Patents

Literature

609results about How to "Avoid oxidation reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

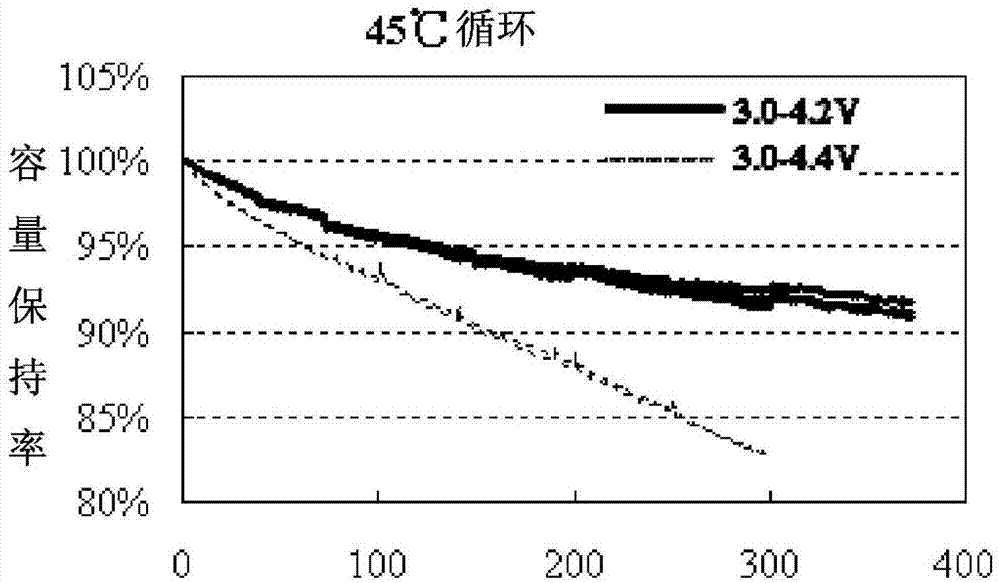

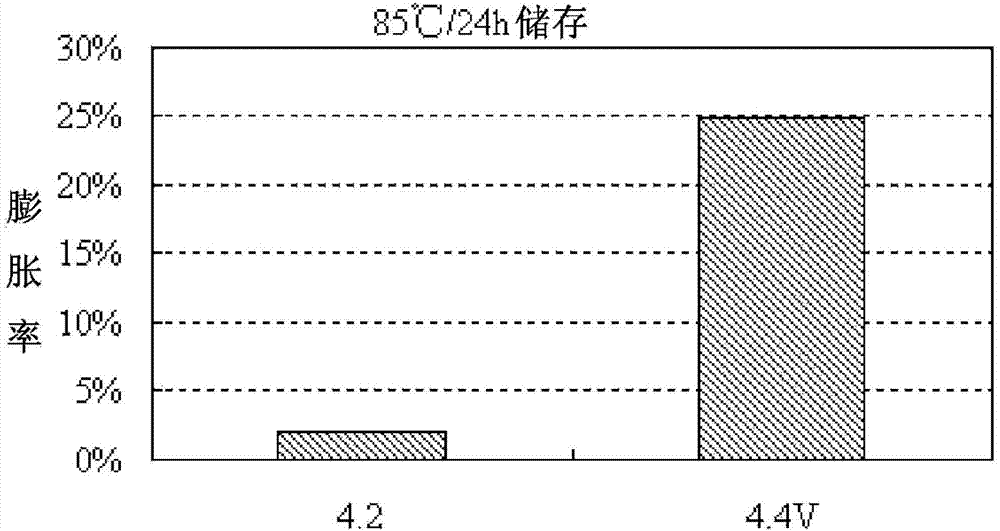

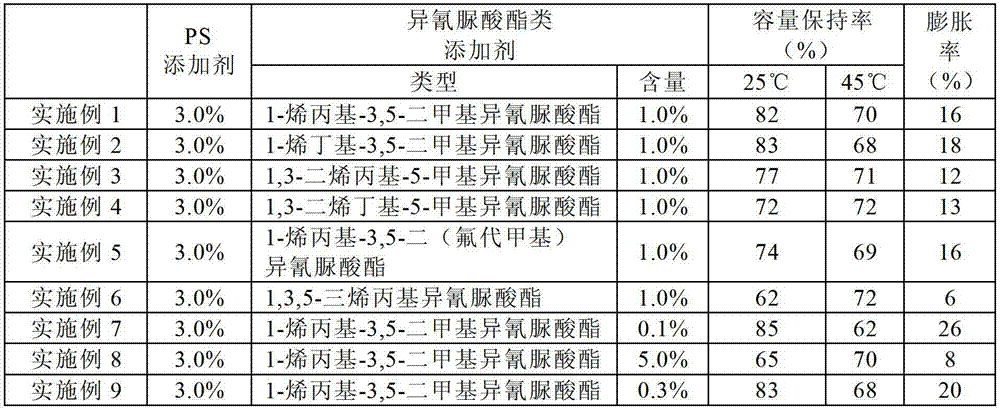

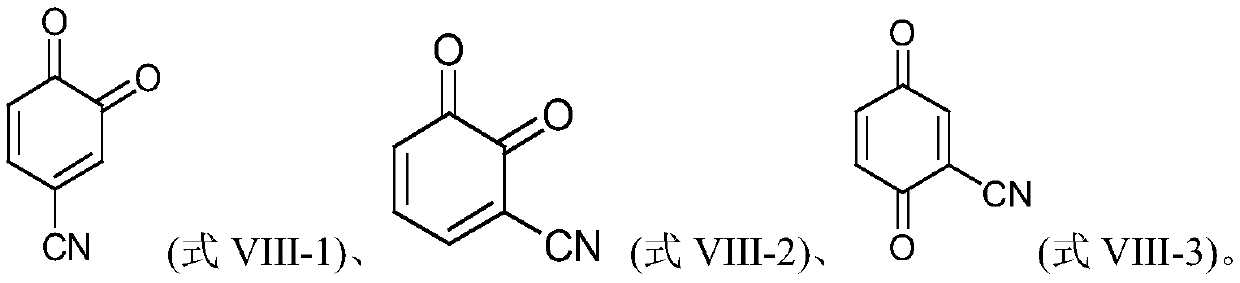

Lithium ion secondary battery and electrolyte thereof

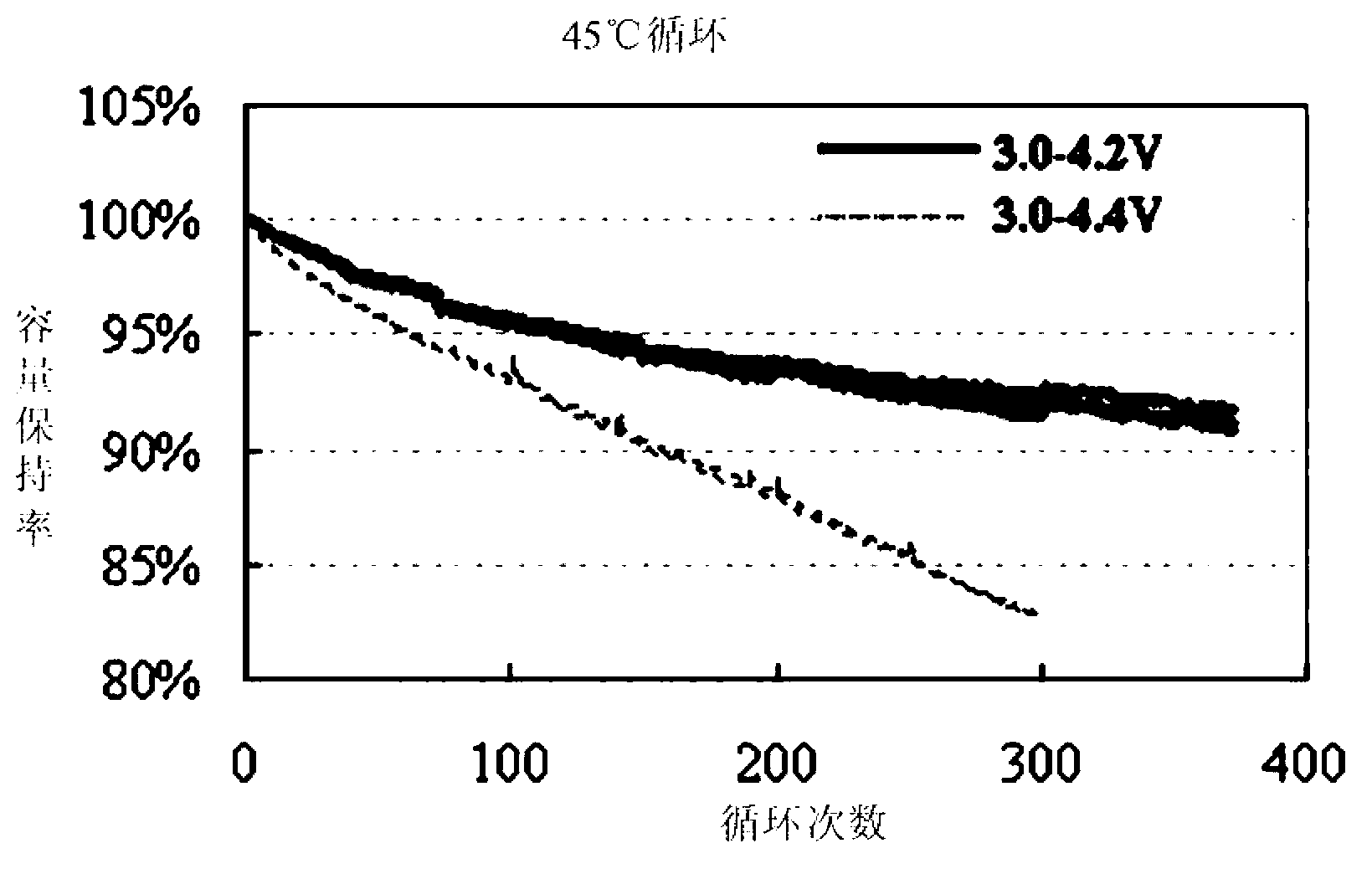

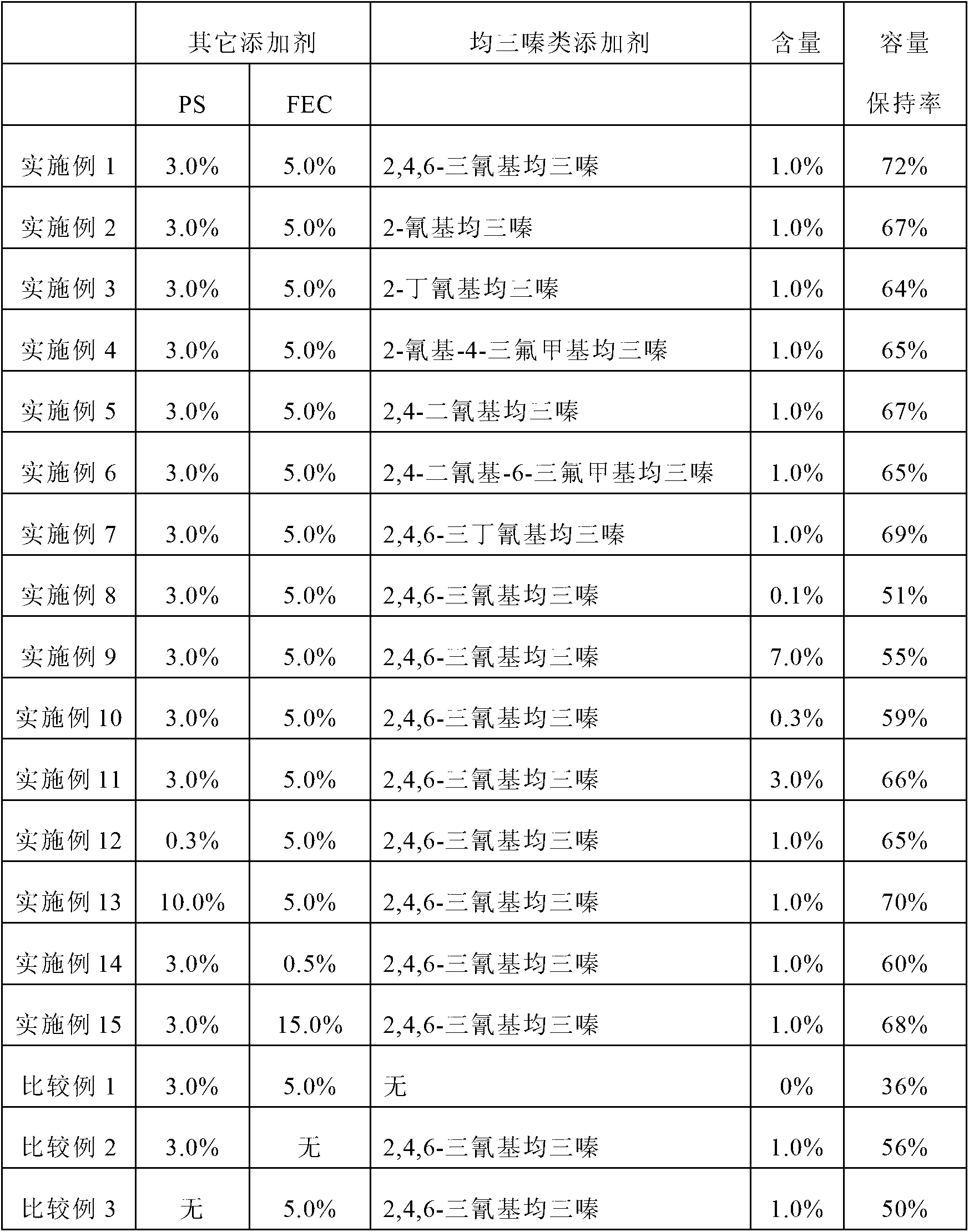

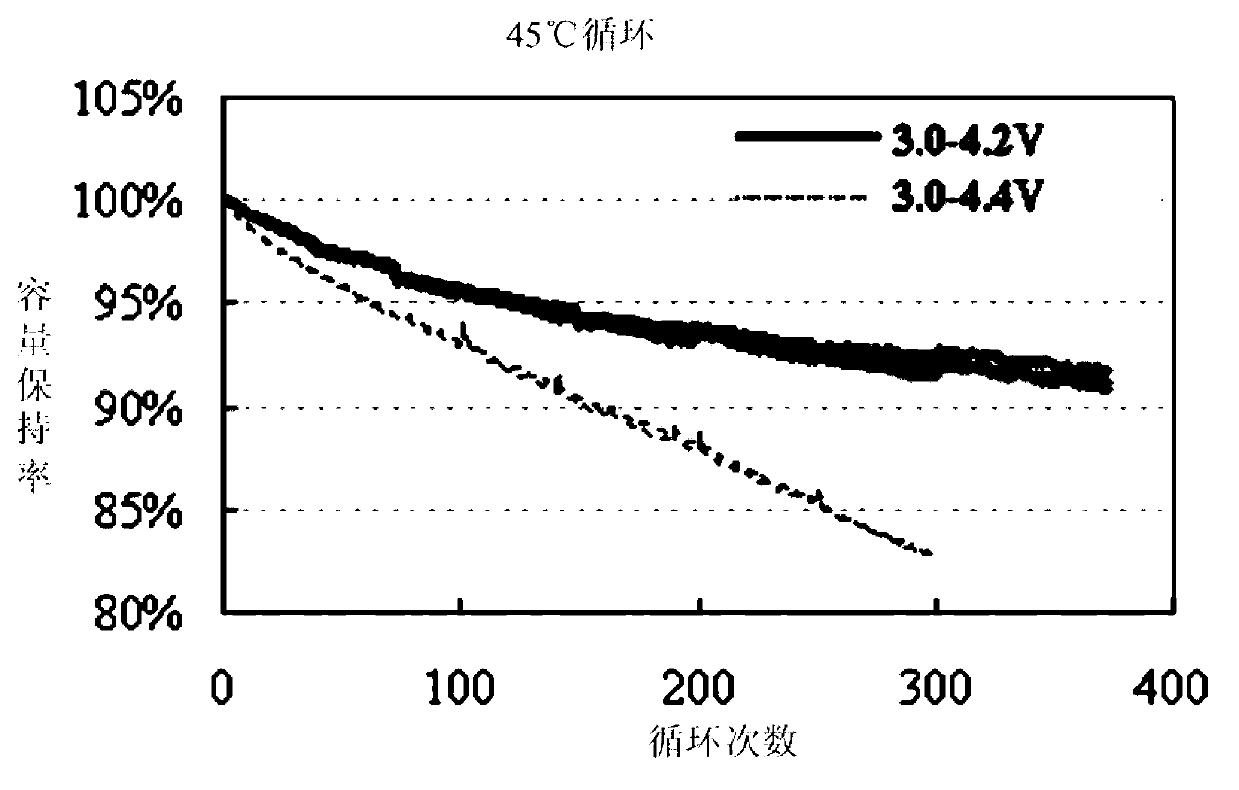

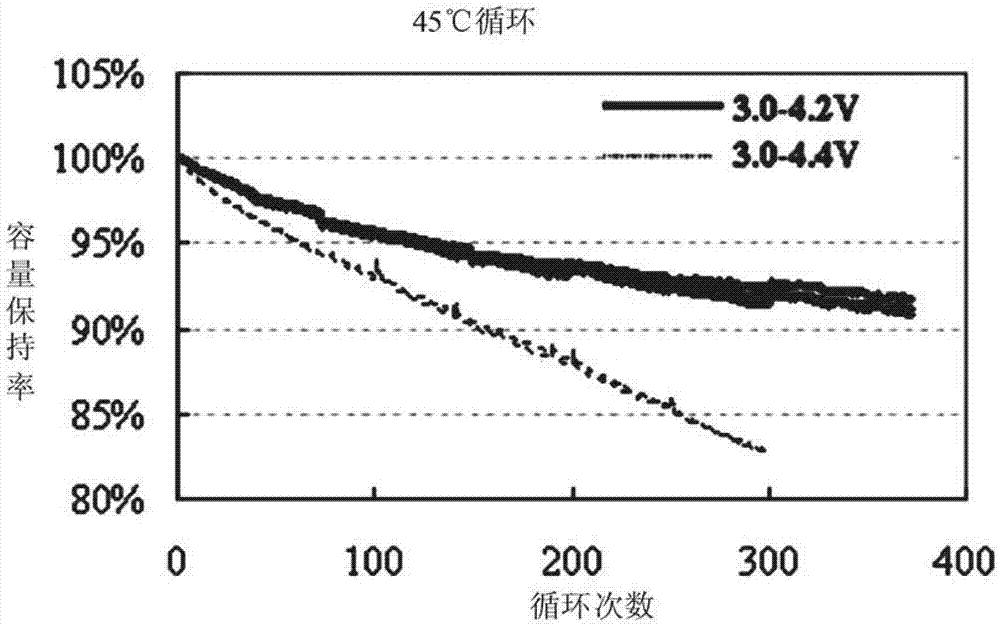

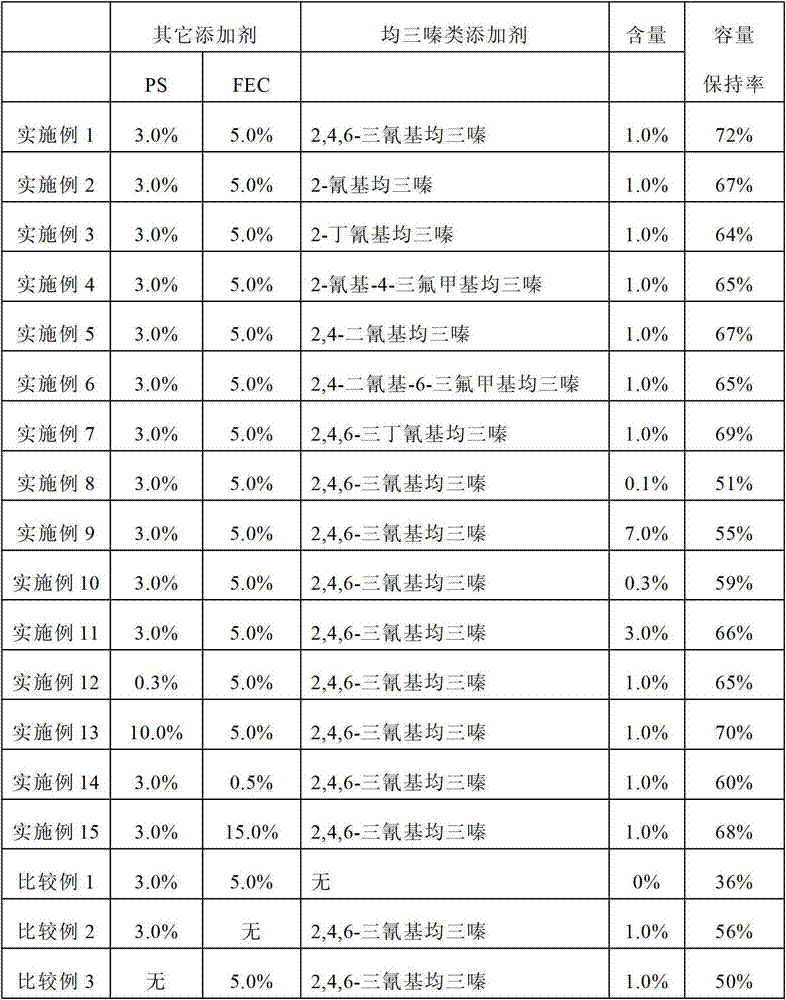

ActiveCN103078140AAvoid oxidation reactionsImprove cycle performanceSecondary cellsSolventHigh pressure

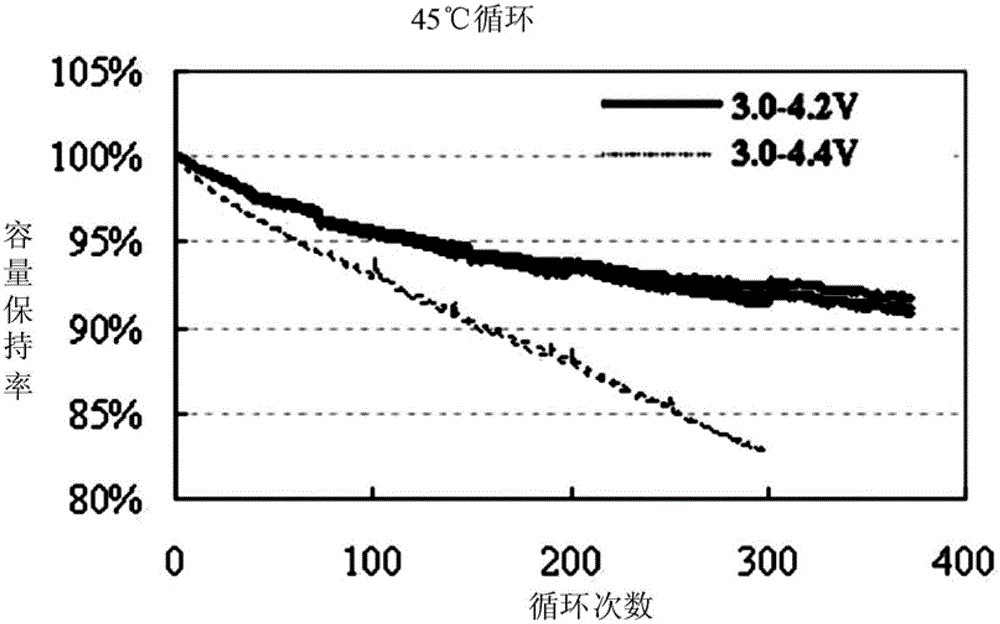

The invention provides a lithium ion secondary battery and an electrolyte thereof. The electrolyte of the lithium ion secondary battery comprises lithium salt, a non-aqueous solvent, and an addition agent at least containing 1, 3-propane sultone (PS), fluoroethylene carbonate (FEC) and an s-triazine structural compound, wherein the s-triazine structural compound is represented by a general formula (1), a general formula (2) or a general formula (3); in the general formula (1), the general formula (2) or the general formula (3), n is an integral number of 0-5, and R1, R2 and R3 are hydrogen atoms or C1-C6 alkyl group; and the hydrogen atoms on the alkyl group can be partially or wholly replaced by fluorine atoms. The lithium ion secondary battery comprises a positive plate, a negative plate, a diaphragm arranged between the adjacent positive