Patents

Literature

411results about "Electrode molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

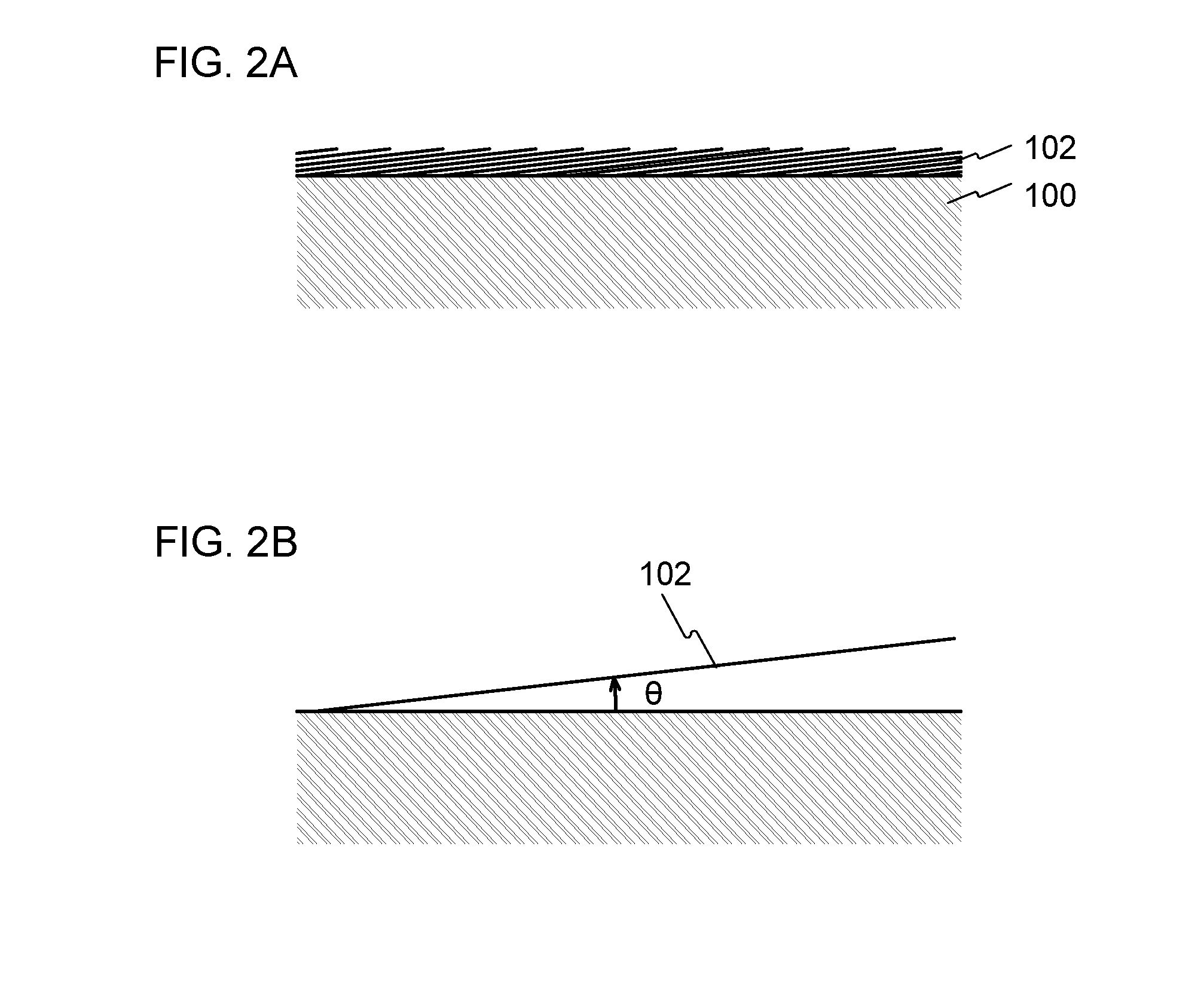

Method for manufacturing positive electrode active material for energy storage device and energy storage device

ActiveUS20120088156A1Reduce loadLow costNon-metal conductorsCarbon compoundsCarbon coatingConductive materials

An energy storage device having high capacity per weight or volume and a positive electrode active material for the energy storage device are manufactured. A surface of a main material included in the positive electrode active material for the energy storage device is coated with two-dimensional carbon. The main material included in the positive electrode active material is coated with a highly conductive material which has a structure expanding two-dimensionally and whose thickness is ignorable, whereby the amount of carbon coating can be reduced and an energy storage device having capacity close to theoretical capacity can be obtained even when a conduction auxiliary agent is not used or the amount of the conduction auxiliary agent is extremely small. Accordingly, the amount of carbon coating in a positive electrode and the volume of the conduction auxiliary agent can be reduced; consequently, the volume of the positive electrode can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

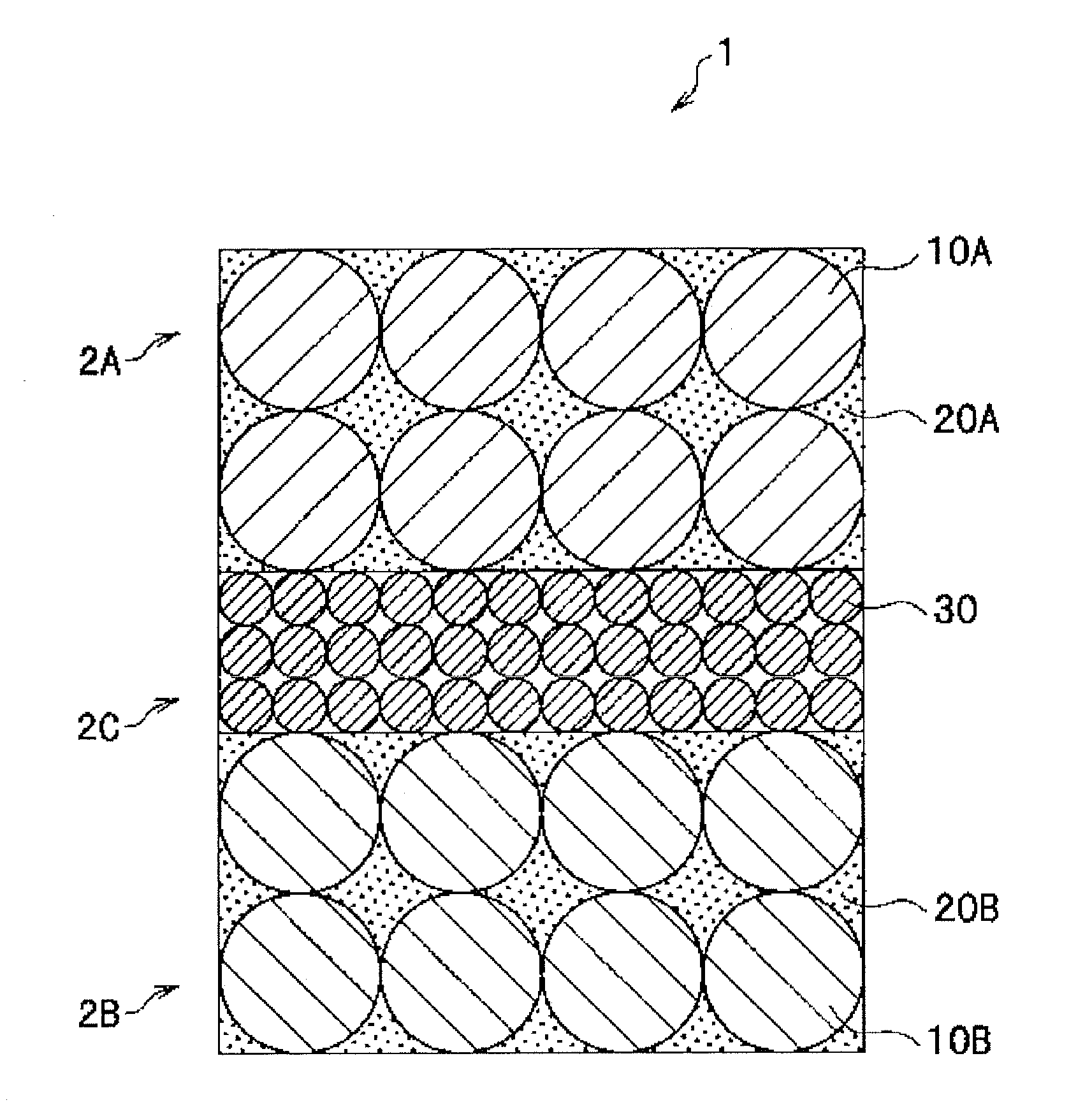

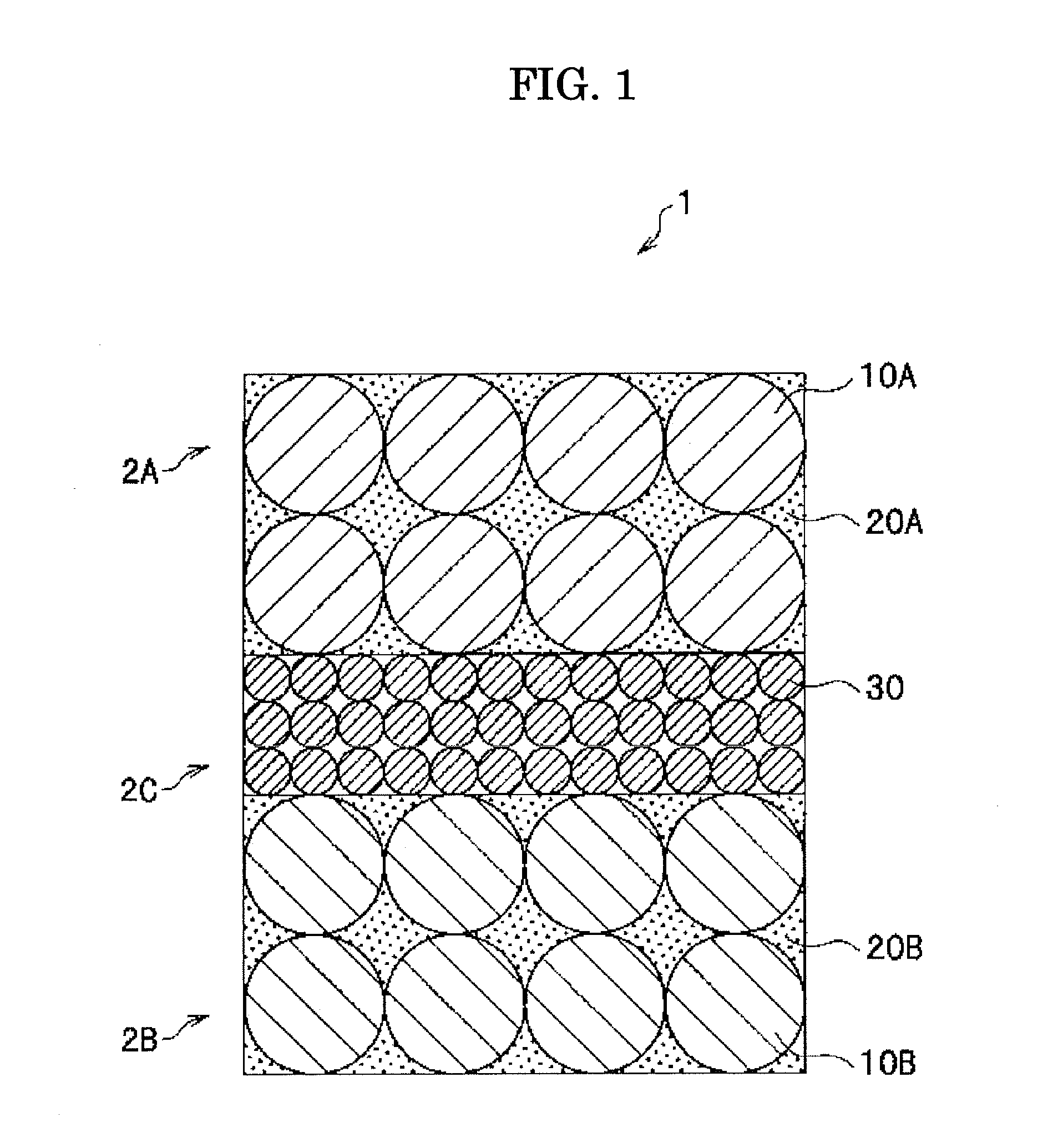

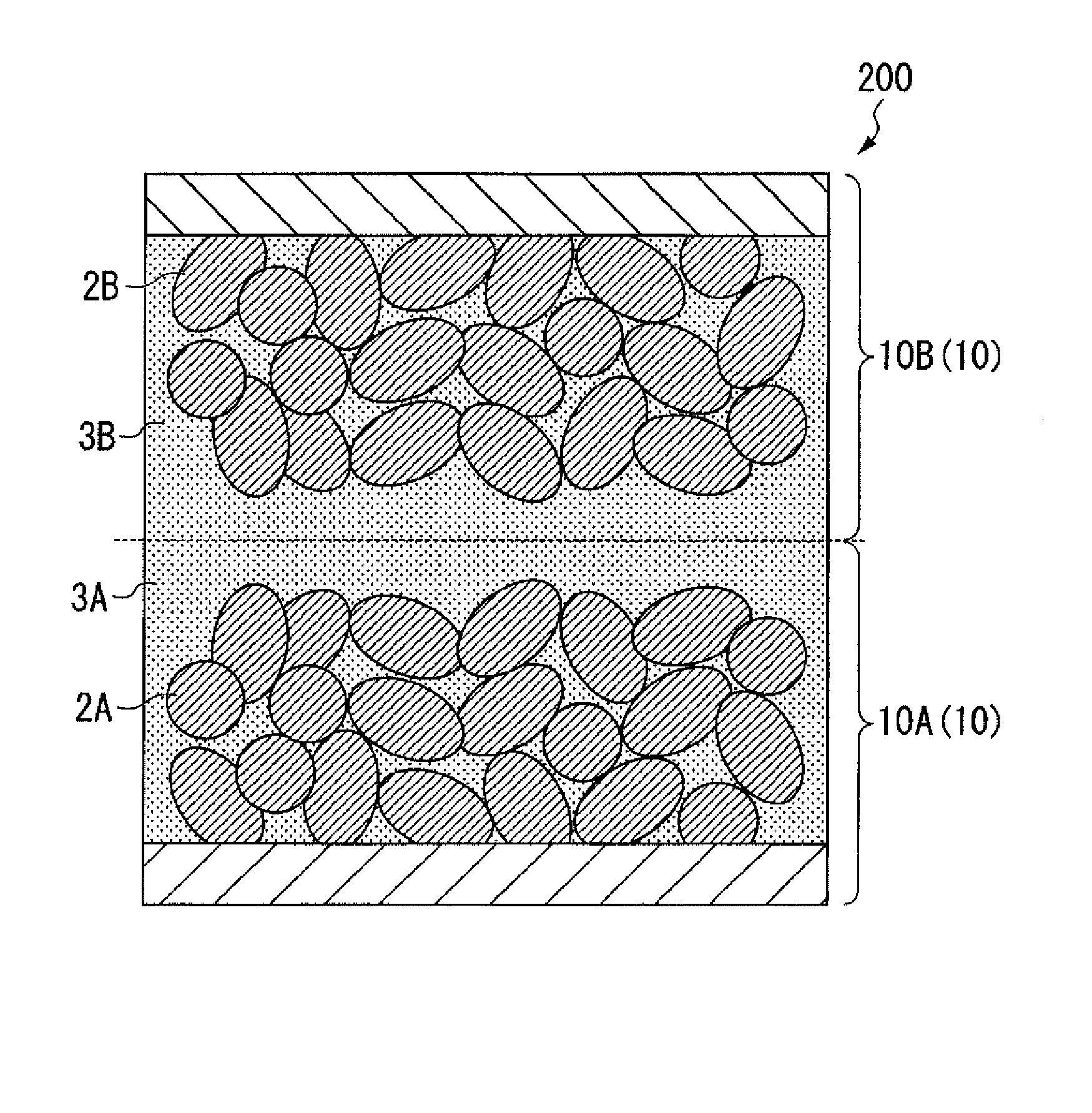

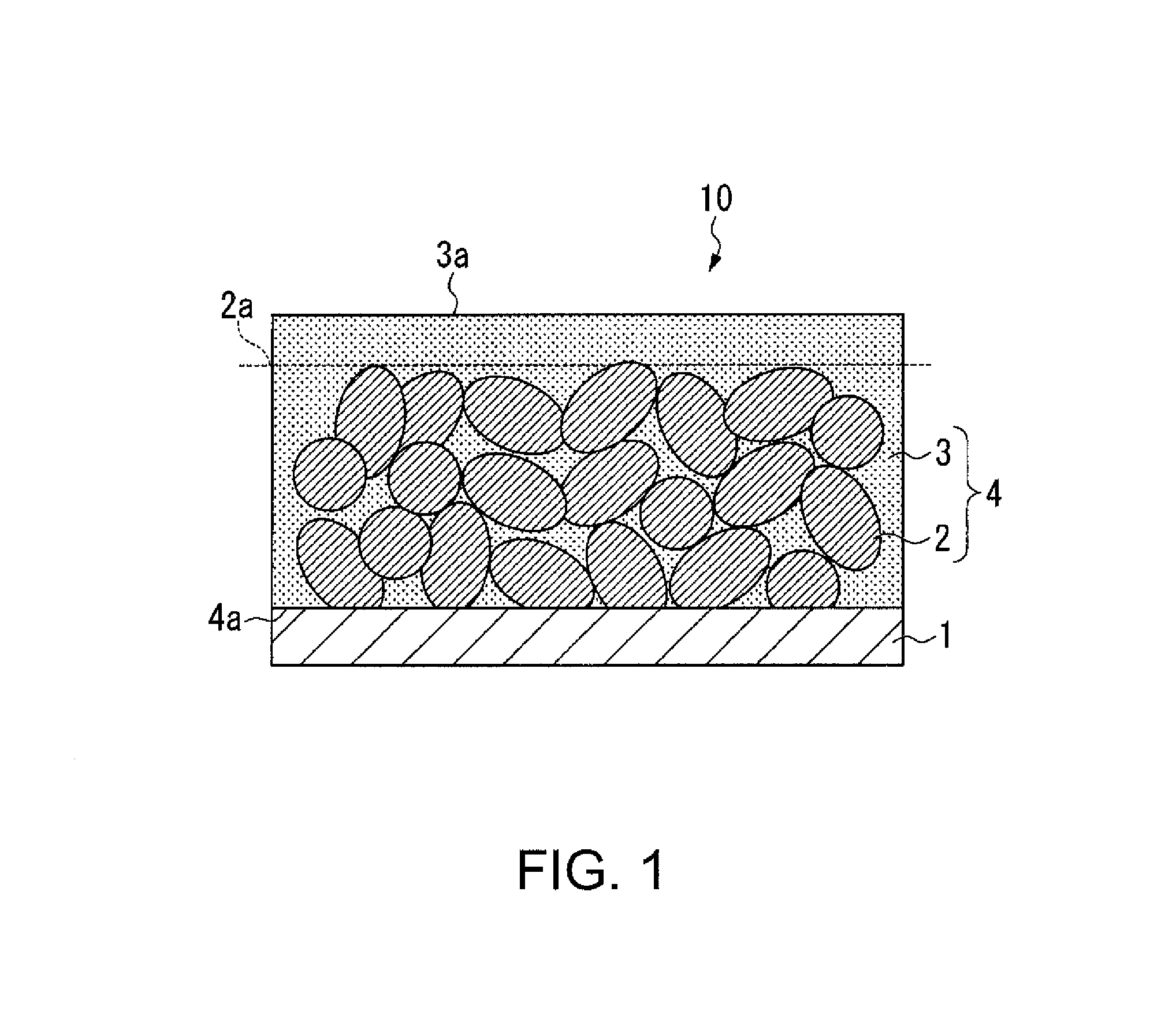

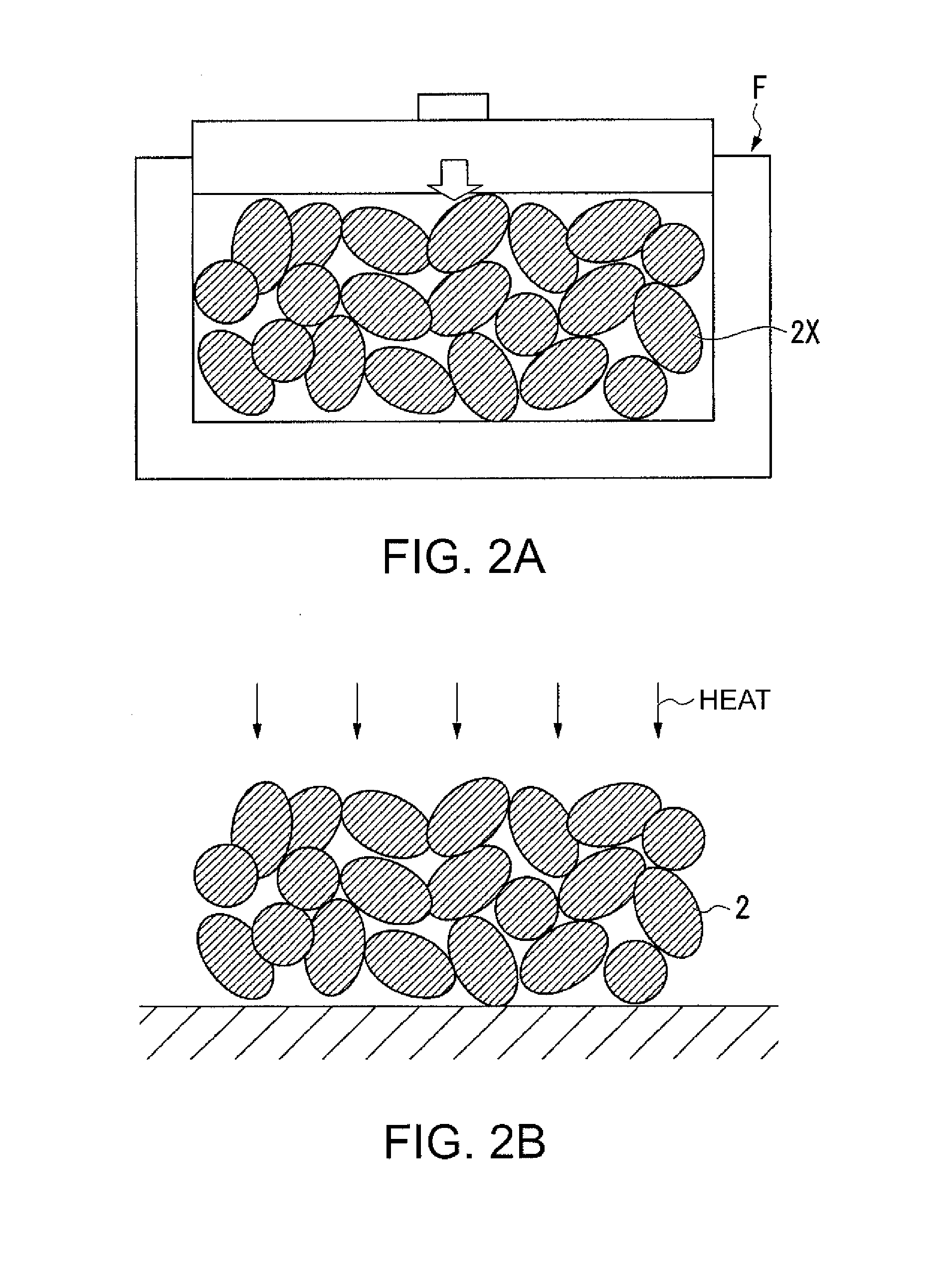

All-solid state battery, electrode for all-solid state battery, and method of manufacturing the same

InactiveUS20160233510A1Improve contact qualityImprove discharge performanceNon-aqueous electrolyte accumulatorsElectrode thermal treatmentAll solid stateEngineering

Provided are an all-solid state battery with a better quality of contact among particles of an active material and with an enhanced discharge capacity; an electrode for an all-solid state battery; and a method of manufacturing the same. The all-solid state battery is manufactured through the steps of: causing a deliquescent solid electrolyte to deliquesce, the deliquescent solid electrolyte having ionic conductivity, electronic conductivity and a deliquescent property; preparing an electrode mixture by mixing the deliquescent solid electrolyte having deliquesced and an active material together; heat-treating and shaping the electrode mixture to produce an electrode; and bonding the thus-produced electrode and a solid electrolyte layer with the solid electrolyte layer interposed between the electrode and another electrode which are paired to serve as a positive electrode and a negative electrode.

