Patents

Literature

88results about How to "Increase electrode density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Neuro-stimulation

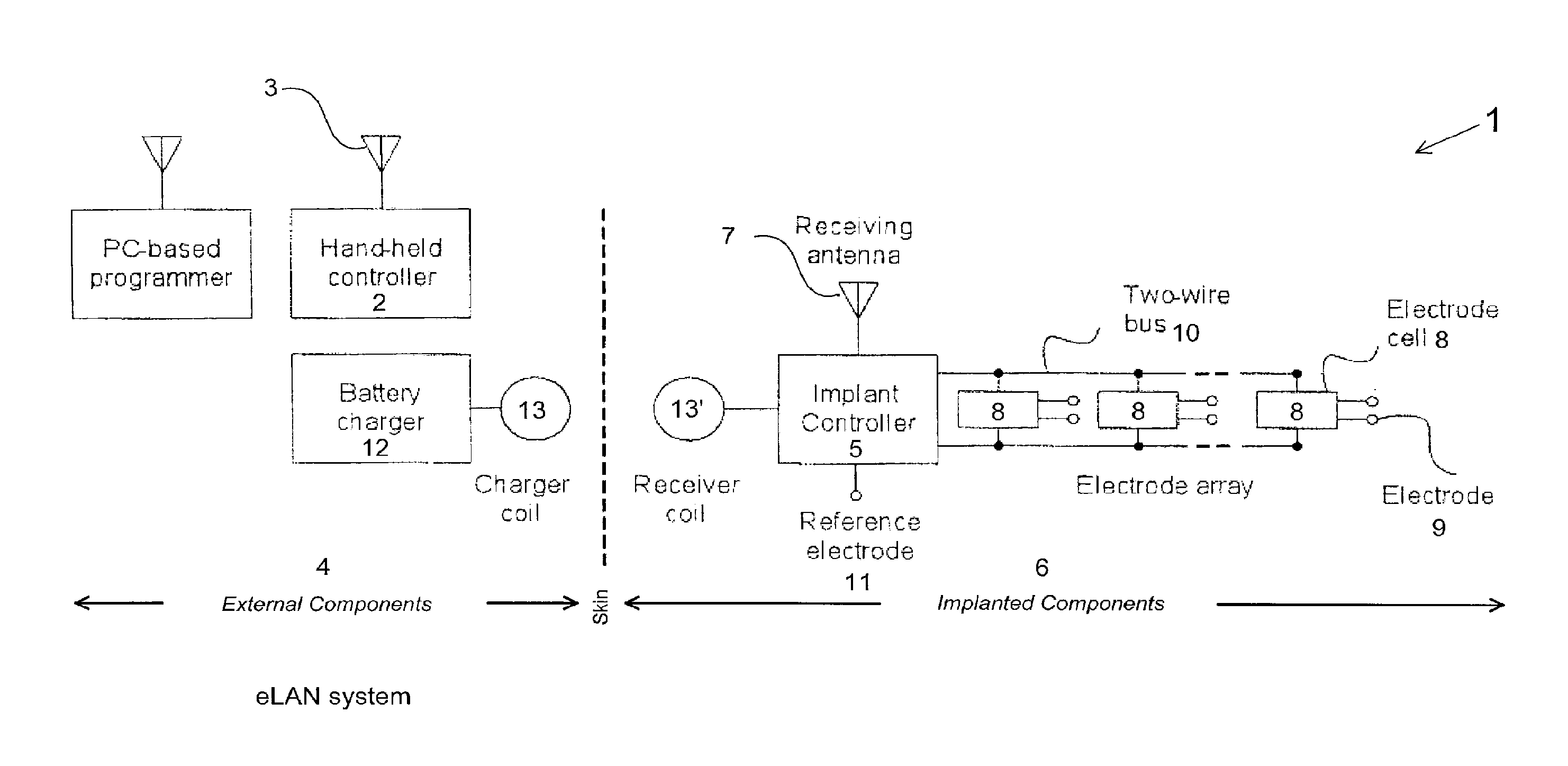

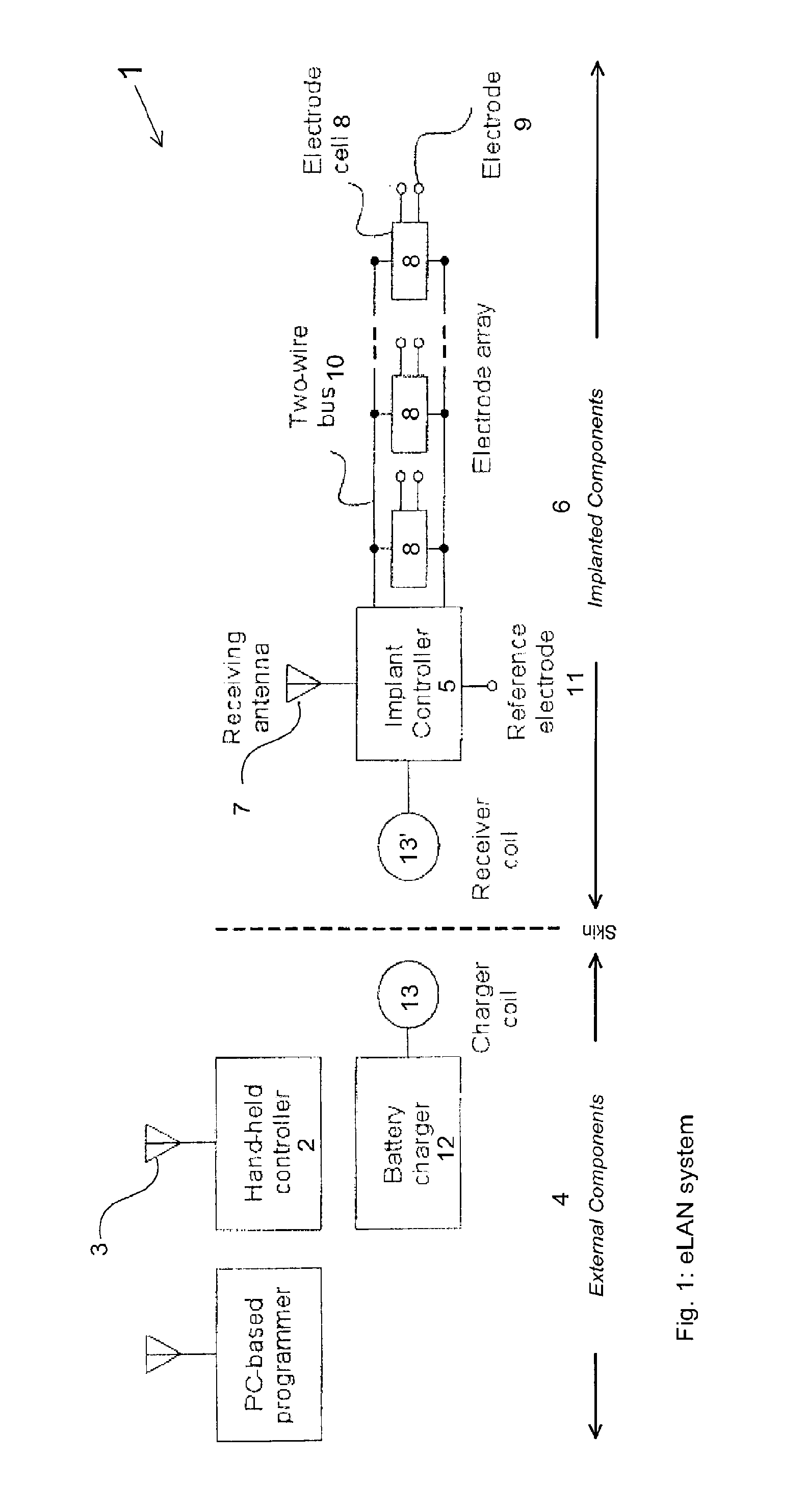

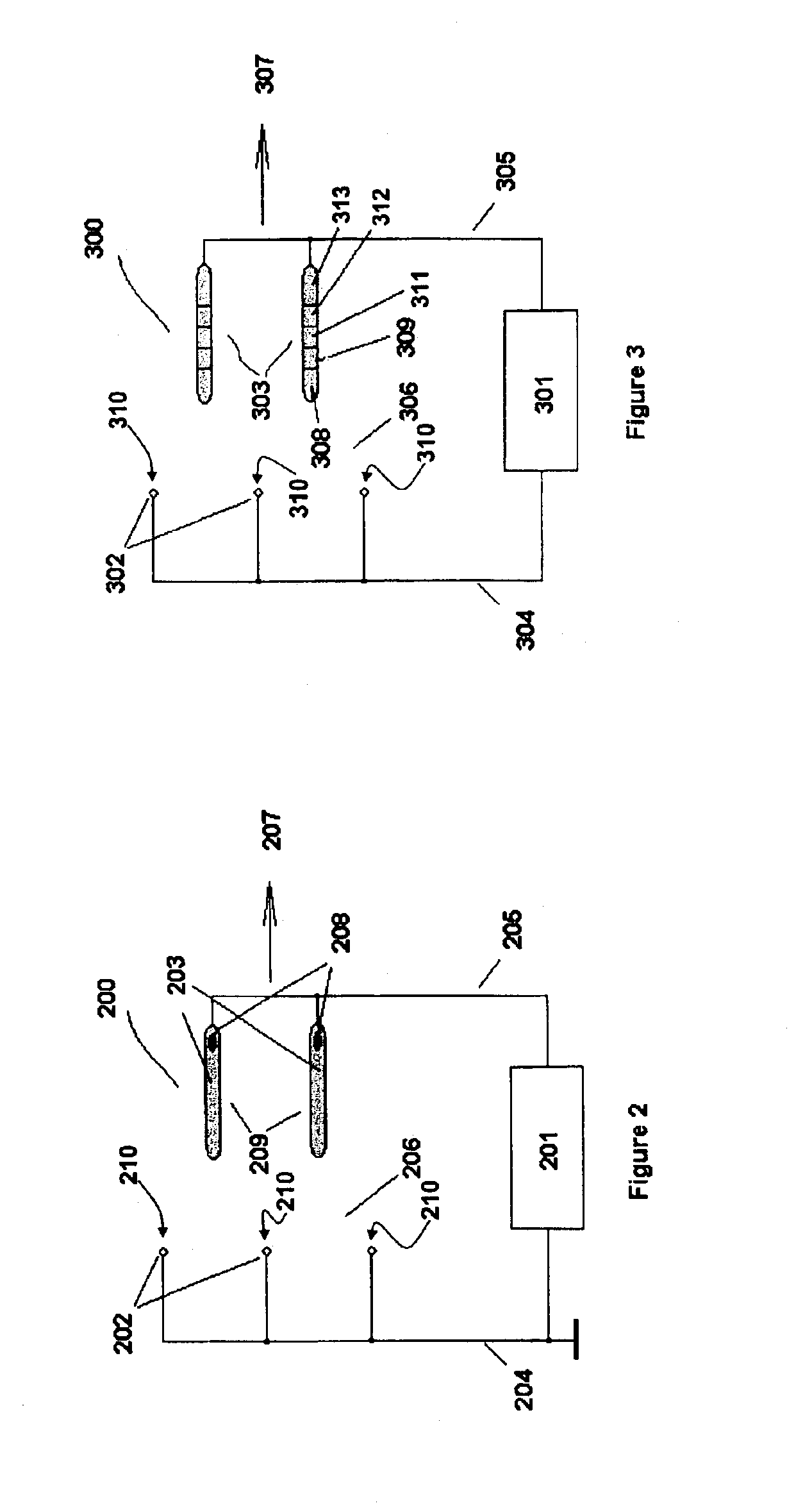

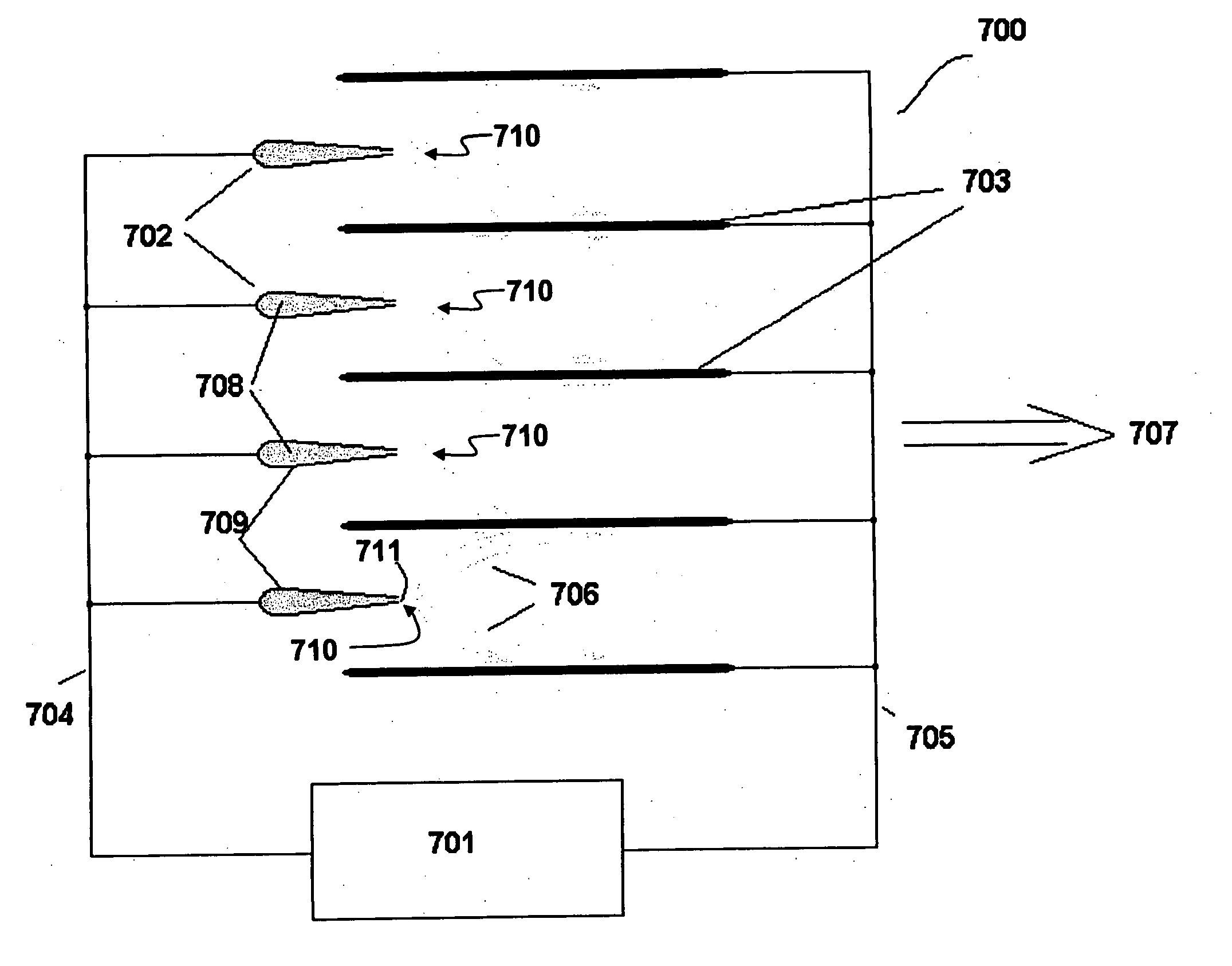

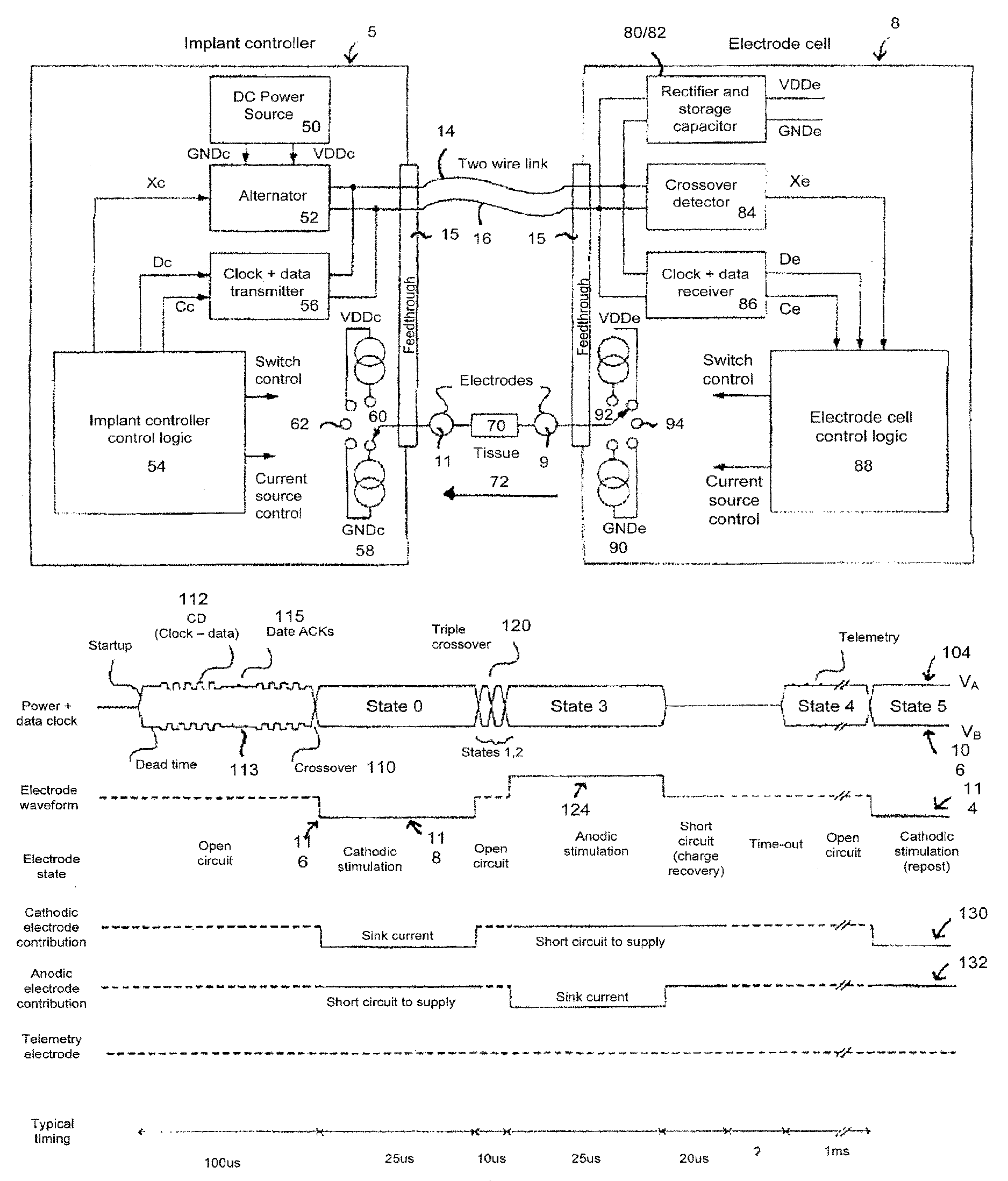

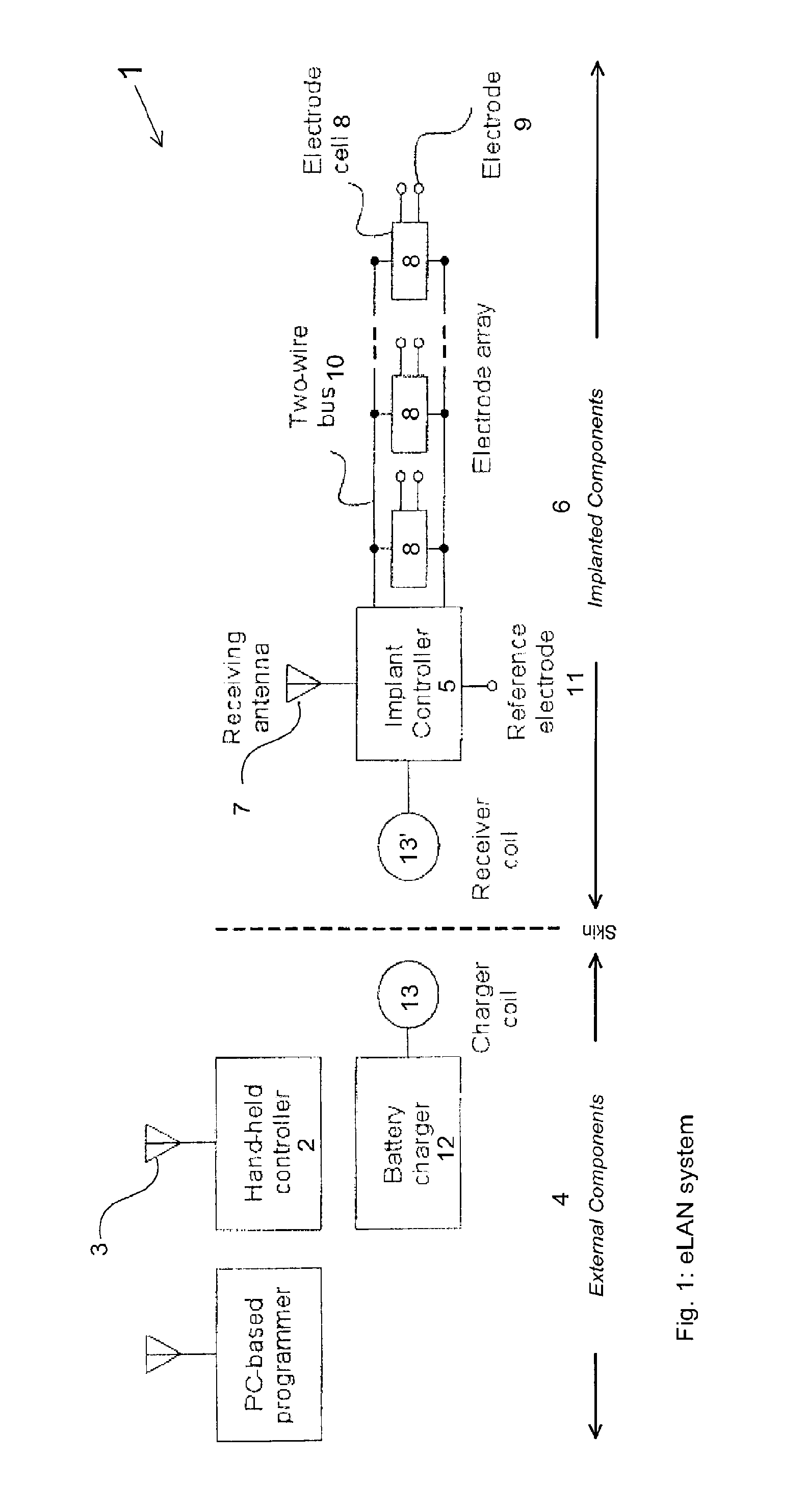

ActiveUS20120161945A1Easy to addEasy to replaceElectric signal transmission systemsInternal electrodesControl logicElectrical and Electronics engineering

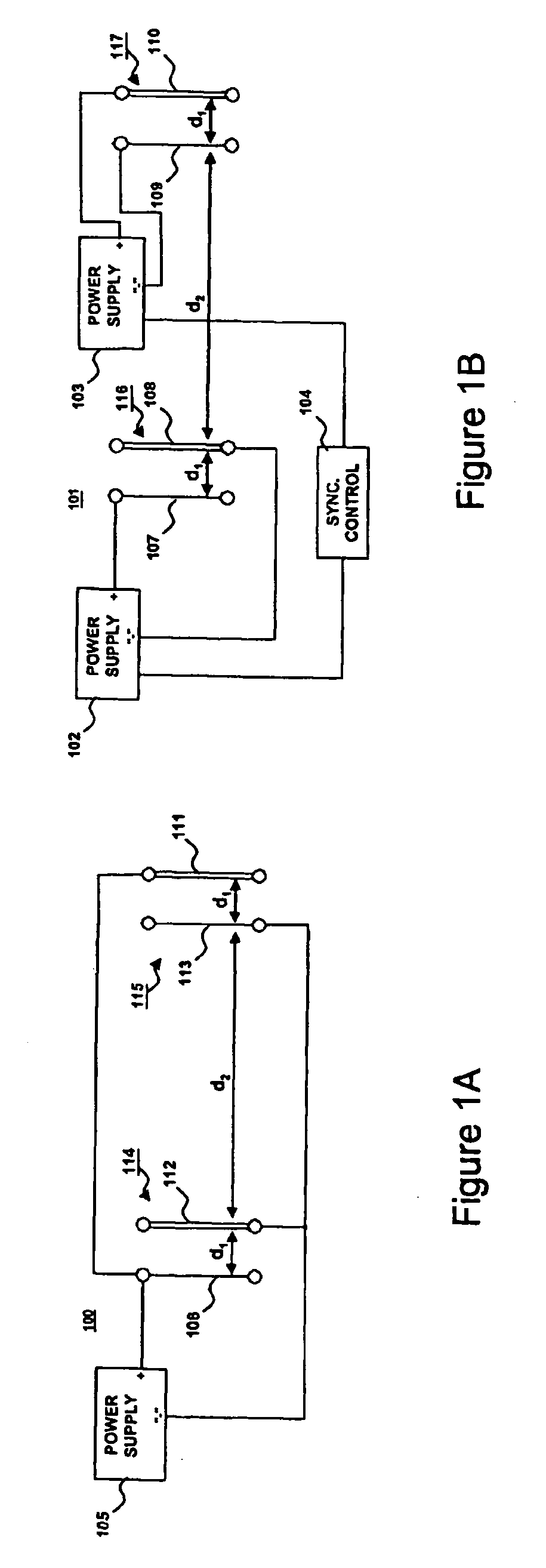

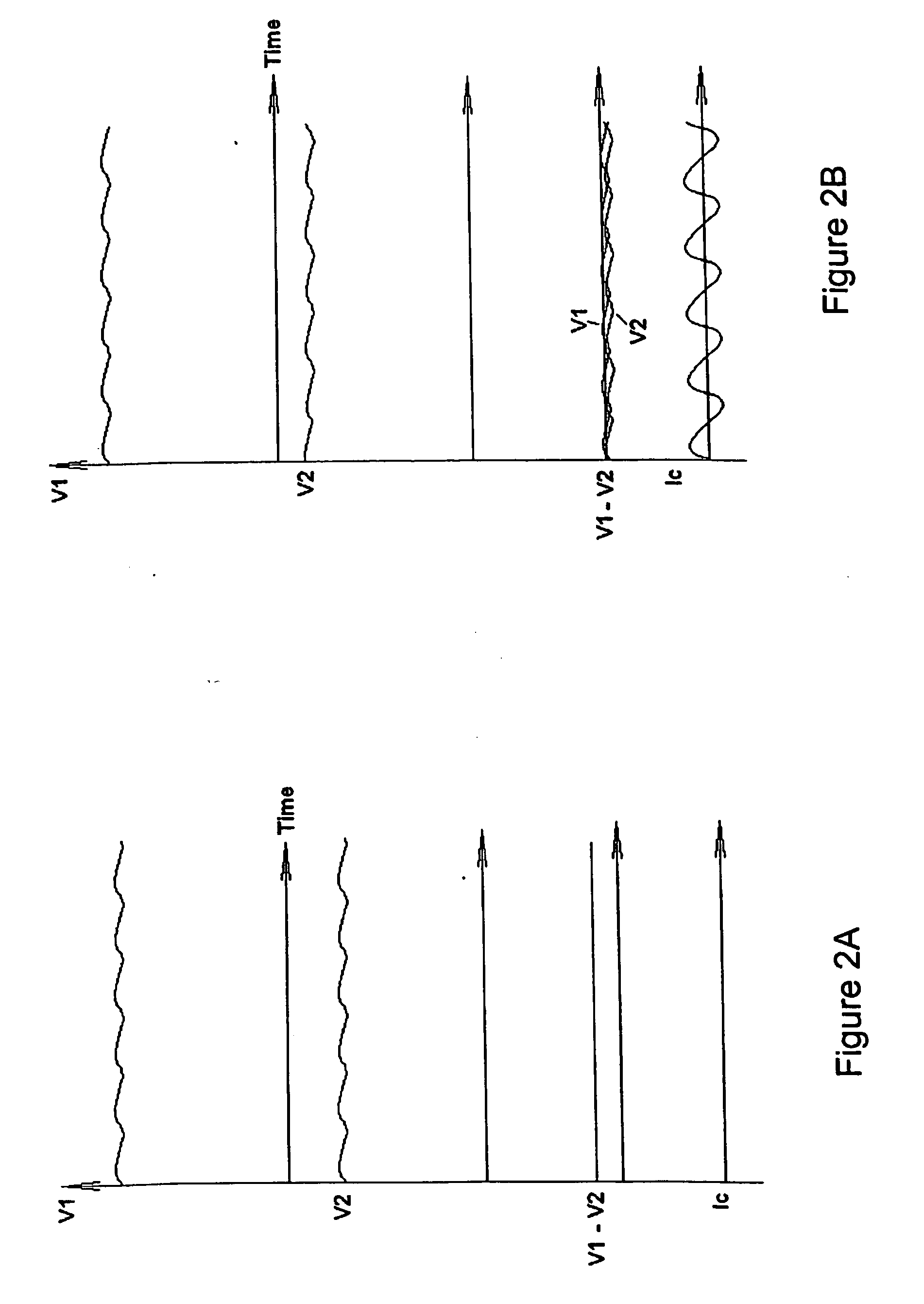

The invention is a distributed implantable neuro-stimulation system, comprising an implant controller including control logic to transmit two time-varying power signals, varying between two levels and out of phase with the other, and a command signal modulated onto at least one of the power signals. One or more electrode cells, each having control logic to extract charge from the power signals and recover commands from the command signal. A two-wire bus interconnecting the implant controller and all the electrode cells, to carry one of the time varying signals in each of the two wires, and to carry the command signal.