plate and the negative plate, and the electrolyte of the lithium ion secondary battery. According to the lithium ion secondary battery and the electrolyte thereof provided by the invention, oxidation reaction between the electrolyte and a cathode material can be inhibited, and the cycle performance under the conditions of high temperature and high voltage is improved.

Owner:NINGDE AMPEREX TECH

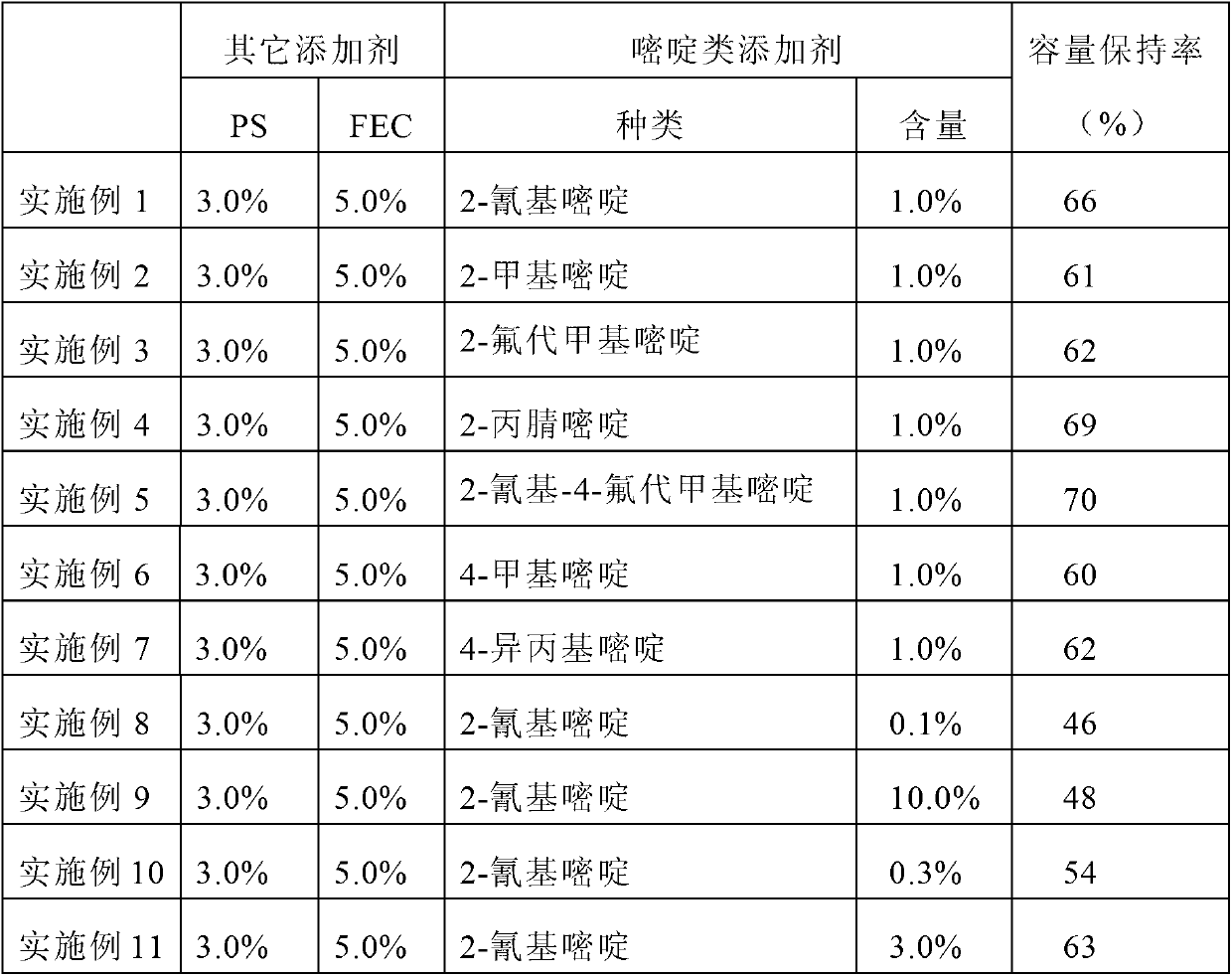

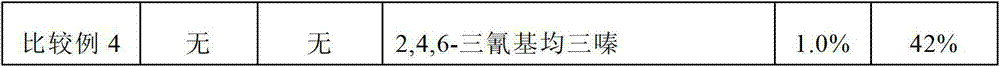

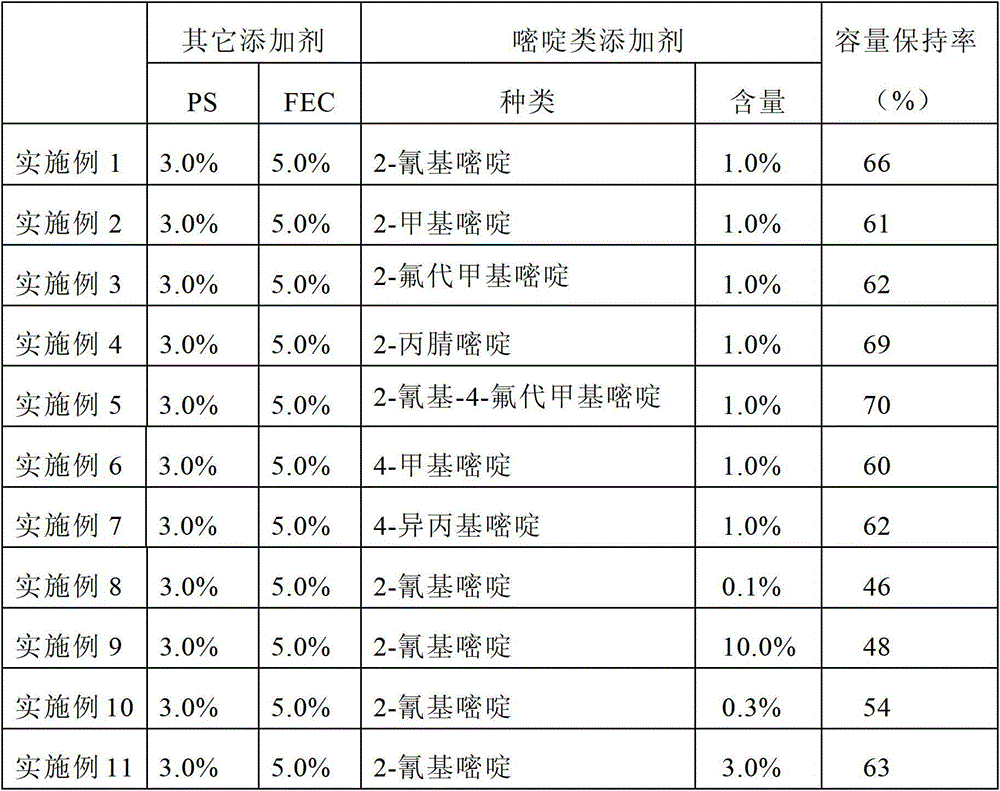

Lithium-ion battery and electrolyte thereof

ActiveCN103022556AAvoid oxidation reactionsImprove cycle performanceSecondary cellsPhysical chemistryPole piece

The invention provides a lithium-ion battery and an electrolyte thereof. The electrolyte of the lithium-ion battery comprises a lithium salt and a non-aqueous solvent and at least comprises 1,3-propane sultone, fluorinated ethylene carbonate and a pyrimidine-structural compound additive. The lithium-ion battery comprises a positive pole piece, a negative pole piece, a diaphragm spaced between the positive pole piece and the negative pole piece which are adjacent, and an electrolyte, wherein the electrolyte is the electrolyte of the lithium-ion battery provided by the invention. According to the lithium-ion battery and the electrolyte thereof, provided by the invention, the oxidation reaction between the electrolyte and a positive-pole material can be inhibited, so that the cycle performance under the conditions of high temperature and pressure is improved.