Owner:HITACHI LTD

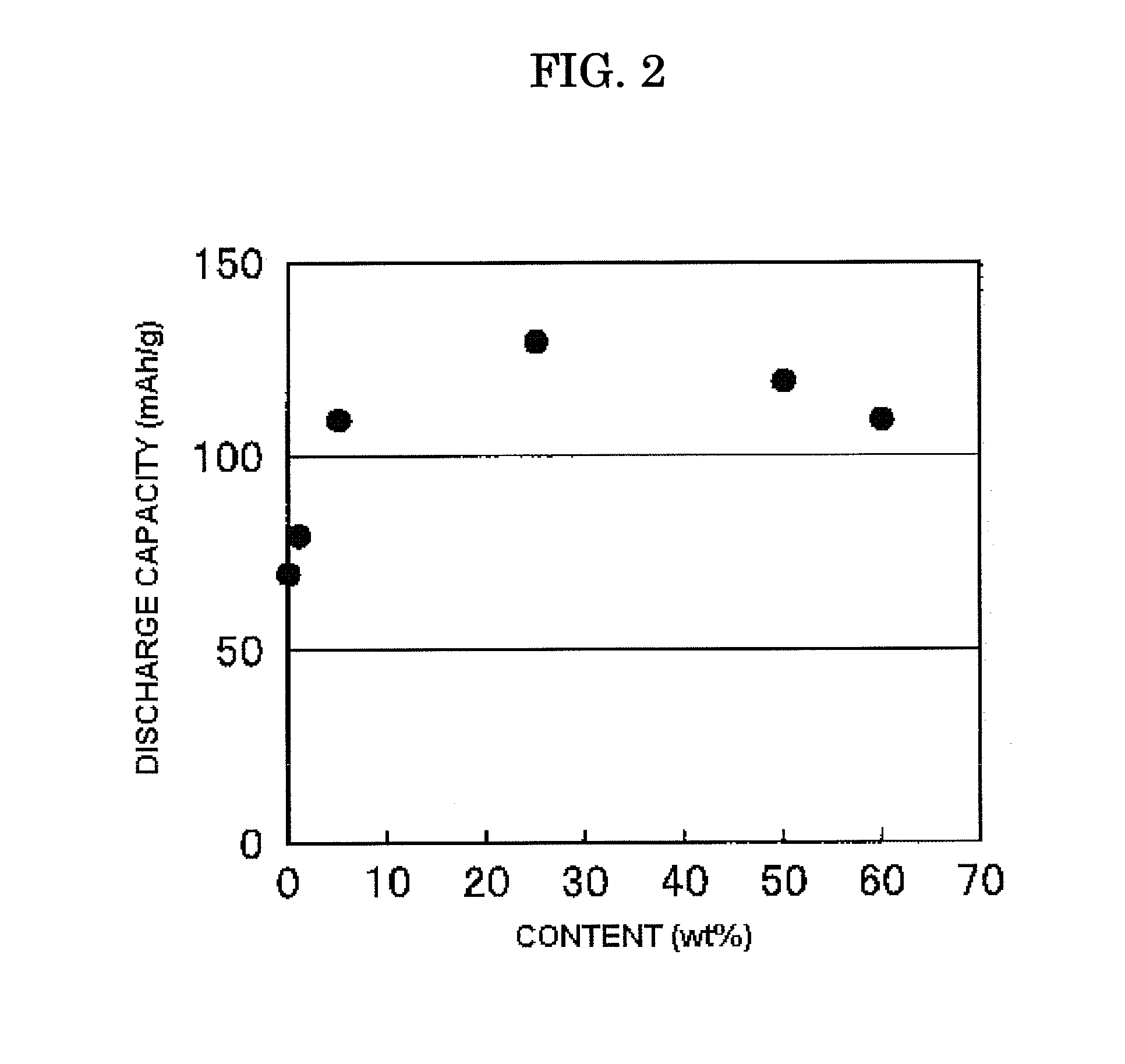

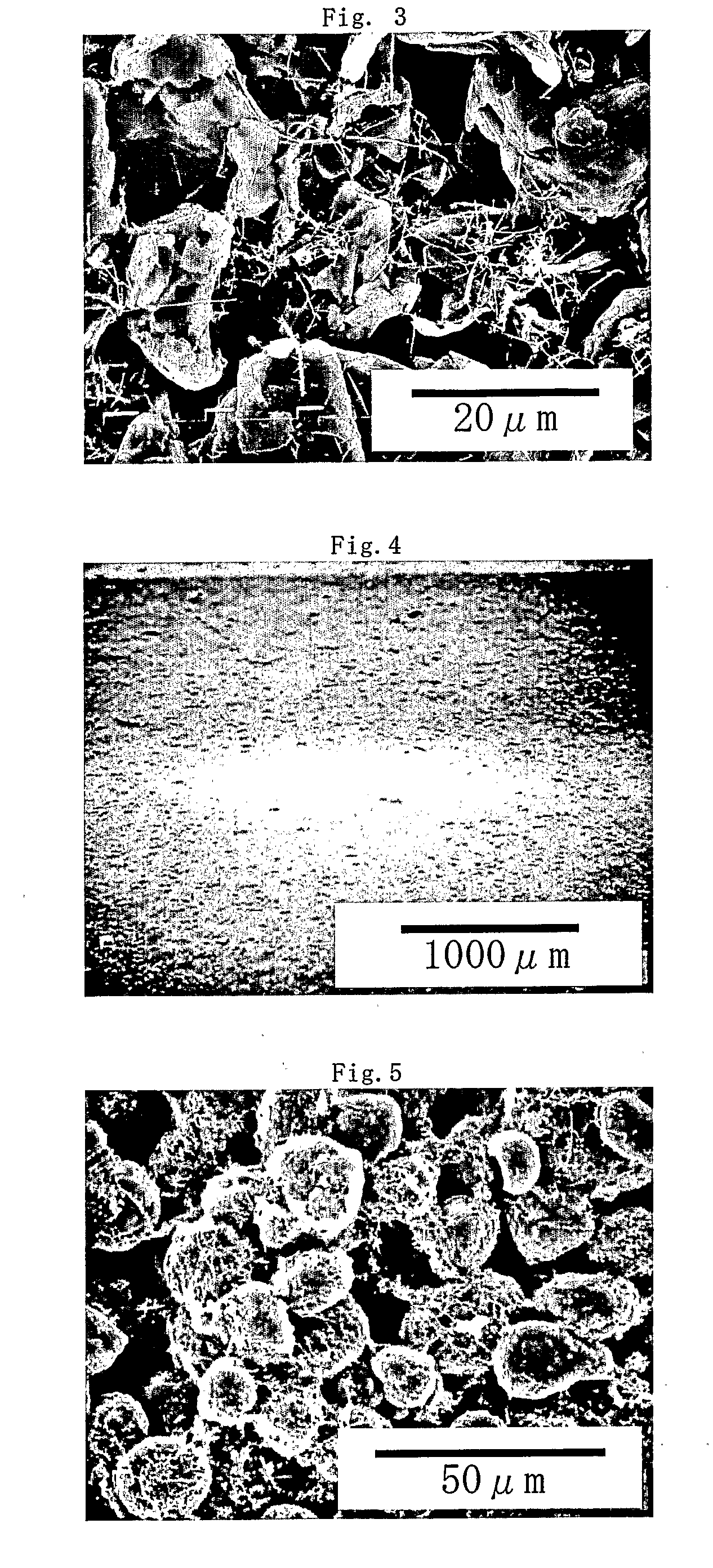

Negative Electrode Material for Lithium Battery, and Lithium Battery

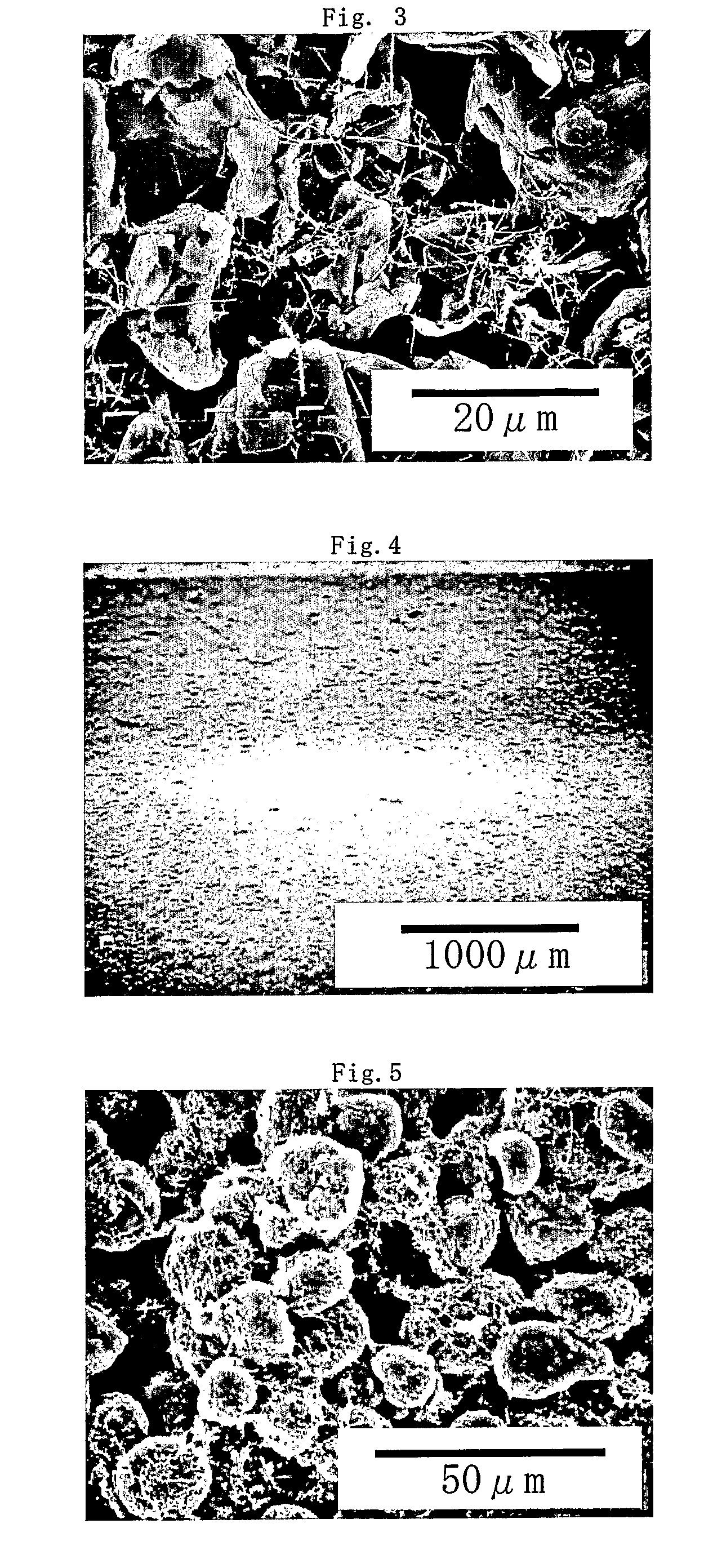

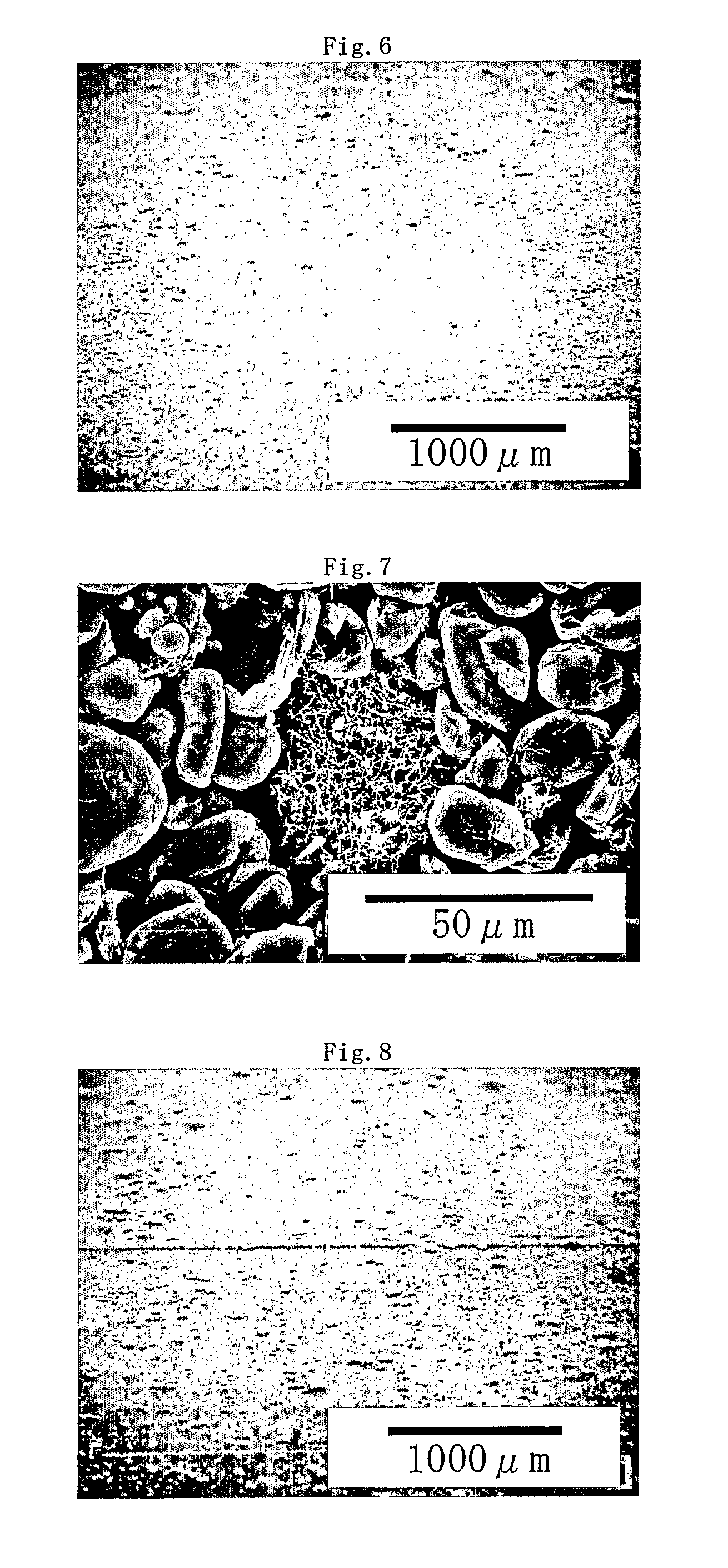

InactiveUS20070275302A1Lower electrode resistanceHigh electrode strengthNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsCarboxymethyl celluloseCarbon fibers

The present invention relates to a negative electrode material for a lithium battery characterized by comprising a carbonaceous negative electrode active substance having a specific surface area of 1 m2 / g or more, a binder formed of styrene-butadiene rubber and a carbon fiber having a fiber diameter of 1 to 1,000 nm; and to a lithium battery using the negative electrode material, which has excellent characteristics, i.e., low electrode resistance, high electrode strength, excellent electrolytic solution permeability, high energy density, and good high-speed charging / discharging performance. The negative electrode material contains carbon fiber in the amount of 0.05 to 20 mass % and the binder formed of styrene-butadiene rubber in 0.1 to 6.0 mass %, and may further contain a thickner such as carboxymethyl cellulose in the amount of 0.3 to 3 mass %.

Owner:SHOWA DENKO KK +1

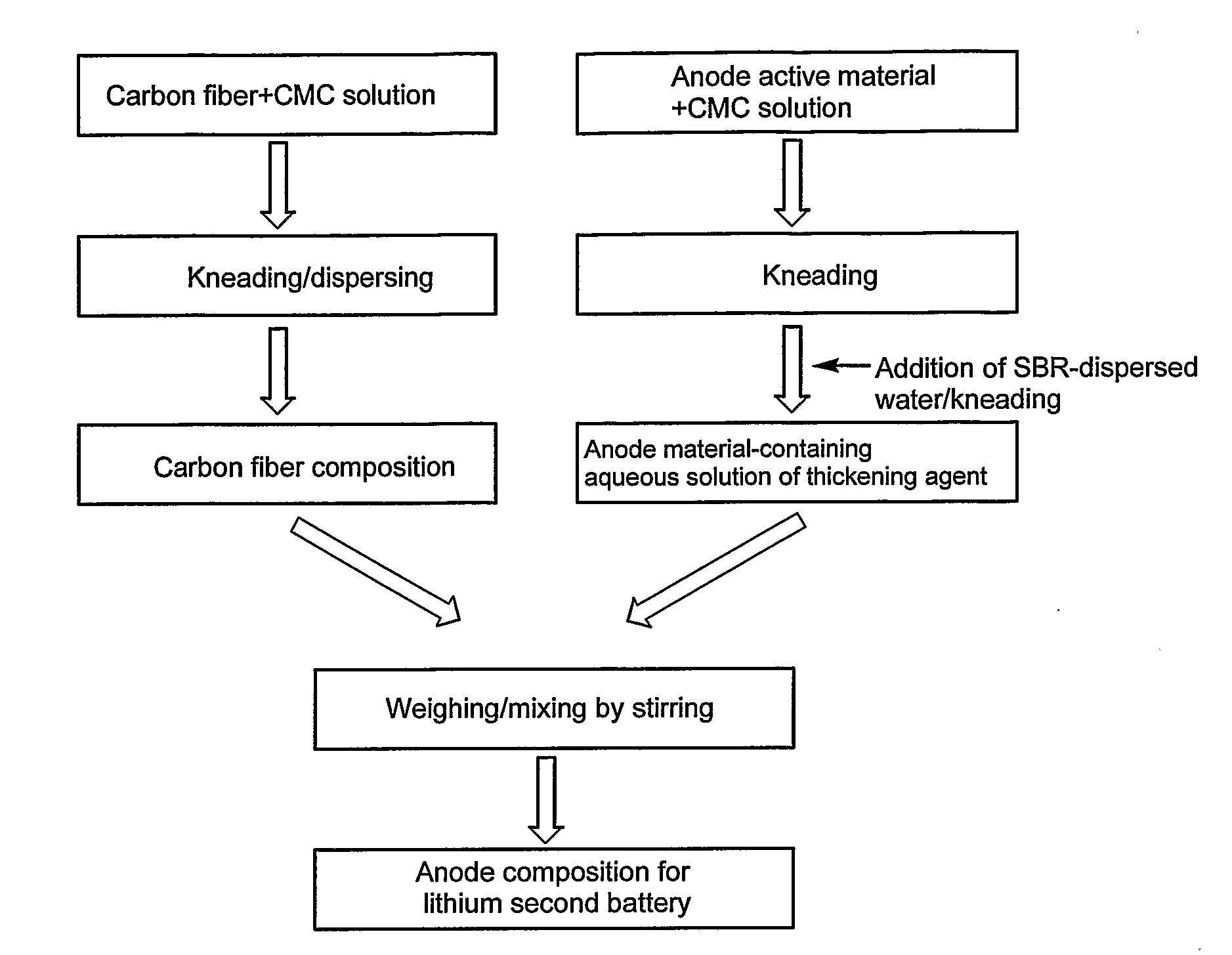

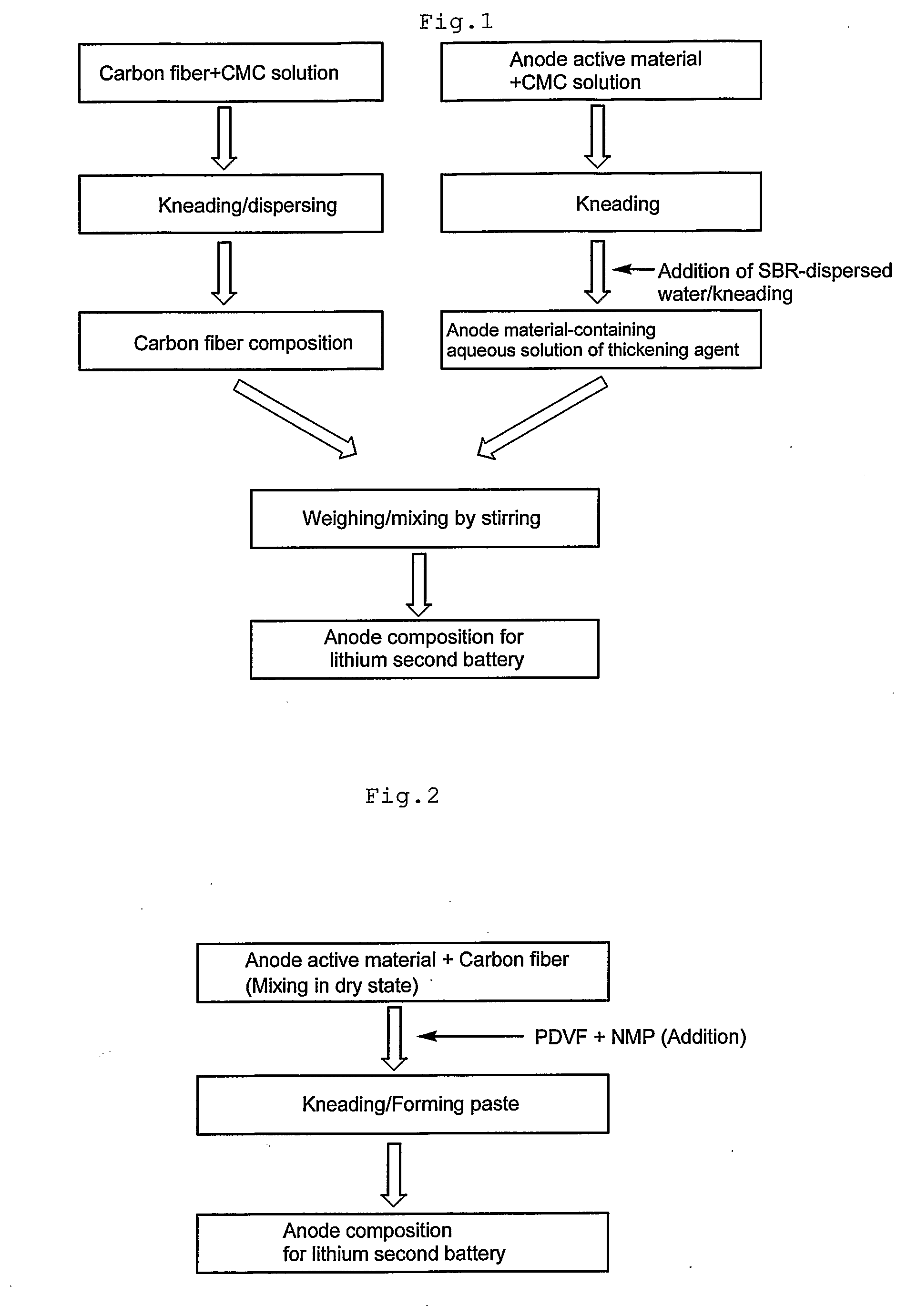

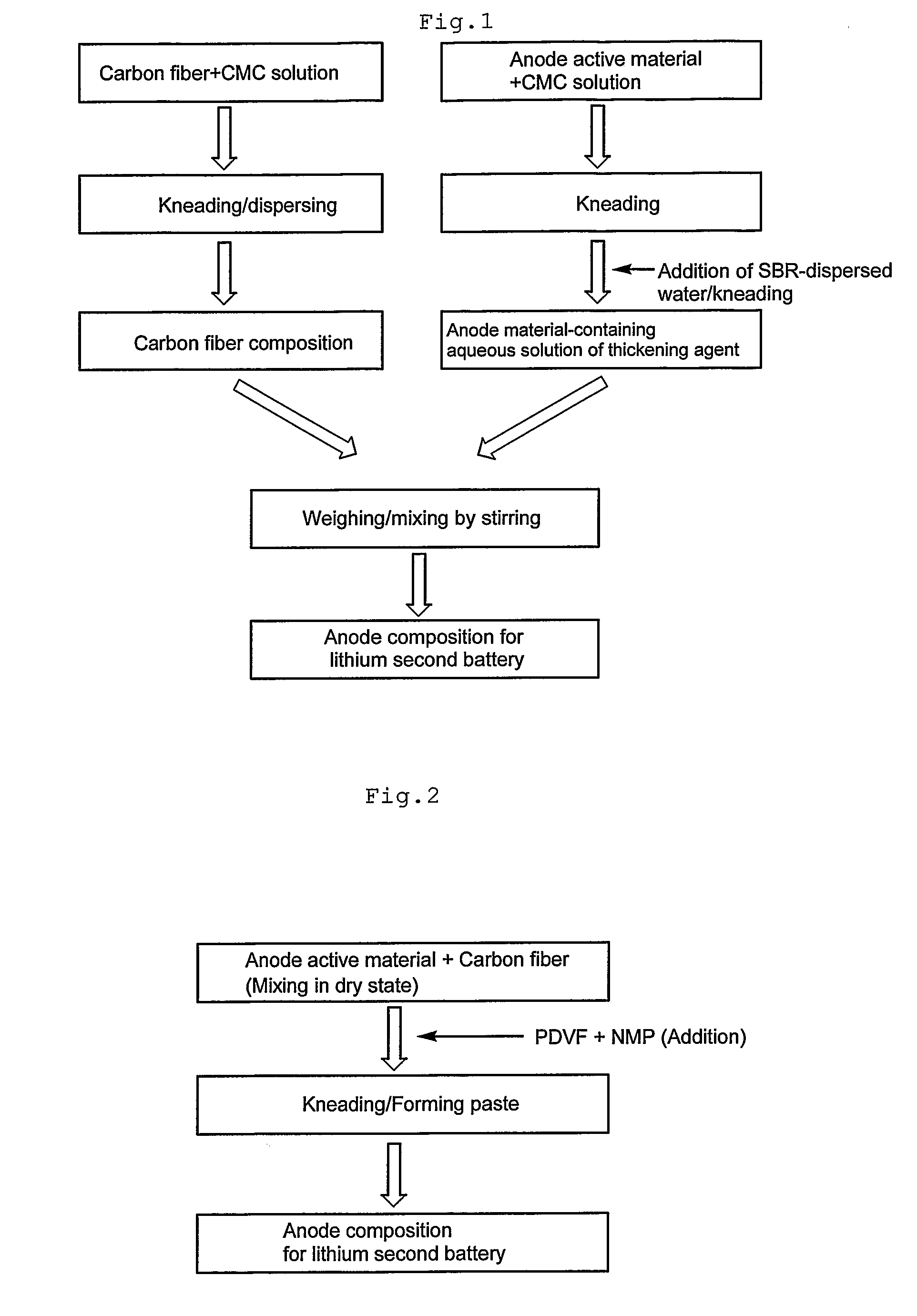

Method for producing anode for lithium secondary battery and anode composition, and lithium secondary battery

ActiveUS20090123850A1High capacity retentionImprove conductivityFinal product manufactureConductive materialFiberCarbon fibers

The invention relates to an anode for lithium secondary battery comprising vapor grown carbon fiber uniformly dispersed without forming an agglomerate of 10 μm or larger in an anode active material using natural graphite or artificial graphite, which anode is excellent in long cycle life and large current characteristics. Composition used for production for the anode can be produced, for example, by mixing a thickening agent solution containing an anode active material, a thickening agent aqueous solution and styrene butadiene rubber as binder with a composition containing carbon fiber dispersed in a thickening agent with a predetermined viscosity or by mixing an anode active material with vapor grown carbon fiber in dry state and then adding polyvinylidene difluoride thereto.

Owner:RESONAC CORP

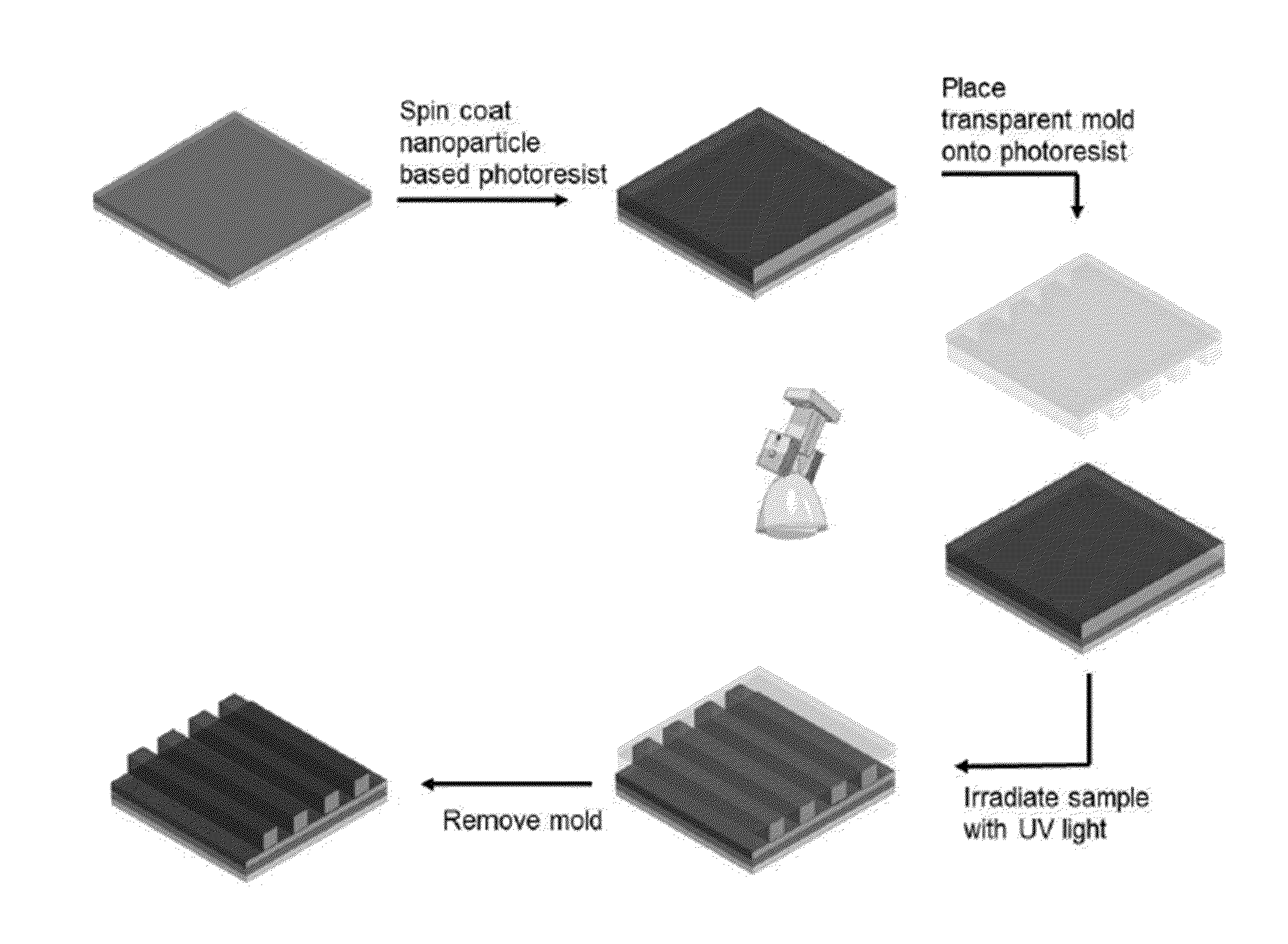

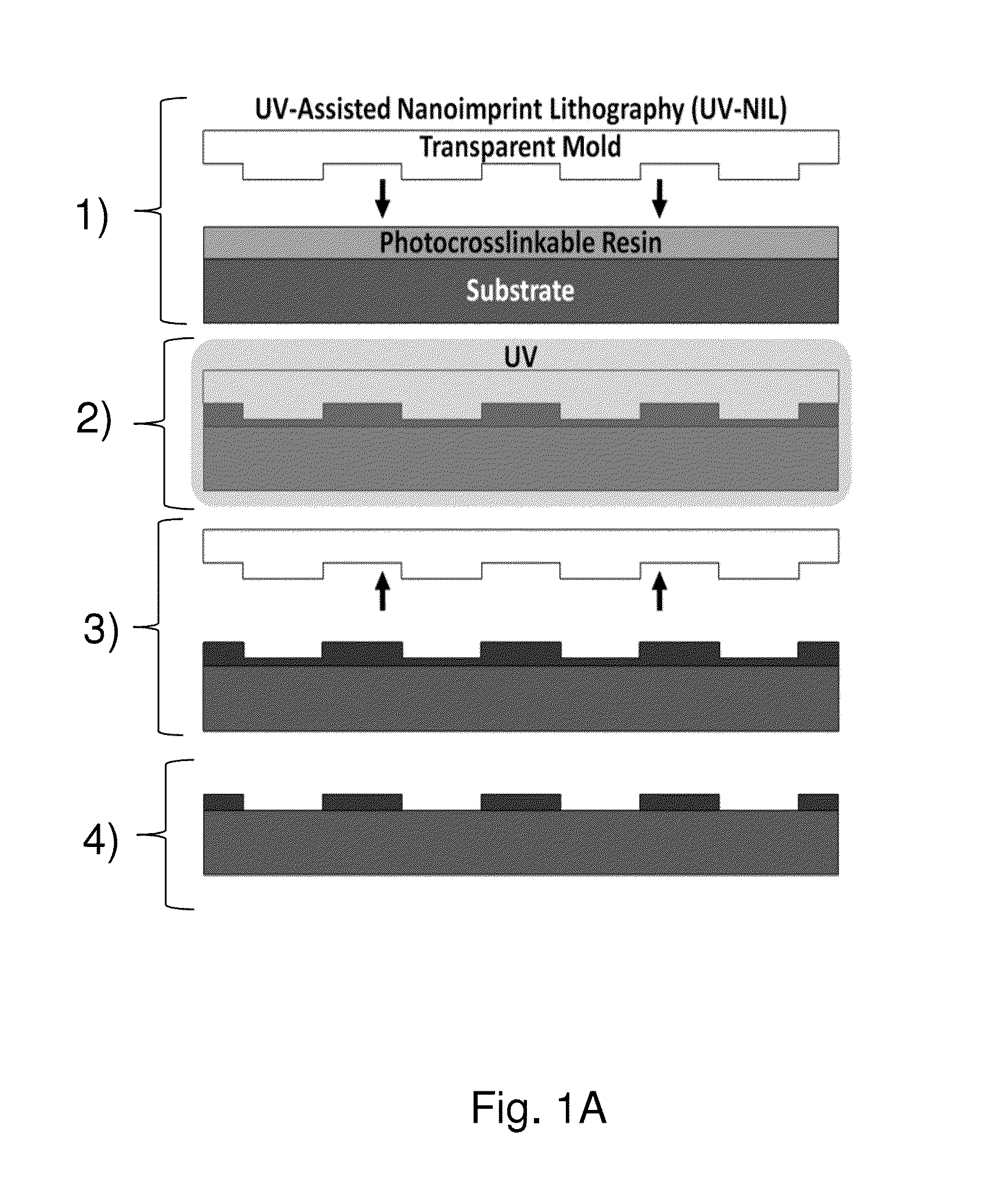

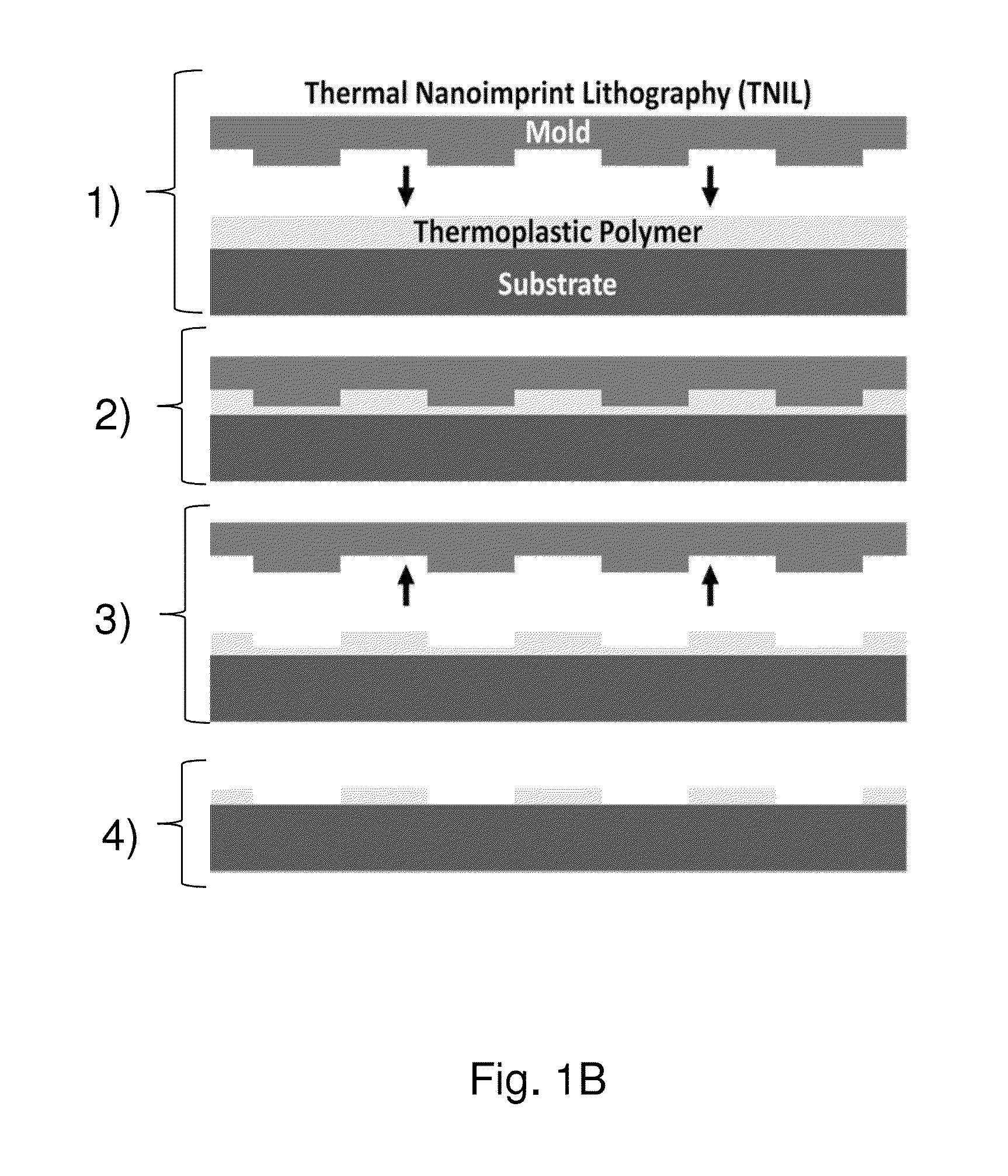

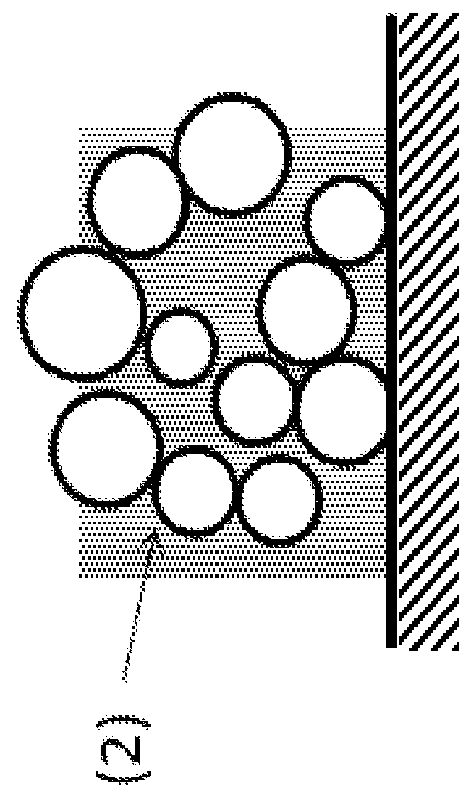

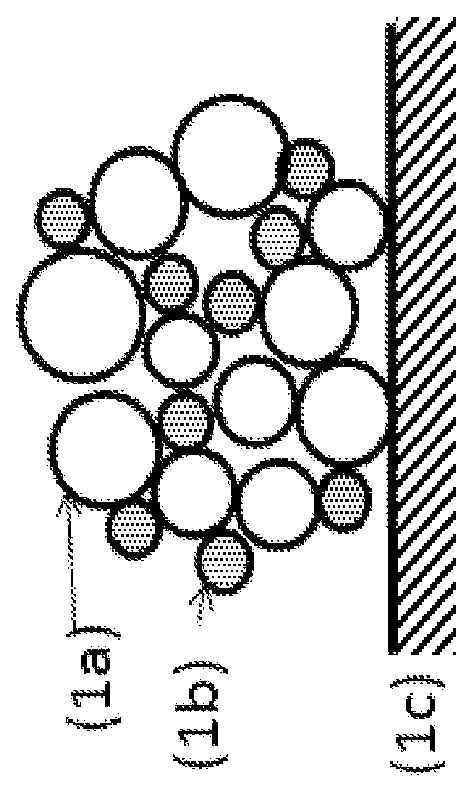

Patterned nanoparticle structures

Aspects relate to patterned nanostructures having a feature size not including film thickness of below 5 microns. The patterned nanostructures are made up of nanoparticles having an average particle size of less than 100 nm. A nanoparticle composition, which, in some cases, includes a binder material, is applied to a substrate. A patterned mold used in concert with electromagnetic radiation function to manipulate the nanoparticle composition in forming the patterned nanostructure. In some embodiments, the patterned mold nanoimprints a suitable pattern on to the nanoparticle composition and the composition is cured through UV or thermal energy. Three-dimensional patterned nanostructures may be formed. A number of patterned nanostructure layers may be prepared and suitably joined together. In some cases, a patterned nanostructure may be formed as a layer that is releasable from the substrate upon which it is initially formed. Such releasable layers may, in turn, be arranged to form a three-dimensional patterned nanostructure in accordance with suitable applications.