Owner:SALUDA MEDICAL PTY LTD

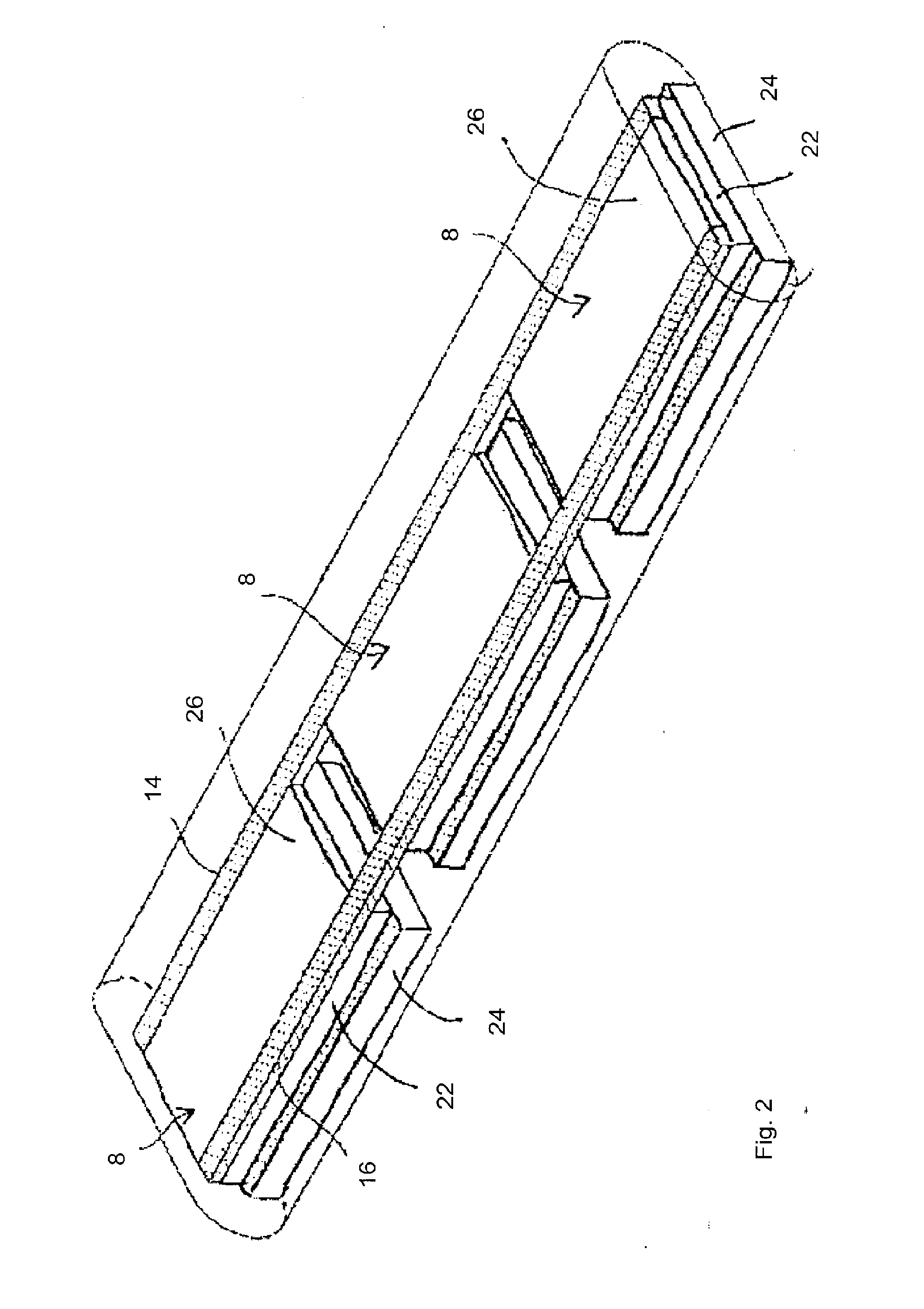

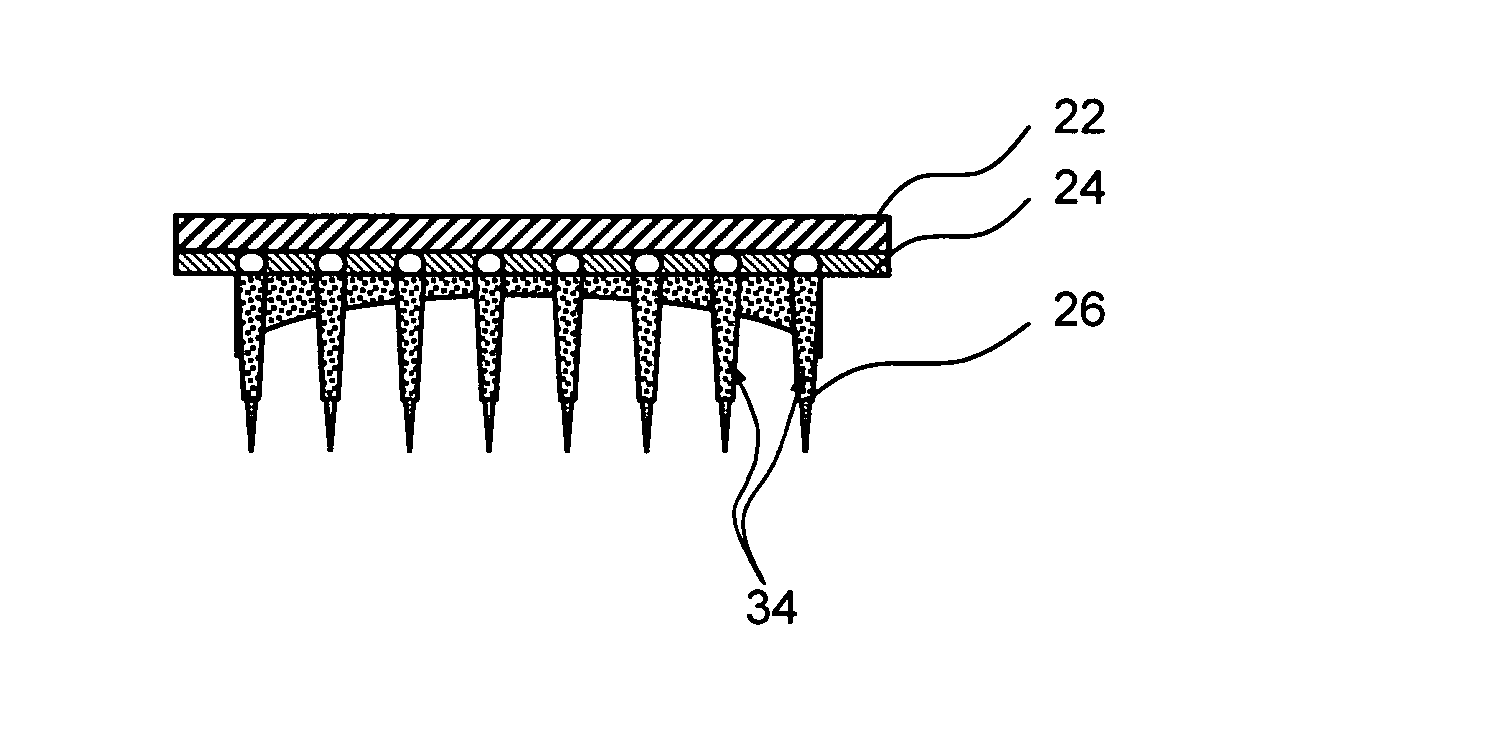

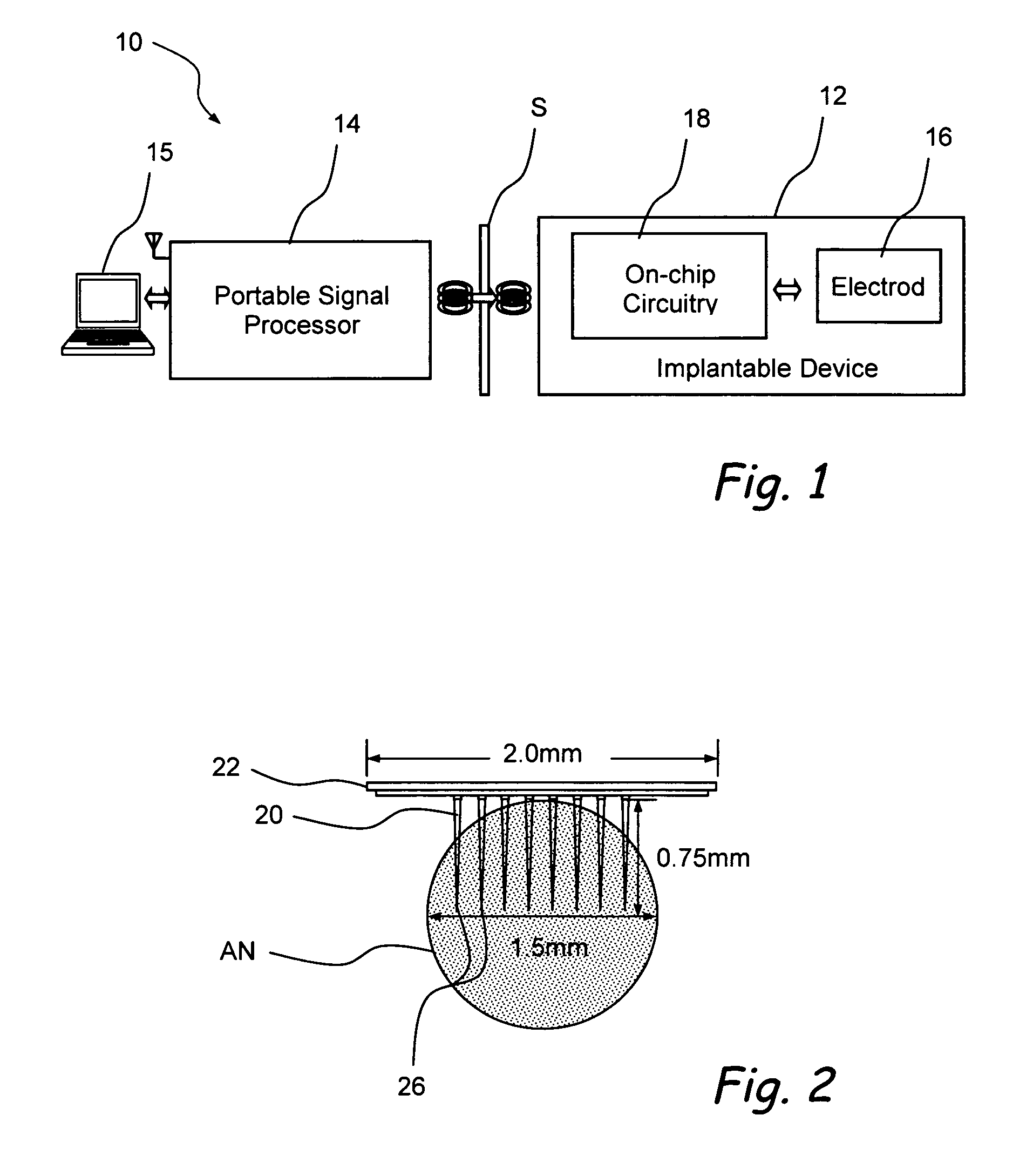

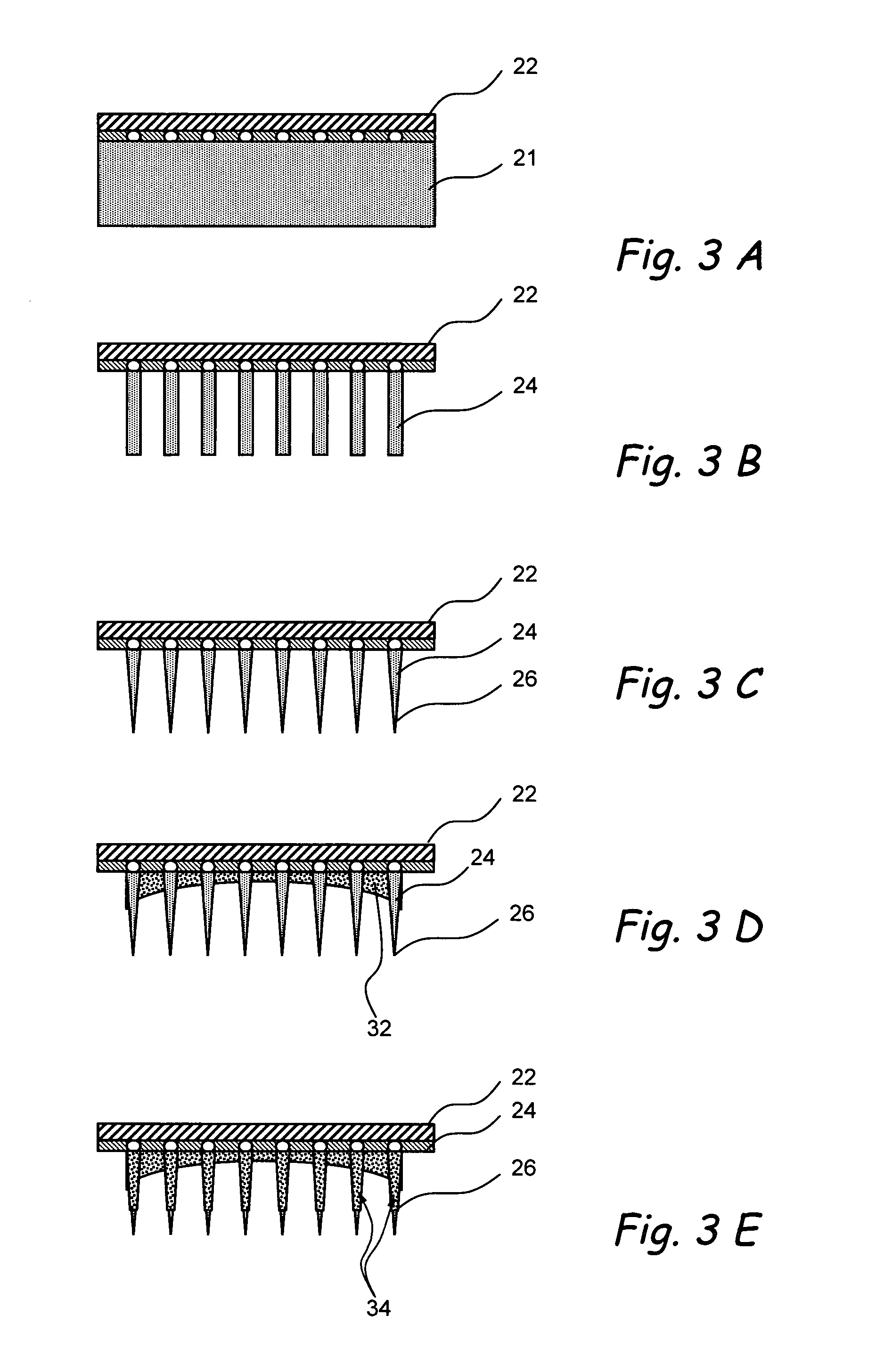

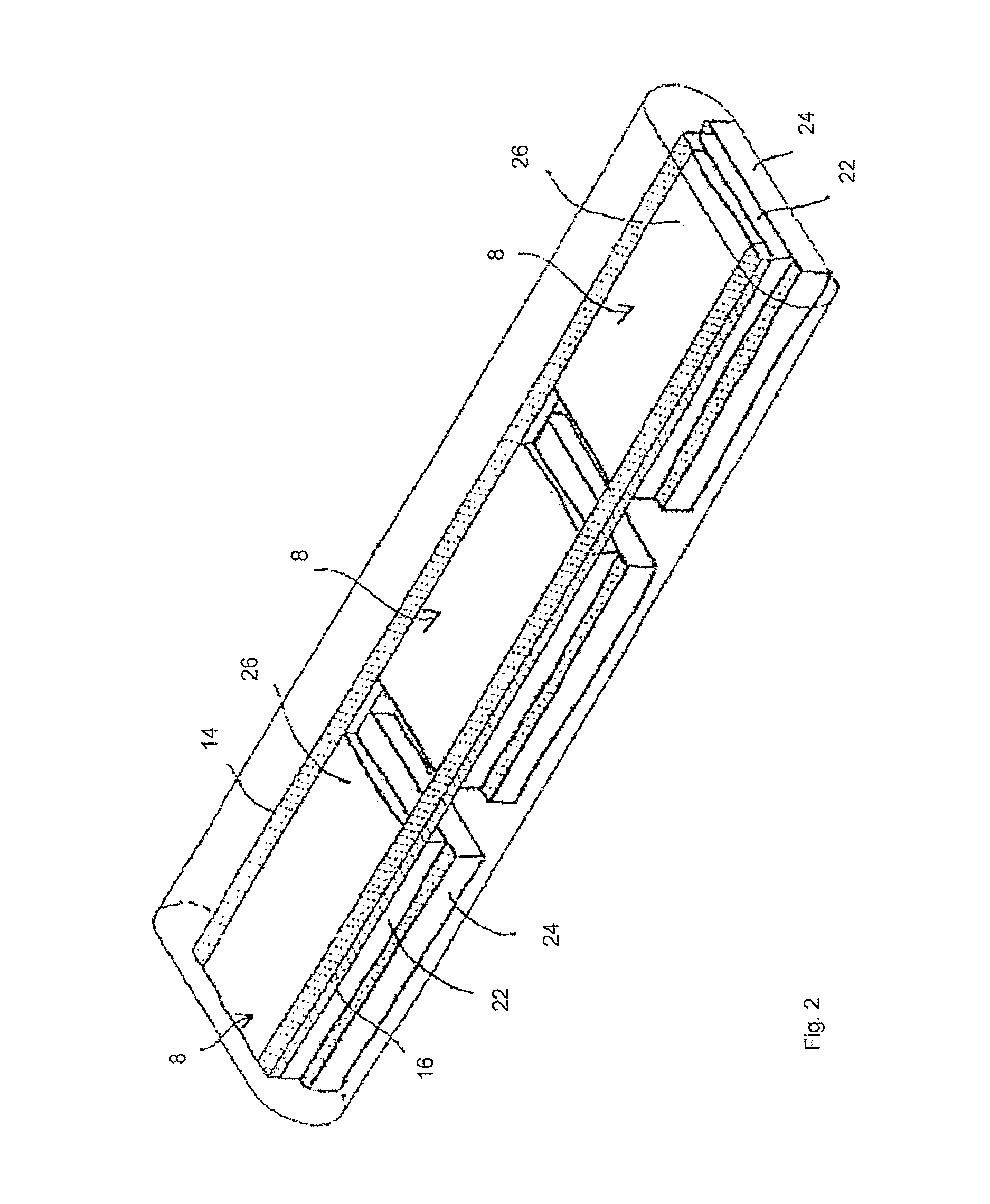

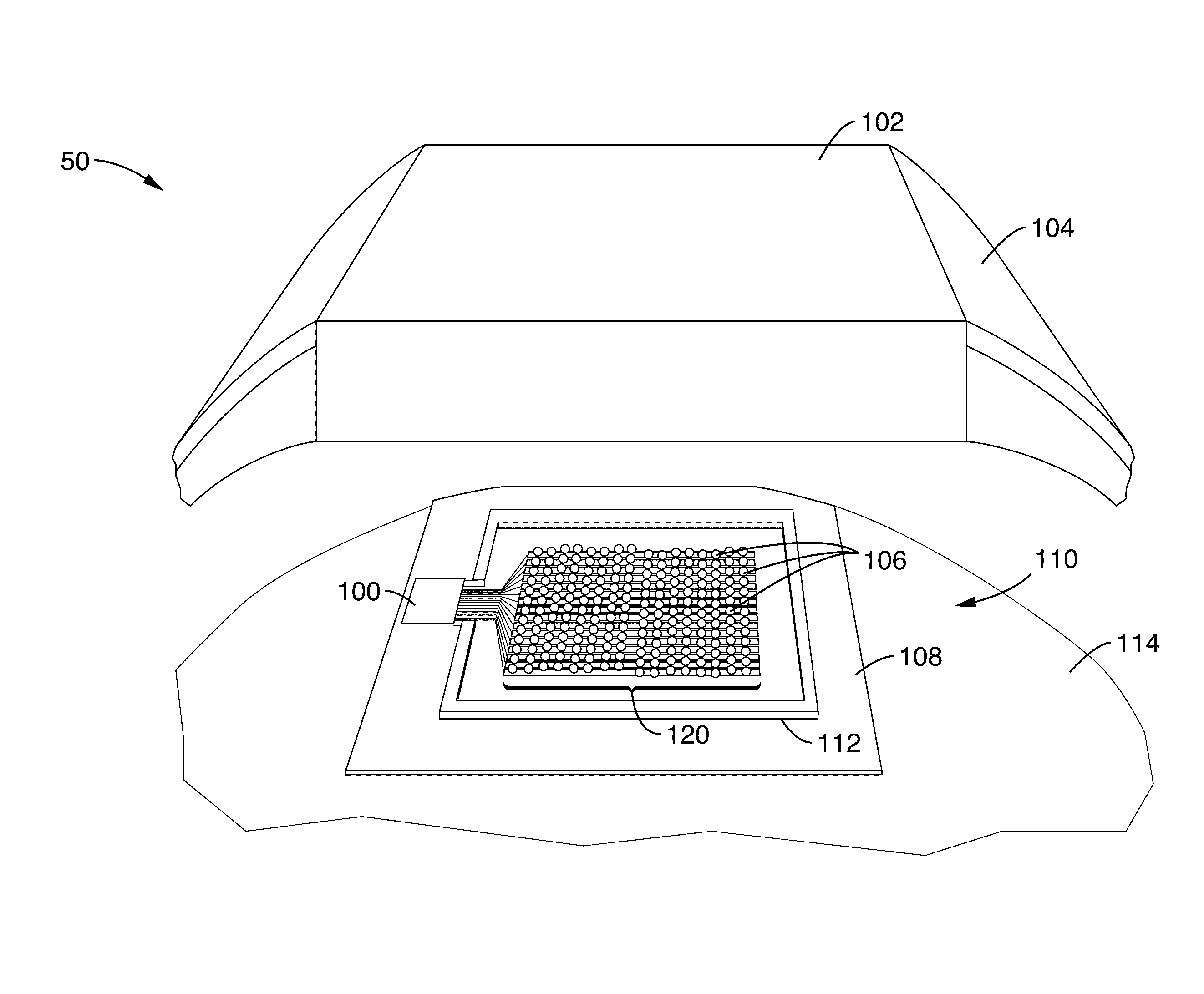

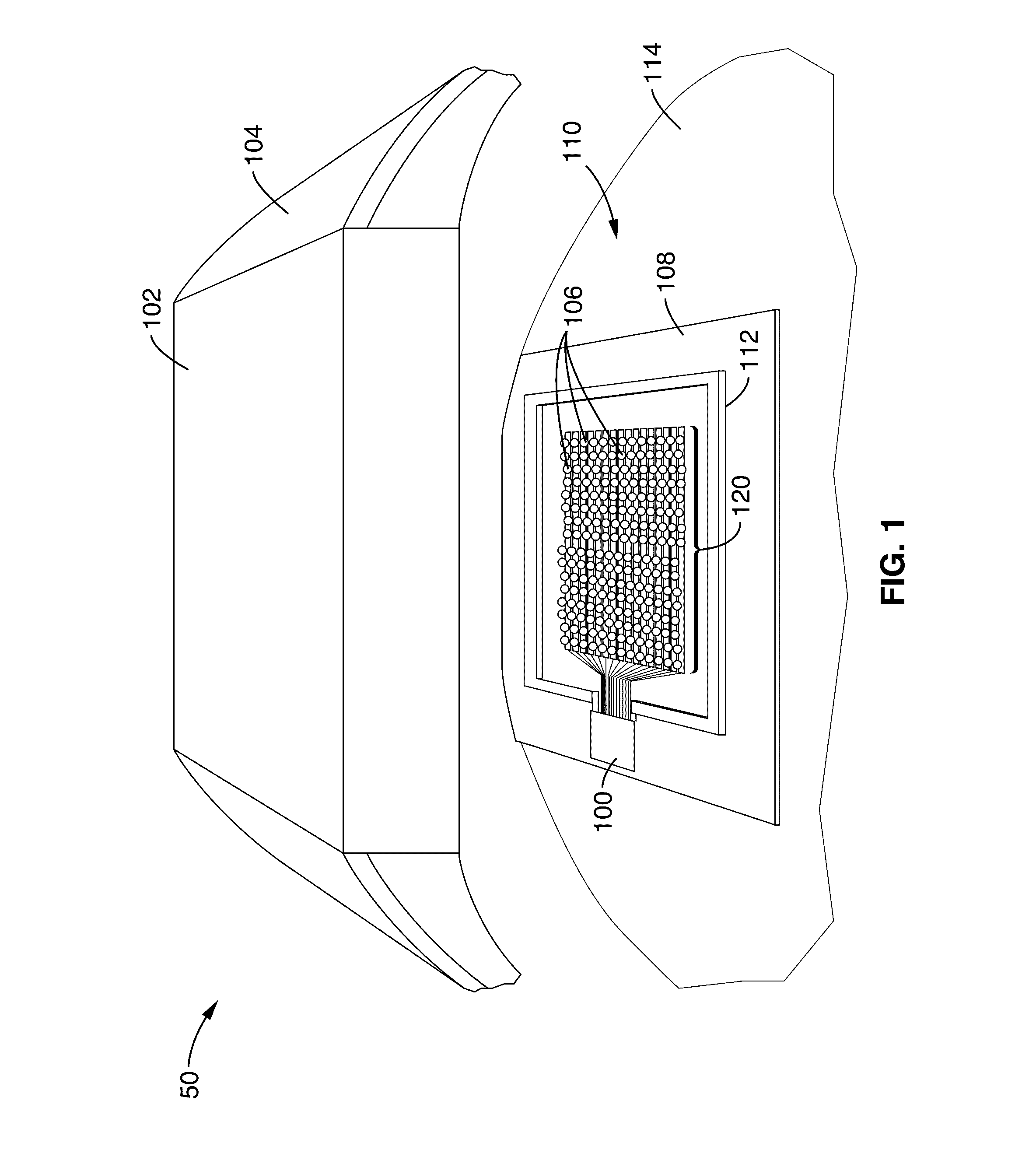

High density micromachined electrode arrays useable for auditory nerve implants and related methods

ActiveUS7991475B1Heat dissipationPrecise positioningHead electrodesSensorsImplantable ElectrodesHigh density

Devices, systems and methods that comprise or utilize implantable electrode arrays for neural stimulation and / or sensing. In some embodiments, the electrode array is implanted or inserted into the auditory nerve and is used to deliver electrical impulses to / receive data from the auditory nerve in the treatment of hearing disorders.

