Patents

Literature

663results about How to "Avoid unexpected situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

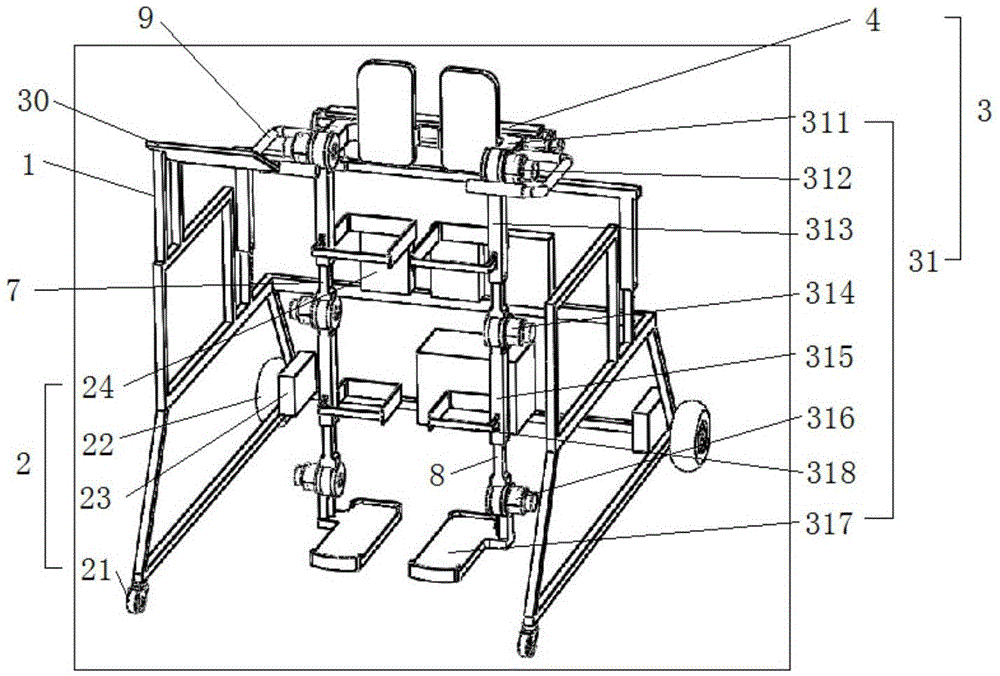

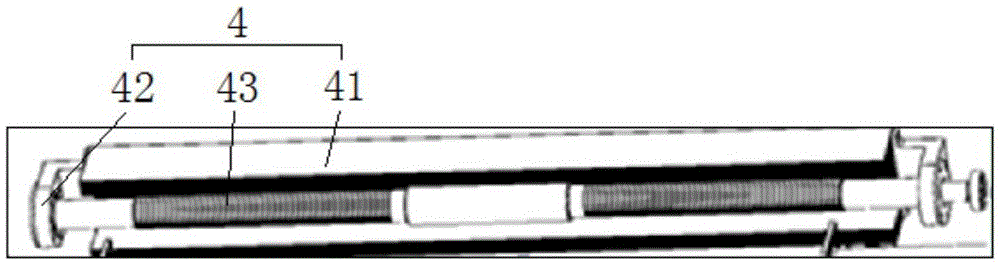

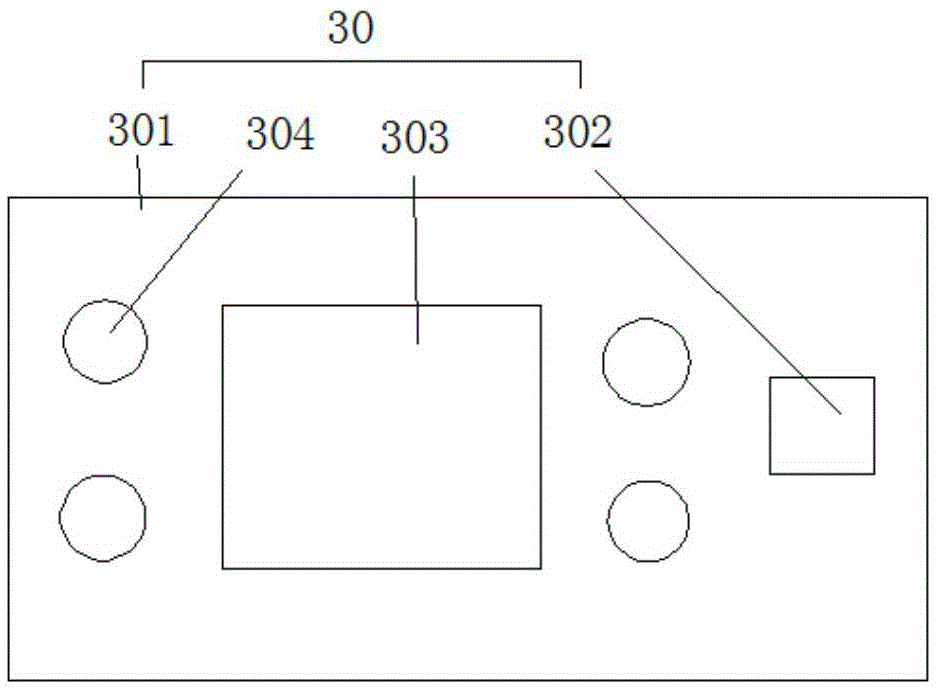

Exoskeleton type moving and walking rehabilitation training device and method

ActiveCN105456004ACompact structureGood stabilityProgramme-controlled manipulatorGymnastic exercisingEngineeringExoskeleton

The invention relates to an exoskeleton type moving and walking rehabilitation training device and method which can be used for walking rehabilitation training of the lower limbs of the human body. The device comprises an embedded upper computer, a moving motion control unit, a walking motion control unit, a gait measuring unit and a man-machine interaction unit. Under coordination control of all the units, the lower limbs of the human body can be driven by exoskeleton mechanical legs to conduct walking rehabilitation training in a movable platform. According to the main power of the lower limbs of the human body, the walking training modes can be divided into an active training mode and a passive training mode. The device can provide lower limb standing walking training in different lower limb rehabilitation stages for people with lower limb disabilities.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

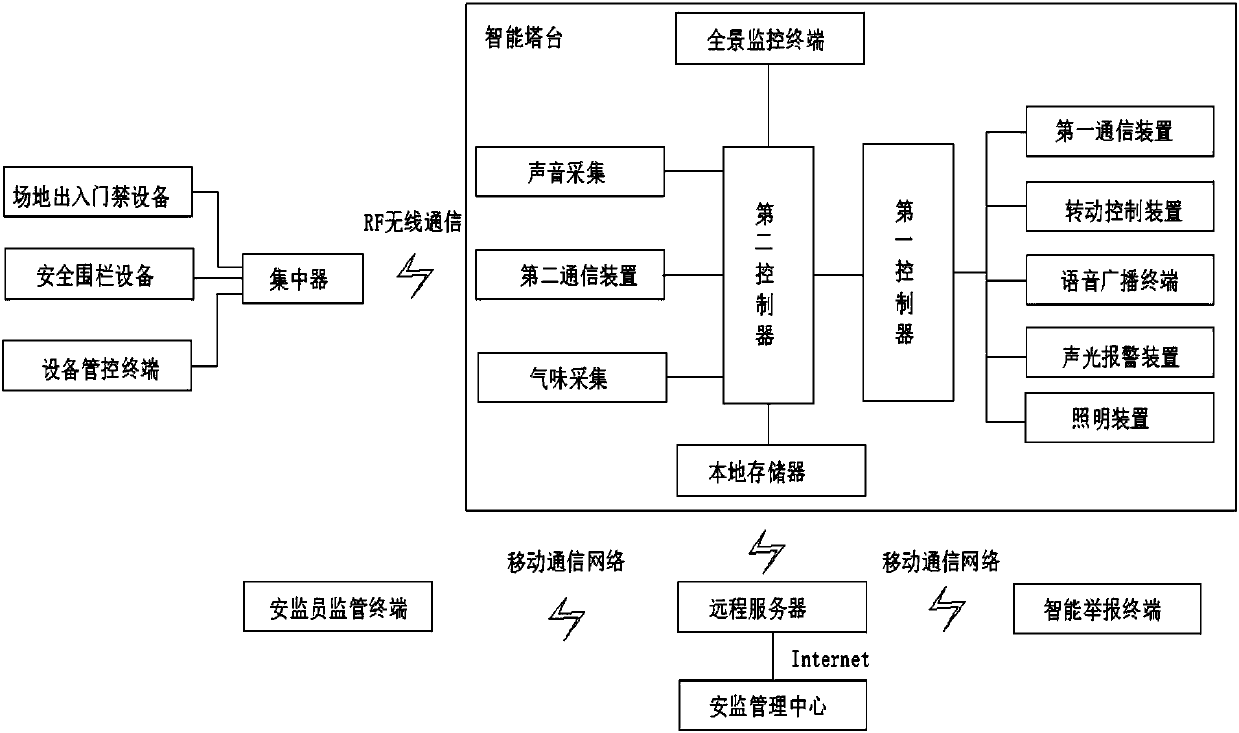

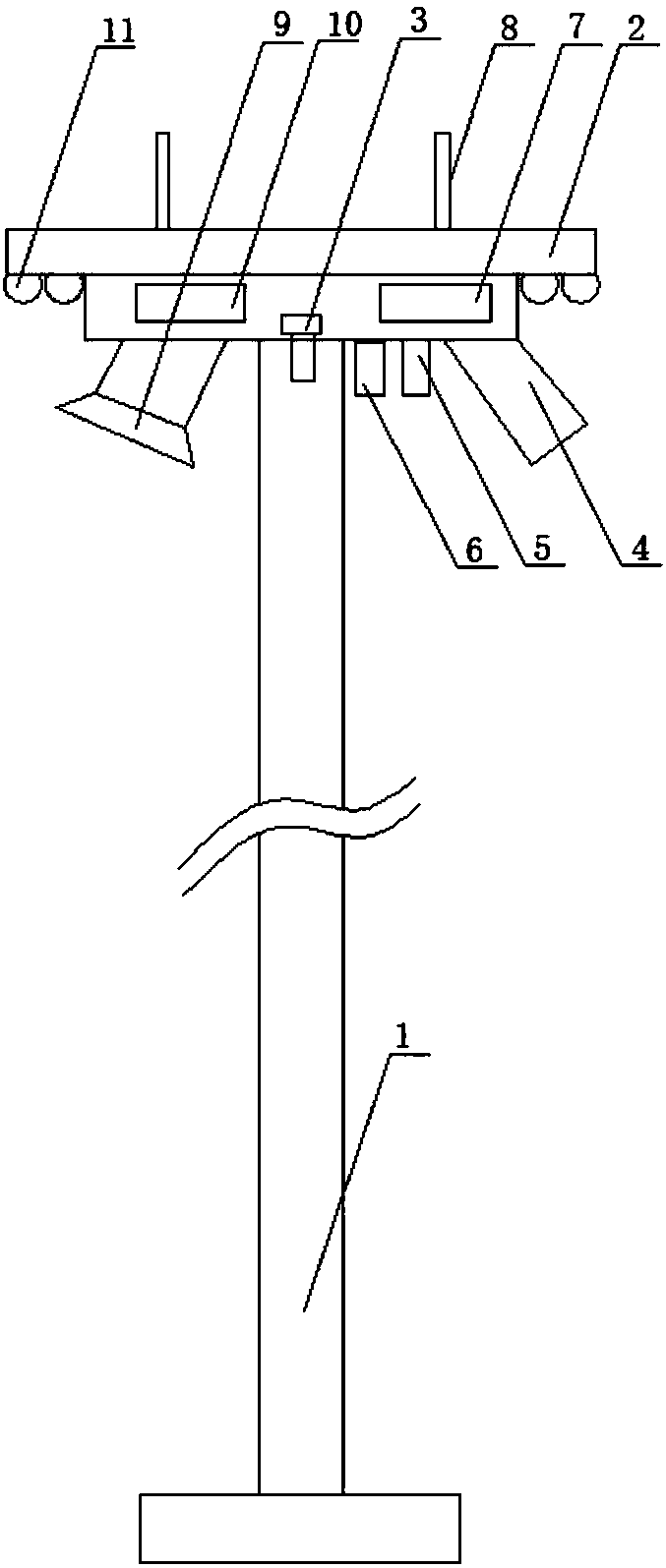

Construction site intelligent safety supervision system and control method thereof

ActiveCN107730428ARealize security monitoringAvoid undocumented jobsData processing applicationsAlarmsInternet networkComputer terminal

The invention provides a construction site intelligent safety supervision system and a control method thereof. The system comprises a site access control device, a safety fence device, a device control terminal, a smart tower and a remote server, wherein the intelligent tower is used for realizing construction site panoramic view monitoring, construction on-site sound collection, odor collection,on-site lighting and voice broadcast and realizing sound-light alarm under abnormal circumstances, and the remote server is in communication connection with the intelligent tower, the safety supervision terminal and an intelligent reporting terminal through a mobile communication network and transmits corresponding data to a safety supervision management center through an Internet network. With the construction site intelligent safety supervision system and the control method thereof of the invention, the image information and environmental information of a construction site can be acquired inreal time; the unified control of construction workers and construction equipment can be realized; auxiliary lighting can be realized; alarm prompts can be given out when an abnormal condition occurs, and the abnormal condition is reported to the a safety monitoring management department; and actual all-round and no-dead-corner safety supervision can be realized.

Owner:浙江龙腾畅想软件有限公司

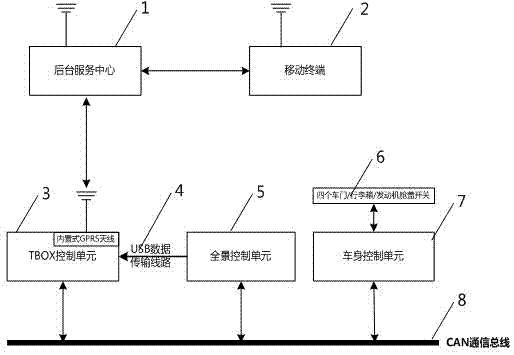

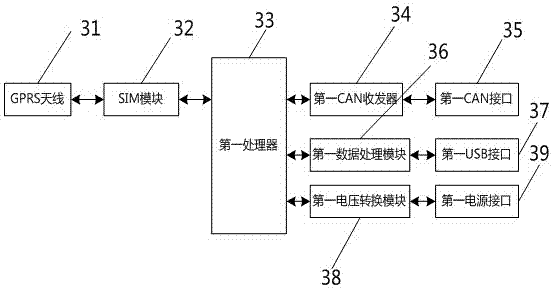

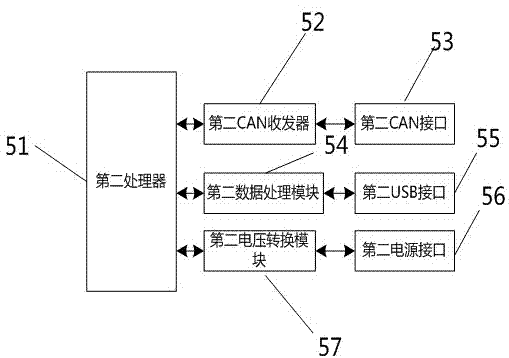

System for remotely monitoring surrounding condition of vehicle and method thereof

ActiveCN104331003AEasy to masterAvoid unexpected situationsProgramme controlComputer controlControl cellData transmission

The invention discloses a system for remotely monitoring the surrounding condition of a vehicle and a method thereof. The system comprises a mobile terminal, a background service center, a TBOX control unit, a panoramic video-shooting control unit and a vehicle body control unit. The TBOX control unit, the panoramic video-shooting control unit and the vehicle body control unit communicate with each other via a CAN bus. The panoramic video-shooting control unit is also connected with the TBOX control unit via a USB data transmission line. The TBOX control unit communicates with the background service center via a wireless network. The background service center communicates with the mobile terminal via the wireless network. After the vehicle shuts down and powers off, the vehicle condition can be actively checked by a user remotely. When the unusual condition of the vehicle is monitored, the vehicle condition can be actively sent to the user.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

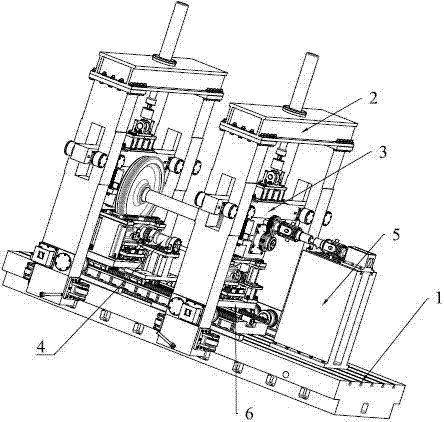

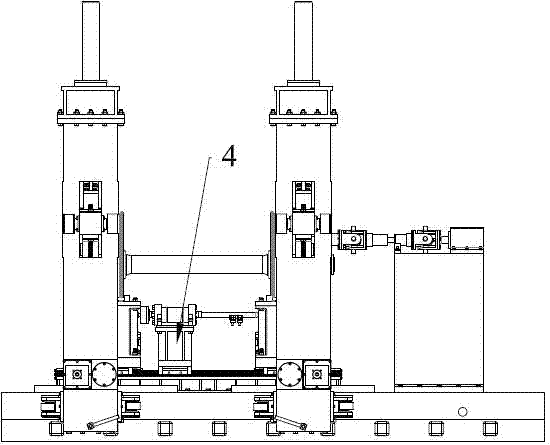

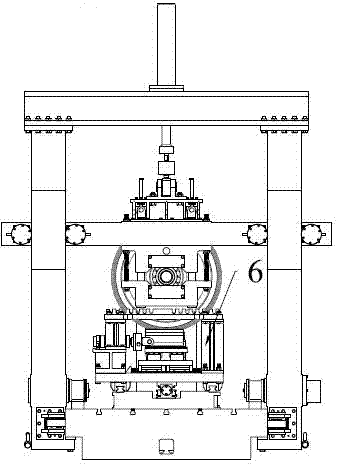

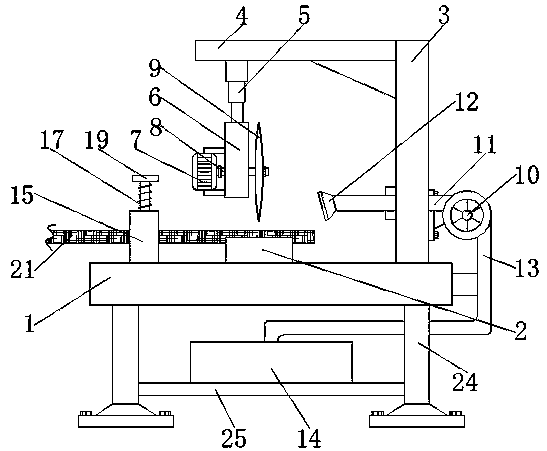

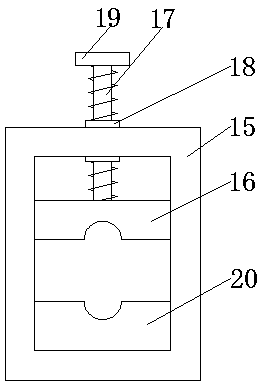

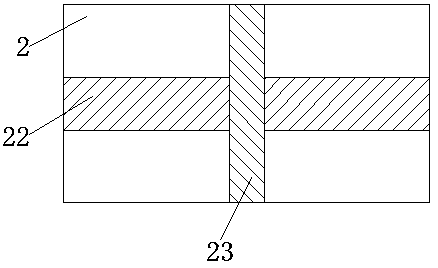

Force measurement wheel set calibration test stand

ActiveCN103759885AEasy to operateHigh precisionForce/torque/work measurement apparatus calibration/testingTransverse forceEngineering