Owner:UNIV OF MASSACHUSETTS

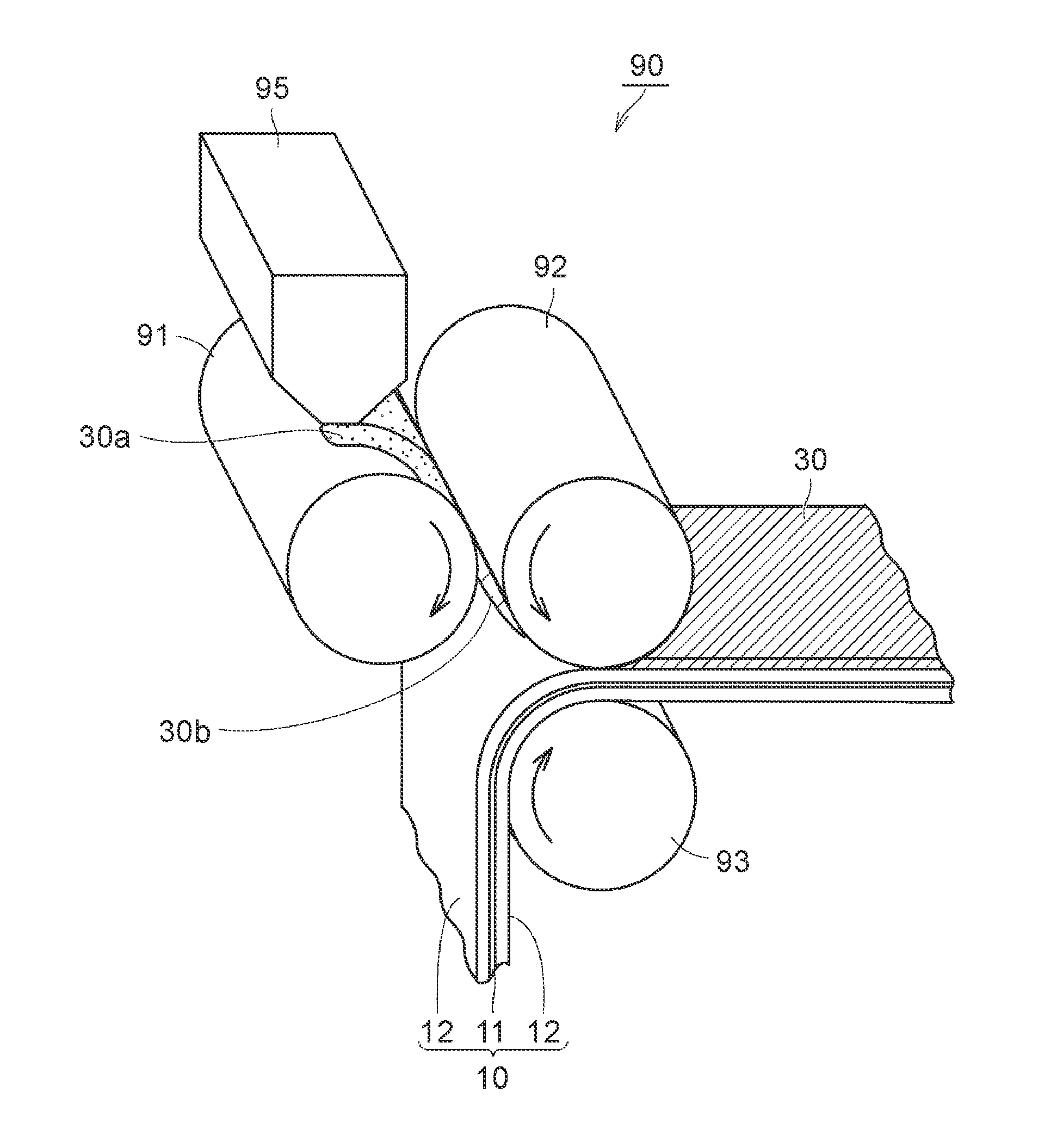

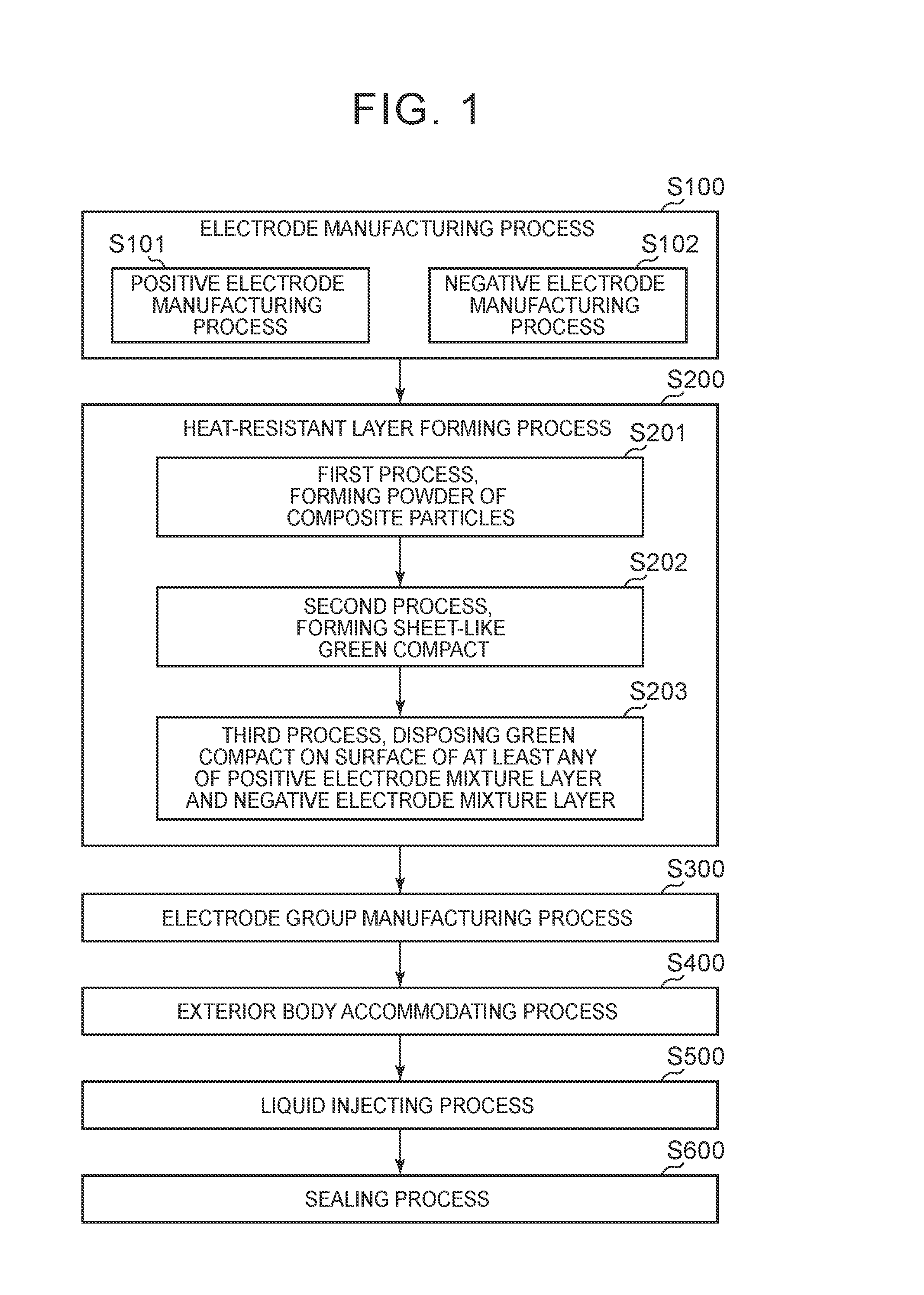

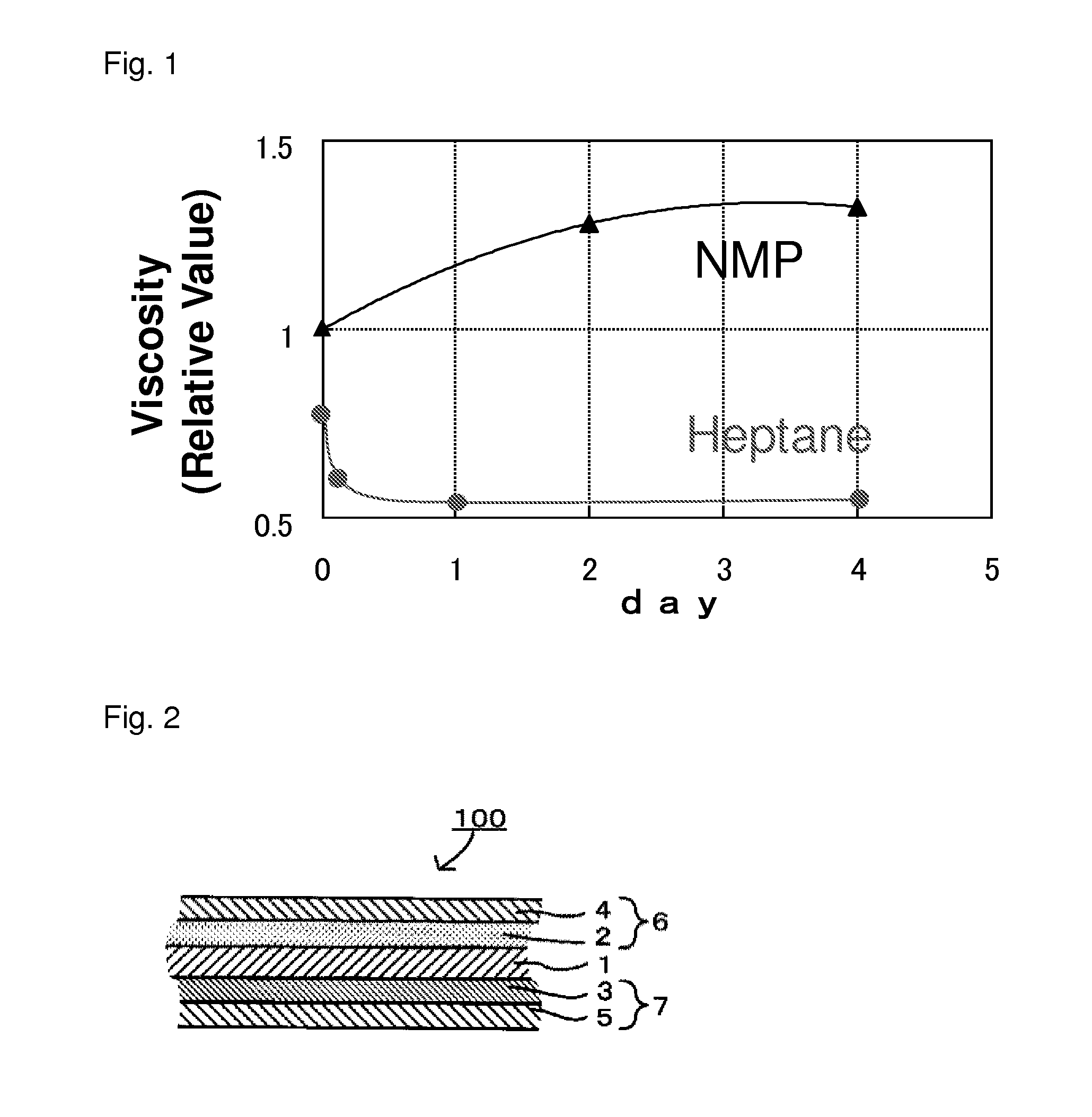

Manufacturing method for non-aqueous electrolyte secondary battery

ActiveUS20160240839A1Reduce the amount requiredHigh strengthElectrode rolling/calenderingNon-aqueous electrolyte accumulatorsSolventInorganic filler

A manufacturing method for a non-aqueous electrolyte secondary battery includes: forming a powder; forming a sheet-like green compact; and forming a heat-resistant layer. The powder contains composite particles and a solvent. The composite particles contain inorganic filler particles and a binder. The green compact is formed by pressing the powder in a state in which the solvent remains. The heat-resistant layer is formed by disposing the green compact on a surface of at least any of a positive electrode mixture layer and a negative electrode mixture layer after the green compact is formed.