Owner:RGT UNIV OF CALIFORNIA

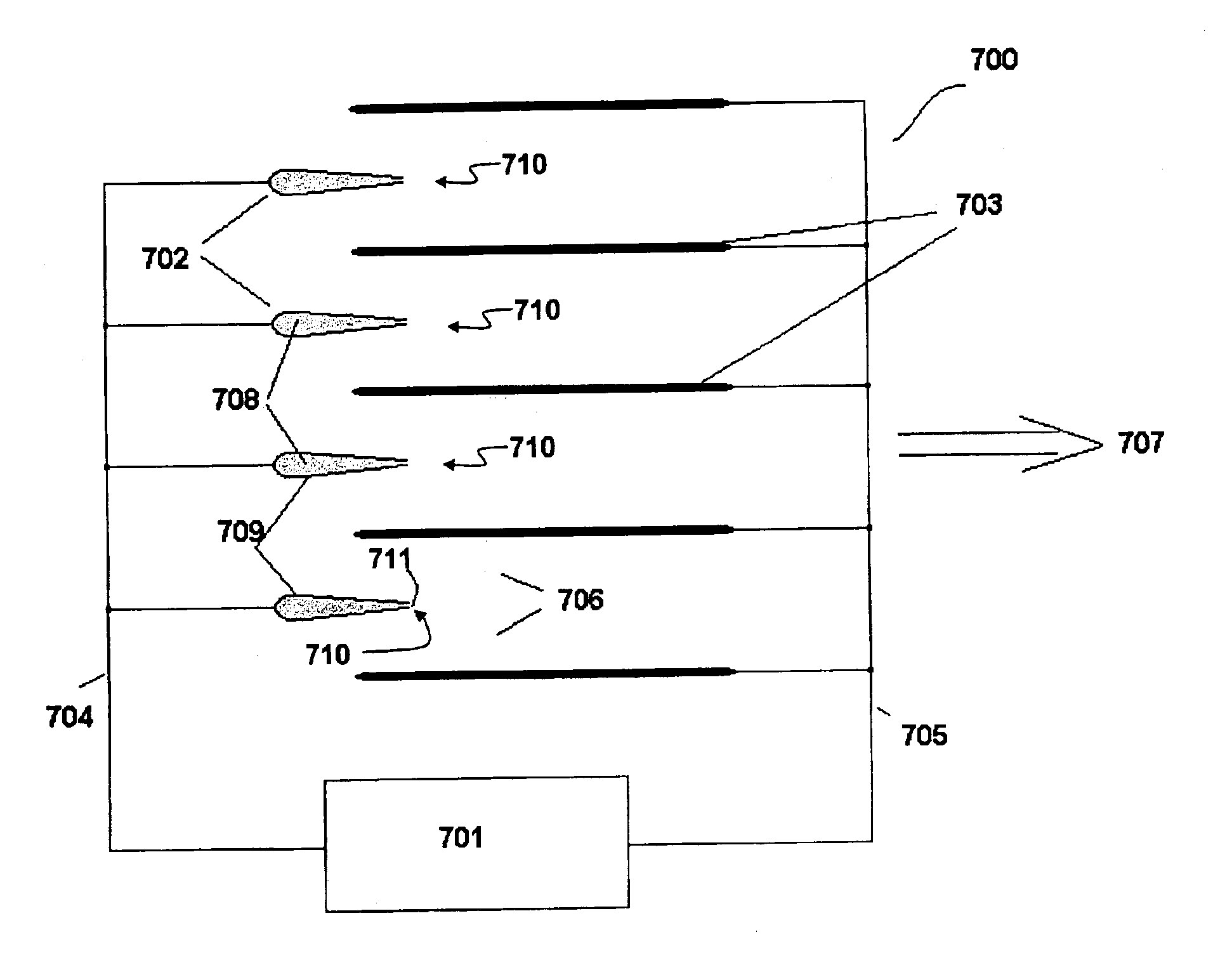

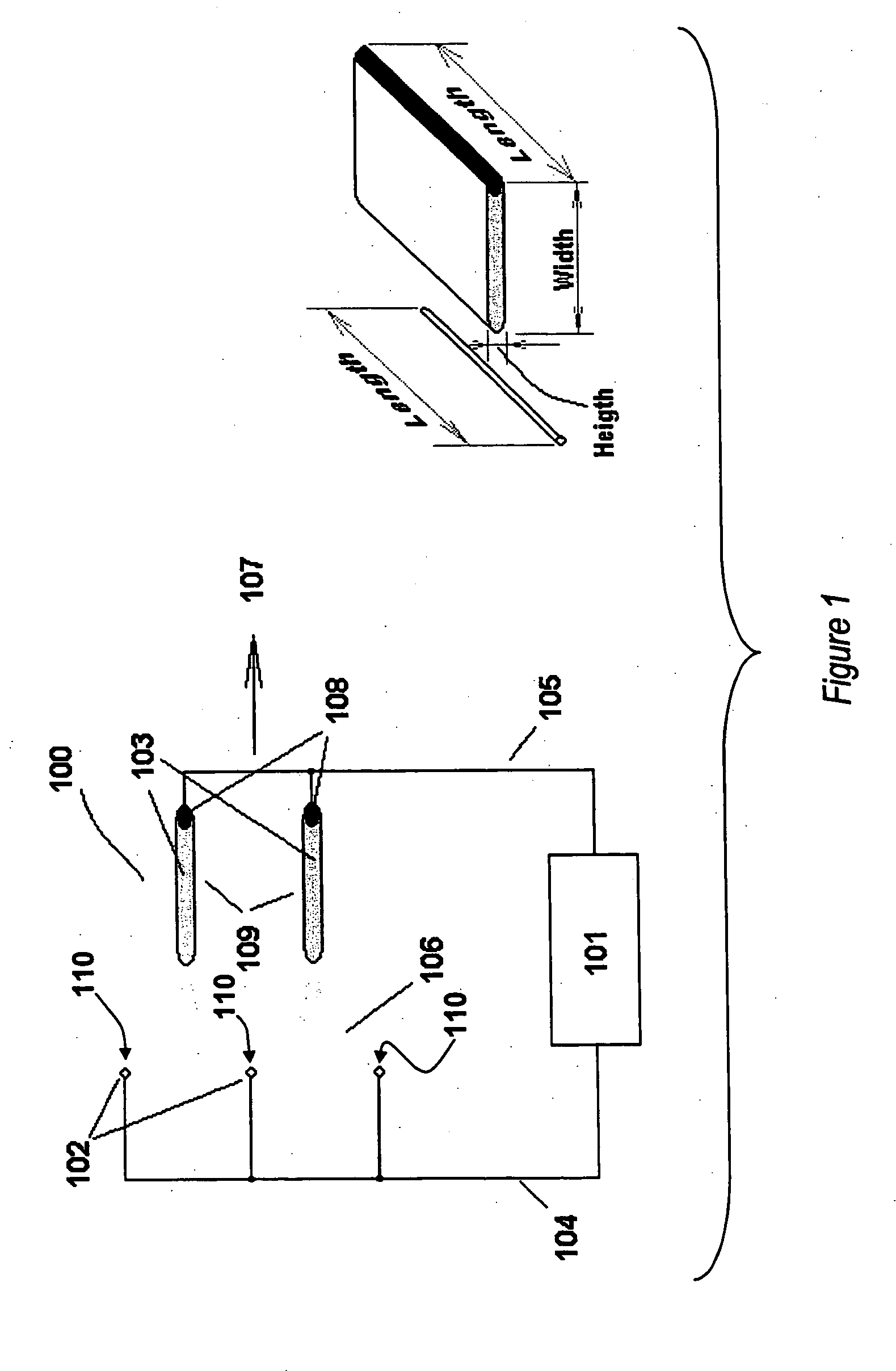

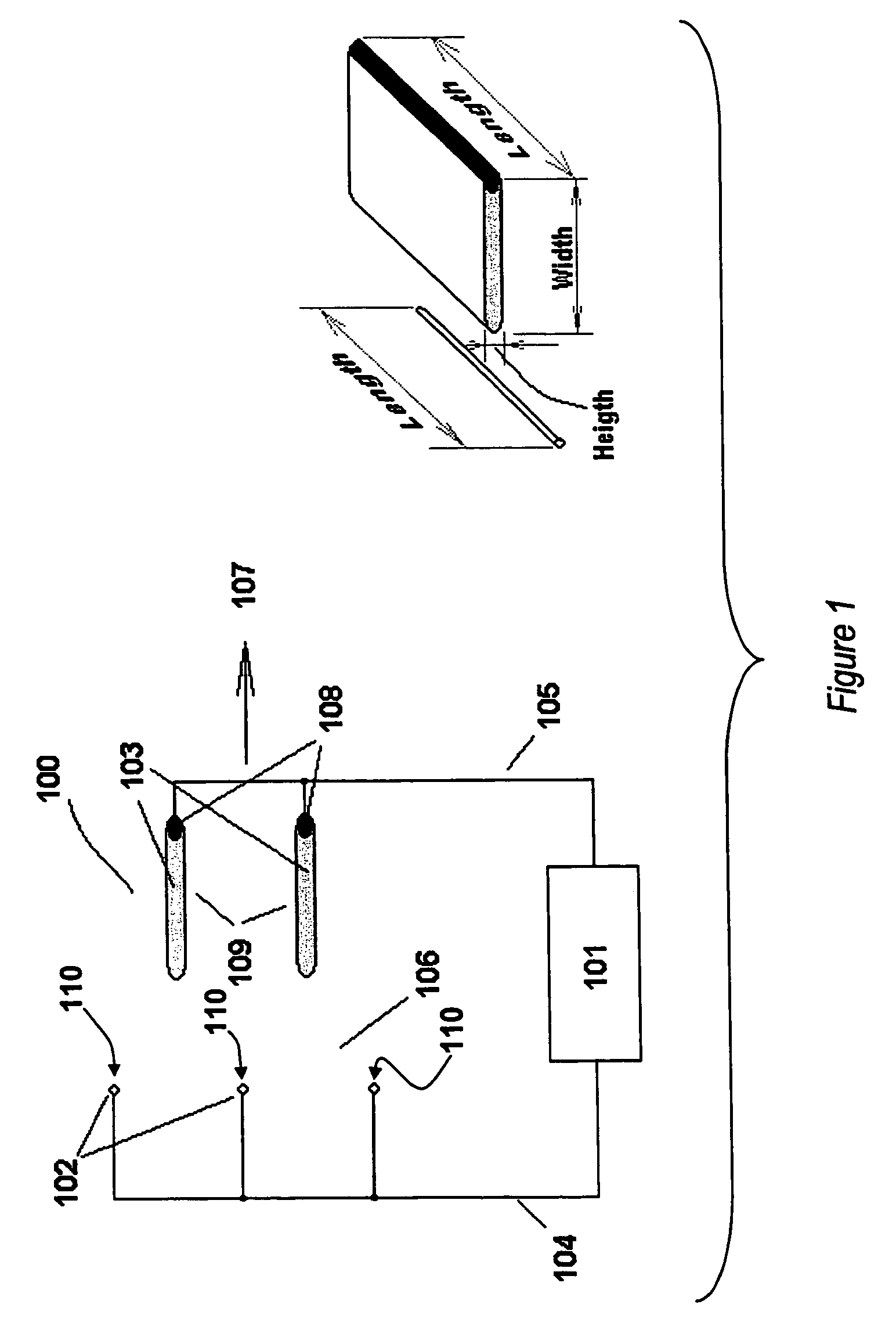

Electrostatic fluid accelerator for and method of controlling a fluid flow

InactiveUS6919698B2Increase electrode densityReduce fluid resistanceTransit-time tubesOzone preparationHigh intensityElectric field

An electrostatic fluid accelerator includes a first number of corona electrodes and a second number of accelerating electrodes spaced apart from and parallel to adjacent ones of the corona electrodes. An electrical power source is connected to supply the corona and accelerating electrodes with an operating voltage to produce a high intensity electric field in an inter-electrode space between the corona electrodes and the accelerating electrodes. The accelerating electrodes may be made of a high electrical resistivity material, each of the electrodes having mutually perpendicular length and height dimension oriented transverse to a desired fluid flow direction and a width dimension oriented parallel to the desired fluid flow direction. A length of the electrodes in a direction transverse to a desired fluid flow direction is greater than a width of the electrodes parallel to the fluid flow direction, and the width of the electrodes is at least ten times a height of the electrodes in a direction transverse to both the desired fluid flow direction and to the length.

Owner:TESSERA INC

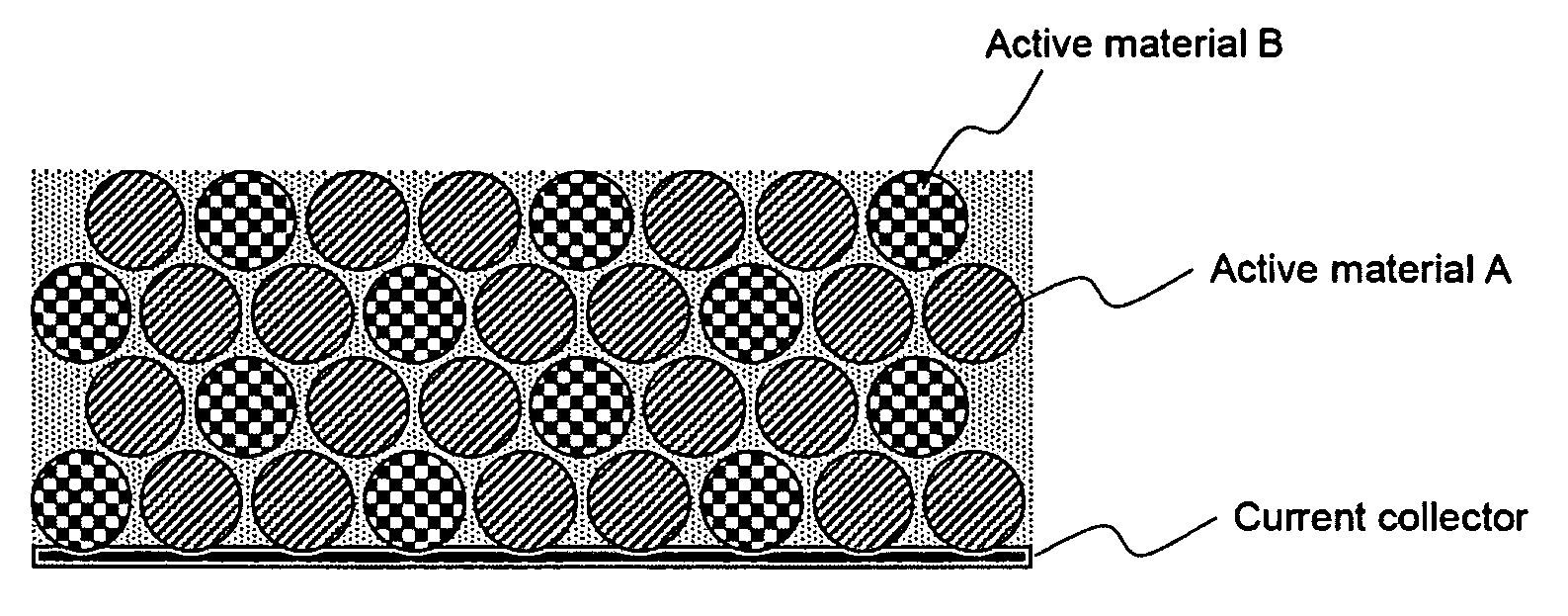

Secondary battery of improved lithium ion mobility and cell capacity

ActiveUS20060204845A1Improve discharge characteristicsIncrease battery capacityPositive electrodesBedsLithiumHigh rate

Provided is a lithium secondary battery having improved discharge characteristics in a range of high-rate discharge while minimizing a dead volume and at the same time, having increased cell capacity via increased electrode density and electrode loading amounts, by inclusion of two or more active materials having different redox levels so as to exert superior discharge characteristics in the range of high-rate discharge via sequential action of cathode active materials in a discharge process, and preferably having different particle diameters.

Owner:LG ENERGY SOLUTION LTD

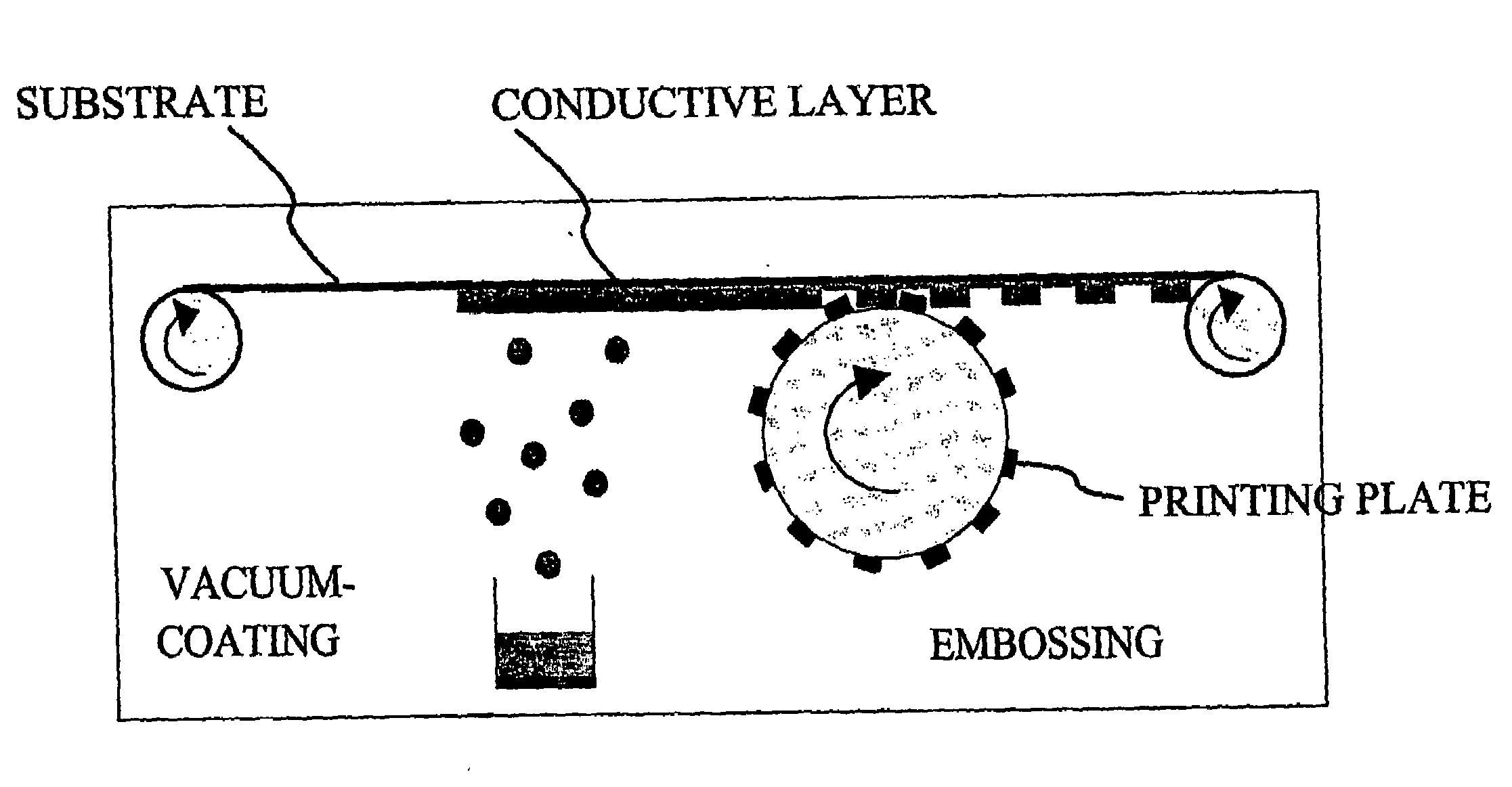

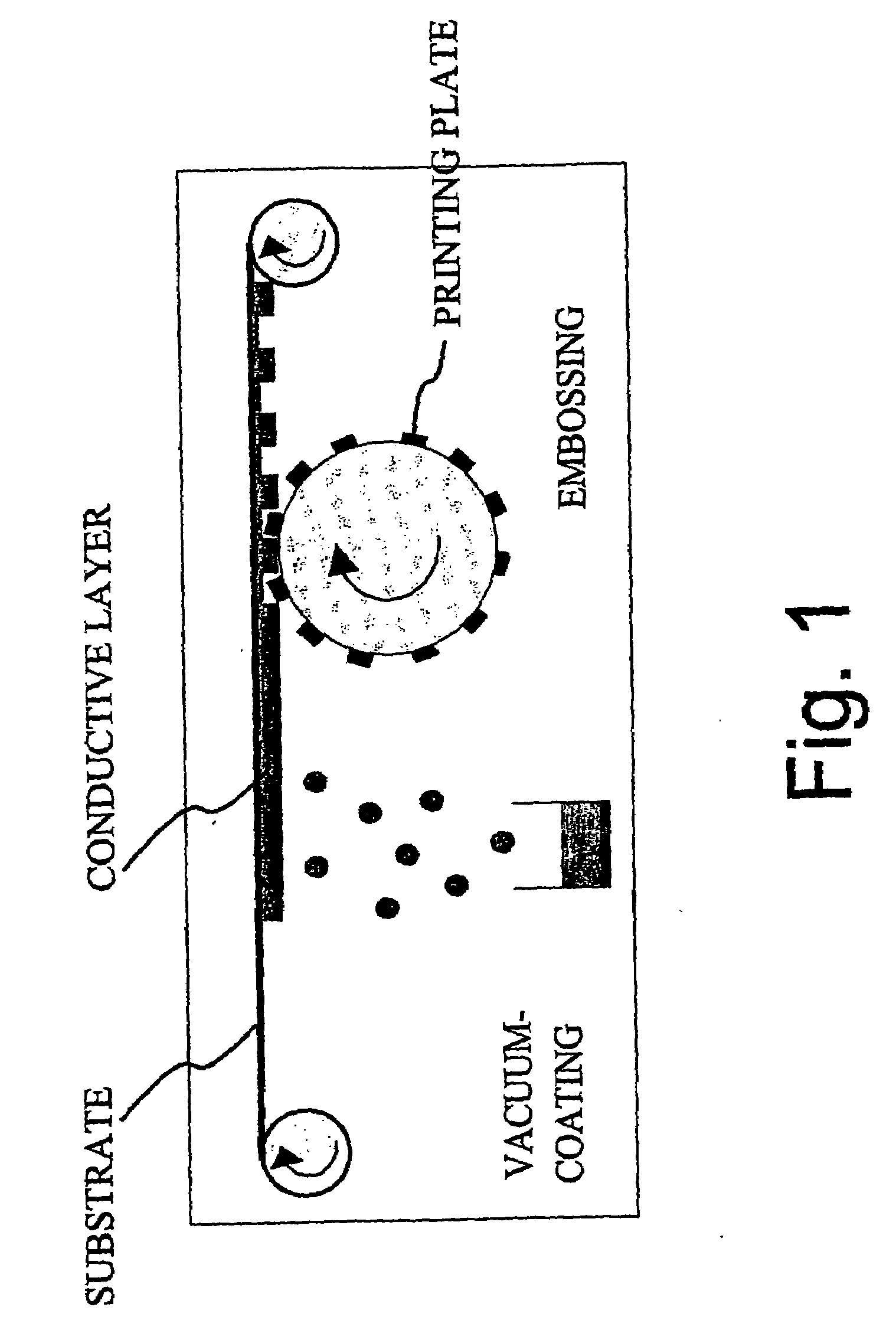

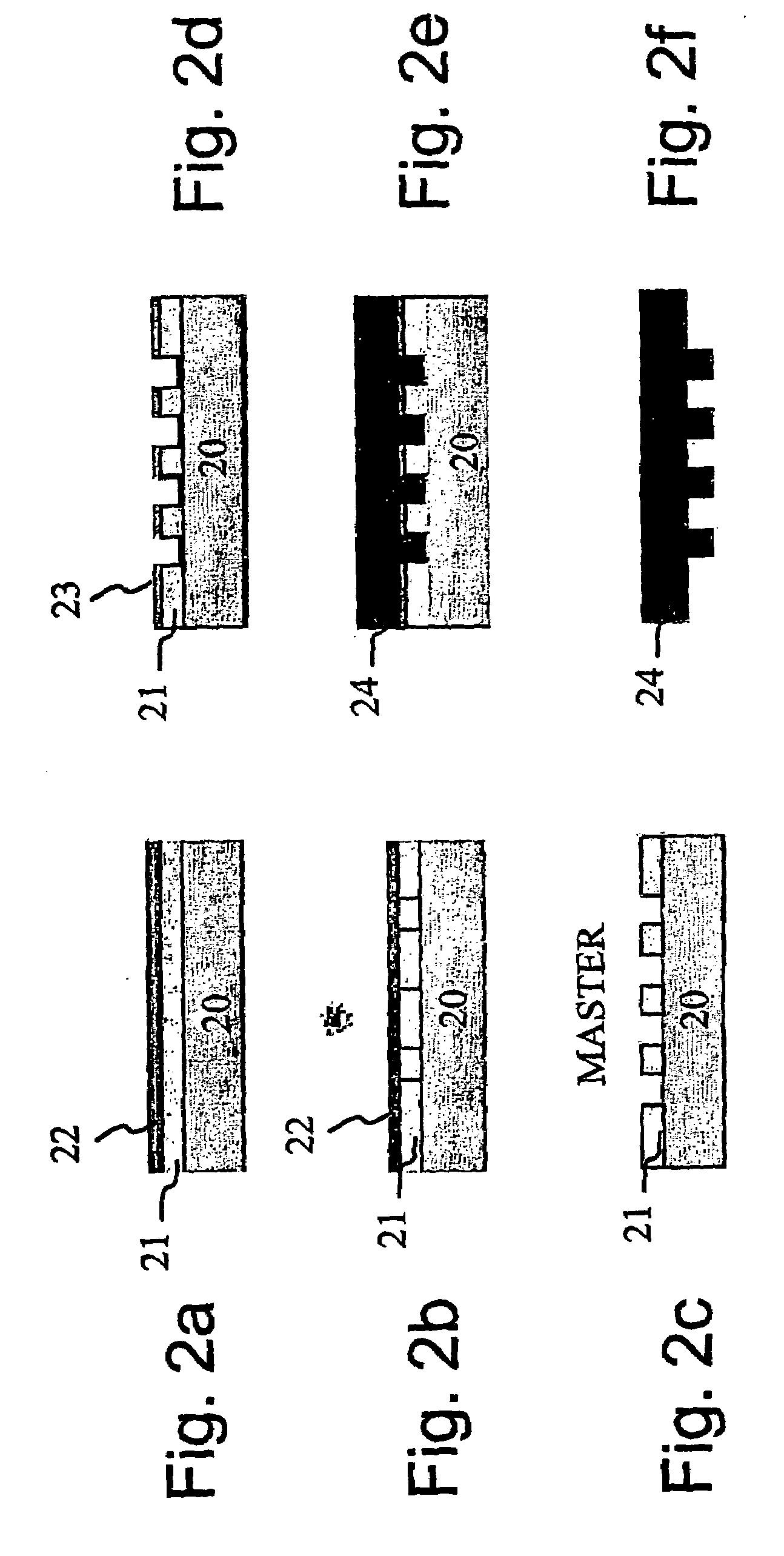

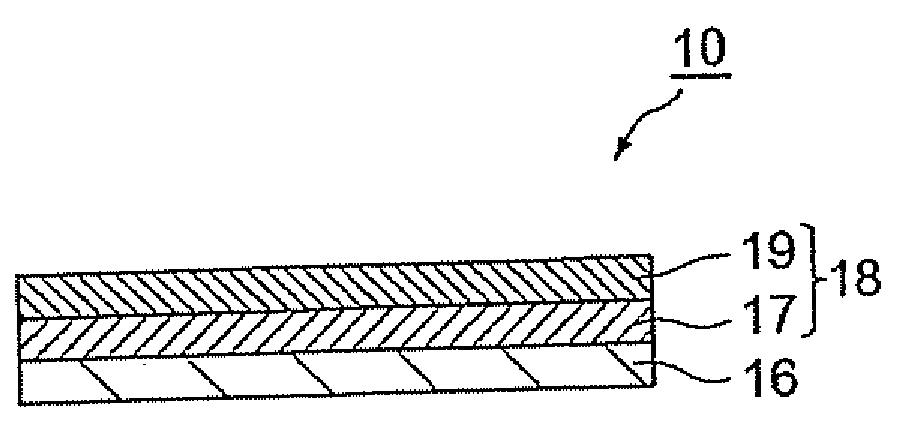

Method and an Apparatus for Manufacturing an Electronic Thin-Film Component and an Electronic Thin-Film Component

InactiveUS20080012151A1Increase contactSurface area of efficientlyLiquid surface applicatorsFinal product manufactureDielectric substrateConductive materials

A method for manufacturing an electronic thin-film component, an apparatus implementing the method, and an electronic thin-film component manufactured according to the method. A lowermost, galvanically uniform conductive layer of electrically conductive material is first formed on a substantially dielectric substrate, from which lowermost conductive layer conductive areas are galvanically separated from each other to form an electrode pattern. On top of the electrode pattern it is then possible to form one or several upper passive or active layers required in the thin-film component. The separation of the lowermost conductive layer into an electrode pattern takes place by exerting on the lowermost conductive layer a machining operation based on die-cut embossing, i.e. embossing, wherein the relief of the machining member used in the machining operation causes a permanent deformation on the substrate and at the same time embosses areas from the conductive layer into conductive areas galvanically separated from each other. The method and apparatus are suitable for manufacturing thin-film components in a roll-to-roll process.

Owner:AVANTONE OY

Composite material containing a mixed lithium-metal oxide

InactiveUS20120129052A1High compression densityIncrease electrode densityMaterial nanotechnologySecondary cellsLithium metalLithium-ion battery

A composite material containing particles, in part provided with a pyrocarbon coating, of a mixed lithium metal oxide, as well as particles, in part provided with a pyrocarbon layer, of elementary carbon. Also, a process for producing such a composite material as well as an electrode containing the composite material and a secondary lithium-ion battery containing an electrode comprising the composite material.