Owner:NINGDE AMPEREX TECH

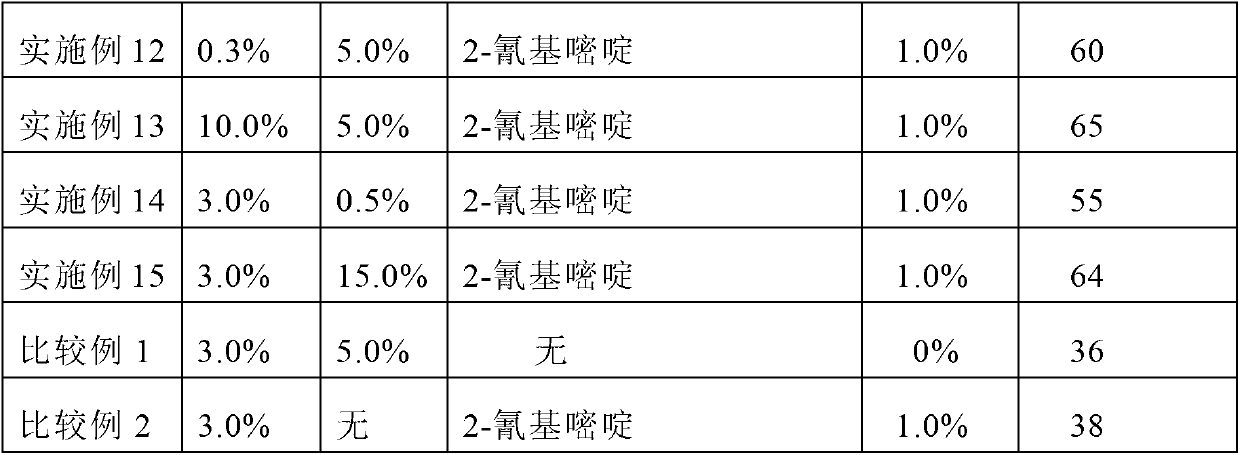

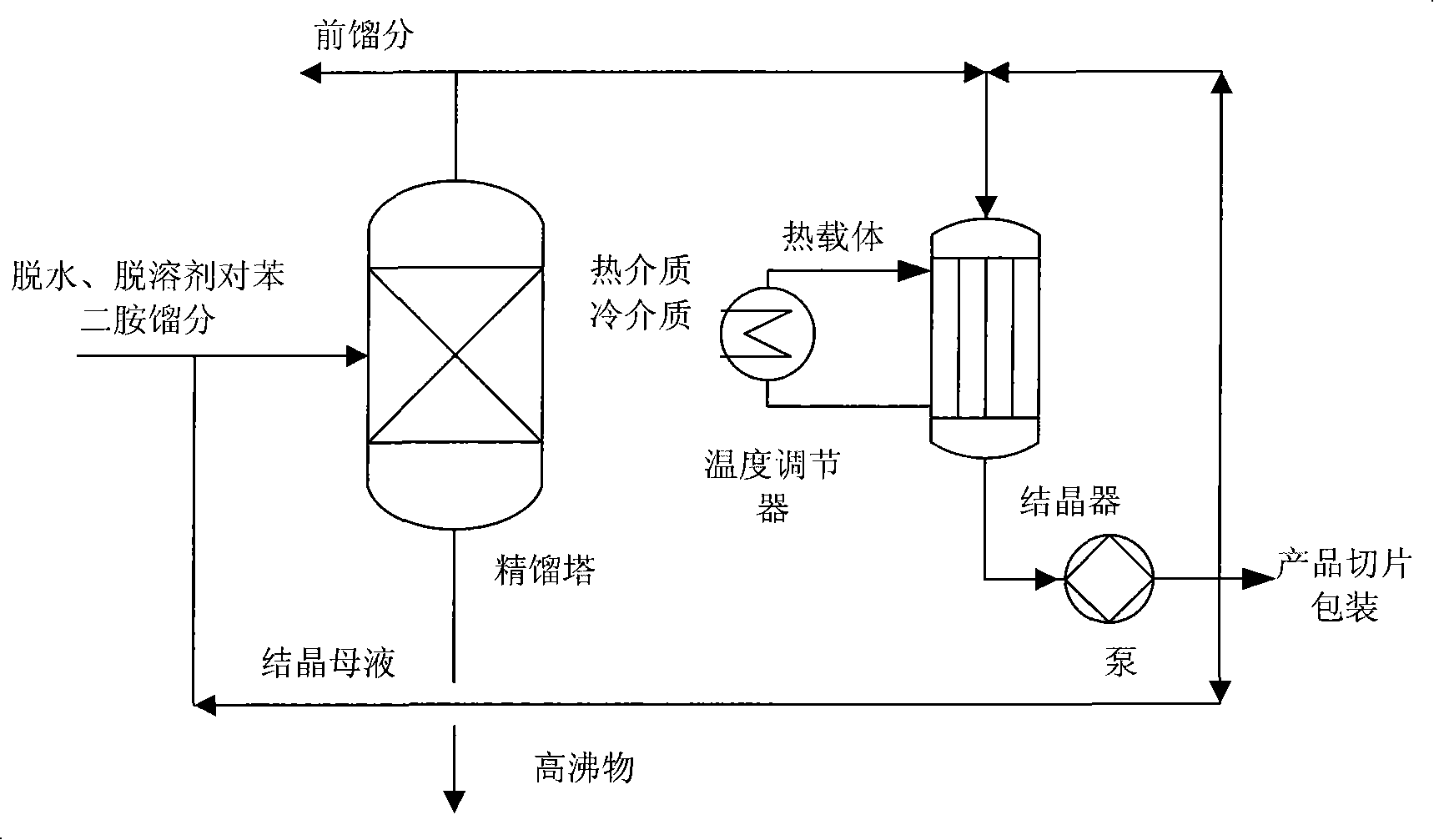

Method for refining p-phenylene diamine

The invention provides a refining method of p-phenylenediamine, which combines distillation and melting crystallization, uses the distillation product condensate to directly process melt crystallization for purification and processes fractional crystallization composed of one crystallization at least and one transpiration to obtain high-purity product. The invention combines distillation and melting crystallization to refine p-phenylenediamine and the invention can obtain high-purity and high-qaulity p-phenylenediamine product whose purity can reach 99.99-99.999% via controlling operation parameters, while the product quality can satisfy the quality demand of polymerization level product and the high-quality p-phenylenediamine can not be produced only by distillation. The refining method of p-phenylenediamine has the advantages of high product purity and flexible production set according to different standards, high yield of high-quality product and low cost, while the operation is processed without solvent to reduce pollution.

Owner:上海鸿源鑫创材料科技有限公司 +2

Lithium ion secondary battery and electrolyte thereof

ActiveCN103078140BAvoid oxidation reactionsImprove cycle performanceSecondary cellsHydrogen atomHydrogen

Owner:NINGDE AMPEREX TECH

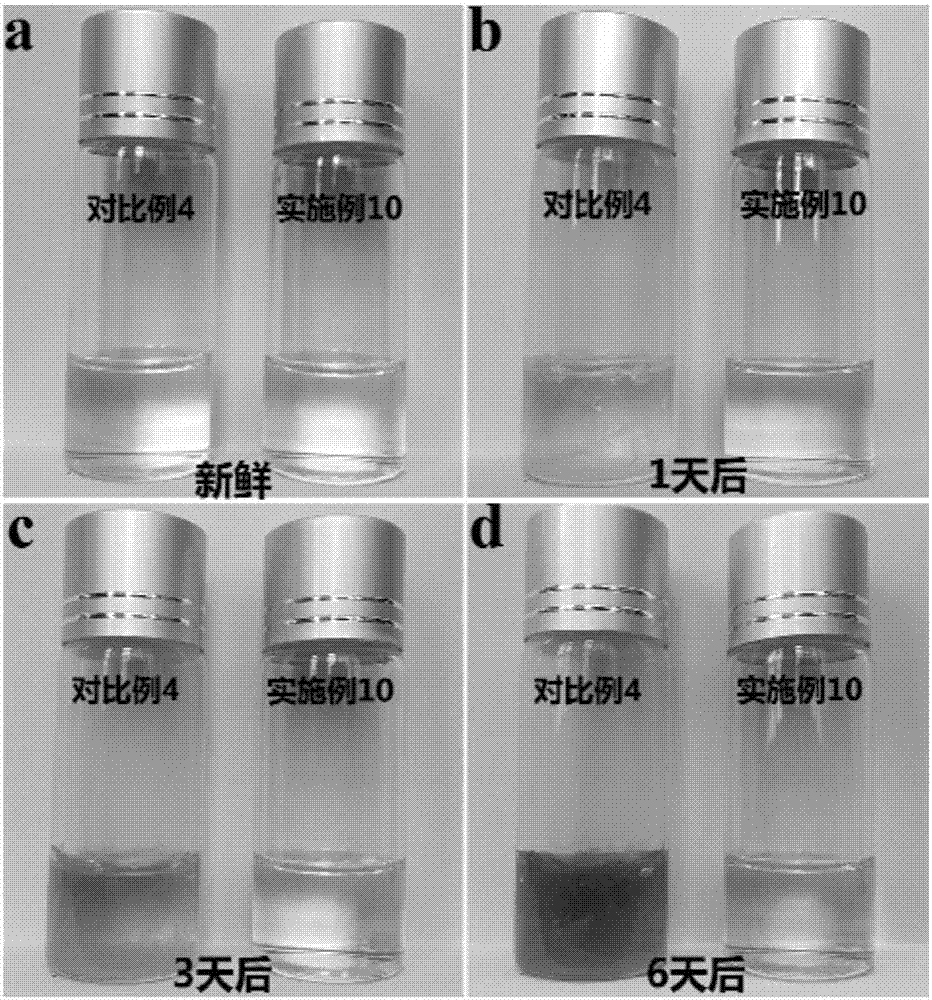

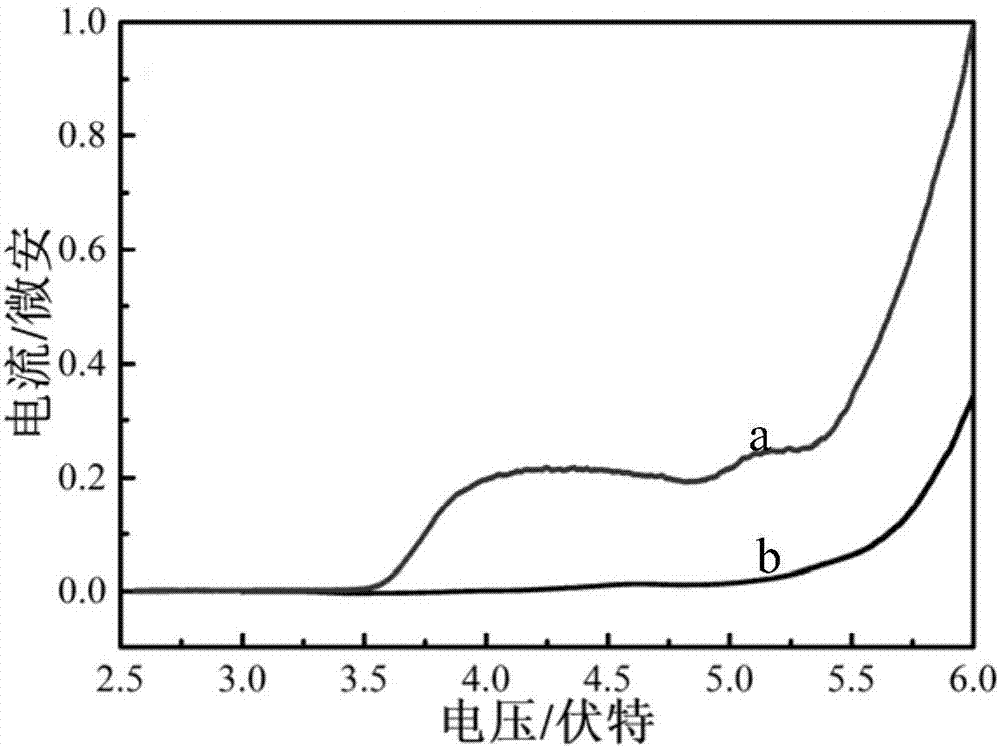

Electrolyte and lithium-ion battery using the same

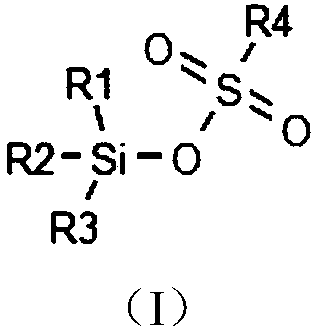

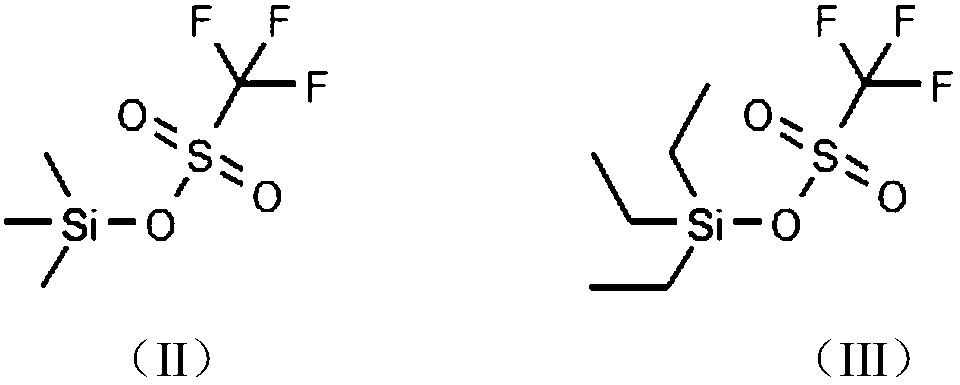

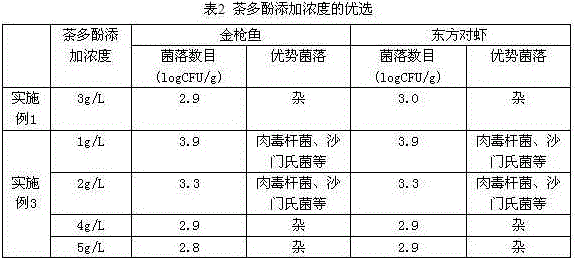

ActiveCN109585925ALower oxidation potentialImprove toughnessSecondary cellsOrganic electrolytesCyclic processSilanes