A force measurement wheel set calibration test stand comprises a T-shaped stand base, portal systems and a transverse loading system. The force measurement wheel set calibration test stand is characterized in that perpendicular guide systems are installed on the portal systems and used for fixing a wheel set and achieving perpendicular loading; a bottom plate system is arranged at the position, below two portal top beams of the two portal systems, of the T-shaped stand base and used for adjusting track gauge, provides a platform for applying longitudinal force and transversely limiting the wheel set; a wheel set rotating indexing system is arranged at one end of the T-shaped stand base and used for achieving loading of any automatic rotating angle of the wheel set. According to the force measurement wheel set calibration test stand, perpendicular force and transverse force are independently loaded on the wheel set, and combined loading of loads in three directions can also be conducted on the wheel set; the force measurement wheel set calibration test stand has the wide track gauge calibration capacity, and meets the requirement for calibrating force measurement wheel sets of railway vehicles with the meter gauge, railway vehicles with the standard track gauge, railway vehicles with the wide gauge and other different railway vehicles; the force measurement wheel set calibration test stand has the capacity for adjusting lateral moving amount of wheel track contact points, and provides required perpendicular, transverse and longitudinal loads in a hydraulic loading mode.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

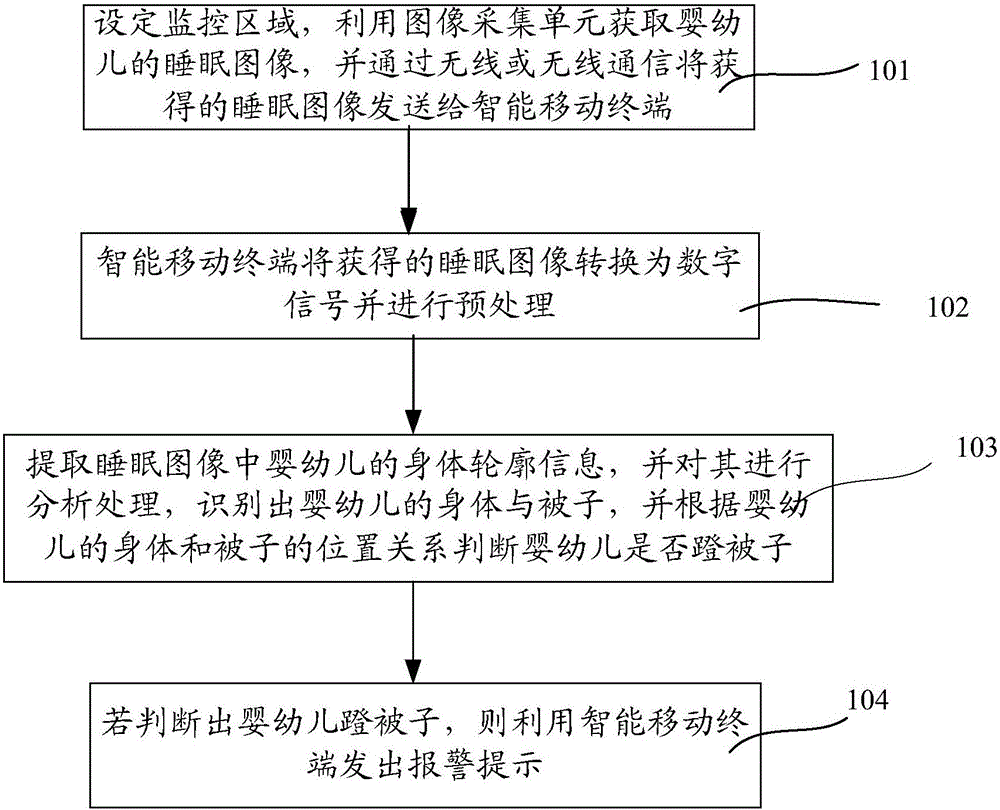

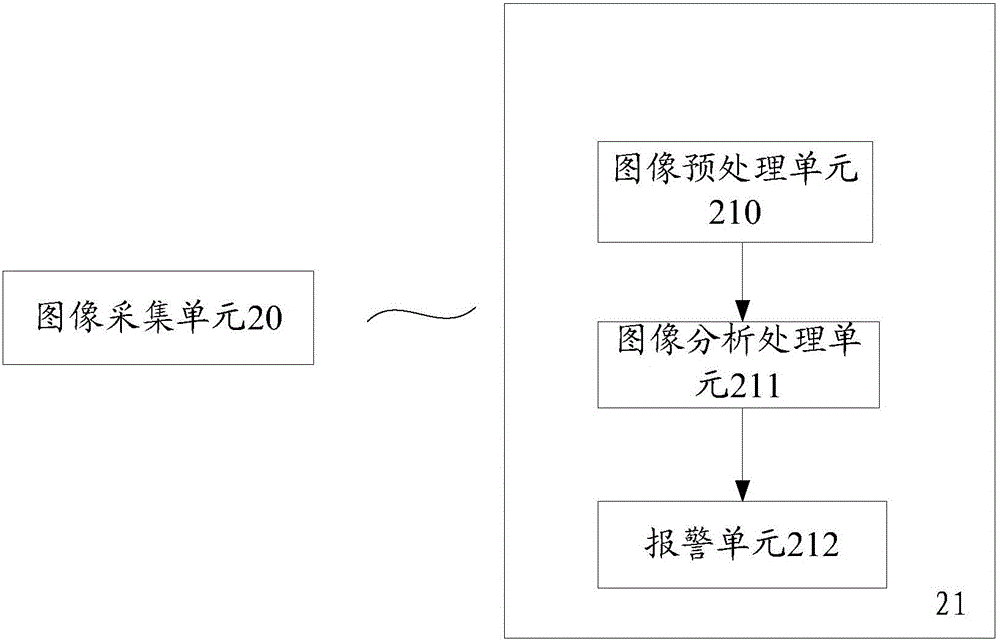

Monitoring and alerting method and system based on child's sleep state

InactiveCN105096527AAvoid unexpected situationsAlarmsAcquiring/recognising facial featuresSleep stateEmergency medicine

The invention discloses a monitoring and alerting method and system based on child's sleep state. The method comprises the following steps: setting a monitoring area, using an image acquisition unit to obtain sleep images of an infant, and sending the sleep images obtained to a smart mobile terminal via radio or wireless communication; the smart mobile terminal converting the sleep images obtained to digital signals and conduct preprocessing on the digital signals; extracting body profile information of the infant from the sleep images, and analyzing and processing the body profile information, identifying the body of the infant and a quilt, and based on the relative positions of the body of the infant and the quilt, determining whether the infant has pushed the quilt. If the infant has pushed the quilt, an alarming alter is sent from the smart mobile terminal. According to the invention, the embodiments can send alert about the abnormity of the child's sleep state in time and prevent occurrence of incidents during child's sleeping.

Owner:SHANGHAI DROI TECH CO LTD

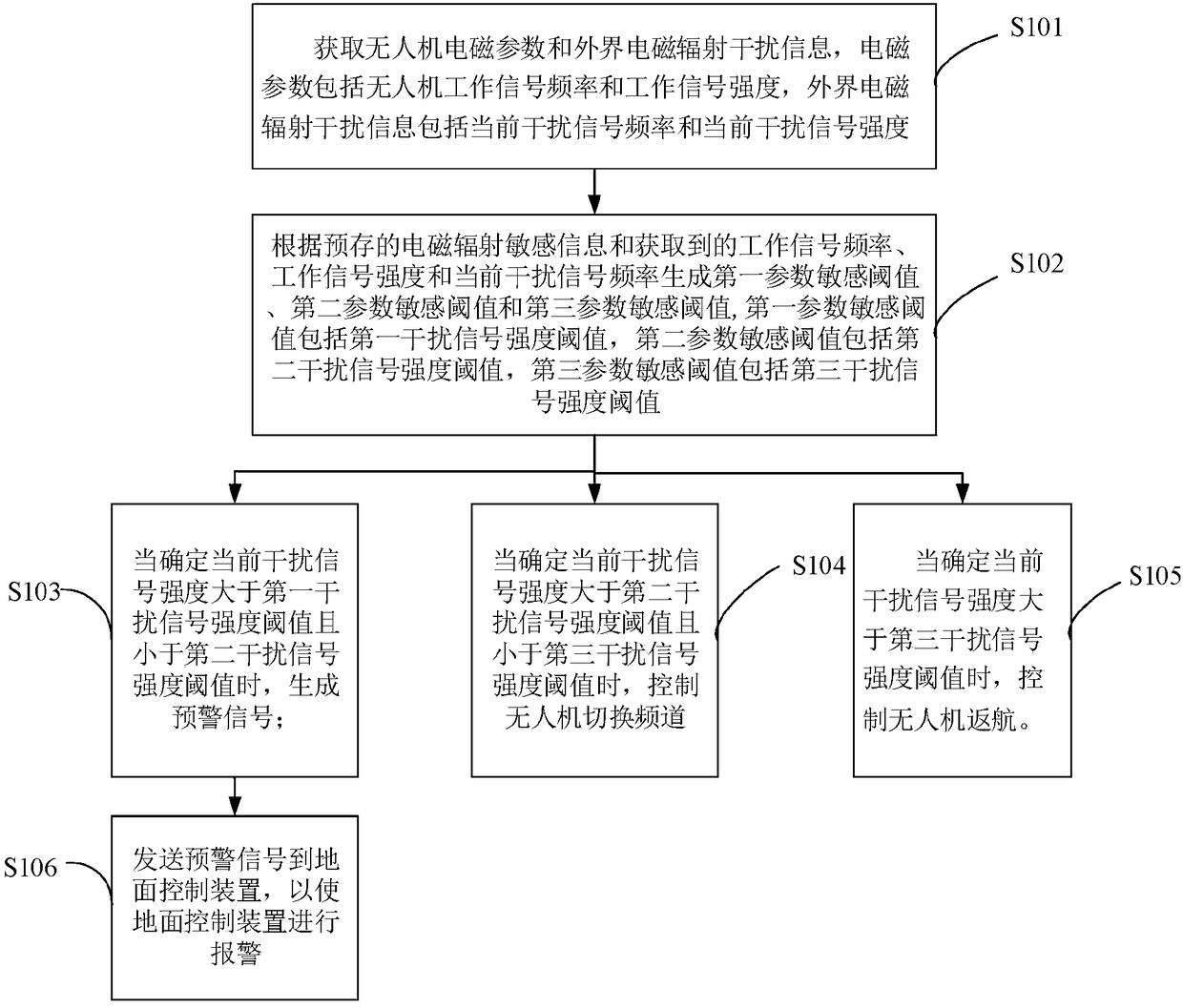

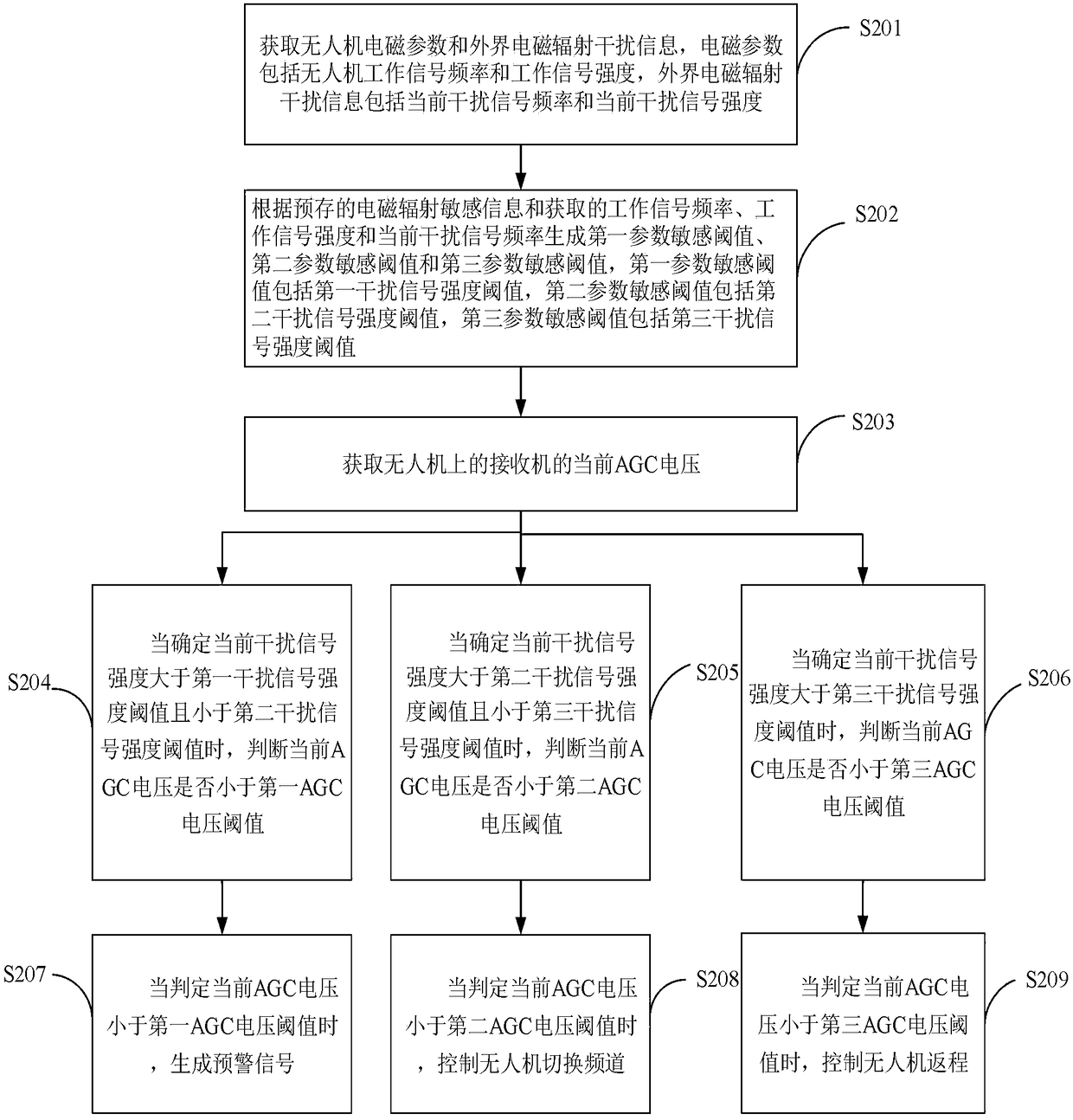

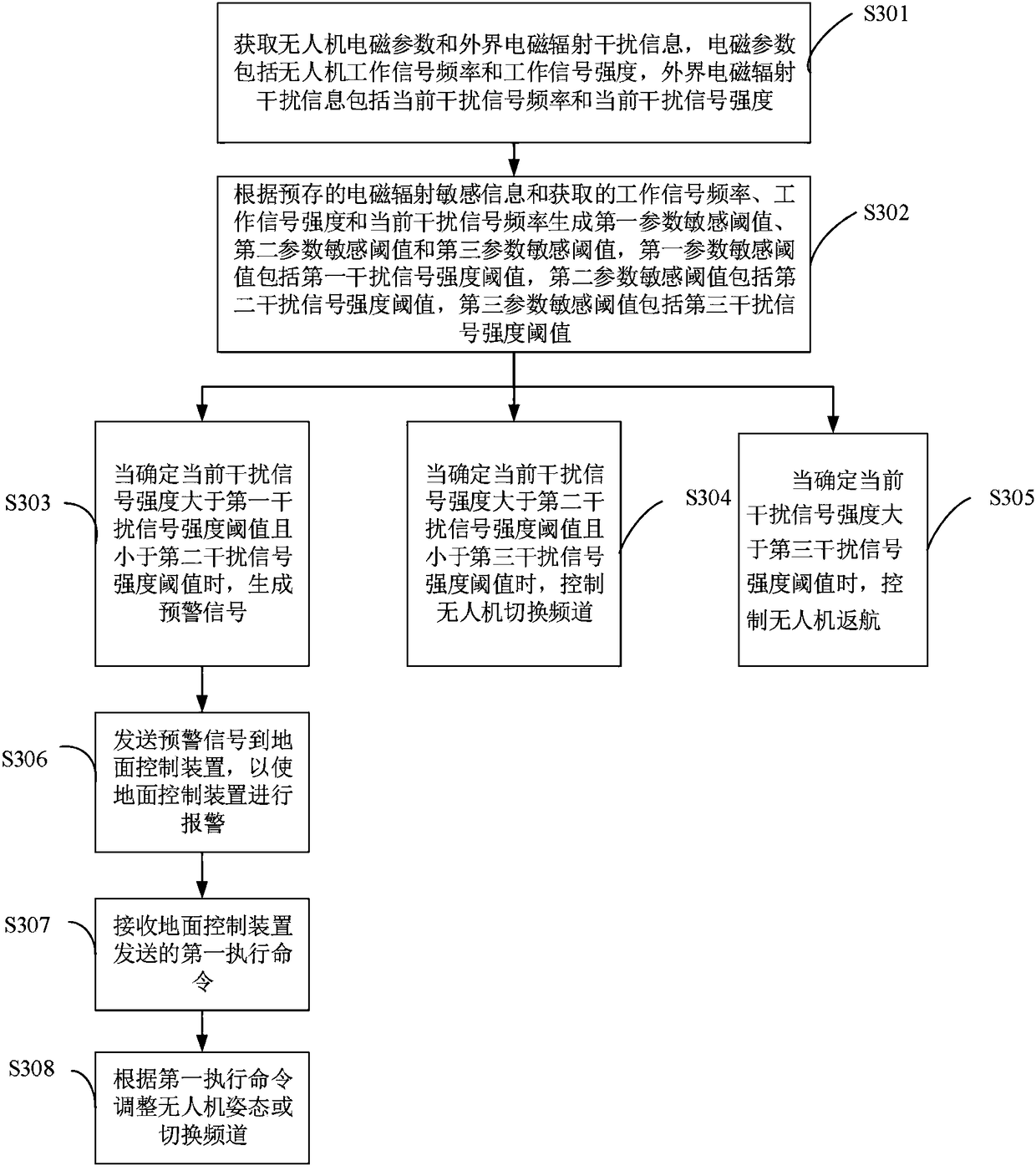

Electromagnetic radiation interference resisting method and device for information link of unmanned aerial vehicle

ActiveCN108153321AReduce the degree of impactAvoid unexpected situationsAttitude controlPosition/course control in three dimensionsElectromagnetic interferenceContinuous wave

The invention provides an electromagnetic radiation interference resisting method and device for an information link of an unmanned aerial vehicle. The electromagnetic radiation interference resistingmethod comprises the steps that unmanned aerial vehicle electromagnetic parameters and external electromagnetic radiation interference information are obtained, and a first parameter sensitive threshold, a second parameter sensitive threshold and a third parameter sensitive threshold are generated according to electromagnetic radiation sensitive information; an early warning signal is generated if the current interference signal intensity is greater than a first interference signal intensity threshold and less than a second interference signal intensity threshold; the unmanned aerial vehicleautomatically switches the channel if the current interference signal intensity is greater than the second interference signal intensity threshold and less than a third interference signal intensity threshold; and the unmanned aerial vehicle automatically executes a return instruction if the current interference signal intensity is greater than the third interference signal intensity threshold. According to the invention, the unmanned aerial vehicle can be avoided from being trapped in a strong electromagnetic interference area suddenly or having a sudden unexpected situation, the electromagnetic threat perception ability of the unmanned aerial vehicle is improved, the degree of influences imposed on unmanned aerial vehicle equipment by external continuous wave in-band electromagnetic radiation interference is reduced, and the intelligent development level of the equipment is improved.