Owner:JOHNSON MATTHEY PLC

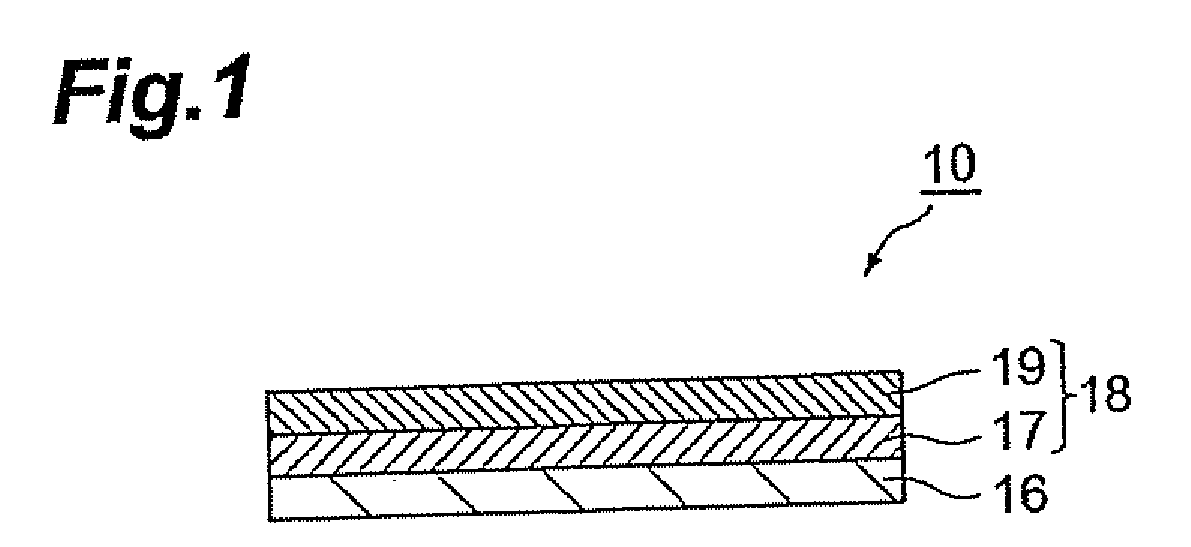

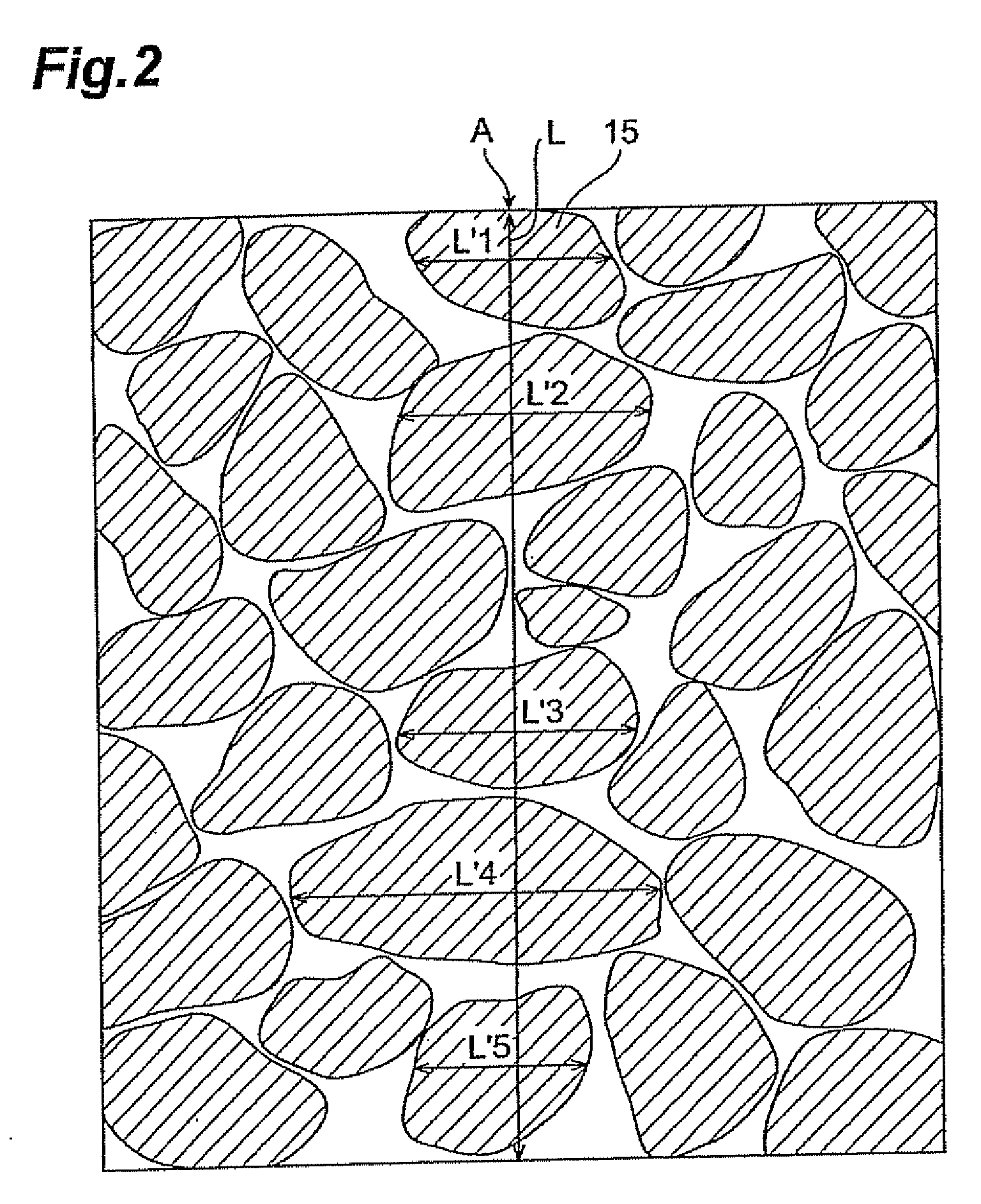

Positive electrode for secondary battery, and secondary battery

ActiveUS20150050555A1Prevent crackingReduce stressNon-aqueous electrolyte accumulator electrodesLi-accumulatorsPolymer chemistryMeth-

A positive electrode for a secondary battery wherein the electrode includes a collector and a positive electrode active material layer which is stacked upon the collector, and which includes a positive electrode active material, a conductive agent, and a binder; the binder includes a first polymer and a second polymer; the first polymer is a fluorine-containing polymer; the second polymer includes a polymerized moiety having a nitrile group, a polymerized moiety having a hydrophilic group, a polymerized (meth)acrylic acid ester moiety, and a straight-chain polymerized alkylene moiety having a carbon number of at least 4; the proportion of the first polymer and the second polymer in the binder, expressed as a mass ratio, is in the range of 95:5 to 5:95.

Owner:ZEON CORP

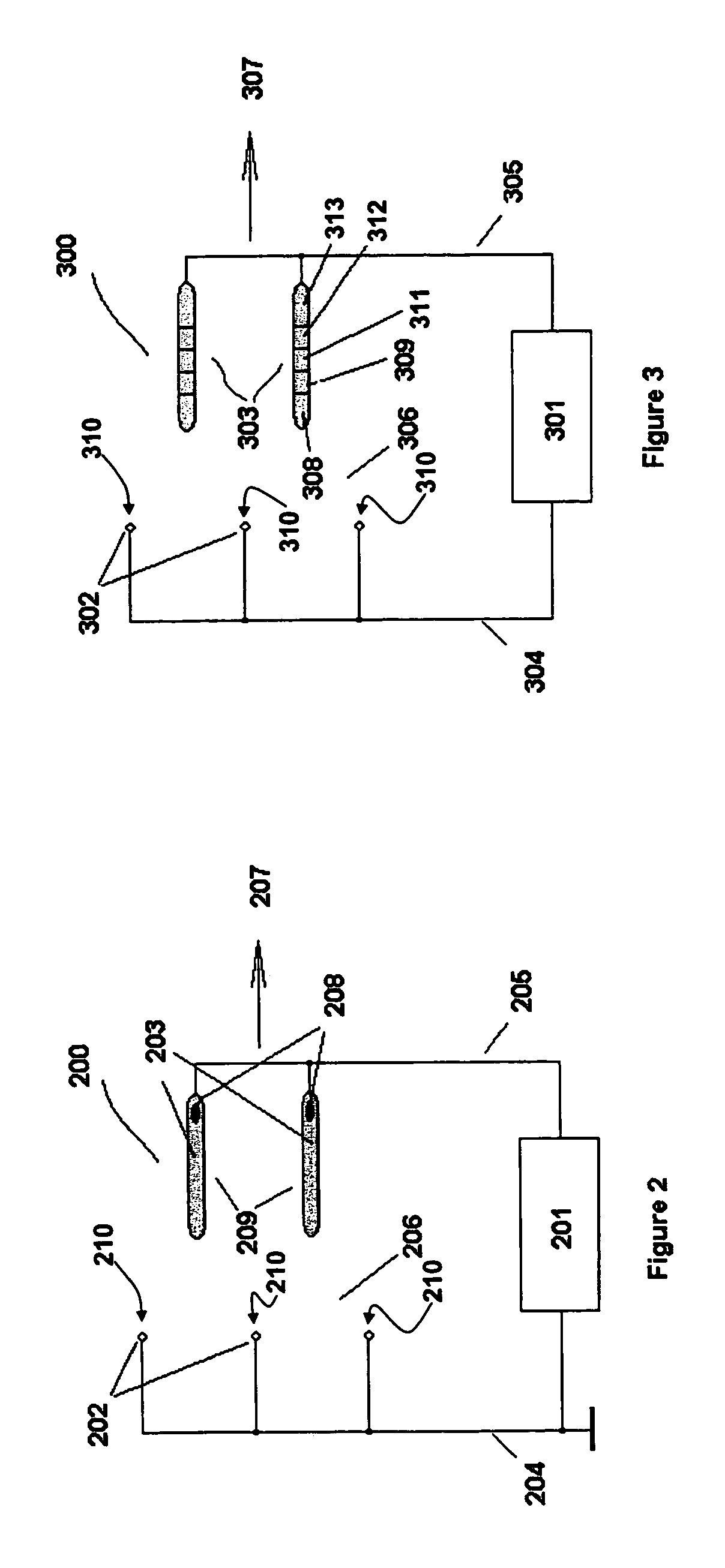

Electrostatic fluid accelerator for and method of controlling a fluid flow

InactiveUS20050151490A1Efficiently employedIncrease fluid velocityOzone preparationElectric supply techniquesHigh intensityElectric field

An electrostatic fluid accelerator includes a first number of corona electrodes and a second number of accelerating electrodes spaced apart from and parallel to adjacent ones of the corona electrodes. An electrical power source is connected to supply the corona and accelerating electrodes with an operating voltage to produce a high intensity electric field in an inter-electrode space between the corona electrodes and the accelerating electrodes. The accelerating electrodes may be made of a high electrical resistivity material, each of the electrodes having mutually perpendicular length and height dimension oriented transverse to a desired fluid flow direction and a width dimension oriented parallel to the desired fluid flow direction. A length of the electrodes in a direction transverse to a desired fluid flow direction is greater than a width of the electrodes parallel to the fluid flow direction, and the width of the electrodes is at least ten times a height of the electrodes in a direction transverse to both the desired fluid flow direction and to the length.

Owner:TESSERA INC

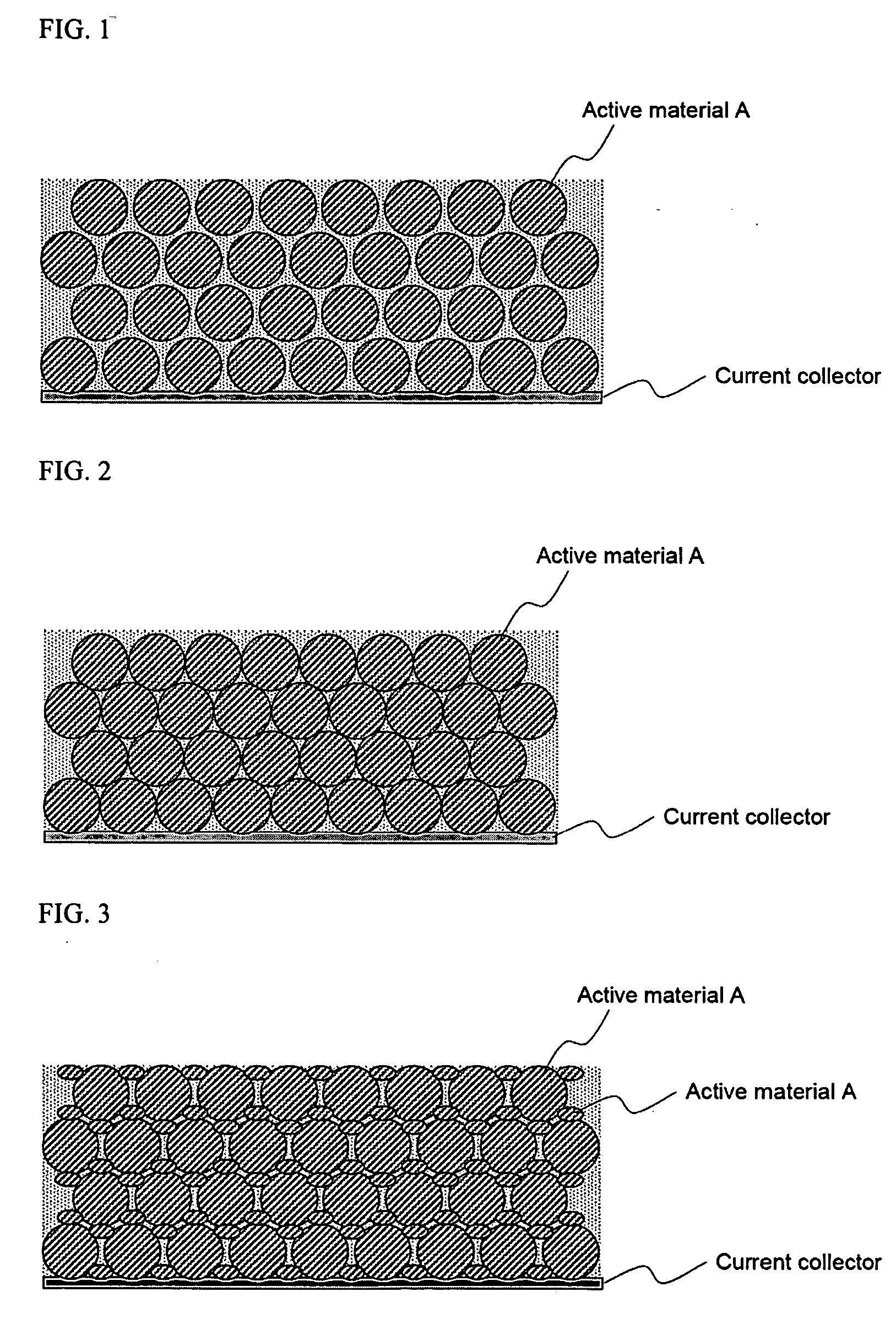

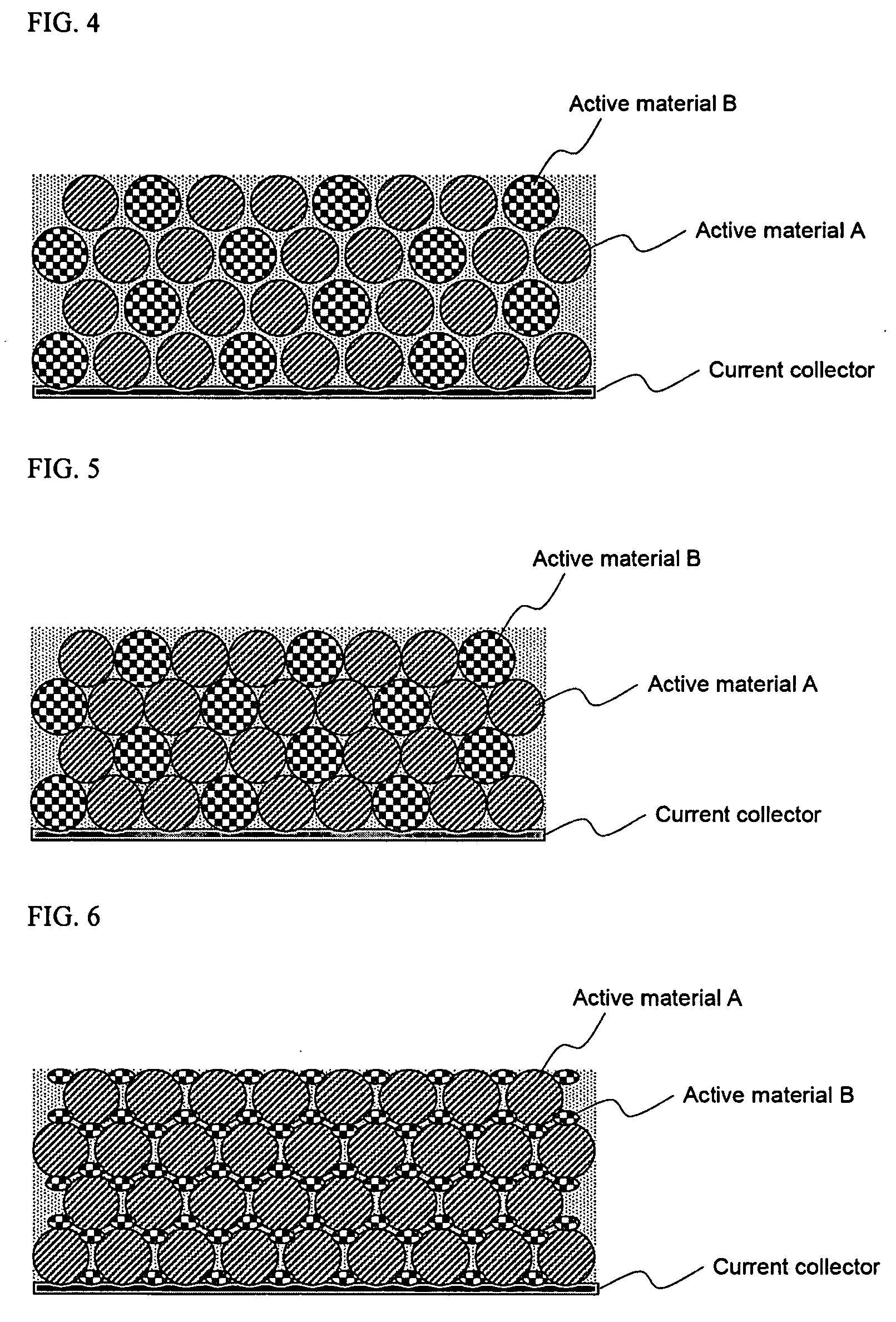

Anode and lithium-ion secondary battery

ActiveUS20080241685A1Improve high rate discharge performanceLarge capacityActive material electrodesAlkaline accumulator electrodesLithiumHigh rate

An anode for lithium-ion secondary battery is provided as one capable of ensuring sufficient safety (suppression of dendrites) while achieving a higher capacity (higher density of the electrode), and permitting formation of a lithium-ion secondary battery with excellent high-rate discharge performance. An anode for lithium-ion secondary battery has a current collector, and an active material-containing layer formed on the current collector, the active material-containing layer is comprised of an outermost layer disposed on the farthest side from the current collector, and a lower layer composed of at least one layer disposed between the outermost layer and the current collector, and a degree of flexion of the outermost layer is smaller than that of the lower layer.

