Patents

Literature

158results about How to "Lower electrode resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

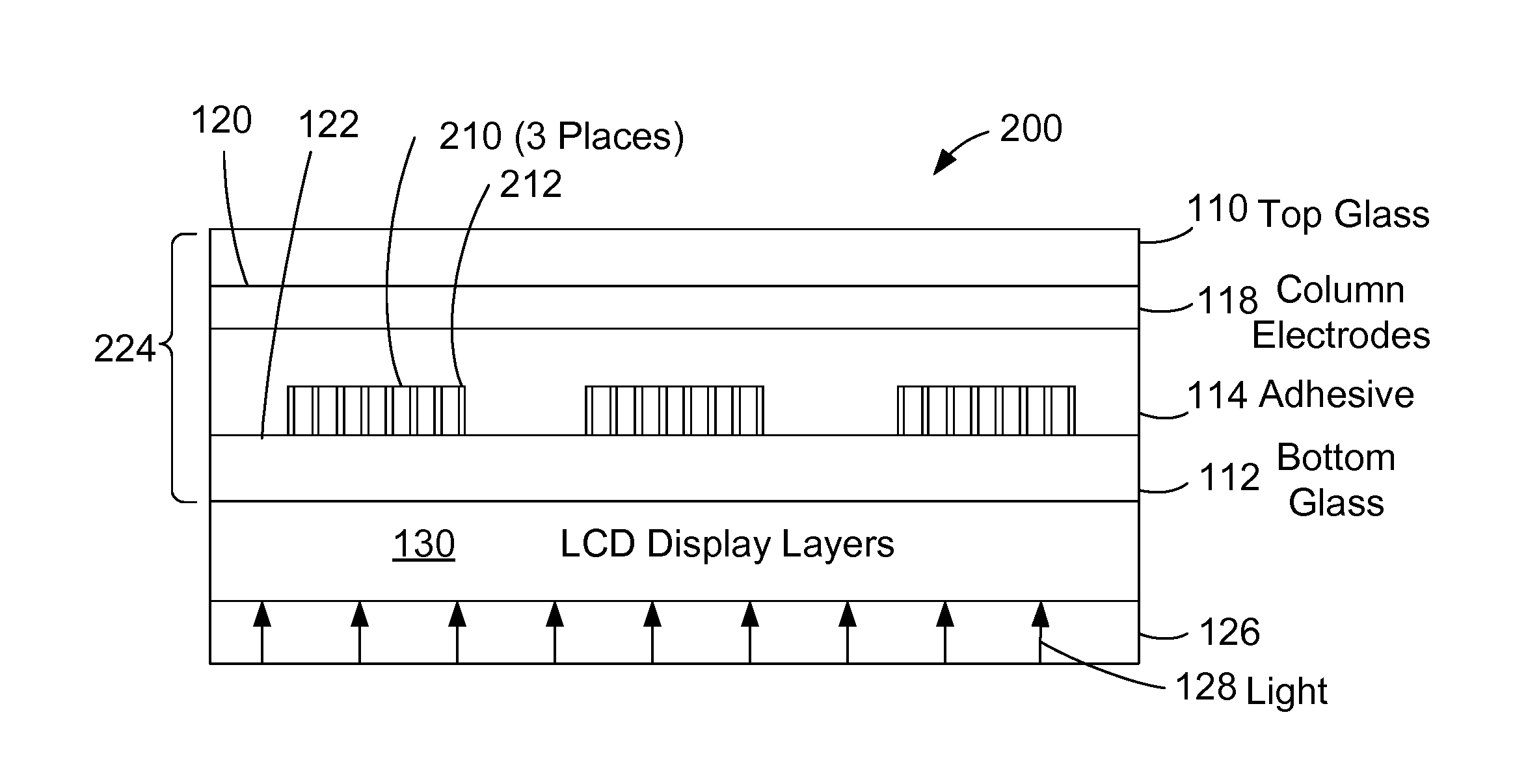

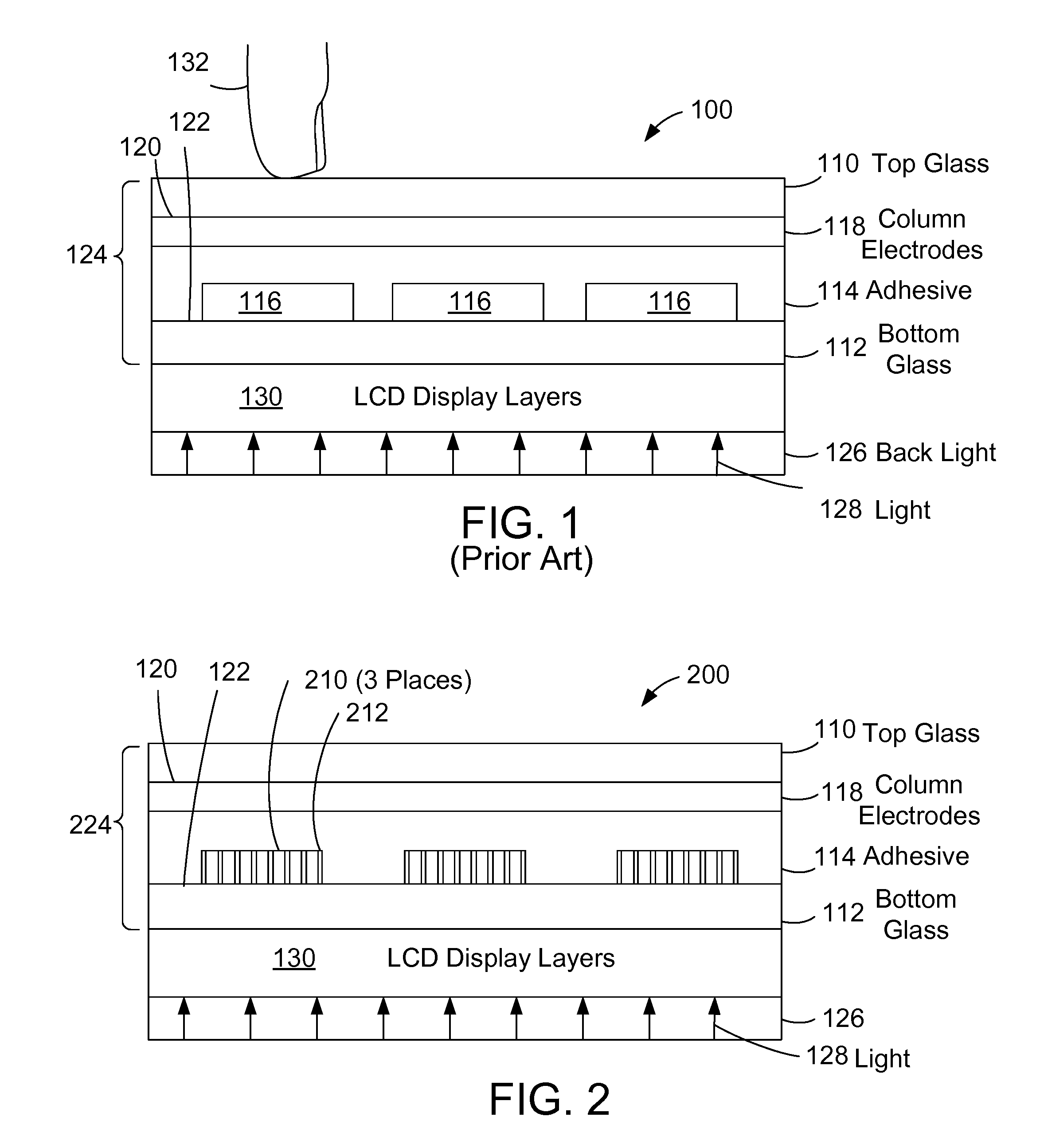

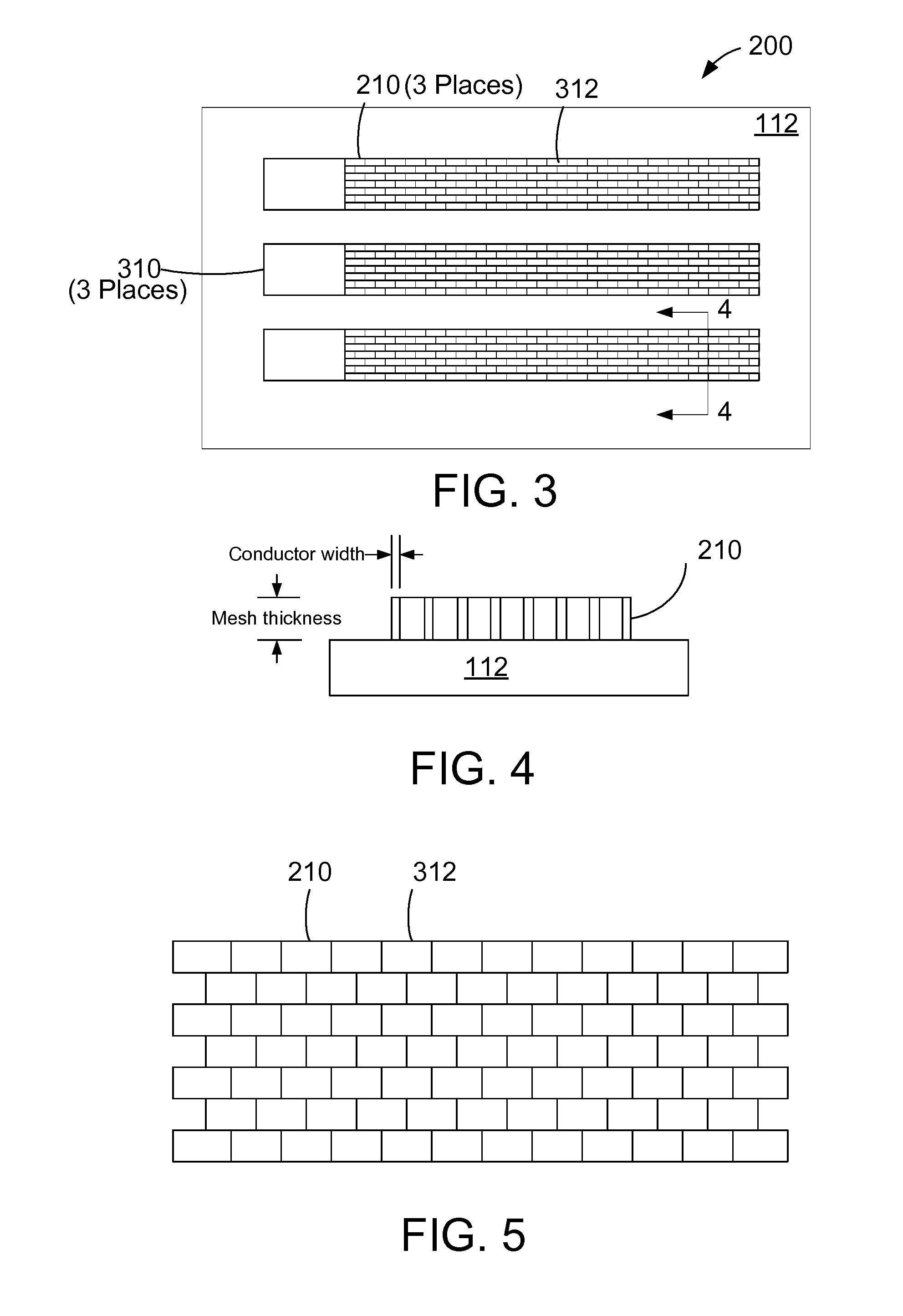

Capacitive touch screen with a mesh electrode

InactiveUS20110007011A1Improve electrical performanceImprove optical qualityInput/output processes for data processingElectrical resistance and conductanceConductive materials

An improved touch screen provides enhanced electrical performance and optical quality. The electrodes on the touch screen are made of a mesh of conductors to reduce the overall electrode resistance thereby increasing the electrical performance without sacrificing optical quality. The mesh electrodes comprise a mesh pattern of conductive material with each conductor comprising the mesh having a very small width such that the conductors are essentially invisible to the user of the touch screen.

Owner:OCULAR LCD

Display device and method for manufacturing the same

InactiveUS20050051776A1Lower electrode resistanceReduce resistanceStatic indicating devicesSemiconductor/solid-state device detailsElectrical resistance and conductanceDisplay device

An object of the present invention is to decrease substantial resistance of an electrode such as a transparent electrode or a wiring, and furthermore, to provide a display device for which is possible to apply same voltage to light-emitting elements. In the invention, a auxiliary wiring that is formed in one layer in which a conductive film of a semiconductor element such as an electrode, wiring, a signal line, a scanning line, or a power supply line is connected to an electrode typified by a second electrode, and a wiring. It is preferable that the auxiliary wiring is formed into a conductive film to include low resistive material, especially, formed to include lower resistive material than the resistance of an electrode and a wiring that is required to reduce the resistance.