Owner:TOYOTA JIDOSHA KK

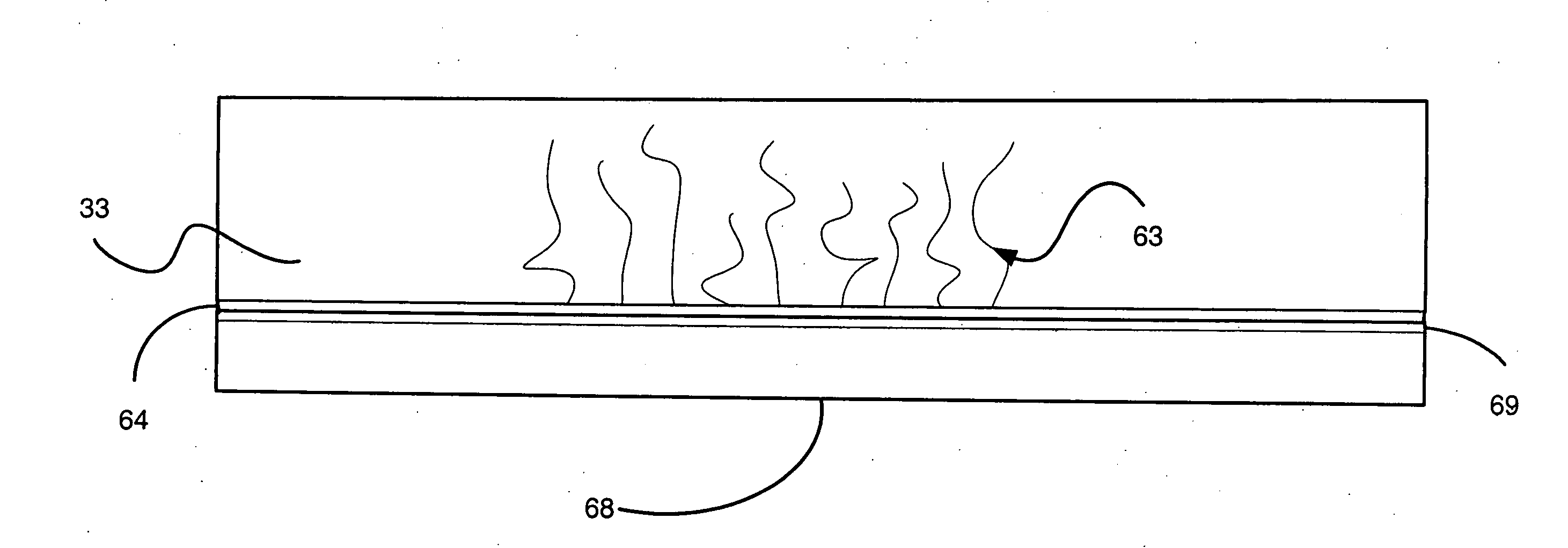

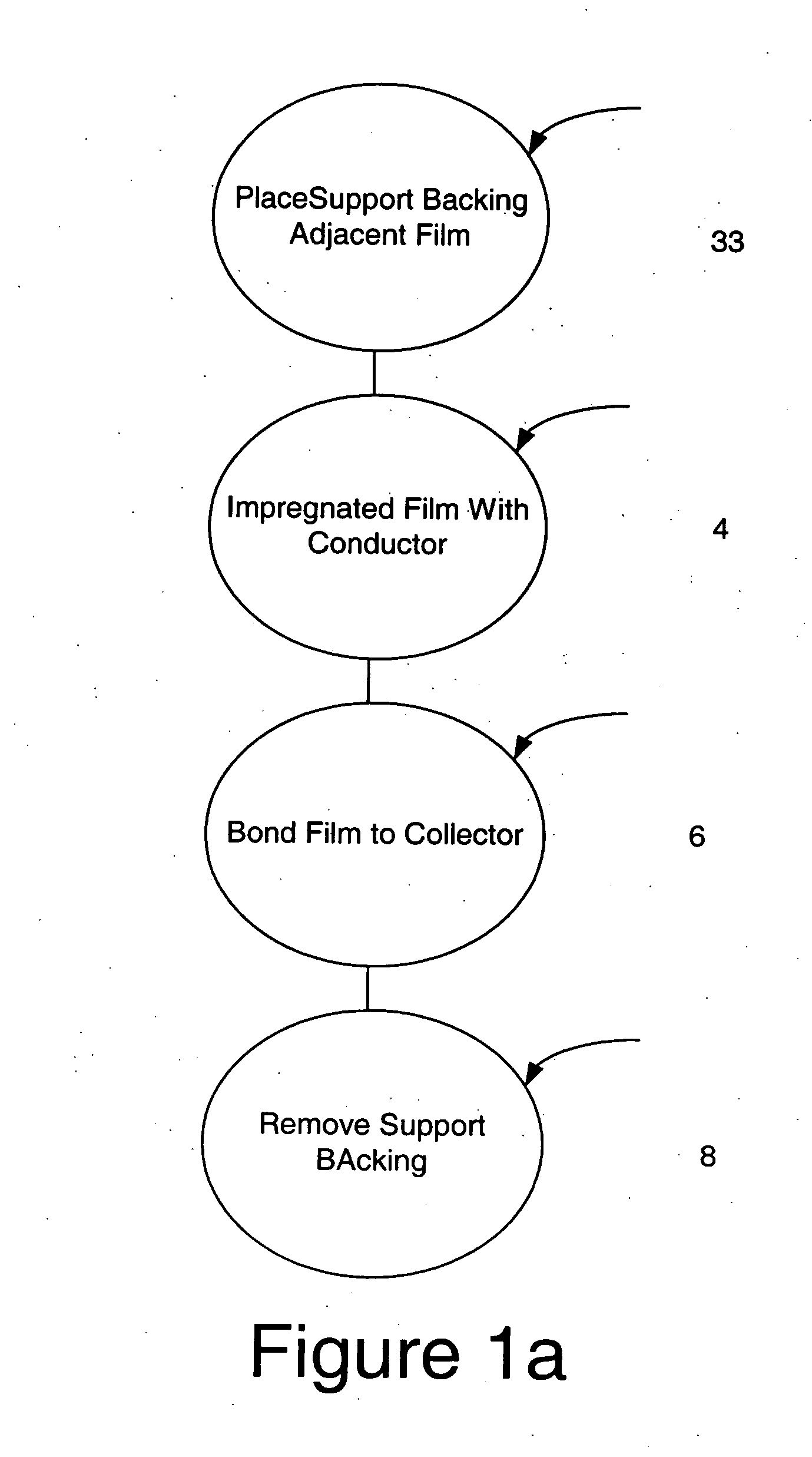

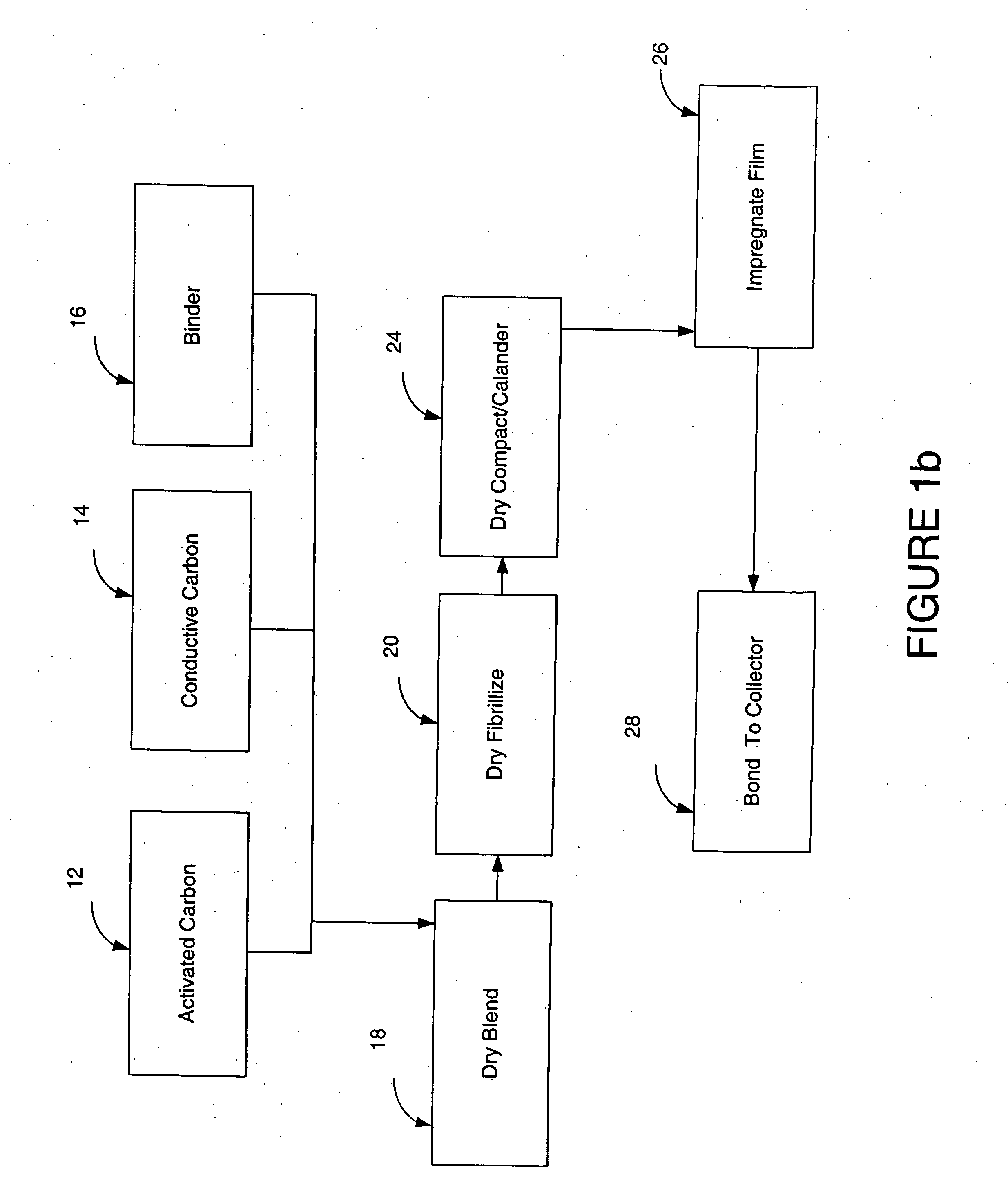

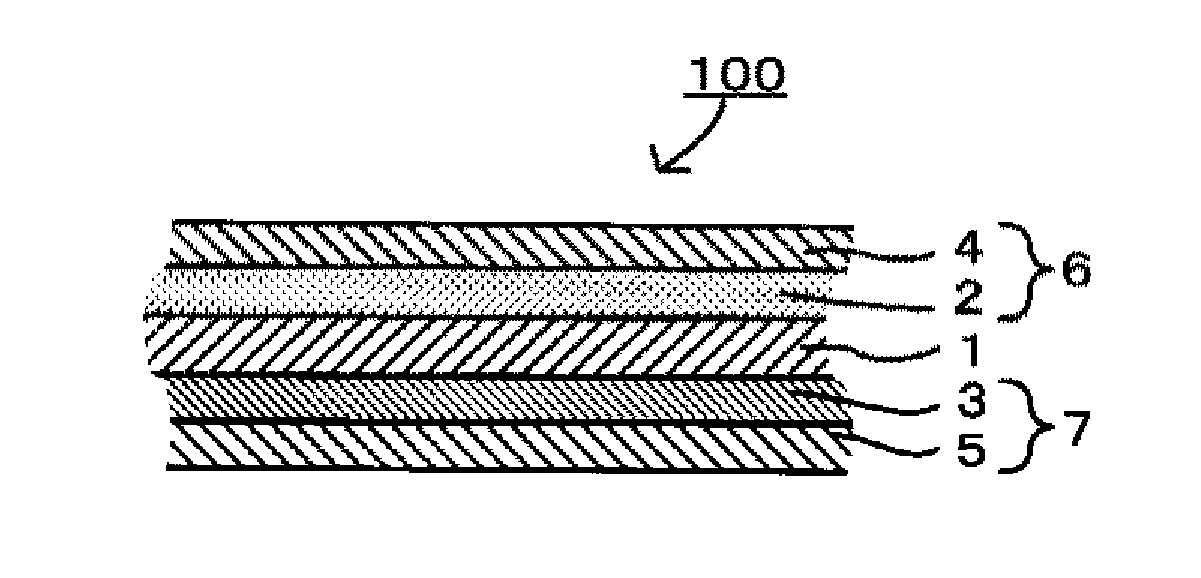

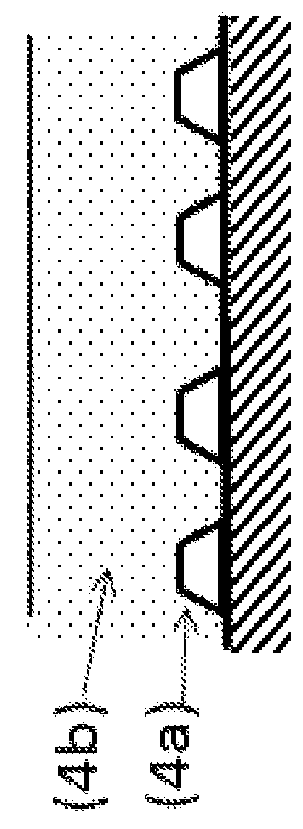

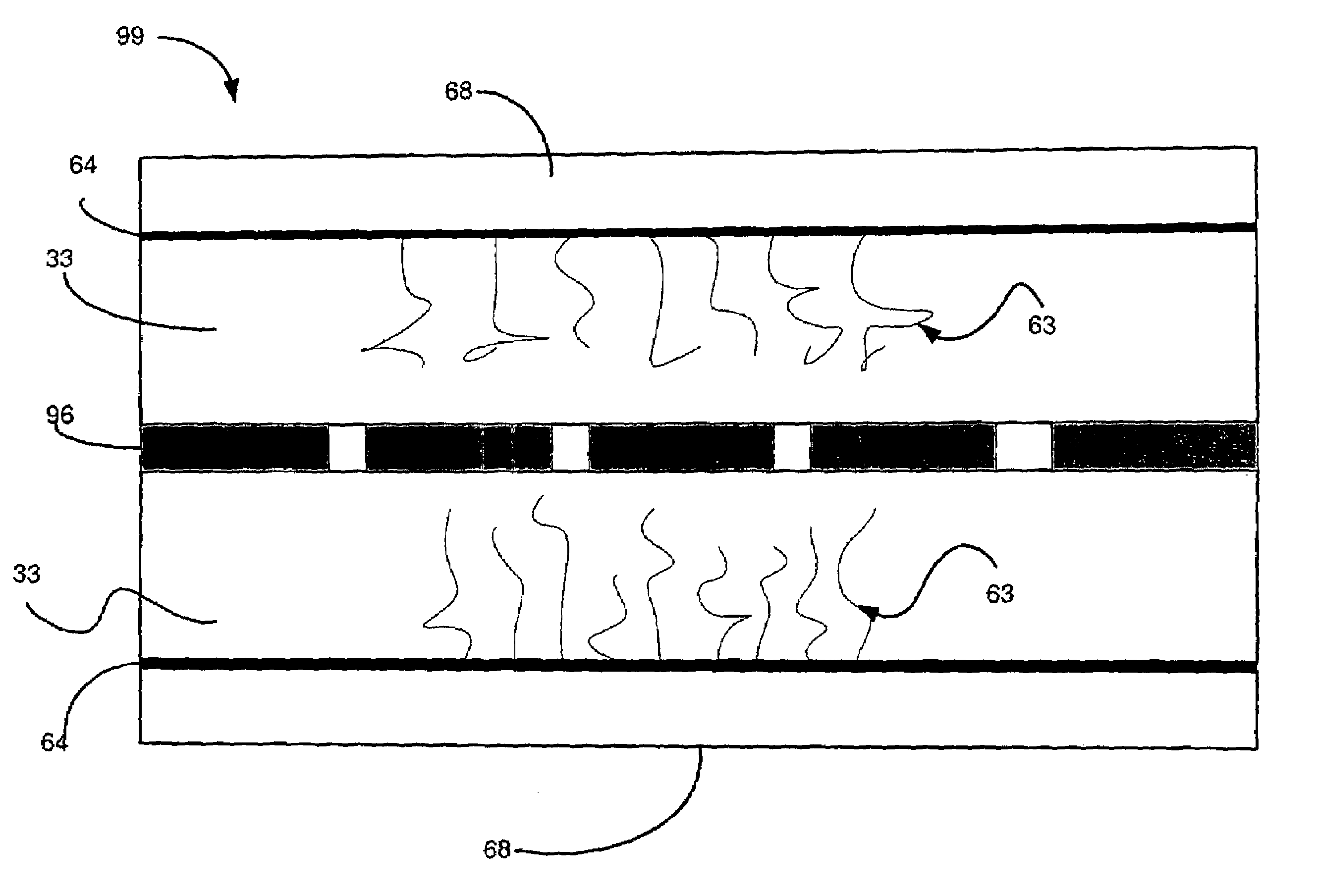

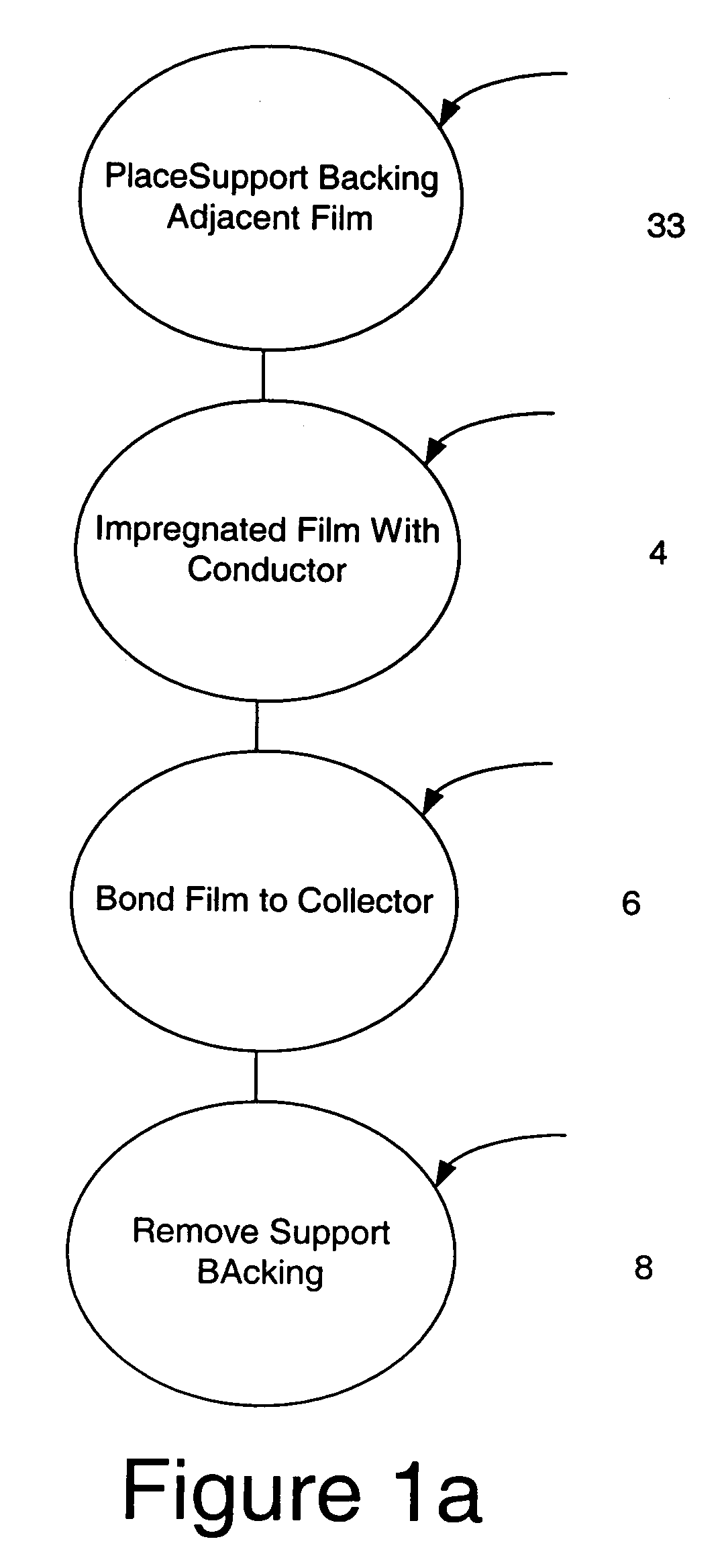

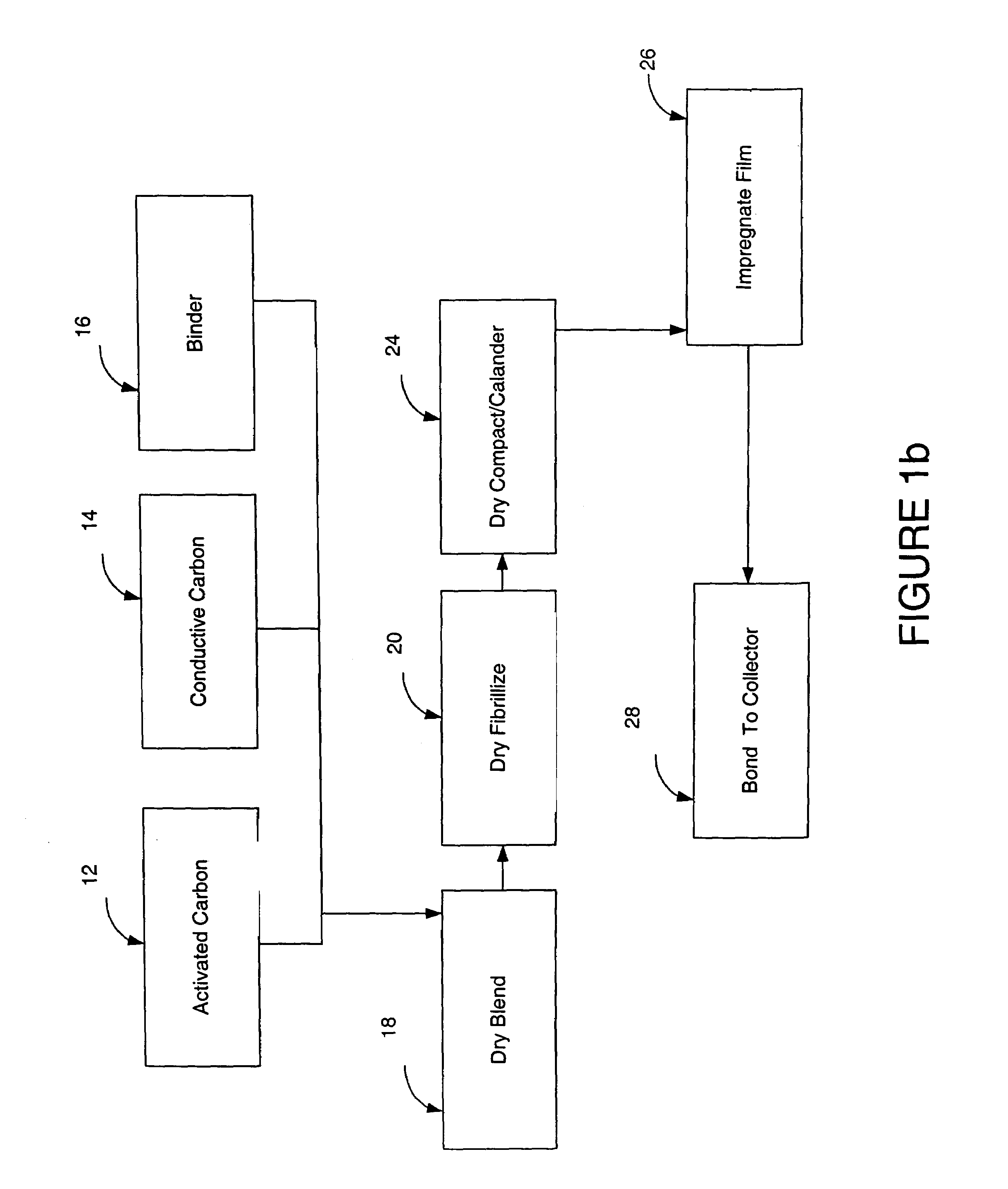

Electrode impregnation and bonding

ActiveUS20050057888A1Long-lasting and durable and inexpensive to produceLower internal resistanceElectrolytic capacitorsHybrid capacitor electrodesEngineeringConductive materials

A method for making an electrode including a particle based film is disclosed in which the film is coated and / or impregnated with veins of conductive material. A support backing is placed adjacent to one side of the film to provide support and prevent damaging the film while the conductive material is applied onto the opposite side of the film. The film is bonded directly to a current collector of an energy storage device.

Owner:TESLA INC

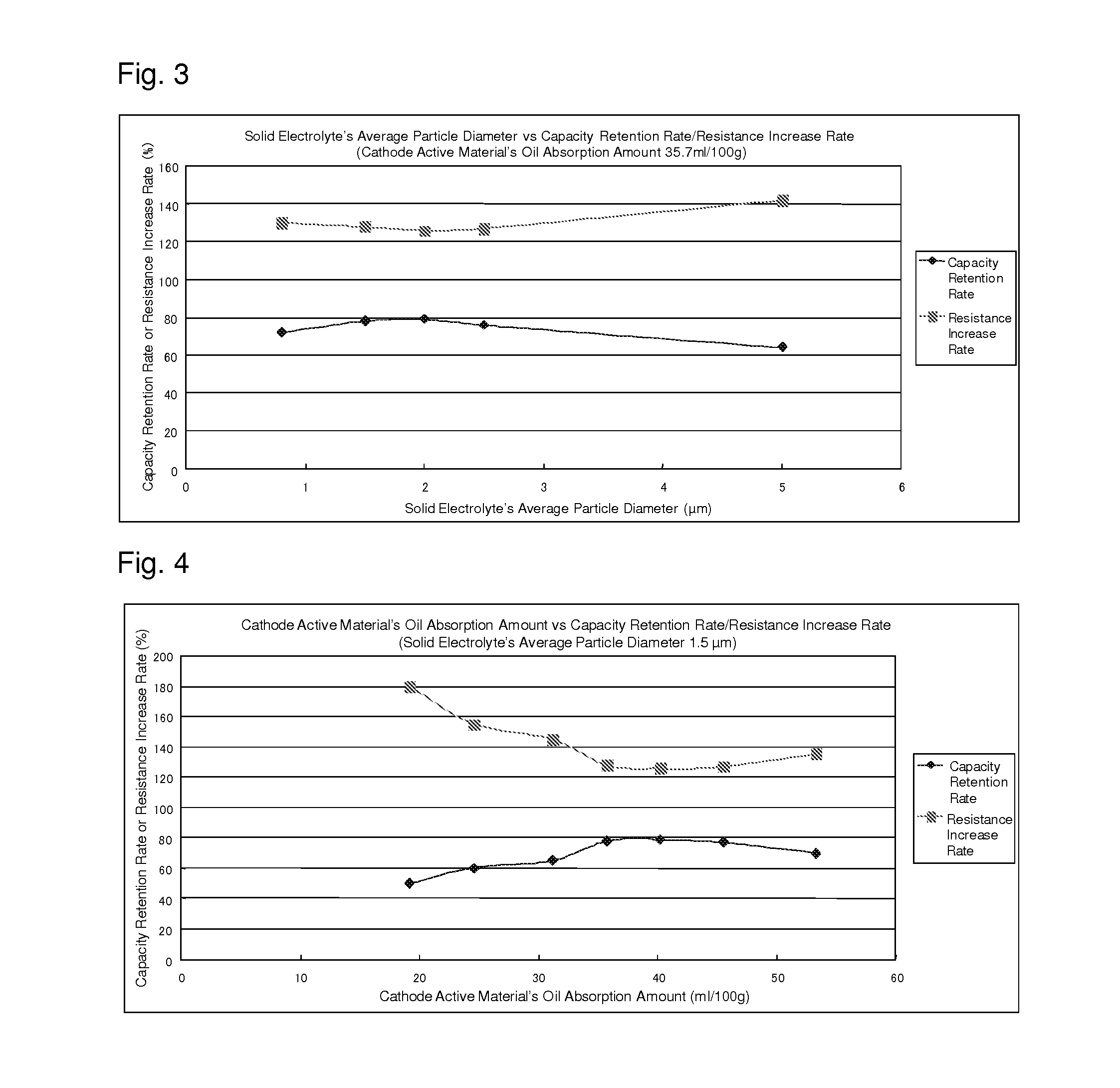

Cathode for secondary batteries, method for producing cathode for secondary batteries, and all-solid-state secondary battery

ActiveUS20150325844A1High capacity retentionSolid electrolytesFinal product manufactureAll solid stateEngineering

To provide: a cathode for secondary batteries, which has a high capacity retention rate; a method for producing a cathode for secondary batteries; and an all-solid-state secondary battery comprising the cathode. This object has been achieved providing by a cathode for secondary batteries, which is characterized by comprising a cathode active material layer containing at least a cathode active material and a solid electrolyte, wherein the cathode active material has an oil absorption amount of 35 to 50 ml per 100 g; wherein the solid electrolyte has an average particle diameter of 1.5 to 2.5 μm; and wherein the cathode active material layer is formed by mixing the cathode active material and the solid electrolyte in the absence of solvent and pressure-forming the resulting mixture.

Owner:TOYOTA JIDOSHA KK

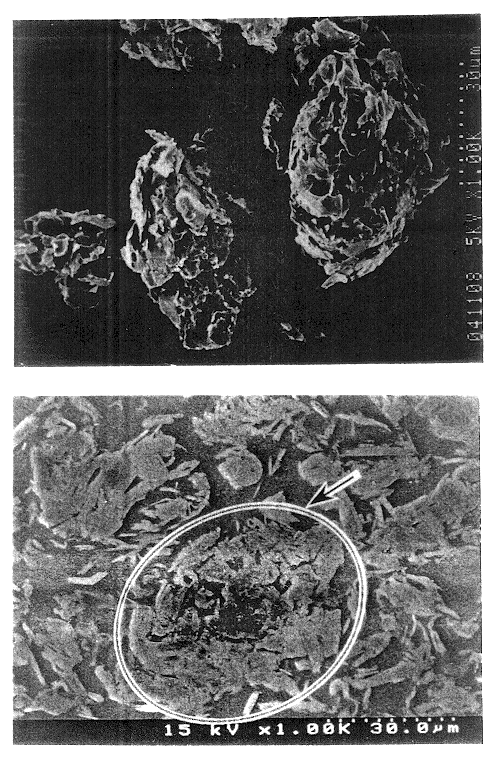

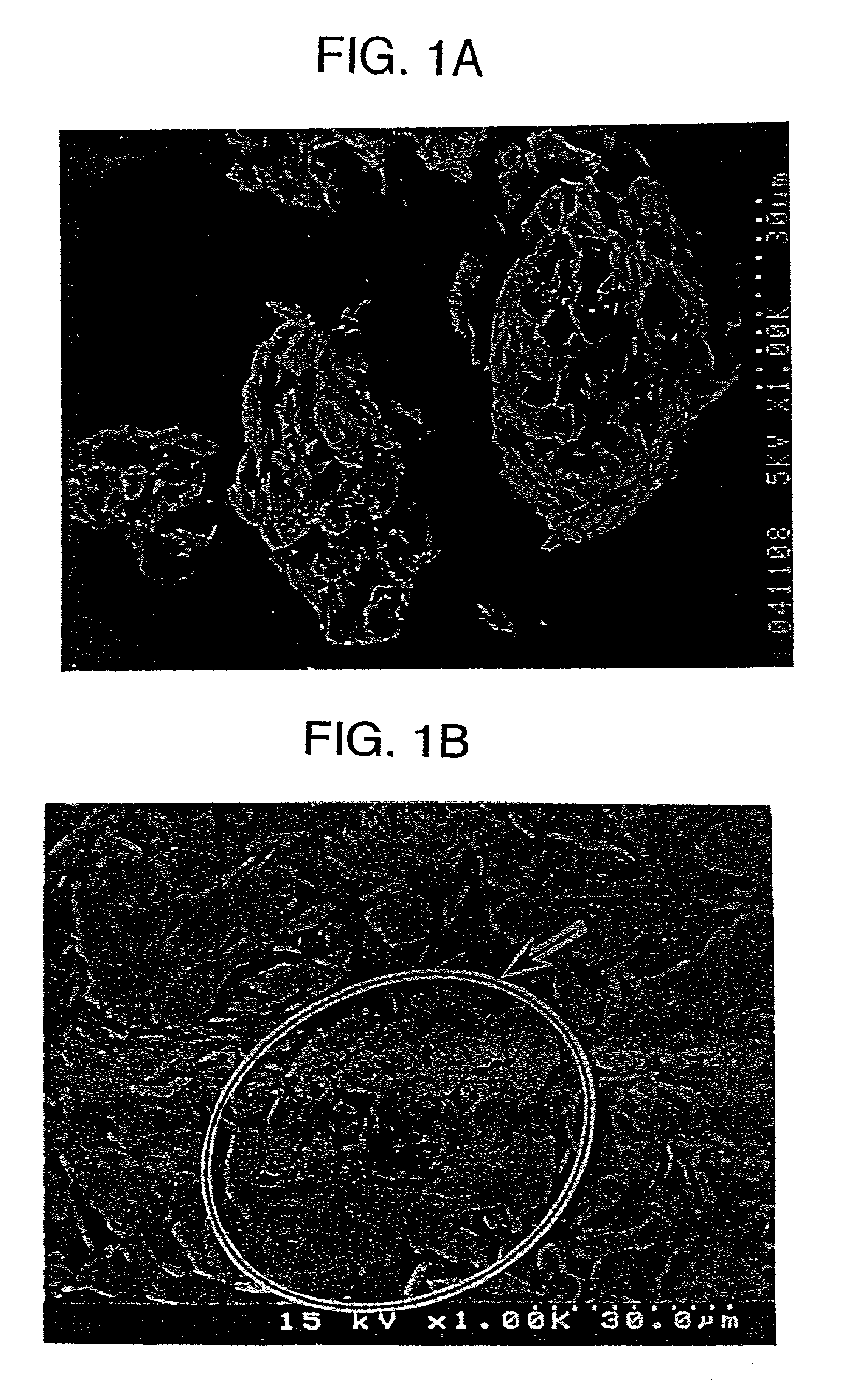

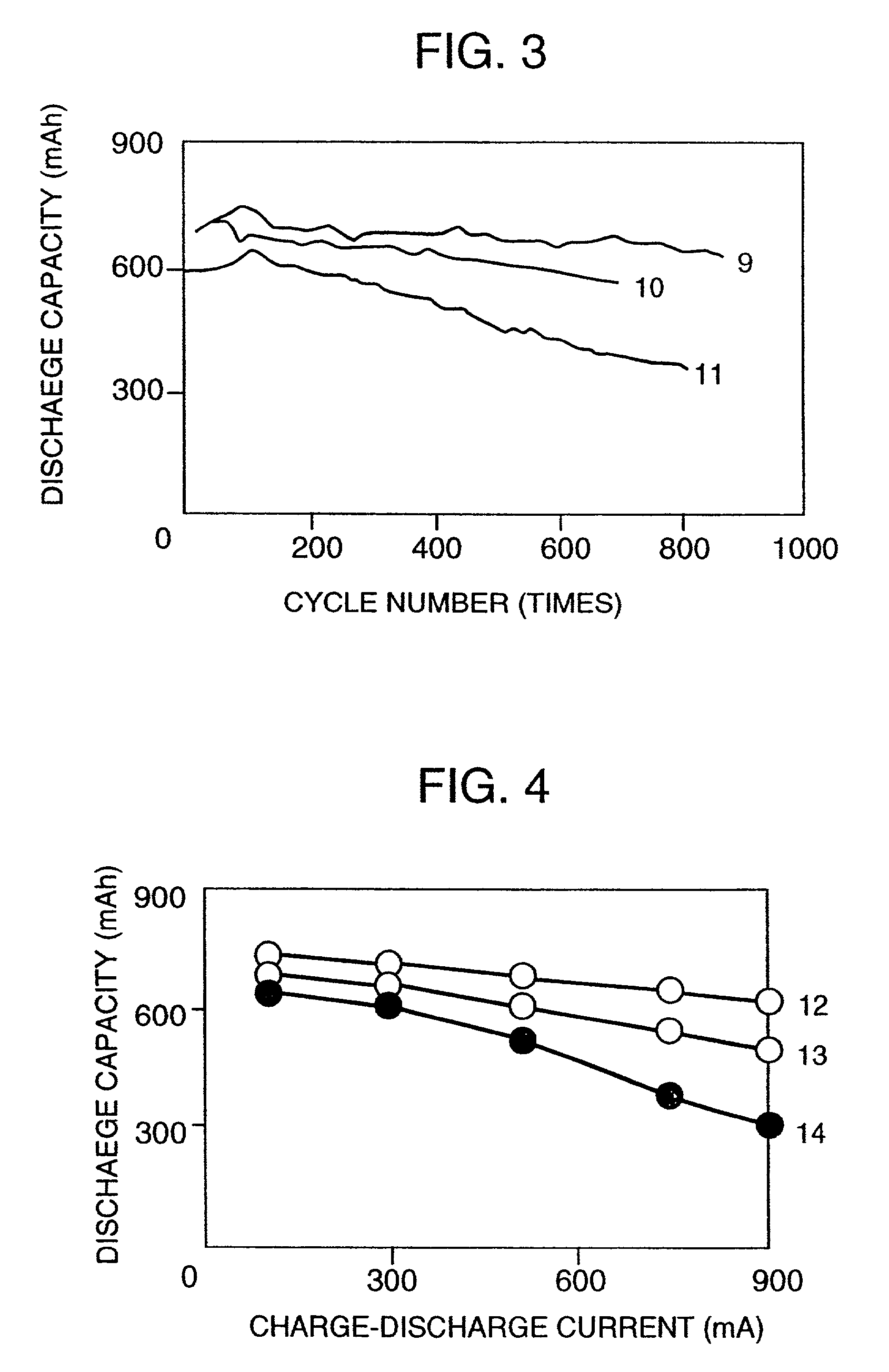

Graphite particles and lithium secondary battery using the same as negative electrode

InactiveUS6344296B1Improve featuresSolve large capacityGraphiteFinal product manufactureX-rayCharge discharge

A graphite particle obtained by assembling or binding together a plurality of flat-shaped particles so that the planes of orientation are not parallel to one another, or a graphite particle in which aspect ratio is 5 or less or specific surface area is 8 m2 / g or less or the size of crystallite in the direction of c-axis of the crystal is 500 Å or more and the size of crystallite in the direction of plane is 1,000 Å or less as measured by X ray broad angle diffraction, or a graphite particle in which pore volume of the pores having a size falling in a range of 102 to 106 Å is 0.4 to 2.0 cc / g per weight of graphite particle or pore volume of the pores having a size falling in a range of 1x102 to 2x104 Å is 0.08 to 0.4 cc / g per weight of graphite particle is suitable for production of negative electrode of lithium secondary battery, and a lithium secondary battery obtained therefrom is excellent in rapid charge-discharge characteristics, cycle characteristics, etc.

Owner:RESONAC CORPORATION

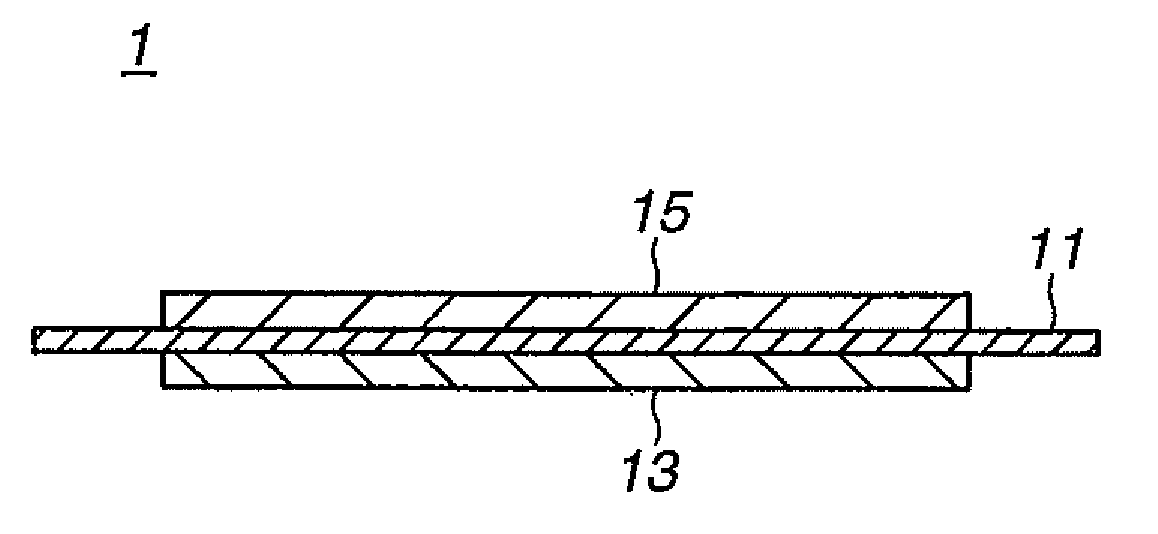

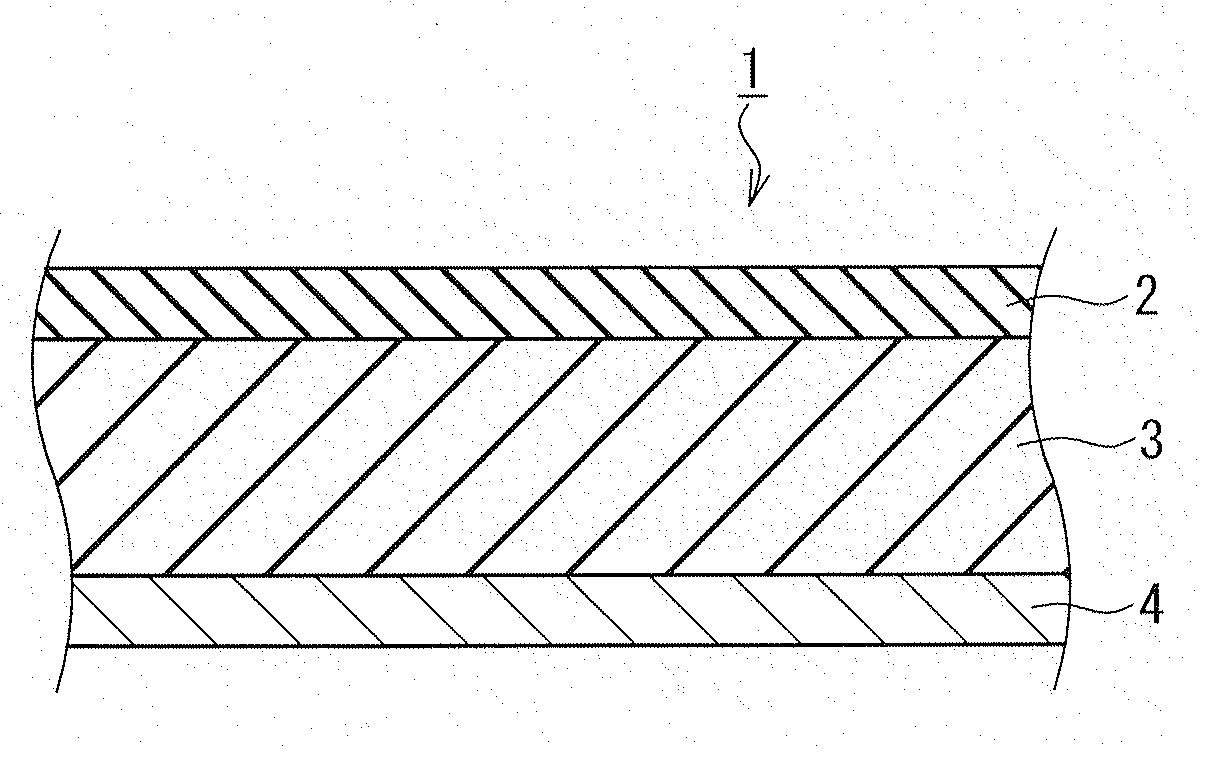

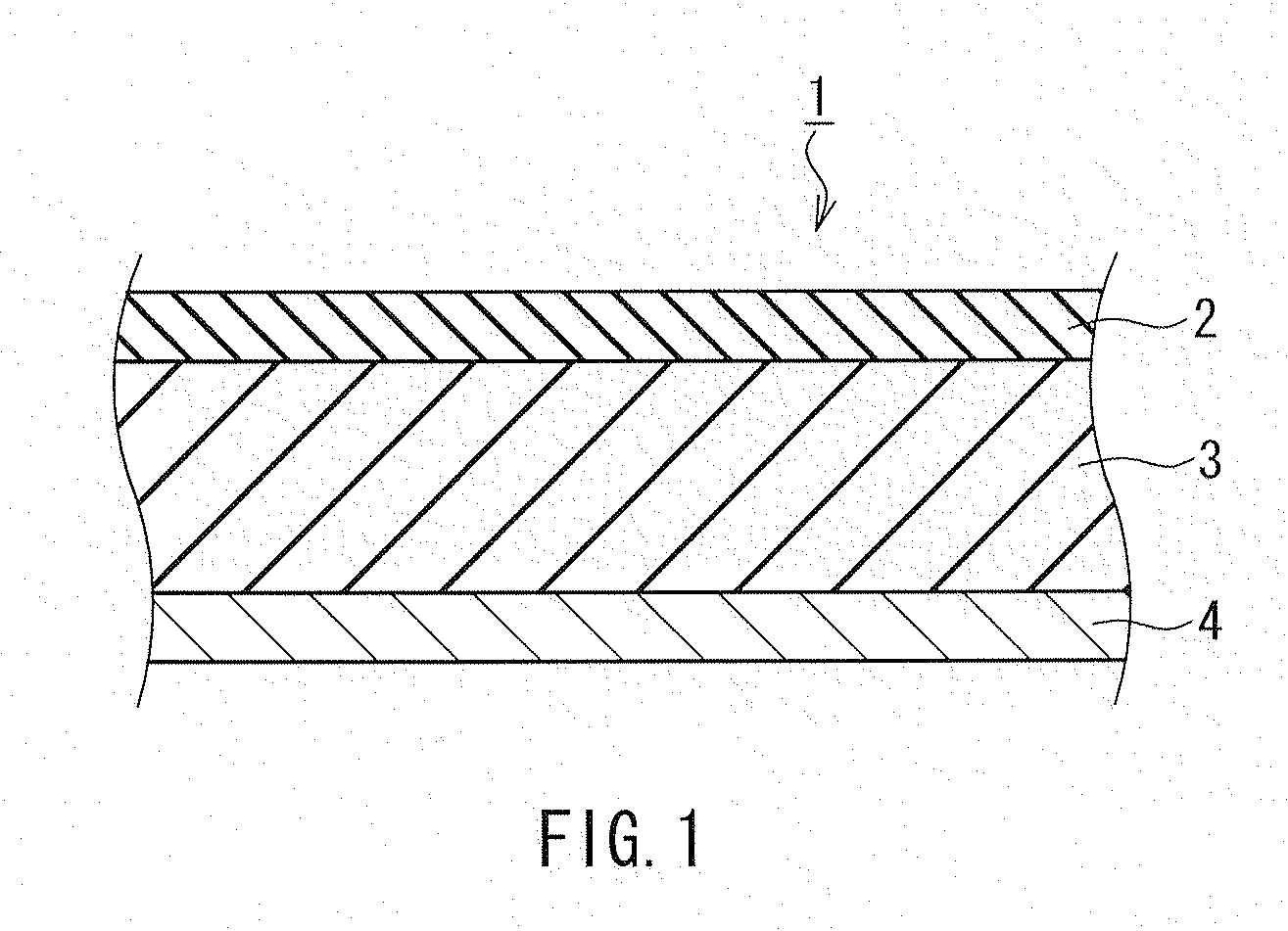

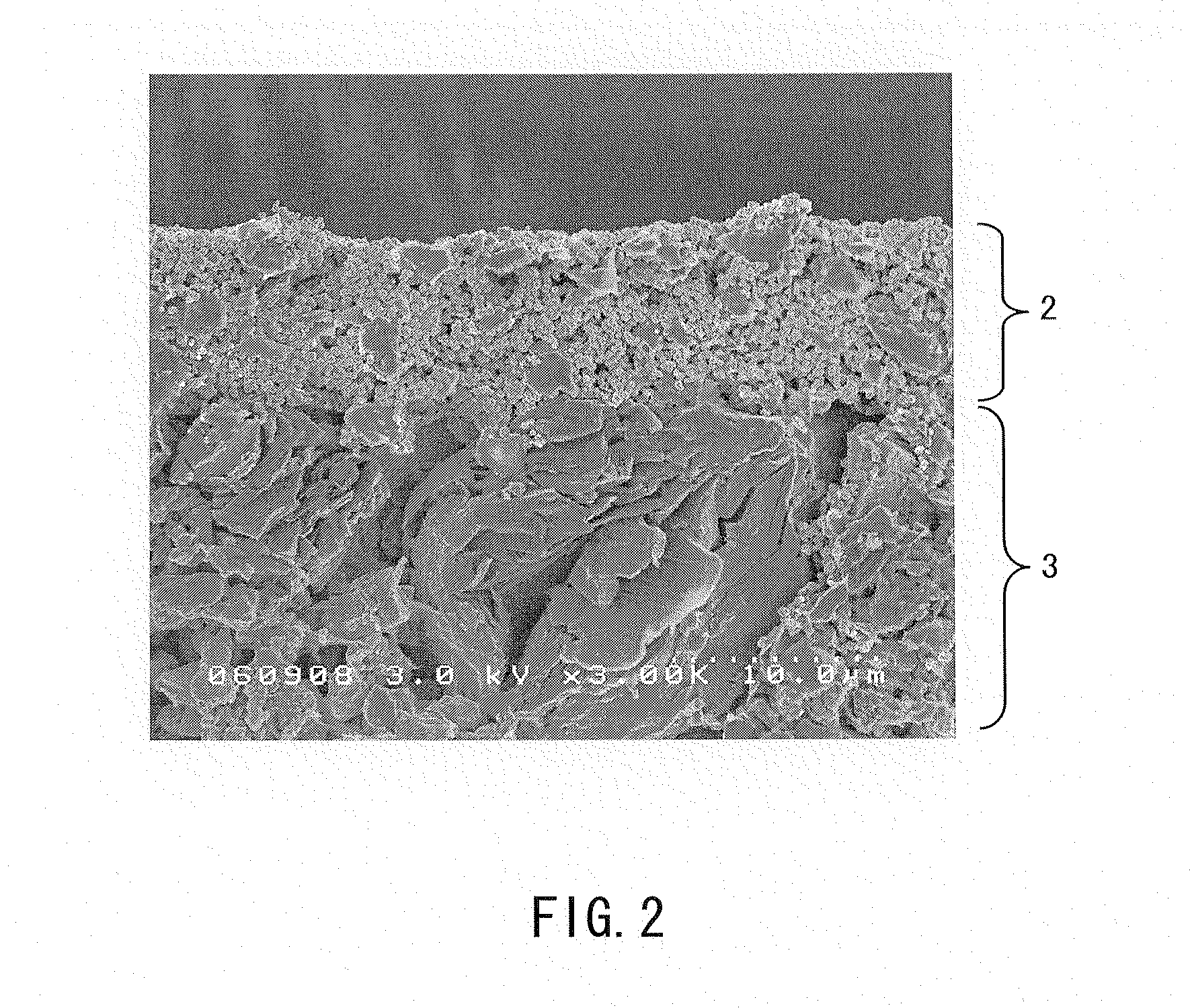

Electrode and production method thereof

ActiveUS20110206974A1Improve adhesionAvoid separationFinal product manufactureElectrode carriers/collectorsMethods of productionPolymer

An electrode includes a collector formed with a conductive resin layer and an active material layer formed on the conductive resin layer. The active material layer comprises an active material and a binder polymer, and the conductive resin layer is bonded by thermal fusion bonding to the active material layer.