Owner:TDK CORPARATION

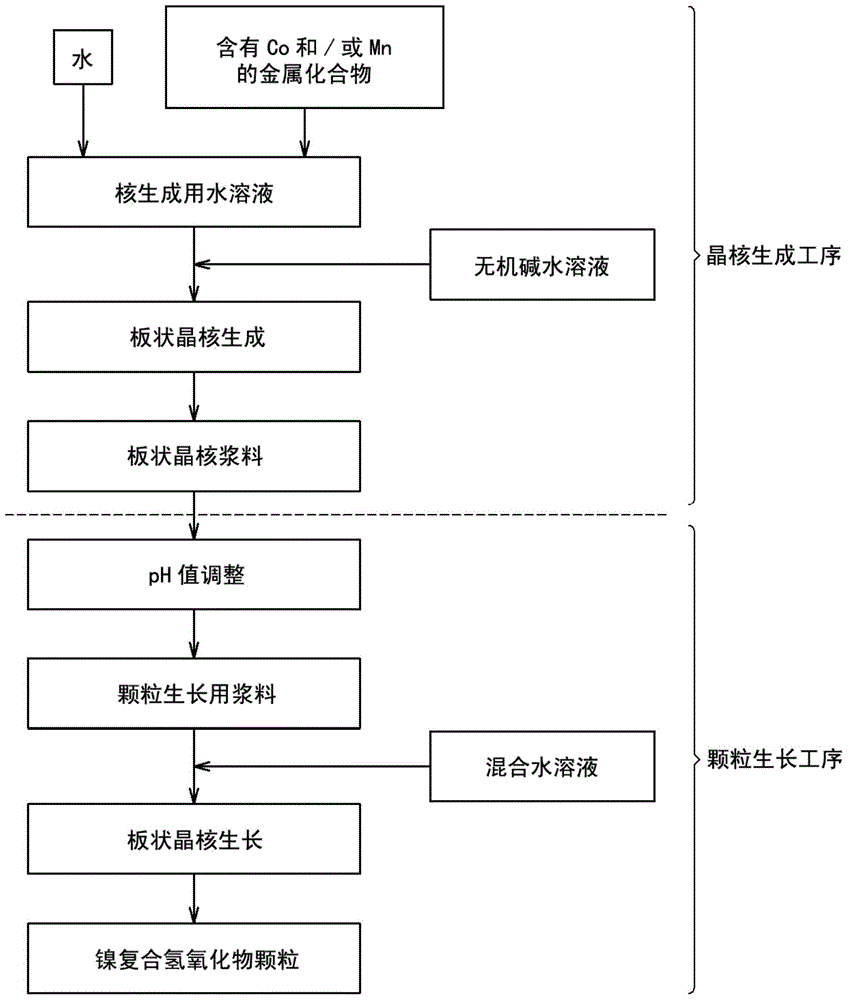

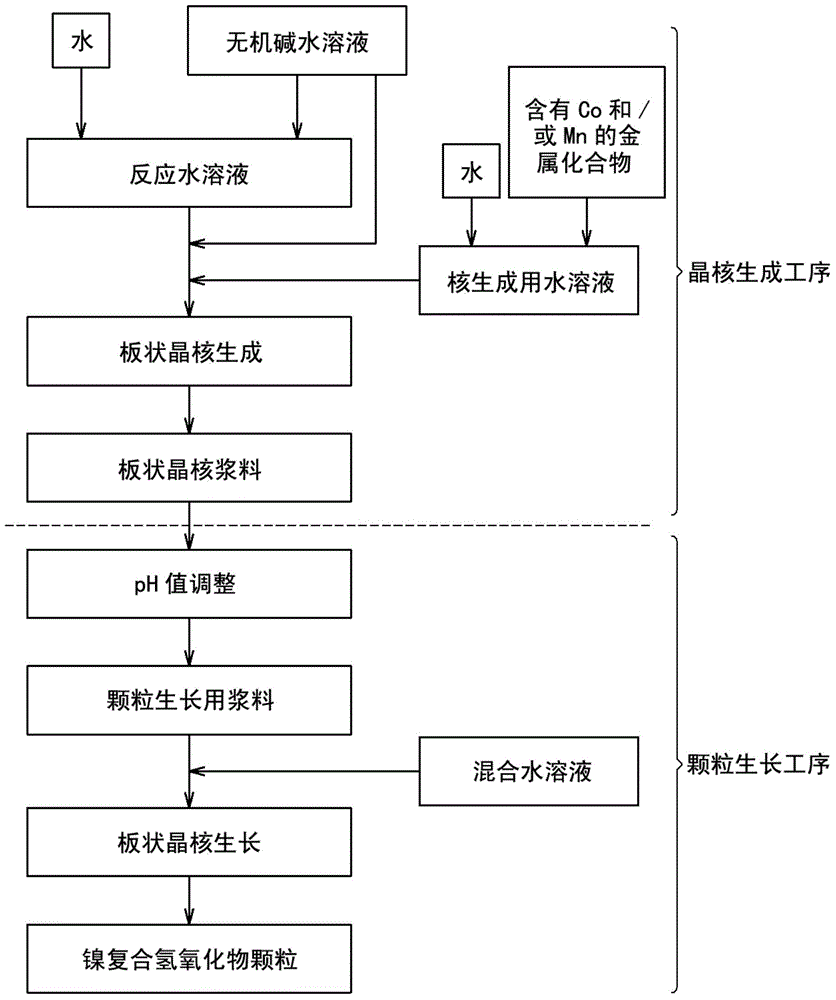

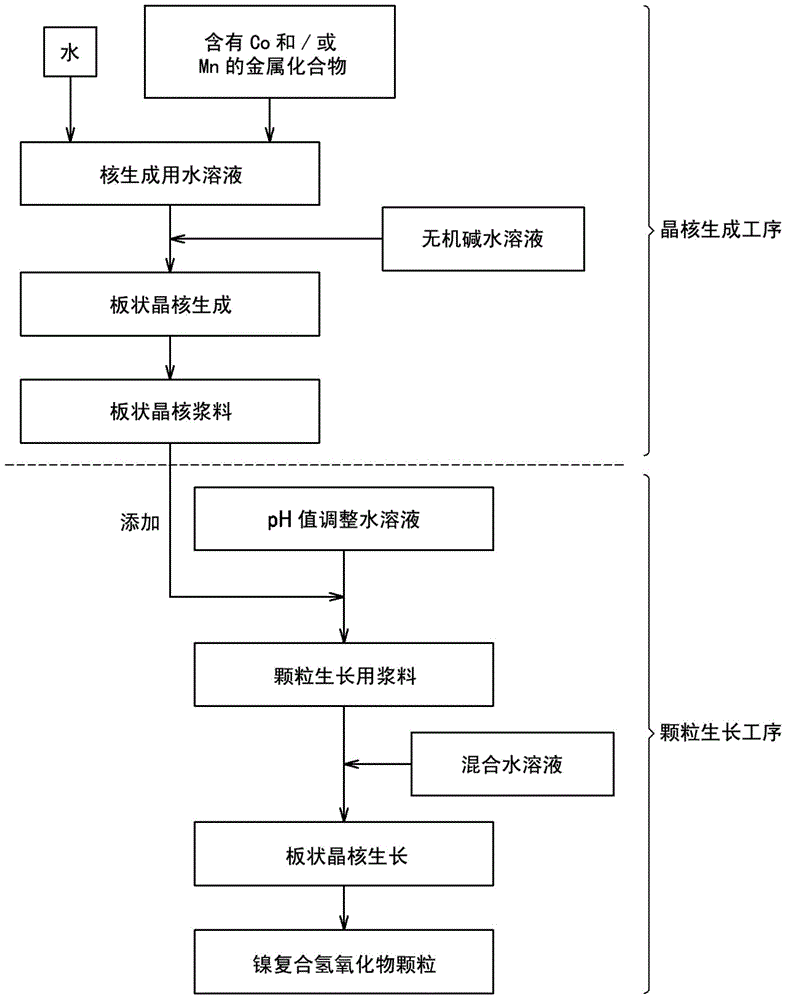

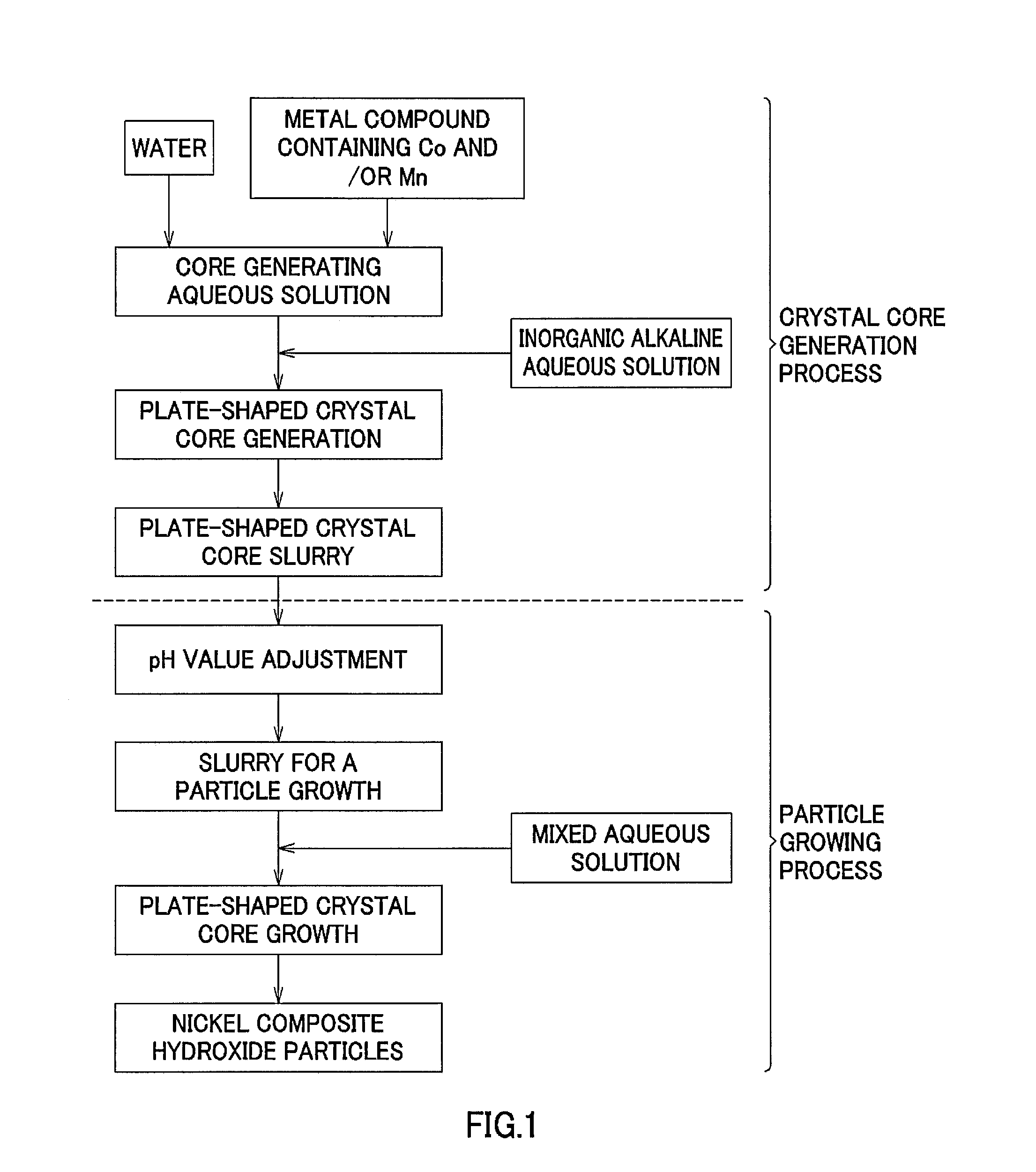

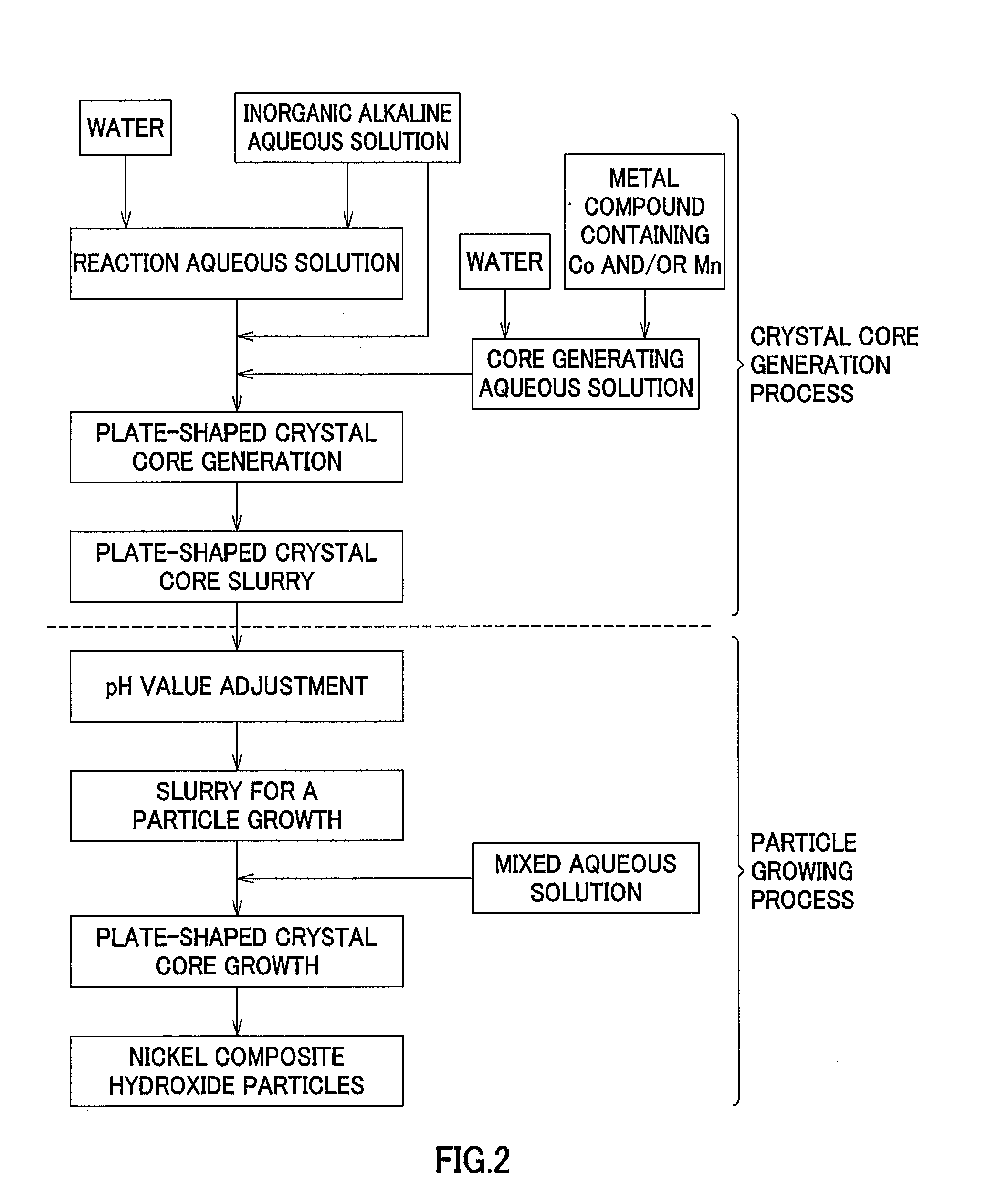

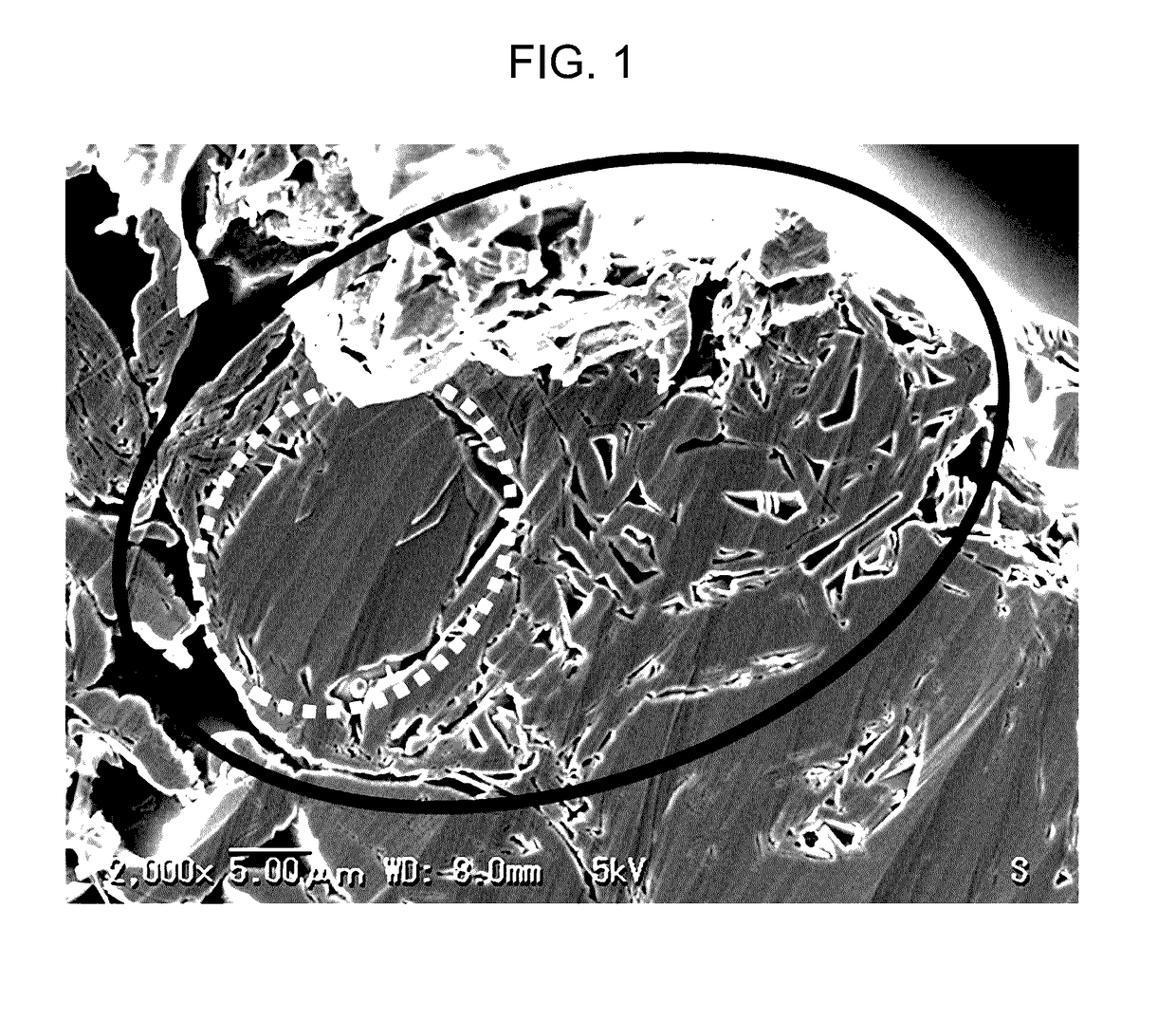

Nickel composite hydroxide and method for producing the same, positive electrode active material and method for producing the same as well as nonaqueous electrolytic secondary cell

ActiveCN103915618AIncrease electrode densityImprove featuresFrom normal temperature solutionsCell electrodesLiquid temperatureManganese

A nickel composite hydroxide represented by Ni1-x-y-zCoxMnyMz(OH)2+A (where 0<=x<=0.35, 0<=y<=0.35, 0<=z<=0.1, 0<x+y, 0<x+y+z<=0.7, 0<=A<=0.5, with M being at least one of V, Mg, Al, Ti, Mo, Nb, Zr and W), a plate-shaped crystal core is generated by allowing a crystal core generating aqueous solution containing cobalt and / or manganese to have a pH value of 7.5 to 11.1 at a standard liquid temperature of 25 DEG C., and slurry for the particle growth containing the plate-shaped crystal core is adjusted to a pH value of 10.5 to 12.5 at a standard liquid temperature of 25 DEG C., while a mixed aqueous solution containing a metal compound containing at least nickel is being supplied thereto, so that the crystal core is grown as particles.

Owner:SUMITOMO METAL MINING CO LTD

Nickel composite hydroxide and method for producing the same, positive electrode active material and method for producing the same as well as nonaqueous electrolytic secondary cell

ActiveUS20140186710A1Increase cell capacityHigh characteristicPolycrystalline material growthFrom normal temperature solutionsLiquid temperatureManganese

A nickel composite hydroxide represented by Ni1-x-y-zCoxMnyMz(OH)2+A (where 0≦x≦0.35, 0≦y≦0.35, 0≦z≦0.1, 0<x+y, 0<x+y+z≦0.7, 0≦A≦0.5, with M being at least one of V, Mg, Al, Ti, Mo, Nb, Zr and W), a plate-shaped crystal core is generated by allowing a crystal core generating aqueous solution containing cobalt and / or manganese to have a pH value of 7.5 to 11.1 at a standard liquid temperature of 25° C., and slurry for the particle growth containing the plate-shaped crystal core is adjusted to a pH value of 10.5 to 12.5 at a standard liquid temperature of 25° C., while a mixed aqueous solution containing a metal compound containing at least nickel is being supplied thereto, so that the crystal core is grown as particles.

Owner:SUMITOMO METAL MINING CO LTD

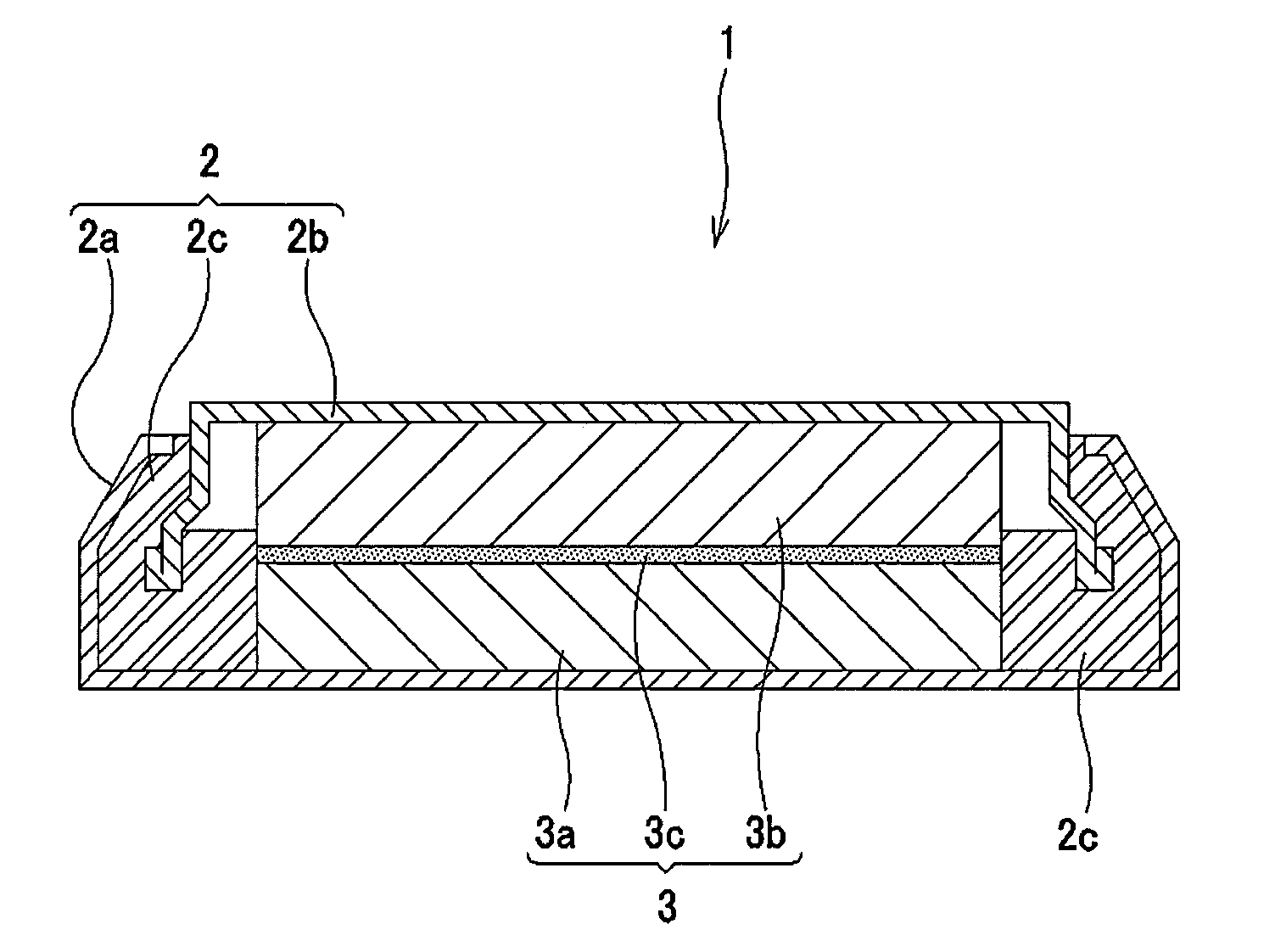

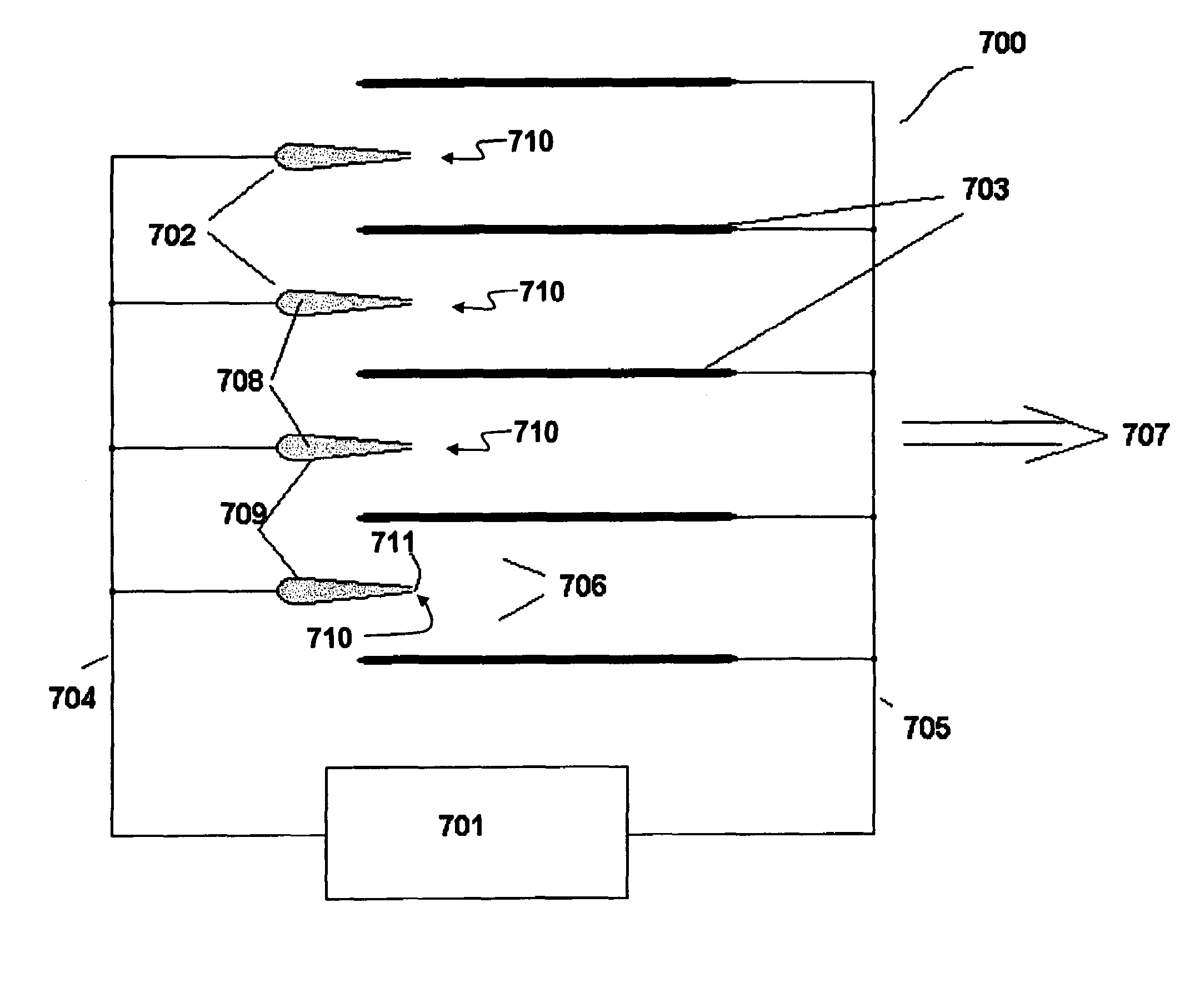

Neuro-stimulation

ActiveUS9566439B2Easy to addEasy to replaceElectric signal transmission systemsInternal electrodesEngineeringSignal restoration

The invention is a distributed implantable neuro-stimulation system, comprising an implant controller including control logic to transmit two time-varying power signals, varying between two levels and out of phase with the other, and a command signal modulated onto at least one of the power signals. One or more electrode cells, each having control logic to extract charge from the power signals and recover commands from the command signal. A two-wire bus interconnecting the implant controller and all the electrode cells, to carry one of the time varying signals in each of the two wires, and to carry the command signal.

Owner:SALUDA MEDICAL PTY LTD

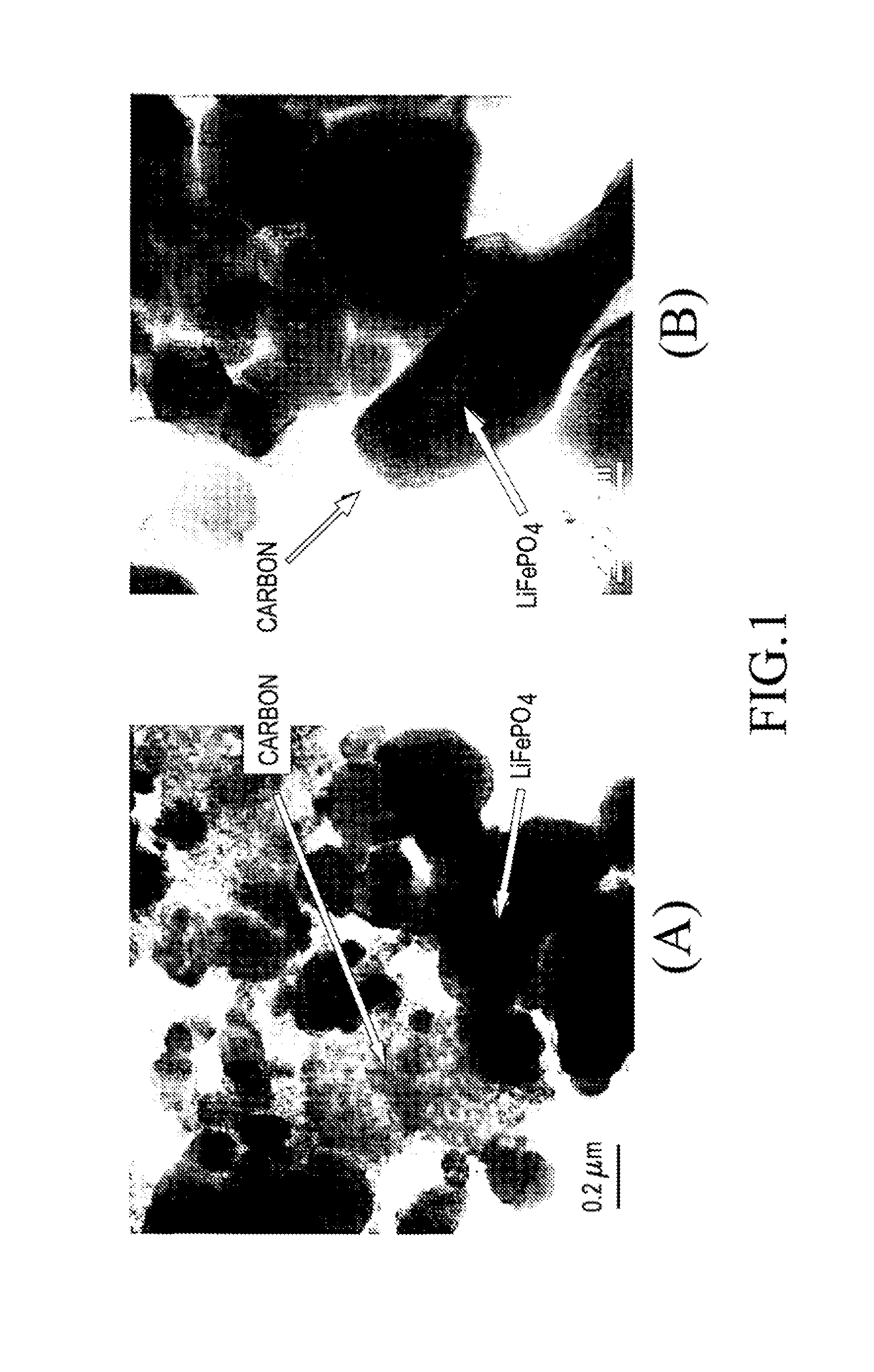

Lithium iron phosphate of olivine crystal structure and lithium secondary battery using the same

ActiveUS20130029226A1Improve conductivityAvoid separationFinal product manufactureNon-aqueous electrolyte accumulator electrodesLithium iron phosphatePhysical chemistry

Disclosed is lithium iron phosphate having an olivine crystal structure wherein carbon (C) is coated on particle surfaces of the lithium iron phosphate, wherein, when a powder of the lithium iron phosphate is dispersed in water, water is removed from the resulting dispersion and the resulting lithium iron phosphate residue is quantitatively analyzed, a ratio of the carbon-released lithium iron phosphate with respect to the total weight of the carbon-coated lithium iron phosphate is 0.005% by weight or less. Advantageously, the olivine-type lithium iron phosphate is not readily separated through uniform thin film coating on the surface of the lithium iron phosphate and exhibits superior conductivity and density, since carbon is coated on particle surfaces of lithium iron phosphate in a state in which the amount of carbon released in water is considerably small.

Owner:LG ENERGY SOLUTION LTD

Carbon-coated lithium iron phosphate of olivine crystal structure and lithium secondary battery using the same

ActiveUS20130216902A1Improve conductivityAvoid separationFinal product manufactureOperating modesChemical LinkageLithium iron phosphate

Disclosed is a lithium iron phosphate with an olivine crystal structure wherein the lithium iron phosphate has a composition represented by the following Formula 1 and carbon (C) is coated on the surface of the lithium iron phosphate by chemical bonding via a heterogeneous element other than carbon. Li1+aFe1−xMx(PO4−b)Xb (1) (wherein M, X, a, x, and b are the same as defined in the specification).