Owner:SEMICON ENERGY LAB CO LTD

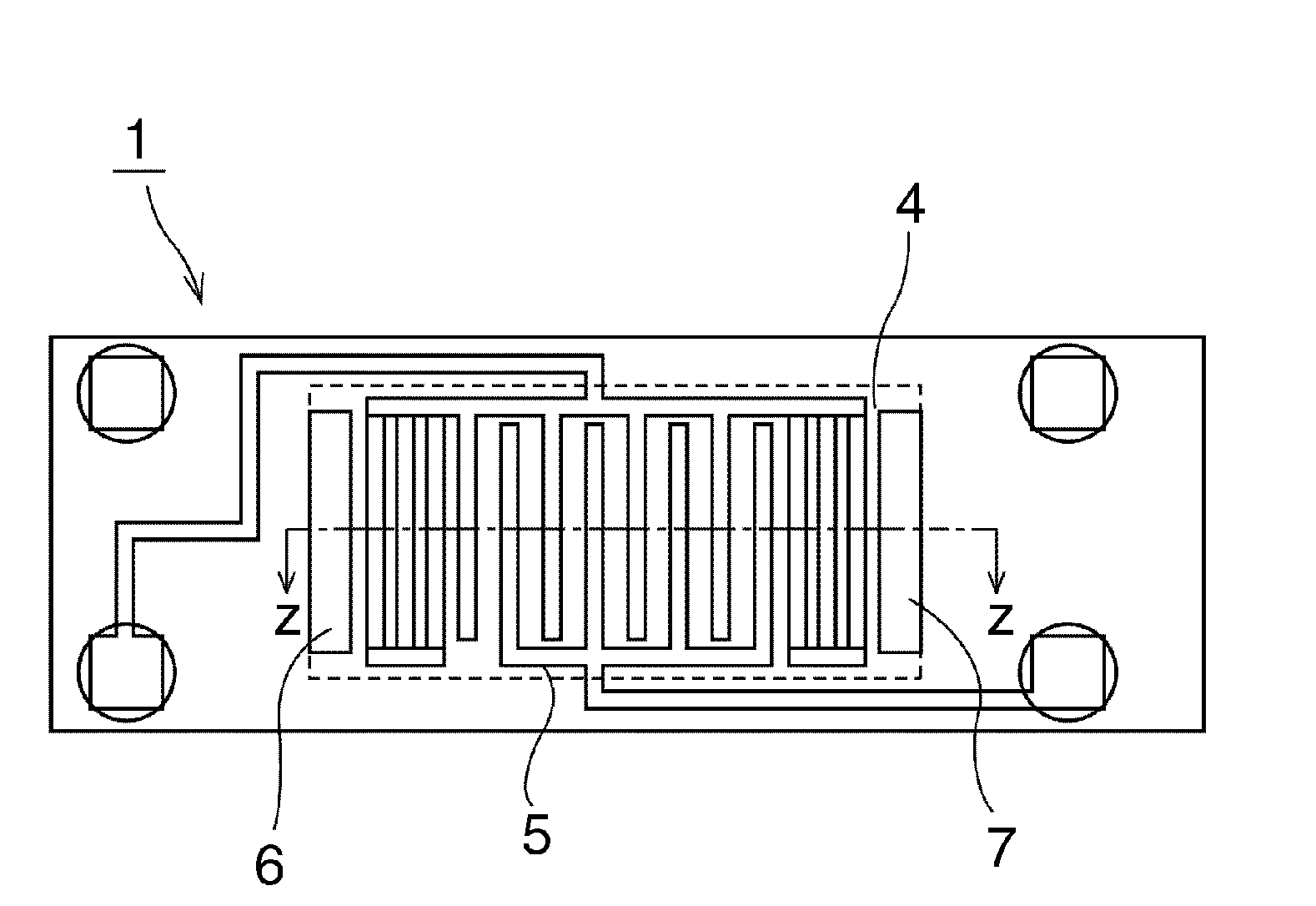

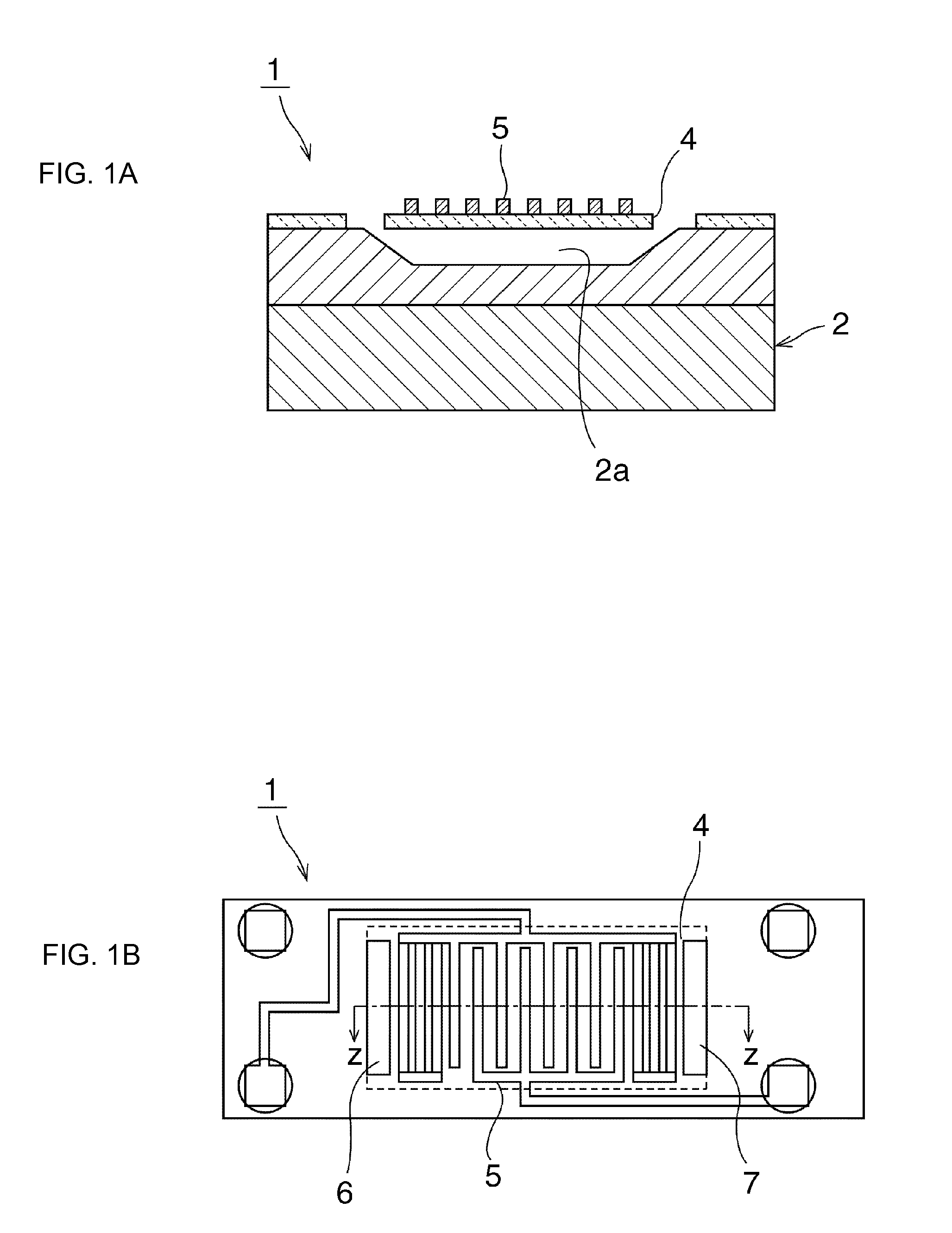

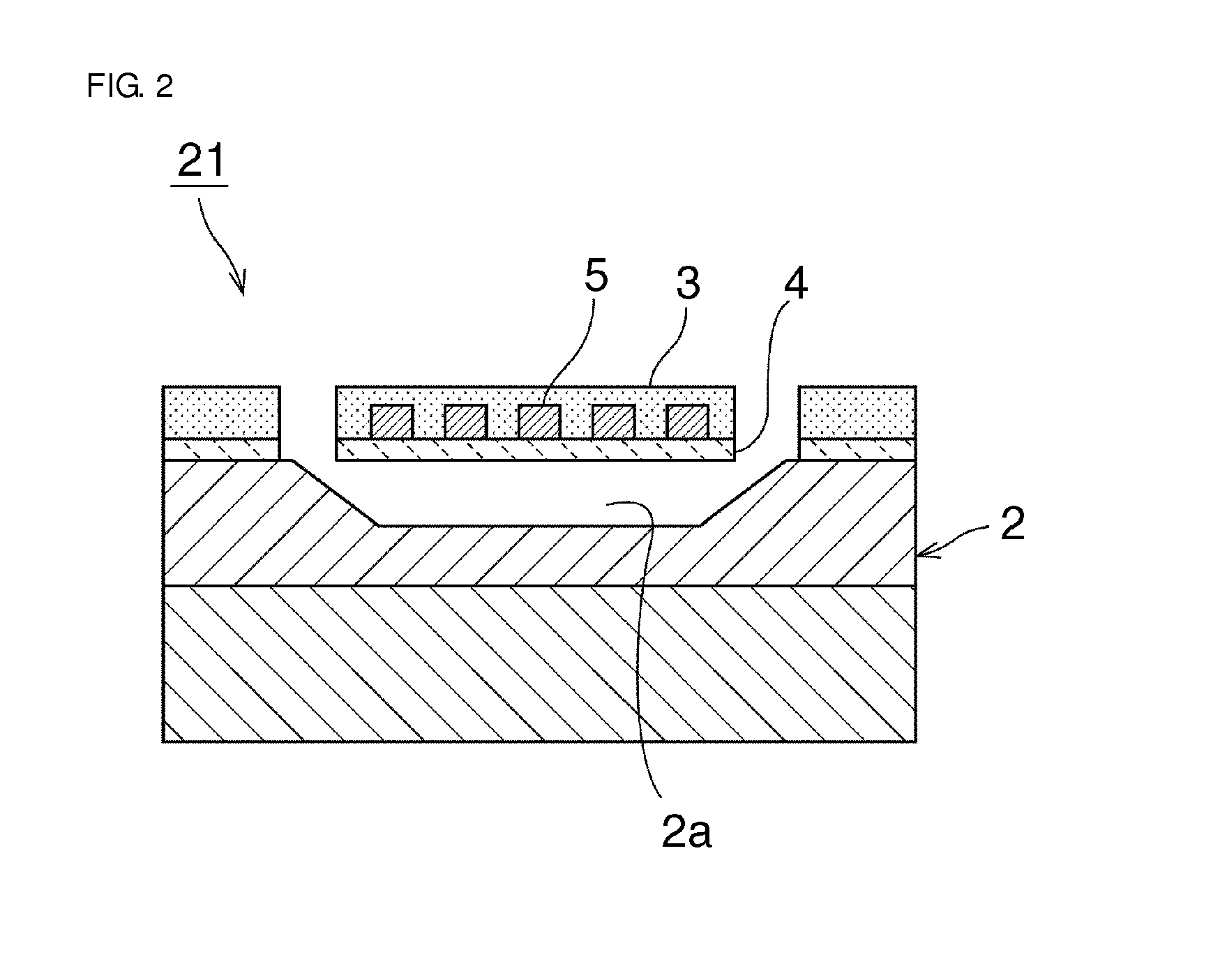

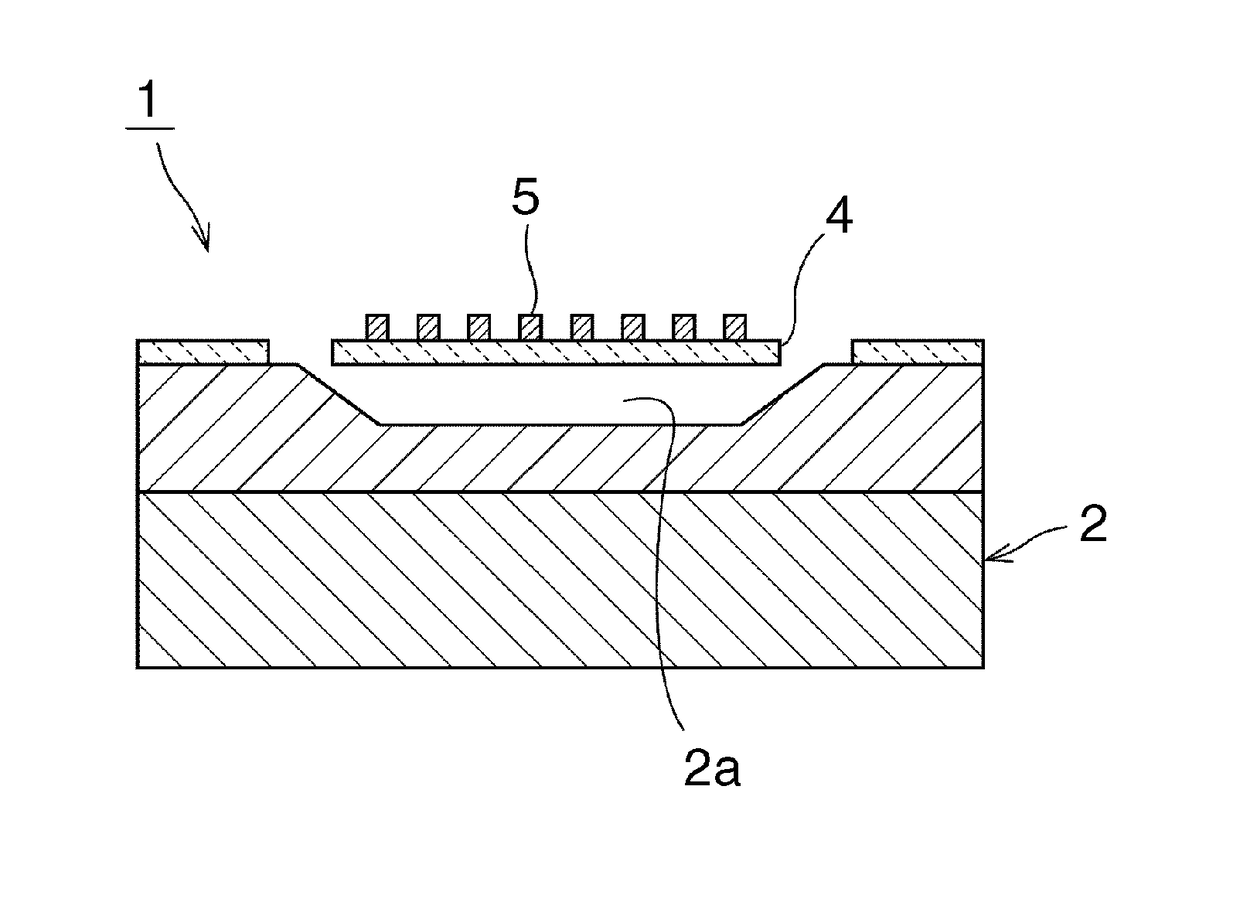

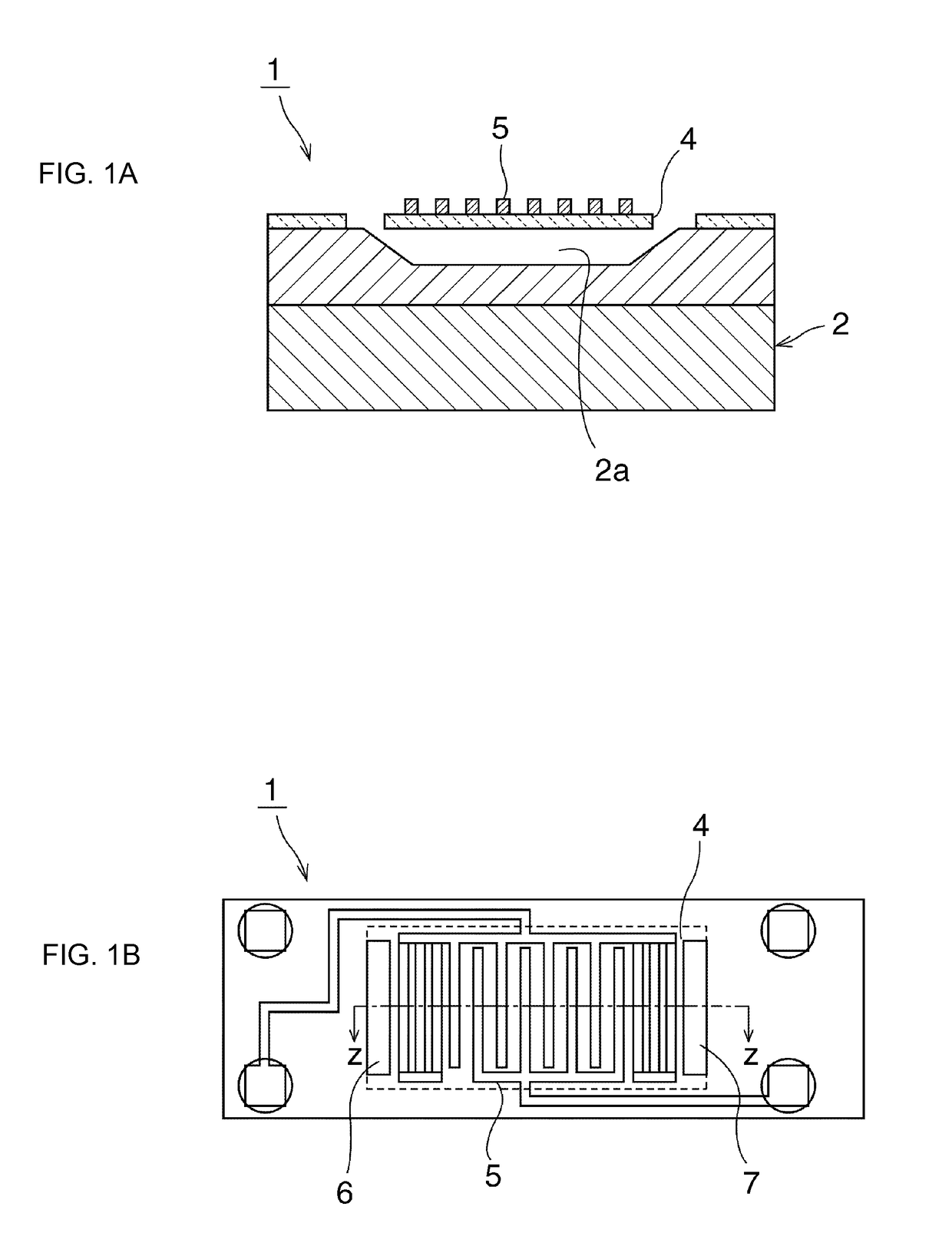

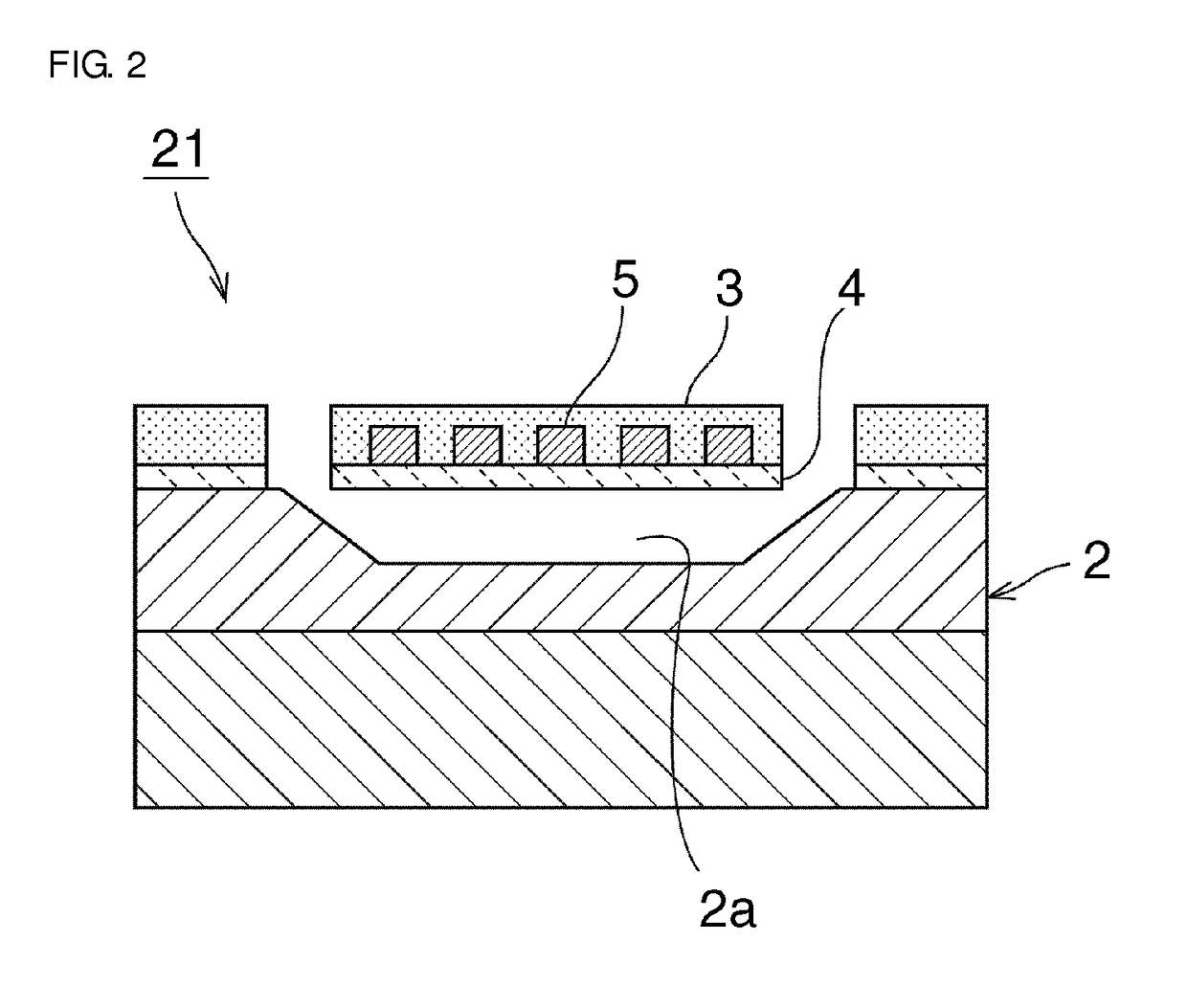

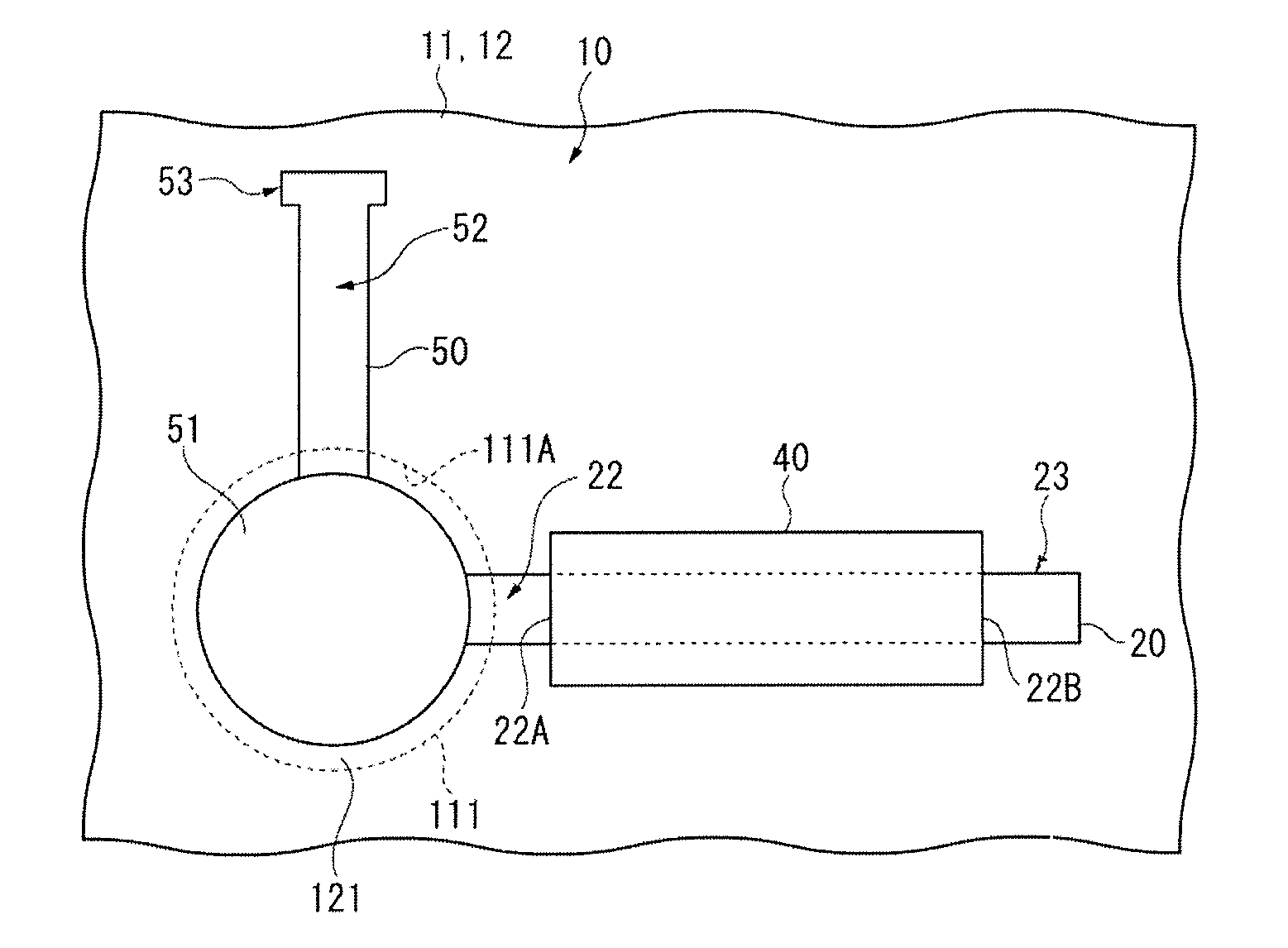

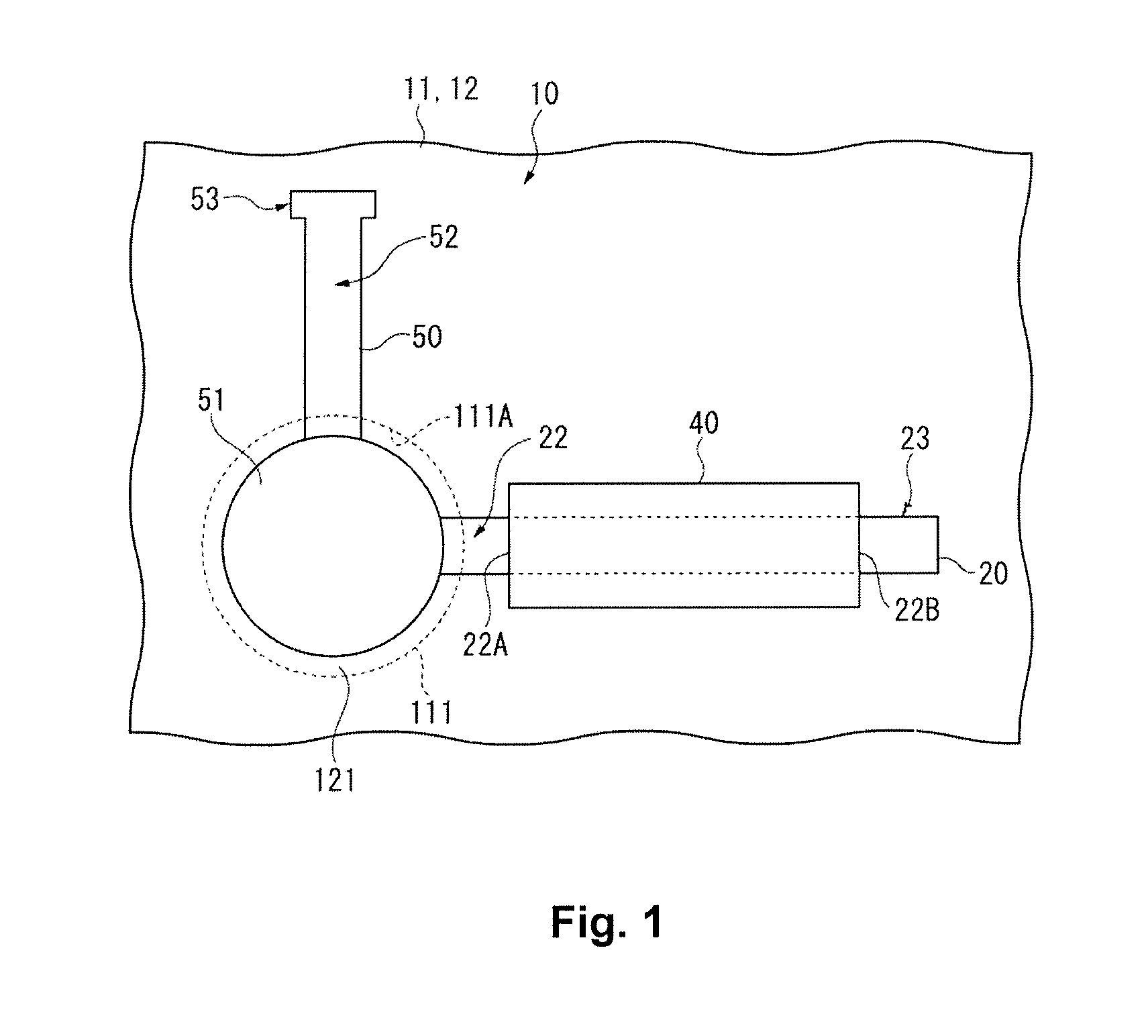

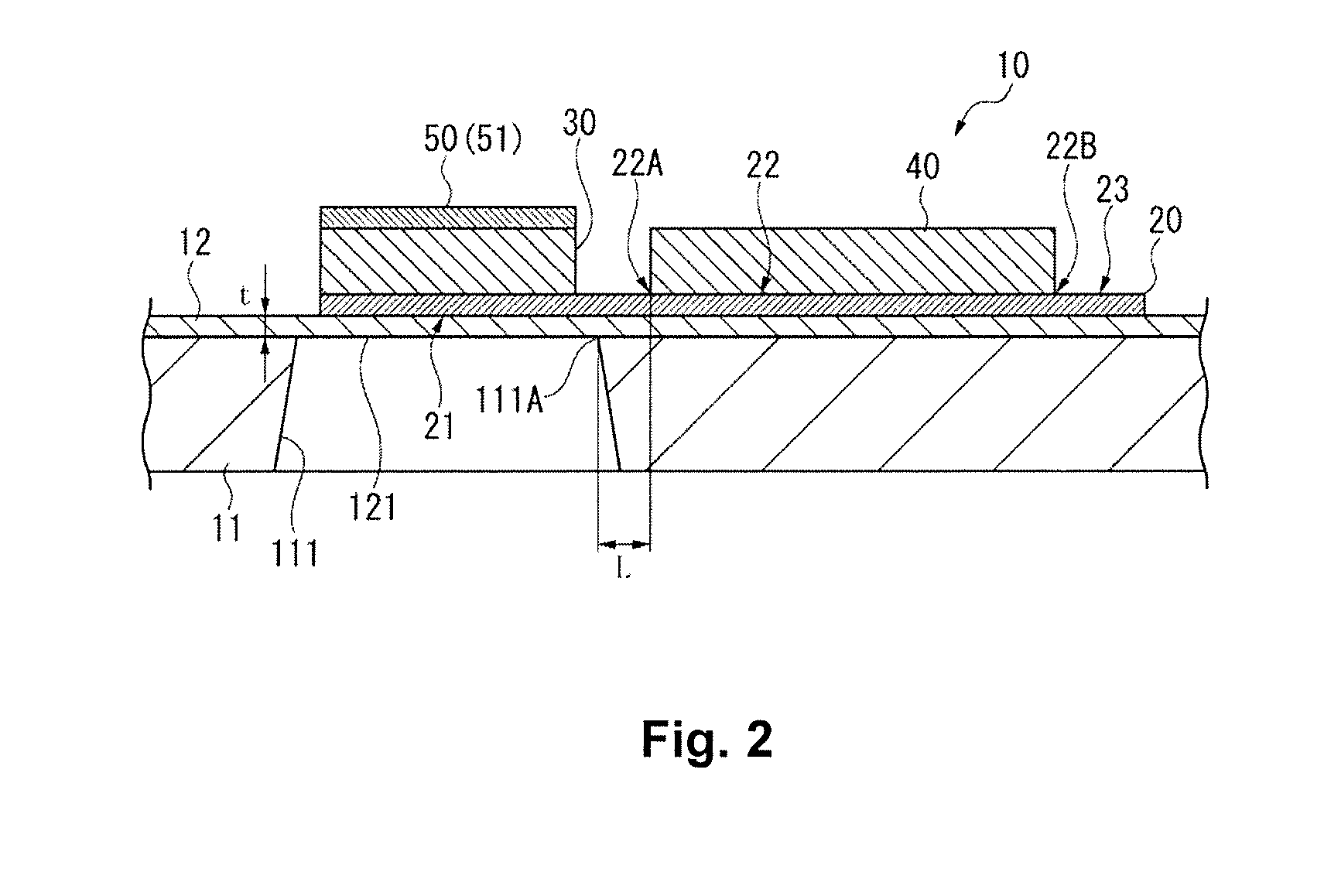

Elastic wave device and manufacturing method for same

ActiveUS20140152145A1Easily realizeSmall sizePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksEngineeringEuler angles

An elastic wave device includes a support layer with a through-hole or a recess opened at an upper surface thereof, a piezoelectric thin film arranged on the support layer to extend above the recess or the through-hole of the support layer, and an IDT electrode defined on at least one of upper and lower surfaces of the piezoelectric thin film in a region of the piezoelectric thin film, the region extending above the recess, or the through-hole. A secondary mode of a plate wave, which contains a U1 component as a main component, is utilized. The piezoelectric thin film is made of LiTaO3, and Euler angles (φ, θ, ψ) of the LiTaO3 fall within specific ranges.

Owner:MURATA MFG CO LTD

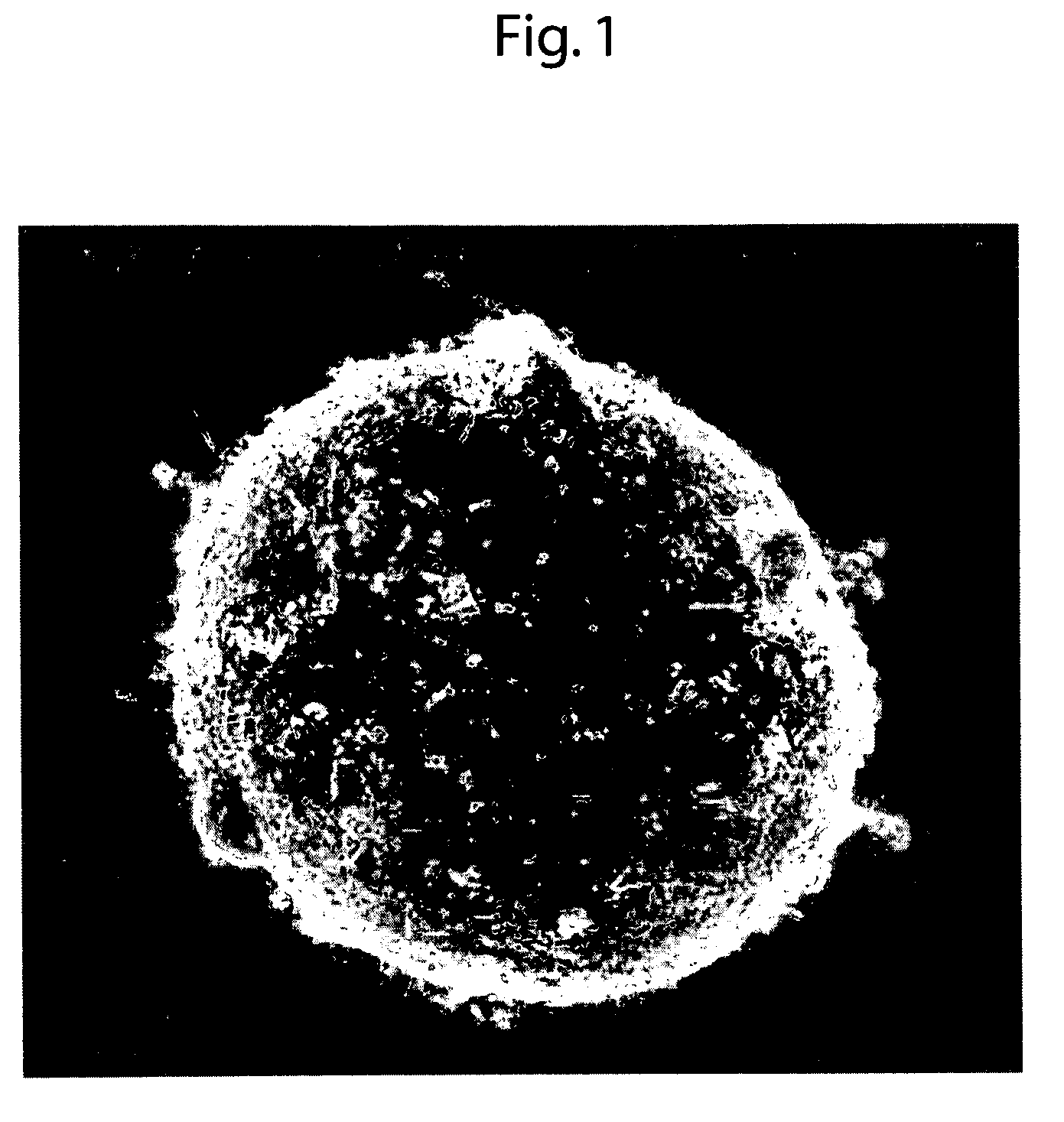

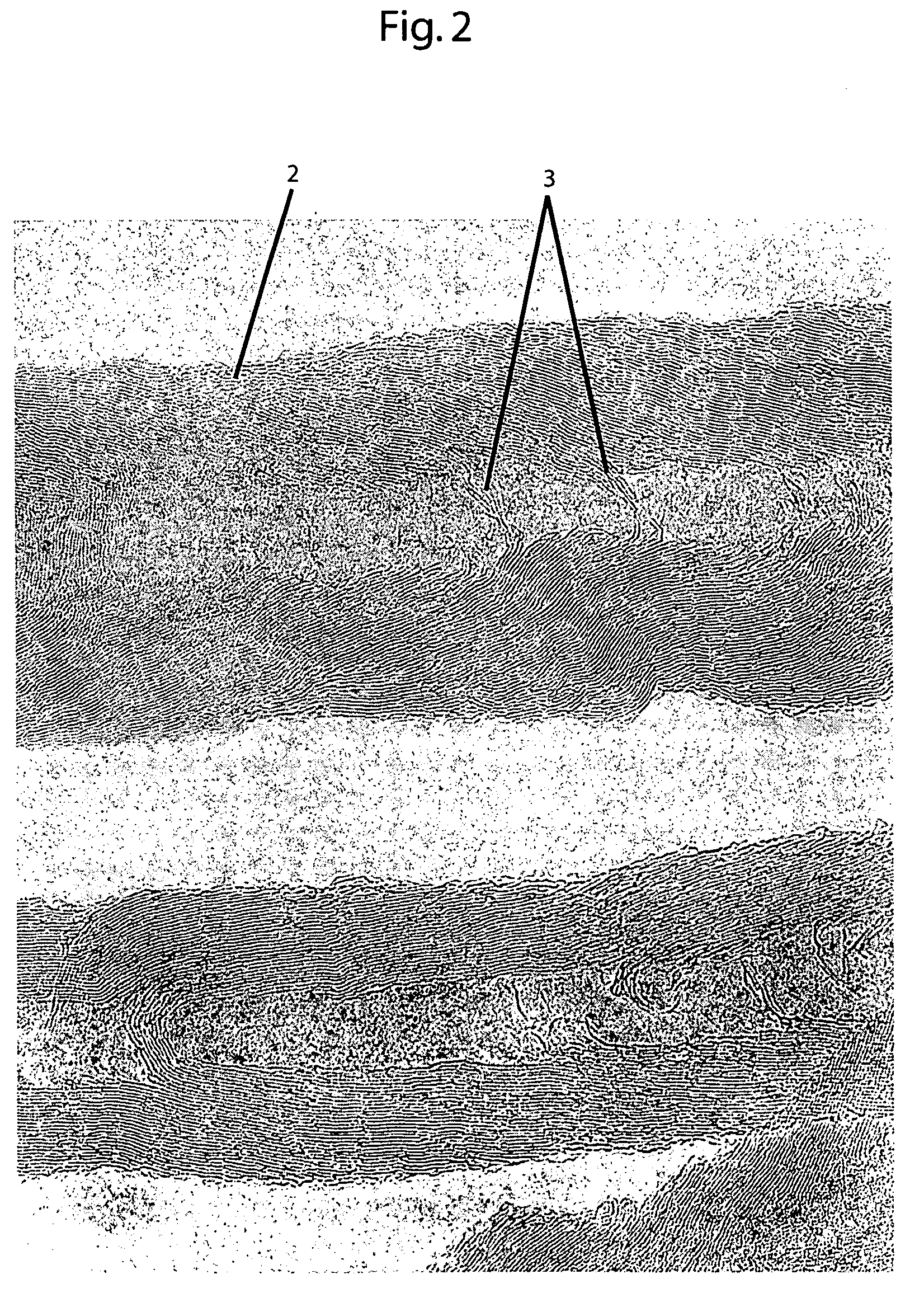

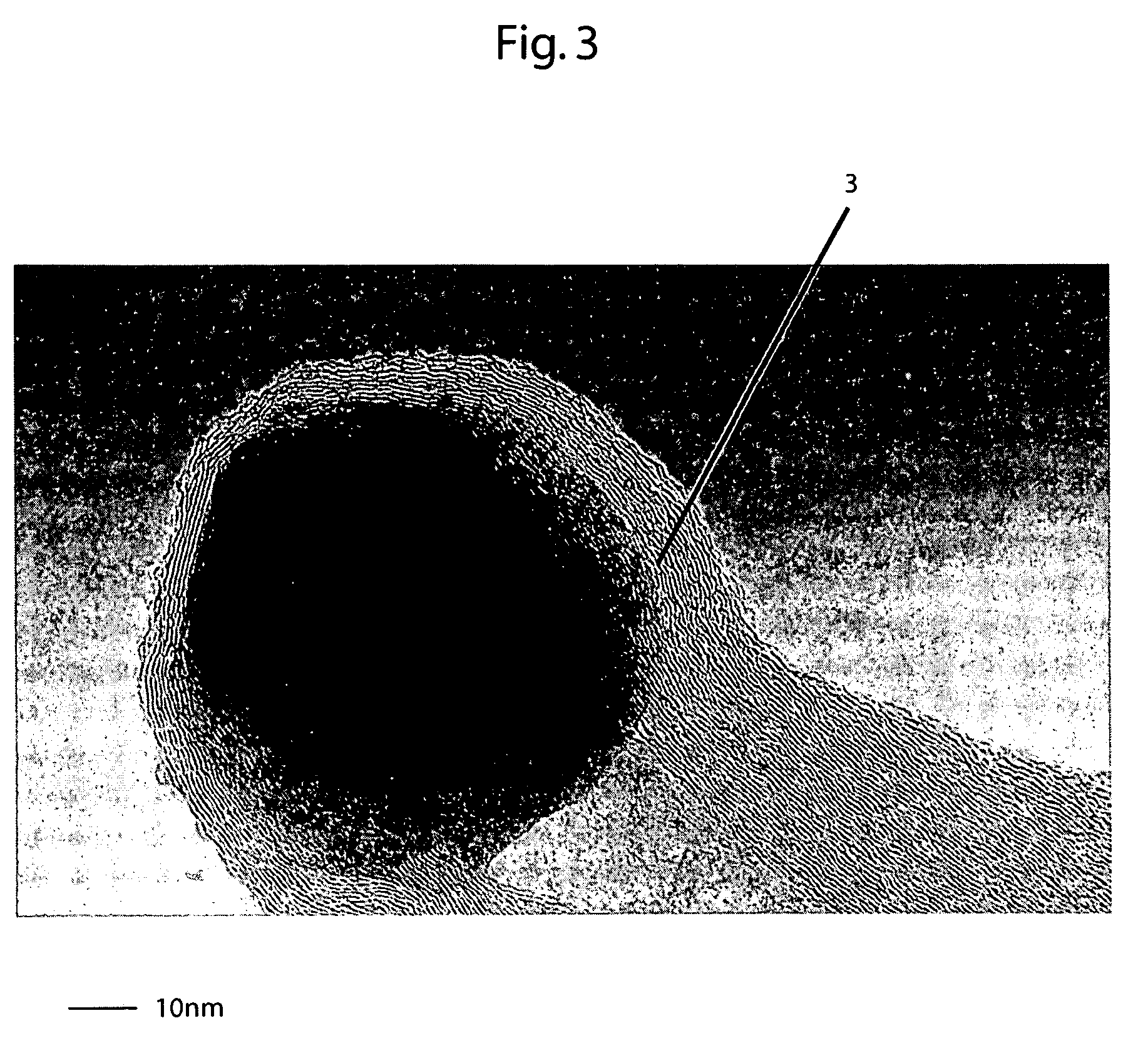

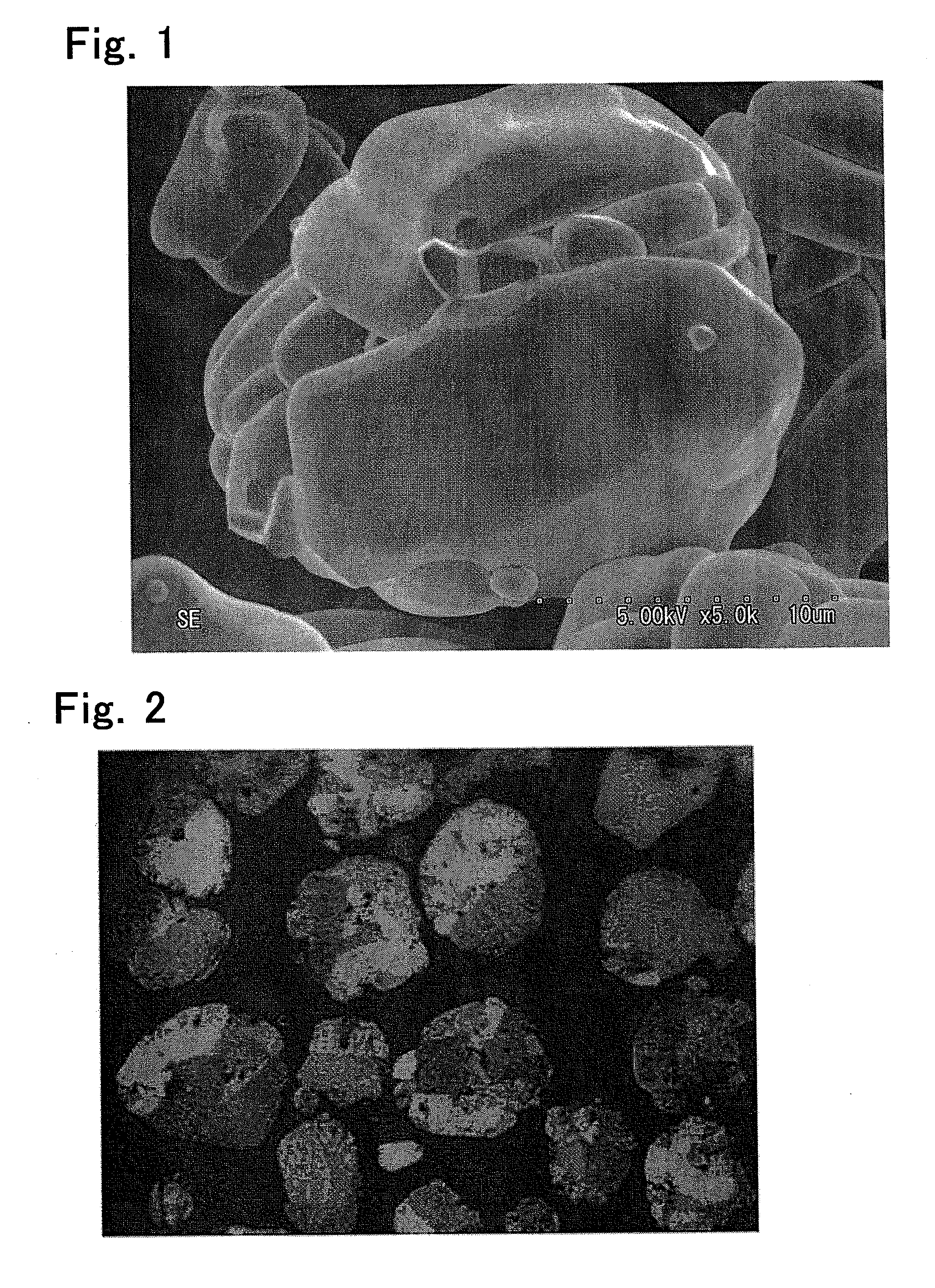

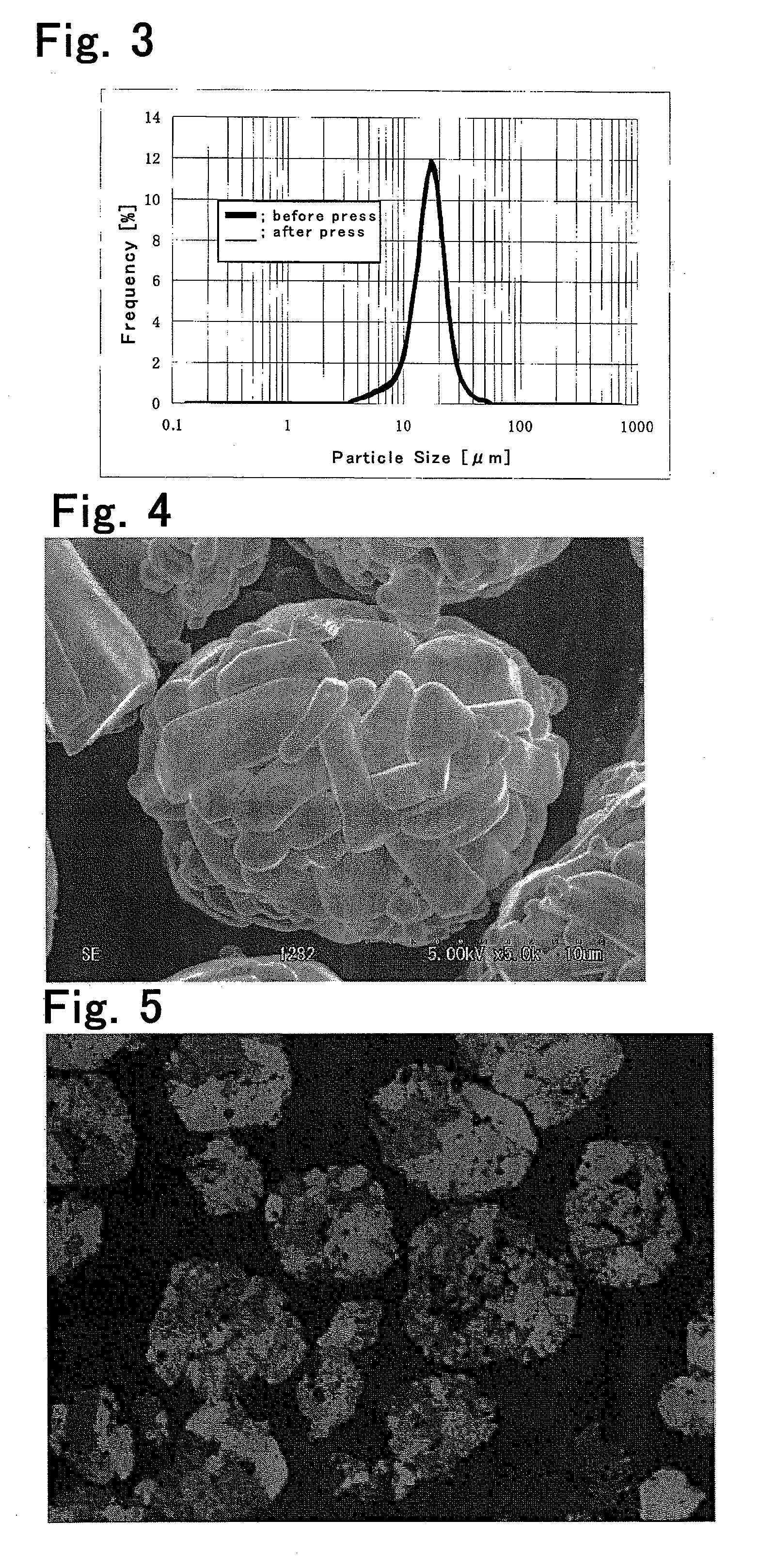

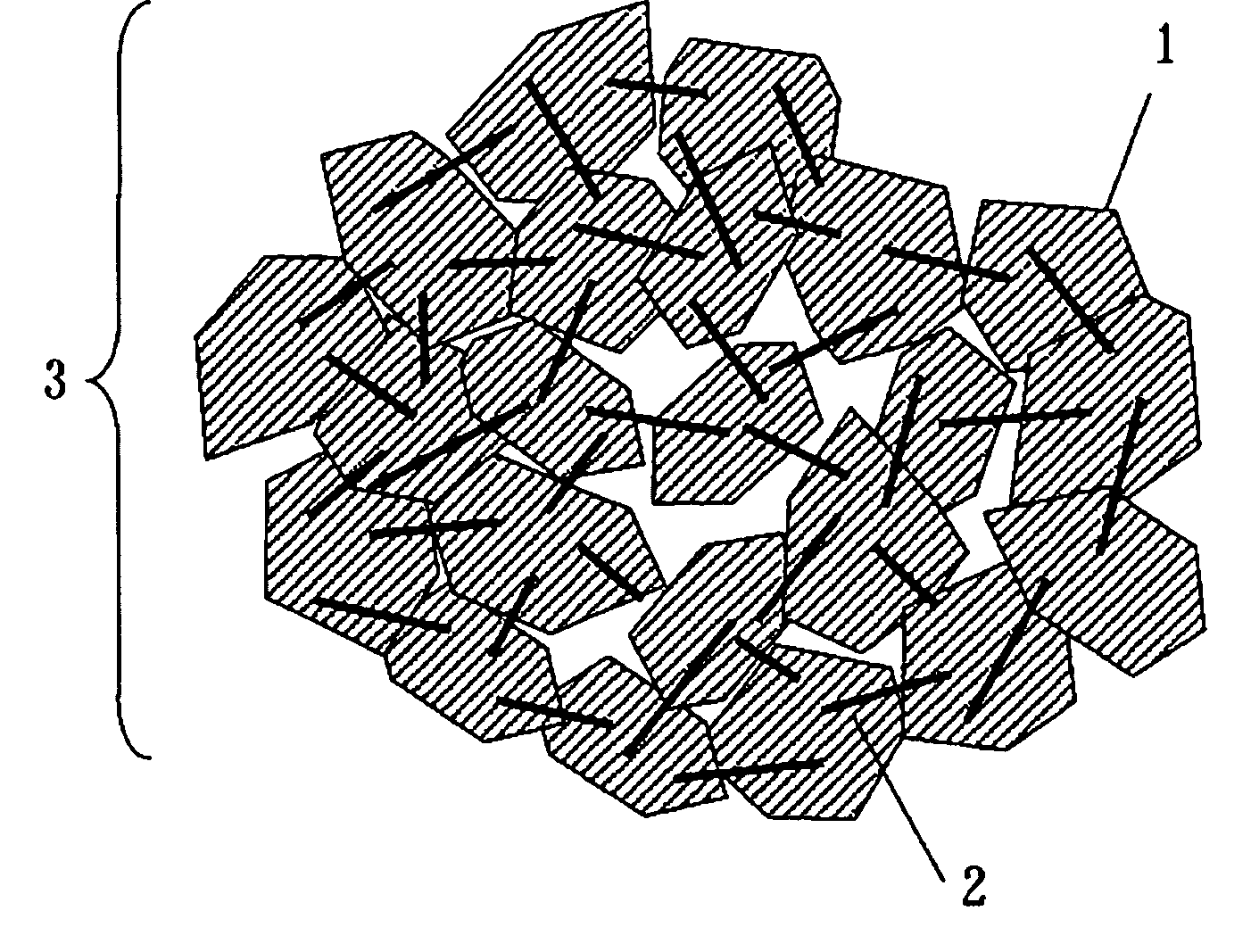

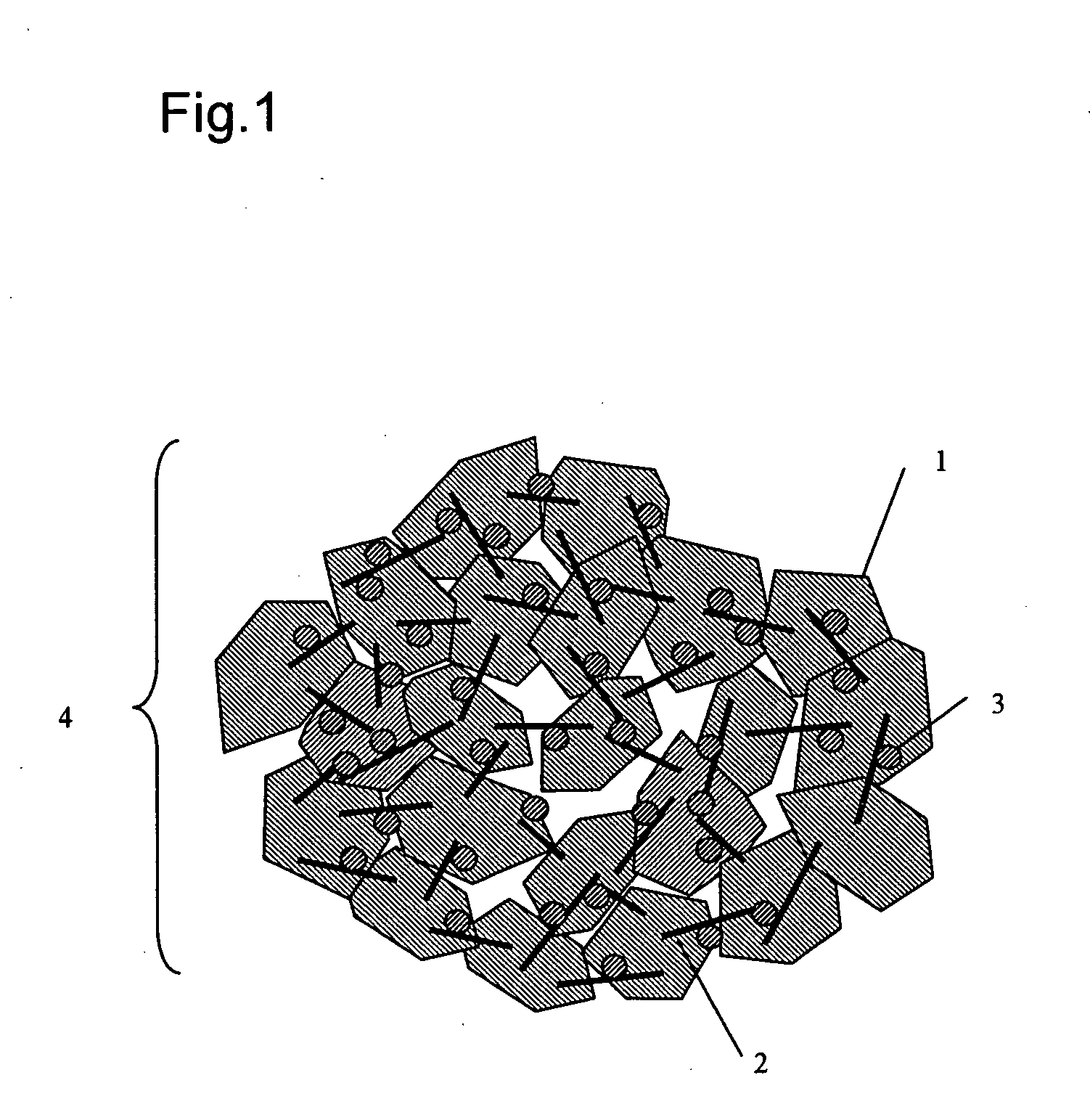

Negative electrode active material for an electricity storage device and method for manufacturing the same

InactiveUS20080220329A1Improve conductivityIncrease electrode densityMaterial nanotechnologyElectrode manufacturing processesElectricityCarbon composites

To provide a negative electrode active material for an electricity storage device, which has considerably enhanced low-temperature characteristic, increased energy density, and increased output power. A negative electrode active material is made of a carbon composite containing carbon particles as a core and a fibrous carbon having a graphene structure, which is formed on the surfaces and / or the inside of the carbon particles, wherein the carbon composite has a volume of all mesopores within 0.005 to 1.0 cm3 / g, and a volume of the mesopores each with a pore diameter ranging from 100 to 400 Å of not less than 25% of the volume of all mesopores.