Owner:ENVISION AESC JAPAN LTD

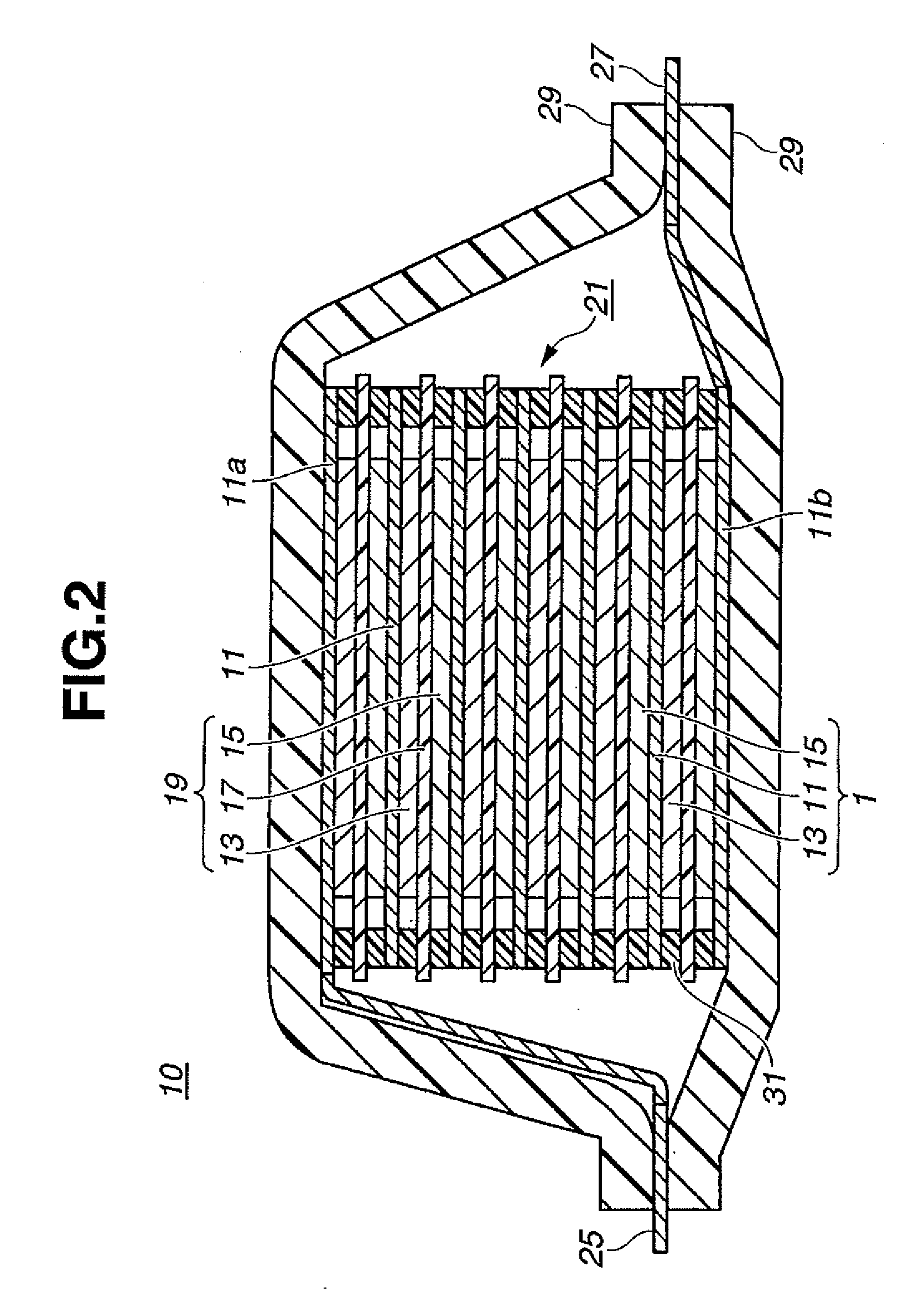

Stationary semi-solid battery module and method of manufacture

An electrochemical cell includes an anode, a semi-solid cathode, and a separator disposed therebetween. The semi-solid cathode includes a porous current collector and a suspension of an active material and a conductive material disposed in a non-aqueous liquid electrolyte. The porous current collector is at least partially disposed within the suspension such that the suspension substantially encapsulates the porous current collector.

Owner:24M TECH INC

Thin film lithium conducting powder material deposition from flux

ActiveUS9362546B1Improve efficiencyReadily and conveniently incorporated into battery cell designZirconium compoundsElectrode collector coatingLithiumElectrolyte

The present invention is directed to battery technologies and processing techniques thereof. In various embodiments, ceramic electrolyte powder material (or component thereof) is mixed with two or more flux to form a fluxed powder material. The fluxed powder material is shaped and heated again at a temperature less than 1100° C. to form a dense lithium conducting material. There are other variations and embodiments as well.