Owner:ARMY ENG UNIV OF PLA

Capsule and battery containing the same

InactiveCN101471434AResponse to pressure release is sensitiveAvoid unexpected situationsSecondary cellsCell component detailsPositive currentCurrent collector

The invention provides a capsule, which comprises a shell and a material in the shell, wherein the shell is made of a incombustible material with a melting point of 100 to 130 DEG C and capable of stably existing in the a battery electrolyte; and the gasification temperature of the material in the shell is lower than the melting point of the shell, and can generate a fire retardant gas when being gasified. The invention also provides a battery, which comprises an electrode core, an electrolyte and a battery shell, which the electrode core and the electrolyte are arranged in the battery shell; the electrode core includes a positive electrode, a negative electrode and a diaphragm between the positive electrode and the negative electrode; the positive electrode contains a positive current collector and a negative active material attached on the positive current collector; and the negative electrode includes a negative current collector and a negative active material attached on the negative current collector. The battery also includes the capsule provided in the invention, wherein the capsule is arranged in the battery shell. An anti-explosion hole of the battery having the capsule can be opened to respond to the melting temperature of the capsule shell material to achieve more sensitive battery discharge response.

Owner:BYD CO LTD

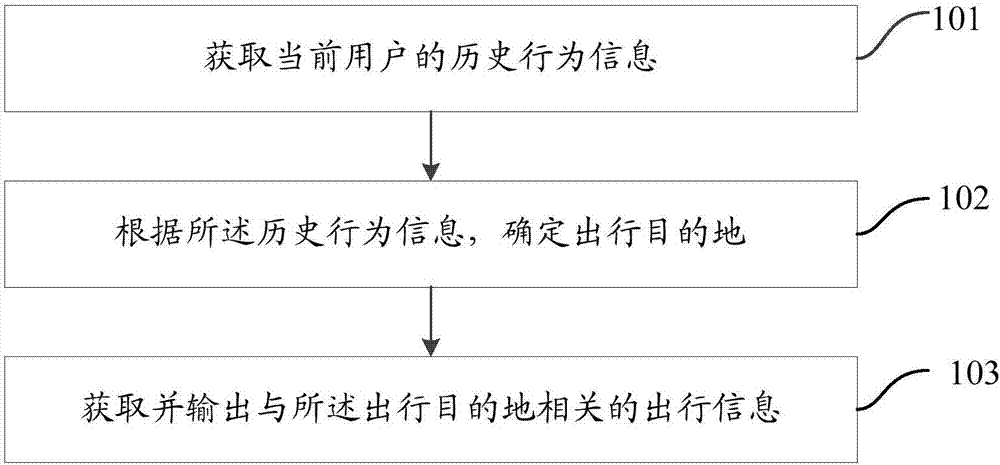

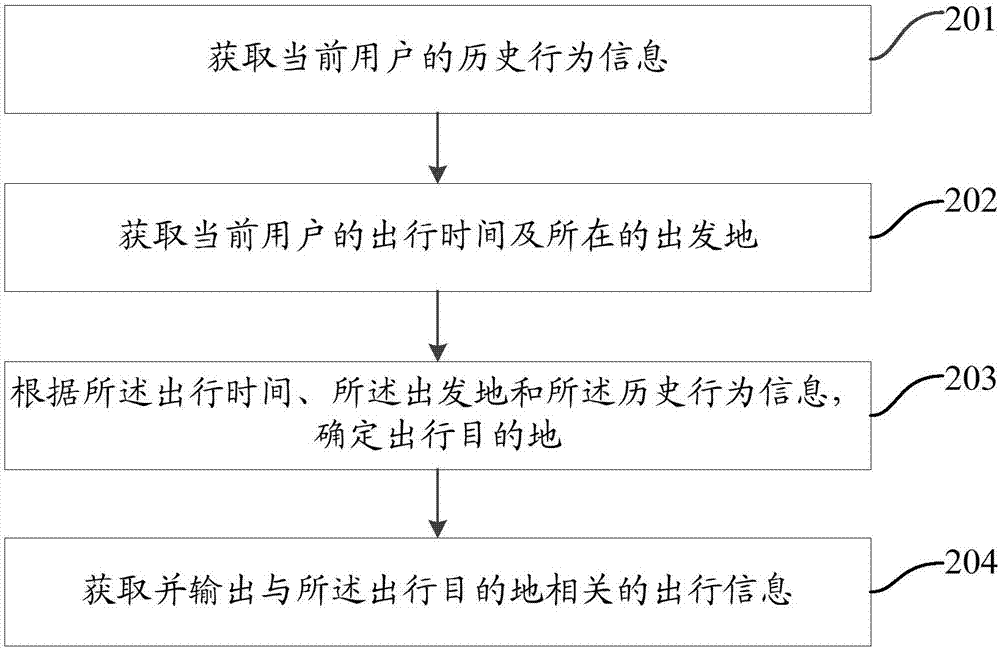

Travel information prompting method and mobile terminal

ActiveCN107230046AReduce cumbersome operationsRealize timely reminderOffice automationSpecial data processing applicationsReal-time computingCurrent user

The invention provides a travel information prompting method and a mobile terminal. The travel information prompting method comprises the steps of: acquiring historical behavior information of a current user; determining a travel destination according to the historical behavior information; and acquiring and outputting travel information associated with the travel destination. The travel information prompting method is used for determining the travel destination according to the historical behavior information of the user, and further outputting the travel information associated with the travel destination and used for prompting the user, is simple in operation, and omits the tedious operation of querying relates issues when the user travels, so that the user can travel in a more intelligent manner, and the timely prompt for the user can be realized, so as to avoid the user from encountering unexpected circumstances.

Owner:VIVO MOBILE COMM CO LTD

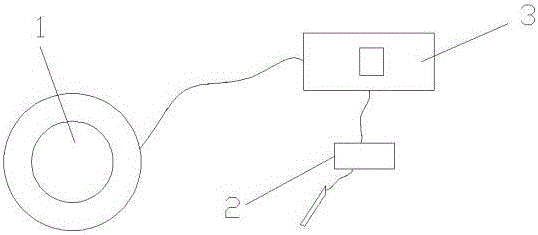

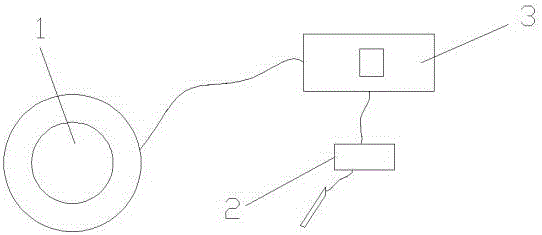

Method for determining firmness degree of pine tree by detection equipment

The invention discloses a method for determining the firmness degree of a pine tree by detection equipment. The measuring equipment consists of a radar, a soil compaction determinator and a control instrument, and the radar and the soil compaction determinator are connected to the control instrument. According to the method, the control instrument sends an instruction of discriminating the stability of the pine tree to a detection device, the radar in the measuring equipment detects the pine tree root distribution width, the vertical root depth, the pine tree height and the diameter of the pine tree trunk, the soil compaction determinator measures the soil compaction degree, the radar and the soil compaction determinator transmit the measured data to the control instrument, the control instrument is internally provided with operation control program for discriminating the pine tree safety performance, receives data, performs data analysis and processing, and outputs the determination result to a display screen of the controller. By determining the stability of the pine tree, tipping of the pine tree can be effectively prevented, also personal safety and property of people can be protected without loss, and accidents can be avoided.

Owner:XINING GONGJIN NEW MATERIAL TECHNOLOGY CO LTD

Method for detecting cedar wind-resistant stability

ActiveCN106198879AHigh general heightGuaranteed reliabilityEarth material testingTesting plants/treesSoil scienceSoil compaction

The invention discloses a method for detecting cedar wind-resistant stability. A measuring device comprises a radar, a soil compaction tester and a controller, wherein the radar and the soil compaction tester are connected with the controller. The method includes the steps: transmitting an instruction distinguishing cedar stability to a detection device by the controller; detecting the distribution breadth of a cedar root system, the vertical depth of a cedar root, the cedar height and the diameter of a cedar trunk by the radar in the measuring device; measuring soil compaction by the soil compaction tester; transmitting measured data to the controller by the radar and the soil compaction tester; setting operation control procedures distinguishing cedar safety in the controller; receiving the data, analyzing and processing the data, and outputting a detection result on a display screen of the controller. The cedar stability is detected, cedar tipping is effectively prevented, personal safety can be protected, properties cannot be lost, and accidents are avoided.

Owner:广东双木林科技有限公司

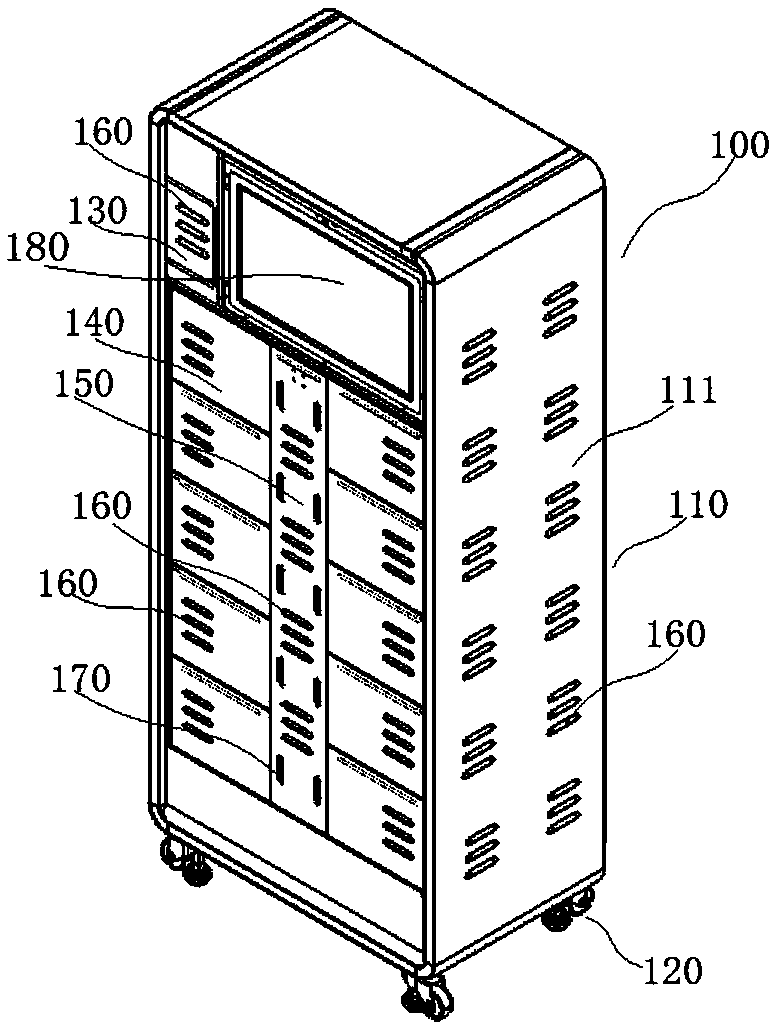

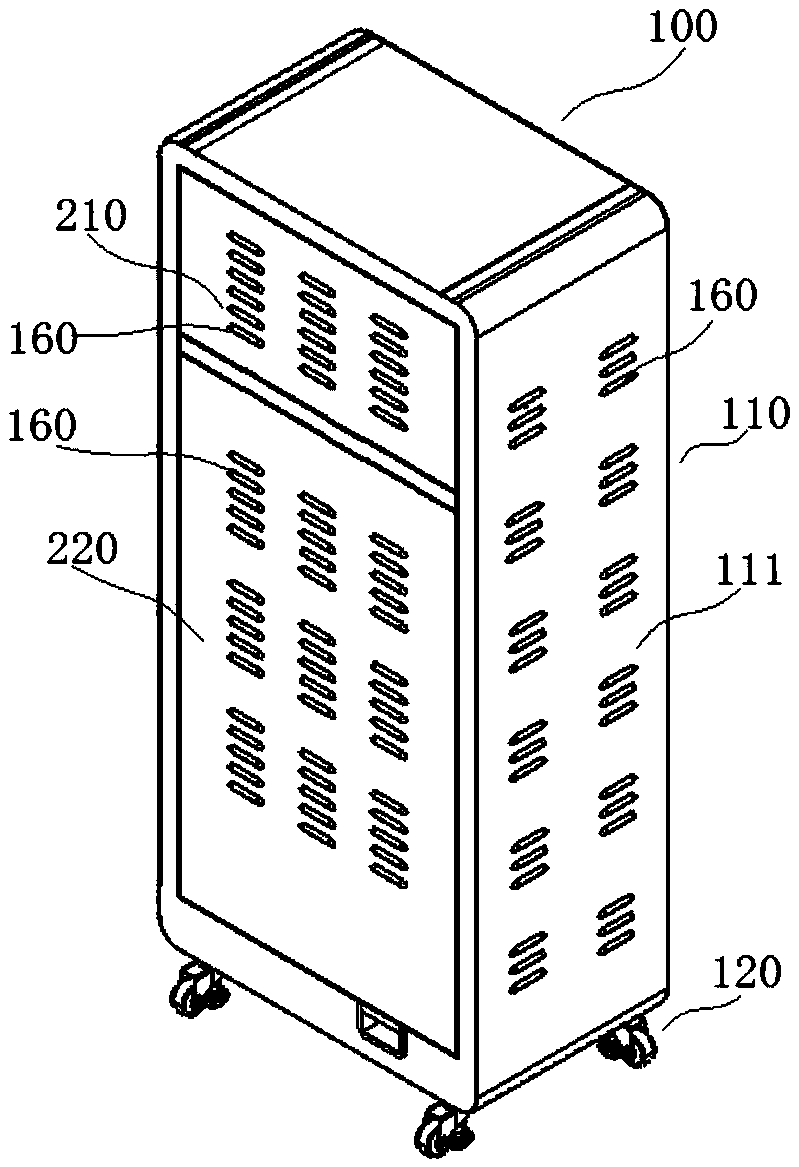

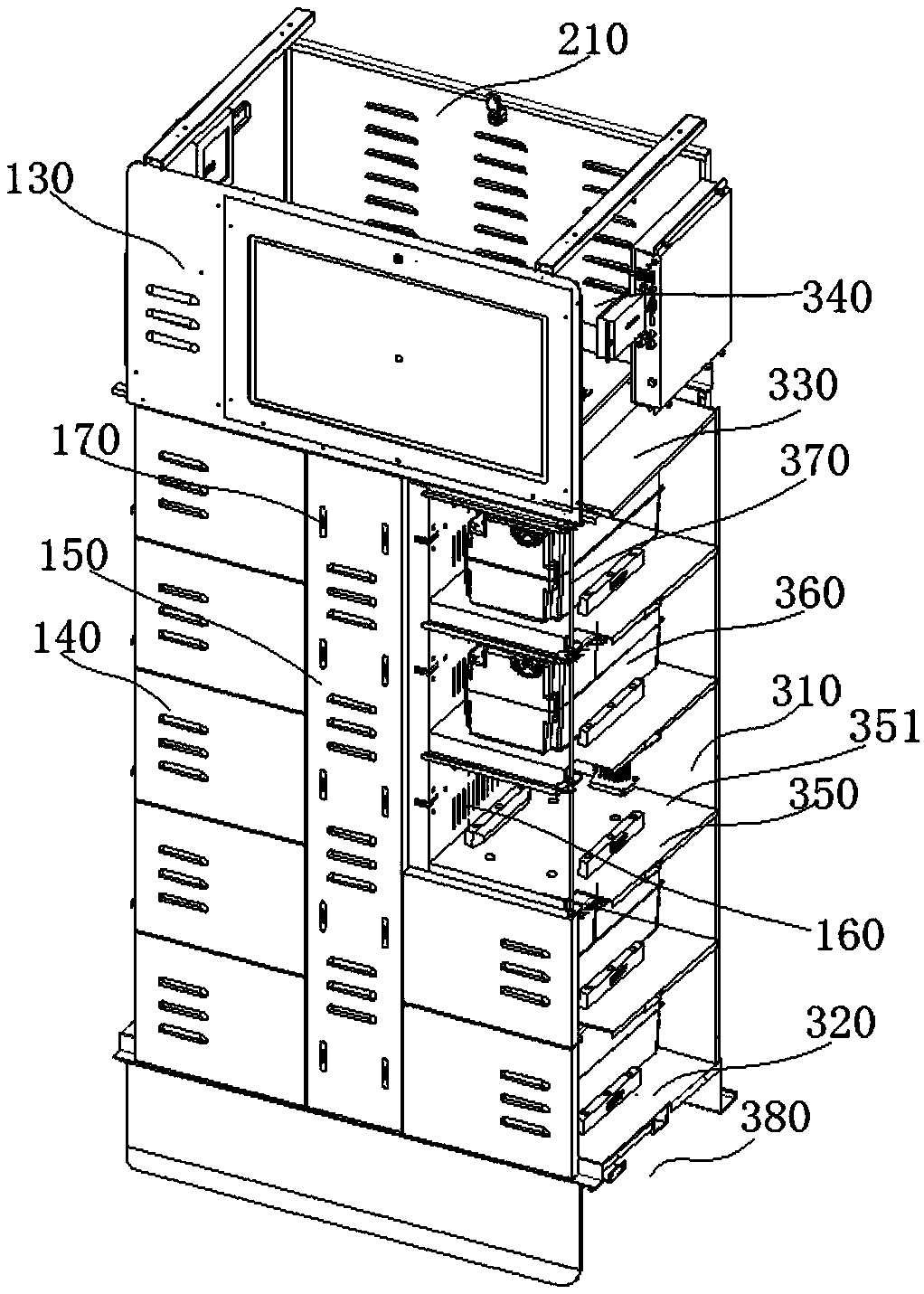

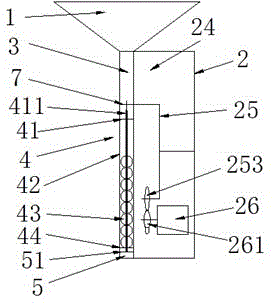

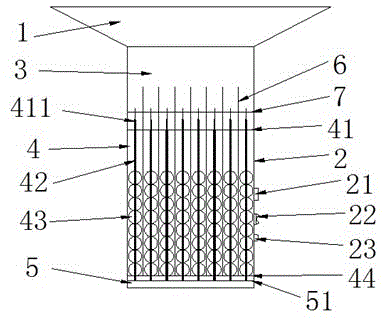

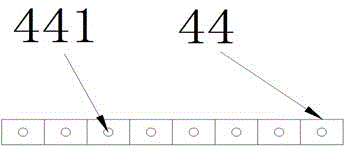

Charging cabinet, management system for charging cabinet and commercial application method thereof

PendingCN109677288AEasy to charge outdoorsOvercoming complexityCharging stationsSafety/protection battery circuitsSupply managementBattery charge

The invention relates to the technical field of battery charge, in particular to a charging cabinet, a management system for the charging cabinet and a commercial application method thereof. The charging cabinet comprises a cabinet body which comprises a cabinet main body. A plurality of independent charging cabins are arranged in the cabinet main body for placing a rechargeable battery. A power supply management device and a plurality of charging devices in one to one correspondence to the charging cabin are arranged in the cabinet main body. Each charging device comprises a charging interface corresponding to the charging cabin. The power supply management device is used for managing the charging devices which are used for charging the rechargeable battery through the charging interface.The management system can be applied to the charging cabinet better. The commercial application method is achieved based on the charging cabinet. The invention can provide equipment for charging an existing electric mobile outdoors better.