Owner:SUBARU CORP

Elastic wave device and manufacturing method for same

ActiveUS9748923B2Lower electrode resistanceImprove featuresImpedence networksEngineeringPiezoelectric thin films

An elastic wave device includes a support layer with a through-hole or a recess opened at an upper surface thereof, a piezoelectric thin film arranged on the support layer to extend above the recess or the through-hole of the support layer, and an IDT electrode defined on at least one of upper and lower surfaces of the piezoelectric thin film in a region of the piezoelectric thin film, the region extending above the recess, or the through-hole. A secondary mode of a plate wave, which contains a U1 component as a main component, is utilized. The piezoelectric thin film is made of LiTaO3, and Euler angles (φ, θ, ψ) of the LiTaO3 fall within specific ranges.

Owner:MURATA MFG CO LTD

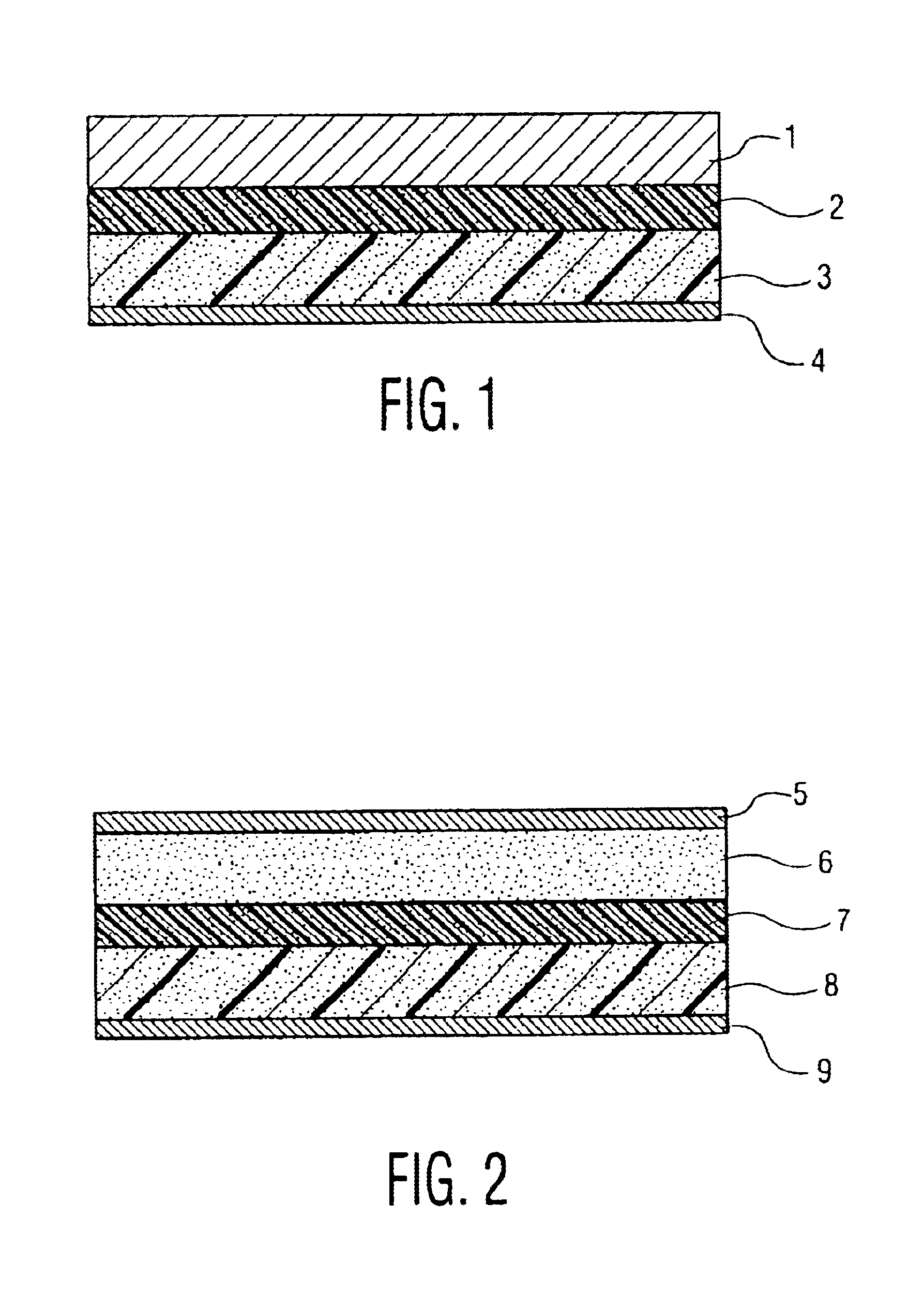

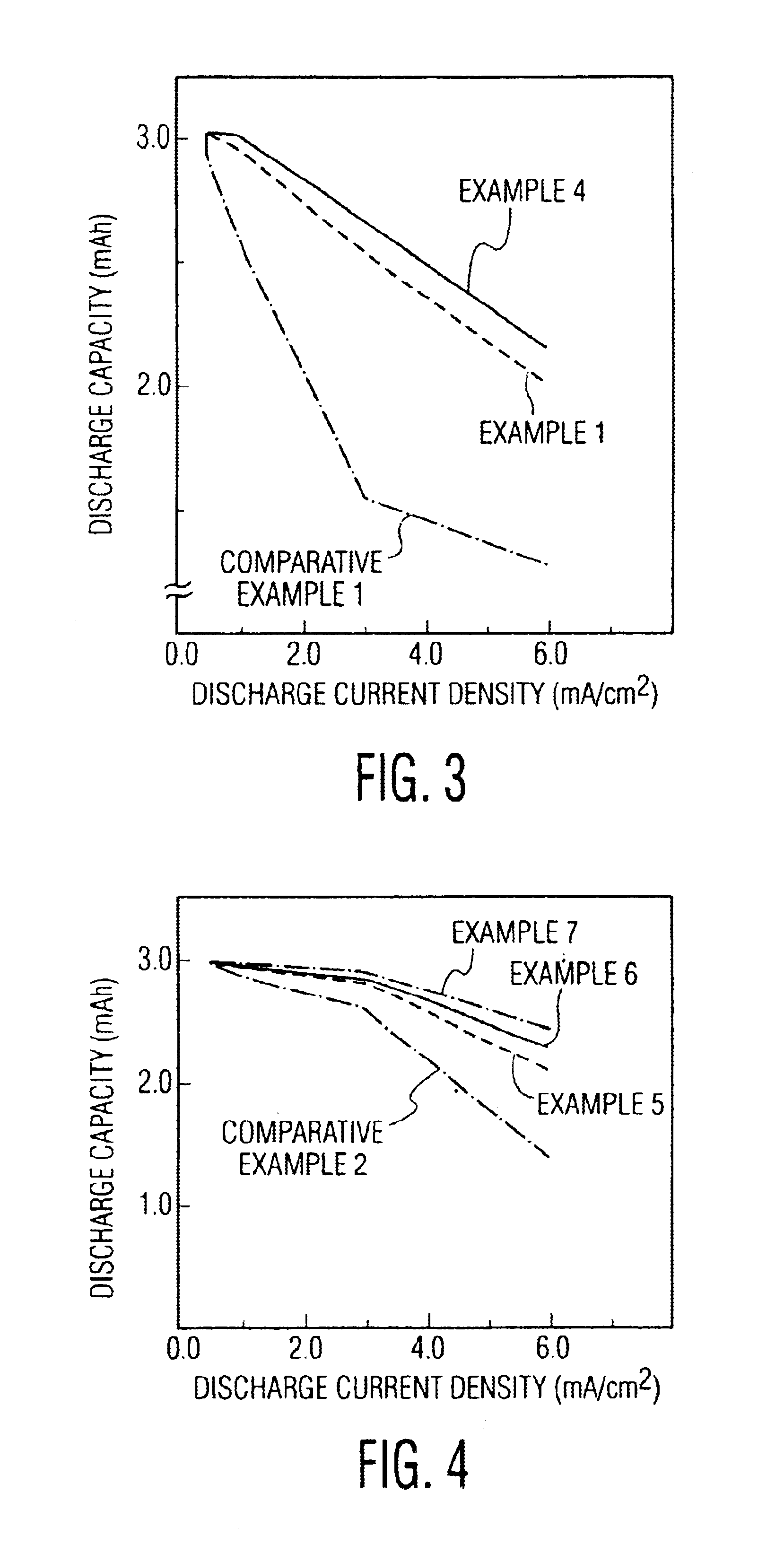

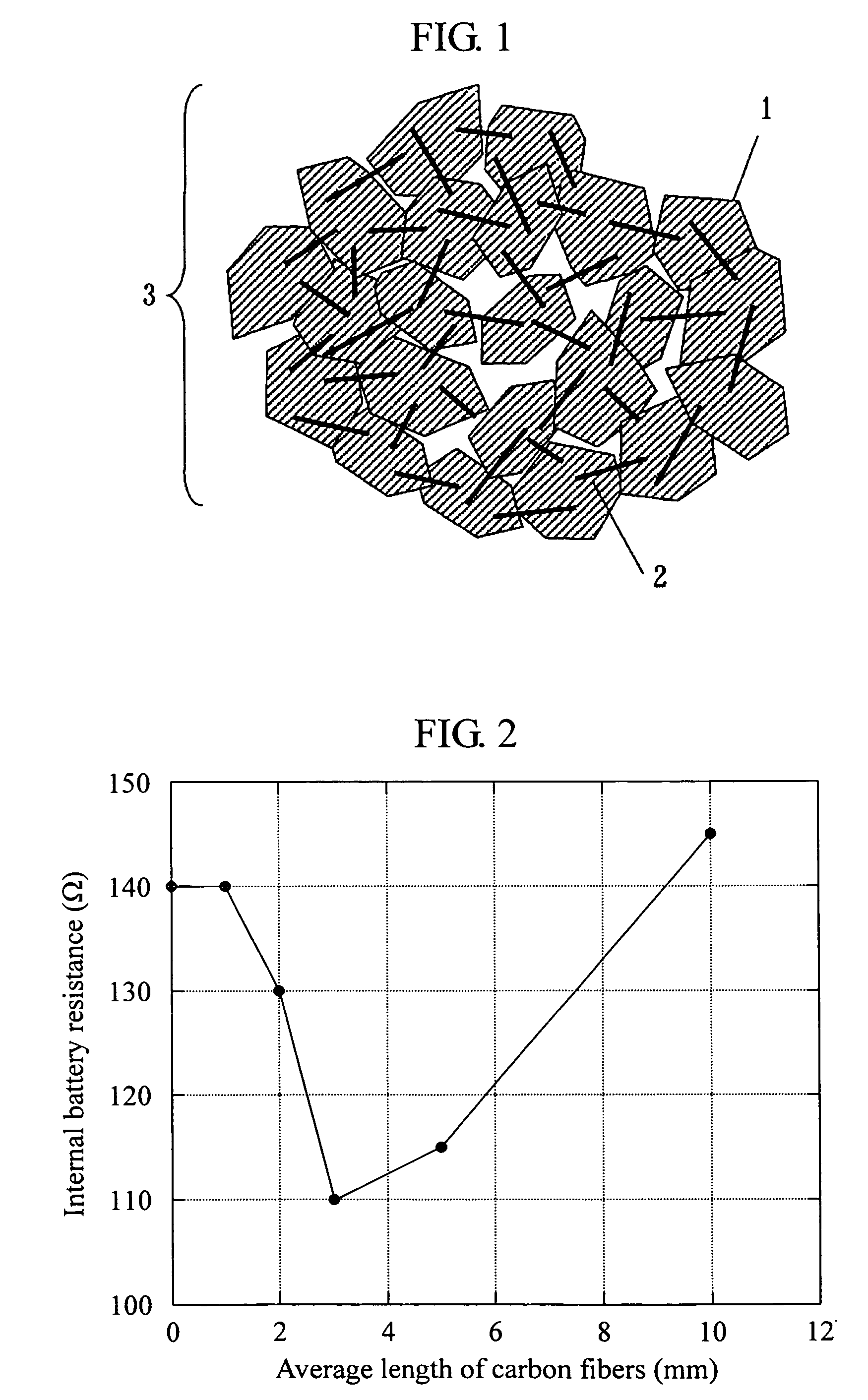

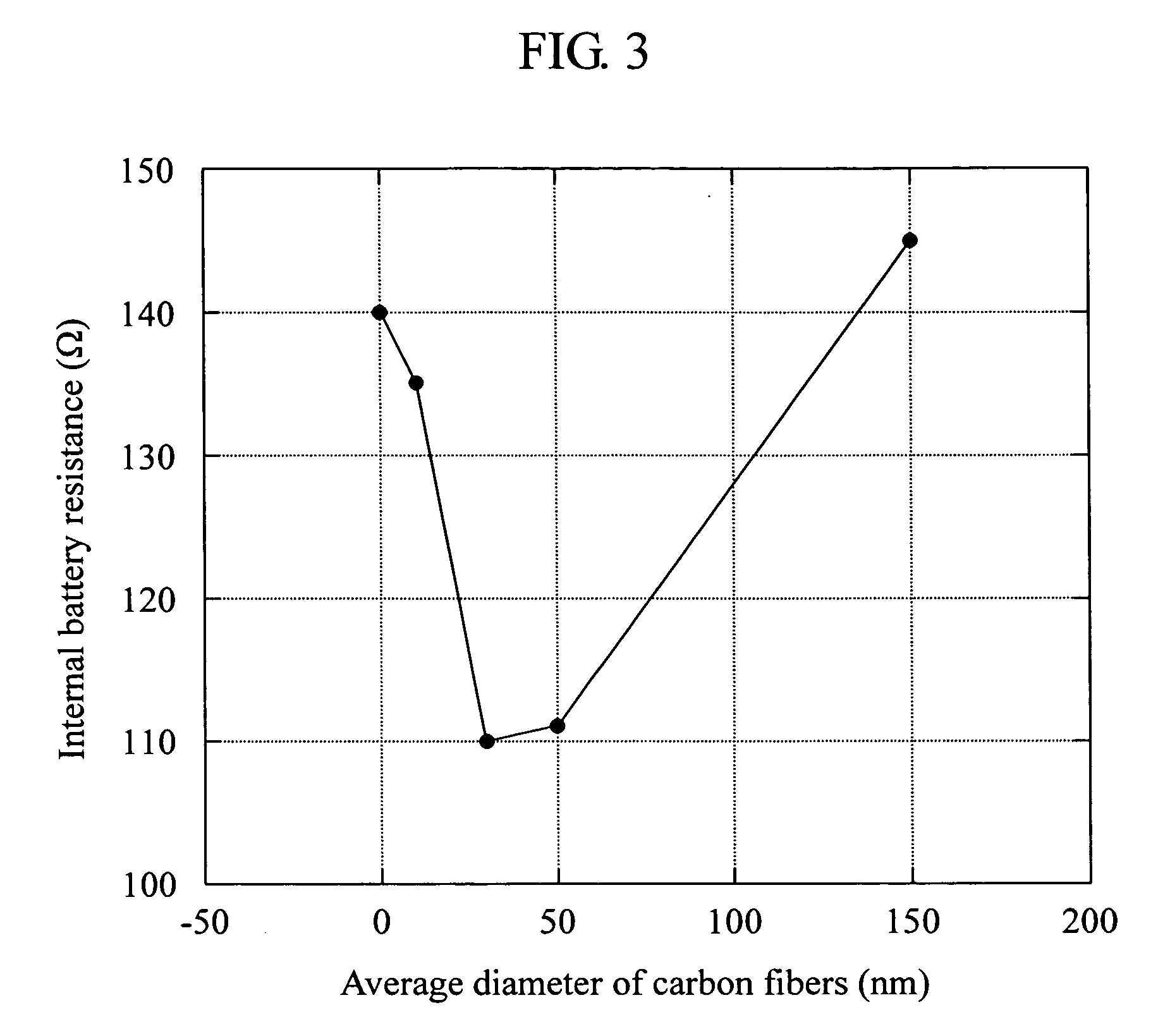

Negative Electrode Material for Lithium Battery, and Lithium Battery

InactiveUS20070275302A1Lower electrode resistanceHigh electrode strengthNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsCarboxymethyl celluloseCarbon fibers

The present invention relates to a negative electrode material for a lithium battery characterized by comprising a carbonaceous negative electrode active substance having a specific surface area of 1 m2 / g or more, a binder formed of styrene-butadiene rubber and a carbon fiber having a fiber diameter of 1 to 1,000 nm; and to a lithium battery using the negative electrode material, which has excellent characteristics, i.e., low electrode resistance, high electrode strength, excellent electrolytic solution permeability, high energy density, and good high-speed charging / discharging performance. The negative electrode material contains carbon fiber in the amount of 0.05 to 20 mass % and the binder formed of styrene-butadiene rubber in 0.1 to 6.0 mass %, and may further contain a thickner such as carboxymethyl cellulose in the amount of 0.3 to 3 mass %.