Owner:QUANTUMSCAPE BATTERY INC

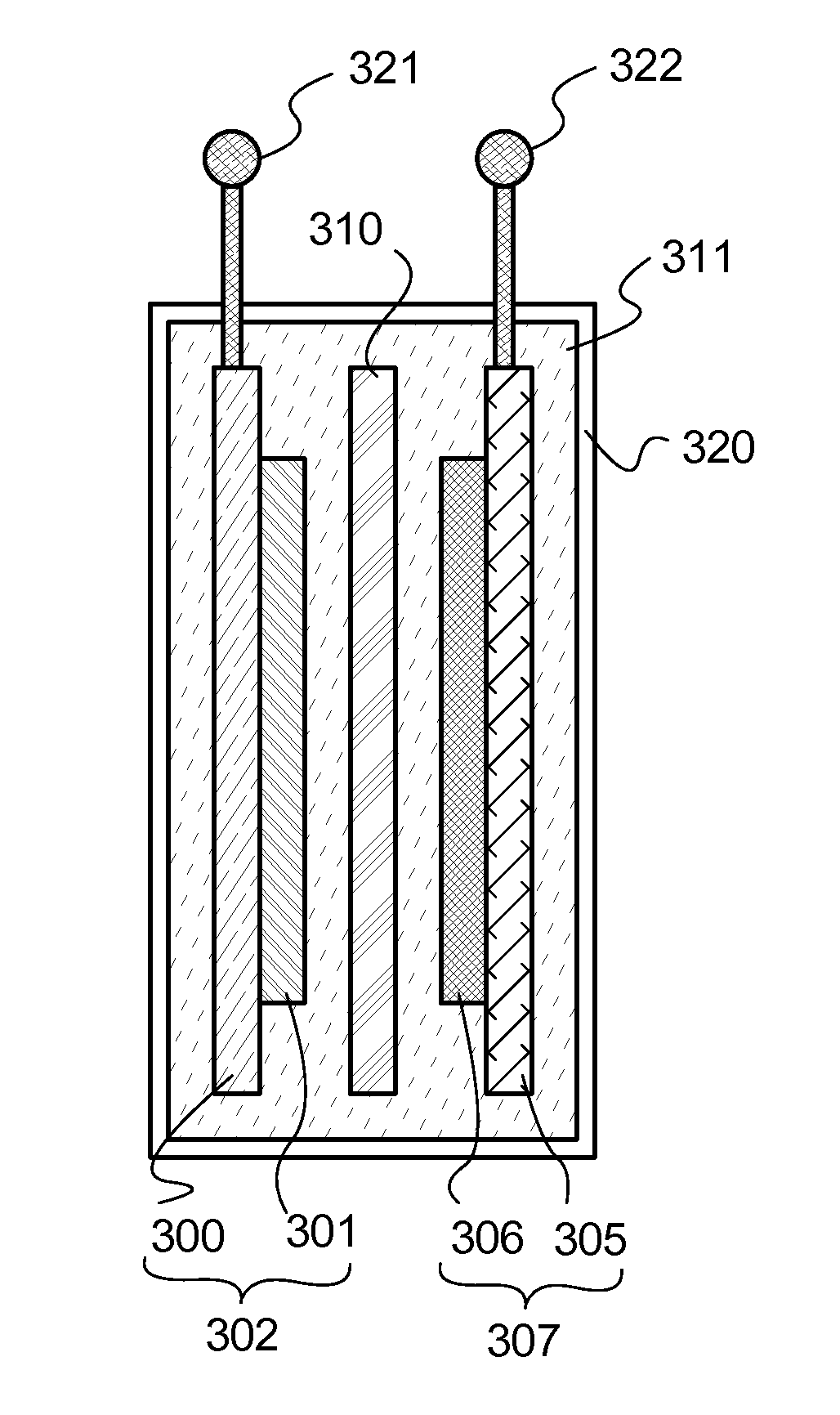

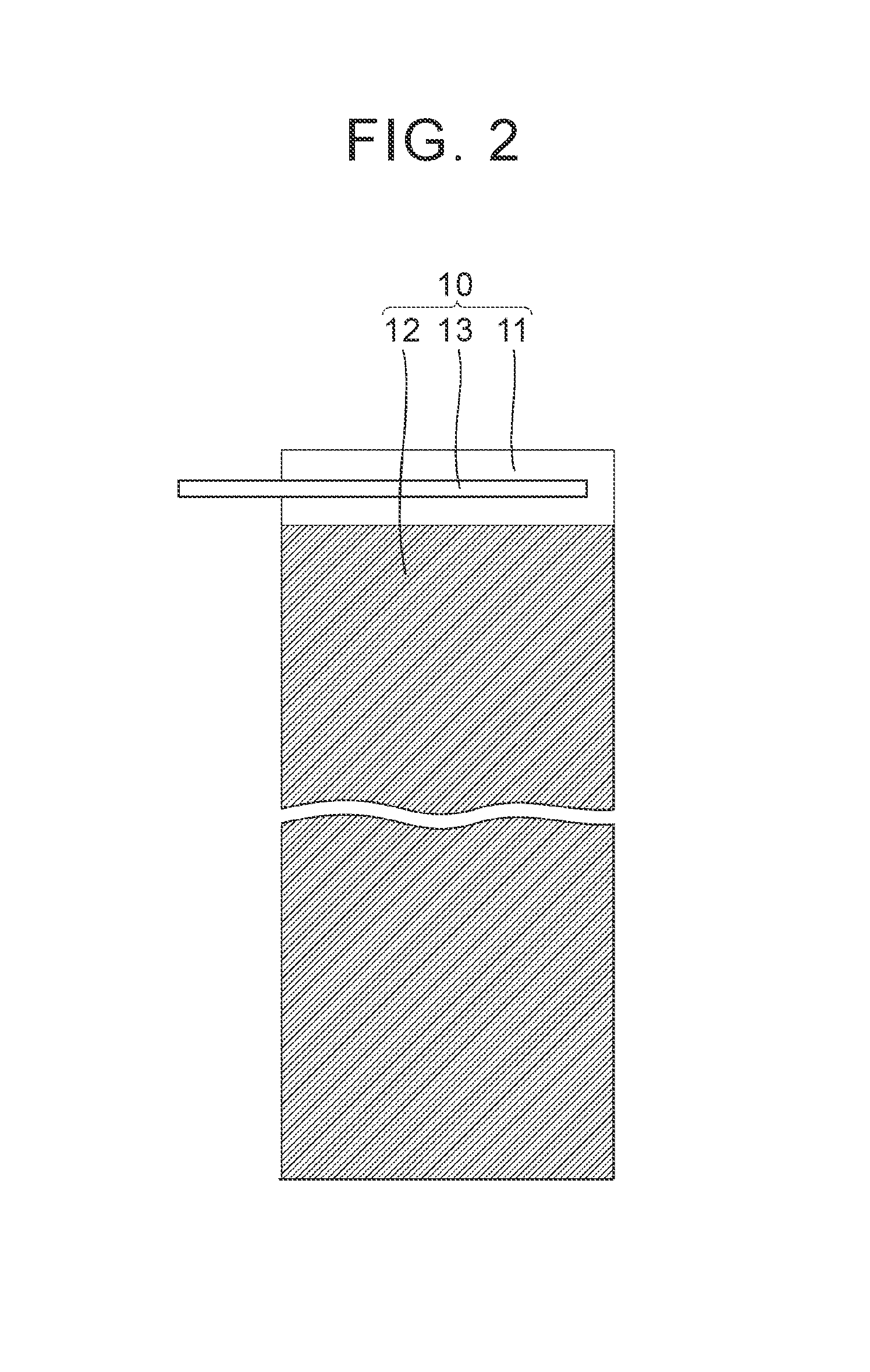

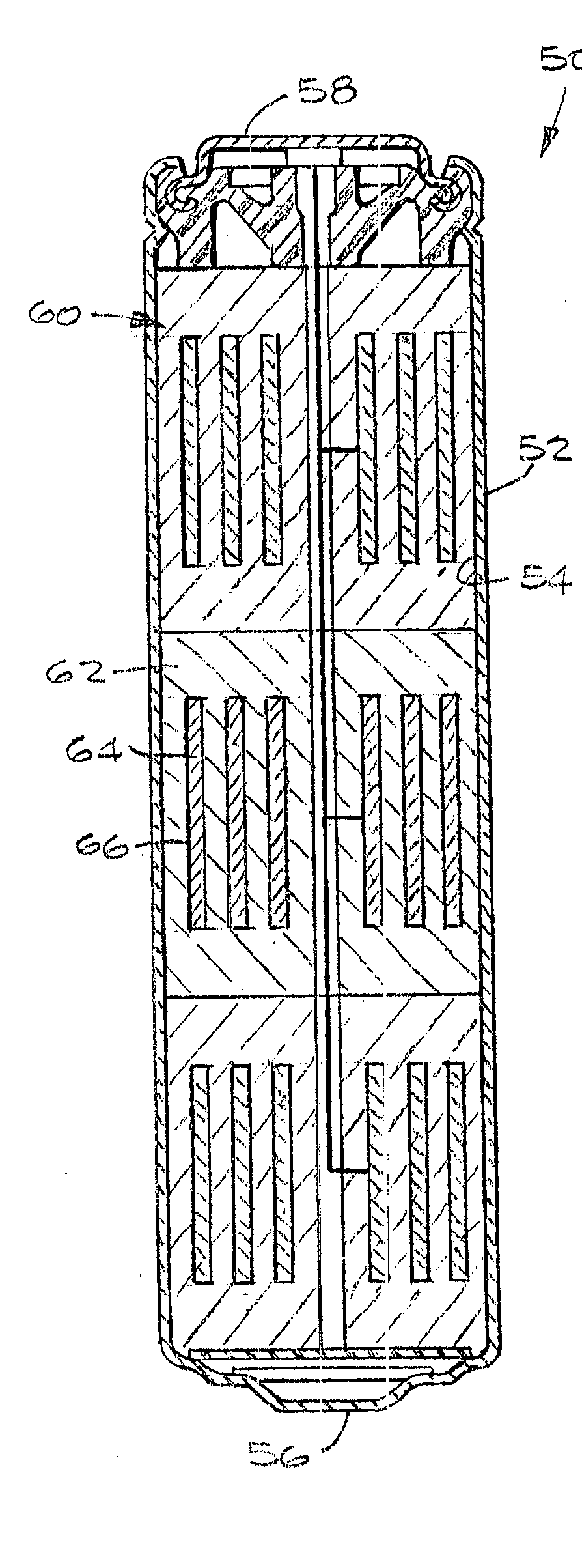

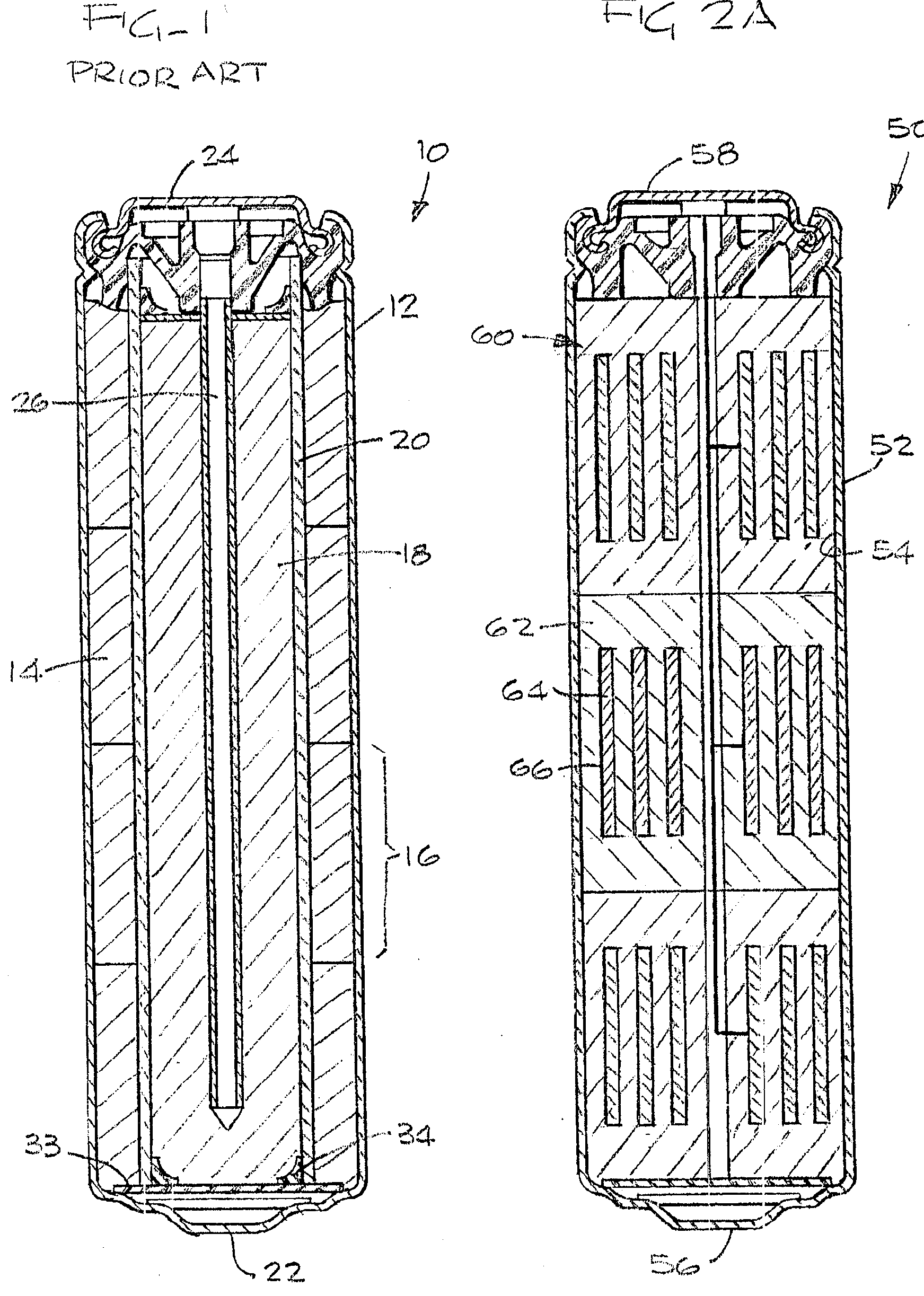

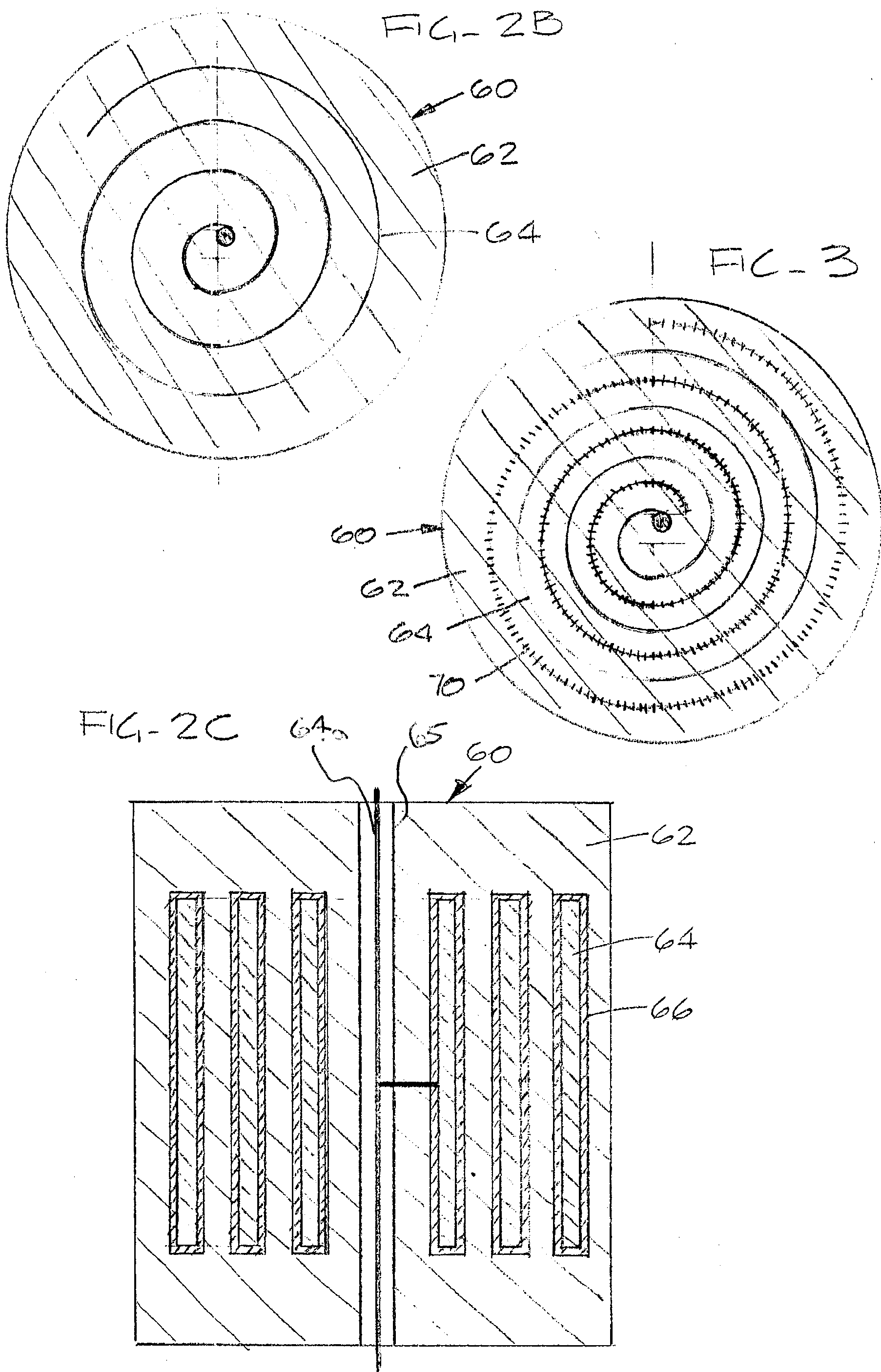

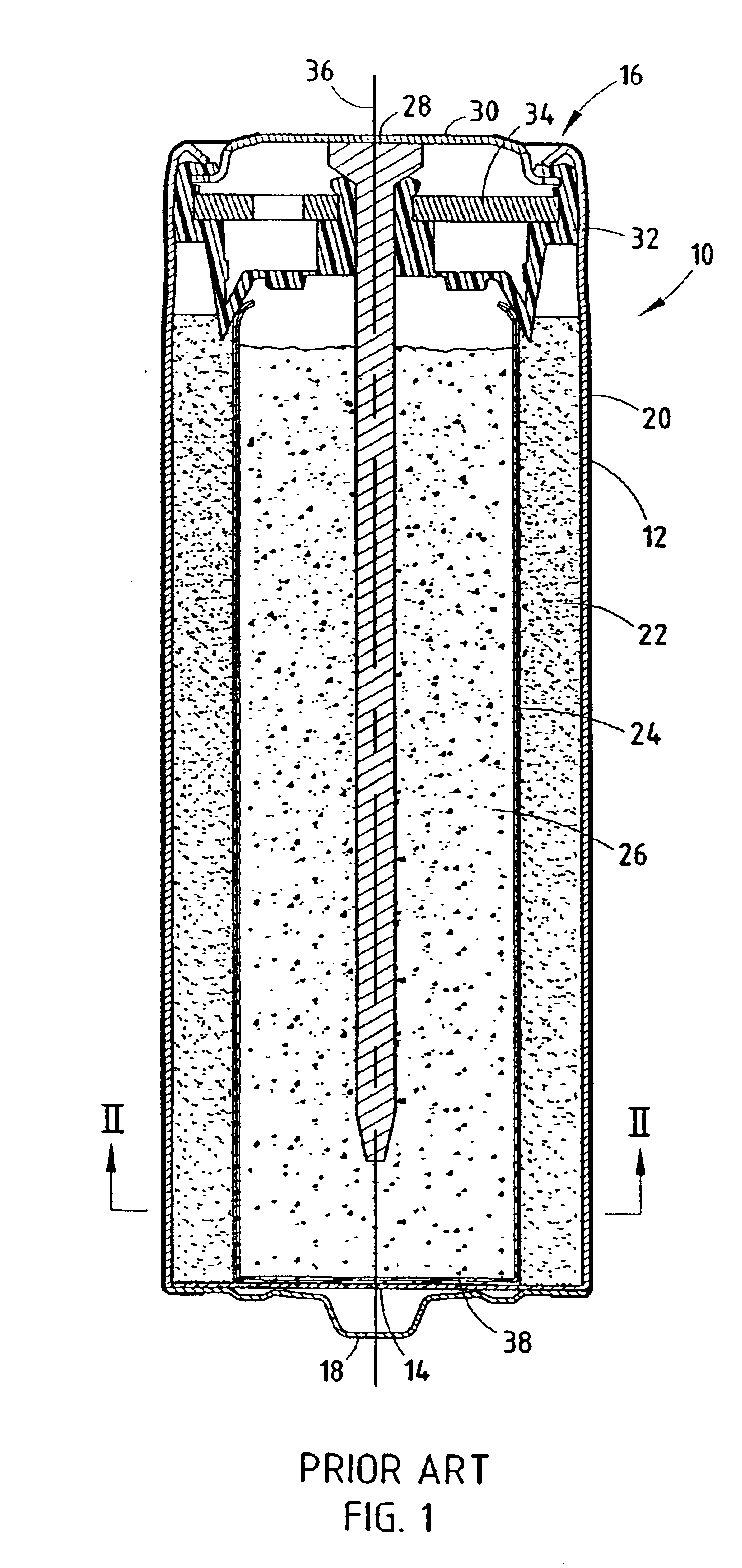

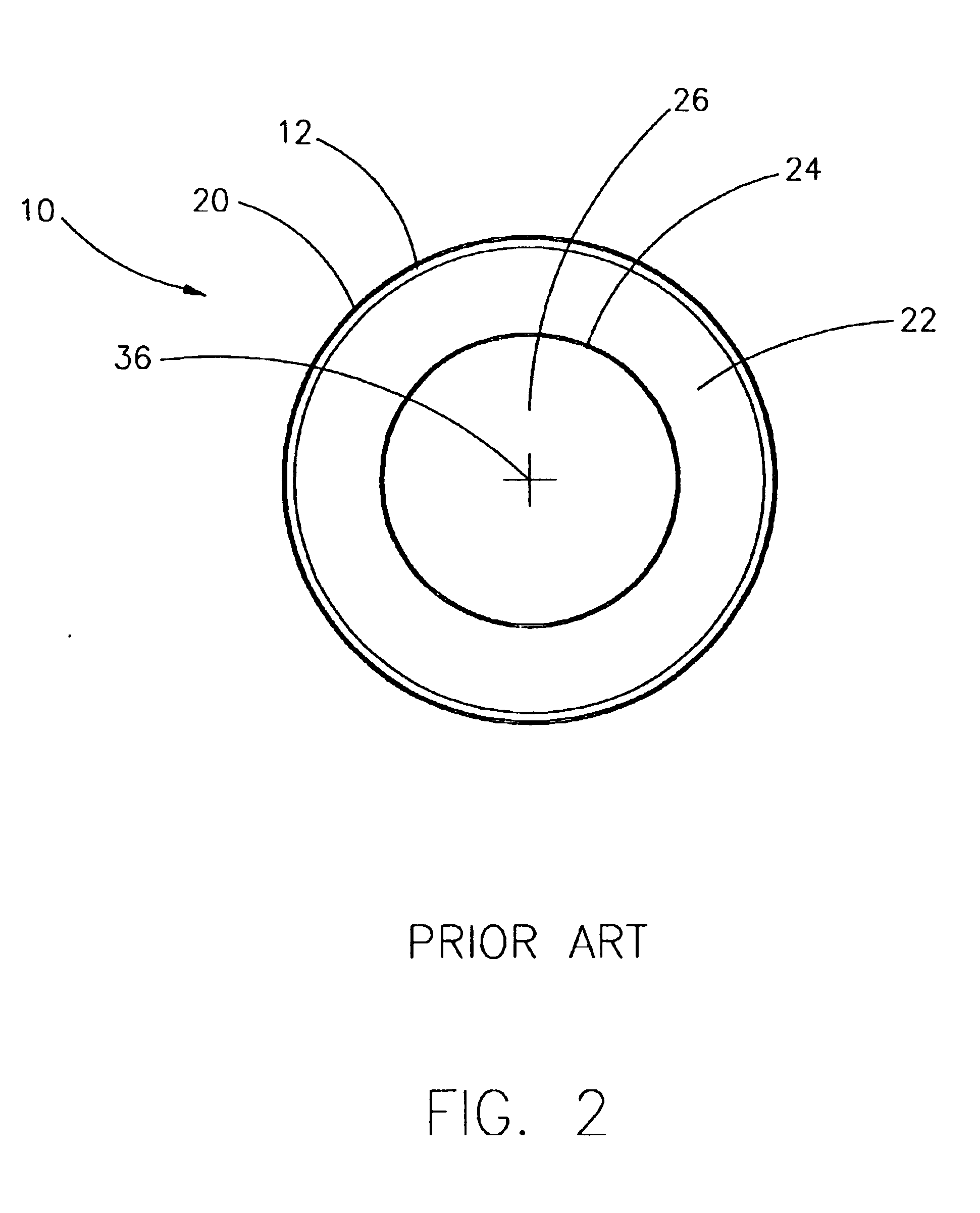

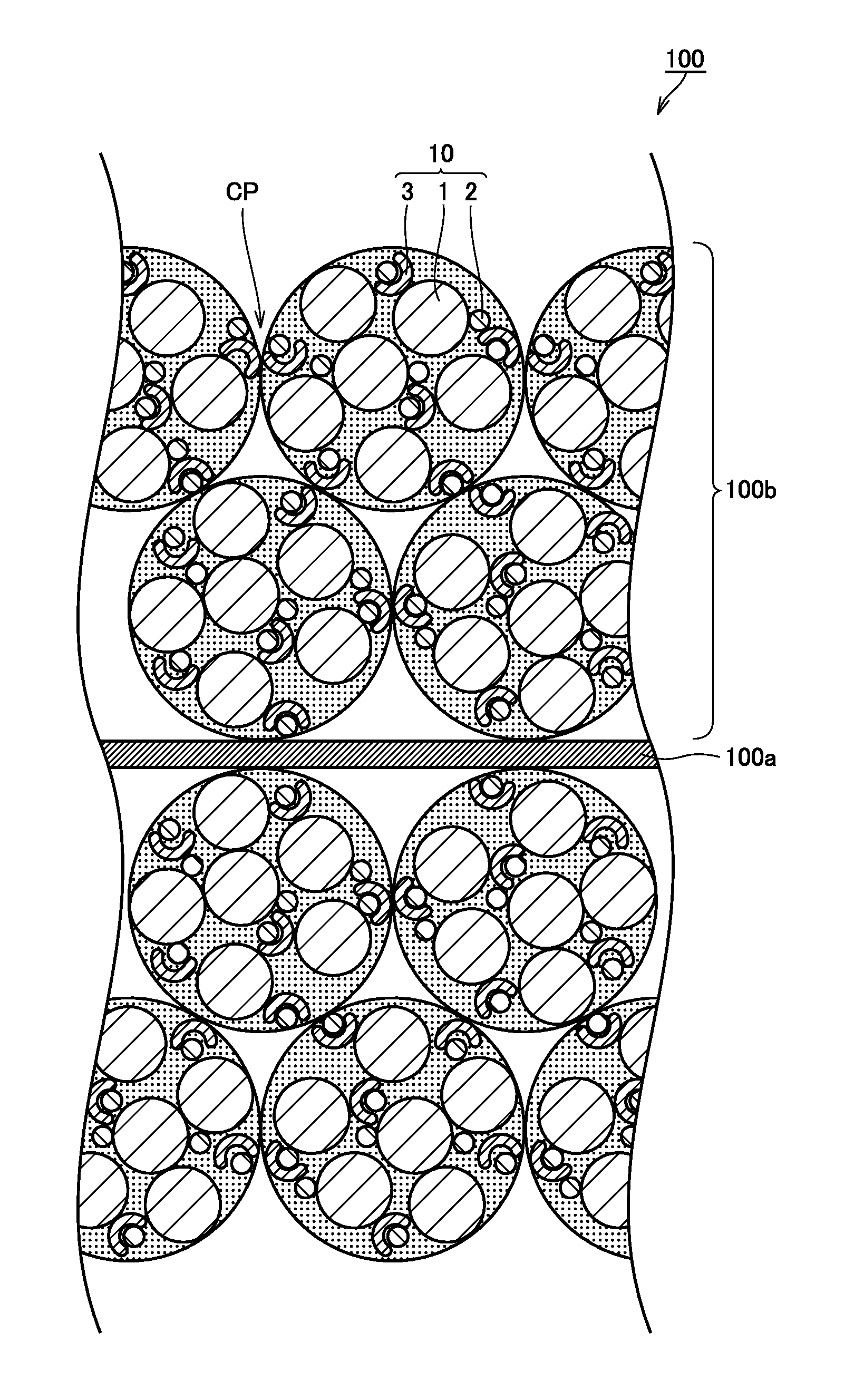

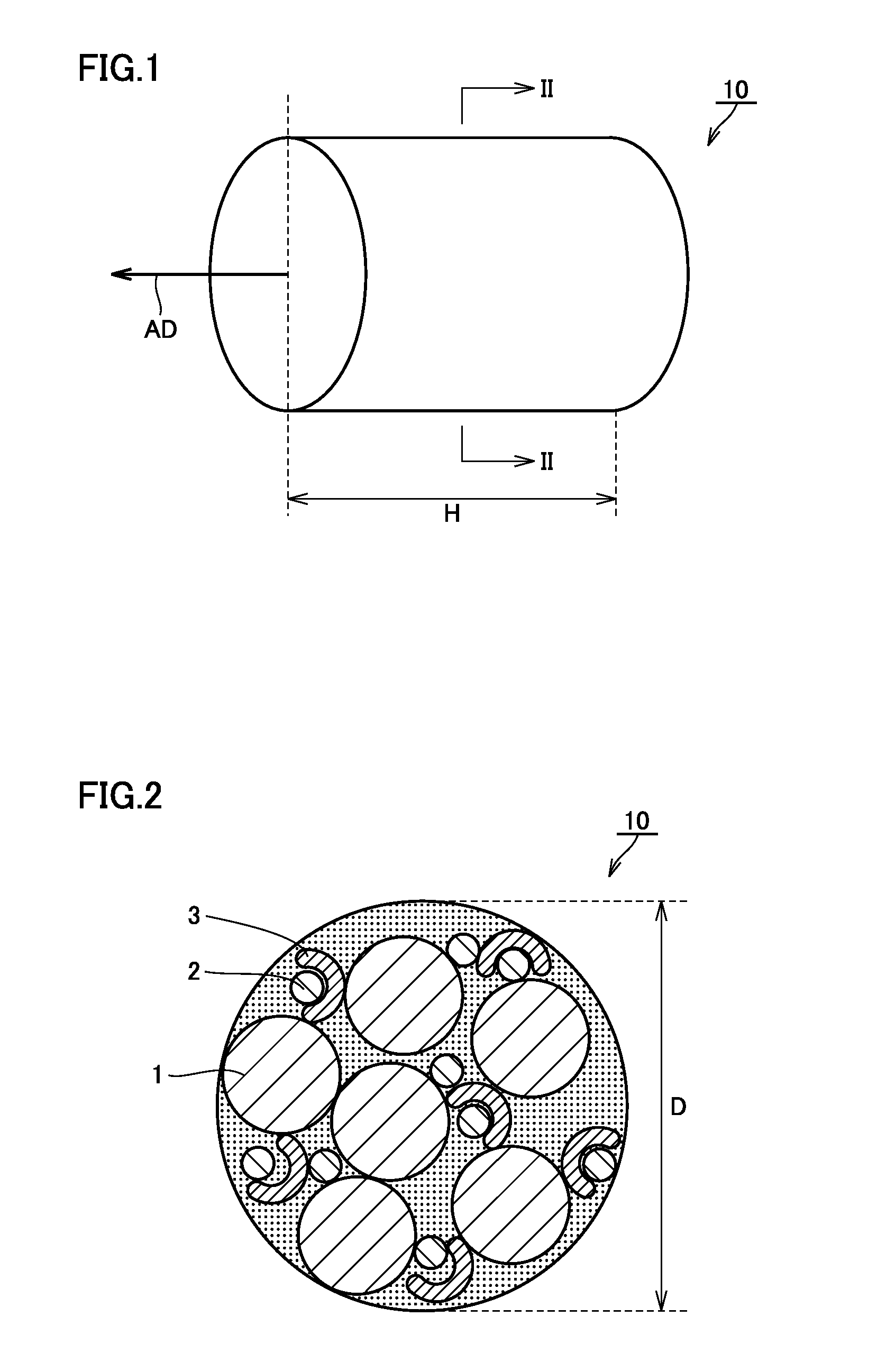

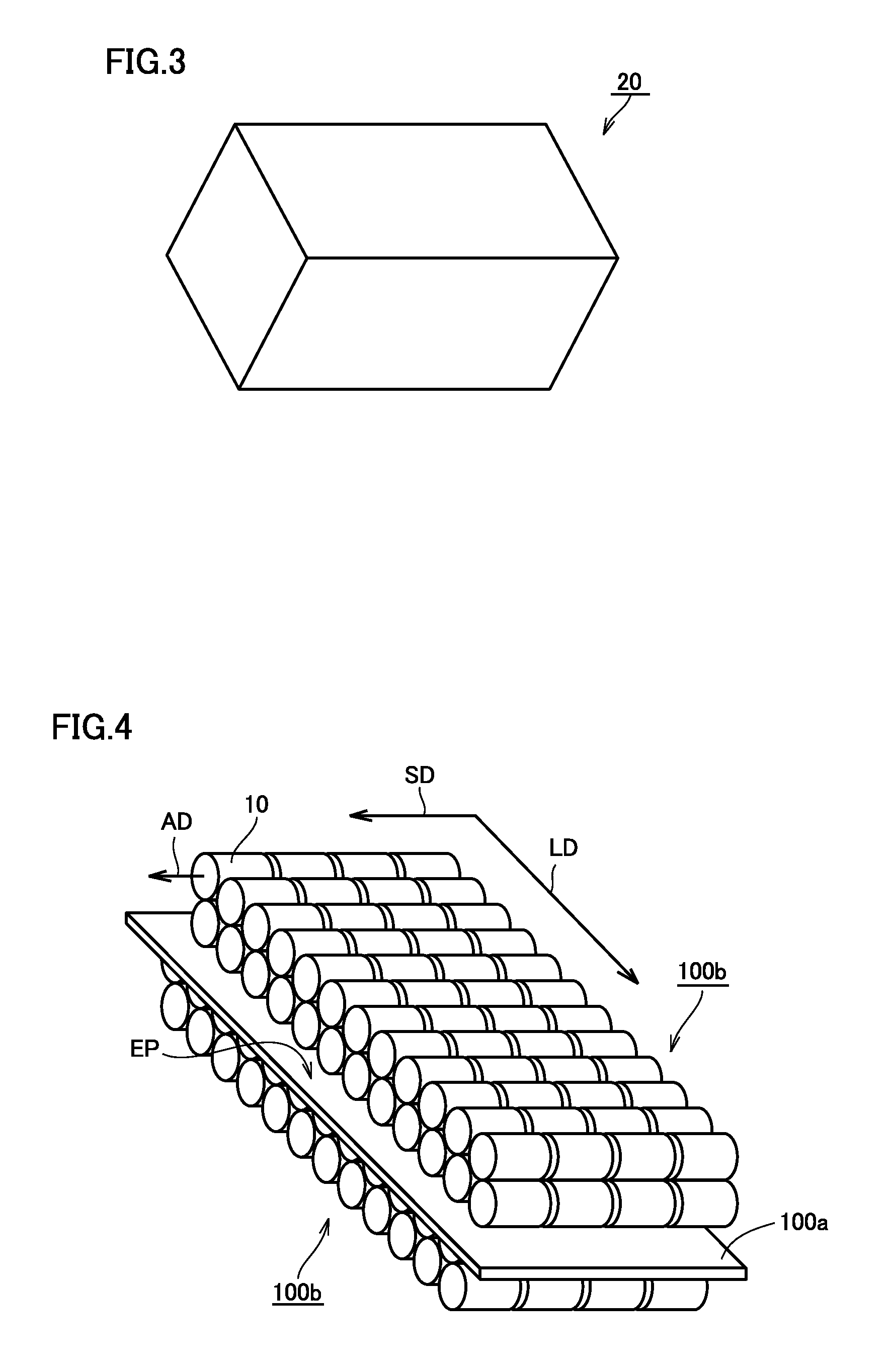

Battery employing an electrode pellet having an inner electrode embedded therein

InactiveUS20040258982A1Easy to integrateNot adversely affect performance characteristicElectrode carriers/collectorsActive material electrodesInterior spaceEngineering

An electrochemical battery cell comprising a cell housing defining an inner space, a first terminal and a second terminal; and at least one pre-formed pellet disposed within the inner space of the cell housing. The pellet includes an outer electrode portion formed from a material to geometrically define the pellet in a solid form. The outer electrode portion is in electrical communication with the first terminal of the cell housing. The pellet also includes an inner electrode encapsulated by a separator and embedded within the material of the outer electrode portion. The inner electrode is in electrical communication with the second terminal of the cell housing and electrically insulated from the outer electrode material. In a preferred embodiment, the inner electrode comprises an anode and the outer electrode portion comprises a cathode portion. The integrated anode / cathode pellet configuration facilitates lowers costs, a more robust design and ease of manufacturability while maintaining and allowing increased performance characteristics of the battery cell.

Owner:RECHARGEABLE BATTERY CORP

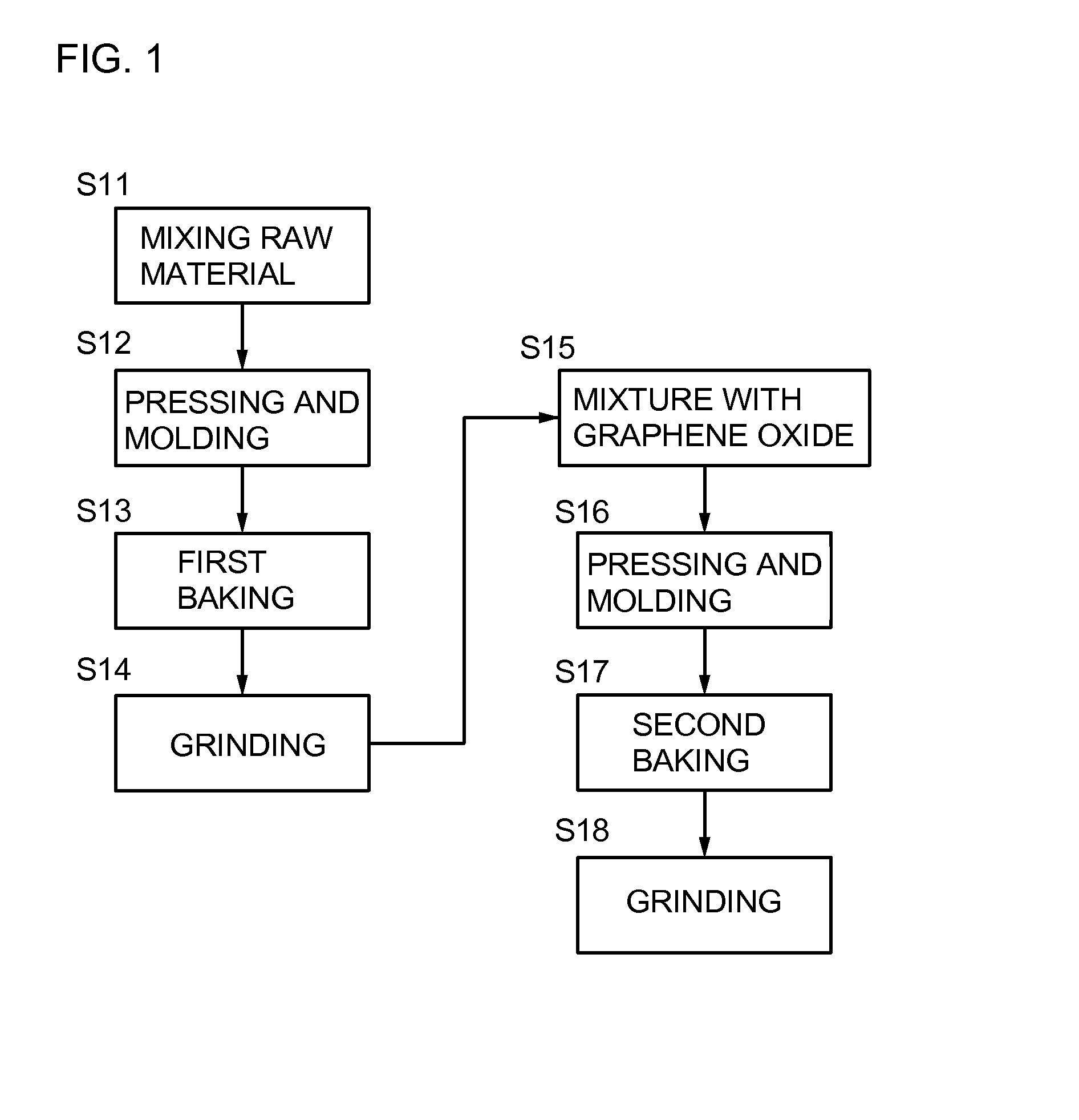

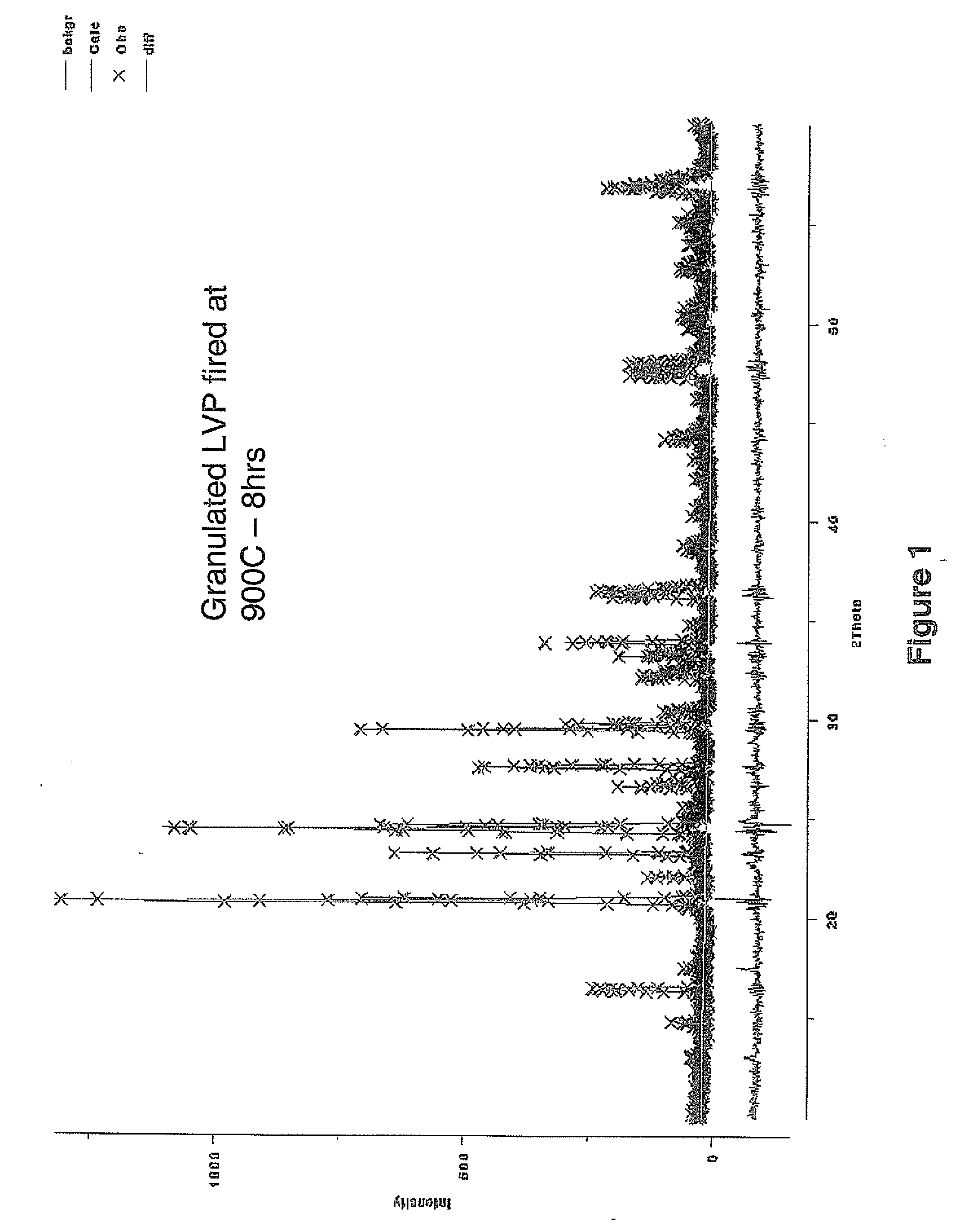

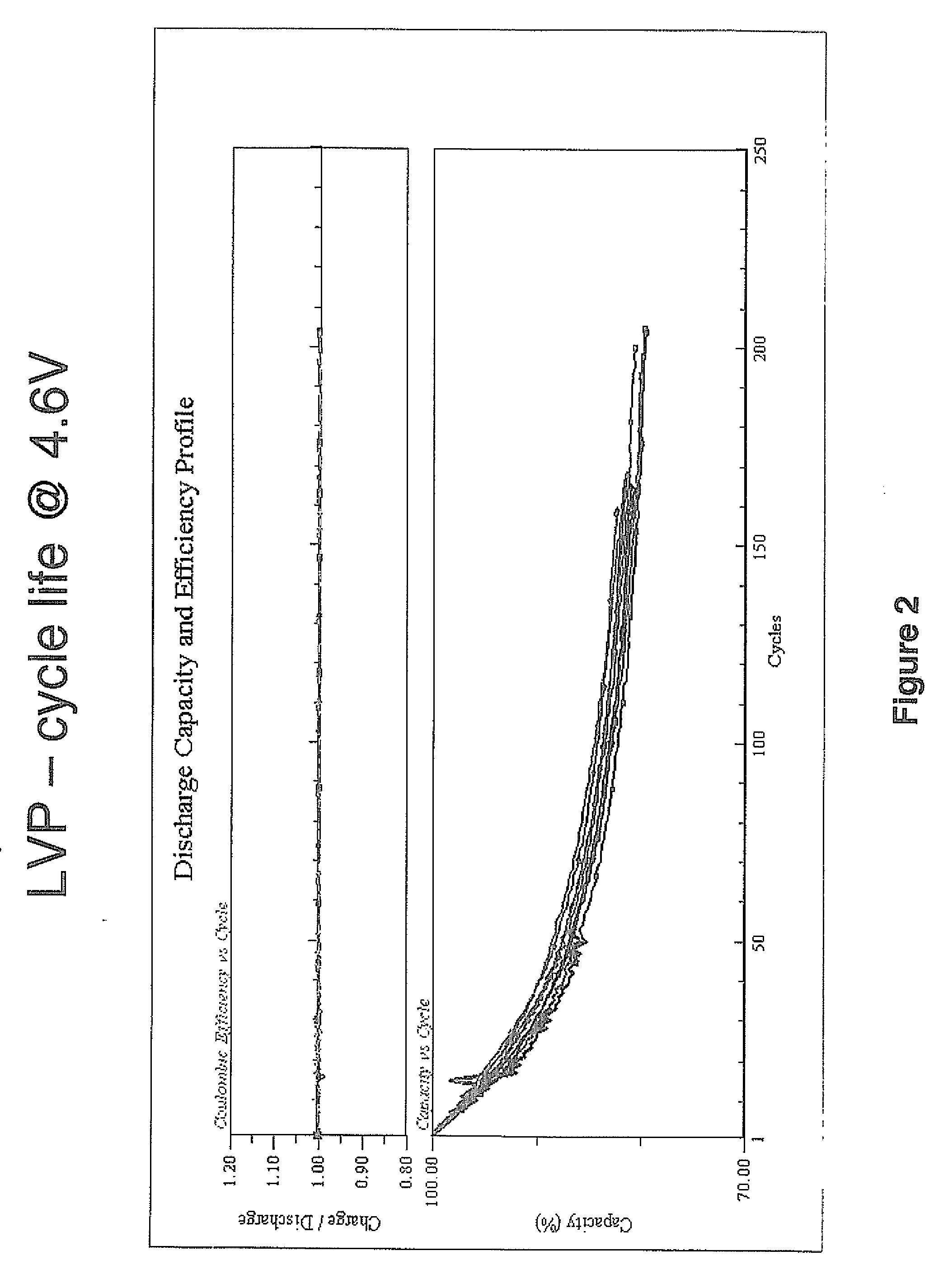

Process For Producing Electrode Active Material For Lithium Ion Cell

InactiveUS20090148377A1Reduce moisture contentPhosphatesElectrode thermal treatmentPhosphateElectrical battery

The present invention relates to a method for preparing a lithium vanadium phosphate material comprising mixing water, lithium dihydrogen phosphate, V2O3 and a source of carbon to produce a first slurry; wet blending the first slurry; spray drying the wet blended slurry to form a precursor composition; milling the precursor composition to obtain a milled precursor composition; compacting the milled precursor to obtain a compacted precursor; pre-baking the compacted precursor composition to obtain a precursor composition with low moisture content; and calcining the precursor composition with low moisture content at a time and temperature sufficient to produce a lithium vanadium phosphate. The lithium vanadium phosphate so produced can optionally be further milled to obtain the desired particle size. The electrochemically active lithium vanadium phosphate so produced is useful in making electrodes and batteries and more specifically is useful in producing cathode materials for electrochemical cells.

Owner:CARUS CORP +1

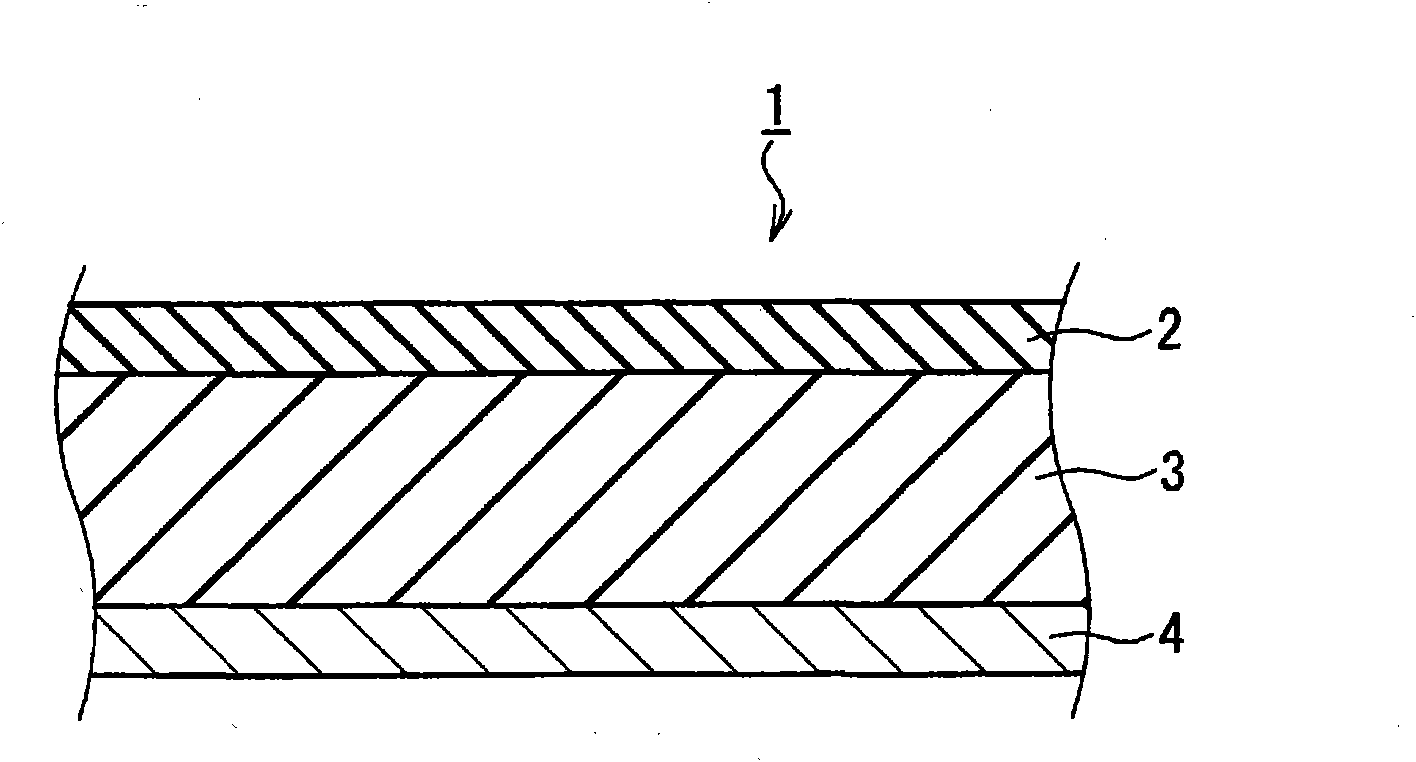

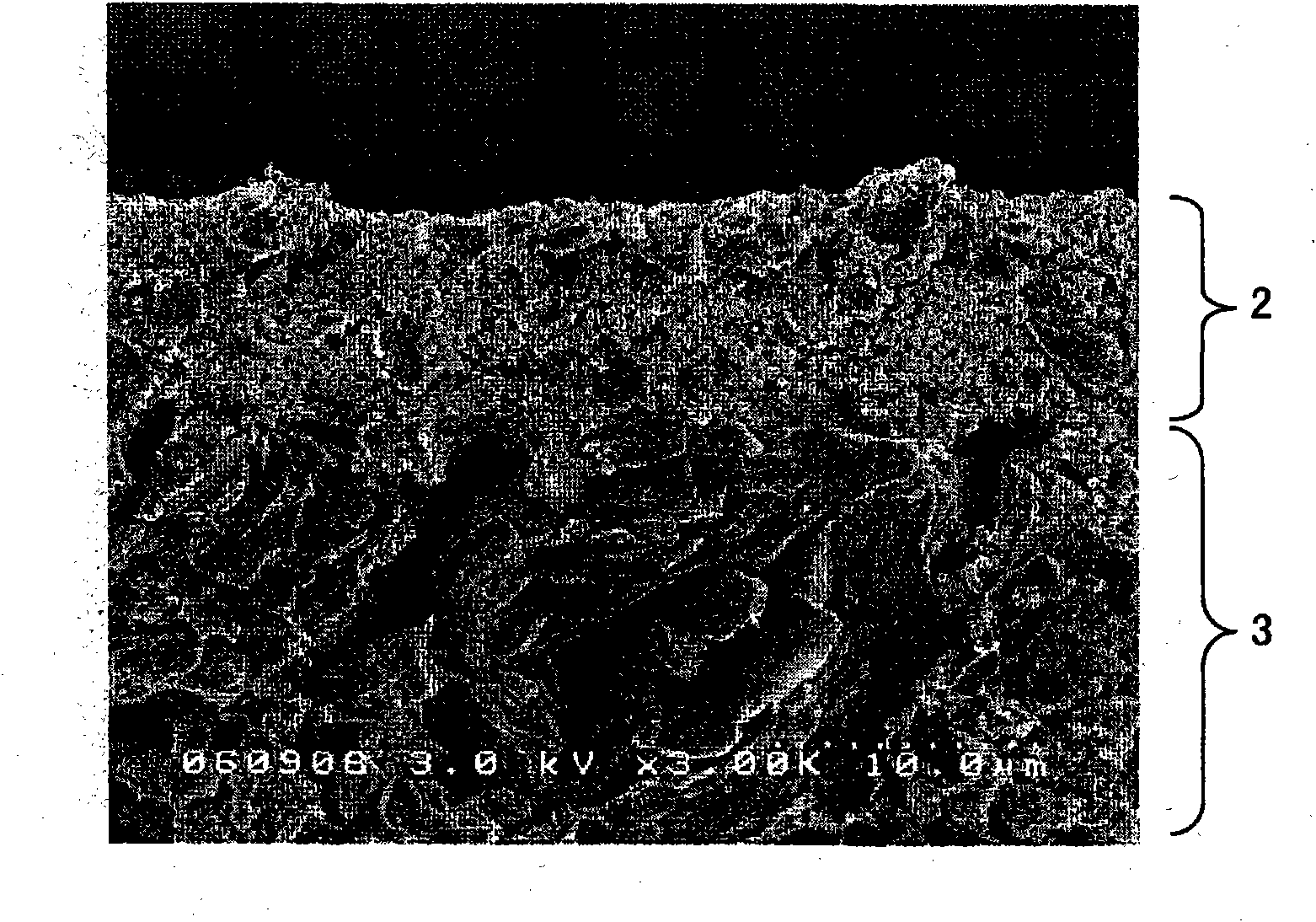

Electrode for nonaqueous secondary battery, nonaqueous secondary battery using the same, and method for producing electrode

InactiveUS20100203392A1Large capacityImprove charge and discharge cycle characteristicsElectrode thermal treatmentNon-aqueous electrolyte accumulator electrodesPorous layerPolyamide-imide

The non aqueous secondary battery electrode of the present invention includes a mixture layer and a porous layer formed on the surface of the mixture layer. The mixture layer includes an electrode material expressed by the composition formula SiOx where x in the composition formula satisfies 0.5≦x≦1.5, a conductive material and at least one binder selected from the group consisting of polyimide, polyamideimide and polyamide. The porous layer includes an insulating material unreactive with Li.

