Surface modified graphitized interphase carbon micro-powder and preparation method thereof

A technology of mesophase carbon micropowder and surface modification, which is applied in the field of materials, can solve the problems of not improving the compaction performance of materials, not being able to greatly improve the lithium storage capacity, and not being very significant in product yield, and to achieve comprehensive battery integration. Excellent performance, improved initial discharge capacity, simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

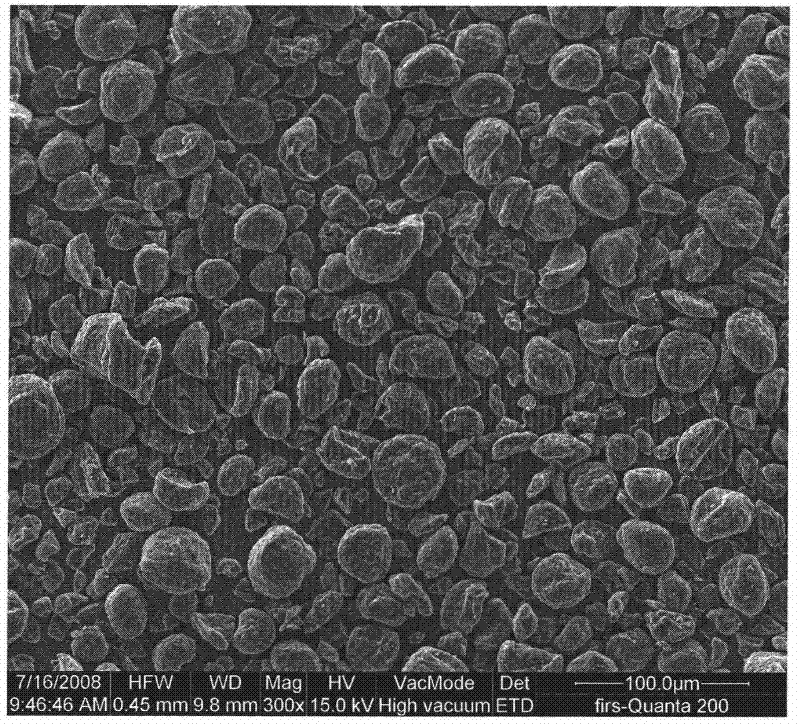

Embodiment 1

[0030] Weigh 120kg of mesophase carbon micropowder (D 50 = 41.2 μm), evenly add it into the crushing classifier, adjust the main frequency of the crushing and classifier to 15.35Hz, set the external classification speed to 1000 rpm, and obtain F1 (D) after crushing and classifying. 50 = 25.6 μm) material 113 kg. Mix 113kg of mesophase carbon powder F1 with 5kg of additives (Fe 2 O 3 : SiO 2 = 1:3, weight ratio) alternately added to the cantilever double-spiral conical mixer, after mixing for 2 hours, the material was subjected to catalytic graphitization (2500° C.) for 6 hours to obtain 100 kg of graphitized post-material F1a. It is mixed with 100kg of ball material (polyurethane composite ball diameters are Φ15, Φ20, Φ30 each accounting for 1 / 3 of the weight) and put into a ball mill, set the ball mill rotational speed to 60 rev / min, and run for 20 hours to obtain the intermediate phase of the present invention. The graphite carbon anode material was 98kg, and the yield w...

Embodiment 2

[0032] Weigh 120kg of mesophase carbon micropowder (D 50 = 38.5μm), evenly add it into the crushing and classifying machine, adjust the frequency of the main machine of the crushing and classifying machine to 13.26Hz, set the external classification speed to 1000 rpm, and obtain F1 (D) after crushing and classifying. 50 = 26.4 μm) material 115 kg. Mix 115kg of mesophase carbon powder F1 with 5kg of additives (Fe 2 O 3 : SiO2 =1:1, weight ratio) was alternately added to the cantilever double-spiral conical mixer, and after mixing for 2 hours, the material was subjected to catalytic graphitization (2600° C.) for 5 hours to obtain 103 kg of graphitized material F1a. After mixing it with 100kg of ball material (same as Example 1), it was loaded into a ball mill, and the rotation speed of the ball mill was set to 60 rev / min, and it was operated for 20 hours to obtain 101kg of the mesophase graphite carbon negative electrode material of the present invention, and the yield was 84....

Embodiment 3

[0034] Weigh 120kg of mesophase carbon micropowder (D 50 =40.07μm), evenly add it into the crushing and classifying machine, adjust the frequency of the main machine of the crushing and classifying machine to 14.00Hz, set the external classification speed to 1000 rpm, and obtain F1 (D) after crushing and classifying. 50 = 26.7 μm) material 115 kg. Mix 115kg of mesophase carbon powder F1 with 5kg of additives (Fe 2 O 3 : SiC=1:3, weight ratio) was alternately added to the cantilever double-spiral conical mixer, mixed for 2 hours, and then subjected to catalytic graphitization (2800° C.) for 3 hours to obtain 99 kg of graphitized post-material F1a. After mixing it with 100kg of ball material (same as Example 1), it was loaded into a ball mill, the ball mill rotation speed was set to 60 rpm, and it was operated for 20 hours to obtain 97kg of the mesophase graphite carbon negative electrode material of the present invention, and the yield was 80.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com