Owner:SHOWA DENKO KK +1

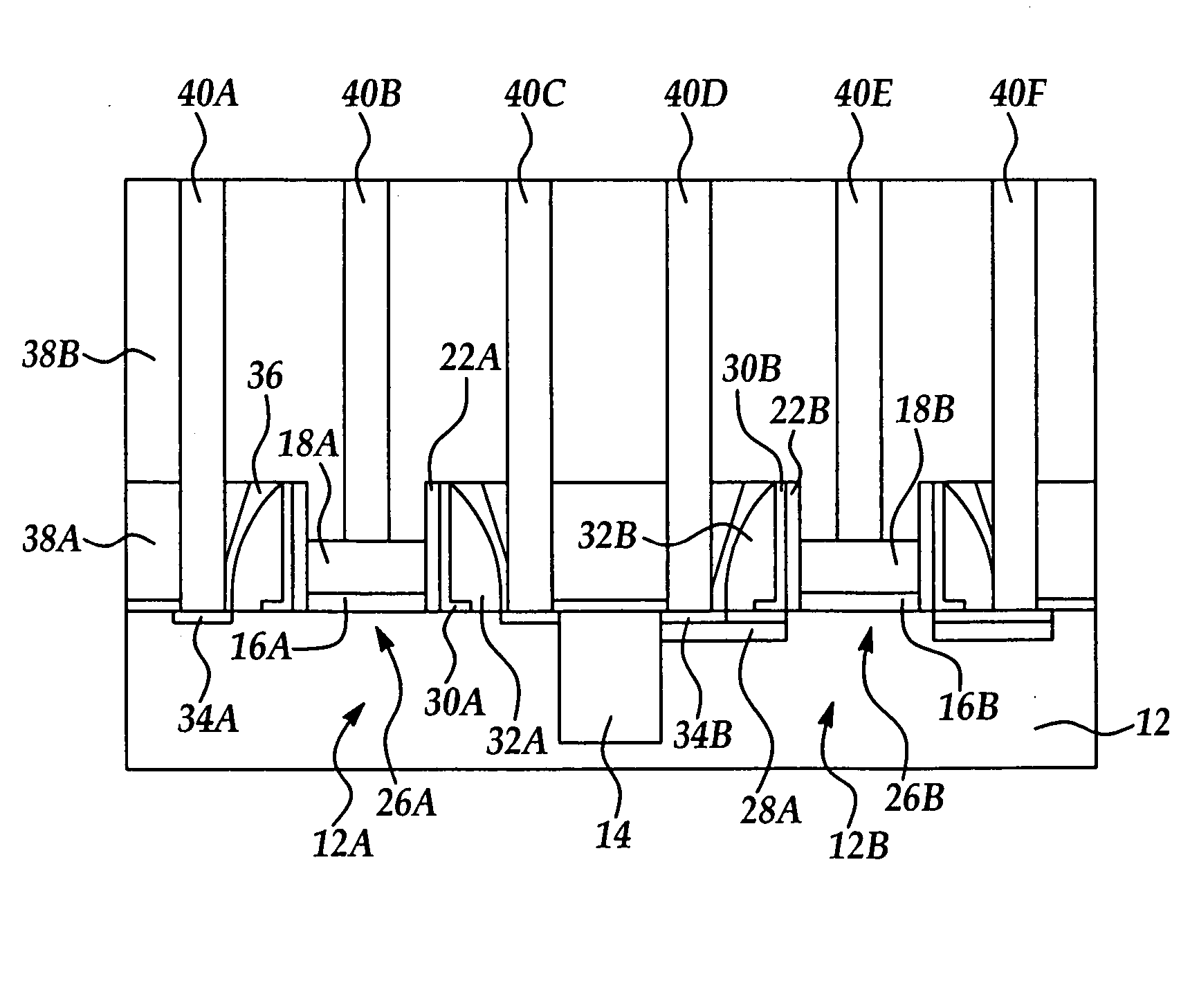

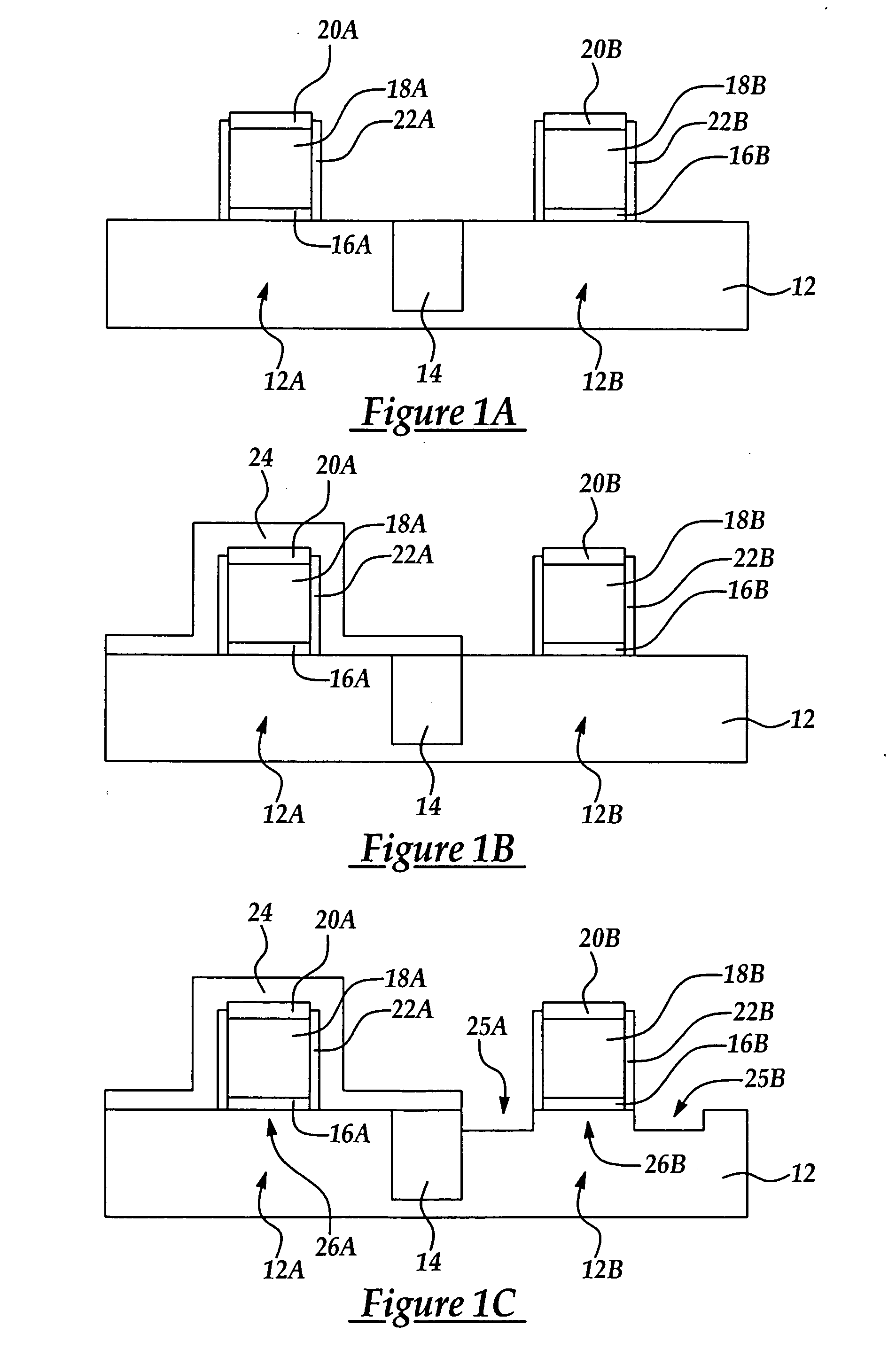

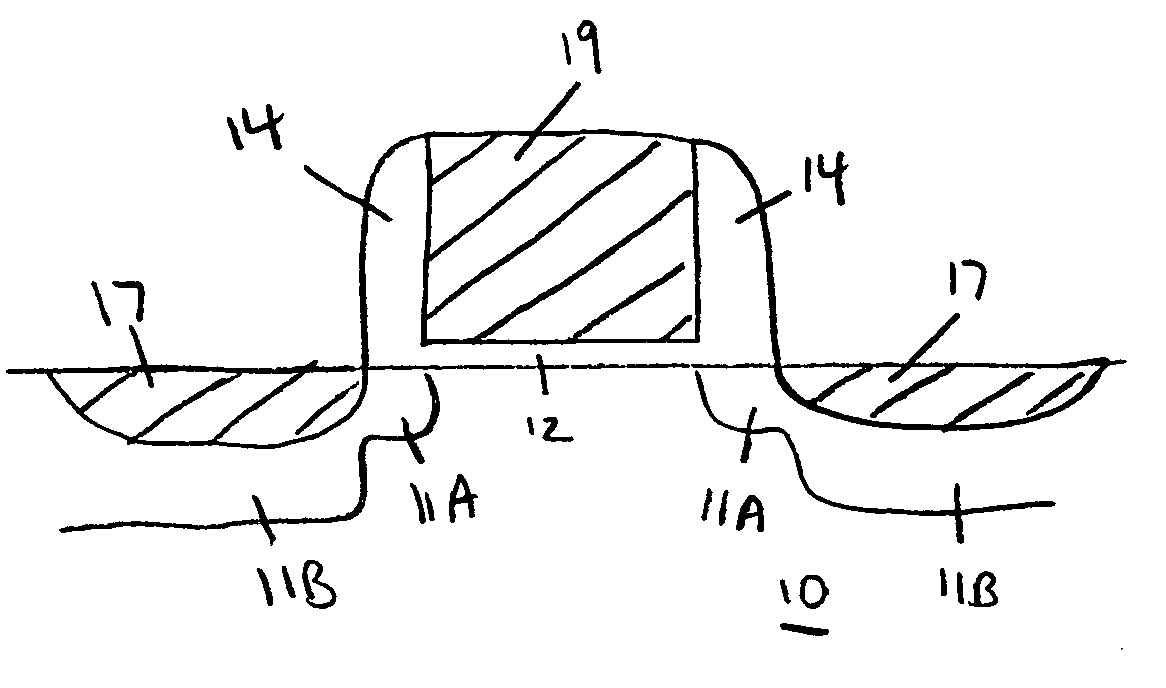

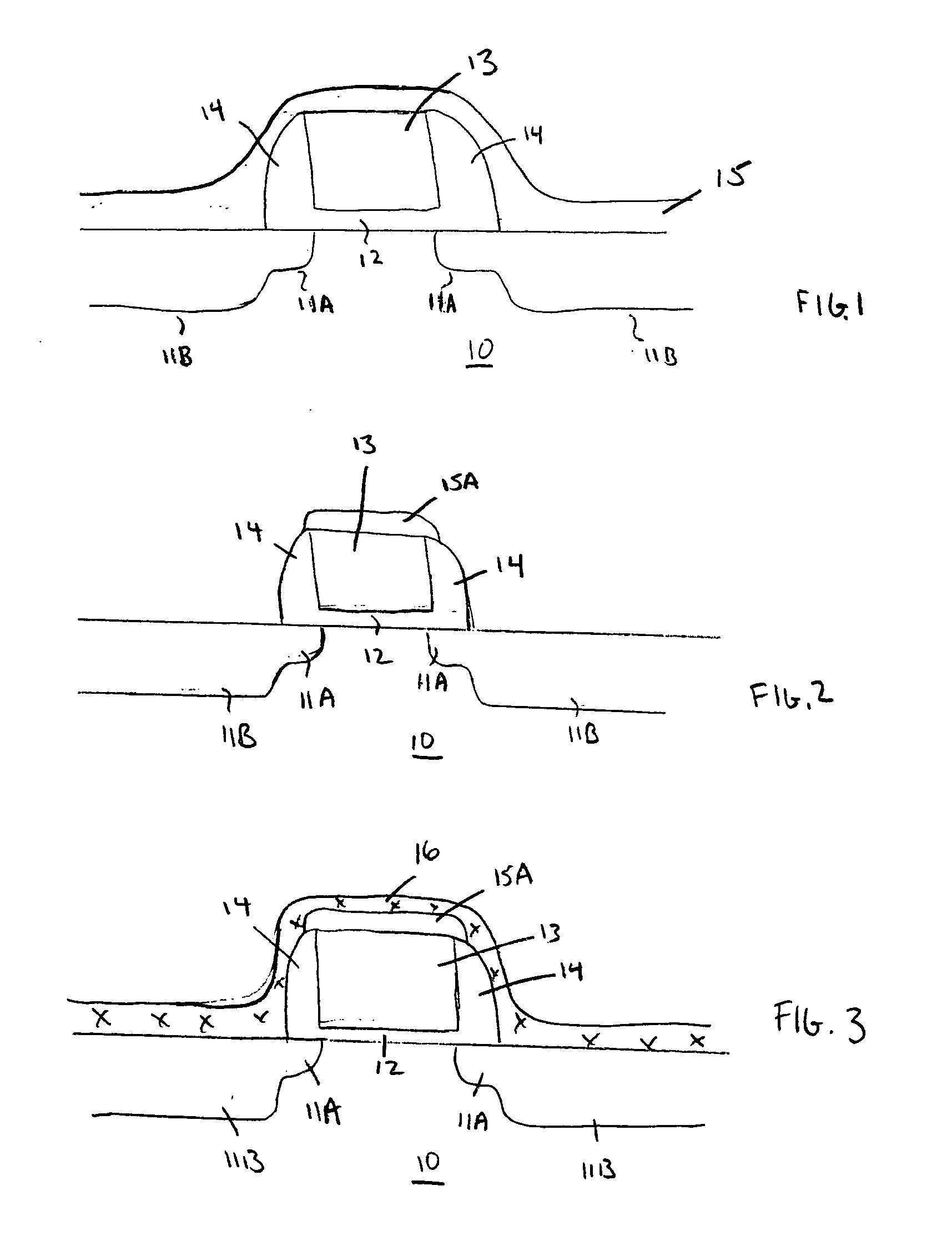

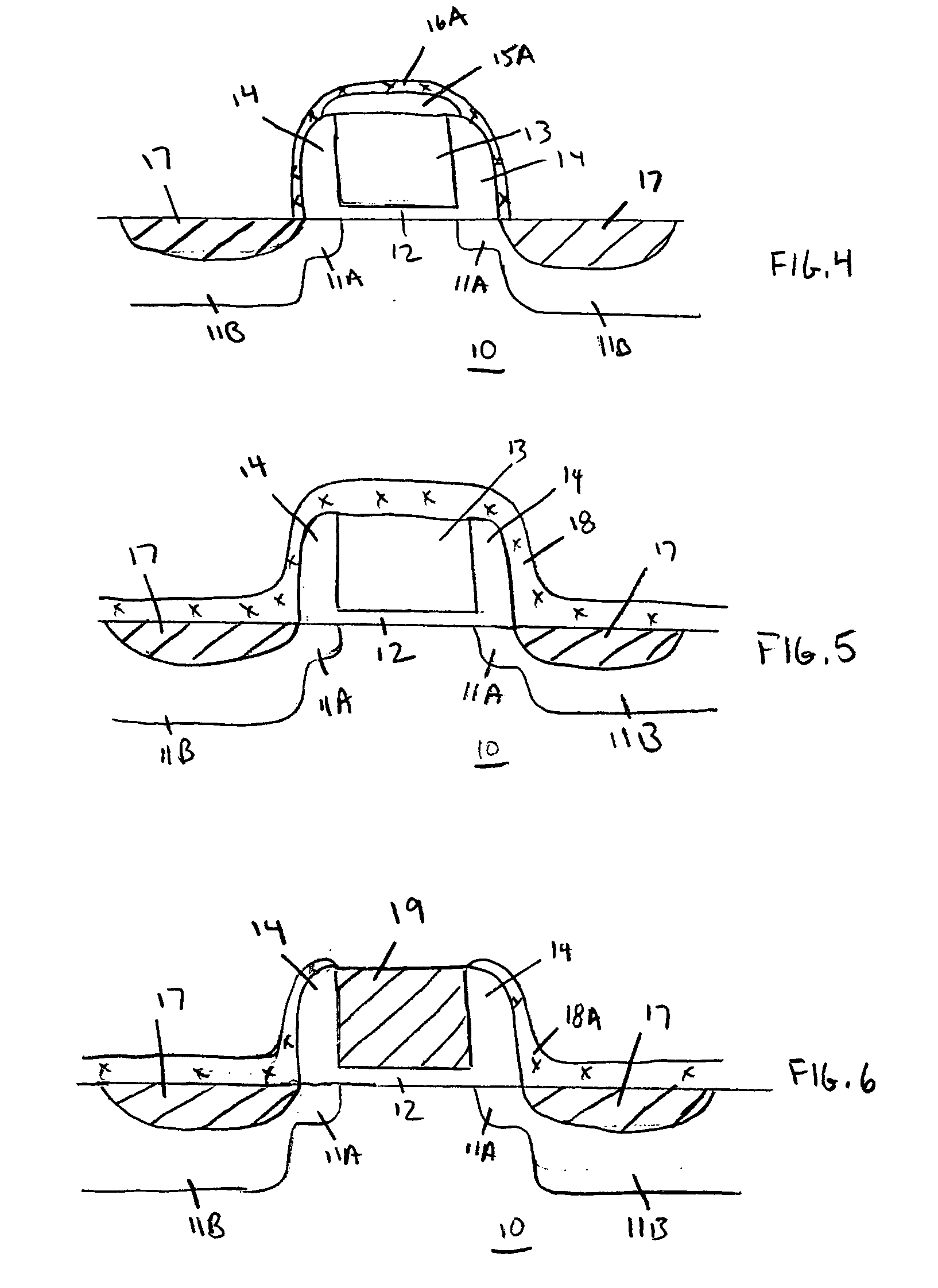

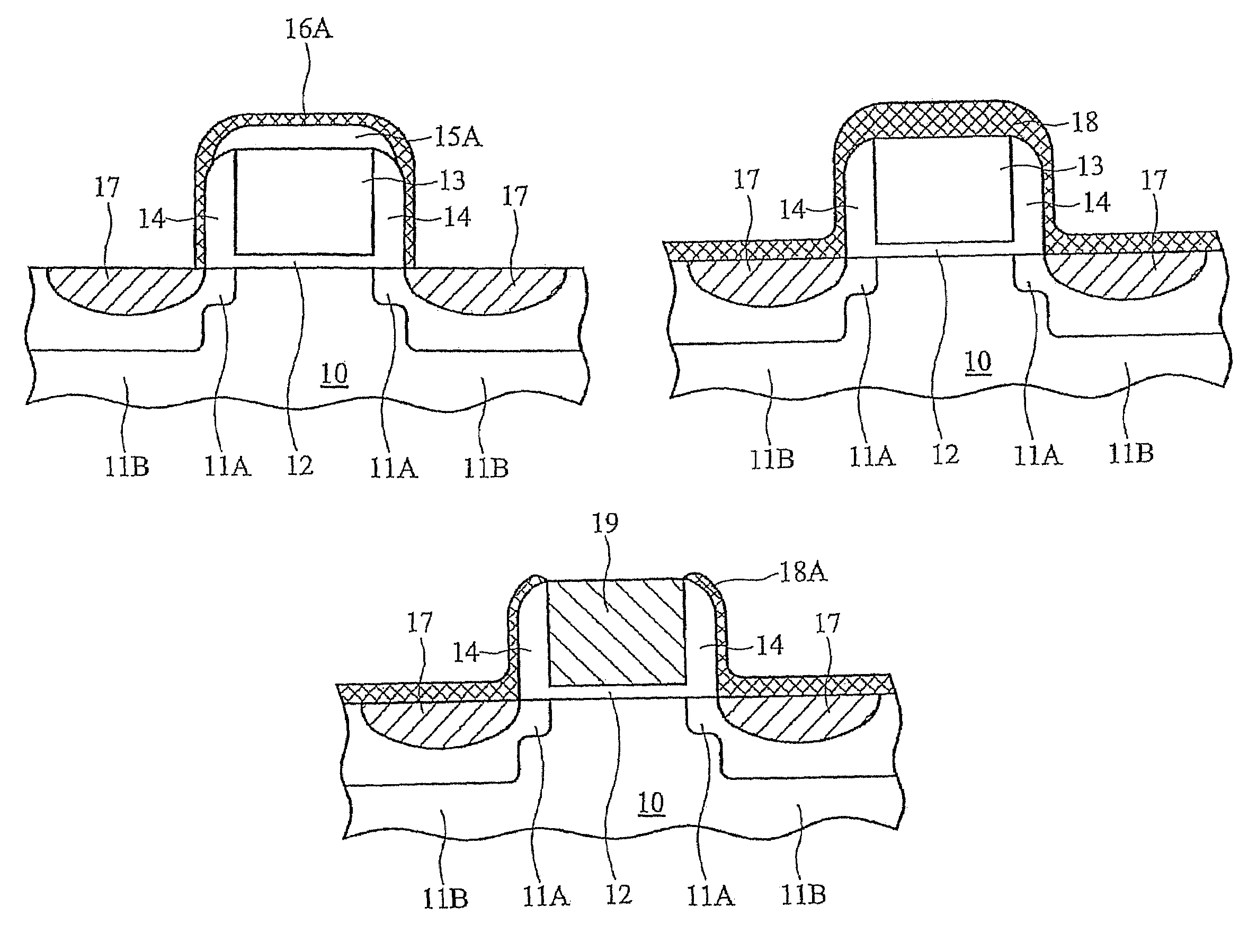

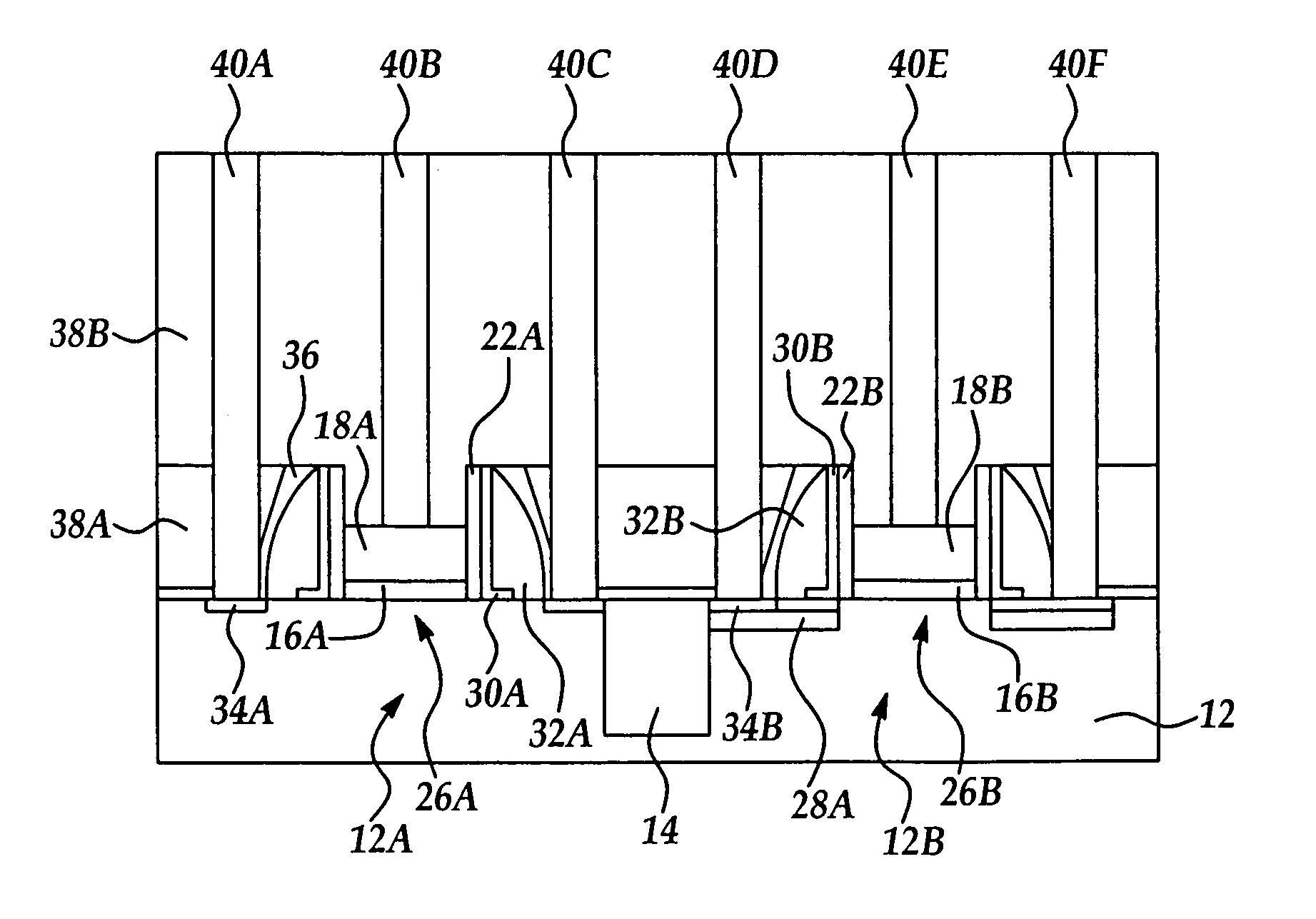

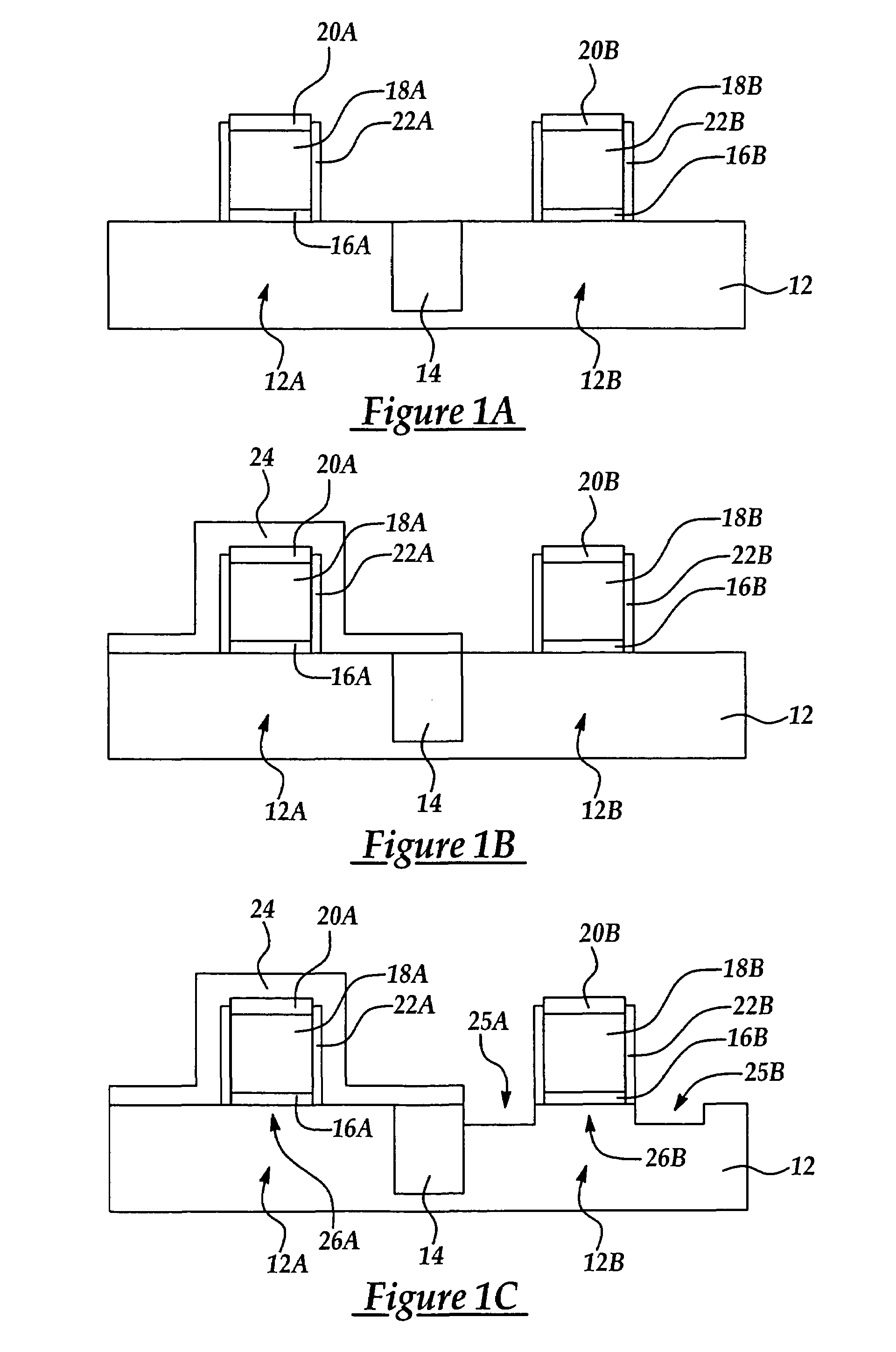

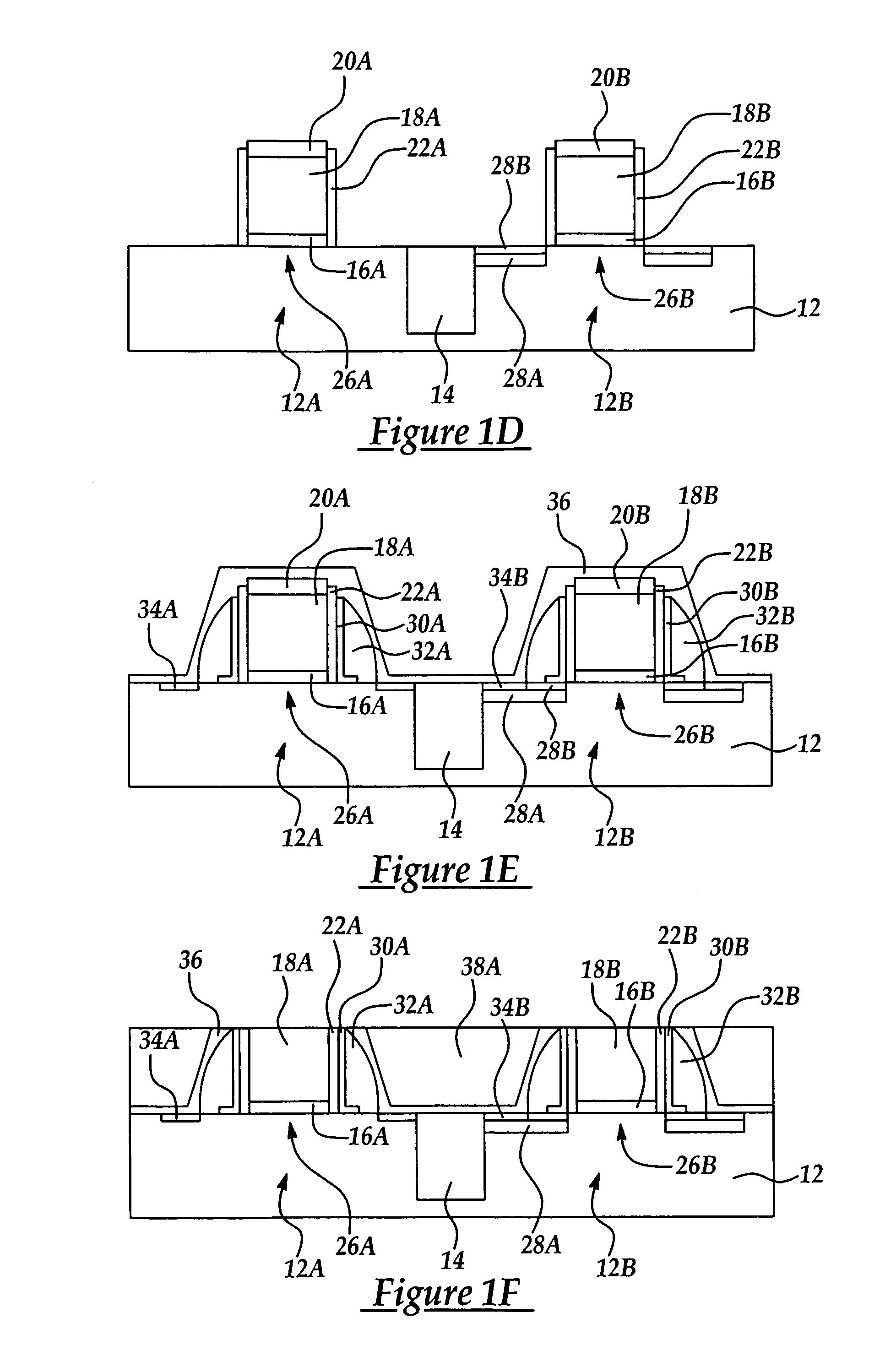

Strained channel CMOS device with fully silicided gate electrode

InactiveUS20060148181A1Lower electrode resistanceInhibitionSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon alloyMetal silicide

A strained channel NMOS and PMOS device pair including fully silicided gate electrodes and method for forming the same, the method including providing a semiconductor substrate including NMOS and PMOS device regions including respective gate structures including polysilicon gate electrodes; forming recessed regions on either side of a channel region including at least one of the NMOS and PMOS device regions; backfilling portions of the recessed regions with a semiconducting silicon alloy to exert a strain on the channel region; forming offset spacers on either side of the gate structures; thinning the polysilicon gate electrodes to a silicidation thickness to allow full metal silicidation through the silicidation thickness; ion implanting the polysilicon gate electrodes to adjust a work function; and, forming a metal silicide through the silicidation thickness to form metal silicide gate electrodes.

Owner:TAIWAN SEMICON MFG CO LTD

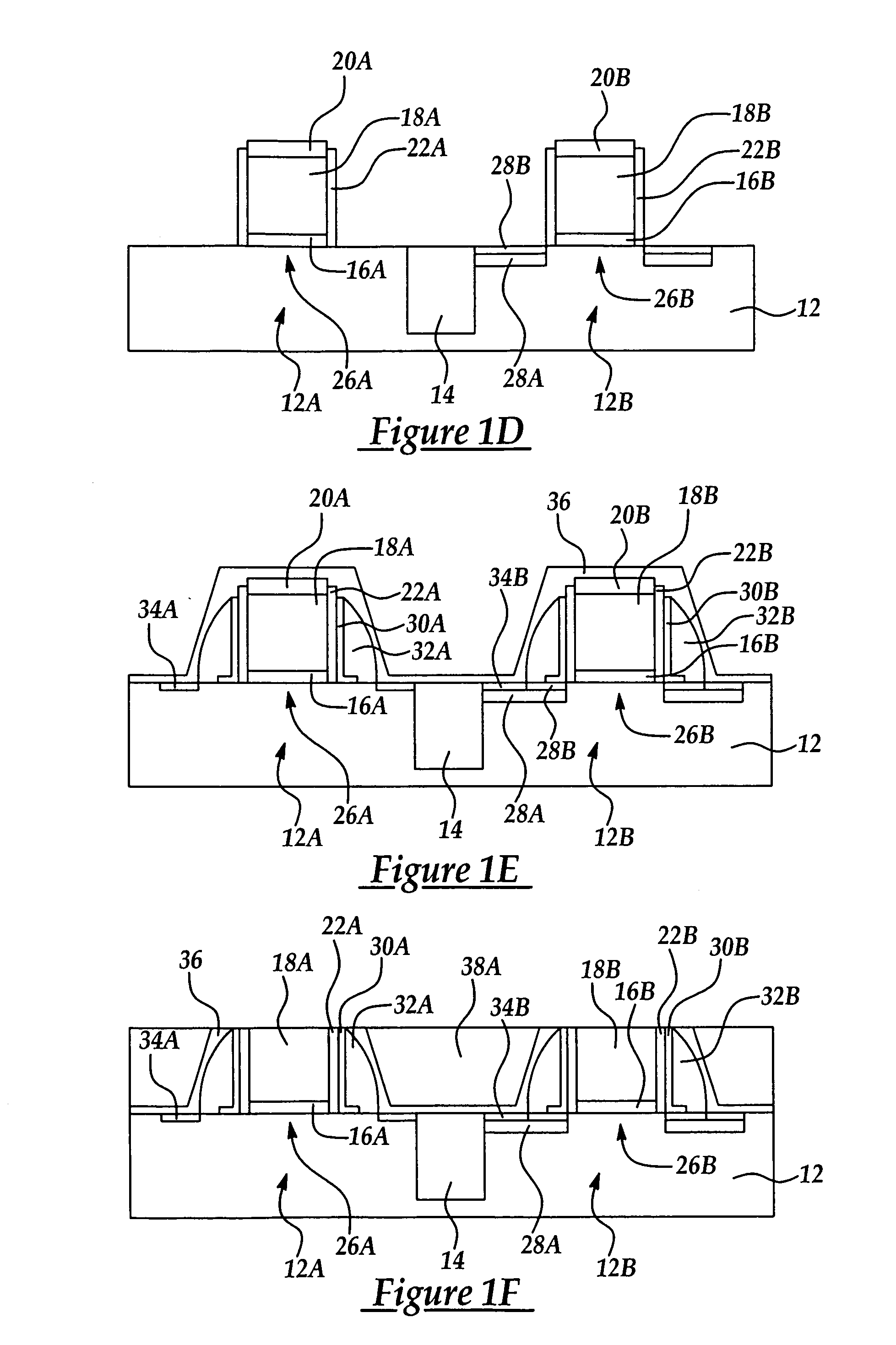

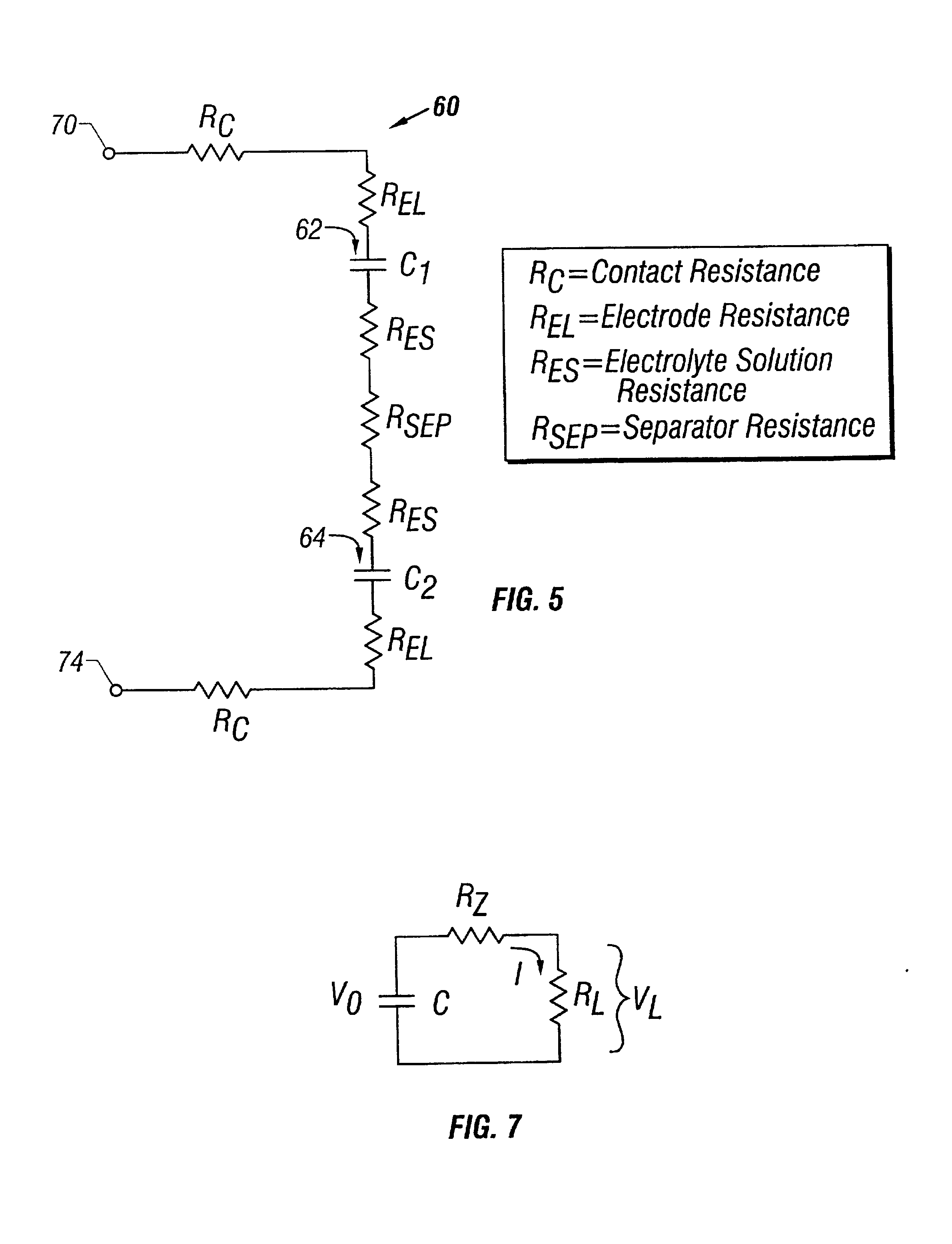

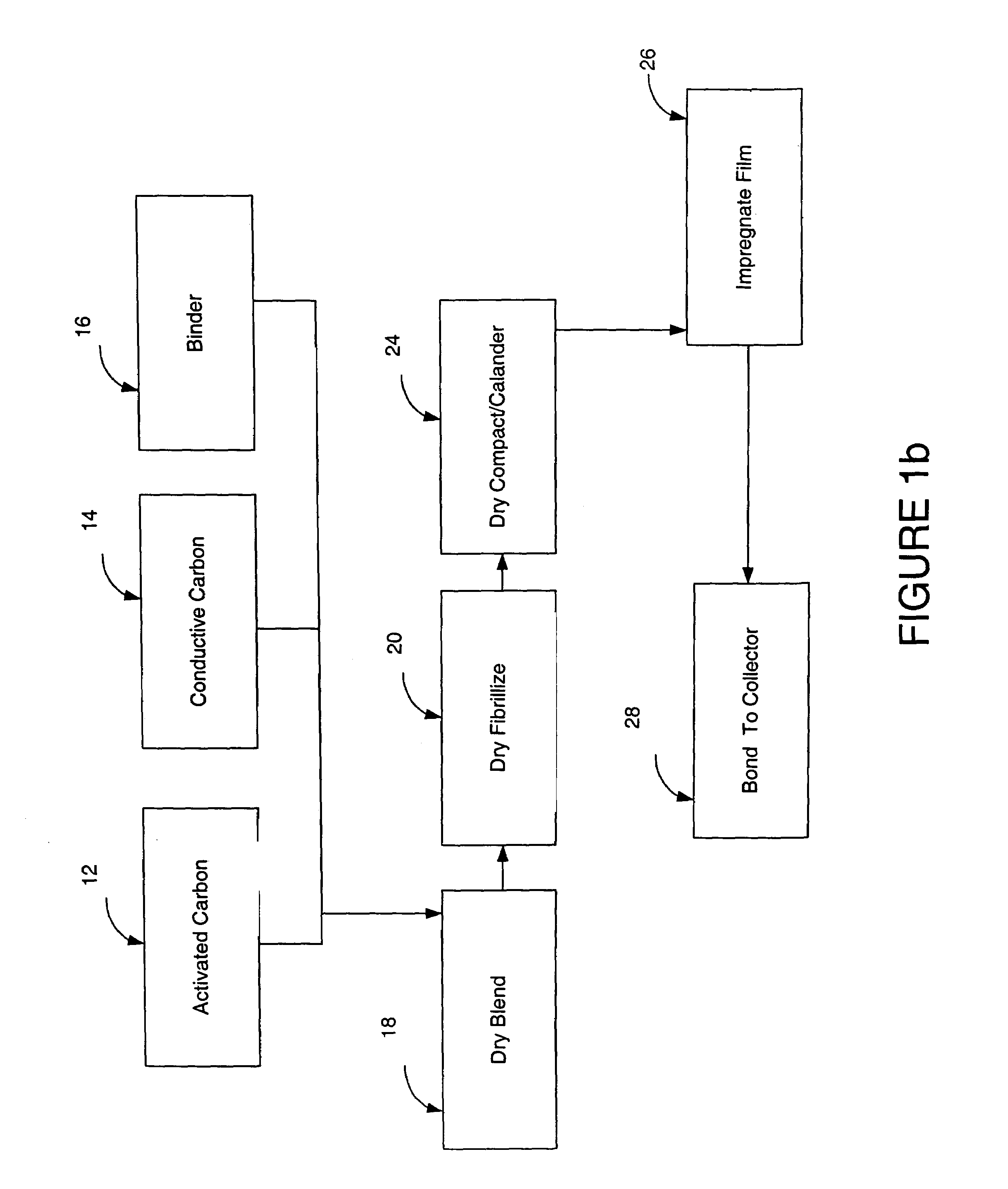

Method of making a multi-electrode double layer capacitor having single electrolyte seal and aluminum-impregnated carbon cloth electrodes

InactiveUS20010020319A1Reduces transverse resistanceReduce contact resistanceDouble layer capacitorsPrinted circuit manufactureElectrolytic agentMetal

<heading lvl="0">Abstract of Disclosure< / heading> A method of making a double layer capacitor consists of the steps of: impregnating each of a plurality of carbon preforms with a metal; forming a plurality of current collector foils, each of the plurality of current collector foils having a tab portion and a paddle portion; forming a plurality of electrodes by positioning one of the plurality of carbon preforms against respective paddle portions of each of the plurality of current collector foils, wherein each of the plurality of electrodes comprises one of the plurality of current collector foils and one of the plurality of carbon preforms; stacking each of the plurality of electrodes such that tab portions of adjacent ones of the plurality of current collector foils are offset, thereby forming an electrode stack; interposing respective porous separator portions between each of the plurality of electrodes, wherein the porous separator portions function as electrical insulators between the adjacent ones of the plurality of electrodes preventing electrical shorting against each other; applying a modest constant pressure against the electrode stack; saturating the electrode stack with an electrolytic solution; and maintaining the electrode stack immersed within the electrolytic solution.

Owner:TESLA INC

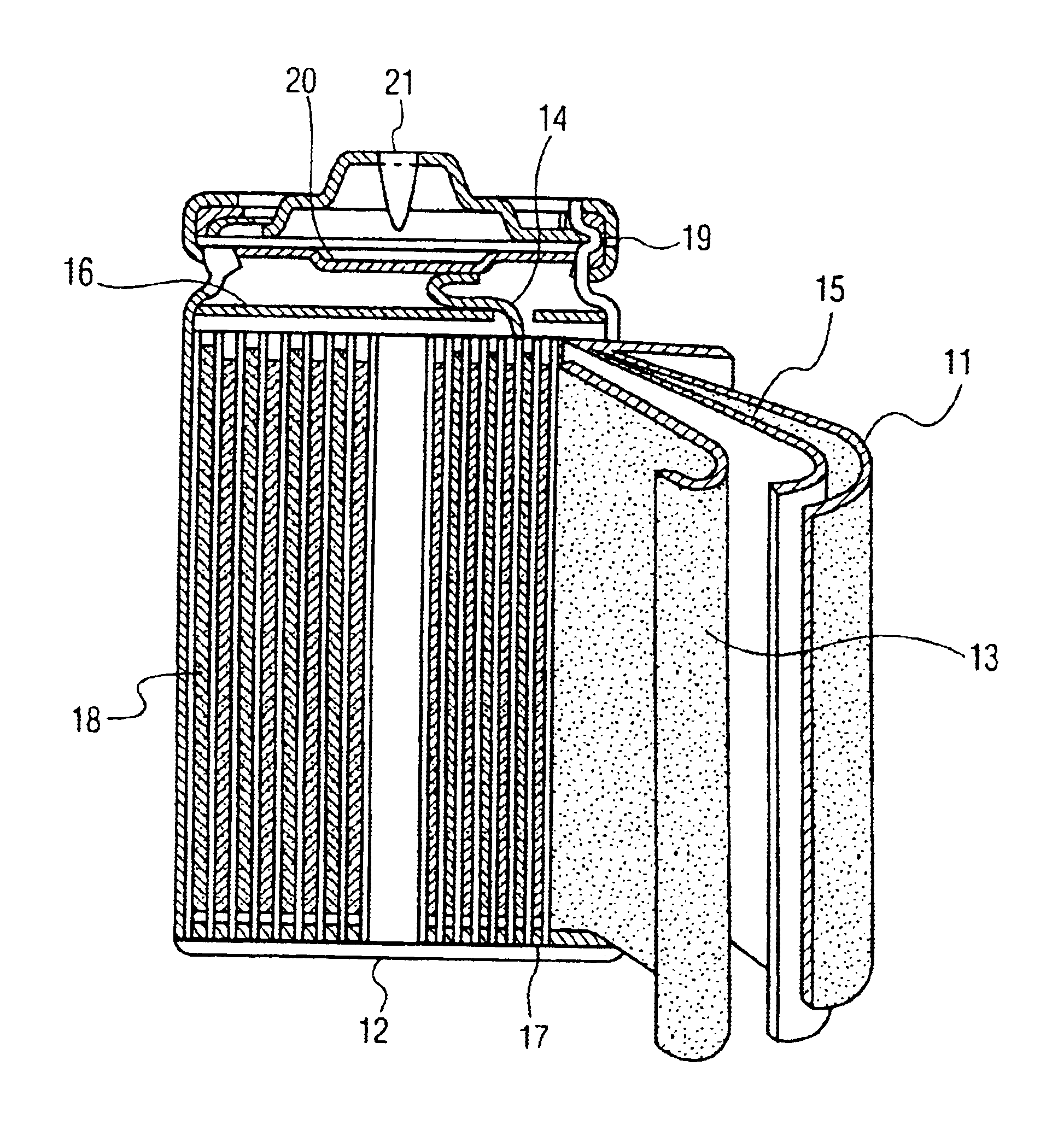

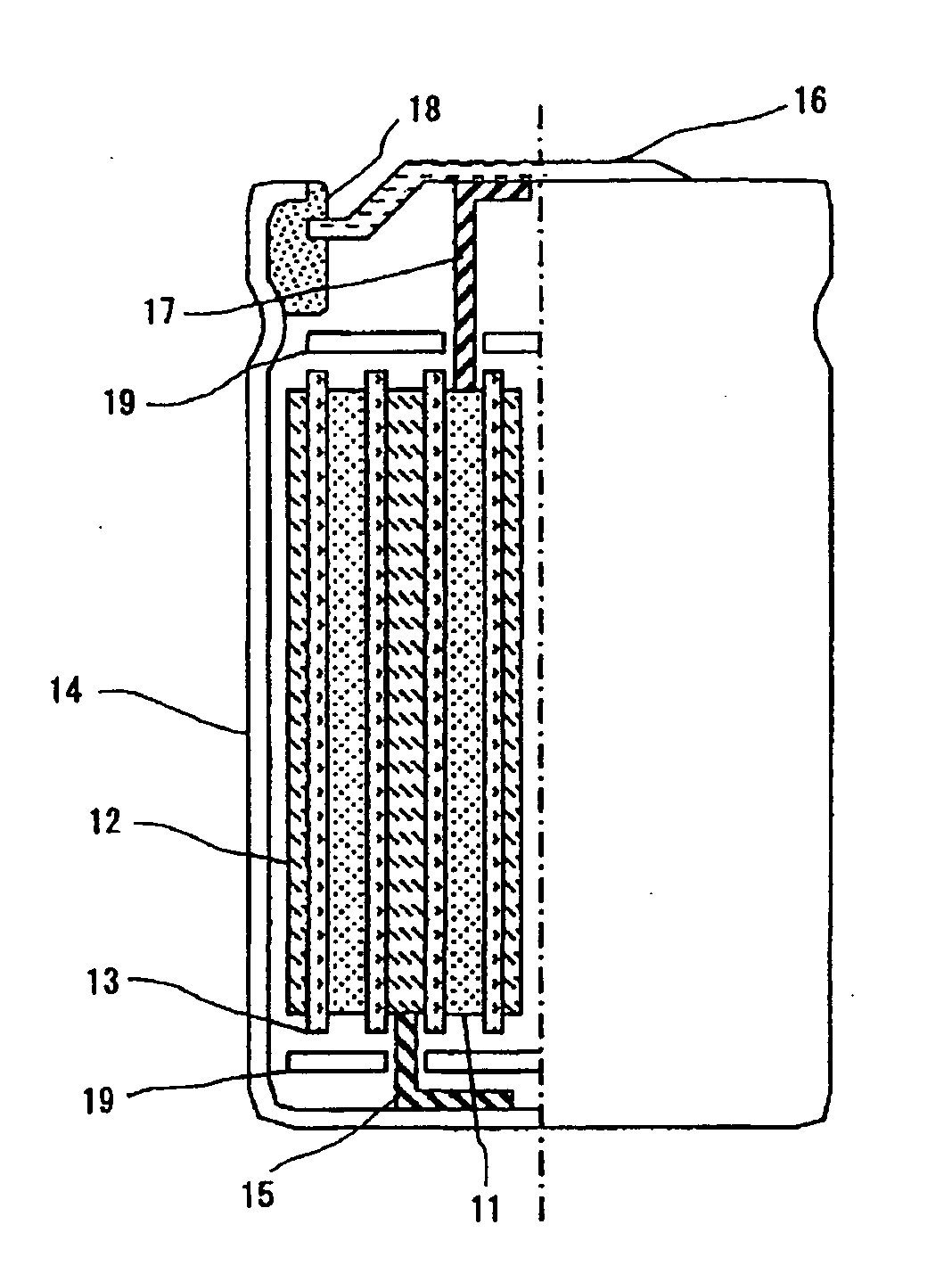

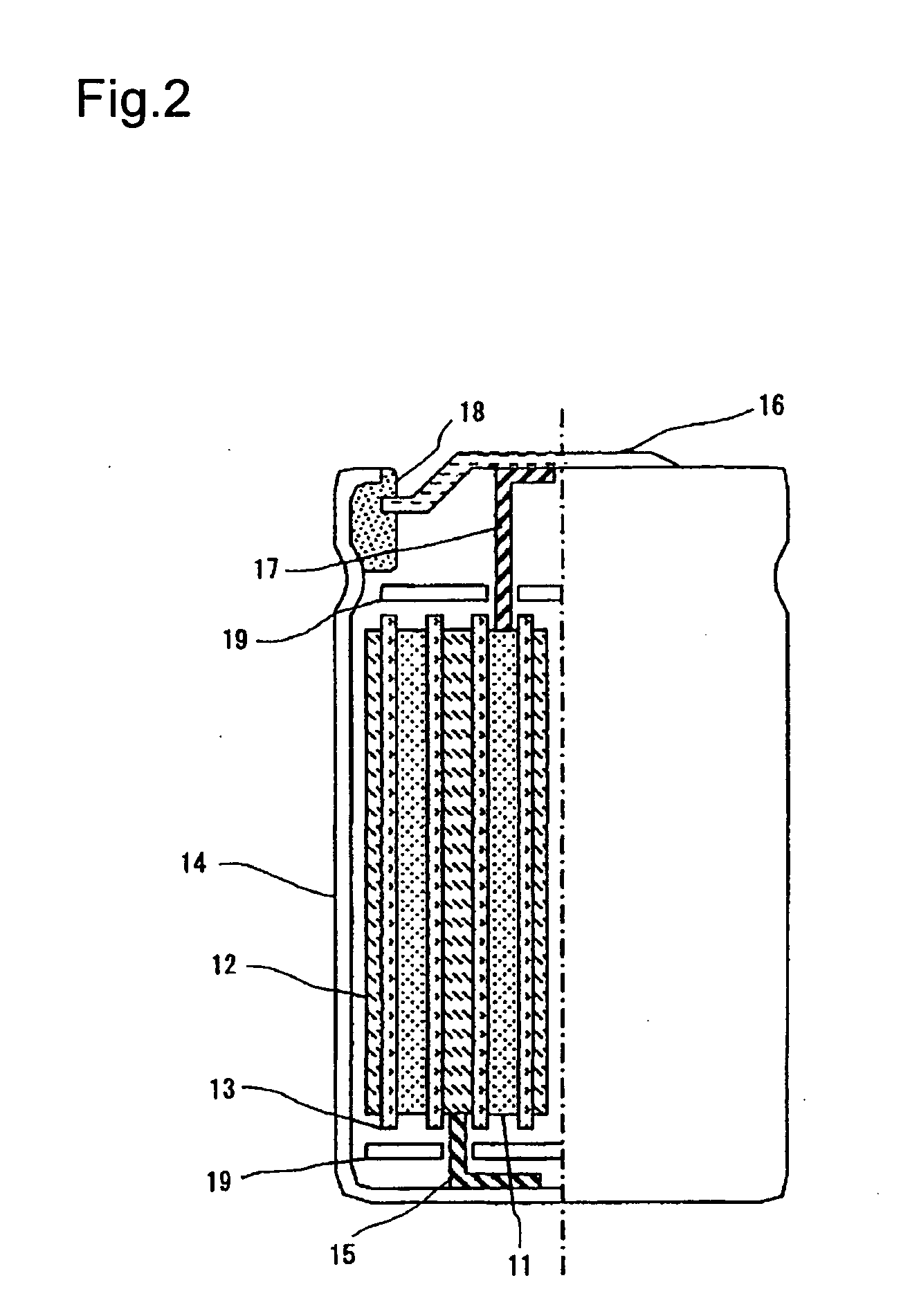

Lithium secondary battery

InactiveUS6905796B2Large capacityImprove ionic conductivityOrganic electrolyte cellsNegative electrodesHigh rateInternal resistance

A lithium secondary battery has high capacity and excellent current characteristics. The lithium battery comprises of a positive electrode, a negative electrode and an electrolyte; the negative electrode comprising Al2O3 particles not relating to the charge-and discharge reactions of the battery. The presence of the ceramics particles in the electrode leads to a decrease in the internal resistance of the battery because of the enhancement of ion conductivity in the electrode, resulting in higher capacity at high rate discharge of the lithium secondary battery.