The invention discloses an electrolyte and a lithium-ion battery using the same. The electrolyte comprises a non-aqueous solvent, a lithium salt and additives, wherein the additives comprise vinylenecarbonate, vinylethylene carbonate and fluoroethylene carbonate, and further comprises sulfonate and / or sulfate compounds containing silane functional groups, wherein the alkyl groups in the silane functional groups are independently selected from alkanes or olefins of which the number of carbon atoms is 1-3, or the alkanes or olefins of which the number of halogen-substituted carbon atoms is 1-3.The sulfonate or sulfate compounds can generate a dense and tough passivation film on the surface of a positive electrode material, effectively suppress the oxidation reaction in the system, and playa positive electrode protection role. And meanwhile, the compounds can synergize with other additives to form a dense and stable SEI film on the surface of a negative electrode, effectively prevent the reduction reaction of the electrolyte on the surface of the negative electrode and the deposition of transition metal, improve the interface between the negative electrode and the electrolyte, slowdown the secondary reaction of the electrode interface in a storage or circulation process, and further improve the battery performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

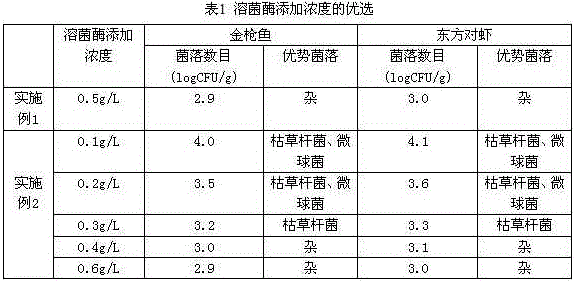

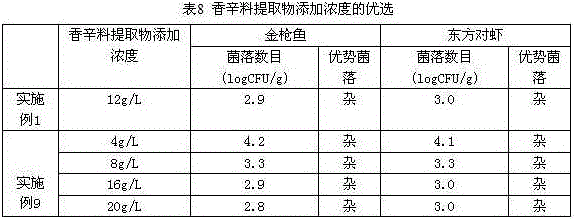

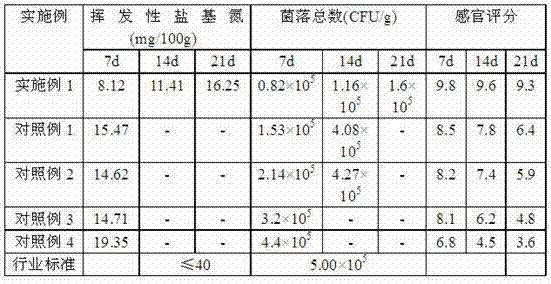

Formula of aquatic product composite preservative

InactiveCN106259830AStrong Broad Spectrum ResistanceEnhanced inhibitory effectNatural extract food ingredientsMeat/fish preservation using chemicalsPropolisAllium sativum

The invention relates to a formula of an aquatic product composite preservative. The formula of the aquatic product composite preservative is characterized in that the aquatic product composite preservative in each liter of distilled water comprises the following components: 0.4 to 0.6 g of muramidase, 2.5 to 3.5 g of tea polyphenol, 16 to 20 g of carboxymethyl chitosan, 10 to 14 g of nisin, 25 to 35 g of potassium sorbate, 17 to 23 g of sodium alginate, 20 to 30 g of lactobacillus, 1.5 to 2.5 g of propolis extracts and 10 to 14 g of spice extracts; and the spice extracting liquid comprises the raw materials: galangal, garlic, onion, cinnamon, clove and rosemary. The aquatic product composite preservative provided by the invention is prepared by compounding biological preservatives, is safe and non-toxic, has simple preparation and application methods, prominent microbial inhibition effect and good preservation effect, can greatly prolong the shelf life of frozen aquatic products, and has important industrial value.

Owner:黎建波

Lithium ion secondary battery and electrolyte thereof

ActiveCN103199302AAvoid oxidation reactionsImprove cycle performanceSecondary cellsHigh pressureSolvent

Owner:NINGDE AMPEREX TECH

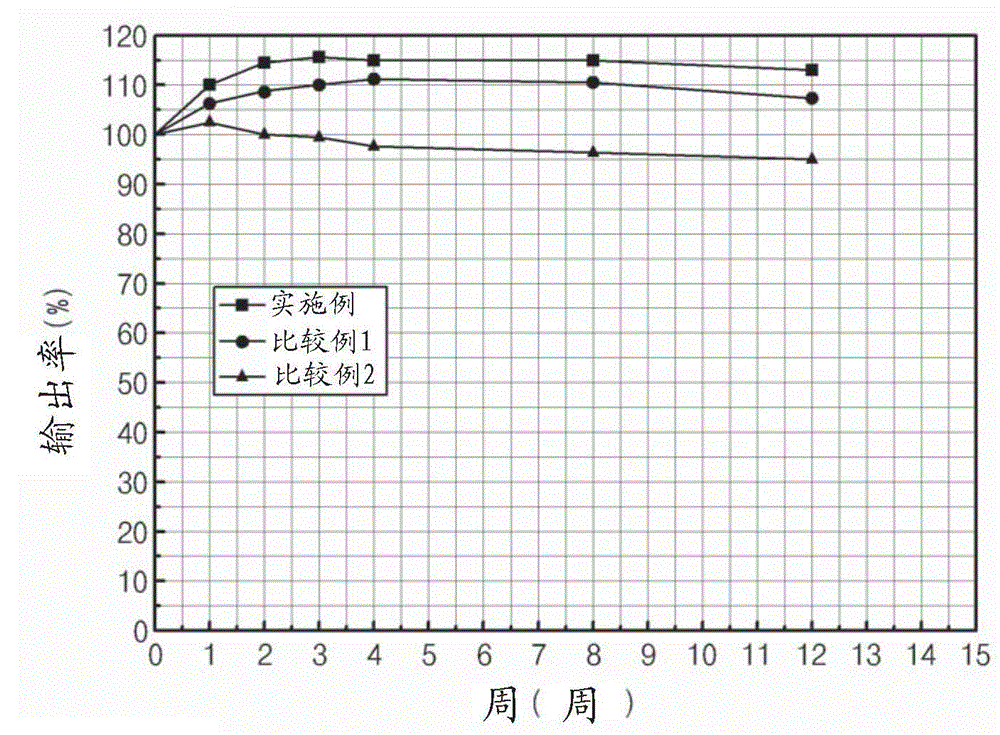

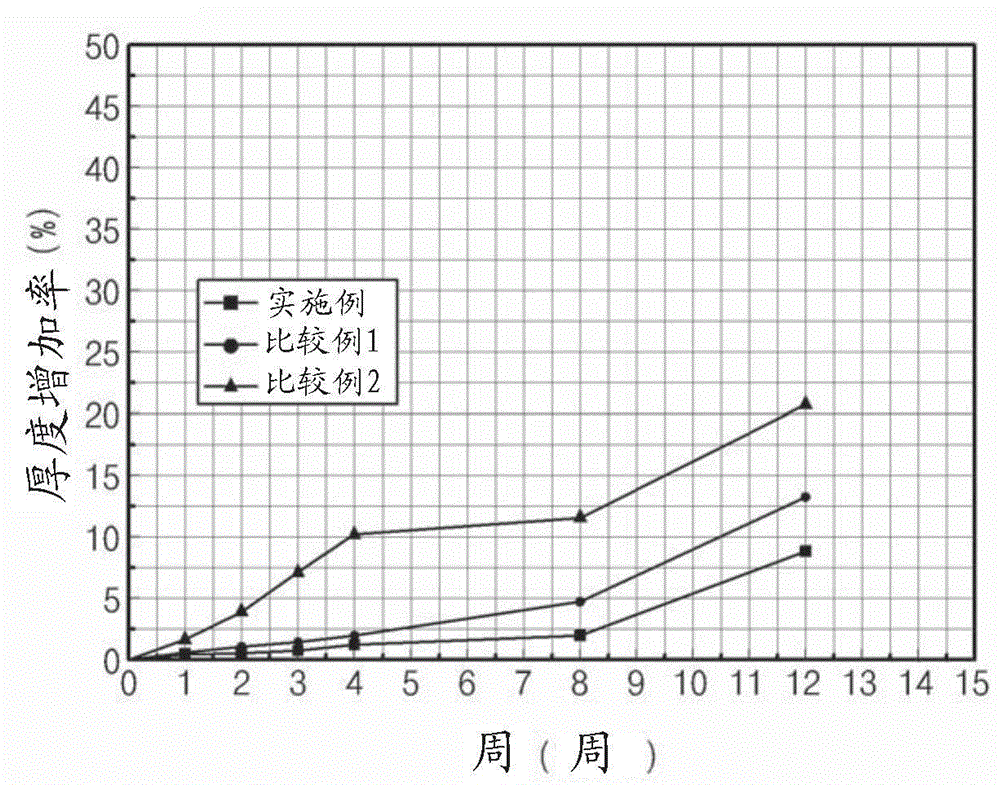

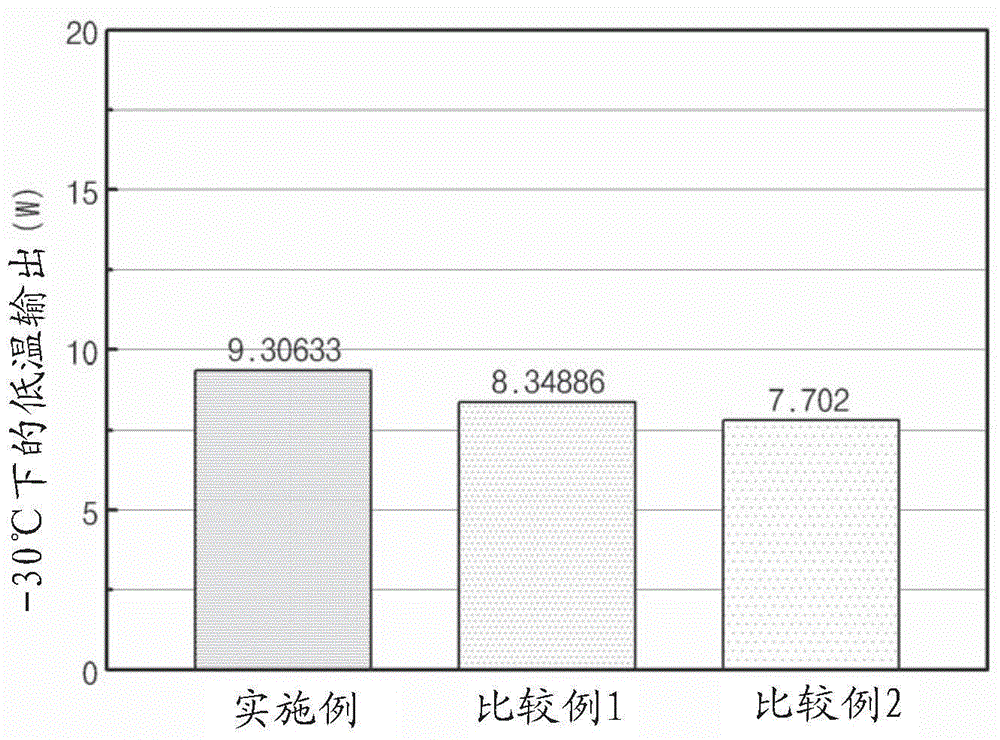

Electrolyte additive for lithium secondary battery, non-aqueous electrolyte comprising electrolyte additive, and lithium secondary battery

ActiveCN104823319AAvoid oxidation reactionsInhibition of swellingCell electrodesLi-accumulatorsImideOrganic solvent

The present invention provides a non-aqueous electrolyte comprising: a non-aqueous organic solvent; an imide-based lithium salt; and, as an electrolyte additive, at least one additive selected from the group consisting of lithium difluorooxalate phosphate (LiDFOP), trimethylsilylpropyl phosphate (TMSPa), 1,3-propenesultone (PRS), and ethylene sulfate (Esa). The electrolyte additive for a lithium secondary battery of the present invention can suppress the PF6- decomposition of a positive electrode surface, which may occur at the time of high-temperature cycle operation of a lithium secondary battery, and prevent an oxidation reaction of an electrolyte, thereby improving output characteristics at high and low temperatures and suppressing a swelling phenomenon.

Owner:LG ENERGY SOLUTION LTD

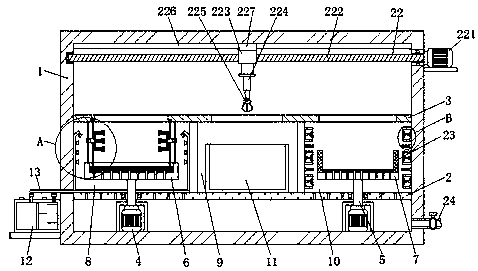

Rust removal device of artware

PendingCN109536978AQuick and effective removalNo manual operationDrying gas arrangementsCleaning using toolsAcid washingEngineering

The invention discloses a rust removal device of an artware. The rust removal device comprises a box body; a first partition board and a second partition board are arranged inside the box body correspondingly, the outer side faces of the first partition board and the second partition board are fixedly connected with the inner side wall of the box body correspondingly, the left side and the right side of the inner bottom wall of the box body are fixedly connected with first driving motors correspondingly, and rotating rods are fixedly connected to the top ends of the output shafts of the two first driving motors correspondingly, and the top ends of the two rotating rods penetrate through and extend to the upper part of the first partition board. According to the device, an acid washing liquid is used for reacting with rusty chips on the artware, so that the rust chips on the artware can fall off conveniently, and cleaning water can be used for washing the rust chips and the acid washingliquid on the artware; and two electromagnetic valves are controlled, so that the washing water is closed when the acid washing liquid is needed, and the acid washing liquid is closed when the washing water is used; and the purposes of economical using the acid washing liquid and the washing water are effectively achieved.

