Force measurement wheel set calibration test stand

A force-measuring wheelset and test-bed technology, which is applied in the calibration/testing of force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problem that the test-bed cannot complete the automatic adjustment of the gauge and the influence of the test results is relatively large. , the operation process is cumbersome and other problems, to achieve the effect of simple rotation process, wide indexing range and high indexing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

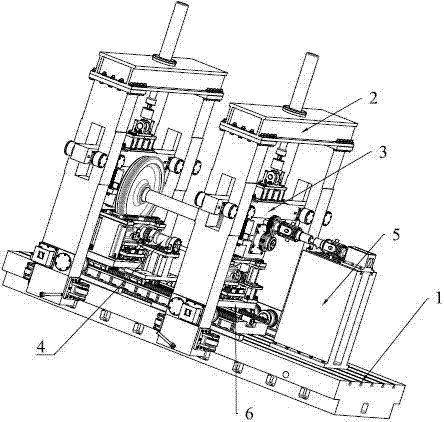

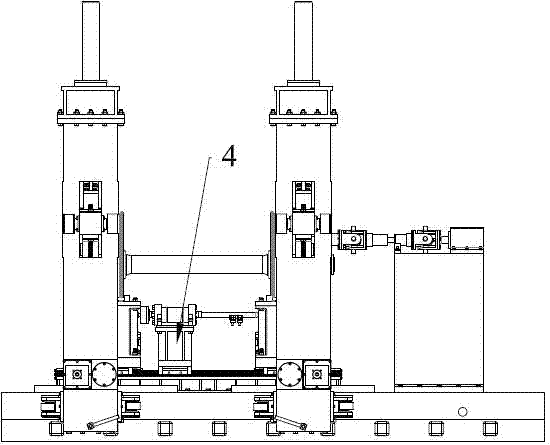

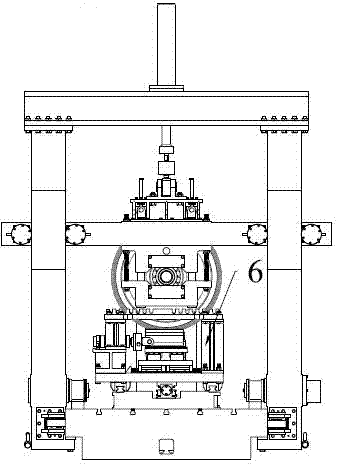

[0030] refer to Figure 1-4 , the force-measuring wheelset calibration test bench of the present invention comprises a T-type platform base 1, a gantry system 2, and a lateral loading system 4, and a vertical guide system 3 is installed on the gantry system, which is used to fix the wheelset and realize vertical loading. Loading in the direction of loading, the bottom plate system 6 is provided under the two gantry beams of the two gantry systems on the catwalk base 1, which is used to adjust the gauge, provide a platform for applying longitudinal force, and implement lateral limit on the wheel set, T One end of the type table base 1 is also provided with a wheel set rotation indexing system 5, which is used to realize the automatic rotation of the wheel set to load at any angle. The T-shaped platform base 1 is a cuboid structure, cast and processed, and the table is processed with T-shaped grooves for fixing the portal system 2 and the floor system 6 .

[0031] refer to Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com