Owner:PANASONIC CORP

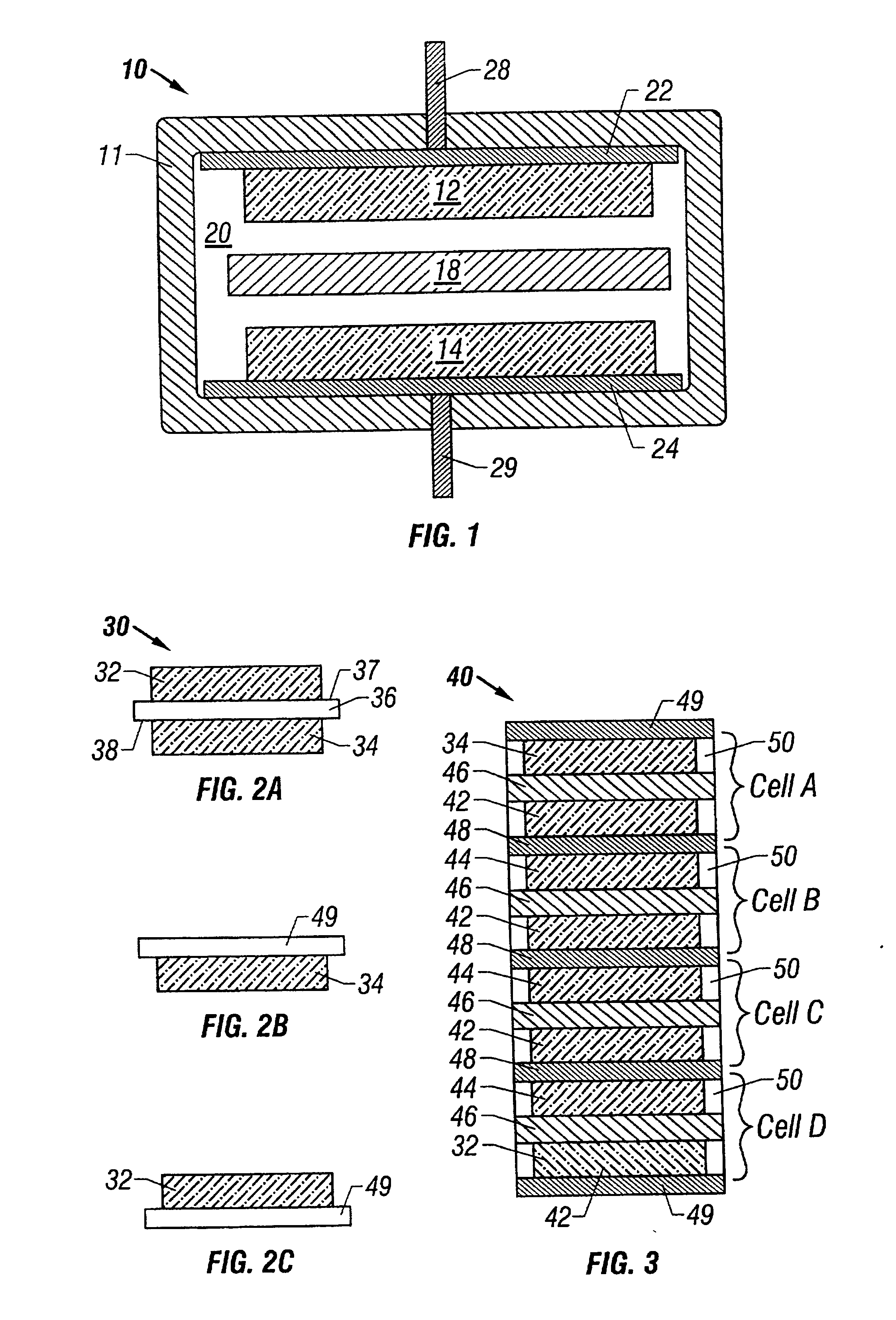

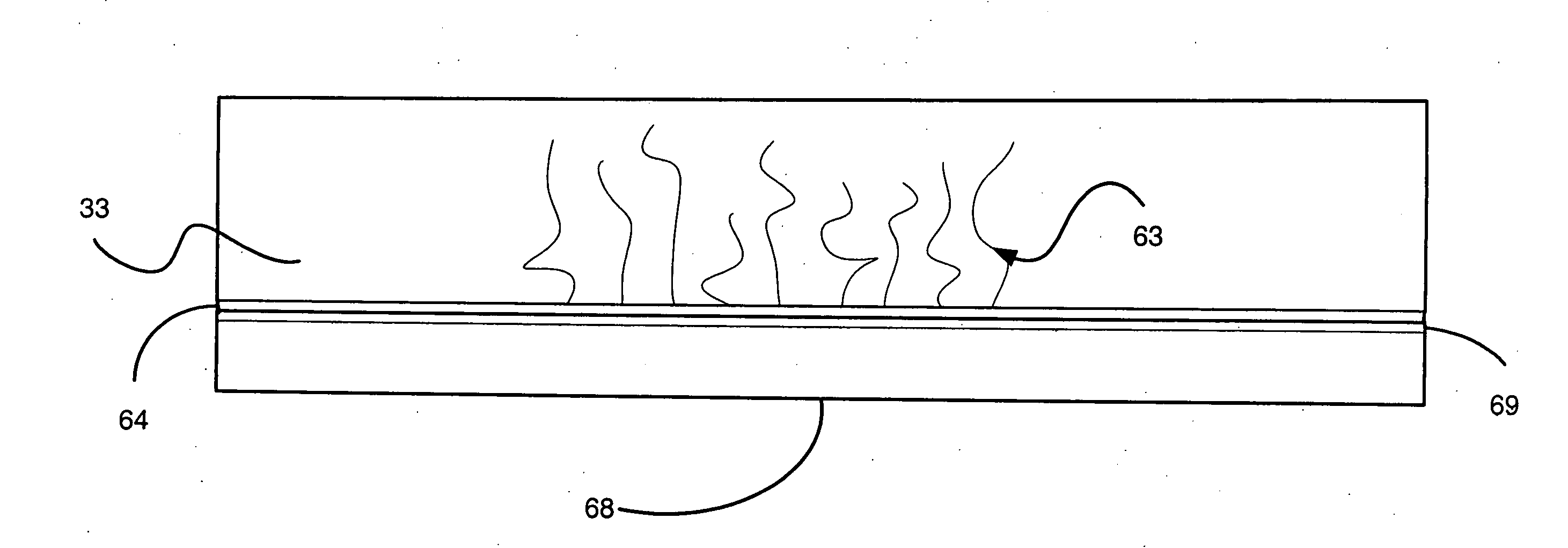

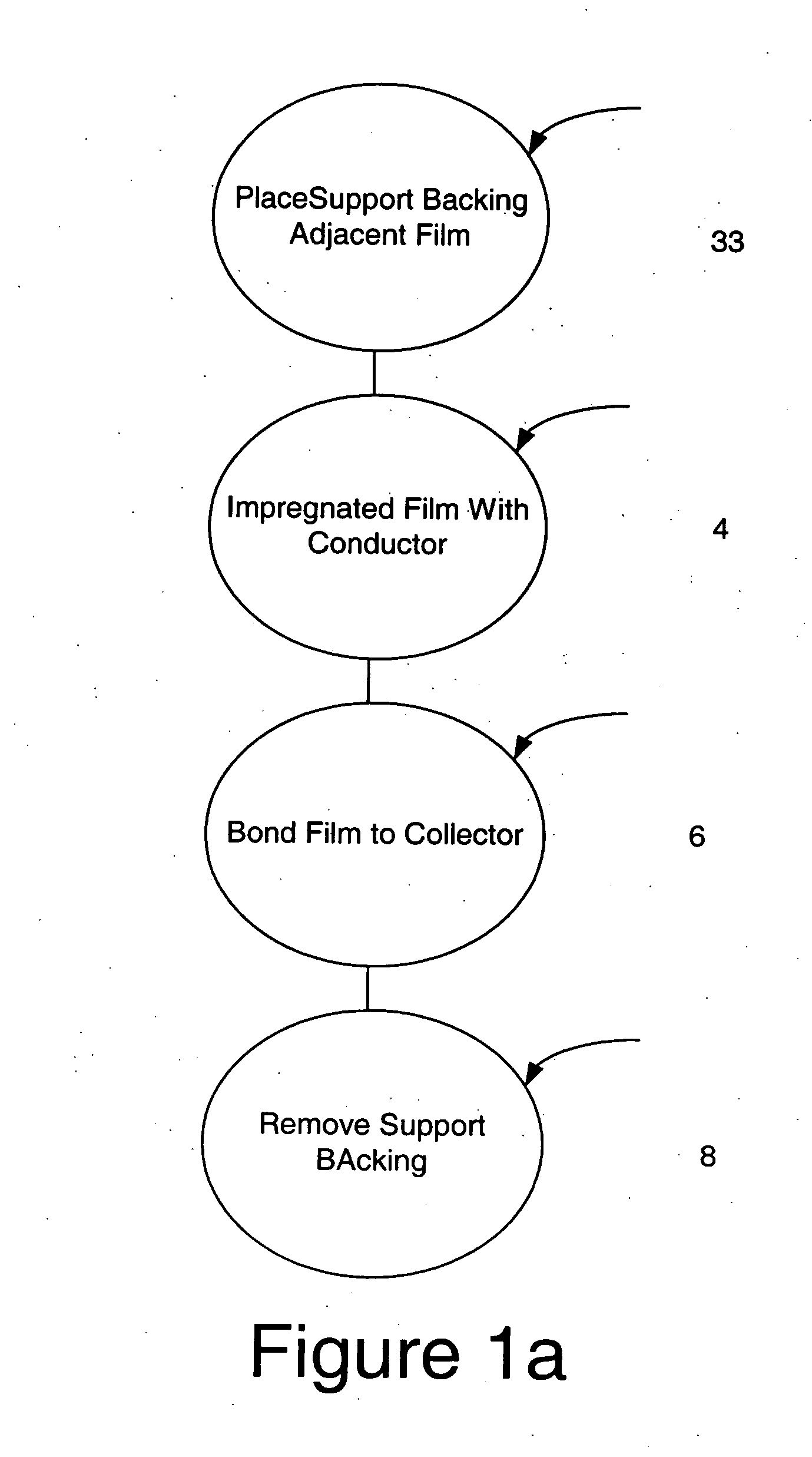

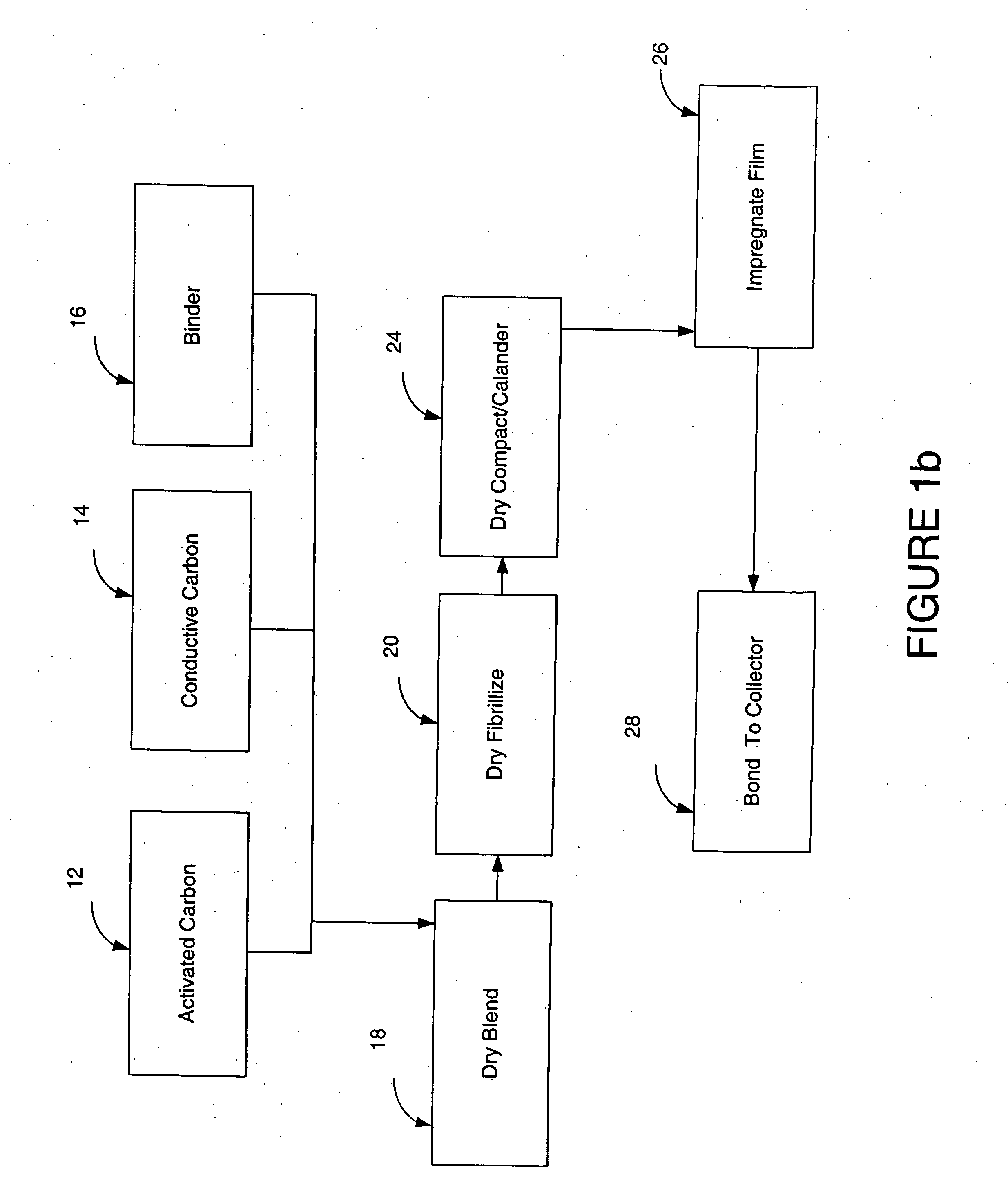

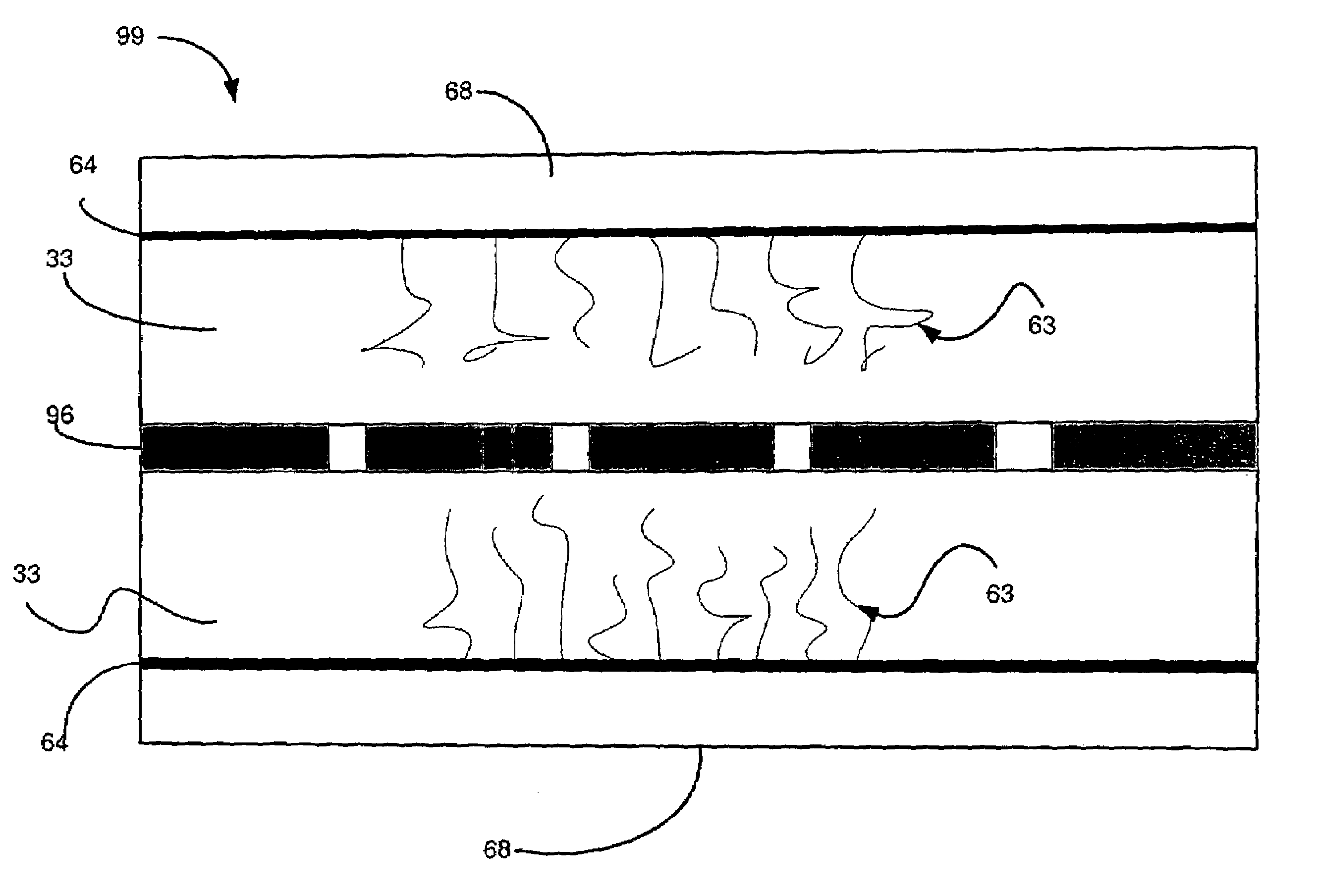

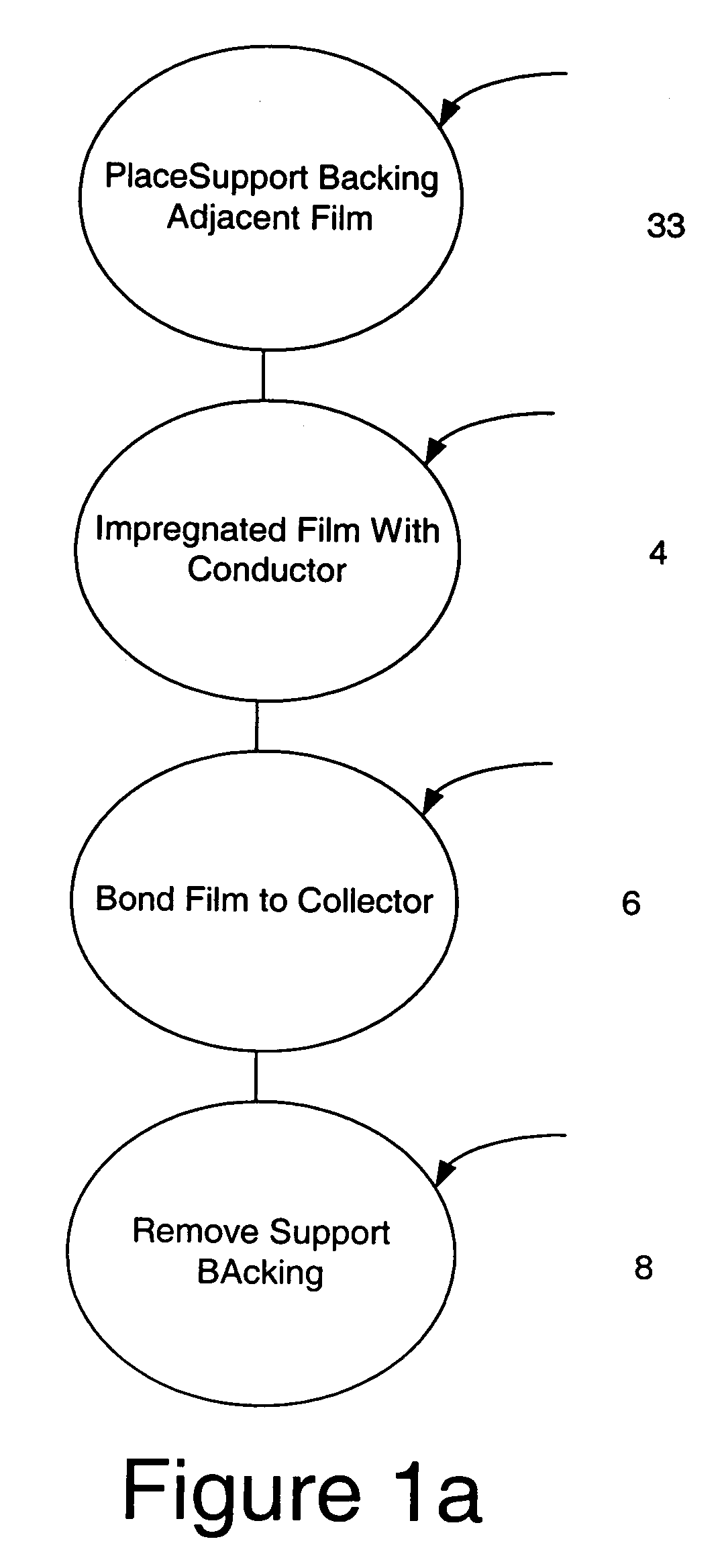

Electrode impregnation and bonding

ActiveUS20050057888A1Long-lasting and durable and inexpensive to produceLower internal resistanceElectrolytic capacitorsHybrid capacitor electrodesEngineeringConductive materials

A method for making an electrode including a particle based film is disclosed in which the film is coated and / or impregnated with veins of conductive material. A support backing is placed adjacent to one side of the film to provide support and prevent damaging the film while the conductive material is applied onto the opposite side of the film. The film is bonded directly to a current collector of an energy storage device.

Owner:TESLA INC

Positive electrode active material for nonaqueous electrolyte secondary battery, positive electrode and secondary battery

InactiveUS20100019194A1Good dispersibilityGood fluidityActive material electrodesLi-accumulatorsRechargeable cellSingle crystal

Provided is a cathode active material for nonaqueous electrolyte rechargeable batteries which allows production of batteries having improved load characteristics with stable quality, and also allows production of batteries having high capacity. Also provided are a cathode for nonaqueous electrolyte rechargeable batteries and a nonaqueous electrolyte rechargeable battery. The cathode active material includes secondary particles each composed of a plurality of primary particles, and / or single crystal grains, and has a specific surface area of not smaller than 20 m2 / g and smaller than 0.50 m2 / g, wherein average number A represented by formula (1) is not less than 1 and not more than 10:A=(m+p) / (m+s)(m: the number of single crystal grains; p: the number of primary particles composing the secondary particles; s: the number of secondary particles).

Owner:SANTOKU CORP

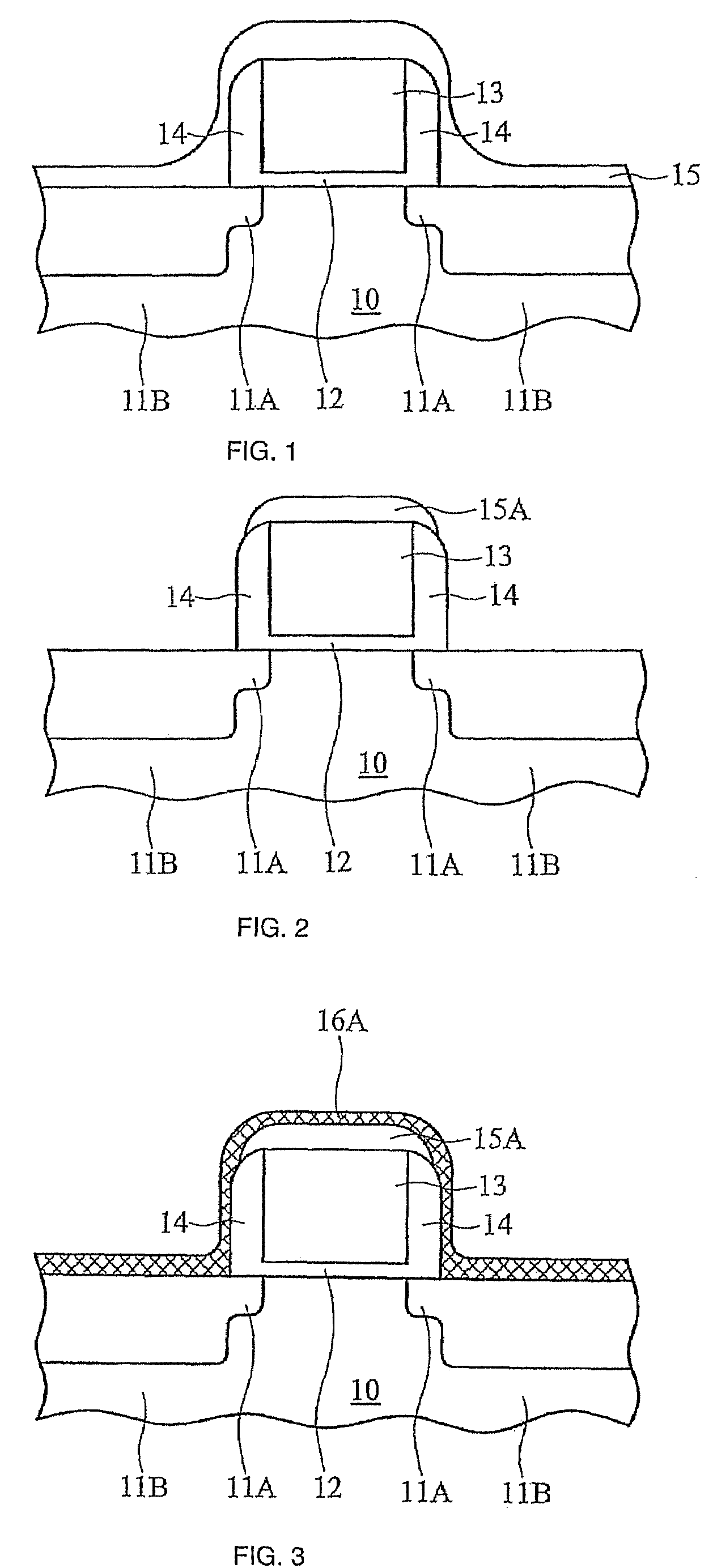

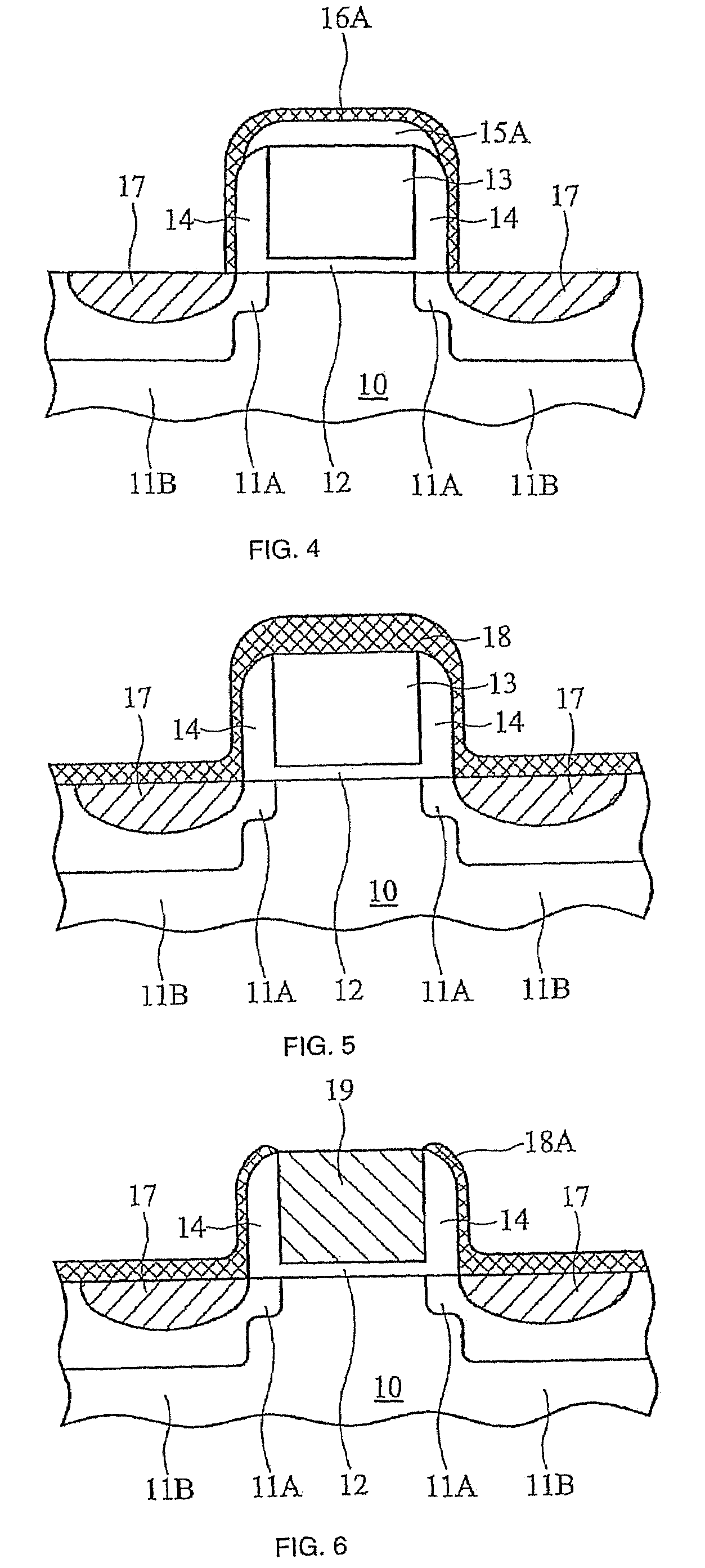

Semiconductor structure including silicide regions and method of making same

ActiveUS20060011996A1Improve reliabilityIncreasing junction leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureSilicide

A method of forming a silicided gate on a substrate having active regions, comprising the steps of: forming a first silicide in the active regions from a first material; and forming a second silicide in the gate from a second material, wherein the first silicide forms a barrier against the second material forming a silicide in the active regions during the second silicide forming step, wherein said second silicide is thicker than said first silicide.