Owner:杭州宇谷科技股份有限公司

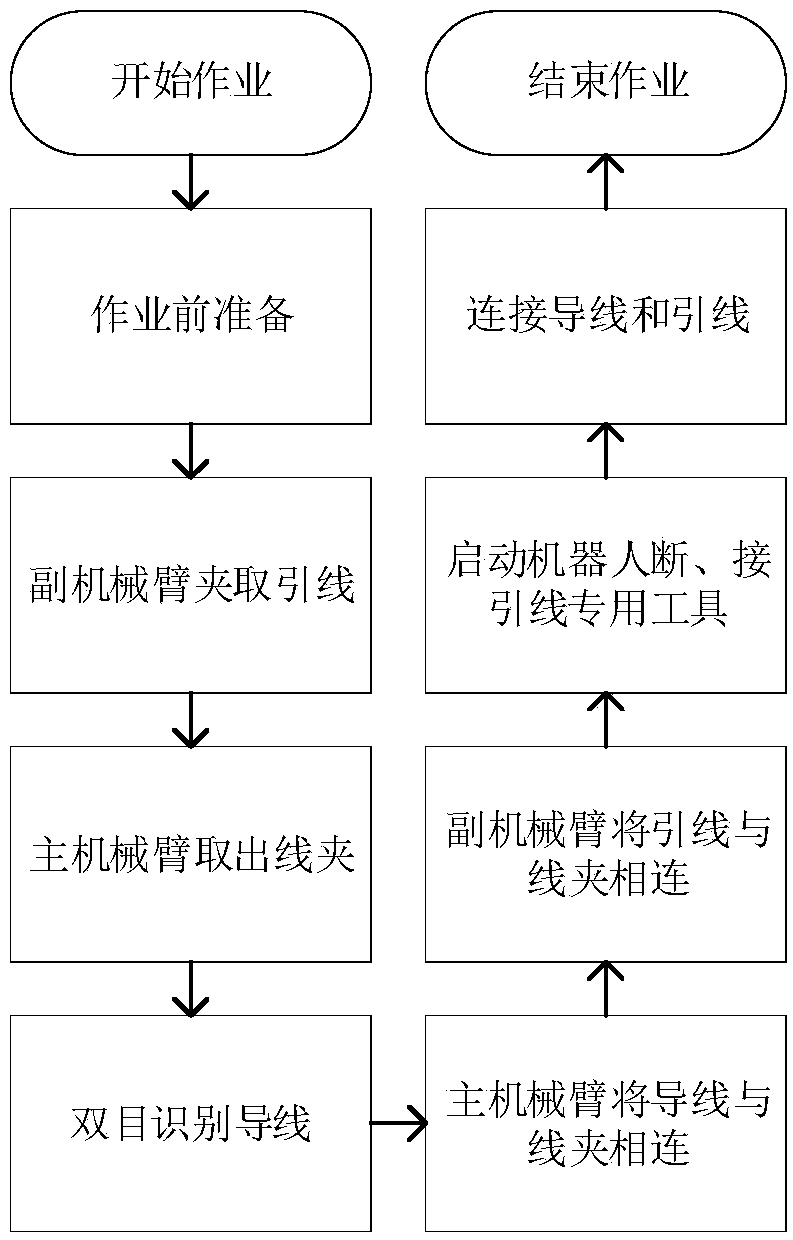

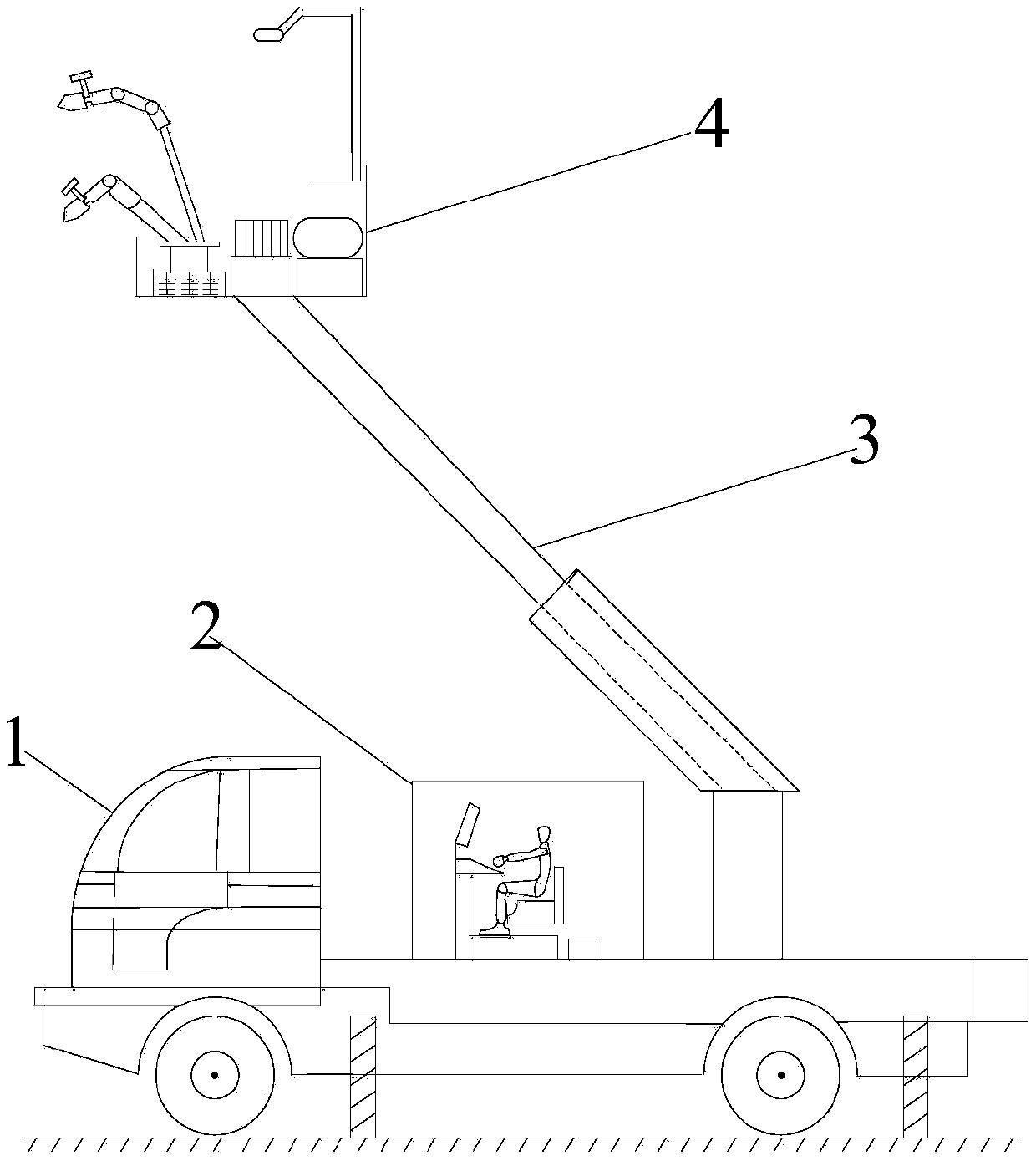

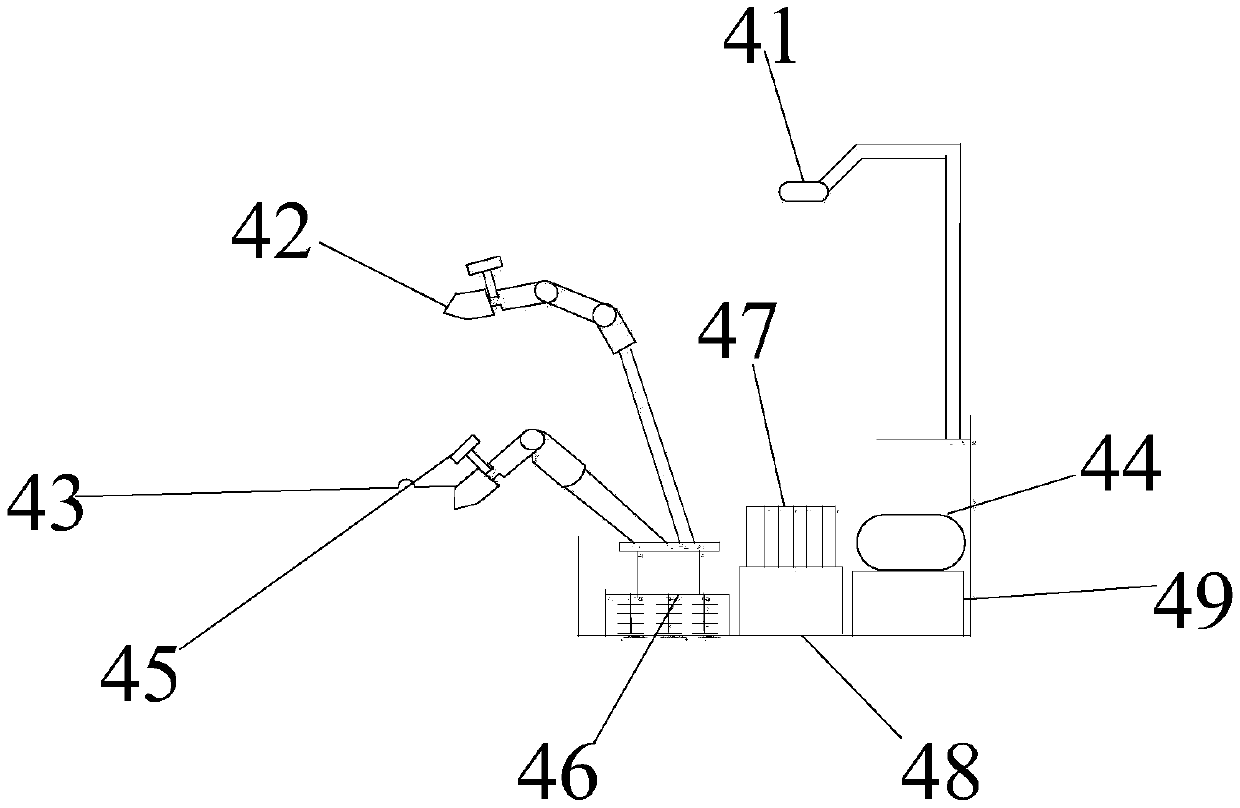

Lead wire connecting method for live working robot

ActiveCN108683050AAvoid negative effectsImprove power supply reliabilityLine/current collector detailsManipulatorWrenchToolbox

The invention provides a lead wire connecting method for a live working robot. On the basis of a main mechanical arm, an auxiliary mechanical arm and a camera collecting image data of a work scene ona robot platform, the mechanical arms are controlled by a control chamber to complete the following works: the auxiliary mechanical arm clamps a lead wire; the main mechanical arm takes out a wire clamp from a toolbox; the main mechanical arm hangs the wire clamp on the lead wire through a wire groove on one end of the wire clamp; the auxiliary mechanical arm threads the lead wire through a wire groove on the other end of the wire clamp; a pneumatic wrench at the end of the main mechanical arm aligns a nut on the wire clamp and screws the nut; and the main mechanical arm and the auxiliary mechanical arm release clamping jaws and withdraw. According to the method, the lead wire can be bridged on the lead wire through the mechanical arms of the live working robot under the condition of continuous power supply, and so negative influence caused by the power outage is avoided and the reliability of power supply is improved.

Owner:NANJING UNIV OF SCI & TECH

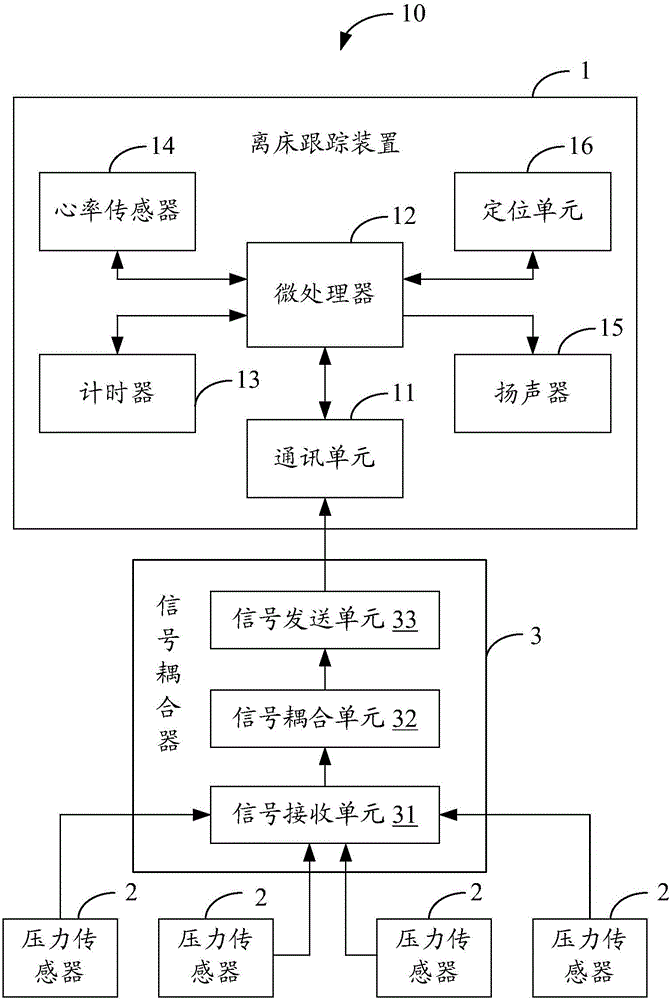

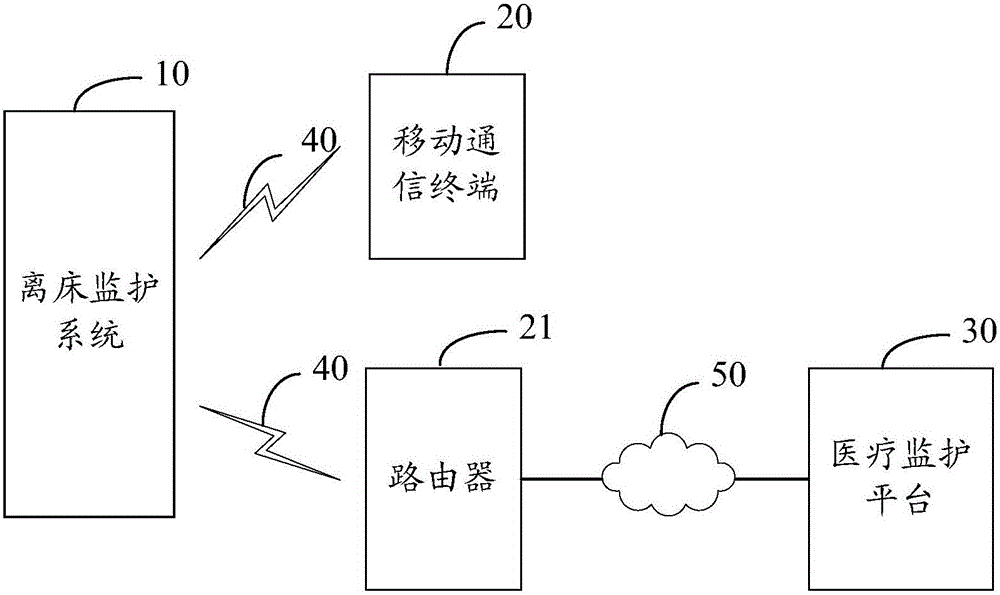

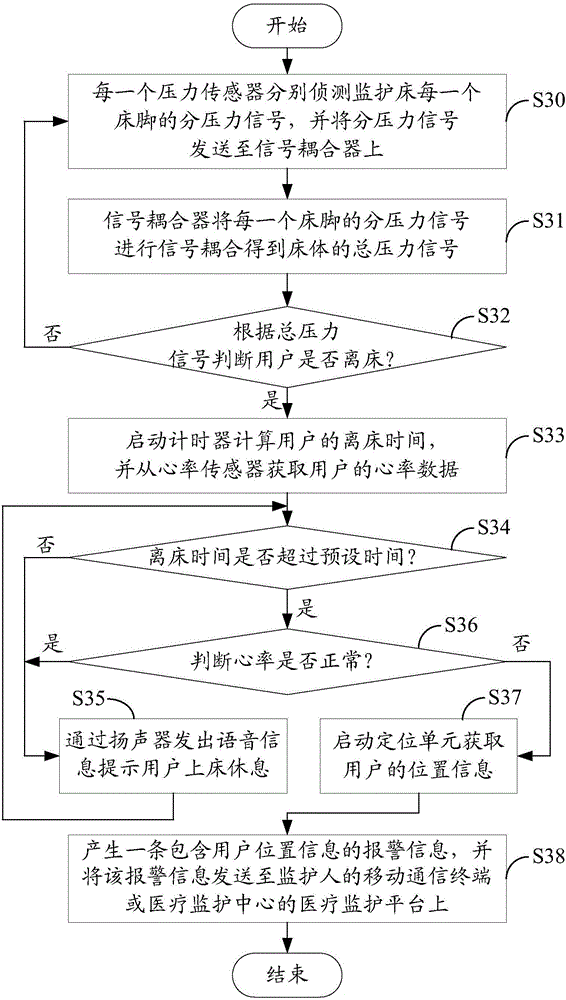

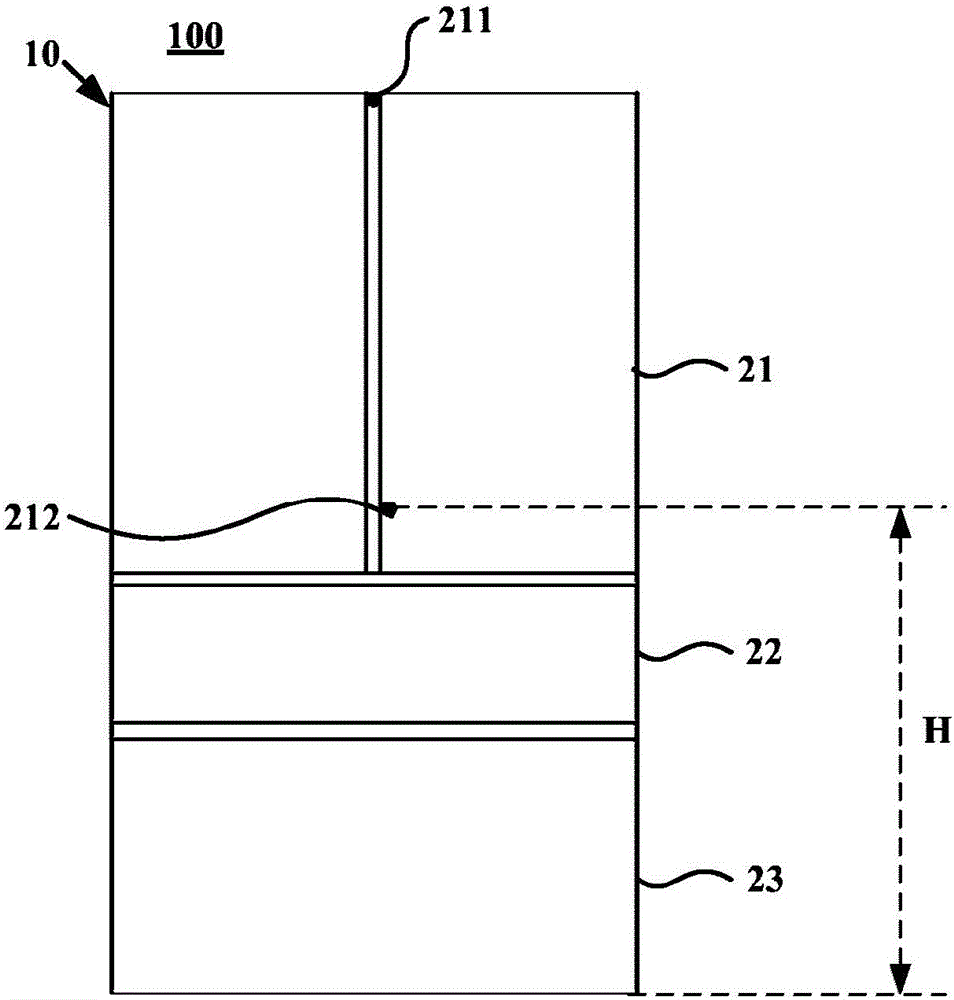

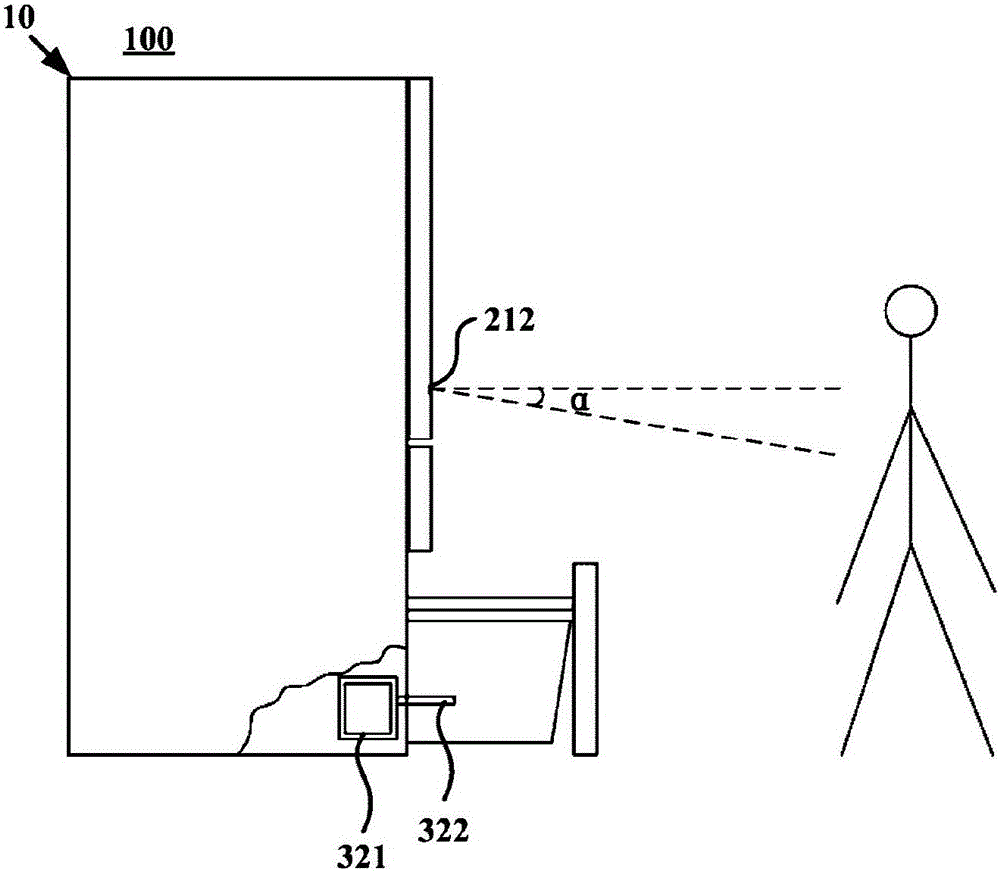

Off-bed monitoring system and method based on Internet of Things

InactiveCN105877759AReal-time monitoring of leaving the bedAvoid unexpected situationsSensorsMeasuring/recording heart/pulse rateInternet of ThingsEngineering