Owner:HITACHI MAXELL ENERGY LTD

Graphite particles and lithium secondary battery using the same as negative electrode

InactiveUS20010033822A1Excellent cycle characteristicsSmall in irreversible capacityGraphiteFinal product manufactureX-rayCharge discharge

A graphite particle obtained by assembling or binding together a plurality of flat-shaped particles so that the planes of orientation are not parallel to one another, or a graphite particle in which aspect ratio is 5 or less or specific surface area is 8 m2 / g or less or the size of crystallite in the direction of c-axis of the crystal is 500 Å or more and the size of crystallite in the direction of plane is 1,000 Å or less as measured by X ray broad angle diffraction, or a graphite particle in which pore volume of the pores having a size falling in a range of 102 to 106 Å is 0.4 to 2.0 cc / g per weight of graphite particle or pore volume of the pores having a size falling in a range of 1x102 to 2x104 Å is 0.08 to 0.4 cc / g per weight of graphite particle is suitable for production of negative electrode of lithium secondary battery, and a lithium secondary battery obtained therefrom is excellent in rapid charge-discharge characteristics, cycle characteristics, etc.

Owner:HITACHI CHEM CO LTD

Manufacturing method of an electrode for electrochemical element and an electrochemical element

ActiveUS20140023922A1Electrode rolling/calenderingHybrid capacitor electrodesProduction rateCoated surface

Disclosed is a manufacturing method of an electrode for an electrochemical element having a superior adhesion and is used for an electrochemical element with excellent productivity due to a short predoping time. Specifically disclosed is that the method is characterized by comprising a step for compression forming of electrode material (a mixed powder or composite particles) including an alkaline metal powder or an alkaline earth metal powder each having a coated surface.

Owner:ZEON CORP

Electrode impregnation and bonding

ActiveUS7102877B2Avoid heat damageAvoid inertiaHybrid capacitor electrodesElectrolytic capacitorsEngineeringConductive materials

A method for making an electrode including a particle based film is disclosed in which the film is coated and / or impregnated with veins of conductive material. A support backing is placed adjacent to one side of the film to provide support and prevent damaging the film while the conductive material is applied onto the opposite side of the film. The film is bonded directly to a current collector of an energy storage device.

Owner:TESLA INC

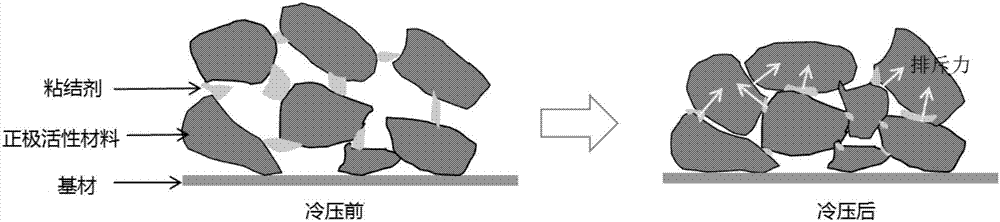

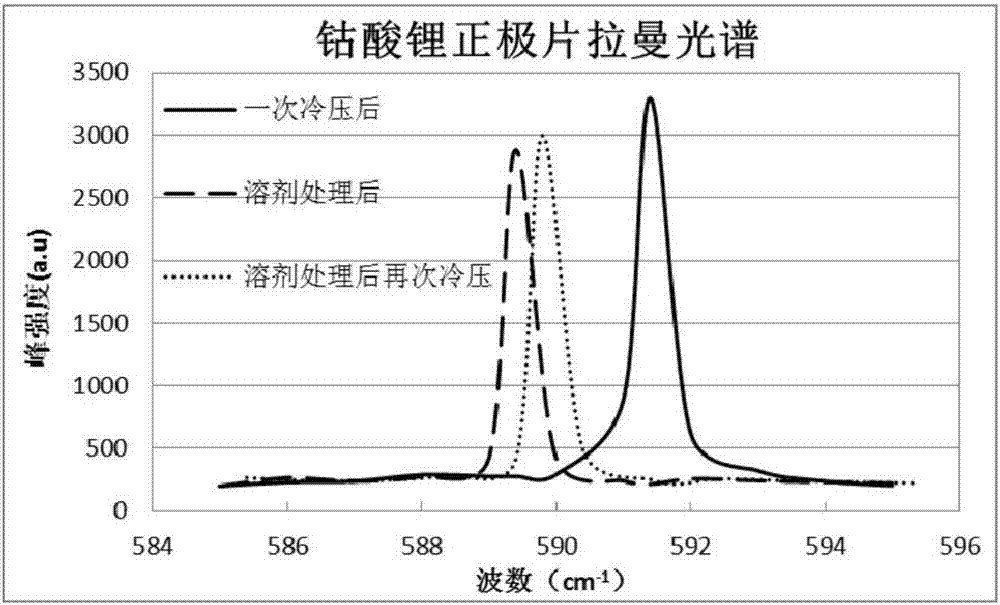

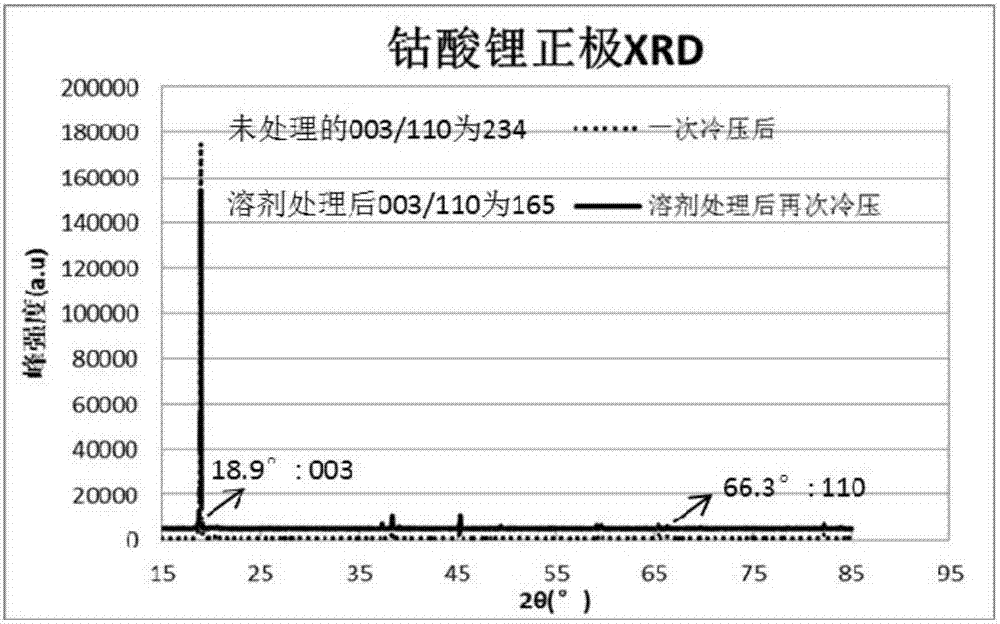

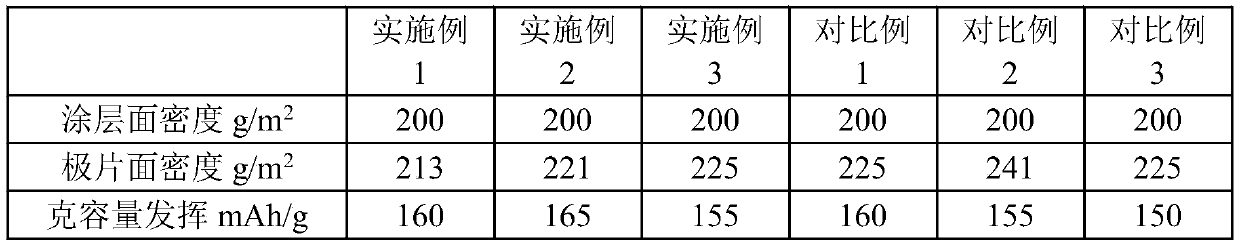

Lithium ion battery positive plate and manufacture method thereof

ActiveCN107403905AReduce stickingReduce thicknessSecondary cellsElectrode collector coatingSodium-ion batterySlurry

The invention discloses a manufacture method of a lithium ion battery positive plate. The manufacture method comprises the following steps: providing a positive current collector; preparing positive slurry containing an positive active material with a stratified-structured crystal form, uniformly distributing the positive slurry onto the positive current collector, drying, and carrying out primary cold pressing and slicing, so as to obtain a positive plate; carrying out infiltration on the positive plate by virtue of a solvent; and drying, and carrying out secondary cold pressing, so as to obtain the lithium ion battery positive plate. By carrying out infiltration on the positive plate which is subjected to primary cold pressing, residual stress of the positive plate can be effectively reduced, the expansion of the positive plate can be reduced, a lithium ion battery is thinned, and the energy density of the lithium ion battery is increased. The contact among particles of the positive active material is relatively close in a subsequent charging-discharging cycle process, and the cycle performance of the lithium ion battery is improved. Besides, the invention further discloses the lithium ion battery positive plate manufactured by the method and the lithium ion battery adopting the lithium ion battery positive plate.

Owner:NINGDE AMPEREX TECH

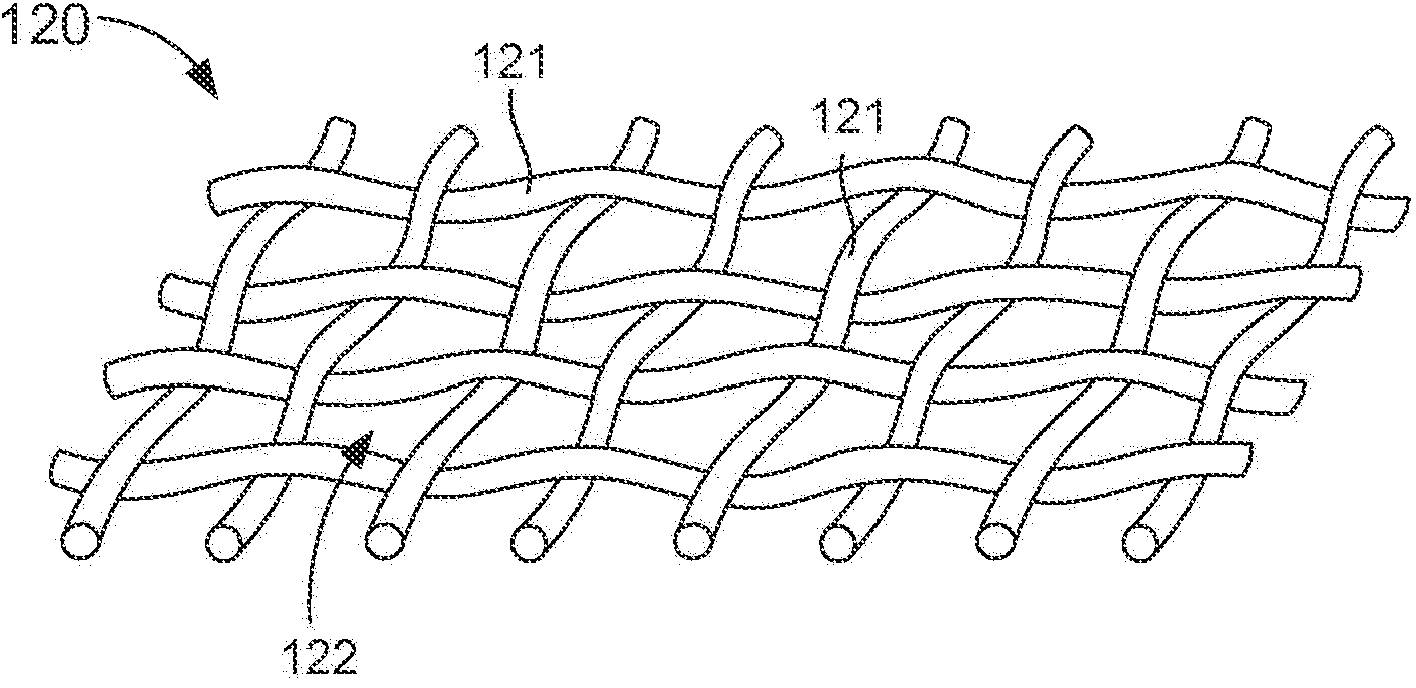

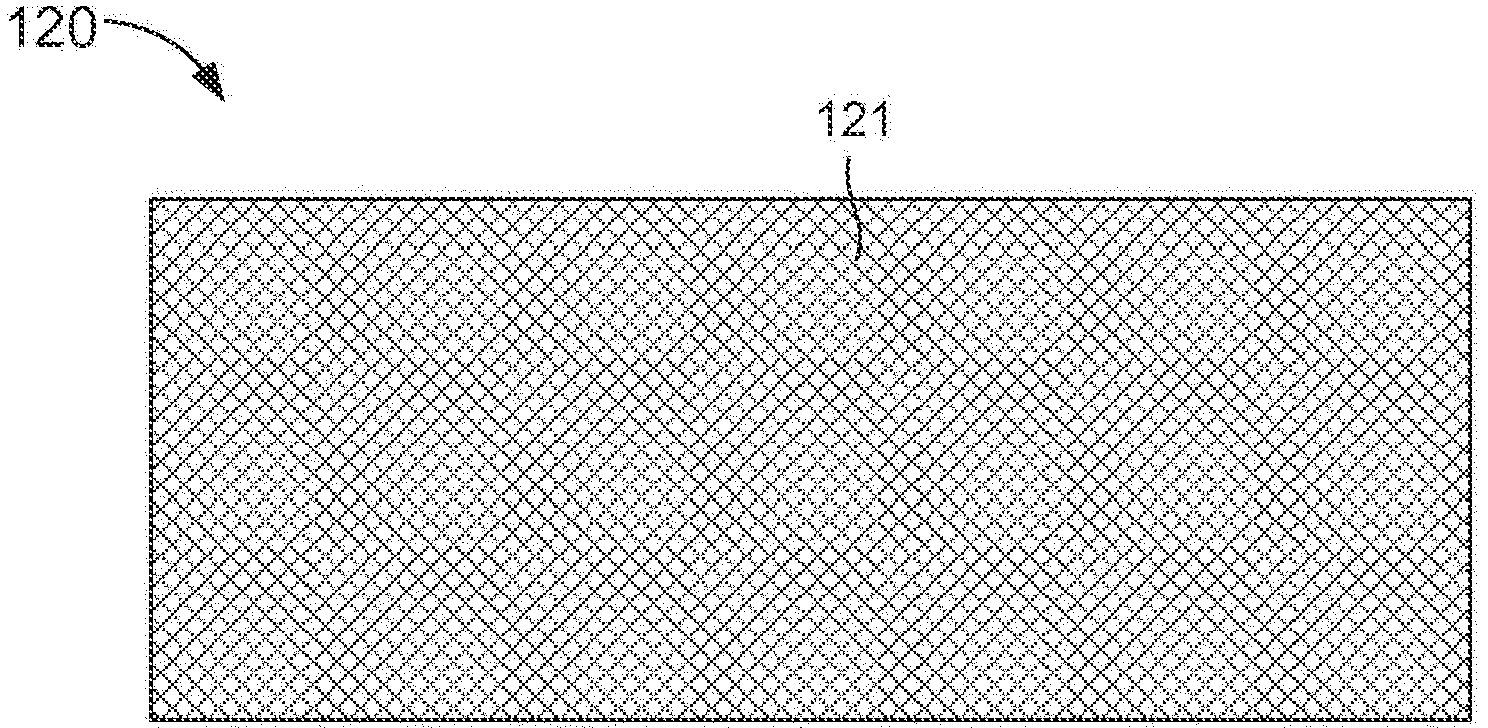

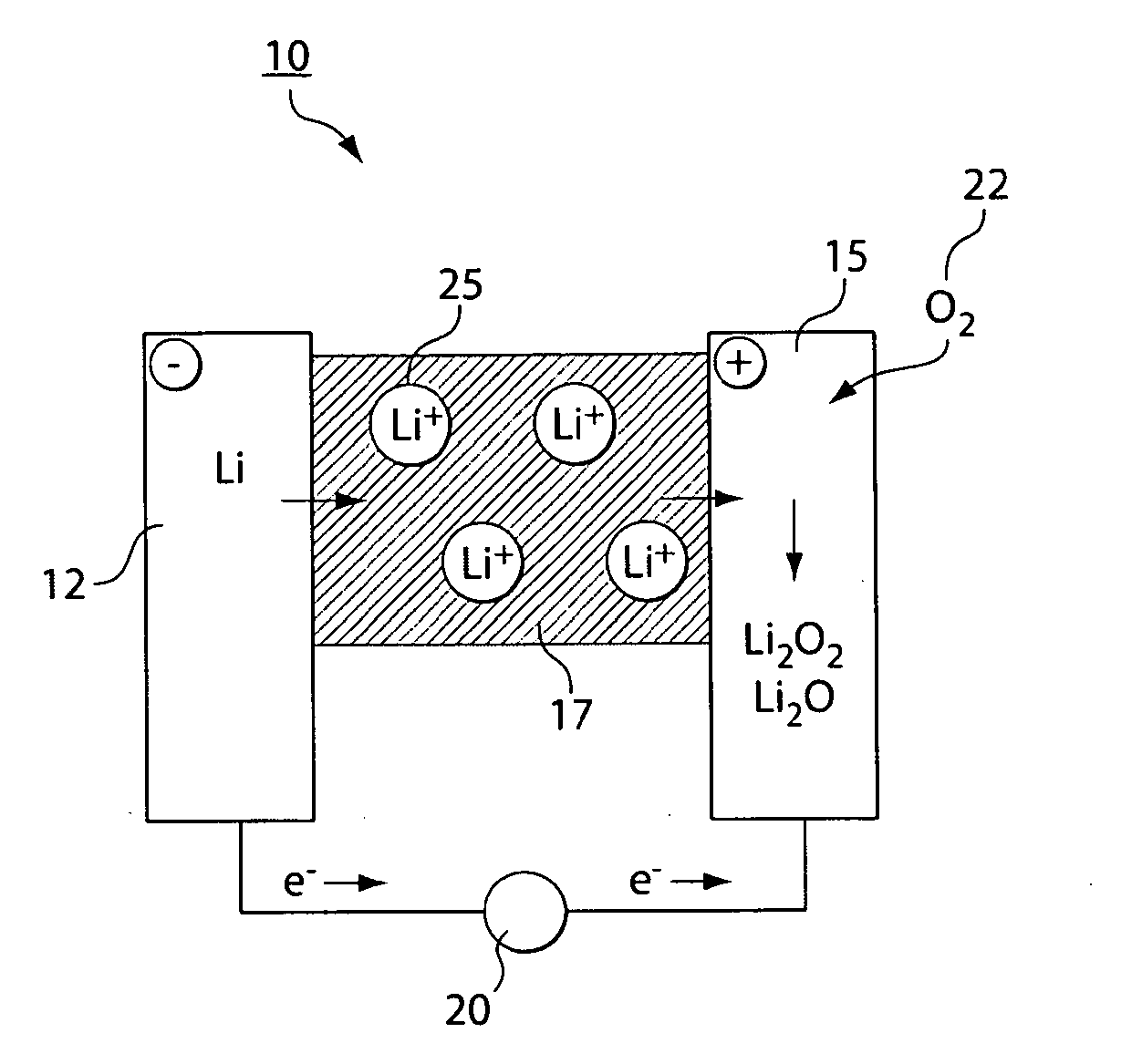

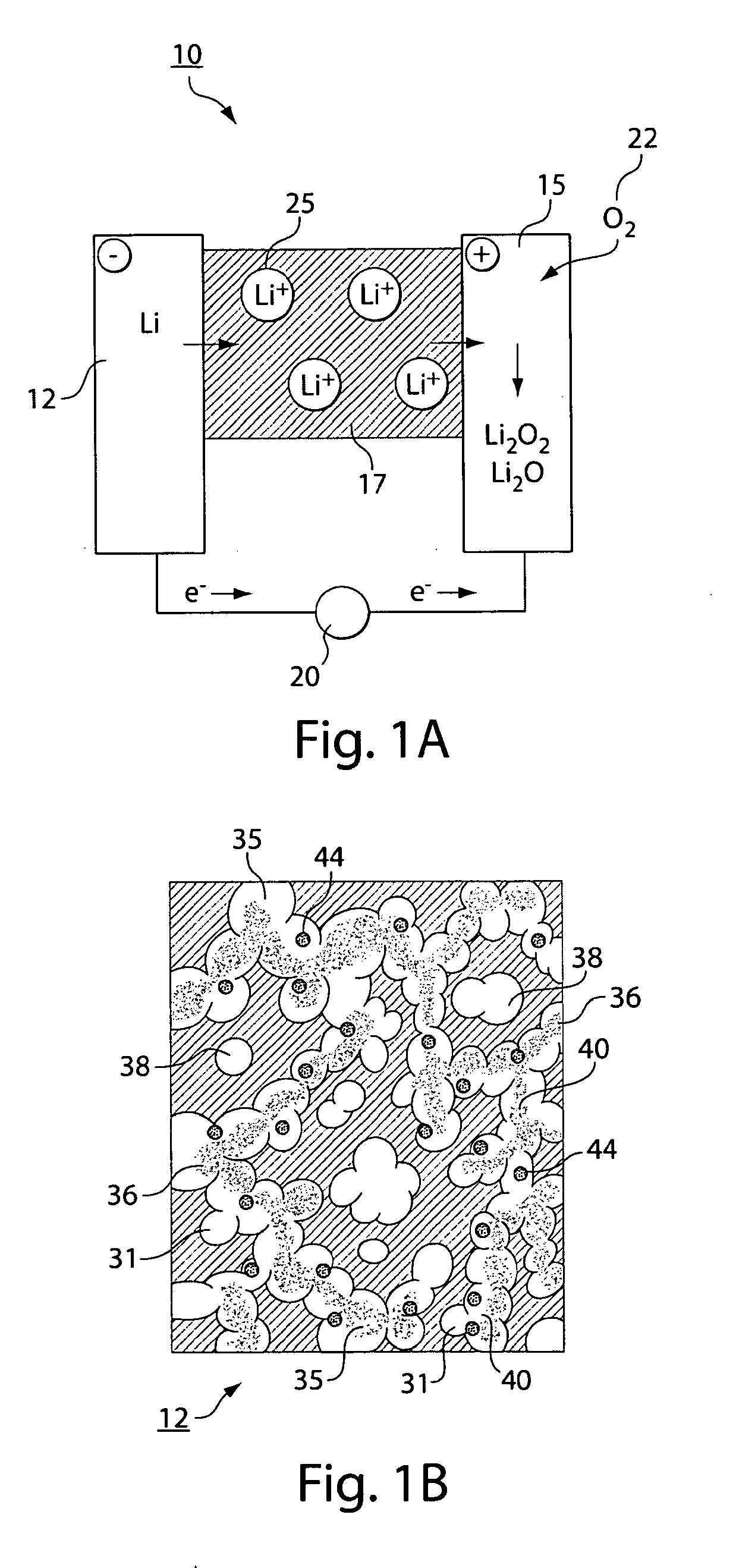

Gas diffusion electrodes for batteries such as metal-air batteries

InactiveUS20130089795A1Fuel and primary cellsFuel and secondary cellsReactive siteLithium–air battery

The present invention generally relates to batteries and, in particular, to electrodes for use in batteries such as non-aqueous metal-air batteries, for example, lithium-air batteries, as well as in other electrochemical devices. Such devices may exhibit improved performance characteristics (e.g. power, cycle life, capacity, etc.). One aspect of the present invention is generally directed to electrodes for use in such devices containing one or more pores or channels for transport of gas and / or electrolyte therein, e.g., forming an open porous network. In certain embodiments, the electrolyte may be a gel or a polymer. In some embodiments, there may be network of such channels or pores within the electrode such that no active site within the electrode is greater than about 50 micrometers distant from a gas channel. In some embodiments, such systems may be created using electrodes containing gel or electrolyte polymers, and / or by forming electrodes having different wettabilities such that certain regions preferentially attract the electrolyte compared to other regions, thereby causing self-organization of the electrolyte within the electrode. Other aspects of the invention are generally directed to methods of making such batteries or electrochemical devices, methods of using such batteries or electrochemical devices, kits involving such batteries or electrochemical devices, or the like.