Owner:LG ENERGY SOLUTION LTD

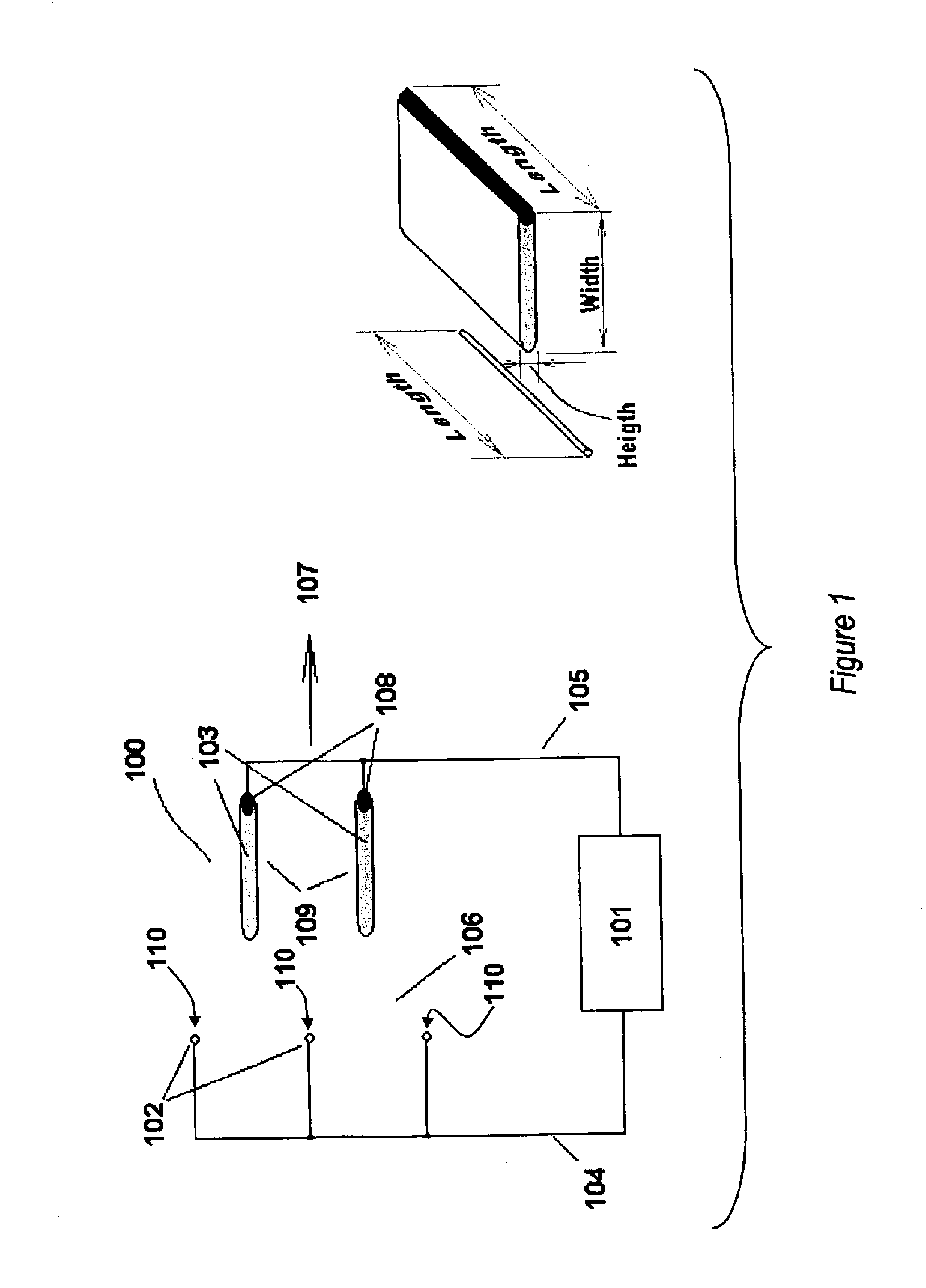

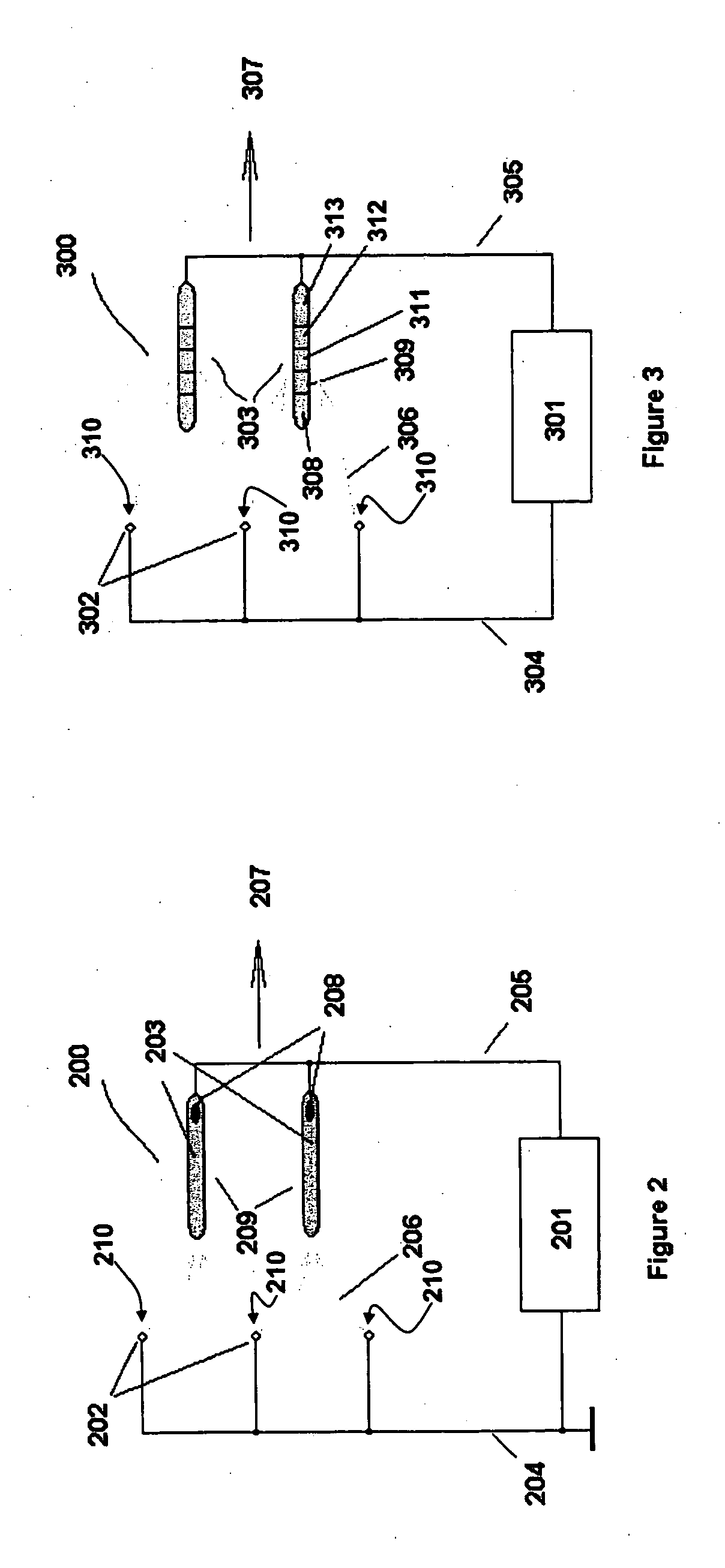

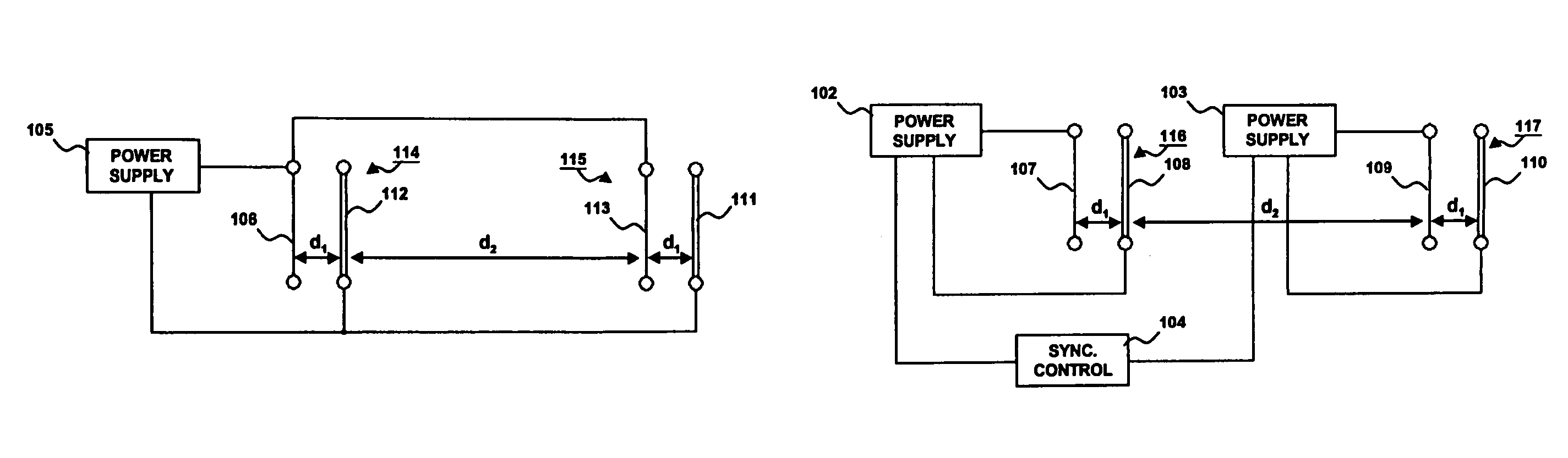

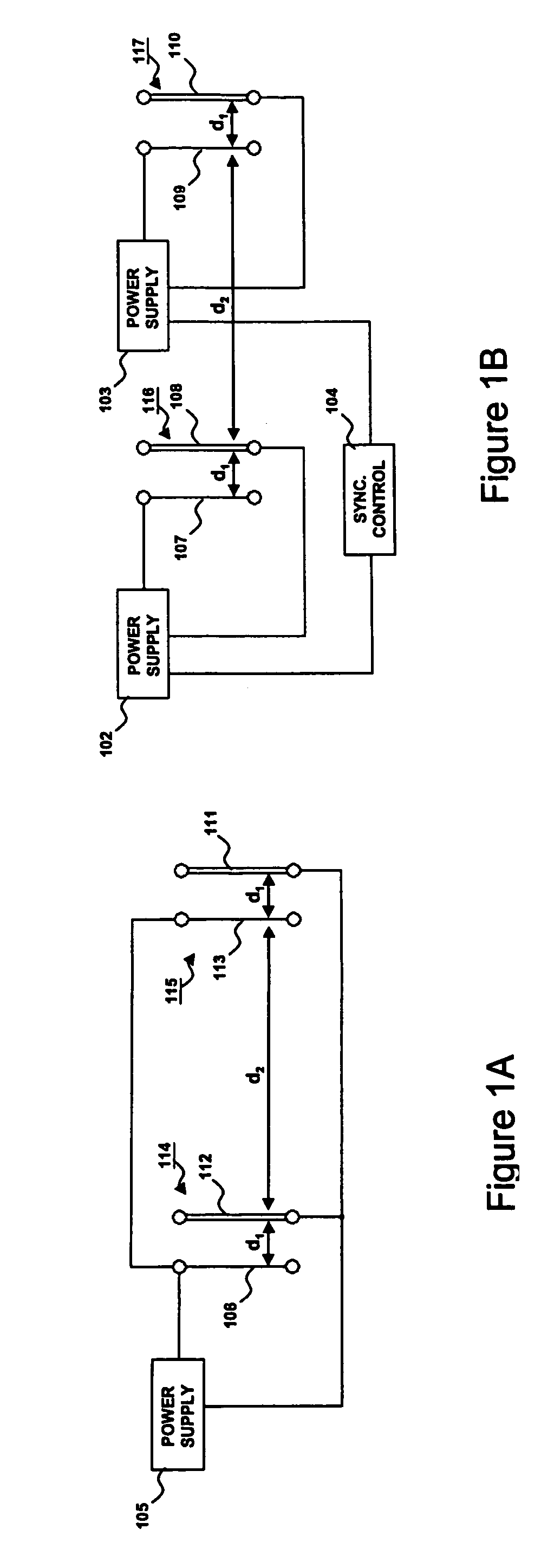

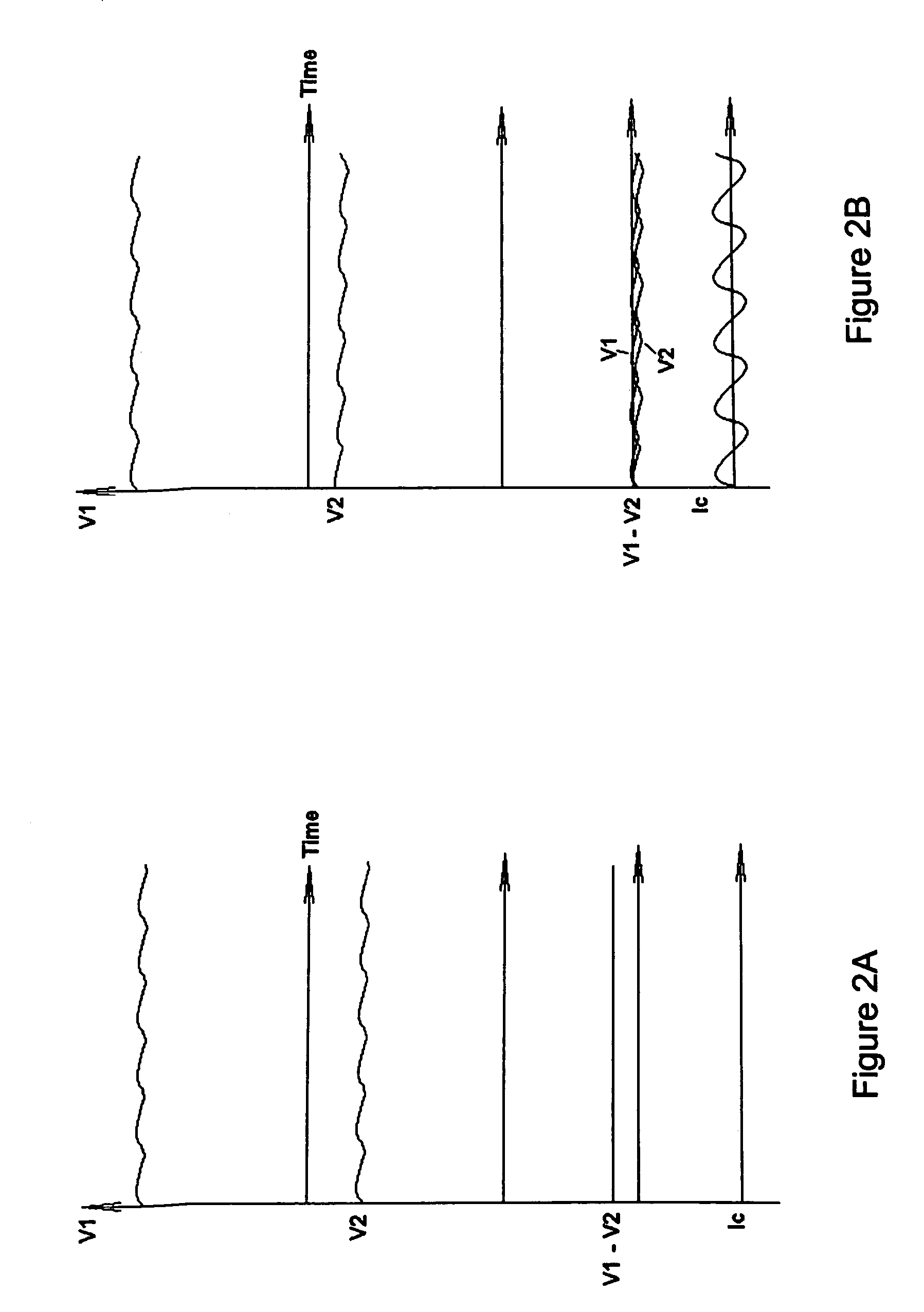

Electrostatic fluid accelerator for and a method of controlling fluid flow

InactiveUS20070046219A1Minimizing and avoiding introductionIncrease airflowTransit-time tubesDirect voltage acceleratorsPhase controlHigh pressure

An electrostatic fluid acceleration and method of operation thereof includes at least two synchronously powered stages with final or rear-most electrodes of one stage maintained at substantially the same instantaneous voltage as the immediately adjacent initial or forward-most electrodes of a next stage in an airflow direction. A single power supply or synchronized and phase controlled power supplies provide high voltage power to each of the stages such that both the phase and amplitude of the electric power applied to the corresponding electrodes are aligned in time. The frequency and phase control allows neighboring stages to be closely spaced at a distance of from 1 to 2 times an inter-electrode distance within a stage, and, in any case, minimizing or avoiding production of a back corona current from a corona discharge electrode of one stage to an electrode of a neighboring stage. Corona discharge electrodes of neighboring stages may be horizontally aligned, complementary collector electrodes of all stages being similarly horizontally aligned between and horizontally offset from the corona discharge electrodes.

Owner:KRONOS ADVANCED TECH INC

Positive electrode active material for secondary battery, positive electrode for secondary battery and secondary battery comprising the same

ActiveUS20180241036A1Increase electrode densityImprove featuresPositive electrodesLi-accumulatorsLithiumElectrical battery

The present invention provides a positive electrode active material for a secondary battery, a positive electrode for a secondary battery, and a secondary battery including the same, the positive electrode active material including a first lithium-nickel oxide particle having an average particle size (D50) of more than 8 μm to 20 μm or less, and a second lithium-nickel oxide particle having an average particle size (D50) of 8 μm or less, wherein the first lithium-nickel oxide particle has a particle strength of 100 MPa to 250 MPa, the second lithium-nickel oxide particle has a particle strength of 50 MPa to 100 MPa, a ratio r of the strength of the first lithium-nickel oxide particle to the strength of the second lithium-nickel oxide particle satisfies Equation 1 set forth herein.

Owner:LG ENERGY SOLUTION LTD

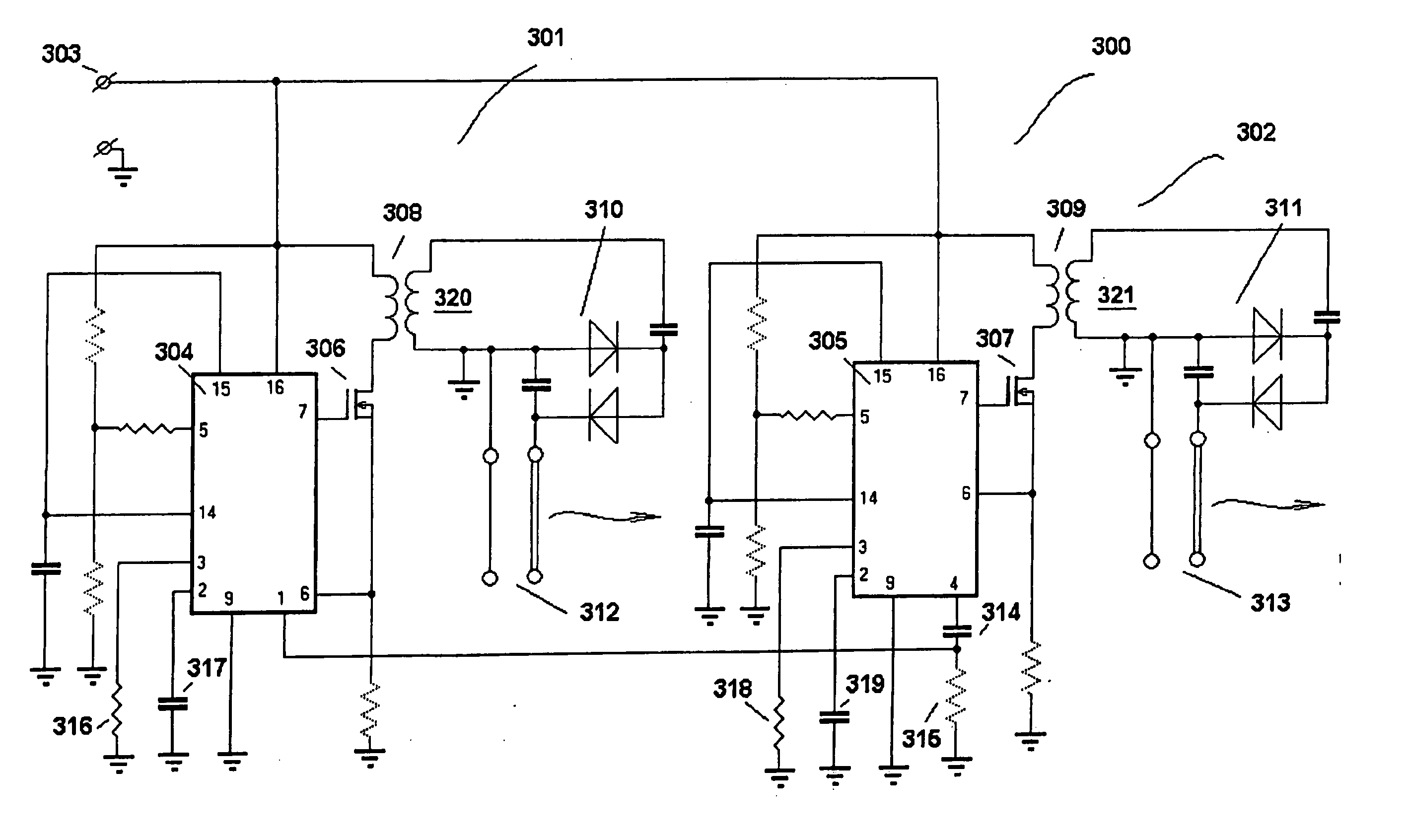

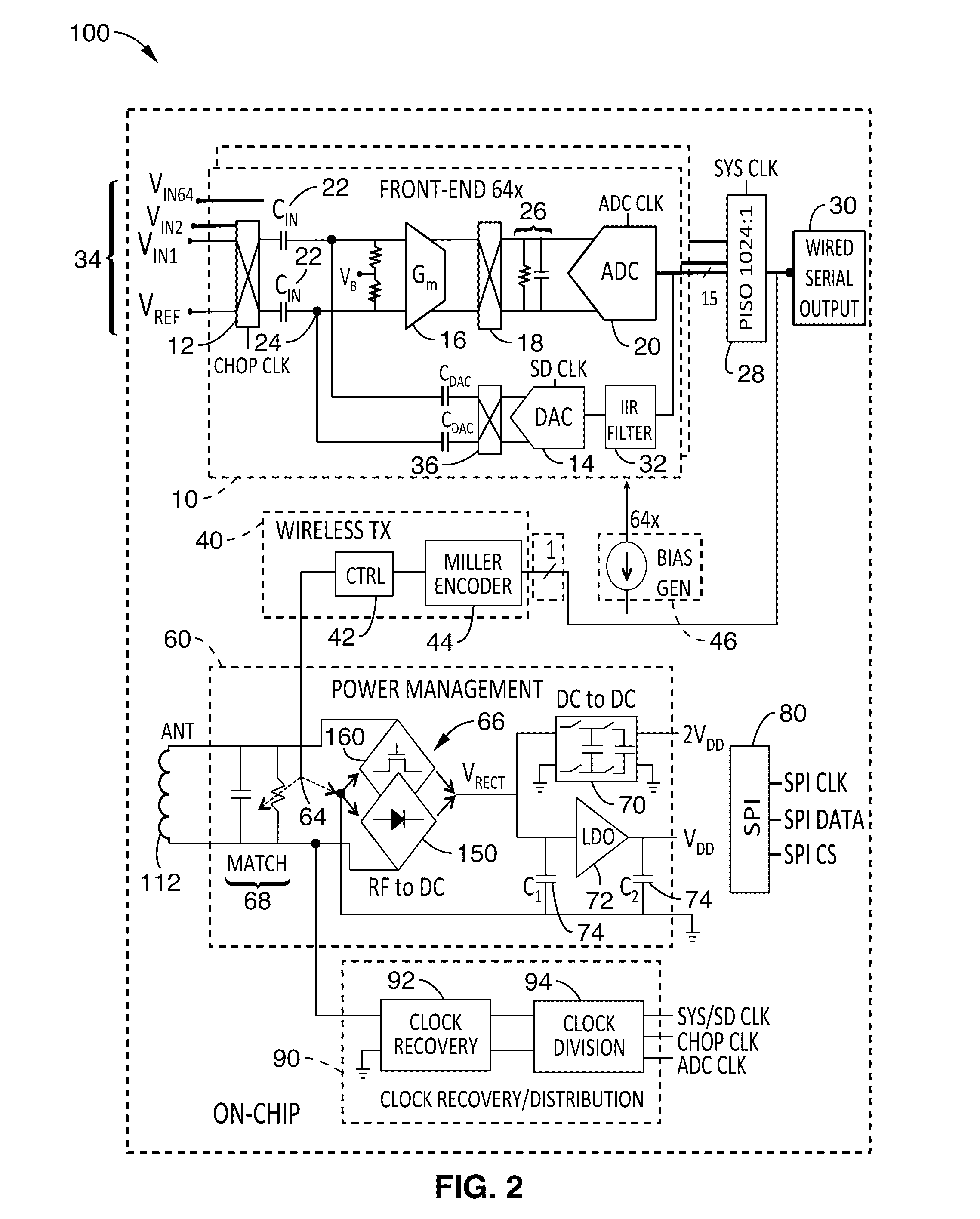

Wireless high-density micro-electrocorticographic device

InactiveUS20170031441A1Reduce cortical scarringSpatial resolution be lowInput/output for user-computer interactionSensors% area reductionForeign matter

A minimally invasive, wireless ECoG microsystem is provided for chronic and stable neural recording. Wireless powering and readout are combined with a dual rectification power management circuitry to simultaneously power to and transmit a continuous stream of data from an implant with a micro ECoG array and an external reader. Area and power reduction techniques in the baseband and wireless subsystem result in over 10×IC area reduction with a simultaneous 3× improvement in power efficiency, enabling a minimally invasive platform for 64-channel recording. The low power consumption of the IC, together with the antenna integration strategy, enables remote powering at 3× below established safety limits, while the small size and flexibility of the implant minimizes the foreign body response.