The invention discloses an off-bed monitoring system and method based on Internet of Things, and the system and the method are applied to a monitoring bed. The off-bed monitoring system comprises an off-bed tracking device, one or more pressure sensors and a signal coupler. Each pressure sensor measures a partial pressure signal of one bed leg of the monitoring bed and sends the partial pressure signal of each bed leg to the signal coupler; the signal coupler couples the partial pressure signal of all the bed legs to obtain a total pressure signal of a bed body and sends the total pressure signal of the bed body to the off-bed tracking device; the off-bed tracking device judges whether a user gets off the bed or not according to the total pressure signal of the bed body and gives an alarm to the abnormal conditions in the off-bed process of the user. The off-bed monitoring system can track and monitor off-bed conditions of the user in real time according to heart rate data of the user and gives an alarm according to the abnormal conditions in the off-bed process of the user to prevent unexpected incidents of the user due to the long time off-bed condition.

Owner:ANYCHECK INFORMATION TECH

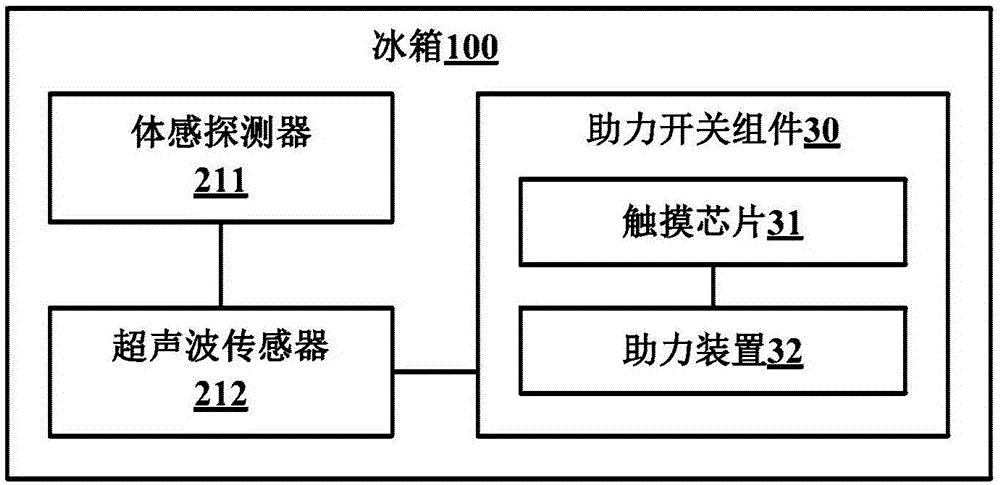

Opening method for refrigerator door body and refrigerator

InactiveCN105953519AAvoid interferenceSave electricityLighting and heating apparatusCooling fluid circulationRefrigerator carUltrasonic sensor

The invention provides an opening method for a refrigerator door body and a refrigerator. The refrigerator is provided with a somatosensory detector and an ultrasonic sensor which face towards the front area of the refrigerator. The opening method for the refrigerator door body comprises the steps that the front area of the refrigerator is detected through the somatosensory detector to judge whether a user appears in an area away from the refrigerator by a first preset distance; after the user appears in the area away from the refrigerator by the first preset distance, the ultrasonic sensor is started to obtain an ultrasonic signal reflected by the user, the sensing range of the ultrasonic sensor is configured to be an area away from the refrigerator by a second preset distance, and the second preset distance is smaller than the first preset distance; and after the ultrasonic signal is obtained, a power-assisted switch assembly of the refrigerator door body enters a work preparing state. According to the scheme, the situation that the refrigerator door body is automatically opened due to accidental touch can be effectively avoided, and the user experience in using is improved.

Owner:HAIER SMART HOME CO LTD

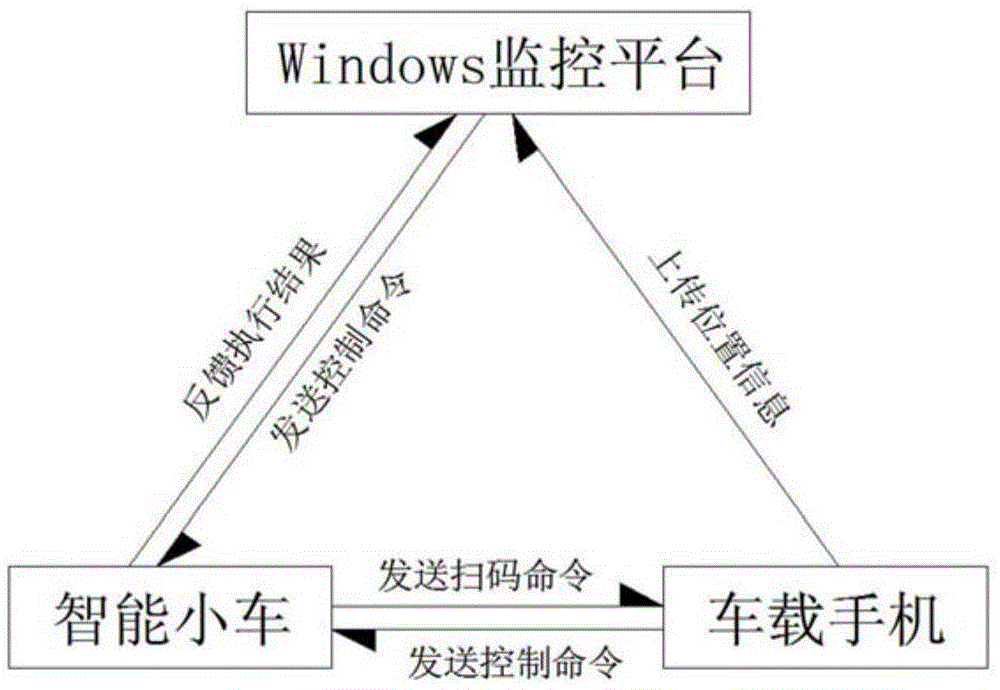

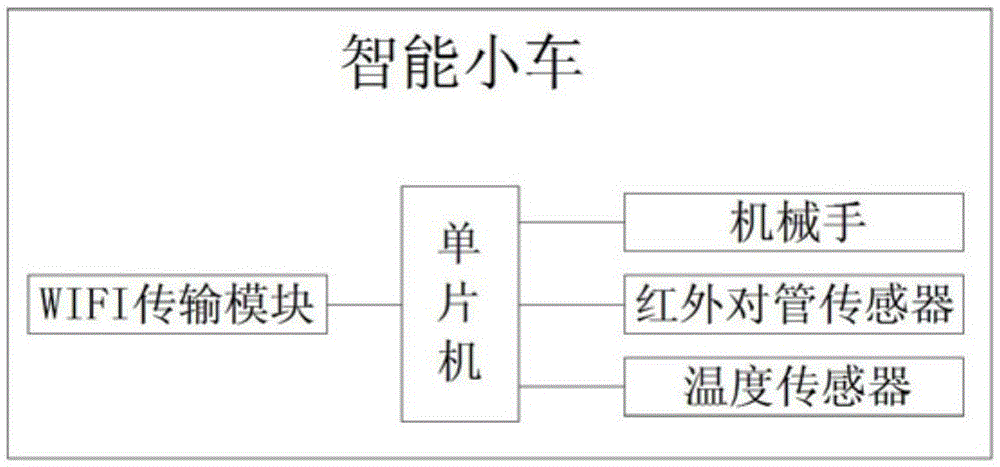

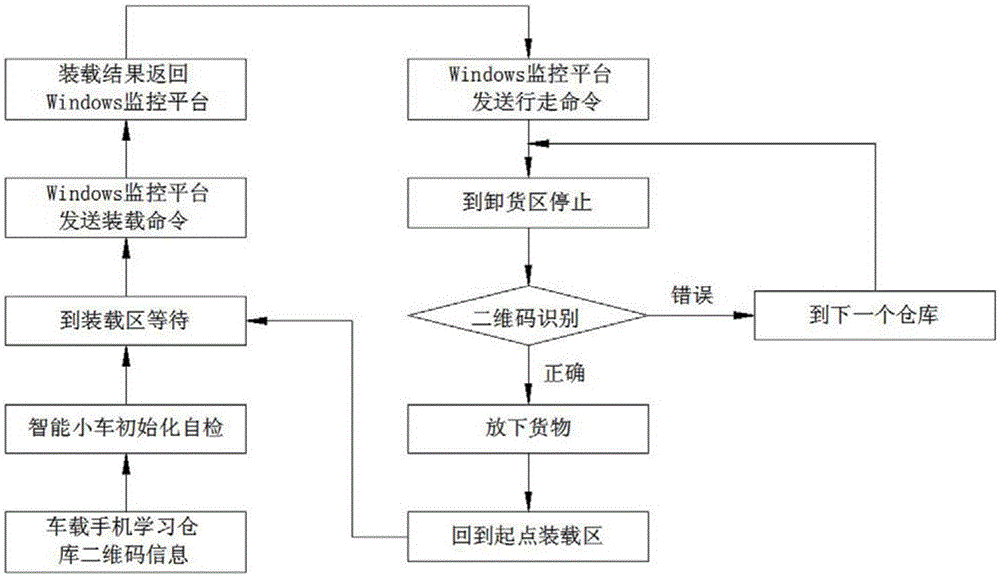

Two-dimensional code navigation based logistics delivery system and delivery method thereof

InactiveCN105574695ACoordinationAvoid unexpected situationsCo-operative working arrangementsLogisticsData transmissionCode navigation

The invention discloses a two-dimensional code navigation based logistics delivery system and a delivery method thereof. The logistics delivery system comprises an intelligent vehicle, a vehicle-mounted cellphone and a Windows monitoring platform which form a local area network and are communicated by using a WIFI technique, wherein duplex exchange data is carried out based on a TCP / IP communication protocol, the control of the intelligent vehicle adopts a singlechip, and the singlechip is communicated with the vehicle-mounted cellphone and the Windows monitoring platform through a WIFI transmission module. The logistics delivery system has the advantages that the three platforms of the vehicle-mounted platform, the singlechip and the Windows monitoring platform are integrated, cross-platform data transmission and intelligent vehicle control are perfectly fulfilled; a two-dimensional code technology is first used for storing positional information of the vehicle and controlling shipping of the vehicle, the positional information of the vehicle is rapidly recorded and also restored by 100%, and an important guarantee is provided for rapidly and accurately judging the position of the intelligent vehicle.

Owner:XIAN UNIV OF SCI & TECH

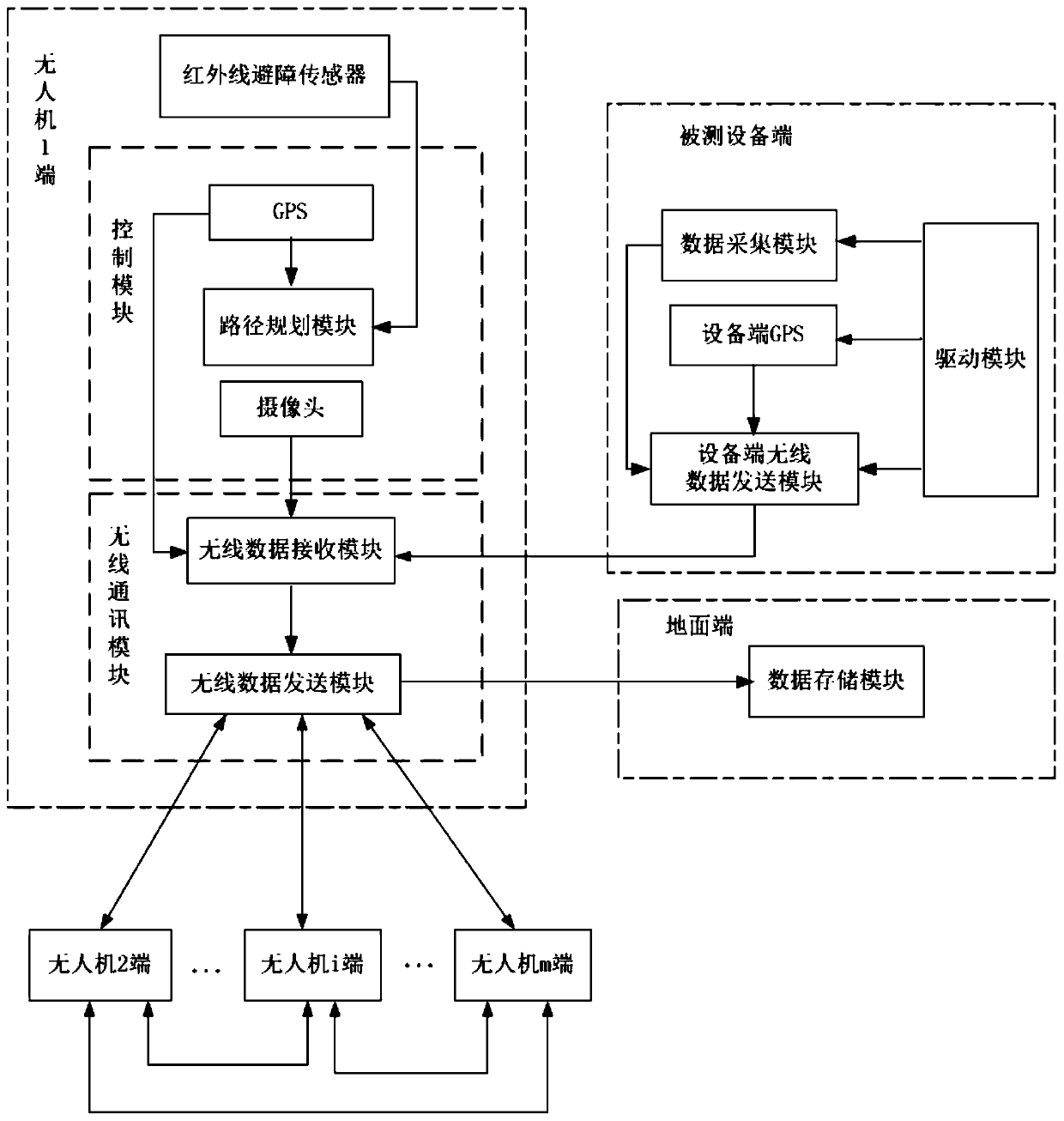

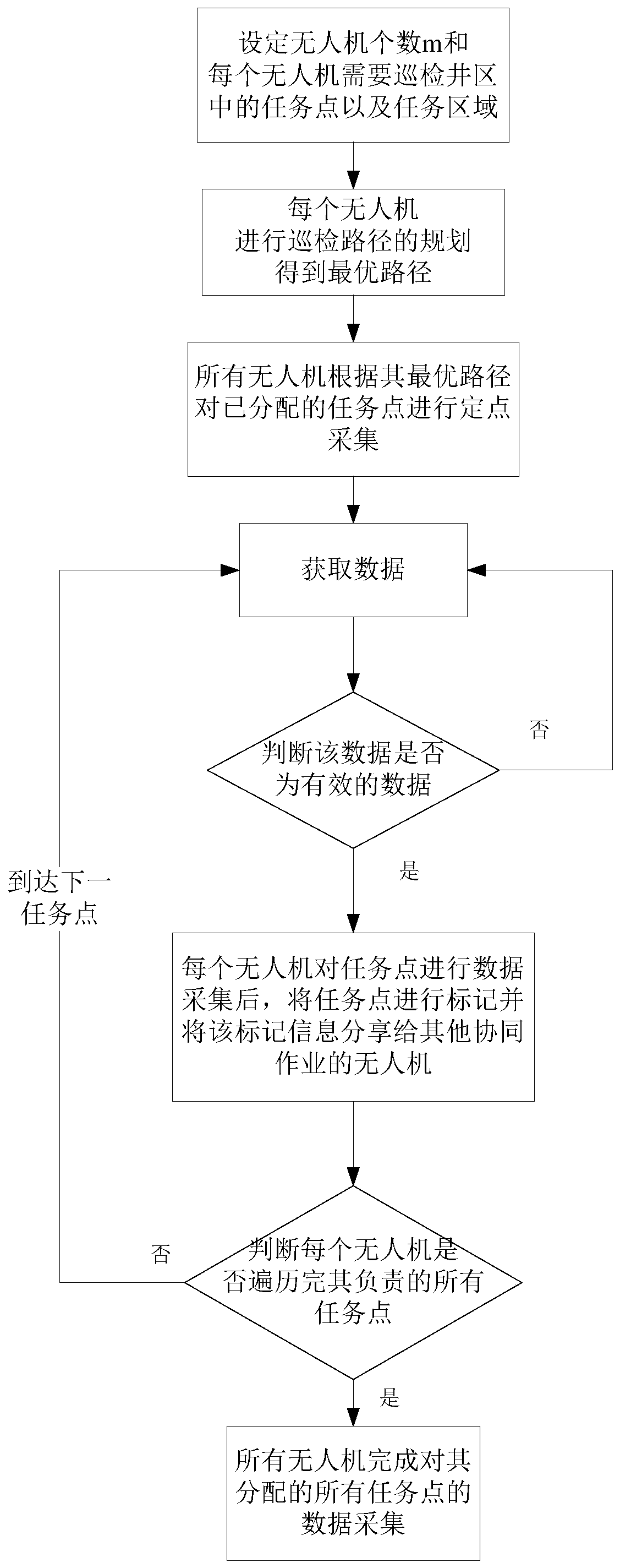

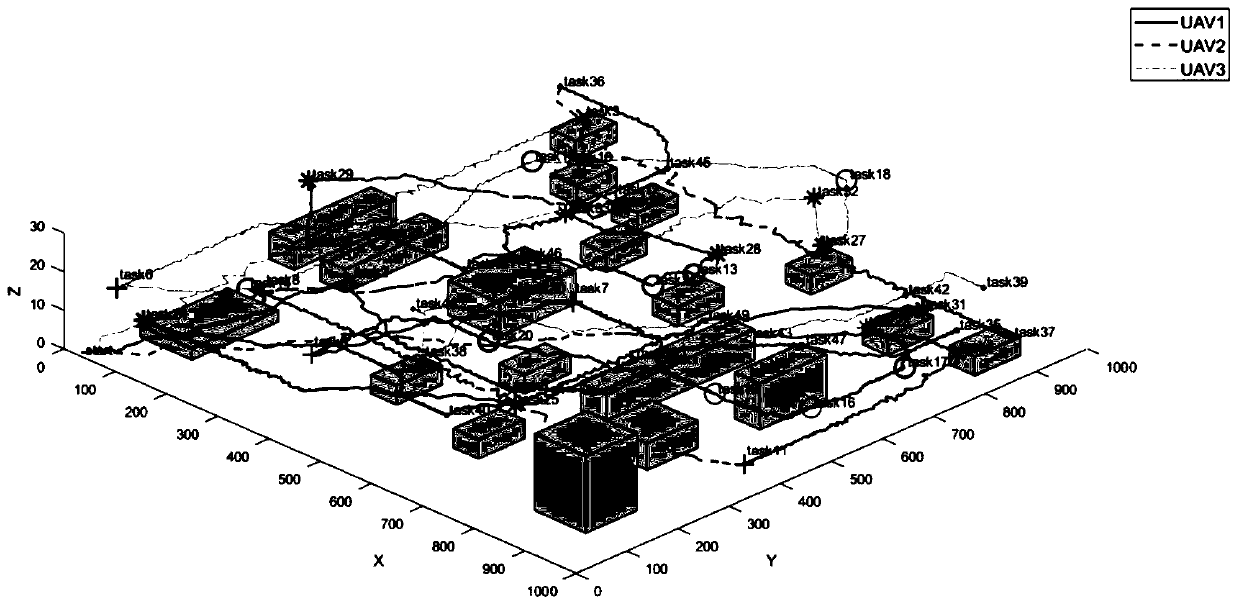

Oil field routing inspection fixed-point data acquisition system and method based on multiple unmanned aerial vehicles

