Online detection method for crane tracks

A detection method and crane technology, applied in the direction of measuring devices, instruments, load hanging components, etc., can solve the problems of large investment of manpower, potential safety hazards, low efficiency, etc., and achieve the effect of improving measurement efficiency and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

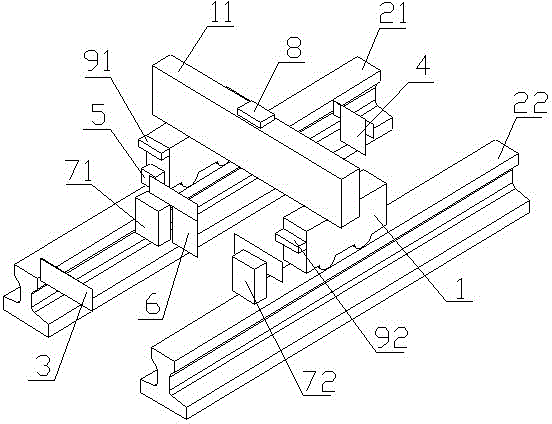

[0017] Implementation example figure 1 As shown, the crane track online detection method of the present invention includes the following steps:

[0018] Step 1. Establish a collimation reference system. Set up a laser collimator 3 at one end of the rail 21 on the motor track side of the crane 1, and set a fixed laser receiving target 4 on the other end of the track 21 at the same level as the laser collimator 3, and fix it The laser receiving target 4 receives the laser spot signal of the laser collimator 3 and corrects the laser drift, and uses the linear collimated laser of the laser collimator 3 as the reference reference for the detection of the entire crane track;

[0019] Step 2: Set the mileage sensor 5 at the position of the anti-collision device of the crane 1 to accurately measure the distance between the crane 1 on the track and the end of the track, and perform the mileage measurement of the crane 1;

[0020] Step 3. Set an automatic lifting mobile laser receiving target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com