Owner:LIOX POWER

Buffer layer for sulfide solid-state battery, preparation method of buffer layer, and solid-state battery

ActiveCN110034275AFast film formationIncrease relative volatilityFinal product manufactureSecondary cellsSolid state electrolyteElectrical battery

The invention provides a buffer layer for a sulfide solid-state battery. The buffer layer comprises a polymer material and ethylene carbonate, and is formed in situ on an electrode plate through a buffer layer solution; and due to the existence of a polymer, poor physical contact between an electrode and an electrolyte caused by volume deformation of a positive electrode material in a charging / discharging process can be improved. The buffer layer is existent between the positive electrode and the solid electrolyte of the solid-state battery and between the negative electrode and the solid-state electrolyte, so that the solid-solid interface impedance can be reduced; and meanwhile, good ionic conductivity of the buffer layer can improve the lithium ion transmission capacity. The sulfide composite positive electrode in the solid-state battery provided by the invention contains the polymer material, and the existence of the polymer can improve the poor physical contact between the electrode and the electrolyte caused by the volume deformation of the positive electrode material in the charging / discharging process; and meanwhile, the solid-state battery contains the buffer layer, so that the solid-state battery has low interface resistance and high ionic conductivity, and is excellent in capacity and cycling performance.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

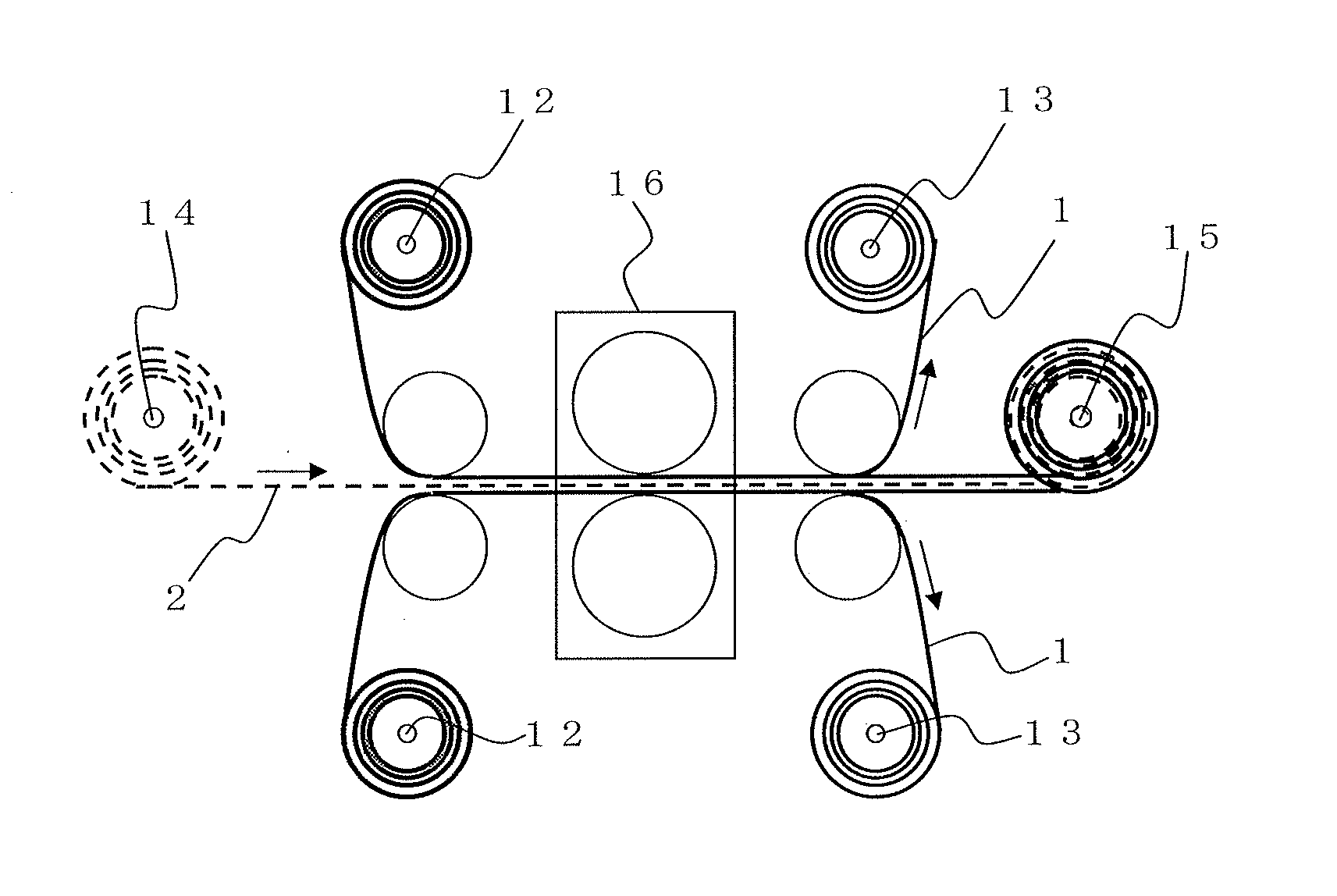

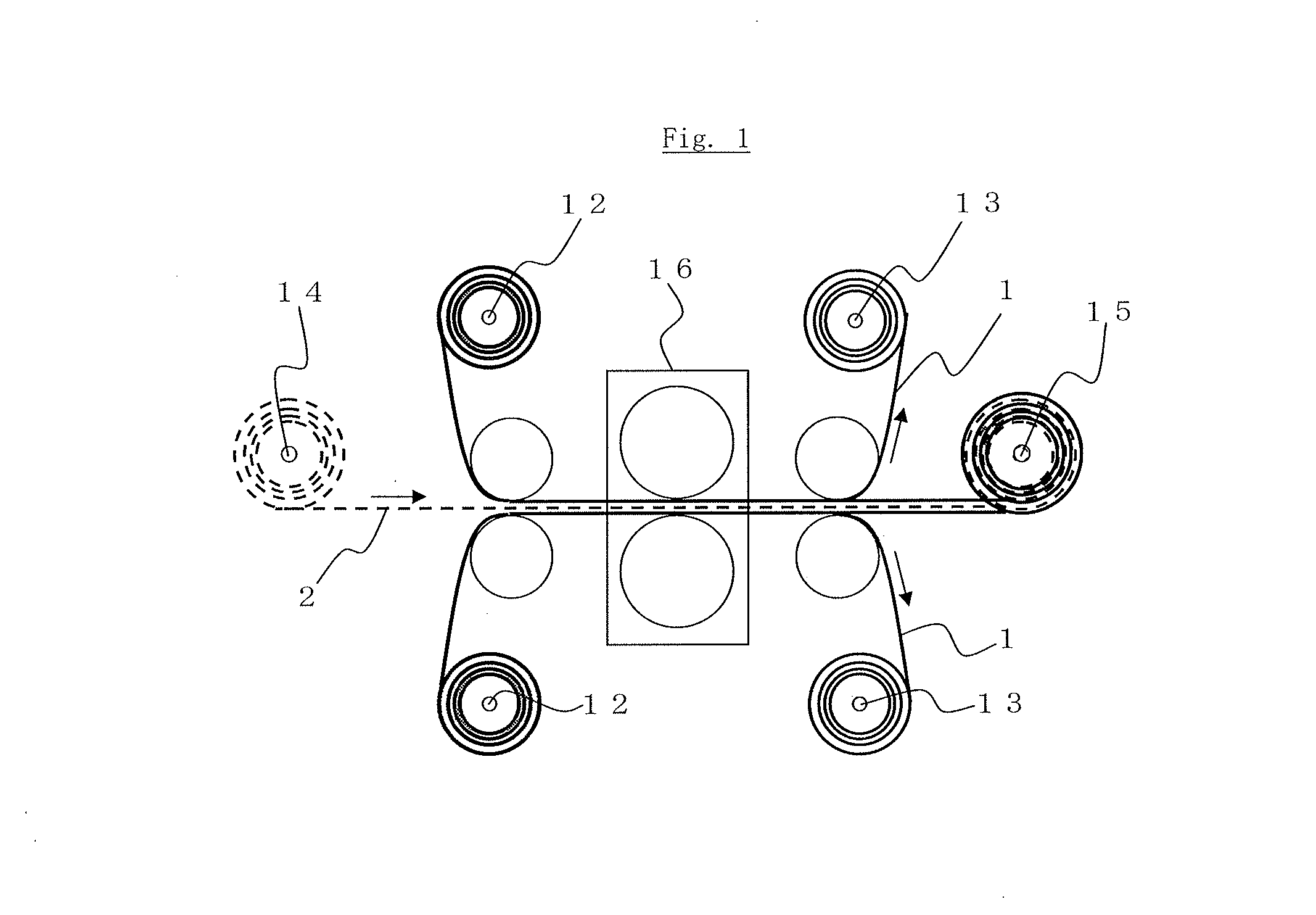

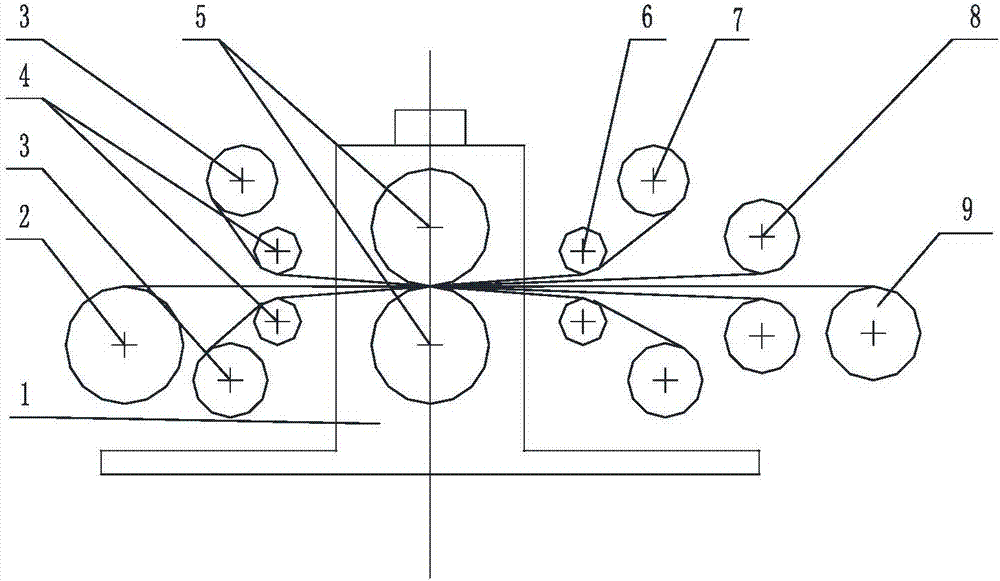

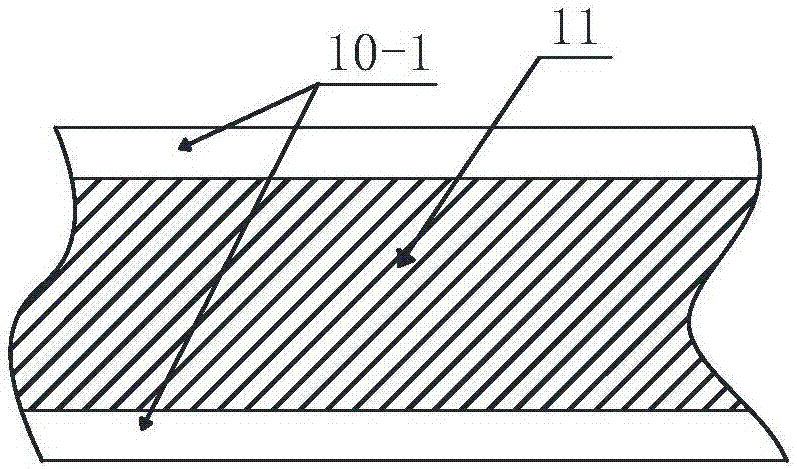

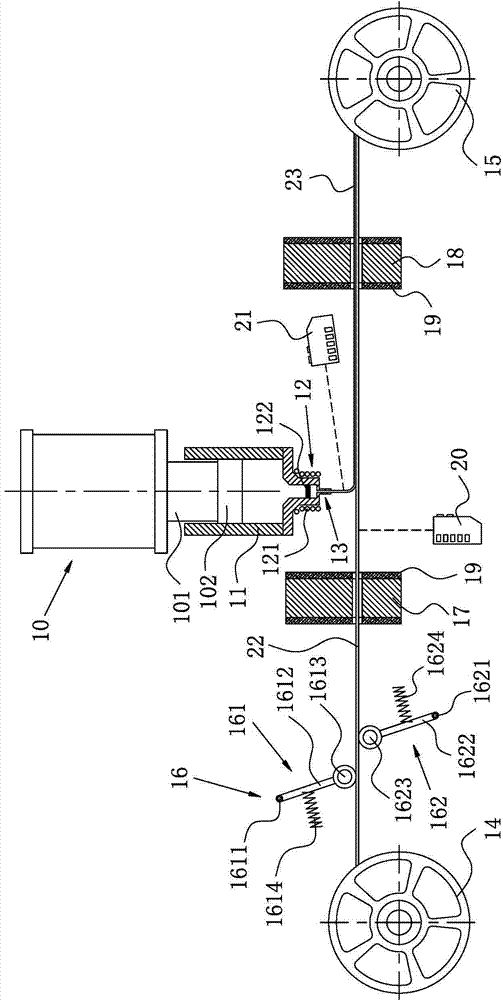

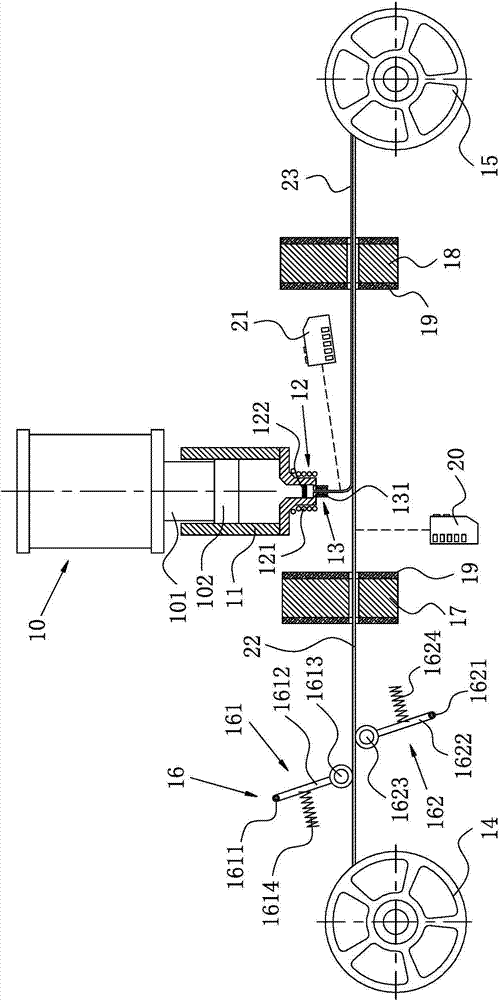

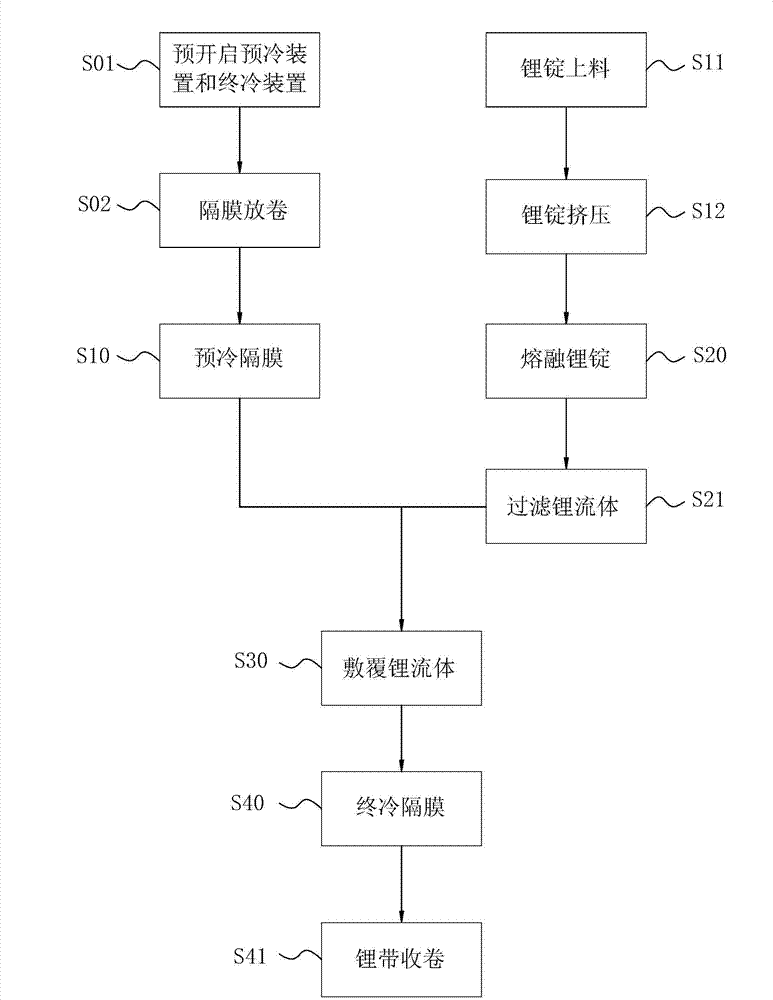

Production method of composite lithium ribbon

InactiveCN106981625ARealize automatic roll productionIncrease productivityElectrode moldingLithiumAlloy

The invention discloses a production method of a composite lithium ribbon. Roll forming is adopted, a protection film is adopted to cover a lithium ribbon or a lithium alloy ribbon during rolling, and the protection film, the lithium ribbon or the lithium alloy ribbon and a current collector synchronously run during roll production. A rolling machine is adopted for roll forming and provided with a rack, an upper roller and a lower roller are mounted on the rack, a current collector unwinding device, a lithium ribbon unwinding device and a protection film unwinding device are arranged on the upper reach of the rollers, an unwinding guide roller is arranged on the lower reach of the protection film unwinding device, a composite lithium ribbon winding device and a protection film winding device corresponding to the protection film unwinding device are arranged on the lower reach of the rollers, and a winding guide roller is arranged on the uppe reach of the protection film winding device. Rolling technology is adopted, the protection film is adopted to protect the lithium ribbon or the lithium alloy ribbon in the process of production, automatic roll production can be realized, small-amount piece production can be realized, production efficiency can be improved greatly, and product quality is well guaranteed.

Owner:CHINA ENERGY LITHIUM

Electrode plate for secondary battery with nonaqueous electrolyte

InactiveUS6051338AElectrode rolling/calenderingElectrode melt handlingEngineeringElectrical and Electronics engineering

An electrode plate for a secondary battery with a nonaqueous electrolyte composed of a collector and an active material layer which is formed of at least an active material and a binder disposed on the collector, and said electrode plate is provided with a terminal mounting portion provided with a collector surface exposed to mount a terminal. In such electrode plate, the exposed collector surface of the terminal mounting portion has the same shape and size substantially as those of an area to which the terminal is actually mounted. The electrode plate may further be provided with an identification mark made by forming the active material layer in shape of pattern on an area at which the collector surface is exposed or by exposing the collector surface in the shape of pattern on an area at which the collector is covered with the active material layer.

Owner:DAI NIPPON PRINTING CO LTD

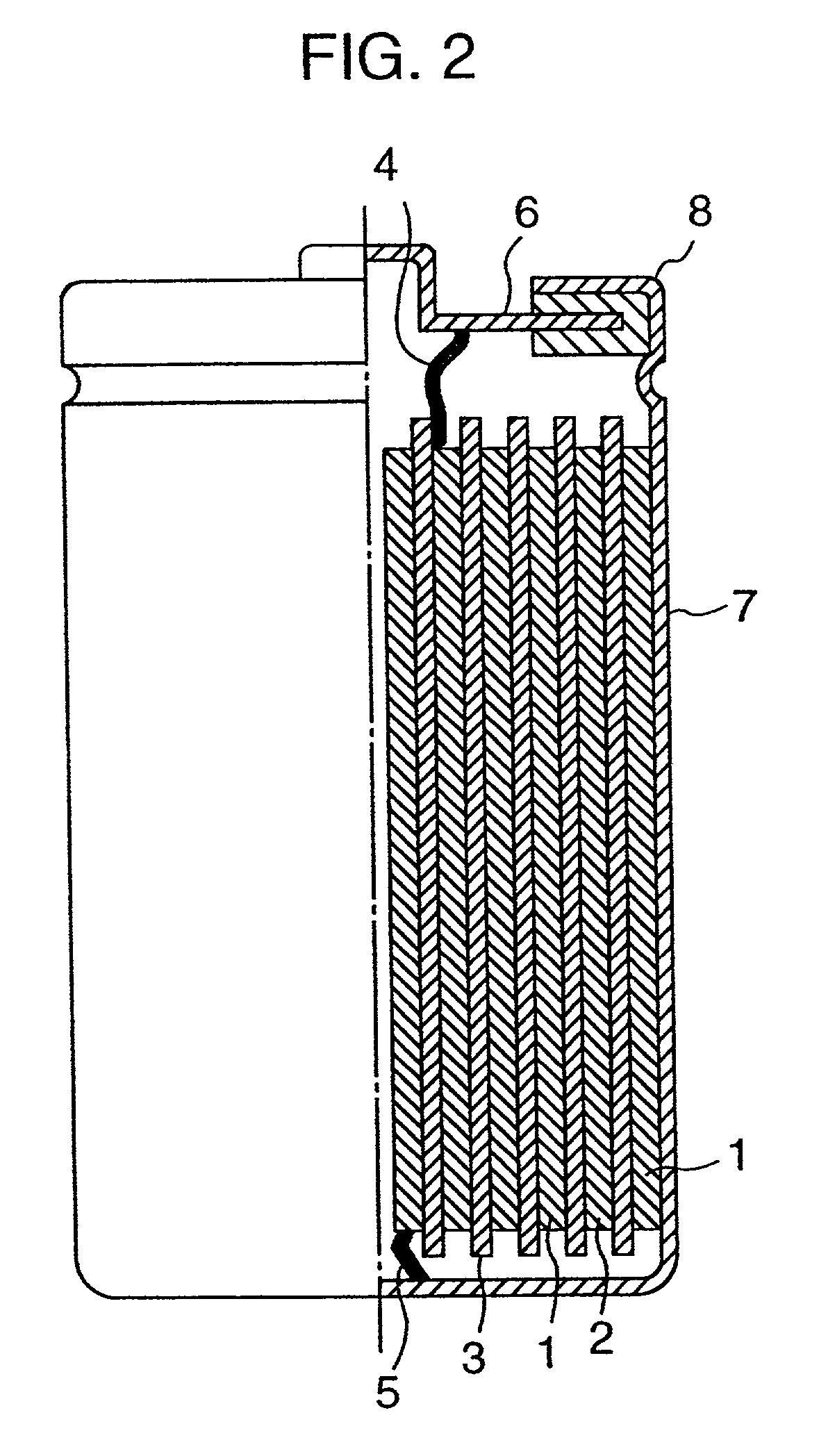

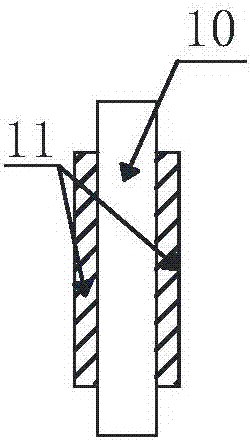

Battery with high electrode interfacial surface area

InactiveUS6869727B2Increase speedIncrease internal resistanceAlkaline accumulatorsSmall-sized cells cases/jacketsHigh rateEngineering

An electrochemical battery cell in accordance with the invention has a high electrode interfacial surface area to improve high rate discharge capacity, and the shapes of the electrodes facilitate the manufacture of cells of high quality and reliability at high speeds suitable for large scale production. The interfacial surfaces of the solid body electrodes have radially extending lobes that increase the interfacial surface area. The lobes do not have sharp corners, and the concave areas formed between the lobes are wide open, to facilitate assembly of the separator and insertion of the other electrode into the concave areas without leaving voids between the separator and either electrode.

Owner:EVEREADY BATTERY CO INC

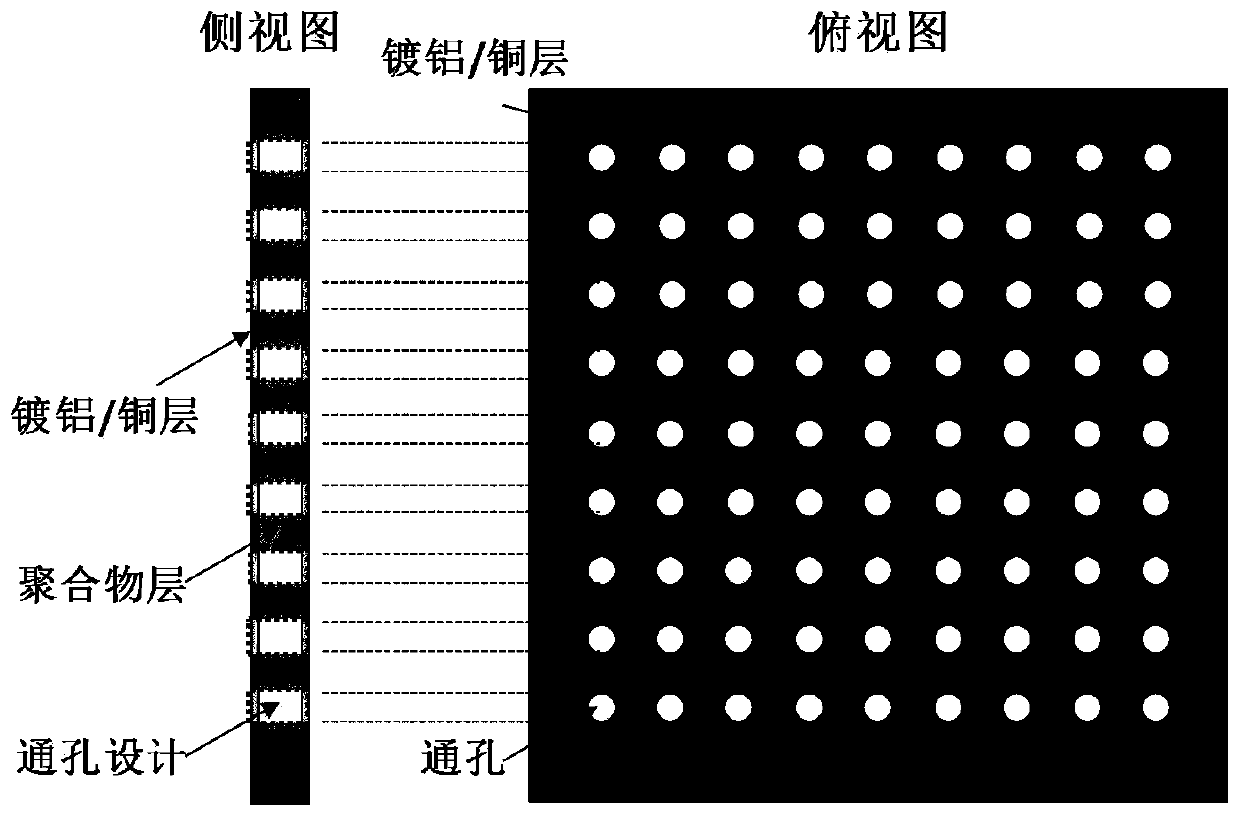

Composite current collector with electrical interconnection and through-hole structure, preparation method thereof, battery pole pieces and lithium ion battery

InactiveCN109698359AImprove conductivityImproved current distributionElectrode thermal treatmentFinal product manufacturePolymeric surfaceMetal coating

The invention relates to a composite current collector with electrical interconnection and a through-hole structure, a preparation method thereof, battery pole pieces and a lithium ion battery, and belongs to the technical field of lithium ion batteries. The preparation method of the composite current collector includes the following steps: (1) coloring, casting and forming to prepare a polymer base layer; (2) carrying out first vacuum metal plating on the surface of the polymer base layer; (3) making holes in the surface of the metal-coated polymer layer; and (4) carrying out second vacuum metal plating on the surface of the polymer layer. The prepared current collector is of an inner and outer double-layer structure with the through-hole structure. The inner layer is a polymer layer withthe through-hole structure, and the surface layers are metal coatings. The metal coatings cover the surface of the through holes, the through holes communicate the metal coatings. The preparation method is simple and easy in large-scale production, and can customize the thickness and hole structure distribution according to specific application indicator. Compared with a conventional foil material, the composite current collector with the electrical interconnection and the through-hole structure has the advantages of light weight, bending resistance, low cost and the like, and has a significant effect on the energy density improvement of the battery.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

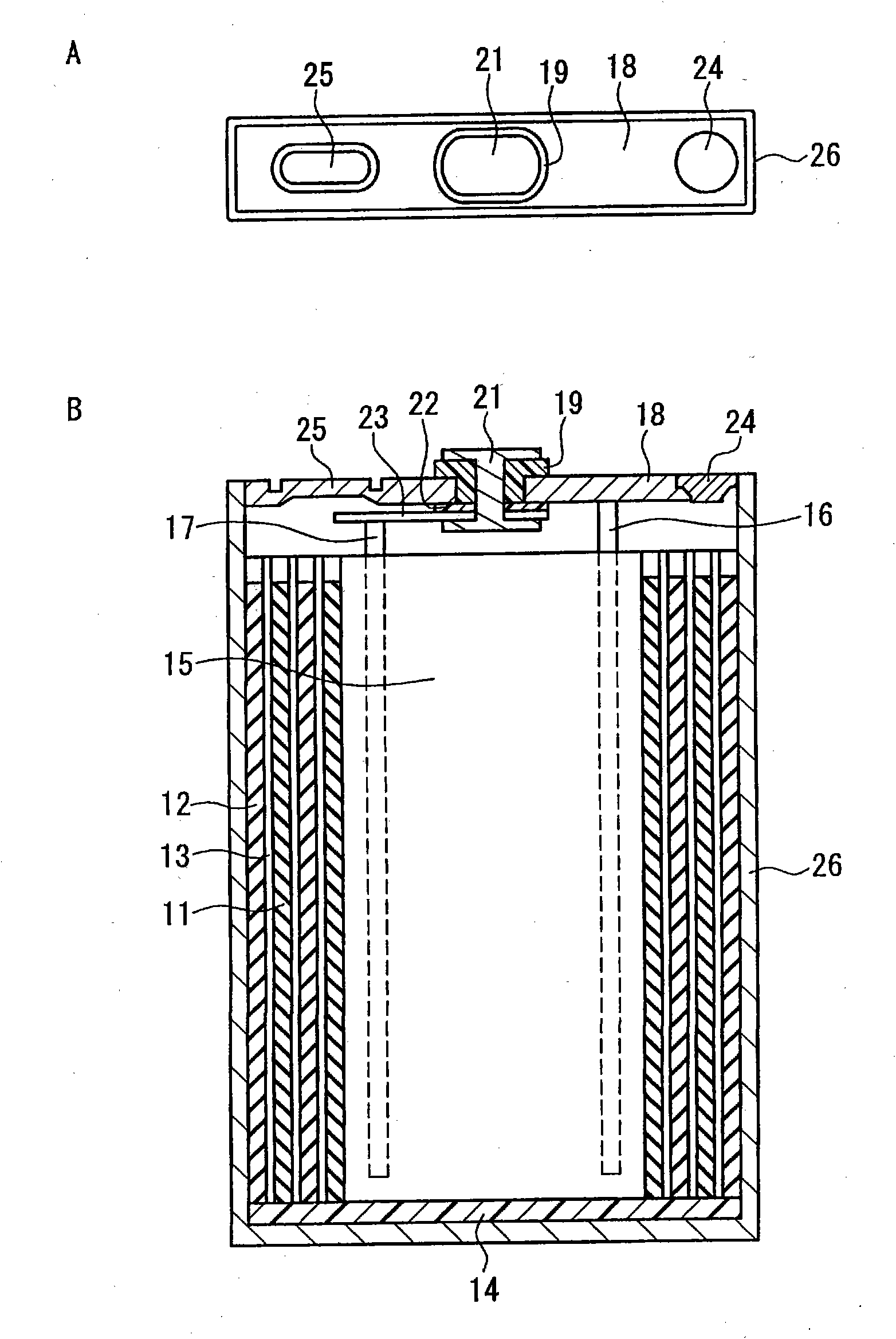

Nonaqueous electrolyte secondary battery and method of producing same

ActiveUS20150333324A1Reaction resistance increaseOutput characteristic is limitedElectrode rolling/calenderingFinal product manufactureLithium iron phosphateGraphite

A nonaqueous electrolyte secondary battery includes: a positive electrode collector core material; and a sheet body including a plurality of granulation bodies. The sheet body is disposed on the positive electrode collector core material. The granulation bodies each contain a first positive electrode active material particle, a second positive electrode active material particle, and expanded graphite, the first positive electrode active material particle including lithium-nickel composite oxide, the second positive electrode active material particle including lithium iron phosphate.

Owner:TOYOTA JIDOSHA KK

Method for producing anode for lithium secondary battery and anode composition, and lithium secondary battery

ActiveUS8003257B2Improve conductivityImprove cycle lifeFinal product manufactureConductive materialFiberCarbon fibers

The invention relates to an anode for lithium secondary battery comprising vapor grown carbon fiber uniformly dispersed without forming an agglomerate of 10 μm or larger in an anode active material using natural graphite or artificial graphite, which anode is excellent in long cycle life and large current characteristics. Composition used for production for the anode can be produced, for example, by mixing a thickening agent solution containing an anode active material, a thickening agent aqueous solution and styrene butadiene rubber as binder with a composition containing carbon fiber dispersed in a thickening agent with a predetermined viscosity or by mixing an anode active material with vapor grown carbon fiber in dry state and then adding polyvinylidene difluoride thereto.

Owner:RESONAC CORP

Production method and production equipment of ultrathin lithium belt

ActiveCN104332586AEasy to produceEfficient productionFinal product manufactureSecondary cells manufactureLithiumIngot

The invention discloses a production method of an ultrathin lithium belt. The production method comprises the following steps: S10, diaphragm pre-cooling: reducing the temperature of a cell diaphragm in advance by a pre-cooling device; S20, lithium ingot melting: raising the temperature of a metal lithium ingot by a heating device so as to convert the solid metal lithium into melt lithium liquid; S30, lithium liquid coating: coating the melt lithium liquid over the surface of the pre-cooled cell diaphragm; S40, diaphragm final cooling: reducing the temperature of the cell diaphragm, which has been coated by the lithium liquid, by a final cooling device so as to solidify the lithium liquid to form a lithium belt. The invention further discloses production equipment using the preparation method mentioned above to produce ultrathin lithium belts. The provided production method and production equipment of ultrathin lithium belt replace the conventional ultrathin lithium belt production mode, which produces ultrathin lithium belt through rolling and pressing, thus solve the problems of color fading and uncontrollable thickness uniformity of ultrathin lithium belt during the rolling and pressing process, and can produce ultrathin lithium belts simply, high efficiently, and reliably.

Owner:EVE ENERGY CO LTD

Electrode for nonaqueous secondary battery, nonaqueous secondary battery using the same, and method for producing electrode

Disclosed is an electrode for nonaqueous secondary batteries, which comprises a mixture layer and a porous layer formed on the surface of the mixture layer. This electrode for nonaqueous secondary batteries is characterized in that the mixture layer contains an electrode material represented by the following composition formula: SiOx, wherein x satisfies 0.5 = x = 1.5, a conductive material, and at least one binder selected from the group consisting of polyimides, polyamideimides, and polyamides. The electrode for nonaqueous secondary batteries is further characterized in that the porous layer contains an insulating material which does not react with Li.

Owner:HITACHI MAXELL ENERGY LTD

Method for producing electrode assembly

A method for producing an electrode assembly includes: obtaining a porous active material molded body by molding a constituent material containing a lithium multiple oxide in the form of particles by compression, and then performing a heat treatment at a temperature of 850° C. or higher and lower than the melting point of the used lithium multiple oxide; forming a solid electrolyte layer by applying a liquid containing a constituent material of an inorganic solid electrolyte to the surface of the active material molded body including the inside of each pore of the active material molded body, and then performing a heat treatment; and bonding a current collector to the active material molded body exposed from the solid electrolyte layer.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com