InactiveCN110231833AIncrease flexibilityLow costNavigational calculation instrumentsParticular environment based servicesComplete dataData acquisition

The invention provides an oil field routing inspection fixed-point data acquisition system and method based on multiple unmanned aerial vehicles and relates to the technical field of oil field production. The method comprises the following steps: setting number m of unmanned aerial vehicles as well as task points and a task area in a well area needing to be subjected to routing inspection performed by each unmanned aerial vehicle, and performing routing inspection path planning by each unmanned aerial vehicle, thus obtaining an optimal path; performing fixed-point acquisition on distributed task points by all the unmanned aerial vehicles according to respective optimal paths; acquiring data and judging whether the data is valid data or not, acquiring the data again if the data is invalid,if the data is valid, after each unmanned aerial vehicle performs data acquisition on the task points, marking the task points and sharing the marked information to other unmanned aerial vehicles in collaborative operation, judging whether each unmanned aerial vehicle traverses all the set task points, if yes, marking the task points and sharing the marked information until all the unmanned aerialvehicles complete data acquisition on all the distributed task points, and if not, arriving at the next task point by each unmanned aerial vehicle for acquiring data. The system and method provided by the invention can improve oil field routing inspection efficiency and oil production security and management.

Owner:BOHAI UNIV

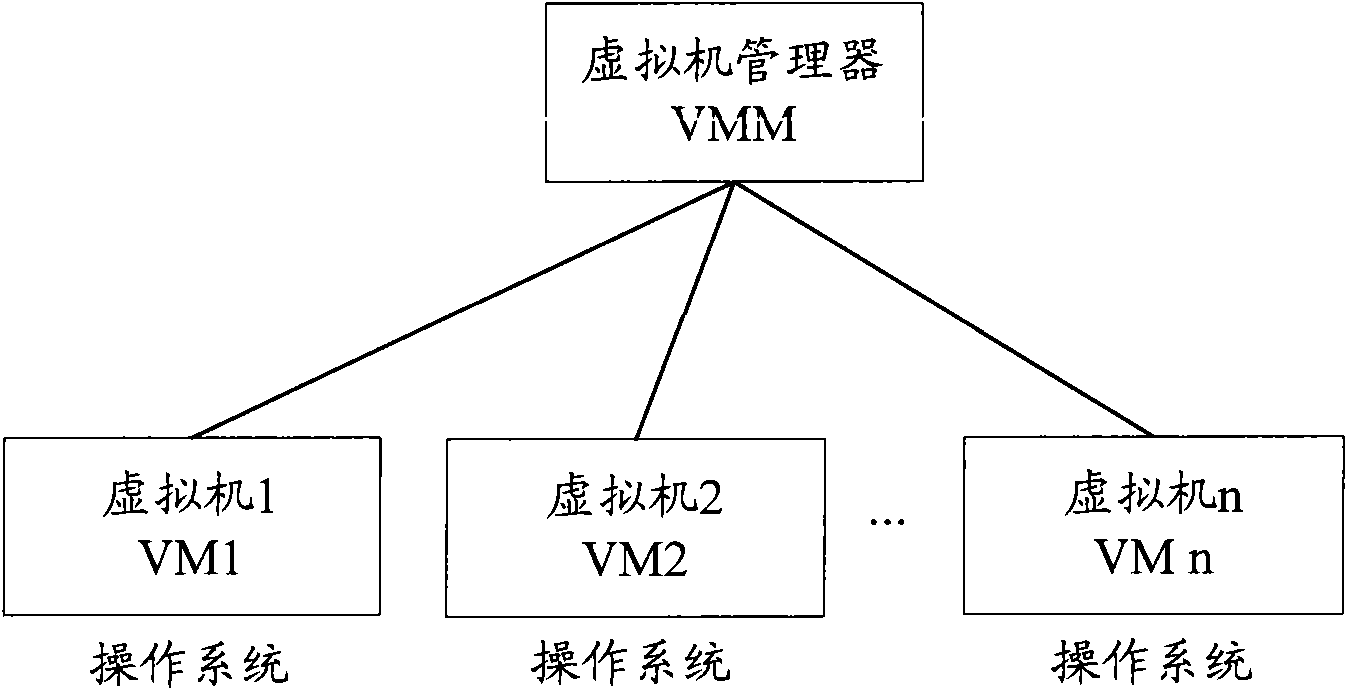

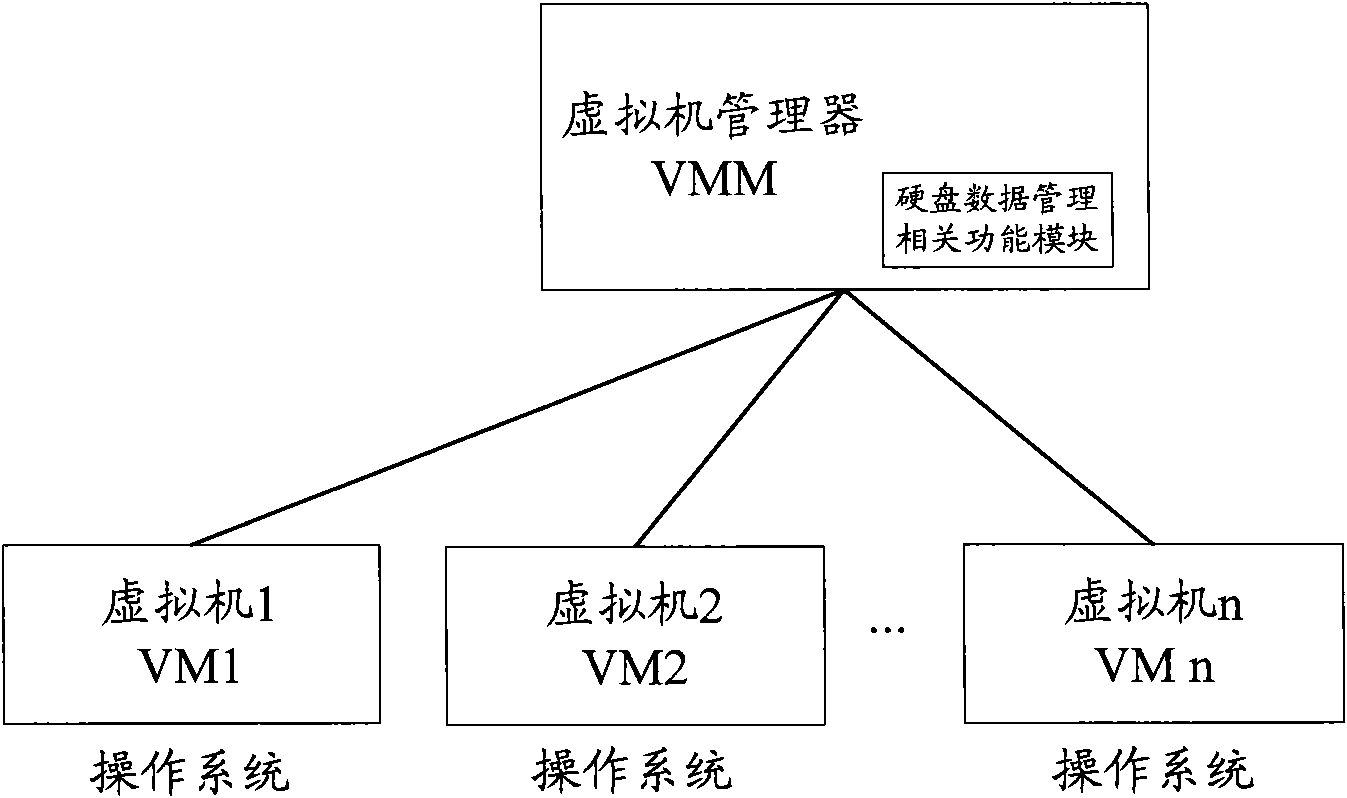

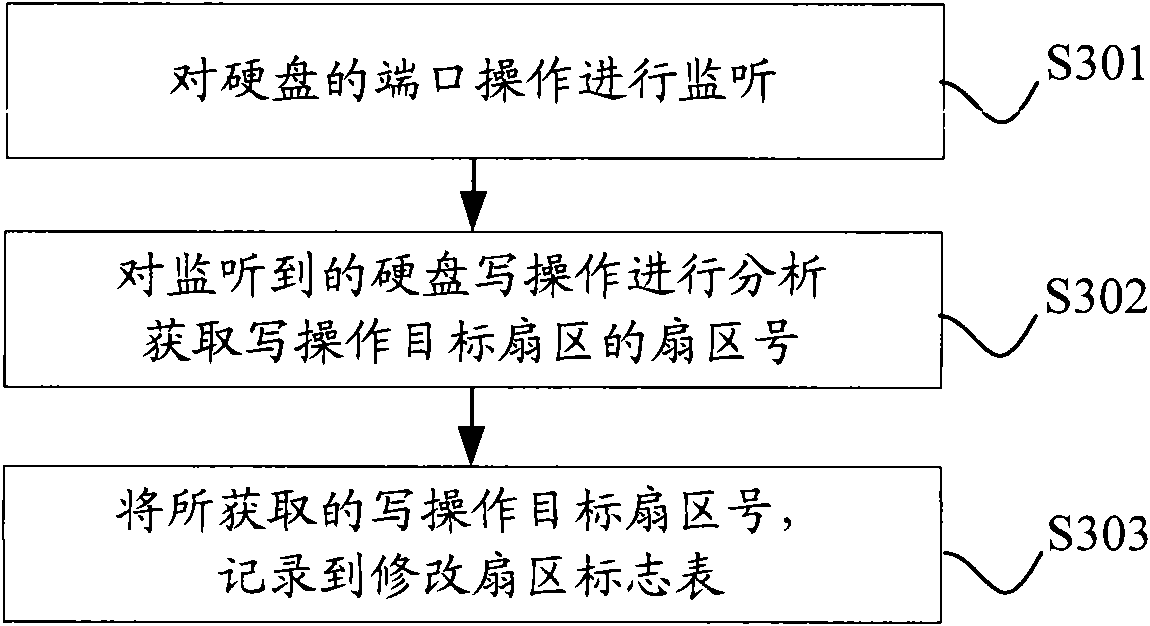

Hard disk data backup and restore method, system and computer

ActiveCN101685412ARealize read and write monitoringImplement backupRedundant operation error correctionCurrent timeVirtual machine

The invention discloses a hard disk data backup and restoring method, a system and a computer; the hard disk data backup and restoring method comprises the following steps: on a virtual machine manager layer, weather write operation of at least one operation system which is operated on the virtual machine manager layer is carried out to a hard disk port is monitored, when the write operation is monitored to be carried out, a sector number of a target sector, corresponding to the write operation, is recorded; according to the sector number, the data in the sector is backed up, and the backup isthat the data in the sector is stored in a protective subarea; in addition, the current time point is used as a first identification of a first time point; according to the first identification, thebackup data at the first time point and the backup data before the first time point are restored to the corresponding sector, and the backup data before the first time point comprises original backupdata.

Owner:LENOVO (BEIJING) CO LTD

Retractable infrared image acquisition instrument

ActiveCN106713863AEasy to watchAvoid unexpected situationsNon-electrical signal transmission systemsClosed circuit television systemsUniversal jointComputer science

The present invention provides a retractable infrared image acquisition instrument. The retractable infrared image acquisition instrument comprises an image acquisition device, a retractable supporting device and a terminal fixing support; the image acquisition device is fixed at the top end of the retractable supporting device through a universal tube; the terminal fixing support is fixed to the lower end of the retractable supporting device through a universal joint; the image acquisition device includes a shell, a camera mounted within the shell, an LED light compensating lamp, an infrared emitter and an infrared receiver, wherein the LED light compensating lamp, the infrared emitter and the infrared receiver are mounted below the camera; the retractable supporting device comprises a retractable insulating rod and an insulating battery cabin; the top of the insulating battery cabin is connected with the bottom of the shell through the universal tube; the lower end of the retractable insulating rod is provided with a fixing ring; the fixing ring is provided with a fixing clamping position; and the terminal fixing support is fixed onto the fixing clamping position through the universal joint. The retractable infrared image acquisition instrument of the invention is convenient to carry and is simple to operate. With the retractable infrared image acquisition instrument of the invention adopted, power outage is not required, a user does not need to carry a heavy ladder and can read a meter and take pictures without climbing to a high place. According to the retractable infrared image acquisition instrument, data are transmitted wirelessly, so that work efficiency can be improved.

Owner:广州市华蓝佳声计算机科技有限公司

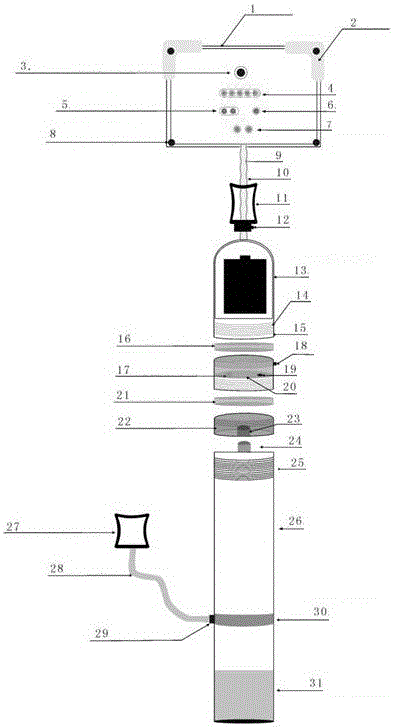

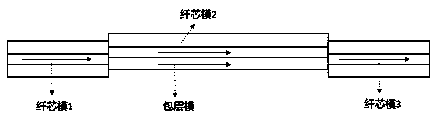

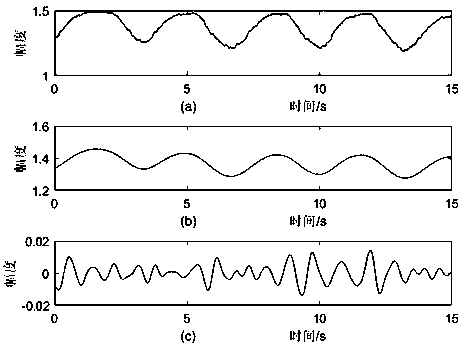

Vital sign monitoring device

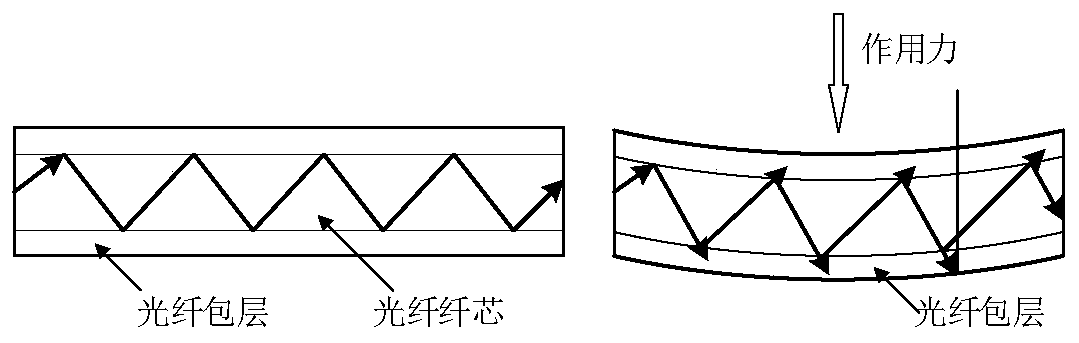

ActiveCN110558956AAccurate monitoringEasy to detectDiagnostics using lightSensorsOptical powerEngineering

The invention provides a vital sign monitoring device; vital sign information is monitored on the basis of a bending loss principle, optical phase fading and polarization influences can be reduced, and vital signs such as respiration and heartbeat signals can be monitored more accurately; by arrangement of a small-core-diameter optical fiber, optical fiber bending change is caused by tiny vibration caused by extrusion caused by respiration and heartbeat, obvious intensity modulation can be carried out on optical signals in the small-core-diameter optical fiber with more sensitive bending loss,optical power changing along with correlation of respiration and heartbeat is output at the output end of a sensing optical fiber, the sensitivity is higher, and the accuracy is better; hard lines are arranged, so that the sensitization effect can be achieved.