Owner:RGT UNIV OF CALIFORNIA

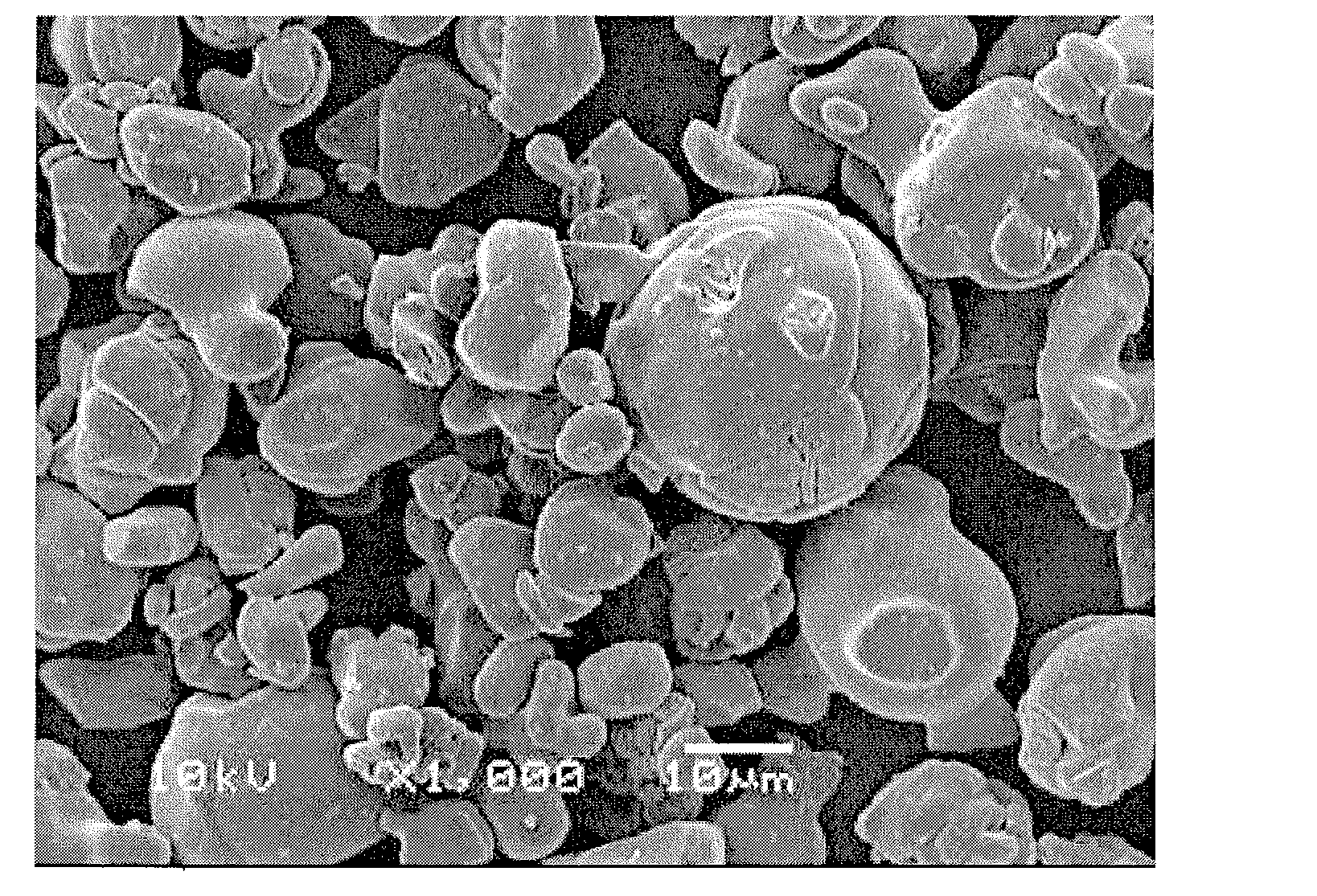

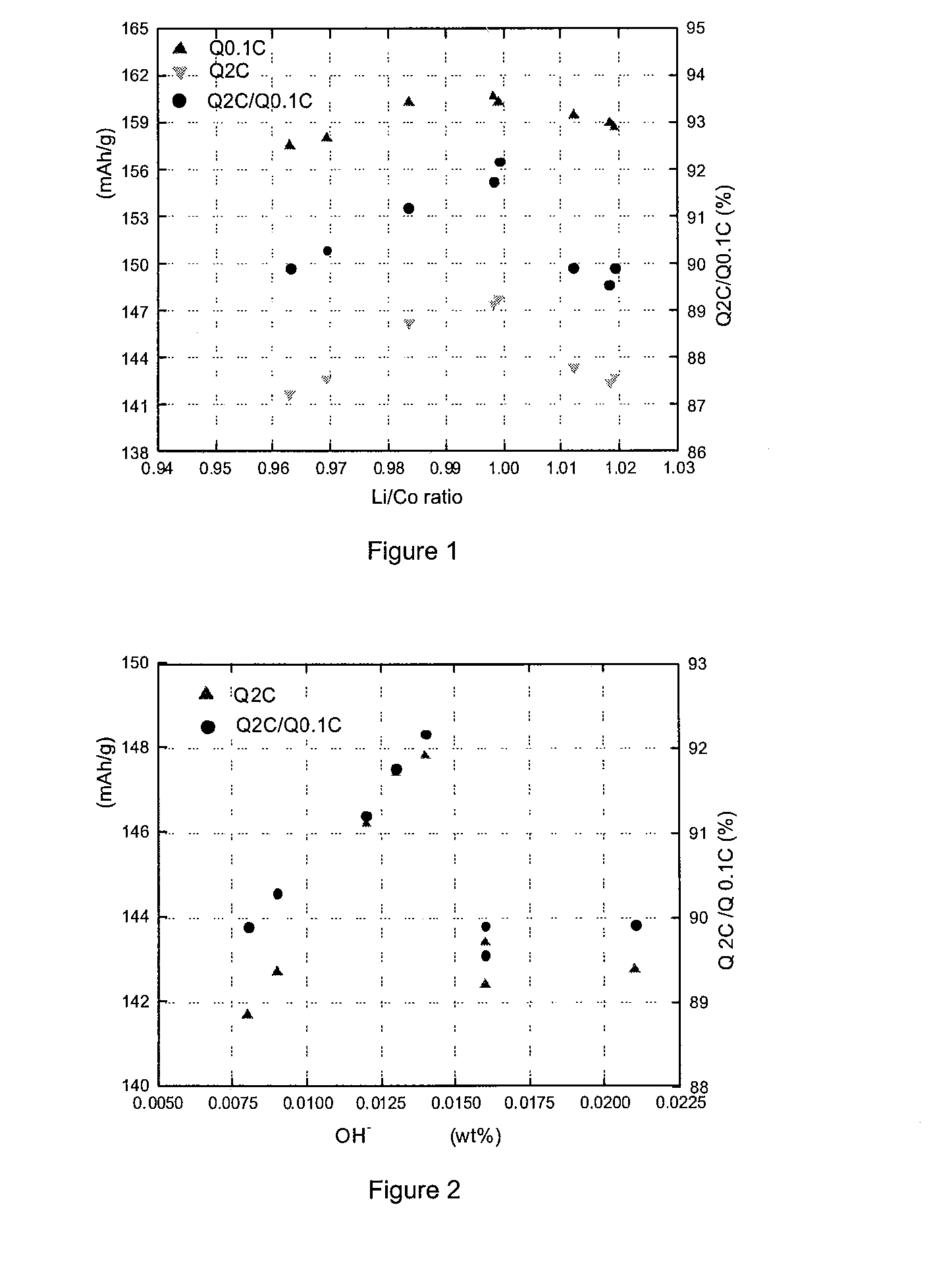

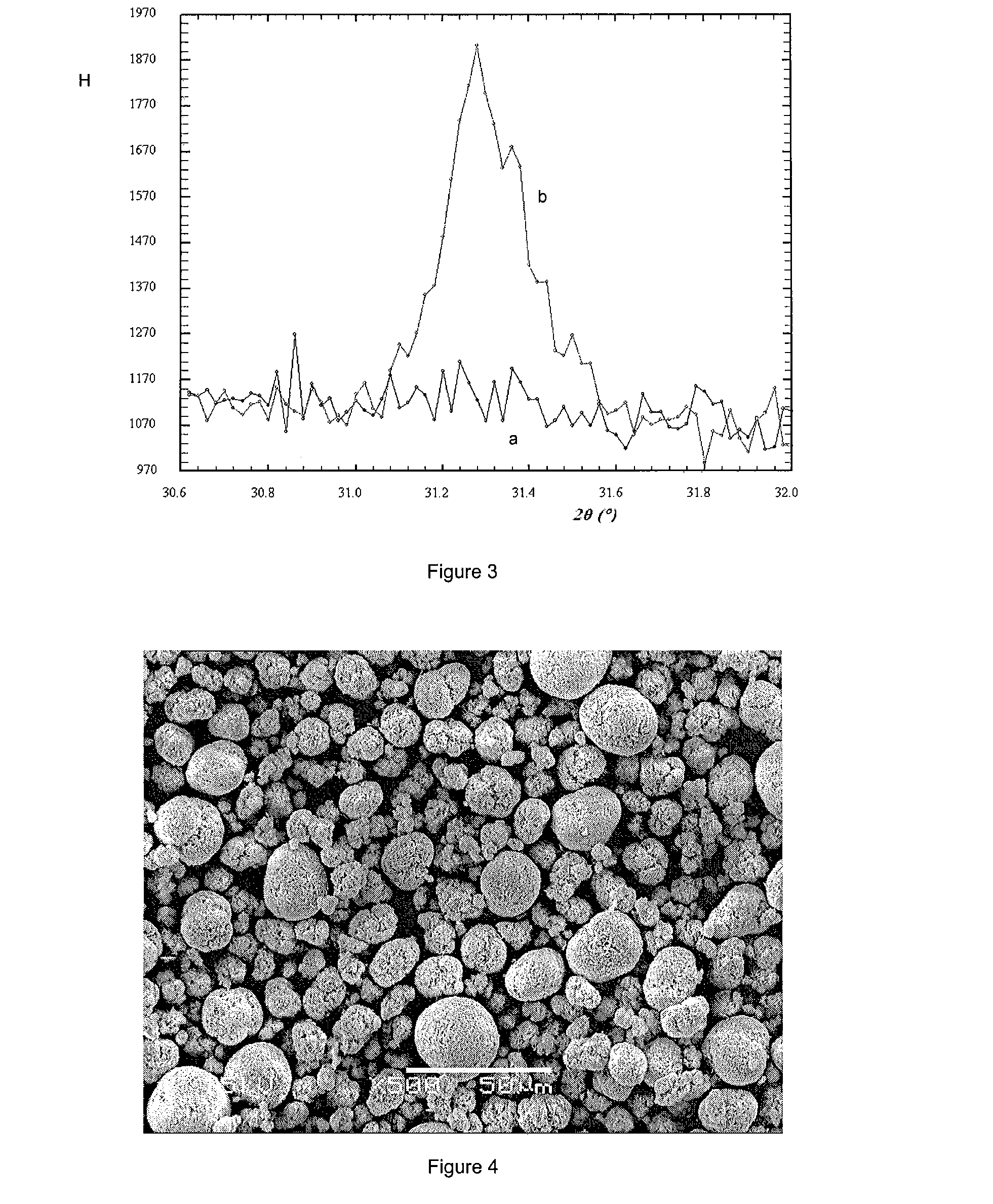

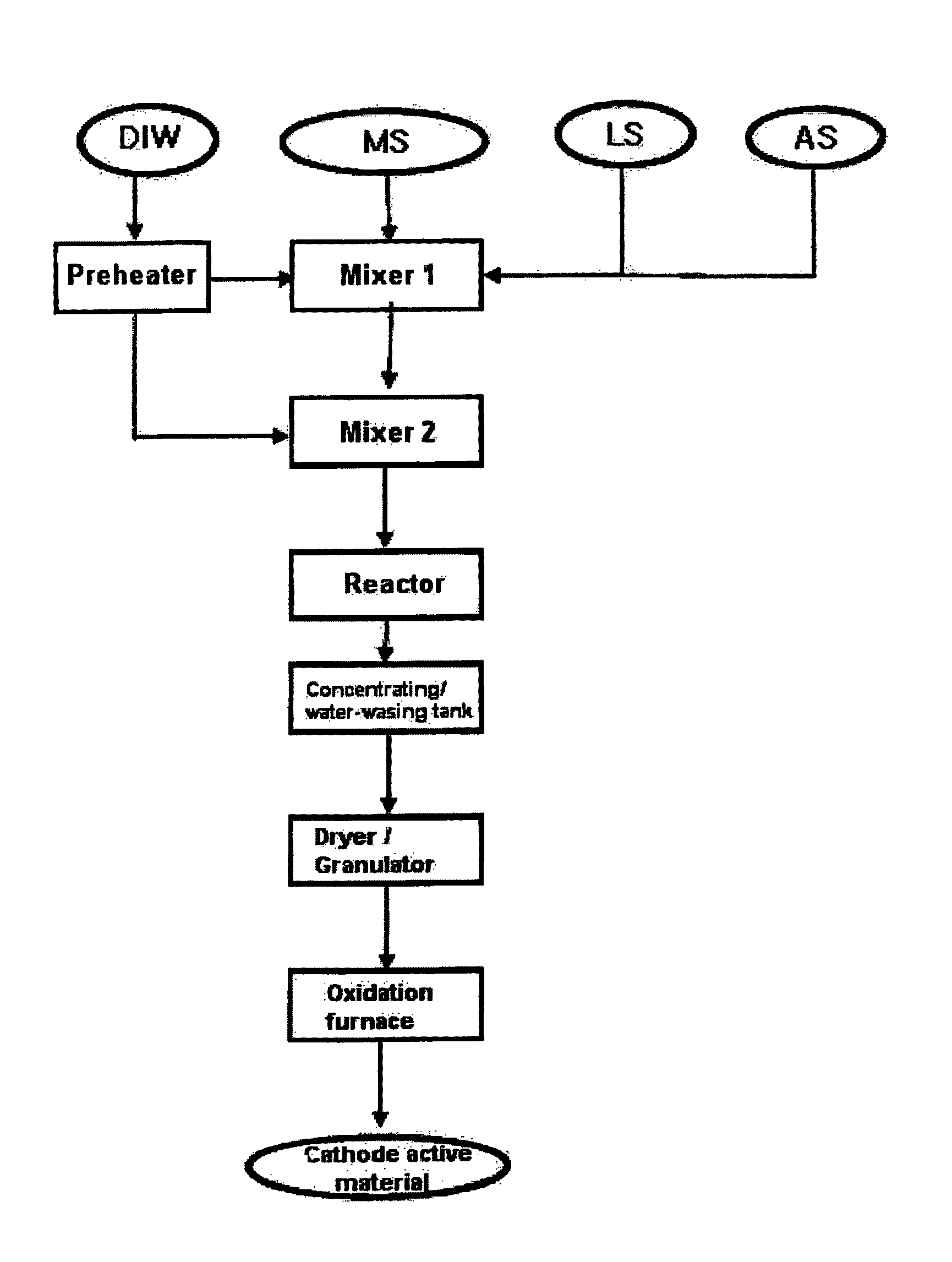

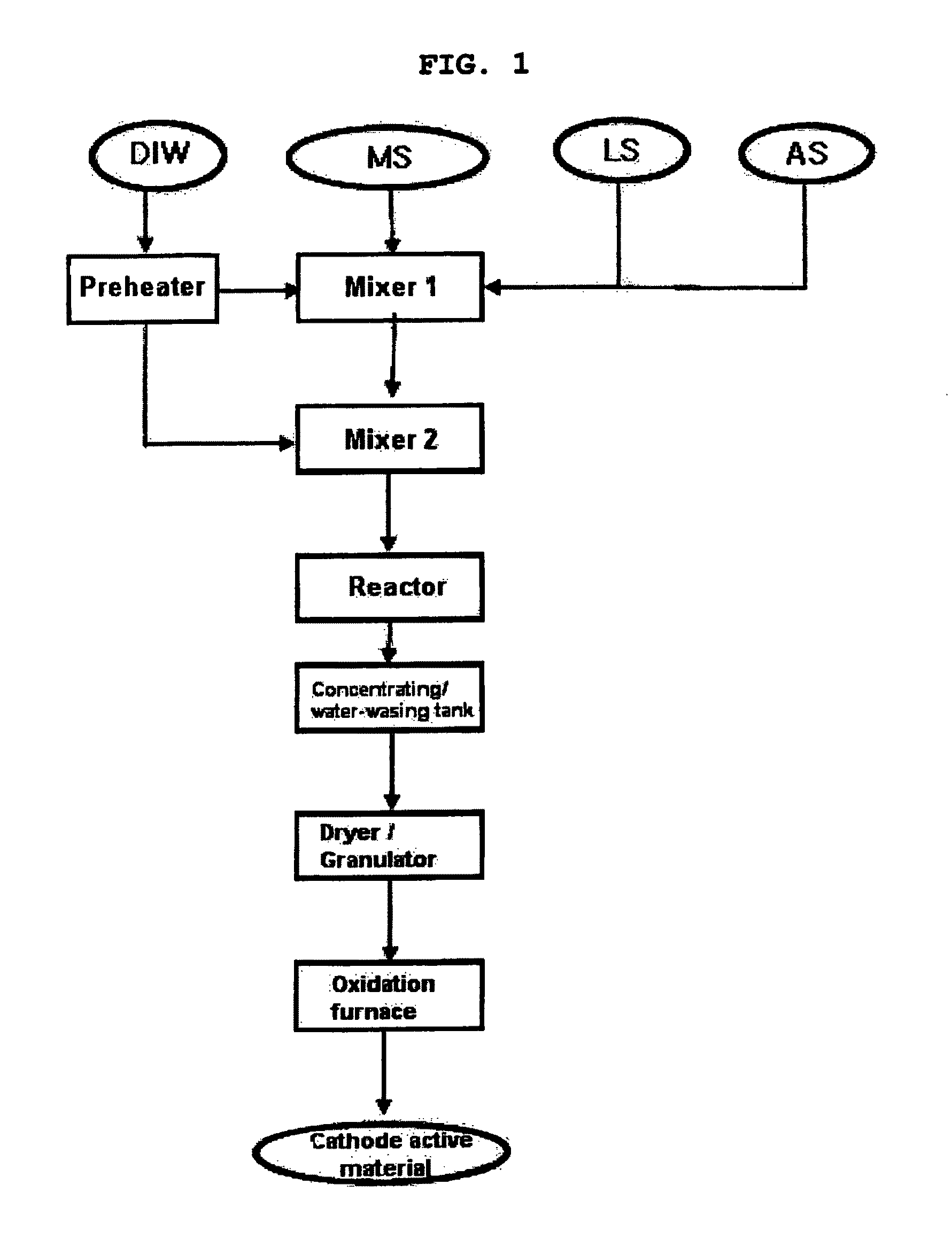

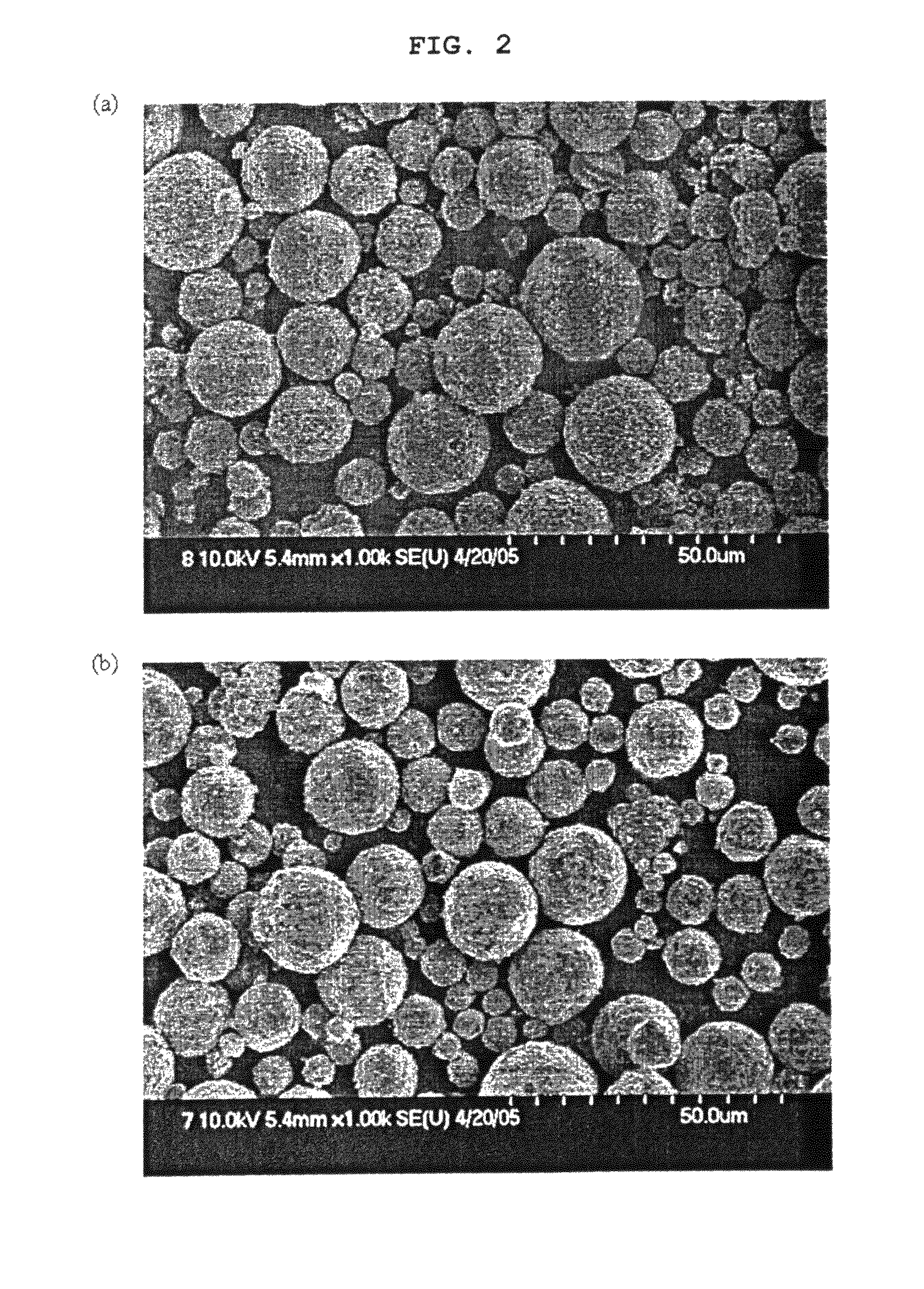

High Density Lithium Cobalt Oxide for Rechargeable Batteries

InactiveUS20130071661A1Increase energy densityIncrease electrode densityCell electrodesSynthetic resin layered productsHigh densityRechargeable cell

The disclosure relates to positive electrode material used for Li-ion batteries, a precursor and process used for preparing such materials, and Li-ion battery using such material in its positive electrode. The disclosure describes a higher density LiCoO2 positive elecdtrode material for lithium secondary batteries, with a specific surface area (BET) below 0.2 m2 / g, and a volumetric median particle size (d50) of more than 15 μm. This product has improved specific capacity and rate-capability. Other embodiments of the disclosure are an aggregated Co(OH)2, which is used as a precursor, the electrode mix and the battery manufactured using above-mentioned LiCoO2.

Owner:UMICORE AG & CO KG

Electrostatic fluid accelerator for and method of controlling a fluid flow

InactiveUS7248003B2Increase electrode densityReduce fluid resistanceOzone preparationAcceleratorsHigh intensityElectric field

An electrostatic fluid accelerator includes a first number of corona electrodes and a second number of accelerating electrodes spaced apart from and parallel to adjacent ones of the corona electrodes. An electrical power source is connected to supply the corona and accelerating electrodes with an operating voltage to produce a high intensity electric field in an inter-electrode space between the corona electrodes and the accelerating electrodes. The accelerating electrodes may be made of a high electrical resistivity material, each of the electrodes having mutually perpendicular length and height dimension oriented transverse to a desired fluid flow direction and a width dimension oriented parallel to the desired fluid flow direction. A length of the electrodes in a direction transverse to a desired fluid flow direction is greater than a width of the electrodes parallel to the fluid flow direction, and the width of the electrodes is at least ten times a height of the electrodes in a direction transverse to both the desired fluid flow direction and to the length.

Owner:TESSERA INC

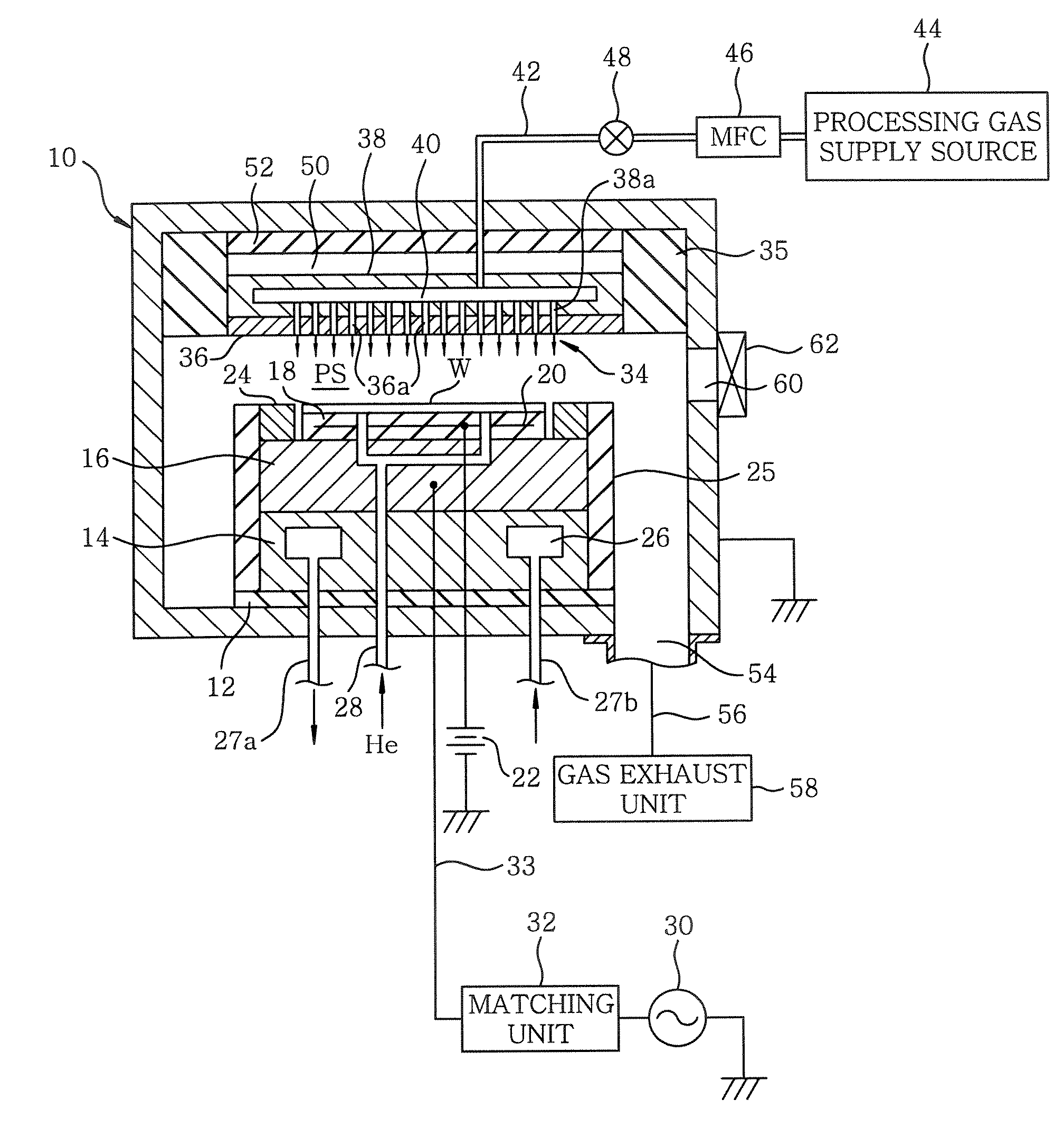

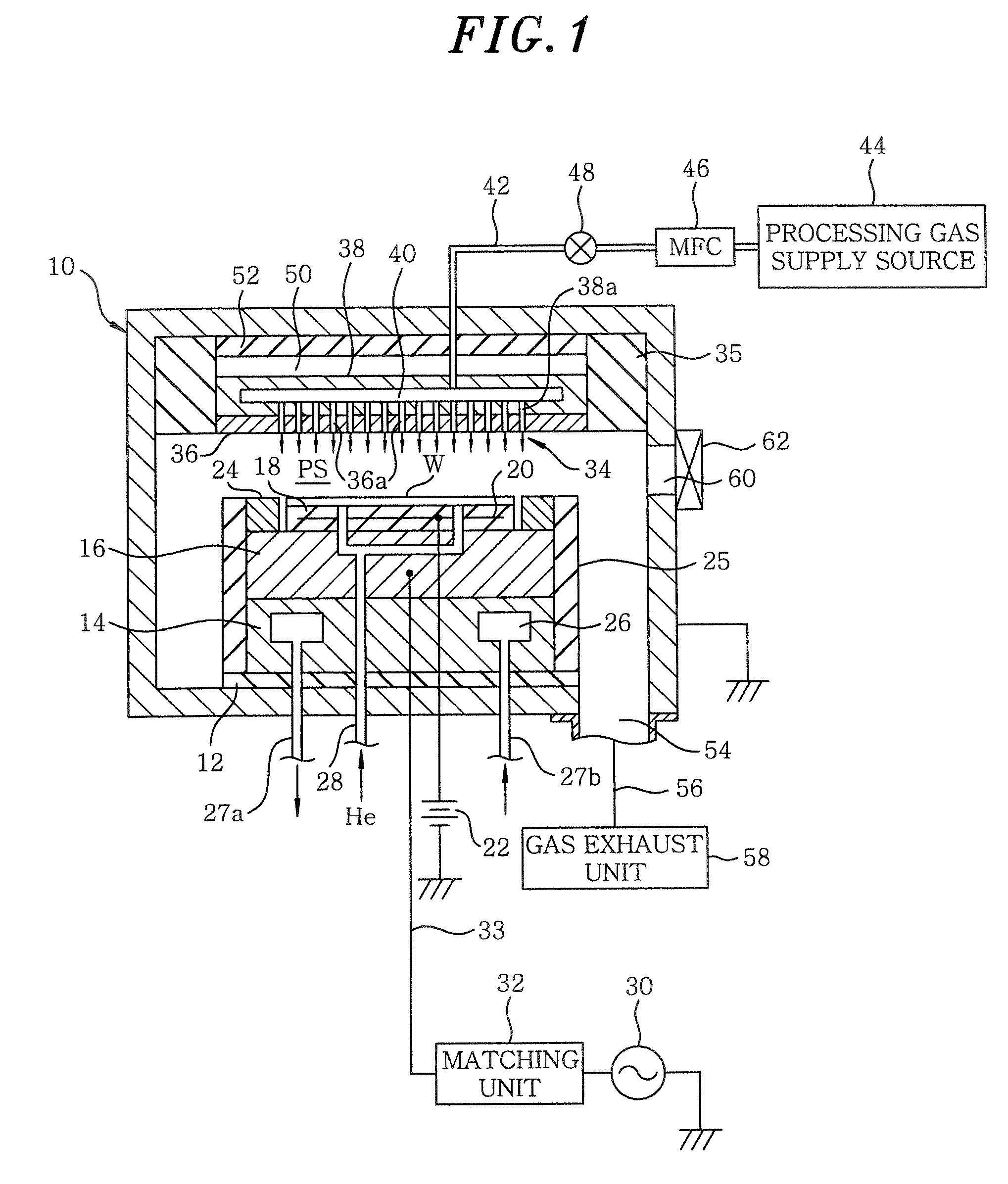

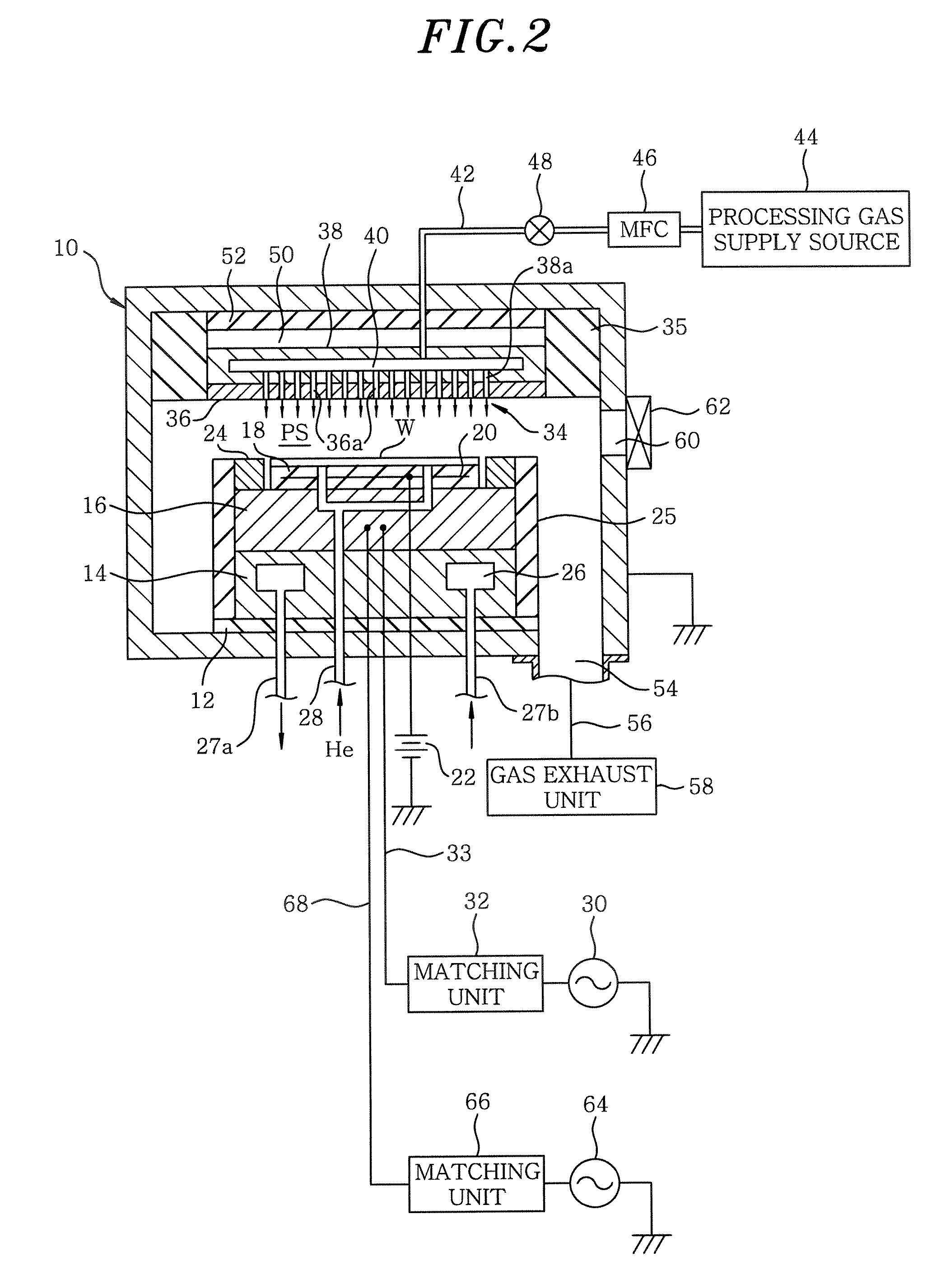

Plasma processing apparatus and plasma processing method

ActiveUS20070227664A1Reduces plasma densityIncrease electrode densityElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceElectricity

A plasma processing apparatus includes a processing vessel capable of being vacuum evacuated; a first electrode disposed in the processing vessel in a state electrically floating via an insulating member or a space; a second electrode, arranged in the processing vessel to face and be in parallel to the first electrode with a specific interval, supporting a substrate to be processed; a processing gas supply unit for supplying a desired processing gas into a processing space surrounded by the first electrode, the second electrode and a sidewall of the processing vessel; and a first radio frequency power supply unit for applying a first radio frequency power to the second electrode to generate a plasma of the processing gas in the processing space. An electrostatic capacitance between the first electrode and the processing vessel is set such that a desired plasma density distribution is obtained for the generated plasma.