Owner:湖州艺雅斋湖笔有限公司

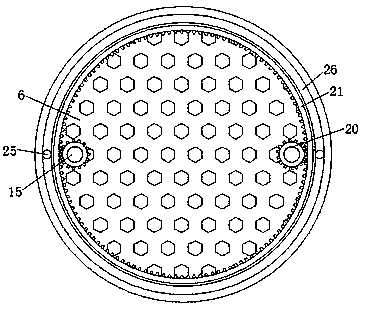

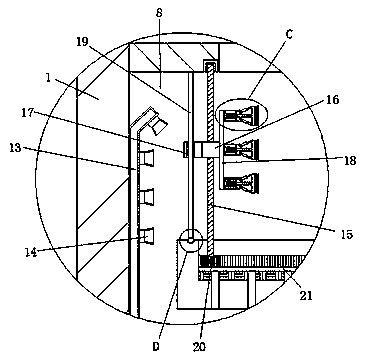

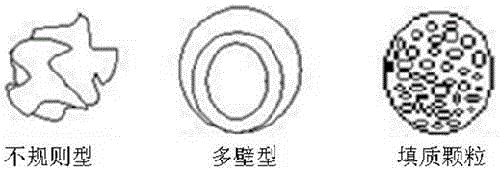

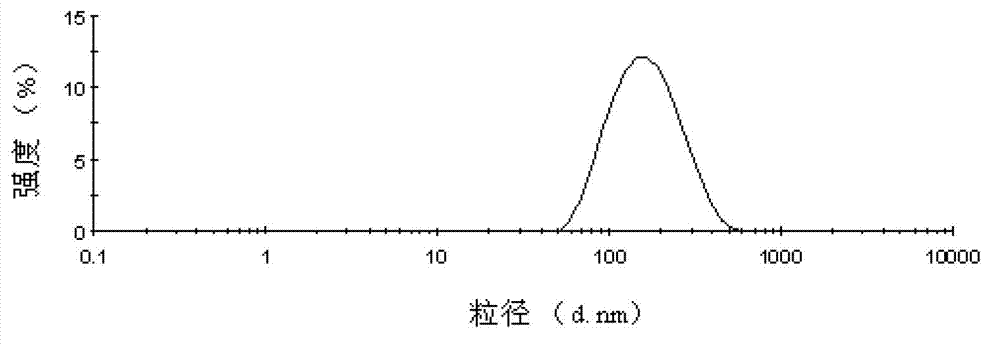

High specific energy battery pack internal flame-retardant cooling method

The present invention relates to the technical field of secondary battery pack manufacturing, and provides a high specific energy battery pack internal flame-retardant cooling method. According to the method, a flame retardant agent is subjected to a microencapsulation treatment and the treated flame retardant agent is filled inside the battery pack, such that the problem that the sharp temperature change caused by the electrical core short circuit and other failures causes firing burning even explosion can be solved. According to the present invention, the method has the following effects that after the temperature in the battery pack is increased to a certain value, the shell of the microcapsule filled with the flame retardant agent is rapidly dissolved or broken to release the flame retardant agent, and oxygen is consumed or diluted through the physical pathway of the isolation film forming on the local high-temperature area and the surrounding in the battery pack and the chemical pathway of the free radical terminating so as to achieve the functions of flame retardant effect and cooling, terminate the spreading of the high temperature area, eliminate and reduce the firing risk, and improve the safety performance of the battery pack; and the method has advantages of high safety and high reliability, and with the microcapsule flame retardant agent, the installation of the larger fire extinguishing device is avoided, and the advantages of lightweight and environmental protection are provided.

Owner:江苏海四达电源有限公司 +1

Lithium-ion battery and electrolyte thereof

ActiveCN103022556BAvoid oxidation reactionsImprove cycle performanceSecondary cellsPhysical chemistryPropane sultone

The invention provides a lithium-ion battery and an electrolyte thereof. The electrolyte of the lithium-ion battery comprises a lithium salt and a non-aqueous solvent and at least comprises 1,3-propane sultone, fluorinated ethylene carbonate and a pyrimidine-structural compound additive. The lithium-ion battery comprises a positive pole piece, a negative pole piece, a diaphragm spaced between the positive pole piece and the negative pole piece which are adjacent, and an electrolyte, wherein the electrolyte is the electrolyte of the lithium-ion battery provided by the invention. According to the lithium-ion battery and the electrolyte thereof, provided by the invention, the oxidation reaction between the electrolyte and a positive-pole material can be inhibited, so that the cycle performance under the conditions of high temperature and pressure is improved.

Owner:NINGDE AMPEREX TECH

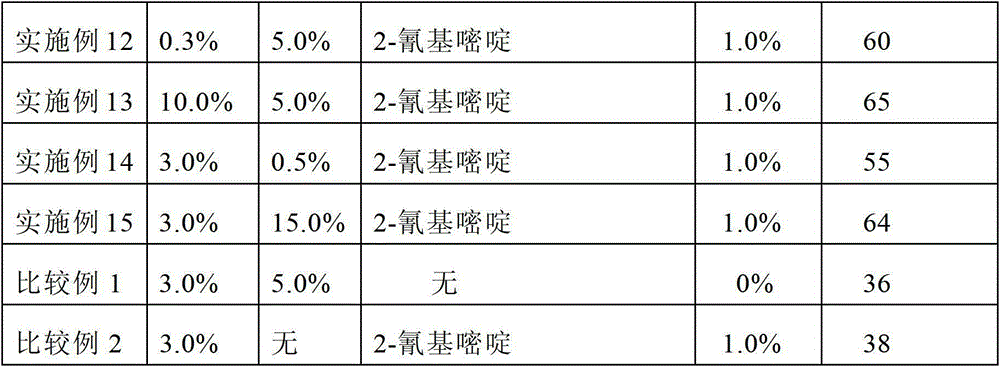

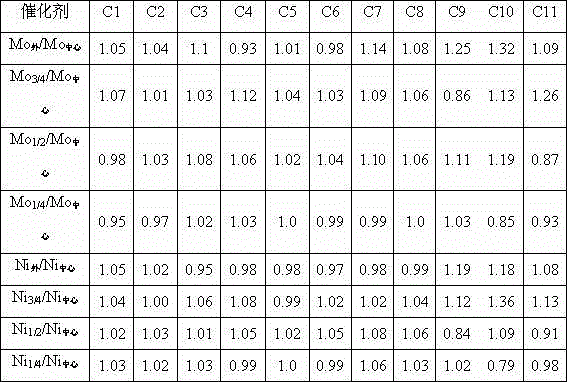

Method for preparing residual oil hydro-demetallization catalyst

ActiveCN104549328AEvenly distributedIncrease contentCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPolyol

The invention discloses a method for preparing a residual oil hydro-demetallization catalyst. The method comprises the following steps: (1) utilizing a polyhydric alcohol and / or a monosaccharide water solution for impregnation of an alumina carrier, carrying out hydrothermal carbonization treatment in a sealed vessel after the impregnation, and carrying out drying; (2) utilizing hydrogen peroxide for surface modification treatment of the alumina carrier which is hydrothermally carbonized in step (1), carrying out drying, loading the modified alumina carrier with active constituents, and carrying out drying again; (3) utilizing the alumina carrier which is loaded with the active constituents in step (2) for calcination in a nitrogen atmosphere or an inertia atmosphere, and then for calcination again in an oxygen-containing atmosphere to obtain the residual oil hydro-demetallization catalyst. The prepared residual oil hydro-demetallization catalyst is characterized in that the functions of the active constituents and a carrier are relatively poor, and the active constituents are uniformly distributed on the carrier, so that the active constituents are easy to vulcanize, and the demetallization activity and the desulfurization activity of the residual oil hydro-demetallization catalyst are obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Active component extraction method of plant polyphenol kind substance

ActiveCN1824084AAvoid oxidation reactionsHigh activityMagnoliophyta medical ingredientsPlant ingredientsMicrowaveActive component

A process for extracting the active polyphenol substances from the natural plants includes such steps as washing, drying, pulverizing, loading it along with the deoxidizing purified water in an extractor, heating at 50-90 deg.C under the protection of inertial gas while stirring for 30-60 min in order to extract the active components or ultrasonic or microwave extracting for 10-40 min 1-5 times, collecting liquid extract, filtering, cooling concentrating and drying.

Owner:谢君

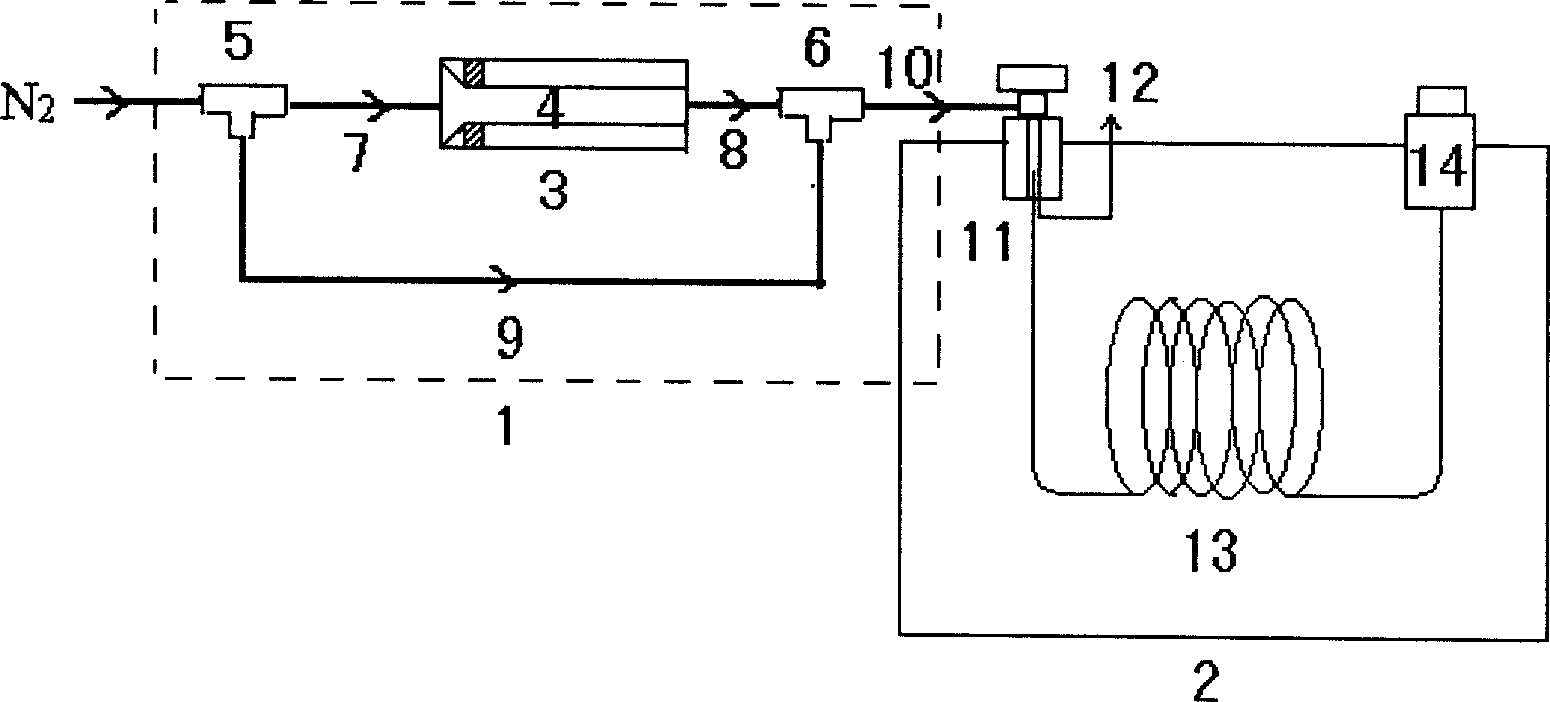

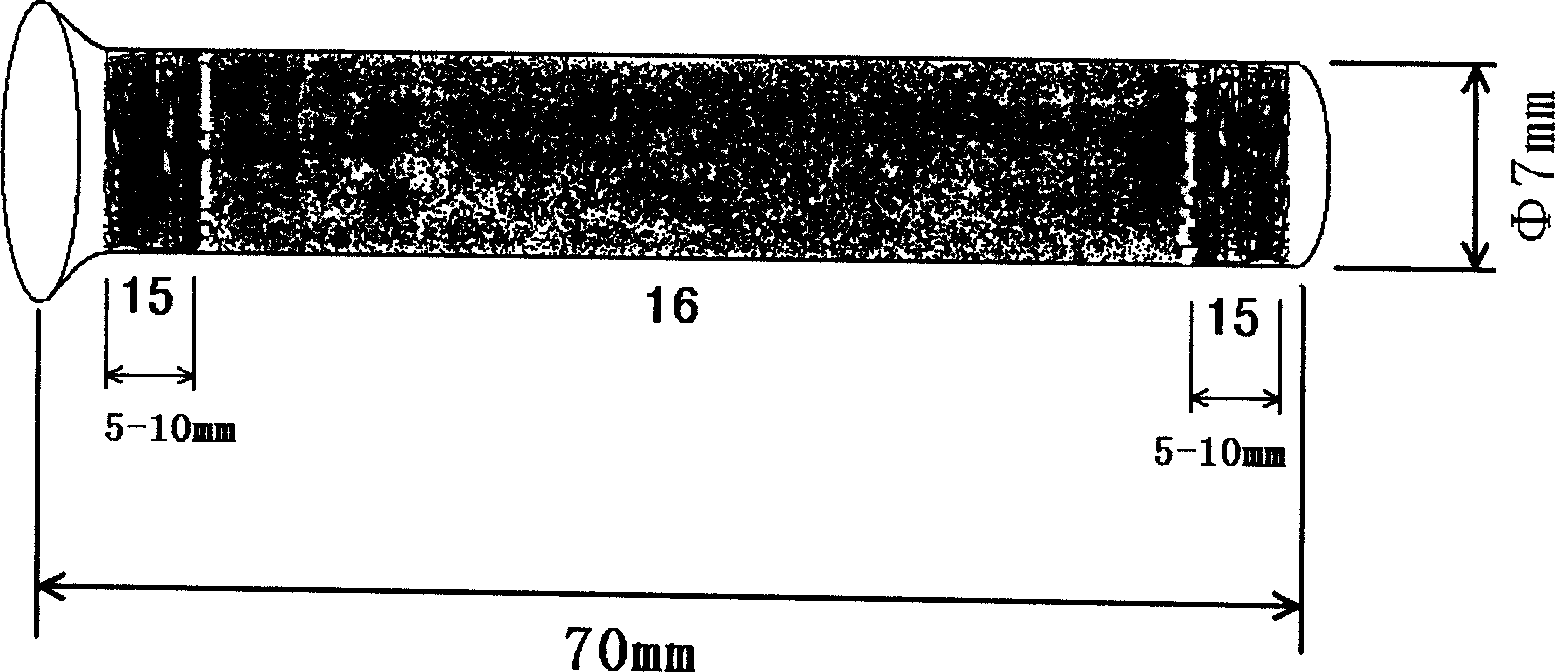

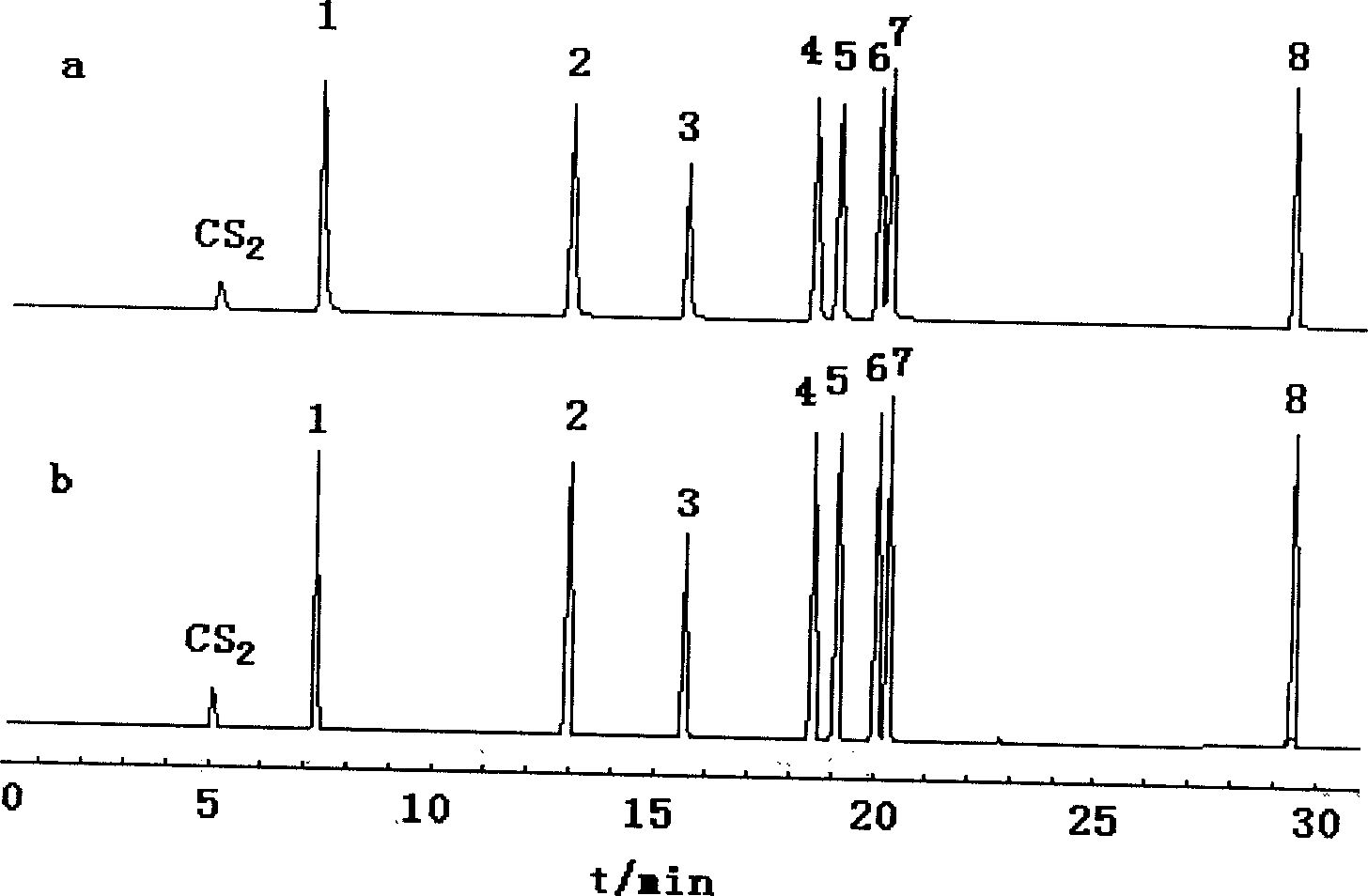

Determination method of volation organic metter in air

InactiveCN1719249AWon't widenDoes not cause wideningComponent separationWithdrawing sample devicesProtein secondary structureChromatography column

