Silicon-containing negative plate and lithium ion battery comprising same

A lithium-ion battery and negative electrode technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large electrolyte wettability, and achieve the effects of improving hydrophilicity, increasing energy density, and improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

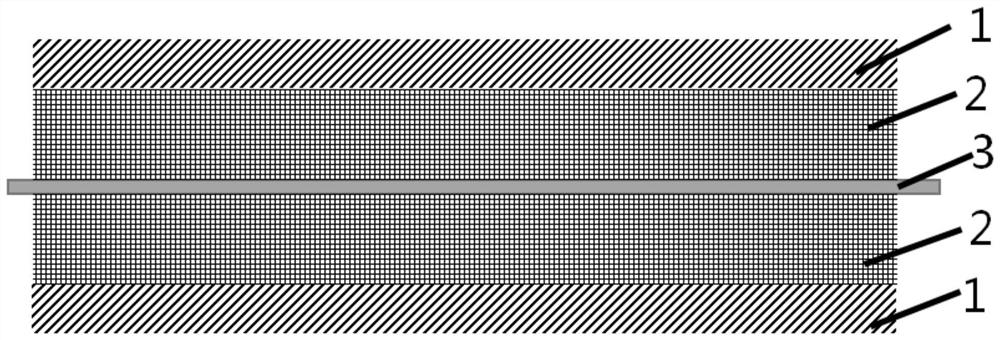

[0059] Such as figure 1 As shown, this embodiment provides a negative electrode sheet, including a current collector 3, a first active layer 1, and a second active layer 2, and the second active layer 2 is arranged on the current collector 3 and the first active layer 1, the second active layer 2 is formed on both surfaces of the current collector 3 .

[0060] Wherein, the active material in the first active layer is graphite and silicon-oxygen material, the active material in the second active layer is graphite, and the current collector is composed of carbon-coated copper foil.

[0061] Preparation of lithium ion battery negative electrode sheet:

[0062] Mix the active material with conductive agent, dispersant, and binder according to the mass ratio of 93%: 1.1%: 0.9%: 5%, and then disperse them in the water solvent to make the first active layer slurry; wherein, the active material is composed of The weight percentage is composed of 60% graphite and 40% silicon-oxygen m...

Embodiment 2

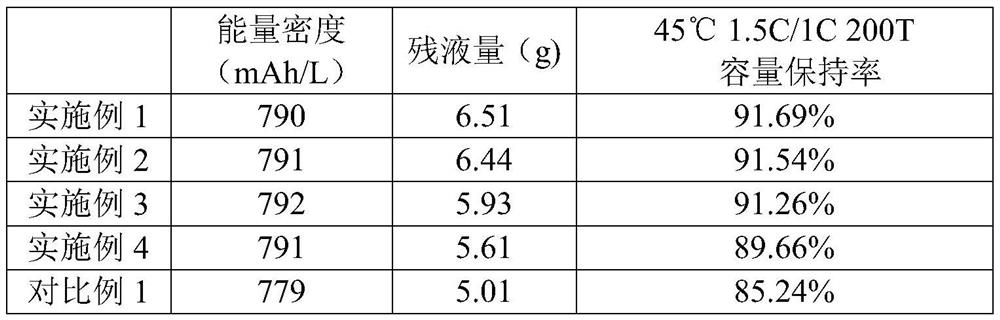

[0073] The difference between the negative electrode sheet and its preparation method and the lithium-ion battery provided in this example and Example 1 is that the active material in the first active layer is composed of 70% by weight of graphite and 30% of silicon oxide, so The active material, conductive agent, dispersant, and binder in the first active layer 1 are in mass ratios of 94%:1.1%:0.9%:4%, and θ1 / a=250, θ2 / b=400.

[0074] Other conditions are all the same as in Example 1.

Embodiment 3

[0076] The difference between the negative electrode sheet and its preparation method and the lithium ion battery provided in this example and Example 1 is that the active material in the first active layer is composed of 80% by weight of graphite and 20% of silicon oxygen, and the first The active material, conductive agent, dispersant, and binder in the active layer 1 are in mass ratios of 94.5%: 1.1%: 0.9%: 3.5%, and θ1 / a=300, θ2 / b=400.

[0077] Other conditions are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com