A preparing method of a Li(Ni<0.8>Co<0.1>Mn<0.1>)O2 ternary material

A ternary material and material package technology, applied in electrode manufacturing, electrical components, electrochemical generators, etc., can solve the problems of difficulty in ensuring battery safety performance, narrow median particle size range requirements, and general cycle life. The effect of improving heat dissipation performance and rate performance, thin coating thickness, and improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

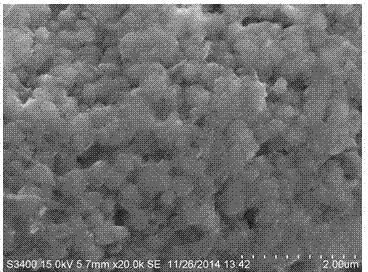

Image

Examples

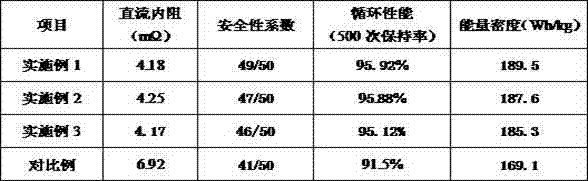

Embodiment 1

[0014] A highly cyclic Li(Ni 0.8 co 0.1 mn 0.1 )O 2 The preparation method of ternary material comprises the following steps: 1, configuration LiAlO 2 Solution: Weigh 2.04 grams (0.01mol) of aluminum isopropoxide, 0.42 grams (0.01mol) of LiOH·H 2 O is added in 16.4 grams of secondary distilled water, stirred into a homogeneous sol, and continues to add 0.328 grams cetyltrimethylammonium bromide , ultrasonic treatment for 1.0 h, hydrothermal reaction at 190 °C for 96 h; vacuum filtration, washing, and aging at room temperature for 24 h; filtration under reduced pressure again, and dispersing in absolute ethanol, vacuum drying at 80 °C, and heat treatment at 500 °C for 5 h to get LiAlO 2 Mesoporous material B, then weighed 2.46 g LiAlO 2 , 2.5 grams of sodium dodecylbenzenesulfonate solution and 492 grams of double distilled water were mixed uniformly to obtain a lithium metaaluminate solution A with a concentration of 0.5%;

[0015] 2. Preparation of Li(Ni 0.8 co 0....

Embodiment 2

[0018] 1. Configure LiAlO 2 Solution: Weigh 2.04 grams (0.01mol) of aluminum isopropoxide, 0.42 grams (0.01mol) of LiOH·H 2 O was added into 24.6 grams of double distilled water, stirred into a homogeneous sol, and continued to add 0.246 grams cetyltrimethylammonium bromide , sonicated for 1.5 h, hydrothermal reaction at 190 °C for 72 h; filtered under reduced pressure, washed, and aged at room temperature for 24 h; filtered again under reduced pressure, dispersed in absolute ethanol, dried in vacuum at 80 °C, and heat-treated at 500 °C for 5 h to get LiAlO 2 Mesoporous material B, then weighed 2.46 g LiAlO 2, 24.6 grams of sodium dodecylbenzenesulfonate solution and 464 grams of double distilled water were mixed uniformly to obtain a lithium metaaluminate solution A with a concentration of 0.5%;

[0019] 2. Preparation of Li(Ni 0.8 co 0.1 mn 0.1 )O 2 : Add 21 grams (0.08mol) NiSO to the reactor 4 ·6H 2 O. 2.81 g (0.01 mol) CoSO 4 ·7H 2 O, 1.51 g (0.01 mol) MnSO 4 ...

Embodiment 3

[0022] 1. Configure LiAlO 2 Solution: Weigh 2.04 grams (0.01mol) of aluminum isopropoxide, 0.42 grams (0.01mol) of LiOH·H 2 O is added in 12.3 grams of secondary distilled water, stirred into a homogeneous sol, and continues to add 0.246 grams cetyltrimethylammonium bromide , sonicated for 2 hours, hydrothermal reaction at 190°C for 48 hours; filtered under reduced pressure, washed, and aged at room temperature for 24 hours; filtered again under reduced pressure, dispersed in absolute ethanol, dried in vacuum at 80°C, and heat-treated at 500°C for 5 h Get LiAlO 2 Mesoporous material B, then weighed 2.46 g LiAlO 2 , 12.3 grams of sodium dodecylbenzenesulfonate solution and 477 grams of double distilled water were mixed uniformly to obtain a lithium metaaluminate solution A with a concentration of 0.5%;

[0023] 2. Add 21 grams (0.08mol) NiSO to the reactor 4 ·6H 2 O. 2.81 g (0.01 mol) CoSO 4 ·7H 2 O, 1.51 g (0.01 mol) MnSO 4 Put it into 1000ml NaOH (4g NaOH) solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com