Owner:TAIWAN SEMICON MFG CO LTD

Positive electrode material for lithium secondary battery, production method thereof, and lithium secondary battery

InactiveUS20060141361A1Improve electronic conductivityIncrease the areaElectrode thermal treatmentPositive electrodesLithiumFiber

A positive electrode material for lithium secondary battery having high electron conductivity even at very low temperatures, a production method thereof, and a lithium secondary battery with the use of the positive electrode material are provided. The characteristic feature of this positive electrode material for lithium secondary battery is that a positive electrode active material having secondary particles formed of primary particles made of lithium complex oxides and ultrathin carbon fibers having lengths equal to or smaller than the diameters of the secondary particles of the positive electrode active material are composited.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

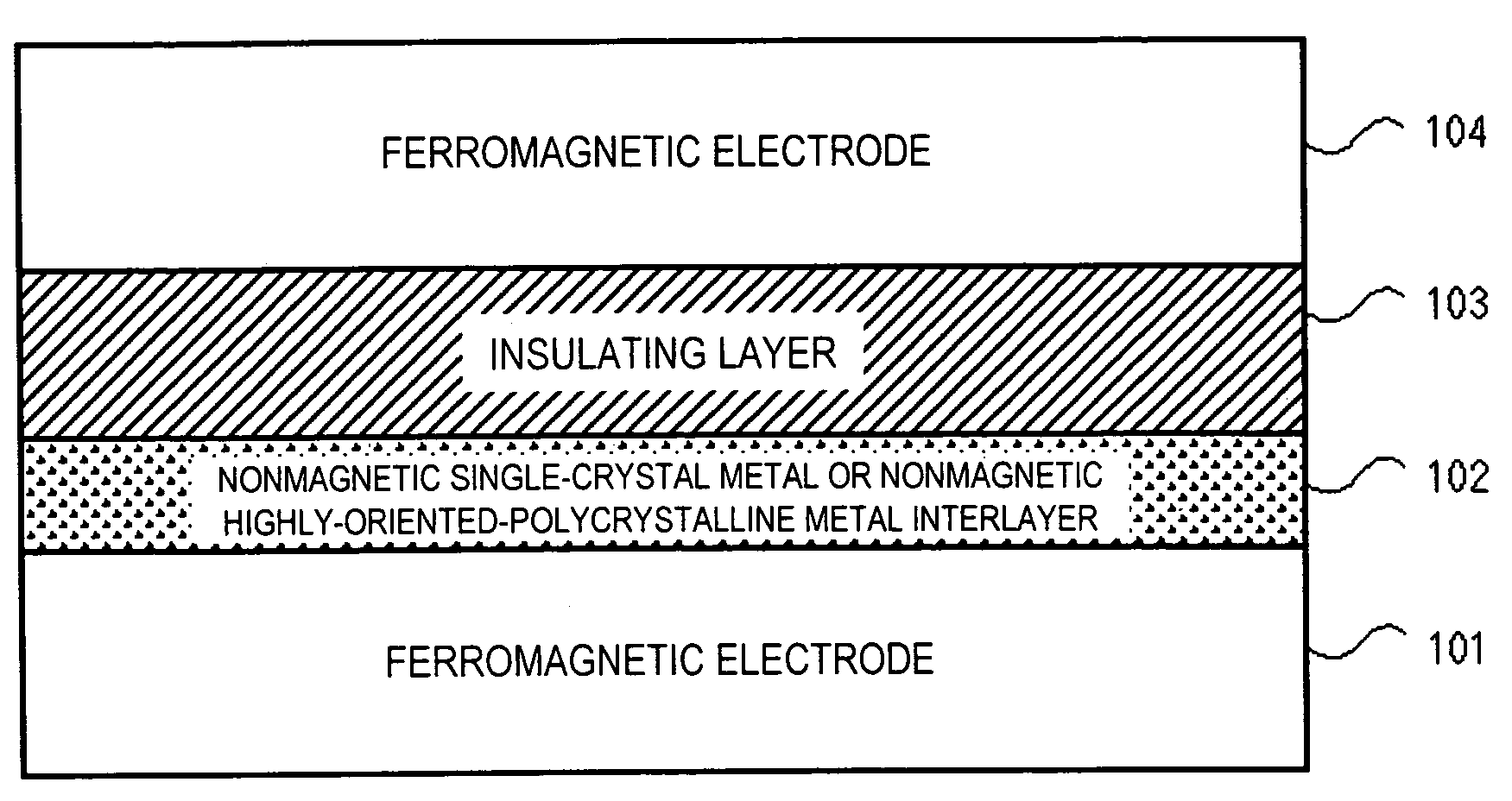

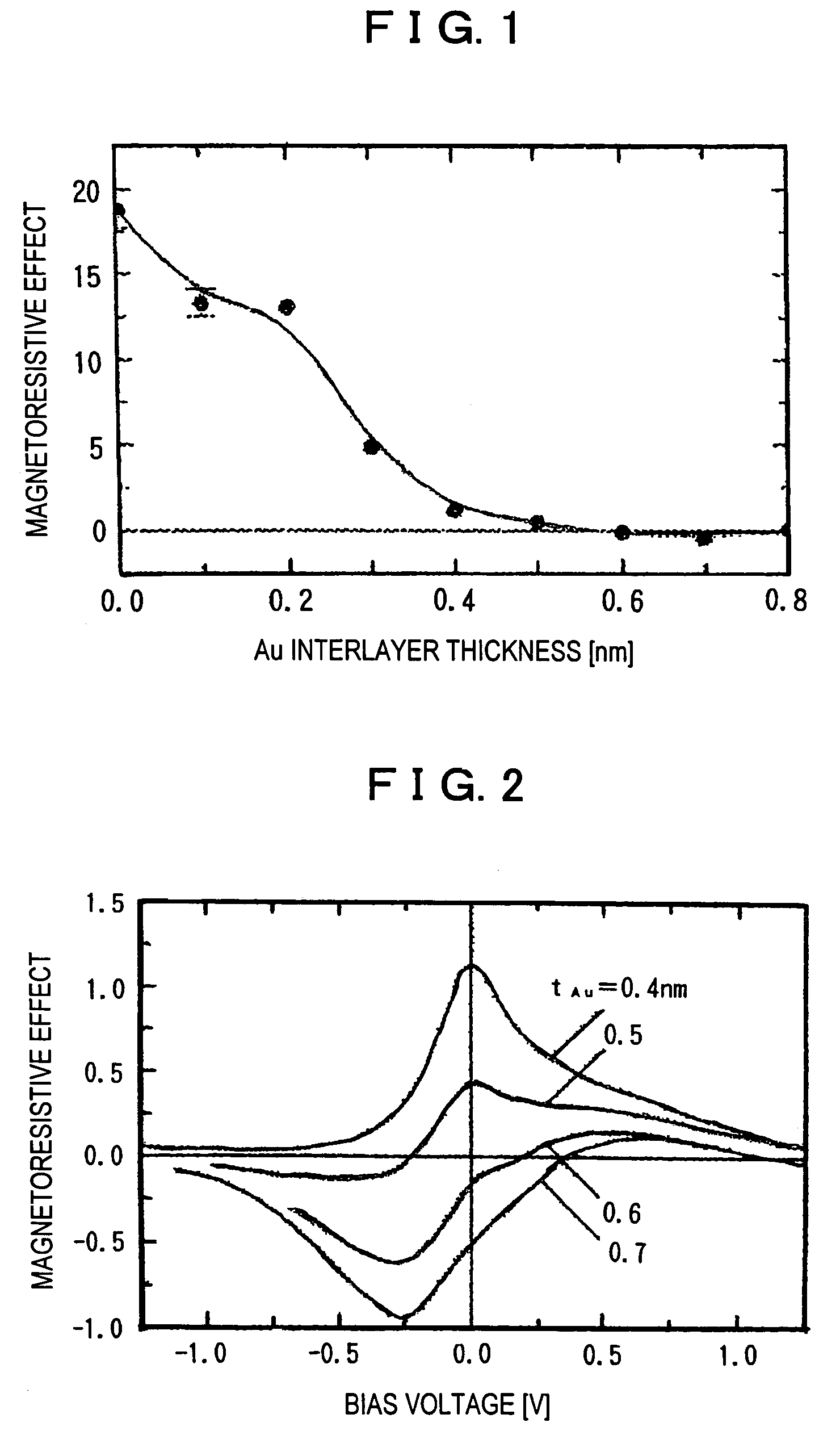

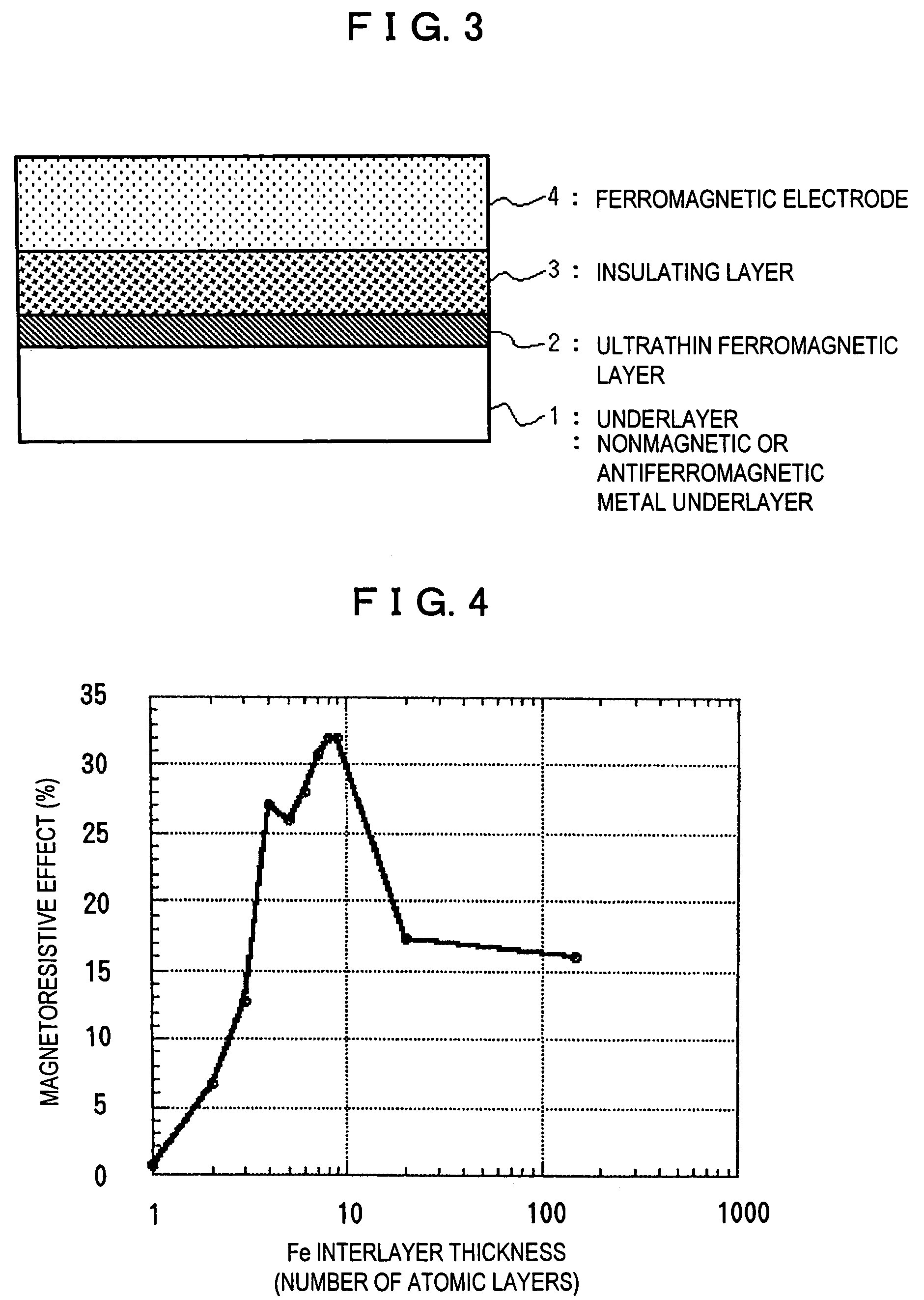

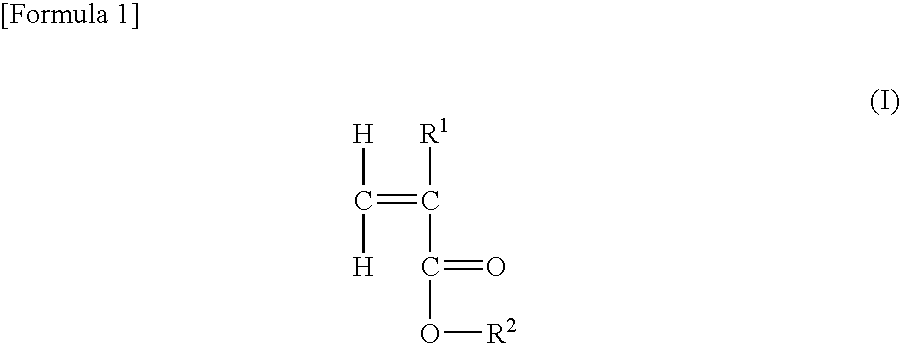

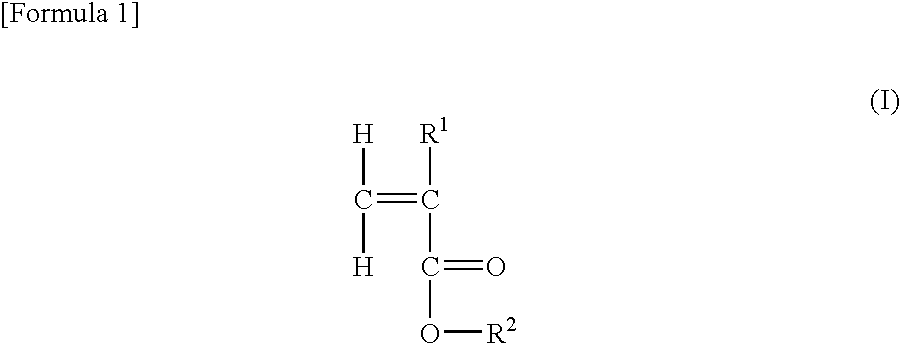

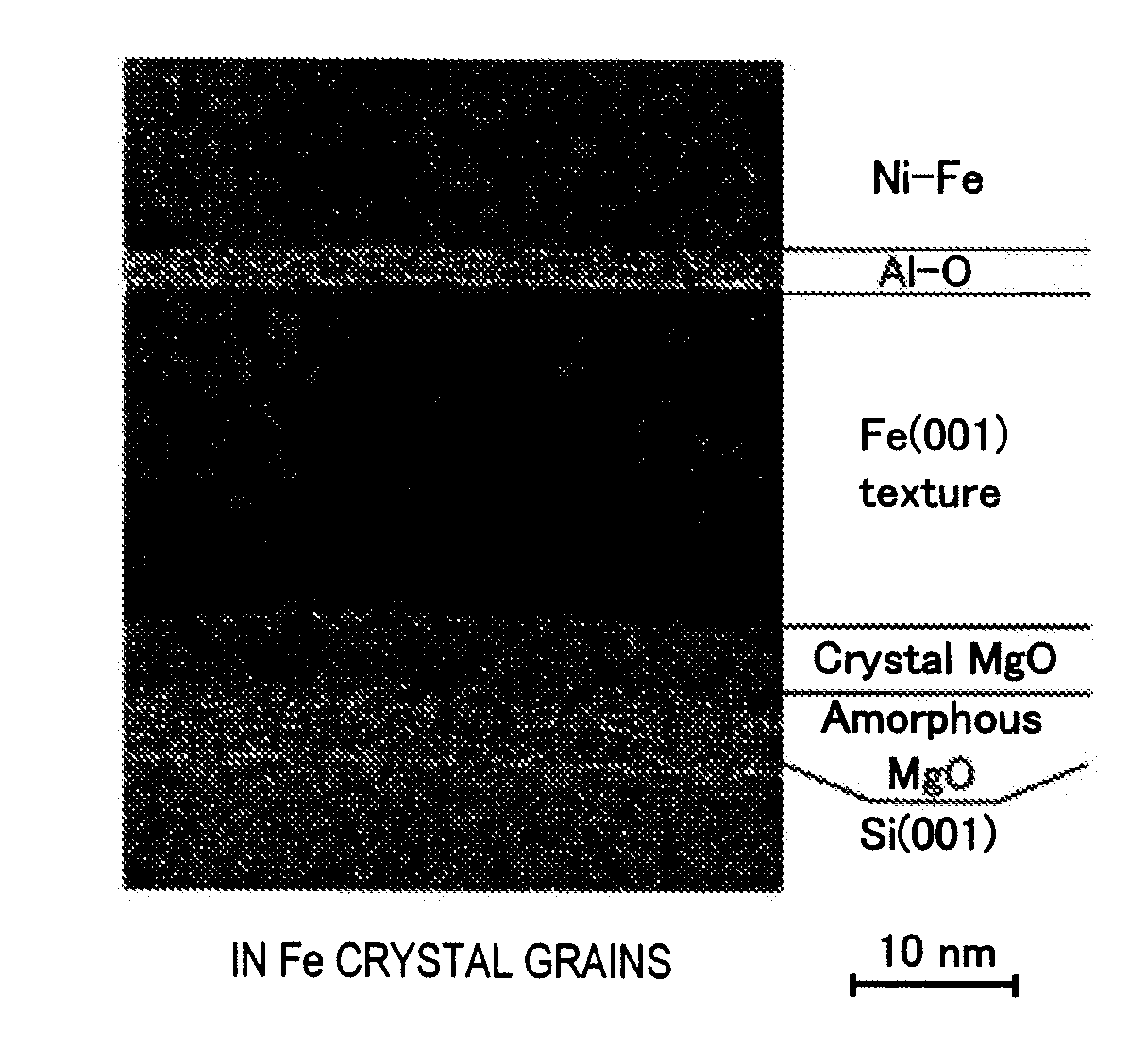

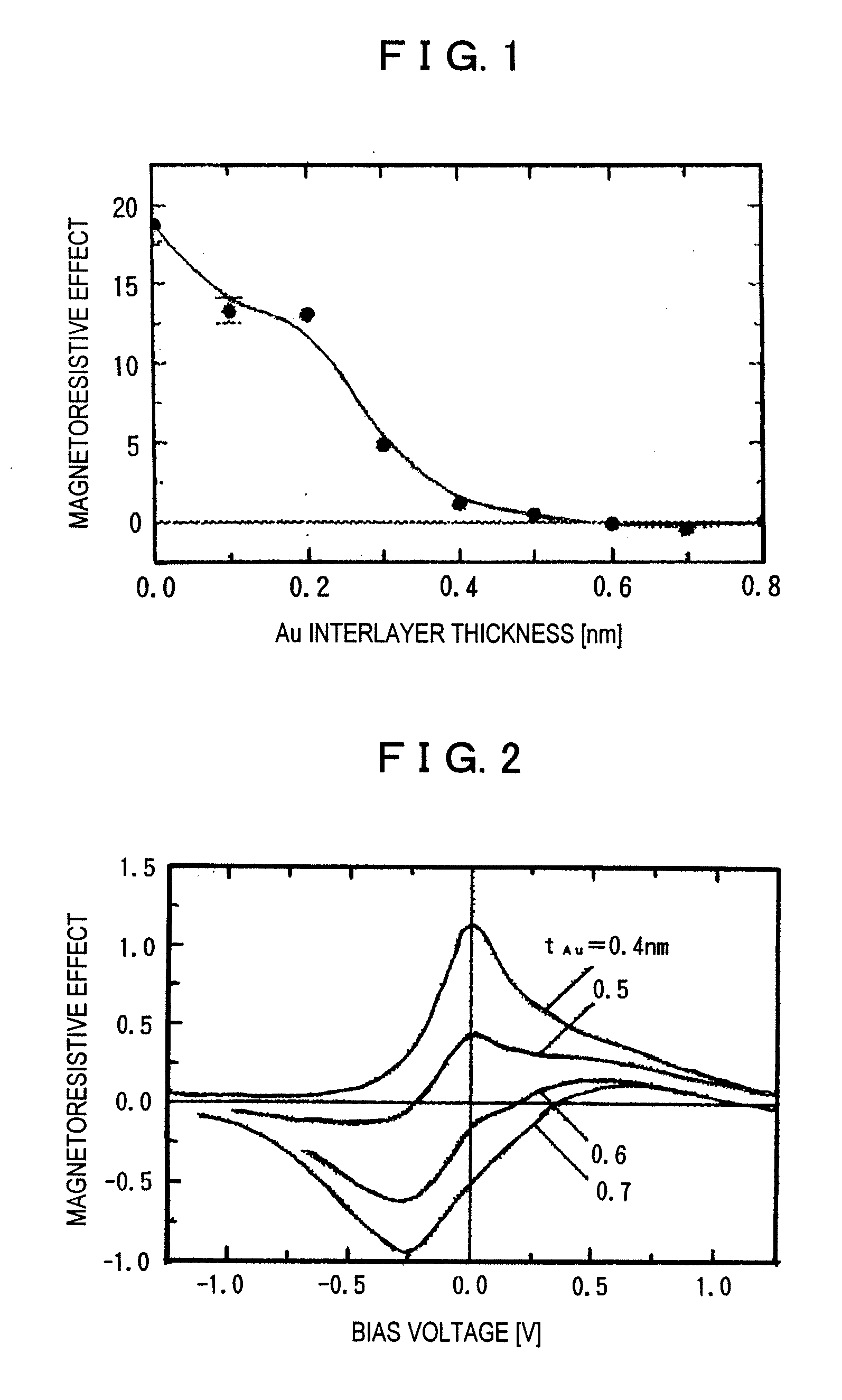

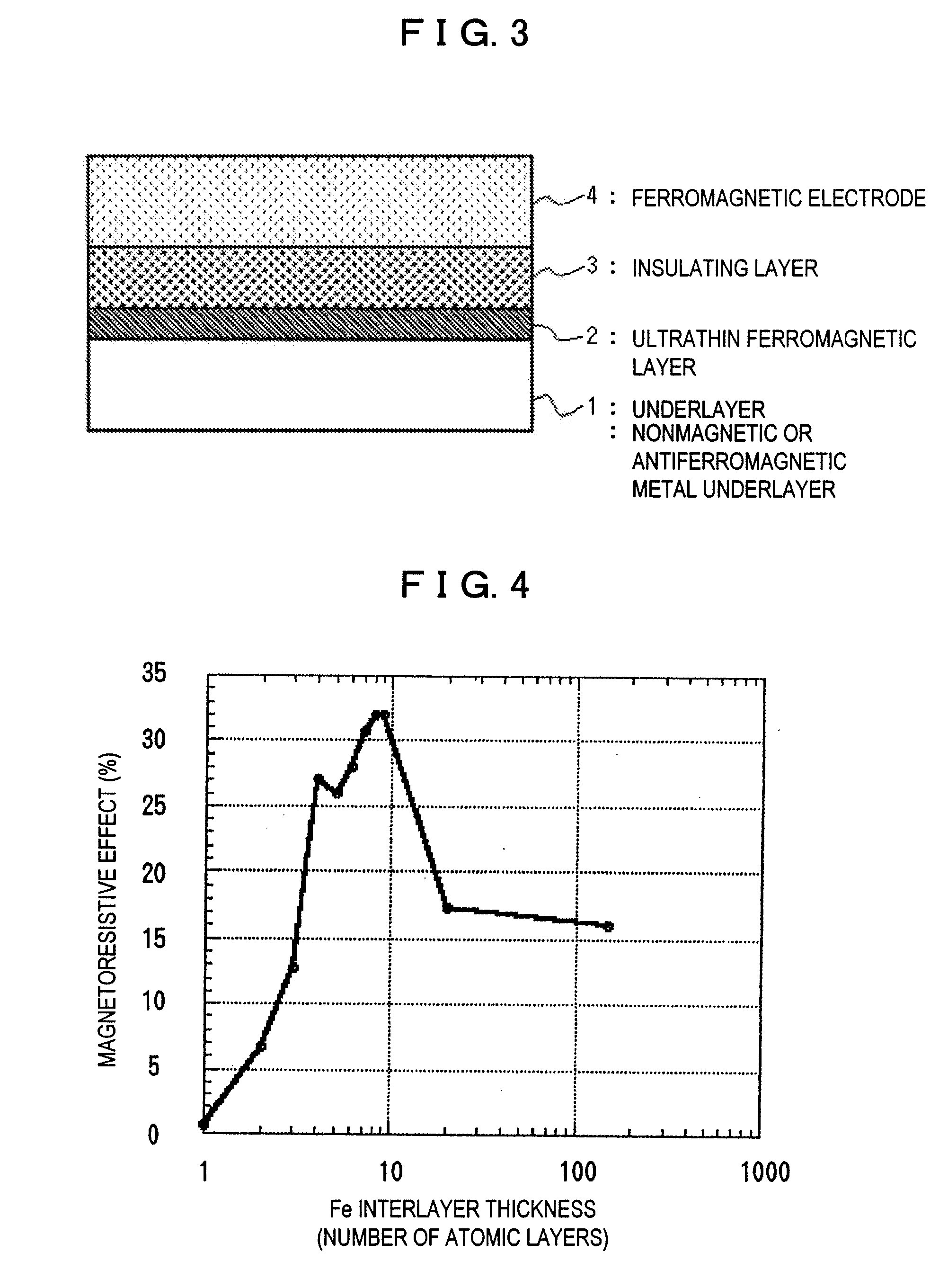

Tunnel magnetoresistance element

InactiveUS7220498B2Electron scattering of a nonmagnetic interlayer is preventedGood effectNanomagnetismNanoinformaticsChemical compositionMagnetic reluctance

By varying only the thickness of a known material having superior magnetic characteristics to increase spin polarization without changing the chemical composition, a tunnel magnetoresistive element capable of producing a larger magnetoresistive effect is provided. The tunnel magnetoresistive element includes an underlayer (nonmagnetic or antiferromagnetic metal film); an ultrathin ferromagnetic layer disposed on the underlayer; an insulating layer disposed on the ultrathin ferromagnetic layer; and a ferromagnetic electrode disposed on the insulating layer.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

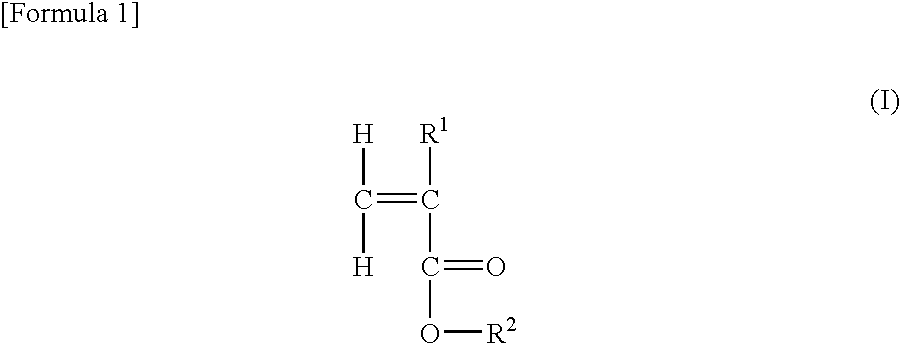

Binder for secondary battery electrode, secondary battery electrode, and secondary battery

InactiveUS20100112441A1Interface resistanceLower electrode resistanceActive material electrodesNon-aqueous electrolyte accumulator electrodesBattery electrodeTO-18

The present invention aims at improving binding continuity, rate property, cycle property and short circuit ratio by lowering a inner resistance of electrode in a secondary battery.A binder for secondary battery electrode according to the present invention is comprised a polymer having weight-average molecular weight of 5000 to 2500000 formed by polymerizing a monomer composition including fluorine atom containing monomer represented by following formula (I).(R1 is hydrogen or methyl group, R2 is hydrocarbon group having carbon number 6 to 18 containing fluorine atom).

Owner:ZEON CORP

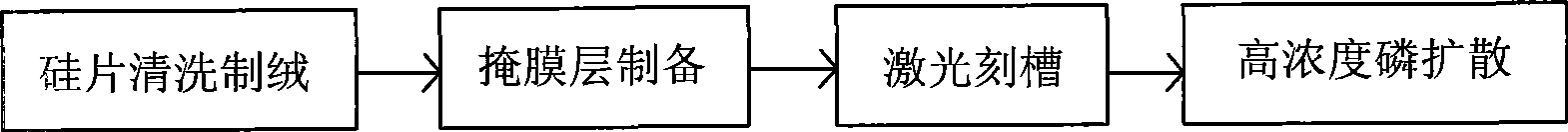

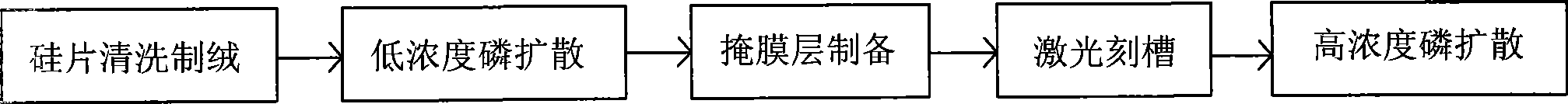

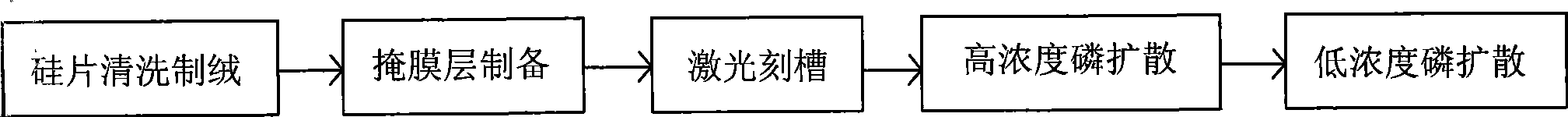

Selective diffusion technology for crystalline silicon solar cell

InactiveCN101533871AHigh shortwave efficiencyLower electrode resistancePhotovoltaic energy generationSemiconductor devicesHigh concentrationSilicon dioxide

The invention relates to selective diffusion technology for a crystalline silicon solar cell, which comprises high-concentration phosphorous diffusion in a facade electrode grid line area and low-concentration phosphorous diffusion out of the facade electrode grid line area, and comprises the following steps: after a silicon chip is cleaned and made to be velvet, preparing a layer of dense silicon dioxide film on the silicon chip as a diffusion blocking layer, then selectively removing an oxidation film in the electrode grid line area by adopting laser grooving technology and forming a groove with a definite depth, and performing the high-concentration phosphorous diffusion to form heavy doping in the electrode area. The selective emitter solar cell prepared by the technology not only has high short wave efficiency, but also has lower electrode resistance and contact resistance; and compared with the conventional corrosion electrode figures adopting photoetching technology, the technology has the advantages of low equipment cost and high production efficiency, and is applicable to industrialized production of the crystalline silicon solar cell.

Owner:TRINA SOLAR CO LTD

Semiconductor structure including silicide regions and method of making same

ActiveUS7396767B2Improve reliabilityIncreasing junction leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesSalicideSemiconductor structure

A method of forming a silicided gate on a substrate having active regions, comprising the steps of: forming a first silicide in the active regions from a first material; and forming a second silicide in the gate from a second material, wherein the first silicide forms a barrier against the second material forming a silicide in the active regions during the second silicide forming step, wherein said second silicide is thicker than said first silicide.

Owner:TAIWAN SEMICON MFG CO LTD

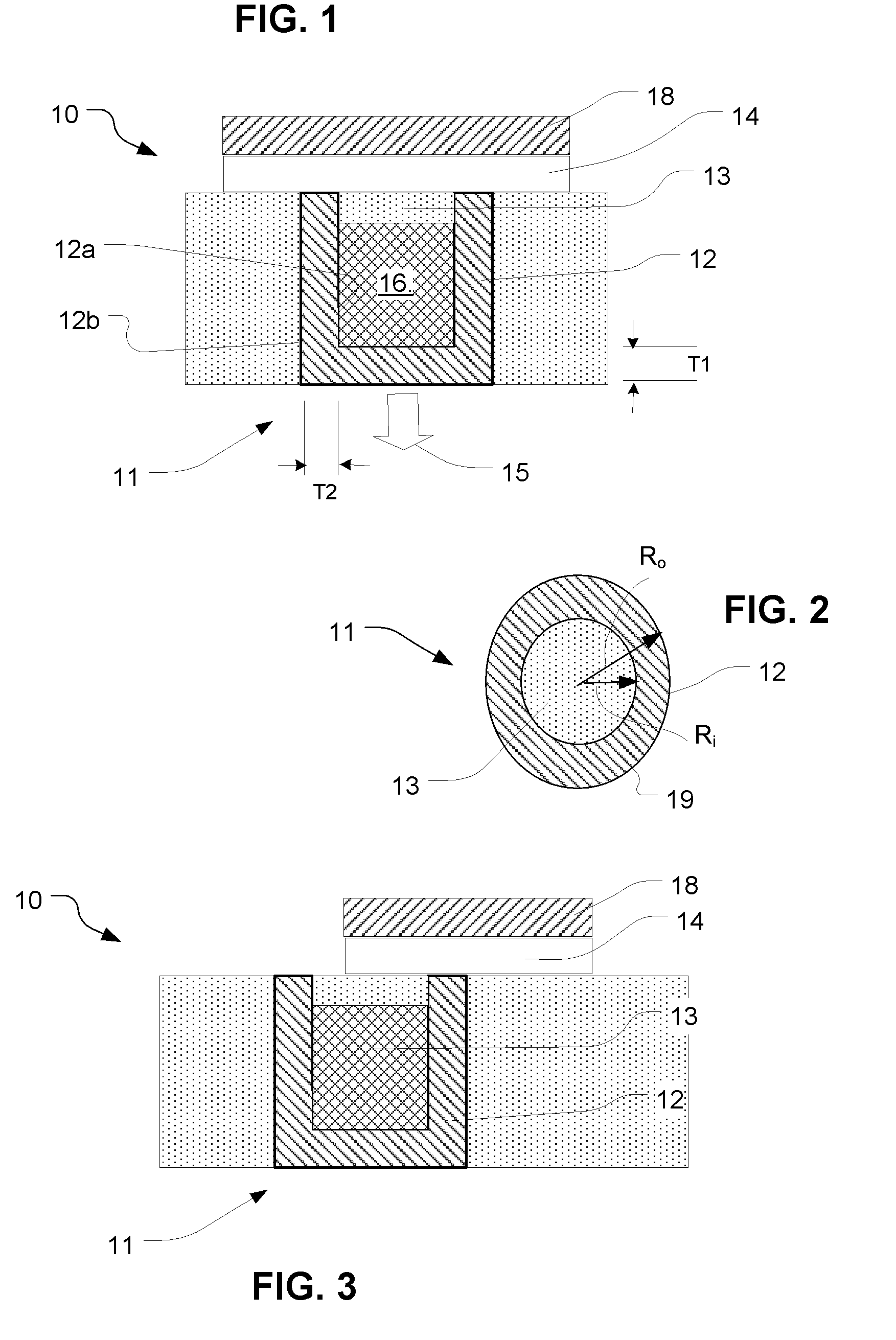

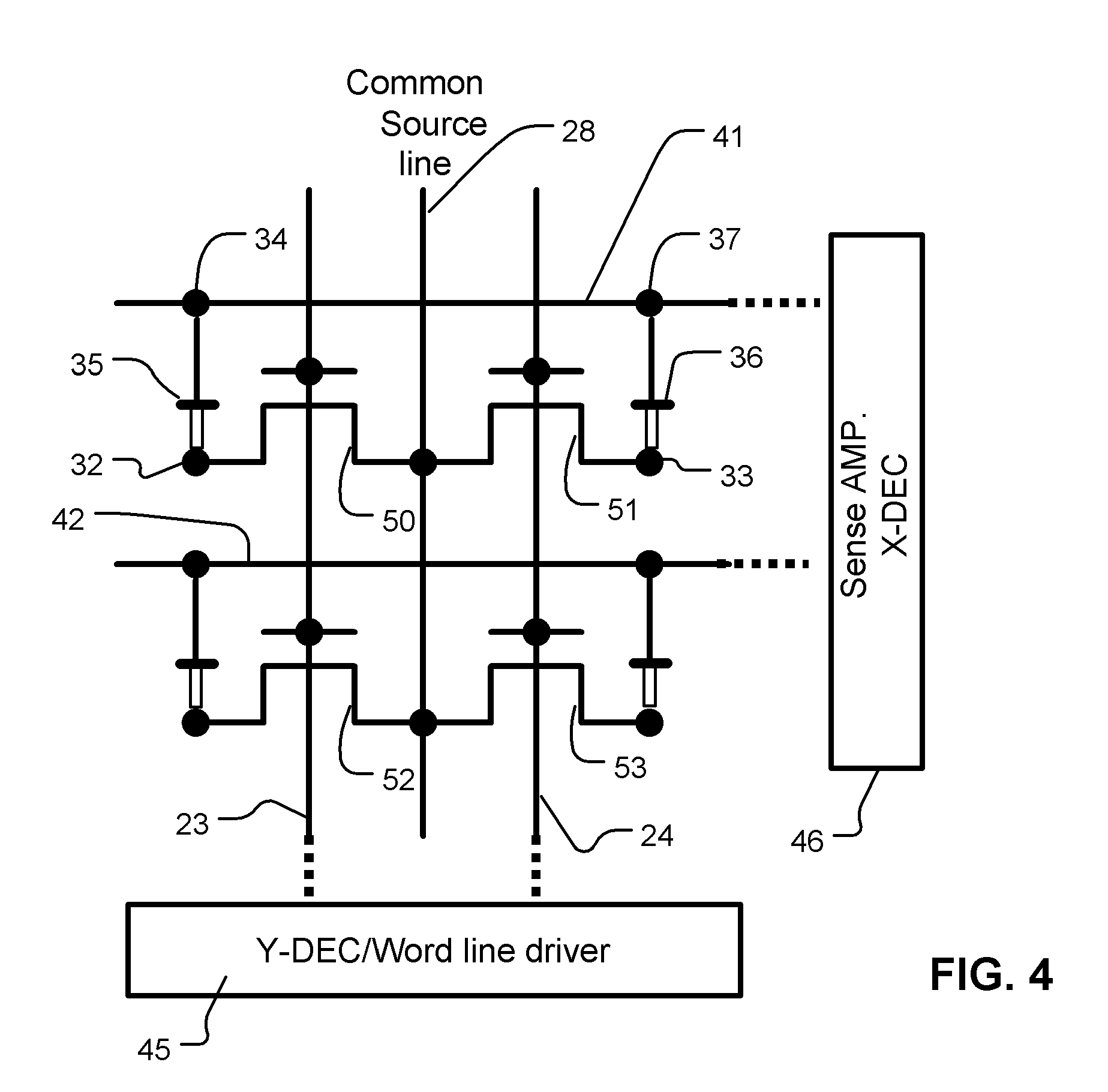

Ring-shaped electrode and manufacturing method for same

ActiveUS20100264396A1Lower resistanceHigh yieldSolid-state devicesSemiconductor/solid-state device manufacturingConductive materialsEngineering

An electrode structure and a method for manufacturing an integrated circuit electrode includes forming a bottom electrode comprising a pipe-shaped member, filled with a conductive material such as n-doped silicon, and having a ring-shaped top surface. A disc-shaped insulating member is formed on the top of the pipe-shaped member by oxidizing the conductive fill. A layer of programmable resistance material, such as a phase change material, is deposited in contact with the top surface of the pipe-shaped member. A top electrode in contact with the layer of programmable resistance material.