The present invention relates to a method for determining volatile organic compound in the air. Said method uses the sampling tube in which poly 2.6-diphenyl p-benzoether is held to collect air at normal temperature, the volatile organic compound can be adsorbed in the sampling tube, then the sampling tube is placed in first-order thermal desorption instrument to make thermal desorption, and the volatile organic compound can be fed into gas chromatograph from thermal desorption instrument with carrier gas to make separation and determination.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

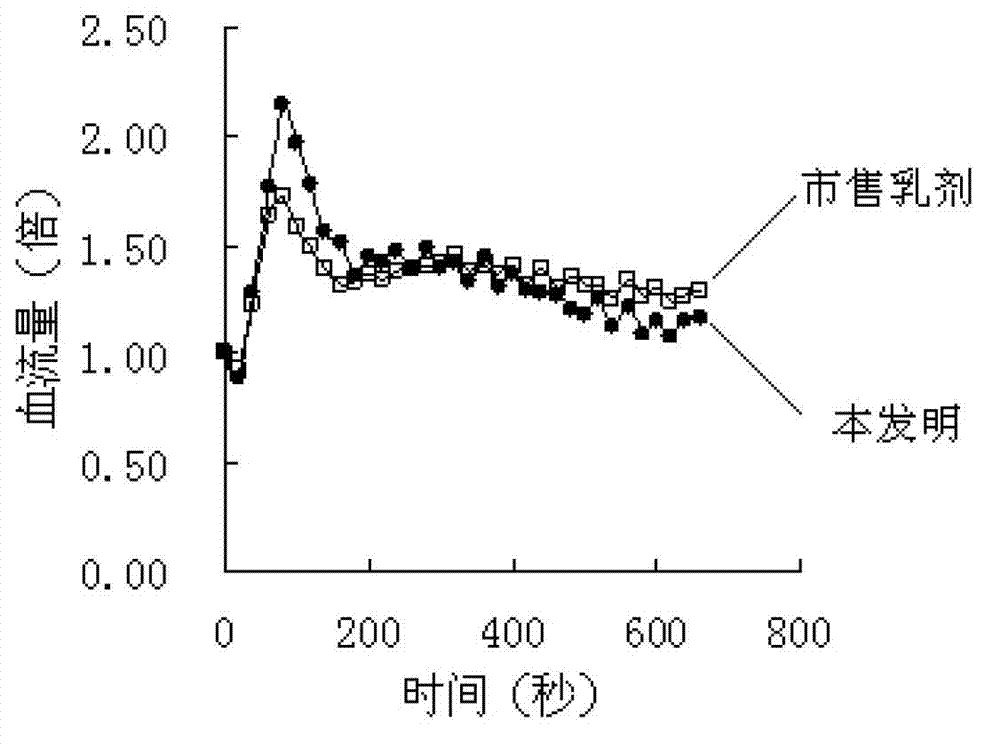

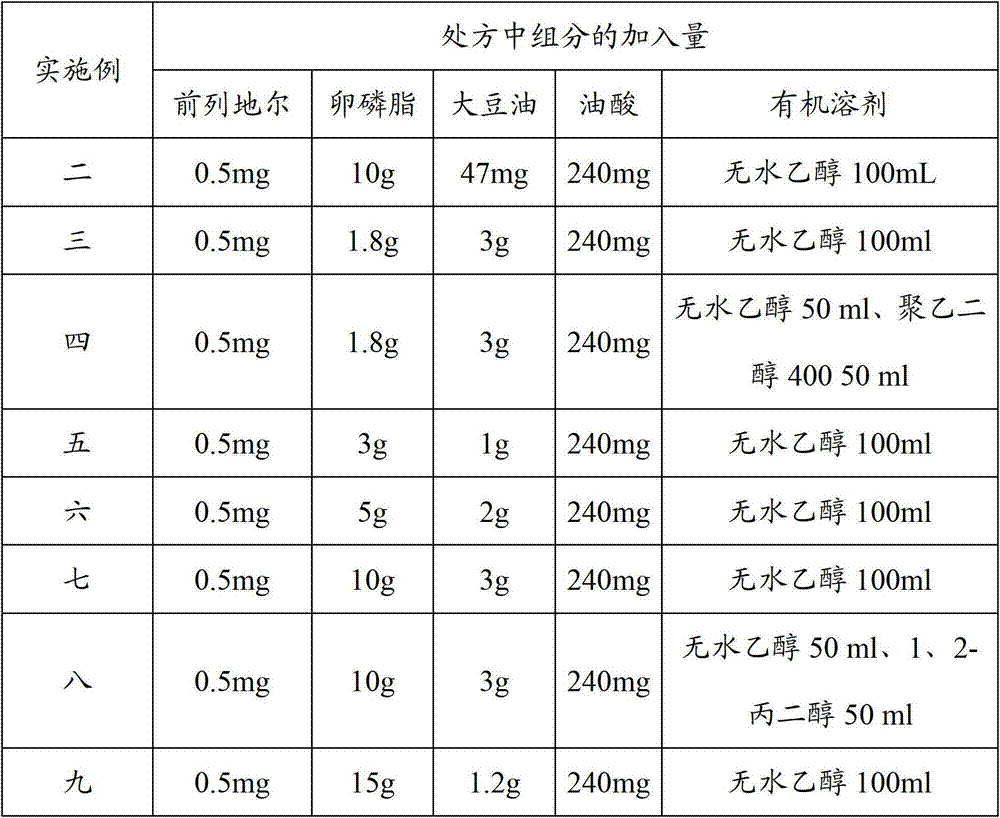

Alprostadil injection

ActiveCN103110579AAvoid oxidation reactionsImprove stabilityOrganic active ingredientsEmulsion deliveryDrugDegradation reaction

The invention belongs to the field of a pharmaceutical preparation, and in particular relates to an alprostadil injection. The injection consists of 0.001-0.05mg / ml of alprostadil, 0.01-100mg / ml of an oil phase, 10-500mg / ml of phospholipid and the balance of an organic solvent. The injection disclosed by the invention is constantly an anhydrous system in storage process, and is used right as long as being ready, so that the injection can prevent oxidization reaction of the phospholipid and degradation reaction of the medicine, and can improve the stability of the alprostadil injection. An alprostadil composition provided by the invention can prepare the alprostadil injection which is excellent in stability, and the preparation process is quite simple.

Owner:北京德立英捷医药科技有限公司

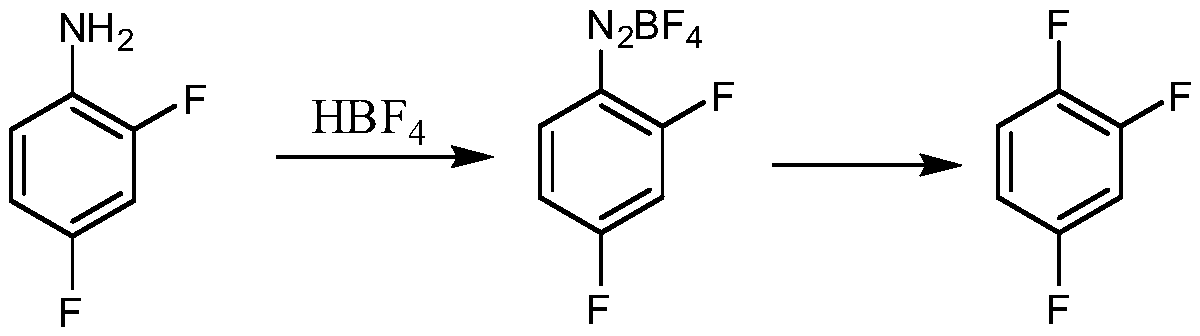

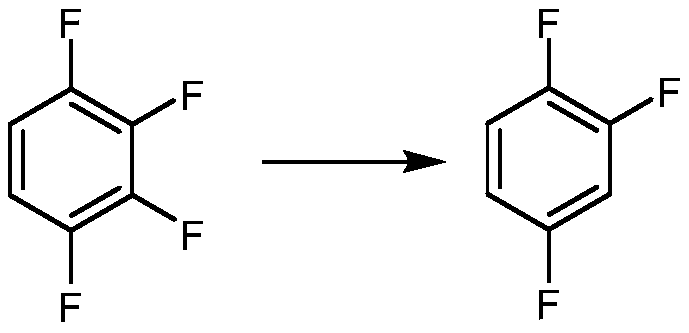

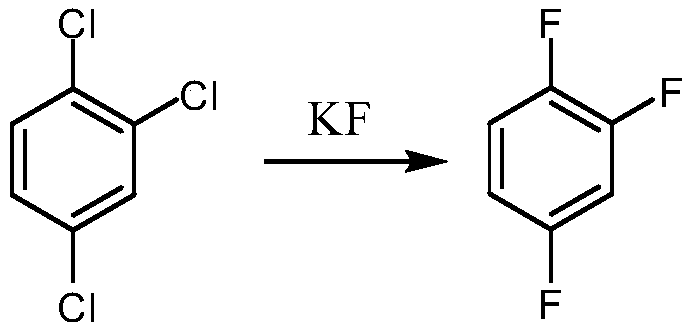

Synthetic method for 1,2,4-trifluorobenzene

ActiveCN110498730ALow costEasy to realize industrializationOrganic compound preparationSulfuric acid amide preparationNitrosylsulfuric acidPotassium fluoride

The invention provides a synthetic method for 1,2,4-trifluorobenzene, belongs to the field of pesticide, medicine, and liquid crystal material intermediate preparation, and solves the problem of harshreaction conditions of a current method for synthesizing 1,2,4-trifluorobenzene. The synthetic method for the 1,2,4-trifluorobenzene is characterized by comprising the following steps: performing nitration by using 2,4-dichlorofluorobenzene as a raw material and nitric acid as a nitrating agent to form 2,4-dichloro-5-fluoronitrobenzene in the presence of sulfuric acid; dissolving the 2,4-dichloro-5-fluoronitrobenzene into an organic solvent, adding potassium fluoride and a first catalyst, and performing fluorination under the catalysis of the first catalyst to obtain 2,4,5-trifluoronitrobenzene; dissolving the 2,4,5-trifluoronitrobenzene into a solvent, and performing hydrogenation reduction with hydrogen under the catalysis of a second catalyst to obtain 2,4,5-trifluoroaniline; and performing a reaction on the 2,4,5-trifluoroaniline and sulfuric acid, after a salt is formed, performing a diazotization reaction on the salt and nitroso-sulfuric acid, performing a deamination reductionreaction with sodium hypophosphite under the catalysis of a copper salt, and finally performing steam distillation to obtain the 1,2,4-trifluorobenzene. The method provided by the invention has the advantages of mild reaction conditions and the like

Owner:ZHEJIANG LINJIANG CHEM

an alkaline battery

ActiveCN102299323AImprove discharge capacityPromote circulationFinal product manufactureAlkaline accumulator electrodesBorideChemical reaction

The invention discloses an alkaline cell, belonging to the field of alkaline cells. Evenly dispersed borides are selected as negative electrode materials of the alkaline cell; and the borides are obtained by thermally treating precursors obtained through solution chemical reaction and cooling-vacuum treatment at low temperature. The alkaline cell with the negative electrode materials has the advantages of high discharge capacity and good cycle performance. In the method for preparing the borides in the negative electrode materials of the alkaline cell, a reactor is placed in an environment with the temperature being minus 20 DEG C to 4 DEG C, thus the temperature of a reaction system can be reduced, and the reaction can be carried out the mildly. The cooling-vacuum treatment at the low temperature is used to restrain the generation of grain agglomeration effectively, thus the borides with high specific area and even grain size distribution are obtained.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

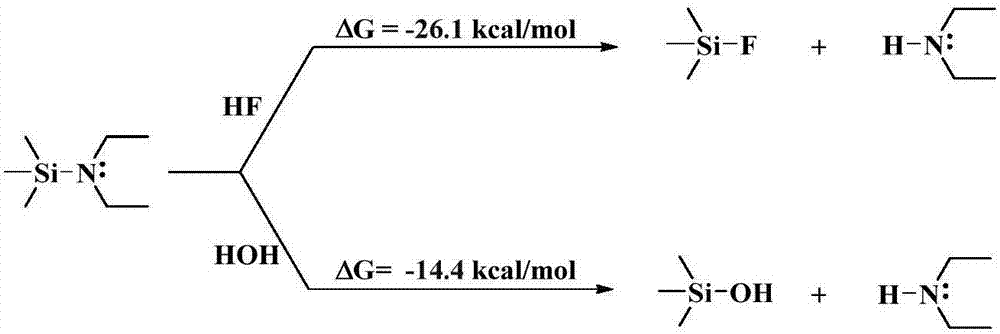

Lithium ion battery electrolyte with consideration to water removal, acid reduction and improvement of high-voltage performance

The invention discloses lithium ion battery electrolyte with consideration to water removal, acid reduction and improvement of high-voltage performance, and relates to lithium ion batteries. The lithium ion battery electrolyte with the consideration to the water removal, the acid reduction and the improvement of the high-voltage performance comprises, by weight, 5.0%-18.0% of lithium salt, 83.0%-94.0% of non-aqueous organic solvents, 0.1%-5.0% of silazane additives and 0.1%-5.0% of other functional additives. The lithium ion battery electrolyte has the advantages of simple preparation process,low cost, easiness in implementation and good market prospect.