Owner:TOKYO ELECTRON LTD

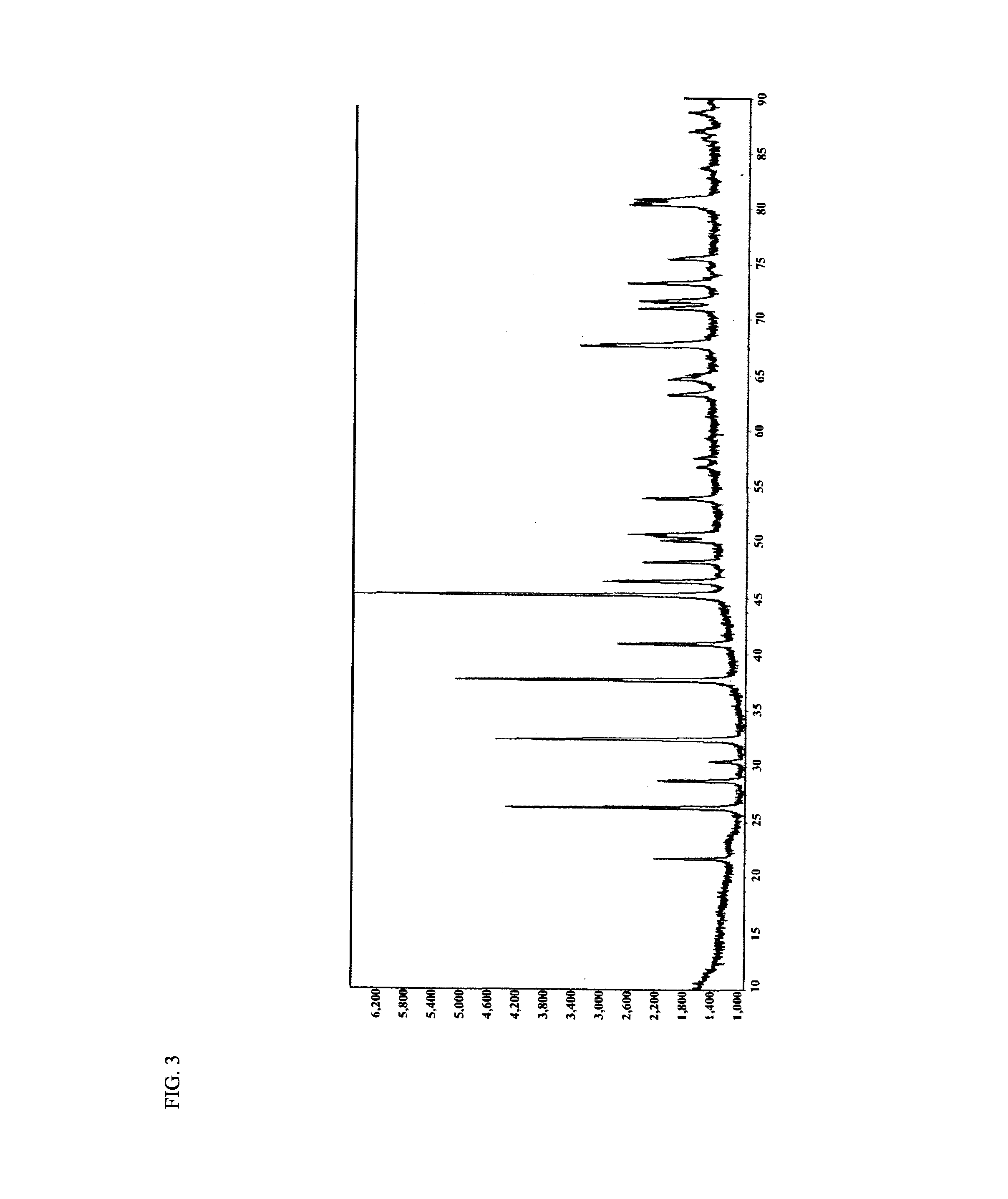

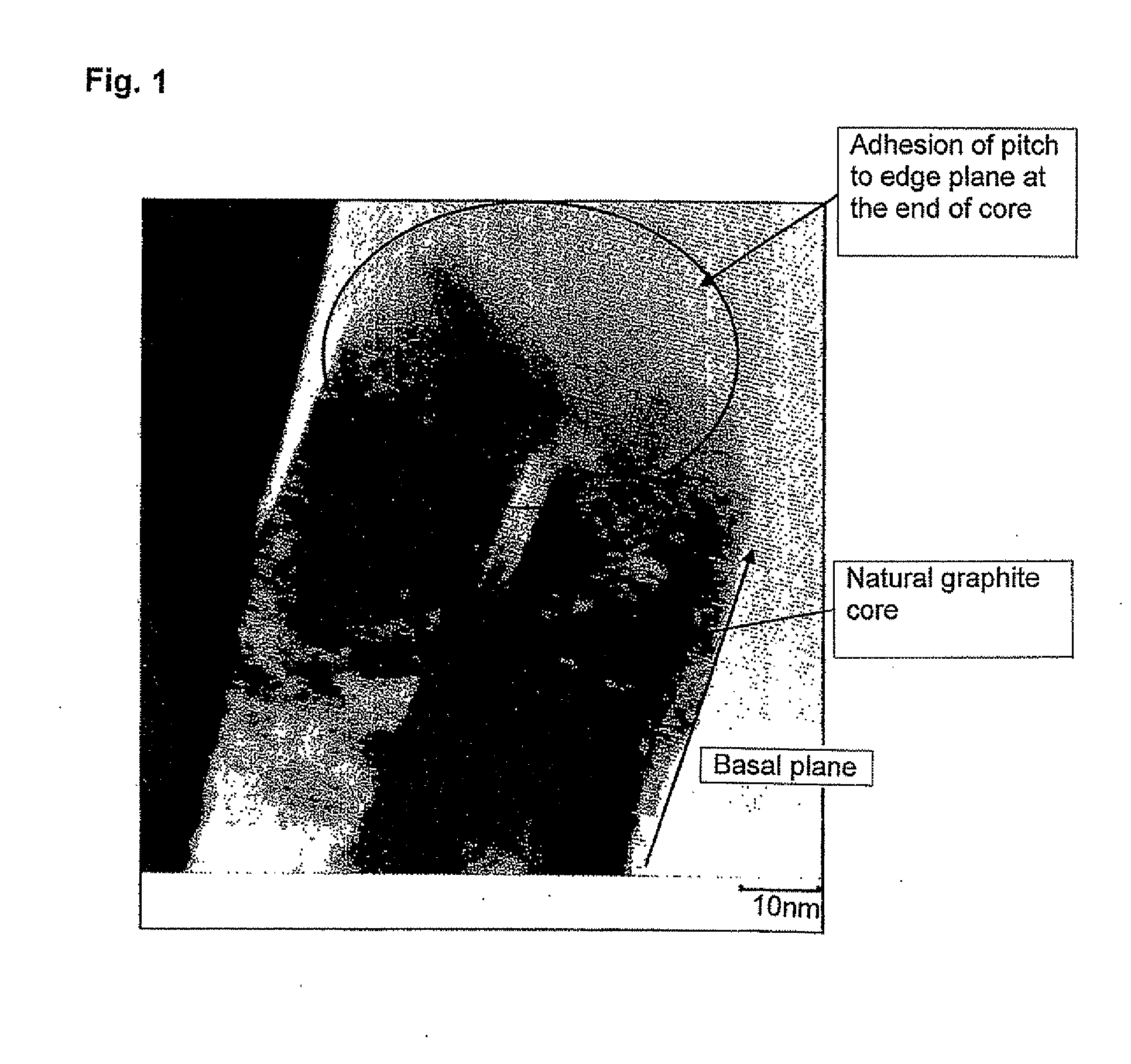

Carbon powder for use in cathode materials of non-aqueous secondary battery

InactiveCN1907848AImprove discharge capacityExcellent rate characteristicsMaterial nanotechnologyNon-aqueous electrolyte accumulatorsPore distributionDesorption

The invention provides low cost carbon powder which does not decompose propylene carbonate to be used as a negative electrode material of a low temperature-operable nonaqueous secondary battery. The carbon powder obtained by depositing low temperature fired carbon originating in pitch on a part of the surface of natural graphite powder is made by mixing the natural graphite powder with pitch powder of a carbon precursor in a solid state and heating at 900-1,500 deg C to carbonize the pitch. The quantity of the pitch powder is controlled so that the ratio V2 / V1 of the pore volume (V1) of poreshaving 2-50 nm pore diameter to the pore volume (V2) of pores having 50-200 nm pore diameter in the pore distribution curve determined by analyzing nitrogen desorption side isotherm of the resultant carbon powder by the BJH method is >=1.

Owner:CHUO DENKI KOGYO CO LTD

Lithium-rich lithium metal complex oxide

InactiveUS20140225031A1Increase electrode densityAlkali metal oxidesNon-aqueous electrolyte accumulator electrodesLithium metalMetal

A lithium-rich lithium metal complex oxide contains at least 50 mol % of Mn with respect to a total amount of metals other than lithium, and at least one other metal. The lithium metal complex oxide has a tapped density in a range of 1.0 g / ml to 2.0 g / ml.

Owner:TANAKA CHEM

Preparation method of lithium-metal composite oxides

ActiveUS8895190B2Easily improve rateHigh tap densityPrimary cellsElectrode carriers/collectorsLithium metalElectrochemistry

Owner:HANWHA CHEMICAL CORPORATION +1

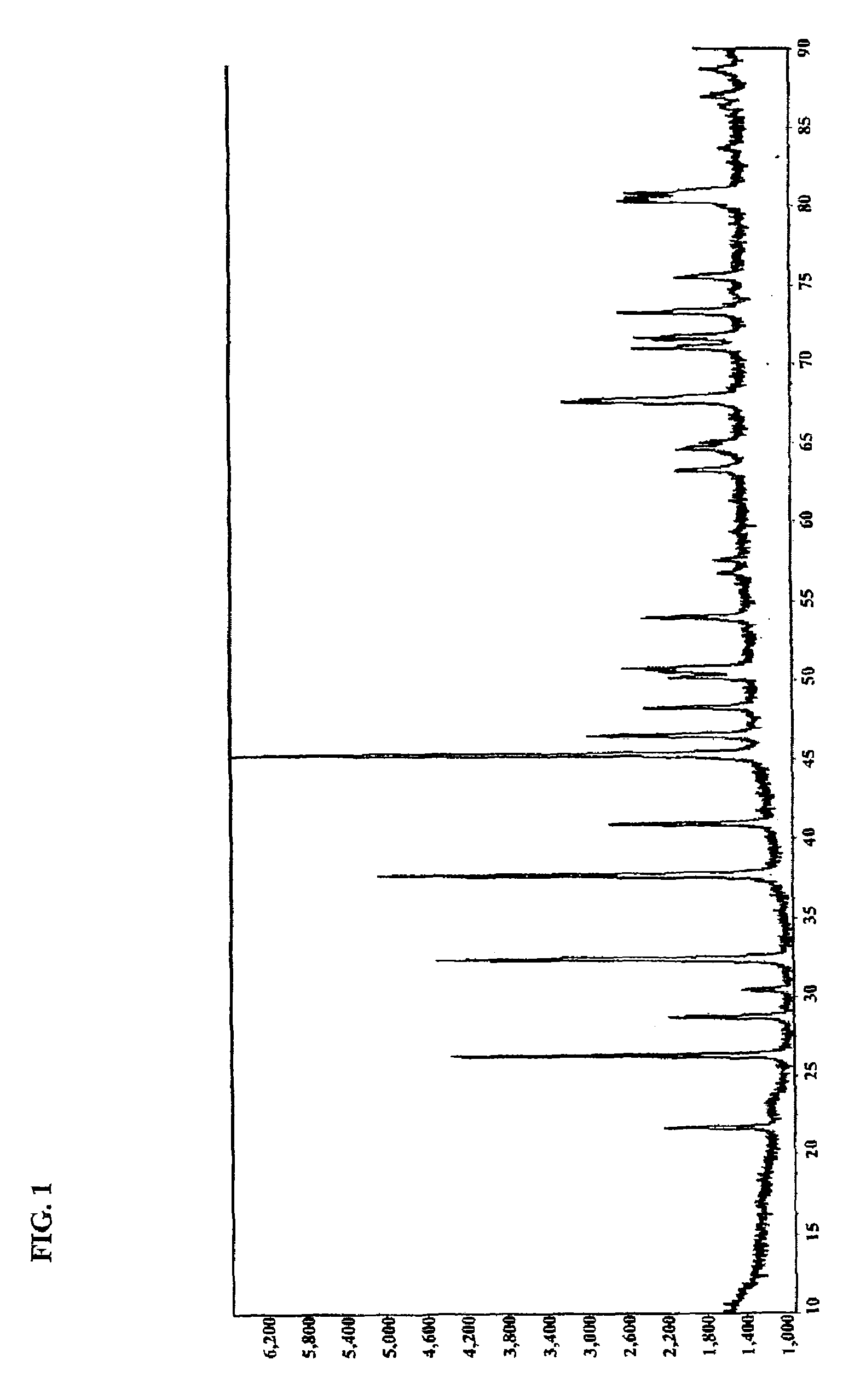

Negative electrode material for lithium-ion secondary battery,method for manufacturing negative electrode material for lithium-ion secondary battery, negative electrode material slurry for lithium-ion secondary battery, negative electrode for lithium-ion secondary battery, and lithium-ion secondary battery

ActiveUS20170110729A1Improve high load characteristicElectrode density be increaseElectrode thermal treatmentGraphitePore diameterLithium

A negative electrode material for a lithium-ion secondary battery, in which the negative electrode material includes a composite particle including a spherical graphite particle and plural graphite particles that have a compressed shape and that aggregate or are combined so as to have nonparallel orientation planes, and the negative electrode material has an R-value in a Raman measurement of from 0.03 to 0.10, and has a pore volume as obtained by mercury porosimetry of from 0.2 mL / g to 1.0 mL / g in a pore diameter range of from 0.1 μm to 8 μm.

Owner:HITACHI CHEM CO LTD

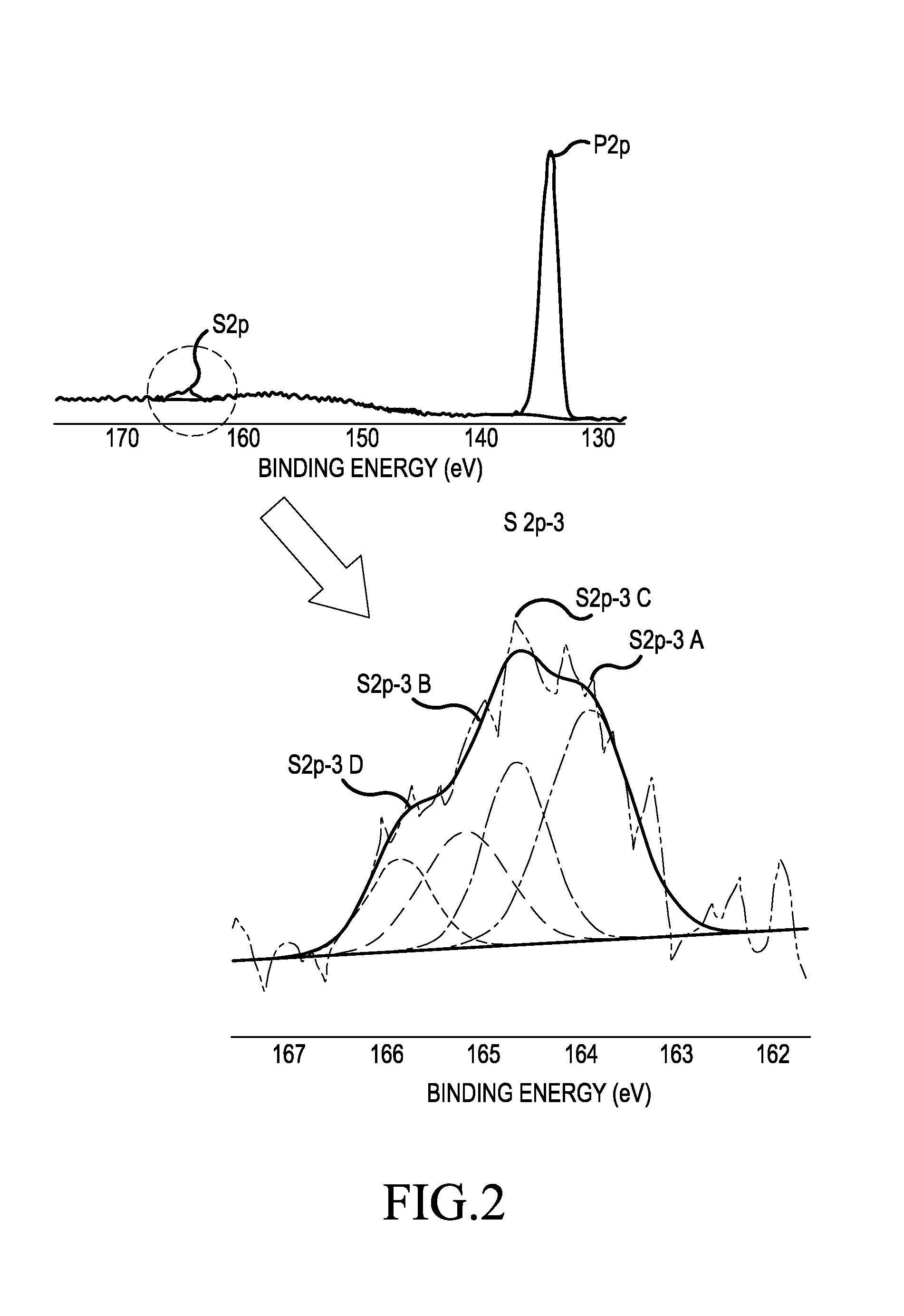

Carbon-coated lithium iron phosphate of olivine crystal structure and lithium secondary battery using the same

ActiveUS20130022866A1Improve conductivityIncrease electrode densityPhosphatesFinal product manufactureLithium iron phosphateSulfur

Disclosed is lithium iron phosphate having an olivine crystal structure, wherein the lithium iron phosphate has a composition represented by the following Formula 1 and carbon (C) is coated on the particle surface of the lithium iron phosphate containing a predetermined amount of sulfur (S).Li1+aFe1−xMx(PO4−b)Xb (1)(wherein M, X, a, x, and b are the same as defined in the specification).

Owner:LG ENERGY SOLUTION LTD

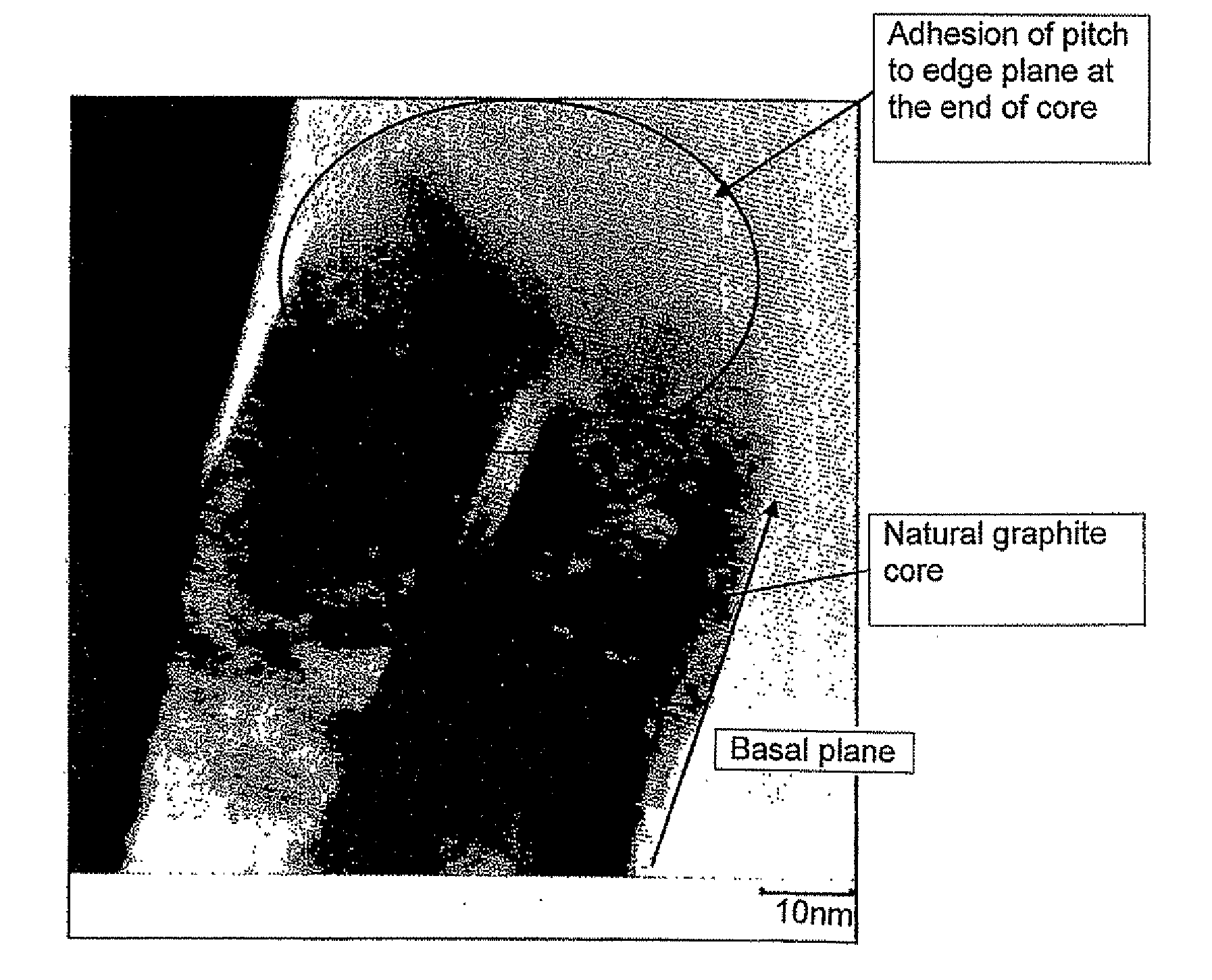

Carbon material and a process for its manufacture

InactiveUS20100035149A1High densityDecomposition is suppressedSecondary cellsActive material electrodesStationary conditionsDecomposition

A carbon material suitable as a negative electrode material for a lithium ion battery which can suppress decomposition of a nonaqueous electrolytic solution, which has excellent compressibility capable of highly dense packing, and which can form an electrode of high capacity without worsening charge and discharge efficiency or cycling performance. Graphite powder A having an average particle diameter of 10-30 μm and a specific surface area S1 of at most 12.5 m2 / g and pitch powder B having a softening point of 80-180° C. and an average particle diameter of 15-150 μm are mixed in proportions such that the mass ratio A / B is 98 / 2-95.5 / 4.5, and the resulting mixed powder is subjected to heat treatment in a stationary condition in an inert atmosphere at 900-1100° C. to carbonize the pitch and thereby manufacture a carbon material having carbon adhered to the surface of the above-described graphite powder. Carbon preferentially adheres to the edge planes of the graphite particles. The carbon material has a specific surface area S2 of 1.0-5.0 m2 / g, and it satisfies 0.4≦S2 / S1≦0.8.

Owner:NIPPON DENKO CO LTD

Electrostatic fluid accelerator for and a method of controlling fluid flow

InactiveUS7262564B2Minimizing and avoiding introductionIncrease airflowElectric arc lampsKlystronsElectricityEngineering

An electrostatic fluid acceleration and method of operation thereof includes at least two synchronously powered stages. A single power supply or synchronized and phase controlled power supplies provide high voltage power to each of the stages such that both the phase and amplitude of the electric power applied to the corresponding electrodes are aligned in time. The frequency and phase control allows neighboring stages to be closely spaced at a distance of from 1 to 2 times an inter-electrode distance within a stage, and, in any case, minimizing or avoiding production of a back corona current from a corona discharge electrode of one stage to an electrode of a neighboring stage. Corona discharge electrodes of neighboring stages may be horizontally aligned, complementary collector electrodes of all stages being similarly horizontally aligned between and horizontally offset from the corona discharge electrodes.

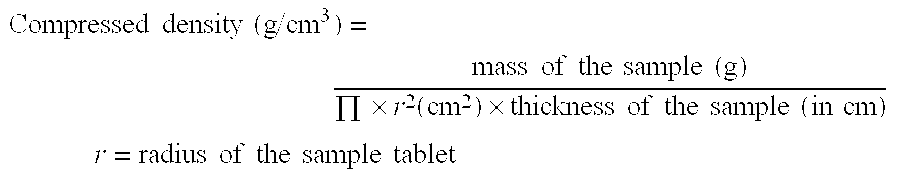

Mixed carbon material and negative electrode for a nonaqueous secondary battery

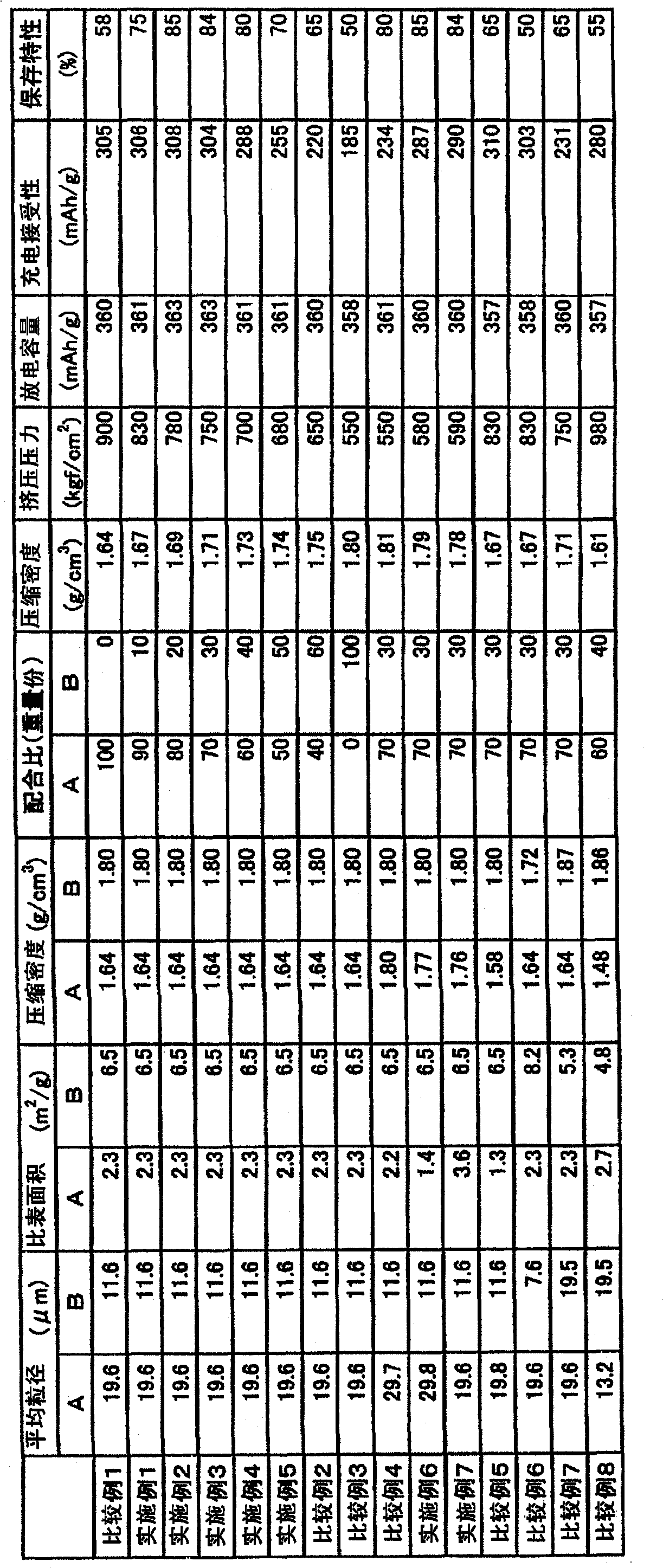

InactiveUS20120037845A1Increase electrode densityImprove high temperature storage performanceNon-aqueous electrolyte accumulatorsGraphiteHigh temperature storageHigh density

A negative electrode material provided by the present invention capable of suppressing a decrease in charge acceptance and high temperature storage properties in an electrode with a high capacity and a high density is a mixed carbon material comprising carbon material A having cores of graphite powder with amorphous carbon and / or turbostratic carbon adhered to or coated on the surface of the cores and carbon material B which is graphite powder, the compressibility which is the density (g / cm3) of the material when 1.00 grams of the material are packed into a cylindrical mold with an inner diameter of 15 mm and compressed by applying a pressing force of 8.7 kN and reducing the pressing force to 0.15 kN is 1.60-1.78 g / cm3 for carbon material A and 1.75-1.85 g / cm3 for carbon material B, the compressibility of carbon material A is less than the compressibility of carbon material B, and the mixing ratio (carbon material A / carbon material B) is 1-9 as a mass ratio.

Owner:CHUO DENKI KOGYO CO LTD

Multi layered electrode and method of manufacturing the same

ActiveUS20140377661A1High rate characteristicReduce conductivityElectrode carriers/collectorsElectrode collector coatingCurrent collectorAverage diameter

Disclosed are an electrode for secondary batteries including an electrode mixture coated on one surface or opposite surface of an electrode current collector, and a method of manufacturing the same. The electrode mixture includes an electrode mixture layer A, which is a portion close to a current collector, and an electrode mixture layer, which is a portion distant from a current collector. The electrode mixture layer A includes a mixture of two active materials, average diameters of which are different, and the electrode mixture layer B includes active materials, average diameters of which are the same.

Owner:LG ENERGY SOLUTION LTD

Mixed carbon material and negative electrode for nonaqueous rechargeable battery

InactiveCN102150307AAvoid damageIncrease electrode densityNon-aqueous electrolyte accumulatorsGraphiteHigh temperature storageHigh density

A negative electrode material provided by the present invention capable of suppressing a decrease in charge acceptance and high temperature storage properties in an electrode with a high capacity and a high density is a mixed carbon material comprising carbon material A having cores of graphite powder with amorphous carbon and / or turbostratic carbon adhered to or coated on the surface of the cores and carbon material B which is graphite powder, the compressibility which is the density (g / cm 3 ) of the material when 1.00 grams of the material are packed into a cylindrical mold with an inner diameter of 15 mm and compressed by applying a pressing force of 8.7 kN and reducing the pressing force to 0.15 kN is 1.60 - 1.78 g / cm 3 for carbon material A and 1.75 - 1.85 g / cm 3 for carbon material B, the compressibility of carbon material A is less than the compressibility of carbon material B, and the mixing ratio (carbon material A / carbon material B) is 1 - 9 as a mass ratio.

Owner:CHUO DENKI KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com