Owner:MACRONIX INT CO LTD +1

Electrode impregnation and bonding

ActiveUS7102877B2Avoid heat damageAvoid inertiaHybrid capacitor electrodesElectrolytic capacitorsEngineeringConductive materials

A method for making an electrode including a particle based film is disclosed in which the film is coated and / or impregnated with veins of conductive material. A support backing is placed adjacent to one side of the film to provide support and prevent damaging the film while the conductive material is applied onto the opposite side of the film. The film is bonded directly to a current collector of an energy storage device.

Owner:TESLA INC

Fixed-array anisotropic conductive film using surface modified conductive particles

InactiveUS20120295098A1Improves fixed-array ACFTrend downNon-macromolecular adhesive additivesSynthetic resin layered productsEngineeringAnisotropy

Structures and manufacturing processes of an ACF array and more particularly a non-random array of microcavities of predetermined configuration, shape and dimension. The manufacturing process includes fluidic filling of conductive particles surface-treated with a coupling agent onto a substrate or carrier web comprising a predetermined array of microcavities. The thus prepared filled conductive microcavity array is then over-coated or laminated with an adhesive film, the conductive particles are transferred to the adhesive film such that they are only partially embedded in the film.

Owner:TRILLION SCI INC

Positive electrode material for lithium secondary battery, positive electrode plate for lithium secondary battery, and lithium secondary battery using the same

InactiveUS20100261061A1Increase speedEasily penetrated into carbon fiberActive material electrodesNanotechnologyLithium oxideCarbon composites

A positive electrode material for a lithium secondary battery according to the invention includes a positive electrode active material containing lithium oxide and a carbon composite obtained by dispersing carbon fiber and a clamped shape carbon material, and the positive electrode active material is combined with the carbon composite. In the positive electrode material for a lithium secondary battery constructed as described above, a conductive network between primary particles is formed by the carbon composite while the positive electrode active material (primary particles) are condensed to form secondary particles.

Owner:HITACHI LTD

Tunnel magnetoresistance element

InactiveUS20070128470A1Electron scattering of a nonmagnetic interlayer is preventedGood effectNanomagnetismNanoinformaticsChemical compositionMagnetic reluctance

By varying only the thickness of a known material having superior magnetic characteristics to increase spin polarization without changing the chemical composition, a tunnel magnetoresistive element capable of producing a larger magnetoresistive effect is provided. The tunnel magnetoresistive element includes an underlayer (nonmagnetic or antiferromagnetic metal film); an ultrathin ferromagnetic layer disposed on the underlayer; an insulating layer disposed on the ultrathin ferromagnetic layer; and a ferromagnetic electrode disposed on the insulating layer.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Strained channel CMOS device with fully silicided gate electrode

InactiveUS7195969B2Lower electrode resistanceInhibitionSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon alloyMetal silicide

A strained channel NMOS and PMOS device pair including fully silicided gate electrodes and method for forming the same, the method including providing a semiconductor substrate including NMOS and PMOS device regions including respective gate structures including polysilicon gate electrodes; forming recessed regions on either side of a channel region including at least one of the NMOS and PMOS device regions; backfilling portions of the recessed regions with a semiconducting silicon alloy to exert a strain on the channel region; forming offset spacers on either side of the gate structures; thinning the polysilicon gate electrodes to a silicidation thickness to allow full metal silicidation through the silicidation thickness; ion implanting the polysilicon gate electrodes to adjust a work function; and, forming a metal silicide through the silicidation thickness to form metal silicide gate electrodes.

Owner:TAIWAN SEMICON MFG CO LTD

Piezoelectric element, piezoelectric sensor, electronic device, and method for manufacturing piezoelectric element

ActiveUS20110221306A1Lower electrode resistanceReduce resistancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringMechanical engineering

A piezoelectric element includes a support body having a displacing part capable of undergoing displacement, a lower electrode layer having a lower main electrode body and a lower electrode wire part with the lower main electrode body being formed on the support body and provided within the displacing part in a plan view and the lower electrode wire part being connected to the lower main electrode body and provided across an interior and an exterior of the displacing part, a first piezoelectric layer provided on the lower main electrode body, an upper electrode layer provided across the interior and exterior of the displacing part with at least a part of the upper electrode layer being layered on the first piezoelectric layer and insulated from the lower electrode layer, and a second piezoelectric layer provided on the support body to cover at least a part of the lower electrode wire part.

Owner:SEIKO EPSON CORP

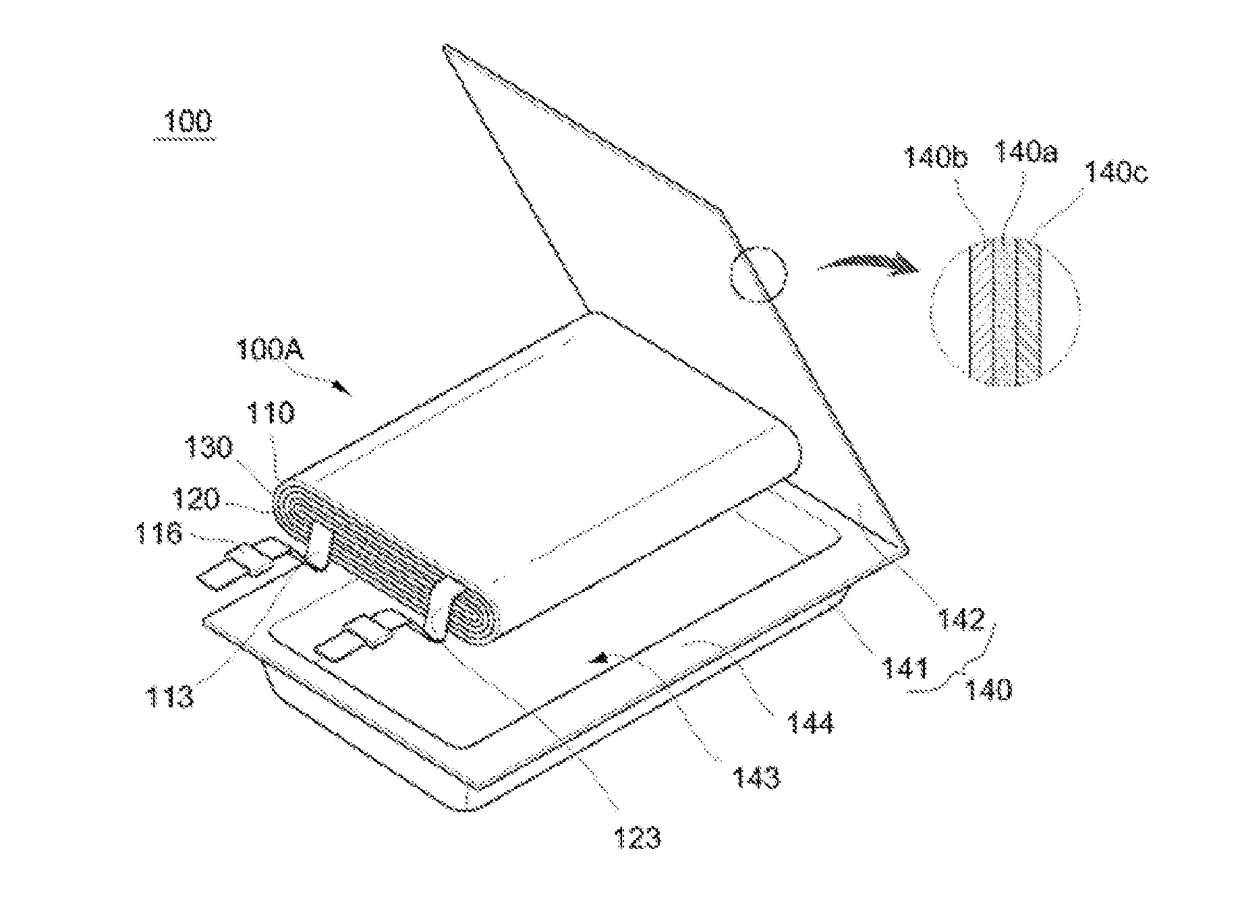

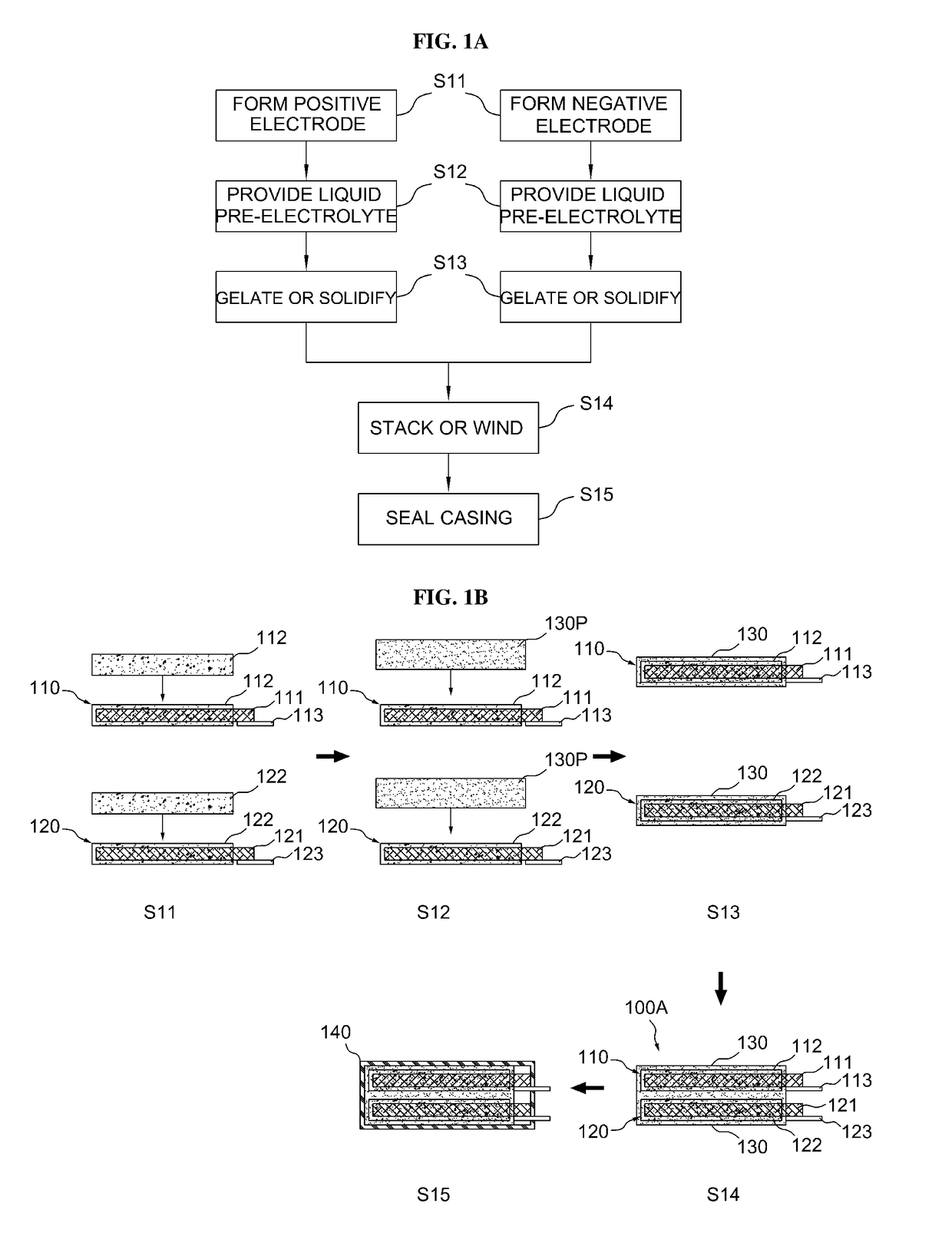

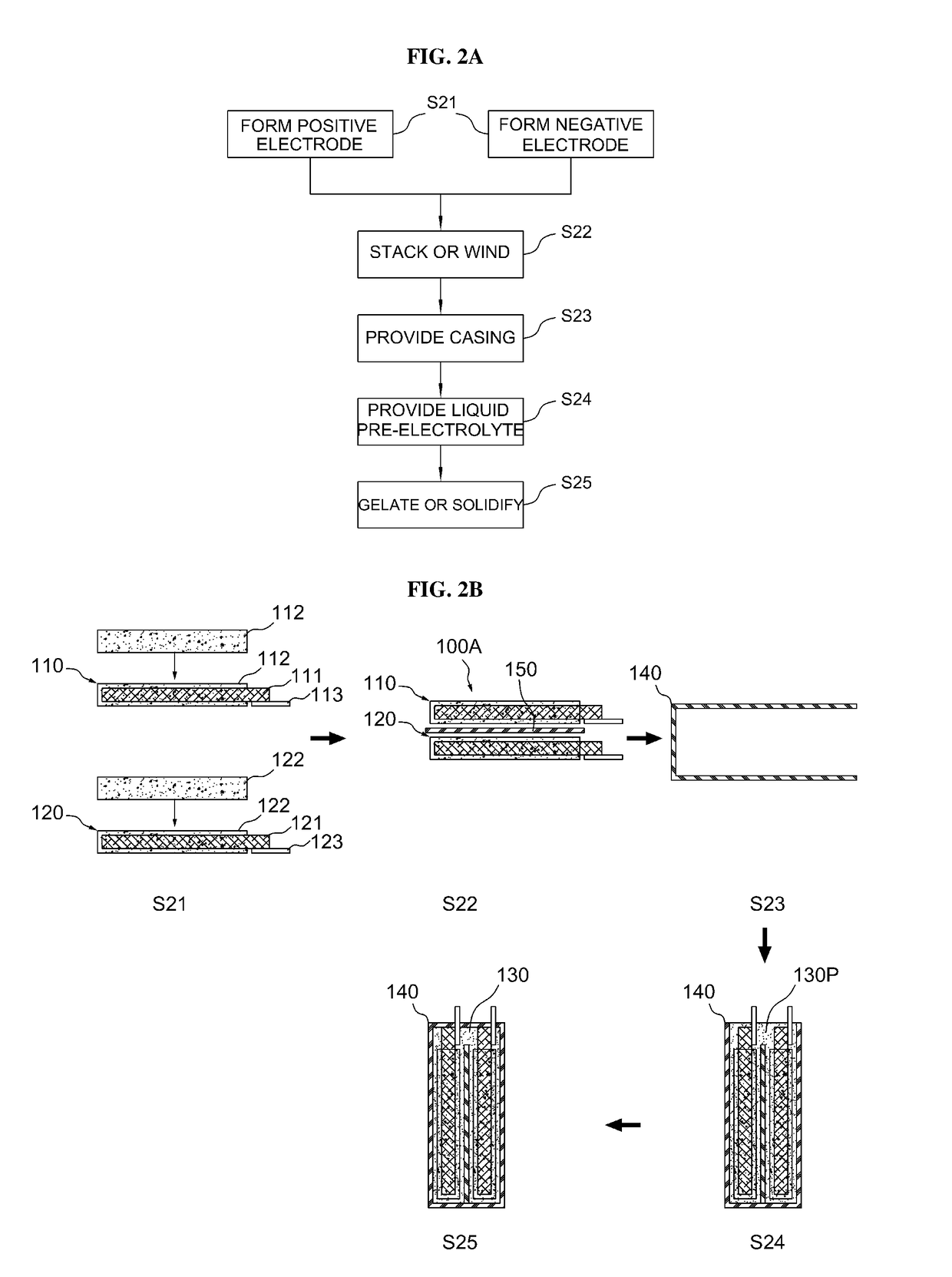

Flexible secondary battery and method for manufacturing same

ActiveUS20170288255A1High-temperature operationImprove wettabilityFinal product manufactureElectrode carriers/collectorsElectrical batteryEngineering

Provided are a flexible secondary battery and a method of manufacturing the same. The method includes forming an electrode including a metal fiber-like current collector and an active material combined with the metal fiber-like current collector; and providing a liquid pre-electrolyte that may be either thermally polymerized or crosslinked to the electrode and applying heat thereto, such that the liquid pre-electrolyte is integrated with the electrode and forms a gelated or solidified polymer electrode.

Owner:JENAX

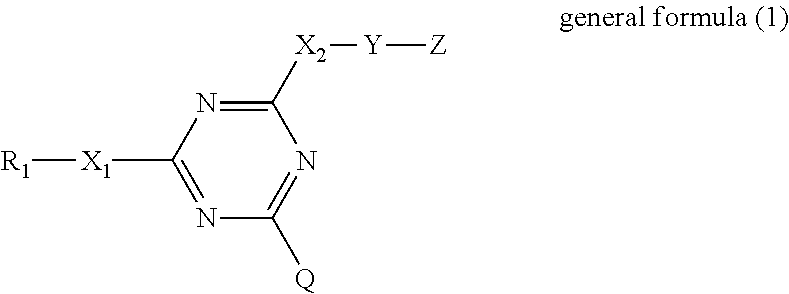

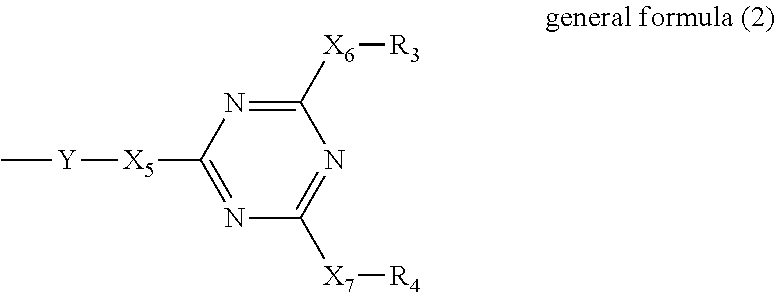

Composition for battery

InactiveUS20100028773A1Improve dispersion stabilityLower electrode resistanceNon-metal conductorsElectrode manufacturing processesLithiumPhysical chemistry

A composition for a battery containing an electroconductive assistant improves battery performance of a battery produced using this composition as a result of achieving dispersion stabilization without inhibiting electroconductivity of the electroconductive assistant. The invention provides a composition for a battery comprising at least one type of dispersant selected from an organic pigment derivative having an acidic functional group(s) or a triazine derivative having an acidic functional group(s), a carbon material as an electroconductive assistant, and as necessary, a solvent, a binder and a positive electrode active substance or negative electrode active substance; and also provides a lithium secondary battery comprising a positive electrode having a positive electrode composite layer on a current collector, a negative electrode having a negative electrode composite layer on a current collector, an electrolyte containing lithium, and as necessary, an electrode foundation layer, wherein the positive electrode composite layer, the negative electrode composite layer or the electrode foundation layer is formed using the composition for a battery described above.

Owner:TOYO INK SC HOLD CO LTD

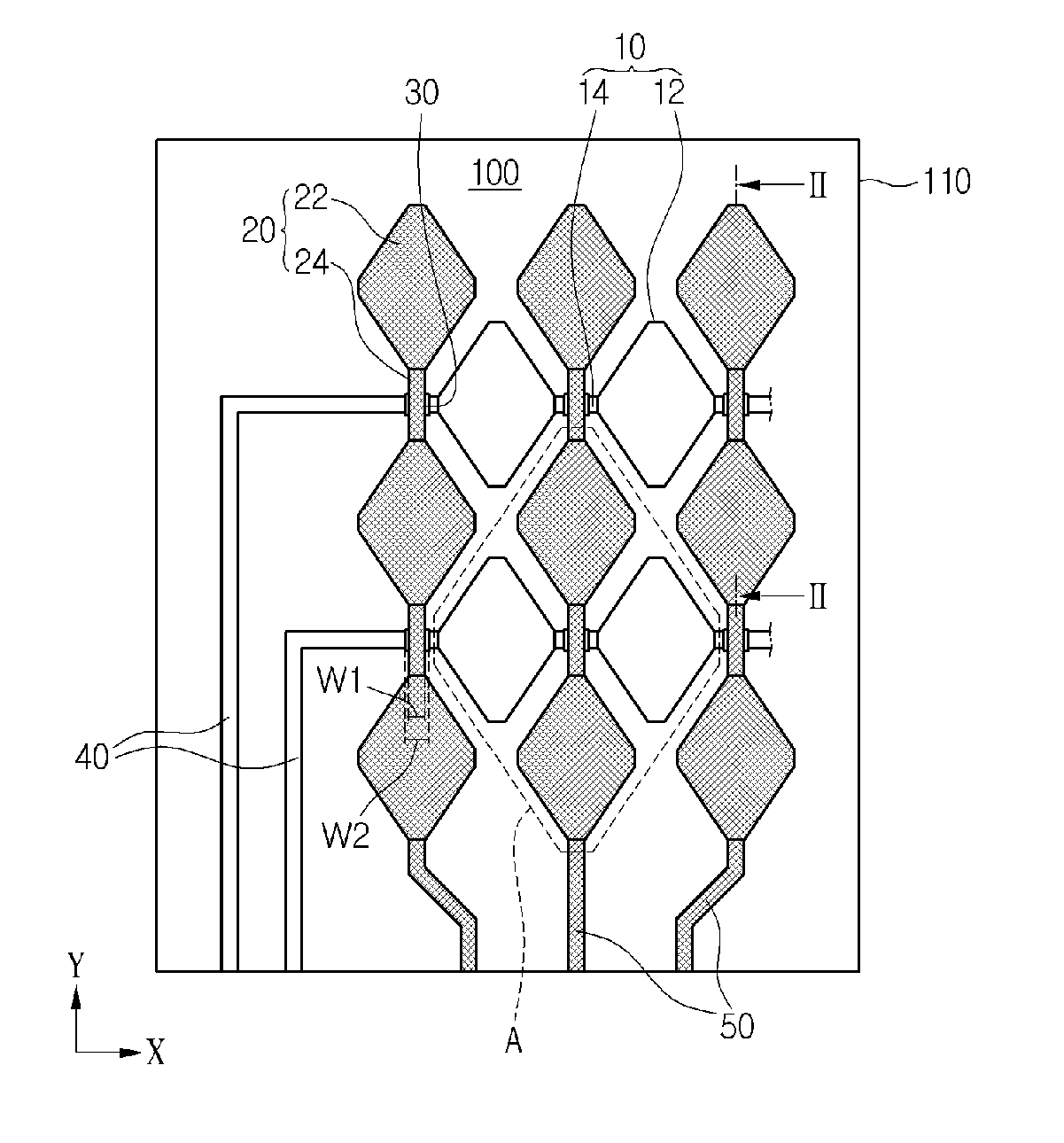

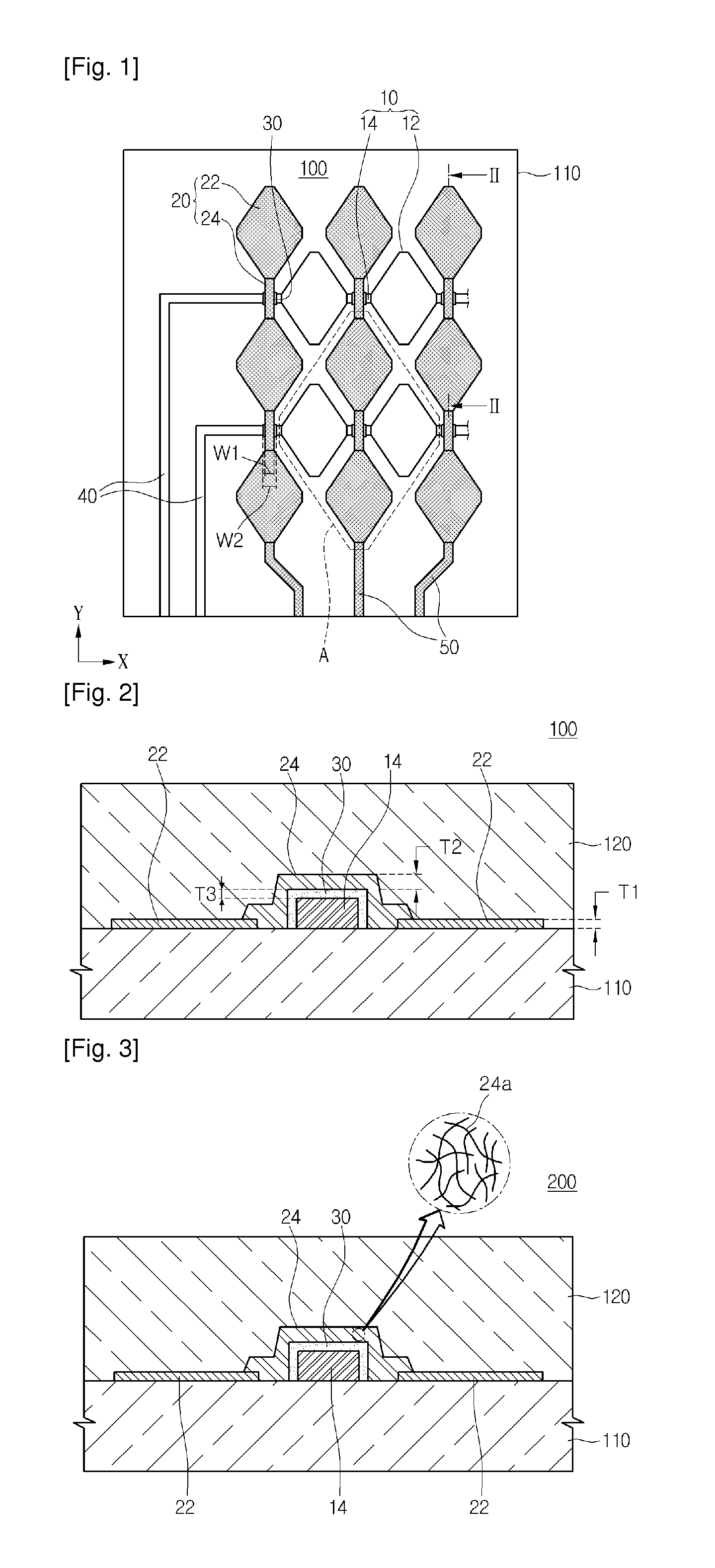

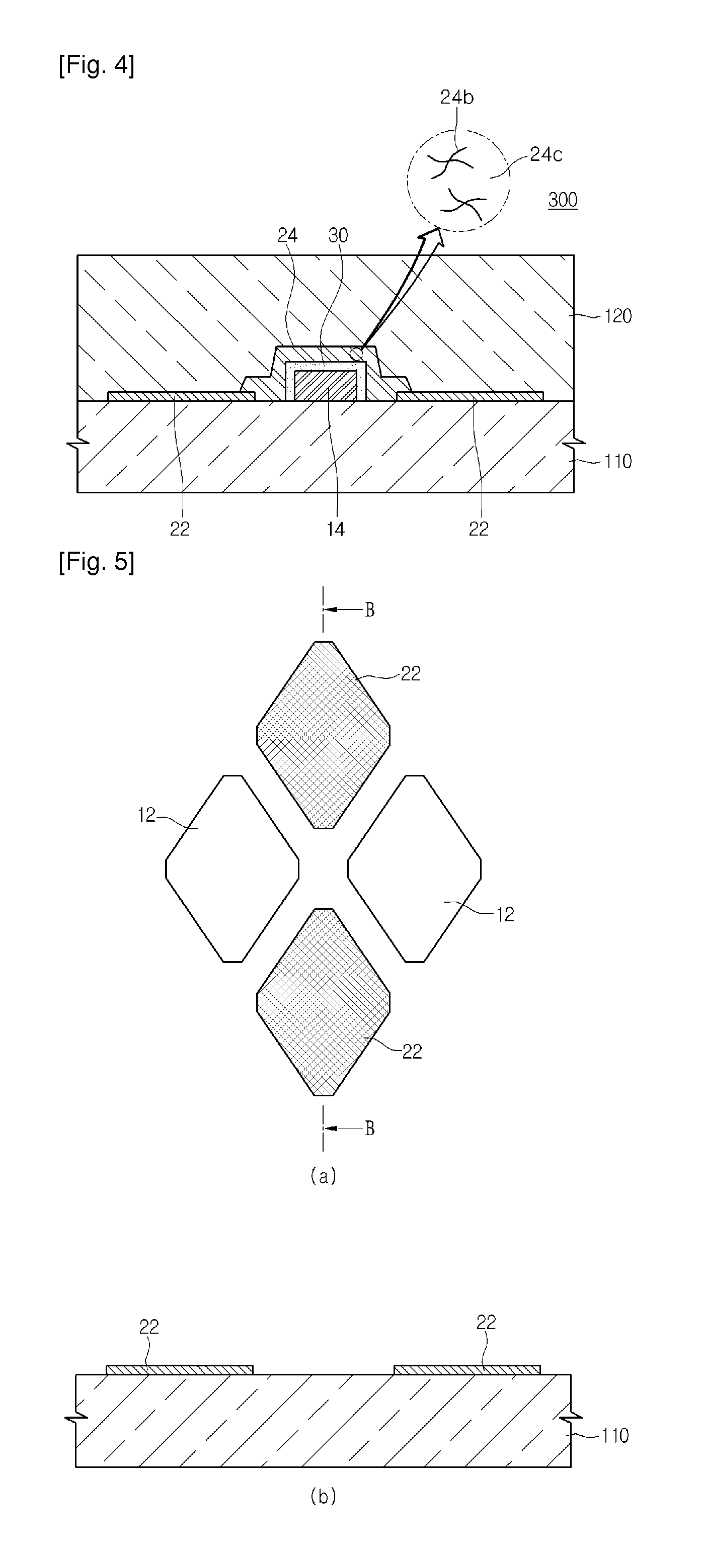

Touch panel and method for manufacturing the same

InactiveUS20130181944A1Improve electrical stabilityImprove touch sensitivityLiquid/solution decomposition chemical coatingPrinted circuit manufactureConductive materialsTouch panel

A touch panel according to the embodiment includes a substrate; a first electrode formed on the substrate in a first direction and including a plurality of sensor parts and connection parts connecting the sensor parts with each other; and a second electrode formed in a second direction crossing the first direction while being insulated from the first electrode and including a plurality of sensor parts and connection parts connecting the sensor parts with each other. The sensor parts and the connection parts include transparent conductive materials, and the connection parts have resistance lower than resistance of the sensor parts in at least one of the first and second electrodes.

Owner:LG INNOTEK CO LTD

Carbonaceous material for anode of nonaqueous electrolyte secondary battery, and method for manufacturing the same

InactiveUS20150188137A1Excellent electrical propertiesMaterial efficiencyFinal product manufactureConductive materialAlkaline earth metalElemental analysis

The object of the present invention is to provide a carbonaceous material for an anode of a nonaqueous electrolyte secondary battery which uses a plant-derived organic material as a raw material, has high purity so that alkali metals such as the potassium element and alkali earth metals such as the calcium element are sufficiently removed by de-mineral treatment, and has excellent discharge capacity and efficiency, a novel manufacturing method capable of efficiently mass-producing the carbonaceous material, and a lithium ion secondary battery using the carbonaceous material.The problem described above can be solved by a carbonaceous material for an anode of a nonaqueous electrolyte secondary battery obtained by carbonizing a plant-derived organic material, the atom ratio (H / C) of hydrogen atoms and carbon atoms according to elemental analysis being at most 0.1, the average particle size Dv50 being from 2 to 50 μm, the average interlayer spacing of the 002 planes determined by powder X-ray diffraction being from 0.365 nm to 0.400 nm, the potassium element content being at most 0.5 mass %, and the calcium element content being at most 0.02 mass %.

