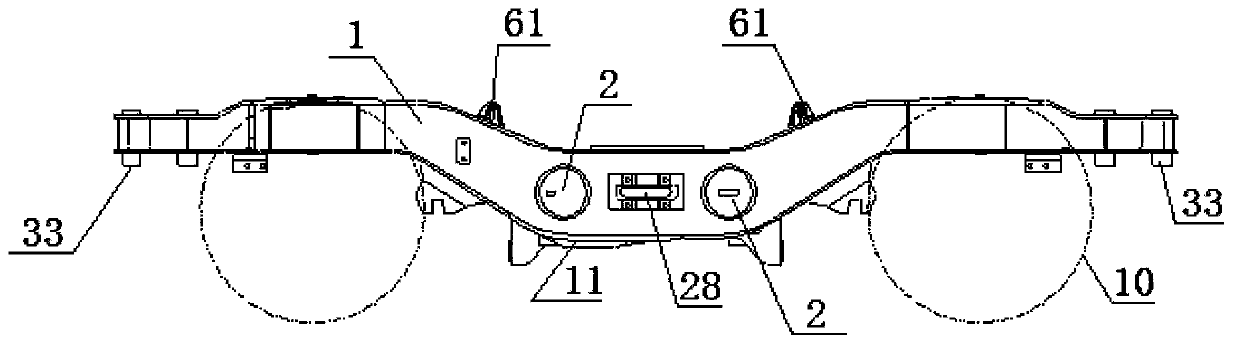

[0038] Such as Figure 4 to Figure 6 As shown, the frame is composed of two side beams 1, two beams 2, and two end beams 3, the two ends of the two side beams 1 are conn...

Embodiment 2

[0072] Such as Figure 12 As shown, this embodiment provides a narrow-gauge passenger car trailer bogie.

[0073] The difference from Embodiment 1 is that there is no need to weld the traction motor mounting base 36 and the gear box suspender seat 38 on the sides of the two beams 2 of the frame, that is, there is no need to install the traction motor 5 and the gear box 6, only need to weld and fix The traction rod seat 37 and the integral lifting seat 39 are integrated in the installation suspension seat 35 in an integrated structure.

[0074] Through the improvement of the above internal structure, the matching combination of various components and the optimization of performance parameters, the performance of the whole bogie is obviously improved, so as to meet the design requirements. It is suitable for 1067mm narrow gauge railway, and the speed can reach 160km / h. Good stability, safety and comfort.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com