3D (three-dimensional) glass processing technology

A processing technology, 3D technology, applied in the field of 3D glass processing technology, can solve problems such as glare and oxidation, achieve low surface haze, excellent optical properties, and improve visible brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

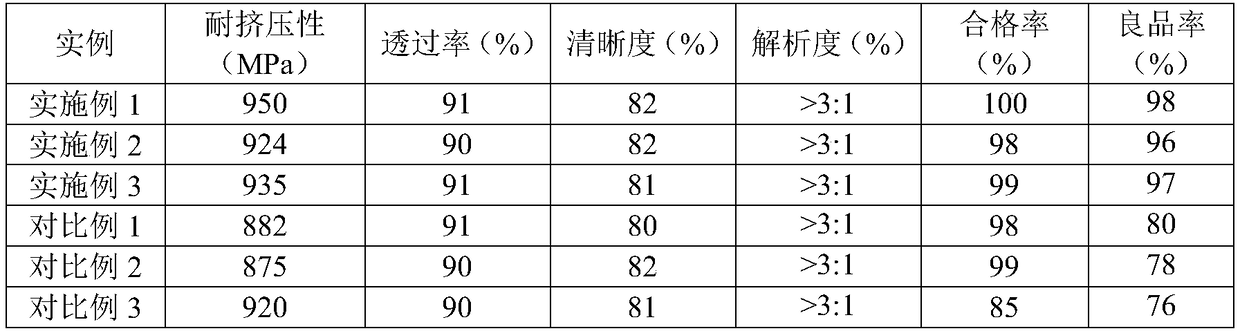

Examples

Embodiment 1

[0031] A kind of processing technology of 3D glass, its technological process comprises the following steps:

[0032] (1) After the 2D glass substrate is cut and processed, the CNC shape is processed, and then soaked, sprayed, cleaned and inspected to obtain the 2D glass substrate-1;

[0033] (2) The 2D glass substrate-1 in step (1) is heated to a softened state in an electric furnace and subjected to hot bending and forming through a mold. At the same time, nitrogen gas is introduced, and then ultrasonic cleaning and inspection are performed to obtain 3D glass substrate-1;

[0034] (3), strengthening the 3D glass substrate-1 in step (2), and then soaking and inserting to obtain the 3D glass substrate-2;

[0035] (4) Etch the designed pattern on the steel plate and apply ink, realize the transfer printing of the pattern on the surface of the 3D glass substrate-2 in step (3) through the glue head, and perform ultrasonic cleaning, inspection and insertion after baking , to obt...

Embodiment 2

[0048] KNO in step (3) 3 with NaNO 3 The mass ratio of the mixed salt is set to 2:1, and all the other process conditions are the same as in Example 1.

Embodiment 3

[0050] KNO in step (3) 3 with NaNO 3 The mass ratio of the mixed salt is set to 1:2, and the rest of the process conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com