Owner:KURARAY CO LTD

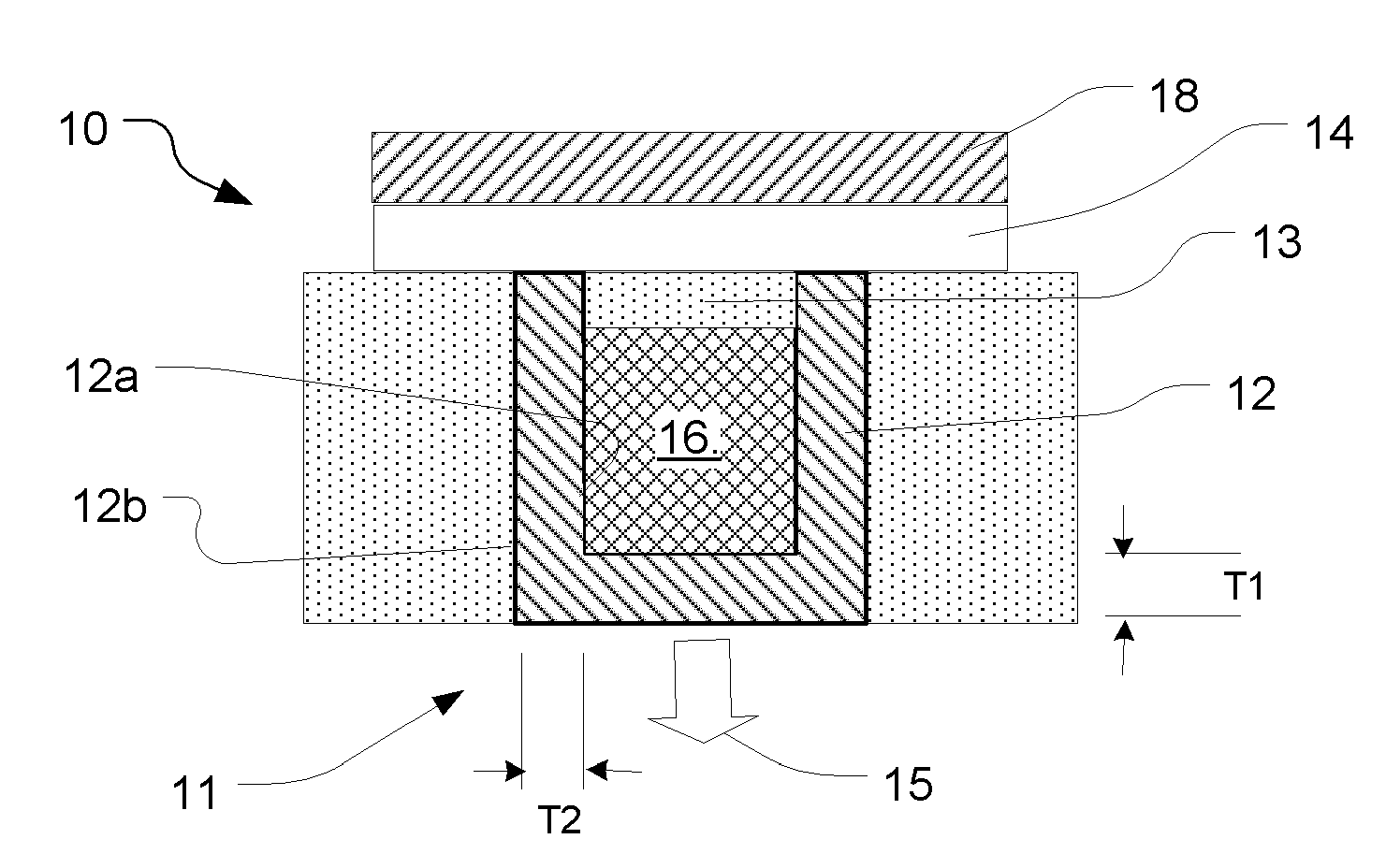

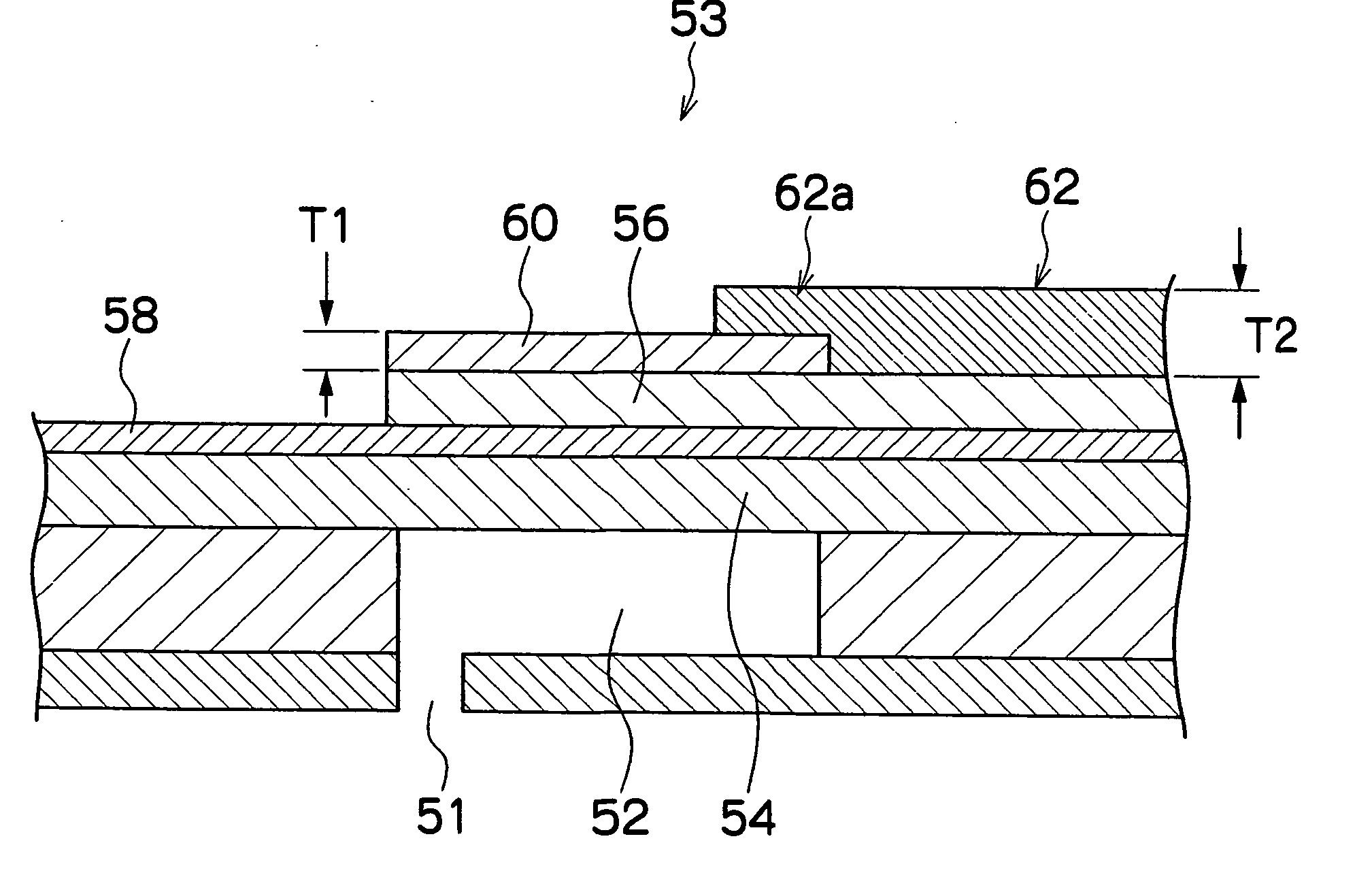

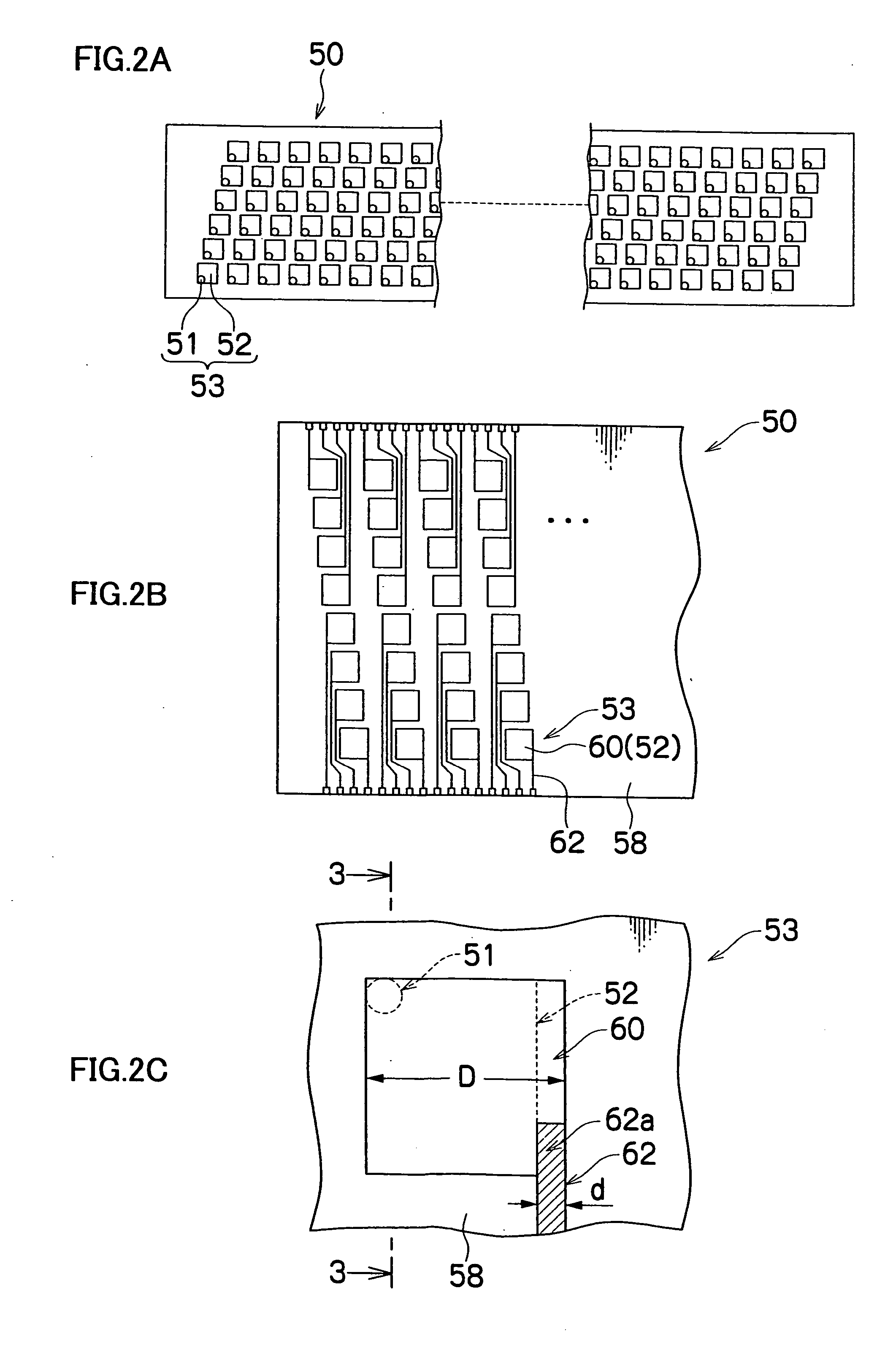

Inkjet head and manufacturing method thereof

The inkjet head comprises: a plurality of ink discharge nozzles which are arranged two-dimensionally; a plurality of pressure chambers which are in communication with the ink discharge nozzles so as to store ink, the pressure chambers being two-dimensionally arranged in correspondence with the ink discharge nozzles; a plurality of piezoelectric elements; a common electrode which is disposed on pressure chamber sides of the piezoelectric elements; a plurality of discrete electrodes which are disposed on sides of the piezoelectric elements opposite to the common electrode; and a plurality of discrete lead electrodes which feed electricity to the discrete electrodes, wherein: each of the piezoelectric elements is deformed by applying voltage to the common electrode and the discrete electrode so that a volume of the pressure chamber is varied to discharge a droplet of the ink from the ink discharge nozzle; and with respect to each pair of the discrete electrode and discrete lead electrode corresponding to each of the pressure chambers, when T1 is a thickness of the discrete electrode and T2 is a thickness of the discrete lead electrode which feed electricity to the discrete electrode, the discrete electrode and the discrete lead electrode are configured so that T1 and T2 satisfy the following formula: T1<T2.

Owner:FUJIFILM CORP

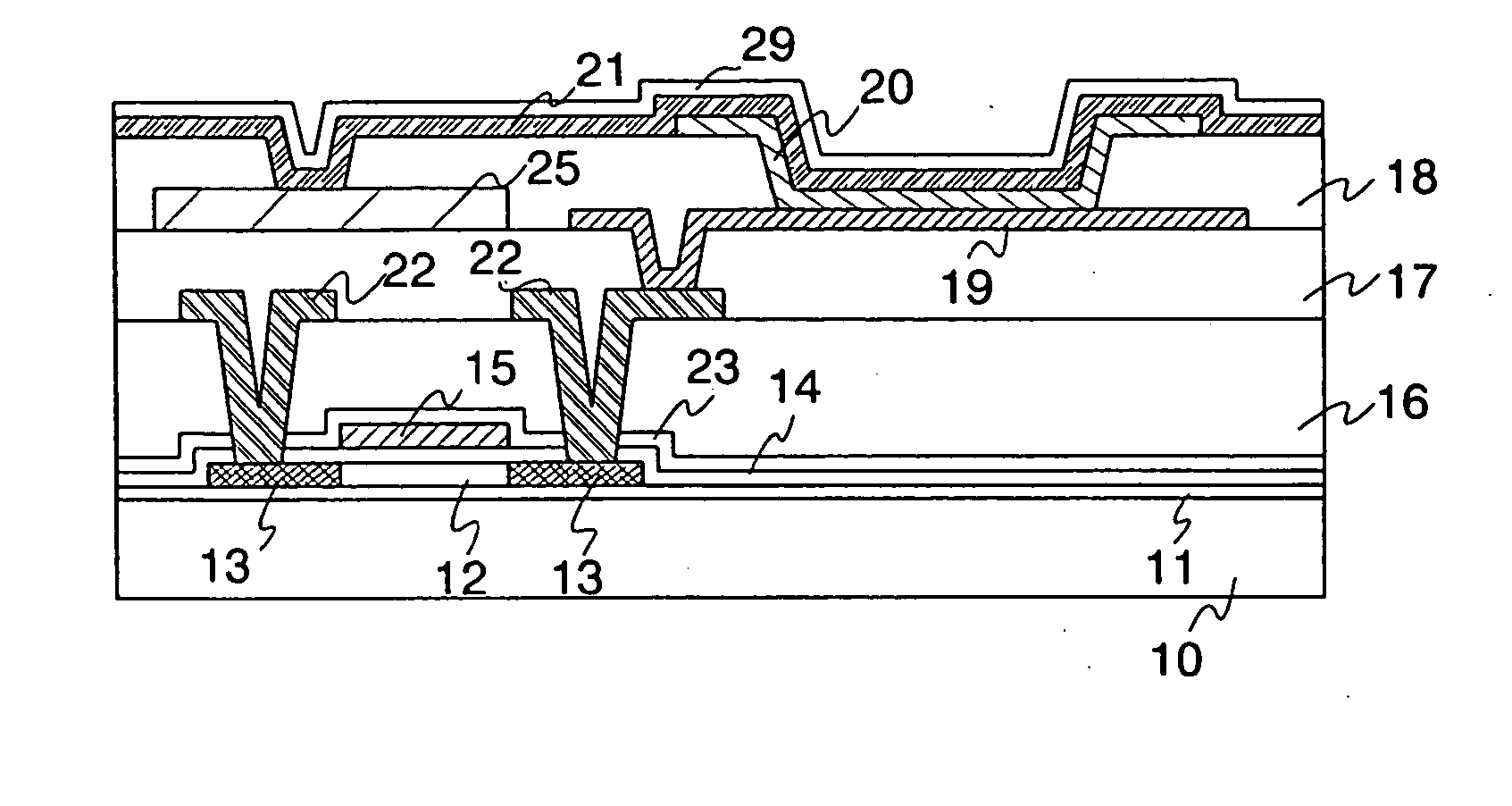

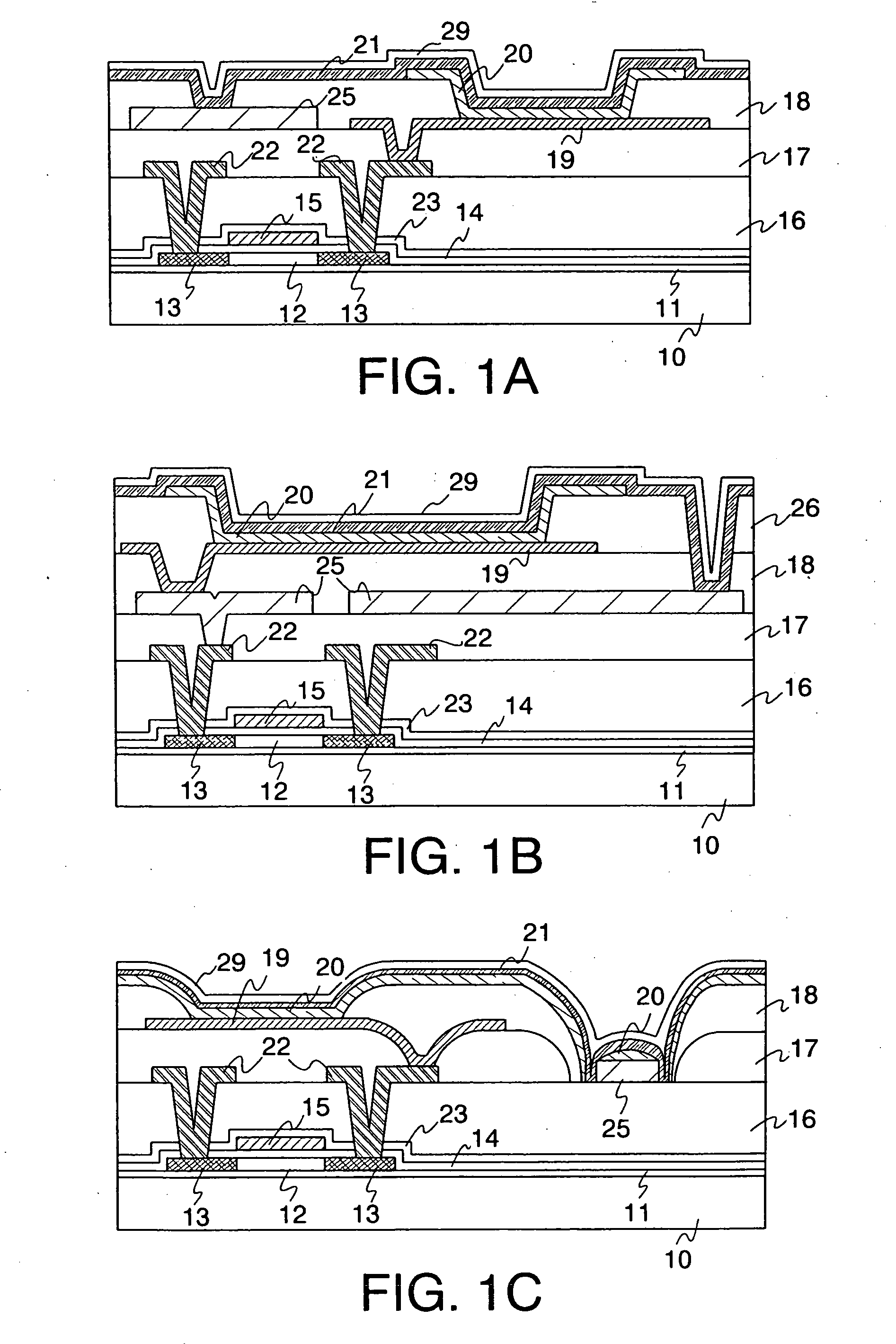

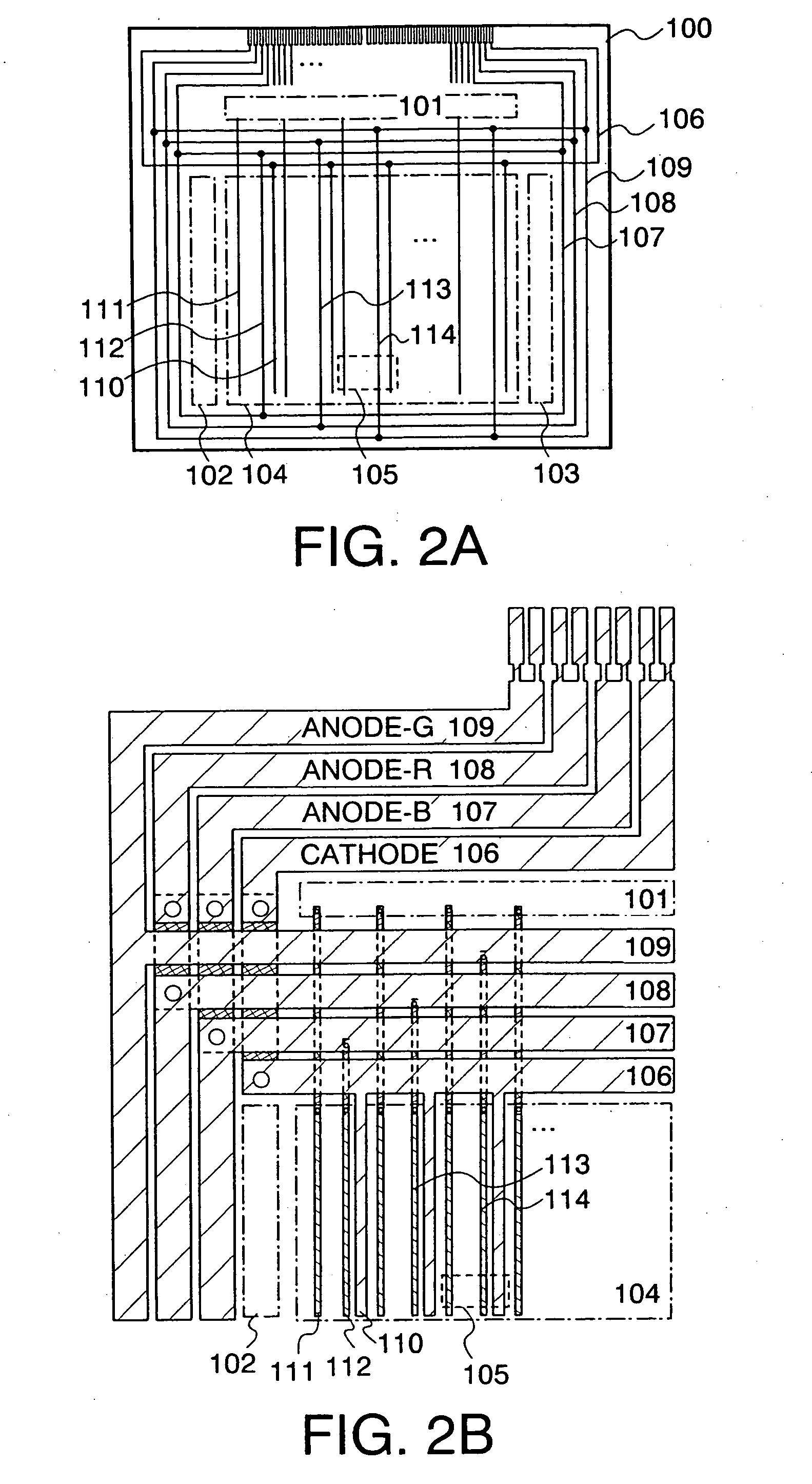

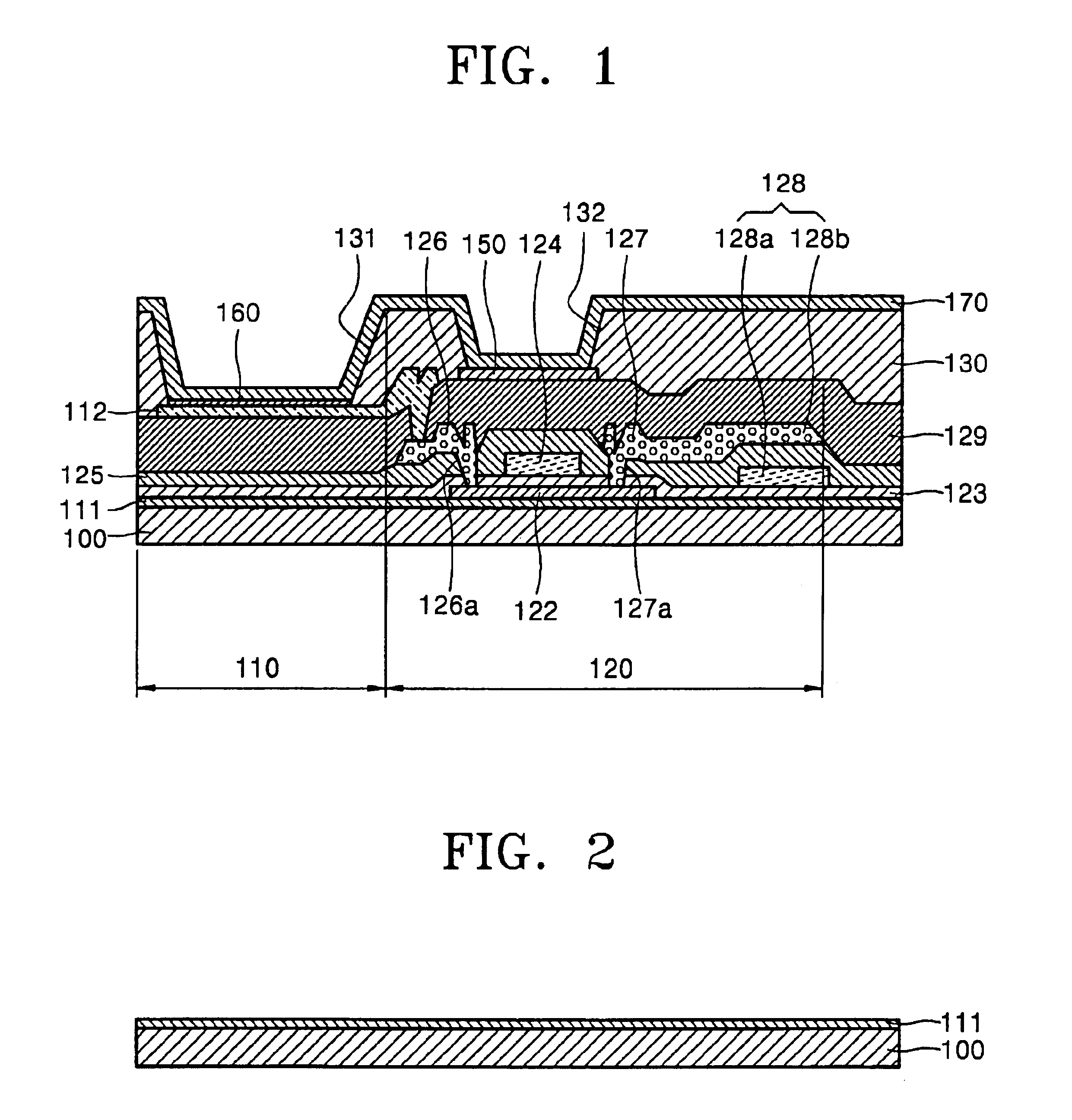

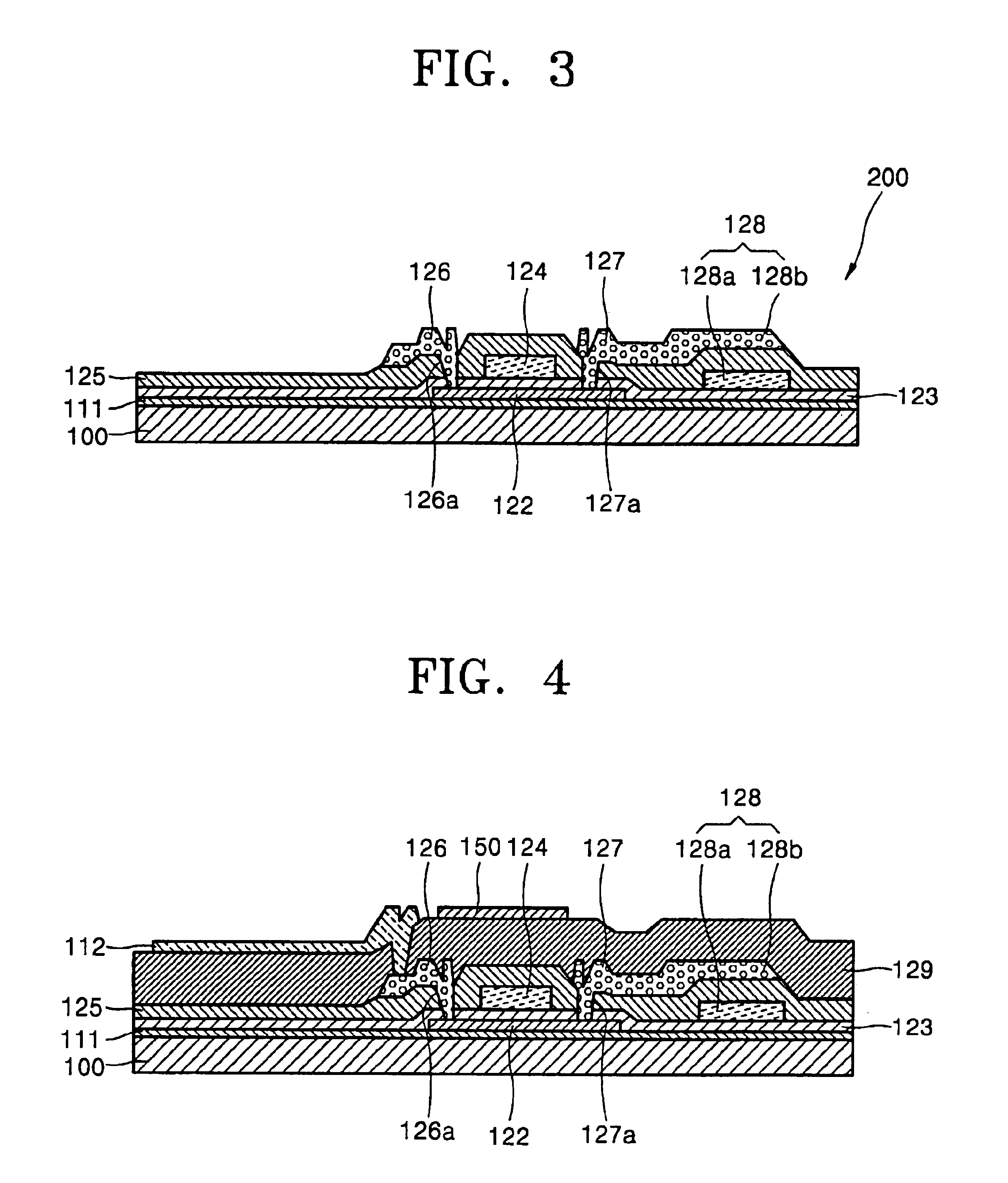

Organic electroluminescent display and method of manufacturing the same

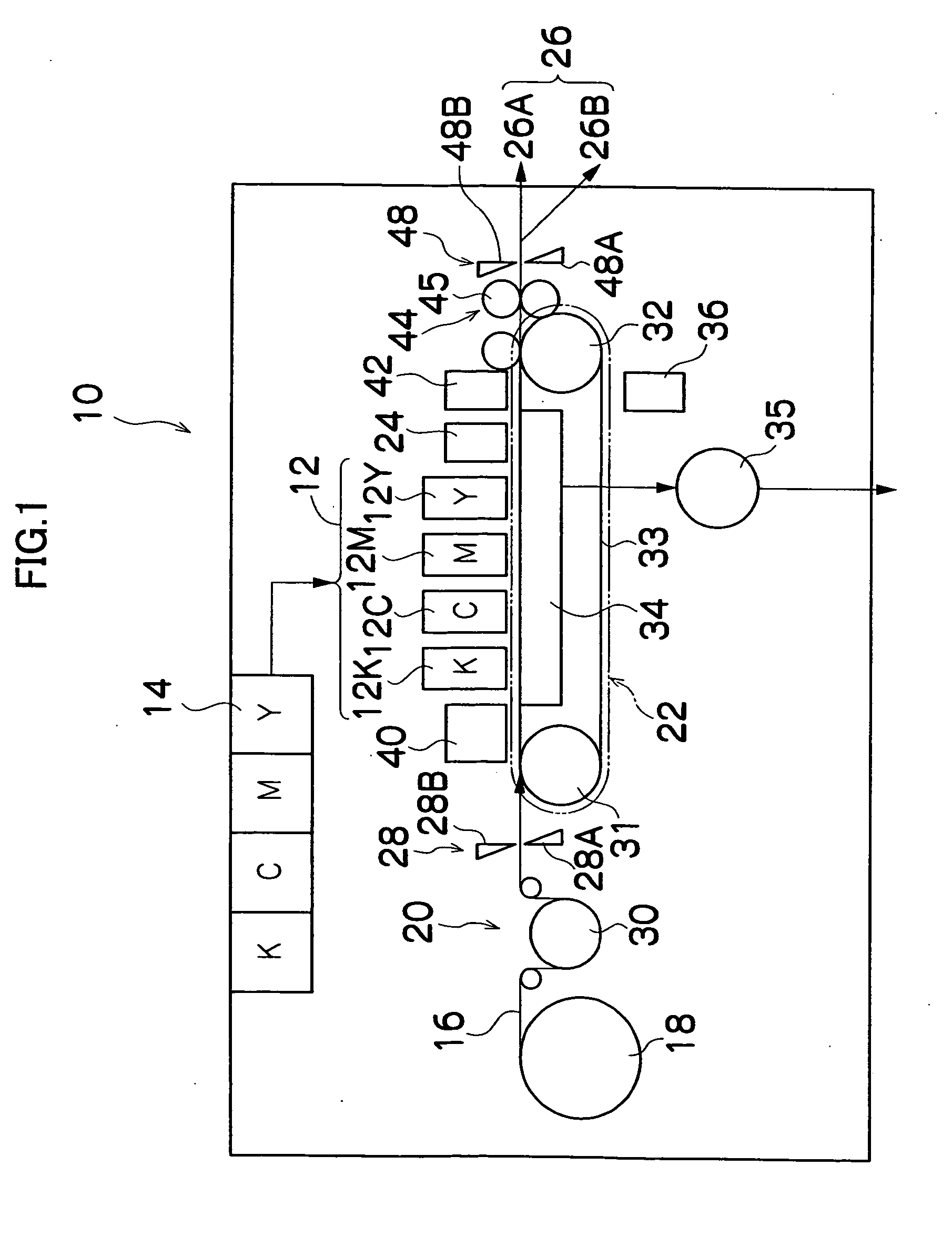

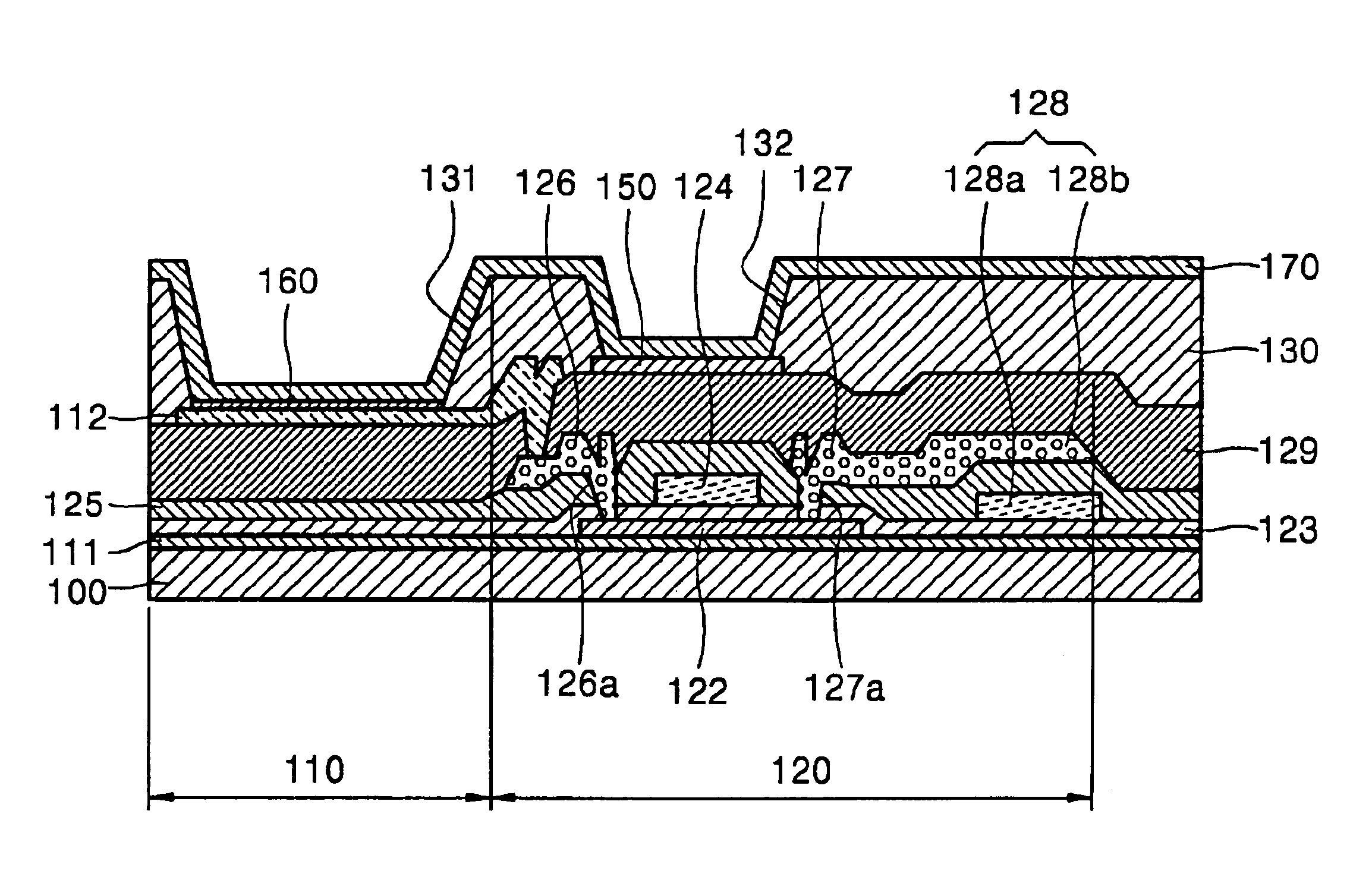

ActiveUS6917160B2Lower electrode resistanceBrightness of image can be preventedDischarge tube luminescnet screensElectroluminescent light sourcesInsulation layerOrganic layer

An organic electroluminescent display and a method of manufacturing the same are provided. The organic electroluminescent display includes a substrate, at least a thin-film transistor, which is formed on the substrate, at least an insulation layer, which cover the thin-film transistor, first electrodes, which are formed in a predetermined pattern on a top surface of the insulation layer and to which a voltage is selectively applied through the thin-film transistor, bus electrodes, which are insulated from the first electrodes, a planarization layer, which is an insulation layer and has openings exposing the first electrodes and the bus electrodes, organic layers, which are formed on a top surface of the first electrodes, and second electrodes, which are formed on a top surface of the organic layer and a top surface of the planarization layer and are electrically connected to the bus electrodes.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com