Owner:武汉凯锐普医疗科技有限公司

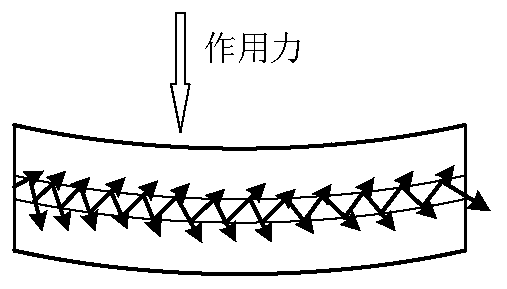

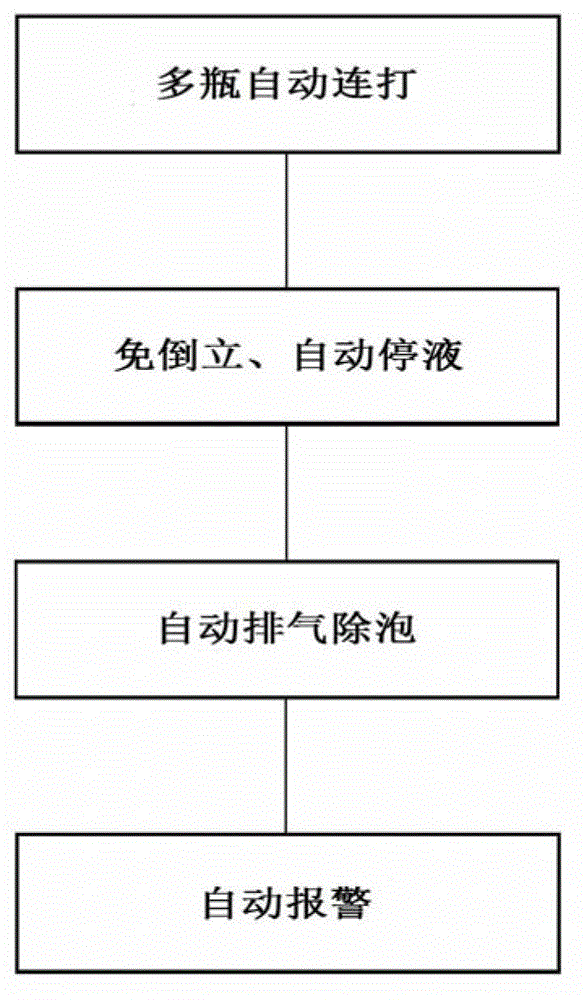

Multifunctional venous infusion apparatus

The invention relates to a multifunctional venous infusion apparatus, which comprises a multi-bottle automatic connection portion, an automatic exhausting and defoaming portion and an automatic alarming portion, wherein a headstand-free and automatic infusion stopping portion is arranged between the multi-bottle automatic connection portion and the automatic exhausting and defoaming portion additionally; the headstand-free and automatic infusion stopping portion comprises an observation window and a second biswitch float valve; a cavity of the second biswitch float valve communicates with the observation window; an air filter core and a valve switch are arranged at an outlet at top end of the second biswitch float valve, and the outlet at lower end of the second biswitch float valve is connected with a flow regulator; a biswitch float body is installed in the cavity of the second biswitch float valve; the upper end and the lower end of the biswitch float body are provided with one sealing piece, respectively; an inlet of the observation window is connected with the outlet of the biswitch float valve in the multi-bottle automatic connection portion. Through the adoption of the multifunctional venous infusion apparatus, the operation of nursing staff to invert the observation window of the infusion apparatus is cancelled; the air and bubble are automatically removed; multiple bottles of medicinal liquids are automatically connected; and the medicinal liquid is stopped to alarm after infusion. Therefore, the workload of the nursing staff is alleviated, and the working quality and efficiency are improved.

Owner:唐敏峰

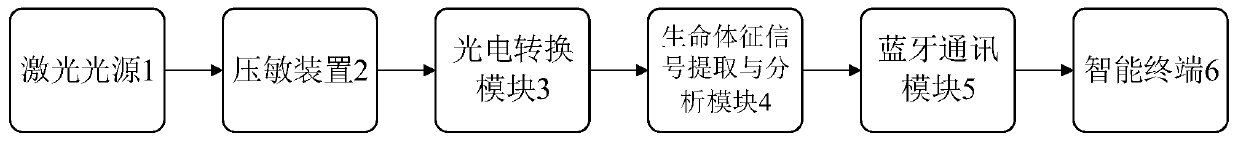

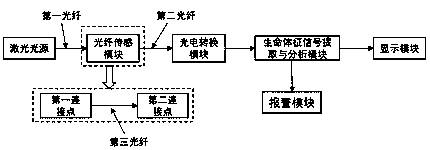

Modular interference based vital sign monitoring device

InactiveCN107854119ASimple structureHigh sensitivityDiagnostic signal processingDiagnostics using lightComputer moduleElectromagnetic interference

The invention discloses a modular interference based vital sign monitoring device. The modular interference based vital sign monitoring device comprises a laser source, a first optical fiber, an optical fiber sensing module, a second optical fiber, a photovoltaic conversion module, a vital sign signal extraction and analysis module, a display module and an alarm module. Two ends of the first optical fiber are connected with an output end of the laser source and an input end of the optical fiber sensing module respectively. Two ends of the second optical fiber are connected with an output end of the optical fiber sensing module and an input end of the photovoltaic conversion module respectively. An output end of the photovoltaic conversion module is connected with an input end of the vitalsign signal extraction and analysis module. An output end of the vital sign signal extraction and analysis module is connected with the display module and the alarm module. The modular interference based vital sign monitoring device has advantages of simple structure, high sensitivity, high comfort, high electromagnetic interference resistance, convenience in use and the like, and real-time monitoring of physical conditions of a user is realized.

Owner:ANLIGHT OPTOELECTRONICS TECH INC

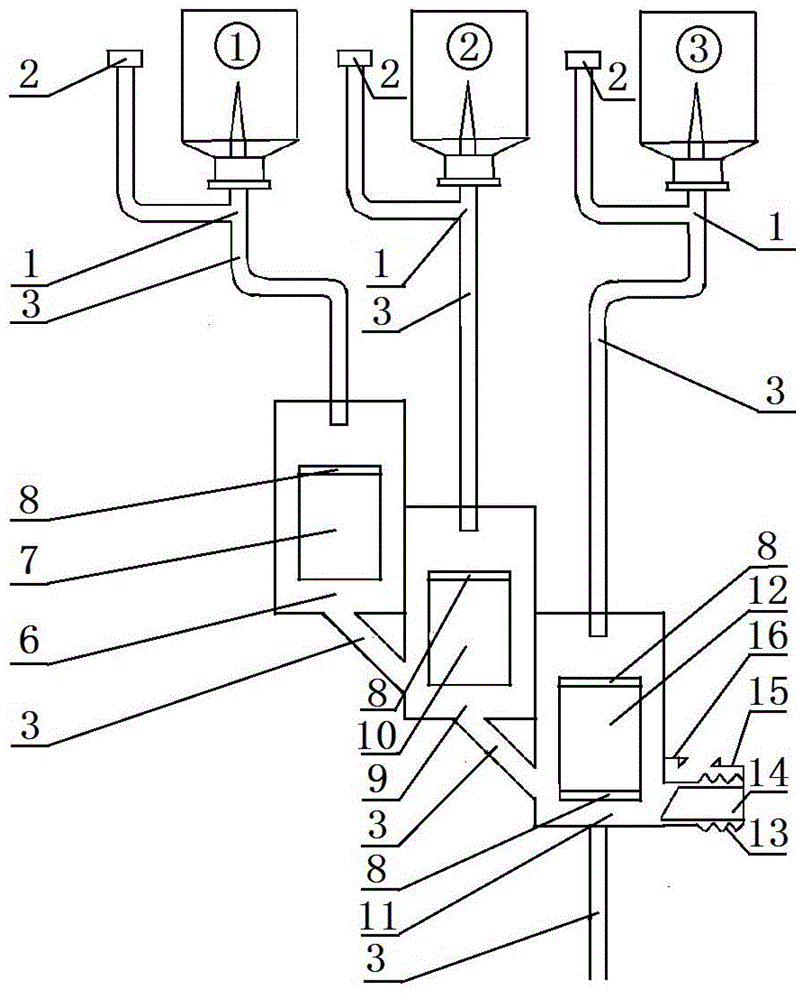

Novel automatic beading device

The invention is a novel automatic beading device, which comprises a feed port, a buffer zone arranged below the feed port, and a track zone below the buffer zone, a chassis arranged below the track zone. A vibration plate is arranged below the buffer zone; an upper fixing board is arranged below the vibration plate; the upper fixing plate is provided with a beading needle; a bead wire is connected below the beading needle; a lower fixing plate is arranged on the chassis; a placing plate is arranged above the lower fixing plate; an isolation plate is connected above the placing plate; a casing is connected below the feed port; the right side of the casing is provided with an emergency stop switch, a shift switch and a stop switch; the inside of the casing is provided with a work zone; the inside of the work zone is provided with a motor and a connecting rod connected with the casing; the motor is provided with a cam; the upper end of the connecting rod is provided with a clamping piece; the lower end of the connecting rod is provided with a circular wheel. The device can replace manual beading, and has the characteristics of high efficiency and large output.

Owner:ZHONGSHAN JUCHANG AUTOMATION EQUIP TECH CO LTD

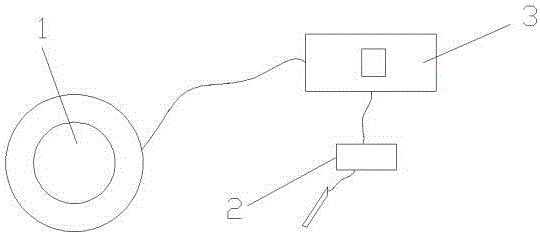

Method for detecting polar stability by utilizing measuring equipment

InactiveCN106198877AAvoid unexpected situationsGuaranteed scientific and reliableTesting plants/treesData transmissionMeasuring equipment

The invention discloses a method for detecting polar stability by utilizing measuring equipment. The measuring device comprises a radar, a soil compactness determinator and a controller, wherein the radar and the soil compactness determinator are connected with the controller. The method comprises the following steps: sending an instruction judging stability of a polar to a detector by the controller, detecting breadth of root distribution of the polar, vertical depth of roots, height of the polar and diameter of a trunk of the polar by the radar in the measuring device, measuring the soil compactness by the soil compactness determinator, transmitting the measured data to the controller by the radar and the soil compactness determinator, wherein an operation control program used for judging safety performance of the polar is arranged in the controller, receiving data, analyzing and processing data, and outputting a determination result on a display screen of the controller. The stability of the polar is determined, so that the polar can be effectively prevented from tipping, personal safety of a person can be protected and property of the person can not lose, and an accident is avoided.

Owner:陈显桥

Cutting device for steel bar machining

InactiveCN109201959ASolve the problem of not having the function of iron filings collectionAvoid legacyDirt cleaningArchitectural engineeringElectric machinery

The invention discloses a cutting device for steel bar machining. The cutting device comprises a base. A workbench is fixedly connected to the center position of the top of the base. A fixing column is fixedly connected to the right side of the top of the base. A supporting plate is transversely and fixedly connected to the top of the left side of the fixing column. An electric telescopic rod is fixedly connected to the left side of the bottom of the supporting plate. A fixing base is fixedly connected to the bottom of the electric telescopic rod. A motor is arranged at the bottom of the leftside of the fixing base. Through cooperation of the workbench, the fixing column, the supporting plate, the electric telescopic rod, the fixing base, the motor, the rotation shaft, a cutting blade, anair suction pump, a communication pipe, a ventilation head, a connecting pipe and a collection box, iron scraps generated in the steel bar cutting process can be sucked in and collected, and the problem that a traditional cutting device does not have an iron scrap collecting function is solved; and a large number of iron scraps are prevented from being left after steel bar cutting, convenience isbrought to next cutting for users, and the cutting device is worthy of being used and popularized.

Owner:河南永益同丰智能科技有限公司

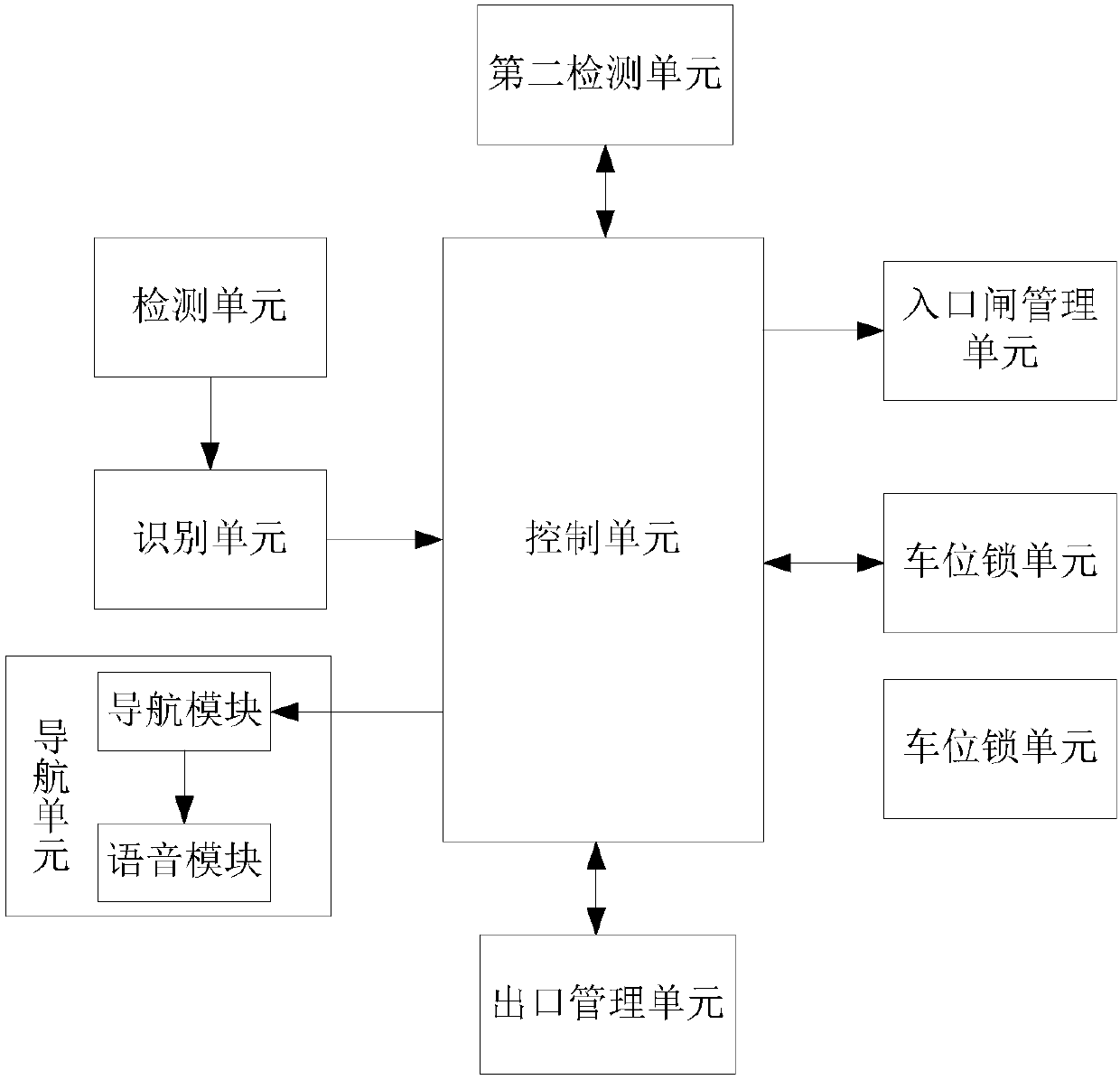

Parking lot management system with parking guiding function

InactiveCN107919026AAvoid random parkingAvoid time seekingIndication of parksing free spacesParking areaManagement unit

The invention discloses a parking lot management system with a parking guidance function, which includes a detection unit for collecting identification information of a vehicle to be entered and transmitting it to an identification unit; an identification unit for receiving the identification information and judging whether the vehicle corresponding to the identification information belongs to Fix the vehicle or temporary vehicle, and transmit the judgment information to the control unit; the entrance gate management unit is used to receive the information from the control unit and open the entrance; the navigation unit is used to receive the parking position information sent by the control unit, and guide the entering vehicle Park at the designated parking space; the parking space lock unit is used to collect the license plate information of the vehicle and transmit it to the control unit; the control unit receives and processes the judgment information, and sends a message to the entrance gate management unit to open the entrance; at the same time, the control unit allocates the corresponding parking space. In the parking lot, one vehicle corresponds to one parking space, which ensures the regular parking of vehicles in the parking lot; the navigation unit guides the location of the parking space to improve parking efficiency.

Owner:成都领域弱电工程有限公司

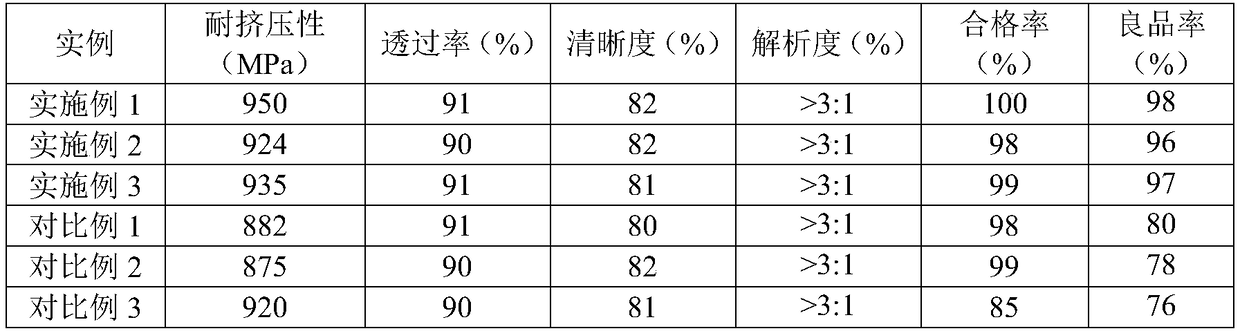

3D (three-dimensional) glass processing technology

InactiveCN109206002AImprove pass rateAvoid temporary blindnessGlass reforming apparatusGlass tempering apparatusEtchingMobile phone

The invention provides a 3D (three-dimensional) glass processing technology. According to the technology, 2D (two-dimensional) glass is subjected to the steps of cutting, CNC (computer numerical control) outline processing, hot bending shaping, strengthening, transfer printing, laser irradiation, AG (anti-glare) etching and the like, finally a 3D (three-dimensional) glass finished product is prepared, and therefore the problems of oxidization, glare, hook surface decoration and the like in the hot bending shaping process of glass in the processing and manufacturing process of 3D (three-dimensional) glass can be solved, meanwhile, the manufactured 3D (three-dimensional) glass product is excellent in performance and low in cost, and the application in the mobile phone industry, the computerindustry, the digital industry and optical lenses can be realized.