Owner:XIAMEN UNIV

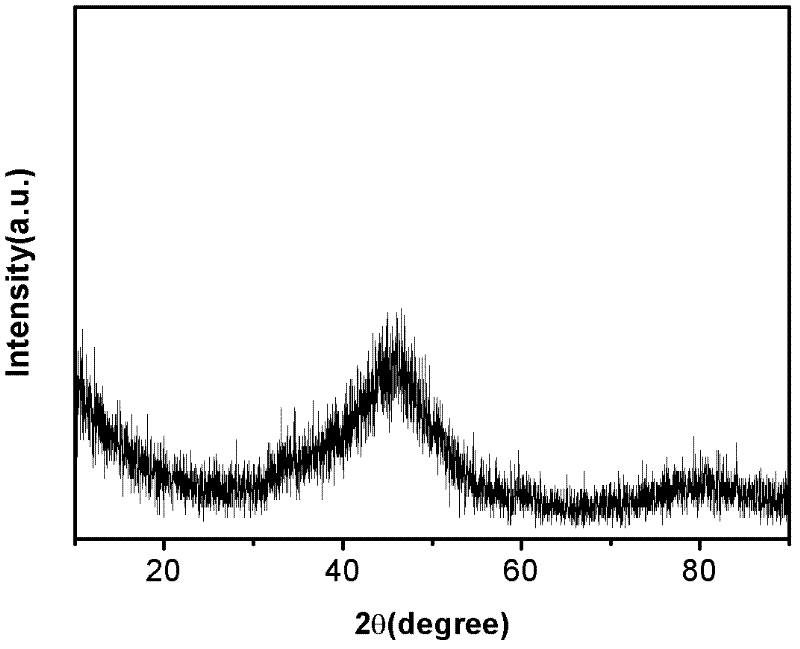

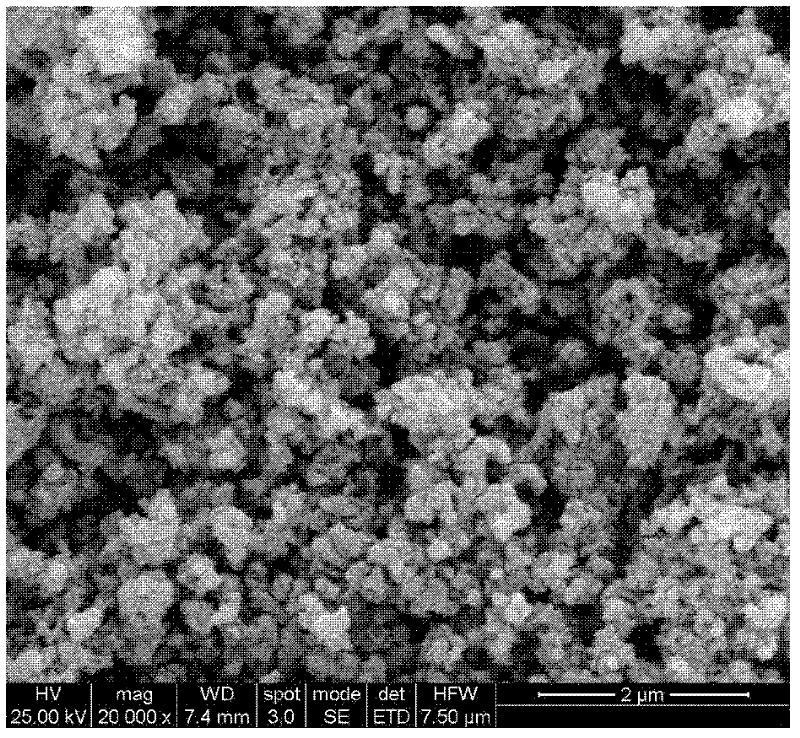

Hydroborate hydrolysis catalyst for preparing hydrogen and its preparation method

InactiveCN102350356ANarrow size distributionLow costHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsBorideChemical reaction

The invention discloses a hydroborate hydrolysis catalyst for preparing hydrogen and its preparation method, belonging to the technical field of hydrogen production and energy sources. The chemical composition of the catalyst is represented as MxB, wherein, M represents one or more of Fe, Ti, Cu, Zn, Al, Zr, Nd, Mo, V, Cr, Co, Ni, Ag or Mg, x is no less than 1 and no larger than 4 and can be a non-integer. The catalyst comprises a monodispersed boride material, and the catalyst has high specific surface area, uniform particle size distribution, and high catalytic activity, and the dehydrogenation rate can reach more than 95 %. The invention also discloses a preparation method of the catalyst, characterized by carrying out solution chemical reaction and vacuum freeze treatment at low temperature to obtain a predecessor, then carrying out heat treatment to obtain the catalyst. The preparation method has the advantages of rapid early-stage reaction, simple and convenient post-treatment and strong operability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for preparing boron nitride/sialon ceramic composite material by using boron-rich slag

The invention relates to a preparation method of boron nitride / sialon composite material by adopting boron-rich slag. The preparation method comprises two steps: the first step is that synthesis sialon powder BN / (Ca, Mg) Alpha' : 1. crushing, 2. ball milling, 3. screening, 4. magnetic separating, 5. proportioning according to mass percent: 7.94 to 45.79 portions of boron-rich slag, 12.19 to 58.78 portions of silicon fume, 3.82 to 19.78 portions of bauxite, 21.70 to 35.41 portions of carbon black, 6. wet mixing with anhydrous ethanol as the medium, 7. drying with the temperature 60 DEG C; 8. dry mixing, 9. molding forming, 10. high-temperature sintering under one atmospheric pressure, temperature of 1450 to 1500 DEG C, insulation for 6 to 10 hours and protection of nitrogen; 11. eliminating carbon residual by burning; the second step is that mixing the powder obtained by the first step and additive CaCO3, and after the molding forming, the final product sialon ceramic composite material BN / (Ca, Mg) Alpha' is made by sintering through burying powder in furnace under temperature 1600 to 1700 DEG C; all properties of the product are good. The invention has simple process, low production cost, and starts a new way for boron-rich slag integrating utilization and decreases environment pollution.

Owner:NORTHEASTERN UNIV

Pseudosciaena crocea ice temperature fresh-keeping method

InactiveCN102511538AImprove the bactericidal effectReduce the temperatureMeat/fish preservation by freezing/coolingFlavorIce water

The invention discloses a pseudosciaena crocea ice temperature fresh-keeping method, which comprises the steps of: ice spreading box loading, ice water cleaning, fluidized ozone ice pre-cooling, heat insulation box loading and ice temperature storage. The ozone ice and the fluidized ozone ice are sequentially adopted, the dual effects of lowering the fish body temperature and inhibiting the germ propagation are realized, further, the ice temperature storage is adopted, the freezing of the pseudosciaena crocea in the storage process is avoided, the original flavor and the fresh degree of the pseudosciaena crocea are more perfectly maintained, the quality guarantee period of the pseudosciaena crocea is greatly prolonged, and the pseudosciaena crocea is still fresh after being stored for 21 days.

Owner:福建海鑫龙水产发展有限公司

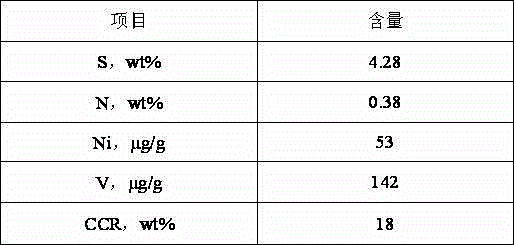

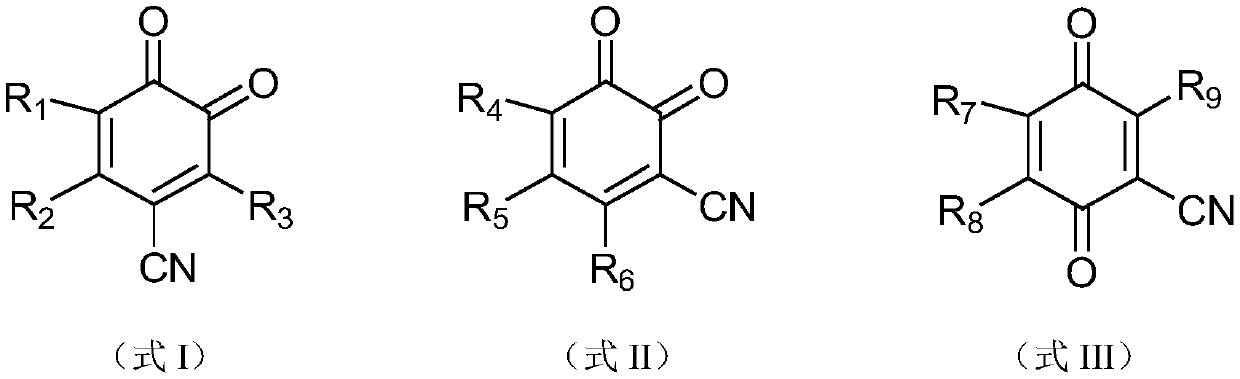

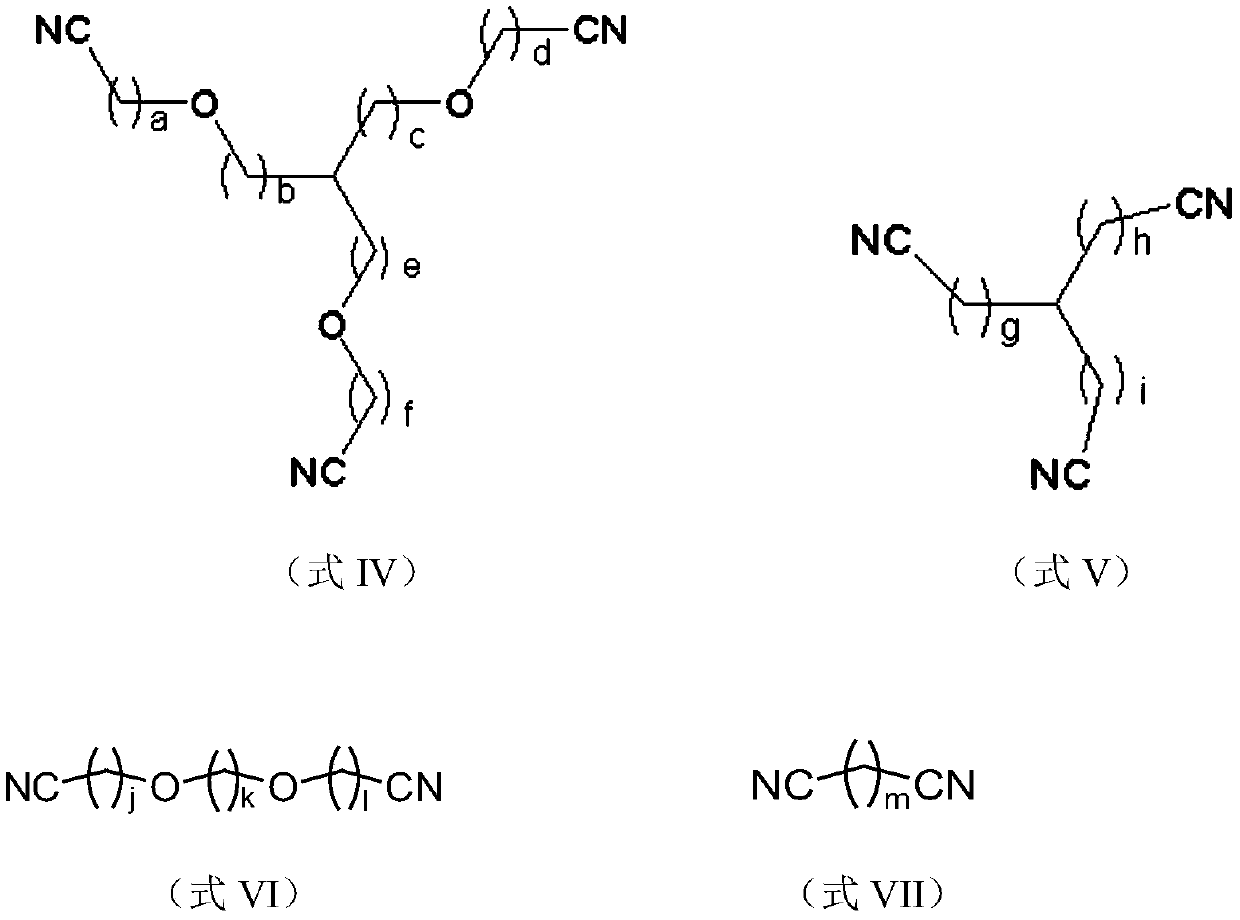

Electrolyte and electrochemical device comprising same, and electronic device

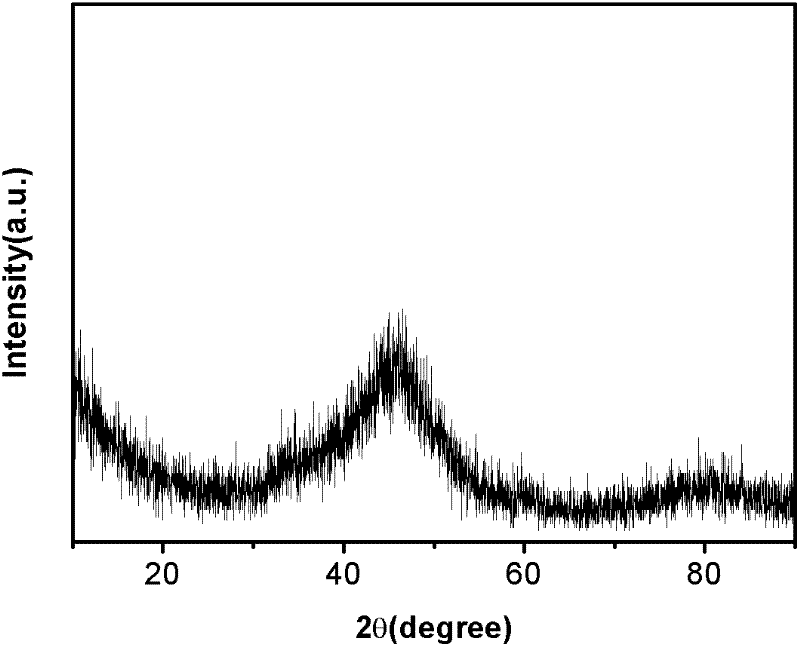

ActiveCN110429335AAvoid oxidation reactionsHigh battery capacity retentionOrganic chemistrySecondary cells servicing/maintenanceHigh temperature storageBenzoquinone Compound

The present application relates to an electrolyte and an electrochemical device comprising the same, and an electronic device. The electrolyte comprises one or more nitrile benzoquinone compounds selected from the group consisting of compounds represented by a formula I, a formula II and a formula III, wherein substituents R1-R9 are respectively independently selected from the group consisting ofhydrogen, C2-C12 ether groups, C1-C12 alkoxy groups, halogens, C1-C12 alkyl groups, C2-C12 alkenyl groups, C2-C12 alkynyl groups, and C6-C26 aryl groups. The electrolyte can form a stable protective film on the cathode to effectively improve the cycle capacity retention rate and high-temperature storage performance of the electrochemical device.

Owner:NINGDE AMPEREX TECH

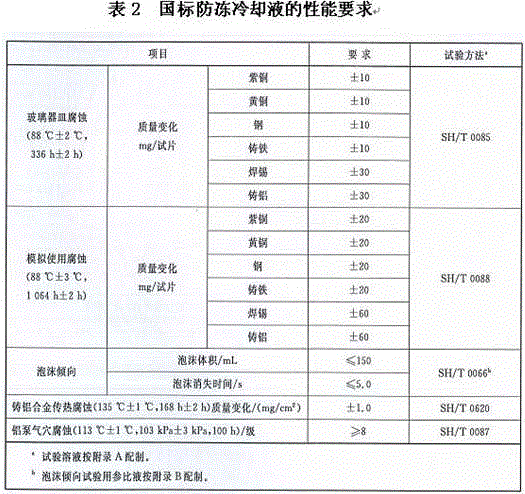

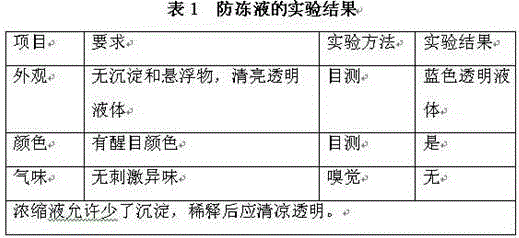

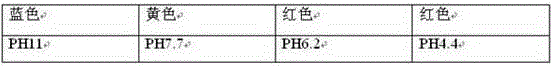

Variable color antifreezing solution composition formula and production process thereof

The invention relates to a variable color antifreezing solution composition formula and a production process thereof. According to the invention, triethanolamine, diethanolamine and monoethanolamine are adopted as the buffering agent to make the system maintain a weak alkaline system and cause no corrosion to metals, at the same time the finally added triethanolamine can passivate white oil and a metal surface contacting it to form a mineral oil protective film, and disodium edentate and butylated hydroxyanisole can effectively inhibit oxidation reaction. The invention can effectively prompt a user about the use condition of the antifreezing solution and remind the user to replace the antifreezing solution timely. The antifreezing solution system provided by the invention contains an organosilicon defoamer, only 0.01-0.1% of the defoamer can effectively inhibit the foam generation of the system, thereby effectively inhibiting a lot of air from entering an engine cooling system, and effectively inhibiting and reducing metal oxidation reaction. The formula provided by the invention does not involve fluorescein, and is safe and environment-friendly. The antifreezing solution does not contain toxic substance methanol and redundant organic solvents, and further alleviates the environmental load.

Owner:张强

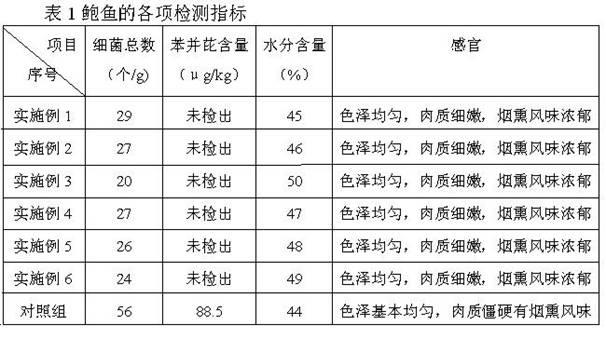

Processing method of liquid smoked abalone

ActiveCN102160673AImprove antioxidant capacityExtended shelf lifeFood preservationBiotechnologyMicroorganism

The invention discloses a processing method of liquid smoked abalone, comprising the steps of: carrying out pretreatment on the abalone, then using a liquid smoked agent for soaking treatment and salting under the vacuum condition, finally packaging, sterilizing and storing. In the processing method disclosed by the invention, the growth of microorganisms in the abalone product can be effectively restricted, the spoilage of the abalone is avoided, the abalone has special smoked flavor and the meat is fresh and smooth.

Owner:福州日兴水产食品有限公司

Brewing technology of yacon fruit vinegar

The invention provides a brewing technology of yacon fruit vinegar. Fresh and ripe yacon is used as the raw materials of the yacon fruit vinegar, and the yacon fruit vinegar is brewed by the steps of raw material processing, enzymolysis, sugaring, alcoholic fermentation, acetic fermentation, filtering, homogenizing, sterilization, canning and the like. According to the brewing technology, color protection treatment is conducted after the yacon is sliced, so that yacon pieces are prevented from being subjected to oxidizing reaction, and the color and luster of finished yacon fruit vinegar products are improved. Through complex enzyme treatment, nutrient substance in the raw materials is fully separated out, and the utilization ratio of the raw materials is improved. Yacon fruit vinegar primary pulp is homogenized repeatedly, so that the taste and the quality of the finished yacon fruit vinegar products are improved, and the yacon fruit vinegar is sour and sweet, excellent in quality and balanced in nutrition. The yacon fruit vinegar has the healthcare functions of keeping fit, improving human body immunity, clearing heat and the like.

Owner:彭常安

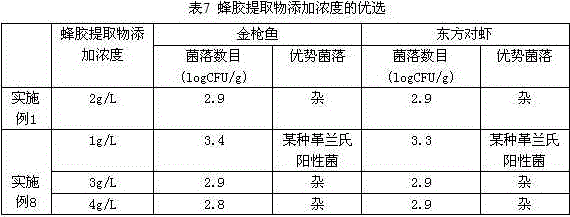

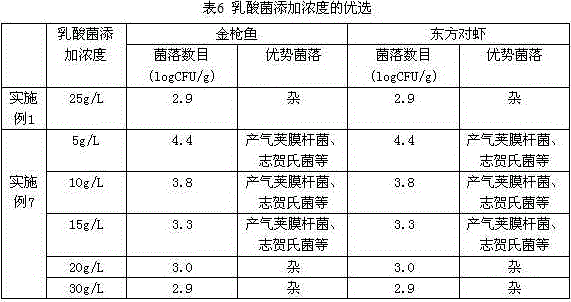

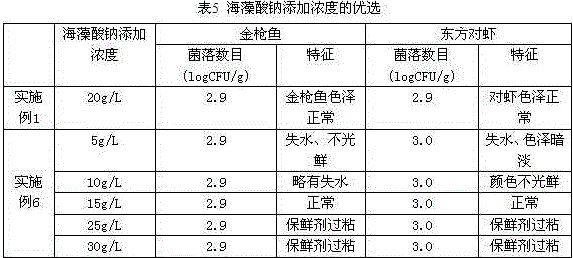

Biological-source nutritional preservative for seafood

InactiveCN106070538AStrong Broad Spectrum ResistanceEnhanced inhibitory effectStrepto/lacto-coccusNatural extract food ingredientsPropolisRosmarinus

The invention relates to a biological-source nutritional preservative for seafood. The biological-source nutritional preservative is characterized in that each liter of the distilled water of the biological-source nutritional preservative contains 0.4-0.6g of lysozyme, 2.5-3.5g of tea polyphenols, 20-28g of carboxymethyl chitosan, 10-14g of nisin, 17-23g of sodium alginate, 20-30g of lactobacillus, 1.5-2.5g of propolis extract and 10-14g of spice extract, wherein the spice extract is made of rhizoma galangae, garlic, onion, cinnamon, clove and rosemary. The biological-source nutritional preservative has the advantages that the biological-source nutritional preservative is compound by biological preservatives and is safe, nontoxic, simple in preparation and application method, outstanding in microorganism inhibition effect, good in preservation effect, capable of greatly prolonging the shelf life of the seafood and high in industry value.

Owner:黎建波

Green plum juice making method

The invention provides a green plum juice preparing process which comprises green prune sorting, afterripening, cleaning, choosing, sugar stain leaching, zymosis prevention by hot boiling, cold soaking and temperature control. The invention realizes a novel process for green prune finely processing and comprehensive utilization.

Owner:SOUTH CHINA AGRI UNIV

Anti-ultraviolet plastic woven-bag filament

InactiveCN103710787AEnhanced Anti-PurpleStay resilientConjugated synthetic polymer artificial filamentsArtifical filament manufactureWaxChemistry

The invention discloses an anti-ultraviolet plastic woven-bag filament. Through blending, melting, filtration, extrusion film-formation, water cooling, filament dividing, filament drawing and rolling, the anti-ultraviolet plastic woven-bag filament is prepared from 100 parts by weight of polypropylene, 10-12 parts by weight of polyoxymethylene, 20-24 parts by weight of linear low density polyethylene, 1.2-1.5 parts by weight of polyethylene wax, 3-3.5 parts by weight of an ethylene-methyl acrylate copolymer (EMA1125AC), 1.4-1.8 parts by weight of tributyl citrate, 0.4-0.8 parts by weight of turpentine, 0.4-0.6 parts by weight of a ultraviolet ray absorber (UV-531) and 3-3.5 parts by weight of an assistant. Through use of the ultraviolet ray absorber, ultraviolet resistance and oxidation resistance of the plastic woven product are improved, toughness of the existing plastic ribbon-like filament is kept and a cost is low. The plastic woven-bag prepared from the anti-ultraviolet plastic woven-bag filaments can effectively prevent an ultraviolet ray illumination-caused oxidation reaction so that the problem that the packaging bag prepared from the existing plastic ribbon-like filaments has a short service life.

Owner:ANHUI ANYUAN PLASTIC

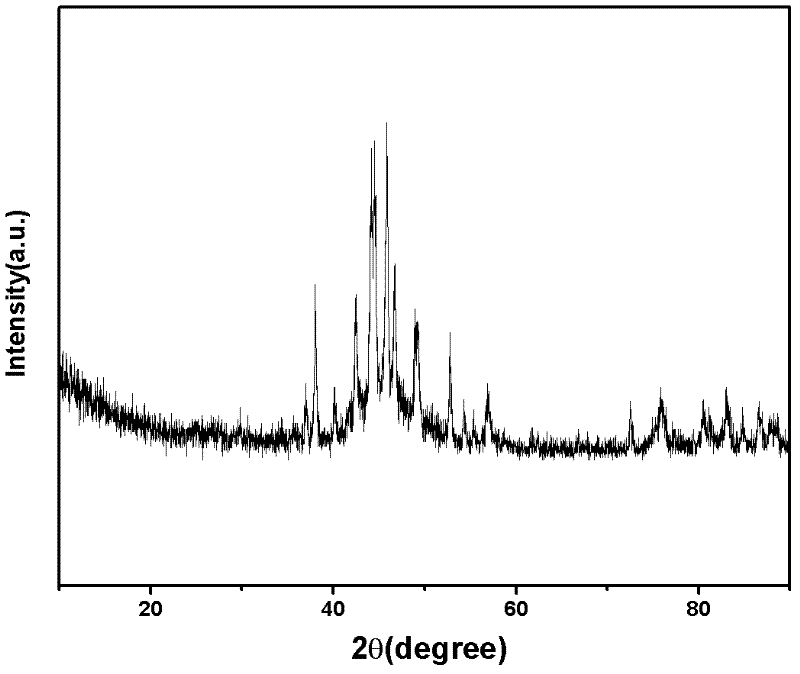

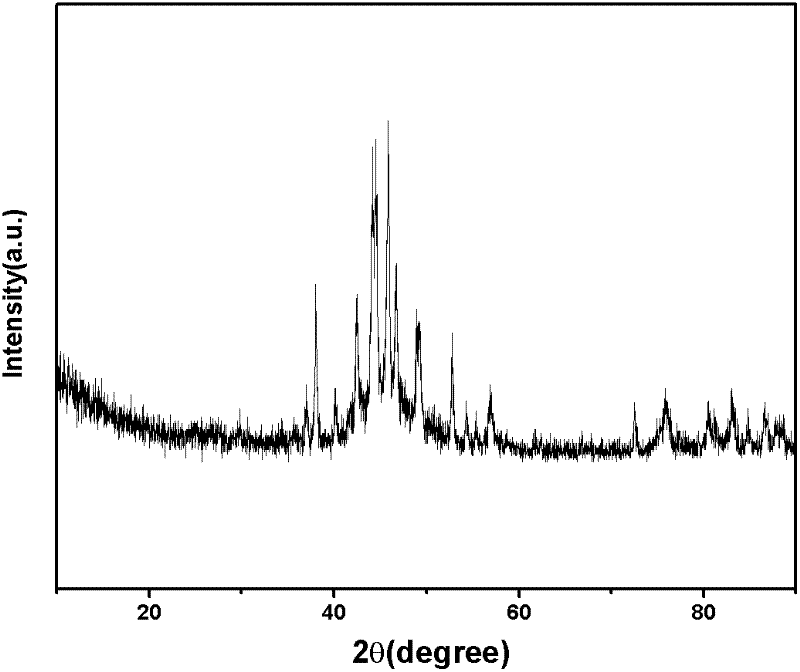

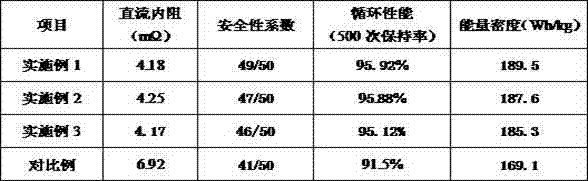

A preparing method of a Li(Ni<0.8>Co<0.1>Mn<0.1>)O2 ternary material

ActiveCN104766959AIncrease gram capacityImprove cycle performanceElectrode manufacturing processesSecondary cellsMaterials scienceLarge capacity

A preparing method of a Li(Ni<0.8>Co<0.1>Mn<0.1>)O2 ternary material is provided. The preparing method includes 1) a step of preparing a LiAlO2 solution, 2) a step of preparing Li(Ni<0.8>Co<0.1>Mn<0.1>)O2, and 3) a step of material cladding. The ternary material prepared by the method has characteristics of high capacity density (not less than 180 mAh / g), excellent cycle performance (with discharge capacity after 500 times of cycling being not less than 95%), high safety performance, and the like, and is particularly suitable for the field of electric cars, and other fields.

Owner:JIANGSU LENENG BATTERY INC

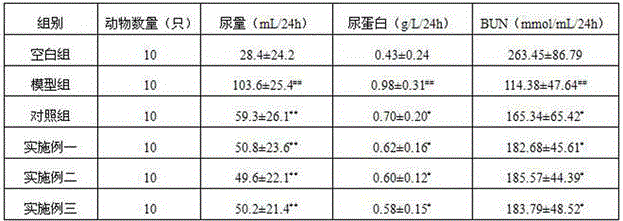

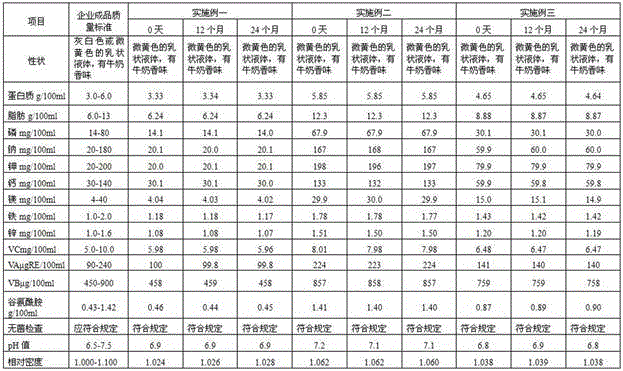

Enteral nutritional composition for patients with chronic renal disease and preparing method thereof

InactiveCN106307504AEssential amino acidsMeet needsSugar food ingredientsInorganic compound food ingredientsIntestinal structurePotassium

The invention discloses a composition for patients with chronic renal disease and preparing method thereof, and belongs to the technical field of medical food. The composition is prepared from, 33.4-58.6 g / l of protein, 62.5-123 g / l of fat, 204-305 g / l of carbohydrates, 5.0-20 g / l of dietary fiber, 0.14-0.68 g / l of phosphorus, 0.2-1.68 g / l of sodium, 0.2-2.00 g / l of potassium, 0.3-1.33 g / l of calcium, 0.04-0.30 g / l of magnesium, 1.0-2.25 mg RE / L of vitamin A, 4.6-8.6 mg RE / L of vitamin B complex, microelement, other vitamins, and water. The invention matches scientifically, and has high heat,low phosphorus ,sodium and potassium.The content of vitamin A is low while the content of vitamin B is high, conforming to the principle of nutrition support. The composition is easy to digest and is the main nutrient source of patients with chronic renal disease.

Owner:HUAREN PHARMACEUTICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com