Owner:江苏优视光学科技有限公司

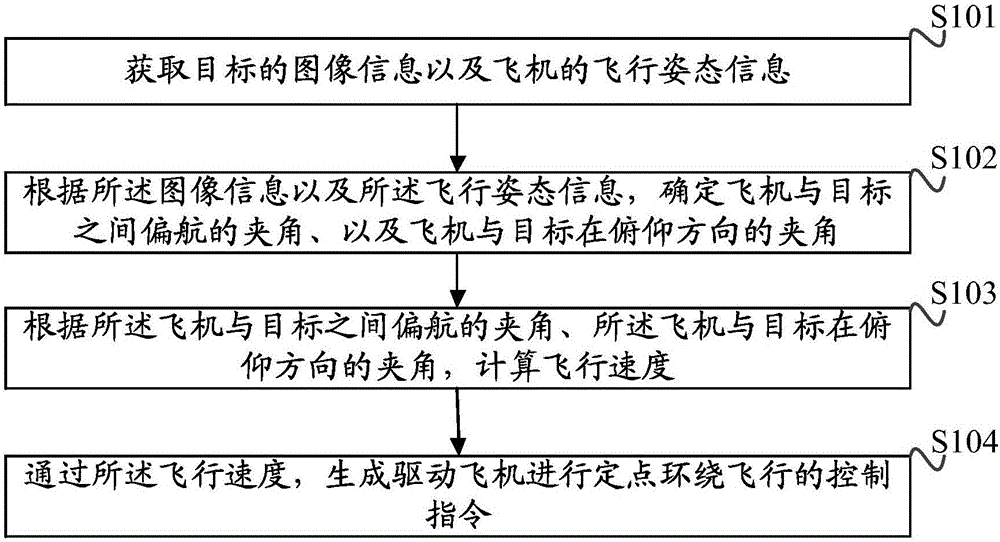

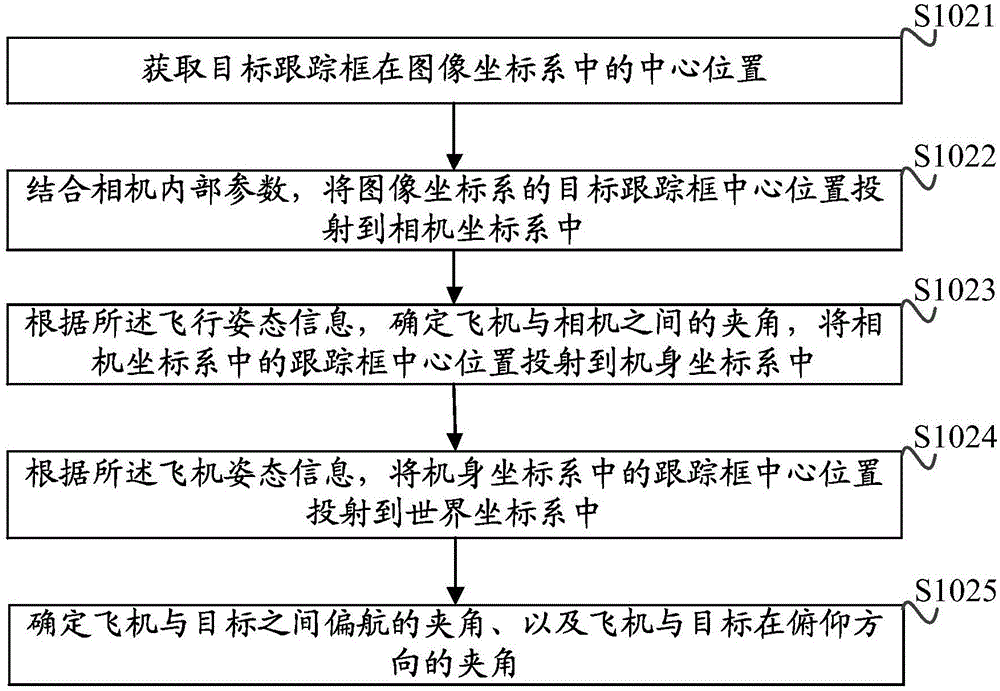

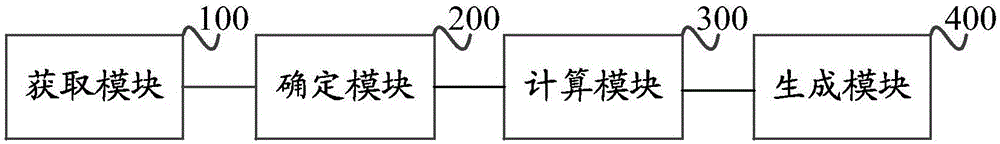

Fixed point flying-about method, device and system for unmanned aerial vehicle

ActiveCN106843275AAvoid unexpected situationsAvoid flying around precise pointsPosition/course control in three dimensionsAutomatic controlSatellite

The invention discloses a fixed point flying-about method and a fixed point flying-about device for an unmanned aerial vehicle. The method comprises the steps of obtaining image information of a target and flight attitude information of an aircraft; determining a yaw included angle between the aircraft and the target and an included angle between the aircraft and the target in a pitching direction according to the image information and the flight attitude information; calculating the flight speed according to the yaw included angle between the aircraft and the target and the included angle between the aircraft and the target in the pitching direction; and generating a control instruction for driving the aircraft to fly around a fixed point according to the flight speed. Automatic control on fixed point flying-about of the unmanned aerial vehicle is achieved, an unexpected situation caused by artificial misoperation is prevented, the condition that accurate fixed point flying-about cannot be achieved due to inaccurate positioning of a satellite is avoided and the accuracy is improved. In addition, the invention further provides a fixed point flying-about system for the unmanned aerial vehicle with the technical advantages.

Owner:CHENGDU TOPPLUSVISION TECH CO LTD

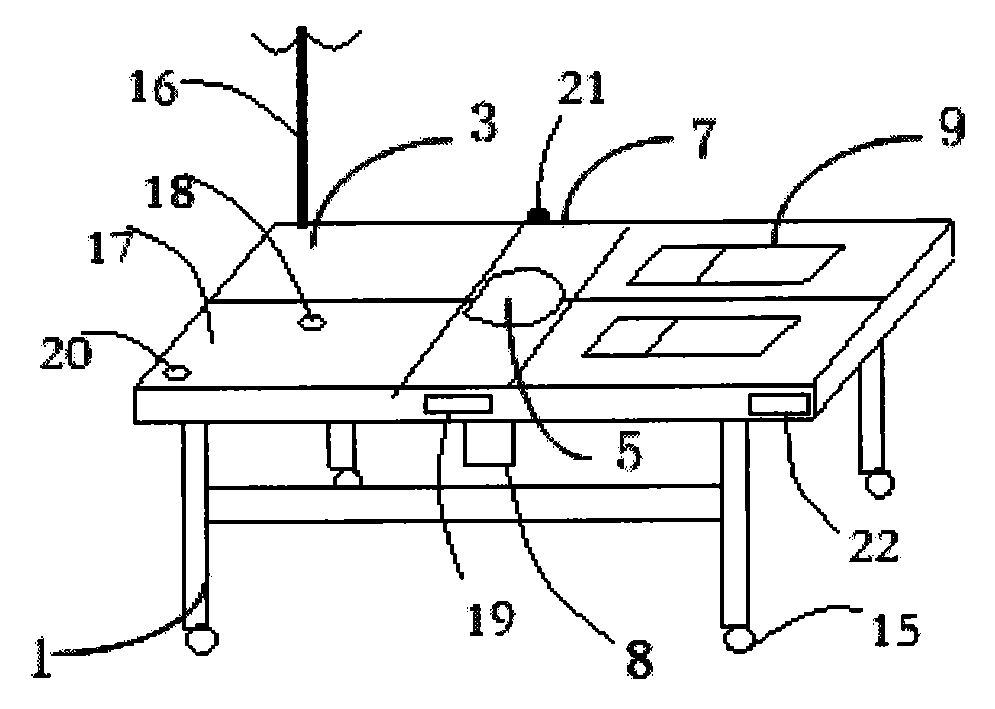

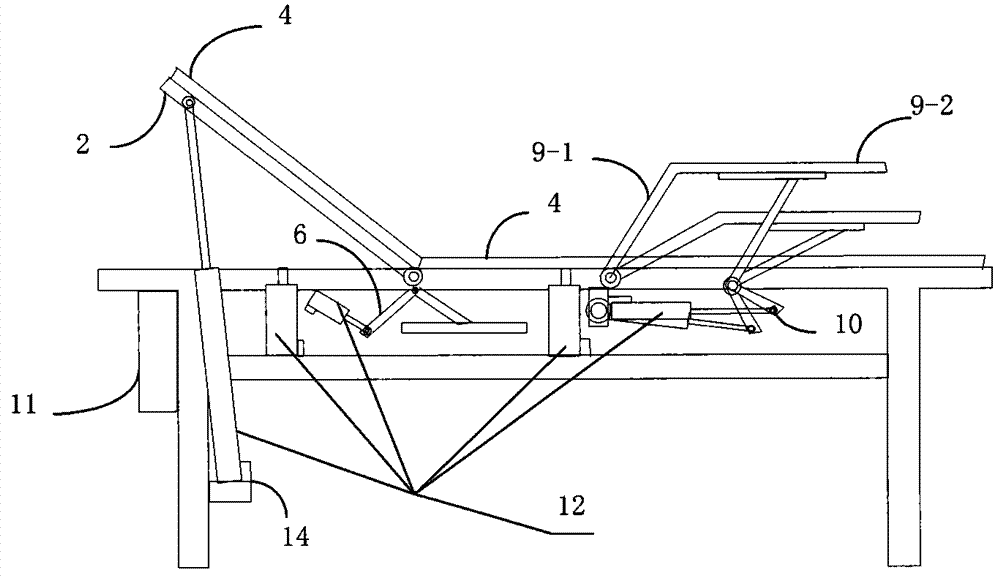

Nursing bed control system

InactiveCN104116599AConvenient hyperthermiaTreat as soon as possibleChiropractic devicesNursing bedsLeg muscleAir pump

The invention discloses a nursing bed control system which comprises a bed frame, universal wheels, an infusion bottle support, a back bed frame, a back bed plate, a turnover bed frame, a closestool cover, a closestool cover frame, a middle bed plate, a closestool, a leg bed plate, a leg bed plate support, a controller, an air pressure air cylinder, an air pump, a pneumatic control valve, a temperature sensor, an electric blanket, a remote control, a human body inductor, an emergency button and an audible and visual alarm. The controller controls the pneumatic control valve to control the stretching out and drawing back of the air pressure air cylinder and the stretching-out and drawing-back speed of the air pressure air cylinder, the moving of the back bed plate, the closestool cover and the leg bed plate is controlled through the stretching out and drawing back of the air pressure air cylinder, turning over, sitting up, defecation and moving of muscles of the legs of a patient are completed, and the labor intensity of medical staff is lowered. The nursing bed control system is simple in structure, convenient to use and convenient for long-term bedridden patients to use, and the clinical medical level is improved to a certain degree.

Owner:管勇丽

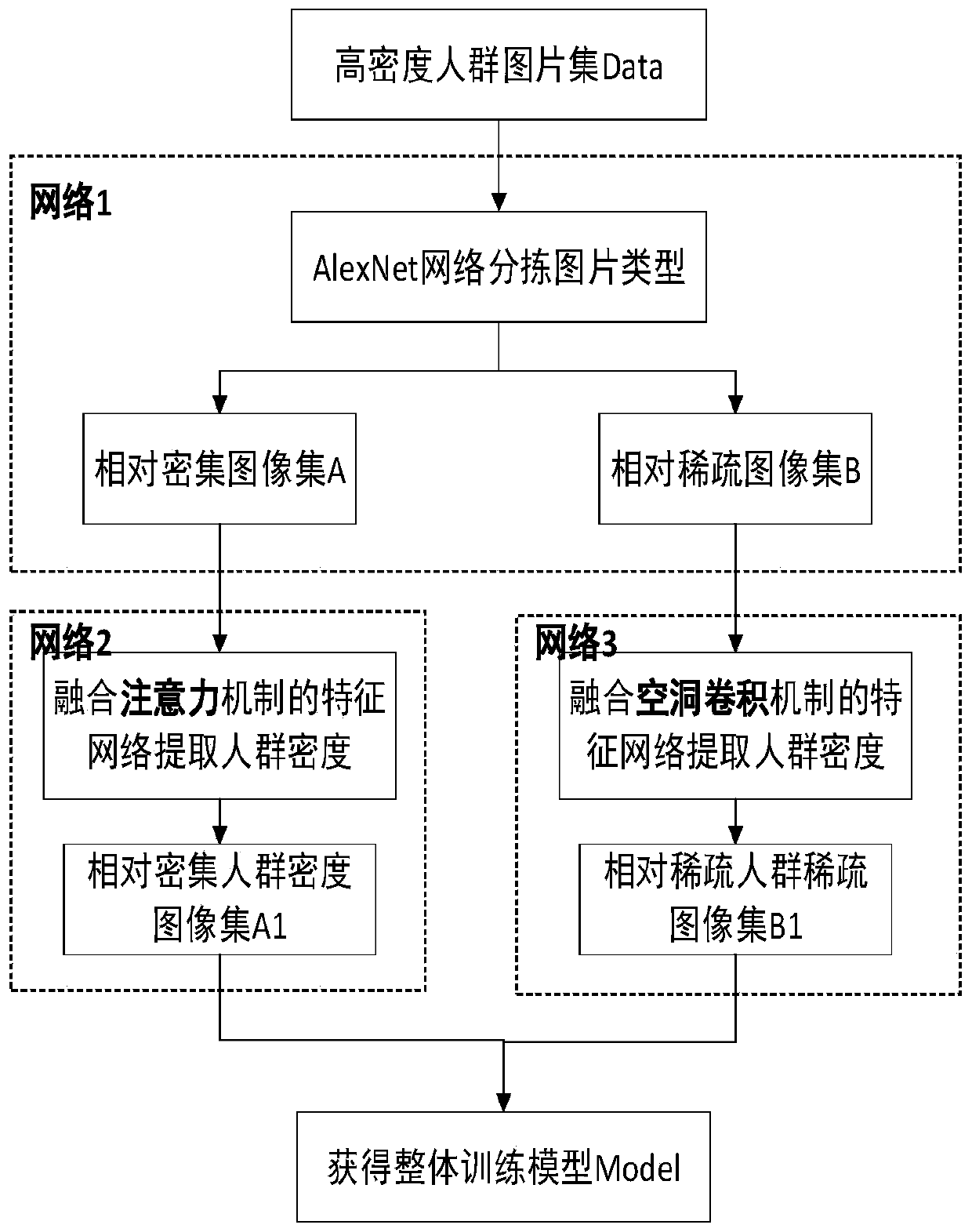

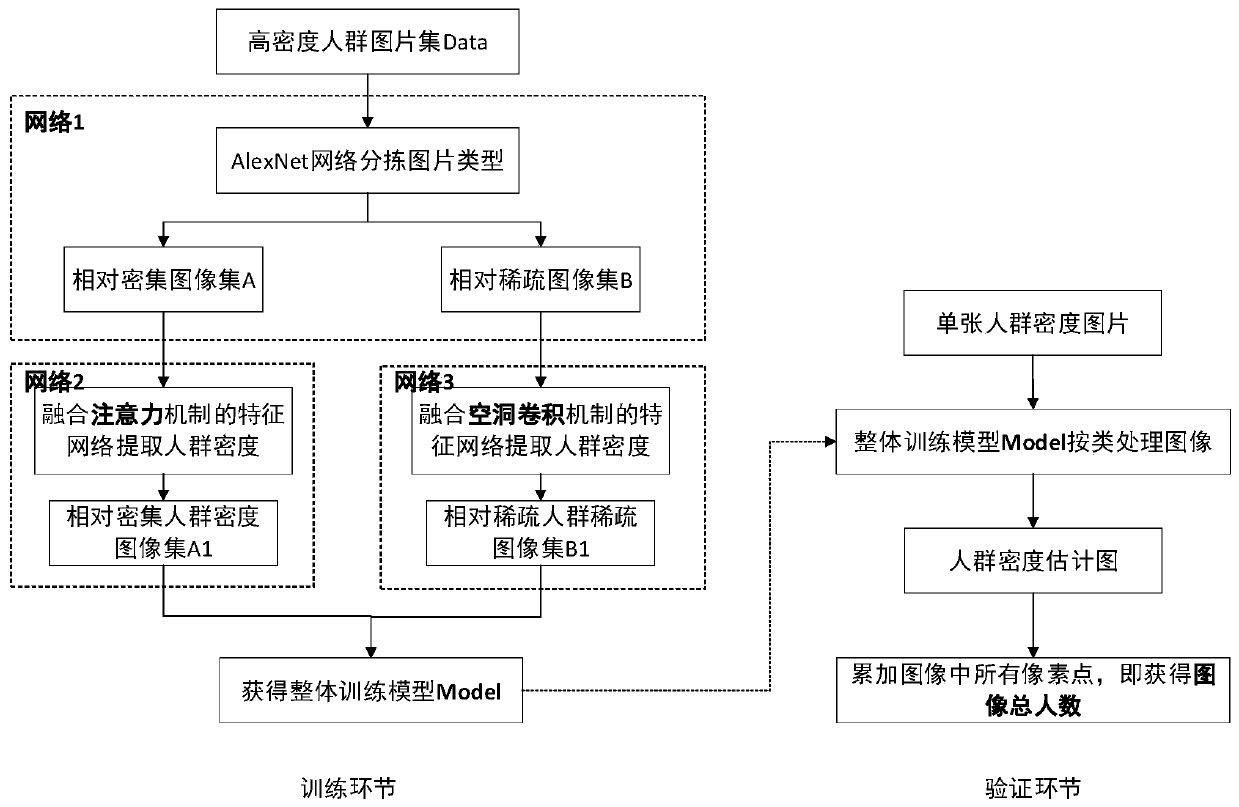

Crowd density estimation method

PendingCN110942015APrevent overcrowdingGood crowd density estimation featureCharacter and pattern recognitionAlgorithmData mining

The invention provides a crowd density estimation method. The method comprises the steps: enabling a crowd image data set to be divided into a dense image data set and a sparse image data set throughemploying an AlexNet network, and respectively transmitting the dense image data set and the sparse image data set to corresponding feature extraction networks according to the difference of density features of the two types of images, thereby obtaining better and more effective crowd density estimation features. The method is used for estimating the number of crowds in the high-density crowd picture, and can prevent accidents caused by excessive crowding of the crowds. The invention relates to a combined network crowd density estimation algorithm. Crowd density estimation is carried out on crowd density and sparseness. According to the method, effective crowd density estimation features can be better provided, the problem that density map distribution is not similar can be solved, and themethod has good robustness.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

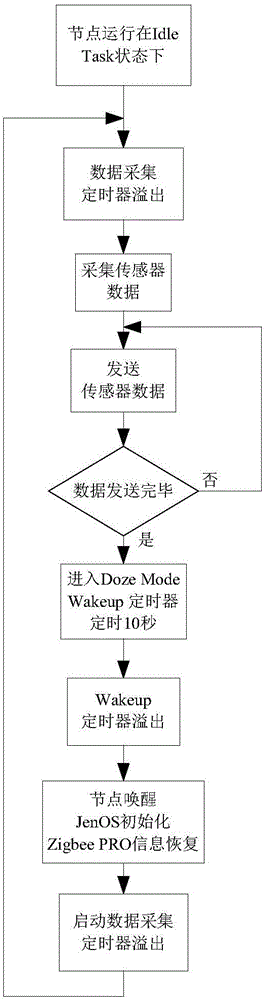

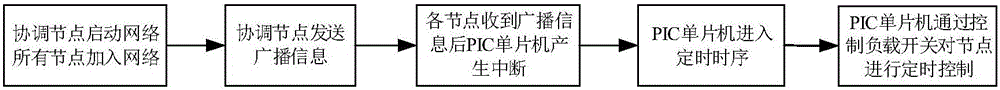

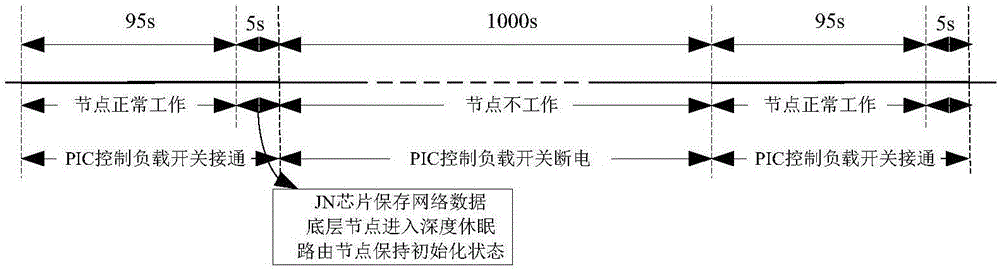

Intelligent wireless network sensor system possessing power supply management

InactiveCN106572183AReal time monitoringEffective monitoringNetwork topologiesData switching current supplyMicrocontrollerDormancy

The invention discloses an intelligent wireless network sensor system possessing power supply management and belongs to the instrument and meter detection technology field. Wireless sensor nodes in the system comprise ground floor nodes, a routing node and a coordination node. The ground floor nodes are distributed on each monitoring point. According to a Zigbee protocol, the routing node and the coordination node are communicated with an upper computer so as to realize real-time control of a network. Each sensor node is formed by a base circuit, a core module, a function circuit and a power supply management module respectively. In the invention, based on a PIC single chip microcomputer, through using a mode of controlling on and off of a load power supply, about 70% average node power consumption is reduced; a dormancy mechanism is added in the nodes and on and off of a node load power supply are controlled in a fixed time mode; micromation, low power consumption, low cost and other characteristics are possessed; the nodes possess certain anti-interference performance and high robustness of adaptability; an expansion interface is reserved in the nodes and scalability is high.

Owner:王亚慧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com